Page 1

Continuous Flow Gas Water Heaters (External Models)

HydroPower

TF250-8G(10H)/ TF325-8G(13H)/ TF400-8G(16H)

Installation Manual and Operating Instructions

Read installation manual prior to installation of this unit!

Read user manual before putting this unit in operation!

Observe the warnings in the manuals!

The installation room must fulfill the ventilation requirements!

Installation by an authorised person only!

8 716 473 071 (2015/04) AU

Page 2

2 | Table of contents

Table of contents

1 Safety information and symbols . . . . . . . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . 3

2 Technical Characteristics and Dimensions . . . . . . . 4

2.1 General Description . . . . . . . . . . . . . . . . . . . 4

2.2 Explanation of Model Code . . . . . . . . . . . . . . 4

2.3 Package contents . . . . . . . . . . . . . . . . . . . . . 4

2.4 Product overview . . . . . . . . . . . . . . . . . . . . . 4

2.5 Description of the Hot Water Unit . . . . . . . . 4

2.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7 Electrical scheme . . . . . . . . . . . . . . . . . . . . . 7

2.8 Technical characteristics . . . . . . . . . . . . . . . 7

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Important information . . . . . . . . . . . . . . . . . . 9

4.2 Requirements of the installation location . 10

4.3 Hot Water Unit mounting . . . . . . . . . . . . . . 11

4.4 Water connection . . . . . . . . . . . . . . . . . . . . 12

4.5 Gas connection . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Before starting up the heater . . . . . . . . . . . 12

5.2 Remove the front cover . . . . . . . . . . . . . . . . 12

5.3 Inlet pressure adjustment . . . . . . . . . . . . . . 13

5.4 Burner pressure adjustment . . . . . . . . . . . . 13

5.5 Conversion to a different type of gas . . . . . 14

10 Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11 Warranty details . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Consumer gas adjustment . . . . . . . . . . . . . 14

6.2 Consumer temperature/flow adjustment . 14

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1 Problem/cause/solution . . . . . . . . . . . . . . . 16

9 Environmental protection . . . . . . . . . . . . . . . . . . . . 17

8 716 473 071 (2015/04) HydroPower

Page 3

Safety information and symbols | 3

1 Safety information and symbols

1.1 Key to symbols

Warnings

Warnings in this document are identified by

a warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

The following keywords are defined and used in this document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

This symbol indicates important information

where there is no risk to people or property.

Additional symbols

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

•List entry

– List entry (second level)

Table 1

1.2 Safety information

If you smell gas:

▶ Close the gas supply valve to the appliance.

▶ Isolate gas supply from gas meter or LPG bottle.

▶ Do not operate any electrical appliances or switches (on/

off).

▶ Extinguish other sources of ignition.

▶ Go to a different location and call the gas supplier or an

authorised technician in order to check the gas supply.

If you notice dark combustion gases or sooting:

▶ Isolate the Gas supply to the heater.

▶ Notify an authorised technician.

Installation, Assembly and Modifications

▶ The installation, assembly and modifications to the heater

must only be performed by an authorised installer.

Maintenance

▶ The water heater is required to have a service and safety

inspection every two years.

▶ The Installer is responsible for the safety and

environmental compatibility of the installation.

▶ The Owner/User is responsible for keeping the area around

the water heater free from debris.

▶ Safe access to inspect and service the water heater is the

responsibilty of the property owner.

▶ Only original spare parts must be used, supplied by an

authorised distributor of Genuine Bosch parts.

Explosive and highly flammable material

▶ Do not store or use flammable material (paper, spray cans,

solvents, paints, etc) near the heater.

Combustion air and surrounding air

▶ To avoid corrosion, the combustion air and surrounding air

must be free from harmful substances.

▶ Do not spray aerosols or use chemicals around the heater

unless heater is isolated. (All valves closed).

Risk of damage due to operator error

Operator errors can result in injury and damage to property.

▶ Ensure that children never operate this appliance

unsupervised.

▶ Ensure that only personnel who can operate this appliance

correctly have access to it.

▶ Refer to the operating and user instructions before

adjusting the water heater.

To be installed and serviced only by an authorised person

The “authorised installing person” is responsible for:

▶ Correct installation and commissioning of this appliance.

▶ Ensuring the appliance performs to the specifications

stated on the rating label.

▶ Demonstrating the operation of the appliance to the

customer before leaving.

▶ Handing these instructions to customer.

THIS APPLIANCE IS NOT SUITABLE FOR POOL, SPA POOL OR

SOLAR BOOSTER APPLICATION.

NOT SUITABLE FOR COMMERCIAL BOOSTING OF A WARM

WATER RECIRCULATION SYSTEM.

8 716 473 071 (2015/04)HydroPower

Page 4

4 | Technical Characteristics and Dimensions

2 Technical Characteristics and Dimensions

2.1 General Description

Models Bosch Hydropower TF250/325/400

Category CONTINUOUS FLOW

Type GAS - EXTERNAL INSTALLATION

Table 2

2.2 Explanation of Model Code

TF (Top Flue) 250 (10 litres/min

@ 25 °C Rise)

TF (Top Flue) 325 (13 litres/min

@ 25 °C Rise)

TF (Top Flue) 400 (16 litres/min

@ 25 °C Rise)

Table 3

G (Hydrogenerator)

G (Hydrogenerator)

G (Hydrogenerator)

2.3 Package contents

•Gas hot water unit

• Documentation

2.4 Product overview

HydroPower Ignition is exclusive to Bosch - it does not require

a 240V power supply.

• HydroPower uses the energy created by the water flow to

ignite the burner and begin the heating process. The unit

only starts when a hot water tap is opened. Once the tap is

turned off, the unit turns off.

– Flame rod to check for accidental extinction of the

burner flame

– Overtemperature switch to prevent overheating.

• Water filter on the inlet water supply

Economical

Only heating water when required, the Bosch range is

extremely economical to run.

Versatile

LPG models are particularly popular in country areas, where

Natural Gas is not available.

Low Temperature Areas

In areas where the atmospheric temperature may drop to 0 °C

for brief periods, the installation of an EXOGEL valve (part

number H707 060 151) will minimise the possibility of

damage to the appliance if the water freezes.

NOTICE:

This water heater MUST NOT be installed in

areas where the temperature remains below

0 °C for extended periods.

