Page 1

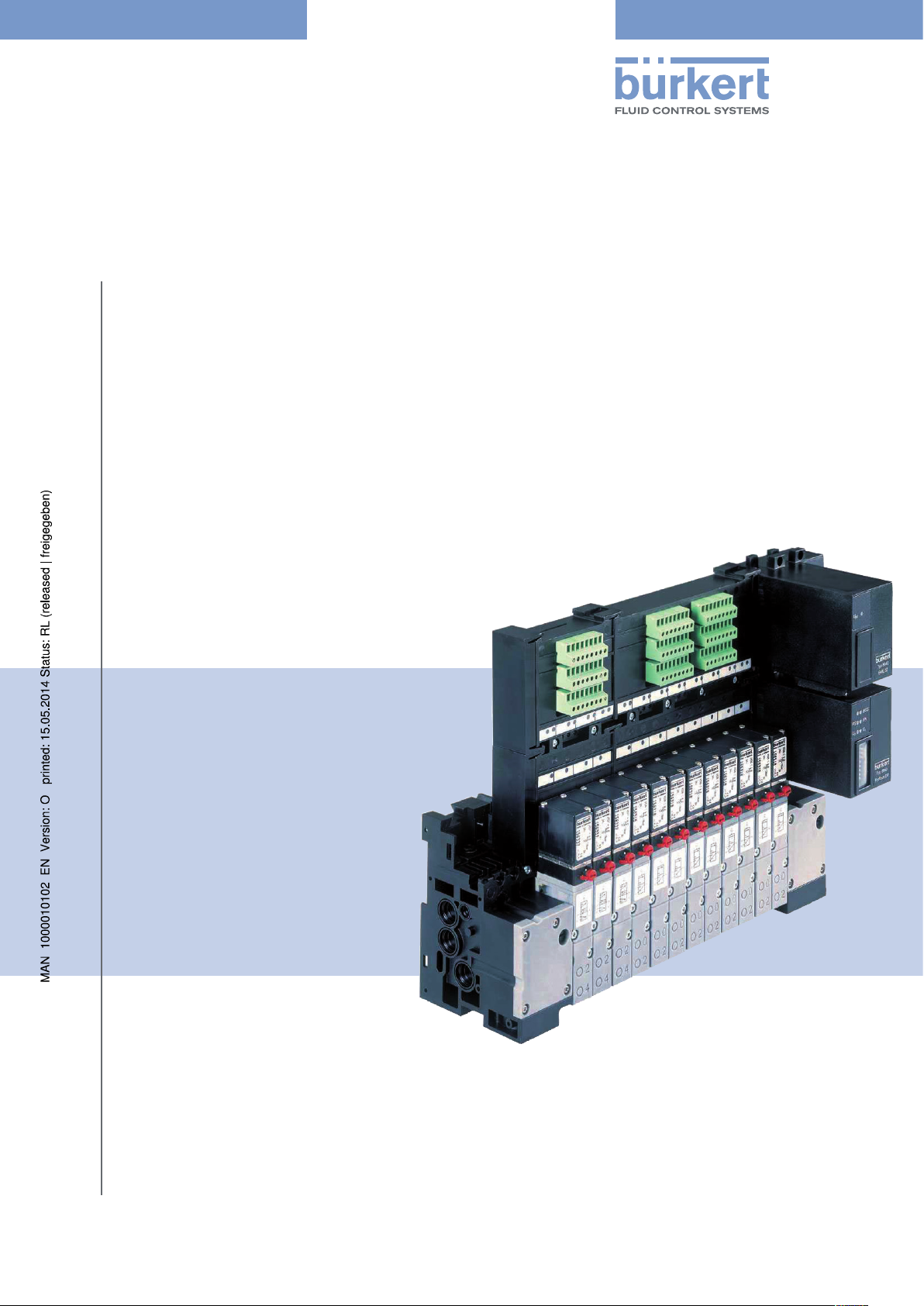

Type 8640

AirLINE

Modular valve terminal

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert Werke GmbH, 2000–2014

Operating Instructions 1405/23_EU-en_00800665 / Original DE

Page 3

Type 8640

Valve terminal type 8640

Table of ConTenTs

1. OPERATING INSTRUCTIONS ........................................................................................................................................................6

1.1. Symbols ......................................................................................................................................................................................6

2. AUTHORIZED USE .............................................................................................................................................................................7

2.1. Restrictions ...............................................................................................................................................................................7

3. BASIC SAFETY INSTRUCTIONS .................................................................................................................................................8

4. GENERAL INFORMATION .............................................................................................................................................................10

4.1. Contact addresses .............................................................................................................................................................10

4.2. Warranty ...................................................................................................................................................................................10

4.3. Information on the Internet ............................................................................................................................................10

5. PRODUCT DESCRIPTION ............................................................................................................................................................11

5.1. Application area ...................................................................................................................................................................11

5.2. General description ...........................................................................................................................................................11

5.3. Structure of the system ...................................................................................................................................................12

6. TECHNICAL DATA .............................................................................................................................................................................13

6.1. Operating conditions ........................................................................................................................................................13

6.2. Conformity ..............................................................................................................................................................................13

6.3. Standards ................................................................................................................................................................................13

6.4. General technical data .....................................................................................................................................................14

7. MODULES FOR CONVENTIONAL ELECTRICAL CONNECTION TECHNOLOGY ............................................15

8. FIELD BUS MODULE PROFIBUS DP/V1 .............................................................................................................................18

8.1. PROFIBUS DP/V1, IP20 - overview ...........................................................................................................................18

8.2. PROFIBUS DP/V1, IP54 - overview ...........................................................................................................................20

8.3. DIP switch (PROFIBUS address) ...............................................................................................................................21

8.4. LED status display ..............................................................................................................................................................22

9. CONFIGURATION AND PARAMETER SETTINGS FOR PROFIBUS DP ................................................................24

9.1. Representation of the PROFIBUS-DP communication process ...............................................................24

9.2. Start-Up ....................................................................................................................................................................................25

9.3. Mode inputs ...........................................................................................................................................................................42

9.4. Input filter ................................................................................................................................................................................43

9.5. Special parameterization functions ..........................................................................................................................43

9.6. Diagnosis .................................................................................................................................................................................44

9.7. Configuration and parameterization errors ..........................................................................................................45

english

3

Page 4

Type 8640

10. BUS MODULE RIO SLAVE (RIO/VA) ......................................................................................................................................46

10.1. Power supply (Power) RIO slave ................................................................................................................................47

10.2. Field bus connection RIO slave ..................................................................................................................................47

10.3. LED Status Display ............................................................................................................................................................48

10.4. DIP switch settings ............................................................................................................................................................49

11. FELDBUS MODULE DEVICENET .............................................................................................................................................52

11.1. DeviceNet, IP20 - overview ............................................................................................................................................52

11.2. DeviceNet, IP54 - overview ............................................................................................................................................54

11.3. Position of the DIP switches .........................................................................................................................................55

11.4. LED status display ..............................................................................................................................................................56

11.5. Applications object ............................................................................................................................................................58

12. CONFIGURATION AND PARAMETER SETTINGS FOR DEVICENET .....................................................................59

12.1. Configuration of process data .....................................................................................................................................59

12.2. Configuration of the safety position of solenoid valves if bus error .......................................................59

12.3. Mode inputs ...........................................................................................................................................................................60

12.4. Input filter ................................................................................................................................................................................61

13. FELDBUS MODULE CANOPEN.................................................................................................................................................62

13.1. CANopen, IP20 - overview .............................................................................................................................................62

13.2. CANopen, IP54 - overview .............................................................................................................................................63

13.3. Position of the DIP switches .........................................................................................................................................65

13.4. LED status display ..............................................................................................................................................................66

14. CONFIGURATION AND PARAMETER SETTINGS FOR CANOPEN .........................................................................68

14.1. Description of the CANopen field bus node ........................................................................................................68

14.2. Object overview ...................................................................................................................................................................68

14.3. Detailed description of the supported objects ...................................................................................................69

14.4. Input filter ................................................................................................................................................................................72

14.5. Mode inputs ...........................................................................................................................................................................72

14.6. Outputs .....................................................................................................................................................................................74

14.7. Example for start-up .........................................................................................................................................................75

15. FIELD BUS MODULES PROFINET IO, ETHERNET/IP AND MODBUS TCP ......................................................77

15.1. PROFINET IO, EtherNet/IP and MODBUS TCP, IP20 - overview ..............................................................77

15.2. LED status display ..............................................................................................................................................................79

15.3. Mode inputs ...........................................................................................................................................................................81

15.4. Input filter ................................................................................................................................................................................82

15.5. Fault Action and Fault Value .........................................................................................................................................83

15.6. Web server ..............................................................................................................................................................................83

16. CONFIGURATION AND PARAMETER SETTINGS FOR PROFINET IO ..................................................................86

16.1. Hardware configuration by GSDML based on the example of Siemens STEP 7 .............................86

4

16.2. Parameter settings for the PROFINET IO slave .................................................................................................89

english

Page 5

Type 8640

17. CONFIGURATION AND PARAMETER SETTINGS FOR ETHERNET/IP ................................................................91

17.1. Addressing .............................................................................................................................................................................91

17.2. EDS file .....................................................................................................................................................................................91

17.3. Object model .........................................................................................................................................................................91

17.4. Configuration of process data .....................................................................................................................................93

17.5. Applications object ............................................................................................................................................................94

18. CONFIGURATION AND PARAMETER SETTINGS FOR MODBUS TCP ................................................................95

18.1. Modbus application protocol ........................................................................................................................................95

18.2. Modbus data model ...........................................................................................................................................................96

18.3. Mapping to TCP/IP .............................................................................................................................................................96

18.4. Connection-oriented structure ....................................................................................................................................96

18.5. 8640 objects ..........................................................................................................................................................................97

19. ELECTRICAL BASE MODULE OUTPUT ................................................................................................................................99

19.1. Collective socket .................................................................................................................................................................99

19.2. Valve outputs ..................................................................................................................................................................... 100

19.3. Valve outputs with manual / automatic switching ........................................................................................ 101

19.4. Valve outputs with external switch-off ................................................................................................................. 103

20. ELECTRICAL BASE MODULE INPUT .................................................................................................................................. 104

20.1. Terminal inputs for repeaters (initiators) ............................................................................................................ 104

20.2. Plug inputs (M8 circular plugs) for repeaters (initiators) ...........................................................................105

21. PNEUMATIC BASE MODULE .................................................................................................................................................. 106

21.1. General description ........................................................................................................................................................106

21.2. Pneumatic base module with integrated P shut-off ..................................................................................... 107

22. VALVES ................................................................................................................................................................................................ 109

22.1. General description ........................................................................................................................................................109

23. INSTALLATION OF AIRLINE QUICK .....................................................................................................................................112

23.1. Safety instructions .......................................................................................................................................................... 112

23.2. Installation on standard rail ........................................................................................................................................ 113

23.3. Installation of AirLINE Quick ......................................................................................................................................113

23.4. Dimensions of the flange images for AirLINE Quick .................................................................................... 115

24. PACKAGING, TRANSPORT ....................................................................................................................................................... 117

25. STORAGE ........................................................................................................................................................................................... 117

26. DISPOSAL ......................................................................................................................................................................................... 117

english

5

Page 6

Type 8640

Operating instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user, and make these instructions available to every new owner of the device.

WARNING!

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous situations.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderate or minor injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips and recommendations.

Refers to information in these operating instructions or in other documentation.

→ designates a procedure which you must carry out.

6

english

Page 7

Type 8640

Authorized use

2. AUTHORIZED USE

Use of the valve terminal type 8640 for purposes other than those for which it is intended may represent a hazard to persons, nearby equipment and the environment.

• Do not use the device outdoors unprotected.

• Use according to the authorized data, service and operating conditions specified in the contract documents

and operating instructions. These are described in the chapter on “Technical data”.

• The device may be used only in conjunction with third-party devices and components recommended and

authorized by Bürkert.

• Correct transportation, storage, and installation, as well as careful use and maintenance are essential for reliable and faultless operation.

• Use the device only as intended.

The pneumatic modular valve terminal type 8640 was developed in compliance with accepted safety regulations and is state-of-the-art. Nevertheless, dangerous situations may occur.

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

english

7

Page 8

Type 8640

Basic safety instructions

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any:

• Contingencies and events which may arise during the installation, operation and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing these regulations, also with reference to the

installation personnel.

Danger – high pressure!

• Before dismounting pneumatic lines and valves, turn off the pressure and vent the lines.

Risk of electric shock!

• Before reaching into the device or the equipment, switch off the power supply and secure to prevent

reactivation!

• Observe applicable accident prevention and safety regulations for electrical equipment!

Risk of burns/risk of fire if used continuously through hot device surface!

• Keep the device away from highly flammable substances and media and do not touch with bare hands.

General Hazardous Situations.

To prevent injuries:

• Do not supply the medium connectors of the system with aggressive or flammable media.

• Do not physically stress the body (e.g. by placing objects on it or standing on it).

• Note that pipes and valves must not become detached in systems which are under pressure.

• Before any work is done on the system, always switch off the power supply.

• Design the pressure supply with the largest possible volume to prevent a pressure drop when the system is

switched on.

• Ensure that the system cannot be activated unintentionally.

• Installation and maintenance work may be carried out only by authorized technicians with the appropriate tools.

• After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a defined

or controlled manner.

• The device may be operated only when in perfect condition and in consideration of the operating instructions.

• The general rules of technology must be observed for application planning and operation of the device.

8

english

Page 9

Type 8640

Basic safety instructions

NOTE!

Prevent a pressure drop!

To prevent a pressure drop, design the system pressure supply with the largest possible volume.

Electrostatic sensitive components/modules!

The device contains electronic components, which react sensitively to electrostatic discharge (ESD). Contact

with electrostatically charged persons or objects is hazardous to these components. In the worst case scenario,

they will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1 and 5-2 to minimize/avoid the possibility of

damage caused by a sudden electrostatic discharge!

• Also, ensure that you do not touch electronic components when the power supply voltage is present!

english

9

Page 10

4. GENERAL INFORMATION

4.1. Contact addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Type 8640

General information

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

4.2. Warranty

The warranty is only valid if the device is used as intended in accordance with the specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Type 8640 can be found on the Internet at:

www.buerkert.com

10

english

Page 11

Type 8640

Product description

5. PRODUCT DESCRIPTION

5.1. Application area

The valve terminal type 8640 is intended for use in an industrial environment. The valves can be combined very easily

and efficiently thanks to the modular design.

