Page 1

Type 8681

Control Head

Operating Instructions

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2010 - 2011 Bürkert Werke GmbH

Operating Instructions 1110/04_EN_00806150 / Original DE

Page 3

Control Head Type 8681

Control Head Type 8681

In h a l t

1. OPERATING INSTRUCTIONS .......................................................................................................................................................8

2. AUTHORIZED USE .............................................................................................................................................................................9

2.1. Export Restrictions ................................................................................................................................................................9

2.2. Predictable Misuse ................................................................................................................................................................9

3. BASIC SAFETY INSTRUCTIONS .............................................................................................................................................10

4. GENERAL INFORMATION ...........................................................................................................................................................12

4.1. Contact address ..................................................................................................................................................................12

4.2. Warranty ...................................................................................................................................................................................12

4.3. Information on the Internet ............................................................................................................................................12

5. SYSTEM DESCRIPTION ...............................................................................................................................................................13

5.1. Intended Application Area ..............................................................................................................................................13

5.2. General Description ...........................................................................................................................................................13

5.3. Special Features ..................................................................................................................................................................13

5.4. Functions / Options / Designs ....................................................................................................................................14

5.4.1. Structure of the Control Head .....................................................................................................................14

5.4.2. Fluid diagram ........................................................................................................................................................15

5.4.3. Number of solenoid valves............................................................................................................................16

5.4.4. Pneumatic Interfaces........................................................................................................................................16

5.4.5. Manual Control .....................................................................................................................................................16

5.4.6. Position Measuring System ..........................................................................................................................17

5.4.7. Other Features ....................................................................................................................................................17

6. TECHNICAL DATA .............................................................................................................................................................................18

6.1. Operating Conditions ........................................................................................................................................................18

6.2. Conformity with the following Standards ..............................................................................................................18

6.3. Mechanical data ...................................................................................................................................................................19

6.4. Pneumatic Data ...................................................................................................................................................................20

6.5. Position Measuring System Data ...............................................................................................................................21

6.6. Factory Settings in the Firmware ...............................................................................................................................22

english

3

Page 4

4

english

Control Head Type 8681

7. INSTALLATION ...................................................................................................................................................................................23

7.1. Safety instructions .............................................................................................................................................................23

7.2. Assembly of the Control Head .....................................................................................................................................23

7.2.1. Hub flange ..............................................................................................................................................................23

7.2.2. Assembly Sequence on the Example of a Double-seated Valve .............................................24

7.2.3. Realignment of the Control Head ..............................................................................................................25

7.2.4. Assembly of the Pneumatic and Electrical Connections ..............................................................25

7.2.5. Recommended Auxiliary Materials ...........................................................................................................25

8. OPENING AND CLOSING THE HOUSING.........................................................................................................................26

8.1. Safety instructions .............................................................................................................................................................26

8.2. Opening and Closing the Housing ............................................................................................................................26

8.2.1. Opening the Housing .......................................................................................................................................26

8.2.2. Closing the Housing ......................................................................................................................................... 27

9. PNEUMATIC INSTALLATION ......................................................................................................................................................28

9.1. Safety instructions .............................................................................................................................................................28

9.2. Pneumatic Connection of the Control Head ........................................................................................................28

9.3. Flow Restriction Function of the Solenoid Valves .............................................................................................29

10. 24 V DC - DESIGN ...........................................................................................................................................................................31

10.1. Electrical connection options ......................................................................................................................................31

10.2. Electrical Data ......................................................................................................................................................................31

10.3. Design Aid ..............................................................................................................................................................................33

10.4. Safety instructions .............................................................................................................................................................34

10.5. Electrical Installation / Start-up ..................................................................................................................................34

10.5.1. Cable Gland with Screw-type Terminals ................................................................................................34

10.5.2. Multi-pole Connection ......................................................................................................................................37

11. AS INTERFACE - DESIGN ...........................................................................................................................................................38

11.1. Definition .................................................................................................................................................................................38

11.2. Electrical Connection Options for AS Interface ................................................................................................39

11.3. Number of Connectable Control Heads and Maximum Length of the Bus Line .............................. 39

11.4. Electrical Data ......................................................................................................................................................................40

Page 5

5

english

Control Head Type 8681

11.5. Design Aid ..............................................................................................................................................................................42

11.6. Safety instructions .............................................................................................................................................................43

11.7. Electrical installation AS Interface ............................................................................................................................44

11.8. Programming Data .............................................................................................................................................................46

12. DEVICENET - DESIGN ..................................................................................................................................................................47

12.1. Definition .................................................................................................................................................................................47

12.2. Electrical connection option ........................................................................................................................................47

12.3. DeviceNet specification ...................................................................................................................................................47

12.3.1. Total line length and maximum line length according to DeviceNet specification .........48

12.3.2. Drop Line Length.................................................................................................................................................48

12.4. Electrical Data ......................................................................................................................................................................49

12.5. Safety Position if the Bus Fails ...................................................................................................................................49

12.6. Design Aid ..............................................................................................................................................................................50

12.7. Safety instructions .............................................................................................................................................................51

12.8. Electrical Installation - DeviceNet ..............................................................................................................................51

12.9. Network Topology of a DeviceNet System ............................................................................................................53

12.10. Configuring the DeviceNet address / baud rate ................................................................................................53

12.10.1. Settings of the DeviceNet address .......................................................................................................54

12.10.2. Setting the baud rate....................................................................................................................................55

12.11. Configuration of Process Data ....................................................................................................................................55

12.11.1. Static Input Assemblies ..............................................................................................................................55

12.11.2. Static Output Assembly ..............................................................................................................................56

12.12. Configuration of the device ...........................................................................................................................................56

12.12.1. Configuration of the Safety Position of Solenoid Valves if Bus Error ................................56

12.12.2. Configuration example ...............................................................................................................................57

12.13. Display of the Status LEDs in the event of a bus error ..................................................................................58

12.13.1. Status of the device status LED "Modules" .....................................................................................58

12.13.2. State of bus status LED "Network" .......................................................................................................59

13. 120 V AC - DESIGN .......................................................................................................................................................................60

13.1. Electrical connection options ......................................................................................................................................60

13.2. Electrical Data ......................................................................................................................................................................60

Page 6

6

english

Control Head Type 8681

13.3. Design Aid ..............................................................................................................................................................................62

13.4. Safety instructions .............................................................................................................................................................63

13.5. Electrical Installation / Start-up ..................................................................................................................................63

14. CONNECTION OF AN EXTERNAL INITIATOR...................................................................................................................66

15. POSITION MEASURING SYSTEM ..........................................................................................................................................67

15.1. Setting the Position Measuring System (Teach-In) ..........................................................................................67

15.2. Teach-In Functions .............................................................................................................................................................68

15.2.1. Teach-In Functions and Teach-In Reset .................................................................................................68

15.2.2. Autotune functions ............................................................................................................................................69

15.2.3. Autotune sequence ..........................................................................................................................................69

16. LED - COLOR ASSIGNMENTS .................................................................................................................................................72

16.1. Setting the Color Combinations .................................................................................................................................73

16.2. Blinking Pattern & Fault Signaling ............................................................................................................................. 73

16.3. Signal Priorities ....................................................................................................................................................................74

17. SERVICE MODE / MANUAL CONTROL ..............................................................................................................................75

17.1. Magnetic Manual Control ................................................................................................................................................75

17.2. Mechanical Manual Control ...........................................................................................................................................76

18. MAINTENANCE, TROUBLESHOOTING ...............................................................................................................................77

18.1. Safety instructions .............................................................................................................................................................77

18.2. Safety Positions ...................................................................................................................................................................78

18.3. Maintenance ..........................................................................................................................................................................79

18.4. Cleaning ...................................................................................................................................................................................79

18.5. Malfunctions ..........................................................................................................................................................................79

19. REPLACEMENT OF COMPONENTS AND MODULES .................................................................................................81

19.1. Safety instructions .............................................................................................................................................................81

19.2. Changing the Electronics Module ..............................................................................................................................82

19.3. Changing the Valves ..........................................................................................................................................................83

19.4. Changing the Position Measuring System ............................................................................................................84

Page 7

7

english

Control Head Type 8681

20. SPARE PARTS ....................................................................................................................................................................................87

21. SHUTDOWN ........................................................................................................................................................................................88

21.1. Safety instructions .............................................................................................................................................................88

21.2. Dismantling the Control Head Type 8681 ..............................................................................................................88

22. PACKAGING AND TRANSPORT ...............................................................................................................................................89

23. STORAGE ..............................................................................................................................................................................................89

24. DISPOSAL ............................................................................................................................................................................................89

Page 8

8

Operating Instructions

english

Control Head Type 8681

OPERATING INSTRUCTIONS1.

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user, and make these instructions available to every new owner of the device.

WARNING!

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous situations.

The operating instructions must be read and understood.•

Symbols:

DANGER!

Warns of an immediate danger!

Failure to observe the warning will result in a fatal or serious injury.•

WARNING!

Warns of a potentially dangerous situation!

Failure to observe the warning may result in serious injuries or death. •

CAUTION!

Warns of a possible danger!

Failure to observe this warning may result in a moderate or minor injury. •

NOTE!

Warns of damage to property!

Failure to observe the warning may result in damage to the device or the equipment. •

indicates important additional information, tips and recommendations which are important for your safety

and the flawless functioning of the device.

refers to information in these operating instructions or in other documentation.

designates a procedure which you must carry out.

→

Page 9

9

Authorized use

english

Control Head Type 8681

AUTHORIZED USE2.

Non-authorized use of the Control Head Type 8681 may be a hazard to people, nearby equipment and

the environment.

The Control Head has been designed for use as actuation of pneumatically operated process valves and / or •

for recording the switching states of these.

Use according to the authorized data, operating conditions and conditions of use specified in the contract •

documents and operating instructions. These are described in the chapter 6. Technical Data.

In view of the large number of options for use it might be necessary to test prior to installation whether the •

control head is suitable for the concrete use.

If you have any questions, please contact your Bürkert Service Center.

The device may be used only in conjunction with third-party devices and components recommended and •

authorized by Bürkert.

Any unauthorized reconstructions and changes to the control head are prohibited for safety reasons.•

Correct transportation, correct storage and installation and careful use and maintenance are essential for •

reliable and faultless operation.

For connecting the control head, use line installations that do not cause any mechanical stresses.•

Use the device only as intended.•

Export Restrictions2.1.

If exporting the system/device, observe any existing restrictions.

Predictable Misuse2.2.

Do not supply the medium connectors of the system with aggressive or flammable media.•

Do not supply the medium connectors with any liquids.•

Do not physically stress the housing (e.g. by placing objects on it or standing on it, or using it as attachment point •

for transport work).

Do not make any external modifications to the device housings. Do not paint the housing parts or screws.•

In the explosion-risk area, only wipe the control head with a damp or anti-static cloth to avoid electro-static •

charges!

Page 10

10

Basic Safety Instructions

english

Control Head Type 8681

BASIC SAFETY INSTRUCTIONS3.

These safety instructions do not make allowance for any

contingencies and events which may arise during the installation, operation and maintenance of the devices.•

local safety regulations - the operator is responsible for observing these regulations, also with reference to the •

installation personnel.

