Page 1

Brother Laser Printer

SERVICE MANUAL

MODEL

HL-2290/2295D/2590DN/2595DW/B2000D/

B2050DN/B2080DW/L2310D/L2312D/

L2325DW/L2330D/L2331D/L2335D/

L2336D/L2350DW/L2351DW/L2352DW/

L2357DW/L2370DN/L2370DW(XL)/

L2371DN/L2372DN/L2375DW/L2376DW/

L2385DW/L2386DW

Read this manual thoroughly before maintenance work.

Keep this manual in a convenient place for quick and easy reference at all times.

August 2017

SM-PRN111

84UH*

Ver.4

Confidential

Page 2

Trademarks

BROTHER is either a trademark or a registered trademark of Brother Industries, Ltd.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and/or

other countries.

Apple and Mac are trademarks of Apple Inc., registered in the U.S. and other countries.

AirPrint and the AirPrint logo are trademarks of Apple Inc.

App Store is a service mark of Apple Inc.

Wi-Fi is a registered trademark of Wi-Fi Alliance

Android is a trademark of Google Inc.

Google Play is a trademark of Google Inc.

®

.

Mopria

®

and the Mopria® Logo are registered trademarks and service marks of Mopria Alliance, Inc. in

the United States and other countries. Unauthorized use is strictly prohibited.

Each company whose software title is mentioned in this manual has a Software License Agreement

specific to its proprietary programs.

Software Trademarks

FlashFX

FlashFX

FlashFX

®

is a registered trademark of Datalight, Inc.

®

Pro™ is a trademark of Datalight, Inc.

®

Tera™ is a trademark of Datalight, Inc.

Reliance™ is a trademark of Datalight, Inc.

Reliance Nitro™ is a trademark of Datalight, Inc.

Datalight

®

is a registered trademark of Datalight, Inc.

Any trade names and product names of companies appearing on Brother products, related

documents and any other materials are all trademarks or registered trademarks of those

respective companies.

Confidential

Page 3

Open Source Licensing Remarks

This product includes open-source software.

Go to the manual download selection of your model’s home page of Brother Solutions Center at

support.brother.com

to view the Open Source Licensing Remarks and Copyright Information.

Copyright and License

©2017 Brother Industries, Ltd. All rights reserved.

This product includes software developed by the following vendors:

©1983-1998 PACIFIC SOFTWORKS, INC. ALL RIGHTS RESERVED.

©2008 Devicescape Software, Inc. All rights reserved.

This product includes the “KASAGO TCP/IP” software developed by ZUKEN ELMIC, Inc.

Copyright 1989-2014 Datalight, Inc., All Rights Reserved.

FlashFX

U.S.Patent Office 5,860,082/6,260,156

®

Copyright 1998-2014 Datalight, Inc.

Confidential

Page 4

CONTENTS

SAFETY INFORMATION

CHAPTER 1 SUPPLEMENTAL SPECIFICATIONS

1. GENERAL ................................................................................................................................... 1-1

2. NETWORK CONNECTIVITY ....................................................................................................... 1-6

3. SERVICE INFORMATION ........................................................................................................... 1-6

4. SUPPLIES ................................................................................................................................... 1-7

CHAPTER 2 ERROR INDICATIONS AND TROUBLESHOOTING

1. INTRODUCTION ......................................................................................................................... 2-1

1.1 Precautions ......................................................................................................................... 2-1

1.2 Checks before Commencing Troubleshooting .................................................................... 2-3

2. OVERVIEW ................................................................................................................................. 2-5

2.1 Cross-section Drawing ........................................................................................................ 2-5

2.2 Paper Feeding .................................................................................................................... 2-7

2.3 Operation of Each Part and Location of Parts .................................................................... 2-9

2.4 Block Diagram .................................................................................................................. 2-11

2.5 Main Components ............................................................................................................. 2-12

3. ERROR INDICATIONS .............................................................................................................. 2-13

3.1 Error Codes ...................................................................................................................... 2-13

3.2 Error Message .................................................................................................................. 2-21

3.2.1 LCD models .......................................................................................................... 2-21

3.2.2 LED Display (LED Models) ................................................................................... 2-27

4. TROUBLESHOOTING .............................................................................................................. 2-33

4.1 Error Cause and Remedy ................................................................................................. 2-33

4.2 Troubleshooting for Paper Feeding Problems .................................................................. 2-53

4.2.1 No paper feeding from paper tray ........................................................................ 2-53

4.2.2 No paper feeding from MP tray ............................................................................ 2-54

4.2.3 No paper feeding from manual feed slot .............................................................. 2-55

4.2.4 Multiple sheets of paper are fed ........................................................................... 2-55

4.2.5 Paper becomes wrinkled ...................................................................................... 2-56

4.2.6 Paper is fed at an angle ....................................................................................... 2-56

4.2.7 Paper curls ........................................................................................................... 2-57

4.2.8 Unable to perform 2-sided printing ....................................................................... 2-57

4.2.9 Paper jam ............................................................................................................. 2-58

4.3 Troubleshooting for Image Defects ................................................................................... 2-63

4.3.1 Image defect examples ........................................................................................ 2-63

4.3.2 Troubleshooting image defect .............................................................................. 2-64

i

Confidential

Page 5

4.4 Troubleshooting for Software Problems ........................................................................... 2-78

4.4.1 Unable to receive data ......................................................................................... 2-78

4.5 Troubleshooting for Network Problems ............................................................................ 2-79

4.5.1 Cannot make a print through network connection ................................................ 2-79

4.5.2 Cannot connect to access point ........................................................................... 2-79

4.6 Troubleshooting for Control Panel Problems .................................................................... 2-80

4.6.1 Nothing is displayed on the LCD .......................................................................... 2-80

4.6.2 Nothing is displayed on the LED .......................................................................... 2-80

4.6.3 Unable to perform panel operation ....................................................................... 2-80

4.7 Troubleshooting for Toner Cartridge and Drum Unit Problems ........................................ 2-81

4.7.1 New toner not detected ........................................................................................ 2-81

4.7.2 Toner cartridge not detected ................................................................................ 2-81

4.7.3 Toner replacement message displayed on LCD is not cleared ............................ 2-82

4.7.4 Drum error ............................................................................................................ 2-82

4.7.5 Drum replacement message displayed on LCD is not cleared ............................ 2-82

4.8 Troubleshooting for Fuser Unit Problems ......................................................................... 2-83

4.8.1 Fuser unit failure ................................................................................................... 2-83

4.9 Troubleshooting for Laser Unit Problems ......................................................................... 2-83

4.9.1 Laser unit failure ................................................................................................... 2-83

4.10 Troubleshooting for PCB Problems .................................................................................. 2-84

4.10.1 Main PCB failure .................................................................................................. 2-84

4.10.2 Full memory .......................................................................................................... 2-84

4.11 Troubleshooting for Other Problems ................................................................................. 2-85

4.11.1 Cannot make print ................................................................................................ 2-85

4.11.2 Cannot update firmware ....................................................................................... 2-86

4.11.3 “Paper Low” message does not disappear ........................................................... 2-86

4.11.4 Message indicating that the report is full does not disappear .............................. 2-87

4.11.5 Paper tray cannot be recognized ......................................................................... 2-87

CHAPTER 3 DISASSEMBLY/REASSEMBLY

1. SAFETY PRECAUTIONS ............................................................................................................ 3-1

2. PACKING .................................................................................................................................... 3-2

3. SCREW CATALOGUE ................................................................................................................ 3-3

4. SCREW TORQUE LIST .............................................................................................................. 3-4

5. LUBRICATION ............................................................................................................................ 3-6

6. OVERVIEW OF GEARS .............................................................................................................. 3-7

7. HARNESS ROUTING .................................................................................................................. 3-9

8. DISASSEMBLY FLOW CHART ................................................................................................ 3-16

9. DISASSEMBLY PROCEDURE ................................................................................................. 3-17

9.1 Preparation ....................................................................................................................... 3-17

9.2 Back cover ........................................................................................................................ 3-18

ii

Confidential

Page 6

9.3 Outer chute ASSY ............................................................................................................ 3-19

9.4 Front cover ASSY / Support flap ....................................................................................... 3-20

9.5 Side cover R ..................................................................................................................... 3-23

9.6 Fuser cover ....................................................................................................................... 3-24

9.7 Inner chute ASSY ............................................................................................................. 3-25

9.8 Side cover L ...................................................................................................................... 3-26

9.9 Top cover ASSY ............................................................................................................... 3-27

9.10 Fuser unit .......................................................................................................................... 3-31

9.11 Low-voltage power supply PCB ASSY ............................................................................. 3-33

9.12 New toner sensor PCB ASSY ........................................................................................... 3-35

9.13 HVPS flat cable / High-voltage power supply PCB ASSY ................................................ 3-36

9.14 Fan ................................................................................................................................... 3-38

9.15 Relay PCB ASSY (For toner box models and MP models) /

Toner box new PCB ASSY (For models with toner box) .................................................. 3-39

9.16 Laser unit flat cable / Laser unit ........................................................................................ 3-41

9.17 Filter .................................................................................................................................. 3-43

9.18 Wireless LAN PCB (Only for wireless network models) ................................................... 3-44

9.19 Roller holder ASSY ........................................................................................................... 3-45

9.20 Main PCB ASSY ............................................................................................................... 3-46

9.21 T1 clutch / Registration clutch ........................................................................................... 3-47

9.22 Frame L unit ...................................................................................................................... 3-50

9.23 Paper feed motor / Paper feed motor flat cable ................................................................ 3-53

9.24 Fuser gear 64R/36R ......................................................................................................... 3-55

9.25 Toner sensor PCB ASSY (Only for models with Toner box) ............................................ 3-56

9.26 Front cover sensor ............................................................................................................ 3-57

9.27 Eject sensor PCB ASSY ................................................................................................... 3-58

9.28 Registration front/rear actuator holder ASSY ................................................................... 3-60

9.29 Paper feed roller ASSY / Paper feed sensor PCB ASSY ................................................. 3-63

CHAPTER 4 ADJUSTING AND UPDATING SETTINGS AS

REQUIRED AFTER PARTS REPLACEMENT

1. IF YOU REPLACE THE MAIN PCB ASSY ................................................................................. 4-1

1.1 Setting by Spec .................................................................................................................... 4-2

1.2 Installing Firmware (Sub firmware and main firmware) ...................................................... 4-4

1.2.1 Checking firmware version ..................................................................................... 4-4

1.2.2 Installing firmware .................................................................................................. 4-5

1.3 Setting Serial Number and Entering Adjusted Value of Laser Unit ..................................... 4-6

2. IF YOU REPLACE THE LOW-VOLTAGE POWER SUPPLY PCB ASSY ................................. 4-9

2.1 Reset Irregular Power Supply Detection Counter of

the Low-voltage Power Supply PCB ................................................................................... 4-9

3. IF YOU REPLACE THE LASER UNIT ...................................................................................... 4-10

3.1 Entering Adjusted Value of Laser Unit .............................................................................. 4-11

iii

Confidential

Page 7

CHAPTER 5 SERVICE FUNCTIONS

1. MAINTENANCE MODE ............................................................................................................... 5-1

1.1 How to Enter Maintenance Mode ....................................................................................... 5-1

1.1.1 Method of entering maintenance mode for service personnel ............................... 5-1

1.1.2 Method of entering end-user accessible maintenance mode ................................. 5-2

1.2 List of Maintenance Mode Functions .................................................................................. 5-3

1.2.1 List of maintenance mode functions for LCD models ............................................. 5-3

1.2.2 List of maintenance mode functions using [Go] (LED models) .............................. 5-4

1.3 Details of Maintenance Mode Functions for LCD Models ................................................... 5-6

1.3.1 Initialize EEPROM parameters (Function code 01, 91) .......................................... 5-6

1.3.2 Transition to shipping state (Function code 03) ..................................................... 5-7

1.3.3 Monochrome print quality test pattern (Function code 09) ..................................... 5-9

1.3.4 Set worker switches (WSW) and

print worker switch setting data (Function code 10, 11) ....................................... 5-10

1.3.5 Check LCD operation (Function code 12) ............................................................ 5-13

1.3.6 Check control panel key operation (Function code 13) ........................................ 5-14

1.3.7 Display software version (Function code 25) ....................................................... 5-15

1.3.8 Check sensor operation (Function code 32) ........................................................ 5-16

1.3.9 Display LAN connection status (Function code 33) .............................................. 5-17

1.3.10 Change USB No. return value / Adjust left-end print position /

Adjust upper-end print position /

Change ON/OFF setting for lower case compensation /

Change ON/OFF setting for fixation strength improvement

(Function code 45) ............................................................................................... 5-18

1.3.11 Check toner cartridge (Models with cartridge sensor only) (Function code 57) ... 5-22

1.3.12 Continuous print test (Function code 67) ............................................................. 5-24

1.3.13 Print frame pattern (single-side printing) (Function code 69) ............................... 5-28

1.3.14 Print frame pattern (duplex printing) (Function code 70) ...................................... 5-29

1.3.15 Print test pattern (Function code 71) .................................................................... 5-30

1.3.16 Setting by spec (Function code 74) ...................................................................... 5-33

1.3.17 Print maintenance information (Function code 77) ............................................... 5-36

1.3.18 Check fan operation (Function code 78) .............................................................. 5-38

1.3.19 Display machine log information (Function code 80) ........................................... 5-39

1.3.20 Display machine error code (Function code 82) ................................................... 5-41

1.3.21 Reset irregular power supply detection counter of

low-voltage power supply PCB (Function code 88) .............................................. 5-41

1.3.22 Quit maintenance mode (Function code 99) ........................................................ 5-41

1.4 Details of Maintenance Mode Functions Using [Go] (LED models) .................................. 5-42

1.4.1 Test printing .......................................................................................................... 5-42

1.4.2 Change USB No. return value .............................................................................. 5-43

1.4.3 Factory reset / Settings reset ............................................................................... 5-43

1.4.4 Engine error ignore mode ..................................................................................... 5-44

1.4.5 Check sensor operation ....................................................................................... 5-45

iv

Confidential

Page 8

1.4.6 Print continuous lattice pattern ............................................................................. 5-46

1.4.7 Check RAM .......................................................................................................... 5-46

1.4.8 Change ON/OFF setting for duplex printing ......................................................... 5-47

1.4.9 Change A4/Letter setting for paper size ............................................................... 5-47

1.4.10 Maintenance printing ............................................................................................ 5-48

1.4.11 Print maintenance data and frame pattern ........................................................... 5-49

1.4.12 Resetting to factory shipping state ....................................................................... 5-50

1.4.13 Change Ready LED light intensity in sleep mode ................................................ 5-50

1.4.14 Reset irregular power supply detection counter of

low-voltage power supply PCB ............................................................................. 5-51

1.4.15 Firmware installing mode ..................................................................................... 5-51

1.4.16 Ready state of maintenance mode for service personnel .................................... 5-51

2. OTHER SERVICE FUNCTIONS ................................................................................................ 5-52

2.1 Print Printer Settings ......................................................................................................... 5-52

2.2 Drum Cleaning .................................................................................................................. 5-54

2.3 Resetting Drum Counter ................................................................................................... 5-56

2.4 Change Active/Inactive Setting for Quiet Mode (LED models only) ................................. 5-56

2.5 Change Active/Inactive Setting for Auto Power Down Mode (LED models only) ............. 5-57

2.6 Change Active/Inactive Setting for Eco Mode (LED models only) .................................... 5-57

2.7 Change Active/Inactive Setting for Toner Save Mode (LED models only) ....................... 5-57

2.8 Change Continue/Stop Mode for Toner Cartridge (LED models only) ............................. 5-58

CHAPTER 6 WIRING DIAGRAM

1. WIRING DIAGRAM ..................................................................................................................... 6-1

CHAPTER 7 PERIODICAL MAINTENANCE

1. PERIODICAL REPLACEMENT PARTS ..................................................................................... 7-1

APPENDIX 1 SERIAL NUMBERING SYSTEM

APPENDIX 2 DELETING USER SETTING INFORMATION

APPENDIX 3 INSTALLING THE MAINTENANCE PRINTER DRIVER

v

Confidential

Page 9

SAFETY INFORMATION

Definitions of Warnings, Cautions, Notes and Memos

The following conventions are used in this manual:

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injuries.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injuries.

