Page 1

Type 8631

TOP Control on/off

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2000 - 2012 Bürkert Werke GmbH

Operating Instructions 1202/13_EU-ML_00801872 / Original DE

Page 3

C

ONTENTS

Contents

Operating Instructions

TOP Control on/off Type 8631

GENERAL NOTES

Symbols........................................................................................................................................................................................................................................................ 6

Intended use .......................................................................................................................................................................................................................................... 6

Safety notes............................................................................................................................................................................................................................................ 6

Notes for units with EEx-i approval..................................................................................................................................................................... 7

Notes for use in the Ex-area........................................................................................................................................................................................... 7

Scope of delivery............................................................................................................................................................................................................................ 7

Warranty conditions..................................................................................................................................................................................................................... 7

english

T r ansport, storage .......................................................................................................................................................................................................................... 8

Disposal........................................................................................................................................................................................................................................................ 8

TECHNICAL DATA

Construction and function.................................................................................................................................................................................................. 10

Features........................................................................................................................................................................................................................................................ 11

Operating conditions ................................................................................................................................................................................................................. 12

Conformity................................................................................................................................................................................................................................................. 12

Mechanical data............................................................................................................................................................................................................................... 12

Pneumatic data.................................................................................................................................................................................................................................. 12

Electrical data without bus control........................................................................................................................................................................ 13

Electrical data with bus control (AS interface).................................................................................................................................... 13

Electrical data with bus control (DeviceNet).......................................................................................................................................... 13

Electrical data with EEx-i approval...................................................................................................................................................................... 14

8631 - 1

Page 4

C

ONTENTS

COMMISSIONING

Fluidic installation .......................................................................................................................................................................................................................... 16

Installation of the valve.................................................................................................................................................................................................. 16

Turning the T OP Control on/off........................................................................................................................................................................... 16

Fluidic connection of the TOP Control on/off................................................................................................................................ 16

Opening the housing........................................................................................................................................................................................................ 16

Electrical installation ................................................................................................................................................................................................................. 17

Connection terminals for cable bushings..................................................................................................................................................... 17

24 V - version with inductive proximity switches (make contacts)

english

24 V - version with mechanical limit switches

230 V - version with mechanical limit switches

....................................................................................................................................... 18

.................................................................................................................................... 19

............................................................................. 18

Electrical installation of the TOP Control on/off with EEx-i approval ................................................................ 19

Connection terminals for cable connections............................................................................................................................................ 19

Setting the initiators or limit switches (option)..................................................................................................................................... 20

AS INTERFACE

Programming data......................................................................................................................................................................................................................... 22

Status display....................................................................................................................................................................................................................................... 23

Electrical connection................................................................................................................................................................................................................. 24

4-pole M12-circular plug connector..................................................................................................................................................................... 24

Cable bushing with connection terminals

.................................................................................................................................................... 24

DEVICENET

Explanation of terms.................................................................................................................................................................................................................. 26

Technical data..................................................................................................................................................................................................................................... 27

Maximum line lengths.............................................................................................................................................................................................................. 27

Overall line length....................................................................................................................................................................................................................... 27

Drop line length

............................................................................................................................................................................................................................. 27

Safety positions on bus failure ................................................................................................................................................................................... 27

Interfaces..................................................................................................................................................................................................................................................... 28

Electrical connection................................................................................................................................................................................................................. 28

Bus connection (circular plug M12, 5-pole).............................................................................................................................................. 28

Termination for DeviceNet systems

Network topology of a DeviceNet system

.................................................................................................................................................................... 29

................................................................................................................................................. 29

Configuring the T OP Control on/off...................................................................................................................................................................... 30

DIP switches .................................................................................................................................................................................................................................... 30

2 - 8631

Page 5

C

ONTENTS

Configuring of the process data............................................................................................................................................................................... 31

LED status display........................................................................................................................................................................................................................ 32

Statuses of the MNS LED............................................................................................................................................................................................... 33

Example of configuration.................................................................................................................................................................................................... 34

Installation of the EDS file................................................................................................................................................................................................ 34

Setting upt the process map

SAFETY SETTINGS AND MAINTENANCE

......................................................................................................................................................................................... 34

Safety positions following failure of electrical and pneumatic auxiliary power................................. 38

Maintenance .......................................................................................................................................................................................................................................... 38

ANNEXE

EC Declaration on conformity 8631 EEx-i................................................................................................................................................ A02

Qualification Test Certificate PTB 00 ATEX 2077 X (complete unit)................................................................. A05

Qualification Test Cer tificate PTB 01 ATEX 2173 (for integral solenoid valve)................................A07

english

Manufacturer's Declaration from Pepperl & Fuchs

(for integrated proximity switch)................................................................................................................................................................................ A10

8631 - 3

Page 6

C

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Bürkert Company Locations

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Bürkert Company Locations

Contact addresses / Kontaktadressen

ONTENTS

english

4 - 8631

Page 7

GENERAL NOTES

GENERAL

NO TES

Symbols................................................................................................................................................................................................................................................................. 6

Intended use................................................................................................................................................................................................................................................... 6

Safety notes..................................................................................................................................................................................................................................................... 6

Notes for units with EEx-i approval.............................................................................................................................................................................. 7

Notes for use in the Ex-area................................................................................................................................................................................................... 7

Scope of delivery..................................................................................................................................................................................................................................... 7

Warranty conditions............................................................................................................................................................................................................................. 7

english

T r ansport, storage................................................................................................................................................................................................................................... 8

Disposal................................................................................................................................................................................................................................................................ 8

8631 - 5

Page 8

GENERAL NOTES

Symbols

The following symbols are used in these operating instructions:

Marks a work step that you must carry out.

A TTENTION!

NOTE

Intended use

english

In order for the device to function perfectly and have a long service life, you must observe the information

given in these operating instructions and comply with the operating conditions and the permissible data

for the TOP Control on/off, in addition to the information for the respective pneumatically actuated v alv e,

which is specified in the „Technical Data“ chapter of these instructions and in the valve instructions.

Please note that the Top control on/off may not be used out-of-doors.

In view of the large number of possible applications and categories of use, you should check whether the

Top control on/off is suitable for y our specific application, and carry out tests where necessary .

Safety notes

• Keep to standard engineering rules in planning the use of and operating the device!

Marks notes on whose non-observance your health or the functioning of the device will

be endangered.

Marks important additional information, tips and recommendations.

• Installation and maintenance work are only allowed by specialist personnel using suitable tools!

• Observe the current regulations on accident prevention and safety during operation and maintenance

of the device!

• Switch off the supply voltage in all cases before intervening in the system!

• Note that in systems under pressure, piping and valves may not be loosened!

• T ak e suitable precautions to prev ent inadvertent operation or damage by unauthorized action!

• Make sure that after an interruption to the electrical or pneumatic supply , the process starts up again in

a well-defined, controlled manner!

• On non-observance of these notes and unauthorized interference with the device, we will refuse all

liability and the warranty on device and accessories will become void!

6 - 8631

Page 9

GENERAL NOTES

Notes for units with EEx-i approval

• Take suitable measures to av oid an electrostatic discharge from the plastic

parts of the housing (see EN 100 015 - 1).

• No component should be connected to the inputs and outputs of the circuit

board whose electrical data is outside the limits determined for intrinsically safe

operation quoted in the data sheet of the positioner.

• Work out on the device with the housing open should not be carried in very

damp or aggressive atmospheres. Take precautions to exclude unintentional

mechanical damage to the circuit boards or their components. Limit the period

during which the unit is opened to that which is absolutely necessary.

Notes for use in the Ex-area

Please comply with the following:

• In the case of installation and operation in areas that have a risk of explosion, the respective national

regulations. In Germany, this is VDE 0165.

• When making electrical connections to the inherently safe circuit, the information given in the

corresponding conformity certificates.

• Always f ollow the inf ormation contained in the ATEX approval.

english

Scope of delivery

Conformity

In accordance with the EC Declaration of conformity, Type 8631 is compliant with the EC Directives.

Immediately after receipt of a shipment, make sure that the contents are undamaged and match the

scope of delivery stated on the packing slip. In the event of discrepancies, please contact our service

department immediately:

Standards

Conformity with the EC Directives is verified by the following standards:

EN 60079-0

Warranty conditions

This document contains no warranty promises. W e refer in this connection to our General Conditions of

Sale and Business. The condition for the w arranty is use of the unit f or the intended purpose under the

Warranty

specified application conditions.

A TTENTION!

The guarantee only covers faults in the TOP Control on/off series, and in the integrated

pneumatically-driven valve . No liability will, howe v er , be accepted for subsequent

damage of any kind that may arise as a result of the failure or incorrect functioning of

the device.

Bürkert Steuer- und Regelungstechnik, Service Department

Chr.-Bürkert-Str . 13-17, D-76453 Ingelfingen

T el.: (07940) 10-586 / F ax: (07940) 10-428

eMail: service@buerkert.com

8631 - 7

Page 10

GENERAL NOTES

Transport, storage

Disposal

english

A TTENTION!

T r ansport and store the appliance in its original packing only .

A TTENTION!

When disponsing of the appliance, observe the national standards for refuse disposal.

8 - 8631

Page 11

TECHNICAL DATA

TECHNICAL DATA

Construction and function........................................................................................................................................................................................................... 10

Features................................................................................................................................................................................................................................................................ 11

Operating conditions.......................................................................................................................................................................................................................... 12

Conformity.......................................................................................................................................................................................................................................................... 12

Mechanical data........................................................................................................................................................................................................................................ 12

Pneumatic data.......................................................................................................................................................................................................................................... 12

english

Electrical data without bus control................................................................................................................................................................................. 13

Electrical data with bus control (AS interface)............................................................................................................................................. 13

Electrical data with bus control (DeviceNet).................................................................................................................................................. 13

Electrical data with EEx-i approval.............................................................................................................................................................................. 14

