Brother HE-800A User Manual

HE-800A

ELECTRONIC LOCKSTITCH BUTTON HOLER

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please read the safety

instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts such as the

needle and thread take-up lever, and consequently there is always a danger of injury that can be caused by these parts.

Follow the instructions from training personnel and instructors regarding safe and correct operation before operating the

machine so that you will know how to use it correctly.

SAFETY INSTRUCTIONS

1. Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

Symbols

DANGER

CAUTION

This symbol ( ) indicates something that you should be careful of. The picture inside the triangle

윤윤윤윤윤윤

indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

The instructions which follow this term indicate situations where failure to follow the

instructions will result in death or serious injury.

The instructions which follow this term indicate situations where failure to follow the

instructions could cause injury when using the machine or physical damage to equipment

and surroundings.

윤윤윤윤윤윤

윤윤윤윤윤윤

This symbol ( ) indicates something that you must not do.

This symbol ( ) indicates something that you must do. The picture inside the circle indicates the

nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

HE-800A

i

2. Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the face plate of the control box. Touching areas where high voltages are present can result in

severe injury.

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from

sources of strong electrical noise such as electrical

line noise or static electric noise.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage should

be within r10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than the

requirements for the sewing machine’s power

consumption.

Insufficient power supply capacity may cause problems with correct operation.

Installation

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs approximately 56 kg.

The installation should be carried out by two or more

people.

Do not connect the power cord until installation is

complete, otherwise the machine may operate if the

treadle is depressed by mistake, which could result in

injury.

Use both hands to hold the machine head when tilting

it back or returning it to its original position. If only

one hand is used, the weight of the machine head

may cause your hand to slip, and your hand may get

caught.

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct

operation may also occur.

The ambient temperature should be within the range

of 5qC to 35qC during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation should

occur in any devices.

Excessively dry or humid environments and dew formation may cause problems with correct operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation.

All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too firmly

with staples, otherwise there is the danger that fire or

electric shocks could occur.

Install the belt covers to the machine head and motor.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin, otherwise

inflammation can result.

Furthermore, do not drink the oil or eat the grease

under any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

ii

HE-800A

CAUTION

Sewing

This sewing machine should only be used by operators who have received the necessary training in safe

use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may enter

your eyes and injury may result.

Turn off the power switch at the following times,

otherwise the machine may operate if the treadle is

depressed by mistake, which could result in injury.

x When threading the needle

x When replacing the needle and bobbin

x When not using the machine and when leaving the

machine unattended

Cleaning

Turn off the power switch before carrying out

cleaning, otherwise the machine may operate if the

treadle is depressed by mistake, which could result in

injury.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the

machine.

Do not touch the motor cover during operation and for

one hour after operation has finished, otherwise

burns may result.

If an error occurs in machine operation, or if abnormal

noises or smells are noticed, immediately turn off the

power switch. Then contact your nearest Brother

dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin, otherwise

inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times,

otherwise the machine may operate if the treadle is

depressed by mistake, which could result in injury.

x When carrying out inspection, adjustment and main-

tenance

x When replacing consumable parts such as the ro-

tary hook

Turn off the power switch before inserting or

removing the plug, otherwise damage to the control

box could result.

If the power switch needs to be left on when carrying

out some adjustment, be extremely careful to observe

all safety precautions.

Use both hands to hold the machine head when tilting

it back or returning it to its original position. If only

one hand is used, the weight of the machine head

may cause your hand to slip, and your hand may get

caught.

Use only the proper replacement parts as specified

by Brother.

If any safety devices have been removed, be absolutely sure to re-install them to their original positions

and check that they operate correctly before using

the machine.

Any problems in machine operation which result from

unauthorized modifications to the machine will not be

covered by the warranty.

HE-800A

iii

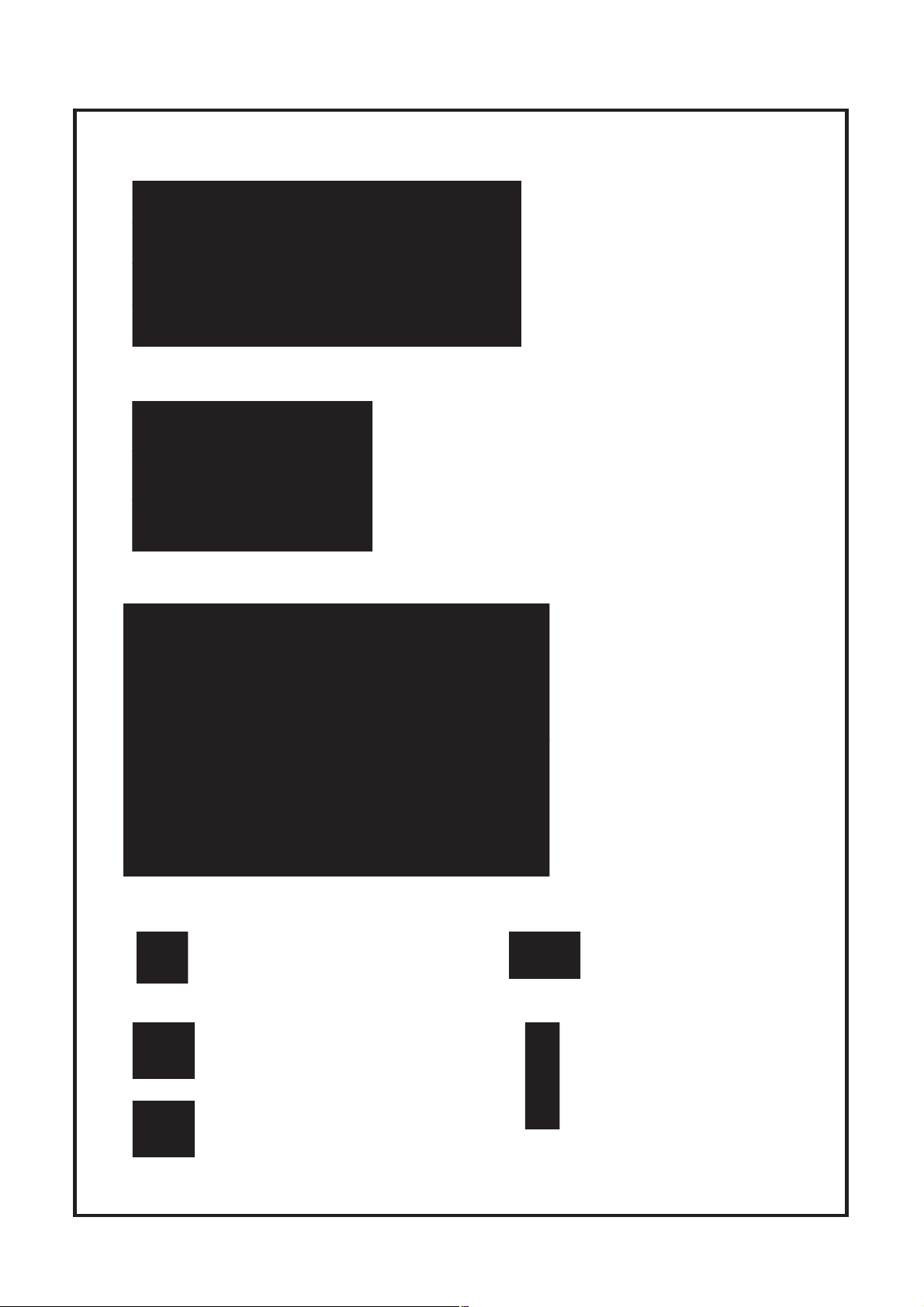

3. Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are

difficult to read, please contact your nearest Brother dealer.

