Page 1

Type 8644

AirLINE

Quickstart

English Deutsch Français

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2011 - 2012 Bürkert Werke GmbH

Operating Instructions 1207/01_EU-ML_00809514 / Original DE

Page 3

Type 8644

Contents

1. QUICKSTART .....................................................................................................4

1.1. Definition of the term "Device" ...................................................... 4

1.2. Symbols

2. INTENDED USE ................................................................................................5

2.1. Restrictions

3. GENERAL SAFETY INFORMATION ........................................................5

4. GENERAL INFORMATION ...........................................................................6

4.1. Contact address ............................................................................... 6

4.2. Warranty

4.3. Informations in the Internet ............................................................. 6

5. TECHNICAL DATA ...........................................................................................7

5.1. Conformity

5.2. Standards

5.3. General Technical Data .................................................................. 7

.............................................................................................. 4

........................................................................................ 5

............................................................................................. 6

.........................................................................................7

........................................................................................... 7

6. ASSEMBLY

6.1. Safety instructions ...........................................................................8

6.2. Assembly

6.3. Removing the valve block from the standard rail ....................12

7. INSTALLATION

7.1. Fluid Installation ..............................................................................13

7.2. Fluid deinstallation .........................................................................15

7.3. Electrical Installation ......................................................................15

8. START-UP

8.1. Safety instructions .........................................................................16

8.2. Fluid start-up ...................................................................................16

8.3. Electrical start-up ...........................................................................16

9. MAINTENANCE

10. TRANSPORT, STORAGE, DISPOSAL ..............................................16

..........................................................................................................8

............................................................................................9

...............................................................................................13

.........................................................................................................16

.............................................................................................. 16

english

3

Page 4

Type 8644

Quickstart

1. QUICKSTART

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

Important Safety Information!

Read Quickstart carefully and thoroughly. Study in particular the

chapters entitled “General safety information” and “Intended use”.

Quickstart must be read and understood.

•

The Quickstart explains, for example, how to install and start-up the

device.

A detailed description of the device can be found in the operating

instructions for Type 8644.

The operating instructions can be found on the enclosed CD

and on the Internet at:

www.burkert.com

1.1. Definition of the term "Device"

In these instructions, the term "device" always refers to the system

AirLINE type 8644.

1.2. Symbols

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderately severe

or minor injury.

NOTE!

Warns of damage to property!

Important tips and recommendations.

Refers to information in these operating instructions or in

other documentation.

→ designates a procedure which you must carry out.

4

english

Page 5

Type 8644

Intended use

2. INTENDED USE

Non-intended use of the AirLINE Type 8644 may be a hazard

to people, nearby equipment and the environment.

• The device is designed for use in an environment where there is a

risk of explosion (only Type 8644 Siemens and Wago). Pneumatically operated devices may be used for control.

• Do not supply the medium connectors of the system with

aggressive or flammable media.

• Do not use the device outdoors unprotected.

• Do not physically stress the housing (e.g. by placing objects on

it or standing on it).

• Use according to the authorized data, service and operating conditions specified in the contract documents and operating instructions. These are described in the chapter entitled “Technical data”.

The device may be used only in conjunction with third-party devices

•

and components recommended and authorized by Bürkert.

• Correct transportation, storage, and installation, as well as careful use and maintenance are essential for reliable and faultless

operation.

Use the device only as intended.

•

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

3. GENERAL SAFETY INFORMATION

This safety information does not cover:

• Haphazard situations that can arise during installation, operation and

maintenance of the use.

• Locally applicable safety regulations which the operator and installation personnel are obligated to follow.

General Hazardous Situations.

To prevent injuries:

• Ensure that the system cannot be activated unintentionally.

• Note that pipes and valves must not become detached in systems

which are under pressure.

• Before reaching into the system, always switch off the power

supply.

Design the pressure supply with the largest possible volume to

•

prevent a pressure drop when the system is switched on.

• Installation and maintenance work may be carried out only by

authorized technicians with the appropriate tools.

• After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

The device may be operated only when in perfect condition and

•

in consideration of the operating instructions.

• The general rules of technology must be observed for application

planning and operation of the device.

english

5

Page 6

Type 8644

General information

Risk of burns/risk of fire if used continuously through hot

device surface!

• Keep the device away from highly flammable substances and media

and do not touch with bare hands.

The Type 8644 AirLINE was developed with due consideration

given to accepted safety rules and is state-of-the-art. Nevertheless, dangerous situations may occur.

NOTE!

Electrostatic sensitive components/modules!

The device contains electronic components, which react sensitively

to electrostatic discharge (ESD). Contact with electrostatically

charged persons or objects is hazardous to these components. In

the worst case scenario, they will be destroyed immediately or will

fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1

and 5-2 to minimize/avoid the possibility of damage caused by a

sudden electrostatic discharge!

• Also, ensure that you do not touch electronic components when

the power supply voltage is present!

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses are found on the final pages of this operating

manual.

And also on the Internet under: www.burkert.com

4.2. Warranty

The warranty is only valid if the AirLINE Type 8644 is used as intended

in accordance with the specified application conditions.

4.3. Informations in the Internet

The operating manual and the data sheets on Type 8644 can be found

on the Internet under: www.burkert.com

6

english

Page 7

Type 8644

Technical data

5. TECHNICAL DATA

5.1. Conformity

The system AirLINE type 8644 conforms with the EC Directives

according to the EC Declaration of Conformity.

5.2. Standards

The applied standards, which verify conformity with the EC Directives, can be found on the EC-Type Examination Certificate and / or

the EC Declaration of Conformity.

5.3. General Technical Data

Technical Data Pilot valve type 0460,

6524, 6525

Pressure range Vac. up to 10 bar Vac. up to 10 bar

Operating

voltage

Voltage tolerance +20 % / -15 %

Ambient

temperature

24 V DC 24 V DC

(when using

Type 0460: ± 10 %)

0 ... +55 °C

(when using Type 0460 and 0461: 0 ... +50 °C)

Pilot valve type 0461,

6526, 6527

+20 % / -15 %

(when using

Type 0461: ± 10 %)

5.3.1. Rating plate

Type

Operating principle

Orifice

6525 H 4,0

PN 2,5 - 7 bar

24 V DC 1W

450000Y

MADE IN GERMANY

W14UN

Identification number

Voltage (±10 %), capacity

Pressure range

Fig. 1: Location and description of the rating plate

english

7

Page 8

Type 8644

Assembly

5.3.2. Fluid connection

Type 6524

X*

3/R

2/A

1/P

Fig. 2: Fluid connection. Types 6524 and 6525

Type 6525

X*

5/R

4/A

1/P

2/B

3/S

Design the pressure supply

with the largest possible

volume!

X* - pilot control exhaust air

5.3.3. Fluid and electrical connection

Type 6524

(2 x 2/3-way valve)

- Pin coil 12

controlled via bit “n+1”

+ Pin

- Pin coil 14

controlled via bit

“n”

12

14

X*

5/R

4/A

1/P

2/B

3/S

Observe pin

assignment!

Hand lever

assignment

X* - pilot control

exhaust air

Bit “n+1”

6. ASSEMBLY

6.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening lines or valves, turn off the pressure and vent

the lines.

Risk of injury due to electrical shock!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper assembly!

• Installation may only be carried out by authorized technicians with

the appropriate tools!

Risk of injury from unintentional activation of the system and

uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

Bit “n”

Fig. 3: Fluid and electrical connection. Type 6524

8

english

Page 9

Type 8644

Assembly

CAUTION!

Escape of medium and malfunction!

If the seals are not seated correctly, leaks and malfunctions may occur

due to pressure losses.

• Ensure that the seals are seated correctly in the area of the electronics and pneumatics.

Short-circuit, malfunction!

The electrical connection requires exact contacting.

• Do not bend contacts.

• If connections are damaged or bent, replace the affected

components.

Do not switch on the system unless the components are in perfect

•

condition.

NOTE!

Operate the system with direct current only!

To prevent damage to the system, use only direct current for the

system power supply.

Prevent a pressure drop!

To prevent a pressure drop, design the system pressure supply with

the largest possible volume.

6.2. Assembly

DANGER!

Danger of explosion!

If systems in the explosion-protected area are installed in a control

cabinet, the following requirements must be met:

• The control cabinet must be authorized for use in the explosionprotected area.

• The control cabinet must be large enough to allow the resulting lost

heat to be dissipated in a suitable manner to the outside.

• The internal temperature of the control cabinet must not exceed

the max. permitted ambient temperature for the device.

