Page 1

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODELS: MFC-8460N/8860DN/8870DW

DCP-8060/8065DN

Confidential

Page 2

© Copyright Brother 2006

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

Confidential

Page 3

PREFACE

This Service Manual is intended for use by service personnel and details the specifications,

construction, theory of operation, and maintenance for the Brother machines noted on the front

cover. It includes information required for troubleshooting and service--disassembly, reassembly,

and lubrication--so that service personnel will be able to understand equipment function, repair the

equipment in a timely manner and order spare parts as necessary.

To perform appropriate maintenance so that the machine is always in the best possible condition

for the customer, service personnel must adequately understand and apply this manual.

HOW THIS MANUAL IS ORGANIZED

This manual is made up of nine chapters and appendices.

CHAPTER 1 PARTS NAMES AND FUNCTIONS

Contains external views and names of components and describes their functions. Information

about the keys on the control panel is included to help you check operation or make adjustments.

CHAPTER 2 SPECIFICATIONS

Lists the specifications of each model, which enables you to make a comparison of different

models.

CHAPTER 3 THEORY OF OPERATION

Gives an overview of the scanning and printing mechanisms as well as the sensors, actuators, and

control electronics. It aids in understanding the basic principles of operation as well as locating

defects for troubleshooting.

CHAPTER 4 TRANSFER OF DATA LEFT IN THE MACHINE TO BE SENT FOR REPAIR

Describes how to transfer data left in the machine to be sent for repair. The service personnel

should instruct end users to follow the transfer procedure given in this chapter if the machine at the

user site cannot print received data due to the printing mechanism defective. End users can

transfer received data to another machine to prevent data loss.

CHAPTER 5 DISASSEMBLY/REASSEMBLY AND LUBRICATION

Details procedures for disassembling and reassembling the machine together with related notes.

The disassembly order flow provided enables you to see at a glance the quickest way to get to

component(s) involved.

At the start of a disassembly job, you check a disassembly order flow that guides you through a

shortcut to the object components.

This chapter also covers screw tightening torques and lubrication points to which the specified

lubricants should be applied during reassembly jobs.

CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS

REPLACEMENT

Details adjustments and updating of settings, which are required if the head/carriage unit, main

PCB and some other parts have been replaced.

CHAPTER 7 CLEANING

Provides cleaning procedures not covered by the User's Manual. Before starting any repair work,

clean the machine as it may solve the problem concerned.

i Confidential

Page 4

CHAPTER 8 MAINTENANCE MODE

Describes the maintenance mode which is exclusively designed for the purpose of checks, settings

and adjustments using the keys on the control panel.

In the maintenance mode, you can update memory (EEPROM: electrically erasable programmable

read-only memory) contents for optimizing the drive conditions of the head/carriage unit, paper

feed roller or paper ejection roller (if they have been replaced) or for setting the CCD scanner area,

for example. You can also customize the EEPROM according to the shipment destination of the

machine concerned. In addition, you can perform operational checks of the LCD, control panel

PCB or sensors, perform a print test, display the log information or error codes, and modify

firmware switches (WSW).

CHAPTER 9 ERROR INDICATION AND TROUBLESHOOTING

Details error messages and codes that the incorporated self-diagnostic functions display if any

error or malfunction occurs. If any error message appears, refer to this chapter to find which

components should be checked or replaced.

The latter half of this chapter provides sample problems that could occur in the main sections of

the machine and related troubleshooting procedures. This will help service personnel pinpoint and

repair defective components.

APPENDIX 1 SERIAL NUMBERING SYSTEM

Shows the location of serial number labels put on some parts and lists the coding information

pertaining to the serial numbers.

APPENDIX 2 FIRMWARE INSTALLATION

Provides instructions on how to update firmware stored in the flash ROM on the main PCB or load

firmware to a new main PCB from the host PC.

No hardware replacement is required for updating.

APPENDIX 3 CUSTOMIZING CODES ACCORDING TO SHIPPING DESTINATION

Lists the customizing codes for the various preferences exclusively designed for each destination

(e.g. language). Those codes are stored in the memory (EEPROM) mounted on the main PCB. If

the main PCB is replaced with a new one, therefore, you will need to set the proper customizing

codes with the machine in the maintenance mode.

APPENDIX 4 FIRMWARE SWITCHES (WSW)

Describes the functions of the firmware switches, which can be divided into two groups: one is for

customizing preferences designed for the shipping destination (as described in Appendix 3) and

the other is for modifying preferences that match the machine to the environmental conditions.

Use the latter group if the machine malfunctions due to mismatching.

APPENDIX 5 WIRING DIAGRAM

Provides the wiring diagram that helps you understand the connections between PCBs.

APPENDIX 6 CIRCUIT DIAGRAMS

Provides the circuit diagrams of the NCU PCB and power supply PCB.

APPENDIX 7 VIEWING THE EVENT LOG FILE

When installing the printer driver, the installer logs events that occur during the installation

process in the event log file. This appendix views a sample of the event log file. Selecting Start |

Program | Brother | MFL-Pro Suite model name | Installation Diagnostics reads out the event log

file.

This manual describes the models and their versions destined for major countries.

The specifications and functions are subject to change depending upon each destination.

ii Confidential

Page 5

TABLE OF CONTENTS

CHAPTER 1 PARTS NAMES & FUNCTIONS

1.1 EQUIPMENT OUTLINE.............................................................................................1-1

1.2 CONTROL PANEL .................................................................................................... 1-2

1.3 COMPONENTS .........................................................................................................1-7

CHAPTER 2 SPECIFICATIONS

2.1 GENERAL..................................................................................................................2-1

2.1.1 General Specifications ......................................................................................... 2-1

2.1.2 Paper Specifications............................................................................................. 2-2

2.1.2.1 Paper handling ...............................................................................................2-2

2.1.2.2 Media specifications ....................................................................................... 2-2

2.1.3 Printable Area ................................................................................................................ 2-5

2.1.3.1 PCL5e/EPSON/IBM emulation .......................................................................2-5

2.1.3.2 PCLXL, PS (BR-Script 3)................................................................................2-8

2.1.4 Print Speeds with Various Settings .............................................................................2-9

2.1.5 Toner Cartridge Weight Information .........................................................................2-10

2.2 SPECIFICATIONS LIST ..........................................................................................2-11

CHAPTER 3 THEORY OF OPERATION

3.1 OVERVIEW................................................................................................................3-1

3.2 MECHANICAL COMPONENTS ................................................................................ 3-2

3.2.1 Scanner Mechanism ............................................................................................3-3

3.2.2 Overview of Gear .................................................................................................3-9

3.2.3 Paper Transfer ...................................................................................................3-10

3.2.3.1 Paper supply ..............................................................................................3-10

3.2.3.2 Paper registration....................................................................................... 3-12

3.2.3.3 Drum unit....................................................................................................3-12

3.2.3.4 Developing ................................................................................................. 3-13

3.2.3.5 Fixing stage................................................................................................ 3-14

3.2.3.6 Paper eject................................................................................................. 3-15

3.2.3.7 Duplex printing (For the models with the DX only).....................................3-16

iii Confidential

Page 6

3.2.3.8 Paper feeding from the MP tray ................................................................. 3-17

3.2.3.9 LT tray........................................................................................................ 3-17

3.2.4 Toner Cartridge .................................................................................................. 3-18

3.2.4.1 Toner life end mode ................................................................................... 3-18

3.2.4.2 New toner detection mechanism................................................................ 3-20

3.2.4.3 Counter reset during indication of “Toner Life End” ................................... 3-21

3.2.5 Print Process ...................................................................................................... 3-22

3.2.5.1 Charging..................................................................................................... 3-22

3.2.5.2 Exposure stage ..........................................................................................3-22

3.2.5.3 Transfer......................................................................................................3-23

3.2.6 Sensors .............................................................................................................. 3-24

3.3 CONTROL ELECTRONICS ....................................................................................3-25

3.3.1 Components .......................................................................................................3-25

CHAPTER 4 TRANSFER OF DATA LEFT IN THE MACHINE TO BE SENT FOR REPAIR

4.1 TRANSFERRING RECEIVED FAX DATA ................................................................ 4-1

CHAPTER 5 DISASSEMBLY/REASSEMBLY AND LUBRICATION

5.1 DISASSEMBLY/REASSEMBLY ............................................................................... 5-1

Safety Precautions............................................................................................................5-1

Tightening Torque ............................................................................................................5-2

Harness Routing............................................................................................................... 5-4

Preparation .....................................................................................................................5-21

How to Access the Object Component........................................................................... 5-21

Disassembly Flowchart................................................................................................... 5-22

5.1.1 AC Cord..............................................................................................................5-23

5.1.2 Drum/Toner ASSY.............................................................................................. 5-23

5.1.3 DX Feed ASSY (For the models with the DX only) ............................................5-24

5.1.4 Paper Tray.......................................................................................................... 5-24

5.1.5 Back Cover.........................................................................................................5-27

5.1.6 DX Blank Cover (For models with out the DX only) ...........................................5-27

5.1.7 Outer Chute ASSY .............................................................................................5-28

iv Confidential

Page 7

5.1.8 Access Cover/Side Cover L ...............................................................................5-30

5.1.9 ADF Unit.............................................................................................................5-31

5.1.10 Hinge Base R .....................................................................................................5-32

5.1.11 Hinge Arm R.......................................................................................................5-33

5.1.12 Hinge ASSY L..................................................................................................... 5-33

5.1.13 ADF Cover ASSY ...............................................................................................5-34

5.1.14 ADF Side Cover F ..............................................................................................5-34

5.1.15 ADF Side Cover R ..............................................................................................5-35

5.1.16 ADF Chute ASSY ............................................................................................... 5-36

5.1.17 SB Chute ASSY (For the models with the DX only) /

SX Chute (For the models with out the DX only) ...............................................5-38

5.1.18 Exit Chute Cover ASSY...................................................................................... 5-38

5.1.19 Earth Spring ....................................................................................................... 5-39

5.1.20 PF Roller Holder ASSY ...................................................................................... 5-40

5.1.21 LF Roller 1 ASSY ............................................................................................... 5-41

5.1.22 SB Roller ASSY (For the models with the DX only) ...........................................5-42

5.1.23 ADF Motor ..........................................................................................................5-44

5.1.24 SB Solenoid ASSY (For the models with the DX only)....................................... 5-45

5.1.25 PF Solenoid ASSY (For the models with the DX only)....................................... 5-45

5.1.26 ADF Relay PCB..................................................................................................5-46

5.1.27 Paper Feed Chute ASSY ...................................................................................5-47

5.1.28 Actuator Front 1/Photo Interrupter

(For the models with the DX only) ...................................................................... 5-48

5.1.29 Actuator Front 2/Photo Interrupter

(For the models with the DX only) ...................................................................... 5-49

5.1.30 ADF Film/Spring Plate ADF Front A ASSY/Separation Rubber/Rubber Holder/

Separation Spring............................................................................................... 5-50

5.1.31 Pressure Roller/LF Spring .................................................................................. 5-50

5.1.32 LF Roller 2 ASSY ............................................................................................... 5-51

5.1.33 Exit Roller ASSY.................................................................................................5-52

5.1.34 LF Roller 3 ASSY ............................................................................................... 5-53

5.1.35 LF Roller 4 ASSY ............................................................................................... 5-54

5.1.36 Flap A ASSY (For the models with the DX only)/

Flap A (For models with out the DX only)...........................................................5-55

v Confidential

Page 8

5.1.37 Document Hold/Document Hold Spring .............................................................5-56

5.1.38 Upper Main Chute ASSY/Lower Main Chute ASSY ...........................................5-56

5.1.39 Actuator R/Photo Interrupter .............................................................................. 5-58

5.1.40 Flap B .................................................................................................................5-59

5.1.41 Actuator SB/Photo Interrupter (For the models with the DX only)...................... 5-59

5.1.42 Document Ejection Tray .....................................................................................5-60

5.1.43 Document Cover Sensor .................................................................................... 5-61

5.1.44 Eject Roller B4.................................................................................................... 5-61

5.1.45 Presser Roller..................................................................................................... 5-62

5.1.46 Panel Cover ASSY .............................................................................................5-63

5.1.47 Scanner Unit ASSY ............................................................................................5-64

5.1.48 Top Cover ASSY ................................................................................................5-65

5.1.49 Lock Lever B/Lock Lever ASSY ......................................................................... 5-65

5.1.50 CCD Module.......................................................................................................5-66

5.1.51 FFC Cable ASSY ...............................................................................................5-68

5.1.52 Scanner Motor FB .............................................................................................. 5-69

5.1.53 Pulley ASSY .......................................................................................................5-70

5.1.54 Photo Interrupter ................................................................................................5-70

5.1.55 Panel Unit........................................................................................................... 5-71

5.1.56 Panel PCB ASSY ...............................................................................................5-72

5.1.57 Printed Rubber Key ............................................................................................5-73

5.1.58 LCD Cover/Backlight Module/LCD .....................................................................5-74

5.1.59 NCU PCB ASSY (For the models with the NCU only) .......................................5-75

5.1.60 Speaker ASSY ................................................................................................... 5-77

