Page 1

CHAPTER 5 SERVICE FUNCTIONS

1. MAINTENANCE MODE

Maintenance mode is exclusively designed for checking, setting and adjusting the machine

using the keys on the control panel. Using maintenance mode functions, you can conduct

operational checks of sensors or test printing, display the log information or error codes, and

change the worker switches (WSW) etc.

1.1 How to Enter Maintenance Mode

1.1.1 Method of entering maintenance mode for service personnel

<Operating Procedure>

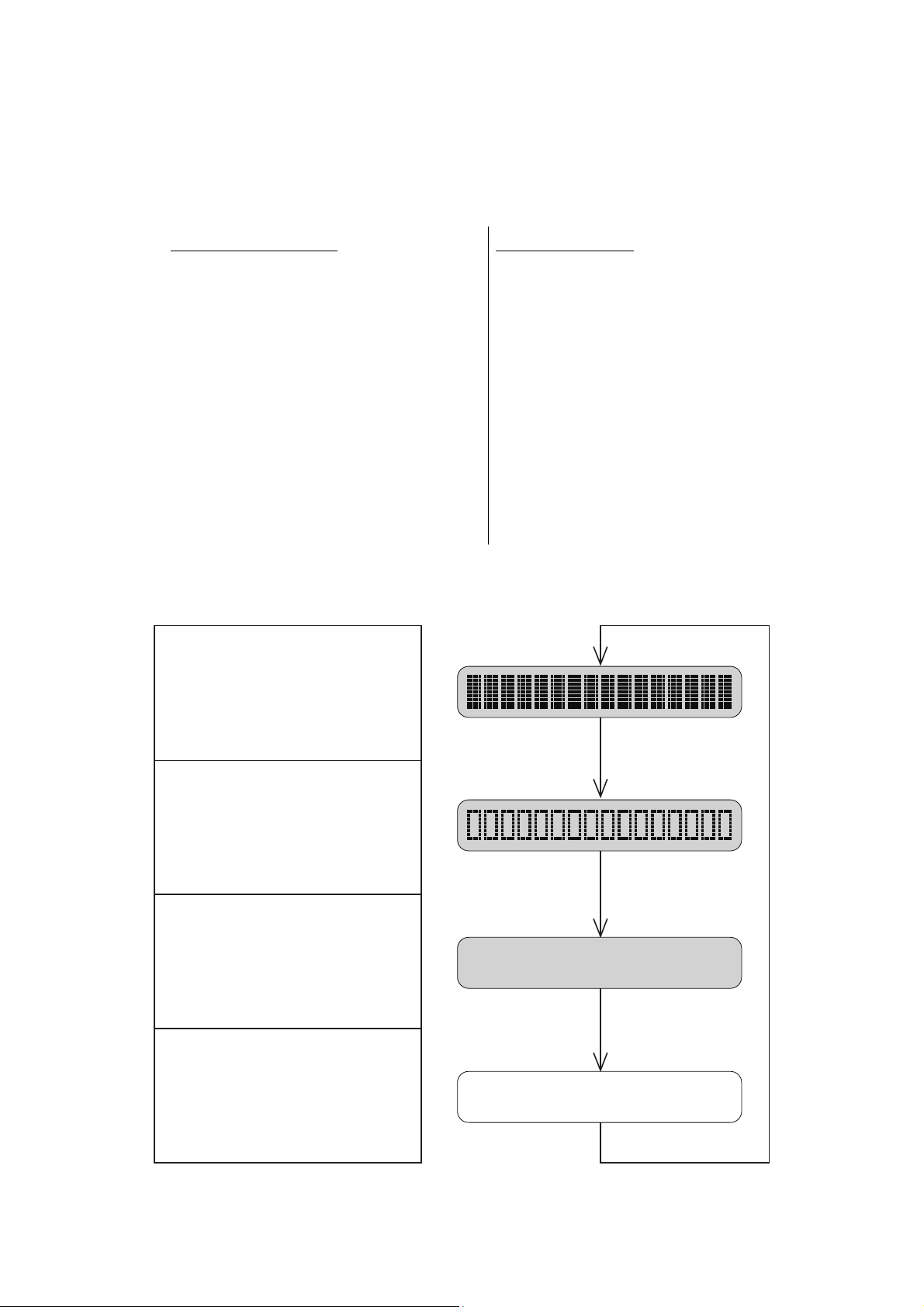

Non touch panel models

(1) Press the [OK] key and then the [Go] key while the machine is in the ready state. Then,

press the [▲] key four times to enter the maintenance mode.

Note:

• To enter the maintenance mode, press the [Go] key in two seconds after pressing the

[OK] key. Similarly, press the [▲] key in two seconds after pressing the [Go] key.

(2) "■■ MAINTENANCE ■■■" is displayed on the LCD to indicate that the machine entered

the initial state of maintenance mode. The machine is ready to accept entry via keys.

(3) To select any of the maintenance mode functions shown in the “1.2 List of Maintenance

Mode Functions”, press the [▲] or [▼] key. Check that the desired maintenance mode is

displayed on the LCD, and press the [OK] key.

5-1

Confidential

Page 2

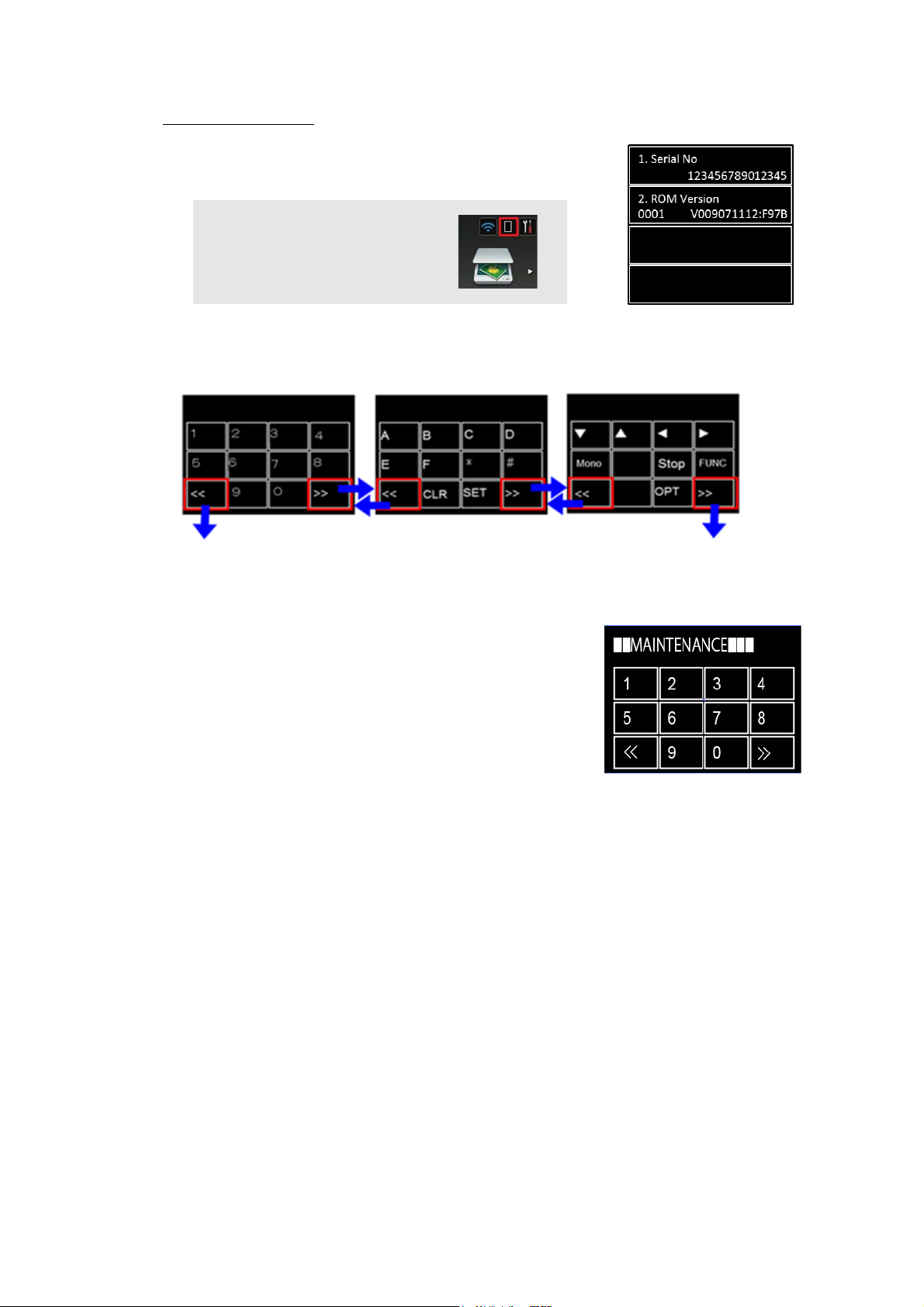

Touch panel models

<1> <2> <3>

To <3> To <1>

(1) Press and hold the [Home] key for approximately five

seconds while the machine is in the ready state. The

display shown on the right appears on the LCD.

Memo:

• If you can not find the [Home]

key, press the [Toner] key to light

the [Home] key.

(2) Press the blank field at the bottom on the LCD. The display below appears on the LCD.

Input keys can be changed by pressing the [<<] or [>>] key (refer to the figure below).

Fig. 5-1

(3) Press the [*], [2], [8], [6], and [4] keys in this order. The

display shown on the right appears on the LCD, and the

machine enters into maintenance mode.

(4) To select any of the maintenance mode functions shown

in the “1.2 List of Maintenance Mode Functions”, use the

keypad to enter the maintenance mode function code to

be executed.

5-2

Confidential

Page 3

1.1.2 Method of entering end-user accessible maintenance mode

The maintenance mode functions should only be accessed by service personnel. However,

end users are allowed to use some of these functions under the guidance of service

personnel over the phone. End users can only use the functions shaded in the table “1.2 List

of Maintenance Mode Functions” (function code: 09, 12, 25, 28, 45, 61, 77, 80, 82, 91).

<Operating Procedure>

Non touch panel models

(1) Press the [OK], [Go], and [OK] keys in this order while the machine is in the ready state.

"0" is displayed on the LCD.

(2) Press the [▲] or [▼] key several times until the desired maintenance mode function is

displayed on the LCD. Check that the desired maintenance mode is displayed on the

LCD, and press the [OK] key.

(3) Each time the selected maintenance mode function is completed, the machine returns to

the ready state automatically. For function codes 12, 25, 28, 45, 80, and 82, pressing the

[X] key returns the machine to the ready state.

Touch panel models

(1) Press and hold the [Home] key for approximately five

seconds while the machine is in the ready state. The

display shown on the right appears on the LCD.

Memo:

• If you can not find the [Home]

key, press the [Toner] key to light

the [Home] key.

(2) Press the blank field at the bottom on the LCD.

The display shown on the right appears on the LCD.

(For functions of the [<<] or [>>] key, refer to the Fig. 5-1)

(3) Press the [*], [0], and [#] keys on the LCD in this order. The

machine enters into ready state to accept function code

entry, so press the function code you want to execute.

(4) Each time the selected maintenance mode function is

completed, the machine returns to the ready state

automatically.

