Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

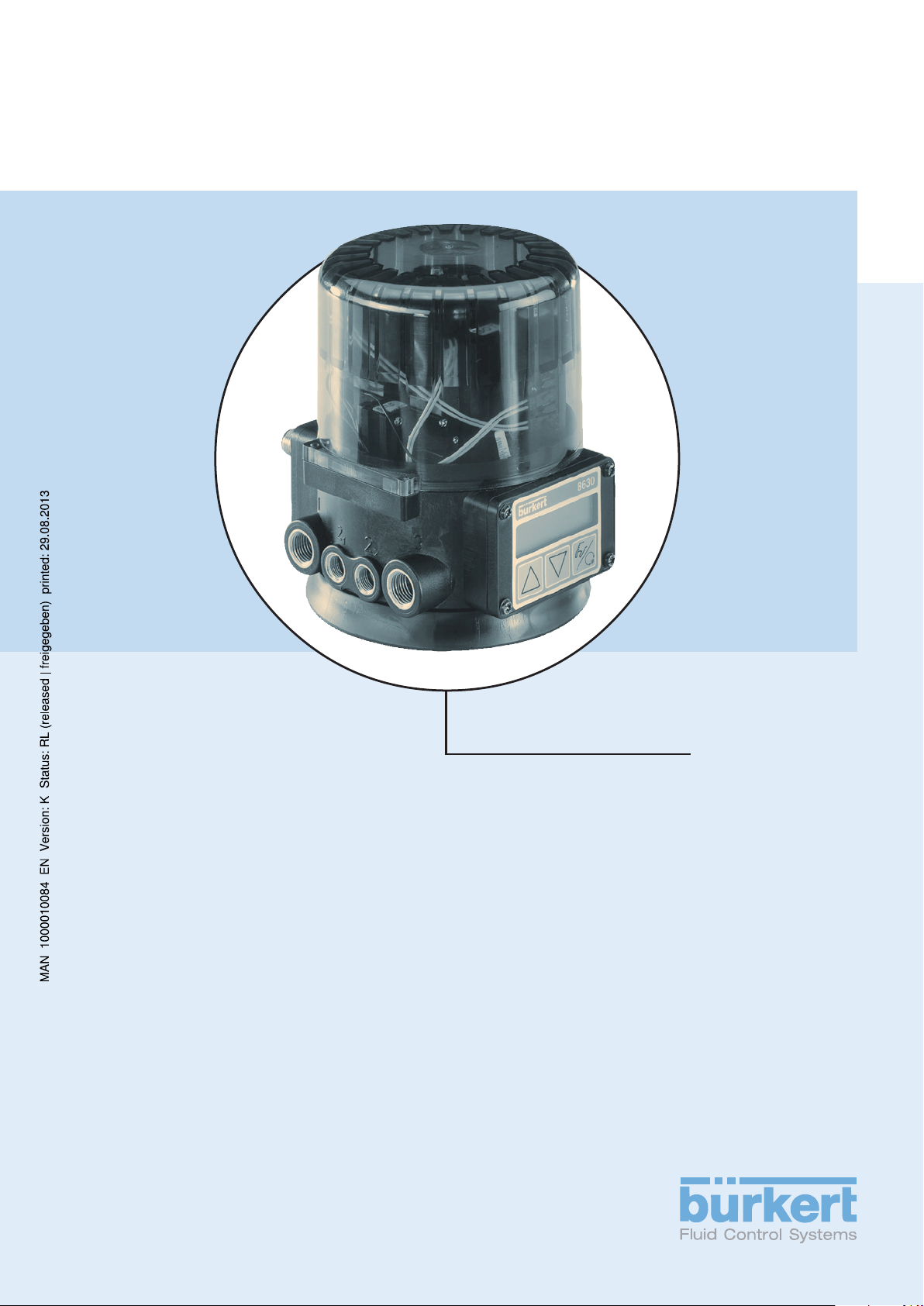

Type 8630

TOP Control Continuous

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2001 Bürkert Werke GmbH & Co KG.

Operating Instructions 0507/11_EU-EN_00804575

Page 3

Overall Operating Instructions

C

ONTENTS

TOP Control

Continuous 8630

GENERAL NOTES

Symbols.......................................................................................................................................................................................................................................................... 10

Intended use ............................................................................................................................................................................................................................................ 10

Safety notes .............................................................................................................................................................................................................................................. 10

Protection from damage by electrostatic charging ......................................................................................................................... 11

Scope of delivery .............................................................................................................................................................................................................................. 11

Warranty conditions ...................................................................................................................................................................................................................... 11

Master code .............................................................................................................................................................................................................................................. 12

Transport, storage ............................................................................................................................................................................................................................ 12

Disposal ......................................................................................................................................................................................................................................................... 12

SYSTEM DESCRIPTION

Valve types................................................................................................................................................................................................................................................. 14

Characteristics of the valve types

Construction of TOP Control Continuous ..................................................................................................................................................... 16

Illustrations (cover removed)

Design features

Functional diagram as a positioner with single-acting actuator

..................................................................................................................................................................................................................................... 17

Operation as a positioner ..................................................................................................................................................................................................... 19

Schematic representation of positioning control

Characteristics of the positioner software

...................................................................................................................................................................................... 15

................................................................................................................................................................................................... 16

............................................................................................................ 18

.................................................................................................................................................. 20

.................................................................................................................................................................. 21

*

Alternative chapters or functions depending on device configuration

8630 - 1

Page 4

C

ONTENTS

*Operation as a process controller (option)............................................................................................................................................... 22

Example of process control: TOP Control Continuous with sensor

Schematic representation of process control

Characteristics of the process controller software

......................................................................................................................................................... 23

............................................................................................................................................. 24

................................................................................................... 22

* Operation as a flow rate controller (option).......................................................................................................................................... 25

Characteristics of the flow rate controller software

Schematic representation of process control with flow rate controller

......................................................................................................................................... 25

....................................................................................... 26

* Interfaces of the TOP Control Continuous in the multipole variant .................................................................. 27

* Interfaces of the TOP Control Continuous in the variants with

cable bushings

.................................................................................................................................................................................................................................. 28

Technical data........................................................................................................................................................................................................................................ 29

Safety settings on failure of auxiliary electrical or pneumatic energy

Factory settings on the TOP Control Continuous

Data of the TOP Control Continuous

............................................................................................................................................................................. 31

............................................................................................................................................. 30

......................................................................................... 29

FIRST COMMISSIONING

Fluidic installation............................................................................................................................................................................................................................. 34

*Electrical installation - multipole connector ............................................................................................................................................ 35

*Electrical installation - connection terminals for cable bushings............................................................................ 36

Basic settings of the TOP Control Continuous..................................................................................................................................... 37

Settings in the menu items

Entering the position setpoint in the AUTOMATIC mode

Manual opening and closing of the valve actuator in the MANUAL mode

....................................................................................................................................................................................................... 38

.......................................................................................................................... 38

............................................................................. 39

INSTALLATION

Installation of the valve ............................................................................................................................................................................................................ 42

Turning the TOP Control Continuous.................................................................................................................................................................. 42

Procedure

................................................................................................................................................................................................................................................... 42

Fluidic connection of the TOP Control Continuous....................................................................................................................... 43

*

Alternative chapters or functions depending on device configuration

2 - 8630

Page 5

C

ONTENTS

*Electrical connection - multipole connectors ....................................................................................................................................... 44

Marking of the multipole plugs or sockets and the contacts

Output signals for SPS (circular plug M 16)

Operating voltage (circular plug M 12)

Inductive proximity switches (circular socket M 8)

Process value (circular plug M 8)

....................................................................................................................................................................................... 46

............................................................................................................................................................. 45

............................................................................................................................................................................ 45

........................................................................................................................................... 45

Process value with the option flow rate controller (2 circular plugs M 8)

Option: with temperature sensor input (3 circular plugs M 8)

................................................................................................................... 44

.............................................................................................................. 46

*Electrical connection - terminals for cable bushing.................................................................................................................... 47

Connection PCB of the TOP Control Continuous with screw terminals and jumpers ................................................ 47

Terminal configuration with cable bushings

Choice of binary outputs or process value input

............................................................................................................................................................ 47

............................................................................................................................................... 48

*Setting the inductive proximity switches (option)........................................................................................................................... 50

Opening the housing of the TOP Control Continuous

Positioning the inductive proximity switches

.......................................................................................................................................................... 50

................................................................................................................................. 50

OPERATION AND CONTROLLER FUNCTIONS

Operating and display elements ................................................................................................................................................................................ 52

Operating levels.................................................................................................................................................................................................................................. 52

Commissioning and set-up as a positioner............................................................................................................................................... 53

Procedure for specifying the basic settings

Main menu for the settings on commissioning

Description of the procedure

.................................................................................................................................................................................................. 55

Configuring the supplementary functions .................................................................................................................................................... 59

Keys in the configuration level

Configuration menu

.......................................................................................................................................................................................................................... 59

Supplementary functions

.............................................................................................................................................................................................. 59

........................................................................................................................................................................................................... 62

Operating the process............................................................................................................................................................................................................... 86

Changeover between operating modes

Operating mode AUTOMATIC....................................................................................................................................................................................... 87

Meaning of the keys in the AUTOMATIC mode

Display of the AUTOMATIC mode

..................................................................................................................................................................................... 87

............................................................................................................................................................ 53

.................................................................................................................................................... 54

...................................................................................................................................................................... 86

.................................................................................................................................................. 87

Operating mode MANUAL.................................................................................................................................................................................................. 88

Meaning of the keys in the MANUAL mode

Display of the MANUAL mode

*

Alternative chapters or functions depending on device configuration

.............................................................................................................................................................................................. 88

............................................................................................................................................................ 88

8630 - 3

Page 6

C

ONTENTS

OPERATING THE PROCESS CONTROLLER

Factory settings on the process controller................................................................................................................................................... 90

Setting up a process control system .................................................................................................................................................................... 90

Self-parametrization of the positioner -

Supplementary function

Basic settings of the function

P.Q’LIN

P.CO TUNE -

P.CO LEAK -

- Starting the routine for linearization of the process curve ..................................................................... 105

Display during call-up and execution of the routine

Self-optimization of the process controller (process tune) ..................................................... 106

Leakage characteristic for flow rate control ................................................................................................... 110

P.CONTRL

P.CONTRL

X.TUNE

.................................................................................................................................................................... 91

................................................................................................................................................................... 92

............................................................................................................................... 91

.......................................................................................................................................... 105

Operating the process ............................................................................................................................................................................................................... 112

Changeover between the operating modes

................................................................................................................................................................ 112

Operating mode AUTOMATIC....................................................................................................................................................................................... 113

Meaning of the keys

Displays

........................................................................................................................................................................................................................................................ 113

Operating structure and procedures

......................................................................................................................................................................................................................... 113

.................................................................................................................................................................................. 113

Manually changing the process setpoint ...................................................................................................................................................... 114

Operating mode MANUAL.................................................................................................................................................................................................. 114

Meaning of the keys

Displays

........................................................................................................................................................................................................................................................ 115

Operating structure and procedures

......................................................................................................................................................................................................................... 114

.................................................................................................................................................................................. 115

PROFIBUS DP

General notes......................................................................................................................................................................................................................................... 118

Technical data ....................................................................................................................................................................................................................................... 118

Safety settings on bus failure ......................................................................................................................................................................................... 118

Interfaces....................................................................................................................................................................................................................................................... 119

Electrical connections ............................................................................................................................................................................................................... 119

Connection with one plugged bus connector

Connection with 2 plugged bus connectors

Operating voltage (circular plug M12)

Bus connection (circular socket M12)

........................................................................................................................................................... 119

.............................................................................................................................................................. 120

............................................................................................................................................................................. 120

............................................................................................................................................................................ 120

4 - 8630

Page 7

C

ONTENTS

Inductive proximity switches (circular socket M8)............................................................................................................................................. 121

Process value (circular plug M8)

Termination connection for PROFIBUS systems

......................................................................................................................................................................................... 121