5.1.61 Driver PCB .........................................................................................................5-78

5.1.62 Fuser Unit...........................................................................................................5-79

5.1.63 Tray MP ASSY ................................................................................................... 5-81

5.1.64 MP Tray Cover ASSY/Process Cover ASSY......................................................5-82

5.1.65 Main PCB ........................................................................................................... 5-85

5.1.66 Gear Plate Calking ASSY AL/Develop Joint/Main Motor ASSY AL.................... 5-86

5.1.67 Main Shield Plate ASSY ..................................................................................... 5-88

vi Confidential

Page 9

5.1.68 Relay Rear PCB ASSY/Connector .....................................................................5-90

5.1.69 Relay Front PCB ASSY ......................................................................................5-92

5.1.70 MP Solenoid ASSY............................................................................................. 5-93

5.1.71 Drive Release Link .............................................................................................5-94

5.1.72 T1 Solenoid ASSY.............................................................................................. 5-95

5.1.73 Toner Sensor PCB ............................................................................................. 5-95

5.1.74 Register Solenoid ASSY.....................................................................................5-96

5.1.75 Ejector Solenoid ASSY (For the models with the DX only) ................................5-96

5.1.76 Interlock SW ASSY ............................................................................................ 5-97

5.1.77 New Toner Actuator ...........................................................................................5-97

5.1.78 Gear 17/20 .........................................................................................................5-98

5.1.79 Thermistor ASSY.............................................................................................. 5-100

5.1.80 Side Cover R .................................................................................................... 5-100

5.1.81 Joint Cover ASSY............................................................................................. 5-101

5.1.82 Filter ................................................................................................................. 5-102

5.1.83 Laser Unit .........................................................................................................5-103

5.1.84 PS PCB Unit .....................................................................................................5-104

5.1.85 High-Voltage PS PCB ASSY ............................................................................5-107

5.1.86 Toner LED PCB Unit ASSY.............................................................................. 5-109

5.1.87 Fan Motor 60 Unit.............................................................................................5-110

5.1.88 Fan Motor 60 Unit LV .......................................................................................5-110

5.1.89 Frame L ............................................................................................................ 5-111

5.1.90 Frame R ...........................................................................................................5-111

5.1.91 MP Unit............................................................................................................. 5-112

5.1.92 Regist Actuator Rear/Regist Actuator Spring ...................................................5-117

5.1.93 Regist Actuator Front/Regist Actuator Spring ..................................................5-119

5.1.94 Roller Holder ASSY.......................................................................................... 5-120

5.1.95 PE Actuator, Edge Actuator, Edge Actuator Spring .........................................5-121

5.1.96 PE PG Sensor ASSY .......................................................................................5-123

5.1.97 Wireless PCB (PCB T60H929.00 ASSY 02) (For the model with the Wireless only)5-124

5.2 DISASSEMBLY/REASSEMBLY (LT-5300) .......................................................... 5-125

5.2.1 Paper Tray........................................................................................................ 5-125

vii Confidential

Page 10

5.2.2 LT Front Cover ASSY....................................................................................... 5-128

5.2.3 LT Rear Cover.................................................................................................. 5-129

5.2.4 LT Side Cover L ...............................................................................................5-129

5.2.5 LT Side Cover R............................................................................................... 5-130

5.2.6 LT PCB ASSY ..................................................................................................5-131

5.2.7 Connector: 55533-1219....................................................................................5-132

5.2.8 Connector: 54702-1219....................................................................................5-132

5.2.9 Gear 24 LT .......................................................................................................5-133

5.2.10 Collar 6 .............................................................................................................5-134

5.2.11 LT Solenoid ASSY............................................................................................ 5-138

5.2.12 Roller Holder ASSY.......................................................................................... 5-139

5.2.13 Edge Actuator Spring ....................................................................................... 5-140

5.2.14 PE Actuator, Edge Actuator .............................................................................5-141

5.2.15 LT Sensor PCB ASSY......................................................................................5-142

5.3 LUBRICATION ......................................................................................................5-144

CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS, REQUIRED AFTER PARTS

REPLACEMENT

6.1 IF YOU REPLACE THE MAIN PCB.......................................................................... 6-1

6.1.1 Load Update Programs/data ................................................................................6-1

6.1.2 Initialize the EEPROM on the Main PCB (Function code 01)............................... 6-1

6.1.3 Customize the EEPROM on the Main PCB (Function code 74)...........................6-1

6.1.4 Check the Control Panel PCB for Normal Operation (Function code 13) ............6-1

6.1.5 Make a Sensor Operation Check (Function code 32) ..........................................6-1

6.1.6 Acquire of White Level Data and Set the CCD Scanner Area

(Function code 55) .................................................................................................6-1

6.1.7 Setting the Serial Number ....................................................................................6-1

6.1.8 Switch Back to Standby........................................................................................ 6-2

6.2 IF YOU REPLACE THE DOCUMENT SCANNER UNIT........................................... 6-2

6.2.1 Acquire of White Level Data and Set the CCD Scanner Area

(Function code 55) ...............................................................................................6-2

6.3 IF YOU REPLACE THE DRUM UNIT .......................................................................6-2

6.4 PERIODICAL REPLACEMENT PARTS ...................................................................6-3

6.4.1 Periodical Replacement Parts .............................................................................. 6-3

viii Confidential

Page 11

6.4.2 Procedures to Replace Periodical Replacement Parts ........................................6-4

6.4.2.1 Fuser unit and laser unit...............................................................................6-4

6.4.2.2 Paper feeding kit for tray 1, 2 ..................................................................... 6-32

6.4.2.3 Paper feeding kit for MP tray......................................................................6-39

CHAPTER 7 CLEANING

CHAPTER 8 MAINTENANCE MODE

8.1 ENTRY INTO THE MAINTENANCE MODE .............................................................8-1

8.2 LIST OF MAINTENANCE-MODE FUNCTIONS ....................................................... 8-2

8.3 USER-ACCESS TO THE MAINTENANCE MODE ...................................................8-3

8.4 DETAILED DESCRIPTION OF MAINTENANCE-MODE FUNCTIONS....................8-4

8.4.1 EEPROM Parameter Initialization (Function code 01/91) .................................... 8-4

8.4.2 Printout of Scanning Compensation Data (Function code 05) ............................. 8-5

8.4.3 Placement of CCD Unit in Position for Transportation (Function code 06) ..........8-9

8.4.4 ADF Performance Test (Function code 08) .........................................................8-9

8.4.5 Test Pattern 1 (Function code 09)...................................................................... 8-10

8.4.6 Firmware Switch Setting and Printout ................................................................8-11

8.4.6.1 Firmware switch setting (Function code 10) ..............................................8-11

8.4.6.2 Printout of firmware switch data (Function code 11) .................................. 8-13

8.4.7 Operation Check of LCD (Function code 12) .....................................................8-14

8.4.8 Operational Check of Control Panel PCB (Function code 13) ...........................8-15

8.4.9 Sensor Operational Check (Function code 32) ..................................................8-16

8.4.10 Received Data Transfer Function (Function code 53)

(Not applicable to DCP-8060/8065DN.)............................................................. 8-18

8.4.11 Fine Adjustment of Scan Start/End Positions (Function code 54) .....................8-20

8.4.12 Acquisition of White Level Data and CCD Scanner Area Setting

(Function code 55) .............................................................................................8-22

8.4.13 Paper Feeding and Ejecting Test (Function code 67) ........................................8-23

8.4.14 EEPROM Customizing (Function code 74) ........................................................8-23

8.4.15 Display of the Equipment’s Log Information (Function code 80)........................ 8-24

8.4.16 Machine Error Code Indication (Function code 82)............................................ 8-26

8.4.17 Output of Transmission Log to the Telephone Line (Function code 87)

(Not applicable to DCP-8060/8065DN.)............................................................. 8-26

ix Confidential

Page 12

8.4.18 Counter Reset After Replacing the Fuser Unit, Laser Unit and

Paper Feed Kit (Function code 88).................................................................... 8-27

8.4.19 Cancellation of the Memory Security Mode

(Not applicable to with out the NCU models and the Japanese model.) ........... 8-27

CHAPTER 9 ERROR INDICATION AND TROUBLESHOOTING

9.1 ERROR INDICATION ................................................................................................ 9-1

9.1.1 Equipment Errors .................................................................................................9-1

9.1.1.1 Error messages appearing on the LCD ..........................................................9-1

9.1.1.2 Error codes shown in "MACHINE ERROR X

9.1.2 Communications Errors......................................................................................9-11

9.2 TROUBLESHOOTING ............................................................................................ 9-15

9.2.1 Introduction......................................................................................................... 9-15

9.2.2 Precautions ........................................................................................................ 9-15

9.2.3 Checking Prior to Troubleshooting..................................................................... 9-15

9.2.4 Troubleshooting Based on Problem Type.......................................................... 9-16

9.2.4.1 Paper feeding problems ...............................................................................9-16

9.2.4.2 Software setting problems ............................................................................ 9-18

9.2.4.3 Malfunction ................................................................................................... 9-21

9.2.4.4 Image defects ............................................................................................... 9-27

9.2.4.5 Incorrect printout...........................................................................................9-47

9.2.4.6 Network problem ..........................................................................................9-49

9.2.4.7 Troubleshooting of the control panel ............................................................ 9-56

X" messages ...........................9-4

9.2.4.8 Troubleshooting of fax functions ..................................................................9-58

APPENDIX 1 SERIAL NUMBERING SYSTEM

APPENDIX 2 FIRMWARE INSTALLATION

A2.1 INSTALLING THE UPDATE DATA TO THE MACHINE..................................APP. 2-1

A2.2 SETTING ID CODES TO MACHINES..............................................................APP. 2-7

APPENDIX 3 CUSTOMIZING CODES ACCORDING TO SHIPPING DESTINATION

x Confidential

Page 13

APPENDIX 4 FIRMWARE SWITCHES (WSW)

APPENDIX 5 WIRING DIAGRAM

APPENDIX 6 CIRCUIT DIAGRAMS

NCU PCB

POWER SUPPLY PCB 100V

POWER SUPPLY PCB 200V

APPENDIX 7 VIEWING THE EVENT LOG FILE

APPENDIX 8 READMARKS

xi Confidential

Page 14

SAFETY PRECAUTIONS

To use the machine safely

Please keep these instructions for later reference and read them before attempting any maintenance.

NOTE: If there are faxes in the machine's memory, you need to print them or save them before you

turn off the power and unplug the machine.

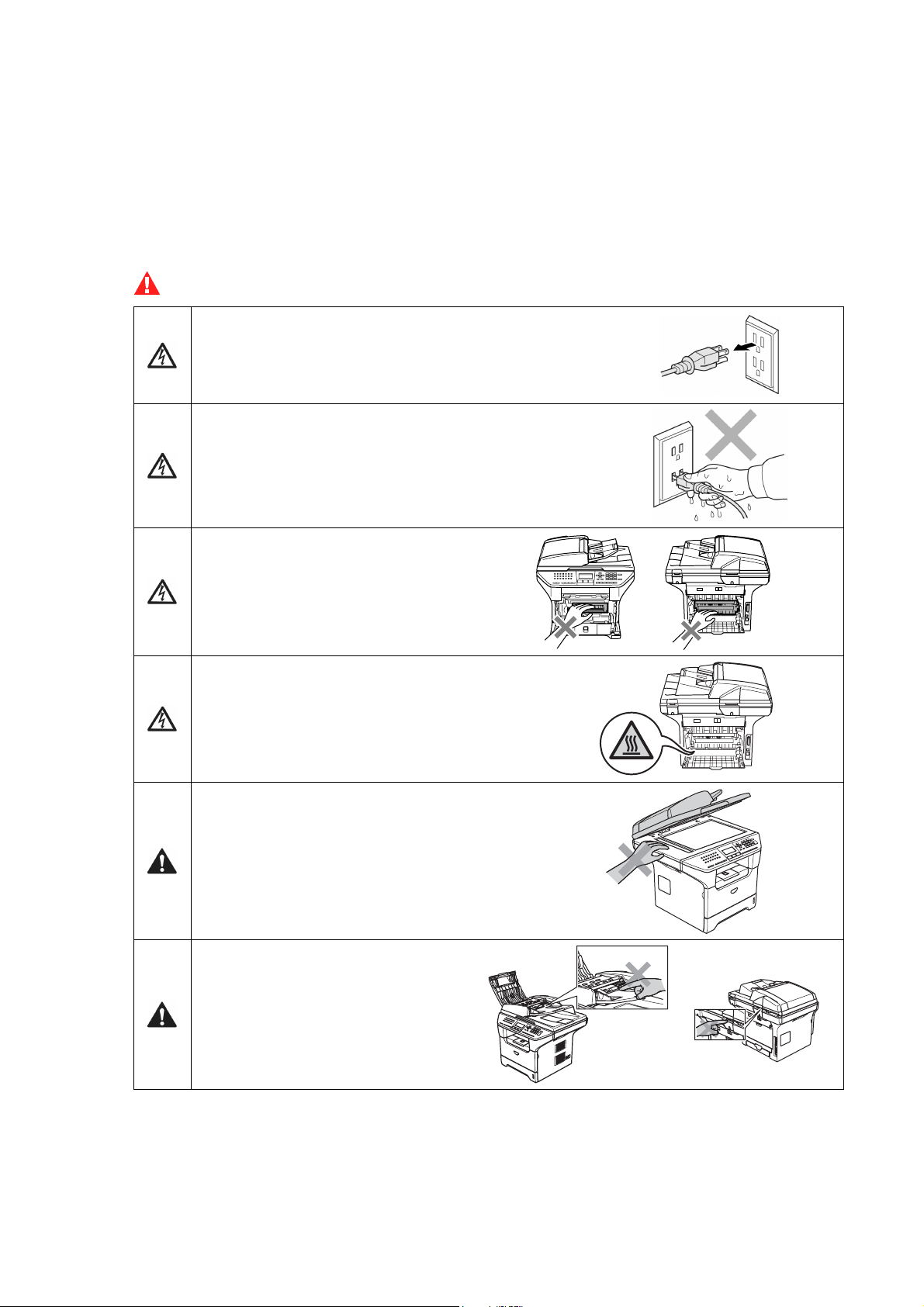

WARNING

There are high voltage electrodes inside the machine.