IMPORTANT

IMPORTANT indicates a potentially hazardous situation which, if not avoided, may result

in damage to property or loss of product functionality.

Prohibition icons indicate actions that must not be performed.

Electrical Hazard icons alert you to possible electrical Shock.

Fire Hazard icons alert you to the possibility of a fire.

Hot Surface icons warn you not to touch product parts that are hot.

Note Notes tell you how you should respond to a situation that may arise or give tips

about how the operation works with other features.

vi

Confidential

Page 10

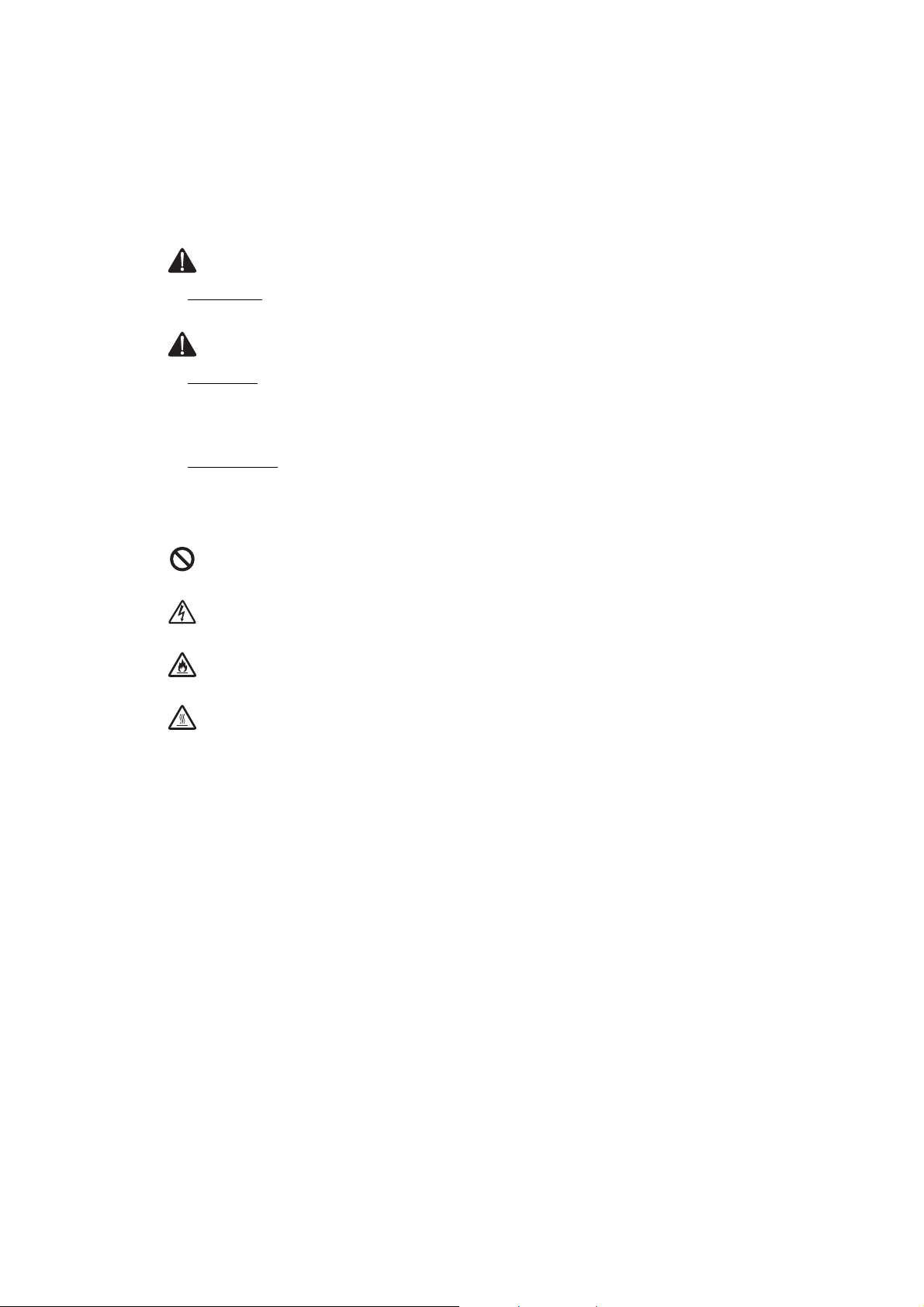

To use the Machine Safely

Please keep these instructions for later reference and read them before attempting any

maintenance. If you do not follow these safety instructions, there is a possibility of a fire,

electrical shock, burn or suffocation.

WARNING

ELECTRICAL HAZARDS

Failure to follow the warnings in this section may create the risk of an electrical shock. In

addition, you could create an electrical short, which may create the risk of a fire.

There are high voltage electrodes inside the product. Before you access the inside of the

product, including for routine maintenance such as cleaning, make sure you have

unplugged the power cord from the AC power outlet, as well as Ethernet (RJ-45) cables

(Network models only) from the product. DO NOT push objects of any kind into this

product through slots or openings in the product, as they may touch dangerous voltage

points or short-out parts.

DO NOT handle the plug with wet hands.

DO NOT use this product during an electrical storm.

Always make sure the plug is fully inserted. DO NOT use the product or handle the cord if

the cord has become worn or frayed.

DO NOT allow this product to come into contact with water.

This product should be connected to an AC power source within the range indicated on

the rating label. DO NOT connect it to a DC power source or inverter.

WARNING

When removing the Low-voltage power supply, do not touch it

within 3 minutes after disconnecting the AC cord as it may cause

an electric shock due to the electric charge accumulated in the

capacitor.

vii

Confidential

Page 11

Power Cord Safety:

• This product is equipped with a 3-wire grounded plug. This plug will only fit into a

grounded power outlet. This is a safety feature. DO NOT attempt to defeat the purpose

of the grounded plug.

• DO NOT pull on the middle of the AC power cord; pulling on the middle may cause the

cord to separate from the plug. Doing this might cause an electrical shock.

• Only use the power cord supplied with this product (for certain models only).

• DO NOT use any undesignated cables (or optional devices). It may cause a fire or

injuries. Installation must be performed properly according to the user's guide.

• This product should be positioned so that nothing pinches or constricts the power cord.

• DO NOT allow anything to rest on the power cord.

• DO NOT place this product where people may step on the cord.

• DO NOT place this product in a position where the cord is stretched or strained, as it

may become worn or frayed.

• DO NOT use the product if the power cord is frayed or damaged. Doing so may cause

an electrical shock or fire.

• Brother strongly recommends that you DO NOT use any type of extension cord.

• DO NOT drop any metallic hardware or any type of liquid on the power plug of the

product. It may cause an electrical shock or a fire.

DO NOT put a toner cartridge or a toner cartridge and drum unit assembly into a fire. It

could explode, resulting in injuries.

DO NOT use flammable substances, any type of spray, or an organic solvent/liquid

containing alcohol or ammonia to clean the inside or outside of the product. Doing so

could cause a fire or electrical shock. Instead, use only a dry, lint-free cloth.

DO NOT attempt to operate this product when a paper jam or stray pieces of paper are

inside the product. Prolonged contact of the paper with the fuser unit could cause a fire.

DO NOT use a vacuum cleaner to clean up scattered toner. Doing this might cause the

toner dust to ignite inside the vacuum cleaner, potentially starting a fire. Carefully clean the

toner dust with a dry, lint-free soft cloth and dispose of it according to local regulations.

viii

Confidential

Page 12

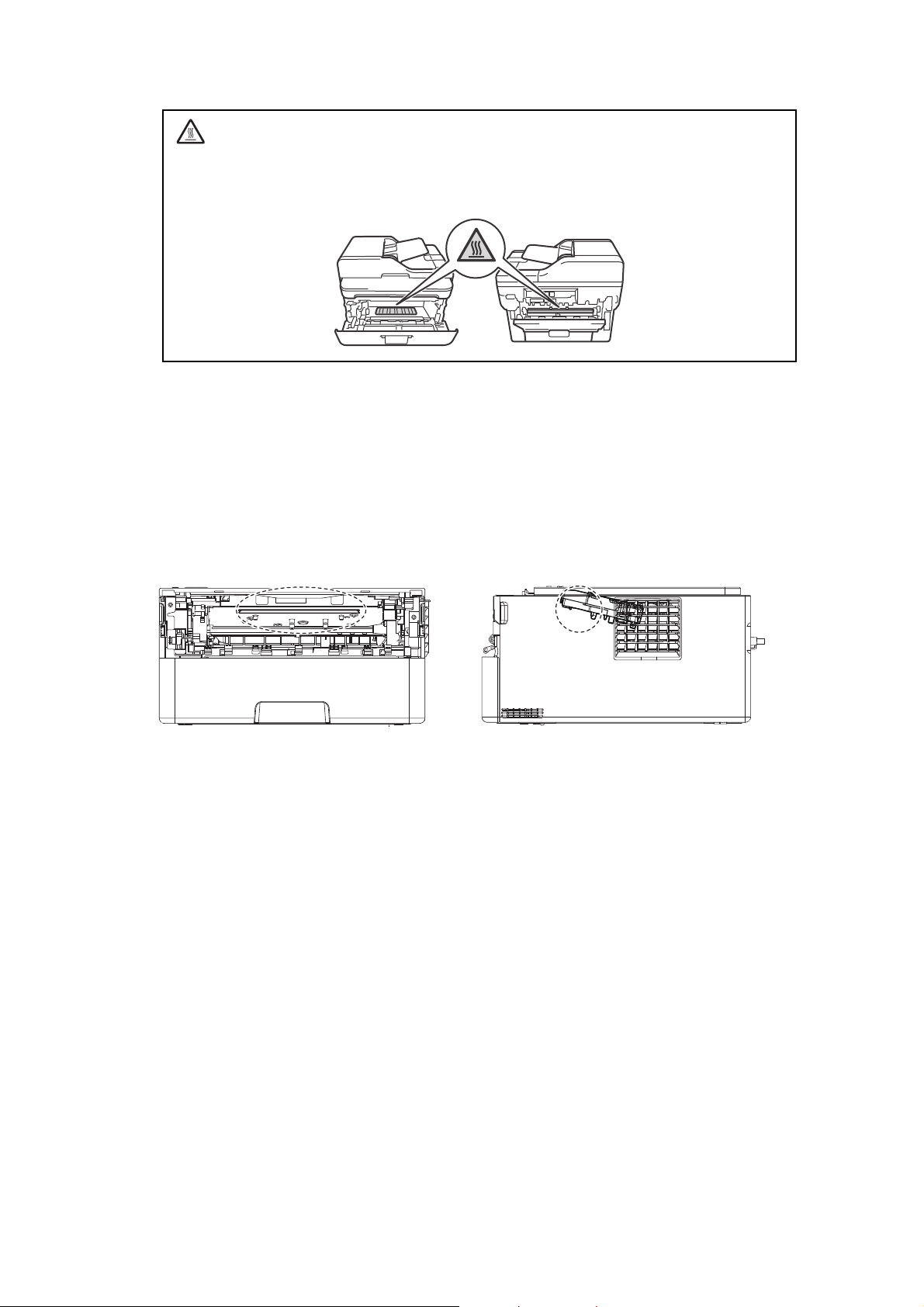

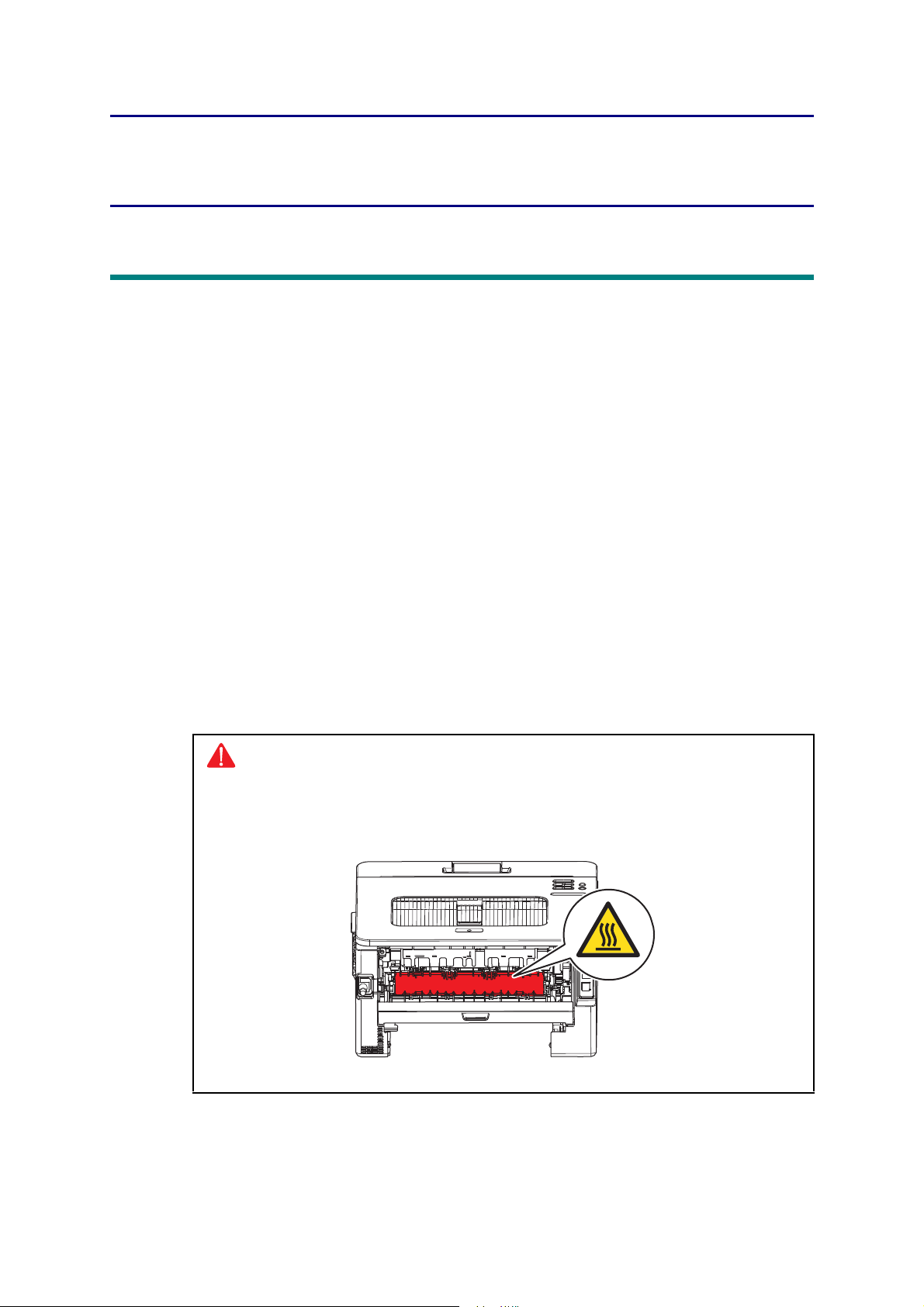

HOT SURFACE

<Location of the laser beam window>

Immediately after using the product, some internal parts of the product will be extremely

hot. Wait at least 10 minutes for the product to cool down before you touch the internal

parts of the product.

Caution for Laser Product (WARNHINWEIS für Laserdrucker)

CAUTION: In case of any trouble with the laser unit, replace the laser unit itself. To

prevent direct exposure to the laser beam, do not try to open the enclosure

of the laser unit.

