Page 1

I/O-Box with PROFIBUS

a

d

d

l

e

e

r

g

m

m

n

b

t

n

n

n

c

t

PA Connection

Quickstart

Installation and Operation

GB

Fluid Control Systems

GENERAL INSTRUCTIONS

To ensure that the device functions correctly, and will have a long

service life, please comply with the information in these Operating

Instructions, as well as the application conditions and additional data

given in the data sheet. For more detailed information regarding the

commissioning of a PROFIBUS PA branch, we recommend the

"PROFIBUS PA Commissioning Handbook" of the PNO.

Safety Instructions

• When planning the application of the device, and during its

operation, observe the general technical rules!

• Work on the device should only be carried out by

specialist staff using suitable tools!

• Observe the valid accident prevention and safety

regulations for electrical equipment during the operation,

maintenance and repair of the equipment!

• Always switch off the voltage supply before working on

the system!

• Only use lines fitted with an earth line, and connect the

earth!

• Take suitable measures to prevent unintentional operation

or impermissible impairment!

ATTENTION!

CAUTION ON HANDLING!

COMPONENTS/MODULES LIABLE TO

ELECTROSTATIC DAMAGE!

The device contains electronic components that are sensitive to

electrostatic charging (ESD). These components are

endangered by contact with statically charged persons or

objects. In the worst case they are immediately destroyed or fail

after putting into operation.

Observe the requirements of EN 100 015-1 in order to minimize

or avoid the risk of damage by instantaneous electrostatic

discharge. Make sure also that you do not touch electronic

components when they are under supply voltage.

GENERAL INSTRUCTIONS TECHNIC

Use for the intended purpose

Please observe the notes in these operating instructions

together with the conditions of use and permitted data that are

specified on the rating plate in order that the device will

function perfectly and remain operable for a long time.

On nonobser-vance of these notes and unauthorized

interference with the device, we will refuse all liability and the

warranty on device and accessories will become void!

The device serves exclusively to drive process valves of

types 6520 and 6521 NAMUR. Any different use or use going

beyond this is considered improper use. Bürkert is not liable

for damage resulting from such use. The risk is carried solely

by the user.

General description

• For installation and operation in potentially explosive environments,

observe the relevant national regulations. (in Germany: VDE 0165)

• The device serves exclusively to drive process valves of types

6520 and 6521 NAMUR

- Driving of four type 6520/6521valves (PTB n° Ex-97.D.2089x)

- Connection of two sensors per valve (see table)

• The line resistance to the sensors and valves shall be not more than

20 Ohm for a max. cable length of 30 m.

• Use only shielded cable for connecting the sensors and valves.

Note also that the screening must be connected, e.g. at the front

panel of the housing.

The values of the capacity and inductance are specified in the

conformity certificate. Please observe the instructions of the

Conformity Certificate PTB Nr. EX-97.D.2089X for the supply of the

valve. More information regarding the operation and installation of

the type 6115 (6520) valve can be found in the operating

instructions for these valves.

• The Design Inspection Certificates are to be found in the

Instructions

on the CD.

