Page 1

Type 8691

Control Head

Steuerkopf

Tête de commande

Quickstart

English Deutsch Français

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2007 - 2013 Bürkert Werke GmbH

Quickstart 1312/04_EU-ML_00806079 / Original DE

Page 3

Type 8691

Contents

1 QUICKSTART ..................................................................................................4

1.1 Definition of term / abbreviation .............................................4

1.2 Symbols .......................................................................................4

2 AUTHORIZED USE ......................................................................................5

2.1 Restrictions .................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................5

4 GENERAL INFORMATION ........................................................................7

4.1 Contact address ........................................................................7

4.2 Warranty ......................................................................................7

4.3 Information on the Internet ......................................................7

5 SYSTEM DESCRIPTION ............................................................................7

5.1 Structure and function..............................................................7

5.2 Control head for integrated installation on the 21xx series

8

5.3 Model for control of process valves belonging to the 20xx

series 8

6 TECHNICAL DATA ........................................................................................9

6.1 Conformity ................................................................................... 9

6.2 Standards .................................................................................... 9

6.3 Operating conditions ................................................................9

6.4 Mechanical data.........................................................................9

6.5 Type label ....................................................................................9

6.6 Pneumatic data ........................................................................10

6.7 Electrical data ...........................................................................10

7 INSTALLATION ............................................................................................ 12

7.1 Safety instructions ...................................................................12

7.2 Installation of the control head on process valves

of series 21xx ...........................................................................12

7.3 Installation of the control head on process valves

of series 20xx ...........................................................................13

8 PNEUMATIC INSTALLATION ...............................................................15

9 ELECTRICAL INSTALLATION ...............................................................16

9.1 Safety instructions ...................................................................16

9.2 Electrical installation 24 V DC .............................................17

9.3 Display elements 24 V DC ....................................................19

9.4 Programming data AS-Interface ..........................................19

9.5 Electrical installation AS-Interface........................................20

9.6 Display elements AS-Interface .............................................22

9.7 Electrical installation DeviceNet ............................................23

9.8 Display elements DeviceNet ................................................25

10 TEACH FUNCTION ................................................................................... 27

10.1 Starting the teach function ....................................................27

11 SAFETY POSITIONS ................................................................................ 29

12 ACCESSORIES ...........................................................................................29

13 PACKAGING, TRANSPORT, STORAGE ..........................................30

english

3

Page 4

Type 8691

Quickstart

1 QUICKSTART

The Quickstart describe the entire life cycle of the device. Keep the

Quickstart in a location which is easily accessible to every user and

make the Quickstart available to every new owner of the device.

Important Safety Information.

Read Quickstart carefully and thoroughly. Study in particular the

chapters entitled “Basic safety instructions” and “Authorized use”.

▶ Quickstart must be read and understood.

Quickstart explains, for example, how to install and start-up the

device.

A detailed description of the device can be found in the operating

instructions for control head Type 8691.

The operating instructions can be found on the enclosed CD

and on the Internet at:

www.burkert.com

1.1 Definition of term / abbreviation

The term “device” used in these instructions always stands for the

control head Type 8691.

In these instructions, the abbreviation “Ex” always refers to “potentially explosive”.

1.2 Symbols

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning may result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a medium or minor

injury.

NOTE!

Warns of damage to property.

indicates important additional information, tips and

recommendations.

refers to information in these operating instructions or in

other documentation.

▶ Designates an instruction to prevent risks.

→ designates a procedure that must be carried out.

4

english

Page 5

Type 8691

Authorized use

2 AUTHORIZED USE

Non-authorized use of the control head Type 8691 may be a

hazard to people, nearby equipment and the environment.

▶ The device is designed to be mounted on pneumatic actuators

of process valves for the control of media.

▶ Do not expose the device to direct sunlight.

▶ Use according to the authorized data, operating conditions and

conditions of use specified in the contract documents and oper-

ating instructions. These are described in the chapter entitled “6

Technical data”.

▶ The device may be used only in conjunction with third-party

devices and components recommended and authorized by

Bürkert.

▶ In view of the large number of options for use, before installa-

tion, it is essential to study and if necessary to test whether the

control head is suitable for the actual use planned.

▶ Correct transportation, correct storage and installation and

careful use and maintenance are essential for reliable and fault-

less operation.

▶ Use the control head Type 8691 only as intended.

2.1 Restrictions

If exporting the system/device, observe any existing restrictions.

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing

these regulations, also with reference to the installation personnel.

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

english

5

Page 6

Type 8691

Basic safety instructions

General hazardous situations.

To prevent injury, ensure:

▶ In the potentially explosion-risk area the control head Type 8691

may be used only according to the specification on the separate

approval sticker. For use observe the additional instructions

enclosed with the device together with safety instructions for the

explosion-risk area.

▶ Devices without a separate approval sticker may not be used in a

potentially explosive area.

▶ Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The device may be operated only when in perfect condition and

in consideration of the operating instructions.

▶ The general rules of technology apply to application planning and

operation of the device.

To prevent damage to property on the device, ensure:

▶ Do not feed any aggressive or flammable media into the pilot air

port.

▶ Do not feed any liquids into the pilot air port.

▶ When unscrewing and screwing in the body casing or the trans-

parent cap, do not hold the actuator of the process valve but the

connection housing of Type 8691.

▶ Do not put any loads on the housing (e.g. by placing objects on

it or standing on it).

▶ Do not make any external modifications to the device housing. Do

not paint the housing parts or screws.

6

english

Page 7

Type 8691

General information

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2 Warranty

The warranty is only valid if the control head Type 8691 is used as

intended in accordance with the specified application conditions.

4.3 Information on the Internet

The operating instructions and data sheets for Type 8691 can be found

on the Internet at: www.burkert.com

5 SYSTEM DESCRIPTION

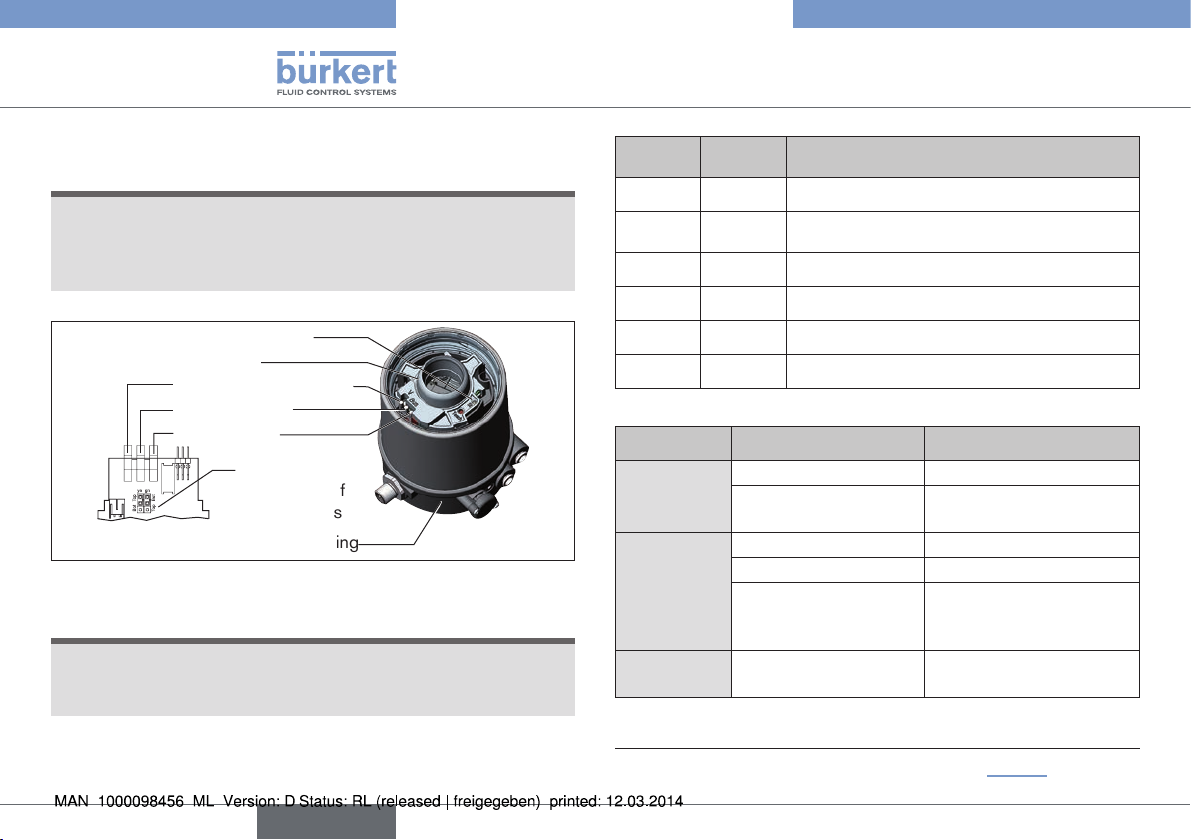

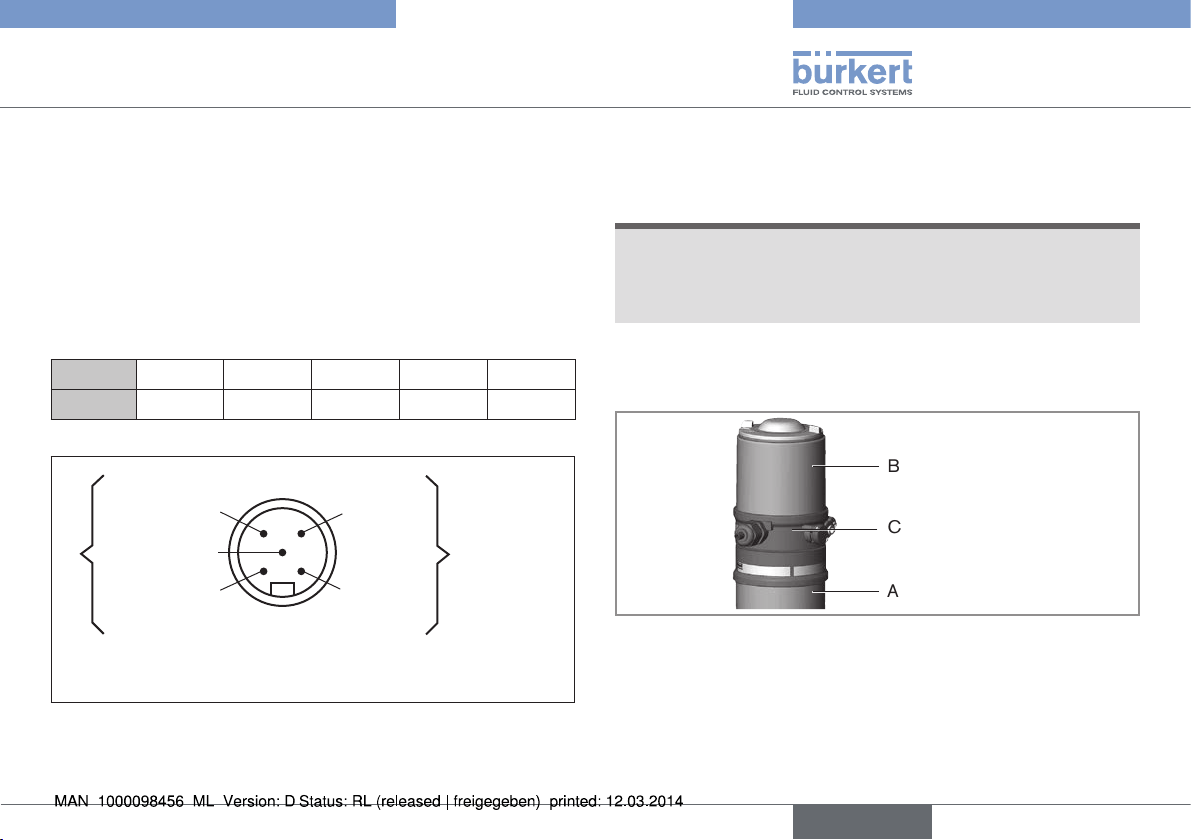

5.1 Structure and function

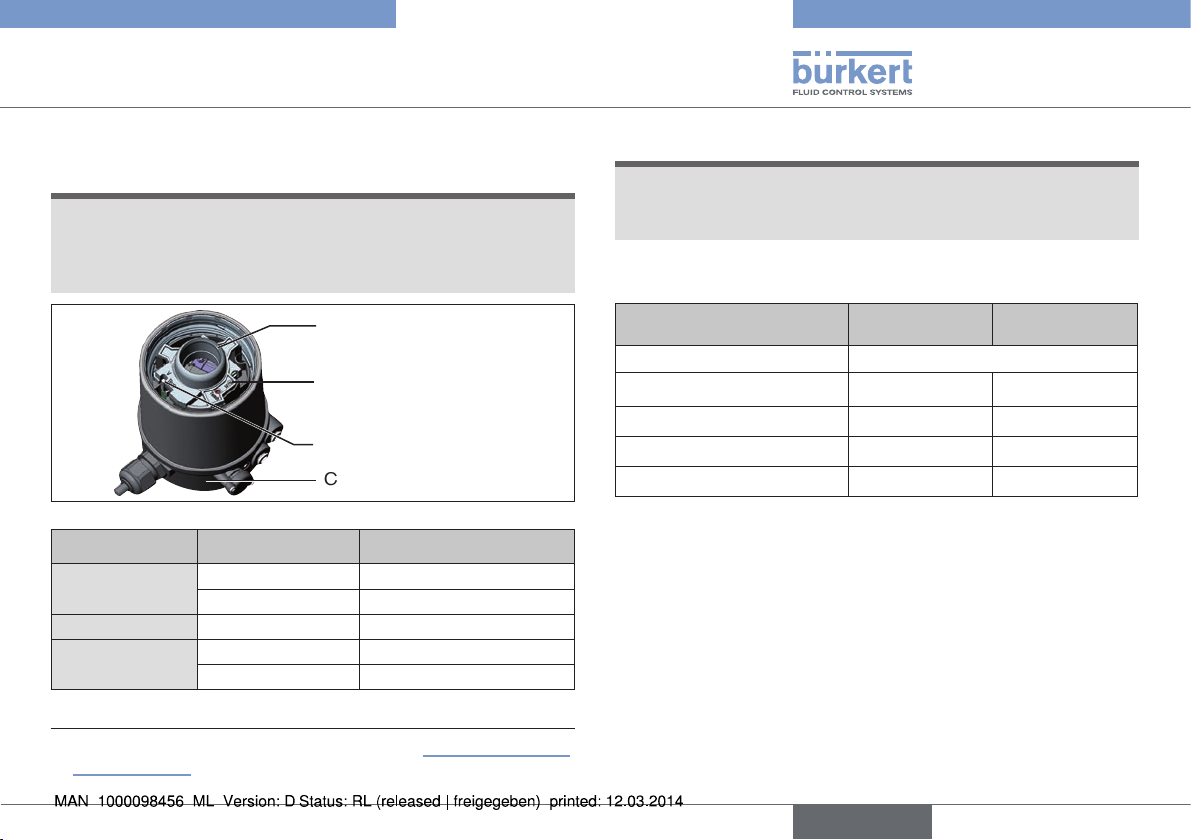

Control head

Actuator

Process valve

Valve body

Fig. 1: Structure

The control head Type 8691 can control single or double-acting

process valves and has been optimized for the integrated modular fitting

of series 21xx process valves (Element) . Various expansion stages are

possible thanks to the modular design.

