Page 1

Page 2

© Copyright Brother 1998

All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in

writing from the publisher.

Specifications are subject to change without notice.

Trademarks:

The brother logo is a registered trademark of Brother Industries, Ltd.

Apple, the Apple Logo, and Macintosh are trademarks, registered in the United States and other

countries, and True Type is a trademark of Apple computer, Inc.

Epson is a registered trademark and FX-80 and FX-850 are trademarks of Seiko Epson

Corporation.

Hewlett Packard is a registered trademark and HP Laser Jet is a trademark of Hewlett Packard

Company.

IBM, IBM PC and Proprinter are registered trademarks of International Business Machines

Corporation.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

Page 3

PREFACE

This service manual contains basic information required for after-sales service of the laser printer

(here- in-after referred to as "this machine" or "the printer"). This information is vital to the service

technician to maintain the high printing quality and performance of the printers.

This service manual covers the HL-820, 1020, 1040 and 1050 laser printers. (Note that any figures

for the printer body are based on the HL-1040 printer.)

This manual consists of the following chapters:

CHAPTER I : FEATURES AND SPECIFICATIONS

Features, specifications, etc.

CHAPTER II : THEORY OF OPERATION

Basic operation of the mechanical system, the electrical system and the electrical

circuits, and their timing information.

CHAPTER III : DISASSEMBLY AND REASSEMBLY

Procedures for disassembling and reassembling the mechanical system.

CHAPTER IV : MAINTENANCE AND TROUBLESHOOTING

Reference values and adjustments, troubleshooting image defects, troubleshooting

malfunctions, etc.

APPENDICES :

Information in this manual is subject to change due to improvement or re-design of the product. All

relevant information in such cases will be supplied in service information bulletins (Technical

Information).

A thorough understanding of this printer, based on information in this service manual and service

information bulletins, is required for maintaining its print quality performance and for improving the

practical ability to find the cause of problems.

SERIAL NO. DESCRIPTIONS, CONNECTION DIAGRAMS, PCB CIRCUIT

DIAGRAMS.

Page 4

CONTENTS

CHAPTER I FEATURES AND SPECIFICATIONS..........................................I-1

1. FEATURES.........................................................................................................................I-1

2. SPECIFICATIONS..............................................................................................................I-3

2.1 Printing.......................................................................................................................................I-3

2.2 Functions ...................................................................................................................................I-3

2.3 Electrical and Mechanical..........................................................................................................I-4

2.4 Paper Specification....................................................................................................................I-5

2.5 Print Delivery..............................................................................................................................I-5

2.6 Paper .........................................................................................................................................I-6

2.7 Effective Printing Area ...............................................................................................................I-7

3. SAFETY INFORMATION....................................................................................................I-9

3.1 Laser Safety (110 - 120V Model only).......................................................................................I-9

3.2 FDA Regulations (110 - 120V Model only) ................................................................................I-9

3.3 Caution for Laser Product........................................................................................................I-10

CHAPTER II THEORY OF OPERATION........................................................ II-1

1. ELECTRONICS..................................................................................................................II-1

1.1 General Block Diagram.............................................................................................................II-1

1.2 Main PCB Block Diagram .........................................................................................................II-4

1.3 Main PCB..................................................................................................................................II-7

1.3.1 CPU Core....................................................................................................................II-7

1.3.2 ASIC............................................................................................................................II-9

1.3.3 ROM..........................................................................................................................II-15

1.3.4 DRAM........................................................................................................................II-16

1.3.5 Optional RAM............................................................................................................II-17

1.3.6 Optional Serial I/O.....................................................................................................II-18

1.3.7 EEPROM...................................................................................................................II-18

1.3.8 Reset Circuit..............................................................................................................II-19

1.3.9 CDCC I/O..................................................................................................................II-19

1.3.10 Engine I/O..................................................................................................................II-21

1.3.11 Paper Feed Motor Drive Circuit.................................................................................II-23

1.4 Panel Sensor PCB..................................................................................................................II-24

1.5 Power Supply..........................................................................................................................II-24

1.5.1 Low-voltage Power Supply........................................................................................II-24

1.5.2 High-voltage Power Supply, SR PCB........................................................................II-25

2. MECHANICS....................................................................................................................II-26

2.1 Overview of Printing Mechanism............................................................................................II-26

2.2 Paper Transfer........................................................................................................................II-27

2.2.1 Paper Supply.............................................................................................................II-27

2.2.2 Paper Registration.....................................................................................................II-27

2.2.3 Paper Eject................................................................................................................II-28

i

Page 5

2.3 Sensors...................................................................................................................................II-29

2.3.1 Cover Sensor.............................................................................................................II-29

2.3.2 Toner Empty Sensor..................................................................................................II-29

2.4 Drum Unit................................................................................................................................II-30

2.4.1 Photosensitive Drum.................................................................................................II-30

2.4.2 Primary Charger........................................................................................................II-30

2.4.3 Developer Roller........................................................................................................II-30

2.4.4 Transfer Roller...........................................................................................................II-30

2.4.5 Cleaner Roller............................................................................................................II-30

2.4.6 Erase Lamp ..............................................................................................................II-30

2.5 Print Process ..........................................................................................................................II-30

2.5.1 Charging ...................................................................................................................II-30

2.5.2 Exposure Stage.........................................................................................................II-31

2.5.3 Developing.................................................................................................................II-32

2.5.4 Transfer.....................................................................................................................II-32

2.5.5 Drum Cleaning Stage................................................................................................II-33

2.5.6 Erasing Stage............................................................................................................II-33

2.5.7 Fixing Stage...............................................................................................................II-33

CHAPTER III DISASSEMBLY AND REASSEMBLY.......................................III-1

1. SAFETY PRECAUTIONS..................................................................................................III-1

2. DISASSEMBLY FLOW......................................................................................................III-2

3. DISASSEMBLY PROCEDURE.........................................................................................III-3

3.1 Output Tray ASSY ...................................................................................................................III-3

3.2 Drum Unit.................................................................................................................................III-3

3.3 Top Cover................................................................................................................................III-4

3.4 Rear Cover ..............................................................................................................................III-4

3.5 MP Sheet Feeder ASSY..........................................................................................................III-5

3.6 Fixing Unit................................................................................................................................III-6

3.7 Scanner Unit............................................................................................................................III-8

3.8 Main PCB ASSY....................................................................................................................III-10

3.9 Base Plate ASSY...................................................................................................................III-10

3.10 Panel Sensor PCB ASSY ......................................................................................................III-11

3.11 Low-voltage Power Supply PCB ASSY .................................................................................III-12

3.12 High-voltage Power Supply PCB ASSY.................................................................................III-13

3.13 Sub Fan Motor ASSY ............................................................................................................III-14

3.14 Fan Motor ASSY ...................................................................................................................III-14

3.15 Drive Unit...............................................................................................................................III-15

3.16 Main Motor ASSY ..................................................................................................................III-16

3.17 Sub Motor ASSY....................................................................................................................III-16

3.18 Paper Support........................................................................................................................III-17

3.19 Extension Support Wire.........................................................................................................III-17

4. PACKING........................................................................................................................III-18

ii

Page 6

i

CHAPTER IV MAINTENANCE AND TROUBLESHOOTING..........................IV-1

1. INTRODUCTION..............................................................................................................IV-1

1.1 Initial Check........................................................................................................................IV-1

1.2 Basic Procedure.................................................................................................................IV-2

2. CONSUMABLE PARTS.................................................................................................... IV-3

2.1 Drum Unit...........................................................................................................................IV-3

2.2 Toner Cartridge.................................................................................................................. IV-3

2.3 Periodical Replacement Parts.............................................................................................IV-3

3. IMAGE DEFECTS ............................................................................................................IV-4

3.1 Image Defect Examples .....................................................................................................IV-4

3.2 Troubleshooting Image Defects.......................................................................................... IV-5

3.3 Location of High-voltage Contacts and Grounding Contacts..............................................IV-19

3.4 Location of Feed Roller Shaft and Grounding Contacts.....................................................IV-20

4. PAPER JAM...................................................................................................................IV-21

5. TROUBLESHOOTING MALFUNCTIONS .......................................................................IV-22

6. INSPECTION MODE......................................................................................................IV-27

6.1 Incorporated Inspection Modes.........................................................................................IV-27

6.2 Error Codes......................................................................................................................IV-29

APPENDICES

1. Serial No. Descriptions......................................................................................................A-1

2. Connection Diagram, HL-820/1020...................................................................................A-2

3. Connection Diagram, HL-1040..........................................................................................A-3

4. Connection Diagram, HL-1050..........................................................................................A-4

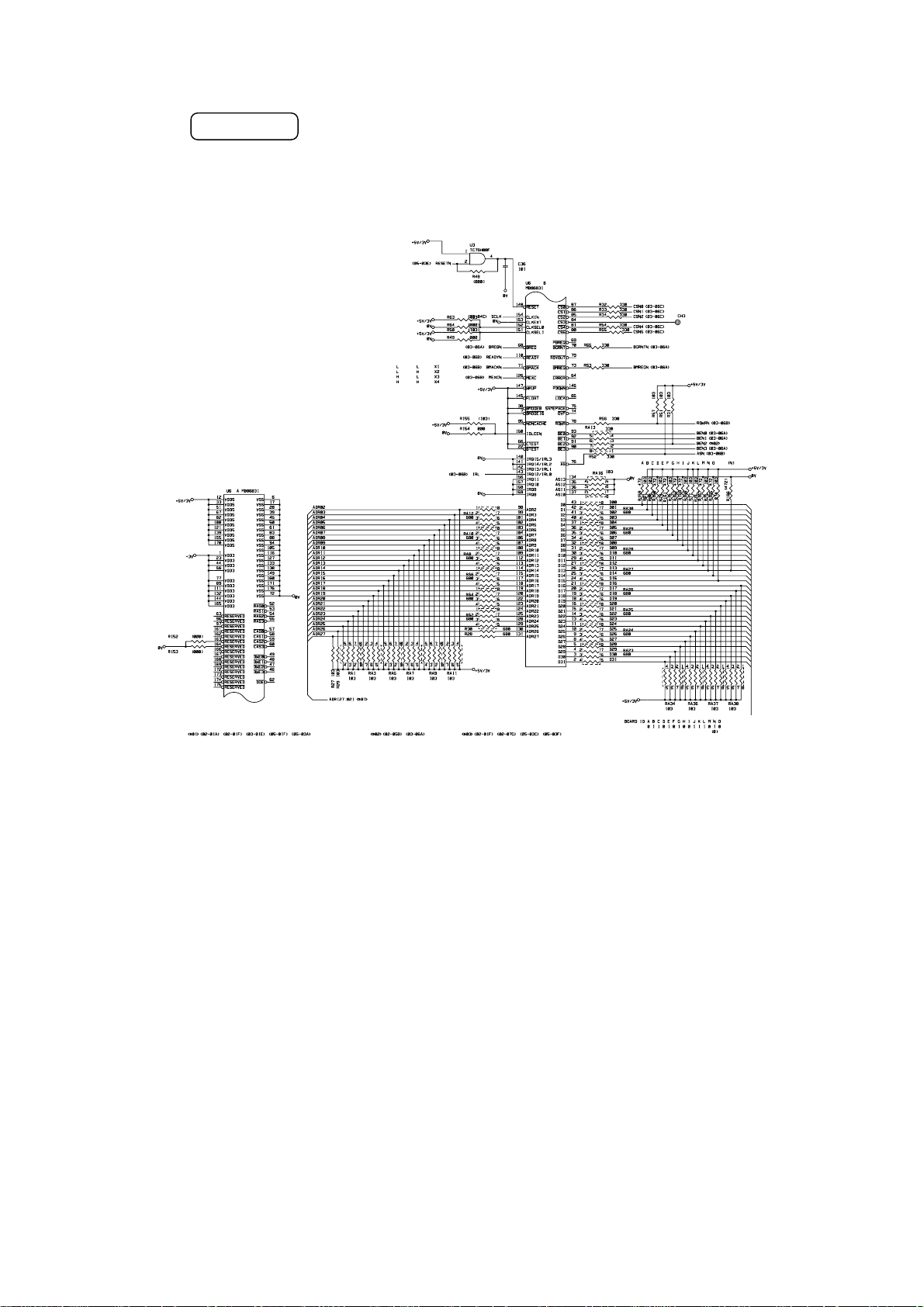

5. Main PCB Circuit Diagram, (HL-820/1020/1040), (1/2)......................................................A-5

6. Main PCB Circuit Diagram, (HL-820/1020/1040), (2/2)......................................................A-6

7. Main PCB Circuit Diagram, (HL-1050), (1/5)......................................................................A-7

8. Main PCB Circuit Diagram, (HL-1050), (2/5)......................................................................A-8

9. Main PCB Circuit Diagram, (HL-1050), (3/5)......................................................................A-9

10.Main PCB Circuit Diagram, (HL-1050), (4/5)....................................................................A-10

11.Main PCB Circuit Diagram, (HL-1050), (5/5)....................................................................A-11

12.Panel Sensor PCB Circuit Diagram.................................................................................A-12

13.Low-voltage Power Supply PCB Circuit Diagram, HL-820/1020/1040 (110 - 120V)........A-13

14.Low-voltage Power Supply PCB Circuit Diagram, HL-820/1020/1040 (220 - 240V)........A-14

15.Low-voltage Power Supply PCB Circuit Diagram, HL-1050 (110 - 120V)........................A-15

16.Low-voltage Power Supply PCB Circuit Diagram, HL-1050 (220 - 240V)........................A-16

17.High-voltage Power Supply PCB Circuit Diagram............................................................A-17

18.How to Know Drum Unit Life & Page Counter.................................................................A-18

19.Diameter / Circumference of Rollers................................................................................A-20

ii

Page 7

CHAPTER I FEATURES AND SPECIFICATIONS

1. FEATURES

This printer has the following features:

High Resolution and Fast Printing Speed

<HL-820>

True 600 dots per inch (dpi) with microfine toner and 8 pages per minute (ppm) printing

speed (A4 or Letter paper).

<HL-1040/1020>

True 600 dots per inch (dpi) with microfine toner and 10 pages per minute (ppm) printing

speed (A4 or Letter paper).

<HL-1050>

True 600 dots per inch (dpi) and 1200 x 600 dpi for graphics with microfine toner and 10

pages per minute (ppm) printing speed (A4 or Letter paper).

Enhanced Printing Performance and User-Friendly Operation for Windows

The dedicated printer driver and TrueType

and Windows 95 are available on the floppy disk and CD-ROM supplied with your printer.

You can easily install them into your Windows system using our installer program. The

driver supports our unique compression mode to enhance printing speed in Windows

applications and allows you to set various printer settings including toner saving mode,

custom paper size, sleep mode, gray scale adjustment, resolution, and so forth. You can

easily setup these print options in the graphic dialog boxes through the Printer Setup

menu within the Windows Control Panel.

TM

-compatible fonts for Microsoft® Windows 3.1

Printer Status Monitor with Bi-directional Parallel Interface

The printer driver can monitor your printer’s status using bi-directional parallel

communications.

