Page 1

Type 8635

SIDE Control Positioner

Operating Instructions

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2003 – 2011 Bürkert Werke GmbH

Op e ra ti ng I n st ru ct io ns 1111/06 _E U- EN _00 8 04 60 8 / Or ig in al DE

Page 3

C

ONTENTS

Operating Instructions for

SIDE Control Positioner Type 8635

(S/HART, PROFIBUS PA,

HART-Hand Terminal)

GENERAL NOTES

Symbols....................................................................................................................................................................................................................................................... 10

General safety notes

................................................................................................................................................................................................................. 10

Protection from damage by electrostatic charging ...................................................................................................................... 11

Device-related notes ................................................................................................................................................................................................................ 11

Scope of delivery ........................................................................................................................................................................................................................... 11

Warranty conditions ................................................................................................................................................................................................................... 12

Master code

SYSTEM DESCRIPTION

Construction of SIDE Control

Illustration............................................................................................................................................................................................................................................14

Features

(S/HART)

..........................................................................................................................................................................................................

(S/HART)

(S/HART)

............................................................................................................................................................................................................................................... 15

.................................................................................................................................................... 14

12

Functional diagram of the SIDE Control

valve with single-acting diaphragm actuator.......................................................................................................................................... 16

Operation as a positioner

Characteristics of the positioner software ................................................................................................................................................18

Schematic illustration of position control

Operation as a process controller

Characteristics of the process controller software (option)...............................................................................................20

Schematic illustration of process control

(S/HART)

(S/HART, option)

(S/HART)

................................................................................................................................................................

.................................................................................................................................................... 19

................................................................................................................................................... 22

in connection with a control

................................................................................................................

17

20

8635 - 1

Page 4

C

ONTENTS

Interfaces

Technical data of the SIDE Control

Technical data

Factory settings

SYSTEM DESCRIPTION

Construction of Side Control PA

(S/HART)

(S/HART)

(S/HART)

.................................................................................................................................................................................................................. 23

(S/HART)

................................................................................................................................................................................................

...........................................................................................................................................................................................

..................................................................................................................................

(PROFIBUS PA)

(PROFIBUS PA)

...................................................................................................................... 28

Illustration............................................................................................................................................................................................................................................ 28

Design features

Options

................................................................................................................................................................................................................................................... 29

Functional diagram of SIDE Control

.......................................................................................................................................................................................................................... 29

(PROFIBUS PA)

in connection with a control

valve with single-acting diaphragm actuator.......................................................................................................................................... 30

Operating as a positioner

(PROFIBUS PA)

........................................................................................................................................... 31

24

24

26

Characteristics of the positioner software................................................................................................................................................32

Schematic illustration of position control

Interfaces

Technical data of SIDE Control

Technical data

Factory settings

(PROFIBUS PA)

(PROFIBUS PA)

(PROFIBUS PA)

.............................................................................................................................................................................................

(PROFIBUS PA)

........................................................................................................................................................................... 35

.................................................................................................................................................... 33

.........................................................................................................................

......................................................................................................................................................................

INSTALLATION

Attachment and assembly................................................................................................................................................................................................ 38

Complete system with Bürkert continuous valve from series 27xx........................................................................ 38

Attachment to a continuous valve with linear actuator acc. to NAMUR

Attachment to a continuous valve with part-turn actuator

.................................................................................................... 42

Fluidic connection ........................................................................................................................................................................................................................ 44

........................................................... 39

34

35

36

Electrical connection

Electrical connection

2 - 8635

(S/HART)

..............................................................................................................................................................................

(PROFIBUS PA)

.........................................................................................................................................................

45

46

Page 5

C

ONTENTS

INDUCTIVE PROXIMITY SWITCHES

(S/HART, PROFIBUS PA, OPTION)

Description of the inductive proximity switches............................................................................................................................... 48

Configuration of the adjusting wheels

(option)

.................................................................................................................................

Settings......................................................................................................................................................................................................................................................... 49

Setting with one inductive proximity switch ............................................................................................................................................ 49

Setting with two inductive proximity switches

..................................................................................................................................... 49

Definition of the end positions with part-turn actuators ........................................................................................................ 49

OPERATING AND CONTROLLER FUNCTIONS

Operating and display elements............................................................................................................................................................................. 52

Operating levels

.............................................................................................................................................................................................................................. 52

48

Commissioning and set-up as a positioner

............................................................................................................................................ 53

Procedure for specifying the basic settings ........................................................................................................................................... 53

Main menu for settings on commissioning

Description of the procedure

...................................................................................................................................................................................... 55

............................................................................................................................................... 55

Configuring the supplementary functions ................................................................................................................................................. 59

Keys in the configuration level.................................................................................................................................................................................. 59

Configuration menu

Supplementary functions

................................................................................................................................................................................................................ 59

................................................................................................................................................................................................ 62

Operating the process ............................................................................................................................................................................................................ 85

Changing between operating modes ............................................................................................................................................................... 85

Operating mode AUTOMATIC

Meaning of the keys in the operating mode AUTOMATIC .................................................................................................... 86

Displays in the operating mode AUTOMATIC

(S/HART)

..................................................................................................................................................

...................................................................................................................................... 86

86

Operating mode AUTOMATIC

(PROFIBUS PA)

.............................................................................................................................

87

Meaning of the keys in the operating mode AUTOMATIC .................................................................................................. 87

Displays in the operating mode AUTOMATIC

...................................................................................................................................... 87

Operating mode MANUAL............................................................................................................................................................................................... 88

Meaning of the keys in the operating mode MANUAL ............................................................................................................. 88

Displays in the operating mode MANUAL

................................................................................................................................................ 88

8635 - 3

Page 6

C

ONTENTS

OPERATING THE PROCESS CONTROLLER

(S/HART)

Factory settings of the process controller.................................................................................................................................................. 90

Setting up a process control system

Self-parametrization for controllers -

Supplementary function

Basic settings of the function

P.Q’LIN

P.CO TUNE

- starting the routine for linearization of the process characteristic .......................................... 99

Displays during call-up and execution of the routine ..................................................................................................................99

- self-optimization of the process controller (process tune)................................................100

Operation......................................................................................................................................................................................................................................... 101

P.CONTRL

P.CONTRL

................................................................................................................................................................. 90

X.TUNE

.................................................................................................................................................................

...................................................................................................................................

.................................................................................................................................................

Operating the process ........................................................................................................................................................................................................ 104

91

91

92

Changing between operating modes ........................................................................................................................................................... 104

Operating mode AUTOMATIC ................................................................................................................................................................................ 105

Meaning of the keys in operating mode AUTOMATIC ........................................................................................................... 105

Displays in operating mode AUTOMATIC

............................................................................................................................................. 105

Manual changing of the process setpoint ............................................................................................................................................. 106

Operating mode MANUAL........................................................................................................................................................................................... 107

Meaning of the keys in operating mode MANUAL .................................................................................................................... 107

Displays in operating mode MANUAL

CONFIGURATION FOR BUS COMMUNICATION

........................................................................................................................................................ 107

(PROFIBUS PA)

GSD file.................................................................................................................................................................................................................................................... 110

Setting the device address.......................................................................................................................................................................................... 113

Cyclic parameters ............................................................................................................................................................................................................... 113

Configuration parameters

4 - 8635

........................................................................................................................................................................................... 114

Page 7

C

ONTENTS

OPERATING VIA THE HART HAND TERMINAL

(HART)

General ..................................................................................................................................................................................................................................................... 120

System description

Illustration of the system ............................................................................................................................................................................................. 121

Menu description and key assignment

Data entry

....................................................................................................................................................................................................................................... 122

.................................................................................................................................................................................................................. 121

..................................................................................................................................................... 121

Commissioning............................................................................................................................................................................................................................. 123

Preparation.................................................................................................................................................................................................................................... 123

AUTOTUNE

procedure (required on first commissioning) ............................................................................................ 123

Operating the positioners via the HART hand terminal................................................................................................... 125

Configuration .............................................................................................................................................................................................................................. 125

Display of the process variables

Changing the process variables

...................................................................................................................................................................... 125

........................................................................................................................................................................ 126

Operating the process controller via the HART hand terminal.............................................................................127

Configuration .............................................................................................................................................................................................................................. 127

Display of the process variables

Changing the process variables

...................................................................................................................................................................... 130

........................................................................................................................................................................ 130

Memory organization ........................................................................................................................................................................................................... 132

MAINTENANCE AND ERROR ELIMINATION ON THE POSITIONER

Maintenance ...................................................................................................................................................................................................................................... 134

Error messages and malfunctions .................................................................................................................................................................... 134

Error messages on the LC display

Other malfunctions

............................................................................................................................................................................................................. 135

................................................................................................................................................................ 134

MAINTENANCE AND ERROR ELIMINATION ON THE PROCESS

CONTROLLER

(S/HART)

Maintenance ...................................................................................................................................................................................................................................... 138

Error messages and malfunctions .................................................................................................................................................................... 138

Error messages on the LC display

Other malfunctions

............................................................................................................................................................................................................. 139

................................................................................................................................................................ 138

8635 - 5

Page 8

C

ONTENTS

Appendix

GENERAL RULES

Selection criteria for continuous valves.................................................................................................................................................... 142

Characteristics of PID controllers....................................................................................................................................................................... 144

P fraction

I fraction

D fraction

Superposition of P, I and D fractions

Realized PID controller

.......................................................................................................................................................................................................................................... 144

............................................................................................................................................................................................................................................ 145

......................................................................................................................................................................................................................................... 146

............................................................................................................................................................ 147

................................................................................................................................................................................................. 148

Setting rules for PID controllers ............................................................................................................................................................................ 149

Setting rules after Ziegler and Nichols (oscillation method)

Setting rules after Chien, Hrones and Reswick (output step method)

........................................................................................... 149

............................................................. 150

OPERATING STRUCTURE

Operating structure of the SIDE Control

Operating structure of the SIDE Control

Operating structure of the HART hand terminal

(S/HART)

................................................................................................................ 154

(PROFIBUS PA)

(HART)

........................................................................................... 159

............................................................................................... 160

TABLE FOR POSITIONER............................................................................................................................................................................ 165

TABLES FOR PROCESS CONTROLLER

MASTER CODE (

6 - 8635

S/HART)

............................................................................................................................................................................. 169

(S/HART)

......................................................................... 167

Page 9

C

ONTENTS

APPROVALS

Declaration of Conformity for Positioner Type 8635 SIDE Control S/HART .................................... 174

EC Design Inspection Certificate for Positioner Type 8635 SIDE Control S/HART .............175

APPROVALS

Declaration of Conformity for Positioner Type 8635 SIDE Control PA ....................................................... 180

EC Design Inspection Certificate for Positioner Type 8635 SIDE Control PA ............................... 181

1st Supplement ....................................................................................................................................................................................................................... 184

APPROVALS

EC Design Inspection Certificate (ATEX) for slot initiators Types SJ ... and SC .................... 186

(S/HART)

(PROFIBUS PA)

(S/HART, PROFIBUS PA)

Inductive proximity switch NAMUR

.............................................................................................................................................................. 189

8635 - 7

Page 10

C

ONTENTS

8 - 8635

Page 11

GENERAL NOTES

GENERAL NOTES

Symbols......................................................................................................................................................................................................................................................... 10

General safety notes

Protection from damage by electrostatic charging ........................................................................................................................ 11

Device-related notes .................................................................................................................................................................................................................. 11

Scope of delivery

Warranty conditions

Master code

(S/HART)

................................................................................................................................................................................................................... 10

............................................................................................................................................................................................................................. 11

..................................................................................................................................................................................................................... 12

............................................................................................................................................................................................................