8631 - 9

Page 12

TECHNICAL DATA

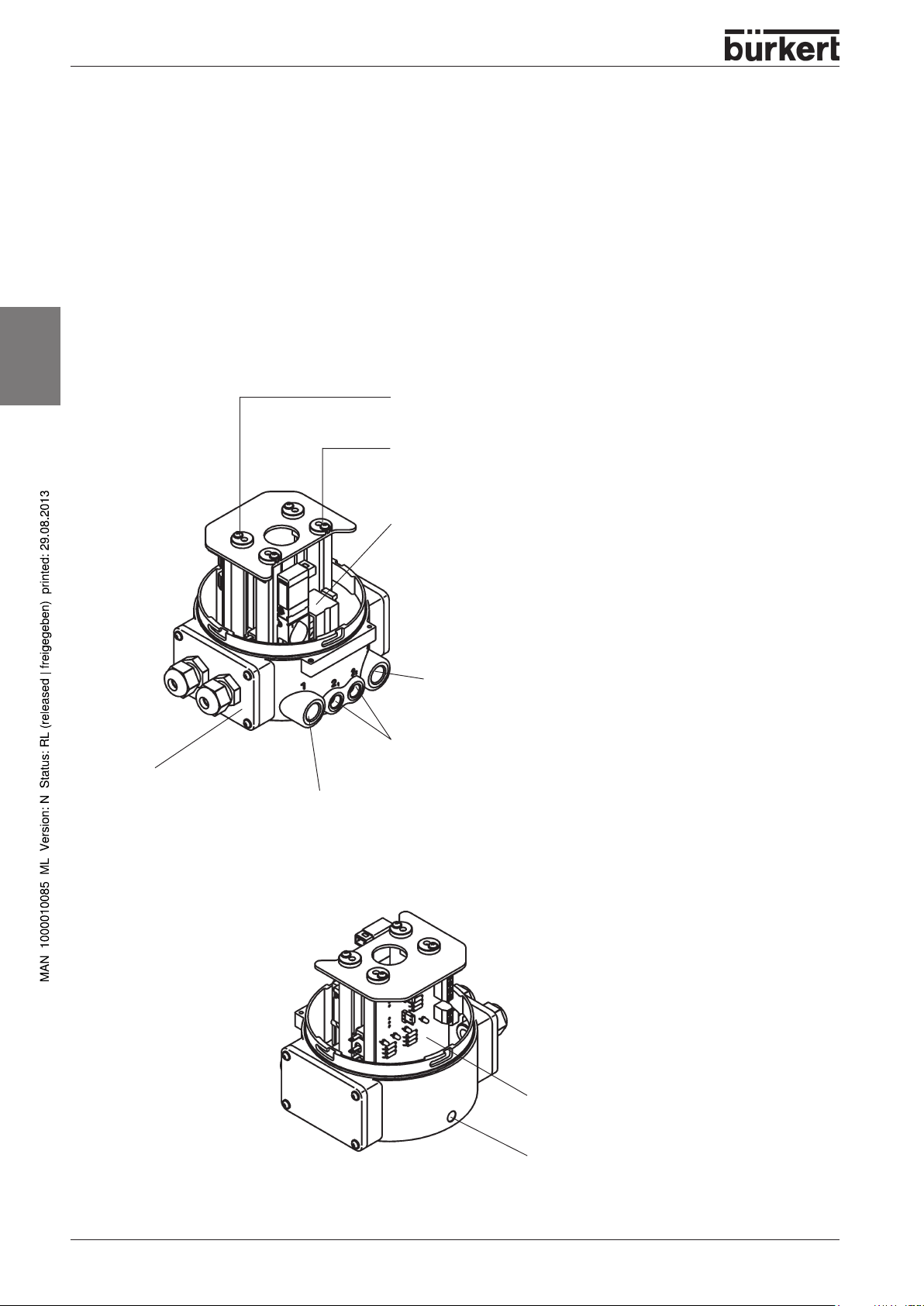

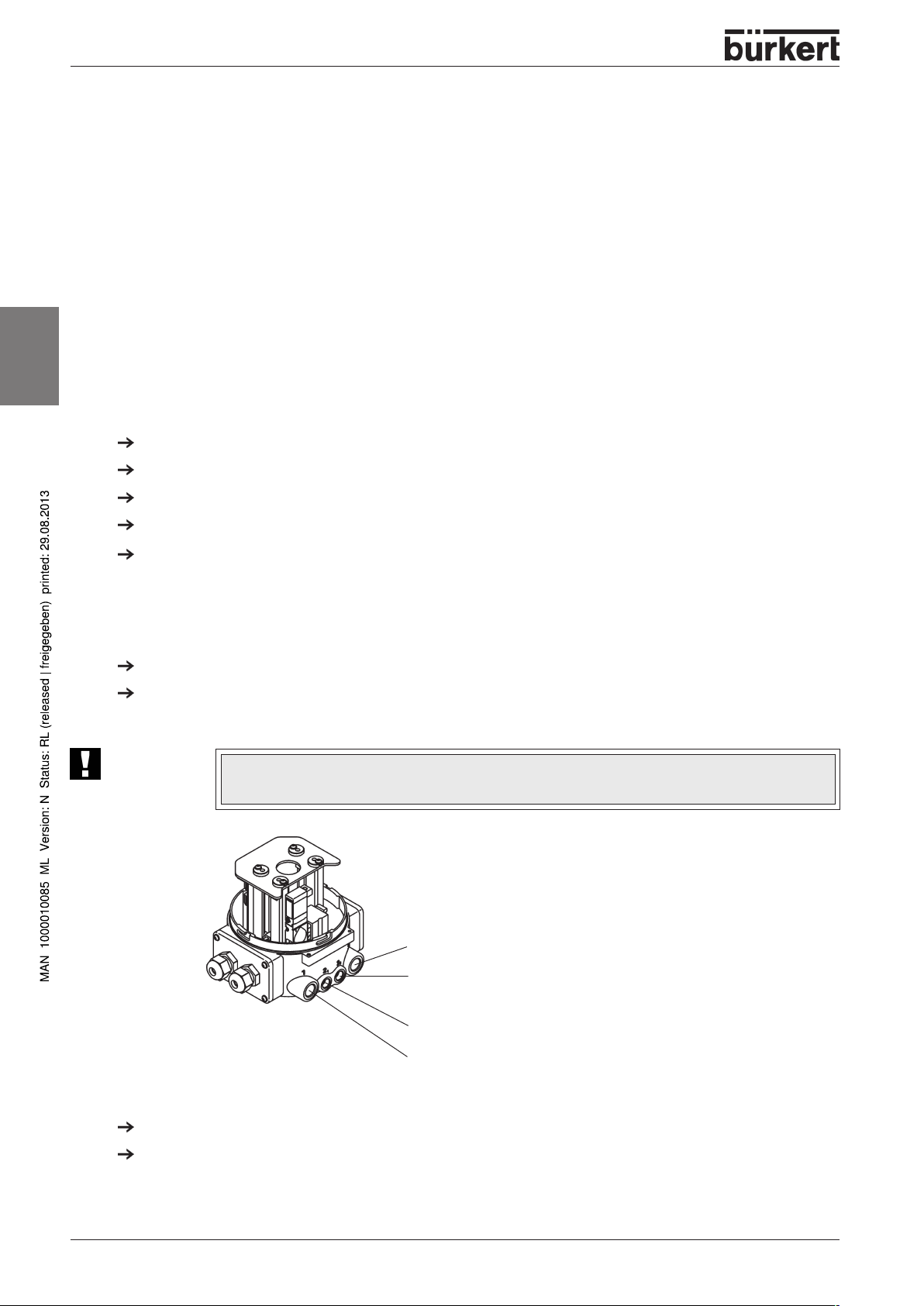

Construction and function

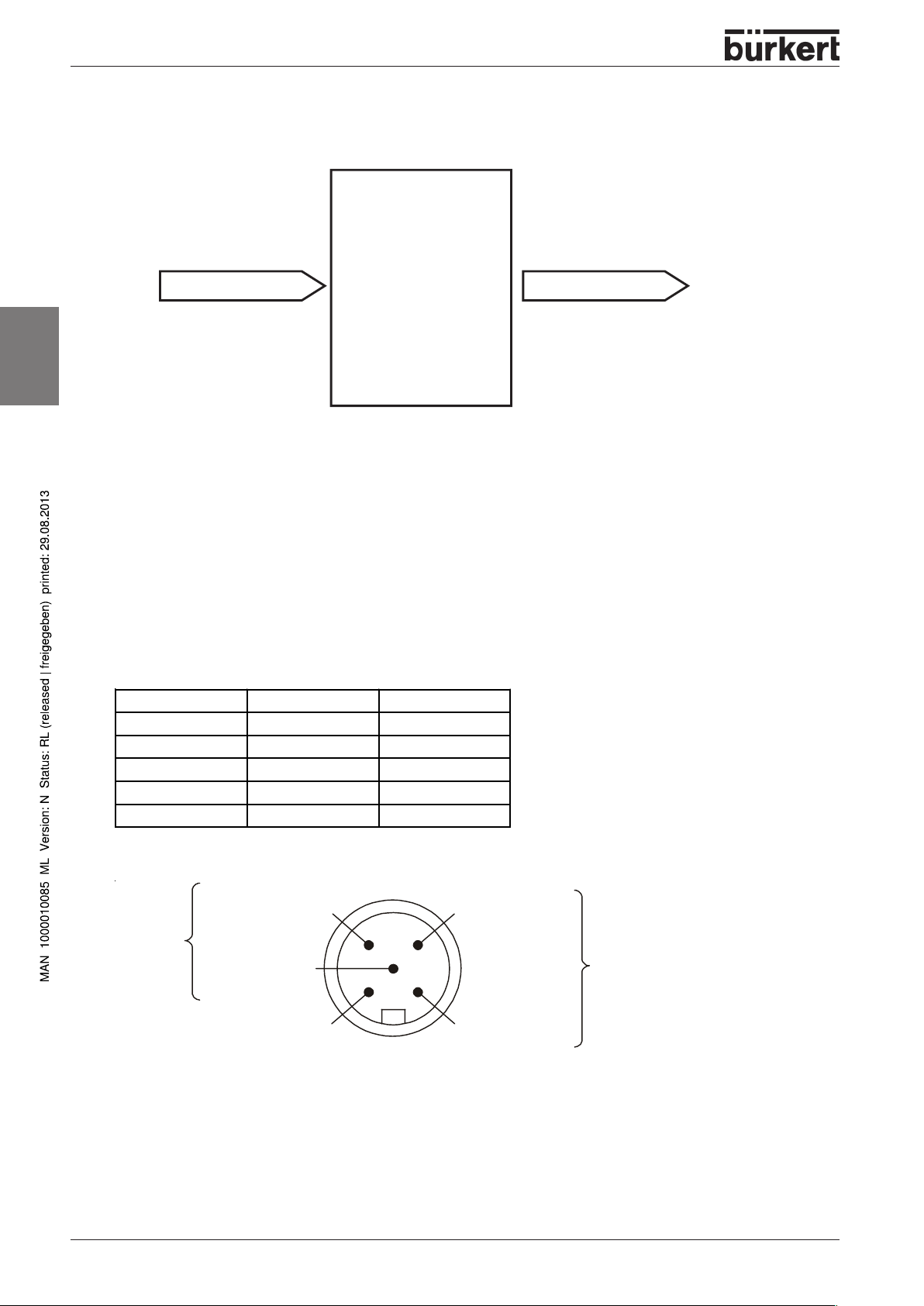

The TOP Control on/off serves to drive pneumatically actuated process v alv es. It may be combined with

various vbalve types from the Bürkert process valve range (see data sheets f or types 2000, 2001, 2002,

2012, 2030, 2031, 2031K, 2652, 2655 and 2658).

TOP Control and process valve are connected b y an adapter . This results in an integral system consisting

of repeater, actuator and v alve function.

V arious electrical and pneumatic connection variants are available.