................................................................................................................................................ 122

Settings on the TOP Control Continuous ..................................................................................................................................................... 123

Explanation of the menu items .............................................................................................................................................................................................. 124

Functional deviations from the standard version.............................................................................................................................. 124

Configuration in the Profibus DP master ...................................................................................................................................................... 125

Configuration of the process values

................................................................................................................................................................................. 125

Bus status display ........................................................................................................................................................................................................................... 127

Example 1 with COM-Profibus V3.3 .................................................................................................................................................................... 128

Example for a positioner

............................................................................................................................................................................................................... 128

Example 2 with COM-Profibus V3.3 .................................................................................................................................................................... 131

Example for a process controller

......................................................................................................................................................................................... 131

DEVICE NET

General notes......................................................................................................................................................................................................................................... 134

Explanation of terms .................................................................................................................................................................................................................... 134

Technical data ....................................................................................................................................................................................................................................... 135

Safety settings on bus failure ......................................................................................................................................................................................... 135

Interfaces....................................................................................................................................................................................................................................................... 136

Electrical connection................................................................................................................................................................................................................... 136

Operating voltage (4-pole M12 circular plug)

Bus connection (4-pole M12 circular plug)

Inductive proximity switches (4-pole M8 circular socket)

Process value (circular plug M8)

......................................................................................................................................................................................... 137

Termination connection for DeviceNet systems

Net topology of a DeviceNet system

............................................................................................................................................................................... 138

Settings on the TOP Control Continuous ..................................................................................................................................................... 139

Explanation of the menu items in the program run-off schematic

Settings in the main menu

......................................................................................................................................................................................................... 140

........................................................................................................................................................... 137

................................................................................................................................................................. 137

........................................................................................................................... 137

................................................................................................................................................... 138

...................................................................................................... 139

Configuring the process data ......................................................................................................................................................................................... 141

Static input assemblies

Static output assemblies

................................................................................................................................................................................................................. 141

............................................................................................................................................................................................................. 143

8630 - 5

Page 8

C

ONTENTS

Bus status display ........................................................................................................................................................................................................................... 144

Configuration example 1 ....................................................................................................................................................................................................... 145

Installation of the EDS file

Address allocation

Offline parametrization of the device

Online parametrization of the device

.............................................................................................................................................................................................................................. 145

......................................................................................................................................................................................................... 145

............................................................................................................................................................................... 146

............................................................................................................................................................................... 147

Configuration example 2 ....................................................................................................................................................................................................... 148

Setting up the process map (mapping)

.......................................................................................................................................................................... 149

MAINTENANCE AND ERROR CORRECTION ON THE POSITIONER

Maintenance ............................................................................................................................................................................................................................................ 152

Error messages and malfunctions .......................................................................................................................................................................... 152

Error messages on the LC display

Other malfunctions

............................................................................................................................................................................................................................. 152

..................................................................................................................................................................................... 152

MAINTENANCE AND ERROR CORRETION ON THE

PROCESS CONTROLLER

Maintenance ............................................................................................................................................................................................................................................ 154

Error messages and malfunctions .......................................................................................................................................................................... 154

Error messages on the LC display

Other malfunctions

............................................................................................................................................................................................................................. 156

..................................................................................................................................................................................... 154

Appendix

6 - 8630

Page 9

C

ONTENTS

GENERAL RULES

Selection criteria for continuous valves .......................................................................................................................................................... 158

Characteristics of PID controllers............................................................................................................................................................................. 160

P component

I component

D component

Superimposing the P, I and D components

Function of a real PID controller

Rules for setting PID controllers ................................................................................................................................................................................ 165

Setting rules of Ziegler and Nichols (oscillation method)

Setting rules of Chien, Hrones and Reswick (controller output step method)

............................................................................................................................................................................................................................................ 160

.............................................................................................................................................................................................................................................. 161

............................................................................................................................................................................................................................................ 162

............................................................................................................................................................... 163

........................................................................................................................................................................................... 164

............................................................................................................................ 165

........................................................................ 166

OPERATING STRUCTURE

Operating structure of the TOP Control Continuous..................................................................................................................... 170

TABLE FOR POSITIONER

Table for noting your settings on the positioner .................................................................................................................................. 178

TABLE FOR PROCESS CONTROLLER

Tables for noting your settings on the process controller ..................................................................................................... 180

MASTER CODE

Code number .......................................................................................................................................................................................................................................... 182

8630 - 7

Page 10

C

ONTENTS

8 - 8630

Page 11

G

ENERAL NOTES

GENERAL NOTES

Symbols.............................................................................................................................................................................................................................................................. 10

Intended use

Safety notes

Protection from damage by electrostatic charging

Scope of delivery

Warranty conditions

................................................................................................................................................................................................................................................ 10

.................................................................................................................................................................................................................................................. 10

............................................................................................................................. 11

.................................................................................................................................................................................................................................. 11

.......................................................................................................................................................................................................................... 11

Master code .................................................................................................................................................................................................................................................. 12

Transport, storage

................................................................................................................................................................................................................................ 12

Disposal ............................................................................................................................................................................................................................................................. 12

8630 - 9

Page 12

GENERAL NOTES

Symbols

The following symbols are used in these operating instructions:

marks a work step that you must carry out.

ATTENTION!

NOTE

Intended use

In order for the device to function perfectly and have a long service life, you must observe the information

given in these operating instructions and comply with the operating conditions and the permissible data

for the TOP Control Continuous, in addition to the information for the respective pneumatically actuated

valve, which is specified in the „Technical Data“ chapter of these instructions and in the valve

instructions.

Please note that the Top control Continuous may not be used out-of-doors.

In view of the large number of possible applications and categories of use, you should check whether the

Top control Continuous is suitable for your specific application, and carry out tests where necessary.

Safety notes

marks notes on whose non-observance your health or the functioning of the device

will be endangered.

marks important additional information, tips and recommendations.

• Keep to standard engineering rules in planning the use of and operating the device!

• Installation and maintenance work are only allowed by specialist personnel using suitable tools!

• Observe the current regulations on accident prevention and safety during operation and maintenance

of the device!

• Switch off the supply voltage in all cases before intervening in the system!

• Note that in systems under pressure, piping and valves may not be loosened!

• Take suitable precautions to prevent inadvertent operation or damage by unauthorized action!

• Make sure that after an interruption to the electrical or pneumatic supply, the process starts up again in

a well-defined, controlled manner!

• On non-observance of these notes and unauthorized interference with the device, we will refuse all

liability and the warranty on device and accessories will become void!

10 - 8630

Page 13

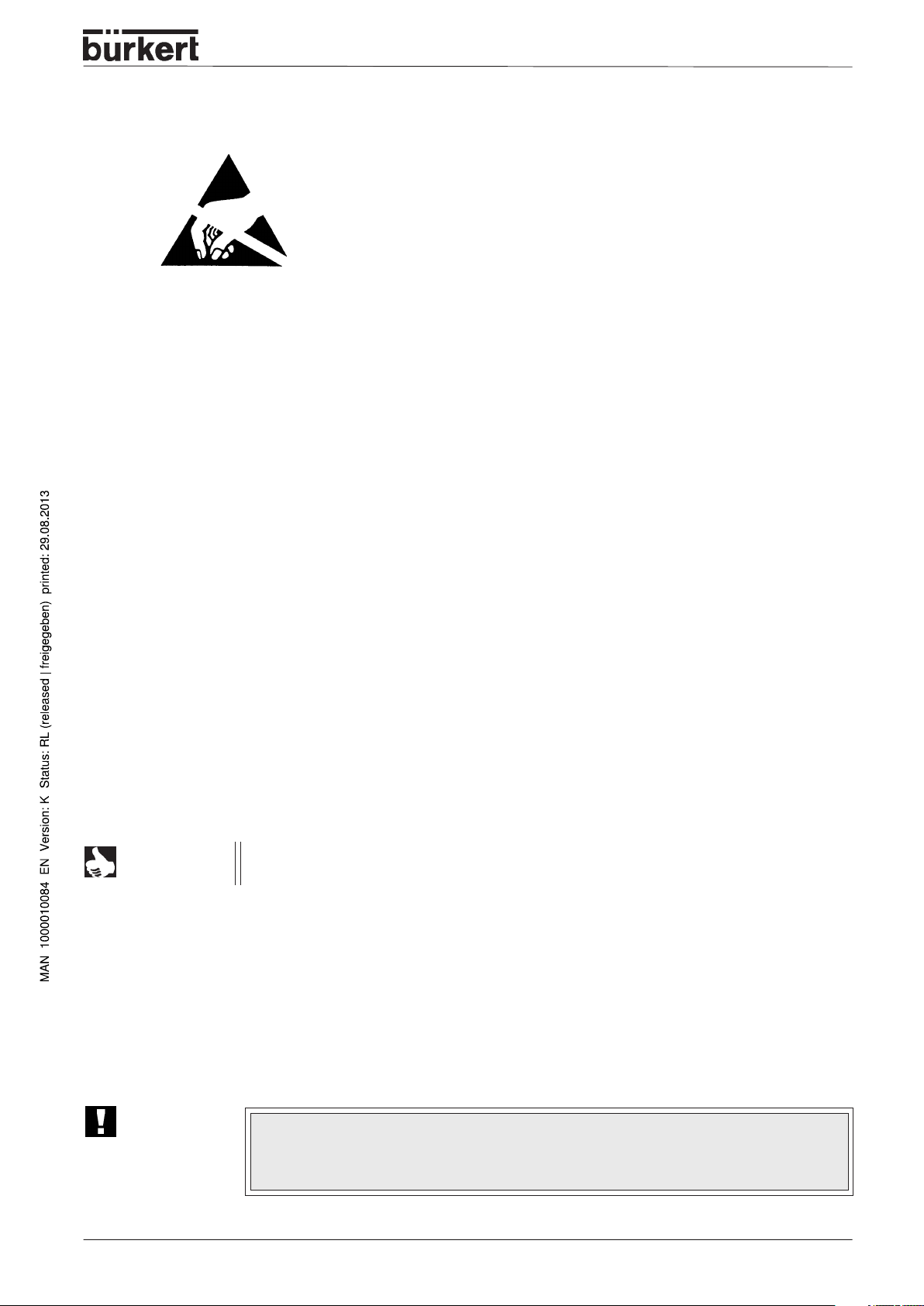

Protection from damage by electrostatic charging

This device contains electronic components that are sensitive to

electrostatic discharge (ESD). Contact to electrostatically charged

persons or objects will endanger these components. In the worst

case, they will be immediately destroyed or will fail after

commissioning.

GENERAL NOTES

ATTENTION

EXERCISE CAUTION ON HANDLING!

ELECTROSTATICALLY SENSITITVE

COMPONENTS/MODULES

Observe the requirements of EN 100 015 - 1 in order to minimize

the possibility of, or avoid, damage from instantaneous electrostatic

discharge. Also take care not to touch components that are under

supply voltage.

Scope of delivery

Immediately after receipt of a shipment, make sure that the contents are undamaged and match the

scope of delivery stated on the packing slip. In general this consists of:

• Pneumatically actuated valve of type 2652, 2655, 2672, 2700, 2712, 2730, 2731 or 2731K with attached

TOP Control

• Operating Instructions for the TOP Control

If there are discrepancies, please contact immediately our customer service:

Continuous,

Continuous and for the valve with pneumatic actuation.

Bürkert Fluid Control Systems

Chr.-Bürkert-Str. 13-17

Service Department

D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

E-Mail: info@de.buerkert.com

NOTE

Suitable cable plugs for the multipole connection are available as accessoires.

Warranty conditions

This document contains no warranty promises. We refer in this connection to our General Conditions of

Sale and Business. The condition for the warranty is use of the unit for the intended purpose under the

specified application conditions.

ATTENTION!

The warranty covers only faultless condition of the TOP Control Continuous and the

attached valve with pneumatic actuation. No liability will be accepted for consequential

damage of any kind that may arise from failure or malfunctioning of the device.