For installation on the 20xx series (Classic) there is a special model

which is described in chapter “5.3”.

The valve position is recorded via a contactless, analog sensor element

which automatically detects and saves the valve end positions by means

of the teach function during start-up.

english

7

Page 8

Type 8691

System description

Apart from the electrical position feedback, the status of the device

is optically displayed on the control head itself by a colored highpower LED.

Option: Communication possible via AS-Interface or DeviceNet.

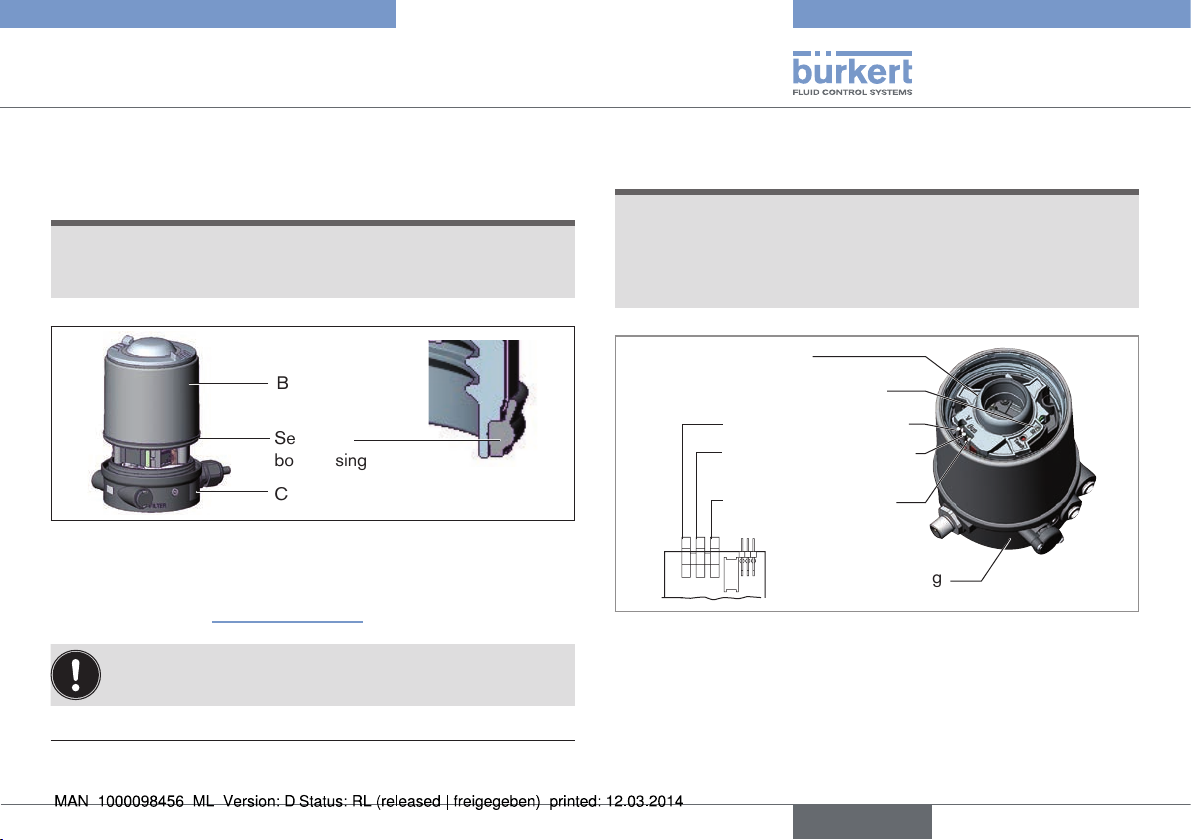

5.2 Control head for integrated

installation on the 21xx series

Electrical connection

Cable gland

M16 x 1.5 or

Circular plug-in

connector M12 x 1

Body casing

Air intake filter

View without transparent cap

Fig. 2: Structure for process valves belonging to the 21xx series

Connection housing

Pressure limiting valve

(for protection against too

high internal pressure in

Top LEDs

Teach function

case of error)

Exhaust air port

(label: 3)

Pilot air port

(label: 1)

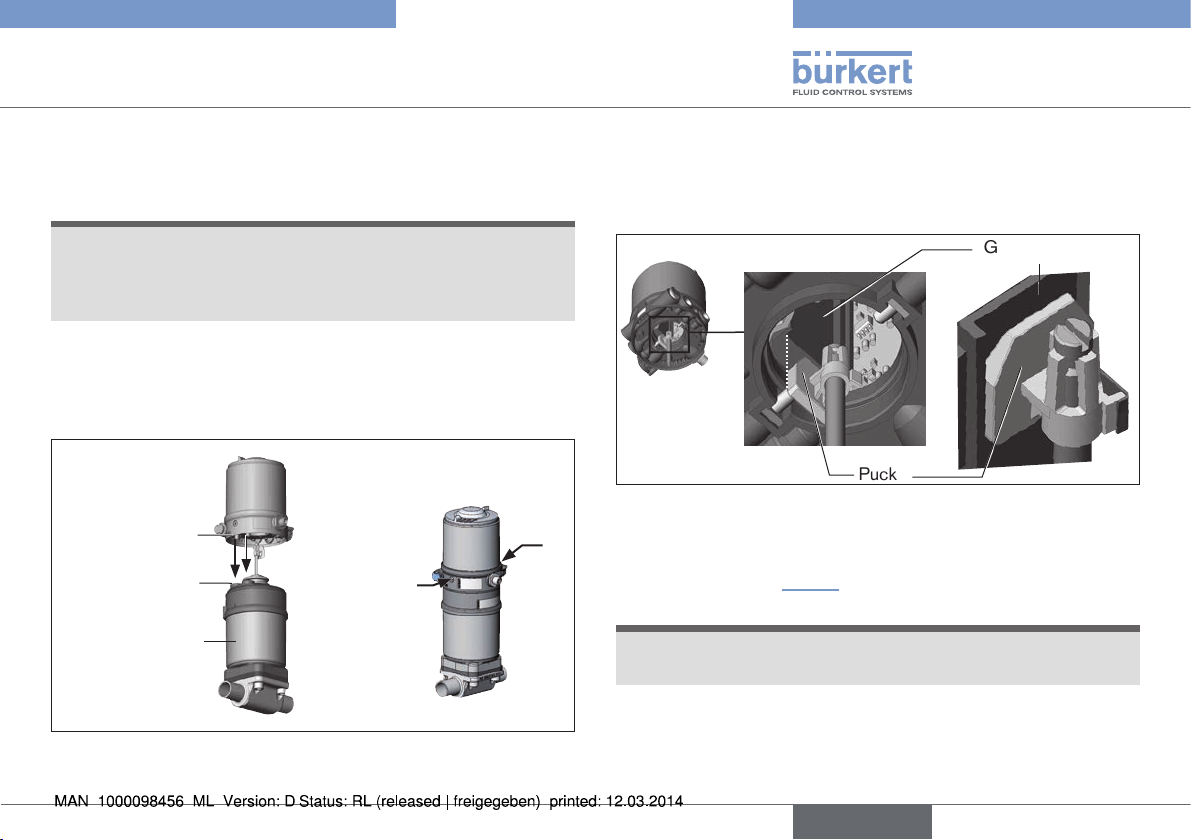

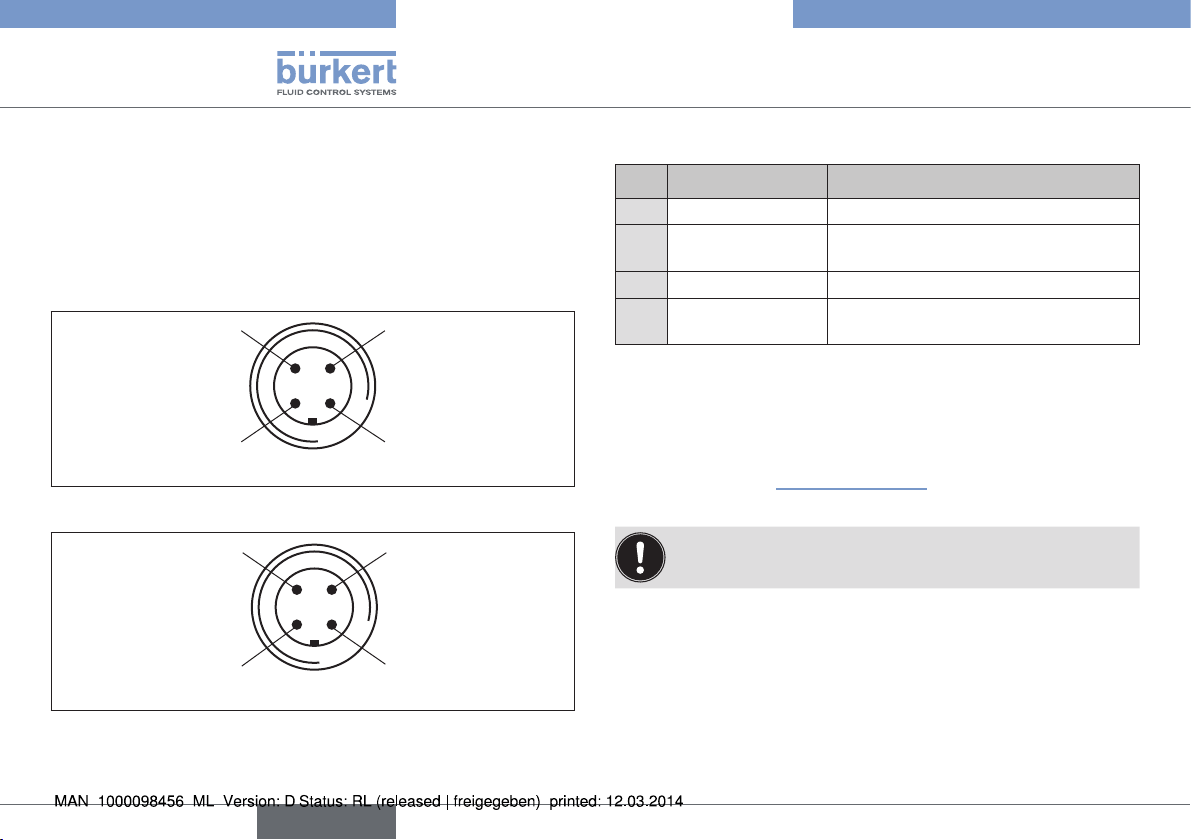

5.3 Model for control of process valves

belonging to the 20xx series

A special model enables the control head Type 8691 to be attached

to process valves belonging to the 20xx series.

This model features has a different connection housing so that the pilot

air ports can be connected to the outside of the actuator (see “Fig. 3”).

Pilot air outlet 2

Pilot air outlet 2

Fastening screws (2 x)

Connection housing

Fig. 3: Structure for process valves belonging to the 20xx series

1

2

8

english

Page 9

Type 8691

Technical data

6 TECHNICAL DATA

6.1 Conformity

In accordance with the EC Declaration of conformity, the control head

Type 8691 is compliant with the EC Directives.

6.2 Standards

The applied standards on the basis of which compliance with the EC

Directives is confirmed are listed in the EC type examination certificate

and/or the EC Declaration of Conformity.

6.3 Operating conditions

WARNING!

Solar radiation and temperature fluctuations may cause malfunctions or leaks.

▶ If the device is used outdoors, do not expose it unprotected to

the weather conditions.

▶ Ensure that the permitted ambient temperature does not exceed

the maximum value or drop below the minimum value.

Ambient temperature see type label

Degree of protection IP65 / IP67 according to EN 60529

(only if cables, plugs and sockets have

been connected correctly

and in compliance with the exhaust

air concept in chapter “8 Pneumatic

installation”).