ACHTUNG: Im Falle von Störungen der Lasereinheit muß diese ersetzt werden. Das

Gehäuse der Lasereinheit darf nicht geöffnet werden, da sonst

Laserstrahlen austreten können.

ix

Confidential

Page 13

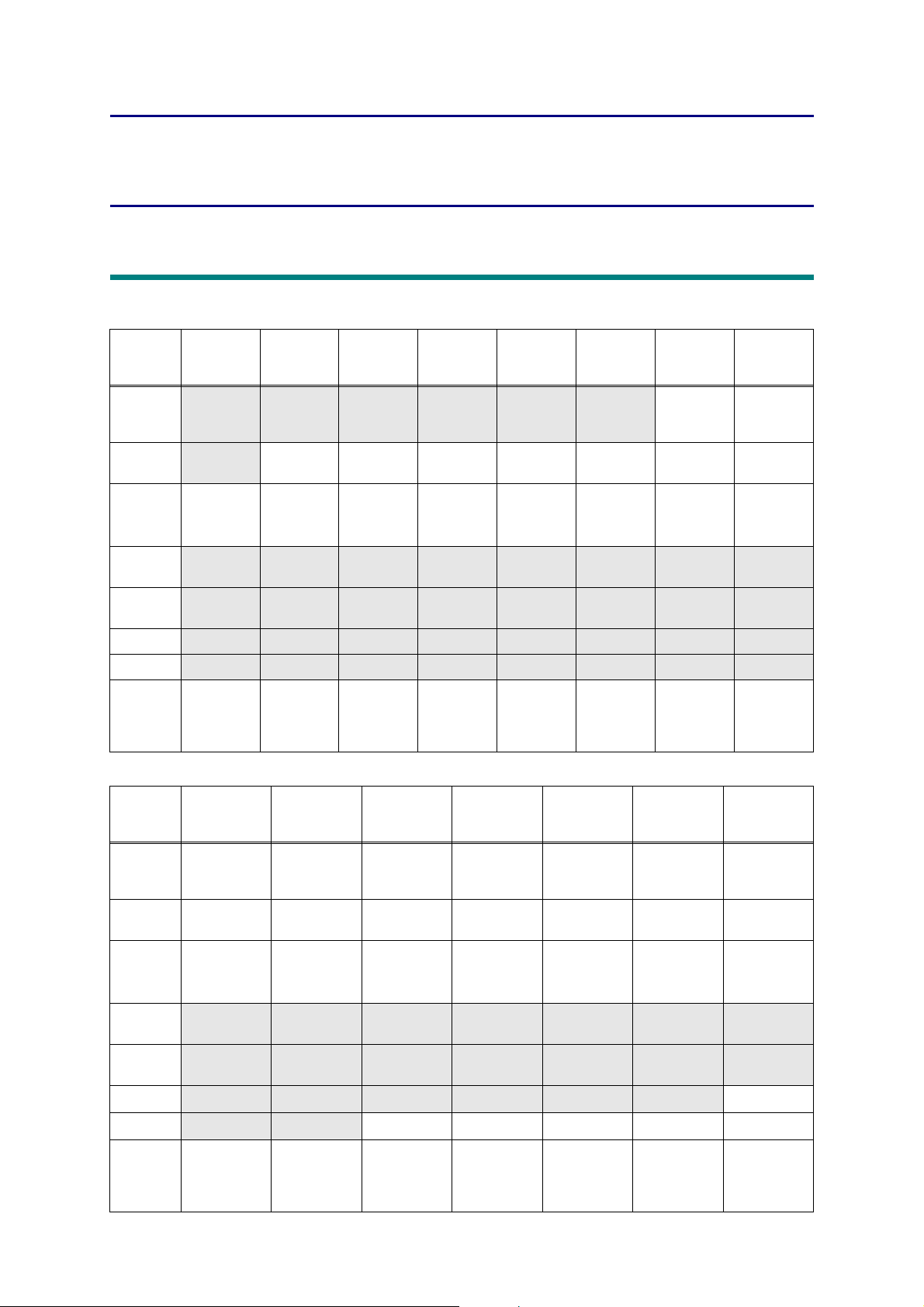

Additional Information

When servicing the optical system of the machine, be careful not to place a screwdriver or

other reflective object in the path of the laser beam. Be sure to take off any personal

accessories such as watches and rings before working on the machine. A reflected beam,

though invisible, can permanently damage the eyes.

Since the beam is invisible, the following caution in print is attached on the laser unit.

x

Confidential

Page 14

CHAPTER 1 SUPPLEMENTAL

SPECIFICATIONS

1. GENERAL

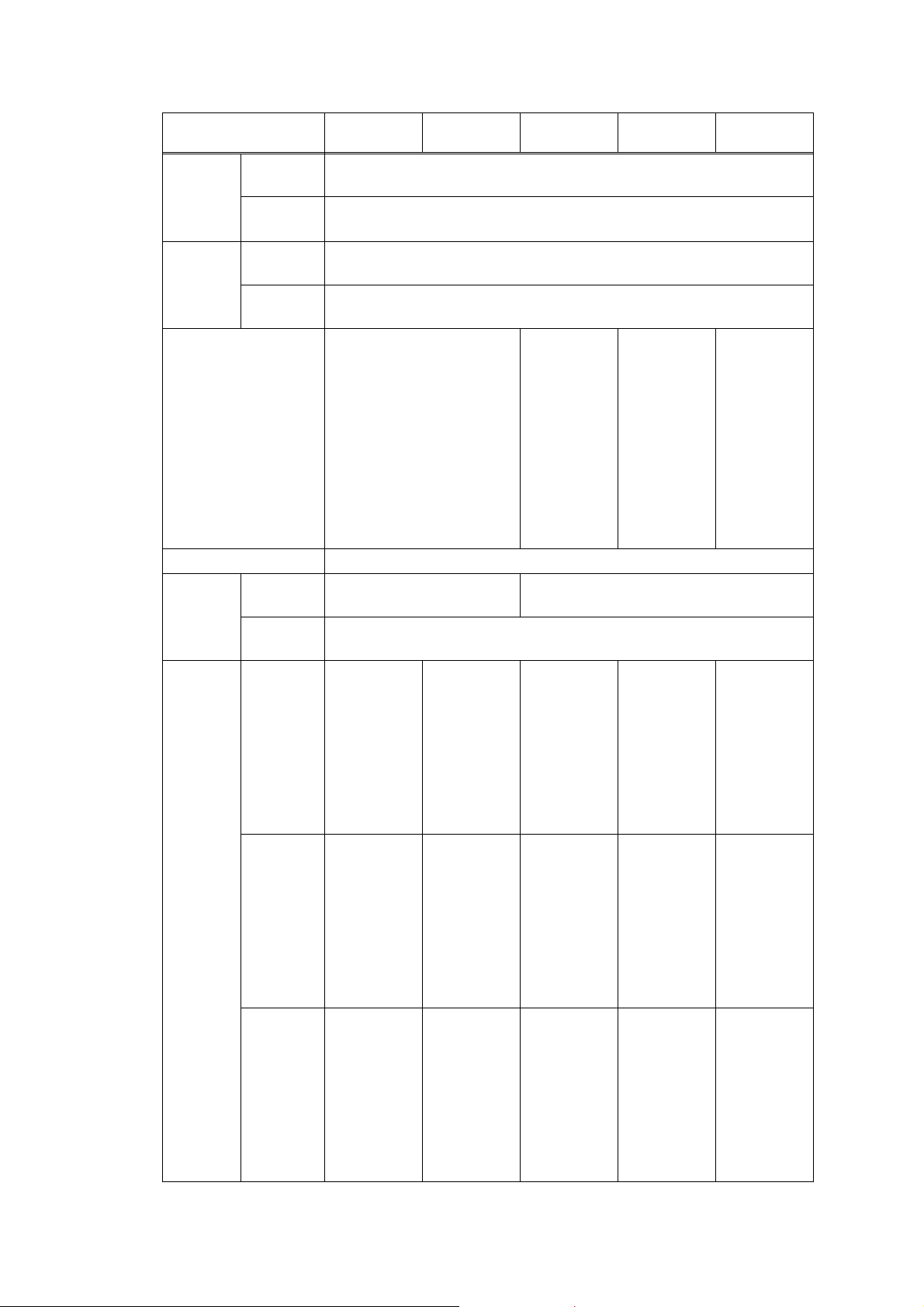

The function comparative table for models as described in this Service Manual are shown below.

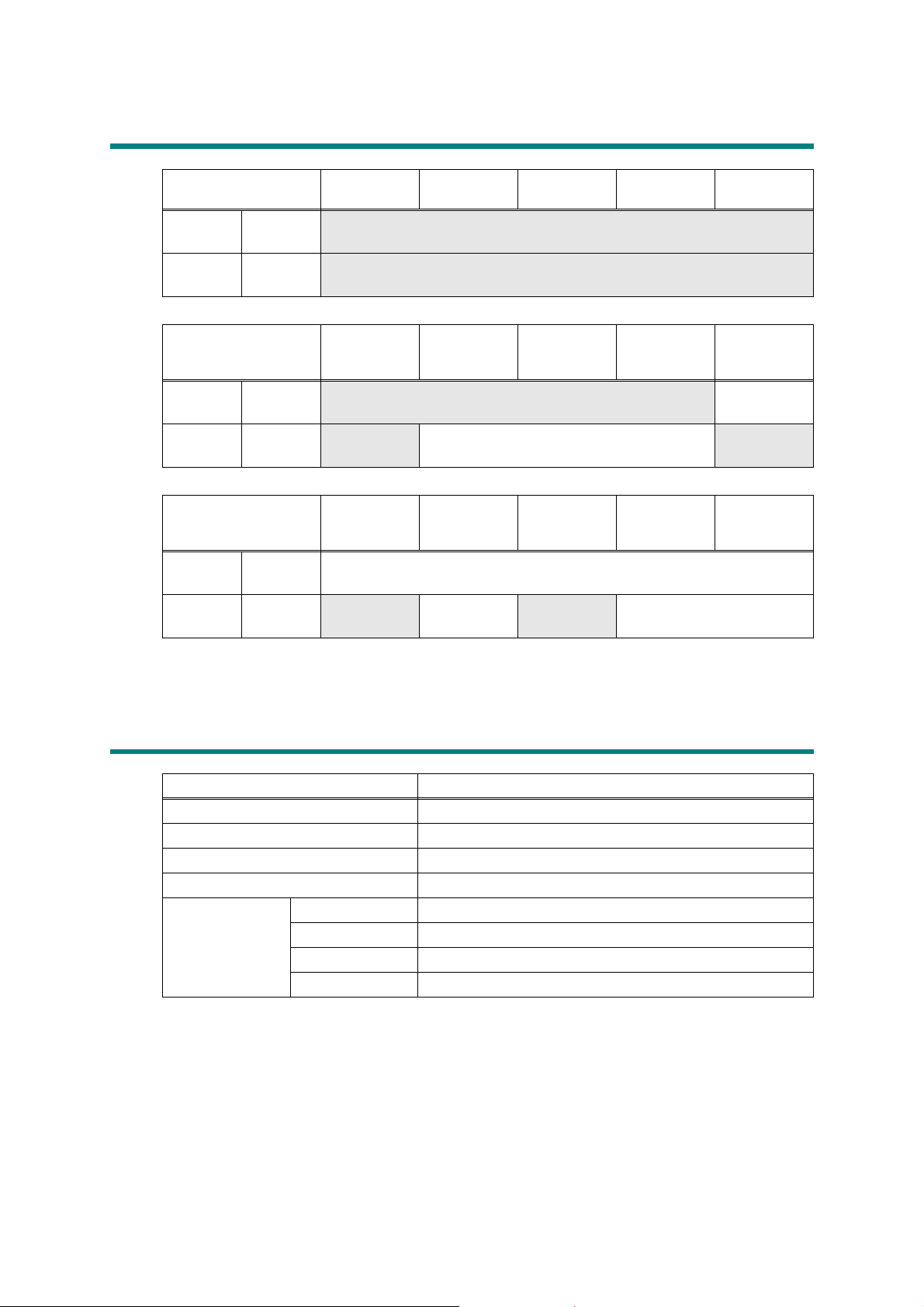

Model HL-2290 HL-2295D

Wired/

Wireless

LAN

Duplex

Printing

LCD Type

USB Host

(front)

USB Host

(rear)

NFC

PCL/PS

Paper

Input/

Standard

Tray

N/A N/A N/A N/A N/A N/A Wireless Wireless

N/A

LED LED LED LED LED LED

N/A N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A N/A

250 sheets 250 sheets 250 sheets 250 sheets 250 sheets 250 sheets 250 sheets 250 sheets

HL-L2310D

HL-L2312D

HL-L2330D

HL-L2331D

HL-L2335D

HL-L2336D

HL-B2000D

HL-L2350DW

HL-L2351DW

HL-L2352DW

16 characters

x

1 line

HL-L2357DW

16 characters

x

1 line

HL-L2370DN

Model

Wired/

Wireless

LAN

Duplex

Printing

LCD Type

USB Host

(front)

USB Host

(rear)

NFC

PCL/PS

Paper

Input/

Standard

Tray

Specifications are subject to change without notice.

HL-L2325DW

Wireless Wired Wired

HL-2590DN

16 characters

x

1 line

N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

N/A N/A

250 sheets 250 sheets 250 sheets 250 sheets 250 sheets 250 sheets 250 sheets

16 characters

x

1 line

HL-L2371DN

HL-L2372DN

16 characters

x

1 line

HL-L2370DW(XL)

