Page 1

Operating Instructions

Bedienungsanleitung

Instructions de service

Type 8644 AirLINE

with Inline (Phoenix Contact)

mit Inline (Phoenix Contact)

avec Inline (Phoenix Contact)

Page 2

We reserve the right to make technical changes without notice.

T echnische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2002 Bürkert Werke GmbH & Co. KG

Operating Instructions 0511/11_EU-EN_00804636

Page 3

0460

6525

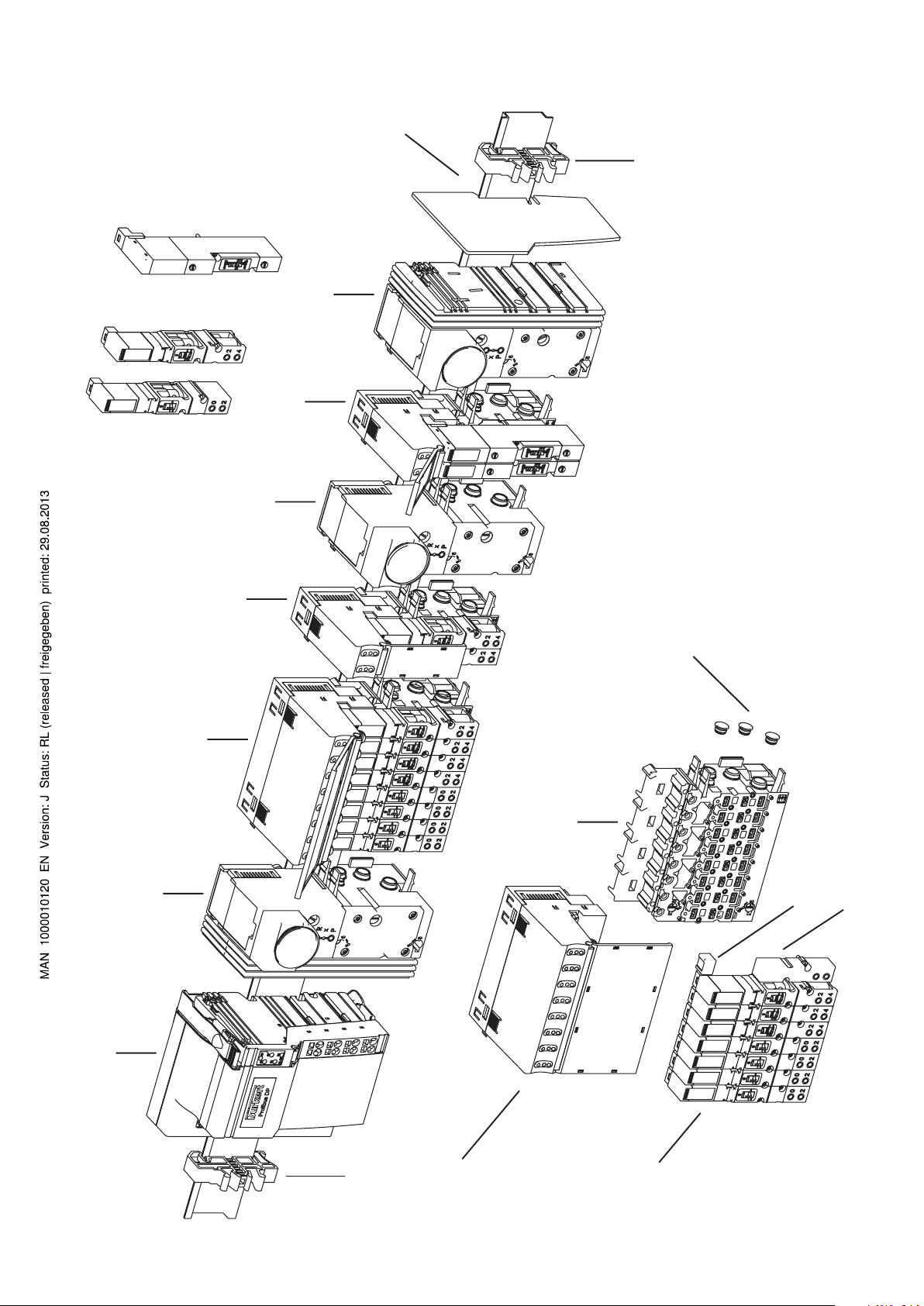

Accessories

Accessories

Me02

6524

Syst

Me02

Syst

Accessories

Syst

Mp11

Me02

Me02

Accessories

Me02

Cover

Valves

Add-on dimension 11 mm

Cover plate

Page 4

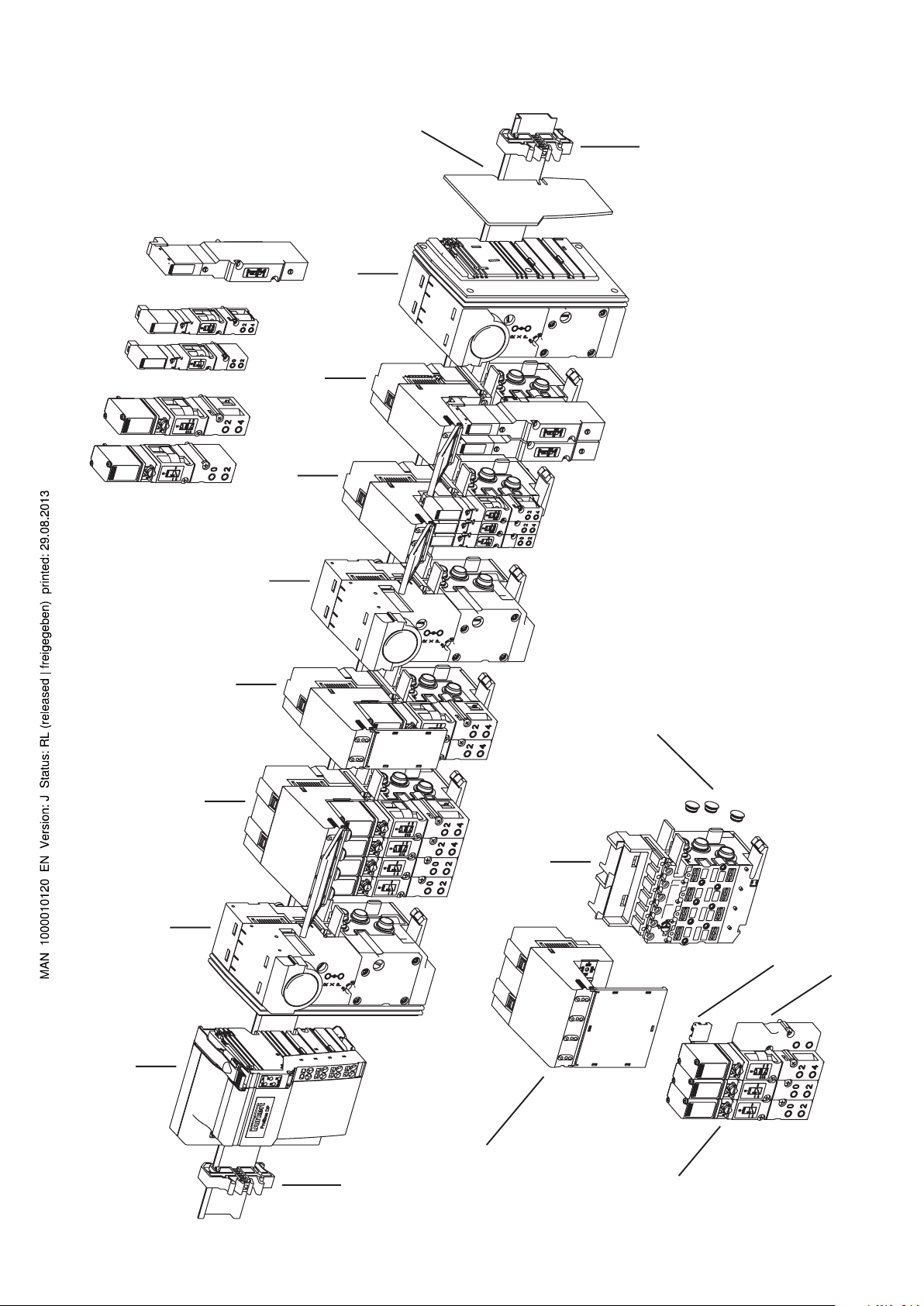

6527

6526

Accessories

Accessories

0461

Me03

6525

6524

Syst

Syst

Me03

Me02

Me03

Syst

Syst

Mp12

Accessories

Cover

Cover plate

Accessories

Me03

Valves

Add-on dimension 16,5 mm

Page 5

C

ONTENTS

List of contents

Type 8644 AirLINE -Phoenix

GENERAL NOTES .................................................................................................................................................................................................................................3

Symbols

Intended use

General safety notes

Scope of delivery

Warranty conditions

Approvals

Assembly note

Information of the Internet

..................................................................................................................................................................................................................................................... 4

......................................................................................................................................................................................................................................... 4

................................................................................................................................................................................................................ 4

........................................................................................................................................................................................................................... 6

.................................................................................................................................................................................................................... 6

................................................................................................................................................................................................................................................. 6

.................................................................................................................................................................................................................................. 6

................................................................................................................................................................................................... 6

INSTALLATION/COMMISSINONING ....................................................................................................................................................................... 7

Installation instructions

Illustration of the Valve block

Removing the valve block from the top-hat rail

Installation of the AirLINE system

........................................................................................................................................................................................................... 8

........................................................................................................................................................................................... 8

....................................................................................................................................... 9

........................................................................................................................................................................ 10

deutsch

Fluidic installation

Labelling of the connections

Elektrical installation

Fluidic commissioning

Electrical commissioning

...................................................................................................................................................................................................................... 11

........................................................................................................................................................................................ 12

.............................................................................................................................................................................................................. 13

......................................................................................................................................................................................................... 13

................................................................................................................................................................................................. 13

MAINTENANCE AND TROUBLESHOOTING ........................................................................................................................................ 15

Troubleshooting

............................................................................................................................................................................................................................ 16

8644/phoenix - 1

Page 6

C

ONTENTS

SYSTEM DESCRIPTION ......................................................................................................................................................................................................... 18

Bürkert-AirLINE modulare elektrical / pneumatic automation system

Valve block

Field bus node Profibus DP

Field bus node Profibus DPV1

Connector modules

Electronic pressure measurement module (PMM)

Basic electronic modules

Basic pneumatic module

Valves

......................................................................................................................................................................................................................................... 22

......................................................................................................................................................................................... 26

................................................................................................................................................................................. 42

................................................................................................................................................................................................................. 90

...................................................................................................................... 104

............................................................................................................................................................................................. 111

............................................................................................................................................................................................... 119

.................................................................................................................................................................................................................................................... 121

................................................................... 19

deutsch

ANNEX ................................................................................................................................................................................................................................................................. A1

EC Declaration of Conformity

Certificate of Conformity

................................................................................................................................................................................... A2

................................................................................................................................................................................................. A3

2 - 8644/phoenix

Page 7

General Notes

GENERAL NOTES

SYMBOLS

INTENDED USE

GENERAL SAFETY NOTES

..........................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................

.............................................................................................................................................................................................

Protection from damage by electrostatic charging

Safety notes for the valve

SCOPE OF DELIVERY

WARRANTY CONDITIONS

APPROVALS

..............................................................................................................................................................................................................................................

ASSEMBLY NOTE

................................................................................................................................................................................................................ 5

................................................................................................................................................................................................................

.................................................................................................................................................................................................

..............................................................................................................................................................................................................................

.......................................................................................................................................... 5

4

4

4

6

6

6

6

INFORMATION ON THE INTERNET

.....................................................................................................................................................................

8644/phoenix - 3

6

Page 8

GENERAL NOTES

SYMBOLS

The following symbols are used in these operating instructions:

marks a work step that you must carry out

ATTENTION!

NOTE

marks notes on whose non-observance your health or the functioning of the device will be

endangered.

marks important additional information, tips and recommendations

INTENDED USE

The device is used exclusively as an electrical/pneumatic automation system in conjunction with Phoenix

electronics modules. It is designed for use in the switching cabinet or control box. The de vice must only be

operated using the values indicated in the "Technical data f or the ov erall system" and "Technical data for

the valve block" sections and on the type plates.

Read the instructions for use carefully. In particular, follow the chapter "Gener al safety inf ormation". The

operating manual describes the entire life cycle of the device. Retain the operating instructions so that they

are accessible for the respectiv e user.

The safety features of the device may not be circumvented under any circumstances. It is imperative to

comply with all accident prevention stipulations . The components mounted on commissioning must not be

disassembled without express, written working instructions.

The system must only be installed and maintained by trained specialist personnel.

Unauthorized rebuilding or changes within the system are not allowed for saf ety reasons. When e xchanging

parts due to failure or normal wear, use only original replacement parts.

Attention must be paid to the working instructions in the individual sections. The saf ety inf ormation must be

complied with at all times. Should working instructions, their sequence, safety information or the safety

label not be complied with, the claim for liability shall lapse.

GENERAL SAFETY NOTES

• Keep to standard engineering rules in planning the use of and operating the device!

• Installation and maintenance work are only allowed by specialist personnel using suitable tools!

• Observe the current regulations on accident prevention and safety for electrical devices during

operation, maintenance and repair of the device!

• Always switch off the power supply before intervening in the system!

• Note that in systems under pressure, piping and valves may not be loosened!

• T ake suitab le precautions to prevent inadv ertent operation or damage by unauthorized action!

• After interruption of the electrical or pneumatic supply , make sure the process is restarted in a welldefined, controlled manner!

• On non-observance of these notes and unauthorized interference with the device, we will refuse all

liability and the warranty on device and accessories will become void!