12

8635 - 9

Page 12

GENERAL NOTES

Symbols

The following symbols are used in these operating instructions:

marks a work step that you must carry out.

ATTENTION!

NOTE

(S/HART)

(PROFIBUS PA)

(HART)

marks notes on whose non-observance your health or the functioning of the device

will be endangered.

marks important additional information, tips and recommendations.

indicate chapters or sections of the text which are valid only for certain versions of the

SIDE Control.

General safety notes

Please observe the notes in these operating instructions together with the conditions of use and permitted

data that are specified in the data sheets of the electropneumatic positioner, in order that the device will

function perfectly and remain operable for a long time:

• This device left the manufacturer's factory in a faultless condition with regard to technical safety and

was tested. Proper transport, storage and installation are the prerequisites for continued correct

functioning.

• Keep to standard engineering rules in planning the use of and operating the device!

• Installation and intervention for maintenance work are only allowed by qualified personnel using suitable

tools!

• Observe the current regulations on accident prevention and safety for electrical devices during

operation and maintenance of the device!

• Take suitable precautions to prevent inadvertent operation or damage by unauthorized action!

• On non-observance of these notes and unauthorized interference with the device, we will refuse all

liability and the warranty on device and accessories will become void!

10 - 8635

Page 13

GENERAL NOTES

Protection from damage by electrostatic charging

This device contains electronic components that are sensitive to

electrostatic discharge (ESD). Contact to electrostatically charged persons

or objects will endanger these components. In the worst case, they will be

immediately destroyed or will fail after commissioning.

ATTENTION

EXERCISE CAUTION ON HANDLING!

ELECTROSTATICALLY SENSITIVE

COMPONENTS / MODULES

Device-related notes

• For installation and operation in potentially hazardous (explosive) locations, observe the regulations.

These are to be found in EN 60079-14 (IEC 60079-14).

• On electrical connection of the inherently safe circuits, observe the data in the relevant certificate of

conformity.

• Take suitable precautions to prevent electrostatic charging of plastic parts of the housing

(see EN 100015-1 / IEC 61340-5-1).

• No components shall be connected to the inputs and outputs of the boards whose electrical data lie

outside the limits determined for inherently safe operation and stated on the data sheet for the

positioner.

• In potentially explosive locations, only inherently safe devices (of EN 50020 / IEC 60079-11) shall

be connected to the serial interface.

• The plastic covering shall be removed only by the manufacturer!

• Interventions in the device with the housing open shall not be carried out in very humid or aggressive

atmospheres. Take precautions to prevent inadvertent mechanical damage to the boards or their

components. Limit the duration of opening of the housing to that which is absolutely necessary.

Observe the requirements of EN 100015-1 (IEC 61340-5-1) in order to

minimize the possibility of, or avoid, damage from instantaneous

electrostatic discharge. Also take care not to touch components that are

under supply voltage.

Scope of delivery

Immediately after receipt of a shipment, make sure that the contents are undamaged and match the

scope of delivery stated on the packing slip. In general this consists of:

• SIDE Control

• Operating Instructions for the SIDE Control

Add-on kits for linear and part-turn actuators may be obtained as accessories.

If there are discrepancies, please contact immediately our customer service:

Bürkert Fluid Control System

Bürkert Fluid Control Systems / Service Department

Sales Center

Chr.-Bürkert-Str. 13-17

Christian-Bürkert-Str. 13-17

D-76453 Ingelfingen

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Tel.: (+49 7940) 10-111 Fax: (+49 7940) 10-448

Fax + 49 (0) 7940 - 10 91 448

E-Mail: info@de.buerkert.com

E-mail: info@de.buerkert.com

8635 - 11

Page 14

GENERAL NOTES

Warranty conditions

Warranty

The warranty is only valid if the device is used as intended in accordance with the specified application conditions.

This document contains no SURPLVHRIJXDUDQWHH . 3OHDVH refer to our general WHUPVRIsales andGHOLYHU\.

The warranty is only valid if the device is used as authorized in accordance with the

specified application conditions.

ATTENTION!

Master code

Operation of the SIDE Control

of this, there exists an unchangeable master code with which you can execute all operative actions on

the device. This 4-digit master code is to be found in the Appendix of these operating instructions in the

Chapter

The warranty covers only faultless condition of the SIDE Control. No liability will be

accepted for consequential damage of any kind that may arise from failure or

malfunctioning of the device.

(S/HART)

Master code (S/HART)

(S/HART)

.

can be blocked with a freely selectable user code. Independent

If required, cut out this code and keep it separate from these operating instructions.

12 - 8635

Page 15

SYSTEM DESCRIPTION (S/HART)

SYSTEM DESCRIPTION

(S/HART)

Construction of SIDE Control

Illustration.............................................................................................................................................................................................................................................. 14

Features

Functional diagram of the SIDE Control

valve with single-acting diaphragm actuator ............................................................................................................................................ 16

.................................................................................................................................................................................................................................................. 15

Operation as a positioner

Characteristics of the positioner software ................................................................................................................................................... 18

Schematic illustration of position control

Operation as a process controller

Characteristics of the process controller software (option) .................................................................................................. 20

Schematic illustration of process control

Interfaces

(S/HART)

.................................................................................................................................................................................................................. 23

Technical data of the SIDE Control

(S/HART)

(S/HART)

(S/HART, option)

...................................................................................................................................................... 14

(S/HART)

...................................................................................................................................................................

....................................................................................................................................................... 19

..................................................................................................................................................... 22

(S/HART)

in connection with a control

................................................................................................................

...................................................................................................................................

17

20

24

Technical data

Factory settings

(S/HART)

(S/HART)

..................................................................................................................................................................................................

..............................................................................................................................................................................................

8635 - 13

24

26

Page 16

SYSTEM DESCRIPTION (S/HART)

