Bosch GAM 270 MFL Operating/Safety Instructions

IMPORTANT:

Read Before Using

Operating/Safety Instructions

Consignes de sécurité/d’utilisation

Instrucciones de funcionamiento

y seguridad

IMPORTANT :

Lire avant usage

IMPORTANTE:

Leer antes de usar

GAM 270 MFL

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer

Information and

Service Locations

For English Version

See page 7

Pour obtenir des informations

et les adresses de nos centres

de service après-vente, appelez

ce numéro gratuit

Version française

Voir page 19

Llame gratis para obtener

información para el consumidor

y ubicaciones de servicio

Versión en español

Ver la página 33

11

12

9

10

ab cdef fedcg

IN/FT

13

1

2

3

4

5

6

7

8

hi jkmihomkn

19 2018

15 16 1714

IN/FT

21

22

GAM 270 MFL

2

A

B

IN/FT

+

90°= 0% = 0 IN/FT

6

5

12 IN/FT =

IN/FT

+

C

D

0°= 0%= 0 IN/FT

w

3

E

1

4

w

10

4

w

1

F

4

H

G

21

1

v

w

4

21

1

w

v

4

5

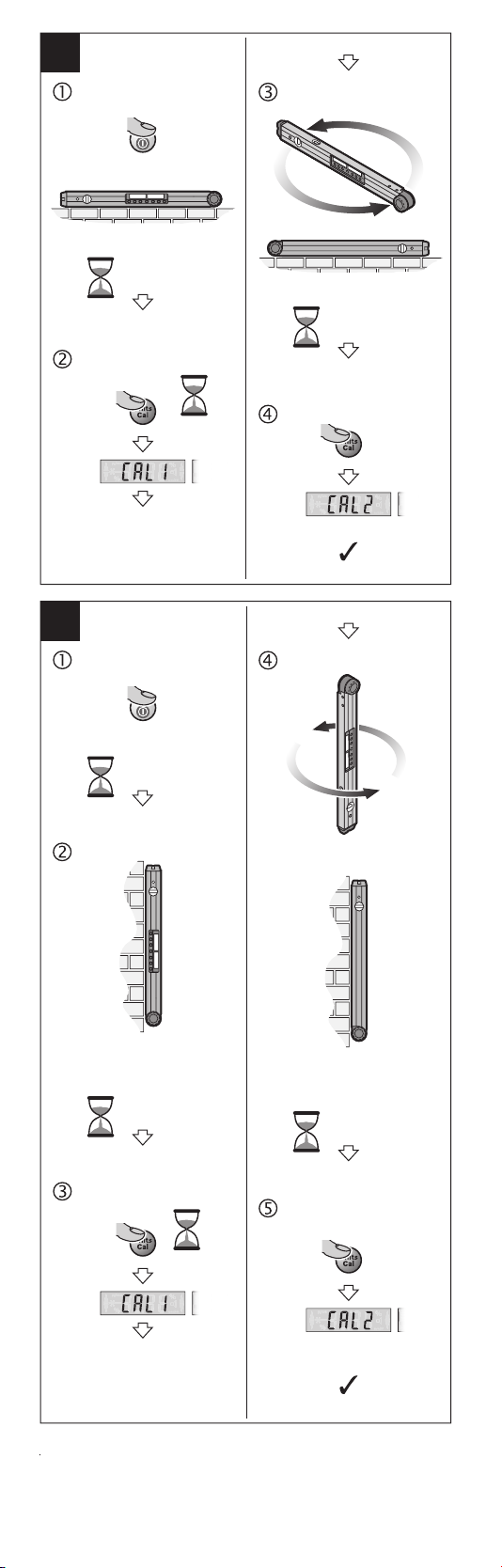

I

ON

180°

10 s

10 s

CAL

2 s

CAL

J

ON

10 s

10 s

180°

10 s

CAL

2 s

6

CAL

Safety Rules for Laser Measures

Read all instructions. Failure to fol-

result in hazardous radiation exposure, electric shock,

fire and/or serious injury.

The term “laser measure” in the warnings listed below

refers to your battery-operated (cordless) laser anglefinder/digital level.

SAVE ALL WARNINGS AND INSTRUCTIONS

The following label is on your

laser measure for your safety.