The printer status monitor program can show the current status of your printer. When

printing, an animated dialog box appears on your computer screen to show the current

printing process. If an error occurs, a dialog box will appear to let you know what to

correct. For example: when your printer is out of paper, the dialog box will display “No

Paper” and instructions for the corrective action to take.

Versatile Paper Handling

The printer has a multi-purpose sheet feeder and a straight paper path mechanism.

Using this mechanism, you can load A4, letter, legal, B5, A5, A6, and executive sizes of

paper, and various types of media including envelopes, organizer paper, or your custom

paper size. The multi-purpose sheet feeder also allows manual paper loading, so you

can also use labels and transparencies.

Environment-Friendly

Economy Printing Mode

This feature will cut your printing cost by saving toner. It is useful to obtain draft copies

for proof-reading. You can select from two economy modes, 25% toner saving and 50%

toner saving, through the Windows printer driver supplied with your printer.

Sleep Mode (Power Save Mode)

Sleep mode automatically reduces power consumption when the printer is not in use.

The printer consumes less than 13W when in sleep mode.

I-1

Page 8

Low Running Cost

The toner cartridge is separate from the drum unit. You need to replace only the toner

cartridge after around 2,400 pages, which is cost effective and ecologically friendly.

The actual number of pages printed with each toner cartridge may vary depending on

your average type of print job.

Enhanced Memory Management

The printer provides its own data compression technology in its printer hardware and the

supplied printer driver software, which can automatically compress graphic data and font

data efficiently into the printer's memory. You can avoid memory errors and print most

full page 600dpi graphic and text data, including large fonts, with the standard printer

memory.

Remote Printer Console Program for DOS (for HL-1040/1050 only)

The utility program, Remote Printer Console (RPC), is available on the floppy disk and

CD-ROM supplied with your printer. When you operate your computer in the DOS (Disk

Operating System) environment, this program allows you to easily change the default

settings of the printer such as fonts, page setup, emulations and so on.

This program also provides a status monitor program, which is a Terminate-and-Stay

Resident (TSR) program. It can monitor the printer status while running in the

background and report the current status or errors on your computer screen.

Popular Printer Emulation Support (for HL-1040/1050 only)

These printers support the following printer emulation modes;

The HL-1040 supports HP LaserJet IIP, Epson FX-850, and IBM Proprinter XL

The HL-1050 supports HP LaserJet 6P/6L, Epson FX-850 and IBM Proprinter XL.

When you use DOS application software or Windows™ version 3.0 or earlier, you can

use any of these emulations to operate the printer in the 300 dpi resolution mode. The

printers also support Auto-emulation switching between HP and Epson or HP and IBM. If

you want to set the printer emulation, you can do it using the Remote Printer Console

Program.

USB Interface (for HL-1050 only)

The Universal Serial Bus Interface is an interface which allows the printer to connect to

multiple peripheral devices.

High Resolution Control & Advanced Photoscale Technology (for HL-1050 only)

High resolution control (HRC) technology provides clear and crisp printouts. Use this

function to get smooth text print quality.

Advanced Photoscale Technology enables the printer to print graphics in 256 grayscales,

producing nearly photographic quality. Use this function when you want to print

photographic images.

Optional Apple Macintosh

®

Interface (for HL-1040/1050 only)

An optional Apple Macintosh serial interface is available which allows your printer to be

connected to Apple Macintosh computers. With this option, you can use your printer with

both an IBM PC (or compatible) and an Apple Macintosh at the same time. This optional

interface board can be used as an RS-422A interface for Macintosh or an RS-232C serial

interface for an IBM PC or compatible.

I-2

Page 9

2. SPECIFICATIONS

2.1 Printing

Print method Electrophotography by semiconductor laser beam scanning

Laser: Wave length: 780nm

Output: 5mW max

Resolution HL-820/1020: 600 x 600dots/inch (for Windows)

HL-1040: 600 x 600dots/inch (for Windows or DOS)

HL-1050: 1200(H) x 600(V)dots/inch (for Windows DIB

Print speed HL-820: Up to 8 pages/minute

HL-1020/1040/1050: Up to 10 pages/minute

(when loading Letter-size paper from the multipurpose sheet feeder)

Warm-up Max. 30 seconds at 23°C (73.4°F)

300 x 300dots/inch (under Apple Macintosh, DOS,

or other operating system)

graphics)

600 x 600dots/inch (for Windows or DOS)

300 x 300dpi (under Apple Macintosh using

optional RS-100M)

First print 15 seconds

Print media Toner cartridge

Developer Drum unit, separated from toner cartridge

2.2 Functions

CPU HL-820/1020/1040: MC68EC000 16Mhz

Emulation HL-820/1020: Brother Printing Solution for Windows

(when loading Letter-size paper from the multipurpose sheet feeder)

Life Expectancy: 2,400 pages/cartridge

(when printing A4 or letter-size paper at 5% print coverage)

Life Expectancy: 20,000 pages/drum unit at 20 pages per job

8,000 pages at 1 page per job

HL-1050: MB86831 66Mhz

HL-1040: Brother Printing Solution for Windows

Automatic emulation selection among HP LaserJet

IIP (PCL level 4), EPSON FX-850, and IBM

Proprinter XL

HL-1050: Brother Printing Solution for Windows

Automatic emulation selection among HP LaserJet

6P (PCL level 6), EPSON FX-850, and IBM

Proprinter XL

Printer driver Windows

supporting Brother Native Compression mode and bi-directional

capability.

Optional Macintosh driver available for System 6.0.7 or higher (for HL1040/1050 only)

TM

3.1/3.11, Windows 95 and Windows NT 4.0 driver,

I-3

Page 10

Interface Bi-directional parallel

Universal Serial Bus (USB) (HL-1050 only)

RS-422A/RS-232C serial (RS-100M) is optionally available. (HL1040/1050 only)

Memory HL-820/1020/1040: 2.0 Mbytes

HL-1050: 4.0 Mbytes

Control panel 1 switch and 4 lamps

Diagnostics Self-diagnostic program

2.3 Electrical and Mechanical

Power source U.S.A. and Canada: AC 110 to 120V, 50Hz/60Hz

Europe and Australia: AC 220 to 240V, 50Hz/60Hz

Power consumption Printing (peak): 820W or less

Printing (average): 280W or less

Standing by: 60W or less

Sleep: 13W or less

PR99017

Expandable up to 36 Mbytes by installing an

industry standard SIMM

Noise Printing: 49dB A or less

Standing by: 33dB A or less

Temperature Operating: 10 to 32.5°C (50 to 90.5°F)

Storage: 0 to 40°C (38 to 104°F)

Humidity Operating: 20 to 80% (non condensing)

Storage: 10 to 85% (non condensing)

Dimensions 390 x 365 x 245 mm (15.4 x 14.4 x 9.7 inches)

(W x D x H) (when the output tray is closed.)

Weight Approx. 7.2kg (15.7lb.) including the drum unit and toner cartridge

Note:

x

The peak figure of power consumption is worked out when the halogen heater lamp is

turned ON.

x

The peak figure of power consumption is worked out excluding inrush current value.

x

Be sure that the peak figure of power consumption is reference value and should be

used inside the Brother offices only.

I-4

Page 11

2.4 Paper Loading

(1) Multi-purpose sheet feeder loading

Paper size: A4, Letter, Legal, B5, A5, A6, and Executive. Other sizes of media that

can be handled by the feed mechanism can be loaded.

69.8 to 229 mm

105 to 356mm (face down)

Feeding direction

Feedable paper weight: 60 (16lb.) to 158 (42lb.) g/m

2

Maximum load height : 22mm (200 sheets of 80g/m2 paper) letter or A4 size

Setting method: Pull the MP sheet feeder cover toward you, insert the

stack of paper into the feeder, aligning the top edge of

the sheets, then push the cover back to its original

position.

(2) Manual slot loading

Paper size: Same as in (1) for the multi-purpose sheet feeder.

Feedable paper weight: Same as in (1) for the multi-purpose sheet feeder.

Setting methods: Place the side of the paper to be printed on face down

into the manual feed slot after selecting orientation. Align

the paper at the center of the manual feed slot, and be

sure to insert it fully into the feed slot. Move the paper

guide of the manual feed slot to the paper width.

Cautions:

Before loading paper with holes such as organizer sheets, be sure to fan the stack

well.

When printing on the back of pre-printed paper, be sure to straighten the paper as

much as possible.

2.5 Print Delivery

(1) With the output tray opened

Tray capacity: Maximum 100 sheets (80g/m

(2) With the output tray closed

Tray capacity: 1 sheet (80g/m

Note:

Face down: Deliver the printed face of the paper downward.

Environment : 23°C

2

2

), face-down only

I-5

), face-down only

Page 12

2.6 Paper

(1) Paper type

(a) Normal paper (60 to 157g/m

• A4 size

• Letter size

• Legal size

• B5 (JIS ISO) size

• A5 size

• A6 size

• Executive size

PR98184

2

, specified types of high-quality paper)

* The recommended types of plain paper are as follows:

Letter : Xerox 4200 (75g/m

A4 : Xerox 80 Premier Paper (80g/m

(b) Special paper (specified types)

• Labels

• Envelopes (DL, C4, C5, COM10, Monarch)

• Organizers (K, L, and J sizes of DAY-TIMERS)

(C) Other detailed specifications

Cut Sheet Envelope

Basis Weight 60 to 158 g/m2 (16 to 42 lb.)

Caliper

Moisture Content 4% to 6% by weight 4% to 6% by weight

Smoothness 100 to 250 (Sheffield) 100 to 250 (Sheffield)

0.03 to 0.08 in.

(0.08 to 0.2 mm)

2

)

2

)

2

75 to 90 g/m

single thickness

0.0033 to 0.0058 in.

(0.084 to 0.14 mm)

single thickness

(20 to 24 lb.)

Caution:

Although the printer can handle 9 inches (229mm) width paper such as the C4 size

envelope, you may get stains on the paper outside 8.5 inches width or on the back of

the paper.

It is recommended to use long-grained paper for the best print quality. If short-grained

paper is being used, it might be the cause of paper jams.

Use neutral paper. Do not use acid paper to avoid any damage to the printer drum

unit.

(2) Paper feed conditions

Type Name Feeder Manual feed

60 to 80 g/m

Normal paper (cut sheet) 80 g/m2 paper (Legal)

158 g/m

Labels

Special paper (cut sheet) Envelopes

Organizers

2

2

I-6

(200 sheets)

(100 sheets)

(30 sheets)

(50 sheets)

(10 sheets)

(10 sheets)