1

2a

2b

NOTE:

Either the 2a or the 2b label is displayed on the sewing

machine.

*Safety devices

Eye guard, Finger guard, Thread take-up cover, Belt cover,

Belt cover plate, etc.

3

Be sure to connect the ground. If the

ground connection is not secure, you

run a high risk of receiving a serious

electric shock, and problems with

correct operation may also occur.

6

High temperature warning display

iv

4

5

Do not touch any of the cutter or press

any objects against the machine while

sewing, as this may result in personal

injury or damage to the machine.

Do not touch any of the fan or press

any objects against the machine, as

this may result in personal injury or

damage to the machine.

HE-800A

7

Direction of operation

Thread take-up cover

Belt cover

Eye guard

Belt cover plate

Finger guard

4404M

HE-800A

v

CONTENTS

1. NAME OF EACH PART........................ 1

2. SPECIFICATIONS ................................

2-1. Specifications ................................................. 2

2-2. Standard sewing pattern list ........................... 3

2

3. OPTIONAL PARTS............................... 4

3-1. Special needle plate ....................................... 4

3-2. Leg parts......................................................... 4

3-3. Standing operation pedal................................ 5

3-4. Ruler ............................................................... 5

3-5. Tape guard ..................................................... 6

4.INSTALLATION...................................... 7

4-1. Table processing diagram .............................. 7

4-2. Installing the motor ......................................... 8

4-3. Installing the flange nut................................... 9

4-4. Installing the control box................................. 9

4-5. Installing the power switch..............................10

4-6. Installing the bed base.................................... 10

4-7. Installing the machine head............................ 11

4-8. Installing the head rest ................................... 11

4-9. Installing the operation panel ......................... 12

4-10. Routing the connector cord and

installing the oil stopper plate ....................... 12

4-11. Connecting the cords.................................... 13

4-11-1. Connecting the ground wire..............13

4-11-2. Connecting the machine

head harness .................................... 13

4-11-3. Connecting the motor harness.......... 14

4-11-4. Connecting the power cord...............15

4-11-5. Connecting the standing operation

pedal harness (option) ...................... 16

4-11-6. Installing the transformer .................. 17

4-12. Installing the V-belt....................................... 19

4-13. Installing the belt cover plate........................ 20

4-14. Installing the treadle connecting rod............. 21

4-14-1. Changing the treadle unit

installation position

(horizontal positioning only) .............. 22

4-15. Installing the spool stand.............................. 23

4-16. Installing the eye guard ................................23

4-17. Lubrication .................................................... 24

4-17-1. Lubricating the bed base................... 24

4-17-2. Lubricating the arm ...........................25

4-17-3. Lubricating the rotary hook ............... 25

4-18. Installing the belt cover................................. 26

4-19. Installing the auxiliary table .......................... 26

5. OPERATION......................................... 27

5-1. Name and function of each operation panel item..27

5-2. Home position detection (preparation)............29

5-3. Operating the treadle ......................................30

5-3-1. Operating the standing operation

pedal (option) ......................................31

5-4. Program setting method..................................32

5-4-1. Program setting examples...................33

5-4-2. Checking the length of knife ................35

5-5. Parameter table ..............................................36

5-5-1. Available sewing area..........................45

5-5-2. Setting the knife length ........................46

5-5-3. Buttonhole sewing size........................46

5-5-4. Main restrictions when setting

parameters ..........................................46

5-6. Rear tack vector shape programs...................48

5-7. Underlay programs .........................................49

5-8. Cutter operation ..............................................50

5-9. Cycle program.................................................51

5-10. Production counter........................................52

5-11. Bobbin thread counter...................................53

5-12. Using the program memos............................53

5-13. Adding patterns created using the

programming software for electronic

pattern sewer.................................................54

6. CHECKING THE SEWING PATTERN .55

6-1. Test feed mode...............................................55

6-2. Manual mode ..................................................56

7. CORRECT USE ....................................57

7-1. Installing the needle........................................57

7-2. Threading the upper thread ............................58

7-3. Winding the lower thread ................................59

7-4. Threading the bobbin case .............................60

7-5. Thread tension ................................................61

7-5-1. Lower thread tension...........................61

7-5-2. Upper thread tension...........................62

7-5-3. Thread take-up spring height ..............63

7-5-4. Thread take-up spring tension.............63

7-5-5. Adjusting arm thread guide .................63

8. SEWING ...............................................64

8-1. Sewing ............................................................64

8-2. If the stop switch is pressed during sewing ....65

8-3. If the thread breaks during sewing..................66

8-4. Thread breakage before sewing is finished....67

8-5. When resuming sewing in test feed mode

or manual mode ..............................................68

HE-800A

9.CLEANING AND MAINTENANCE .........69

9-1. Cleaning ......................................................... 69

9-2. Draining the oil................................................ 70

9-3. Cleaning the control box air inlet port............. 70

9-4. Cleaning the eye guard .................................. 70

9-5. Checking the needle....................................... 71

9-6. Cleaning the length feed plate........................ 71

10. STANDARD ADJUSTMENTS ............72

10-1. Adjusting the needle bar height....................72

10-2. Adjusting the needle and hook timing ..........73

10-3. Adjusting the clearance between needle

and hook point .............................................. 73

10-4. Adjusting the inner rotary hook and

rotary hook holder overlap ............................ 74

10-5. Adjusting the work clamp pressure ..............74

10-6. Adjusting the cutter installation..................... 74

10-7. Adjusting the upper thread trimming ............75

10-7-1. Adjusting the installation height of

the upper thread scissors.................. 75

10-7-2. Adjusting the upper thread scissors

opening timing................................... 76

10-8. Adjusting the lower thread clamp timing....... 77

10-9. Adjusting the bobbin presser........................ 77

10-10. Adjusting the needle up stop position......... 77

11. CHANGING FUNCTIONS USING

THE MEMORY SWITCHES ................78

11-1. Memory switch table.....................................79

12. PROGRAM INITIALIZATION..............80

12-1. Initializing all programs................................. 80

12-2. Initializing a single program.......................... 80

13. CHANGING FUNCTIONS USING

THE DIP SWITCHES ..........................

