Page 1

BOSCH

Industrieausriistung

) .*

/-

. -

LC>

6

tC

g-

'rWY

T\

gt;'

BOSCH

Industricausriistung

q*L;

I

I

I

I

I

I

I

\

to&, 8Ue5

HEf

tN

91L723

,rrr*

BOSCH

546049

LIM

scH

Produktabteilung

E,lektronische Steuerungen

Robert Bosch GmbFI

D-6120

Telefon:

A utomatisierungssysteme

Robert Bosch GmbH

D-7500 Karlsruhe 4l

Telefbn:

Telex:7826604 iaas-d

Maschinenbau und

Robert Bosch

D-7000 Stuttgart 30

Telefon:

Telex:

Robert

I)

7Un

Stralle 25

Berliner

Erbach/Odenwald

(0CI62)

Telex: 4l9l617

Produktabteilung

Ottostra8e

Produktabteilung

KruppstraBe

Produktabteilung

Entgrattechnik

Kruppstralle

Stuttgart 30

Telcfon:

Telex: 725n ry+0.441

22 a

404056

07 2D

Montagetechnik

GmbH

(Feuerbach)

(07

ll) 8 ll-l

440441

72521

Bosch Gmbll

(Feucrbach)

(07

ll) 8 ll-l

78-l

I

I

rlt*.,

Page 2

INDEX

INTRODUCTION

Foreword

Control Operating

Manual Positioning

MANUAL

Traverse

Positioning

Manual

TOOL

TOOL

EDIT MODES

Program

Operation via Interface

Program

progra

Subprogram

Dwell C4

M30

Unconditional/conditional

EDIT MODES

AUTOMATIC PROGRAM

SVITCHABLE FUNCTIONS

Inch/Metric

Raciius,

Fixed

Transfer

DISPLAYS

Ceneral

to Reference Point

Data Input

COMPENSATIONS

MEASURING

Memory

Input via the Operating

m ident if

Branching

Diameter

Points

Rates

Panel

and

OPERATING

Axes Manually

-

TEACH IN

ication:

Call-Up G22

contrd

Operating

drawing

keys,

switch-on

Panel

drawing

operating

SEQUENCES

interaction of

manua.l

examples

immediate

SBP call-up

General

Input

principles

establishing

establishing l-X,

enabling, inhibiting

displaying

loading

part

Panel

main

label

G23

I

jumps

G20 I G2l

modifying,

deleting

ACTUATION

Program

Program

"INCH"

"DISPLAY'',

I'PREX"

'|VCRT", I'BAUD"

Input

Error fulessages in Clear Text;

Battery

Error

of

modes

on the Operating

program

program

G79 subprogram G98lG99

Dialogues; Status

Codes

operation,

elements

operating elements on

panel

actioning of informationl

LX, LZ simultaneously

LZ

contents, clearing

part programs

output

G78lM2,

deleting, inserting words

inserting

blocks,

Call-up by Block

Number,

I'DRC)G'I

bis

22"

"CH

Change

conditions on

Panel

separately

access to the memory

blocks

Number,

Program

Messages

Label

BOSCH

Operating

memory

CNC ALPHA

Instructions

Page

I

I

6

9

l0

10

ll

l2

t3

l4

t5

l6

t7

l8

19

20

2l

22

ll

23

23

24

24

25

26

28

29

?n

)I

32

3)

Page 3

INTRODUCTION

FOREWORD

BOSCH

Operating

CNC

ALPH

Instructions

BOSCH CNC

The

developed

th d

wi

With

mind the

in

edures

to be as

possible

ergonomic

In

the

operation the

guides

the

data.

In

the

errors

helps

detailed

as an MDI

j-

al-ogue

the usage of

have been

easy and short

and comply with

principles.

different modes of

the operator towards

input of the

event of operating

etc. the

user through

the

error

ALPHA 2 was

guidance

the

operating

designed

dialogue

required

control

displays.

control

.

control

proc-

as

Thr' ALPHA

sui ted

lathes with

2

is

for

the control-

2 NC

speci tically

of

and

axes

a controlled mai-n spindle.

This manual

operating

NC

and only applies to

describes the

procedures

for the

the

control.

Machine

procedures

specific operating

described

are

in the machine tool builder's

1i

terature.

