Canon LBP-3260 Service Manual

SERVICE

MANUAL

REVISION 0

COPYRIGHT 1999 CANON INC. CANON LBP-3260 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

RY8-1390-000

JAN. 1999

COPYRIGHT © 1999 CANON INC

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

PERIPHERAL PRODUCTS QUALITY ADVANCEMENT DIV.

PERIPHERAL PRODUCTS TECHNICAL DOCUMENTATION DEPT.

CANON INC.

5-1, Hakusan 7-chome, Toride-City, Ibaraki-Pref. 302-8501, Japan

PREFACE

This Service Manual contains basic information required for after-sales service of the laser beam

printer LBP-3260 (hereinafter referred to as the "printer"). This information is vital to the service technician in maintaining the high print quality and performance of the printer.

This manual consists of the following chapters:

Chapter 1: Product information

Features, specifications, operation, and installation

Chapter 2: Operation and Timing

A description of the operating principles and timing sequences of the electrical and

mechanical systems.

Chapter 3: The Mechanical System

Explanation of mechanical operation, disassembly, reassembly and adjustment procedures

Chapter 4: Troubleshooting

Troubleshooting procedures, reference values and adjustments, maintenance and

servicing, etc.

Appendix: General timing chart, general circuit diagram, etc.

Information in this manual is subject to change as the product is improved or redesigned. All

relevant information in such cases will be supplied in the Service Information Bulletins.

A thorough understanding of this printer, based on information in this Manual and Service

Information bulletins, is required for maintaining its performance and for locating and repairing

the causes of malfunctions.

DTP system

This manual was produced on an Apple PowerMacintosh 9500/233 personal computer and output by an

Apple LaserWriter 16/600 PS laser beam printer; final pages were printed on DAINIPPON SCREEN MFG

CO. LTD DT-R3100.

All graphics were produced with Macromedia FreeHand (J), and all documents and page layouts were

created with QuarkXPress (E).

The video images were captured with SONY degital video camcorder and Radius PhotoDV capture board

system, and modified with Adobe Photoshop (J).