8630 - 11

Page 14

GENERAL NOTES

Master Code

Operation of this device can be locked by means of a freely selectable user code. Independent of this,

there exists an unchangeable master code with which you can execute all operative actions on the

device. This 4-digit code is to found on the last page of these operating instructions.

If required, cut out this code and keep it separate from these operating instructions.

Transport, storage

ATTENTION!

Transport and store the appliance in its original packing only.

Disposal

ATTENTION!

When disponsing of the appliance, observe the national standards for refuse disposal.

12 - 8630

Page 15

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

Valve types ................................................................................................................................................................................................................................................ 14

Characteristics of the valve types .......................................................................................................................................................................... 15

Construction of TOP Control Continuous.................................................................................................................................................... 16

Illustrations (cover removed) ........................................................................................................................................................................................ 16

Design features

Functional diagram as a positioner with single-acting actuator

.............................................................................................................................................................................................................................. 17

....................................................................................... 18

Operation as a positioner.................................................................................................................................................................................................... 19

Schematic representation of positioning control ................................................................................................................................. 20

Characteristics of the positioner software

................................................................................................................................................... 21

* Operation as a process controller (option) .......................................................................................................................................... 22

Example of process control: TOP Control Continuous with sensor ............................................................................ 22

Schematic representation of process control

Characteristics of the process controller software

.......................................................................................................................................... 23

............................................................................................................................ 24

* Operation as a flow rate controller (option)......................................................................................................................................... 25

Characteristics of the flow rate controller software.......................................................................................................................... 25

Schematic representation of process control with flow rate controller

................................................................... 26

* Interfaces of the TOP Control Continuous in the multipole variant ................................................................. 27

* Interfaces of the TOP Control Continuous in the variants with cable bushings ........................... 28

Technical data

Safety settings on failure of auxiliary electrical or pneumatic energy ...................................................................... 29

Factory settings on the TOP Control Continuous

Data of the TOP Control Continuous

* Alternative chapters or functions depending on device configuration

....................................................................................................................................................................................................................................... 29

............................................................................................................................... 30

.................................................................................................................................................................. 31

8630 - 13

Page 16

SYSTEM DESCRIPTION

By the combination of the TOP Control with pneumatically actuated process valves, the functionality of

the Bürkert process valve series is extended. These valves, in connection with the TOP Control, may

also be employed in those control applications requiring continuous behaviour of the actuator.

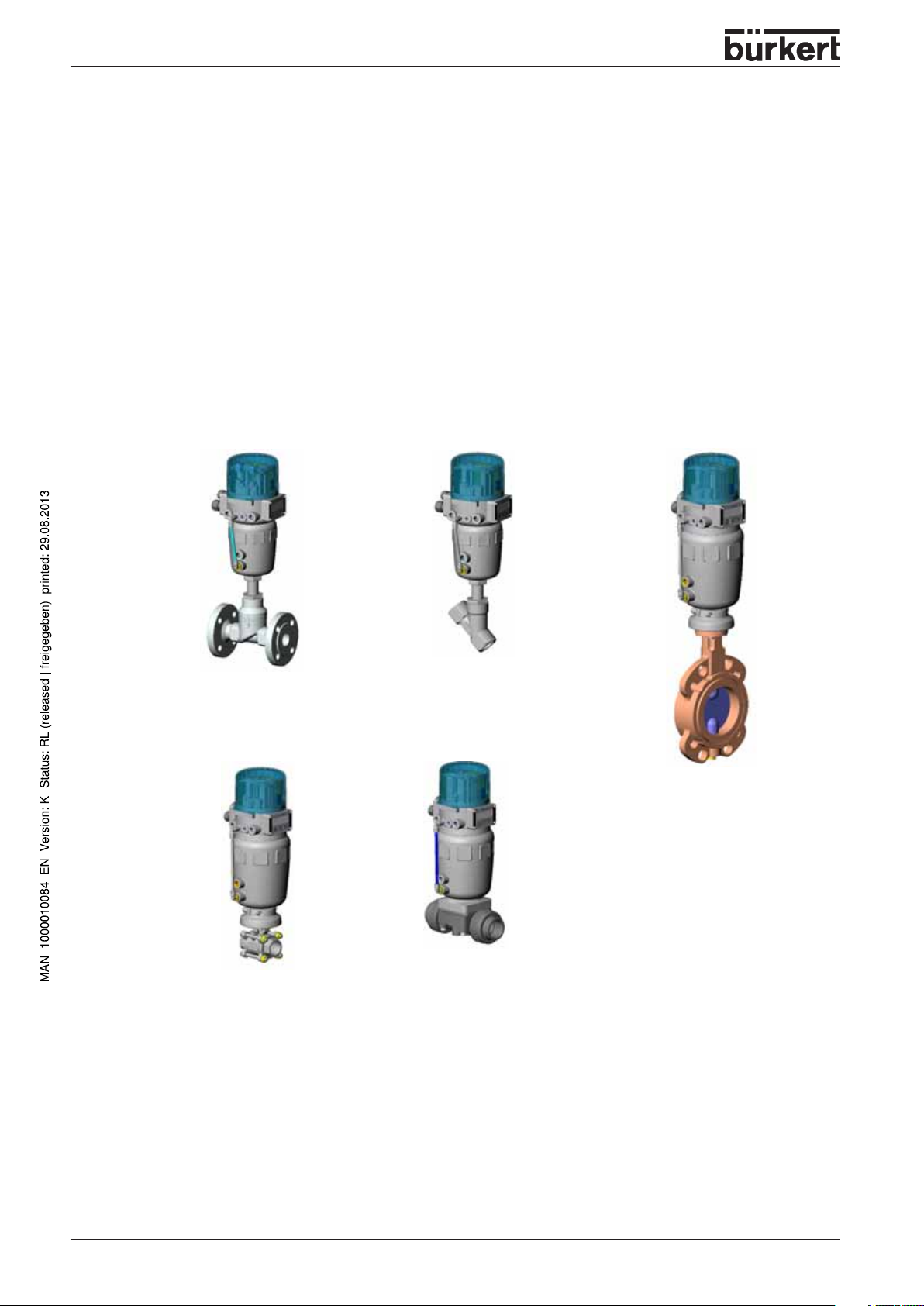

Valve types

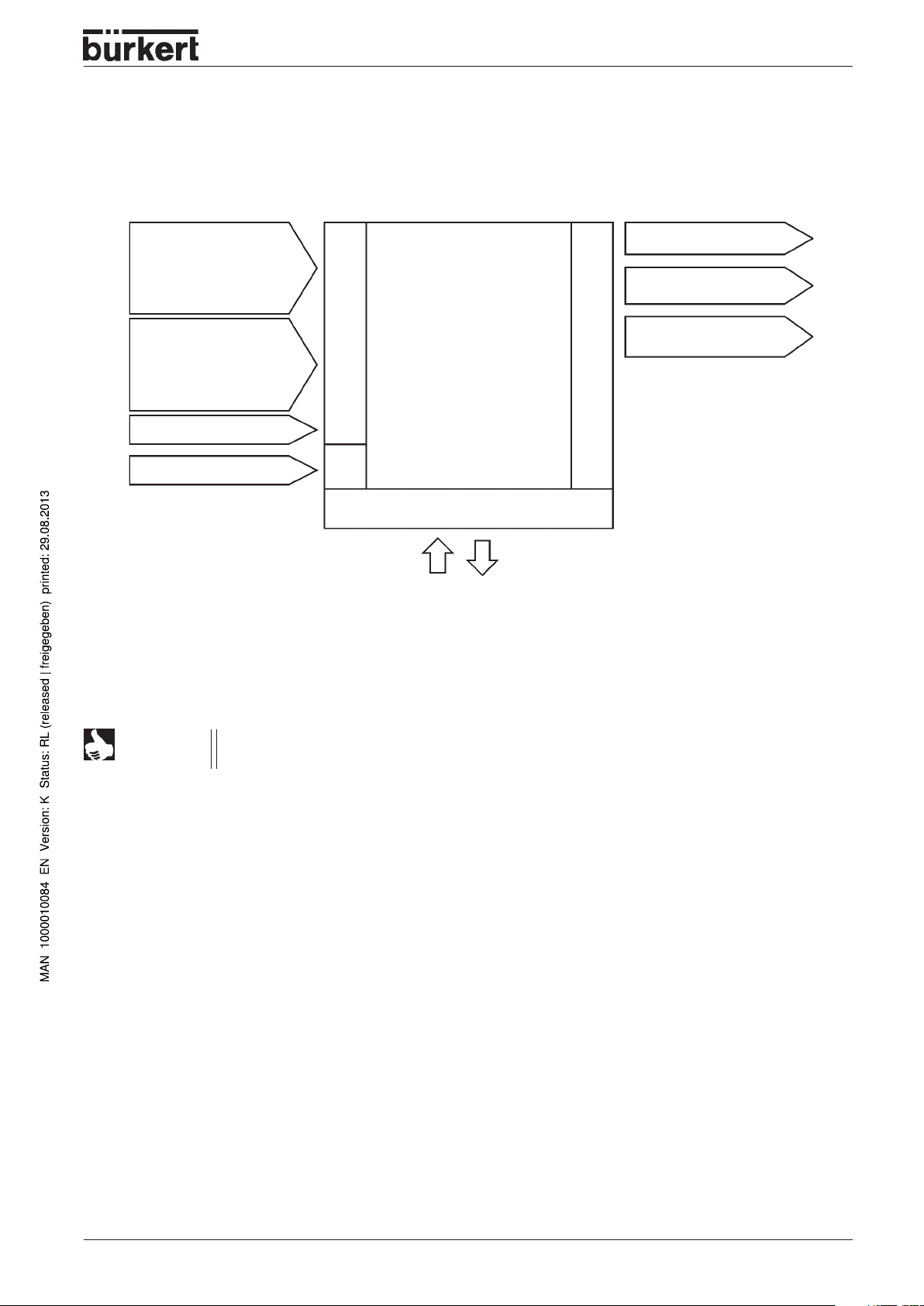

The figure below gives an overview of the possible combinations of TOP Control and various

pneumatically actuated valves. For each type, various actuator sizes and valve sizes are available (not

shown). More detailled information is to be found on the respective data sheets. The product range is

being extended continually.

TOP Control

Continuous

Type 8630

with flat-seat valve

Type 2712

(here with flange connection)

TOP Control

Continuous

Type 8630

with ball valve

Type 2655

with Y-valve Type 2700

with butterfly valve

Type 2672

with diaphragm valve

Type 2730

Various process valves from the Bürkert range can be combined with the TOP Control to suit different

applications. Y-, diaphragm or ball valves with control cones are suitable.

14 - 8630

Page 17

SYSTEM DESCRIPTION

Pneumatically driven piston and rotary actuators may be used to operate them. Both single-acting and doubleacting actuators are offered in combination with TOP Control Continuous.

With single-acting actuators, only one chamber in the actuator is pressurized and vented. The pressure

produced works against a spring. The piston moves until an equilibrium is set up between the pressure and the

spring force.

With double-acting actuators, the chambers on both sides of the piston are pressurized. When the one

chamber is pressurized, the other is vented and vice versa. No spring is installed in this actuator version.

Characteristics of the valve types

Typ es

Characteristic

Y-valves

Flat seat valves

• 2700

• 2712

• Inlet flow under seat

• Non-impact closure

• Straight flow of

medium

• Self-adjusting packed

gland for very tight seal

Diaphram valves Ball valves Flap valves

• 2730 (plastic)

• 2731 (metal)

• 2731K (pipe housing)

• Medium is hermeti cally separated from

actuator and the

ambient

• Self-draining housing

design without dead

spaces

• Either flow direction

with low turbulence

flow

• May be steam

sterilized

• CIP compatible

• Non-impact closure

• Actuator and dia phragm are de tachable with the

housing

• 2652 (2-part,VA)

• 2655 (3-part,VA)

• 2658 (plastic)

• Piggable

• Low and dead space

• insensitive to

contamination

• Lower pressure loss

than with other valve

types

• with 3-part ball valve,

seat and seal can be

exchaged while

installed

Note

Only usable as process

controller.