Before you clean the inside of the machine, make sure

you have unplugged the telephone line cord first and

then the power cord from the AC power outlet.

Do not handle the plug with wet hands.

Doing this might cause an electrical shock.

After you use the machine, some

internal parts are extremely HOT!

To prevent injuries, be careful not to

put your fingers in the areas shown

in the illustration.

The fuser unit is marked with a caution label.

Please do not remove or damage the label.

To prevent injuries, be careful not to put your

hands on the edge of the machine under the

scanner cover.

To prevent injuries, be careful not to

put your fingers in the area shown in

the illustrations.

Do not use a vacuum cleaner to clean up scattered toner. Doing this might cause the toner dust to

ignite inside the vacuum cleaner, potentially starting a fire. Please carefully clean the toner dust with

a dry, lint-free cloth and dispose of it according to local regulations.

Confidential

xii

Page 15

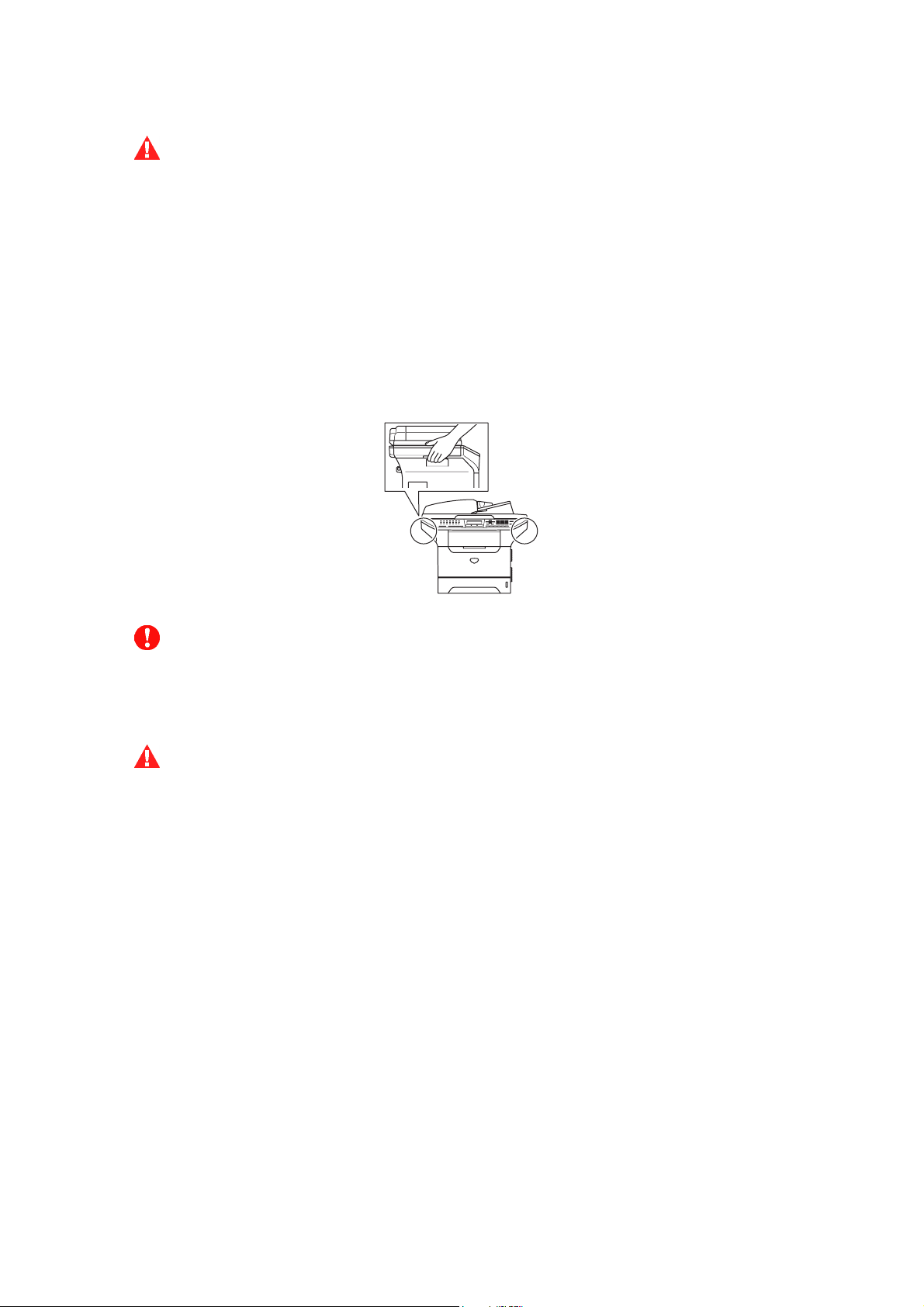

WARNING

- When you move the machine, grasp the side hand holds that are under the scanner. DO NOT

carry the machine by holding it at the bottom.

- Use caution when installing or modifying telephone lines.

Never touch telephone wires or

jack. Never install telephone wiring during a lightning storm. Never install a telephone wall

jack in a wet location.

- This product must be installed near an AC power outlet that is easily accessible.

In case of

an emergency, you must disconnect the power cord from the AC power outlet to shut off the

power completely.

- To reduce the risk of shock or fire, use only a No. 26 AWG or larger telecommunication line

cord.

CAUTION

Lightning and power surges can damage this product! We recommend that you use a quality

surge protection device on the AC power line and on the telephone line, or unplug the cords

during a lightning storm.

WARNING

IMPORTANT SAFETY INSTRUCTIONS

When using your telephone equipment, basic safety precautions should always be followed to

reduce the risk of fire, electric shock and injury to people, including the following:

1. Do not use this product near water, for example, near a bath tub, wash bowl, kitchen sink or

washing machine, in a wet basement or near a swimming pool.

2. Avoid using this product during an electrical storm. There may be a remote risk of electric

shock from lightning.

3. Do not use this product to report a gas leak in the vicinity of the leak.

4. Use only the power cord provided with the MACHINE.

SAVE THESE INSTRUCTIONS

Confidential

xiii

Page 16

CHOOSING A LOCATION

Place your machine on a flat, stable surface that is free of vibration and shocks, such as a desk.

Put the machine near a telephone wall jack and a standard, grounded AC power outlet.

Choose a location where the temperature remains between 50°F and 90.5°F (10°C and 32.5°C).

CAUTION

- Avoid placing your machine in a high-traffic area.

- Do not place the machine near heaters, air conditioners, water, chemicals, or refrigerators.

- Do not expose the machine to direct sunlight, excessive heat, moisture, or dust.

- Do not connect your

timers.

- Disruption of power can wipe out information in the

- Do not connect your machine to an AC power outlet on the same circuit as large appliances or

other equipment that might disrupt the power supply.

- Avoid interference sources, such as speakers or the base units of cordless phones.

machine to an AC power outlet controlled by wall switches or automatic

machine’s memory.

Confidential

xiv

Page 17

CHAPTER

PARTS NAMES & FUNCTIONS

1

Confidential

Page 18

CHAPTER 1 PARTS NAMES & FUNCTIONS

This chapter contains external views and names of components and describes their functions.

Information about the keys on the control panel is included to help you check operation or make

adjustments.

CONTENTS

1.1 EQUIPMENT OUTLINE ...................................................................................................1-1

1.2 CONTROL PANEL...........................................................................................................1-2

1.3 COMPONENTS................................................................................................................ 1-7

Confidential

Page 19

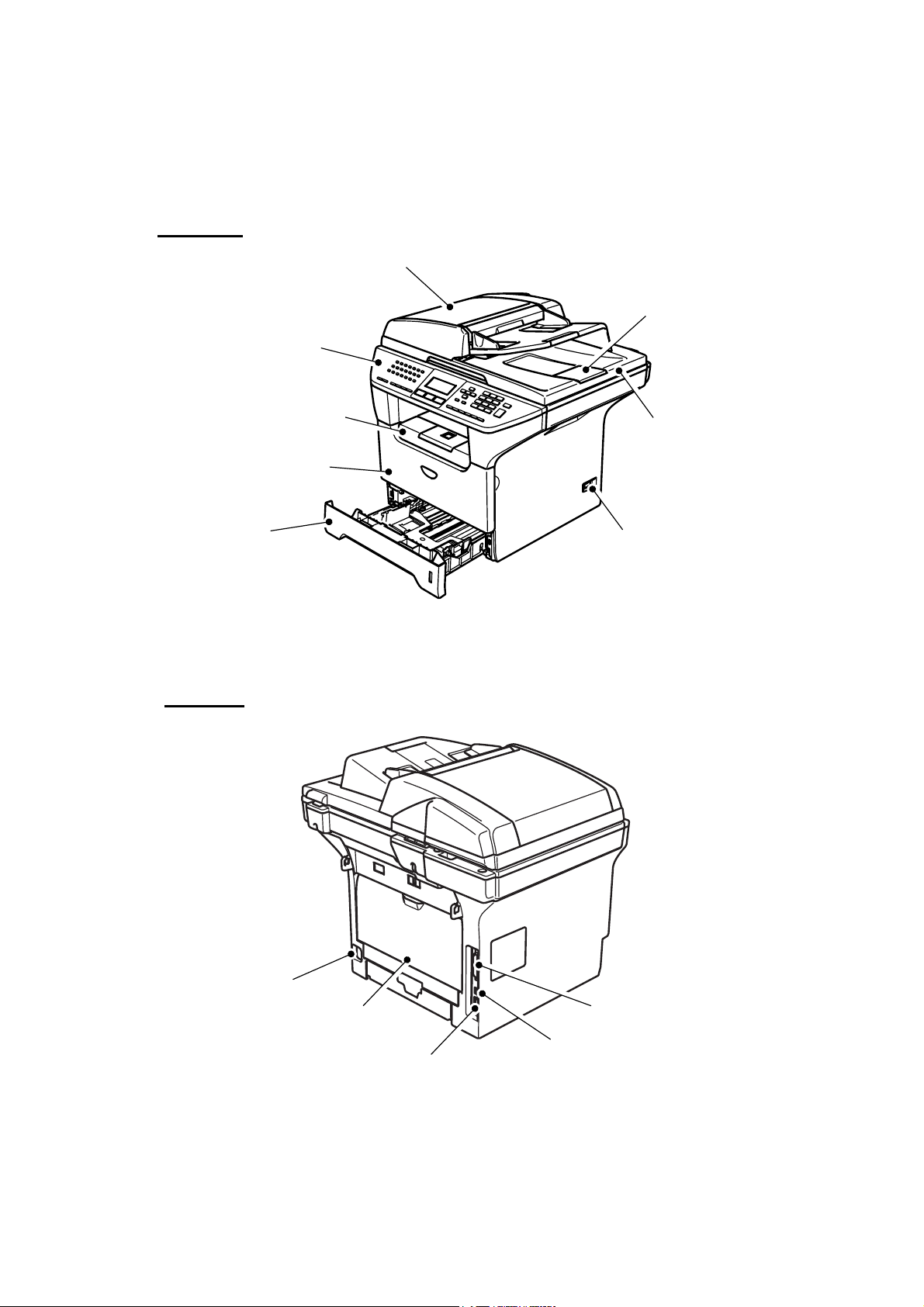

1.1 EQUIPMENT OUTLINE

Front view

Automatic Document Feeder (ADF)

Control Panel

Face-down Output Tray

Support Flap with Extension

(Support Flap)

