Bmw R1150GS (2000) User Manual [ru]

Repair Manual

R 1150 GS

BMW Motorrad

After Sales

Publisher © BMW Motorrad

After Sales

UX-VS-2

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written

permission.

Errors and omissions excepted; subject to technical amendment.

Printed in Germany 02/00

Order number 01 79 0 021 120

Introduction

This Repair Manual will help you to perform all the main maintenance and repair work correctly and efficiently. It should be consulted regularly by workshop personnel as an addition to the practical and theoretical knowledge obtained in Training School courses. It is a contribution towards achieving even higher

Service quality.

A new issue of this repair manual will be published if amendments or additions (supplements) are needed.

The latest issue date is shown in the header of the microfiche. Microfiches rendered invalid by the new issue

should be destroyed without delay.

All information in both text and illustrations refers to motorcycles in standard condition or with genuine

BMW accessories installed, and not to motorcycles which have been modified in any way to depart from

the manufacturer’s specification.

● The Repair Manual is structured in the logical sequence of the work to be performed: Removal, Disas-

sembly, Repair, Assembly, Installation.

● The entire contents are divided into individual chapters, corresponding to the Construction Groups.

11 . 10

Chap. Page number within chapter

● Work to be performed during an Inspection is described in Group “00”. The various inspection routines

are numbered I, II, III and IV. This numbering is repeated in the work descriptions which follow, so that

work can take place without interruption.

● Use of the BMW special tools needed for certain tasks is described in the work instructions.

If the need arises, repair instructions are also issued in the form of Service Information. This information is

of course incorporated into the next issue of the Repair Manual. We also recommend you to consult the

detailed illustrations on the Parts microfiches as an additional source of information.

BMW Motorrad

After Sales

Published by: BMW Motorrad

Hufelandstr. 6

D - 80937 München

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written

permission.

Errors and omissions excepted; subject to technical amendment.