Risk of electric shock!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

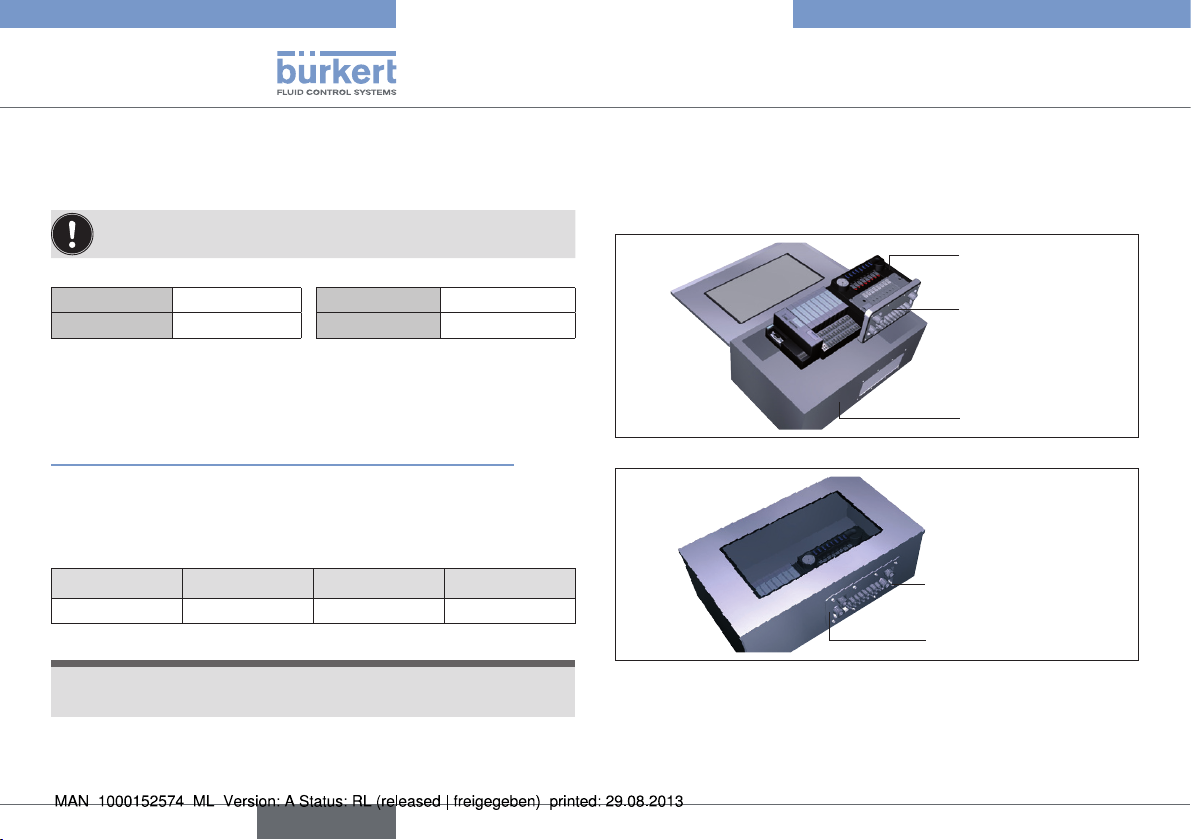

6.2.1. Installation on standard rail

Converter

Module

Field bus

Module

Converter

Terminator

Fig. 4: Installation of a valve block into a control cabinet

english

9

Page 10

Type 8644

Assembly

→ Fasten the standard rail firmly in the control cabinet.

→ Establish a short, wide PE connection between the standard rail

and the control cabinet.

The valve terminal must be freely accessible from above.

Ensure good heat dissipation!

Recommended distance when installing in a control cabinet:

A

B

30 mm

30 mm

C

D

6.2.2. Installation of AirLINE Quick

To install AirLINE Quick, a notch must be first of all provided on the

base or the wall of the control cabinet, e.g. through lasing or punching.

For the dimensions of the relevant flange image, refer to chapter

“Tab. 1: Dimensions of the flange images for AirLINE Quick”.

The distances to the left, right, front and top depend on the selected

valve terminal configuration.

Recommended distance in the control cabinet to the valve

terminal:

left right front top

30 mm 60 mm 30 mm 50 mm

HINWEIS!

The opening on the control cabinet must be burr-free to

prevent damage to the seal of the AirLINE Quick adapter.

30 mm

60 mm

→ Position the valve terminal in the control cabinet on the prepared

opening.

→ From outside attach the stability plate to prevent distortion and

secure with screws M 5 x 10 from the enclosed fastening set.

Valve terminal

Type 8644

AirLINE Quick

adapter

Control cabinet

Fig. 5: Placing the valve terminal in the control cabinet

Screws M 5 x 10

Stability plate

Fig. 6: Attaching the stability plate

→ Without damaging the seal of the AirLINE Quick adapter, insert it

into the groove of the flange opening.

10

english

Page 11

Type 8644

Assembly

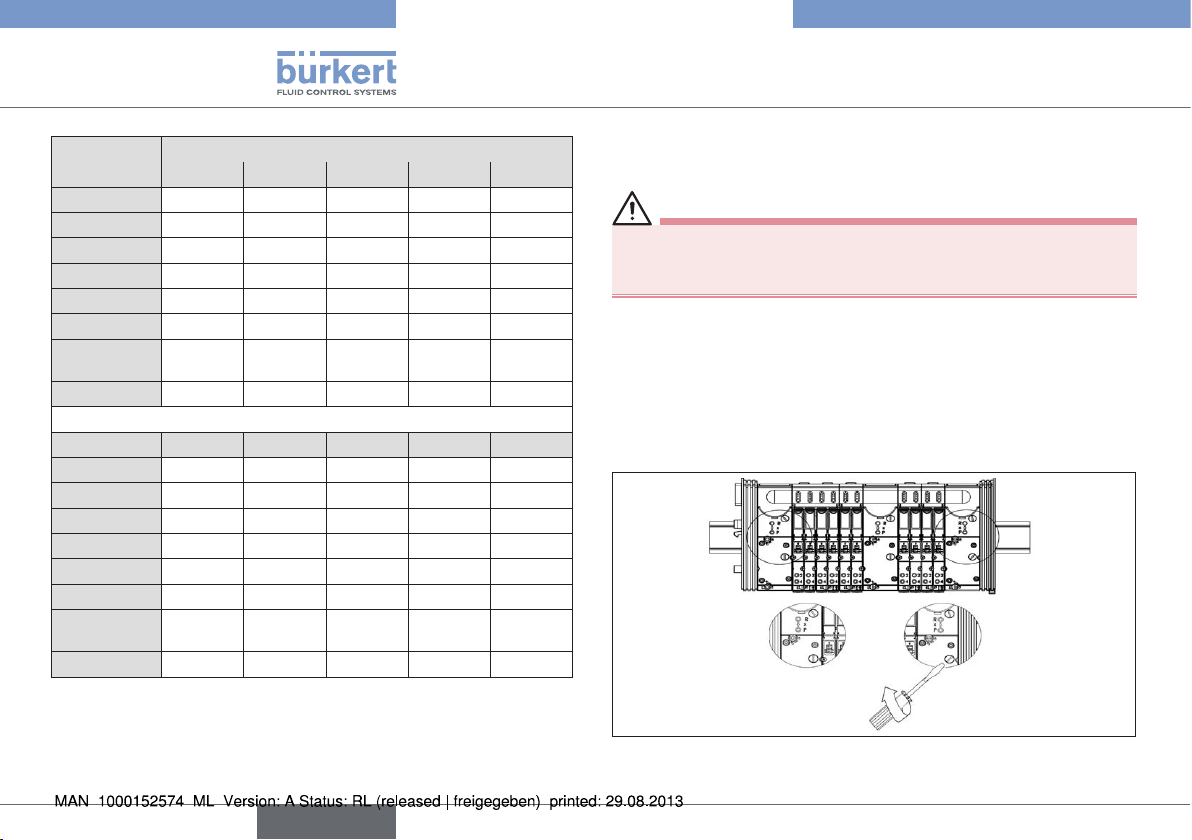

6.2.3. Dimensions of the flange images for AirLINE Quick

Inside wall control cabinet

N4

N3

N2

t>=1.5

>=8

N1

Ø 5.3 ± 0.2

R 6.5

only at O= 6 and O = 10

M

G

Space requirements reinforcing frame outside

Fig. 7: Dimensions of the flange images for AirLINE Quick – for dimensions see “Tab. 1”, page 12

english

59 ± 0.3

73 ± 0.3

(96)

11

Page 12

Type 8644

Assembly

Version

8-fold 12-fold 16-fold 16-fold 20-fold

Feature

M

N1

N2

N3

N4

O (Number of

bores)

G

– – –

155 ±0.4 199 ±0.4 243 ±0.4 276 ±0.4 287 ±0.4

54 ±0.3 68 ±0.3 123 ±0.4 140 ±0.4 145 ±0.4

158 ±0.4 202 ±0.4 246 ±0.4 279 ±0.4 290 ±0.4

– – – – –

– – – – –

8 8 10 10 10

192 236 280 313 324

1) 2)

20-fold 24-fold 24-fold 32-fold

Feature

M

N1

N2

N3

N4

O (Number of

bores)

G

Tab. 1: Dimensions of the flange images for AirLINE Quick

1) with intermediate feed

2) on request

3) with intermediate feed on request

3)

320 ±0.4 331 ±0.4 364 ±0.4 452 ±0.4

65 ±0.3 66 ±0.3 73 ±0.3 65 ±0.3

193 ±0.4 200 ±0.4 219 ±0.4 195 ±0.4

323 ±0.4 334 ±0.4 367 ±0.4 325 ±0.4

– – –

12 12 12 16

357 368 401 489

–

1) 3)

455 ±0.4

6.3. Removing the valve block from the

standard rail

DANGER!