13-1. Panel DIP switches....................................... 81

13-2. Circuit board DIP switches ........................... 83

14. ERROR CODE TABLE .......................85

15. GAUGE PARTS LIST .........................

16. TROUBLESHOOTING........................

16-1. Upper thread breakage................................. 92

16-2. Skipped stitches ...........................................93

16-3. Uneven seams (1) ……

At the sewing start..................................... 94

81

89

92

16-4. Uneven seams (2) ……

Lower thread is lifted up at

the sewing start .........................................95

16-5. Uneven seams (3) ……

Seam lifts up at the sewing start................96

16-6. Uneven seams (4) ……

Uneven sewing pitch at the sewing start

16-7. Uneven seams (5) ……

Poor rounding of seam .................................96

16-8. Uneven seams (6) ……

Around rear tack or front tack ....................96

16-9. Uneven seams (7) ……

Loose thread end at end backtack ............97

16-10. Uneven seams (8) ……

Thread sticking out at end backtack........97

16-11. Uneven seams (9) ……

Sticking in needle plate............................97

16-12. Uneven seams (10) ……

All stitches................................................98

16-13. Upper thread run out...................................99

16-14. Unraveling of thread trimmed by upper

thread trimmer assembly...........................101

16-15. Upper thread mis-trimming .......................102

16-16. Needle strikes upper thread trimmer ........102

16-17. Needle breakage.......................................103

16-18. Imperfect cutter function

(imperfect material cutting)........................104

16-19. Cutter does not return...............................105

16-20. Cutter and upper thread scissors touch....105

16-21. Seam is cut ...............................................105

16-22. Upper thread mis-winding.........................106

16-23. Work clamp is not raised (1) Pulse motor

stepping sound cannot be heard...............106

16-24. Work clamp is not raised (2) Pulse motor

stepping sound can be heard....................107

16-25. Lower thread is not trimmed

(pulls when material is removed)...............108

16-26. Feed mechanism does not operate or

motor is out of step....................................108

16-27. Needle does not zigzag or noise occurs

when needle zigzags.................................109

16-28. Sewing machine stops during sewing.......109

16-29. Upper shaft does not rotate as far as

the needle up stop position .......................109

....96

HE-800A

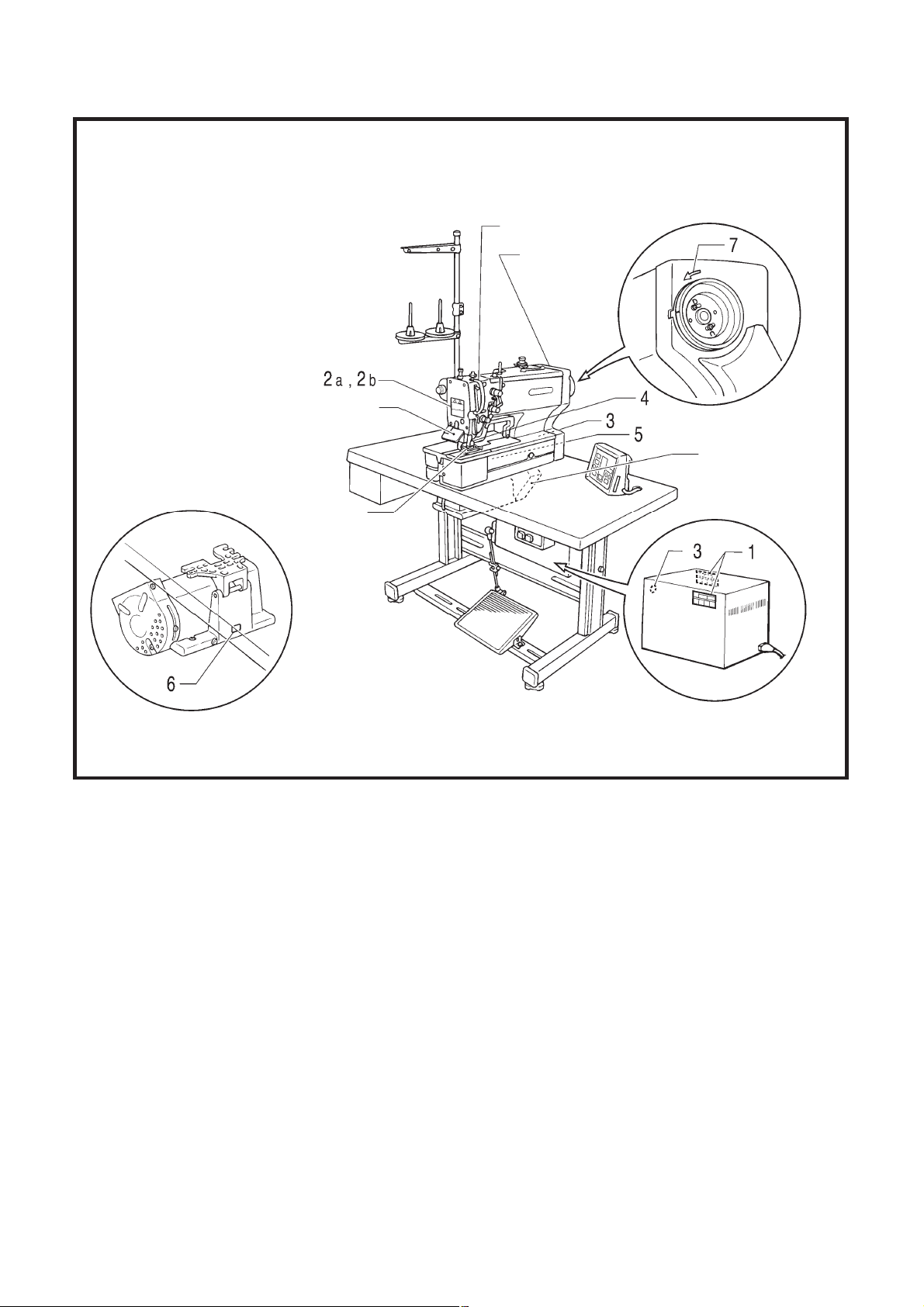

1. NAME OF EACH PART

㧝

. NAME OF EACH PART

(1) Power switch (2) Control box (3) Operation panel

(4) Treadle (5) AC servo motor (6) Stop switch

(7) Spool stand (8) Pulley (9) Tension release lever

Safety devices

(10) Eye guard (11) Thread take-up cover (12) Belt cover

(13) Belt cover plate (14) Finger guard (15) Finger protector

(16) Belt retainer

4110M

1

HE-800A

㧞

㧞-㧝

. SPECIFICATIONS

2. SPECIFICATIONS

. Specifications

Buttonholes for clothing such as dress

shirts, blouses, work clothes and women's

clothes

-2

Buttonholes for knitted garments such as

knitted underwear, sweaters, cardigans

and jerseys

-3

Max. sewing speed

Zigzag mechanism

Feed mechanism

Work clamp lifter mechanism

Height of work clamp

Knife mechanism

Lower thread holding device

Bobbin presser

Standard sewing pattern

Memory pattern

Max. number of stitch

Needle

Data storage method

Power supply

Main use Buttonhole size

B

700 stitches / program (Overall cycle program stitch no. 3,000 stitches)

