Page 1

Type 8625-2

Standard

Compact Temperature Controller

Kompakter Temperaturregler

Régulateur compact de température

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2002 - 2009 Bürkert Werke GmbH

Operating Instructions 0912/07_EU-ML_00803261 / Original DE

Page 3

CONTENTS

1 GENERAL NOTES................................................................................................................ 3

1.1 Symbols..................................................................................................................................................... 3

1.2 Safety notes .......................................................................................................................................... 3

1.3 Protection from damage by electrostatic charging .......................................... 4

2 FUNCTION ....................................................................................................................................... 5

3 APPLICATION AREA

4 TECHNICAL DATA

5 COMMISSIONING

5.1 Connection to the proportional valve ............................................................................. 8

5.2 Changing the cable outlet direction ................................................................................. 9

5.3 Connection configuration on the temperature controller

type 8625-2 .......................................................................................................................................... 10

5.4 First commissioning.................................................................................................................... 12

....................................................................................................... 6

................................................................................................................ 7

.................................................................................................................. 8

6 OPERATING THE TEMPERATURE CONTROLLER

TYPE...................................................................................................................................................... 13

6.1 Operating modes ............................................................................................................................ 13

6.2 Indications on the display ..................................................................................................... 14

6.3 Key allocation.................................................................................................................................... 15

6.4 Standard mode ................................................................................................................................. 16

6.4.1 Standard mode and internal setpoint............................................................. 16

6.4.2 Standard mode and external setpoint ........................................................... 17

english

6.5 Manual mode ..................................................................................................................................... 18

6.6 Configuration mode ...................................................................................................................... 19

6.6.1 Menu of configuration mode ................................................................................. 21

6.6.2

UNIT

- setting of unit of temperature ............................................................... 22

8625-2 Standard - 1

Page 4

6.6.3

MODE

- setting of setpoint mode ....................................................................... 23

AMPL

6.6.4

6.6.5

6.6.6

- setting of amplification K

INTG

- setting of reset time T

INV

- heating (non-inverted control)/cooling

...............................................................................

p

..........................................................................................

N

(inverted control) ............................................................................................... 31

6.6.7

ZERO

- zero point switch-off .................................................................................. 32

VALV

- adaptation of controller output signal ........................................... 33

END

- storage of the values ................................................................................... 35

english

6.6.8

6.6.9

6.7 Settings on delivery .................................................................................................................... 36

7 ERROR MESSAGES....................................................................................................... 37

25

26

2 - 8625-2 Standard

Page 5

1 GENERAL NOTES

1.1 Symbols

The following symbols are used in these operating instructions:

marks a work step that you must carry out.

ATTENTION!

NOTE

marks notes on whose non-observance your health or the

functioning of the device will be endangered.

marks important additional information, tips and

recommendations.

1.2 Safety notes

Please observe the notes in these operating instructions together with the

conditions of use and permitted data that are specified in the data sheets of the

proportional valve used and of the controller type 8625-2, in order that the

device will function perfectly and remain operable for a long time:

• Keep to standard engineering rules in planning the use of and operating the

device!

• Interference with the device is only allowed by specialist personnel using

suitable tools!

• Observe the current regulations on accident prevention and safety for

electrical devices during operation, maintenance and repair of the device!

• Before interfering with the system, always switch off the voltage!

english

• Take suitable precautions to prevent unintended operation or damage by

unauthorized action!

• On non-observance of this note and unauthorized interference with the

device, we will refuse all liability and the guarantee on device and

accessories will become void!

8625-2 Standard - 3

Page 6

1.3 Protection from damage by electrostatic charging

english

EXERCISE CAUTION ON HAND-

This device contains electronic components that are sensitive to electrostatic

discharge (ESD). Contact to electrostatically charged persons or objects will

endanger these components. In the worst case, they will be immediately

destroyed or will fail after commissioning.

Observe the requirements of EN 100 015 - 1 in order to minimize the

possibility of, or avoid, damage from instantaneous electrostatic discharge.

Also take care not to touch components that are under supply voltage.

ATTENTION

LING !

ELECTROSTATICALLY

SENSITIVE

COMPONENTS/MODULES

4 - 8625-2 Standard

Page 7

2 FUNCTIONS

The temperature controller type 8625-2 is designed, in connection with a proportional valve and a temperature sensor, to keep the temperature in a flowing

medium constant or to follow a given setpoint profile.

The functionality of the device is characterized by:

• Compact design, capable of direct installation on the proportional valve.

• May be combined with valve types 6022, 6023, 6024, 6223, 2832, 2834.

• Controller ouput directly to proportional valve in the form of a PWM signal;

this minimizes hysteresis and optimizes the control performance.

• Connection of PT100 sensor of any type to the actual value input (e.g.

types ST20 - 24).

• The standard signal input can be scaled to the control range actually

required (standard model only).

• Setting of setpoint value via standard 4 - 20 mA or 0 - 10 V signal, keypad

or bus.

• Digital control with a PI control algorithm and settable control parameters.

• Applications in heating and cooling possible.

• Display of setpoint or actual values (to choice) on an LCD display.

• Configuration with three keys.

For measured variables such as pressure, flow rate, conductivity,etc. we offer

suitable controllers, e.g:

• Type 8623-2 for flow rate control with frequency input for the sensor

• Type 8624-2 for pressure, flow rate, conductivity,etc. with standard

signal input for connection of a transmitter.

english

8625-2 Standard - 5

Page 8

3 APPLICATION AREA

The compact temperature controller type 8625-2 is used in the area of mixing

temperature control.

Setpoint

english

Actual value (PT100)

Controller type 8625-2

cold

Medium with controlled temperature

Fig.: Structure of a temperature control system with the compact temperature

controller type 86235-2 (schematic)

6 - 8625-2 Standard

hot

Proportional valve

Temperature sensor PT 100

Page 9

4 TECHNISCHE DATEN

Operating voltage 24 V DC

Power consumption max. 0.3 W (without proportional valve)

Output current (to valve) max. 1.0 A

Operating temperature - 10 °C ... + 60 °C / 14 °F ... 140 °F

Interference resistance to EN50082-2

Interference emission to EN50081-2

Inputs

Sensor input PT100

temperatur range - 50 °C ... 150 °C / - 58 °F ... 302 °F

resolution 0.25 °C or 0.45 °F

precision 1.5 °C bzw 2.7 °F

1)

1)

1 standard signal input 4 - 20 mA / 0 - 10 V, adjustable

resolution 10 Bit

input impedance (4 - 20 mA) < 200 Ω

input impedance (0 - 10 V) > 300 kΩ

Output

PWM output 24 V - pulse width modulated

Controller

Control algorithm PI control

Scan time T

Amplification factor K

Reset time T

Scaling -50 °C ... 150 °C or -58 °F ... 302 °F

A

p

N

50 ms

0,00 - 10,00 %/K

0,1 - 200,1 s

Housing

Cable outlet rotatable in 90° steps

System of protection IP 65

Material polyamide

Dimensions (WxHxD) 54 x 54 x 61 mm

english

Order no. 143 571

1)

Calibrated to 1 m conductor length and 0.5 mm² conductor cross-section.

8625-2 Standard - 7

Page 10

5 COMMISSIONING

NOTE

Interference with the device is only allowed by specialist

personnel using suitable tools!

Before interfering with the temperature controller, always

switch off the voltage!

5.1 Connecting to the proportional valve

english

Fig.: Connecting the temperature controller to the proportional valve

Î Unscrew the 4 screws on the front panel of the temperature controller and

remove the cover carefully.

Î Place the housing of the temperature controller with the seal onto the valve.

Î Screw the temperature controller tightly to the valve.

ATTENTION!

Î Place the conver on the temperature controller and screw it tight with the 4

screws

ATTENTION!

8 - 8625-2 Standard

On screwing the temperature controller onto the proportional

valve, make sure the seal is correctly seated!

Make sure the cover is placed on the right way round

(pinned strips must engage in the sockets).

Page 11

5.2 Changing the cable outlet direction

Î Unscrew the 4 screws on the front panel

of the temperature controller and remove

the cover carefully.

Î Remove the screw to the valve and

remove the plastic cross.

Î Detach the plate from the cube.

Î Pull out the cube downwards and replace

in the desired orientation.

Î Place the plate onto the cube (the pins

must engage in the guides).

Î Lay on the plastic cross and insert the

screw through the cube.

Î Connect the temperature controller to the

proportional valve (see 5.1).

english

8625-2 Standard - 9

Page 12

5.3 Connection configuration of temperature controller

type 8625-2

M12, 4-pole

Supply voltage

and standard

english

signal input

External setpoint

M8, 3-pole

PT100 input

Fig.: Connections on temperature controller type 8625-2

M12 (4-pole): Supply voltage and standard signal for setpoint

3 (blue) 2 (white)

1 (brown)*4 (black)

M8 (PT100-input):

4 (black)

1 (brown)

3 (blue)*

Configuration:

1 24 V DC supply voltage

2 Standard signal input, external setpoint

3 GND external setpoint

4 GND supply voltage

* wire colours when using standard cables

with M12 plug (4-pole)

Configuration:

1 PT100 supply (0.5 mA)

3 GND

4 Temperature input PT100

* wire colours when using standard cables

with M8 plug (3-pole)

10 - 8625-2 Standard

Page 13

connection of temperature sensor PT 100

Temperature

sensor PT 100

1

2

Type 8625-2 temperature controller

M8 (3-pole)

Bridge pin 1 and pin 4 of

temperature controller directly at

the temperature sensor PT100 and

connect to pin 1 of PT100.

Connect pin 3 of temperature

controller to pin 2 of temperature

sensor PT100.

1

(brown)

4 (black)

3 (blue)

Fig.: Connecting temperature sensor PT 100 to type 8625-2

ATTENTION!

Do not connect a voltage to pin 1 of the 3-pole plug! Pin 1

is a 0.5 mA output to supply the sensor (PT100)

english

8625-2 Standard - 11

Page 14

5.4 First commissioning

Settings absolutely necessary on first commissioning

• Type and range of standard signal (4 - 20 mA or 0 - 10 V) with external

setpoint.

