Page 1

Operating Instructions

Type 8685 / 8686

Feedback Head / Control Head Robolux

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert Werke GmbH & Co. KG, 2011 - 2018

Operating Instructions 1810/04_EU-EN_00809600 / Original DE

Page 3

3

Table of contents

1 OPERATING INSTRUCTIONS ................................................................5

1.1 Symbols ....................................................................................... 5

1.2 Definition of term ...................................................................... 5

2 AUTHORIZED USE ......................................................................................6

2.1 Restrictions ................................................................................. 6

3 BASIC SAFETY INSTRUCTIONS ..........................................................6

4 GENERAL INFORMATION ........................................................................8

4.1 Contact address ........................................................................8

4.2 Warranty ...................................................................................... 8

4.3 Information on the Internet ......................................................8

5 SYSTEM DESCRIPTION ............................................................................8

5.1 Intended application area ........................................................ 8

5.2 General description ..................................................................8

5.3 Structure of feedback head Type 8685 ............................... 9

5.4 Structure of control head Type 8686 ...................................9

5.5 Structure of adapter set for actuator Type 2036 .............10

6 TECHNICAL DATA .....................................................................................10

6.1 Conformity .................................................................................10

6.2 Standards ..................................................................................10

6.3 Operating conditions ..............................................................10

6.4 Mechanical data.......................................................................11

6.5 Type label .................................................................................11

6.6 Pneumatic data ........................................................................11

6.7 Electrical data for feedback head Type 8685 ...................12

6.8 Electrical data control head Type 8686 .............................13

7 ASSEMBLY

.................................................................................................... 14

7.1 Safety instructions ...................................................................14

7.2 Assembly of Type 8685 and Type 8686 on the

actuator Type 2036.................................................................14

8 PNEUMATIC INSTALLATION ...............................................................19

8.1 Safety instructions .................................................................... 19

8.2 Pneumatic installation of feedback head Type 8685 ......20

8.3 Pneumatic installation of control head Type 8686 ..........20

9 ELECTRICAL INSTALLATION ............................................................... 21

9.1 Safety instructions ...................................................................21

9.2 Device version 24 V DC ........................................................21

9.3 Device version AS-Interface .................................................27

10 CONTROL AND DISPLAY ...................................................................... 31

10.1 Control and display elements for feedback head

Type 8685 .................................................................................31

10.2 Control and display elements for control head

Type 8686 ......................................................................................... 33

10.3 Control .......................................................................................34

11 SAFETY POSITIONS ................................................................................ 39

12 MAINTENANCE

........................................................................................... 39

12.1 Safety instructions ...................................................................39

12.2 Service at the air intake filter.................................................40

13 MALFUNCTIONS

........................................................................................ 41

English

Type 8685 / 8686

Page 4

4

14 SHUTDOWN

.................................................................................................42

14.1 Safety instructions ...................................................................42

14.2 Disassembly..............................................................................42

15 ACCESSORIES

........................................................................................... 44

16 TRANSPORT, STORAGE, PACKAGING .......................................... 44

English

Type 8685 / 8686

Page 5

5

Operating instructions

1 OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

The operating instructions contain important safety

information.

Failure to observe these instructions may result in hazardous

situations.

▶ The operating instructions must be read and understood.

1.1 Symbols

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a moderate or

minor injury.

NOTE!

Warns of damage to property.

▶ Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

▶ Indicates an instruction to prevent risks.

→ Designates a procedure which you must carry out.

1.2 Definition of term

The term “device” used in these instructions always stands for the

feedback head Type 8685 and control head Type 8686.

English

Type 8685 / 8686

Page 6

6

Authorized use

2 AUTHORIZED USE

Non-intended use of the feedback head Type 8685 and the

control head Type 8686 may be a hazard to people, nearby

equipment and the environment.

The device is designed to be mounted on pneumatic actuators of

process valves for the control of media.

▶ Do not expose the device to direct sunlight.

▶ Use according to the authorized data, service and operating

conditions specified in the contract documents and operating

instructions. These are described in the chapter on “6 Technical

data”.

▶ The device may be used only in conjunction with third-party

devices and components recommended and authorized by

Bürkert.

▶ In view of the large number of options for use, it is essential

prior to installation to study and, if necessary, to test whether

the feedback head or control head is suitable for the specific

application case.

▶ Correct transportation, storage, and installation, as well as care-

ful use and maintenance are essential for reliable and faultless

operation.

▶ Use the device only as intended.

2.1 Restrictions

If exporting the system/device, observe any existing restrictions.

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the assembly,

operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing

these regulations, also with reference to the installation personnel.

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

English

Type 8685 / 8686

Page 7

7

Basic safety instructions

General hazardous situations

To prevent injuries:

▶ The feedback head Type 8685 and control head Type 8686 must

not be used in areas where there is a risk of explosion.

▶ Ensure that the system cannot be activated unintentionally.

▶ Installation and maintenance work may be carried out only by

authorized technicians with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The device may be operated only when in perfect condition and

in consideration of the operating instructions.

▶ The general rules of technology must be observed for applica-

tion planning and operation of the device.

To prevent damage to property of the device, ensure:

▶ Do not feed any aggressive or flammable media into the pilot air

port for Type 8686

▶ Do not feed any liquids into the pilot air port for Type 8686.

▶ Do not physically stress the body (e.g. by placing objects on it or

standing on it).

▶ Do not make any external modifications to the device bodies.

NOTE!

Electrostatic sensitive components/modules.

The device contains electronic components, which react sensitively

to electrostatic discharge (ESD). Contact with electrostatically

charged persons or objects is hazardous to these components. In

the worst case scenario, they will be destroyed immediately or will

fail after start-up.

▶ Observe the requirements in accordance with EN 61340-5-1

to minimize/avoid the possibility of damage caused by a sudden

electrostatic discharge.

▶ Also, ensure that you do not touch electronic components when

the power supply voltage is present.

English

Type 8685 / 8686

Page 8

8

General information

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@burkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2 Warranty

The warranty is only valid if the feedback head and control head are used

as intended in accordance with the specified application conditions.

4.3 Information on the Internet

The operating instructions and data sheets for Type 8685 and Type

8686 can be found on the Internet at:

www.burkert.com

5 SYSTEM DESCRIPTION

5.1 Intended application area

The feedback head Type 8685 and the control head Type 8686

are designed to be mounted on pneumatic actuators of valves Type

2036 for the control of media.

5.2 General description

The feedback head Type 8685 and the control head Type 8686 are

designed exclusively for integrated mounting on an actuator of the

diaphragm valve Type 2036 in sizes RV50, RV70, RV110.

The actuator size is adjusted with DIP switches.

The valve position is recorded by a permanent magnet on the

spindle extension. When a stroke movement occurs, the spindle

extension is guided along a reed sensor (lower/upper end position).

In addition to the electrical position feedback, the device status on

the feedback head and control head are represented visually by

colored LEDs. The status of the integrated pilot valve is also indicated by LEDs for the control head.

In the variant with AS-Interface communication, bus status LEDs are

also active.

