Bosch B8512G-U, B9512G-U Installation Manual

Control Panels

B9512G/B8512G (B9512G-E/B8512G-E)

en UL Installation Guide

!

!

Control Panels Introduction | en 3

1

1.1

Introduction

This section includes an introduction to documents for this product and other documentrelated instructions.

About documentation

This document contains instructions for a trained installer to properly install, configure, and

operate this control panel, and optional peripheral devices. Review this document before

beginning the installation to determine the hardware and wiring requirements for the features

used.

(Bosch Security Systems, Inc. recommends that installers follow good wiring practices such as

those descibed in NFPA 731, Standard for the Installation of Electronics Premises Security

Systems.)

Throughout this document, the words “control panel” refer to all control panels covered by

this document (B9512G/B8512G/B9512G-E/B8512G-E).

Notifications

This document uses Notices, Cautions, and Warnings to draw your attention to important

information.

Notice!

These include important notes for successful operation and programming of equipment, or

indicate a risk of damage to the equipment or environment.

1.1.1

Caution!

These indicate a hazardous situation which, if not avoided, could result in minor or moderate

injury.

Warning!

These indicate a hazardous situation which, if not avoided, could result in death or serious

injury.

Copyright

This document is the intellectual property of Bosch Security Systems, Inc. and is protected by

copyright. All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

Related documentation

Control panel documents

Control Panels (B9512G/B8512G) Release Notes *

Control Panels (B9512G/B8512G) Installation and System Reference Guide (P/N: F01U303996)

Control Panels (B9512G/B8512G/B5512/B4512/B3512) Owner’s Manual (English) (P/N:

F01U307371)*

Control Panels (B9512G/B8512G) Program Entry Guide (P/N: F01U303998)

+

+

+

Control Panels (B9512G/B8512G) UL Installation Guide+ (this document) (P/N: F01U304001)*

+

Bosch Security Systems, Inc. UL Installation Guide 2016.05 | 05 | F.01U.304.001

4 en | Introduction Control Panels

Control Panels (B9512G/B8512G) SIA Quick Reference Guide (P/N: F01U304000)*

+

Control Panels (B9512G/B8512G/B6512/B5512/B4512/B3512) ULC Installation Guide (P/N:

F01U321698)

*Shipped with the control panel.

+

Located on the documentation CD shipped with the control panel.

Keypad documents

Basic Keypad (B915) Installation Guide (P/N: F01U297873)*

Two-line Alphanumeric Keypad (B920) Installation Guide (P/N: F01U265450)*

Fire Keypads (B925F/B926F) Installation Guide (P/N: F01U305193)*

Two-line Capacitive Keypad with Inputs (B921C) Installation Guide (P/N: F01U297887)*

ATM Style Alphanumeric Keypad (B930) Installation Guide (P/N: F01U265451)*

Touch Screen Keypad (B942/B942W) Installation Guide (P/N: F01U294527)*

*Shipped with the keypad.

Optional module documents

Octo-input Module (B208) Installation and Operation Guide (P/N: F01U265456)*

POPEX Module (B299) Installation Guide (P/N: F01U300043)*

Octo-output Module (B308) Installation and Operation Guide (P/N: F01U265458)*

Conettix Ethernet Communication Module (B426) Installation and Operation Guide (P/N:

F01U281208)*

+

Plug-in Telephone Communicator (B430) Installation Guide Installation Guide (P/N:

F01U265454)*

Conettix Plug-in Cellular Communicator (B440) Installation and Operation Guide (P/N:

F01U265455)*

Conettix Plug-in CDMA Cellular Communicator (B441) Installation and Operation Guide (P/N:

F01U282233)*

Conettix Plug-in GPRS Cellular Communicator (B442) Installation and Operation Guide (P/N:

F01U283180)*

Conettix Plug-in HSPA+ Cellular Communicator (B443) Installation and Operation Guide (P/N:

F01U283181)*

Conettix Plug-in Communicator Interface (B450) Installation and Operation Guide (P/N:

F01U300740)*

+

Auxiliary Power Supply (B520) Installation and Operation Guide (P/N: F01U265445)*

Retrofit ZONEX Module (B600) Installation Guide (P/N: F01U300237)

RADION receiver SD (B810) Installation Guide (P/N: F01U261834)*

SDI2 Inovonics Interface Module (B820) Installation Guide (P/N: F01U265460)*

Access Control Module (B901) Installation Guide (P:/N: F01U300416)

Dual Class B Initiating Module (D125B) Installation Instructions (P/N: F01U036340)

2016.05 | 05 | F.01U.304.001 UL Installation Guide Bosch Security Systems, Inc.

Control Panels Introduction | en 5

Multiplex Bus Interface (D8125MUX) Operation and Installation Guide (P/N: F01U034973)

OctoPOPIT Module (D8128D) Installation Guide (P/N: F01U070537)

Access Control Interface Module (D9210C) Installation and Operation Guide (P/N:

F01U215232)

*Shipped with the module.

+

Located on the documentation CD shipped with the module.