DANGER!

Risk of electric shock!

• Before reaching into the device or the equipment, switch off the power supply and secure to prevent

reactivation.

• Observe applicable accident prevention and safety regulations for electrical equipment.

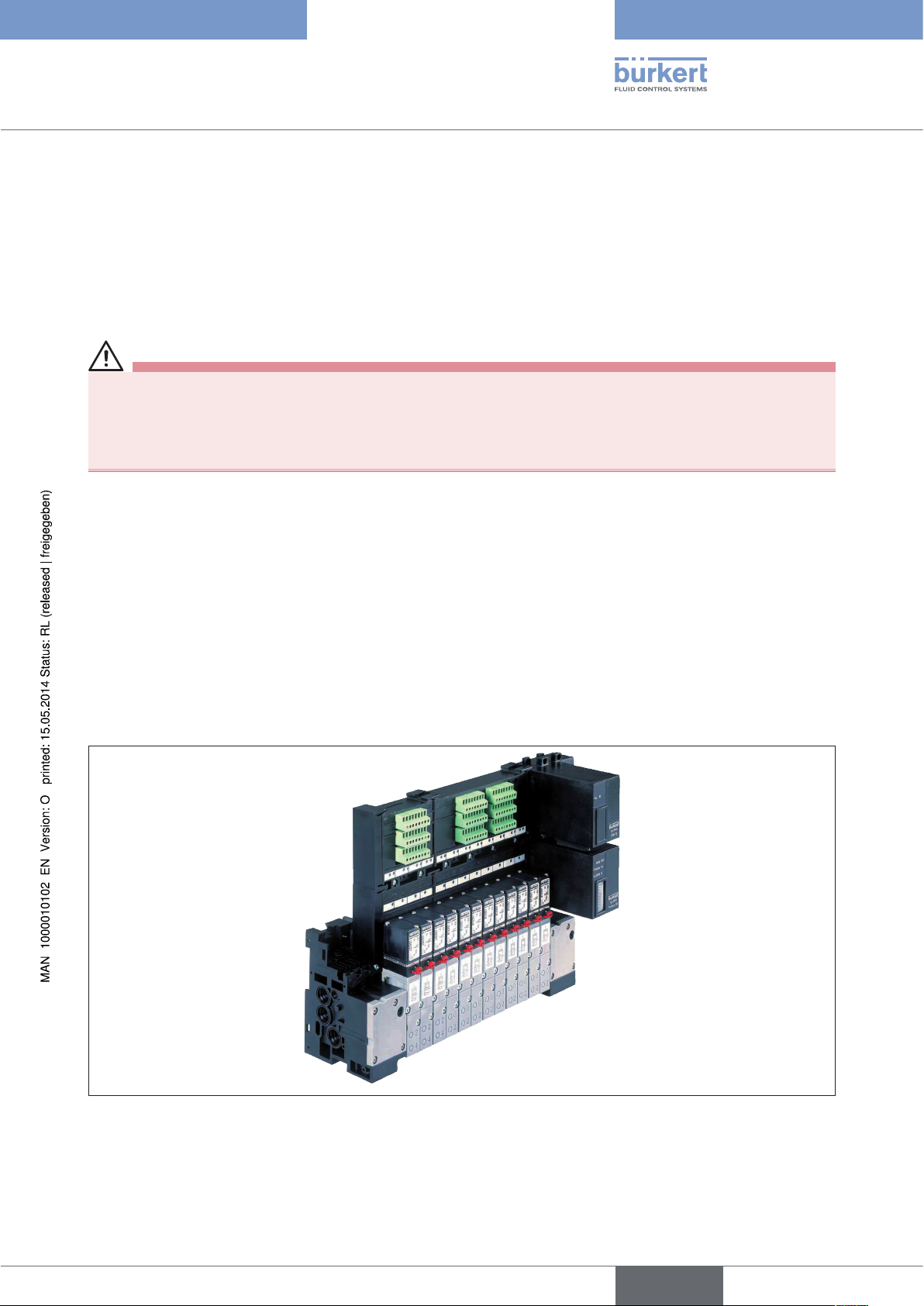

5.2. General description

Thanks to its strictly modular construction in terms of the pneumatic and electrical interfaces the type 8640 valve

terminal is suitable for a wide range of tasks, including complex ones. By aligning pneumatic modules in sequence

with varying numbers of valves it is possible to configure up to 24 valve functions on one valve terminal.

The electrical connection technology can be implemented as required via field bus interfaces, collective sockets

(parallel connection technology) or multi-pole interfaces. The valves are designed for various usage scenarios. The

body and connection modules are manufactured using high quality plastic (polyamide) and can be connected and

released easily thanks to an integrated attachment mechanism.

Figure 1: Example of usage for pneumatic modular valve terminal type 8640

11

english

Page 12

Type 8640

Product description

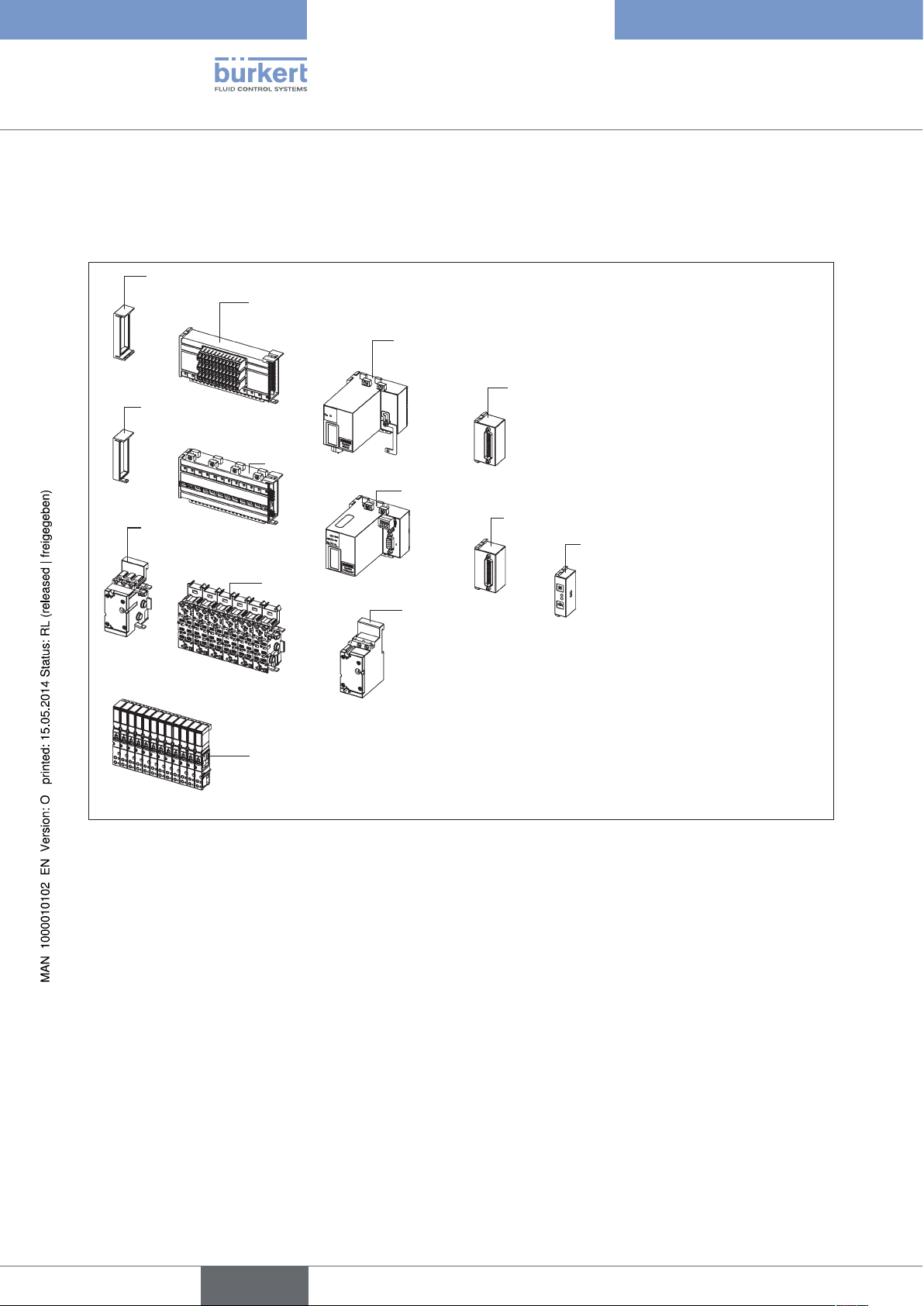

5.3. Structure of the system

Each valve terminal is configured according to customer requirements. To ensure optimal performance for the task

in question a large range of electrical and fluid-related components is available.

Electric cable termination module

Terminal module for feedback indicator

Extension module for electrical inputs

Multipole feedback indicator inputs (initiators)

Electric cable

termination module

Electric base module

Field bus module

Pneumatic connection

module

Pneumatic base module

Pneumatic

connection module

Valves of type 6525 (5/2-way)

Figure 2: Example for the configuration of the modular electric valve terminal type 8640

Multipole valve outputs

Multiple connection module

12

english

Page 13

Type 8640

Technical data

6. TECHNICAL DATA

6.1. Operating conditions

Ambient temperature: 0 ... +50 °C

Storage temperature: -20 ... +60 °C

Nominal operating mode: Long-term operation (100% ED)

Operating voltage: 24 V / DC ± 10 %, residual ripple for field bus interface 1 Vss

Protection class: 3 in accordance with VDE 0580

Power consumption: Power consumption is dependent on the type of electrical connection technology.

1. For the collective socket (parallel connection technology), and multi-pole interfaces power consumption is

determined by the valve type used, but limited to a total current of 3 A maximum. For a multi-pole solution

combined with repeaters there is a further summed current, also limited to a maximum of 3 a.

2. For the field bus interface the total current can be determined according to the equation:

l

= I

total

I

base

+ (n x I

base

base current dep. on field bus system

) + (m x l

valve

repeater

)

PROFIBUS-DP V1 200 mA

DeviceNet 200 mA

CANopen 200 mA

n number of valves

m number of repeaters

I

valve

l

power consumption of repeater

repeater

nominal current of valve type

(m x I

) = max. 650 mA

repeater

NOTE!

Always use safety low voltage according to protection class 3 VDE 0580!

6.2. Conformity

Type 8640 conforms with the EC Directives according to the EC Declaration of Conformity.

6.3. Standards

The applied standards, which verify conformity with the EC Directives, can be found on the EC-Type Examination

Certificate and / or the EC Declaration of Conformity.

english

13

Page 14

Type 8640

Modules for conventional electrical

connection technology

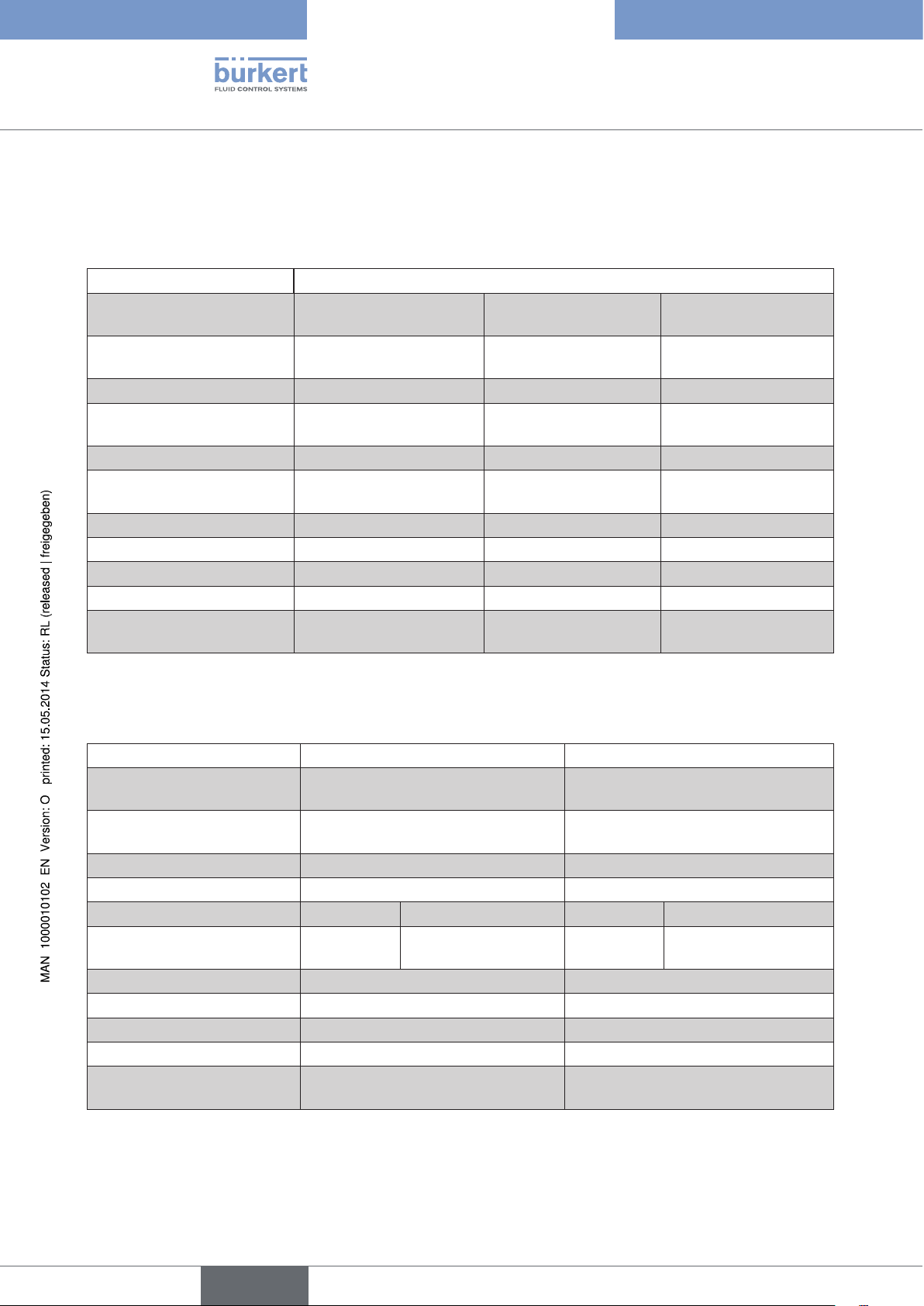

6.4. General technical data

6.4.1. Add-on dimension 11 mm

Add-on dimension 11 mm

Operating principle

Valve

Operating principle

Valve

Flow rate [l/min] 300 300 200

Pressure range [bar] 2.5 ... 7

Power rating [W] 1 2 x 0.25 2 x 0.9

Current before/after power

reduction [mA]