Front Cover

ADF Document Output Support Flap

Document Cover

Paper Tray

Rear view

Power Switch

Fig. 1-1

AC Power Connector

Back Cover

10/100 Baser TX Port

Parallel Interface Connector

USB Interface Connector

Fig. 1-2

1-1 Confidential

Page 20

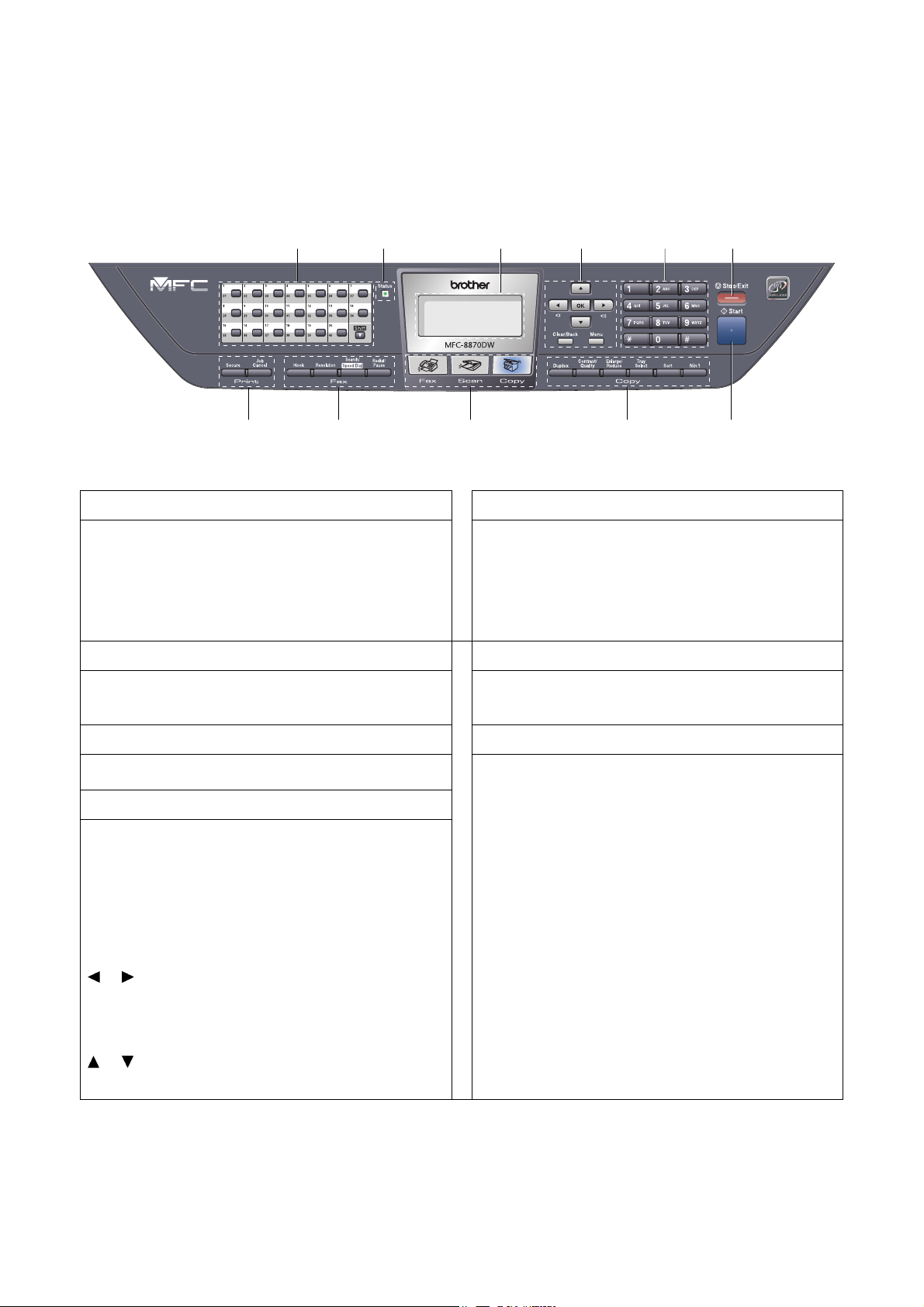

1.2 CONTROL PANEL

MFC-8460N, MFC-8860DN and MFC-8870DW have similar control keys.

3 4 5 6 2 1

1. One-Touch Keys

These 20 keys give you instant access to 40

previously stored numbers.

Shift

Lets you access One-Touch numbers 21 to 40 when

held down.

2. Status LED

The LED will flash and change color depending on

the machine status.

3. LCD 7. Start Key

Displays messages to help you use your machine.

4. Menu Keys

Menu

Accesses the main menu.

8 9 10 11

Fig. 1-3

Used to enter telephone and fax numbers or to

enter text.

The [#] key temporarily switches the dialing mode

from Pulse to Tone during a telephone call.

Stops an operation or exits from a menu.

Starts sending a fax, making a copy or scanning.

5. Dial pad Keys

6. Stop/Exit Key

7

Clear/Back

Deletes entered data or lets you exit the menu.

OK

Selects a setting.

or

Scrolls backwards or forwards through menu

selections.

Changes the volume when in fax or standby mode.

or

Scrolls through the menus and options.

1-2 Confidential

Page 21

8. Copy Keys

Duplex (For MFC-8860DN and MFC-8870DW)

You can choose Duplex to copy on both sides of

the paper.

Contrast/Quality

(For MFC-8860DN and MFC-8870DW)

Lets you change the quality or contrast for the next

copy.

Contrast (For MFC-8460N)

Lets you change the contrast for the next copy.

Quality (For MFC-8460N)

Lets you change the quality for the next copy.

Enlarge/Reduce

Reduces or enlarges copies.

Tray Select

Lets you change which tray will be used for the

next copy.

Sort

Sorts multiple copies using the ADF.

N in 1

You can choose N in 1 to copy 2 or 4 pages onto

one page.

Hook

10. Fax and Telephone Keys

Press before dialing if you want to make sure a fax

machine answers, and then press [Start] key.

Also, press this key after you pick up the handset

of an external telephone during the F/T ring (fast

double-rings).

Resolution

Sets the resolution when sending a fax.

Search/Speed Dial

Lets you look up numbers stored in the dialing

memory and LDAP server* (* MFC-8860DN and

MFC-8870DW).

You can search the stored number by

alphabetically.

It also lets you look up the stored number in SpeedDial numbers by pressing [Shift] key and [Speed-

Dial] key simultaneously and then the three digit

number.

Redial/Pause

Redials the last number called. It also inserts a

pause when programming quick dial numbers.

9. Mode Keys

Fax

Puts the machine in Fax mode.

Scan

Puts the machine in Scan mode.

(For details about scanning. See Software User’s

Guide on the CD-ROM.)

Copy

Puts the machine in Copy mode.

Secure

11. Print Keys

Prints data saved in memory when you enter your

four-digit password.

Job Cancel

Cancels a print job and clears the machine memory.

1-3 Confidential

Page 22

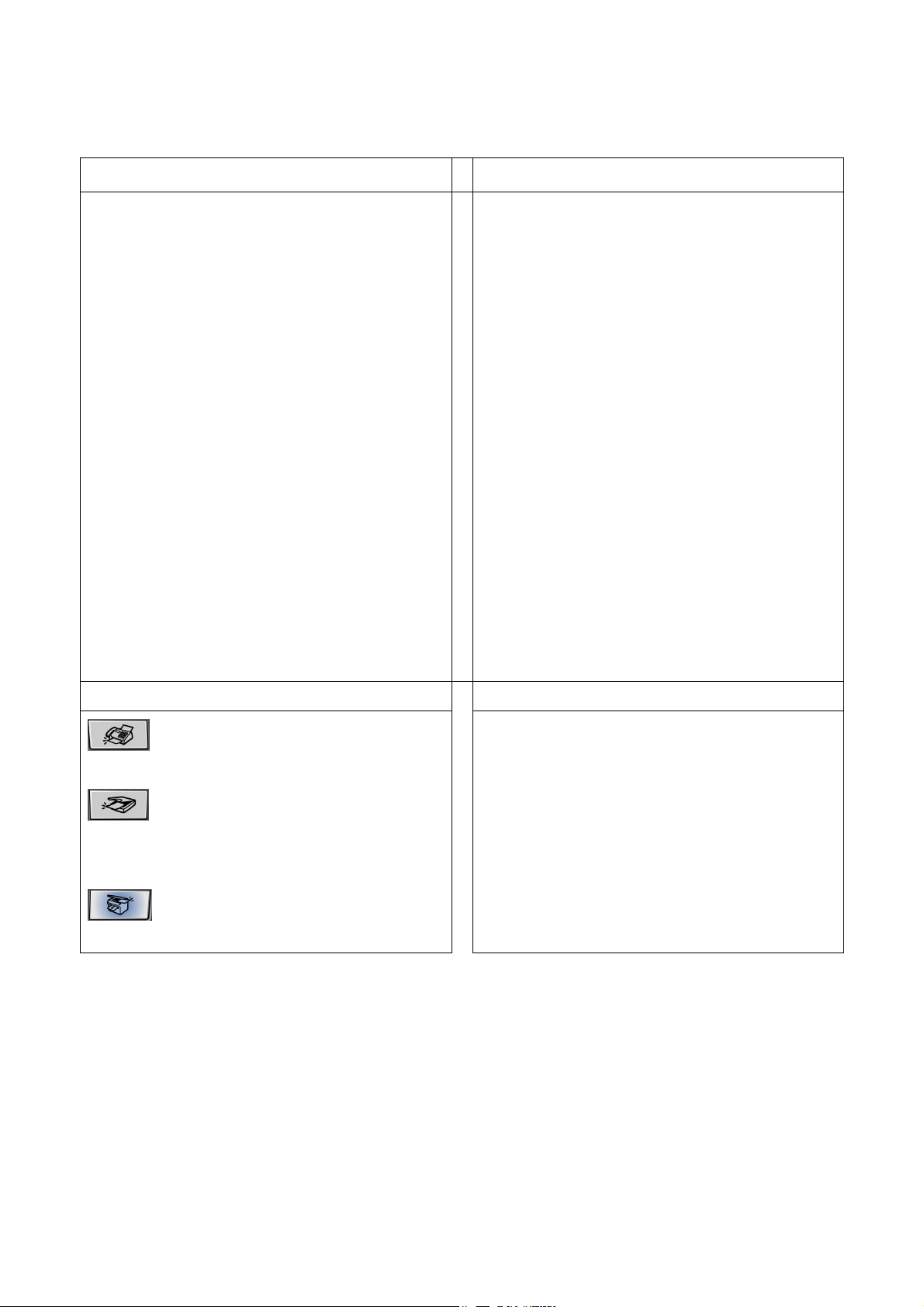

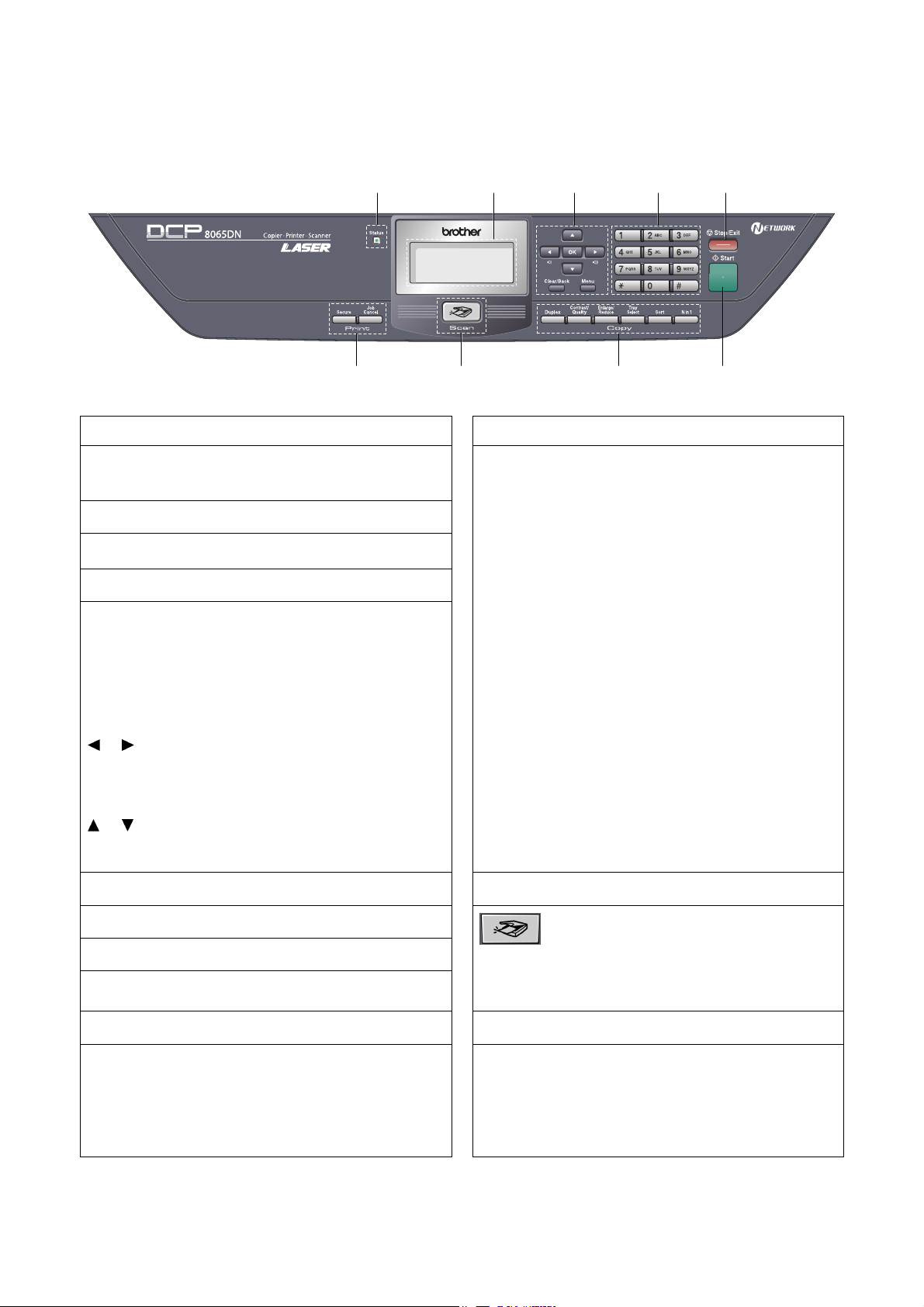

DCP-8060 and DCP-8065DN have similar control keys.