4 - 8644/phoenix

Page 9

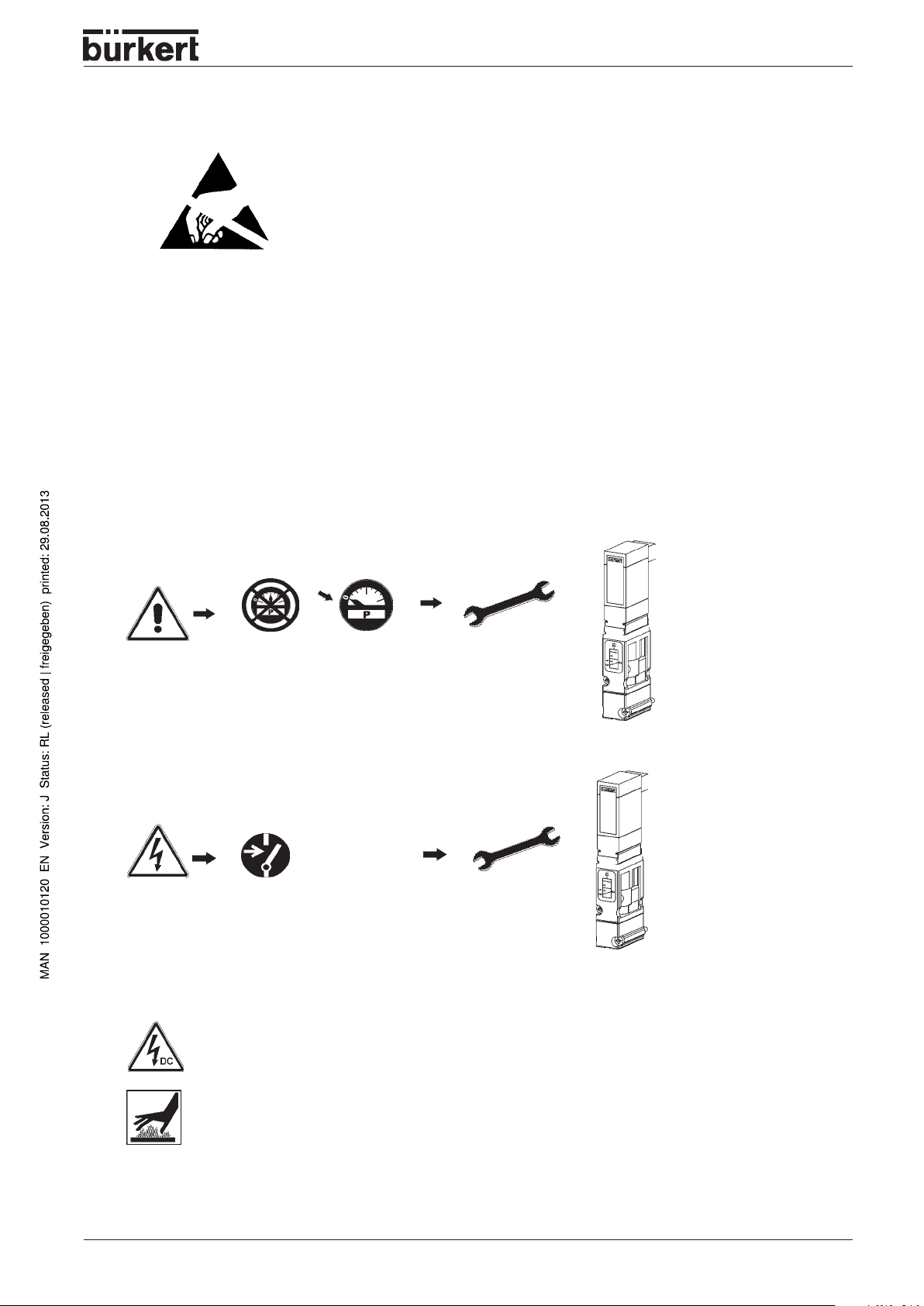

Protection from damage by electrostatic charging

The unit contains electronic components that are very sensitive to

electrostatic discharge (EDS). Contact to electrostatically charged

persons or objects will endanger these components. In the worst case,

they will be immediately destroyed or will fail after commissioning.

GENERAL NOTES

A TTENTION

EXERCISE CAUTION ON

HANDLING !

ELECTROST ATICALLY

SENSITIVE COMPONENTS /

MODULES!

Observe the requirements of EN 100 015 - 1 in order to minimize the

possibility of, or avoid, damage from instantaneous electrostatic

discharge. Also take care not to touch components that are under

supply voltage.

Safety notes for the valve

• Keep to standard engineering rules in planning the use of and operating the device!

• T ak e suitable precautions to prev ent inadvertent operation or damage by unauthorized action!

• Note that in systems under pressure, piping and valves may not be loosened!

0 bar, psi, kPa

• Always switch off the power supply before intervening in the system !

• To avoid pressure drop on switching, make the v olume of the pressure supply as large as possible!

• The device shall only be operated on direct current!

• Risk of injury!

In continuous operation, the coil can become very hot!

8644/phoenix - 5

Page 10

GENERAL NOTES

SCOPE OF DELIVERY

Immediately after receipt of the goods, make sure the contents are undamaged and agree with the scope of

delivery stated on the packing slip.

In case of any discrepancies, please contact our Call Center

Bürkert Fluid Control Systems

Call-Center

Chr.-Bürkert-Str . 13-17

D-76453 Ingelfingen

T el.: (07940) 10-111

Fax: (07940) 10-448

E-mail: inf o@de.bue rkert.com

or your local Bürkert Sales Center immediately .

WARRANTY CONDITIONS

This document contains no warranty statements. In this connection we refer to our general sales and

business conditions. A prerequisite for validity of the warranty is use of the device as intended with

observance of the specified conditions of use.

ATTENTION!

The warranty covers only faultless condition of the automation system and the attached

valves supplied. No liability will be accepted for consequential damage of any kind that

may arise from failure or malfunctioning of the device.

APPROVALS

The approval marks on Bürkert rating plates refer to the Bürkert products. In order that the complete v alv e

island is approved, a gateway with a design inspection certificate must be used. In this case, a valv e

island may be extended with appro v ed units ha ving design inspection certificates up to 64 valves .

More detailed information on the approvals of the v alves is to be found in the chapter Valves.

ASSEMBLY NOTE

If the configuration of the valve block also provides of Type 0461 (5/2- way pulsed valv e , 5/3- way valve), a

profile rail EN 50022-35x15 must be used.

INFORMATION ON THE INTERNET

Operating instructions and data sheets for type 8644 may be found on the Internet under:

www.buerkert.com Germany Produkte Downloads Betriebsanleitungen Typ 8644 Phoenix

Furthermore, a complete documentation is available on CD . The complete Operating instructions ma y be

ordered under the following indentification number: 804 636

HINWEIS

6 - 8644/phoenix

T echnical data, configur ation files and a detailed description of bus terminals and electrical

function terminals by the Phoenix Contact company are available on the Internet web site:

www.phoenixcontact.com Download & Documetation Interbus & A utomation

Documentation

Then enter in the search window e.g. "IL" as joker or the exact product designation.

Bürkert has no influence upon the update status of the latter home page or on changes in

technical data or presentation on the pages linked thereto.

Page 11

INSTALLATION / COMMISSIONING

Installation / Commissioning

Installation instructions..................................................................................................................... 8

Illustration of the Valve block............................................................................................................. 8

Removing the valve block from the top-hat rail..................................................................................9

Installation of the AirLINE system.................................................................................................... 10

Fluidic installation............................................................................................................................. 11

Labelling of the connections............................................................................................................. 12

Electrical installation ........................................................................................................................ 13

Fluidic commissioning...................................................................................................................... 13

Electrical commissioning ................................................................................................................. 13

8644/phoenix - 7

Page 12

INSTALLATION / COMMISSIONING

Installation instructions

The AirLINE system Type 8644 may be combined with the electrical automation systems of various

manufacturers. You should follow the respective installation instructions .

ATTENTION!

Before starting installation work, switch off the voltage in the vicinity and secure it

against being switched on again.