Page 13

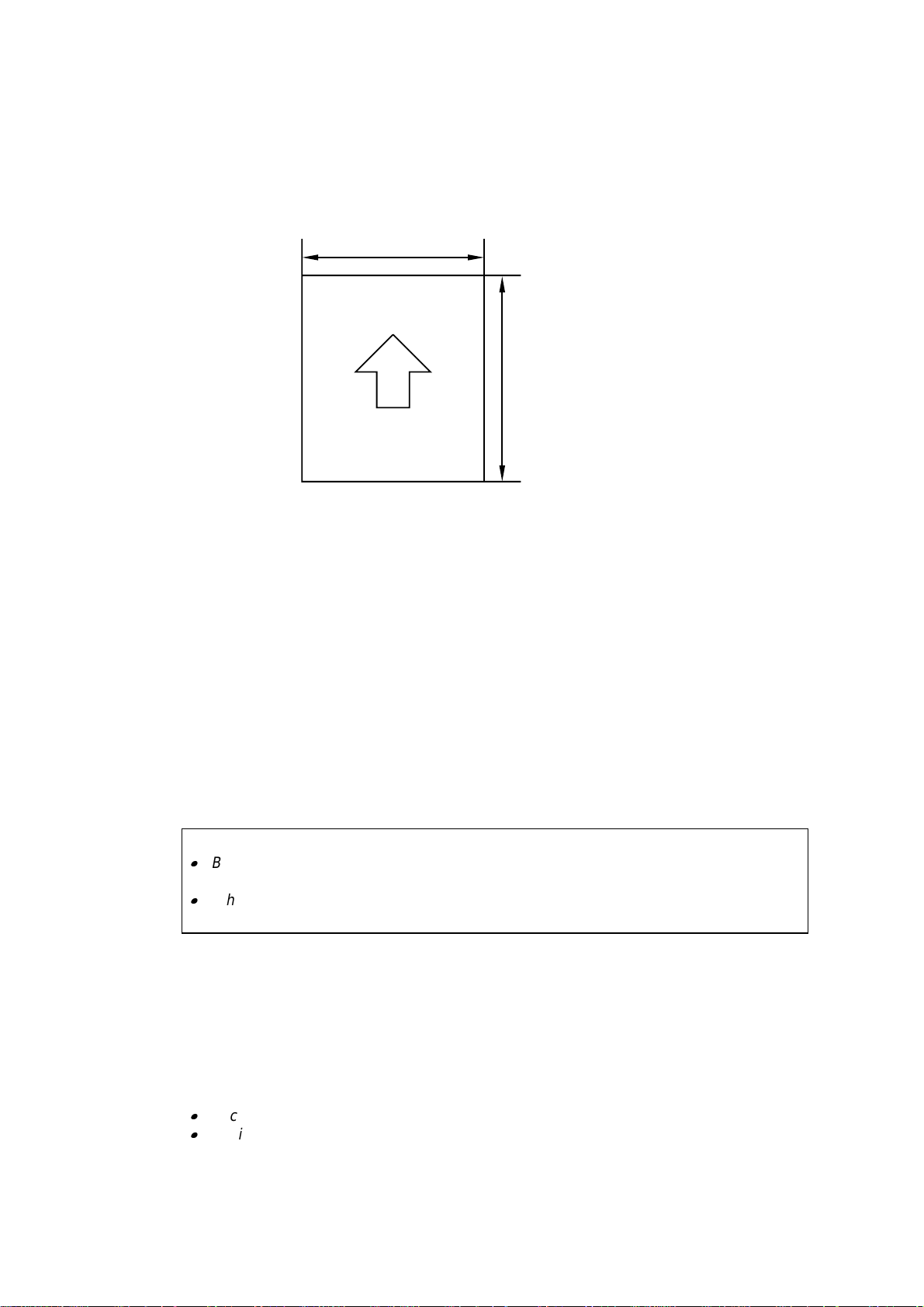

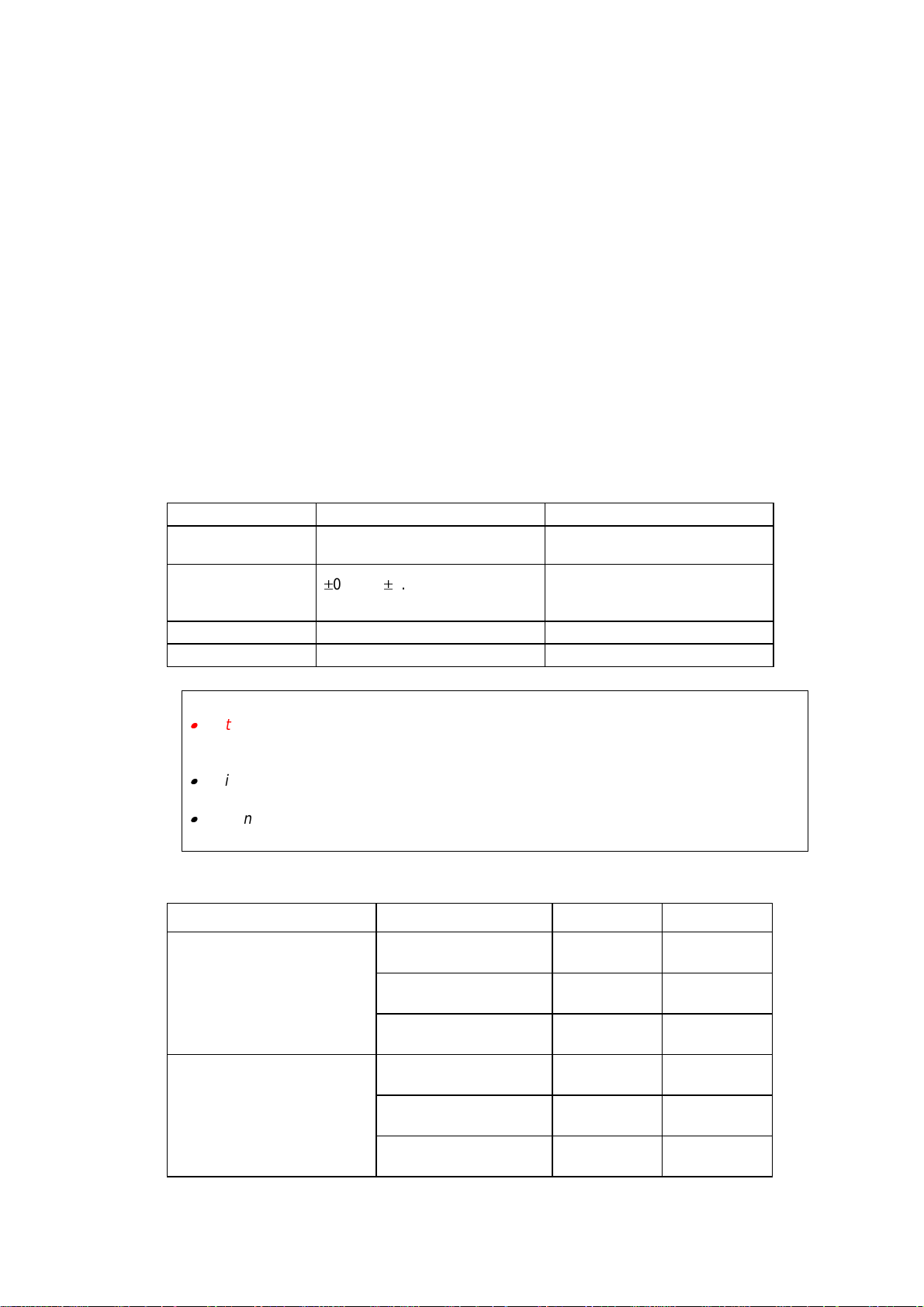

2.7 Effective Printing Area

Printable area

F

E

B

D

F

A

CE

The effective printing area means the area within which the printing of all the data

received without any omissions can be guaranteed.

I-7

Page 14

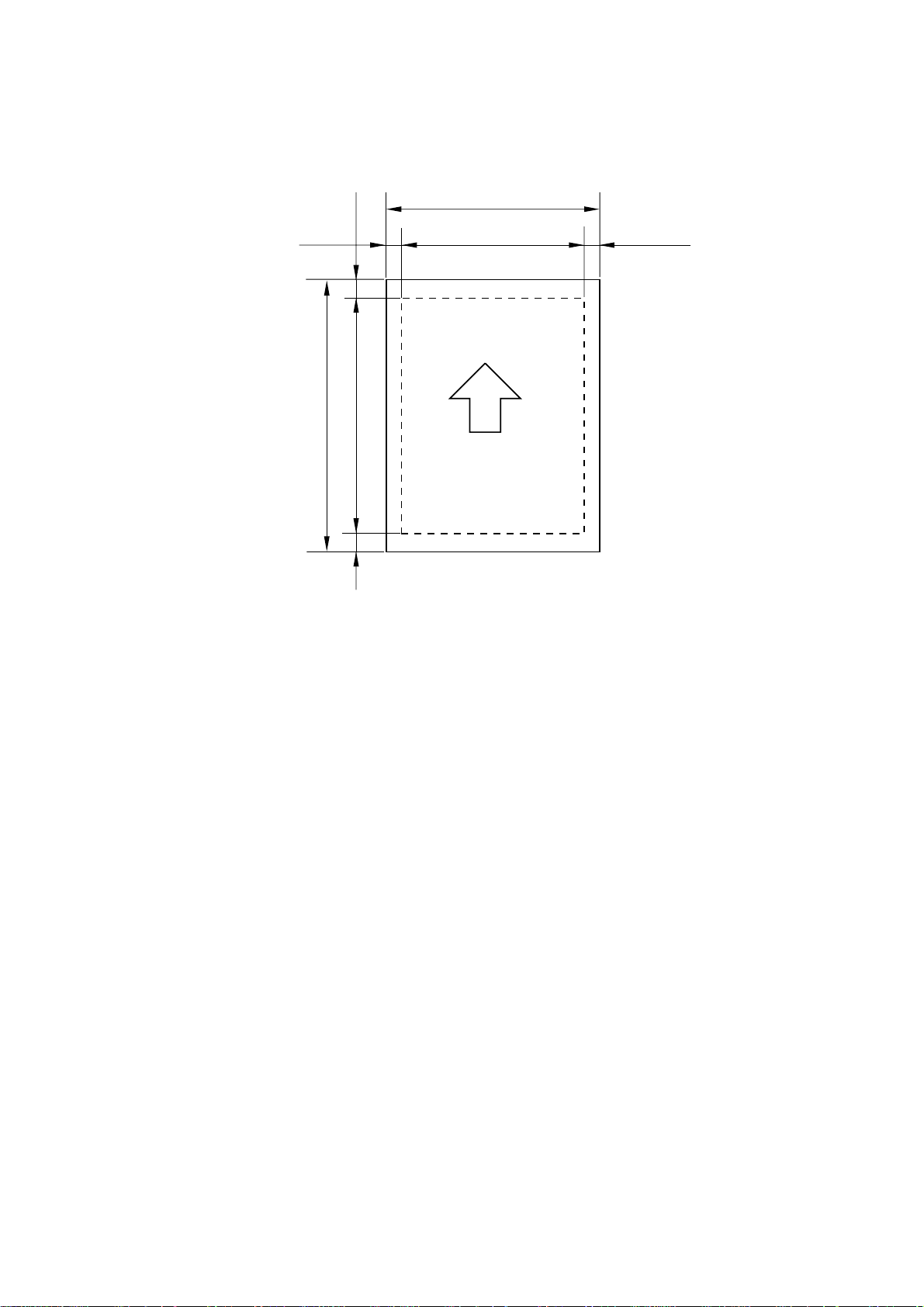

The table below shows the effective printing areas.

Size A B C D E F

A 4

Letter

Legal

B 5 (JIS)

B 5 (ISO)

Executive

A 5

A6

Organizer

(J size)

Organizer

(K size)

Organizer

(L size)

COM-10

MONARCH

C 4

C 5

DL

(Note that the paper sizes indicated here should conform to the nominal dimensions

specified by JIS.)

210.0mm

8.27”

(2,480 dots)

215.9mm

8.5”

(2,550 dots)

215.9mm

8.5”

(2,550 dots)

182.0mm

7.16”

(2,149 dots)

176.0mm

6.93”

(2,078 dots)

184.15mm

7.25”

(2,175 dots)

148.5mm

5.85”

(1,754 dots)

105.0mm

4.13”

(1,240 dots)

69.85mm

2.75”

(825 dots)

95.25mm

3.75”

(1,125 dots)

139.7mm

5.5”

(1,650 dots)

104.78mm

4.125”

(1,237 dots)

98.43mm

3.875”

(1,162 dots)

228.6mm

9.0”

(2,700 dots)

162mm

6.38”

(1,913 dots)

110mm

4.33”

(1,299 dots)

A4 paper must accommodate 80 characters printed in pica pitch (203.2 mm).

The dot size is based on 300 dpi resolution.

Organizer is not supported by any printer emulations (commands).

297.0mm

11.69”

(3,507 dots)

279.4mm

11.0”

(3,300 dots)

355.6mm

14.0”

(4,200 dots)

257.0mm

10.12”

(3,035 dots)

250.0mm

9.84”

(2,952 dots)

266.7mm

10.5”

(3,150 dots)

210.0mm

8.27”

(2,480 dots)

148.5mm

5.85”

(1,754 dots)

127.0mm

5.0”

(1,500 dots)

171.45mm

6.75”

(2,025 dots)

215.9mm

8.5”

(2,550 dots)

241.3mm

9.5”

(2,850 dots)

190.5mm

7.5”

(2,250 dots)

304.8mm

12.0”

(3,600 dots)

229mm

9.01”

(2,704 dots)

220mm

8.66”

(2,598 dots)

203.2mm

8.0”

(2,400 dots)

203.2mm

8.0”

(2,400 dots)

203.2mm

8.0”

(2,400 dots)

173.5mm

6.83”

(2,007 dots)

164.0mm

6.46”

(1,936 dots)

175.7mm

6.92”

(2,025 dots)

136.5mm

5.37”

(1,612 dots)

93.0mm

3.66”

(1,098 dots)

56.2mm

2.21”

(675 dots)

86.78mm

3.42”

(975 dots)

131.23mm

5.17”

(1,500 dots)

92.11mm

3.63”

(1,087 dots)

85.7mm

3.37”

(1,012 dots)

203.2mm

8.0”

(2,400 dots)

150.0mm

5.9”

(1,771 dots)

98.0mm

3.86”

(1,157 dots)

288.5mm

11.36”

(3,407 dots)

270.9mm

10.67”

(3,200 dots)

347.1mm

13.67”

(4,100 dots)

248.5mm

9.78”

(2,935 dots)

241.5mm

9.5”

(2,852 dots)

258.2mm

10.17”

(3,050 dots)

201.5mm

7.93”

(2,380 dots)

140.0mm

5.51”

(1,654 dots)

118.5mm

4.66”

(1,400 dots)

162.98mm

6.42”

(1,925 dots)

207.43mm

8.17”

(2,450 dots)

232.8mm

9.16”

(2,750 dots)

182.0mm

7.16”

(2,150 dots)

296.3mm

11.66”

(3,500 dots)

220.5mm

8.68”

(2,604 dots)

211.5mm

8.33”

(2,498 dots)

3.4mm

0.13”

(40 dots)

6.35mm

0.25”

(75 dots)

6.01mm

0.24”

(71 dots)

6.35mm

0.25”

(75 dots)

6.01mm

0.24”

(71 dots)

6.35mm

0.25”

(75 dots)

12.7mm

0.5”

(150 dots)

6.01mm

0.24”

(71 dots)

PR98184

4.23mm

0.17”

(50 dots)

I-8

Page 15

3. SAFETY INFORMATION

3.1 Laser Safety (110 - 120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and

Human Services (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. This means that the printer does not produce

hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective

housings and external covers, the laser beam cannot escape from the machine during

any phase of user operation.

3.2 FDA Regulations (110 - 120V Model only)

The US Food and Drug Administration (FDA) has implemented regulations for laser

products manufactured on and after August 2, 1976. Compliance is mandatory for

products marketed in the United States. One of the following labels on the back of the

printer indicates compliance with the FDA regulations and must be attached to laser

products marketed in the United States.

The label for Japanese manufactured products

MANUFACTURED: K

BROTHER INDUSTRIES, LTD.

15-1, Naeshiro-cho, Mizuho-ku, Nagoya 467-8561, Japan.

This product complies with FDA radiation

performance standards, 21 CFR Subchapter J.

The label for Chinese manufactured products

MANUFACTURED : C

BROTHER Corporation (Asia) Ltd.

Shenzen Buji Nan Ling Factory

Gold Garden Ind., Nan Ling Village, Buji, Rong Gang,

Shenzhen, CHINA

This product complies with FDA radiation

performance standards, 21 CFR Subchapter J.

I-9

Page 16

3.3 Caution for Laser Product (Warnhinweis für Laserdrucker)

CAUTION: When the machine during servicing is operated with the cover open, the

regulations of VBG 93 and the performance instructions for VBG 93 are

valid.

CAUTION: In case of any trouble with the laser unit, replace the laser unit itself. To

prevent direct exposure to the laser beam, do not try to open the enclosure

of the laser unit.

ACHTUNG: Im Falle von Störungen der Lasereinheit muß diese ersetzt werden. Das

Gehäuse der Lasereinheit darf nicht geöffnet werden, da sonst

Laserstrahlen austreten können.

(1) Location of the laser beam window.