Risk of electric shock!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation.

The valve block is bolted securely onto the standard rail. Additional

electrical modules / terminals can be aligned in rows on the sides of

the valve block.

Procedure:

→ Detach the adjacent modules/terminals (if fitted).

→ Release the attachment of the valve block on the standard rail. To

do this, turn the fastening screws all the way counter-clockwise.

Fig. 8: Releasing the attachment of the valve block on the standard rail

→ Lift the valve block vertically off the standard rail.

12

english

Page 13

Type 8644

Installation

There must be adequate space between valve block and predecessor module > 6 mm.

→ Detach the modules/terminals from the standard rail according to

the manufacturer’s description.

NOTE!

The interface of the left connection module contains elements

which may break off if force is used.

• Never place the valve block on its side and observe the permitted

installation position.

Fig. 9: Detaching the modules/terminals from the standard rail

NOTE!

•

When screwing the valve block back onto the standard rail,

observe a max. torque of 2 Nm!

7. INSTALLATION

7.1. Fluid Installation

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening lines or valves, turn off the pressure and vent

the lines.

• Design the connections with the largest possible volume.

• Close the open connections not required with lock screws.

• The connections for the pilot control exhaust air (x) must not be

sealed.

Check correct assignment of the connections 1 and 3 or 5. They

•

may by no means be interchanged.

7.1.1. Pneumatic connections - feed

Exhaust air

X channel:

Standard version:

Deaeration of the control valves

Control assist air version:

P connection for control valves

Pressure supply connection

Fig. 10: Pneumatic Connections

Procedure:

→ Depending on the version, plug the connections in the corre-

sponding working connections or screw them in.

english

13

Page 14

Type 8644

Installation

NOTE!

For the plug-in connections the hose pipes must meet the following

requirements:

•

Minimum hardness of 40 Shore D (in accordance with DIN

53505 or ISO 868);

• Outer diameter in accordance with DIN 73378 (max. permitted

deviation ± 0.1 mm of the nominal dimension);

• Burr-free, cut off at right angles and undamaged on the outer

diameter;

The hose pipes must be pressed all the way into the plug-in

connections.

7.1.2. Removing the plug-in connections

→ To detach the pipes, press in the thrust ring and pull out the hose

pipe.

7.1.3. Pneumatic connections –

AirlINE standard

Inscription areas

Working connections

for 5/2-way valves

Working connections

for 3/2-way valves

Fig. 11: Pneumatic connections - valve discs

Procedure:

→ Depending on the version, plug the connections in the corre-

sponding working connections or screw them in.

→ Connection nipples can be used for threaded versions.

Inscription of the connections:

→ Label the inscription areas with the data of the valve

connections.

7.1.4. Pneumatic connections –

AirLINE Quick

Fig. 12: Pneumatic connections – AirLINE Quick

Procedure:

→ Depending on the version, plug the connections in the corre-

sponding working connections.

14

english

Page 15

Type 8644

Installation

7.1.5. Fluid connection AirLINE Quick

Example of

connection adapter

Air discharge connection R/S

Supply connection P

Fig. 13: Fluid connection AirLINE Quickk

Procedure:

→ Screw connection adapter G1/4" or NPT 1/4" to connections P

and R/S.

NOTE!

Risk of leakage if screw connection is too tight!

• When fitting the fluid connection adapters to the connections

P, R/S, observe the max. torque of 12 Nm. In doing so, counter

with a suitable tool to prevent the connections from turning!

7.2. Fluid deinstallation

NOTE!

Irreversible damage to the seal in the thread of the screw

connection!

When loosening the connection adapters, use a suitable tool to

•

prevent the corresponding supply or air discharge connection

from turning.

7.3. Electrical Installation

DANGER!

Risk of injury due to electrical shock!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

The electrical installation of the AirLINE system corresponds to the

installation of the decentralized peripheral device (depending on the

relevant cooperation partner Siemens, Wago, Phoenix or Rockwell).

Refer to the manuals provided by the cooperation partners for a more

detailed description.

english

15

Page 16

Type 8644

Start-Up

8. START-UP

8.1. Safety instructions

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the

device and the area around it.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

Observe the safety instructions and intended use.

•

• Only adequately trained personnel may start up the equipment/

the device.

8.2. Fluid start-up

NOTE!

•

Switch on the supply pressure.

• Only then switch on the power supply!

Procedures before fluid start-up:

→ Check connections, voltage and operating pressure.

→ Ensure that max. operating data are not exceeded.

→ Check correct assignment of the connections 1 and 3 or 5. They

may by no means be interchanged.

→ Release manual actuation during electrical operation.

8.3. Electrical start-up

The start-up of the AirLINE system corresponds to the installation of the

decentralized peripheral device (depending on the relevant cooperation

partner Siemens, Wago, Phoenix or Rockwell).

Refer to the manuals provided by the cooperation partners for a more

detailed description.

9. MAINTENANCE

See“7.2. Fluid deinstallation”, page 15.

10. TRANSPORT, STORAGE, DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the permitted storage

temperature.

Incorrect storage may damage the device!

• Store the device in a dry and dust-free location!

• Storage temperature: -20 ... +60 °C.

Damage to the environment caused by device components

contaminated with media!

• Ensure the device and packaging are disposed of in an environmentally sound manner.

• Observe applicable regulations relating to refuse disposal and

the environment.

• Observe the national waste disposal regulations.

16

english

Page 17

Typ 8644

Inhaltsverzeichnis

1. DER QUICKSTART ....................................................................................... 18

1.1. Begriffsdefinition Gerät .................................................................18

1.2. Darstellungsmittel

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ...................................19

2.1. Beschränkungen

3. GRUNDLEGENDE SICHERHEITSHINWEISE ................................. 19

4. ALLGEMEINE HINWEISE .......................................................................... 20

4.1. Kontaktadresse

4.2. Gewährleistung...............................................................................20

4.3. Informationen im Internet ..............................................................20

5. TECHNISCHE DATEN ................................................................................ 21

5.1. Konformität

5.2. Normen

5.3. Allgemeine technische Daten ......................................................21

.............................................................................................21

...........................................................................18

............................................................................19

...............................................................................20

.......................................................................................21

6. MONTAGE

6.1. Sicherheitshinweise

6.2. Montage

6.3. Entfernen des Ventilblocks von der Normschiene ..................26

7. INSTALLATION

7.1. Fluidische Installation ....................................................................27

7.2. Fluidische Deinstallation ...............................................................29

7.3. Elektrische Installation ...................................................................29

8. INBETRIEBNAHME

8.1. Sicherheitshinweise

8.2. Fluidische Inbetriebnahme ...........................................................30

8.3. Elektrische Inbetriebnahme ..........................................................30

9. WARTUNG

10. TRANSPORT, LAGERUNG, VERPACKUNG ..................................30

........................................................................................................ 22

.......................................................................22

...........................................................................................23

...............................................................................................27

......................................................................................30

.......................................................................30

........................................................................................................30

deutsch

17

Page 18

Typ 8644

Der Quickstart

1. DER QUICKSTART

Der Quickstart beschreibt den gesamten Lebenszyklus des Geräts.

Bewahren Sie diese Anleitung so auf, dass sie für jeden Benutzer gut

zugänglich ist und jedem neuen Eigentümer des Geräts wieder zur

Verfügung steht.

Wichtige Informationen zur Sicherheit!

Lesen Sie den Quickstart sorgfältig durch. Beachten Sie vor allem

die Kapitel „Grundlegende Sicherheitshinweise“ und „Bestimmungsgemäße Verwendung“.

Der Quickstart muss gelesen und verstanden werden.