1.2

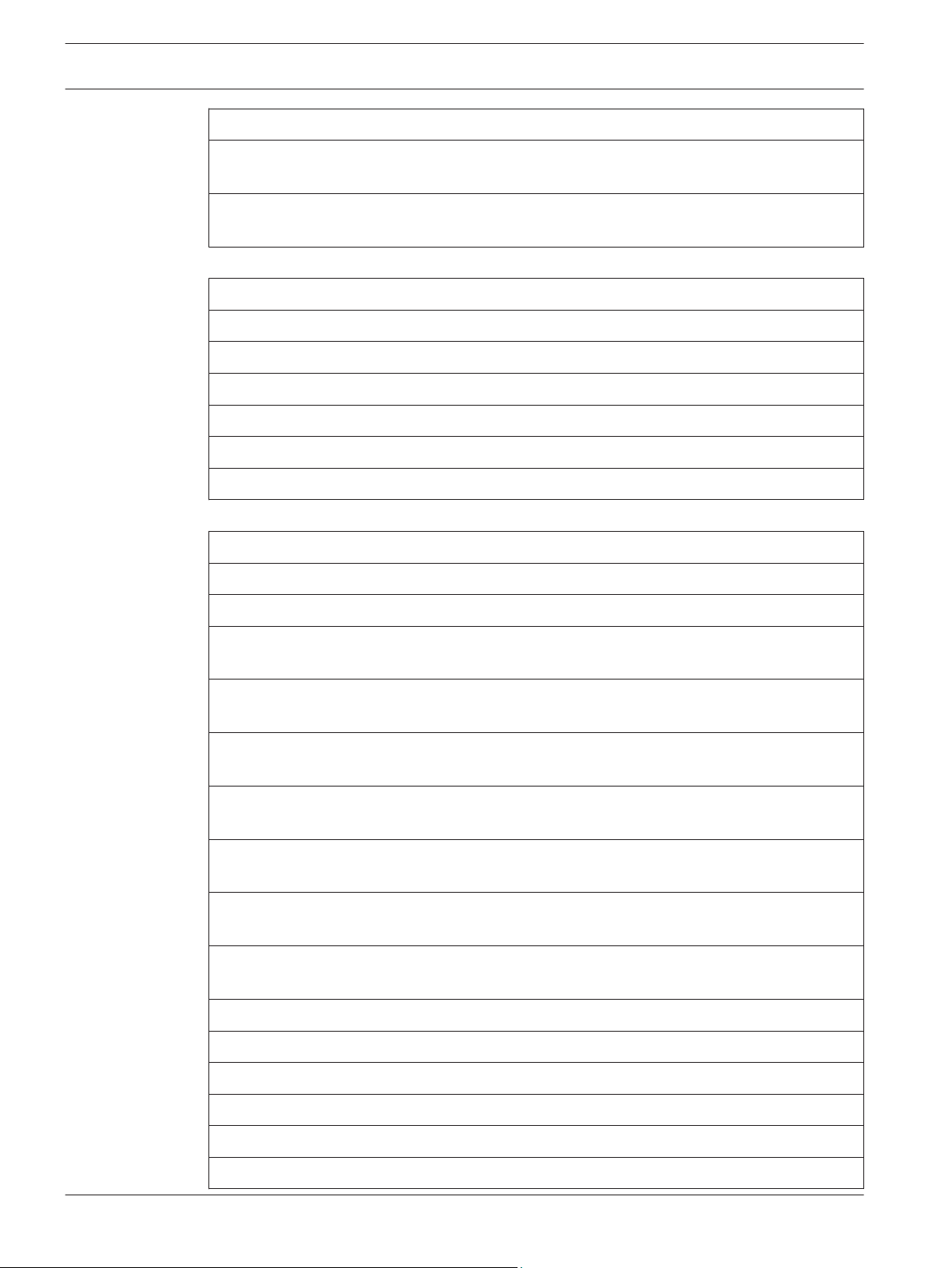

Bosch Security Systems, Inc. product manufacturing dates

Use the serial number located on the product label and refer to the Bosch Security Systems,

Inc. website at http://www.boschsecurity.com/datecodes/.

The following image shows an example of a product label and highlights where to find the

manufacturing date within the serial number.