Fig. 1-1

(2) Location of Caution Label for Laser Product. (200V only)

CLASS 1LASER PRODUCT

APPAREIL Å LASER DE CLASSE 1

LASER KLASSE 1 PRODUKT

Window

Fig. 1-2

I-10

Page 17

CHAPTER II THEORY OF OPERATION

1. ELECTRONICS

1.1 General Block Diagram

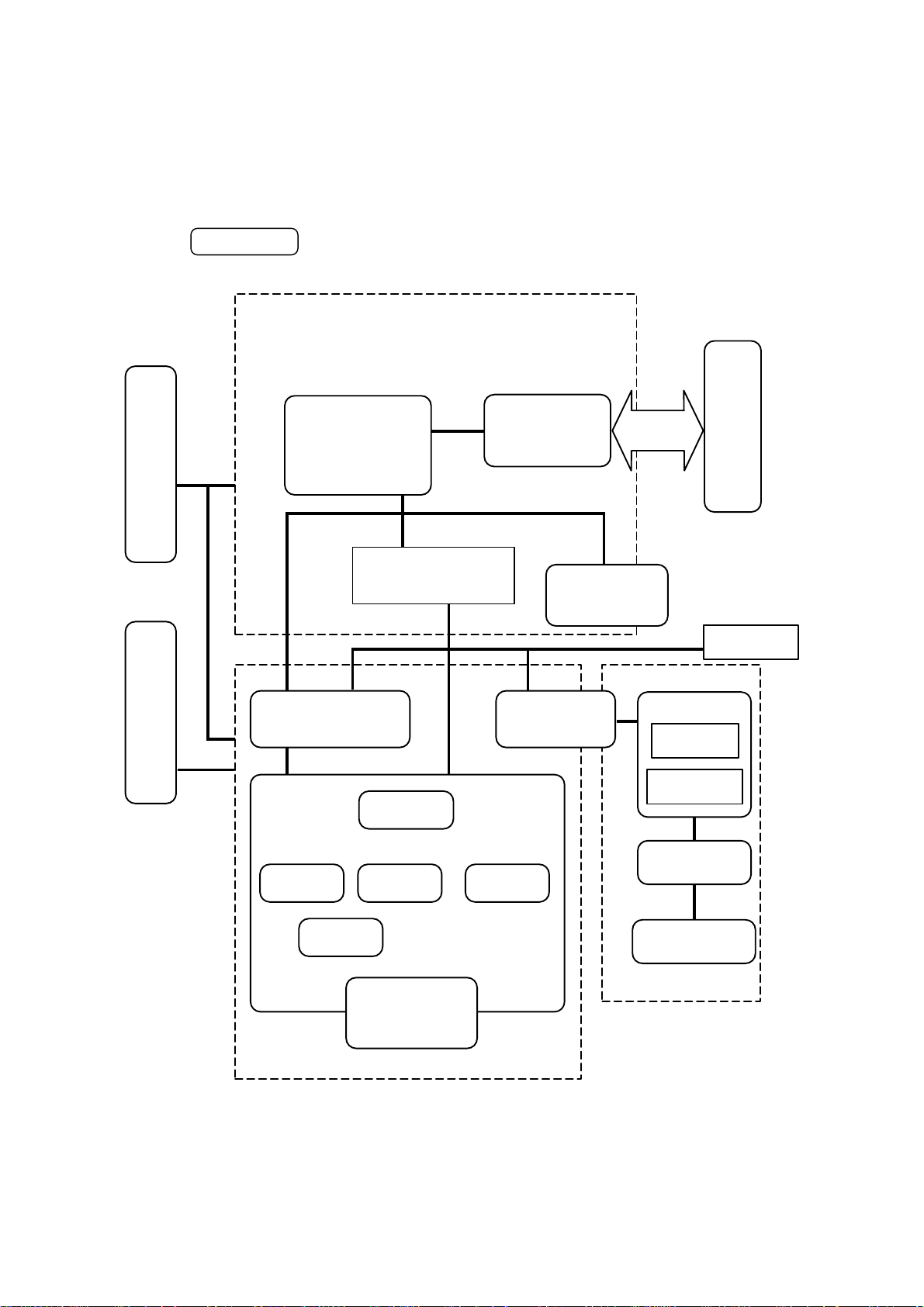

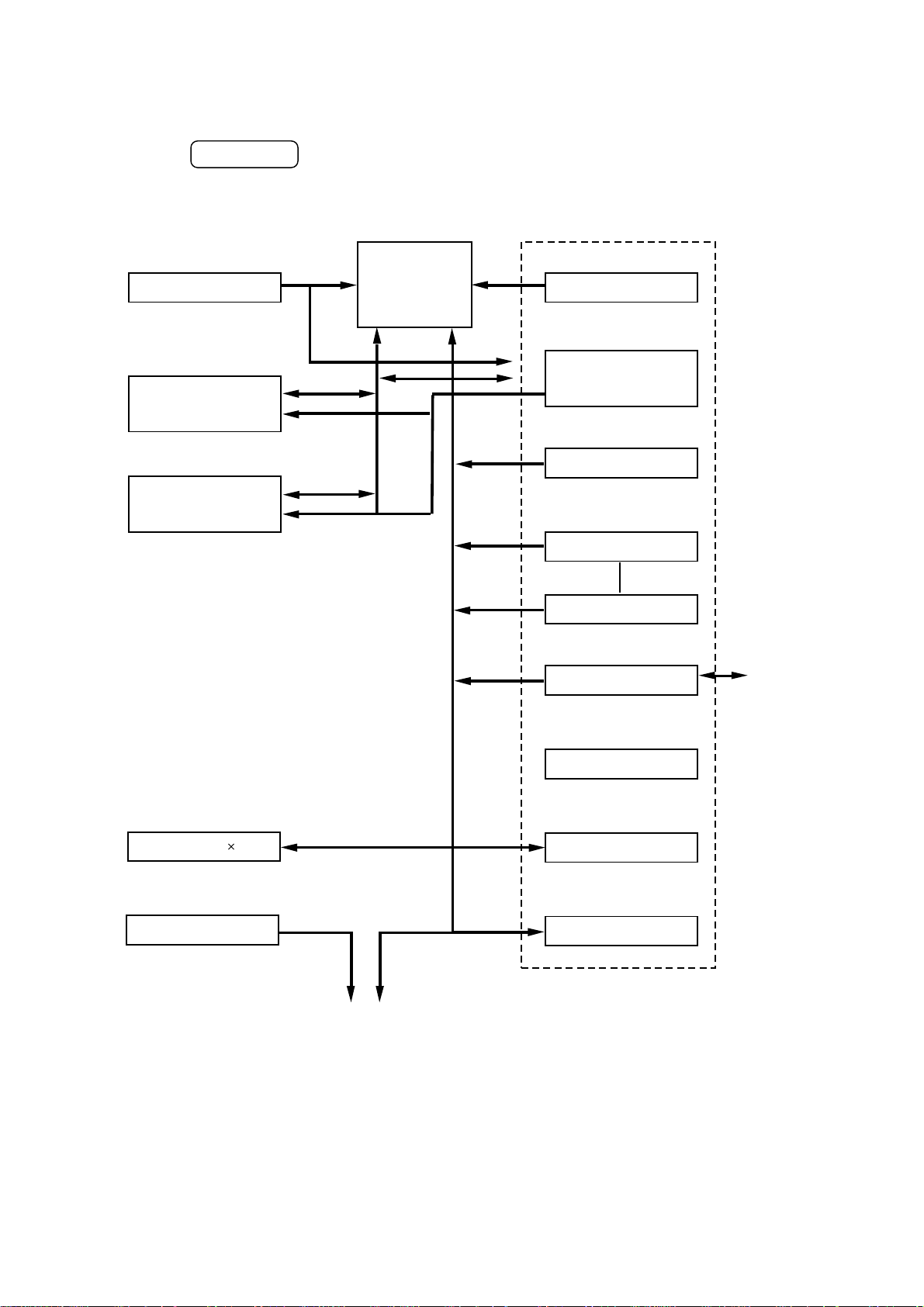

Fig. 2-1 shows a general block diagram of the HL-820/1020 printer.

supply block

Low-voltage power

HL-820/1020

Control system

Video control block

Engine control block

Interface block

External device

Operation block

(Operation panel)

Erase lamp

supply block

High-voltage power

Image generation system

Laser scanner unit

Drum unit

Developing

block

Charging

block

Transfer block

Drum

Toner cartridge

Fig. 2-1

Drive block

(Stepping motor)

Cleaner

block

Paper tray unit

Paper tray

Manual feed

Fixing unit

Paper eject block

Paper feed system

II-1

Page 18

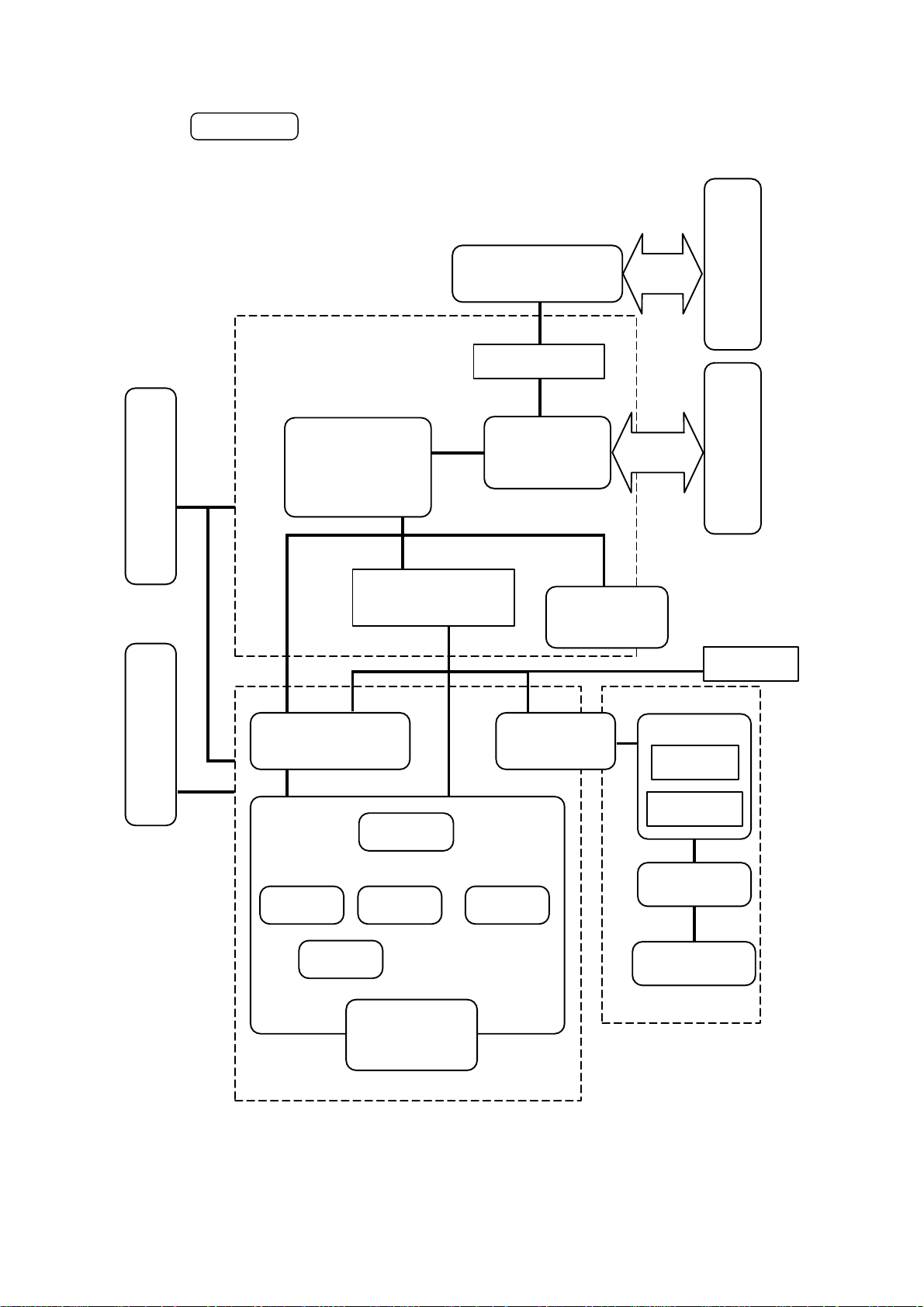

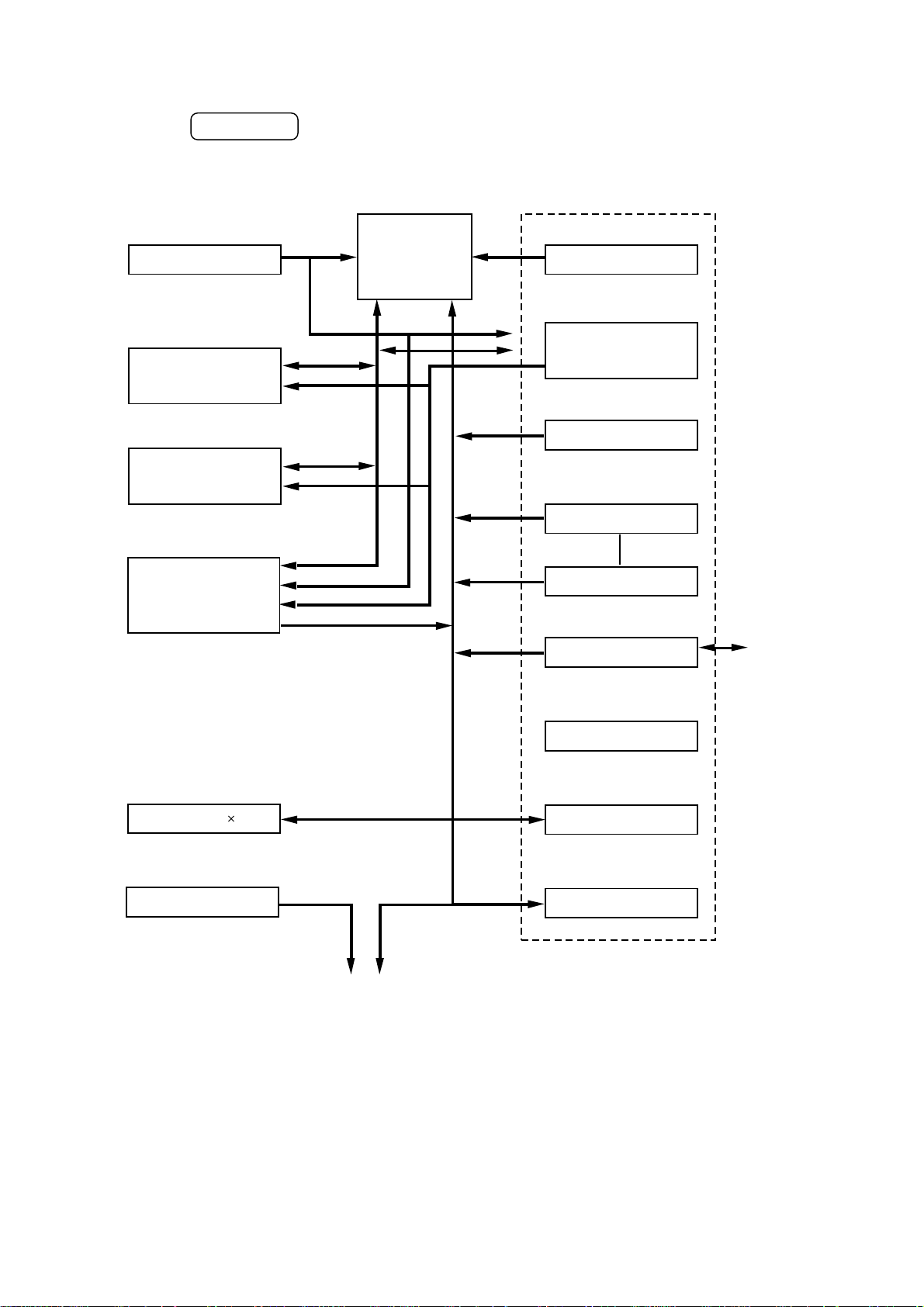

HL-1040

Fig. 2-2 shows a general block diagram of the HL-1040 printer.