English

Type 8685 / 8686

Page 9

9

System description

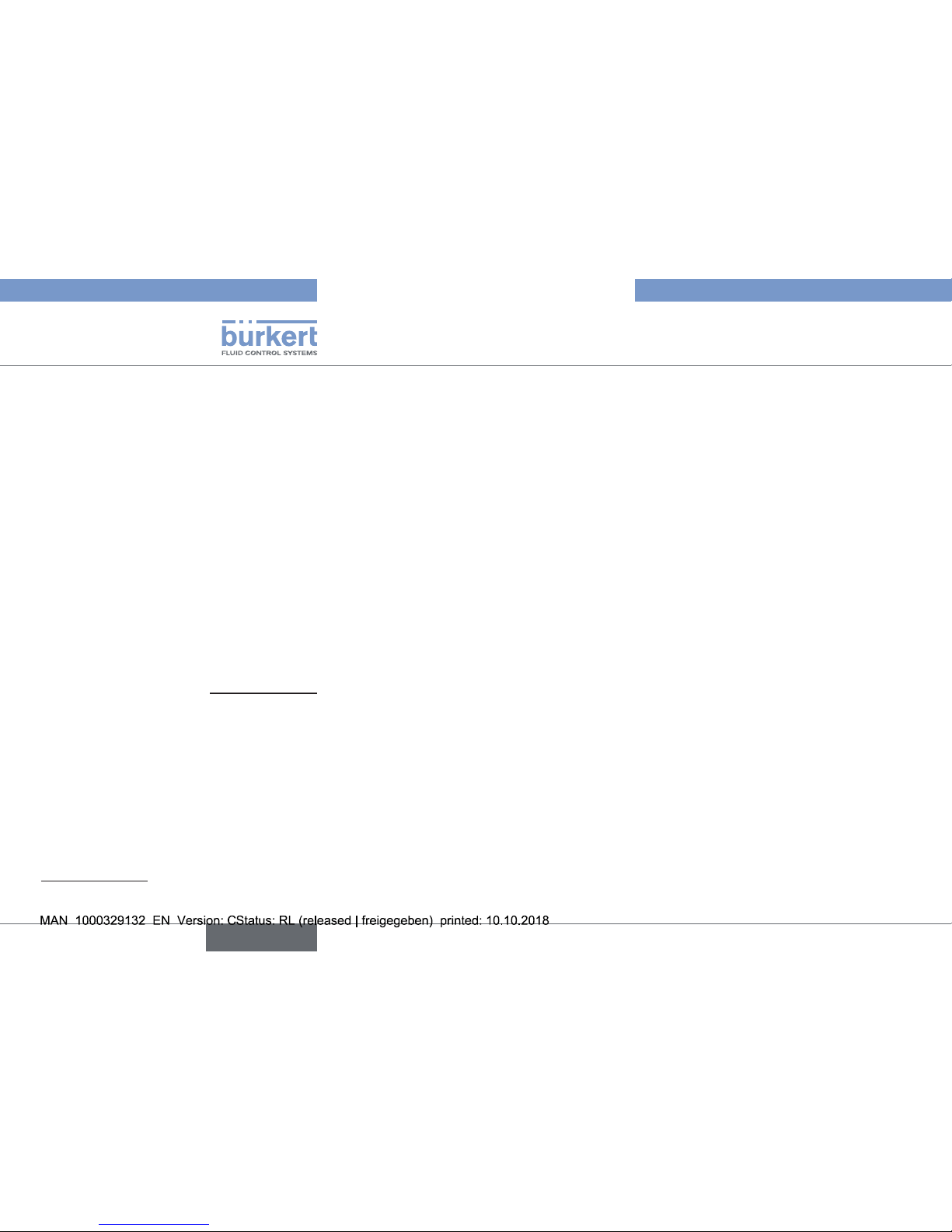

5.3 Structure of feedback head Type

8685

Electrical connection

Cable gland M12 x 1.5 or circular

plug-in connector M12 x 1

Pressure limiting valve

(for protection against

too high internal pressure

in case of error)

AS interface

status LEDs

Drive status OPEN/

CLOSED LEDs

(end position)

DIP switches

Select RV50/70/110

Slide switch

Color selection of

end position

View without

transparent cap:

Fig. 1: Structure of feedback head Type 8685

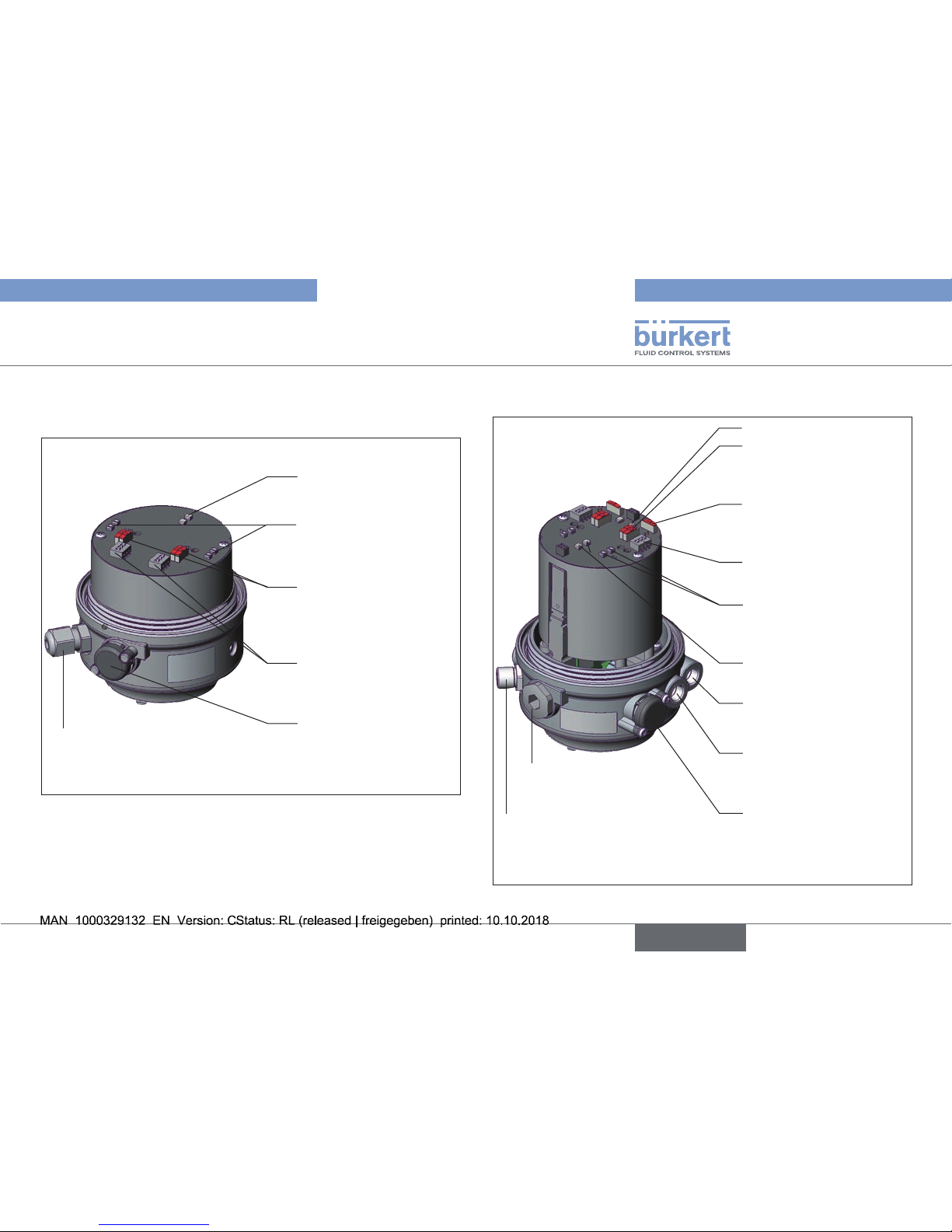

5.4 Structure of control head Type 8686

Dummy plug

M16 x 1.5

Electrical connection

Cable gland M12 x 1.5

or circular plug-in connector M12 x 1

Pressure limiting valve

(for protection against too

high internal pressure in

case of error)

Exhaust air port

(label: 3)

Pilot air port

(label: 1)

AS-Interface status

LEDs

Actuator status OPEN/

CLOSED LEDs (end

position)

DIP switches

Select RV50/70/110

Slide switch

Color selection of end

position

Slide switch

Pilot valve

(Service switch)

Control valve status LED

View without transparent

cap and body casing:

Fig. 2: Structure of control head Type 8686

English

Type 8685 / 8686

Page 10

10

Technical data

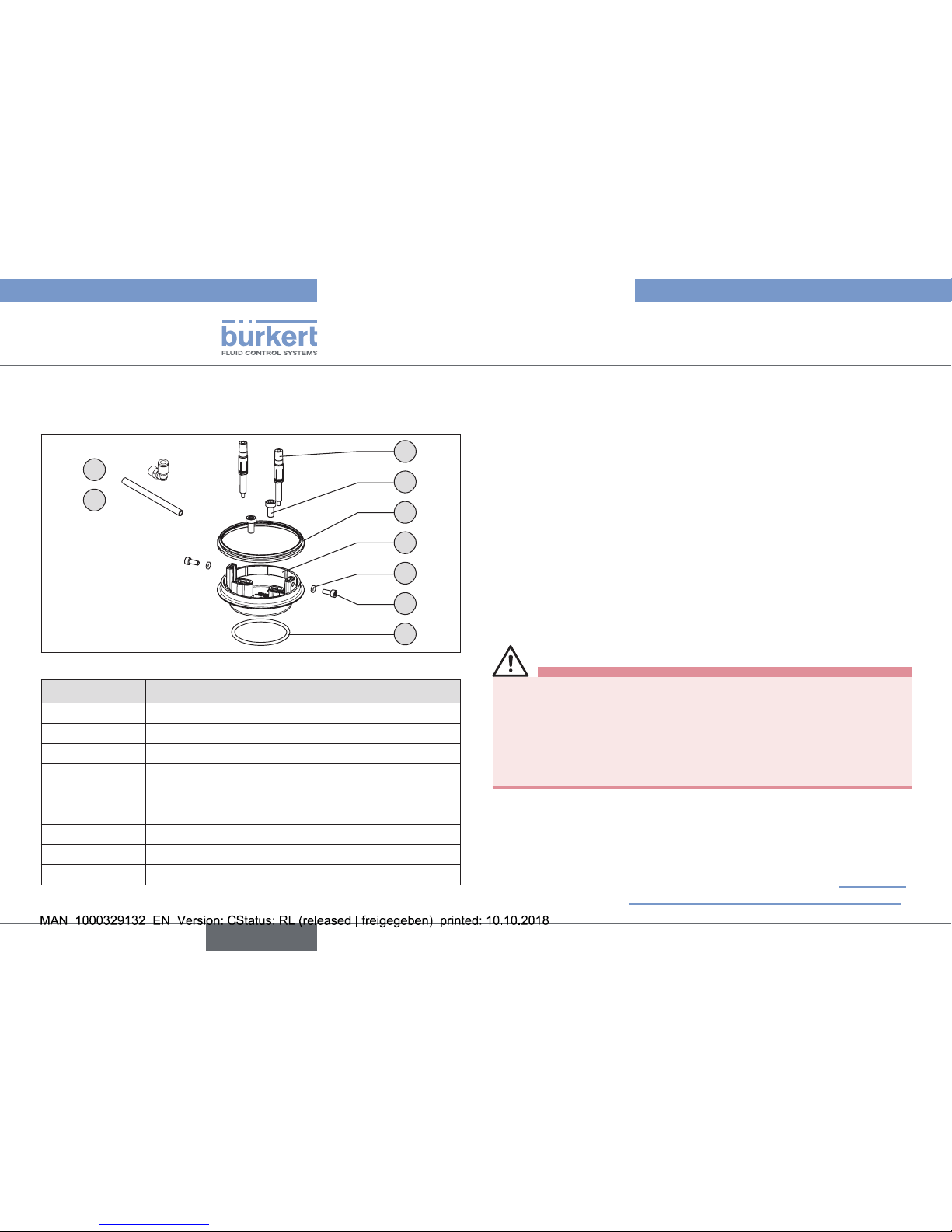

5.5 Structure of adapter set for

actuator Type 2036

2

5

4

1

7

6

3

9

8

Fig. 3: Adapter set for Type 2036

Item Quantity Designation

1 1 Robolux adaptation body

2 6 2 units each Switch spindle RV50, RV70, RV110 cpl.

3 1 O-ring 52 x 3 EPDM 75

4 1 Form seal

5 2 Cylinder head screw M6 x 12 A2 DIN 912

6 2 Cylinder head screw M4 with shaft

7 2 O-ring 3.5 x 1.5 EPDM 70

8 2 Hose 280 mm

9 4 Angular connection G1/8 SL6 Legris

Tab. 1: Parts list for adapter set

6 TECHNICAL DATA

6.1 Conformity

The feedback head Type 8685 and the control head Type 8686 comply

with EU directives in accordance with the EU Declaration of Conformity.

6.2 Standards

The applied standards, which verify conformity with the EU Directives, can be found on the EU Type Examination Certificate and / or

the EU Declaration of Conformity.

6.3 Operating conditions

WARNING!

Solar radiation and temperature fluctuations may cause malfunctions or leaks.

▶ If the device is used outdoors, do not expose it unprotected to

the weather conditions.

▶ Ensure that the permitted ambient temperature does not exceed

the maximum value or drop below the minimum value.

Ambient temperature 0 – +55 °C

Degree of protection IP65 / IP67 according to EN 60529

(only if cables, plugs and sockets have been

connected correctly and in compliance with

the exhaust air concept in chapter “8.3 Pneumatic installation of control head Type 8686”.

English

Type 8685 / 8686

Page 11

11

Technical data

6.4 Mechanical data

Dimensions See data sheet

Body material PPS, PC, VA

Sealing material outside EPDM

inside NBR

Stroke range of valve spindle RV50 actuator size 6 mm

RV70 actuator size 9.5 mm

RV110 actuator size 13.5 mm

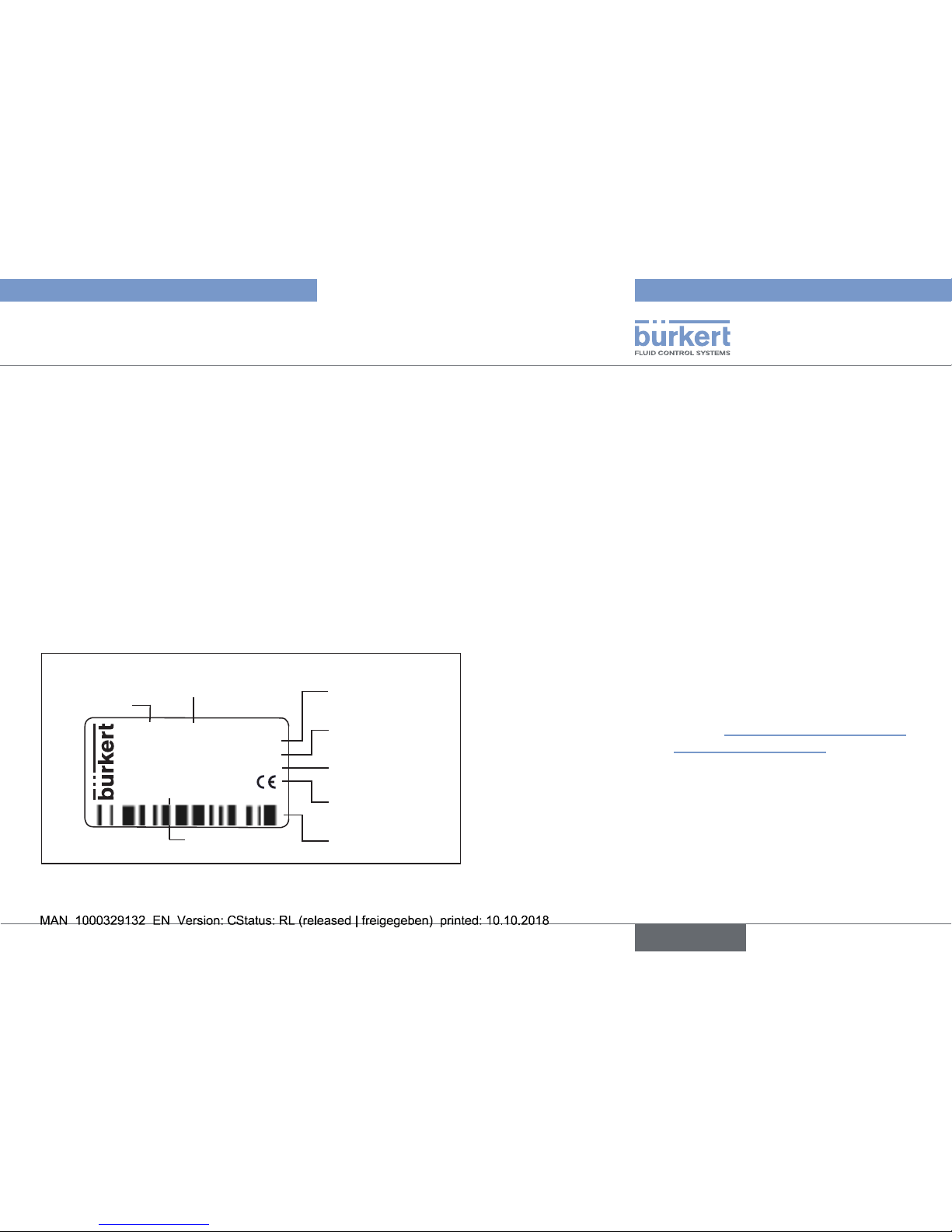

6.5 Type label

Example:

8686 AS-i S-7.A.E

2x single pilot 3.0

Pmax 7bar

Tamb 0 ... +55°C

Ser. No. 001000

00XXXXXX

D-74653 Ingelfingen

W14UN

Identification number

Supply voltage, control or

AS-Interface profile

Max operating

pressure

Type

Control function,

pilot valve

Barcode

Serial number,

CE marking

Ambient

temperature

Fig. 4: Example of type label

6.6 Pneumatic data

Control medium neutral gases, air

Quality classes in accordance with

ISO 8573-1

Dust content Class 7 Max. particle size 40 µm,

max. particle density 10 mg/m³

Water content of Class 3 max. pressure dew point - 20 °C or

min. 10 °C below the lowest

operating temperature

Oil content Class X max. 25 mg/m³

Temperature range

Control medium -10 – + 50 °C

Pressure range

Control medium 6 – 7 bar

(for further details see operating

instructions Type 2036 and

chapter “8.3 Pneumatic installation of

control head Type 8686”)

Air output of pilot valve 250 lN / min (for aeration and deaeration)

(QNn value according to definition for

pressure drop from 7 to 6 bar absolute)

Connections Plug-in hose connector Ø 6 mm / 1/4"

Socket connection G1/8

English

Type 8685 / 8686

Page 12

12

Technical data

6.7 Electrical data for feedback head

Type 8685

6.7.1 Electrical data without bus control

24 V DC

Connections Cable gland M12 x 1.5, wrench size 15

(clamping area 3 – 6.5 mm)

with screw terminals

(nominal cross section 1.0 mm²,

min. cable cross-section 0.25 mm²)