Printed in Germany

BMW Motorrad

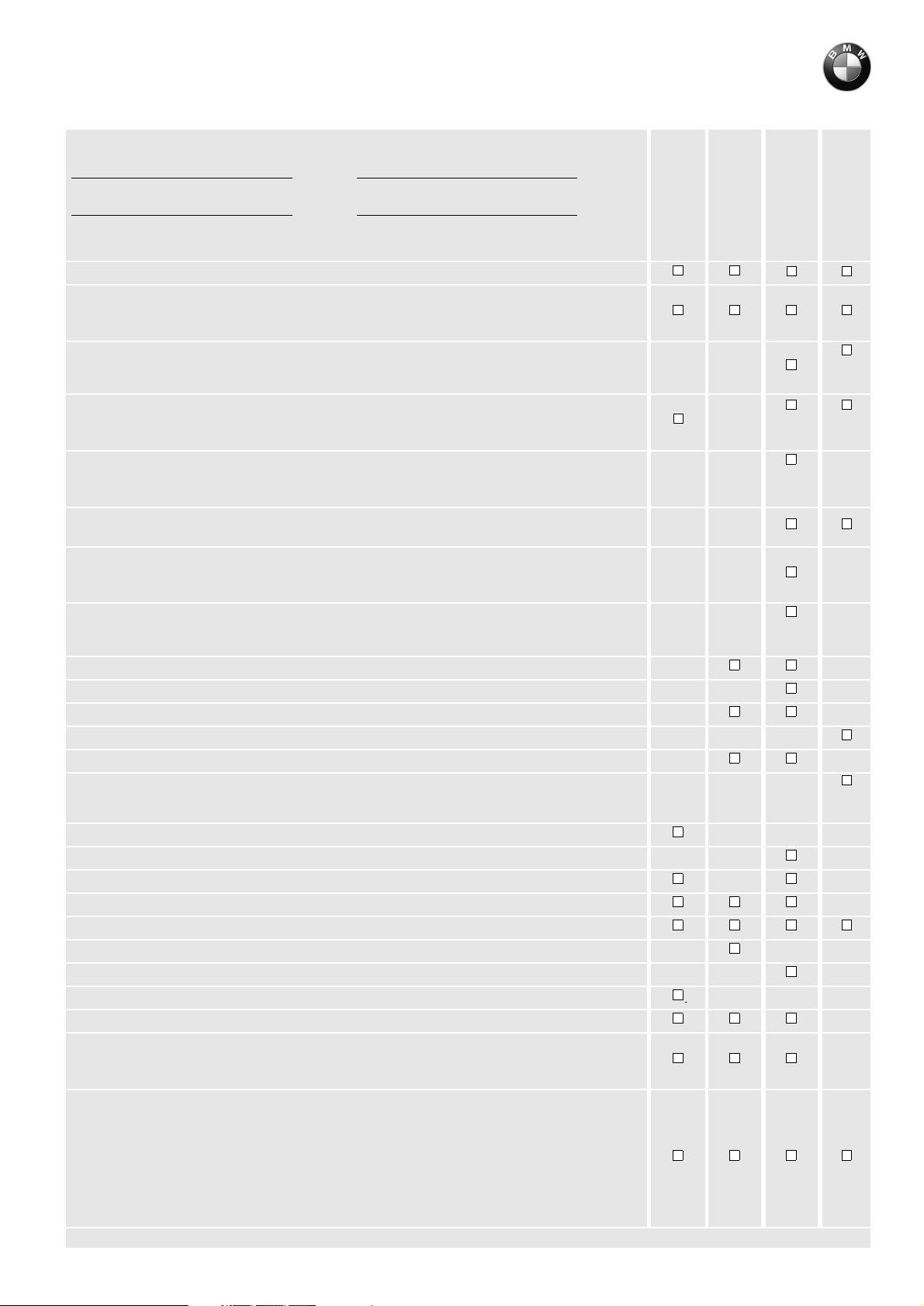

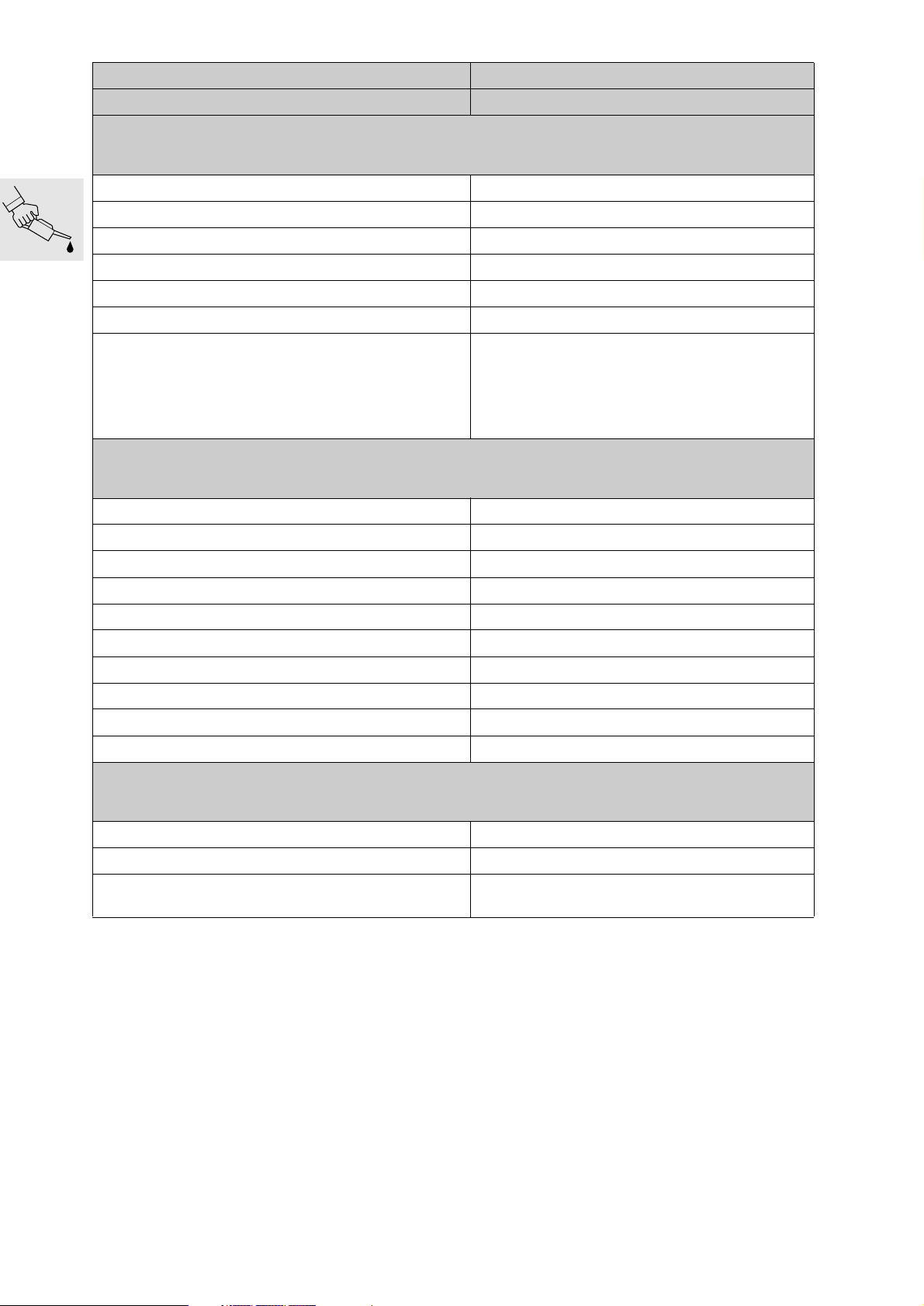

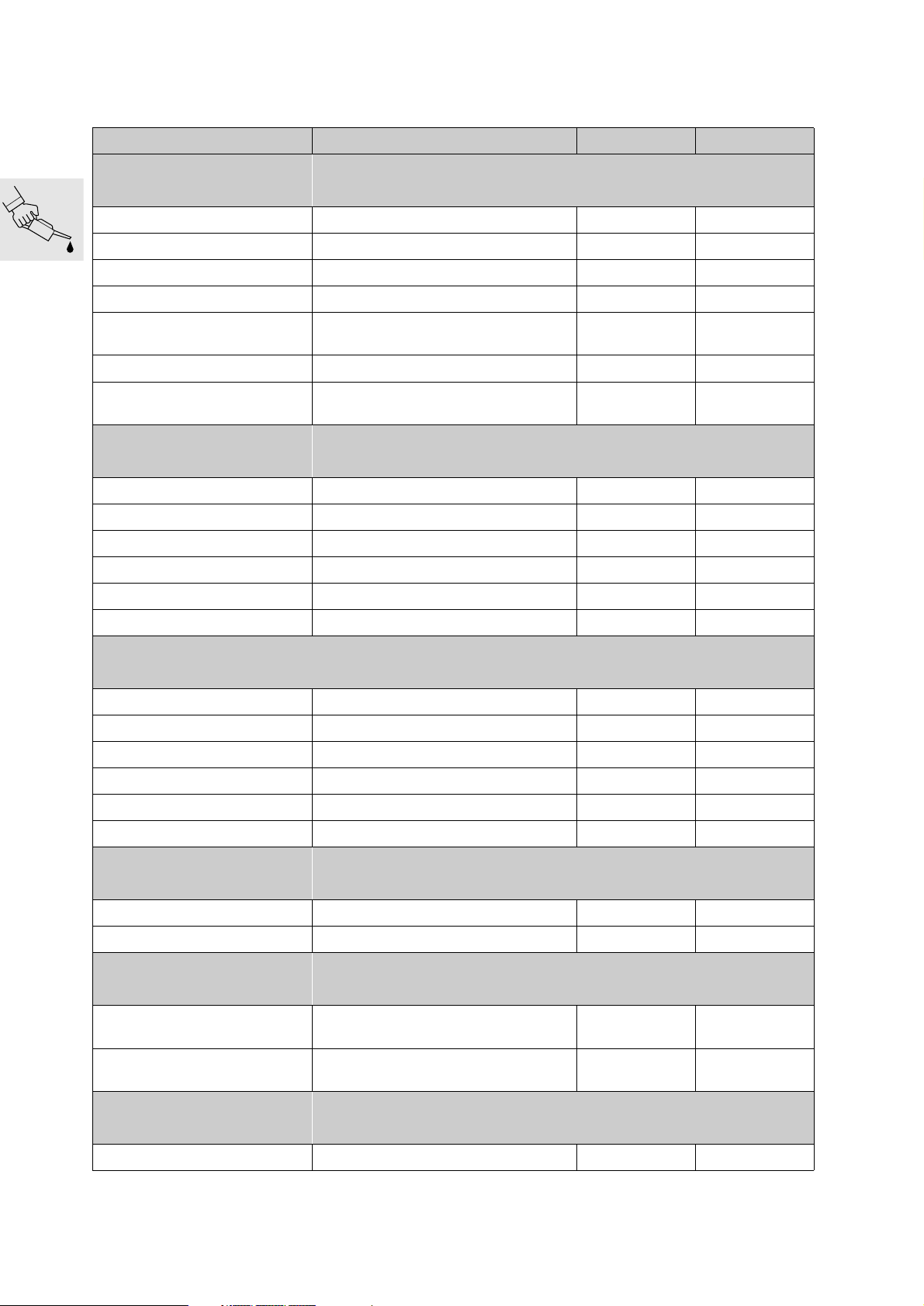

Maintenance schedule

R 1100 S / R 850/1200 C / R 1150 GS

Customer Licence plate No.

Order No. Mechanic’s signature

Read the fault code memory with the MoDiTeC

Change oil while at regular operating temperature and renew the oil filter element

if motorcycle is used only for short journeys or at outside temperatures under 0°C (32 °F), every

3 months, but at least every 3 000 km (1 800 miles)

)

*

BMW Inspection

at 1000 km

(600 miles)

BMW Service

every 10 000 km

(6 000 miles)

BMW Inspection

every 20 000 km

(12000 miles)

BMW

Annual Service

Change oil in gearbox while at operating temperature

at least every 2 years*

)

Change oil in rear wheel drive while at regular operating temperature;

if necessary, clean inductive sensor on rear wheel

every 40 000 km (24 000 miles) or at least every 2 years *

Renew fuel filter *

normally every 40 000 km (24 000 miles), if fuel quality is poor every 20000 km (12 000 miles)

)

)

Check battery acid level, if necessary add distilled water

Clean and grease the battery terminals, if necessary

Renew intake air filter element

in very dusty or dirty operating conditions, renew the intake air filter element every 10 000 km

(6 000 miles) or even more often if necessary

Renew Poly-V belt *

renew Poly-V belt every 60 000 km (36 000 miles); do not adjust

)

)

*

Check brake fluid level at front and rear

Check operation of brake system and freedom from leaks; repair/replace items if nec. *

Examine brake pads and discs for wear, renew if necessary *

)

Change the brake fluid annually

Check clutch fluid level

Change the clutch fluid

at least every 2 years *

)

Check tightness of rear wheel studs

Check rear wheel bearing play by tilting wheel

Check swinging arm bearings (zero play); adjust if necessary *

)

Grease the side stand pivot

Check function of side stand contact switch

Check condition of spark plugs

Renew spark plugs

Check security of cylinder head nuts

Check/adjust valve clearances

Check throttle cable for free movement, abrasion and kinking; renew if necessary *

Check cable play

Check synchronisation and eliminate leaks *

)

Final inspection with road safety and functional check:

– Condition of tyres and wheels, rims and spokes if applicable, tyre pressures

– Lights and signalling equipment

– Telltale and warning lights

– Clutch, gear shift

– Front and rear brakes, steering

– Instruments

– If necessary, test ride

)

*

Charged as an additional item

every

2years

40 000

(24 000)

40 000

(24 000)

60 000

(36 000)

)

)