2.5 Description of the Hot Water Unit

• Hot Water Unit for external wall-mounting only

• Available in Natural gas or LP gas

• Hydrogenerator produces sufficient energy to ignite and

control the heater

– Water enters the Hydrogenerator

– The turbine spins with water flow

– A voltage is generated by the turbine

– This voltage causes the ignition control unit to light a

temporary pilot

– The water pressure opens the main burner gas valve

and the pilot ignites the main burner, the pilot then

goes out

– The water flows through the heat exchanger where it is

heated

•Safety devices:

8 716 473 071 (2015/04) HydroPower

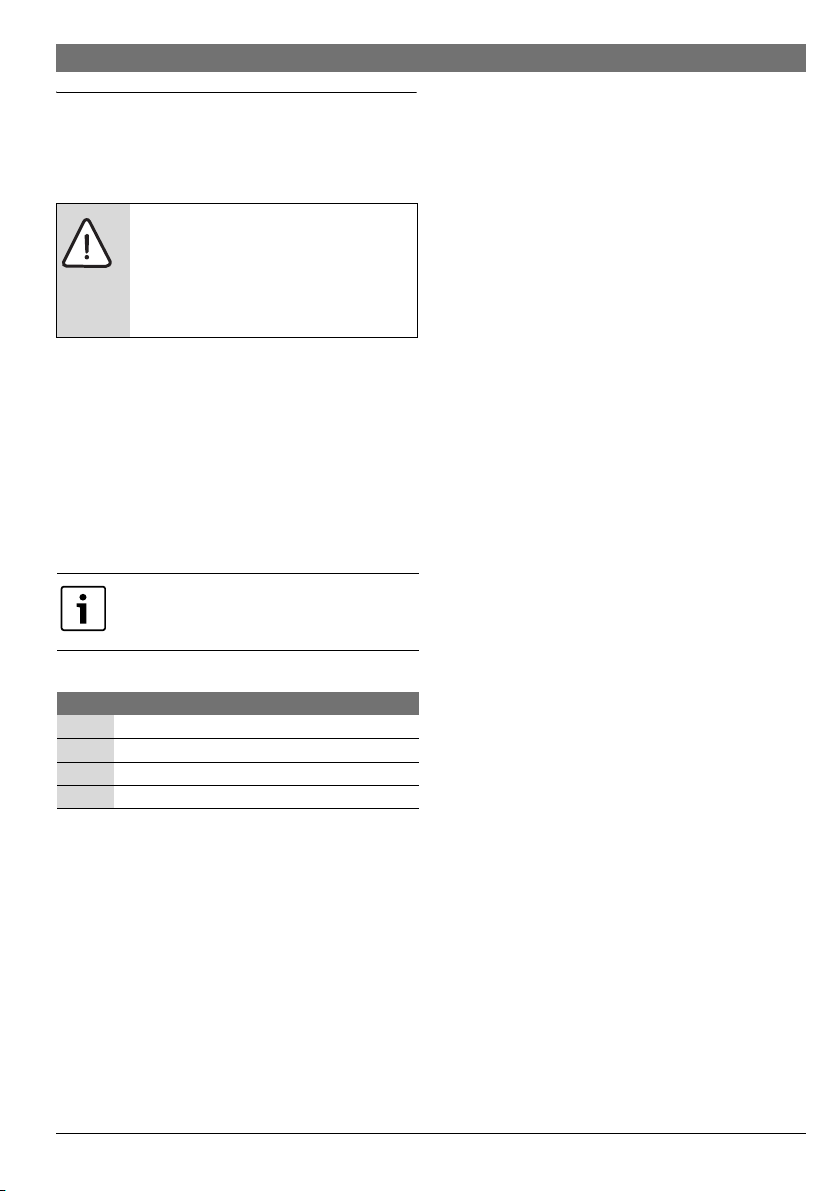

Fig. 1 EXOGEL valve

[1] Hot water

[2] Cold water

[3] EXOGEL valve

Page 5

Low Flow Rates

This gas water heater is designed to operate at a minimum flow

rate between 3.2 to 4.0 litres per minute. Sufficient flow must

be provided to ensure the correct operation of the appliance.

There are various causes of a low flow rate including, but not

limited to:

• Low flow tapware

• Flow restrictors/aerators

•Hand held showers

• Poor inlet pressure to property

• Restrictive pipework and/or fittings

Water fixtures with a flow rate of 7.5 litres per min for hand

basins and 9 litres per min for shower roses are recommended.

Failure of the unit to operate correctly due to poor flow rate will

not be covered by warranty.

Technical Characteristics and Dimensions | 5

8 716 473 071 (2015/04)HydroPower

Page 6

6 | Technical Characteristics and Dimensions

265

B

9708069951-01.2V

A

C

E

2

D

3

6

1

50

120120

Ø1/2" Ø1/2"

NG: Ø3/4"

LPG: Ø1/2"

4 4

7

5

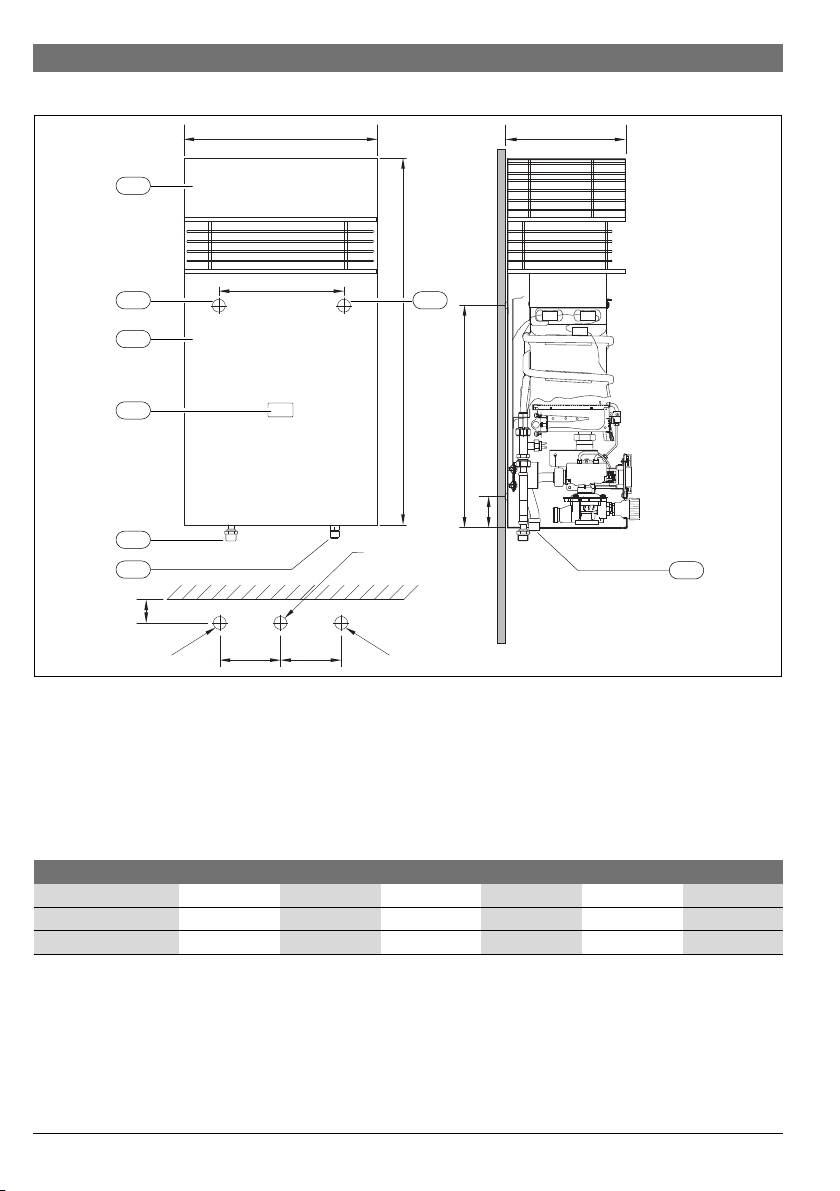

2.6 Dimensions

Fig. 2

[1] Top flue

[2] Front cover

[3] Inspection window

[4] Wall mounting point

[5] Cold water inlet

[6] Gas inlet

[7] Hot water outlet

Dimensions (mm) A B C D E Weight (kg)