Operating

Page 2

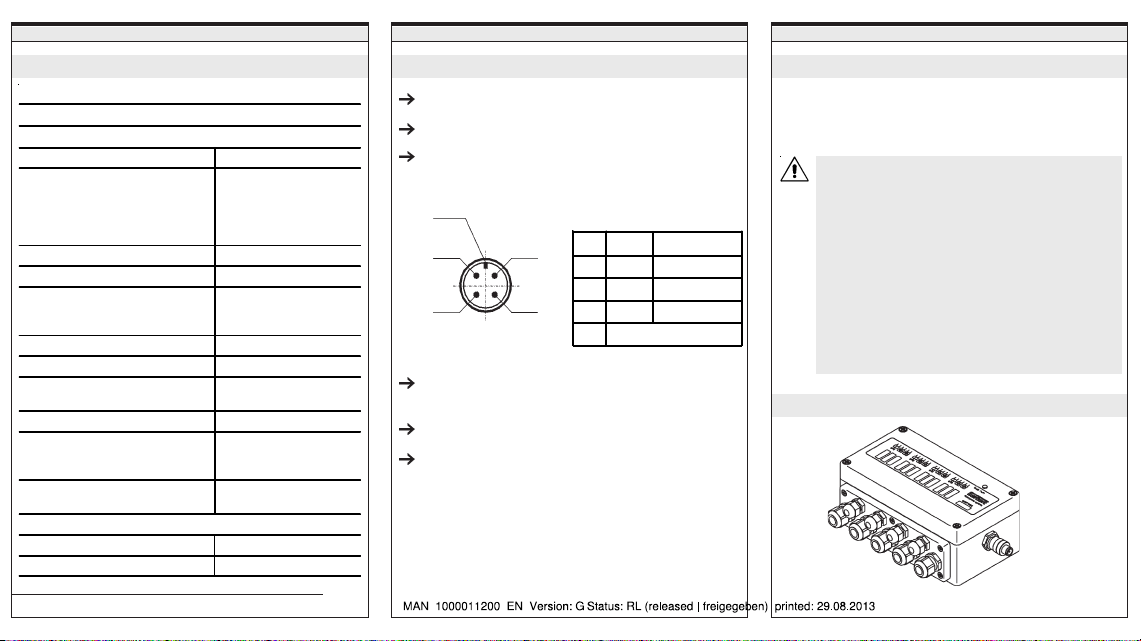

Technical data

Field bus interface according to IEC 1158-2

Communication device following the FISCO model

Electrical data

Permitted operating voltage 9 - 24 V

Permitted operating voltage,

intrinsically safe: referring to power

supply device with

– trapezoidal characteristic curve

– linear characteristic curve

Operating current 16.5 mA ± 6 %

Maximum current in case of a fault < 22.5 mA

max. permissible power of the

power supply with intrinsically safe

bus supply

Operating conditions

Permissible temperature range -25 to 60 °C

Climatic test

Insulation class 3

Protection class of housing

Explosion protection to

Conditions of the EMC law fulfilled

Resistance to interference EN 50052-2

Transmitted interference EN 50081-2

We reserve the right to make technical changes without notice!

9 - 15 V

9 - 17,5 V

2 W

DIN IEC Part 2 - 38

exposure 10 cycles à 24 h

IP 65

(when using corresponding screwed fittings)

EN 50020 and EN 50014

II 2 (1) G EEx ia IIC T6

INSTALLATION AND COMMISSIONING

Installation and Commissioning

Preferred fitting position: Attachment screws pointing

downwards!

If EMV screwed fittings are used, position the screens

according to manufacturer's instructions!

On using a Weidmüller plugged connector for PROFIBUS PA,

the following configuration applies:

Positioning dimensions

B

S

On the front panel threads to M20 and M16 are provided; on

the side a thread to M16.

The terminals may only be removed when not under voltage!

The front panel is designed for a maximum of 5 changes.

The fixing screws of the front panel may be tightened with a

maximum of 1.5 Nm.

View onto pin base and pins:

Pin Colour PROFIBUS PA

n.c.

AbluePA-

S black screen

A

BbrownPA+

n.c. not connected

INSTALLATION AND COMMISSIONING

Measures to be taken before installation

Check the connections, voltage and operating pressure!

Ensure that the max. operating data (see name plate) is not

exceeded!

This device complies with the European Community EMC

guideline No. 89/336/EWG.

Observe the installation instructions in order to fulfil the

regulations of this guideline. Connect the screw terminal

TE (technical earth) to the earth potential using a cable that

is as short as possible, or take suitable measures to

prevent undesired electro-magnetic interference affecting

the device.

