Page 1

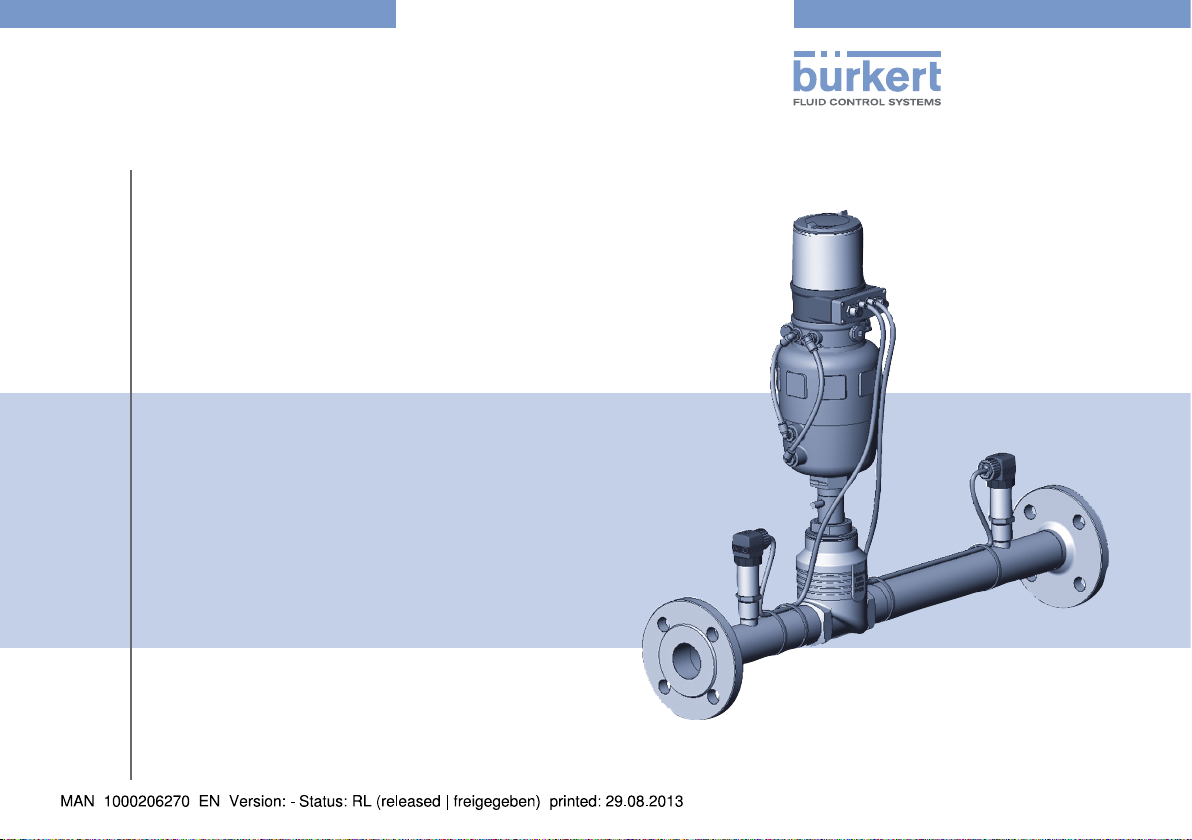

Type 8750

Classic with Type 8693

Flow controller

Quickstart

English

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2012 Bürkert Werke GmbH

Operating Instructions 1210/00_EU-EN_00810234 / Original DE

Page 3

Typ 8750

Inhaltsverzeichnis

1. QUICKSTART GUIDE.....................................................................................5

1.1. Definition of terms / Abbreviation ................................................. 5

2. SYMBOLS ............................................................................................................5

3. AUTHORIZED USE .........................................................................................6

3.1. Restrictions ........................................................................................6

4. BASIC SAFETY INSTRUCTIONS .............................................................6

5. GENERAL INFORMATION ...........................................................................7

5.1. Contact address ............................................................................... 7

5.2. Warranty ............................................................................................. 7

5.3. Information on the Internet ............................................................. 7

6. SYSTEM DESCRIPTION ...............................................................................8

6.1. General description ......................................................................... 8

6.2. Structure ............................................................................................8

7. TECHNICAL DATA ........................................................................................10

7.1. Conformity .......................................................................................10

7.2. Standards .........................................................................................10

7.3. Operating conditions .....................................................................10

7.4. Mechanical data .............................................................................10

7.5. Type label .........................................................................................11

7.6. Fluidic data ......................................................................................11

7.7. Electrical data..................................................................................12

8. CONTROL AND DISPLAY ELEMENTS ................................................... 14

8.1. Function of the keys ........................................................................ 14

8.2. Operating state ................................................................................ 15

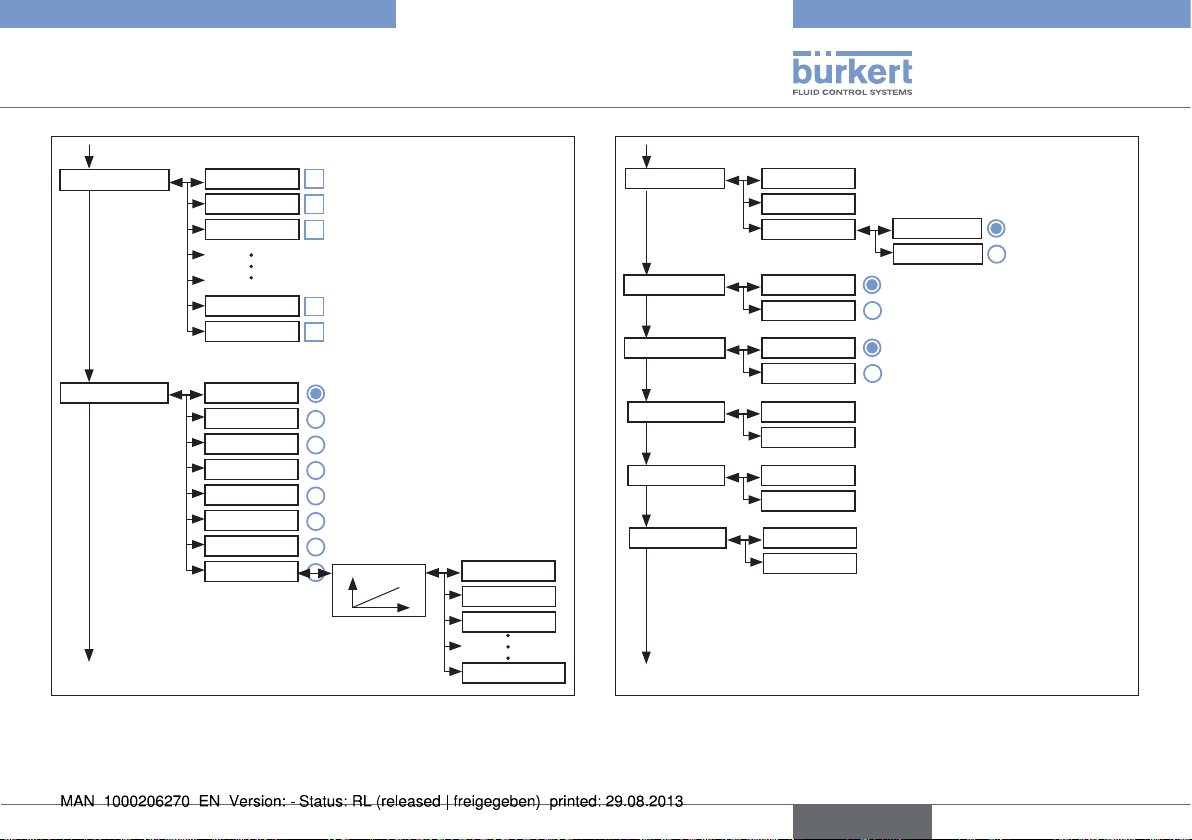

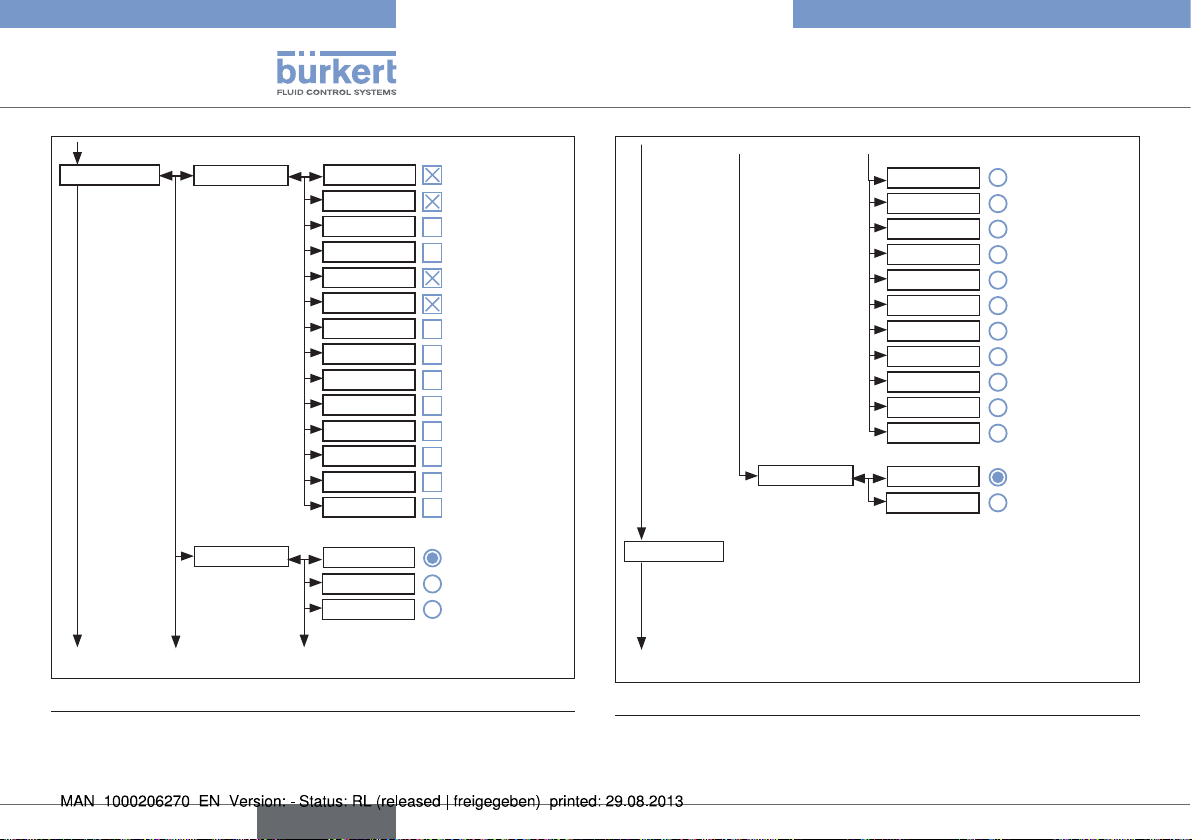

8.3. Operating levels ............................................................................... 16

8.4. Display in AUTOMATIC operating state ...................................16

8.5. Master code.....................................................................................17

9. ASSEMBLY .......................................................................................................18

9.1. Safety instructions .........................................................................18

9.2. Before installation ...........................................................................18

9.3. Pneumatic connection of the process controller ....................18

10. ELECTRICAL INSTALLATION ............................................................... 20

10.1. Electrical installation, 24 V DC with circular plug-in

connector (multi-pole variant) ...................................................... 20

10.2. Electrical installation PROFIBUS DP ......................................22

10.3. Electrical installation DeviceNet ...............................................23

11. START-UP 24 V DC ...................................................................................25

11.1. General procedure for creating settings for the flow

controller ........................................................................................25

11.2. Define basic settings ...................................................................26

11.3. Automatic adjustment (X.TUNE) ............................................... 27

11.4. Configuring the F.CONTROL auxiliary function ....................... 28

12. ADDITIONAL FMR FUNCTIONS ......................................................... 30

12.1. Activating and deactivating auxiliary functions ......................32

12.2. CAL.USER - Changing the factory calibration ....................32

12.3. OUTPUT - Configuration of the analog output ....................34

english

3

Page 4

13. PROFIBUS DP START-UP ..................................................................... 35

13.1. Settings in BUS.COMM ....................................................... 35

13.2. Configuration of the process values ........................................36

14. DEVICENET START-UP ........................................................................... 39

14.1. Settings in BUS.COMM ....................................................... 39

14.2. Configuration of the process data ...........................................41

15. SAFETY END POSITIONS ..................................................................... 46

16. ERROR MESSAGES .................................................................................46

16.1. Error messages on field bus devices ......................................48

16.2. Other error messages .................................................................49

17. ACCESSORIES ...........................................................................................50

18. SHUTDOWN .................................................................................................. 50

18.1. Disassembly ..................................................................................50

19. OPERATING STRUCTURE ..................................................................... 51

20. TRANSPORT, STORAGE, PACKAGING .......................................... 62

Typ 8750

4

english

Page 5

Typ 8750

Quickstart Guide

1. QUICKSTART GUIDE

The quickstart guide describes the entire life cycle of the device. Keep

these instructions in a location which is easily accessible to every user

and make these instructions available to every new owner of the device.