ALWAYS BE AWARE of its

location when using the laser

measure.

tion and complies with 21 CFR 1040.10 and 1040.11

except for deviations pursuant to Laser Notice No. 50,

dated June 24, 2007. This can lead to persons being

blinded.

low all instructions listed below may

FOR FUTURE REFERENCE

DO NOT direct the laser beam at persons

or animals and do

not stare into the laser beam yourself. This

laser measure produces class 2 laser radia-

DO NOT stare directly at the laser beam or project the

laser beam directly into the eyes of others. Serious eye

injury could result.

DO NOT place the laser measure in a position that may

cause anyone to stare into the laser beam intentionally

or unintentionally. Serious eye injury could result.

DO NOT operate the laser measure around children or

allow children to operate the laser measure. Serious eye

injury could result.

ALWAYS: Make sure that any bystanders in the vicinity

of use are made aware of the dangers of looking directly

into the laser measure.

Never aim the beam at a workpiece with a reflective

surface. Bright shiny reflective sheet steel or similar

reflective surfaces are not recommended for laser use.

Reflective surfaces could direct the beam back towards

the operator.

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

DO NOT use any optical tools such as, but not limited

to, telescopes or transits to view the laser beam. Seri-

ous eye injury could result.

DO NOT leave the laser measure “ON” unattended in

any operation mode. ALWAYS turn the laser measure

“OFF” when not in use. Leaving the laser measure “ON”

increases the risk of someone inadvertently staring into

the laser beam.

DO NOT operate the laser measure in combustible areas such as in the presence of flammable liquids, gases

or dust.

Do not use the laser viewing glasses as safety goggles.

The laser viewing glasses are used for improved visualization of the laser beam, but they do not protect against

laser radiation.

Do not use the laser viewing glasses as sun glasses or in

traffic. The laser viewing glasses do not afford complete

UV protection and reduce color perception.

ALWAYS position the laser measure securely. Damage to

the laser measure and/or serious injury to the user could

result if the laser measure falls.

Take care to recognize the accuracy and range of the

laser measure. Measurement may not be accurate if used

beyond the rated range of the laser measure.

DO NOT remove or deface any warning or caution labels. Removing labels increases the risk of exposure to

laser radiation.

7

Safety Rules for Anglefinders

When using the angle information provided by this tool

to cut materials, always observe all of your saw’s instructions, including those for positioning and clamping the

workpiece. In some cases, it may not be possible to set

the required angles on a particular saw or type of saw,

and an alternative means of performing the cut will need

to be used.

For extremely acute (sharp) angles, it may be necessary

to make the cut using a taper jig with a table saw or circular saw.

Electrical safety

Batteries can explode or leak, cause injury or fire. To reduce this risk, always follow all instructions and warnings on the battery label and package.

DO NOT short any battery terminals.

DO NOT charge alkaline batteries.

DO NOT mix old and new batteries. Replace all of them

at the same time with new batteries of the same brand

and type.

DO NOT mix battery chemistries.

Dispose of or recycle batteries per local code.

DO NOT dispose of batteries in fire.

Keep batteries out of reach of children.

Remove batteries if the device will not be used for sev-

eral months.

Maintenance

DO NOT disassemble the anglefinder/digital level. There

are no user serviceable parts inside. Disassembling the

anglefinder/digital level will void all warranties on the

product. Do not modify the product in any way. Modify-

ing the anglefinder/digital level may result in hazardous

laser radiation exposure.

DO NOT use this anglefinder/digital level for any purpose other than those outlined in this manual. This

could result in serious injury.

ALWAYS use only the accessories that are recommended by the manufacturer of your anglefinder/digital level.

Use of accessories that have been designed for use with

other anglefinder/digital levels could result in serious injury.

Repair and servicing must always be performed by a

qualified repair facility. Repairs performed by unquali-

fied personnel could result in serious injury.

8

Technical Data

Angle finder/Digital level GAM 270 MFL

Article number 3 601 K76 410

“HOLD” function ●

“Simple Miter” Operating Mode ●

“Compound Miter” Operating Mode ●

“Grade Measurement” Operating Mode ●

Display Illumination ●

Calibration ●

Measuring range 0°...270°

Measuring accuracy angle ±0.1°

Lowest indication unit 0.1°

Operating temperature 14 °F...122 °F

Storage temperature -4 °F...158 °F

Alkaline Batteries 4 x1.5V LR6 (AA)

Operating time approx.