• Lower limit for correcting variable (controller output), (see 6.6.8 VALV).

english

12 - 8625-2 Standard

Page 15

6 OPERATING THE TEMPERATURE CONTROLLER TYPE

8625-2

6.1 Operating modes

Three modes are possible for operating the temperature controller type 8625-2:

• Standard mode

• Configuration mode

• Manual mode

english

Standard

Mode

press key briefly

press key for 5 sec.

Configuration

Mode

Menu

.

.

.

END

press key

Fig.: Switching between operating modes

Manual

mode

8625-2 Standard - 13

Page 16

NOTE

english

• After the supply voltage is switched on, the controller is in

the standard mode.

• Change to the other modes is possible by the actions

shown in the figure.

• After the configuration mode is ended, the parameters set

are transferred to the memory of the controller.

• After the operating voltage is switched off, the parameters

last active are stored; on next switching on again, these will

be active again.

6.2 Indications on the display

4-digit display to

indicate the

process values ans

parameters

Bus active

Manual

Indication of specified setpoint value

- internal setpoint (no display)

- external setpoint (1)

- setpoint via bus (1)

Fig.: Display of the compact temperature controller type 8625-2

14 - 8625-2 Standard

mode

4-digit text display, e.g.

of temperature unit in

°C or °F.

Page 17

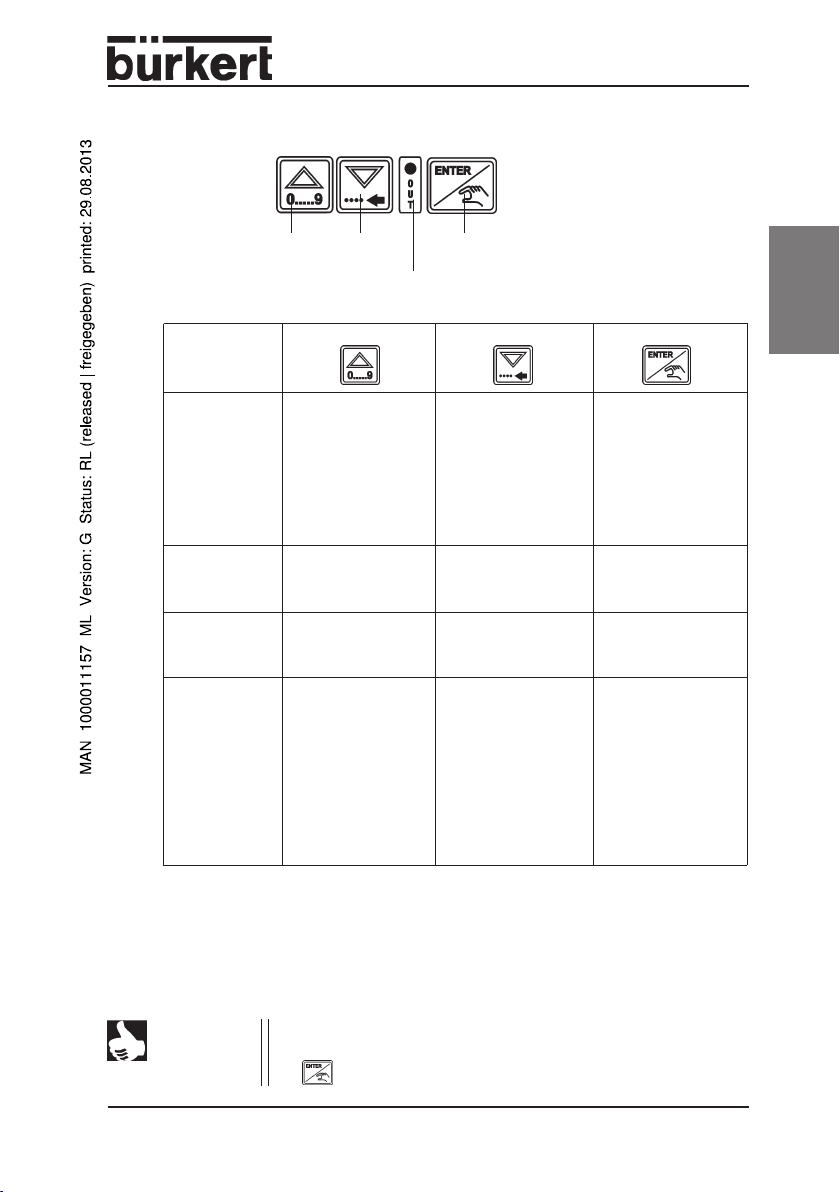

6.3 Key allocation

Mode

Standard mode

Manual mode

Configuration

mode

Menu items

Configuration

mode

Edititing menu

items

key

"INC"

"DEC"

press key:

switchover of display

between set and

actual value

press key:

open valve

(inc)

press key:

backwards in menu

press key:

increase the selected

digit*

ENTER-keykey

No function on this model

press key:

switchover of display

between set and actual

value

press key:

close valve

(dec)

press key:

forwards in menu

press key briefly:

to next digit

press key for 2 sec:

set decimal point

behind the place

selected ***

english

press key briefly:

enters manual mode

press key for 5 sec:

enters configuration

mode

press key briefly:

back to standard mode

press key:

to edit the menu item

press key:

concludes setting,

back to menu item**

* In the menu item

VALV

, setting is not digit-by-digit but in increasing

sequence within the limits 00 ... 100.

** The values set are transferred to the memory.

*** In the

MODE

mode, a change of sign is possible at the 4th place from the

right.

NOTE The values set are valid for current control procedure only after

the configuration mode has been left in the menu item END with

the key.

8625-2 Standard - 15

Page 18

6.4 Standard mode

In this mode, the device works after switching on the operating voltage. The

current temperature is now indicated.

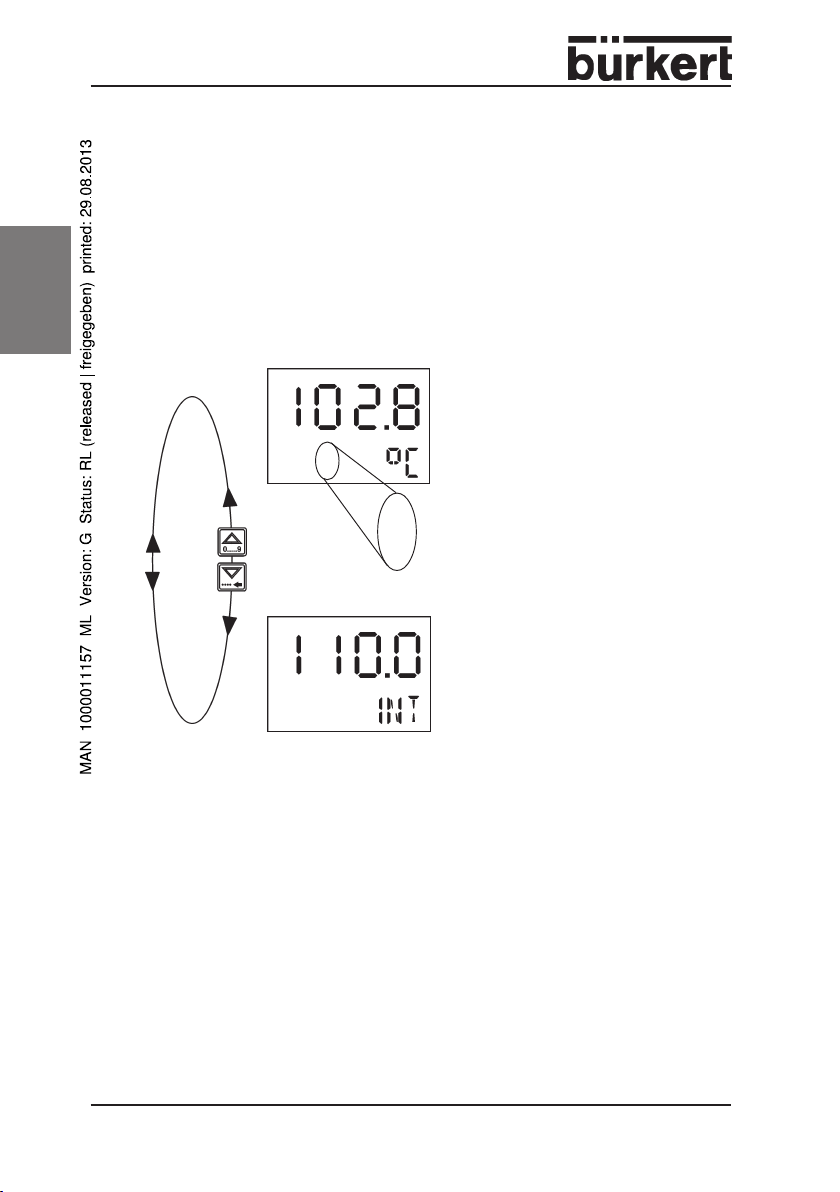

6.4.1 Standard mode and internal setpoint

In this mode, the setpoint is specified via the keys of the display.

english

Display of actual value (°C)

Setting internal

setpoint

Display of setpoint value (°C)

Fig.: Possible display in standard mode with internal setpoint

16 - 8625-2 Standard

Page 19

6.4.2 Standard mode and external setpoint

Here the controller receives the setpoint value via the 4 - 20 mA or 0 - 10 V signal

present on pins 2 ans 3 of the 4-pole M12 plug.

Display of actual value ( °C)

1

Setting external setpoint

Display of setpoint value (°C)

Fig.: Possible display in standard mode with external setpoint

english

8625-2 Standard - 17

Page 20

6.5 Manual mode

The manual mode can be activated from the standard mode by briefly pressing

the key.

In the manual mode there is no control: the value of correcting variable last

calculated is a first retained. By pressing the arrow keys, the correcting variable

can be increased or decreased.

english

Display in manual mode

Display of actual value

manual mode activated

Î With this key you increase the pulse-duty factor of the proportional

valve, i.e. the latter opens up to a max. of 100 %.

Î With this key you reduce the pulse-duty factor of the proportional

valve.

Î Press the key in the manual mode. On release of the key, you

will return to the standard mode.

Î After switching to the manual mode,

the current actual value is displayed.

Fig.: Displayed after switching to the manual mode

Display of the pulse-duty factor of the valve

Fig.: Display of the pulse-duty factor of the valve

NOTE

18 - 8625-2 Standard

The display

of the PWM signal set in the menu item

corresponds to a pulse-duty factor of 100 %.