Important Safety Information.

Read Quickstart carefully and thoroughly. Study in particular the

chapters entitled Basic Safety Instructions and Authorized Use.

▶ Quickstart must be read and understood.

The Quickstart guide illustrates the installation and commissioning of

the equipment with examples.

A detailed description of the process controller can be found in the

operating instructions for Type 8693.

The operating instructions can be found on the Internet at:

www.burkert.com

1.1. Definition of terms / Abbreviation

In these instructions, the term “device” always refers to the flow

controller Type 8750.

FMR = Flow controller

2. SYMBOLS

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in a serious or fatal injury.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a moderate or minor

injury.

NOTE!

Warns of damage to property.

Important tips and recommendations.

Refers to information in these operating instructions or in

other documentation.

▶ Indicates an instruction to prevent risks.

→ designates a procedure which you must carry out.

english

5

Page 6

Typ 8750

Authorized use

3. AUTHORIZED USE

Non-authorized use of the flow controller Type 8750 may be a

hazard to people, nearby equipment and the environment.

• The device is designed as a simple system for determining and

controlling the volumetric flow rate of gases.

• Do not expose the device to direct sunlight.

• Do not use the device outdoors.

• Use according to the authorized data, operating conditions, and

conditions of use specified in the contract documents and operating instructions. These are described in Chapter “7. Technical

data”.

• Use the device only in conjunction with third-party devices and

components recommended and authorized by Bürkert.

• Correct transportation, storage, and installation, as well as careful use and maintenance are essential for reliable and faultless

operation.

• Use the device only as intended.

3.1. Restrictions

If exporting the system/device, observe any existing restrictions.

4. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• Contingencies and events which may arise during the installation,

operation, and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing

these regulations, also in relation to the installation personnel.

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before reaching into the device, switch off the power supply and

secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

Risk of burns/risk of fire if used during long-term operation

through hot device surface.

▶ Keep the device away from highly flammable substances and media

and do not touch with bare hands.

General hazardous situations.

▶ Devices without a separate Ex type label may not be used in a

potentially explosive area.

▶ Only trained technicians may perform installation and maintenance

work.

6

english

Page 7

Typ 8750

General information

▶ That the system cannot be activated unintentionally.

▶ After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The device may be operated only when in perfect condition and

in consideration of the operating instructions.

▶ The general rules of technology apply to application planning and

operation of the device.

▶ Do not supply the pilot air port with aggressive or flammable media.

▶ Do not supply the pilot air port with liquids.

▶ Do not physically stress the body (e.g. by placing objects on it or

standing on it).

▶ Do not make any internal or external changes on the device.

NOTE!

Electrostatic sensitive components/modules.

The device contains electronic components which react sensitively

to electrostatic discharge (ESD). Contact with electrostatically

charged persons or objects are hazardous to these components.

In the worst case scenario, they will be destroyed immediately or

will fail after start-up.

▶ Observe the requirements specified in EN 61340-5-1 to minimize/

avoid the possibility of damage caused by a sudden electrostatic

discharge.

▶ Do not touch electronic components while the supply voltage is

switched on.

5. GENERAL INFORMATION

5.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at:

www.burkert.com

5.2. Warranty

The warranty is only valid if the flow controller Type 8750 is used as

intended in accordance with the specified application conditions.

5.3. Information on the Internet

The operating instructions and data sheets for Type 8750 / Type 8693

can be found on the Internet at:

www.burkert.com

english

7

Page 8

Typ 8750

System description

6. SYSTEM DESCRIPTION

6.1. General description

To determine and control the volumetric flow rate, the pressure drop

over the control valve is measured continuously by the two pressure

sensors. This pressure difference and the valve flow characteristic

are the parameters used to determine the volumetric flow. This measured volumetric flow is compared with the set point – internally via

display/keyboard or externally via standard signal or bus protocol –

evaluated in a PID controller and set on the position controller as the

new set point.

The system consists of:

• Control valve Type 2712 with process controller Type 8693

• Two pressure sensors Type 8323

Options:

• Binary input

• Analog feedback

• 2 binary outputs

• Bus communication (PROFIBUS DP or DeviceNet)

Other:

• The flow controller is supplied with a factory setting.

• The device is operated via 4 function keys and a display.

• The valve seat can be exchanged.

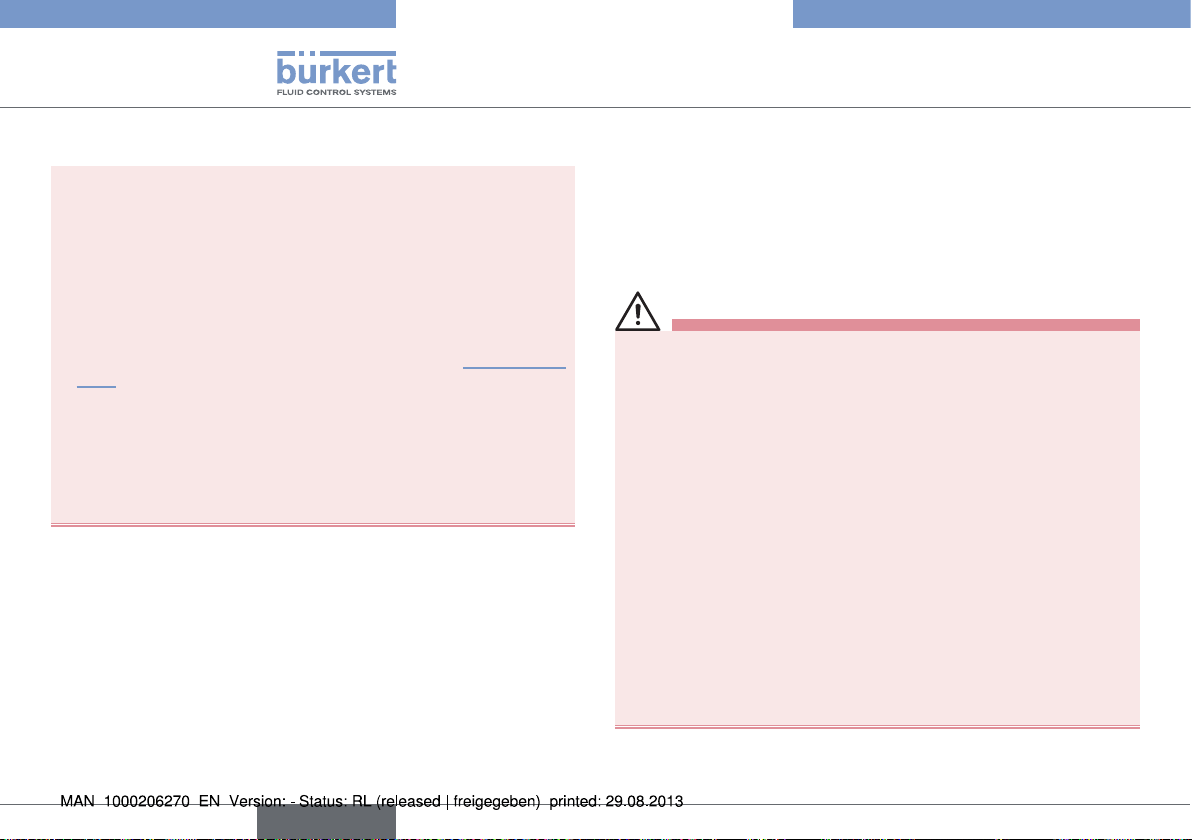

6.2. Structure

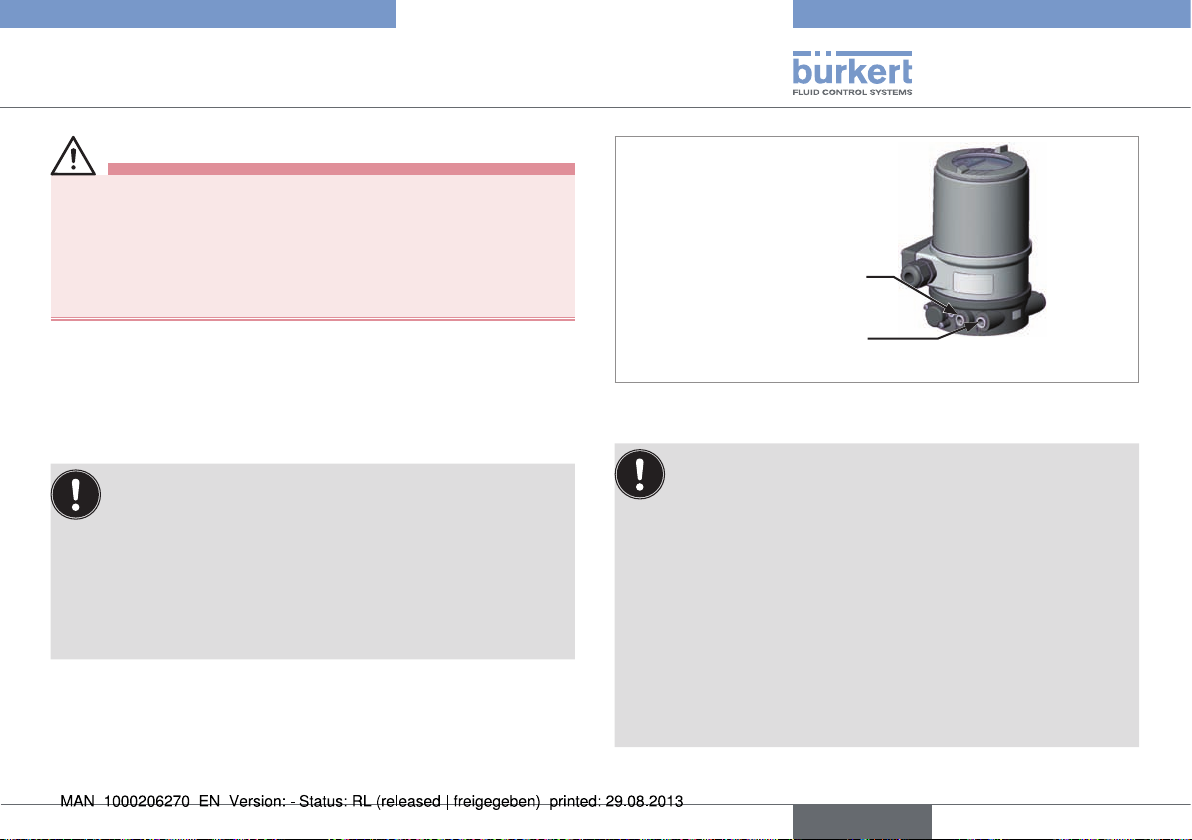

Process controller Type 8693

Actuator control valve Type 2712

Signal line from pressure sensor to

the process controller

Valve body control valve

Type 2712

Pressure sensor Type 8323

Fig. 1: Structure

6.2.1. Action diagram of the FMR

Pressure P1 Pressure P2

Temperature T

(Option)

P1 P2

Fig. 2: Action diagram

Kv value

PV

Flow

controller

(FMR)