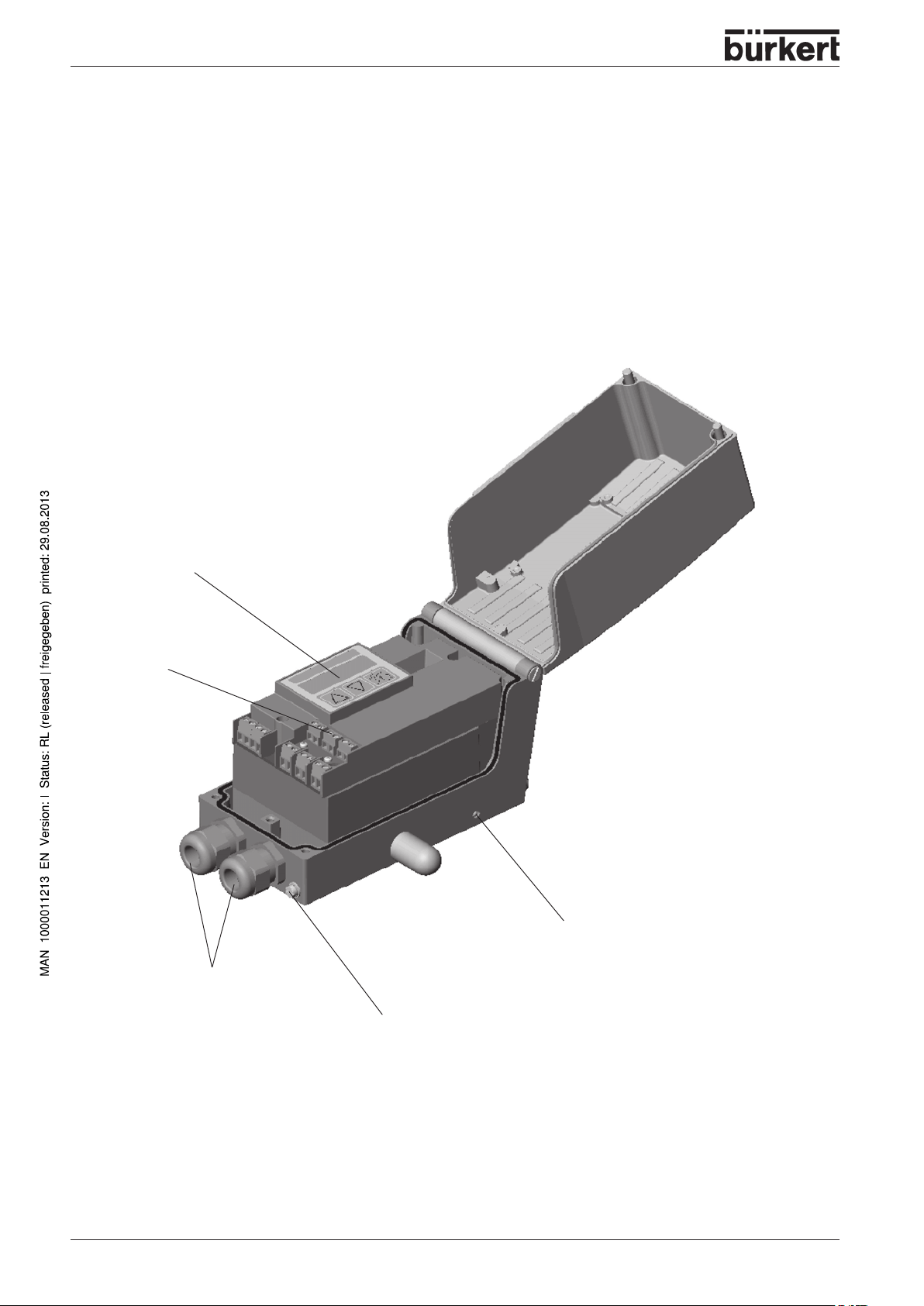

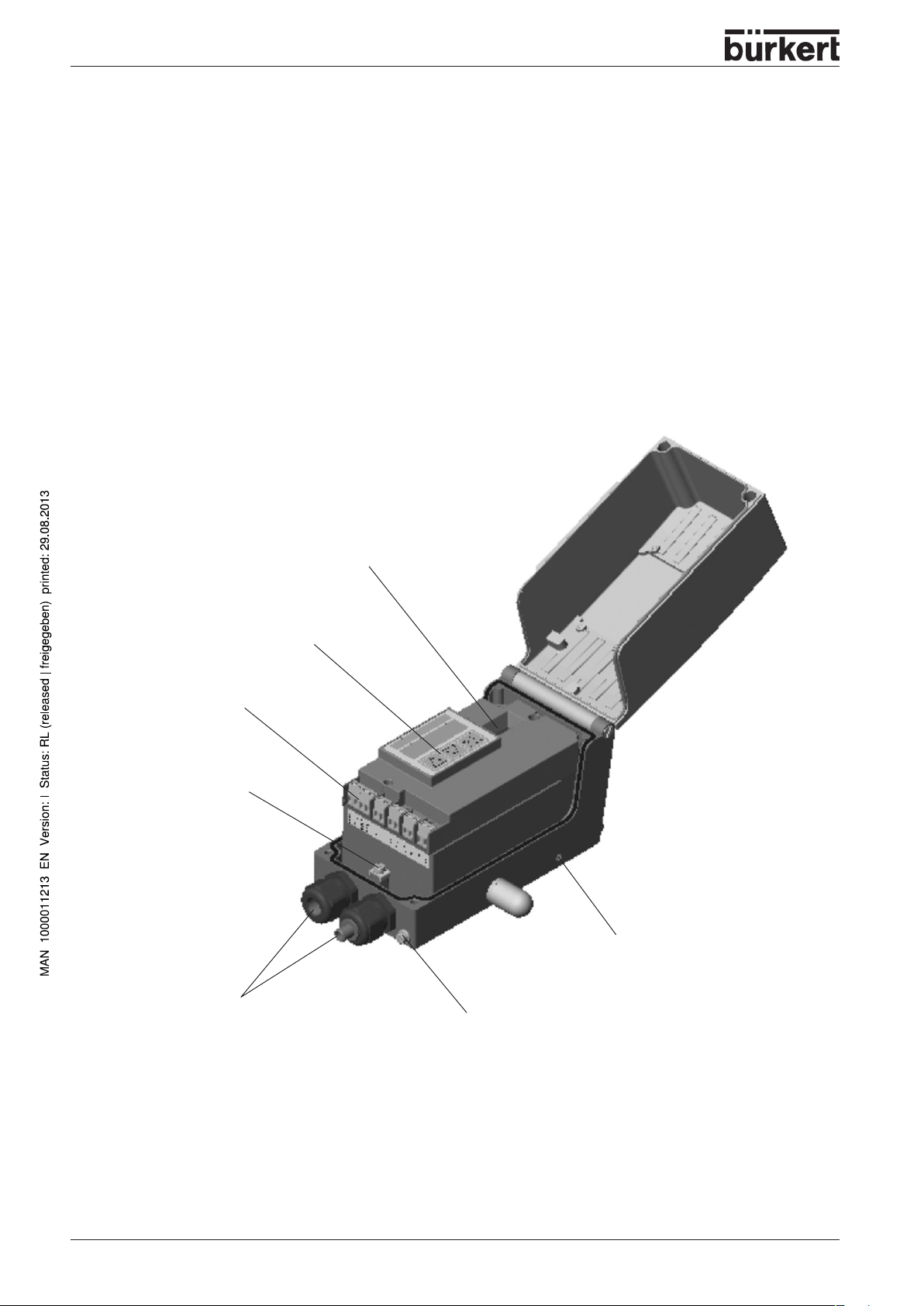

Construction of SIDE Control

The SIDE Control

single-acting linear or part-turn actuators.

The SIDE Control

communication to the HART protocol.

Illustration

Display with 3 operating keys

(S/HART)

(S/HART)

is a digital positioner for pneumatically operated continuous valves with

can be operated via a keypad with display. An optional extra is

(S/HART)

Screw terminals

Bushings M20x1.5

Throttle screw

Earthing (grounding) screw

14 - 8635

Page 17

SYSTEM DESCRIPTION (S/HART)

Features

•

Position sensor

Very high resolution conductive plastic potentiometer

• Microprocessor controlled electronics

for signal processing, control and driving the piezoelectric positioning system; setpoint entry and

power supply are via a 4 ... 20 mA standard signal.

•

Operating elements

The device can be set (configuration and parametrization) locally via three inside keys. An inside, 8digit, 16-segment LC display is provided, which can also show the setpoint or actual value.

Positioning system

•

A piezoelectric positioning system serves to drive the valve actuator.

•

Position repeater

via 2 inductive proximity switches (initiators)

•

Electrical interfaces

Cable bushing (M20x1.5) with screw terminals

Pneumatic interfaces

•

G1/4’’ interior thread

(option)

•

Housing

Aluminium housing (hard anodized and plastic-coated) with swing-up cover and captive screws.

•

Attachment

to linear actuators to NAMUR recommendation (DIN IEC 534 T6) or to part-turn actuators to

VDI/VDE 3845.

Option: integral attachment to Bürkert continuous valves

8635 - 15

Page 18

SYSTEM DESCRIPTION (S/HART)

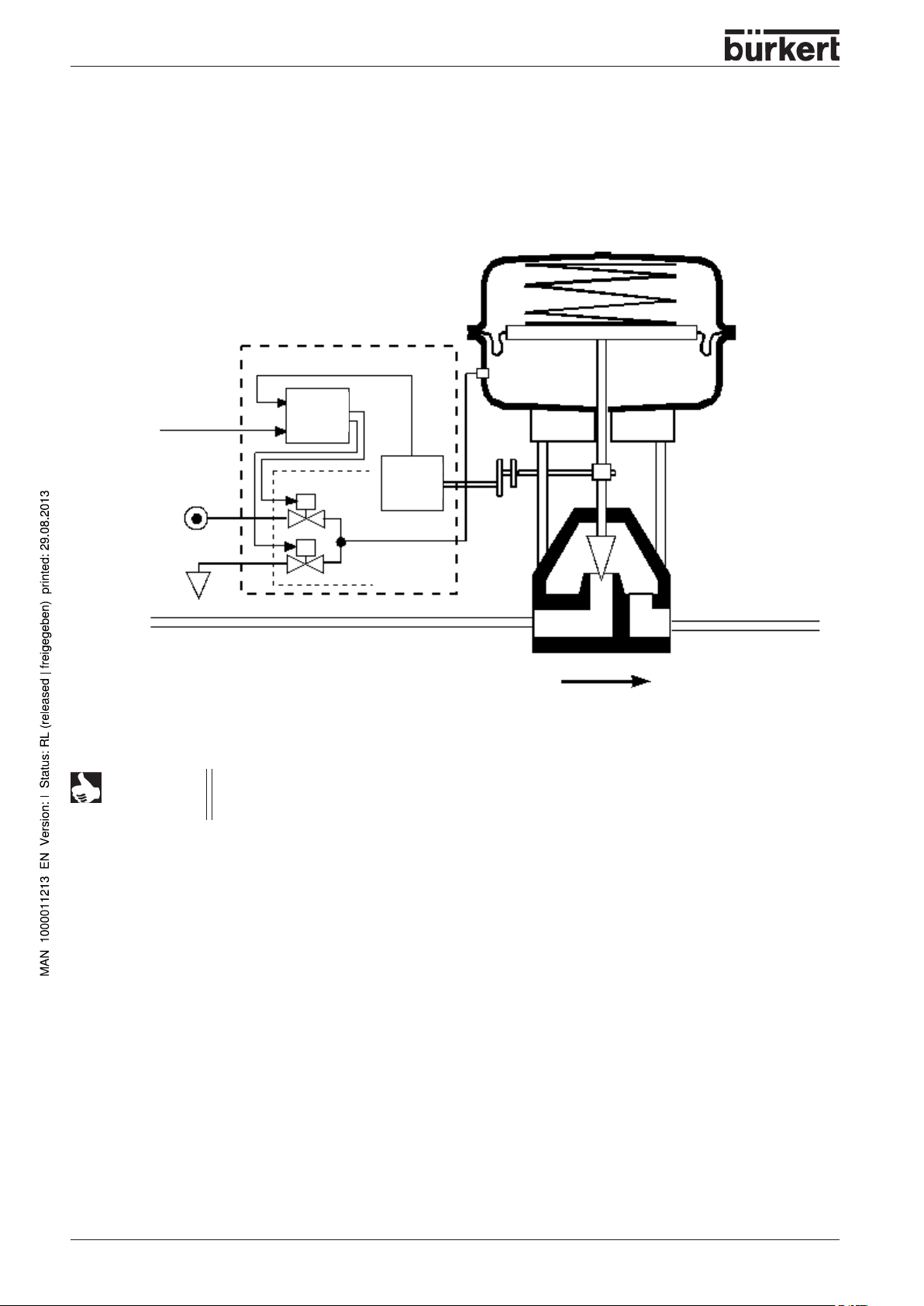

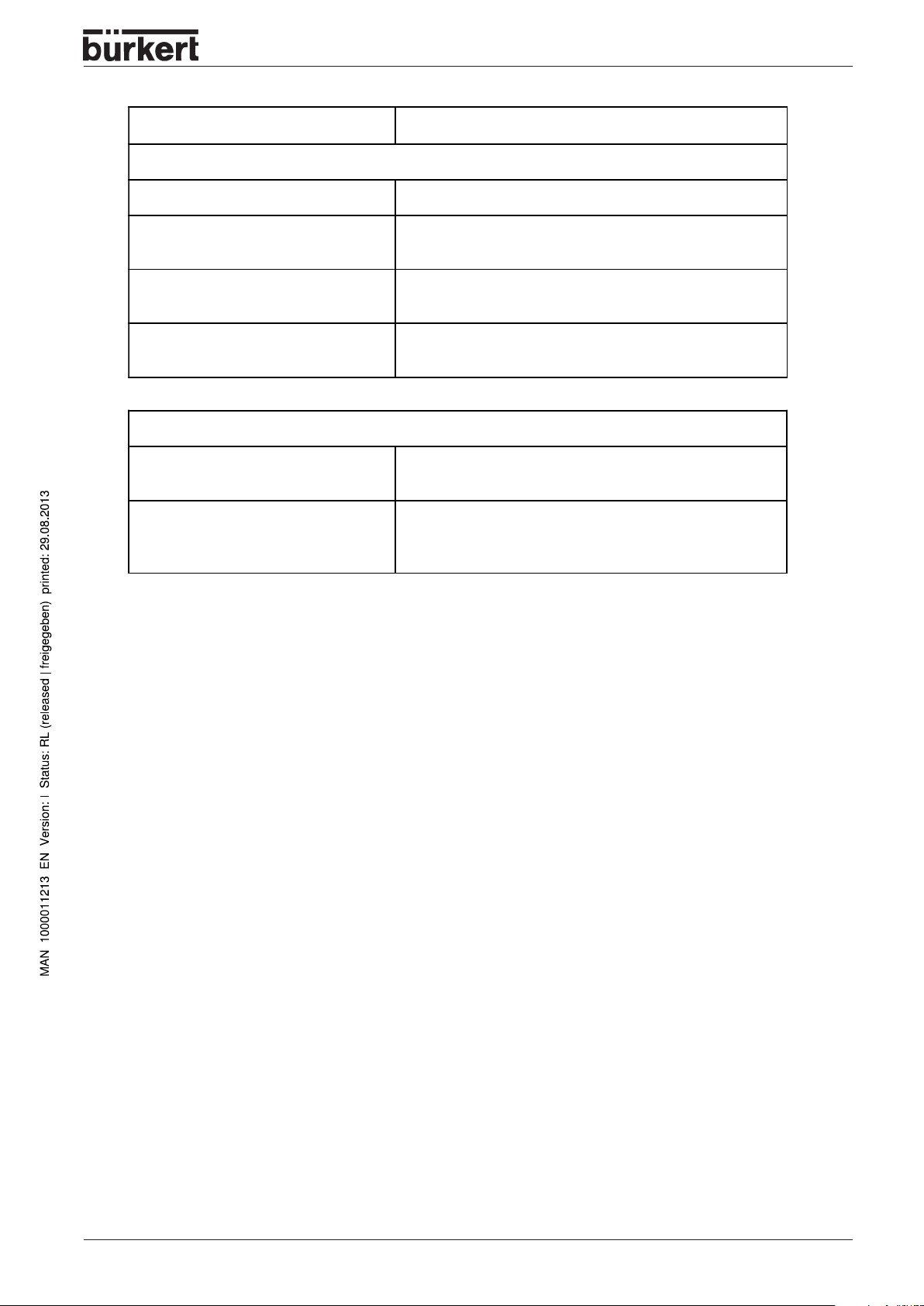

Functional diagram of the SIDE Control

(S/HART)

connected to a

control valve with single-acting diaphragm actuator

SIDE Control

(S/HART)