Valve locations max. 24 max. 12 max. 12

Repeater max. 32 max. 32 max. 32

Electrical modules 6-fold*, 8-fold, 12-fold 6-fold*, 8-fold, 12-fold 6-fold*, 8-fold, 12-fold

Pneumatic modules 2-fold, 8-fold 2-fold, 8-fold 2-fold, 8-fold

Protection class in terminal

design

C/D (3/2-way)

Type 6524

H (5/2-way)

Type 6525

2,5 ... 10

43/28 2 x 43/18 2 x 41/-

IP40

IP20

2xC (2x3/2-way)

Type 6524

2.5 ... 7

2,5 ... 10

IP40

IP20

LN (5/3-way)

H (5/2-impulse)

Type 0460

Type 0460

2.5 ... 7

IP40

IP20

* Configuration with 6-fold modules on request

6.4.2. Add-on dimension 16.5 mm and 19 mm

Add-on dimension

Operating principle

Valve

Operating principle

Valve

Flow rate [l/min] 700 300

Pressure range [bar] 2 ... 10 2 ... 8

Power rating [W] 1 2 1 2

Current before/after power

reduction [mA]

Valve locations max. 24 max. 24

Repeater max. 32 max. 32

Electrical modules 4-fold, 6-fold, 8-fold 2-fold, 5-fold, 6-fold

Pneumatic modules 2-fold, 4-fold 2-fold, 3-fold

Protection class in terminal

design

42/33 85/52 42/- 84/-

16,5 mm 19 mm

C/D (3/2-way)

Type 6526

H (5/2-way)

Type 6527

IP54

IP20

C/D (3/2-way)

Type 5470

G (4/2-way)

Type 5470

IP54

IP20

14

english

Page 15

Type 8640

Modules for conventional electrical

connection technology

7. MODULES FOR CONVENTIONAL

ELECTRICAL CONNECTION TECHNOLOGY

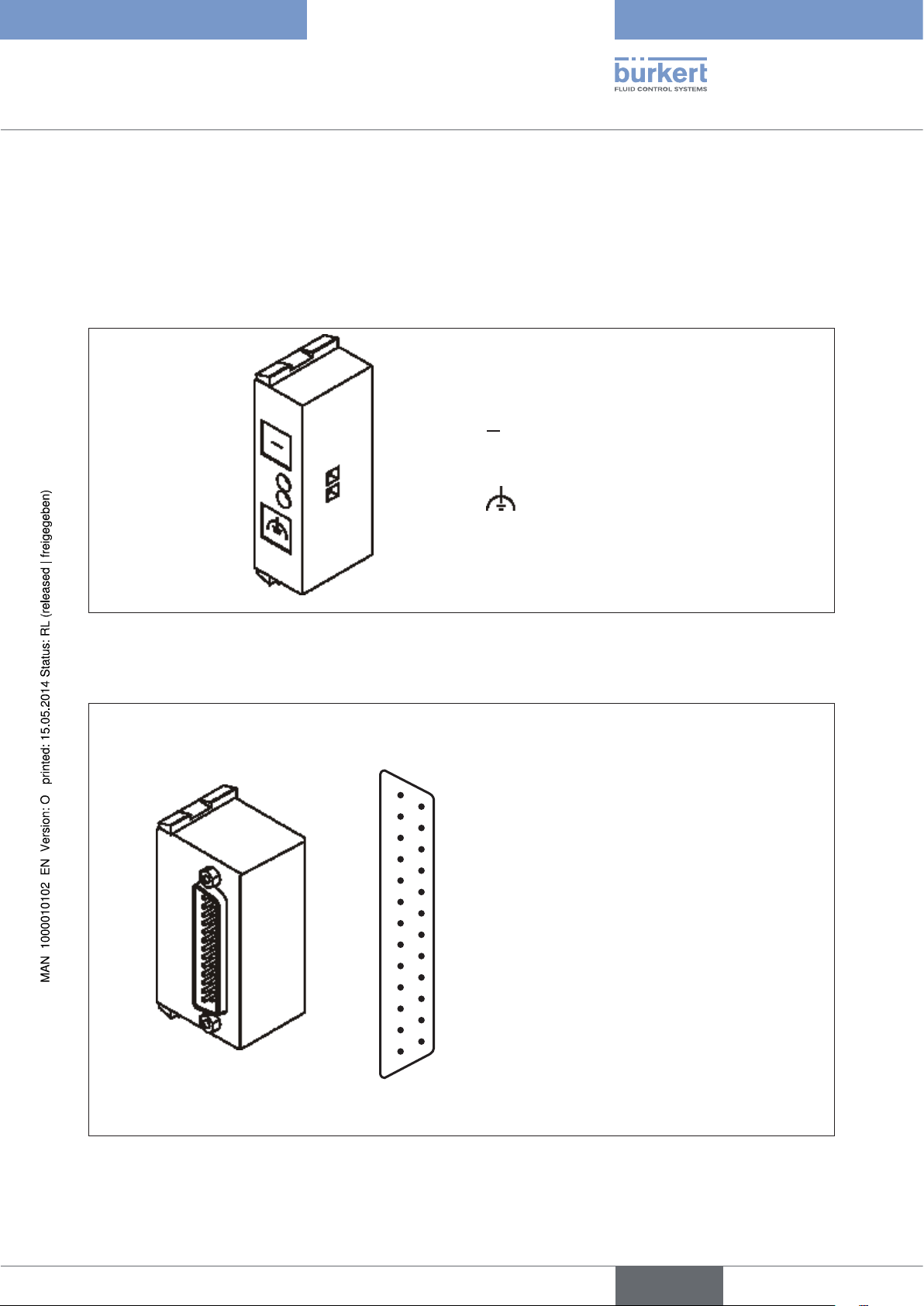

7.4.1. Collective socket module

The collective socket module serves as a central connecting element for ground and functional earth.

Allocation plan

Ground

Functional earth

Figure 3: Collective socket module for valve outputs

7.4.2. Multi-pole connection for valve outputs

Pin 1 Valve 1

Pin 2 Valve 2

Pin 3 Valve 3

Pin 4 Valve 4

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

Pin 5 Valve 5

Pin 6 Valve 6

Pin 7 Valve 7

Pin 8 Valve 8

Pin 9 Valve 9

Pin 10 Valve 10

Pin 11 Valve 11

Pin 12 Valve 12

Pin 13 Valve 13

Pin 14 Valve 14

Pin 15 Valve 15

Pin 16 Valve 16

Pin 17 Valve 17

Pin 18 Valve 18

Pin 19 Valve 19

Pin 20 Valve 20

Pin 21 Valve 21

Pin 22 Valve 22

Pin 23 Valve 23

Pin 24 Valve 24*

Pin 25 Ground

Figure 4: Multi-pole module for valve outputs D-SUB IP54 and allocation of the D-SUB plug

* Multi-pole for manual automation only 23 bit, as Pin 24 used for permanent 24 V.

english

15

Page 16

Type 8640

Modules for conventional electrical

connection technology

Accessories

D-SUB plug 25-pin IP54 5 m cable Id.-No. 917 494

D-SUB plug 25-pin IP54 10 m cable Id.-No. 917 495

Colour code for D-SUB cable

The wires are soldered 1:1 to the D_SUB plug, i.e. wire 1 ws to Pin 1 D-SUB etc.

Pin/Wire Wire colour Code Pin/Wire Wire colour Code

1 white ws 14 brown-green brgn

2 brown br 15 white-yellow wsge

3 green gn 16 yellow-brown gebr

4 yellow ge 17 white-grey wsgr

5 grey gr 18 grey-brown grbr

6 pink rs 19 white-pink wsrs

7 blue bl 20 pink-brown rsbr

8 red rt 21 white-blue wsbl

9 black sw 22 brown-blue brbl

10 violet vi 23 white-red wsrt

11 grey-pink grrs 24 brown-red brrt

12 red-blue rtbl 25 white-black wssw

13 white-green wsgn

16

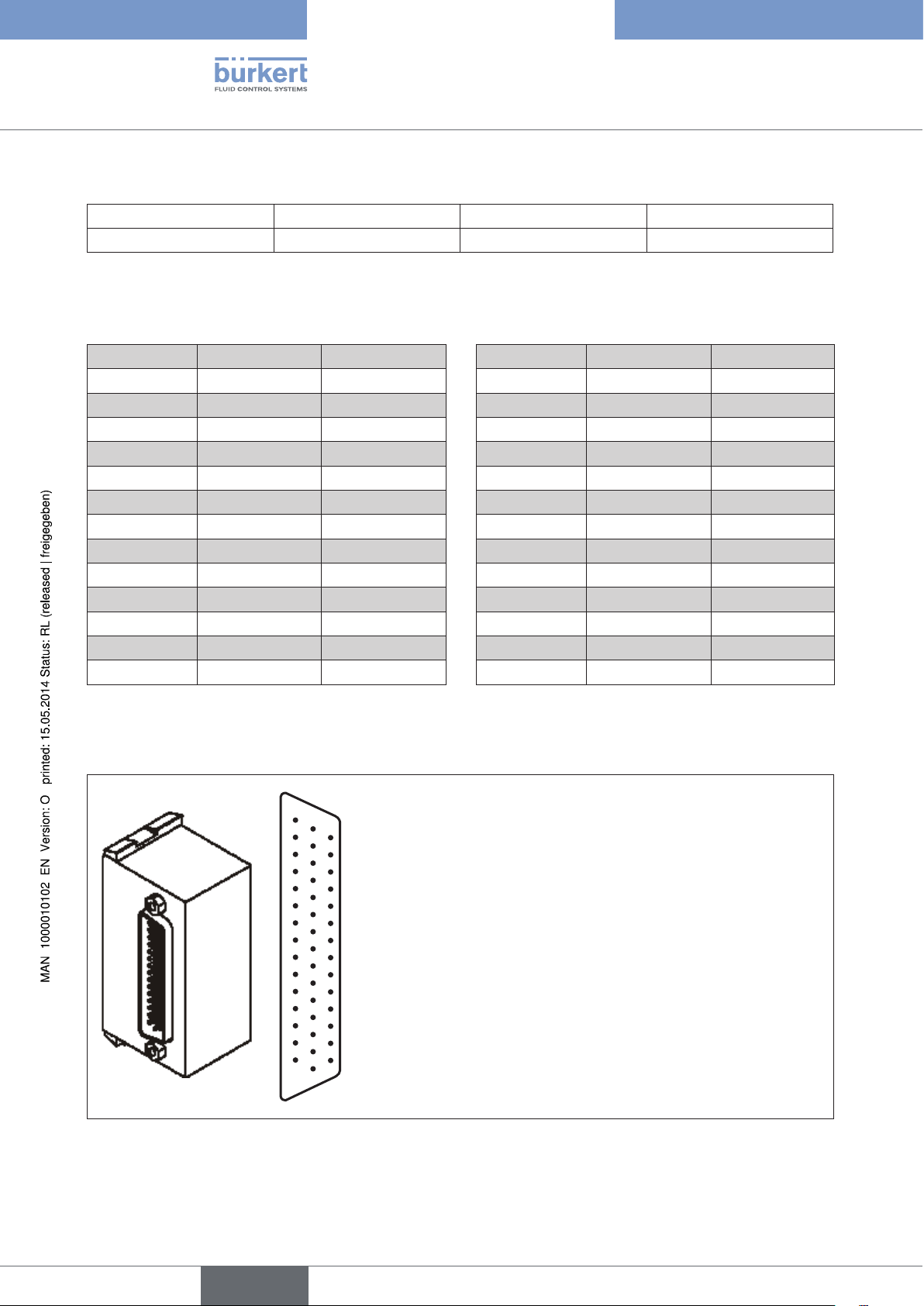

7.4.3. Multi-pole connection with repeater inputs (initiators)

Pin 1 Input 1

Pin 2 Input 2

15

30

14

44

29

13

43

28

12

42

27

11

41

26

10

40

25

9

39

24

8

38

23

7

37

22

6

36

21

5

35

20

4

34

19

3

33

18

2

32

17

1

31

16

Pin 3 Input 3

Pin 4 Input 4

Pin 5 Input 5

Pin 6 Input 6

Pin 7 Input 7

Pin 8 Input 8

Pin 9 Input 9

Pin 10 Input 10

Pin 11 Input 11

Pin 12 Input 12

Pin 13 Input 13

Pin 14 Input 14

Pin 15 Input 15

Pin 16 Input 16

Pin 17 Input 17

Pin 18 Input 18

Pin 19 Input 19

Figure 5: Multi-pole module for repeater inputs D-SUB IP54 and allocation of the D-SUB plug

Pin 20 Input 20

Pin 21 Input 21

Pin 22 Input 22

Pin 23 Input 23

Pin 24 Input 24

Pin 25 Input 25

Pin 26 Input 26

Pin 27 Input 27

Pin 28 Input 28

Pin 29 Input 29

Pin 30 Input 30

Pin 31 Input 31

Pin 32 Input 32

...

Pin 43 24 V

Pin 44 Ground

english

Page 17

Type 8640

Modules for conventional electrical

connection technology

Accessories

D-SUB plug 44-pin IP54 5 m cable Id.-No. 917 496

D-SUB plug 44-pin IP54 10 m cable Id.-No. 917 497

Colour code for D-SUB cable

The wires are soldered 1:1 to the D_SUB plug, i.e. wire 1 ws to Pin 1 D-SUB etc.