TF250(10H) 405 845 533 240 68 21

TF325(13H) 405 845 533 240 68 22

TF400(16H) 460 936 533 240 82 25

Table 4 Dimensions

8 716 473 071 (2015/04) HydroPower

Page 7

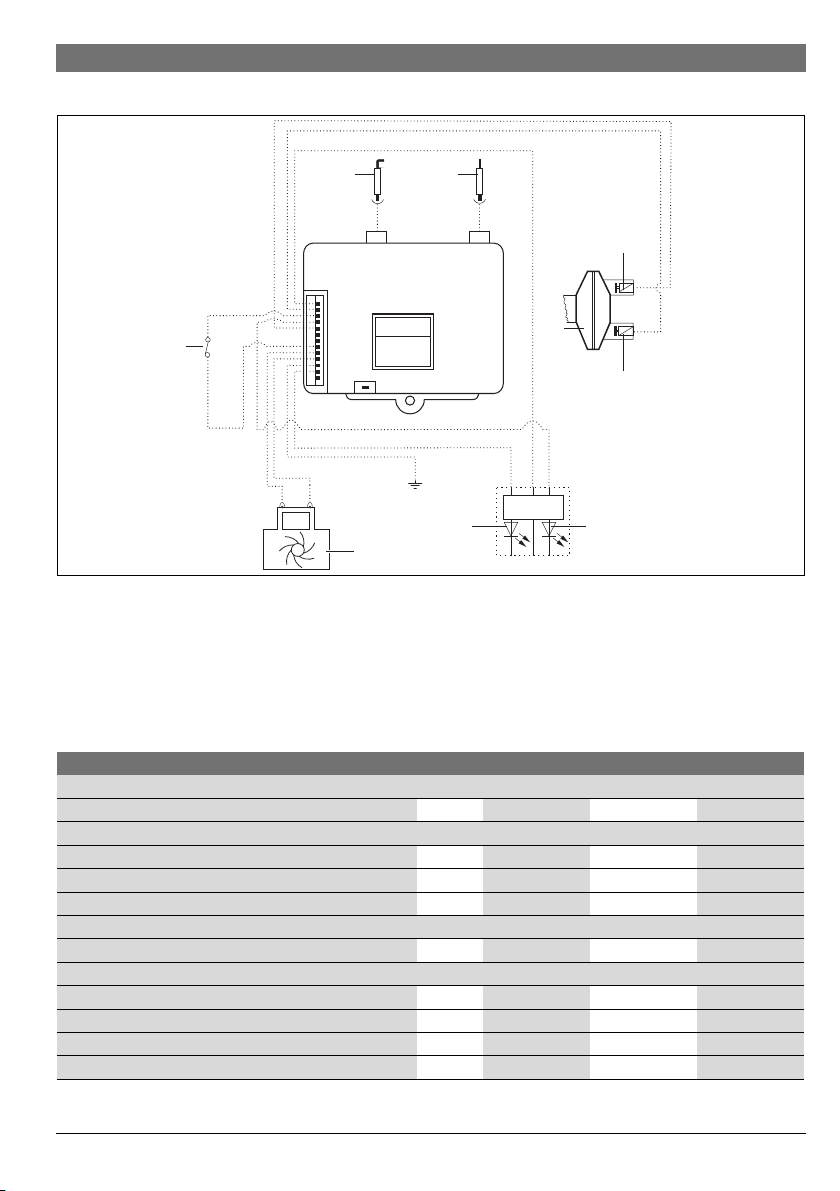

2.7 Electrical scheme

45

3

1

2

9

6

8

SHV

9708069951-11.1V

7

Fig. 3

[1] Main Solenoid Valve

[2] Diaphragm Switch

[3] Pilot Solenoid Valve

[4] Ionisation electrode (Flame Rod)

[5] Ignition electrode (Spark Electrode)

Technical Characteristics and Dimensions | 7

[6] Temperature limiter

[7] Hydrogenerator

[8] LED (green)

[9] LED (red)

2.8 Technical characteristics

Technical characteristics Units TF250H / 10H TF325H / 13H TF400H / 16H

Gas Consumption

Nominal Gas Consumption MJ/h 79 104 130

Supply pressure flowing

Natural gas (When operating) kPa 1.13 1.13 1.13

LP gas (When operating) kPa 2.75 2.75 2.75

Number of injectors 12 14 18

Water data

Maximum permissible pressure (Static) kPa 800 800 800

Temperature selector in fully clockwise position

Temperature rise (Above incoming water temperature) °C 50 50 50

Water flow range (Litres per minute) l/min 3.2 to 5 3.2 to 6.5 3.2 to 8

Minimum operating water pressure kPa 30 40 50

Minimum constant water pressure for minimum flow kPa 60 100 130

Table 5

8 716 473 071 (2015/04)HydroPower

Page 8

8 | Regulations

400 mm

850 mm

230 mm

=

9708069951-12.1V

=

Technical characteristics Units TF250H / 10H TF325H / 13H TF400H / 16H

Temperature selector in fully anti-clockwise position

Temperature rise (Above incoming water temperature) °C 25 25 25

Water flow range (Litres per minute) l/min 4 to 10 4 to 13 4 to 16

Minimum operating water pressure kPa 45 45 45

Minimum constant water pressure for maximum flow kPa 100 140 170

Table 5

3Regulations

All local by-laws and regulations pertaining to installation and

use of gas appliances must be observed.

This appliance must be installed in accordance with the

manufacturers installation instructions, AS/NZS5601, AS/

NZS3500 and all Local Building & Gas fitting regulations.

This appliance must not be installed indoors or in an enclosed

space. This appliance is approved for outdoor installation only.

Do not install this appliance with any modification or alteration.

Failure to install this appliance in accordance with these

installation instructions will void the warranty and may create

an unsafe situation.

4 Installation

DANGER:

This appliance must not be installed indoors

or in an enclosed space in accordance with

AS/NZS5601.

DANGER: Explosion Risk!

▶ Always turn off the gas valve before

carrying out any work on components

which carry gas.

NOTICE: Property damage!