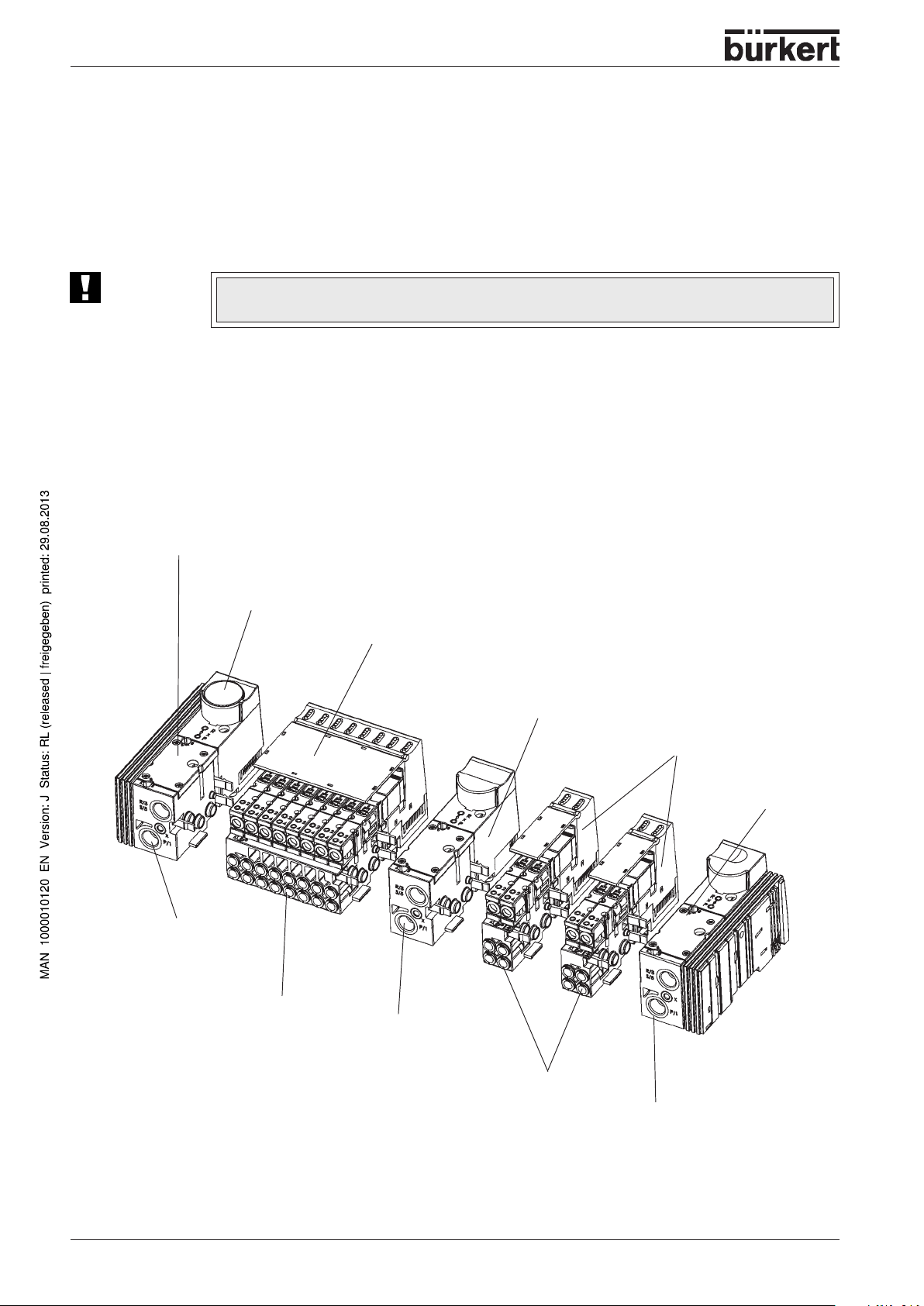

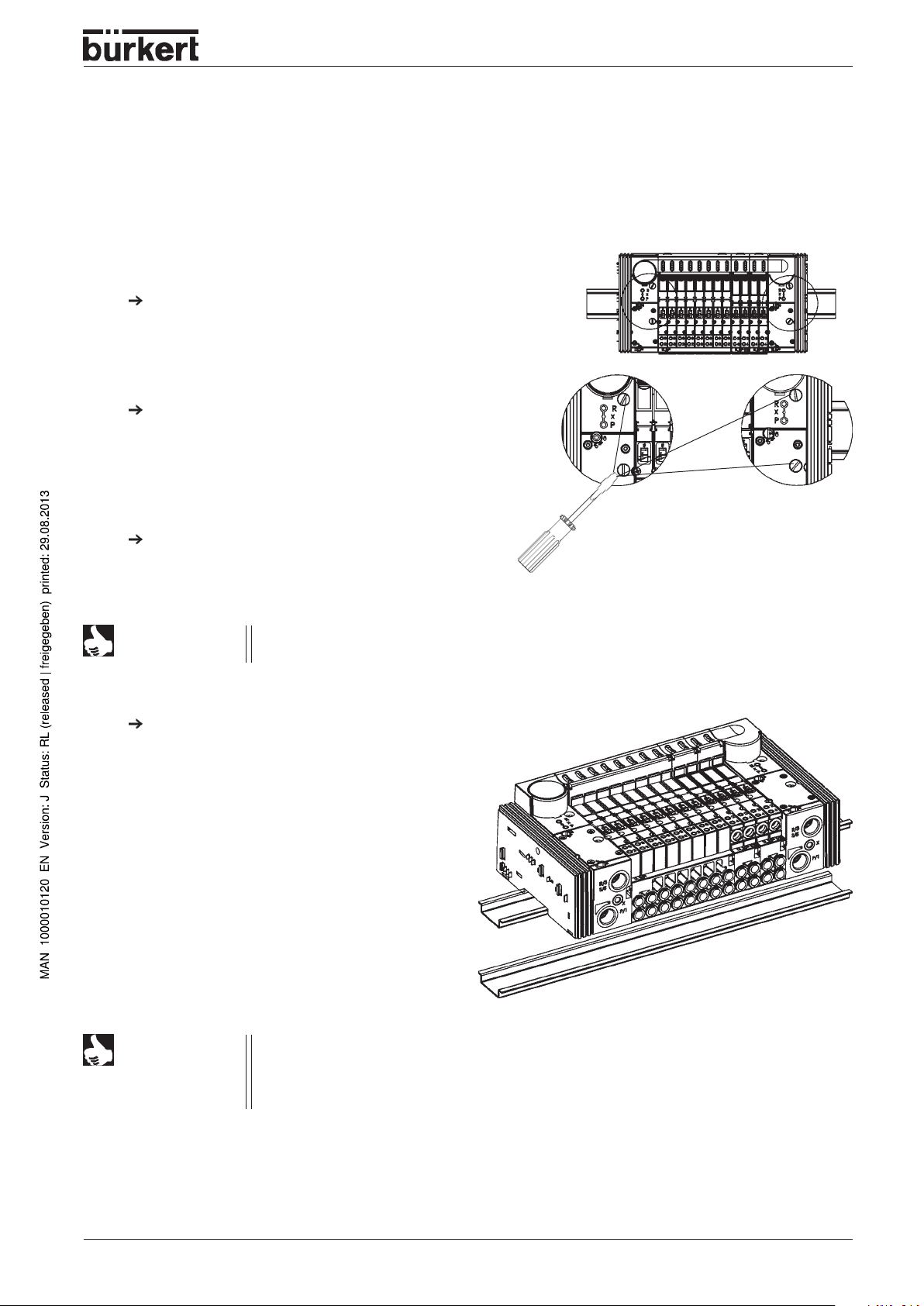

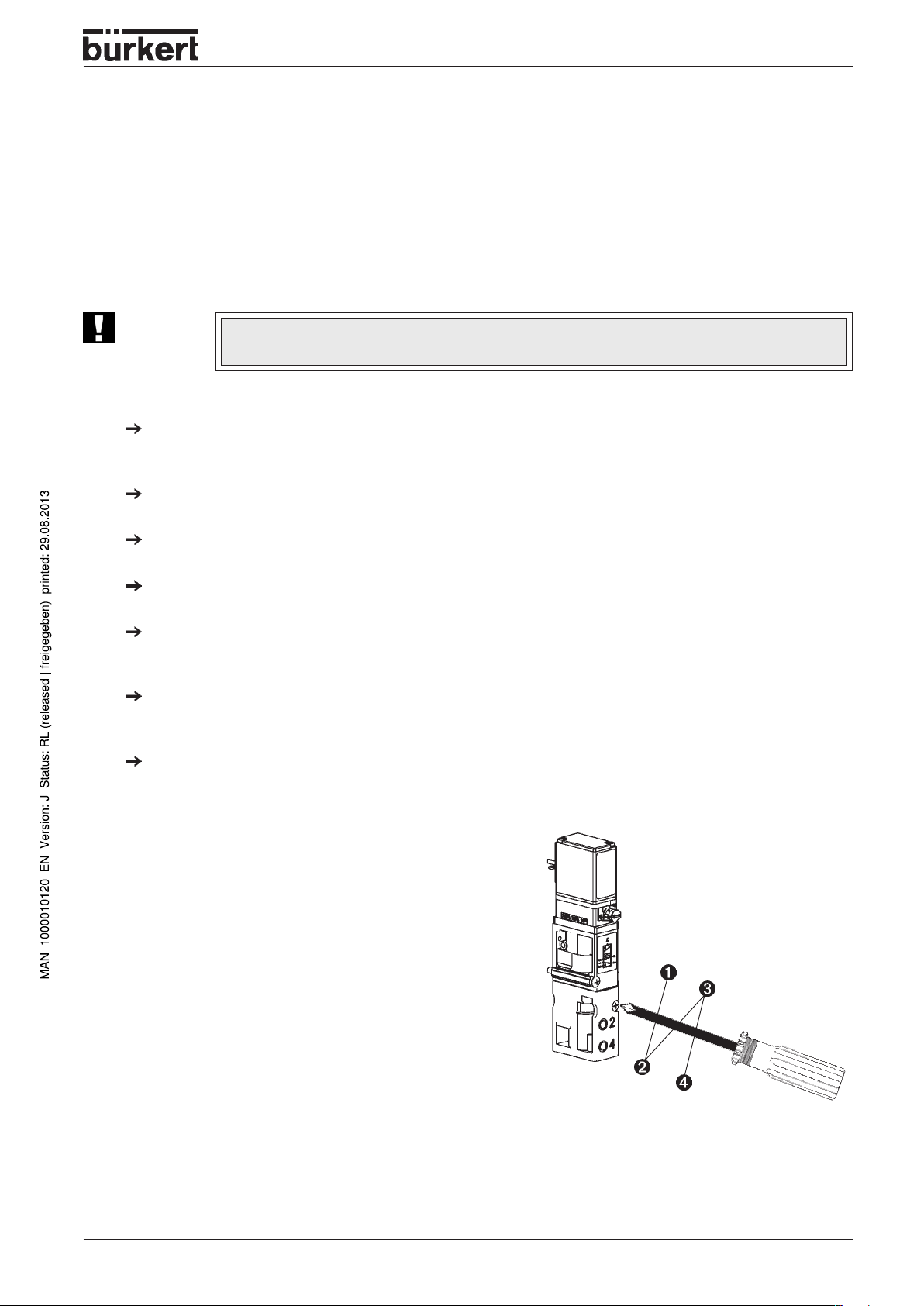

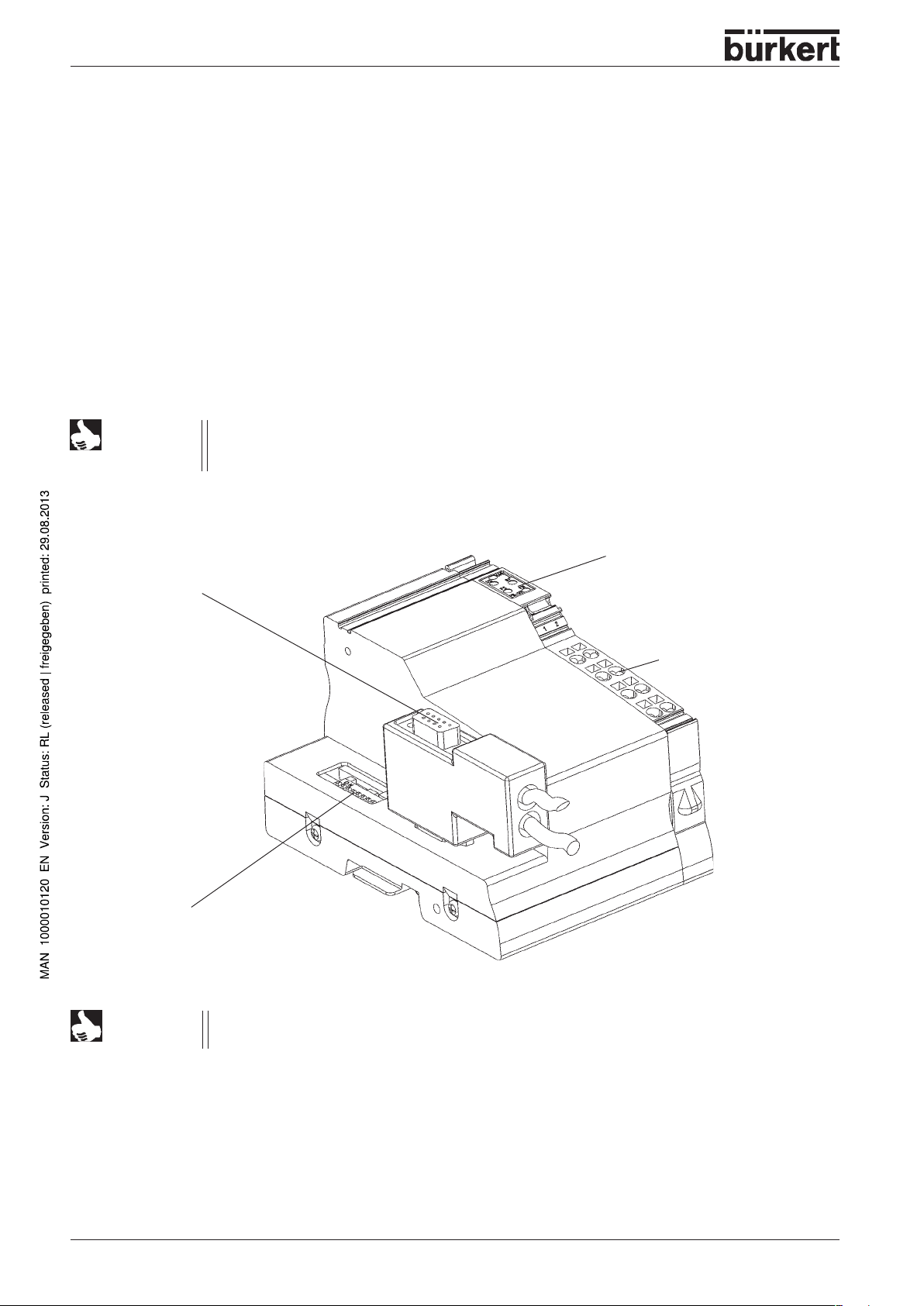

Illustration of the Valve block

Connector

module left

Manometer for indication of operating

pressure at the station

8-fold valve unit

Intermediate supply

Supply and exhaust

ports

Service ports

Illustration of the modules

of the Bürkert AirLINE system

2-fold valve units

Connection

module right

Supply and exhaust ports

Service ports

Supply and exhaust

ports

8 - 8644/phoenix

Page 13

INSTALLATION / COMMISSIONING

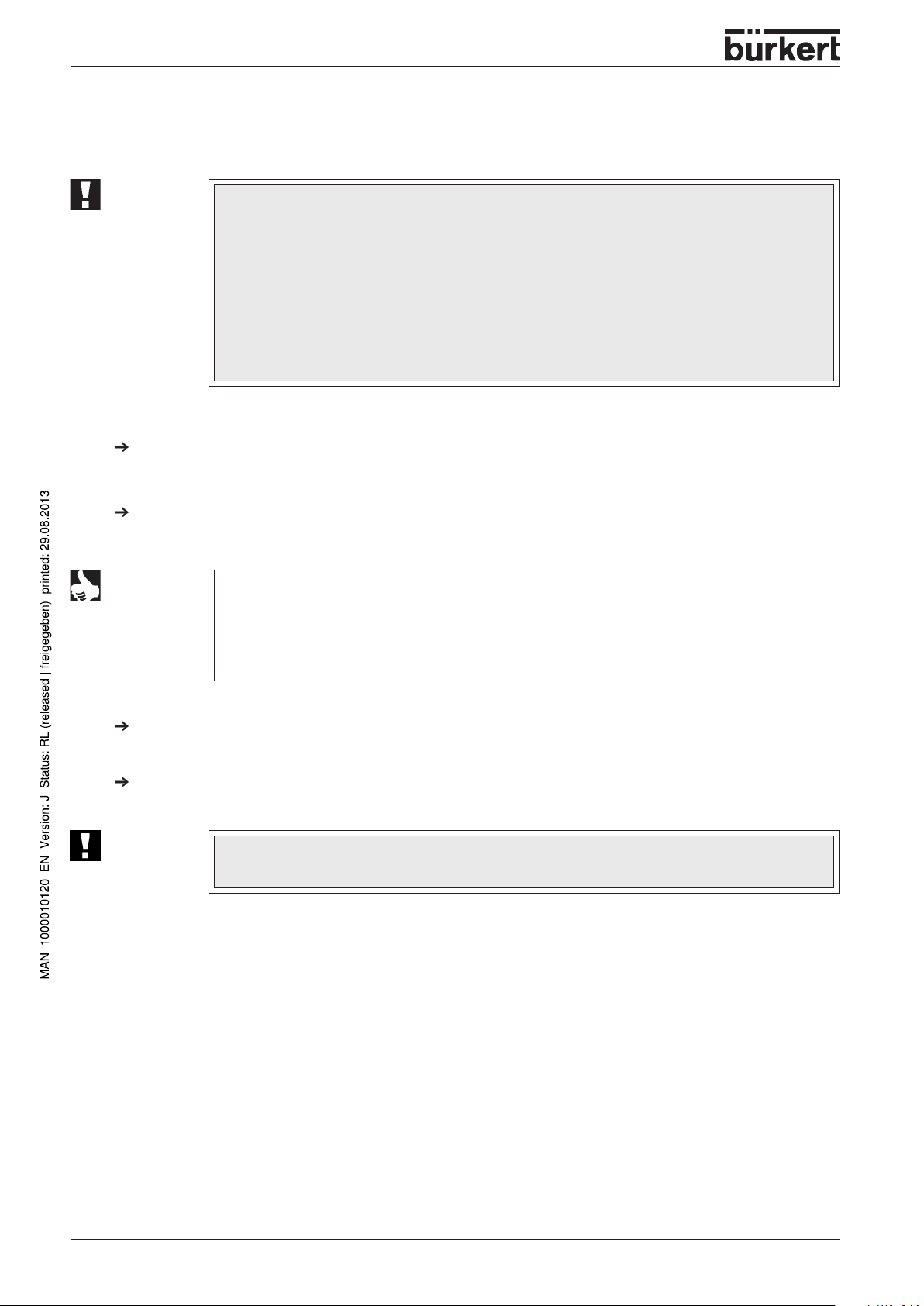

Removing the valve block from the top-hat rail

The valve block is firmly screwed to a standard rail. Additional electrical modules / terminals can be

mounted on this.