Only those

admissible-

are

procedures

described

-1

Page 4

INTRODUCTION

BOSCI{

Operati

CNC

ng Instructions

ALPH

INTRODUCTION

BOSCH

Operating Instructions

CNC

ALPHA

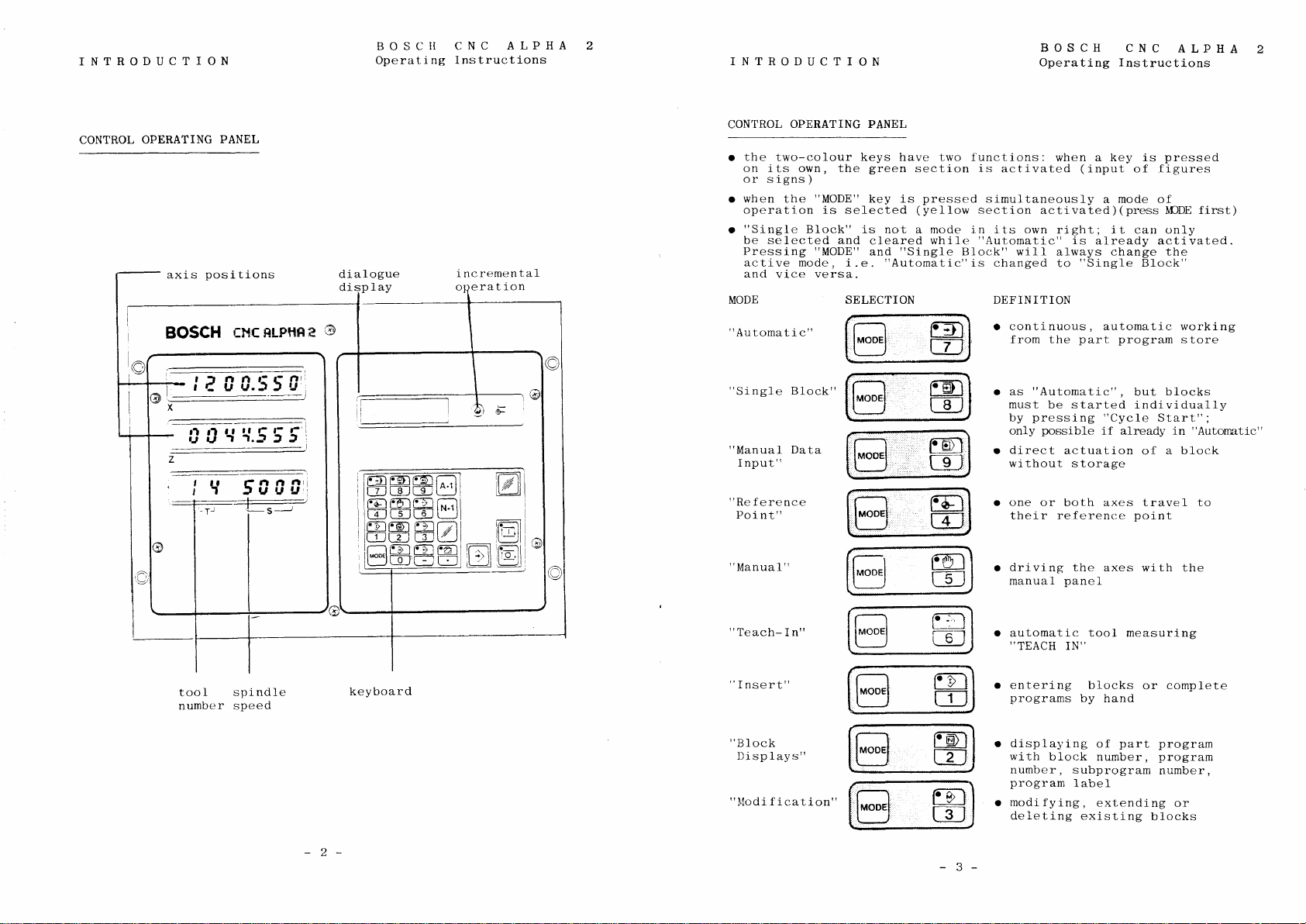

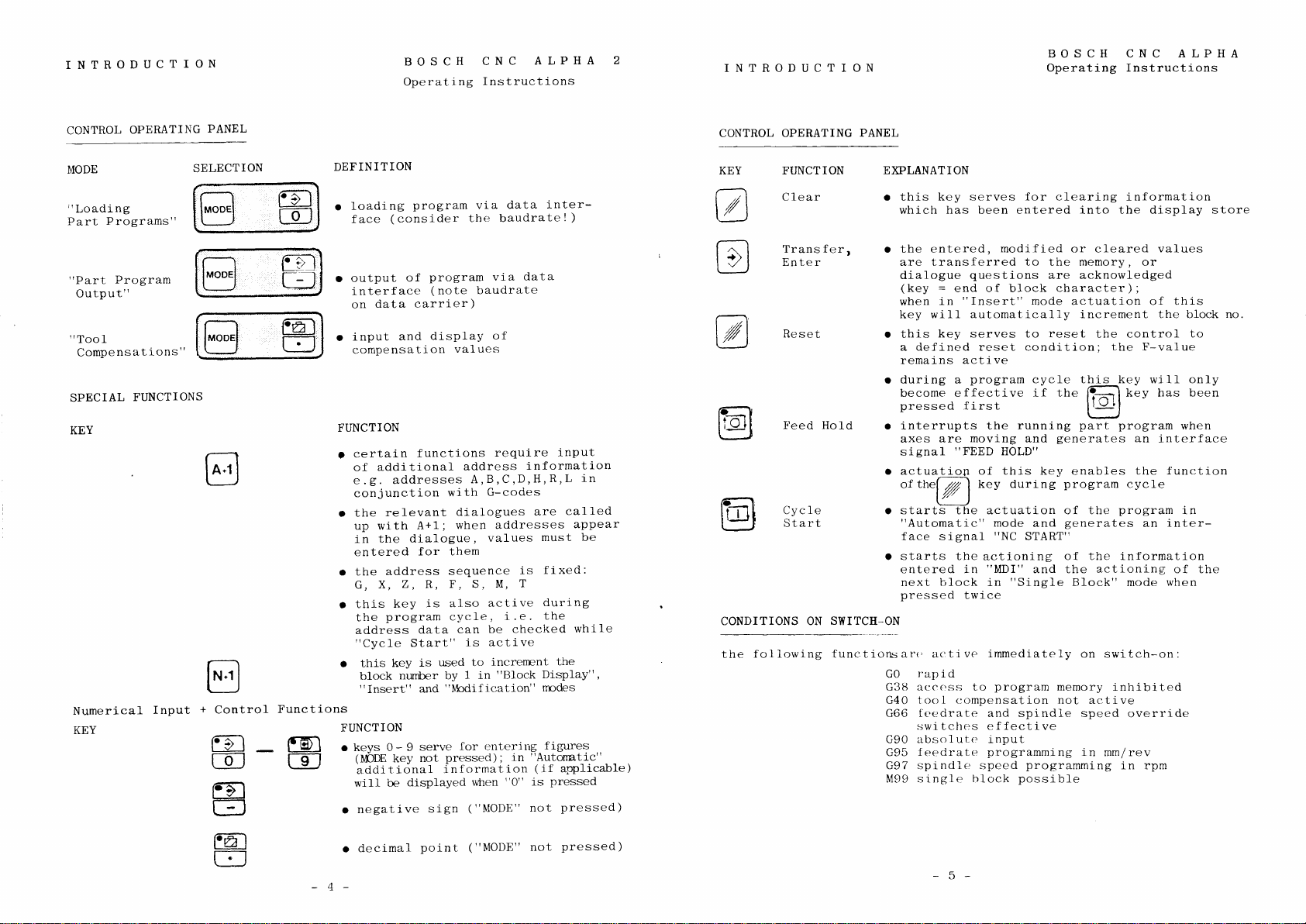

CONTROL

OPERATING

axis nositions

PANEL

BOSCH

r-

|

ffit

l-

u

',lc'ii.-q551

rttr *LP?!ff

s.J t

,

I

50001r

e

dialogue

disp

@

1 ay

CONTROL

o the two-colour keys have two functions:

on i!= oyn, the

or

o when

operation

a

"Single

be

Pressing

active mode, i.e.

and

MODE

Automat i c"

"

"Single

"Manual

I nput

"Referenc.e

Point"

Manua1

"

OPERATING PANEL

s1gns

)

the

"MODE"

selected

is

Block"

selected

vice

B1ock"

Data

"

"

and

"MODE"

versa.

SELECTION

green

section

key is

is not a mode i n its own

cleared

and

pressed

(yellow

while

"Single

"Automatlc"is

Ff)

@

ftl

'ffi

,.

@.,

1,,;r,,,'

FE-I

,,",'8

@

fc

ED

r--7-1

@i

L--?-J

is

activated

simultaneously

section

"Automatic"

Block"

will

changed

DEFINITION

a contlnuous, automati-c working

from the

as

must

by

only

direct

without storage

one or

their

driving

manual

when a key is

(input

mode

activated)(press LODE first)

right; it can c-rnly

always

to

"Automatic",

be started individually

pressing

possible

refe.rence

a

is

already activated.

change the

"Single

part

program

"Cyc1e

lf

actuation

both axes travel

the

axes with the

panel

pressed

of figures

of

Block"

blocks

but

Start";

already in

of a block

point

store

"Automatic"

to

tool

number speed

spindle

-2-

keyboard

Teach-

"

" I nsert"

"B1ock

Displays"

"Modlfication"

I n"

n

t1:1

tTl

f

t__eJ

@ffi

@

[Cl

@

E

-3-

^---I

automatic tool measuring

''TEACH

entering blocks

programs

displaying

with

number,

program

modifying,

deleting

IN''

by hand

part

block number,

of

subprogram

labe]

extending

existing

complete

or

program

program

number,

blocks

or

Page 5

INTRODUCTION

BOSCH

Operating

CNC

Instructions

ALPH

INTRODUCTION

BOSCH CNC

Operating Instructions

ALPH

CONTROL

MODE

ng

Loadi

"

Programs"

Part

Program

"Part

Output"

"Tool

Compensat

SPECIAL

KEY

Numerical

KEY

OPERATING

SELECTION

ions"

FUNCTIONS

Input

PANEL

[58

@

@

f*n

t_J

Control

ET

@

t6.'l

l--J

t3

m.

fJ

@)

r

Func

fE-l

@

DEFINITION

loading

.

face

output

o

interface

on

input

r

compensation

FT]NCTION

certain

t

of

e.g.

conjunction

r the

up with

in the

entered

o the

G,X,Z,R,F,S,M,T

this

o

the

address

"Cycle

. this

block

"Insert"

lons

t

FUNCTION

o keys 0-

(MODE

addlticjnal

will

negative

o

program via

(consider

program

of

(note

carrier)

data

displaY

and

additional

addresses

relevant

address

keY

program cYcle,

keY

mlrber by

9 serve

key

disptayed

be

values

functions

with

dialogues

when addresses

A+1;

dialogue,

for them

sequence

is also

can

data

Start"

used to

is

"I4cdif

and

for etrtering

pressecl); in

not

information

sign

address

inter-

data

the

baudrate

data

via

baudrate

of

require

A,B,C,D,H,R,L

is active

1

in

when

("MODE"

information

G-codes

are

is

i.e.

"Block

"0"

must be

fixed:

during

the

Display",

nrodes

figures

"Autonatic"

(if

pressed

is

not

values

active

be checked

increnent

ication"

!