-2 -3

Schmetz 134 Nm90 Schmetz 134 Nm75

P-ROM (Custom made pattern can be added by the programming software for

Three phase 220 V, 380 V, 400 V 600 VA

A

C D

A: Max.6 mm

B: Max. zigzag stitch length 39 mm

C: Length of knife 4 – 32 mm

D: Max. buttonhole length 40 mm

4,000 sti/min

Pulse motor driven mechanism

Pulse motor driven mechanism

Pulse motor driven mechanism

13 mm max. (adjustable)

Double position solenoid

Standard equipment

Standard equipment

21

90

electronic pattern sewer)

Single phase 110 V, 220 V, 230 V

2193Q

HE-800A

2

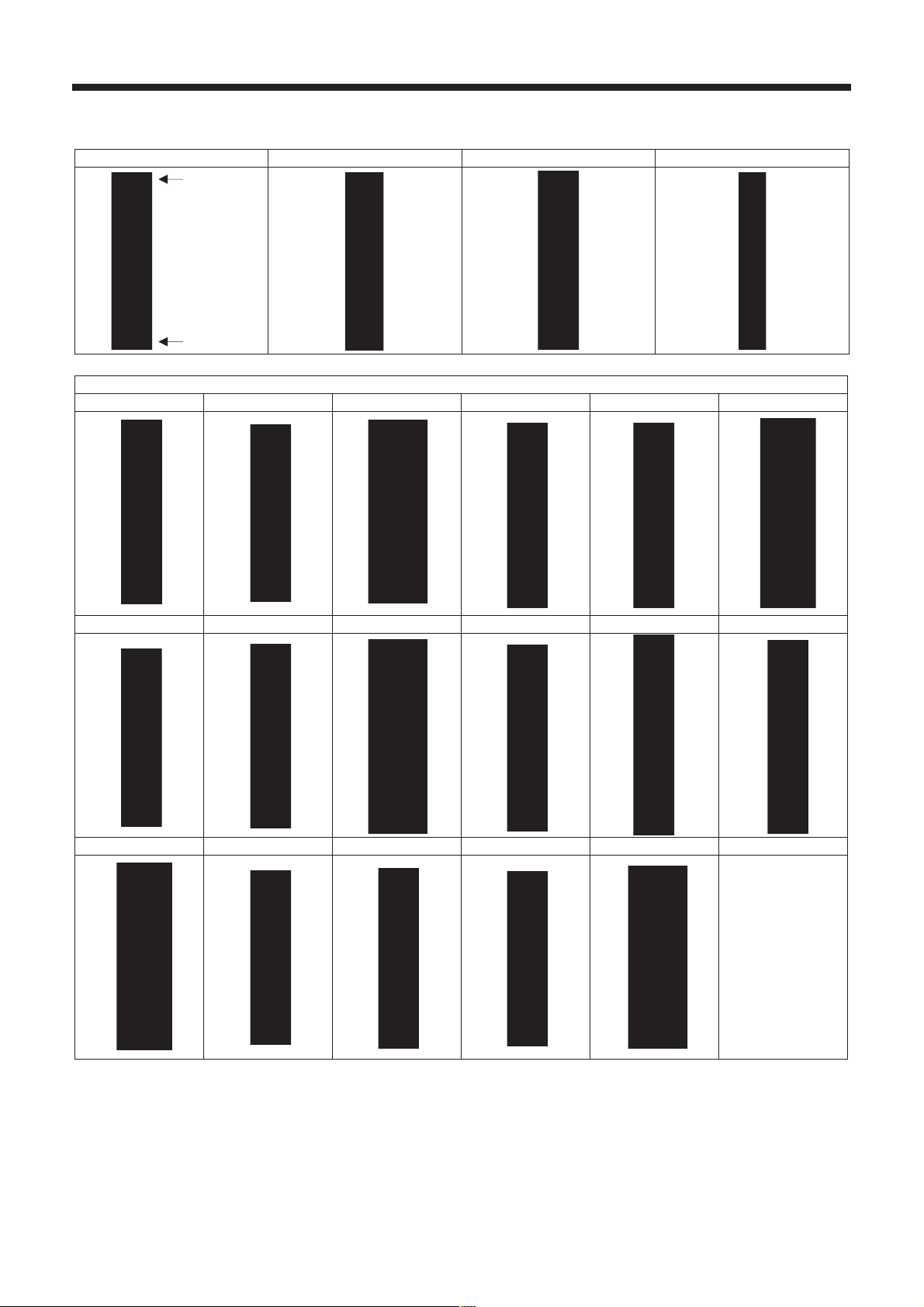

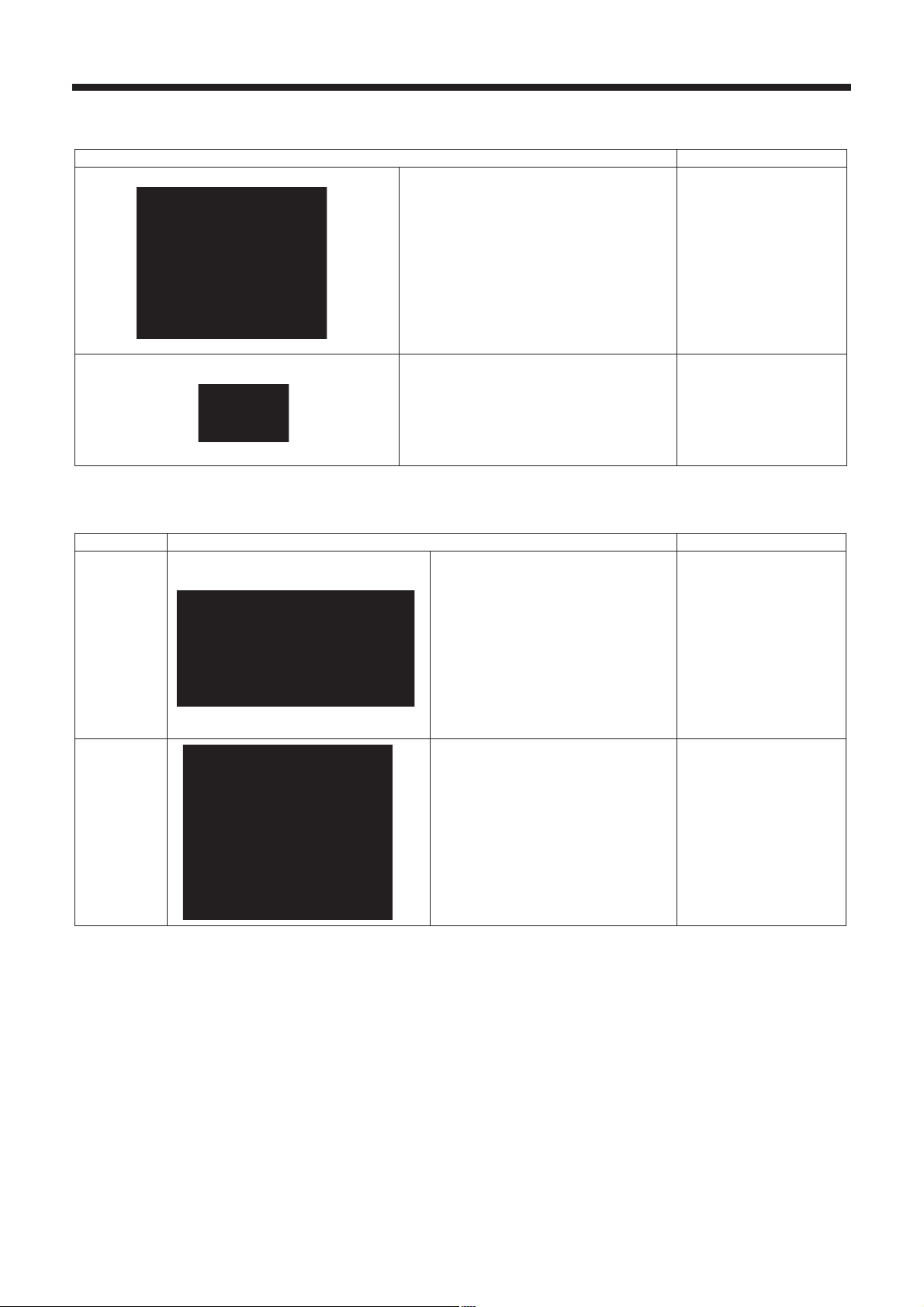

2. SPECIFICATIONS

㧞-㧞

. Standard sewing pattern list

[1] Rectangle [2] Radial [3] Round [4] Straight bar tack

Rear tack

Front