1

Automatic switch-off after approx. 30 min

Leg length 23.6 in (600 mm)

Weight according to EPTA-Procedure

01/2003

Measuring range of grade measuring device

– 0°/90°

– 1°–89°

Working range of laser

2

Vertical levelling accuracy of laser ±0.5 mm/m

Horizontal levelling accuracy of laser ±1 mm/m

Clearance of laser exit – bottom edge of

anglefinder/digital level

Laser class 2

Laser type 650 nm, < 1 mW

Laser beam diameter (at 25 °C) approx.

– at 5 m distance

– at 10 m distance

Relative air humidity, max. 90 %

Dimensions

(length x width x height)

IP 54 (dust and splash proof) ●

(–10 °C...+50 °C)

(–20 °C...+70 °C)

50 h

3.3 lbs (1.5 kg)

±0.05°

±0.1°

100 ft (30 m)

1.2 in (30 mm)

0.1 in (3 mm)

0.3 in (8 mm)

26.9 x 2 x 2.4 in

(684 x 52 x 60 mm)

1)

Operating duration without laser

2)

The working range can be decreased by unfavorable

environmental conditions (e.g. direct sun irradiation).

The anglefinder/digital level can be clearly identified

with the serial number 13 on the type plate.

Intended Use

The anglefinder/digital level is intended for measuring

and transferring angles and for calculating simple and

compound miter angles, checking and aligning horizontals and verticals. It is suitable for indoor and outdoor

use.

9

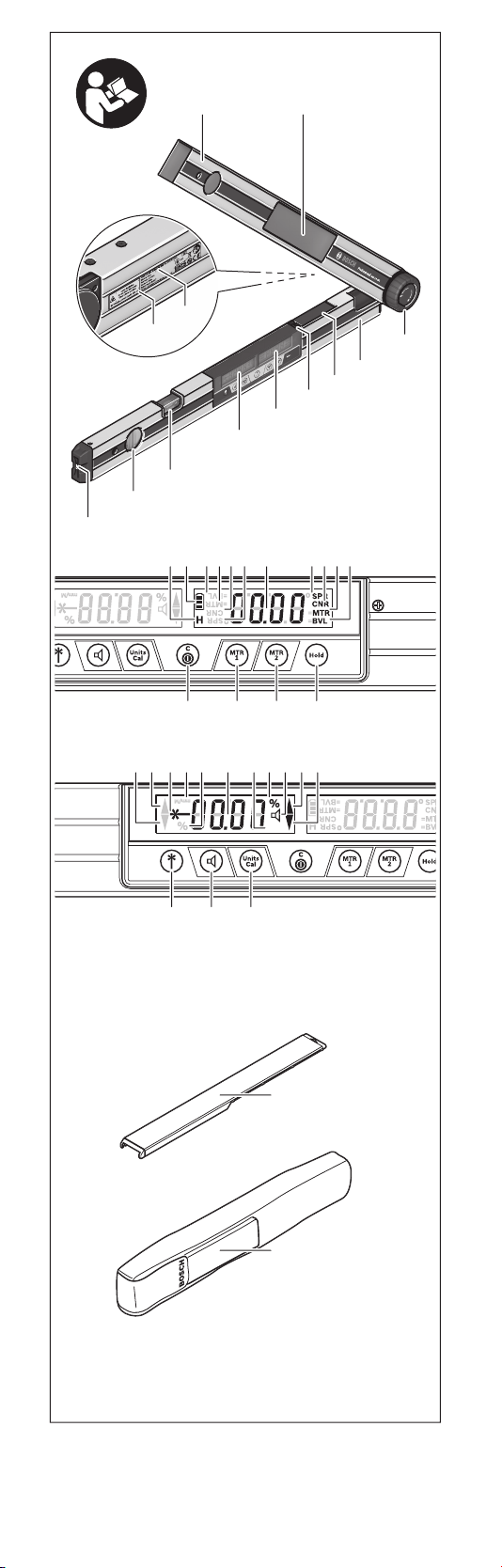

Features

The numbering of the product features shown refers

to the illustration of the anglefinder/digital level on the

graphic page.