HL-L2375DW

HL-L2376DW

Wired/

Wireless

16 characters

x

1 line

HL-B2050DN

Wired

16 characters

x

1 line

HL-B2080DW

Wired/

Wireless

16 characters

x

1 line

HL-L2385DW

HL-L2386DW

HL-2595DW

Wired/

Wireless

16 characters

x

1 line

1-1

Confidential

Page 15

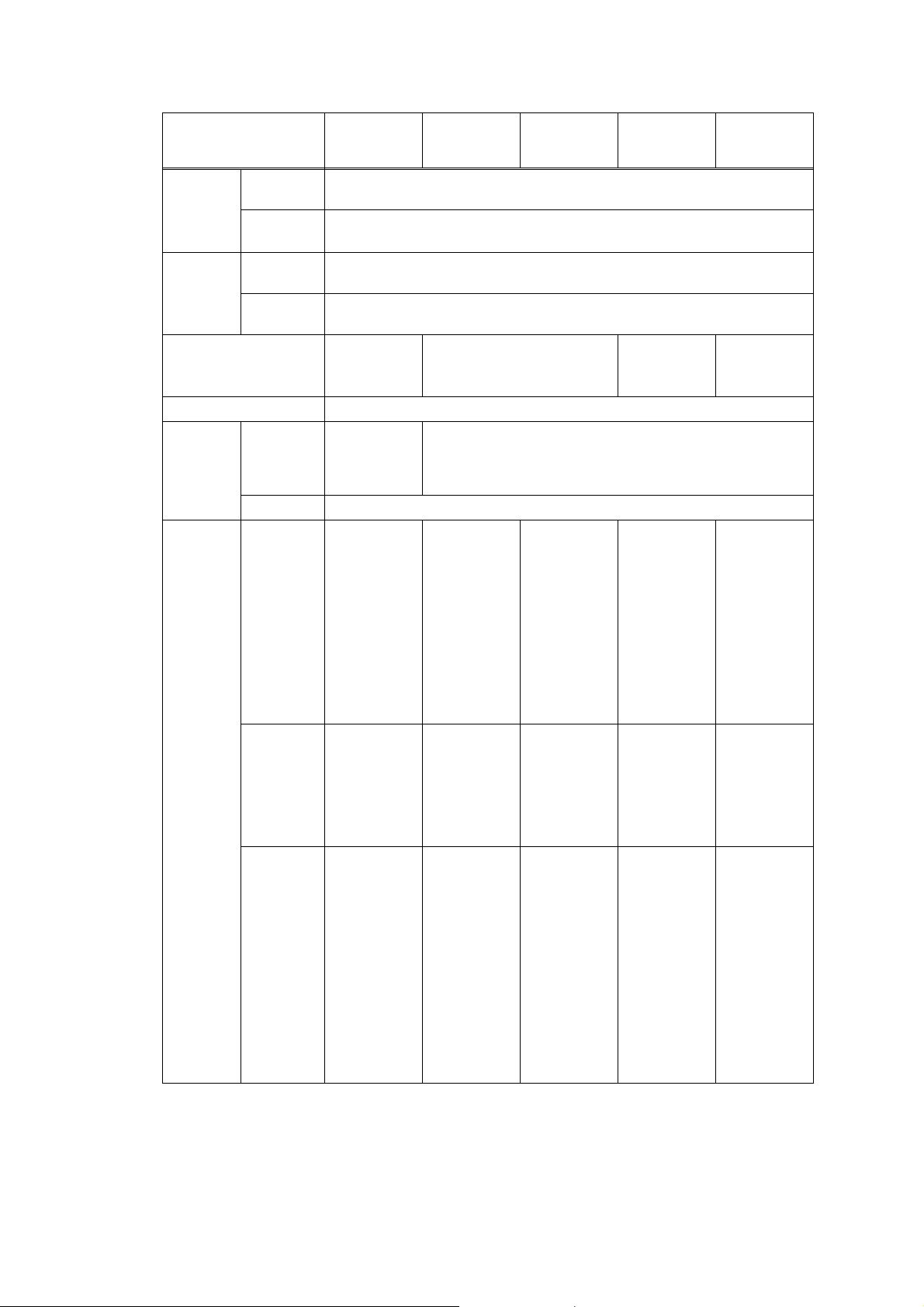

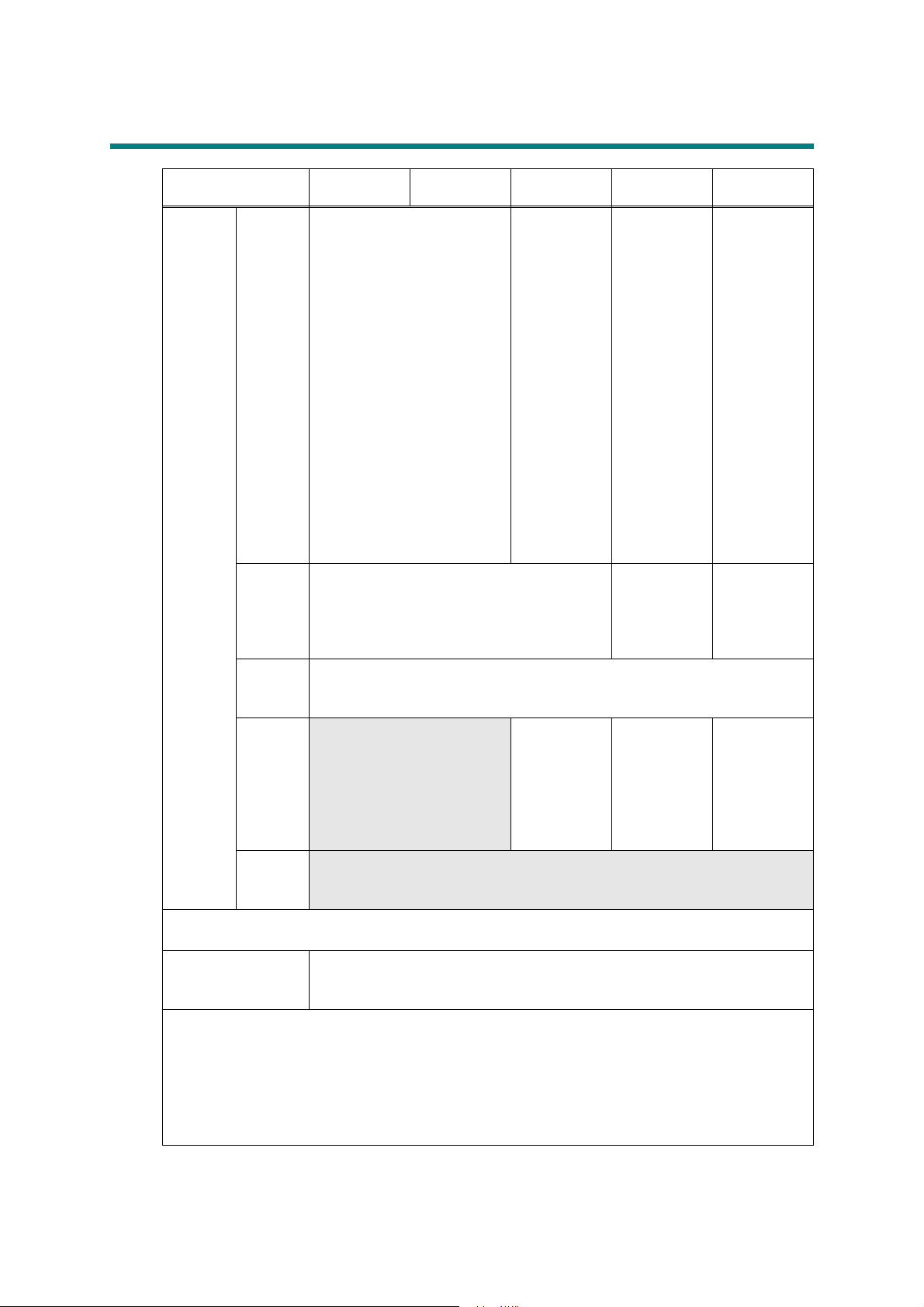

Model HL-2290 HL-2295D

Warm-up

time

From Sleep

mode

From Power

OFF

ON

First print

time

From Ready

mode

From Sleep

mode

Printing speed (A4/Letter)

CPU

Dimensions

Carton size

(W x D x H)

Machine

size

Weights with Carton

without

Carton with

toner/drum

HL-L2310D

HL-L2312D

HL-L2330D

HL-L2331D

Less than 9 seconds at 73.4F / 50% (23°C / 50%)

Less than 26 seconds at 73.4F / 50% (23°C / 50%)

Less than 8.5 seconds at 73.4F (23°C)

Less than 17.5 seconds at 73.4F (23°C)

Up to 30/32 ppm

(Quiet Mode:

Up to 13/13 ppm)

Up to 28/28 ppm

(Engine spec:

Up to 30/32 ppm)

Up to 30/32 ppm

(Quiet Mode:

Up to 13/13 ppm)

(Quiet Mode:

Up to 13/13 ppm)

(for the USA)

Up to 30/32 ppm

(Quiet Mode:

Up to 13/13 ppm)

(except for the

USA)

600 MHz

444 x 449 x 366 mm

(17.5" x 17.7" x 14.4")

438 x 283 x 519 mm

(17.2" x 11.1" x 20.4")

356 x 360 x 183 mm

(14.0" x 14.2" x 7.2")

TBD TBD

8.3 kg / 18.2 lb

(for HL-L2310D)

8.5 kg / 18.7 lb

(for HL-L2312D)

8.3 kg / 18.2 lb

(HL-L2330D for

the USA)

TBD

(HL-L2330D for

Latin America,

and HL-L2331D)

TBD TBD

7.2 kg / 15.9 lb

7.2 kg / 15.9 lb

(HL-L2330D for

the USA)

HL-L2335D

HL-L2336D

Up to 34/36 ppm

(Quiet Mode:

Up to 13/13 ppm)

8.4 kg / 18.4 lb

(HL-L2335D for

Korea)

9.0 kg / 19.9 lb

(HL-L2335D for

Gulf)

TBD

(for HL-L2336D)

7.2 kg / 15.9 lb

(HL-L2335D for

Korea)

without

TBD TBD

Carton nor

toner/drum

Specifications are subject to change without notice.

1-2

6.3 kg / 13.9 lb

(for HL-L2310D)

6.1 kg / 13.4 lb

(for HL-L2312D)

TBD

(HL-L2330D for

Latin America,

and HL-L2331D)

7.4 kg / 16.3 lb

(HL-L2335D for

Gulf)

TBD

(for HL-L2336D)

6.3 kg / 13.9 lb

(HL-L2330D for

the USA)

TBD

(HL-L2330D for

Latin America,

and HL-L2331D)

6.3 kg / 13.9 lb

(HL-L2335D for

Korea)

6.1 kg / 13.4 lb

(HL-L2335D for

Gulf)

TBD

(for HL-L2336D)

Confidential

Page 16

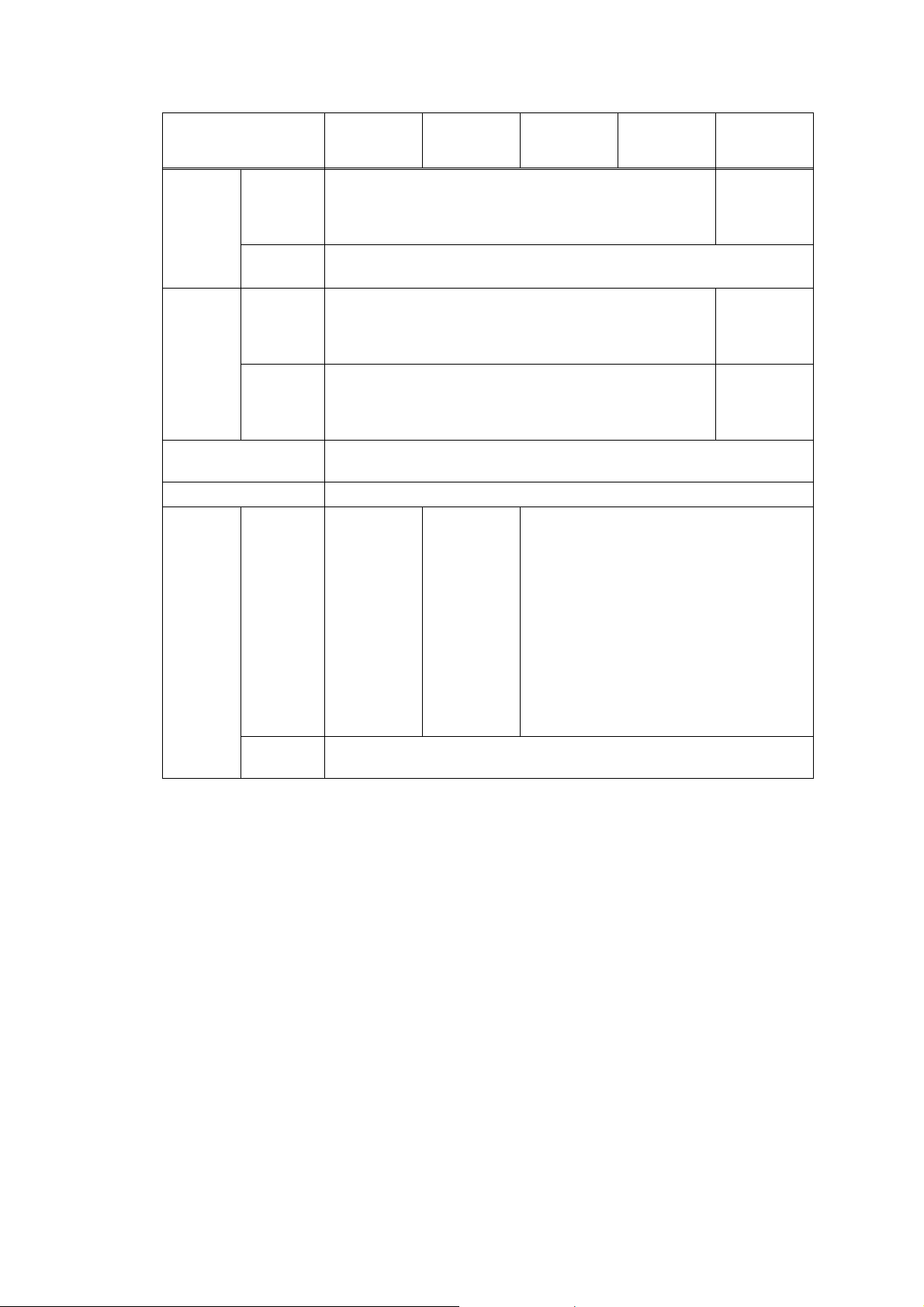

Model HL-B2000D

Warm-up

time

First print

time

From Sleep

mode

From Power

OFF

ON

From Ready

mode

From Sleep

Less than 9 seconds at 73.4F / 50% (23°C / 50%)

Less than 26 seconds at 73.4F / 50% (23°C / 50%)

Less than 8.5 seconds at 73.4F (23°C)

Less than 17.5 seconds at 73.4F (23°C)

mode

Printing speed (A4/Letter)

Up to 34/36 ppm

(Quiet Mode:

Up to 13/13 ppm)

CPU

Dimensions

(W x D x H)

Carton size

600 MHz

444 x 449 x

366 mm

(17.5" x 17.7" x

14.4")

Machine size

356 x 360 x 183 mm (14.0" x 14.2" x 7.2")

Weights with Carton 9.0 kg / 19.9 lb

HL-L2350DW

HL-L2351DW

HL-L2357DW HL-L2325DW

HL-L2352DW

Up to 30/32 ppm

(Quiet Mode: Up to 13/13 ppm)

438 x 283 x 519 mm

(17.2" x 11.1" x 20.4")

8.3 kg / 18.2 lb

8.5 kg / 18.7 lb

(for HL-L2350DW)

HL-2590DN

Up to 24 ppm (LTR)

(Quiet Mode:

Up to 13 ppm)

Up to 34/36 ppm

(Quiet Mode:

Up to 13/13 ppm)

TBD TBD

without

Carton with

toner/drum

without

Carton nor

toner/drum

7.4 kg / 16.3 lb

6.5 kg / 14.3 lb

8.3 kg / 18.4 lb

(for HL-L2351DW)

8.5 kg / 18.7 lb

(for HL-L2352DW)

TBD

(for HLL2350DWR)

7.2 kg / 15.9 lb

(except for

HL-L2350DWR)

TBD

(for HLL2350DWR)

6.3 kg / 13.9 lb

(HL-L2350DW

for the USA, and

HL-L2351DW)

6.1 kg / 13.4 lb

(except for

HL-L2350DW

for the USA, and

HL-L2352DW)

7.2 kg / 15.9 lb

6.1 kg / 13.4 lb

TBD TBD

TBD TBD

TBD

(for HLL2350DWR)

Specifications are subject to change without notice.

