Page 1

Conettix Plug-in Communicator Interface

B450

en Installation and Operation Guide

Page 2

Page 3

Conettix Plug-in Communicator

Interface

Table of contents

Table of Contents | en 3

1

2

2.1 About documentation 5

2.2 Bosch Security Systems, Inc. product manufacturing dates 5

2.3 Installation workflow 6

3

3.1 Module overview 7

3.2 B450 cellular interface compatibility 8

3.3 Bus address settings overview 9

4

4.1 Setting the bus address 11

4.2 Insert the communication module 12

4.2.1 Insert the B44x communication module (required and available separately) 13

4.2.2 Insert the B44x communication module with SIM card (required and available

4.3 Mount the module in the enclosure 14

4.3.1 Mount and wire the tamper switch (option for SDI2 bus only) 15

4.4 Install and mount the plug-in communicator antenna 16

4.5 Wire to the control panel 16

4.5.1 Wire to an SDI2 control panel 17

4.5.2 Wire to an SDI control panel 18

4.5.3 Wire to an option bus control panel 19

5

5.1 Configuration for SDI2 control panels 20

5.1.1 Configuring and viewing status from RPS 20

5.2 Use USB to configure the B450 26

5.2.1 Install a communication program 28

5.2.2 Log into the USB interface 32

5.2.3 USB Main menu 34

5.2.4 USB menu structure 35

5.2.5 USB menu 36

5.3 Short Message Service (SMS) configuration 49

5.3.1 Use SMS to configure the B450 49

5.4 Firmware Update page 52

6

6.1 USB menu access disabled 56

6.2 LED status indicators 56

6.3 Show the firmware version 60

6.4 SIM card 60

6.5 Diagnostic log 60

6.6 Understanding network polling 61

6.7 Control panel programming using cellular 61

7

7.1 Technical specification 62

7.2 Certifications 64

Safety 4

Introduction 5

System overview 7

Installation 11

13

separately)

Configuration 20

Maintenance and troubleshooting 56

Specifictions and certifications 62

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 4

!

4 en | Safety

Conettix Plug-in Communicator

Interface

1

Safety

ESD Precaution

Please note that while the B450 comes in a plastic case, and is protected from ESD, the plugin cellular communicator (B44x) does not. All plug-in cellular communicator components may

potentially be exposed to finger touches - therefore extra attention must be paid to ESD

(electrostatic discharge) precaution. Make sure there is no static interference when using the

board. Appropriate ESD protections must be taken and wearing electrostatic equipment is

recommended, such as anti-static wrist strap.

ESD damage can range from subtle performance degradation to complete device failure.

Precision integrated circuits may be more susceptible to damage because very small

parametric changes could cause the device not to meet its published specifications.

Warning!

Failure to follow these instructions can result in a failure to initiate alarm conditions. Bosch

Security Systems, Inc. is not responsible for improperly installed, tested, or maintained

devices. Follow these instructions to avoid personal injury and damage to the equipment.

Notice!

Inform the operator and the local authority having jurisdiction (AHJ) before installing the

module in an existing system.

Disconnect all power to the control panel before installing the module.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 5

Conettix Plug-in Communicator

Interface

Introduction | en 5

2

2.1

2.2

Introduction

This document supports the B450 with firmware version v3.02

About documentation

Copyright

This document is the intellectual property of Bosch Security Systems, Inc. and is protected by

copyright. All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

Bosch Security Systems, Inc. product manufacturing dates

Use the serial number located on the product label and refer to the Bosch Security Systems,

Inc. website at http://www.boschsecurity.com/datecodes/.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 6

!

6 en | Introduction

Conettix Plug-in Communicator

Interface

2.3

Installation workflow

To install and configure the module, use the workflow below and follow in sequential order

from top to bottom, checking off each box as you complete a step.

Caution!

Always power down the control panel when connecting a module. To power down the control

panel, unplug the transformer and disconnect the battery.

Plan the installation of the B450 Conettix Plug-in Communicator Interface

Unpack the device contents

Power down the system

Select the bus address value for the compatible control panel (This will automatically

configure the module to work with a compatible control panel. Refer to Setting the bus

address, page 11)

Insert the desired plug-in communicator into the B450 (Refer to Insert the communication

module, page 12)

Mount the B450 into the enclosure (Refer to Mount the module in the enclosure, page 14)

Wire the B450 to a compatible control panel (Refer to Wire to the control panel, page 16)

Power up the system

Install a communication program (if required) (Refer to Install a communication program,

page 28)

Configure the communication module (non SDI2 control panels)

Verify LED activity

Review signal strength on the cellular communicator. Refer to your cellular communicator

Installation Guide for more information on signal strength.

Installation is complete

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 7

1

2

7

5

6

3

4

8

9

Conettix Plug-in Communicator

Interface

System overview | en 7

3

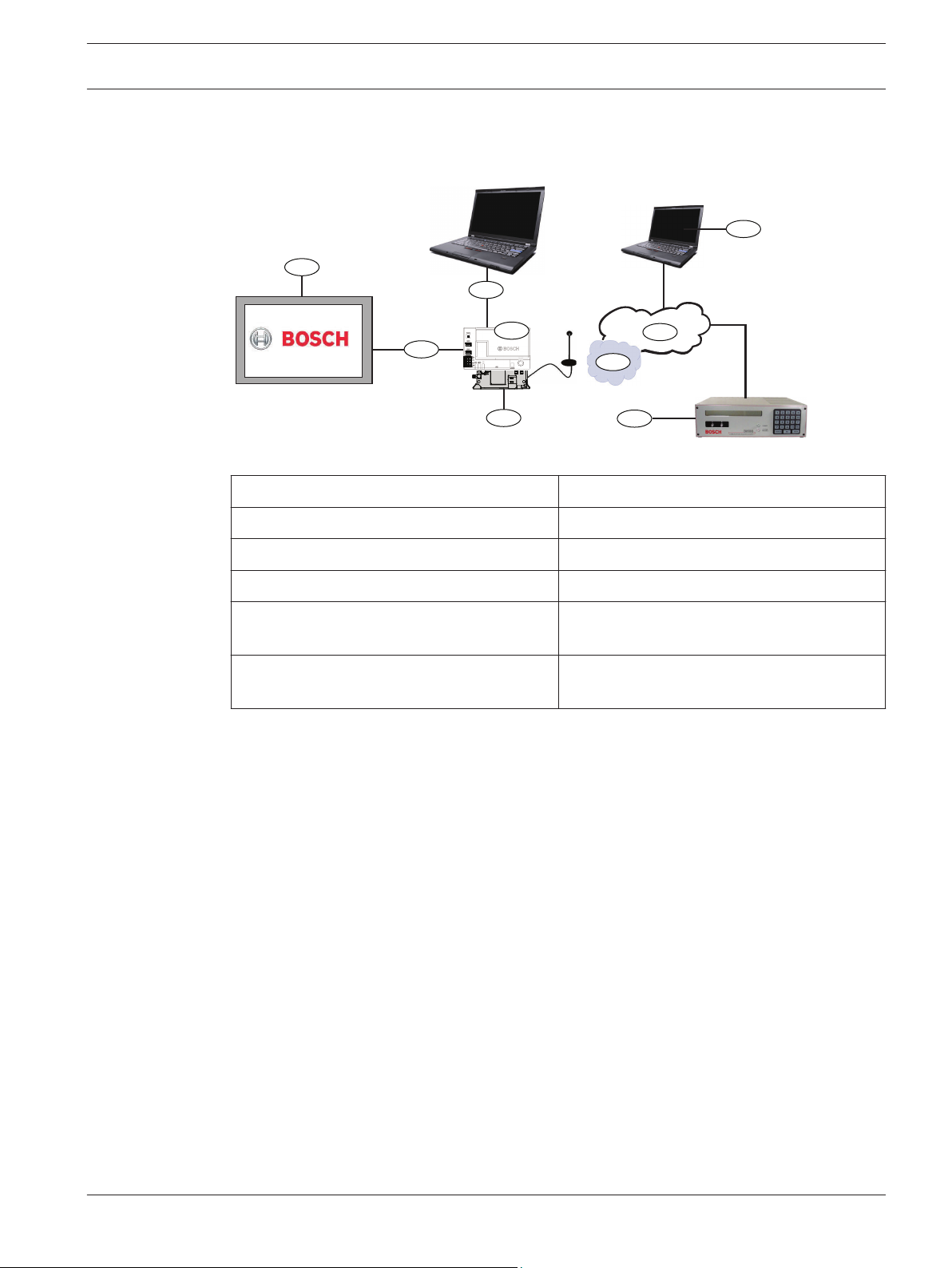

System overview

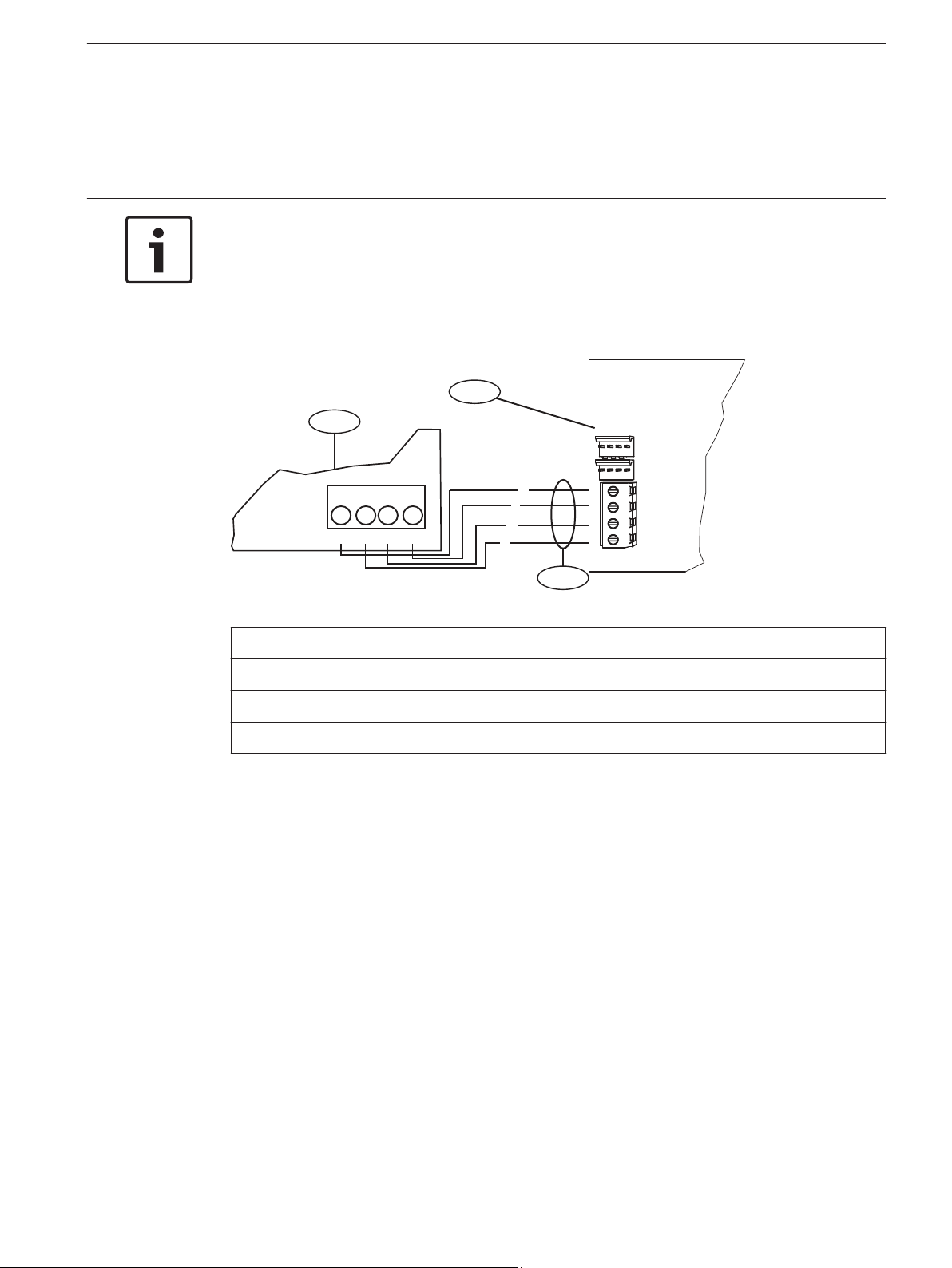

Refer to the graphic below for the complete B450 system configuration.