0 %

corresponds to the minimum pulse-duty factor

As soon as the correcting variable is

changed by pressing the key or

key, the display switches

automatically to the value of the

correcting variable. After releasing the

key, the curent value is shown again.

VALV

: 100 %

Page 21

6.6 Configuration mode

STANDARD

CONFIGURATION

MODE

press key for 5 sec

Fig.: Switching over from standard to configuration mode

NOTE

Values that are changed within the configuration mode only

become active when this mode is left in the menu item END by

pressing the key or after switching the device off and on

again.

MODE

MENU

.

.

.

END

press

key

english

8625-2 Standard - 19

Page 22

Key allocation in configuration mode

english

Menu level

Edit menu items

UNIT, MODE,

AMPL, INTG,

INV, ZERO

Edit menu item

VALV

Menu item

END

press key:

backwards in menu

press key:

increase the selected

digit or select the

respective menu

subitem

press key:

increase the value,

e.g. 00 ... 100

press key:

forwards in menu

press key briefly:

to next digit

Press key for 2 sec:

set decimal point

behind the position

selected

***

press key:

decrease the value,

e.g. 100 ... 00

press key:

to edit the menu item

press key:

conclude setting,

return to menu item

(menu level)*

press key:

conclude setting,

return to active menu

item (menu level) *

press key:

conclude settings,

return to standard

mode **

* The values set are stored inthe memory,but become active only after

leaving the configuration mode for the current control procedure.

** On leaving the configuration mode, the values currently set become valid

for the controller. The current control is continued with the new parameters!

*** In the

MODE

mode, a change of sign is possible at the 4th place from the

right.

20 - 8625-2 Standard

Page 23

6.6.1 Menu of configuration mode

STANDARD

MODE

5 s

Settings

Unit of temperature

(see 6.6.2)

Setpoint mode

(see 6.6.3)

english

Fig.: Menu of the configuration mode

Amplification K

(see 6.6.4)

Reset time T

(see 6.6.5)

Heating/cooling

(see 6.6.6)

Zero point switch-off

(see 6.6.7)

Adaptation of controller

output (see 6.6.8)

p

N

Storage of the

values set (see

6.6.9)

8625-2 Standard - 21

Page 24

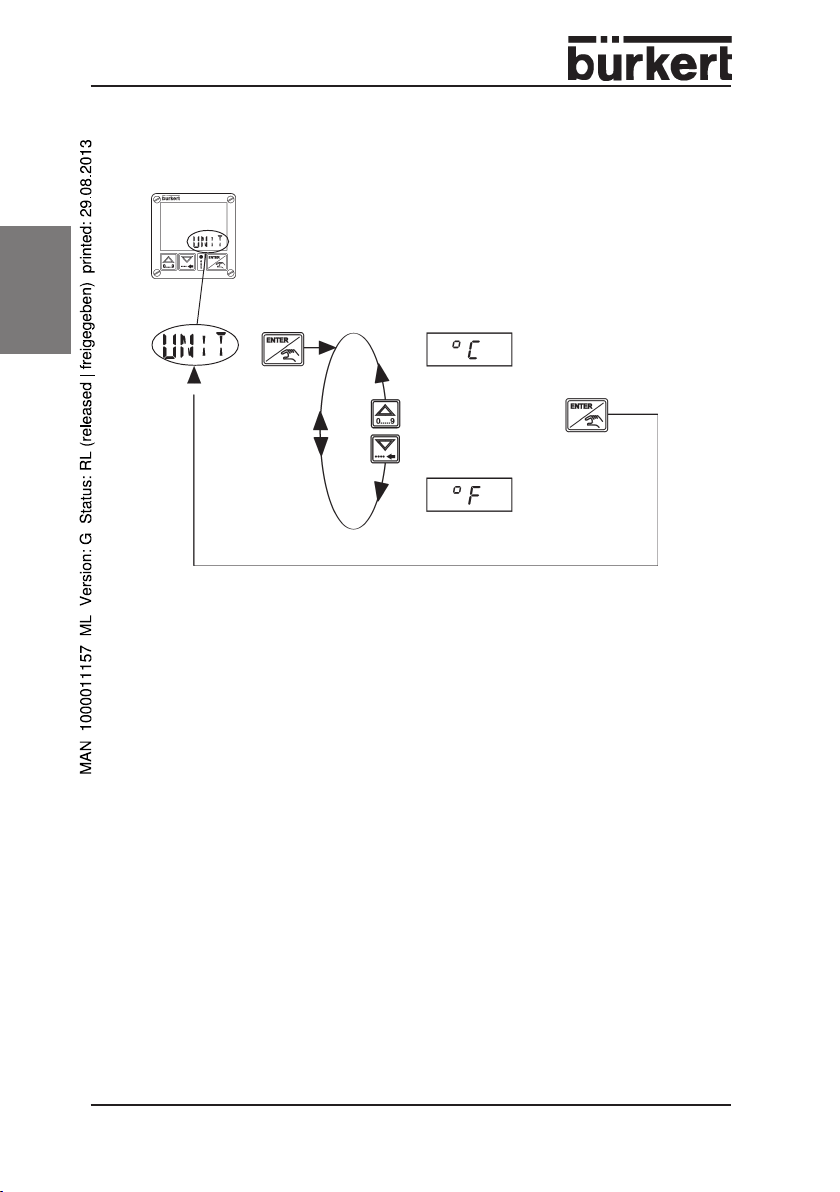

6.6.2

english

UNIT

- setting the unit of the temperature

Î Select here wheter the device is to

display the temperature in °C or °F

(factory setting: °C)

Unit = °C

Unit = °F

Fig.: Setting the unit of the temperature

22 - 8625-2 Standard

Page 25

6.6.3

MODE

Fig.: Setting the setpoint mode

- setting the setpoint mode

Setting the setpoint: internal setpoint

Î Select here wheter the device shall work with internal or

external setpoint. The choice

the number 1 in the lower display line

(factory setting: external setpoint)

External Setpoint

Internal

setpoint

external

1

setpoint

is shown by

english

With internal setpoint setting, the setpoint value for the temperature is entered in

the previously set unit (°C or °F) and stored. The device controls to this value.

Settings are possible between -50 °C and 150 °C or -58 °F and 302 °F.

If it is attempted to set a value outside this range, the display will jump automatically

to 0 and a value must be entered within the range.

The unit corresponds to the value set in the menu item UNIT.

(Factory setting: 0.0).

increase digit

next digit

change sign at 4th place from

2 s

right

Fig.: Setting the setpoint: internal setpoint

8625-2 Standard - 23

Page 26

english

Setting the setpoint: external setpoint

For external setpoint setting you state a scaling. The temperature range

corresponding to the standard signal (4 - 20 mA, 0 - 10 V) must be set, i.e. the

temperature is entered at 4 mA or 0 V (lower limit) and at 20 mA or 10 V (upper

limit).

Settings are possible within -50 °C and 150 °C or -58 °F and 302 °F . If it is

attempted to set a value outside this range, the display will jump automatically to 0

and a value must be entered within the range. The unit corresponds to the value

set in the menu item UNIT (factory setting: EXLO=0.0 °C; EXHI=100.0 °C).

Example:

Lower limit (

Upper limit (

EXLO

) 20 °C 4 mA

EXHI

) 60 °C 20 mA

For example, a standard signal of 12 mA corresponds to a setpoint of 40 °C.

Standard signal 4 - 20 mA

increase digit

next digit

change sign at 4th

2 s

Standard signal 0 - 10 V

place from right

Fig.: Setting the setpoint: external setpoint

If the value for EXHI was selected lower than that for EXLO or equal

to it, the texts MODE and ERR9 appear flashing alternately on the

text display.

In this case the newly set values are not stored!

24 - 8625-2 Standard

2 s

increase digit

next digit

change sign at 4th

place from right

Page 27

6.6.4

AMPL

Î Select the amplification factor KP in a range from 0.00 to 10.00 %/K (factory

Setting aid:

• If excessive overshoot occurs at the value of KP set or the control

• On the other hand, unsatisfactory control dynamics may be improved by

- setting the amplification Kp

setting: 1.00). If it is attempted to set a higher value, the display will jump

automatically to 0 and a value must be entered within the range.

becomes unstable, you should decrease KP.

raising KP as long as the abovementioned instability does not occur.

english

Fig.: Setting the amplification K

increase digit

next digit

2 s set decimal point

P

8625-2 Standard - 25

Page 28

6.6.5

english

INTG

- setting the reset time T

The reset time TN is the time that is needed to obtain the same magnitude of

change in the controller output with the I fraction as occurs with the P fraction.

Î Select the reset time TN in a range from 0.1 to 200.1 sec (works setting:

0.50).

Higher values result automatically in the display 0.1 and a value within the

range must be entered.