CONTENTS

CHAPTER 1 PRODUCT INFORMATION

I. FEATURES ............................ 1-1

II. SPECIFICATIONS .................. 1-3

III. SAFETY INFORMATION .... 1-6

IV. PARTS OF THE PRINTER ...... 1-7

V. INSTALLATION ...................... 1-9

VI. MAINTENANCE AND

SERVICING BY THE

CUSTOMER ........................... 1-18

VII. OPERATION .......................... 1-21

CHAPTER 2 OPERATION AND TIMING

CHAPTER 3 THE MECHANICAL SYSTEM

I. BASIC OPERATION................. 2-1

A. Functions.......................... 2-1

B. Basic Operation Sequences 2-2

C. Power On Sequence ........... 2-3

II. ENGINE CONTROL SYSTEM.... 2-4

A. DC Controller Circuit ........ 2-4

B. Fixing Control ................... 2-10

C. High-Voltage Power

Supply............................... 2-16

D. Power Supply..................... 2-19

E. Video Interface Control ..... 2-21

F. Other Controls .................. 2-23

III. LASER/SCANNER SYSTEM..... 2-26

A. Outline.............................. 2-26

B. Laser Control Circuit......... 2-27

C. Scanning System............... 2-30

IV. IMAGE FORMATION SYSTEM . 2-32

A. Outline.............................. 2-32

B. Printing Process ................ 2-34

V. PICK-UP/FEED SYSTEM......... 2-42

A. Outline.............................. 2-42

B. Paper Pick-up .................... 2-45

C. Fixing and Delivery Unit.... 2-57

D. Paper Jam Detection ......... 2-59

VI. OVERALL CONTROL SYSTEM. 2-61

A. Video Controller PCB......... 2-61

B. Control Panel .................... 2-65

C. Self Test............................ 2-66

I. PREFACE ............................... 3-1

II. EXTERNALS ........................... 3-2

A. Locations .......................... 3-2

B. Control Panel Unit............. 3-7

III. MAIN UNITS........................... 3-8

A. Laser/Scanner Unit ........... 3-8

B. Drive Unit ......................... 3-8

C. Pick-up Unit ...................... 3-9

D. Multi-purpose Tray Pick-up

Unit.................................. 3-12

E. Registration Roller Unit .... 3-12

F. Delivery Unit ..................... 3-13

G. Fixing Unit ........................ 3-13

H. Feed Unit .......................... 3-14

IV. MAIN PARTS .......................... 3-15

A. Locations .......................... 3-15

B. Multi-purpose Tray Pick-up

Roller ............................... 3-16

C. Separation Pad .................. 3-16

D. Pick-up/Feed/Separation

Rollers ............................. 3-17

E. Registration Lower Roller.. 3-17

F. Transfer Charging Roller ... 3-18

G. Fixing Roller Heater .......... 3-18

H. Fixing Upper Roller ........... 3-19

I. Fixing Lower Roller ........... 3-22

J. Cleaning Roller.................. 3-23

V. SWITCHES/SENSORS............. 3-24

A. Locations .......................... 3-24

B. Thermoswitch ................... 3-25

C. Door Switch ...................... 3-25

D. Upper Cassette Paper-size

Sensing Switch/Lower Cassette

Paper-size Sensing Switch . 3-26

E. Thermistor ........................ 3-26

F. Registration Paper Sensor . 3-27

G. Pick-up Unit Paper Sensor . 3-28

H. Pick-up Unit Door Sensor .. 3-28

I. Lower Cassette Sensor/

Upper Cassette Sensor/

Lower Cassette Paper-level

Sensor 1/Lower Cassette

Paper-level Sensor 2/Upper

Cassette Paper-level Sensor 1/

Upper Cassette Paper-level

Sensor 2/Lower Cassette

Paper-out Sensor/Upper

Cassette Paper-out Sensor. 3-29

J. Multi-purpose Tray Paper

Sensor /Lifting Plate

Position Sensor ................. 3-29

K. Face-down Tray Paper Full

Sensor /Face-down Tray

Delivery Sensor /Fixing

Unit Delivery Sensor ......... 3-30

VI. CLUTCHS/SOLENOIDS ........... 3-31

A. Locations .......................... 3-31

B. Multi-purpose Tray Pick-up

Clutch ............................... 3-32

C. Feed Clutch....................... 3-32

D. Registration Clutch ........... 3-33

E. Lifting Plate Solenoid ........ 3-33

F. Cassette Pick-up Solenoid . 3-34

G. Face-up Solenoid Unit ....... 3-34

VII. MOTORS/FANS ...................... 3-35

A. Locations .......................... 3-35

B. Main Motor........................ 3-36

C. Pick-up Motor.................... 3-36

D. Fans ................................. 3-37

VIII.PCBS...................................... 3-41

A. Locations .......................... 3-41

B. Video Controller PCB Unit . 3-42

C. DC Controller PCB ............ 3-43

D. Pick-up PCB ..................... 3-44

E. Multi-purpose Tray PCB ... 3-44

F. Switch/Sensor PCB .......... 3-45

G. High-voltage Power Supply

Unit .................................. 3-47

H. Cassette Paper-size Sensing

PCB .................................. 3-47

I. Power Supply ................... 3-48

I. PREFACE ............................... 4-1

A. Malfunction Diagnosis

Flowchart ......................... 4-1

B. Initial Check ..................... 4-4

C. Test Print.......................... 4-5

II. IMAGE DEFECTS.................... 4-8

III. PAPER JAMS

TROUBLESHOOTING .............. 4-14

IV. PAPER TRANSPORT

TROUBLESHOOTING .............. 4-18

V. MALFUNCTION

TROUBLESHOOTING .............. 4-20

VI. MALFUNCTION STATUS

TROUBLESHOOTING .............. 4-21

VII. MEASUREMENT AND

ADJUSTMENT ........................ 4-28

A. Mechanical Adjustment ..... 4-28

B. Electrical Adjustment........ 4-29

C. Variable Resistors, LEDs,

Test Pins, Jumpers and

Switches on PCBs.............. 4-30

VIII.MAINTENANCE AND

CHAPTER 4 TROUBLESHOOTING

APPENDIX

I. GENERAL TIMING CHART ...... A-1

II. GENERAL CIRCUIT DIAGRAM A-3

III. LIST OF SIGNALS................... A-5

IV. MESSAGES TABLE ................. A-11

SERVICING............................. 4-35

A. Periodic Replacement

Parts ................................ 4-35

B. Expected Service Life of

Consumable Parts.............. 4-35

C. Periodic Service ................ 4-35

D. Cleaning during a Service

Visit .................................. 4-36

E. Standard Tools .................. 4-38

F. Special Tools ..................... 4-39

G. Special Tools (printer driver

tester) Explanation........... 4-40

H. Solvents and Oil List ......... 4-47

IX. LOCATION OF CONNECTORS . 4-48

CHAPTER 1

PRODUCT INFORMATION

I. FEATURES ............................ 1-1

II. SPECIFICATIONS .................. 1-3

III. SAFETY INFORMATION .... 1-6

IV. PARTS OF THE PRINTER ...... 1-7

V. INSTALLATION ...................... 1-9

VI. MAINTENANCE AND

SERVICING BY THE

CUSTOMER ........................... 1-18

VII. OPERATION .......................... 1-21

I. FEATURES

1. High speed printing

Equipped with Motorola's PowerPC 603e, the printer is capable of printing about 32 pages per

minute (A4/Letter).

2. Superior print quality

Combination of high resolution printing at 600 DPI and the use of super fine toner offers clear

print images.

3. Duplex printing

With the optional duplexing unit installed, the printer can print on both sides of paper.

4. Continuous printing

With the optional paper deck installed in the printer in addition to the standard equipped multipurpose tray and upper and lower cassettes, up to about 3,100 sheets of paper (75g/m2) can be

loaded, enabling continuous printing in large volume.

5. 6-way paper pick-up

Optional 2x500 sheet paper deck and envelope feeder in addition to the standard equipped

multi-purpose tray and upper and lower cassettes offer 6-way paper pick-up. The printer can

change the paper pick-up source automatically according to the paper type in addition to the

paper size.

6. Delivery

With the optional staple stacker installed in addition to the standard face-down tray, up to 2,300

sheets of A4 or Letter size paper (75g/m2) can be delivered (simple stacking).

7. Various delivery methods

With the optional sorter attached to the printer, paper can be delivered in 4 modes: mail box, job

separator, stacker and collator.

8. Memory saving technology

Memory Reduction Technology accomplishes printing at 600 DPI with standard equipped memory (8 MB). It also decreases errors, such as memory over flow, and provides stable printing.

9. Energy saving/Toner saving

The printer cuts off the power to the fixing heater when it remains idle for a specified length of

time. It can also reduce toner consumption by selecting the economy mode to print light images

with less toner.

10.Automatic emulation switching

The printer supports Hewlett-Packard's enhanced PCL6. With the optional PostScript ROM

DIMM (Canon Translator Module A-72) installed, the printer can automatically switch between

the standard PCL and Adobe®PostScript®3™.

11.Automatic interface switching

In addition to the standard built-in bicentronics parallel port, optional interfaces can be

installed in the printer. The printer can automatically switch between the parallel and expansion interface according to which interface port the data sent from the host computer enters.

1 - 1

CHAPTER 1

This page intentionally left blank

1 - 2

CHAPTER 1

II. SPECIFICATIONS

A. Printer

1. Printer Engine

1) Type Desktop page printer (console type when paper deck is installed)

2) Printing method Electrophotography

3) Printing speed (Note 1) About 32 pages/min. (A4/Letter), about 18 pages/min. (A3)

4) First print time (Note 2) 12.9 sec. or less (A4), 14.3 sec. or less (A3)

5) Wait time (Note 3) 90 sec. or less

6) Resolution

Horizontal 600 DPI

Vertical 600 DPI

7) Image formation system

Laser Semiconductor laser

Scanning system Rotating six-faced prism mirror (Scanning mirror)

Photosensitive drum OPC

Charging Roller charging

Exposure Laser scanning

Toner Magnetic single-component dry toner

Development Toner projection development

Toner supply By EP-72 cartridge replacement (about 20,000 A4- or Letter-sized

prints; with "DENSITY" in "CONFIG MENU" set to "7" and 4% dot

density)

Transfer Roller transfer

Separation Curvature/discharge bias

Cleaning Blade

Fixing Heated rollers (600W, 450W)

8) Paper pick-up Multi-purpose tray

Cassette

Envelope feeder EF-9 (option)

2,000 Sheet paper deck PD-82 (option)

2x500 Sheet paper deck PD-82K (option)

Print paper Plain paper, colored paper, labels, OHT, envelopes, rough paper,

bond paper, tarnsparency paper, recycled paper, letterhead

Paper sizes

Multi-purpose tray Min. 98.4mm(W) × 190.5mm(L) to max. 297mm(W) × 432mm(L)

sized plain paper (64g/m2to 128g/m2recommended paper) and

paper mentioned above.

Upper cassette B4, A4, Legal, Letter-sized plain paper (64g/m2to 105g/m2rec-

ommended paper), and colored paper.

Lower cassette A3, B4, A4, Ledger, Legal, Letter-sized plain paper (64g/m2to

105g/m2recommended paper), and colored paper.

Multi-purpose tray

capacity 10mm stack (about 100 sheets of 75g/m2paper)

Cassette capacity 50mm stack (about 500 sheets of 75g/m2paper)

Cassette types

Upper cassette Universal (accommodates B4, A4, Legal, Letter sizes)

Lower cassette Universal (accommodates A3, B4, A4, Ledger, Legal, Letter sizes)

9) Print delivery Face-down/face-up

10) Print tray capacity

Face-down About 500 sheets (75g/m2paper)

Face-up About 100 sheets (75g/m

2

paper)

1 - 3

CHAPTER 1

11) Duplex print

Auto-duplexing When duplex unit (option) is installed, and plain paper (64g/m2to

105g/m2recommended paper) only.

Manual duplexing

(Note 4) Plain paper (64g/m2to 128g/m2recommended paper) on multi-

purpose tray only.

12) Environment

Temperature 10 to 32.5°C

Humidity 20 to 80%RH

Air pressure 760 to 1013hPa (560 ~ 760mmHg/equivalent to 0 ~ 2,600m above

the sea level)

13) Maximum power

consumption About 1,220W (20°C room temperature, rated voltage)

14) Noise level (Officially announced level based on ISO 9296)

Sound power level (1B=10dB) 6.9B or less (printing)

5.3B or less (standby)

Sound pressure level 54dB or less (printing)

(Bystander position) 38dB or less (standby)

15) Dimensions 566 (w) × 520 (D) × 540 (H) mm (excluding some projections)

16) Weight About 50kg (printer)

Aabout 3.4kg (cartridge)

17) Line voltage requirements

220 to 240V (-10%, +6%) 50/60Hz (±2Hz)

18) Options Duplex unit DU-82, envelope feeder EF-9, 2000 sheet paper deck

PD-82, 2x500 sheet paper deck PD-82K, sorter S-82, stapler

stacker SS-72

Notes: 1. A test print at room temperature of 20°C with rated voltage input.