Supply voltage 24 V DC ± 10%,

max. residual ripple 10%

Output max. 100 mA per output /

short circuit-proof

Display max. 20 mA

(2 end positions = 2 LEDs)

6.7.2 Electrical data with AS-Interface bus

control

Connections Remote 975 mm AS-Interface cable

with circular plug-in connector

(M12 x 1, 4-pole)

Supply voltage 29.5 V – 31.6 V DC

(according to specification)

Max. power consumption 35 mA

English

Type 8685 / 8686

Page 13

13

Technical data

6.8 Electrical data

control head Type 8686

6.8.1 Electrical data without bus control

24 V DC

Connections Cable gland M12 x 1.5, wrench size 15

(clamping area 3 – 6.5 mm) with screw terminals

(nominal cross section 1.0 mm²,

min. cable cross-section 0.25 mm²)

Circular plug-in connector (M12 x 1, 8-pole)

Pilot valve

Supply voltage 24 V DC ± 10% ,

max. residual ripple 10%

Power input 2 x 0.8 W

Output max. 100 mA per output / short

circuit-proof

Display max. 20 mA

(2 end positions = 2 LEDs)

Service:

Power consumption 90 mA

(2 end positions + 2 valves /

service switch on)

6.8.2 Electrical data with AS-Interface bus

control

Connections Remote 975 mm AS-Interface cable

with circular plug-in connector

(M12 x 1, 4-pole)

Supply voltage 29.5 V – 31.6 V DC

(according to specification)

Outputs

Max. switching capacity: 2 x 0.8 W via AS-Interface

Watchdog function integrated

Max. power consumption 120 mA

(2 valves when activated +

2 end positions)

Service:

Power consumption 105 mA

(2 end positions

+ 2 valves /

service switch on)

English

Type 8685 / 8686

Page 14

14

Assembly

7 ASSEMBLY

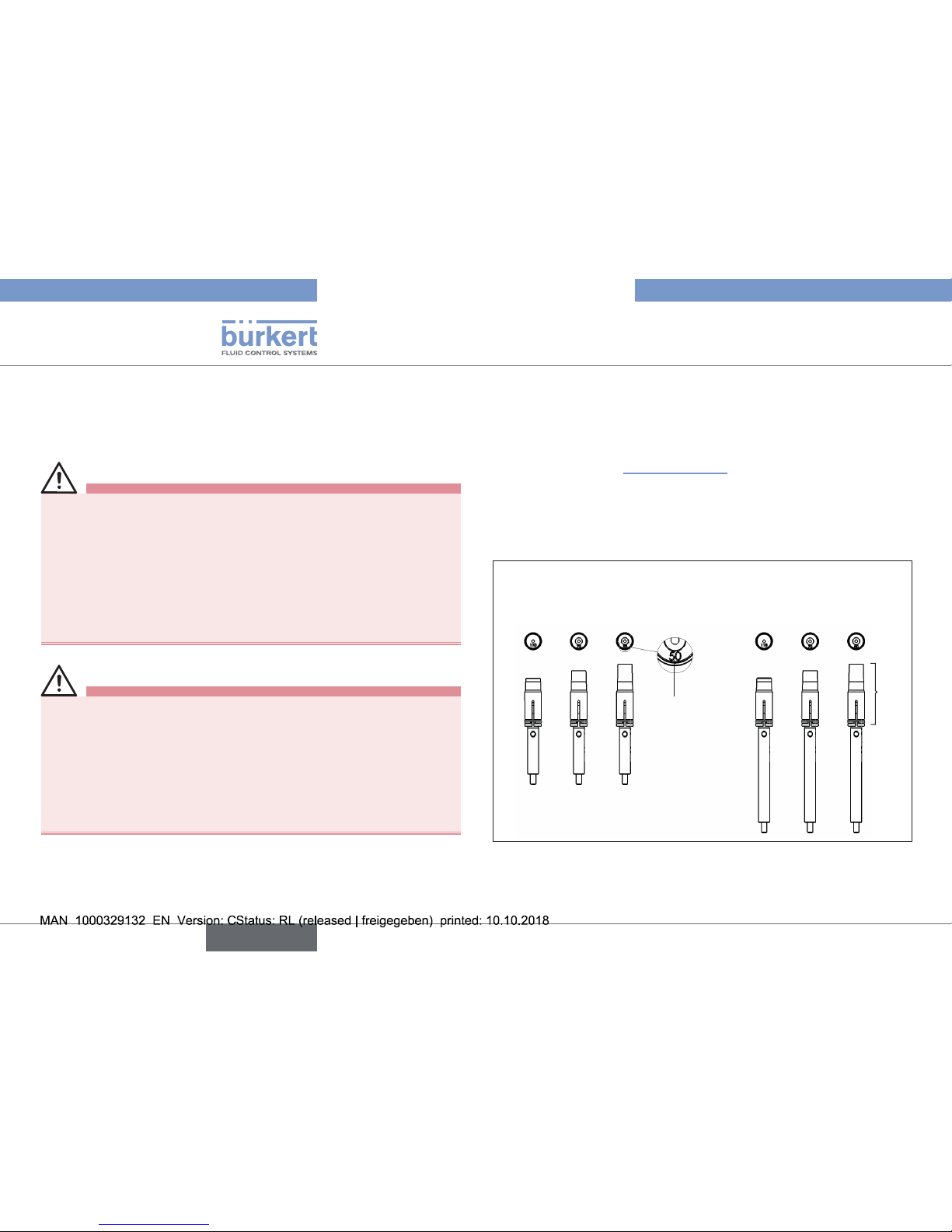

7.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper assembly.

▶ Installation may only be carried out by authorized technicians

with the appropriate tools.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

7.2 Assembly of Type 8685 and Type

8686 on the actuator Type 2036

An adapter set is required for assembly on the actuator Type 2036.

The adapter set (see “Fig. 3”, page 10) includes an adaptation body,

a form seal, three O-rings, four cylinder screws and three switch spindle

pairs. There are different adapter sets for feedback head and control

head. Because of the different working height for actuator sizes RV50,

RV70 and RV110, an adapter set contains different spindle lengths.

Switch spindle Type 8685

Switch spindle Type 8686

RV110 RV70

RV50

RV110 RV70

RV50

Actuator size

identification

Cap

Fig. 5: Switch spindle identification

English

Type 8685 / 8686

Page 15

15

Assembly

Designation Order no.

Adapter set for Type 8685 684267

Adapter set for Type 8686 684268

Tab. 2: Adapter sets

Procedure:

Step 1: Assembly of adaptation body on the actuator

→ Unscrew the transparent cap from the actuator.

→ Remove cover foil, if present. This makes the coding holes and M6

threads accessible.

→ Place the 52 x 3 O-ring in the profile on the bottom of the adap-

tation body.

→ Place the adaptation body on the actuator, paying close attention

to the coding pin.

→ Screw the adaptation body tightly onto the actuator with two

cylinder screws M6 x 12.

O-ring 52 x 3

Adaptation body

Coding pin

Cylinder screws M6 x 12

Actuator

Fig. 6: Assembly of adaptation body

NOTE!

Using a switch spindle that does not fit will result in irreparable destruction of the feedback head and/or control head

and the actuator.

▶ Use only switch spindles that match the actuator size. The cor-

responding actuator size identification (RV50, RV70, RV110)

for switch spindles are embossed on the front of the PVC cap

(see “Fig. 5”).

→ Select the switch spindle that matches the actuator size (see

“Fig. 5: Switch spindle identification”).

→ Wet the thread of two switch spindles that match the actuator

size with Loctite screw locking M290.

NOTE!

Using the wrong spindle lead-through will result in

malfunction.

▶ Use only the spindle lead-through that matches the actuator

size (see “Fig. 7”).

Spindle lead-through

for actuator size

RV50

Spindle lead-through

for actuator sizes

RV70 and RV110

Fig. 7: Spindle lead-through

English

Type 8685 / 8686

Page 16

16

Assembly

NOTE!

No detection or faulty detection of end positions.

▶ Do not change the position of the cap on the switch spindle.

▶ Use the hole ∅ 2.3 for fastening the switch spindle.

→ Push the switch spindles through the matching spindle lead-

throughs. The outside lead-throughs are designed for actuator

size RV70/110, while the inside lead-throughs for actuator size

RV50 (see “Fig. 7”).

→ Attention: Do not bring the screw locking into contact with the

spindle seal.

Hole ∅ 2.3 for

screwing in the

switch spindle

Form seal

Cap

Fig. 8: Assembly of switch spindles and form seal

→ Using a suitable tool, screw the two switch spindles onto the

actuator spindles. There is a hole ∅ 2.3 on the spindle side for

this purpose (torque 1.0 Nm ± 0.1 Nm).