)

lnPut

i-n

ca1led

appear

while

the

applicable)

pressed)

CONTROL

KEY

OPERATING

FT]NCTION

Clear

PANEL

E)PLANATION

a this

@

Trans fer,

E

@

CONDITIONS

the

Enter

Reset

Feed Hold

Cycle

St art

SWITCH-ON

ON

following func-tions arc a,crti

key serves for clearing information

has

which

the entered,

are transferred

dialogue

=

(key

when

key will

this

a

remains

during a

o

become ef

pressed

r interrupts the

axes

signal

o

actuation

ottnefry)Uev

r starts

"Automatic"

face signal

o starts

entered

next block in

pressed

G0

G3t] acccss to

G40 tooL compensation not actlve

G66

G90

G95

G97 sp

M99 single block

end of block

in " f nsert" mode actuation of thi-s

key

defined reset condi-tion:

active

first

are moving and

"FEED

u:__)

the actuation

the

in

twice

ve irnmediately

r'ap

i d

feedrate

switches effective

absol uter input

feedrate

j.ndle

entered into the display store

been

modifled or cleared values

questions

automatically increment the block no.

serves to

program

fective

to the memory, or

are acknowledged

character);

reset

cycle thls

if the

running

HOLD"

of this key

during

mode and

START"

"NC

actioning

speed

and the

"MDf"

"Single

program

and spindle speed

programming

programming

possj-b1e

[',-;1]

lr-)4!l

part program

generates

enables

program

of the

generates

of the information

Block" mode

on swi-tch-on:

memory inhibited

in

the control

the F-va1ue

actioning

mm/rev

to

will only

.key

key has been

when

an interface

function

the

cycle

program

override

in rpm

in

an inter-

of the

when

@

ft

-4

decimal

o

point

("MODE"

not

pressed)

Page 6

INTRODUCTION

BOSCH

Operaling

CNC

Instructions

ALPH

INTRODUCTION

BOSCH CNC ALPH

Operating Instructions

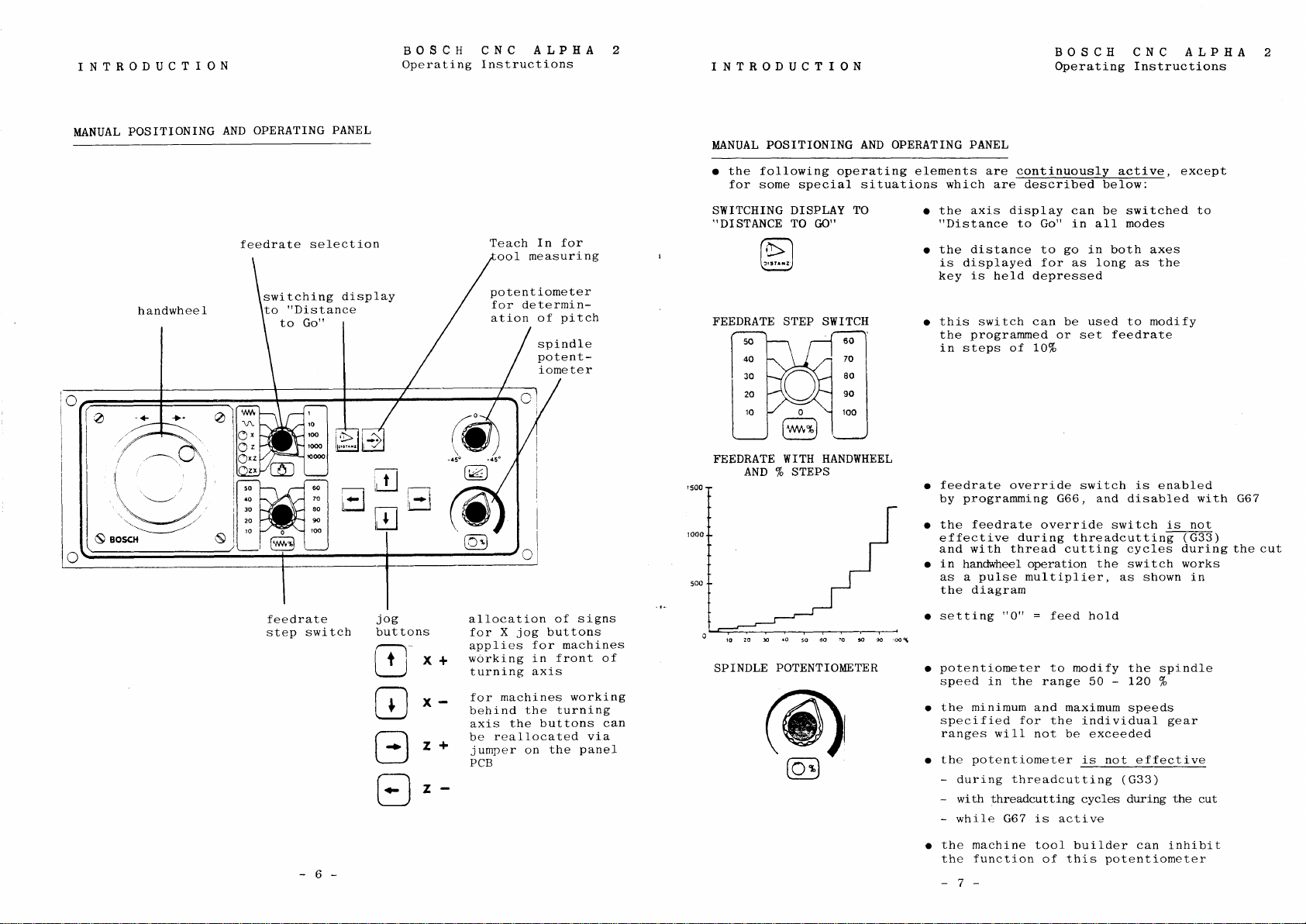

MANUAL

POSITIONING

handwhee

1

OPERATING

AND

feedrate

50

ao

30

20

selectlon

switching

to

"Distance

Go"

to

feedrate

switch

step

-6-

PANEL

display

iog

buttons

rt i

\-j

x+

Dx-

E

z+

z-

tr

Teach

potent iometer

for determination

allocation of

for

applies

working in

turning axis

for

behind the

axis

be

jumper

PCB

In

measuring

oo1

of

spindle

potent-

iometer

jog

X

buttons

for machines

front

machines working

reallocated via

the

buttons

the

on

turning

for

pitch

signs

panel

of

can

MANUAL

. the following operating elements are

SWITCHING

''DISTANCE

FEEDRATE STEP SWITCH

FEEDRATE

SPINDLE

POSITIONING

for some special situations

DISPLAY

TO

WITH HANDWHEEL

AND

tO20I.o50dOTO90rrma

STEPS

%

POTENTIOMETER

@r

AND OPERATING PANEL

TO

GO''

which areffi

axis

the

.

"Distance

the distance to

is displayed for as

is

key

this switcb can be used

the

in

feedrate override

by

the

ef

and with thread cutting cycles

in

as a

the diagram

setting

potentiometer

speed in the range

the minimum and maximum

specified

ranges

t

-

-

-

the machine

the

-7-

held depressed

programmed

steps

programming

feedrate

fective

handwheel

pulse

will not

potent

he

during

with threadcutting cycles

while G67

function

continuously

display

to Go" in all modes

go

or

70%

of

G66, and disabled with G67

override switch is not

during

otrreration

multiplier, as shown in

=

"0"

feed hold

to

for

the

be exceeded

iometer

threadcutting

is

active

tool builder

thi.s

of

actj-ve,

can be

set

switch

threadcuttinElEsSl

modify the spindle

switched

in both axes

long

as the

to

feedrate

is

the

switch

-

t2O

50

speeds

individual

j-s

not e f f

(G33)

during

can

ootentiometer

except

to

modify

enabled

during the cut

works

7o

gear

ive

ect

the

cut

inhibit

Page 7

INTRODUCTION

BOSCH CNC ALPH

Operating Instructions

MANUAL

SEQUENCE

PERATING

O

S

BOSCH CNC ALPHA

Operating

Instructions

MANUAL

.

FEEDRATE

SELECTOR

SWITCH

followj-ng operating

the

"Manual"

POSITIONING

and

"Teach

JOG

BUTTONS

r0

I

10o

I

t:::.1

B

HANDWHEEL

AND

OPERATING

In"

t-

r0000

PANEL

elements are

mode:

o in

possibilities

jogging

1

the

constant

is entered manuallv

.JVW\f

.1/\;

oex

.oz

oQxZ

oQzx

continuous manual feed, for as long

as the

the

constant

is

ry!.rq,

button

machine constant GX. GZ

handwheel 1 axis

handwheel 1

ha"ndwheel 2

handwheel- 2

for

the

Znd

the angle

set with

only

effective

"Manual"

incr.

manual feedrate is active

manuaL feedrate is active

entered

"handwheel

1st

axis is the

mode the following

are

in

incremental steps

=

1

or

J.t

MAN"

"F

jog

button

MAN" ) unless a

"F

manually

for

is depressed

axis is

as

axis

axes,

axes,

between

the

"Trailing

long

operation with 2 axes"

in

available

(dep.

p

10

unless a

)

is

depressed;

as the

(X)

(Z)

X = leading

-

Z

leading

the main axis.

trailed axis;

the two

Ang1e"

:

resofution)

on

feedrate

feedrate

jog

axes is

(n/c

(m/c

axis

axis

the

pot.