Optional I/F board

(Mac. RS-232C)

External deviceExternal device

Control system

Expansion I/O

supply block

Low-voltage power

supply block

High-voltage power

Video control block

Laser scanner unit

Drum unit

Developing

block

Engine control block

Transfer block

Drum

Interface block

Drive block

(Stepping motor)

Cleaner

block

Operation block

(Operation panel)

Erase lamp

Paper tray unit

Paper tray

Manual feed

Fixing unit

Charging

block

Toner cartridge

Image generation system

Paper eject block

Paper feed system

Fig. 2-2

II-2

Page 19

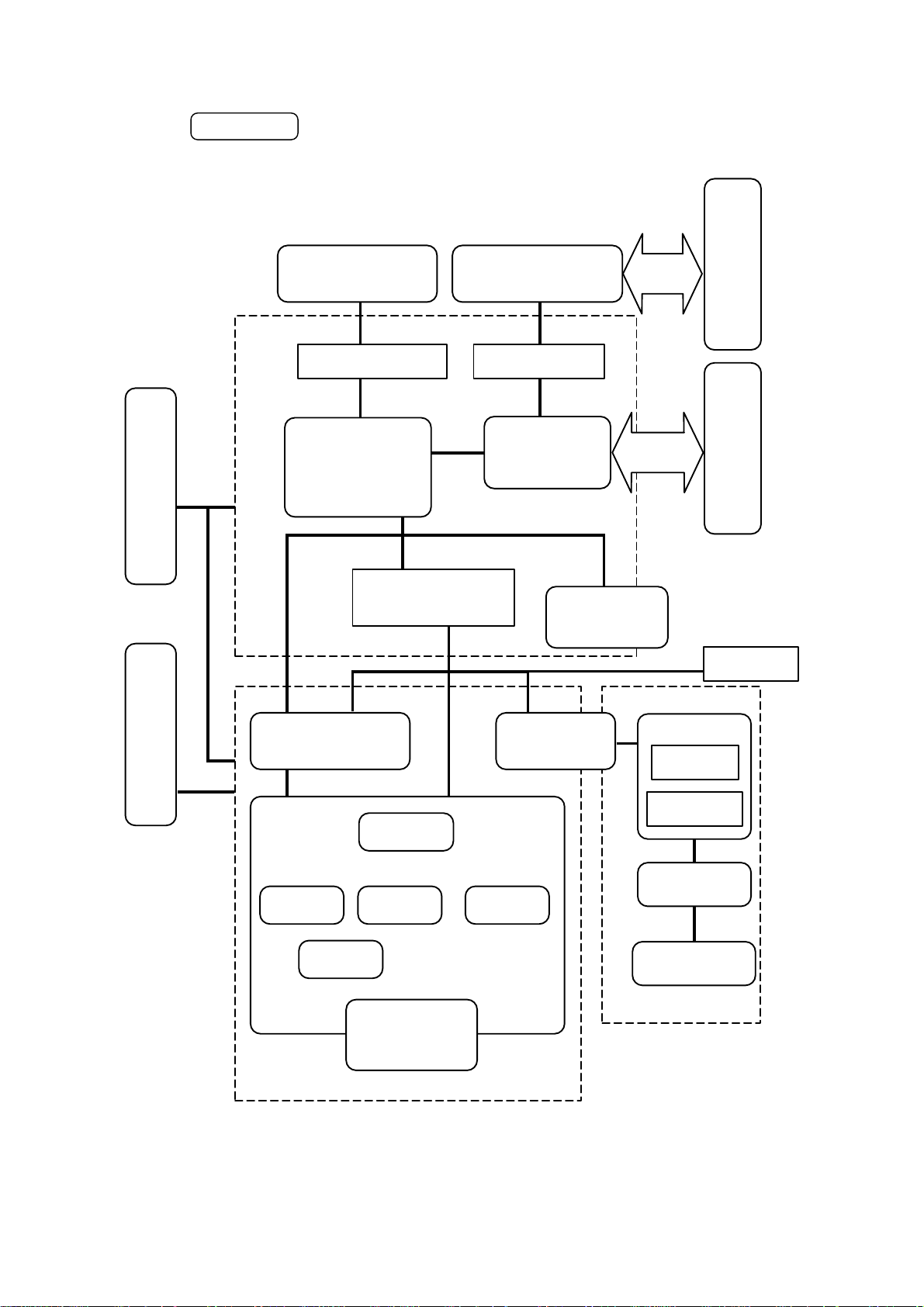

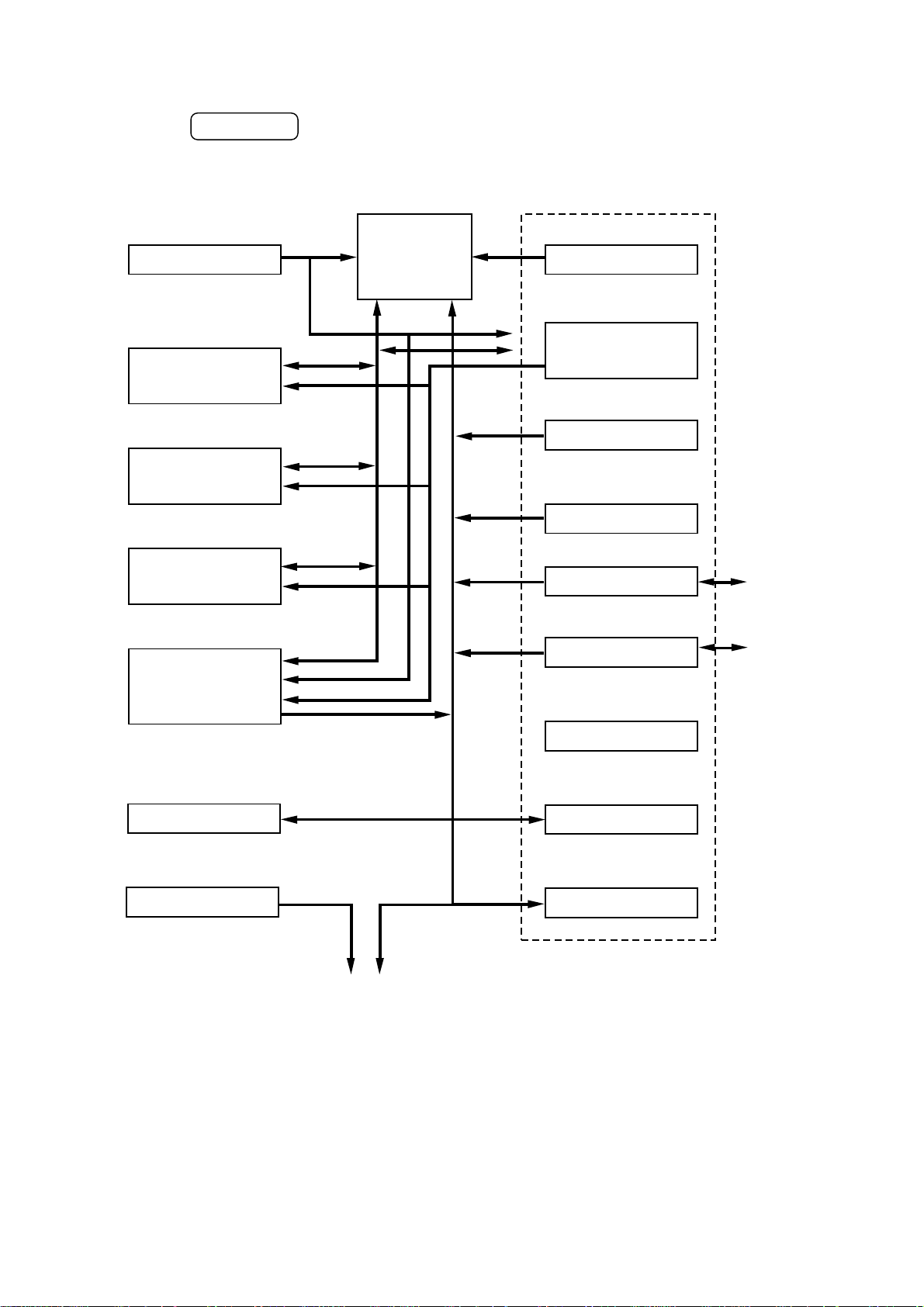

HL-1050

Fig. 2-3 shows a general block diagram of the HL-1050 printer.

Control system

supply block

Low-voltage power

Optional RAM (SIMM)

(max. 32Mbytes)

Expansion memory I/O Expansion I/O

Video control block

Engine control block

Optional I/F board

(Mac. RS-232C)

Interface block

External deviceExternal device

Operation block

(Operation panel)

Erase lamp

supply block

High-voltage power

Image generation system

Laser scanner unit

Drum unit

Developing

block

Charging

block

Transfer block

Drum

Toner cartridge

Fig. 2-3

Drive block

(Stepping motor)

Cleaner

block

Paper tray unit

Paper tray

Manual feed

Fixing unit

Paper eject block

Paper feed system

II-3

Page 20

1.2 Main PCB Block Diagram

HL-820/1020

Fig. 2-4 shows the block diagram of the main PCB.

Reset Circuit

Program + Font ROM

512 Kbytes

RAM

(2.0 Mbytes)

CPU Core

(MC68EC000)

BUS

A S I C

Oscillator (15.3MHz)

INT

Address Decoder

DRAM Control

Timer

FIFO

EEPROM (128 8 bits)

Motor Driver

To Panel Sensor PCB

DATA EXTENSION

CDCC Parallel I/O

Soft Support

EEPROM I/O

Engine Control I/O

To PC

Fig. 2-4

II-4

Page 21

Fig. 2-5 shows the block diagram of the main PCB.

Reset Circuit

Program + Font ROM

512 Kbytes

RAM

(2.0 Mbytes)

HL-1040

CPU Core

(MC68EC000)

BUS

A S I C

Oscillator (15.3MHz)

INT

Address Decoder

DRAM Control

Timer

FIFO

Option Serial I/O

(RS232C & RS422A)

EEPROM (128 8 bits)

Motor Driver

To Panel Sensor PCB

Fig. 2-5

DATA EXTENSION

CDCC Parallel I/O

Soft Support

EEPROM I/O

Engine Control I/O

To PC

II-5

Page 22

Fig. 2-6 shows the block diagram of the main PCB.

Reset Circuit

Program + Font ROM

4.0 Mbytes

RAM

(4.0 Mbytes)

HL-1050

CPU Core

(MB86831)

BUS

A S I C

Oscillator (33.3MHz)

INT

Address Decoder

DRAM Control

Timer

FIFO

Option RAM (SIMM)

(max. 32Mbytes)

Option Serial I/O

(RS232C & RS422A)

EEPROM (512 x 8 bits)

Motor Driver

To Panel Sensor PCB

CDCC Parallel I/O

USB I/O

Soft Support

EEPROM I/O

Engine Control I/O

To PC

To PC

Fig. 2-6

II-6

Page 23

1.3 Main PCB

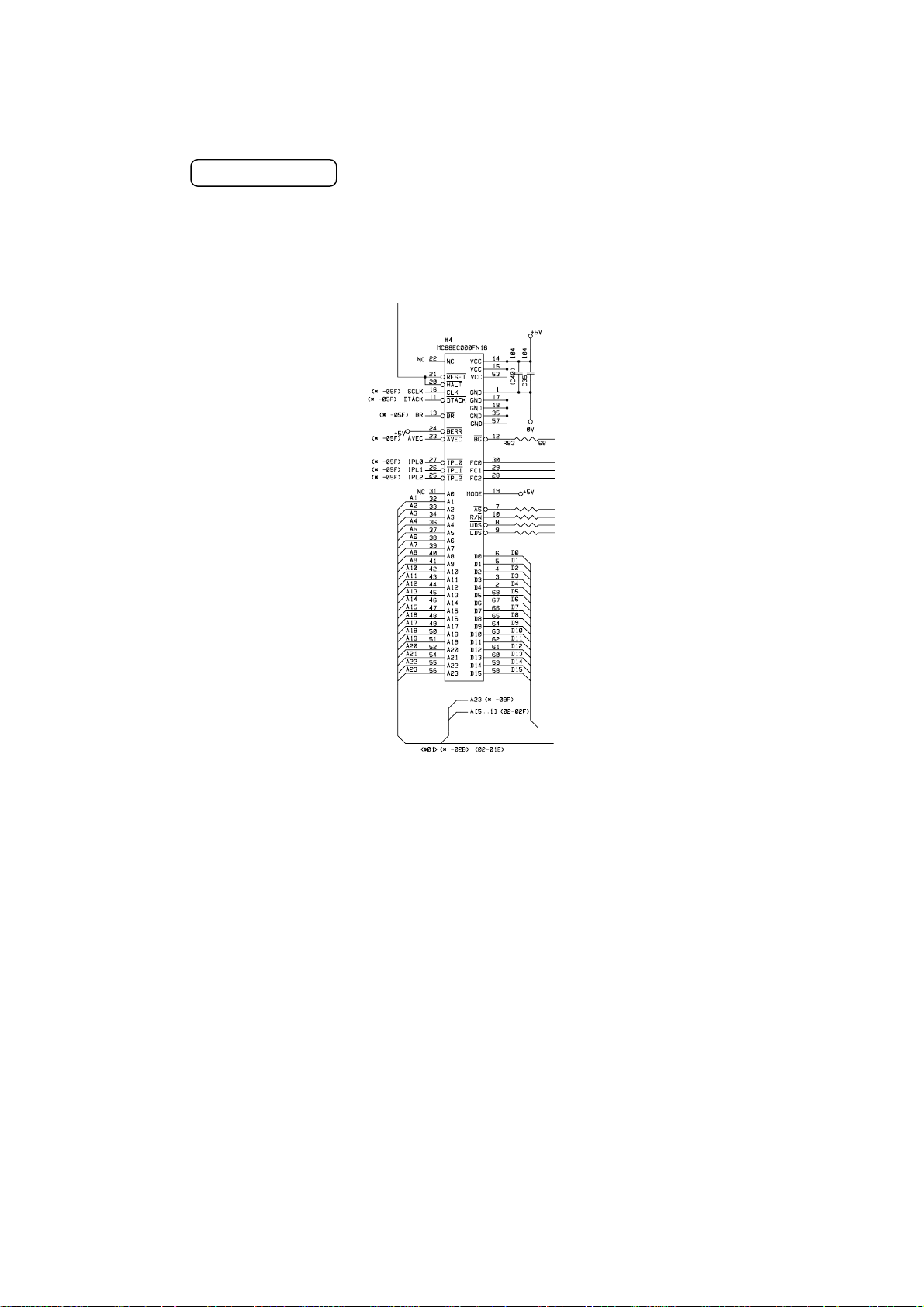

1.3.1 CPU Core

HL-820/1020/1040

Fig. 2-7 shows the CPU circuit block on the main PCB.

The CPU is a Motorola MC68EC000FN16 which is driven with a clock frequency of

15.3MHz. This clock frequency is made by dividing the source clock of 30.67 MHz into

two.

Fig. 2-7

II-7

Page 24

HL-1050

Fig. 2-8 shows the CPU circuit block on the main PCB.

The CPU is a Motorola MB86831 which is driven with a clock frequency of 33MHz. The

CPU itself runs at 66MHz.

Fig. 2-8

II-8

Page 25

1.3.2 ASIC

HL-820/1020/1040

The ASIC is composed of a Cell Based IC that contains the following functional blocks.

(1) Oscillator circuit

Generates the main clock for the CPU by dividing the source clock frequency into

two.

(2) Address decoder

Generates the CS for each device.

(3) DRAM control

Generates the RAS, CAS, WE, OE and MA signals for the DRAM and controls

refresh processing (CAS before RAS self-refreshing method).

(4) Interrupt control

Interrupt levels:

Priority High 7 NMI

6 FIFO

5 EXINT(Option Serial I/O)

4 BD / Timer 1

3 SCANINT

2 CDCC / BOISE / DATA EXTENSION

Low 1 Timer 2

(5) Timers

The following timers are incorporated:

Timer 1 16-bit timer

Timer 2 10-bit timer

Timer 3 Watch-dog timer

(6) FIFO

A 5,120-bit FIFO is incorporated. Data for one raster scan is transferred from the

RAM to the FIFO by DMA transmission and is output as serial video data. The

data cycle is 10.22 MHz.