2 s set decimal point

N

increase digit

next digit

Fig.: Setting the reset time T

26 - 8625-2 Standard

N

Page 29

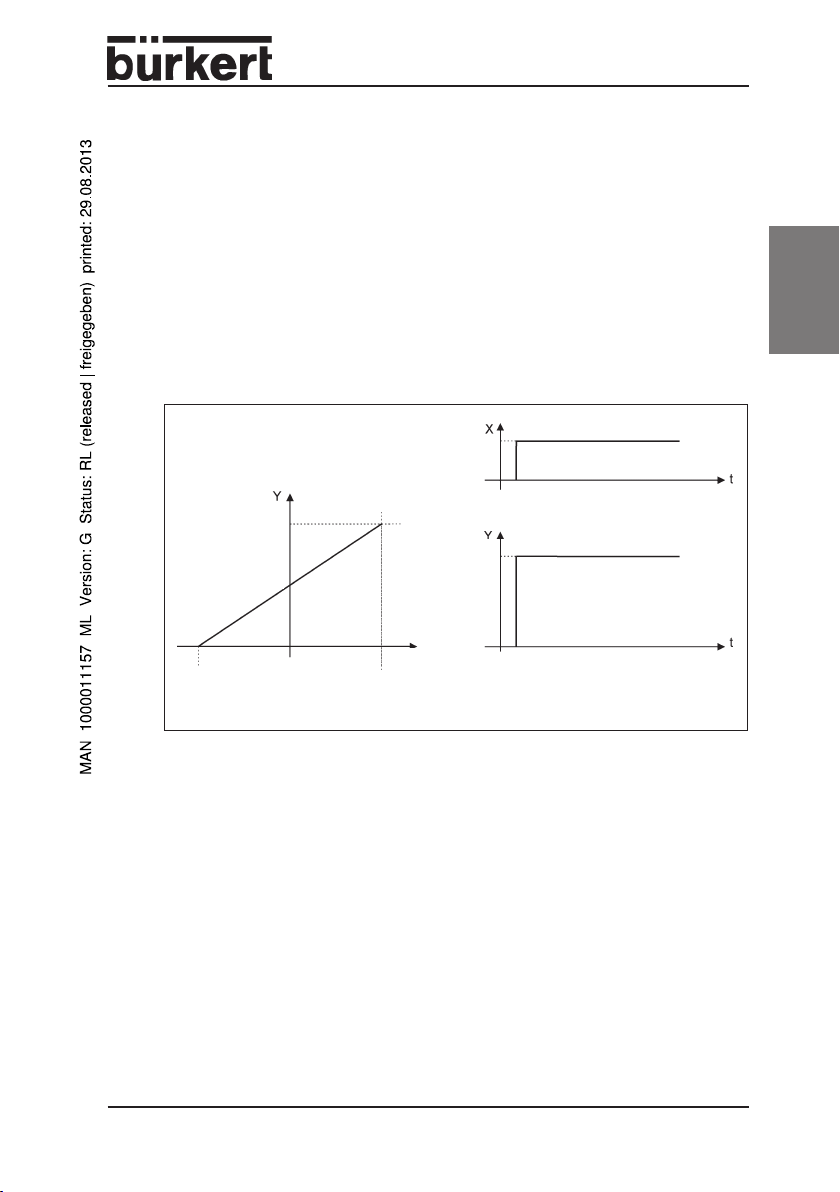

Characteristics of PI controllers

A PI controller has a proportional and an integral fraction (P and I fractions).

P fraction:

Function:

y = Kp · x

d

Kp is the proportionality index (amplification factor). It is the ratio of the controller

output range ∆Y to the proportional range ∆xd.

Characteristic and step response of the P fraction of a PI controller

x

d

y

max

kp*x

y

0

y

min

Proportional range ∆x

Correcting range ∆y

x

d

d

d

Characteristic Step response

Characteristics:

A purely P controller works theoretically undamped, i.e. it is fast and hence

dynamically favourable. It has a residual control difference, i.e. it does not

completely eliminate the effects of disturbances and is thus relatively unfavourable

from a static viewpoint.

english

8625-2 Standard - 27

Page 30

I fraction:

1

Function:

y =

T

i

∫ ∫

∫ xd dt

∫ ∫

Ti is the integration or floating time. It is the time that expires until the controller

output has run through the entire correcting range.

english

characteristic and step response of the P fraction of a PI controller

x

x

d

y

max

x

d

y

Control range ∆x

Characteristic

min

c

Floating time T

i

Step response

Correcting range ∆y

Characteristic:

A purely I controller completely eliminates the effects of disturbances. It thus has a

favourable static behaviour. Because of its finite correcting speed, it works more

slowly than a P controller and tends to oscillation. It is hence dynamically relatively

unfavourable.

Superimposing:

With a digital controller with sampling time TA and noting that Ti = Kp/T

write:

y = Kp (xd + TA/TN

∑∑

∑ xd)

∑∑

y : controller output

Kp: amplification factor

xd : deviation (xd = w - x)

TA : sampling time

TN : reset time

28 - 8625-2 Standard

one can

N,

Page 31

Rules for adjusting PI controllers

The literature on control technology contains a number of rules by which a

favourable setting of the controller parameters can be determined experimentally.

In order to avoid incorrect settings, the conditions under which the rules were set

up in each case must be kept in mind. Apart from the characteristics of the

controlled member and the controller itself, it makes a difference whether a

change in disturbance or a command variable is to be compensated.

Adjustment rules of Ziegler and Nichols (oscillation method)

With this method, the controller parameters are set on the basis of the behaviour

of the control loop at the limit of stability. These parameters are initially set such

that the control loop begins to oscillate. Critical characteristic values occurring

allow one to deduce a favourable setting of the control parameters. A prerequisite

for using this method is naturally that the control loop is permitted to oscillate.

Procedure:

• Set the controller to P control (i.e. TN = 200 s), KP initially small.

• Set the desired set point.

• Increase KP until the controller output executes continuous, undamped

oscillation.

The proportionality index (amplification factor) set at the limit of stability is

designated K

Curve of controller output at the limit of stability

X

. The resulting oscillation period is designated T

crit

actual value

.

crit

english

Tcrit

t

8625-2 Standard - 29

Page 32

english

From K

following table.

and T

crit

, the controller parameters can then be calculated using the

crit

Parameter setting according to Ziegler and Nichols:

Controller type Parameter setting

PK

PI Kp = 0,45 K

= 0,5 K

p

krit

krit

-

TN = 0,85 T

krit

The adjustment rules of Ziegler and Nichols have been determined for P members

with first order time increase and dead time. However, they apply only for

controllers with disturbance behaviour and not for those with command behaviour.

30 - 8625-2 Standard

Page 33

6.6.6

INV

- heating (non-inverted control)/cooling

(inverted control)

Î Via this function you set the sense of action between the input signal and

the setpoint of the valve (factory setting: NO).

non-inverted control

y = Kp (xd + TA/TN ∑ xd )

inverted control

y = - KP (xd + TA/TN ∑ xd )

Heating (non-inverted control):

Output signal y of the PI controller

increases with increasing positive

control difference xd = w-x.

Cooling (inverted control):

Output signal Y of the PI controller

increases with increasing negative

control difference xd = w-x.

Fig.: Heating (non-inverted control)/cooling (inverted control)

Example of applications:

Heating: : In the case of „heating“, a warmer fluid is added to a fluid flow by

means of a proportional valve. The temperature of the mixed fluid is measured

and the addition of the warmer fluid controlled.

english

NO

YES

Cooling: In the case of „cooling“, a cooler fluid is added to a fluid flow by

means of a proportional valve. The temperature of the mixed fluid is measured

and the addition of the cooler fluid controlled.

8625-2 Standard - 31

Page 34

6.6.7

english

ZERO

Zero point switch-off enables the proportional valve to assume a tight-closing

function in addition to the control function.To obtain tight closure when the set point

is 0, at set points below 2% of the overall range, no signal is sent to the valve, so

that the entire spring force is available for tight closure. The lower 2% of the set

point range is hence not available for control purposes.

Without zero point switch-off, a signal is sent to the valve also when the set point

is 0. This signal generates just enough magnetic force for the start of opening. This

acts in opposition to the spring force, so that the valve is not perfectly tight in most

cases.

(works setting: NO)

- zero point switch-off

No zero point switch-off (NO):

The control is continuous down to the lower limit, i.e. until the

minimum pulse-duty ratio set in the menu item „VALC“ is

reached. The valve is closed but usually not leak-free.

Zero point switch-off (

The control is continuous until the input signal has reached a

value of less than 2%, then the valve will be closed.

Fig.: Zero point switch-off

Preconditions for zero

• Zero point switch-off (YES) has been selected;

• The setpoint is less than 2 %;

• Non-inverted control.

32 - 8625-2 Standard

YES

):

Page 35

6.6.8

VALV

- adaptation of controller output signal

In this menu item, the controller output can be adapted optimally to the working

range of the actuator currently covered in the application. The proportional valve

is driven by a pulse width modulated (PWM) signal from the controller. Opening of

the valve does not begin at a pulse-duty factor of 0 of the PWM signal, but on

account of the spring force opposing the magnetic force, only at a certain value.

This start of opening depends upon the nominal diameter of the valve, the

admission temperature, and because of temperature dependence of the coil

resistance, also on the coil temperature. The function of the controller can be

optimized by having its output range begin not at 0, but at the start of opening in

the current application.

Display of actual value

In the menu item

actual value is displayed.

VALV

english

, the

Display of pulse-duty factor of valve

As soon as the controller output is changed by pressing

the or key, the display changes automatically to

controller output. On releasing the key, the actual value

is again displayed.

Î With this key, the pulse-duty factor of the

proportional valve is increased, i.e. it opens

up to a max. of 100%.

Î With this key, the pulse-duty factor of the

proportional valve is decreased.

Fig.: Adaptation of controller output signal

8625-2 Standard - 33

Page 36

english

To determine the start of opening of the proportional valve in the current

application, the following steps are executed (on first operation of the device. This

is done immediately after switching on, while the coil is still cold):

Î On using a direct acting proportional valve (Types 6022, 6023, 6024, 2832,

2834), set the greatest operating temperature expected in the application

(the start of opening is lowered with increasing admission temperature).

With a pilot controlled proportional valve (Type 6223), on the other hand, set

the lowest admission temperature to be expected in operation (in this case,

the start of opening is raised with increasing admission temperature).

Î Select the menu item VALV in the configuration mode. The actual value is

displayed.

Î If at the controller output obtaining no recognizable flow is present, first

increase the pulse-duty factor by pressing the key until flow is detected.

Î Now lower the pulse-duty factor by pressing the key until the valve is

just closed, i.e. now flow is present.

Î Press the key: the value for start of opening will be stored.

34 - 8625-2 Standard

Page 37

6.6.9

END

STANDARD

MODE

Fig.: Storing the values

- storing the values

english

NOTE

The parameters set in the menu items of the configuration mode

will already be transferred to memory after leaving the respective

menu item and hece be valid after the next time the device is

switched off and on. Only after leaving the configuration mode in

the menu item

valid for the current control process.

END

with the key will the parameters also be

8625-2 Standard - 35

Page 38

6.7 Settings on delivery

Menu Parameter Value set

english

UNIT

MODE

EXLO

EXHI

SET

AMPL

INTG

INV

ZERO

VALV

Unit °C

Type of setpoint setting External setpoint 0 - 10 V

Lower limit 0 °C

Upper limit 100 °C

Setpoint 0 °C

K

p

T

N

Heating/cooling Heating

Zero point switch-off deactivated

Lower limit of controll output to valve 0 %

1.00 %/K

0.50 s

36 - 8625-2 Standard

Page 39

7 ERROR MESSAGES

Display Cause Remedy

ERR0

ERR1

ERR2

ERR9

Sensor breakage at PT 100 Check sensor if applicable or its

sensor input or current connection to controller.

temperature lies outside range

(- 50 °C ... 150 °C,

58 °F ... 302 °F)

Standard signal of external Check standard signal.

setpoint lies outside range

(4 - 20 mA, 0 - 10 V)

Controller output to proportional Increase the pressure in order to

valve is greater than 95%. reach the required setpoint with the

Only in mode "external setpoint" Set the values correctly

with

EXLO

≥

EXHI

Actual value too great (can no

longer be compensated) or in

manual mode, the valve cannot

be closed.

proportional valve selected.