B450 system connections overview

Callout ᅳ Description

1 ᅳ Compatible Bosch control panel 6 ᅳ Cellular carrier network

2 ᅳ Panel data bus (SDI2, SDI, or Option) 7 ᅳ Internet/LAN/WAN

3 ᅳ B450 Plug-in Communicator Interface 8 ᅳ Remote Programming Workstation

Callout ᅳ Description

3.1

4 ᅳ USB connection for B450 configuration 9 ᅳ Compatible IP receiver (Bosch D6100IPv6

shown)

5 ᅳ B44x Plug-in Cellular Communicator

(available separately)

Module overview

The B450 Conettix Plug-in Communicator Interface (wired to a compatible control panel) is a

four-wire powered SDI2, or SDI device that provides two-way communication over commercial

cellular networks using a plug-in communicator.

The B450 Conettix Plug-in Communicator Interface bus address switch determines the bus

address of the device. When required, configuration of the module is managed through the

control panel, a local USB connection, or using SMS.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 8

1

8

6

2

9

10

3

7

5

4

TX

RX

8 en | System overview

B450 module overview

Conettix Plug-in Communicator

Interface

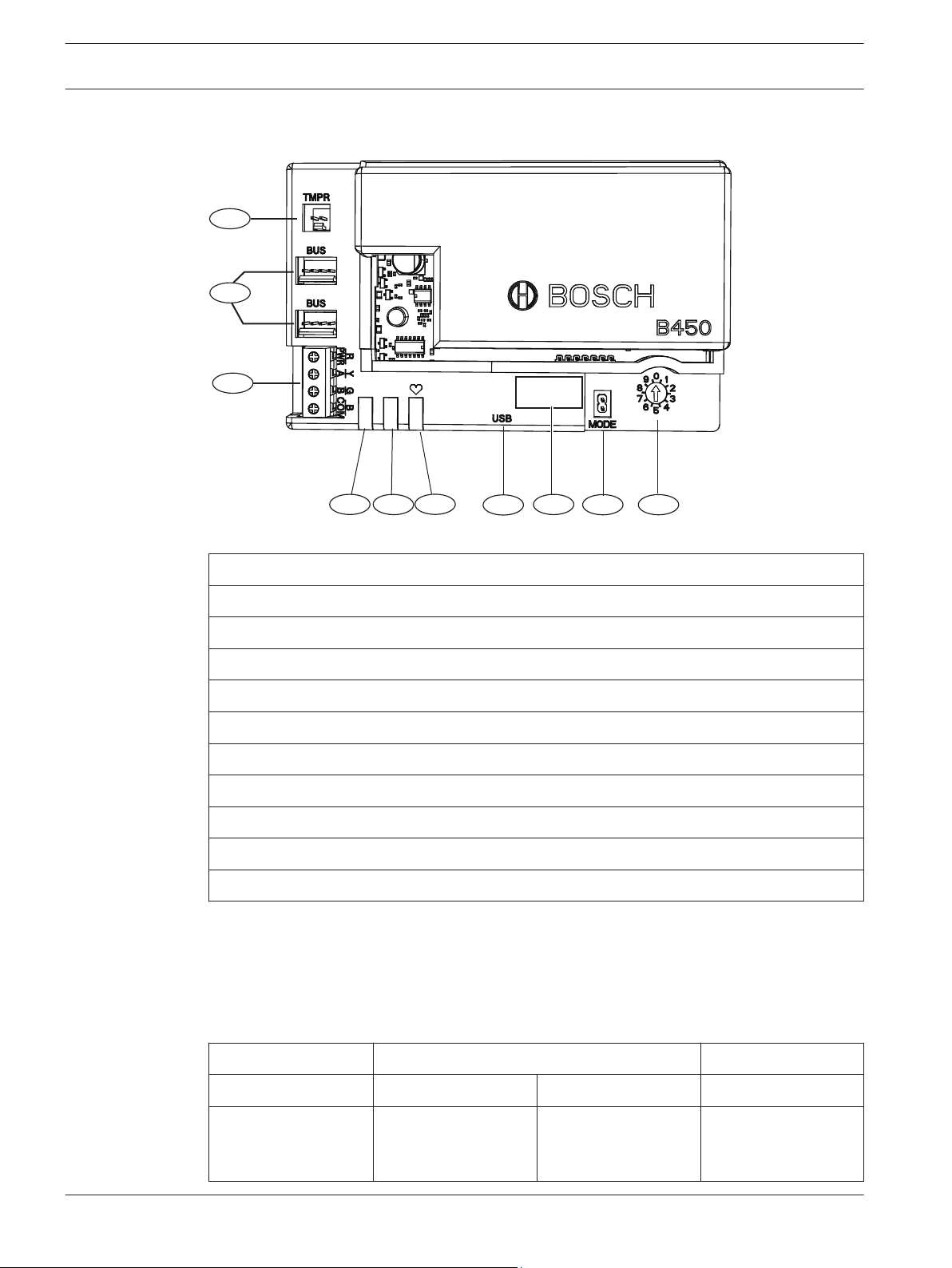

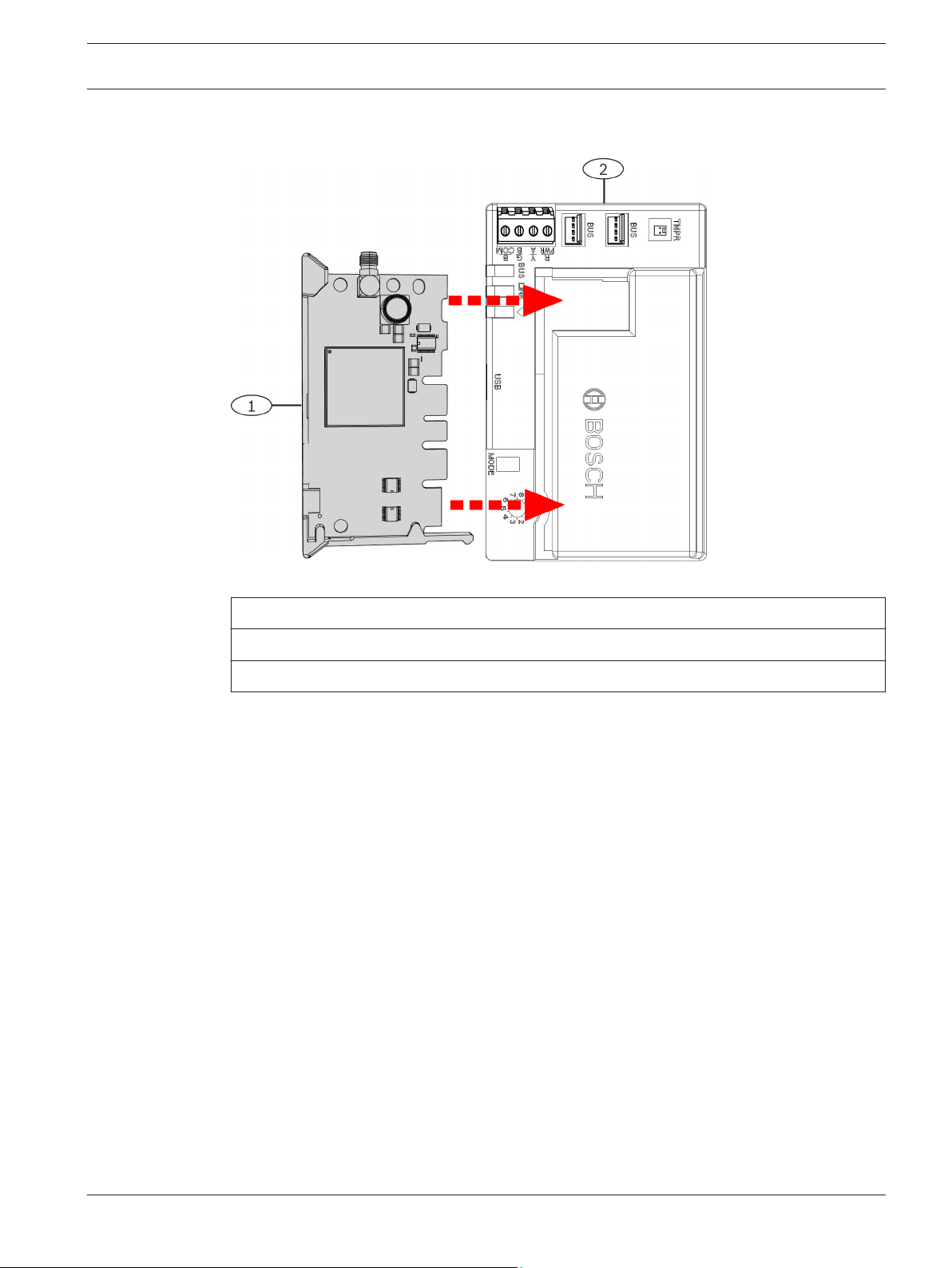

Figure 3.1: B450 Plug-in Communicator Interface

Callout ᅳ Description

1 ᅳ Tamper switch connector

2 ᅳ Bus address switch

3 ᅳ MODE 2-pin jumper connector (for future use)

4 ᅳ Bus address label

5 ᅳ USB connector (Type A)

6 ᅳ Heartbeat LED

7 ᅳ RX LED (indicates packets received from the wireless network)

8 ᅳ TX LED (indicates packets transmitted over the wireless network)

9 ᅳ Terminal strip (to control panel)

10 ᅳ Interconnect wiring connectors (to control panel or other compatible modules)

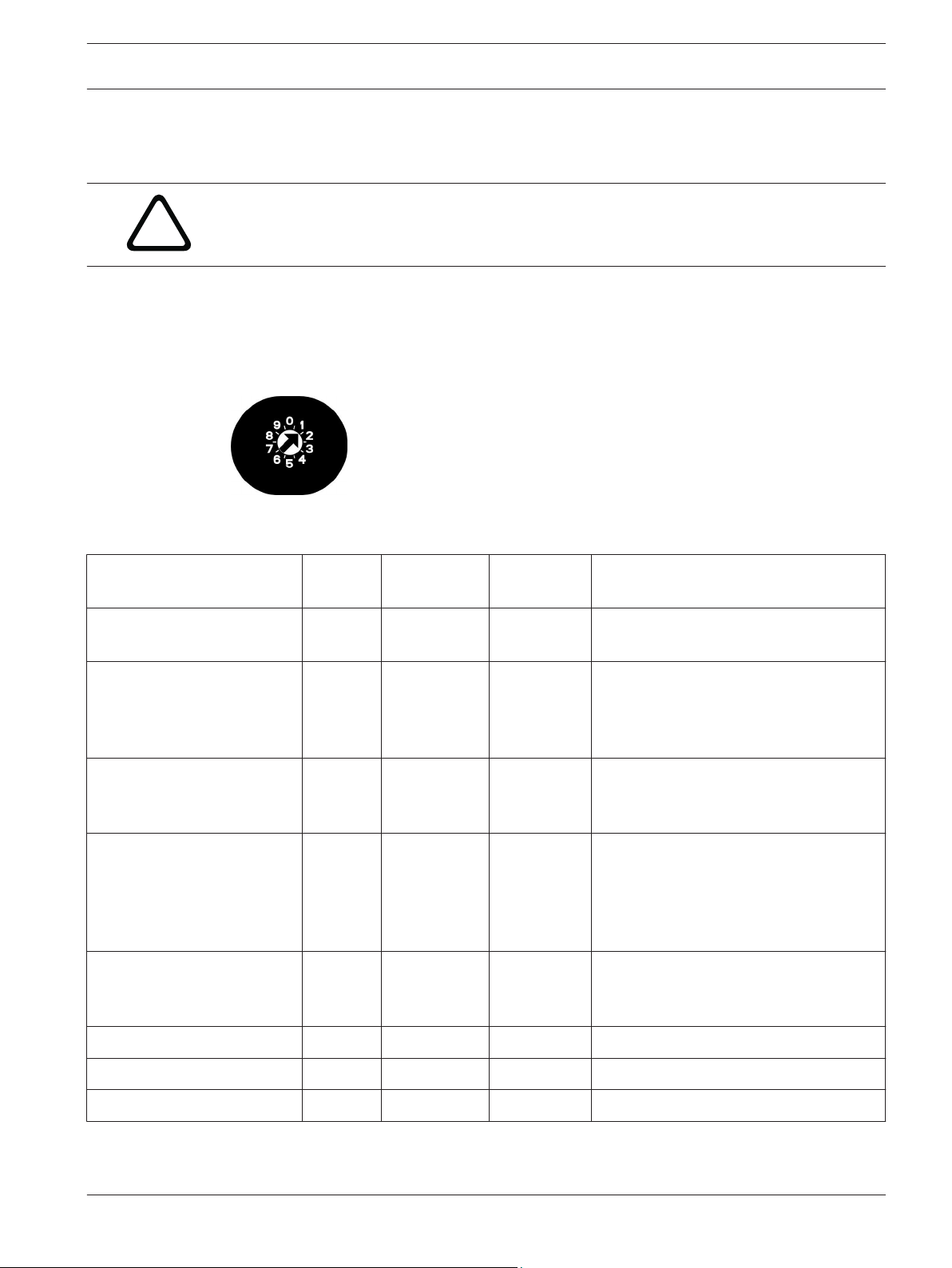

3.2

B450 cellular interface compatibility

The B450 supports multiple bus types. Use the following table to determine the supported

applications and features by bus type. the following table for supporting compatibility

applications.