Bosch Security Systems, Inc. UL Installation Guide 2016.05 | 05 | F.01U.304.001

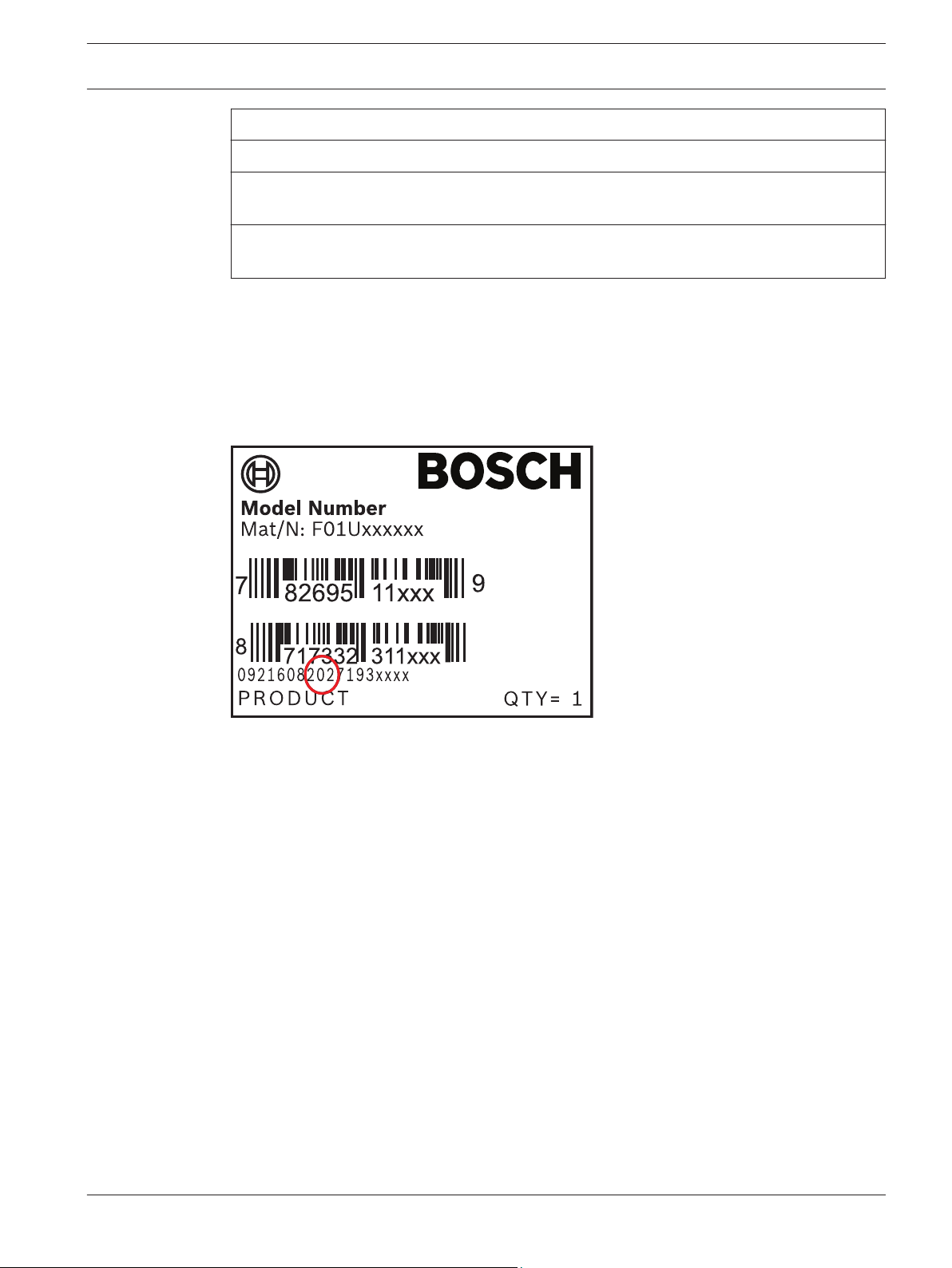

B430

Plug-in Tephone Communicator

provides a single

telephone RJ-45 connector

to allow communication

over telephone lines.

Control

Panel

On-board Points

1 to 8

B44x

Conettix Plug-In Cellular

Communicator allows

communciation over

a cellular network.

B208

Octo-input modules allow

the addition of up to 8

input devices.

B308

Octo-output modules allow

the addition of up to 8

output devices.

B520

Auxiliary Power Supply modules

expand power by connecting to

an SDI2 device bus or

other 12 volt devices.

B810

RADION receiver SDs

connect RADION wireless devices

to the control panel

.

B820

SDI2 Inovonics Interface modules

interface with an Inovonics

wireless receiver.

B91x/B92x/B93x/B94x

Use keypads* to operate

the control panel by area.

B9512 control panels support up to 32 areas.

B8512 control panels support up to 8 areas.

Each area can have its own account number

or you can group together areas

with a common account number.

B450

Conettix Plug-In Communicator

Interface allows communciation

over a cellular network through

the SDI2 bus.

B426

The B426 provides off-board

communication over a network.

B299

POPEX modules provide

support for up to 100 POPIT

devices over a single

expansion loop.

B600

The ZONEX modules allows

the connection of ZONEX

expansion modules.

6 en | System overview Control Panels

2

System overview

*Up to 8 of the keypads can be models D1260, D1257/D1257RB, D1256/D1256RB, or

D1255/D1255R/D1255RB on the SDI bus (SDIx configured as SDI).

2016.05 | 05 | F.01U.304.001 UL Installation Guide Bosch Security Systems, Inc.

Control Panels Control panel installation | en 7

3

Control panel installation

This section explains how to mount the control panel enclosure, how to mount the control

panel into the enclosure, and provides an overview of how to wire modules to the control

panel.