6.4 Mechanical data

Dimensions see data sheet

Housing material exterior: PPS, PC, VA

Sealing material exterior: EPDM

interior: NBR

Stroke range of valve spindle: 2 – 28 mm

2 – 47 mm

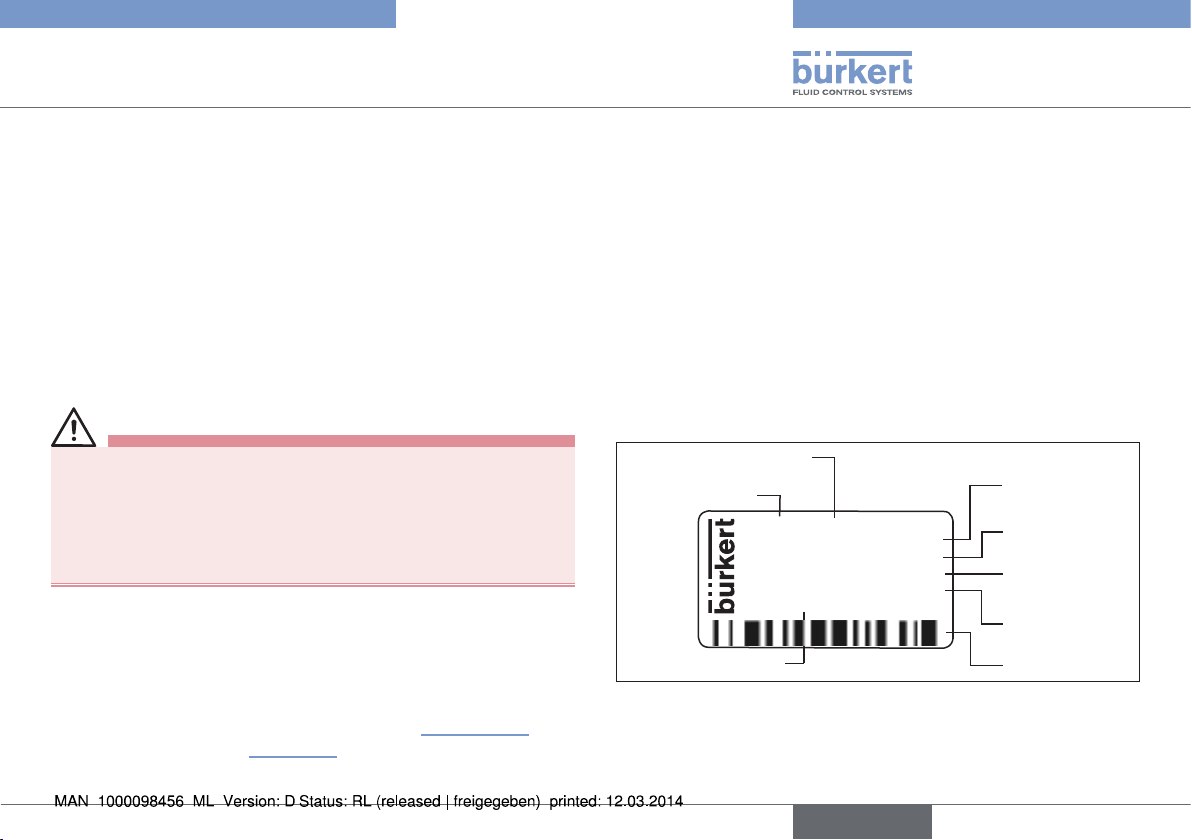

6.5 Type label

Example:

Supply voltage / Control

Typ

8691 AS-i 62SI

single act Pilot 3,0

Pmax 7bar

Tamb 0°C - +55°C

Ser.-Nr. 001000

00179024

D-74653 Ingelfingen

Identification number

Fig. 4: Type label (example)

CE

W14UN

Control function

- Pilot valve

Max. operating

pressure

Max. ambient

temperature

Serial number CE mark

Bar-code

english

9

Page 10

Type 8691

Technical data

6.6 Pneumatic data

Control medium neutral gases, air

Quality classes in accordance with DIN ISO 8573-1

Dust content Class 5 max. particle size 40 µm,

max. particle density 10 mg/m³

Water content Class 3 max. pressure dew point

- 20 °C or min. 10 °C below the

lowest operating temperature

Oil content Class 5 max. 25 mg/m³

Temperature range

control medium -10 – +50 °C

Pressure range

control medium 3 – 7 bar

Air output of pilot valve 250 l

Connections Plug-in hose connector ∅ 6 mm / 1/4“

/ min

N

(for aeration and deaeration)

(QNn - value according to definition for

pressure drop from 7 to 6 bar absolute)

Socket connection G 1/8

6.7 Electrical data

6.7.1 Electrical data without bus control

24 V DC

Connections Cable gland M16 x 1.5, wrench size 22

(clamping area 5 – 10 mm)

with screw-type terminals for cable crosssections 0.14 – 1.5 mm²

Circular plug-in connector

(M12 x 1, 8-pole)

Pilot valve

Supply voltage 24 V DC ± 10%

max. residual ripple 10 %

Power input max. 1 W

Output max. 100 mA per output

Display max. 20 mA per illustrated illuminated

display (LED)

10

english

Page 11

Type 8691

Technical data

6.7.2 Electrical data with AS-Interface bus

control

Connections Circular plug-in connector

(M12 x 1, 4-pole)

Supply voltage 29.5 V – 31.6 V DC

(according to specification)

Outputs

Max. switching capacity 1 W via AS-Interface

Watchdog function integrated

Devices without external supply voltage

Max. power consumption 120 mA

Power consumption input during

normal operation

(after current reduction;

valve + 1 end position reached) 90 mA

Devices with external supply voltage

External supply voltage 24 V ± 10 %

The power supply unit must include a secure disconnection in

accordance with IEC 364-4-41 (PELV or SELV)

Max. power consumption 55 mA (after current reduction

≤ 30 mA)

Max. power consumption

from AS-Interface 55 mA

6.7.3 Electrical data with DeviceNet bus

control

Connections Circular plug-in connector

(M12 x 1, 5-pole)

Supply voltage 11 V – 25 V

Max. power consumption < 80 mA

Output

Pull-in current current ≤ 50 mA

Holding current ≤ 30 mA

english

11

Page 12

Type 8691

Installation

7 INSTALLATION

Only for control head without pre-assembled process valve.

7.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

Risk of injury from unintentional activation of the system and

an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

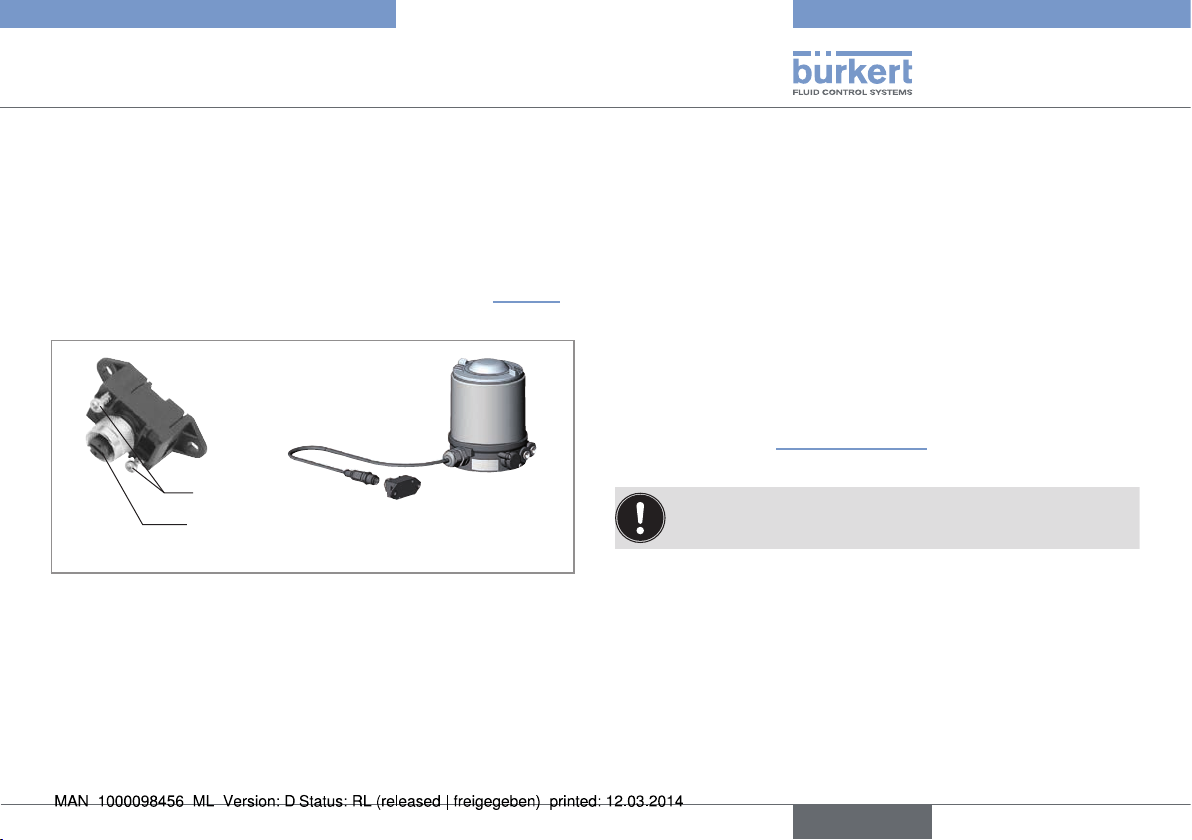

7.2 Installation of the control head on

process valves of series 21xx

Procedure:

When the control head is being installed, the collets of the

pilot air ports must not be fitted to the actuator.

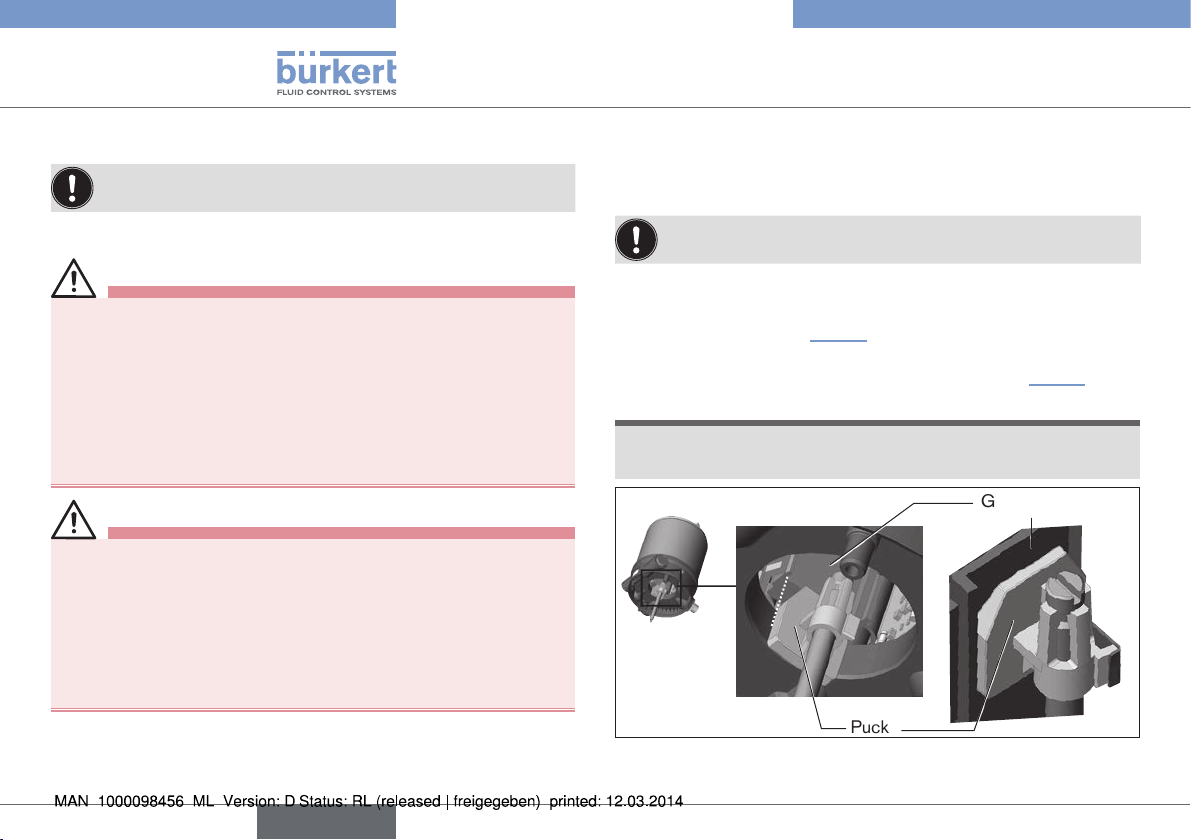

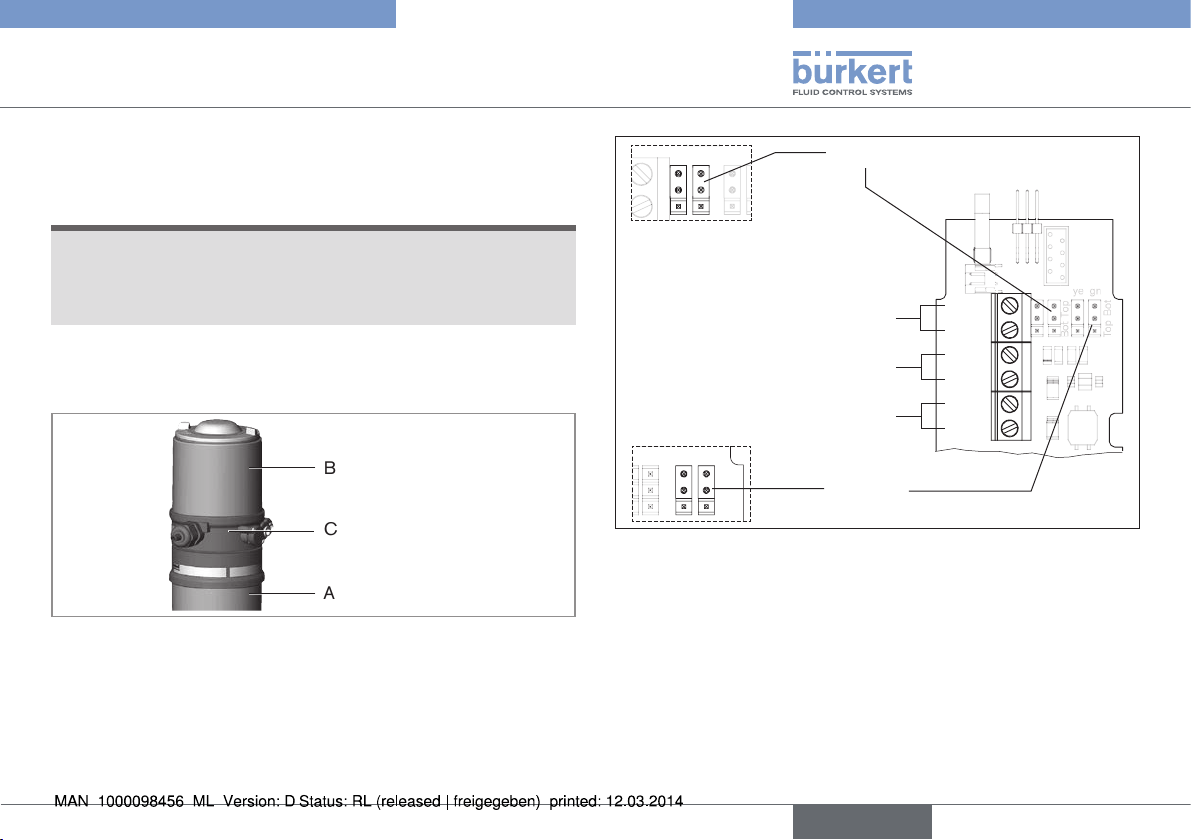

→ Align the puck and the control head until

1. the puck can be inserted into the guide rail of the

control head (see “Fig. 5”) and

2. the connection pieces of the control head can be inserted

into the pilot air ports of the actuator (see also “Fig. 6”).