1-3

Confidential

Page 17

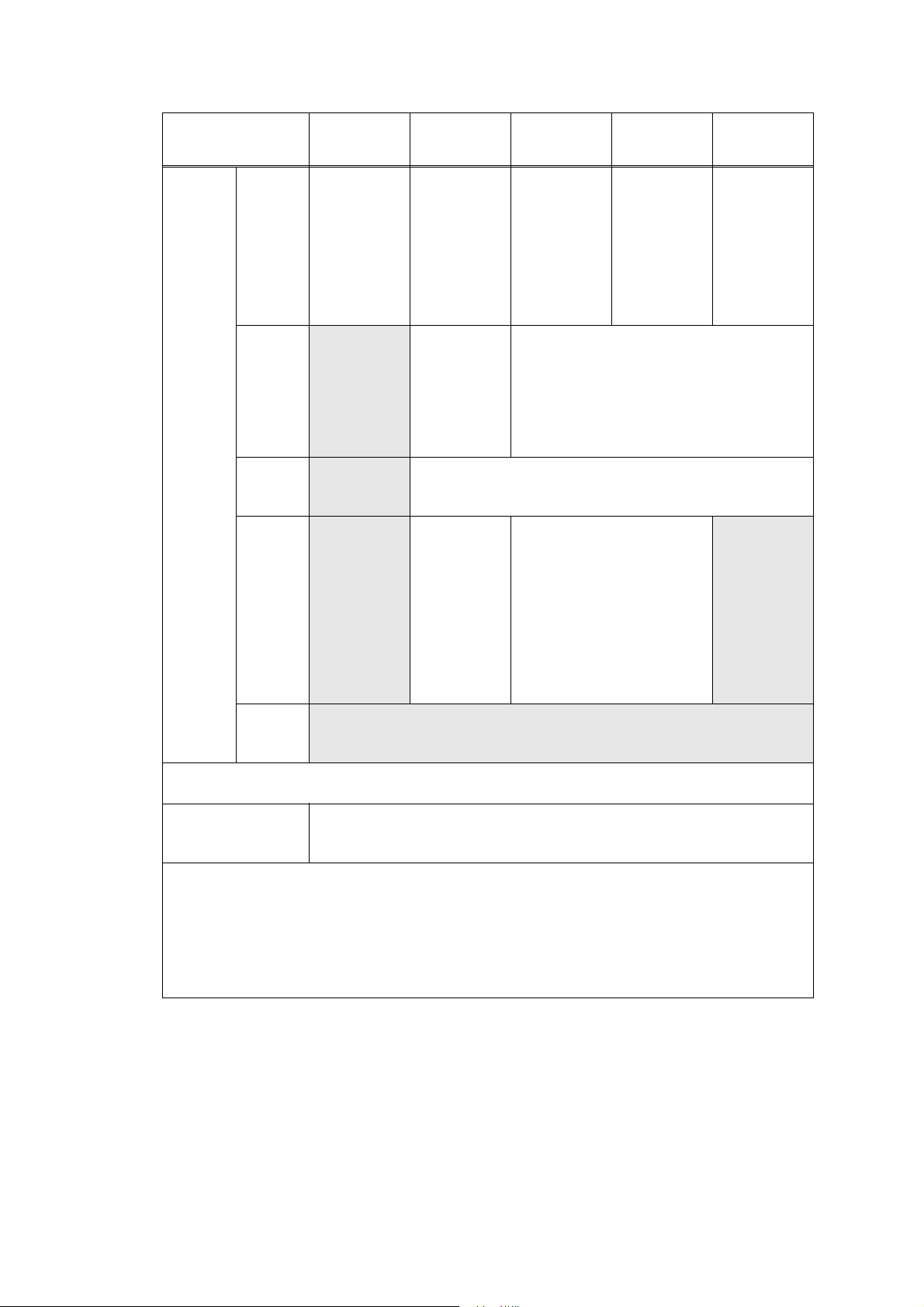

Model

Warm-up

time

From Sleep

mode

From Power

ON

First print

time

OFF

From Ready

mode

From Sleep

mode

Printing speed (A4/Letter)

CPU

Dimensions

Carton size

(W x D x H)

HL-L2370DN

HL-L2371DN

HL-L2372DN

HL-L2370DW(XL)

HL-L2375DW

HL-L2376DW

HL-B2050DN HL-B2080DW

Less than 9 seconds at 73.4F / 50% (23°C / 50%)

Less than 26 seconds at 73.4F / 50% (23°C / 50%)

Less than 8.5 seconds at 73.4F (23°C)

Less than 17.5 seconds at 73.4F (23°C)

Up to 34/36 ppm

(Quiet Mode: Up to 13/13 ppm)

600 MHz

438 x 283 x

519 mm

(17.2" x 11.1" x

20.4")

438 x 283 x

519 mm

(17.2" x 11.1" x

20.4")

444 x 449 x 366 mm

(17.5" x 17.7" x 14.4")

(except for HLL2370DW(XL))

HL-L2385DW

HL-L2386DW

HL-2595DW

Less than 4

seconds at

73.4F / 50%

(23°C / 50%)

Less than 7

seconds at

73.4F (23°C) /

230V

Less than 11

seconds at

73.4F (23°C) /

230V

Machine

size

444 x 449 x

366 mm

(17.5" x 17.7" x

14.4")

(for HLL2370DW(XL))

356 x 360 x 183 mm

(14.0" x 14.2" x 7.2")

1-4

Confidential

Page 18

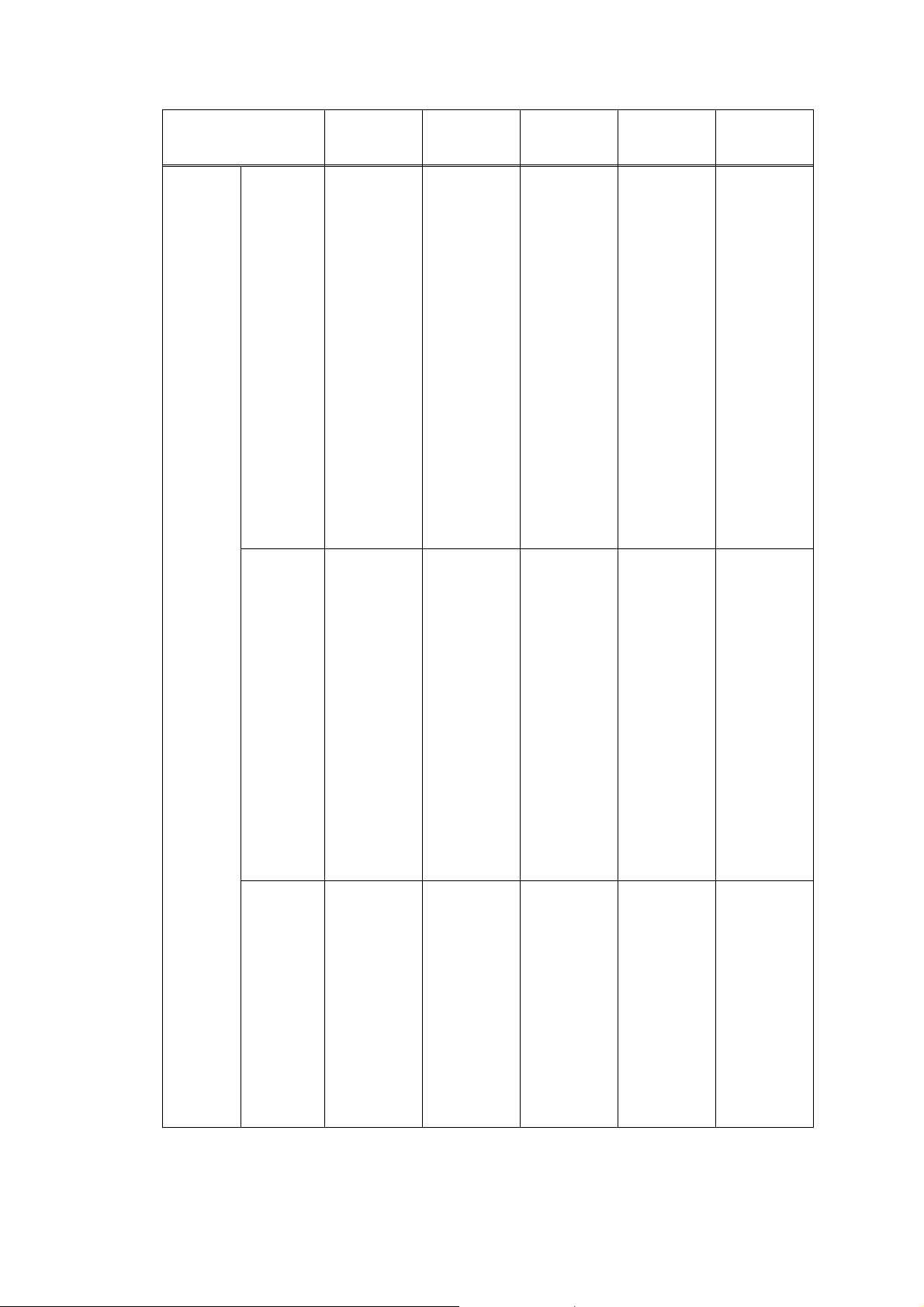

Model

Weights with Carton

HL-L2370DN

HL-L2371DN

HL-L2372DN

8.3 kg / 18.2 lb

(HL-L2370DN

for Europe and

HL-L2371DN for

Europe)

HL-L2370DW(XL)

HL-L2375DW

HL-L2376DW

8.3 kg / 18.2 lb

(HL-L2370DW for

the USA, and

except for

HL-L2375DW for

Asia)

8.5 kg / 18.7 lb

(for HL-

L2372DN)

TBD

(HL-L2370DW for

Latin America)

9.0 kg / 19.9 lb

(HL-L2370DN

for Asia)

9.3 kg / 20.5 lb

(for HL-

L2370DWXL)

TBD

(HL-L2370DN

for Russia and

HL-L2371DN for

9.0 kg / 19.9 lb

(HL-L2375DW for

Asia)

Asia)

8.4 kg / 18.4 lb

(for HL-

L2376DW)

without

Carton with

toner/drum

7.2 kg / 15.9 lb

(HL-L2370DN

for Europe,

HL-L2371DN for

Europe, and

HL-L2372DN)

7.2 kg / 15.9 lb

(HL-L2370DW for

the USA, except

for

HL-L2375DW for

Asia, and

HL-L2376DW)

7.4 kg / 16.3 lb

(HL-L2370DN

for Asia)

TBD

(HL-L2370DW for

Latin America)

TBD

(HL-L2370DN

for Russia and

HL-L2371DN for

7.8 kg / 17.1 lb

(for HL-

L2370DWXL)

Asia)

7.4 kg / 16.3 lb

(HL-L2375DW for

Asia)

without

Carton nor

toner/drum

6.1 kg / 13.4 lb

(HL-L2370DN

for Europe and

Asia, HLL2371DN for

Europe, and HL-

6.3 kg / 13.9 lb

(HL-L2370DW for

the USA,

HL-L2370DWXL

and HL-

L2376DW)

L2372DN)

TBD

TBD

(HL-L2370DN

(HL-L2370DW for

Latin America)

for Russia and

HL-L2371DN for

Asia)

6.1 kg / 13.4 lb

(for HL-

L2375DW)

Specifications are subject to change without notice.

HL-L2385DW

HL-B2050DN HL-B2080DW

HL-L2386DW

HL-2595DW

9.0 kg / 19.9 lb 9.2 kg / 20.2 lb

(for Europe)

TBD

(HL-L2385DW

for Oceania)

9.0 kg / 19.9 lb

(for Asia)

9.8 kg / 21.7 lb

(HL-L2385DW

for Asia)

9.5 kg / 21.0 lb

(for HLL2386DW)

8.3 kg / 18.3 lb

(for HL2595DW)

7.4 kg / 16.3 lb 7.4 kg / 16.3 lb TBD

(HL-L2385DW

for Oceania)

8.1 kg / 17.9 lb

(HL-L2385DW

for Asia)

7.9 kg / 17.4 lb

(for HLL2386DW and

HL-2595DW)

6.5 kg / 14.3 lb 6.3 kg / 13.9 lb

(for Europe)

TBD

(HL-L2385DW

for Oceania)

6.5 kg / 14.3 lb

(for Asia)

6.8 kg / 15.0 lb

(HL-L2385DW

for Asia)

7.0 kg / 15.4 lb

(for HLL2386DW and

HL-2595DW)

1-5

Confidential

Page 19

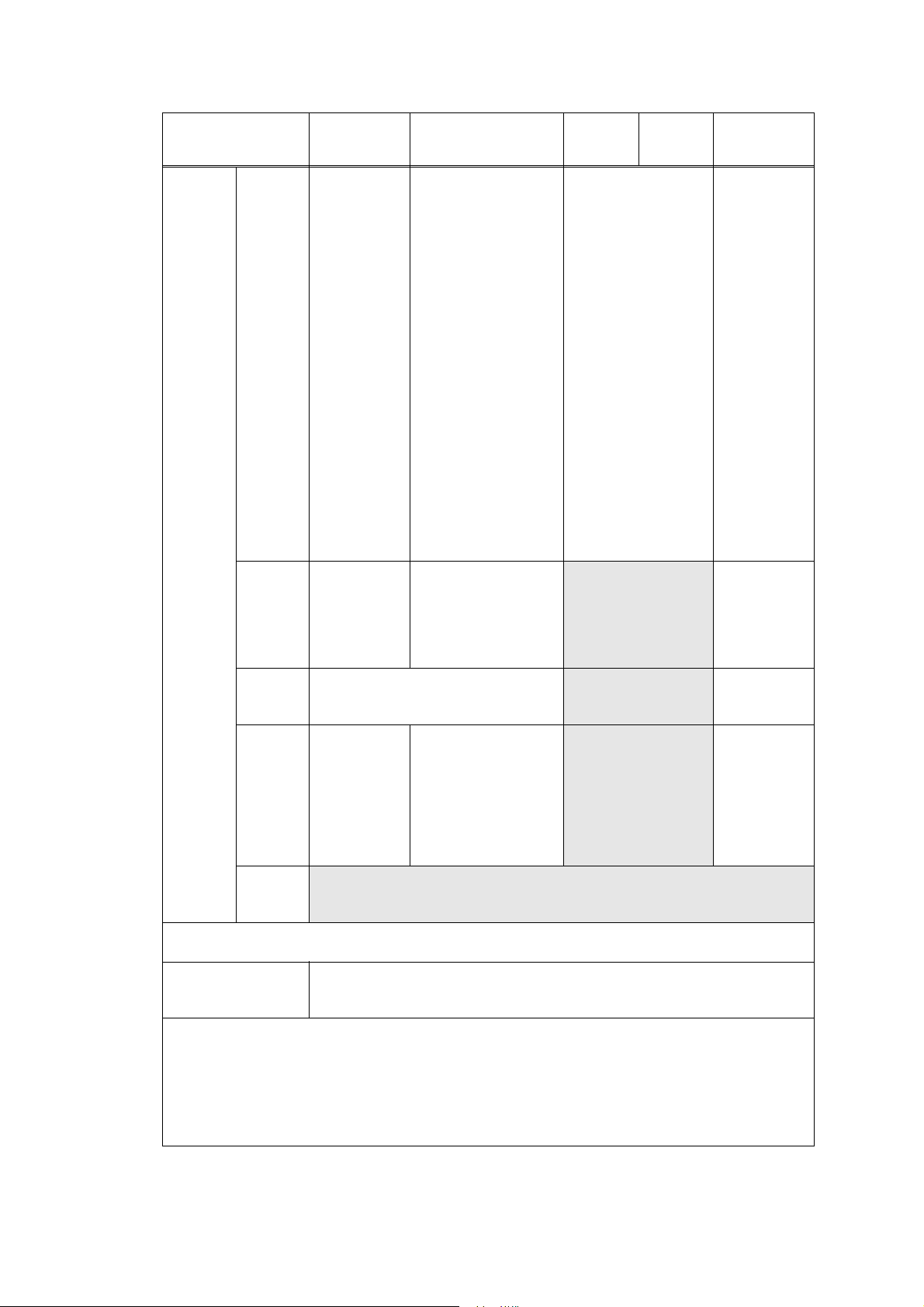

2. NETWORK CONNECTIVITY

Model HL-2290 HL-2295D

Wired

network

Wireless

network

Wired

network

Wireless

network

Wired

network

Wireless

network

Specifications are subject to change without notice.

Network

node type

Network

node type

Model HL-B2000D

Network

node type

Network

node type

Model

Network

node type

Network

node type

N/A

N/A

N/A NC-9300h

N/A NC-8800w N/A

HL-L2370DN

HL-L2371DN

HL-L2372DN

NC-9300h

N/A NC-8800w N/A NC-8800w

HL-L2350DW

HL-L2351DW

HL-L2352DW

HL-L2370DW(XL)

HL-L2375DW

HL-L2376DW

HL-L2310D

HL-L2312D

HL-L2357DW HL-L2325DW

HL-B2050DN

HL-L2330D

HL-L2331D

HL-B2080DW

HL-L2335D

HL-L2336D

HL-2590DN

HL-L2385DW

HL-L2386DW

HL-2595DW

3. SERVICE INFORMATION

Model All models

Machine life 50,000 pages (A4 / LTR) or 5 years

MTBF 4,000 hours

MTTR 0.5 hours

Maximum monthly volume Up to 15,000 pages

Maintenance

parts life

(Non-Periodical

Spare Parts)

Specifications are subject to change without notice.