→ Place the form seal on the adaptation body (smaller diameter

points upwards).

Step 2: Assembly of the feedback head / control head on the

adaptation body

If the electrical connection is made with a cable gland, we

recommend connecting the wires at this point, since otherwise

the feedback head / control head will have to be removed again

for the electrical connection.

For electrical installation see: “9.2 Device version 24 V DC”

“Device connection for cable gland Type 8685”

“Device connection for cable gland Type 8686”

NOTE!

Faulty detection of end positions.

▶ For actuators with control function B (CFB, NO), the lower end

position must be approached before the feedback head / control

head is placed on the adaptation body. To do this, pressurize the

appropriate pilot air port of the actuator (“Fig. 9”).

▶ Make certain the feedback head / control head is correctly posi-

tioned relative to the actuator: The dummy plug or pressure-relief

valve must be located on the side of the pneumatic connections

of the actuator (see “Fig. 9”).

→ Place the feedback head / control head on the actuator. As you

do, note:

- The dummy plug or pressure-relief valve must be located on the

side of the pneumatic connections of the actuator.

-

The caps must be in the starting position. If not, move the caps

to the starting position (see “Fig. 5”)

- The switch spindles must lodge inside the recesses on the bottom

of the feedback head / control head. Do not move the caps onto

the switch spindles.

English

Type 8685 / 8686

Page 17

17

Assembly

Form seal

Dummy plug

Pressure-relief

valve

Connection

CFB

Connection

CFA

Type 2036

Type 8686

Type 8685

Pneumatic actuator

connections

Switch spindle

Recess

Fig. 9: Assembly of feedback head / control head

→ Push the feedback head / control head onto the adaptation body

until no gap is visible on the form seal. Now align the mounting hole

of the feedback head / control head on each side with the square

nut of the adaptation body.

Fastening screw M4

Mounting hole of the

feedback head / control

head concentric with

square nut of the adap-

tation body

O-ring 3.5 x 1.5

Fig. 10: Fastening of feedback head / control head

NOTE!

If the torque is too high when screwing in the fastening screw

or if the O-ring is missing, degree of protection IP65 / IP67 is

not ensured.

▶ The fastening screw may only be tightened to a maximum torque

of 0.5 Nm ± 0.1 Nm.

▶ Check the position of the O-ring.

→ Use the two fastening screws M4 and matching O-rings to

fasten the feedback head / control head onto the adaptation

body (torque: 0.5 Nm ± 0.1 Nm).

The mechanical connection is already completed for the feedback

head after these two assembly steps. “Step 3: Assembly of pneumatic connection - install the actuator” must still be performed for

the control head.

English

Type 8685 / 8686

Page 18

18

Assembly

Control head Type 8686 only:

Step 3: Assembly of pneumatic connection - install the actuator

→ Screw the plug-in hose connectors onto the control head and the

actuator.

→ Cut the enclosed hoses (2 x 280 mm) to length as appropriate

for the device layout.

→ Using the hoses supplied in the accessory kit, make the pneumatic

connection between the control head and actuator according to

the control function (CF) with the following “Tab. 3: Overview of

pneumatic connections for actuator variants”.

Plug-in hose

connectors

Hoses

Fig. 11: Assembly of pneumatic connections

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To comply with degree of protection IP65 / IP67, install an

exhaust air line on the unneeded pilot air port (for CFA, NC and

CFB, NO) in the dry area.

Pilot air port

2 (P2)

Pilot air port

4 (P4)

Pilot air port

3 (P3)

Pilot air port

1 (P1)

Actuator 1

(left)

Actuator 2

(right)

Pilot air outputs for

control head

Fig. 12: Pneumatic connection

English

Type 8685 / 8686

Page 19

19

Pneumatic installation

Type 2036 Actuator 1 Actuator 2

CF Connection CF Connection

D11, D55

CFA/CFA

CFA

2

1

P1

P2: Deaeration

CFA

2

2

P3

P4: Deaeration

D12

CFA/CFB

CFA

2

1

P1

P2: Deaeration

CFB

2

2

P4

P3: Deaeration

D21

CFB/CFA

CFB

2

1

P2

P1: Deaeration

CFA

2

2

P3

P4: Deaeration

D22

CFB/CFB

CFB

2

1

P2

P1: Deaeration

CFB

2

2

P4

P3: Deaeration

Tab. 3: Overview of pneumatic connections for actuator variants

CFA, NC: Valve closed in rest position (by spring force)

CFB, NO: Valve open in rest position (by spring force)

For the assignment of control connections see the installation and dimensional drawing included with delivery of the

valve or in the Type 2036 operating instructions.

8 PNEUMATIC INSTALLATION

The dimensions of the feedback head / control head and the different

complete device models, consisting of control, feedback head / control

head, actuator and valve, can be found in the relevant data sheets.

8.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may only be carried out by authorized technicians

with the appropriate tools.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

English

Type 8685 / 8686

Page 20

20

Pneumatic installation

8.2 Pneumatic installation of

feedback head Type 8685

The feedback head does not require a pilot air supply.

A description of the pneumatic installation of the actuator is

included in the valve operating instructions.

8.3 Pneumatic installation of control

head Type 8686

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Procedure:

→ Connect the control medium to the pilot air port (1)

(6 – 7 bar; instrument air, free of oil, water and dust).

→ Mount the exhaust air line or a silencer on the exhaust air port (3)

(see “Fig. 13: Pneumatic connection Type 8686”).

Important information for the problem-free functioning of

the device:

▶ The installation must not cause back pressure to build up.

▶ To make the connection, select a hose with sufficient cross

section.

▶ The exhaust air line must be designed in such a way that

no water or other liquid can get into the device through the

exhaust air connection (3).

Pilot air port

Label: 1

Exhaust air port

Label: 3

Fig. 13: Pneumatic connection Type 8686

Caution (exhaust air concept): In compliance with degree

of protection IP65 / IP67, an exhaust air line must be

installed in the dry area.

Always maintain an applied control pressure of at least

0.5 – 1 bar above the pressure which is required to move the

actuator to its end position.

English

Type 8685 / 8686

Page 21

21

Electrical installation

9 ELECTRICAL INSTALLATION

9.1 Safety instructions

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may only be carried out by authorized technicians

with the appropriate tools.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

9.2 Device version 24 V DC

9.2.1 Electrical installation for feedback

head Type 8685

Device connection for cable gland Type 8685

→ Use a cable cross-section of 0.25 mm² for the electrical

connection.

Fastening

screws

M4 (2x)

Screw terminals

Fig. 14: Position of screw terminals Type 8685

→ Loosen the fastening screws M4 and pull the feedback head up

(only if the feedback head is already installed).

→ Install the cable gland, if necessary (approx. 1,5 Nm).

→ Guide the cables through the cable gland.

English

Type 8685 / 8686

Page 22

22

Electrical installation

GND24V

Top1

Bot1

Top2

Bot2

Fig. 15: Designation on PCB Type 8685

Designation

on PCB

Assignment

1)

24 V

Supply voltage + 24 V DC ±10%

GND

Supply voltage - GND

Top 1

Top end position Top actuator 1

24 V / 0 V (max. 0.1 A)

GND

Bot 1

Bottom end position Bot actuator 1

24 V / 0 V (max. 0.1 A)

GND

Top 2

Top end position Top actuator 2

24 V / 0 V (max. 0.1 A)

GND

Bot 2

Bottom end position Bot actuator 2

24 V / 0 V (max. 0.1 A)

GND

Tab. 4: Connection for cable gland Type 8685

1) Actuator assignment see “Fig. 16”.

Pilot air port

2 (P2)

Pilot air port

4 (P4)

Pilot air port

3 (P3)

Pilot air port

1 (P1)

Actuator 1

(left)

Actuator 2

(right)

Fig. 16: Pneumatic connection

→ Connect the wires (see pin assignment in “Tab. 4”).

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To ensure degree of protection IP65 / IP67, tighten the union

nut of the cable gland according to the cable size you are using

(approx. 1.5 Nm).

→ Tighten the union nut of the cable gland on the body (approx. 1.5

Nm).

English

Type 8685 / 8686

Page 23

23

Electrical installation

NOTE!

Faulty detection of end positions.

▶ For actuators with control function B (CFB, NO), the lower end

position must be approached before the feedback head is placed

on the adaptation body. To do this, pressurize the appropriate pilot

air port of the actuator (“Fig. 9”).

▶ Make certain the feedback head is correctly positioned relative

to the actuator: The dummy plug or pressure-relief valve must be

located on the side of the pneumatic connections of the actuator

(see “Fig. 9”).

→ Place the feedback head on the actuator. As you do, note:

- The dummy plug or pressure-relief valve must be located on the

side of the pneumatic connections of the actuator.

