BMW c1 c1-200 Service Manual

Repair manual

C1

C1 200

BMW Motorrad

After Sales

Published by BMW Motorrad

After Sales

UX-VS-2

All rights reserved. Reprints, translation and duplication allowed exclusively with prior written permission

from the publisher.

Errors and omissions excepted. We reserve the right to introduce technical modifications at any time.

Printed in Germany 03/01

Preface

This Repair Manual is intended to assist you in performing all essential maintenance and repair operations

to a professional standard. In its role as a reference source for service personnel, it supplements and expands upon the theoretical and hands-on instruction provided at our training centres to enhance the quality

of our service.

A new edition of this manual will be issued in response to required revisions or the need to incorporate additional information (supplements).

The illustrations and descriptions contained in this manual apply exclusively to standard, unmodified BMW

Motorcycles and/or BMW Motorcycles equipped with factory-approved BMW accessories and options.

The Repair Manual's structure reflects the logical sequence in which the operations it describes will be

•

performed: removal, dismantling, repairs, assembly and installation.

The individual chapters in this manual correspond to the motorcycle's individual assembly groups.

•

11 10.

Chap. chapter page continued

A reference arrow with chapter and page calls your attention to additional information contained in another

section of the manual.

e.g. a ................ Refer to Assembly Group 46

Group "00" describes the operations carried out in the course of each Inspection. The various inspec-

•

tion routines are numbered I, II, III and IV. To help in maintaining a continuous, logical work sequence,

these same numerical designations are employed to identify the subsequent sections describing the actual repair operations.

Use of the BMW special tools needed for certain operations is described in the work instructions.

•

When the need arises, repair instructions are also issued in the form of Service Information Bulletins. This

information is then incorporated into subsequent editions of the repair manual. We also recommend the

lavishly illustrated Electronic Parts Catalogue as a supplementary source of information.

When individual steps within an overall operation only apply to motorcycles with specific accessories or

optional equipment, the options to which the steps refer are identified by brackets at the start of the line,

such as

Please devote your careful attention to the following pages with their explanations describing the symbols

used in the manual and their significance.

BMW Motorrad

After Sales

[with heated grips]

.

Published by BMW Motorrad

After Sales

UX-VS-2

80788 München

All rights reserved. Reprints, duplication and translation, in whole or part, are allowed exclusively with prior

written permission.

We reserve the right to introduce technical modifications at any time. Errors and omissions excepted.

Printed in Germany

How to use this manual

Each chapter starts with a table of contents.

Following the table of contents is a table containing the techical data and specifications for the chapter's

subject.

Chapter 00 describes maintenance procedures and provides general information as well as the pre-delivery

inspection; it furnishes all torque specifications along with listings of fluids and lubricants.

Explanation of symbols

This repair manual for the C1 employs the following symbols; please refer to the table for their meanings.

Special notices for more efficient procedures

L

Note:

These special notices help technicians work more efficiently when operating, inspecting, adjusting and

maintaining motorcycles.

e

Attention:

Special information and precautionary notices to prevent damage to the motorcycle. Failure to observe

these mandatory precautions may invalidate the warranty.

d

Warning:

Precautions intended to protect the rider and/or other individuals against injury as well as potentially fatal

hazards.

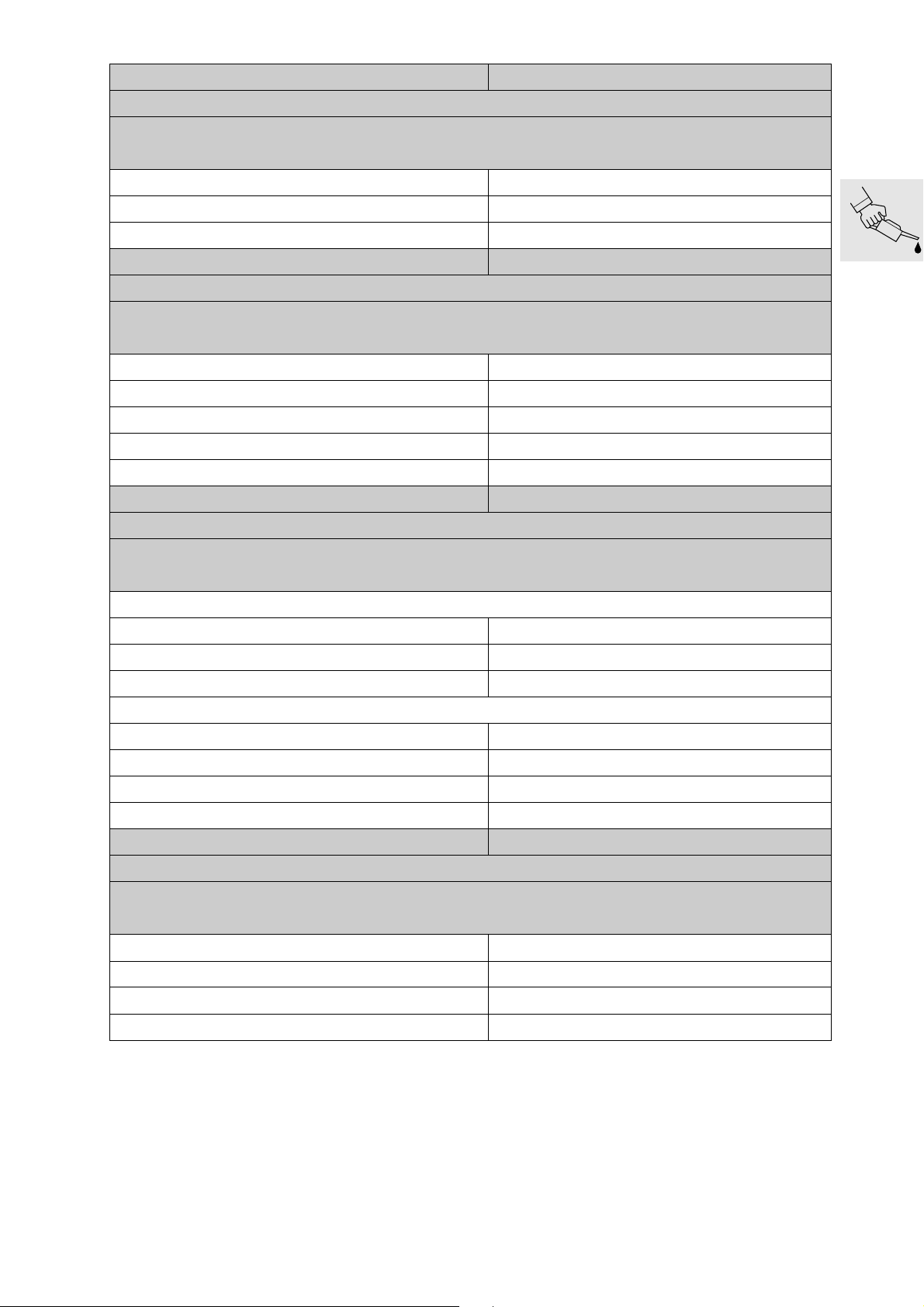

Contents

The titles of the operations described in this chapter ............. together with the page numbers

Operations

Operations

•

A dot or period identifies individual procedures described under a title

•

– Previous operations

– The hyphen identifies procedures described in more detail under a different title or in another chapter

Remove means:

to completely unscrew a retaining component (such as a bolt or screw)

or

to detach a component (such as an injection rail) and move it enough to gain access to assemblies installed

behind it (such as a throttle-valve).