Pin/Wire Wire colour Code Pin/Wire Wire colour Code

1 white ws 23 white-red wsrt

2 brown br 24 brown-red brrt

3 green gn 25 white-black wssw

4 yellow ge 26 brown-black brsw

5 grey gr 27 grey-green grgn

6 pink rs 28 yellow-grey grgr

7 blue bl 29 pink-green rsgn

8 red rt 30 yellow-pink gers

9 black sw 31 green-blue gnbl

10 violet vi 32 yellow-blue gebl

11 grey-pink grrs 33 green-red gnrt

12 red-blue rtbl 34 yellow-red gert

13 white-green wsgn 35 green-black gnsw

14 brown-green brgn 36 yellow-black gesw

15 white-yellow wsge 37 grey-blue grbl

16 yellow-brown gebr 38 pink-blue rsbl

17 white-grey wsgr 39 grey-red grrt

18 grey-brown grbr 40 pink-red rsrt

19 white-pink wsrs 41 grey-black grsw

20 pink-brown rsbr 42 pink-black rssw

21 white-blue wsbl 43 blue-black blsw

22 brown-blue brbl 44 red-black rtsw

english

17

Page 18

Type 8640

Field bus module PROFIBUS DP/V1

8. FIELD BUS MODULE PROFIBUS DP/V1

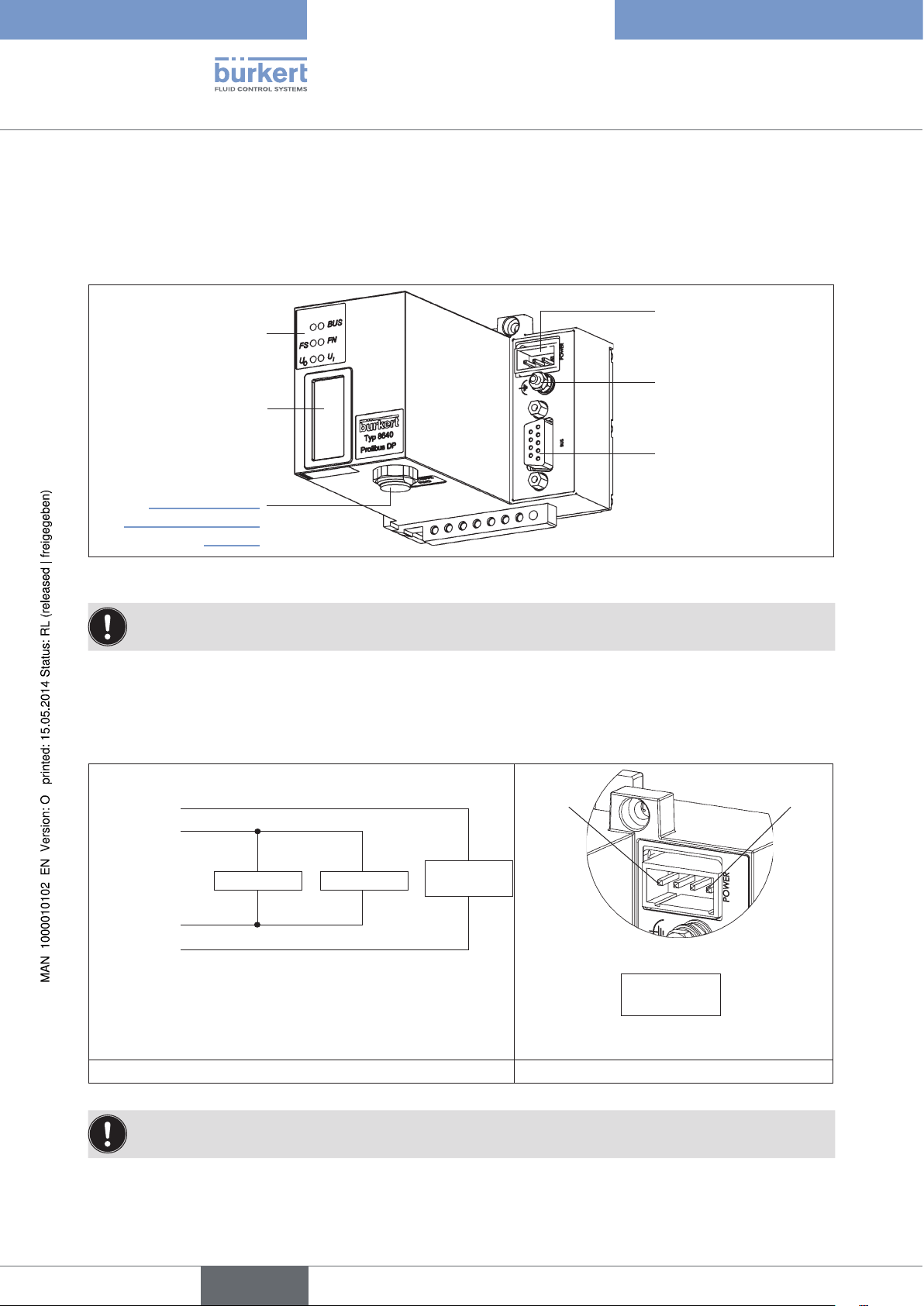

8.1. PROFIBUS DP/V1, IP20 - overview

Power Supply

LED Status Display

Functional earth

DIP Switches

Connection for RIO

slave bus module –

see “10. Bus Module

Rio Slave (RIO/VA)”,

page 46

Figure 6: Overview of field bus module PROFIBUS DP IP20

The DIP switches can be operated through the covering film.

8.1.1. Power supply IP20

The 4-pole plug-in connector for the power supply is configured as follows:

24 V DC (2)

valves /

outputs

24 V DC (4)

logic

GND (3)

logic

GND (1)

valves /

outputs

Electronics Inputs

Valves /

Outputs

Pin 1 Pin 4

1 2 3 4

Pin

-

Field bus connection

-+

+

18

Valves /

Outputs

Figure 7: Power supply configuration Figure 8: Cutaway POWER connection

Logic

inputs

Pin 2 of the power supply must be supplied with a 4 A medium time-lag fuse; Pin 4 with 1 A.

english

Page 19

Type 8640

Field bus module PROFIBUS DP/V1

NOTE!

To ensure electromagnetic compatibility (EMC) connect the screw terminal FE (functional earth) to earth

potential using a short cable (30 cm).

Accessories

Plug-in connector (No. 918 226) for power supply (supplied).

8.1.2. IP20 field bus connection

A 9-pole D-SUB connection is used for an IP20 protection class field bus connection. The following shows the

wiring layout according to Standard 19245 Part 1.

Pin-No. Signal name (socket in device,

plug on cable)

1 n.c. 2 n.c. 3 RxD/TxD-P Receive / Send data P

4 CNTR-P (RTS) Request to send (repeater control

5 DGND Data reference potential

6 +5 V Supply voltage - plus

7 n.c. 8 RxD/TxD-N Receive / Send data N

9 n.c. -

Description

signal)

english

19

Page 20

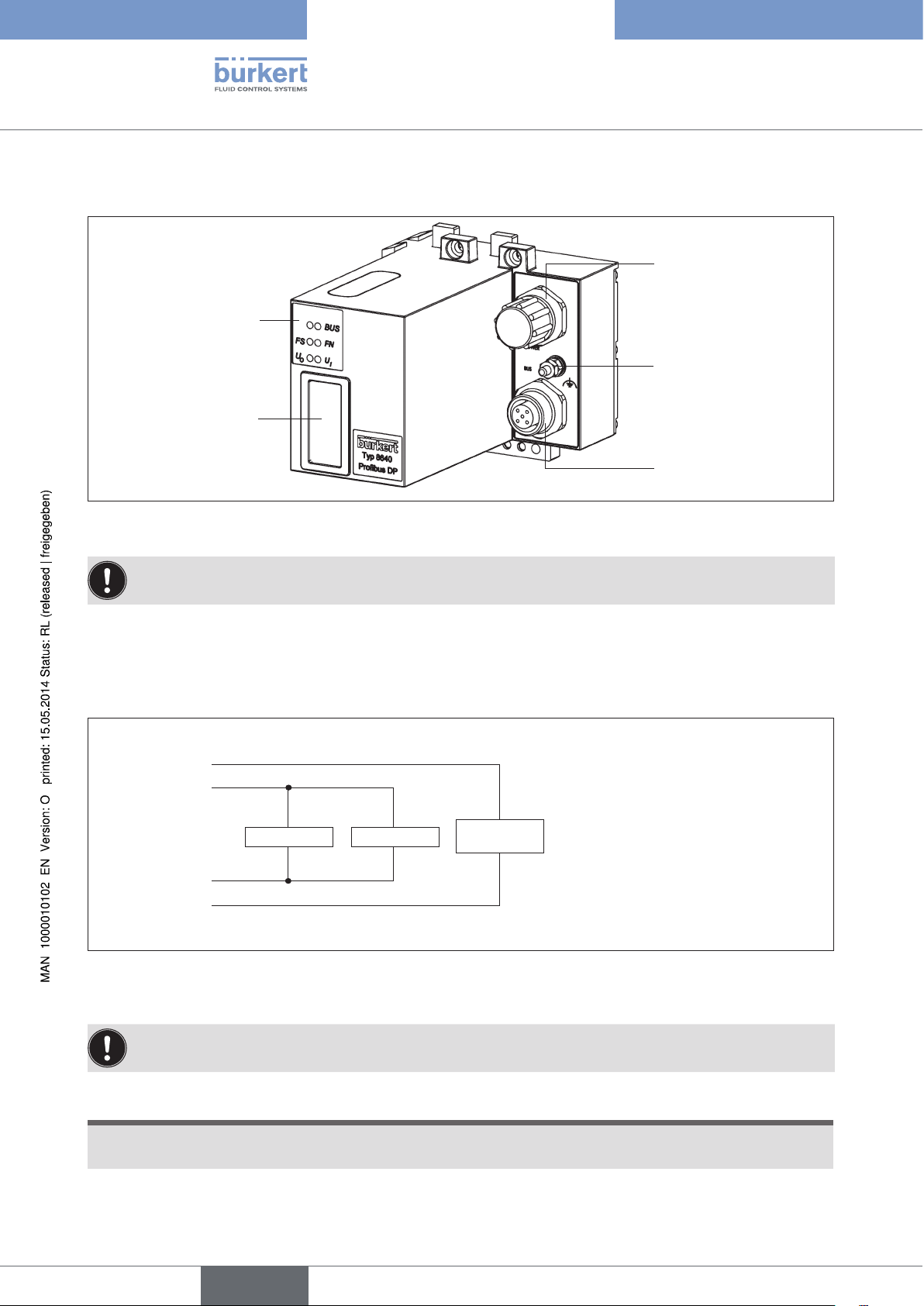

8.2. PROFIBUS DP/V1, IP54 - overview

LED Status Display

DIP Switches

Type 8640

Field bus module PROFIBUS DP/V1

Power Supply

Functional earth

Field bus connection

Figure 9: Overview field bus module PROFIBUS-DP IP54

The DIP switches can be operated through the covering film.

8.2.1. Power supply IP54

The 4-pole circular plug-in connector for the power supply is configured as follows:

24 V DC (1)

valves /

outputs

24 V DC (2)

logic

GND (3)

logic

GND (4)

valves /

outputs

Electronics Inputs

Valves /

Outputs

Pin 1: +24 V - valves (outputs)

Pin 2: +24 V - logic + inputs

Pin 3: GND - logic + inputs

Pin 4: GND - valves (outputs)

20

Figure 10: Power supply configuration

Pin 1 of the power supply must be supplied with a 4 A medium time-lag fuse; Pin 2 with 1 A.

NOTE!

To ensure electromagnetic compatibility (EMC) connect the screw terminal FE (functional earth) to earth

potential using a short cable (30 cm).

english

Page 21

Type 8640

Field bus module PROFIBUS DP/V1

8.2.2. IP54 field bus connection

The M12 plug-in system is used for an IP54 protection class field bus connection. To avoid confusion between

the bus and the supply slot the Reserve Key coding is used. Layout for plugs and sockets:

Pin No. Signal Description

1 VP Supply voltage - plus (P5V)

2 RxDx / TxD-N Receive / Send data N, A connection

3 DGND Data transmission potential (reference potential to VP)

4 RxDx / TxD-P Receive / Send data P, B connection

5 Shielding Shielding / protective earth

Thread Shielding Shielding / protective earth

Accessories

PROFIBUS plug-in connector (configurable), socket

(Reserve Key coding)

PROFIBUS plug-in connector (configurable), plug

(Reserve Key coding)

PROFIBUS T-piece (12 MBaud) Id.-No. 902 098

M12 power supply, socket Id.-No. 902 552

M12 terminal resistance, plug Id.-No. 902 553

for connection without T-piece this ID is needed

Id.-No. 918 447

Id.-No. 918 198

8.3. DIP switch (PROFIBUS address)

→ Set the DIP switch through the film using a screwdriver (the film is very durable).

DIP Value Description Note

1 (above) 1 PROFIBUS address The PROFIBUS address equals the sum of all the

2 2 PROFIBUS address

...

...

6 32 PROFIBUS address

7 64 PROFIBUS address

8 (below) - reserved Switch to 'OFF'

...

...

PROFIBUS address

DIP switch values from 1 to 7 in 'ON' setting.