(7) CDCC parallel I/O

<Data receiving>

There are two modes in this unit. One is the CPU receiving mode and the other is

the DMA receiving mode. In the CPU receiving mode the CPU receives the

command data from the PC, and after the CPU is switched to the DMA mode, it

receives the image data and writes to the DRAM directly.

II-9

Page 26

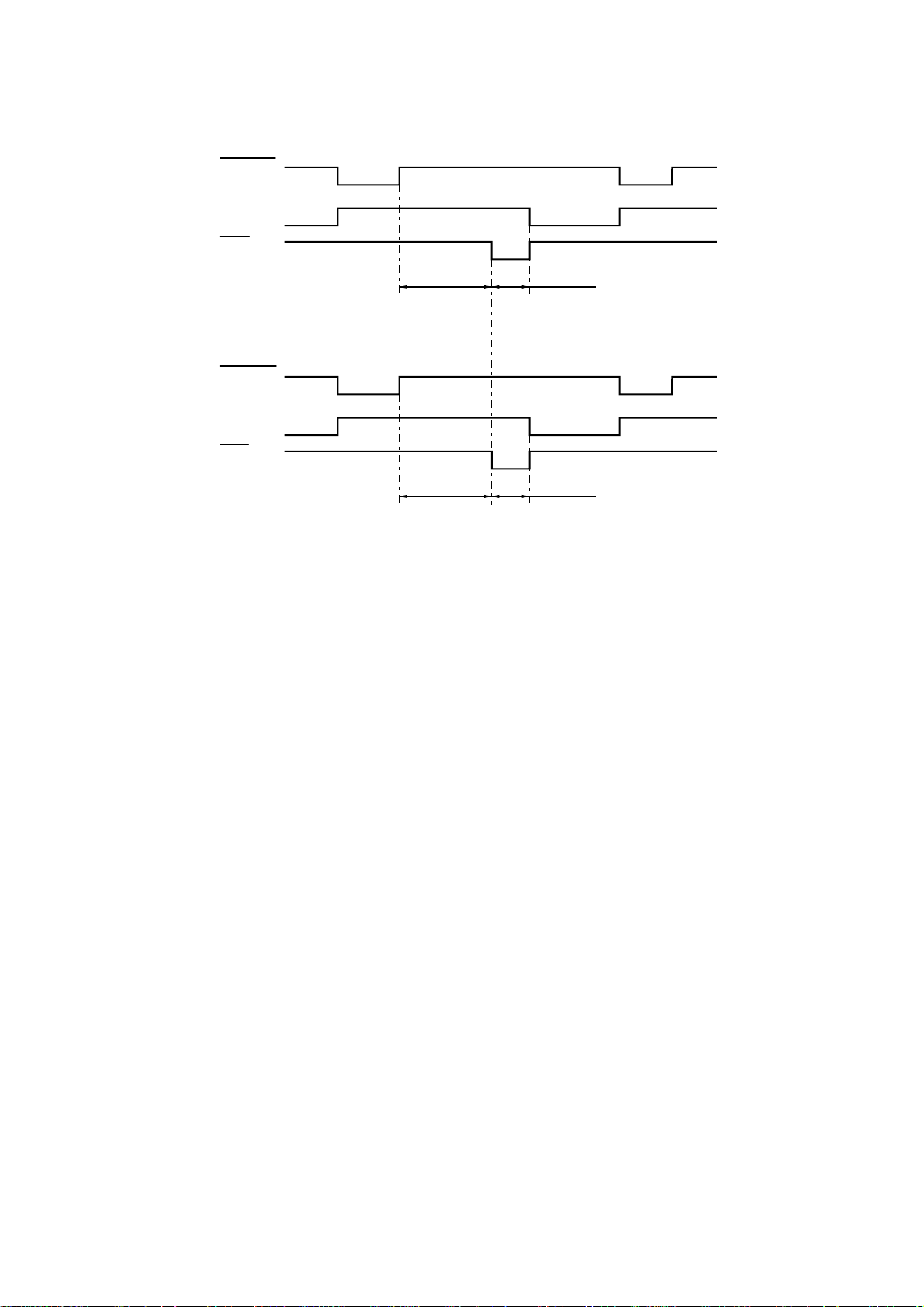

CPU Receive Mode

STROBE

BUSY

ACK

90 µsec

0.5 µsec

DMA Receive Mode

STROBE

BUSY

ACK

0.5 µsec1.5 µsec

BUSY goes HIGH at the falling edge of STROBE. The data (8 bits) from the PC is

latched in the data buffer at the rising edge of STROBE. The pulse width of ACK

differs according to the speed MODE as shown above. BUSY goes LOW at the

rising edge of ACK.

<IEEE1284 support>

This supports the IEEE1284 data transfer with the following modes.

Nibble mode

Byte mode

(8) Data expansion

This circuit expands the compressed image data received from the PC, and writes

the bit map data to the FIFO.

(9) Software support

Supports 16 x 16 rotation, bit expansion, and bit search.

(10) EEPROM I/O

One output port and one I/O port are assigned.

II-10

Page 27

(11) Engine control I/O

This I/O is used for the connection to the panel sensor PCB. It controls the main

motor, solenoid, sensors, etc.

Fig. 2-9

II-11

Page 28

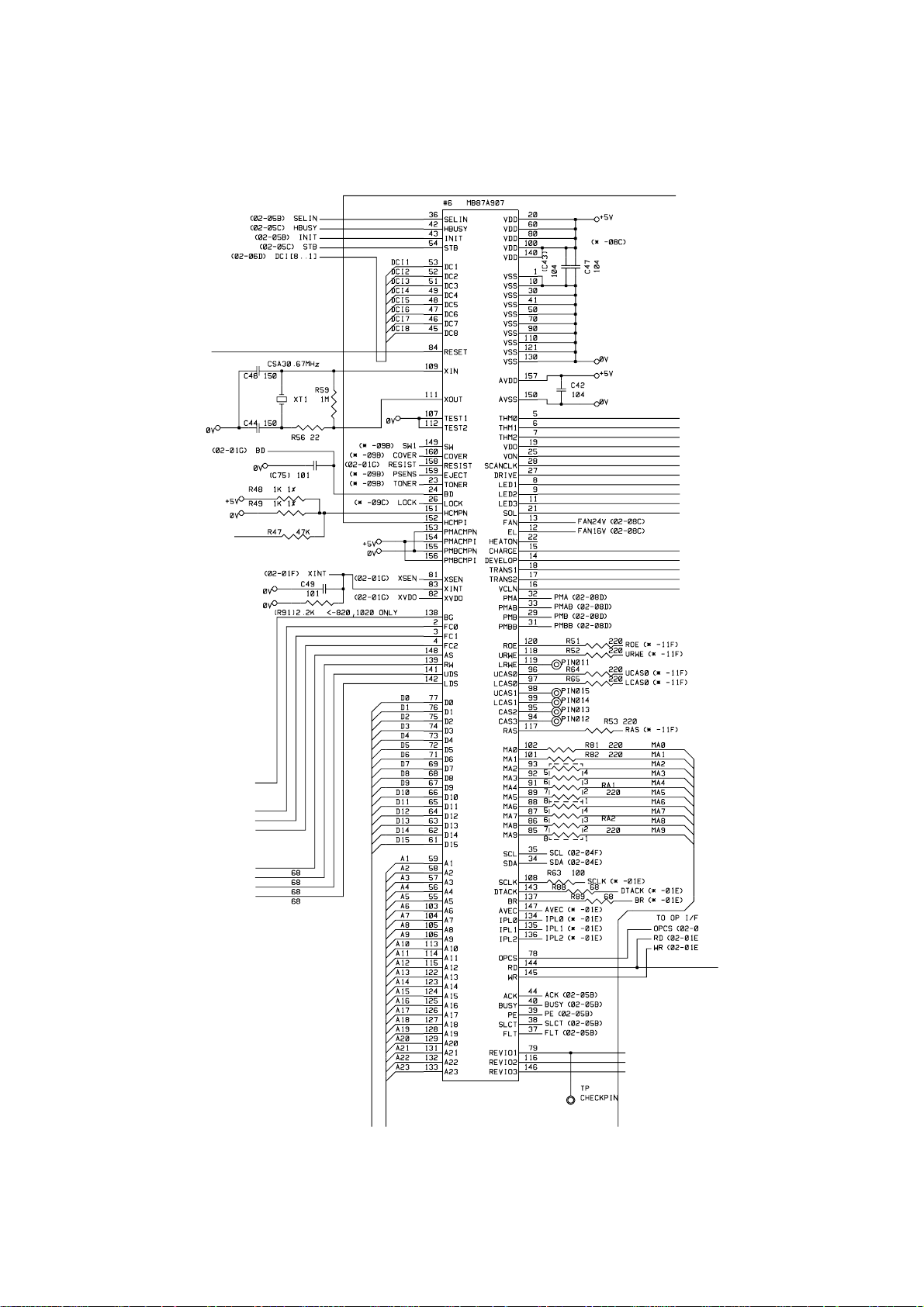

HL-1050

The ASIC is composed of a Cell Based IC that contains the following functional blocks.

(1) Oscillator circuit

Generates the main clock for the CPU.

(2) Address decoder

Generates the CS for each device.

(3) DRAM control

Generates the RAS, CAS, WE, OE and MA signals for the DRAM and controls

refresh processing (CAS before RAS self-refreshing method).

(4) Interrupt control

Interrupt levels:

Priority High 10 Reserve interrupt 1 (for debug)

9 Watch Dog Timer

8 LSB EMPTY (for VDO FIFO)

7 Timer 1

6 USB

5 XIO interrupt (RS-100M) or MIO interrupt

4 BD (for engine check)

3 Reserve interrupt 2

2 CDCC

Low 1 Timer 2

Note:

All the interrupts can be masked.

The priority of levels 7, 6, and 5 are changeable from the program.

(5) Timers

The following timers are incorporated:

Timer 1 32-bit timer

Timer 2 32-bit timer

Timer 3 Watch-dog timer

(6) FIFO

A 10Kbit FIFO is included. Data for one raster scan is transferred from the RAM to

the FIFO by DMA transmission and is output as serial video data. The data cycle is

10.43MHz.

(7) Parallel I/O

<Data receive Mode>

There are two modes in this unit. One is the CPU receive mode and the other is

the DMA receive mode. In the CPU receive mode the CPU receives the command

data from the PC, and after the CPU is switched to the DMA mode, it receives the

image data and writes it to the DRAM directly.

II-12

Page 29

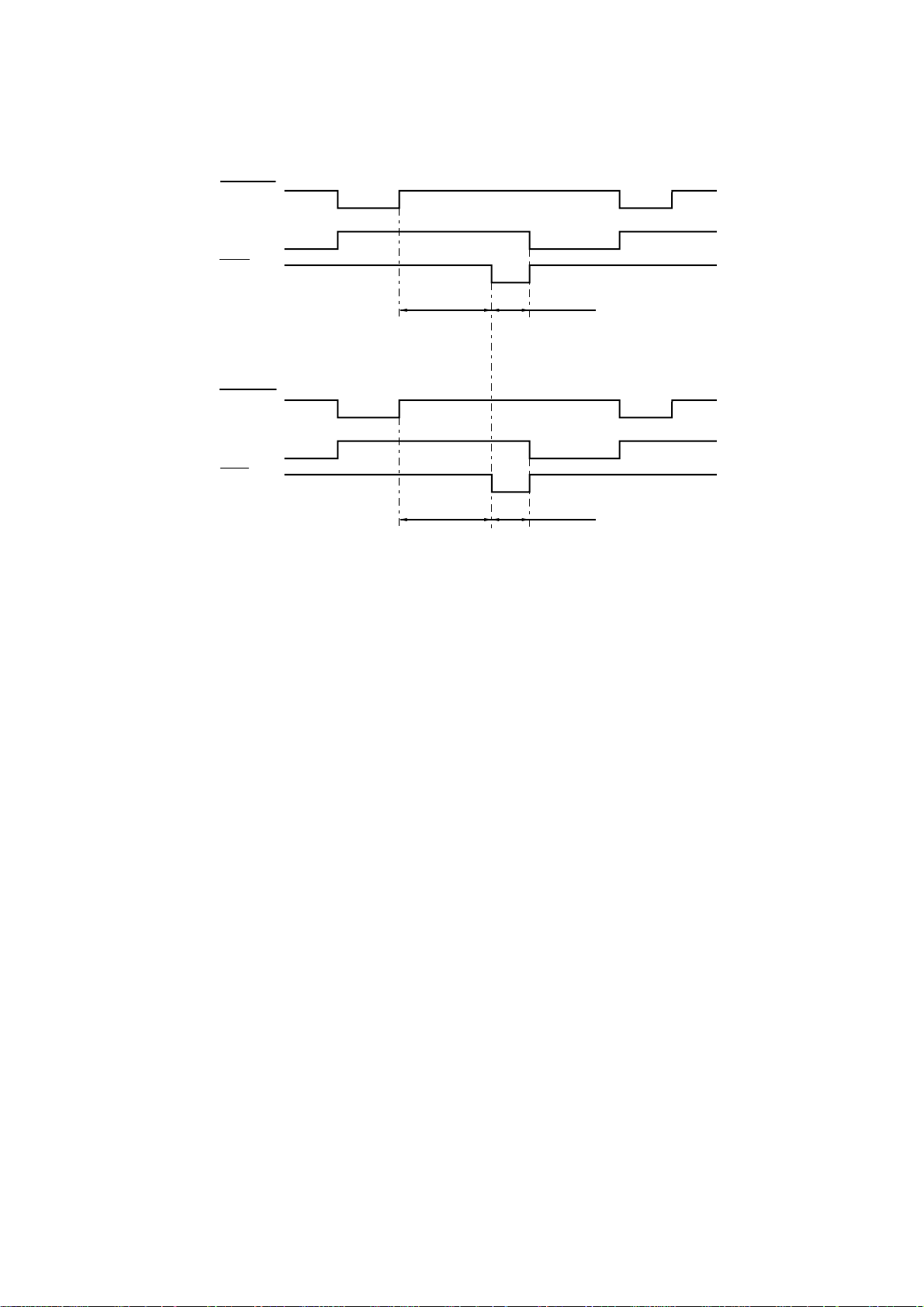

CPU Receive Mode

STROBE

BUSY

ACK

90 µsec

0.5 µsec

DMA Receive Mode

STROBE

BUSY

ACK

0.5 µsec1.5 µsec

BUSY goes HIGH at the falling edge of the STROBE signal. The data (8 bits) from

the PC is latched into the data buffer at the rising edge of the STROBE signal. The

pulse width of ACK varies according to the speed MODE as shown above. BUSY

goes LOW on the rising edge of ACK.

<IEEE1284 support>

This supports the IEEE1284 data transfer with the following mode.

Nibble mode

Byte mode

ECP mode

(8) Data expansion

This circuit expands the compressed image data received from the PC, and writes

the bit map data to the FIFO.