english

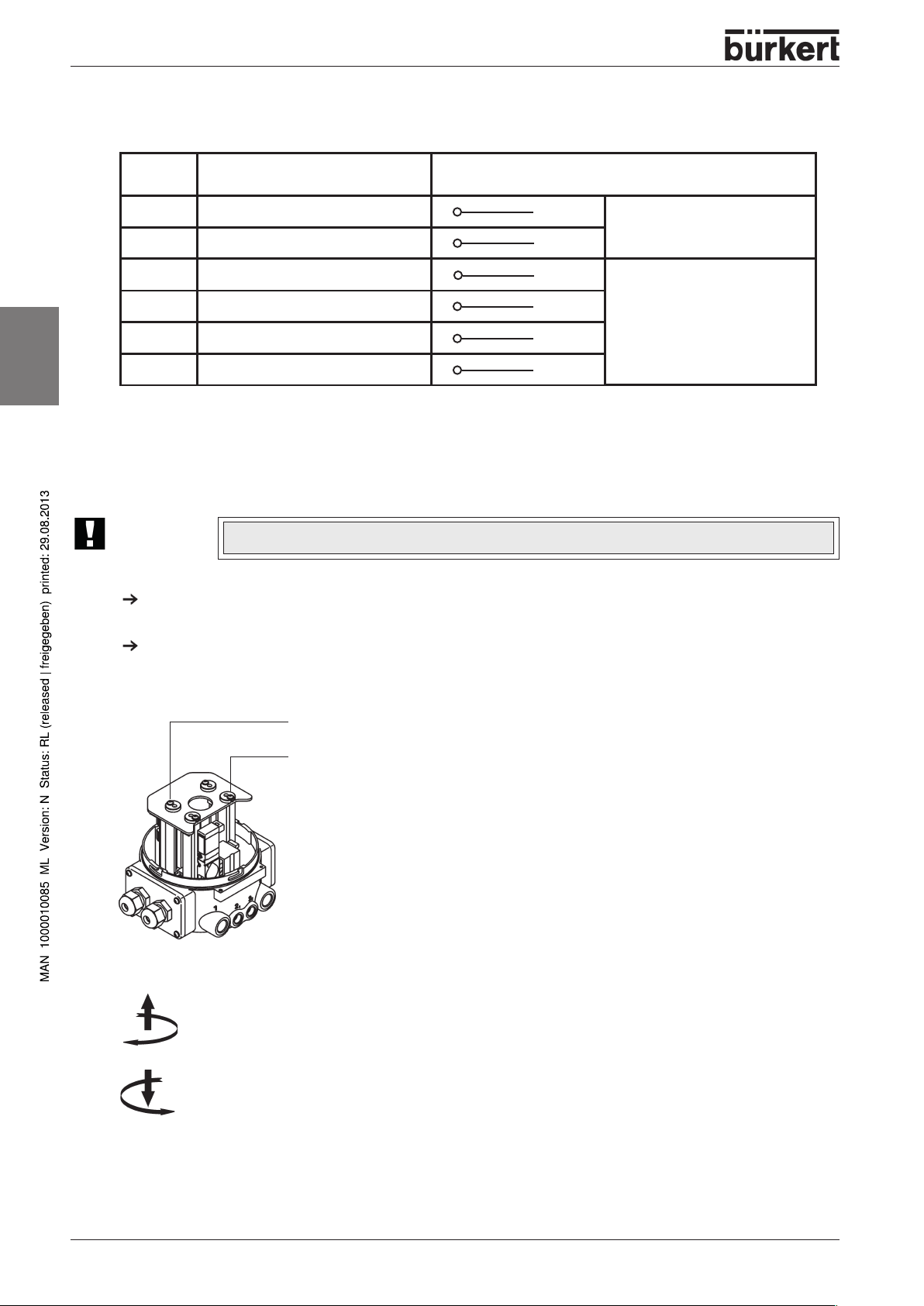

Electrical connection module

Screw for adjusting the lower proximity switch

With AS interface control: Initiator 2 / Data bit D2

Screw for adjusting the upper proximity switch

With AS interface control: Initiator 1 / Data bit D3

Pilot valve

(3/2 or 5/2-way solenoid valve)

With AS interface control: Pilot valve / Data bit D0

Exhaust connection

(marked: 3)

Control connections (connected in

the factory)

Pressure supply connection

(marked: 1)

10 - 8631

Board with connection terminal + LED

Grub screw

Figure: Construction of the TOP Control on/off with cover removed

Page 13

Features

Versions

for single and double-acting solenoid valves

Control valves

Solenoid valve working on the rocker principle

1 x 3/2-way control valve with single-acting valve actuators

2 x 3/2-way control valve with double-acting valve actuators

TOP Contr ol on/off with EEx-i approval:

Pilot valve - solenoid v alv e with EEx-i appro val (PTB 01 A TEX 2173)

Electrical interfaces

Cable bushings with screw terminals

Multipole circular plug connector, 12-pole

With bus control (AS interface), the 4-pole M12 circular plug connectors standardized for this purpose or

cable bushings with screw terminals are used.

TECHNICAL DATA

english

TOP Contr ol on/off with EEx-i approval:

Cable connector with screw terminals

Pneumatic interfaces

1/4’’connectors in v arious threads (G, NPT , RC)

Housing

The housing of the TOP Control on/off is protected by a pressure relief v alv e from excessiv e internal

pressure, e.g. resulting from leaks.

TOP Contr ol on/off with EEx-i approval:

Housing cover secured against unauthorised opening with a self-tapping screw .

Options

Position repeater and displa y

24 V device:

Inductive proximity switches (initiators)

Position repeat via binary outputs (make contacts)

24 V, 110 V or 230 V device:

Mechanical limit switches

Position repeat via binary outputs (make or break contacts)

Adjustment of the switching points on the position repeat s witches is done during assembly of the TOP

Control on/off on the valve actuator .

TOP Contr ol on/off with EEx-i approval:

Namur sensors with manufacturer´s declaration

The sensors can be changed by the operator via adjusting screws.

Intelligent communication circuit

AS interface / DeviceNET

Automatic reduction of the holding current for the control valves.

8631 - 11

Page 14

TECHNICAL DATA

Operating conditions

ATTENTION!

Operating temperature -10 ... + 50 °C

Protection type IP 65 to EN 60529

TOP Control on/off with EEx-i appr oval:

Type of "e" protection II 2 G EEx ia IIC T6

Conformity

english

CE - symbol conformity wrt. EMC Guideline 89/336/EEC

(only with correctly connected cable or plugs and sockets)

TOP Control on/off with EEx-i appr oval:

PTB approval according to DIN EN 50014 and 50020

The T OP Control on/off is not suitab le for outdoor use!

TOP Control on/off with EEx-i appr oval:

Note the Manufacturer's Declaration for proximity switches.

Mechanical data

Dimensions see data sheet

Housing material outer: PPE / PA, PSU; inner: PA 6

Sealing material outer: EPDM; inner: NBR

Pneumatic data

Control medium quality classes to DIN ISO 8573-1

Dust content class 5: max. particle size 40 µm, max. par ticle density

Water content class 3: max. pressure dew point - 20°C or min. 10

Oil content class 5: max. 25 mg/m³

T emperature range of

compressed air -10 ... +50°C

Pressure range 3 ... 7 bar

V ariation of supply pressure Air flow rate of control valve 100 lN / min (for pressurizing and exhausting)

Internal air consumption as

dimensioned 0.0 lN/min

Connections 1/4’’ internal thread G / NPT / RC

3

10 mg/m

degrees below the lowest operating temperature

(QNn-value to definition for pressure drop from 7 to 6 bar abs.)

12 - 8631

Page 15

Electrical data without bus control

Connections 2 x M16 cable bushings with screw terminals for

cable cross-sections 0,14 ... 1,5 mm²

V oltage supply 24 V DC ± 10 % residual ripple 10%

TECHNICAL DATA

ATTENTION

110 V AC / 230 V AC

Pow er consumption < 2 W

: Do not use industrial DC!

Electrical data with bus control (AS interface)

Connections M12 circular plug connectors or

M20 cable bushings with screw terminals for

cable cross-sections 0,14 ... 1,5 mm² (seal for AS interface flat

cable is enclosed)

V oltage supply 29.5 ... 31.6 V DC (to specification)

Max. current consumption 120 mA

in normal operation ≤ 80 mA

after current reduction ≤ 50 mA

Outputs

Max. switching capacity 1 W via AS interf ace

Watchdog function integral

Inputs

english

Sensor supply via AS interface

Sensor supply voltage 24 V ± 10 %

Current loading capacity max. 60 mA, short-circuit proof

Switching level of 1 signal ≥ 10 V

Input current limited to 6.5 mA

Input current for 0 signal ≤ 1.5 mA

Electrical data with bus control (DeviceNet)

Connection M12 - Micro Style circular plug 5-pole

V oltage supply 11 ... 24 V

Max. current consumption 125 mA

Outputs

Pick-up current 120 mA

Holding current 80 mA

Inputs

"0" 0 ... 1.5 V

"1" ≥ 8 V

8631 - 13

Page 16

TECHNICAL DATA

Electrical data with EEx-i approval

Connections 2 x M16 cable connector with screw terminals for

cable cross-sections 0,14 ... 1,5 mm²

Sensor power supply see Manufacturer's Declaration form Fa. P epperl & Fuchs

(siehe Anhang)

V alve pow er supply see Qualification Test Certificate PTB 01 ATEX 2173

(siehe Anhang)

Safety requirements

english

he maximum permissible voltages and the associated maximum permissible short-circuit currents for the

corresponding gas group may be taken from Table A1 in the standard DIN EN 50020, 1994 Edition.

In order that the maximum permissible temperature at the solenoid coil of the valve installed is not

exceeded, the following limits to the applied power for use in the corresponding temperature class must be

observed:

1)

Temperature class

T6

T5

Max. permissible ambient

temperature

1)

[°C]

+50 0,4

+45 0,5

+40 0,7

+35 0,8

+50 0,8

+45 1,0

+40 1,1

Max. permissible

power [W]

Ambient temperature for compl. TopControl 8631 (temperature inside the device is higher by max. 5°C)

ATTENTION!

The control head must not be exposed directly to sunshine or strong light sources: this

would cause additional warming!

Functional data

Resistance at 20°C (R20) 510 ohm

Minimum terminal voltage 11.7 V

Minimum current 23 mA

The maximum voltage and current values are determined by the permissible electrical operating

equipment.

14 - 8631

Page 17

COMMISSIONING

COMMISSIONING

Fluidic installation .................................................................................................................................................................................................................................. 16

english

Installation of the valve

Turning the T OP Control on/off

Fluidic connection of the TOP Control on/off

Opening the housing

................................................................................................................................................................................................................. 16

......................................................................................................................................................................................... 16

.................................................................................................................................................. 16

....................................................................................................................................................................................................................... 16

Electrical installation .......................................................................................................................................................................................................................... 17

Connection terminals for cable bushings

24 V version with inductive proximity switches (make contacts)

24 V version with mechanical limit switches

230 V version with mechanical limit switches

............................................................................................................................................................. 17

......................................................................................... 18

.................................................................................................................................................. 18

................................................................................................................................................ 19

Electrical installation of the TOP Control on/off with EEx-i approval....................................................................... 19

Connection terminals for cable connections

.................................................................................................................................................... 19

Setting the initiators or limit switches (option).............................................................................................................................................. 20

8631 - 15

Page 18

COMMISSIONING

Fluidic installation

See the relevant data sheet f or dimensions of TOP Control on/off and the variants of the complete

device, consisting of TOP Control on/off, pneumatic actuator and v alve.

Installation of the valve

For dimensions and threads, see data sheet for the process valve.

Turning the TOP Control on/off

If, after installation of the continuous valv e, the LEDs of the TOP Control on/off are poorly visible or it is

difficult to attach the cable or hoses, the TOP Control on/off may be rotated relative to the pneumatic

actuator.

english

Procedure:

Disconnect the fluidic connection between TOP Control on/off and pneumatic actuator .

Loosen the grub screws (hex socket SW 3) recessed into the side of the housing.

Rotate the T OP Control on/off

Retighten the grub screws with moderate torque.

Remake the fluidic connection between TOP Control on/off and pneumatic actuator , using longer hoses

if necessary.

without lifting

into the desired position.

Fluidic connection of the TOP Control on/off

Apply the supply pressure to connection 1 (3...7 bar, instrument air , free from oil, water and dust).

Attach an exhaust line or a silencer to connection 3.

ATTENTION!

No back pressure shall be built up as a result of the installations. This could be

detrimental to the functioning of the device! Use a hose with sufficient cross-section!

Opening the housing

16 - 8631

3 Exhaust connection

2

double-acting pressurized at zero current

2

single-acting not driven

2

pressurized when pilot valve under current

1

1 Pressure supply connection

Remove any lead seals or fastenings present between cover and housing.

Turn the transparent cover of the TOP Control on/off slightly anticlockwise and lift it off.

Page 19

Electrical installation

For making electrical contact to the T OP Control on/off, v arious connection concepts are av ailable.

Terminal allocation for cable bushings or plug connectors f or bus control is e xplained in the f ollowing.