If the appliance is to be installed on a

combustible surface:

▶ Use a heat shield as per AS/NZS5601 -

accessory

9 708 061 400.ZG1 ( Fig. 4).

Fig. 4 Heat shield

The installation and the initial startup are to

be carried out only by an authorised person.

DANGER: Appliance malfunction!

This appliance must be installed with no

obstructions to air entry openings at the

front, rear, side, or top.

▶ Periodic checking of openings to ensure

no blockage or obstruction of the air

openings from plants, debris, or insects

must be carried out.

Not suitable for pool, spa pool, or solar

booster application.

Not suitable for commercial boosting of a

warm water recirculation system.

This appliance should only be installed in

applications where incoming cold water

temperature does not exceed 40 °C.

8 716 473 071 (2015/04) HydroPower

Page 9

Installation | 9

Minimum water supply pressure must meet

the requirements set out in table 5.

Water fixtures with a flow rate of 7.5 litres

per min for hand basins and 9 litres per min

for shower roses are recommended.

To reduce the chance of corrosion,

installation in a marine environment should

be avoided. Premature corrosion due to the

installation environment would not be

covered by warranty.

All gas appliances require adequate air

intake to ensure correct combustion. Insects

and dirt ingress may affect combustion

causing sooting. If you notice sooting from

the flue outlet the unit would require

servicing.

Pest and dirt ingress is not covered by the

manufacturers warranty.

4.1 Important information

▶ Determine most suitable location for the appliance. Install

only on an external wall as close as possible to the most

frequently used hot water outlet. If the unit is to be installed

on a combustible surface, use a heat shield. (part number

9708 061 400.ZG1). Allow a minimum air gap of 10mm

between the flue and the heat shield.

▶ Ensure the mounting structure is capable of supporting the

weight of the appliance once installed. Secure the

appliance to the wall using fixings suitable for the weight of

the appliance and the wall material.

▶ As the water temperature at the outlet may exceed 50 °C, a

temperature limiting device (such as a tempering valve)

must be fitted to pipework feeding sanitary fixtures used

for the purpose of personal hygiene as per AS3498.

▶ Install gas and water isolation valves as close as possible to

the heater. Only use gate valve or full flow ball valve (fixed

mechanism type) for cold water.

▶ Check the cold water supply pressure to ensure it meets

the required supply pressure for the appliance. (

table 5).

▶ If the inlet water pressure exceeds 800 kPa, a pressure

limiting valve (500 kPa) MUST be fitted. The preferable

location for the pressure limiting valve is at the water

meter.

▶ Where the pressure limiting valve is less than 3 metres from

the hot water unit, it must be fitted in conjunction with a

cold water expansion valve (700 kPa), between the water

heater and the pressure limiting valve.

▶ Failure to comply with this requirement may void the

warranty.

▶ Refer to AS/NZS5601 for the relevant gas pipe sizing.

▶ After finishing the gas piping system, the pipes must be

thoroughly purged and leak tested. This test must be

performed with the gas isolation valve of the appliance

closed.

▶ Ensure the gas pressure and flow through the regulator are

appropriate for the consumption of the heater (à table 5).

Refer to AS/NZS5601 and AS3500.1 for the releva nt pipe

size.

Note: Incorrect pipe sizing or gas supply pressure may cause

the appliance to underperform. Service calls for incorrect pip e

sizing and/or gas pressure, will NOT be covered under

warranty.