Type

8750

Flange acc. to

DIN EN 1092-1

8

english

Page 9

Typ 8750

System description

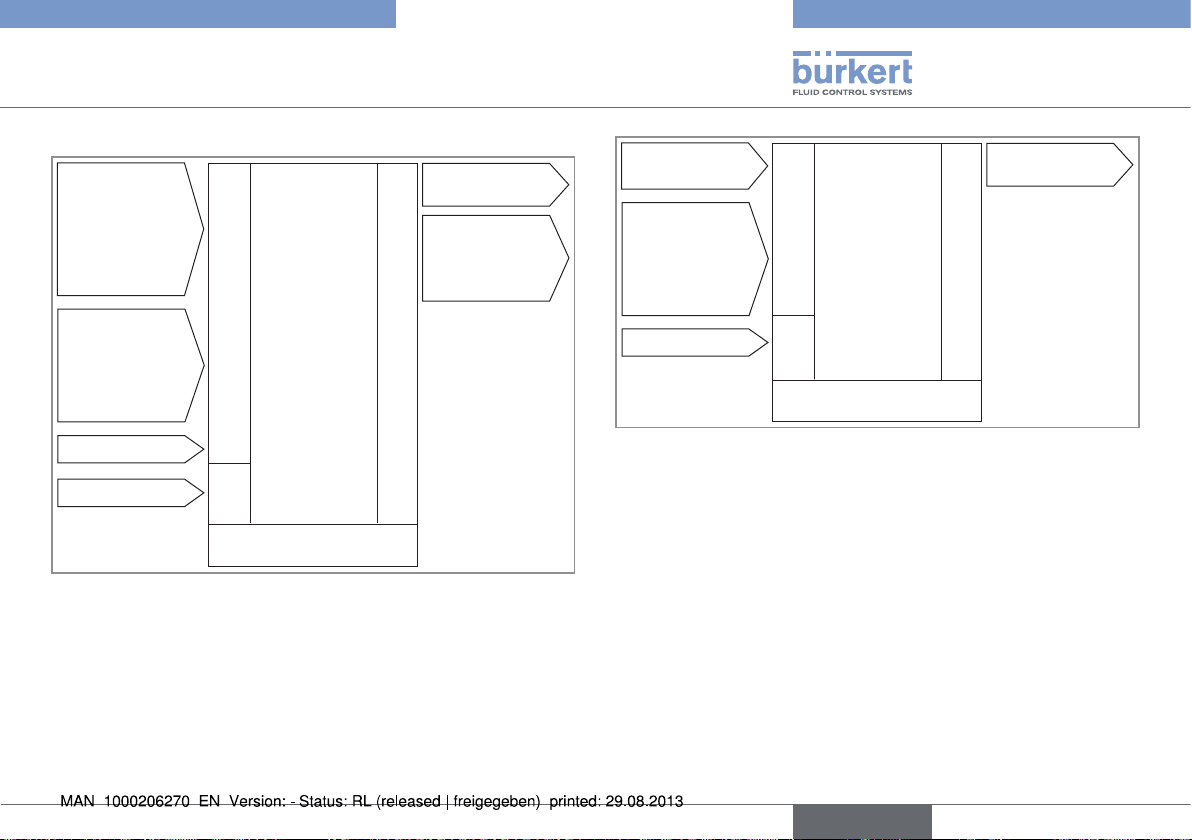

6.2.2. Electrical interfaces

Inputs for position

or process setpoint value

0 – 20 mA

4 – 20 mA

0 – 5 V

0 – 10 V

Inputs for process

actual value

(4 – 20 mA)

P1

P2

T (optional)

Binary input

24 V DC

Fig. 3: Interfaces

Inputs

Power

supply

Process controller

Type 8693

Operation

(keys)

2 binary outputs

(option)

Analog

position

feedback

(option)

Outputs

Bus

Inputs for process

actual value

(4 – 20 mA)

P1

P2

T (optional)

24 V DC

Fig. 4: Interfaces - Bus

Process controller Type

Inputs

8693

PROFIBUS DP

DeviceNet

Power

supply

Operation

Bus

Outputs

english

9

Page 10

Typ 8750

Technical data

7. TECHNICAL DATA

7.1. Conformity

Type 8750 conforms to the EC directives according to the EC Declaration of Conformity.

7.2. Standards

The applied standards which are used to demonstrate compliance with

the EC Directives are listed in the EC type test certificate and/or the

EC Declaration of Conformity.

7.3. Operating conditions

Ambient temperature 0 – +55 °C

Degree of protection

IP65 / IP67 according to EN 60529 (only if cables, plugs and

sockets have been connected correctly and in compliance with

the exhaust air concept in Chapter “9.3. Pneumatic connection

of the process controller”)

7.4. Mechanical data

Materials

Valve body stainless steel cast 1.4404/316L

Sensor connection 1.4301 or 1.4404

Flange stainless steel 316L

Actuator Polyamide (PA)

Process controller PPS, PC, stainless steel

seals EPDM

Packing gland PTFE rings with silicone grease

Other wetted parts stainless steel 1.4571

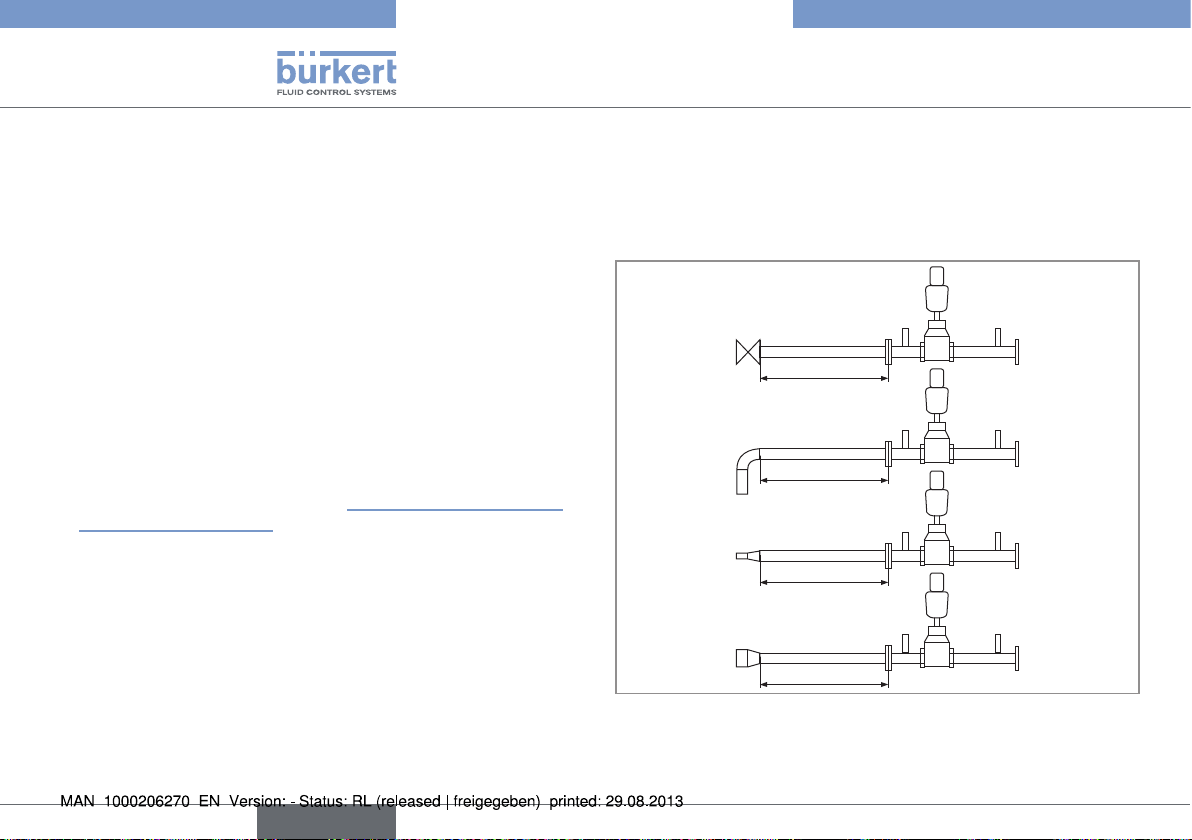

Inlet and outlet sections acc. to EN ISO 5167-1

Inlet sections

Valve completely open

20 x D

90° bend or T-piece

20 x D

Widening

18 x D

Reduction

15 x D

Fig. 5: Inlet sections

Outlet sections already integrated in the system (6 x DN)

10

english

Page 11

Typ 8750

Technical data

Dimensions

∅ 91

∅ E

HG

2x DN

L

Fig. 6: Dimensions

6x DN

DN pipe connection [mm] L [mm] HG [mm] ∅ E [mm]

15 330 414 101

25 500 412 101

40 700 501 127

50 800 538 157

65 1000 567 157

80 1200 637 261

100 1400 647 261

Tab. 1: Dimensions

7.5. Type label

Example:

Operating voltage /

Fig. 7: Example of type label

control

Type

8750 24 V DC

single act Pilot 0,6

Pmax 7 bar

Tamb 0°C - +55°C

S/N 001000

00179026

D-74653 Ingelfingen

CE

W14UN

Identification number

Control function

Pilot valve

Maximum pressure

Max. ambient

temperature

Serial number,

CE symbol

Bar code

7.6. Fluidic data

Control medium neutral gases, air

Quality classes as per DIN ISO 8573-1

Dust content Class 5: max. particle size 40 μm,

max. particle density 10 mg/m

Water content Class 3: max. pressure dew point -20 °C or

min. 10 °C below the lowest operating

temperature

Oil content Class 5: max. 25 mg/m

3

3

english

11

Page 12

Typ 8750

Technical data

Temperature range

control medium 0 – +50 °C

Pressure range

control medium 5.5 – 7 bar (DN 15 – DN 65)

5 – 6 bar (DN 80 – DN 100)

Intrinsic air consumption 0 l/min

Connections plug-in hose connector 6 mm / 1/4”

threaded connection G 1/8

Flow media air and gases

steam on request

Temperature range

Media 0 – +80 °C

Pressure range

Media 0 – 16 bar

Connections flange acc. to DIN EN 1092-1, ANSI,

JIS

Pressure measurement

range of sensor 0 – 6/10 or 16 bar

depending on the pressure range of

media others available on request

Measurement section acc. to DIN EN 60534-2-3

Orifices DN 15 - DN 100

Sensor connections threaded connection G 1/2

7.7. Electrical data

Connections

Operating voltage circular plug-in connector M12 x 1, 4-pole

External signals circular plug-in connector M12 x 1, 8-pole

circular plug-in connector M8 x 1, 8-pole

Operating voltage 24 V DC

- maximum residual ripple 10 %

Power consumption < 5 W

Set-point value default 0/4 – 20 mA or

0 – 5/10 V

field bus as option

Display multifunction display

User interface 4 function keys

12

english

Page 13

Typ 8750

Technical data

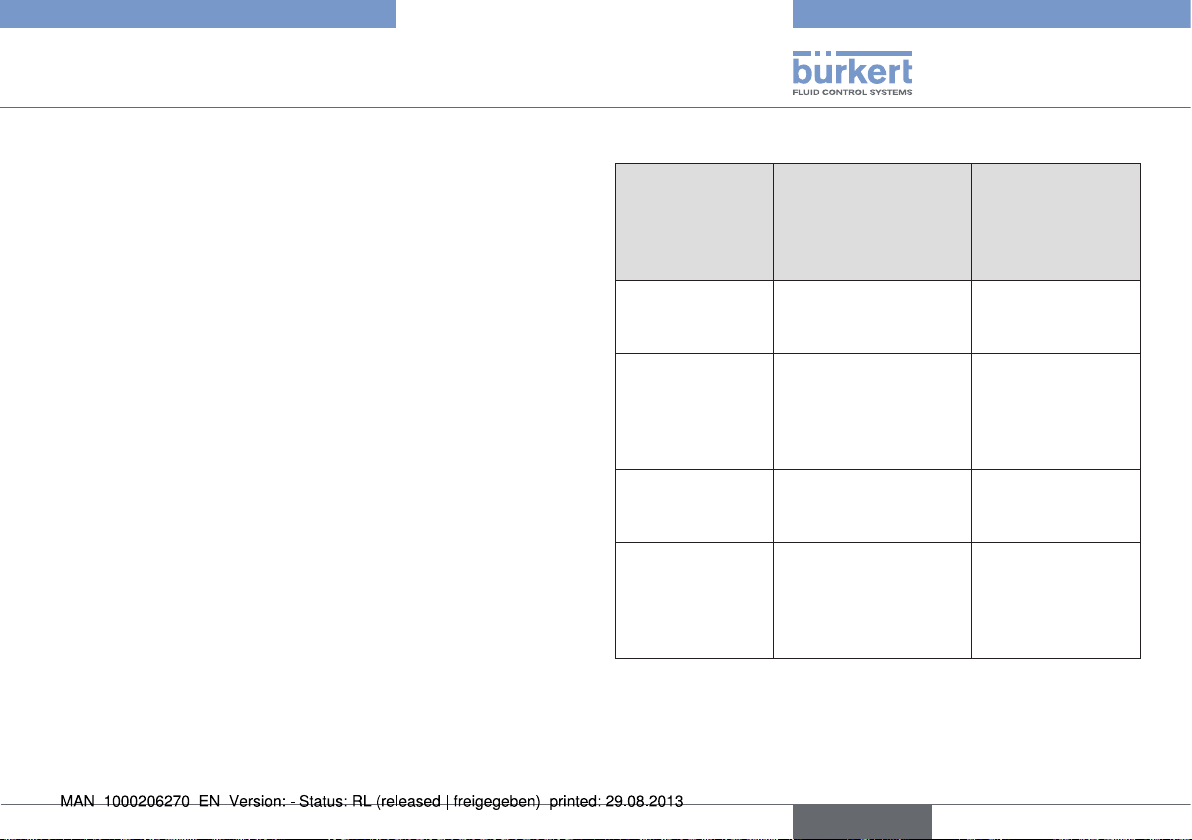

Kv value table for FMR versions (specifications for valve stroke and flow rate in %)

The measured set of values for each seat combination is stored in the FMR memory at the factory.