Loosen means:

to unscrew an attachment (such as a bolt or screw) without removing it entirely from its threaded socket or

retainer

X

Torque specifications:

These data are indicated whenever torques deviate from the standards defined in DIN EN 24 014 and

DIN 912 ISO.

Contents

<< Back

Group / Chapter

00 Tightening torques operating fluids

00 Pre-delivery check

00 Maintenance

11 Engine

12 Engine electrics

13 Fuel preparation and control

16 Fuel tank and lines

17 Radiator

18 Exhaust system

21 Clutch

24 Gearbox

31 Front forks

32 Steering

>> Continuation

Group / Chapter

33 Rear wheel drive

34 Brakes

36 Wheels and tyres

46 Frame

51 Equipment

>> Continuation

52 Seat

61 General electrical equipment

62 Instruments

63 Lights

65 Optional extras

72 Seat belts

<< Back

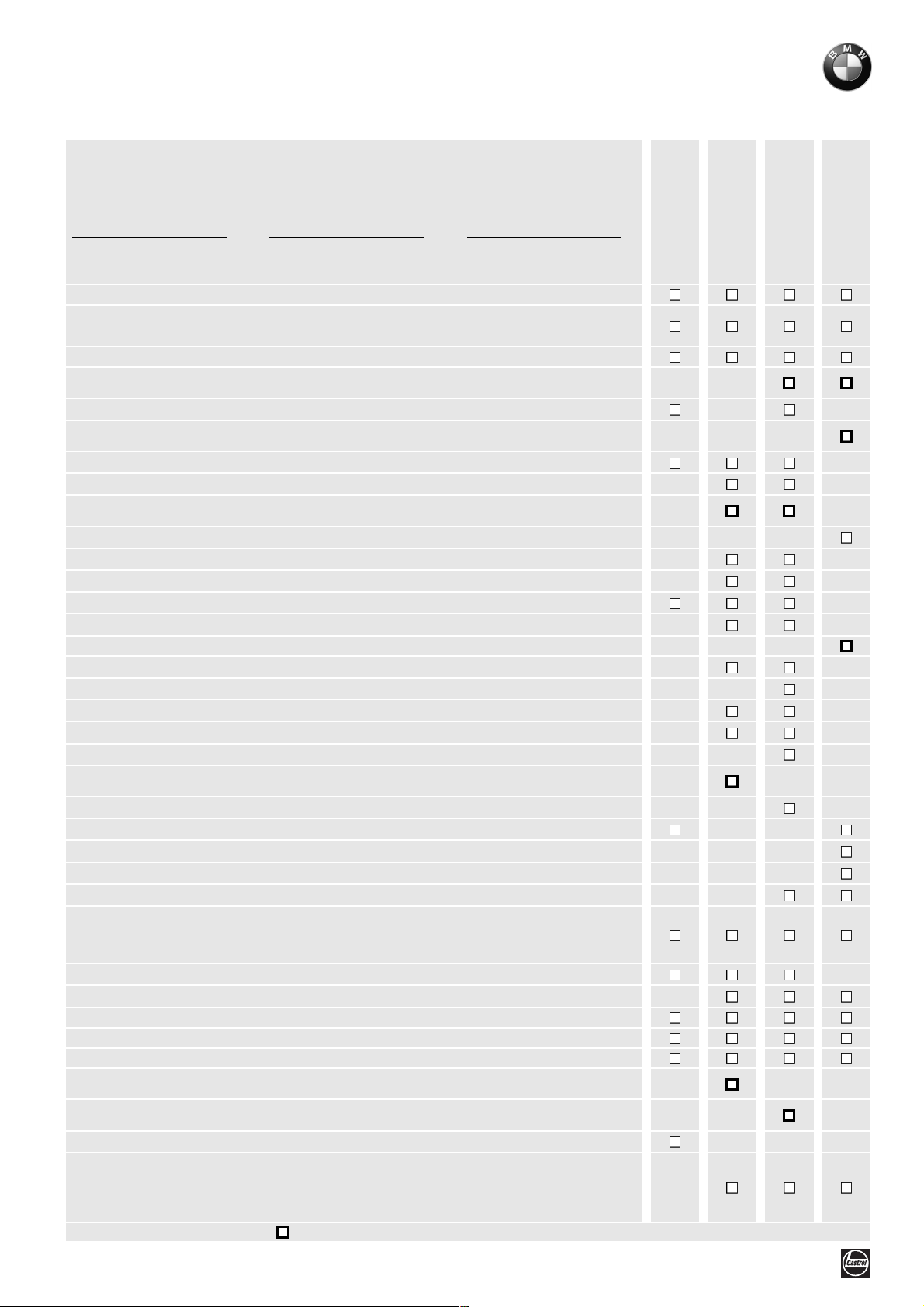

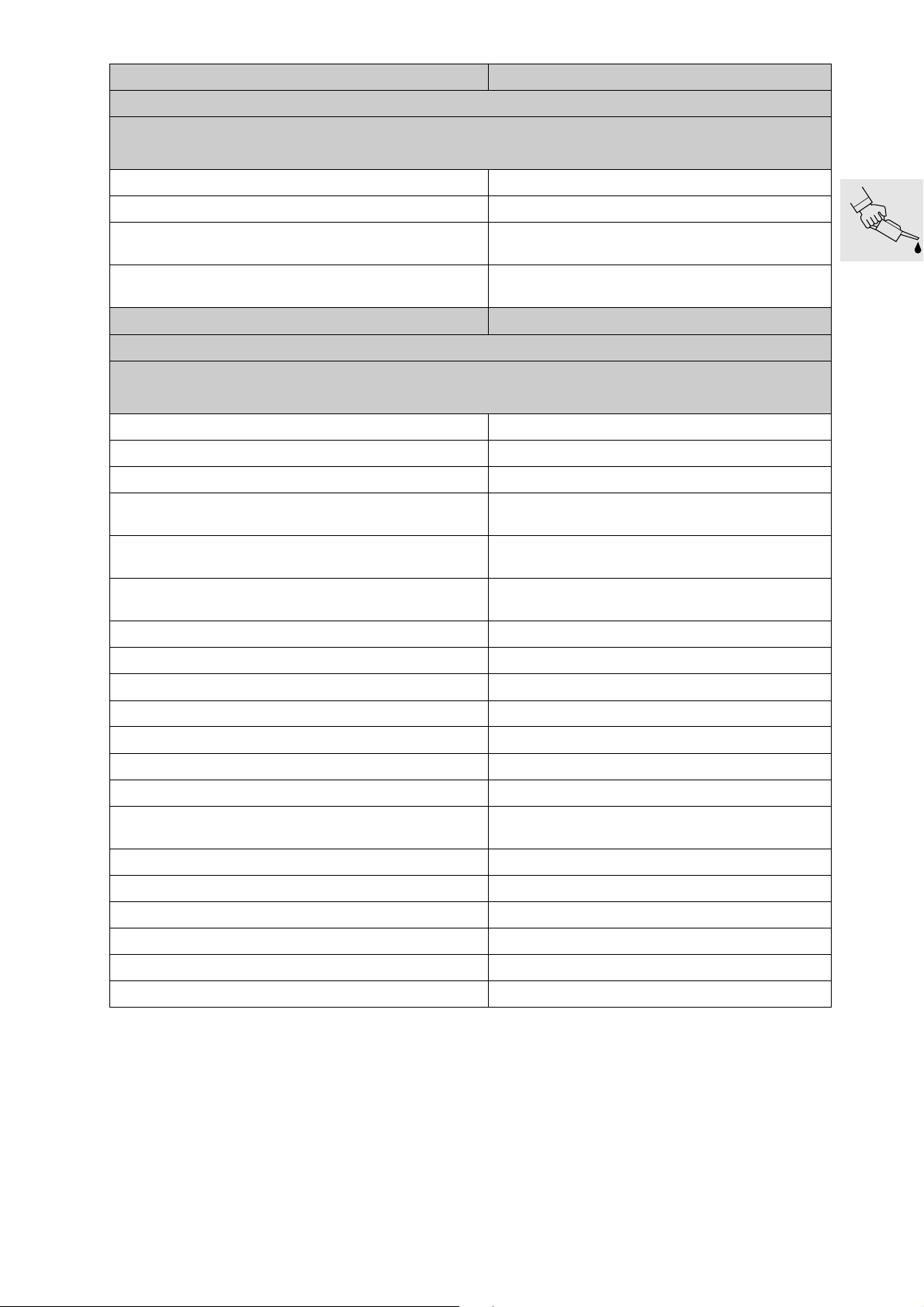

BMW Motorrad

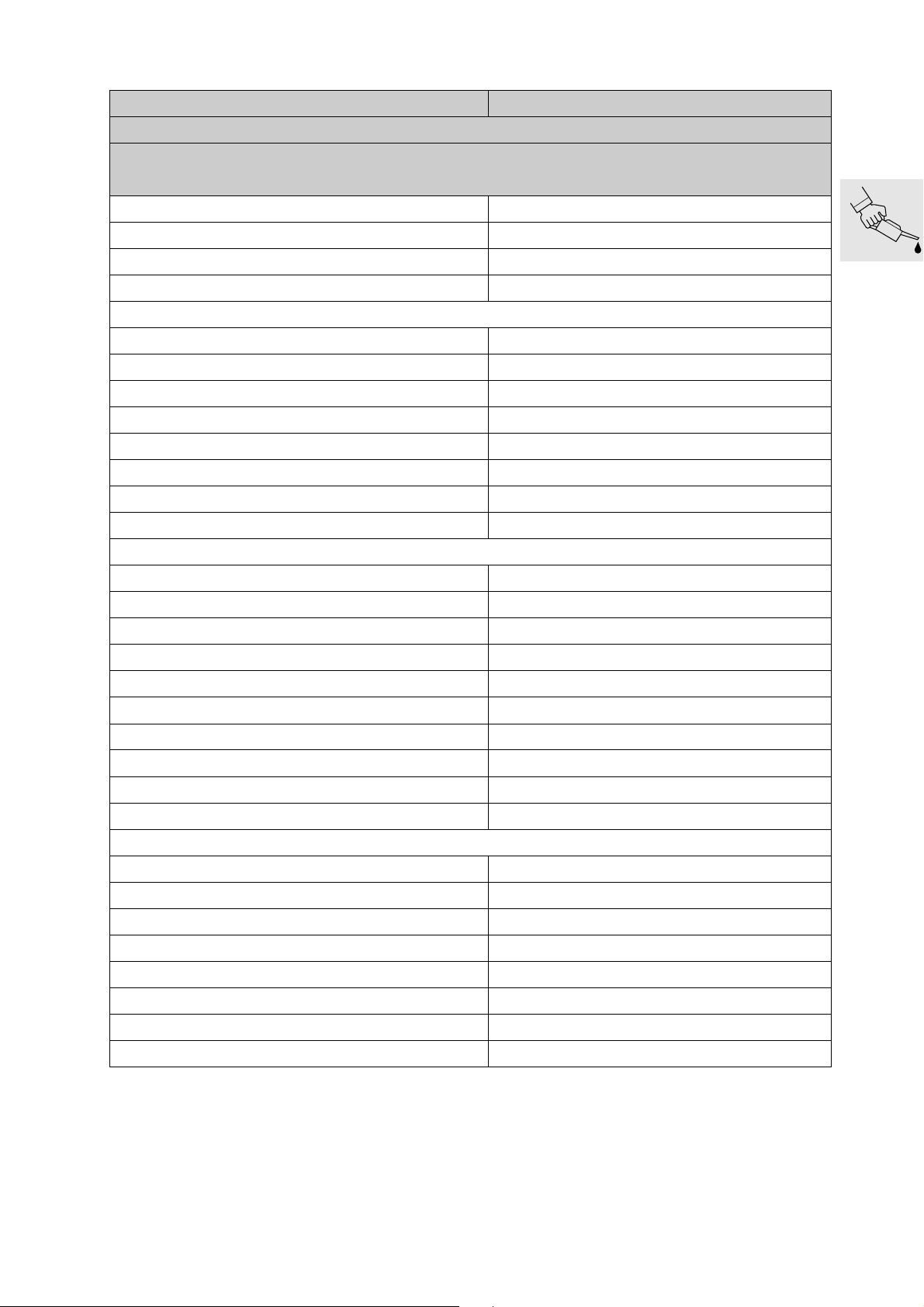

Maintenance schedule

C1, C1 200

Customer Licence No. Mileage

Job Order No. Date Mechanic's signature

MoDiTeC/DIS plus

Change the engine oil while at regular operating temperature and replace the oil filter element

If the vehicle is ridden for short distances only or at outside temperatures below 0° C (32° F): every 3 months or after

every 3,000 km (1,800 miles) at the latest

Clean oil strainer and magnetic plug

Change transmission fluid

every 30,000 km/18,000 miles or 3 years

Inspect coolant level, top up if necessary, inspect hoses for damage, chafing points

Change the coolant

every 2 years

Check valve clearances and adjust if necessary

Replacing spark plug

Replace air filter element

shorten change interval if severely dirty or dusty

Drain condensate drain hose from air manifold

Brake hoses and connections: check condition and routing

Check operation of brake system and check for leaks; repair/replace as necessary

Inspect brake fluid level at front/rear

Examine brake pads and discs for wear, renew if necessary

brake fluid

Renew

Replace variator belt

Check clutch liner, replace if necessary

Cleaning mesh filter of variator

Grease driving variator (greased version)

Check and clean driving variator (ungreased version, replace variator if necessary)

Replace complete driving variator

every 22,500 km/14,000 miles, greased version only

Check wheel bearings for play; replace if necessary

Checking that leading-link mounts are free of play

Battery: check battery acid level, if necessary add distilled water

Clean and grease the battery terminals, if necessary

Check freedom of movement of Bowden cables, check for abrasion and damage

Easy-lift mechanism:

– Check operation of mechanism and check freedom of movement

– Inspect Bowden cables for damage and signs of wear and chafing, ensuring that mechanism moves

freely without binding; check free travel and adjust as required

Check windscreen washer system; adjust nozzles if necessary and top up washer fluid in reservoir

Check windscreen wiper; replace wiper blade if necessary

Safety elements: check cable for release, belt buckles, belt strap, inertia reels, and belt locks

Check crash element for damage

Inspect shoulder bar for damage, replace deformation element if necessary

Replace fuel filter

every 37,50 0 km/22,500 miles

Only ABS: Replace seal in brake master cylinder

every 30,000 km/18,000 miles

Check tightness of bolts and nuts at engine mountings and quick-release axles

Final inspection with road safety and functional check:

– Clutch engagement, steering, front and rear brake

– Condition of tyres and wheels, tyre inflation pressure

– Lights and signalling equipment, telltale and warning lights, instruments

– If necessary, test ride

*) Write up on separate invoice; Not part of standard service procedure

, read fault code memory

*)

at least

*)

*)

once a year

*)

*)

*)

*)

*)

*)

*)

*)

BMW Inspection

at 10,00 km/600 miles

BMW Maintenance

Service every

7,500 km/4,500 miles

BMW Inspection

every 15,000 km/

9,000 miles

BMW

Annual Service

UX-VS-2, 10.2001

BMW recommends Castrol

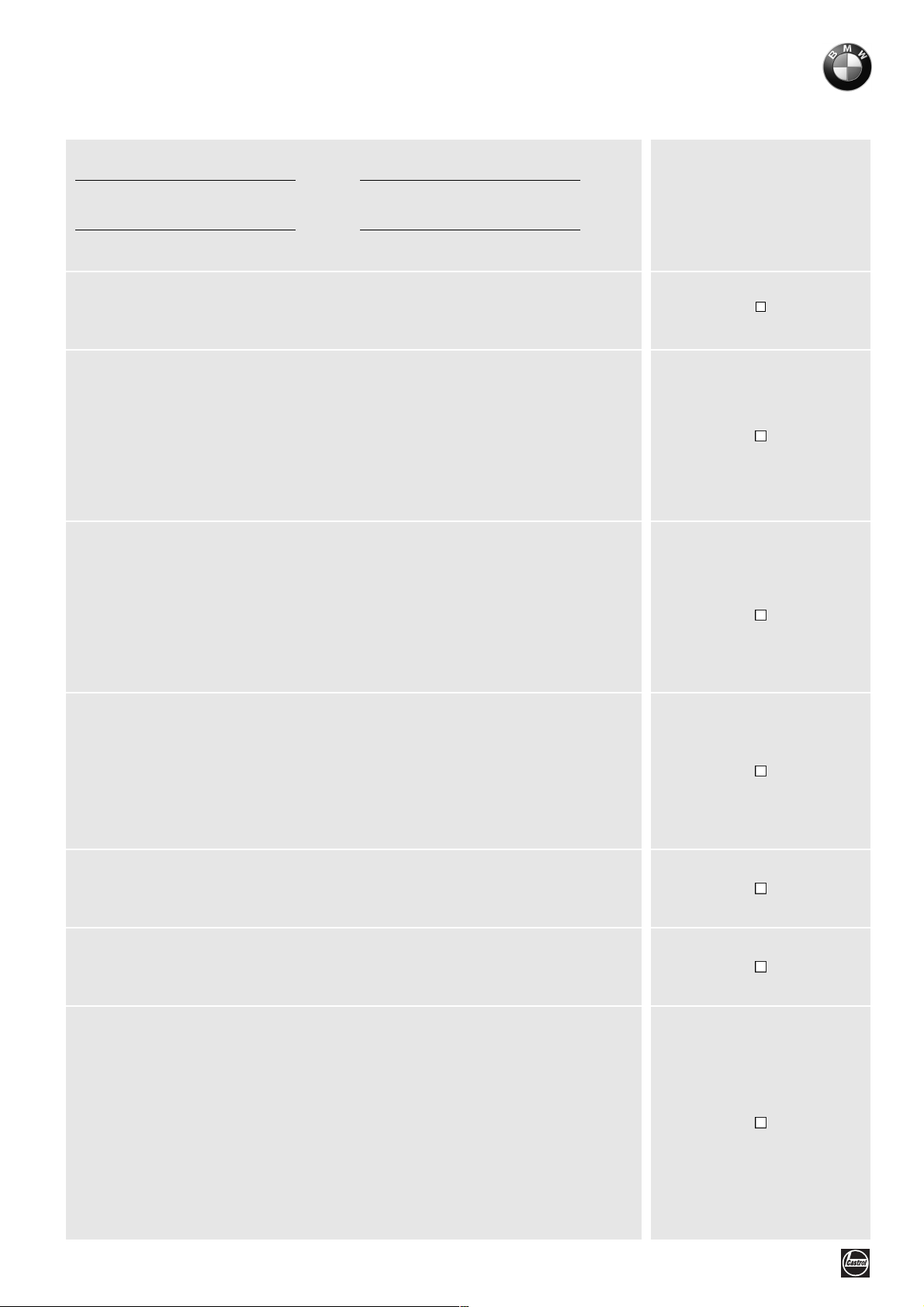

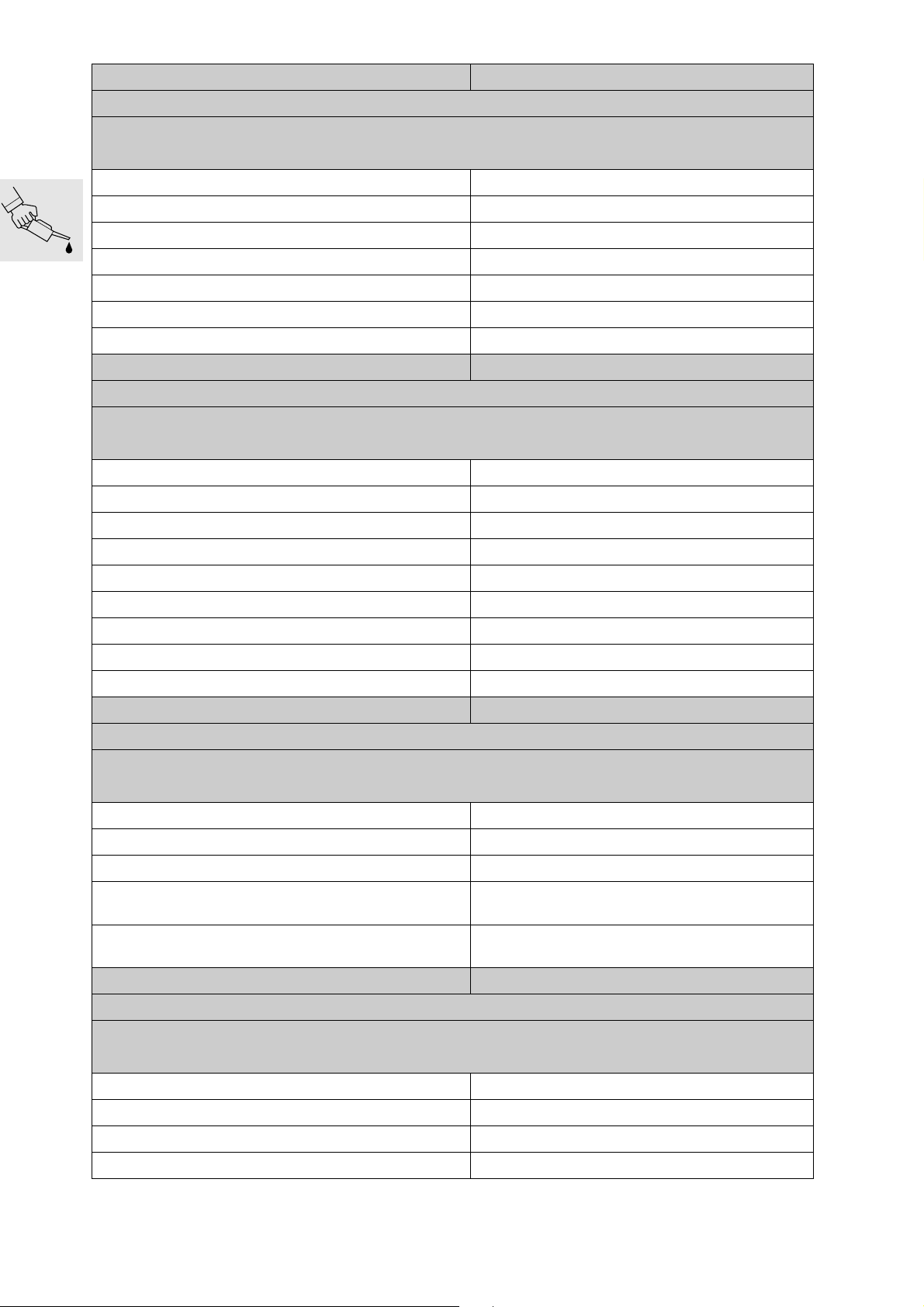

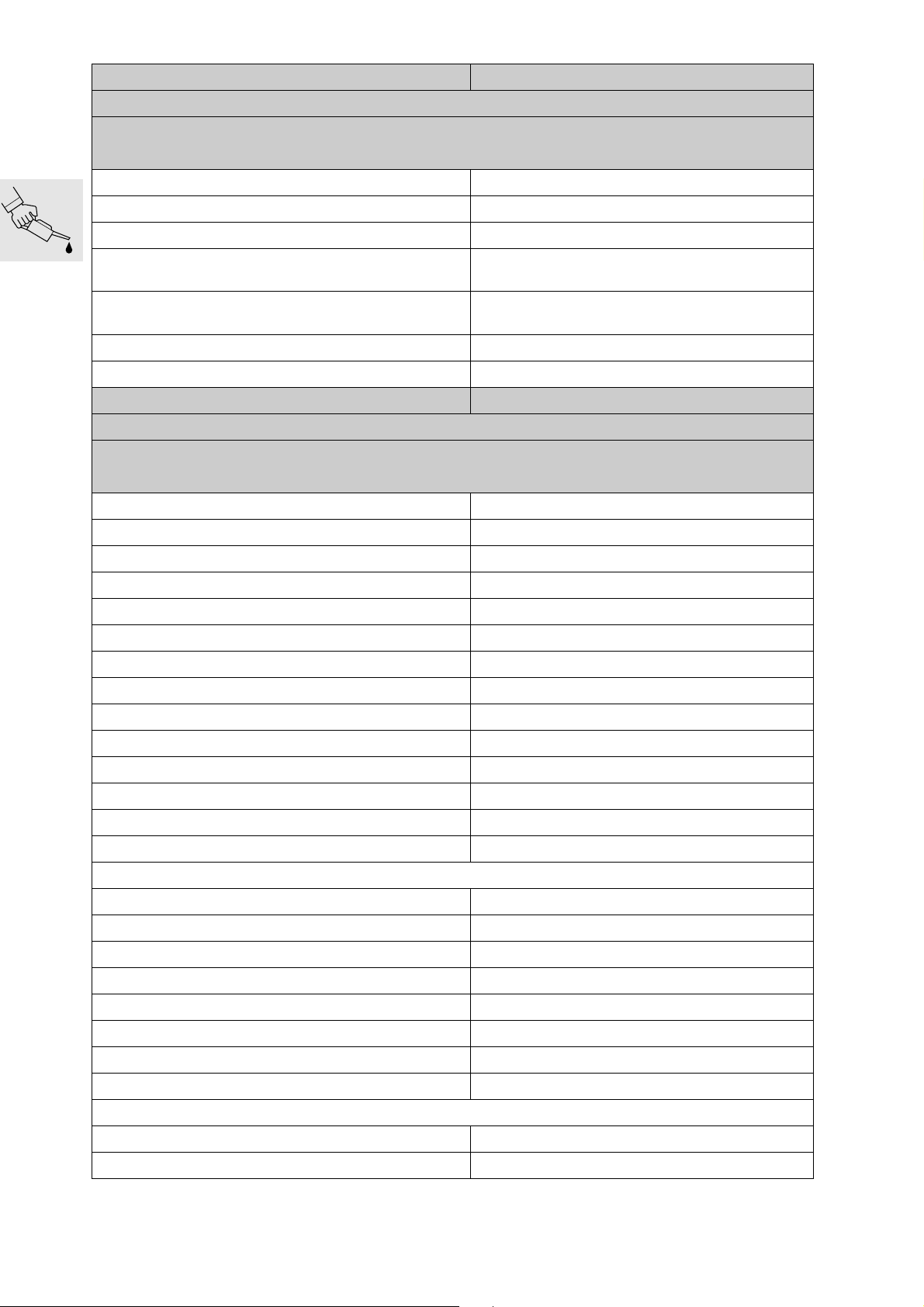

BMW Motorrad

Pre-delivery Check

C1, C1 200

Customer Registration number

Order no. Signature of mechanic

Inspect transportation packaging for damage

C1:

–Unpack

– Inspect for damage

–Attach parts

–Clean

Battery:

–Remove

– Pour in electrolyte

–Charge

–Grease terminals

– Install (mark date of installation)

BMW

Pre-delivery Check

Inspect complete scope of supply:

– Toolkit

– Documentation

–Keys

– Scope of optional equipment

Inspect tyre inflation pressure

Pour in fuel

Operational check as final inspection:

– Engine idling

– Clutch, clutch engagement

–Steering

–Seat belt

– Easy-lift mechanism

– Brakes, front and rear

– Lights and signalling equipment, telltale and warning lights, instruments

–Set headlight

– If necessary, test ride

UX-VS-2, 10.2001

BMW recommends Castrol

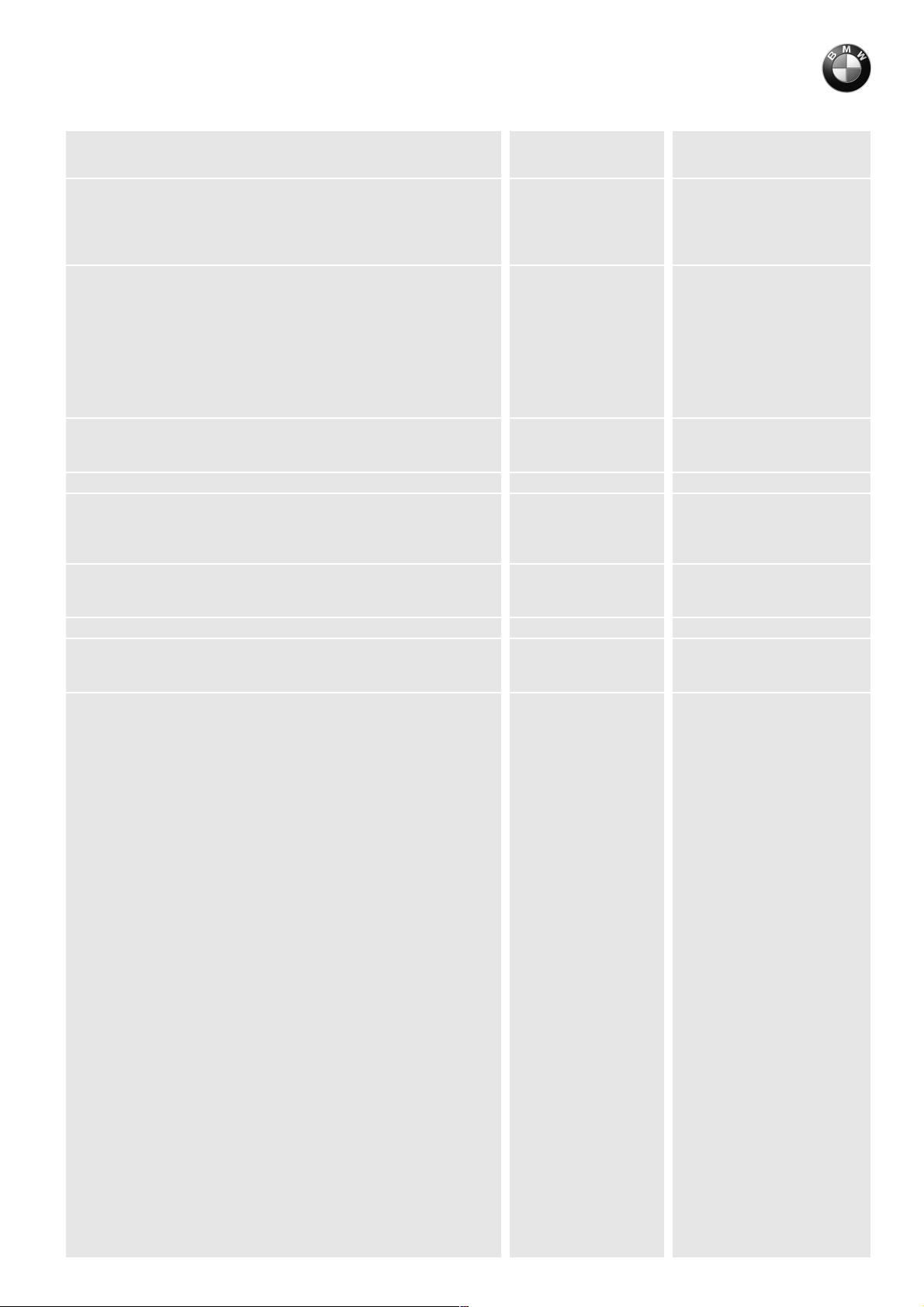

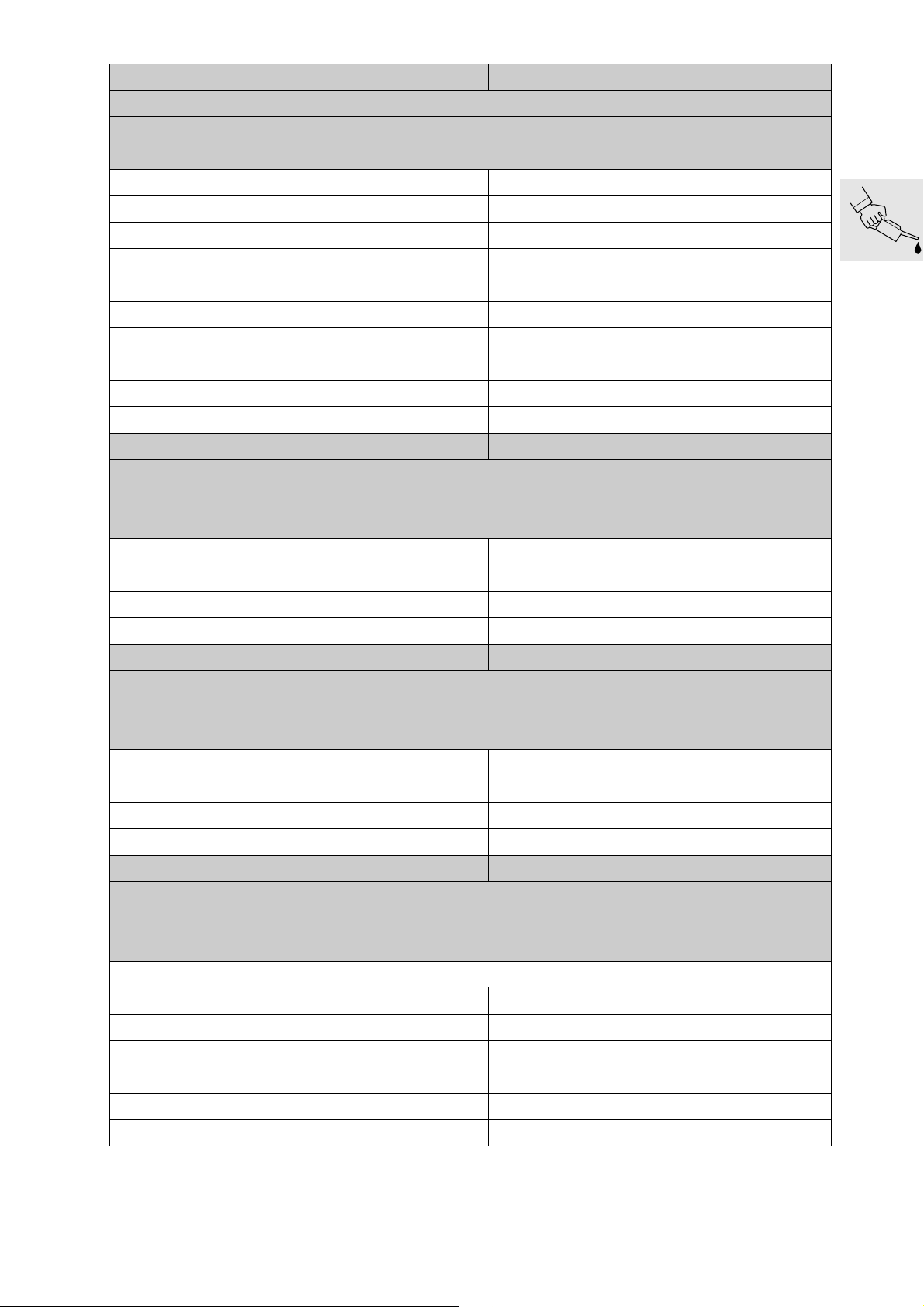

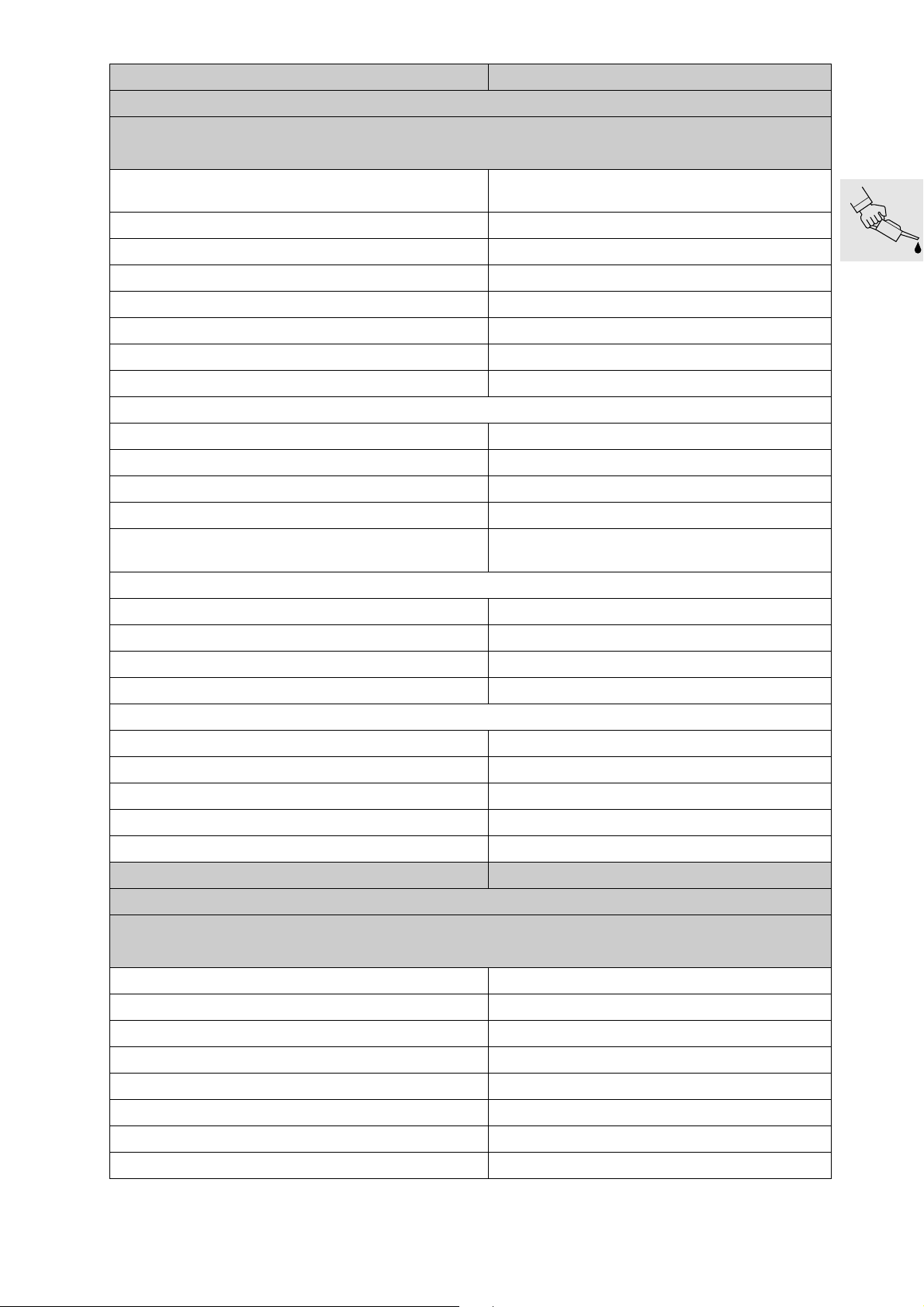

BMW Motorrad

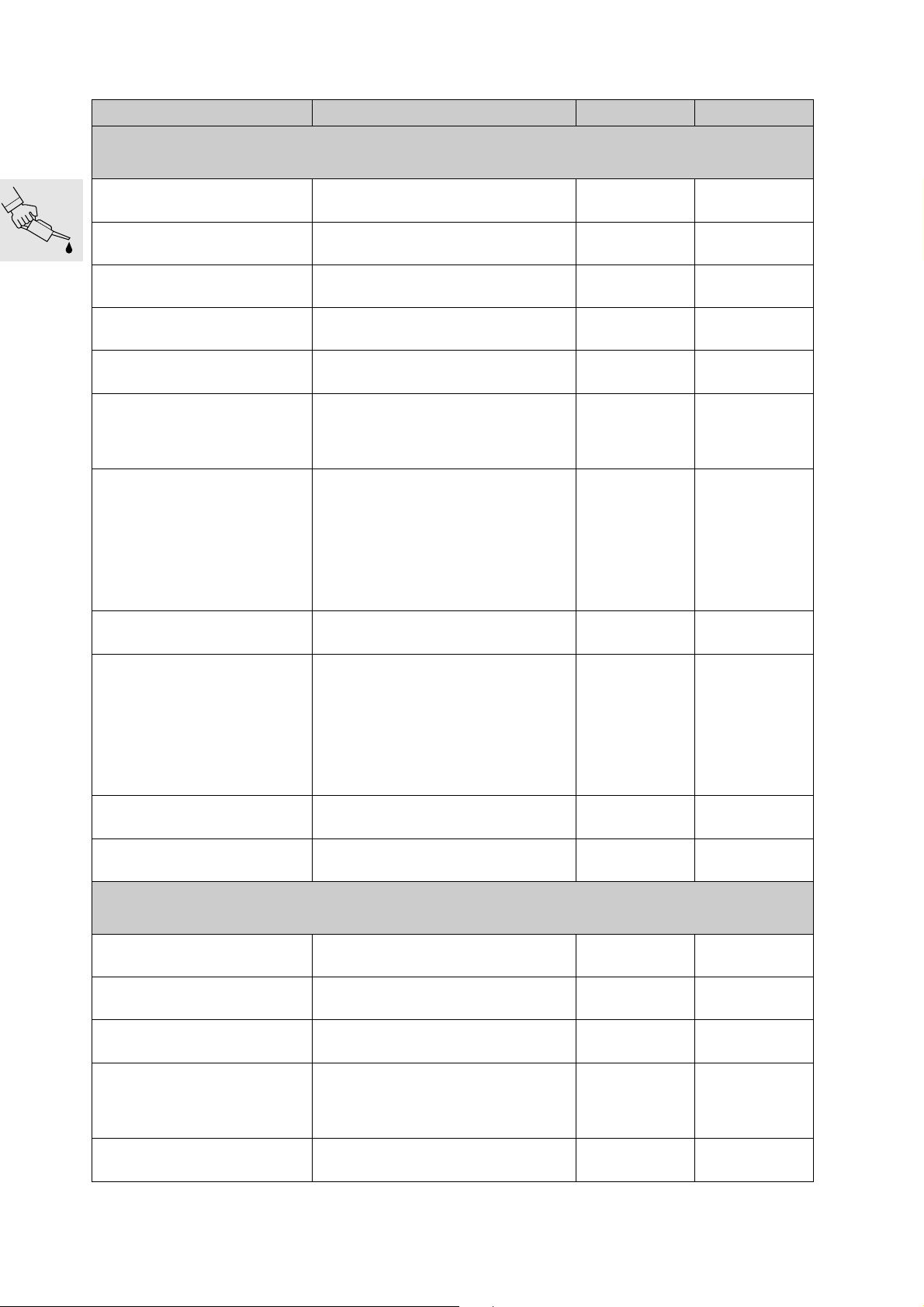

Service data

C1, C1 200

Item Specified

value

Oil capacities

Engine (with filter)