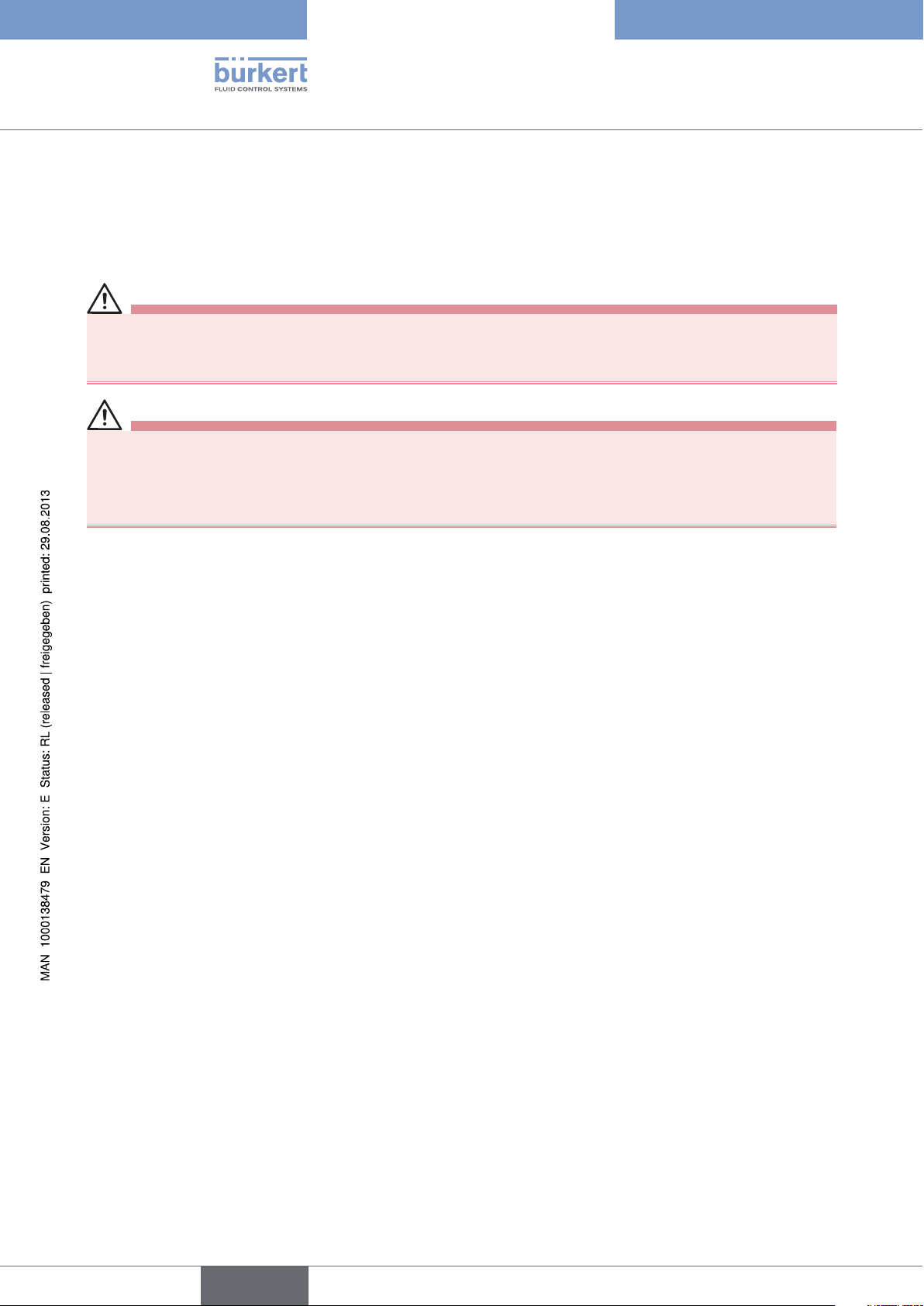

DANGER!

Danger – high pressure!

Before loosening pneumatic lines and valves, turn off the pressure and vent the lines.•

Danger of explosion in explosive atmosphere (only in the event of a fault as zone 2)!

Opening the hood or the housing in an explosive atmosphere is only allowed in the isolated state!•

WARNING!

Risk of electric shock!

Before reaching into the system (except for the Teach-In procedure in a non-explosive atmosphere) switch off •

the power supply and secure it to prevent restarting!

Observe applicable accident prevention and safety regulations for electrical equipment!•

General Hazardous Situations.

To prevent injuries, ensure that:

the system cannot be activated unintentionally.•

Installation and maintenance work, as well as operator control actions may be carried out by authorized, quali-•

fied technicians only and with the appropriate tools.

After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a defined •

or controlled manner.

The device may be installed and operated only when in perfect condition and in consideration of the operating •

instructions.

The general rules of technology apply to application planning and operation of the device. •

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components, which react sensitively to electrostatic discharge (ESD). Contact •

with electrostatically charged persons or objects may be hazardous to these components. In the worst case

scenario, they will be destroyed immediately or will fail after start-up.

Observe the requirements in accordance with DIN EN 61340-5-1 and 5-2 to minimize or avoid the possibility •

of damage caused by sudden electrostatic discharge!

Also, ensure that you do not touch electronic components when the power supply voltage is present! •

Page 11

11

Basic Safety Instructions

english

Control Head Type 8681

NOTE!

Connection of the Control Head

Do not connect any mechanically rigid connection parts, in particular those with long lever arms, as such connections could generate torques that might damage the control head.

Operation of the Control Head in Explosive Atmosphere

The housing may not be opened when devices are charged! It should be secured against unintentional opening •

using plastic self-cutting screws or seal (or comparable)!

Layers of dust on the housing may not exceed 5 mm! Lint, conductive and non-conductive dust particles are •

allowed.

The inside of the housing may not be dirty!

Activating the DIP switches on the circuit board, using the service plug and the Teach buttons is • not allowed in

explosive atmosphere!

Cleaning

In the explosion-risk area, only wipe the control head with a damp or anti-static cloth to avoid electro-static •

charges.

Only use compatible cleaning agents for cleaning the securely closed control head and always rinse thoroughly •

with clean water.

For further information refer to the corresponding chapters of these operating instructions!

Control Head Type 8681 was developed with due consideration given to accepted safety rules and is stateof-the-art. Nevertheless, dangerous situations may occur.

Failure to observe this operating manual and its operating instructions as well as unauthorized tampering

with the device release us from any liability and also invalidate the warranty covering the devices and

accessories!

Page 12

12

Basic Safety Instructions

GENERAL INFORMATION4.

english

Control Head Type 8681

Contact address4.1.

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Straße 13-17

D-74653 Ingelfingen

Tel. : +49 7940 10 91 111

Fax: +49 7940 10 91 448

E-mail: info@de.buerkert.com

Homepage: www.buerkert.com, www.buerkert.de

Warranty4.2.

The warranty is only valid if the control head is used as intended in accordance with the specified application

conditions.

Information on the Internet4.3.

The operating instructions and data sheets for control head type 8681 can be found on the Internet at:

www.buerkert.com

Page 13

13

System Description

english

Control Head Type 8681

SYSTEM DESCRIPTION5.

Intended Application Area5.1.

The Control Head Type 8681 has been designed for use as actuation of pneumatically operated process valves

and / or for recording the switching states of these.

General Description5.2.

The Control Head Type 8681 is used for actuating pneumatically operated process valves.

For process valve actuation, the control head can be equipped with up to three solenoid valves.

For the recording and feedback of the process valve switching positions to a higher-level control, the control head

has been equipped with a contactless position measuring system, which works with three discrete, adjustable

feedback signals (Teach-In Function).

The control head and the process valve are interconnected by an adapter. This produces an integrated, compact

and decentralized system of feedback, actuation and valve function. The following advantages over centralized

solutions working with valve clusters are achieved:

low installation expenditure•

easy start-up•

higher application-specific flexibility•

shorter switching times and less air consumption due to shorter distances between the pilot valve and the •

process valve.

Various pneumatic and electrical connection variants are available.

Special Features5.3.

Special features of the Control Head Type 8681 include:

easy-to-clean design with IP65 / IP67 protection •

high cleaning agent compatibility•

use of high-quality materials•

modular structure•

restrictable R- and P-connections for all pilot valves (solenoid valves)•

integrated pressure-relief valve in the inside of the housing for discharging leakage air with connection into the •

common exhaust air connection

collected exhaust air of all valve locations into one common exhaust air connection (by default equipped with a •

silencer)

if equipped with several working connections: one integrated non-return valve per connection in the exhaust air •

duct as protection against faulty switching of the process valves due to return pressure

central, super-bright optical display showing the process valve switching positions and design-specific addi-•

tional information in three signal colors

Page 14

14

System Description

english

Control Head Type 8681

short mechanical and pneumatic installation times.•

For increased safety requirements (e.g. in the explosion-risk area) a seal or a hood safeguard using plastic self-•

cutting screws (3 mm diameter, approx. 10 mm length; e.g. Ejot PT screws K 30 x 10) are required.

conform to the ATEX Directive 94/9/EC (Dust ATEX category 3D and Gas ATEX category 3G - see chapter •

6.2. )

Functions / Options / Designs5.4.