1 Fold-out leg

2 Viewing window for

display

3 Locking wheel

4 Base leg

5 Battery lid

6 Latch of battery lid

7 Display Angle measur-

ing device

8 Display Grade measur-

ing device

9 Spirit level for horizon-

tal alignment

10 Spirit level for vertical

alignment

11 Laser beam outlet

opening

Display elements

The numbering of the product features shown refers

to the illustration of the anglefinder/digital level on the

graphic page.

a “H” indicator for “HOLD” memory value

b Battery indicator

c Bevel angle indicator “BVL”

d Miter angle indicator “MTR”

e Corner angle indicator “CNR”

f Spring angle indicator “SPR”

g Reading Angle measuring device

h/i Alignments arrows

j Laser operation indicator

k/m Unit of measure indicator

n Measuring value Grade Measurement

o Indicator for audio signal

12 Laser warning label

13 Serial number

14 “ON/OFF” button

15 “MTR1” button for

simple miter

16 “MTR2” button for

compound miter

17 “HOLD” button

18 On/Off button for laser

beam

19 Audio signal button

20 Calibration/change

units button

21 Leg extension

22 Protective pouch

Assembly

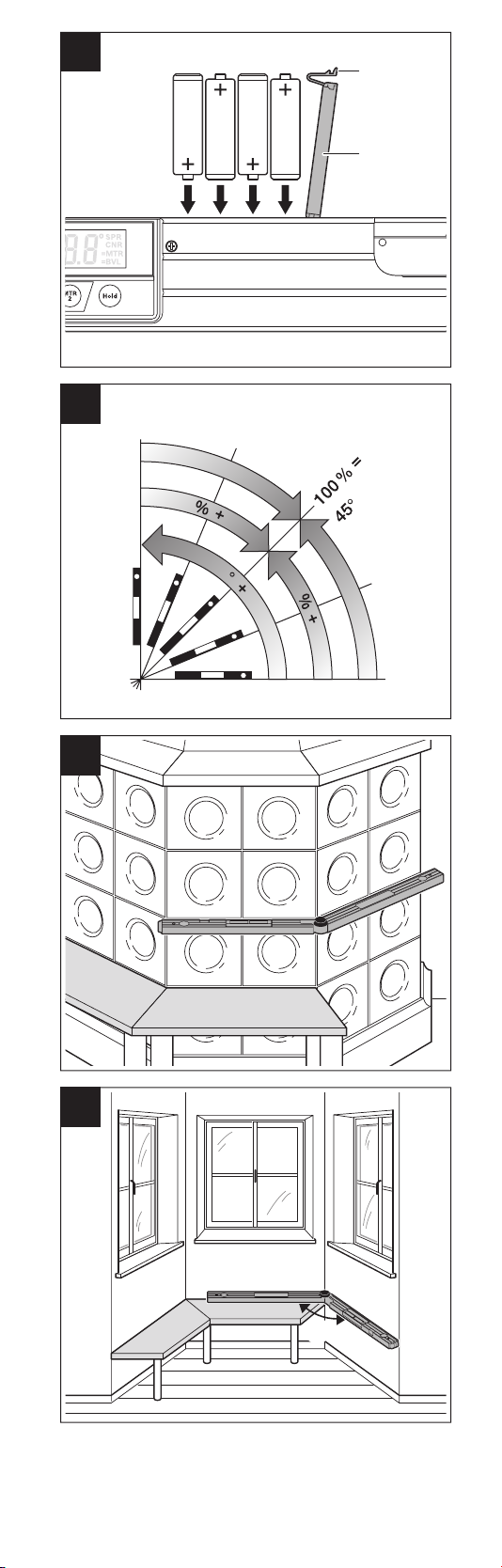

Inserting/Replacing the Batteries

Use alkaline (4 x AA) batteries to operate the anglefinder/

digital level.

Ensure polarity of each battery

correct battery polarity may cause fire or personal injury.

To open the battery lid 5, press on the latch 6 and fold the

battery lid up. Insert the batteries (Fig. A).

Battery Indicator

The battery indicator b always displays the current battery status:

The battery is over 90 % full

The battery is between 60 % and 90 % full

The battery is between 30 % and 60 % full

The battery is between 10 % and 30 % full

The empty battery indicator flashes. The battery

level is under 10 %. Once the battery indicator begins flashing, you can measure for approximately

another 15-20 minutes until the tool shuts down.

Always replace all batteries at the same time. Do not use

different brands or types of batteries together.

Remove the batteries from the angle finder/digital level

when not using it for longer periods. When storing for

longer periods, the batteries can corrode and self-discharge.