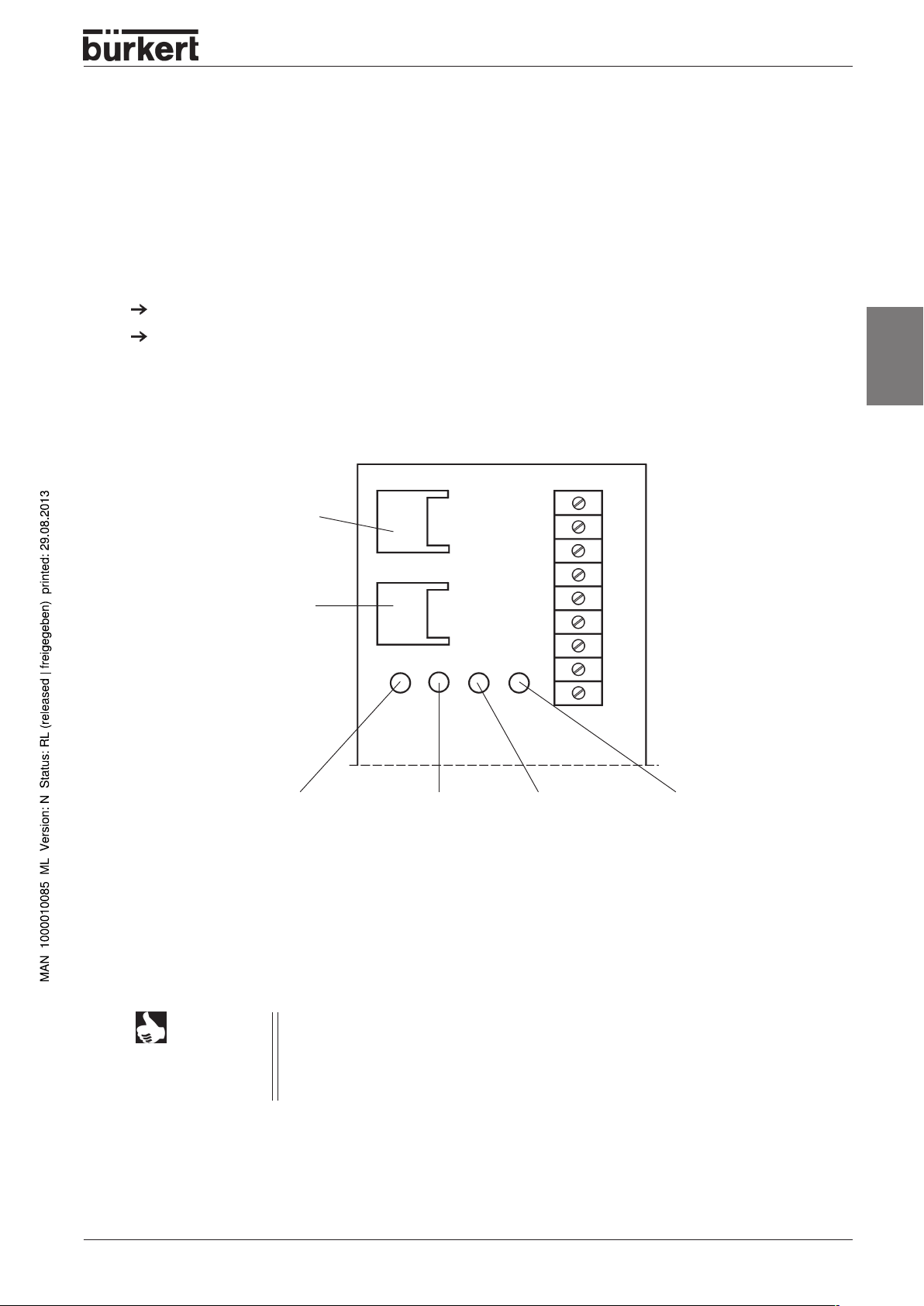

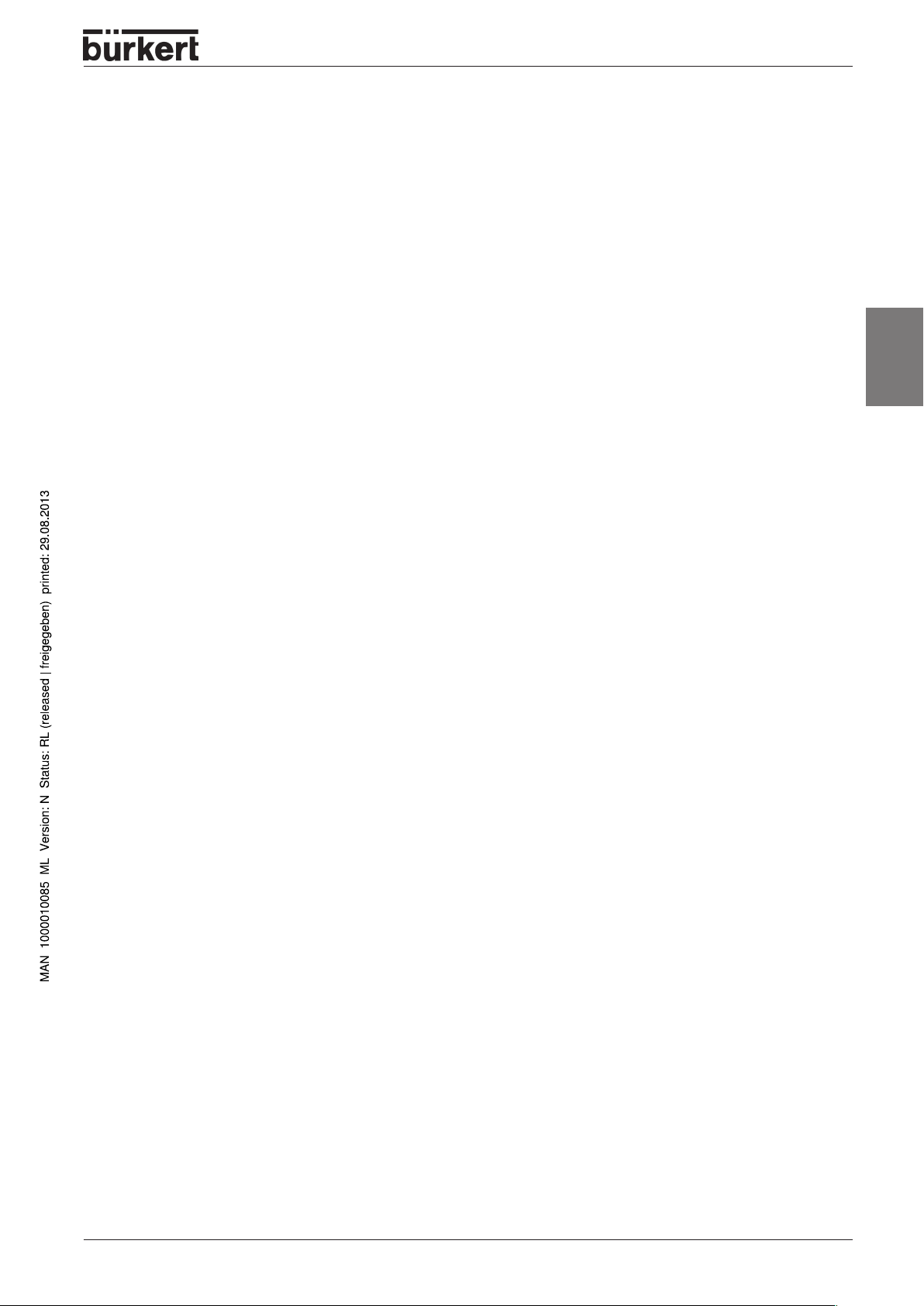

Connection terminals for cable bushings

Open the housing.

Connect the wires th the terminals (see connection allocation).

COMMISSIONING

The board with designation of the terminals and LEDs is shown in the following diagram.

Plug connector for initiatior

Limit switch 1

Plug connector for initiatior

Limit switch 2

LED initiator

Limit switch 1

operated

LED initiator

Limit switch 2

operated

LED supply

Initiators

Limit switches

LED

Valve on

english

NOTE

Limit switches: may be used as make (terminals NO) or

break (terminals NC) contacts.

Control LEDs: light when respective limit switch is operated

mechanically , i.e . when the valve end position is reached.