• 2672 (metal)

• 2675 (plastic)

• insusceptible to dirt

• less pressure loss

compared to other

valve types

• good value for money

• smaller volume

Typ ica l me dia

• Water, steam and

gases

• Alcohols, oils, fuels,

hydraulic fluides

• Salt solutions, lyes

(organic)

• Organic solvents

• Neutral gases and

liquids

• contaminated, ab rasive and aggressive

media

• high purity or sterile

media

• high viscosity media

• Neutral gases and

liquids

• pure water

• slightly aggressive

media

• Neutral gases and

fluides

• slightly aggressive

media

8630 - 15

Page 18

SYSTEM DESCRIPTION

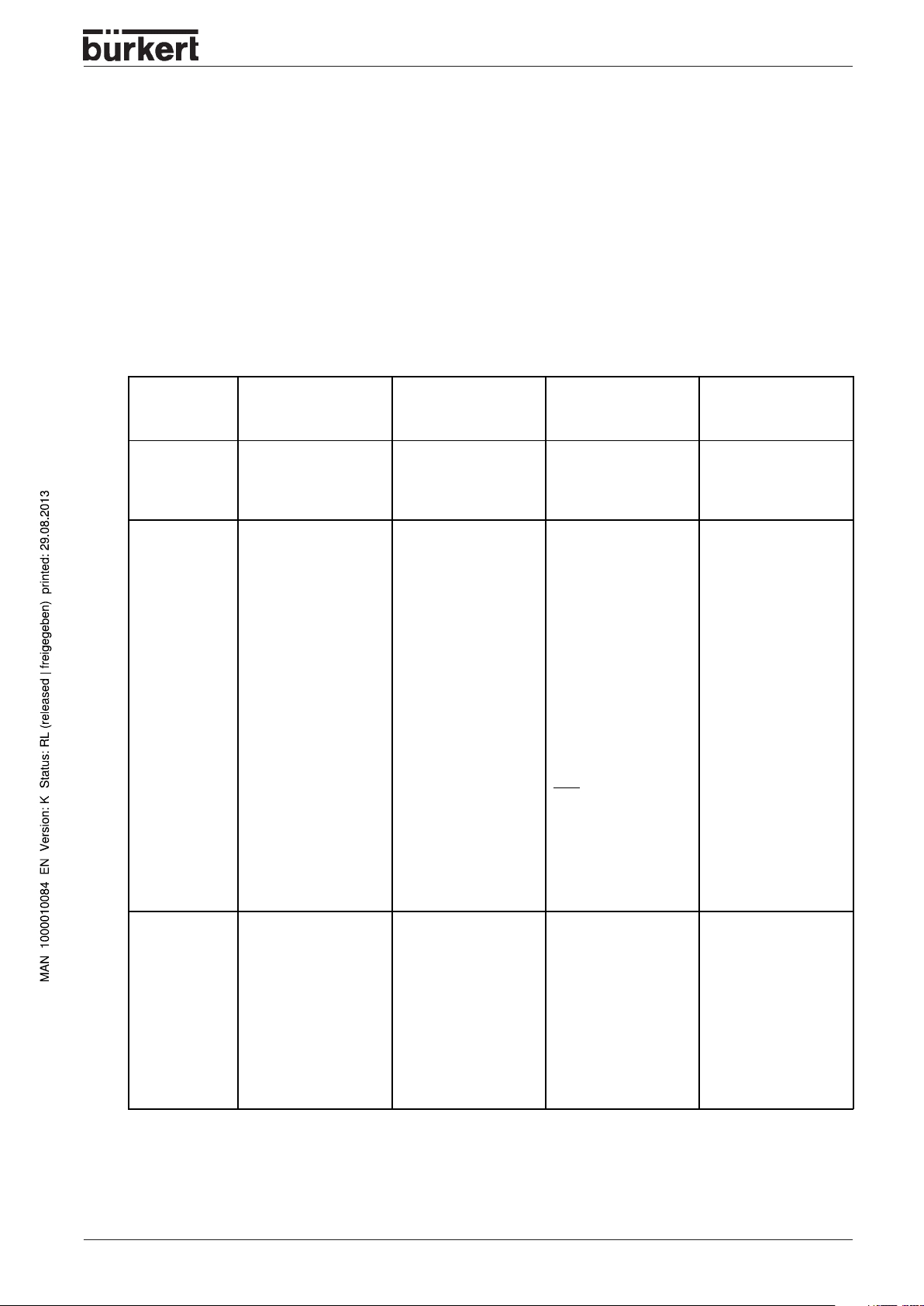

Construction of TOP Control Continuous

Illustrations (cover removed)

Positioning system

with 2, 3 or 4 solenoid valves

Screw for adjusting the lower proximity

switch

Screw for adjusting the upper proximity

switch

Pressure supply port

(marked: 1)

Control ports

(connected in the

factory)

Operating module with display and

keys

Exhaust air ports

(marked 3)

16 - 8630

Fixing screw for fixing the

TOP Control Continuous

on the drive

Max. torque 1.2 Nm

Electrical connection module,

here with multipole connectors

Page 19

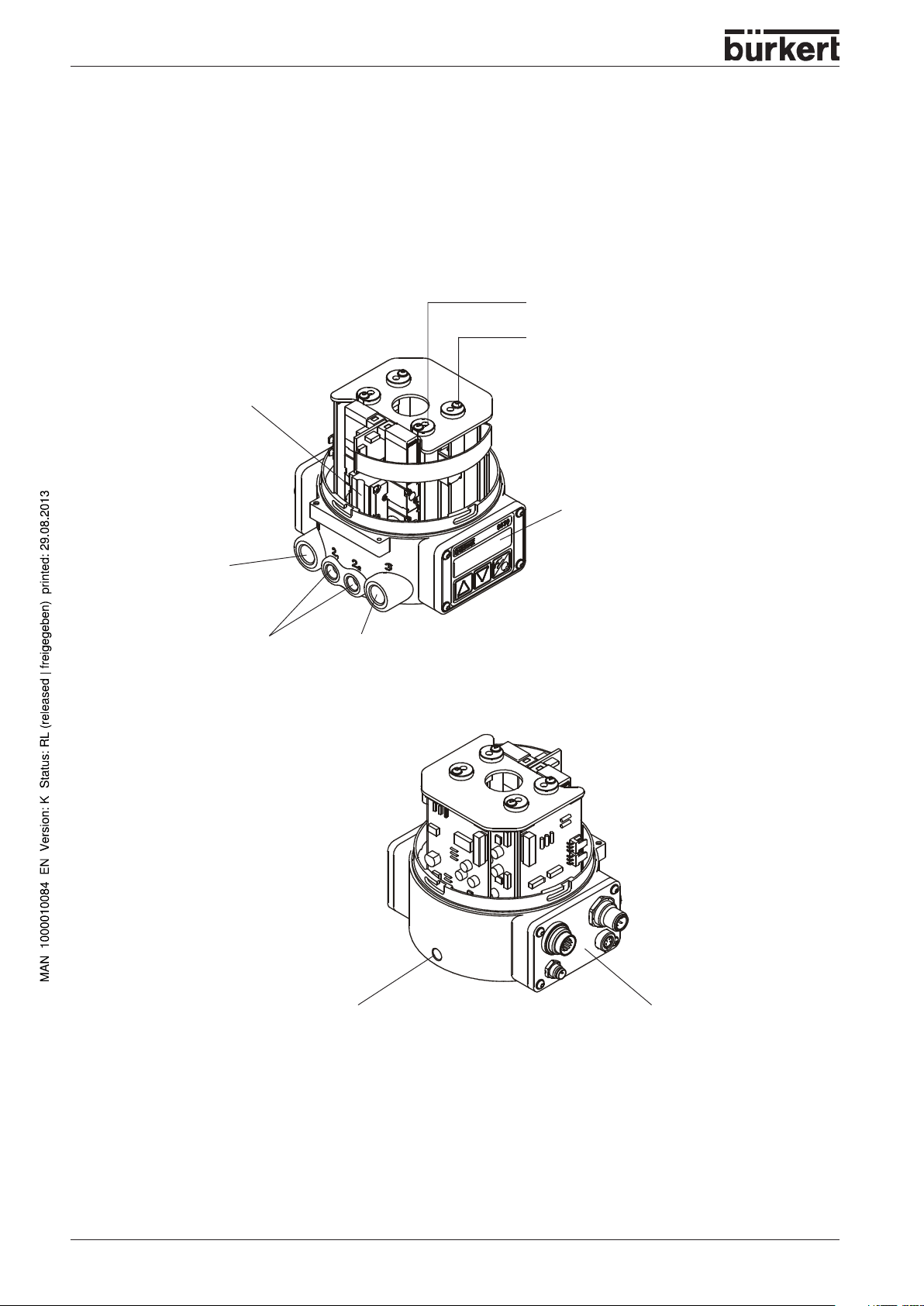

Design features

•

Versions

for single and double acting valve actuators

Position sensor

•

very high resolution conductive plastic potentiometer, coupled without play to the piston rod of the

pneumatic actuator

Microprocessor controlled electronics

•

for signal processing, control and driving the valve

Operating module

•

The device is operated via 3 keys. 8-digit, 16-segment LC display for showing the setpoint or actual

value and for configuration and parametrization via menu functions.

Positioning system

•

With single-acting actuators, the positioning system consists of 2 solenoid valves; with double-acting

actuators of four solenoid valves. With single-acting actuators, one valve serves to pressurize the

pneumatic piston drive and another to exhaust it. Double-acting actuators contain 2 valves for

pressurization and 2 for exhausting.The solenoid valves work on the rocker principle and are driven

via the controller with a PWM voltage. This enables great flexibility with regard to actuator volumes

and floating speed. For larger pneumatic actuators, the solenoid valve are equipped with diaphragm

boosters.

SYSTEM DESCRIPTION

As an option, with single-acting actuators, there are fast pressurizing/exhaust variants with an additional pressurizing valve and an additional exhaust valve. These enable the actuator to be completely

pressurized and exhausted more rapidly. This is used with the tight-closure function (see section

"

CUTOFF

Position repeater (optional)

•

2 inductive proximity switches (initiators) or mechanical limit switches.

Attainment of an upper or lower position of the valve can be relayed via binary outputs e.g. to a PLC.

The end settings on the initiators can be adjusted by the owner by means of setscrews.

") and on activation of a safety position of 0 or 100% (see section "

BIN-IN

").

•

Pneumatic interfaces

1/4’’- connectors in various threads

(G, NPT, RC)

•

Housing

The housing of the TOP Control is protected by a pressure relief valve from excessive internal

pressure, e.g. resulting from leaks.

The cover may be secured against unauthorized opening with a lead seal or with a self-tapping

screw.

