Page 1

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifi cations

techniques.

© 2010 - 2011 Bürkert Werke GmbH

Operating Instructions

1105/02_EU-ml_00806166

/ Original DE

Type 8681

Control Head

Steuerkopf

Tête de commande

Quickstart

2

THE QUICKSTART1.

WARNING!

Important safety information!

Read quickstart carefully and thoroughly. Study in particular the chapters entitled 4. Basic Safety Instructions

and 3. Authorized use .

The operating instructions must be read and understood.•

Quickstart explains, for example, how to install and start-up

the device.

The detailed description of the device can be found in the

operating instructions for Control Head Type 8681.

The operating instructions can be found on the

Internet at:

www.burkert.com Documentation Type 8681

english

3

SYMBOLS2.

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger!

Failure to observe the warning will result in a fatal or •

serious injury.

WARNING!

Warns of a potentially dangerous situation!

Failure to observe the warning may result in serious •

injuries or death.

CAUTION!

Warns of a possible danger!

Failure to observe this warning may result in a moderate •

or minor injury.

NOTE!

Warns of damage to property!

Important tips and recommendations for safe and

the fl awless functioning of the device.

designates a procedure which you must carry out.

english

Page 2

4

3. AUTHORIZED USE

Non-authorized use of the Control Head Type 8681

may be a hazard to people, nearby equipment and

the environment.

The Control Head has been designed for use as •

actuation of pneumatically operated process valves

and / or for recording the switching states of these.

Use according to the authorized data, operating condi-•

tions and conditions of use specifi ed in the contract

documents and operating instructions.

In view of the large number of options for use it might •

be necessary to test prior to installation whether the

control head is suitable for the concrete use.

If you have any questions, please contact your Bürkert

Service Center.

The device may be used only in conjunction with third-•

party devices and components recommended and

authorized by Burkert.

Any unauthorized reconstructions and changes to the •

control head are prohibited for safety reasons.

Correct transportation, correct storage and installation •

and careful use and maintenance are essential for

reliable and faultless operation.

For connecting the control head, use line installations •

that do not cause any mechanical stresses.

Use the device only as intended.•

english

5

Predictable Misuse3.1.

Do not supply the medium connectors of the system with •

aggressive or fl ammable media.

Do not supply the medium connectors with any liquids.•

Do not physically stress the housing (e.g. by placing objects •

on it or standing on it, or using it as attachment point for

transport work).

Do not make any external modifi cations to the device •

housings. Do not paint the housing parts or screws.

In the explosion-risk area, only wipe the control head with a •

damp or anti-static cloth to avoid electro-static charges!

english

6

4. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any

contingencies and events which may arise during the instal-•

lation, operation and maintenance of the devices.

local safety regulations - the operator is responsible for •

observing these regulations, also with reference to the

installation personnel.

DANGER!

Danger – high pressure!

Before loosening pneumatic lines and valves, turn off •

the pressure and vent the lines.

Danger of explosion in explosive atmosphere (only in

the event of a fault as zone 2)!

Opening the hood or the housing in an explosive atmo-•

sphere is only allowed in the isolated state!

WARNING!

Risk of electric shock!

Before reaching into the system (except for the •

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

english

7

restarting!

Observe applicable accident prevention and safety •

regulations for electrical equipment!

WARNING!

General Hazardous Situations.

To prevent injuries, ensure that:

the system cannot be activated unintentionally.•

installation and maintenance work, as well as operator •

control actions may be carried out by authorized, qualifi ed technicians only and with the appropriate tools.

after an interruption in the power supply or pneu-•

matic supply, ensure that the process is restarted in a

defi ned or controlled manner.

the device may be installed and operated only when in •

perfect condition and in consideration of the operating

instructions.

the general rules of technology apply to application •

planning and operation of the device.

english

Type 8681

Page 3

8

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components, which react •

sensitively to electrostatic discharge (ESD). Contact

with electrostatically charged persons or objects may

be hazardous to these components. In the worst case

scenario, they will be destroyed immediately or will fail

after start-up.

Observe the requirements in accordance with DIN EN •

61340-5-1 and 5-2 to minimize or avoid the possibility of

damage caused by sudden electrostatic discharge!

Also, ensure that you do not touch electronic components •

when the power supply voltage is present!

Control Head Type 8681 was developed with due

consideration given to accepted safety rules and

is state-of-the-art. Nevertheless, dangerous situations may occur.

Failure to observe this operating manual and its operating instructions as well as unauthorized tampering with

the device release us from any liability and also invalidate

the warranty covering the devices and accessories!

english

9

Explosive Atmosphere4.1.

NOTE!

Operation of the Control Head in Explosive

Atmosphere

The housing may not be opened when devices are •

charged! It should be secured against unintentional

opening using plastic self-cutting screws or seal (or

comparable)!

Layers of dust on the housing may not exceed 5 mm! •

Lint, conductive and non-conductive dust particles are

allowed.

The inside of the housing may not be dirty!

Activating the DIP switches on the circuit board, using •

the service plug and the Teach buttons is not allowed in

explosive atmosphere!

english

10

GENERAL INFORMATION5.

Scope of Supply5.1.

Check immediately upon receipt of the delivery that the contents are not damaged and that the type and scope agree

with the delivery note and packing list.

If there are any discrepancies, please contact us immediately.

Contact address5.2.

Germany:

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Straße 13-17

D-74653 Ingelfi ngen

Tel.: +49 7940 10 91 111

Fax: +49 7940 10 91 448

E-mail: info@de.buerkert.com

International:

The contact addresses can be found on the Internet at:

www.burkert.com

Bürkert Company Locations

english

11

STRUCTURE AND FUNCTION6.

The Control Head Type 8681 has been designed for use

as actuation of pneumatically operated process valves and/

or for recording the switching states of these.

For the recording and feedback of the process valve

switching positions to a higher-level control, the control

head has been equipped with a contactless position measuring system, which works with three discrete, adjustable

feedback signals (Teach-In Function).

Various pneumatic and electrical connection variants are

available.

Positions and status information can be indicated by means

of three signal colors.

Manual Control6.1.

Standardly, the control head provides the following:

a magnetic manual control that is easily accessible from •

the outside on the basis of encoded magnetic fi elds for

Solenoid Valve 1 (Connection 2/A1), as well as

a mechanical manual control accessible when the hood •

is open on each equipped solenoid valve.

english

Type 8681

Page 4

12

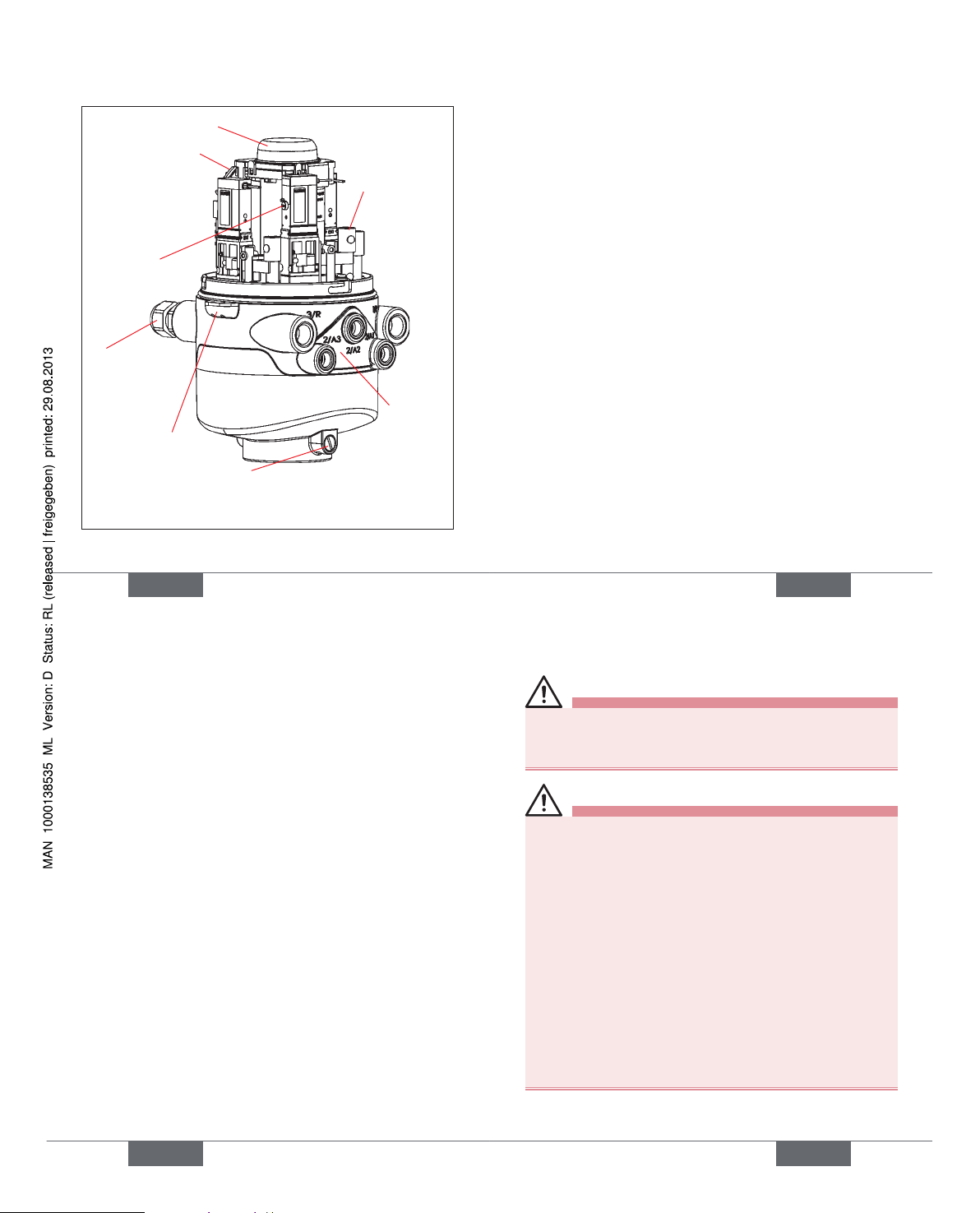

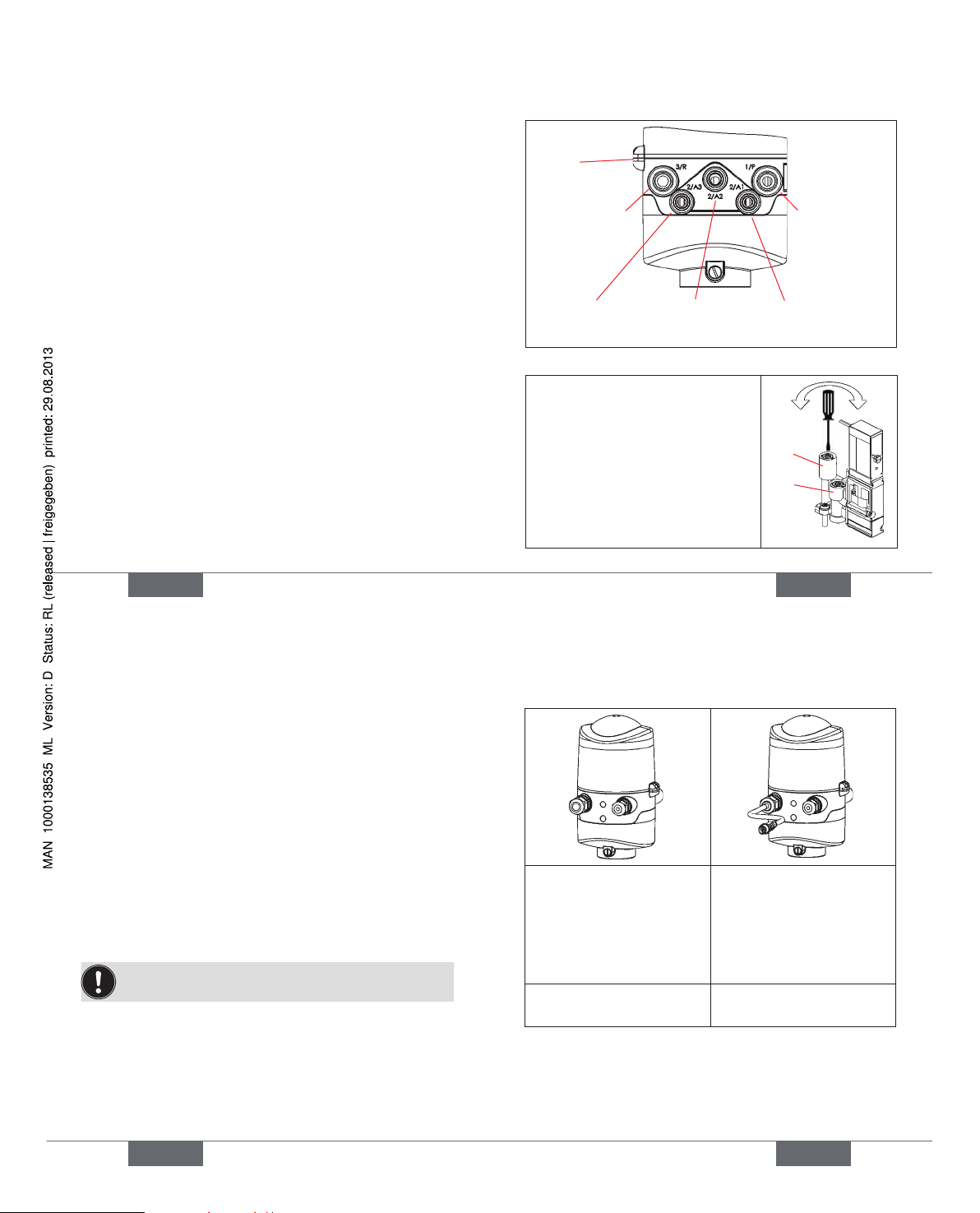

Structure6.2.