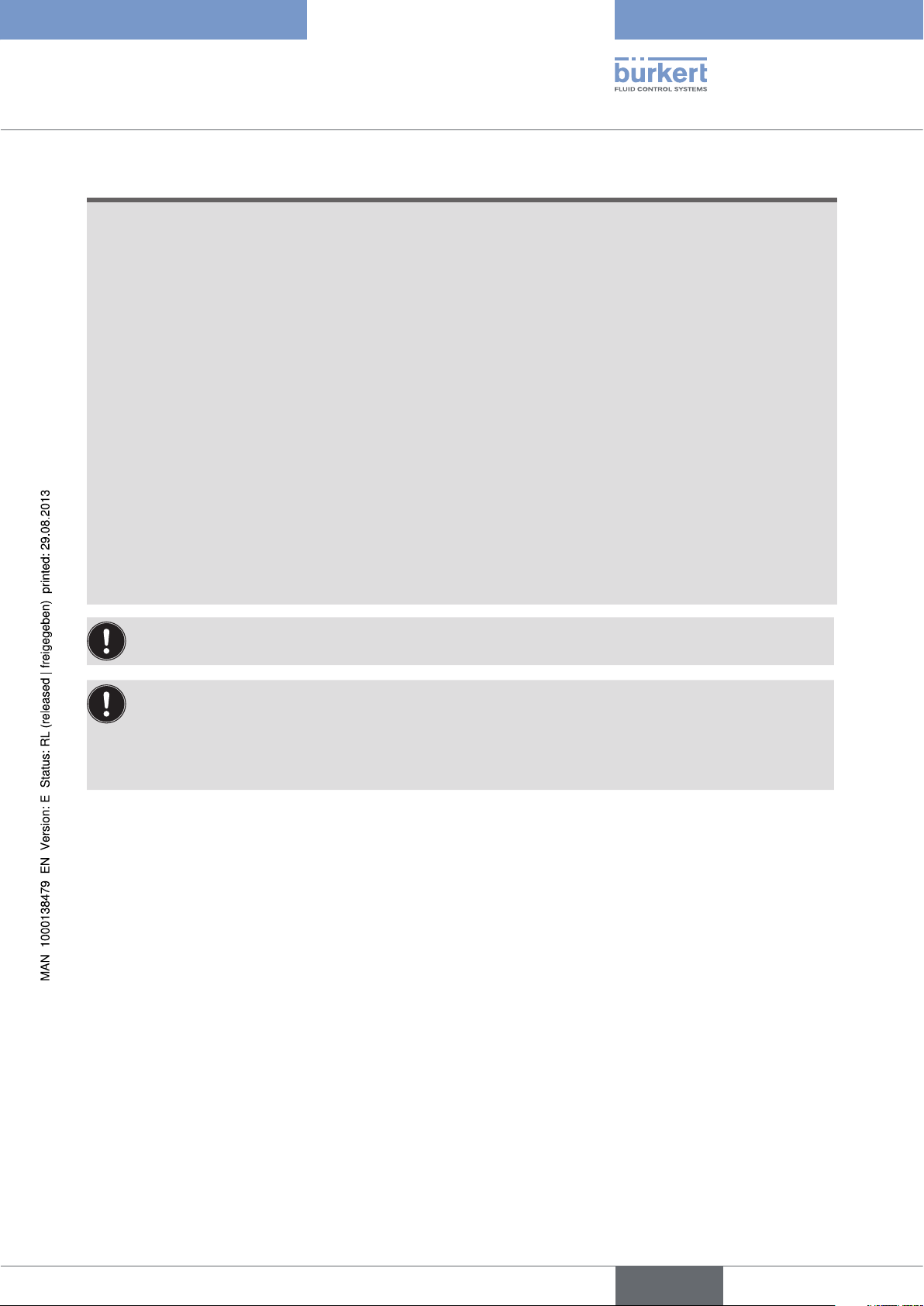

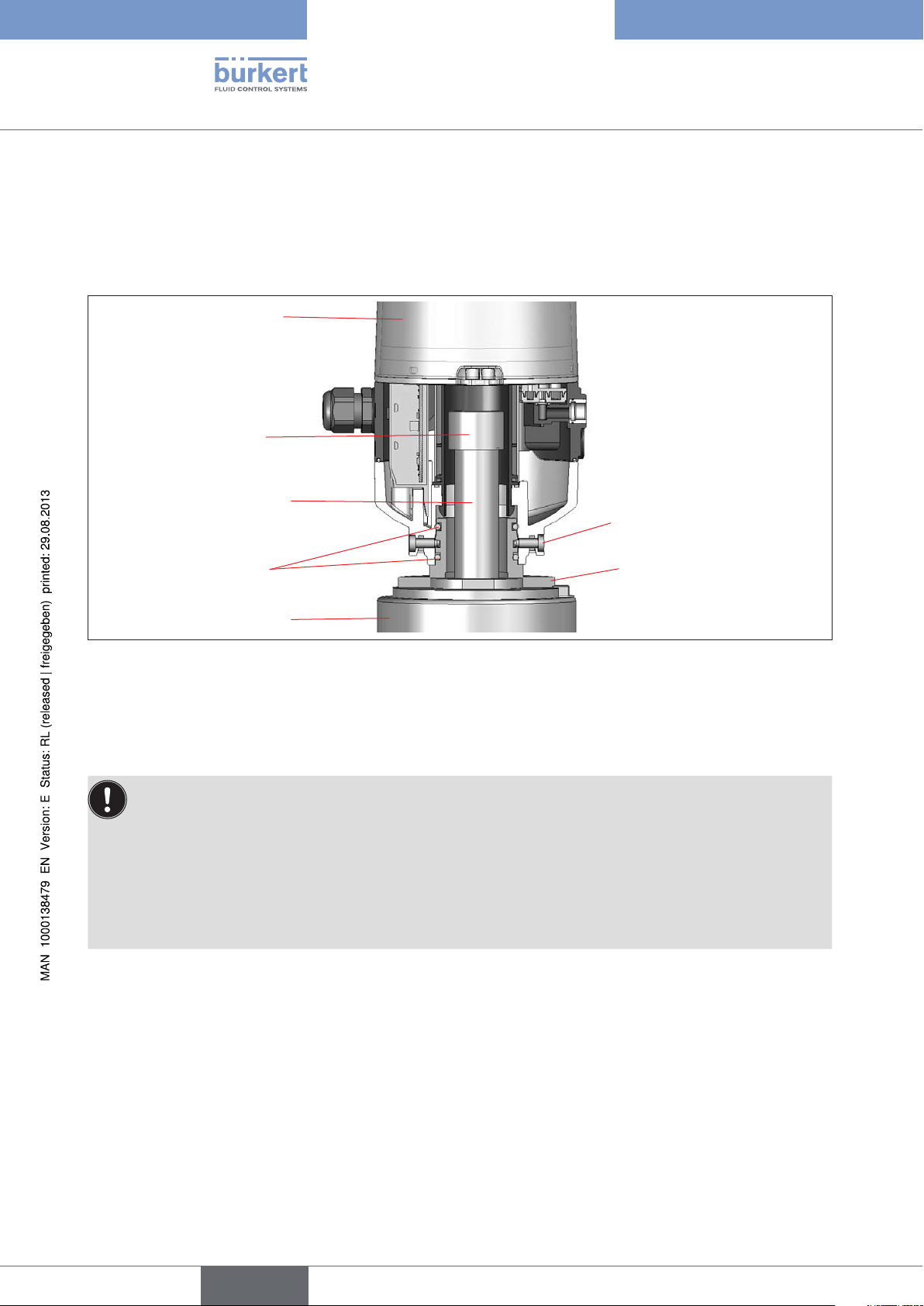

Structure of the Control Head5.4.1.

Position measuring system

with LED's in three colors

Electronics module with

connection terminals,

service interface and

Teach-In buttons

(back side)

Solenoid valve 1

Solenoid valve 2

Solenoid valve 3

Cable gland

(back side)

Sealing lug

(on lower housing part)

2 locking screws (shoulder

screws M5); no sealing

function, merely as protection

against pulling off from the

hub flange

Mechanical manual

control (red lever)

Exhaust air connection (3/R)

Silencer in the exhaust air

connection (3/R), not shown

Flow restriction screw(s)

for P and R

(2 per solenoid valve)

Locking groove (3x)

Supply pressure

connection(1/P)

Solenoid valve 1 (2/A1)

Solenoid valve 2 (2/A2)

Solenoid valve 3 (2/A3)

Working connections

(2/A1 - 3)

Fig. 1: Structure of Control Head Type 8681

Page 15

15

System Description

english

Control Head Type 8681

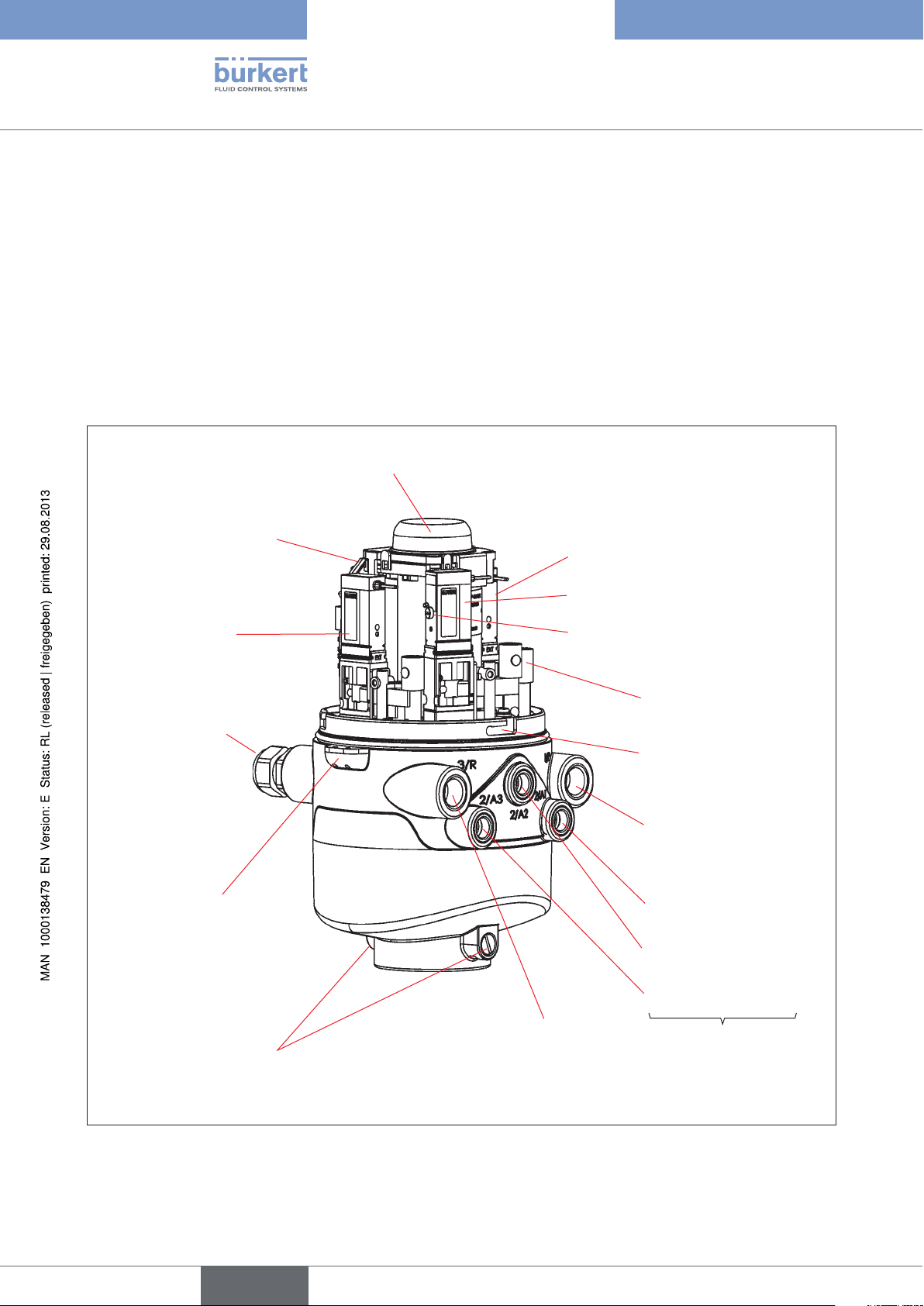

5.4.2. Fluid diagram

Control Head Type 8681 - Fluid diagram (with restriction capability for each solenoid valve):

Model with three Type 6524 solenoid valves,

e.g. for double-seated valve

Fluid diagram (model: 3 solenoid valves) Fig. 2:

The functions and designs of Control Head Type 8681 are described in the following chapters.