Installed Bus

Function Option/SDI SDI2 Details

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

IP Event Reporting Y Y TCP communication

is only supported on

SDI2

Page 9

Conettix Plug-in Communicator

Interface

Installed Bus

System overview | en 9

3.3

Remote Program

(RPS or A-link)

Y Y Requires Bosch

Cellular service or

other cellular network

access

Configure B450 from

control panel

Personal Notification

via SMS or Email

N Y GV4/B Series require

v2.03+

N Y Requires compatible

control panel and

cellular plan

Remote Security

Control App

N Y Requires Bosch

Cellular service or

other cellular network

access

Table 3.1: B450 cellular interface compatibility

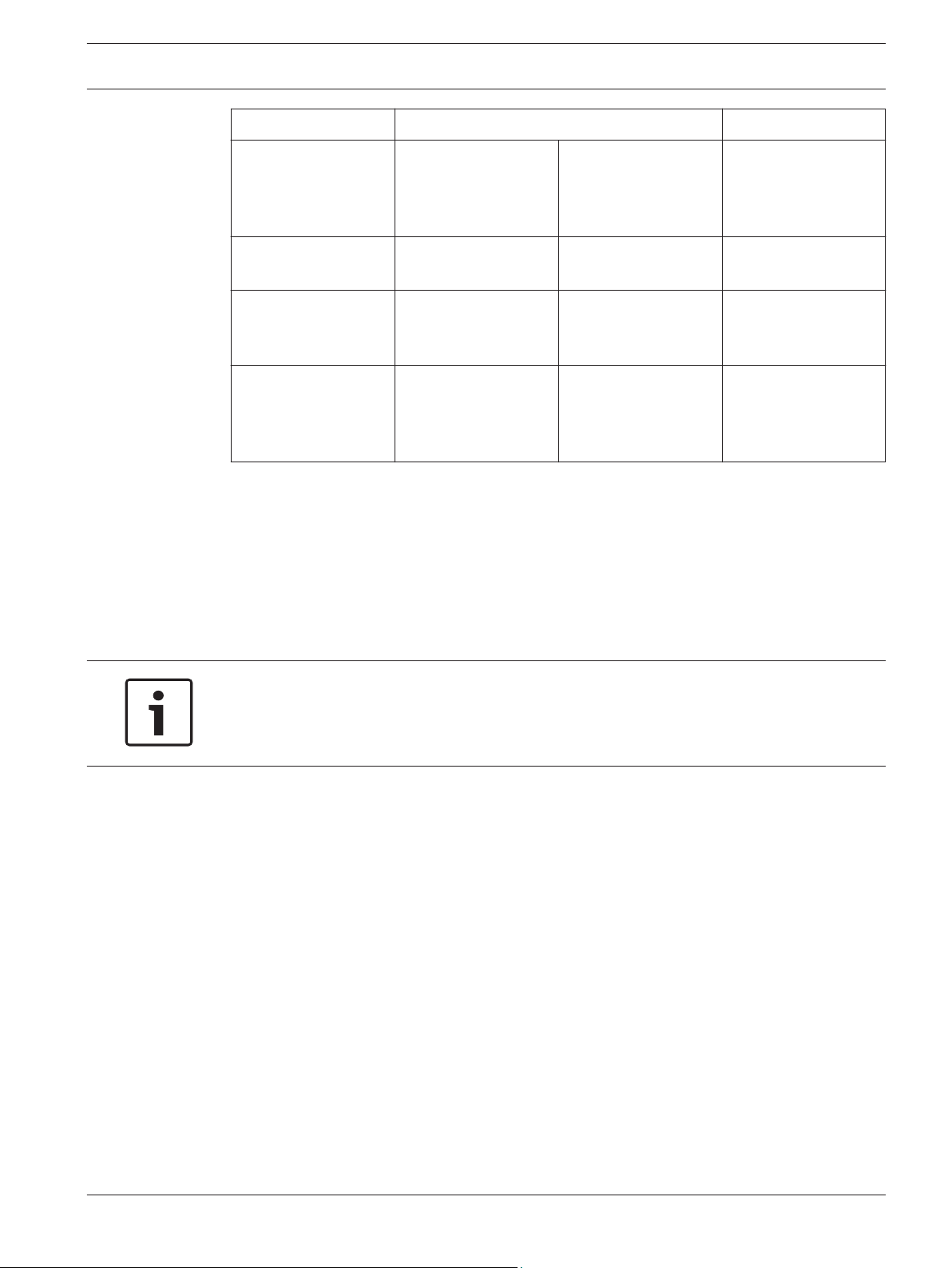

Bus address settings overview

The address switch determines the bus address for the B450 Conettix Plug-in Communicator

Interface. The control panel uses the address for communications. Use a slotted screwdriver

to set the address switch.

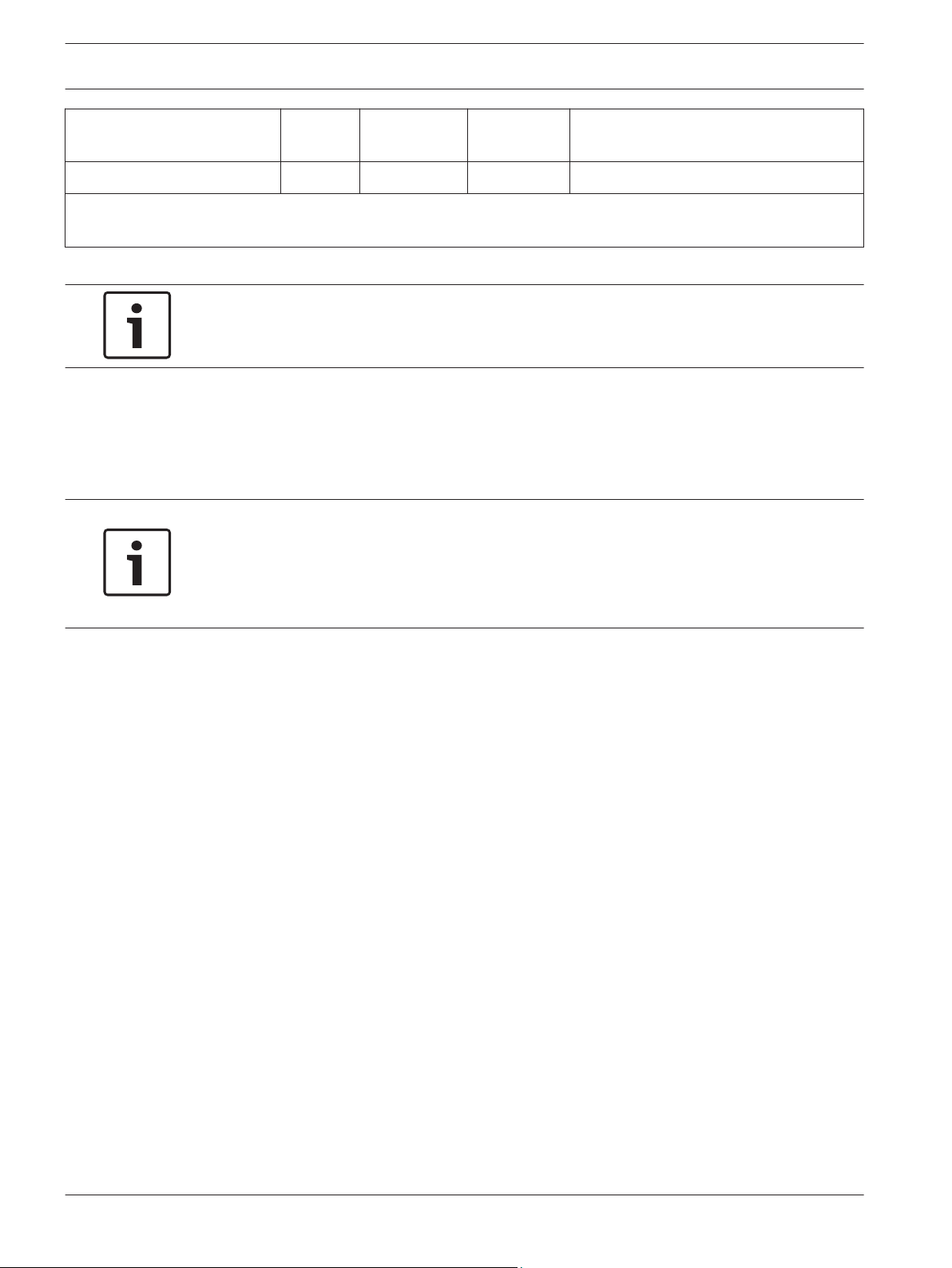

Notice!

The B450 reads the bus address switch setting only during power up. If you change the

switch after you apply power to the module, you must cycle the power to the module in order

for the new bus address setting to be used for bus communication.

Bus address label

Use the bus address label to select the desired setting on the bus address switch, depending

on your control panel.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 10

PANEL ADDRESSES

TX

RX

0 1 2 4 5 6 7 8 9

Bus cfg 1 2 88 92 250

Addr SDI2

SDI

Option

134

13

14

10 en | System overview

Conettix Plug-in Communicator

Interface

Figure 3.2: Bus address label

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 11

!

Conettix Plug-in Communicator

Interface

Installation | en 11

4

4.1

Control panels

Installation

Perform the following steps to install the B450.

Caution!

Remove all power (AC and battery) before making any connections. Failure to do so might

result in personal injury and/or equipment damage.

Setting the bus address

The B450 Conettix Plug-in Communicator Interface address switch provides the value for the

module's address. The figure below shows the address switch setting for address 1. Refer to

the table below for panel-specific settings.

Figure 4.1: Address switch set to address 1

Switch

position

Control panel

bus address

Bus type Function

USB or SMS configuration

setting

B5512/B4512/

B3512,D9412GV4/

D7412GV4/D7212GV4

Solution 2000/3000

D9412GV4/D7412GV4/

D7212GV4

Solution 2000/3000

D9412GV4/D7412GV4/

D7212GV4, D9412GV3/

D7412GV3/D7212GV3,

D9412GV2/

D7412GV2/7212GV2 v7.06+

D9412GV4/D7412GV4/

D7212GV4, D9412GV3/

D7412GV3/D7212GV3

AMAX 2000/2100/3000/4000 6 134 Option Remote Programming or Reporting

CMS 6/8, CMS 40 6 134 Option Remote Programming or Reporting

0 N/A Any Change configuration

1 1 SDI2 Automation, Remote Programming, or

Reporting

2 2 SDI2 Automation, Remote Programming, or

Reporting

4 88 SDI

5 92 SDI

1

1

Remote Programming or Reporting

Remote Programming or Reporting

Easy Series v3+ 6 134 Option Remote Programming or Reporting

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 12

12 en | Installation

Conettix Plug-in Communicator

Interface

Control panels Switch

position

Control panel

bus address

Bus type Function

FPD-7024 9 250 Option Remote Programming or Reporting

1

For D9412GV4/D7412GV4/D7212GV4 configurations, SDI2 bus connection is the recommended configuration

option, but SDI bus configuration is also supported.