Radial-rectangle Round-rectangle Eyelet-rectangle Rectangle-radial Round-radial Eyelet-radial

Rectangle-round Radial-round Eyelet-round

Eyelet-taper tack Rectangle-tack Radial-tack Round-tack Eyelet-tack

tack

[0] Free (Combinations of rear tack shapes and the front tack shapes - 17 patterns)

Rectangle-taper tack

Radial-taper tack Round-taper tack

* [0] to [4] indicate the setting range for parameter No. 1. (Refer to "5-5. Parameter table".)

* In addition to the above shapes, you can create and use up to 9 additional custom made patterns using the

programming software for electronic pattern sewer.

3

HE-800A

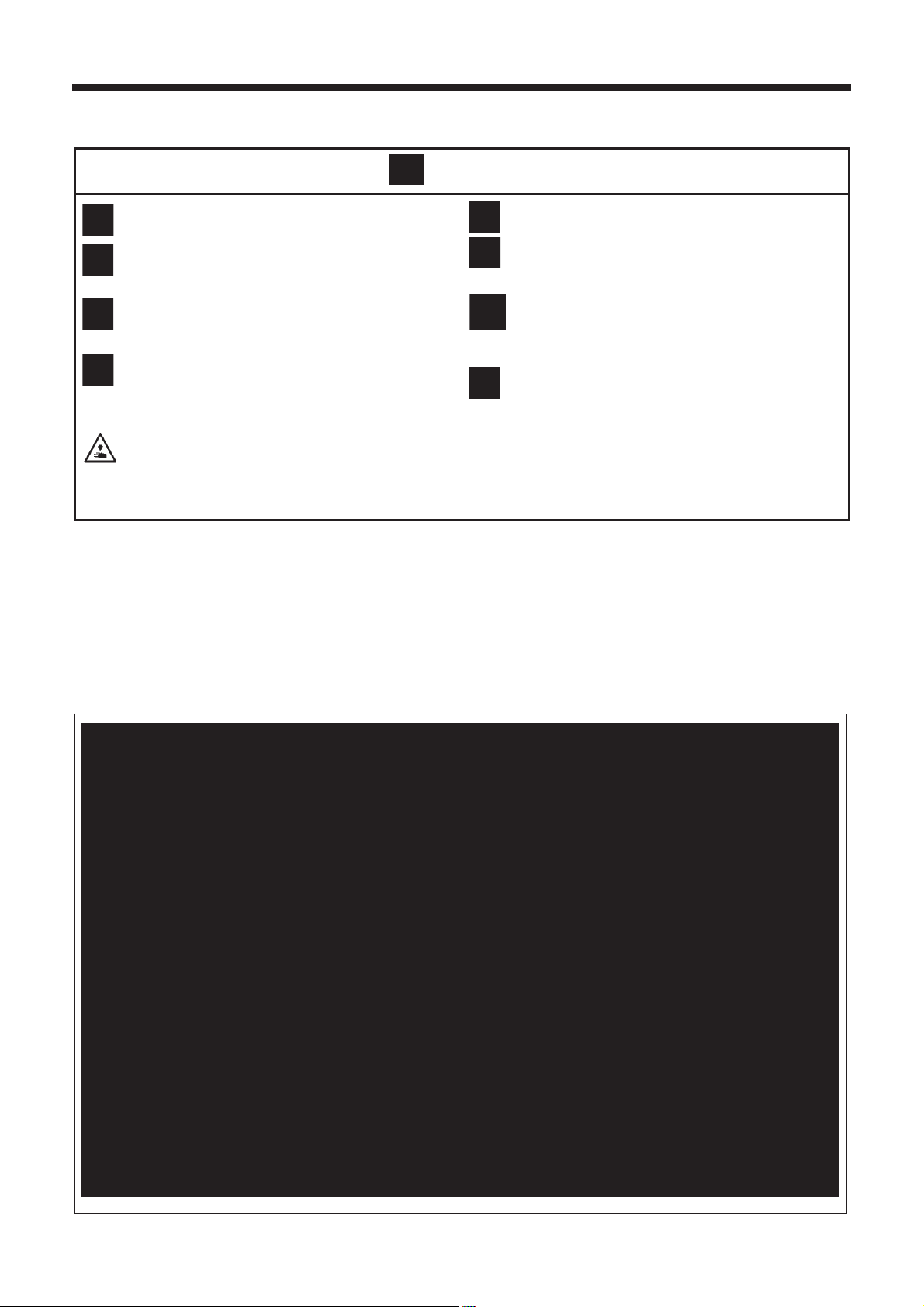

㧟

㧟-㧝

㧟-㧞

. OPTIONAL PARTS

3. OPTIONAL PARTS

. Special needle plate

. Leg parts

This needle plate uses the elasticity of rubber to

prevent the cutter from getting stuck and not returning.