Page 16

16

System Description

english

Control Head Type 8681

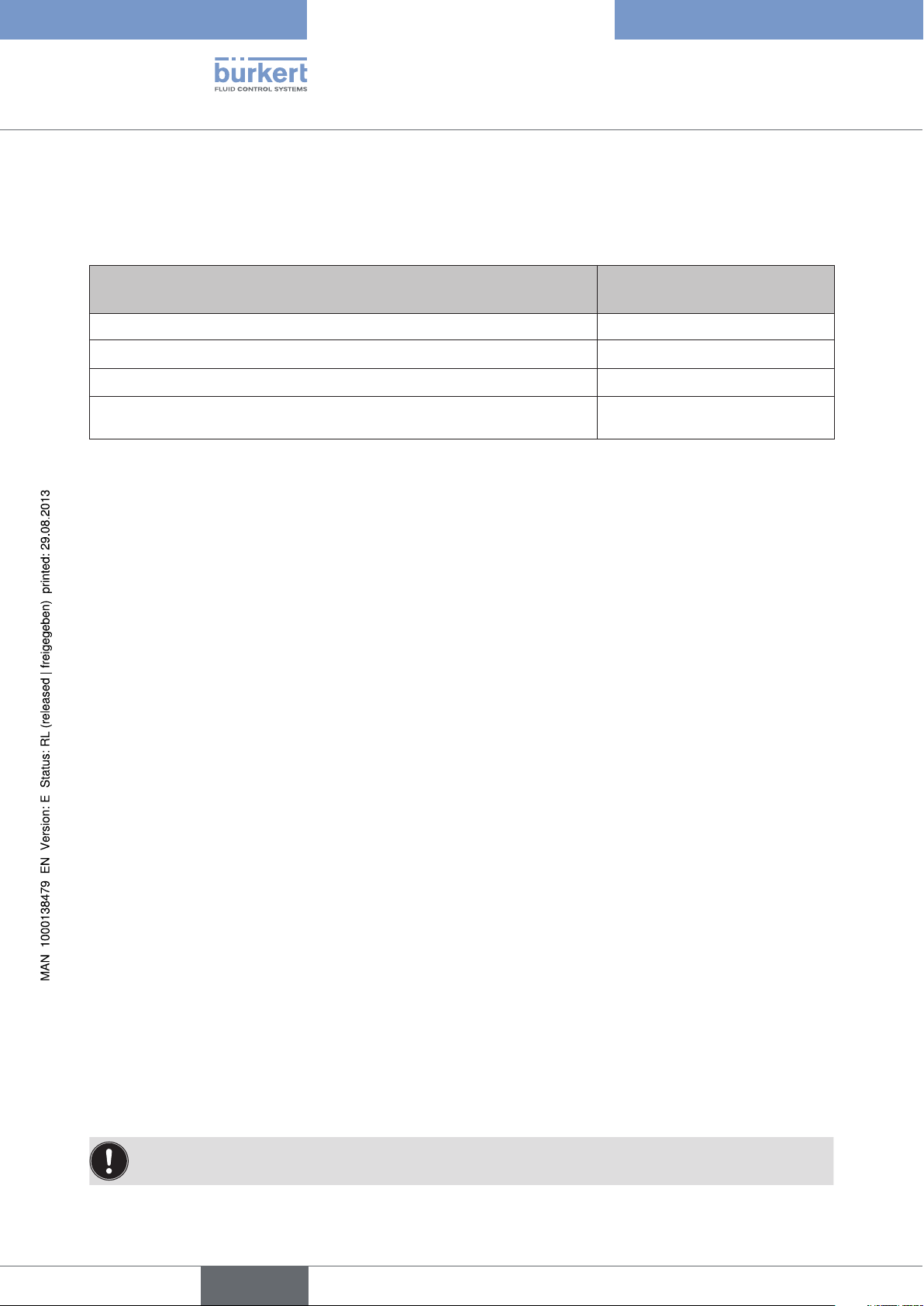

Number of solenoid valves5.4.3.

The control head for process valves has been designed for single-acting and double-acting valve actuators as

well as for double-seated and multi-position valves.

Type of use

Repeater 0

Control head for single-acting actuators 1

Control head for double-acting actuators ** 2

Control head for double-seated valves with integrated aeration of both

valve seats

* WWC = circuit function C = 3/2-way valve; closed in rest position, output A unloaded

** both drive chambers currentless deaerated

Number of solenoid valves

(3/2-Way Solenoid Valve WWC*)

Pneumatic Interfaces5.4.4.

Intake & exhaust air connections: G 1/4 •

Working connections: G 1/8

Integrated non-return valves in the solenoid valves' exhaust air duct •

Actuation of Connection 2/A1 (Solenoid Valve 1; normally the main stroke of the process valve) using the mag-•

netic manual control that is externally accessible.

Special silencers with a high flow-rate capacity to connection 3/R have already been mounted.•

The interior of the housing is protected against excessive overpressure, for example due to leakages, by a •

pressure-relief valve with output into the joint exhaust air connection 3/R.

3

Manual Control5.4.5.

Standardly, the control head provides the following:

a magnetic manual control that is easily accessible from the outside on the basis of encoded magnetic fields •

for Solenoid Valve 1 (Connection 2/A1), as well as

a mechanical manual control accessible when the hood is open on each equipped solenoid valve.•

The magnetic manual control has the following advantages:

the control head does not need to be opened•

a simple activation tool for opening & closing Solenoid Valve 1 (main stroke) - •

helpful for maintenance on the process valve

LED-display for the Activated Manual Control status, meaning service mode •

(see chapter 16. LED - Color Assignments and 17. Service Mode / Manual Control )

For a detailed description of the manual control, see chapter 17. Service Mode / Manual Control .

Page 17

17

System Description

english

Control Head Type 8681

Position Measuring System5.4.6.

The switching positions of the process valves are reported to the higher-level control by feedback signals from

the contactless position measuring system. Connection to the control head is done by means of a simple adaptation to the process valve's piston.

The recordable stroke range is between 0 and 80 mm.

Three binary feedback signals are evaluated:

- Position 1 (discrete S1OUT signal)

- Position 2 (discrete S2OUT signal)

- Position 3 (discrete S3OUT signal).

The 24 V DC design is additionally available in the order variant "Analog":

Order variant: - Position 1 (discrete S1OUT signal)

- Position 2 (discrete S2OUT signal)

- Position 3 (analog (4...20 mA) S3OUT signal).

Three Teach-In buttons have been provided for comparison with the actual stroke range (see chapter 15. Position

Measuring System). The switching positions for the position measuring system can be determined with these

buttons or by means of the service interface (on the electronics module).

An discrete, external feedback signal (standard proximity switch) can also be processed (S4IN, S4OUT).

If an explosive atmosphere is present the housing may not be opened when voltage is present.

For a detailed description of the electrical installation, see chapter 10. 24 V DC - Design or

chapter 11. AS Interface - Design.

For the setting of the Teach-In buttons, see chapter 15. Position Measuring System.

Other Features 5.4.7.

Central optical position indicator for showing the process valve switching positions: •

Positions and status information can be indicated by means of three signal colors.

The assignment of the signal colors and the blinking pattern, which indicates the type of fault, are described in

chapter 16. LED - Color Assignments.

Simple adaptation of the control head (for the position measuring system) to the process valve piston rod•

Simple adjustment of the position measuring system by three Teach-In buttons on the electronics module•

The capability of restricting the pilot valve (solenoid valve) for the individual setting of the expansion and •

retraction rates of the process valve and the individual setting of the flow-rate of the working connections

More energy efficient solenoid valve control by lowering the holding current during long-term operation•

Page 18

18

Technical Data

english

Control Head Type 8681

6. TECHNICAL DATA

Operating Conditions6.1.

DANGER!

Danger of explosion in explosive atmosphere (only in the event of a fault as zone 2)!

Do not expose the device to any mechanical or thermal loads that will exceed the limits described in the oper-•

ating instructions.

WARNING!

Risk of injury from overheating of the control head.

Heating above the permitted temperature range can endanger people, the device and the environment.

Do not expose the device to any mechanical or thermal loads that will exceed the limits described in the oper-•

ating instructions.

Ambient temperature: Standard version: -10 ... +55 °C

Explosive atmosphere (zone2): +5 ... +55 °C

Protection class: Standard version:

IP65 / IP67 according to EN 60529

(only if cables, plugs and sockets have been connected correctly, the VA hood

has been closed correctly and the adaptation to the process valve was done

correctly)

IP69K according to IEC 40050-9

(Housing seal with connected exhaust air line instead of silencer and ideally

closed cable glands confirmed through IP69K Standard testing)

Version for use in explosive atmosphere (zone 2):

IP64 according to EN 60529 and requirements to EN 60079-0: 2009

(only if cables, plugs and sockets have been connected correctly, the VA hood

has been closed correctly and the adaptation to the process valve was done

correctly)

6.2. Conformity with the following Standards

According to EC Declaration of Conformity (CE mark)

EMC Directive 2004/108/EC (previously: 89/336/EMC)

(only if cables, plugs and sockets have been connected correctly)

A Declaration of Conformity for the specific device can be requested from Bürkert.

ATEX Directive 94/9/EC

Ignition protection type:

Ex tc IIIC T135°C

Gas ATEX category 3G Ex nA IIC T4 or

Ex nAc IIC T4

Dust ATEX category 3D Ex tD A22 T135°C or

Page 19

19

Technical Data

english

Control Head Type 8681

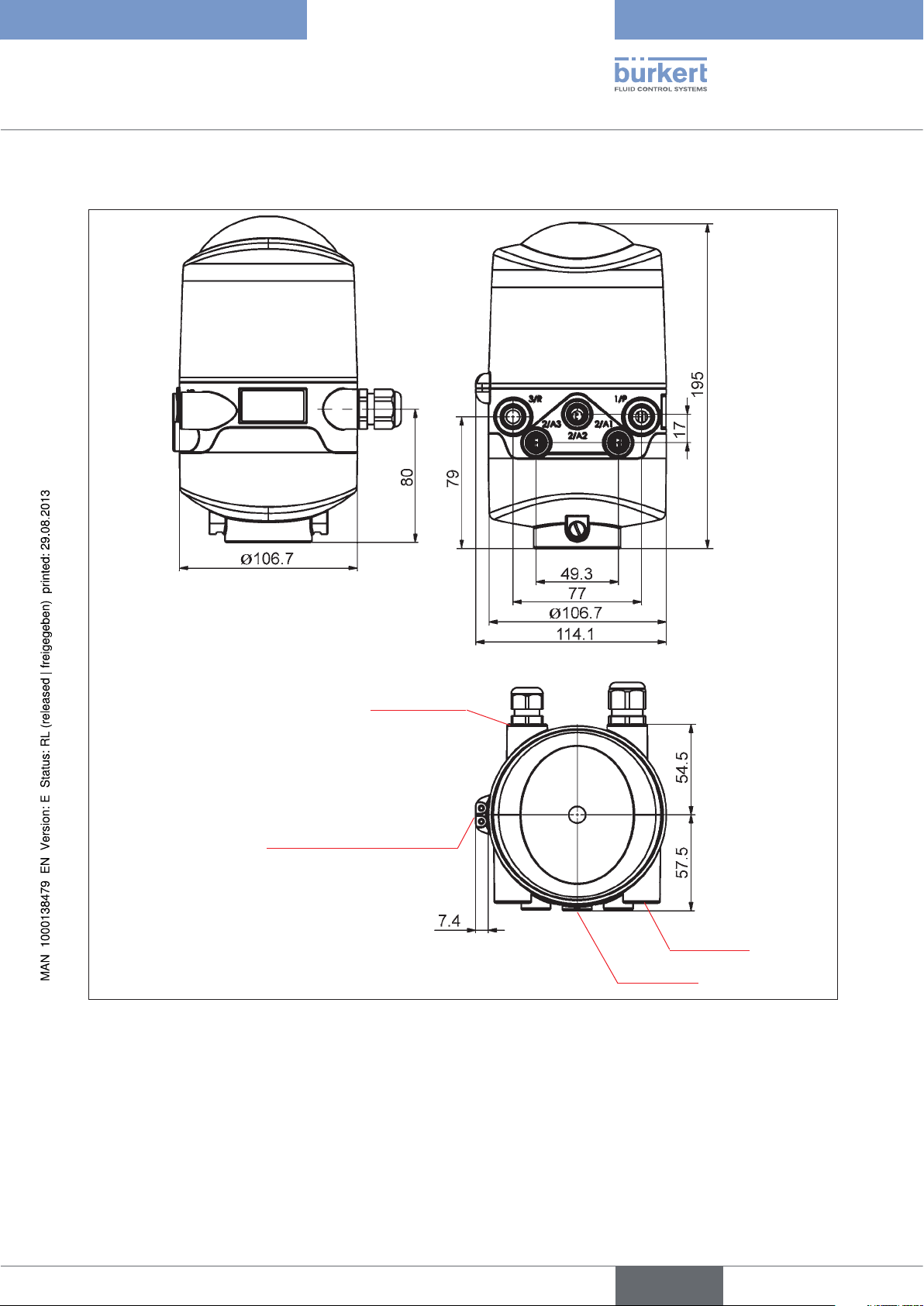

Mechanical data6.3.

M16x1.5 (2x)

Cover safeguard:

- Seal max Ø2

and / or

- plastic self-cutting

screw 3.0x10

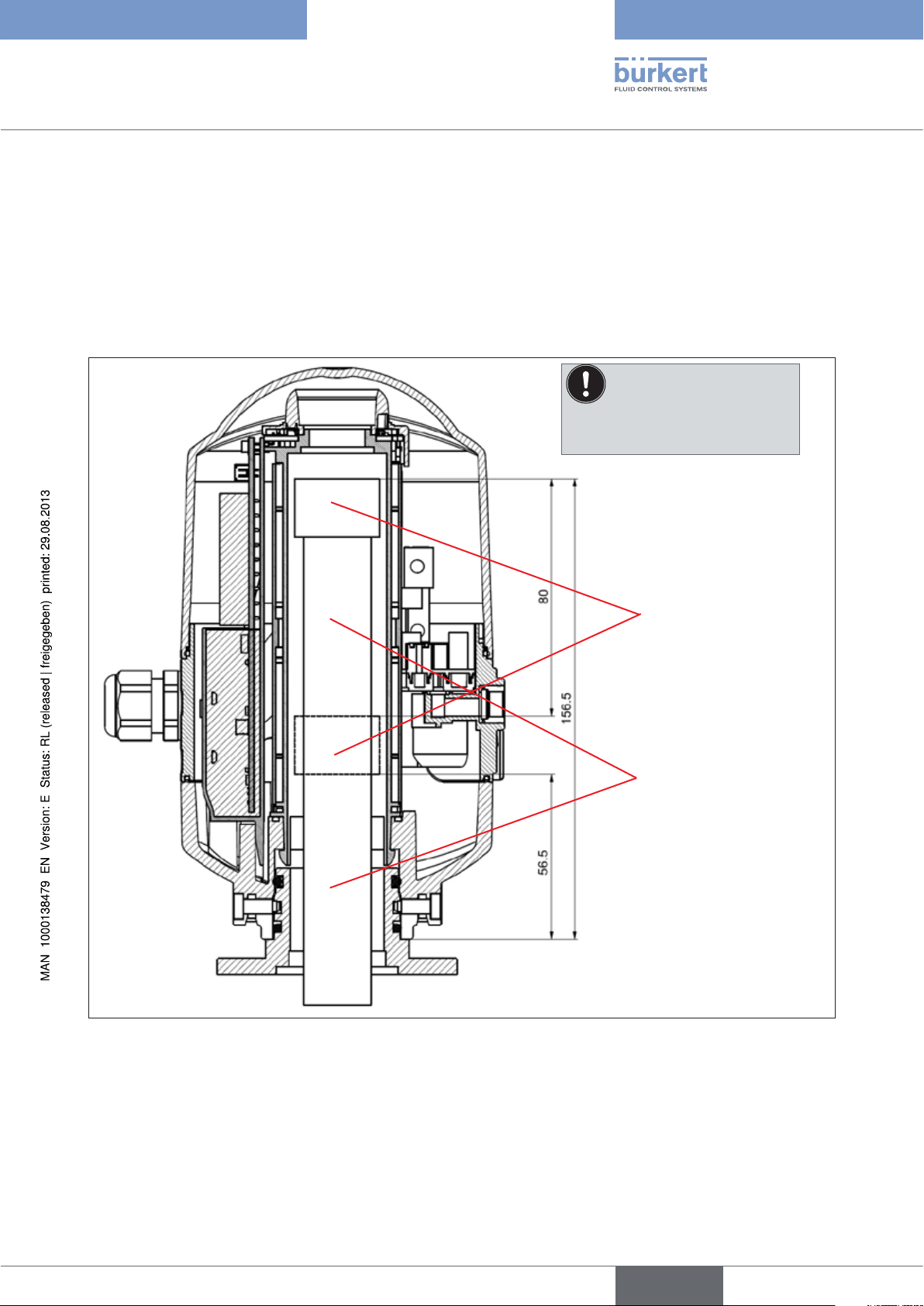

Dimensional drawingFig. 3:

Weight: ca. 0.8 kg

Housing material: outside: PA, PP, PPO, VA

inside: ABS, PA, PMMA

G1/4 (2x)

G1/8 (3x)

Sealing material: outside: CR, EPDM

inside: EPDM, FKM, NBR

Page 20

20

Technical Data

6.4. Pneumatic Data

english

Control Head Type 8681

Control medium: oil-free and dry air, neutral gases

Quality classes in accordance with DIN ISO 8573-1

(5 µm filter recommended)

Dust content Quality class 5: max. particle size 40 µm,

max. particle density 10 mg/m

3

Water content Quality class 3: max. pressure dew point -20 °C or min. 10 °C below

the lowest operating temperature

Oil content Quality class 5: max. 25 mg/m

3

Temperature range

of compressed air: -10 - +50 °C

Pressure range: 2.5 to 8 bar

Air rate solenoid valve: 110 I

/min (for aeration and deaeration, ventilation)

N

(110 IN/min - supplied state

200 IN/min - maximum typical flow-rate)

(QNn value according to definition for pressure drop from 7 to 6 bar absolute

at +20 °C)

Connections: Intake and exhaust air connection G1/4

Working connections G1/8

The intake and exhaust air can be set separately for each solenoid valve using flow restriction screws, in order to

be able to affect the expansion and retraction rates of the process valve (see figure below).

Flow restriction screws

for:

Exhaust R

Intake P

Flow restriction screws of the solenoid valvesFig. 4:

Mechanical

manual control

Red lever:

left: 0

right: 1

When setting the retraction and expansion rates of the pneumatic actuator consider that constant

"primary pressure" is not present during deaeration!

Keep in mind that the working conditions in the process valve area on the side of the product

(flow types, pressure variations) may result in changes in the set aeration and deaeration times.

Page 21

21

Technical Data

english

Control Head Type 8681

6.5. Position Measuring System Data

Stroke range (measuring range): 0 ... 80 mm

Resolution: ≤ 0.1 mm

Total fault:

Material 1.4021 and a piston rod (Ø 22 mm, Material - see (*))

(Fault refers to the reproducibility of a taught position)

The illustration in Fig. 5 shows the dimensional relationships between the control head and the piston with a target.

± 0.5 mm - when using a target in accordance with the dimensional drawing,

Note upper end position of

the target (H 156.5 mm) to prevent

putting control head at risk!

Target (1.4021)

and

Piston rod (*)

(both depicted in the upper

and lower end positions,

maximum stroke: 80 mm)

Fig. 5: Cross-section of the control head and piston with target (in upper and lower end position)

(*) The fastening materials for target and piston rod may not be made of material with very good electrical

conductivity (e.g. copper, aluminum) or of ferromagnetic material.

Stainless steels such as e.g. 1.4404 are suitable.