Fuser unit 50,000 pages

Laser unit 50,000 pages

PF kit 1 50,000 pages

PF kit MP 50,000 pages

1-6

Confidential

Page 20

4. SUPPLIES

Model HL-2290 HL-2295D

Toner

cartridge

When printing A4/Letter size one-sided pages in accordance with ISO/IEC 19752

Shelf life: 2 years without opening (6 months after opening)

Drum unit Life expectancy: Approximately 12,000 pages (page/job)

The shelf life of toner cartridge and drum unit is guaranteed under the normal condition as below;

(Temperature) Normal condition: 0 to 40°C

* Storage condition at the temperature of 50°C: Up to 5 days

* Storage condition at the temperature of -20°C: Up to 5 days

(Humidity) Normal condition: 35 to 85%RH (without condensation)

* Storage condition at the humidity of 85 to 95%RH: Up to 5 days (without condensation)

* Storage condition at the humidity of 10 to 35%RH: Up to 5 days (without condensation)

*1

Toner supplied with the machine.

Specifications are subject to change without notice.

Starter

toner

Standard

toner

High

capacity

toner

Super

high

capacity

toner

Ultra high

capacity

toner

Approximately 3,000 pages

*1

Approximately 1,200 pages

Approximately 3,000 pages

N/A

N/A

The life expectancy varies according to the use condition.

Shelf life: 2 years

HL-L2310D

HL-L2312D

Approximately

700 pages

Approximately

4,500 pages

(for the USA and

Europe)

N/A

(for Russia and

Oceania)

HL-L2330D

HL-L2331D

Approximately

700 pages

(for HL-L2330D)

Approximately

3,000 pages

(HL-L2331D for

India)

Approximately

1,200 pages

(for HL-L2330D)

N/A

(for HL-L2331D)

Approximately

4,500 pages

HL-L2335D

HL-L2336D

Approximately

1,200 pages

(HL-L2335D for

Asia)

Approximately

3,000 pages

(HL-L2335D for

Gulf and

Philippines)

Approximately

700 pages

(HL-L2335D for

Ta iw a n)

Approximately

3,000 pages

(HL-L2336D for

Vietnam /

Indonesia)

Approximately

1,200 pages

Approximately

4,500 pages

(for HL-L2335D)

N/A

(for HL-L2336D)

1-7

Confidential

Page 21

HL-L2350DW

Model HL-B2000D

HL-L2351DW

HL-L2357DW HL-L2325DW HL-2590DN

HL-L2352DW

Toner

cartridge

Starter

toner

Approximately

*1

2,600 pages

Approximately

700 pages

Approximately

1,200 pages

Approximately

700 pages

Approximately

3,000 pages

(except for HLL2351DW)

Approximately

3,000 pages

(for HLL2351DW)

Standard

toner

N/A

Approximately

1,200 pages

Approximately 1,200 pages

(except for HLL2351DW)

N/A

(for HLL2351DW)

High

N/A Approximately 3,000 pages

capacity

toner

Super

high

capacity

toner

N/A

Approximately

4,500 pages

(except for HLL2350DW for

Approximately 4,500 pages N/A

Russia and

Oceania)

N/A

(HL-L2350DW

for Russia and

Oceania)

Ultra high

N/A

capacity

toner

When printing A4/Letter size one-sided pages in accordance with ISO/IEC 19752

Shelf life: 2 years without opening (6 months after opening)

Drum unit Life expectancy: Approximately 12,000 pages (page/job)

The life expectancy varies according to the use condition.

Shelf life: 2 years

The shelf life of toner cartridge and drum unit is guaranteed under the normal condition as below;

(Temperature) Normal condition: 0 to 40°C

* Storage condition at the temperature of 50°C: Up to 5 days

* Storage condition at the temperature of -20°C: Up to 5 days

(Humidity) Normal condition: 35 to 85%RH (without condensation)

* Storage condition at the humidity of 85 to 95%RH: Up to 5 days (without condensation)

* Storage condition at the humidity of 10 to 35%RH: Up to 5 days (without condensation)

*1

Toner supplied with the machine.

Specifications are subject to change without notice.

1-8

Confidential

Page 22

Toner

cartridge

Model

Starter

toner

HL-L2370DN

HL-L2371DN

HL-L2372DN

Approximately

*1

4,500 pages

(HL-L2371DN for

Europe)

N/A

(HL-L2371DN for

Asia)

Approximately

700 pages

(HL-L2370DN for

Europe and

Russia, and

HL-L2372DN)

Approximately

1,200 pages

(HL-L2370DN for

Asia)

Approximately

HL-L2370DW(XL)

HL-L2375DW

HL-L2376DW

Approximately 700 pages

(for HL-2370DW)

Approximately 7,500 pages

(for HL-2370DW(XL))

Approximately 1,200 pages

(HL-L2375DW for Europe,

Russia and Asia)

Approximately 700 pages

(HL-2370DW for Oceania)

Approximately 3,000 pages

(HL-L2375DW for Gulf,

Korea and Philippines)

Approximately 700 pages

(HL-L2375DW for Taiwan)

N/A

(for HL-L2376DW)

HL-B2050DN

HL-B2080DW

Approximately

2,600 pages

HL-L2385DW

HL-L2386DW

HL-2595DW

Approximately

700 pages

(HL-L2385DW for

Oceania)

Approximately

3,000 pages

(HL-L2385DW for

Asia)

Approximately

4,500 pages

(HL-L2385DW for

Korea and

Philippines)

N/A

(for HL-L2386DW)

Approximately

3,000 pages

(for HL-2595DW)

3,000 pages (HLL2370DN for

Korea)

Standard

toner

Approximately

1,200 pages

Approximately 1,200

pages

N/A

Approximately

1,200 pages

(except for HLL2371DN)

N/A

(for HL-L2371DN)

High

capacity

Approximately 3,000 pages

N/A

Approximately

3,000 pages

toner

Super

high

capacity

toner

Approximately

4,500 pages

(except for HLL2370DN for

Russia)

N/A

Approximately 4,500 pages

(except for HL-L2375DW for

Oceania and Russia)

N/A

(HL-L2375DW for Oceania

and Russia)

N/A

Approximately

4,500 pages

(HL-L2370DN for

Russia)

Ultra high

N/A

capacity

toner

When printing A4/Letter size one-sided pages in accordance with ISO/IEC 19752

Shelf life: 2 years without opening (6 months after opening)

Drum unit Life expectancy: Approximately 12,000 pages (page/job)

The life expectancy varies according to the use condition.

Shelf life: 2 years

The shelf life of toner cartridge and drum unit is guaranteed under the normal condition as below;

(Temperature) Normal condition: 0 to 40°C

* Storage condition at the temperature of 50°C: Up to 5 days

* Storage condition at the temperature of -20°C: Up to 5 days

(Humidity) Normal condition: 35 to 85%RH (without condensation)

* Storage condition at the humidity of 85 to 95%RH: Up to 5 days (without condensation)

* Storage condition at the humidity of 10 to 35%RH: Up to 5 days (without condensation)

*1

Toner supplied with the machine.

Specifications are subject to change without notice.

1-9

Confidential

Page 23

CHAPTER 2 ERROR INDICATIONS AND

TROUBLESHOOTING

1. INTRODUCTION

Troubleshooting is the countermeasure procedures that the service personnel should follow if

an error or malfunction occurs with the machine. It is impossible to anticipate all of the possible

troubles which may occur in future and determine the troubleshooting procedures, so this

chapter covers some sample troubles. However, those samples will help the service personnel

pinpoint and repair other defective elements.

1.1 Precautions

Be sure to observe and follow all the precautions to prevent any secondary problems from

happening during troubleshooting.

(1) Always turn OFF the power and unplug the power cable before removing any covers or

PCBs, adjusting the machine and so on. If you need to take voltage measurements with the

power switched on, take the greatest of care not to receive an electric shock.

(2) When connecting or disconnecting cable connectors, make sure that you hold the

connector body and not the cables.

(3) Static electricity charged in your body may damage electronic parts. Before handling the

PCBs, touch a metal portion of the machine to discharge static electricity charged in your

body. When transporting PCBs, be sure to wrap them in conductive sheets.

When replacing the PCBs, put on a grounding wrist band and perform the job on an

antistatic mat. Also take care not to touch the conductor sections on the flat cables.

(4) Follow the warning by all means.

Warning

Hazard labels as shown below are attached to the machine. Fully understand the

descriptions on the hazard labels and observe them during troubleshooting.

Take extreme care not to remove or damage the hazard labels.

2-1

Confidential

Page 24

Warning

DO NOT use any flammable spray or flammable solvent such as alcohol,

benzine, or thinner in or around the machine. Otherwise a fire or electric shock

may result.

(5) Check again that the portions and parts repaired or removed during the repair work

function properly when the repair is completed.

A certain interface or function could be set to invalid to serve the needs of customers. Ask sales

representative if this is the case before performing the check.

2-2

Confidential

Page 25

1.2 Checks before Commencing Troubleshooting

Check the following items before attempting to repair the machine.

Operating environment

(1) The machine is placed on a flat, stable surface.

(2) The machine is used in a clean environment where the temperature is between 10°C

(50°F) and 32°C (89.6°F) and the relative humidity is maintained between 20% and 80%.

(3) Ensure the machine is not exposed to direct sunlight, excessive heat, moisture, or dust.

(4) Keep the machine horizontal when you carry it. To prevent injuries when moving or lifting

this machine, make sure to use at least two people.

Power supply

(1) The AC input power supply described on the rating plate of the machine should be within

±10% of the rated voltage.

(2) The AC input power supply is within the regulated value.

(3) The cables and harnesses are connected correctly.

(4) The fuses are not blown.

Paper

(1) A recommended type of paper is being used.

(2) The paper is not damp.

(3) The paper is not short-grained paper or acid paper.

Consumable parts

(1) The drum unit (including the toner cartridge and toner box) is installed correctly.

Others

(1) Condensation

When the machine is moved from a cold place into a warm room, condensation may occur

inside the machine, causing various problems as listed below.

• Condensation on the surface of optical devices such as the lens, reflecting mirror, and

protection glass, etc., may cause light print image.

• If the exposure drum is cold, the electrical resistance of the photosensitive layer is

increased, making it impossible to obtain the correct contrast when printing.

• Condensation on the charge unit may cause corona charge leakage.

• Condensation on the plate and separation pad may cause paper feed problems.

If condensation has occurred, leave the machine for at least two hours to allow it to reach

room temperature.

If the drum unit is unpacked soon after it is moved to a warm room from a cold location,

condensation may occur inside the unit which may cause printing failure. Leave the drum

unit for one or two hours until it reaches room temperature, and then unpack it.

(2) Low temperature

The motor may not drive normally under the low temperature environment. This is due to

there being too much load to drive each unit. In this case, increase the room temperature.

2-3

Confidential

Page 26

Cleaning

Use a soft dry lint-free cloth.

Warning

DO NOT use any flammable spray or flammable solvent such as alcohol, benzine,

or thinner to clean the machine. DO NOT use these articles near the machine.