Table 4.1: B450 address switch settings

Notice!

Address switches 3, 7, and 8 are not supported on the B450.

4.2

Insert the communication module

Insert the desired B44x communication module into the slot of the B450 until you feel the

module “click” into place.

Notice!

Review your communication module prior to insertion into the B450. Depending on the

physical attributes of your communication module, insert your module accordingly using the

supported installation process (Section 4.2.1 without a SIM card, or Section 4.2.2 with a SIM

card).

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 13

Conettix Plug-in Communicator

Interface

Installation | en 13

4.2.1

Insert the B44x communication module (required and available separately)

Figure 4.2: Inserting the communication module into the B450

4.2.2

Callout ᅳ Description

1 ᅳ B44x Plug-in Communicator module (available separately)

2 ᅳ B450 Conettix Plug-in Communicator Interface

Insert the B44x communication module with SIM card (required and available separately)

Insert the desired B44x communication module with supporting SIM card into the slot of the

B450 until you feel the module “click” into place.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 14

2

3

1

14 en | Installation

Conettix Plug-in Communicator

Interface

4.3

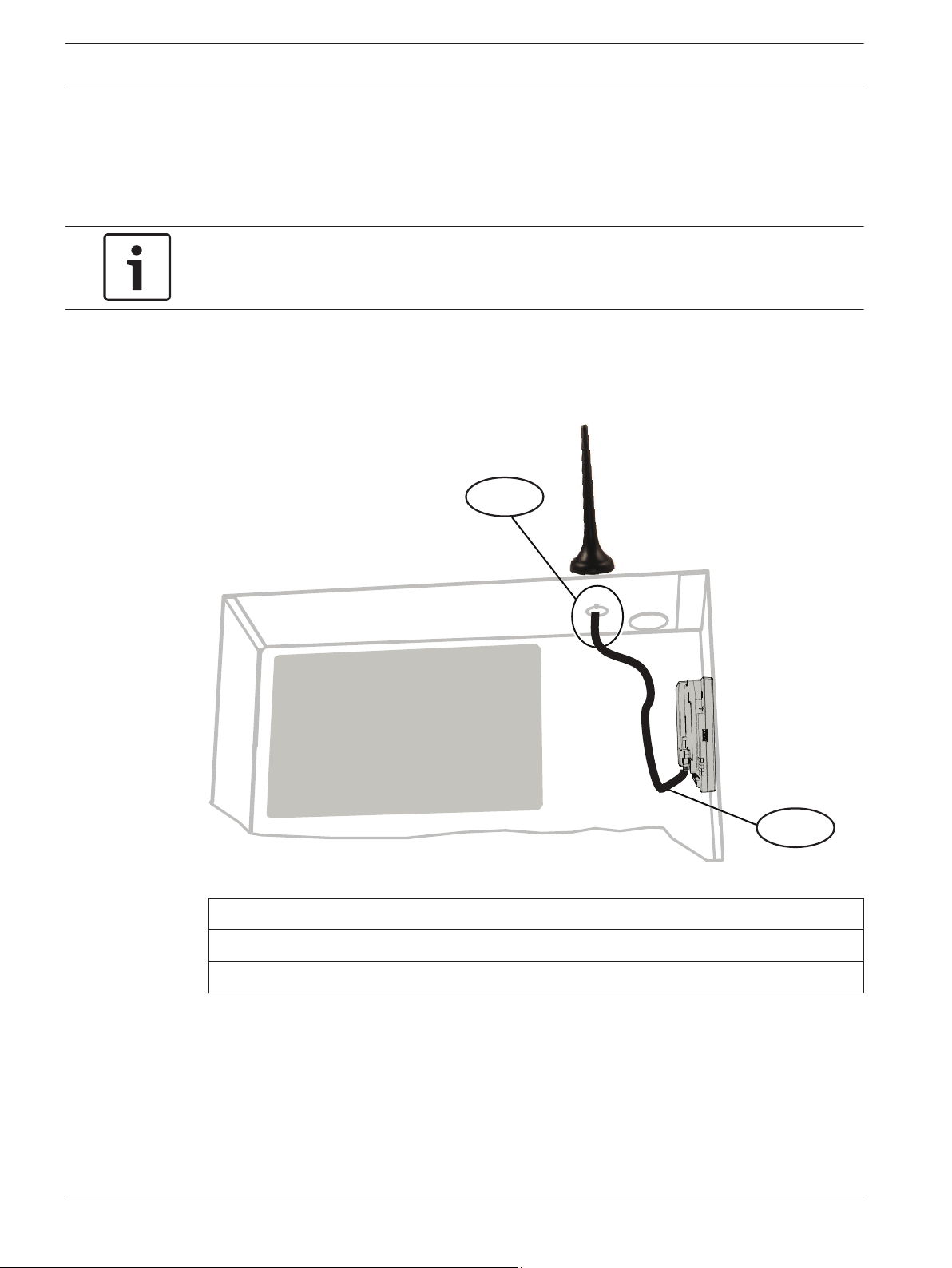

Figure 4.3: Inserting the communication module with supporting SIM card into the B450

Callout ᅳ Description

1 ᅳ B44x Plug-in Communicator SIM card insertion (required and, available separately)

2 ᅳ B44x Plug-in Communicator module (available separately)

3 ᅳ B450 Conettix Plug-in Communicator Interface

Mount the module in the enclosure

Notice!

If you are not using the interconnect cable, it is recommended to wire the B450 module to

the compatible control panel via the terminal strip prior to mounting the B450 into the

enclosure. Failure to do so will complicate the mounting procedure.

Mount the B450 Conettix Plug-in Communicator Interface using the interior wall of the

enclosure’s 3-hole mounting pattern and the supplied mounting screws.

Notice!

UL requirement

Mount the module in the control panel enclosure, or in a UL listed enclosure. For Commercial

Burglary applications, house all communicators in tampered enclosures.

All communicators shall be housed in tampered enclosures. If the unit is used in a commercial

burglar environment, and is enclosed in a commercial enclosure, that enclosure must be

tampered.

If the installation is a local or police station connection, then the B450 must be mounted

inside an attack resistant enclosure.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 15

Conettix Plug-in Communicator

Interface

Figure 4.4: Mounting the module to the exterior wall of the enclosure

Installation | en 15

4.3.1

Callout ᅳ Description

1 ᅳ B450

2 ᅳ Enclosure (outside wall shown)

3 ᅳ Mounting screws (3 screws included)

Installing in a control panel enclosure

Install the B450 on the inside enclosure wall that also contains the supported control panel.

The control panel powers the B450 via the terminal block or bus connection.

Installing in a separate enclosure

Install the B450 on the inside wall of a separate enclosure. The control panel in a nearby,

separate enclosure powers the B450 via the terminal block or bus connection.

Installing in a separate enclosure with separate power supply

Install the B450 on the inside wall of a separate enclosure that also has a separate external

power supply such as the B520 Auxiliary Power Supply Module.

Mount and wire the tamper switch (option for SDI2 bus only)

When the tamper input is shorted, the firmware version flashes, then the B450 LEDs are

disabled to conserve power. To see the troubleshooting LEDs, open the tamper circuit or

jumper.

You can connect an enclosure door tamper switch for one module in an enclosure.

Installing the optional tamper switch for use with a B450:

1. Mount the tamper switch into the enclosure’s tamper switch mounting location.

2. Plug the tamper switch wire onto the module’s tamper switch connector. For the tamper

switch connector location, refer to Module overview, page 7.

3. Verify the B450 module is configured with tamper enabled ON within the SDI2 supported

control panel.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 16

1

2

16 en | Installation

Conettix Plug-in Communicator

Interface

4.4

Install and mount the plug-in communicator antenna

Installing and mounting the magnetic antenna:

1. Place the magnetic antenna on top of the enclosure, or vertically on another metal

surface.

Notice!

If you are experiencing a weak signal, place the antenna on top of a metal surface that has a

radius of 10.16 cm (4 in) for optimal performance.

2. Route the antenna cable through a knock-out in the enclosure wall.

3. Connect the antenna cable to the module.

4. Secure the antenna cable to the inside of the enclosure.

5. Secure the extra antenna cable length inside the enclosure.

Figure 4.5: Antenna installation

Callout ᅳ Description

1 ᅳ B44x plug-in cellular communicator antenna (routed through any knock-out)

2 ᅳ B44x plug-in cellular communicator antenna cable (connected to the module)

4.5

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

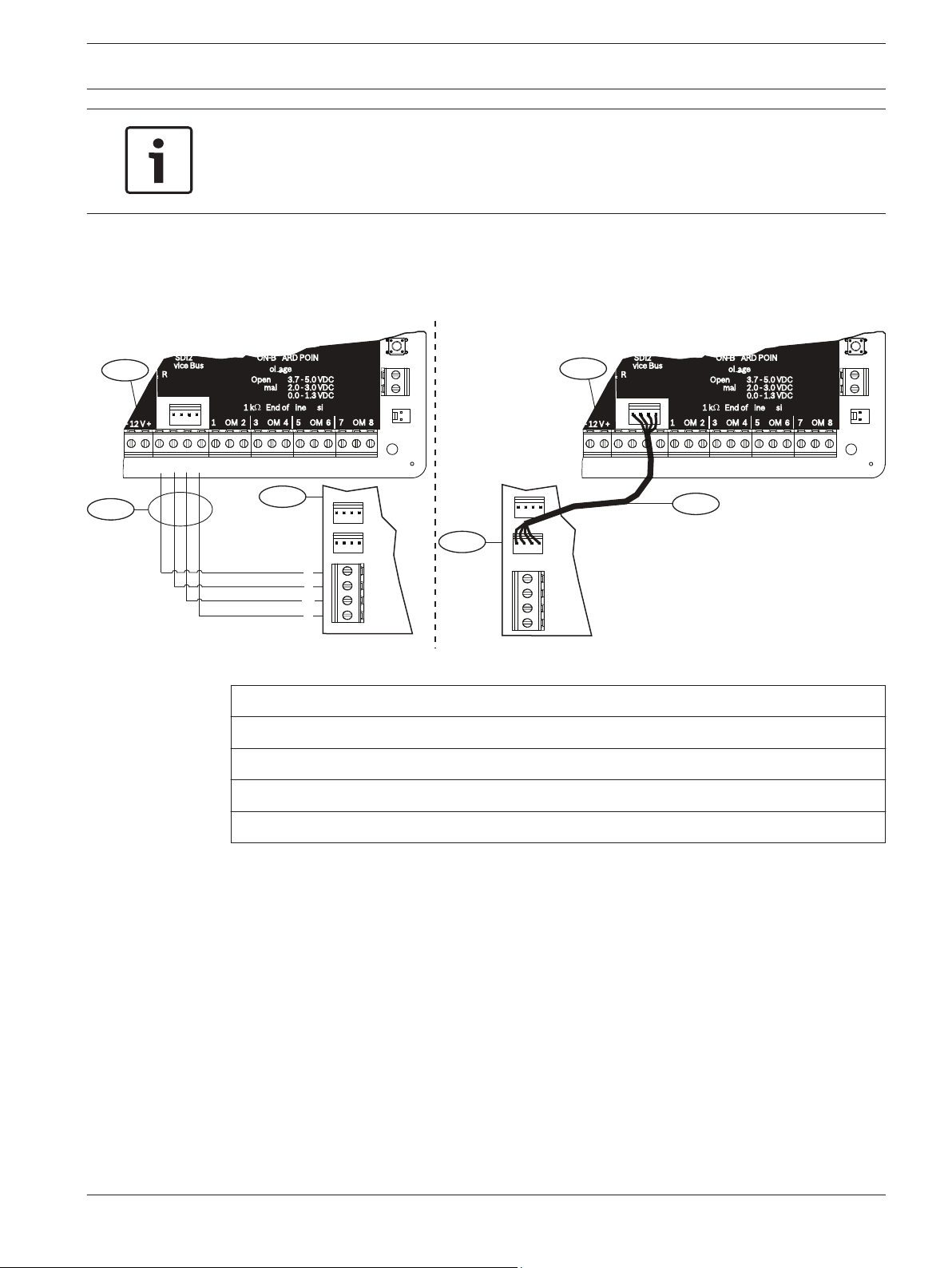

Wire to the control panel

When you wire a module to an SDI, or SDI2 control panel, you can use either the module's

terminal strip labeled R, Y, G, B (PWR, A, B, COM) or the module's interconnect wiring

connectors (wire included). The figure below indicates the location of both the terminal strip

and the interconnect wiring connectors on the module.