If present, release the adjacent modules /

terminals!

Unlock the Vavle block from the standard rail by

turning the fixing screws anticlockwise as far as

they will go.

Lift the Valve block vertically from the rail.

NOTE

Disconnect the modules / terminals from the

standard rail following the manuf acturer’s

instructions.

There must be sufficient clearance > 6 mm between Valve block and previous module.

NOTE

The interface of the left-hand connection module contains elements that can be

damaged if force is used.

Never place the valve block on its side, and ensure that you use an approved

installation position!

8644/phoenix - 9

Page 14

INSTALLATION / COMMISSIONING

Installation of the AirLINE system (e.g. in a control cabinet)

ATTENTION!

During work in the control cabinet, observe the relevant safety regulations!

Before mounting, check whether the mounting rail is properly anchored in the control

cabinet or in the system.

Observe the sequence of installation specified in the configuration file(s).

Observe the notes for the connected system!

Observing manufacturer’s instructions, snap all electrical modules / terminals to the left of the valve

block onto the standard rail.

Slide the valve block onto the rail along the interface of the preceding module.

NOTE

Screw the valve block to the rail by tightening the fixing screws clockwise.

Mount all other modules / terminals on the rail.

ATTENTION!

Alternative for large valve blocks:

- Remove the preceding module

- Snap the valve block onto the standard rail

- Slide the block to its final position

- Snap on the preceding module again

The v alve block is not securely fastened to the standard rail until the fixing screws have

been firmly tightened. Throughout the installation, you m ust ensure that it cannot fall.

10 - 8644/phoenix

Page 15

Fluidic installation

Safety notes

INSTALLATION / COMMISSIONING

ATTENTION!

The pneumatic connections shall not be pressurized during installation!

Make the connections with as large a volume as possible.

Close off unused, open ports with screw caps!

The ports for the pilot valve e xhaust (x) shall not be closed off!

Check allocation according to instructions of ports 1 and 3 or 5: these shall under no

circumstances be swapped!

Pneumatic connections - supply units

Exhaust air

W

(R/S) 3/5

X

W

Standard model: V enting of the pilot valves

Auxiliary air control model: P-port for the pilot valves

(P) 1

W

Pressure supply port

Procedure

Plug (D10) or screw (G 1/4, NPT 1/4) the connections, depending on the version, into the respective

service ports.

Notes on plug connections

NOTE

For the plug connections the hoses must fulfil the following requirements:

• Minimum hardness of 40 Shore D (to DIN 53505 or ISO 868);

• Outside diameter to DIN 73378 (max. permissible deviation ± 0.1 mm from nominal

dimension);

• Free from burrs, cut off at right angles and undamaged ov er outer circumference;

• The hoses shall be pushed into the plug connectors as far as they will go .

Disassembly of the plug connections

T o release the hoses , depress the pressure ring and pull out the hose.

8644/phoenix - 11

Page 16

INSTALLATION / COMMISSIONING

Pneumatic connections - valve units

NOTE

With 3/2-way valv es, the upper ports remain free!

Labelling area

Service ports with 5/2way valves

Service ports with 3/2way valves

8-fold valve unit or

4 / 2-fold valve units

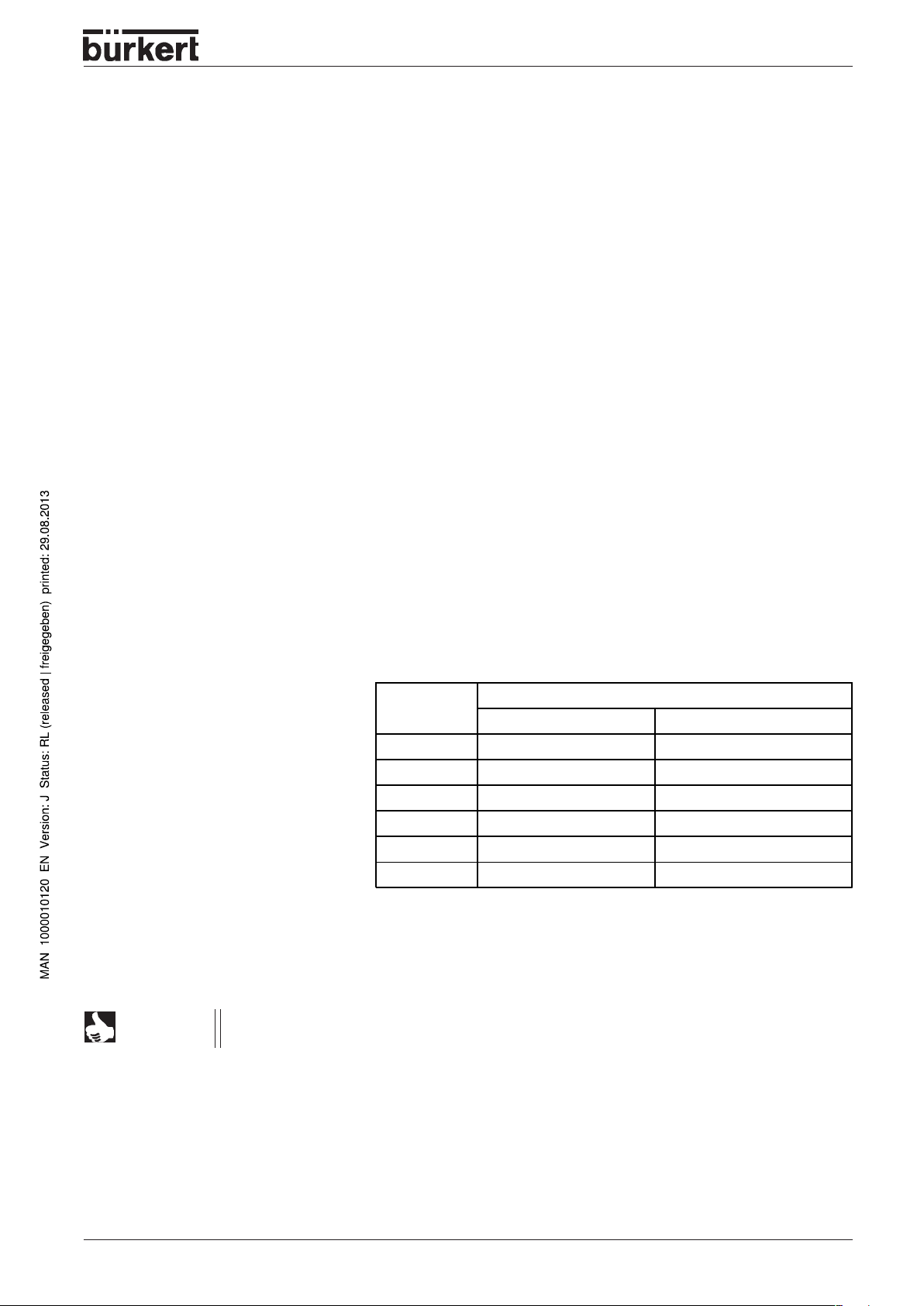

Variants

5/2-way valves

Variant 1 Variant 2 Variant 3

Service port above (2)

Service part below (4)

M 5 M 7 D 6, D4, D1/4

M 5 M 7 D 6, D4, D1/4

3/2-way valves

Variant 1 Variant 2 Variant 3

Service port above (0)

Service port below (2)

internally closed off internally closed off internally closed off

M 5 M 7 D 6, D4, D1/4

Assembly

Plug (D6, D4, D1/4) or screw (M 5, M7) the connections, depending on the version, into the respective

service ports.

With threaded versions, connecting nipples may be used.

Labelling of the connections

Write the valve port data on the provided Labels.

12 - 8644/phoenix

Page 17

INSTALLATION / COMMISSIONING

Elektrical installation

You can find information regarding the electrical installation:

- in the Phoenix Contact handbook

- or in the

System Description

Interbus - Inline IB IL SYS PRO UM

chapter, P aragraph

Field Bus Nodes Profibus DP

Fluidic commissioning

Measures to be taken before fluidic initialization

Check the connections, voltage and operating pressure!

Make sure that the max. operating data (see rating plate) are not exceeded!

Check allocation according to instructions of ports 1 and 3 or 5: these shall under no circumstances be

swapped!

For electrical operation, unlock the manual override!

Fluidic commissioning

Switch on the pressure supply .

Only then switch on the voltage!

Electrical commissioning

bar

You can find information regarding the electrical initialization:

- in the Phoenix Contact handbook

- or in the

System Description

Interbus - Inline IB IL SYS PRO UM

chapter, P aragraph

Field Bus Nodes Profibus DP

8644/phoenix - 13

Page 18

INSTALLATION / COMMISSIONING

14 - 8644/phoenix

Page 19

MAINTENANCE AND TROUBLESHOOTING

Maintenance

and

troubleshooting

TROUBLESHOOTING

.................................................................................................................................................................................................................. 16

8644/phoenix - 15

Page 20

MAINTENANCE AND TROUBLESHOOTING

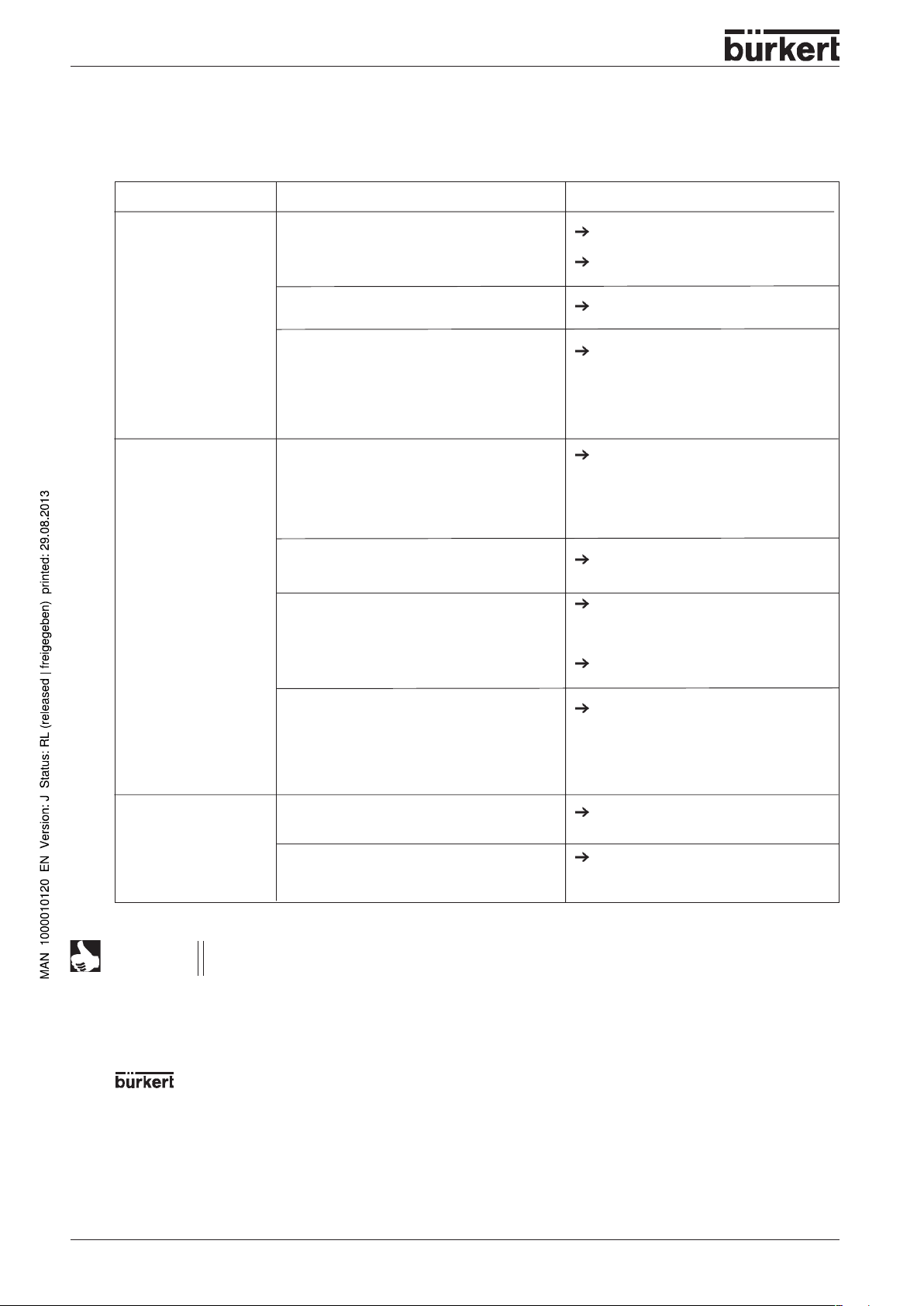

TROUBLESHOOTING

Fault

Valves do not switch:

Valves switch with

delay or blow out at the

vent connections:

Possible cause

Operating voltage not present or insufficient;

Manual override knob not in neutral position;

Pressure supply insufficient or not present.

Pressure supply insufficient or not present;

Valves not in basic position (no power) during

pressure build-up;

Venting of exhaust aire channels insufficient

because silencers are too small or

contaminated (backpressure);

Remedy

Check the electrical connection.

Provide operating voltage acc. to

nameplate.

Turn knob to zero position.

Execute pressure supply with as large a

volume as possible (also for upstream

devices such as pressure controllers,

maintenance units, shut-off valves, etc.).

Minimum operating pressure

Execute pressure supply with as large a

volume as possible (also for upstream

devices such as pressure controllers,

maintenance units, shut-off valves, etc.).

Minimum operating pressure

Pressurize the valve block

valve switch!

Use matching, large-sized silencers or

expansion vessels.