every

2years

every

2years

UX-VS-2, 04.00 Printed in Germany

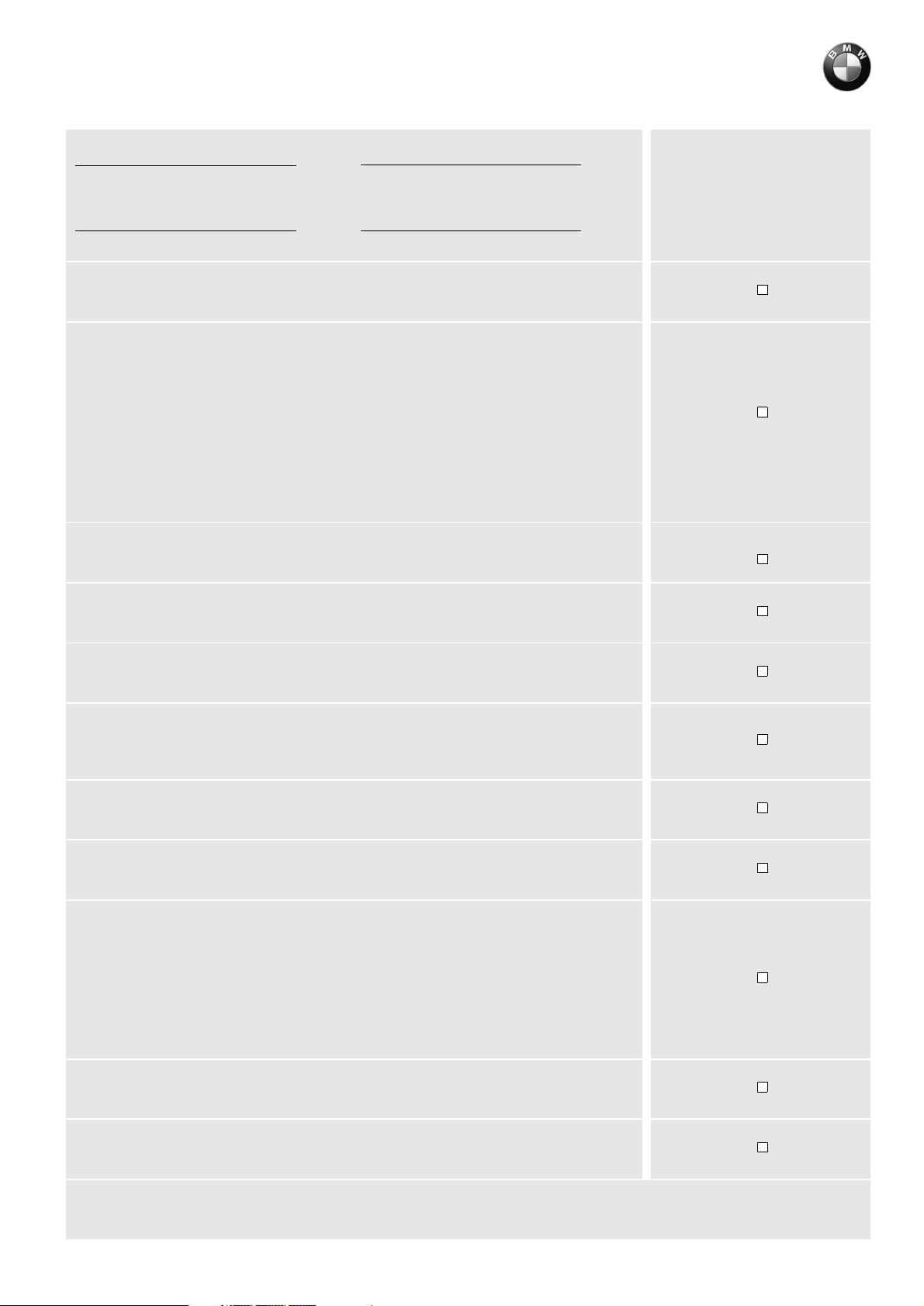

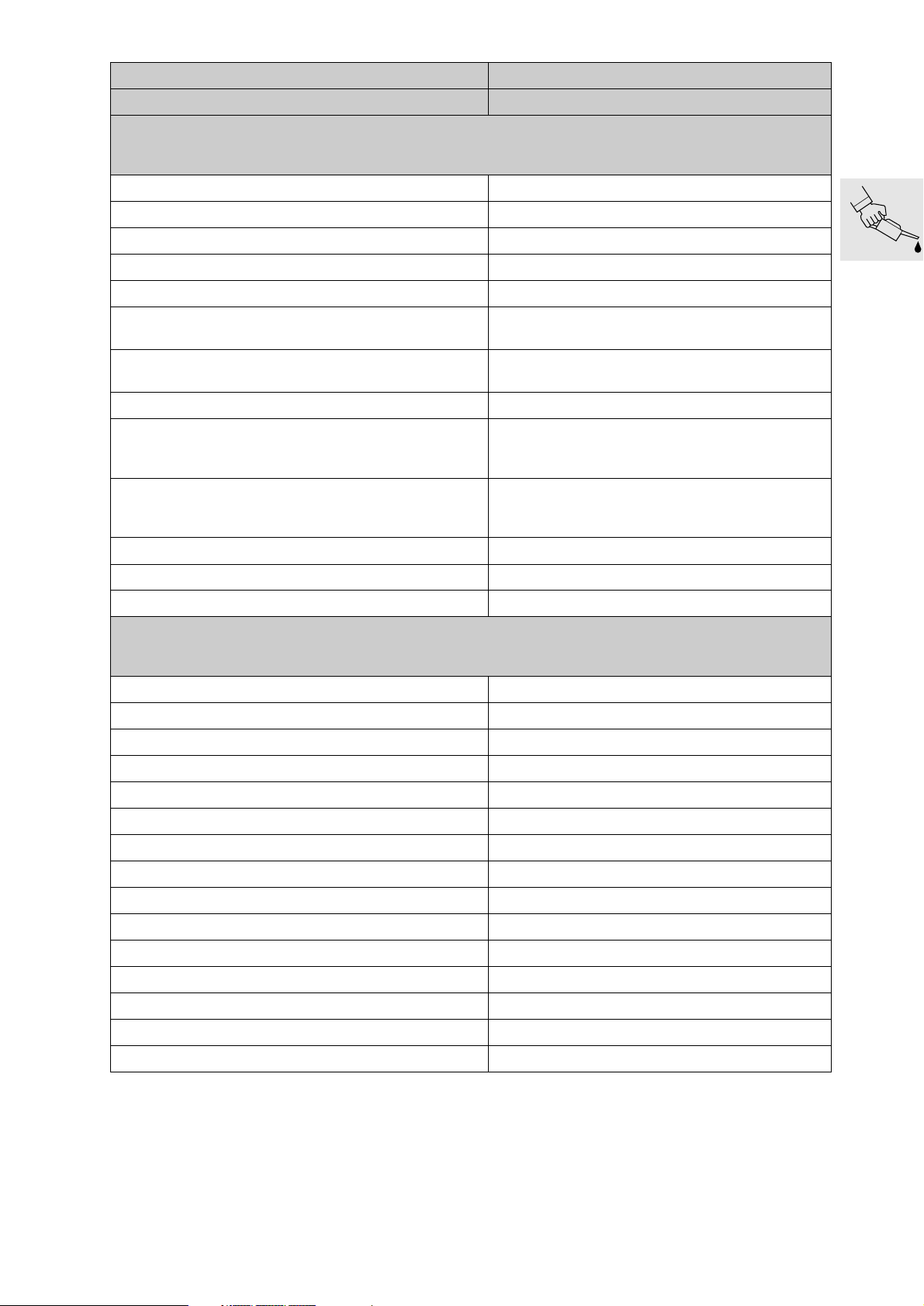

BMW Motorrad

Pre-delivery check

R 1100 S / R 850/1200 C / R 1150 GS

Customer Licence plate No.

Order No. Mechanic’s signature

Check the shipping crate for damage

Motorcycle:

– unpack

– install remaining items

– inspect for damage

– check that delivery is complete: tools

documentation

keys

correct optional extras

Fill and charge the battery (mark with charging date)

Check engine oil level when cold; add oil if necessary

BMW

Pre-delivery check

Check headlight beam angle, adjust if necessary

Check security of rear wheel studs

(comply with correct tightening torque)

Check tyre pressures

Fill fuel tank

Final inspection as functional check:

– Clutch, gear shift

– Front and rear brakes

– Lights and signalling equipment, telltale and warning lights, instruments

– Check operation of optional extras, ABS

– If necessary, test ride

Confirm pre-delivery check in Service and Technical Booklet

Final cleaning

Motorcycle handed over on:

UX-VS-2, 04.00 Printed in Germany

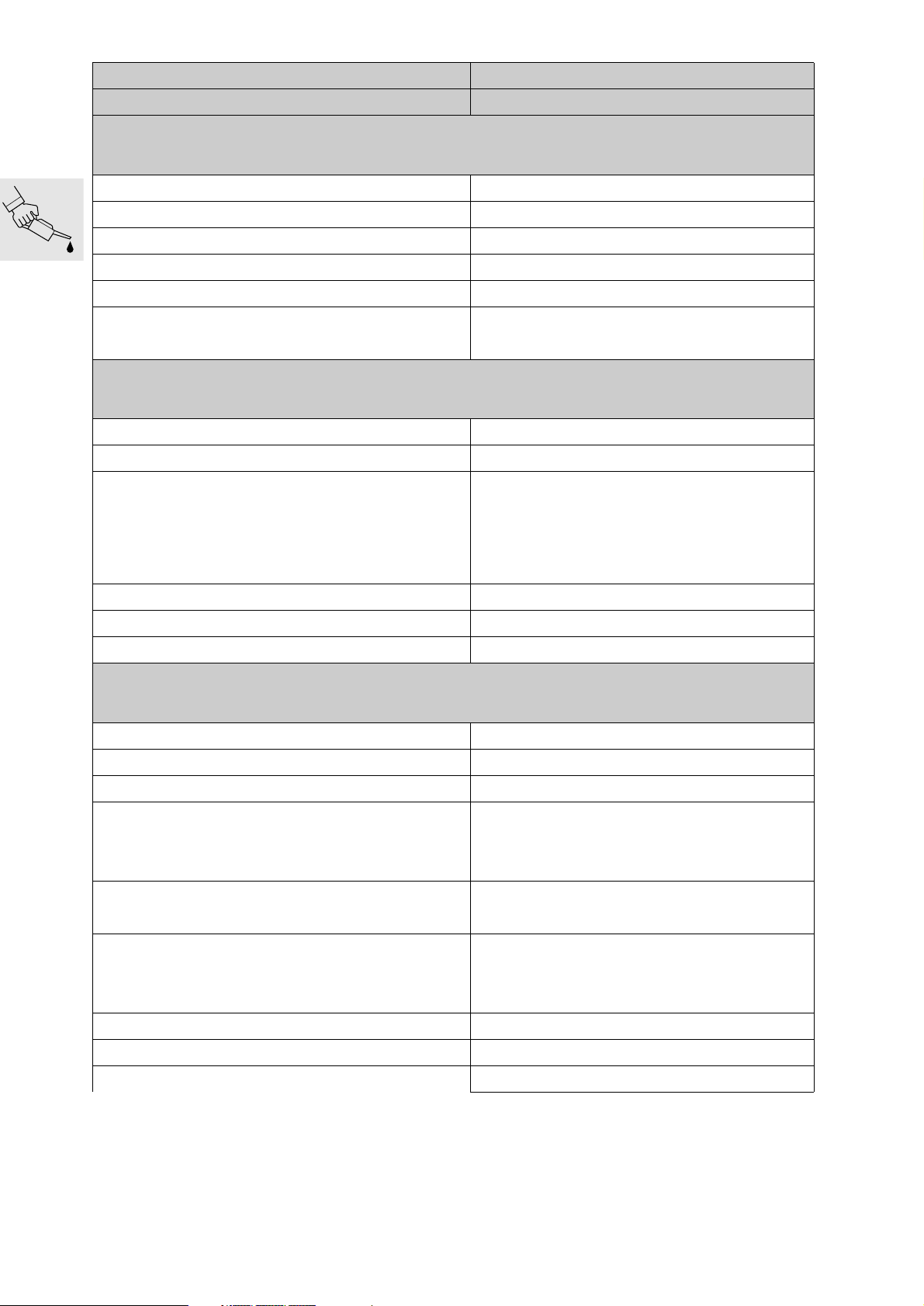

BMW Motorrad

Service data

R 1150 GS

Item Desired value Unit of measurement/

Oil capacities

Engine (with filter)

(without filter)

3.75 (6.60)

3.50 (6.16)

specification

litres (Imp. pints)

litres (Imp. pints)

Engine oil grade: brand-name HD oil for

four-stroke spark-ignition engines, API

classes SE, SF, SG; combination with CC

[SI 11 048 90]

or CD specification

Gearbox Initial filling/oil changes

Rear wheel drive Initial filling/oil changes

approx. 1.0 (1.76)

up to lower edge of

filler hole

approx. 0.25 (0.44)

oil level with bottom

of filler neck

Brand-name hypoid gear oil, SAE class

GL 5 SAE 90

litres (Imp. pints)

litres (Imp. pints)

Brand-name hypoid gear oil, SAE class

GL 5 SAE 90

Valve clearances

Measured cold (max. 35 °C/95 °F)

Inlet: 0.15 (0.006)

Exhaust: 0.30 (0.011)

mm (in)

mm (in)

Ignition timing

Static setting

adjust at TDC

Spark plugs

Electrode gap

Wear limit

Idle speed

0.8 (0.03)

1.0 (0.04)

1100±

50

mm (in)

mm (in)

min

Throttle cable setting

for cold-start (increased idle) speed

for throttle (twistgrip) cable

for divider cable

Brakes

Minimum front pad thickness

Minimum rear pad thickness

Minimum front disc thickness

Minimum rear disc thickness

Tyre pressures

depending on load

zero play

app. 0.5 (0.02)

zero play

1.0 (0.04)

wear mark

4.5 (0.18)

4.5 (0.18)

front: 2.2 – 2.5

(31.3 – 35.6)

mm (in) free travel

DOT 4 brake fluid

mm (in)

mm (in)

mm (in)

bar (psi)

rear: 2.5 – 2.9

(35.6 – 41.2)

bar (psi)

Tightening torques:

Oil filter

Engine oil drain plug

Gearbox oil filler plug

Gearbox oil drain plug

11

32

30

30

Nm

Nm

Nm

Nm

Rear wheel drive oil filler/drain plug 23 Nm

Fuel tank to rear frame

Fuel pump unit to tank

Poly-V belt preload

Alternator to alternator carrier cover

21

6

8

20

Nm

Nm

Nm

Nm

Brake calliper mounting, front/rear 40 Nm

Rear wheel studs initial torque 72

105

Tightening cylinder heads Nut

slacken/20

180

M 10 screw

slacken/40

° tightening angle

Nm

Nm

Nm

Nm

Locknut, valve adjusting screw 8 Nm

Cylinder head cover 8 Nm

Spark plugs 20 Nm

-1

Order No. 01 71 0 008 851 UX-VS-2, 06.99 Printed in Germany

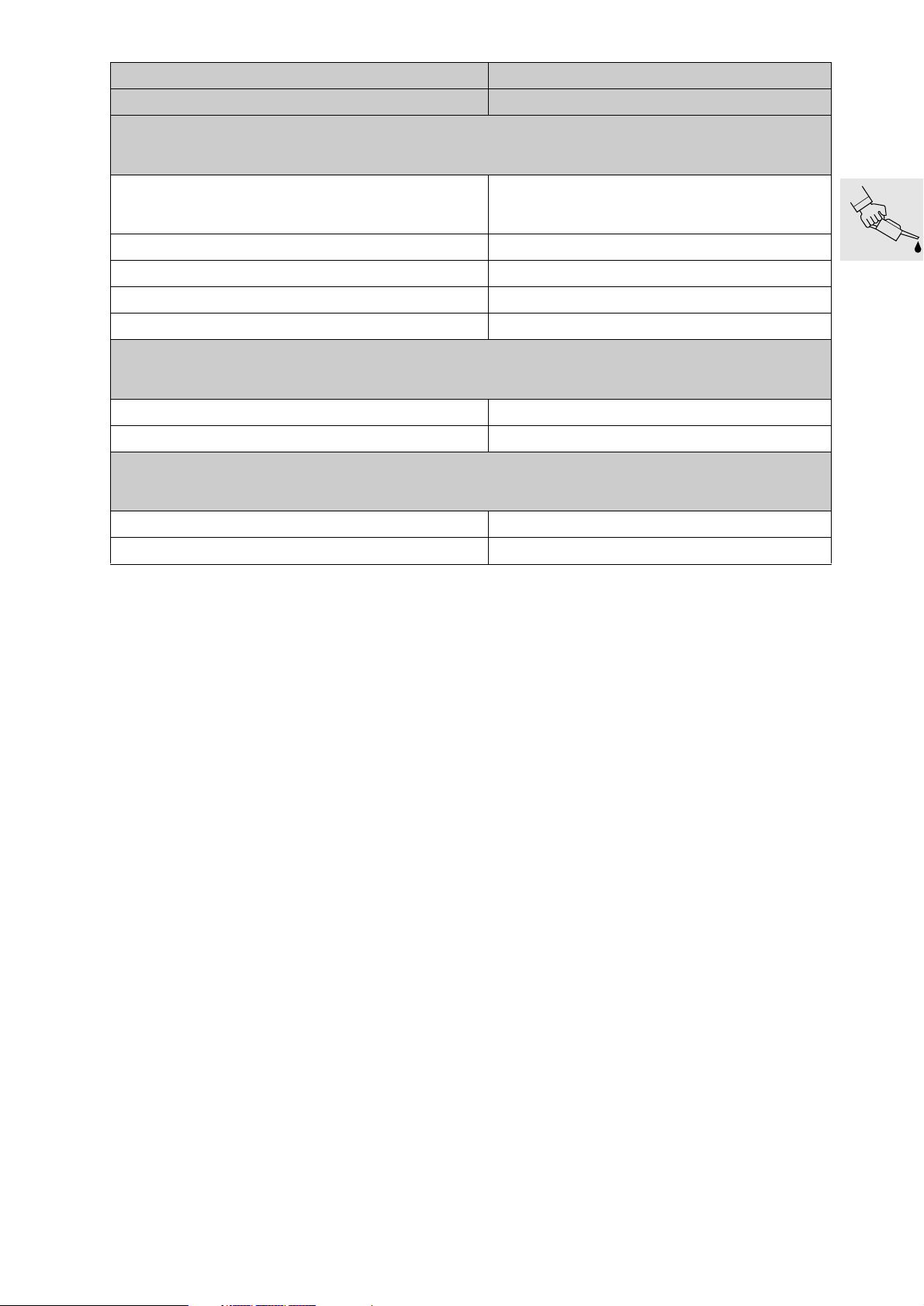

General table of contents

<< Back

Group / Section

Group / Section

00 Maintenance and general instructions

11 Engine

12 Engine electrics

13 Fuel preparation and control

16 Fuel tank and lines

18 Exhaust system

21 Clutch

23 Transmission

31 Front forks

32 Steering

33 Rear wheel drive

>> Next

Group / Section

Group / Section

34 Brakes

36 Wheels and tyres

46 Frame

51 Equipment

52 Seat

>> Next

61 General electrical equipment

62 Instruments

63 Lights

<< Back

00

00 Maintenance and general instructions

Tightening torques and table of consumables

Pre-delivery check

Maintenance

Contents Page

Tightening torques .......................................................................................................................5

Table of operating fluids .........................................................................................................12

00.1

P

re-delivery chec

k

Contents - Pre-delivery check Page

Pre-delivery check .....................................................................................................................13

General view of crated motorcycle ...................................................................................13

Check the shipping crate for damage ............................................................................14

In case of damage in Germany ...............................................................................................14

In case of damage in importer markets ..............................................................................14

Unpacking the motorcycle ....................................................................................................14

Inspecting motorcycle for damage ...................................................................................15

Checking that delivery is complete ..................................................................................15

Installing remaining items on motorcycle .....................................................................16

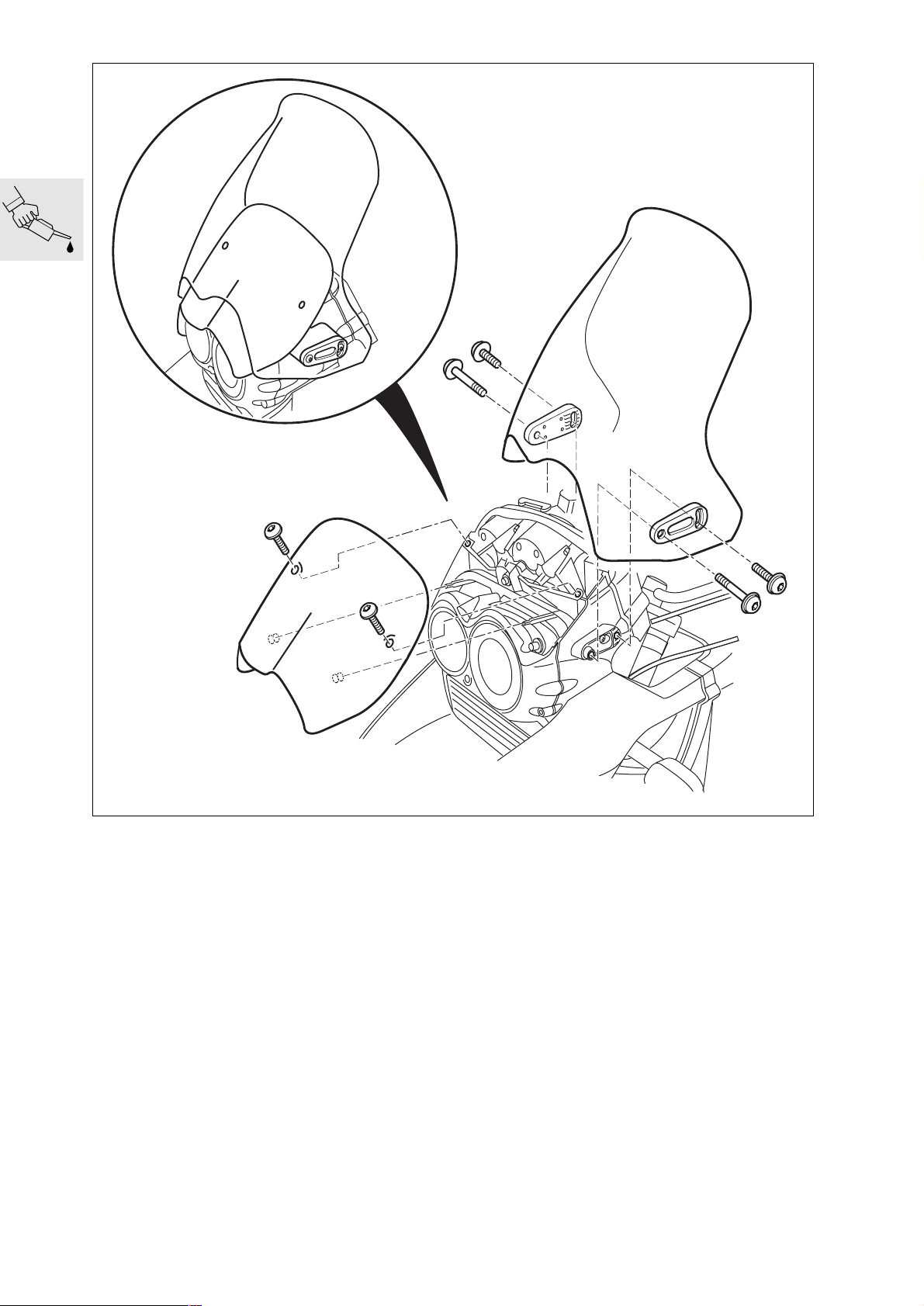

Install the windscreen .................................................................................................................16

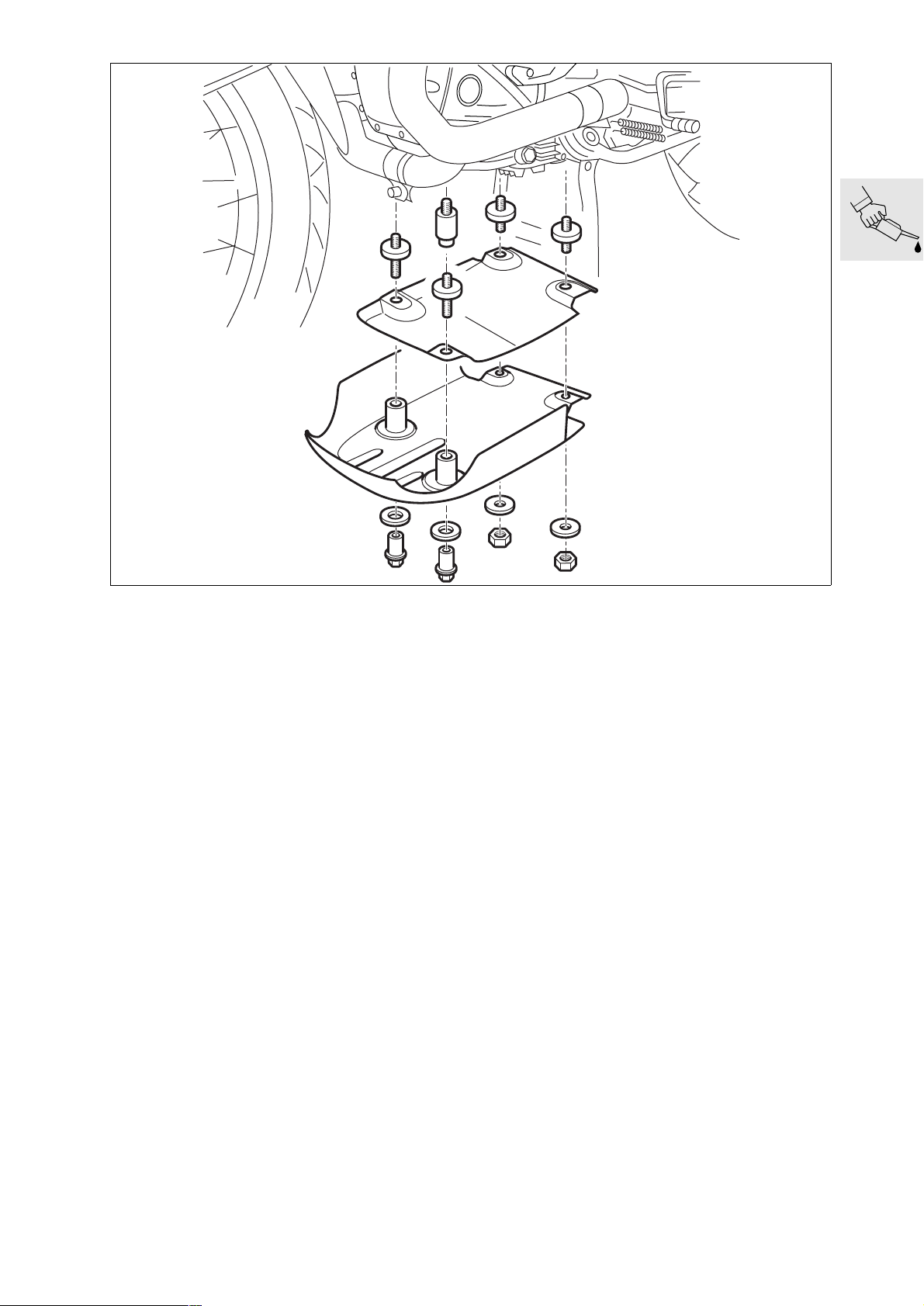

Installing sump guard ..................................................................................................................17

Filling and charging the battery ..........................................................................................18

Disengaging and raising the fuel tank .................................................................................18