8631 - 17

Page 20

COMMISSIONING

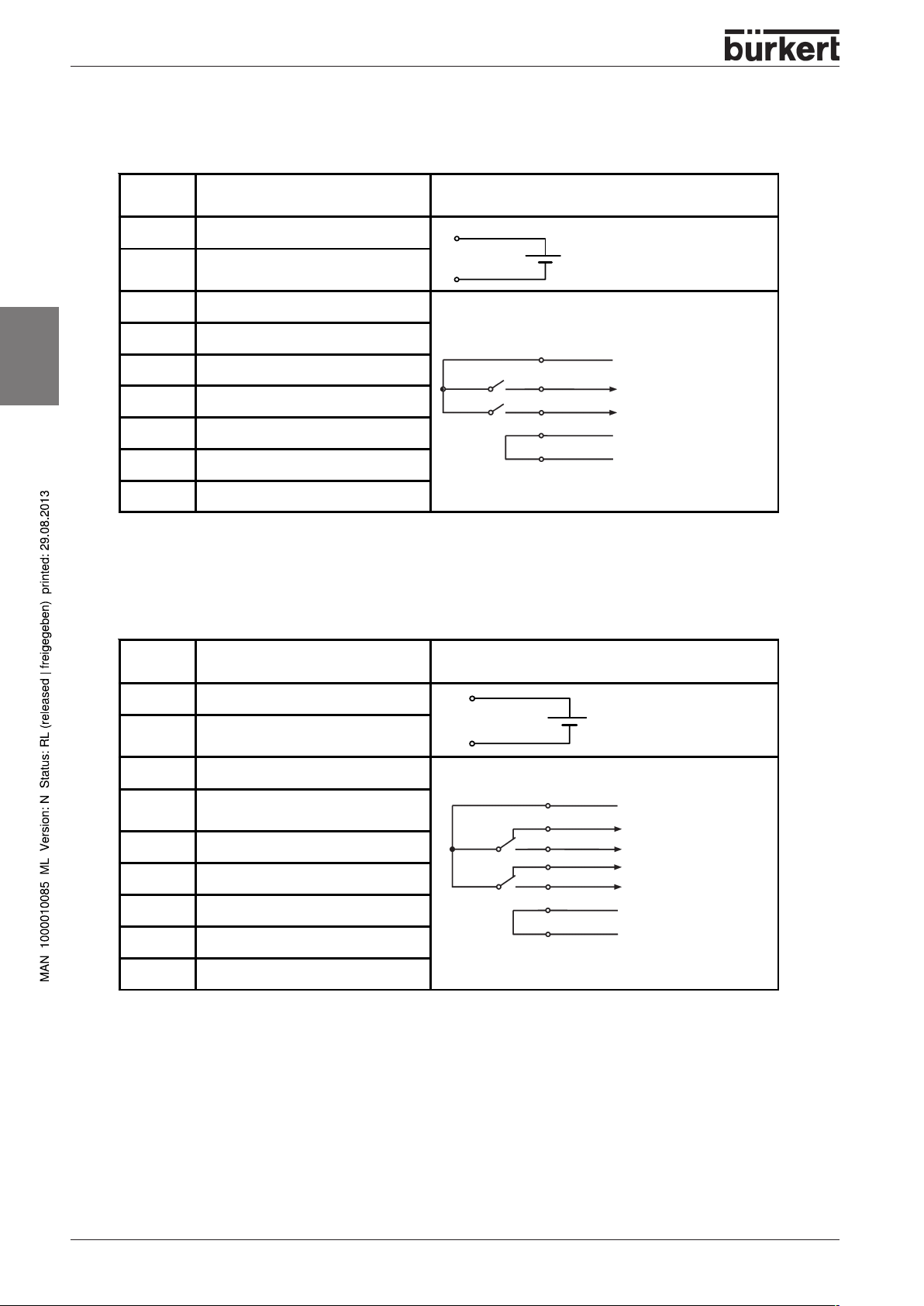

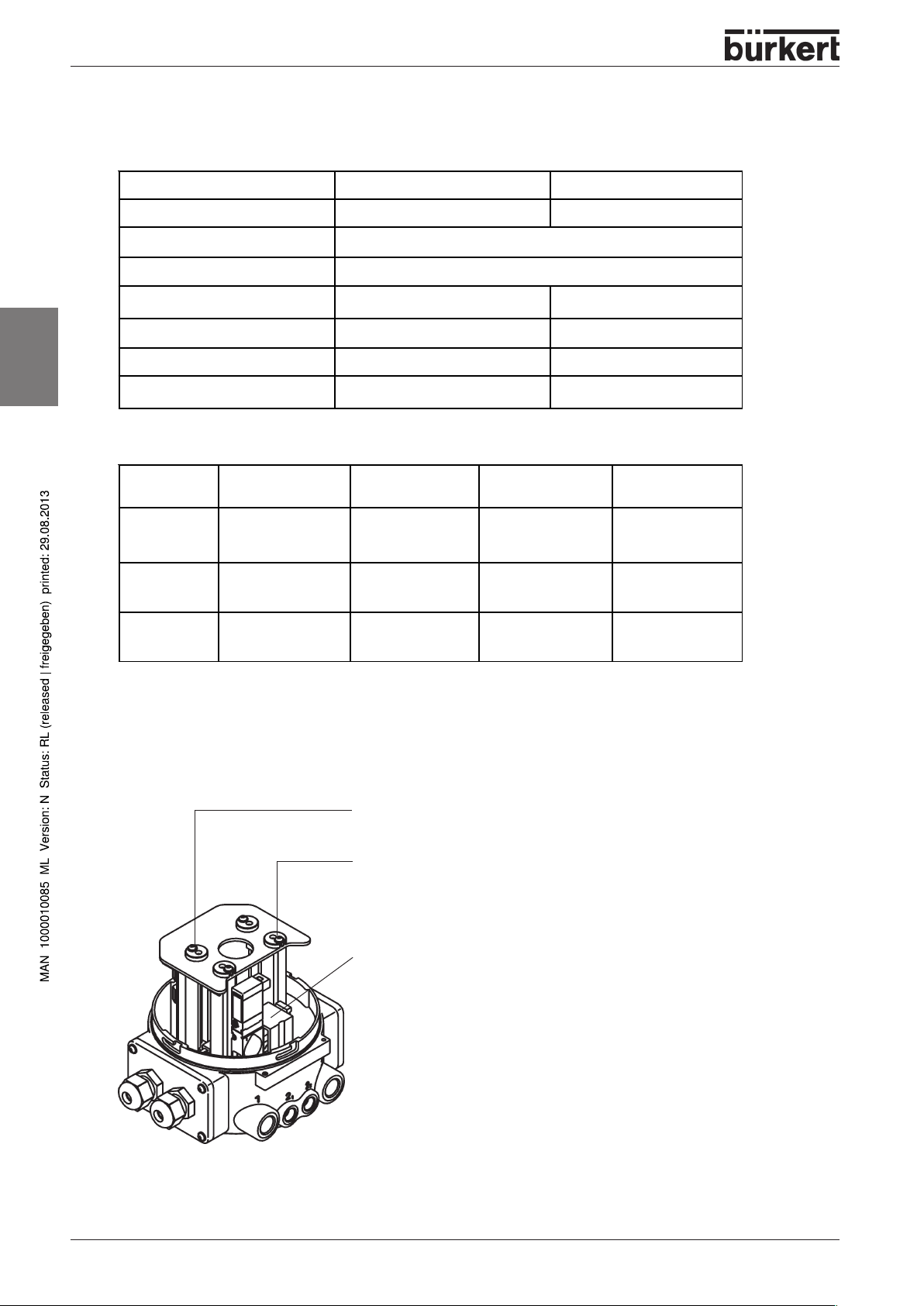

24 V - version with inductive proximity switches (make contacts)

english

Terminal

no.

2 Valve act uation 0 V / 24 V

Allocation External connection

1 Valve actuation GND

2

1

0/24 V DC ± 10 %

residual ripple 10 %

3 Initiator supply GND

4 Common reference for initiators GND

9

5 not connected

6 Binary output initiator 2 (NO)

7 not connected

S2

S1

8

6

4

3

8 Binary output initiator 1 (NO)

9 Initiator supply + 24 V

24 V - version with mechanical limit switches

+24 V DC

Output 1 (0V/24V)

Output 2 (0V/24V)

GND

GND

Terminal

no.

Allocation External connection

1 Valve actuation GND

2 Valve act uation 0 V / 24 V

3 Limit switch supply GND

4

Common reference for limit switches

GND

5 Output limit switch 2 (NC)

6 Output limit switch 2 (NO)

7 Output limit switch 1 (NC)

8 Output limit switch 1 (NO)

9 Limit switch supply + 24 V

2

1

9

7

S2

S1

8

5

6

4

3

0/24 V DC ± 10 %

residual ripple 10 %

+24 V DC

NC1 24V/0V (max. 5 A)

NO1 0V/24V (max. 5 A)

NC2 24V/0V (max. 5 A)

NO2 0V/24V (max. 5 A)

GND

GND

18 - 8631

Page 21

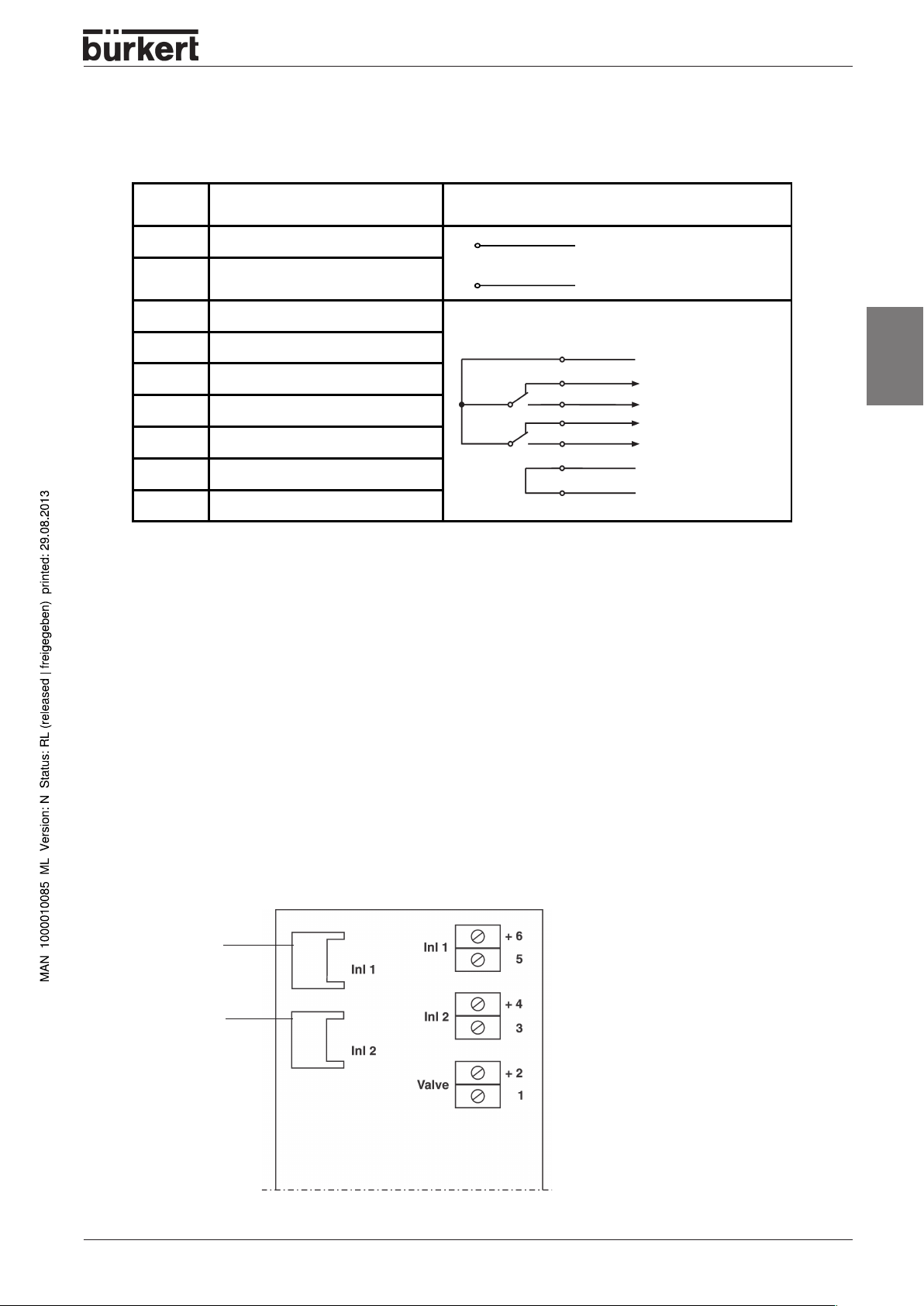

230 V - version with mechanical limit switches

COMMISSIONING

Terminal

no.

2 Valve actua tion L1

3 Limit switch supply

4 Output common pole

5 Output limit switch 2 (NC)

6 Output limit switch 2 (NO)

7 Output limit switch 1 (NC)

8 Output limit switch 1 (NO)

9 Limit switch supply

Allocation External connection

1 Valve actuation N

2

1

L1

N

9

7

S2

S1

8

5

6

4

3

L1

NC1 (max. 5 A)

NO1 (max. 5 A)

NC2 (max. 5 A)

NO2 (max. 5 A)

Output common pole

N

Electrical installation of the TOP Control on/off with EEx-i

approval

english

The electrical connection of the T OP Control on/off with EEx-i approv al is made using the connection

terminals.

Connection terminals for cable connections

➔➔

➔ Open the housing.

➔➔

➔➔

➔ Connect the wire according to the T erminal Allocation Plan.

➔➔

T erminal Allocation Plan

Plug for initiator /

proximity sensor 1

Plug for initiator /

proximity sensor 2

8631 - 19

Page 22

COMMISSIONING

Terminal allocation - TOP Control on/off with EEx-i approval

Terminal

no.

2+ lortnoc evlaV2

1- lortnoc evlaV1

4+2 rosnes ytimixorP4

3- 2 rosnes ytimixorP3

6+1 rosnes ytimixorP6

5- 1 rosnes ytimixorP5

yrtiucric lanretxEnoitcennoC

8 V

GND

8 V

GND

english

Settings the initiators or limit switches (option)

ATTENTION!

Open the housing of the TOP Control on/off to adjust the initiatiors/proximity switches or limit

switches.

Switch off the operating voltage before making this intervention!

Signal from barriers

see PTB 01 ATEX 2173

(according to NAMUR

recommendation)

Please also note the

Manufacturer's Declaration from

Pepperl & Fuchs!

Adjust the initiators with the setscrews.

Screw to adjust the lower proximity switch

Screw to adjust with the upper proximity switch

Sense

Turning clockwise: causes upward adjustment

20 - 8631

Turning anticlockwise: causes downward adjustment

Page 23

AS INTERFA CE

AS NTERFACE

english

Programming data................................................................................................................................................................................................................................. 22

Status display............................................................................................................................................................................................................................................... 23

Electrical connection .......................................................................................................................................................................................................................... 24

4-pole M12 circular plug connector

Cable bushing with connection terminals

.............................................................................................................................................................................. 24

........................................................................................................................................................... 24

8631 - 21

Page 24

AS INTERFACE

Programming data

Certifi cati on: Approval no. 32901 (to V.2.11) Approval no. 47601 (to V.2.11)

Programming data:

E/A-configuration D hex (1 output, 3 inputs)

ID-Code F hex (for allocation see below) A hex (for allocation see below)

ext. ID-Code 1 F hex 7 hex

ext. ID-Code 2 F hex E hex

standard Device Device for A/B-Slave addressing

english

Profil S-D.F.F S-D.A.E

Data bit D3 D2 D1 D0

Signal Input initiator 1 Input initiator 2

Value 0 Position not reached Position not reached ok Control valve off

Value 1 Position reached Position reached

Parameter bits are not occupied

Initiator 2 / Data bit D2

Input diagnosis coil

current

Error

(interruption)