Actual position

External

position

setpoint

Pressure

supply

Positioner

Positioning system

pressurize

exhaust

Position

sensor

Lever

mechanism

Pneumatic actuator

(single-acting)

Valve (actuator)

NOTE

Exhaust air

In the case of integral attachment of the SIDE Control

(S/HART)

to a Bürkert

continuous valve, the position sensor is situated outside the SIDE Control

on the actuator and is connected to the latter with a cable.

(S/HART)

16 - 8635

Page 19

SYSTEM DESCRIPTION (S/HART)

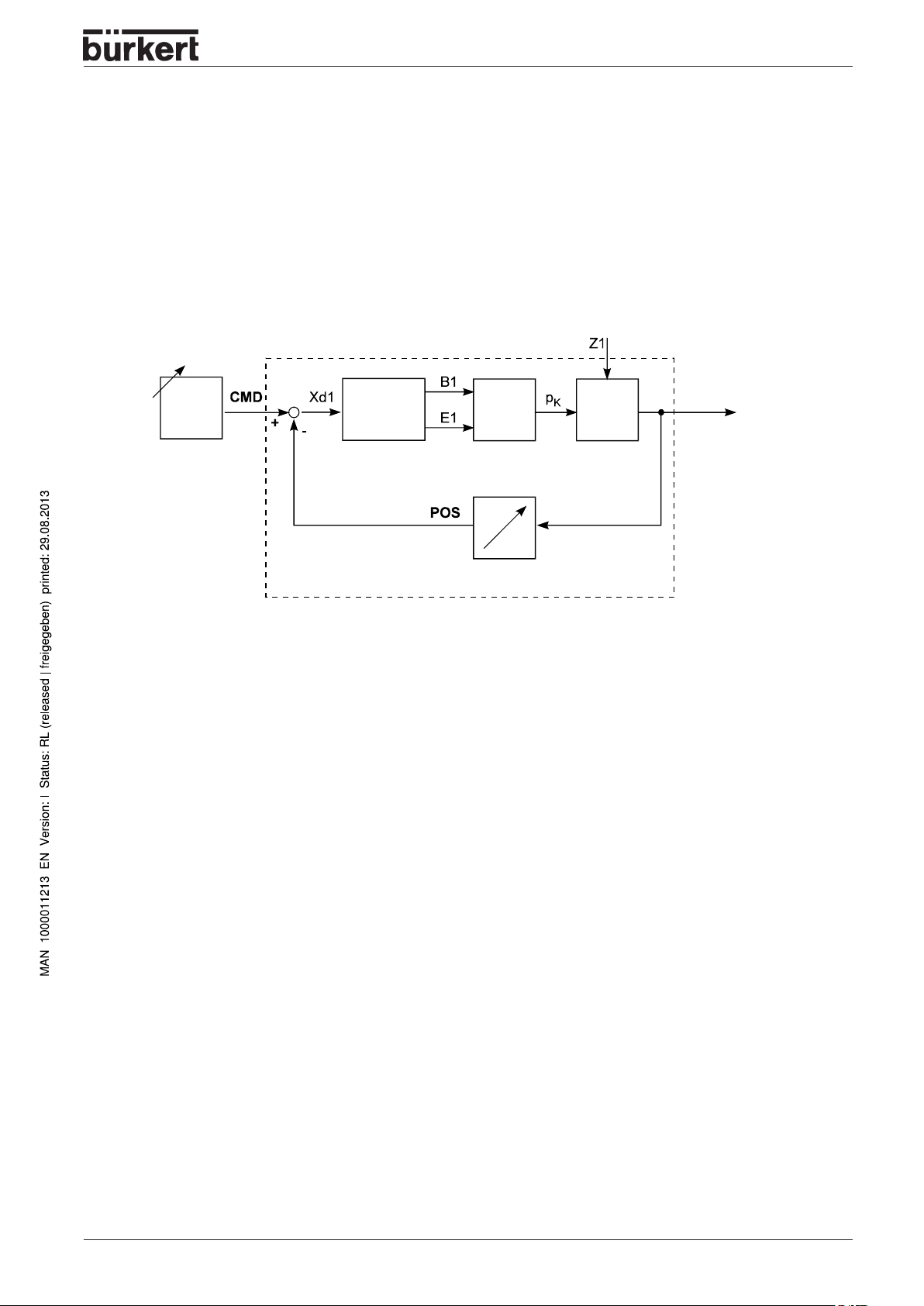

Operation as a positioner

The SIDE Control

measures the actual position (POS) of the actuator. The controller compares this actual value of the

position with the setpoint (CMD), which is presented as a standard signal. If a control difference (Xd1)

exists, a pulse-width modulated voltage signal is sent to the positioning system as the correcting variable. If the difference is positive, the pressurizing piezoelectric valve is driven via output B1; if it is negative,

the exhausting piezoelectric valve is driven via output E1. In this way, the position of the actuator is

altered until the control difference is 0. Z1 represents a disturbance.

Position

setpoint

(S/HART

controls the position of the pneumatic actuator, whereby the position sensor

Position control loop

(S/HART)

Positioner

Positioning system

(piezoelectric valves)

Position sensor

Valve opening

Continuous

valve

8635 - 17

Page 20

SYSTEM DESCRIPTION (S/HART)

Characteristics of the positioner software

Supplementary function Effect

Positioner with supplementary functions

AUTOT UNE

Tight-closing function

Stroke limitation

Limitation of correcting speed

Signal range splitting

Correction charakteristic for

adaptation to the operating curve

Insensitivity range

Direction of action of the controller

setpoint

Direction of action of the actuator Reserve of direction of action of the actuator.

Automatic adaptation of positioner to the control valve

in use.

Valve closes tight outside the control range. A value is

specified (in %) from which the actuator is completely

exhausted (at 0%) or pressurized (at 100%).

Mech. valve piston movement only within a defined

stroke range.

Actuator takes a preset time to move from OPEN to

CLOSED or from CLOSED to OPEN.

Splitting of the standard signal range over 2 or more

SIDE Controls.

Linearization of the process curve can be carried out.

The positioner responds only above a control difference

to be specified.

Reserve of direction of action of the setpoint.

Safety position Valve moves to a defined safety position

Code protection Blocking of the keypad or menu

Factory reset Reset to factory settings

Repeater (option)

Analog feedback of position Feedback of the values POS and CMD

Binary outputs

Hierarchic operating concept for simple operation with the following levels

Process operation

Configuration

Communication via HART protocol (option)

Feedback of various controller conditions (e.g. sensor

breakage or controller in safety position).

In this level, you switch between Automatic and Manual

operation.

In this level, you specify on commissioning certain

basic functions and configure supplementary functions

as required.

HART Hand Terminal Operation of the SIDE Control via a HART Hand Terminal

18 - 8635

Page 21

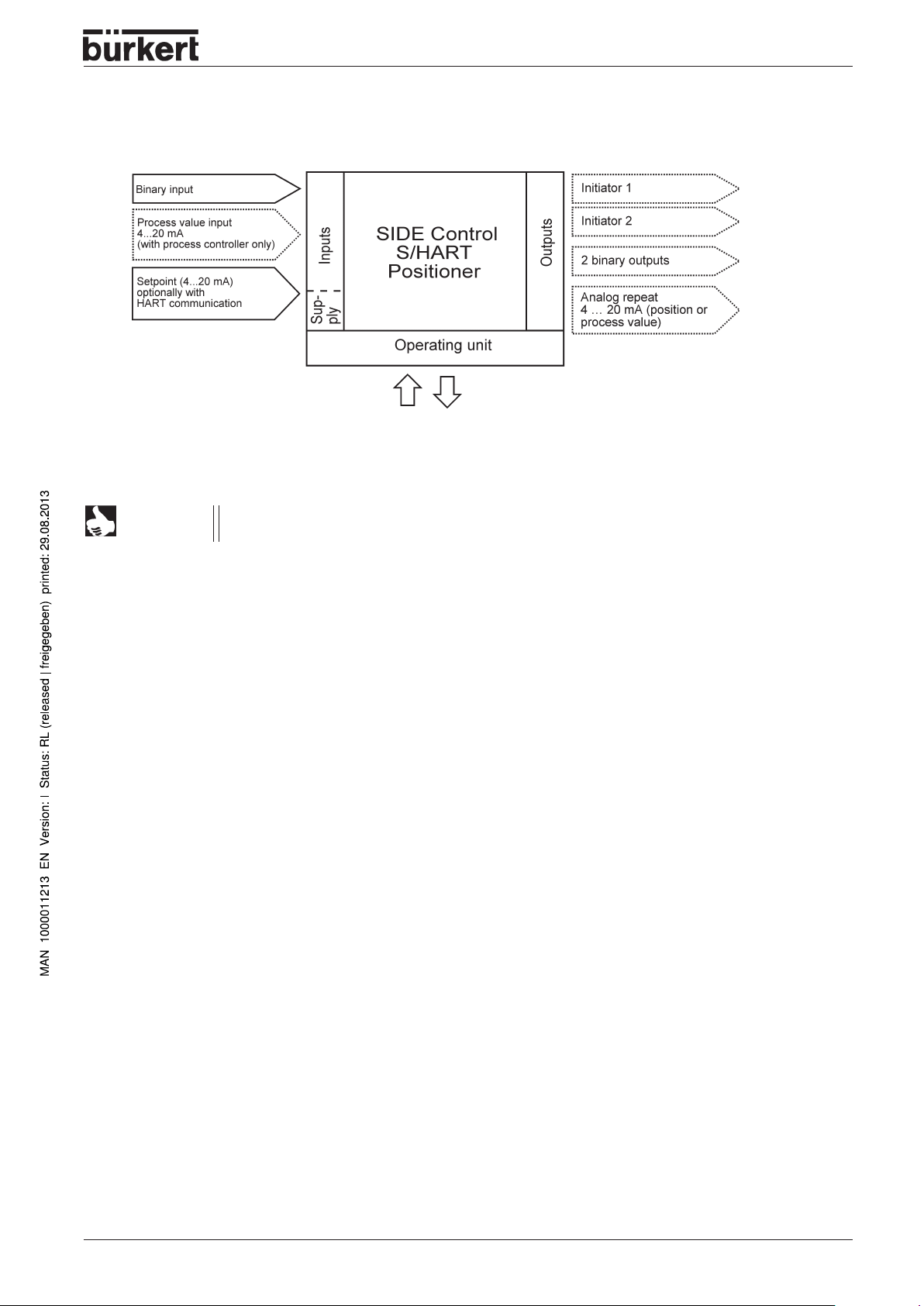

SYSTEM DESCRIPTION (S/HART)