2. When the printer is in READY state at a room temperature of 20°C, the time from

reception of the PRINT signal from the video controller until an A4 or A3-sized print

is delivered onto the face-down tray.

3. At a room temperature of 20°C with rated voltage input, the time from turning ON

the printer until the end of the WAIT period.

4. When manual duplexing, correct the curl of the print delivered in the face-down tray

before setting it in the multi-purpose tray.

2. Video Controller

1) CPU RISC processor: Motorola PowerPC 603e

2) RAM Standard: 8MB

Maximum: 40MB

3) ROM 4MB

4) ROM DIMM socket 2

5) RAM DIMM socket 3

6) Host interface Standard: IEEE 1284 compliant parallel

Option: expansion interface (Ethernet, Token Ring)

7) Language Standard: PCL 5e/PCL 6

Option: Adobe®PostScript®3™

8) Resident fonts 45 Scalable fonts (MicroType font), 8 Bitmap font

9) Optional fonts 136 fonts

10) Scaler UFST

1 - 4

CHAPTER 1

B. Option

1. Hard disk

1) Memory 2.16GB

2) Interface ATA-3 (IDE)

3) Dimensions 70 (w) × 12.7 (D) × 100 (H) mm (excluding mounting materials and

connector.)

4) Weight About 0.15kg

5) Power supply DC5V (supplied from the printer)

Specifications are subject to change with product modification.

1 - 5

CHAPTER 1

III. SAFETY INFORMATION

A. Laser Safety

An invisible laser beam is irradiated within the laser/scanner unit.

Since the laser beam can injure the eye if it strikes it, be sure not to disassemble the

laser/scanner unit. It cannot be adjusted in the field, anyway.

The label shown below is attached to the laser/scanner unit cover.

Figure 1-3-1

B. Toner Safety

Composed of plastic and minute colored components, toner is a non-poisonous substance.

If toner adheres to your skin or clothes, remove as much of it as possible with dry tissue

paper, then wash with cold water. If you use hot water, the toner will gel and become difficult

to remove.

As toner easily breaks down vinyl materials, avoid letting toner come into contact with vinyl.

C. Ozone Safety

An infinitesimal amount of ozone gas (O3) is generated during corona discharge from the charging roller used in this printer. The ozone gas is emitted only when the printer is operating.

This printer meets the ozone emission reference value set by Underwriters Laboratory (UL) at

the time it is shipped from the factory.

D. Power Supply Unit Safety

Care is needed as even though the printer switch may be OFF, there is a possibility that a current may still flow on the primary side. Be sure to remove the power plug before disassembly

and assembly of this printer.

1 - 6

CHAPTER 1

DANGERCAUTION

!

ATTENTION

VORSICHT

ATTENZIONE

PRECAUCION

VARO!

VARNING!

ADVARSEL!

ADVARSEL

RAYONNEMENT LASER INVISIBLE EN CAS D'O UVERTURE.

-

EXPOSITION DANGEREUSEAU FAISCEAU.

UNSICHTBARE LASERSTRAHLUNG.WENN ABDECKUNG GEÖFFNET.

-

NICHT DEM STRAHL AUSSETZEN.

RADIAZIONE LASER INVISIBILE IN CASO DI APERTURA.

-

EVITARE L'ESPOSIZIONE AL FASCIO.

RADIACION LASER INVISIBLE CUANDO SE ABRE.

-

EVITAR EXPONERSE AL RAYO.

AVATTAESSA OLET ALTTIINA NÄKYMÄTTÖMÄLLE

-

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

OSYNLIG LASERSTRÅLNING NAR DENNA DEL ÄR ÖPPNAD.

-

BETRAKTA EJ STRÅLEN.

USYNLIG LASER STRÅLING,NÅR DENNE ER ÅBEN.

-

UNDGÅ BESTRÅLING.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES.

UNNGÅ EKSPONERING FOR STRÅLEN.

Invisible laser radiation when open.

AVOID DIRECT EXPOSURETO BEAM.

INVISIBLE LASER RADIATIONWHEN OPEN.

-

AVOID EXPOSURE TO BEAM.

-

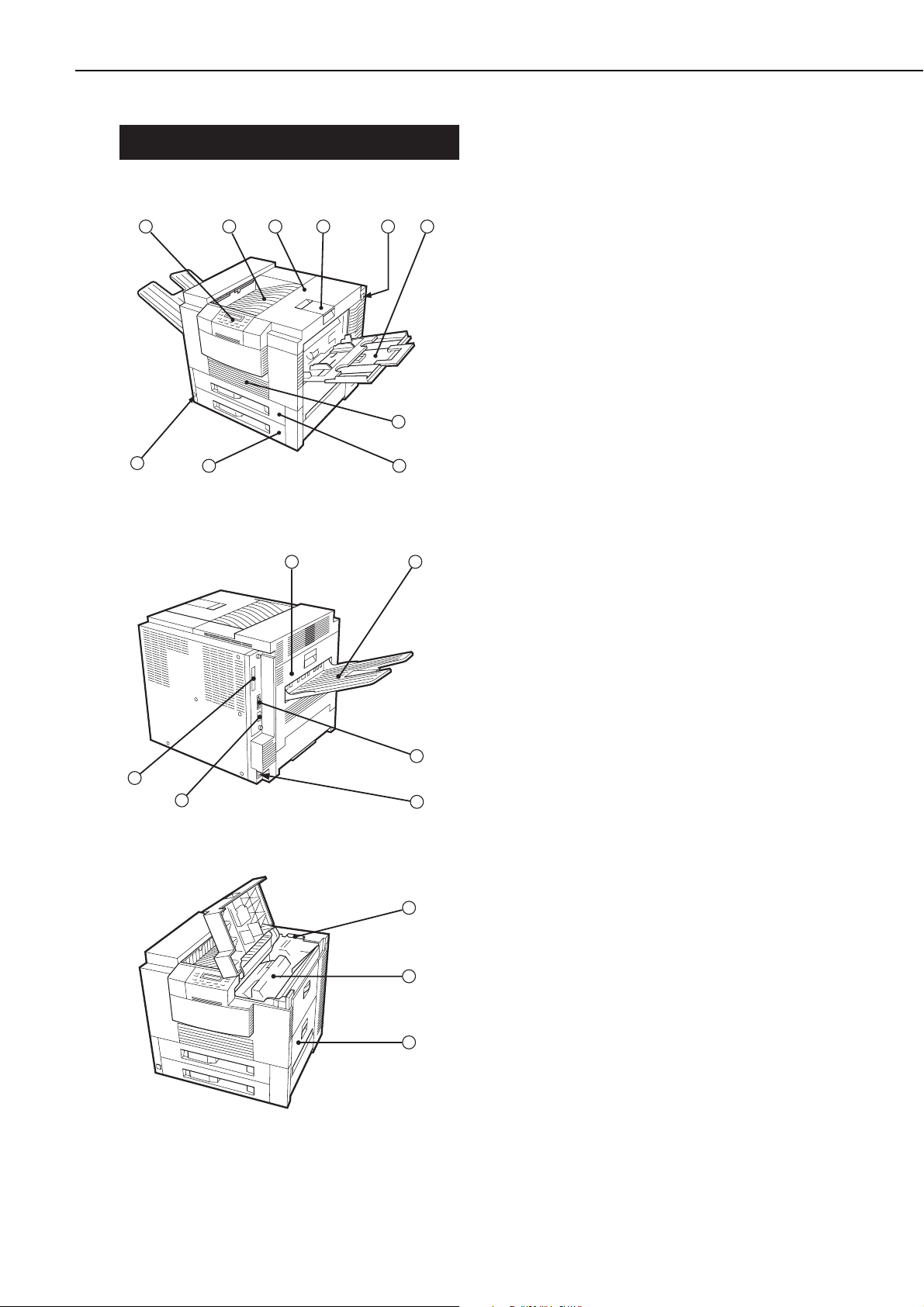

IV. PARTS OF THE PRINTER

A. External Views

Figure 1-4-1

Figure 1-4-2

Figure 1-4-3

1: Operation panel unit

2: Face-down tray

3: Upper cover

4: Delivery stopper

5: Test print switch

6: Multi-purpose tray

7: Duplex unit door

8: Upper cassette

9: Lower cassette

10: Power switch

11: Delivery cover

12: Face-up tray

13: Parallel interface connector

14: Power receptacle

15: Option interface connector (option)