(see 6.6.3).

Set the lower limit for valve drive

correctly

(see 6.6.8

VALV

).

english

8625-2 Standard - 37

Page 40

english

38 - 8625-2 Standard

Page 41

INHALT

1 ALLGEMEINE HINWEISE........................................................................................ 41

1.1 Darstellungsmittel ......................................................................................................................... 41

1.2 Sicherheitshinweise .................................................................................................................... 41

1.3 Schutz gegen Beschädigung durch elektrostatische

Aufladung .............................................................................................................................................. 42

2 FUNKTION .................................................................................................................................... 43

3 EINSATZBEREICH

4 TECHNISCHE DATEN

5 INBETRIEBNAHME

............................................................................................................ 44

.................................................................................................. 45

.......................................................................................................... 46

5.1 Anschluss an das Proportionalventil ..........................................................................46

5.2 Richtungsänderung des Kabelabgangs .................................................................... 47

5.3 Anschlussbelegung des Temperaturreglers Typ 8625-2 ............................48

5.4 Erstinbetriebnahme ...................................................................................................................... 50

6 BETRIEB DES TEMPERATURREGLERS

TYP 8625-2 ....................................................................................................................................51

6.1 Betriebsmodi ...................................................................................................................................... 51

6.2 Anzeigen im Display................................................................................................................... 52

6.3 Tastenbelegung ................................................................................................................................53

6.4 Standardmodus ............................................................................................................................... 54

6.4.1 Standardmodus und interner Sollwert .......................................................... 54

6.4.2 Standardmodus und externer Sollwert ......................................................... 55

6.5 Handmodus ......................................................................................................................................... 56

deutsch

6.6 Konfigurationsmodus .................................................................................................................. 57

6.6.1 Menü des Konfigurationsmodus ........................................................................ 59

6.6.2

UNIT

- Einstellung der Einheit der Temperatur ....................................... 60

8625-2 Standard - 39

Page 42

6.6.3

MODE

- Einstellung der Sollwertvorgabe ................................................. 61

AMPL

6.6.4

6.6.5

6.6.6

- Einstellung der Verstärkung K

INTG

- Einstellung der Nachstellzeit T

INV

- Heizen (nicht invertierte Regelung) /

........................................................ 63

p

.................................................................

N

Kühlen (invertierte Regelung) ............................................................................. 69

6.6.7

ZERO

- Nullpunktabschaltung ............................................................................. 70

VALV

6.6.8

6.6.9

- Anpassung Regler - Stellgröße ........................................................ 71

END

- Speichern der Werte ................................................................................... 73

6.7 Einstellungen bei Auslieferung ......................................................................................... 74

7 FEHLERMELDUNGEN ................................................................................................ 75

deutsch

64

40 - 8625-2 Standard

Page 43

1 ALLGEMEINE HINWEISE

1.1 Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder die Funktionsfähigkeit des Gerätes gefährdet ist.

kennzeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen

1.2 Sicherheitshinweise

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten, die in den Datenblättern des verwendeten

Proportionalventils sowie des Reglers Typ 8625-2 spezifiziert sind, damit das

Gerät einwandfrei funktioniert und lange einsatzfähig bleibt:

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die

allgemeinen Regeln der Technik!

• Eingriffe dürfen nur durch Fachpersonal und mit geeignetem Werkzeug

erfolgen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmun-

gen für elektrische Geräte während des Betriebs, der Wartung und der

Reparatur des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

deutsch

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder

unzulässige Beeinträchtigung auszuschließen!

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das

Gerät entfällt jegliche Haftung unsererseits, ebenso erlischt die Garantie

auf Geräte und Zubehörteile.

8625-2 Standard - 41

Page 44

1.3 Schutz gegen Beschädigung durch elektrostatische

Aufladung

deutsch

Das Gerät enthält elektronische Bauelemente, die gegen elektrostatische

Entladung (ESD) empfindlich reagieren. Berührung mit elektrostatisch aufgeladenen Personen oder Gegenständen gefährdet diese Bauelemente. Im

schlimmsten Fall werden sie sofort zerstört oder fallen nach der Inbetriebnahme aus.

Beachten Sie die Anforderungen nach EN 100 015 - 1, um die Möglichkeit

eines Schadens durch schlagartige elektrostatische Entladung zu minimieren

bzw. zu vermeiden. Achten Sie ebenso darauf, dass Sie elektronische Bauelemente nicht bei anliegender Versorgungsspannung berühren.

VORSICHT BEI HANDHABUNG !

ACHTUNG

ELEKTROSTATISCH

GEFÄHRDETE

BAUELEMENTE / BAUGRUPPEN

42 - 8625-2 Standard

Page 45

2 FUNKTION

Der Temperaturregler Typ 8625-2 ist darauf abgestimmt, in Verbindung mit

einem Proportionalventil und einem Temperatursensor die Temperatur

eines fliessenden Mediums konstant zu halten oder einem vorgegebenen

Sollwertprofil nachzuführen.

Die Funktionalität des Gerätes wird gekennzeichnet durch:

• Kompakte Bauform, direkt auf ein Proportionalventil aufsteckbar

• Kombinierbarkeit mit den Proportionalventiltypen 6022, 6023, 6024,6223,

2832, 2834

• Ausgabe der Stellgröße in Form eines PWM-Signals direkt an das

Proportionalventil; dadurch wird die Hysterese minimiert und die Regelgüte

optimiert.

• Anschluss von PT100 - Sensoren beliebiger Art an den Istwerteingang (z.B.:

Typen ST20 - 24).

• Der Normsignaleingang kann auf den tatsächlich geforderten Regelbereich

skaliert werden (nur Standardvariante).

• Sollwertvorgabe über Normsignal 4 - 20 mA bzw. 0 - 10 V, über Tastatur

oder über Bus

• Digitale Regelung mit einem PI-Regelalgorithmus und einstellbaren Regelparametern

• Einsatzmöglichkeit für Heiz- und Kühlprozesse

• Anzeige von Soll- oder Istwert (wahlweise) auf einem LCD-Display

• Konfiguration mit drei Tasten

Für Messgrößen wie z.B. Druck, Durchfluss, Leitfähigkeit u.a. bieten wir geeignete

Regelgeräte an :

• Typ 8623-2 für Durchflussregelung mit Frequenzeingang für den Sensor

• Typ 8624-2 für Druck, Durchfluss, Leitfähigkeit u. a. mit Normsignaleingang

zum Anschluss eines Transmitters

deutsch

8625-2 Standard - 43

Page 46

3 EINSATZBEREICH

Der kompakte Temperaturregler Typ 8625-2 kommt im Bereich der Mischtemperatur-Regelung zweier Medien zum Einsatz.

Sollwert

Istwert (PT100)

deutsch

Regler Typ 8625-2

kalt

Medium mit geregelter Temperatur

Bild: Aufbau einer Regelung mit dem kompakten Temperaturregler

Typ 8625-2 (Schema)

44 - 8625-2 Standard

warm

Proportionalventil

Temperatursensor PT 100

Page 47

4 TECHNISCHE DATEN

Betriebsspannung 24 V DC

Leistungsaufnahme max. 0,3 W (ohne Proportionalventil)

Ausgangsstrom (zum Ventil) max. 1,0 A

Betriebstemperatur - 10 °C ... + 60 °C / 14 °F ... 140 °F

Störfestigkeit nach EN50082-2

Störaustrahlung nach EN50081-2

Eingänge

Sensoreingang PT100

Temperaturbereich - 50 °C ... 150 °C / - 58 °F ... 302 °F

Auflösung 0,25 °C bzw. 0,45 °F

Genauigkeit 1,5 °C bzw 2,7 °F

1 Normsignaleingang 4 - 20 mA / 0 - 10 V einstellbar

Auflösung 10 Bit

Eingangsimpedanz (4 - 20 mA) < 200 Ω

Eingangsimpedanz (0 - 10 V) > 300 kΩ

Ausgang

PWM-Ausgang 24 V - pulsweitenmoduliert

Regler

1)

1)

deutsch

Regelalgorithmus PI-Regler

Abtastzeit T

Verstärkungsfaktor K

Nachstellzeit T

Skalierung -50 °C ... 150 °C bzw -58 °F ... 302 °F

A

p

N

50 ms

0,00 - 10,00 %/K

0,1 - 200,1 s

Gehäuse

Kabelabgang in 90° - Schritten drehbar

Schutzart IP 65

Werkstoff Polyamid

Abmessungen (BxHxT) 54 x 54 x 61 mm

Bestell-Nr. 143 571

1)

Kalibriert auf 1 m Leitungslänge und 0,5 mm2 Leitungsquerschnitt

8625-2 Standard - 45

Page 48

5 INBETRIEBNAHME

HINWEIS

Eingriffe dürfen nur durch Fachpersonal und mit geeignetem

Werkzeug erfolgen!

Schalten Sie den Temperaturregler vor Eingriffen spannungsfrei!

5.1 Anschluss an das Proportionalventil

deutsch

Bild: Anschluss des Temperaturreglers an das Proportionalventil

Î Lösen Sie die 4 Schrauben an der Frontseite des Temperaturreglers und

nehmen Sie den Deckel vorsichtig ab.

Î Setzen Sie den Temperaturregler mit der Dichtung auf das Ventil auf.

Î Schrauben Sie den Temperaturregler am Ventil fest.

ACHTUNG!

Î Stecken Sie den Deckel auf den Temperaturregler auf und schrauben Sie

ihn mit den 4 Schrauben fest.

ACHTUNG!

46 - 8625-2 Standard

Achten Sie beim Verschrauben des Temperaturreglers mit dem

Proportionalventil auf einwandfreien Sitz der Dichtung!

Achten Sie darauf, dass der Deckel richtigherum aufgesetzt wird

(Stiftleisten müssen in die Buchsen eingreifen).