•

Electrical interfaces

Multipole plug connector or cable bushing

8630 - 17

Page 20

SYSTEM DESCRIPTION

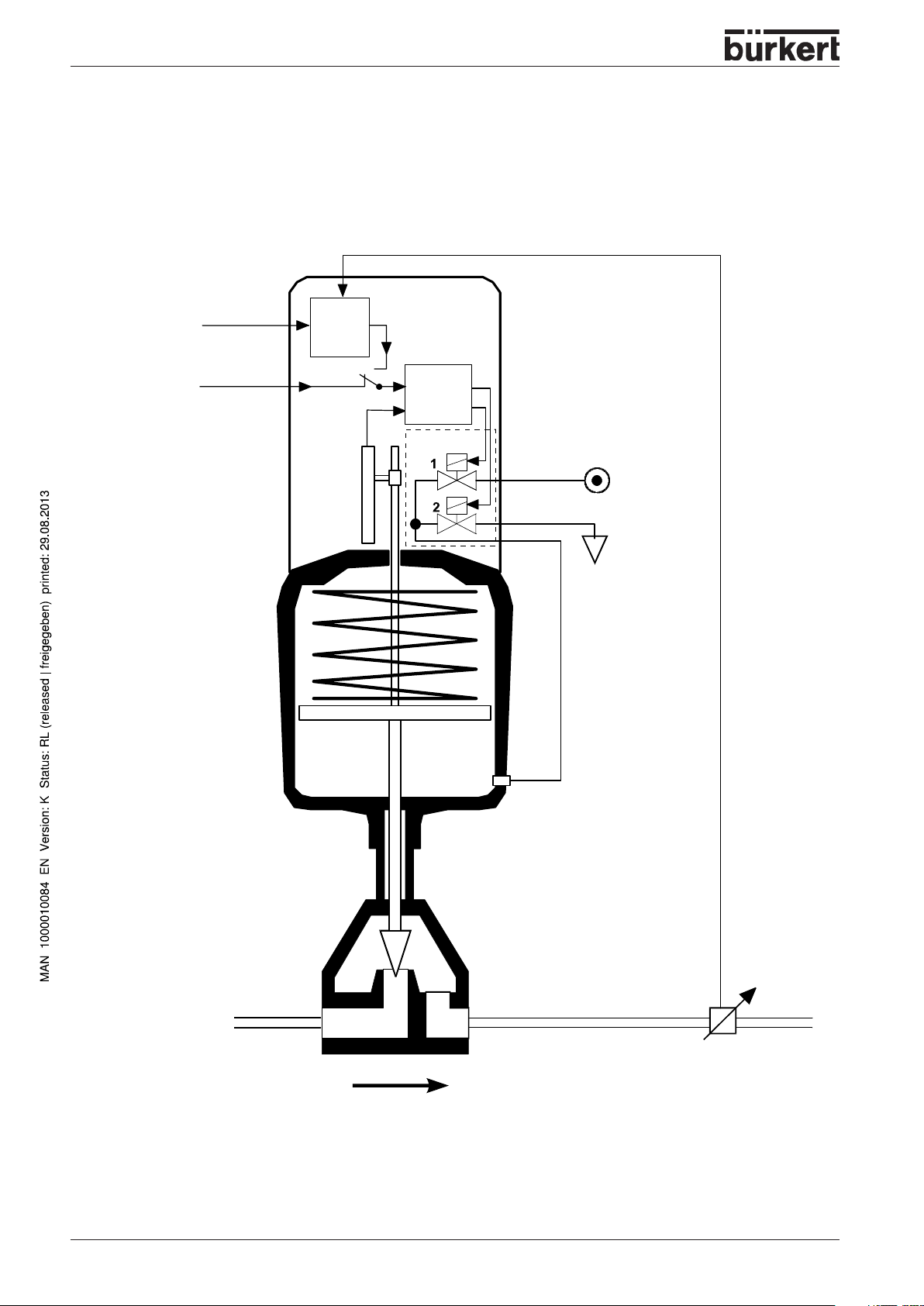

Fuctional diagram as a positioner with single-acting actuator

Actual process value

Process

setpoint

external

position

setpoint

TOP Control Continuous

Process

controller

Actual

position

Position

sensor

Setpoint position

Positioner

Positioning

system

Positioning system

1: pressurizing valve

2: exhaust valve

Compressed air

supply

Pneumatic

actuator

(single-acting)

Valve

(actuator)

Exhaust air

Sensor

18 - 8630

Actual process value

(flow rate, pressure, level,

temperature etc.)

Page 21

SYSTEM DESCRIPTION

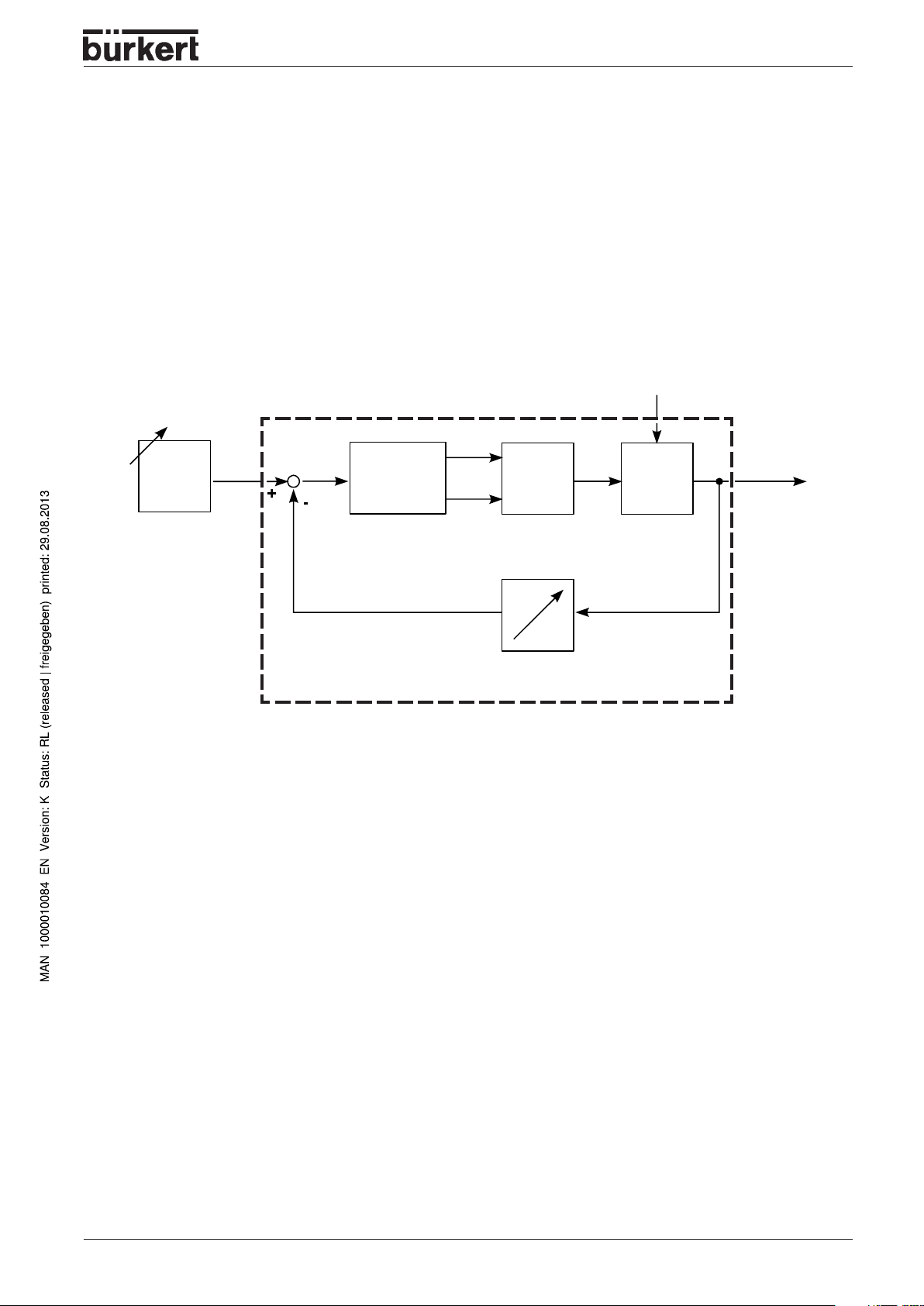

Operating as a positioner

The actual position (POS) of the pneumatic actuator is measured via the position sensing system. The

controller compares this actual value of the position with the setpoint (CMD) , which can be specified as

a standard signal. If a control difference (Xd1) exists, a pulse-width modulated voltage signal is sent to

the positioning system as the correcting variable. With single-acting actuators, if the difference is positive, the pressurizing valve is driven via output B1; if it is negative, the exhaust valve is driven via output

E1. In this way, the position of the actuator is altered until the control difference is zero. Z1 represents a

disturbance.

Z1

CMD

Position setpoint Positioner

Xd1

Position control

loop

B1

E1

Positioning

system Solenoid

POS

Wegmeßsystem

Position sensor

P

K

Continious valve

Valve opening

8630 - 19

Page 22

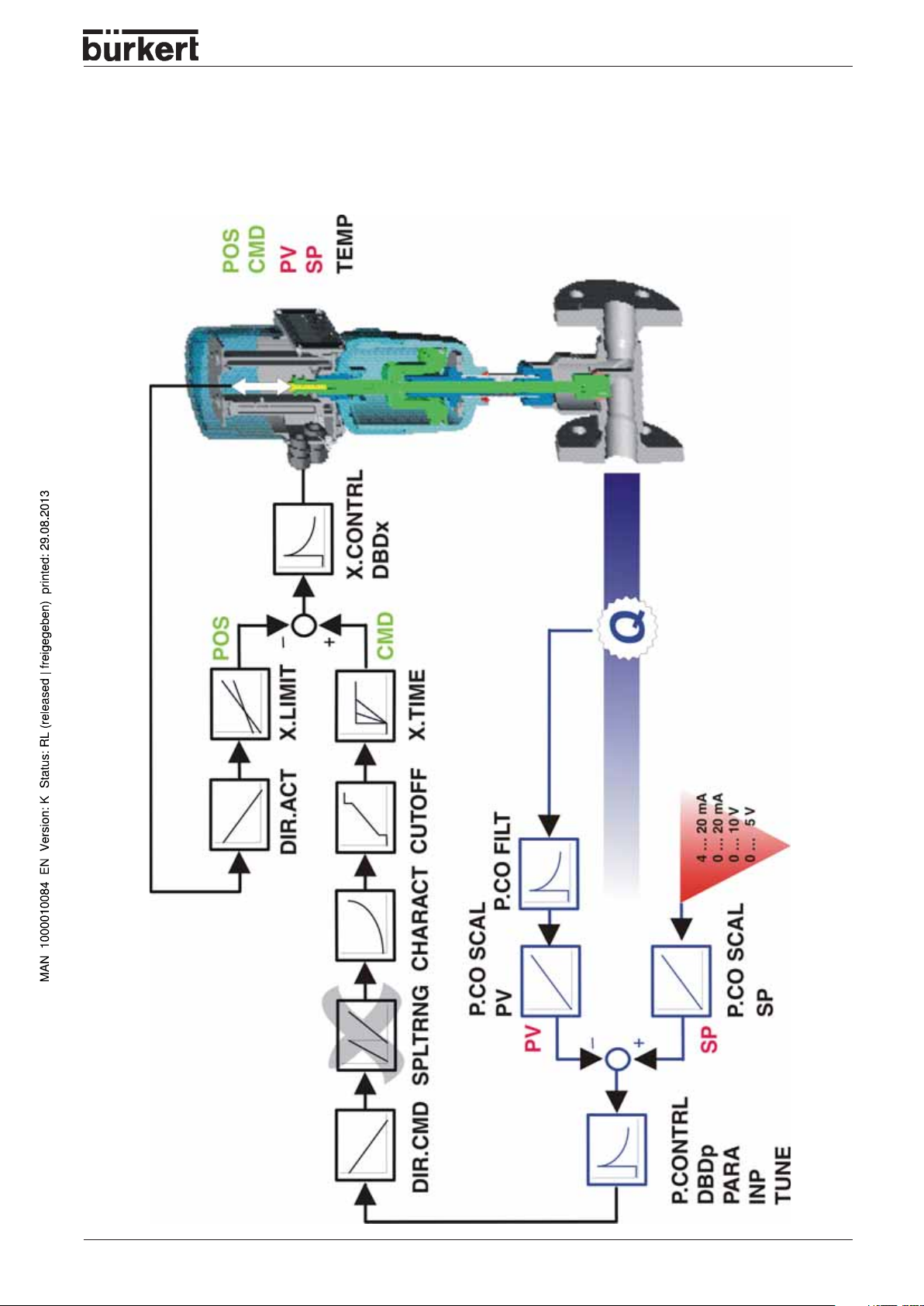

SYSTEM DESCRIPTION

POS

CMD

INP

X.CONTRL

DBDx

POS

X.LIMIT

DIR.ACT

CMD

X.TIME

CUTOFF

20 - 8630

Schematic representation of positioning control

4 … 20 mA

0 … 20 mA

0 … 10 V

0 … 5 V

DIR.CMD SPLTRNG CHARACT

INP

Page 23

Characteristics of the positioner software

Supplementary function Effect

Positioner with supplementary functions

Valve closes tight outside control range. A value is

Tight-closing function

given (at %) from which the actuator is completely

exhausted (at 0%) or pressurized (at 100 %).