5-3

Confidential

Page 4

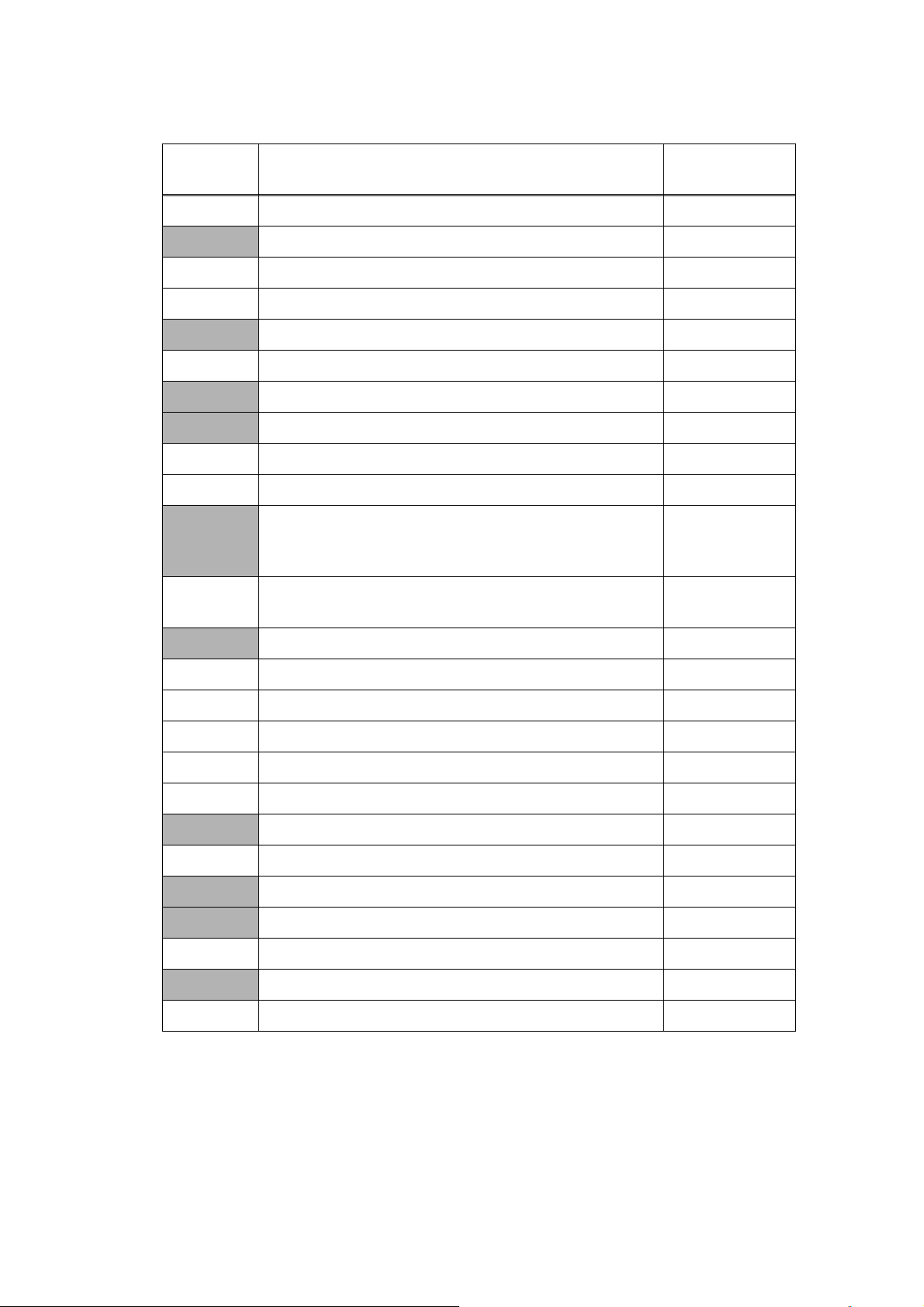

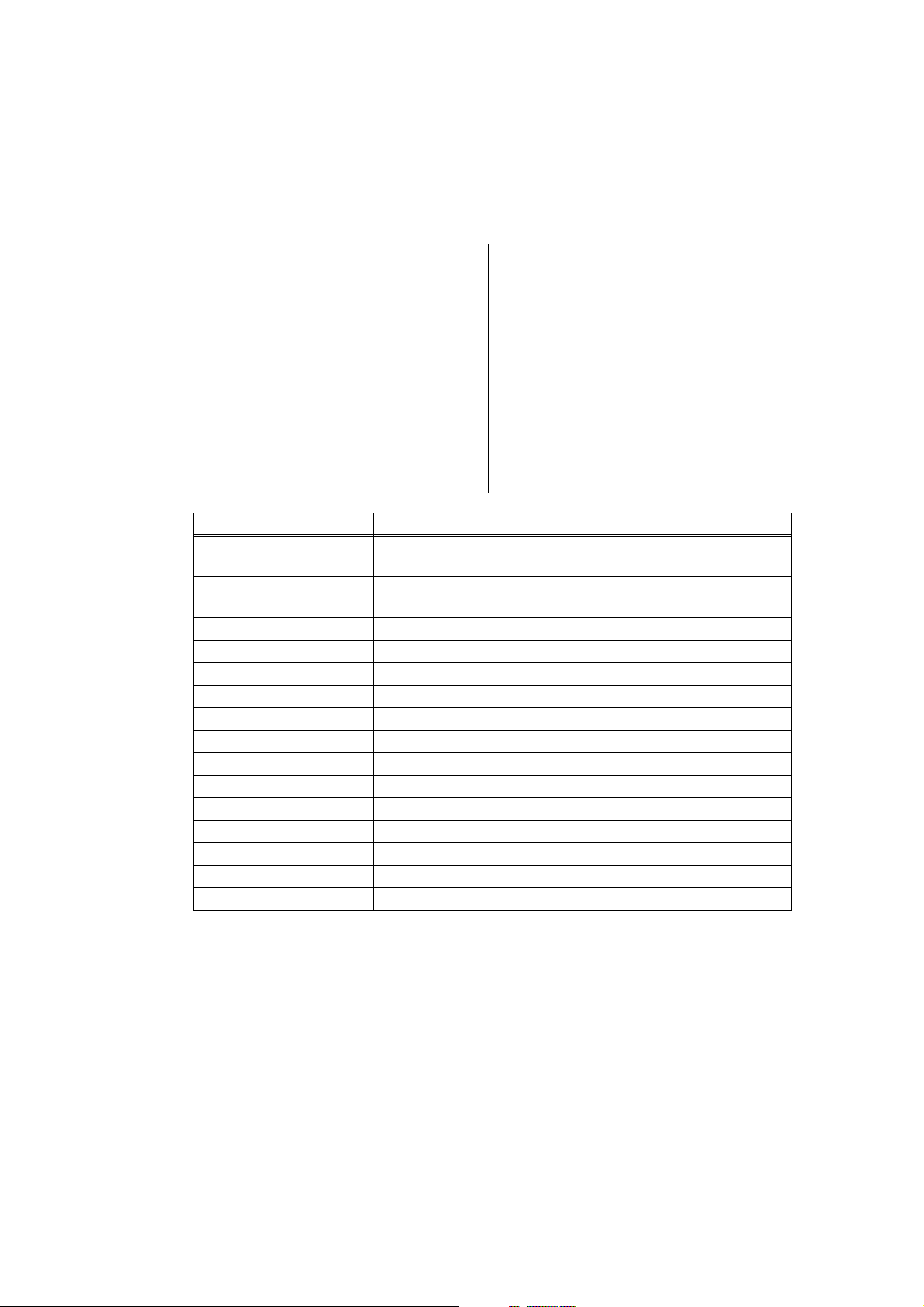

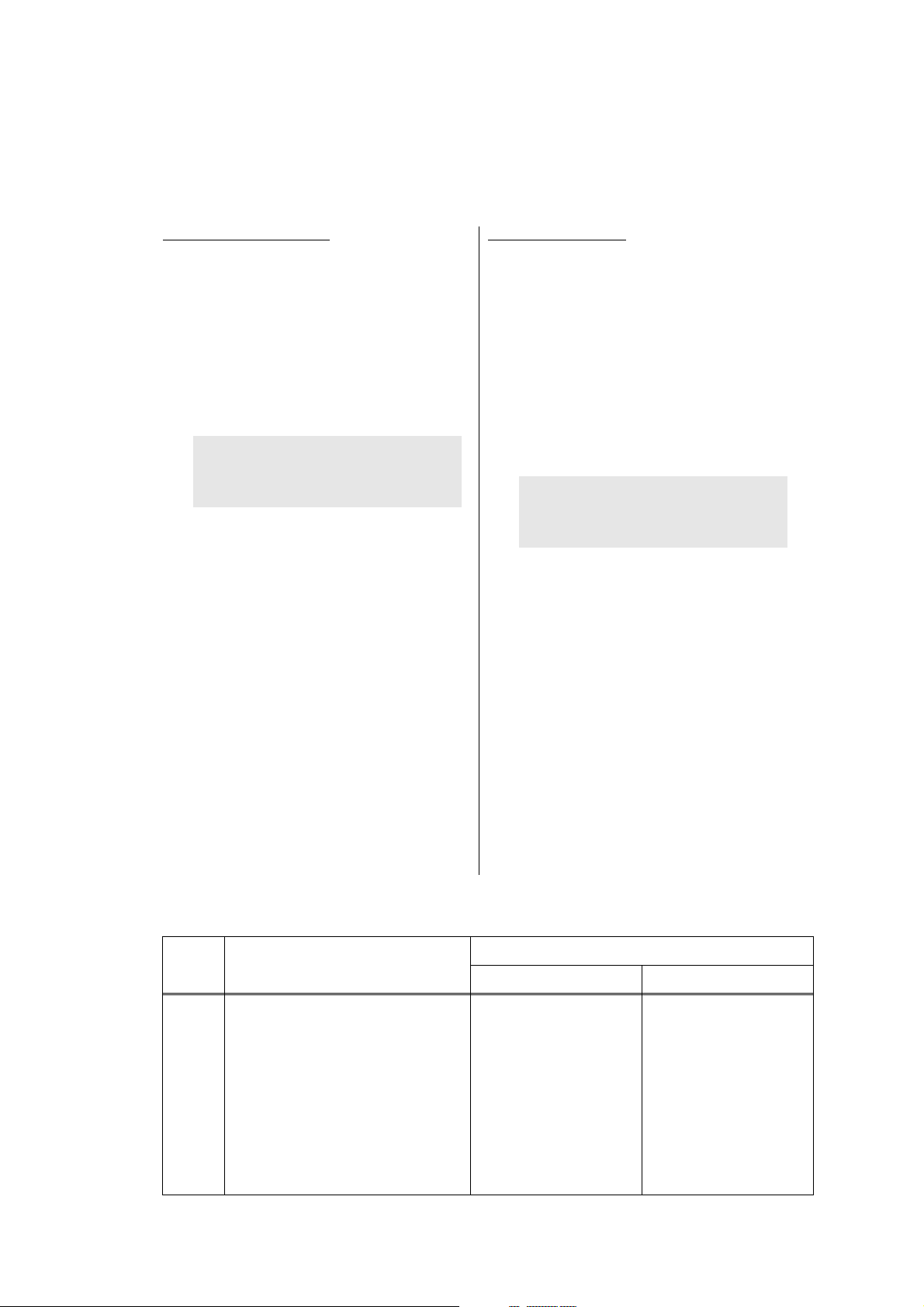

1.2 List of Maintenance Mode Functions

Function

code

01 Initialize EEPROM parameters 1.3.1

09 Print quality test pattern 1.3.2

10 Set worker switches (WSW) 1.3.3

11 Print worker switch (WSW) setting data 1.3.3

12 Check LCD operation 1.3.4

13 Check control panel key operation 1.3.5

25 Display software version 1.3.6

28 Change setting for OnePushDemo function 1.3.7

32 Check sensor operation 1.3.8

33 Display LAN connection status 1.3.9

Change USB No. return value / Adjust left-end print

45

46

position / Adjust upper-end print position / Set HEXDUMP

mode

Adjust printable range for each speed level

(Full speed / Half speed for thick paper / Quiet Mode)

Function Refer to:

1.3.10

1.3.11

61 Adjust touch panel 1.3.12

67 Continuous print test 1.3.13

69 Print frame pattern (single-side printing) 1.3.14

70 Print frame pattern (duplex printing) 1.3.15

71 Print test pattern 1.3.16

74 Configure for country/region and model 1.3.17

77 Print maintenance information 1.3.18

78 Check main fan operation 1.3.19

80 Display machine log information 1.3.20

82 Display machine error code 1.3.21

88 Reset counters for consumable parts 1.3.22

91 Initialize EEPROM parameters 1.3.1

99 Quit maintenance mode 1.3.23

* The maintenance mode functions shaded in the table can be used by end users.

5-4

Confidential

Page 5

1.3 Details of Maintenance Mode Functions

1.3.1 Initialize EEPROM parameters (function code: 01, 91)

<Function>

This function is used to initialize the setting values for operation parameters, user switches,

and worker switches (WSW) registered in the EEPROM.

Entering function code 01 initializes most EEPROM areas. Entering function code 91

initializes only the specified areas as shown in the table below.