Slide the leg extension 21 onto the fold-out leg 1 from the

front. Slide the leg extension as far as possible over the

joint of the anglefinder/digital level.

matches the instructions in Fig. A. In-

Mounting the Leg Extension

10

Operation

Initial Operation

Protect the anglefinder/digital level

against moisture and direct sun light.

Do not subject the anglefinder/digital

ations in temperature. As an example, do not leave it in

vehicles for a long time. In case of large variations in temperature, allow the anglefinder/digital level to adjust to

the ambient temperature before putting it into operation.

In case of extreme temperatures or variations in temperature, the accuracy of the anglefinder/digital level can be

impaired.

severe exterior effects to the anglefinder/digital level, it is

recommended to carry out an accuracy check (see “Accuracy Check and Calibration of the Anglefinder/digital

level”, page 22) each time before continuing to work.

must be clean. Protect the anglefinder/digital level

against impact and shock. Debris particles or deforma-

tions can lead to faulty measurements.

Do not leave the switched-on anglefinder/digital level

unattended and switch the anglefinder/digital level off

after use. Other persons could be blinded by the laser

beam.

Press the “ON/OFF” switch 14 to switch the anglefinder/

digital level on or off.

If the “H” indicator lights up, the value from the last

measurement is still saved. This value can be deleted by

briefly pressing the “ON/OFF” button 14.

The anglefinder/digital level will shut down after approx.

30 minutes of inactivity to preserve battery life.

The anglefinder/digital level can be aligned horizontally

with spirit level 9 and vertically with spirit level 10.

When you rotate the measuring device 180°, the display

will also rotate automatically to make the displayed value

easier to read.

After switching on, the anglefinder/digital level is always

in normal measuring mode.

In “Normal Measuring” mode, angle measurement and

grade measurement are carried out simultaneously.

Angle Measurement Operating Mode

The anglefinder/digital level is in the “Angle Measurement” operating mode every time it is switched on.