SYSTEM DESCRIPTION

Stroke limitation

Signal range splitting

Correction characteristic to match

the operating curve

Insensitivity range

Direction of action of the controller

setpoint

Safety position Valve moves to a specified safety position.

Hierarchical concept for simple operation with the following levels

Process operation

Configuration

Mech. valve piston movement only withhin a specified

stroke range.

Splitting of the standard signal range over two or more

TOP Control Continuous.

Linearization of the process characteristic can be

performed.

The positioner cuts in only above a specified control

difference.

Reversal of the setpoint action direction

In this level your switch between automatic and manual

operation.

In this level you specify on commissioning certain basic

functions and configure supplementary functions as

needed.

8630 - 21

Page 24

SYSTEM DESCRIPTION

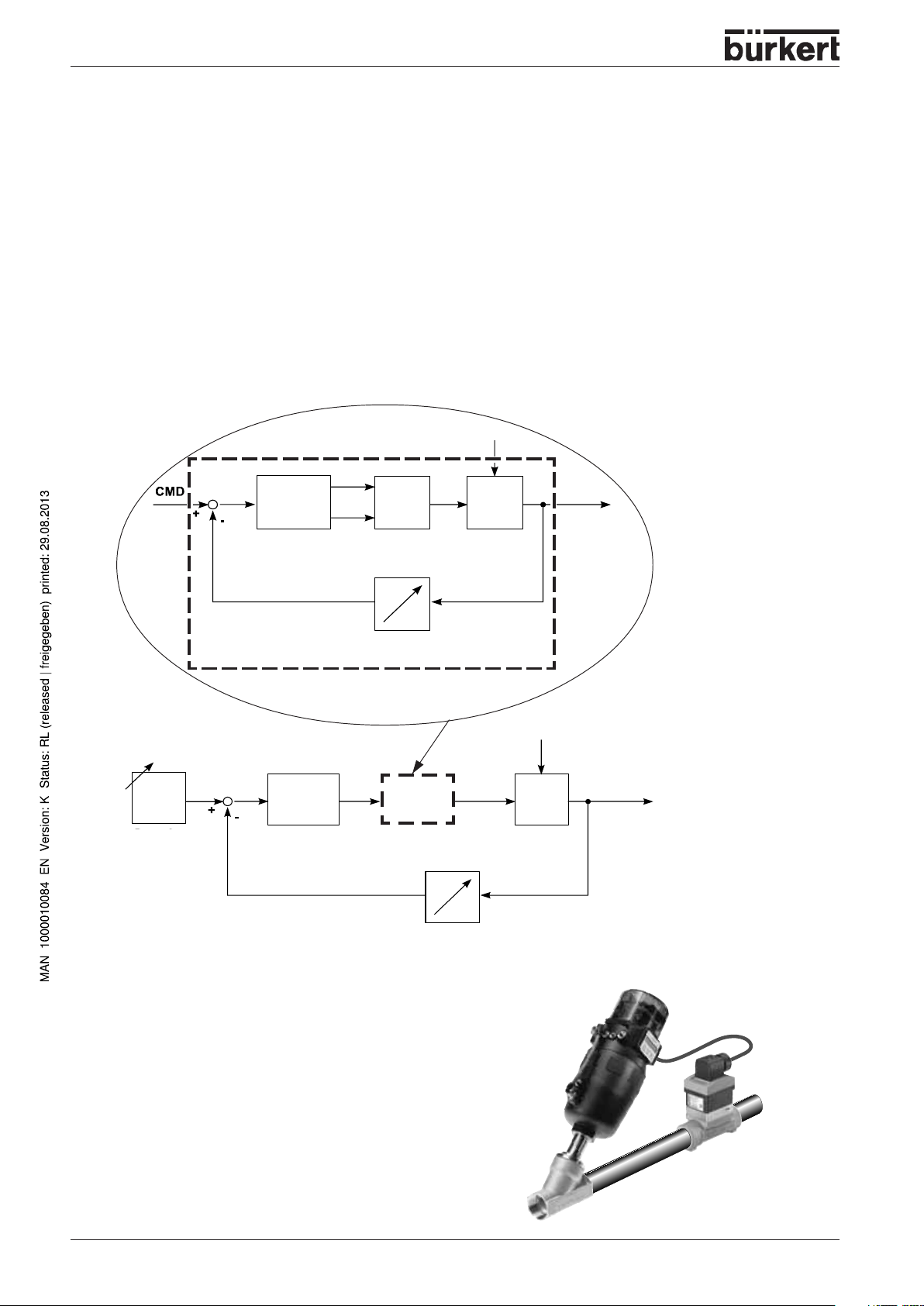

* Operation as a process controller (option)

On operation of the TOP Control Continuous as a process controller, the abovementioned position

control becomes a subordinate auxiliary control loop; the result is a cascade control. The process

controller in the main loop of the TOP Control Continuous has a PID function. The setpoint specified is

the process setpoint (SP) and it is compared with the process variable to be controlled. The actual

position (XPOS) of the pneumatic actuator is measured via the position sensing system. The controller

compares this actual value of the position with the setpoint (CMD) , which can be specified as a

standard signal. If a control difference (Xd1) exists, a pulse-width modulated voltage signal is sent to the

positioning system as the correcting variable. With single-acting actuators, if the difference is positive,

the pressurizing valve is driven via output B1. If it is negative, the exhaust valve is driven via output E1.

In this way, the position of the actuator is altered until the control difference is zero. Z2 represents a

disturbance.

Z1

Process

setpoint

Xd1

Positioner

XPOS

Position control loop

SP

Xd2

Process controller

B1

E1

Positioning

system Solenoid valves

Position sensor

Process

CMD

control

loop

PV

P

K

Continuous

Valve

Valve

opening

Valve

opening

Z2

Process variable

Process

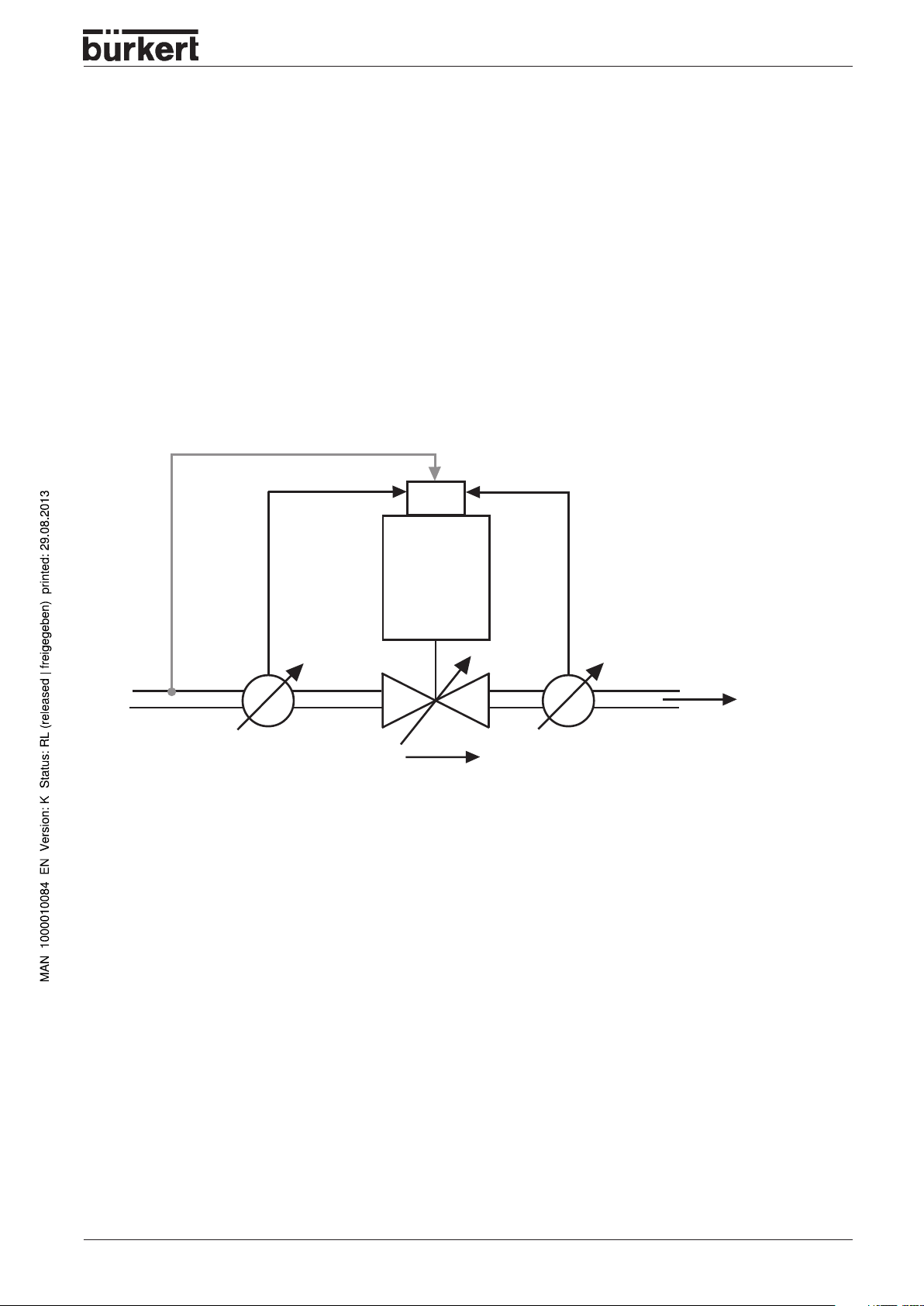

Example of process control:

TOP Control Continuous with sensor

22 - 8630

Transmitter

Page 25

SYSTEM DESCRIPTION

Schematic representation of process control

8630 - 23

Page 26

SYSTEM DESCRIPTION

Characteristics of the process controller software

Supplementary function Effect

Positioner with supplementary functions

Valve closes tight outside control range. A value is

Tight-closing function

Stroke limitation

Signal range splitting

Correction characteristic to match

the operating curve

Insensitivity range

Direction of action of the controller

setpoint

Safety position Valve moves to a specified safety position

Analog feedback (option)

given (at %) from which the actuator is completely

exhausted (at 0%) or pressurized (at 100%).

Mech. valve piston movement only within a specified

stroke range.

Splitting of the standard signal range over two or more

TOP Control Continuous.

Linearization of the process characteristic can be

performed.

The positioner cuts in only after a specified control

difference.

Reserval of the setpoint action direction

Feedback of the position/process values

Binary outputs

Connectable process controller with the following characteristics (Option)

Controller structure PID

Parameters that can be set

Scalable input

Method of setpoint setting Setting either via standard signal input or via keys

Hierarchical concept for simple operation with the following levels

Process operation

Configuration

Proportional action factor, reset time, rate time and

operating point

Decimal point position, upper and lower sacle valures

of process value and setpoint

In this level your switch between automatic and manual

operation.

In this level you specify on commissioning certain basic

functions and configure supplementary functions as

needed.