2 3 4 5 1

9

1. Status LED

The LED will flash and change color depending on

the machine status.

2. LCD

Displays messages to help you use your machine.

3. Menu Keys

Menu

Accesses the main menu.

Clear/Back

Deletes entered data or lets you exit the menu.

OK

Selects a setting.

or

Scrolls backwards or forwards through menu

selections.

Changes the volume when in standby mode.

or

Scrolls through the menus and options.

4. Dial pad

6

Fig. 1-4

Duplex (For DCP-8065DN)

7 8

7. Copy Keys

You can choose Duplex to copy on both sides of

the paper.

Contrast/Quality (For DCP-8065DN)

Lets you change the quality or contrast for the next

copy.

Contrast (For DCP-8060)

Lets you change the contrast for the next copy.

Quality (For DCP-8060)

Lets you change the quality for the next copy.

Enlarge/Reduce

Reduces or enlarges copies.

Tray Select

Lets you change which tray will be used for the

next copy.

Sort

Sorts multiple copies using the ADF.

N in 1

You can choose N in 1 to copy 2 or 4 pages onto

one page.

8. Scan Key

Used to enter text.

5. Stop/Exit Key

Stops an operation or exits from a menu.

6. Start Key

Starts making a copy or scanning.

Puts the machine in Scan mode.

(For details about scanning. See Software User’s

Scan

Guide on the CD-ROM.)

Secure

9. Print Keys

Prints data saved in memory when you enter your

four-digit password.

Job Cancel

Cancels a print job and clears the machine memory.

1-4 Confidential

Page 23

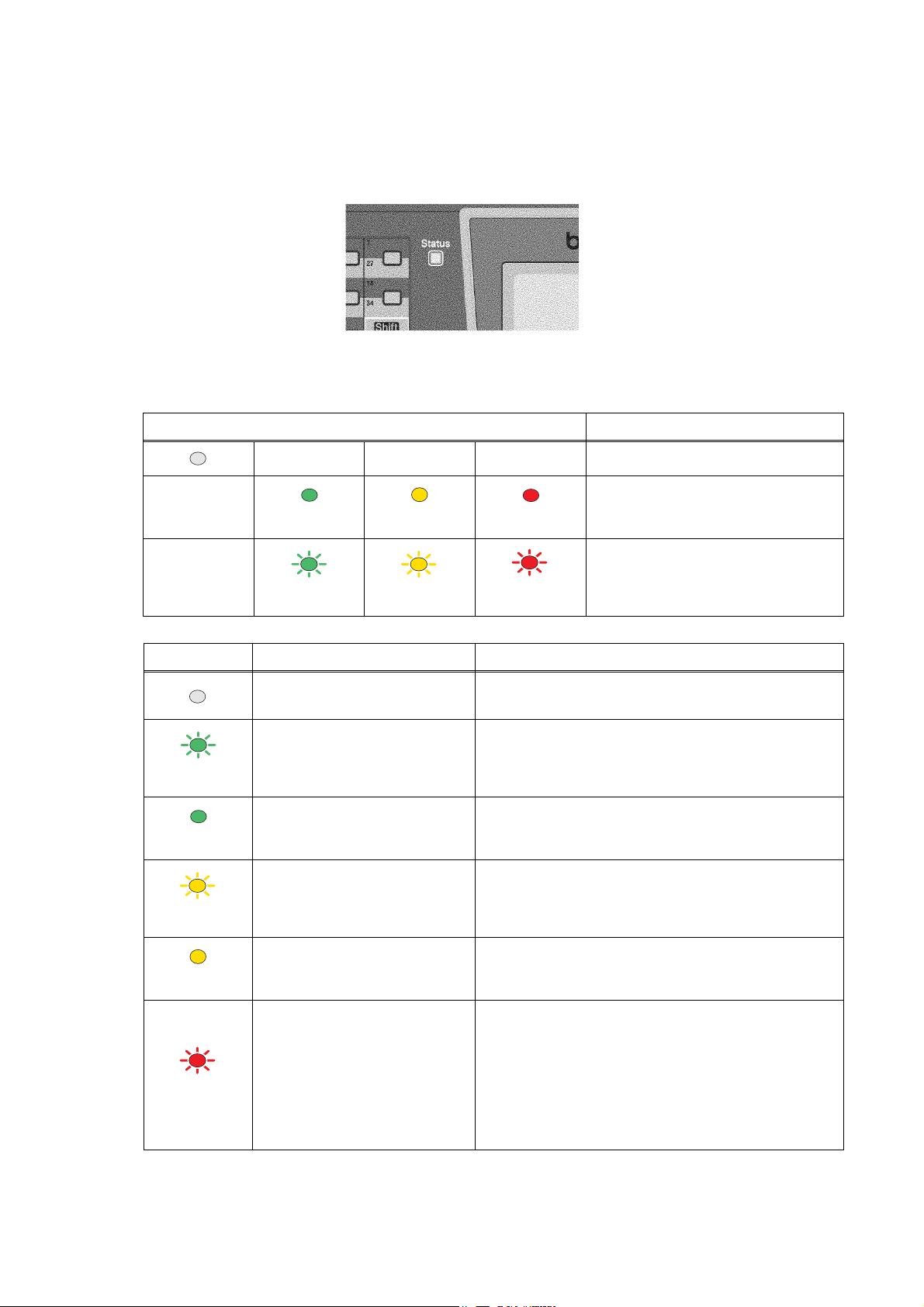

< Status LED indications >

The Status LED (Light Emitting Diode) will flash and change color depending on the machine status.

Fig. 1-5

The LED indications shown in the table below are used in the illustrations in this chapter.

LED LED Status

LED is off.

Green

Yellow

Red

LED is on.

LED is blinking.

Green

Yellow

Red

LED Machine Status Description

Sleep Mode The power switch is off or the machine is in Sleep

mode.

Warming Up The machine is warming up for printing.

Green

Ready The machine is ready to print.

Green

Receiving Data The machine is either receiving data from the

Yellow

computer, processing data in memory or printing

data.

Data Remaining in Memory Print data remains in the machine memory.

Yellow

Service error Follow the steps below.

1. Turn off the power switch.

2. Wait a few seconds, and then turn it back on and

Red

try to print again.

If you cannot clear the error and see the same

service call indication after turning the machine

back on, please call Brother Customer Service.

1-5 Confidential

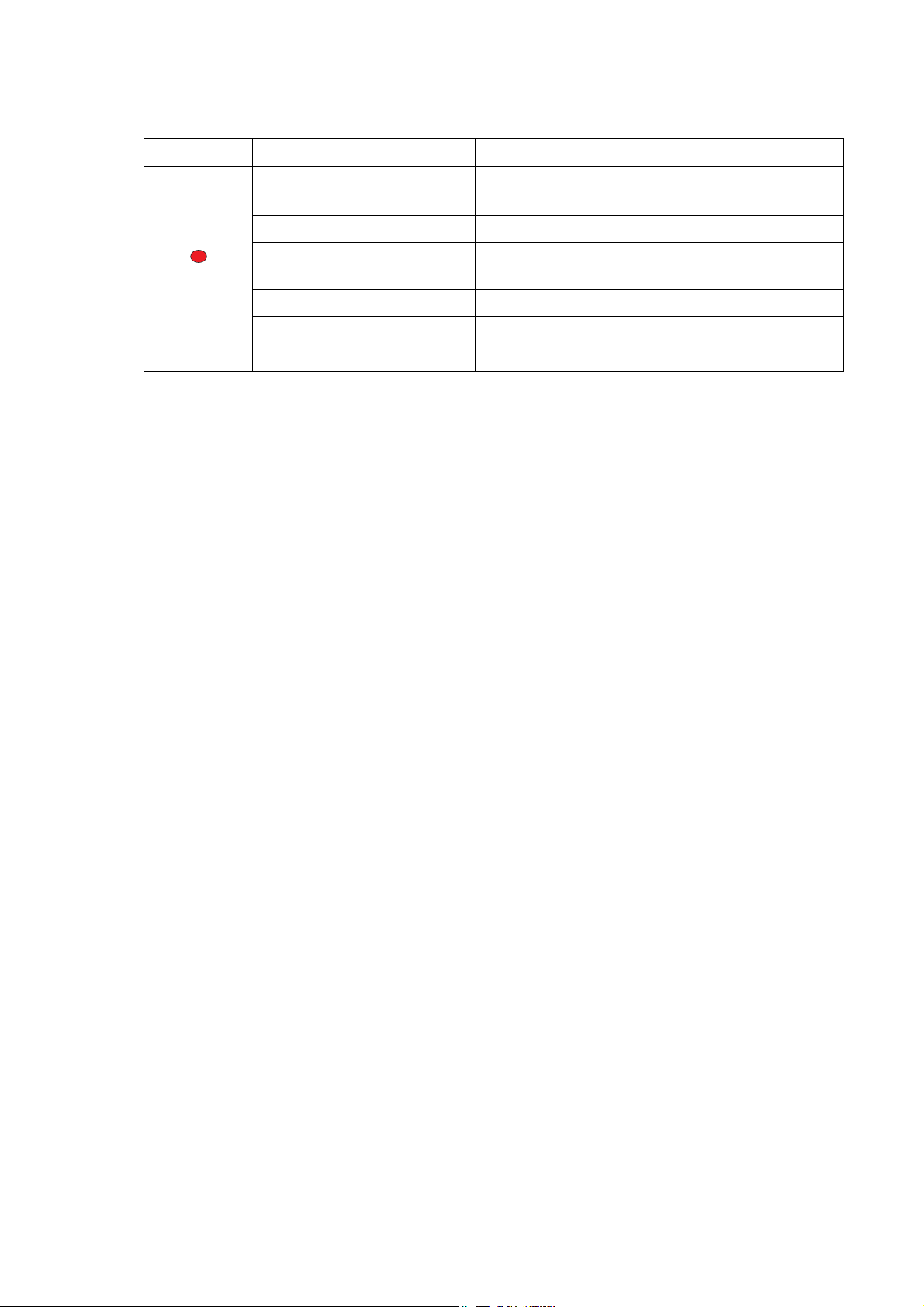

Page 24

LED Machine Status Description

Cover open The front cover or the back cover is open.

Close the cover.

Toner Life End Replace the toner cartridge with a new one.

Red

Paper error Put paper in the tray or clear the paper jam.

Check the LCD message.

Scan lock Check that the scanner lock lever is released.

Others Check the LCD message.

Out of memory Memory is full.

NOTE: When the power switch is off or the machine is in Sleep mode, the LED is off.