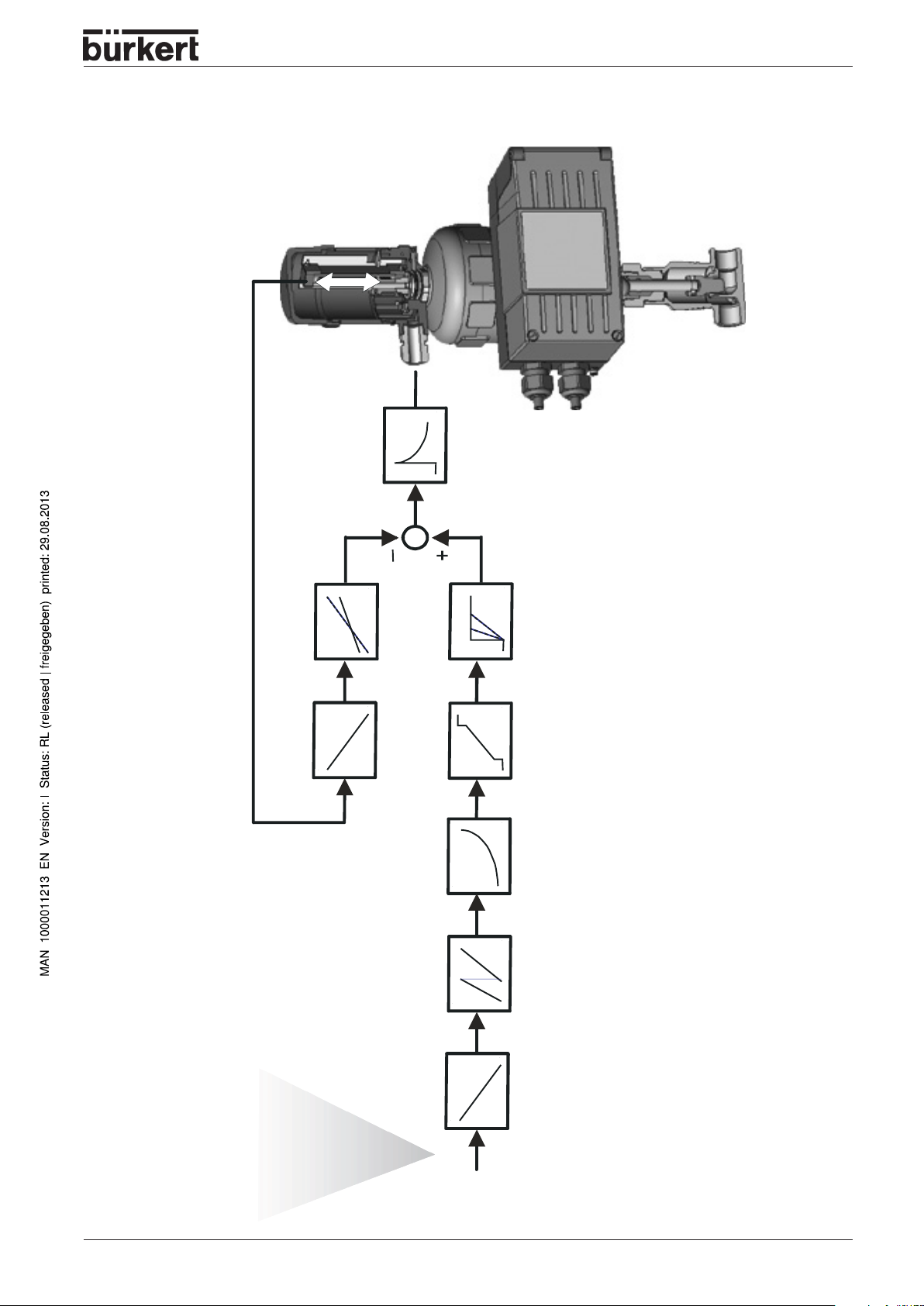

D

POS

POS

CM

INP

X.CONTRL

DBDx

CMD

X.LIMIT

DIR.ACT

X.TIME

Schematic illustration of position control

DIR.CMD SPLTRNG CHARACT CUTOFF

4 … 20 mA

INP

8635 - 19

Page 22

SYSTEM DESCRIPTION (S/HART)

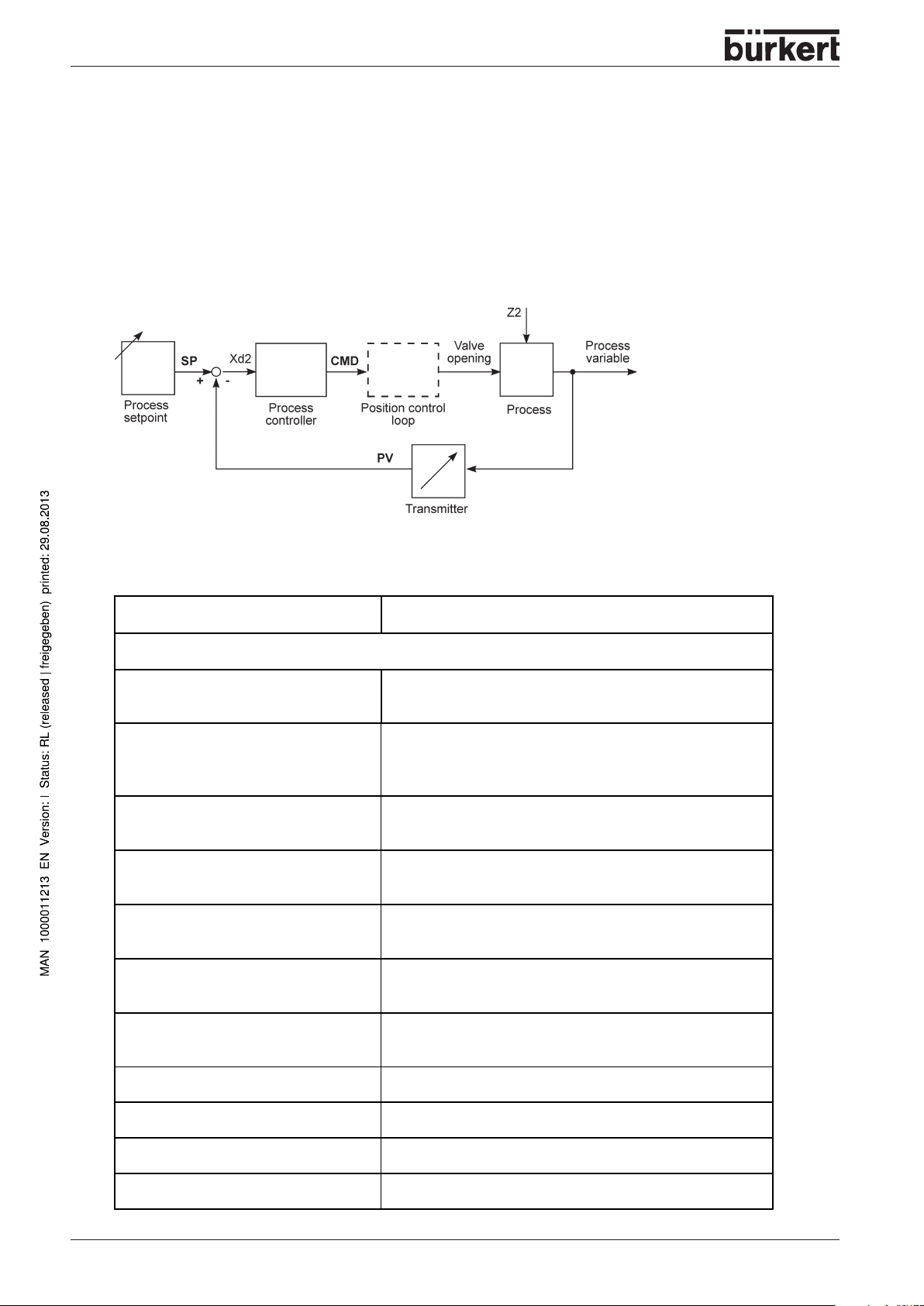

Operation as a process controller

If the SIDE Control

becomes a lower-ranking auxiliary control loop. The overall result is a cascade control system.

The process controller (as a main control loop) is implemented in the SIDE Control

controller. In this case the process setpoint (SP) is preset and compared with the actual value (PV) of

the process variable to be controlled, which is supplied by a sensor. Formation of the correcting variable

is done according to the description of the positioner. Z2 represents a disturbance acting on the

process.

Characteristic of the process controller software

(S/HART)

is operated as a process controller, the abovementioned position control

(S/HART, option)

(S/HART

(option)

as a PID

Supplementary function Effect

Positioner with supplementary functions

AUTOT UNE

Tight-closing function

Stroke limitation

Limitation of correction speed

Correction characteristic for

adaptation to the operating curve

Insensitivity range

Direction of action of the controller

setpoint

Automatic adaptation of positioner to the control valve

in use.

Valve closes tight outside the control range. A value is

specified (in %) from which the actuator is completely

exhausted (at 0 %) or pressurized (at 100 %) .

Mech. valve piston movement only within a defined

stroke range.

Actuator takes a preset time to move from OPEN to

CLOSED or from CLOSED to OPEN.

Linearization of the process curve can be carried out.

The positioner responds only above a control difference

to be specified.

Reverse of direction of action of the setpoint.

Direction of action of the actuator Reverse of direction of action of the actuator.

