Canon ipf 8000 User Manual

canon ipf 8000 user manual

File Name: canon ipf 8000 user manual.pdf

Size: 4192 KB

Type: PDF, ePub, eBook

Category: Book

Uploaded: 14 May 2019, 19:54 PM

Rating: 4.6/5 from 823 votes.

Status: AVAILABLE

Last checked: 4 Minutes ago!

In order to read or download canon ipf 8000 user

manual ebook, you need to create a FREE account.

Download Now!

eBook includes PDF, ePub and Kindle version

✔ Register a free 1 month Trial Account.

✔ Download as many books as you like (Personal use)

✔ Cancel the membership at any time if not satisfied.

✔ Join Over 80000 Happy Readers

Book Descriptions:

We have made it easy for you to find a PDF Ebooks without any digging. And by having access to our

ebooks online or by storing it on your computer, you have convenient answers with canon ipf 8000

user manual . To get started finding canon ipf 8000 user manual , you are right to find our website

which has a comprehensive collection of manuals listed.

Our library is the biggest of these that have literally hundreds of thousands of different products

represented.

Home | Contact | DMCA

Book Descriptions:

canon ipf 8000 user manual

Service Manual If an error occurs during printing, the printer status is also displayed on the status

monitor of the printer driver. The following three types of errors are displayed on the display

Warning Status where the print operation can be continued without remedying the cause of the

problem. This can, however, adversely affect the printing results. Error Status where the print

operation is stopped, and the regular operation cannot be recovered until the cause of the problem

is remedied. Service call error When a service call error occurs, the error is not cleared and the

error indication remains on the operation panel even if the printer is powered off and on again.

Occurrence of the service call error is indicated again at poweron. This measure is taken to prevent

users recovery of the service call error and damages to the printer. Service call errors can be

cleared, however, by starting up the printer in the service mode. Download Service Manual for

Canon imagePROGRAF iPF8000 All trademarks and copyrights in the published materials belong to

their respective owners. This page requires Javascript. Modify your browsers settings to allow

Javascript to execute. See your browsers documentation for specific instructions. To install your

download click on the name of the downloaded file.The driver may be included in your OS or you

may not need a driver. Recommended Drivers File Name Date File Size Optional Drivers File Name

Date File Size Recommended Software File Name Date File Size Optional Software File Name Date

File Size Recommended Manuals File Name Date File Size Optional Manuals File Name Date File

Size During the relevant warranty period, Canon shall, in its sole discretion and without charge,

repair or replace any defective part with a new or comparable rebuilt part or replace the Product

with a new or rebuilt Product. Warranty replacement shall not extend the warranty period of the

defective Product.http://farcornerssafaris.com/Uploads/ibm-thinkpad-g40-service-manual.xml

canon ipf 8000 user manual, canon ipf 8000 service manual, canon ipf8000 service

mode, 1.0, canon ipf 8000 user manual, canon ipf 8000 service manual, canon ipf8000

service mode.

This warranty shall not extend to consumables, such as paper, ink cartridges and print heads, as to

which there shall be no warranty or replacement. Canon may attempt to correct the malfunction

remotely, with your assistance. You will be charged at the thencurrent service call rates of Canon or

the Service Provider if the defects in the Product are not covered by this limited warranty, or if the

applicable warranty period for the Product has expired or warranty coverage has not been

sufficiently established by appropriate documentation. During the relevant warranty period, Canon

shall, in its sole discretion and without charge, repair or replace any defective Printhead with a new

or comparable rebuilt Printhead. Warranty replacement shall not extend the warranty period of the

defective Printhead. Scroll down to easily select items to add to your shopping cart for a faster,

easier checkout. Visit the Canon Online Store Ideal for desktop publishing and POS signage.This

media is a great Artist Canvas for fine art and photo applications. In the event of major changes in

the contents of this manual over a long or short period, Canon will issue a new edition of this

manual. Indicates an item requiring care to avoid electric shocks. Indicates an item requiring care to

avoid combustion fire. Indicates an item prohibiting disassembly to avoid electric shocks or

problems. In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric signal. Replace the cutter

unit when it gets dull. F15 1.2.5 Roll holder 00205421 The roller holder accepts paper tubes having

inside diameters of both 2 and 3 inches. It is furnished with attachments for 2 and 3inch diameter

paper tubes. The roll holder clamps the paper tube of a roll not exceeding 150 mm in outside

diameter from the inside. Equipped with casters so that the printer can be easily moved. F110 T12