'ON' setting = DIP switch to the right

english

21

Page 22

8.4. LED status display

Type 8640

Field bus module PROFIBUS DP/V1

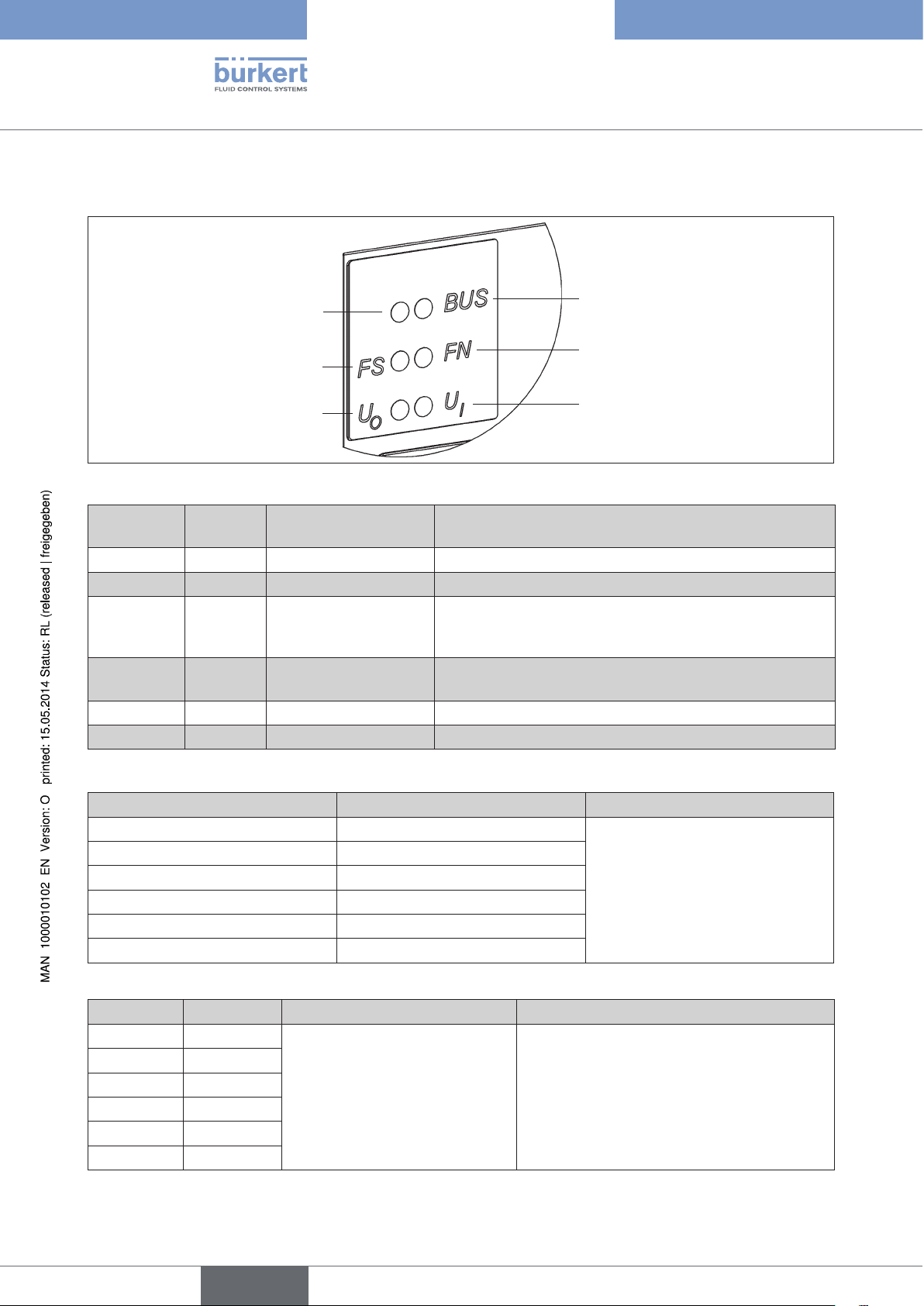

BUS_OK (BO)

FAILURE_SELECT (FS)

U_TREIBER_OK (U

Figure 11: LED state display (detail)

Abbre-

Colour Description Explanation

)

0

BUS_FAULT (BF)

FAILURE_NUMBER (FN)

U_LOGIK_OK (U

)

l

viation

BO green Bus OK Bus communication active

BF red Bus Fault Bus fault

FS yellow Failure Select Determines the function of the FN LED:

FS lit up: FN displays fault type

FS not lit up: FN displays failure number

FN red Failure Number The number of flash impulses indicates the fault type or the

failure number depending on whether FS is lit up or not

U

l

U

0

green U LOGIC OK Voltage for logic supply, inputs and bus interface present

green U driver OK Voltage for outputs present

22

Normal state

LED Status Description

BUS (BO) ON

BUS (BF) OFF

FS OFF

Error-free operation of the valve

terminal on PROFIBUS DP

FN OFF

U

0

U

L

ON

ON

bus fault

LED Status Description Fault cause / remedial action

BUS (BO) OFF Signal monitoring time on valve

BUS (BF) ON

FS OFF

terminal elapsed without receipt

of signal from master

During operation:

→ Check master (control) and bus cable

During start-up:

FN OFF

U

0

U

L

ON

ON

→ Check network configuration on master

and station address on terminal

english

Page 23

Type 8640

Field bus module PROFIBUS DP/V1

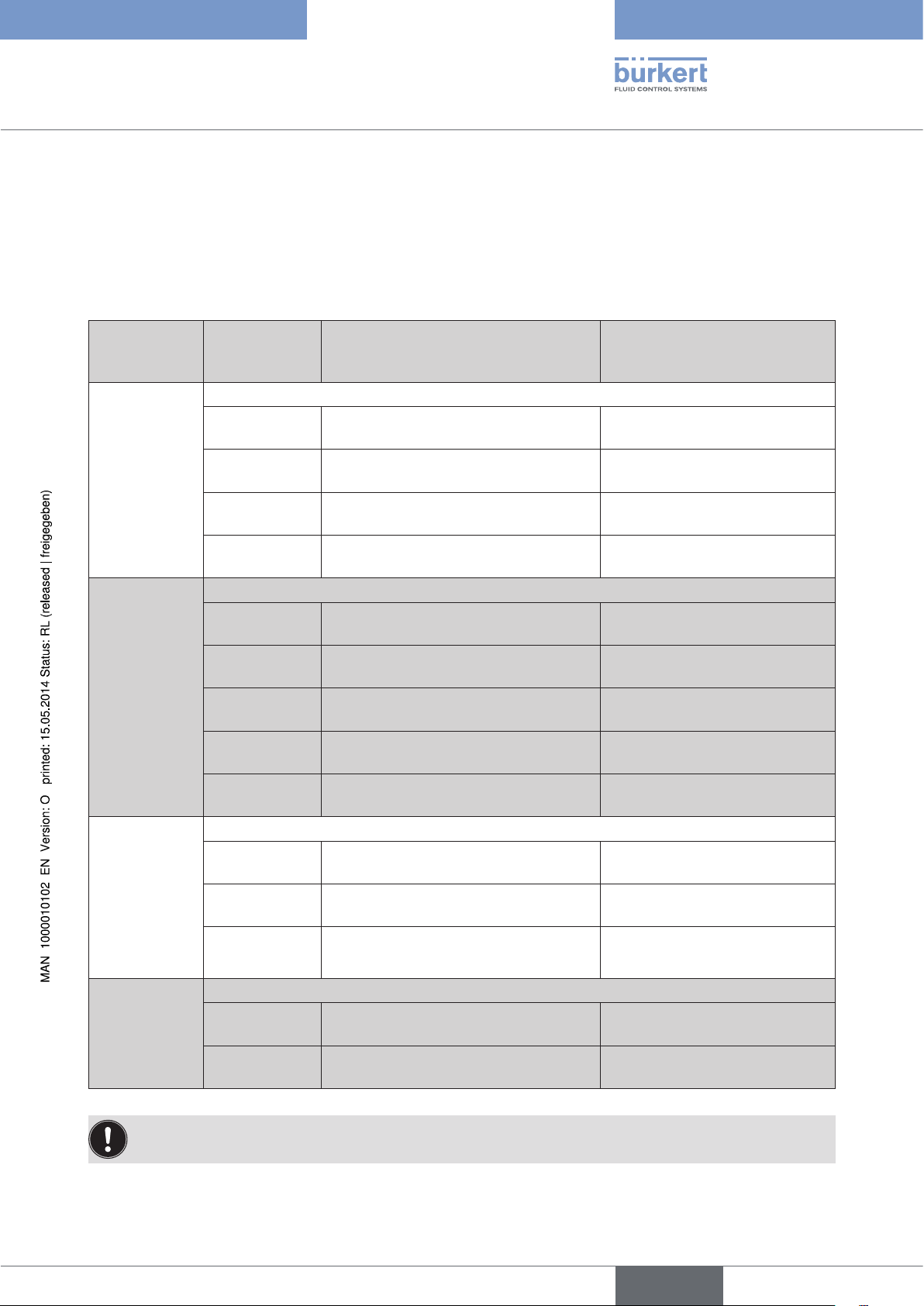

8.4.1. Errors and warnings displayed via FN (Failure Number)

and FS (Failure Select) LEDs

The following table contains errors and warning messages displayed via the FN (Failure Number) and FS

(Failure Select) LEDs.

The error type is indicated by the number of times FN flashes when FS is set to ON.

The error number is indicated by FN flashing when FS is set to OFF.

Number FN

when FS ON

error type

1

2

3

Number FN

when FS OFF

error number

Parameterization error (Set_Prm_Telegramm)

1 Too many inputs for one valve terminal

(bitwise composition)

2 Too many outputs for one valve terminal

(bitwise composition)

3 Parameterization telegram too long → Check user parameters and

4 Parameterization telegram too short → Check user parameters and

Configuration error (Chk_Cfg_Telegramm)

1 Too many inputs for one valve terminal → Check identification bytes and

2 Too many outputs for one valve terminal → Check identification bytes and

3 Too few inputs for one valve terminal

(preset in parameterization telegram)

4 Too few outputs for one valve terminal

(preset in parameterization telegram)

5 An identifier has the wrong code → Check identification bytes and

Main terminal error

1 No supply voltage for main terminal

outputs

2 Setting for station address is outside

permitted range (0 ... 125)

3 Error accessing EEPROM → Replacement of electronics

Description Remedial action

→ Check user parameters and

DIP switch

→ Check user parameters and

DIP switch

DIP switch

DIP switch

DIP switch

DIP switch

→ Check identification bytes and

DIP switch

→ Check identification bytes and

DIP switch

DIP switch

→ Check supply voltage

→ Check PROFIBUS address

on main terminal

may be necessary

Peripheral terminal error

1 No supply voltage for peripheral terminal

4

2 Complete failure of a peripheral terminal → Check peripheral terminal

After the error has been rectified the valve terminal must be reset by briefly shutting down the supply

voltage.

outputs

→ Check supply voltage

RIO bus

english

23

Page 24

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9. CONFIGURATION AND PARAMETER SETTINGS FOR PROFIBUS DP

The purpose of the bus system is to enable rapid connection of the decentralized periphery (valve terminal) with

the central master (control). As well as input and output data, parameter, configuration and diagnostic data is also

transmitted.

Many PROFIBUS masters (controls) need a configuration program which lays down the network structure. These

programs require the device base data file (GSD file).

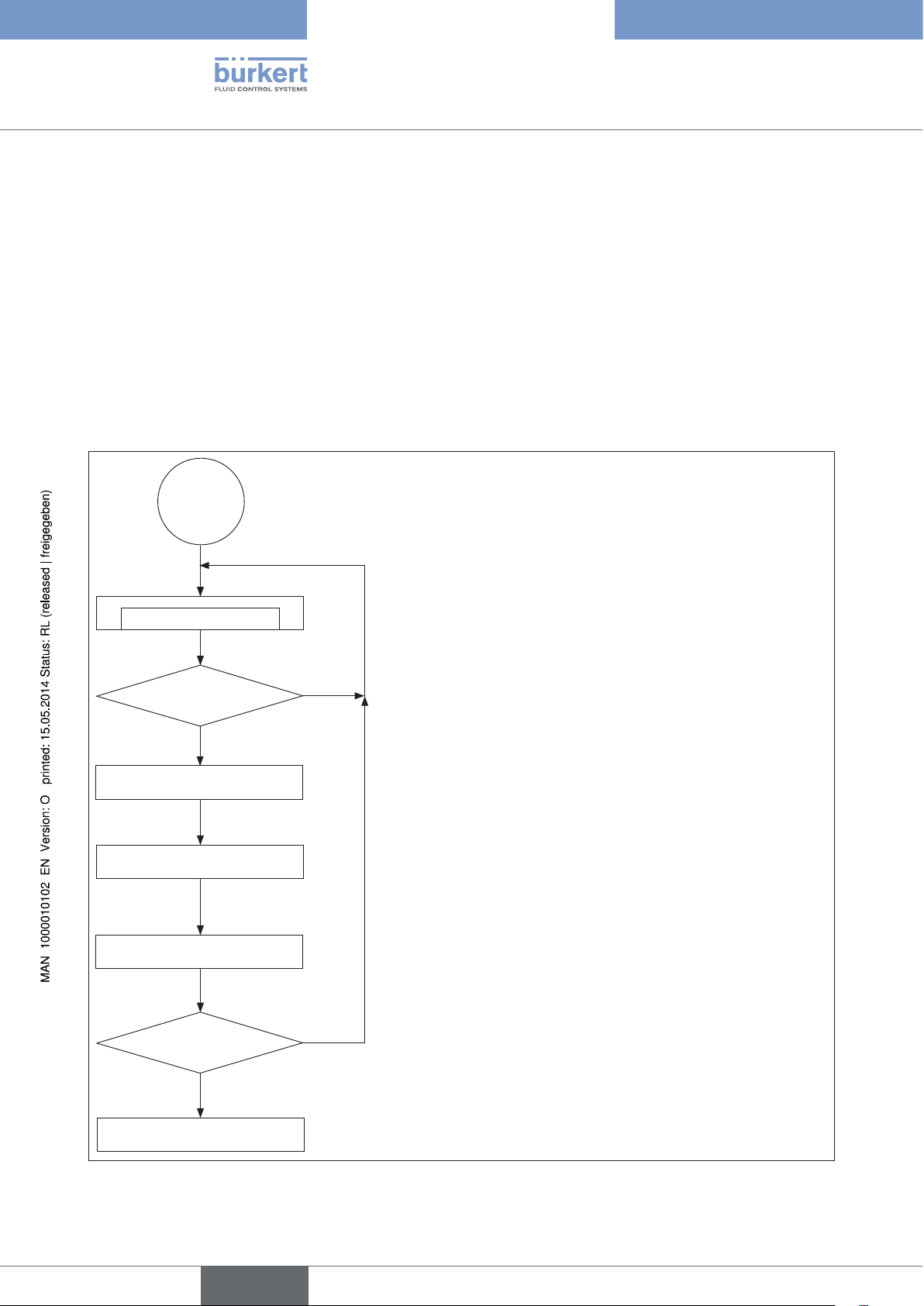

9.1. Representation of the PROFIBUS-DP communication process

Start

Read diagnosis

Diagnosis OK ?

Yes

Write parameter

Write configuration

Read diagnosis

Error ?

No

Yes

The diagnostics routine is requested for as long as is necessary until the component responds and is not blocked by

another master.

Master transmits parameterization data

- bus-specific data (e.g. signal monitoring)

- User-specific parameterization data (as required) errors are

displayed in the diagnosis.

Master transmits required configuration

Required configuration is compared to actual configuration

in slave

Errors are displayed in the diagnosis.

Master reads diagnosis.

If there is a parameterisation or configuration error, the communication is restarted from the beginning.