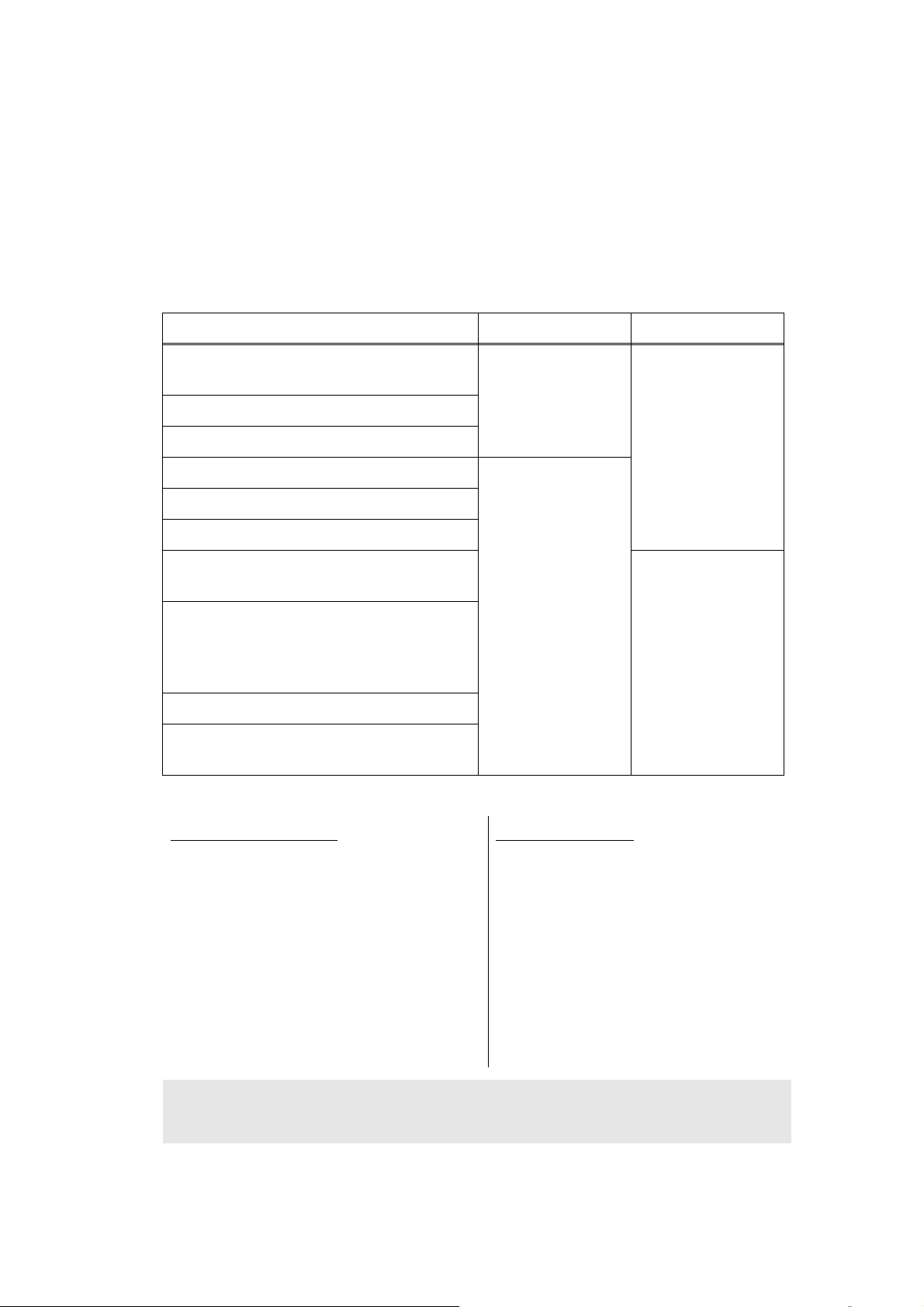

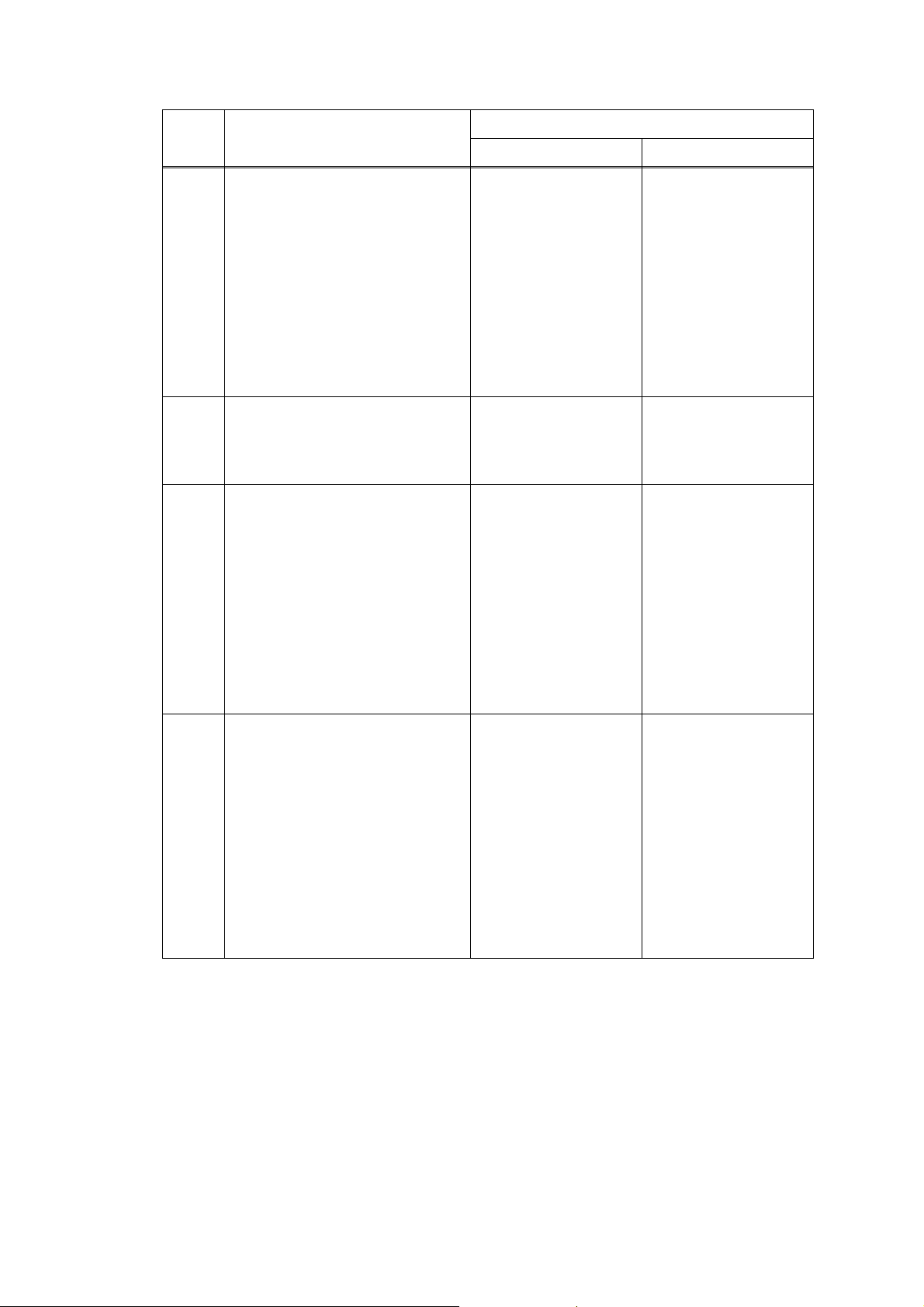

Data item 01 91

Printer switch

(Counter information)

Error history

Mac Address (Ethernet Address)

Password for control panel operation lock Areas to be

Secure function lock

Worker switches

User switches (items initialized when

"Factory Reset" is executed)

Function settings except user switches

(settings not subject to "Factory Reset")

- Language

- Interface

LAN setting

PCL core area

(Emulation setting values)

Areas not to be

initialized

initialized

<Operating Procedure>

Areas not to be

initialized

Areas to be

initialized

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"Maintenance 01" (or "Maintenance

91" as required) on the LCD, and

press the [OK] key.

"PARAMETER INIT" is displayed on

the LCD.

(2) When initializing parameters is

completed, the machine returns to the

initial state of maintenance mode.

Note:

• Function code 01 is for service personnel. Function code 91 is for user support.

Touch panel models

(1) Press the [0], and then the [1] key (or

press the [9] and then the [1] key as

required) in the initial state of

maintenance mode. "PARAMETER

INIT" is displayed on the LCD.

(2) When initializing parameters is

completed, the machine returns to the

initial state of maintenance mode.

5-5

Confidential

Page 6

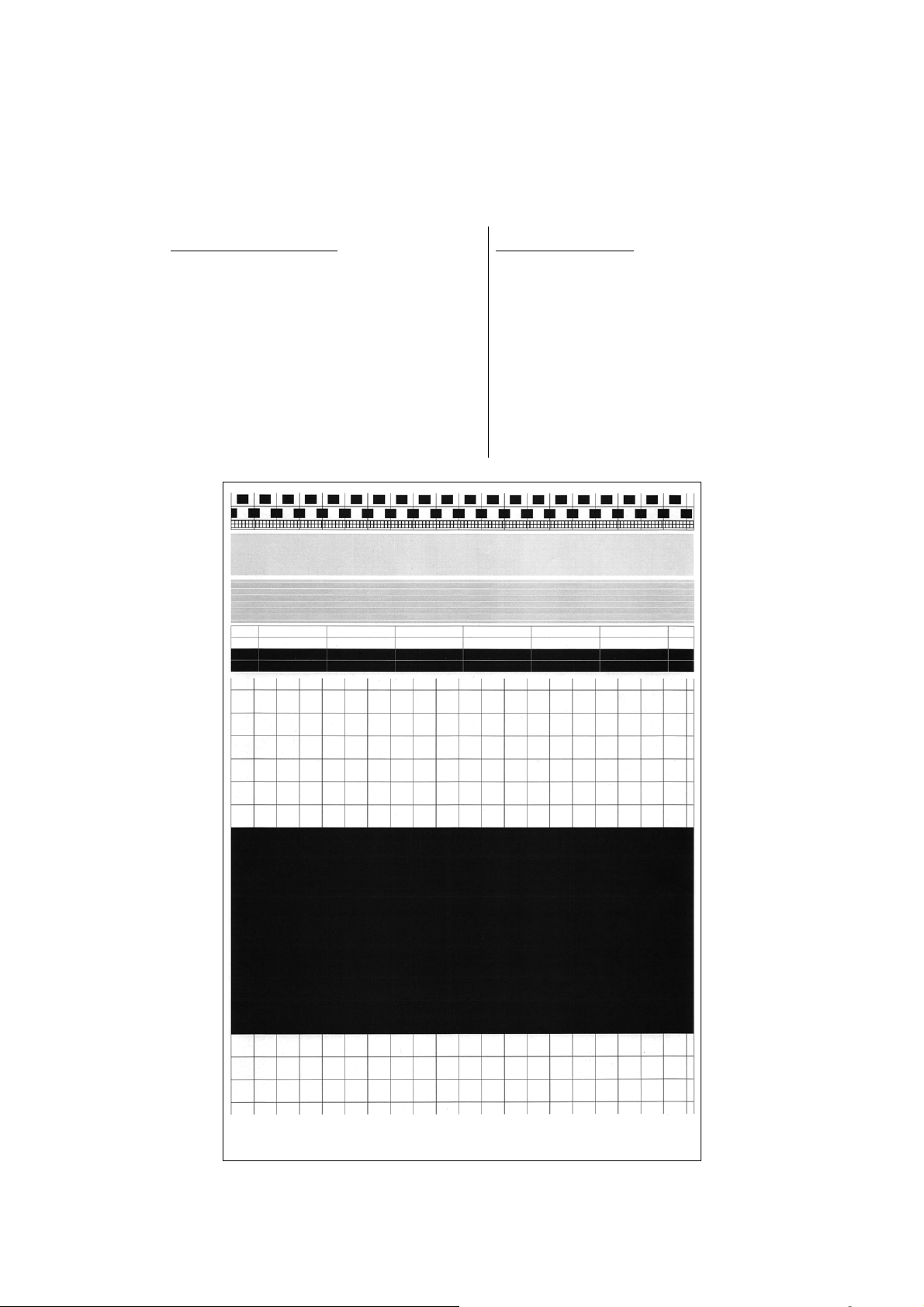

1.3.2 Print quality test pattern (function code: 09)

<Function>

This function is used to print test patterns to check any missing image and print quality.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 09" on the LCD, and

press the [OK] key. It starts printing

the print quality test pattern (refer to

the figure below).

(2) When printing is completed, the

machine returns to the initial state of

maintenance mode.

Touch panel models

(1) Press the [0], and then the [9] key in the

initial state of maintenance mode.

"MAINTENANCE 09" is displayed on

the LCD, and the machine starts

printing the print quality test pattern

(refer to the figure below).

(2) When printing is completed, the

machine returns to the initial state of

maintenance mode.

Fig. 5-2

5-6

Confidential

Page 7

1.3.3 Set worker switches (WSW) and print worker switch setting data (function code: 10, 11)

[1] Set worker switches (function code: 10)

<Function>

The worker switches shown in the table below can be used to set the function to satisfy

various requirements. These switch settings can be changed using the keys on the control

panel.

The worker switches are factory set to conform to the laws and regulations of the country the

machine is shipped to. Do not change these settings unless necessary.

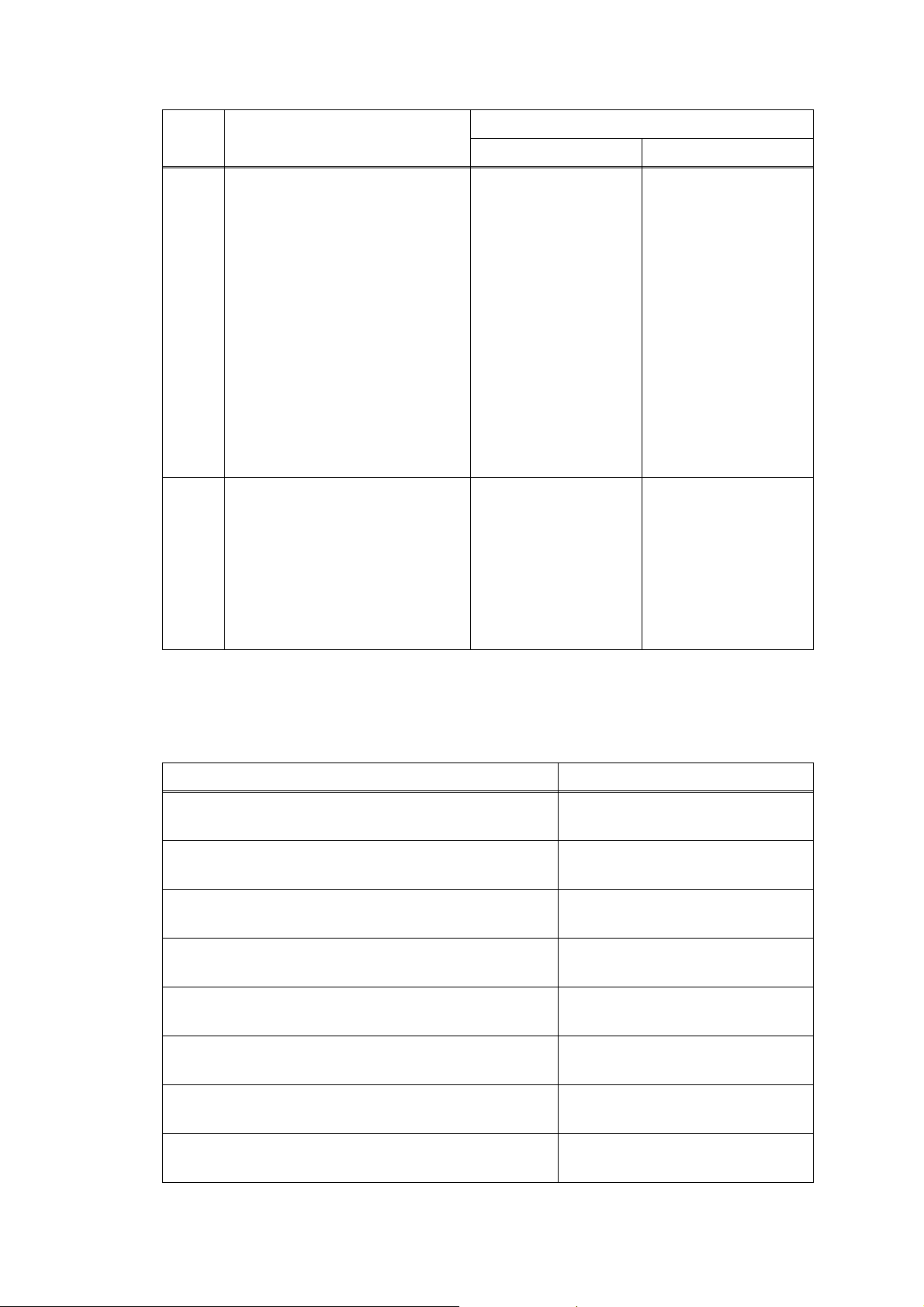

WSW No. Function

WSW17 selector 5

WSW47 selector 8 Change USB High/Full Speed

WSW56 selector 1

WSW56 selector 6 Change coverage type display

Change time display method

(American: MM/DD/YY or European: DD/MM/YY)

Change ON/OFF setting for models without PS emulation

function.

WSW56 selector 7

WSW59 selector 1 Change ON/OFF setting for USB serial number sending

WSW63 selector 1-2 Change printing speed

WSW63 selector 3

WSW63 selector 4-7 Demo printing type

WSW63 selector 8 Change ON/OFF setting for Israeli font support

WSW64 selector 1-6 Language setting

WSW64 selector 7-8 Default paper size

WSW65 selector 1-2 Default media type

WSW65 selector 3 Change ON/OFF setting for Bond Paper support

WSW65 selector 4 Change ON/OFF setting for Postcard support

WSW65 selector 6 Change ON/OFF setting for Label support

WSW78 selector 1

WSW81 selector 1

Change ON/OFF setting for models without PCL emulation

function.

Change time display method

(Japanese: YY/MM/DD or others)

Change continue/stop setting for printing when the drum

reach the life limit.

Change ON/OFF setting for models with PS emulation

function.

WSW81 selector 2

* Refer to the separate manual for details of worker switches.

Change ON/OFF setting for models with PCL emulation

function.

5-7

Confidential

Page 8

<Operating Procedure>

WSWXX = 0 0 0 0 0 0 0 0

Selector No. 1 Selector No. 8

WSWXX = 0 0 0 0 0 0 0 0

Selector No. 1 Selector No. 8

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 10" on the LCD.

(2) Press the [OK] key. "WSW00" is

displayed on the LCD, indicating that

the machine is ready for worker switch

number entry.

(3) Press the [▲] or [▼] key to display the

worker switch number for which you

want to change the setting on the

LCD.

(4) Press the [OK] key. The following

message is displayed on the LCD,

and selector No.1 flashes.

(5) Pressing the [▲] key enters "1", and

pressing the [▼] key enters "0". Press

either to enter desired number to

Selector No.1. The next digit starts

flashing.

(6) Keep entering numbers to Selector

No.8 using the [▲] or [▼] key as

described in the procedure (5).

(7) Press the [OK] key. The new selector

setting value is stored in the

EEPROM, and the LCD returns to the

ready state for worker switch number

entry ([WSW00]).