≥≥

≥

≥≥

before

2,5 bar

≥≥

≥

2,5 bar

≥≥

the

Leaky valve blocks:

NOTES

The further error descriptions, see User´s Manual

chapter

System Descriptions,

Service address:

Service-Department

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

E-mail: info@de.buerkert.com

Fluid Control Systems

Contamination or foreign bodies in pilot or

main valve.

O-rings missing or pinched between the

modules;

missing or wrongly positioned profile seals

between the valve and the basic pneumatic

module.

section

Field Bus Nodes Profibus DP

Clean the contaminated silencers.

Change the valve

Determine the point of leakage or missing

seals.

Insert missing seals or replace damaged

seals.

Interbus - Inline IB IL SYS PRO UM

.

or the

or your Bürkert distribution center (see list of addresses on the last few pages)

16 - 8644/phoenix

Page 21

SYSTEM DESCRIPTION

System description

BÜRKERT AIRLINE MODULAR ELECTRICAL / PNEUMATIC

AUTOMATION SYSTEM.................................................................................................... 19

Features ........................................................................................................................................... 19

Advantage ........................................................................................................................................ 19

Design of the system ....................................................................................................................... 20

VALVE BLOCK

Connector modules / feeders........................................................................................................... 22

Valve units

Technical data for the valve block.................................................................................................... 24

Technical data for the complete system ..........................................................................................25

............................................................................................................................................................................................................................................................ 23

.......................................................................................................................................................................................................................................

22

FIELD BUS NODE PROFIBUS DP...................................................................................26

Description of the Profibus DP field bus node ................................................................................. 26

Technical data of the field bus module Profibus DP bus node......................................................... 31

Installation and electrical commissioning of the field bus node Profibus DP

Electrical installation of the field bus node Profibus DP................................................................... 35

Configuration of the Profibus DP bus node...................................................................................... 37

Diagnosis and error elimination at the Profibus DB bus nodev ....................................................... 40

.................................................................. 33

FIELD BUS NODE PROFIBUS DPV1 .............................................................................. 42

New functions .................................................................................................................................. 42

Overview of firmware functionalities................................................................................................ 43

Description of field bus node............................................................................................................ 44

PCP via process data (PCP in DPV0) ............................................................................................ 54

Parameterization .............................................................................................................................. 62

Failsafe values ................................................................................................................................. 65

Watchdog ......................................................................................................................................... 68

Acknowledgement of peripheral errors ............................................................................................70

Behaviour in PLC stop (new) ........................................................................................................... 71

8644/phoenix - 17

Page 22

SYSTEM DESCRIPTION

Diagnosis (new) ............................................................................................................................... 72

Parameter telegram f ormat............................................................................................................... 76

Switching round bytes for IB IL24 DI16 / IB IL24 DO16 .................................................................. 78

Switching round bytes for IB IL24 DI32 / IB IL24 DO32 .................................................................. 78

Data Exchange and Global Command Operate .............................................................................. 79

DPV1 field bus node object directory .............................................................................................. 80

Error codes during DPV1 communication ....................................................................................... 82

Error codes during PCP communication ......................................................................................... 83

Error description .............................................................................................................................. 85

CONNECTOR MODULES ................................................................................................. 90

Connector Module, pneumatic - left Type ME02 .............................................................................. 92

Connector Module, pneumatic - left Type ME03 .............................................................................. 94

Connector Module, pneumatic - middle Type ME02......................................................................... 96

Connector Module, pneumatic - middle Type ME03......................................................................... 98

Connector Module, pneumatic - right T ype ME02 .......................................................................... 100

Connector Module, pneumatic - right Type ME03

........................................................................................................................................... 102

ELECTRONIC PRESSURE MEASUREMENT MODULE (DMM) .................................. 104

BASIC ELECTRONIC MODULES .................................................................................. 111

Basic electronic module ME02 / 2-fold monostable ....................................................................... 112

Basic electronic module ME02 / 8-fold monostable ....................................................................... 113

Basic electronic module ME02 / 2-fold bistable

Basic electronic module ME03 / 2-fold monostable ....................................................................... 115

Basic electronic module ME03 / 4-fold monostable ....................................................................... 116

................................................................................................................................................ 114

Basic electronic module ME03 / 3-fold 10 mm monostable ........................................................... 117

Basic electronic module ME03 / 2-fold bistable

................................................................................................................................................ 118

BASIC PNEUMATIC MODULE .......................................................................................119

Basic pneumatic module with integral pressure shut-off ............................................................... 120

VALVES...........................................................................................................................121

18 - 8644/phoenix

Page 23

SYSTEM DESCRIPTION

MODULAR ELECTIRCAL / PENUMATIC AUTOMATION SYSTEM TYPE

8644 AirLINE

AirLINE Type 8644 is an electrical and pneumatic automation system which has been developed for use in

control cabinets or boxes. In a through system, all electronic and pneumatic components are standardized

so that if simple rules are complied with, electrical and electronic modules of differing functionality may be

combined in a very simple manner. All components are connected via a snap-on mechanism. This includes

the necessary electrical connections. In this way, for example, valv es and po wer outputs may be combined

with only one field bus connection. A number of electrical modules (terminals) may be combined very

simply with valves mounted on special pneumatic modules (valve units).

Features

Characteristics of AirLINE are:

• Simple handling

• Functional block construction of switched box or cabinet.

• Automatic build-up of potential groups, current, data and safety circuits.

• Combination of valve units and terminals in differing cluster size (2-fold, 4-fols, ...) for space and price

optimized station construction.

Advantages

This principle brings the following advantages:

• Flow-optimized valve structure

Pressure range from vacuum to 10 bar

Flow rates of approx. 300l/min or 700 l/min with a valve width of 10 mm and/or 16 mm.

• Integration of non-return valves into the pneumatic base module (optional).

• High service life through rocker technology with oiled and non-oiled air .

• Simple combination of different functions, configuration and e xtension through high lev el of modularity .

• Numerous valve functions: 3/2, 5/2 (monostable, bistable) and 5/3 way functions.

• Mechanical Manual-Emergency operation.

• Different pressure levels possible in a single chain.

• Integration of pressure gauges for display of the operational pressure.

• Central compressed air supply via connection modules possible on both sides, as well as intermediate

supply.

8644/phoenix - 19

Page 24

SYSTEM DESCRIPTION

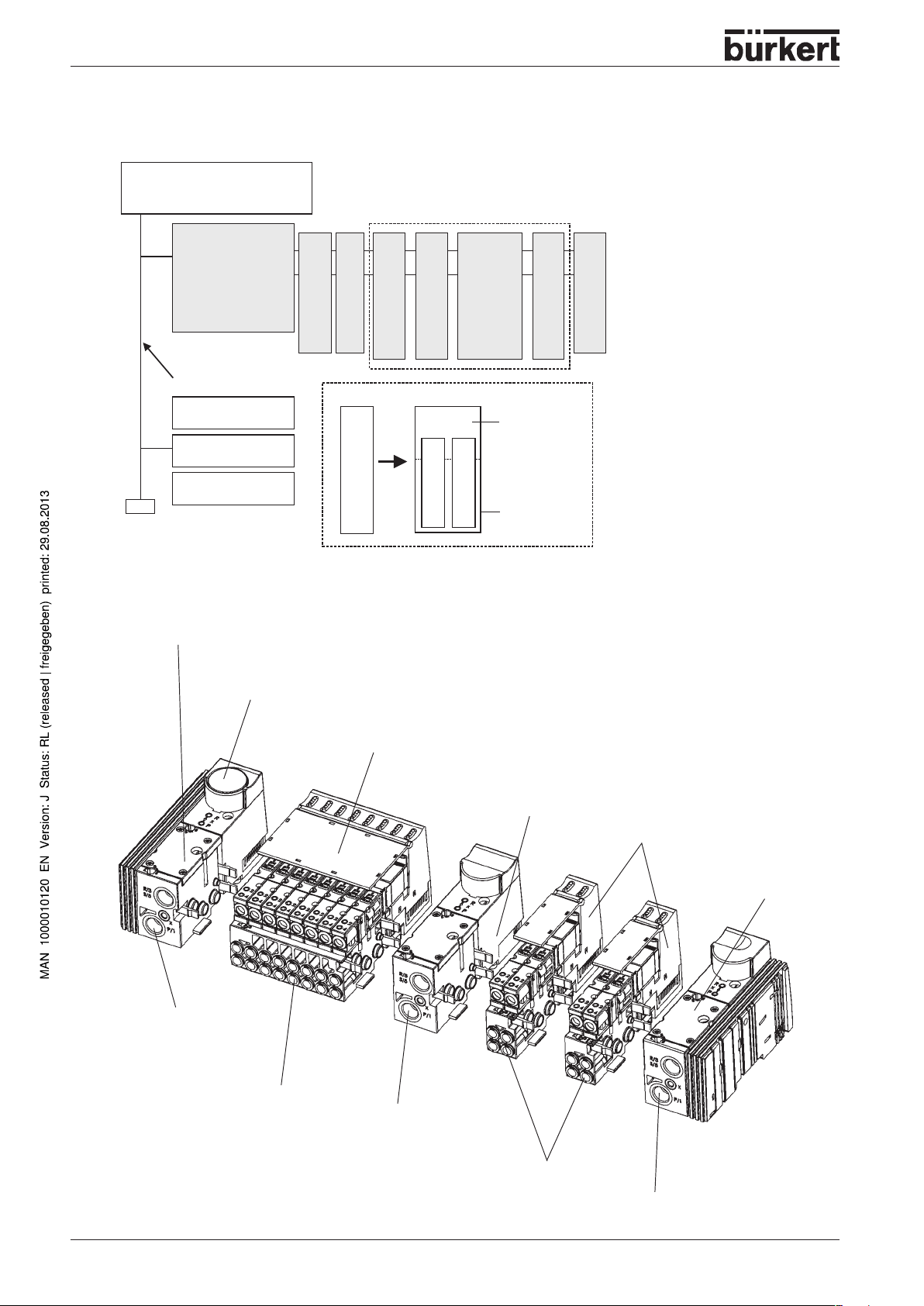

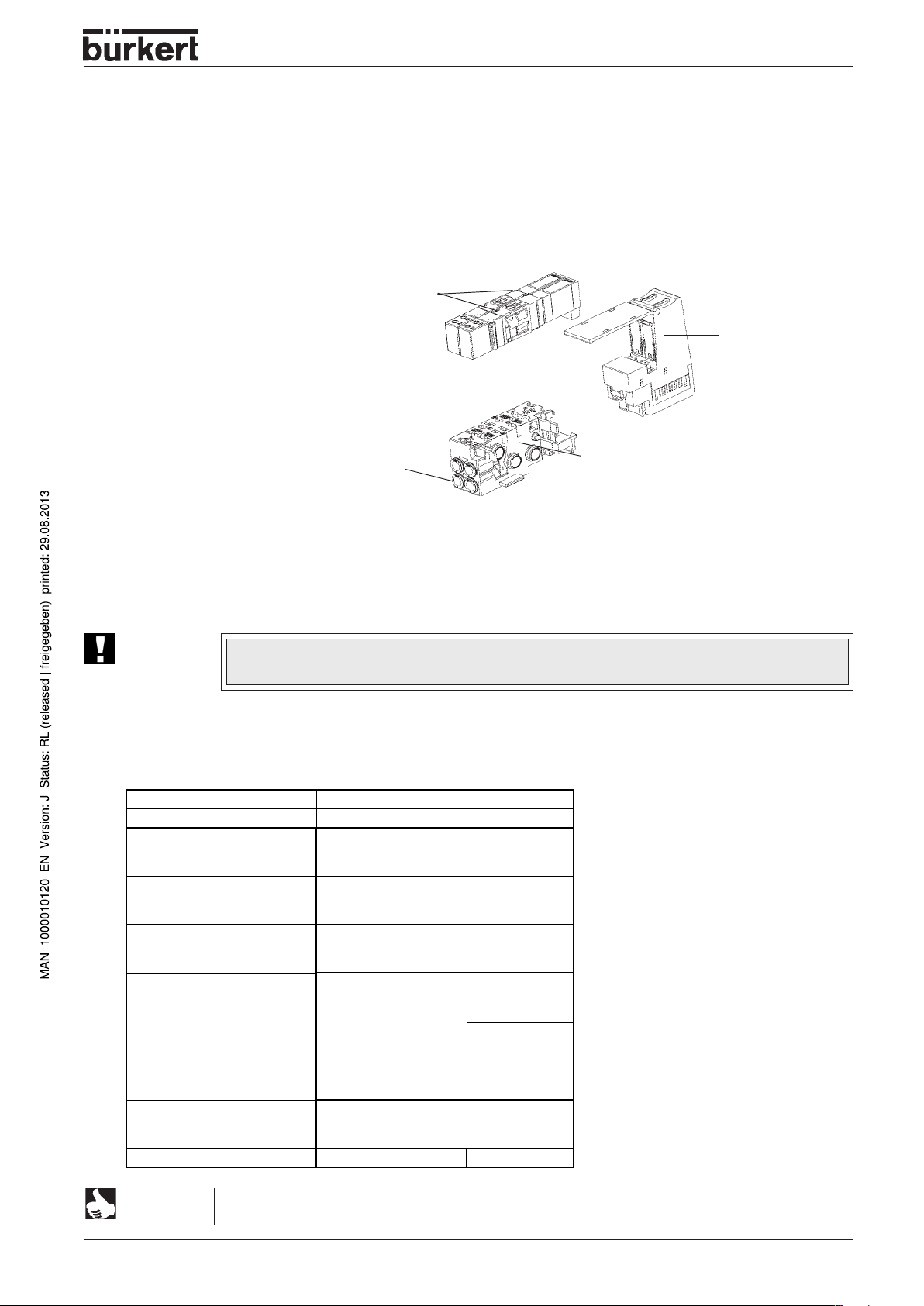

Design of the system

Central control

(e.G. SPC)

Field bus node 1

(e.G. Profibus DP))

Valve block

DO DI AI

2x 4x 2x 2x

Field bus

Field bus node 2

Field bus node …

Field bus node n

2x

llustration of the valve block

Connector module left

Manometer for indication of

operating pressure at the station

8-fold valve unit

Connection module

Valve plate

Valve plate

Valve

Valve plate

8x

Electronic base

module

Valve

Pneumatic base

module

Connection module

Schematic representation of

the Bürkert AirLine system

Supply and exhaust

ports

Service ports

Illustration of the modules of

the Bürkert AirLine system

Intermediate supply

2-fold valve unit

Connector module

right

Supply and exhaust ports

Service ports

Supply and exhaust

ports

20 - 8644/phoenix

Page 25

SYSTEM DESCRIPTION

System description

In its minimal configuration, the system consists of field bus nodes and the Valve block.