24 - 8630

Page 27

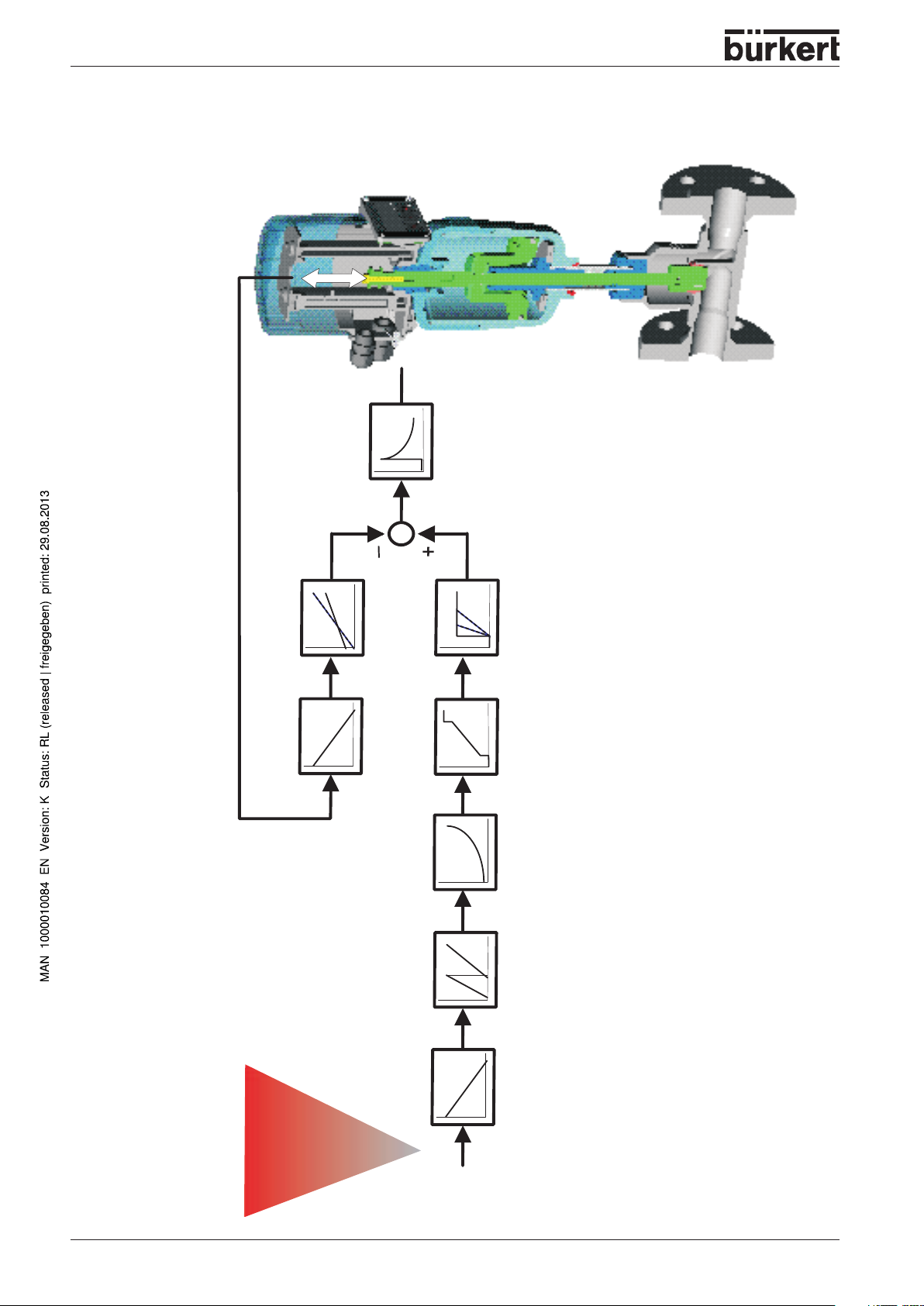

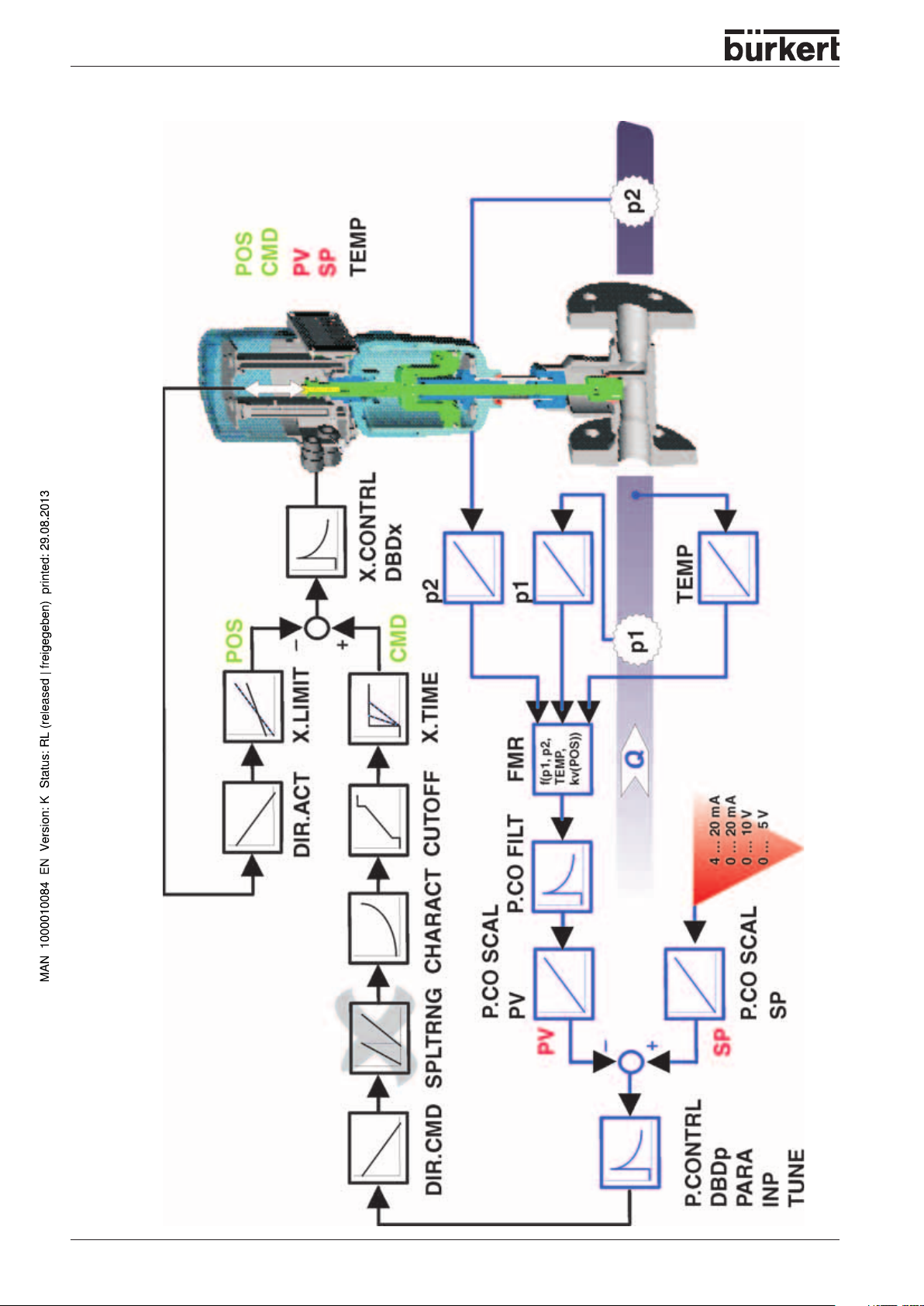

* Operation as a flow rate controller (option)

The flow rate controller is a special type of process controller. The process value (PV) is not measured

directly via an analog input but calculated in the device by the dp method. According to the algorithm,

the flow rate is dependent on the parameters

dium temperature

for 2 pressure transmitters and a temperature transmitter which can be optionally connected.

One pressure transmitter measures the pressure before the valve and a second one after the valve. The

temperature is either entered manually in the operating menu or is provided as a standard signal by a

temperature transmitter. The kv value is determined internally from the current position of the control

valve. For this purpose, a kv characteristic curve is provided in the control valve used.

The density of the medium is entered via the operating menu.

Temperature (optional)

(T) and the kv value. For this reason, the

pressure before valve

TOP Control Continuous FMR

SYSTEM DESCRIPTION

(p1),

pressure after valve

(p2),

me-

has inputs

Pressure

p1 p2

kv value

T

p1

In the case of the flow rate controller, the process parameters are either the volumetric flow rate or, for

special applications, the transport velocity at the end of a pumping section.

The volumetric flow rate is represented in m

gas pressure of 1013 mbar (abs).

There are special applications for flow rate controllers in which a pumping section is set up after the

valve, in which bulk goods enter via an airlock. These bulk goods are blown through the pumping

section by the pumping pressure that builds up behind the valve.

PV

8630

Flow rate

controller

e.g. valve

type 2712

3

/h STP, i.e. referred to 0 °C (medium temperature) and a

Pressure

p2

The transport velocity corresponds to the volumetric flow rate of the medium, referred to the piping

diameter of the pumping section. However, it is not specified for standard conditions, but reflects the

velocity of the gas particles at the existing medium temperature. The diameter is entered in the

operating menu.

Characteristics of the flow rate controller software

The flow rate controller offers the same functions as the process controller.

8630 - 25

Page 28

SYSTEM DESCRIPTION

Schematic representation of process control with flow rate controller

26 - 8630

Page 29

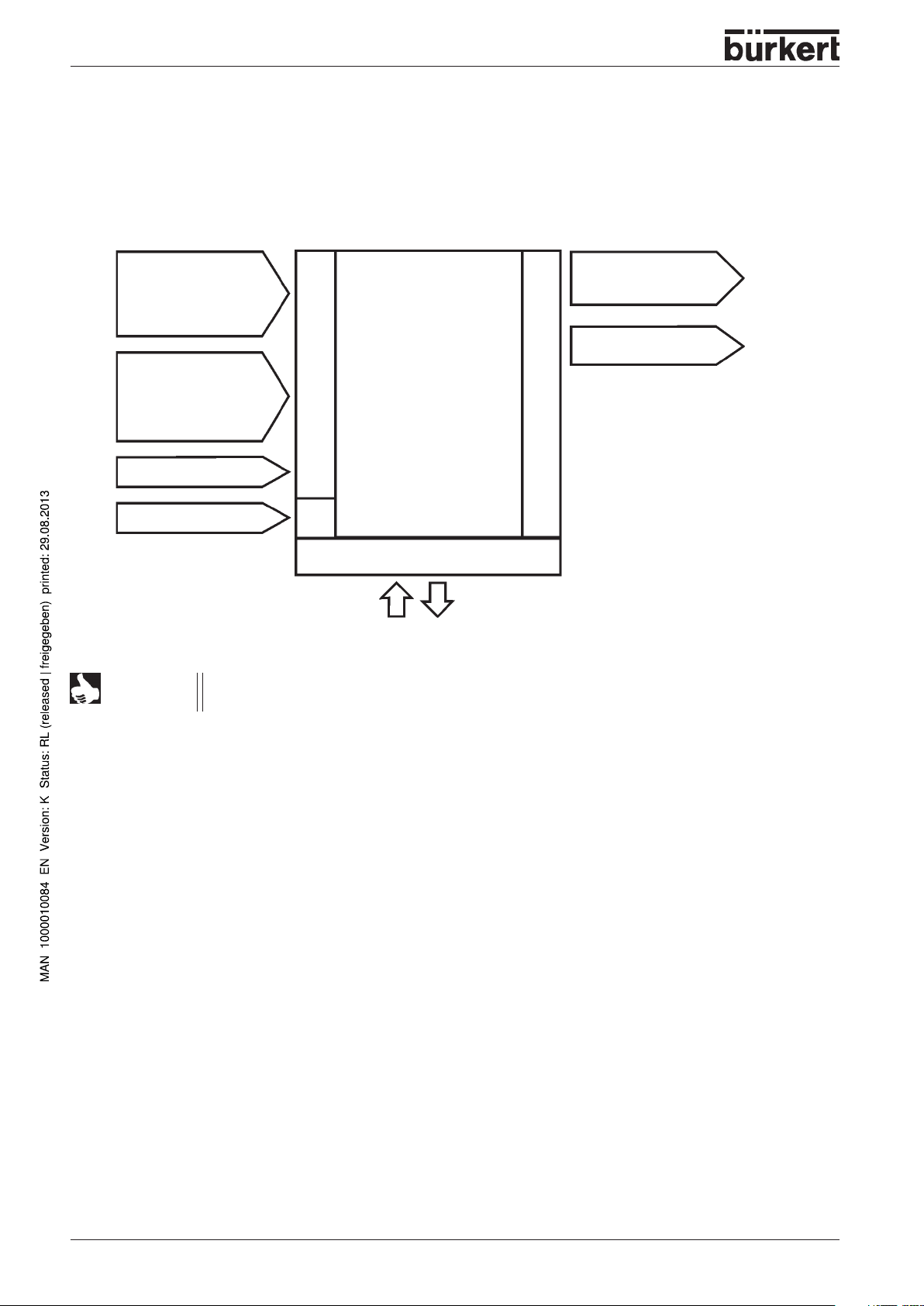

* Interfaces of the TOP Control Continuous

in the multipole variant

SYSTEM DESCRIPTION

Inputs for position or

process setpoint

4..20 mA

0..20 mA

0..10 V

0..5 V

Input for process setpoint

4..20 mA

Frequency

Pt 100

* Flow rate controller

Binary input

24 V DC

* Note:

Inputs for process value with flow rate controller (option): p1, p2, T (optional).