-

The caps must be in the starting position. If not, move the caps

to the starting position (see “Fig. 5”)

- The switch spindles must lodge inside the recesses on the

bottom of the feedback head. Do not move the caps onto the

switch spindles.

→ Push the feedback head onto the adaptation body until no gap is

visible on the form seal. Now align the mounting hole of the feedback

head on each side with the square nut of the adaptation body.

NOTE!

If the torque is too high when screwing in the fastening screw

or if the O-ring is missing, degree of protection IP65 / IP67 is

not ensured.

▶ The fastening screw may only be tightened to a maximum torque

of 0.5 Nm ± 0.1 Nm.

▶ Check the position of the O-ring.

→ Use the two fastening screws M4 and matching O-rings to

fasten the feedback head onto the adaptation body (torque: 0.5

Nm ± 0.1 Nm).

When the supply voltage is applied, the feedback head is operating.

→ Before the device can be used, the basic settings (see section

“10.3.1 Basic settings”) must still be made on the feedback

head.

English

Type 8685 / 8686

Page 24

24

Electrical installation

9.2.2 Electrical installation of control head

Type 8686

Device connection for circular plug-in connector Type 8686

→ Connect the circular plug-in connector of the control head as

described in “Tab. 5”.

6

1

7

5

4

3

2

8

Fig. 17: Assignment of circular plug (M12 x 1, 8-pole)

Use only straight connecting socket.

Pilot air port

2 (P2)

Pilot air port

4 (P4)

Pilot air port

3 (P3)

Pilot air port

1 (P1)

Actuator 1

(left)

Actuator 2

(right)

Fig. 18: Pneumatic connection

When the supply voltage is applied, the control head is operating.

→ Before the device can be used, the basic settings (see section

“10.3.1 Basic settings”) must still be made on the control head.

Pin

Wire

color

2)

Assignment

3)

External circuit

1

white

Bottom end position Bot actuator 2

24 V / 0 V (max. 0.1 A)

GND (7)

1

2

brown

Top end position Top actuator 2

24 V / 0 V (max. 0.1 A)

GND (7)

2

3

green

Bottom end position Bot actuator 1

24 V / 0 V (max. 0.1 A)

GND (7)

3

4

yellow

Top end position Top actuator 1

24 V / 0 V (max. 0.1 A)

GND (7)

4

5

gray

Valve control Y2

Actuator 2 activated

high active, to activate

connect with 24 V

5

6

pink

Valve control Y1

Actuator 1 activated

high active, to activate

connect with 24 V

6

7

blue Supply voltage – GND

7

8

8

red Supply voltage + 24 V DC ±10%

Tab. 5: Connection for circular plug-in connector Type 8686

2) The indicated colors refer to the connecting cable available as an

accessory (919061).

3) Actuator assignment see “Fig. 18”.

English

Type 8685 / 8686

Page 25

25

Electrical installation

Device connection for cable gland Type 8686

→ Use a cable cross-section of 0.25 mm² for the electrical connection.

Fastening

screws

M4 (2x)

Screw terminals

Cable holder

Fig. 19: Position of screw terminals Type 8686

→ Loosen the fastening screws M4 and pull the control head up

(only if the control head is already installed).

→ Install the cable gland, if necessary (approx. 1,5 Nm).

Valve1

GND

24V

Valve2

Top1

Bot1

Top2

Bot2

Fig. 20: Designation on PCB Type 8686

→ Guide the cables through the cable gland.

→ Connect the wires (see pin assignment in “Tab. 6”).

Designation

on PCB

Assignment

4)

External circuit

Bot2

Bottom end position Bot actuator 2

24 V / 0 V (max. 0.1 A)

GND

Top2

Top end position Top actuator 2

24 V / 0 V (max. 0.1 A)

GND

Bot1

Bottom end position Bot actuator 1

24 V / 0 V (max. 0.1 A)

GND

Top1

Top end position Top actuator 1

24 V / 0 V (max. 0.1 A)

GND

Valve2

Valve control Y2

Actuator 2 activated

high active, to activate

connect with 24 V

Valve1

Valve control Y1

Actuator 1 activated

high active, to activate

connect with 24 V

GND

Supply voltage - GND

24V

Supply voltage + 24 V DC ±10%

Tab. 6: Connection for cable gland Type 8686

4) Actuator assignment see “Fig. 18”.

English

Type 8685 / 8686

Page 26

26

Electrical installation

NOTE!

Malfunction due to damaged wires.

▶ To keep the spindle guides free, guide all wires through the

cable holders.

Damage or malfunction due to ingress of dirt and moisture.

▶ To ensure degree of protection IP65 / IP67, tighten the union

nut of the cable gland according to the cable size you are using

(approx. 1.5 Nm).

→ Guide all wires through the cable holders.

→ Tighten the union nut of the cable gland on the body (approx. 1.5

Nm).

NOTE!

Faulty detection of end positions.

▶ For actuators with control function B (CFB, NO), the lower end

position must be approached before the control head is placed

on the adaptation body. To do this, pressurize the appropriate pilot

air port of the actuator (“Fig. 9”).

▶ Make certain the control head is correctly positioned relative to

the actuator: The dummy plug or pressure-relief valve must be

located on the side of the pneumatic connections of the actuator

(see “Fig. 9”).

→ Place the control head on the actuator. As you do, note:

- The dummy plug or pressure-relief valve must be located on the

side of the pneumatic connections of the actuator.

-

The caps must be in the starting position. If not, move the caps

to the starting position (see “Fig. 5”)

- The switch spindles must lodge inside the recesses on the bottom

of the control head. Do not move the caps onto the switch spindles.

→ Push the control head onto the adaptation body until no gap is

visible on the form seal. Now align the mounting hole of the control

head on each side with the square nut of the adaptation body.

NOTE!

If the torque is too high when screwing in the fastening screw

or if the O-ring is missing, degree of protection IP65 / IP67 is

not ensured.

▶ The fastening screw may only be tightened to a maximum torque

of 0.5 Nm ± 0.1 Nm.

▶ Check the position of the O-ring.

→ Use the two fastening screws M4 and matching O-rings to

fasten the control head onto the adaptation body (torque:

0.5 Nm ± 0.1 Nm).

When the supply voltage is applied, the control head is operating.

→ Before the device can be used, the basic settings (see section

“10.3.1 Basic settings”) must still be made on the control head.

English

Type 8685 / 8686

Page 27

27

Electrical installation

9.3 Device version AS-Interface

9.3.1 Electrical installation feedback head

and control head

The feedback head and control head are electrically connected by a

multi-pole cable (M12 circular plug-in connector) and flat cable terminal. The circular plug can simply be connected with the flat cable

terminal (see “Fig. 21”).

Screws

M12 plug-in connector branch circuit

Fig. 21: Feedback head / control head with multi-pole cable and

flat cable terminal

Wiring diagram of circular plug M12

The view shows the image from the front looking at the pins, the solder

connections are behind them.

Pin 4:

NC

Pin 1:

Bus +

Pin 3:

Bus –

Pin 2:

NC

Fig. 22: Bus connection

Pin Designation Assignment

1

Bus + AS-Interface bus line +

2

NC not used

3

Bus – AS-Interface bus line –

4

NC not used

Tab. 7: Pin assignment of circular plug-in connector for

AS-Interface

English

Type 8685 / 8686

Page 28

28

Electrical installation

Handling the flat cable terminal

The multi-pole cable features a flat cable terminal - with M12 plug-in

connector branch circuit - for AS-Interface cable harness. The flat cable

terminal contacts the AS-Interface flat cable by means of penetration

technology which allows installation by “clipping in” the AS-Interface

flat cable without cutting and without removing insulation.

Procedure:

→ Open the flat cable terminal

(loosen screws and remove cover).

→ Insert flat cable to fit closely.

→ Close flat cable terminal again.

→ Tighten the screws

Loosen the thread-forming screws slightly (approx. 3/4 turn to the

left) and position them on the existing threaded hole and screw in.

9.3.2 AS-Interface connection

AS-Interface (Actuator Sensor Interface) is a field bus system

which is used primarily for networking binary sensors and actuators

(slaves) with a higher-level control (master).

Bus line

Unshielded two-wire line (AS-Interface line as AS-Interface flat

cable) along which both information (data) and energy (power

supply voltage for the actuators and sensors) are transmitted.