Filling and charging the battery ..............................................................................................18

Checking engine oil when engine is cold, topping up if necessary ...............19

Checking headlight beam angle, adjusting if necessary ......................................20

Checking tightness of rear wheel studs ........................................................................20

Checking tyre pressures ........................................................................................................20

Attaching adhesive label ........................................................................................................20

Final inspection and function check ................................................................................21

Final cleaning ...............................................................................................................................21

Handing over the motorcycle ...............................................................................................21

00.2

Maint

enance

Contents - Maintenance Page

Maintenance ..................................................................................................................................22

Key to maintenance intervals ..............................................................................................22

Reading out MoDiTeC fault memory ................................................................................22

(Inspections I, II, III and IV)

Changing engine oil, replacing oil filter element ......................................................22

(Inspections I, II, III and IV)

Changing oil in gearbox ..........................................................................................................23

(Inspections III and IV)

or at the latest every 2 years

Changing the oil in the rear wheel drive ........................................................................23

(Inspections I, III and IV)

Every 40,000 km (24,000 miles) or at the latest every 2 years

Replacing fuel filter ...................................................................................................................24

(Inspection III)

In normal operating conditions every 40,000 km (24,000 miles); if fuel quality is poor every

20,000 km (12,000 miles)

Checking battery fluid level and topping up if necessary; cleaning and

greasing the battery posts ....................................................................................................26

(Inspections III and IV)

Replacing intake air filter element ....................................................................................26

(Inspection III)

In very dirty and dusty operating conditions, replace every 10,000 km (6,000 miles) or even

more frequently if necessary

Replacing Poly-V belt ...............................................................................................................27

(Inspection III)

(every 60,000 km/36,000 miles)

Checking brake system for correct operation and freedom from leaks;

repairing/replacing if necessary ........................................................................................28

(Inspection III)

Checking brake fluid level .....................................................................................................28

(Inspections II and III)

Front brake .......................................................................................................................................28

Rear brake ........................................................................................................................................28

Checking brake pads and discs for wear/replacing ...............................................29

(Inspections II and III)

Checking front brake pad wear ..............................................................................................29

Checking rear brake pad wear ................................................................................................29

Checking brake disc wear ........................................................................................................29

Replacing brake pads, front brake ........................................................................................30

Replacing brake pads, rear brake .........................................................................................30

00.3

Contents - Maintenance Page

Changing brake fluid and bleeding brake system ....................................................31

Change the brake fluid annually

(Inspection IV)

Bleeding front brake circuit/changing brake fluid ...........................................................31

Additional information for [ABS]

Bleeding rear brake circuit/changing brake fluid ............................................................33

Checking clutch operating fluid level ..............................................................................34

(Inspections II and III)

Changing the clutch fluid .......................................................................................................34

(Inspections IV)

at the latest every 2 years

Checking tightness of rear wheel studs ........................................................................35

(Inspection I)

Checking rear wheel bearing play by tilting wheel ..................................................35

(Inspection III)

Checking swinging arm bearings, adjusting if necessary ...................................35

(Inspections I and III)

Greasing the side stand pivot ..............................................................................................36

(Inspections I, II and III)

Checking function of side stand contact switch ......................................................36

(Inspections I, II, III and IV)

Checking/replacing spark plugs ........................................................................................36

(Inspection II) check/(Inspection III) replace

Tightening cylinder heads .....................................................................................................37

(Inspection I)

Checking/adjusting valve clearances .............................................................................37

(Inspections I, II and III)

Checking freedom of throttle cable, checking for chaffing and kinks,

replacing if necessary

Checking throttle-cable play

Checking and adjusting idle speed and throttle-valve synchronisation ...... 38

(Inspections I, II and III)

Final inspection with road safety and functional check .......................................39

(Inspections I, II, III and IV)

Road safety check

Roadworthiness check

00.4

00

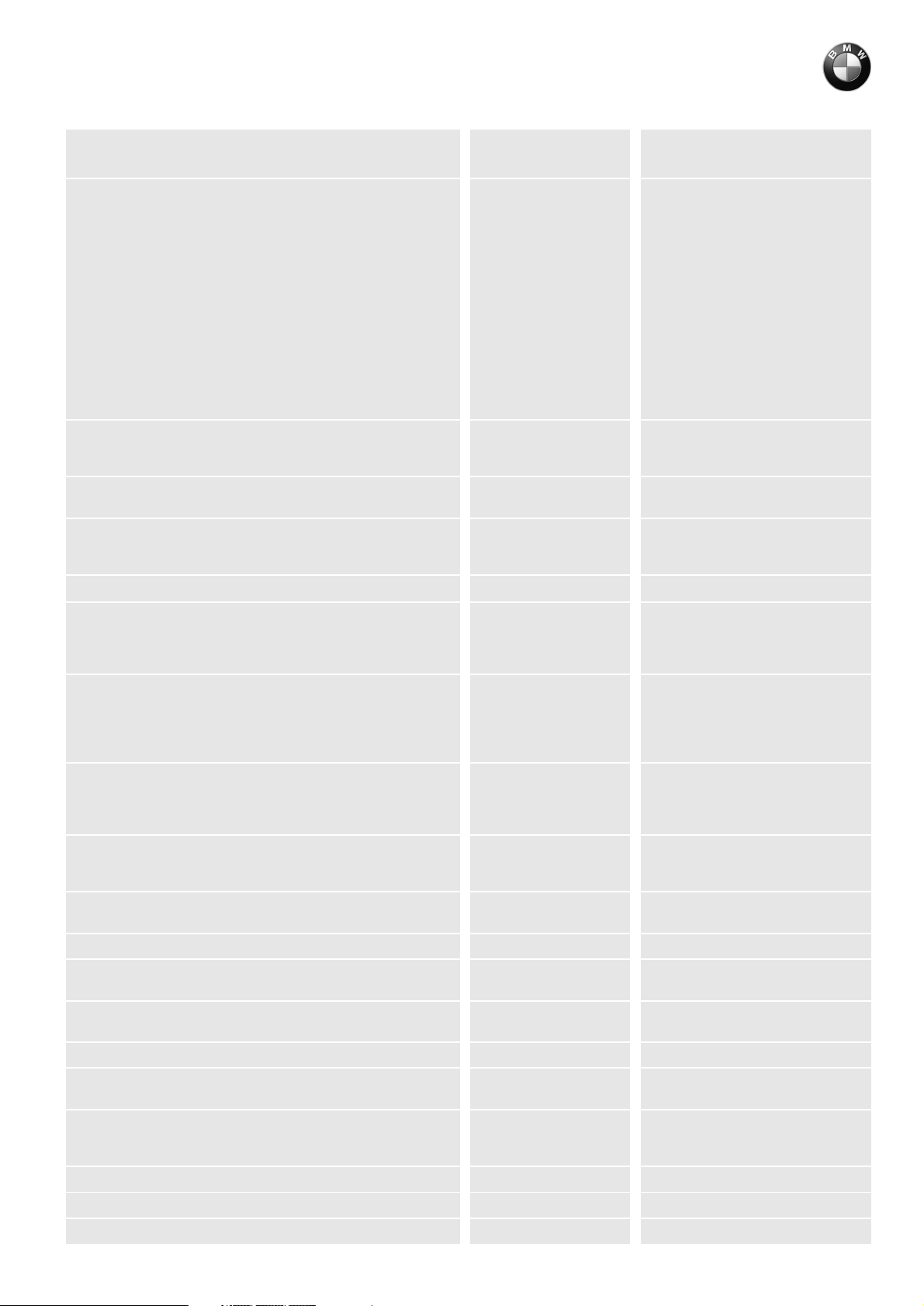

Tightening torques

Model R 1150 GS

Connection Nm

11 Engine

Cylinder head

Tightening sequence:

1. Tighten cylinder head nuts (oiled) in diagonally

opposite sequence

1.1 Tighten all nuts to closing torque 20

1.2 Tighten all nuts to correct angle 90°

1.3 Tighten all nuts to correct angle 90°

2. M 10 screw 40

3. M 6 screw 9

After 1,000 km (600 miles), tighten cylinder head nuts

in diagonally opposite sequence:

1. Slacken one nut

2. Tighten nut to initial torque 20

3. Tighten nut to wrench angle 180°

4. Slacken and retighten M 10 screw 40

Timing gear carrier to cylinder head

Bearing cap on rocker shaft 18

Locknut, valve adjusting screw 8

Cylinder head cover to cylinder head 8

Camshaft end cover to cylinder head

Air intake connection to cylinder head

Camshaft

Chain sprocket to camshaft 65

Camshaft bearing cap 15

Alternator mount cover

M 6 screw 9

M 8 screw 20

Auxiliary shaft

Chain sprocket to crankshaft 10

9

9

9

Chainwheel to auxiliary shaft 70

Chain tensioner housing to engine block 9

Oil filter

Oil filter 11

Oil drain plug 32

00.5

Model R 1150 GS

Connection Nm

11 Engine

Oil pump

Mesh filter basket to engine block 10

Oil pump cover 9

Pressure relief valve 42

Oil pressure switch 30

Oil cooler

Cooling oil line to engine block 10

Cooling oil line - banjo screw with oil vent valve 25

Oil lines to oil cooler 25

Oil cooler to bracket 9

Oil cooler return line to engine block 35

Oil cooler connection to crankcase 9

Cylinders

Tightening sequence:

1. M 8 screw 20

2. M 6 screw 9

3. Chain guide rail pivot screw 18

Timing chain

Chain tensioner 32

Connecting rod

Big end cap Closing torque 20

Wrench angle 80°

Crankcase

Tightening sequence:

M 10 screw (oiled) Initial torque 25

Wrench angle 90°

M 8 screw (oiled) 22

M 6 screw 9

12 Engine electrics

Starter motor to engine 20

Starter cover to gearbox housing 7

Positive lead to starter motor 10

Alternator to alternator support cover 20

Tensioning and retaining link to alternator 21

00.6

Model R 1150 GS

Connection Nm

12 Engine electrics

Spacer to alternator 21

Positive lead to alternator 15

Belt pulley to alternator

Standard alternator 560 W

Special alternator 700 W

Belt pulley to crankshaft 50

Poly-V belt preload 8

Spark plug 20

13 Fuel preparation and control

Temperature sensor, oil, in crankcase 25

Temperature sensor, air, in air-filter housing 10

16 Fuel tank and lines

Do not release

50

Fuel tank to rear frame 21

Fuel pump assembly to tank 6

18 Exhaust system

Manifold to cylinder head 21

Clamp for manifold 45 (apply Optimoly TA to clamp seat)

Front silencer to manifold 45 (apply Optimoly TA to clamp seat)

Front silencer to main-stand link 20

Silencer to rear frame at top 35

Oxygen sensor to silencer 45 (apply Optimoly TA to thread)

End cap to rear silencer 8 (threads greased)

Bracket to rear silencer 15 (threads greased)

21 Clutch

Clutch housing Closing torque

Wrench angle 32°

Housing cover to housing 12

40 (oil screw threads lightly)