Stand Stopper.http://assignmentmart.com/tempimg/ibm-thinkpad-g40-user-manual.xml

Taking up begins automatically when a sensor attached to the bottom of the stand detects a roll

delivered after printing falling down due to the weight of a weight roller. Saving print jobs will offer

the following benefits Eased computer workload A print job may be automatically preserved to the

hard disk when printing or may be preserved to the hard disk without printing. There are four types

of tabs on which the relevant printer status, menu, and error information are displayed. The tab

appears as the icon to the top field of display. The tab moves by key or key. F125 2 Remove the front

Basket Rod from the left and right Basket Rods, and remove the back Basket Rod and the black cord

from the Rod Holder.Next, remove the Rod Holder Adapter, leaving the Rod Holder attached, and

put it in front of the printer. F127 4 Pull out the Basket Hooks from the left and right side of the

Ejection Guide. F128 5 Attach the Basket Rod to the Basket Hooks so that the white tag of the

Basket Cloth is on the left side. Roll up the Basket Cloth and put it at the back of the Bottom Stand

Stay. F132 F133 Arrange the Basket Cloth and Basket Rod so they do not interfere with the Media

Takeup Sensor.These include the carriage unit activated by the carriage motor, carriage belt, ink

tube and flexible cable; feed motordriven feed roller and pinch roller; and purge motordriven purge

unit. The ink flows through the ink tank unit, carriage unit, purge unit, maintenancejet tray,

borderless print ink groove, maintenance cartridge and the ink tubes that relay ink to each unit. The

ink mist is collected in the printer by the airflow. However, uncollected ink mist may stain the platen

unit, carriage unit, main rail unit, external unit, or purge unit. These stains may soil the print media

or hands and clothes when servicing the printer, wipe them off carefully with a soft, wellwrung

damp cloth.