1-6 Confidential

Page 25

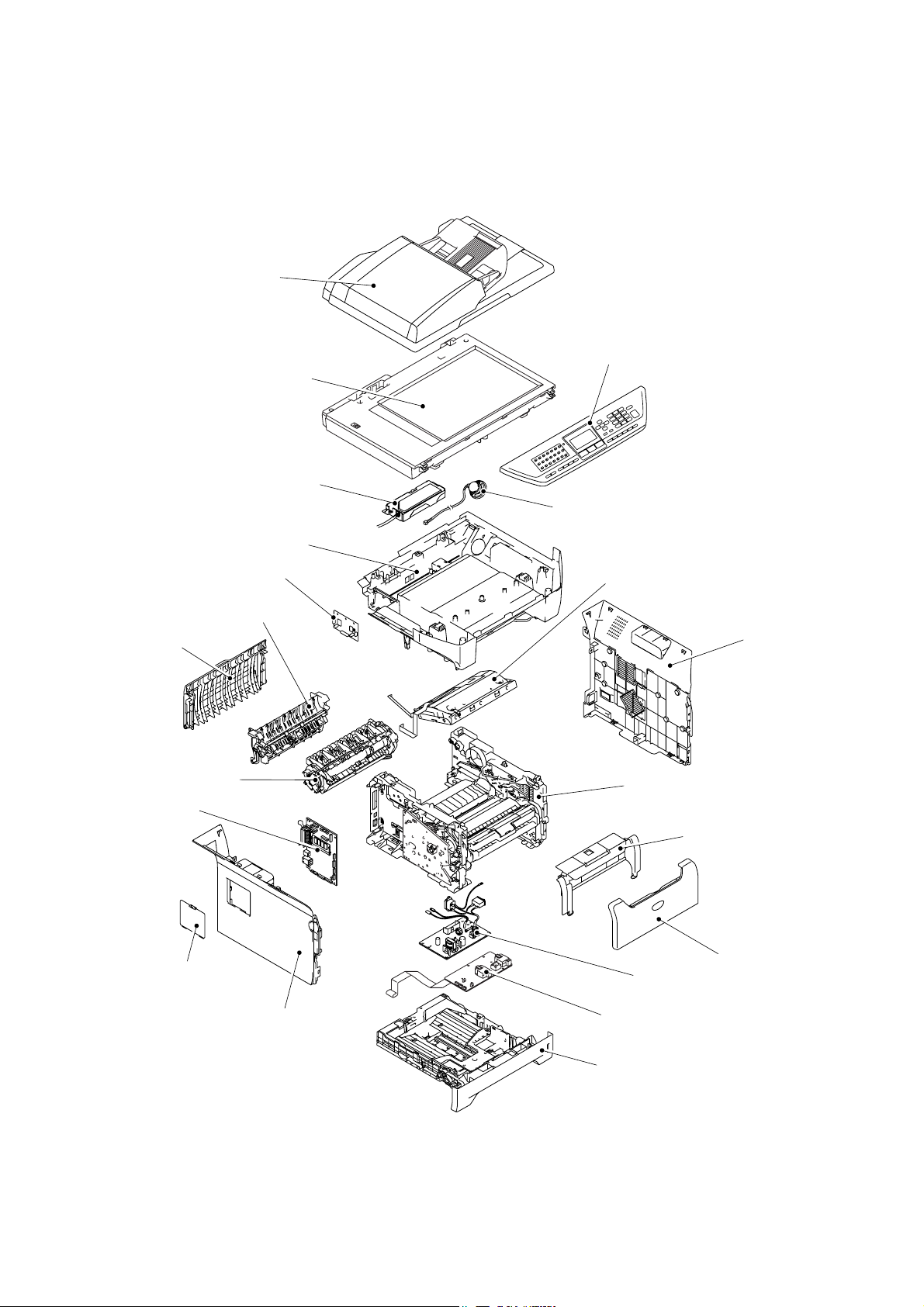

1.3 COMPONENTS

N

The equipment consists of the following major components:

ADF Unit

Scanner Unit

CU PCB

Joint Cover ASSY

Driver PCB

Outer Chute ASSY

Panel Unit

Speaker ASSY

Laser Unit

Back Cover

Fuser Unit

Main PCB

Access Cover

Side Cover L

Side Cover R

Frame Unit

Process Cover ASSY

Front Cover

PS PCB

High-voltage PS PCB

Paper Tray

Fig. 1-6

1-7 Confidential

Page 26

CHAPTER

SPECIFICATIONS

2

Confidential

Page 27

CHAPTER 2 SPECIFICATIONS

This chapter lists the specifications of each model, which enables you to make a comparison of

different models.

CONTENTS

2.1 GENERAL ........................................................................................................................2-1

2.1.1 General Specifications ......................................................................................... 2-1

2.1.2 Paper Specifications............................................................................................. 2-2

2.1.2.1 Paper handling ...............................................................................................2-2

2.1.2.2 Media specifications ....................................................................................... 2-2

2.1.3 Printable Area ................................................................................................................ 2-5

2.1.3.1 PCL5e/EPSON/IBM emulation .......................................................................2-5

2.1.3.2 PCLXL, PS (BR-Script 3)................................................................................2-8

2.1.4 Print Speeds with Various Settings .............................................................................2-9

2.1.5 Toner Cartridge Weight Information .........................................................................2-10

2.2 SPECIFICATIONS LIST.................................................................................................2-11

Confidential

Page 28

2.1 GENERAL

2.1.1 General Specifications

Memory Capacity 32 MB

Automatic Document Feeder (ADF) Up to 50 sheets (Staggered)

Paper Tray 250 Sheets (20 lb (80 g/m 2 ))

Printer Type Laser

Print Method Electrophotography by semiconductor laser beam

Liquid Crystal Display (LCD) 22 characters x 5 lines

Power Source 120V AC 50/60Hz (U.S.A./Canada)

Power Consumption Sleep: 17W (Average) (For the models with the NCU)

Dimensions (W x D x H) 531 mm x 450 mm x 475 mm (20.9” x 17.7” x 18.7”)

scanning

220 to 240V AC 50/60Hz (Europe/Asia/Oceania)

: 15W (Average) (For the models with out NCU)

Standby: 85W (Average)

Peak: 1092W (U.S.A./Canada)

1104W (Europe/Asia/Oceania)

(with out carton)

Weight Without Drum/Toner Unit:

MFC-8460N: 16.5 kg (36.4 lb)

MFC-8860DN/8870DW: 16.7 kg (36.81 lb)

Noise Operating: 55 dB A or less (when ADF scanning)

Standby: 30 dB A or less

Temperature Operating: 10 to 32.5°C (50°F to 90.5°F)

Storage: 0 to 40°C (32°F to 104°F)

Humidity Operating: 20 to 80% (without condensation)

Storage: 10 to 90% (without condensation)

2-1 Confidential

Page 29

2.1.2 Paper Specifications

2.1.2.1 Paper handling

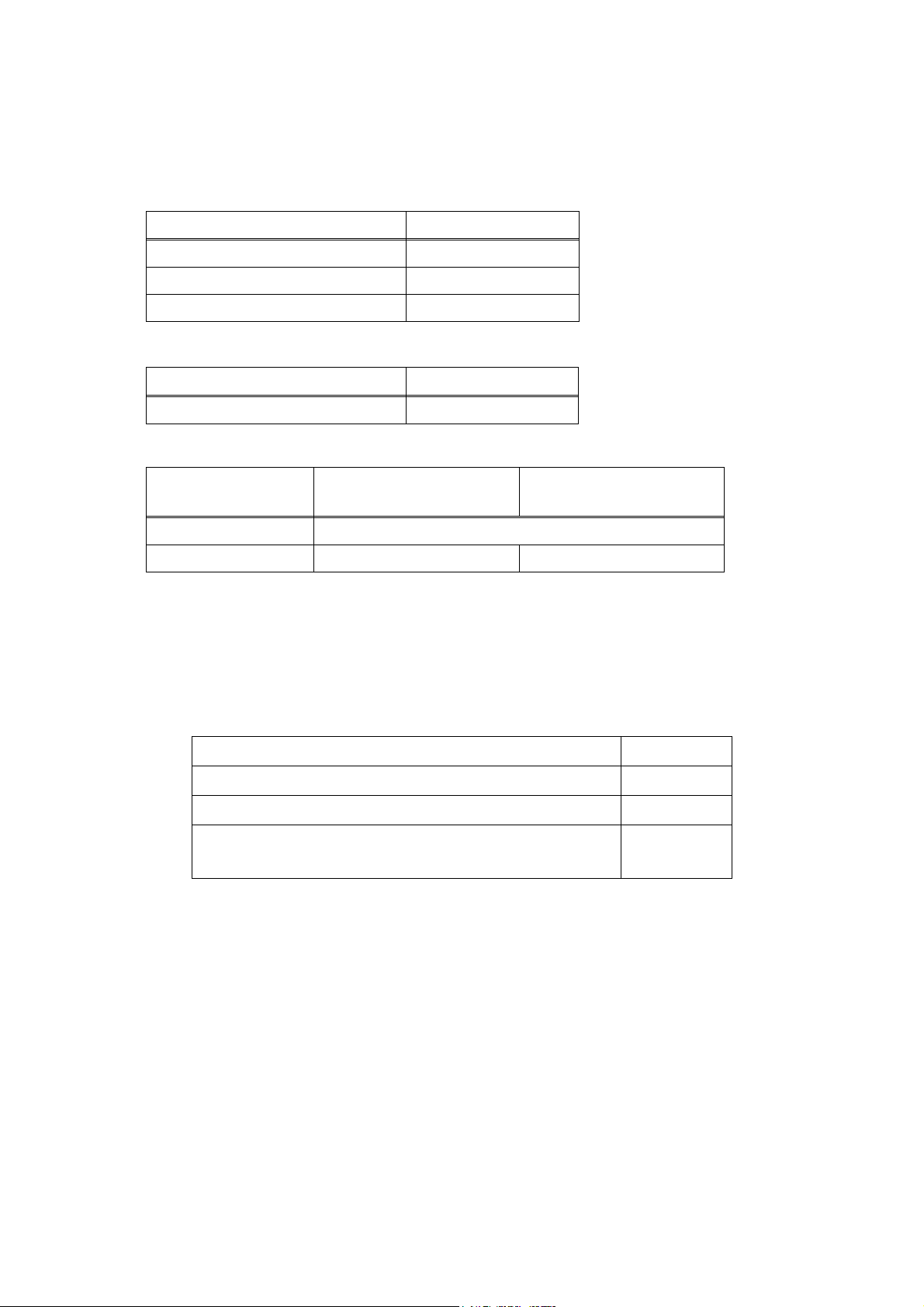

Paper Input* All models

Multi-purpose tray 50 sheets

Paper tray (Standard) 250 sheets

Lower tray (Option) 250 sheets

* Calculated with 80 g/m2 (21 lb) paper.

Paper Input* All models

Face-down 150 sheets

* Calculated with 80 g/m2 (21 lb) paper.

Duplex MFC-8460N/DCP8060

Manual Duplex Yes

Automatic Duplex N/A Yes

2.1.2.2 Media specifications

(1) Media types

The machine loads paper from the installed paper tray or the multi-purpose tray. The feedable

media type and size are different depending on the paper tray installed. The names for the

paper trays in the printer driver and this guides are as follows;

Paper tray Tray 1

Multi-purpose tray MP Tray

Optional lower tray unit Tray 2

Duplex tray for automatic duplex printing

(for MFC-8860DN/8870DW, DCP-8065DN)

The table in the next page shows the feedable media of each paper tray described above.

MFC-8860DN/8870DW

DCP-8065DN

DX

2-2 Confidential

Page 30

Choose the media

Tray 1/2 MP Tray DX

type from the

printer driver

Plain paper

75 g/m

2

to 105 g/m

2

Yes Yes

Yes Plain paper

(20 to 28 lbs.)

Recycled paper Yes Yes Yes Recycled paper

Bond paper

Rough paper60 g/m

2

to 161 g/m

(16 to 43 lbs.)

60 g/m

2

Yes

2

to 105 g/m2

(16 to 28 lbs.)

Yes

2

60 g/m

to 161 g/m2

(16 to 43 lbs.)

N/A Bond paper

Thin paper

60 g/m

2

to 75 g/m

2

Yes Yes

Yes Thin paper

(16 to 20 lbs.)

Thick paper

105 g/m

2

to 161 g/m

2

N/A Yes

(28 to 43 lbs.)

Yes

Transparency

Up to 10 sheets

A4 or Letter **

Labels N/A

Yes

Up to 10 sheets

A4 or Letter

Yes

A4 or Letter

N/A

N/A Transparencies

N/A Thicker Paper

Thick Paper or

Thicker Paper

Envelopes,

Envelopes N/A Yes N/A

Env. Thin,

Env. Thick

* Up to 10 sheets

** Not available for the optional Tray 2.

(2) Media size

Tray 1 (Standard) Tray 2 (Option)

A4, Letter, Legal*,

B5 (ISO), Excutive,

A5, A6, B6 (ISO)

A4, Letter, Legal*,

B5 (ISO), Excutive,

A5, B6 (ISO)

* Legal size paper is not available in some regions outside the U.S.A. and Canada.

(3) Media weights

Tray 1

Lower tray unit

(Option) (LT-5300)

60 to 105 g/m2

(16 to 28 lb.)

60 to 105 g/m2

(16 to 28 lb.)

Tray 2

MP Tray DX

Width:

69.9 to 215.9 mm

(2.75 to 8.5 in.)

Length:

116 to 406.4 mm

(4.57 to 16 in.)

MP Tray DX

60 to 161 g/m2

(16 to 43 lb.)

A4, Letter, Legal*

60 to 105 g/m2

(16 to 28 lb.)

2-3 Confidential

Page 31

(4) Recommended paper

Europe U.S.A.

Plain paper Xerox Premier 80 g/m

Xerox Business 80 g/m

2

2

Xerox 4200DP 20lb

Hammermill Laser Paper 24lb

M-real DATACOPY 80 g/m2

Recycled paper Xerox Recycled Supreme N/A

Transparency 3M CG3300 3M CG 3300

Label Avery laser label L7163 Avery laser label #5160

* This machine can use recycled paper that meets the DIN 19309 specification.