Page 17

R

Y

G

B

R

Y

G

B

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3

R

Y

G

B

1

1

2

4

2

7 COM 8

C

OUTPUT

B

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

AUX

- 12 V +

7 COM 8

C

OUTPUT

B

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

AUX

- 12 V +

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

COM AUX R Y G B

PWR A B COM

B C

OUTPUT

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

COM AUX R Y G B

PWR A B COM

B C

OUTPUT

Conettix Plug-in Communicator

Interface

Notice!

Use either the terminal strip wiring or interconnect cable to wire to the control panel. Do not

use both. When connecting multiple modules, you can combine terminal strip and

interconnect wiring connectors to daisy-chain the modules in series.

Installation | en 17

4.5.1

Wire to an SDI2 control panel

Run the wiring connections from the module to the data bus terminals on the compatible

control panel.

Figure 4.6: Using terminal strip or interconnect cable wiring on an SDI2 control panel (B Series control panel shown)

Callout ᅳ Description

1 ᅳ Compatible SDI2 control panel (B Series control panel shown)

2 ᅳ B450

3 ᅳ Terminal strip wiring

4 ᅳ Interconnect cable

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 18

R

Y

G

B

R

Y

G

B

3

R

Y

G

B

1

1

2

4

2

Commercial Protected-Premises Control Panel

D9412GV3 Control Panel is UL Listed For Central Station, Remote Station, Local, Auxiliary,

Proprietary, and Household Fire Alarm, and Central Station, Local, Proprietary,

Police Station Connect, Household Burglar Alarm

and Encrypted Line Security when

communicating via a network.

System is intended to be checked by a Qualified Technician at least every 3 years.

The types of initiating circuits the control panel has been approved for are A, M, W, SS.

The types of signaling the control panel has been approved for are DAC, OT, NC, RevPol.

VOLTAGE RANGES

Open 3.7 - 5.0 VDC Short 0.0 - 1.3 VDC

Normal 2.0 - 3.0 VDC

Reset Pin

Disable all except Battery

Charging and Programming

PERIPHERAL DEVICE CONNECTIONS

RED

POWER +

YELLOW

DATA BUS A

GREEN

DATA BUS B

BLACK

COMMON

ZONEX OUT 1

ZONEX IN 1

NFPA

Style 4.0

Signaling

Line

Circuits

This equipment should be installed in accordance with the NFPA 70 (National Electrical Code) and

NFPA 72 (National Fire Alarm Code).

D9412GV3

26

25

ZONEX POWER +

24

ZONEX COMMON

23

SDI Connector

ZONEX OUT 2

ZONEX IN 2

Refer to the D9412GV3/D7412GV3 Approved Applications Compliance Guide (P/N: F01U143069)

for System Wiring Diagram, Issue A and for compatible smoke detectors. 2-wire Compatible Identifier “A”.

POWER SUPPLY REQUIREMENTS

The Power Supply provides a maximum of 1.4 Amps for the Control Panel and all

Accessory Devices. For System Loading, refer to the D9412GV3/D7412GV3 Operation

and Installation Guide (P/N: F01U143070).

(P/N: F01U143070) for Power Requirements relating to Terminals 6 and 7 .

All external connections except Terminal 5 (battery positive) are inherently power

limited. Requirements for battery standby time might reduce allowable output.

Battery: Replace every 3 to

5 years with one or two Model

D126 or D1218 12 V Lead Acid

Batteries.

Operation Monitor LED

Pulses when Normal

Flickers when Ringing

GREEN

Point 8, S3 Option

Closed = 1 kΩ EOL

Normal Operation

Open =AB-12 UL

Bell Box 220 kΩ

25

Point 3

Point 4

1614

Point 1

Point 2

11 13

Point 5

Point 6

17 19

Point 7

Point 8

21

20

22

Minimum system requirements for Classification in accordance with ANSI/SIA CP-01-2007:

UL Listed and Classified control unit Model D9412GV3, D7412GV3, or D7212GV3;

UL Listed and Classified keypad Model D1256, D1257, D1260, D1255, D1255R, or D1255RW;

UL Listed Local Bell

WARNING!

To prevent risk of

electric shock,

disconnect AC

power and

telephone lines

before servicing.

181512

Not suitable for remote station protected premises services where separate transmission circuits

are required for fire, supervisory (when applicable) and trouble signals when using D185.

Commercial Protected-Premises Control Panel

D9412GV3 Control Panel is UL Listed For Central Station, Remote Station, Local, Auxiliary,

Proprietary, and Household Fire Alarm, and Central Station, Local, Proprietary,

Police Station Connect, Household Burglar Alarm

and Encrypted Line Security when

communicating via a network.

System is intended to be checked by a Qualified Technician at least every 3 years.

The types of initiating circuits the control panel has been approved for are A, M, W, SS.

The types of signaling the control panel has been approved for are DAC, OT, NC, RevPol.

VOLTAGE RANGES

Open 3.7 - 5.0 VDC Short 0.0 - 1.3 VDC

Normal 2.0 - 3.0 VDC

Reset Pin

Disable all except Battery

Charging and Programming

PERIPHERAL DEVICE CONNECTIONS

RED

POWER +

YELLOW

DATA BUS A

GREEN

DATA BUS B

BLACK

COMMON

ZONEX OUT 1

ZONEX IN 1

NFPA

Style 4.0

Signaling

Line

Circuits

This equipment should be installed in accordance with the NFPA 70 (National Electrical Code) and

NFPA 72 (National Fire Alarm Code).

D9412GV3

26

25

ZONEX POWER +

24

ZONEX COMMON

23

SDI Connector

ZONEX OUT 2

ZONEX IN 2

Refer to the D9412GV3/D7412GV3 Approved Applications Compliance Guide (P/N: F01U143069)

for System Wiring Diagram, Issue A and for compatible smoke detectors. 2-wire Compatible Identifier “A”.

POWER SUPPLY REQUIREMENTS

The Power Supply provides a maximum of 1.4 Amps for the Control Panel and all

Accessory Devices. For System Loading, refer to the D9412GV3/D7412GV3 Operation

and Installation Guide (P/N: F01U143070).

(P/N: F01U143070) for Power Requirements relating to Terminals 6 and 7 .

All external connections except Terminal 5 (battery positive) are inherently power

limited. Requirements for battery standby time might reduce allowable output.

Battery: Replace every 3 to

5 years with one or two Model

D126 or D1218 12 V Lead Acid

Batteries.

Operation Monitor LED

Pulses when Normal

Flickers when Ringing

GREEN

Point 8, S3 Option

Closed = 1 kΩ EOL

Normal Operation

Open =AB-12 UL

Bell Box 220 kΩ

25

Point 3

Point 4

1614

Point 1

Point 2

11 13

Point 5

Point 6

17 19

Point 7

Point 8

21

20

22

Minimum system requirements for Classification in accordance with ANSI/SIA CP-01-2007:

UL Listed and Classified control unit Model D9412GV3, D7412GV3, or D7212GV3;

UL Listed and Classified keypad Model D1256, D1257, D1260, D1255, D1255R, or D1255RW;

UL Listed Local Bell

WARNING!

To prevent risk of

electric shock,

disconnect AC

power and

telephone lines

before servicing.

181512

Not suitable for remote station protected premises services where separate transmission circuits

are required for fire, supervisory (when applicable) and trouble signals when using D185.

18 en | Installation

Conettix Plug-in Communicator

Interface

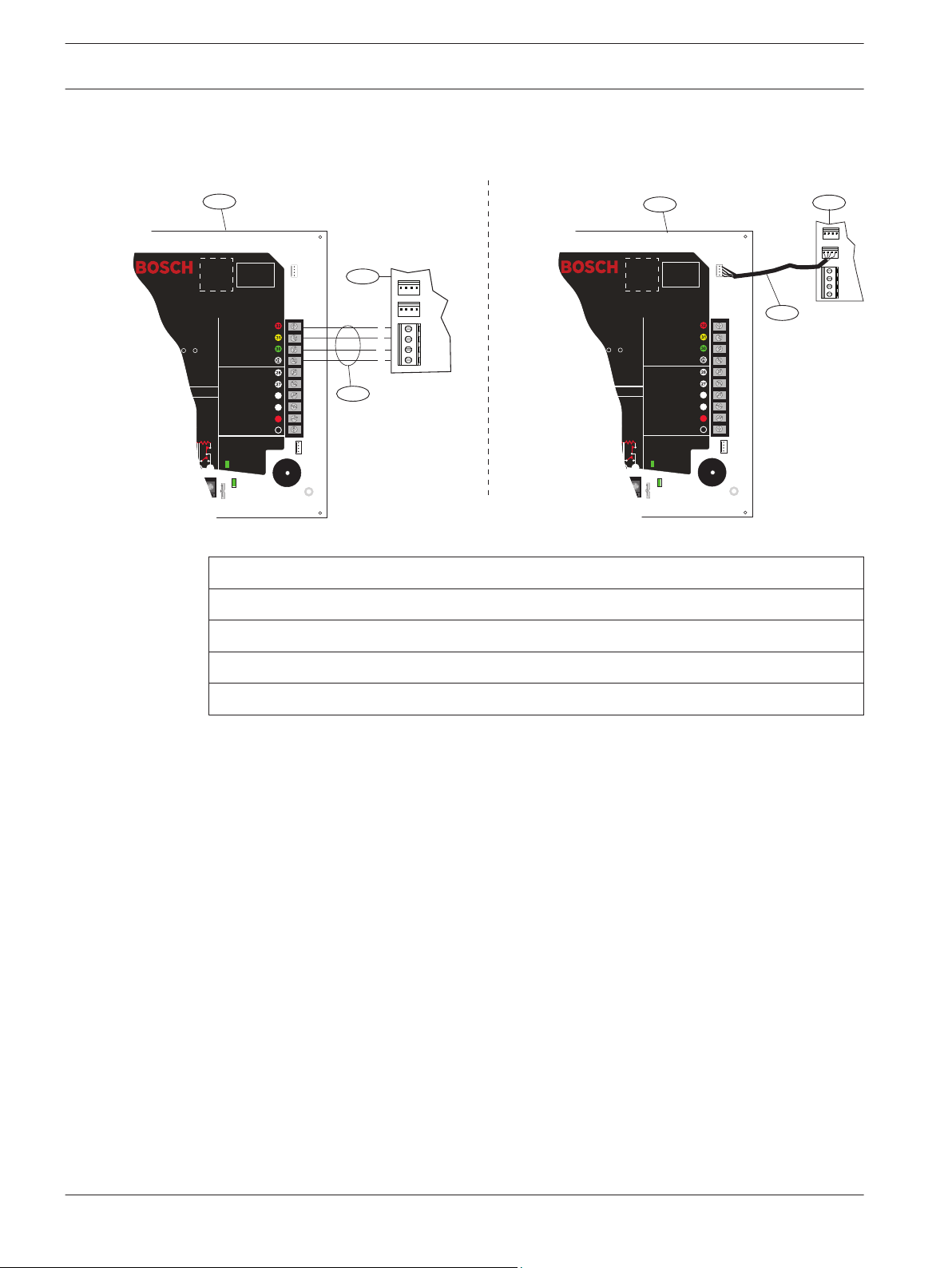

4.5.2

Wire to an SDI control panel

Figure 4.7: Using terminal strip or interconnect cable wiring on an SDI control panel (GV3 Series control panel shown)

Callout ᅳ Description

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

1 ᅳ Compatible SDI control panel (GV3 Series control panel shown)

2 ᅳ B450

3 ᅳ Terminal strip wiring

4 ᅳ Interconnect cable

Page 19

R

Y

G

B

R YGB

2

1

3

R

Y

G

B

Conettix Plug-in Communicator

Interface

Installation | en 19

4.5.3

Wire to an option bus control panel

Run the wiring connections from the module to the data bus terminals on the compatible

control panel.

Notice!