REFERENCE POINT

TRAVERSE

before

must be

EXAMPLE

INPUT DISPLAY

,

TO

traverse

cleared, e .g.

1: X

to

AND Z_AXIS ARE

reference

by ITIDI

REF X?

Z?

REF

point

T0, 2 x

of

TO TRAVERSE

X

any existing

actuation of

TO THE

select

select

Reference

X-reference

tool compensations

Cycle

REFERENCE

Point mode

Start

POINT

point

tr

E

@tr

Note:

after the

after

these should be

this

software limit switches are active

if

operation

Traverse

REF X? XZ

REF XZ

XZINREF

first actuation of

switch-onrthe control will

function must

will be

to

noted if

inhibited.

Reference Point

be

work

carried

will

select

start

it

whether the axes have

"IN

reference

reached,

displayed in the axis

displavs and

ref^erehce values

Traverse

Z-reference

traverse to

then

points

position

to

switch-on

-

possible

Reference

otherwise

is

POSITION"

display the

is to be done with G92.

out on

not affect

ooint

ref.

pressing

by

have been

values are

wilI

be

from then on

PREset

-

position

to check

reached

position

valid

Poi-nt

especially

further

point

"0"

as

values:

values

X,Z;

TRAILING

TEACH IN

ANGLE

@

set the

to

and trailing

when in

rr+'r

angle = axes drive

direction

!r-'r

angle

directions

for storing tool

key

data established

-8-

angle between main

axis; only

2-axis

(both

=

axes

(one

operation

+

or

drive

+

the other

in Teach In mode

effective

in

same

-)

both

in

opposite

compensation

TRAVERSE TO

axis

EXAMPLE

2:

ONLY

Z-AXIS

REF

REF

IS

X?

Z?

TO

no

THE

REFERENCE

traverse to X-reference noint

POINT

@

REF

Z

select

Z-reference polnt

r-t

-)

start traverse

Z-reference

to

@

Z IN REF

reference

posi-tion

PREset

posi-tion

-9-

point

display

parameter

value

)

has

Z

value

been

l-oaded w11.h

is

(va1id

point

reached,

as

Page 8

MANUAL

SEQUENC

OPE

ES

RATING

BOSCH

Operating

CNC

Instructions

ALPHA

MANUAL

SEQUENCES

OP

ERATING

BOSCH

Operating

CNC

Instructions

ALPH

POSITIONING

in

"Manual"

to be carried

some

out

at the fixed

the feedrate

example: F

of

A)GS

mode

out via

procedures

the

can, however,

:

100

Flooo

@

functional interaction

o

MANUALLY

control

the

the

manuaf

mm/min

Floo

60

70

80

90

100

al1ows

operating erements

actuate

feedrate

be

is required

manuaL

axis movements,

(machine

determined

E

of

the operating

_

_

10

positioning

of the

constant

by the

delete

enter

press

elements

sel-etion

of feed

trailing

for 2-axis

operating

(

reduction

selected

axis

movements

manual

which

to

are

F

operator;

new va1ue,

ENTER key

actuate movement

movement

carried

MAN)

o1d val-ue,

of type

(submode)

angIe,

operation

elements

of

feedrate

panel

the

only

DISPLAY

F

A)GS

with

with

handwheel

60

70

80

90

100

handwheel

1-axis,

2-axes.

o

-45"

45"

mode selection

F 100%

handwheel

turning

is converted

X-axis

1 full turn corresponds

to approx.

angle

effective

F 50%

leading axi-s X,

trailing

angle

45"

in same

the

of

movement

pot.

axis

between

(both

dlrection at

speed)

same

into

1300

not

axes

pulses

Z;

X and Z

travel

EXAMPLES

INPUT

G

E)GMPLE

E)GMPLB

vw!

3x

3z

9xz

POSITIONING

OF

F6'l'

[E.

positioning

1:

positioning

2:

1

'to

100

100()

10000

9zx

positioning

EXAMPLE

)

VYll

EXAMPLE

3:

1

10

100

1

000

10000

4: driving

50

30

20

10

in incremental

at

t-1""./

70O7o

joo

J

60

70

80

90

,eo

-.J

rapid

80i

eoi

steps

travel

button

each

travel

will

long

as

is

feedrate

actuation

key

the

1 mm in

effective

constant)

the

depressed

axis

at

the axis

for as

jog

1O%

manual

at

of the

will

the mi-nus direction;

"FMAN"

(machine

I

i

I

I

I

I

11

-

lr

Page 9

MAN

SEQ

UAL

UENCES

OPERATING

BOSCH

Operating

CNC

Instructions

ALPHA

2

TOOL

COUPENSATIONS

BOSCH

Operating

CNC

Instructions

ALPHA

MANUAL

EXAMPLE:

INPUT

DATA

m

E

tr

@

E

E]

Ef

@

E

@

E

E

E

@

F5t

m

@

tE

tTl

r

trtr

NOTE

!

old

EXAMPLE:

(-o-l

@

@

al

E

tr

@

@

@

INPUT

c1,

x1.2

Btr

m

@

@

values

carl-up

re^l

@

@

must

ofsBp

E

G)

tr

(MDI

)

22

F700

DISPLAY

G

X

Z

F

S

M

M3

GXZFSM

be

z

G

GSBP:A7

GREP=80

X

S50

creared

for

imrnediate

-

M3

before

10

LZ

select

addresses

enter

enter

enter

enter

enter

enter

the

determined

(output

command

displaSr

values

Cycle

the

out

select

must

on its

call

no

immediate

value

value

value

val-ue

value

value

effectiveness

have

Start

entered

immediately

new

actuatlon

IIDI

be

own

up

repeti

-

MDI

mode;

:

G,

X, Z,

for

for

fol.

for

for

for

by

with

values

addresses

been

block

values

mode;

t.ion

actionlng

machine

)

can

with

of

suitable

subprogram

input possible

R,

F,

'G,

"X"

,,2"

"F"

"S"

"M',

of

M3

is

parameter

or

after

for

entered

is

the

to

7

which

carried

be

entered

subprogram

be

carried

of

subprogram

S,

out

for

M,

GENERAL

following

lht

for

up

to

d$

the

input

resolut

tool

tool

!

when

tool

all

the

(without

Automatic

in

compensation

different

tool

o

with

ion

length

wear

in

AUTOMATTC

compensation

the

values

tool-

wear

order

to

numbers

N+l

complete

data

16

tools:

-

tool

-

tool

-

radius

type

ranges

compensation

'

LX

.

LZ

these

"Teach

tool

compensation

DX

DZ

these

enabli.ng

(operatlng

from

from

compensation

G3z);

when

should

values

check

group

can

be

with

be

can

be

entered

length

wear

of

apply

=

tool

=

tool

values

table

=

tool

=

tool

values

"TOOL

mode

table

on"

the

pressed

tool_

(see

A+1

called

compensation

comp.

comp.

comp.

tool_

for

0.5 p

values:

length

length

In"

function

values:

wear

wear

the

precedure

NBR"

it

is

(by

corplnsation

values

new

compensations

next page)

up

-

into

values

values

value

nose

and 1

compensation

compensation

can

be

compensation

compensation

can

be

program

possible

piessing

var-ues

13

modified

onwards)

DX

have

u.nd go

directly

numbers

-

the

tool

LX,

DX.

R

J

p

measuring

established

and

stored

for

for

on

been

can

without

page

carf

+

Tool

can

bz

"un

select

inrougn

be

entered

memory (G3Z)

as

to

MODE

group

ind

you

conpensati.on

LZ

o.001

DZ

0.001

0.001

J0

system

for

X

for

Z

with

in

the

X

Z

74,

up

the

Comp.);

be

checked

be

modified

the

the

skipped

to

the

MODE

-

999.

-

9.0

-

32.000

J9

with

+

store

999

mn

A+1;

mm

mm

Page 10

TOOL

COMPENSATIONS

BOSCH

Operating

CNC

Instructions

ALPHA

TOOL

UEASURING.

TEACII IN

BOSCH

Operating Instructions

CNC

ALPHA 2

ON

INPUT

EMMPLE:

INPUT

OPERATING

THE

FtrI

PANEL

input

LX=15mm

:

DX

=

R

DISPLAY

G

r

m

r

Btr

ffiBtr

,AE

Y) tn ffl L:J

a

WEE

o @trylr-;l

Wf

@EEE1DZo,1oo

@EEE

P]

Fd)@

f

sFl

tt

f-t

r.J

LZ

lij

NIEM.