Safety position Valve moves to a defined safety position

Code protection Blocking of the keypad or menu

Factory reset Reset to factory settings

20 - 8635

Page 23

SYSTEM DESCRIPTION (S/HART)

Supplementary function Effect

Connectable process controller with the following characteristics (option)

Control structure PID

Parameters which can be set

Scalable inputs

Selection of setpoint specification

Hierarchic operating concept for simple operation with the following levels

Process operation

Configuration

Proportional action factor, reset time, rate time and

operating point

Position of decimal points, lower and upper scale

values of process value and setpoint

Setpoint specified either via standard signal input or via

keys

In this level, you switch between Automatic and Manual

operation.

In this level, you specify on commissioning certain

basic functions and configure supplementary functions

as required.

8635 - 21

Page 24

SYSTEM DESCRIPTION (S/HART)

POS

CMD

PV

SP

POS

X.LIMIT

DIR.ACT

X.CONTRL

DBDx

CMD

X.TIME

CUTOFF

CHARACT

P.CO FILT

P.CO SCAL

PV

Q

4 … 20 mA

SP

P.CO SCAL

22 - 8635

Schematic illustration of process control

SPLTRNGDIR.CMD

PV

SP

P.CONTRL

DBDp

PARA

INP

TUNE

Page 25

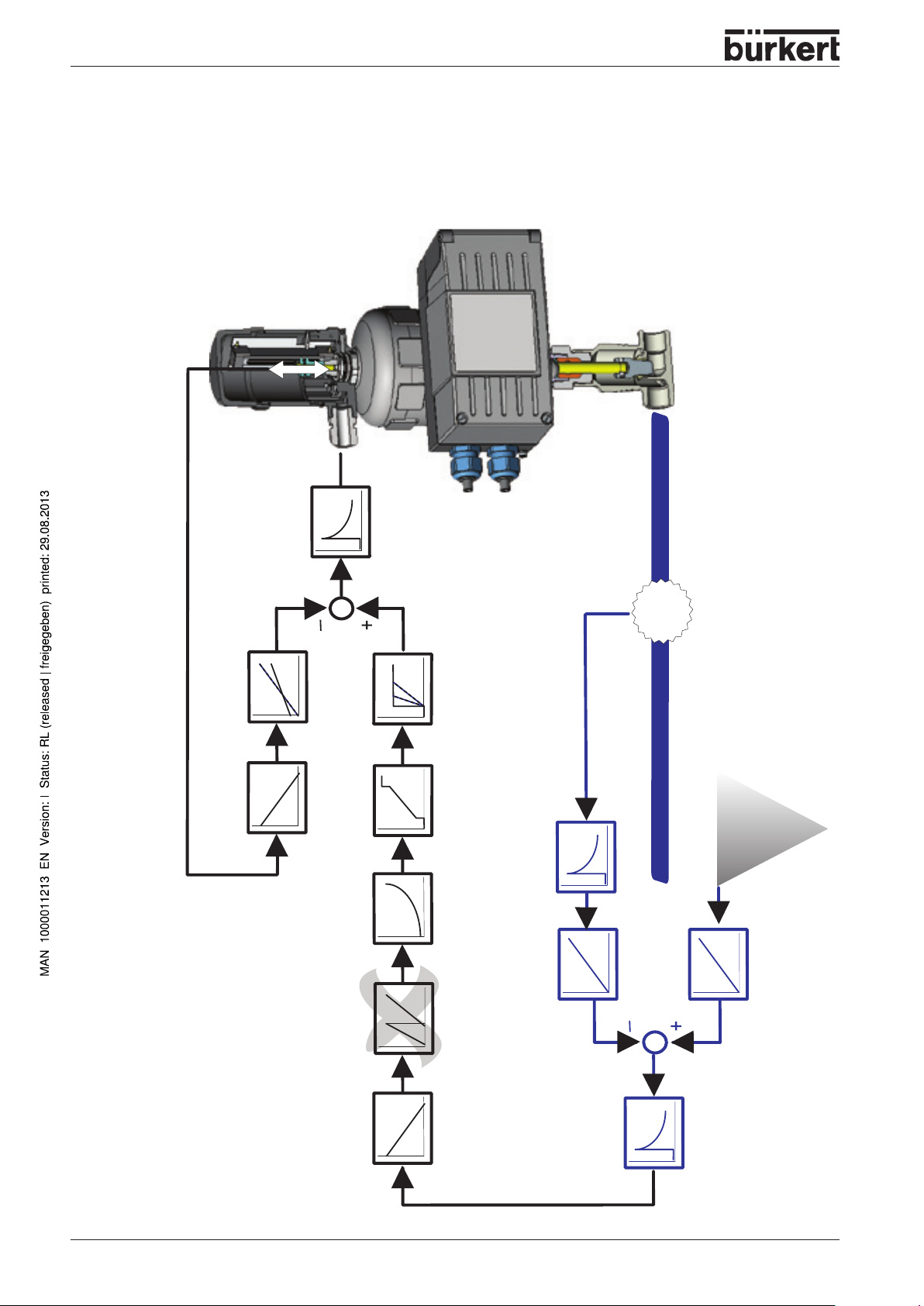

SYSTEM DESCRIPTION (S/HART)

Interfaces

Note: Optional inputs and outputs are enclosed by dotted lines.

NOTE

(S/HART)

The SIDE Control

the 4 ... 20 mA signal.

(S/HART)

is a 2-conductor device, i.e. the voltage supply is provided via

8635 - 23

Page 26

SYSTEM DESCRIPTION (S/HART)

Technical data of the SIDE Control

Technical data

OPERATING CONDITIONS

Permissible ambient temperature -25 ... +65 °C (with non-Ex devices or T4/T5)

System of protection IP 65 to EN 60529

CONFORMITY TO THE FOLLOWING STANDARDS

CE Symbol Conformity wrt. EMC Guideline 89/336/EEC

Low Voltage Guidline 73/23/EEC

Explosion protection (optional) EEX ia IIC T4/T5/T6

MECHANICAL DATA

Housing dimensions, outside (WxHxD) 174 x 88 x 93 mm

Housing material Aluminium

Seal material NBR / Neoprene

Other exterior parts stainless steel (V4A)

Mass approx. 1.5 kg

(S/HART)

-25 ... +60 °C (with T6)

(only with correctly connected cable)

hard anodized and plastic-coated

(S/HART)

ELECTRICAL DATA

Connections 2 M20x1.5 bushings

with screw terminals 0.14 ... 1.5 mm

Power supply via setpoint input 4-20 mA

Burden voltage < 12 V DC

Burden resistance 590 Ω at 20 mA and 11.8 V DC

Process value input (option) 4-20 mA

Burden voltage 200 mV at 20 mA

Burden resistance 10 Ω

Binary input mechanical make/break contact

Inductive proximity switch (optional) to DIN EN 60947-5-6 (NAMUR)

Structural shape SJ3.5-G-N

Manufacturer Pepperl+Fuchs

Output signal for

switching amplifier to DIN EN 50227 (NAMUR)

Rated voltage U

Current (sensor uncoated) ≥ 2.1 mA

Current (sensor coated) ≤ 1.2 mA

0

8 V

2

24 - 8635

Page 27

SYSTEM DESCRIPTION (S/HART)

Analog repeat (optional) 4 ... 20 mA (electrically isolated)

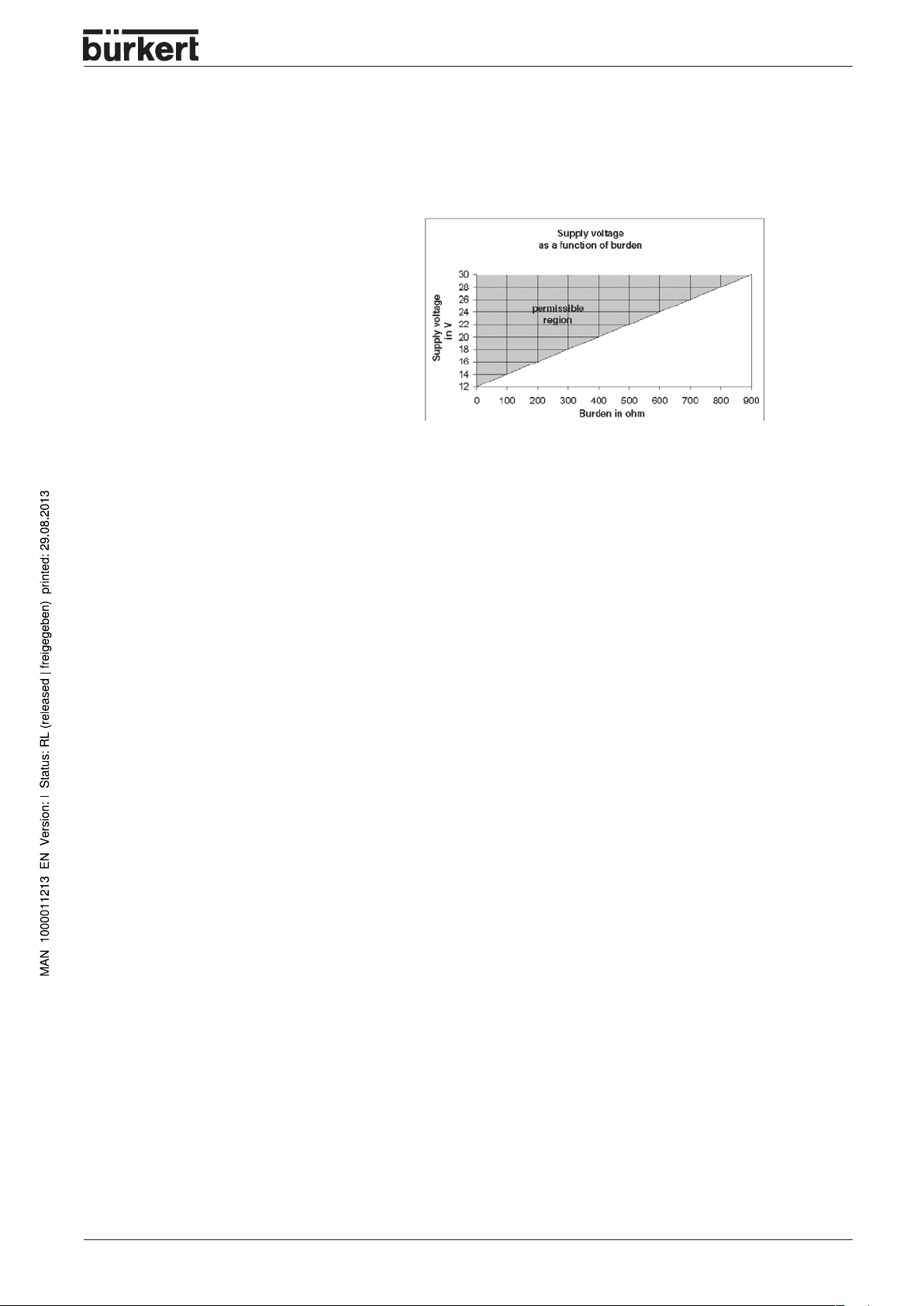

Supply voltage U

Burden U

Binary outputs (optional) to EN 50 227 (electrically isolated)

