Canon DADF-H1 Service Manual

DADF-H1

REVISION 0

MAR.2001

COPYRIGHT © 2001 CANON INC. 2001 CANON DADF-H1 REV. 0 MAR. 2001 PRINTED IN U.S.A.

FY8-13HA-000

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical

theory, installation, maintenance, and repair of products. This manual covers all

localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to

improvements or changes in products. When changes occur in applicable products or in

the contents of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period,

Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered

trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced or translated into another language, in whole or

in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in U.S.A.

Imprimé au U.S.A.

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT © 2001 CANON INC. 20 CANON DADF-H1 REV. 0 MAR. 2001 PRINTED IN U.S.A.

INTRODUCTION

1 Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution,

or W arning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Indicates an item intended to provide notes assisting the understanding of the

Memo

topic in question.

REF.

COPYRIGHT

©

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Refers to the Copier Basics Series for a better understanding of the contents.

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

i

INTRODUCTION

2 Outline of the Manual

This Service Manual contains basic facts and figures needed to service the DADF-H1 in

the field, and it consists of the following chapters:

Chapter 1 General Description: features, specifications, methods of operation

Chapter 2 Outline of Operation: mechanical systems by function, electrical systems

in reference to principles of operation, timing of operation; construction and outline of electrical circuitry

Chapter 3 Mechanical Systems construction of mechanical systems; disassembly,

assembly, and adjustments

Chapter 4 Maintenance and Inspection:

periodically replacement parts, durables and

consumables; scheduled servicing chart

Chapter 5 Troubleshooting standards, adjustments, troubleshooting tables

Appendix: general timing chart, list of signals/abbreviations,

general circuit diagrams

For installation, refer to the Installation Procedure found in the shipping box; this manual

omits descriptions of the installation work.

ii

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

INTRODUCTION

The descriptions in this Service Manual are based on he following rules:

1. In each chapter, the uses of the function in question and its relationship to electrical and

mechanical systems are discussed and the timing of operation of its associated parts is

explained by means of outlines and diagrams.

In the diagrams, the symbol

represents a mechanical path, while the symbol

with a name next to it indicates the flow of an electric signal.

The expression “turn on the power” means turning on the power switch, closing the

front door, and closing the delivery door so that the machine will be supplied with

power.

2. In circuit diagrams (digital), a signal whose level is High is expressed as being ‘1’,

while a single whose level is Low is expressed as being ‘0’; the level of voltage, however, varies from circuit to circuit.

The machine uses CPUs, whose internal mechanisms cannot be checked in the field,

and, therefore, are not explained. In addition, the machine’s PCBs are not intended for

repairs at the user’s and, therefore, are explained by means of block diagrams: two types

are used, i.e., between sensors and inputs of PCBs equipped with a control or drive

function and between outputs equipped with a control or drive function and loads; in addition, functional block diagrams are used at times.

Changes made to the machine for product improvement are communicated in the form of

a Service Information bulletin as needed. All service persons are expected to go through all

service documentation including the bulletins and be equipped to respond to the needs of

the field (as by being able to identify possible causes of problems).