16: Expansion board slot

17: Cleaning brush

18: EP-72 cartridge

19: Pick-up unit door

1 - 7

CHAPTER 1

123456

7

10

98

11

12

13

16

15

14

17

18

19

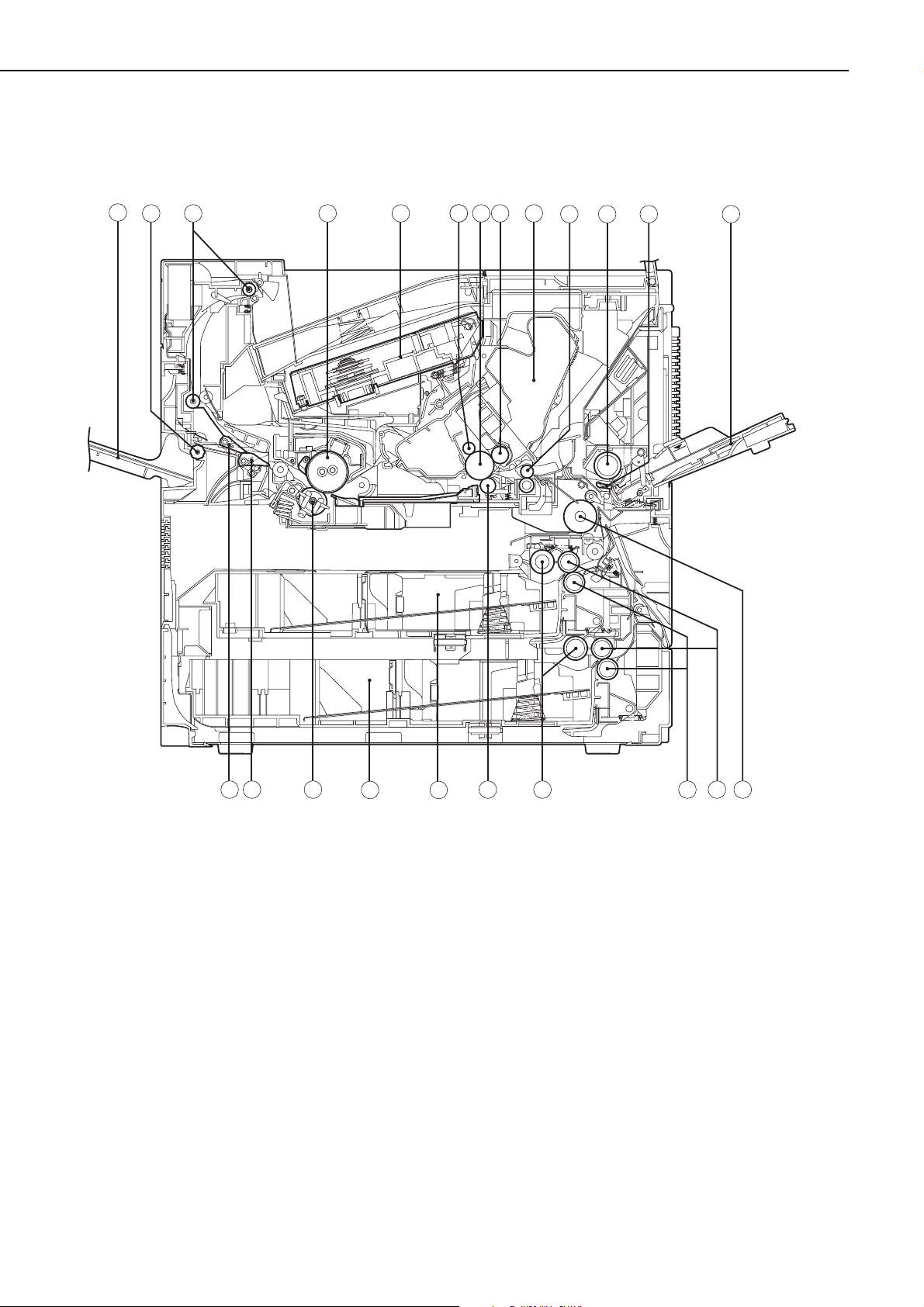

B. Cross-sectional Views

Figure 1-4-4

1: Face-up tray 13: Multi-purpose tray

2: Face-up delivery roller 14: Feed roller 1

3: Face-down delivery roller 15: Feed roller 2

4: Upper fixing roller 16: Separation roller

5: Laser/scanner unit 17: Pick-up roller

6: Primary charging roller 18: Transfer charging roller

7: Photosensitive drum 19: Upper cassette

8: Developing cylinder 20: Lower cassette

9: EP-72 cartridge 21: Lower fixing roller

10: Registration roller 22: Duplex deflector

11: Multi-purpose tray pick-up roller 23: Face-up deflector

12: Separation pad

1 - 8

CHAPTER 1

1

2 3 4 5 6 76 8 9

10 11

12 13

22

23

20

19

141516171821

V. INSTALLATION

A. Notes

This printer is packaged and shipped from the factory after careful adjustments and rigorous

inspections.

When installing the printer, it is important to demonstrate its performance in the same way as

when it passes the factory inspection.

The service engineer must sufficiently understand the performance of the printer, install it

correctly in a location with an appropriate environment, and conduct sufficient checks of the

unit.

B. Location Selection

Before taking the printer to the customer's premises, you should confirm the following conditions at the installation location.

1. Power supply

Use the following power supplies:

• Alternating current (AC): -10%, +6% of the rated voltage

• Power frequency: 50/60Hz±2Hz

2. Operating environment

Install in a location that meets the following conditions:

• Level, flat surface

• Temperature, humidity within the following ranges:

Surrounding temperature: 10to 32.5°C

Surrounding humidity: 20 to 80%RH (relative humidity), without condensation

• Cool, well-ventilated space

Do not install in the following locations:

• Exposed to direct sunlight

If you cannot avoid such a location, hang heavy curtains, etc. to shut out the direct sunlight.

• Near magnets and devices that emit a magnetic field.