(8) When all switch setting is completed,

press the [OK] or [X] key to return the

machine to the initial state of

maintenance mode.

Touch panel models

(1) Press the [1], and then the [0] key in the

initial state of maintenance mode.

"WSW00" is displayed on the LCD.

(2) Enter the worker switch number that

you want to change the setting.

The following display appears on the

LCD.

(3) Press the [ ] or [ ] key to move the

cursor to the desired selector, and

change the setting by pressing the [1]

or [0] key.

(4) When changing the setting is

completed, press the [SET] key. The

new selector setting value is stored in

the EEPROM, and the LCD returns to

the ready state for worker switch

number entry ("WSW00").

(5) When all switch setting is completed,

press the [X] key to return the

machine to the initial state of

maintenance mode.

Note:

• To cancel operation and return to the initial state of maintenance mode, press the [X] key.

• If there is no entry for one minute or longer on 2-digit worker switch number selection after

the first digit was entered, the machine returns to the initial state of maintenance mode

automatically.

5-8

Confidential

Page 9

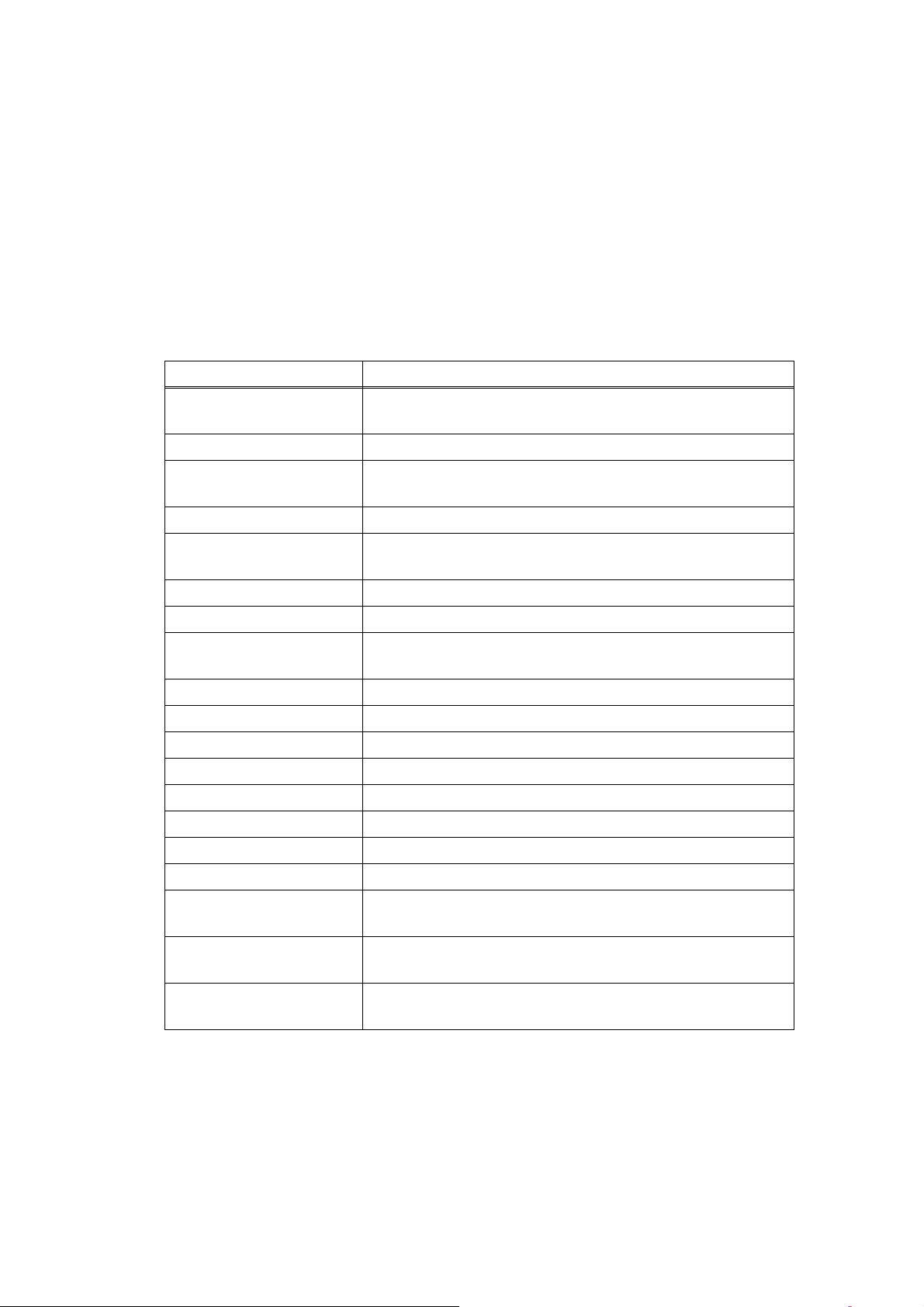

[2] Print worker switch (WSW) setting data (function code: 11)

<Function>

This function is used to print the worker switch settings and details.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 11" on the LCD, and

press the [OK] key.

(2) "PRINTING" is displayed on the LCD,

and printing the CONFIGURATION

LIST (refer to the figure below) starts.

(3) When printing is completed, the

machine returns to the initial state of

maintenance mode.

Touch panel models

(1) Press the [1] key twice in the initial

state of maintenance mode.

"PRINTING" is displayed on the LCD,

and printing the CONFIGURATION

LIST (refer to the figure below) starts.

(2) When printing is completed, the

machine returns to the initial state of

maintenance mode.

Fig. 5-3

5-9

Confidential

Page 10

1.3.4 Check LCD operation (function code: 12)

<Function>

This function is used to check that the LCD on the control panel is operating normally.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 12" on the LCD, and

press the [OK] key.

(2) Each press of the [Go] key cycles

through the displays as shown in the

figure below.

(3) When you press the [X] key, the

machine returns to the initial state of

maintenance mode, regardless of the

display status.

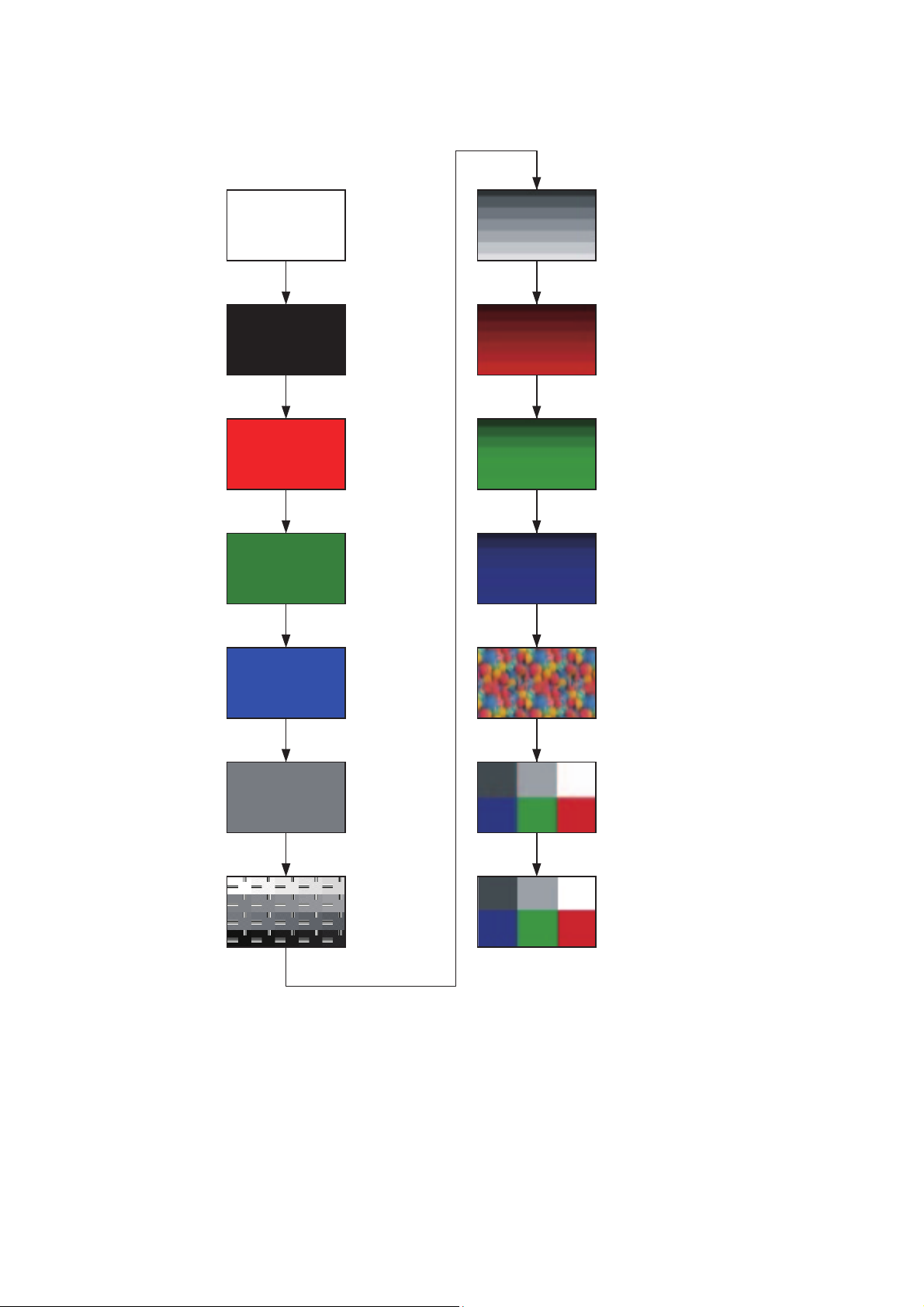

■ LCD

<Non touch panel models>

<Display 1>

Back light: OFF

LCD: Displays all dots

Touch panel models

(1) Press the [1], and then the [2] key in

the initial state of maintenance mode.

(2) Each press of the [

through the displays as shown in Fig.

5-5. Also, pressing the [

the LCD display to the previous state.

Pressing the [

display returns the display to Display

1.

(3) When you press the [X] key, the

machine returns to the initial state of

maintenance mode, regardless of the

display status.

Display 1

˄

] key cycles

˅

˄

] key at the end of

] key returns

<Display 2>

Back light: OFF

LCD: Displays 16 frames

in a line

<Display 3>

Back light: OFF

LCD: Displays no dots

<Display 4>

Back light: ON (white)

LCD: Hides all dots

Display 2

Display 3

Display 4

Fig. 5-4

5-10

Confidential

Page 11

<Touch panel models>

<Display 1>

<Display 2>

<Display 3>

<Display 4>

<Display 5>

<Display 6>

<Display 7>

<Display 8>

<Display 9>

<Display 10>

<Display 11>

<Display 12>

<Display 13>

<Display 14>

Fig. 5-5

5-11

Confidential

Page 12

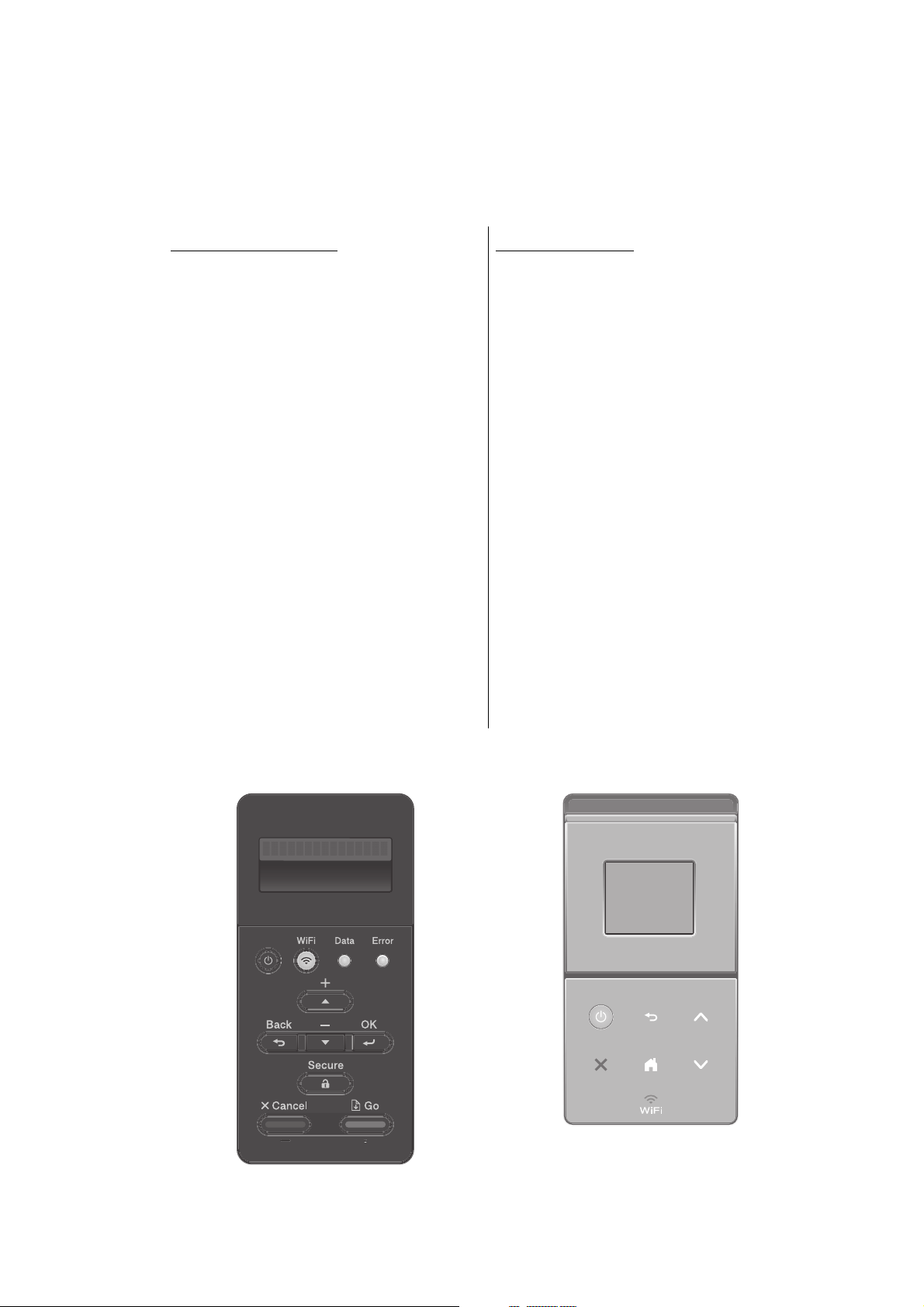

1.3.5 Check control panel key operation (function code: 13)

123

45 6

<Function>

This function is used to check that keys on the control panel are operating normally.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 13" on the LCD, and

press the [OK] key. "00" is displayed

on the LCD.