Pneumatic

connections

Locking/(shoulder) screws

as protection against pulling

off from the hub fl ange

Electrical

connections

(Cable

glands)

Sealing lug

Electronics module

(24VDC- or AS-iDesign with service

interface, connection

terminals, DIP, TeachIn-buttons)

Position measuring system with LED’s

Flow restriction

screw(s) of

solenoid valves

Mechanical

manual control

at solenoid

valves (red

levers)

english

13

TECHNICAL DATA7.

Operating Conditions7.1.

Ambient temperature: -10 ... +55 °C

Protection class: IP65 / IP67 according to EN 60529 or

IP69K according to IEC 40050-9

Mechanical Data7.2.

Dimensions: see data sheet

Housing material: outside: PA, PP, PPO, VA

inside: ABS, PA, PMMA

Sealing material: outside: CR, EPDM

inside: EPDM, FKM, NBR

Pneumatic Data7.3.

Control medium: Oil-free and dry air, neutral gases,

Quality classes in accordance with

DIN ISO 8573-1 (5 µm fi lter

recommended)

Dust content: max. particle size 40 µm,

(quality class 5) max. particle density 10 mg/m

3

Water content: max. pressure dew point -20 °C or

(quality class 3) min. 10 °C below the lowest

operating temperature

english

14

Oil content: max. 25 mg/m

3

(quality class 5)

Temperature range

of compressed air: -10 to +50 °C

Pressure range: 2.5 to 8 bar

Air rate of solenoid

valve: 110 I

N

/min (for de-/aeration, ventilation)

(110 IN/min - supplied state

200 IN/min - maximum typical fl ow-rate)

(QNn value according to defi nition for

pressure drop from 7 to 6 bar absolute

at +20 °C)

Connections: Intake and exhaust air connection G1/4

Working connections G1/8

Position Measuring System Data7.4.

Stroke range: 0 ... 80 mm (measuring range)

Resolution: 0.1 mm

Total fault:

± 0.5 mm - when using a target as

mentioned in the manual

Electrical Data7.5.

see chapter 9. 24 V DC - Design or 10. AS-I - Design or

11. DeviceNet- Design or 12. 120 V AC - Design .

english

15

ASSEMBLY / INSTALLATION8.

DANGER!

Risk of injury from high pressure in the equipment!

Before loosening pneumatic lines and valves, turn off •

the pressure and vent the lines.

WARNING!

Risk of injury due to electrical shock!

Before reaching into the system (except for the •

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

restarting!

Observe applicable accident prevention and safety •

regulations for electrical equipment!

Risk of injury from improper installation!

Installation may be carried out by authorized techni-•

cians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

Secure system from unintentional activation.•

Following assembly, ensure a controlled restart.•

english

Type 8681

Page 5

16

Assembly8.1.

For the installation of the Control Head Type 8681 to a

process valve, you will require a process valve-specifi c hub

fl ange as an adapter. The hub fl ange must be adapted to

the design of the process valve.

Mount the piston rod with the target on the process

valve spindle. Observe reference dimensions!

Fasten the hub fl ange on the process valve.

During this, observe central alignment and sealing

conditions!

Check the secure fi t of the sealing rings (in the upper

and lower grooves).

Mount the control head on the hub fl ange (seamlessly

360° rotatable).

Secure the control head with the two locking screws

(shoulder screws M5) in the middle grove of the hub

fl ange (see operating instructions).

Pneumatic Installation8.2.

Connect the required working connections 2/A1 to 2/

A3 (each according to model) with the corresponding

connections on the process valve.

Connect the supply line to supply pressure connection

1/P (2.5 to 8 bar).

english

17

A silencer has already been mounted on the Exhaust

Air Connection (3/R) in the supplied state.

1/P

Supply pressure

connection

3/R

Exhaust air

connection

(Silencer)

2/A3: SV 3 2/A2: SV 2 2/A1: SV 1

2/A1 ... A3 - Working connections - Solenoid valves (SV)

Sealing lugs

at the

housing

The fl ow restriction screws

R and P of the solenoid valves

(see operating instructions) are

used for setting the air intake and

exhaust for the working connections (for setting of the control

speed of the process valves).

R

P

open close

english

18

Opening and Closing the 8.3.

Housing

Opening:

Loosen plastic self-cutting screws or seal, if housing

has been secured.

Open the plastic hood by turning counterclockwise (all

the way, approx. 1.5 cm).

Closing:

Put the plastic hood on the lower part such that the

inner lugs are positioned over the fastening grooves

and the external sealing lugs are positioned almost over

each other. Press the hood completely over the seal of

the lower part.

Turn the hood by approx. 1.5 cm clockwise (meaning

until the sealing lugs are positioned over each other).

A seal or a hood safeguard using plastic self-cutting

screws is required in the explosion-risk area!

Electrical Installation8.4.

see chapter

9. 24 V DC - Design , 10. AS-I - Design ,

11. DeviceNet- Design or 12. 120 V AC - Design .

english

19

9. 24 V DC - DESIGN

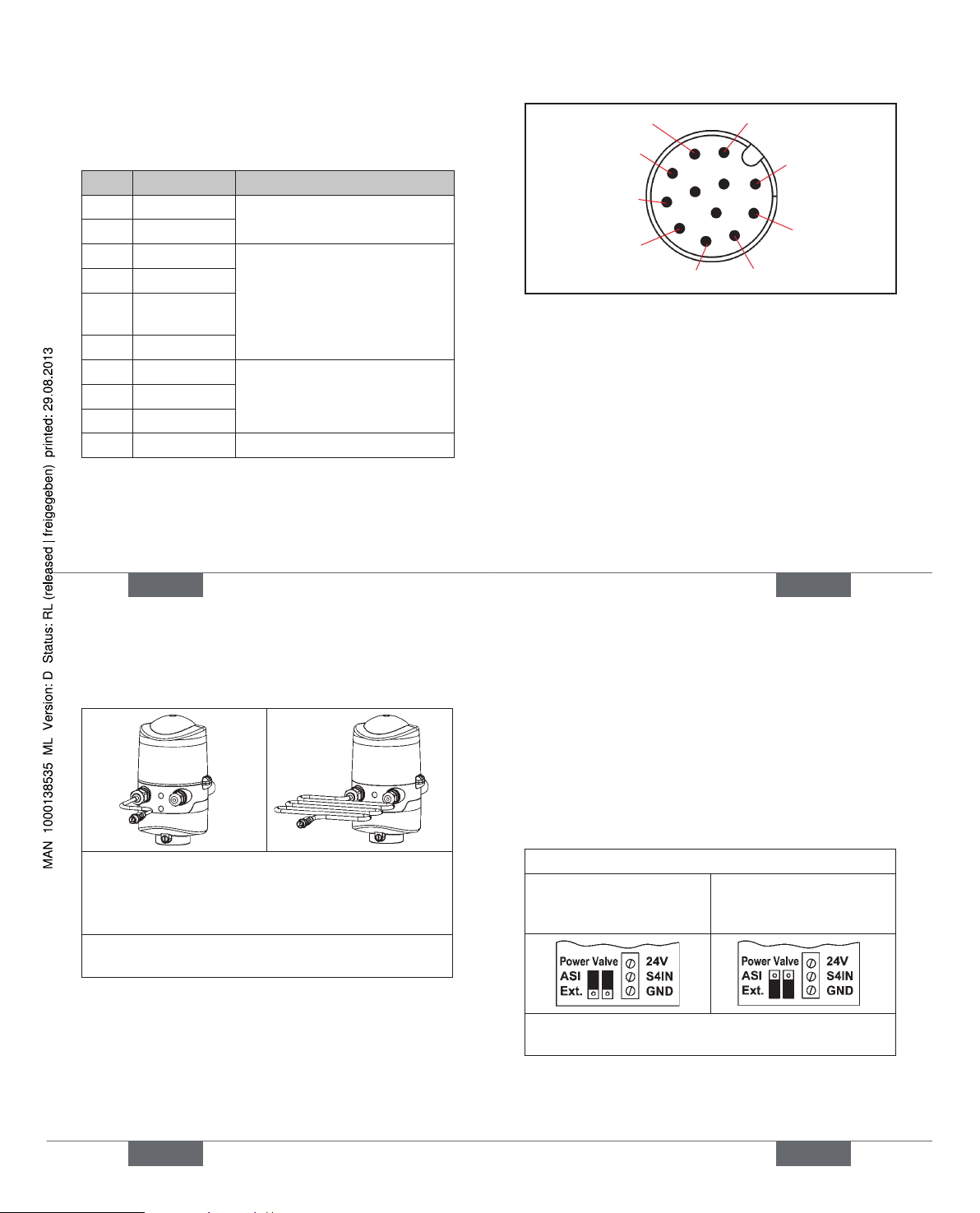

Connection options9.1.

left: 1 x M16 x 1,5 cable

gland

for power supply and

signals

left: 1 x M16 x 1,5 cable

gland with multi-pole

connection (M12 plug

according to IEC 610762-101, 12-pole) on a cable

of 8 cm length

right: 1 x M16 x 1,5 cable

gland for external initiator

right: 1 x M16 x 1,5 cable

gland for external initiator

english

Type 8681

Page 6

20

Electrical Data9.2.

Power supply: 12 ... 28 V DC, residual ripple 10 %

Power consumption:

(standby current): 30 mA at 24 V DC

Solenoid valves:

Power input per max. 0.8 W

solenoid valve: (0.9 W during activation)

Operating mode: Long-term operation (100 %)

Central display of the

switching states: 42 mA with a power supply of

24 V DC per illuminated display;

Outputs/binary

feedback signals: S1 out - S4 out

Design: Normally open contact, PNP output

short-circuit-proof, with self-clocking

short-circuit protection

Switchable

output current: max. 100 mA per feedback signal

Option: Analog feedback signal:

Signal output: S3 out (binary feedback signal

S3out not available)

Type: Current source (4 to 20 mA)

english

21

Input / proximity switches (external initiator: S4 in):

Power supply:

Voltage present at control head - 10 %

Current carrying

capacity, sensor

power supply: max. 90 mA;

short-circuit protection

Design: DC 2- and 3-conductor, NO or NC

(factory setting NO), PNP output

Valve control inputs (Y1 - Y3):

Signal level - active: U > 10 V, max. 24 V DC + 10 %

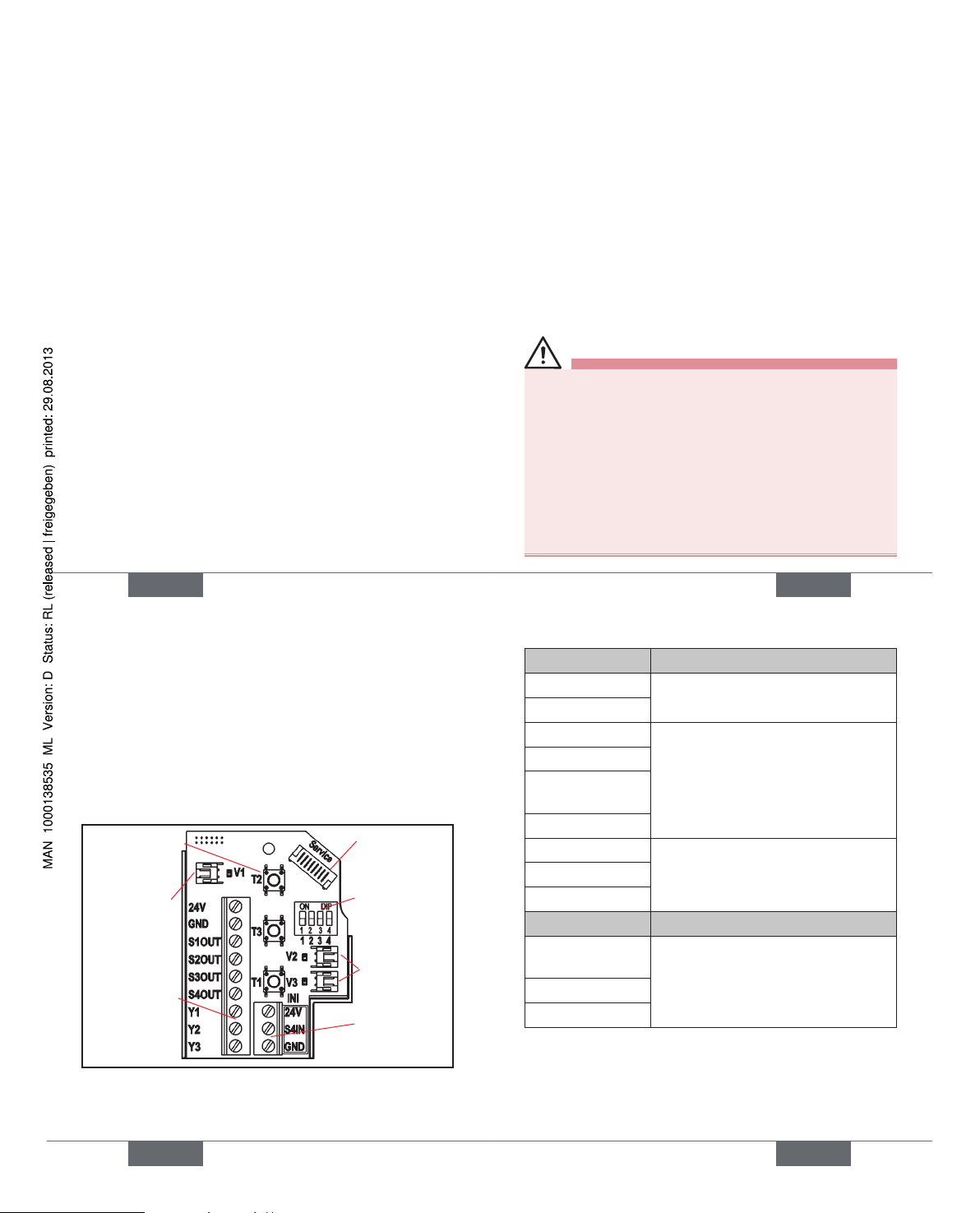

Electrical Installation 9.3. (24 VDC)

WARNING!