Page 22

22

Technical Data

english

Control Head Type 8681

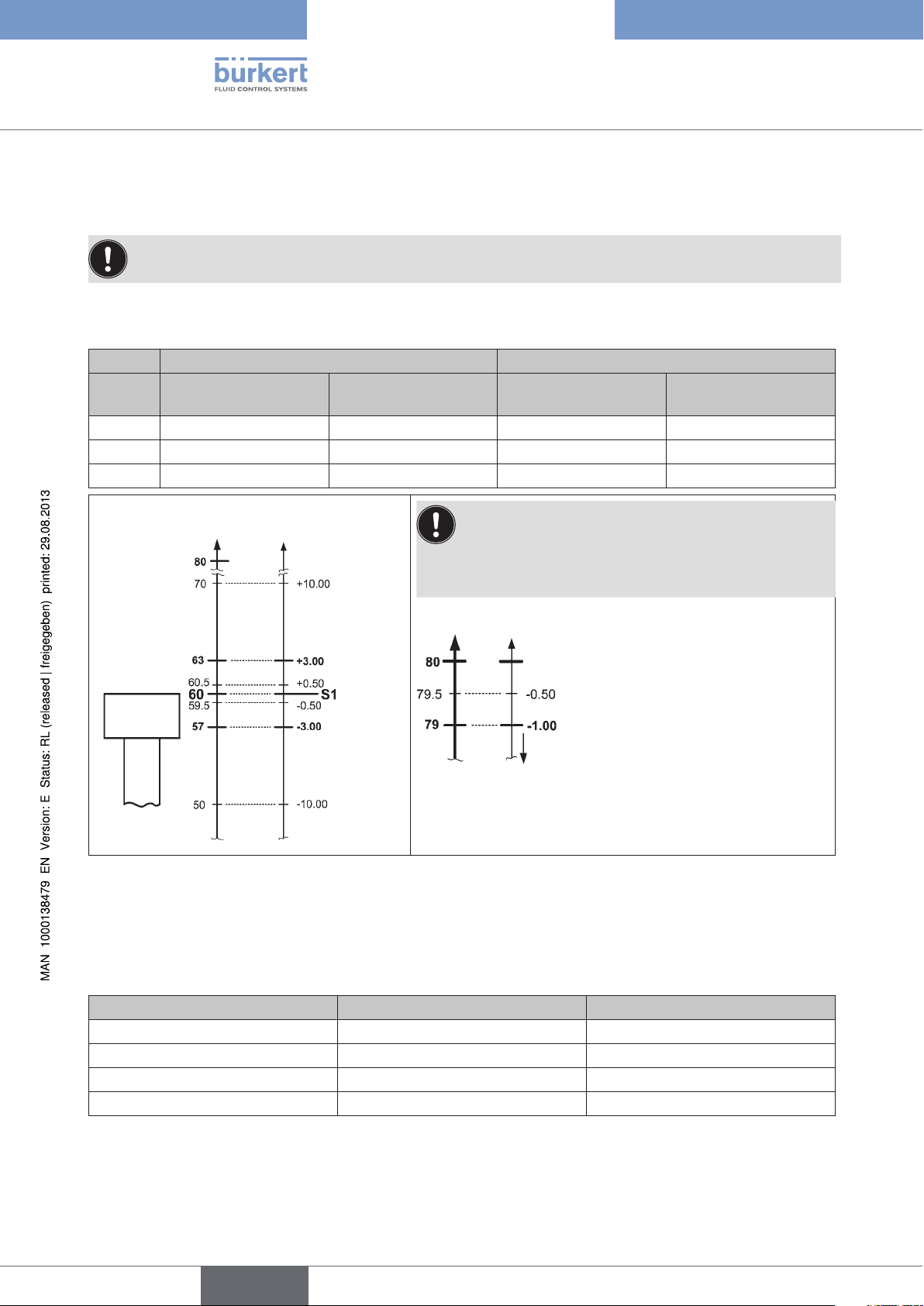

6.6. Factory Settings in the Firmware

The control head is supplied with the following factory settings of the firmware:

The service interface may only be used in non-explosive atmosphere.

Feedback areas (position measuring system):

(A feedback area is the area, within which a position (e.g. S1) is reported back.)

Signal Feedback area, top Feedback area, bottom

Factory setting

[mm]

S1 + 3.00 + 10.00 ... + 0.50 - 3.00 - 0.50 ... - 10.00

S2 + 3.00 + 10.00 ... + 0.50 - 3.00 - 0.50 ... - 10.00

S3 + 0.50 + 10.00 ... + 0.50 - 0.50 - 0.50 ... - 10.00

Adjustment range

[mm]

Factory setting

[mm]

Adjustment range

[mm]

Stroke

[mm]

Target

Schematic diagram (not to scale) of the feedback areas, on the example of Position S1 Fig. 6:

Service function (maintenance request):

The service function is deactivated at the time of delivery. It can be activated via the service interface. Feedback

indicating that service is required (service function) is triggered by the following counter states:

Feedbackarea S1 [mm]

The feedback area is automatically reduced in the area

of the end positions:

The firmware ensures that a tolerance of at least 1 mm

towards the center position is present in the end

positions.

Exemplary illustration of the upper end position:

upper end position as taught position

(selected feedback area towards

center position)

actual feedback area ensured by

the firmware

Towards center position

Overlaps between S1, S2 and S3 are possible

(see chapter 16.3. Signal Priorities).

Counter states Factory setting Adjustment range

Switching cycle counter V1 10,000 (1 ... 255) x 1000

Switching cycle counter V2 50,000 (1 ... 255) x 1000

Switching cycle counter V3 50,000 (1 ... 255) x 1000

Operating duration 365 days 1 ... 65,535 days

Manual control function (magnetic) - Factory setting: active

It can be deactivated via the service interface.

Page 23

23

Installation

english

Control Head Type 8681

7. INSTALLATION

Safety instructions7.1.

DANGER!

Risk of injury from high pressure in the equipment!

Before loosening pneumatic lines and valves, turn off the pressure and vent the lines.•

WARNING!

Risk of injury due to electrical shock!

Before reaching into the system (except for the Teach-In procedure in a non-explosive atmosphere) switch off •

the power supply and secure it to prevent restarting!

Observe applicable accident prevention and safety regulations for electrical equipment!•

Risk of injury from improper installation!

Installation may be carried out by authorized technicians only and with the appropriate tools!•

Risk of injury from unintentional activation of the system and an uncontrolled restart!

Secure system from unintentional activation.•

Following assembly, ensure a controlled restart.•

Assembly of the Control Head7.2.

The control head can be installed in any installation position, preferably with the hood face up.

The control head should be installed such that layers of dust thicker than 5 mm cannot form; meaning that such

should be ensured through correspondingly regular cleaning.

If the control head is used in explosive atmosphere (zone 2) it has to be installed in a protected installation

position according to IEC / EN 60079-0.

Hub flange7.2.1.

WARNING!

Risk of injury from improper installation!

Do not improperly stress the control head.•

Do not apply any leverage effect on the head and do not climb on it.•

When sealing the flange from the outside to the inside, make sure that the inflow of cleaning agent is consid-•

ered and that the drive space of the process valve towards the control head is sealed.

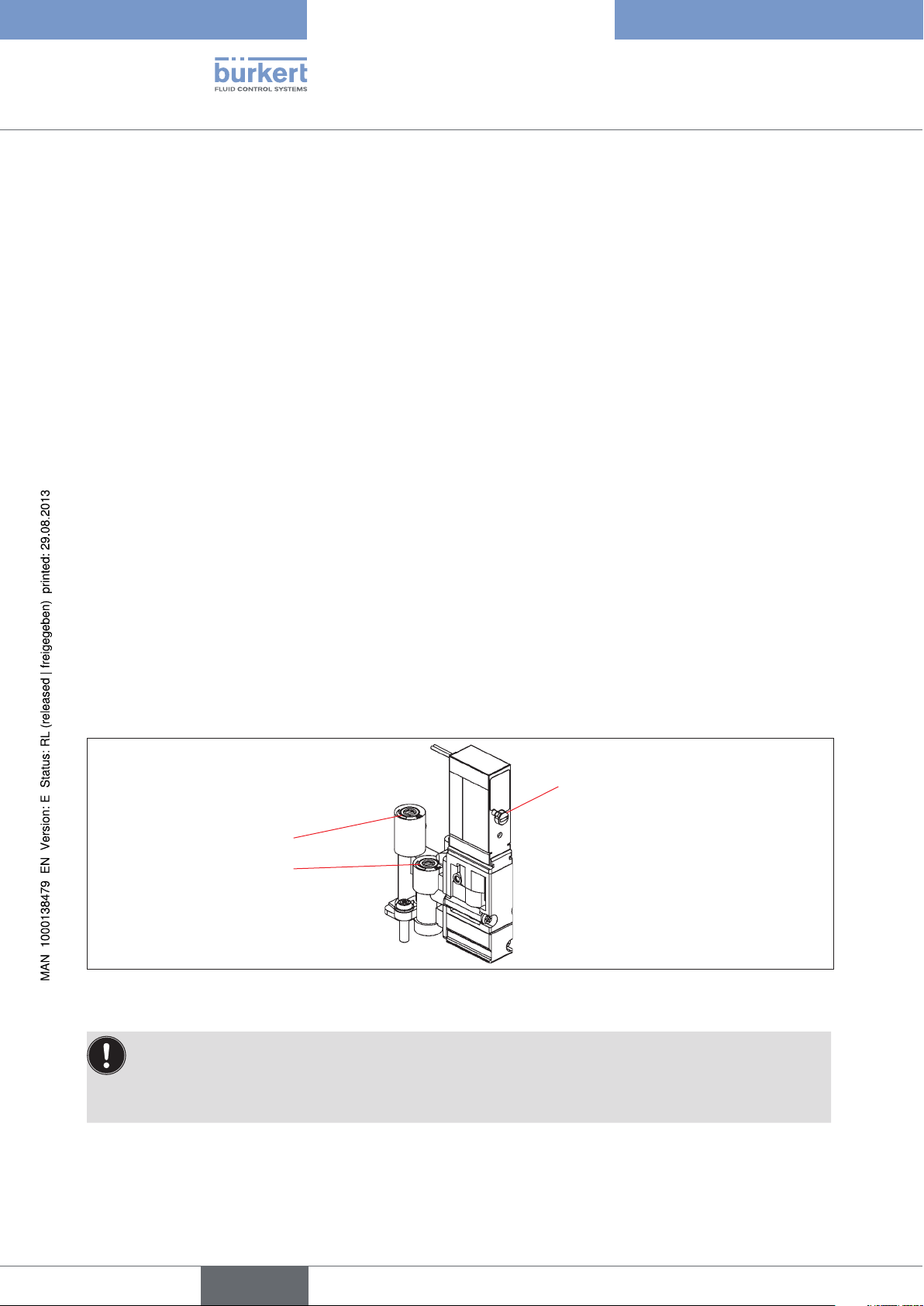

For the installation of the Control Head Type 8681 to a process valve, you will require a process valve-specific

hub flange as an adapter.

The hub flange must be adapted to the design of the process valve and produce the mechanical connection

between the process valve and the control head. The axial fastening is done by two locking screws (shoulder

Page 24

24

Installation

english

Control Head Type 8681

screws M5), which engage in the middle groove of the hub flange (protection against pulling off). The control

head can radially slide into any position in 360° arc, seamlessly.

The hub flange and non ferromagnetic piston rod with the target that is used to record the position must comply

with the specifications with regard to material and stability (see chapter 6.5. Position Measuring System Data.

Control head

Target made of

1.4021

Piston rod (*)

(max. Ø 30)

Fastening

screws (2x)

O-rings Hub flange

Process valve

Fig. 7: Dimensional diagram of the control head - process valve adaptation

(*) The fastening materials for target and piston rod may not be made of material with very good electrical con-

ductivity (e.g. copper, aluminum) or of ferromagnetic material.

Stainless steels such as e.g. 1.4404 are suitable.

To ensure the proper function of the position measuring system, the axial deviation of the adapter must •

be less than ± 0.1 mm to the spindle when mounted!

Use exclusively Bürkert adaptations.•

Prior to assembling the control head onto the hub flange, lightly grease the O-rings with a silicone •

grease (e.g. Paraliq GTE 703).

A seal or a hood safeguard using plastic self-cutting screws is required in the explosion-risk area, so •

that unintentional opening of the housing will be prevented!

For dimensional relationships, see also chapter 6.5. Position Measuring System Data.

Assembly Sequence on the Example of a Double-seated 7.2.2.

Valve

Procedure:

→

Mount the piston rod with the target on the process valve spindle. Observe reference dimensions!

Fasten the hub flange on the process valve. →

During this, observe central alignment and sealing conditions!

Page 25

25

Installation

english

Control Head Type 8681

Check the secure fit of the sealing rings (in the upper and lower grooves). →

Mount the control head on the hub flange (seamlessly 360° rotatable). →

Secure control head with the two locking screws (shoulder screws M5) in the middle groove of the hub flange →

to prevent pulling off from the hub flange – tightening torque: max. 3.2 Nm (see Fig. 7: Dimensional diagram

of the control head - process valve adaptation and 7.2.3. Realignment of the Control Head).

7.2.3. Realignment of the Control Head

If necessary, the control head can be realigned, in particular if properly accessible installation of the pneumatic supply

lines is not possible due to spatial conditions. This might also be required for operational aspects (accessibility of

the manual control) and because of electrical connection possibilities.