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

iii

CONTENTS

Contents

CHAPTER 1 GENERAL DESCRIPTION

1 Features...............................................1-1

2 Specifications...................................... 1-2

2.1 Specifications ............................. 1-2

3 Names of Parts .................................... 1-4

3.1 Exterior View ............................. 1-4

3.2 Cross-Sectional Vie w ................. 1-5

CHAPTER 2 OUTLINE OF OPERATION

4 Operation Descriptions ....................... 1-6

4.1 Document Set LED .................... 1-6

4.2 Alarm Indications and Corrective

Action......................................... 1-6

4.3 Daily Customer Checks ............. 1-7

1 Basic Configuration ............................ 2-1

1.1 Electrical Circuit Schematics .... 2-1

1.2 ADF Controller Circuit Board

Input ........................................... 2-2

1.3 ADF Controller Circuit Board

Output ........................................ 2-3

2 Basic Operations ................................. 2-4

2.1 Overview....................................2-4

2.2 Operations .................................. 2-6

2.2.1 Overview.............................. 2-6

2.2.2 Forwarding pickup/delivery

(Single-sided document ->

Single-sided print) ...............2-7

2.2.3 Forwarding pickup/reversal

delivery

(Double-sided document ->

Double-sided print).............. 2 -8

2.2.4 Idle feed/reversal pickup/

reversal delivery (Double-sided

documents of different sizes adhering to different systems ->

Double-sided print)............ 2-10

2.2.5 Idle feed/reversal pickup/delivery (Single-sided documents of

different sizes adhering to different systems -> Single-sided

print) .................................. 2-13

2.3 Document Set Detection .......... 2-15

2.3.1 Overview............................ 2-15

2.3.2 Detecting the presence or

absence of a document in the

document pickup tray ........ 2-17

2.3.3 Detecting whether the document

being fed is the last document

or not.................................. 2-18

2.3.4 Initial document size detection

(feed direction) .................. 2-19

2.3.5 Initial document size detection

(width direction) ................ 2-20

2.3.6 Final document size

detection ............................ 2-23

2.4 Document Pickup/Separation .. 2-26

2.4.1 Basic pickup operation ...... 2-26

2.4.2 Pickup station and stopper . 2-28

2.4.3 Pickup timing chart ........... 2-29

2.4.4 Pickup motor (M2)control. 2-30

2.5 Reversing .................................2-31

2.5.1 Operation ........................... 2-31

2.5.2 Operating sequences..........2-32

2.6 Document Feed/Delivery ......... 2-33

2.6.1 Operation ........................... 2-33

2.6.2 Operating sequence ........... 2-34

2.6.3 Feed motor (M1) control ... 2-35

3 Jams .................................................. 2-36

4 Power Supply.................................... 2-39

iv

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 3 MECHANICAL SYSTEMS

CONTENTS

1 Basic Arrangement.............................. 3-1

1.1 Exterior Covers .......................... 3-1

1.1.1 Removing the ADF.............. 3-1

1.1.2 Detaching the front cover ....3-3

1.1.3 Detaching the rear cover ...... 3-3

1.1.4 Detaching the feeder cover .. 3-4

1.1.5 Removing the feed roller

guide .................................... 3-4

2 Drive Mechanism................................ 3-5

2.1 Pickup Motor ............................. 3-5

2.1.1 Releasing the pickup motor.3-5

2.1.2 Mounting the pickup motor. 3-6

2.2 Feed Motor................................. 3-7

2.2.1 Releasing the feed motor ..... 3-7

2.2.2 Mounting the feed motor..... 3-8

2.2.3 Disassembling the drive

mechanism ........................... 3-9

3 Feed System......................................3-12

3.1 Feeder Cover............................ 3-12

3.1.1 Releasing the pickup roller as-

sembly................................ 3-12

3.1.2 Removing the pickup roller/

separation roller ................. 3-12

3.1.3 Mounting the pickup roller as-

sembly................................ 3-13

3.1.4 Releasing the registration roller,

upper .................................. 3-14

3.2 Feed System............................. 3-15

3.2.1 Removing the separation plate/

separation pad .................... 3-15

3.2.2 Removing the feed station.3-16

3.2.3 Removing the delivery reversal

roller, upper ....................... 3-17

3.2.4 Removing read roller 2...... 3-18

3.2.5 Removing the platen roller 3-19

3.2.6 Removing read roller 1...... 3-20

3.2.7 Removing the registration roller,

lower .................................. 3-21

3.2.8 Adjusting platen guide L ... 3-23

3.2.9 Removing the delivery reversal

roller, lower........................ 3-24

3.2.10 Detaching read roller 2

roller .................................. 3-25

3.2.11 Replacing the separation

guide sheet ......................... 3-26

4 Electrical ........................................... 3-27

4.1 ADF Controller PCB ............... 3-27

4.1.1 Removing the ADF controller

circuit board ....................... 3-27

4.2 Feed Station Sensors................3-27

4.2.1 Removing the sensor

assembly ............................ 3-27

4.2.2 Removing sensors.............. 3-28

4.3 Document Pickup Tray Sensors3-28

4.3.1 Removing the document width

detection variable resistor .. 3-28

4.3.2 Installing the document width

detection variable resistor .. 3-29

4.4 Other Sensors and Solenoids ... 3-30

4.4.1 Removing the ADF open/closed

sensor switch ..................... 3-30

4.4.2 Removing the cover open/

closed sensor......................3-30

4.4.3 Removing the document set

sensor ................................. 3-30

4.4.4 Removing the locking

solenoid.............................. 3-31

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

v

CONTENTS

CHAPTER 4 MAINTENANCE AND INSPECTION

1 Parts Requiring Periodic

Replacement ....................................... 4-1

2 Expendable Parts Durability Table ..... 4 - 1

3 Periodic Service List........................... 4-2

4 Cleaning .............................................. 4-4

4.1 Reader Station Parts ................... 4-4

4.1.1 Document table glass........... 4-4

4.1.2 document table glass retainer4-4

4.2 ADF Parts .................................. 4-4

4.2.1 Platen guide ......................... 4-4

4.2.2 Blank plate (crimp plate) ..... 4-4

4.3 rollers and Guides ...................... 4- 5

4.3.1 Blank paper feed cleaning ... 4-5

4.3.2 Document pickup tray ......... 4-6

4.3.3 Pickup roller, separation

roller .................................... 4-6

4.3.4 Separation pad, separation

plate ..................................... 4-6

4.3.5 Registration roller, upper,

registration roller, lower,

separation guide...................4-7

4.3.6 Delivery reversal roller, upper,

delivery reversal roller,

lower .................................... 4-7

4.3.7 Reversal flapper ................... 4-8

5 Replacement ....................................... 4-9

5.1 Replacing the Feed Roller

Guide (Dust-collecting tape)...... 4-9

5.2 Replacing the Stamp ................ 4-10

6 Adjustment........................................ 4-11

6.1 Adjusting the Height................4-11

CHAPTER 5 TROUBLESHOOTING

1 Specifications and Adjustments .......... 5-1

1.1 Basic Adjustments...................... 5-1

1.1.1 Height adjustment................ 5-1

1.1.2 Squareness adjustment ......... 5-3

1.1.3 Scanning position

adjustment............................ 5-4

1.1.4 Horizontal registration

adjustment............................ 5-6

1.1.5 Scale adjustment.................. 5-9

1.1.6 Trailing registration

adjustment.......................... 5-13

1.2 Making Adjustments Following

Replacement of Key Parts........ 5-17

1.2.1 Overview............................ 5-17

1.2.2 Tray width detection variable

resistor adjustment mode ... 5-17

2 Troubleshooting................................ 5-19

2.1 Corrective Actions by Fault ..... 5-19

2.1.1 E420 lit .............................. 5-19

2.1.2 E421 lit .............................. 5-19

2.1.3 E422 lit .............................. 5-19

2.1.4 Black streaks appearing in a

printed image in the sub

scanning direction.............. 5-19

3 Electrical Parts Layout...................... 5-20

3.1 Sensors ..................................... 5-20

3.2 Motors, clutches, solenoids,

PCB, etc. ..................................5-21

4 LEDs, Check Pins, and Switches

by PCB.............................................. 5-22

4.1 ADF Controller PCB ............... 5-22

4.1.1 Component layout .............5-22

4.1.2 DIP switch function list.....5-23

4.2 Junction PCB ...........................5-26

4.3 Document Set LED PCB .........5-27

5 Self-Testing....................................... 5-28

5.1 Overview.................................. 5-28

5.2 Alarms......................................5-29

5.3 Jams ......................................... 5-29

5.4 Errors ....................................... 5-30

5.5 Host I/O Displays .................... 5-31

vi

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

APPENDIX

CONTENTS

1 General Timing Charts....................... A-1

1.1 Flow-Scanning a Single-sided A4

Document .................................. A-1

1.2 Scanning a Double-sided A4

Document, Face First,

Back Next.................................. A-2

2 Signal Name/Designation List........... A-3

3 General Block Diagram ..................... A-5

4 ADF Controller Block Diagram ........ A-6

5 Document Set Display Block

Diagram ........................................... A-11

6 Junction PCB Block Diagram ......... A-11

7 Jam Code List .................................. A-12

8 Special T ools List............................. A-13

9 Solvent/Grease List.......................... A-13

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

vii

CHAPTER 1

GENERAL DESCRIPTION

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 1 GENERAL DESCRIPTION

1 Features

a. Flow scanning

Scanning is effected by flow scanning in all modes.

b. Document size recognition

The ADF recognizes document sizes in the length direction (feed direction) and in the

width direction and forwards the document size information to the host to which the ADF is

attached.

c.Double-sided document handling

Their reversal feature enables the ADF to handle double-sided documents.

d. Long-document mode

Long-document mode, when specified, allows the ADF to scan documents up to 630 mm

long.

e.Mixed loading of different sizes of documents adhering to different systems

The ADF supports mixed loading of documents of two different sizes.

* Mixed loading of documents of different sizes adhering to the AB and inch system is not

permitted.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

1-1

CHAPTER 1 GENERAL DESCRIPTION

2 Specifications

2.1 Specifications

Item

Document pickup

method

Document set direction

Document set position

Document separation

method

Document type

Document size

Document tray loading

capacity

Document delivery station loading capacity

Document processing

mode

Document size recognition

Leftover document recognition

Mixed document loading feature

Book document

Specifications

Automatic pickup/delivery method

Document tray pickup: Face-up loading

Document tray pickup: Center standard

Top separation

Single-sided sheet document:

AB system 38 to 128 g/m

Inch system 50 to 128 g/m

Double-sided sheet document: 50 to 128 g/m

AB system

Inch system STMT/LTR/LTRR/LGL/11"x 17"

Document width: 148 (A5R) to 297 (A3) mm /

5.83 (A5R) to 11.69 (A3) in

Document length: 128 (STMT) to 432 (11" x

17") mm / 5.04 (STMT) to 17.01 (11 x 17) in

50 sheets

50 sheets

Single-sided and double-sided document handling

Yes (Standard sizes only)

Available in conjunction with the host

Mixed loading of documents of different sizes

adhering to the same system

Mixed loading of documents of different sizes

adhering to different systems

• Mixes of document sizes adhering to different

systems available for loading

AB system A3/B4 A4/B5 B4/A4R B5/A5

Handled (documents up to 50 mm / 1.97 in in

thickness only)

B6/A5/B5/A4/A5R/A4R/B4/A3

2

2

Remarks

60 to 90 g/m2 for documents longer than 432

mm / 17.01 in

2

Single-sided documents up

to 630 mm / 24.80 in long

available for scanning in

long-document mode

With paper weighing 80

g/m2 or lighter

With paper weighing 80

g/m2 or lighter

With paper weighing 80

g/m2 or lighter

With paper weighing 80

g/m2 or lighter

1-2

COPYRIGHT

©

T01-201-01

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 1 GENERAL DESCRIPTION

Item

Communication with the

host

Input power requirement

Mass

Physical dimensions

Unit addresses

Operating environment

Temperature range

Humidity range

Specifications and other information are subject to change without notice.