24

No

Cyclical data exchange

Figure 12: Simplified representation of the PROFIBUS-DP communication process

If the slave is in data exchange mode then a cyclical

exchange of data takes place.

english

Page 25

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.2. Start-Up

Setting the PROFIBUS address

via DIP switch

DP bus

DIP Switches

DP main

terminal

No

Configuration

Example

1

2

3

4

DP bus

No

Should the default

input mode or filter be

modified

Are extension terminals (RIO)

present

1)

Yes

Parameterization

Parameterization

Configuration

Example

DP main

terminal

Yes

How should inputs /

outputs be put

together

2)

RIO extension

bitwisebytewise

Parameterization

Configuration

Example

5

6

1)

Extension terminals are connected to the valve terminal via the RIO interface

2)

Advantage of bitwise distribution:

1. If the number of inputs or outputs does not correspond to the byte pattern then bits remain unused with bytewise configuration. For instance, with a valve terminal with 4 valves and a valve terminal with 10 valves that amounts to 10 bits with

bytewise configuration (4+6 bits), because the first valve terminal requires 1 byte and the second one requires 2 bytes.

With bitwise distribution the outputs can be combined. This means that only 2 bytes are needed and 2 bits remain unused.

2. The bitwise composition means that the identifiers / slots (assignation in process image) can be selected at will in the

configuration program.

Figure 13: Start-Up

english

25

Page 26

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.2.1. Parameterization without extension terminal

(hex parameter / User_Prm_Data)

The default value for the parameterization is:

• Extension terminal none

• Input mode normal inputs

• Filter ON

The parameterization can be used to modify the settings selected for the input mode and the filter.

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte Bus parameters (normal parameters) 7 bytes

Lock_Rep Unlock_Re Sync_Req Freeze_Req WD_On

00 min TSDR and slave spec. data

01 release for other masters

10 lock for other masters

11 release for other masters

2

WD_Fact_1

3

WD_Fact_2

4

TSDR

5 Ident_Number high byte (manufacturer identification 00 Hex)

6 Ident_Number low byte (manufacturer identification 81 Hex)

7 Group_Ident (For group generation; each bit represents one group.)

8 DPV1_Status_1

9 DPV1_Status_2

10 DPV1_Status_3

11 See table below:

Slave being

operated in

Sync mode

(range 1-255 signal monitoring in [s] = 10 ms x WD_Fact_1 x WD_Fact_2)

(range 1-255 signal monitoring in [s] = 10 ms x WD_Fact_1 x WD_Fact_2)

(time in Tbits in which the slave may respond. At least 11 Tbit; 0 old value remains)

User_Parm_Data (DPV1_Status)

User_Prm_Data (user parameters)

Slave being

operated in

Freeze mode

Signal monitoring

0: deactivated

1: activated

reserved reserved reserved

26

Byte 11 User_Prm_Data (user parameters)

Input mode Input filter OFF Input filter ON

no inputs 04 hex 44 hex

normal inputs 14 hex 54 hex

shifted inputs 24 hex 64 hex

halved inputs 34 hex 74 hex

For a description of the input modes, refer to Section “9.3. Mode inputs”Mode inputs".

Many configuration tools do not allow for direct access to bytes 1 to 7. For Siemens (Step 5 and Step 7)

the parameters (Hex parameters) start at byte 8.

english

Page 27

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.2.2. Configuration of the valve terminal without extension

terminals

The settings of the desired configuration, i.e. setting of various identifiers, is generally done with the help of the GSD

file. Up to 7 identifiers (slots) can be assigned.

When the configuration is written, the number of input and output bytes is set in the process image and checked

against permitted limits. By using different identifiers the user can assign the input and output bytes in the

process image at will.

A valve terminal has a maximum of 32 inputs and a maximum of 24 outputs. This corresponds to a maximum of 4

input bytes and a maximum of 3 output bytes. For this reason never more than the above specified number of input /

output bytes may be configured in the process image of a valve terminal- However, taking the limits specified above

into account (32 inputs, 24 outputs; 4 input bytes, 3 output bytes) it is possible to configure both less than, but also

more than the number of input / output bytes that are actually physically present on the valve terminal.

Example:

Physically present Configuration Consequence

1 bytes Only valves 1 to 8 can be addressed

2 bytes Valves 1 to 16 can be addressed

16 valves

3 bytes Valves 1 to 16 can be addressed,

1 byte remains unusable in process image

4 bytes Configuration errors

Manual configuration

If no GSD file is available the configuration must be performed manually. The following specifications apply. One

configuration telegram can contain one or several identifications, whereby the user can make the necessary allocations at will. the identifications have the following structure:

Bit 7 Bit 6 Bit 5 - 4 Bit 3 - 0

Consistency

0 = byte/word

1 = total length

Hex Decimal Description

10 016 1 byte input; consistency via byte

11 017 2 bytes input; consistency via byte

12 018 3 bytes input; consistency via byte

13 019 4 bytes input; consistency via byte

20 032 1 byte output; consistency via byte

21 033 2 bytes output; consistency via byte

22 034 3 bytes output; consistency via byte

00 000 Placeholder (empty position)

bytes/words

0 = bytes

1 = words (2 bytes)

Input/Output

00 = spec. identifier format

01 = input

10 = output

11 = input/output

Data length (number)

0000 = 1 byte/word

...

0010 = 3 bytes/words

...

1111 = 16 bytes/words

english

27

Page 28

Type 8640

Configuration and parameter

settings for PROFIBUS DP

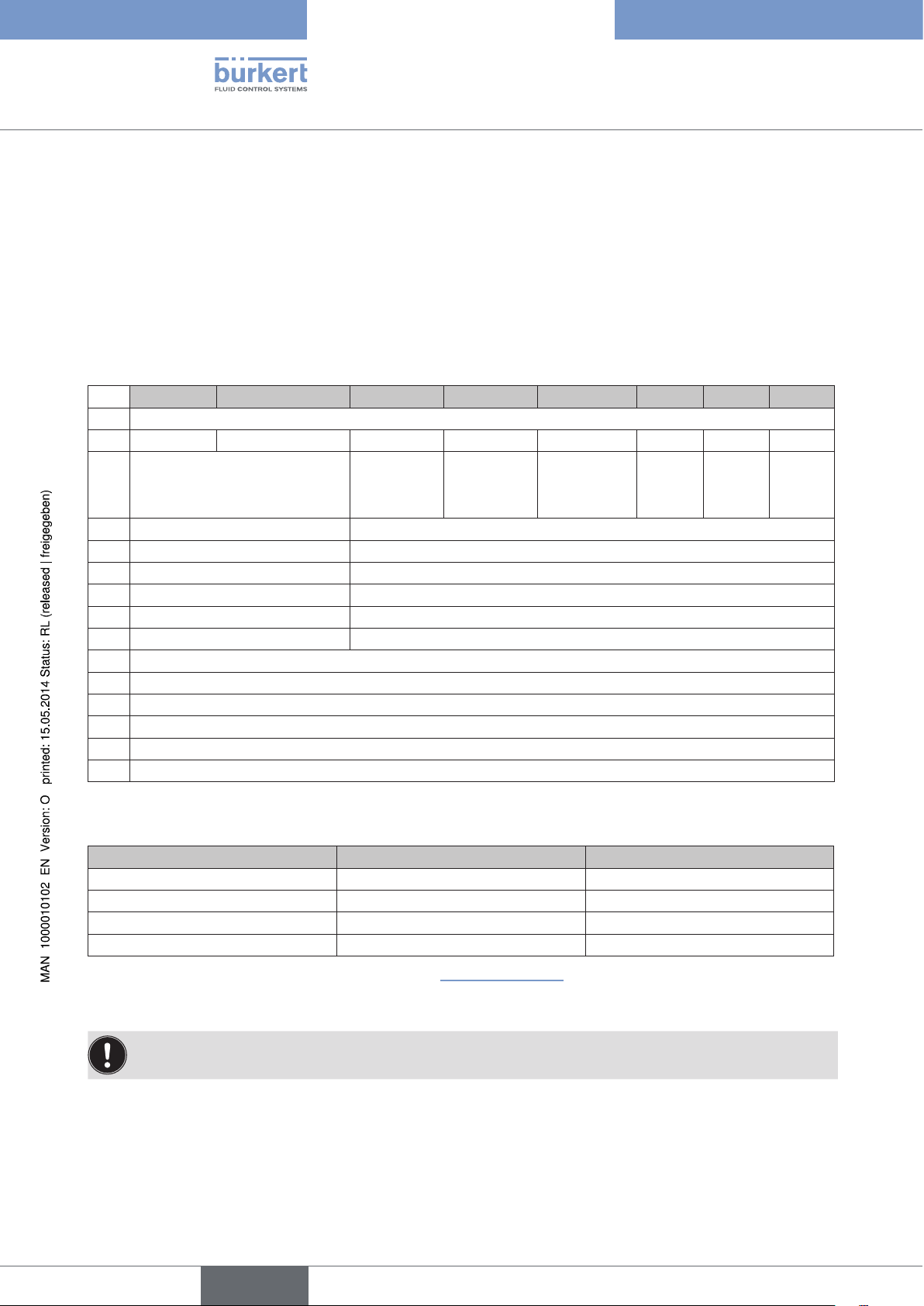

Example 1 - valve terminal with 16 valves (outputs) and 32 repeaters (inputs)

• PROFIBUS-DP address 4

• The valves 1-16 are assigned to outputs (PAA) bytes 11-12 in the process image.

• The repeaters 1-32 are assigned to inputs (PAE) bytes 20-23 in the process image.

• Mode: Normal input mode

• Input filter active

DIP Switches

1 2 3 4 5 6 7 8

OFF OFF ON OFF OFF OFF OFF OFF

User parameter byte 11 User_Prm_Data 54 hex

Configuration:

Byte No. (slot) 1* (0**) 2 (1)

Identification in Hex (Dec) 13 (019) 21 (033)

Process image output (PAA) 11-12

Process image input (PAE) 20-23

* Standard

** Siemens

Allocation of inputs and outputs to control process image

Process image Inputs (PAE)

28

Valve

Valve

Valve

Valve

Valve

Valve

Process image

Figure 14: Allocation of inputs and outputs to control process image

Valve

Valve

Valve

Valve

Outputs (PAA)

Valve

Valve

english

Valve

Valve

Valve

Valve

Page 29

Type 8640

Configuration and parameter

settings for PROFIBUS DP

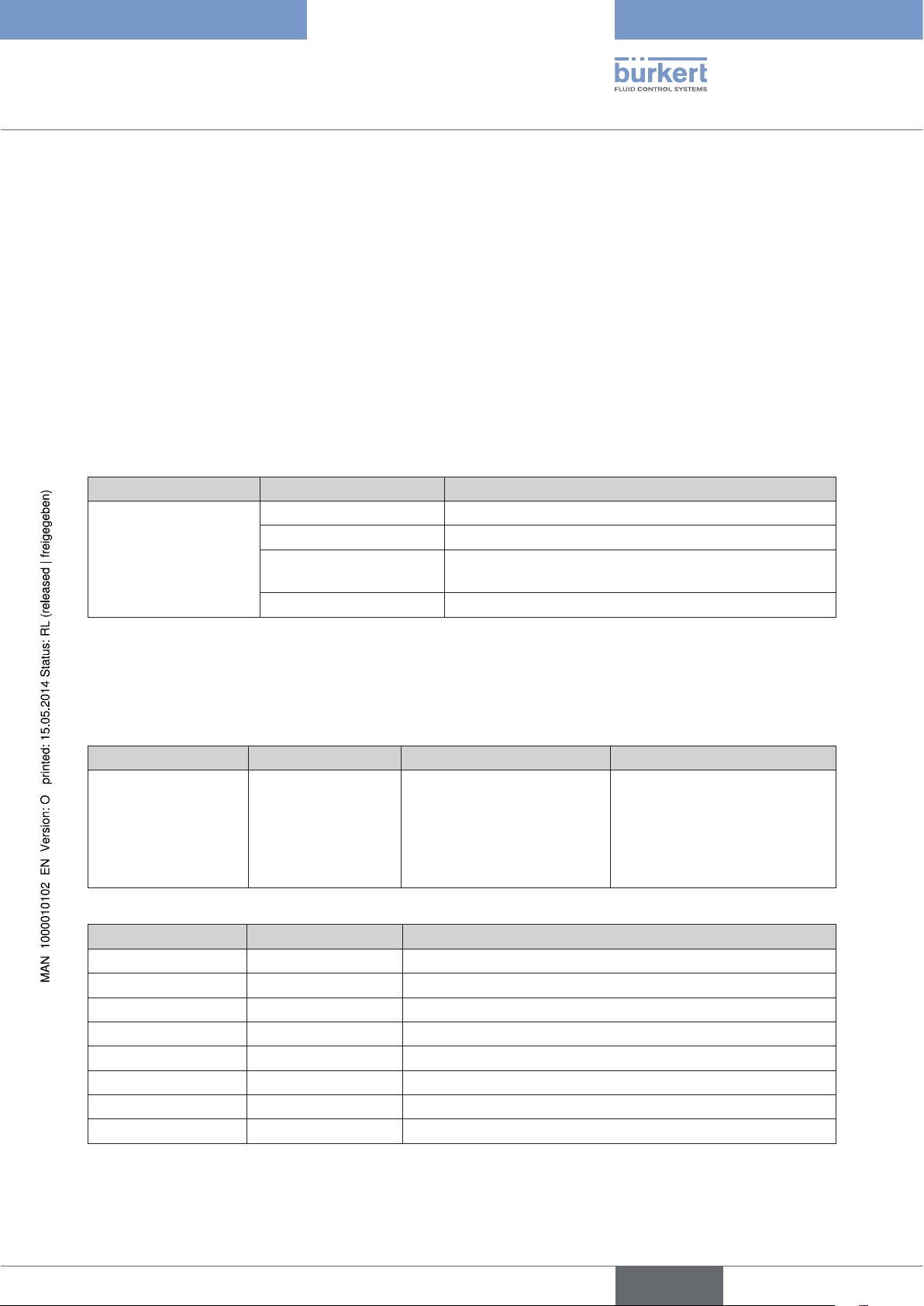

Example 2 - valve terminal with 16 valves (outputs) and 32 repeaters (inputs)

• PROFIBUS-DP address 5

• The valves 1-8 are assigned to outputs (PAA) byte 11 in the process image.

• The valves 9-16 are assigned to outputs (PAA) byte 20 in the process image.

• The repeaters 1-8 are assigned to inputs (PAE) byte 10 in the process image.

• The repeaters 9-16 are assigned to inputs (PAE) byte 15 in the process image.

• The repeaters 17-32 are assigned to inputs (PAE) bytes 20-21 in the process image.