2-4

Confidential

Page 27

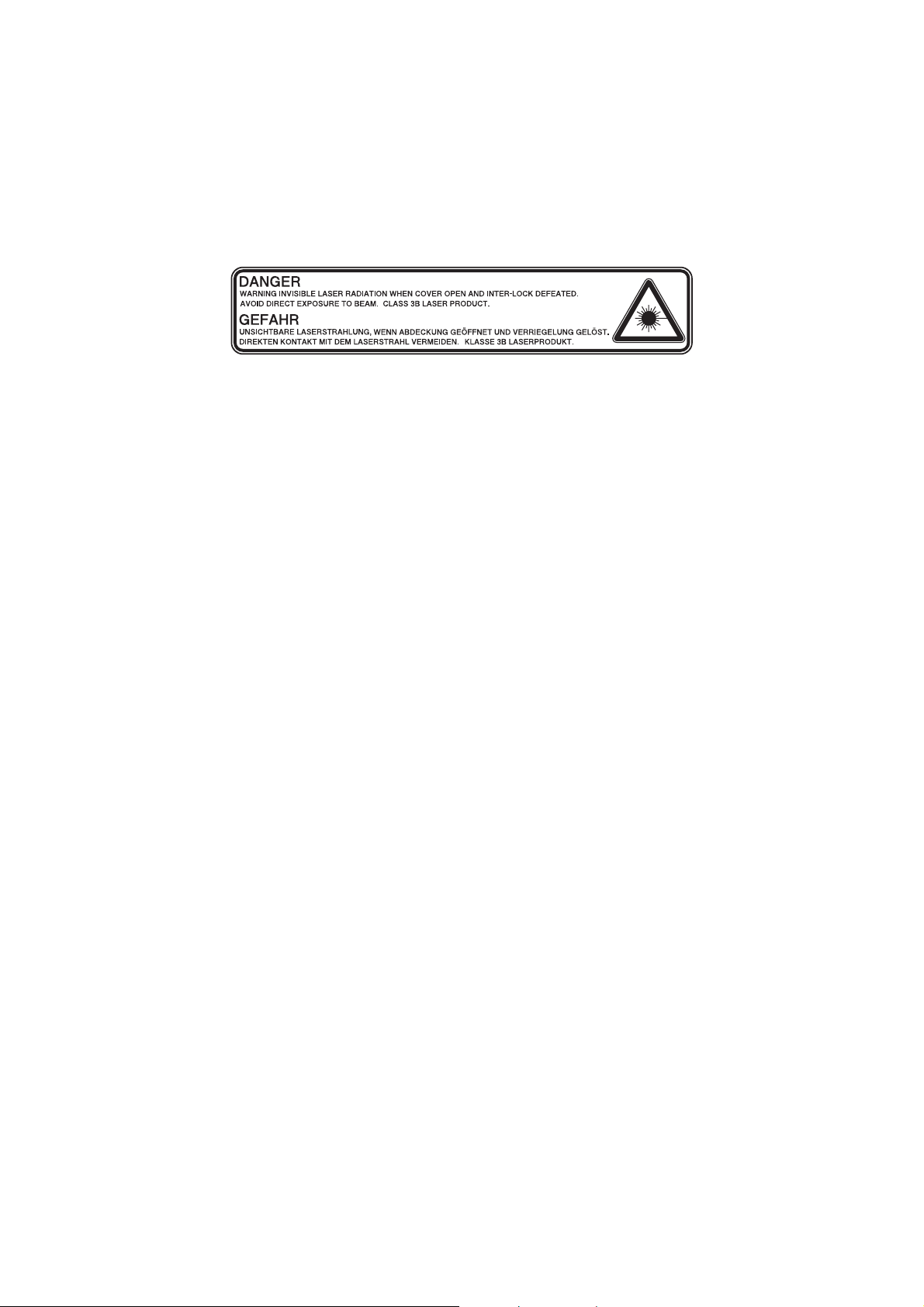

2. OVERVIEW

<Back side>

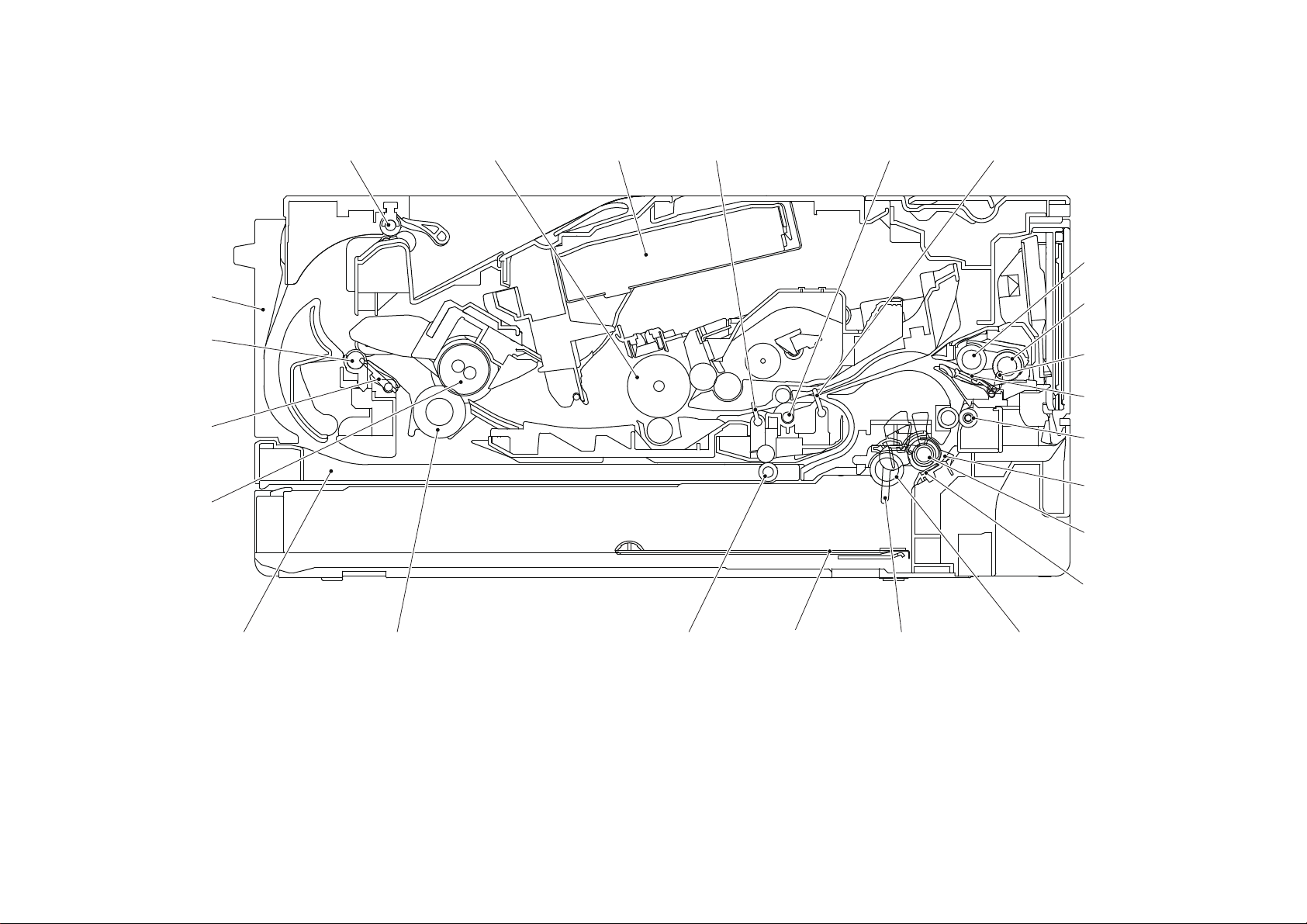

Eject roller 2 Exposure drum Laser unit Registration rear actuator

<Front side>

Registration front actuator

Manual feed

slot

Paper dust

cleaning roller

Paper feed

actuator

Paper pick up rollerPlateDuplex paper feed rollerPressure rollerDuplex tray

Heat roller

Back cover

Registration roller

Separation

roller

Separation

pad

Eject actuator

Eject roller 1

2.1 Cross-section Drawing

Manual feed slot models

Fig. 2-1

2-5

Confidential

Page 28

MP models

Eject roller 2 Exposure drum Laser unit Registration rear actuator Registration front actuator

MP separation

roller

Paper dust

cleaning roller

Paper feed

actuator

Paper pick up rollerPaper empty actuatorPlateDuplex paper feed rollerPressure rollerDuplex tray

Heat roller

Back cover

Registration roller

Separation

roller

Separation

pad

Eject actuator

Eject roller 1

MP paper empty

actuator

MP paper pick-up

roller

MP separation pad

<Back side> <Front side>

Fig. 2-2

2-6

Confidential

Page 29

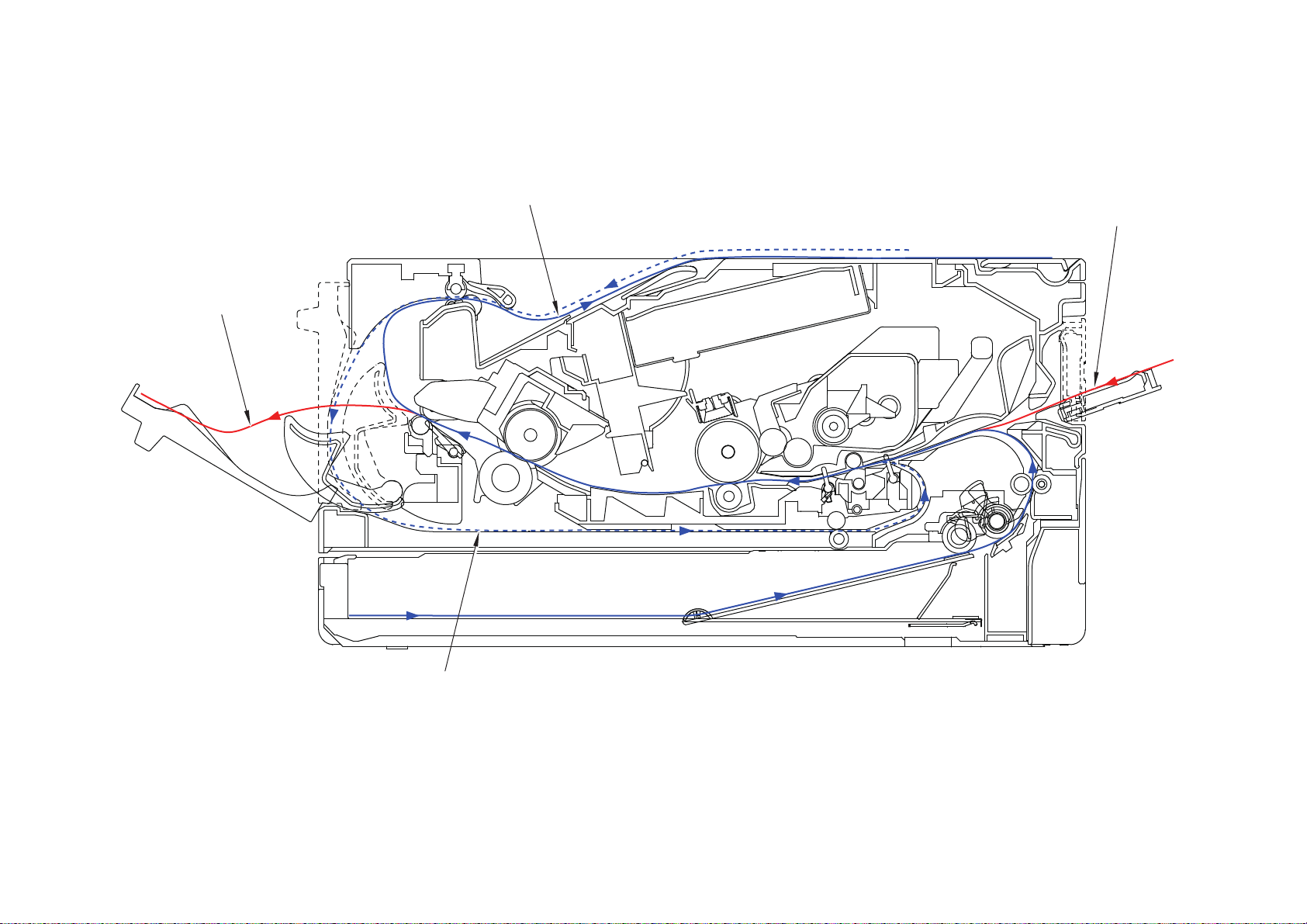

2.2 Paper Feeding

Eject to output tray

Feed from

manual feed slot

Duplex path

Eject to back side

<Back side> <Front side>

Manual feed slot models

Fig. 2-3

2-7

Confidential

Page 30

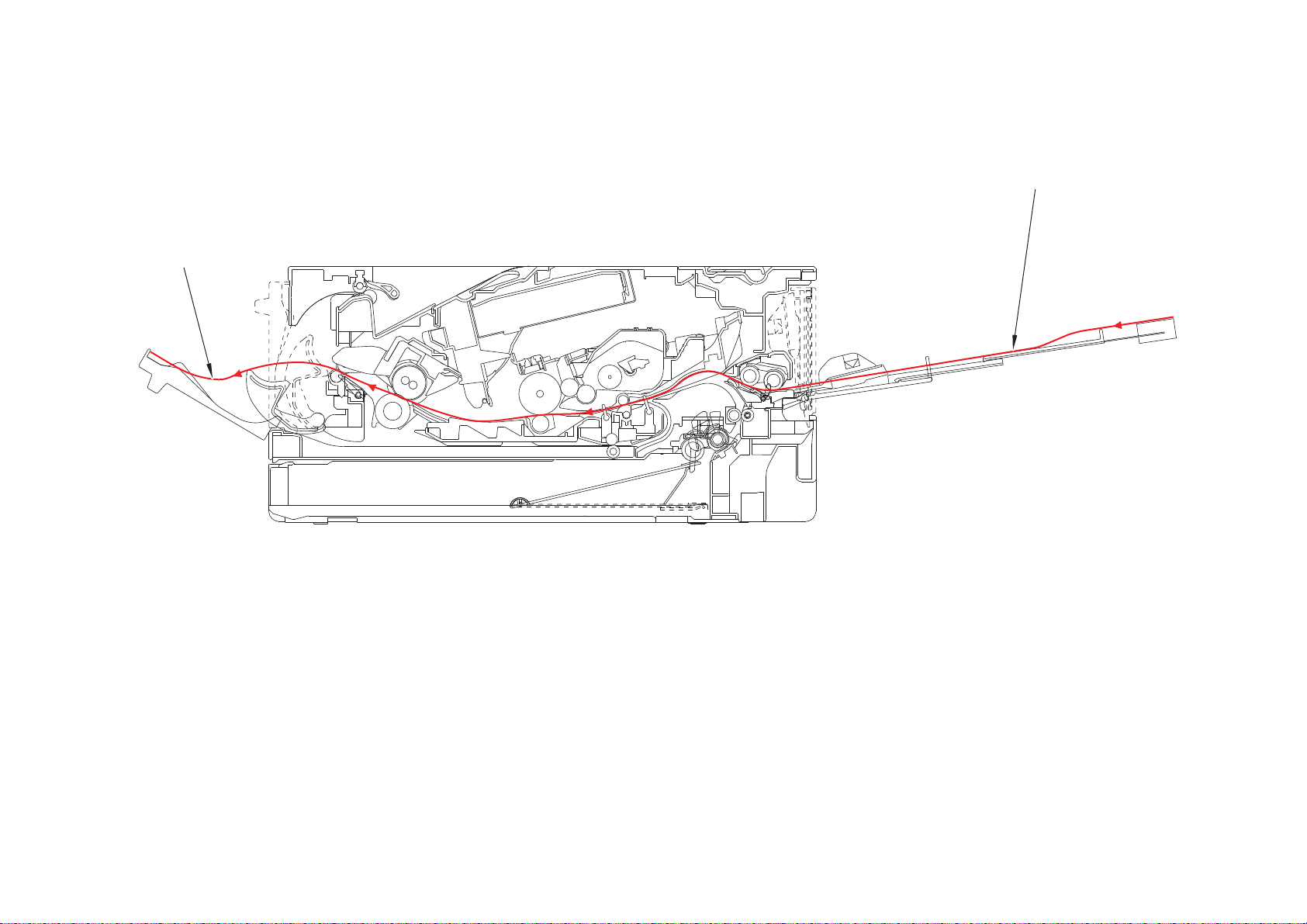

MP models

Feed from MP tray

Eject to back side

<Back side> <Front side>

Fig. 2-4

2-8

Confidential

Page 31

2.3 Operation of Each Part and Location of Parts

Part name Operation

Paper pick up roller

Separation roller,

Separation pad

Paper feed actuator

(Paper feed sensor)

Registration front actuator

(Registration front sensor)

Registration roller Corrects the paper alignment when the paper makes

Registration rear actuator

(Registration rear sensor)

Heat roller,

Pressure roller

Eject actuator

(Eject sensor)

Feeds the paper to the separation roller from the paper tray.

Separates paper fed from the paper tray into single sheets.

Detects paper trays (open / closed).

Detects paper jams in paper trays.

Determines whether paper is fed from the paper tray.

Detects the front edge of the paper to control the

registration roller drive.

Detects paper jams in the front section of the machine.

Determines whether paper is fed from the paper tray.

contact with the stopped registration roller. After the

correction, it rotates to feed the paper to the process.

Detects paper pass and adjusts the writing start position for

the paper.

Detects paper jams in the front or center section of the

machine.

Detects the rear edge of the paper to determine the paper

size.

Fuses the toner transferred to paper by heat and pressure,

and feeds paper to the eject roller 1.

Detect whether or not paper is ejected from the fuser unit.

In the case of the 2-sided printing, detect the rear edge of

paper and adjust the timing of the eject roller 2 switching.

Detects paper jam in the rear section of the machine.

Detects open fuser cover.

Eject roller 1 Feeds the paper ejected from the fuser unit to eject roller 2.

Eject roller 2 Eject the paper to the face-down output tray. In the case of

the 2-sided printing, after the front of the sheet is printed

and the paper is fed up to a certain point, eject roller 2

rotates conversely, and the paper is fed to the duplex tray.

Duplex paper feed roller Feeds the paper passing through the duplex tray to the

registration roller.

Front cover sensor Detects open / closed front cover.

Paper empty actuator Detects the paper in the paper tray 1.

Detects paper jams in the paper tray 1.

MP paper pick-up roller Feeds paper from the MP tray to the MP separation roller.

MP separation roller,

MP separation pad

MP paper empty actuator

(MP paper empty sensor)

Back cover/duplex tray sensor Detects open / closed back cover or the duplex tray is set.

New toner sensor When exchange to the new toner cartridge, detects the

Toner sensor Detects the toner cartridge is set.

Separates the paper fed from the MP tray into single

sheets.

Detects the paper in the MP tray.

Detects paper jams in the MP tray.

kinds of toner and add 1 to the reset of the developing bias

and to the exchange count.

2-9

Confidential

Page 32

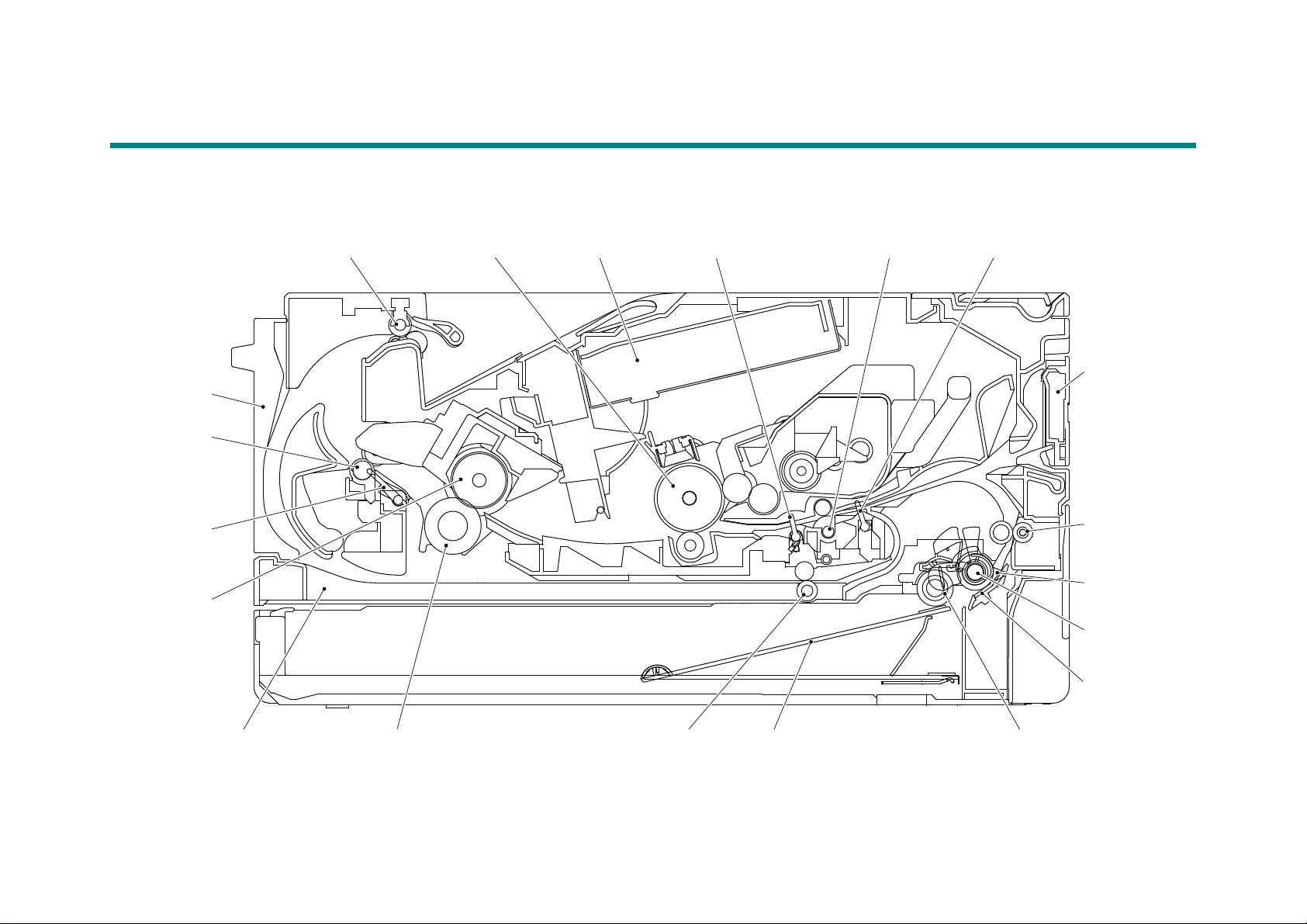

Part name Operation

T1 clutch

New toner sensor PCB ASSY

Registration clutch

Registration rear sensor

Registration

front sensor

Paper feed sensor PCB ASSY

Toner box solenoid

*1

Eject sensor PCB ASSY

Back cover/duplex

tray sensor

Front cover sensor

Toner box new PCB ASSY

*1

Toner sensor

PCB ASSY

*1

*1

: For models with Toner box

*2

: For models without Toner box

Relay PCB ASSY*1

*2

External temperature/humidity

sensor

Detects external temperature and humidity around the

machine.