(2) Press the keys on the control panel

according to the numbers provided in

the figure below. Each time the key is

pressed, the corresponding figure is

displayed on the LCD in decimal

notation. Check that the number and

the key name displayed on the LCD

matches the number assigned to the

key that has been pressed. If the keys

are pressed in the incorrect order,

"INVALID OPERATE" is displayed on

the LCD. Press the [X] key and try

again with the correct key.

(3) When the key operation is normal, the

machine returns to the initial state of

maintenance mode when the last key

is pressed.

To cancel operation and return to the

initial state of maintenance mode,

press the [X] key.

Touch panel models

(1) Press the [1], and then the [3] key in

the initial state of maintenance mode.

"00" is displayed on the LCD.

(2) Press the keys on the control panel

according to the numbers provided in

the figure below. Each time the key is

pressed, the corresponding figure is

displayed on the LCD in decimal

notation. Check that the number

displayed on the LCD matches the

number assigned to the key that has

been pressed. If the keys are pressed

in the incorrect order, "INVALID

OPERATE" is displayed on the LCD.

Press the [X] key and try again with

the correct key.

(3) When the key operation is normal, the

machine returns to the initial state of

maintenance mode when the last key

is pressed. To cancel operation and

return to the initial state of

maintenance mode, press the [X] key.

■ Order of pressing keys

<Non touch panel models>

12

3

456

7

89

Fig. 5-6

<Touch panel models>

Fig. 5-7

5-12

Confidential

Page 13

1.3.6 Display software version (function code: 25)

<Function>

This function is used to check the version information of the firmwares and programs, or

check sum information.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 25" on the LCD, and

press the [OK] key. "MAIN:Ver*.** (#)"

is displayed on the LCD.

(2) Pressing the [Go], [▲] or [▼] key

changes the display item as shown in

the table below.

(3) Press the [X] key, and the machine

returns to the initial state of

Touch panel models

(1) Press the [2], and then the [5] key in

the initial state of maintenance mode.

"MAIN:Ver*.** (#)" is displayed on the

LCD.

˄

(2) Pressing the [▲], [

], or [Mono] key

changes the display to the next item.

(3) When you press the [X] key, this

operation is finished and the machine

returns to the initial state of

maintenance mode.

maintenance mode.

LCD Description

MAIN: Ver1.00 (A)

*1

Main firmware version information

((A): Revision information)

SUB1 : Ver1.00 (P)

*1

Sub firmware version information

((P): Identifier for PCL/PS)

*2

ENG: Ver.1.00 Do not refer to this item because it has nothing to do with DL.

NET : Ver1.00 Network program version information

MX :Ver1.00 MX firmware version information

TT :Ver1.00 TT firmware version information

LT1 :Ver1.00 LT1 firmware version information

LT2 :Ver1.00 LT2 firmware version information

LT3 :Ver1.00 LT3 firmware version information

*1

B0608071049:5708

U0612271600:7B0A

D----------:----

*4

F0612312359:1234

P0612271602:BD40

ROM Check Sum Check sum self-diagnosis function

*1

How to display the check sum information

Boot program creation date

*1

Main firmware creation date

Demo firmware data creation date

*5

Font firmware creation date

*1

Sub firmware (PCL/PS) creation date

*3

You can check the check sum information by pressing the [OK] key while each version

is displayed. When the [OK] key is pressed again, the LCD returns to the version

display.

*2

(P) indicates that the firmware supports PCL/PS.

*3

There are two types of check sum information that can be checked with this function.

This function checks if the two types of check sum information match each other.

When the [OK] key is pressed while "ROM Check Sum" is displayed, check is

automatically conducted for each ROM of each software part. When the check sum

matches, "OK" is displayed on the LCD. When all ROMs result in OK, "ROM Check

Sum OK" is displayed at the end, and the operation is finished. When the check sum

of any ROM does not match, "NG" is displayed, and the display stops.

*4

This is displayed on the LCD even no firmware is installed.

*5

Displayed only for font firmware support model.

5-13

Confidential

Page 14

1.3.7 Change OnePushDemo function setting (function code: 28)

<Function>

This function is used to implement Demo printing by pressing a certain key, and is mainly

used for sales promotion at dealers. This function is disabled once printing is performed from

the computer. Change the setting to enable the function again.

OnePushDemo = ON(Enabled) / OFF(Disabled).

The setting currently selected is marked "*".

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 28" on the LCD, and

press the [OK] key.

"OnePushDemo=ON" is displayed on

the LCD.

(2) Press the [▲] or [▼] key to display

"OnePushDemo=ON" when enabling

this function or "OnePushDemo=OFF"

when disabling this function.

(3) Press the [OK] key. The setting

currently displayed is saved, and the

machine returns to the initial state of

maintenance mode.

Note:

• To cancel operation and return to the initial state of maintenance mode, press the [X] key.

• Once the OnePushDemo function is enabled, this will not be disabled even when

printing is performed from the computer as long as the power switch is not turned OFF.

However, if the power switch is turned OFF and then ON again after the OnePushDemo

function was enabled, this function will be disabled when printing is performed from the

computer.

Touch panel models

(1) Press the [2], and then the [8] key in

the initial state of maintenance mode.

"OnePushDemo=ON" is displayed on

the LCD.

(2) Press the [

"OnePushDemo=ON" when enabling

this function or "OnePushDemo=OFF"

when disabling this function.

(3) Press the [SET] or [Mono] key. The

setting currently displayed is saved,

and the machine returns to the initial

state of maintenance mode.

˄

] or [˅] key to display

5-14

Confidential

Page 15

1.3.8 Check sensor operation (function code: 32)

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 32" on the LCD, and

press the [OK] key. "TNNT--C2P2****" is

displayed on the LCD. The machine

makes buzzing sound continuously.

Information related to the LT, TT, and MX

are not displayed on the LCD when

those are not connected.

(2) Pressing the [Go] key changes the

display to the next item.

(3) Change the conditions subject to sensor

detection shown below and check that

the display on the LCD changes

depending on the sensor status. For

example, feed the paper through the

registration front/rear sensor, open the

front cover or back cover, remove the

toner cartridge, or create paper jam at

the exit.

(4) When you press the [X] key, this

operation is finished and the machine

returns to the initial state of maintenance

mode.

Touch panel models

(1) Press the [3], and then the [2] key in the

initial state of maintenance mode. Either

of the following examples is displayed

on the LCD

e.g. TNNTSTC2P2**TT**

e.g. TNNTST----MCTT

The machine makes buzzing sound

continuously.

Information related to the LT, TT, and MX

are not displayed on the LCD when

those are not connected.

(2) Pressing the [Mono] key changes the

display to the next item.

(3) Change the conditions subject to sensor

detection shown below and check that

the display on the LCD changes

depending on the sensor status. For

example, feed the paper through the

registration front/rear sensor, open the

front cover or back cover, remove the

toner cartridge, or create paper jam at

the exit.

(4) When you press the [STOP] key, this

operation is finished and the machine

returns to the initial state of maintenance

mode.

Note:

• Press the [OK] key to stop the

buzzing sound.

Note:

• Press the [SET] key to stop the

buzzing sound.

<Function>

This function is used to check whether the sensors, solenoids, and clutches are operating normally.

<Operating Procedure>

<Sensor check>

The table below summarizes the displays on the LCD, sensor names and detection status.

LCD Sensor name

TN Toner amount detection sensor Beam obstructed Beam not obstructed

NT New toner sensor Sensor not pressed Sensor pressed

ST Output tray stack sensor

C2 T2LT Paper feed sensor Paper tray 2 closed Paper tray 2 open

P2 T2LT paper empty sensor No paper Paper set

MC MX back cover sensor MX back cover closed MX back cover open

TT TT connection sensor TT connected TT not connected

5-15

With display No display

Ejected paper not yet full

Detection status

Ejected paper full

Confidential

Page 16

LCD Sensor name

Detection status

With display No display

C1 T1 paper feed sensor Paper tray 1 closed Paper tray 1 open

P1 T1 paper empty sensor No paper Paper set

MP MP paper empty sensor No paper Paper set

CV Front cover sensor Front cover closed Front cover open

RC Back cover/duplex tray sensor Back cover closed Back cover open

PO Eject sensor No paper Paper set

RM Registration front sensor No paper Paper set

RA Registration rear sensor No paper Paper set

MACxx Internal temperature sensor

OTxx External temperature sensor

XX

XX

C

C

NG

NG

OHxx External humidity sensor XX% NG

S1

S2

S3

S4

MX 1bin stack sensor Ejected paper not yet full

MX 2bin stack sensor Ejected paper not yet full

MX 3bin stack sensor Ejected paper not yet full

MX 4bin stack sensor Ejected paper not yet full

B2 MX 2bin sensor

B4 MX 4bin sensor

MX 2bin paper set MX 2bin no paper

MX 4bin paper set MX 4bin no paper

Ejected paper full

Ejected paper full

Ejected paper full

Ejected paper full

ML MX JAM lower sensor No paper Paper set

MU MX JAM upper sensor No paper Paper set

C2 T2LT paper feed sensor

Paper tray 2 closed Paper tray 2 open

(When LT is in use)

P2 T2LT paper empty sensor

No paper Paper set

(When LT is in use)

C3 T3LT paper feed sensor

Paper tray 3 closed Paper tray 3 open

(When LT is in use)

P3 T3LT paper empty sensor

(When LT is in use)

C4 T4LT paper feed sensor

(When LT is in use)

No paper Paper set

Paper tray 4 closed Paper tray 4 open

5-16

Confidential

Page 17

LCD Sensor name

Detection status

With display No display

E2 T2TT paper feed sensor TT paper tray 2 closed

and No paper

TT paper tray 2 open

and Paper set

D2 T2TT paper empty sensor No paper Paper set

E3 T3TT paper feed sensor TT paper tray 3 closed

and No paper

TT paper tray 3 open

and Paper set

D3 T3TT paper empty sensor No paper Paper set

E4 T4TT paper feed sensor TT paper tray 4 closed

and No paper

TT paper tray 4 open

and Paper set

D4 T4TT paper empty sensor No paper Paper set

E5 T5TT paper feed sensor TT paper tray 5 closed

and No paper

TT paper tray 5 open

and Paper set

D5 T5TT paper empty sensor No paper Paper set

J2 T2 JAM sensor No paper Paper set

J3 T3 JAM sensor No paper Paper set

J4 T4 JAM sensor No paper Paper set

J5 T5 JAM sensor No paper Paper set

AL TT balance sensor L With attachment No attachment

AR TT balance sensor R With attachment No attachment

<Solenoid and clutch check>

Check the corresponding solenoid and clutch by activating the sensor below.

Both solenoid and clutch can not detect error or fault. They only check if they are functioning.

Sensor operation Solenoid/clutch operation

Change the status of the T1 paper feed sensor from

Paper tray 1 open to Paper tray 1 closed.

Change the status of the T2LT paper feed sensor from

Paper tray 2 open to Paper tray 2 closed.

Change the status of the T2LT paper empty sensor from

No paper to Paper set.

Change the status of the T3LT paper feed sensor from

Paper tray 3 open to Paper tray 3 closed.

Change the status of the T3LT paper empty sensor from

No paper to Paper set.

Change the status of the T4LT paper feed sensor from

Paper tray 4 open to Paper tray 4 closed.

The T1 pickup clutch remains ON

for the specified time.

The T2LT pickup clutch remains ON

for the specified time.

The T2LT release clutch remains ON

for the specified time.

The T3LT pickup clutch remains ON

for the specified time.

The T3LT release clutch remains

ON for the specified time.

The T4LT pickup clutch remains ON

for the specified time.

Change the status of the T4LT paper empty sensor from

No paper to Paper set.

Change the status of the MP paper empty sensor from

No paper to Paper set.

5-17

The T4LT release clutch remains

ON for the specified time.

The MP solenoid remains ON for

the specified time.

Confidential

Page 18

Sensor operation Solenoid/clutch operation

Change the status of the registration rear sensor from

No paper to Paper set.

Change the status of the new toner sensor from

Not pressed to Pressed.

Change the status of the MX 1bin stack sensor from

Not full to Full.

Change the status of the MX 2bin stack sensor from

Not full to Full.

Change the status of the MX 3bin stack sensor from

Not full to Full.

Change the status of the MX 1bin stack sensor from

Full to Not full.

Change the status of the MX 2bin stack sensor from

Full to Not full.

Change the status of the MX 3bin stack sensor from

Full to Not full.

The registration clutch remains ON

for the specified time.

The develop clutch remains ON for the

specified time.

Erase Lamp is ON (keep the develop

clutch ON until the new toner sensor

gets pressed)

MX solenoid is moved to MX 1bin

side.

MX solenoid is moved to MX 2bin

side.

MX solenoid is moved to MX 3bin

side.

MX solenoid is moved to the side

which does not eject paper to the

MX 1bin.

MX solenoid is moved to the side

which does not eject paper to the

MX 2bin.

MX solenoid is moved to the side

which does not eject paper to the

MX 3bin.

Change the status of the

TT paper tray 2 open to TT paper tray 2 closed.

Change the status of the

TT paper tray 3 open to TT paper tray 3 closed.

Change the status of the

TT paper tray 4 open to TT paper tray 4 closed.

Change the status of the

TT paper tray 5 open to TT paper tray 5 closed.

Change the status of the T3TT paper empty sensor from

No paper to Paper set.

Change the status of the T4TT paper empty sensor from

No paper to Paper set.

Change the status of the T5TT paper empty sensor from

No paper to Paper set.

T2TT paper feed sensor from

T3TT paper feed sensor from

T4TT paper feed sensor from

T5TT paper feed sensor from

The T2TT pickup clutch remains

ON for the specified time.

The T3TT pickup clutch remains

ON for the specified time.

The T4TT pickup clutch remains

ON for the specified time.

The T5TT pickup clutch remains ON

for the specified time.

The T3TT release clutch remains

ON for the specified time.

The T4TT release clutch remains

ON for the specified time.

The T5TT release clutch remains

ON for the specified time.

Note:

• LCD display changes by activating the sensors above. However, it does not affect to the

operation of the solenoid and clutch. If the sensors to operate the solenoid and clutch are

faulty, they are inoperable.