It also helps to keep the cutter blade sharp.

* The standard cutter can be used.

Parts name Parts code

Needle plate set 1.2RB S51361-001

-2

Needle plate set 1.4RB S51362-001

Needle plate set 1.6RB S51363-001

Needle plate set 1.2RB-3 S51364-001

-3

Needle plate set 1.4RB-3 S51365-001

2037Q

Parts name Parts code

Spacer set 183504-109

2038Q

Caster set 183501-001

2039Q

Needle plate set 1.6RB-3 S51366-001

HE-800A

4

3. OPTIONAL PARTS

㧟-㧟

㧟-㧠

Horizontal

ruler

Vertical

ruler

. Standing operation pedal

Parts name Parts code

<Except for Europe>

J80380-040

Three pedals

<For Europe only>

2041Q

Harness for standing operation pedal S47750-000

3854Q

J80380-0E0

. Ruler

Parts name Parts code

Ruler assy 800E S50350-001

2043Q

Ruler assy S50477-001

2044Q

5

HE-800A

㧟-㧡

3. OPTIONAL PARTS

. Tape guard

2042Q

Tape guard winder assy

S50346-001

Tape winder assy

143767-102

Tape guard assy

S51896-001

HE-800A

6

4. INSTALLATION

㧠

㧠-㧝

. INSTALLATION

CAUTION

Machine installation should only be carried out by

a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may need

to be done.

The sewing machine weighs approximately 56 kg.

The installation should be carried out by two or

more people..

Do not connect the power cord until installation is

complete, otherwise the machine may operate if

the treadle is depressed by mistake, which could

result in injury.

Use both hands to hold the machine head when

tilting it back or returning it to its original position.

If only one hand is used, the weight of the

machine head may cause your hand to slip, and

your hand may get caught.

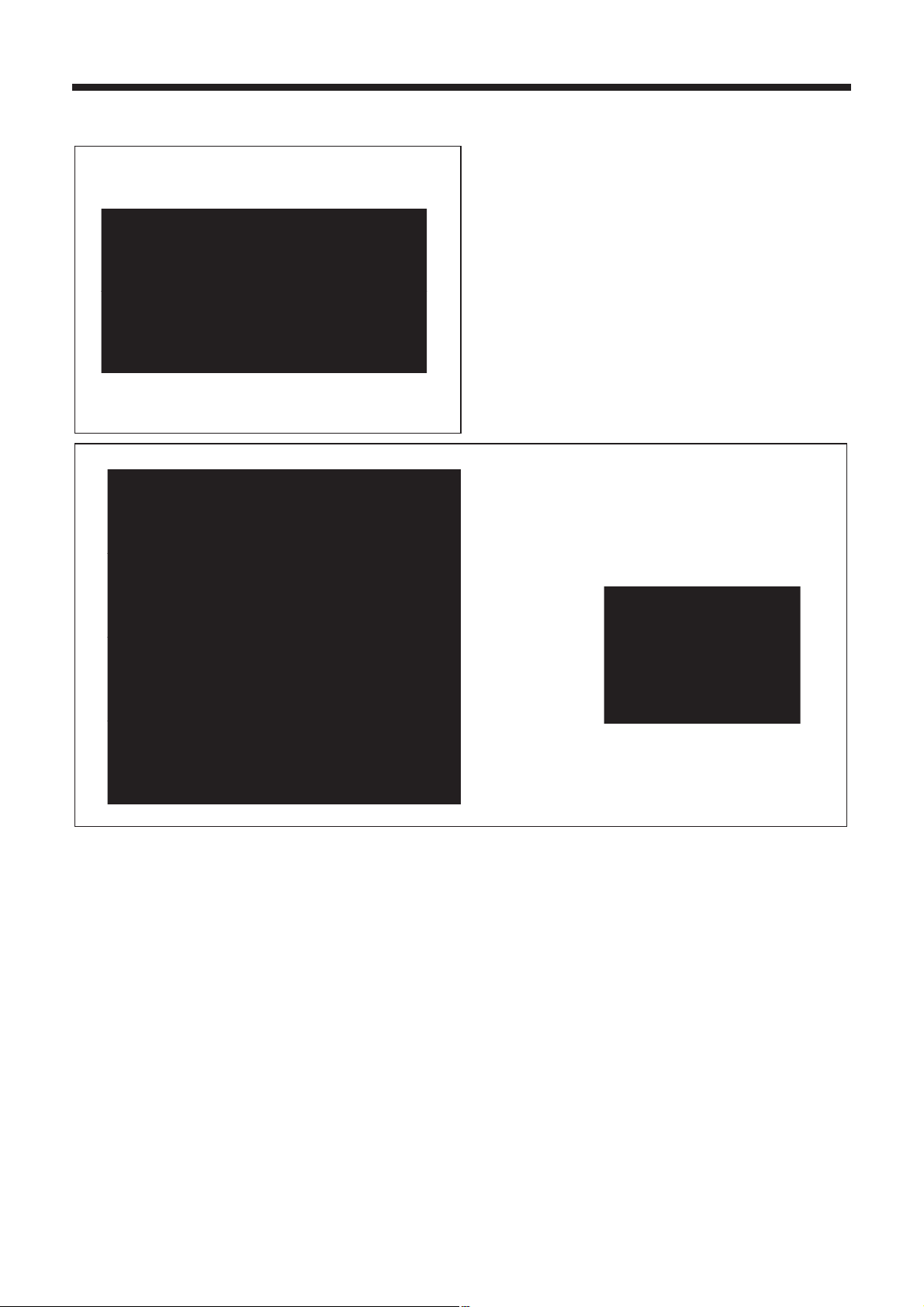

x The thickness of the table should be at least 40 mm, and it should be strong enough to bear the weight and vibration

x The method for processing the table will vary depending on whether the positioning method is vertical or horizontal.

. Table processing diagram

of the sewing machine.

Make the holes in the correct places while referring to the table processing diagram which matches the positioning

method.

All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too

firmly with staples, otherwise there is the danger

that fire or electric shocks could occur.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

Install the belt covers to the machine head and

motor.

[Vertical positioning]

7

4091M

HE-800A

㧠-㧞

[Horizontal positioning]

4. INSTALLATION

4095M

. Installing the motor

3856Q

Install the motor (1) with the three bolts (2), flat

washers (3), spring washers (4) and nuts (5).

HE-800A

8

4. INSTALLATION

㧠-㧟

㧠-㧠

Note: When opening the cover, hold it securely so that it does not fall down.