(5) Moisture content

Moisture content: 4% to 6% by weight

CAUTION

When you are choosing print media, be sure to follow the information given below to prevent

any paper jams, print quality problems or machine damage;

- It is recommended to use long-grained paper for the best print quality. If short-grained

paper is being used, it might be the cause of paper jams.

- Use neutral paper. Do not use acid paper to avoid any damage to the drum unit.

- Avoid using coated paper such as vinyl coated paper.

- Avoid using preprinted or highly textured paper.

- It is recommended to use labels or transparencies which are designed for use in laser

machines.

- Avoid feeding labels with the carrier sheet exposed, or the machine will be damaged.

- Before loading paper with holes such as organizer sheets, be sure to fan the stack well.

- Do not use organizer sheets that are stuck together. The glue that is used might caused

damaged to the machine.

- When printing on the back of pre-printed paper, if the paper is curled, be sure to straighten

the paper as much as possible.

Different types of paper should not be loaded at the same time in the paper tray to avoid any

paper jams or misfeeds.

2-4 Confidential

Page 32

2.1.3 Printable Area

2.1.3.1 PCL5e/EPSON/IBM emulation

When using PCL emulation, the edges of the paper that cannot be printed on are shown below.

Portrait

G

E

G

G

C

A

F

E

B

D

G

F

B Physical page length

D

F

NOTE:

- “Logical page” shows the printable area for a PCL driver.

Physical page

Printable area

Logical page

Maximum logical page length

Distance from edge of physical page to

edge of logical page

- “Printable area” shows mechanical printable area of the machine.

- Therefore, the machine can only print within the shaded area when you use a PCL driver.

2-5 Confidential

Page 33

The table below shows the printable areas when printing on Portrait for each paper size.

Size A B C D E F G

Letter

Legal

Folio

Executive

A4

A5

A6

B5 (JIS)

B5 (ISO)

B6 (ISO)

COM10

MONARCH

C5

DL

DLL

215.9 mm

8.5”

(2,550 dots)

215.9 mm

8.5”

(2,550 dots)

215.9 mm

8.5”

(2,550 dots)

184.15 mm

7.25”

(2,175 dots)

210.0 mm

8.27”

(2,480 dots)

148.5 mm

5.85”

(1,754 dots)

105.0 mm

4.13”

(1,240 dots)

182.0 mm

7.1”

(2,130 dots)

176.0 mm

6.93”

(2,078 dots)

125.0 mm

4.92”

(1,476 dots)

104.78 mm

4.125”

(1,237 dots)

98.43 mm

3.875”

(1,162 dots)

162.0 mm

6.38”

(1,913 dots)

110.0 mm

4.33”

(1,299 dots)

220.0 mm

8.66”

(2,598 dots)

279.4 mm

11.0”

(3,300 dots)

355.6 mm

14.0”

(4,200 dots)

330.2mm

13.0”

(3,900 dots)

266.7 mm

10.5”

(3,150 dots)

297.0 mm

11.69”

(3,507 dots)

210.0 mm

8.27”

(2,480 dots)

148.5 mm

5.85”

(1,754 dots)

257.0 mm

10.11”

(3,033 dots)

250.0 mm

9.84”

(2,952 dots)

176.0 mm

6.93”

(2,078 dots)

241.3 mm

9.5”

(2,850 dots)

190.5 mm

7.5”

(2,250 dots)

229.0 mm

9.01”

(2,704 dots)

220.0 mm

8.66”

(2,598 dots)

110.0 mm

4.33”

(1,299 dots)

203.2 mm

8.0”

(2,400 dots)

203.2 mm

8.0”

(2,400 dots)

203.2 mm

8.0”

(2,400 dots)

175.7 mm

6.92”

(2,025 dots)

198.0 mm

7.79”

(2,338 dots)

136.5 mm

5.37”

(1,612 dots)

93.0 mm

3.66”

(1,098 dots)

170.0 mm

6.69”

(2,007 dots)

164.0 mm

6.46”

(1,936 dots)

164.0 mm

4.44”

(1,334 dots)

92.11 mm

3.63”

(1,087 dots)

85.7 mm

3.37”

(1,012 dots)

150.0 mm

5.9”

(1,771 dots)

98.0 mm

3.86”

(1,157 dots)

207.4 mm

8.17”

(2,450 dots)

279.4 mm

11.0”

(3,300 dots)

355.6 mm

14.0”

(4,200 dots)

330.2mm

13.0”

(3,900 dots)

266.7 mm

10.5”

(3,150 dots)

297.0 mm

11.69”

(3,507 dots)

210.0 mm

8.27”

(2,480 dots)

148.5 mm

5.85”

(1,754 dots)

257.0 mm

10.11”

(3,033 dots)

250.0 mm

9.84”

(2,952 dots)

176.0 mm

6.93”

(2,078 dots)

241.3 mm

9.5”

(2,850 dots)

190.5 mm

7.5”

(2,250 dots)

229.0 mm

9.01”

(2,704 dots)

220.0 mm

8.66”

(2,598 dots)

110.0 mm

4.33”

(1,299 dots)

6.35 mm

0.25”

(75 dots)

6.35 mm

0.25”

(75 dots)

6.35 mm

0.25”

(75 dots)

6.35 mm

0.25”

(75 dots)

6.01 mm

0.24”

(71 dots)

6.01 mm

0.24”

(71 dots)

6.01 mm

0.24”

(71 dots)

6.01 mm

0.24”

(71 dots)

6.01 mm

0.24”

(71 dots)

6.01 mm

0.24”

(71 dots)

6.35 mm

0.25”

(75 dots)

6.35 mm

0.25”

(75 dots)

6.01 mm

0.24”

(71 dots)

6.01 mm

0.24”

(71 dots)

6.27 mm

0.25”

(74 dots)

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

NOTE:

- The paper sizes indicated here should confirm to the nominal dimensions specified by JIS

except B5 (ISO), B6 (ISO).

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

6.27 mm

0.25”

(74 dots)

- The dot size is based on 300 dpi resolution.

2-6 Confidential

Page 34

Landscape

G

E

G

G

C

A

F

E

D

B

G

F

NOTE:

- “Logical page” shows the printable area for a PCL driver.

Physical page

Printable area

Logical page

B Physical page length

D Maximum logical page length

F Distance from edge of physical

page to edge of logical page

- “Printable area” shows mechanical printable area of the machine.

- Therefore, the machine can only print within the shaded area when you use a PCL driver.

2-7 Confidential

Page 35

The table below shows the printable areas when printing on Landscape for each paper size.

Size A B C D E F G

Letter

Legal

Folio

Executive

A4

A5

A6

B5 (JIS)

B5 (ISO)

B6 (ISO)

COM10

MONARCH

C5

DL

DLL

279.4 mm

11.0”

(3,300 dots)

355.6 mm

14.0”

(4,200 dots)

330.2mm

13.0”

(3,900 dots)

266.7 mm

10.5”

(3,150 dots)

297.0 mm

11.69”

(3,507 dots)

210.0 mm

8.27”

(2,480 dots)

148.5 mm

5.85”

(1,754 dots)

257.0 mm

10.11”

(3,033 dots)

250.0 mm

9.84”

(2,952 dots)

176.0 mm

6.93”

(2,078 dots)

241.3 mm

9.5”

(2,850 dots)

190.5 mm

7.5”

(2,250 dots)

229.0 mm

9.01”

(2,704 dots)

220.0 mm

8.66”

(2,598 dots)

110.0 mm

4.33”

(1,299 dots)

215.9 mm

8.5”

(2,550 dots)

215.9 mm

8.5”

(2,550 dots)

215.9 mm

8.5”

(2,550 dots)

184.15 mm

7.25”

(2,175 dots)

210.0 mm

8.27”

(2,480 dots)

148.5 mm

5.85”

(1,754 dots)

105.0 mm

4.13”

(1,240 dots)

182.0 mm

7.1”

(2,130 dots)

176.0 mm

6.93”

(2,078 dots)

125.0 mm

4.92”

(1,476 dots)

104.78 mm

4.125”

(1,237 dots)

98.43 mm

3.875”

(1,162 dots)

162.0 mm

6.38”

(1,913 dots)

110.0 mm

4.33”

(1,299 dots)

220.0 mm

8.66”

(2,598 dots)

269.3 mm

10.6”

(3,180 dots)

345.5 mm

13.6”

(4,080 dots)

320.0 mm

12.6”

(3,780 dots)

256.6 mm

10.1”

(3,030 dots)

287.0 mm

11.2”

(3,389 dots)

200.0 mm

7.87”

(2,362 dots)

138.5 mm

5.45”

(1,636 dots)

247.0 mm

9.72”

(2,916 dots)

240.0 mm

9.44”

(2,834 dots)

166.4 mm

6.55”

(1,960 dots)

231.1 mm

9.1”

(2,730 dots)

180.4 mm

7.1”

(2,130 dots)

219.0 mm

8.62”

(2,586 dots)

210.0 mm

8.26”

(2,480 dots)

97.5 mm

3.84”

(1,151 dots)

215.9 mm

8.5”

(2,550 dots)

215.9 mm

8.5”

(2,550 dots)

215.9 mm

8.5”

(2,550 dots)

184.15 mm

7.25”

(2,175 dots)

210.0 mm

8.27”

(2,480 dots)

148.5 mm

5.85”

(1,754 dots)

105.0 mm

4.13”

(1,240 dots)

182.0 mm

7.1”

(2,130 dots)

176.0 mm

6.93”

(2,078 dots)

125.0 mm

4.92”

(1,476 dots)

104.78 mm

4.125”

(1,237 dots)

98.43 mm

3.875”

(1,162 dots)

162.0 mm

6.38”

(1,913 dots)

110.0 mm

4.33”

(1,299 dots)

220.0 mm

8.66”

(2,598 dots)

5.0 mm

0.2”

(60 dots)

5.0 mm

0.2”

(60 dots)

5.0 mm

0.2”

(60 dots)

5.0 mm

0.2”

(60 dots)

4.8 mm

0.19”

(59 dots)

4.8 mm

0.19”

(59 dots)

4.8 mm

0.19”

(59 dots)

4.8 mm

0.19”

(59 dots)

4.8 mm

0.19”

(59 dots)

4.8 mm

0.19”

(59 dots)

5.0 mm

0.2”

(60 dots)

5.0 mm

0.2”

(60 dots)

4.8 mm

0.19”

(59 dots)

4.8 mm

0.19”

(59 dots)

6.27 mm

0.25”

(74 dots)

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

0 mm

NOTE:

- The paper sizes indicated here should confirm to the nominal dimensions specified by JIS

except B5 (ISO), B6 (ISO).

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

4.2 mm

0.16”

(50 dots)

6.27 mm

0.25”

(74 dots)

- The dot size is based on 300 dpi resolution.

2.1.3.2 PCLXL, PS (BR-Script 3)

You can not print within 4.2 mm (50dots in 300 dpi mode) on all four sides of the paper.

2-8 Confidential

Page 36

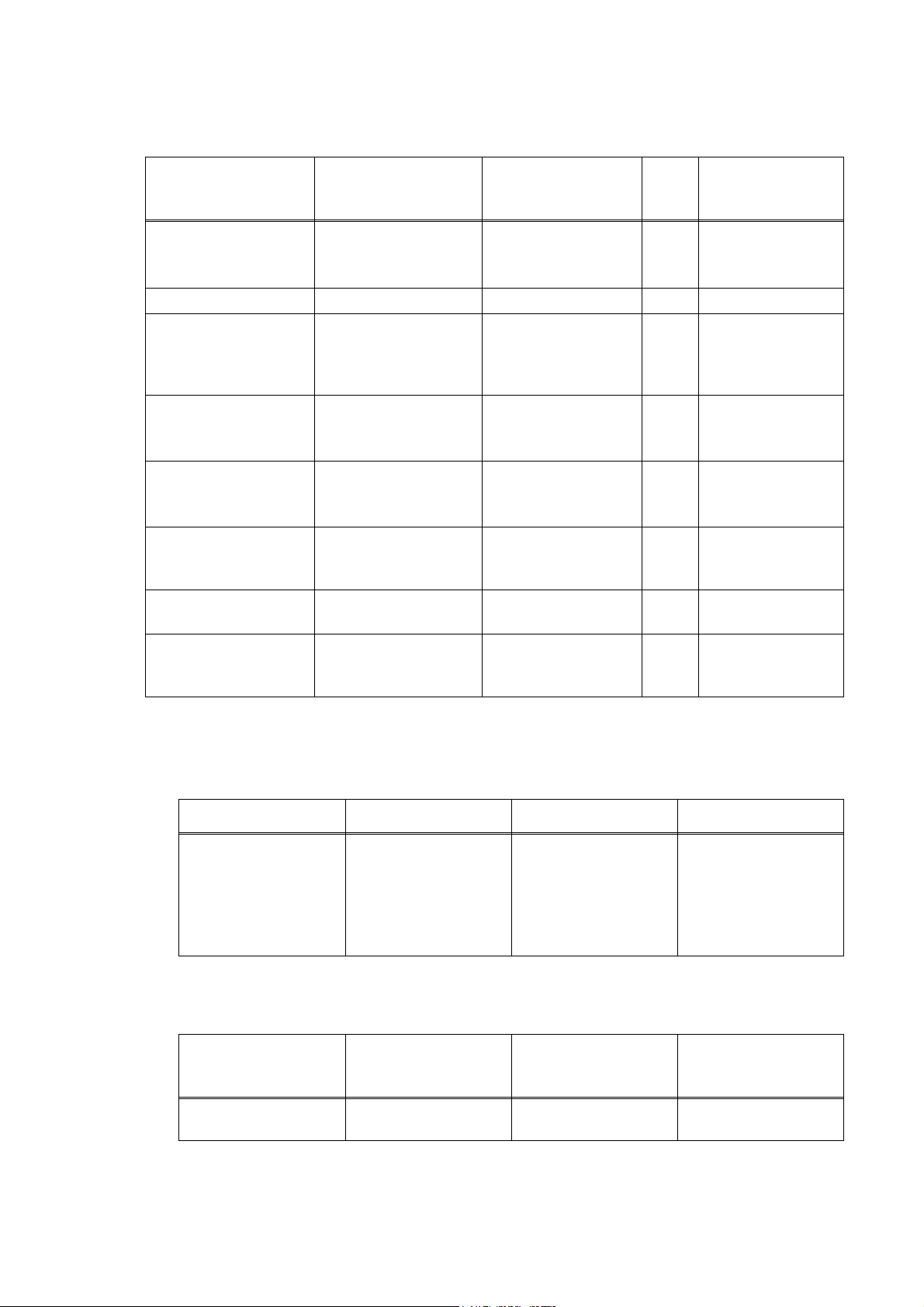

2.1.4 Print Speeds with Various Settings

Print speed is up to 28 ppm for A4 size and 30 ppm for Letter size when loading A4 or Letter size

paper from the paper tray in the plain paper mode.