•

Der Quickstart erläutert beispielhaft die Montage und Inbetriebnahme

des Geräts. Die ausführliche Beschreibung des Geräts finden Sie in

der Bedienungsanleitung für den Typ 8644.

Die Bedienungsanleitung finden Sie auf der beigelegten CD

oder im Internet unter: www.buerkert.de

1.1. Begriffsdefinition Gerät

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht immer für

das System AirLINE Typ 8644.

1.2. Darstellungsmittel

In dieser Anleitung werden folgende Darstellungsmittel verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung können schwere Verletzungen oder Tod die

Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur

Folge haben.

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen.

Verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

18

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

deutsch

Page 19

Typ 8644

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz der AirLINE Typ 8644

können Gefahren für Personen, Anlagen in der Umgebung und

die Umwelt entstehen.

• Das Gerät ist für den Einsatz in explosionsgefährdeten Umgebungen konzipiert. Es darf zur Steuerung pneumatisch betriebener

Geräte eingesetzt werden.

• In die Medienanschlüsse des Systems keine aggressiven oder

brennbaren Medien einspeisen.

• Das Gerät nicht ungeschützt im Außenbereich einsetzen.

• Das Gehäuse nicht mechanisch belasten (z. B. durch Ablage von

Gegenständen oder als Trittstufe).

• Für den Einsatz die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs- und

Einsatzbedingungen beachten. Diese sind im Kapitel „Technische

beschrieben.

Daten“

• Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw.

zugelassenen Fremdgeräten und -komponenten einsetzen.

• Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instandhaltung.

• Setzen Sie das Gerät nur bestimmungsgemäß ein.

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls

bestehende Beschränkungen.

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• In Systemen, die unter Druck stehen, dürfen Leitungen und Ventile

nicht gelöst werden.

• Vor Eingriffen in das System in jedem Fall die Spannung abschalten.

• Druckversorgung möglichst großvolumig ausführen, um Druckabfall

beim Schalten zu vermeiden.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt werden.

• Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung

der Bedienungsanleitung betrieben werden.

• Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung ist ein definierter oder kontrollierter Wiederanlauf des

Prozesses zu gewährleisten.

• Für die Einsatzplanung und den Betrieb des Geräts müssen die

allgemeinen Regeln der Technik eingehalten werden.

deutsch

19

Page 20

Typ 8644

Allgemeine Hinweise

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb durch

heiße Geräteoberfläche!

• Das Gerät von leicht brennbaren Stoffen und Medien fernhalten

und nicht mit bloßen Händen berühren.

Typ 8644 AirLINE wurde unter Einbeziehung der anerkannten

sicherheitstechnischen Regeln entwickelt und entspricht

dem Stand der Technik. Trotzdem können Gefahren entstehen.

HINWEIS!

Elektrostatisch gefährdete Bauelemente / Baugruppen!

Das Gerät enthält elektronische Bauelemente, die gegen elektrostatische Entladung (ESD) empfindlich reagieren. Berührung mit

elektrostatisch aufgeladenen Personen oder Gegenständen gefährdet

diese Bauelemente. Im schlimmsten Fall werden sie sofort zerstört

oder fallen nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340-5-1 und 5-2,

um die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

• Achten Sie ebenso darauf, dass Sie elektronische Bauelemente

nicht bei anliegender Versorgungsspannung berühren!

4. ALLGEMEINE HINWEISE

4.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung oder im Internet: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch der AirLINE Typ 8644 unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 8644 finden Sie im

Internet unter: www.buerkert.de

20

deutsch

Page 21

Typ 8644

Technische Daten

5. TECHNISCHE DATEN

5.1. Konformität

Das AirLINE System Typ 8644 ist konform zu den EG-Richtlinien

entsprechend der Konformitätserklärung.

5.2. Normen

Die angewandten Normen, mit denen die Konformität mit den EGRichtlinien nachgewiesen wird, sind in der Baumusterprüfbescheinigung und/oder der EG-Konformitätserklärung nachzulesen.

5.3. Allgemeine technische Daten

Technische

Daten

Druckbereich Vak. bis 10 bar Vak. bis 10 bar

Betriebs-

spannung

Spannungs-

toleranz

Umgebungstemperatur

Pilotventil Typ 0460,

6524, 6525

24 V DC 24 V DC

+20 % / –15 %

(bei Verwendung des

Typs 0460: ± 10 %)

0 ... +55 °C

(bei Verwendung des Typs 0460 und 0461:

0 ... +50 °C)

Pilotventil Typ 0461,

6526, 6527

+20 % / –15 %

(bei Verwendung des

Typs 0461: ± 10 %)

5.3.1. Typschild

Typ

Wirkungsweise

Nennweite

6525 H 4,0

PN 2,5 - 7 bar

24 V DC 1W

450000Y

MADE IN GERMANY

Identnummer

Spannung (± 10 %), Leistung

Druckbereich

Bild 1: Lage und Beschreibung des Typschildes

W14UN

deutsch

21

Page 22

Typ 8644

Montage

5.3.2. Fluidischer Anschluss

Typ 6524

X*

3/R

2/A

1/P

Bild 2: Fluidischer Anschluss. Typen 6524 und 6525

Typ 6525

X*

5/R

4/A

1/P

2/B

3/S

Druckversorgung möglichst

großvolumig ausführen!

X* - Vorsteuerabluft

5.3.3. Fluidischer und elektrischer

Anschluss

Typ 6524

(2 x 2/3-Wege Ventil)

– Pol Spule 12

angesteuert über Bit „n+1“

+ Pol

– Pol Spule 14

angesteuert über Bit „n“

Handhebel-

12

zuordnung

14

X* - Vorsteuerabluft

X*

5/R

4/A

1/P

2/B

3/S

Bit „n+1“

Pinbelegung

beachten!

Bit „n“

6. MONTAGE

6.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entlüften.

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das Gerät oder die Anlage die Spannung abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für

elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage!

• Die Montage darf nur autorisiertes Fachpersonal mit geeignetem

Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Montage einen kontrollierten Wiederanlauf

gewährleisten.

Bild 3: Fluidischer und elektrischer Anschluss. Typ 6524

22

deutsch

Page 23

Typ 8644

Montage

VORSICHT!

Mediumsaustritt und Fehlfunktion!

Bei mangelhaftem Sitz der Dichtungen können Undichtigkeiten und

Funktionsbeeinträchtigungen durch Druckverluste auftreten.

• Auf korrekten Sitz der Dichtungen im Bereich der Elektronik und

Pneumatik achten.

Kurzschluss, Funktionsausfall!

Der elektrische Anschluss erfordert exakte Kontaktierung.

• Kontakte nicht verbiegen.

• Bei beschädigten oder verbogenen Anschlüssen die betroffenen

Komponenten austauschen.

• Das System nur bei einwandfreiem Zustand der Komponenten

einschalten.

HINWEIS!

System nur mit Gleichstrom betreiben!

Um Schäden am System zu vermeiden für die Stromversorgung des

Systems ausschließlich Gleichstrom einsetzen.

Druckabfall vermeiden!

Um einen Druckabfall zu vermeiden die Druckversorgung des

Systems möglichst großvolumig ausführen.

6.2. Montage

GEFAHR!

Explosionsgefahr!

Bei Systemen im explosionsgeschützten Bereich, die in einem

Schaltschrank eingesetzt sind, muss folgendes sichergestellt sein:

• Der Schaltschrank muss für den Einsatz im explosionsgeschützten Bereich zugelassen sein.

• Der Schaltschrank muss so groß dimensioniert werden, dass die

entstehende Verlustwärme in geeigneter Weise nach außen abgeführt werden kann.

• Die Innentemperatur des Schaltschranks darf die maximal zulässige Umgebungstemperatur für das Gerät nicht überschreiten.

Gefahr durch elektrische Spannung!

• Vor Eingriffen in das Gerät oder die Anlage Spannung abschalten

und vor Wiedereinschalten sichern!

6.2.1. Montage auf der Normschiene

Umsetzer

Modul

Feldbus

Modul

Umsetzer

Abschluss

Bild 4: Einbau des Ventilblocks in einen Schaltschrank

deutsch

23

Page 24

Typ 8644

Montage

→ Die Normschiene fest im Schaltschrank montieren.

→ Eine kurze, breite PE-Verbindung zwischen Normschiene und

Schaltschrank herstellen.

Die Ventilinsel muss nach oben frei zugänglich sein.

Für gute Wärmeabfuhr sorgen!

Abstandsempfehlung beim Einbau in den Schaltschrank:

A

B

30 mm

30 mm

C

D

6.2.2. Montage AirLINE Quick

Zur Montage von AirLINE Quick muss zuerst ein Ausbruch am Schaltschrankboden bzw. der Schaltschrankwand vorgesehen werden. Dies

kann z. B. durch Lasern oder Stanzen erfolgen.