5-18

Confidential

Page 19

Location of sensors

Toner amount detection sensor PCB (light reception)

Eject sensor

Eject stack sensor

Registration front/rear sensor

MP paper empty

sensor

T1 paper empty sensor

LT paper feed sensor

LT paper empty sensor

Front cover sensor

T1 paper feed sensor

Internal temperature sensor

Toner amount detection sensor PCB

(light emission)

Back cover/duplex

tray sensor

New toner sensor

Fig. 5-8

5-19

Confidential

Page 20

Fig. 5-9

MX 2bin sensor

MX 1bin stack sensor

MX 4bin sensor

MX 2bin stack sensor

MX 3bin stack sensor

MX 4bin stack sensor

MX JAM lower sensor

MX JAM upper sensor

MX back cover sensor

TT jam sensor PCB ASSY

TT paper feed sensor

PCB ASSY

TT balance sensor L

TT jam sensor

PCB ASSY

TT jam sensor

PCB ASSY

TT paper feed sensor

PCB ASSY

TT paper feed sensor

PCB ASSY

TT paper empty

sensor PCB ASSY

TT paper feed sensor

PCB ASSY

TT paper empty

sensor PCB ASSY

TT paper empty

sensor PCB ASSY

TT jam sensor PCB ASSY

TT balance sensor R

TT paper empty sensor PCB ASSY

Fig. 5-10

5-20

Confidential

Page 21

1.3.9 Display LAN connection status (function code: 33)

<Function>

This function is used to check the connection status of the wired LAN.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 33" on the LCD, and

press the [OK] key.

(2) One of the items in the following table

is displayed on the LCD depending on

the wired LAN connection of the

machine.

(3) Press the [X] key, and the machine

returns to the initial state of

maintenance mode.

LCD LAN connection status

Active 100B-FD 100B-FD

Active 100B-HD 100B-HD

Active 10B-FD 10B-FD

Active 10B-HD 10B-HD

Touch panel models

(1) Press the [3] key twice in the initial

state of maintenance mode. One of

the following items is displayed on the

LCD depending on the wired LAN

connection of the machine.

(2) Press the [X] key, and the machine

returns to the initial state of

maintenance mode.

Inactive Not connected

5-21

Confidential

Page 22

1.3.10 Change USB No. return value / Adjust left-end print position / Adjust upper-end print position / Set HEXDUMP mode (function code: 45)

Change USB No. return value

<Function>

When the operating system (OS) installed on the computer is Windows Vista®, and the

machine is connected to this computer using USB2.0FULL, the OS may not be able to obtain

the USB device serial number depending on the computer and USB device. If the serial

number cannot be obtained, the number of devices increases each time the device is

connected to the computer. To avoid this problem, set this function to "USBNo.=ON" and fix

the USB No. return value to "0".

LCD Description

USBNo. = ON Returns the serial number of the machine.

USBNo. = OFF Returns "0".

The setting currently selected is marked "*" at the end of the display.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 45" on the LCD, and

press the [OK] key. "USBNo." is

displayed on the LCD.

(2) Press the [OK] or [Go] key.

"USBNo.=ON" or "USBNo.=OFF" is

displayed on the LCD.

(3) Press the [▲] or [▼] key to select

"USBNo.=ON" or "USBNo.=OFF",

and then press the [OK] or [Go] key.

(4) "Accepted" is displayed on the LCD,

and the machine returns to the initial

state of maintenance mode.

(5) Turn the power switch OFF.

Note:

• This setting is applied after the power switch is turned OFF and then ON again.

Touch panel models

(1) Press the [4], and then the [5] key in

the initial state of maintenance mode.

"USBNo." is displayed on the LCD.

(2) Press the [Mono] or [SET] key.

"USBNo.=ON" or "USBNo.=OFF" is

displayed on the LCD.

(3) Press the [

"USBNo.=ON" or "USBNo.=OFF",

and then press the [Mono] or [SET]

key.

(4) "Accepted" is displayed on the LCD,

and the machine returns to the initial

state of maintenance mode.

(5) Turn OFF the power switch.

˄

] or [˅] key to select

5-22

Confidential

Page 23

Adjust left-end print position

<Function>

In the event that the left-end print start position deviates, use this function to adjust the

position left and right. The adjustable range is -100 to 750 (1 unit = 0.084 mm = 300 dpi).

(Shifted to the left when the value is negative)

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 45" on the LCD, and

press the [OK] key. "USBNo." is

displayed on the LCD.

(2) Press the [▲] or [▼] key to display "X

Adjust" on the LCD, and press the

[OK] or [Go] key. "XAdjust MP" is

displayed on the LCD.

(3) Refer to <Adjustment option table>

below, press the [▲] or [▼] key to

select from the adjustment options,

and press the [OK] or [Go] key. "XAdj.

**= 0*" is displayed on the LCD.

(Selected option is shown for **.)

(4) To shift the writing start position to the

left, press the [▼] key to decrease the

value. To shift the position to the right,

press the [▲] key to increase the

value.

(5) Press the [OK] or [Go] key after

adjusting the value. "Accepted" is

displayed on the LCD. Return the

machine to the initial state of

maintenance mode.

Touch panel models

(1) Press the [4], and then the [5] key in

the initial state of maintenance mode.

"USBNo." is displayed on the LCD.

(2) Press the [

Adjust" on the LCD, and press the

[Mono] or [SET] key. "XAdjust MP" is

displayed on the LCD.

(3) Refer to <Adjustment option table>

below, press the [▲] or [▼] key to

select from the adjustment options,

and press the [Mono] or [SET] key.

"XAdj. **= 0*" is displayed on the

LCD. (Selected option is shown for

**.)

(4) To shift the writing start position to the

left, press the [

value. To shift the position to the right,

press the [

value.

(5) Press the [Mono] or [SET] key after

adjusting the value. "Accepted" is

displayed on the LCD, and the

machine returns to the initial state of

maintenance mode.

˄

] or [˅] key to display "X

˅

] key to decrease the

˄

] key to increase the

<Adjustment option table>

Adjustment option LCD Adjustment option LCD

MP tray first side *Adjust MP MP tray second side *Adjust DXMP

Paper tray 1 first side *Adjust T1 Paper tray 1 second side *Adjust DXT1

Paper tray 2 first side *Adjust T2 Paper tray 2 second side *Adjust DXT2

Paper tray 3 first side *Adjust T3 Paper tray 3 second side *Adjust DXT3

Paper tray 4 first side *Adjust T4 Paper tray 4 second side *Adjust DXT4

Paper tray 5 first side *Adjust T5 Paper tray 5 second side *Adjust DXT5

Duplex tray *Adjust DX

"X" or "Y" is shown for *.

5-23

Confidential

Page 24

Adjust upper-end print position

<Function>

In the event that the upper-end print start position deviates, use this function to adjust the

position up and down. Adjustable range is -50 to 50 (1 unit = 0.084 mm = 300 dpi). (Shifted

down when the value is negative)

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 45" on the LCD, and

press the [OK] key. "USBNo." is

displayed on the LCD.

(2) Press the [▲] or [▼] key to display

"YAdjust" on the LCD, and press the

[OK] or [Go] key. "YAdjust MP" is

displayed on the LCD.

(3) Refer to

the last page, press the [▲] or [▼] key

to select from the adjustment options,

and press the [OK] or [Go] key. "YAdj.

**= 0*" is displayed on the LCD.

(Selected option is shown for **.)

(4) To shift the writing start position down,

press the [▼] key to decrease the

value. To shift the position up, press

the [▲] key to increase the value.

(5) Press the [OK] or [Go] key after

adjusting the value. "Accepted" is

displayed on the LCD, and the

machine returns to the initial state of

maintenance mode.

<Adjustment option table>

on

Touch panel models

(1) Press the [4], and then the [5] key in

the initial state of maintenance mode.

"USBNo." is displayed on the LCD.

(2) Press the [▲] or [▼] key to display

"Y Adjust" on the LCD, and press the

[Mono] or [SET] key. "YAdjust MP" is

displayed on the LCD.

(3) Refer to

the last page, press the [▲] or [▼] key

to select from the adjustment options,

and press the [Mono] or [SET] key.

"YAdj. **= 0*" is displayed on the LCD.

(Selected option is shown for **.)

(4) To shift the writing start position down,

press the [▲] key to decrease the

value. To shift the position up, press

the [▼] key to increase the value.

(5) Press the [Mono] or [SET] key after

adjusting the value. "Accepted" is

displayed on the LCD.

(6) Press the [X] key to return the

machine to the initial state of

maintenance mode.

<Adjustment option table>

on

Set HEXDUMP mode

<Function>

This function is used to enter HEXDUMP mode (hexadecimal mode) or not when the

machine starts next time.

Note:

• Do not turn this ON, otherwise the machine enters HEXDUMP mode when it starts. If it

is ON and the machine starts in HEXDUMP mode, you can return the machine to the

ready state by turning the power OFF then ON again.

5-24

Confidential

Page 25

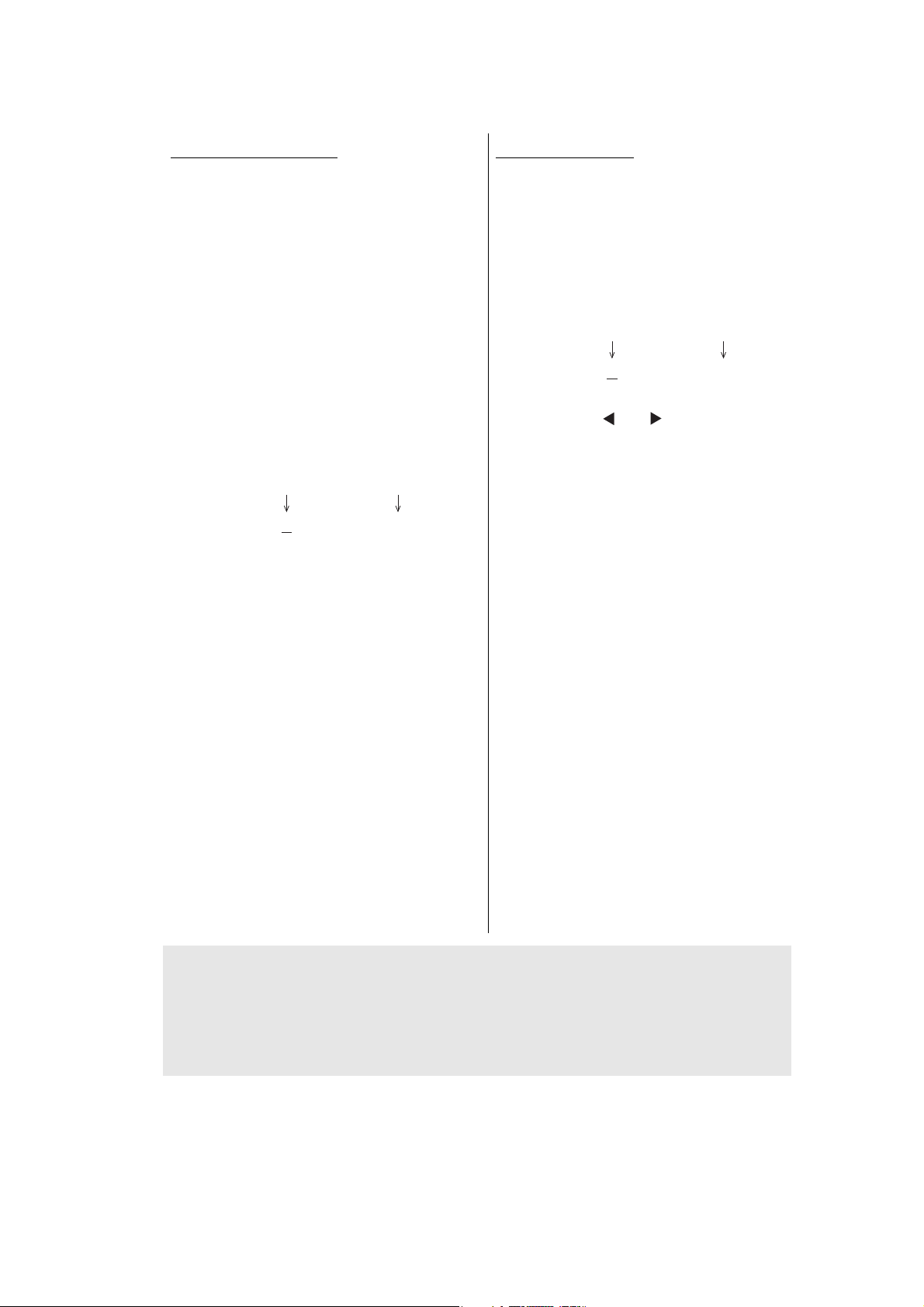

1.3.11 Adjust printable range for each speed level (Full speed / Half speed for thick paper / Quiet Mode) (function code: 46)

<Function>

This function is to adjust the printing position in horizontal / vertical direction when it's

misaligned on Full speed, Half speed for thick paper, or Quiet Mode.

Position can be adjusted in 11 steps from -0.5% to 0.5% (Printing width gets smaller when

the value is negative).

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 46" on the LCD, and

press the [OK] key. "1.PrtSzAdj

Nomal" is displayed on the LCD.

(2) Press the [▲] or [▼] key to display

desired speed on the LCD.

• Full speed → "1.PrtSzAdj Nomal"

• Half speed for thick paper →

"2.PrtSzAdj THalf"

• Quiet Mode → "3.PrtSzAdj QHalf"

Press the [OK] key. "*.1 *:Main" is

displayed on the LCD.

Selected speed is displayed for "*".

(3) Press the [▲] or [▼] key to display

"*.3 *:Print" on the LCD, and press the

[OK] key. "PRINTING" is displayed on

the LCD, and the print adjustment test

pattern (refer to the next page) is

printed on a sheet of paper.

(4) Adjust the line so that the width is

10mm in horizontal / vertical direction.

Press the [▲] or [▼] key to display

desired direction on the LCD.

• Horizontal direction → "*.1 *:Main"

• Vertical direction → "*.2 *:Sub"

Press the [OK] key. "0.0 %" is displayed

on the LCD.

(5) To make the print width smaller, press

the [▼] key to decrease the value.

Press the [OK] key after adjusting the

value.

(6) Press the [X] key to return the

machine to the initial state of

maintenance mode after adjusting the

value.

Touch panel models

(1) Press the [4], and then the [6] key in

the initial state of maintenance mode.

"1.PrtSzAdj Nomal" is displayed on

the LCD.

(2) Press the [

desired speed on the LCD.

• Full speed → "1.PrtSzAdj Nomal"

• Half speed for thick paper →

"2.PrtSzAdj THalf"

• Quiet Mode → "3.PrtSzAdj QHalf"

Press the [Mono] key. "*.1 *:Main" is

displayed on the LCD.

Selected speed is displayed for "*".

(3) Press the [

*:Print" on the LCD, and press the

[Mono] key. "PRINTING" is displayed

on the LCD, and the print adjustment

test pattern (refer to the next page) is

printed on a sheet of paper.