NOTE!

Damaged printed circuit board or malfunction.

▶ Ensure that the puck is situated flat on the guide rail.

Guide rail

Puck

Fig. 5: Aligning the puck

12

english

Page 13

Type 8691

Installation

→ Push the control head, without turning it, onto the actuator until

no gap is visible on the form seal.

NOTE!

Too high torque when screwing in the fastening screw does

not ensure degree of protection IP65 / IP67.

▶ The fastening screws may be tightened to a maximum torque of

0.5 Nm only.

→ Attach the control head to the actuator using the two side fas-

tening screws. In doing so, tighten the screws only hand-tight

(maximum torque: 0.5 Nm).

Connection

pieces

Pilot air ports

Actuator

Fig. 6: Installation of control head, 21xx series

Fastening

screws

max. 0.5 Nm

7.3 Installation of the control head on

process valves of series 20xx

Procedure:

Guide rail

Puck

Fig. 7: Aligning the puck

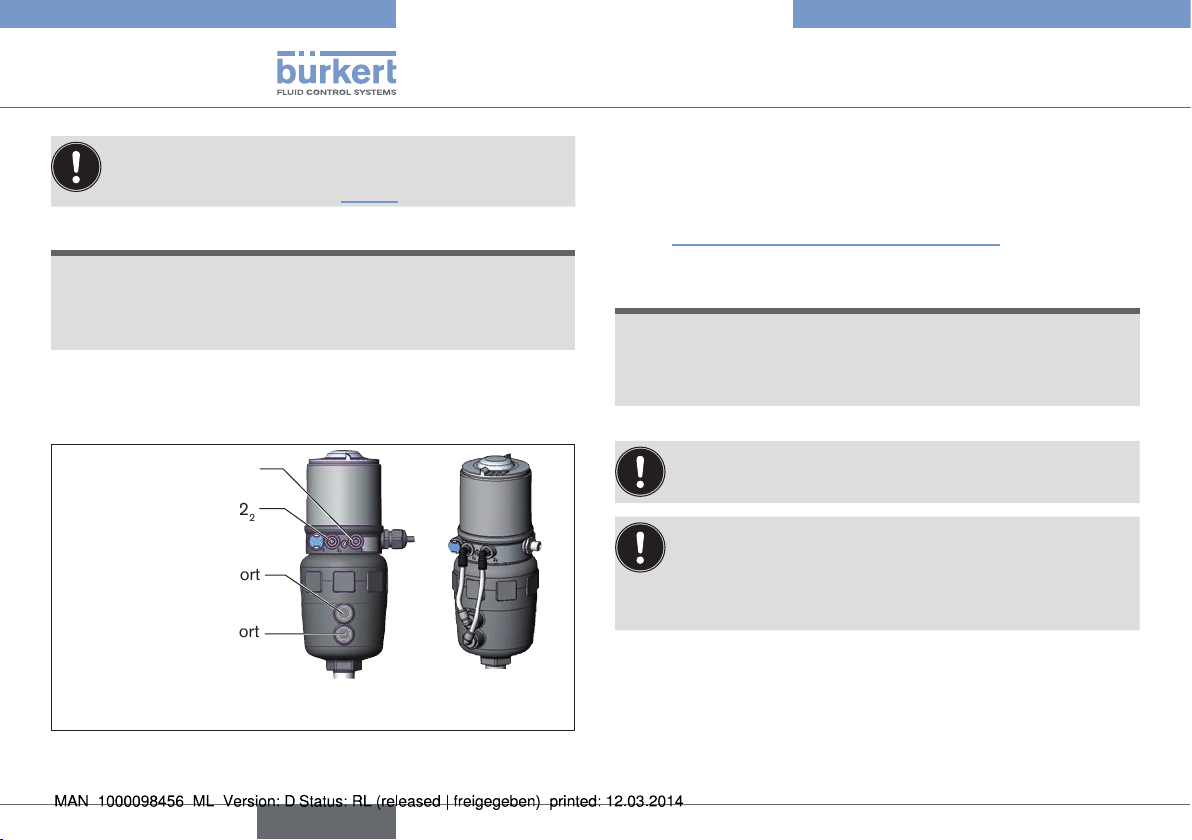

→ Push the control head onto the actuator. The puck must be

aligned in such a way that it is inserted into the guide rail of the

control head (see “Fig. 7”).

NOTE!

Damaged printed circuit board or malfunction.

▶ Ensure that the puck is situated flat on the guide rail.

→ Press the control head all the way down as far as the actuator

and turn it into the required position.

english

13

Page 14

Type 8691

Installation

Ensure that the pneumatic connections of the control head

and those of the valve actuator are situated preferably vertically one above the other (see “Fig. 8”).

NOTE!

Too high torque when screwing in the fastening screw does

not ensure degree of protection IP65 / IP67.

▶ The fastening screws may be tightened to a maximum torque of

0.5 Nm only.

→ Attach the control head to the actuator using the two side fas-

tening screws. In doing so, tighten the fastening screws handtight only (maximum torque: 0.5 Nm).

Pilot air outlet 2

Pilot air outlet 2

Upper pilot air port

Lower pilot air port

Fig. 8: Installing the pneumatic connection, 20xx series

1

2

Example

∅ 80, CFA

→ Screw the plug-in hose connectors onto the control head and

the actuator.

→ Using the hoses supplied in the accessory kit, make the pneu-

matic connection between the control head and actuator with

the “Tab. 1: Pneumatic connection to actuator”.

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To comply with degree of protection IP65 / IP67, connect the

pilot air outlet (only for CFA or CFB) which is not required to the

free pilot air port of the actuator or seal with a plug.

“In rest position” means that the pilot valves of the control head

Type 8691 are isolated or not actuated.

If the ambient air is humid, a hose can be connected between

pilot air outlet 22 of the control head and the unconnected

pilot air port of the actuator for control function A or control

function B. As a result, the spring chamber of the actuator is

supplied with dry air from the vent duct of the control head.

14

english

Page 15

Type 8691

Pneumatic installation

Control function A (CFA)

Process valve closed in rest position (by spring force)

Pilot air outlet

Control

head

Upper pilot air port

Lower pilot air port

Actuator

222

1

222

or

Control function B (CFB)

Process valve open in rest position (by spring force)

Pilot air outlet

Control

head

Upper pilot air port

Lower pilot air port

Actuator

222

1

222

or

Control function I (CFI)

Process valve in rest position closed open

Pilot air outlet

Control

head

222

1

222

Upper pilot air port

8 PNEUMATIC INSTALLATION

DANGER!

1

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Procedure:

→ Connect the control medium to the pilot air port (1)

(3 – 7 bar; instrument air, free of oil, water and dust).

→ Attach the exhaust airline or a silencer to the exhaust air port (3)

1

1

(see “Fig. 9: Pneumatic connection”).

Keep the adjacent supply pressure always at least 0.5 –

1 bar above the pressure which is required to move the

actuator to its end position.

Important information for the problem-free functioning of

the device:

▶ The installation must not cause back pressure to build up.

▶ Select a hose for the connection with an adequate

cross-section.

▶ The exhaust air line must be designed in such a way that

no water or other liquid can get into the device through the

exhaust air port.

Lower pilot air port

Actuator

Tab. 1: Pneumatic connection to actuator

english

15

Page 16

Type 8691

Electrical installation

9 ELECTRICAL INSTALLATION

9.1 Safety instructions

DANGER!

Pilot air port

(label: 1)

Exhaust air port

(label: 3)

Fig. 9: Pneumatic connection

Caution: (Exhaust air concept):

In compliance with degree of protection IP67, an exhaust air

line must be installed in the dry area.

16

english

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

Risk of injury from unintentional activation of the system and

an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

Page 17

ye

gn

y

e

gn

o

p

p

Type 8691

Electrical installation

9.2 Electrical installation 24 V DC

9.2.1 Electrical installation with cable gland

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the body casing, do not hold

the actuator of the process valve but the connection housing.

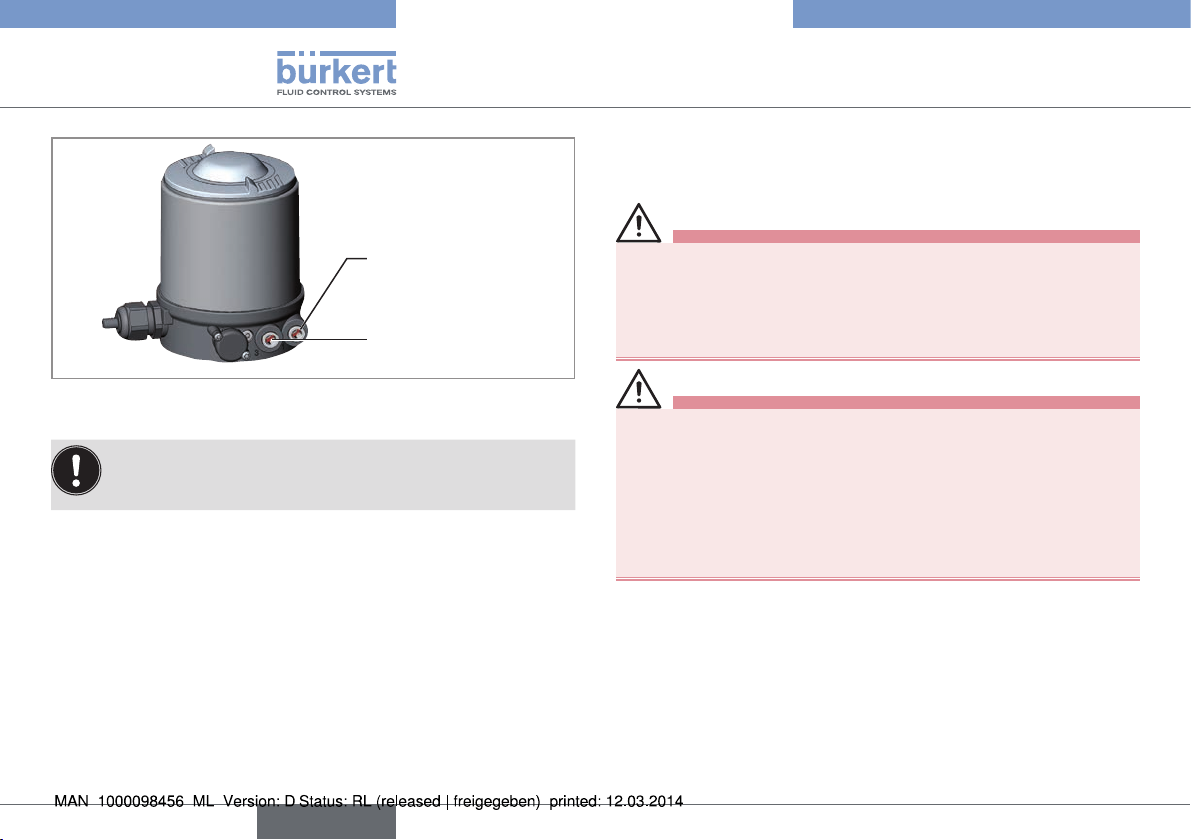

→ Unscrew the body casing (stainless steel) in a counter-clockwise

direction.

Body casing

Connection housing

Actuator

Fig. 10: Open control head

→ Push the cables through the cable gland.

→ Connect the wires.

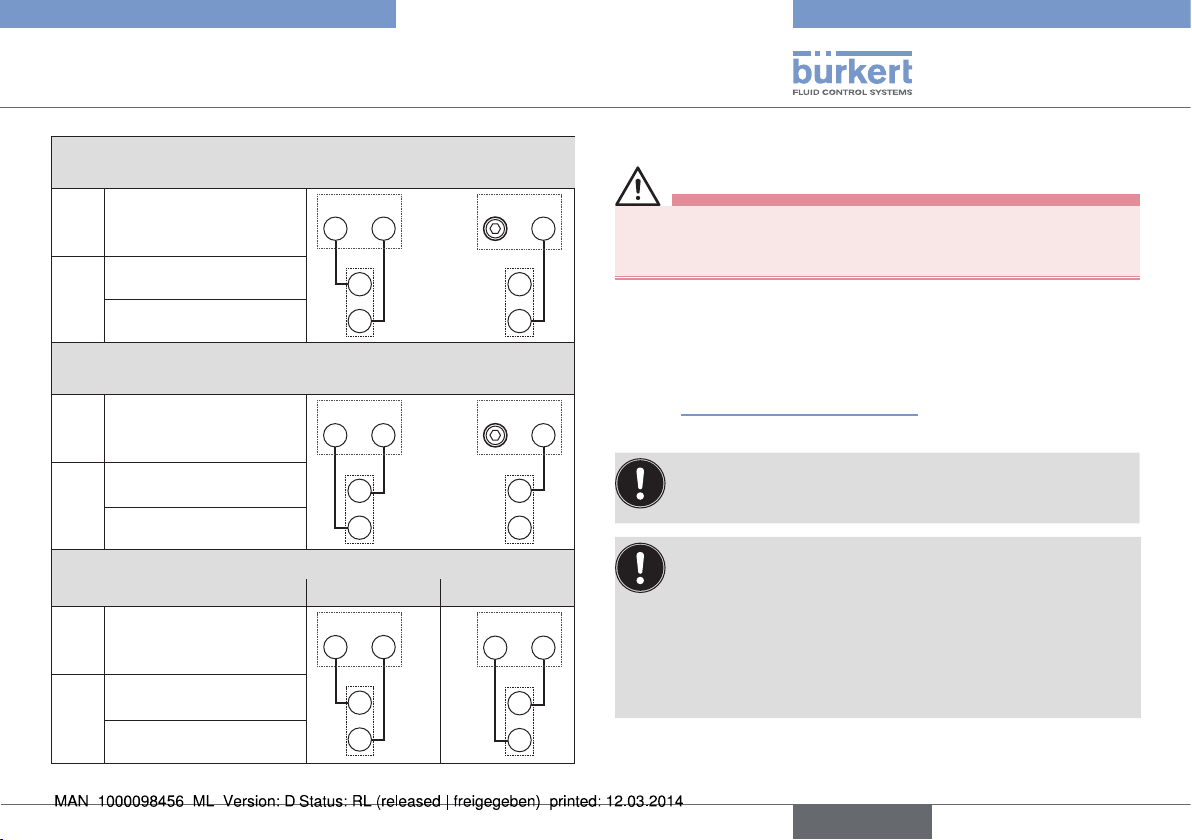

Jumper: assignment p-n-p or n-p-n

To

IN 1 = Top (top)

IN 2 = Bot (bottom)

Screw terminals

end positions

Screw terminals

Supply 24 V DC

Screw terminals

Valve (control)

Bot

Top

Bot

Top

Fig. 11: Connection with cable gland

Jumper:

Color assignment of the Top LEDs

outlet (optional)

IN 1

IN 2

+

24 V

-

+

Valve

-

english

17

Page 18

Body casing

Seal

body casing

Connection housing

Fig. 12: Position of the seal in the body casing

→ Tighten union nut on the cable gland (torque approx. 1.5 Nm).