Die Abmessungen des entsprechenden Flanschbildes siehe Kapitel

„6.2.3. Abmessungen der Flanschbilder für AirLINE Quick“.

Die Abstände nach links, rechts, vorne und oben sind abhängig von

der gewählten Ventilinselkonfiguration.

Empfehlung Abstand im Schaltschrank zur Ventilinsel:

links rechts vorne oben

30 mm 60 mm 30 mm 50 mm

HINWEIS!

Der Ausbruch am Schaltschrank muss gratfrei sein, damit die

Dichtung des AirLINE Quick Adapters nicht beschädigt wird.

30 mm

60 mm

→ Die Ventilinsel im Schaltschrank auf den vorbereiteten Ausbruch

platzieren.

→ Von außen das Stabilisierungsblech zur Vermeidung von Verwer-

fungen anbringen und mit Schrauben M 5 x 10 des beiliegenden

Befestigungssatzes befestigen.

Ventilinsel

Typ 8644

AirLINE Quick

Adapter

Schaltschrank

Bild 5: Platzieren der Ventilinsel im Schaltschrank

Schrauben M 5 x 10

Stabilisierungsblech

Bild 6: Befestigung des Stabilisierungsblechs

→ Dichtung des AirLINE Quick Adapters beschädigungsfrei in die

Nut der Flanschöffnung einlegen.

24

deutsch

Page 25

Typ 8644

Montage

6.2.3. Abmessungen der Flanschbilder für AirLINE Quick

Schaltschrank-Innenwand

N4

N3

N2

t>=1,5

>=8

N1

Ø 5,3 ± 0,2

R 6,5

Platzbedarf Versteifungsrahmen Außenseite

Bild 7: Flanschbilder AirLINE Quick – Maße siehe Tab. 1 auf Seite 26

nur bei O= 6 und O = 10

M

G

deutsch

59 ± 0,3

73 ± 0,3

(96)

25

Page 26

Typ 8644

Montage

Ausführung

8-fach 12-fach 16-fach 16-fach 20-fach

Besonderheit

M

N1

N2

N3

N4

O (Anzahl

Bohrungen)

G

– – –

155 ±0,4 199 ±0,4 243 ±0,4 276 ±0,4 287 ±0,4

54 ±0,3 68 ±0,3 123 ±0,4 140 ±0,4 145 ±0,4

158 ±0,4 202 ±0,4 246 ±0,4 279 ±0,4 290 ±0,4

– – – – –

– – – – –

8 8 10 10 10

192 236 280 313 324

20-fach 24-fach 24-fach 32-fach

Besonderheit

M

N1

N2

N3

N4

O (Anzahl

Bohrungen)

G

Tab. 1: Abmessungen Flanschbilder AirLINE Quick

1) mit Zwischeneinspeisung

2) auf Anfrage

3) mit Zwischeneinspeisung auf Anfrage

3)

320 ±0,4 331 ±0,4 364 ±0,4 452 ±0,4

65 ±0,3 66 ±0,3 73 ±0,3 65 ±0,3

193 ±0,4 200 ±0,4 219 ±0,4 195 ±0,4

323 ±0,4 334 ±0,4 367 ±0,4 325 ±0,4

– – –

12 12 12 16

357 368 401 489

–

1) 3)

1) 2)

455 ±0,4

6.3. Entfernen des Ventilblocks von der

Normschiene

GEFAHR!

Gefahr durch elektrische Spannung!

• Vor Eingriffen in das Gerät oder die Anlage Spannung abschalten

und vor Wiedereinschalten sichern.

Der Ventilblock ist fest auf der Normschiene verschraubt. An seinen

Seiten können weitere elektrische Module/Klemmen angereiht sein.

Vorgehensweise:

→ Die benachbarten Module/Klemmen (falls vorhanden) lösen.

→ Befestigung des Ventilblocks an der Normschiene entriegeln.

Hierzu die Befestigungsschrauben gegen den Uhrzeigersinn bis

zum Anschlag drehen.

Bild 8: Entriegeln der Befestigung des Ventilblocks an der Normschiene

→ Ventilblock senkrecht von der Normschiene abheben.

26

deutsch

Page 27

Typ 8644

Installation

Es muss genügend Platz zwischen Ventilblock und Vorgängermodul sein > 6 mm.

→ Module/Klemmen entsprechend der Herstellerbeschreibung von

der Normschiene lösen.

HINWEIS!

Die Schnittstelle des linken Anschlussmoduls beinhaltet

Elemente, die bei Gewalteinwirkung abbrechen können.

• Ventilblock nie auf die Seite stellen und zulässige Einbaulage

beachten.

Bild 9: Lösen der Modulen/Klemmen von der Normschiene

HINWEIS!

•

Beim Wiederverschrauben des Ventilblocks auf der Normschiene ein max. Drehmoment von 2 Nm beachten!

7. INSTALLATION

7.1. Fluidische Installation

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten

und Leitungen entlüften.

• Die Anschlüsse möglichst großvolumig ausführen.

• Nicht benötigte offene Anschlüsse mit Verschlussschrauben

schließen.

Anschlüsse für Vorsteuerabluft (x) dürfen nicht verschlossen werden.

•

• Die vorschriftsmäßige Belegung der Anschlüsse 1 und 3 bzw. 5

überprüfen. Diese dürfen auf keinen Fall vertauscht werden.

7.1.1. Pneumatische Anschlüsse –

Einspeisung

Abluft R/3, S/5

X-Kanal

Standardausführung:

Entlüftung der Steuerventile

Steuerhilfsluftausführung:

P-Anschluss für Steuerventile

Druckversorgungsanschluss P/1

Bild 10: Pneumatische Anschlüsse

Vorgehensweise:

→ Die Anschlüsse je nach Ausführung an den entsprechenden

Arbeitsanschlüssen einstecken oder einschrauben.

deutsch

27

Page 28

Typ 8644

Installation

HINWEIS!

Für die Steckanschlüsse müssen die Schlauchleitungen folgende

Anforderungen erfüllen:

• Mindesthärte von 40 Shore D (nach DIN 53505 bzw. ISO 868),

• Außendurchmesser entsprechend DIN 73378 (max. zul. Abweichung ± 0,1 mm vom Nennmaß),

• gratfrei, rechtwinklig abgeschnitten und am Außendurchmesser

unbeschädigt.

Die Schlauchleitungen sind bis zum Anschlag in die Steckanschlüsse

einzudrücken.

7.1.2. Demontage der Steckanschlüsse

→ Zum Lösen der Leitungen den Druckring eindrücken und die

Schlauchleitung herausziehen.

7.1.3. Pneumatische Anschlüsse –

AirLINE Standard

Beschriftungsfelder

Arbeitsanschlüsse bei

5/2-Wege-Ventilen

Arbeitsanschlüsse bei

3/2-Wege-Ventilen

Bild 11: Pneumatische Anschlüsse – Ventilscheiben

Vorgehensweise:

→ Die Anschlüsse je nach Ausführung an entsprechenden Arbeits-

anschlüssen einstecken oder einschrauben.

→ Bei Gewindeausführung können Anschlussnippel verwendet

werden.

Beschriftung der Anschlüsse:

→ Beschriftungsfelder mit Daten der Ventilanschlüsse beschriften.

7.1.4. Pneumatische Anschlüsse –

AirLINE Quick

Bild 12: Pneumatische Anschlüsse – AirLINE Quick

Vorgehensweise:

→ Anschlüsse an entsprechenden Arbeitsanschlüssen einstecken.

28

deutsch

Page 29

Typ 8644

Installation

7.1.5. Fluidischer Anschluss AirLINE Quick

Beispiel für

Anschlussadapter

Entlüftungsanschluss R/S

Versorgungsanschluss P

Bild 13: Fluidischer Anschluss AirLINE Quick

Vorgehensweise:

→ Anschlussadapter G1/4 bzw. NPT 1/4 an Anschlüsse P und R/S

schrauben.

HINWEIS!

Gefahr der Leckage bei zu starker Verschraubung!

• Bei Montage der fluidischen Anschlussadapter an die

Anschlüsse P, R/S das max. Drehmoment von 12 Nm beachten.

Hierbei durch Gegenhalten mit einem geeigneten Werkzeug das

Verdrehen der Anschlüsse verhindern!

7.2. Fluidische Deinstallation

HINWEIS!

Irreversible Beschädigung der Dichtung im Gewinde der

Verschraubung!

Beim Lösen der Anschlussadapter das Verdrehen des entspre-

•

chenden Versorgungs- oder Entlüftungsanschlusses mit geeignetem Werkzeug verhindern.