Risk of injury due to electrical shock!

Before reaching into the system (except for the •

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

restarting!

Observe applicable accident prevention and safety •

regulations for electrical equipment!

Risk of injury from improper installation!

Installation may be carried out by authorized techni-•

cians only and with the appropriate tools!

english

22

Cable glands:

Open the housing.

Assemble connection cables for signals and power

supply as well as for the external initiator.

Insert cables through the respective cable glands into

the interior of the housing.

Secure the wires to the terminal strips according to the

pin assignments depicted in the fi gure.

Solenoid valve

connection

with status

LED for SV1

Terminal strip 1

Service

interface

DIP switches

for color

coding the

LED‘s

Terminal strip 2

(for external

initiator)

Teach-Inbuttons T1-3

SV-connections

with status LED

for SV2, 3

english

23

Terminal strip 1 Confi guration

24 V Power supply 24 V

GND GND

S1 OUT Output position 1

S2 OUT Output position 2

S3 OUT Output position 3

(Option: analog signal)

S4 OUT Output external initiator

Y1 Input solenoid valve 1

Y2 Input solenoid valve 2

Y3 Input solenoid valve 3

Terminal strip 2 Confi guration

24 V Power supply 24 V for external

initiator

S4 IN Input external initiator

GND GND external initiator

Close the housing

.

Ensure IP protection (dummy plugs)!

english

Type 8681

Page 7

24

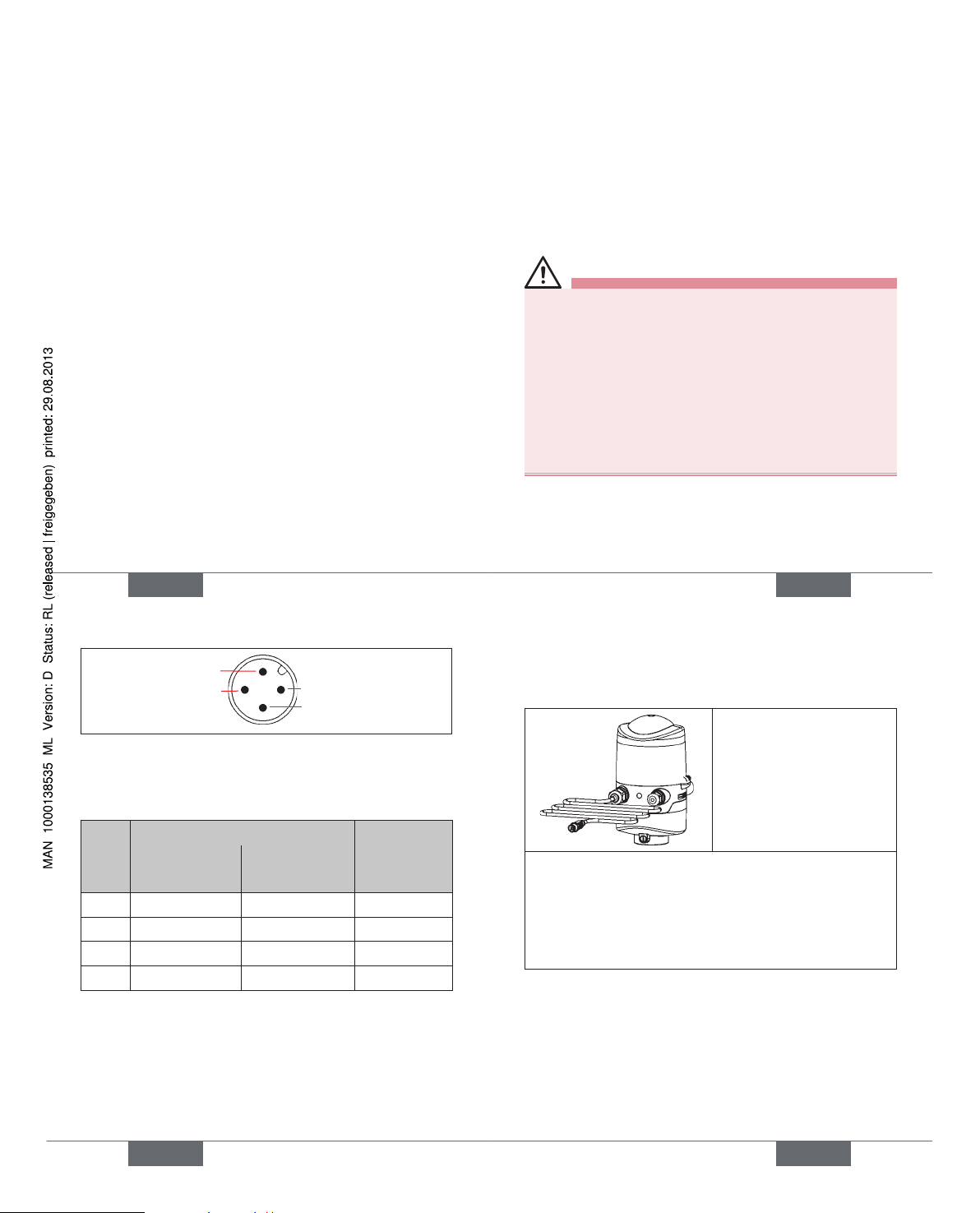

Cable gland with Multi-pole connection:

Internal cabling work is not required for models with multi-pole

connection. But you will require the correspondingly

assembled cable sets with the following pin assignments:

Pin Description Confi guration

1 24 V Power supply 24 V

2 GND GND

3 S1 OUT Output position 1

4 S2 OUT Output position 2

5 S3 OUT Output position 3

(Option: analog signal)

6 S4 OUT Output external initiator

7 Y1 Input solenoid valve 1

8 Y2 Input solenoid valve 2

9 Y3 Input solenoid valve 3

10-12

not used

An external initiator can be connected using the small 3-pin

terminal strip 2 (see fi gure on page 22 or manual, chapter

„Connection of an external initiator“).

english

25

Input and output signals to the higher-level control (PLC):

Pin 9 - Y3

Pin 8 - Y2

12

Pin 6 - S4 out

Pin 7 - Y1

Pin 1 - 24 V

Pin 5 - S3 out

Pin 4 - S2 out

11

Pin 3 - S1 out

Pin 2 - GND

10

(12-pole circular plug-in connector M12 x 0.75 - male,

acc. to IEC 61076-2-101 — view onto the plug pins)

english

26

10. AS-I - DESIGN

Connection options10.1.

left connection:

1 x M16 x 1,5 cable gland with Multi-pole connection

(M12 plug according to IEC 61076-2-101, 4-pole) on a

cable of 8 or 80 cm length

right connection:

1 x M16 x 1,5 cable gland for external initiator

Maximum Length of the Bus 10.2.

Line

The bus cable may be a maximum of 100 m long. When

designing the system, consider the length of the round cable

leading directly to the control head (see example calculation

in the operating instructions).

english

27

Number of Connectable 10.3.

Control Heads

In AS interface versions with extended addressing range

(A/B slave), 1 master can communicate with 62 slaves.

In AS interface versions with addressing range 31 slaves a

maximum of 31 control heads can be connected to a bus line

(the address range restriction).

10.4. Electrical Data

Power supply:

Standard: via AS-i

(29,5 ... 31,6 V DC

acc. specifi cation)

Option: externally

(19,2 V DC to 31,6 V DC)

Setting the valve’s power supply using jumpers on the

AS-interface electronics module.

Input / proximity switches (external initiator: S4 in):

Power supply: AS interface voltage present at

control head - 10 %

english

Type 8681

Page 8

28

Current carrying capacity,

sensor power supply: max. 30 mA;

short-circuit protection

Design: DC 2- and 3-conductor, NO or

NC (factory setting NO), PNP

output

Inputs (from master

perspective): 3 binary feedback signals and

external initiator

Outputs (from master

perspective): 0 to 3 solenoid valves

Switching capacity: max. 0.8 W via AS interface

Pull-in current: 30 mA or 0.9 W / 200 ms

Operating mode: Long-term operation (100 %)

Central display of the switching states:

Power consumption: max. 33 mA or 1 W per illumi nated display (at 30.5 V AS interface voltage)

Power supply via AS interface bus:

Power consumption

from AS interface: max. 200 mA (incl. external

initiator with 30 mA)

Integrated short-circuit protection

english

29

External Power Supply:

Ext. power supply: 19.2 V DC to 31.6 V DC

Max. power consumption

from external power supply: 110 mA at 24 V DC

Integrated short-circuit protection

Electrical Installation (AS-i)10.5.

WARNING!

Risk of injury due to electrical shock!

Before reaching into the system (except for the •

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

restarting!

Observe applicable accident prevention and safety •

regulations for electrical equipment!

Risk of injury from improper installation!

Installation may be carried out by authorized techni-•

cians only and with the appropriate tools!

Internal cabling work is not required for any of the AS Interface

designs with multi-pole connection. However, you will require

the correspondingly assembled cable sets with the following

pin assignments.

english

30

Pin 2

Pin 3

Pin 1

Pin 4

Likewise, the jumpers on the electronics module must be set

correspondingly (power supply via AS-i or externally) - see

page 27 .

Power supply

Pin

(via AS-i)

Confi guration

(externally)

Confi guration Color

1 AS-i+ AS-i+ brown

2 not used GND white

3 AS-i- AS-i- blue

4 not used 24 V+ black

An external initiator can be connected using the small

3-pin terminal strip 2 - see manual, chapter „Connection of

an external initiator“.

english

31

11. DEVICENET- DESIGN

Connection11.1.

left connection:

1 x M16 x 1,5 cable gland with Multi-pole connection

(M12 plug according to IEC 61076-2-101, 5-pole) on a

cable of 80 cm length

right connection:

1 x M16 x 1,5 cable gland for external initiator

DeviceNet Specifi cation11.2.

EDS fi le 8681.EDS

Icons 8681.ICO

Baud rate Factory setting: 125 kBit/s

Address Factory setting: 63

english

Type 8681

Page 9

32

Process data 2 static input assemblies

(Input: from the control head to the

DeviceNet Master/Scanner)

1 static output assembly

Inputs 3 discrete feedback signals of the posi-

tion measuring system (pos. S1 - S3)

1 discrete feedback signal of the

external initiators (S4)

1 analog position signal in mm

Supply via DeviceNet string

(11 to 25 V DC)

Switch level high signal 5 V

Switch level low signal 1,5 V

Outputs 3 solenoid valves

Power consumption

from the bus: max. 5 W, (3 valves with each 0,8 W)

Length of the Bus line11.3.

The maximum total line length (sum of trunk lines and drop

lines) of a network depends on the baud rate.