Output control valve

Control valve on

22 - 8631

Initiator 1 / Data bit D3

Pilot valve / Data bit D0

Page 25

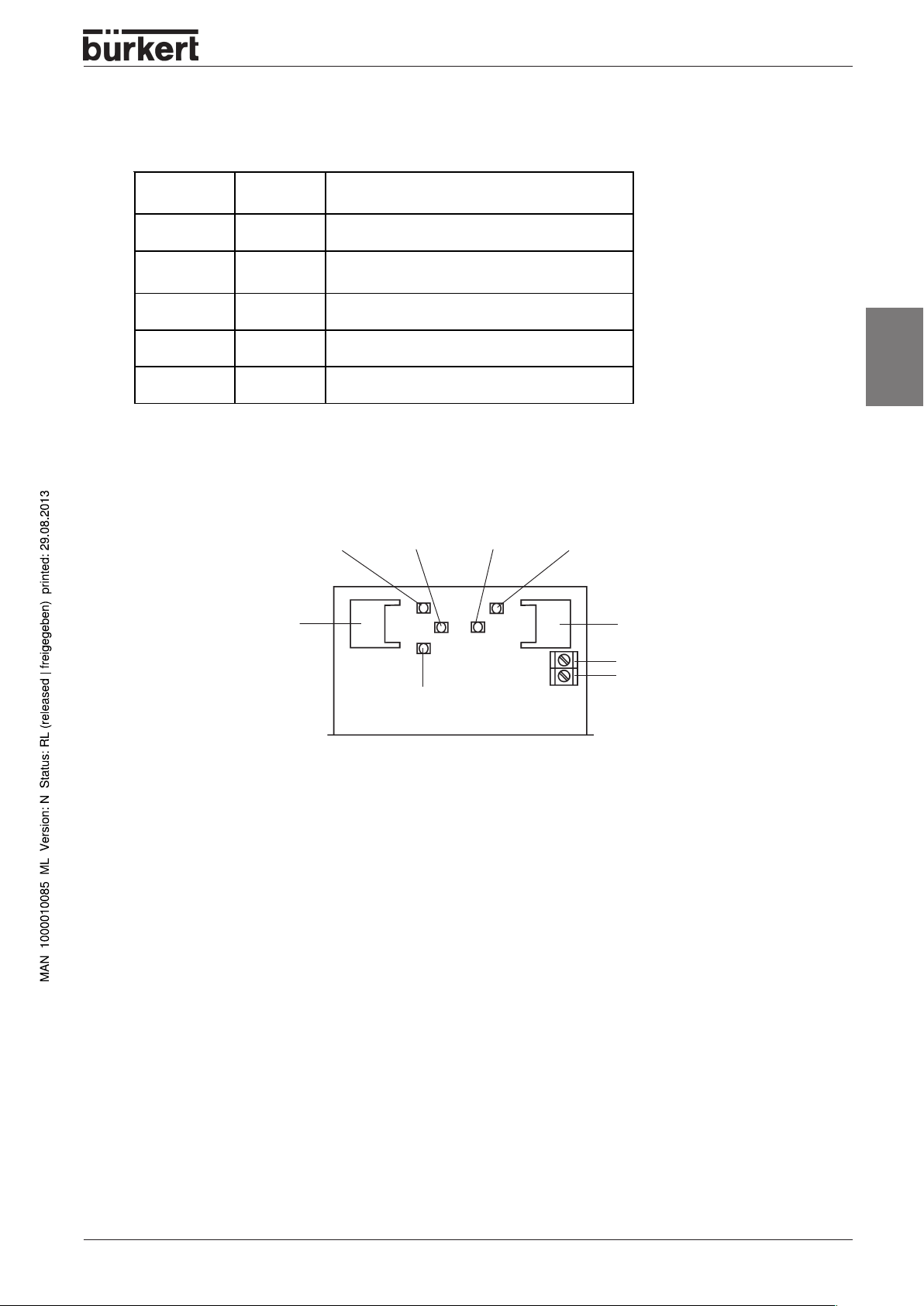

Status display

AS NTERFACE

LED 1 bus

(green)

off off POWER OFF

off on

on off ok

flashes on Slave address 0

off flashes Overload of sensor supply

LED 2 bus

(red)

Status signalled

No data traffic (watchdog expired with slave address

not 0

Connections and LED configuration

Plug for initiator 1

LED (yellow)

Initiator 1

LED 1 bus

(green)

LED 2 bus

(red)

english

LED (yellow)

Initiator 2

Plug for initiator 2

LED (yellow)

valve on

ASI +

ASI -

8631 - 23

Page 26

AS INTERFACE

Electrical connection

4-pole M12 circular plug connector

english

4

Pin 1: Bus +

Pin 3: Bus -

2

Cable bushing with screw terminals

Open the housing.

If needed, insert the enclosed seal for AS interface flat cable into the cable b ushing.

Connect the wires to the terminals as in illustration under

Status display

.

24 - 8631

Page 27

DEVICENET

DEVICENET

Explanation of terms .......................................................................................................................................................................................................................... 26

Technical data............................................................................................................................................................................................................................................... 27

Maximum line lengths....................................................................................................................................................................................................................... 27

Overall line length

Drop line length

............................................................................................................................................................................................................................... 27

..................................................................................................................................................................................................................................... 27

Safety positions on bus failure............................................................................................................................................................................................. 27

Interfaces............................................................................................................................................................................................................................................................. 28

Electrical connection.......................................................................................................................................................................................................................... 28

Bus connection (circular plug M12, 5-pole)

Termination for DeviceNet systems

............................................................................................................................................................................. 29

Network topology of a DeviceNet system

....................................................................................................................................................... 28

............................................................................................................................................................ 29

Configuring the TOP Control on/off.............................................................................................................................................................................. 30

DIP switches

.............................................................................................................................................................................................................................................. 30

english

Configuration of the process data

.................................................................................................................................................................................. 31

LED status display................................................................................................................................................................................................................................. 32

Statuses of the MNS LED

........................................................................................................................................................................................................ 33

Example of configuration............................................................................................................................................................................................................. 34

Installation of the EDS file

Setting up the process map

........................................................................................................................................................................................................ 34

................................................................................................................................................................................................... 34

8631 - 25

Page 28

DEVICENET

Explanation of terms

DeviceNet

• DeviceNet is a field bus system based on the CAN (Controller Area Network) protocol. It enables

networking of actuators and sensors (slaves) with higher-level control systems (masters).

• In DeviceNet TOP Control on/off is a slave device according to the Predefined Master/Slave

Connection Set specified in the DeviceNet specification. The following I/O connection var iants are

supported: Polled I/O, Bit Strobed I/O and Change of State (COS).

• With DeviceNet one distinguishes between cyclic or event-driven transmitted process messages of

high priority (I/O messages) and acyclic management messages of low priority (Explicit Messages).

english

• The protocol sequence corresponds to DeviceNet

Specification Release 2.0

.

26 - 8631

Page 29

Technical data

DEVICENET

EDS file

Icons

Network data rate

BUE8631.EDS

BUE8631.ICO

125 kBit/s, 250 kBit/s, 500 kBit/s (set via DIP switches);

Factory setting: 125 kBit/s

Address

0 ... 63 (set via DIP switches);

Factory setting: 63

Process data

2 static input assemblies

(Input: from TOP Control on/off to DeviceNet-Master/Scanner)

1 static output assembly

Maximum line lengths

Maximum overall line length (sum of all main and drop lines) of a network as a function of the network

data rate:

Overall line length

to DeviceNet specification

english

Network da t a

rate

125 kBaud 500 m

250 kBaud 250 m

500 kBaud 100 m

1)

To DeviceNet specification. On use of another cable type, lower maximum values apply (see DeviceNet specification).

Drop line length

Network data

rate

125 kBaud

250 kBaud 78 m

500 kBaud 39 m

6 m for all network data rates

Maximum overall line length

Thick cable Thin cable

(Drop Lines)

Length of drop lines

Maximum overall length of drop lines in network

Safety positions on bus failure

1)

100 m for all network

data rates

156 m

On bus failure, the position corresponding to set point "0" is taken up.

8631 - 27

Page 30

DEVICENET

Interfaces

Bus + supply

english

Electrical connection

TOP

Control

on/off

DeviceNet

Bus

The bus line is a 4-wire cable + screen which must comply with the DeviceNet specification. Over ist,

both the information (data) and energy are transmitted (voltage supply for low-power actuators and

sensors).

Bus connection (circular plug M12, 5-pole)

On the TOP Control on/off there is a 5-pole micro-style circular plug connector M12. The configuration

conforms to the DeviceNet specification.

Pin Signal Colour

1Screen n.c.

2V+ red

3V- black

4CAN_H white

5 CAN_L blue

Data

lines

CAN_H

white

CAN_L

blue

Drain (screen))

n.c.

4

5

12

V-

3

black

V+

red

Voltage supply

11...24 V

max. Power consumption

5 W when all 3 valves are

switched

Plug, looking at the pins from the front (not at the solder connections!)

28 - 8631

Page 31

DEVICENET

Termination for DeviceNet systems

On installation of a DeviceNet system, care must be taken to terminate the data lines correctly. The

termination avoids disturbances by signal reflections on the data lines. For this purpose, the trunk line

must be terminated at both ends, as shown, by resistors of 120 Ω and 1/4 W power dissipation.

Network topology of a DeviceNet system

Line with a trunk line and several drop lines.

Trunk and drop lines are made of identical material (see sketch).

V +

V CAN_H

CAN_L

Terminating

resistor

120 Ohm

¼ W

Trunk Line

DeviceNet cable

Trunk line

(Drop Lines)

T01 Tn

Participant 1 (Node 1)

DeviceNet cable,

max. 6 m long

english

Terminating

resistor

120 Ohm

¼ W

Participant n (Node n)

8631 - 29

Page 32

DEVICENET

Configuring the TOP Control on/off

DIP switches

8 DIP switches are present for configuration:

• DIP switches 1 to 6 DeviceNet address.

• DIP switches 7 and 8 network data rate.

Settings of the DeviceNet address

MAC ID – Medium Access Control Identifier:

english

[DIP 1=off=0 / DIP 1=on=1 / MAC ID=DIP 1*20+DIP 2*21+...+DIP 6*25]

DIP 1

0

[2

=1]

off off off off off off 0

on off off off off off 1

off on off off off off 2

... ... ... ... ... ... ...

offononononon62

on on on on on on 63

DIP 2

[21=2]

DIP 3

[22=4]

DIP 4

[23=8]

DIP 5

[24=16]

DIP 6

[25=32]

MAC ID

Setting the network data rate

Adaptation to the data rate of the network.

DIP 7 DIP 8 Network data rate

off off 125 kBaud

on off 250 kBaud

off on 500 kBaud

on on not allowed

ATTENTION!

30 - 8631

Changes in the settings by operating the DIP switches become effective only

after a restart.

A restart can be performed by disconnecting and reconnecting the TOP Control on/off

to the mains or by sending a corresponding Reset message. Another possibility is the

switching off and on of the network power supply.

Page 33

DEVICENET

Configuration of the process data

For the transfer of process data via an I/O connection, 3 static input and 3 static output assemblies are

available for selection. In these assemblies, selected attributes are collected in an object in order to be

transferred together as process data via an I/O connection.

Access can be made cyclically in the connection variants "Polled I/O" and "Bitstrobed I/O" with "Change

of State" when input values change, or acyclically via Explicit Messages.

The access path for acyclically access is:

class 4

instance 1

attribute 3

With the service

Set_Attribute_Single,

Get_Attribute_Single,

access can be made reading acyclically and with the service

access can be made writing acyclically to the starting data.

1 data byte for inputs (sensors or initiators):

Bit Sensor Value assigned

Bit 0 S1 (i nitiator 1)

Bit 1 S2 (i nitiator 2)

Bit 2 physically unusable

Bit 3

... unused 0 always

Bit 7

0 initiator 1 OFF

1 initiator 1 ON

0 initiator OFF

1 initiator ON

1 data byte for outputs (actuators or valves):

english

Bit Sensor Value assigned

Bit 0 V1 (valve 1)

Bit 1

Bit 2

Bit 3

... unused 0 always

Bit 7

A2 output 2

physically unusable

A3 output 3

physically unusable

0 valve 1 OFF

1 valve 1 ON

8631 - 31

Page 34

DEVICENET

LED status display

2 LEDs are provided for status display:

Name of LED Type/colour Function

POWER single colour green LED lights: device has power

english

MNS

two-colour

red/green

Corresponds to MNS LED acc. to DeviceNet specif icat ion

(MNS-Module Network Status)

32 - 8631

Page 35

DEVICENET

Statuses of the MNS LED

After application of voltage (connection of the network line), the following functional test of the twocolour MNS LED is performed:

• LED lights briefly green (ca. ¼ s).