The standard process controller inputs (4 ... 20 mA, frequency, Pt 100) and the initiators cannot be used with this option.

Inputs

Sup-

ply

TOP Control

Continuous

(multipole - variant)

Operating unit

2 binary outputs

Analog position feedback

*Initiators 1 + 2

Outputs

NOTE

TOP Control Continuous Type 8630 is a 3-conductor device, i.e. the voltage supply (24 V

DC) is separate from the setpoint signal.

8630 - 27

Page 30

SYSTEM DESCRIPTION

* Interface of the TOP Control Continuous in the variants with

cable bushings

Inputs for position or process

setpoint

4..20 mA

0..20 mA

0..10 V

0..5 V

Input for process setpoint*

4..20 mA

Frequency

Pt 100

(alternative to binary outputs)

Binary input

24 V DC

NOTE

TOP Control Continuous Type 8630 is a 3-conductor device, i.e. the voltage supply (24 V

DC) is separate from the setpoint signal.

Inputs

Sup-

ply

TOP Control

Continuous

(PG - variant)

Operating unit

2 binary outputs*

(alternative to input for process

setpoint)

Analog

position feedback

Outputs

*

Note:

The choice between a

process setpoint input and

two binary outputs is made

by positioning the jumper.

28 - 8630

Page 31

SYSTEM DESCRIPTION

Technical data

Safety settings on failure of auxiliary electrical or pneumatic energy

Actuator type Designation Safety position after

failure of auxiliary energy

Electrical Pneumatic

Single-acting down down

SFA

Single-acting up up

SFB

Double-acting down / up undefined

SFI (depending on

connection of

control

conductors)

8630 - 29

Page 32

SYSTEM DESCRIPTION

Factory settings on the TOP Control Continuous

Function Factory setting

ACTFUNC FUNCSNGL

INPUT INP 4'20 A

CHARACT CHA LIN

DIR.CMD DIR.CRISE

CUTOFF CUT

0 %,

CUT

DIR.ACT DIR.ARISE

SPLTRNG SR

X.LIMIT LIM

0 (%),

0 %,

SR

LIM

X.TIME

T.OPN

T.CLS

After execution of

Values calculated by

Values calculated by

SETFACT:

1 s

OUTPUT

OUT ANL:

OUT POS OUT 4´20 A

OUT BIN:

OUT DEV DEV 5.0 NO

BIN-IN

B.IN SPOS SPOS 000 NO

100 %

100 (%)

100 %

AUTOTUNE

AUTOTUNE

Function Factory setting

X.CONTRL

X.CO DBND 1 %

X.CO PARA

KX

KX

After execution of

Values calculated by

Values calculated by

SETFACT:

1

P.CONTRL

P.CO DBND 1 %

P.CO PARA

KP 1.00

TN 999.9

TV 0.0

X0 0

P.CO SETP SETP INT

P.CO INP INP 4´20 A

P.CO FILT 0

P.CO SCAL PV 000.0, PV 100.0

P.CO TUNE D’ACT

P.CO KV FACT

P.CONTRL with flow rate controller

.CO DBND 1 %

P

P.CO PARA

KP 1.0

TN 999.9

TV 0.0

X0 0

P.CO SETP SETP INT

P.CO INP INP P1’P2

P.CO FILT 0

P.CO SCAL PV 000.0, PV 100.0

P.TYP FLOW

UNIT M3/H

TEMP MAN

DENS 1.293

DIAM 0025

P.CO TUNE D’ACT

P.CO KV FACT

AUTOTUNE

AUTOTUNE

NOTE

30 - 8630

CODE CODE 0000

The functions and factory settings shown in grey are valid for the optional

flow rate control.

Page 33

Data of the TOP Control Continuous

OPERATING CONDITIONS

SYSTEM DESCRIPTION

Permissible ambient temperature

Protection type

cable or plug and socket)

ATTENTION!

The TOP Control Continuous is not suitable for outdoor use.

- 10 ... + 50 °C

IP 65 to EN 60529 (only with correctly connected

CONFORMITY TO THE FOLLOWING STANDARDS

CE

conformity wer. EMC Guideline 89/336/EWG

MECHANICAL DATA

Dimensions

Housing material TOP Control

Dichtmaterial

see data sheet

outer: Noryl (PPE/PA), PSU, inner: PA 6

NBR

ELECTRICAL DATA

Connections

Choice between multipole connector or

3 bushings M 16 x 1.5

with screw terminals 0.14 ... 1.5 mm²

Voltage supply

24 V DC ± 10 %

residual ripple 10 %

No industrial DC!

Power consumption

< 5 W

Housing internal temperature

indication

Input resistance for

actual value signal

Input resistance for

setpoint signal

Protection class

- 55 ... + 125 °C, accuracy ± 2 °C

180 Ω at 4 - 20 mA/resolution 12 bit

17 kΩ at frequency, 0 ... 1000 Hz / 1‰ of mean

> 300 V

PT-100 - 20 ... + 220 °C, resolution < 0.1 °C

180 Ω at 0/4 - 20 mA/resolution 12 bit

19 kΩ at 0 - 5/10 V /resolution 12 bit

3 to VDE 0580

Analog position feedback:

max. current

for voltage output 0 ... 5/10 V 10 mA

max. burden

for current output 0/4 ... 20 mA 560 Ω

Inductive proximity switch

current limitation 100 mA

sinus, square-wave, sawtooth

ss

8630 - 31

Page 34

SYSTEM DESCRIPTION

Binary outputs

electrically isolated

current limitation 100 mA, output is clocked

Binary input

electrically isolated

0 ... 5 V = log "0", 10 ... 30 V = log "1"

inverted output reversed accordingly

PNEUMATIC DATA

Control medium Qualitiy Classes to DIN ISO 8573-1

Dust content Class 5

max. particle size 40 µm, max. particle density 10 mg/m

Water content Class 3

max.pressure dew point

- 20 °C or min. 10 deg. below the lowest operating temperature

Oil content Class 5

max. 25 mg/m³

Temperature range of

compressed air -10 ... + 50 °C

Pressure range 3 ... 7 bar

Supply pressure variation max. ± 10 % during operation

3

Air flow capacity of

control valve 100 l

/ min STP (for pressurizing and exhausting)

N

(Q

- value acc. to definition on pressure drop from 7 to 6 bar abs.)

Nn

Intrinsic air consumption

with zero control output 0.0 l

/min STP

N

Connections G 1/4’’ internal thread G / NPT / RC

32 - 8630

Page 35

FIRST COMMISSIONING

FIRST

COMMISSIONING

Fluidic installation............................................................................................................................................................................................................................ 34

* Electrical installation - multipole connector

* Electrical installation - connection terminals for cable bushings

Basic settings of the TOP Control Continuous

Settings in the menu items.............................................................................................................................................................................................. 38

Entering the position setpoint in the AUTOMATIC mode

Manual opening and closing of the valve actuator in the MANUAL mode

......................................................................................................................................... 35

........................................................................ 36

................................................................................................................................... 37

......................................................................................................... 38

......................................................... 39

* Alternative chapters or functions depending on device configuration

8630 - 33

Page 36

FIRST COMMISSIONING

NOTE

This section enable you to put the TOP Control Continuous rapidly into operation for a

functional check. Supplementary functions unnecessary for this purpose are not dealt with

here.

Fluidic installation

➔ Install the valve according to operating

instructions!

➔ Connect supply pressure to connection "1" (3

.. 7 bar; instrument air, free from oil, water

and dust)

➔ Attach the exhaust line or silencer to

connection "3"!

NOTE

Remove the protective caps from the valve and and the TOP Control

Continuous!

34 - 8630

Page 37

* Electrical installation - multipole connector

M12M16

➔ Apply the setpoint signal to the circular

connector M16

FIRST COMMISSIONING

Configuration of the circular connector M 16

Allocation

B

A

➔ Apply the supply voltage to the circular connector M12

Setpoint + (0/4 ... 20 mA

or 0 ... 5/10 V)

Setpoint GND

External connection/Signal levelPin

B

A

+ (0/4 ... 20 mA or 0 ... 5 / 10 V)

GND

Configuration of the circular connector M 12

Pin Allocation External connection

1 + 24 V

2 not connected

3 GND

4 not connected

1

24 V DC ± 10 %

max. residual ripple 10 %

3

NOTE

After application of the supply voltage, the TOP Control Continuous is in operation. Carry out the

necessary basic settings and initiate self-parametrization of the TOP Control.

Further installation notes are to be found in the chapter

Installation

.

8630 - 35

Page 38

FIRST COMMISSIONING

* Electrical installation - connection terminals for cable bushings

➔ Remove the cover with the cable bushings

to gain access to the terminals. This is done

by unscrewing the 4 self-tapping screws.

➔ Apply the setpoint signal and the supply

voltage to the respective terminals (see

Terminal configuration with cable bushings

).

screw terminals

Terminal configuration with cable bushings

Terminal Allocation External connection

1 Setpoint +

2 Setpoint GND

5 Operating voltage +

6 Operating voltage GND

1

2

5

6

+ + (0/4 ... 20 mA or 0 ... 5/10 V)

GND

24 V DC ± 10 %

max. residual ripple 10 %

NOTE

After application of the supply voltage, the TOP Control Continuous is in operation. Carry out the

necessary basic settings and initiate self-parametrization of the TOP Control.

Further installation notes are to be found in the chapter

Installation

.

36 - 8630

Page 39

Basic settings of the TOP Control Continuous

Configuration of the keys

MANUAL/AUTOMATIC-key Switch between main

and subitems,

e.g.

ACT FUNC - FUNCSNGL

Arrow keys Switch between equal-ranking

menu items,

e.g.

ACTFUNC - INPUT

AUTOMATIC

MODE

FIRST COMMISSIONING

MANUAL

MODE

Jump over on first commissioning

8630 - 37

Page 40

FIRST COMMISSIONING

Settings in the menu items

ACTFUNC

INPUT

ADDFUNCT

X.TUNE

END XX

the display

memory.

Actuator function

FUNC SNGL

FUNC DOUB

Standard signal

INP 4’20A

INP 0’20A

INP 0’10V

INP 0’5V

Jump over

Initiate self-parametrization

Return to AUTOMATIC mode

- single-acting

- double-acting

- Current 4 ... 20 mA

- Current 0 ... 20 mA

- Voltage 0 ... 10 V

- Voltage 0 ... 5 V

EEPROM

appears until the settings have been in the

;

Entering the position setpoint in the AUTOMATIC mode

After selection of the basic settings and return to the AUTOMATIC mode, the TOP Control Continuous

works as a positioner.

Enter the position setpoint via the signal.

Switching between the

display options:

Display:

• Actual position of valve actuator

• Setpoint position of valve actuator

• Input signal for setpoint position

(here identical to setpoint position) (0 ... 5/10 V or 0/4 ... 20 mA)

• Temperature inside

TOP Control Continuous housing

POS__XXX

CMD__XXX

INP__XXX