Clutch line to handlebar fitting 14

Slave cylinder to gearbox 9

Grub screw in filler adapter 10

00.7

Model R 1150 GS

Connection Nm

23 Transmission

Oil drain plug 30

Oil filler plug 30

Gearbox to engine block 22

Shift lever to footrest plate 35

Selector lever to selector shaft 9

Housing cover to housing 9

Frame tube to gearbox

1. to gearbox and left footrest plate 42 (clean thread + Loctite 243)

2. clamp block, frame tube to gearbox 9

3. to gearbox and right footrest plate 42 (clean thread + Loctite 243)

31 Front forks

Quick-release axle clamp screws 22

Fastener, fixed tube and fork bridge 45 (free from oil and grease)

Slider tube bridge to slider tube 25 (clean thread + Loctite 243)

Threaded stud to frame 130 (clean thread + Loctite 243)

Ball joint to fork slider bridge 230 (apply light coat of Never Seeze to thread)

Leading link to ball joint 130 (clean thread + Loctite 2701)

Leading link to engine right 73

Screw cap to leading link left 42 (apply light coat of Never Seeze to thread)

Suspension strut to front frame

Spring strut to leading link

32 Steering

Handlebar to fork bridge 21

Handlebar weight to handlebar 21

Pivot screw, handlebar lever 11 (Tuflok Blue thread-locking compound; screw

43

50

can be released and tightened a number of times)

00.8

Model R 1150 GS

Connection Nm

33 Rear wheel drive

Oil filler plug 23

Oil drain plug 23

Threaded ring 160 (clean thread + Loctite 577)

Hexagon nut, input bevel gear

Cover to rear-wheel drive housing 35

Fixed bearing stud, swinging arm to

gearbox/rear axle housing 160 (clean thread + Loctite 2701)

Floating bearing stud, swinging arm to

gearbox/rear axle housing 7 (clean thread + Loctite 2701)

Locknut of floating bearing stud bolt 160

Reaction link to rear wheel drive 43

Reaction link to gearbox 40

Spring strut to rear frame 50

Spring strut to rear swinging arm 58 (clean thread + Loctite 243)

Hydraulic spring preload adjuster to footrest plate 22

34 Brakes

Brake caliper to fork slider tube 40

Brake caliper to rear wheel drive 40

200 (clean thread + Loctite 2701)

(load approx. 85 kg (187 lbs) onto motorcycle and

tighten loose reaction link)

(load approx. 85 kg (187 lbs) onto motorcycle and

tighten loose reaction link)

Brake disc to front wheel 24 (clean thread + Loctite 243)

Brake disc to rear wheel drive 21 (clean thread + Loctite 243)

Master cylinder to footrest assembly 9

Footbrake lever to footrest assembly

Footbrake-lever stop

Brake lines/brake hose to brake components

Brake hose to bracket 9

Brake hose to brake lever fitting 18

Hose bracket to helmet lock 9

Bracket to front frame 9

Bracket to rear frame 9 (clean thread + Loctite 2701)

Bracket to fork bridge 5 (clean thread + Loctite 2701)

ABS sensor 4 (handtight)

21

9

18

00.9

Model R 1150 GS

Connection Nm

34 Brakes

Front brake caliper bleed screw

Rear brake caliper bleed screw

Pressure modulator bleed screw 14

Filler adapter in brake caliper

Grub screw in filler adapter

ABS unit to holder

M 6 screw 8 (clean thread + Loctite 243)

36 Wheels and tyres

Quick-release axle clamp screws 22

Quick-release axle threaded fastener 30

Rear wheel to rear-wheel drive

Hand-tighten wheel studs, then tighten in diagonally

opposite sequence

Initial tightening 72

Final tightening 105

Sensor ring to front/rear wheel 4 (hand tight, clean threads + Loctite 2701)

Spoke nipple 3.5 + 2

Grub screw 1.1

14

6

18 (clean thread + Loctite 243 or new filler adapter)

10

46 Frame

Frame to engine 82

Struts to frame 58

Struts to engine 58 (clean thread + Loctite 2701)

Rear frame to gearbox/engine

to gearbox and footrest plate 42 (clean thread + Loctite 243)

to engine 42

Carrier plate for main stand to engine, right

M 12 screw 72 (clean thread + Loctite 2701)

Pivot mount to engine, left

M 12 screw 72 (clean thread + Loctite 2701)

M 8 screw 21

Pivot mount of main (centre) stand (stud bolt) 21 (clean thread + Loctite 243)

Pivot mount of main (centre) stand (machine screw) 21

Side stand to pivot mount 58 (clean thread + Loctite 2701)

00.10

Model R 1150 GS

Connection Nm

46 Frame

Footrest plate to gearbox/

Rear footrest plate to rear frame

M 8 screws 21

Fairing bracket to front frame 21

Front carrier to fairing bracket 8

Mudguard at bottom to slider tube 4 (clean thread + Loctite 2701)

Mudguard at bottom to slider tube bridge 5 (clean thread + Loctite 2701)

51 Equipment

Mirrors 10

Ignition/steering lock to fork bridge 20 (micro-encapsulated)

61 General electrical equipment

Horn to holder 10 (clean thread + Loctite 243)

Ground (earth) strap to engine block 9

00.11

Table of operating fluids

Item Use Order number Quantity

Lubricant

Staburags NBU 30 PTM High-performance lubricating paste 07 55 9 056 992 75 g tube

Optimoly MP 3 High-performance lubricating paste 07 55 9 062 476 100 g tube

Optimoly TA High-temperature assembly paste 18 21 9 062 599 100 g tube

Silicone grease 300, heavy Damping grease 07 58 9 058 193 10 g tube

Retinax EP2

Contact spray Contact spray 81 22 9 400 208 300 ml spray

Chain spray Drive chain

Sealants

3-Bond 1110 B Surface sealant 07 58 9 056 998 5 g tube

3-Bond 1209 Surface sealant 07 58 9 062 376 30 g tube

OMNI VISC 1002 Surface sealant 07 58 1 465 170 90 g tube

Loctite 574 Surface sealant 81 22 9 407 301 50 ml tube

Loctite 577 Thread locking compounds 07 58 2 328 736 5 g tube

Curil K 2 Heat-conductive sealant 81 22 9 400 243 250 g can

Adhesives and retaining agents

Loctite 648 Joint adhesive (low clearance) 07 58 9 067 732 5 g bottle

Loctite 638 Joint adhesive (greater clearance) 07 58 9 056 030 10 ml bottle

Loctite 243 Thread retainer, medium-strength 07 58 9 056 031 10 ml bottle

Wheel, steering head and taper roller

bearing grease

83 22 9 407 845 100 g tube

72 60 2 316 676

72 60 2 316 667

50 ml spray

300 ml spray

Loctite 270 Thread retainer, strong 81 22 9 400 086 10 ml bottle

Loctite 2701 Thread retainer, strong 33 17 2 331 095 10 ml bottle

Loctite 454 Cyanacrylate adhesive (gel) 07 58 9 062 157 20 g tube

Cleaners

Brake cleaner Brake cleaner 83 11 9 407 848 600 ml spray

Metal Polish Polish for chrome-plated parts 82 14 9 400 890 100 g tube

Testing agents

Penetrant MR 68

Developer MR 70

Installation aids

BMW cooling spray Cooling spray 83 19 9 407 762 300 ml spray

Crack testing agent for aluminum

housings

Crack testing agent for aluminum

housings

83 19 9 407 855 500 ml spray

81 22 9 407 495 500 ml spray

00.12

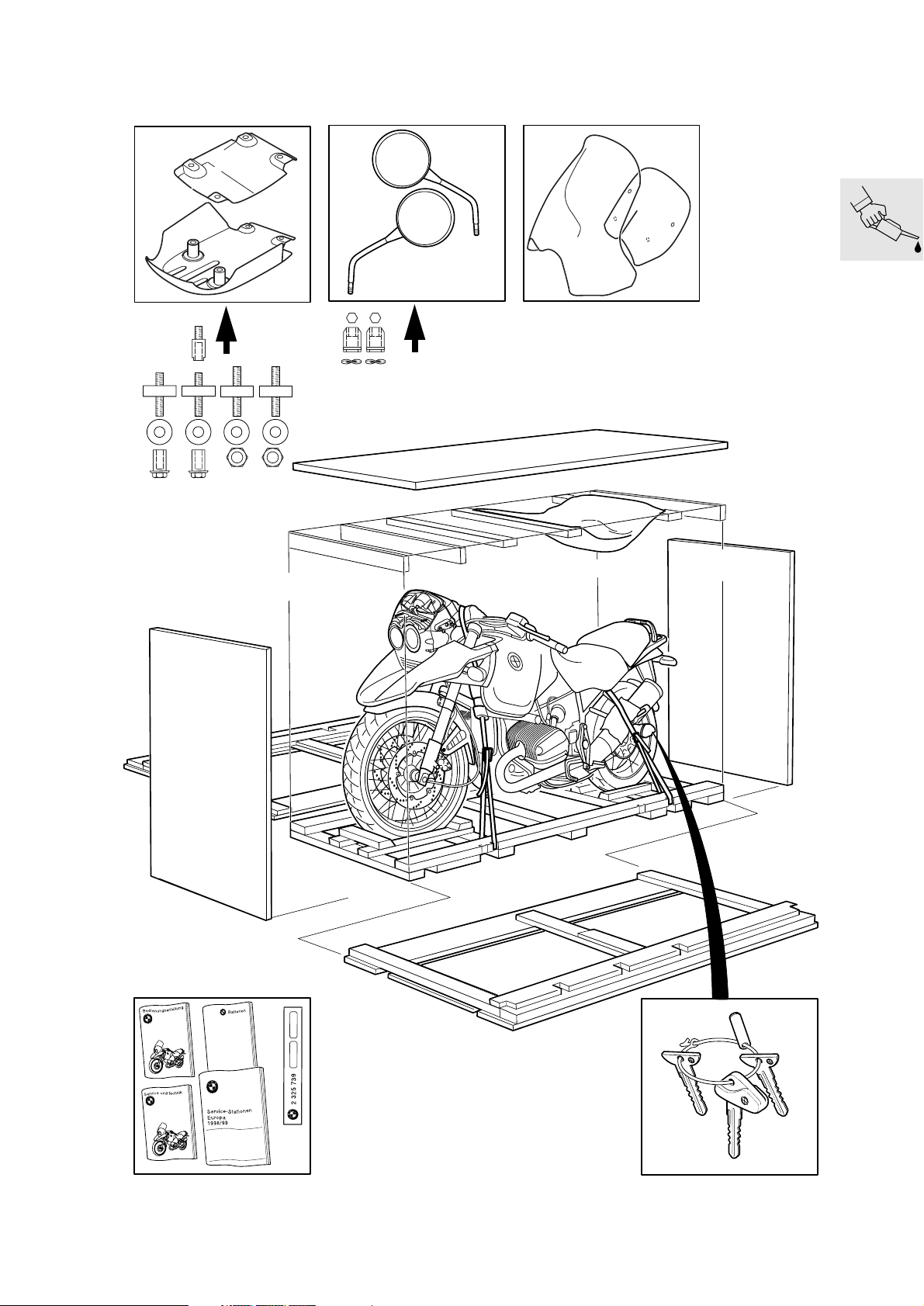

Pre-delivery check

General view of crated motorcycle

00.13

Check the shipping crate for

damage

When the motorcycle arrives, check the packing

•

material immediately for damage and, if necessary, examine the contents for consequential

damage.