The maximum total line length (according to DeviceNet

specifi cation) is for:

english

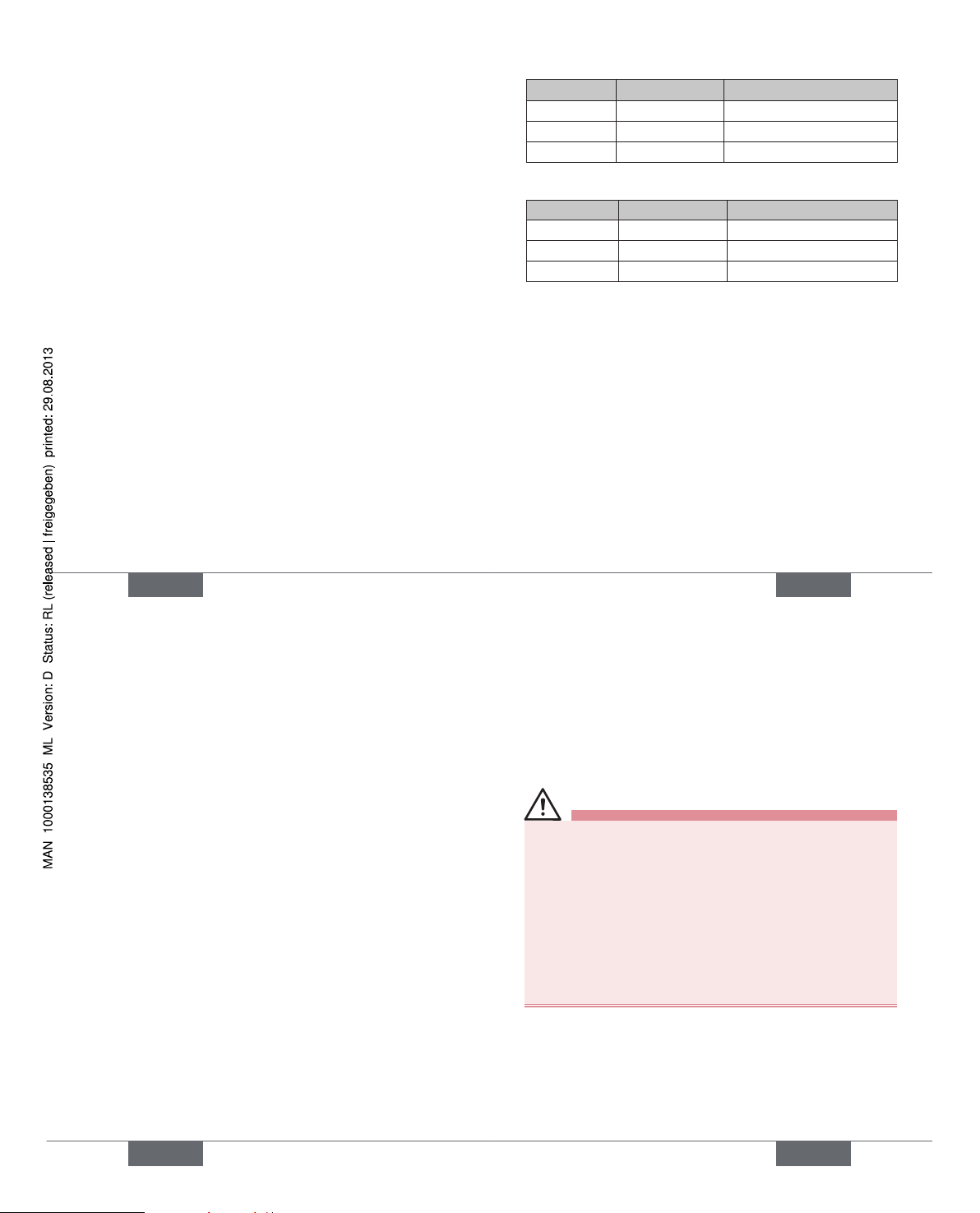

33

Baud rate Thick Cable Thin Cable

125 500 m 100 m

250 250 m 100 m

500 100 m 100 m

The maximum drop line length is for:

Baud rate Drop Line Sum (in Network)

125 6 m 156 m

250 6 m 78 m

500 6 m 39 m

Electrical Data11.4.

Electrical power supply: 11 to 25 V DC (according to

specifi cation)

Max. power consumption: 200 mA at 24 V DC

Input / proximity switches (external initiator: S4 in):

Power supply: via DeviceNet power

supply - 10 %

Current carrying capacity

sensor power supply: max. 30 mA

Short-circuit protection

Design: DC 2- and 3-conductor,

NO contact, PNP output

english

34

Input current 1 signal: I

Sensor

> 6.5 mA, limited

internally to 10 mA

Input voltage 1 signal: U

Sensor

> 10 V

Input current 0 signal: I

Sensor

< 4 mA

Input voltage 0 signal: U

sensor

< 5 V

Inputs (from master perspective) / binary or analog

feedback signals:

The recovery of the 3 valve positions reported back binarily

or of the analog position signalis described in the manual,

chapter “Position Mesuring System”.

Outputs (from master perspective) / solenoid valves:

max. switching capacity 1.0 W

typ. continuous output 0.8 W

Output reduction integrated via DeviceNet

interface electronics

pull-in current 120 mA typ. / 200 ms

(3 valves)

Holding current 100 mA typ. at 24 V DC

(3 valves)

Operating mode Long-term operation

(100 % operation)

Valve types 6524

Central display of the switching states:

Power consumption from

DeviceNet at 24 V DC 42 mA with 24 V DC power

english

35

supply per illuminated display

shown; Color switching see

in the manual, chapter “LED -

Color Assignments”

Electrical Installation (DVN)11.5.

WARNING!

Risk of injury due to electrical shock!

Before reaching into the system (except for the •

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

restarting!

Observe applicable accident prevention and safety •

regulations for electrical equipment!

Risk of injury from improper installation!

Installation may be carried out by authorized techni-•

cians only and with the appropriate tools!

No internal cabling work is required for any of the DeviceNet designs.

However, you will require the correspondingly assembled

cable sets with the pin assignments described below:

english

Type 8681

Page 10

36

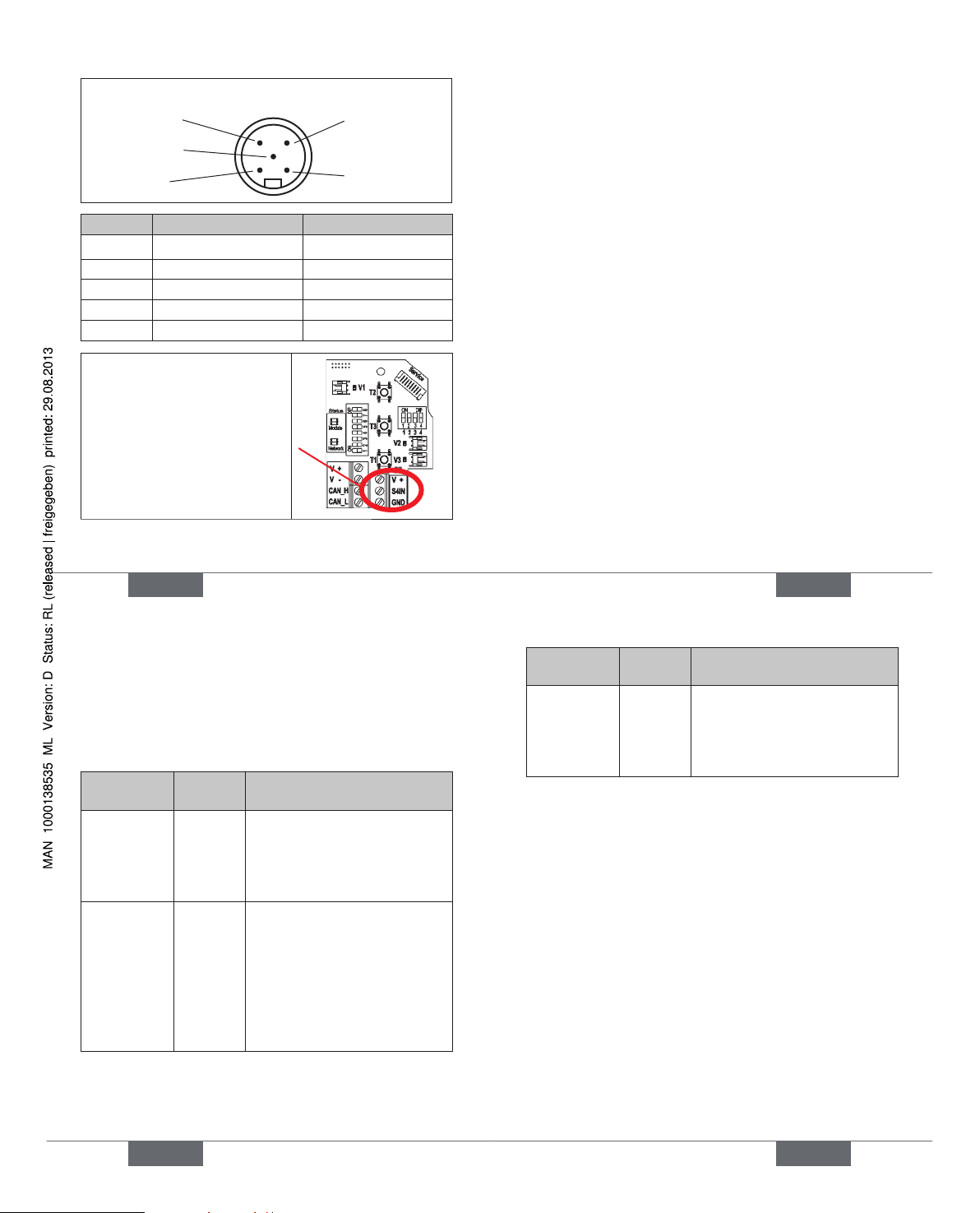

Pin 4: CAN_H

Pin 5: CAN_L

Pin 1: Drain

Pin 3: V–

Pin 2: V+

View of plug from the front onto the pins:

Pin Signal Color

1 Drain

(shield)

2 V+ red

3 V- black

4 CAN_H white

5 CAN_L blue

An external initiator can be

connected using the small

3-pin terminal strip - see

manual, chapter „Connection

of an external initiator“.

english

37

Network Topology11.6.

When installing a DeviceNet system, ensure that the terminating circuit of the data lines is correct. The circuit prevents

the occurrence of interference caused by signals refl ected

onto the data lines.

The trunk line must be terminated at both ends with

resistors of 120

Ω and 1/4 W power loss (see the manual,

chapter „Network Topology of a DeviceNet System“).

Confi guring the Baud rate 11.7.

and DVN address

8 DIP switches are available for confi guration:

DIP switches 1 to 6 for DeviceNet address•

(factory setting: 63, i.e. DIP 1 - 6: on)

DIP switches 7 to 8 for Baud rate•

(factory setting: 125, i.e. DIP 7 + 8: off)

Further confi guring - see manual, chapter „Confi guring the

DeviceNet address / baud rate“

english

38

Confi guration of Process Data11.8.

To transmit process data via an I/O connection, 2 static

input and 1 static output assembly can be selected, see

manual, chapter “Confi guration of Process Data”

„Address“ in the table describes the data attribute of the

assemblies for read access (class, instance, attributes).

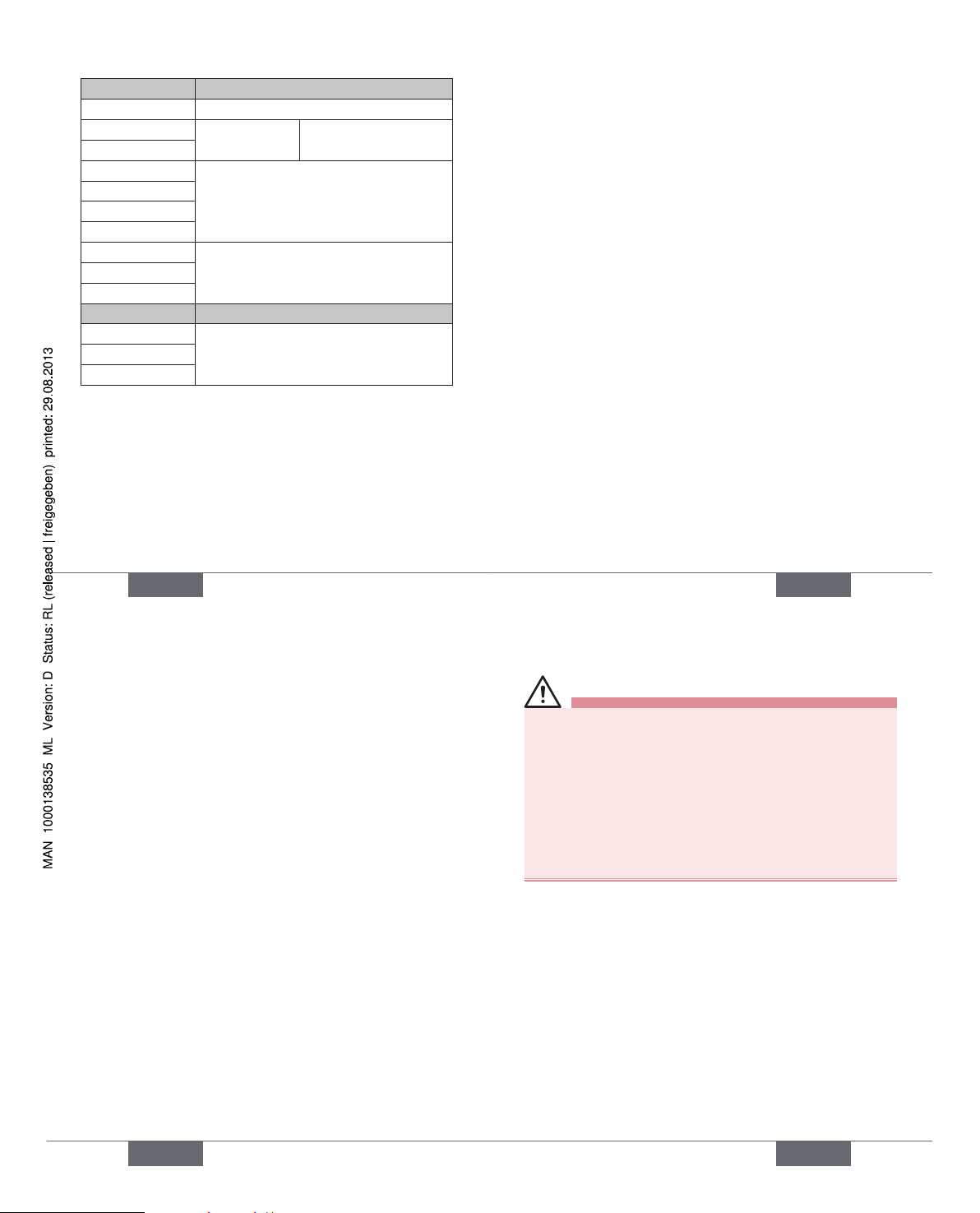

InputAssemblies

Address Format of the Data attribute

value 0: OFF / value 1: ON

S1…S4

(factory

setting)

4, 1, 3 Byte 0:

Bit 0: position S1

Bit 1: position S2

Bit 2: position S3

Bit 3: position S4

S1…S4 +

POS

(with POS:

current

position)

4, 2, 3 Byte 0:

Bit 0: position S1

Bit 1: position S2

Bit 2: position S3

Bit 3: position S4

Bit 4…7: not used

Byte 1:

POS in mm

„Address“ in the table describes the data attribute of the

assemblies for read access (class, instance, attributes).

english

39

OutputAssembly

Address Format of the Data attribute

value 0: OFF / value 1: ON

Solenoid

valve

SV 1 ... 3

4, 21, 3 Byte 0:

Bit 0: SV1

Bit 1: SV2

Bit 2: SV3

Bit 3…7: not used

Confi guration of the Safety 11.9.