TOOL

t2

LX

1

1DXO,3OO

rLZ

1RO,3OO

1r

Ld

of the

0.3

0.3

ENABLE

NBR?

LX

15,ooo

25'ooo

following

LZ=25mm

mm

mm

DZ = 0.1

J=J

select

enable

program

select

(a1so possible in

select

crear

value

new

update

otherwise

update

otherwise

update

otherwise

update

otherwise

update

otherwise

data

mm

MDI

access

memory

tool

the

old

"DX'

"LZtt

ttDZlt

rrRr!

1!

J'r

comP.

for

mode

the

to

comPensation

Automatic)

v:rtue,

transfer

value

value

value

value

value

group

i-f

A+1

if necessary,

A+1

if

A+1

i

i

A+1

comP.

"LX"

and

press

press

Press

press A+1

press

group L2

(e.g.

enter

to

necessary,

necessary'

f

necessary,

f

necessary,

table

1-2)

memorv

ESTABLISIIING

principle

t

preconditions

I

measuring

methods

LX

AND LZ

the tool is

of which are known;

for

X

and tool no. are entered

type

when

-

the

-

the tool

and store these values

traverse

the axis

reference

there

fixed

ESTABLISHING

WITH

CLAMPED

driven

and Z

as well- as tool nose radius,

the Teach In

tool length comp.

length comp.

to

the

position

point position

must be a measuring

point,

to

then

key is

reference

values have

optical device

LX, LZ SIMULTANEOUSLY

DEVICE,

99[i8fiir..

DEV\CE

TOOL

position(s),

pressed

value LX

value LZ

in

values

point

fixed

manually

the NC will cal-culate:

the selected

points

aid on the machine:

has

been set

clamped

or

MECH. FIMD

the

dimensions

coordinates

tool nose

comp.

been carried out;

to the

workpiece

(

cylinder

WITH

group

)

OPTICAL

POINT

--T-

positioning

q

t

Zn--

r1ET

ESTABLISHING LX,

I

x^__

Ktr.F

LZ SEPARATELY

I

!-'l*

l-a-l

l\yl

-1-

1

X

1

(key

required

THROUGH

2

actions for

-

3

(key

t

required

Z coordinates

and

transfer

actuation)

TOUCHING

separate

touching

touching in

transfer actions

actuations)

for

action

positioning

X

in

Z

after

must be

input of

selected

modifications

again.

in

-

"Single

1,1

la

Block"

mode,

"Automatic"

ZRrp

-__;

-15-

Page 11

TOOL

MEASURING

-

TEACH IN

BOSCH

Operating

CNC

Instructions

ALPH

TOOL

MEASURING

-

TEACH

IN

BOSCH CNC

Operating

f nstructions

ALPHA

ESTABLISHING

o

when

reference

to

checked for reference

o

the tool

"Cycle

EXAMPLE

INPUT

.l'5]

'[E

@

l.dl

E

r

foJ

1.6-l

lTl

E]

r

Fd

l5-g-)

tE

r

LX.

getting

should be

Start" twice

E

tr

@

to

point

tTt

tr

@

153-l

tr-l

TOOL

COMPENSATION

-E

@

@

rc-l

E]

tr

tr

tr

tr

E

LZ

SIMULTANEOUSLY

the first

shouLd

point

cfianged

measure

fixed

tooL nose radius

refer"ence

DISPLAY

point

tool- 3

positions

x

z

R

J

T

T3

VALUES

TOOL

3 LX

3 LZ

3

3J3

FOR LX.

NBR

5,253

3,153

R 0,500

?

tool which needs measuring,

carried

be

values

in MDI; actuation

coord. X 20

R

LZ

_

16

out and

select

mm, Z 12

=

R

0.5

X 40,000, Z

enable

as

shown on

enter

radius

enter

enter

enter

sel-ect comp.

position

(jogging

display:

pressing

panel

culation and

LZ

and

HAVE BEEN

CHECKING

select

select

use A+1

different

the

_

the displays

by

comp.

mm, tool nose

access

X fixed

value,

Z

fixed

tool nose

tool nose

tool

or handwheel operation);

e.g. X25,253

this key

initi-ates

values

ESTABLISHED

VALUES :

"TooI

tool 3

to

check

pressing

group

mm

240,000 mm

to

page

point

even if

point

radius value

type

store 3

to the

automatic cal-

storage of the

Compensation"

values

traverse

3

type = 3

program

+

14

select Teach

coordJ-nate,

diameter

display

coordinate

3

fixed

the

on

AND STORED

different

through

memory

point

215,753

manual

LX

exanple

mode

ESTABLISHING

o when

traverse

change

o

EXAI{PLE:

t

T

In

INPUT

f^,";

L--J

@

Q)

m

E]

r-l

LiJ

6-:sl

l--'J

.

'L

E

Lol

rEl

fz)

e_D

r

m

r

tr

eo

@

tr

LX, LZ

getting

to

tool while in MDI

jl

VALUES SEPARATELY

to the first

reference

measure

workpiece details:

tool

ref.

DISPLAY

x

Z

@

R

E

J

I

T

XZR JT

tool

point

nose radius:

positions:

and

mode;

tool 3

press

which

needs

check

Cycle

select

diameter

R

diameter

enable

then

select

touching

enter radius

diameter display

enter touching

enter

enter

select

press

measuring,

displays

Start

=

0.5 mm,

access

dimension X,

radius

tool

nose

compensation

A+1

for ref.

comp.

40

80

to memory

"Teach

value, even if

dimension

R

0.5

carry

twice

group

length 12

mm

,

3

type

mm, length 24Omm

In"

active

J

type

store

position

values

3

(see

mode

Z

=

3

out

mm

p.

14),

(length)

t^"J

x20

move

the tool

handwheel

f

I

EE

ZL2

tr

E

the

touches

on actuation

on the manual panel

automatically

put

move

with

touches

on

on the manual

automatically

lt

press

the compensation

ferred

_17_

the

it

lnto

the tool

the handwheel

the

actuation

into

buffer

"Enter"

to

the compensation

jogging

by

until it

workpiece

of the

buffer

workpiece

of

Teach

calculate LX

by

panel

calculate LZ

key

the NC

store as radius

jogging

until

Teach

the

the NC

storage as the

values are

or with

at Q 40

In

will

and

or

it

72

at

Q

In

will

and

store

key

varue

key

put

length

trans-

Page 12

EDIT

UoDES

BOSCH CNC ALPHA

Operating Instructions

2

I,,I)IT

MODES

BOSCH

Operating

CNC

f

ALPN_'A

nstructions

ENABLING ACCESS

INPUT DISPLAY

TO

THE PROGRAM MEUORY

G

ENABLE

MEM

EEt'

CLEARING fiIE

.;.;.:l:,.::,''i;:

@

Btr

to

tr

"Insert"

can

be entered

INHIBITING ACCESS TO THE

after inhibiting

o

is

not

Program"

only new tool wear compensation

INPUT

PROGRAM

'

;.;.;.l

mode can then

possibLe

and

in

"Teach

MEUORY

G

MEM CLEAR?

CLEABED

UEM

be

PBOGRAM IIMUORY

access to

"Insert",

In"

modes;

DISPLAY

G

select

enable access

select

select

dialogue

is memory really

the complete

program

on

the

selected and

program

the

"Modification",

in

"Tool

values can

select

MDI mode

to memory

mode

MDI

CLEAR PROGRAU

question:

contents

memory will

2nd

actuation of ENTER

the new

memory input

Compensation" mode

MDI mode

part

"Loading

be

entered

MEMORY

to be cleared?

be cleared

programs

of

Part

of the

data

function

PROGRAM

DISPLAY

o

mode;

DISPLAYING

INPUT

OF

contents

the

after

can be

dialogue:

data

selection

chosen

BLOCKS:

['tr,J

tiJ

t2)

ffi, ffitr

@

B

YING MAIN

SPLA

DI

@

F"-l

L-J

@

@

YING SUBPROGRAMS

DISPLA

the

of

be modified

can

of

by

-BLOC

-PROG

-SBP

-LAB

PROGRAMS:

aTr

t-l

E]

CONTENTS

STORE

program

"Block

pressing A+1 the

NO displ-ay

NO

NO

NO display

g.

e.

DISPLAY

NO?

BLOC

15 GXZ

15G

16XF

NO?

BLOC

NO?