In case of damage in Germany

Unpacking the motorcycle

Lever off the cover.

•

Take out the separate pack of items:

•

– Documentation

– Windscreen

– Sump guard with fasteners

Force off cross-struts with a suitable lever.

•

Note the damage on the delivery slip.

•

Read the information sheet on damage in transit.

•

Notify the supplier without delay

•

(e.g. freight company or DB) and also

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

D-80788 München

Tel. 089/14327-632

Fax. 089/14327-709

In case of damage in importer markets

Note the damage on the delivery slip.

•

Comply with specific national market proce-

•

dures.

In case of doubt, please submit enquiries to:

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

D-80788 München

Tel. +49 (0)89 14327-632

Fax. +49 (0)89/14327-709

Notify the supplier (e.g. freight company) without

•

delay.

e Caution:

Do not knock the cross-struts out or the motorcycle

may be damaged.

Remove the end-walls.

•

Remove the side-walls.

•

e Caution:

Remove any nails projecting from the base of the

packing or lying on the base or on the floor.

Loosen the front tensioning straps.

•

Release the handlebar and resecure in correct

•

position (punch marks aligned).

e Caution:

Do not push the motorcycle until the handlebar has

been secured in the correct position.

X Tightening torque:

Handlebar to fork bridge .............................. 21 Nm

Loosen the rear tensioning straps.

•

Push the motorcycle forwards off the pallet.

•

Remove the set of keys from the left rear footrest.

•

Dispose of the packing materials in an environ-

•

mentally responsible manner as described in

Service Information 23/91 - Sales - .

00.14

Inspecting motorcycle for damage

Check for defects.

•

Use the “express handling service” to notify

•

BMW Motorrad, UX-VS-1

Fax: +49 (0)89 382 33220

Rectify the fault.

•

If parts are needed, order them through the usual

•

channel.

Costs are to be processed by the warranty claim

•

system (stage 4). Defect codes:

– Parts missing 10 01 00 00 00

– Parts damaged 10 02 00 00 00

– Incorrect parts delivered 10 03 00 00 00

Checking that delivery is complete

– All optional extras

– Toolkit

– Documentation

00.15

Installing remaining items on

motorcycle

Install the windscreen

Carefully tighten the securing screws by hand.

•

00.16

R21000070

Installing sump guard

Install the spacer bushing at the front left.

•

X Tightening torque:

Bushing to engine block............................... 20 Nm

Install the front rubber mounts with the long

•

thread down.

Install the rear rubber mounts.

•

Install the inner plate with the outer guard.

•

R21000080

00.17

R21000100

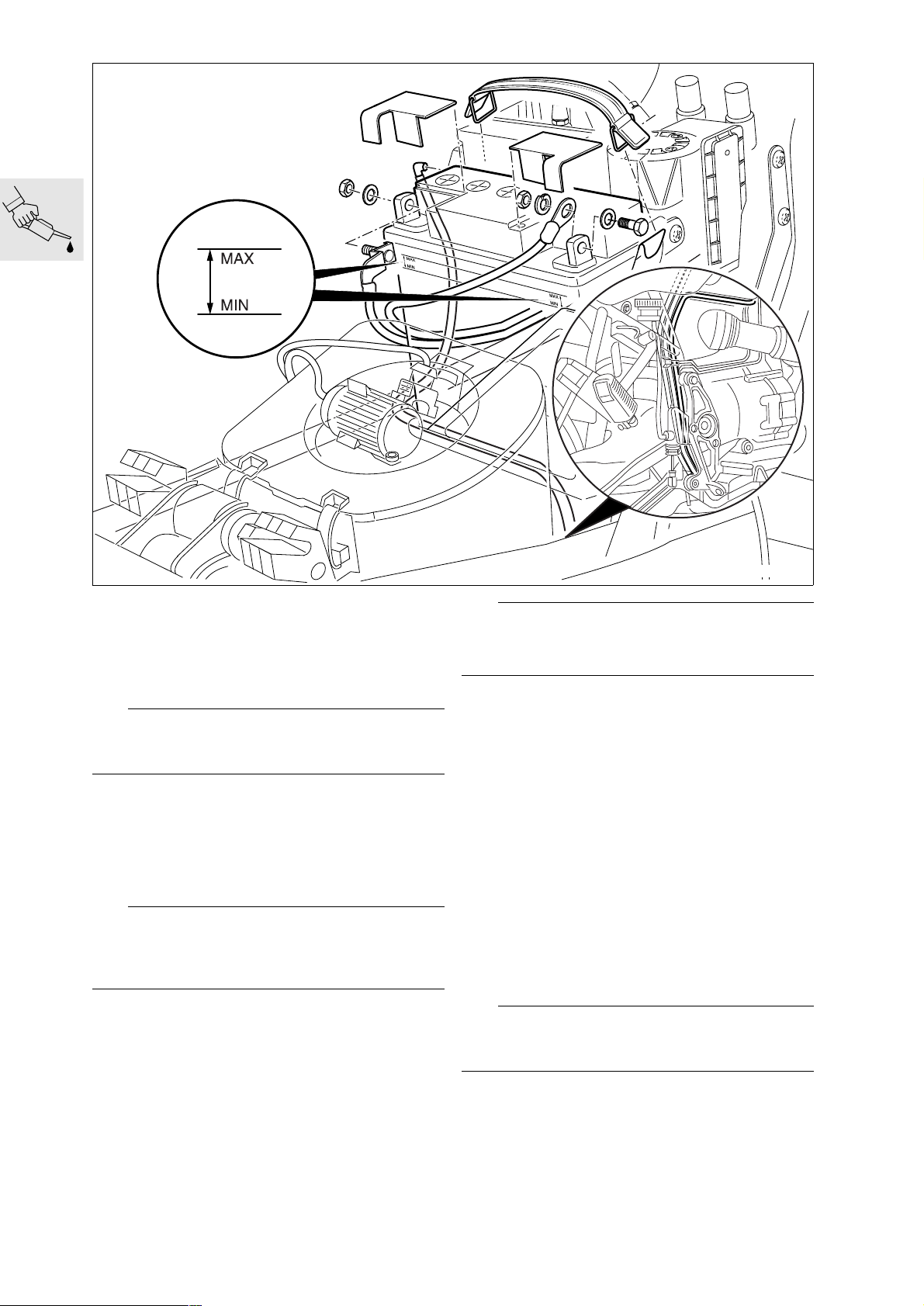

Filling and charging the battery

Disengaging and raising the fuel tank

Remove seat.

•

Remove right side trim.

•

e Caution:

Fuel is flammable and a hazard to health. Observe

relevant safety regulations.

Remove the fastener securing the fuel tank at the

•

rear right.

Raise the rear of the fuel tank and prop it in this

•

position on a wooden block or similar.

Filling and charging the battery

d Warning:

Battery acid is highly caustic.

Protect your eyes, face, hands, clothing and the

paintwork.

Disengage the rubber strap holding the battery.

•

Disconnect the battery breather hose.

•

Remove the battery.

•

Fill all the cells with pure battery acid of

•

density 1.28 to the upper mark.

Allow the battery to stand for approximately

•

30 minutes.

The battery does not achieve full charge capacity

•

from being filled, so it has to be charged with a

battery charger.

L Note:

Follow the instructions for use supplied with the battery charger.

Charge current (amps)

.........................10 % of rated battery capacity (Ah)

Charging time

..............................................................5-10 hours

Battery charge can be measured by checking

•

the density of the battery acid.

Acid density

Battery fully charged .......1.26-1.30 at 20 °C (68 °F)

Shake the battery slightly to allow the gas bub-

•

bles to escape.

Wait until the battery acid has settled, check that

•

no more bubbles rise and if necessary, top up

the acid to the max. mark.

Reinstall the plugs.

•

Make a note of the charging date on the battery.

•

e Caution:

Connect the positive battery terminal first, then the

negative terminal.

Install the battery.

•

Apply acid-proof grease to the battery terminal

•

posts.

Connect the battery breather line.

•

Secure the fuel tank in position.

•

Install the right side trim panel.

•

Install the seat.

•

00.18

Switch on the ignition.

•

Without starting the engine, fully open the throttle

•

once or twice so that the Motronic control unit

can register the throttle-valve positions.

L Note:

Disconnecting the battery deletes all entries (e.g.

faults, settings) stored in the Motronic control unit’s

memory.

Loss of settings can temporarily impair the operating characteristics when the engine is restarted.

Checking engine oil when engine is cold, topping up if necessary

MAX

X Tightening torque:

Fuel tank to frame ........................................ 21 Nm

MIN

S000040

Check oil level with the motorcycle upright.

•

e Caution:

Never top up the engine-oil level past the “MAX”

mark.