1. Remove the 12 screws (1), and then open the covers (main P.C. board mounting plate (2) and sub P.C. board

2. Install the control box with the bolts (4), cushions (5), cushion collars (6), rubber collars (7), flat washers (8) and nuts

3. Close the covers (main P.C. board mounting plate (2) and sub P.C. mounting plate (3)), and provisionally tighten

. Installing the flange nut

Install the four flange nuts (1) to the underside of the

work table.

Note:

When the machine head is positioned horizontally,

some flange nut installation locations may be

inaccessible after the control box has been installed.

3857Q

. Installing the control box

3858Q

mounting plate (3)).

(9) as shown in the illustration. At this time, leave a gap of approximately 2 mm between the work table and the top

of the box.

them with the screws (1). (They will be opened again when the cords are connected.)

9

HE-800A

㧠-㧡

㧠-㧢

4. INSTALLATION

1. Place the bed base (1) on top of the work table, and insert the four collars (2).

2. Provisionally tighten the four flange nuts (4) onto the four bolts (3), and then position the bed base (1).

3. Install the bed base (1) with the three flat washers (5) and wood screws (6), and then install the two rubber caps (7).

4. Remove the four bolts (3).

5. Set the magnet (8) in the position shown in the illustration.

. Installing the power switch

. Installing the bed base

3859Q

1. Install the power switch (1) with the two screws (2).

2. Secure the power switch (1) cord and the motor (4)

cord with the six staples (3).

4069M

HE-800A

10

4. INSTALLATION

㧠-㧣

㧠-㧤

. Installing the machine head

3861Q

3862Q

1. Place the two bed hinges (1) so that they are level

as shown in the illustration at left, and then place

the machine head gently on top of the bed base (3)

so that the cables (2) do not get clamped.

Note:

The bed base (3) is made from plastic, so be

careful not to hit it with the machine head when

placing the machine head on top of it.

2. Install the machine head with the four spring

washers (4) and four bolts (5).

Note:

Make sure that the felt support (6) do not touch

the bed base (3).

11

. Installing the head rest

2778Q

HE-800A

Tap the head rest (1) into the table hole.

Note:

Tap the head rest securely into the table hole.

If the head rest is not pushed in as far as it will go,

the machine head will not be sufficiently stable when

it is tilted back.

㧠-㧥

㧠-㧝㧜

4. INSTALLATION

. Installing the operation panel

Top of work table

Bottom of work table

Table

Table

3863Q

3864Q

The operation panel can be installed to either the top

or bottom of the work table.

1. Install the rear frame (1) to the work table (top or

bottom) with the four wood screws (2).

2. Install the front frame assembly (3) to the rear frame

(1) with the four screws (4).

* The vertical orientation of the front frame assembly

(3) is the same whether it is installed to the top or

the bottom of the work table.

* Pull the harnesses such as the ground harness out

of the way so that the operation panel side cover

(5) can be opened and closed.

3. Insert the connector cord (6) into the control box

through the hole at the side of the box.

. Routing the connector cord and installing the oil stopper plate

3865Q

3866Q

HE-800A

1. Gently tilt back the machine head.

2. Pass the cords (1) through the hole in the work

table.

3. Install the oil stopper plate (2).

4. Move the connector cord (1) so that it will not be

clamped by the machine head and the bed base (3),

and then return the machine head to its original

position.

12

4. INSTALLATION

㧠-㧝㧝

㧠-㧝㧝-㧝

㧠-㧝㧝-㧞

The harness is connected in the same way regardless of whether the machine head is positioned horizontally or

vertically.

1. Remove the 12 screws (1), and then open the covers (main P.C. board mounting plate (2) and sub P.C. board

mounting plate (3)).

Note: When opening the cover, hold it securely so that it does not fall down.

2. Insert the panel harness (4) into the control box.

3. Connect the ground wire (5) which is protruding out from the hole at the side of the control box to the leg (6).

4. Connect the ground wire (7) coming from the machine head to the grounding point (8) inside the control box.

5. Connect the ground wire in the panel harness to the ground point (9) inside the control box.

* Grounding marks are displayed on the machine head and inside the control box.

Note: If the shape of the grounding screw in the leg (6) requires a different ground wire to be connected, replace the

. Connecting the cords

. Connecting the ground wire

CAUTION

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct operation may also occur.

Grounding mark

Grounding mark

3867Q

ground wire with the accessory ground wire.

If the ground wires are not connected, incorrect operation may result.

If the grounding point has been painted over, remove the paint coating before connecting the ground wire.

13

. Connecting the machine head harness

1. Insert the machine head harness (1) into the control

box.

2. Gently tilt back the machine head.

3. Pull the harness (1) through the cord clamp (2) at

the top of the control box.

* This cord clamp is not used when the machine

head is positioned horizontally.

3868Q

HE-800A

㧠-㧝㧝-㧟

4. INSTALLATION

. Connecting the motor harness

3869Q

3870Q

3871Q

1. Pass the motor harness (1) through the cord bush

(2).

2. Connect the connectors (3).

3. Secure the motor harness (1) with staples.

4. Securely insert each of the connectors (4) – (8) as

indicated below.

Harness Mark

Feed motor

(4)

<5-pin>(White)

Presser foot motor

(5)

<5-pin> (Blue)

Cutter solenoid

(6)

<6-pin>

Fan <3-pin>

(7)

Cutter home position

(8)

sensor <12-pin>

S2

S5

S8

S7

Sub P.C. board

P2㧔FDPM㧕

P5㧔FTPM㧕

P8㧔CUTTER㧕

P10㧔FAN1㧕

-

P7㧔OPSEN2㧕

indication

5. Securely insert the connectors (9) and (10) as

indicated below.

Note:

Take note of how these two harnesses are routed

through the control box so as not to confuse them

with any of the other harnesses.

Main P.C. board

indication

P16㧔NPM㧕

P19㧔OPSOL㧕

Zigzag motor

(9)

<6-pin>

Tension release

(10)

solenoid <6-pin>

Harness Mark

M16

M19

HE-800A

14

4. INSTALLATION

㧠-㧝㧝-㧠

3872Q

6. Securely insert each of the connectors (11) – (13)

as indicated below.

Harness Mark Main P.C. board

(11)

Synchronizer <5-pin>

Home position sensor

(12)

<12-pin>

(13)

Stop switch <11-pin>

indication

M3

M11

M10

P3㧔SYNC㧕

P11㧔ORG㧕

P10㧔HEAD㧕

7. Secure the harnesses inside the control box using

cord clamps as shown in the illustration.

Note:

• Make sure that the harnesses do not come into

contact with P.C. board components or with the

main P.C. board heat sink or the sub-P.C. board

heat sink.

• Use the cord clamps at the top of the control box

to adjust the harnesses so that they are not

loose inside the control box, particularly when

using the work table with the machine head

positioned vertically.

8. Gently return the machine head to its original position.

* Check that the harnesses do not touch the belt.

9. Close the covers (main P.C. board mounting plate and sub P.C. mounting plate), and tighten the 12 screws.

. Connecting the power cord

CAUTION

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct operation may also occur.