Network topology

Freely selectable within wide limits, i.e. star, tree and line networks

are possible. Further details are described in the AS-Interface Specification (A/B slave model conforms to the version 3.0 specification

9.3.3 Technical Data for AS-Interface PCBs

Supply: via AS-Interface (29.5 V – 31.6 V)

Control head outputs: Valve Y1 and valve Y2,

each with max. 0.8 W,

Power reduction after approx. 100 ms

with integrated watchdog function

Certification: Feedback head: Certificate No. 94701

based on version 3.0

Control head: Certificate No. 94801

based on version 3.0

9.3.4 Programming data

Programming data for feedback head Type 8685

I/O configuration 0 hex

ID code

A hex (see below for bit

configuration)

Extended ID code 1 7 hex

Extended ID code 2 E hex

Profile S-0.A.E

Tab. 8: Programming data for feedback head Type 8685

English

Type 8685 / 8686

Page 29

29

Electrical installation

Bit configuration

Data bit

Inputs

Function Assignment

5)

D0

Top end position Top actuator 1

0 Top not reached

1 Top reached

D1

Bottom end position Bot actuator 1

0 Bot not reached

1 Bot reached

D2

Top end position Top actuator 2

0 Top not reached

1 Top reached

D3

Bottom end position Bot actuator 2

0 Bot not reached

1 Bot reached

Data bit

Outputs

Function Assignment

5)

D0 - not used

D1 - not used

D2 - not used

D3 - not used

Tab. 9: Bit configuration of AS-Interface for feedback head Type 8685

Parameter bits have no function.

5) Actuator assignment see “Fig. 23”.

Programming data for control head Type 8686:

I/O configuration 7 hex

ID code A hex (see below for bit configuration)

Extended ID code 1 7 hex

Extended ID code 2 E hex

Profile S-7.A.E

Tab. 10: Programming data for control head Type 8686

Pilot air port

2 (P2)

Pilot air port

4 (P4)

Pilot air port

3 (P3)

Pilot air port

1 (P1)

Actuator 1

(left)

Actuator 2

(right)

Fig. 23: Pneumatic connection

English

Type 8685 / 8686

Page 30

30

Electrical installation

Bit configuration

Data bit

Inputs

Function Assignment

6)

D0

Top end position Top actuator 1

0 Top not reached

1 Top reached

D1

Bottom end position Bot actuator 1

0 Bot not reached

1 Bot reached

D2

Top end position Top actuator 2

0 Top not reached

1 Top reached

D3

Bottom end position Bot actuator 2

0 Bot not reached

1 Bot reached

Data bit

Outputs

Function Assignment

6)

D0 Pilot valve Y1

0 Pilot valve OFF

1 Pilot valve ON

D1 Pilot valve Y2

0 Pilot valve OFF

1 Pilot valve ON

D2 - not used

D3 - not used

Tab. 11: Bit configuration of AS-Interface for control head Type 8686

Parameter bits have no function.

6) Actuator assignment see “Fig. 24”.

9.3.5 LED status display for AS-Interface

Status LED 1

(green)

Status LED 2

(red)

off off POWER OFF

off on

No data traffic (expired Watch

Dog at slave address does not

equal 0)

on off OK

flashing on Slave address equals 0

Tab. 12: LED status display for AS-Interface

Pilot air port

2 (P2)

Pilot air port

4 (P4)

Pilot air port

3 (P3)

Pilot air port

1 (P1)

Actuator 1

(left)

Actuator 2

(right)

Fig. 24: Pneumatic connection

English

Type 8685 / 8686

Page 31

31

Control and display

10 CONTROL AND DISPLAY

10.1 Control and display elements for

feedback head Type 8685

10.1.1 Device version 24 V DC

The items listed below are designed separately for actuator 1 and 2.

Display elements:

• Status of actuator (end position)

The display elements are designed in the form of an LED.

Control elements:

• DIP switch for selecting actuator size RV50, RV70, RV110

• Slide switch for color selection of end position

If the transparent cap is unscrewed, follow the instructions

in “Step 4: Closing the transparent cap / body casing”,

page 36.

DIP switch -

actuator 1

DIP switch actuator 2

Slide switch

Color selection of end position

Actuator 2

Slide switch

Color selection of end position

Actuator 1

LEDs

Status of actuator 2

(end position)

LEDs

Status of actuator 1

(end position)

Fig. 25: Control and display elements for 24 V DC feedback head

English

Type 8685 / 8686

Page 32

32

Control and display

10.1.2 Device version AS-Interface

Other than the AS-Interface bus status, the items listed below are

designed separately for actuator 1 and 2.

Display elements:

• AS-Interface bus status

• Status of actuator (end position)

The display elements are designed in the form of an LED.

Control elements:

• DIP switch for selecting actuator size RV50, RV70, RV110

• Slide switch for color selection of end position

If the transparent cap is unscrewed, follow the instructions

in “Step 4: Closing the transparent cap / body casing”,

page 36.

LEDs

AS Interface bus status

DIP switch -

actuator 1

DIP switch actuator 2

Slide switch for

color selection of end position

Actuator 2

Slide switch for

color selection of end position

Actuator 1

LEDs

Status of actuator 2

(end position)

LEDs

Status of actuator 1

(end position)

Fig. 26: Control and display elements for AS-Interface feedback

head

English

Type 8685 / 8686

Page 33

33

Control and display

10.2 Control and display elements for

control head Type 8686

The items listed below are designed separately for actuator 1 and 2.

Device versions 24 V DC and AS-Interface have the same display

and control PCB.

The AS-Interface bus status LEDs are accordingly inactive for the

24 V DC device version.

Display elements:

• AS-Interface bus status

• Status of actuator (end position)

• Status of pilot valve

The display elements are designed in the form of an LED.

Control elements:

• DIP switch for selecting actuator size RV50, RV70, RV110

• Slide switch for color selection of end position

• Slide switch for direct activation of pilot valves (service switch)

If the transparent cap / the body casing is unscrewed,

follow the instructions in “Step 4: Closing the transparent

cap / body casing”, page 36.

DIP switch -

actuator 1

DIP switch actuator 2

Slide switch

Color selection of end position

Actuator 2

Slide switch

Color selection of end position

Actuator 1

Slide switch

(service switch)

Pilot valve for actuator 2

Slide switch

(service switch)

Pilot valve for actuator 1

LED status of pilot valve

Actuator 2

LED status of pilot valve

Actuator 1

LEDs

AS Interface bus status

LEDs

Status of actuator 2

(end position)

LEDs

Status of actuator 1

(end position)

Fig. 27: Control and display elements - control head

English

Type 8685 / 8686

Page 34

34

Control and display

10.3 Control

10.3.1 Basic settings

To ensure the function of Types 8685 and 8686, these basic settings must be made before start-up in the isolated state.

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

→ Unscrew the transparent cap.

→ Perform steps 1 to 4.

Step 1: Select the actuator size

The control elements are designed for one actuator side only.

Switch only one DIP switch element per actuator size to

active, depending on the actuator size (see actuator type

label). Only one uniform actuator size needs to be selected

on both actuator sides.

Incorrect settings of the DIP switches result in malfunctions

or no function of the end position feedback.

→ Pushing a DIP switch element to the “ON” position causes the

end position sensors of the selected actuator size to be activated.

RV110

RV70

RV50

ACTUATOR

1 2 3

ON

ON

Type 8685

Type 8686

Fig. 28: Selection of actuator size via DIP switch

Step 2: Change the assignment of the end position LEDs

(actuator status)

You can set the color assignment of the end positions with these

slide switches. You can indicate for each color whether it applies to

the Top (upper end position) or Bot (lower end position).

The slide switches for color selection must be unambiguously selected inside the actuator chamber, i.e. both

switches must be up or both must be down.

Incorrect settings of these switches will result in an

incorrect visual interpretation of end position detection, but

the end position detection will still be correct.

English

Type 8685 / 8686

Page 35

35

Control and display

Bot

gn ye

Bot

Top

Top

Typ 8685

Typ 8686

Fig. 29: Color assignment of end positions via slide switch

Refer to the PCB labeling in the table below

Switch position for one

actuator side

Actuator status LED

Both switches up End position Top yellow /

End position Bot green

Both switches down End position Top green /

End position Bot yellow

Switch up/down - Invalid state -

Switch down/up - Invalid state -

Tab. 13: Color assignment of end positions

The following function is set in the factory:

Color Actuator status

Green LED lit Lower end position

Yellow LED lit Upper end position

Tab. 14: Assignment of status of actuator LEDs (end position)

Step 3: Reference movement for spindle adjustment

To make the fine adjustment of the spindle for actuator size, it is essential

to move both spindles from the lower to the top end position.

Procedure for Type 8685:

Actuator with design control function A (CFA, NC):

→ Under maximum control pressure, move the spindles up by acti-

vating the actuator chambers.

→ After the end position is reached (preselected LED is lit), turn off

the control pressure. The spindle moves to the lower end position.

LED for end position Bot is lit with the selected color.

Actuator with design control function B (CFB, NO):

→ Under maximum control pressure, move the spindles down by

activating the actuator chambers.

→ After the end position is reached (preselected LED is lit), turn

off the control pressure. The spindle moves to the upper end

position. The corresponding LED for the end position is lit with

the selected color.

English

Type 8685 / 8686

Page 36

36

Control and display

Procedure for Type 8686:

→ Under maximum control pressure, switch the service switch to “On”.

The spindle moves to the upper end position.