8 716 473 071 (2015/04)HydroPower

Page 10

10 | Installation

c

j

j

d

a

n

b

e

f

h

g

k

W

T

MTI

P

D

970806 9951-1 4.2V

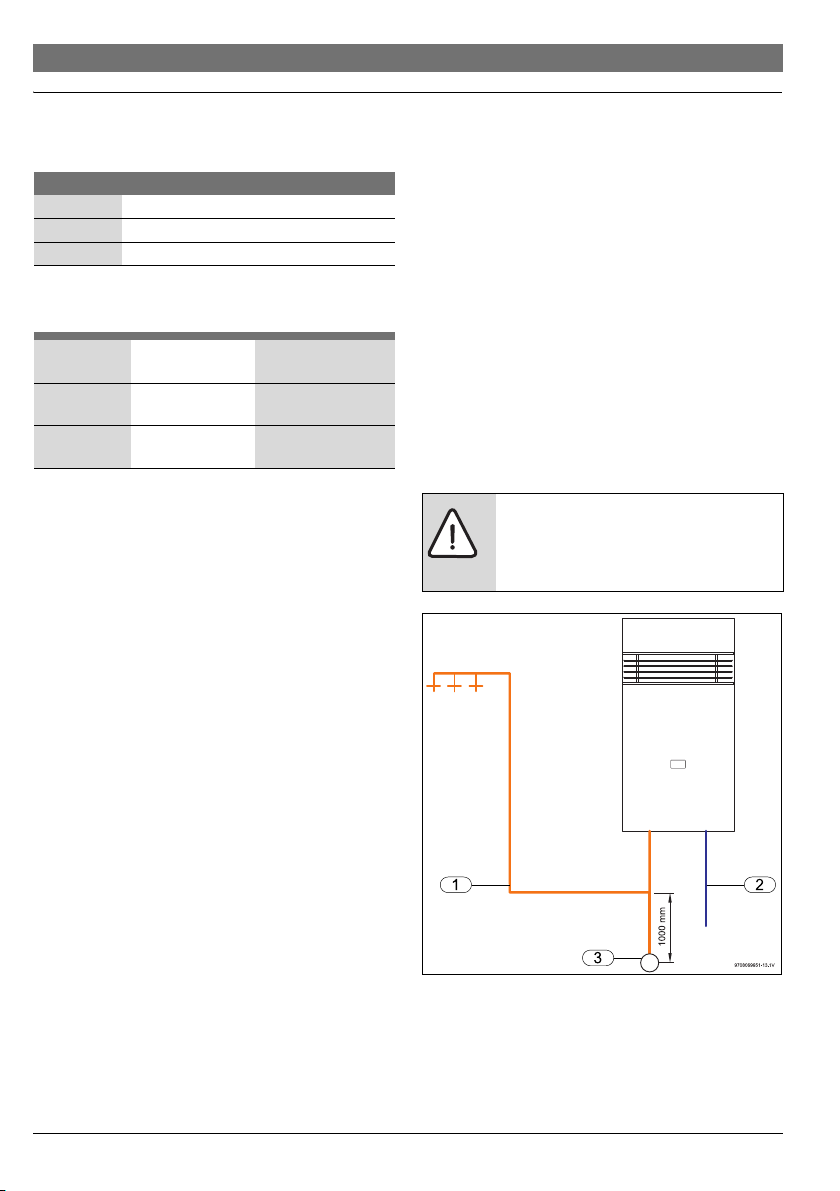

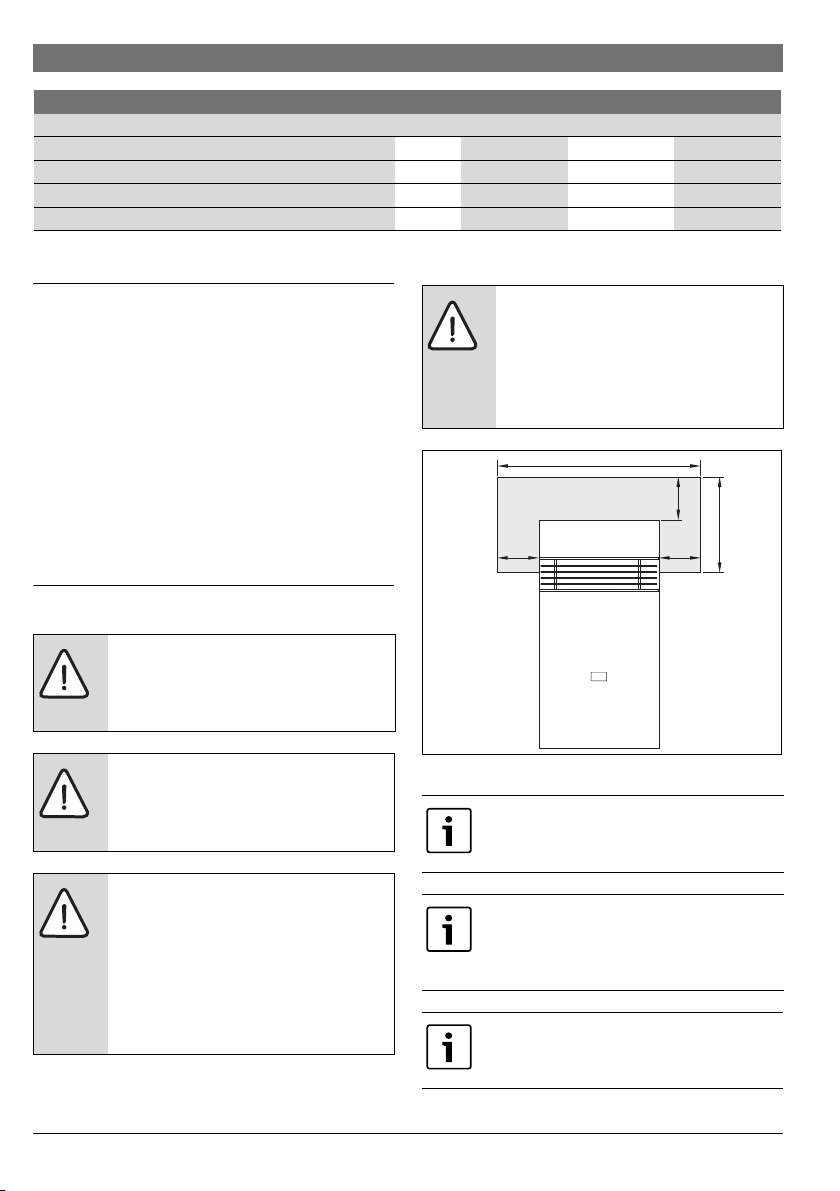

4.2 Requirements of the installation location

• Comply with the specific instructions for each State.

• Install the appliance in an outdoor location where it will not

be exposed to temperatures below zero.

• Install the appliance in accordance with the minimum

installation clearances indicated in Fig. 5, according to

AS5601.

• The gas heater must not be installed over a heat source.

• Do not obstruct the openings at top, bottom and rear of

appliance.

• Maximum of 2 meters from the ground to the base of the

appliance.

• Top and bottom areas must be clear from any obstacles at

least 30 cm.

Fig. 5 Minimum clearances (use as a guide only, always refer to AS/NZS5601)

[D] Openable Door

[T] Flue terminal

[M] Gas meter

[I] Mechanical air inlet

[P] Electricity meter or fuse box

[W] Openable window

8 716 473 071 (2015/04) HydroPower

Page 11

Installation | 11

Ref. Item

clearances (mm)

a Below eaves, balconies and other projections:

Minimum

- Appliances over 50 MJ/h input

b From the ground, above a balcony or other surface

c From a return wall or external corner

1)

1)

500

300

500

d From a gas meter (M) (see 5.11.5.9 of AS/NZS5601 for vent terminal location of regulator) 1000

e From an electricity meter or fuse box [P] 500

f From a drain pipe or soil pipe 150

g Horizontally from any building structure1) or obstruction facing a terminal 500

h From any other flue terminal, cowl, or combustion air intake [T]

1)

500

j Horizontally from an openable window, door, non-mechanical air inlet, or any other opening into a building with the

exception of sub-floor ventilation [W] [D] [T]:

- Appliances up to 150 MJ/h input

500

k From a mechanical air inlet, including a spa blower [I] 1500

n Vertically below an openable window, non-mechanical air inlet, or any other opening into a building with the exception of

sub-floor ventilation [W] [T]

- Appliances over 50 MJ/h input and up to 150 MJ/h input

1000

Table 6

1) Unless appliance is certified for closer installation

Combustion gases

Observe/comply with the minimum

clearances as in AS/NZS5601.

4.3 Hot Water Unit mounting

▶ Fix the appliance vertically, using the fixings appropriate

for the wall material and appliance weight.

Draw a cross in the wall ( Fig. 6, [A]) to

identify the appliance upper right corner

positioning.

Fig. 6 Heater mounting

[A] Appliance upper right corner position

8 716 473 071 (2015/04)HydroPower

Page 12

12 | Commissioning

970806995-08.2V

CAUTION:

Never rest the gas heater on the water or gas

connections.

4.4 Water connection

Purge the water pipes before connection, because the

presence of dirt may reduce the flow and, in extreme cases,

cause a blockage.

▶ Identify the cold water pipe an d the hot water pipe, so as to

avoid any possible cross-connection.

▶ Check and ensure water filter cleanness.

Fig. 7 Water connection

[A] Hot Water Outlet

[B] Cold Water Inlet

CAUTION:

Isolating valve on the water inlet li ne must be

a Gate or ¼ turn full flow Ball Valve. A Stop

Valve, Duo Valve or Non-Return Valve must

not be fitted.

the correct pressure to the appliance regulator.

The gas pressures require setting upon installation.

▶ Open all water and gas isolation valves.

▶ Purge the pipes.

4.6 Testing

▶ Turn on the gas and water valves and check all connections

for leaks. If all connections are sound then follow

procedures set out in Section 5 for adjustment of Gas

Pressures to complete appliance commissioning.

5 Commissioning

5.1 Before starting up the heater

CAUTION:

▶ Initial startup must be performed by an

authorised gas fitter who will provide the

customer with all the necessary

information for optimum operation of

the gas heater.

5.2 Remove the front cover

▶ Loosen the two knurled screws located on the rear side of

the front panel.

4.5 Gas connection

DANGER:

If local regulations are not followed, a fire or

explosion could result causing property

damage, personal injury, or loss of life.

Size gas supply as per AS/NZS5601.