Page 49

5.2 Richtungsänderung des Kabelabgangs

Î Lösen Sie die 4 Schrauben an der

Frontseite des Temperaturreglers und

nehmen Sie den Deckel vorsichtig ab.

Î Entfernen Sie die Schraube zum Ventil und

nehmen Sie das Kunststoffkreuz ab.

Î Nehmen Sie die Platine vom Würfel ab.

Î Ziehen Sie den Würfel nach unten heraus

und setzen ihn in der gewünschten

Richtung wieder ein.

Î Setzen Sie die Platine auf den Würfel auf

(Die Stecker müssen in die Führungen

eingreifen).

Î Setzen Sie das Kunststoffkreuz auf und

stecken Sie die Schraube durch den

Würfel.

Î Schließen Sie den Temperaturregler an das

Proportionalventil an (s. 5.1).

deutsch

8625-2 Standard - 47

Page 50

5.3 Anschlussbelegung des Temperaturreglers Typ 8625-2

M12, 4polig

Versorgungsspannung

und Normsignaleingang

Externer Sollwert

Bild: Anschlüsse des Temperaturreglers Typ 8625-2

M8, 3polig

PT100-Eingang

deutsch

M12 (4polig): Versorgungsspannung und Normsignaleingang für Sollwert

3 (bl) 2 (ws)

1 (br)*4 (sw)

M8 (PT100-Eingang):

4 (sw)

1 (br)

3 (bl)*

Belegung:

1 24 V DC Versorgungsspannung

2 Normsignaleingang externer Sollwert

3 GND externer Sollwert

4 GND Versorgungsspannung

* Aderfarben bei Verwendung von Stan-

dard-Kabeln mit Stecker M12 (4polig)

Belegung:

1 PT100-Versorgung (0,5 mA)

3 GND

4 Temperatureingang PT100

* Aderfarben bei Verwendung von Stan-

dard-Kabeln mit Stecker M8 (3polig)

48 - 8625-2 Standard

Page 51

Anschluss des Temperatursensors PT 100

Temperatursensor PT 100

1

2

Bild: Anschluss des Temperatursensors PT100 an Typ 8625-2

ACHTUNG!

Schließen Sie an Pin1 des 3-poligen Steckers keine Spannung an! Pin 1 ist ein 0,5 mA-Ausgang zur Versorgung des

Sensors (PT 100)

Typ 8625-2 Temperaturregler

M8 (3polig)

1

(br)

4 (sw)

3 (bl)

Pin 1 und Pin 4 des Temperaturreglers direkt am Temperatursensor

PT100 brücken und mit Pin 1 des

PT100 verbinden

Pin 3 des Temperaturreglers mit

Pin 2 des Temperatursensors PT100

verbinden

deutsch

8625-2 Standard - 49

Page 52

5.4 Erstinbetriebnahme

Zwingend notwendige Einstellungen bei Erstinbetriebnahme

• Art und Bereich des Normsignals (4 - 20 mA oder 0 - 10 V) bei externem

Sollwert

• unterer Grenzwert für die Stellgröße (s. 6.6.8

deutsch

VALV

)

50 - 8625-2 Standard

Page 53

6 BETRIEB DES TEMPERATURREGLERS TYP 8625-2

6.1 Betriebsmodi

Beim Betrieb des Temperaturreglers Typ 8625-2 sind drei Modi möglich:

• Standardmodus

• Konfigurationsmodus

• Handmodus

Standard-

Modus

Taste kurz drücken

Taste 5 s

drücken

Konfigurations-

modus

Menü

.

.

.

END

Taste

drücken

Bild: Umschalten zwischen den Betriebsmodi

Hand-

Modus

deutsch

8625-2 Standard - 51

Page 54

HINWEISE

deutsch

6.2 Anzeigen im Display

4stellige Anzeige

zur Anzeige der

Prozessgrößen und

• Nach Einschalten der Versorgungsspannung befindet sich

• Der Wechsel in die anderen Modi ist mit den im Bild gezeigten

• Nach Beenden des Konfigurationsmodus werden die ein-

• Nach Ausschalten der Betriebsspannung bleiben die zuletzt

Parameter

der Regler im Standardmodus.

Aktionen möglich.

gestellten Parameter in den Speicher des Reglers übertragen.

aktiven Parameter gespeichert; diese sind beim nächsten

Einschalten wieder aktiv.

Bus aktiv

Handmodus

Darstellung der Sollwertvorgabe

- interner Sollwert (keine Anzeige)

- externer Sollwert (1)

- Sollwert über Bus (1)

Bild: Display des kompakten Temperaturreglers Typ 8625-2

52 - 8625-2 Standard

4stellige Textanzeige

z. B. Anzeige der

Temperatureinheit in °C

oder °F

Page 55

6.3 Tastenbelegung

Modus

Standardmodus

Hand-Modus

Konfigurationsmodus

Menüpunkte

Konfigurationsmodus

Menüpunkte

bearbeiten

Taste

"INC"

"DEC"

Taste drücken:

Anzeige Umschalten

zwischen Soll- und

Istwert

Taste drücken:

Ventil öffnen

(inc)

Taste drücken:

im Menü zurück

Taste drücken:

Erhöhen der ausgewählten Stelle*

ENTER-TasteTaste

in dieser Gerätevariante ohne Funktion

Taste drücken:

Anzeige Umschalten

zwischen Soll- und

Istwert

Taste drücken:

Ventil schließen

(dec)

Taste drücken:

im Menü vor

Taste kurz drücken:

zur nächste Stelle

Taste 2 Sekunden

drücken:

Dezimalpunkt hinter die

ausgewählte Stelle

setzen ***

Taste kurz drücken:

in den

Hand-Modus

Taste 5 Sekunden

drücken:

in den Konfigurationsmodus

Taste kurz drücken:

zurück in den

Standardmodus

Taste drücken:

zur Bearbeitung des

Menüpunktes

Taste drücken:

Einstellung abschließen, zurück zum

Menüpunkt**

deutsch

* Im Menüpunkt

VALV

wird nicht über Stellen eingestellt, sondern hochgezählt

in den Grenzen 00 ... 100.

** Die eingestellten Werte werden in den Speicher übernommen.

*** Im Modus

MODE

ist an der 4. Stelle von rechts ein Wechsel des Vorzeichens

möglich

HINWEISE Für den aktuellen Regelvorgang haben die eingestellten Werte

erst dann Gültigkeit, wenn der Konfigurationsmodus im Menüpunkt

END

mit der - Taste verlassen wird.

8625-2 Standard - 53

Page 56

6.4 Standardmodus

In diesem Modus arbeitet das Gerät nach dem Einschalten der Betriebsspannung.

Dabei wird die aktuelle Temperatur angezeigt.

6.4.1 Standardmodus und interner Sollwert

In diesem Modus erfolgt die Vorgabe des Sollwerts über die Tasten des Displays.

Anzeige des Istwertes (°C)

deutsch

Einstellung

Interner Sollwert

Anzeige des Sollwertes (°C)

Bild: Mögliche Anzeige im Standardmodus bei internem Sollwert

54 - 8625-2 Standard

Page 57

6.4.2 Standardmodus und externer Sollwert

Hier erhält der Regler den Sollwert über das 0 - 10 V oder 4 - 20 mA - Signal, das an

den Pins 2 und 3 des 4poligen M12-Steckers anliegt.

Anzeige des Istwertes ( °C)

1

Einstellung

Externer Sollwert

Anzeige des Sollwertes (°C)

Bild: Mögliche Anzeige im Standardmodus bei externem Sollwert

deutsch

8625-2 Standard - 55

Page 58

6.5 Handmodus

Der Handmodus kann vom Standardmodus aus durch kurzes Drücken der

-Taste aktiviert werden.

In diesem Modus erfolgt keine Regelung, sondern es wird zunächst die zuletzt

berechnete Stellgröße beibehalten. Durch Drücken der Pfeiltasten kann die

Stellgröße nach oben oder unten verändert werden.

deutsch

Anzeige im Handmodus

Anzeige Istwert

Hand-Modus aktiviert

Î Sie vergrößern mit dieser Taste das Tastverhältnis des

Proportionalventils, d.h. das Proportionalventil öffnet bis max. 100

%.

Î Mit dieser Taste verringern Sie das Tastverhältnis des Proportional-

ventils.

Î Drücken Sie im Handmodus die -Taste. Beim Loslassen

gelangen Sie zurück in den Standardmodus.

Î Nach dem Umschalten in den

Handmodus wird der aktuelle Istwert

angezeigt.

Bild: Anzeige nach Umschalten in den Handmodus

Anzeige des Tastverhältnisses des Ventils

Bild: Anzeige des Tastverhältnisses des Ventils

HINWEIS

56 - 8625-2 Standard

Die Anzeige

ten minimalen Tastverhältnis des PWM-Signals, 100 % entspricht

einem Tastverhältnis von 100 %

0 %

Sobald durch Drücken der - oder

-Taste die Stellgröße verändert wird,

schaltet die Anzeige automatisch auf den

Wert der Stellgröße um, nach Loslassen

der Taste wird wieder der Istwert

angezeigt.

entspricht dem im Menüpunkt

VALV

eingestell-

Page 59

6.6 Konfigurationsmodus

STANDARD-

MODUS

Taste 5 s drücken

KONFIGURATIONS-

MODUS

MENÜ

END

Bild: Umschalten vom Standardmodus in den Konfigurationsmodus

HINWEIS

Werte, die innerhalb des Konfigurationsmodus verändert werden,

werden erst dann aktiviert, wenn dieser im Menüpunkt

verlassen wird oder nach Aus- und Wiedereinschalten des

Gerätes.

.

.

.