(9) Software support

Supports 16 x 16 rotation, bit expansion, bit search, and decimal point conversion.

(10) EEPROM I/O

One output port and one I/O port are assigned.

II-13

Page 30

(11) Engine control I/O

This I/O is used for the connection to the panel sensor PCB. It controls the main

motor, solenoid, sensors, etc.

Fig. 2-10

II-14

Page 31

1.3.3 ROM

HL-820/1020/1040

A program file of 512 Kbytes and the font data are stored in the ROM. A 42-pin IC socket

is provided: a 16 Mbits ROM (42-pin) is mounted into this socket normally, but a 4 Mbits

ROM (40-pin) can be mounted by leaving the 1st and 42nd pins of the socket open

circuit.

Fig. 2-11

HL-1050

A program file of 4.0 Mbytes and the font data are stored in the ROM. Two 42-pin IC

sockets are provided: two 16 Mbits ROMs (42-pin) can be mounted into these sockets.

Fig. 2-12

II-15

Page 32

1.3.4 DRAM

HL-820/1020/1040

A 16M-bit DRAM (x 16bits) is used as the RAM.

Fig. 2-13

HL-1050

Two 16M-bit DRAMs (x 16bits) are used as the RAM.

Fig. 2-14

II-16

Page 33

1.3.5 Optional RAM

HL-1050

A 32bit (72 pin) SIMM can be fitted as optional RAM. The main PCB has one slot and the

capacity of SIMM can be from 1 Mbyte to 32 Mbytes.

Fig. 2-15

II-17

Page 34

1.3.6 Optional Serial I/O

HL-1040/1050

The interrupt of the serial I/O is input to the EXINT terminal of the ASIC, and is

recognized by th e C P U . A 3 2 - b y t e r e g i s t e r i s p r o v i d e d for this I/O, which is read

and written to by the CPU.

Fig. 2-16

1.3.7 EEPROM

HL-820/1020/1040

The EEPROM is an XL24C01AF type of two-wire method with a 128 x 8 bits

configuration.

M62320FP is an IC which transfers the data received from the serial I/O to the parallel

I/O.

Fig. 2-17

HL-1050

The EEPROM is XL24C04AF type of two-wire method with a 512 x 8 bits configuration.

Fig. 2-18

II-18

Page 35

1.3.8 Reset Circuit

HL-820/1020/1040

The reset IC is a PST598DNR. The reset voltage is 4.2V (typ.) and the LOW period of

reset is 200ms (typ).

Fig. 2-19

HL-1050

The reset IC is a PST596DNR. The reset voltage is 4.2V (typ.) and the LOW period of

reset is 50ms (typ).

Fig. 2-20

1.3.9 CDCC I/O

HL-820/1020/1040

Fig. 2-21 shows the CDCC interface circuit.

Fig. 2-21

II-19

Page 36

HL-1050

Fig. 2-22 shows the CDCC interface circuit.

Fig. 2-22

II-20

Page 37

1.3.10 Engine I/O

HL-820/1020/1040

Fig. 2-23 shows the engine interface circuit.

Fig. 2-23

II-21

Page 38

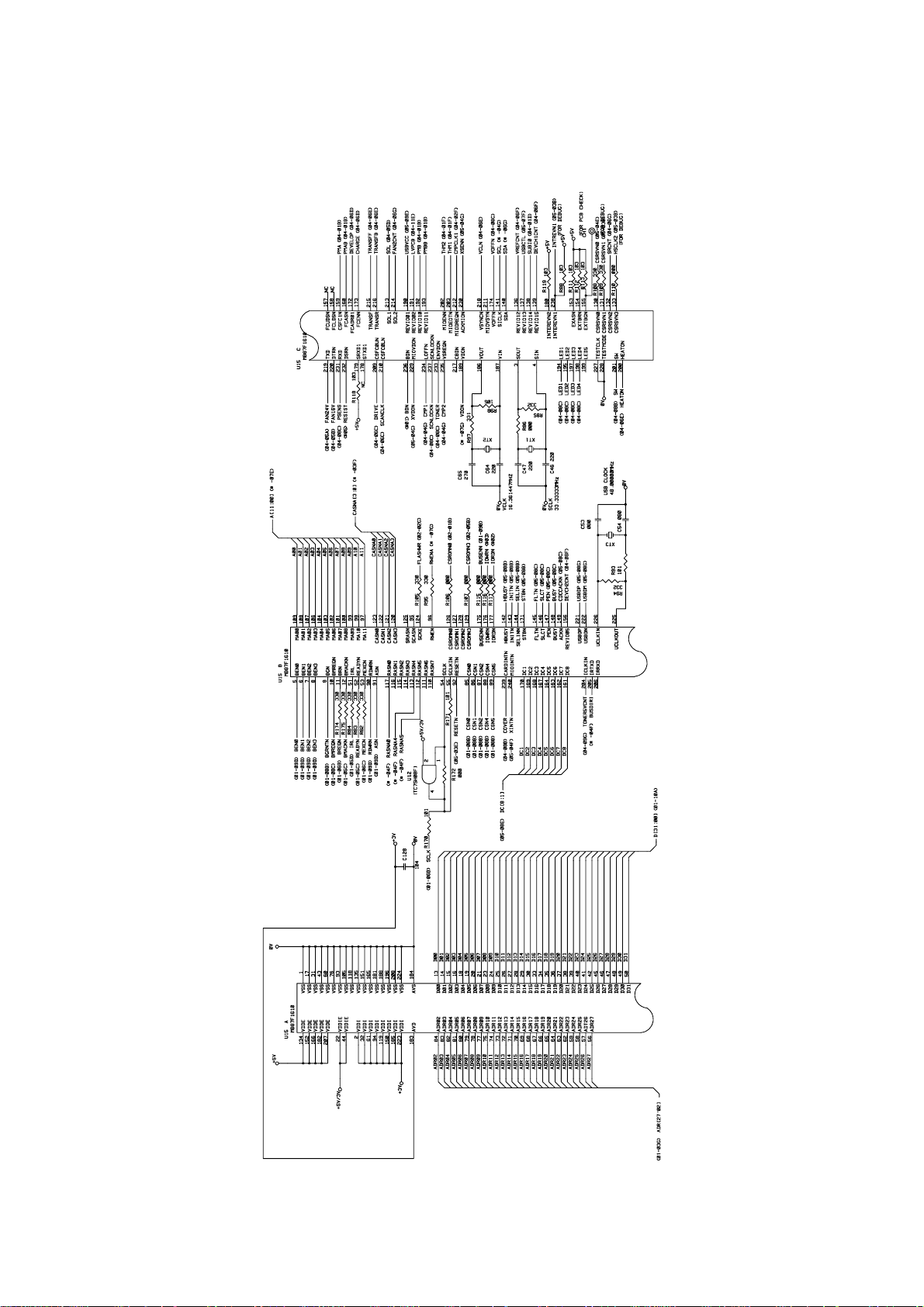

HL-1050

Fig. 2-24 shows the engine interface circuit.

Fig. 2-24

II-22

Page 39

1.3.11 Paper Feed Motor Drive Circuit

HL-820/1020/1040

The motor driver is a TR array. The excitation method is 2-2 phase excitation with a

bipolar drive.

Fig. 2-25

HL-1050

The motor driver is a TR array. The excitation method is 2-2 phase excitation with a

bipolar drive.

Fig. 2-26

II-23

Page 40

1.4 Panel Sensor PCB

The following parts are on the panel sensor.

• Control Panel...........1 Switch, 4 lamps

• Connector................Low-voltage, high-voltage, solenoid, main motor, toner sensor,

• Registration sensor

1.5 Power Supply

1.5.1 Low-voltage Power Supply

The power supply uses a switching regulation system to generate the regulated DC

power (+5V and +24V), which are converted from the AC line.

The regulated output and the production code of each power supply vary depending on

the printer model as listed below;

Model Regulated Output Production Code

HL-820/1020/1040

HL-1050

laser, polygon motor, connector for main PCB

+5V / 0.6 A

+24V / 2.0 A

+5V / 1.2A

+24V / 2.0A

100V: MPW1547

200V: MPW1447

100V: MPW1550

200V: MPW1450

(Heater)

Fuse

Line

Filter

Lightning

Surge

Absorber

Rectifier Oscillator

24V

Regulation

Circuit

Heater

Circuit

Feedback

Thermal

Fuse

(Panel Sensor Circuit)

24V

Lamp

5V

Regulation

Circuit

Fig. 2-27

II-24

5V

Page 41

1.5.2 High-voltage Power Supply

This generates and outputs the voltages and currents for the charging, development and

transfer functions.

24VI

GND

R1

Current

Regulator

B1

Voltage

Regulator

VR22

Current

Regulator

B81 Q81

Voltage

Regulator

B101 Q101

Current

Regulator

Supply

Roller

Developing

Roller

Photosensitive

Drum

Corona

Unit

Transfer Roller

Cleaner

Roller

PAPER

SENSOR

PC141

B121 Q121

Voltage

Regulator

Z51 VR51

Voltage

Regulator

VR71

Voltage

Regulator

VR61

Fig. 2-28

II-25

Page 42

2. MECHANICS

2.1 Overview of Printing Mechanism

Hopper

Plate

Registration Sensor Lever

Toner Cartrid

Polygon Mirror

Papers

ge

Laser Scanner

Multi-purpose Sheet Feeder

Manual Paper Path

MP Feeder Cover

Paper Pick-up Roller

Paper Feed

Roller

Pinch Roller

Toner Empty

Sensor

Supply Roller

Drum Unit

Blade

Scanner Unit

Transfer

Roller

Corona Wire

Photosensitive Drum

Erase Lamp

Fixing Unit

Development

Roller

Cleaning Roller

Pressure Roller

Eject Roller

Eject Sensor

Actuator

Heat Roller

Thermistor

Main Cotrol PCB

Panel

Sensor

PCB

Fig. 2-29

EL PCB

Scanner Unit

Main Motor

Sub Motor

Main Fan Motor

Sub Fan Motor

HighVoltage

Power

Supply

Toner

Empty

Sensor

PCB

Thermistor (for Heat roller)

Solenoid

Primary Charger (Corona Wire)

Primary Charger (Grid)

Developer Roller

Transfer Roller

Cleaner Roller

Supply Roller

Eject Sensor

Registration Sensor

Toner Empty Sensor

Thermistor (for Toner)

Fig. 2-30

II-26

Page 43

2.2 Paper Transfer

2.2.1 Paper Supply

The pick-up roller picks up one sheet of paper from the paper feeder every time it is

rotated and feeds it to the paper feed roller.

p

Hopper plate

Separation pad

Fig. 2-31

Pick-up roller

Registration sensor lever

The paper is gripped between the pick-up roller and the separation pad and separated

into individual sheets.

The pick-up roller is directly connected to the sector gear, whose rotation is forcibly

stopped by the gear stopper. When the pick-up solenoid is activated, the clutch

mechanism is engaged by the solenoid action and the sector gear is driven; when it has

completed one full turn its rotation is stopped again by the gear stopper. The paper

drawn out by the pick-up roller pushes against the top of form sensor lever and the paper

top position/absence of paper is detected by sensing the motion of the lever.

2.2.2 Paper Registration

When paper picked up from the multi-purpose sheet feeder (MPF) pushes against the top

of form sensor actuator, the registration sensor lever is caused to turn, and the photo

sensor detects this motion. When this signal from the sensor is detected the paper feed

roller is stopped temporarily by the clutch. The paper is fed to the nip point between the

paper feed roller and the pinch roller in the multi-purpose sheet feeder, and the skew of

the paper is corrected by pushing the leading edge of the paper against the nip point.

When the paper feed roller starts to be rotated again when it is released by the clutch,

paper with the leading edge correctly aligned, is fed by the paper feed roller and is

transported to the transfer roller.

Paper

Paper feed roller

Clutch mechanism (engaged/released by the solenoid assembly)

Released when the solenoid is ON and engaged when the solenoid is OFF.

Pinch roller

Transfer roller

Drum

Fig. 2-32

II-27

Page 44

2.2.3 Paper Eject

,

,

The completion of paper eject is detected in the following manner:

(a) When the leading edge of the paper pushes down the eject sensor actuator

located in the fixing unit, the photo sensor (photo interrupter) is opened and

detects the start of paper eject.

(b) When the trailing edge of the paper has passed through the paper eject sensor

actuator, the photo sensor is closed and the completion of paper eject is

recognized.

Transfer roller

Pressure roller

Eject sensor actuator

Eject roller

Drum

Heat roller

Eject sensor actuator

High-voltage power

suppl

y PCB

Fig. 2-33

Paper

Sensor

Eject sensor actuator

Sensor

Fig. 2-34

II-28

Page 45

2.3 Sensors

2.3.1 Cover Sensor

Detects opening and closing of the top cover.

Top Cover

Cover Switch

Toner Empty

Sensor

Fig. 2-35

2.3.2 Toner Empty Sensor

Detects if there is toner in the toner cartridge. It also detects whether or not the drum unit

is installed. (The toner cartridge is installed in the drum unit).

Fig. 2-36

II-29

Page 46

2.4 Drum Unit

2.4.1 Photosensitive Drum

Generates the latent electrostatic image and develops the image on the drum surface.

2.4.2 Primary Charger

Forms a uniform charge on the drum surface.

(1) Corona wire

Generates the ion charge on the drum.

(2) Grid

Spreads the ion charge evenly over the drum surface.

2.4.3 Development Roller

Develops the latent electrostatic image on the drum surface by the addition of the toner.

2.4.4 Transfer Roller

Transfers the toner image to the paper from the drum surface.

2.4.5 Cleaner Roller

Removes and recycles the toner remaining on the drum surface.

2.4.6 Erase Lamp

Discharges the electrostatic latent image on the drum.

2.5 Print Process

2.5.1 Charging

The drum is charged to approx. +1150V by an ion charge which is generated by the

primary charger. The charge is generated by ionization of the corona wire, which has a

DC bias from the high-voltage power supply applied to it. The flow of the ion charge is

controlled by the grid to ensure it is distributed evenly on the drum surface. The drum

sleeve is regulated to approx. 280V by the voltage regulator.

Voltage

Regulator

1150V

-

+

-

+

+

+

Corona wire

280V

-

-

-

-

-

-

---

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

Fig. 2-37

Aluminum drum sleeve

Organic Photoconductor layer

Grid

HVPS

Passive Type

Voltage Regulator

Drum

The primary charge uses a corona wire, but since the drum is positively charged, only

less than 1/10 of the usual quantity of ozone is generated compared with the negatively

charged drum. The level of ozone expelled from the printer is therefore not harmful to the

human body. Applicable safety standards have been complied with.

II-30

Page 47

2.5.2 Exposure Stage

After the drum is positively charged, it is exposed to the light emitted from the laser unit.

Laser detector

Drum

Paper

Laser beam

f lens

Polygon mirror

Laser diode

Motor

Lens

Fig. 2-38

Laser Beam

The area exposed to the laser beam is the image to be printed. The surface potential of

the exposed area is reduced, forming the electrostatic image to be printed.