Incorrect gas pipe sizing will not be covered

by the warranty.

Gas regulator

The appliance is supplied with a gas pressure regulator already

installed. A regulator must be fitted to LPG cylinders to supply

8 716 473 071 (2015/04) HydroPower

Fig. 8 Front cover removal

Page 13

5.3 Inlet pressure adjustment

D

9708069951-9.1V

DANGER:

The following procedures must only be

performed by a qualified technician.

Gas pressure adjustment (commissioning) MUST be carried

out upon installation.

▶ Check the gas indicated on the rating plate and front cover

label is the same as the gas to which the heater is

connected.

▶ Loosen the pressure test point screw on the left hand side

of the gas valve (Fig. 10, [A]) and attach a manometer.

Static Pressures should be greate r than or equal to the figures

in table 7.

Adjust the appliance regulato r to achieve the figures in table 7

with the unit operating and all hot water taps open for full water

flow through the unit.

If the operating inlet pressure cannot be achieved there may be

an issue with the gas supply meter (NG), cylinder regulator

(LPG), or pipe sizing (Ref AS/NZS5601). This must be resolved

before proceeding.

▶ Remove manometer and tighten test point screw.

Measurements should be made with unit

operating with all hot water taps opened to

achieve maximum water flow through the

unit.

If possible all other gas appliances (ducted

heating etc.) should be operating at the same

time.

Natural gas LP gas

Inlet Pressure

(kPa)

Table 7 Inlet pressure

TF250/10H

1.13 2.75TF325/13H

TF400/16H

Commissioning | 13

Fig. 9 Burner pressure measurement point

Maximum gas flow adjustment

▶ Turn on the water heater with the gas control slide set to the

Right (maximum gas flow).

▶ Ensure the water control knob is fully open (antic lockwise).

▶ Adjust appliance regulator to the maximum burner

pressure figure on the rating plate (See table 8 below).

▶ Turn the water control knob fully clockwise and check that

the burner pressure does not exceed the maximum.

Natural gas LP gas

Max. Burner

Pressure (kPa)

Table 8 Maximum burner pressure

Minimum gas flow adjustment

▶ With the heater operating, move the gas selector to the Left

(minimum gas position).

▶ Ensure the water control knob is fully closed (clockwise).

▶ Open various hot water taps.

▶ Using the adjusting screw (Fig. 11, [B]) to adjust the gas

pressure to the values indicated in table 9.

▶ Close the hot water taps.

TF250/10H

TF325/13H

TF400/16H

0.89 2.60

0.84 2.60

0.78 2.60

5.4 Burner pressure adjustment

▶ Loosen the burner test point captive screw ( Fig. 9 [D]).

▶ Connect a manometer to the burner pressure measuring

point.

8 716 473 071 (2015/04)HydroPower

Page 14

14 | Operating instructions

9708069951-18.1V

A

9708069951-17.1V

B

▶ Remove manometer and tighten test point screw.

Fig. 10 Gas pressure measurement point

Fig. 11 Minimum gas flow adjusting screw

Fig. 12

For higher water temperature (Fig. 13).

Slide to the right will give higher water temperature but use

more gas.

Fig. 13

6.2 Consumer temperature/flow adjustment

▶Turn anti-clockwise

Increases flow and decreases water temperature (Fig. 14).

Natural gas LP gas

Min Burner

Pressure (kPa)

Table 9 Minimum burner pressure

5.5 Conversion to a different type of gas

It is not recommended to convert these units to a different type

of gas.

6 Operating instructions

6.1 Consumer gas adjustment

For lower water temperature (Fig. 12).

Slide to the left will give lower water temperature and use less

gas.

8 716 473 071 (2015/04) HydroPower

TF250/10H

TF400/16H

0.30 0.64TF325/13H

Fig. 14

▶Turn clockwise.

Decreases flow and increases water temperature.

Regulating the temperature to the minimum required value

reduces energy consumption.

The LED light is not normally visible with the cover on, however

the green LED indicates that the appliance has detected a flame

and is operating correctly.

If the red LED is flashing this indicates a fault condition and

should be investigated by a qualified technician.

Page 15

7Maintenance

To ensure ongoing performance and safety, we require the

appliance be serviced every two years.

DANGER:

Failure to perform maintenance procedures

can lead to appliance malfunction, errors,

service calls and loss of manufacturers

warranty.

▶ Your appliance should only be attended by a Bosch

authorised service agent.

▶ Only use original replacement parts.

Maintenance must only be performed by a

qualified technician. Maintenance

information is contained in a service manual

available to licenced technicians upon

request from Bosch.

Maintenance | 15

8 716 473 071 (2015/04)HydroPower

Page 16

16 | Troubleshooting

8Troubleshooting

8.1 Problem/cause/solution

Assembly, maintenance, and repairs must be performed by qualified technicians only. The following chart offers possible solutions

to problems.

In most instances it is advisable to have a technician attend and inspect the appliance.

Some further trouble shooting advice may be found at http://www.bosch-climate.com.au

Problem Cause Solution

Fluctuation in hot water temperature. Insufficient flow through the hot water

unit.

Increase water flow by opening multiple

hot taps.

If fluctuation ceases then check for

blockages, aerators dirty etc.

Tapware does not give sufficient flow

(section 2.5, Low Flow Rates).

Unit not working. (No Hot Water). Locked out due to failure to ignite.

Unit not working after change in Gas

Supply (Maintenance work on Mains or

change of LPG cylinders).

Not hot enough. Insufficient Natural Gas supply.

Smell of gas. Gas leak. Isolate Gas supply to hot water unit/

Temperature too hot in Summer. Incoming water temperature has

Temperature too cold in Winter. Incoming water temperature has

Table 10

The ignition will lock out after 20 seconds

if a flame is not established.

Air in gas lines. Turn on hot water tap inside house.

Consumer gas and water controls.

Gas Cylinders may be empty / undersized

(45kg cylinders recommended for LPG).

increased with the ambient temperature

and Gas control is on hot position (Fully

right).

decreased with the ambient

temperature.Gas control is on warm

position (Fully Left).

Change tapware to meet requirements.

Turn off all hot water taps and retry.

If unit still does not work - isolate valves at

unit for 20 seconds. Open valves and

retry.

If unit still fails to ignite refer to qualified

technician.

Isolate water valve at unit for 20 seconds.

Open valve and check if unit lights.

Repeat this operation 3-4 times, if unit

still fails to ignite call your Gas Retailer or

a qualified technician.

Requires a service technician to inspect

and test gas supply pressures /

recommission.

Adjust gas and water controls.

premises.

Call your Gas Retailer or a qualified

technician.

Adjust Water and Gas controls at the unit

to achieve desired temperature.

Adjust Water and Gas controls at the unit

to achieve desired temperature.

8 716 473 071 (2015/04) HydroPower

Page 17

Problem Cause Solution

Reduced water flow. Insufficient water supply pressure.