→ Check that the seal is correctly positioned in the body casing.

→ Close the device (assembly tool: 674077

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

To ensure degree of protection IP65 / IP67:

▶ Tighten the union nut on the cable gland according to the cable

size or dummy plugs used. (ca. 1,5 Nm).

▶ Screw the body casing in all the way.

The teach function can now be used to automatically determine

and read in the end positions of the valve (description of the teach

function see chapter “10 Teach function”).

1)

).

Type 8691

Electrical installation

9.2.2 Electrical installation 24 V DC with

circular plug-in connector

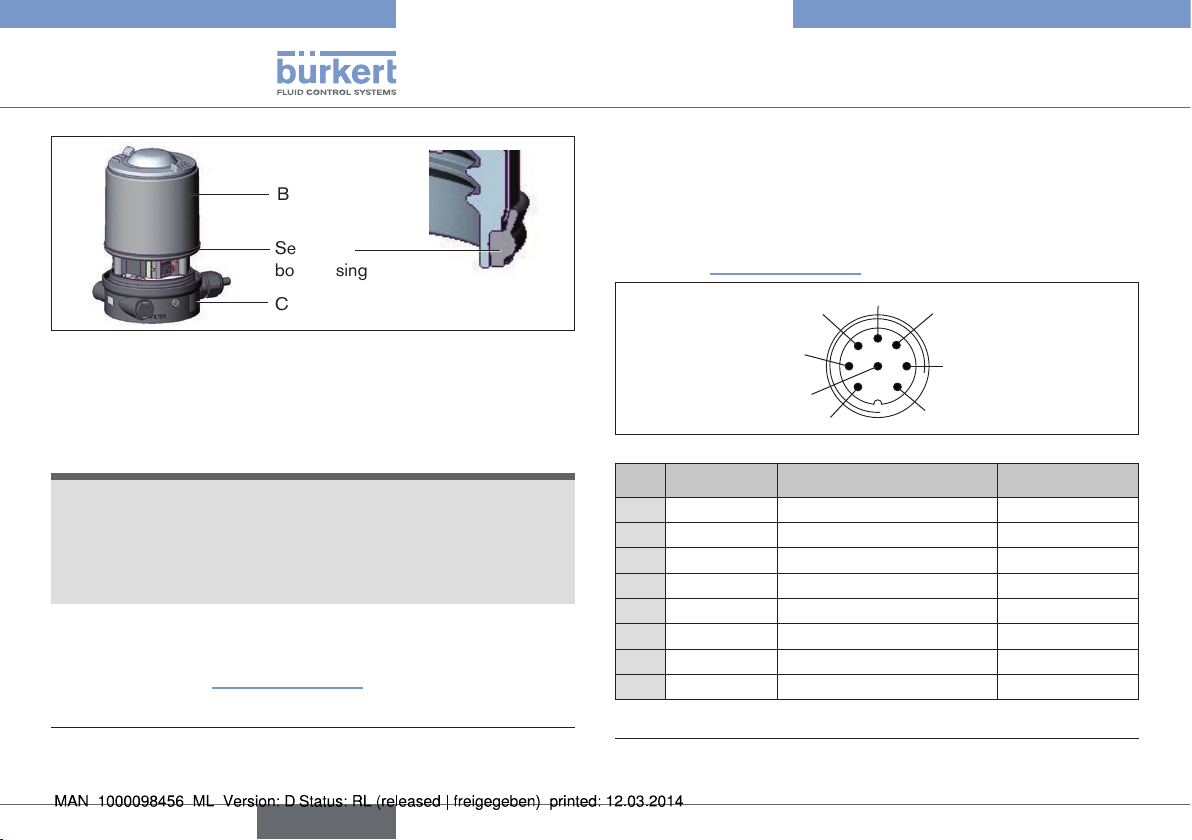

→ Connect the control head according to the table.

The teach function can now be used to automatically determine and

read in the end positions of the valve (description of the teach function

see chapter “10 Teach function”).

6

7

8

Fig. 13: Circular plug M12 x 1, 8-pole

Pin Wire color2)Designation Configuration

white Limit switch top IN 1 (=Top)

1

brown Limit switch bottom IN 2 (=Bot)

2

green Supply voltage GND

3

yellow Supply voltage + 24 V DC

4

grey Valve control unit + Valve +

5

pink Valve control unit - Valve -

6

7

8

Tab. 2: Connection with circular plug-in connector

- not used

- not used

5

4

3

1

2

1) The assembly tool (674077) is available from your Bürkert sales office.

18

english

2) The indicated colors refer to the connecting cable available as an

accessory (919061).

Page 19

Type 8691

Electrical installation

9.3 Display elements 24 V DC

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not

hold the actuator of the process valve but the connection housing.

Top LEDs

Status LED (yellow)

LED pilot valve (yellow)

Connection housing

Fig. 14: Display elements 24 V DC

LED Color

Top LEDs

3)

LED Pilot valve

Status LED

Tab. 3: Display elements 24 V DC

is lit green End postion bottom

is lit yellow End postion top

is lit yellow

Pilot valve is actuated

flashing yellow Teach function is running

flickers yellow Puck PCB not available

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the trans-

parent cap in all the way.

9.4 Programming data AS-Interface

AS-Interface

31 slaves

I/O configuration B hex (1 input, 2 outputs)

ID code F hex A hex

Extended ID code 1 F hex 7 hex

Extended ID code 2 F hex E hex

Profile S-B.F.F S-B.A.E

Tab. 4: Programming data

AS-Interface

62 slaves

3) Color setting ex works. Can be set via jumper (see “Fig. 11: Connection

with cable gland”).

english

19

Page 20

Type 8691

Electrical installation

9.5 Electrical installation AS-Interface

9.5.1 Connection with circular plug-in

connector M12 x 1, 4-pole, male

Connector views

The views show the image from the front looking at the pins, the

solder connections are behind them.

Pin 4:

NC

Pin 1:

Bus +

Fig. 15: Bus connection without external supply voltage

Pin 4:

24 V +

Pin 1:

Bus +

Fig. 16: Bus connection with external supply voltage (optional)

Pin 3:

Bus –

Pin 2:

NC

Pin 3:

Bus –

Pin 2:

GND

Bus connection without external / with external supply voltage

Pin Designation Configuration

Bus + AS-Interface bus line +

1

NC or GND

2

(optional)

Bus – AS-Interface bus line –

3

NC or 24 V +

4

(optional)

Tab. 5: Pin assignment of circular plug-in connector for AS-Interface

not used or external supply voltage –

(optional)

not used or external supply voltage +

(optional)

→ Connect the control head according to the table.

The teach function can now be used to automatically determine

and read in the end positions of the valve (description of the teach

function see chapter “10 Teach function”).

For the bus variant AS-Interface, the teach function can also

be started via the bus protocol.

20

english

Page 21

Type 8691

Electrical installation

9.5.2 Connection with multi-pole cable and

ribbon cable terminal

As an alternative to the bus connection model with 4-pole circular

plug, there is the control head with multi-pole cable (M12 circular plug)

and ribbon cable terminal. The wiring diagram of the circular plug corresponds to the bus connection of the M12 4-pole circular plug and

can easily be connected to the ribbon cable terminal (see “Fig. 17”).

Screws

M12 plug-in connector

branch circuit

Fig. 17: Control head 8691 with multi-pole cable and ribbon cable terminal

Handling the ribbon cable terminal

The multi-pole cable features a ribbon cable terminal - with M12 plug-in

connector branch circuit - for AS-Interface cable harness. The ribbon

cable terminal contacts the AS-Interface cable harness by means of

penetration technology which allows installation by “clipping in” the ASInterface cable harness without cutting and without removing insulation.

Procedure:

→ Open the ribbon cable terminal

(loosen screws and remove cover)

→ Insert cable harness conclusively

→ Close ribbon cable terminal again

→ Tighten screws

Slightly undo thread-forming screws

(approx. 3/4 turn to the left) and position them on the existing

tapped bore and screw in.

The teach function can now be used to automatically determine

and read in the end positions of the valve (description of the teach

function see chapter “10 Teach function”).

For the bus variant AS-Interface, the teach function can also

be started via the bus protocol.

english

21

Page 22

Type 8691

Electrical installation

9.6 Display elements AS-Interface

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not

hold the actuator of the process valve but the connection housing.

Status LED yellow

Top LEDs

Pilot valve LED yellow

Bus LED green

Bus LED red

Jumper: Color

assignment of

the Top LEDs

Connection housing

Fig. 18: Display elements AS-Interface

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the trans-

parent cap in all the way.

Bus LED

(green)

Bus LED

(red)

off off POWER OFF

off on

No data traffic (expired Watch Dog at slave

address does not equal 0)

on off OK

flashing on Slave address equals 0

off flashing Sensor supply overloaded or external reset

flashing flashing Teach function error (Periphery error)

Tab. 6: Display elements bus status

LED Color

Status LED flashing yellow Teach function is running

flickers yellow Puck PCB not available

4)

Top LEDs

is lit green End postion bottom

is lit yellow End postion top

flashing red

alternately with the

green or yellow

LED

Pilot valve

Tab. 7: Display elements AS-Interface

is lit yellow Pilot valve is actuated

no data traffic or

teach function error

22

4) Color setting ex works. Can be set via jumper (see “Fig. 18”).

english

Page 23

Type 8691

Electrical installation

9.7 Electrical installation DeviceNet

9.7.1 Bus connection (circular connector

M12 x 1, 5-pole, male)

The control head features a 5-pole micro-style circular connector.

The following configuration conforms to the DeviceNet specification.

→ Connect the control head according to the table.

Pin

Signal

Tab. 8: Pin assignment circular plug-in connector DeviceNet

Data lines

Fig. 19: View of plug from the front onto the pins, the soldered connections

1 2 3 4 5

Shielding V + V – CAN_H CAN_L

Pin 4: CAN_H

white

Pin 5: CAN_L

blue

Pin 1: Drain

(Shield)

are behind

Pin 3: V–

black

Pin 2: V+

red

max. power 3 W,

if valve is switched

Supply voltage

11 – 25 V DC

9.7.2 Configuring the control head

Setting the DIP switches

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the body casing, do not hold

the actuator of the process valve but the connection housing.

→ Unscrew the body casing (stainless steel) in a counter-clockwise

direction.

Body casing

Connection housing

Actuator

Fig. 20: Open control head

english

23

Page 24

Type 8691

Electrical installation

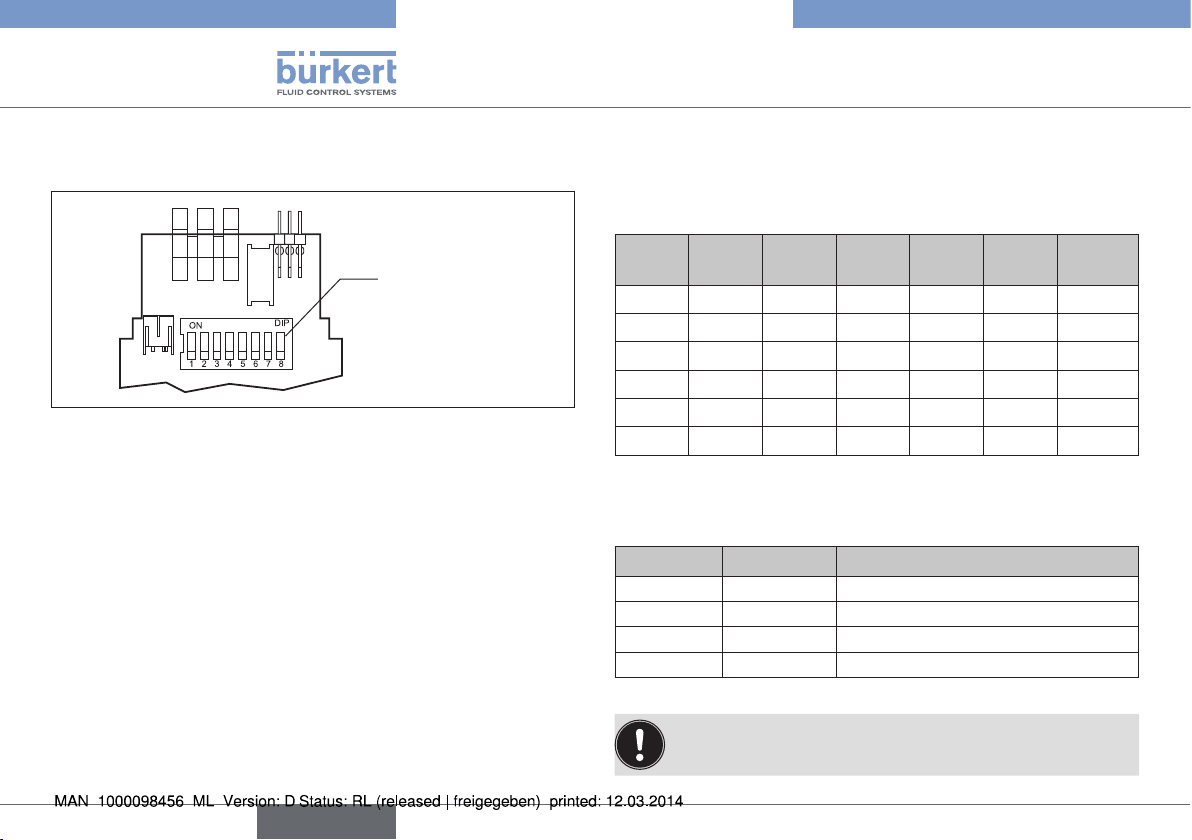

→ Set the DIP switches according to the following tables.