7.3. Elektrische Installation

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das Gerät oder die Anlage Spannung abschalten

und vor Wiedereinschalten sichern!

Die elektrische Installation des AirLINE Systems entspricht der

Installation des dezentralen Peripheriegeräts (abhängig vom jeweiligen

Kooperationspartner Siemens, Wago, Phoenix oder Rockwell).

Alle hier notwendigen Schritte sind den jeweiligen Handbüchern der

Kooperationspartner zu entnehmen.

deutsch

29

Page 30

Typ 8644

Inbetriebnahme

8. INBETRIEBNAHME

8.1. Sicherheitshinweise

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Die Sicherheitshinweise und die bestimmungsgemäße Verwendung müssen beachtet werden.

• Nur ausreichend geschultes Personal darf die Anlage/das Gerät

in Betrieb nehmen.

8.2. Fluidische Inbetriebnahme

HINWEIS!

•

Schalten Sie den Versorgungsdruck ein.

• Schalten Sie erst danach die Spannung ein!

Maßnahmen vor der fluidischen Inbetriebnahme:

→ Anschlüsse, Spannung und Betriebsdruck überprüfen.

→ Beachten, dass max. Betriebsdaten nicht überschritten werden.

→ Die vorschriftsmäßige Belegung der Anschlüsse 1 und 3 bzw. 5

überprüfen. Diese dürfen auf keinen Fall vertauscht werden.

→ Bei elektrischem Betrieb die Handbetätigung entriegeln.

8.3. Elektrische Inbetriebnahme

Die Inbetriebnahme des AirLINE Systems entspricht der Installation

des dezentralen Peripheriegeräts (abhängig vom jeweiligen Kooperationspartner Siemens, Wago, Phoenix oder Rockwell).

Alle hier notwendigen Schritte sind den jeweiligen Handbüchern der

Kooperationspartner zu entnehmen.

9. WARTUNG

Siehe„7.2. Fluidische Deinstallation“ auf Seite 29.

10. TRANSPORT, LAGERUNG,

VERPACKUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den Transport

beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur

vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen!

• Gerät trocken und staubfrei lagern!

• Lagertemperatur: -20 ... +60 °C.

Umweltschäden durch von Medien kontaminierte Geräteteile!

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

•

Die nationalen Abfallbeseitigungsvorschriften beachten.

30

deutsch

Page 31

Type 8644

Sommaire

1. QUICKSTART ..................................................................................................32

1.1. Définition du terme appareil .........................................................32

1.2. Symboles..........................................................................................32

2. UTILISATION CONFORME.......................................................................33

2.1. Restrictions

3. CONSIGNES DE SÉCURITÉ GÉNÉRALES .....................................33

4. INDICATIONS GÉNÉRALES .................................................................... 34

4.1. Adresse

4.2. Garantie légale ................................................................................34

4.3. Information sur Internet .................................................................34

5. CARACTÉRISTIQUES TECHNIQUES ................................................35

5.1. Conformité

5.2. Normes

5.3. Caractéristiques techniques générales ....................................35

......................................................................................33

............................................................................................34

.......................................................................................35

.............................................................................................35

6. MONTAGE

6.1. Consignes de sécurité ..................................................................36

6.2. Montage

6.3. Retrait du bloc de vannes du rail normalisé .............................40

7. INSTALLATION

7.1. Installation fluidique .......................................................................41

7.2. Désinstallation fluidique ................................................................44

7.3. Installation électrique .....................................................................44

8. MISE EN SERVICE ....................................................................................... 44

8.1. Consignes de sécurité ..................................................................44

8.2. Mise en service fluidique ..............................................................44

8.3. Mise en service électrique ...........................................................45

9. ENTRETIEN

10. TRANSPORT, STOCKAGE, ÉLIMINATION ..................................... 45

........................................................................................................ 36

...........................................................................................37

...............................................................................................41

...................................................................................................... 45

français

31

Page 32

Type 8644

Quickstart

1. QUICKSTART

Quickstart décrit le cycle de vie complet de l’appareil. Conservez-le

de sorte qu’il soit accessible à tout utilisateur et à disposition de tout

nouveau propriétaire.

Informations importantes pour la sécurité !

Lisez attentivement Quickstart. Tenez compte en particulier des chapitres « Consignes de sécurité générales » et « Utilisation conforme ».

Les instructions de service Quickstart doivent être lues et

•

comprises.

Quickstart explique par des exemples le montage et la mise en service

de l’appareil.

Vous trouverez la description détaillée de l’appareil dans le manuel

d’utilisation du type 8644.

Vous trouverez les instructions de service sur le cédérom joint

ou sur internet sous :

www.buerkert.fr

1.1. Définition du terme appareil

Le terme « appareil » utilisé dans ces instructions désigne toujours le

système AirLINE type 8644.

1.2. Symboles

Les moyens de représentation suivants sont utilisés dans les présentes

instructions de service.

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement dangereuse !

• Risque de blessures graves, voire la mort en cas de non-respect.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou de

moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

Conseils et recommandations importants.

Renvoie à des informations dans ces instructions de service

ou dans d’autres documentations.

32

→ identifie une opération que vous devez effectuer.

français

Page 33

Type 8644

Utilisation conforme

2. UTILISATION CONFORME

L’utilisation non conforme de l’AirLINE du type 8644 peut présenter des dangers pour les personnes, les installations proches

et l’environnement.

• L’appareil est conçu pour un emploi dans les environnements présentant des risques d’explosion. Il peut être utilisé pour commander

des appareils à entraînement pneumatique.

• Ne pas alimenter les raccords du système en fluides agressifs

ou inflammables.

• N’utilisez pas l’appareil à l’extérieur sans protection.

• Ne pas soumettre le corps à des contraintes mécaniques (par ex.

pour déposer des objets ou en l’utilisant comme marche).

• Lors de l’utilisation, il convient de respecter les données et conditions d’utilisation et d’exploitation admissibles spécifiées dans

les instructions de service et dans les documents contractuels.

Celles-ci sont décrites au chapitre « Caractéristiques techniques ».

L’appareil peut être utilisé uniquement en association avec les

•

appareils et composants étrangers recommandés et homologués

par Bürkert.

• Les conditions pour l’utilisation sûre et parfaite sont un transport,

un stockage et une installation dans les règles ainsi qu’une parfaite

utilisation et maintenance.

• Veillez à ce que l’utilisation de l’appareil soit toujours conforme.

2.1. Restrictions

Lors de l’exportation du système / de l’appareil, veuillez respecter les

restrictions éventuelles existantes.

3. CONSIGNES DE SÉCURITÉ

GÉNÉRALES

Les présentes consignes de sécurité ne tiennent pas compte :

• Des circonstances fortuites et des événements qui peuvent survenir

lors du montage, du fonctionnement et de la maintenance.

• Des prescriptions de sécurité applicables au niveau local, dont le

respect relève de la responsabilité de l’exploitant, y compris pour le

personnel de montage.

Situations dangereuses d’ordre général.

Pour prévenir les blessures, respectez ce qui suit :

• L’installation ne peut pas être actionnée par inadvertance.

• Notez que, dans les systèmes sous pression, il est interdit de

desserrer les conduites et les vannes.

• Avant d’intervenir dans le système, coupez en tous les cas la tension.

• Dimensionnez la pression d’alimentation le plus généreusement

possible, afin d’éviter les chutes de pression lors de la commutation.

• Les travaux d’installation et de maintenance doivent être effectués

uniquement par des techniciens qualifiés et habilités disposant de

l’outillage approprié.

• Après une interruption de l’alimentation électrique ou pneumatique,

un redémarrage défini ou contrôlé du processus doit être garanti.

• L’appareil doit être utilisé uniquement en parfait état et en respectant les instructions de service.

• Les règles générales de la technique sont d’application pour

planifier l’utilisation et utiliser l’appareil.

français

33

Page 34

Type 8644

Indications générales

isque de brûlures/d’incendie en fonctionnement continu dû à

des surfaces d’appareils brûlantes !

• Tenez les substances et les fluides facilement inflammables à l’écart

de l’appareil et ne touchez pas ce dernier à mains nues.

L’AirLINE du type 8644 a été développé dans le respect des

règles reconnues en matière de sécurité et correspond à l’état

actuel de la technique. Néanmoins, des risques peuvent se

présenter.

REMARQUE !

Eléments/sous-groupes sujets aux risques électrostatiques !

L’appareil contient des éléments électroniques sensibles aux

décharges électrostatiques (ESD). Ces éléments sont affectés

par le contact avec des personnes ou des objets ayant une charge

électrostatique. Au pire, ils sont immédiatement détruits ou tombent

en panne après mise en service.