Flow rate Kv in [%]

Valve design

DN

DN

pipe

seat

[mm]

[mm]

8 2,1 0,0 3,3 3,8 4,8 5,2 5,7 6,2 7,6 9,0 11,0 12,9 16,2 20,5 24,8 30,0 37,6 45,2 58,1 76,2 90,5 100,0

15

10 3,1 0,0 2,9 3,5 4,2 4,8 5,5 6,1 7,7 10,0 12,6 15,8 19,7 24,2 29,7 35,5 44,2 54,8 67,7 80,6 92,6 100,0

15 4,3 0,0 3,3 4,0 4,4 5,1 6,5 8,1 9,8 12,1 15,1 18,6 22,8 27,9 34,4 41,9 51,2 62,8 74,4 86,0 94,4 100,0

15 5,3 0,0 2,6 3,2 3,6 4,2 5,1 6,6 8,1 9,8 12,1 15,1 18,5 22,6 27,5 34,0 43,0 54,7 66,0 77,4 88,7 100,0

25

20 7,2 0,0 2,8 3,5 3,9 4,3 5,3 6,5 7,9 9,7 12,2 15,3 18,5 22,2 27,5 34,7 42,8 52,8 63,9 75,0 87,5 100,0

25 12,0 0,0 2,9 3,2 3,9 5,4 6,8 8,3 10,2 12,5 15,0 18,3 22,7 28,3 35,3 42,5 49,6 58,3 67,9 78,3 89,2 100,0

25 13,6 0,0 2,9 3,7 4,5 5,5 6,6 8,1 10,1 12,5 15,4 19,1 23,0 27,9 34,1 41,2 49,6 58,8 68,4 78,7 89,0 100,0

40

32 20,2 0,0 2,4 3,0 3,5 4,2 5,1 6,4 8,2 10,4 12,9 15,8 19,0 22,8 27,8 34,2 43,3 54,5 64,4 74,3 85,6 100,0

40 23,8 0,0 2,5 2,9 3,7 4,6 5,7 7,1 9,0 11,3 13,7 16,8 20,8 25,2 31,5 38,7 47,5 58,0 67,2 76,5 87,0 100,0

32 21,0 0,0 2,3 2,9 3,5 4,3 5,1 6,2 7,9 10,0 12,5 15,2 18,3 21,9 26,7 32,9 43,0 55,2 65,5 76,2 87,4 100,0

50

40 24,6 0,0 2,4 2,8 3,3 4,1 5,4 6,9 8,5 10,6 13,1 16,3 19,8 24,0 29,8 37,4 47,2 56,9 66,3 76,8 87,8 100,0

50 37,0 0,0 2,4 3,0 3,9 5,1 6,4 7,8 9,8 12,2 15,0 18,4 22,7 28,4 34,9 41,9 50,7 59,5 68,9 79,2 89,2 100,0

40 17,5 0,0 2,6 3,7 4,6 5,4 6,3 7,4 8,9 10,9 13,2 16,0 19,2 22,9 26,9 31,4 37,3 44,6 53,9 66,9 82,3 100,0

65

50 26,0 0,0 2,7 3,8 5,0 6,2 7,6 9,2 11,2 13,5 15,9 18,8 22,5 26,5 31,8 37,7 45,2 54,2 64,5 76,5 88,5 100,0

65 52,0 0,0 1,5 2,5 3,3 4,0 4,9 6,2 8,0 10,6 13,5 17,5 22,3 28,3 37,1 47,1 60,6 72,3 80,6 87,7 93,8 100,0

50 42,0 0,0 2,0 2,4 2,9 3,6 4,5 5,5 6,8 8,3 10,0 11,9 14,3 16,9 20,5 25,0

80

65 70,0 0,0 2,0 2,4 2,9 3,6 4,4 5,4 6,7 8,1 9,7 11,7 14,2 17,4 22,0 27,9 36,1 46,4 58,0 71,4 85,7 100,0

80 100,0 0,0 2,1 2,6 3,2 4,2 5,5 7,0 8,6 10,5 12,9 16,0 20,0 25,0 31,9 40,0 49,5 60,0 71,0 83,0 92,4 100,0

100

Tab. 2:

65 75,0 0,0 1,9 2,3 2,8 3,5 4,2 5,1 6,2 7,6 9,1 11,1 13,7 16,8 21,2 26,7 33,6 42,7 54,0 68,0 83,3 100,0

80 115,0 0,0 1,8 2,3 2,9 3,7 4,8 6,1 7,6 9,6 12,0 14,8 18,3 23,0 30,0 38,3 47,4 56,5 66,3 77,4 88,5 100,0

100 140,0 0,0 2,3 2,8 3,3 4,1 5,1 6,4 7,9 9,6 11,8 14,6 18,4 22,9 29,1 36,4 46,1 59,3 72,5 84,3 93,3 100,0

Flow rate Kv

Kvs

[m³/h]

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Valve stroke POS [%]

30,7 38,1 46,8 59,5 76,4 100,0

english

13

Page 14

Typ 8750

Control and display elements

8. CONTROL AND DISPLAY ELEMENTS

Designation:

Function of

the keys

left

POS

POS

XXX

%

MENU INPUT CMD MANU

MENU OPN CLS AUTO

selection key

Arrow key

up arrow

Fig. 8: Description of control elements

Short description

of the value

Display for operating state AUTOMATIC:

Bar running from left to right

Unit or per-

centage of the

POS

value

Save symbol

MENU CMD POS MANU

Display for position

control

Fig. 9: Description of display

0.0

0.0

Function of the keys

Display

right

selection key

Arrow key

down arrow

Value

Symbols

1)

Bar graph

display of the

value

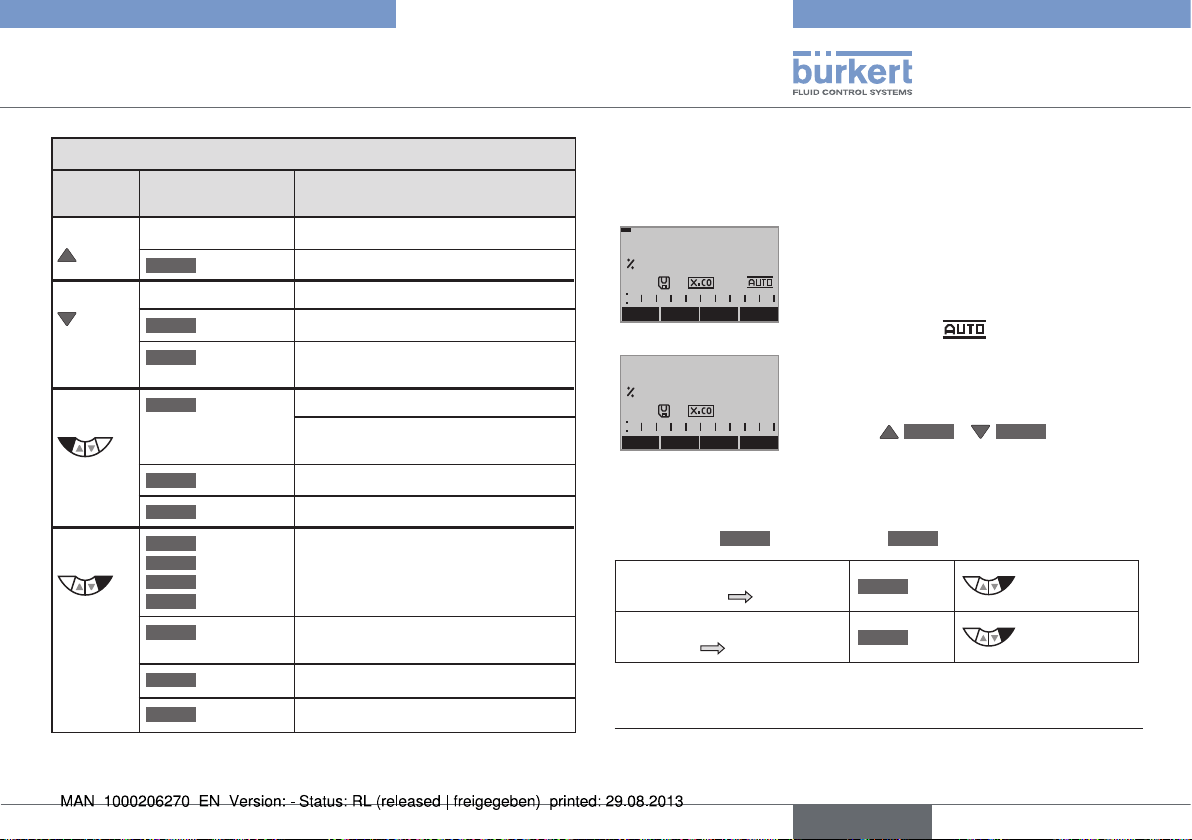

8.1. Function of the keys

The functions of the 4 keys differ depending on the operating state

(AUTOMATIC or MANUAL) and operating level (process level or

setting level).

The function of the keys is displayed in the gray text field which is

above the key.

Function of the keys on the process level:

Key

Arrow key

Arrow key

Selection

key

Selection

key

Function of

the keys

MENU

OPN

(OPEN)

MENU

CLS

(CLOSE)

MENU

MENU

MENU

AUTO

MENU

MANU

Description of the

function

Manual opening of the

actuator

Change the displayed value

(z.B. POS-CMD-TEMP-...)

Manual closing of the actuator

Change the displayed value

(e.g. POS-CMD-TEMP-...)

Change to the setting level

Note: Press key for approx.

3 s.

Return to AUTOMATIC operating state

Change to MANUAL operating

state

Operating

state

MANUAL

AUTOMATIC

MANUAL

AUTOMATIC

AUTOMATIC

or MANUAL

MANUAL

AUTOMATIC

1) Symbols are displayed according to the activated functions

14

english

Page 15

Typ 8750

Control and display elements

Function of the keys on the setting level:

Key

Arrow key Scroll up in the menus

Arrow key

Selection

key

Selection

key

Tab. 3: Function of the keys

Function of the

keys

MENU

+

MENU

–

←

MENU

MENU

EXIT

(BACK)

MENU

ESC

MENU

STOP

MENU

ENTER

MENU

SELEC

MENU

OK

MENU

INPUT

MENU

EXIT

(BACK)

MENU

RUN

MENU

STOP

Description of the function

Increase numerical values

Scroll down in the menus

Decrease numerical values

Change by one digit to the left; when

entering numerical values

Return to the process level

Gradually return from a sub-menu

option

Leave a menu

Stop a sequence

Select, activate or deactivate a menu

option

Gradually return from a sub-menu

option

Start a sequence

Stop a sequence

8.2. Operating state

The process controller has 2 operating states:

AUTOMATIC and MANUAL

POS

MENU CMD POS MANU

POS

MENU OPN CLS AUTO

0.0

0.0

8.2.1. Changing the operating state

Use the right selection key to switch between the two operating states

MENU

AUTOMATIC

AUTO

Switching from

AUTOMATIC MANUAL

Switching from

MANUAL

Tab. 4: Changing the operating state

2) Only possible if POS, CMD, PV (,SP) is displayed.

AUTOMATIC

AUTOMATIC

In the AUTOMATIC operating state, normal

controller mode is implemented.

(Bar running along the upper edge of the

display and symbol

displayed).

MANUAL

In the MANUAL operating state, the valve

can be opened and closed manually via the

arrow keys

and MANUAL

MENU

MANU

MENU

AUTO

MENU

OPN

MENU

MANU

2)

.