DIP switches

for bus address

and baudrate

Fig. 21: DIP switches DeviceNet

8 DIP switches are available for configuration:

• DIP switches 1 to 6 for the DeviceNet address

• DIP switches 7 to 8 for the baudrate

Settings of the DeviceNet address

MAC ID – Medium Access Control Identifier:

[DIP 1=off=0 / DIP 1=on=1 /

MAC ID=DIP 1*2

DIP 1

[20=1]

DIP 2

[21=2]

0

+DIP 2*21+...+DIP 6*25]

DIP 3

[22=4]

DIP 4

[23=8]

DIP 5

[24=16]

DIP 6

[25=32]

off off off off off off 0

on

off

...

off

off off off off off 1

on

off off off off 2

... ... ... ... ... ...

on on on on on

on on on on on on

Tab. 9: Settings of the DeviceNet address

Setting the baudrate

Adjusting the control head to the baudrate of the network.

DIP 7 DIP 8 Baudrate

off off 125 kBaud

on off 250 kBaud

off on 500 kBaud

on on not permitted

Tab. 10: Setting the baudrate

MAC ID

62

63

24

If the settings are changed by actuating the DIP switches,

this change will not take effect until the device is restarted.

english

Page 25

Type 8691

Electrical installation

→ Check that the seal is correctly positioned in the body casing.

→ Close the device (assembly tool: 674077

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the body

casing in all the way.

Body casing

Seal

body casing

Connection housing

Fig. 22: Position of the seal in the body casing

The teach function can now be used to automatically determine

and read in the end positions of the valve (description of the teach

function see chapter “10 Teach function”).

For the bus variant DeviceNet, the teach function can also

be started via the bus protocol.

5) The assembly tool (674077) is available from your Bürkert sales office.

5)

).

9.8 Display elements DeviceNet

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do

not hold the actuator of the process valve but the connection

housing.

Top LEDs

Status LED (yellow)

Pilot valve LED (yellow)

Device status LED (two-

coloured: red/green)

Bus status LED (two-

coloured: red/green)

Connection housing

Fig. 23: LED display, DeviceNet

The device status of the control head (transparent cap) is displayed

optically by colored high-power LEDs (Top LEDs). The assignment of

the green and yellow Top LEDs to the end position can be changed via

Explicit Messages (attribute address: class 150, instance 1, attribute 9).

english

25

Page 26

Type 8691

Electrical installation

LED Color

Status LED flashing yellow Teach function is running

flickers yellow Puck PCB not available

6)

Top LEDs

is lit green End postion bottom

is lit yellow End postion top

• Online, without con-

flashing red

alternately with the

green or yellow

nection to the Master

• Connection time-out

• Critical error

LED

Pilot valve

Tab. 11: Display elements DeviceNet

is lit yellow Pilot valve is actuated

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the trans-

parent cap in all the way.

6) Color setting ex works.

Status of the bus status LED

LED Device status Explanation Troubleshooting

Device is not supplied

with voltage

No power

Off

Green

Flashes

green

Flashes

red

Red Critical fault

Tab. 12: Status of the bus status LED

supply /

not online

Online, connection to

master exists

Online, without

connection to

master

Connection

time-Out

Device has still not

ended Duplicate MAC

ID Test (test lasts

approx. 2 sec)

Device cannot end

Duplicate MAC ID Test.

Normal operating status

with established connection to the master

Normal operating status

without established

connection to the

master

One or more I/O connections are in TimeOut state

Another device with the

same MAC ID address

is in the circuit

No bus connection

due to communication

problems

Connect other devices,

if the device is the only

network subscriber,

Replace device

Check baud rate

Check bus connection

New connection establishment by master to

ensure that the I/O

data is transmitted

cyclically.

Check baud rate

If required, replace

device

26

english

Page 27

Type 8691

Teach function

Status of the device status LED

LED Device status Explanation

Off No supply Device is not supplied with voltage

Green Device is working Normal operating status

Tab. 13: Status of the device status LED

10 TEACH FUNCTION

The teach function can be used to automatically determine and read

in the end positions of the valve.

For the bus variant AS-Interface and DeviceNet, the teach

function can also be started via the bus protocol.

10.1 Starting the teach function

Necessary requirements:

Before you can actuate the teach function, you must

• mount the control head on the actuator,

• connect the supply voltage,

• connect the compressed-air supply,

• AS-Interface: pilot valve OFF (D0 = 0),

• the DeviceNet must be connected to the Master (bus LED

must be lit green).

english

27

Page 28

Type 8691

Teach function

Transparent cap

Body casing

Connection housing

Actuator

Fig. 24: Open control head

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do

not hold the actuator of the process valve but the connection

housing.

→ Open the control head: turning the transparent cap

anti-clockwise.

→ The key in recess for actuating the teach function keep pressed

for approximately 5 seconds.

→ Only for control heads without pilot valve:

When yellow pilot valve LED is lit, move actuator to upper end

position.

When yellow pilot valve LED goes out again, move actuator to

lower end position.

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the trans-

parent cap in all the way.

→ Close the device (assembly tool: 674077

Pilot valve LED (yellow)

Status LED: flashes yellow

when teach function is running

Key in recess for actuating the

teach function (keep pressed

for approximately 5 seconds

Fig. 25: Teach function

Chronological description of the teach function:

• the bottom position is read in internally

• the pilot valve switches

the top position

• the top position is read in internally

• the pilot valve is turned off

home position.

Important: When the teach function is activated the actuator

cannot be actuated via the AS-Interface and DeviceNet

communication.

7) The assembly tool (674077) is available from your Bürkert sales office.

the actuator moves automatically to

the actuator moves back to the

7)

).

28

english

Page 29

Type 8691

Safety positions

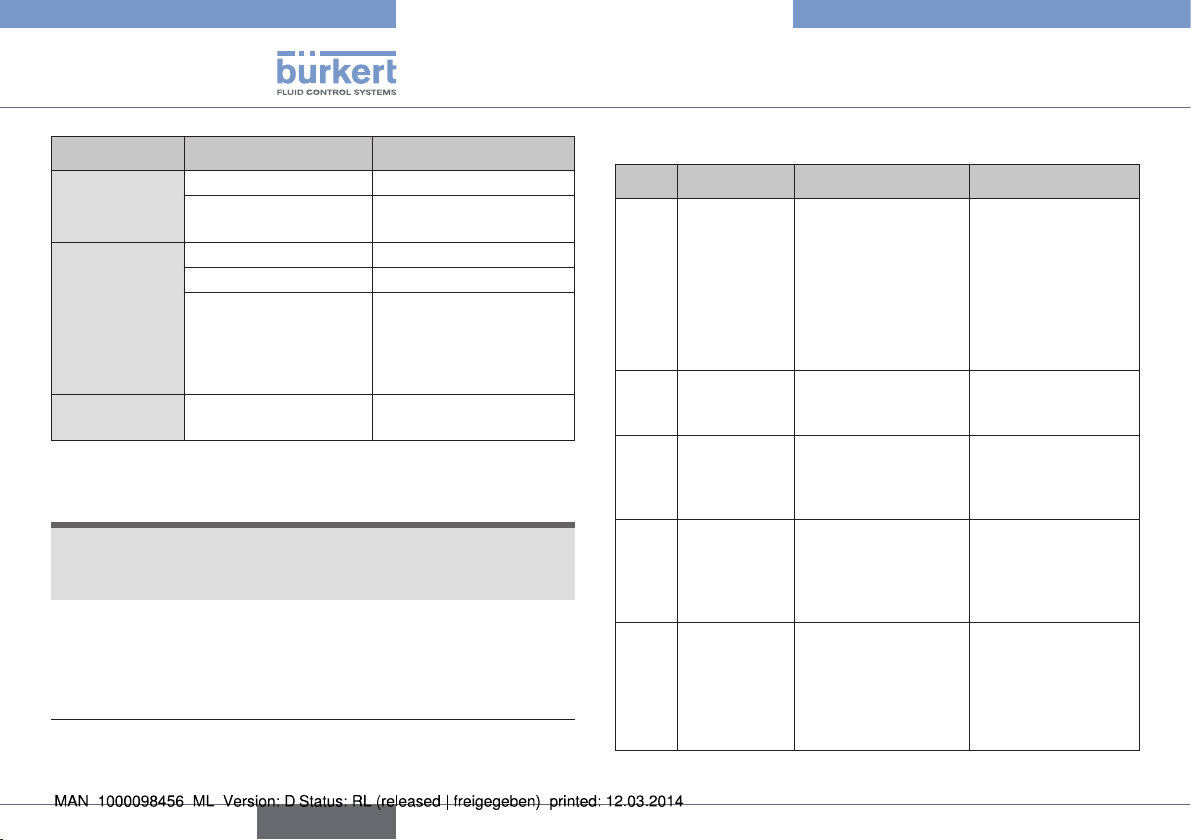

11 SAFETY POSITIONS

Safety positions after failure

Actuator system Designation

single-acting

up

down

up

down

up

down

Tab. 14: Safety positions

Control

function A

single-acting

Control

function B

double-acting

Control

function I

of the auxiliary power

electrical pneumatic

down down

up up

down not defined

12 ACCESSORIES

Designation Order no.

Connection cable M12 x 1, 8-pole 919061

Assembly tool 674077

Tab. 15: Accessories

english

29

Page 30

13 PACKAGING, TRANSPORT,

STORAGE

NOTE!

Transport damages.

Inadequately protected equipment may be damaged during transport.

▶ During transportation protect the device against wet and dirt in

shock-resistant packaging.

▶ Avoid exceeding or dropping below the permitted storage

temperature.

Incorrect storage may damage the device.

▶ Store the device in a dry and dust-free location.

▶ Storage temperature -20 – +65 °C.

Damage to the environment caused by device components

contaminated with media.

▶ Dispose of the device and packaging in an environmentally friendly

manner.

▶ Observe applicable regulations on disposal and the environment.

Type 8691

Packaging, Transport, Storage

30

english

Page 31

Typ 8691

Inhaltsverzeichnis

1 DER QUICKSTART .................................................................................... 32

1.1 Begriffsdefinition / Abkürzung ..............................................32

1.2 Darstellungsmittel ....................................................................32

2 BESTIMMUNGSGEMÄSSE VERWENDUNG................................33

2.1 Beschränkungen ......................................................................33

3 GRUNDLEGENDE SICHERHEITSHINWEISE .............................. 33

4 ALLGEMEINE HINWEISE ....................................................................... 35

4.1 Kontaktadresse ........................................................................35

4.2 Gewährleistung ........................................................................35

4.3 Informationen im Internet .......................................................35

5 SYSTEMBESCHREIBUNG .................................................................... 35

5.1 Aufbau und Funktion ...............................................................35

5.2 Steuerkopf für den integrierten Anbau an 21xx ................36

5.3 Variante zur Ansteuerung von Prozessventilen der

Reihe 20xx.................................................................................36

6 TECHNISCHE DATEN ............................................................................. 37

6.1 Konformität ................................................................................37

6.2 Normen ......................................................................................37

6.3 Betriebsbedingungen .............................................................37

6.4 Mechanische Daten ................................................................37

6.5 Typschild ..................................................................................37

6.6 Pneumatische Daten ..............................................................38

6.7 Elektrische Daten ....................................................................38

7 MONTAGE .....................................................................................................40

7.1 Sicherheitshinweise ................................................................40

7.2 Montage Steuerkopf an Prozessventile der Reihe

21xx ............................................................................................40

7.3 Montage Steuerkopf an Prozessventile der Reihe

20xx ............................................................................................41

8 PNEUMATISCHE INSTALLATION ...................................................... 43

9 ELEKTRISCHE INSTALLATION ...........................................................44

9.1 Sicherheitshinweise ................................................................44

9.2 Elektrische Installation 24 V DC ..........................................45

9.3 Anzeigeelemente 24 V DC ...................................................47

9.4 Programmierdaten AS-Interface ..........................................47

9.5 Elektrische Installation AS-Interface ...................................48

9.6 Anzeigeelemente AS-Interface.............................................50

9.7 Elektrische Installation DeviceNet .......................................51

9.8 Anzeigeelemente DeviceNet .................................................53

10 TEACHFUNKTION ..................................................................................... 55

10.1 Starten der Teachfunktion .....................................................55

11 SICHERHEITSSTELLUNGEN .............................................................. 57

12 ZUBEHÖR .....................................................................................................57

13 TRANSPORT, LAGERUNG, VERPACKUNG .................................. 58

deutsch

31

Page 32

Typ 8691

Der Quickstart

1 DER QUICKSTART

Der Quickstart beschreibt den gesamten Lebenszyklus des Geräts.

Bewahren Sie den Quickstart so auf, dass er für jeden Benutzer gut

zugänglich ist und jedem neuen Eigentümer des Geräts wieder zur

Verfügung steht.

Wichtige Informationen zur Sicherheit.

Lesen Sie den Quickstart sorgfältig durch. Beachten Sie vor allem

die Kapitel „Grundlegende Sicherheitshinweise“ und „Bestimmungsgemäße Verwendung“.