(4) Adjust the line so that the width is

10mm in horizontal / vertical direction.

Press the [

desired direction on the LCD.

• Horizontal direction → "*.1 *:Main"

• Vertical direction → "*.2 *:Sub"

Press the [Mono] key. "0.0 %" is

displayed on the LCD.

(5) To make the print width smaller, press

the [

Press the [Mono] key after adjusting

the value.

(6) Press the [X] key to return the

machine to the initial state of

maintenance mode after adjusting the

value.

˄

] or [˅] key to display

˄

] or [˅] key to display "*.3

˄

] or [˅] key to display

˅

] key to decrease the value.

5-25

Confidential

Page 26

Print adjustment test pattern

Fig. 5-11

5-26

Confidential

Page 27

1.3.12 Adjust touch panel (function code: 61) (Touch panel models only)

<Function>

This function is used to adjust the touch panel.

Note:

• This adjustment requires a touch pen with a thin tip. A commercially available touch pen

designed for electronic dictionaries or personal digital assistance (PDA) can be used. If

one is not available at hand, order a "Touch pen" from Brother's parts list.

<Operating Procedure>

(1) Press the [6], and then the [1] key in the initial state of maintenance mode. The

adjustment screen shown below appears on the LCD.

(2) Use a touch pen and touch the center on the mark at the upper left corner of the screen.

The mark disappears when touched, then touch the mark at the lower left. Similarly

touch the mark at the lower right, upper right and center.

Note:

• Do not use any tools other than a touch pen. In particular, never use a pointed tool (e.g.

screwdriver). Using such a tool will damage the touch panel.

• Do not touch the touch panel with your fingers. The contact area of a finger is too large

to adjust the touch panel precisely.

• If no operation is performed for one minute or the [X] key is pressed, the machine

returns to the initial state of maintenance mode.

Fig. 5-12

(3) When the center (the 5th mark) is touched, "OK" is displayed on the LCD if the specified

area is adjusted correctly. The machine returns to the initial state of maintenance mode.

Note:

• If "NG" is still displayed on the LCD even after this operation is repeated two to three

times, check the connection of the panel flat cable. If the LCD keeps displaying "NG"

even there is no problem, replace the LCD panel ASSY.

5-27

Confidential

Page 28

1.3.13 Continuous print test (function code: 67)

<Function>

This function is used to conduct paper feed and eject tests while printing patterns.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 67" on the LCD, and

press the [OK] key. "SELECT: K

100%" is displayed on the LCD.

(2) Refer to the <Print pattern> table,

press the [▲] or [▼] key to select the

print pattern, and press the [OK] key.

For total pattern printing, proceed to

the procedure (9). Otherwise,

"SELECT: A4" is displayed on the LCD.

(3) Refer to the <Paper size> table, press

the [▲] or [▼] key to select the paper

size, and press the [OK] key. "SELECT:

PLAIN" is displayed on the LCD.

(4) Refer to the <Print specification>

table, press the [▲] or [▼] key to

select the media specification, and

press the [OK] key. "SELECT: TRAY1

SX" is displayed on the LCD.

(5) Refer to the <Print type> table, press

the [▲] or [▼] key to select the print

type, and press the [OK] key. "SELECT:

STD" is displayed on the LCD.

(6) Refer to the <Output tray> table, press

the [▲] or [▼] key to select the output

tray, and press the [OK] key. "SELECT:

1PAGE" is displayed on the LCD.

(MX supported models only)

(7) Refer to the <Print page> table, press the

[▲] or [▼] key to select the pages printing,

and press the [OK] key. For intermittent

pattern printing, "SELECT: 1P/JOB" is

displayed on the LCD. For other printings,

or move on to the procedure (9).

(8) Refer to the <Number of pages per

job> table, press the [▲] or [▼] key to

select the number of pages for 1 job,

and press the [OK] key. (Only for

intermittent pattern printing)

(9) "PAPER FEED TEST" is displayed on

the LCD, and printing test pattern

starts using the selected conditions.

(10) When you press the [X] key, test pattern

printing is stopped, and the machine returns

to the initial state of maintenance mode.

Touch panel models

(1) Press the [6], and then the [7] key in

the initial state of maintenance mode.

"SELECT: K 100%" is displayed on

the LCD.

(2) Refer to the <Print pattern> table,

press the [

print pattern, and press the [SET] key.

For total pattern printing, proceed to

the procedure (9). Otherwise,

"SELECT: A4" is displayed on the LCD.

(3)

Refer to the <Paper size> table, press

the [

size, and press the [SET] key. "SELECT:

PLAIN" is displayed on the LCD.

(4) Refer to the <Print specification>

table, press the [

the media specification, and press the

[SET] key. "SELECT: TRAY1 SX" is

displayed on the LCD.

(5) Refer to the <Print type> table, press the

[

˄

] or [˅] key to select the print type, and

press the [SET] key. "SELECT: STD" is

displayed on the LCD.

(6) Refer to the <Output tray> table, press

the [

tray, and press the [SET] key. "SELECT:

1PAGE" is displayed on the LCD.

(MX supported models only)

(7) Refer to the <Print page> table, press

the [

printing, and press the [SET] key. For

intermittent pattern printing, "SELECT:

1P" is displayed on the LCD. For other

printings, or move on to the procedure

(9).

(8) Refer to the <Number of pages per

job> table, press the [

select the number of pages for 1 job,

and press the [SET] key. (Only for

intermittent pattern printing)

(9) "PAPER FEED TEST" is displayed on

the LCD, and printing test pattern

starts using the selected conditions.

(10) When you press the [X] key, test

pattern printing is stopped and the

machine returns to the initial state of

maintenance mode.

˄

] or [˅] key to select the

˄

] or [˅] key to select the paper

˄

] or [˅] key to select

˄

] or [˅] key to select the output

˄

] or [˅] key to select the pages

˄

] or [˅] key to

5-28

Confidential

Page 29

<Print pattern>

LCD Description

SELECT:K 100% Black 100% solid printing

SELECT:W 100% White 100% solid printing

SELECT:K1% Black 1% intermittent pattern printing *

SELECT:K5% Black 5% intermittent pattern printing *

SELECT:Lattice Lattice printing

SELECT:Total Print total pattern

* For job printing, up to 500 sheets for single-side printing, and 1,000 sheets

for duplex printing.

<Paper size>

LCD Description

SELECT:A4 A4

SELECT:LETTER Letter

SELECT:ISOB5 ISO B5

SELECT:JISB5 JIS B5

SELECT:A5 A5

SELECT:A5L A5L

SELECT:JISB6 JIS B6

SELECT:A6 A6

SELECT:EXECUTE Executive size

SELECT:LEGAL Legal size

SELECT:FOLIO Folio size

SELECT:HAGAKI Postcard size

<Print specification>

LCD Description

SELECT:PLAIN Plain paper

SELECT:THIN Plain paper (thin)

SELECT:THICK Plain paper (thick)

SELECT:THICKER Plain paper (thicker)

SELECT:RECYCLED Recycled paper

SELECT:BOND Bond paper

SELECT:LABEL Label

SELECT:ENVELOPE Envelope

SELECT:ENVTHIN Envelope (thin)

SELECT:ENVTHICK Envelope (thick)

SELECT:HAGAKI Postcard

5-29

Confidential

Page 30

<Print type>

LCD Description

SELECT:TRAY1 SX Single-side printing from paper tray 1

SELECT:TRAY1 DX Duplex printing from paper tray 1

SELECT:TRAY2 SX Single-side printing from paper tray 2

SELECT:TRAY2 DX Duplex printing from paper tray 2

SELECT:TRAY3 SX Single-side printing from paper tray 3

SELECT:TRAY3 DX Duplex printing from paper tray 3

SELECT:TRAY4 SX Single-side printing from paper tray 4

SELECT:TRAY4 DX Duplex printing from paper tray 4

SELECT:TRAY5 SX Single-side printing from paper tray 5

SELECT:TRAY5 DX Duplex printing from paper tray 5

SELECT:MP SX Single-side printing from MP tray

SELECT:MP DX Duplex printing from MP tray

SELECT:AUTO SX Single-side printing to automatically selected tray

SELECT:AUTO DX Double-side printing to automatically selected tray

<Output tray>

LCD Description

SELECT:STD Eject to output tray

SELECT:MX1 Eject to MX 1bin

SELECT:MX2 Eject to MX 2bin

SELECT:MX3 Eject to MX 3bin

SELECT:MX4 Eject to MX 4bin

SELECT:STACKER Eject to an MX automatically selected based on

the free space

SELECT:SORTER

Collating output according to the number of bins

*

* For 4-bin models, 1 copy for each bin, 5 copies in total.

For 2-bin models, 1 copy for each bin, 3 copies in total.

<Print page>

LCD Description

SELECT:1PAGE 1-page printing

SELECT:CONTINUE Continuous printing

SELECT:JOB

Intermittent printing per job

*

* Selectable only when the printing pattern is set to "K1%" or "K5%",

and the print type is not set to the manual feed slot.

5-30

Confidential

Page 31

<Number of pages per job> (Only for intermittent pattern printing)

LCD Description

SELECT:1P/JOB

SELECT:2P/JOB

SELECT:5P/JOB

SELECT:10P/JOB

SELECT:2I/JOB

SELECT:5I/JOB

SELECT:10I/JOB

SELECT:20I/JOB

*1

Selectable only when the SX is set as print type.

*2

Selectable only when the DX is set as print type.

*3

Fifth page will be printed as single-side printing.

Prints 1 page per job

Prints 2 pages per job

Prints 5 pages per job

Prints 10 pages per job

Prints 2 images per job

Prints 5 images per job

Prints 10 images per job

Prints 20 images per job

*1

*1

*1

*1

*2

*2 *3

*2

*2

5-31

Confidential

Page 32

K 100% K 1% W 100%

K 5% Lattice Total

Fig. 5-13

5-32

Confidential

Page 33

1.3.14 Print frame pattern (single-side printing) (function code: 69)

<Function>

This function is used to print the frame pattern on single side of the paper to check for printing

flaws and omission.

<Operating Procedure>

Non touch panel models

(1) Set the paper specified in the default paper

settings (A4 or Letter) to the paper tray.

(2) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 69" on the LCD, and

press the [OK] key. "PRINTING" is

displayed on the LCD, and the frame

pattern (refer to the figure below) is

printed on single side of the paper.

(3) When printing is completed, "WAKU

SX" is displayed on the LCD.

(4) When you press the [X] key, this operation

is finished and the machine returns to the

initial state of maintenance mode.

Note:

• If printing fails, printing is stopped with displaying any of the errors shown in the table below. To

retry printing, refer to the "Remedy" in the table below and eliminate the error cause. "PRINTING"

is displayed on the LCD, and the frame pattern is printed on a single sheet of paper.

Touch panel models

(1) Set the paper specified in the default

paper settings (A4 or Letter) to the

paper tray.

(2) Press the [6], and then the [9] key in

the initial state of maintenance mode.

"PRINTING" is displayed on the LCD,

and the frame pattern (refer to the

figure below) is printed on single side

of the paper.

(3) When printing is completed, "WAKU

SX" is displayed on the LCD.

(4) When the [X] key is pressed, the

machine stops this operation and

returns to the initial state of

maintenance mode.

Error display Remedy

Replace Toner Replace the toner cartridge to release the error.

Cover is Open Close the front cover.

No Paper Refill the paper and close the paper tray to release the error.

Jam Tray1 Remove the jammed paper, and then close the paper tray and all

Jam Rear

covers to release the error.

Frame pattern

Fig. 5-14

5-33

Confidential

Page 34

1.3.15 Print frame pattern (duplex printing) (function code: 70)

(Second side)(First side)

<Function>

This function is used to print the frame pattern on both sides of the paper to check for printing

flaws and omission.

<Operating Procedure>

Non touch panel models

(1) Set the paper specified in the default paper

settings (A4 or Letter) to the paper tray.

(2) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 70" on the LCD, and

press the [OK] key. "PRINTING" is

displayed on the LCD, and the frame

pattern (refer to the figure below) is

printed on both sides of the paper.

(3) When printing is completed, "WAKU

DX" is displayed on the LCD. Press the

[X] key, and the machine returns to the

initial state of maintenance mode.

Note:

• If printing fails, printing is stopped with displaying any of the errors shown in the table below. To

retry printing, refer to the "Remedy" in the table below and eliminate the error cause. "PRINTING"

is displayed on the LCD, and the frame pattern is printed on both sides of a sheet of paper.

Error display Remedy

Replace Toner Replace the toner cartridge to release the error.

Cover is Open Close the front cover.

No Paper Refill the paper and close the paper tray to release the error.

Jam Tray1 Remove the jammed paper, and then close the paper tray and all

covers to release the error.

Jam Rear Remove the jammed paper, and then close all covers to release

the error.

Jam 2-sided Remove the jammed paper, and then close the duplex tray and all

covers to release the error.

2-sided Disabled Refill the paper, and then close the paper tray and all covers to

release the error.

Touch panel models

(1) Set the paper specified in the default paper

settings (A4 or Letter) to the paper tray.

(2) Press the [7], and then the [0] key in

the initial state of maintenance mode.

"PRINTING" is displayed on the LCD,

and the frame pattern (refer to the

figure below) is printed on both sides

of the paper.

(3) When printing is completed, "WAKU

DX" is displayed on the LCD. When

you press the [X] key, this operation is

finished and the machine returns to

the initial state of maintenance mode.

Frame pattern

Fig. 5-15

5-34

Confidential

Page 35

1.3.16 Print test pattern (function code: 71)

<Function>

This function is used to print the test pattern to check whether the develop roller or exposure

drum is dirty or damaged.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 71" on the LCD, and

press the [OK] key. "SELECT:

LETTER" is displayed on the LCD.

(2) Refer to the <Paper size> table, press

the [▲] or [▼] key to select the paper

size, and press the [OK] key.

"SELECT: PLAIN" is displayed on the

LCD.

(3) Refer to the <Print specification>

table, press the [▲] or [▼] key to

select the media specification, and

press the [OK] key. "SELECT: SX" is

displayed on the LCD.

(4) Refer to the <Print type> table, press

the [▲] or [▼] key to select the print

type, and press the [OK] key.

"SELECT: 1PAGE" is displayed on the

LCD.

(5) Refer to the <Print page> table, press

the [▲] or [▼] key to select the pages

printing, and press the [OK] key.

"PRINTING" is displayed on the LCD,

and printing test pattern starts using

the selected conditions.

(6) When printing is completed, "2D3S K"

is displayed on the LCD, and it returns

to the printing pattern display. Press

the [OK] key to perform this again.

Touch panel models

(1) Press the [7], and then the [1] key in

the initial state of maintenance mode.

"SELECT: LETTER" is displayed on

the LCD.