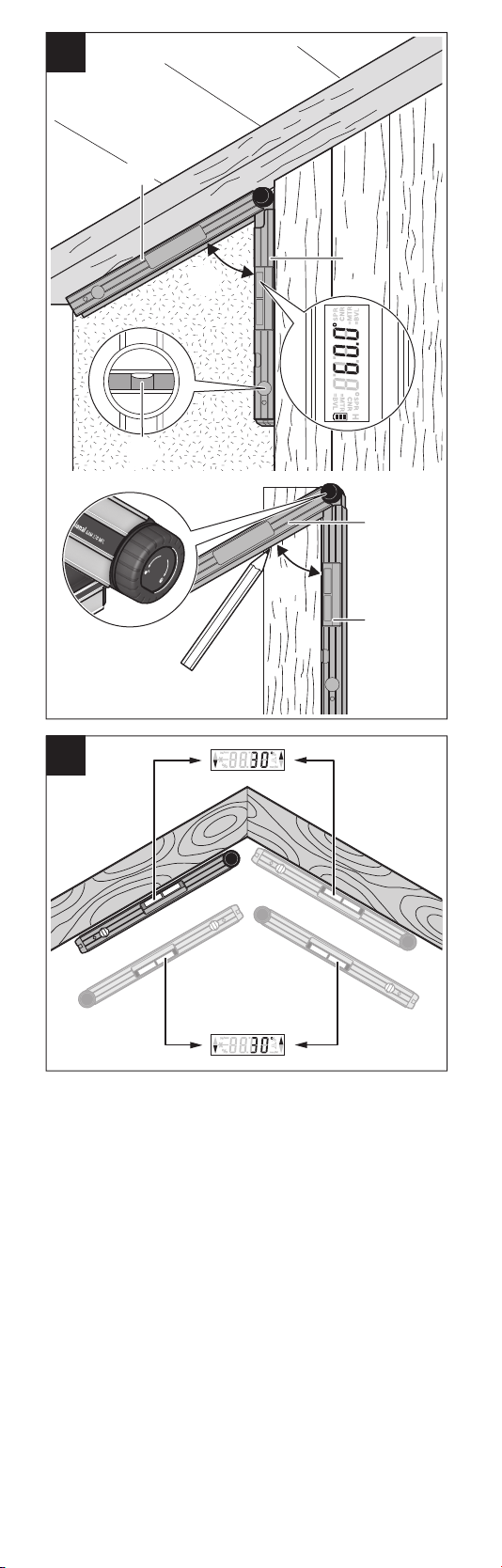

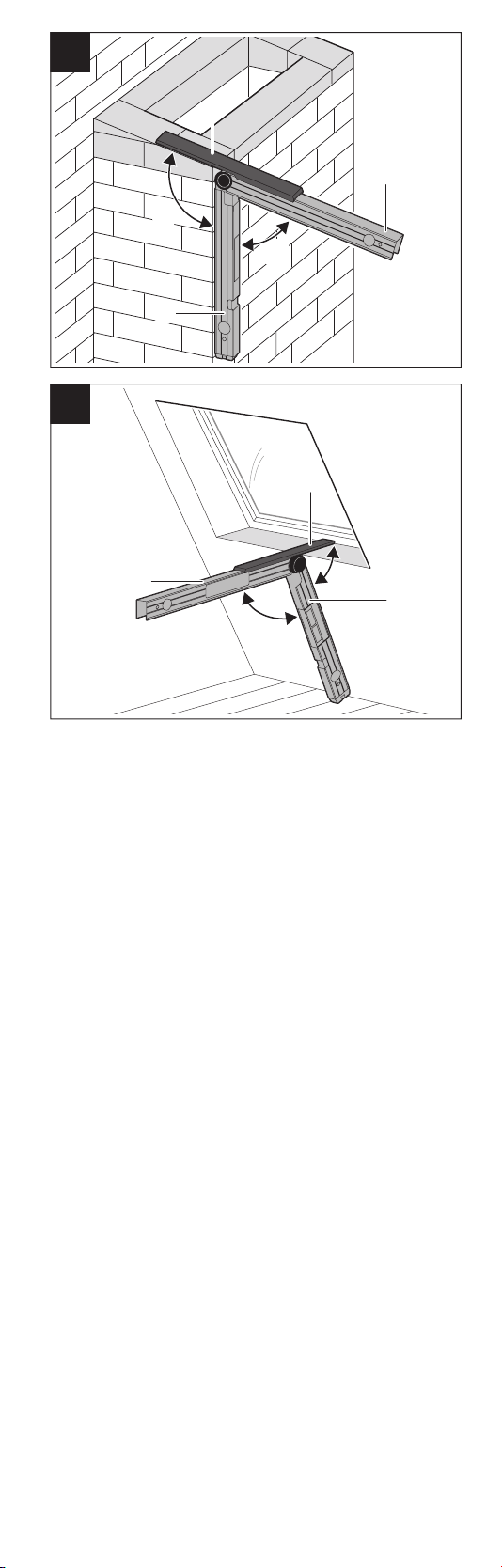

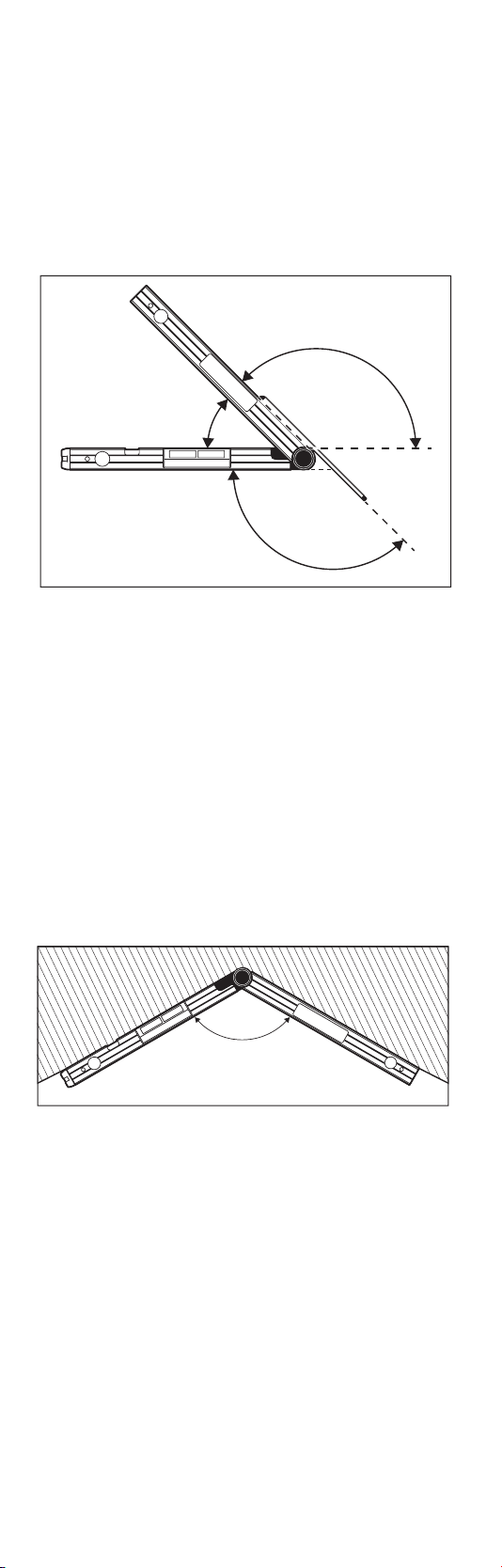

Measuring Angles (see figures C–D)

Place the fold-out leg 1 and the base leg 4 flat on the

surfaces around the angle you wish to measure. The

measured angle value w will display on the display 7 as

measured value c. The measured value will remain on the

display until the angle between fold-out leg 1 and base

leg 4 has changed.

Once you have your desired angle measurement (see

Measuring Angles section), lock the position of the legs

by tightening the locking wheel 3.

Place the anglefinder/digital level in the desired position

against the workpiece. Use the legs as a straight edge to

transfer the angle.

Press the “HOLD” memory button 17 to save the current

measuring value. The a indicator will flash on the display

as confirmation. The currently displayed value is frozen

and will not change even when the leg is moved. If you

press the “HOLD” memory button again, the a indicator

will permanently be shown on the display. The displayed

value will change if you move the legs. The previously frozen value is now saved in the background. If the “HOLD”

memory button 17 is pressed again, the previously saved

value is displayed and the a indicator flashes.

The unit can only store one value at a time. Storing a new

value will automatically overwrite the previously stored

value.

level to extreme temperatures or vari-

Avoid heavy impact to or falling down

of the anglefinder/digital level. After

The contact surfaces and contact

edges of the anglefinder/digital level

Switching On and Off

Aligning with the Spirit Levels

Rotating the Display

“Normal Measuring Mode”

Transferring Angles (see figure E)

Save measured values

11

The held value is saved even when the anglefinder/digital

level is switched off (manually or automatically). However, it is deleted when changing batteries or when the

batteries are empty.

Measuring with Leg Extension (see figures G–H)

The leg extension 21 enables angle measurement when

the contact surface is shorter than the fold-out leg 1.

Place the base leg 4 and the leg extension flat on or

against the edges to be measured.

The reading of the angle w between base leg and fold-out

leg is indicated in the display. The required angle v be-

tween base leg and leg extension is calculated as follows:

v = 180° – w

v

w

v

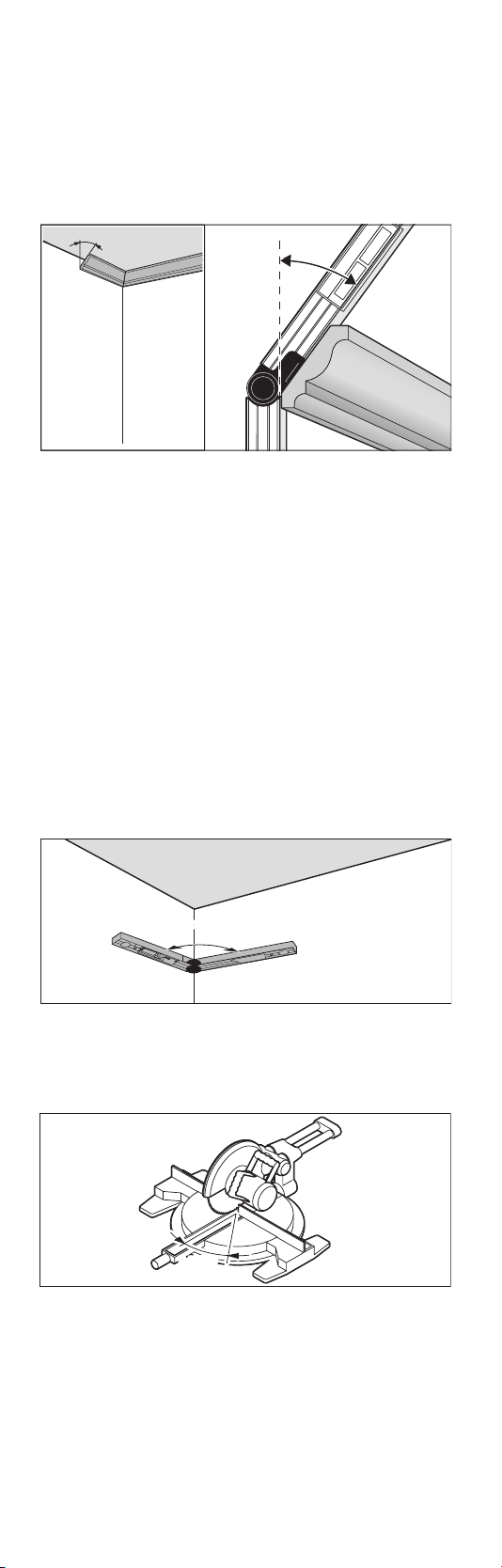

“Simple Miter”Operating Mode

The “Simple MTR” operating mode is used to determine

miter angles for miter cuts that are made with the blade

vertically perpendicular to the workpiece; in other words,

miter cuts for which the bevel setting is set at 0°. Such

applications include mitering baseboard and chair rail,

picture rails, door frames, staircase balusters, and picture

The “Simple Miter” operating mode is activated by pressing the “MTR1” button. The displayed value is always

used for the calculation of the “MTR”. If a saved value

is being displayed (indicator a flashes), the calculation

will be performed with the saved value regardless of the

position of the legs.

x

°

When workpieces are to be fitted into a corner (e.g. for

floor trimmings), measure the corner angle x° by applying

the fold-out leg and the base leg. For given angles (e.g.

picture frames), open the fold-out leg and the base leg

until the desired angle is indicated in the display.

12

MTR

MTR

x

°

x

°

The miter angle “MTR”, by which the two workpieces are

to be shortened, is calculated. For these miter cuts, the

saw blade is vertical to the workpiece (the bevel angle

is 0°).

MTR

Press button 15. The calculated horizontal miter angle

“MTR”, which has to be set on the chop and miter saw,

and the “MTR” indicator will be shown on the display.

Press the “MTR1” button 15 to return from the “Simple

Miter” operating mode to the “Angle Measurement” operating mode.

Pressing the “ON/OFF” button will also take you back to

the “Angle Measurement” operating mode.

Note: The calculated miter angle “MTR” can only be tak-

en over for chop and miter saws, for which the setting for

vertical cuts is 0°. When the setting for vertical cuts is

90°, the angle for the saw must be calculated as follows:

90° – indicated “MTR” angle = angle to be set on the saw.

13

“Compound Miter” Operating Mode

The “Compound MTR” operating mode is used to easily

determine the miter and bevel angles needed to create

precision joints at compound angles. This is particularly

useful when cutting crown molding laid flat on a compound miter saw.

The “Compound Miter” operating mode is activated by

pressing the “MTR2” button.

Carry out the worksteps exactly in the given sequence.

“1. SPR”: Storing the Spring Angle

SPR

To start “Compound Miter” calculation:

– Open the fold-out leg and base leg until the desired

spring angle is shown on the display.

– Measure the spring angle if it is unknown. To

do so, place the workpiece you want to measure between the fold-out leg and the base leg.

If measurement is not possible with the anglefinder/

digital level on especially narrow or small workpieces,

use auxiliary equipment, e.g. a bevel, and then set the

angle on the anglefinder/digital level.

– To use a saved “HOLD” value (indicator a is static on

the display), press “HOLD,” previously saved angle

will flash. Press “MTR2” and held angle will blink

twice with “SPR” indicator flashing. Continue with

step 2 below.

When the angle is greater than 90° yet less than 180°

when pressing button 16, the “SPR” spring angle is automatically converted as follows:

“SPR” = 180° – measured or set angle.

“2. CNR”: Storing the Corner Angle

SPR

SPR

CNR

To measure the corner angle, place the fold-out and base

legs flat against the walls and read the measured corner

angle or set a known corner angle on the anglefinder/

digital level.

“3.MTR”: Calculating the Miter Angle

MTR

Press button 16 again. “MTR” and the calculated miter

angle for the chop and miter saw are indicated on the

display.

14

Loading...

Loading...