→ After the end position is reached (preselected actuator status LED

is lit), switch the service switch back to “Off”. The spindle moves

to its initial position. The corresponding actuator status LED for the

end position is lit with the selected color.

ON

Service

OFF

Service

ON

OFF

Service switch

Pilot valve status LED

Fig. 30: Spindle adjustment

Step 4: Closing the transparent cap / body casing

→ Check that the seal is correctly positioned in the transparent cap

/ body casing (see “Fig. 31”).

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To comply with degree of protection IP65 / IP67, screw in the

transparent cap / body casing all the way.

→ Close the transparent cap / body casing (auxiliary tool for

installing the cover: 6740777)).

Seal

body casing

Body casing

Type 8686

Type 8685

Seal

transparent cap

Transparent cap

Fig. 31: Position of the seal in the transparent cap / body casing

The device is now configured and ready for operation.

7) The auxiliary tool for installing the cover (674077) is available through

your Bürkert sales office.

English

Type 8685 / 8686

Page 37

37

Control and display

10.3.2 Changing the settings

Procedure:

→ Unscrewing the transparent cap makes the slide switches and DIP

switches accessible.

→ Select the actuator size with the DIP switches. Only one uniform

actuator size needs to be selected on both actuator sides (see

valve type label).

→ Use the “Tab. 13: Color assignment of end positions” or the labeling

on the PCB to assign the desired color to the actuator status LEDs

(end position).

→ Check that the seal is correctly positioned in the transparent cap

/ body casing (see “Fig. 31”).

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To comply with degree of protection IP65 / IP67, screw in the

transparent cap / body casing all the way.

→ Close the transparent cap / body casing (auxiliary tool for

installing the cover: 6740778)).

8) The auxiliary tool for installing the cover (674077) is available through

your Bürkert sales office.

10.3.3 Manual activation of pilot valves

with the control head Type 8686

The pilot valves can be switched with the service switches. With

control function A, the spindle moves up with switch position

“On”. With control function A, the spindle moves down with switch

position “On”.

ON

Service

OFF

Service

ON

OFF

Slide switch

(service switch)

Pilot valve for actuator 1

LED status

Pilot valve for actuator 2

Slide switch

(service switch)

Pilot valve for actuator 2

LED status

Pilot valve for actuator 1

Fig. 32: Service switch and status LEDs for pilot valve (Type 8686)

Procedure:

Voltage is absolutely essential on the device!

→ Unscrewing the transparent cap makes the service switches

accessible.

→ Switch the relevant pilot valve with the service switches.

→ Check that the seal is correctly positioned in the transparent cap

/ body casing (see “Fig. 31”).

English

Type 8685 / 8686

Page 38

38

Control and display

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To comply with degree of protection IP65 / IP67, screw in the

transparent cap / body casing all the way.

→ Close the transparent cap / body casing (auxiliary tool for

installing the cover: 6740779)).

Procedure for replacing the diaphragm for Type 2036

Voltage is absolutely essential on the device!

→ Unscrewing the transparent cap makes the service switches

accessible.

→ Replace the diaphragm as described in the operating instruc-

tions for Type 2036.

→ After the diaphragm is replaced, perform a reference movement for

spindle adjustment (see “10.3.1 Basic settings”, step 3).

→ Check that the seal is correctly positioned in the transparent cap

/ body casing (see “Fig. 33”).

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To comply with degree of protection IP65 / IP67, screw in the

transparent cap / body casing all the way.

→ Close the transparent cap (auxiliary tool for installing the cover:

6740779)).

Seal

body casing

Body casing

Type 8686

Fig. 33: Position of the seal in the body casing

9) The auxiliary tool for installing the cover (674077) is available through

your Bürkert sales office.

English

Type 8685 / 8686

Page 39

39

Safety positions

11 SAFETY POSITIONS

Safety positions after failure of the electrical or pneumatic auxiliary

power:

Actuator

type

Designation

Safety positions after failure

of the auxiliary power

electrical pneumatic

up

down

single-acting

Control

function A

down down

up

down

single-acting

Control

function B

up up

Tab. 15: Safety positions

12 MAINTENANCE

12.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper maintenance.

▶ Maintenance may only be carried out by authorized technicians

with the appropriate tools.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

English

Type 8685 / 8686

Page 40

40

Maintenance

12.2 Service at the air intake filter

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

To protect the internal pilot valves and the actuator, the control air is

filtered.

The direction of flow of the air intake filter in installed state is from

the inside to the outside through the filter material.

Air intake filter

Quick connector

O-ring

Fig. 34: Service at the air intake filter

Procedure:

→ Unlock the quick connector by pressing the holding element and

pulling out the air intake filter (if necessary, use a suitable tool in

between the recesses in the head of the filter).

→ Clean the filter or, if necessary, replace the filter.

→ Check inner O-ring and, if required, clean.

→ Insert the air intake filter all the way into the quick connector.

DANGER!

Risk of injury due to improper installation.

▶ Ensure that the air intake filter is installed correctly.

→ Check that the air intake filter is secure.

English

Type 8685 / 8686

Page 41

41

Malfunctions

13 MALFUNCTIONS

Malfunction Cause and remedial action

End position is

not detected

No or inadequate supply voltage

→ Check the electrical connection and supply

voltage

Wrong size of switch spindles from the adapter

set

→ Replace switch spindles

Wrong spindle lead-through selected for

spindle installation

→ Push the switch spindle through the

matching spindle lead-through

Wrong actuator size selected with the DIP

switches

→ Select the matching actuator size

Cap of the switch spindle moved by force

during assembly

→ Remove the feedback head / control head

→ Pull the cap towards the end of the switch

spindle until you can see one groove

→ Install the feedback head / control head

→ Perform a reference movement for spindle

adjustment

Malfunction Cause and remedial action

Faulty detection

of end position

Wrong actuator size selected with the DIP

switches

→ Select the matching actuator size

More than one actuator size selected with the

DIP switches

→ Select the matching actuator size

Feedback head / control head not mounted in

the correct position

→ Mount the feedback head / control head in

the correct position (see “Fig. 9”)

Incorrect

display of

actuator status

LED

Color selection switch not correctly selected

→ Select the color assignment correctly (both

up or both down, see section “10.3.1 Basic

settings” “Fig. 29”)

Actuator does

not switch

No or inadequate supply voltage

→ Check the electrical connection and supply

voltage

Pressure supply too low

→ Check the control pressure

Faulty hose system

→ Check the pneumatic connections

English

Type 8685 / 8686

Page 42

42

Malfunctions

Malfunction Cause and remedial action

AS-Interface

bus status

LEDs off

No or inadequate supply voltage

→ Check contact of ribbon cable terminal with

AS-Interface line

→ Ensure supply voltage is present on the AS-

Interface line

Tab. 16: Malfunctions

14 SHUTDOWN

14.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper removal.

▶ Removal may be carried out by authorized technicians only and

with the appropriate tools.

14.2 Disassembly

Procedure:

→ Turn off the pressure and vent the lines.

→ Switch off the power supply.

1. Pneumatic connection (control head Type 8686 only)

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

→ Loosen pneumatic connection.

→ Release the pneumatic connection to the actuator.

3. Mechanical connections

→ Release the fastening screws.

→ Pull the feedback head / control head up and out.

English

Type 8685 / 8686

Page 43

43

Malfunctions

2. Electrical connection

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

Device with circular plug-in connector:

→ Release the circular plug.

Device with cable gland:

→ Release the cable gland.

→ Loosen the wires from the screw terminals.

Control head

Type 8686

Electrical

connection

Pneumatic

connection

Fastening

screw (2x)

Pneumatic connection

with actuator

Actuator

Feedback head

Type 8685

Fastening screw (2x)

Actuator

Fig. 35: Disassembly

English

Type 8685 / 8686

Page 44

44

Accessories

16 TRANSPORT, STORAGE,

PACKAGING

NOTE!

Transport damage.

Inadequately protected equipment may be damaged during

transportation.

▶ During transportation protect the device against moisture and dirt

in shock-resistant packaging.

▶ Prevent the temperature from exceeding or dropping below the

permitted storage temperature.

▶ Protect the electrical interfaces of the coil and the pneumatic

connections from damage by placing protective caps on them.

Incorrect storage may damage the device.

▶ Store the device in a dry and dust-free location.

▶ Storage temperature -20 – 65 °C.

Damage to the environment caused by device components

contaminated with media.

▶ Ensure the device and packaging are disposed of in an environ-

mentally sound manner.

▶ Observe applicable regulations relating to refuse disposal and

the environment.

15 ACCESSORIES

Designation Order no.

Connecting cable M12 x 1, 8-pole 919061

Auxiliary tool for installing the transparent cap 674077

Tab. 17: Accessories

English

Type 8685 / 8686

Page 45

Page 46

www.burkert.com

Loading...

Loading...