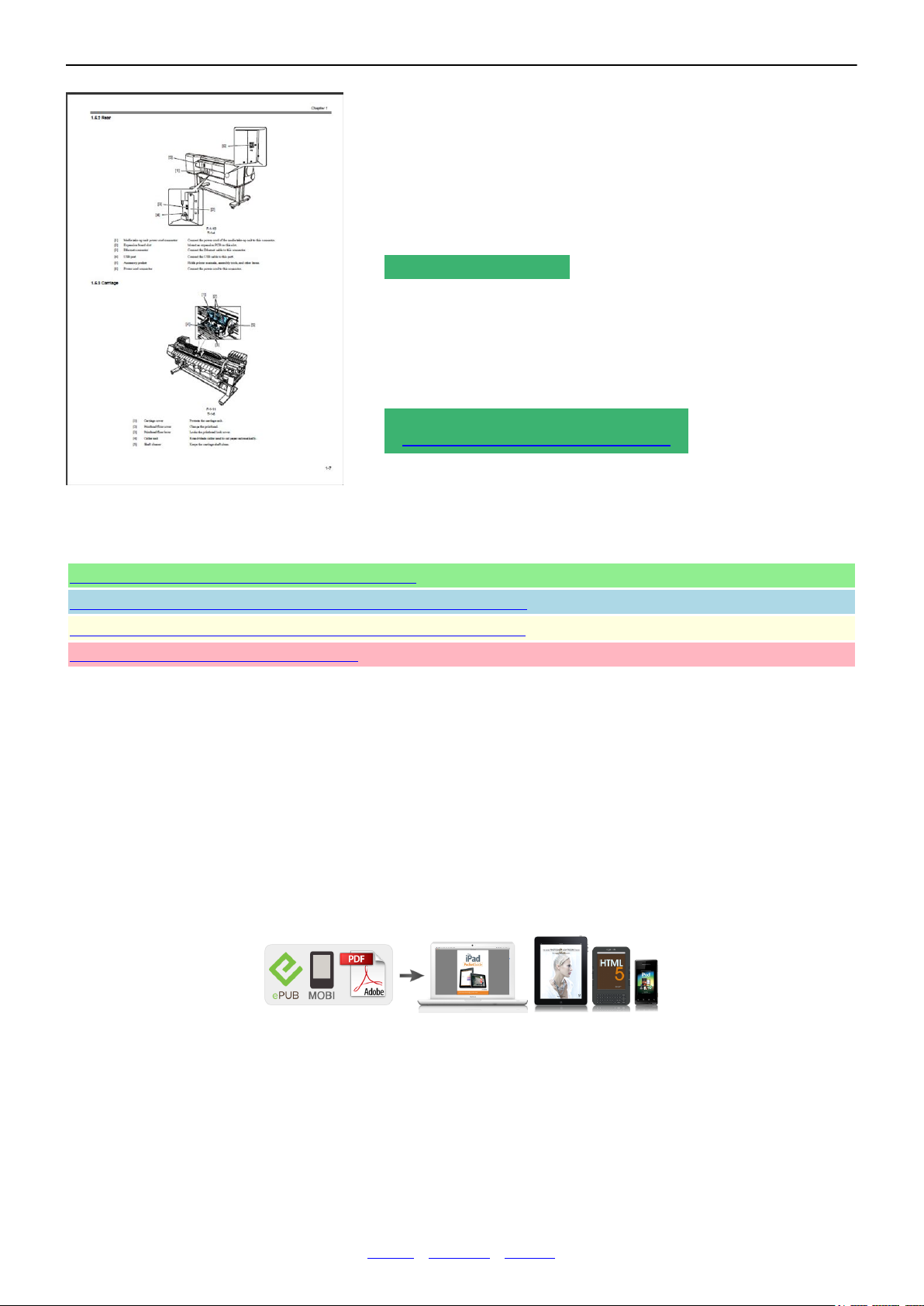

At the rear of the printer are the main controller, power supply, interface connector, and optional

media takeup unit connector. The head relay PCB and carriage relay PCB are incorporated in the

carriage unit, and the operation panel is located on the upper right cover. When installing the ink

tank, be sure to shake it slowly 7 to 8 times before unpacking it. Otherwise, the ink ingredients may

precipitate and degrade the print quality. To prevent foreign matter from entering the ink port,

installed the unpacked ink tank in the printer immediately. Such a charge can damage electrical

devices or change their electrical characteristics.When touching a linear scale and the carriage

shaft, it might cause defective movement of the carriage and a defective print.Image data Host

computer Mask pattern data Heat pulse Printer driver Command data PCI bus Data bus Universal

sirial bus Interface unit. Each printhead has 12 trains of nozzles arranged in a zigzag pattern. This

printer uses two printheads arranged side by side. Evennumbered nozzle data HxxDATAxEV,

oddnumbered nozzle data HxxDATAxOD and the Heat Enable HxxHEx signal are generated for each

nozzle train and controlled individually. If the power cord is disconnected from the wall outlet or the

upper cover or any other cover is opend, the printer cancels the ongoing operation and shuts down

immediately. Print position adjustment work in two modes automatic adjustment, in which print

position adjustment patterns printed are detected by a multi sensor attached to the lower left part of

the carriage, and manual adjustment, in which print position adjustment patterns that are slightly

modified from one another are printed, so that visually verified adjustment values can be set from

the operation panel. It supplies, circulates, sucks and otherwise handles inks. The ink passage per

color is schematically shown below, along with the ink flow.

When an electrode attached to a hollow needle detects no continuity, it displays a message reporting

that the ink tank is nearly empty. If the ink tank runs out of the ink while printing, the ink stored in

the subtank is available, allowing the ink tank to be replaced without having to stop printing.When

the printhead is secured to the carriage, the signal contact of the head relay PCB is pressed against

that of the printhead to convey print signals. Further, the ink passage from the ink tanks is

connected to the printhead via the ink tubes. The multi sensor standard has a white plate attached

Loading...

Loading...