PROG

5GXF

: e.

store

in

Display" one

display

display

N 15

block

F

Yrl-ndrom hn 2

g

o.

no.

s.

can

"Modification"

appropriate

startlng

starting

startj-ng

starting

st'l ccr 1

N(l wi 1 I ask

cntt'r block

i I there

this

a-ddrcsses

iI

number

empty

this

addresses

this

block,

be

select

increment

sp l ay

cll

errter

w11t

,,G78

1

checked

be

of the

with specified

wj-th specif

with specified

with specified "labef"

(jump

"Displ

block number

not, the

is displayed;

"BLOC

j-s

key

with their

is u^sed to

key

the addresses

displayed with

"Dlsplay"

main

call

A2"

in

"Insert"

target

mode

"

block

the

displayed;

call

contents

increnent

of which

A+1

mode

block

"Block

ied

number;

or

following

number of

ay

for

number,

is information

will be

1ast stored

NO?" wiLl

used to

to

Program

program

the

up

Display"

mode;

possibilltles

times:

block

progr.

SBP no.

with G79)

number

storeci

defined

block

store

if

appear

qp

individua-l

the

the

to

can

number

the

which

no.

no.

(GgB)

Jor

is

again

ttext

ag'lrin

.\ii-

irr.:i) 1''-i-

(

G78)

lE-r

m

@

r

access to the

protected

is

G38

active on

(

^l

| 32 I

part

against

PROTECT.

I\,IEM.

program

accidental overwriting

switch-on

memory is

-18-

memory

overwrit

protected

is

ing

lnhibited

and

agalnst

it

BLOC

NO?

select

"Display"

mode

@

the

disPlaY

(e.g.

block

i

)

wir

i.

subProgram

NO?

is

E

a

f]ll

L1l

tr

SBP

6GXF

ineremenr

enter

the

contains

-

-

19

to

subprogram

NC will di-sp1ay

"G9S

number

A1"

Page 13

EDIT

MODES

BOSCH

Operating Instructions

CNC

ALPH

I.]I)IT

MODES

BOSCH

Operating Instructions

CNC ALPH

OPERATION

part

.

or

used

o the

1

start, 7

o disregarding

NC

selected

if

.

up the lowest

from

INPUT

F;)

VIA INTERFACE

programs

(see

that

reader,

section

data must

data,

block

block

a tape

entered

will store

block number

..,....'.,."'

EEtr

,@"

8ffitr

,,,:

ffi

_

LOADING

can

be loaded via

for instance;

"Variable Parameters")

be in

parity,

1

the

block numbers

1st

the

number

empty

block

is selected,

999

store l_ocation;

in ascending

DISPLAY

G

MEM ENABLE

BLOC NO?

15

END INPUT

PART

PROGRAMS

interface

the correct baudrate

ISO

code:

2

stop bits

which

of the

sequence

data

(1

are read in

entered

tnJ nC

will

the

input will

select

enable

seLect

select block

under which

part program

the

and

start loading

the compl-etion

operation

display

frorn

a cassette unit

format:

stop

bit accepted)

part program

MDI mode

access

"Program

of

from

automatically

to

number

the

of

is

indicated

"END

must

tape the

in the

be started

program

Load"

mode

(e.g.

first

INPUT"

block of

is to

operation

the loading

be

call

memory

15),

be stored

by

the

OPERATION

part

r

reader

(see

r data is output

.

it

data

o

the

rnatter

.

the

rvards

only be output

of

a

the

o

within the NC

i.e.

contents

as

the

Ionger

INPUT

VIA

programs

via

section

is

advisabl-e

format:

lst

block

which

NC

always

to

program

the

output

only the

CR, LF,

output

than would

data interface X8;

the

program

are stored; for

spaces,

operation;

Btr

m

E

OR

INTERFACE

can

in ISO code

to note the used

1

start, T data,

of the output

block number was

outputs all stored data from

end of

on its own if it is

store

part programs

programmable

-

PART PROGRAM

be output onto, for instance,

program

the

remains

tabulating characters

an output

correspond to the used

DISPLAY

NO?

BLOC

FORMAT

8

the correct

7

program

selected

stored

are

address characters

the

output all

?

OUTPUT

baudrate

parity,

is always

store; i.

the only one

in

stored

program

select

enter block number

output is

select formated

(tabulated)

TTY

this

will

only

of use

baudrate

on

2

stop bits

e.

the memory

in a compressed

additional codes,

are

is therefore

storage

"Program

to

produce

cassette

data

the

output

the selected

part program

a

or at

and address

generated

capacity

Output"

start

output,

and

for TTY

or

must

carrier:

as N1,

the

always

at

which

start

an output format

or CRT

tape

be used

no

block on-

can

end

format,

such

during

mode

e.g.

output;

for

NorE:

NOTE:

if a

block

information

will

be

of the selected

parts

programs

with

which

input

number

stored

read

will

be cleared

cassettes

on

they were

also with 1200

is selected for

in from

in the

that

block

output

Baud)

program

block

and that

automaticaJ-ly

must

onwards. and

of all subsequent

loaded

be

(e.g.

-20_

which

memory,

with

output

there is

the new

the contents

the same

1200

with

already

data

program

baudrate

Baud,

o

@

FORMAT

8

END

OUTPUT

?

select unformated

for

cassette

start

the

completion

operation

display

-21

-

output

is indicated

of

"END

output,

(not

tabulated) and

of the

OUTPUT"

e.g.

output

by the

Page 14

EDIT

PROGRAM INPUT

o when entering

is

up to 99

a main

r when entering

is

each

up to 99

when entering

a subprogram

INPUT

MODES

VIA

programmed

main

program

programmed

subprogram

SBPs

THE OPERATING

main

first,

programs

must

subprograms

first, followed

number

(99

labels

must be

@-l,

fil

EEtr

(5ll

E

BBEtr

EBA

EEE

programs

followed by

can

concluded by

be

must

x G98)

(fab)

concluded

DISPLAY

G

I{EM

BLOC

29G

29G

294

PANEL

(lvtP)

"G78"

the

stored

be

(SBP)

by the

only

can be stored

the

ENABLE

NO?

PRG=A enter

M2 or

"G98"

stored once

be

same applies

G99

with

select

enable

select

by entering

ernpty

into

be

enter

a

M2 or M30

BOSCH

Operating

program

main

program

(99

x

G78);

M30

subprogram

subprogram

under numbers

MDI

access

"Insert"

block

which

entered

main

MP

MP must be concluded

CNC

Instructions

number;

as with

no

identification

(atso

G20)

identification

number;

the memory;

in

1

G98;

mode

memory

to

mode

select

999

number in the

the first block

with G78 or

program

.

start

12,

ALPHA

-

99;

the

G98

with

first

memory,

can

(G78)

EDIT MODBS Operatinglnstructions

-

SUBPROGRAM CALL-W G22. G23

o

operating sequence

in

a

"Insert"

block

in

"Modification"

cleared before new

be

EXAMPLE:

o

INPUT

ful

EI

to

tf_l

ctr\

crfl-l

|e

@

E

number

G22

mode

by 1 when

A2 94 call-up

for

control automatically

the

mode the old address

data can be entered

initial actuation

DISPLAY

18c

18G 22

18

G SBP=A subprogram

t5

@

e)

fa-l

tC

E

1g G REp=B

1g G REp=B 4

18X

WITH OPTIONAL

"Subprogram

"Enter"

i-s

SBP

of

input of

in block

into memory and incrementing of

block

subprogram

enter

number

to

input figure

number of

5

B=0 for

i-ncrement

pressed

program

BOSCH CNC

REPETITIONS

Ca11-Up" in

contents

2,

be

to

the

N17, transfer of

number by

call-up

number ?

(1-99)

(e.g.

proceed

to input of repetitions

repetitions

runs in

program

1

to next

"Insert"

increments the

must always

repeated 4 times after

last word

1

(G22)

requested

2)

no.

(1-99)

all

run

address

ALPH

mode

(e.g.

the

subprogram

press

and

to determine

(e.g.