• Respectez les exigences selon EN 61340-5-1 et 5-2 pour minimiser ou éviter la possibilité d’un dommage causé par une soudaine

décharge électrostatique !

• Veillez également à ne pas toucher d’éléments électroniques

lorsqu’ils sont sous tension d’alimentation !

4. INDICATIONS GÉNÉRALES

4.1. Adresse

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail : info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages des présentes instructions de service.

Également sur Internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie légale est l’utilisation

conforme de l’appareil type 8644 AirLINE dans le respect des conditions d’utilisation spécifiées.

4.3. Information sur Internet

Les manuels d’utilisation et les fiches techniques concernant le type

8644 peuvent être consultés sur Internet sous : www.buerkert.fr

34

français

Page 35

Type 8644

Caractéristiques techniques

5. CARACTÉRISTIQUES TECHNIQUES

5.1. Conformité

Le systéme AirLINE type 8644 est conforme aux directives CE

comme stipulé dans la déclaration de conformité CE.

5.2. Normes

Les normes appliquées justifiant la conformité aux directives CE

peuvent être consultées dans le certificat d’essai de modèle type CE

et / ou la déclaration de Conformité CE.

5.3. Caractéristiques techniques

générales

Caractéristiques

techniques

Plage de pression Vide jusqu'à 10 bar Vide jusqu'à 10 bar

Tension de

service

Tolérance de

tension

Température

ambiante

Vanne pilote types

0460, 6524, 6525

24 V DC 24 V DC

+20 % / -15 %

(lors utilisation du

type 0460 : ± 10 %)

0 ... +55 °C

(lors utilisation des types 0460 et 0461 :

0 ... +50 °C)

Vanne pilote types

0461, 6526, 6527

+20 % / -15 %

(lors utilisation du

type 0461 : ± 10 %)

5.3.1. Plaque signalétique

Type

Fonctionnement

Diamètre nominal

6525 H 4,0

PN 2,5 - 7 bar

24 V DC 1W

450000Y

MADE IN GERMANY

W14UN

Numéro d’identification

Tension (±10 %), puissance

Plage de pression

Fig. 1 : Emplacement et description de la plaque signalétique

français

35

Page 36

Type 8644

montage

5.3.2. Raccord fluidique

Type 6524

X*

3/R

2/A

1/P

Fig. 2 : Raccord fluidique. Types 6524 et 6525

Type 6525

X*

5/R

4/A

1/P

2/B

3/S

Dimensionnez la pression

d’alimentation le plus

généreusement possible !

X* - Air d’échappement de

commande pilote

5.3.3. Raccord fluide et électrique

Type 6524

(Vanne 2 x 3/2 voies)

- Pôle bobine 12

commandé par Bit «n + 1»

+ Pôle

- Pôle bobine 14

commandé par Bit «n»

Respecter l’affectation

des broches !

Affectation du

12

14

levier à main

X*- Air d’échappement

X*

5/R

4/A

1/P

2/B

3/S

Bit «n+1»

de commande pilote

Bit «n»

6. MONTAGE

6.1. Consignes de sécurité

DANGER !

Risque de blessures dû à la présence de haute pression dans

l’installation !

• Avant de desserrer les conduites et les vannes, coupez la pression et purgez l’air des conduites.

Risque de choc électrique !

• Avant d’intervenir dans l’appareil ou l’installation, coupez la tension et empêchez toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour les appareils électriques en matière de prévention des accidents ainsi

qu’en matière de sécurité !

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme !

• Le montage doit être effectué uniquement par un personnel qualifié

et habilité disposant de l’outillage approprié !

Risque de blessures dû à la mise en marche involontaire de

l’installation et le redémarrage non contrôlé !

• Empêchez tout actionnement involontaire de l’installation.

• Garantissez un redémarrage contrôlé après le montage.

Fig. 3 : Raccord fluide et électrique. Type 6524

36

français

Page 37

Type 8644

montage

ATTENTION !

Sortie de fluide et dysfonctionnement !

Des joints mal positionnés peuvent provoquer des fuites et entraver

le bon fonctionnement suite à des pertes de pression.

• Veillez au bon positionnement des joints dans la zone électronique

et pneumatique.

Court-circuit, panne !

Le raccordement électrique nécessite un contact parfait.

• Ne pliez pas les contacts.

• Remplacez les composants présentant des raccords endommagés

ou pliés.

• Ne mettez le système en service que si les composants sont en

parfait état.

REMARQUE !

Utilisez le système uniquement en courant continu !

Alimentez le système uniquement en courant continu pour ne pas

l’endommager.

Evitez les chutes de pression !

Pour éviter les chutes de pression, dimensionnez la pression d’ali-

mentation du système le plus généreusement possible.

6.2. Montage

DANGER !

Risque d’explosion !

Pour les systèmes utilisés dans une armoire électrique dans une zone

protégée contre les explosions, il faut s’assurer que :

• L’armoire électrique est homologuée pour utilisation dans une zone

protégée contre les explosions.

• Le dimensionnement de l’armoire électrique doit permettre, de

façon appropriée, l’évacuation vers l’extérieur de la chaleur dissipée générée.

• La température à l’intérieur de l’armoire électrique ne doit pas

dépasser la température ambiante maximale admissible de

l’appareil.

Danger présenté par la tension électrique !

• Avant d’intervenir dans l’appareil ou l’installation, coupez la tension

et empêchez toute remise sous tension par inadvertance !

6.2.1. Montage sur le rail normalisé

Convertisseur

Module

Module

Convertisseur

Bus de terrain

Terminaison

français

Fig. 4 : Montage du bloc de vannes dans une armoire électrique

37

Page 38

Type 8644

montage

→ Monter le rail normalisé dans l’armoire électrique.

→ Créer une liaison PE courte et large entre le rail normalisé et

l’armoire électrique.

Le groupe de vannes doit être accessible par le haut.

Assurez-vous d’une bonne dissipation de chaleur !

Conseil de distance lors du montage dans l’armoire électrique :

A

B

30 mm

30 mm

C

D

6.2.2. Montage AirLINE Quick

Pour le montage de l’AirLINE Quick, un percement doit être d’abord

prévu sur le fond ou la paroi de l’armoire électrique. Cela peut se faire

par laser ou poinçonnage.

Les dimensions des réseaux de brides correspondants, voir chapitre

« 6.2.3. Dimensions des réseaux de brides pour AirLINE Quick ».

Les distances par rapport à la gauche, la droite, l’avant et le haut

dépendent du groupe de vannes sélectionné et de la configuration

de celui-ci.

Distance recommandée par rapport au groupe de vannes dans

l’armoire électrique :

gauche droite avant haut

30 mm 60 mm 30 mm 50 mm

REMARQUE !

Le perçage du fond de l’armoire électrique doit être ébavuré afin

que le joint de l’adaptateur AirLINE Quick ne soit pas endommagé.

30 mm

60 mm

→ Insérer le joint de l’adaptateur AirLINE Quick dans la rainure de

l’ouverture de la bride sans l’endommager.

→ Placer le groupe de vannes dans l’armoire électrique sur la sortie

préparée.

→ Pour éviter les gondolements, installer la tôle de stabilisation de

l’extérieur et la fixer avec les vis M 5 x 10 du jeu de fixation fourni.

Groupe de vannes

Type 8644

Adaptateur

AirLINE Quick

Armoire électrique

Fig. 5 : Placer le groupe de vannes dans l’armoire électrique

Vis M 5 x 10

Tôle de stabilisation

Fig. 6 : Fixation de la tôle de stabilisation

38

français

Page 39

Type 8644

montage

6.2.3. Dimensions des réseaux de brides pour AirLINE Quick

Paroi intérieure de l‘armoire électrique

N4

N3

N2

t>=1.5

>=8

N1

Ø 5.3 ± 0.2

R 6.5

uniquement pour O= 6 et O = 10

M

G

Encombrement cadre de raidissement côté externe

Fig. 7 : Dimensions des réseaux de brides pour AirLINE Quick – dimensions voir « Tab. 1 », page 40

français

59 ± 0.3

73 ± 0.3

(96)

39

Page 40

Type 8644

montage

Version

12 fois 16 fois 16 fois 20 fois

– – –

– – – – –

– – – – –

8 8 10 10 10

Particularité

M

N1

N2

N3

N4

O (Nombre

des alésages)

G

octuple

155 ±0.4 199 ±0.4 243 ±0.4 276 ±0.4 287 ±0.4

54 ±0.3 68 ±0.3 123 ±0.4 140 ±0.4 145 ±0.4

158 ±0.4 202 ±0.4 246 ±0.4 279 ±0.4 290 ±0.4

192 236 280 313 324

20 fois 24 fois 24 fois 32 fois

Particularité

M

N1

N2

N3

N4

O (Nombre

des alésages)

G

Tab. 1 : Dimensions des brides pour AirLINE Quick

1) avec alimentation intermédiaire

2) sur demande

3) avec alimentation intermédiaire sur demande

3)

320 ±0.4 331 ±0.4 364 ±0.4 452 ±0.4

65 ±0.3 66 ±0.3 73 ±0.3 65 ±0.3

193 ±0.4 200 ±0.4 219 ±0.4 195 ±0.4

323 ±0.4 334 ±0.4 367 ±0.4 325 ±0.4

– – –

12 12 12 16

357 368 401 489

–

1) 3)

1) 2)

455 ±0.4

6.3. Retrait du bloc de vannes du rail

normalisé

DANGER !