• Areas with vibration

• Dusty places

• Near fire or water

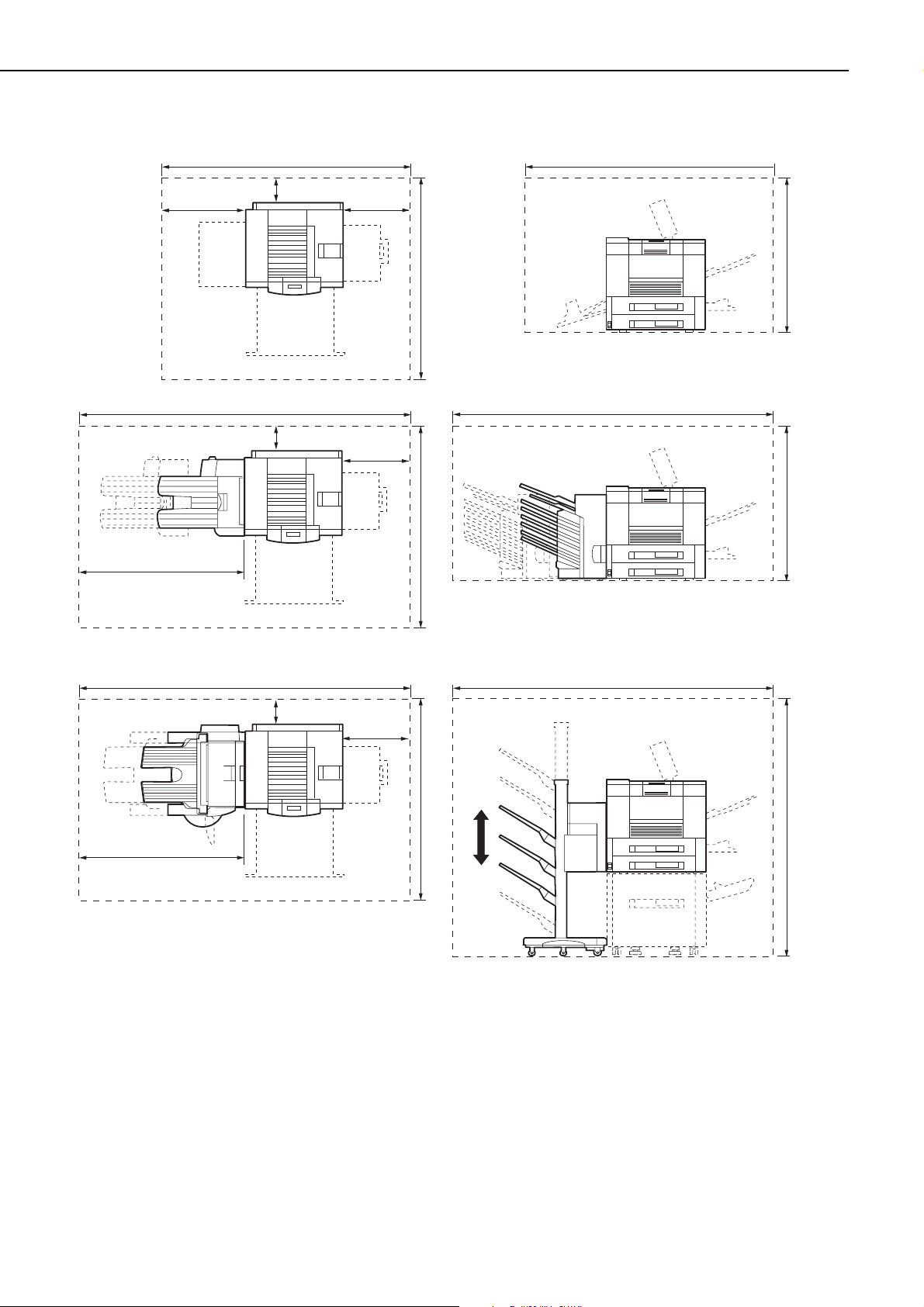

3. Installation space

Install the printer a suitable distance from the wall, leaving enough room to operate it (see Figure

1-5-1).

When installing the printer on a desk, etc., be sure that it is large enough to accommodate

the printer's feet (rubber pads) and sturdy enough to hold its weight.

1 - 9

CHAPTER 1

Figure 1-5-1

1 - 10

CHAPTER 1

900mm

1200mm

2600mm

2300mm

100mm

100mm

2300mm

834mm

900mm

1500mm

2600mm

834mm

900mm1380mm

1500mm1500mm

1200mm

2600mm

2600mm

100mm

834mm

C. Unpacking and Installation

Condensation will form on metal surfaces when brought into a warm room from the cold.

Therefore, when moving the printer to a warm environment, leave it packed in its box for at least

an hour to acclimatize to room temperature.

1. Printer

1) Open the printer packaging.

2) Take out the accessories. Confirm that the power cord, cartridge, and face-up tray are

included.

3) The printer weighs approx. 50kg, therefore 4 people may be needed to lift the printer and to

move to the installation area.

4) Take the plastic bag off the printer and peel the tape off each part. Check that none of the

covers were scratched or deformed during shipment.

5) Open the delivery cover, and remove the pressure release spacer from the fixing unit.

6) Open the upper cover, and remove the tape and the packing materials from inside the print-

er.

7) Pull the two cassettes out of the printer and remove the packaging from the cassette.

2. Cartridge

1) Open the bag holding the cartridge and take out the cartridge.

2) Remove the tape and the black sheet from the cartridge.

3) Hold the cartridge on each side as shown in figure 1-5-2 and slowly rock it 5 to 6 times to

evenly distribute the toner.

4) Place the cartridge on a flat surface. While holding down on the top of the cartridge with one

hand, grasp the tab with the other and gently pull out the sealing tape.

5) Open the upper cover of the printer, and load the cartridge with both hands. Slowly insert it

until it firmly contacts with the back of the slot.