)

E

ZIO)

4

block

A+1

-

@

EE

E]

EE

OR

29G

NBR=A

enter subprogram

enter

or

enter subprogram

subprogram

a

with

this

from address to

the

with this

is

block number is

when

label

G99

key

selected block

transferred

in

must be concluded

is used

key

the

"Insert"mode.

start

(jump

number

to increment

address

into

incremented bv

(G98)

target

(e.g.

within

to input

entered

memory; the

block

G79)

1)

data

INPUT

o E)(AMPLE:

E

OF

DWELL

entering

dwel1 in "Insert"

11 G 4

select

mode

rrc4rr

dwell

TC

11

@

Fo-l

LE

EN

@

G DWELL

11

G DfiIELLSO

t2c

enable

enter

transfer

increment to next block

input of

dweLl time

block

dwell time

(e.g.

memory and

into

50

=

5

sec)

E

1

-23-

Page 15

EDIT

M3O BRANCHING

. input

"fnsert"

jump

o

o when address

be

EXAMPLE:

o

@

r

MODES

of

address

cleared

fa

tC

"M30"

and

before

M30

E

@

E

rrM3Or'

when

which it is

program

control

the

it;

only when Cycle

out this

a

when working from

M3O

a

cancels

(program

which

program

(program

"Modification"

'Crr

must

contents

a new

(C=2)

contained

was specified

will

all stored

in

DISPLAY

8M30

8 M ADR=C

9G

end) has been recognised,

stop at

Start is

tape

BOSCH

Operating Instructions

end

with subsequent

refer

are to

value can be entered

block 8

carried

the beginning

M30

and decoded M-functions.

program

to a

be modified,

enter

enable input

enter

number

this

conclude

out, the control

with the

actuated twice

will not

jump

effect tape rewind

no.

the old

I'M3O'

jump

block

address

of MP

CNC ALPH

jump)

not

,

program

jump

of

target

represents

and

calls up the

2,

without

will-

the

as does

in modes

a block

contents

end

(e.g.2);

the block in

(IP

address

a MP;

2

in

actioning

control

M2

number

must

example)

carry

I'DIT

PROGBAM

o in

1n

INPUT

MODIFYING X-VALUE:

ffiEE

@

MODES

MODIFICATIONS

"Modification"

exj-sting

programs

F"6-li

@,

3

_

MODIFYING

mode

bLocks can be

DISPLAY

G

MEM ENABLE

BLOC

NO?

10

XZT

G

ffiBs

trtr

. if further values in otl.rcr

to the

mode and cal l up

@

next required

EffiBtr

o<:k

bl

r<'t1 rr i rt.d

th<.

BOSCH CNC ALPHA

Operating Instructions

WORDS

modified.

select [.{D I

enable

select

select block in

to be

bl<.rcks need modifying,

N+1,

wi t.h

bl ock number

or

mode

access

"Modification"

modified

lncrement

delete o1d contents

enter new value

display: 10

reselect

direct 1y

cleared

to

which word is

(e.g.

program

either

"Modif

or

mode

N10)

to address

X

ication"

inserted

memory

(-72)

-12

increment

(X),

and

GzO / G2L JUMPS

r input of

"Modificati-on"

EXAMPLE:

o

INPUT

@

E

rer

to

a

jump

input

t5J

g

@

o conditional

UNCONDITIONAL

under

of

DISPLAY

11c

11G

11X

jumps

under

"G20"

GzO

20

ADR=A

or

(A=6)

'tG211'

-24

CONDITIONAL

/

"G21"

in

are

in modes

block

enter

enable input

enter

entered

-

11

unconditional

to

rtG20rr

program

in

"Insert"

program

unconditional

program

of

labe1

the same manner

and

jump

label

label

jump

DELETING

EBE

6

@..@

II'ISERT Z-VALUE

sffitr

8..8tr

F-VALUE

tr

15

15F

20XF

20 z6

select

ZF

G

select

word

f

select

select bl-ock

word

increment

-25-

"Modification"

block

to be deleted

i-nd

word and delete

"Modification"

is

to

to

(e.g.

(

e .

be inserted

Z,

mode

N15)

containing

(

g.

e.

mode as

g.

N20

in which

)

enter value

as above

F-word

above

)

Page 16

EDIT

MODES

BOSCH CNC ALPH

Operating

Instructions

EDIT

MODES

BOSCH

Operating

CNC

Instructions

ALPH

PROGRAM

EXAMPLE:

INPUT

sil

MODIFICATIONS - DELETING

block

12

is

DISPLAY

G

MEM ENABLE

be deleted

to

EE

BLOC

NO?

72cZ

ffiBE

T2

@E

O

the block numbers

a

NOTE:

after carrying out the deletion

can be selected

example:

block

N9

N10

N11 x40

N12

N13

N14

NOTE:

a

o

in the above

after deletion

if

the fast

delete

the

deleted

sequence

G1 X20

Z1.O F30

G2

250

G1

x55 260 F20

M2

the deletion

example G2 is

before

Z\O

of the contents

XZF

of all subsequent

block of

pressed

key

(I{ODE

key + relevant

defetion

of a block

BLOCKS

select MDI

enable access

select

enter block number which

be deleted

block

of what had

as the

blocks are

part program

the

again,

can affect

effective until

the Last but

a different mode

mode key)

block sequence

N9

c1 X20

N10

c2

N11

N12

N13

of block N12

mode

to

"Modification"

(e.g.N12)

N12

is deleted;

been N13 is displayed

new block N12

decreased

is deleted

one block is

of operation

after deletion

zto

Zto

F30

X40

X55

260 F20rPT'"]":?1vt^ -"'block

M2

subsequent

the

end of the

program

mode

contents

by

and

program

memory

is to

1

then

N13

parts

program

PROGRAM

EXAMPLE:

INPUT

t:5

l-_']

m

3)

E

MODIFICATIONS

between blocks

sEl

G]

ga

-

INSERTING BLOCKS

N10 and

DISPLAY

G

ENABI,E

MEM

BLOC NO?

N11

block

"G1

select

enable access to

select

Z2O"

MDI mode

Insert'mode

"

is to be

program

inserted

memory

ril

enter block

the new block

new block

a.

this example

enter

(

G1 ) and increment to

address ( X)

X is skipped without entering

value

a

ffiBtr

ffi@

11

11

LIZ

c

X

E

@

EE

.E

a

block numbers of all subsequent blocks are increased

the

a

example:

block sequence

N8 G21 43

N9

Gl X20

N10 G2

GO Z5

N11

/

N12

N13

N14

G79

directly after carrying out the

operation can

before insertion:

270

210 F30

x40

M2

A3

selected

be

enter

new block

block

G21

N8

G1 X20

N9

G2

N10

N11

c1

N12

G0

N13

N14

N15 G79

insertion

sequence after

number before which

j-s

generated

is

)

G-function

Z-va1ue

into

A3

210 F30

Z2O

ZS

x40

M2

AJ

a different

of

(20)

the

210

(previously

to be

inserted;

new block

next

and transfer

program

by

insertion:

(inserted

mode

(N1L

of

in

store

block)

N11)

-26-

-27

Page 17

AUTOMATIC

ACTUATION

part

up by

carried

program

any

block

programs,

their first

out

onwards

PROGRAM

OF

.

o

CALL-UP

INPUT

',,:,:ffi

@,,,

EEtr

PROGRAM

wh

either

can

be

OR PROGRAM

j.ch

are

bl-ock

in

carried

DISPLAY

BLOC

9GXF

stored

number

"Automatic"

out

LABEL

NO?

in

the

or

their

or

as

a whole

select

(

if then

it is

by a

the

enable

enter

control

block

(containing

start

the

c.arried

by block

BOSCH

Operating

program

program

j-n

"Single

or

"Automatic"

A+1

possible

program

same way

program

program

will

of the

the

selected program

out

CNC ALPH

Instructions

memory,

number

Block"

only from

pressed

is

to

1abe1

as shown for progr.

no.

no.

go

to

selected

"G78"

program;

automaticallv

are

and

mode

a

certain

mode

call

up a

and

start it in

selection

(

e.g. 2)

the first

program

=

main

will

called

then

3

times

program

and

;

program)

be

block

no.

SWITCHABLE

INCH,

DISPLAY, DPROG,

the baudrate require-'d

can be entered

the

baudfates

0-50

-

1

2

3

=

75

110

134.5

4=150

5=300

6=600

=

7

example:

INPUT

72OO

switching

via

are

Baud

Baud

Baud

Baud

Baud

Baud

Baud

Baud

E

FUNCTIONS

PREX,

CH1X, CH2X, CH]-Z,

for

different input

keyboard

the

entered

baudrate to

8

9

10

11

72

13

14

in

-

=

=

=

=

=

tr8...

coded form:

1800

Baud

2000 Baud

24OO Baud

3600

Baud

4800

Baud

Baud

72OO

Baud

9600

300

DISPLAY

BOSCH

Operating Instructions

and output devices

recommended

ASR33:

ASR43:

Alpha

tape

with

wi-thout

CNC ALPH

CH2Z, VCRT, BAUD

rates:

Baud

I]ATID

reader:Baud 6

CRT: VCRT

CRT:VCRT

2

5

14

7

CALL-TJP

start

OF BLOCK

address

@E

ffiffiE

CALL-UP

PROGRAM.