Supply voltage 5 ... 11 V DC

Current in switching status OPEN < 1.2 mA

Current in switch. status CLOSE > 2.1 mA

Sense of action NO (normally open) or NC (normally closed)

max. permissible values see Declaration of Conformity

= 12 ... 30 V DC

supply

≥ 12 V + RB • 20 mA

supply

(may be parametrized)

PNEUMATIC DATA

Control medium Quality classes to DIN ISO 8573-1

Dust content Class 5:

max. 40 µm particle size

max. 10 mg/m³ particle density

Water content Class 3:

max. pressure dew point

- 20 °C or at least 10 degrees below lowest

operating temperature

Oil content Class 3: max. 1 mg/m³

Temperatur range of - 25 ... + 65 °C (with non-Ex devices or T4/T5)

compressed air - 25 ... + 60 °C (with T6)

Pressure range 1.4 ... 6.0 bar

Supply pressure

variation max. ± 10 % during operation

Air flow capacity of control valve

at 1.4 bar pressure drop

over valve ca. 55 L

/min STP for pressurizing and exhausting

N

at 6 bar pressure drop

over valve ca. 170 L

/min STP for pressurizing and exhausting

N

Self-consumption of air

in balanced state 0.0 LN/min STP

Throttle screw adjustment ratio ca.10:1

Connections G1/4'' internal thread

8635 - 25

Page 28

SYSTEM DESCRIPTION (S/HART)

Factory settings

Function Factory setting

CHARACT CHA LIN

CUTOFF CUT

DIR.CMD DIR.CRISE

DIR.ACT DIR.ARISE

SPLTRNG SR

X.LIMIT LIM

X.TIME

T.OPN

T.CLS

After execution of

OUTPUT

OUT ANL:

OUT POS OUT 4

OUT BIN:

OUT DEV DEV 5.0 NORM OPN

SAFEPOS

BIN-IN B.IN SPOS / NORM OPN

(S/HART)

= 0 %;

= 0 (%); SR = 100 (%)

= 0 %,

Values determined by

Values determined by

SETFACT

'

20 A

0

CUT

LIM

:1 s

= 100 %

= 100 %

AUTOTUNE

AUTOTUNE

Function Factory setting

X.CONTRL

X.CO DBND

X.CO PARA

KX

KX

After execution of

P.CONTRL

P.CO DBND

P.CO PARA

KP

TN

TV

X0

P.CO SETP SETP INT

P.CO FILT

P.CO SCAL PV

P.CO TUNE D’ACT

CODE CODE 0000

1 %

Values determined by

Values determined by

SETFACT

1 %

1.00

999.9

0.0

0

0

000.0

:1

, PV

AUTOTUNE

AUTOTUNE

100.0

NOTE

The functions and factory settings shown in grey are optionally valid with

analog repeat

(OUTPUT)

or with process controller

(P.CONTRL)

.

26 - 8635

Page 29

SYSTEM DESCRIPTION (PROFIBUS PA)

SYSTEM DESCRIPTION

(PROFIBUS PA)

Construction of SIDE Control

Illustration ............................................................................................................................................................................................................................................. 28

Features

Options

Functional diagram of the SIDE Control

control valve with single-acting diaphragm actuator ..................................................................................................................... 30

................................................................................................................................................................................................................................................. 29

.................................................................................................................................................................................................................................................... 29

Operation as a positioner

Characteristics of the positioner software ................................................................................................................................................. 32

Schematic illustration of position control

Interfaces

(PROFIBUS PA)

Technical data of the SIDE Control

Technical data

Factory settings

(PROFIBUS PA)

(PROFIBUS PA)

(PROFIBUS PA)

(PROFIBUS PA)

(PROFIBUS PA)

...................................................................................................................................................... 33

.............................................................................................................................................................................................

(PROFIBUS PA)

............................................................................................................................................................................. 35

........................................................................................................................................................................

............................................................................................................................... 28

in connection with a

............................................................................................................................................. 31

.............................................................................................................

34

35

36

8635 - 27

Page 30

SYSTEM DESCRIPTION (PROFIBUS PA)

Construction of SIDE Control

The SIDE Control

with single-acting linear or part-turn actuators.

The SIDE Control

(e.g. process control system). The momentary valve position is reported via the bus.

For detailled information on commissioning a PROFIBUS PA branch, we recommend the

Commissioning Guidelines

(PROFIBUS PA)

(PROFIBUS PA)

by the PROFIBUS Users Organization (PUO).

is a digital positioner for pneumatically operated continuous valves

can be controlled via PROFIBUS PA from a central automation system

(PROFIBUS PA)

Illustration

DIP switch

(device address)

PROFIBUS

Display with 3 operating keys

Screw terminal

Clamping screw

(for attaching the

bus screen)

Bushings

M20 x 1.5

Throttle screw

Earthing

(grounding) screw

28 - 8635

Page 31

SYSTEM DESCRIPTION (PROFIBUS PA)

Features

•

Position sensor

Very high resolution conductive plastic potentiometer

• Microprocessor controlled electronics

for signal processing, control and driving the piezoelectric positioning system

•

Operating elements

The device can be set (configuration and parametrization) locally via three inside keys. An inside, 8digit, 16-segment LC display is provided, which can also show the set point or actual value.

Positioning system

•

A piezoelectric positioning system serves to drive the valve actuator.

•

Electrical interfaces

M20 bushings with screw terminals

•

Pneumatic interfaces

G1/4’’ interior thread

•

Housing

Aluminium housing (hard anodized and plastic-coated) with swing-up cover and captive screws.

Attachment

•

to linear actuators to NAMUR recommendation (DIN 534 T6) or to part-turn actuators to VDI/VDE 3845)

Options

• Position feedback via 2 inductive proximity switches (initiators).

• Integral attachment to Bürkert continuous valves.

8635 - 29

Page 32

SYSTEM DESCRIPTION (PROFIBUS PA)

Functional diagram of the SIDE Control

(PROFIBUS PA)

connected to a control valve with single-acting diaphragm

actuator

SIDE Control

(PROFIBUS PA)

Actual position

External position

setpoint via

PROFIBUS PA

Pressure

supply

Exhaust

air

Positioner

Positioning system

pressurize

exhaust

Position

sensor

Lever

mechanism

Pneumatic

actuator

(single-acting)

Valve

(actuator)

NOTE

In the case of Integral attachment of the SIDE Control

(PROFIBUS PA)

to a Bürkert

continuous valve, the position sensor is situated outside the SIDE Control

BUS PA)

on the actuator and is connected to the latter with a cable.

(PROFI-

30 - 8635

Page 33

S

YSTEM DESCRIPTION

(PROFIBUS PA)

Operation as a positioner

The SIDE Control

sensor measures the actual position (POS) of the actuator. The controller compares this actual value of

the position with the setpoint (CMD), which may be set via the PROFIBUS PA. If a control difference

(Xd1) exists, a pulse-width modulated voltage signal is sent to the positioning system as the correcting

variable. If the difference is positive, the pressurizing piezoelectric valve is driven via output B1; if it is

negative, the exhausting piezoelectric valve is driven via output E1. In this way, the position of the

actuator is altered until the control difference is 0. Z1 represents a disturbance.

Position

setpoint

(PROFIBUS PA)

Positioner Positioning system

(PROFIBUS PA)

controls the position of the pneumatic actuator, whereby the position

Valve opening

Continuous

(piezoelectric valves)

valve

Position control loop

Position sensor

8635 - 31

Page 34

SYSTEM DESCRIPTION (PROFIBUS PA)

Characteristics of the positioner software

Supplementary function Effect

Positioner with supplementary functions

AUTOT UNE

Tight-closing function

Stroke limitation

Limitation of correction speed

Correction characteristic for

adaptation to the operating curve

(via PROFIBUS PA)

Insensitivity range

Direction of action of the controller

setpoint

Direction of action of the actuator Reverse of direction of action of the actuator

Automatic adaptation of positioner to the control valve

in use.

Valve closes tight outside the control range. A value is

specified (in %) from which the actuator is clompletely

exhausted (at 0 %) or pressurized (at 100 %).

Mech. valve piston movement only within a defined

stroke range.

Actuator takes a preset time to move from OPEN to

CLOSED or from CLOSED to OPEN.

Linearization of the process curve can be carried out.

The positioner responds only above a control difference

to be specified.

Reverse of direction of action of the setpoint

Safety position Valve moves to a defined safety position

Factory reset Reset to factory settings

Communication via PROFIBUS PA protocol

32 - 8635

Page 35

POS

SYSTEM DESCRIPTION (PROFIBUS PA)

CMD

POS

X.LIMIT

DIR.ACT

X.CONTRL

DBDx

CMD

X.TIME

CHARACT CUTOFF

Setpoint

setting via

Schematic illustration of position control

CMD

PROFIBUS PA

DIR.CMD

8635 - 33

Page 36

SYSTEM DESCRIPTION (PROFIBUS PA)

Interfaces

Note: Optional inputs and outputs are enclosed by dotted lines

NOTE

(PROFIBUS PA)

The SIDE Control

provided via the PROFIBUS PA signal.

(PROFIBUS PA)

is a 2-conductor device, i.e. the voltage supply is

34 - 8635

Page 37

SYSTEM DESCRIPTION (PROFIBUS PA)

Technical data of the SIDE Control

Technical data

OPERATING CONDITIONS

Permissible ambient - 25 ... + 65 °C (with non-Ex devices or T4/T5)

temperature - 25 ... + 60 °C (with T6)

System of protection IP 65 to EN 60529

CONFORMITY TO THE FOLLOWING STANDARDS

CE symbol Conformity wrt. EMC Guideline 89/336/EEC

Low Voltage Guidline 73/23/EEC

Explosion protection (optional) EEX ia IIC T4/T5/T6

MECHANICAL DATA

Housing dimensions, outside (W x H x D) 174 x 88 x 93 mm

Housing material Aluminium

Seal material NBR / Neoprene

Other exterior parts stainless steel (V4A)

Mass approx. 1.5 kg

(PROFIBUS PA)

(only with correctly connected cable)

hard anodized and plastic-coated

(PROFIBUS PA)

ELECTRICAL DATA

Connections 2 M20 x 1.5

bushings with screw terminals 0.14 ... 1.5 mm

Power supply via PROFIBUS PA signal

to Ex segment coupler 9 ... 15 V DC (Ex)

to segment coupler 9 ... 24 V DC (NonEx)

Operating current from bus 12 mA ± 7 % without FDE

Fault current protection 5 mA ± 10 % FDE

Binary input mechanical make/break contact

Inductive proximity switch (optional) to DIN EN 60947-5-6 (NAMUR)

Structural shape SJ3,5-G-N

Manufacturer Pepperl+Fuchs

Output signal for

switching amplifier to DIN EN 50227 (NAMUR)

Rated voltage U

Current (sensor uncoated) ≥ 2.1 mA

Current (sensor coated) ≤ 1.2 mA

0

8 V

2

8635 - 35

Page 38

SYSTEM DESCRIPTION (PROFIBUS PA)