When wiring the connections between the option bus terminal strip and the B450, verify the

terminal position of the colored wires as they may be in a different orientation (option bus =

R, B, G, and Y) and (B450 = R, Y, G, and B).

Figure 4.8: Wiring to an option bus terminal strip (

Callout ᅳ Description

1 ᅳ Compatible control panel (FPD-7024 control panel shown)

2 ᅳ B450

3 ᅳ Terminal strip wiring

For complete wiring instructions, refer to the control panel documentation.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 20

20 en | Configuration

Conettix Plug-in Communicator

Interface

5

5.1

Configuration

Notice!

Power up the system prior to the configuration workflows described in this chapter.

You can configure the B450 using one of the methods described in this section for your

control panel type.

Configuration for SDI2 control panels

Perform the following to configure the B450 to supporting SDI2 control panels.

Notice!

By default, when connecting a field replacement B450 to an existing SDI2 control panel, the

control panel overrides some of the module settings such as; TCP/UDP Port Number, AES

Encryption, Tamper, Panel Programming, IPv4 DNS Server IP Address, Alternate IPv4 DNS

Server IP Address, and TCP Keep Alive Time. To keep custom module settings when you

connect a module to a configured control panel, you must disable Panel Programming prior to

connecting to the SDI2 bus. This is accomplished by using either USB, or SMS configuration.

If the SDI2 control panel is not defaulted, the control panel sends the network configuration

parameters to the B450.

Address-only configuration conditions

An SDI2 control panel automatically configures a newly connected module.

1. If the control panel is not at factory default, it transfers the configuration settings in the

control panel to the B450.

2. Verify that the address switch is set to the correct address for the control panel (SDI2

control panels use address 1 or 2). If the switch is not set to the correct address, power

down the system, set the correct address, and then power up the system.

3. Program the control panel communication settings using RPS or the keypad.

The control panel stores the module settings and automatically programs a defaulted module

when connected. If manual module programming is required, use USB or SMS configuration to

set the Panel Programming parameter to Disabled before installing.

5.1.1

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Configuring and viewing status from RPS

Configuration

For SDI2 control panels, the networking related parameters in the Networking parameters in

RPS table can be configured through the panel or RPS. When cellular specific parameters need

to be modified, refer to the USB or SMS configuration sections within this installation and

operation guide for programming workflows and operation.

The B450 parameters within RPS can be found under the SDI2 Modules section. Refer to the

chart below for RPS selections:

Page 21

Conettix Plug-in Communicator

Interface

If your control panel configuration is a,…. Then use this menu within RPS,…

GV4 Series v1.00 SDI2 Modules B420 Ethernet Communicator

B Series/GV4 Series v2.00+ SDI2 Modules IP Communicator B450

1

B Series and GV4 Series control panels at firmware version 2.03+ with RPS version 5.19+

can use the B450 submenu to configure GSM cellular parameters specific to B442 and B443

Plug-in Cellular Communicators.

Table 5.1: RPS settings based on control panel firmware versions

Refer to the illustration below to locate the SDI2 Modules parameter within RPS.

Configuration | en 21

1

Figure 5.1: RPS SDI2 Modules location

Common RPS configuration parameters

Refer to the table below for parameters configured in RPS. The parameters listed in the

following table support SDI2 control panel versions v2.00 and higher.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 22

en | Configuration

22

Conettix Plug-in Communicator

Interface

Parameter Value Description

Tamper (for GV4 ([v2.0x or

higher] control panels)

0 = Disabled

1 = Enabled

When enabled, allows tamper

and tamper restore

conditions to be reported to

an SDI2 control panel.

Notice!

Only control panels with a

SDI2 bus connection to the

B450 can report a tamper

condition.

IPv4 DNS Server IP Address IPv4 address format (0.0.0.0) The B450 uses the DNS

server addresses supplied by

the cellular network when the

Primary DNS Server address

option is configured as

0.0.0.0. If the address is not

configured as 0.0.0.0, the

B450 installs the Primary DNS

Server address.

Web/USB access enabled Default: Yes Enabling Web/USB access on

the B450 enables the USB

menu, allowing for

configuration programming.

The B450 USB menu is

enabled when the Web/USB

Access Enabled parameter

remains in the default

selection of Yes.

When disabled, the B450

shows a message stating:

“Menu access disabled.”

Notice! In the B Series and

GV4 Series control panels,

the default setting for

Web/USB Access Enabled is

set to No. USB menu access

is NOT allowed unless the

Web/USB Access Enabled

parameter is changed to Yes

in the control panel

configuration.

In non-SDI2 control panels,

configuration via the control

panel does not occur.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 23

Conettix Plug-in Communicator

Interface

Parameter Value Description

Configuration | en 23

Web/USB access password Enter a 4 – 10 character

password to access module

programming Do not use the

characters ; or !

The web access password is

used to allow access to

module programming. For a

B450 module, the password

controls configuration from

the USB menu and SMS text.

TCP/UDP Port Number 1 to 65535 (7700) Sets the source port for the

B450.

Alternate IPv4 DNS Server IP

Address

IPv4 address format (0.0.0.0) If the address is not

configured at 0.0.0.0, the

B450 installs the Alternate

DNS Server address.

TCP Keep Alive Time 0 – 255 sec (45) This parameter determines

how long to wait between

transmissions to keep an idle

TCP connection to a remote

host from terminating due to

inactivity.

IPv4 Test Address IPv4 address format (0.0.0.0) The IPv4 Test Address is used

by the module to ping an

internet address as part of

the IP diagnostics.

Table 5.2: B450 networking parameters configurable in RPS

B450 IP Communicator settings

The parameters listed below are configurable on control panels with firmware version 2.03+.

Use the following settings to configure your cellular module parameters under the SDI2 IP

Communicator B450 option (applicable for control panels with firmware version 2.03+).

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 24

24 en | Configuration

Conettix Plug-in Communicator

Interface

Figure 5.2: B450 parameters

Notice!

Cellular configuration programming under the IP Communicator – B450 section is not available

in RPS with control panels using firmware version v1.00 - v2.02. Cellular configuration for

control panels with firmware version 1.00 – 2.02 can only be done through the USB interface

connected to the B450. Use RPS settings on Module 1 only. Module 2 must be configured

through from the B450 through the USB menu.

Diagnostics

Information about the B450 such as it's Status, IP Address, Bus Voltage and the assigned

phone number of the plug-in module can be found on the RPS Diagnostics screen. Depending

on the firmware version of your control panel, you will see the following screens.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 25

Conettix Plug-in Communicator

Interface

B450 status with version 2.03+ firmware

Configuration | en 25

Figure 5.3: B450 status shown in RPS Diagnostics with B Series/GV4 Series version 2.03+

B450 status with version 2.00 – 2.02

B450 status as shown as Ethernet Communicator in RPS Diagnostics with GV4 version 2.00 –

2.02.

The following Diagnostic screen shown below is applicable to both B Series and GV4 Series

control panels:

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 26

26 en | Configuration

Conettix Plug-in Communicator

Interface

B450 status with version 1.00

B450 status as shown as Ethernet Communicator in RPS Diagnostics with GV4 v1.00. The

plug-in communicator's phone number (if available) displays in the "Hostname" field. Refer to

the illustration below.

Figure 5.4: B450 status shown as Ethernet Communicator in RPS Diagnostics with GV4 version 1.00

RPS Diagnostics is not available when the module’s connected to SDI or Option bus control

panels.

5.2

Use USB to configure the B450

You can use a USB connection from a laptop PC to the B450 to configure the B450 on-site.

The supported USB cable used to establish connection is a Male A to Male A cable.

Notice!

It is recommended to use a Bosch supported USB cable such as the B99 cable (F01U278853).

Failure to do so may result in communication failures between the B450 and your computer.

Notice!

USB connection is for configuration or diagnostics only. Disconnect when done.

Before you can access the USB user interface, you must install the RBUS1CP.inf file, or have

RPS version 5.16 or greater installed, and USB driver on the target PC or laptop. The

RBUS1CP.inf file and USB driver are available on the supplied CD‑ROM. You need to install

this file only once on the target PC or laptop.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 27

Conettix Plug-in Communicator

Interface

Notice!

If you currently have RPS version 5.16 or greater, you do not have to install USB driver

(RBUS1CP.inf) as described below.

Configuration | en 27

If the B450 CD-ROM is not available:

1. From your Internet browser, go to: http://www.boschsecurity.com to open the Bosch

Web site.

2. Select the web site for your region and country.

3. In the Online Catalogs section on the left, click the Intrusion Alarm Systems link.

4. Under the Intrusion Alarm Systems Products heading, scroll to the Conettix -

Information Transport Solutions section. Click the Show product section link.

5. Click the Conettix IP link.

6. Scroll to the B450 Plug-in Communicator Interface section. Click the section title to

open the product page.

7. Under the product image, click the Software tab.

8. Click OK to accept the license agreement.

9. To the right of the B450, click on the language link (for example, en).

The File Download dialog box opens.

10. Click Save to save the file to the target PC or laptop. Perform this task to download both

the USB driver file, and the RBUS1CP.inf file.

11. Supply power to the B450.

12. Connect the B450 to the target PC or laptop, using a USB Type A to A cable. A New

Hardware Found window appears on the computer.

13. Install the RBUS1CP.inf file onto your PC or laptop. Verify through the device manager

that the appropriate .inf installs properly, and is listed under the Ports (COMM & LPT)

section. The correct .inf file is B450 Config Interface.

14. Install a communication program to configure the B450.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 28

28 en | Configuration

Conettix Plug-in Communicator

Interface

5.2.1

Figure 5.5: RBUS1CP.inf installed inside Device Manager

Install a communication program

To use USB connection from a computer to the B450 to configure the B450, you must use a

communication program.

– Windows XP. The Microsoft Windows XP installation automatically installs HyperTerminal,

a Microsoft communication program, when Windows installs. If HyperTerminal is not

installed, install it from the Windows XP installation disc, or install Tera Term from the

B450 CD.

– Windows Vista and Windows 7/8 installations no longer include a communication

program when the operating system installs. Install Tera Term from the B450 CD.

Install the communication program that supports your configuration (Hyper Terminal or Tera

Term), depending on your laptop or PC’s operating system.

Notice!

Tera Term is preferred in all applications as its operation is understood by Bosch Technical

Support if assistance is required.

Installing Tera Term

When you perform the Tera Term installation, follow the prompts in the installation wizard,

but on the Select Components page of the wizard, select Compact installation from the dropdown list. Refer to the figure below.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 29

Conettix Plug-in Communicator

Interface

Configuration | en 29

Figure 5.6: Setup - Tera Term wizard's Select Components window

Tera Term version interface

After installing the latest Tera Term version, double-click on Tera Term to launch the program.

The Tera Term window opens. Refer to the illustrations below to set up Tera Term defaults.

Setting up Tera Term defaults:

1. Launch the application.

2. Select Setup => Terminal as shown below.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 30

30 en | Configuration

Conettix Plug-in Communicator

Interface

Figure 5.7: Selecting the Terminal Setup window

3. Change the default setting of CR to LF from the Receive pull-down menu and press OK.

Figure 5.8: Changing the Receive: option to LF

4. Select Save setup.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 31

Conettix Plug-in Communicator

Interface

Configuration | en 31

Figure 5.9: Saving the setup

5. Select Save to overwrite the existing TERETERM.INI file. This stores the new setting, and

6. Select the correct port option in the Port: pull-down menu for the B450.

allows you to have the correct display settings when you launch Tera Term in future

sessions.

Figure 5.10: Tera Term Pro window shown

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 32

32 en | Configuration

Conettix Plug-in Communicator

Interface

5.2.2

Log into the USB interface

Notice!

To allow for USB configuration, address switch must be set to 0. Powering down the module

after changing the bus address switch for programming is not required.

1. Ensure that the USB-Type A male-to-male cable is connected to the B450 and the target

PC or laptop.

2. From Windows, start a terminal session by launching Hyper Terminal on Windows XP or

earlier, or launching Tera Term on Windows Vista/Windows 7/Windows 8.

3. Set up a connection on the new virtual serial COM port (for example, Port: COM7: B450

[COM7]). If the B450 is not connected to the computer, or the USB driver is not installed,

the B450 does not appear in the list.

4. After the connection is established, press [Enter].

The B450 USB login window opens.