OF

[r]

IJ

EEtr

@l

tjj

tr@

NUII{BER,

in

the

example

BLOC

10xF

lOXF

SINGLE

BLOC

NO?

GXZF

9

GXZF

9

AUTOMATIC

must

NO?

BLOCK

-28-

contain

select

select

start

select

enable

and enter

select

(

only

"Automatlc"

start

restarting

of

each

a feedrate

"Automatic"

block

the

"Automatic"

program

"Single

possible

the

program

program

program

after

block

number

)

)

(F-word)

mode

mode

number

number

Block"

when

(program

the

(e.g.

in

10)

call-up

mode

needs

completion

tr

@

ffiE

('li1',

procedure

one

of these

operation

reset

pirrirm('t.cr

i n

paramc'Lt'r

the

"Baud"

phzr

A l

mocles

the

"VCRT"

excluslvely f

when a CRT is

if

no CRT is

parameters

for

the same

after

mode of

control

"l,oacl

or

connr-.ct.cri thi.s

connected

kev

lLltpl ics

I)lr"r't Programs"

i ng

rt'ltrcscnLs

phrL

thc A l

V(lItT

INCH, DISPLAY

described

as

parameters

must

be selected without

BAUD 3

BAUD

BAUD

5

for

(lR'l';

pilrameter

musl

etc.

perlpheral

all-

the

baudrate applying

be 7t

the choice

above for

has been changed,

-29-

display active

proceed

delete old baudrl.tc'

enter

(

e.

and

"Part

must

the baudrate

pressing

required

g.

5

devices,

Program

14;

be

is made

a

througir

-

different

bar.rrl r et.t,.

ci

i:r-

baudrirt.

300 Bauct

except

Output"

with

the

1cgue,

e

)

Page 18

DISPLAYS

BOSCH

Operating

CNC ALPH

Instructions

DISPLAYS

BOSCH CNC

Operating

Instructions

ALPHA

2

DIALOGUES

r all

there

-

error messages

-

coded

when

_

error

are two

error

error

GENERAL

messages

the fol-lowing

}

block in

error has

recognised

coded

or

the displayed

mode

with the A+1

o the incorrect

the

the displayed

combination

in

certain

information

which

been

error

switching

and

the addresses

fault cause

are

types of

1n

messages

codes

are

meaning:

i::PR

messages

to a different

block can

kev

address

can

b1ock,

of

si-tuations

when

also be in

program

the

displayed

error

clear

text

displayed

E!J,, iLI

error

can

be

then

of the

can

then

due

or

parts

the control

"0" key

in the

messages

figures

the

(type

code

cleared

mode

by

of operation

be ca11ed

block can

cleared

be

the

to

blocks

an inadmissible

will

pressed

is

alpha-numeric

havet

of error)

pressing

up in

be

the

"Modification"

checked

or modifled

immediately

sequence

give

additional

disptay

through

before

or

key

INPUT

DIALOGUE

DISPLAY

MEM CLEAR?

BLOC NO?

PROG

NO?

SBP=A

NBR=A

REP=B

ADR=A

LAB=A

TOOL NO

NO TOOL

R TOO BIG

LX

NOT

REF

DWELL

DEL M

LZ?

OR

OK

(Z)

X?

=

FUNCI'I..'

READ

MACII

WRIT MACH

EDIT

M-FUNCT

I'AII

PAR

LIST M-FUNCT

ING

MIIAN

Is complete

program

be

to

part

memory

cleared?

Enter block no.

Enter main

program

Enter

number'

subprogram

number

Enter subprogram

number

Enter repetition

factor for SBP

llnt

address

lint.r.r

numb('t'

I,l

er

nt.t't'

ump

J

r>r>

t

I

('l't,ut'lr

1ool

IN)

rrrrmlrt't'

()r)

|

l;l

tvlrt'tt

()l);'r';rI

o

poitrl','

lrtlrll

.

)

t't's I rr

vilr

ll'

i nl

)

vilr

int.t't'

)

I'llr'

irrpl

ltl

LX, |

rl t' i vt'

1ltt'

lltt

I

ltt:t"/

tlc l-

1ayc'd

(M-

, rtt

t":)

tllt'

ItllQlll:i

i ncrort't'<:l t4x,t'rrl

(

kr'1' sltott

st.arl.

pr-t'sst'rl

ix'

'l'

or

is rli*lrIlrvr'<l

I ttcorl'r,('l

rc,

x('s I

A

tI

t't'1.

to

l,l ntct'

(ll

lrr,rlt'lltlrl'r'

Arr'

irc inlrrrt

st'r-ial

Are

be output

serial

EDIT

wi

tlu't'lI

=

O.l st,t')

I

Is I\t-r'o<lr,

(

I'lurr

M-

llrr

I)ril':ln){'1

(

M-piLrrrm.

paran)t't.t't's I

(M-Param.

moder f or

ining

List of M-functi.ons

one

param.

M-paramt:tct's

11 be disp

by one

)

STATUS TMSSAGES

DISPLAY

CLEARED

MEM

FULL

MEM

FRAMING

PROTECT

MEM

ENABLE

IUEM

IN li.ItF

x7,

}IAI,T M RI.]TURN

lV

;1,

UNDEFINE

ullj

NOT IN POS

TRF.

l.<;

o

STOP

HAI,T

AXIS REQ

END OUTPUT

END

INPUT

the messages

RETURN",

STOP" are

rr

is

0r!

MEANING

Complete

memory

cleared

Storage

part program

has

wrong baudrate

Incorrect data

during

no

for

output

Access

program

inhibited

Ac'cess to the

rogram

l)

<'nab

X,

t.ht'ir

a1t.r-.r

M-function the

signal

received

M-function

not

Programmed

has

for

Transfer

output

funct ions

Position request

to the

card

by this card

Data output has

completed

(e.g.

Data input has been

completed

(e.g.

"NOT

AXIS

"HALT

only displayed

pressed

part

has

been

capacity of

memory

been reached

reading

device

connected

formated

to

the

memory is

m('mo ry i s

1ed

Z-axis have

point

ref

.

output

has not been

yet

in

defined

positj-on

not been

instance

stop

of auxiliary

axis control

was not

punch,

+

is correct

t.reader,

POS",

IN

REQ", and

when

program

or

used

format

in

or

data

part

part

reached

of an

return

table

reached,

in GO

during

put

answered

been

cassette)

cassette.

"HALT

M

"TRF

30-

Page 19

,/rr

,t

4 i

l-.

,

'-

rlt'r

DISPLAYS

ERROR

IMSSAGES

SERVO

XZ

BREAK

CY

FEED

HOLD

AXIS

???

TRAVEL

OVERRUN

I]ND. BLOC

PARITY

TRANSMIT

RECEIPT

ERR

N_ADDR

+Z

+X

ERR

ERR

MMORY

ERR

SBLOC

BATTERY

26'6

/-"'"

t'

t*-

IN

CLEAR TEXT

admissible

been

lnput

rn

a stop

input

in

an

o input

control

if

working

already

already

with

referenced

software

been

outside

after

re

ferenced

a

the

max.

formated

a

operat

the

entered

control,

used

parity

thi-s

case

transfer

axis

transfer

or STOP

auxil-iary

N-address

program

software

exceeded

error in

battery

this

and

"0"

it

means

S-functions

o the

built-j-n

unit

it must

ryhen

j-sconnect

d

. if

the

this

exceeded

lag

signal

signal

immedi-ate

signal

"Transfer A11ow"

completion

on

"Axis

"Axis

needs resetting

with

signalled

at

object

software

limj-ts

after

limits

activated

the specified

INCH/METRIC

travel

outpLlt

ion

character

parametric

or

together

error

can

it

can be

card

in one

1n

be caused

error from

(hardware

error from

key has

functi-ons

is incorrect,

output

l-imit

in

the displayed

part

the

fault

)

message

pressed

is

that

appears

the NC

or

battery

towards the

changed

be

changing

the battery

ing

the o1d

position

could

i-ndi-cate

for

the

A1low"

stop

A1low"

"G75",

when

to

be measured

being active

control

and/or

with

the axis(es)

area

switching

range

has

has

been