END

mit

Taste

drücken

deutsch

8625-2 Standard - 57

Page 60

Tastenbelegung im Konfigurationsmodus

deutsch

* Die eingestellten Werte werden in den Speicher übernommen, aber erst

Menüebene

Menüpunkte

bearbeiten

UNIT, MODE,

AMPL, INTG,

INV, ZERO

Menüpunkt

bearbeiten

VALV

Menüpunkt

END

Taste drücken:

im Menü zurück

Taste drücken:

Erhöhen der ausgewählten Stelle oder

Auswahl des jeweiligen

Menüunterpunktes

Taste drücken:

Erhöhen des Wertes,

von 00 ... 100

Taste drücken:

im Menü vor

Taste kurz drücken:

zur nächste Stelle

Taste 2 Sekunden

drücken:

Dezimalpunkt hinter die

ausgewählte Stelle

setzen***

Taste drücken:

Erniedrigen des Wertes,

von 100 ... 00

Taste drücken:

zur Bearbeitung des

Menüpunktes

Taste drücken:

Einstellung abschließen, zurück zum

aktiven Menüpunkt

(Menüebene) *

Taste drücken:

Einstellung

abschließen, zurück

zum aktiven Menüpunkt (Menüebene) *

Taste drücken:

Einstellungen

abschließen, zurück

zum Standardmodus **

nach Verlassen des Konfigurationsmodus für den aktuellen Regelvorgang

aktiv.

** Beim Verlassen des Konfigurationsmodus erhalten die aktuell eingestellten

Werte für den Regler Gültigkeit. Die laufende Regelung wird mit den neuen

Parametern fortgesetzt!

*** Im Modus

MODE

ist an der 4. Stelle von rechts ein Wechsel des Vorzeichens

möglich

58 - 8625-2 Standard

Page 61

6.6.1 Menü des Konfigurationsmodus

STANDARD-

MODUS

5 s

Einstellungen

Einheit der Temperatur

(s. 6.6.2)

Sollwertvorgabe

(s. 6.6.3)

Bild: Menü des Konfigurationsmodus

Verstärkung K

(s. 6.6.4)

Nachstellzeit T

(s. 6.6.5)

Heizen / Kühlen

(s. 6.6.6)

Nullpunktabschaltung

(s. 6.6.7)

Anpassung Regler Stellgröße (s. 6.6.8)

p

N

Übernahme der

eingestellten

Werte (s. 6.6.9)

deutsch

8625-2 Standard - 59

Page 62

6.6.2

UNIT

deutsch

Bild: Einstellung der Einheit der Temperatur

- Einstellung der Einheit der Temperatur

Î Wählen Sie hier aus, ob das Gerät die

Temperatur in °C oder °F anzeigt.

(Werkseinstellung °C)

Einheit = °C

Einheit = °F

60 - 8625-2 Standard

Page 63

6.6.3

MODE

Bild: Einstellung der Sollwertvorgabe

- Einstellung der Sollwertvorgabe

Î Wählen Sie hier aus, ob das Gerät mit internem oder externem

Sollwert arbeiten soll.

Die Auswahl "Externer Sollwert" wird durch die Ziffer „1“ in der

unteren Displayzeile gekennzeichnet.

(Werkseinstellung: externer Sollwert).

Sollwertvorgabe: Interner Sollwert

Interner

Sollwert

deutsch

Externer

1

Sollwert

Bei der internen Sollwertvorgabe wird der Sollwert als Temperatur in der vorher eingestellten Einheit (°C oder °F) eingegeben und gespeichert. Das Gerät regelt auf diesen

Wert aus.

Einstellungen sind zwischen -50 °C und 150 °C bzw. zwischen -58 °F und 302 °F

möglich. Wird versucht einen Wert außerhalb dieses Bereichs einzustellen, so springt

die Anzeige automatisch auf 0 und es muss ein Wert innerhalb des Bereichs eingegeben werden. Die Einheit entspricht dem im Menüpunkt

(Werkseinstellung 0,0)

2 s

Bild: Sollwertvorgabe Interner Sollwert

UNIT

eingestellten Wert.

Erhöhen der Stelle

nächste Stelle

an der 4. Stelle von rechts Wechsel

des Vorzeichens

8625-2 Standard - 61

Page 64

Sie geben bei der externen Sollwertvorgabe eine Skalierung an. Dabei wird der dem

Normsignal (4 - 20 mA, 0 - 10 V) entsprechende Temperaturbereich eingestellt. D. h. es

erfolgt die Eingabe der Temperatur bei 4 mA bzw 0 V (unterer Grenzwert) und bei

20 mA bzw. 10 V (oberer Grenzwert).

Einstellungen sind zwischen - 50 °C und 150 °C bzw. zwischen - 58 °F und

302 °F möglich. Wird versucht, einen Wert außerhalb dieses Bereichs einzustellen, so

springt die Anzeige automatisch auf 0 und es muss ein Wert innerhalb des Bereichs

eingegeben werden. Die Einheit entspricht dem im Menüpunkt

Wert. (Werkseinstellung

deutsch

Sollwertvorgabe: Externer Sollwert

UNIT

EXLO

= 0,0 °C ;

EXHI

= 100,0 °C)

eingestellten

Beispiel:

Unterer Grenzwert (

Oberer Grenzwert (

EXLO

) 20 °C 4 mA

EXHI

) 60 °C 20 mA

Wird z.B. ein Normsignal von 12 mA vorgegebenen, ergibt sich ein Sollwert von

40 °C.

Normsignal 4 - 20 mA

Erhöhen der Stelle

nächste Stelle

an der 4. Stelle von rechts

2 s

Normsignal 0 - 10 V

Wechsel des Vorzeichens

Bild:Sollwertvorgabe: Externer Sollwert

Wurde der Wert für

EXLO

ERR9

In diesem Fall werden die neu eingestellten Werte nicht übernommen!

62 - 8625-2 Standard

Erhöhen der Stelle

nächste Stelle

an der 4. Stelle von rechts

2 s

Wechsel des Vorzeichens

EXHI

kleiner oder gleich gewählt als der Wert für

, erscheint abwechselnd blinkend auf der Textanzeige

.

MODE

und

Page 65

6.6.4

AMPL

Î Wählen Sie den Verstärkungsfaktor Kp in einem Einstellbereich von 0,00 bis

Einstellhilfe

• Falls sich bei dem eingestellten Wert für Kp unzulässig hohe Überschwinger

• Umgekehrt lässt sich eine unbefriedigende Dynamik der Regelung durch

- Einstellung der Verstärkung Kp

10,00 %/K aus (Werkseinstellung 1,00). Wird versucht einen höheren Wert

einzustellen, so springt die Anzeige automatisch auf 0 und es muss ein Wert

innerhalb des Bereichs eingegeben werden.

nach Sollwertsprüngen ergeben bzw. die Regelung instabil wird, sollten Sie K

verringern.

Erhöhung von K

Instabilitäten kommt.

verbessern, solange es nicht zu den oben beschriebenen

p

p

deutsch

2 s Dezimalpunkt setzen

Bild: Einstellung der Verstärkung Kp

Erhöhen der Stelle

nächste Stelle

8625-2 Standard - 63

Page 66

6.6.5

INTG

Die Nachstellzeit TN ist die Zeit, die benötigt wird um durch den I-Anteil eine gleich

große Stellgrößenänderung zu erzielen, wie sie infolge des P-Anteils entsteht.

Î Wählen Sie für die Nachstellzeit TN einen Wert zwischen 0,1 - 200,1 s aus

deutsch

INTG

- Einstellung der Nachstellzeit T

(Werkseinstellung: 0,50).

Wird versucht einen höheren Wert einzustellen, so springt die Anzeige

automatisch auf 0,1 und es muss ein Wert innerhalb des Bereichs eingegeben werden.

INTG

Erhöhen der Stelle

nächste Stelle

2 s Dezimalpunkt setzen

N

Bild: Einstellung der Nachstellzeit T

64 - 8625-2 Standard

N

Page 67

Eigenschaften von PI-Reglern

Ein PI-Regler besitzt einen Proportional- und einen Integralanteil (P-, I-Anteil).

P-Anteil:

Funktion:

y = Kp · x

d

Kp ist der Proportionalbeiwert (Verstärkungsfaktor). Er ergibt sich als Verhältnis

von Stellbereich ∆y zu Proportionalbereich ∆xd.

Kennlinie und Sprungantwort des P-Anteils eines PI-Reglers

x

d

y

max

kp*x

y

0

y

min

Proportionalbereich ∆x

Stellbereich ∆y

x

d

d

d

Kennlinie Sprungantwort

Eigenschaften:

Ein reiner P-Regler arbeitet theoretisch unverzögert, d.h. er ist schnell und damit

dynamisch günstig. Er hat eine bleibende Regeldifferenz, d.h. er regelt die Auswirkungen von Störungen nicht vollständig aus und ist damit statisch relativ ungünstig.

deutsch

8625-2 Standard - 65

Page 68

I-Anteil:

Funktion:

Ti ist die Integrier- oder Stellzeit. Sie ist die Zeit, die vergeht, bis die Stellgröße den

gesamten Stellbereich durchlaufen hat, wenn die Regelabweichung bei 100 %

festgehalten wird.

Kennlinie und Sprungantwort des I-Anteils eines PI-Reglers

deutsch

y =

1

T

i

∫ ∫

∫ xd dt

∫ ∫

x

x

d

y

max

x

d

y

min

Stellbereich ∆y

Regelbereich ∆x

Kennlinie

c

Sprungantwort

Stellzeit T

Eigenschaften:

Ein reiner I-Regler beseitigt die Auswirkungen auftretender Störungen vollständig.

Er besitzt also ein günstiges statisches Verhalten. Er arbeitet aufgrund seiner

endlichen Stellgeschwindigkeit langsamer als der P-Regler und neigt zu Schwingungen. Er ist also dynamisch relativ ungünstig.

Überlagerung von P- und I-Anteil:

Bei einem digitalen Regler mit der Abtastzeit TA lässt sich mit Ti=Kp/TN schreiben:

y = Kp (xd + TA/TN

∑∑

∑ xd)

∑∑

y : Stellgröße

Kp : Verstärkungsfaktor

xd : Regelabweichung (xd = w - x)

TA : Abtastzeit

TN : Nachstellzeit

66 - 8625-2 Standard

i

Page 69

Einstellregeln für PI-Regler

In der regelungstechnischen Literatur werden eine Reihe von Einstellregeln angegeben, mit denen auf experimentellem Wege eine günstige Einstellung der Reglerparameter ermittelt werden kann. Um dabei Fehleinstellungen zu vermeiden, sind

stets die Bedingungen zu beachten, unter denen die jeweiligen Einstellregeln

aufgestellt worden sind. Neben den Eigenschaften der Regelstrecke und des

Reglers selbst spielt dabei eine Rolle, ob eine Störgrößenänderung oder eine

Führungsgrößenänderung ausgeregelt werden soll.