Specifications

IPC Communication 2.1

DC24VSupplied from the host to which the

ADF is attached.

Approx. 14 kg / 30.8 lb

565 (width) x 538 (depth) x 124 (height) mm /

22.24 (width) x 21.18 (depth) x 4.88 (height) in

A-system: XDDxxxxx

Inch/A-system: XDCxxxxx

AB system: XDBxxxxx

Inch/AB system: XDExxxxx

Conforming to the host.

Conforming to the host.

T01-201-02

Remarks

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

1-3

CHAPTER 1 GENERAL DESCRIPTION

3 Names of Parts

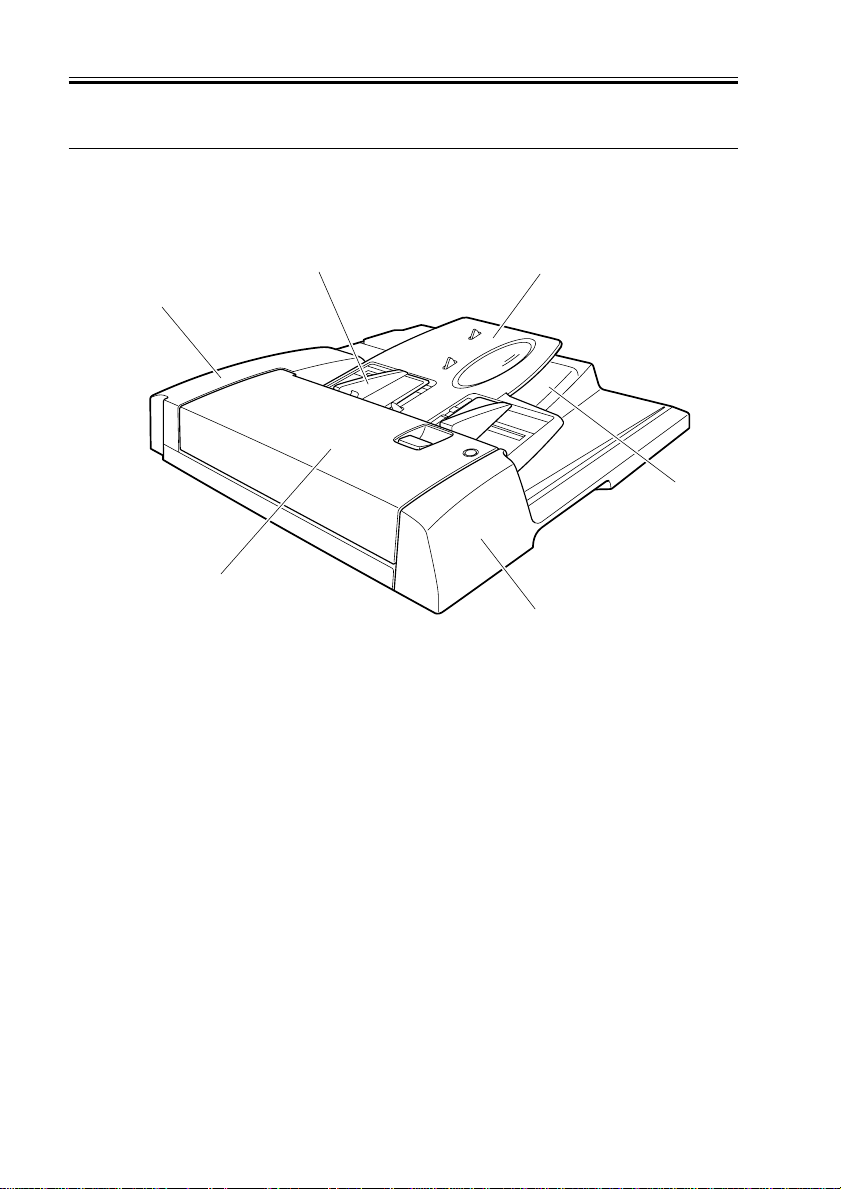

3.1 Exterior View

[2]

[1]

[1] Feeder cover

[2] Rear co ver

[3] Slide guide

[3]

[4]

[6]

[5]

F01-301-01

[4] Document pickup tray

[5] Front cover

[6] Document delivery station

1-4

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

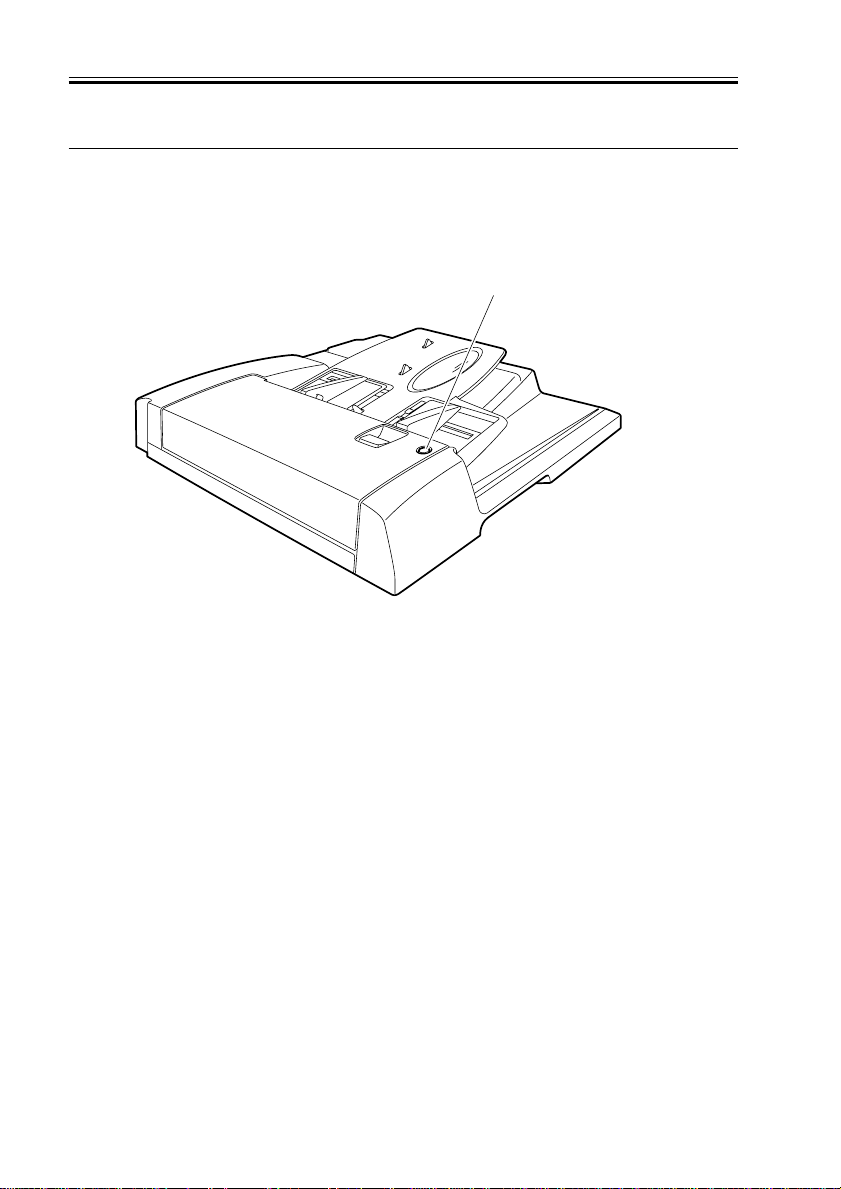

3.2 Cross-Sectional View

CHAPTER 1 GENERAL DESCRIPTION

[1] [2] [3]