Unit makes a loud bang when igniting. Explosive ignition is not normal

Presence of soot/black marks observed at

top of flue / on wall.

Dirty taps or mixers.

Water valve blocked (filter).

Heat exchanger blocked (limescale).

behaviour.

This is not normal behaviour.

This is normally caused by blockages in

the burner causing poor combustion.

Requires a service technician to inspect

and test water supply pressures, and

water components of the hot water unit.

Call a qualified technician.

All gas appliances require adequate air

flow for proper combustion. The ingress

of insects or dirt into the unit are not

covered by warranty as a manufacturing

fault is not present. The unit will need

cleaning and servicing at the owners’ cost.

Environmental protection | 17

One of the causes of blockages is insects

blocking burner orifices, this cannot be

avoided as adequate air flow is required

for complete combustion.

Water takes a long time to reach hot taps. Location of unit. If the unit is located a long way from the

Table 10

To minimise the chance of the issue

recurring, a surface type insecticide can

be used with care, consultation with a

licensed pest controller is recommended.

Isolate the valves to the unit and spray

surrounds with a surface spray.

Leave for 15 minutes before turning hot

water on.

outlet there will be an amount of cold

water that has to leave the pipe before the

hot water is available. As the hot water

unit does not operate at a large flow rate

this may appear to take a long time,

particularly if it has replaced a mains

pressure storage heater.

Open hot tap to full to increase flow rate

and reduce time.

9 Environmental protection

Environmental protection is a basic company strategy of

Bosch. The quality of our products, profitability and

environmental protection are equal-ranking goals for us. Laws

and regulations concerning environmental protection are

strictly observed. We use the best possible technology and

materials, under economic considerations, to protect the

environment.

Packaging

We participate in the recycling program of the respective

country to ensure optimal recycling. All of our packaging

materials are environmental-friendly and can be recycled.

Old appliances

Old appliances contain valuable materials that should be

recycled.

8 716 473 071 (2015/04)HydroPower

Page 18

18 | Water quality

10 Water quality

All Bosch water heating appliances are constructed from high

quality materials and components, and all are certified for

compliance with relevant parts of Australian and New Zealand

gas, electrical and water standards.

While Bosch water heaters are warranted against

manufacturing defects, the warranty is conditional upon

correct installation and use, in accordance with detailed

instructions provided with the heater. In the case of the water

supplied to the heater, it is important that the water quality be

of acceptable standard.

The water quality limits/parameters listed in the water quality

table are considered acceptable, and generally Australian and

New Zealand suburban water supplies fall within these limits/

parameters.

In areas of Australia and New Zealand where water may be

supplied either fully or partly from bores, artesian wells, or

similar, one or more of the important limits may well be

exceeded and the heater could, therefore, be at risk of failure.

Where uncertainty exists concerning water quality, intending

appliance users should seek a water analysis from the water

supplying authority. In cases where it is established that the

water supply does not meet the quality requirements of the

water quality table, the Bosch warranty would not apply.

Water quality table

Maximum levels

Saturation

Index(LSI)

pH

6.5-9.0 +0.4 to -1.0

Table 11

8 716 473 071 (2015/04) HydroPower

(langelier)

at 65 °C

Total

Hardness

200

mg/l

Chlorides Sodium Iron

250

mg/l

180

mg/l1 mg/l

Page 19

Warranty details | 19

11 Warranty details

Robert Bosch (Australia) Pty Ltd

Thermotechnology Division

Voluntary Repair or Replacement Warranty

All Bosch products are carefully checked, tested and certified to Australian and New Zealand standards.

Important Note: Mandatory Australian Consumer Law statement

If you have purchased your product in Australia, you should be aware that:

This warranty is provided in addition to other rights and remedies held by a consumer at law. Our goods come with guarantees that

cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and for

compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if

the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Important Note: New Zealand law

If you have purchased your product in New Zealand, you should be aware that:

This warranty is supplemental to any other rights and remedies you have under the Consumer Guarantees Act 1993 NZ, unless your

purchase is made for commercial purposes, in which case Bosch excludes all consumer guarantees implied in the Consumer

Guarantees Act 1993 NZ in respect of your product.

Warranty

Bosch warrants, at its option, to repair or replace your water heater or relevant part thereof (Product) if such Product are faulty or

defective in manufacture or materials during the warranty period specified below.

The warranty period commences on the date of purchase. If the date of original pur chase cannot be determined, then the warranty

period will commence six (6) months after the date of manufacture stamped on the Product. Bosch may require evidence to verify

the date of purchase.

This warranty only covers repair or replacement of defective Product (including labour costs where indicated). It does not cover:

• any costs incurred by the end user in normal or scheduled maintenance of the Product; or

• subject to any law to the contrary, any damage to property, personal injury, direct or indirect loss, consequential losses or other

expenses arising from breach of this warranty. Any end user conc erned with this exclusion should consider the "Important Note:

Mandatory Australian Consumer Law statement” above

Warranty Period and Coverage

Bosch will provide warranty service for Product purchased and installed in Australia and New Zealand as follows.

The period after purchase within which

Components

Domestic Use (see below for definition)

All components Year [1 to 2] Parts & Labour

Heat exchanger Year [3 to 10] Parts only

Commercial Use (see below for definition)

All components Year [1] Parts & Labour

Heat exchanger Year [1] Parts only

Table 12

"Parts & Labour" means free of charge repair and/or replacement, including labour.

"Parts only" means a replacement heat exchanger, free of charge. All installation and repair labour costs are the responsibility of

the owner.

the fault must appear

What Bosch will do (see below for

definitions)

8 716 473 071 (2015/04)HydroPower

Page 20

20 | Warranty details

"Domestic use" warranty period applies to Product installed to supply hot water for use by individuals in domestic dwellings. For

Product used for all other uses, the commercial use warranty period will apply. This includes, without limitation, installations such

as centralised or bulk hot systems, hotels, sporting complexes, caravan parks, laundry facilities, restaurants and cafes.

For “Parts only” warranty, the end user will be charged for service call costs and service technician fees in effecting the replacement.

For valid claims within "Parts & Labour" warranty periods, the end user will not be charged for costs associated with making a

warranty claim, including service call costs, any service technician fees or the cost of replacement parts and freight, provided that:

• the Product is located within the usual operating area of an authorised service technician; and

• the Product has been installed according to the installation instructions so as to provide adequate service access

If the Product is not located within the usual operating area of an authorised service technician, the end user will be required to pay

the service call costs associated with a service call under this voluntary warranty.

Notwithstanding the above, if the Product has not been installed in accordance with the installation instructions in regards to

access, or has been otherwise installed in location where service access is difficult, the end user will be required to pay charges

associated with the difficult access. This includes, but is not limited to, the removal of walls or doors to gain access and the use of

specialised equipment to move the Product or components to safe working levels. Where the Product cannot be safely accessed,

Bosch may refuse to service the Product under this voluntary warranty.

For invalid claims under this voluntary warranty, the end user will be liable for the costs of making the warranty claim including any

service call costs.