Figure 5.11: B450 USB login window

5. Enter the password to log on. The default password is B450.

The user interface allows three attempts to enter the password correctly. After three

failed attempts, the B450 shows a Too many attempts error message, and the USB

interface enters into an idle state for 30 sec. Repeat Steps 3 through 6. at the conclusion

of 30 sec.

6. Press [Enter] to continue. The USB main menu opens.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 33

Conettix Plug-in Communicator

Interface

Notice!

The default password is case-sensitive. Verify the password for case-sensitivity when

entering.

Configuration | en 33

Menu access disabled error message

Refer to USB menu access disabled, page 56 if you receive the following error message when

accessing the USB menu.

Figure 5.12: USB menu access disabled error window

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 34

:

1

2

3

4

34 en | Configuration

Conettix Plug-in Communicator

Interface

5.2.3

USB Main menu

Figure 5.13: USB Main Menu

Callout Description

1 Installed device

2 Current device status

3 Current access level

4 Main menu options

The USB main menu appears:

– after a user enters a password successfully

– every time the user presses [Enter] without first selecting an option from the main screen

– upon returning from a sub-menu.

The following table describes the USB Main Menu parameters found within callouts 1-3 in the

graphic above.:

Parameter

B44x This field displays one of the following parameters:

Description

– B44x Cellular Communicator

– Plug-in not connected

– Detecting plug-in module

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 35

Conettix Plug-in Communicator

Interface

Link Status This field displays the connection status to the cellular network. The

Bus Status This option includes:

Module Status This option includes:

Tamper This option includes:

Access Level This option includes:

Configuration | en 35

options include:

– OK

– Error

– On Line

– Not Connected

– Normal

– Trouble

– Yes

– No

– Disabled (through configuration)

– Restricted

– Full

Table 5.3: USB Menu parameters

5.2.4

USB menu structure

The following illustration depicts the B450 menu structure.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 36

Advanced

Configuration

Change

Passcode

Status

(Starts with

Basic Status)

Reset Statistics

1

Signal Strength

3

4

2

Main Menu

Reset to

Factory Defaults

5

Exit

Go to Main Menu

Go to Basic Status Menu

1

0

Go to Advanced Status Menu

5

Go to Main Menu

Modify diagnostic settings

Re-print all console messages

Enable console messages

1

2

3

0

Go to Diagnostic Log Menu

1

Cellular Modem Verbose Mode

2

Bus Communication Verbose Mode

2

Product Versions

Diagnostic Log*

Basic

Configuration

Firmware

Update

7

8

0

3

Network Communications Verbose Mode

4

Network Operations Verbose Mode

5

Module Operations Verbose Mode

6

All Verbose Modes Off

0

Go to Main Menu

1

2

5

Set Modem Reset Count

6

Set Reporting Delay for no towers

Set Reporting Delay for single tower

Set TCP Keepalive Time

4

0

Go to Main Menu

4

Panel Programming Enabled

5

Inbound SMS Enabled

6

Reporting Delay for Low Signal Strength

7

GSM/GPRS Configuration

3

6

* The Diagnostic Log option is used in troubleshooting communication issues with the B450. Use of the Diagnostic Log option is to be used

only at the direction of TECHNICAL SUPPORT.

1

TCP/UDP port

2

AES Encryption

3

Tamper Enabled

3

Set Primary DNS Server Address

4

Set Alternate DNS Server Address

0

Basic Configuration Menu

1

Network Access Point Name (APN)

2

Network Access Point User Name

3

Network Access Point Password

4

SIM PIN

5

Session Keep Alive Period (min)

6

Inactivity Timeout (min)

8

Email Server Configuration

0

Basic Configuration Menu

1

Email Server Name/Address

2

Email Server Port Number

3

Email Server Authentication/Encryption

4

Authentication User Name

5

Authentication Password

7

Set TLS Automation Security

36 en | Configuration

Conettix Plug-in Communicator

Interface

Figure 5.14: USB menu structure

5.2.5

Notice!

Changes or edits to programming are discarded if you select the Exit option, and exit the

menu. If you make changes or edits, select the Save and Exit option to ensure programming

changes are saved.

USB menu

For a description of the USB menu options, refer to the tables in the following sections.

To go to a specific menu option, enter the appropriate menu option number.

Notice!

Any and all changes that were not saved will be lost if no keys are pressed within 5 minutes.

The USB menu will automatically logout.

Using the Escape (Esc) key

Press the Escape (Esc) key without making any programming changes will return you to the

previous menu.

USB Main Menu

Pressing the Escape key after entering data will clear data entered.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 37

Conettix Plug-in Communicator

Interface

Configuration | en 37

Option Press

to

Select

1. Status (Starts

1 To access and view the link, modem, and bus status

with Basic

Status)

2. Change

2 To change the login passcode, enter the new passcode twice. The second entry

Passcode

3. Basic

3 Select to program Basic Configuration options. Press 0 to return to the Main menu.

Configuration

4. Advanced

4 Select to program Advanced Configuration options. Press 0 to return to the Main

Configuration

Description

For additional menu descriptions, refer to the USB Status sub-menu parameters table

below for more information.

confirms the new passcode.

Passcodes must be 4-10 characters long, and are case-sensitive.

0-9, A-Z, a-z, and special characters are allowed.

Notice!

If SMS configuration is used, do not use semicolon (;) or exclaimation mark (!) as

part of the passcode.

To change a basic parameter, select the option to change, and then enter in the new

value.

menu.

To change an advanced parameter, select the option to change, and then enter in the

new value.

5. Reset to

Factory Defaults

5 Select to reset all factory default values. All fields are cleared and the factory default

values are restored.

Notice!

A non-defaulted SDI2 control panel will overwrite the default settings if connected to

the defaulted module.

6. Diagnostic Log 6 Select to review the Diagnostic log.

7. Firmware

Update

7 Select this option to update the firmware in the B450.

Notice!

Download your update file from the Bosch website prior to performing an update.

For more information on Firmware update workflows, refer to Firmware Update page,

page 52.

8. Exit 8 Select to exit the menu and log out. You must enter the passcode to log back in.

Notice!

If configuration changes have been made but not saved, you will be prompted to save

or discard them.

Table 5.4: USB Main Menu parameters

Basic Status Menu

The following section describes the description of the Basic Status menu parameters.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 38

38 en | Configuration

Conettix Plug-in Communicator

Interface

Figure 5.15: Basic Status screen

Parameter

Description

Link Status

IP Address This field displays the current Cellular Network IP Address. An IP

address of 0.0.0.0 is listed when no IP address is found.

Link Status This field displays the connection status to the cellular network. This

field displays either OK, or Error.

Encryption This field displays either Normal, or Trouble:

Socket xx: Port

Number

This field displays the current open Port Numbers and Data Types (up to

32).

Modem Status – The information below displays in the appropriate fields. If no modem

status is detected, the following message appears: Modem status is not available.

Telephone Number This field displays the cellular phone number if available. A phone

number of 000-000-0000 is listed when there is no phone number.

Electrical Serial #

This field displays the B44x radio modem serial number.

(ESN)

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 39

Conettix Plug-in Communicator

Interface

Data Status This field displays one of the following; Disconnected, Connecting, or

Signal Strength This field displays the current signal strength. One of the following

Bus Status

Bus Type This field displays the current bus type. One of the following appears;

Bus Address This field displays the current bus address. One of the following

Bus Voltage This field displays the current voltage. One of the following appears;

Module Status – This status displays only if there is a trouble condition.

– B44x Plug-in Missing

– Detecting Plug-in

– No IP Address

Configuration | en 39

Connected.

appears; Very good, Good, Marginal, Unacceptable, or Unavailable.

SDI2, SDI, Option, or None.

appears; 1, 2, 88, 92, 134, or 250.

Good, or Low.

– B44x Plug-in Missing

– B44x Plug-in Invalid

– No IP Address

– Detecting Plug-in

– Signal Strength Low

– Too Few Towers

– No Towers

– B44x Not Active

– B44x Failure

– Configuration Failure

– Low Bus Voltage

– No Bus Communication

– Switch in Position 0

– Firmware Checksum Error

– Configuration Checksum Error

– SIM Missing

– SIM PIN Wrong

– SIM PIN Lockout

– Invalid Access Point

Advanced Status Menu

The following section describes the description of the Advanced Status menu parameters.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 40

40 en | Configuration

Conettix Plug-in Communicator

Interface

Figure 5.16: Advanced Status screen

Parameter Description

Advanced Link Status

Internet (ping) This field displays one of the following; OK, Error, No Status (no ping

has been performed).

IPv4 DNS Server IP

This field displays the current IP sddress.

Address

Alternate IPv4 DNS

This field displays an alternate IP address.

Server IP Address

DNS Status This field displays one of the following; OK, Error, No Status (no DNS

lookup (has been performed).

UDP Packets

This field displays from power up, or Option 3 (Reset Status)

Transmitted

UDP Packets

This field displays from power up, or Option 3 (Reset Status)

Received

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 41

Conettix Plug-in Communicator

Interface

Advanced Modem Status

Configuration | en 41

Transceiver Model

number

This field displays one of the following; DE910-DUAL, CE910-DUAL,

GE910-QUAD

Carrier Name This field displays the carrier network providing service.

Data Status This field displays one of the following; Disconnected, Connecting, or

Connected.

Signal Strength This field displays the current signal strength in dbm.

Towers Available This field displays the number of towers that can be detected by the

module

Base Station ID This field displays information about the tower you are currently

connected to.

Current Band This field displays the current band frequency

Data Class This field displays one of the following; 1xRTT, 3G, GPRS, EDGE,

WCDMA, HSPA

Temperature This field displays the internal temperature of the radio transceiver (in

Celsius)

Advanced Bus Status

Bus Voltage This field displays the voltage measured at the input to the module

Option

1. Basic Status

Menu

2. Advanced

Status Menu

Bus Commands

received

This is a running total of the number of valid bus messages that the

module has received. If the module is on the bus and operating this

number will change when refreshed.

For a description of the Status sub-menu parameters, refer to the table below.

To go to a specific Status menu option (Reset Status, Signal Strength, and Product Versions),

perform the following;

1. Enter the B450 passcode

2. Press [1] Status (Starts With Basic Status).

3. Select the desired parameter (Basic Status, Advanced Status, Reset Status, Signal

Strength, and Product Versions) from the table below.

Press

Description

to

Select

1 This option displays the current IP address, link status, modem status, bus status,

and module status.

2 This option displays various parameters related to the cellular device such as UDP

packets transmitted and received, the carrier name, available towers, and data class,

just to name a few.

3. Reset Status 3 The status display shows several items that are counts of activities, such as UDP

packets transmitted. When reset status is selected, all counts are returned to zero.

This is not required for normal operation.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 42

42 en | Configuration

Conettix Plug-in Communicator

Interface

Option Press

to

Select

4. Signal

4 The current signal strength records every 15 minutes for up to 48 hours worth of

Strength

5. Product

5 This option displays the software version of all entities in the B450. The following list

Versions

Description

data. When signal strength is selected, up to 192 values are displayed representing

the signal strength values over the last 48 hours. If the B450 has been powered up

less than 48 hours, the list shows only the samples taken so far. If it has been less

than 15 minutes, you will see “Not Available” listed.

The screen shot below is an example of what you might see in the signal strength

history.

is an example of the versions displayed:

*** Product Versions ***

B450 Product ID: 88096.16041400007

B450 Application: V 3.01.032

B450 Boot Loader: V 1.05.001

B450 Hardware: V 1.00.000

RTOS: V 3.03.600

Fusion Stack: V 8.07.5603

Cellular Manager: V 2.00.3203

UPKI Encryption: V 3.03.002

AES Lib: V 01.00.000

Modem Firmware: V 15.00.021

Table 5.5: Status sub-menu parameters

Basic Configuration sub-menu parameters – TCP/UDP Port Number

This option sets the source port for the B450.

To go to TCP/UDP Port Number, perform the following:

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [1] TCP/UDP Port Number.

4. Enter the desired port number value.

Basic Configuration sub-menu parameters – AES Encryption

This option allows each receiver path to be configured with a unique AES encryption key.

Refer to the graphic below for entering in the encryption key.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 43

Conettix Plug-in Communicator

Interface

Figure 5.17: Entering the encryption key

Configuration | en 43

Notice!