• LED lights briefly red (ca. ¼ s).

• LED off.

After completion of the functional test, the device statuses described in the following table can be

displayed by the MNS LED.

LED status Device status Explanation / Problem elimination

- Device not supplied with voltage

- Device has not yet ended Dublicate MAC-ID test

OFF No voltage/not online

(last ca. 2 s).

> Connect further devices if device is sole net participant.

> Exchange device.

english

Green

Green flashing

Red flashing

Red Critical error

Online, connection to

Master exists

Online, no connection

to Master

Connection

time-out

- Normal operating status with connection made to Master.

- Normal operating status without connection made to Master.

- One or more I/O connections are in time-out status.

> Make new connection to Master to assure that I/O data are

transmitted cyclically.

- Another device with the same MAC-IDin network

> Change MAC-ID and restart

- BUS OFF because of communication problems.

> Check network data rate; exchange device if u nsuccess ful.

8631 - 33

Page 36

DEVICENET

Example of configuration

This example describes the principle of the procedure for integrating the device in the network

management tool

DeviceNet Master/Scanner.

Installation of the EDS file

RSNetWorx for DeviceNet

(rev. 2.11.51.0) and the setting up of the process map of a

english

Installation of the EDS file supplied on the diskette (bue8631.eds) is done with the aid of the tool

Installation Wizard

the diskette can be allocated (if this is not done automatically).

belonging to

RSNetWorx.

During the installation procedure, the icon also supplied on

EDS

Setting up the process map

Setting up the scanlist

First the

left-hand part of the associated window are stored in the Scanlist on the right-hand side of the window.

Then for each device stored in the Scanlist, the desired I/O connection variant can be selected presetting is

Scanlist

Polled.

of the DeviceNet Master/Scanner is set up. For this purpose, the devices listed on the

34 - 8631

Page 37

Setting up the process map (mapping)

DEVICENET

Using the function

the process map of the DeviceNet Master/Scanner.

In our example, the allocation is as shown in the illustration. For example, the input process values of

the TOP Control on/off with the address 4 are assigned to the internal addresses of the scanner as

follows:

Status sensor (repeater) S1: I:1.2.0 (Bit 0 of I:1.2)

Status sensor (repeater) S2: I:1.2.1 (Bit 1 of I:1.2)

Status sensor (repeater) S3: I:1.2.2 (Bit 2 of I:1.2)

Thus if the status of sensor S1 of the TOP Control on/off with the address 4 is to be read out from a

control program, this is done via an access to I:1.2.0.

Automap

, the input and output data of the devices in the Scanlist can be assigned to

english

8631 - 35

Page 38

DEVICENET

english

36 - 8631

Page 39

SAFETY SETTINGS AND MAINTENANCE

SAFETY SETTINGS AND

MAINTENANCE

english

Safety positions following failure of electrical or pneumatic auxiliary power................................................ 38

Maintenance................................................................................................................................................................................................................................................... 38