Connecting cable for TE (technical earth):

- minimal diameter: 2.5 mm²

- maximum length: 30 cm

Electrical connection

Fig.: I/O-Box Type 8642 NAMUR with PROFIBUS PA circuit

Page 3

INSTALLATION AND COMMISSIONING

Terminal connections

Terminals A (exit) and

E (entry):

Connection for the

PROFIBUS-PA field

bus: any polarity can

be used between

terminal 1 and 2.

Max. permissible

torque for the bus

connections

(Weidmüller): 5 Nm.

INSTALLATION AND COMMISSIONING

Terminal connections

Bürkert piezo-valves type 6520 may be connected to the terminals

for actuators. Observe polarity. More detailed instructions for

connection and operation of the valves are to be found in the PTB

Test Certificate and in the Operating Manual for the valves.

Connection of the sensors to

the terminals:

Pola rit y - +

Terminals 152 151

Terminals 142 141

Terminals 252 251

Terminals 242 241

Terminals 352 351

Terminals 342 341

Terminals 452 451

Terminals 442 441

Two sensors are always allocated to a valve. The sensors report the

end position of a connected process valve. The inputs can also

report other process parameters independent of the valves (e.g.

scraper end positions).

Connection of the actuators

to the terminals:

Pola rit y + -

Terminals 148 147

Terminals 248 247

Terminals 348 347

Terminals 448 447

INSTALLATION AND COMMISSIONING

Setting the station addresses

DIP switch 1 to 7: Bit 1 to Bit 7

The DIP switches are only read in when the unit is switched

on.

In the PROFIBUS PA, each station is given an adress. These

addresses are set up using the DIP switches 1 to 7. The

permissible address range lies between 3 and 124.

Settings:

2021222324252

DIP-1 DIP-2 DIP-3 DIP-4 DIP-5 DIP-6 DIP-7 Address

ON ON OFF O FF OFF OFF OFF 3

OFF OFF ON ON ON ON ON 124

ON OFF ON ON ON ON ON 125

OFFONONONONONON126*

*Delivery state: Address 126

If switch 8 is in the ON position, the internal address is used!

This adress can be set up via the field bus.

6

:

LED display

The LED flashes when the device is engaged in cyclic data

communication. The LED lights briefly on connecting the device. If

the device detectes an internal error, the LED remains lit.

Page 4

BRANCHES

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com Bürkert / Company / Locations