Required level:............................................... MAX

00.19

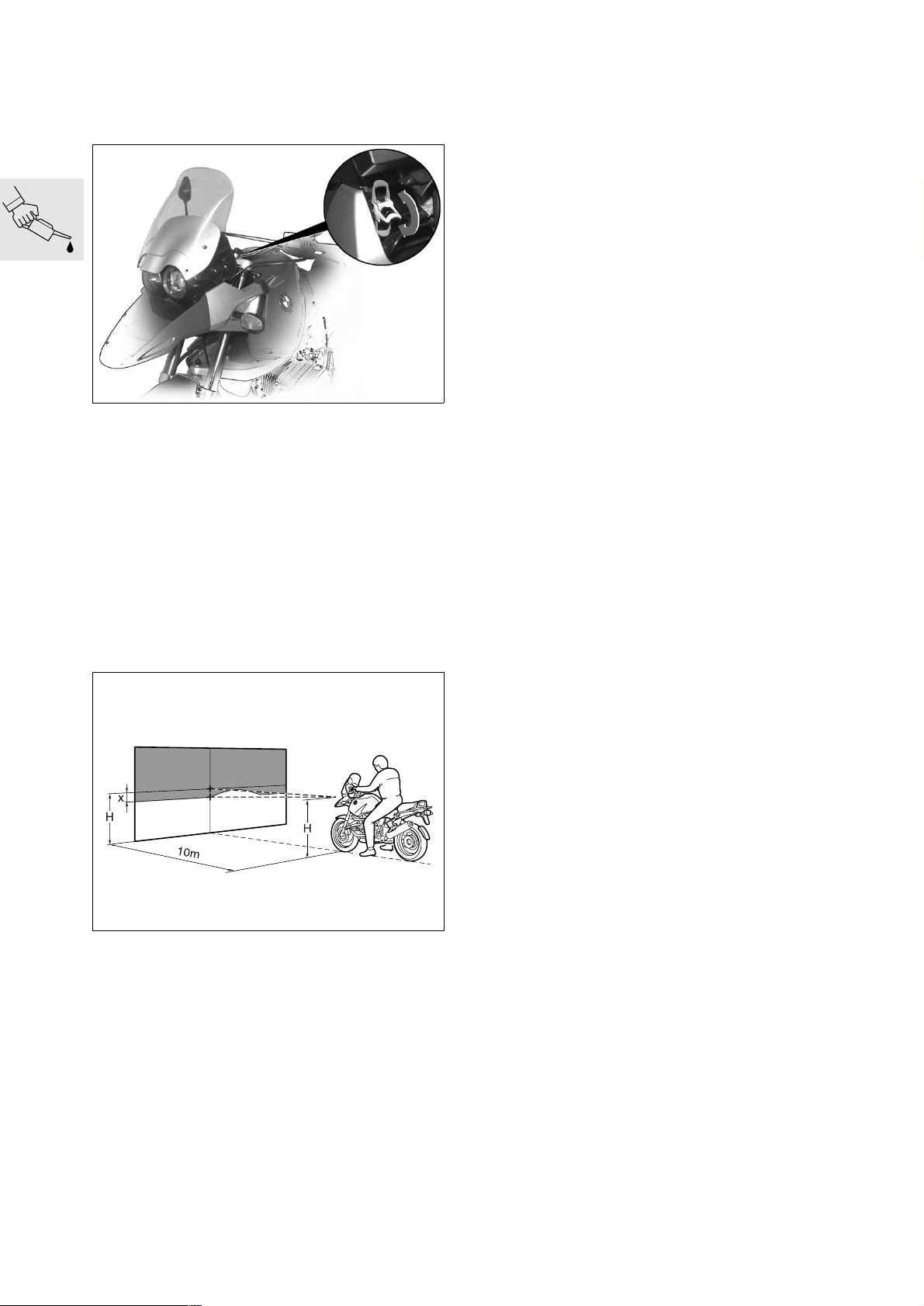

Checking headlight beam angle, adjusting if necessary

R21000140

Motorcycle on level surface.

•

Rider’s weight on motorcycle

•

(approx. 85 kg/176 lbs).

•

Move swivel lever to horizontal position (basic

•

setting).

Turn the adjusting screws to correct the head-

•

light beam throw.

Lateral adjustment:

........................Adjusting screw on left of headlight

Vertical adjustment:

......................Adjusting screw on right of headlight

Turn screw anti-clockwise:............... longer throw

Turn screw clockwise: .....................shorter throw

Checking tightness of rear wheel studs

X Tightening torque:

Rear wheel studs ....................................... 105 Nm

Checking tyre pressures

Check/correct tyre pressures.

•

Tyre pressures:

Solo ..................................... front 2.2 bar (31.3 psi)

............................................. rear 2.5 bar (35.6 psi)

Two-up ................................ front 2.5 bar (35.6 psi)

............................................. rear 2.7 bar (38.4 psi)

Two-up + luggage................ front 2.5 bar (35.6 psi)

............................................. rear 2.9 bar (41.2 psi)

Attaching adhesive label

Remove the adhesive label from the package

•

and fix it in position at the bottom of the glass

cover of the rev. counter.

S000080

Setting for headlight beam angle adjuster

.................................................... -15 cm (- 5.9 in)

........................... over a distance of 10 m (32.8 ft)

00.20

Final inspection and function check

Handing over the motorcycle

Clutch

•

Check gear shift action.

•

Handbrake and foot brake

•

Check lights and signalling equipment:

•

– Front and rear parking lights

– Instrument lighting

– Low and high headlight beams, headlight flasher

– Brake light (operate brake at front and rear)

– Turn signals left/right

– Hazard warning flashers

– Horn

– Telltale and warning lights

– Instruments

Where necessary, check function of optional ex-

•

tras:

– ABS: perform starting test. When a speed of

5 km/h (app. 3 mile/h) is reached, both

ABS warning lights must go out.

If necessary, take the motorcycle for a test ride.

•

Confirm pre-delivery check in Service and Tech-

•

nical Booklet.

See “Checking motorcycle for damage” if defects

•

are found.

Final cleaning

Clean the motorcycle.

•

This is the ideal opportunity to familiarise the customer with the motorcycle in order to ensure the

customer’s satisfaction and safety.

The following points must be demonstrated and

•

explained to the customer:

– documentation and stowage space

– toolkit and stowage space

– suspension preload adjustment to suit total

weight

– checking brake fluid/clutch operating fluid

– provision for adjusting handlebar lever positions

– how to adjust the mirrors

– controls

– instruments and telltale lights

– optional equipment and accessories fitted

– noise during the regular ABS self-diagnosis pro-

cedure

The user must be given the following information:

•

– running-in recommendations and inspection in-

tervals

– safety check

– the clutch fluid level rises gradually as the motor-

cycle is ridden (clutch lining wear)

– before checking the engine oil level, the engine

must be switched off for at least 10 minutes and

the motorcycle must be standing on a flat, level

surface

L Note:

Do not use a steam or high-pressure water jet. The

high steam or water pressure could damage seals,

the hydraulic system or electrical components.

00.21

Maintenance

Key to maintenance intervals

– BMW Inspection at 1,000 km (600 miles) I

– BMW Service every 10,000 km (6,000 miles) II

– BMW Inspection, every 20,000 km

(12,000 miles) III

– BMW Annual Service IV

Reading out MoDiTeC fault memory

(Inspections I, II, III and IV)

Remove the seat.

•

Connect the BMW MoDiTeC to the diagnosis

•

connector.

Read out the fault memory.

•

Perform all requisite repair work.

•

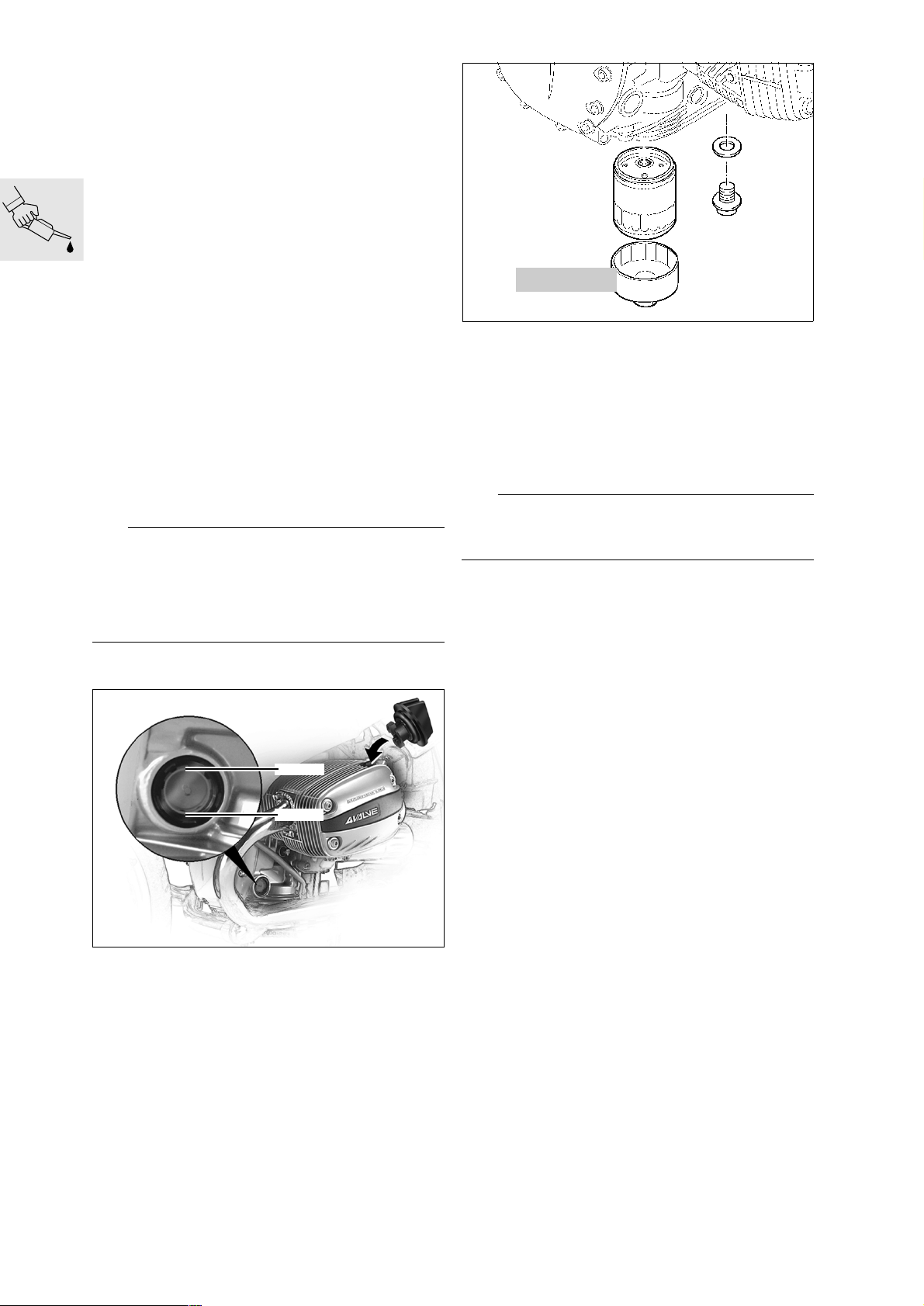

Changing engine oil, replacing oil filter element

(Inspections I, II, III and IV)

L Note:

If the motorcycle is ridden only for short distances or

outside temperatures are below 0°C (32°F) change

the oil and replace the oil filter element every

3 months, or not later than every 3,000 km

(1,800 miles).

11 4 650

C000030

Remove oil drain plug and drain off oil.

•

Reinstall the oil drain plug with a new sealing

•

ring.

Use oil filter wrench, BMWNo.114650, to re-

•

move the oil filter.

Coat sealing ring on new oil filter element with oil

•

and install filter.

Refill with oil to correct level.

•

Install the screw plug.

•

e Caution:

Never top up the engine-oil level past the “MAX”

mark.

X Tightening torque:

Oil filter......................................................... 11 Nm

Oil drain plug................................................ 32 Nm

Change the oil at operating temperature.

•

MAX

MIN

Remove screw plug.

•

Engine oil quantities:

With oil filter change................................................

.....................3.75 l (6.6 Imp. pints/3.96 US quarts)

Without oil filter change...........................................

.....................3.50 l (6.2 Imp. pints/3.69 US quarts)

Quantity of oil between

MIN and MAX marks ...............................................

.......................0.50 l (0.88 Imp. pint/0.52 US quart)

Engine oil grade:

Brand-name HD oil for spark-ignition engines, API

classifications SF, SG, SH; combination with CD or

CE specification.

Brand-name HD oil of CCMC classification G4, G5;

amendment PD2 is permissible.

S000040

00.22

Loading...

Loading...