[11]

[12][13][14]

[4]

[10]

[5] [6]

[9]

[1] Registration roller, lower

[2] Registration roller, upper

[3] Separation roller

[4] Separation pad

[5] Separation plate

[6] Pickup roller

[7] Document pickup tray

[7]

[8]

F01-302-01

[8] Delivery reversal roller, upper

[9] Delivery reversal roller, lower

[10] Read roller 2 roller

[11] Read roller 2

[12] Platen roller

[13] Read roller 1 roller

[14] Read roller 1

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

1-5

CHAPTER 1 GENERAL DESCRIPTION

4.Operation Descriptions

4.1 Document Set LED

The Document Set LED lights when a document is set in the document tray and flashes

when a document jams.

Document Set LED

F01-401-01

4.2 Alarm Indications and Corrective Action

If the Document LED flashes while feeding a document, the document may have jammed.

Take corrective action as follows:

1) Remove the entire document from the document tray.

2) Opening the feeder cover, remove any jammed document.

3) Set the document in the ADF again after aligning it, from the first sheet afterwards.

1-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 1 GENERAL DESCRIPTION

4.3 Daily Customer Checks

Instruct the user to clean the following points at least once each month:

Cleaning point

Rollers

Platen roller

Blank plate (crimp plate)

Document table glass

Document table glass retainer

Cleaning method

After wiping with a cloth

saturated with water, then

wrung tight or moistened

with alcohol, wipe dry.

T01-403-01

Perform cleaning in the following sequence:

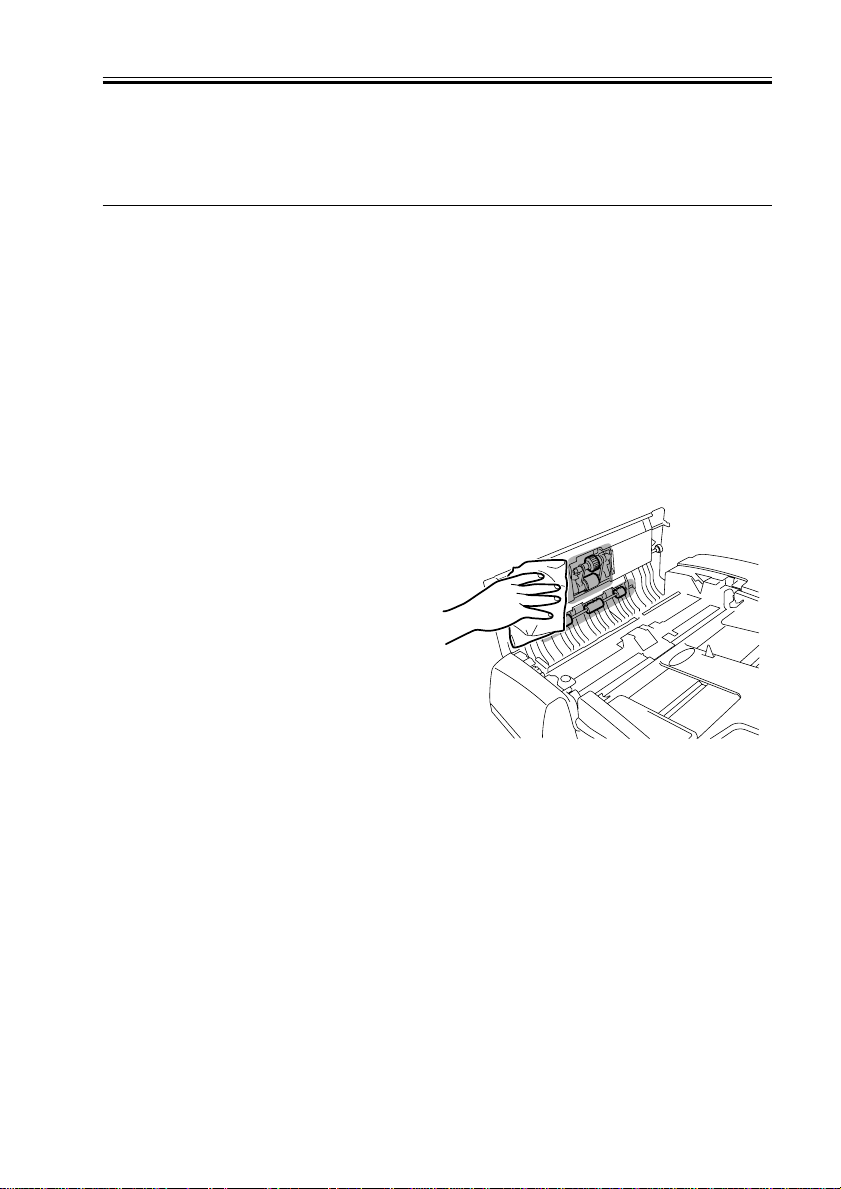

1) Opening the feeder cover, clean the

rollers (5) under the feeder cover with a

cloth saturated with water, then wrung

tight while turning them and then wipe

dry with a soft, dry cloth.

Clean the areas surrounding the rollers

likewise.