Position of Solenoid Valves if

Bus Error

If the bus fails, the solenoid valve is switched to a programmable safety position (factory setting: the solenoid valve

is in the power-off-state) - for details see manual, chapter

„Confi guration of the device“.

The bus status LED „Network“ on the electronic module

specifi es the kind of error by color and blinking pattern - for

details see manual, chapter „Display of the Status LEDs in

the event of a bus error“).

english

Type 8681

Page 11

40

120 V AC - DESIGN12.

Connection 12.1.

left connection:

1 x M16 x 1,5 cable gland for

power supply and signals

right connection:

1 x M16 x 1,5 cable gland for

external initiator

Electrical Data12.2.

Central power supply: 110 ... 130 V AC, 50/60 Hz

Power consumption

(stnd-by current): 10 mA at 120 V AC

Solenoid valves:

power consumption

per solenoid valve: max. 1,4 VA

(1,7 VA during activation)

power consumption

per solenoid valve: 12 mA at 120 V AC

Operation mode: Long-term operation (100 %)

english

41

Central display of the switching states:

13 mA with a power supply of

120 V AC per illuminated display

Outputs/binary

feedback signals: S1out - S3out

Design: NO contact, L switching,

short-circuit protection via auto matically resetting fuse

switchable output

current: max. 50 mA per feedback signal

Output voltage

- active: (operating voltage - 2 V)

- inactive: max. 1 V in unloaded state

Feedback signal output: S4 out is directly connected to

S4 in

Input / proximity switches (external initiator: S4 in):

Power supply: voltage present at control head

U

Nominal

= 120 V AC, 50/60 Hz

Current carrying capacity,

sensor power supply: max. 0.7 A

Short-circuit protection

Design: DC 2- and 3-conductor,

NO contact, L-switching

input current 1-Signal: I

Sensor

< 2 mA

english

42

Valve control inputs (Y1 - Y3):

Signal level - active: U > 60 V AC

Signal level - inactive: U < 20 V AC

Impedance: > 40 kOhm

Electrical Installation12.3.

WARNING!

Risk of injury due to electrical shock (120 V AC)!

When setting the position measuring system •

(Teach-In), do not contact any live components!

Before reaching into the system (except for the •

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

restarting

Observe applicable accident prevention and safety •

regulations for electrical equipment!

Risk of injury from improper installation!

the • PE connection must be connected!

Installation may be carried out by authorized techni-•

cians only and with the appropriate tools!

english

43

Cable gland:

Open the housing.

Assemble connection cables for signals and power

supply as well as for the external initiator.

Insert cables through the respective cable glands into

the interior of the housing.

Connect the wires to the connection terminals

according to the pin assignment described in the

fi gure. Fix them.

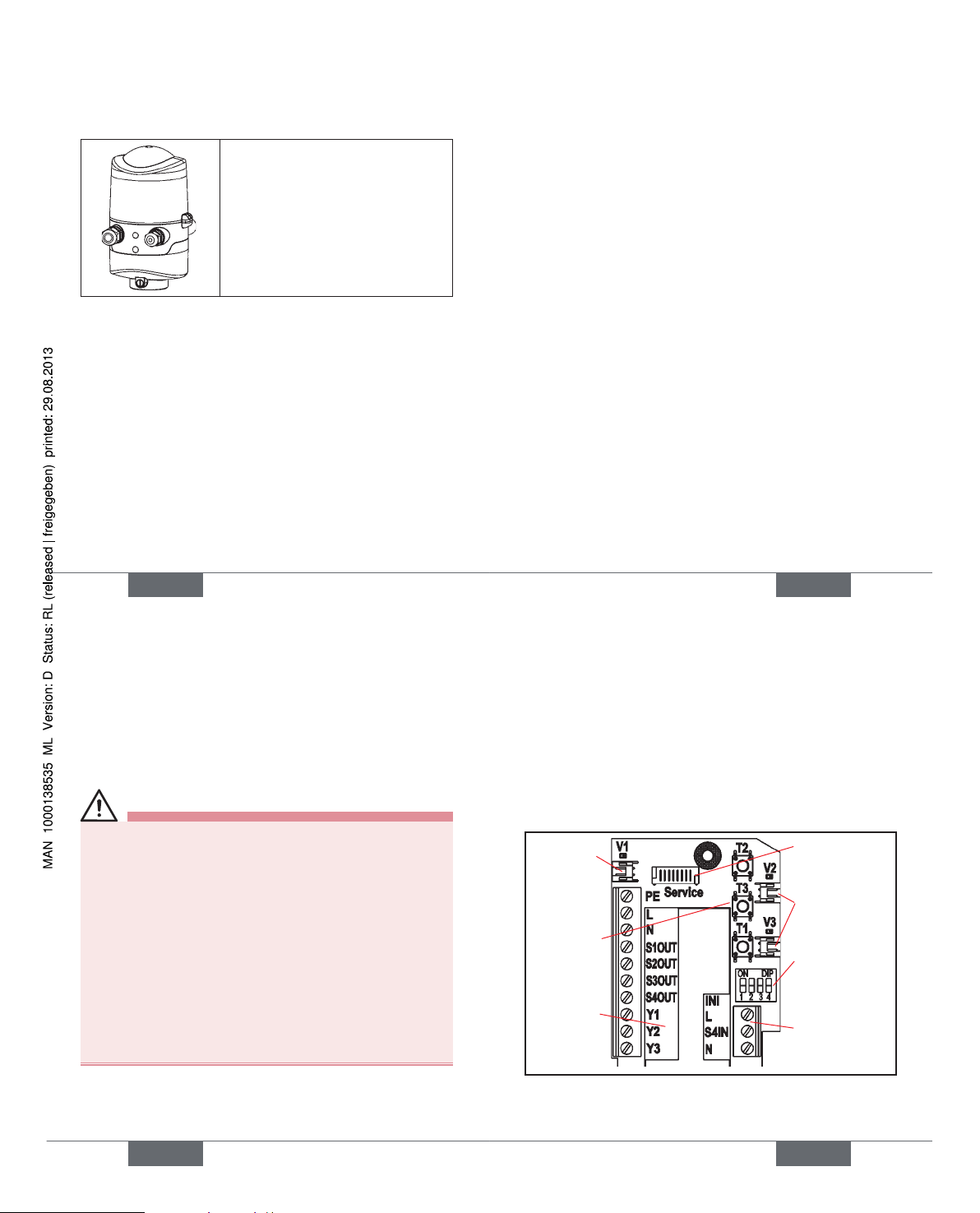

connection

for valve 1

with status

LED

terminal

strip 1

service

interface

DIP-switches

for color

coding the

LED‘s

terminal strip 2

(external

initiator)

Teach-In-

buttons

T1-3

connections for

valve 2, 3 with

status LED

english

Type 8681

Page 12

44

Terminal strip 1 Confi guration

PE Protection Earth - protective conductor

L

Power supply

120 V AC

live conductor

N neutral conductor

S1 OUT Ouput position 1

S2 OUT Ouput position 2

S3 OUT Ouput position 3

S4 OUT Ouput external initiator

Y1 Input solenoid valve 1

Y2 Input solenoid valve 2

Y3 Input solenoid valve 3

Terminal strip 2 Confi guration (external initiator)

L Power supply - live conductor

S4 IN Input external initiator

N Power supply - neutral conductor

Close the housing.

Ensure IP protection (dummy plugs).

An external initiator can be connected using the small

3-pin terminal strip 2 - see manual, chapter „Connection of

an external initiator“.

english

45

POSITION MEASURING 13.

SYSTEM

The recordable stroke range is between 0 and 80 mm.

Three Teach-In buttons have been provided for comparison

with the actual stroke range.

Teach-In13.1.

Open the housing.

Supply electrical power.

Position the process valve at the lower switching

position.

Depress the lower Teach-In button (T1) for approx. 1.5

seconds (the LED corresponding to this position will

fl ash quickly three times during the teaching phase).

Once this position has been stored, the corresponding

LED will remain continuously lit until the position of the

piston is changed.

Afterwards, position the process valve at the upper

switching position to be recorded.

Depress the upper Teach-In button (T2) for approx. 1.5

seconds (the LED corresponding to this position will

fl ash quickly three times during the teaching phase).

Once this position has been stored, the corresponding

LED will remain continuously lit until the position of the

piston is changed.

english

46

The process valve can now be moved into a third,

defi ned position.

Depress the middle Teach-In button (T3) for approx.

1.5 seconds (the LED corresponding to this position

will fl ash quickly three times during the teaching

phase).

Once this position has been stored, the corresponding

LED will fl ash continuously until the position of the

piston is changed.

If necessary, return control head and system to normal

state (switching position, power supply).

Close the housing.

Teach-Reset13.2.

Depress the Teach-In button ( T1+T2) for ca. 2.5 sec.

(optical feedback: Blinking in the fault color)

Autotune13.3.

Autotune functions and Autotune sequences - see operating instructions.

LED - Color Assignments13.4.

S1 - green, continuously lit,

S2 - yellow, continuously lit,

S3 - green, continuously fl ashing (250 ms/250 ms)

(Delivered state of the DIP switches: 0000)

english

47

START-UP14.

WARNING!

Risk of injury from improper operation!

Improper operation may cause injury and damage to the

device and its environment.

Before starting-up must be ensured that the contents •

of the manual operator is known and understood.

The safety instructions and the intended use must be •

followed.

Only adequately trained personnel should take the •

plant / the device in operation.

Assembly of the control head type 8681.

Pneumatic and electrical installation.

S etting the position measuring system (Teach-In).

After assembly, installation and setting of the position measuring system according to the operating instructions the

control head is ready for operation.

english

Type 8681

Page 13

48

PACKAGING, TRANSPORT, 15.

STORAGE, DISPOSAL

NOTE!

Transport / storage damage!

Inadequately protected equipment may be damaged

during transport or storage.

Protect the device during transportation / storage •

against moisture and dirt in shock-resistant packaging.

Avoid the effects of heat and cold which could result •

in temperatures above or below the permitted storage

temperature.

Storage temperature: -20 ... +65 °C.•

NOTE!

Damage to the environment caused by device components contaminated with media.

Observe the relevant disposal and environmental pro-•

tection regulations.

Dispose of the device and packaging in an environmen-

tally friendly manner.

Observe national waste disposal regulations .

english

Type 8681

Page 14

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifi cations

techniques.

© 2010 - 2011 Bürkert Werke GmbH

Operating Instructions

1105/02_EU-ml_00806166

/ Original DE

Typ 8681

Steuerkopf

Quickstart

Deutsch

50

DER QUICKSTART1.

WARNUNG!

Wichtige Informationen zur Sicherheit!

Lesen Sie den Quickstart sorgfältig durch. Beachten Sie

vor allem die Kapitel Grundlegende Sicherheitshinweise

und Bestimmungsgemäße Verwendung.

Der Quickstart muss gelesen und verstanden werden.•

Der Quickstart erläutert beispielhaft die Montage und Inbetriebnahme des Gerätes.

Die ausführliche Beschreibung des Gerätes fi nden Sie in

der Bedienungsanleitung für den Typ 8681.

Die Bedienungsanleitung fi nden Sie im Internet:

www.buerkert.de Dokumentation Typ 8681

deutsch

51

DARSTELLUNGSMITTEL2.

In dieser Anleitung werden folgende Darstellungsmittel

verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

Bei Nichtbeachtung sind Tod oder schwere Verletzun-•

gen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

Bei Nichtbeachtung können schwere Verletzungen oder •

Tod die Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

Nichtbeachtung kann mittelschwere oder leichte Verlet-•

zungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen.

markiert einen Arbeitsschritt den Sie ausführen müssen.

deutsch

Page 15

52

BESTIMMUNGSGEMÄSSE 3.

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des

Steuerkopfes Typ 8681 können Gefahren für Personen, Anlagen in der Umgebung und die Umwelt

entstehen.

Der Steuerkopf ist konzipiert für den Einsatz als An-•

steuerung pneumatisch betätigter Prozessventile und /

oder für die Erfassung von deren Schaltzuständen.

Für den Einsatz sind die in den Vertragsdokumenten •

und der Bedienungsanleitung spezifi zierten zulässigen Daten, Betriebs- und Einsatzbedingungen zu

beachten.

Angesichts der Vielzahl von Einsatz- und Verwen-•

dungsfällen muss vor dem Einbau geprüft und erforderlichenfalls getestet werden, ob der Steuerkopf für

den konkreten Einsatzfall geeignet ist:

Wenden Sie sich bei Unklarheiten an Ihr Bürkert Service Center.

Das Gerät nur in Verbindung mit von Bürkert empfoh-•

lenen bzw. zugelassenen Fremdgeräten und -komponenten einsetzen.

Eigenmächtige Umbauten und Veränderungen am •

Steuerkopf sind aus Sicherheitsgründen verboten.