/

MENU

CLS

press

press

.

english

15

Page 16

Typ 8750

Control and display elements

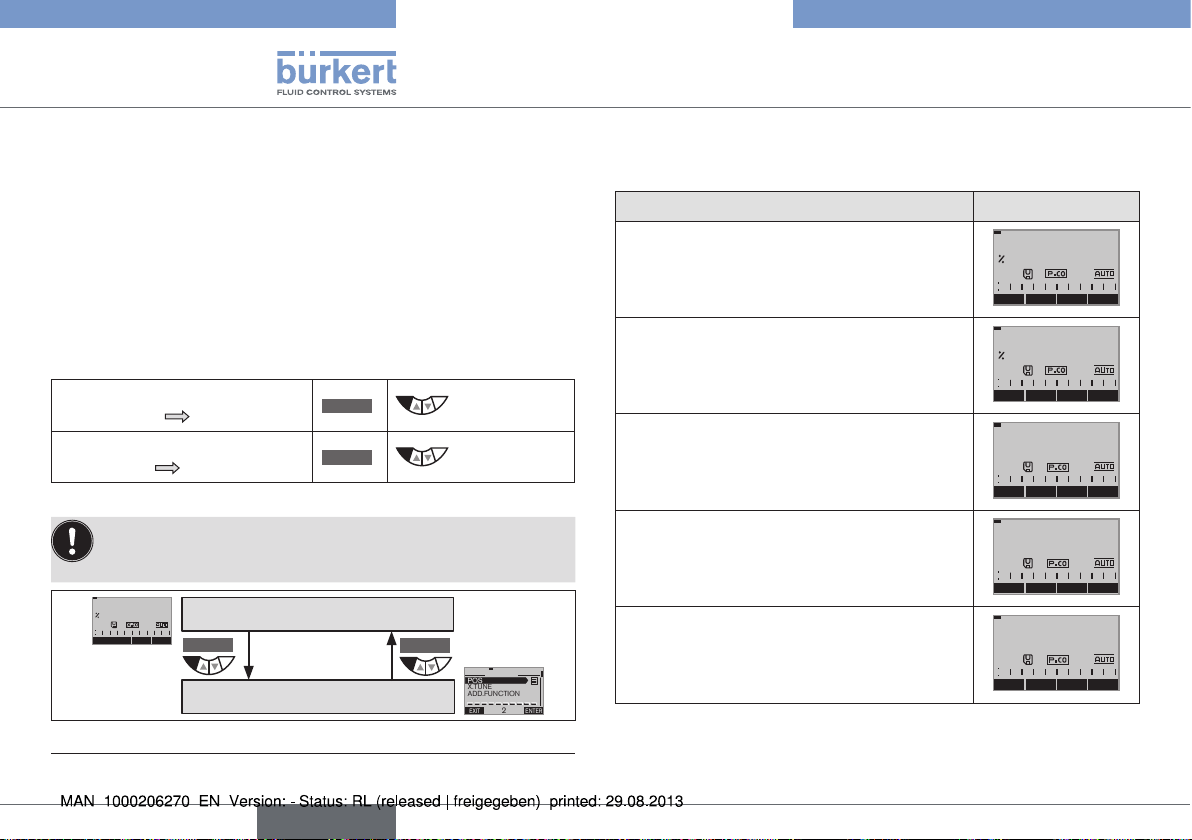

8.3. Operating levels

The process controller has 2 operating levels:

• Process level

Display and operation of the current process

Operating state: AUTOMATIC / MANUAL

• Setting level

Inputting the operating parameters

Supplementing the menu by optional menu options

8.3.1. Switching between the operating levels

Switching from

process level setting level

Switching from

setting level process level

Tab. 5: Changing the operating level

If the device is in the AUTOMATIC operating state when

changing to the setting level, the process continues running

during the setting.

POS

0.0

MENU CMD POS MANU

approx. 3 s

Fig. 10: Operating levels

3)

MENU

MENU

Process level

MENU

MENU

MENU

EXIT

Setting level

press for 3 s

press

MENU

EXIT

M A I N

POS

X.TUNE

ADD.FUNCTION

EXIT ENTER

2

8.4. Display in AUTOMATIC operating

state

Description of the display Display

Set-point position of the valve actuator

(0 – 100 %)

Nominal position of the valve actuator

(0 – 100 %)

3)

Internal temperature in the body of the device

( °C)

Process actual value

Process set-point value

POS

MENU SP/PV CMD MANU

CMD

MENU POS TEMP MANU

TEMP

C

MENU CMD PV

PV

m3/min

MENU TEMP SP MANU

SP

m3/min

MENU PV PV

0.0

0.0

0.0

0.0

0.0

(t)

INPUT

3) During these 3 s (countdown), 2 bars converge.

16

english

Page 17

Typ 8750

Control and display elements

Description of the display Display

Simultaneous display of the nominal position

and the set-point position of the valve

actuator (0 – 100 %)

Graphical display of SP and PV with time

axis

Graphical display of POS and CMD with

time axis

Value overview

Pressure sensor P1 and P2

Time, weekday and date

Automatic adjustment of the position

controller

SP

m3/min

PV

m3/min

CMD/POS

MENU

MENU HOLD

CMD / POS (t)

MENU HOLD

P1 bar

P2 bar

MENU P.LIN SP/PV MANU

12:00

Thu. 01 . 09 . 11

POS

MENU

SP / PV (t)

CLOCK

(t)

X.TUNE

0.0

0.0

POS MANU

0.0

0.0

00

INPUT

X.TUNE

CLOCK

MENU

P.TUNE RUN

Description of the display Display

Automatic optimization of the process controller parameters

Automatic linearization of the process

characteristics

Simultaneous display of the nominal position

and the set-point position of the valve

actuator

(0 – 100 %)

Tab. 6: Display in the AUTOMATIC operating state

P.TUNE

X.TUNE

MENU

P.LIN RUN

P.LIN

CMD/POS

P.TUNE

MENU

CMD

POS

MENU P.LIN SP/PV MANU

RUN

0.0

0.0

8.5. Master code

Operation of the device can be locked via a freely selectable user

code. In addition, there is a non-changeable master code with which

you can perform all operator control actions on the device. This

4-digit master code can be found on the last pages of this quickstart

guide in the Chapter “Master code”.

If required, cut out the code and keep it separate from this quickstart

guide.

english

17

Page 18

Typ 8750

Assembly

9. ASSEMBLY

9.1. Safety instructions

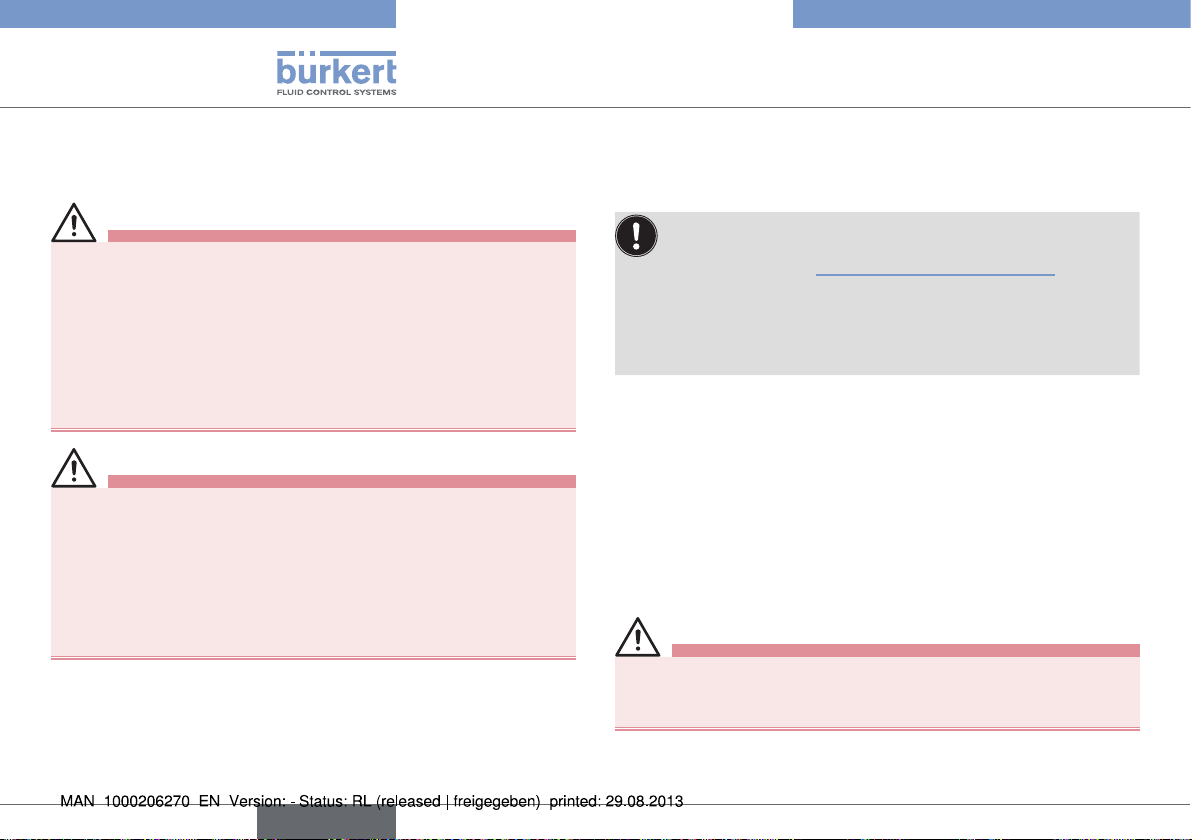

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before reaching into the device, switch off the power supply and

secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for

electrical equipment.

WARNING!

Risk of injury from improper assembly.

▶ Installation must only be carried out by authorized technicians and

with the appropriate tools.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system against unintentional activation.

▶ Following assembly, ensure a controlled restart.

9.2. Before installation

The FMR can be installed in any position, preferably with the

process controller face up.

• To avoid turbulent flows around the pressure sensor, fit an

inlet section upstream of the FMR (dimensions acc. to EN

ISO 5167-1, see “Fig. 5: Inlet sections”, page 10)

• Ensure that the pipelines are correctly lined and are not

twisted. If necessary, pipelines must be suitably attached or

supported.

• Observe flow direction (arrow on valve body).

9.2.1. Installation

→ Clean pipelines and joints (sealing material, swarf, etc.).

→ Connect FMR to pipeline.

9.3. Pneumatic connection of the

process controller

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

18

english

Page 19

Typ 8750

Assembly

WARNING!

Risk of injury from unsuitable connection hoses.

Hoses which cannot withstand the pressure and temperature

range may result in hazardous situations.

▶ Use only hoses which are authorized for the indicated pressure

and temperature range.

▶ Observe the data sheet specifications from the hose manufacturers.

Exhaust air port

label: 3

Procedure:

→ Connect the control medium to the pilot air port (1)

(3 – 7 bar; instrument air, free of oil, water and dust).

→ Fit the exhaust air line or a silencer to the exhaust air port (3).

Important information for the problem-free functioning of the

device:

• The installation must not cause back pressure to build up.

• To make the connection, select a hose with sufficient cross

section.

• The exhaust air line must be designed in such a way that

no water or other liquid can get into the device through the

exhaust air port (3).

Pilot air port

label: 1

Fig. 11: Pneumatic connection

Caution (exhaust air concept):

In compliance with protection class IP67, an exhaust air line

must be installed in the dry area.

The applied pilot pressure must always be maintained at

least 0.5 – 1 bar above the pressure which is required

to move the pneumatic actuator to its end position. This

ensures that the control behavior is not extremely negatively

affected in the upper stroke range on account of too little

pressure difference.

During operation, keep the fluctuations of the pilot pressure

as low as possible (max. ±10 %). If fluctuations are greater,

the control parameters measured with the X.TUNE function

are not optimum.

english

19

Page 20

Typ 8750

Electrical installation

10. ELECTRICAL INSTALLATION

DANGER!

Risk of electric shock.

▶ Before reaching into the device, switch off the power supply and

secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation must only be carried out by authorized technicians and

with the appropriate tools!

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system against unintentional activation.

▶ Following assembly, ensure a controlled restart.

10.1. Electrical installation, 24 V DC with

circular plug-in connector (multi-pole

variant)

Signal values

Operating voltage 24 V DC

Set-point value (process controller) 0 – 20 mA; 4 – 20 mA

0 – 5 V; 0 – 10 V

Actual value 4 – 20 mA

Procedure:

→ Connect the process controller according to the following tables.

When the operating voltage is applied, the process controller is

operating.

→ Now enter the required basic settings and actuate automatic

adjustment of the process controller, as described in Chapter

“11. Start-up 24 V DC”, page 25.

20

english

Page 21

Typ 8750

Electrical installation

3

2

Circular plug M12, 8-pole

4

5

6

3

Input signals from the control

1

center

8

Output signals from the control

7

center (optional)

Circular plug M8, 4-pole

1

Pressure sensor P1, P2

24

2

Circular plug M12, 4-pole

3

1

Operating voltage

4

Fig. 12: Connection with 24 V DC circular plug-in connector

4) The indicated colors refer to the connecting cable available as an

accessory (919061).

5) The indicated colors refer to the connecting cable available as an

accessory (92903474).

6) The indicated colors refer to the connecting cable available as an

accessory (918038).

Circular plug M12, 8-pole

Set-point value, binary input

Pin Wire color

4)

Assignment

8 red Set-point value + (0/4 – 20 mA / 0 – 5/10 V)

7 blue Set-point value GND

1 white Binary input +

Input/output signals - option only

4)

Pin Wire color

Assignment

6 pink Analog position feedback +

5 gray Analog position feedback GND

4 yellow Binary output 1

3 green Binary output 2

2 brown Binary outputs GND

Tab. 7: Circular plug M12, 8-pole

Circular plug M8, 4-pole (pressure sensor)

Pin Wire color5)Assignment

1 brown + 24 V pressure sensor power supply

2 white 4 – 20 mA output from pressure sensor

Tab. 8: Circular plug M8, 4-pole (pressure sensor)

Circular plug M12, 4-pole (operating voltage)

Pin Wire color6)Assignment

1 brown Operating voltage + 24 V DC

3 blue Operating voltage GND

Tab. 9: Circular plug M12, 4-pole (operating voltage)

english

21

Page 22

Typ 8750

Electrical installation

10.2. Electrical installation PROFIBUS DP

Procedure:

→ Connect the process controller according to the following tables.