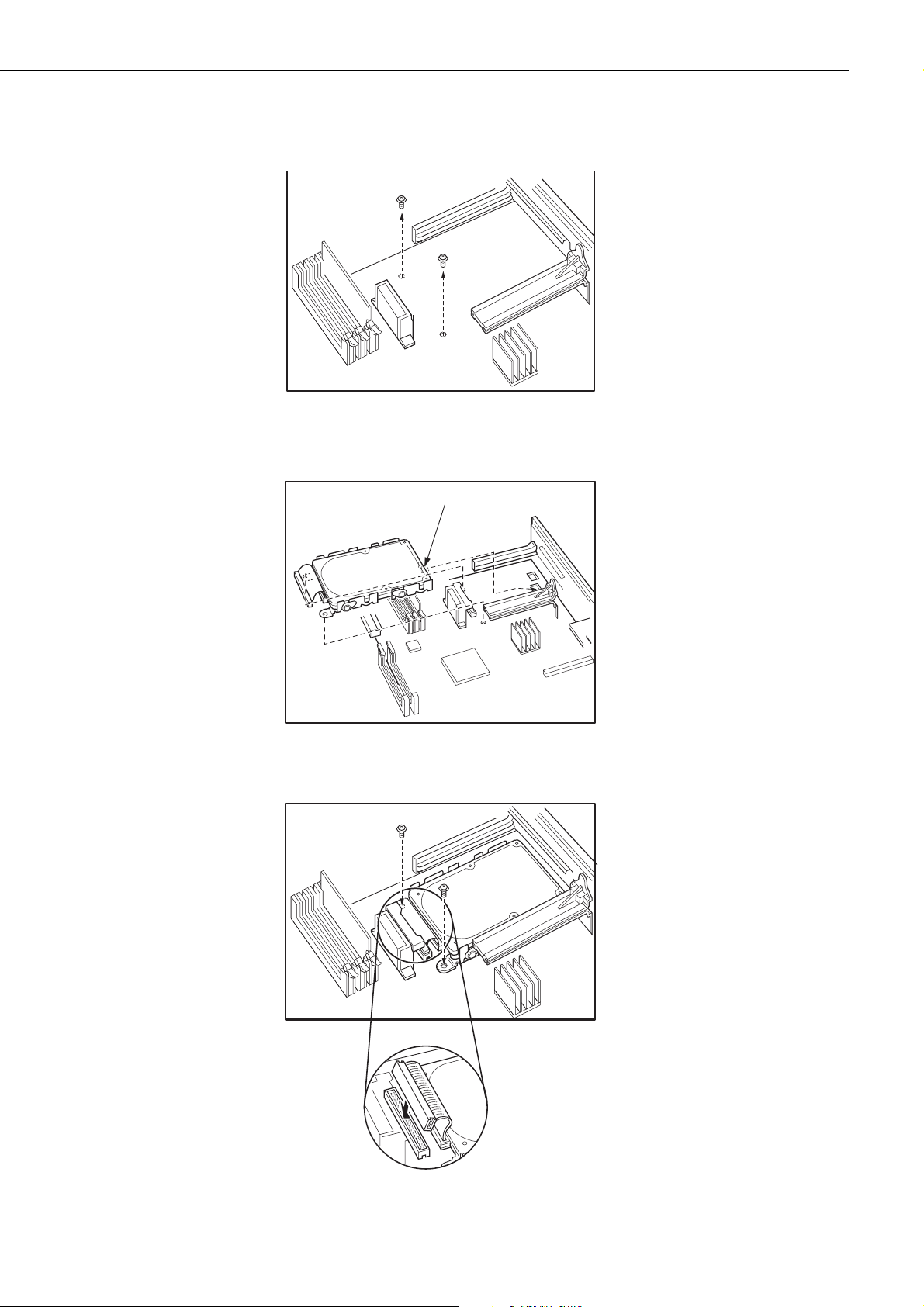

3. Unpacking and installing the hard disk

Note: 1. Before handling the hard disk, be sure to touch the metal part of the printer to dis-

charge electrical static from you body in order to avoid causing damage to the PCB

by the difference in static charge at that time.

2. When removing the PCB at the back of the printer, be sure not to touch the electrical

parts on the PCB. Make sure not to touch especially the electrical elements.

1) Open the hard disk packaging.

2) Remove the pad and then take out the hard disk from its box.

3) Remove the plastic bag holding the hard disk.

4) If the optional expansion board is installed in the printer, remove the board.

5) Loosen the 2 screws at the left back of the printer and pull out the PCB.

1 - 11

CHAPTER 1

6) Remove the 2 screws on the PCB.

Figure 1-5-2

7) Insert the claw of the hard disk into the hole of the PCB.

Figure 1-5-3

8) Fix the hard disk with the enclosed 2 screws and then connect the connector.

Figure 1-5-4

1 - 12

CHAPTER 1

Hook

9) Install the PCB into the printer and fix it with 2 screws.

10) Turn ON the printer switch.

11) Press the On Line key when the printer becomes READY to take the printer off-line.

12) Press the Menu key to select "CONFIG MENU."

13) Press the Item key to select "FORMAT DISK."

14) Press the Enter key.

"+FORMAT DISK -IGNORE DISK" appears in the display.

15) Press the +Plus/-Minus key.

"+REALLY FORMAT -IGNORE DISK" appears in the display.

16) Press the +Plus/-Minus key.

"FORMATTING..." appears in the display, Disk LED lights up and formatting starts.

17) When the printer completes formatting the hard disk, "DISK FMT RESTART" appears in the

display, and the printer restarts automatically.

Figure 1-5-5

1 - 13

CHAPTER 1

Power On

READY

Press On Line key

PAUSED

Press Menu key

CONFIG MENU

Press Item key

CONFIG MENU

FORMAT DISK

Press Enter key

+FORMAT DISK

-IGNORE DISK

Press +Plus/-Minus key

+REALLY FORMAT

-IGNORE DISK

Press +Plus/-Minus key

FORMATTING...

DISK FMT RESTART

4. Operation confirmation

1) Load paper in the lower cassette.

2) Insert the power plug into the outlet and the printer, then turn the power switch ON.

After the printer enters STANDBY mode, press the test print switch to make a test print.

Check that the density of the output image is correct

3) Clean around the printer and ensure that it is ready for use at anytime.

5. Operation precautions

1) Turn ON the power of external equipment then the printer. Turn the power OFF in the

reverse sequence. If the power of external equipment is turned ON/OFF while the printer is

ON, noise may be transmitted through the connection cable between the external equipment

and the printer, and error may occur on the printer.

2) Turn off the power of both the printer and the external equipment before plugging/unplugging the connector between the two. Doing so while the power is ON could cause malfunctions.

1 - 14

CHAPTER 1

D. Storing, Handling the EP-72 Cartridge

Whether the cartridge is still sealed in its box or installed in the printer, the effect of the natural environment will change it over time regardless of the number of prints. As the progression of

this natural change depends on the storage or installation environment, take sufficient care in

storing and handling the cartridges.

1. Before unsealing the box

When the cartridge is stored in a warehouse, workshop, etc., be sure to keep it within the ranges

shown in Table 1-5-1. Note the following points:

1) Avoid locations in direct sunlight.

2) Do not leave in areas exposed to strong vibration.

3) Do not bump or drop.

Table 1-5-1 Storage temperature and humidity conditions

Note: Total storage time is the valid time span following the manufacture date displayed on

the cartridge box.

2. After unsealing the box

As an organic photoconductor (OPC) is used in the photosensitive drum, it will deteriorate if

exposed to strong light. As there is toner in the cartridge, be sure to explain to the customer the

need to be careful in handling and storing unsealed cartridges.

a. Storage environment

1) Be sure to store in the aluminum bag.

2) Avoid locations exposed to direct sunlight, near windows, etc. Do not leave them in cars for

any extended period of time as heat can damage the cartridges.

3) Avoid high, low, and changeable temperature/humidity locations.

4) Avoid sites with corrosive gases (pesticides) or salt in the air.

5) Store the cartridge within a range of 0 to 35°C.

6) Do not leave cartridges near CRT displays, disk drives or floppy disks.

7) Store the cartridges out of reach of children.

1 - 15

CHAPTER 1

Normal (total storage time ×

9/10)

Severe (total storage

time × 1/10)

Temperature

Temperature change (within

3 minutes or so)

Normal (total storage time ×

9/10)

Severe (total storage

time 1/10)

Relative humidity

Air pressure

High

Low –20 to 0°C

High

Low

0to35°C

35 to 40°C

40°C→15°C

–20°C→25°C

35 to 85% RH

85 to 95% RH

10 to 35% RH

345 to 1013 hPa

(460 to 760 mmHg)

b. Effective life

Cartridges are effective for 2.5 years following the date of manufacture, which is displayed in an

abbreviated form on the cartridge. The cartridge life span is also displayed (month and year) on

the cartridge box as 2.5 years from the date of manufacture. Cartridges should be used within

their life spans, as image quality will deteriorate after the expiry date.