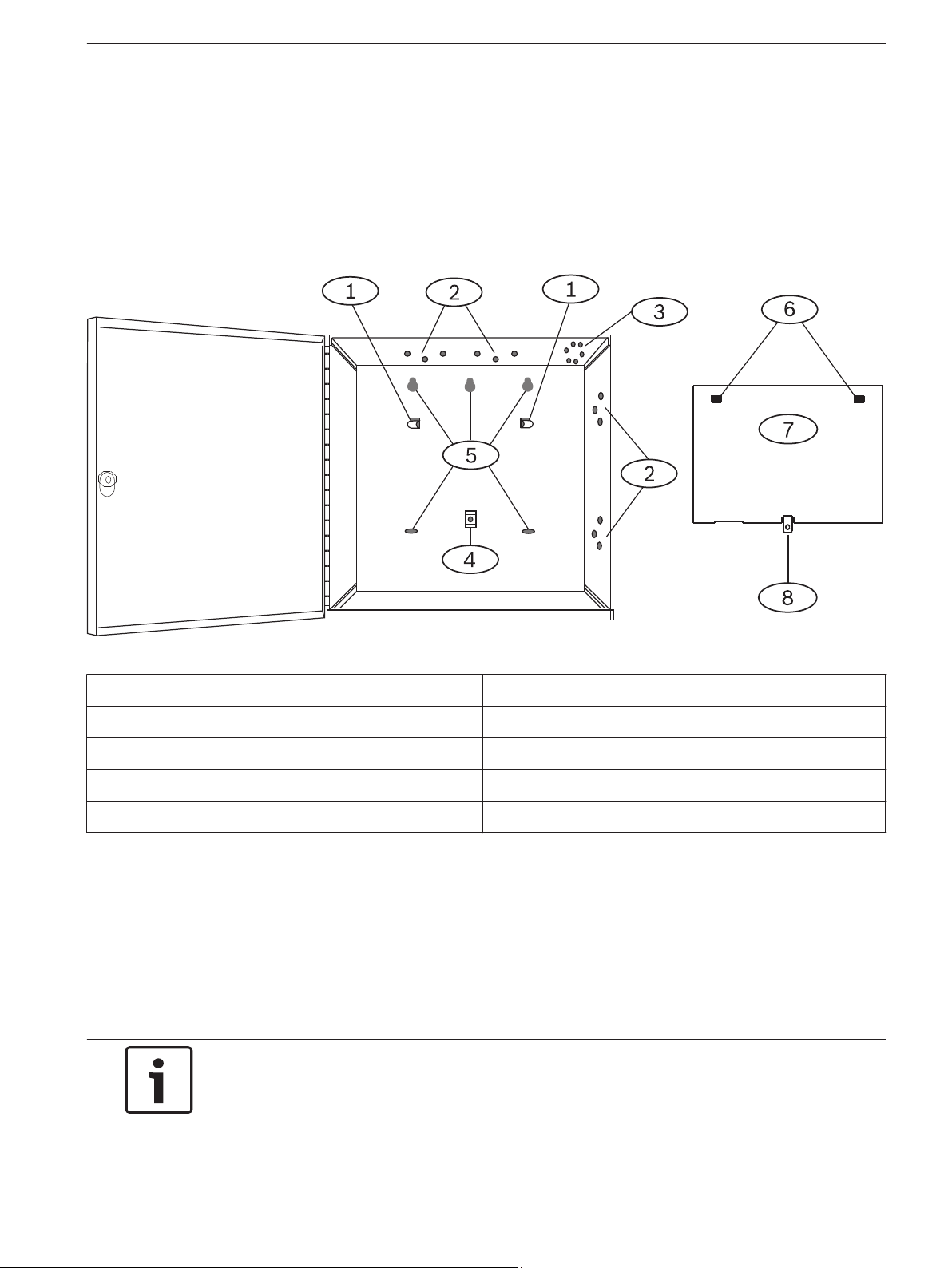

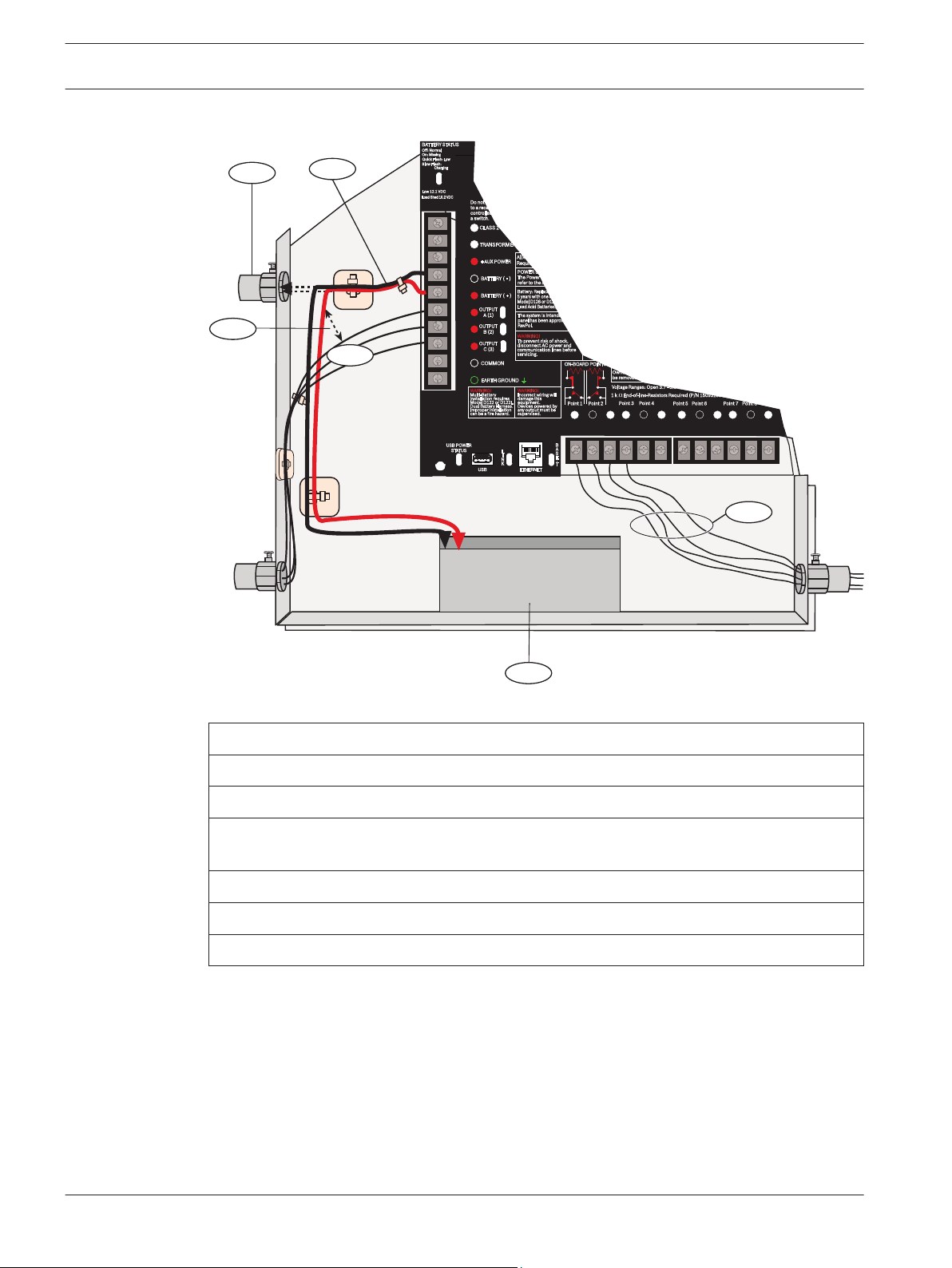

Enclosure overview

Before you begin, review the overview figure:

Figure 3.1: Enclosure and control panel mounting overview

Callout ᅳ Description Callout ᅳ Description

1 ᅳ Mounting skirt attachment hooks (2) 5 ᅳ Enclosure mounting holes (5)

2 ᅳ Module mounting three-hole pattern (4) 6 ᅳ Mounting skirt attachment holes (2)

3 ᅳTamper switch mounting location 7 ᅳ Back of the control panel mounting skirt

4 ᅳ Mounting skirt screw location (1) 8 ᅳ Mounting skirt screw tab

3.1

Install the enclosure

Refer to Enclosures to determine if the application requires a specific enclosure.

Installing the enclosure:

1. Remove any knockouts prior to installing the control panel.

2. Mount the enclosure in the desired location. Use all enclosure mounting holes. Refer to

the mounting instructions supplied with the selected enclosure.

3. Pull the wires into the enclosure.

4. Optionally install the supplied point label chart on the inside of the enclosure door.

Notice!

Electromagnetic interference (EMI) can cause problems on long wire runs.

Bosch Security Systems, Inc. UL Installation Guide 2016.05 | 05 | F.01U.304.001

!