Remarks

• Reader station part

• Reader station part

COPYRIGHT

©

F01-403-01

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

1-7

CHAPTER 1 GENERAL DESCRIPTION

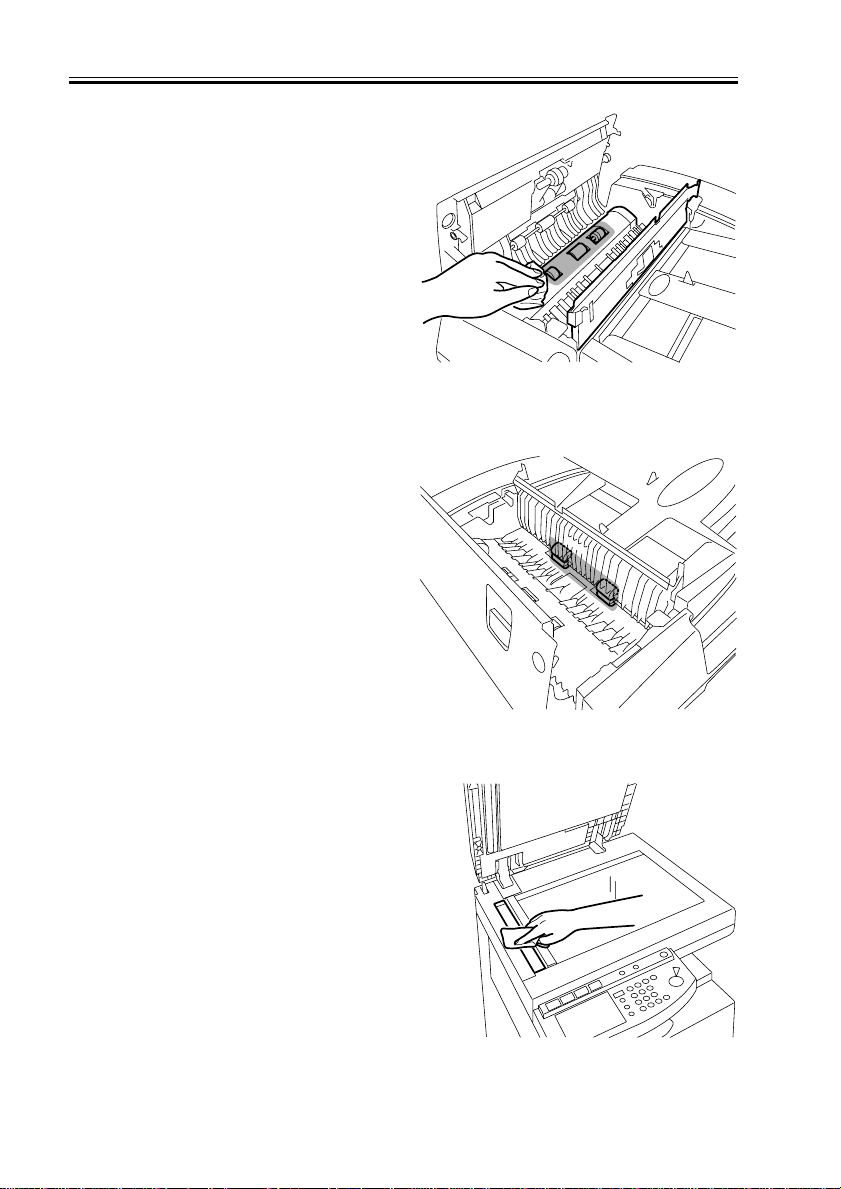

2) Opening the separation guide, clean

rollers (3) with a cloth saturated with

water, then wrung tight while turning

them and then wipe dry with a soft, dry

cloth.

Clean the areas surrounding the rollers

likewise.

3) Turning rollers (4) with knob, clean

them with a cloth saturated with water,

then wrung tight while turning them

and then wipe dry with a soft, dry cloth.

F01-403-02

4) With the separation guide and the feeder

cover closed, open the ADF. Clean the

document table glass with a cloth saturated with water, then wrung tight while

turning them and then wipe dry with a

soft, dry cloth.

1-8

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

F01-403-03

F01-403-04

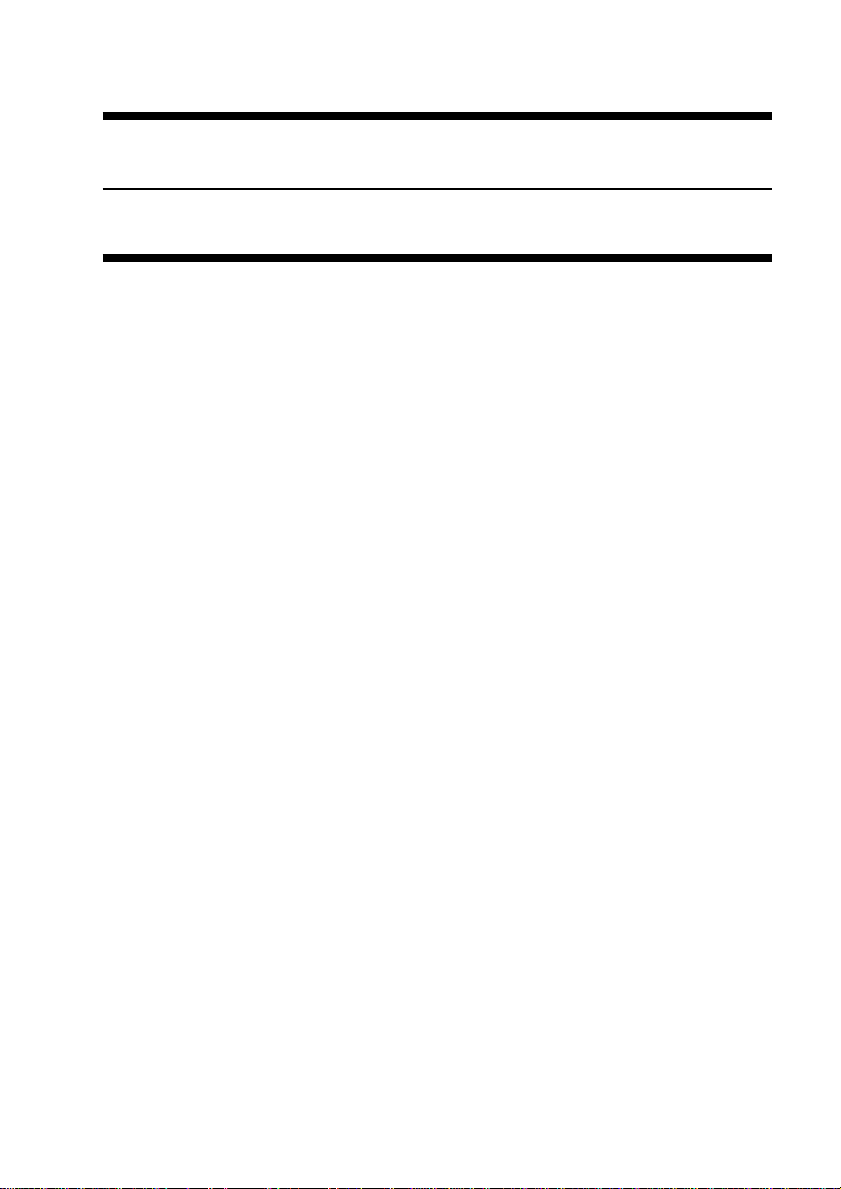

5) Clean the platen roller with a cloth saturated with water, then wrung tight while

turning them and then wipe dry with a

soft, dry cloth.

Clean the sheets surrounding the rollers

likewise.

When the cleaning is completed, close

the ADF .