Actual print speed varies depending on the media type or paper size as shown in the tables below;

<A4/Letter size>

Media type setting All models

Transparency 28/30 ppm

Thin Paper 28/30 ppm

Plain Paper 28/30 ppm

Recycled Paper 28/30 ppm

Thick Paper, Envelopes, Env.Thin 14 ppm

Thicker/Bond Paper, Env.Thick 3 ppm

< Smaller size than A4 or Letter

Media type setting All models

Transparency 28/30 ppm

Thin Paper 28/30 ppm

Plain Paper 90 sec 28/30 ppm Æ 14 ppm

Recycled Paper 90 sec 28/30 ppm Æ 14 ppm

Env.Thin 14 ppm

Thick Paper, Envelopes 14 ppm

Thicker/Bond Paper, Env.Thick 3 ppm

NOTE:

- The print speed may vary according to conditions, such as paper size and paper tray.

- When a smaller size paper than A4 or Letter is printed, the temperature on both edges of the

fuser unit is much higher than the temperature on the center of the unit where the paper is fed

depending on the setting or model. Therefore, the print speed is slowed in order to decrease the

temperature on the edges after the specified time, it is maximum print speed when you first start

printing.

- The actual print speed varies depending on the paper size.

2-9 Confidential

Page 37

2.1.5 Toner Cartridge Weight Information

<Toner Cartridge Weight (approximate weight)>

TN580

(U.S.A./Canada)

Brand new Toner Cartridge Weight

Toner Weight at Brand New Toner Cartridge

Toner Cartridge Weight at Toner Near Empty

Remain Toner Weight at Toner Near Empty

Toner Cartridge Weight at Toner Life End

Remain Toner Weight at Toner Life End

TN550

(U.S.A./Canada)

TN-3170

(Europe)

727g

190g

617g (± 13g)

77g

605g (± 10g)

68g

TN-3130

(Europe)

TN-3185

(Asia/Oceania)

TN-3145

(Asia/Oceania)

Brand new Toner Cartridge Weight 663g

Toner Weight at Brand New Toner Cartridge 126g

Toner Cartridge Weight at Toner Near Empty 617g (± 13g)

Remain Toner Weight at Toner Near Empty 77g

Toner Cartridge Weight at Toner Life End 602g (± 10g)

Remain Toner Weight at Toner Life End 65g

NOTE:

- Without yellow protector, DR cover.

- Toner cartridge weight may vary within 2 to 3g depending on the cartridge weight.

- You can print about 630 pages

with 10g toner.

(A4 size, 5% coverage, continuous printing)

- The figure has varied quite a bit, for example from 590 pages to 720 pages, on a comparison of

printing test results.

2-10 Confidential

Page 38

2.2 SPECIFICATIONS LIST

p

y

y

,

,

(

MFC-8460N

(1/5)

Model Name

GENERAL

Print Engine

CPU Speed

Back up Clock

Operating Environment

On/Off Switch

Demo Print

Demo Model

Starter Toner

Simultaneous Operation

Supported OS Version

Paper Input Capacity

Paper Output Capacity

Input Media Size

Media Types MP Tray

Media Weights

LCD Size

LCD Dimention

LCD Back-Lit

Memory Capacity (Standard : MByte)

Memory BackUp

Optional Memory

Function Lock

Setting Lock

Dimensions w/ Carton (WxDxH)

Dimensions w/o Carton (WxDxH)

Weight w/ Carton

Weight w/o Carton

Color

Power Source

Power Consumption (Copying)

Power Consumption (Sleep/Standby/Peak)

Power Save ( CPU Sleep )

Temperature

Humidity

ADF

Pa

Optional Tra

Multi-Purpose Tray

ADF

MP Tray

Paper Tray (Standard)

Paper Tray (Option)

Paper Tray

Paper Tray (Option)

ADF

MP Tray

Paper Tray

W x L) *7

er Tra

US/Canada Europe Asia/Pacific

20% - 80% (without condensation)

Yes

Win/98(SE)/Me, WinNT4.0/2K/XP

MacOS 9.1 - 9.2/ OSX 10.2.4 or greater

(XX4024 or 4200 20lbs, environment: temp. 20-30C humiditiy 50-70%)

Yes (up to 50 sheets by 20lbs paper)

Width 148.0 to 215.9 mm, Length 148.0 to 355.6 mm

(Width 5.8" to 8.5", Length 5.8" to 14")

Width 69.9 to 215.9 mm, Length 116 to 406.4 mm

A4, Letter, B5 (ISO), A5,

A6, Exe, Legal, Folio

B6

A4, Letter, B5 (ISO), A5,

Exe, Legal, Folio

B6

Plain Paper, Bond Paper, Recycled Paper, Envelopes, Labels, and

1 DIMM (144pin) slot (64, 128, 256, 512MB) ; expandable up to 544MB

120V AC 50/60(Canada)Hz

Average 17W/85W/1092W

(Width 2.75" to 8.50", Length 4.57" to 16")

Plain Paper, Bond Paper, Recycled Paper, Transparencies

Plain Paper, Bond Paper, Recycled Paper

22 characters x 5 lines (Full Dot)

maximum message is 16 characters

Yes (up to 4 days for standard memory)

Front/TOP Cover : 1581Gray , Side cover/Panel : 1736Gray

AL-FB Base

MFC-8460N

Laser ( AL )

266MHz

Yes (up to 4 days)

10 - 32.5 degrees Centigrade

Yes

N/A

N/A

Standard Toner (3.5K)

Yes

up to 50 sheets

250 sheets

250 sheets x 1 (LT-5300)

up to 150 sheets

A4, Letter, B5 (ISO), A5, B6, A6, Exe

A4, Letter, B5 (ISO), A5, B6, Exe

Transparencies

64 - 90 g/m2 (17 - 24 lb)

60 -161 g/m2 (16 - 43 lb)

60 - 105 g/m2 (16 - 28 lb)

2.76 x 1.06 inch

Yes (1-color)

32 Mbyte (RAM)

Yes

Yes

746mmX567mmX575mm

29.4" x 22.3" x 22.6"

531mmX450mmX475mm

20.9" x 17.7" x 18.7"

22kg/ 48.5lbs.

18kg/ 39.7lbs.

220-240V AC 50/60Hz

Average 660W

Average 17W/85W/1104W

N/A

2-11 Confidential

Page 39

(2/5)

E

g

X

p

y

g

A

Model Name

GENERAL

Sleep Mode (00-99min : w/ OFF mode)

Energy Star Compliant ( USA Only )

Total Print pages Counter (LCD / Print)

Copy pages Counter (LCD / Print)

PC print pages Counter (LCD / Print)

Fax RX/List pages counter (LCD / Print)

TELEPHON

Handset

Off Hook Alarm

Power Failure Phone

Power Failure Dilalling

Chain Dialing

Automatic Redial

PBX Feature

Speaker Phone

Handset Volume

Beeper Volume

Speaker Volume

Ring Volume

Hook/ Tel Key

Hold/Mute Key

Music on Hold

Monitoring the Line on Hold with Music

One-Touch Dial

Speed Dial

Figures of One-Touch & Speed Dial

Resisterable Number Of Characters

Group Dial

Telephone Index

Caller ID

Call Waiting Caller ID

Call waitin

Distinctive Ringing

Ready ( Only for USA )

US/Canada Europe Asia/Pacific

Yes

N/A

Yes (with Search/Speed dial key)

Yes N/A

Yes Yes (U.K., Denmark only)

L-FB Base

MFC-8460N

Yes

N/A

Yes / Yes

Yes / Yes

Yes / Yes

Yes / Yes

N/A

N/A

N/A

N/A

Yes

Yes

Yes

N/A

N/A

Yes (3 steps + OFF)

Yes (3 steps + OFF)

Yes (3 steps + OFF)

Yes

N/A

N/A

N/A

40 (20 x 2) locations

300 locations

20 digits

15 characters

Yes (up to 20 groups)

Yes(Australia/New

Zealand/Singapore/

Hong Kong only)

N/A

N/A

Yes(Australia/New

Zealand/Singapore/

Hong Kong only)

FA

Modem Speed

Transmission Speed

ITU-T Group

Coding Method

Color FAX (Document Send / Receive)

Color FAX (Memory Send / Receive)

Fax/Tel Switch

er Fine

Su

Gra

Scale

Contrast

Smoothin

Dual Access

Enhanced Remote Activate

Station ID

Remote Maintenance

33.600bps (Fax)

Approx. 2second. (Brother#1,JBIG)

Super G3

MH / MR / MMR / JBIG

N/A / N/A

N/A / N/A

Yes

Yes (TX & RX)

256

Yes (Auto/Light/Dark)

N/A

Yes

Yes

Yes (20digits / 20characters)

Yes

2-12 Confidential

Page 40

(3/5)

X

T

E

g

p

A

Model Name

FA

RX Mode Indication

Resolution Indication

Delayed Timer

Polled Sending

Multi Transmission

Multi Resolution Transmission

Next-Fax Reservation

Batch Transmission

Call Reservation Over Auto TX

Call Reservation Over Manual TX

Quick-Scan(Memory transmission)

Memory Transmission (ITU-T Chart)

ECM(Error Correction Mode)

Error Re-Transmission

Broadcasting

Manual Broadcasting

Easy Receive/Fax Detect

Polling Receiving

Auto Reduction

Duplex Fax Receive

Out-of-Paper Reception (ITU-T Chart)

LIST/REPOR

Activity Report/Journal Report

Transmission Verification Report

Coverpage

Help List

Call Back Message

Caller ID List

Tel Index List

Memory Status List

System Setup(User Setting) List

Order Form

Numeric

Alphabetic

US/Canada Europe Asia/Pacific

Approx. 2 second./page (A4 standard)

up to 500 pages (ITU-T Test Chart, Standard Resolution)

up to 600 pages ((Brother #1Chart, Standard Resolution)

up to 500 pages (ITU-T Test Chart, Standard Resolution)

up to 600 pages ((Brother #1Chart, Standard Resolution)

Yes N/A Yes

N/A

L-FB Base

MFC-8460N

LCD

LCD

Yes (up to 50)

Yes

N/A

N/A

N/A

Yes

N/A

N/A

Yes

Yes

Yes (390 locations)

Yes (50 locations )

Yes

Yes

Yes

N/A

Yes (up to 200)

Yes

Yes

Yes

N/A

Yes

Yes

N/A

Yes

Yes

INTERFAC

External TAD Interface

Host Interface (Serial)

Host Interface (IEEE1284)

Host Interface (Hi-Speed USB2.0)

Ether Net (10/100base-TX)

Cable included

Acceptable Media Card Slot

PRINTER

Color/Mono

ine Type

En

Resolution

Windows 95 / 98 /Me

and NT4.0 / 2000 / XP

DOS

Mac OS

Linux

1200 dpi, HQ1200 (2400x600dpi), 600 dpi, 300 dpi

1200 dpi, HQ1200 (2400x600dpi), 600 dpi, 300 dpi

Yes

N/A

Yes

Yes

Yes

N/A

N/A

Mono

Laser (AL)

600 d

i

600 dpi, 300 dpi

2-13 Confidential

Page 41

Model Name

X

T

E

g

A

p

FA

RX Mode Indication