8 en | Control panel installation Control Panels

3.2

3.2.1

3.2.2

Install the control panel

This section includes instructions to mount the control panel in the enclosure, connect earth

ground, and make other control panel connections.

Mount the control panel

Refer to the figure Enclosure overview, page 7.

Mounting the control panel:

1. Place the control panel over the inside back of the enclosure, aligning the large

rectangular openings of the mounting skirt with the enclosure mounting attachment

hooks. Slide the control panel down so that it hangs on the hooks.

2. Remove the tape from the #6 x 1/4-in screw in the mounting skirt screw tab on the

control panel. The screw passes through the mounting tab and into the skirt mounting

hole in the enclosure.

3. Tighten the screw to secure the control panel in the enclosure.

Notice!

Connect earth ground to the control panel before making any other connections.

Connect earth ground

To help prevent damage from electrostatic discharges or other transient electrical surges,

connect the system to earth ground before making other connections. The

10) indicates the earth ground terminal. Use a recommended earth ground reference, such as

a grounding rod or a cold water pipe. Make the connection using 14 AWG (1.8 mm) to 16 AWG

(1.5 mm) wire.

icon (Terminal

3.2.3

Notice!

Do not use telephone or electrical ground for the earth ground connection. Do not connect

other control panel terminals to earth ground.

Caution!

Avoid electrostatic discharge. Always touch the earth ground connection with the icon first,

before beginning work on the control panel.

Ground Fault Detect enable

To meet UL 864 requirements, enable Ground Fault Detect.

A ground fault is a circuit impedance to ground sufficient to result in the annunciation of a

trouble condition.

The control panel has a ground fault detection circuit that when enabled, detects ground

faults on Terminals 1 to 9 and 11 to 30.

If a ground fault condition occurs, the keypads annunciate a ground fault and the control panel

transmits a trouble message.

When the control panel recognizes that the ground fault condition is corrected, and remains

corrected for between 5 to 45 consecutive seconds, the control panel clears the fault from the

keypad display and sends a restoral report.

The control panel detects ground fault at ≤ 300 Ω.

2016.05 | 05 | F.01U.304.001 UL Installation Guide Bosch Security Systems, Inc.

Control Panels Control panel installation | en 9

Enable Ground Fault Detect

To enable fault detection, use RPS. Refer to RPS Help.

3.2.4

Ground fault detection troubleshooting

Measure earth ground (Terminal 10) and common (Terminal 9) to determine whether the

control panel has the necessary -2.1 V decay to 0.

Measuring and comparing voltage for ground fault detection:

1. Set your digital voltmeter (DVM) to measure VDC.

2. Connect the red DVM lead to control panel Terminal 10, and the black DVM lead to

Terminal 9.

3. Compare this voltage to the following table:

Control panel voltage at Terminals 9 and 10) Terminal potentially causing ground fault