1. Attach an appropriate plug to the power cord (1).

(The green and yellow wire is the ground wire.)

2. Insert the plug into properly-grounded AC power

supply.

Note:

• Do not use extension cord, otherwise machine

operation problems may result.

• Do not connect a power supply which is not of the

rated voltage, otherwise machine operation

problems may result.

Green and yellow wire

(ground wire)

15

4027Q

HE-800A

㧠-㧝㧝-㧡

4. INSTALLATION

. Connecting the standing operation pedal harness (option)

4111M

1. Pass the marked tube of the standing operation pedal harness (1) into the control box through the hole in the control

box.

2. Connect the standing operation pedal harness (1) to connector P9 on the main circuit board.

3. Remove the screw (2) which is securing the ground wires, and then add the ground wire (3) of the standing

operation pedal harness (1) and re-tighten the screw (2). (The green-and-yellow wire is the ground wire.)

4. Connect the harness (4) to the standing operation pedal harness (1).

* Connect the harness (4) and the standing operation pedal harness (1) inside the control box.

HE-800A

16

4. INSTALLATION

㧠-㧝㧝-㧢

. Installing the transformer

The transformer can be installed on the floor, on the work table leg (on top of the leg or on the treadle support plates)

or underneath the work table.

Check the power supply rating label on the transformer to confirm that the voltage ratings for the transformer and the

control box are identical.

1) Floor installation

Select a suitable location, and place the transformer

on the floor in that location.

* Select a location where the transformer will not be an

obstruction to people walking past.

2069Q

2) Table leg installation (on top of table leg)

2070Q

Mounting

bracket

112.5mm

Screw (M5 x 8)

2071Q

3) Table leg installation (treadle support plates)

3875Q

3876Q

Washer

Screw (M6 x 14)

4035Q

Secure the transformer to the top of the table leg using

the mounting bracket and screws.

* The mounting bracket and screws must be obtained

separately.

1. Remove the four screws (1), and then remove the

two handles (2).

2. Place the transformer on top of the two treadle

support plates (3) as shown in the diagram, and

then secure it to the handle (2) using the washers

and screws.

* The washers and screws must be obtained

separately.

17

HE-800A

4) Installation underneath the work table

Work table hole positions

4. INSTALLATION

3878Q

2075Q 3877Q 3879Q

Standard BROTHER work tables are provided with installation holes for use in installing the transformer.

1. Remove the four screws (1), and then remove the two handles (2).

2. Use the bolts (4), flat washers (5), spring washers (6) and nuts (7) to install the transformer as shown in the

illustration, while leaving a gap of 2 mm between the work table and the cushion collars (3).

* Use the bolts, flat washers, spring washers, nuts and cushion collars which are included.

Connecting the cords

3880Q 3881Q

1. Loosen the four screws (1), and then remove the transformer cover (2).

2. Connect the control box connector (3) to the transformer connector (4).

3. Secure the connected cords with the cord holder (5) and the screw (6), and place them inside the transformer cover

(2).

4. Install the transformer cover (2) with the four screws (1).

5. Secure the cords to the work table using staples.

HE-800A

18

4. INSTALLATION

㧠-㧝㧞

. Installing the V-belt

3882Q

3883Q

3884Q

1. Remove the four screws (1), and then remove the

motor belt cover (2).

2. Gently tilt back the machine head, and then place

the V-belt (3) into the V grooves in the machine

head pulley and the motor pulley.

3. Turn the two nuts (4) to adjust so that there is 10 14 mm of deflection in the V-belt (3) when it is

pressed at the midway point with a force of 5 N.

Note:

If the V-belt tension is too loose, or if the V-belt is

stretched, the following problems could occur.

a. The stopping position may shift,

b. The needle bar may drift when the machine stops,

c. An extra stitch may be sewing when the machine

stops,

d. An abnormal noise may be heard due to V-belt

slipping, and

e. The V-belt may become too loose and contact

with the cover.

If any such problems occur, adjust by following the

procedure described above.

4. Secure the motor belt cover (2) and the auxiliary

motor belt cover (5) with the four screws (1) as

shown in the illustration so that they do not touch

the V-belt (3).

19

HE-800A

㧠-㧝㧟

4. INSTALLATION

Adjusting the belt holder

1. Loosen the screw (1).

2. Align the boss of the belt holder (2) with the mark

(3).

3. After adjusting, tighten the screw (1).

Adjusting the finger protector

1. Loosen the screw (4).

2. Align the center of the screw (4) with the mark (5) to

adjust the position of the finger protector (6).

3. After adjusting, tighten the screw (4).

3885Q

Note: If the machine head is positioned horizontally, there is no need to install the belt cover plate.

Install the belt cover (1) with the two wood screws (3) so that it does not touch the motor belt cover (2).

* Set the belt cover plate (1) so that there is a gap of 3 mm or more in the longer motor direction, and also should not

be projected out from the edge of the work table.

. Installing the belt cover plate

3 mm or more

3887Q3886Q

HE-800A

20

4. INSTALLATION

㧠-㧝㧠

. Installing the treadle connecting rod

Install the connecting rod (1) to the treadle lever (2)

with the nut (3).

3888Q

Fig. A Fig. B

3890Q3889Q

Adjusting the treadle pressure

If the machine starts running when your foot is simply resting on the treadle, or if the treadle pressure is too weak,

adjust the position (a to c) at which the treadle spring (4) is hooked onto the treadle lever (2).

The treadle pressure will increase from position a to position c.

Adjusting the treadle return pressure

1. Loosen the nut (5) and turn the bolt (6).

* The treadle return pressure becomes heavier as the bolt (6) is tightened, and becomes lighter as the bolt (6) is

loosened.

2. Tighten the nut (5).

Adjusting the treadle stroke

Remove the nut (3), and then move connecting rod joint (7) from the position in figure A to the position in figure B.

The treadle stroke will increase by approximately 1.25 times.

* This adjustment will also affect the treadle pressure and the treadle return pressure, so these settings should be

readjusted if necessary.

21

HE-800A

㧠-㧝㧠-㧝

4. INSTALLATION

. Changing the treadle unit installation position (horizontal positioning only)

Note: If the machine head is positioned horizontally, install the treadle unit to the motor.

3891Q

1. Disconnect the connector (2) of the treadle unit (1) inside the control box.

2. Remove the screw (3), and then disconnect the ground wire. Then, re-tighten just the screw (3).

3. Remove the three screws (4), and then remove the treadle unit (1).

4. Install the V cord bushing (6) to the treadle setting plate (5).

5. Install the treadle setting plate (5) and the treadle unit (1) to the motor with the three screws (4).

6. Install the ground wire with the screw (7).

7. Re-connect the connector (2) of the treadle unit (1) inside the control box.

3893Q3892Q

HE-800A

22

Loading...

Loading...