Voraussetzungen für den sicheren und einwandfreien •

Betrieb sind sachgemäßer Transport, sachgemäße

deutsch

53

Lagerung und Installation sowie sorgfältige Bedienung

und Instandhaltung.

Verwenden Sie für den Anschluss des Steuerkopfes •

Leitungsinstallationen, die keine unzulässigen mechanischen Belastungen verursachen.

Setzen Sie das Gerät nur bestimmungsgemäß ein.•

Vorhersehbarer Fehlgebrauch3.1.

Speisen Sie in die Medienanschlüsse des Systems keine •

aggressiven oder brennbaren Medien ein.

Speisen Sie in die Medienanschlüsse keine Flüssigkeiten •

ein.

Belasten Sie das Gehäuse nicht mechanisch (z.B. durch •

Ablage von Gegenständen, als Trittstufe oder als Befestigungspunkt bei Transportarbeiten).

Nehmen Sie keine äußerlichen Veränderungen an den •

Gerätegehäusen vor. Gehäuseteile und Schrauben nicht

lackieren.

Im Ex-Bereich den Steuerkopf zur Vermeidung elektrosta-•

tischer Aufl adungen nur mit einem feuchten oder antistatischen Tuch abwischen!

deutsch

54

GRUNDLEGENDE 4.

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

Zufälligkeiten und Ereignisse, die bei Montage, Betrieb •

und Wartung der Geräte auftreten können.

ortsbezogenen Sicherheitsbestimmungen, für deren •

Einhaltung, auch in Bezug auf das Montagepersonal, der

Betreiber verantwortlich ist.

GEFAHR!

Gefahr durch hohen Druck!

Vor dem Lösen von Leitungen oder Ventilen den Druck •

abschalten und Leitungen entlüften.

Explosionsgefahr in Ex-Atmosphäre (nur im Störfall,

da Zone 2)!

Das Öffnen der Haube bzw. des Gehäuses unter •

Ex-Atmosphäre ist nur im spannungslosen Zustand

zulässig!

WARNUNG!

Gefahr durch elektrische Spannung!

Vor Eingriffen ins System (außer Teach-In-Vorgang in •

Nicht-Ex-Atmosphäre) die Spannung abschalten, vor

deutsch

55

Wiedereinschalten sichern!

Die geltenden Unfallverhütungs- und Sicherheitsbe-•

stimmungen für elektrische Geräte beachten!

WARNUNG!

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

Dass die Anlage nicht unbeabsichtigt betätigt werden •

kann.

Installations- und Instandhaltungsarbeiten sowie •

Bedienhandlungen dürfen nur von autorisiertem,

qualifi zier tem Fachpersonal mit geeignetem Werkzeug

ausgeführt werden.

Nach einer Unterbrechung der elektrischen oder pneu-•

matischen Versorgung ist ein defi nierter oder kontrollierter Wiederanlauf des Prozesses zu gewährleisten.

Das Gerät darf nur in einwandfreiem Zustand und unter •

Beachtung der Bedienungsanleitung eingebaut und

betrieben werden.

Für die Einsatzplanung und den Betrieb des Gerätes •

müssen die allgemeinen Regeln der Technik eingehalten werden

deutsch

Typ 8681

Page 16

56

HINWEIS!

Elektrostatisch gefährdete Bauelemente /

Baugruppen!

Das Gerät enthält elektronische Bauelemente, die gegen •

elektrostatische Entladung (ESD) empfi ndlich reagieren.

Berührung mit elektrostatisch aufgeladenen Personen

oder Gegenständen können diese Bauelemente

gefährden. Im schlimmsten Fall werden sie sofort zerstört

oder fallen nach der Inbetriebnahme aus.

Beachten Sie die Anforderungen nach DIN EN •

61340-5-1 und 5-2, um die Möglichkeit eines Schadens

durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

Achten Sie ebenso darauf, dass Sie elektronische Bau-•

elemente nicht bei anliegender Versorgungsspannung

berühren!

Der Steuerkopf Typ 8681 wurde unter Einbeziehung der anerkannten sicherheitstechnischen

Regeln entwickelt und entspricht dem Stand der

Technik. Trotzdem können Gefahren entstehen.

Bei Nichtbeachtung dieser Bedienungsanleitung und ihrer

Hinweise sowie bei unzulässigen Eingriffen in das Gerät

entfällt jegliche Haftung unsererseits, ebenso erlischt die

Gewährleistung auf Geräte und Zubehörteile!

deutsch

57

Ex-Atmosphäre4.1.

HINWEIS!

Betrieb des Steuerkopfes in Ex-Atmosphäre

Das Gehäuse darf bei Geräten unter Spannung nicht •

geöffnet werden! Es ist mit Kunststoffschneidschrauben

oder Verplombung (oder Vergleichbarem) gegen unbeabsichtigtes Öffnen zu sichern!

Staubschichten auf dem Gehäuse dürfen 5 mm nicht •

überschreiten! Es sind Flusen, leitfähige und nichtleitfähige Stäube zulässig.

Das Innere des Gehäuses darf nicht verschmutzt sein!

Das Betätigen der DIP-Schalter auf der Platine, die •

Nutzung des Service-Steckers und der Teach-Tasten

ist unter Ex-Atmosphäre nicht zulässig!

deutsch

58

ALLGEMEINE HINWEISE5.

Lieferumfang5.1.

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung,

dass der Inhalt nicht beschädigt ist und in Art und Umfang mit

dem Lieferschein bzw. der Packliste übereinstimmt.

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an

uns.

Kontaktadressen5.2.

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfi ngen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen fi nden Sie im Internet unter:

www.burkert.com

Bürkert Company Locations

deutsch

59

AUFBAU UND FUNKTION6.

Der Steuerkopf Typ 8681 ist konzipiert für den Einsatz als

Ansteuerung pneumatisch betätigter Prozessventile und /

oder für die Erfassung von deren Schaltzuständen.

Zur Erfassung der Prozessventilschaltstellungen und deren

Rückmeldung an eine übergeordnete Steuerung ist der

Steuerkopf mit einem berührungslosen Wegmesssystem

ausgestattet, welches mit 3 einstellbaren diskreten Rückmeldesignalen arbeitet (Teach-In-Funktion).

Es sind verschiedene pneumatische und elektrische

Anschlussvarianten verfügbar.

Positionen und Statusinformationen können mittels 3 Signalfarben angezeigt werden.

Handbetätigung6.1.

Der Steuerkopf stellt standardmäßig zur Verfügung:

eine leicht von außen zugängliche • magnetische Handbetätigung auf Basis codierter Magnetfelder für das

Magnetventil 1 (Anschluss 2/A1) sowie

eine bei geöffneter Haube zugängliche • mechanische

Handbetätigung an jedem bestückten Magnetventil.

deutsch

Typ 8681

Page 17

60

Aufbau6.2.

Pneumatische

Anschlüsse

Sicherungsschraube (Ansatzschraube)

gegen das Abziehen vom Aufnahmefl ansch

Elektrische

Anschlüsse

(Kabelverschraubungen)

Verplombungsnase

Elektronikmodul

(24VDC- oder

AS-i-Ausführung mit

Serviceschnittstelle,

Klemmleisten, DIP,

Teach-In-Tasten)

Wegmesssystem mit LED‘s

Drosselschrauben der

Magnetventile

mechanische

Handbetätigung

am MV (roter

Hebel)

deutsch

61

TECHNISCHE DATEN7.

Betriebsbedingungen7.1.

Umgebungstemperatur: -10 ... +55 °C

Schutzart: IP65 / IP67 nach EN 60529 bzw.

IP69K nach IEC 40050-9

Mechanische Daten7.2.

Maße: siehe Datenblatt

Gehäusematerial: außen: PA, PC, PPO, VA

innen: ABS, PA, PMMA

Dichtungsmaterial: außen: CR, EPDM

innen: EPDM, FKM, NBR

Pneumatische Daten7.3.

Steuermedium: ölfreie und trockene Luft, neutrale Gase

Qualitätsklassen nach DIN ISO 8573-1

(Filter 5 µm empfohlen)

Staubgehalt max. Teilchengröße 40 µm,

(Qualitätskl. 5) max. Teilchendichte 10 mg/m

3

Wassergehalt max. Drucktaupunkt -20 °C oder

(Qualitätskl. 3) min. 10 °C unterhalb der niedrigsten

Betriebstemperatur

deutsch

62

Ölgehalt (Qualitätskl. 5) max. 25 mg/m

3

Temperaturbereich der Druckluft: -10 ... +50 °C

Druckbereich: 2,5 ... 8 bar

Luftleistung

Magnetventil: 110 I

N

/min (für Be-, Ent-, Anlüftung)

(110 IN/min - Lieferzustand

200 I

N

/min - max. typischer Durchfl uss)

(QNn-Wert nach Defi nition bei Druckabfall von 7 auf 6 bar absolut

bei +20 °C)

Anschlüsse: Zu- und Abluftanschluss G1/4

Arbeitsanschlüsse G1/8

Daten Wegmesssystem7.4.

Hubbereich: 0 ... 80 mm

Aufl ösung: 0,1 mm

Gesamtfehler: ± 0,5 mm (bei Verwendung eines

geeigneten Targets)

Elektrische Daten7.5.

siehe Kapitel 9. 24 V DC - Ausführung ,

10. AS-I - Ausführung ,

11. DeviceNet - Ausführung und

12. 120 V AC - Ausführung .

deutsch

63

MONTAGE / INSTALLATION8.

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

Vor dem Lösen von Leitungen oder Ventilen den Druck •

abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr durch Stromschlag!

Vor Eingriffen ins System (außer Teach-In-Vorgang in •

Nicht-Ex-Atmosphäre) die Spannung abschalten, vor

Wiedereinschalten sichern!

Die geltenden Unfallverhütungs- und Sicherheitsbe-•

stimmungen für elektrische Geräte beachten!

Verletzungsgefahr bei unsachgemäßer Montage!

Die Montage darf nur autorisiertes Fachpersonal mit •

geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten

der Anlage und unkontrollierten Wiederanlauf!

Anlage vor unbeabsichtigtem Betätigen sichern.•

Nach der Montage einen kontrollierten Wiederanlauf •

gewährleisten.

deutsch

Typ 8681

Page 18

64

Montage8.1.

Zur Montage des Steuerkopfes Typ 8681 an ein Prozessventil benötigen Sie einen prozessventilspezifi schen Aufnahmefl ansch als Adapter. Der Aufnahmefl ansch muss der

Bauform des Prozessventiles angepasst sein.

Die Kolbenstange mit Target auf die Prozessventil-

spindel montieren. Referenzmaße beachten!

Aufnahmefl ansch auf dem Prozessventil befestigen.

Dabei die Zentrierung und die Abdichtungsbedingungen beachten!

Sitz der beiden Dichtungsringe (in oberster und

unterster Nut) prüfen.

Steuerkopf auf den Aufnahmefl ansch montieren (stu-

fenlos 360° drehbar).

Steuerkopf mit den zwei Sicherungsschrauben (Ansatz-

schrauben M5) in der mittleren Nut des Aufnahmefl ansches sichern (siehe Bedienungsanleitung).

Pneumatische Installation8.2.

Die benötigten Arbeitsanschlüsse 2/A1 bis 2/A3 (je

nach Variante) mit den zugehörigen Anschlüssen des

Prozessventils verbinden.

Versorgungsleitung mit dem Versorgungsdruckan-

schluss 1/P (2,5 … 8 bar) verbinden.

deutsch

65

Am Abluftanschluss (3/R) ist im Lieferzustand bereits

ein Schalldämpfer montiert.

1/P

Versorgungsdruckanschluss

3/R

Abluftanschluss

(Schalldämpfer)

2/A3: MV 3 2/A2: MV 2 2/A1: MV 1

2/A1 ... A3 - Arbeitsanschlüsse Magnetventile (MV)

Verplombungsnasen

am Gehäuse

Die Drosselschrauben der

Magnetventile R und P

(siehe Bedienungsanleitung)

dienen der Einstellung der Luftzufuhr und -abfuhr der Arbeitsanschlüsse (für die Einstellung

der Stellgeschwindigkeit der

Prozessventile).

R

P

auf zu

deutsch

66

Öffnen/Schließen des 8.3.

Gehäuses

Öffnen:

Kunststoffschneidschrauben oder Verplombung lösen,

falls Gehäuse gesichert.

Kunststoffhaube durch Drehen gegen den Uhrzei-

gersinn (bis Anschlag, ca. 1,5 cm) öffnen.

Schließen:

Kunststoffhaube so auf das Unterteil aufsetzen, dass

die inneren „Nasen“ über den Befestigungsnuten liegen

und die äußeren Verplombungsnasen fast übereinander

liegen. Haube vollständig über die Dichtung des Unterteiles drücken.

Drehen der Haube um ca. 1,5 cm im Uhrzeigersinn

(bzw. bis Verplombungsnasen übereinander liegen).

Im Ex-Bereich wird eine Verplombung bzw. eine

Sicherung der Haube mit Kunststoffschneidschrauben gefordert!

Elektrische Installation8.4.

siehe Kapitel 9. 24 V DC - Ausführung ,

10. AS-I - Ausführung ,

11. DeviceNet - Ausführung und

12. 120 V AC - Ausführung .

deutsch

67

9. 24 V DC - AUSFÜHRUNG

Anschlussmöglichkeiten9.1.

links: 1 x M16 x 1,5 Kabelverschraubung

für Spannungsversorgung

und Signale

links: 1 x M16 x 1,5

Kabelverschraubung mit

Multipolanschluss (M12Stecker nach IEC 610762-101, 12-polig) an Kabel

von 8 cm

rechts: 1 x M16 x 1,5

Kabelverschraubung für

externen Initiator

rechts: 1 x M16 x 1,5

Kabelverschraubung für

externen Initiator

deutsch

Typ 8681

Page 19

68

Elektrische Daten9.2.