The closing plate protects both the system and persons from improper contact.

T erminals can be arranged bef ore and after the valve b lock

Procedure for changing the electrical function module:

ACHTUNG!

Do not introduce foreign parts into the basic module (24V supply bus)-

-> Risk of short circuit

Switch off the electricity and compressed air supplies to the AirLINE

system

Unscrew fixing screws of the valves with a screwdriver

Pull valve off valve plug

Keep dirt awa y from flange seal and O-ring (3/2 valve)

Loosen the functional module at the rear latching mechanism and pull

away upwards from the distributor module (backplane bus) without tilting it.

Set the new functional module vertically on the distributor module (backplane bus) and press downwards until it can be heard to latch in.

Place valve with clean inserted flange seals/O-rings onto the valve position

and tighten the screws according to the adjacent assembly drawing.

20 Ncm

20 Ncm

30 Ncm

30 Ncm

8644/phoenix - 21

Page 26

SYSTEM DESCRIPTION

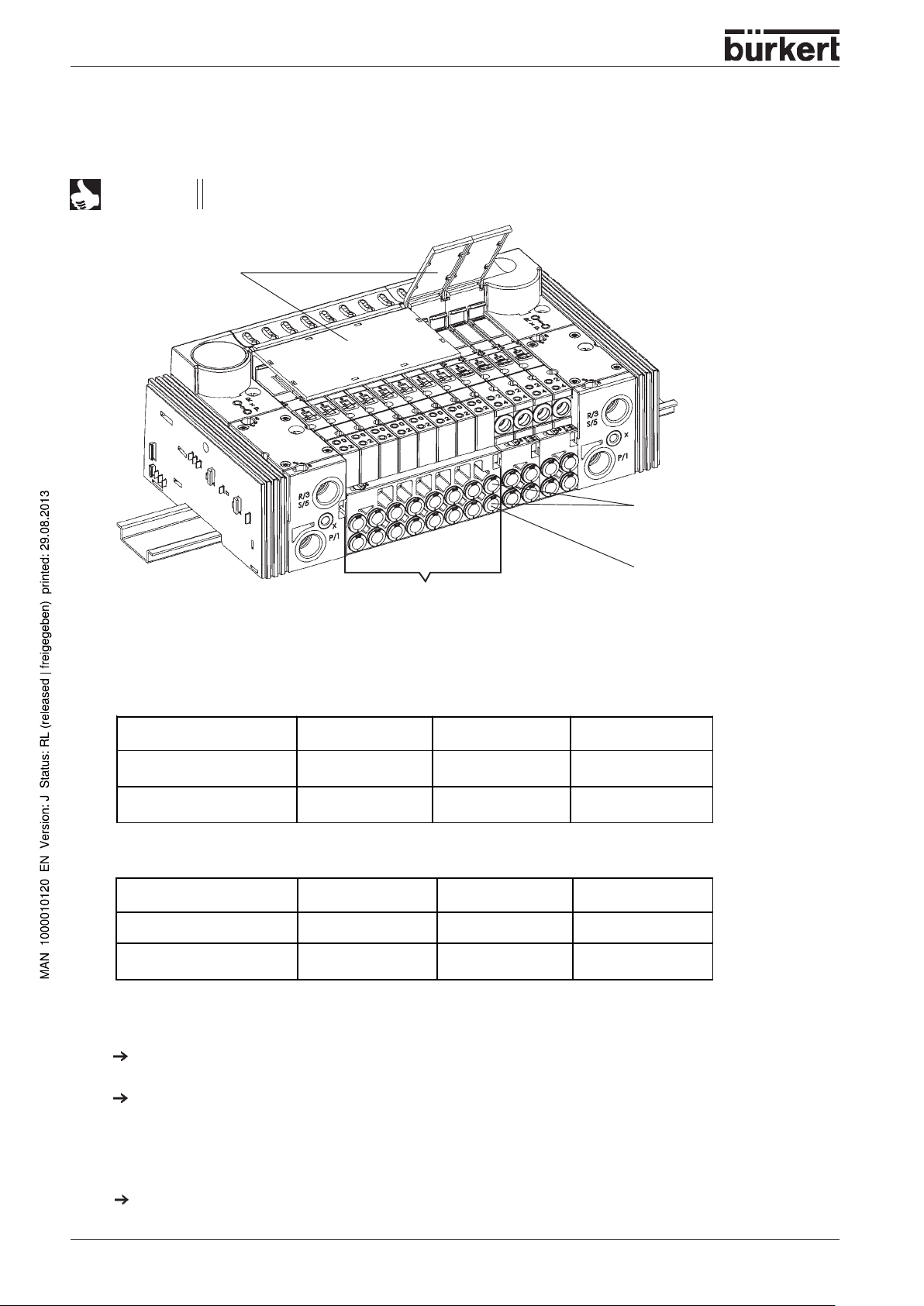

VALVE BLOCK

The valve block is composed of the following modules:

•

Connector modules/supply units

•

V alve units

(service ports , miscellaneous vales)

(collective ports for supply, exhaust and auxiliary control air)

interface

Electrical

Connector

module left

Example of a valve block, schematic

Viewed from the outside, the pneumatic automation system represents a closed electrical unit. Owing to

the modular construction, the number of internal bus participants and the current consumption of the valve

block may v ary. The valv e bloc k and each electrical module/terminal provide a standardized electrical

interface to the outside.

left

Supply units

8-fold valve

units

Intermediate

supply

2-fold valve units

2-fold valve units

Connector

module right

Supply unit

Connector modules / feeders

Feeders in the form of pneumatic connector modules form the fluidic interface between the supply line and

the internal supply structure. The fluid is passed on via the f eeder from one valve unit to the next. In order

that the supply pressure remains almost constant over the entire path, additional feeders may be

necessary . It is recommend to insert a feeder after 24 (ME02) or 16 (ME03) valve positions. The use of

intermediate feeders also enables segments to be built up when the pneumatic channels are closed

between individual valve units.

right

interface

Electrical

Electr . connector

module

Pneumatic

supply module

Connector

module left

22 - 8644/phoenix

Electrical

1:1 shunting

Pneumatic

supply module

Intermediate

supply

Electr. connector module

Pneumatic

supply module

Connector

module right

Schematic

representation of supply

Page 27

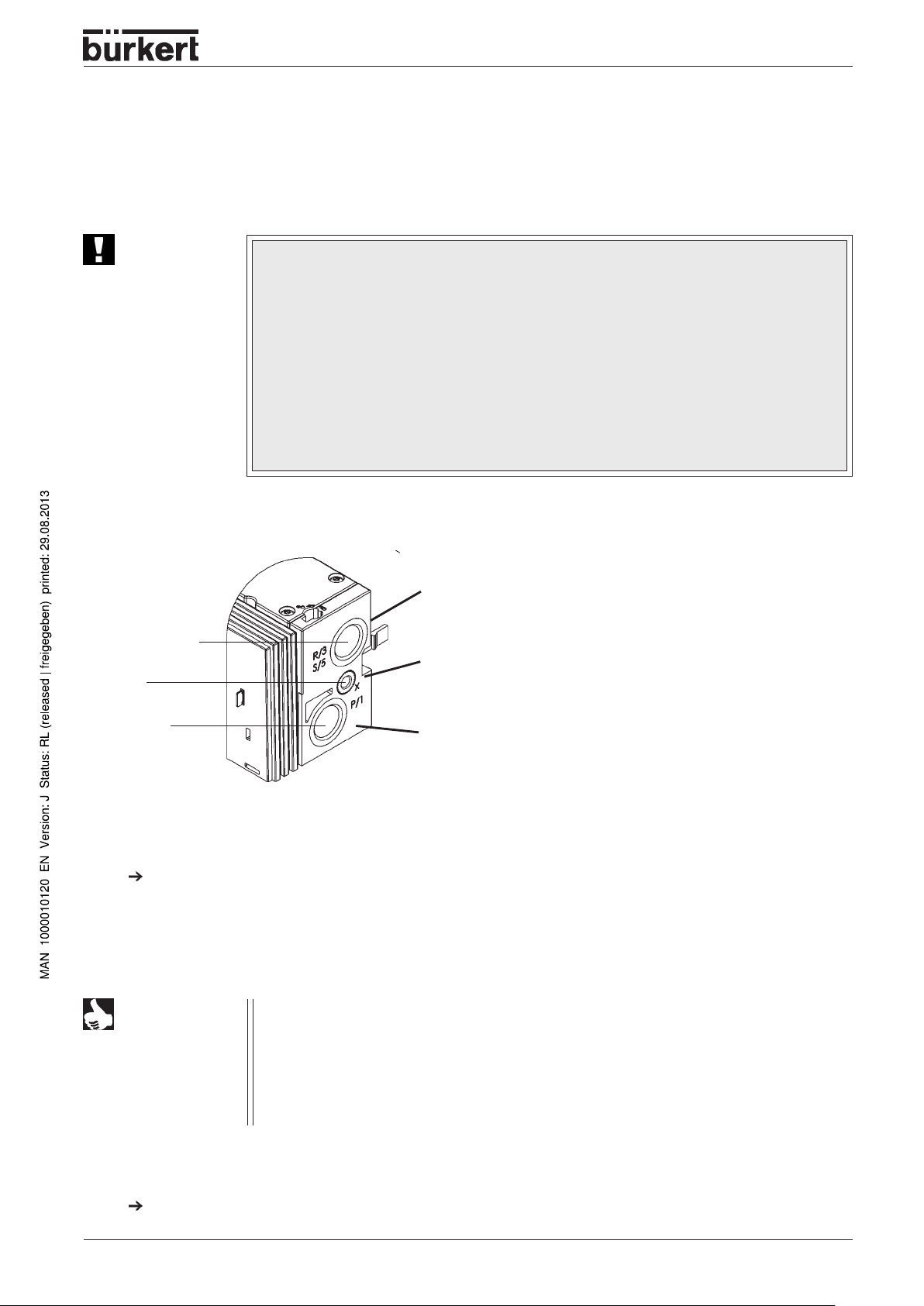

VALVE UNITS

Construction

V alve units are of modular construction and consist of:

• Basic electronic modules

• Basic pneumatic modules

• Valves

Valves

SYSTEM DESCRIPTION

Basic electronic

module

Service ports

(outputs)

Modular construction of the valve units

Basic pneumatic module

The digital outputs, on which the valves sit, are switched on the basic electronic module. Depending ont he

function, these switch the internal P channel to the service ports (outputs) of the pneumatic module .

ATTENTION!

Plugged-on valves may only be changed if the pressure in the AirLINE is relieved. If a

pressure shut-off is used, the valves may also be exchanged under pressure.

Variants

The modular construction of the valve units permits of serveral variants.

Types: pneumatic / electronic

Add-on dimens ion

Valve types

No. of valve positions on

basic electronic module

No. of valve positions on

basic pneumatic module

Connection t yp e

(on basic pneumatic module)

Non-return valve (optional)

Pressure shut-off (otional)

MP11/ ME02 MP12 / ME03

11 mm 16,5 mm

6524

6525

0460

2fold

---8fold

2fold

8fold

D6

D4

D1/4"

M5

M7

Without non-return valve

Non-return valve in R channel

Non-return valve in R+S channel

With pressure shut-off*** not available

6526

6527

0461

2fold

3fold*

4fold

2fold

3fold*

4fold

D8

G1/8"

NPT 1/8"

D4

D1/4

D6**

M5**

M7**

*

Width of basic electron/pneumatic module

= 33 mm, with 3 plug-on positions for 10

mm valves 6524 / 6525

**

Special version 3-fold, 10 mm valves

***

Available only for certain valve types and

with functional limitation.

See also the technical data of the valve

block and the description of the basic

pneumatic module.

NOTE

You can obtain information about the correct assembly of modules, valves and accessories

via our Configurator . If y ou hav e any questions, please consult our Distribution Center .

8644/phoenix - 23

Page 28

SYSTEM DESCRIPTION

Technical data of the valve block

(using electronic modules and valve types 6524, 6525, 6526, 6527, 0460, 0461)

Mounting dimension

V alve operation

Flow

Pressure range

(with pressure shut-off) 5 - 7 bar - - -

Po wer

Current

power reduction)

(before / after 43/26 mA 38/ - mA 42/33 mA / 96/48 mA 38/ - mA

Valve places (max.)