• Mode: Normal input mode

• Input filter active

DIP Switches

1 2 3 4 5 6 7 8

ON OFF ON OFF OFF OFF OFF OFF

User parameter byte 11 User_Prm_Data 54 hex

Configuration:

Byte No. (slot) 1 (0) 2 (1) 3 (2) 4 (3) 5 (4)

Identification in Hex (Dec) 10 (016) 10 (016) 11 (017) 20 (032) 20 (032)

Process image output (PAA) 11 20

Process image input (PAE) 10 15 20-21

Allocation of inputs and outputs to control process image

Process image

Inputs (PAE)

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Process image

Figure 15: Allocation of inputs and outputs to control process image

Valve

Valve

Valve

Outputs (PPA)

Valve

Valve

Valve

Valve

Valve

Valve

29

english

Page 30

Type 8640

Configuration and parameter

settings for PROFIBUS DP

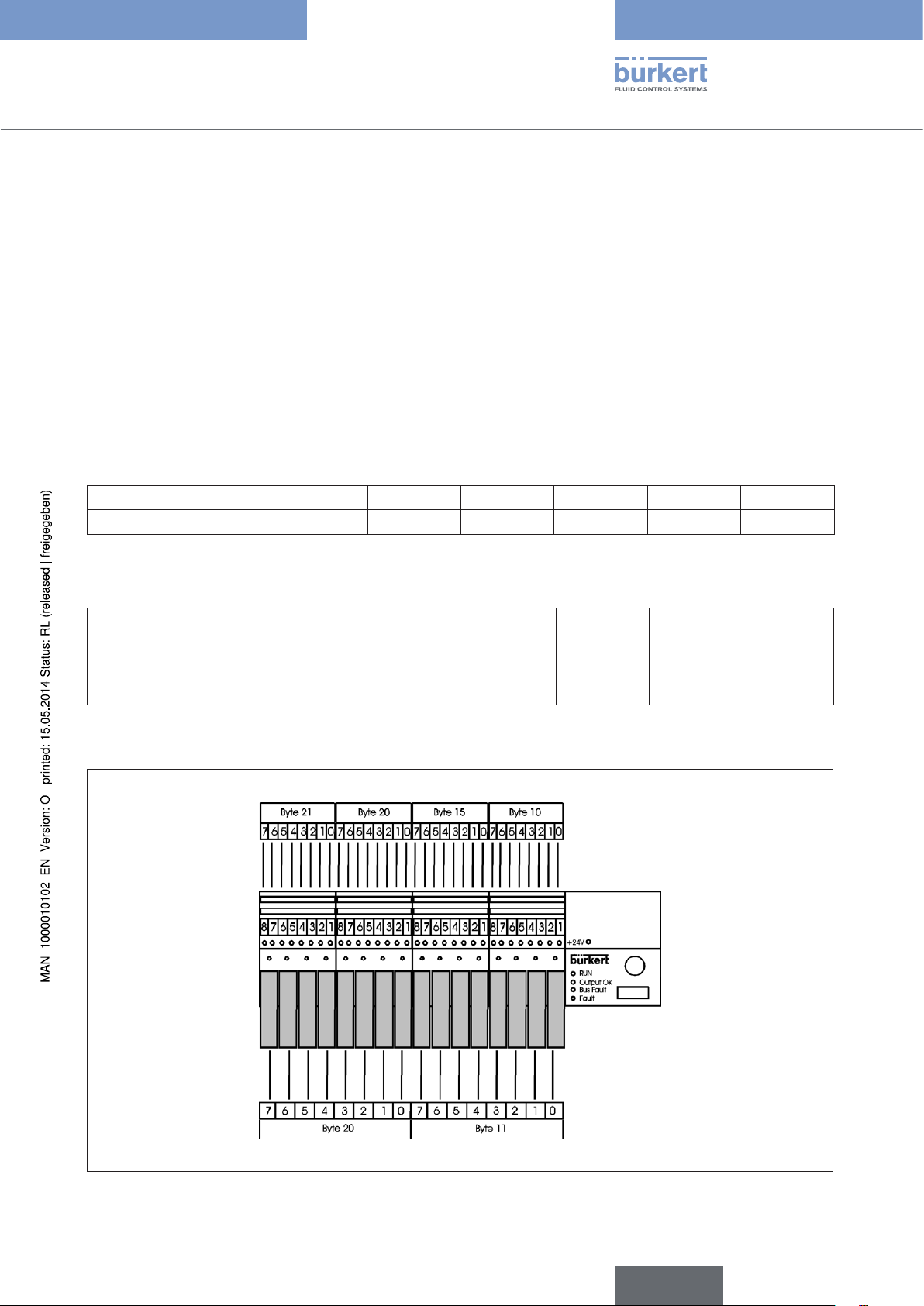

Example 3 - valve terminal with 16 valves (outputs) and 32 repeaters (inputs)

• PROFIBUS-DP address 6

• The valves 1-16 are assigned to outputs (PAA) bytes 11+12 in the process image.

• Repeaters 1, 3, 5, ... 15 are assigned to inputs (PAE) byte 10 in the process image.

• Repeaters 2, 4, 6, ... 16 are assigned to inputs (PAE) byte 16 in the process image.

• Repeaters 1, 17, 19, ... 31 are assigned to inputs (PAE) byte 11 in the process image.

• Repeaters 1, 18, 20, ... 32 are assigned to inputs (PAE) byte 17 in the process image.

• Mode: Shifted inputs

• Input filter active

DIP Switches

1 2 3 4 5 6 7 8

OFF ON ON OFF OFF OFF OFF OFF

User parameter byte 11 User_Prm_Data 64 hex

Configuration:

Byte No. (slot) 1 (0) 2 (1) 3 (2) 4 (3) 5 (4)

Identification in Hex (Dec) 10 (016) 10 (016) 10 (016) 10 (016) 21 (032)

Process image output (PAA) 11-12

Process image input (PAE) 10 16 11 17

Allocation of inputs and outputs to control process image

Process image

Inputs (PAE)

30

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Process image

Figure 16: Allocation of inputs and outputs to control process image

Outputs (PPA)

Valve

Valve

Valve

Valve

english

Valve

Valve

Valve

Valve

Page 31

Type 8640

Configuration and parameter

settings for PROFIBUS DP

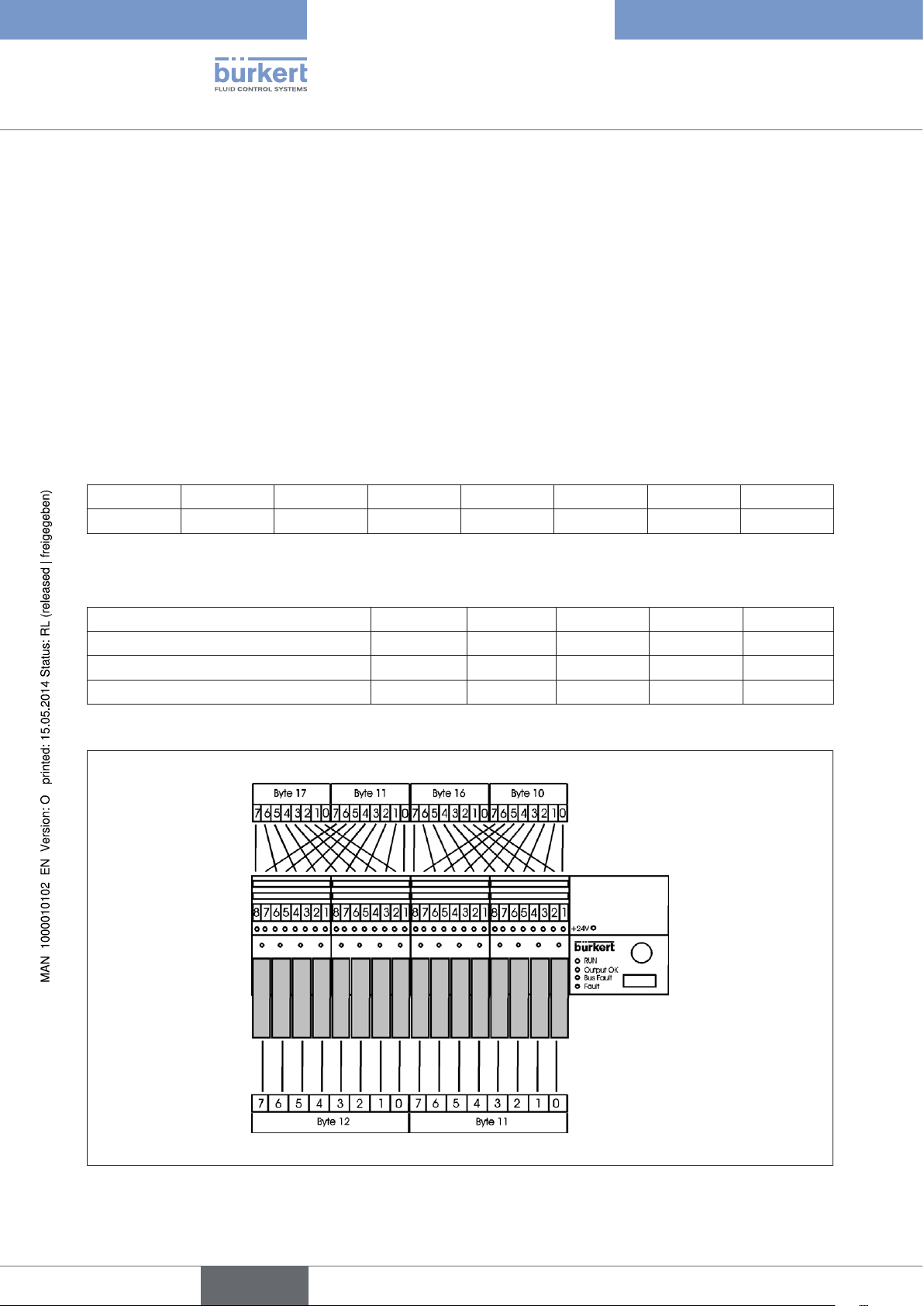

Example 4 - valve terminal with 16 valves (outputs) and 32 repeaters (inputs), every second repeat signal

not taken into account

• PROFIBUS-DP address 7

• The valves 1-8 are assigned to outputs (PAA) byte 17 in the process image.

• The valves 9-16 are assigned to outputs (PAA) byte 10 in the process image.

• Repeaters 1, 3, 5, ... 15 are assigned to inputs (PAE) byte 18 in the process image.

• Repeaters 1, 17, 19, ... 31 are assigned to inputs (PAE) byte 21 in the process image.

• Mode: Halved inputs

• Input filter active

DIP Switches

1 2 3 4 5 6 7 8

ON ON ON OFF OFF OFF OFF OFF

User parameter byte 11 User_Prm_Data 74 hex

Configuration:

Byte No. (slot) 1 (0) 2 (1) 3 (2) 4 (3)

Identification in Hex (Dec) 10 (016) 10 (016) 20 (032) 20 (032)

Process image output (PAA) 17 10

Process image input (PAE) 18 21

Allocation of inputs and outputs to control process image

Process image

Inputs (PAE)

Valve

Process image

Figure 17: Allocation of inputs and outputs to control process image

Outputs (PPA)

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

31

english

Page 32

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.2.3. Parameterization of the valve terminal with extension

terminal - bytewise composition of the inputs and outputs

The default value for the parameterization of the main terminal is:

• Extension terminal - none (must be adjusted bytewise on RIO)

• Input mode - normal inputs

• Filter - ON

When extension terminals are used the parameterization option extension terminals RIO bytewise must be

selected.

The parameterization can be used to modify the settings selected for the input mode and the filter.

Further, you may set the length of the device-related diagnosis, whereby the long diagnosis only makes sense

when more than four extension terminals are used. The following settings are permitted in the parameter telegram:

User parameter byte 11 User_Prm_Data

Input mode Input filter OFF Input filter ON Input filter OFF

long diagnosis

no inputs 05 hex 45 hex 85 hex C5 hex

normal inputs 15 hex 55 hex 95 hex D5 hex

shifted inputs 25 hex 65 hex A5 hex E5 hex

halved inputs 35 hex 75 hex B5 hex F5 hex

For a description of the input modes and the input filter refer to Section "9.3 Input modes".

Input filter ON long

diagnosis

9.2.4. Configuration of the valve terminal with extension terminal bytewise composition of the inputs and outputs

The settings of the desired configuration, i.e. setting of various identifiers, is generally done with the help of the GSD

file. Up to 18 identifiers (slots) can be assigned. Each extension terminal starts with a new byte in the process image.

For the main terminal and for each extension terminal 2 identifications are used, i.e. for bytewise configuration the

identifications for a single valve terminal must be contiguous. Each valve terminal can be configured with 4 input

bytes and 3 output bytes.

If there are no inputs / outputs present for a valve terminal, the identification 0 (space) must be entered

here.

Manual configuration: If no GSD file is available the configuration must be performed manually. The following

specifications apply:

32

Bit 7 Bit 6 Bit 5-4 Bit 3-0

Consistency

0 = byte/word

1 = total length

english

Bytes / Words

0 = bytes

1 = words (2 bytes)

Input / Output

00 = spec. identifier format

01 = input

10 = output

11 = input/output

Length (amount of data)

0000 = 1 byte / word

...

0010 = 3 bytes / words

...

1111 = 16 bytes / words

Page 33

Type 8640

Configuration and parameter

settings for PROFIBUS DP

Examples:

Hex Decimal Description

10 016 1 byte input; consistency via byte

11 017 2 bytes input; consistency via byte

12 018 3 bytes input; consistency via byte

13 019 4 bytes input; consistency via byte

20 032 1 byte input; consistency via byte

21 033 2 bytes input; consistency via byte

22 034 3 bytes input; consistency via byte

00 000 Placeholder (empty position)

Configuration

Slot Function Valve terminals

1 (0) Inputs Main terminal

2 (1) Outputs

3 (2) Inputs Extension terminal 0

4 (3) Outputs

(DIP switch on EI 0 S1=OFF, S2=OFF, S3=OFF)

5 (4) Inputs Extension terminal 1

6 (5) Outputs

(DIP switch on EI 1 S1=ON, S2=OFF, S3=OFF)

7 (6) Inputs Extension terminal 2

8 (7) Outputs

(DIP switch on EI 2 S1=OFF, S2=ON, S3=OFF)

9 (8) Inputs Extension terminal 3

10 (9) Outputs

(DIP switch on EI 3 S1=ON, S2=ON, S3=OFF)

11 (10) Inputs Extension terminal 4

12 (11) Outputs

(DIP switch on EI 4 S1=OFF, S2=OFF, S3=ON)

13 (12) Inputs Extension terminal 5

14 (13) Outputs

(DIP switch on EI 5 S1=ON, S2=OFF, S3=ON)

15 (14) Inputs Extension terminal 6

16 (15) Outputs

(DIP switch on EI 6 S1=OFF, S2=ON, S3=ON)

17 (16) Inputs Extension terminal 7

18 (17) Outputs

(DIP switch on EI 7 S1=ON, S2=ON, S3=ON)

english

33

Page 34

Type 8640

Configuration and parameter

settings for PROFIBUS DP

Example 5 - main terminal and 3 extension terminals Main terminal with 8 valves (outputs) and 16

repeaters (inputs)

• PROFIBUS-DP address 8

• The valves 1-8 are assigned to outputs (PAA) byte 30 in the process image.