~ 0 VDC 4, 9, 12, 15, 17, 21

~ 13.65 VDC 5, 6, 7, 8, 26, 30

~ 2.51 VDC 11, 13, 14, 16, 17, 19, 20, 22

~ 2.44 to 3.2 VDC 24

~ 10.9 to 11.2 VDC 25

~ 7.2 VDC 28

~ 5.8VDC 29

~ 7.35 VDC 1, 2

3.3

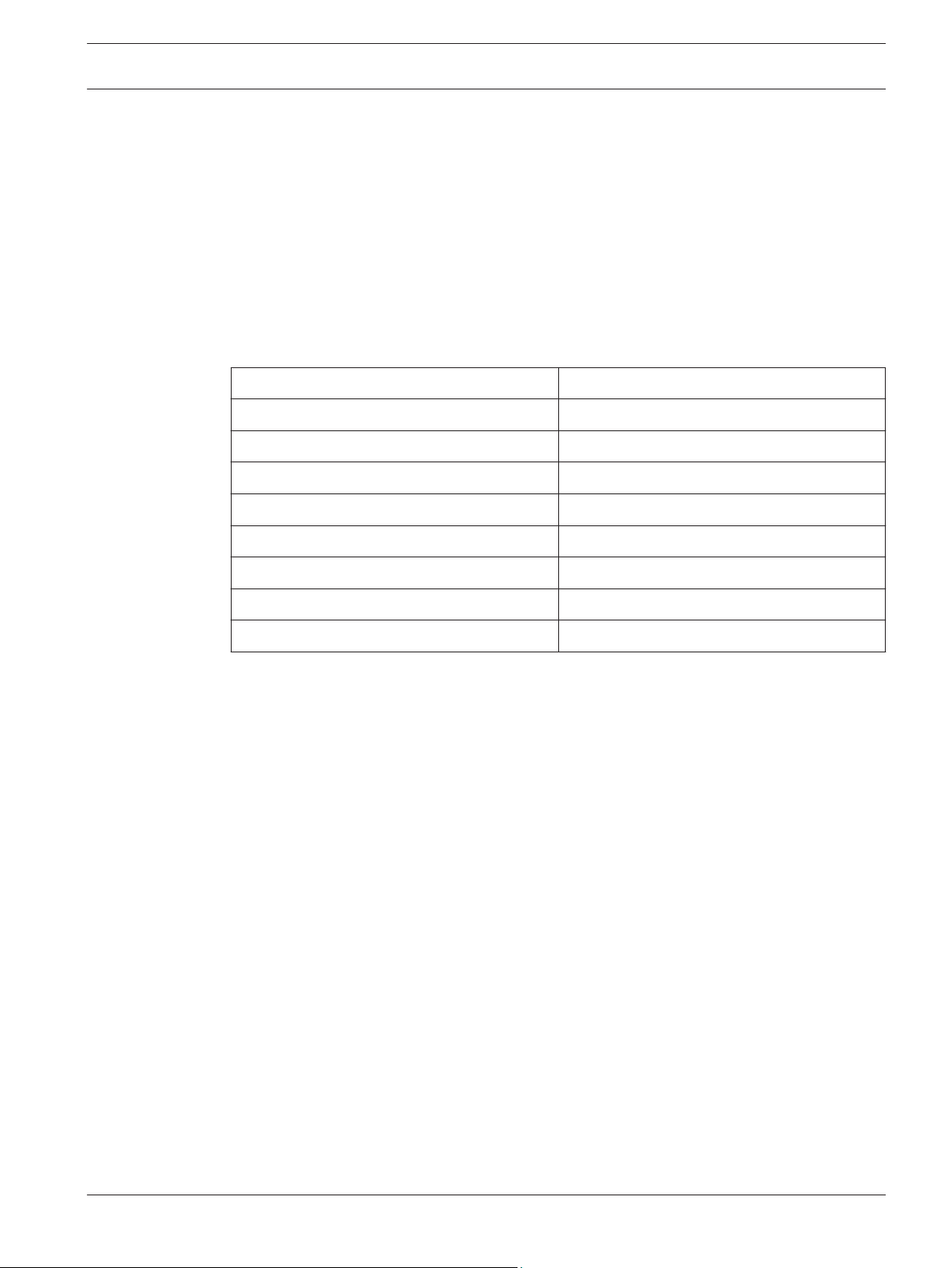

Control panel to module wiring overview

In the following sections, this document provides instructions for wiring devices to your

control panel. You can use interconnect or terminal wiring.

If SDIx is configured for SDI2, use either SDI2 bus.

Using terminal wiring

For terminal wiring, use 18 AWG to 22 AWG (1.02 mm to 0.65 mm) wire.

Bosch Security Systems, Inc. UL Installation Guide 2016.05 | 05 | F.01U.304.001

RESETZONEX

TAMPER

SDI2

PWR+/R

A/Y

B/G

COM/B

PWR+/R

A/Y

B/G

COM/B

24

25

26

27

28

29

23

26

SDIx

ire

olice

ting

RESETZONEX

TAMPER

SDI2

PWR+/R

A/Y

B/G

COM/B

PWR+/R

A/Y

B/G

COM/B

25

26

28

29

30

23

27

SDIx

ire

olice

ting

24

ZONEX TMPR

SDIx SDI2

MODULE RELEASE

MOD-2

MOD-1

en | Control panel installation Control Panels

10

SDI2 devices daisy chained with terminal wiring

Using interconnect wiring

Interconnect wiring connectors parallel the SDI2 terminals (27 through 30 (or 23 through 26 if

configured for SDI2)). In installations with multiple SDI2 modules, using interconnect wiring

makes the installation quicker and easier than using terminal strip wiring. You use any

combination of terminal and interconnect wiring to wire multiple modules in parallel, but do

not wire a single module to the control panel using both terminal and interconnect wiring.

The interconnect wiring connectors are "keyed" (interconnect wiring plug can fit in only one

direction).

2016.05 | 05 | F.01U.304.001 UL Installation Guide Bosch Security Systems, Inc.

RESETZONEX

TAMPER

SDI2

PWR+/R

A/Y

B/G

COM/B

PWR+/R

A/Y

B/G

COM/B

24

25

26

27

28

29

23

26

SDIx

ire

olice

ting

RESETZONEX

TAMPER

SDI2

PWR+/R

A/Y

B/G

COM/B

PWR+/R

A/Y

B/G

COM/B

25

26

28

29

30

23

27

SDIx

ire

olice

ting

24

ZONEX TMPR

SDIx SDI2

MODULE RELEASE

MOD-2

MOD-1

Control Panels Control panel installation | en 11

SDI2 devices daisy chained with interconnect wiring

Bosch Security Systems, Inc. UL Installation Guide 2016.05 | 05 | F.01U.304.001

2

1

!

12 en | Power supply Control Panels

4

4.1

Power supply

This section provides information on installing and maintaining primary power, batteries, and

auxiliary power.

Primary (AC) power

The control panel uses a 16.5 VAC, 40 VA, internally-fused transformer (D1640) for its primary

power source. The control panel draws 190 mA when idle and 265 mA when in the alarm

state.

The auxiliary power available for powered devices is 1.4 A.

Surge protection

Transient suppressors and spark gaps protect the circuit from power surges. This protection

relies on the ground connection at the earth ground terminal (Terminal 10), marked with the

icon. Ensure that you connect the terminal to a proper ground.

Refer to Connect earth ground, page 8.

AC power fail

The system indicates an AC power failure when the transformer input terminals do not have

sufficient voltage. The AC Fail Time parameter sets the amount of time without AC power

before the control panel reports the failure, and the amount of time after the power returns

before the control panel reports restored power.

When the control panel loses AC power long enough for the battery to become low, the

control panel adds a Battery Low event to the event log. If the battery continues to discharge

below the load shed threshold, the system ceases to operate and generates no further events.

4.1.1

Install the transformer

Caution!

Do not short-circuit the terminals of the transformer: Shorting the terminals opens the

internal fuse, causing permanent failure. Connect the transformer to the control panel's AC

power terminals before plugging it into the power source.

Notice!

Plan ahead

Route telephone, SDI2 bus wiring, and sensor loop wiring away from any AC conductors,

including the transformer wire. AC wiring can induce noise and low level voltage into adjacent

wiring.

1. Use 18 AWG (1.02 mm) wire minimum (12 AWG [2 mm] maximum) and connect the

transformer to the control panel. Make the wire length as short as possible. Do not

exceed 50 ft (15 m).

2. Connect the wire to the control panel.

3. Connect the wire to the transformer.

4. Plug the transformer into an unswitched, 120 VAC, 60 Hz power outlet only.

5. Secure the transformer to the outlet with the screw provided (not applicable in

Cananda).

2016.05 | 05 | F.01U.304.001 UL Installation Guide Bosch Security Systems, Inc.

4 5

!

!

Control Panels Power supply | en 13

D8004 Transformer Enclosure required for fire systems

Use the D8004 Transformer Enclosure for the D1640 Transformer in fire and combined fire

and burglary applications.

Notice!

Check with the Authority Having Jurisdiction (AHJ) about mounting transformers on specific

circuits.