8631 - 37

Page 40

SAFETY SETTINGS AND MAINTENANCE

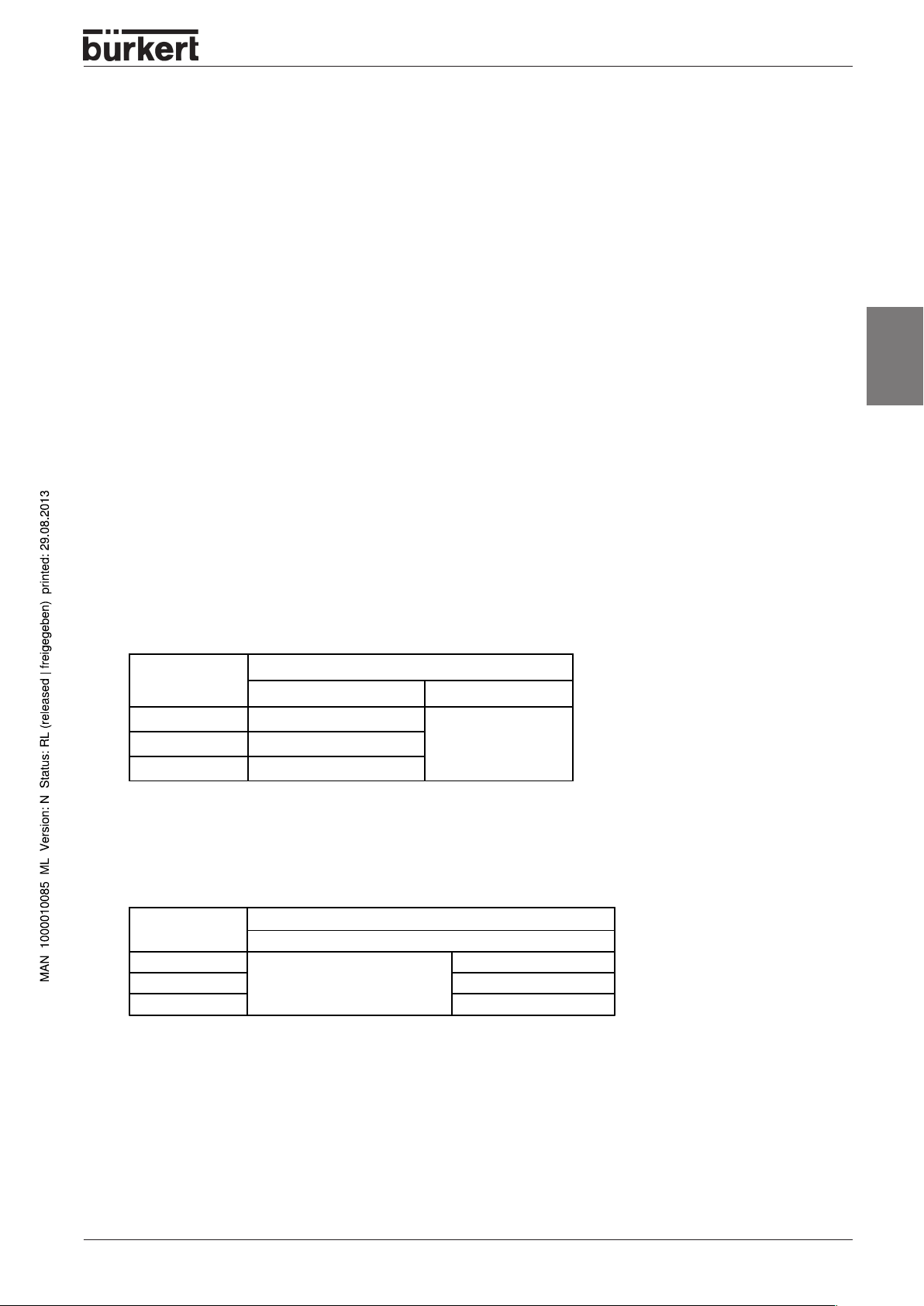

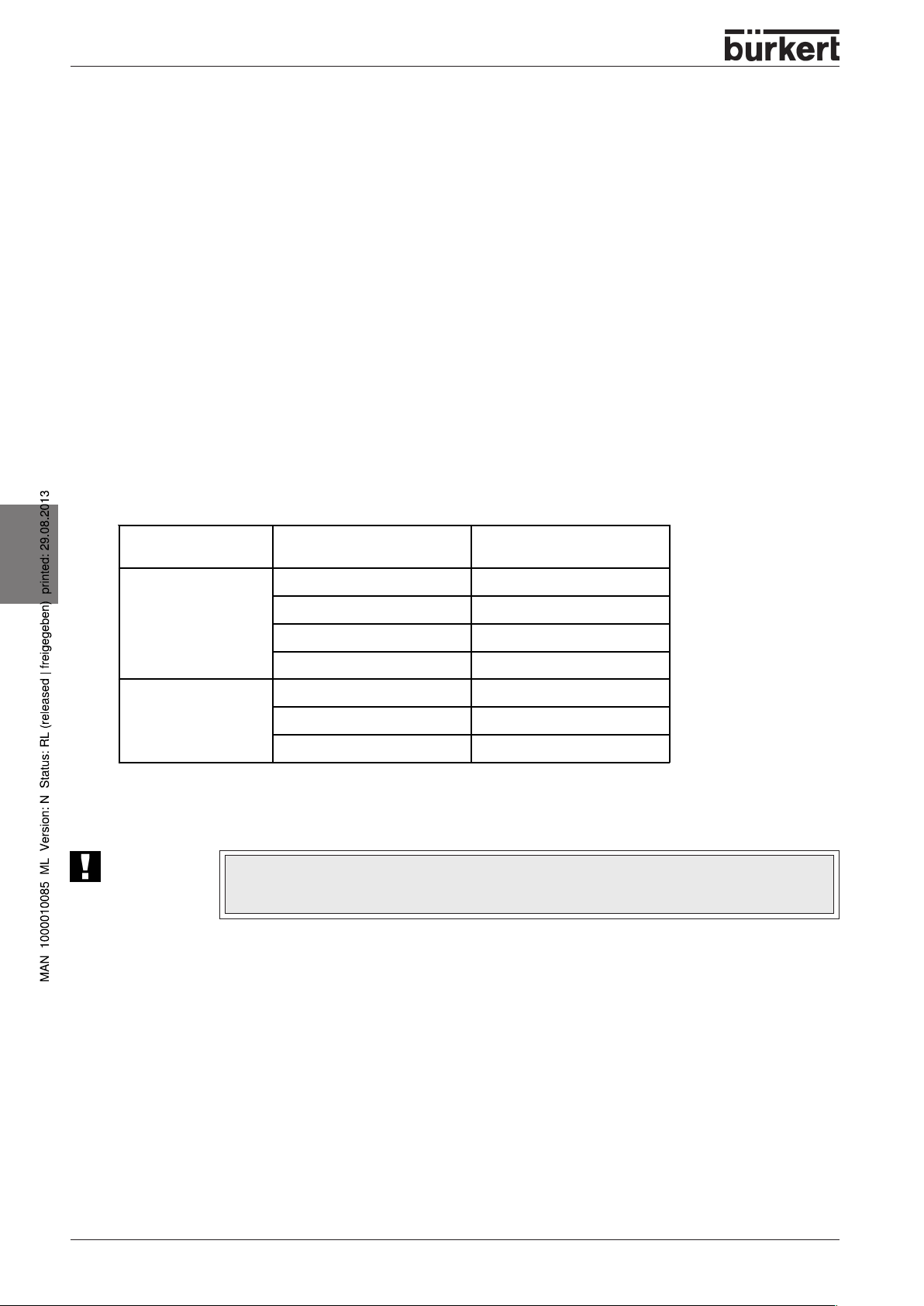

Safety positions following failure of electrical or pneumatic

auxiliary power

Safety settings following failure or auxillary power

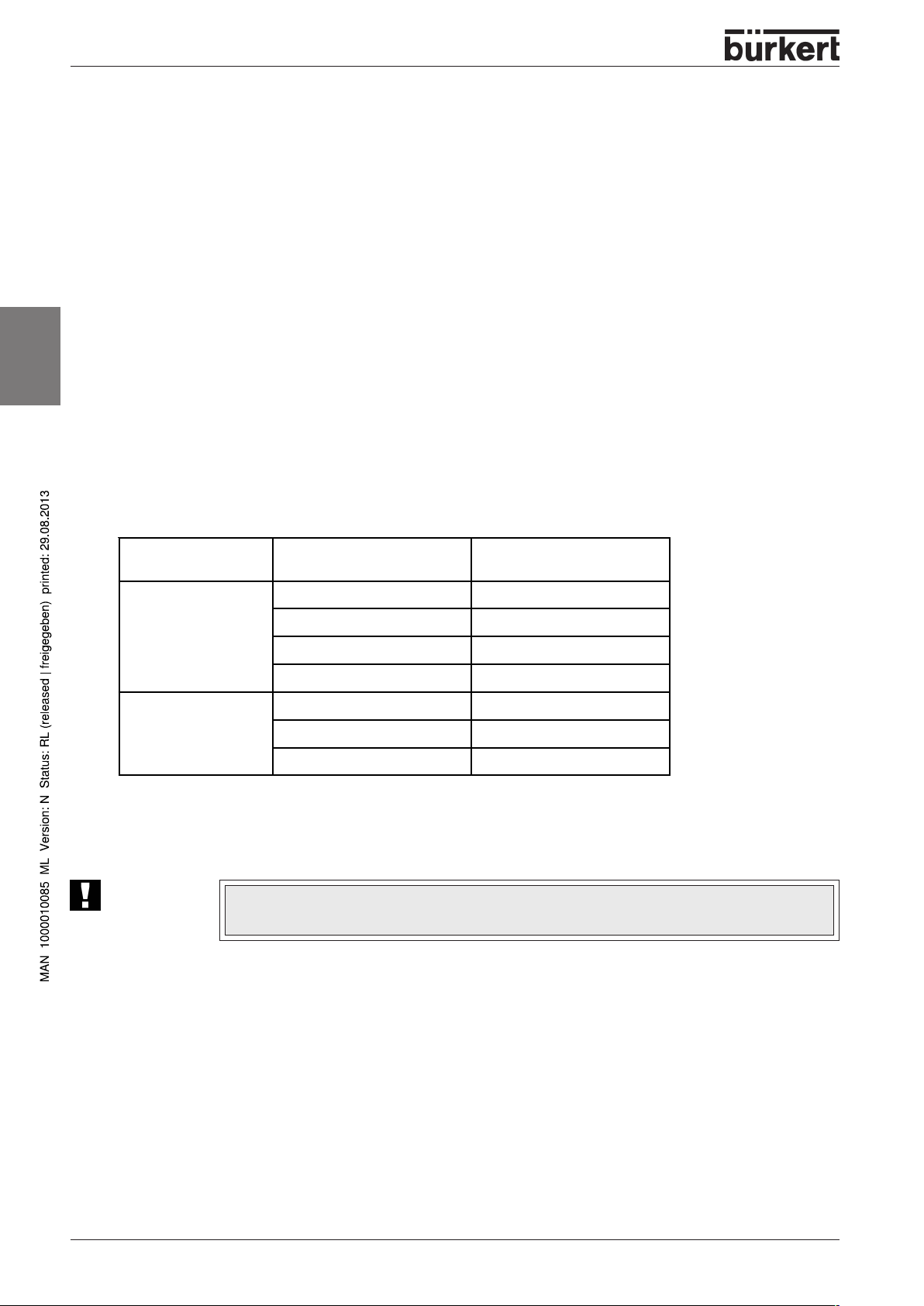

Type of driving Designation

supply

electrical pneumatic

english

up

down

up

down

up

down

single-acting

WW A

single-acting

WW B

double-acting

WW I

down down

up up

down / up

(depending on connection

of control lines)

not defined

Maintenance

The T OP Control on/off is maintenance-free if operated according to hte directions giv en in these

instructions.

38 - 8631

Page 41

INHALT

Inhaltsverzeichnis

der Betriebsanleitung

TOP Control

ALLGEMEINE HINWEISE

Darstellungsmittel ........................................................................................................... 44

Bestimmungsgemäße Verwendung ................................................................................ 44

Sicherheitshinweise........................................................................................................ 44

Hinweise für Geräte mit EEx-i-Zulassung ....................................................................... 45

Hinweise zum Einsatz im Ex-Bereich ............................................................................. 45

Lieferumfang ................................................................................................................... 45

Garantiebestimmungen................................................................................................... 45

on/off Typ 8631

deutsch

Transport und Lagerung .................................................................................................. 46

Entsorgung......................................................................................................................46

TECHNISCHE DATEN

Aufbau und Funktion....................................................................................................... 48

Merkmale ........................................................................................................................49

Betriebsbedingungen...................................................................................................... 50

Konformität ...................................................................................................................... 50

Mechanische Daten ........................................................................................................ 50

Pneumatische Daten....................................................................................................... 50

Elektrische Daten ohne Busansteuerung........................................................................ 5 1

Elektrische Daten mit Busansteuerung (AS-Interface) .................................................... 51

Elektrische Daten mit Busansteuerung (DeviceNet) ....................................................... 51

Elektrische Daten mit EEx-i-Zulassung........................................................................... 52

8631 - 39

Page 42

INHALT

INBETRIEBNAHME

Fluidische Installation ..................................................................................................... 54

Installation des V entils ................................................................................................ 54

Drehen des TOP Control on/off................................................................................... 54

Fluidischer Anschluss des TOP Control on/off............................................................ 54

Öffnen des Gehäuses ................................................................................................. 54

Elektrische Installation .................................................................................................... 55

Anschlussklemmen für Kabelverschraubungen ..................................................................... 55

24 V - Variante mit induktiven Näherungsschaltern (als Schließer) ....................................... 56

24 V - V ariante mit mechanischen Endschaltern .................................................................... 56

230 V - Variante mit mechanischen Endschaltern .................................................................. 57

Elektrische Installation des T OP Control on/off mit EEx-i-Zulassung ............................. 57

deutsch

Anschlussklemmen für Kabelverschraubungen ..................................................................... 57

Einstellen der Initiatoren bzw. Endschalter (Option) ........................................................ 58

AS-INTERFACE

Programmierdaten .......................................................................................................... 60

Statusanzeige ................................................................................................................. 61

Elektrischer Anschluss.................................................................................................... 6 2

4poliger M12-Rund-Steckverbinder........................................................................................ 62

Kabelverschraubung mit Anschlussklemmen ........................................................................ 62

DEVICENET

Begriffsklärung ................................................................................................................ 64

Technische Daten ........................................................................................................... 65

Maximale Leitungslängen ............................................................................................... 65

Gesamtleitungslänge .............................................................................................................. 65

Stichleitungslänge................................................................................................................... 65

Sicherheitseinstellung bei Ausfall des Busses ............................................................... 6 5

Schnittstellen ..................................................................................................................66

Elektrischer Anschluss.................................................................................................... 6 6

Bus-Anschluss (Rundstecker M12, 5polig)............................................................................ 66

Abschlussbeschaltung für DeviceNet – Systeme.................................................................. 67

Netztopologie eines DeviceNet-Systems .............................................................................. 67

Konfigurieren des T OP Control on/off .............................................................................. 68

DIP-Schalter ........................................................................................................................... 68

40 - 8631

Page 43

INHALT

Konfiguration der Prozessdaten ............................................................................................. 69

LED-Zustandsanzeige .................................................................................................... 70

Zustände der MNS-LED ......................................................................................................... 71

Konfigurierbeispiel .......................................................................................................... 72

Installation der EDS-Datei ......................................................................................................72

Einrichten des Prozessabbildes ............................................................................................. 72

SICHERHEITSSTELLUNGEN UND WARTUNG

Sicherheitsstellungen

nach Ausfall der elektrischen bzw . pneumatischen Hilfsenergie ..................................... 76

Wartung .......................................................................................................................... 76

ANHANG

EG-Konformitätserklärung 8631 EEx-i ............................................................................A03

Baumusterprüfbescheinigung PTB 00 ATEX 2077 X (Komplettgerät).............................A05

Baumusterprüfbescheinigung PTB 01 ATEX 2173 (für eingebautes Magnetventil) ........A07

deutsch

Herstellererklärung Fa. Pepperl & Fuchs (für eingebaute Näherungsschalter) ...............A10

8631 - 41

Page 44

INHALT

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Bürkert Company Locations

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Bürkert Company Locations

Contact addresses / Kontaktadressen

deutsch

42 - 8631

Page 45

ALLGEMEINE HINWEISE

ALLGEMEINE

HINWEISE

Darstellungsmittel............................................................................................................................................................................................................................... 44

Bestimmungsgemäße Verwendung........................................................................................................................................................................ 44

Sicherheitshinweise....................................................................................................................................................................................................................... 44

Hinweise für Geräte mit EEx-i-Zulassung...................................................................................................................................................... 45

Hinweise zum Einsatz im Ex-Bereich.................................................................................................................................................................. 45

Lieferumfang............................................................................................................................................................................................................................................... 45

Garantiebestimmungen ............................................................................................................................................................................................................. 45

deutsch

Transport und Lagerung............................................................................................................................................................................................................ 46

Entsorgung.................................................................................................................................................................................................................................................... 46

8631 - 43

Page 46

ALLGEMEINE HINWEISE

Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

Markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

Kennzeichn et Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder die Funktionsfähigkeit des Gerätes gefährdet ist.

Kennzeichnet wichtige Zusatzinf ormationen, Tipps und Empfehlungen.

Bestimmungsgemäße V erwendung

Beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten,

für den T OP Control on/off , sowie für das je weilige pneumatisch betätigte V entil, die im Kapitel "Technische Daten" dieser Anleitung und in der Ventilanleitung spezifiziert sind, damit das Gerät einwandfrei

funktioniert und lange einsatzfähig bleibt.

deutsch

Beachten Sie, dass der Top Control on/off nicht im Außenbereich eingesetzt werden darf .

Prüfen Sie, angesichts der Vielzahl möglicher Einsatz- und V erwendungsfälle, ob der Top Control on/off für

den konkreten Einsatzfall geeignet ist und testen Sie dies falls erforderlich aus.

Allgemeine Sicherheitshinweise

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen Regeln der

Technik!

• Installation und War tungsarbeiten dürfen nur durch Fachpersonal und mit geeignetem Werkzeug

erfolgen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen während des Betriebes

und der W artung des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Beachten Sie, dass in Systemen, die unter Druck stehen, Leitungen und Ventile nicht gelöst werden

dürfen!

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung auszuschließen!

• Gewährleisten Sie nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung einen definierten und kontrollierten Wiederanlauf des Prozesses!

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung unsererseits, ebenso erlischt die Garantie auf Geräte und Zubehörteile!

44 - 8631

Page 47

ALLGEMEINE HINWEISE

Hinweise für Geräte mit EEx-i-Zulassung

• Ergreifen Sie geeignete Maßnahmen, die eine elektrostatische Aufladung von

Kunststoff-Gehäuseteilen verhindern (siehe EN 100 015 - 1).

• An die Ein- und Ausgänge der Platinen dürfen k eine Komponenten angeschlossen werden, deren elektrische Daten außerhalb der für den eigensicheren Betrieb ermittelten und im Datenblatt des Stellungsreglers angegebenen Grenzen

liegen.

• Eingriffe in das Gerät bei offenem Gehäuse dürfen nicht in sehr feuchter oder

aggressiver Atmosphäre vorgenommen werden. Treffen Sie V orkehrungen, die

unbeabsichtigte mechanische Beschädigungen der Platinen oder ihrer Bauelemente ausschließen. Beschränken Sie die Zeitdauer der Öffnung des Gehäuses

auf das unbedingt notwendige Maß.

Hinweise zum Einsatz im Ex-Bereich

Beachten Sie:

• für Installation und Betrieb in explosionsgefährdeten Bereichen die jeweiligen nationalen V orschriften. In

Deutschland ist dies die VDE 0165.

• beim elektrischen Anschluss der eigensicheren Stromkreise die Angaben der jeweiligen Konf ormitätsbescheinigungen.

• unbedingt die in der A TEX-Zulassung enthaltenen Angaben.

deutsch

Lieferumfang

Konformität

Der Typ 8631 ist konform zu den EG-Richtlinien entsprechend der EG-Konformitätserklärung.

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung, dass der Inhalt nicht beschädigt ist und mit

dem auf dem beigelegten Pack zettel angegebenen Lieferumf ang übereinstimmt. Bei Unstimmigkeiten

wenden Sie sich bitte umgehend an Ihre Bürkert-Niederlassung oder an unseren Kundenservice:

Normen

Durch folgende Normen wird die Konformität mit den EG-Richtlinien erfüllt:

EN 60079-0

Garantiebestimmungen

Diese Druckschrift enthält keine Garantiezusagen. Wir verw eisen hierzu auf unsere allgemeinen Verkaufs-

Gewährleistung

und Geschäftsbedingungen. V oraussetzung für die Garantie ist der bestimm ungsgemäße Gebrauch des