Einstellregeln nach Ziegler und Nichols (Schwingungsmethode)

Bei dieser Methode erfolgt die Einstellung der Reglerparameter auf der Basis des

Verhaltens des Regelkreises an der Stabilitätsgrenze. Die Reglerparameter werden dabei zunächst so eingestellt, dass der Regelkreis zu schwingen beginnt. Aus

dabei auftretenden kritischen Kennwerten wird auf eine günstige Einstellung der

Reglerparameter geschlossen. Voraussetzung für die Anwendung dieser Methode

ist natürlich, dass der Regelkreis in Schwingungen gebracht werden darf.

Vorgehensweise:

• Regler als P-Regler einstellen (d.h. TN = 200 s), KP zunächst klein wählen

• gewünschten Sollwert einstellen

•Kp solange vergrößern, bis die Regelgröße eine ungedämpfte Dauerschwingung ausführt.

Der an der Stabilitätsgrenze eingestellte Proportionalitätsbeiwert (Verstärkungsfaktor) wird als K

T

genannt.

krit

bezeichnet. Die sich dabei ergebende Schwingungsdauer wird

krit

deutsch

Verlauf der Regelgröße an der Stabilitätsgrenze

X

Istwert

Tcrit

t

8625-2 Standard - 67

Page 70

Aus K

berechnen.

Einstellung der Parameter nach Ziegler und Nichols:

Die Einstellregeln von Ziegler und Nichols sind für P-Strecken mit Zeitvergrößerung

erster Ordnung und Totzeit ermittelt worden. Sie gelten allerdings nur für Regler mit

Störverhalten und nicht für solche mit Führungsverhalten.

deutsch

und T

krit

Reglertyp Einstellung der Parameter

P-Regler Kp = 0,5 K

PI-Regler Kp = 0,45 K

lassen sich dann die Reglerparameter gemäß folgender Tabelle

krit

krit

krit

-

TN = 0,85 T

krit

68 - 8625-2 Standard

Page 71

6.6.6

INV

- Heizen (nicht invertierte Regelung) /

Kühlen (invertierte Regelung)

Î Über diese Funktion stellen Sie den Wirksinn zwischen dem Eingangssignal

und der Sollposition des Ventils ein.

(Werkseinstellung: NO)

nicht invertierte Regelung

y = Kp (xd + TA/TN ∑ xd )

invertierte Regelung

y = - KP (xd + TA/TN ∑ xd )

Heizen (nicht invertierte Regelung):

NO

Ausgangssignal y des PI-Reglers

steigt mit wachsender positiver

Regeldifferenz xd = w-x.

Kühlen (invertierte Regelung):

YES

Ausgangssignal y des PI-Reglers

steigt mit wachsender negativer

Regeldifferenz xd = w-x.

deutsch

Bild: Heizen (nicht invertierte Regelung) / Kühlen (invertierte Regelung)

Anwendungsbeispiele :

Heizen: Beim „Heizen“ wird einem Flüssigkeitsstrom eine wärmere Flüssig-

keit mittels des Proportionalventils zugemischt. Hierbei wird die Temperatur

der gemischten Flüssigkeit gemessen und der Zustrom der wärmeren Flüssigkeit geregelt.

Kühlen: Beim „Kühlen“ wird einem Flüssigkeitsstrom eine kältere Flüssigkeit

mittels des Proportionalventils zugemischt. Hierbei wird die Temperatur der

gemischten Flüssigkeit gemessen und der Zustrom der kälteren Flüssigkeit

geregelt.

8625-2 Standard - 69

Page 72

6.6.7

ZERO

Die Nullpunktabschaltung ermöglicht es, dass das Proportionalventil neben der Regelfunktion auch noch eine Dichtschließfunktion übernimmt. Um bei einem Sollwert von

0 das Dichtschließen zu erreichen, wird bei Sollwerten unter 2% der Gesamtspanne

kein Signal an das Ventil ausgegeben, so dass die gesamte Federkraft als Dichtfkraft

zur Verfügung steht. Die unteren 2% des Sollwertbereiches stehen damit der Regelung nicht zur Verfügung.

Ohne Nullpunktabschaltung wird auch bei Sollwert = 0 ein Signal an das Ventil ausgegeben, das gerade die für den Öffnungsbeginn notwendige Magnetkraft erzeugt. Diese

wirkt der Federkraft entgegen, so dass das Ventil in den meisten Fällen nicht perfekt

dicht ist.

(Werkseinstellung: NO)

deutsch

- Nullpunktabschaltung

Keine Nullpunktabschaltung (NO):

Die Regelung erfolgt stetig bis zum unteren Grenzwert,

d.h. bis das im Menüpunkt

Tastverhältnis erreicht ist. Hierbei ist das Ventil zwar geschlossen

aber meist nicht leckagefrei.

VALV

eingestellte minimale

Nullpunktabschaltung (

Die Regelung erfolgt stetig bis das Eingangssignal einen Wert

< 2 % erreicht hat, anschließend wird das Ventil geschlossen.

Bild: Nullpunktabschaltung

Voraussetzungen für die Nullpunktabschaltung:

• Die Nullpunktabschaltung (

• der Sollwert ist kleiner als 2 %;

• nicht invertierte Regelung.

70 - 8625-2 Standard

YES

YES

):

) ist ausgewählt;

Page 73

6.6.8

VALV

- Anpassung Regler - Stellgröße

In diesem Menüpunkt kann der Ausgang des Reglers optimal an den aktuell in der

Anwendung überstrichenen Arbeitsbereich des Stellgliedes angepasst werden. Das

Proportionalventil wird vom Regler durch ein pulsweitenmoduliertes Signal angesteuert. Die Öffnung des Ventils beginnt dabei nicht bei Tastverhältnis 0 des PWM-Signal,

sondern wegen der der Magnetkraft entgegenwirkenden Federkraft erst ab einem

bestimmten Wert. Dieser Öffnungsbeginn ist abhängig von der Ventilnennweite, dem

Vordruck und wegen der Temperaturabhängigkeit des Spulenwiderstandes auch von

der Spulentemperatur. Die Funktion des Reglers kann dadurch optimiert werden, dass

der vom Regler ausgegebene Stellgrößenbereich nicht bei 0, sondern bei dem in der

aktuellen Applikation vorliegenden Öffnungsbeginn beginnt.

Anzeige Istwert

Im Menüpunkt

aktuelle Istwert angezeigt.

VALV

deutsch

wird der

Anzeige Tastverhältnis Ventil

Sobald durch Drücken der - der -Taste die Stellgröße

verändert wird, schaltet die Anzeige automatisch auf den

Wert der Stellgröße um, nach Loslassen der Taste wird

wieder der Istwert angezeigt.

Bild: Anpassung Regler - Stellgröße

Î Sie vergrößern mit dieser Taste das Tast-

verhältnis des Proportionalventils, d.h. das

Proportionalventil öffnet bis max. 100%.

Î Mit dieser Taste verringern Sie das

Tastverhältnis des Proportionalventils.

8625-2 Standard - 71

Page 74

Zur Ermittlung des Öffnungsbeginns des Proportionalventils in der aktuellen Applikation führen Sie - bei der ersten Inbetriebnahme des Gerätes unmittelbar nach dem

Einschalten, bei noch kalter Spule - die nachfolgenden Schritte aus:

Î Stellen Sie bei Verwendung eines direktwirkenden Proportionalventils (Typen

6022, 6023, 6024, 2832, 2834) den maximalen in der Anwendung zu erwartenden Betriebsdruck ein (hier sinkt der Öffnungsbeginn mit zunehmendem

Vordruck), in Verbindung mit einem vorgesteuerten Proportionalventil (Typ

6223) dagegen den geringsten im Betrieb zu erwartenden Vordruck (hier steigt

der Öffnungsbeginn mit zunehmendem Vordruck).

Î Wählen Sie im Konfigurationsmodus den Menüpunkt

Î Falls bei vorliegendem Stellgrößenwert kein erkennbarer Durchfluss vorhanden

deutsch

Î Verringern Sie nun durch Drücken der -Taste das Tastverhältnis

Î Drücken Sie die -Taste, der Wert für den Öffnungsbeginn wird gespei-

VALV

Istwert wird angezeigt.

ist, erhöhen Sie zunächst durch Drücken der -Taste das Tastverhältnis

solange, bis sich ein detektierbarer Durchfluss einstellt.

solange, bis das Ventil gerade geschlossen ist, d.h. kein Durchfluss mehr

vorhanden.

chert.

aus. Der aktuelle

72 - 8625-2 Standard

Page 75

6.6.9

END

STANDARD-

MODUS

Bild: Speichern der Werte

- Speichern der Werte

deutsch

HINWEIS

Die in den einzelnen Menüpunkten des Konfigurationsmodus

eingestellten Parameter werden bereits nach Verlassen des

entsprechenden Menüpunktes in den Speicher übernommen und

damit nach dem nächsten Aus- und Wiedereinschalten des

Gerätes gültig. Erst nach dem Verlassen des Konfigurationsmodus im Menüpunkt

meter auch für den laufenden Regelvorgang gültig.

END

mit der -Taste werden die Para-

8625-2 Standard - 73

Page 76

6.7 Einstellungen bei Auslieferung

Menü Parameter eingestellter Wert

UNIT

MODE

EXLO

EXHI

SET

AMPL

deutsch

INTG

INV

ZERO

VALV

Einheit °C

Art der Sollwertvorgabe externer Sollwert 0 - 10 V

unterer Grenzwert 0 °C

oberer Grenzwert 100 °C

interner Sollwert 0 °C

K

p

T

N

Heizen / Kühlen Heizen

Nullpunktabschaltung deaktiviert

unterer Grenzwert Stellgröße Ventil 0 %

1,00 %/K

0,50 s

74 - 8625-2 Standard

Page 77

7 FEHLERMELDUNGEN

Anzeige Ursache Abhilfe

ERR0

ERR1

ERR2

ERR9

Fühlerbruch des Sensorein- Überprüfen Sie ggf. den Sensor

gangs PT100 oder Ist-Tempe- oder dessen Verbindung zum

ratur außerhalb des Bereichs Regler

(- 50 °C ... 150 °C,

58 °F ... 302 °F)

Normsignal außerhalb des Überprüfen Sie das Normsignal