▶ Der Quickstart muss gelesen und verstanden werden.

Der Quickstart erläutert beispielhaft die Montage und Inbetriebnahme

des Geräts.

Die ausführliche Beschreibung des Geräts finden Sie in der Bedienungsanleitung für den Steuerkopf Typ 8691.

Die Bedienungsanleitung finden Sie auf der beigelegten CD

oder im Internet unter:

www.buerkert.de

1.1 Begriffsdefinition / Abkürzung

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht immer für

den Steuerkopf Typ 8691.

Die in dieser Anleitung verwendete Abkürzung „Ex“ steht immer für

„explosionsgefährdet“.

1.2 Darstellungsmittel

In dieser Anleitung werden folgende Darstellungsmittel verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr.

▶ Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation.

▶ Bei Nichtbeachtung können schwere Verletzungen oder Tod die

Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung.

▶ Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden.

Wichtige Tipps und Empfehlungen.

verweist auf Informationen in dieser Anleitung oder in

anderen Dokumentationen.

▶ markiert eine Anweisung zur Gefahrenvermeidung.

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

32

deutsch

Page 33

Typ 8691

Bestimmungsgemäße Verwendung

2 BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Verwendung des Steuerkopfs Typ 8691 können Gefahren für Personen, Anlagen in der

Umgebung und die Umwelt entstehen.

▶ Das Gerät ist für den Anbau an pneumatische Antriebe von Pro-

zessventilen zur Steuerung von Medien konzipiert.

▶ Gerät nicht der direkten Sonneneinstrahlung aussetzen.

▶ Für den Einsatz die in den Vertragsdokumenten und der Bedie-

nungsanleitung spezifizierten zulässigen Daten, Betriebs- und

Einsatzbedingungen beachten. Diese sind im Kapitel „6 Techni-

sche Daten“ beschrieben.

▶ Gerät nur in Verbindung mit von Bürkert empfohlenen bzw. zuge-

lassenen Fremdgeräten und -komponenten einsetzen.

▶ Angesichts der Vielzahl von Einsatz- und Verwendungsfällen,

muss vor dem Einbau geprüft und erforderlichenfalls getestet

werden, ob das Gerät für den konkreten Einsatzfall geeignet ist.

▶ Voraussetzungen für den sicheren und einwandfreien Betrieb

sind sachgemäßer Transport, sachgemäße Lagerung und Instal-

lation sowie sorgfältige Bedienung und Instandhaltung.

▶ Gerät nur bestimmungsgemäß verwenden.

2.1 Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls

bestehende Beschränkungen.

3 GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und

Wartung der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

GEFAHR!

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶ Vor Arbeiten an Anlage oder Gerät, den Druck abschalten und

Leitungen entlüften/entleeren.

Gefahr durch Stromschlag.

▶ Vor Arbeiten an Anlage oder Gerät, die Spannung abschalten und

vor Wiedereinschalten sichern.

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten.

deutsch

33

Page 34

Typ 8691

Grundlegende Sicherheitshinweise

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

▶ Im explosionsgefährdeten Bereich darf der Steuerkopf Typ 8691

nur entsprechend der Spezifikation auf dem separaten Klebeschild

für die Zulassung eingesetzt werden. Für den Einsatz muss die

dem Gerät beiliegende Zusatzanleitung mit Sicherheitshinweisen

für den Ex-Bereich beachtet werden.

▶ Geräte ohne separates Klebeschild für die Zulassung dürfen nicht

im explosionsgefährdeten Bereich eingesetzt werden.

▶ Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

▶ Installations- und Instandhaltungsarbeiten dürfen nur von auto-

risiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

▶ Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung ist ein definierter oder kontrollierter Wiederanlauf des

Prozesses zu gewährleisten.

▶ Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung

der Bedienungsanleitung betrieben werden.

▶ Für die Einsatzplanung und den Betrieb des Geräts müssen die

allgemeinen Regeln der Technik eingehalten werden.

Zum Schutz vor Sachschäden am Gerät ist zu beachten:

▶ In den Steuerluftanschluss keine aggressiven oder brennbaren

Medien einspeisen.

▶ In den Steuerluftanschluss keine Flüssigkeiten einspeisen.

▶ Beim Abschrauben und Einschrauben des Gehäusemantels oder

der Klarsichthaube nicht am Antrieb des Prozessventils, sondern

am Anschlussgehäuse des Typs 8691 gegenhalten.

▶ Gehäuse nicht mechanisch belasten (z. B. durch Ablage von

Gegenständen oder als Trittstufe).

▶ Keine äußerlichen Veränderungen an den Gerätegehäusen vor-

nehmen. Gehäuseteile und Schrauben nicht lackieren.

34

deutsch

Page 35

Typ 8691

Allgemeine Hinweise

4 ALLGEMEINE HINWEISE

4.1 Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter:

www.burkert.com

4.2 Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des Steuerkopfs Typ 8691 unter Beachtung der spezifizierten Einsatzbedingungen.

4.3 Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 8691 finden Sie

im Internet unter:

www.buerkert.de

5 SYSTEMBESCHREIBUNG

5.1 Aufbau und Funktion

Steuerkopf

Pneumatischer

Antrieb

Prozessventil

Ventilgehäuse

Bild 1: Aufbau

Der Steuerkopf Typ 8691 kann einfach- oder doppeltwirkende Prozessventile ansteuern und ist für den integrierten, modularen Anbau

an Prozessventile der Reihe 21xx optimiert. Der modulare Aufbau

ermöglicht verschiedene Ausbaustufen.

Für den Anbau an die Reihe 20xx gibt es eine spezielle Variante, die

in Kapitel „5.3“ beschrieben ist.

Die Erfassung der Ventilstellung erfolgt über ein kontaktloses, analoges

Sensorelement, welches bei der Inbetriebnahme die Ventilendstellungen automatisch mittels Teachfunktion erkennt und speichert.

deutsch

35

Page 36

Typ 8691

Systembeschreibung

Neben der elektrischen Stellungsrückmeldung wird der Gerätestatus

am Steuerkopf selbst optisch durch farbige Hochleistungs-LEDs (Top

LEDs) dargestellt.

Option: Kommunikation über AS-Interface oder DeviceNet möglich.

5.2 Steuerkopf für den integrierten

Anbau an 21xx

Elektrischer Anschluss

Kabelverschraubung

M16 x 1,5 oder

Rundsteckverbinder

M12 x 1

Gehäusemantel

Zuluftfilter

Ansicht ohne Klarsichthaube

Bild 2: Aufbau für Prozessventile der Reihe 21xx

Anschlussgehäuse

Druckbegrenzungsventil

(zum Schutz vor zu hohem

Innendruck im Fehlerfall)

Top LEDs

Teachfunktion

Abluftanschluss

(Beschriftung: 3)

Steuerluftanschluss

(Beschriftung: 1)

5.3 Variante zur Ansteuerung von

Prozessventilen der Reihe 20xx

Mit einer speziellen Variante kann der Steuerkopf an Prozessventile

der Reihe 20xx angebaut werden.

Diese Variante besitzt ein anderes Anschlussgehäuse damit die Steuerluftanschlüsse extern am Antrieb angeschlossen werden können

(siehe „Bild 3“).

Steuerluftausgang 2

Steuerluftausgang 2

Befestigungsschrauben (2 x)

Anschlussgehäuse

Bild 3: Aufbau für Prozessventile der Reihe 20xx

1

2

36

deutsch

Page 37

Typ 8691

Technische Daten

6 TECHNISCHE DATEN

6.1 Konformität

Der Steuerkopf Typ 8691 ist konform zu den EG-Richtlinien entsprechend der EG-Konformitätserklärung.

6.2 Normen

Die angewandten Normen, mit denen die Konformität mit den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformtätserklärung nachzulesen.

6.3 Betriebsbedingungen

WARNUNG!

Sonneneinstrahlung und Temperaturschwankungen können

Fehlfunktionen oder Undichtheiten bewirken.

▶ Gerät bei Einsatz im Außenbereich nicht ungeschützt den Wit-

terungsverhältnissen aussetzen.

▶ Darauf achten, dass die zulässige Umgebungstemperatur nicht

über- oder unterschritten wird.

Umgebungstemperatur siehe Typschild

Schutzart IP65 / IP67 nach EN 60529

(nur bei korrekt angeschlossenem Kabel

bzw. Stecker und Buchsen und bei

Beachtung des Abluftkonzeptes im Kapitel

„8 Pneumatische Installation“.

6.4 Mechanische Daten

Abmessungen siehe Datenblatt

Gehäusematerial außen: PPS, PC, VA

Dichtungsmaterial außen: EPDM

innen: NBR

Hubbereich Ventilspindel: 2 ... 28 mm

2 ... 47 mm

6.5 Typschild

Beispiel:

Betriebsspannung

/ Ansteuerung

Typ

8691 AS-i 62SI

single act Pilot 3,0

Pmax 7bar

Tamb 0°C - +55°C

Ser.-Nr. 001000

00179024

D-74653 Ingelfingen

Bild 4: Typschild Beispiel

CE

W14UN

Identnummer

Steuerfunktion

- Steuerventil

Max. Betriebsdruck

Max. Umgebungstemperatur

Seriennummer

CE-Zeichen

Bar-Code

deutsch

37

Page 38

Typ 8691

Technische Daten

6.6 Pneumatische Daten

Steuermedium neutrale Gase, Luft

Qualitätsklassen nach DIN ISO 8573-1

Staubgehalt Klasse 5 max. Teilchengröße 40 µm,

max. Teilchendichte 10 mg/m

Wassergehalt Klasse 3 max. Drucktaupunkt -20 °C oder

min. 10 °C unterhalb der

niedrigsten Betriebstemperatur

Ölgehalt Klasse 5 max. 25 mg/m

3

Temperaturbereich

Steuermedium -10 ... +50 °C

Druckbereich

Steuermedium 3 ... 7 bar

Luftleistung Steuerventil 250 I

/min (für Be- und Entlüftung)

N

(QNn-Wert nach Definition bei

Druckabfall von 7 auf 6 bar absolut)

Anschlüsse Schlauchsteckverbinder Ø 6 mm / 1/4“

Muffenanschluss G 1/8

3

6.7 Elektrische Daten

6.7.1 Elektrische Daten ohne

Busansteuerung 24 V DC

Anschlüsse Kabelverschraubung M16 x 1,5 SW22

(Klemmbereich 5 - 10 mm)

mit Schraubklemmen für

Leitungsquerschnitte 0,14 ... 1,5 mm

Rundsteckverbinder (M12 x 1, 8-polig)

Steuerventil

Betriebsspannung 24 V DC ± 10 %

max. Restwelligkeit 10 %

Leistungsaufnahme max. 1 W

Ausgang max. 100 mA je Ausgang

Anzeige max. 20 mA je dargestellte

Leuchtanzeige (LED)

2

38

deutsch

Page 39

Typ 8691

Technische Daten

6.7.2 Elektrische Daten mit Busansteuerung

AS-Interface

Anschlüsse Rundsteckverbinder

(M12 x 1, 4-polig)

Betriebsspannung 29,5 V ... 31,6 V DC

(gemäß Spezifikation)

Ausgänge

Max. Schaltleistung 1 W über AS-Interface

Watchdogfunktion integriert

Geräte ohne externe Versorgungsspannung:

Max. Stromaufnahme 120 mA

Stromaufnahme im Normalbetrieb

(nach Stromabsenkung;

Ventil + 1 Endstellung erreicht) 90 mA

Geräte mit externer Versorgungsspannung:

Externe Versorgungsspannung 24 V ± 10 %

Das Netzgerät muss eine sichere Trennung nach

IEC 364-4-41 (PELV oder SELV) enthalten

Max. Stromaufnahme 55 mA (nach Strom-

absenkung

Max. Stromaufnahme

aus AS-Interface 55 mA

≤ 30 mA)

6.7.3 Elektrische Daten mit Busansteuerung

DeviceNet

Anschlüsse Rundsteckverbinder (M12 x 1, 5-polig)

Betriebsspannung 11 V ... 25 V

Max. Stromaufnahme < 80 mA

Ausgang

Anzugsstrom

Haltestrom

≤ 50 mA

≤ 30 mA

deutsch

39

Page 40

Typ 8691

Montage

7 MONTAGE

Nur für Steuerkopf ohne vormontiertes Prozessventil.

7.1 Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶ Vor Arbeiten an Anlage oder Gerät, den Druck abschalten und

Leitungen entlüften/entleeren.

Gefahr durch Stromschlag.

▶ Vor Arbeiten an Anlage oder Gerät, die Spannung abschalten und

vor Wiedereinschalten sichern.

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage.

▶ Die Montage darf nur autorisiertes Fachpersonal mit geeigne-

tem Werkzeug durchführen.

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf.

▶ Anlage vor unbeabsichtigtem Betätigen sichern.

▶ Nach der Montage einen kontrollierten Wiederanlauf gewährleisten.

7.2 Montage Steuerkopf an

Prozessventile der Reihe 21xx

Vorgehensweise:

Bei der Montage des Steuerkopfs dürfen die Collets der

Steuerluftanschlüsse am Antrieb nicht montiert sein.

→ Puck und Steuerkopf so ausrichten, dass

1. der Puck in die Führungsschiene des Steuerkopfs

(siehe „Bild 5“) und

2. die Verbindungsstutzen des Steuerkopfs in die Steuerluftanschlüsse des Antriebs (siehe „Bild 6“) hineinfinden.

HINWEIS!

Beschädigung der Platine oder Funktionsausfall.

▶ Darauf achten, dass der Puck plan auf der Führungsschiene

aufliegt.

Führungsschiene

Puck

Bild 5: Ausrichten des Pucks

40

deutsch

Page 41

Typ 8691

Montage

→ Steuerkopf ohne Drehbewegung soweit auf den Antrieb

schieben, dass an der Formdichtung kein Spalt mehr sichtbar ist.

HINWEIS!

Durch ein zu hohes Drehmoment beim Einschrauben der

Befestigungsschraube kann die Schutzart IP65 / IP67 nicht

sichergestellt werden.

▶ Die Befestigungsschraube darf nur mit einem maximalen Dreh-

moment von 0,5 Nm angezogen werden.