Chr.-Bürkert-Straße 13-17 Berlin Ph: (0 30) 67 97 17 - 0

74653 Ingelfingen Dortmund Ph: (0 23 73) 96 81 - 0

Ph: (0 79 40) 10-111 Frankfurt Ph: (0 61 03) 94 14 - 0

Fax (0 79 40) 10-448 Hannover Ph: (05 11) 9 02 76 - 0

www.buerkert.com München Ph: (0 89) 82 92 28 - 0

info@de.buerkert.com Stuttgart Ph: (07 11) 4 51 10 - 0

BÜRKERT INTERNATIONAL

A Ph. (01) 894 13 33 F ax (01) 894 13 00

AUS Ph. (02) 1300 888 868 Fax (02) 1300 888 076

B Ph. (03) 325 89 00 F ax (03) 325 61 61

BRA Ph. (011) 51 82 00 11 F ax (011) 51 82 88 99

CDN Ph. (905) 847 55 66 Fax (905) 847 90 06

CH Ph. (041) 785 66 66 Fax (041) 785 66 33

CN Ph. (21) 58 68 21 19 Fax (21) 58 68 21 20

CZ Ph. (543) 25 25 05 Fax (543) 25 25 06

DK Ph. (44) 50 75 00 Fax (44) 50 75 75

E Ph. (93) 477 79 80 Fax (93) 477 79 81

EST Ph. (372)644 06 98 Fax (372)631 3 7 5 9

F Ph. (0388) 58 91 11 Fax (0388) 57 20 08

HKG Ph. 24 80 12 02 Fax 24 18 19 45

I Ph. (02) 95 90 71 Fa x (02) 95 90 72 51

IND Ph. (044)52 30 34 56 Fax (044)52 30 32 32

J Ph. (03) 53 05 36 10 Fax (03) 53 05 36 11

KOR Ph. (02) 34 62 55 92 Fax (02) 34 62 55 94

N Ph. (63) 84 44 10 Fax (63) 84 44 55

NL Ph. (0346) 58 10 10 Fax (0346) 56 37 17

NZ Ph. (09) 622 28 40 Fa x (09) 622 28 47

P Ph. (21)212 84 90 Fax (21)212 84 91

PL Ph. (022) 840 60 10 Fax (022) 840 60 11

RC Ph. (02) 26 53 78 68 Fax (02) 26 53 79 68

RP Ph. (02) 776 43 8 4 Fax (02)776 43 82

S Ph. (040) 664 51 00 Fax (040) 664 51 01

SA Ph. (011)574 60 00 Fax (011) 454 14 77

SF Ph. (09) 54 97 06 00 Fa x (09) 503 12 75

SIN Ph. 68 44 22 33 Fax 68 44 35 32

TR Ph. (0232) 459 53 95 Fax (0232) 459 76 94

TT Ph. (04)643 50 08 Fax (04)643 70 10

UK P h. (01453) 73 13 53 Fa x (01453) 73 13 43

USA Ph. (949) 223 31 00 Fax (949) 223 31 98

Operating Instructions 0510/04_EU-EN_00804398

CONFIGURATION CONFIGURATION

Memory allocation for the effective data traffic

Basis: handbook for your PLC

• In order to be able to carry out the correct settings of the

configuration program, copy the unit-specific file (buer6521.GSD)

from Bürkert into the directory that contains the configuration

software. For reading in and editing the configuration, please read

the documentation for your PLC or process control system.

• Further informations regarding memory allocation can be found in

the handbook.

Block parameters of the transducers Block p

Parameter Description

SELF_CALIB_CMD Initiat ion of a device-specific calibration

SENSOR_WIRE

_CHECK

procedure, manufacturer specific 0default.

------xy

y = 0 active undamped

y = 1 active damped

x = 0 sensor 1 indicates "valve open"

x = 1 sensor 1 indicates "valve

closed"

Enables the lead breakage and short circuit

detection.

List of valid values:

0 Lead breakage and short circuit

detection enable

1 Lead breakage detection enable,

short circuit detection disable

2 Lead breakage detection disable,

short circuit detection enable

3 Lead breakage and short circuit

detection disable

Page 5

CONFIGURA

READBACK_D: This parameter indicates the position of the valve

TION

and the sensors.