Pickup clutch Drives the pick up roller at the timing of paper feeding.

Registration clutch Controls the activation of the registration roller for the paper

alignment adjustment.

MP solenoid Presses the MP paper pick-up roller against the paper

when feeding from the MP tray.

Location of sensors and clutches

Fig. 2-5

2-10

Confidential

Page 33

2.4 Block Diagram

Wireless LAN PCB

NFC PCB

Toner box model only

Toner box solenoid

New toner box sensor

PCB

New toner sensor PCB

MP model only

MP solenoid

MP paper empty

sensor PCB

T1 paper empty/paper feed sensor PCB

T1 paper empty sensor

T1 paper feed sensor

Manual feed slot model only

T1 paper feed sensor

T1 paper feed sensor

Relay PCB

Relay PCB

PCB

Main PCB

LED model only

Panel PCB

LCD model only

Panel PCB

LCD

High-voltage

power supply

PCB

Toner box

model only

New toner

sensor

light emission

New toner

box sensor

light emission

Front cover sensor

Cartridge sensor model only

Cartridge sensor

Laser unit PCB

Fan

New toner sensor PCB

Registration front/rear

sensor PCB

Laser unit

Back cover/duplex tray

sensor

Fuser unit

Center thermistor

Side thermistor

Main heater

MP model only

Sub heater

Eject

sensor PCB

Eject sensor

Low-voltage

power supply

PCB

Polygon motor

Paper feed motor

Registration clutch

T1 clutch

Fig. 2-6

2-11

Confidential

Page 34

Side cover R

Back cover

Low-voltage power

supply PCB ASSY

Registration front/rear

actuator holder ASSY

Paper feed sensor PCB ASSY

Front cover ASSY

Paper tray

Side cover L

T1 clutch

Registration clutch

Fan

Laser unit

Inner chute ASSY

Outer chute ASSY

Fuser unit

Main shield plate

Main PCB ASSY

Motor drive sub

ASSY

Duplex tray

Paper feed motor

Fuser gear

64R/36R

Eject sensor

PCB ASSY

New toner sensor PCB ASSY

High-voltage power

supply PCB ASSY

Fuser cover

Toner

cartridge

Drum unit

Top cover ASSY

2.5 Main Components

Fig. 2-7

2-12

Confidential

Page 35

3. ERROR INDICATIONS

This machine includes a self-diagnosis function. If the machine does not work normally it judges

that an error has occurred, and indicates the corresponding error message on the LCD, which

in turn helps the service personnel to quickly find out the problem.

3.1 Error Codes

The shaded errors hardly occur under normal use. They may be caused by noise around the

installation site, variation in power supply voltage, or software failure.

Error

Codes

0101 --- 050A

ASIC error or motor driver error

0102

occurred.

Cannot detect the synchronized signal

of the paper feed motor. The speed of

0201

the paper feed motor does not stabilize

within the specified time.

0202 ---

0203 ---

Cannot detect the lock signal of the

0300

polygon motor for the laser unit.

(second time)

Cannot detect the lock signal of the

0305

polygon motor for the laser unit. (first time)

0401 BD sensor failure (second time) 2-34 0900

0402 --- 0A01 ---

0405 BD sensor failure (first time) 2-34 0A02 Detected a fan failure. 2-36

The center thermistor of the fuser unit

0501

has not reached the specified

temperature within the specified time.

The center thermistor of the fuser unit has

not reached the specified temperature

0502

within the specified time after it was

heated normally to the certain level.

The center thermistor of the fuser unit

0503

detected a temperature higher than the

specified value.

After the heat unit was heated normally, the

0504

center thermistor of the fuser unit detected a

temperature lower than the specified value.

The center thermistor of the fuser unit

detected a temperature rise greater than

0505

the specified value within the specified time.

The center thermistor of the fuser unit

detected a temperature fall greater than the

0506

specified value within the specified time.

Temperature of the end part didn’t rise by 1

0508

°C when the fuser unit heater was turned ON.

Description

Refer

2-33 050B

2-33 050C

2-33 050F ---

2-33 0800 ---

2-35

2-35 0B01

2-35 0B02

2-35 0C00 ---

2-35 0D01 ---

2-35 0D02 ---

2-35 0D03 ---

to:

Error

Codes

The hardware detected a temperature

error through the center thermistor or

the side thermistor of the fuser unit.

When the center thermistor of the fuser unit

was lower than the idle temperature, the

side thermistor detected a temperature

higher than the specified temperature.

When the center thermistor of the fuser unit

was higher than the idle temperature, the

side thermistor detected a temperature

lower than the specified temperature.

050D ---

Detected irregular power supply for

more than 100 times.

0A03 ---

An error occurred in the high-voltage

power supply PCB ASSY while

operating.

An error occurred in the high-voltage

power supply PCB ASSY when the

machine was in the ready state.

Description

Refer

to:

2-35

2-35

2-35

2-36

2-37

2-37

2-13

Confidential

Page 36

Error

Codes

Description

Refer

to:

Error

Codes

Toner cartridge could not

0D04 --- 2500

communicate with the cartridge

sensor.

0E00 --- 2501 ---

1003 --- 2502 ---

1004 --- 2503 ---

110 0 --- 2601 ---

1200 --- 2602 ---

1300 --- 2603 ---

1400 --- 2604 ---

1500 --- 2605 ---

1701 --- 2701 ---

1801 --- 2702 ---

1802 --- 2703 ---

1803 --- 2801 ---

1808 --- 2802 ---

1901 --- 2803 ---

1A01 --- 2804 ---

1B01 --- 2805 ---

1C00 --- 2806 ---

1D01 --- 2901 ---

1D02 --- 2902 ---

1D03 --- 2903 ---

1D04 --- 2904 ---

1E01 --- 2905 ---

1E02 --- 2906 ---

1F00 --- 2A01 ---

1F02 --- 2A02 ---

2000 --- 2A03 ---

2001 --- 2A04 ---

2002 --- 2A05 ---

2003 --- 2B01 ---

2100 --- 2B02 ---

2101 --- 2C01 ---

2102 --- 2C02 ---

2103 --- 2D01 ---

Cartridge sensor detected that the

2200

incompatible toner cartridge was

installed.

2-37 2E00

Could not communicate with the

cartridge sensor on the machine side.

2201 --- 2E01 ---

2202 --- 2E03 ---

2203 --- 2F01 ---

Toner cartridge is not recognized by

2400

the cartridge sensor.

2-37 2F03 ---

2401 --- 3001 ---

2402 --- 3002 ---

2403 --- 3003 ---

Description

Refer

to:

2-37

2-37

2-14

Confidential

Page 37

Error

Codes

Description

Refer

to:

Error

Codes

3102 --- 4900 ---

3202 --- 4A00 ---

3301 --- 4B01

3302 --- 4B02 ---

3401 --- 4B03 ---

3402 --- 4B04 ---

3501 --- 4B06

3601 --- 4C01

3701 --- 4C02 ---

3702 --- 4C03 ---

3703 --- 4C04 ---

3801 --- 4C05 ---

3802 --- 4C06

3900 --- 4D01

A communication error occurred

3A00

between the controller and engine in

2-37 4E01

main PCB.

Number of the drum unit rotations

4000

reaches the upper limit soon.

2-38 4F01

4001 --- 4F02

4002 --- 4F03

4003 --- 4F04

4004 --- 4F05

Number of the drum unit rotations has

4200

reached the upper limit.

2-38

5001

4201 --- 5002

4202 --- 5003

4203 --- 5004

4204 --- 5005

4209 --- 5006

4300 --- 5100 ---

4400 --- 5200 ---

4500 --- 5301 ---

4600 --- 5302 ---

4700 --- 5401 ---

4800 --- 5402 ---

Description

Dot counter of the toner cartridge or

develop roller counter reaches the

upper limit soon.

The amount of toner supplied of the

toner box reaches the upper limit soon.

Dot count or develop roller counter of

the toner cartridge in models without

toner box has reached the upper limit

in the toner stop mode.

The amount of toner supplied of the

toner box has reached the upper limit.

Dot count or develop roller counter of

the toner cartridge in models without

toner box is reaching the upper limit in

the continuous printing mode.

Toner cartridge in models without toner

box has reached the upper limit in the

continuous printing mode.

The new toner sensor of the toner

cartridge could not detect a new

cartridge properly.

New process sensor could not detect

the new drum unit correctly.

Refer

to:

2-38

2-38

2-38

2-38

2-38

2-38

2-39

2-39

2-15

Confidential

Page 38

Error

Codes

Description

Refer

to:

Error

Codes

5406 --- 6300 ---

5502 --- 6400 ---

5602 --- 6602 ---

5702 --- 6701 ---

The side thermistor detected a

5801 --- 6801

temperature higher than the specified

value.

5802 --- 6802 ---

Some fuser unit errors occurred at

5902 --- 6901

power-ON or upon recovery from sleep

mode.

After the error was detected at the

fuser unit, power was turned ON again

5A02 --- 6902

and the error is being checked. (If

power is turned OFF and ON after

error code 6901 occurred, this code is

displayed for about 15 minutes.)

Electric discharge that may be caused

5B02 --- 6A00

by dirt on the corona wire of the drum

unit was detected.

5C02 --- 6B01 ---

5D02 --- 6B02 ---

New toner box sensor could not detect

5E00

the new toner box correctly.

The front cover sensor detected that

6001

the front cover was open.

2-39 6B03 ---

2-40 6B04 ---

6002 --- 6B0A ---

6003 --- 6C01 ---

The eject sensor detected that the

6004

fuser cover was open.

2-40 6C02 ---

6007 --- 6C03 ---

The new toner sensor detected that no

6101

toner cartridge was set.

2-41 6C04 ---

6102 --- 6D00 ---

6103 --- 6E00 ---

6104 --- 6F00

The new toner box sensor detected

6106

that no toner box was set.

Detected that the drum unit was not set

6200

by detecting the electrodes current.

2-41 7000

2-41

Detected that supply power is

unstable. (less than 100 times)

After the registration rear sensor

detects paper pass, the eject sensor

does not detect paper pass.

7001 ---

6201 --- 7002 ---

6202 --- 7003 ---

6203 --- 7004 ---

After the registration rear sensor

detects the end of paper pass and the

6204 --- 7100

specified period of time has passed,

the eject sensor continues to detect

paper pass.

6208 --- 7101 ---

6209 --- 7102 ---

620A --- 7103 ---

Description

Refer

to:

2-43

2-43

2-43

2-44

2-44

2-44

2-45

2-16

Confidential

Page 39

Error

Codes

Description

Refer

to:

Error

Codes

7104 --- 8100 ---

7105 --- 8401 ---

7106 --- 8402 ---

When the paper is fed from the MP

tray, after the MP paper empty sensor

detects paper pass, the registration

7200

2-45 8403 ---

rear sensor does not detect paper pass

after a set period of time.

7300 --- 8501 ---

7301 --- 8502 ---

When printing from the paper tray, the

registration front sensor does not

7302

detect paper pass within the specified

2-46 8503 ---

time after the T1 paper feed sensor

detected paper pass.

7400 --- 8504 ---

7401 --- 8505 ---

7402 --- 8506 ---

7500 --- 8507 ---

7501 --- 8508 ---

7502 --- 8601 ---

7601 --- 8602 ---

7602 --- 8603 ---

7701 --- 8604 ---

7702 --- 8701 ---

After the first side is printed in 2-sided

printing mode, the registration front

7800

sensor does not detect paper pass

2-46 8702 ---

after a set period of time.

7801 --- 8703 ---

7802 --- 8708 ---

7803 --- 8709 ---

7804 --- 870A ---

7805 --- 870B ---

7900 --- 870C ---

7A01 --- 870D ---

7A02 --- 870E ---

7B01 --- 870F ---

7B02 --- 8801 ---

7B03 --- 8802 ---

7B04 --- 8808 ---

7B05 --- 8809 ---

7C00 --- 880A ---

7D00 --- 8901 ---

7E00 --- 8902 ---

The back cover sensor detected the

7F00 --- 8903

open state when 2-sided printing is

started (before the registration of

printing in the engine).

The back cover sensor detected the

8000 --- 8904

open state during 2-sided printing

(after the registration of printing in the

engine).

Description

Refer

to:

2-47

2-47

2-17

Confidential

Page 40

Error

Codes

Description

Refer

to:

Error

Codes

The registration rear sensor detected

that the paper fed was smaller or larger

8A01

than the specified size in duplex

2-47 9203 ---

printing mode.

8A02 --- 9204 ---

8B01 --- 9205 ---

There is no paper set in the manual

8C00

feed slot on the manual feed slot

2-48 9206 ---

printing.

When paper was fed from the MP tray,

8D01 --- 9301

the MP paper empty sensor detected

that no paper was in the MP tray.

When paper was fed from the paper

8D02 --- 9302

tray, the T1 paper feed sensor

detected that no paper was in the

paper tray.

8E01 --- 9303 ---

8E02 --- 9304 ---

8F01 --- 9305 ---

8F02 --- 9306 ---

Detected that there was no paper set

8F03 --- 9309

in all trays when TrayAuto was

selected for printing.

The size of paper loaded in the MP

tray and the one specified from the

9001

driver are not same when paper is fed

2-48

930A ---

from the MP tray.

The size of paper loaded in the paper

tray and the one specified from the

9002

driver are not same when paper is fed

2-48 9501 ---

from the paper tray.

9003 --- 9502 ---

9004 --- 9503 ---

9005 --- 9504 ---

9006 --- 9505 ---

9102 --- 9601 ---

9103 --- 9608 ---

For 2-sided printing, paper size setting

9104 --- 9701

of the printer driver that was not

supported by 2-sided printing was

selected.

For printing by feeding paper from the

9105 --- 9702

paper tray, the size of paper specified

from the driver set the size which was

not supported by the paper tray.

9200 --- 9703

When printing from the MP tray, paper

9201

type setting in the machine does not

2-48 9704

match the setting in the driver.