Procedure:

→

Loosen the locking screws (shoulder screws M5) slightly until the underside of the screw head is flush with

the auxiliary surface of the housing.

The locking screw has

been loosened sufficiently

if the lower side of the

screw head is flush with

the auxiliary surface of the

housing.

Rotate the control head until the desired alignment has been achieved. →

Secure the control head with locking screws again until the upper side of the screw head is flush with the →

auxiliary surface of the housing. The locking screws have no sealing function. The control head is not fixed in

place by the locking screws; it is merely protected against being pulled off the hub flange.

The locking screw is sufficiently

tightened when the upper side of

the screw head is flush with the

auxiliary surface of the housing.

Tightening torque: max. 3.2 Nm

Assembly of the Pneumatic and Electrical Connections7.2.4.

Pneumatic Installation

See chapter 9. Pneumatic Installation

Electrical Installation

24 V DC: See chapter 10. 24 V DC - Design,

AS Interface: See chapter 11. AS Interface - Design

DeviceNet: See chapter 12. DeviceNet - Design

120 V AC: See chapter 13. 120 V AC - Design

Recommended Auxiliary Materials7.2.5.

Silicone grease Paraliq GTE 703 for easy lubrication of the EPDM seals.

Page 26

26

Opening and Closing the Housing

english

Control Head Type 8681

8. OPENING AND CLOSING THE HOUSING

Safety instructions8.1.

DANGER!

Risk of injury from high pressure in the equipment!

Before loosening pneumatic lines and valves, turn off the pressure and vent the lines.•

Danger of explosion in explosive atmosphere (only in the event of a fault as zone 2)!

Opening the hood or the housing in an explosive atmosphere is only allowed in the isolated state! •

WARNING!

Risk of injury due to electrical shock!

Before opening the hood and prior to reaching into the system (aside from a Teach-In procedure in a non-•

explosive atmosphere), switch off the power supply and secure to prevent restarting!

Observe applicable accident prevention and safety regulations for electrical equipment!•

Risk of injury from improper installation!

Installation may be carried out by authorized technicians only and with the appropriate tools!•

Risk of injury from unintentional activation of the system and an uncontrolled restart!

Secure system from unintentional activation.•

Following installation, ensure a controlled restart.•

Opening and Closing the Housing8.2.

Opening the Housing8.2.1.

NOTE!

Improper handling will damage the plastic hood / seal!

Do not use excessive force (e.g. by knocks) for opening.•

Make sure that the lubricated seal contour is not soiled when the hood is placed down as this might reduce •

the IP protection!

Loosen plastic self-cutting screws or seal, if housing has been secured.

→

Open the plastic hood by turning counterclockwise (all the way, approx. 1.5 cm). Due to the tightness of the →

sealing, loosen the plastic hood by carefully tilting it laterally and lift it upwards to remove it.

Page 27

27

Opening and Closing the Housing

english

Control Head Type 8681

Closing the Housing8.2.2.

If necessary, clean the seal contour of the seal and of the hood, and lightly lubricate it using a recommended silicone grease (e.g. Paraliq GTE 703).

Caution:

Do not use any petroleum-based or synthetic lubricants (except for silicone grease)!

Procedure:

Put the plastic hood on the lower part such that the inner lugs are positioned over the fastening grooves and

→

the external sealing lugs are positioned almost over each other. Press the hood completely over the seal of the

lower part.

Turn the hood by approx. 1.5 cm clockwise (meaning until the sealing lugs are positioned over each other).

→

Potentially, apply more sealing and plastic self-cutting screws. →

A seal or a hood safeguard using plastic self-cutting screws is required in the explosion-risk area!

Page 28

28

Pneumatic Installation

english

Control Head Type 8681

9. PNEUMATIC INSTALLATION

Safety instructions9.1.

DANGER!

Risk of injury from high pressure in the equipment!

Before loosening pneumatic lines and valves, turn off the pressure and vent the lines.•

WARNING!

Risk of injury from improper installation!

Installation may be carried out by authorized technicians only and with the appropriate tools!•

Risk of injury from unintentional activation of the system and an uncontrolled restart!

Secure system from unintentional activation.•

Following installation, ensure a controlled restart.•

9.2. Pneumatic Connection of the Control Head

DANGER!

Risk of injury from high pressure in the equipment!

Before loosening pneumatic lines and valves, turn off the pressure and vent the lines.•

Exhaust air

connection (3/R)

(Silencer

not shown!)

Pneumatic ConnectionFig. 8:

Solenoid valve 3

(2/A3)

Working connections

Solenoid valve 2

(2/A2)

(2/A1 - 3)

Solenoid valve 1

(2/A1)

Supply pressure

connection

(1/P)

Page 29

29

Pneumatic Installation

english

Control Head Type 8681

Procedure:

→ 7.2.3. Realignment of the Control Head)

If necessary, realign the control head (see chapter

A silencer has already been mounted on the Exhaust Air Connection (3/R) in the supplied state. As needed,

→

the silencer can be replaced by an exhaust air hose (e.g. after screwing in an appropriate plug-in hose

connectors).

Connect the required working connections 2/A1 to 2/A3 (each according to model) with the corresponding

→

connections on the process valve.

Connect the supply line to supply pressure connection 1/P (2.5 to 8 bar).

→

NOTE!

Hose pipes!

Only use calibrated hose pipes with • ∅6 mm (or 1/4") or ∅8 mm (or 5/16") outer diameters (tolerance:

+0.05 / -0.1 mm).

Only use a suitable hose cutter when cutting hose pipes. This will safeguard against damage and impermis-•

sible deformation.

Accordingly dimension hose length to prevent that the hose ends in the plug-in hose connectors generate any •

diagonally pulling stresses (curved outlet without eccentric stress).

Only use suitable hose qualities (in particular for high ambient temperatures) that bear up under common •

stresses caused by the quick connector.

Silencer or exhaust air hose!

When using an exhaust air hose, accordingly dimension its length to ensure that a QNn value > 620 l/min is •

reached.

Tip:

Dimension the hose lengths so that the control head can be removed from the process valve if required

without any additional disassembly work.

Flow Restriction Function of the Solenoid Valves9.3.

Set the flow restriction screws of the solenoid valves only when needed and after completion of all necessary installations!

The flow restriction screws of the solenoid valves (see Fig. 9) are used for setting the air intake and exhaust for

the working connections:

Factory setting: QNn approx. 110 l/min.•

The flow restriction screws do not serve any sealing function.•

Only tighten the flow restriction screws to the stopper, otherwise damage to device may occur.•

Only use appropriate screw drivers (width • ≤ 3 mm).

Page 30

30

Pneumatic Installation

english

Control Head Type 8681

Settings of the Flow-Rate or the Control Speed with the Help of the Flow Restriction Screws:

→ 8. Opening and Closing the Housing.

Open the housing observing the notes contained in chapter

For proper setting, it is advisable to turn the two flow restriction screws initially into the minimum flow-rate

→

position. The process valve will then initially move slowly so that you have more time to find the optimum

setting during a switching operation.

Minimizing the flow-rate: Turn clockwise

Maximizing the flow-rate: Turn counterclockwise

Observing the safety guidelines, activate the valve location to be set (either using the system control or the

→

manual controls).

Turn the flow restriction screw, "P", counterclockwise to set the desired flow-rate and thus the opening time for →

the process valve. (Tool: flat-blade screwdriver, width ≤ 3 mm). (Tool: flat-blade screwdriver, width ≤ 3 mm).

Activate valve location. →

Turn the flow restriction screw, "R", counterclockwise to set the desired flow-rate and thus the closing time for →

the process valve.

Hand lever of the

mechanical manual

Flow restriction screw

Exhaust R

Flow restriction screw

Intake P

Fig. 9: Flow restriction screws of the solenoid valves

actuation facility

NOTE!

Makes sure that all manual controls have been deactivated (manual lever all the way left, as pictured) after the •

setting work has been completed!

Close the housing observing the notes contained in chapter

→ 8. Opening and Closing the Housing.

If no system status is available during setting, readjust the system under system operation conditions if

necessary.

Observe the safety guidelines during this!

Page 31

31

24 V DC - Design

english

Control Head Type 8681

10. 24 V DC - DESIGN

Electrical connection options 10.1.

The following connection concepts are available for the electrical connection of the control head:

Cable gland Cable gland with multi-pole connection

(M12 plug according to IEC 61076-2-101, 12-pole)

Connection left: Voltage, signals

Connection right: external initiator

Connection Concepts 24 V DCFig. 10:

Connection left: Voltage, signals

Connection right: external initiator

Electrical Data10.2.

Power supply: 12 ... 28 V DC, residual ripple 10 %

Connections:

Cable gland version 1 x M16 x 1.5 cable gland / A/F22

for power supply and signals

clamping area 5 to 10 mm, with dummy plugs

with screw terminals for cable cross-sections of 0.14 to 1.5 mm

1 x M16 x 1.5 cable gland / A/F19

for external initiator

clamping area 3 to 6 mm, with dummy plugs

with screw terminals for cable cross-sections 0.14 to 1.5 mm²

Multi-pole connection version 1 x M16 x 1.5 cable gland / A/F22 with multi-pole connection

(M12 plug according to IEC 61076-2-101, 12-pole on a cable of

8 cm length for power supply and signal)

2

1 x M16 x 1.5 cable gland / A/F19

for external initiator

clamping area 3 to 6 mm, with dummy plugs

with screw terminals for cable cross-sections 0.14 to 1.5 mm²

Power consumption (standby current): 30 mA at 24 V DC

Page 32

32

24 V DC - Design

english

Control Head Type 8681

Solenoid valves:

Power input per solenoid valve: max. 0.8 W (0.9 W during activation)

Power consumption per solenoid valve

: 67 mA at 12 V DC

34 mA at 24 V DC

29 mA at 28 V DC

Operating mode: Long-term operation (100 % ED)

Central display of the switching states: 42 mA with a power supply of 24 V DC per illuminated display;

Color switching see chapter 16. LED - Color Assignments

Outputs/binary feedback signals: S1 out - S4 out

Design: Normally open contact, PNP output

short-circuit-proof,

with self-clocking short-circuit protection

Switchable output current: max. 100 mA per feedback signal

Output voltage - active: ≥ (operating voltage - 2 V)

Output voltage - inactive: max. 1 V in unloaded state

Output/analog S3 out feedback signal (separate order variant "Analog"!):

Signal output: S3 out (binary feedback signal S3out not available)

Type: Current source (4 to 20 mA)

Max. burden: ≤ 500 Ohm

Max. fault: ±1 mm (incl. measurement fault by the position measuring system)

Input / proximity switches (external initiator: S4 in):

Power supply: Voltage present at control head - 10 %

Current carrying capacity, sensor power supply: max. 90 mA

Short-circuit protection

Design: DC 2- and 3-conductor,

NO or NC (factory setting NO), PNP output

Input current 1 signal: I

Input voltage 1 signal: U

Input current 0 signal: I

Input voltage 0 signal: U

> 6.5 mA, limited internally to 10 mA

Sensor

> 10 V

Sensor

< 4 mA

Sensor

< 5 V

Sensor

Valve control inputs (Y1 - Y3):

Signal level - active: U > 10 V, max. 24 V DC + 10 %

Signal level - inactive: U < 5 V

Impedance: > 30 kOhm

Page 33

33

24 V DC - Design

english

Control Head Type 8681

Design Aid10.3.