Danger présenté par la tension électrique !

• Avant d’intervenir dans l’appareil ou l’installation, coupez la tension et empêchez toute remise sous tension par inadvertance.

Le bloc de vannes est vissé sur le rail normalisé. D’autres modules /

bornes électriques peuvent être ajoutés à ses côtés.

Procédure à suivre :

→ Dévisser les modules / bornes voisins (si présents).

→ Déverrouiller la fixation du bloc de vannes du rail normalisé. Pour

ce faire, tourner les vis de fixation dans le sens contraire des

aiguilles d’une montre jusqu’en butée.

Fig. 8 : Déverrouillage de la fixation du bloc de vannes sur le rail normalisé

40

français

Page 41

Type 8644

Installation

→ Soulever le bloc de vannes verticalement du rail normalisé.

Il faut y avoir suffisamment d’espace entre le bloc de vannes et

le module précédent > 6 mm.

→ Dévisser le module / borne du rail normalisé selon la description

du fabricant.

REMARQUE !

L’interface du module de raccordement gauche comprend

des éléments susceptibles de casser sous l’effet de la force.

• Ne jamais placer le bloc de vannes sur le côté et respecter

l’emplacement de montage autorisé.

Fig. 9 : Dévisser les modules / bornes du rail normalisé

REMARQUE !

•

Respecter le couple de serrage maximal de 2 Nm lorsque vous

revissez le bloc de vannes sur le rail normalisé !

7. INSTALLATION

7.1. Installation fluidique

DANGER !

Risque de blessures dû à la présence de haute pression dans

l’installation !

• Avant de desserrer les conduites et les vannes, coupez la pression

et purgez l’air des conduites.

• Dimensionner les raccords le plus généreusement possible.

• Fermer les raccords ouverts non utilisés avec les vis de fermeture.

• Les raccords destinés à l’air d’échappement de commande pilote

(x) ne doivent pas être obturés.

• Contrôler l’affectation dans les règles des raccords 1 et 3 ou 5.

Ceux-ci ne doivent en aucun cas être inversés.

7.1.1. Raccordements pneumatiques

- Alimentation

Echappement

Canal X :

Version standard :

échappement d’air des vannes pilotes

Version air auxiliaire de commande :

raccord P pour vannes pilotes

Raccord de pression d’alimentation

Fig. 10 : Raccordements pneumatiques

français

41

Page 42

Type 8644

Installation

Procédure à suivre :

→ Ficher ou visser les raccords selon leur modèle dans les rac-

cords de travail correspondants.

REMARQUE !

En ce qui concerne les raccords enfichables, les tuyaux flexibles

doivent satisfaire aux exigences suivantes :

• Dureté minimale de 40 Shore D (selon norme DIN 53505 ou

ISO 868) ;

• Diamètre extérieur conformément à DIN 73378 (tolérance maximale admise de ± 0,1 mm par rapport à la cote nominale) ;

• Sans ébarbures, coupe franche et droite, exempt de dommages

sur le diamètre externe ;

Les tuyaux flexibles doivent être enfoncés dans les raccords enfichables jusqu’en butée.

7.1.2. Démontage des raccords enfichables

→ Pour le démontage des conduites presser la bague de pression

et retirer le flexible.

7.1.3. Raccordements pneumatiques AirLINE standard

Champs d’inscription

Raccords de travail pour

les vannes à 5/2 voies

Raccords de travail pour

les vannes à 3/2 voies

Fig. 11 : Raccordements pneumatiques - Disques de vanne

Procédure à suivre :

→ Ficher ou visser les raccords selon leur modèle dans les raccords

de travail correspondants.

→ Pour les versions filetées, des raccords de connexion peuvent

être utilisés.

Inscription sur les raccords :

→ Ecrire les champs d’inscription avec les dates des raccords de

vannes.

42

français

Page 43

Type 8644

Installation

7.1.4. Raccordements pneumatiques -

AirLINE Quick

Fig. 12 : Raccordements pneumatiques – AirLINE Quick

Procédure à suivre :

→ Ficher les raccords dans les raccords de travail correspondants.

7.1.5. Raccord fluidique AirLINE Quick

Exemple pour adaptateur de raccordement

Raccord de purge d’air R/S

Raccord d’alimentation P

Fig. 13 : Raccord fluidique AirLINE Quick

Procédure à suivre :

→ Visser l’adaptateur de raccordement G1/4 et NPT 1/4 aux

raccords P et R/S.

REMARQUE !

Risque de fuite en cas de vissage trop fort !

• Respecter le couple de serrage maximal de 12 Nm lors du montage des adaptateurs de raccordement fluidiques aux raccords

P, R/S. Ce faisant, empêcher la rotation des raccords en les

retenant avec un outil approprié !

français

43

Page 44

Type 8644

Mise en service

7.2. Désinstallation fluidique

REMARQUE !

Dommages irréversibles du joint dans le filetage du raccord

vissé !

• Empêcher la rotation des raccords d’alimentation et de purge

d’air en les retenant avec un outil approprié lors du desserrage

de l’adaptateur de raccordement.

7.3. Installation électrique

DANGER !

Risque de choc électrique !

• Avant d’intervenir dans l’appareil ou l’installation, coupez la tension

et empêchez toute remise sous tension par inadvertance !

L’installation électrique du système AirLINE correspond à l’installation

des appareils périphériques décentralisés (en fonction des partenaires

Siemens, Wago, Phoenix ou Rockwell).

Toutes les étapes nécessaires se trouvent décrites dans les manuels

correspondants de nos partenaires.

8. MISE EN SERVICE

8.1. Consignes de sécurité

AVERTISSEMENT !

Risque de blessures dû à une exploitation non conforme !

Une utilisation non conforme peut entraîner des blessures et endommager l’appareil et son environnement.

• Avant la mise en service, il faut s’assurer que le contenu des

instructions de service est connu et parfaitement compris par les

opérateurs.

Respectez les consignes de sécurité et l’utilisation conforme.

•

• L’appareil/l’installation doit être mis(e) en service uniquement par

un personnel suffisamment formé.

8.2. Mise en service fluidique

REMARQUE !

•

Enclenchez la pression d’alimentation.

• N’enclenchez la tension qu’après !

Mesures à prendre avant la mise en service fluidique :

→ Contrôler les raccords, la tension et la pression de service.

→ Faites attention à ce que les données d’exploitation maxi. ne soient

pas dépassées.

→ Contrôler l’affectation dans les règles des raccords 1 et 3 ou 5.

Ceux-ci ne doivent en aucun cas être inversés.

→ Déverrouillez la commande manuelle en fonctionnement électrique.

44

français

Page 45

Type 8644

Transport, Stockage, Élimination

8.3. Mise en service électrique

La mise en service du système AirLINE correspond à l’installation des

appareils périphériques décentralisés (en fonction des partenaires

Siemens, Wago, Phoenix ou Rockwell).

Toutes les étapes nécessaires se trouvent décrites dans les manuels

correspondants de nos partenaires.

9. ENTRETIEN

Voir « 7.2. Désinstallation fluidique », page 44.

10. TRANSPORT, STOCKAGE,

ÉLIMINATION

REMARQUE !

Dommages dus au transport !

Les appareils insuffisamment protégés peuvent être endommagés

pendant le transport.

• Transportez l’appareil à l’abri de l’humidité et des impuretés et

dans un emballage résistant aux chocs.

• Évitez le dépassement vers le haut ou le bas de la température

de stockage admissible.

Un mauvais stockage peut endommager l’appareil !

• Stockez l’appareil au sec et à l’abri des poussières !

• Température de stockage : -20 ... +60 °C.

Dommages à l’environnement causés par des pièces d’appareil contaminées par des fluides !

• Eliminez l’appareil et l’emballage dans le respect de l’environnement !

• Respectez les prescriptions en matière d’élimination des déchets

et de protection de l’environnement en vigueur.