Electrical module

Pneumatic module

Protection Class in

(in terminal model)

Ambient temperature

Storage temperature

Nominal operating

11 mm 16.5mm

C/D (3/2-way) L/N (5/3-way) C/D (3/2-way) L/N (5/3-way)

T ype 6524 T ype 0460 Type 6526 T ype 0461

H (5/2-way) H (5/2-pulsed) H (5/2-way) H (5/2-pulsed)

T ype 6525 T ype 0460 Type 6527 T ype 0461

300 l/min 200 l/min 700 l/min 500 l/min

2,5 - 7 bar 2,5 - 7 bar 2 - 10 bar 2,5 - 7 bar

1 Watt 2 x 1 W att 1 Watt / 2 Watt 2 x 1 Watt

64 32 32 24

2; 8 2 bistable 2; 4; 3* 2 bistable

2; 8 2 bistable 2; 4; 3* 2 bistable

IP 20 IP 20 IP 20 IP 20

0 to +55°C 0 to +50°C 0 to +55°C 0 to +50°C

-20 to +60°C -20 to +60°C -20 to +60°C -20 to +60°C

Continuous operation (100 % ED)

mode

Operating voltage

Protection Class

T otal current

24 V / DC; -15 +20 % tolerance**; residual ripple at field bus interf ace 5 %

3 according to VDE 0580

Dependent on the connection technology , the expansion stage and the control

Interface (Profibus)

Profibus Copper conductor (RS-485), connected via Profibus

connector; Po wer supply potentialseparated; screen

electrically connected to the functional earth

Recommended cable lengths see Profibus system data

Local bus

No. of connectable AirLINE terminals

Limited by software max. 64

Limited by power supply unit max. logic current consumption of connected local bus

ATTENTION!

module: I

Observe current consumption of the modules!

On project planning of an AirLINE station, observe the current consumption of the logic of

each participant! This is given in each module-specific data sheet. It may differ from

module to module. Hence the number of possible participants that can be connected

depends on the specific construction of the station.

≤ 2 A DC

max

*3 x 10 mm valves for add-on dimension 16.5 mm

** in the case of the EEx n version, maximum +10 %

24 - 8644/phoenix

Page 29

Technical data for the complete system

Voltage supply:

Rated voltage 24 V/DC

Tolerance - 15% / + 20%

V alve types 0460, 0461 - 10% / + 10%

Current carrying capacity:

Contacts max. 8 A

Valv e block max. 2.5 A

(via connector module left)

Maximum current consumption:

Logic current I_Log = I_Log_FBKN + Σ I_Modul

SYSTEM DESCRIPTION

I_Log Current consumption logic range

I_Log_FBKN proportional current in field bus nodes max. 1.25 A/DC

(0.75 A/DC for logic supply; 0.5 A/DC for analog voltage supply)

I_Module proportional current logic range of the elec. base module max. 15 mA

I_V alve Valv e current - before and after po wer reduction

Valve type

6524

6525

6526

6527

0460

0461

before power reduction after power reduction

43 mA 26 mA

43 mA 26 mA

96 mA 48 mA

96 mA 48 mA

38 mA 38 mA

Valve current

Temperature:

Storage temperature - 20 to + 60 °C

NOTE

Field bus nodes Profibus DP (standard) 0 to + 55 °C

V alve type 6524, 6525, 6526, 6527 0 to + 55 °C

V alv e type 0460, 0461 0 to + 50 °C

The admissible ambient temperature is depent on the modules used. During

assembly, the crucial factor is the most critical module.

8644/phoenix - 25

Page 30

SYSTEM DESCRIPTION

FIELD BUS NODE PROFIBUS DP

Description of the field bus node Profibus DP / technical data

The bus terminal couples an AirLINE station to the Profibus and provides the supply voltages for the

connected participants.

Features:

- Profibus connection using copper technology

- Data rate: all defined transmission rates up to 12 MBd

- Error diagnosis through LEDs on the bus terminals

- Galvanic isolation of the field bus

NOTE

9-pole SUB-D Profibus connector

Profibus DP / DPV1 field bus node

The field bus node has expanded functions in DPV1 mode from serial number 37344

onwards.

Display / LEDs

Supply terminal

DIP switch for

addressing

NOTE

The cover plate is included with the bus terminal. Use this plate to terminate the AirLINE station. The cover

plate has no electrical function. It protects the station from ESD pulses and the user from touching

dangerous voltages.

26 - 8644/phoenix

The Profibus plug is not included in the delivery . Please order the plug according to the

ordering data in the data sheet.

Page 31

SYSTEM DESCRIPTION

Special features with DIP switch 8

As is not the case for the PROFIBUS bus terminal up to serial number 37343 (GSD file: BUER00F0.gsd,

device entry: „Typ8644“), for new devices from serial number 37344 onw ards DIP switch 8 will no longer be

used for setting the stop behaviour , b ut for diff erentiating between DPV0 and DPV1 mode.

For new devices, stop behaviour is set via the parameter telegram:

DIP switch 8 - Position OFF (default setting)

The device is exchange-compatible with the predecessor up to serial number 37343 and provides the

following new functions:

• acyclical communication with e.g. RS232 modules, including in the process data channel

• various diagnosis formats

• acknowledgement of peripheral errors from the application program

• adaptation of the high-byte/low byte format to the control format on 16 and 32-channel input and output

modules.

These functions are, howe ver , only availab le on new devices from serial number 37344 onw ards.

When scheduling projects for the device, use the „BUER00F0.gsd“ GSD or the device entry „8644-

DPV1(DIP8=OFF) ME02“ in the S7 hardware configurator.

DIP switch 8 - Position ON

The device provides all new functions in the ON position.

Stop behaviour, which w as set via DIP s witch 8 in the old de vice , is now adjusted via parameterization.

When scheduling projects for the device, use the „BUER06BA.gsd“ GSD or the device entry „8644-

DPV1(DIP8=ON) ME02“ in the S7 hardware configurator.

8644/phoenix - 27

Page 32

SYSTEM DESCRIPTION

POWER LOSS

Formula for calculation of the power loss of the electronics

PEL = P

PEL = 2,6 W + (1,1 x

Bus

+ P

Peri

W

A

ab

Σ Σ

ΙΙ

Σ

Ι

) + (0,7 x

ΙΙ

Σ Σ

Ln

n=0 m=0

W

A

Σ Σ

Σ

Σ Σ

ΙΙ

Ι

ΙΙ

Lm

)

Where

P

EL

P

BUS

P

PERI

I

LN

T otal po wer loss in the terminal

Pow er loss for bus operation without peripheral loading (constant)

Pow er loss with periphery connected

Current consumption of participant n from logic supply

n Index designating the number of participants connected (n = 1 to a)

a Number of participants connected (supply with logic voltage)

Σ I

a

n=0

I

LM

Ln

Sum of all current consumed by participants from the 7.5 V logic supply (max. 2 A)

Current consumption of participant m from analog supply

m Index designating the n umber of nalog participants connected (m = 1 to b)

b Number of analog participants connected (supply with analog voltage)

b

Σ I

m=0

Lm

Sum of all current consumed by participants from the 24 V analog supply (max. 0.5 A)

Derating

Substituting the maximum currents of 2 A (logic) and 0.5 A (for analog terminals) in the formula for

calculation of the power loss with periphery connected, we obtain:

P

= 2.2 W + 0.35 W = 2.55 W

PERI

This 2.55 W corresponds to 100 % network loading capacity in the derating curves.

ATTENTION!

Make sure that at an ambient temperature above 40 °C, the nominal loading capacity

given by the derating curves is not exceeded. As can be seen from the formula, the total

loading with attached periphery (P

) is the relevant quantity. If for e xample no current is

PERI

consumed by the analog supply, the fraction of the current from the logic supply may be

greater.

28 - 8644/phoenix

Page 33

SYSTEM DESCRIPTION

Derating of the logic power supply and the power supply of the analog terminals

•

At a current loading of the peripheral supply at the bus terminal of max. 8 A

P [%] Loading capacity of the logic and analog power supplies in %

T u [°C] Ambient temperature in °C

•

At a current loading of the peripheral supply at the bus terminal of max. 4 A

P [%] Loading capacity of the logic and analog power supplies in %

T u [°C] Ambient temperature in °C

8644/phoenix - 29

Page 34

SYSTEM DESCRIPTION

Example:

Current loading of periphery supply: 8A

Ambient temperature: 55 °C

1. Nominal loading capacity of the logic and analog supply: 50 % (from graph)

I

= 1 A, I

LLogik

P

= 1.1 W + 0.175 W

PERI

P

= 1.275 W (equals 50 % of 2.55 W)

PERI

2. P ossible logic current when analog supply is not loaded:

P

= 1.1 W/A x I

PERI

P

/ 1.1 W/A = I

PERI

I

= 1.275 W / 1.1 W/A

LLogik

LAnalog

= 0.25 A

LLogik

LLogik

+ 0 W

I

= 1.159 A

LLogik

Protective features

Overvoltage Protective diodes at input (destroyed on continuous

(segment supply /main supply) overloading)

Loading peaks up to 1500 W are short-circuited by the input

diode.

False polarity Parallel polarity protection diodes; in case of error, the

(segment supply /main supply) high current through the diodes causes the upstream fuse

toblow.

Common potentials

Main and segment supply lie electrically at the same potential. Their common mass is led from the bus

terminal via the potential shunter as reference mass GND to the participants.

Analog supply and 7.5 V logic supply are gener ated from the main supply. Their common mass LGND lies

electrically at the same potential as GND and is led from the bus terminal via the potential shunter as

reference mass LGND to the participants.

30 - 8644/phoenix

Page 35

SYSTEM DESCRIPTION

Technical data of the field bus module Profibus DP bus node

Connection technique T ension spring terminals

Recommended cable lengths max. 30 m;

cable routing over free areas not permissible

Forwarding Via potential shunting

Behaviour on voltage drop and The voltages forwarded from the bus

interruption terminal to the potential shunters (main and segment

voltage) follow the appliedsupply voltages without delay.

Rated voltage 24 V DC

Tolerance - 15 % / + 20 % (to EN 61131-2)

Ripple ± 5 %

Permissible range 19.2 V to 30 V

Current loading Max. 8 A

Min. current consumption at rated voltage 0.10 A DC

main power supply (at open circuit, i.e. incoming remote bus attached, no local

bus participants connected, bus inactive)

Max. current consumption at rated voltage 1.25 A DC

main power supply consisting of: 0.75 A DC for logic supply

0.5 A DC for analog voltage supply

Protective features

Overvoltage yes

False polarity yes

ATTENTION!

Protect 24 V section externally!

This 24 V section must be protected e xternally with a fuse. The power supply unit must be

capable of supplying 4 times the rated current, so that in case of a fault, blowing of the

fuse is assured.

Minimize heat generation!

For supplying the main voltage and for supplying or tapping the segment voltage, use both

adjacent contacts.

Observe current carrying capacity!

The maximum cumulative current through the potential shunter is 8 A.

8644/phoenix - 31

Page 36

SYSTEM DESCRIPTION

T ec hnical data of the field bus Profibus DP node

Housing dimensions (width x height x depth) 48,8 mm x 120 mm x 71,5 mm

Weight 210 g (without plug)

Permissible temper ature (storage/transport) -20 °C to +60 °C

Permissible air humidity 75% mean, 85% occasionally

ATTENTION!

Permissible air pressure (operation) 80 kPa to 106 kP a (up to 2000 m üNN)

Permissible air pressure (storage/transport) 70 kPa to 106 kPa (up to 3000 m üNN)

Protection type IP 20 to IEC 60529

Protection class Class 3 to VDE 0106, IEC 60536

In the range of 0 to +55 °C, suitable precautions must be taken against elevated humidity

(> 85%).

Slight condensation of short duration on the outside of the housing is permissible, e.g.

when the terminal is brought from a vehicle into a closed room.

32 - 8644/phoenix

Page 37

SYSTEM DESCRIPTION

Installation and electrical commissioning of the field bus node

Profibus DP

The Profibus bus node

Address setting

9-pole SUB-D Profibus connector

Display / LEDs

Supply terminals

(for configuration, see

following page)

Configuration of the 9-pole SUB-D connector

As a general rule, a 9-pole SUB-D connector with pins is used in the PROFIBUS. In the profibus DP field

bus coupler , the matching part (sock et) is always present. In the first and last plugs of a segment, a

closing resistor of 220 ohm and two terminating resistors of 390 ohm must be present. The A line (RxD/

TxD-P) is always earthed via one terminating resistor, the B line (RxD/TxD-P) is alwa ys connected to +5V

via the other one. These resistors must be pro vided in the plug (e.g. Phoenix Contact SUNCON-PLUSPROFIB, Art. no. 27 44 34 8).

Pin No. Designation (socket in device, plug on

cable)

1n. c. 2n. c. 3 RxD / TxD-P Receive / send data P (+) (conducto r B)

4 CNTR-P Control signal for repeater (+), direction control

5 DGND* Reference potential of 5 V

6 VP* Supply voltage + 5 V for closing resistors

7n. c. 8 RxD/TxD-N Receive / send data N (-) (conductor A)

9n. c. -

Meaning

* Removal of potential separation

Separate potentials

The interface supply for the Profib us has a separate potential from that of the power supplies . When using

an L WL converter, the voltage shut-off to the 5 V logic supply to the b us terminal can be cancelled via DIP

switches 9 an 10. This makes the higher current required f or operating the LWL converter available at the

interface.

8644/phoenix - 33

Page 38

SYSTEM DESCRIPTION

T erminal configuration of the power supply terminal

T erminals

1.1

1.2

1.3

1.4

Configuration of the terminal points

Left Right Colour Abbrev. Meaning

1.1 2.1 black U

1.2 2.2 red U

1.3 2.3 blue GND Reference potential

1.4 2.4 --- FE Functional earth

ATTENTION!

S

M

Main, bus, logic and interface supply (+24V DC)

Segment supply (+24V DC)

Earth (ground) the bus terminal!

Earth the bus terminal via one of the FE connections of connector 1.3 or 2.4. For this

purpose, connect the relevant contact to an earthing terminal.

2.1

2.2

2.3

2.4

24 V segment power supply / 24 V main power supply

The reference potential of the segment power supply must be the same as that of the main po wer supply.

Hence no separate potential structure is possible on the periphery side.