Spannungsversorgung: 12 ... 28 V DC, Restwelligkeit 10 %

Stromaufnahme

(Ruhestrom): 30 mA bei 24 V DC

Magnetventile: Leistungsaufnahme je Magnetventil:

max. 0,8 W

(0,9 W beim Einschalten)

Betriebsart: Dauerbetrieb (100 % ED)

Zentrale Anzeige der Schaltzustände:

42 mA bei Spannungsversorgung

24 V DC je dargestellter Leucht anzeige

Ausgänge/binäre

Rückmeldesignale: S1 out - S4 out

Bauart: Schließer (normally open),

PNP-Ausgang; kurzschlussfest,

schaltbarer

Ausgangsstrom: max. 100 mA je Rückmeldesignal

Option: analoges Rückmeldesignal:

Signalausgang: S3 out (binäres Rückmeldesignal

S3out entfällt hierbei)

Typ: Stromquelle (4 ...20 mA)

deutsch

69

Eingang/Näherungsschalter (externer Initiator: S4 in):

Spannungs- angelegte Spannung am

versorgung: Steuerkopf - 10 %

Strombelastbarkeit

Sensorversorgung: max. 90 mA; Kurzschlussschutz

Bauart: DC 2- und 3-Draht, NO od. NC;

PNP-Ausgang

Eingänge Ventilansteuerung (Y1 - Y3):

Signalpegel - aktiv: U > 10 V, max. 24 V DC + 10 %

Elektrische Installation (24 V DC)9.3.

WARNUNG!

Verletzungsgefahr durch Stromschlag!

Vor Eingriffen ins System (außer Teach-In-Vorgang in •

Nicht-Ex-Atmosphäre) die Spannung abschalten, vor

Wiedereinschalten sichern!

Die geltenden Unfallverhütungs- und Sicherheitsbe-•

stimmungen für elektrische Geräte beachten!

Verletzungsgefahr bei unsachgemäßer Installation!

Die Installation darf nur autorisiertes Fachpersonal mit •

geeignetem Werkzeug durchführen!

deutsch

70

Kabelverschraubung:

Das Gehäuse öffnen.

Anschlusskabel für Signale und Spannungsversorgung

sowie gegebenenfalls für den externen Initiator

konfektionieren.

Kabel durch die entsprechenden Kabelverschrau-

bungen in das Gehäuseinnere einführen.

Adern entsprechend der im Bild beschriebenen

Anschlussbelegungen an den Klemmleisten fi xieren.

Anschluss

mit Status-LED

für MV1

Klemmleiste 1

ServiceSchnittstelle

DIP-Schalter

zur Farbcodierung

der LED‘s

Klemmleiste 2

(externer

Initiator)

Teach-In-

Tasten T1-3

Anschlüsse mit

Status-LED

für MV2, 3

deutsch

71

Klemmleiste 1 Belegung

24 V Spannungsversorgung 24 V

GND GND

S1 OUT Ausgang Position 1

S2 OUT Ausgang Position 2

S3 OUT Ausgang Position 3

(Option: Analogsignal)

S4 OUT Ausgang externer Initiator

Y1 Eingang Magnetventil 1

Y2 Eingang Magnetventil 2

Y3 Eingang Magnetventil 3

Klemmleiste 2 Belegung

24 V Spannungsversorgung 24 V für

externen Initiator

S4 IN Eingang externer Initiator

GND GND externer Initiator

Gehäuse schließen.

Sicherstellung des IP-Schutzes (Blindstopfen)

deutsch

Typ 8681

Page 20

72

Kabelverschraubung mit Multipolanschluss:

Bei Varianten mit Multipolanschluss sind keine internen

Verkabelungsarbeiten notwendig. Sie benötigen allerdings

entsprechend konfektionierte bzw. montierte Kabelsätze mit

folgender Pin-Belegung:

Pin Bezeichnung Belegung

1 24 V Spannungsversorgung 24 V

2 GND GND

3 S1 OUT Ausgang Position 1

4 S2 OUT Ausgang Position 2

5 S3 OUT Ausgang Position 3

(Option: Analogsignal)

6 S4 OUT Ausgang externer Initiator S4

7 Y1 Eingang Magnetventil 1

8 Y2 Eingang Magnetventil 2

9 Y3 Eingang Magnetventil 3

10-12

nicht belegt

Ein externer Initiator kann über die 3-fach-Klemmleiste 2

angeschlossen werden (siehe Bild Seite 70 bzw. siehe

Bedienungsanleitung, Kapitel „Anschluss eines Externen

Initiators“).

deutsch

73

Ein- und Ausgangssignale zur übergeordneten Steuerung

(SPS):

Pin 9 - Y3

Pin 8 - Y2

12

Pin 6 - S4 out

Pin 7 - Y1

Pin 1 - 24 V

Pin 5 - S3 out

Pin 4 - S2 out

11

Pin 3 - S1 out

Pin 2 - GND

10

(12-poliger Rundsteckverbinder M12 x 0,75 - male

nach IEC 61076-2-101 — Blick auf Steckerstifte)

deutsch

74

10. AS-I - AUSFÜHRUNG

Anschlussmöglichkeiten10.1.

linker Anschluss:

1 x M16 x 1,5 Kabelverschraubung mit Multipolan-

schluss (M12-Stecker nach IEC 61076-2-101, 4-polig)

an Kabel von 8 cm oder 80 cm Länge

rechter Anschluss:

1 x M16 x 1,5 Kabelverschraubung für externen Initiator

Anzahl anschließbarer 10.2.

Steuerköpfe

Bei der AS-Interface-Version mit erweitertem Adressbereich

(A/B-Slave) kann 1 Master mit 62 Slaves kommu nizieren.

Bei der AS-Interface-Version mit Adressbereich 31 Slaves

können maximal 31 Steuerköpfe an eine Busleitung angeschlossen werden (Restriktion Adress bereich).

deutsch

75

Länge der Busleitung10.3.

Das Buskabel darf maximal 100 m lang sein. Bei der Anlagenauslegung muss die Länge des unmittelbar zum Steuerkopf führenden Rundkabels berücksichtigt werden (siehe

Beispielrechnung in Bedienungsanleitung).

10.4. Elektrische Daten

Spannungsversorgung:

Einstellung der Spannungsversorgung der Ventile über

Jumper auf dem AS-Interface-Elektronikmodul.

Standard: über AS-i

(29,5 ... 31,6 V DC

gemäß Spezifi kation)

Option: extern

(19,2 V DC bis 31,6 V DC)

Eingang/Näherungsschalter (externer Initiator: S4 in):

Spannungs- angelegte AS-i-Spannung am

versorgung: Steuerkopf - 10 %

Strombelastbarkeit

Sensorversorgung: max. 30 mA; Kurzschlussschutz

deutsch

Typ 8681

Page 21

76

Bauart: DC 2- und 3-Draht, NO od. NC;

PNP-Ausgang

Eingänge: 3 binäre Rückmeldesignale und

(aus Mastersicht) 1 x externer Initiator

Ausgänge: 0 bis 3 Magnetventile

(aus Mastersicht)

max. Schaltleistung: 0,8 W über AS-i, je MV

Anzugsstrom: 30 mA bzw. 0,9 W / 200 ms

Betriebsart: Dauerbetrieb (100 % ED)

Zentrale Anzeige der Schaltzustände:

Stromaufnahme max. 33 mA bzw. 1 W je darge-

stellter Leuchtanzeige (bei

30,5 V AS-i-Spannung)

Spannungsversorgung über AS-Interface - Bus:

max. Stromaufnahme

aus AS-i: 200 mA

(inkl. externer Initiator mit 30 mA)

integrierter Kurzschlussschutz

Externe Spannungsversorgung:

Externe Spannungs versorgung: 19,2 V DC bis 31,6 V DC

max. Stromaufnahme aus externer Spannungs-

versorgung: 110 mA bei 24 V DC

integrierter Kurzschlussschutz

deutsch

77

Elektrische Installation (AS-i)10.5.

WARNUNG!

Verletzungsgefahr durch Stromschlag!

Vor Eingriffen ins System (außer Teach-In-Vorgang in •

Nicht-Ex-Atmosphäre) die Spannung abschalten, vor

Wiedereinschalten sichern!

Die geltenden Unfallverhütungs- und Sicherheitsbe-•

stimmungen für elektrische Geräte beachten!

Verletzungsgefahr bei unsachgemäßer Installation!

Die Installation darf nur autorisiertes Fachpersonal mit •

geeignetem Werkzeug durchführen!

Bei Varianten mit Multipolanschluss sind keine internen

Verkabelungsarbeiten notwendig. Sie benötigen allerdings

entsprechend konfektionierte bzw. montierte Kabelsätze mit

folgenden Pin-Belegungen .

Pin 2

Pin 3

Pin 1

Pin 4

Ebenso müssen die Jumper auf dem Elektronikmodul entsprechend gesetzt werden (Spannungsversorgung über AS-i-Bus

oder extern) - siehe Seite 75 .

deutsch

78

Spannungsversorgung

Pin

(über AS-i)

Belegung

(extern)

Belegung Farbe

1 AS-i+

AS-i+ braun

2 n.b. GND weiß

3 AS-i- AS-i- blau

4 n.b. 24 V+ schwarz

Ein externer Initiator kann über die 3-fach-Klemmleiste „INI“

angeschlossen werden - siehe Bedienungsanleitung, Kapitel

„Anschluss eines Externen Initiators“.

deutsch

79

DEVICENET - AUSFÜHRUNG11.

Anschlussmöglichkeit11.1.

linker Anschluss:

1 x M16 x 1,5 Kabelverschraubung mit Multipolan-

schluss (M12-Stecker nach IEC 61076-2-101, 5-polig)

an Kabel von 80 cm Länge

rechter Anschluss:

1 x M16 x 1,5 Kabelverschraubung für externen Initiator

Spezifi zierung DeviceNet11.2.

EDS-Datei 8681.EDS

Icons 8681.ICO

Baudrate Werkseinstellung 125 kBit/s

Adresse Werkseinstellung: 63

deutsch

Typ 8681

Page 22

80

Prozessdaten 2 statische Input-Assemblies

(Input: vom Steuerkopf zum

DeviceNet-Master/Scanner)

1 statisches Output-Assembly

Eingänge 3 diskrete Rückmeldesignale des Weg

messsystems (Positionen S1 - S3)

1 diskretes Rückmeldesignal des

externen Initiators (S4)

1 analoges Wegsignal in mm

Versorgung über DeviceNet-Strang

(11 ... 25 V DC)

Schaltpegel High-Signal 5 V

Schaltpegel Low-Signal 1,5 V

Ausgänge 3 Magnetventile

Leistungsaufnahme

aus dem Bus: max. 5 W, (3 Ventile mit je 0,8 W)

Länge der Busleitung11.3.

Die maximale Gesamtleitungslänge (Summe von Hauptund Stichleitungen) eines Netzwerks ist abhängig von der

Baudrate.

Die maximale Gesamtleitungslänge (nach DeviceNetSpezifi kation) beträgt für:

deutsch

81

Baudrate Dickes Kabel Dünnes Kabel

125 500 m 100 m

250 250 m 100 m

500 100 m 100 m

Die maximale Stichleitungslänge (Drop Line) beträgt für:

Baudrate Stichleitung Summe (im Netzwerk)

125 6 m 156 m

250 6 m 78 m

500 6 m 39 m

Elektrische Daten11.4.

Spannungsversorgung: 11 … 25 V DC (gemäß

Spezifi kation)

max. Stromaufnahme: 200 mA bei 24 V DC

Eingang / Näherungsschalter (externer Initiator: S4 in):

Spannungsversorgung: über DeviceNet-Spannungs-

versorgung - 10 %

Strombelastbarkeit

Sensorversorgung: max. 30 mA

Kurzschlussschutz

deutsch

82

Bauart: DC 2- und 3-Draht,

Schließer (NO),

PNP-Ausgang

Eingangsstrom 1-Signal: I

Sensor

> 6,5 mA, intern

auf 10 mA begrenzt

Eingangsspannung 1-Signal: U

Sensor

> 10 V

Eingangsstrom 0-Signal: I

Sensor

< 4 mA

Eingangsspannung 0-Signal: U

Sensor

< 5 V

Eingänge (aus Mastersicht) / binäre bzw. analoge

Rückmeldesignale:

Die Gewinnung der 3 binär zurückgemeldeten Ventilpositionen bzw. des analogen Wegsignals ist in der Bedienungsanleitung im Kapitel „Wegmesssystem“ beschrieben.

Ausgänge (aus Mastersicht) / Magnetventile:

max. Schaltleistung 1,0 W

typ. Dauerleistung 0,8 W

Leistungsabsenkung über DeviceNet Elektronik integriert

Anzugsstrom 120 mA typ. / 200 ms

(3 Ventile)

Haltestrom 100 mA typ. bei 24 V DC

(3 Ventile)

Betriebsart Dauerbetrieb (100 % ED)

Ventiltypen 6524

deutsch

83

Zentrale Anzeige der Schaltzustände:

Stromaufnahme aus

DeviceNet bei 24 V DC ca. 42 mA bzw. 1 W je

dargestellter Leuchtanzeige

Elektrische Installation (DVN)11.5.