CHAPTER 1 GENERAL DESCRIPTION

F01-403-05

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

1-9

CHAPTER 1 GENERAL DESCRIPTION

1-10

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 2

OUTLINE OF OPERATION

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 2 OUTLINE OF OPERATION

1 Basic Configuration

1.1 Electrical Circuit Schematics

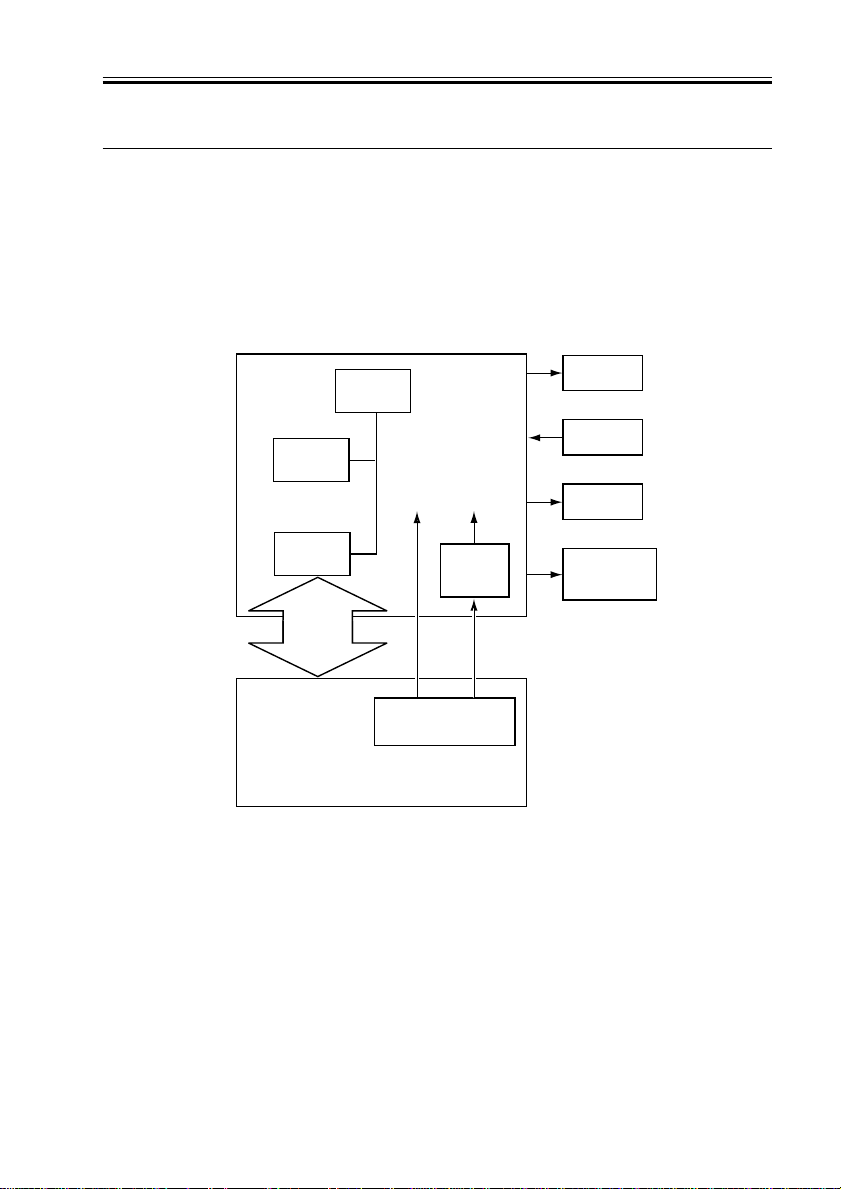

This ADF is electrically controlled by the ADF controller PCB. A CPU (IC1) mounted

on the ADF controller PCB decodes signals input signals from sensors and other sources

and signals from the host and generates signals at predetermined timings for driving DC

loads, such as motors and solenoids.

ADF Controller PCB

EEPROM

(IC5)

IPC

(IC2)

IPC

Communication

2.1

Host Machine

CPU

(IC1)

+24V

F02-101-01

+5V

DC5V

power

(IC4)

J2-2

Power

Supply PCB

Motor

Sensor

Solenoid

Document

Set LED

J1-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

2-1

CHAPTER 2 OUTLINE OF OPERATION

1.2 ADF Controller PCB Input

ADF controller PCB input (1/1)

ADF

open/close

sensor

AR4/LTRR

identification

sensor

Tray

sensor 1

Tray

sensor 2

End-ofdocument

sensor

Document

width

detection

variable

resistor

Registration

roller paper

sensor

Read

sensor

Delivery

reversal

sensor

Cover

open/close

sensor

Document

set sensor

PI1

PI2

PI3

PI4

PI5

VR1

PI6

PI7

PI8

PI9

PI10

J301

-3

-1

-2

J305

-3

-2

-1

J306

-3

-1

-2

J307

-3

-1

-2

J308

-3

-2

-1

J302

-3

-1

-2

J303

-3

-1

-2

J304

-3

-1

-2

J309

-3

-1

-2

J310

-3

-1

-2

J102

J102

J102

J102

-10

-12

-11

J102

-13

-14

-15

+5V

ADF controller PCB

J3

-1

-3

-2

+5V

+5V

+5V

+5V

+5V

-1

-2

-3

-4

-5

-6

-7

-8

-9

?????

J13

-1

-2

-3

-4

-5

-6

-7

-8

-9

-1

-2

-3

-4

-6

-5

-7

-9

-8

J101

-1

-2

-3

-4

-5

-6

-7

-10

-12

-11

J5

-1

-2

-3

J6

-1

-2

-3

-4

J3

-4

-6

-5

J3

-7

-9

-8

J3

J4

-4

-6

-5

J4

-1

-3

-2

Set to 1 when the

ADFOP

+5V

Set to 1 when the paper loaded is AR4

A4R/LTR

Set to 0 when the paper loaded is LTRR

Set to 1 when paper is present

LENG1S

Set to 1 when paper is present

LENG2S

ENDS

Set to 1 when paper is present

VR

Detects the document width

(analog information)

For more details. see Section 2-19.

+5V

Set to 0 when paper is present

REGS

+5V

Set to 1 when paper is present

READS

+5V

Set to 1 when paper is present

EJTS

+5V

Set to 1 when the cover opens

COVERS

+5V

Set to 1 when paper is present

EMPS

ADF

opens

2-2

COPYRIGHT

©

F02-102-01

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

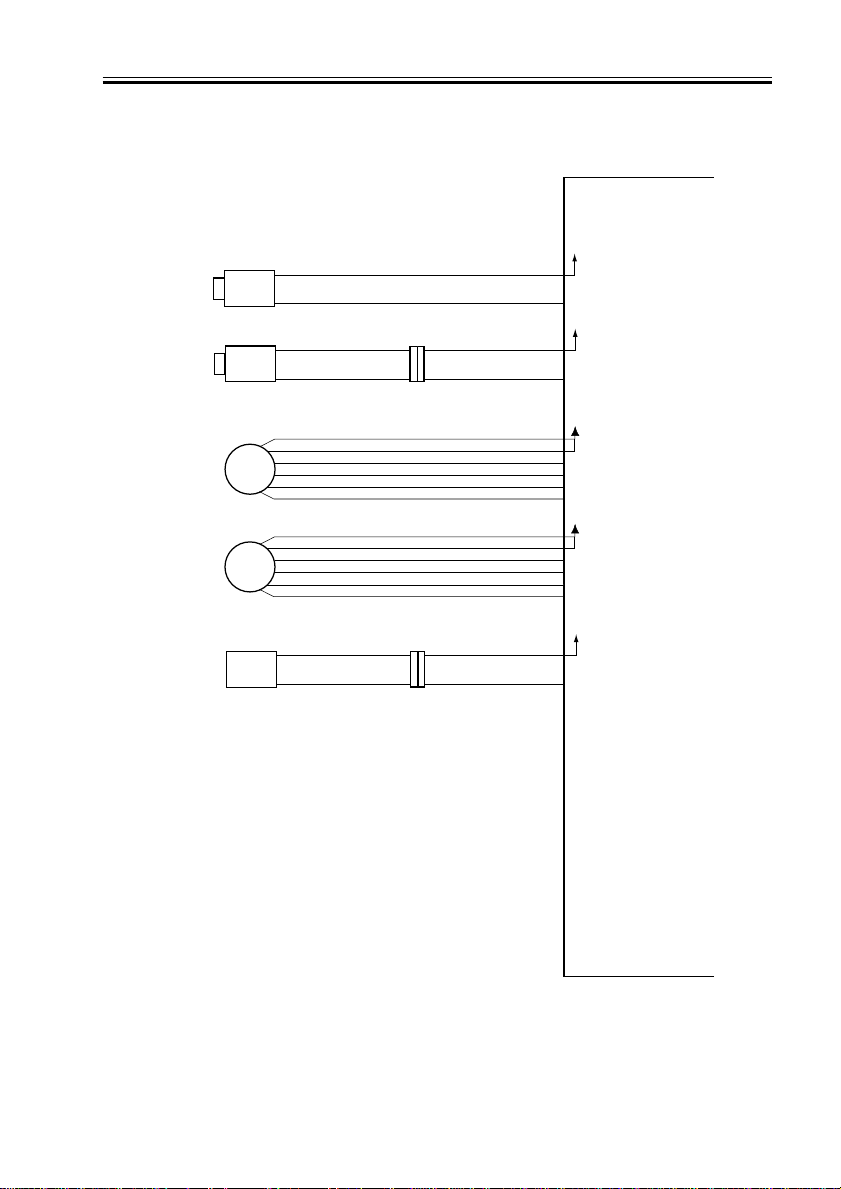

1.3 ADF Controller PCB Output

ADF controller PCB output (1/1)