• The repeaters 1-16 are assigned to inputs (PAE) bytes 15+16 in the process image.

• Mode: Normal input mode

• Input filter active

• RIO interface

DIP switch main terminal

1 2 3 4 5 6 7 8

OFF OFF OFF ON OFF OFF OFF OFF

Extension terminal 0 with 8 valves (outputs) and 16 repeaters (inputs)

• Address 0 (extension terminal 0 always has the address 0)

• The valves 1-8 are assigned to outputs (PAA) byte 12 in the process image.

• The repeaters 1-16 are assigned to inputs (PAE) bytes 20+21 in the process image.

• Mode: Normal input mode

• Input filter active

DIP switch extension terminal 0

1 2 3 4 5 6 7 8 9 10 11 12

OFF OFF OFF ON OFF OFF ON OFF ON OFF ON OFF

Extension terminal 1 with 8 valves (outputs) and 16 repeaters (inputs)

• Address 1 (extension terminal 1 always has the address 1)

• The valves 1-8 are assigned to outputs (PAA) byte 15 in the process image.

• The repeaters 1-16 are assigned to inputs (PAE) bytes 17+18 in the process image.

• Mode: Normal input mode

34

• Input filter active

DIP switch extension terminal 1

1 2 3 4 5 6 7 8 9 10 11 12

ON OFF OFF ON OFF OFF ON OFF ON OFF ON OFF

english

Page 35

Type 8640

Configuration and parameter

settings for PROFIBUS DP

Extension terminal 2 with 8 valves (outputs) and 16 repeaters (inputs)

• Address 2 (extension terminal 2 always has the address 2)

• The valves 1-8 are assigned to outputs (PAA) byte 16 in the process image.

• The repeaters 1-16 are assigned to inputs (PAE) bytes 22+23 in the process image.

• Mode: Normal input mode

• Input filter active

DIP switch extension terminal 2

1 2 3 4 5 6 7 8 9 10 11 12

OFF ON OFF ON OFF OFF ON OFF ON OFF ON OFF

User parameter byte 11 User_Prm_Data 55 hex

Configuration

Byte No. (slot) 1* (0)** 2 (1) 3 (2) 4 (3) 5 (4) 6 (5) 7 (6) 8 (7)

Identification in Hex

11 (017) 20 (032) 11 (017) 20 (032) 11 (017) 20 (032) 11 (017) 20 (032)

(Dec)

Process image output

30 12 15 16

(PAA)

Process image input

15+16 20+21 17+18 22+23

(PAE)

Main terminal Extension terminal 0 Extension terminal 1 Extension terminal 2

* Standard

** Siemens

35

english

Page 36

Allocation of inputs and outputs to control process image

Type 8640

Configuration and parameter

settings for PROFIBUS DP

Main terminal

Extension terminal 0

Extension terminal 1

Extension terminal 2

36

Figure 18: Allocation of inputs and outputs to control process image

english

Page 37

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.2.5. Parameterization (Hex parameter* / User_Prm_Data**)

of the valve terminal with extension terminal - bitwise

composition of the inputs and outputs

With bitwise composition of the inputs and outputs it is necessary to transmit user data (Hex parameters) via the

parameterization. The minimum information required in addition to the settings consists of the number of inputs

present on the main terminal, on the extension terminal 0, etc.

The default value for the parameterization of the main terminal is

• Extension terminal - none (must be adjusted bitwise on RIO)

• Input mode - normal inputs

• Filter - ON

When extension terminals are used the parameterization option extension terminals RIO bitwise must be

selected.

The parameterization can be used to modify the settings selected for the input mode and the filter.

Further, you may set the length of the device-related diagnosis, whereby the long diagnosis only makes sense

when more than four extension terminals are used.

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bus parameters (normal parameters) 7 bytes

Byte

Lock_Rep Unlock_Re Sync_Req

1

00 min TSDR and slave

spec. data

01 release for other masters

10 lock for other masters

11 release for other masters

WD_Fact_1 (range 1-255 signal monitoring in [s] = 10 ms x WD_Fact_1 x WD_Fact_2)

2

WD_Fact_2 (range 1-255 signal monitoring in [s] = 10 ms x WD_Fact_1 x WD_Fact_2)

3

TSDR (time in Tbits in which the slave may respond. At least 11 Tbit; 0 old value

4

Ident_Number high byte (manufacturer identification 00 Hex)

5

Ident_Number low byte (manufacturer identification 81 Hex)

6

Group_Ident (For group generation; each bit represents one group.)

7

Slave being

operated in

Sync mode

remains)

Freeze_Req

Slave being

operated in

Freeze mode

WD_ON

Signal monitoring

0: deactivated

1: activated

reserved reserved reserved

* Siemens

** Standard

37

english

Page 38

Type 8640

Configuration and parameter

settings for PROFIBUS DP

The following settings are permitted in the parameter telegram:

Byte No. Description

8 (0) DPV1_Status_1

9 (1) DPV1_Status_2

10 (2) DPV1_Status_3

11 (3) Input mode / Input filter / Diagnosis length See table below

12 (4) Number of bits inputs main terminal

13 (5) Number of bits outputs main terminal

14 (6) Number of bits inputs extension terminal 0 DIP switch on El 0: S1=OFF,

15 (7) Number of bits outputs extension terminal 0

S2=OFF, S3=OFF

16 (8) Number of bits inputs extension terminal 1 DIP switch on El 1: S1=ON,

17 (9) Number of bits outputs extension terminal 1

S2=OFF, S3=OFF

18 (10) Number of bits inputs extension terminal 2 DIP switch on El 2: S1=OFF,

19 (11) Number of bits outputs extension terminal 2

S2=ON, S3=OFF

20 (12) Number of bits inputs extension terminal 3 DIP switch on El 3: S1=ON,

21 (13) Number of bits outputs extension terminal 3

S2=ON, S3=OFF

22 (14) Number of bits inputs extension terminal 4 DIP switch on El 4: S1=OFF,

23 (15) Number of bits outputs extension terminal 4

S2=OFF, S3=ON

24 (16) Number of bits inputs extension terminal 5 DIP switch on El 5: S1=ON,

25 (17) Number of bits outputs extension terminal 5

S2=OFF, S3=ON

26 (18) Number of bits inputs extension terminal 6 DIP switch on El 6: S1=OFF,

27 (19) Number of bits outputs extension terminal 6

S2=ON, S3=ON

28 (20) Number of bits inputs extension terminal 7 DIP switch on El 7: S1=ON,

29 (21) Number of bits outputs extension terminal 7

S2=ON, S3=ON

38

Byte 11 (3)

Input mode Input filter OFF Input filter ON Input filter OFF

long diagnosis

no inputs 03 hex 43 hex 83 hex C3 hex

normal inputs 13 hex 53 hex 93 hex D3 hex

shifted inputs 23 hex 63 hex A3 hex E3 hex

halved inputs 33 hex 73 hex B3 hex F3 hex

For a description of the input modes and the input filter refer to Section “9.3. Mode inputs”.

Input filter ON

long diagnosis

english

Page 39

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.2.6. Configuration of the valve terminal with extension terminal bitwise composition of the inputs and outputs

The settings of the desired configuration, i.e. setting of various identifiers, is generally done with the help of the

GSD file.

By using different identifiers the user can assign the input and output bytes in the process image at will. The identifiers are independent of the individual valve terminals.

The inputs / outputs are composed to one bitstream each in accordance with the parameterization from the

main terminal and the extension terminals. The bytes can be distributed in the process image on the basis of the

identifiers.

Example with inputs: (Z - Assignment; K - Identifier)

Bit 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Z Main terminal Extension terminal 0 Extension terminal 1 U U

K 24DE (12hex)

or

Bit 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Z Main terminal Extension terminal 0 Extension terminal 1 U U

K 8DE (10 hex) 16DE (11 hex)

or

Bit 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Z Main terminal Extension terminal 0 Extension terminal 1 U U

K 16DE (11 hex) 8DE (10 hex)

or

Bit 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Z Main terminal Extension terminal 0 Extension terminal 1 U

K 8DE (10 hex) 8DE (10 hex) 8DE (10 hex)

U

Main terminal 4 bit inputs

Extension terminal 0 12 bit inputs

Extension terminal 1 6 bit inputs

U unused bit

Manual configuration

If no GSD file is available the configuration must be performed manually. The following specifications apply. One

configuration telegram can contain one or several identifications, whereby the user can make the necessary allocations at will. the identifications have the following structure:

Bit 7 Bit 6 Bit 5 - 4 Bit 3 - 0

Consistency

0 = byte/word

1 = total length

Bytes / Word

0 = bytes

1 = words (2 bytes)

Input / Output

00 = spec. identifier

format

01 = input

10 = output

11 = input/output

Length (amount of data)

0000 = 1 byte / word

...

0010 = 3 bytes / words

...

1111 = 16 bytes / words

39

english

Page 40

Type 8640

Configuration and parameter

settings for PROFIBUS DP

Example 6 - main terminal with 3 extension terminals Main terminal with 3 valves (outputs) and 3

repeaters (inputs), every second repeat signal not taken into account

• PROFIBUS-DP address 9

• Mode: halved inputs

• Input filter active

• RIO interface

DIP switch main terminal

1 2 3 4 5 6 7 8

ON OFF OFF ON OFF OFF OFF OFF

Extension terminal 0 with 4 valves (outputs) and no repeaters

• Address 0 (extension terminal 0 always has the address 0)

DIP switch extension terminal 0

1 2 3 4 5 6 7 8 9 10 11 12

OFF OFF OFF ON OFF OFF ON OFF OFF OFF OFF OFF

Extension terminal 1 with 2 valves (outputs) and 4 repeaters (inputs)

• Address 1 (extension terminal 1 always has the address 1)

• Mode: normal input mode

• Input filter active

DIP switch extension terminal 1

1 2 3 4 5 6 7 8 9 10 11 12

ON OFF OFF ON OFF OFF ON OFF ON OFF ON OFF

Extension terminal 2 with 3 valves (outputs) and 6 repeaters (inputs), every second repeat signal remains

unprocessed

• Address 2 (extension terminal 2 always has the address 2)

• Mode: halved inputs

• Input filter active

40

DIP switch extension terminal 2

1 2 3 4 5 6 7 8 9 10 11 12

OFF ON OFF ON OFF OFF ON OFF ON ON ON OFF

Parameter diagram

Here only the user parameters (User_Prm_Data) without the 3 DPV1 status bytes are shown. Counting in

brackets starting at zero (most configuration programs only show user parameters). Value in Hex format.

english

Page 41

Type 8640

Configuration and parameter

settings for PROFIBUS DP

Byte No. 11 (3) 12 (4) 13 (5) 14 (6) 15 (7) 16 (8) 17 (9) 18 (10) 19 (11)

Value

73 03 03 00 04 04 02 03 03

(HEX)

Mean-

ing

Parameter type

Input Output Input Output Input Output Input Output

Main terminal Extension terminal 0 Extension terminal 1 Extension terminal 2

Configuration

Byte No. (slot) 1 (0) 2 (1) 3 (2) 4 (3)

Identification in Hex (Dec) 10 (016) 10 (016) 20 (032) 20 (032)

Process image output (PPA) 11 14

Process image input (PAE) 15 20

Allocation of inputs and outputs to control process image

Main terminal

Extension terminal 0

Extension terminal 1

Figure 19: Allocation of inputs and outputs to control process image

Extension terminal 2

41

english

Page 42

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.3. Mode inputs

With the help of the input modes the inputs (repeaters) can be assigned diversely in the process image of

the outputs (PAE). The mode selection takes place in the parameter telegram.

9.3.1. Normal mode

In normal mode all outputs are read in from right to left.

Input module (e.g. 16-fold)

Power supply earth

Power supply +24 V

Inputs

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

Input module (e.g. 16-fold)

Power supply earth

Power supply +24 V

Inputs

EME 32

inputs

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Byte 3

Figure 20: Normal mode

Byte 2

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Byte 1

Byte 0

Extension module

9.3.2. Shifted inputs mode

In shifted inputs mode the first 16 inputs are placed alternatingly in byte 0 and byte 1 of the transmission log. The

same procedure is carried out for the following 16 inputs with byte 2 and byte 3.

Input module (e.g. 16-fold)

Power supply earth

Input module (e.g. 16-fold)

Power supply earth

EME 32

42

Power supply +24 V

Inputs

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Byte 3

Figure 21: Shifted inputs mode

Byte 2

english

Power supply +24 V

Inputs

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Byte 1

Byte 0

inputs

Extension module

Page 43

Type 8640

Configuration and parameter

settings for PROFIBUS DP

9.3.3. Halved inputs mode

In halved inputs mode every second input is skipped. Only the inputs 1, 3, 5, ... are transmitted, so for 32 physically existing inputs only 2 bytes are needed.

Input module (e.g. 16-fold)

Power supply earth

Power supply +24 V

Inputs

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

Input module (e.g. 16-fold)

Power supply earth

Power supply +24 V

Inputs

EME 32

inputs

8 7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

Extension module

Byte 1 Byte 0

Figure 22: Halved inputs mode

9.4. Input filter

The input filter suppresses disturbances which affect the input modules. Therefore the activation of this input filter

is always recommended.

When the filter is activated only signals are recognized which have a duration of ≥ 2 ms. The regulations

contained in EMC legislation require that the input filter be activated.

9.5. Special parameterization functions

Parameter 0x0E : Delete EEPROM