(2) Refer to the <Paper size> table, press

the [

˄

] or [˅] key to select the paper

size, and press the [SET] or [Mono]

key. "SELECT: PLAIN" is displayed on

the LCD.

(3) Refer to the <Print specification>

table, press the [

the media specification, and press the

[SET] or [Mono] key. "SELECT: SX" is

displayed on the LCD.

(4) Refer to the <Print type> table, press

the [

˄

] or [˅] key to select the print

type, and press the [SET] or [Mono]

key. "SELECT: 1PAGE" is displayed

on the LCD.

(5) Refer to the <Print page> table, press

the [

˄

] or [˅] key to select the pages

printing, and press the [SET] or

[Mono] key. "PRINTING" is displayed

on the LCD, and printing test pattern

starts using the selected conditions.

(6) When printing is completed, "2D3S K"

is displayed on the LCD, and it returns

to the printing pattern display. Press

the [SET] or [Mono] key to perform

this again.

˄

] or [˅] key to select

(7) Press the [X] key, and the machine

returns to the initial state of

maintenance mode.

Note:

• If printing fails, printing is stopped with displaying any of the errors shown in the <Error

display> table. To retry printing, refer to the "Remedy" in the table and eliminate the

error cause. "PRINTING" is displayed on the LCD, and the test pattern is printed.

5-35

(7) Press the [X] key, and the machine

returns to the initial state of

maintenance mode.

Confidential

Page 36

<Paper size>

LCD Description

SELECT:A4 A4

SELECT:ISOB5 ISOB5

SELECT:JISB5 JISB5

SELECT:A5 A5

SELECT:A5L A5L

SELECT:JISB6 JISB6

SELECT:A6 A6

SELECT:EXECUTE Executive size

SELECT:LEGAL Legal size

SELECT:FOLIO Folio size

SELECT:HAGAKI Postcard size

SELECT:LETTER Letter

<Print specification>

LCD Description

SELECT:PLAIN Plain paper

SELECT:THICK Plain paper (thick)

SELECT:THIN Plain paper (thin)

SELECT:THICKER Plain paper (thicker)

SELECT:RECYCLED Recycled paper

SELECT:BOND Bond paper

SELECT:LABEL Label

SELECT:ENVELOPE Envelope

SELECT:ENVTHIN Envelope (thin)

SELECT:ENVTHICK Envelope (thick)

SELECT:GLOSSY Glossy paper

SELECT:HAGAKI Postcard

<Print type>

LCD Description

SELECT:SX Single-side printing from paper tray 1

SELECT:DX Duplex printing from paper tray 1

<Print page>

LCD Description

SELECT:1PAGE 1-page printing

SELECT:CONTINUE Continuous printing

5-36

Confidential

Page 37

<Error display>

LCD Remedy

Replace Toner Replace the toner cartridge to release the error.

Cover is Open Close the front cover.

No Paper Refill the paper and close the paper tray to release

the error.

Jam Tray1 Remove the jammed paper, and then close the

paper tray and all covers to release the error.

Jam Rear Remove the jammed paper, and then close all

covers to release the error.

Test pattern

Fig. 5-16

5-37

Confidential

Page 38

1.3.17 Configure for country/region and model (function code: 74)

<Function>

This function is used to customize the machine according to language, function settings, and

worker switch settings.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 74" on the LCD, and

press the [OK] key. The spec code

currently set is displayed on the LCD

(The first digit is flashing).

(2) Press the [▲] key to enter "1", or the

[▼] key to enter "0". Then press the

[OK] key. The second digit starts to

flash.

(3) Press the [▲] key to enter "1", or the

[▼] key to enter "0" similarly. Then

press the [OK] key. The second digit is

completed and the fourth digit starts to

flash.

(4) The third digit and fourth digit changes

at once when the [▲] or [▼] key is

pressed. Press the [Go] key when the

desired value is shown on the LCD.

The new setting is saved, and

"PARAMETER INIT" is displayed on

the LCD. The machine then returns to

the initial state of maintenance mode.

Touch panel models

(1) Press the [7], and then the [4] key in

the initial state of maintenance mode.

The spec code currently set is

displayed on the LCD.

(2) Enter the spec code (four digits) you

want to set.

(3) Press the [Mono] key to save the new

setting, and "PARAMETER INIT" is

displayed on the LCD. The machine

then returns to the initial state of

maintenance mode.

5-38

Confidential

Page 39

■ Setting by spec code list

Model Spec code

HL-5580D China 0120

HL-5585D China 0020

HL-5590DN China 0120

HL-5595DN China 0320

HL-L5000D Canada 0101

CEE-General 0103

France/Belgium/

Netherlands

0103

Germany 0103

India 0140

Iran 0035

Israel 0117

Italy/Iberia 0103

Pan-Nordic 0103

Russia 0103

Singapore 0140

Switzerland 0103

U.S.A 0101

UK 0103

HL-L5100DN (T)

Argentina 0136

Australia 0106

CEE-General 0103

Chile 0136

France/Belgium/

Netherlands

0103

Germany 0103

India 0140

Israel 0117

Italy/Iberia 0103

Korea 0140

New Zealand 0127

Pan-Nordic 0103

Philippines 0121

Russia 0103

Singapore 0140

Switzerland 0103

Taiwan 0123

U.S.A 0101

UK 0103

HL-L5102DW Brazil 0042

Model Spec code

HL-L5200DW (T)

Australia 0206

Canada 0201

CEE-General 0203

France/Belgium/

Netherlands

0203

Germany 0203

Gulf 0241

Italy/Iberia 0203

New Zealand 0227

Pan-Nordic 0203

Russia 0203

Switzerland 0203

U.S.A 0201

UK 0203

HL-L5202DW Brazil 0242

HL-L6200DW (T)

Argentina 0336

Australia 0306

Canada 0301

Gulf 0341

India 0340

New Zealand 0327

Singapore 0340

U.S.A 0301

HL-L6202DW Brazil 0342

HL-L6250DN CEE-General 0303

GENERIC 0303

Germany 0303

Italy/Iberia 0303

Switzerland 0303

UK 0303

HL-L6250DW U.S.A 0401

HL-L6300DW (T)

CEE-General 0003

GENERIC 0003

Germany 0003

Israel 0017

Italy/Iberia 0003

Pan-Nordic 0003

Russia 0003

Switzerland 0003

U.S.A 0001

UK 0003

Note:

• If there is no entry for one minute or longer, the machine returns to the initial state of

maintenance mode automatically, regardless of the display status.

• The spec code list above is current as of March 2016.

• Please contact Brother distributors for the latest information.

5-39

Confidential

Page 40

Note:

Model Spec code

HL-L6400DW (T)

Argentina 0136

Australia 0106

Canada 0101

CEE-General 0103

Chile 0136

GENERIC 0103

Germany 0103

Gulf 0141

Israel 0117

Italy/Iberia 0103

Korea 0144

New Zealand 0127

Pan-Nordic 0103

Philippines 0121

Russia 0103

Singapore 0140

Switzerland 0103

Taiwan 0123

U.S.A 0101

UK 0103

HL-L6402DW Brazil 0142

• If there is no entry for one minute or longer, the machine returns to the initial state of

maintenance mode automatically, regardless of the display status.

• The spec code list above is current as of March 2016.

• Please contact Brother distributors for the latest information.

5-40

Confidential

Page 41

1.3.18 Print maintenance information (function code: 77)

1

6

7

2345

8

9

0

A

B

C

D

E

F

I

J

G

H

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

[

\

]

^

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

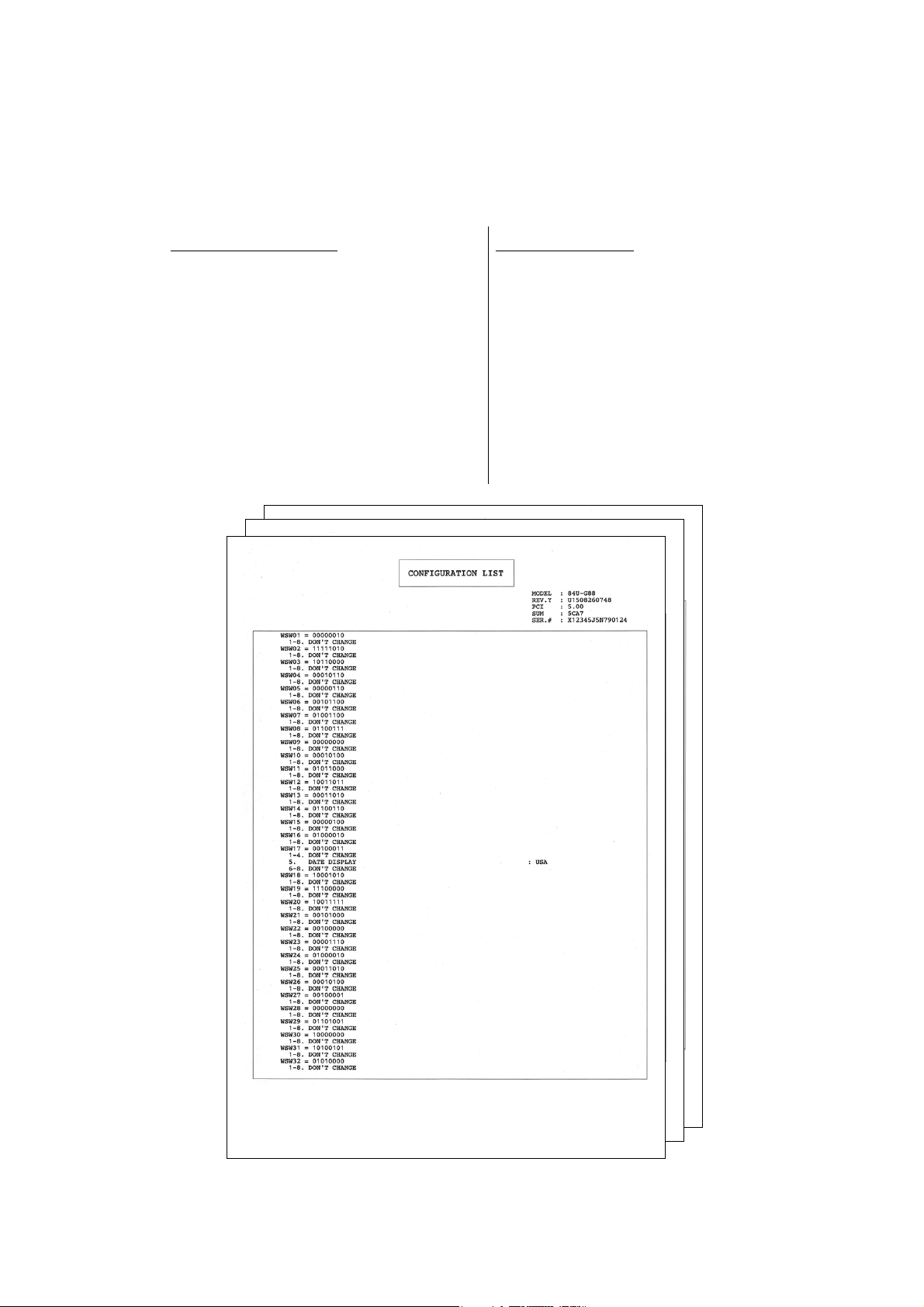

<Function>

This function is used to print the maintenance information, such as remaining amount of

consumables, the number of replacements, and counter information.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 77" on the LCD, and

press the [OK] key. Printing

maintenance information starts.

(2) When printing is completed, the

Touch panel models

(1) Press the [7] key twice in the initial

state of maintenance mode. Printing

maintenance information starts.

(2) When printing is completed, the

machine returns to the initial state of

maintenance mode.

machine returns to the initial state of

maintenance mode.

Maintenance information

Fig. 5-17

5-41

Confidential

Page 42

1 Model name 29 Remaining life of PF kit 1

2 Serial number 30 Total printed pages

3 Model code 31 Total PC printed pages

4 Spec code 32 Total pages printed by other methods

Switch check sum (factory use)

5

and comparison of default / current value

Main firmware version

6

Sub firmware version

7

Accumulated average coverage

33

Average coverage by the current toner

34

cartridge

Average coverage by the previous

35

toner cartridge

8 Boot ROM version 36 Latest job average coverage

9 Font ROM version 37 Drum page count

10 Engine archive version 38 Rotations of the drum

ROM version for LT2 control PCB

11

Total rotations of the developer roller

39

(currently use/previously used toner cartridge)

12 ROM version for LT3 control PCB 40 Total printed pages per paper tray

13 ROM version for LT4 control PCB 41 Total printed pages per output tray

TT firmware version

14

MX firmware version

15

ROM check sum

16

Total printed pages per paper size /

42

paper type

Printed pages per (currently / previously

43

used) toner cartridge

Total number of rotations of the developer

roller per toner cartridge (currently /

44

previously used toner cartridge)

USB ID code

17

18 RAM size 46

First digit of main PCB serial number /

Wireless LAN setting by country /

19

Wireless LAN output peak /

Pages printed per specified coverage

45

range

Paper jams by sections of the product

Machine error log /

Total pages printed at the time of the

47

error / Temperature and humidity

WLAN Setup YES/NO setting /

One Push Demo setting

Toner type of currently set toner cartridge /

20

Toner type of previously set toner cartridge

Main PCB inspection log /

Number of times each consumable has

48

been replaced

Developing bias voltage value

High voltage inspection log /

The number of times that the discharge error,

21

fuser unit error, polygon motor lock error,

49

irregular power supply detection error

occurred / Process status

Next Power On setting for Power Button /

22

Process status / Process checksum

Estimated remaining toner amount

23

Engine sensor log /

50

Status log (Not necessary for maintenance)

Current temperature and humidity /

51

Highest and lowest temperature and

humidity in the past

24 Remaining life of drum unit 52 Total power distribution time

Remaining life of fuser unit

25

The number of times that the power is

53

turned ON

26 Remaining life of laser unit 54 Start date for machine operation

27 Toner Low threshold setting 55 Latest paper type used

28 Remaining life of PF kit MP 56 New toner cartridge detection log

5-42

Confidential

Page 43

1.3.19 Check main fan operation (function code: 78)

<Function>

This function is used to check that the main fan is operating normally. Switch the setting

among rotation speed 100%, 50%, and OFF.

LCD Name Description

F Main fan Emits the heat in the fuser unit.

<Operating Procedure>

Non touch panel models

(1) Press the [▲] or [▼] key in the initial

state of maintenance mode to display

"MAINTENANCE 78" on the LCD, and

press the [OK] key. "F100" is

displayed on the LCD and the main

fan rotates at 100% speed.

(2) By pressing the [Go] key, "F50" is

displayed on the LCD and the main

fan rotates at 50% speed.