The main power supply and the segment power supply are equipped with elements for protection against

false polarity and transient overvoltage.

24 V segment power supply

You can supply or generate the segment voltage at the bus terminal or one of the supply terminals. There

are several options for providing the segment voltage at the bus terminal:

You can supply the segment voltage at the terminal points 1.1/2.1 and 1.3/2.3 (GND) of the power

supply connector separately .

You can bridge the connections 1.1/2.1 and 1.2/2.2 to assure supply of the segment circuit from the

main circuit.

With a switch between terminal points 1.1/2.1 and 1.2/2.2, you can build up a switched segment circuit

(e.g. also an EMERGENCY OFF circuit).

34 - 8644/phoenix

Page 39

Electrical installation of the field bus node Profibus DP

SYSTEM DESCRIPTION

ATTENTION!

Electrical wiring shall not be connected under voltage!

Connection of the electrical inputs and outputs (terminals)

Open the plug contact with a screwdriver .

Insert the cable.

Pull out the screwdriver .

The cable is connected.

8644/phoenix - 35

Page 40

SYSTEM DESCRIPTION

DIP switches

Display / LEDs

Addressing

The PROFIBUS address and the behaviour of the PROFIBUS terminal can be adjusted by using the 10 x

DIP switch.

The relevance of DIP switches for the PROFIBUS bus terminal from serial number 37344 onwards can be

ascertained in the following table.

Configuration of the 10-fold DIP switch

DIP switch Meaning

1 ... 7 PROFIBUS address in binary display ( 0 to 127 in decimal display)

Switch 1 establishes the least significant bit (LSB) (2

Switch 7 establishes the highest significant bit (HSB) (2

0

)

6

)

8 Inline station operating mode:

ON: New mode with DPV1 support, security values and parameterization;

OFF: Compatible mode ( to PROFIBUS bus ter m ina l up to serial number 37343)

9 ... 10 When an LWL plug connector is used, both switches are set to ON to allow for the

increased current requirements of the LWL connector. The interface power supply is

then no longer isolated in potential.

NOTE

You will find a detailed illustration of individual functions under

field bus node PPROFIBUS-

DPV1 / Description of field bus node.

Diagnosis LEDs directly on the station

Abb-rev Colour Meaning Explanation

UM green Main supply

US green Segment supply

Supply voltage in main circuit for field bus nodes, logic supply and

interrfaces present.

Supply voltage present in segment circuit.

BF red Bus Fault

FS red Failure Select

FN red Failure Number

36 - 8644/phoenix

No data exchange with master.

Select function of LED FN:

FS lights: FNshow the error type.

FS does not light: FN show the error number.

The number of flashes indicates the error tyoe of error number,

depending on whether FS lights or not.

Page 41

Configuration of the Profibus DP bus node

Modules from the GSD file

SYSTEM DESCRIPTION

NOTE

Attachment modules are "passive" and are not configured.

"V alve discs" summarized analogously with electrical digital modules.

8644/phoenix - 37

Page 42

SYSTEM DESCRIPTION

Addressing in the process diagram 1

unused bits

unused bits

Addressing in the process diagram 2

unused bits

unused bits

38 - 8644/phoenix

Page 43

Addressing in the process diagram 3

SYSTEM DESCRIPTION

Diagnosis of the Profibus connection

Standard

Byte

Byte

Byte

Byte

Byte

Status 1

Status 2

Status 3

Master Address

Manufacturer

Device-related

Byte

Byte

Byte

Byte

Identifier

Byte

Byte

Manufacturer

Identifier

Byte

Byte

Byte

Byte

Header byte:

Diagnosis type: 0x00

Software version

Error type:

1 - Par ameter

2 - Config. Profibus

3 - Config. Interbus

4 - Interbus

Error number

Module number before error

Module number after error

ID code

Linear code

Byte

Reserve

8644/phoenix - 39

Page 44

SYSTEM DESCRIPTION

DIAGNOSIS AND ERROR ELIMINATION AT THE PROFIBUS DP BUS NODE

Diagnosis LEDs directly at the station

Display / LEDs

Abb-rev Colour Meaning Explanation

UM green Main supply

US green Segment supply

BF red Bus Fault

FS red Failure Select

FN red Failure Number

Supply voltage in main circuit for field bus nodes, logic supply and

interrfaces present.

Supply voltage present in segment circuit.

No data exchange with master.

Select function of LED FN:

FS lights: FNshow the error type.

FS does not light: FN show the error number.

The number of flashes indicates the error tyoe of error number,

depending on whether FS lights or not.

Determining the cause of error

The error type and number may be determined from the LEDs FS and FN, which are to be found above the

supply terminal of the field bus nodes. If diode FS lights, the number of flashes of FN shows the error

type. If diode FS is off , the n umber of flashes of FN shows the error n umber.

Error type and number are simultaneously notified via the PROFIBUS to the control system.

Example:

LED FS lights and LED FN simultaneously flashes three times. Then LED FS e xtinguishes and LED

FN flashes four times (error type 3, number 4). The cause of error is the use of an INTERB US Loop-1

module which is not permissible.

40 - 8644/phoenix

Page 45

Error codes during DPV1 communication

SYSTEM DESCRIPTION

ATTENTION!

If there is an error present during DPV1 or PD-PCP communication in relation to an E/A module, this is

displayed via 0x44 on byte 2 of the data block.

DPV1 error:

Error codes during DPV1 communication are errors in relation to DPV1/PCP.

During DPV1 communication you will find the error code on byte 3, during communication

in the process data channel, error code 1 is located on byte 2 of the response.

Pa y attention to the individual displa ys in your w orking environment at all times.

Function_Num = 0xDE (Error Read) or 0xDF (Error Write)

Error_Decode = 0x80 (DPV1 communication)

Error codes during DPV1 communication

Error_Code_1 Error_Code_2 Comment

0xA0 0 Object from the field bus modul e canno t be read.

0xA1 0 Object from the field bus modul e canno t be writt en.

0xB0 0 wrong index from th e field bus modul e

0xB1 0 The PB-PDU leng th is t oo sma ll.

0xB2 0 wrong slot

0xB5 0 Module is busy.

0xB7 0 Error while writing on index 47 or 48

0xD1 0 no PCP connec tion

0xD2 0 Module has no P CP

0xD3 0 Timeout from modul e

0xD4 0 wrong servi ce

0xD5 0 VC1 sequence not corre ct

0xD6 0 VC1 length incorrect

0xF.. Error while wr itin g modul e param eter

0xF1 0 An incorrect module num ber was used.

0xF2 0 The parameter block is incomplet e.

0xF3 0 The data length of the paramet er block is too smal l.

0xF4 0 The data length of the paramet er block is too big .

0xF5 0 The intern al block for configuration, se cur ity value and

PCP is too small .

0xF6 0 Header byte from the m odule p aramet er block is not

correct.

0xF7 0 PCP initialisation for a mod ule that has no PCP

functionality.

0xF8 0 too many data blocks for the module

8644/phoenix - 41

Page 46

SYSTEM DESCRIPTION

FIELD BUS NODE PROFIBUS DPV1

New functions

As part of the expansion of field bus node Profibus DPV1 (article no . 00148837) ne w functions hav e been

added and suggestions taken into account:

• DPV1 for category 1and category 2 masters

• acyclical communication with e. g. RS232 modules, including in the process data channel

• Parameterization of E/A modules

• Failsaf e v alues

• various diagnosis formats

• acknowledgement of peripheral errors from the application program

• adaptation of the high-byte/low-byte format to the control format on 16 and 32-channel input and output

modules

Special features of the DIP 8 switches

Position OFF

The device is exchange-compatible with the predecessor up to serial number 37343 and provides the

following new functions:

• acyclical communication with e.g. RS232 modules, including in the process data channel

• various diagnosis formats

• acknowledgement of peripheral errors from the application program

• adaptation of the high-byte/low-byte format to the control format on 16 and 32-channel input and

output modules

These functions are, howe ver , only av ailable on new devices from serial number 37344 onw ards.

When scheduling projects for the device, use the „BUER00F0.gsd“ GSD or the device entry „8644-

DPV1(DIP8=OFF) ME02“) in the S7 hardware configurator .

Position ON

The device provides all new functions in the ON position.

Stop behaviour, which was set via DIP switch 8 in the old device, is no w adjusted via the

parameterization.

When scheduling projects for the device, use the „BUER06BA.gsd“ GSD or the device entry „8644-

DPV1(DIP8=ON) ME02“) in the S7 hardware configurator .

(default setting)

DIP switch assignment

DIP switch settings on PROFIBUS bus terminal from serial number 37344 onwards

DIP swi t ch Releva nc e

1 to 7 PROFIBUS address in binar y displ ay ( 0 to 127 in decim al disp lay)

Switch 1 establishes the least sig nifica nt bit (LSB ) ( 2

Switch 7 establishes the highes t signi ficant bit (HS B) (2

8 Inline stati on operating m ode;

ON: New mode with DPV1support, secur ity values and parame ter izat ion;

OFF: Compatible mode (to PROFIBUS bus terminal up to ser ial num ber 373 43)

9 and 10 When using an LWL connector, both switches are on ON in order take account of t he

increased current re quirem ent of th e LWL connector. There is then no voltage shut-off

to the interface power supply.

42 - 8644/phoenix

0

)

6

)

Page 47

Overview of firmware functionalities

SYSTEM DESCRIPTION

PROFIBUS PROFIBUS

up to serial

number 37343

Device entry Model 8644 8644-DP

PROFIBUS bus terminal

from serial number 37344 onwards

DPV0 mode DPV1 mode

8644-DPV1

(DIP8=OFF)

ME02

(DIP8=ON)

ME02

GSD file BUER00F0.gsd BUV100F0.gsd BUER06BA.gsd

PROFIBUS bus terminal exchangeability old

XX--

and new version

DPV0 suppor t

(cyclical c ommunic atio n)

Maximum 184

bytes Process

data

Maximum 184

bytes Process

data

Maximum 184

bytes Pr o ce s s

data

Operation of PCP modules -- X X

DPV1-Read and DPV1-Wr it e suppo rt

-- -- X

(acyclical communication),

Category 1 and c ategory 2 masters

Communication with PCP modul es via

-- X X

„norma l“ proc ess data ( DPV0 )

Parameterization of lar ge number of E/ A' s via

-- -- X

dialogues in the proje ct pla nning too l

Security values set via th e proj ect pl anning

-- -- X

tool

Bytes switched round on IB IL24 DI16 and

-- X X

IB IL24 DO16 to adapt to the co ntrol format

Bytes switched round on IB IL24 DI32 and IB

IL24 DO32

Bus stop acknowledgement, eithe r

-- New from Firm-

ware B onwards

-- X X

automatically or vi a applic ation pr ogram

Peripheral error acknowledgement, either

-- X X

automatically or vi a applic ation pr ogram

Diagnosis in the PROFIBUS bus termina l X X X

Diagnosis in the ident ificat ion for mat -- -- X

Diagnosis as status P DU -- -- X

Stop behaviour can be adjusted v ia DIP

X----

switch

Stop behaviour can be adjusted v ia

-- X

1)

parameter telegram

Invoke ID transfer

(e.g. for IB IL POS 200)

Dynamic configuration

-- New from Firm-

ware B onwards

-- -- New from

(Reservation of E /A´s in t he PLC,

e.g. for easy expansion)

New from Firmware B onwards

1)

X

New from Firmware B onwards

Firmware B

onwards

Station ID can be a llocat ed f reely (2 bytes )

for improved identification in the networ k

Failsafe values set via project planning tool --

1)

see illustration Adjus ting the st op behaviour on new devices from ser ial number 3 744 onwards

-- -- New from Firm-

ware B onwards

--

X

8644/phoenix - 43

Page 48

SYSTEM DESCRIPTION

PROFIBUS PROFIBUS

up to serial

number 37343

Device entry Model 8644 8644-DP

GSD file BUER00F0.gsd BUV100F0.gsd BUER06BA.gsd

Failsafe values al so wihou t conne ction to PLC --

Improved diagnosis of E/A's dur i ng start-up --

Configuration con be saved

(additional verificatio n based o n the las t valid

configuration)

Adjusting the stop behaviour via the parameter telegram

--

PROFIBUS bus terminal

from serial number 37344 onwards

DPV0 mode DPV1 mod e

8644-DPV1

(DIP8=OFF)

ME02

--

--

--

(DIP8=ON)

ME02

New from

Firmware B

New from

Firmware B

New from

Firmware B

44 - 8644/phoenix

Page 49

SYSTEM DESCRIPTION

Description of field bus node

DPV1 is the expansion of the cyclical data exchange according to IEC61158 to acyclical services.

Complex devices can be oper ated easily with this e xpansion. Acyclical data are particularly suitable for

data which do not have to be transmitted on a regular basis or are of variable length, as is the case for

example with an RS232 interface.

The following differences can be found:

1 . Acyclical communication via the category 1 master (C1 master)

The C1 master carries out the parameterization during slave start-up and is master in the cyclical data

traffic. If it necessary to use an RS232 interface acyclically from the C1 master or to read a parameter

optionally from the device, corresponding write and read accesses are defined. Since the C1 master is

already connected to the slave in the cyclical data traffic, no explicit connection is established, but

direct communication can be made with the slave via read and write.

2 . Acyclical communication via the category 2 master (C2 master)

The C2 master can be realized in various forms, for example in the form of a display device or control

terminal. In the display device, data is fetched by the sla ve only on request, for example (if a certain

parameter is to be read), while accesses are acyclical in the control terminal. Accordingly, write and read

accesses are provided for the C2 master. Since the C2 master does not communicate in the cyclical

traffic, it must establish and cut the connection explicitly.

3 . Acyclical communication in cyclical data exchange (C1 master)

DPV1 is still relatively new. In contrast, the service life of controls and facilities is very long, so that