Locking

solenoid

Stamp

solenoid

Pickup

motor

Feed

motor

Document

Set LED

SL1

SL2

M2

M1

LED

-2

-1

-2

J14

J201

-1-2-1

CHAPTER 2 OUTLINE OF OPERATION

ADF controller PCB

+24V

J10

-1

-2

A_SL SL1 turns on when 0

+24V

J11

-1

-2

STAMP_SL

SL2 turns on when 0

J8

+24V

-1

-2

-3

M2A

-4

-5

-6

J7

-1

-2

-3

-4

-5

-6

-1

-2

J11

-3

-4

For more details,

M2A*

see 2-30

M2B

M2B*

+24V

M1A

For more details,

M1A*

see 2-35

M1B

M1B*

+24V

LED

LED turns on when 0

COPYRIGHT

©

F02-103-01

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

2-3

CHAPTER 2 OUTLINE OF OPERATION

2.Basic Operations

2.1 Overview

This machine is a flow-scanning document feeder that uses two motors to drive document

pickup and feeding.

Name (Symbol)

Pickup motor (M2)

Feed motor (M1)

Function

Separates and feeds documents.

Feeds documents.

T02-201-01

2-4

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

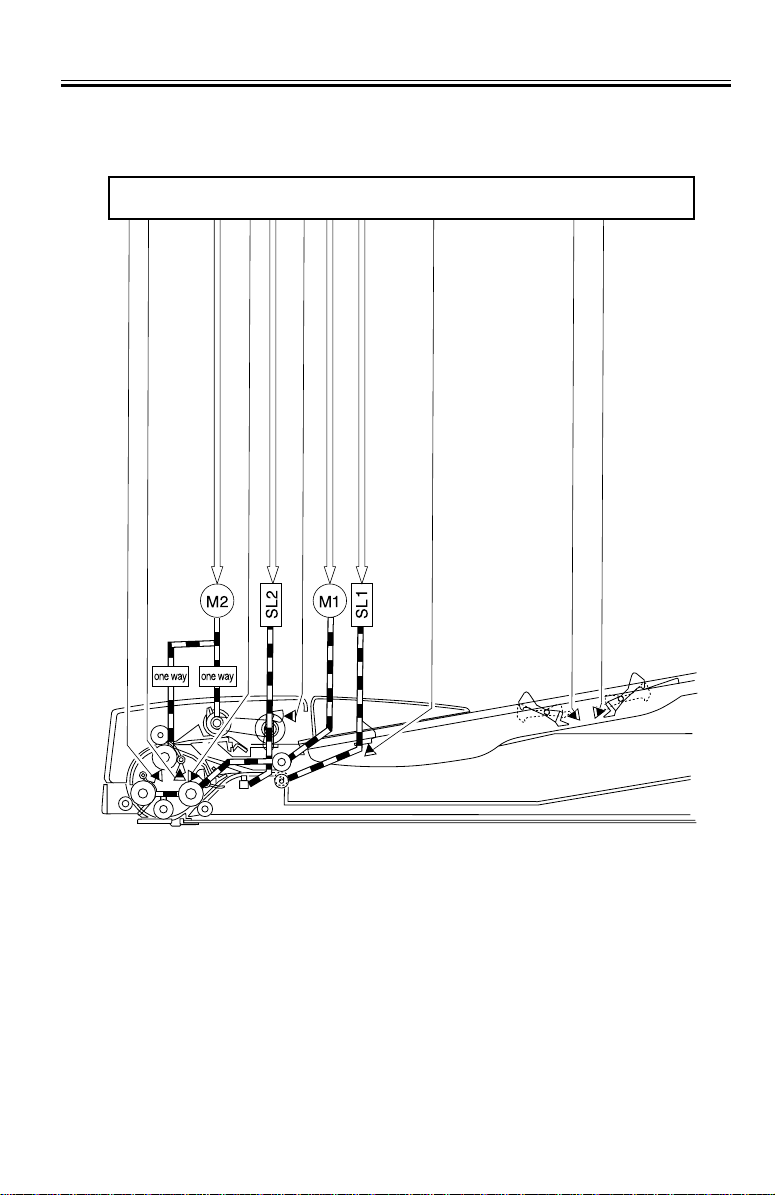

CHAPTER 2 OUTLINE OF OPERATION

A drive block diagram of this ADF is shown below.

ADF controller PCB

Pickup motor drive signal J8

Document detection signal (REGS) J3-6

Document detection signal (READS) J3-9

PI6

PI7

Document detection signal (EJTS) J3-12

PI8

Feed motor drive signal J7

Document set signal (EMPS) J4-3

Locking solenoid drive signal (A-SL) J3-9

Stamp solenoid drive signal (STAMP_SL) J11-2

PI10

F02-201-01

End-of-document detection signal (ENDS) J6-3

PI5

Paper size identification signal 1 (LENG2S) J6-1

Paper size identification signal 2 (LENG2S) J6-2

PI3

PI4

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

2-5

CHAPTER 2 OUTLINE OF OPERATION

2.2 Operations

2.2.1 Overview

This ADF supports four modes of operation as mentioned below. It chooses from among

these operation modes as directed from the host and executes the specified print operation.

The table below lists the names of the operation modes supported by this ADF, along with

summary descriptions of their operations and the associated print modes.

Operation mode name

[1] Forwarding pickup/delivery

[2] Forwarding pickup/reversal delivery

[3] Idle feed/reversal

pickup/reversal delivery

[4] Idle feed/reversal pickup

/delivery

Operation summary

Picks up a document, then delivers it when its scan is completed.

Picks up a document, then delivers it, reversed, when its

scan is completed.

Idle-feeds a document first to

establish its document size,

then to scan it on its surface,

and picks it again for scanning,

followed by reversal and delivery.

Idle-feeds a document to establish its document size, then reverses it for scanning, followed

by delivery.