The electrical connection module of Type 8693 features a setscrew

with nut which is used to connect the Technical Earth (TE)

(see “Fig. 13: Connection with PROFIBUS DP”).

→ Connect setscrew (TE connection) to a suitable grounding point.

To ensure electromagnetic compatibility (EMC), ensure that the

cable is as short as possible (max. 30 cm, Ø 1.5 mm2).

When the operating voltage is applied, the process controller is

operating.

→ Now make the required basic settings and actuate automatic

adjustment of the process controller, as described in

Chapter “13. PROFIBUS DP start-up”, page 35.

The settings in the BUS.COMM menu option are described

in Chapter “13. PROFIBUS DP start-up”.

1

4

3

3

Socket M12, 5-pole

5

(inversely coded)

2

(PROFIBUS DP)

Circular plug M8, 4-pole

1

Pressure sensor P1, P2

24

2

Circular plug M12, 4-pole

3

1

Operating voltage

4

TE terminal

Fig. 13: Connection with PROFIBUS DP

Socket M12, 5-pole (bus connection)

Pin Signal

1 VP+5

2 RxD/TxD-N

3 DGND

4 RxD/TxD-N

5 Shielding

Tab. 10: Socket M12, 5-pole (bus connection)

22

english

Page 23

Typ 8750

Electrical installation

Circular plug M8, 4-pole (pressure sensor)

Pin Wire color7)Assignment

1 brown + 24 V pressure sensor power supply

2 white 4 – 20 mA output from pressure sensor

Tab. 11: Circular plug M8, 4-pole (pressure sensor)

Circular plug M12, 4-pole (operating voltage)

Pin Wire color8)Assignment

1 brown Operating voltage + 24 V DC

3 blue Operating voltage GND

Tab. 12: Circular plug M12, 4-pole (operating voltage)

7) The indicated colors refer to the connecting cable available as an

accessory (92903474).

8) The indicated colors refer to the connecting cable available as an

accessory (918038).

10.3. Electrical installation DeviceNet

Procedure:

→ Connect the process controller according to the following tables.

The electrical connection module of Type 8693 features a setscrew

with nut which is used to connect the Technical Earth (TE)

(see “Fig. 14: Connection with DeviceNet”).

→ Connect setscrew (TE connection) to a suitable grounding point.

To ensure electromagnetic compatibility (EMC), ensure that the

cable is as short as possible (max. 30 cm, Ø 1.5 mm2).

When the operating voltage is applied, the process controller is

operating.

→ Now make the required basic settings and actuate automatic

adjustment of the process controller, as described in

Chapter “14. DeviceNet start-up”, page 39.

The settings in the BUS.COMM menu option are described

in Chapter “14. DeviceNet start-up”.

english

23

Page 24

Typ 8750

Electrical installation

2

3

4

3

2

3

4

Fig. 14: Connection with DeviceNet

Circular plug M12, 5-pole

DeviceNet

1

5

Circular plug M8, 4-pole

1

Pressure sensor P1, P2

24

Circular plug M12, 4-pole

1

Operating voltage

TE terminal

Circular plug M12, 5-pole (bus connection)

Pin Signal

1 Shielding

2 V+

3 V4 CAN H

5 CAN L

Tab. 13: Circular plug M12, 5-pole (bus connection)

Circular plug M8, 4-pole (pressure sensor)

Pin Wire color9)Assignment

1 brown + 24 V pressure sensor power supply

2 white 4 – 20 mA output from pressure sensor

Tab. 14: Circular plug M8, 4-pole (pressure sensor)

Circular plug M12, 4-pole (operating voltage)

Pin Wire color

10)

Assignment

1 brown Operating voltage + 24 V DC

3 blue Operating voltage GND

Tab. 15: Circular plug M12, 4-pole (operating voltage)

9) The indicated colors refer to the connecting cable available as an

accessory (92903474).

10) The indicated colors refer to the connecting cable available as an

accessory (918038).

24

english

Page 25

Typ 8750

Start-up 24 V DC

11. START-UP 24 V DC

WARNING!

Risk of injury from improper operation.

Improper operation may result in injuries as well as damage to the

device and the area around it.

▶ Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

▶ Observe the safety instructions and intended use.

▶ Only adequately trained personnel may operate the system/the

device.

A detailed description of the start-up and operating procedures

for Type 8693 can be found in the operating instructions for

Type 8693.

To set up the flow controller, perform the following steps:

• Specify the standard settings of the process controller (input signal

(standard signal)).

• Perform the automatic adjustment (X.TUNE) of the process controller.

• Add the F.CONTROL auxiliary function to the main menu using the

configuration menu (ADDFUNCTION) and create settings.

11.1. General procedure for creating

settings for the flow controller

Key Action Description

MENU

MENU

Press for 3 s

(countdown in the

Switching from

process level

setting level

display)

→ Execute settings.

MENU

EXIT

Press

Tab. 16: General procedure for creating settings

You must exit the main menu by pressing the left selection

MENU

EXIT

key

before the modified data is saved to the

memory (EEPROM). During the save process, the save symbol

is indicated

on the display.

Switching from

setting level

process level

english

25

Page 26

Typ 8750

Start-up 24 V DC

11.2. Define basic settings

Setting the input signal

Procedure:

Key Action Description

MENU

MENU

Press for 3 s

(countdown in the

display)

/ Select INPUT Selection INPUT menu

MENU

ENTER

Press

Select 4 - 20 mA, 0 - 20

/

mA, 0 – 10 V or 0 – 5 V

MENU

SELEC

MENU

MENU

Tab. 17: Setting the input signal

EXIT

EXIT

Press

Press

Press

Switching from

process level

Change to INPUT menu

Select the input signal

Specifying the input signal

Exit INPUT menu

Switching from

setting level

setting level

process level

MENU

ENTER

INPUT

4-20 mA

0-20 mA

0-10 V

MENU

EXIT

Fig. 15: Operating structure INPUT (select input signal)

0- 5 V

You must exit the main menu by pressing the left selection

MENU

EXIT

key

before the modified data is saved to the

memory (EEPROM). During the save process, the save symbol

is indicated

on the display.

MENU

SELEC

26

english

Page 27

Typ 8750

Start-up 24 V DC

11.3. Automatic adjustment (X.TUNE)

WARNING!

Danger of injury due to the valve position changing when the

X.TUNE function is run at operating pressure.

▶ Never run X.TUNE while the process is running.

▶ Secure system against unintentional activation.

NOTE!

An incorrect control pressure or incorrectly connected operating pressure at the valve seat may cause the controller to

be wrongly adjusted.

• X.TUNE must always be run at the control pressure available

during subsequent operation (= pneumatic auxiliary energy).

• Run the X.TUNE function preferably without operating medium

pressure to exclude interference caused by flow forces.

The following functions are actuated automatically:

• Adjustment of the sensor signal to the (physical) stroke of the

actuating element used.

• Determination of parameters of the PWM signals to control the

control valves integrated in Type 8693.

• Setting the controller parameters of the process controller. Optimization occurs according to the criteria of the shortest possible

correction time with simultaneous freedom from overshoot.

Procedure:

Taste Action Description

MENU

MENU

Press for 3 s

(countdown in the

Switching from

process level

setting level

display)

/ Select X.TUNE Selection X.TUNE menu

MENU

RUN

Press

(countdown in the

for 5 s

Start of the automatic adjustment

X.TUNE

display)

Messages on the progress of the

X.TUNE on the display:

„TUNE #1....“-„X.TUNE READY“

MENU

EXIT

Press any key Exit X.TUNE menu

MENU

EXIT

Press

Tab. 18: Setting the input signal

Switching from

setting level

process level

You must exit the main menu by pressing the left selection

MENU

EXIT

key

before the modified data is saved to the

memory (EEPROM). During the save process, the save symbol

is indicated

on the display.

11)

To stop X.TUNE, press the left or right selection key

STOP

11) „TUNE err/break“ if a fault occurs.

english

27

Page 28

Typ 8750

Start-up 24 V DC

11.4. Configuring the F.CONTROL auxiliary

function

→ Add the auxiliary function F.CONTROL to the main menu using

the configuration menu (ADDFUNCTION).

Procedure:

Key Action

MENU

MENU

Press for approx. 3 s

/ Select ADD.FUNCTION

MENU

ENTER

Press

/ Select F.CONTROL

MENU

ENTER

MENU

EXIT

Press

Press

The F.CONTROL function is now activated and incorporated into

the main menu (MAIN).

Tab. 19: Incorporating F.CONTROL into the main menu (MAIN)

→ Enter the basic settings for the flow controller under F.CONTROL.

F.CONTROL

Fig. 16: Operating structure - basic settings for flow controller

12) The SP SCALE function is indicated only if the external set-

ENTER ENTER

EXIT

PID.PARAM

F.PARAM

SETUP

EXIT

ENTER

EXIT

ENTER

EXIT

DBND 1 %

KP 1,00

TN 999,9

TV 0,0

X0 0,0 %

FILTER 0

MTMP

DENS

MTMP.INPUT

DIAMETER

PV-INPUT

PV-SCALE

SP-INPUT

SP-SCALE

P.CO INIT

VALVE

point value default (external) menu option is activated under SP

INPUT.

12)

28

english

Page 29

Typ 8750

Start-up 24 V DC

F.CONTROL - Settings:

PID.PARAM

DBND 0,1 %

KP 0,00

TN 0,5

TV 0,0

X0 0,0 %

FILTER 0

F.PARAM

MTMP

DENS

SETUP

MTMP.INPUT

DIAMETER

PV-INPUT

Parameter settings for the PID process

controller

Insensitivity area (dead band) of the PID

process controller

Amplification factor of the process controller

Reset time

Hold-back time

Working point

Filtering of the process actual value input

Parameter settings for the flow controller

Manually specifying the medium temperature

MTMP.INPUT: In this case, manual refers to:

Density: Enter the density of the medium

Setting up the flow controller

Specify the medium temperature: can be set

either via temperature transmitter or via bus

Enter the pipe diameter

Indication of the signal type for process actual

value

PV-SCALE

SP-INPUT

SP-SCALE

P.CO-INIT

VALVE

Tab. 20: Basic settings for the flow controller

Scaling the process controller

(m/s or m³/h only)

Type of the set-point value default

(internal or external)

Scaling the position controller

13)

(for external set-point value default only)

Enables a smooth switchover between

AUTOMATIC and MANUAL operating state

Save a valve-specific Kv characteristic and the

Kvs value, customer settings also possible

The parameter settings for the PID process controller can be

created automatically with the help of the P.TUNE function

(description see “operating instructions for Type 8693”).

13) The SP SCALE function is indicated only if the external set-point

value default (external) menu option is activated under SP INPUT

english

29

Page 30

Typ 8750

Additional FMR functions

11.4.1. Change the process set-point value

Procedure:

1. Set the set-point value default on the setting level:

In the main menu (MAIN), select the F.CONTROL function

F.CONTROL

→ Use the

ENTER

MENU

EXIT

SETUP

key (press 4 x) to return to the process level.

ENTER

SP-INPUT

intern

2. On the process level, manually change the process set-point

value:

→ Use the arrow keys to select the

display for the process set-point value (SP).

MENU

INPUT

→ Press

key.

SP

m3/min

MENU PV PV

30.0

(t)

→ Enter the process set-point value (see image below).

SET VALUE

SP:

[m3/min]

+ <

ESC

Fig. 17: Enter values

70.0

+

070.

-

OK

Change by one position to the left

Increase number

Return without change

Changeable number

0

Accept set value

SELEC

INPUT

12. ADDITIONAL FMR FUNCTIONS

Overview

ADD.FUNCTION

ENTER

EXIT

Fig. 18: Overview of FMR auxiliary functions

CHARACT

CUTOFF

DIR.CMD

DIR.ACT

SPLTRNG

X.LIMIT

X.TIME

X.CONTROL

F.CONTROL

SECURITY

SAFEPOS

SIG.ERROR

BINARY.IN

OUTPUT

CAL.USER

SET.FACTORY

SER. I/O

EXTRAS

SERVICE

SIMULATION

DIAGNOSE

1

2

3

4

14)

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

30

english

Page 31

Typ 8750

Additional FMR functions

No Description

1

Selecting the transfer characteristic between input signal and

stroke (correction characteristic)

2

Sealing function for position controller

3

Effective sense of direction between input signal and nominal

position

4

Assignment of the aeration state of the actuator chamber to

the set-point position

5

Signal split range

14)

; input signal as a % for which the valve

runs through the entire stroke range.