Power consumption of the electronics:

P

El

Power consumption of a valve during activation (200 ms):

P

Valve-On

Power consumption of a valve after reduction:

P

Valve

Power consumption of an optical position report:

P

LED

= 0.7 W or I

= 0.9 W or I

= 0.8 W or I

= 1.0 W or I

El

Valve-On

Valve

LED

= 30 mA at 24 V

= 38 mA at 24 V

= 34 mA at 24 V

= 42 mA at 24 V

Also, if several control head valves were to be opened simultaneously, the switch signal will be sent staggered to the valves. Only one valve will consume 0.9 W at any time.

Calculation Examples:

Example 1:

3 valves are activated simultaneously, one position is reported (state for 200 ms):

P

Total

= P

El

+ 1 x P

Valve-On

+ 2 x P

Valve

+ 1 x P

LED

4,2 W = 0.7 W + 1 x 0.9 W + 2 x 0.8 W + 1 x 1.0 W

or

I

Total

= I

El

+ 1 x I

Valve-On

+ 2 x I

Valve

+ 1 x I

LED

178 mA = 30 mA + 1 x 38 mA + 2 x 34 mA + 1 x 42 mA

Example 2:

3 valves have been activated simultaneously, one position is reported (persistent state):

P

Total

= P

El

+ 3 x P

Valve

+ 1 x P

LED

4.1 W = 0.7 W + 3 x 0.8 W + 1 x 1.0 W

or

I

Total

= I

El

+ 3 x I

Valve

+ 1 x I

LED

174 mA = 30 mA + 3 x 34 mA + 1 x 42 mA

When using an external initiator, its power requirement should be added.

Page 34

34

24 V DC - Design

english

Control Head Type 8681

Safety instructions10.4.

DANGER!

Danger of explosion in explosive atmosphere (only in the event of a fault as zone 2)!

Opening the hood or the housing in an explosive atmosphere is only allowed in the isolated state!•

WARNING!

Risk of injury due to electrical shock!

Before reaching into the system (except for the Teach-In procedure in a non-explosive atmosphere) switch off •

the power supply and secure it to prevent restarting!

Observe applicable accident prevention and safety regulations for electrical equipment!•

When setting the position measuring system (Teach-In), do not touch any live components!•

Risk of injury from improper installation!

Installation may be carried out by authorized technicians only and with the appropriate tools!•

Risk of injury from unintentional activation of the system and an uncontrolled restart!

Secure system from unintentional activation.•

Following installation, ensure a controlled restart.•

10.5. Electrical Installation / Start-up

10.5.1. Cable Gland with Screw-type Terminals

Procedure:

→ 8. Opening and Closing the Housing.

Open the housing observing the notes contained in chapter

Assemble connection cables for signals and power supply as well as for the external initiator where necessary

→

in observance of the rules of technology.

Insert cables through the respective cable glands into the interior of the housing.

→

Secure the wires to the connection terminals according to the pin assignments depicted in Fig. → 11.

If necessary, secure the cable with a cable tie!

Close the housing observing the notes contained in chapter

→ 8. Opening and Closing the Housing.

NOTE!

Ensure IP protection!

To ensure IP protection, the union nuts of the cable glands must be tightened in accordance with the cable •

sizes or dummy plugs used (approx. 1.5 Nm).

If an external initiator is not used, the cable gland (wrench size 19, Ø 3 - 6 mm) must be tightly sealed with •

the dummy plug (Ø 5 - 6 mm) supplied from the factory!

Page 35

35

24 V DC - Design

english

Control Head Type 8681

NOTE!

Use of the Control Head in Explosive Atmosphere

Only use cables and cable glands that are allowed for the respective application area, and mount the cable •

gland according to the respective operating instructions!

Close all unnecessary openings with lock screws/plugs approved for explosions area!•

24 V DC Electronics Module, Terminal Strip Configuration:

Teach-In buttons

T1-3

Solenoid valve

connection with

status

LED for Valve 1

Service

interface

Terminal strip

Power

supply

Feedback

signals

S1-S4 OUT

Control sole-

noid valves

Y1-3

Fig. 11: 24 V DC electronics module

Designation

Terminal strip

Configuration

24 V Power supply 24V 24 V

Designation

Terminal strip

DIP switches for

color coding the

LEDs

Solenoid valve con-

nection with status

LEDs for

Valves 2 & 3

Connection

for the external

initiator

Configuration

Power supply 24 V for external

initiator

GND GND S4 IN External initiator input

S1 OUT Output position 1 GND GND external initiator

S2 OUT Output position 2

S3 OUT

Output position 3

(order variant "Analog":

output - analog signal)

S4 OUT External initiator output

Y1 Solenoid valve 1 input

Y2 Solenoid valve 2 input

Y3 Solenoid valve 3 input

Page 36

36

24 V DC - Design

Circuit diagram 24 V DC:

english

Control Head Type 8681

*) Order variant "Analog": output - analog signal

Circuit diagram 24 V DC Fig. 12:

Page 37

37

24 V DC - Design

english

Control Head Type 8681

Multi-pole Connection10.5.2.

Internal cabling work is not required for models with multi-pole connection, which makes installation and start-up

on site considerably easier and quicker, reducing the risk of leaks. However, you will require the correspondingly

assembled cable sets with the following pin assignments:

Input and output signals to the higher-level control (PLC):

12-pole circular plug-in connector M12 x 0.75 - male (acc. to IEC 61076-2-101)

Pin 3 - S1 out Pin 2 - GND

Pin 4 - S2 out

Pin 1 - 24 V

Pin 5 - S3 out

11

10

12

Pin 6 - S4 out

12-pole multi-pole connection (view onto the plug pins)Fig. 13:

Pin 7 - Y1

Pin 9 - Y3

Pin 8 - Y2

The center pins

(10, 11 and 12)

are not used.

Pin Designation Configuration

1 24 V Power supply 24V

2 GND GND

3 S1 out Output position S1

4 S2 out Output position S2

5 S3 out Output position S3 (order variant "Analog": output - analog signal)

6 S4 out External initiator output S4

7 Y1 Solenoid valve 1 input

8 Y2 Solenoid valve 2 input

9 Y3 Solenoid valve 3 input

10 not used

11 not used

12 not used

Page 38

38

AS Interface - Design

english

Control Head Type 8681

11. AS INTERFACE - DESIGN

Definition11.1.

AS Interface Connection

AS interface (Actuator Sensor Interface) is a field bus system which is used primarily for networking binary sensors

and actuators (slaves) with a higher-level control (master).

Connecting the control heads to higher bus systems is possible using commercially available gateways.

Contact your distribution partner in this regard.

Bus line

Unshielded two-wire line (AS interface line as AS interface cable harness) along which both information (data) and

energy (power supply for the actuators and sensors) are transmitted.

Network topology

Freely selectable within wide limits, i.e. star, tree and line networks are possible. Further details are described in the

AS Interface Specification (A/B slave model conforms to the version 3.0 specification).

Technical Data of the AS Interface of the Control Head:

See chapter 6. Technical Data

The control heads have been configured as AS interface version with an extended address range (A/B slaves)

for 62 slaves or optionally as an AS interface version for 31 slaves. For details, see chapter 11.8. Programming

Data.

Page 39

39

AS Interface - Design

english

Control Head Type 8681

Electrical Connection Options for AS Interface 11.2.

The following connection concepts are available for the electrical connection of the control head:

Cable gland with multi-pole connection on a cable (8 cm length) •

Cable gland with multi-pole connection on a cable (80 cm length)•

with multi-pole connection (M12 plug

according to IEC 61076-2-101, 4-pole)

on 8 cm cable

left: AS interface

right: external initiator

Connection Concepts for AS InterfaceFig. 14:

with multi-pole connection (M12 plug according to

IEC 61076-2-101, 4-pole) on 80 cm cable

left: AS interface

right: external initiator

11.3. Number of Connectable Control Heads and Maximum Length of the Bus Line

The bus cable may be a maximum of 100 m long.

The level of expansion that is actually possible depends on the total number of all individual operating currents for each

control head, which are supplied via the bus at the common AS interface bus segment (see example calculation).

Default: AS interface / 62 slaves (AS interface version with extended addressing range (A/B slave))

In AS interface versions with extended addressing range (A/B slave), 1 master can communicate with 62 slaves.

Option: AS interface / 31 slaves (AS interface version with 31 slave addressing range)

In this case, a maximum of 31 control heads can be connected to a bus line (the address range restriction).

Page 40

40

AS Interface - Design

english

Control Head Type 8681

Table of calculated line length of the control head versions:

When designing the system, consider the length of the round cable leading directly to the control head (see following table and example calculation).

Model Calculated line length (incl. internal cabling)

Multi-pole (cable 8 cm) 0.3 m

Multi-pole (cable 80 cm) 1.0 m

Example:

for multi-pole connection with 8 cm cable:

The AS interface cable harness may still be 81.4 m (100 m - 62 * 0.3 m) at maximum when using 62 control

heads.

If the calculated line length of 100 m were to be exceeded, a commercially available AS interface repeater may be

used, as needed.

Observe the maximum power supply using certified AS Interface power supplies ≤ 8 A!

For details, refer to the AS Interface Specification.

Observe the optional design "AS Interface with External Power Supply" to reduce the load on the AS interface

bus segment!

Use cables according to the AS Interface Specification.

The maximum cable length may change when using other cables.

Electrical Data11.4.

Comments / Notes:

Outputs (from master perspective): 0 to 3 solenoid valves

Inputs (from master perspective): 3 binary feedback signals and 1 external initiator

Watchdog: If bus communication fails for more than 50 up to 100 ms, the

outputs are set to 0

Setting the valve's power supply using jumpers on the AS interface electronics module:

via AS interface Externally

(Connection see chapter 11.7. Electrical installation

AS Interface)

Jumper

Jumper

The Control Head Type 8681 was developed according to the Complete Specification (V.3.0) and the Profile

S-7.A.E and S-7.F.F of the AS International Association.

Page 41

41

AS Interface - Design

english

Control Head Type 8681

Connections:

Multi-pole connection version 1 x M16 x 1.5 cable gland / A/F19 with multi-pole connection

(M12 plug according to IEC 61076-2-101, 4-pole on a cable of 8 or

80 cm length for power supply and signal)

1 x M16 x 1.5 cable gland / A/F19

for external initiator

clamping area 3 to 6 mm, with dummy plugs

with screw terminals for cable cross-sections 0.14 to 1.5 mm²

Power supply: 29.5 to 31.6 V DC (according to specification)

Input / proximity switches (external initiator: S4 in):

Power supply: AS interface voltage present at control head - 10 %

Current carrying capacity, sensor

power supply: max. 30 mA

Short-circuit protection