T02-202-01

The small and large document sizes are as follows:

Associated print modes

Single-sided document

-> Single-sided print

Single-sided document

-> Double-sided print

Double-sided document

-> Double-sided print

Double-sided document

-> Single-sided print

Double-sided documents of different

sizes adhering to different systems

-> Double-sided print

Double-sided documents of different

sizes adhering to different systems

-> Single-sided print

Single-sided documents of different

sizes adhering to different systems

-> Single-sided print

Single-sided documents of different

sizes adhering to different systems

-> Double-sided print

Long document -> Single-sided

print

Small sizes: B6, A5R, A5, A4, B5, L TR, STMT

Large sizes: A4R, B5R, A3,B4,LTRR, LGL, 279.4 X 431.8mm (11" X 17")

T02-202-02

2-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 2 OUTLINE OF OPERATION

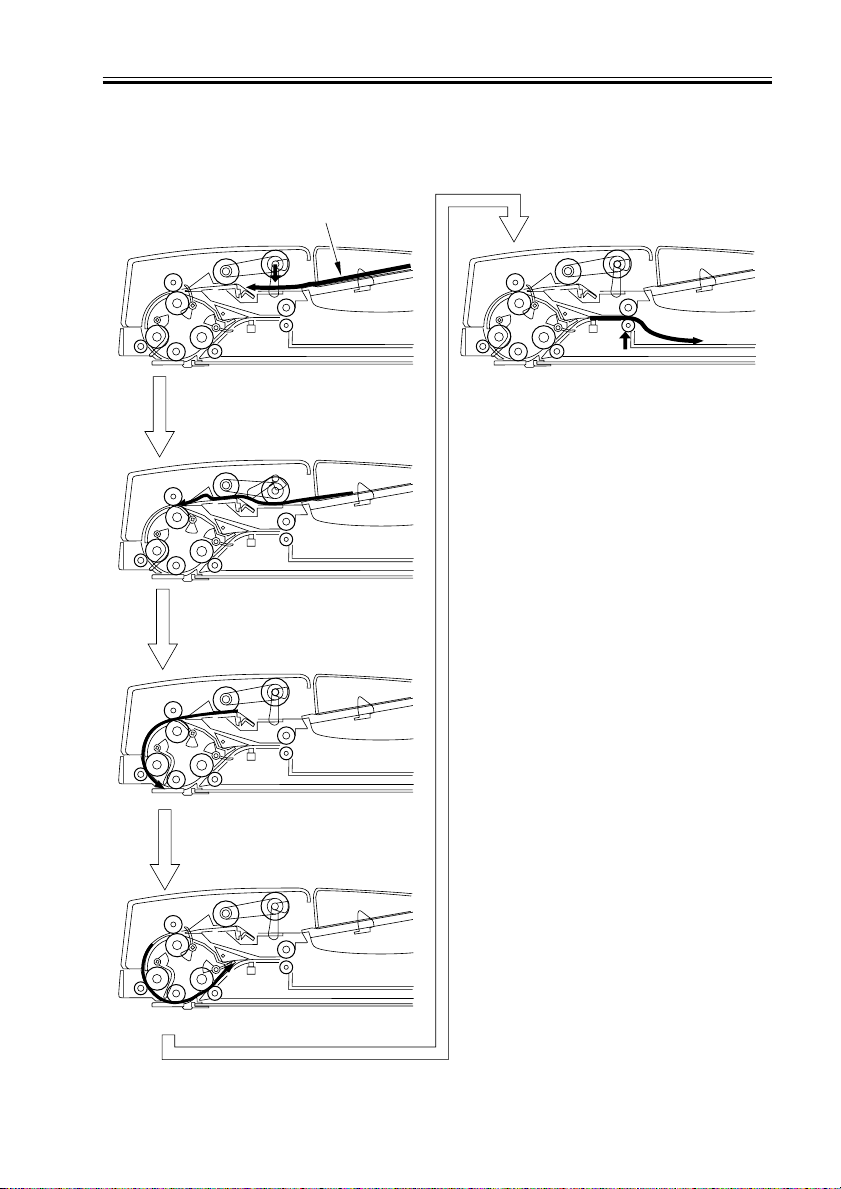

2.2.2 Forwarding pickup/deliv ery

(Single-sided document -> Single-sided print)

The flow of document handling is schematically shown below.

Document

Pickup

Looping

Scanning standby

Delivery

COPYRIGHT

©

Scanning

F02-202-01

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

2-7

CHAPTER 2 OUTLINE OF OPERATION

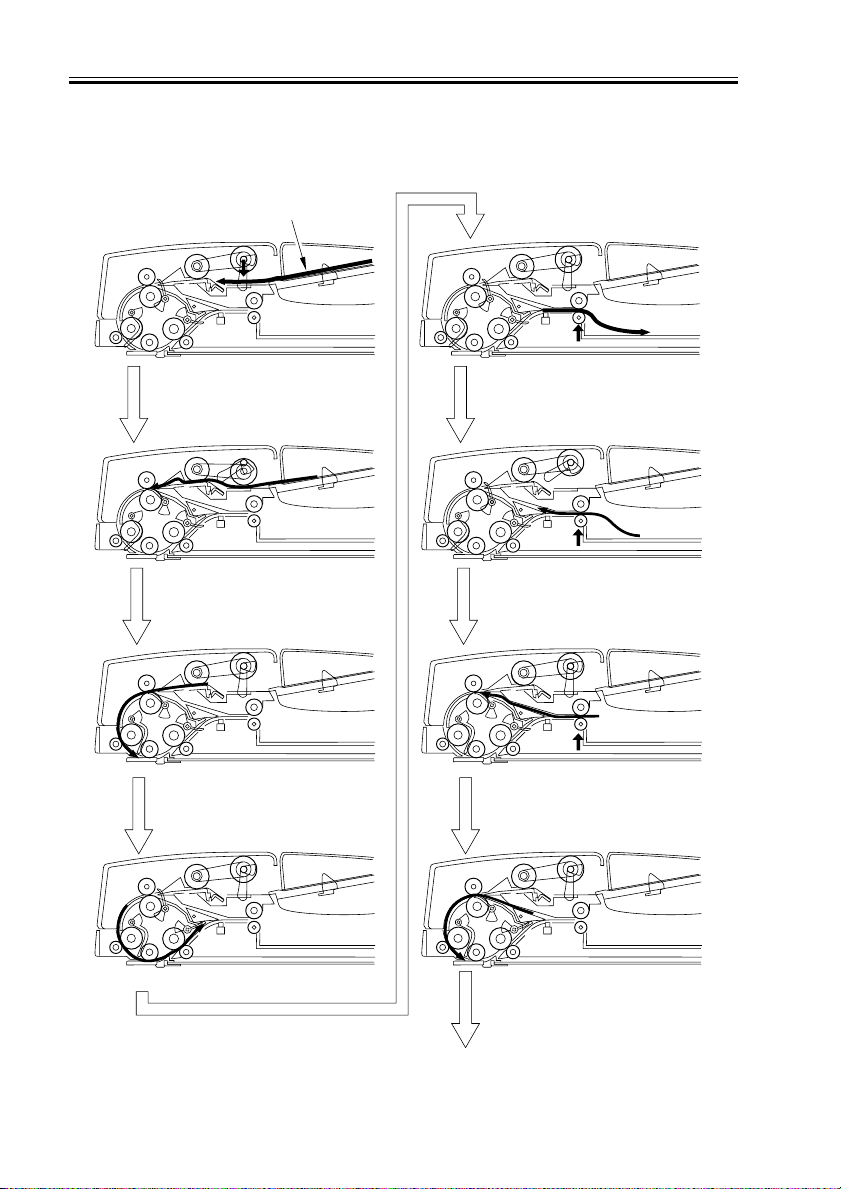

2.2.3 Forwarding pickup/re v ersal deliv ery

(Double-sided document -> Double-sided print)

The flow of document handling is schematically shown below.

Document

Pickup

Looping

Scanning standby

Feed

Reversal

Looping

2-8

Scanning

COPYRIGHT

©

Scanning standby

To next page

F02-202-02a

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

CHAPTER 2 OUTLINE OF OPERATION

Back scanning

Feed

Reversal

Feed

Idle feed

Delivery

COPYRIGHT

©

Feed

F02-202-02b

2001 CANON INC. 2000 2000 2000 2000 CANON DADF-H1 REV.0 MAR. 2001

2-9

Loading...

Loading...