Enter in your 32 digit encryption key. Verify your 32 digit key does not exceed the arrow

prompt as viewed in the graphic above. The module says "Invalid Entry: Incorrect key length",

if you enter more or less then the required key length. It also detects that you entered hex

values 0-9 and A-F. Any other hex values result in an error.

To go to AES Encryption, perform the following:

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [2] AES Encryption.

4. Enter the desired option:

– 0 = Go to Basic Configuration Menu

– 1 = Disabled

– 2 = 128 Bits

– 3 = 192 Bits

– 4 = 256 Bits

Basic Configuration sub-menu parameters – Module Enclosure Tamper

This option sets the enclosure tamper indication of a particular SDI2 device when enabled.

To go to Module Enclosure Tamper, perform the following:

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [3] Module Enclosure Tamper.

4. Enter the desired option.

Basic Configuration sub-menu parameters – Panel Programming

This option sets the enables/disabled configuration of the B450 by the control panel.

To go to Panel Programming, perform the following:

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 44

44 en | Configuration

Conettix Plug-in Communicator

Interface

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [4] Panel Programming.

4. Enter the desired option.

Basic Configuration sub-menu parameters – Inbound SMS

This option allows the B450 to be configured via SMS configuration.

To go to Inbound SMS, perform the following:

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [5] Inbound SMS.

4. Enter the desired option.

Basic Configuration sub-menu parameters – Reporting Delay for Low Signal Strength

This option sets the duration of time when the B450’s signal strength is measured.

To go to Reporting Delay for Low Signal Strength, perform the following:

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [6] Reporting Delay for Low Signal Strength.

4. Enter the desired option. The range is from 0 to 3600.

5. Then press Enter.

Basic Configuration sub-menu parameters – GSM/GPRS Configuration

For a description of the Basic Configuration sub-menu parameters (Access Point Name, Access

Point Login Name, Access Point Login Password, or SIM PIN), refer to the table below.

To go to a specific Basic Configuration menu option – GSM/GPRS Configuration (Access Point

Name, Access Point Login Name, Access Point Login Password, or SIM PIN), perform the

following:

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [7] GSM/GPRS Configuration.

4. Select the desired parameter (Network Access Point Name, Network Access Point User

Name, Network Access Point Password, or SIM PIN) from the table below.

Option

Press

Description

to

Select

1.Network Access

Point Name (APN)

1 The Network Access Point Name is required for modems that use a SIM card such

as the B442 or B443.

The Network Access Point Name must be 0-99 characters long, and is case

sensitive.

The default is: wyless.apn

2. Network

Access Point User

Name

2 The Network Access Point User Name is used on the B442 and B443.

The Network Access Point User Name allows users to connect to the access point.

The Network Access Point User Name must be 0-30 characters long, and is case

sensitive.

The default is: None

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 45

Conettix Plug-in Communicator

Interface

Configuration | en 45

Option Press

Description

to

Select

3. Network

Access Point

Password

3 The Network Access Point Password is used on the B442 and B443

Some carriers require a password to access the Access point. The Network Access

Point Password must be 0-30 characters long, and is case sensitive.

The default is: None

4. SIM PIN 4 To set the PIN in the B450 to match the SIM card pin in the cellular communicator

module (for B442 and B443 only)

Notice! To erase text, you must type in the word None to erase the previous text.

This is NOT case-sensitive.

The default is None:

5. Session Keep

Alive Period (min)

5 This parameter sets the length of time in minutes between session keep alive

reports to verify that an idle connection is still active. Leave the default value.

The default is: 0

The range is 0 to 1000 minutes

6. Inactivity

Timeout

6 This parameter specifies the time before the control panel will disconnect a session

with no data traffic. Leave the default value.

When enabled, the control panel verifies an active connection exists with the

module.

When disabled, the control panel does not verify the connection is active.

The default is: 0

The range is 0 to 1000 minutes

Basic Configuration sub-menu parameters – Email Server Configuration

For a description of the Basic Configuration sub-menu parameters – Email Server

Configuration (Email Server Name/Address, Email Server Port Number, Email Server

Authentication/Encryption, Authentication User Name, or Authentication Password), refer to

the table below.

To go to a specific Basic Configuration menu option (Email Server Name/Address, Email

Server Port Number, Email Server Authentication/Encryption, Authentication User Name, or

Authentication Password), perform the following:

1. Enter the B450 passcode

2. Press [3] Basic Configuration.

3. Press [8] Email Server Configuration.

4. Select the desired parameter (Email Server Name/Address, Email Server Port Number,

Email Server Authentication/Encryption, Authentication User Name, or Authentication

Password from the table below.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 46

46 en | Configuration

Conettix Plug-in Communicator

Interface

Option Press

to

Select

1. Email Server

1 This parameter specifies either the name or the address of the SMTP (Simple Mail

Name/Address

2. Email Server

2 This parameter specifies the port number for the email server.

Port Number

3. Email Server

3 Use this parameter to set the security level required by the email server to receive

Authentication/

Encryption

4. Authentication

4 This parameter specifies the user name for the email account that is set up to

User Name

5. Authentication

5 This parameter sets the password that the SMPT server uses to send emails to the

Password

Diagnostic Log sub-menu parameters

For a description of the Diagnostic Log sub-menu parameters (Modify Diagnostic Settings, Reprint All Console Messages, and Enable Console Messages), refer to the table below.

Description

Transfer Protocol) for the email server chosen to transfer event messages from the

control panel to a designated email address. (Example:smtp.gmail.com)

The default is: 25

messages from the control panel.

Authentication means that the email server requires an authentication username

and authentication password. This is sometimes referred to as SMTP-AUTH.

The Encryption used is Transport Layer Security (TLS)

The default is: Authenticate

receive messages from the SMPT server sent by the control panel.

The default is: None

Range is: 0 – 255 ASCII printable characters

Personal Notification destinations.

The default is: None

Range is: 0 – 49 ASCII printable characters

Notice!

The Diagnostic Log option is used in troubleshooting communication issues with the B450 .

Use of the Diagnostic Log option is to be used only at the direction of TECHNICAL SUPPORT.

Refer to Diagnostic log, page 60 for more information.

To go to a specific Diagnostic Log menu option (Modify Diagnostic Settings, Re-print All

Console Messages, and Enable Console Messages), perform the following:

1. Enter the B450 passcode

2. Press [6] Diagnostic Log.

3. Sect the desired parameter (Modify Diagnostic Settings, Re-print All Console Messages,

and Enable Console Messages) from the table below.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 47

Conettix Plug-in Communicator

Interface

Configuration | en 47

Option Press

Description

to

Select

1. Modify

Diagnostic

1 The Diagnostic logging is intended for use only under Bosch direction. Diagnostic

settings determine which types of messages to display.

Settings

2. Re-print Saved

Console Message

2 The Re-Print Saved option prints any diagnostic messages that have already occurred

and are stored in the B450’s buffer. This can print what just happened if an issue

occurs.

3. Enable Live

Console

Messages

Table 5.6: Diagnostic Log sub-menu parameters

3 Enable live console messages provides real time output of diagnostic messages. This

allows the PC running TeraTerm to log what is occurring in the module and can log

for longer periods of time.

SMS and USB configuration parameters

Notice!

The table below shows all parameters available through SMS or USB configuration. Values in

bold are default settings.

ID Parameter Values Description

1 Current Password 4 to 10 characters (B450) Mandatory and case sensitive.

Notice!

Make sure you record and record your password.

2 New Password 4 to 10 characters New password, as desired. Case sensitive.

13 TCP/UDP Port

1 to 65535 (7700) Sets the source port for the B450.

Number

15 AES Encryption 0 = Disabled

1 = 128 bit, 2 = 192 bit, 3 = 256

bit

Security encryption on or off. The setting must

match the encryption settings in the receiver.

Notice!

This setting applies to SDI, and GV4 v1.0.x control

panels only.

16 AES Encryption Key 32, 48, or 64 digits max.

0-9, A-F, a-f allowed

01020304050607080910111213

14151601020304050607080910

111213141516

The AES Encryption Key must match the encryption

key in the receiver.

Notice!

This setting applies to SDI, and GV4 v1.0.x control

panels only.

19 Module Enclosure

Tamper (for GV4

v1.0.x control

panels)

0 = Disabled

1 = Enabled

When enabled, allows tamper and tamper restore

conditions to be reported to an SDI2 control panel.

Notice!

Only control panels with a SDI2 bus connection to

the B450 can report a tamper condition.

Bosch Security Systems, Inc. Installation and Operation Guide 2014.12 | 06 | F.01U.300.740

Page 48

48 en | Configuration

ID Parameter Values Description

Conettix Plug-in Communicator

Interface

20 Inbound SMS 0 = Disabled

1 = Enabled

65 IPv4 DNS Server IP

IPv4 address format (0.0.0.0) The B450 uses the DNS server addresses supplied

Address

66 Alternate IPv4 DNS

IPv4 address format (0.0.0.0) If the address is not configured at 0.0.0.0, the B450

Server IP Address

67 Panel Programming 0 = Disabled

1 = Enabled

68 Reporting Delay for

0 – 3600 sec. (1800) Sets the duration of time when the B450’s signal

Low Signal

Strength

Allows the B450 to be configured via SMS

configuration.

Notice! When this option is set to Disabled, no

inbound SMS text messages are processed.

by the cellular network when the Primary DNS

Server address option is configured as 0.0.0.0. If

the address is not configured as 0.0.0.0, the B450

installs the Primary DNS Server address.

installs the Alternate DNS Server address.

Select to enable or disable control panel

programming. This enables/disabled configuration

of the B450 by the control panel.

strength is measured. The value selected

determines how long the signal strength must be at

a low condition before reporting as low, or how

long the signal strength must be normal before

reporting as normal.

69 Reporting Delay for

0 – 3600 sec. (1800) Amount of delay before the module reports a

No Towers

70 Reporting Delay for

0 – 3600 sec. (0) Amount of time delay before module reports a

Single Tower

71 Modem Reset

Count

72 TCP Keep Alive

0 – 99 communication attempts

(5)

0 – 255 sec (45) This parameter determines how long to wait

Time

Table 5.7: SMS and USB configuration parameters

trouble for not being able to receive signals from a

cell tower.

trouble due to getting signals from only one tower

instead of multiple towers.

This parameter determines how many times a

packet of data must be sent without a reply before

the cell module modem is reset to attempt

restoring communications.

Note: When connected to a B5512/B4512 or

D9412GV4/D7412GV4 control panel at v2.03 or

higher, the default is zero and controlled by the

above mentioned control panel, unless control

panel programming is disabled.

between transmissions to keep an idle TCP

connection to a remote host from terminating due

to inactivity.

2014.12 | 06 | F.01U.300.740 Installation and Operation Guide Bosch Security Systems, Inc.

Page 49

Conettix Plug-in Communicator

Interface

Configuration | en 49

5.3

5.3.1

Short Message Service (SMS) configuration

The B450 supports configuration by SMS connection. When enabled via the Inbound SMS

parameter, the Short Message Service feature allows an installer to configure the B450

through the use of a mobile phone, or any other service that sends compatible SMS text

messages.

Notice!

SMS text messages are not processed when the Inbound SMS parameter is set to: Disabled.

The default setting is Enabled.

Use SMS to configure the B450

The SMS string follows a specific format. If the configuration message exceeds 160

characters, you must send multiple messages. Refer to Compose the Configuration SMS for

more details.

When the B450 receives the final valid part of an SMS message, it accepts the configuration.

Notice!

To allow the receipt of SMS data, the bus address switch must be set at position 0. Refer to

the tables in this section for LED activity.

If the bus address switch is not set to 0, incoming SMS data is discarded.

Enter CONFIG MODE

Ensure that the bus address switch is set to 0.

Compose the Inbound SMS

Use the appropriate SMS template for the selected mode of operation, and compose the

configuration SMS message on your mobile phone. SMS can contain only 160 characters.

Refer to Multiple SMS Messages (for Messages Longer than 160 Characters) for instructions

for sending a multiple SMS configuration.

The information in the tables below contain only the essential configuration IDs. For additional

configuration IDs, refer to the SMS configuration parameters. To configure a B450 parameter

using SMS text, format the text as follows : %1;1=B450;19=1;!

The configuration message must begin with the sequence number (%1) and must include the