+1150

1 Cycle of drum

123

(a)

4

Primary charging

1

2

Laser beam exposure and developing

(a) Unexposed area

( Non image area )

(b) Exposed area

( Image area )

+700

Surface Potential (V)

+400

+300

Drum

Sleeve

(b)

Time

Fig. 2-39

3

Transfer the image to paper

Erase the residual potential

4

II-31

Page 48

2.5.3 Developing

(a)

]

(b)

]

g

Developing causes the toner to be attracted to the electrostatic image on the drum so as

to transform it into a visible image.

The developer consists of a non-magnetic toner. The development roller is made of

conductive rubber and the supply roller (which is also made of conductive sponge) rotate

against each other. The toner is charged and carried from the supply roller to the

development roller. The toner adheres to the development roller and is conveyed to the

drum at an even thickness controlled by the blade. The toner is nipped between the

development roller and the drum and developed onto the latent image on the drum. The

electrostatic field between the drum and the development roller, which is DC-biased from

the high-voltage power supply, creates the electrostatic potential to attract toner particles

from the development roller to the latent image area on the drum surface.

Blade

Toner

Separator

Auger

Develop housing

Supply roller

SR-bias

2.5.4 Transfer

(a) Transfer process

After the drum has been charged and exposed, and has received a developed

image, the toner formed is transferred onto the paper by applying a negative

charge to the back of the paper. The negative charge applied to the paper causes

the positively charged toner to leave the drum, and adhere to the paper. As a

result, the image is visible on the paper.

(b) Cleaning process of transfer roller

If the toner is not transferred onto the paper perfectly, it is possible that there may

be residual toner on the drum which will adhere to the transfer roller. The transfer

voltage changes to a positive voltage during non-printing rotation of the drum.

Therefore the transfer roller is cleaned by returning the positively charged toner

adhering to the transfer roller onto the photo-conductive drum.

DC-bias

Transfer roller

Development

roller

Fig. 2-40

Cleanin

Transfer process [ON

Cleaning process [ON

Drum

Erase lamp

(a) Collecting process

(b) Discharging process

roller

II-32

Page 49

2.5.5 Drum Cleaning Stage

,,,

,

,,

,,,,

,,,,,

,,,,,

,,,,

,,

,

,,,

,,

,,,,

,,

,

,

,

,

In the image transfer stage, not all the toner on the photosensitive drum is transferred

onto the paper but some remains on the drum. In the drum cleaning stage, the drum

surface is cleaned by the cleaning roller, so that residual toner on the drum surface is

removed and collected on the cleaning roller itself. The residual toner on the cleaning

roller will be discharged to the drum during starting or non-printing time. The toner will be

collected by the developing roller and reused (for further developing).

2.5.6 Erasing Stage

Before the cleaning stage, the drum surface is exposed to the light emitted from the

erase lamp (LED lamp). This stage prepares the drum by decreasing its surface voltage

uniformly, ready to receive a uniform charge in the primary charging stage.

2.5.7 Fixing Stage

The image transferred to the paper by static electricity is fixed by heat and pressure when

passing through the heat roller and the pressure roller in the fixing unit. The thermistor

ASSY keeps the surface temperature of the heat roller constant by detecting the surface

temperature of the heat roller and turning on or off the halogen heater lamp.

Pressure roller

Thermistor ASSY

Halogen heater lamp

Heat roller

Cleaner ASSY

Fig. 2-41

II-33

Page 50

CHAPTER III DISASSEMBLY AND REASSEMBLY

1. SAFETY PRECAUTIONS

To avoid creating secondary problems by mishandling, be careful to follow the following

precautions during maintenance work.

(1) Always turn off the power switch and unplug the power cord from the power outlet

before accessing any parts inside the printer.

(2) Be careful not to lose screws, washers, or other parts removed.

(3) Be sure to apply grease to the gears and applicable positions specified in this

chapter.

(4) When using soldering irons or other heat-generating tools, take care not to

accidentally damage parts such as wires, PCBs, and covers.

(5) Before handling any PCBs, touch a metal portion of the equipment to discharge

any static electricity charge on your body, or the electronic parts or components

may be damaged.

(6) When transporting PCBs, be sure to wrap them in the correct protective packaging.

(7) Be sure to replace self-tapping screws correctly, if removed. Unless otherwise

specified, tighten screws to the following torque values.

TAPTITE, BIND or CUP B

M3 : 7kgf • cm

M4 : 10kgf • cm

TAPTITE, CUP S

M3 : 8kgf • cm

SCREW

M3 : 7kgf • cm

M4 : 8kgf • cm

(8) When connecting or disconnecting cable connectors, hold the connector body, not

the cables. If the connector has a lock, release the connector lock first to release

it.

(9) After a repair, check not only the repaired portion but also all connectors. Also

check that other related portions are functioning properly before operational

checks.

III-1

Page 51

2. DISASSEMBLY FLOW

PS PCB ASSY

HIGH-VOLTAGE

MAIN FAN MOTOR

12

LOW-VOLTAGE

PS PCB ASSY

11

14

DRIVE UNIT

15

MAIN MOTOR ASSY

16

SUB MOTOR ASSY

17

B

BOTTOM

MAIN PCB ASSY

8

A

OUTPUT TRAY ASSY

1

BASE PLATE ASSY

9

B

DRUM UNIT

2

PANEL SENSOR PCB ASSY

10

TOP COVER

3

SUB FAN MOTOR ASSY

13

REAR COVER

MP SHEET FEEDER ASSY

4

5

III-2

FIXING UNIT

6

A

SCANNER UNIT

7

PAPER SUPPORT

EXTENSION SUPPORT WIRE

19

18

Page 52

3. DISASSEMBLY PROCEDURE

3.1 Output Tray ASSY

(1) Open the output tray toward you.

(2) Press the hinges at the left and right sides of the output tray inwards to release the

output tray from the main cover.

Output Tray

Output Tray

Main Cover

3.2 Drum Unit

(1) Open the top cover.

(2) Lift out the drum unit.

Fig. 3.1

Drum Unit

Top Cover

Main Cover

Fig. 3.2

III-3

Page 53

3.3 Top Cover

(1) Open the top cover.

(2) Press the hinges at the left and right sides of the top cover inwards to release the

top cover from the main cover.

Note:

It is recommended for easy removal to press the side of the top cover (

the side of the main cover (

Main Cover

➁

).

) while pulling

➀

Top Cover

2

1

Top Cover

3.4 Rear Cover

(1) Remove the two M4x12 tapping screws.

(2) Remove the rear cover.

Taptite, bind M4x12

Rear Cover

Main Cover

Main Cover

Fig. 3-3

Multi-purpose Sheet Feeder

Taptite, bind M4x12

Fig. 3-4

Note:

When re-assembling the rear cover, hook the two hooks at the right and left hand side

(rear), then secure the two screws.

III-4

Page 54

3.5 MP Sheet Feeder ASSY

Caution:

When disassembling the MP sheet feeder ASSY, if you get the grease on your fingers,

take care not to touch the separation pad or the paper pick-up roller, the grease spread to

the paper and the drum unit. It might cause black spots to appear on the printed page.

(1) Push the left rib outwards and pull out the MP sheet feeder. It is not necessary to

release the right rib.

Multi-purpose

Sheet Feeder

Rib

Fig. 3-5

Note:

When re-assembling, apply a suitable amount of grease (2 rice-grain size) between the

heat sink of the motor and the ground leaf spring in case of grease shortage. (Refer to

the figure below.)

Ground leaf spring

Grease: FLOIL GE-676

(or FLOIL GE-334C)

Fig. 3-6

Motor heat sink

6.2MM

III-5

Page 55

3.6 Fixing Unit

g

(1) Remove the two M4x16 tapping screws.

(2) Lifting the fixing unit, disconnect the thermistor connector on the EL PCB first, then

the two heater harnesses.

Taptite, cup M4x16

Thermistor connector

Fixing Unit

Taptite, cup M4x16

EL PCB

Thermistor harness

Heater harness (Brown)

Heater harness

(Blue)

Fig. 3-7

Note:

The eject sensor actuator may also be removed when removing the fixing unit. In this

case be sure to re-assemble the eject sensor actuator when re-assembling the fixing unit.

(3) Remove the two M3x12 tapping screws.

(4) Open the fixing unit cover along the open side of the fixing unit cover.

Fixing unit cover

Taptite, bind M3x12

Fixing unit

vr

Pressure roller

Shaft

Fixin

unit frame

Fig. 3-8

III-6

Page 56

PR98292

j

(5) Release the right side of the paper eject roller shaft.

(6) Remove the four eject pinch rollers and the pinch springs from the fixing unit

frame. Then, remove the pinch spring from each pinch roller.

Paper eject roller shaft

Pinch Spring

E

ect Pinch Roller

Fig. 3-8a

(7) Remove the M3x10 self tapping screw securing the connector plate.

(8) Remove the connector plate from the fixing unit frame and loosen the other M3x10

tapping screw securing the fixing unit cover.

(9) Remove the idle gear 16 from the fixing unit frame to remove the heat roller. Then,

Caution :

Never touch the surface of the halogen heater lamp and the heat roller.

Heat Roller Washer

Retaining ring

Heat roller gear

Taptite, pan M3x10

Connector plate

remove the halogen heater lamp from the heat roller.

Halogen heater lamp

(Blue 100V, Red 200V)

Groove

Heat Roller Bearing

Idle gear 16

Heat roller

Fixing unit frame

Heat Roller Bearing

Taptite, pan

M3x10

Fig. 3-9

Note:

When re-assembling the bearing at the both ends of the heat roller, ensure that the

direction of the bearing is correct referring to the above figure.

The heat roller itself is very similar to the one for HL-1060/1070 printers. The heat

roller for the HL-820/1020/1040/1050 printers can be distinguished by the groove on

the edge of the roller. (Refer to the above figure.)

III-7

Page 57

When replacing the heat roller cleaner with a new one, attach the cleaner referring to

,

the figure below;

Follow the instructions below when installing the thermistor in the fixing unit.

-1mm ~ +1mm

4mm ~ 5mm

Fig. 3-10

i) Place the cleaner felt of the cleaner ASSY for the thermistor under the heat roller.

ii) Place the end of the thermistor on the heat roller.

iii) Insert boss1 of the thermistor into the hole of the fixing unit frame.

iv) Do no place the thermistor on boss2 of the fixing unit frame.

Boss2

Thermistor

Heat Roller

3.7 Scanner Unit

(1) Remove the three M4x12 tapping screws.

(2) Lift out the scanner unit.

Taptite, bind M4x12

Scanner Unit

Boss1

Fixing unit frame

Cleaner ASSY for thermistor

Fig. 3-11

Taptite, bind M4x12

Main cover

Panel Sensor PCB

Fig. 3-12

III-8

Page 58

Note:

When replacing the scanner unit, ensure to assemble the ferrite core using the cable

binder as follows;

Ferrite Core

Cable binder

Flat cable

LD harness

Fig. 3-13

(3) Disconnect the three connectors from the panel sensor PCB.

(4) Remove the M3x8 tapping screw, and lift the toner sensor PCB from the scanner

unit.

Caution:

Never touch the inside of the scanner unit or the mirror when disassembling or

reassembling. If there is any dirt or dust on the mirror, blow it off.

Taptite, cup M3x8

Toner Sensor PCB

Fig. 3-14

III-9

Scanner Unit

Page 59

3.8 Main PCB ASSY

(1) Remove the three M4x6 screws.

(2) Hold the hooks at the left and right of the mounting frame to pull out the main PCB

ASSY.

Screw, pan M4x6

Screw, pan M4x6

Hook

Main PCB ASSY

Hook

Fig. 3-15

3.9 Base Plate ASSY

Caution:

Prior to turning the printer upside-down, ensure that the drum unit has been removed

from the printer.

(1) Turn the printer upside down.

(2) Remove the eight M4 and five M3 self tapping screws.

Taptite, bind M4x12

Taptite, cup M3x6

Taptite, bind M4x12

Base plate ASSY

Taptite, cup M3x6

Taptite, bind M4x12

Taptite, bind M4x12

Fig. 3-16

III-10

Page 60

(3) Lift the base plate ASSY and remove the grounding screw.

y

3.10 Panel Sensor PCB ASSY

Fig. 3-17

Base Plate ASSY

Ground wire

Screw pan(washer),

M3.5x6

Low-voltage Power

Suppl

PCB ASSY

(1) Remove the main shield.

(2) Remove the M4x12 screw securing the panel sensor PCB ASSY.

Taptite, bind M4x12

Main shield

C

Panel Sensor PCB ASSY

Fig. 3-18

A

Main shield

Panel Sensor PCB ASSY

B

Note:

When re-assembling the main shield, ensure that you fit PCB A to underneath the

main shield.

When re-assembling the panel sensor PCB, ensure that you fit the PCB into hook B

and hook C first. Then, fit the two bosses to the PCB and secure the screw.

III-11

Page 61

Panel Sensor

PCB ASSY

10

9

8

7

(3) Disconnect the eight connectors from the PCB. (Three connectors have already

been disconnected when removing the scanner unit.)

1

2

3

Main frame

4

5

Fig. 3-19

6

(Name of the Harnesses)

1. Low-voltage harness

2. Erase lamp harness

3. Toner harness

4. Scan motor flat cable

5. Laser harness

6. Solenoid harness

7. Main / sub motor connector

8. Fan motor 1 harness

9. Fan motor 2 harness

10. High-voltage flat cable

Note:

When re-assembling, the cable connectors must be inserted securely into the PCB

connectors and the PCB must not be stressed by the harnesses.

The connectors should be inserted by matching the housing color and the number of

pins.

3.11 Low-voltage Power Supply PCB ASSY

(1) Remove the one M4x12 tapping screw securing the low-voltage power supply PCB

ASSY.

(2) Disconnect the two connectors for the heater harness and the LV harness from the

PCB.

Low-voltage Power Supply ASSY

Hr hrn

LV harness

Fig. 3-20

III-12

Page 62

(3) Remove the one M4x12 screw to remove the inlet holder. Then, remove the inlet

and the PCB.

Note:

When re-assembling the inlet holder and AC inlet, be sure to insert the part A of the

holder into the hole of the ferrite core.

Inlet Holder

A

AC Inlet

Main Cover

Ferrite Core

Fig. 3-21

3.12 High-voltage Power Supply PCB ASSY

(1) Remove the one M4x12 screw securing the high-voltage power supply PCB ASSY.

(2) Remove the film covering the PCB.

(2) Disconnect the HV flat cable from the PCB.

Taptite, bind

M4x12

Insulation Sheet

High-voltage Power

Supply PCB ASSY

HV flat cable

Fig. 3-22

III-13

Main Cover

Page 63

3.13 Sub Fan Motor ASSY

,

(1) Slide the sub fan motor ASSY upwards.

Manufacturer sticker side

Main Cover

Note:

When re-assembling the sub fan motor, ensure that the side on which the manufacturers

sticker is attached is facing the main frame.

Sub Fan Motor

Fig. 3-23

3.14 Main Fan Motor ASSY

(1) Remove the two M4x12 screws securing the fan motor holder.