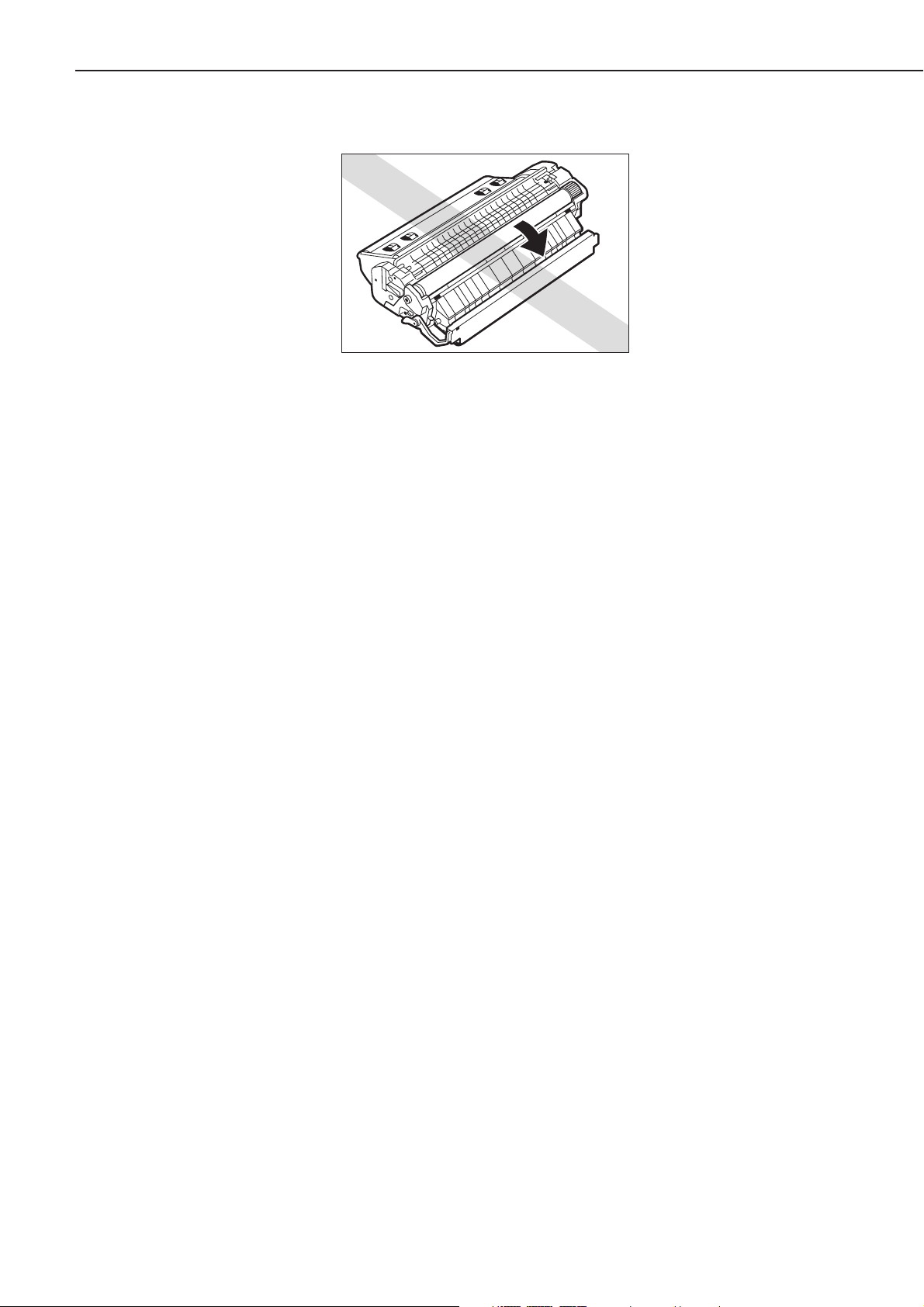

3. Handling

1) When loading a new cartridge into the printer, or when the toner in an already loaded cartridge hardens and blank spots appear on output images, hold the cartridge at each end as

shown in the below figure and slowly rock it about 45° in each direction 5 to 6 times. This

will evenly distribute the toner, and then reload it into the printer. Do not shake the cartridge

in any other way, as toner may leak from the developing cylinder or the cleaning unit.

Figure 1-5-6

To ensure that toner does not leak and dirty the images, be sure to print 3 to 5 pages of test

patterns after loading the cartridge in the printer.

2) When transporting the printer, remove the cartridges.

Either insert the cartridge in the aluminum bag or wrap it in a thick cloth to ensure light

does not penetrate it.

3) Do not leave the cartridge near CRT displays, disk drives, or floppy disks.

The magnetism generated by the cartridge may destroy their data.

4) As the photosensitive drum is sensitive to strong light, do not expose the cartridge to direct

sunlight or strong light (1500 lux or more). If it is exposed to strong light, blank spots or

black lines may appear on images.

Should this happen, temporarily turn OFF the printer. The distorted images such as blank

spots or black lines are likely to disappear. However, if the drum was exposed to strong light

for a long period of time, it is possible the black lines, etc., will remain.

5) Do not open the photosensitive drum protective shield by hand nor touch the drum surface.

Do not clean the drum.

6) Do not place the cartridge on its end or upside down. Always place it with the label side fac-

ing upward.

7) Do not disassemble the cartridge.

1 - 16

CHAPTER 1

Figure 1-5-7

1 - 17

CHAPTER 1

VI. MAINTENANCE AND SERVICING BY THE CUSTOMER

To maintain the optimum performance of the printer, the following maintenance should be performed by the customer.

1. Cartridge

Shake or replace the cartridge as the occasion demands.

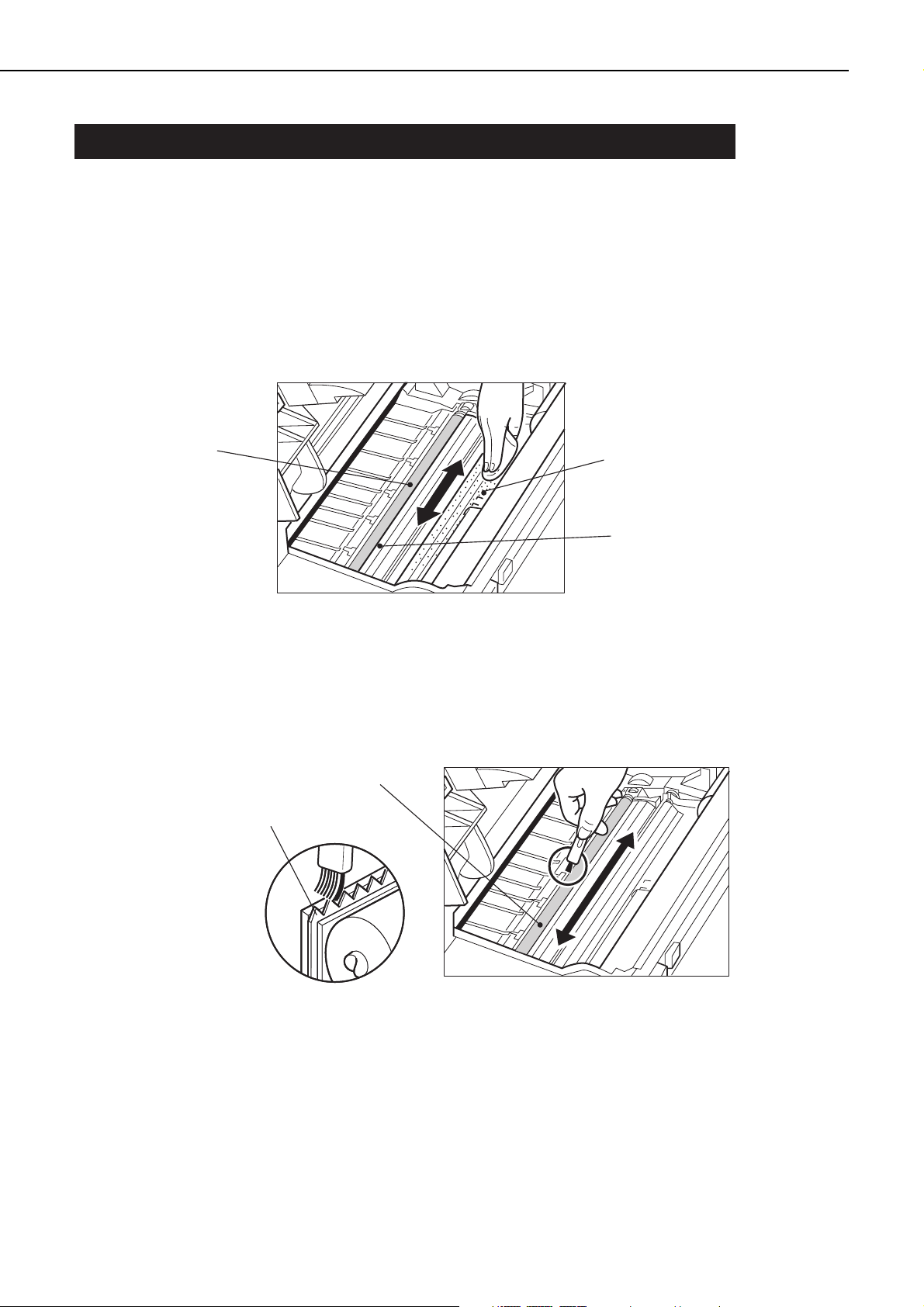

2. Transfer guide, registration guide

When replacing the cartridge, clean the transfer guide and registration guide with soft flannel

cloth.