Bit76543210

not initialised

0 0

closed

0 1

open

1 0

moving

1 1

State sensor 1

Short circuit sensor 1

Lead break sensor 1

State sensor 2

Short circuit sensor 2

Lead break sensor 2

1 = activ

0 = inactiv

SP_D: Setpoint

Bit 0 in the value indicates the valve position. The status

transferred must be a "good" status, e.g. 0x80

SENSORSION

Manufacturer Pepperl+Fuchs

Sensor type: single, proximity

Id. no. Description

32571 NCB1.5-6.5M25-NO

38181 NCB1.5-6.5M25-NO-V1

32570 NCB1.5-8GM25-NO

39848 NCB1.5-8GM25-NO 1OM

39847 NCB1.5-8GM25-NO 5M

33876 NCB1.5-8GM25-NO-V1

27419 NCB2-12GM35-NO

39850 NCB2-12GM35-NO 1OM

39849 NCB2-12GM35-NO 5M

33877 NCB2-12GM35-NO-V1

29627 NCB2-F1-NO

27426 NCB5-18GM4O-NO

39854 NCB5-18GM4O-NO 1OM

39853 NCB5-18GM4O-NO 5M

33879 NCB5-18GM4O-NO-V1

27422 NC N4-12GM35-NO

39852 NCN4-12GM35-NO 1OM

39851 NCN4-12GM35-NO 5M

33878 NCN4-12GM 35-NO-V1

27427 NC N8-18GM4O-NO

39855 NCN8-18GM4O-NO 5M

33880 NCN8-18GM 4O-NO-V1

11498 NJ 0.8-4.5-N

11497 NJ 0.8-5GM-N

40165 NJ 0.8-5GM-N 5M

35986 NJ 0.8-5GM-N 10M

1828 NJ 1.5-6.5-N

35706 NJ 1.5-6.5-N 15M

2497 NJ 1.5-6.5-N 5M

1830 NJ 1.5-8GM-N

35270 NJ 1.5-8GM-N 10M

5129 NJ 1.5-8GM-N 5M

SENSORS SENSORS

Manufacturer Pepperl+Fuchs

Sensor type: single, proximity

Id. no. Descr iption

17547 NJ 1.5-8GM-N-V1

5000 NJ 2-11-SN

31194 NJ 2-11-SN

31195 NJ 2-11-SN-G

43566 NJ 2-11-SN-G 1 0M

36164 NJ 2-11-SN-G 10M

43565 NJ 2-11-SN-G 5M

14622 NJ 2-12GM-N

23801 NJ 2-12GM-N 1 0M

35578 NJ 2-12GM-N 21M

14623 NJ 2-12GM-N 5M

18306 NJ 2-12GM-N-V1

7893 NJ 2-12GK-N

36906 NJ 2-12GK-N 5M

17905 NJ 2-V3-N

15658 NJ 2-V3-N-V5

28408 NJ 3-18GK-S1N

7830 NJ 5-11-N

9329 NJ 5-11-N 15 M KA.

1539 NJ 5-11-N 5M KA.

7831 NJ 5-11-N-G

28419 NJ 5-11-N-G 10M KA.

1653 NJ 5-11-N-G 5M KA.

35273 NJ 5-11-N-G 6M

14848 NJ 5-30GK-S1N

31606 NJ 5-30GK-S1N 10M

36241 NJ 5-30GK-S1N 5M

5200 NJ 6-22-SN

35784 NJ 6-22-SN 10M

5204 NJ 6-22-SN-G

37686 NJ 6-22-SN-G 10M

35964 NJ 6-22-SN-G 3M

Page 6

SENSORS SENSORS SENSORS

Andere Hersteller

Manufacturer Pepperl+Fuchs

Sensor type: double, proximity

Id. no. Description

85169 NCN3-F24L-N4

85168 NCN3-F24R-N4

38142 NCN3-F25F-N4-V1

37852 NCN3-F25-N4-014

41943 NCN3-F25-N4-075

38139 NCN3-F25-N4-V1

47571 NCN3-F31-N4-K

48105 NCN3-F31-N4-K-K

NCN3-F31-N4-K-V1

NCN3-F31-N4-K-V1

NCN3-F31-N4-K-V16

NCN3-F31-N4-K-V16

NCN3-F31-N4-V16- K

NCN3-F31-N4-V16- V1

43736 NCN3-F31-N4-V16-V16

48258 NCN3-F31-N4-V18

Manufacturer Pepperl+Fuchs

Sensor type: single, slit

Id. no. Description

37316 SC2-N0

35372 SC3.5-N0

47942 SC3.5-N0

35376 SC3.5-N0 BLUE

35373 SC3.5-N0 YELLOW

35375 SC3.5-N0 GREEN

35374 SC3.5-N0 WHITE

8698 SJ 2-N

36195 SJ 2-N 5M KA

22146 SJ 2-SN

31192 SJ 2-SN

32583 SJ 2-SN

36643 SJ 2-SN XM KA

35400 SJ 3.5-G-N

1657 SJ 3.5-N

1654 SJ 3.5-N BLUE

Other manufacturers

Manufacturer: Turck

Description Sensor type

BIM-AKT-Y1X single, proximity

Si 3.5-K10-Y1 singl e, slit

Manufacturer: Ifm

Description Sensor type

NN5022 double, inductive

proximity switch

Loading...

Loading...