6

Limit the mechanical stroke range

7

Limit the control speed

8

Parameterization of the position controller

9

Parameterization of the PID process controller

10

Code protection for settings

11

Input the safety position

12

Configuration of signal level fault detection

13

Activation of the binary input

14

Configuration of outputs (option)

15

Calibration

16

Reset to factory settings

17

Configuration of serial interface

18

Adjusting the display

No Description

19

For internal use only

20

Simulation of set-point value, process valve, process

21

Diagnosis menu (option)

Tab. 21: Description of auxiliary functions

14) The auxiliary function SPLTRNG can only be selected if

F.CONTROL (process control) is not activated.

The auxiliary functions listed here can be activated and set in accordance with the control task.

A detailed description of the auxiliary functions and settings

can be found in the user instructions for Type 8693.

The following auxiliary functions differ from Type 8693 and are

described in these instructions:

• CAL.USER see Chapter “12.2. CAL.USER - Changing the

factory calibration”

• OUTPUT see Chapter “12.3. OUTPUT - Configuration of

the analog output”

english

31

Page 32

Typ 8750

Additional FMR functions

12.1. Activating and deactivating

auxiliary functions

You can activate the auxiliary functions on the setting level by adding

them to the main menu (MAIN). The parameters for the auxiliary

functions can then be set.

To deactivate an auxiliary function, remove it from the main menu.

The previous settings created using this auxiliary function will then

be rendered invalid again as a result.

12.1.1. Including auxiliary functions in the

main menu

Procedure:

Key Action

MENU

MENU

MENU

ENTER

MENU

ENTER

MENU

EXIT

The auxiliary function is now activated and added to the main menu

(MAIN).

Tab. 22: Adding auxiliary functions to the main menu (MAIN)

Press for approx. 3 s

/ Select ADD.FUNCTION

Press

/ Select the auxiliary function

Press

Press

You must exit the main menu by pressing the left selection

MENU

EXIT

key

before the modified data is saved to the

memory (EEPROM). During the save process, the save symbol

is indicated

on the display.

12.2. CAL.USER - Changing the factory

calibration

→ Add the CAL.USER auxiliary function to the main menu using the

configuration menu (ADDFUNCTION).

→ Enter the settings for the flow controller under CAL.USER.

32

english

Page 33

Typ 8750

Additional FMR functions

CAL.USER

ENTER

calibr. POS

ENTER

POS. pMIN

INPUT

OK

Enter value

(POS.lower:)

EXIT

POS. pMAX

INPUT

OK

Enter value

(POS.upper:)

CAL.FMR

ENTER

CAL.PLIM

CAL.P1

CAL.P2

CAL.P1‘P2

CAL.TLIM

EXIT

CAL.TEMP

Fig. 19: Operating structure CAL.USER - changing the factory calibration

- 1

calibr. SP

16)

INPUT

OK

16)

INPUT

OK

16)

INPUT

OK

16)

INPUT

OK

Create and

confirm

minimum

value

Create and

confirm

minimum

value

Create and

confirm

minimum

value

Create and

confirm

minimum

value

EXIT

Press for approx. 3 s

ENTER

EXIT

17)

calibr. PV

ENTER

EXIT

copyFACT->User

RUN

SP 4 mA 0

SP 20mA 0

PV 4 mA 0

PV 20mA 0

Reset the settings of CAL.USER to

factory settings

Fig. 20: Operating structure CAL.USER - changing the factory calibration - 2

MENU

15) If you press the key

16) The specified input signal type is displayed.

17) If the specified signal type for the process actual value is Pt 100,

ESC

the value remains unchanged.

the input screen for the temperature value appears.

english

33

Page 34

CAL.USER - Settings:

calibr. POS

POS. pMIN

POS. pMAX

Calibration of the position actual value

Set the minimum position of the valve

Set the maximum position of the valve

Typ 8750

Additional FMR functions

calibr. PV

for input signal 4 - 20 mA:

PV 4mA 0

PV 20mA 0

Calibrating the process actual value

Minimum value of the input signal

Maximum value of the input signal

CAL.FMR

CAL.PLIM

CAL.P1

CAL.P2

CAL.P1‘P2

CAL.TLIM

CAL.TEMP

calibr. SP

SP 4mA 0

SP 20mA 0

34

Calibration of the flow controller

Measurement range of the pressure sensor

Calibration of pressure sensor 1

Calibration of pressure sensor 2

P1-P2 comparison increase in accuracy

Measurement range of the temperature

transmitter

Calibrating the temperature transmitter

Calibrating the process set-point value

Minimum value of the input signal

Maximum value of the input signal

english

for input signal Pt 100:

0000

copyFACT->USER

Tab. 23: CAL.USER settings

Temperature

Reset to factory settings

12.3. OUTPUT - Configuration of the

analog output

The analog output can send feedback regarding the current position

(POS) or the set-point value (CMD), the process actual value (PV),

the process set-point value (SP), the pressure at the input (P1), the

pressure at the output (P2) or the medium temperature (MTMP) to

the control center.

→ Add the auxiliary function OUTPUT to the main menu using the

configuration menu (ADDFUNCTION).

→ Create the settings for the flow controller under OUT ANALOG.

Page 35

Typ 8750

PROFIBUS DP start-up

OUT ANALOG

ENTER

EXIT

Fig. 21: Operating structure OUT ANALOG - analog output

POS

CMD

MTMP

OUT type

PV

SP

P1

P2

ENTER

EXIT

SELEC

Output of set-point position

Output of nominal position

Output of the process actual value

Output of the process set-point value

Output of the pressure P1 (input)

Output of the pressure P2 (output)

Output of medium temperature

SELEC

4 - 20 mA

0 - 20 mA

0 - 10 V

0 - 5 V

Selection

of the

standard

signal

13. PROFIBUS DP START-UP

Procedure:

• Perform the automatic adjustment (X.TUNE) of the process controller.

• Add the F.CONTROL auxiliary function to the main menu using the

configuration menu (ADDFUNCTION) and make settings.

• Make settings in the BUS.COMM function.

• Configuration of the process values.

13.1. Settings in BUS .COMM

Address 0

BUS FAIL

SafePos off

SafePos on

SAFEPOS activated:

The actuator moves to the safety position which is specified in the

SAFEPOS auxiliary function.

SAFEPOS deactivated:

The actuator moves to the safety end position which it would

assume if the electrical and pneumatic auxiliary energy failed.

See Chapter “15. Safety end positions”.

Enter a device address (value between 0 and 126)

Activate or deactivate approach of the safety

position

The actuator remains in the position which corresponds to the set-point value last transferred

(default setting).

If there is a fault in the bus communication, the

behavior of the actuator depends on the activation of the SAFEPOS auxiliary function.

english

35

Page 36

BUS.COMM

Typ 8750

PROFIBUS DP start-up

ENTER

Address 0

INPUT

+

–

18)

OK

BUS FAIL

ENTER

EXIT

BUS PDI

ENTER

EXIT

Fig. 22: Operating structure BUS.COMM - 1

Enter

value

Input device

address.

Adjustment

range: 0 – 126

SELEC

SafePos off

SafePos on

POS

CMD

Temperature

Operation mode

Errors

P1

P2

Mtmp

P.CONTROL active

Start up of

the safety

position

SELEC

Process

values

which are

transferred

to the

controller

EXIT

BUS PDO

ENTER

EXIT

CMD

Operation mode

Error reset

Mtmp

P.CONTROL active

SELEC

Process

values

which are

transferred

from the

controller

Fig. 23: Operating structure BUS.COMM - 2

MENU

18) If you press the key

ESC

, the value remains unchanged.

13.2. Configuration of the process

values

The following components are required for the configuration:

• Software suitable for the configuration. For example Step7 from

Siemens.

• GSD file (Download from the Bürkert homepage)

For more detailed information see supplementary instructions on the

Bürkert homepage:

• “Configuration on the PROFIBUS by means of GSD file”

www.burkert.com → Type 8793 → Config. PROFIBUS by GSD file

→ First input the PDI (Process Data Input).

36

english

Page 37

Typ 8750

PROFIBUS DP start-up

PDI: Process Data Input (from the process controller to the controller)

Name Description Identifier

PDI:POS

PDI:CMD

PDI:PV

PDI:SP

Actual position (position)

Actual value of positioner as ‰.

Value range 0 – 1000.

Values < 0 or > 1000 are

possible if e.g. X.TUNE has not

run through correctly.

Set-point position (command)

Set-point value of positioner

as ‰.

Value range 0 – 1000.

Process actual value

(process value)

Actual value of process controller

in physical unit (as set in the menu

P.CO INP or P.CO SCAL),

max. value range -999 – 9999,

depending on internal scaling.

Process set-point value (set-point)

Set-point value of process

controller in physical unit

(as set in the menu P.CO INP or

P.CO SCAL),

max. value range -999 – 9999,

depending on internal scaling.

GSD file:

PDI:POS

Identifier (HEX):

41, 40, 00

GSD file:

PDI:CMD

Identifier (HEX):

41, 40, 01

GSD file:

PDI:PV

Identifier (HEX):

41, 40, 02

GSD file:

PDI:SP

Identifier (HEX):

41, 40, 03

Name Description Identifier

PDI:TEMP

PDI:MODE

PDI:ERR

Device temperature (temperature)

Temperature of 0.1 °C is

measured on the CPU board by

the sensor,

value range -550 (-55 °C) –

+1250 (+125 °C).

Operating state (operation mode)

Operating state:

0: AUTO

1: MANUAL

2: XTUNE

9: P.QLIN

10: P.TUNE

12: BUSSAFEPOS

Error

Indicates the number of the

process value (output) which was

not written. The value is retained

until it is deleted with PDO:ERR.

HEX

14 PDO:CMD / SP

16 PDO:MODE

GSD file:

PDI:TEMP

Identifier (HEX):

41, 40, 04

GSD file:

PDI:MODE

Identifier (HEX):

41, 00, 05

GSD file:

PDI: ERR

Identifier (HEX):

41, 00, 06

english

37

Page 38

Typ 8750

PROFIBUS DP start-up

Name Description Identifier

PDI:P1

PDI:P2

PDI:MTMP

PDI:

PCONact

Tab. 24: Process Data Input, PROFIBUS DP

Pressure before the valve

0000-XXXX depending on sensor

range

Pressure before the valve

0000-XXXX depending on sensor

range

Medium temperature

Temperature in °C on 1 °C exactly

Value range 0 °C – 150 °C

0: Positioner

1: Process controller

GSD file:

PDI:P1

Identifier (HEX):

41, 40, 07

GSD file:

PDI:P2

Identifier (HEX):

41, 40, 08

GSD file:

PDI:MTMP

Identifier (HEX):

41, 40, 09

GSD file:

PDI:PCONact

Identifier (HEX):

41, 00, 0A

→ Then input the process data output.

PDO: Process Data Output (from the controller to the process

controller)

Name Description Identifier

PDO:

CMD/SP

PDO:

MODE

Process set-point value

(set-point)

Set-point value of process controller in physical unit (as set in the

menu P.CO INP or P.CO SCAL),

max. value range -999 – 9999,

depending on internal scaling.

If the value is too small or too

large, the last valid value is used

and is indicated in ERR with HEX

14.

Operating state (operation mode)

Value range 0, 1 or 12:

Operating state:

0: AUTO

1: MANUAL

12: BUSSAFEPOS

If the value is too small or too

large, the last valid value is used

and is indicated in ERR with HEX

16.

GSD file:

PDO:CMD/SP

Identifier (HEX):

81, 40, 14

GSD file:

PDO:MODE

Identifier (HEX):

81, 00, 16

38

english

Page 39

Typ 8750

DeviceNet start-up

Name Description Identifier

PDO:ERR

PDO:

MTMP

PDO:

CONact

Tab. 25: Process Data Output, PROFIBUS DP

Reset error display

If the value > 0, ERR is reset.

Medium temperature

Temperature in °C on 1 °C exactly

Value range 0 °C – 150 °C

0: Positioner

1: Process controller

GSD file:

PDO: ERR

Identifier (HEX):

81, 00, 17

GSD file:

PDO:MTMP

Identifier (HEX):

81, 40, 18

GSD file:

PDO:CONact

Identifier (HEX):

81, 00, 19

14. DEVICENET START-UP

Procedure:

• Perform the automatic adjustment (X.TUNE) of the process controller.

• Add the F.CONTROL auxiliary function to the main menu using the

configuration menu (ADDFUNCTION) and create settings.

• Make settings in the BUS.COMM function.

• Configuration of the process values.