WARNUNG!

Verletzungsgefahr durch Stromschlag!

Vor Eingriffen ins System (außer Teach-In-Vorgang in •

Nicht-Ex-Atmosphäre) die Spannung abschalten, vor

Wiedereinschalten sichern!

Die geltenden Unfallverhütungs- und Sicherheitsbe-•

stimmungen für elektrische Geräte beachten!

Verletzungsgefahr bei unsachgemäßer Installation!

Die Installation darf nur autorisiertes Fachpersonal mit •

geeignetem Werkzeug durchführen!

Bei Varianten mit Multipolanschluss sind keine internen

Verkabelungsarbeiten notwendig. Sie benötigen allerdings

entsprechend konfektionierte bzw. montierte Kabelsätze mit

der folgenden Pin-Belegung:

deutsch

Typ 8681

Page 23

84

Pin 4: CAN_H

Pin 5: CAN_L

Pin 1: Drain

Pin 3: V–

Pin 2: V+

Steckeransicht von vorn auf die Stifte:

Pin Belegung Farbe

1 Drain

(Schirm)

2 V+ rot

3 V- schwarz

4 CAN_H weiß

5 CAN_L blau

Ein externer Initiator kann

über die 3-fach-Klemmleiste

angeschlossen werden - siehe

Bedienungsanleitung, Kap.

„Anschluss eines Externen

Initiators“.

deutsch

85

Netztopologie11.6.

Bei der Installation eines DeviceNet-Systems ist auf die korrekte Abschlussbeschaltung der Datenleitungen zu achten.

Die Beschaltung verhindert die Entstehung von Störungen

durch Signalrefl exionen auf den Datenleitungen.

Die Hauptleitung ist dazu an beiden Enden mit Widerständen von je 120

und 1/4 W Verlustleistung abzu-

schließen (siehe Bedienungsanleitung, Kap. „Netztopologie

eines DeviceNet-Systems“).

Konfi guration von Baudrate 11.7.

und DVN-Adresse

Zur Konfi gurierung sind 8 DIP-Schalter vorhanden:

DIP-Schalter 1 bis 6 für die DeviceNet-Adresse•

(Werkseinstellung: 63, d. h. DIP 1 - 6: on/ein)

DIP-Schalter 7 bis 8 für die Baudrate•

(Werkseinstellung: 125, d. h. DIP 7 + 8: aus)

Weitere Einstellungen - siehe Bedienungsanleitung, Kap.

„Konfi gurieren der DeviceNet-Adresse / Baudrate“

deutsch

86

Konfi guration der Prozess-11.8.

daten

Zur Übertragung von Prozessdaten über eine I/O-Verbin dung stehen 2 statische Input- und 1 statisches OutputAssembly zur Auswahl - Details siehe Bedienungsanleitung, Kapitel „Konfi guration der Prozessdaten“.

„Adresse“ in der Tabelle beschreibt das Datenattribut der

Assemblies für Lesezugriff (Class, Instance, Attribute).

InputAssemblies

Adresse Format des Datenattributs

Wert 0: OFF / Wert 1: ON

S1…S4

(Werkseinstellung)

4, 1, 3 Byte 0:

Bit 0: Position S1

Bit 1: Position S2

Bit 2: Position S3

Bit 3: Position S4

S1…S4 +

POS

(mit POS:

Ist-Position

(Actual

Position))

4, 2, 3 Byte 0:

Bit 0: Position S1

Bit 1: Position S2

Bit 2: Position S3

Bit 3: Position S4

Bit 4…7: nicht benutzt

Byte 1:

POS in mm

deutsch

87

„Adresse“ in der Tabelle beschreibt das Datenattribut der

Assemblies für Lesezugriff (Class, Instance, Attribute).

OutputAssembly

Adresse Format des Datenattributs

Wert 0: OFF / Wert 1: ON

Magnetventil

1 ... 3

4, 21, 3 Byte 0:

Bit 0: MV1

Bit 1: MV2

Bit 2: MV3

Bit 3…7: nicht benutzt

Sicherheitsstellung der 11.9.

Magnetventile bei Busfehler

Bei Busausfall wird das Magnetventil in eine programmierbare Sicherheitsstellung geschaltet (Default: Magnetventil stromlos) - Details siehe Bedienungsanleitung,

Kapitel „Konfi guration des Gerätes“.

Die Bus-Status-LED „Network“ auf dem Elektronikmodul

gibt durch Farbe und Blinkmuster genauere Hinweise auf

die Art des Fehlers - Details siehe Bedienungsanleitung,

Kapitel „Anzeige der Status-LEDs bei Busfehler“).

deutsch

Typ 8681

Page 24

88

120 V AC - AUSFÜHRUNG12.

Anschlussmöglichkeit12.1.

linker Anschluss:

1 x M16 x 1,5 Kabelverschraubung

für Spannungsversorgung und

Signale

rechter Anschluss:

1 x M16 x 1,5 Kabelverschraubung

für externen Initiator

Elektrische Daten12.2.

Zentrale Spannungsversorgung: 110 ... 130 V AC, 50/60 Hz

Stromaufnahme

(Ruhestrom): 10 mA bei 120 V AC

Magnetventile:

Leistungsaufnahme

je Magnetventil: max. 1,4 VA

(1,7 VA beim Einschalten)

Stromaufnahme

je Magnetventil: 12 mA bei 120 V AC

Betriebsart: Dauerbetrieb (100 % ED)

deutsch

89

Zentrale Anzeige der Schaltzustände:

13 mA bei Spannungsver-

sorgung 120 V AC je dargestellter Leuchtanzeige

Ausgänge/binäre

Rückmeldesignale: S1out - S3out

Bauart: Schließer (NO), L-schaltend,

Kurzschlussschutz durch

selbstrückstellende Sicherung

schaltbarer

Ausgangsstrom: max. 50 mA je Rückmeldesignal

Ausgangsspannung

- aktiv: (Betriebsspannung - 2 V)

Ausgangsspannung

- inaktiv: max. 1 V im unbelasteten

Zustand

Ausgang Rückmeldesignal: S4 out ist direkt mit S4in

verbunden

Eingang / Näherungsschalter (externer Initiator: S4 in):

Spannungsversorg.: angelegte Spannung am Steuer-

kopf U

Nenn

= 120 VAC, 50/60 Hz

Strombelastbarkeit

Sensorversorgung: max. 0,7 A

Kurzschlussschutz

deutsch

90

Bauart: DC 2- und 3-Draht,

Schließer (NO), L-schaltend

Eingangsstrom 1-Signal: I

Sensor

< 2 mA

Eingänge Ventilansteuerung (Y1 - Y3):

Signalpegel - aktiv: U > 60 V AC

Signalpegel - inaktiv: U < 20 V AC

Impedanz: > 40 kOhm

Elektrische Installation12.3.

WARNUNG!

Verletzungsgefahr durch Stromschlag (120 V AC)!

Beim Einstellen des Wegmesssystems (Teach-in) •

keine spannungsführenden Bauteile berühren!

Vor Eingriffen ins System (außer Teach-In-Vorgang in •

Nicht-Ex-Atmosphäre) die Spannung abschalten, vor

Wiedereinschalten sichern!

Die geltenden Unfallverhütungs- und Sicherheitsbe-•

stimmungen für elektrische Geräte beachten!

Verletzungsgefahr bei unsachgemäßer Installation!

Der • PE-Anschluss muss angeschlossen sein!

Die Installation darf nur autorisiertes Fachpersonal mit •

geeignetem Werkzeug durchführen!

deutsch

91

Kabelverschraubung:

Das Gehäuse öffnen.

Anschlusskabel für Signale und Spannungsversorgung

sowie gegebenenfalls für den externen Initiator

konfektionieren.

Kabel durch die entsprechenden Kabelverschrau-

bungen in das Gehäuseinnere einführen.

Adern entsprechend der im Bild beschriebenen

Anschlussbelegungen an den Klemmleisten fi xieren.

Anschluss

mit Status-

LED für

MV1

Klemm-

leiste 1

ServiceSchnittstelle

DIP-Schalter

zur Farbcodierung

der LED‘s

Klemmleiste 2

(externer

Initiator)

Teach-In-

Tasten T1-3

Anschlüsse mit

Status-LED für

MV2, 3

deutsch

Typ 8681

Page 25

92

Klemmleiste 1 Belegung

PE Schutzleiter Protection Earth

L

Spannungsversorgung 120 V AC

Leiter

N Nullleiter

S1 OUT Ausgang Position 1

S2 OUT Ausgang Position 2

S3 OUT Ausgang Position 3

S4 OUT Ausgang externer Initiator

Y1 Eingang Magnetventil 1

Y2 Eingang Magnetventil 2

Y3 Eingang Magnetventil 3

Klemmleiste 2 Belegung (externer Initiator)

L Spannungsversorgung - Leiter

S4 IN Eingang externer Initiator

N Spannungsversorgung - Nullleiter

Gehäuse schließen.

Sicherstellung des IP-Schutzes (Blindstopfen)

Ein externer Initiator kann über die Klemmleiste 2 angeschlossen werden - siehe Bedienungsanleitung, Kapitel

„Anschluss eines Externen Initiators“.

deutsch

93

WEGMESSSYSTEM13.

Der erfassbare Hubbereich beträgt 0 ... 80 mm.

Für den Abgleich auf den realen Hubbereich sind 3 Teach-

In-Tasten vorgesehen.

Teach-In13.1.

Das Gehäuse öffnen.

Spannungsversorgung herstellen

Prozessventil in die untere Schaltposition fahren.

Untere Teach-In-Taste (T1) ca. 1,5 s gedrückt halten

(entsprechende LED blinkt 3 mal kurz auf).

Ist diese Position abgespeichert, leuchtet die entsprechende LED dauerhaft, bis die Position des Hubkolbens verändert wird.

Danach Prozessventil in die obere zu erfassende

Schaltposition fahren.

Obere Teach-In-Taste (T2) ca. 1,5 s gedrückt halten

(entsprechende LED blinkt 3 mal kurz auf).

Ist diese Position abgespeichert, leuchtet die entsprechende LED dauerhaft, bis die Position des Hubkolbens verändert wird.

Das Prozessventil kann in eine dritte defi nierte Position

gefahren werden.

deutsch

94

Mittlere Teach-In-Taste (T3) ca. 1,5 s gedrückt halten

(entsprechende LED blinkt 3 mal kurz auf).

Ist diese Position abgespeichert, blinkt die entsprechende LED dauerhaft, bis die Position des Hubkolbens verändert wird.

Steuerkopf und Anlage gegebenenfalls zurück

in den Normalzustand bringen (Schaltstellung,

Spannungsversorgung).

Gehäuse schließen.

Teach-Reset13.2.

Teach-In-Tasten (T1 + T2) ca. 2,5 s gedrückt halten

(optische Rückmeldung: Blinken in Fehlerfarbe)

Autotune13.3.

Autotune-Funktionen und Autotune-Ablauf - siehe

Bedienungsanleitung

LED - Farbzuordnungen13.4.

S1 - grün, dauerhaft leuchtend,

S2 - gelb, dauerhaft leuchtend,

S3 - grün, dauerhaft blinkend (250 ms/250 ms)

(Auslieferungszustand DIP-Schalter: 0000)

deutsch

95

INBETRIEBNAHME14.

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen, sowie

Schäden am Gerät und seiner Umgebung führen.

Vor der Inbetriebnahme muss gewährleistet sein, dass •

der Inhalt der Bedienungsanleitung dem Bedienungspersonal bekannt ist und vollständig verstanden wurde.

Die Sicherheitshinweise und die bestimmungsgemäße •

Verwendung müssen beachtet werden.

Nur ausreichend geschultes Personal darf die Anlage/•

das Gerät in Betrieb nehmen.

Montage des Steuerkopfs 8681.

Pneumatische und elektrische Installation.

Einstellen des Wegmesssystems (Teach-In).

Nach Montage, Installation und Einstellen des Wegmesssystems gemäß Bedienungsanleitung ist der Steuerkopf

betriebsbereit.

deutsch

Typ 8681

Page 26

96

VERPACKUNG, TRANSPORT, 15.

LAGERUNG, ENTSORGUNG

HINWEIS!

Lagerungs- / Transportschäden!

Unzureichend geschützte Geräte können durch

Transport oder Lagerung beschädigt werden.

Gerät vor Nässe und Schmutz geschützt in einer stoß-•

festen Verpackung transportieren/lagern.

Eine Über- bzw. Unterschreitung der zulässigen Lager-•

temperatur vermeiden.

Lagertemperatur. -20 … +65 °C. •

HINWEIS!

Umweltschäden durch von Medien kontaminierte

Geräteteile.

Geltende Entsorgungsvorschriften und Umweltbestim-•

mungen einhalten.

Entsorgen Sie das Gerät und die Verpackung

umweltgerecht.

Beachten Sie die nationalen Abfallbeseitigungs-

vorschriften.

deutsch

Typ 8681

Page 27

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifi cations

techniques.

© 2010 - 2011 Bürkert Werke GmbH

Operating Instructions

1105/02_EU-ml_00806166

/ Original DE

Type 8681

Tête de commande

Quickstart

Français

98

QUICKSTART1.

AVERTISSEMENT !

Important safety information!

Lisez Quickstart attentivement. Tenez compte en particulier les chapitres 4. Consignes de sécurité fondamen-

tales et 3. Utilisation conforme .