PNEUMATIC DATA

Control medium Quality classes to DIN ISO 8573-1

Dust content Class 5:

max. 40 µm particle size

max. 10 mg/m³ particle density

Water content Class 3:

max. pressure dew point

- 20 °C or at least 10 degrees below lowest

operating temperature

Oil content Class 3: max. 1 mg/m³

Temperature range of - 25 ... + 65 °C (with non-Ex devices or T4/T5)

compressed air - 25 ... + 60 °C (with T6)

Pressure range 1.4 ... 6.0 bar

Supply pressure

variation ± 10 % during operation

Air flow capacity of control valve

at 1.4 bar pressure drop

over valve ca. 55 l

at 6 bar pressure drop

over valve ca. 170 l

Self-consumption of air in

balanced state 0.0 lN/min

Throttle screw adjustment ratio ca. 10:1

Connections G1/4'' internal thread

/min STP for pressurizing and exhausting

N

/min STP for pressurizing and exhausting

N

Factory settings

Function Factory setting

CUTOFF CUT

(PROFIBUS PA)

= 0 %;

DIR.CMD DIR.CRISE

DIR.ACT DIR.ARISE

X.LIMIT LIM

= 0 %,

X.TIME

T.OPN

T.CLS

After execution of

Values determined by

Values determined by

SETFACT

:1 s

CUT

LIM

= 100 %

= 100 %

AUTOTUNE

AUTOTUNE

Function Factory setting

SAFEPOS

0

BIN-IN B.IN SPOS / NORM OPN

X.CONTRL

X.CO DBND

1 %

X.CO PARA

KX

KX

After execution of

Values determined by

Values determined by

SETFACT

:1

AUTOTUNE

AUTOTUNE

36 - 8635

Page 39

INSTALLATION

INSTALLATION

Attachment and assembly ............................................................................................................................................................................................... 38

Complete system with Bürkert continuous valve from series 27xx ............................................................................ 38

Attachment to a continuous valve with linear actuator acc. to NAMUR

Attachment to a continuous valve with part-turn actuator

...................................................................................................... 42

................................................................ 39

Fluidic connection......................................................................................................................................................................................................................... 44

Electrical connection

Electrical connection

(S/HART)

...............................................................................................................................................................................

(PROFIBUS PA)

..........................................................................................................................................................

45

46

8635 - 37

Page 40

INSTALLATION

Attachment and assembly

The SIDE Control may be attached to different continuous valves. The valves which may be used are

continuous valves with a linear activator to NAMUR recommendation (DIN IEC 534 T6) and such with a

part-turn actuator to VDI/VDE 3845. Furthermore, the SIDE Control is available completely

preassembled on a Bürkert continuous valve from series 27xx.

Complete system with Bürkert continuous valve from series 27xx

The SIDE Control is available in combination with Bürkert continuous valves from the series 27xx as a

completely preassembled and tested system.

ATTENTION!

38 - 8635

The connecting line from the SIDE Control to the external positioning sensor shall

not be lengthened. Only the positioning sensor supplied shall be connected to the

SIDE Control.

If manipulations are carried out, the EX approval will become void!

Page 41

INSTALLATION

Attachment to a continuous valve with linear actuator acc. to NAMUR

Transmission of the valve position to the position sensor built into the SIDE Control is via a lever (to

NAMUR).

Add-on kit to linear activator (Id no. 787 215)

(obtainable from Bürkert as an accessory)

Serial

no.

1 1 NAMUR attachment bracket IEC 534

2 1 U-piece

3 2 Clamping piece

4 1 Driving pin

5 1 Conical roller

6a 1 NAMUR lever for stroke range 3 - 35 mm

6b 1 NAMUR lever for stroke range 35 - 130 mm

7 2 U-bolt

8 4 Hex screw DIN 933 M8 x 20

9 2 Hex screw DIN 933 M8 x 16

10 6 Lock washer DIN 127 A8

11 6 Washer DIN 125 B 8.4

12 2 Washer DIN 125 B 6.4

Quantity

Designation

13 1 Spring VD-115E 0.70 x 11.3 x 32.7 x 3.5

14 1 Spring washer DIN 137 A6

15 1 Retaining washer DIN 6799 - 3,2

16 3 Lock washer DIN 127 A6

17 3 Hex screw DIN 933 M6 x 25

18 1 Hex nut DIN 934 M6

19 1 Square nut DIN 557 M6

21 4 Hex nut DIN 934 M8

22 1 Guide bushing 6.2 x 9.9 x 15 x 3.5

8635 - 39

Page 42

INSTALLATION

Assembly

Mount U-piece (2) using clamping pieces (3), hex screws (17) and lock washers (16) on actuator

spindle.

Select the short lever (Table

to linear actuator,

Assemble the lever (if not preassembled).

The distance of the driving pin from the axle should be

equal to the actuator stroke. This results in a swing angle of

the lever of 60°. This assures that the position sensor works

with good resolution. The scale printed on the lever is irrelevant.

Serial no. 6b), depending on the actuator stroke.

Add-on kit to linear actuator,

Serial no. 6a) or long lever (Table

Add-on kit

Swing angle of

lever (60°)

Separation = stroke of actuator

Push the lever onto the axle of the SIDE Control and screw it tight.

Fix attachment bracket (1) with hex screws (9), lock washers (10) and washers (11) to the rear side

of the SIDE Control.

NOTE

Which M8 thread on the SIDE Control is

chosen depends on the size of the actuator

To determine the correct position, hold the

SIDE Control with bracket against the

actuator. The conical roller (5) on the lever

of the position sensor must be able to move

freely in U-piece (2) on the actuator over

the entire stroke. At 50% stroke, the lever

position should be roughly horizontal (see

under

Alignment of the lever mechanism

).

40 - 8635

Page 43

INSTALLATION

Actuator with cast frame

Fix the SIDE Control with bracket by means of one or more hex screws (8), washers (11) and lock

washers (10) to the cast frame.

Actuator with post yoke

Fix the SIDE Control with bracket with U-bolts (7),

washers (11), lock washers (10) and hex nuts (21) to the post yoke.

Alignment of the lever mechanism

The lever mechanism can only be aligned properly when the device has been connected electrically

and pneumatically.

In the manual mode, move the actuator to half stroke (corresponding to scale on actuator).

Move the device vertically until the lever is horizontal.

Fix the device finally to the actuator.

8635 - 41

Page 44

INSTALLATION

Attachment to a continuous valve with part-turn actuator

The axle of the position sensor built into the SIDE Control is coupled directly to the axle of the part-turn

actuator.

Add-on kit to part-turn activator (Id no. 651 741)

Serial

no.

1 1 Adapter

2 2 Setscrew DIN 913 M4 x 4

3 4 Cap screw DIN 933 M6 x 12

4 4 Lock washer B6

Quan-

tity

Designation

(obtainable from Bürkert as an

accessory)

Other accessories required

Attachment bracket with fixing screws (acc. to VDI/VDE 3845) - available from the manufacturer of the

part-turn actuator.

Assembly

Determine the orientation of attachment of the

SIDE Control (parallel to the actuator or rotated

by 90°).

Determine the basic position and direction of

rotation of the actuator.

Push adapter (1) onto the axle of the SIDE

Control and fix it with 2 setscrews (2). One of

the setscrews should press onto the flat on the

axle (

to prevent slip!

the axle of the SIDE Control can move only in

one of the ranges shown below in the drawings

observe the flat on the axle!

Swing angle 90°

Flat on shaft!

). It must be assured that

.

Swing angle 90°

Flat on shaft!

42 - 8635

Page 45

INSTALLATION

Place the SIDE Control on the bracket and fix it with 4 cap screws (3) and lock washers (4).

Place the SIDE Control with the bracket on the part-turn actuator and fix it.

NOTE

If after starting the function

alignment of the axle of the SIDE Control to the axle of the actuator is incorrect.

In this case, check the alignment as described above.

X.TUNE

the message

X.ERR 5

appears in the LC display, the

Then repeat the function

X.TUNE.

8635 - 43

Page 46

INSTALLATION

Fluidic connection

The locations of the fluidic connections are shown in the following drawing:

Exhaust

connection

3

Connect supply pressure to connection 1.

Connect the service connection 2 to the chamber of the single-acting actuator.

If possible, connect a silencer or the like to connection 3. If the connection is left open, there is a risk

of water splashes entering the SIDE Control.

Supply

pressure

connection

1

Service

connection

2

44 - 8635

Page 47

INSTALLATION

Switch (make contact

or break contact)

11

12

81

82

13

14

41

42

51

52 31

32

86

85

83

84

Electrical connection

To make electrical connections, open the cover of the SIDE Control

screws.

Terminal

designation

Allocation External connection

(S/HART)

(S/HART)

by unscrewing the 2

11 + Setpoint + 4 ... 20 mA signal

12 - Setpoint - GND

13 + Process value + (option) 4 ... 20 mA signal

14 - Process value - (option) GND

31 Actual value output + (option)

32 Actual value output - (option)

41 + Initiator 1+ (option)

42 - Initiator 1- (option)

51+ Initiator 2+ (option)

52 - Initiator 2- (option)

81 Binary input +

82 Binary input -

83 Binary output 1+ (option)

84 Binary output 1- (option)

85 Binary output 2+ (option)

Switching amplifier

to EN 50227

Switching amplifier

to EN 50227

86 Binary output 2- (option)

ATTENTION!

During the electrical connection of the inherently safe circuits, always observe the

data in the attached Certificate of Conformity!

HINWEIS

Connection of a potential equalization conductor (PE) to the electronics is unnecessary.

1) Burden resistance RB: see Chapter

Technical Data

8635 - 45

Page 48

INSTALLATION

Electrical connection

To make electrical connections, open the cover of the SIDE Control

unscrewing the 2 screws.

Configuration of the terminals

Bus (+)

Bus (-)

Bus (+)

Bus (-)

81

82

N.C.

N.C.

41 (+)

42 (-)

51 (+)

52 (-)

(PROFIBUS PA)

(PROFIBUS PA)

by

Terminal

designation

BUS (+) PROFIBUS-PA (IN) to IEC 1158-2 (either polarity between input terminals)

BUS (-) PROFIBUS-PA (IN)

BUS (+) PROFIBUS-PA (OUT) to IEC 1158-2 (either polarity between output terminals)

BUS (-) PROFIBUS-PA (OUT)

81 Binary input connected via switch (make contact)

82 Binary input

N.C. not connected

N.C. not connected

41 + Initiator 1 + (option)

42 - Initiator 1 - (option)

51 + Initiator 2 + (option)

52 - Initiator 2 - (option)

Allocation External connection

to terminal 82

Switching amplifier

to EN 50227

Switching amplifier

to EN 50227

Use screened cable for connecting the bus and the binary input in order to assure reliability and EC

conformity. The cable screens can be attached using the clamping screw (on the post between the M20

bushings). The cable screens must be attached at both ends. On the outside of the housing there is a