14.1. Settings in BUS .COMM

Address 0

BAUD RATE

• The baud rate can be changed either by pressing the operator keys

on the device or via the bus.

• A change has no effect until a reset (send a reset message to

the identity object) or power up is implemented. This means if the

changed baud rate attribute is accessed before a reset or power up,

the read (changed) value does not agree with the still current baud

rate (to be changed) of the network.

Select 125 kbit/s, 250 kbit/s or 500 kbit/s

Enter a device address (value between 0 and 63)

Selection of the baud rate

english

39

Page 40

Typ 8750

DeviceNet start-up

BUS FAIL

Activate or deactivate approach of the safety

position

SafePos off

The actuator remains in the position which corresponds to the set-point value last transferred

(default setting).

SafePos on

If there is a fault in the bus communication, the

behavior of the actuator depends on the activation of the SAFEPOS auxiliary function.

SAFEPOS activated: The actuator moves to the safety position

which is specified in the SAFEPOS auxiliary function.

SAFEPOS deactivated: The actuator moves to the safety end

position which it would assume if the electrical and pneumatic auxiliary energy failed.

See Chapter “15. Safety end positions”.

BUS.COMM

ENTER

EXIT

Fig. 24: Operating structure BUS.COMM - DeviceNet

Address 0

INPUT

OK

BAUD RATE

ENTER

EXIT

BUS FAIL

ENTER

EXIT

18)

+

–

Enter

value

125 kBd

250 kBd

500 kBd

SafePos off

SafePos on

Input device

address.

Adjustment range:

0 – 63

SELEC

Selection

of the baud

rate

SELEC

Activate /

deactivate

approach

of the

safety

position

40

english

Page 41

Typ 8750

DeviceNet start-up

14.2. Configuration of the process data

The following components are required for the configuration:

• Software suitable for the configuration. For example RSNetWorx for

DeviceNet (Rev. 4.12.00).

• ESD file (is on the supplied CD).

Transferring process data

The process data is transferred via an I/O connection. 5 static input

and 2 static output assemblies can be selected for the transfer. In these

assemblies selected attributes are combined in one object.

Selecting the process data

The process data is selected by setting the device parameters during

initialization of the I/O connection according to the DeviceNet specification. The following device parameters can be set:

• Active Input Assembly and Active Output Assembly or

• Produced Connection Path and Consumed Connection Path

- if supported by the DeviceNet Master/Scanner -.

14.2.1. Static Input Assemblies

Name Address of data

attribute of the

assemblies for

read access. Class,

instance, attributes

POS+ERR

(factory setting)

POS+CMD+ERR

PV+ERR

PV+SP+ERR

4, 1, 3 Byte 0: POS low

4, 2, 3 Byte 0: POS low

4, 3, 3 Byte 0: PV low

4, 5, 3 Byte 0: PV low

Format of the data

attribute

Byte 1: POS high

Byte 2: ERR

Byte 1: POS high

Byte 2: CMD low

Byte 3: CMD high

Byte 4: ERR

Byte 1: PV high

Byte 2: ERR

Byte 1: PV high

Byte 2: SP low

Byte 3: SP high

Byte 4: ERR

english

41

Page 42

Typ 8750

DeviceNet start-up

Name Address of data

attribute of the

assemblies for

read access. Class,

instance, attributes

PV+SP+CMD+

ERR

PV+P1+P2+

MTMP+ERR

4, 5, 3 Byte 0: PV low

4, 6, 3 Byte 0: PV low

Format of the data

attribute

Byte 1: PV high

Byte 2: SP low

Byte 3: SP high

Byte 4: CMD low

Byte 5: CMD high

Byte 6: ERR

Byte 1: PV high

Byte 2: P1 low

Byte 3: P1 high

Byte 4: P2 low

Byte 5: P2 high

Byte 6: MTMP low

Byte 7: MTMP high

Byte 8: ERR

Name Address of data

attribute of the

assemblies for

read access. Class,

instance, attributes

PV+SP+CMD+

P1+P2+

MTMP+ERR

PV+POS+ERR+

PCON

4, 7, 3 Byte 0: PV low

4, 8, 3 Byte 0: PV low

Format of the data

attribute

Byte 1: PV high

Byte 2: SP low

Byte 3: SP high

Byte 4: CMD low

Byte 5: CMD high

Byte 6: P1 low

Byte 7: P1 high

Byte 8: P2 low

Byte 9: P2 high

Byte 10: MTMP low

Byte 11: MTMP high

Byte 12: ERR

Byte 1: PV high

Byte 2: POS low

Byte 3: POS high

Byte 4: ERR

Byte 5: PCON

active

42

english

Page 43

Typ 8750

DeviceNet start-up

Name Address of data

attribute of the

assemblies for

read access. Class,

instance, attributes

PV+POS+ERR+

PCON+P1

Tab. 26: Static Input Assemblies, DeviceNet

The addresses indicated in “Tab. 26” can be used as a path

statement for the Produced Connection Path attribute of an

I/O connection.

This I/O connection can be used to transfer the attributes described

in more detail in the following “Tab. 27” as input process data.

Nevertheless, by using this address data, the attributes combined

in the assemblies can also be accessed acyclically at any time via

Explicit Messages.

4, 9, 3 Byte 0: PV low

Format of the data

attribute

Byte 1: PV high

Byte 2: POS low

Byte 3: POS high

Byte 4: ERR

Byte 5: PCON

active

Byte 6: P1 low

Byte 7: P2 low

Name Description of the input data

attributes

POS

CMD

PV

SP

Actual position

Actual value of process controller

as ‰.

Value range 0 – 1000.

However, values <0 or >1000 are

also possible if e.g. X.TUNE has not

run through correctly.

Set-point position

Set-point value of positioner as ‰.

Value range 0 – 1000.

Process actual value (process value)

Actual value of process controller

in physical unit (as set in the

menu P.CO INP or P.CO SCAL),

max. value range -999 – 9999,

depending on internal scaling.

Process set-point value

Set-point value of process con-

troller in physical unit (as set in the

menu P.CO INP or P.CO SCAL),

max. value range -999 – 9999,

depending on internal scaling.

Attribute

Address Class,

Instance,

Attribute; Data

type, Length

111, 1, 59;

INT, 2 byte

111, 1, 58;

UINT, 2 byte

120, 1, 3;

INT, 2 byte

120, 1, 2;

INT, 2 byte

english

43

Page 44

Typ 8750

DeviceNet start-up

Name Description of the input data

attributes

ERR

Error

Indicates the number of the process

value (output) which was not written.

The value is retained until it is deleted

with "1" by acyclically writing the

"Error" attribute (access via Explicit

Message – Set Attribute Single).

HEX

0X14 INP

0X15 SP

P1

P2

MTMP

PCONact

Tab. 27: Input data attributes; DeviceNet

Pressure before the valve in bar 120, 1, 7;

Pressure after the valve in bar 120, 1, 8;

Medium temperature in °C 120, 1, 9;

P.CONTROL active 120, 1, 10;

Attribute

Address Class,

Instance,

Attribute; Data

type, Length

100, 1, 1;

USINT, 1 byte

INT, 2 byte

INT, 2 byte

INT, 2 byte

USINT, 1 byte

14.2.2. Static Output Assemblies

Name Address of data

attribute of the

Format of the data

attribute

assemblies for

read access. Class,

instance, attributes

INP

(factory setting)

SP

4, 21, 3 Byte 0: INP low

Byte 1: INP high

4, 22, 3 Byte 0: SP low

Byte 1: SP high

MTMP

4, 23, 3 Byte 0: MTMP low

Byte 1: MTMP high

SP+MTMP

4, 24, 3 Byte 0: SP low

Byte 1: SP high

Byte 2: MTMP low

Byte 3: MTMP high

MTMP+SP+

ERR+PCON

4, 25, 3 Byte 0: MTMP low

Byte 1: MTMP high

Byte 2: SP low

Byte 3: SP high

Byte 4: ERR

Byte 5: PCON

active

Tab. 28: Static Output Assemblies, DeviceNet

The addresses indicated in “Tab. 28” can be used as a path

statement for the Consumed Connection Path attribute of an I/O

connection.

44

english

Page 45

Typ 8750

DeviceNet start-up

This I/O connection can be used to transfer the attributes described

in more detail in the following “Tab. 29” as output process data.

Nevertheless, by using this address data, the attributes combined

in the assemblies can also be accessed acyclically at any time via

Explicit Messages.

Name Description of the output data

attributes

INP

Set-point position

Set-point value of process con-

troller as ‰. Value range 0 – 1000.

In "pure" position controller

mode (F.CONTROL inactive)

the transfer of the INP set-point

position is required; as a process

controller (F.CONTROL active)

the transfer of INP is not possible.

If the value is too small or too large,

the last valid value is used and is

indicated in ERR with HEX 14.

Attribute

Address Class,

Instance,

Attribute; Data

type, Length

111, 1, 58;

UINT, 2 byte

Name Description of the output data

attributes

SP

MTMP

PCONact

Tab. 29: Output data attributes; DeviceNet

Process set-point value

Set-point value of process con-

troller in physical unit (as set in the

menu P.CO INP or P.CO SCAL),

max. value range -999 – 9999,

depending on internal scaling.

If the value is too small or too large,

the last valid value is used and is

indicated in ERR with HEX 15.

Medium temperature in °C 120, 1, 9;

P.CONTROL active 120, 1, 10;

Attribute

Address Class,

Instance,

Attribute; Data

type, Length

120, 1, 2;

INT, 2 byte

INT, 2 byte

USINT, 1 byte

english

45

Page 46

Typ 8750

Safety end positions

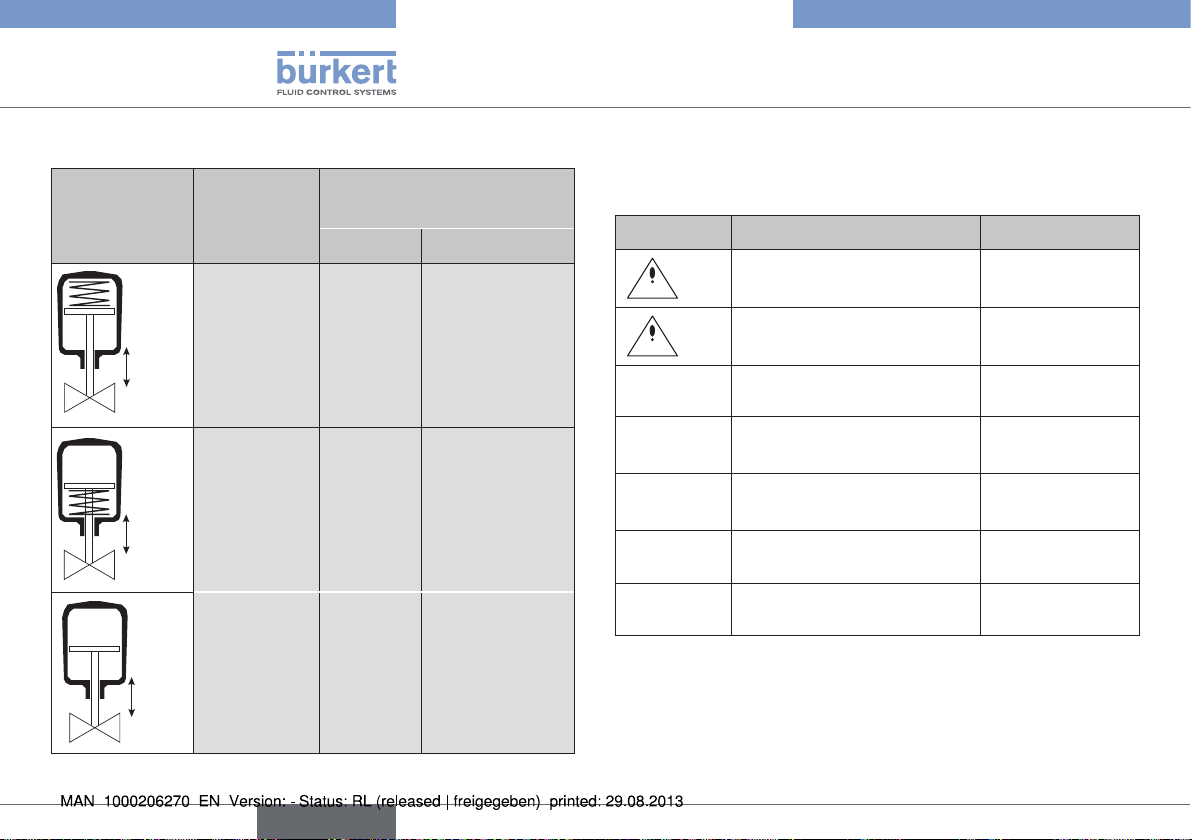

15. SAFETY END POSITIONS

Safety end positions after

Actuator

system

up

down

up