→ Steuerkopf mit den beiden seitlichen Befestigungsschrauben auf

dem Antrieb befestigen. Dabei die Schrauben nur leicht anziehen

(maximales Drehmoment: 0,5 Nm).

Verbindungs-

stutzen

Steuerluft-

anschlüsse

Antrieb

Bild 6: Montage Steuerkopf, Reihe 21xx

Befestigungsschrauben

max. 0,5 Nm

7.3 Montage Steuerkopf an

Prozessventile der Reihe 20xx

Vorgehensweise:

Führungsschiene

Puck

Bild 7: Ausrichten des Pucks

→ Steuerkopf auf den Antrieb schieben. Dabei den Puck so aus-

richten, dass er in die Führungsschiene des Steuerkopfs hineinfindet (siehe „Bild 7“).

HINWEIS!

Beschädigung der Platine oder Funktionsausfall.

▶ Darauf achten, dass der Puck plan auf der Führungsschiene

aufliegt.

→ Steuerkopf ganz bis zum Antrieb herunterdrücken und durch Drehen

in die gewünschte Position ausrichten.

deutsch

41

Page 42

Typ 8691

Montage

Darauf achten, dass die pneumatischen Anschlüsse des

Steuerkopfs und die des Antriebs vorzugsweise vertikal übereinander liegen (siehe „Bild 8“).

HINWEIS!

Durch ein zu hohes Drehmoment beim Einschrauben der

Befestigungsschraube kann die Schutzart IP65 / IP67 nicht

sichergestellt werden.

▶ Die Befestigungsschraube darf nur mit einem maximalen Dreh-

moment von 0,5 Nm angezogen werden.

→ Steuerkopf mit den beiden seitlichen Befestigungsschrauben auf

dem Antrieb befestigen. Dabei die Befestigungsschrauben nur

leicht anziehen (maximales Drehmoment: 0,5 Nm).

Steuerluftausgang 2

Steuerluftausgang 2

Steuerluftanschluss

Steuerluftanschluss

Bild 8: Montage der pneumatischen Verbindungen, Reihe 20xx

1

2

oben

unten

Beispiel

∅ 80, SFA

→ Pneumatische Verbindung zwischen Steuerkopf und Antrieb mit

„Tab. 1: Pneumatische Verbindung mit Antrieb“ herstellen.

HINWEIS!

Beschädigung oder Funktionsausfall durch Eindringen von

Verschmutzung und Feuchtigkeit.

▶ Zur Einhaltung der Schutzart IP65 / IP67 den nicht benötigten

Steuerluftausgang (bei SFA und SFB) mit dem freien Steuerluftanschluss des Antriebs verbinden oder mit einem Verschlussstopfen verschließen.

„In Ruhestellung“ bedeutet, dass das Steuerventil des Steuerkopfs Typ 8691 stromlos bzw. nicht betätigt ist.

Bei feuchter Umgebungsluft kann bei Steuerfunktion A bzw.

bei Steuerfunktion B eine Schlauchverbindung zwischen

Steuerluftausgang 22 des Steuerkopfs und der nicht angeschlossenen Steuerluftanschluss des Antriebs hergestellt

werden.

Dadurch wird die Federkammer des Antriebs mit trockener

Luft aus dem Entlüftungskanal des Steuerkopfs versorgt.

42

deutsch

Page 43

Typ 8691

Pneumatische Installation

Steuerfunktion A (SFA)

Prozessventil in Ruhestellung geschlossen (durch Federkraft)

Steuerluftausgang

Steuer-

kopf

Steuerluftanschluss oben

Steuerluftanschluss unten

Antrieb

222

1

oder

222

Steuerfunktion B (SFB)

Prozessventil in Ruhestellung offen (durch Federkraft)

Steuerluftausgang

Steuer-

kopf

Steuerluftanschluss oben

Steuerluftanschluss unten

Antrieb

222

1

oder

222

Steuerfunktion I (SFI)

Prozessventil in Ruhestellung geschlossen offen

Steuerluftausgang

Steuer-

kopf

222

1

222

Steuerluftanschluss oben

8 PNEUMATISCHE INSTALLATION

GEFAHR!

1

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶ Vor Arbeiten an Anlage oder Gerät, den Druck abschalten und

Leitungen entlüften/entleeren.

Vorgehensweise:

→ Steuermedium an den Steuerluftanschluss (1) anschließen

(3 ... 7 bar; Instrumentenluft, öl-, wasser- und staubfrei).

1

1

→ Abluftleitung oder einen Schalldämpfer an den Abluftanschluss

(3) montieren (siehe „Bild 9: Pneumatischer Anschluss“).

Die anliegende Druckversorgung unbedingt mindestens 0,5

... 1 bar über dem Druck halten, der notwendig ist, den Antrieb

in seine Endstellung zu bringen.

Wichtiger Hinweis zur einwandfreien Funktion des Geräts:

▶ Durch die Installation darf sich kein Rückdruck aufbauen.

▶ Für den Anschluss einen Schlauch mit ausreichendem

Querschnitt wählen.

▶ Die Abluftleitung muss so konzipiert sein, dass kein Wasser

oder sonstige Flüssigkeit durch den Abluftanschluss in das

Gerät gelangen kann.

Steuerluftanschluss unten

Antrieb

Tab. 1: Pneumatische Verbindung mit Antrieb

deutsch

43

Page 44

Typ 8691

Elektrische Installation

9 ELEKTRISCHE INSTALLATION

9.1 Sicherheitshinweise

GEFAHR!

Steuerluftanschluss

(Beschriftung: 1)

Abluftanschluss

(Beschriftung: 3)

Bild 9: Pneumatischer Anschluss

Achtung (Abluftkonzept):

Für die Einhaltung der Schutzart IP67 muss eine Abluftleitung in den trockenen Bereich montiert werden.

44

Gefahr durch Stromschlag.

▶ Vor Arbeiten an Anlage oder Gerät, die Spannung abschalten und

vor Wiedereinschalten sichern.

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Installation.

▶ Die Installation darf nur autorisiertes Fachpersonal mit geeigne-

tem Werkzeug durchführen.

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf.

▶ Anlage vor unbeabsichtigtem Betätigen sichern.

▶ Nach der Installation einen kontrollierten Wiederanlauf

gewährleisten.

deutsch

Page 45

ye

gn

y

e

gn

o

p

p

Typ 8691

Elektrische Installation

9.2 Elektrische Installation 24 V DC

9.2.1 Elektrische Installation mit

Kabelverschraubung

HINWEIS!

Bruch der pneumatischen Verbindungsstutzen durch

Dreheinwirkung.

▶ Beim Abschrauben und Einschrauben des Gehäusemantels nicht

am Antrieb des Prozessventils sondern am Anschlussgehäuse

gegenhalten.

→ Gehäusemantel (Edelstahl) gegen den Uhrzeigersinn abschrauben.

Gehäusemantel

Anschlussgehäuse

Antrieb

Bild 10: Steuerkopf öffnen

→ Kabel durch die Kabelverschraubung schieben.

→ Adern anklemmen.

Jumper: Zuordnung PNP- oder NPN-

To

Ausgang (nur Option)

IN 1 = Top (oben)

IN 2 = Bot (unten)

Schraubklemmen

Endlagen

Schraubklemmen

Versorgung 24 V DC

Schraubklemmen

Ventil (Ansteuerung)

Bot

Top

Bot

Top

Bild 11: Anschluss mit Kabelverschraubung

Jumper:

Farbzuordung der Top LEDs

IN 1

IN 2

24 V

Valve

+

-

+

-

deutsch

45

Page 46

Gehäusemantel

Dichtung

Gehäusemantel

Anschlussgehäuse

Typ 8691

Elektrische Installation

9.2.2 Elektrische Installation mit

Rundsteckverbinder

→ Steuerkopf entsprechend der Tabelle anschließen.

Mit Hilfe der Teachfunktion können nun die Endstellungen des

Ventils automatisch ermittelt und eingelesen werden (Beschreibung

der Teachfunktion siehe Kapitel „10 Teachfunktion“).

6

5

4

Bild 12: Position Dichtung Gehäusemantel

→ Überwurfmutter der Kabelverschraubung anziehen (Drehmoment

ca. 1,5 Nm).

→ Korrekte Position der Dichtung im Gehäusemantel prüfen.

→ Gehäuse schließen (Schraubwerkzeug: 674077

HINWEIS!

Beschädigung oder Funktionsausfall durch Eindringen von

Verschmutzung und Feuchtigkeit.

Zur Sicherstellung der Schutzart IP65 / IP67:

▶ Überwurfmutter der Kabelverschraubung entsprechend der ver-

wendeten Kabelgröße bzw. Blindstopfen anziehen (ca. 1,5 Nm).

▶ Gehäusemantel bis auf Anschlag einschrauben.

Mit Hilfe der Teachfunktion können die Endstellungen des Ventils

automatisch ermittelt und eingelesen werden (Beschreibung der

Teachfunktion siehe Kapitel „10 Teachfunktion“).

1) Schraubwerkzeug über Bürkert-Vertriebsniederlassung erhältlich.

46

1)

).

deutsch

7

8

1

Bild 13: Belegung Rundstecker (M12 x 1, 8-polig)

3

2

Pin Aderfarbe2)Bezeichnung Belegung

weiß Näherungsschalter oben IN 1 (= Top)

1

braun Näherungsschalter unten IN 2 (= Bot)

2

grün Betriebspannung GND

3

gelb Betriebspannung + 24 V DC

4

grau Ventilansteuerung + Ventil +

5

rosa Ventilansteuerung - Ventil -

6

7

8

Tab. 2: Anschluss Rundsteckverbinder

2) Die angegebenen Farben beziehen sich auf das als Zubehör erhältliche

Anschlusskabel (919061).

- nicht belegt

- nicht belegt

Page 47

Typ 8691

Elektrische Installation

9.3 Anzeigeelemente 24 V DC

HINWEIS!

Bruch der pneumatischen Verbindungsstutzen durch

Dreheinwirkung.

▶ Beim Abschrauben und Einschrauben der Klarsichthaube nicht

am Antrieb des Prozessventils sondern am Anschlussgehäuse

gegenhalten.

Top LEDs

Status LED (gelb)

LED Steuerventil (gelb)

Anschlussgehäuse

Bild 14: Anzeigeelemente 24 V DC

LED Farbe Anzeige

Top LEDs

3)

LED Steuerventil

Status LED

Tab. 3: Anzeigeelemente 24 V DC

leuchten grün untere Endstellung

leuchten gelb obere Endstellung

leuchtet gelb

Steuerventil wird angesteuert

blinkt gelb Teachfunktion läuft

flackert gelb Puckplatine nicht vorhanden

HINWEIS!

Beschädigung oder Funktionsausfall durch Eindringen von

Verschmutzung und Feuchtigkeit.

▶ Zur Einhaltung der Schutzart IP65 / IP67 die Klarsichthaube bis

auf Anschlag einschrauben.

9.4 Programmierdaten AS-Interface

AS-Interface

31 slaves

E/A-Konfiguration B hex (1 Ausgang, 2 Eingänge)

ID-Code F hex A hex

Erweiterter ID-Code 1 F hex 7 hex

Erweiterter ID-Code 2 F hex E hex

Profil S-B.F.F S-B.A.E

Tab. 4: Programmierdaten

AS-Interface

62 slaves

3) Farbeinstellung ab Werk. Kann über Jumper eingestellt werden (siehe

„Bild 11: Anschluss mit Kabelverschraubung“).

deutsch

47

Page 48

Typ 8691

Elektrische Installation

9.5 Elektrische Installation AS-Interface

9.5.1 Elektrischer Anschluss mit

Rundsteckverbinder M12 x 1, 4-polig

Steckeransichten

Die Ansichten zeigen jeweils das Bild von vorn auf die Stifte, die Lötanschlüsse liegen dahinter.

Pin 4:

NC

Pin 1:

Bus +

Bild 15: Busanschluss ohne externe Versorgungsspannung

Pin 4:

24 V +

Pin 1:

Bus +

Bild 16: Busanschluss mit externer Versorgungsspannung (optional)

Pin 3:

Bus –

Pin 2:

NC

Pin 3:

Bus –

Pin 2:

GND

Busanschluss ohne externe / mit externer Versorgungsspannung

Pin Bezeichnung Belegung

Bus + Busleitung AS-Interface +

1

NC oder GND

2

(optional)

Bus – Busleitung AS-Interface –

3

NC oder 24 V +

4

(optional)

Tab. 5: Pin-Belegung Rundsteckverbinder AS-Interface

nicht belegt oder externe Versorgungsspannung –

(optional)

nicht belegt oder externe Versorgungsspannung + (optional)

→ Steuerkopf entsprechend der Tabelle anschließen.

Mit Hilfe der Teachfunktion können nun die Endstellungen des

Ventils automatisch ermittelt und eingelesen werden (Beschreibung

der Teachfunktion siehe Kapitel „10 Teachfunktion“).

Bei der Bus-Variante AS-Interface kann die Teachfunktion

auch über das Busprotokoll gestartet werden.

48

deutsch

Page 49

Typ 8691

Elektrische Installation

9.5.2 Anschluss mit Multipolkabel und

Flachkabelklemme

Alternativ zur Bus-Anschlussausführung mit 4-poligem Rundstecker,

gibt es den Steuerkopf mit Multipolkabel (M12 Rundstecker) und

Flachkabelklemme. Das Anschlussbild des Rundsteckers entspricht

dem Busanschluss M12 Rundstecker 4-polig und kann einfach mit der

Flachkabelklemme (siehe „Bild 17“) verbunden werden.

Schrauben

M12 Steckverbinder

Abgang

Bild 17: Steuerkopf 8691 mit Multipolkabel und Flachkabelklemme

Handhabung der Flachkabelklemme

Am Multipolkabel befindet sich eine, mit M12 Steckverbinder Abgang

versehene, Flachkabelklemme für AS-Interface-Formkabel. Die Flachkabelklemme realisiert die Kontaktierung des AS-Interface-Formkabels

in Form einer Durchdringungstechnik, die eine Installation durch „Einklipsen“ des AS-Interface-Formkabels ohne Schneiden und Abisolieren