Figure 1-6-1

3. Static charge eliminator

When replacing the cartridge, clean the static charge eliminator with the cleaning brush

attached inside the printer.

Figure 1-6-2

1 - 18

CHAPTER 1

Transfer chargin

roller

g

Registration guide

(metal part)

Transfer guide

(metal part)

Transfer charging roller

Static charge eliminator

4. Fixing unit

When replacing the cartridge, clean the fixing unit following the procedure below.

1) Open the multi-purpose tray and load one sheet of A4 or Letter size paper into the tray.

2) Press the On Line key to take the printer off-line.

3) Press the Menu key to select "PCL MENU."

4) Press the Item key to select "PAGESIZE."

5) Press the +Plus/-Minus key to select either A4 or Letter, and then press the Enter key.

6) Press the Menu key to select "FEEDER MENU."

7) Press the Item key to select "MPTSIZE."

8) Press the +Plus/-Minus key to select either A4 or Letter, and then press the Enter key.

9) Press the Menu key to select "TEST MENU."

10) Press the Item key to select "CLEANING PAGE" , and then press the Enter key. "LOAD PLAIN

A4 (or LETTER) IN MANUAL" will appear in the display and the Continue LED and Form Feed

LED will light up.

11) Press the Continue key to print the Cleaning Page. "LOAD BLANK SIDE UP IN MANUAL" will

appear and the Continue LED will light up.

Figure 1-6-3

1 - 19

CHAPTER 1

Load this sheet, thisside down, in MPT

Læg dette ark, meddenne side nedad, iuniversalbakke

Laad dit vel metdeze kant naar benedenin MPT

Lattaa tämä arkki, tämäpuoli alaspäin, MPT:hen

Introduire cette page, cecôté vers le bas,dans le tiroir polyvalent

Legen Sie dieses Blattmit dieser Seite nachunten in den MPTein

Caricare questa pagina, conquesta facciata verso ilbasso, nel MDT

Legg i arket meddenne siden ned iden manuelle materen

Coloque esta página, comeste lado para baixo,no MPT

Cargue esta hoja enMPT,conesta cara hacia abajo

Lägg detta ark medtextsidan nedåt på dinMPT

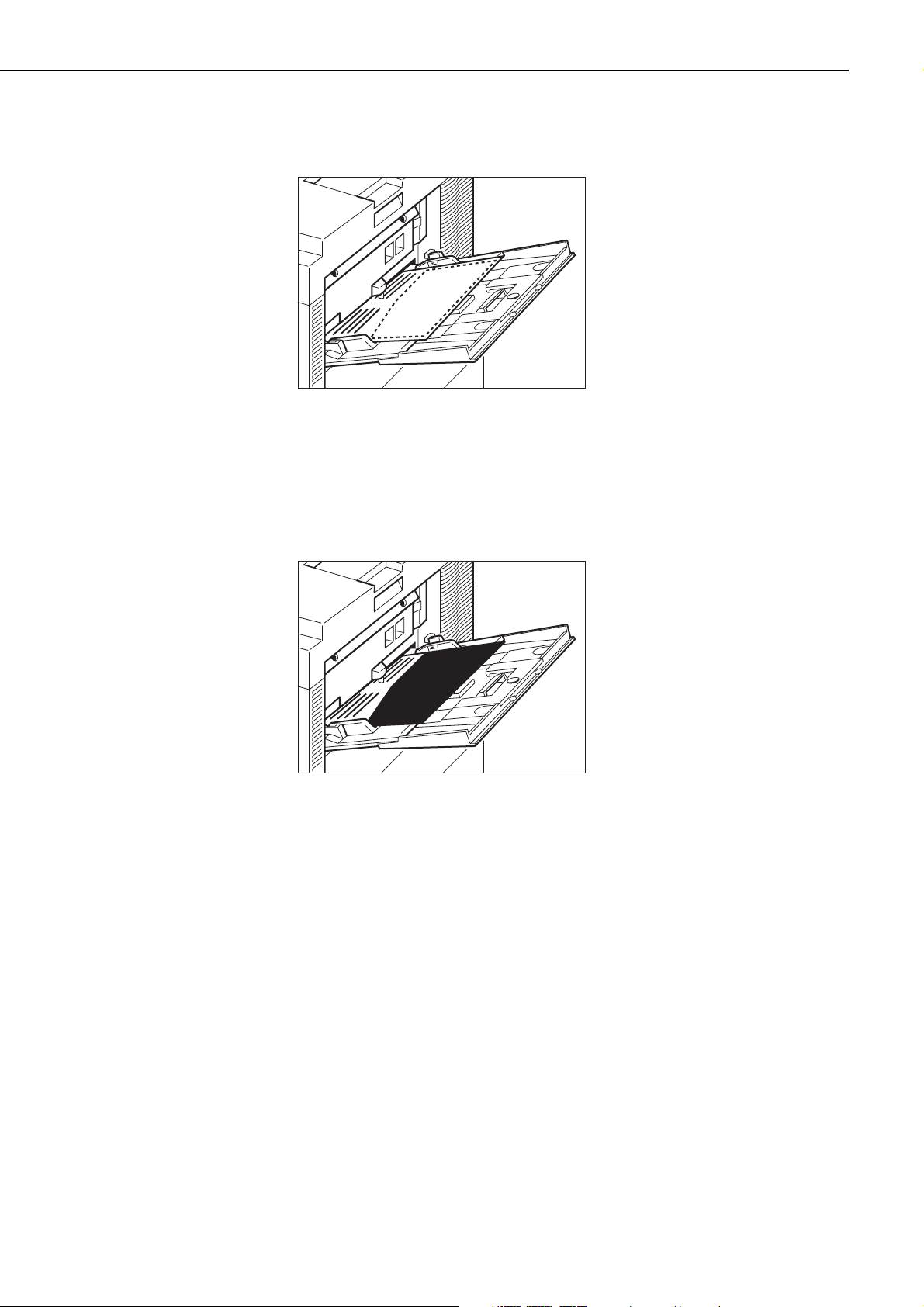

12) Place the printed Cleaning Page into the multi-purpose tray with the printed side face-down.

Figure 1-6-4

13) Press the Continue key to feed the Cleaning Page on the other side of the paper. "LOAD

CLEANING PAGE IN MANUAL" will appear and the Continue LED will light up.

14) Place the Cleaning Page into the multi-purpose tray.

Figure 1-6-5

15) Press the Continue key to feed the Cleaning Page through the printer to clean the fixing unit.

1 - 20

CHAPTER 1

Loading...

Loading...