4.2

4.2.1

Secondary (DC) power

A 12 V sealed lead-acid rechargeable battery (such as the D126/D1218) supplies secondary

power to maintain system operation during interruptions of primary (AC) power.

Notice!

Use sealed lead acid batteries only

The charging circuit is calibrated for lead-acid batteries. Do not use gel-cell or NiCad

batteries.

Extra batteries

To increase battery back-up time, connect a second 12 V battery in parallel to the first battery.

Use a D122/D122L Dual Battery Harness to ensure proper and safe connection.

Refer to Standby battery requirements and calculations.

D1218 Battery

The D1218 is a 12 V, 18 Ah battery for use in applications requiring extended battery standby

time. The control panel does not support more than 38 Ah of battery.

Install the battery

1. Place the battery upright in the base of the enclosure.

2. Locate the red and black leads supplied in the hardware pack.

3. Connect the black battery lead to Terminal 4 and then to the negative (-) side of the

battery.

4. Connect the red battery lead to Terminal 5, and then to the positive (+) side of the

battery.

Bosch Security Systems, Inc. UL Installation Guide 2016.05 | 05 | F.01U.304.001

Warning!

High current arcs are possible. The positive (red) battery lead and Terminal 5 can create high

current arcs if shorted to other terminals or the enclosure. Use caution when working with

the positive lead and Terminal 5. Always disconnect the positive (red) lead from the battery

before removing it from Terminal 5.

Caution!

The battery terminals and wire are not power limited. Maintain a 0.250 in (6.4 mm) space

between the battery terminals, battery wiring, and all other wiring. Battery wiring cannot

share the same conduit, conduit fittings, or conduit knockouts with other wiring.

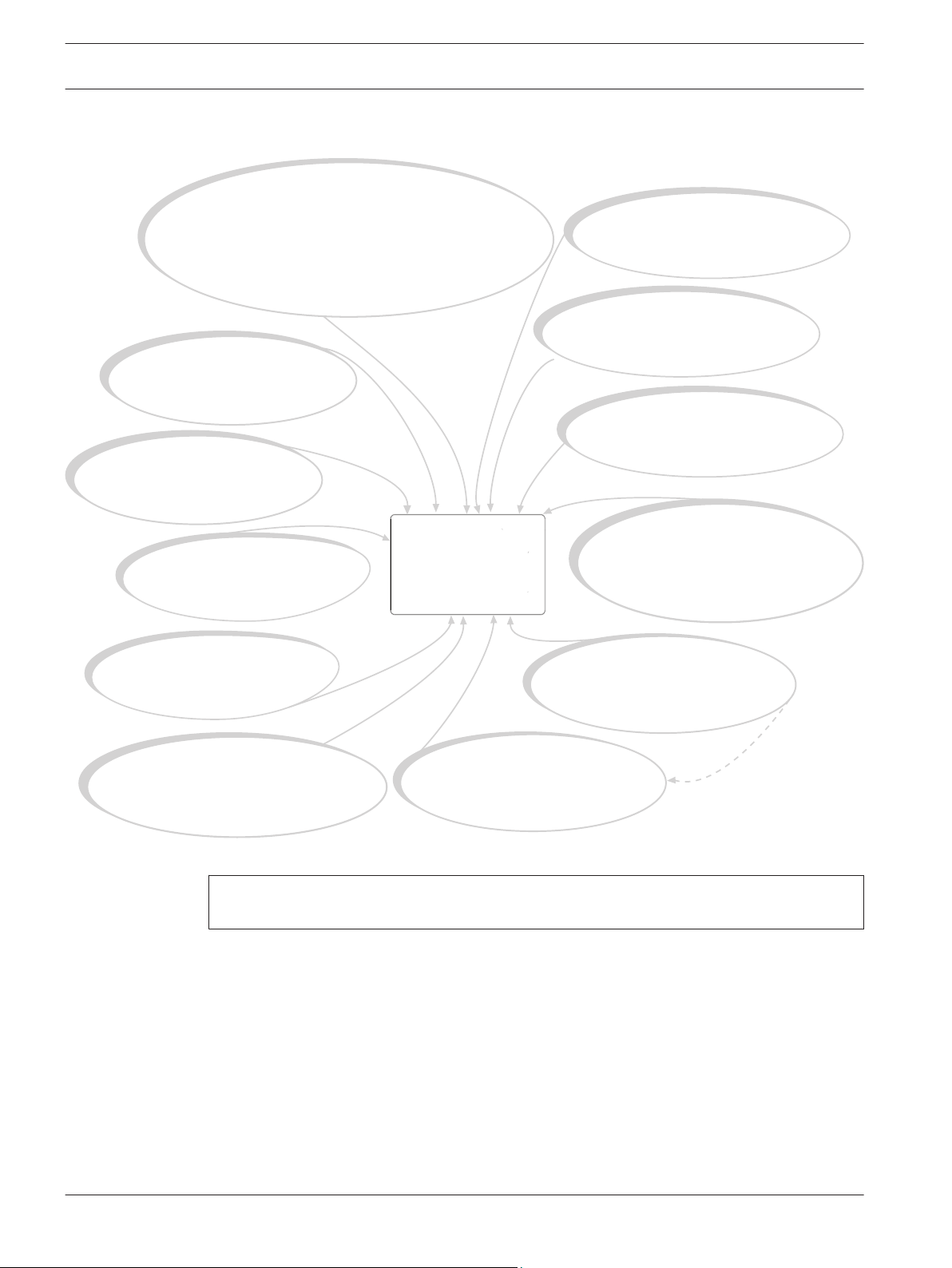

USB POWER

STATUS

L

I

N

K

ETHERNETUSB

B

A

S

E

T

11

13 14

16

17

19

20

22

12

15

18

21

Quick Flash:

Low

BATTERY STATUS

Slow Flash:

Charging

Off: Normal

On:

Missing

Low 12.1 VDC

Load Shed 10.2 VDC

EARTH GROUND

COMMON

BATTERY ( - )

+ AUX POWER

BATTERY ( + )

CLASS 2

16.5 VAC 40 VA 60 Hz

TRANSFORMER

10

9

8

7

6

5

4

3

2

1

OUTPUT

B (2)

OUTPUT

A (1)

OUTPUT

C (3)

Do not connect

to a receptacle

controlled by

a switch.