Warranty Conditions

This voluntary warranty is subject to the following conditions:

• The Product must have been installed and correctly commissioned by an authorised and licensed installer in compliance with

applicable Australian Plumbing and Gas Standards. Proof may be required of correct commissioning of the Product (such as

certificate of compliance). Claims for failures due to incorrect installation or commissioning are not covered under this

voluntary warranty and may be rejected by Bosch.

• Where a Product or part thereof is replaced or repaired under this voluntary warranty, the balance of the original voluntary

warranty will apply. The replacement Product or part does not carry a new voluntary warranty.

• The Product must have its original serial numbers and rating labels intact.

• The warranty does not extend to any Product that have bee n completely or partially disassembled.

• These warranty terms cannot be amended except in writing by an authorised officer of Bosch.

• The warranty only applies to Product installed for an end user in Australia or New Zealand and purchased from Bosch or from a

reseller where the Product have been originally sold by Bosch.

• Any claim made under this voluntary warranty meets the requirements set out below in the “How to Make a Warranty Claim”

section.

Warranty Exclusions

This warranty will not apply to a defect or fault to the extent to which it arises:

• due to storage, handling or installation of the Product otherwise than in accordance with instructions provided for the Product

by Bosch or without reasonable care, including installation of a Product which is of inappropriate size or type for the intended

purpose;

• due to operation, use or maintenance of the Product otherwise than in accordance with instructions provided for the Product

by Bosch or without reasonable care, including use of the Product with faulty or unsuitable plumbing, water pressu re, power or

gas supply;

• due to accidental damage or use of the Product for a purpose or in environmental conditions for which the Product were not

designed or sold, or use of the products outside the specified or normal operating ranges for such Product.

• as a result of changes which occur in the condition or operational qualities of the Product due to climate or other environmental

influence, foreign material contamination or water entry or as a result of exposure to excessive heat or solvents or because of

use of non-potable water or bore water in the Product or damage as result of an Act of Natur e including but not limited to storms,

fires, floods and lightning strikes;

• from normal wear and te ar or when replacement or repair of parts would be part of normal maintenance or service of the Product

or where the damage is only to surface coating, varnish or enamel;

8 716 473 071 (2015/04) HydroPower

Page 21

Warranty details | 21

• as a result of repairs, alterations or modifications to the Product whic h have been performed by a person who is not suitably

qualified and experienced to perform works on the Product; or

• from the use of any spare parts not manufactured, sold or approved by Bosch in connection with the repair or replacement of

Product.

This voluntary warranty does not apply to damage that has been caused by continued use of a Product after it is known, or would

have been known with regular servicing, it is defective.

Failure to service Product in accordance with recommendations in instruction manuals for Product may result in a warranty claim

under this voluntary warranty being rejected by Bosch. Bosch alerts end users that instruction manuals for Product contain

specific recommendations for servicing and safety checks to be carried out on Product.

Table 13

Wrong Deliveries and Transit Damage

Wrong deliveries, incorrect or damaged packing and transit damage claims are not warranty claims. Such cases should be directed

to Bosch's Customer Service line in Australia on ph: 1300 307 037 or in New Zealand on ph: 0800 543 352.

How to Make a Warranty Claim

If a Product fails within the warranty period, the end user must stop using the Product and make a claim as soon as possible, in any

event before the end of the Warranty Period (see Deadlines for Submitting Warranty Claims below).

To make a warranty claim under this voluntary warranty, call the Bosch C ustomer Contact Centre (in Australia on ph: 1300 307 037

or in New Zealand on ph: 0800 543 352). Please be ready to provide the mode l and serial number, date of installation, purchase

details and a full description of the problem. Al ter nati vel y, fo r cla ims in Au str alia , yo u can pos t det ail s of y our clai m to Robert Bosch

(Aust) Pty Ltd, Attn TT Warranty Department, Locked Bag 66, Clayton Sth, Victoria, 3169. Claims received by post will take longer

to process and we encourage you to call. Bosch may refer you to one of its Bosch Warranty Authorised Service Dealers.

Proof of purchase and purchase date, as well as proof of installation and proper commissioning by a licensed installer, may be

required by Bosch or an authorised service technician.

All warranty service calls will be conducted by an authorised service technician during normal business hours. Bosch will not accept

claims under this voluntary warranty for attendance and repair of the Product by third parties not authorised by Bosch.

Deadlines for Submitting Warranty Claims

Bosch aims to rectify genuine quality problems as a priority. This is generally achieved by investigating why defective products have

failed and by introducing immediate corrective action measures to prevent re-occurring w arr anty fail ure s. It is t here for e cri tical that

all warranty claims are promptly submitted to Bosch as soon as the product fails, and in any event before the end of the warranty

period.

Product Liability and Product Safety

Bosch should be informed immediately about any potential product safety concerns within and outside the warranty period. Bosch

is well aware of its product liability and product safety obligations and responsibilities. It is our aim to ensure appropriate product

safety standards are met in order to avoid injury, loss and damage caused by defects in any Product.

Privacy

Bosch is required to seek personal information from an end user who seeks to make a claim under this warranty.

Such personal information may be used by Bosch and/or any authorised servic e technician (who is authorised to process warranty

claims and/or carry out warranty repairs on behalf of Bosch) for the purpose of processing such warranty claim and also for the

provision of customer support and further information about Bosch’s products and services (Purpose).

If an end user does not wish to provide Bosch and/or its authorised service technician with personal information, Bosch may be

unable to process the end user’s warranty claim or to provide the end user with additional customer support, services and

information.

8 716 473 071 (2015/04)HydroPower

Page 22

22 | Warranty details

Bosch is committed to protecting the privacy of personal information and will act in compliance with applicable privacy laws,

including the National Privacy Principles under the Australian Pri vacy Act 1988 (Cth) (as amended) and New Zealand’s Information

Privacy Principles described in the Privacy Act 1993 (NZ).

Bosch takes security measures in order to protect any personal information collected in the warranty claim process against

manipulation, loss, destruction, access by unauthorized persons or unauthorized disclosure.

Bosch will not disclose any personal information to third parties other than for the Purpose or except as required by law.

An end user has the right to access the personal information Bosch or its authorised service technician hold about them. The end

user can request to see, change or modify the personal information held about them, or withdraw consent for its usage, by

contacting Bosch at the Bosch Contact Details below.

Bosch Contact Details

This warranty is offered by Robert Bosch (Australia) Pty Ltd (ACN 004 315 628) of 1555 Centre Road, Clayton, Victoria 3168.

Please call the Customer Contact Centre on 1300 30 70 37 in Australia or 0800 543 352 in New Zealand if you have any queries

in relation to this warranty or contact us using the online form at www.bosch-climate.com.au

.

8 716 473 071 (2015/04) HydroPower

Page 23

Notes

| 23

8 716 473 071 (2015/04)HydroPower

Page 24

Loading...

Loading...