Point 5 Point 6

Point 3 Point 4

Point 1 Point 2 Point 7 Point 8

ON-BOARD POINTS

1 k End-of-line-Resistors Required (P/N 15093130-004),

WARNING!

Multi-Battery

installation requires

Model D122 or D122L

Dual Battery Harness.

Improper installation

can be a fire hazard

.

WARNING!

Incorrect wiring will

damage this

equipment.

Devices powered by

any output must be

supervised.

POWER SUPPL

The Power S

refer to the B

The system is intended

panel has been approv

RevPol.

Battery: Replace every 3 to

5 years with one or two

Model D126 or D1218 12V

Lead Acid Batteries.

WARNING!

To prevent risk of shock,

disconnect AC power and

communication lines before

servicing.

All exte

Require

Voltage Ranges: Open 3.7 - 5.0 VDC,

Owner I

be removed by

POINT 1 COM POINT 2 POINT 3 COM POINT 4 POINT 5 COM POINT 6 POINT 7 COM POINT 8

1

2

3

4

5

6

14 en | Power supply Control Panels

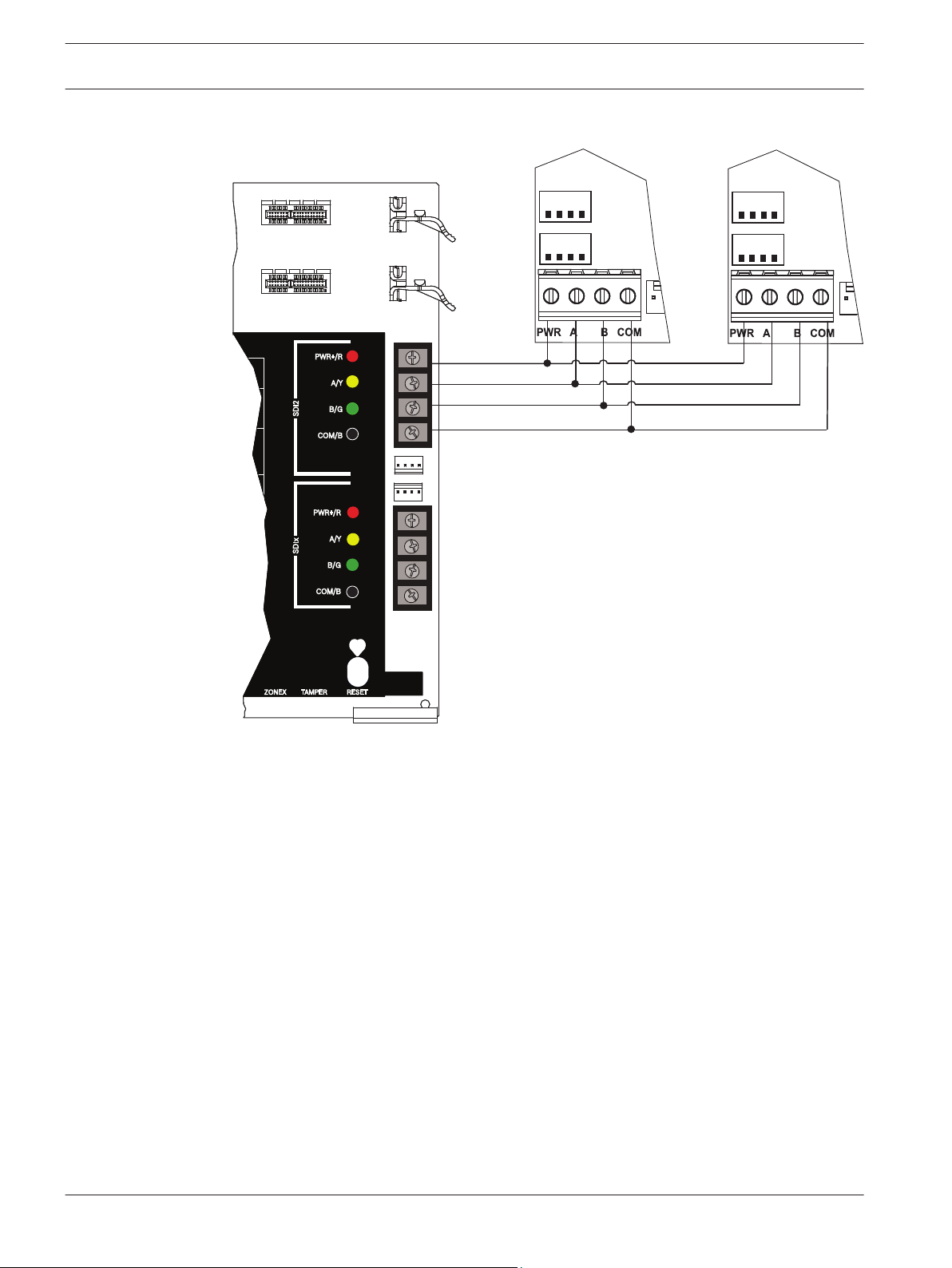

Non-power-limited wiring

Figure 4.1: Non-power-limited wiring

Callout ᅳ Description

1 ᅳ Conduit required for use with external batteries

2 ᅳ Battery wires

3 ᅳ 0.25 in (6.4 mm) minimum. To ensure proper spacing, use tie-wraps or similar devices to

secure wires.

4 ᅳ Output wires

5 ᅳ Sensor loop wires

4.2.2

2016.05 | 05 | F.01U.304.001 UL Installation Guide Bosch Security Systems, Inc.

6 ᅳ 12 V sealed lead-acid rechargeable battery (D126/D1218)

Charge the battery

Connect the battery and then the transformer to allow the control panel to charge the battery

while you complete the installation.

BATTERY STATUS LED

The control panel includes one BATTERY STATUS LED with 4 LED patterns to indicate the

battery status.

Loading...

Loading...