Gearbox

Coolant

Cooling system

Expansion tank

Windshield washer fluid

Brake fluid

Valve clearances

Measured cold, maximum 35 °C (95 °F)

Spark plugs

Electrode gap 0.8…0.9

Idle speed

Tyre pressures (tyres cold)

Solo

Full load

Tightening torques:

Engine oil drain plug

Oil strainer to engine

Engine water drain plug

Oil filter cover

Camshaft gears to camshaft

Guide rail to camshaft support

Chain tensioner plug

Camshaft bearing bridge

Valve cover

Machine bolt TDC setting

Spark plug

Driving variator

Driving variator cover

Driven variator

Locknut of clutch to driven variator

Variator cover to power train link

Ventilation cover for variator

Front stub axle

Clamping bolts for front stub axle

Brake calliper at fork slider tube

Bleed screw in brake calliper

Cover of handbrake control

Rear stub axle,

Exhaust to cylinder head

Auxiliary link to power train link M8

Auxiliary link to power train link M10

Silencer to auxiliary link

Suspension strut to power train link/brake calliper holder

Link mounting to power train link

Tubular link to frame

Stand to frame

Rubber element to tubular link

Cladding bolts

Order no. 01 71 0 136 450 UX-VS-2, 03.2001 Printed in Germany

use nut only once

1.0 (0.22)

0.090 (0.020)

1.25 (2.2)

0.2 (0.35)

1.0 (1.8) litres (Imp pints)

Inlet: 0.05…0.14

(0.002…0.006)

Exhaust: 0.20…0.29

(0.009…0.010)

(0.031…0.035)

1900 rpm

Front/rear

1.9/2.1 (27.6/30.5)

1.9/2.4 (27.6/34.8)

20

30

10

10

30

10

35

10

10

15

15

60

4

60

50

10

9

30

21

41

14

Hand-tight

130

15

21

60

21

21

73

73

41

42

2.8

Unit of measure or

specification

litres (Imp pints)

15W40

litres (Imp pints)

API GL 4

litres (Imp pints)

litres (Imp pints)

Mixing ratio:

Water: 50%

Antifreeze: 50%

Protection down to

–25 °C (-13 °F)

Water and cleaning prod-

uct, antifreeze as required

DOT 4

mm

(in)

mm

(in)

NGK CR8 EB

mm

(in)

bar (psi)

bar (psi)

Nm

Nm

Nm

Nm

Nm (Loctite 243)

Nm (Loctite 243)

Nm

Nm

Nm

Nm

Nm

Nm (Loctite 243)

Nm

Nm

Nm (Loctite 243)

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm (Loctite 243)

Nm

Nm

Nm

Nm

Nm

Nm

Nm

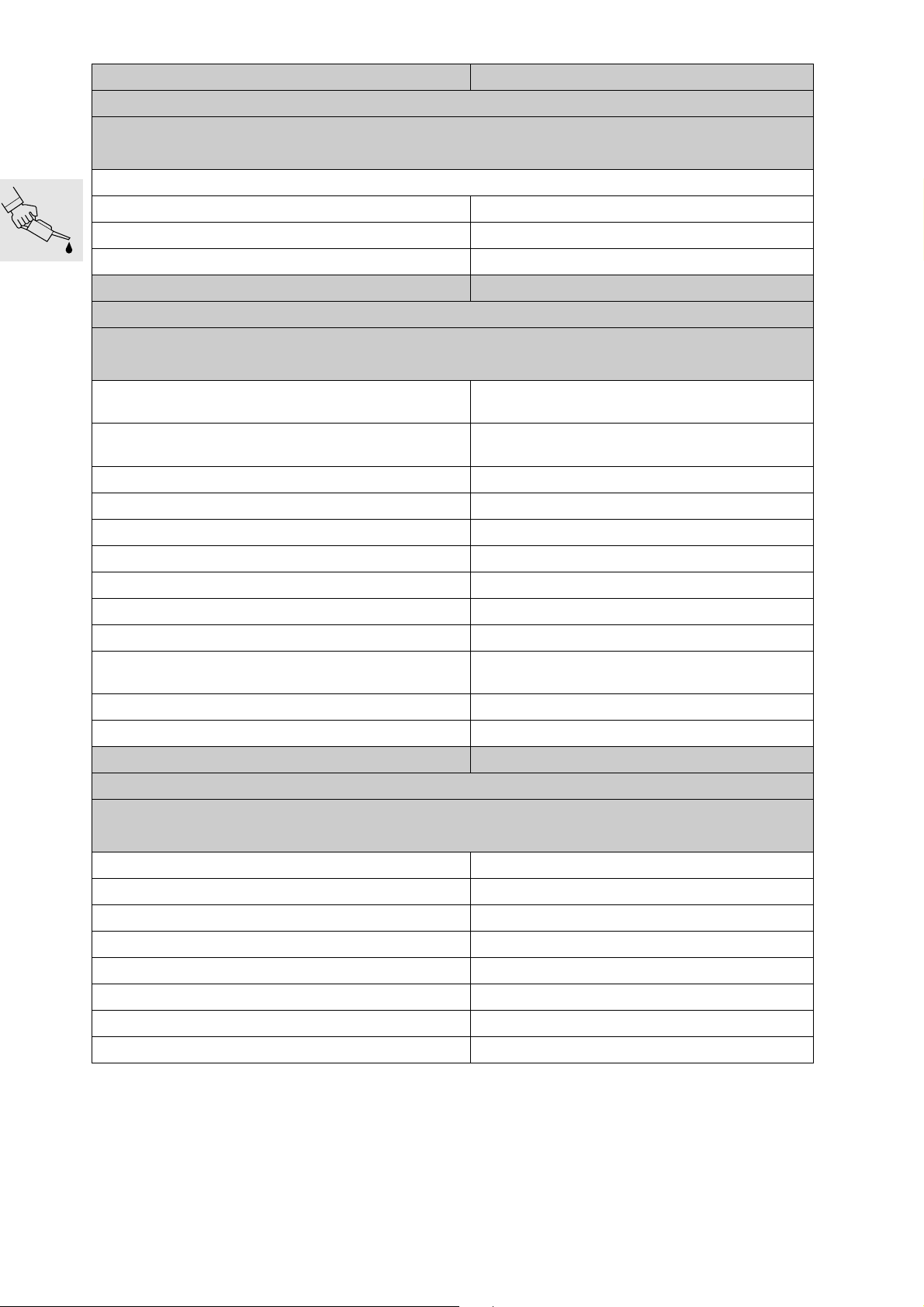

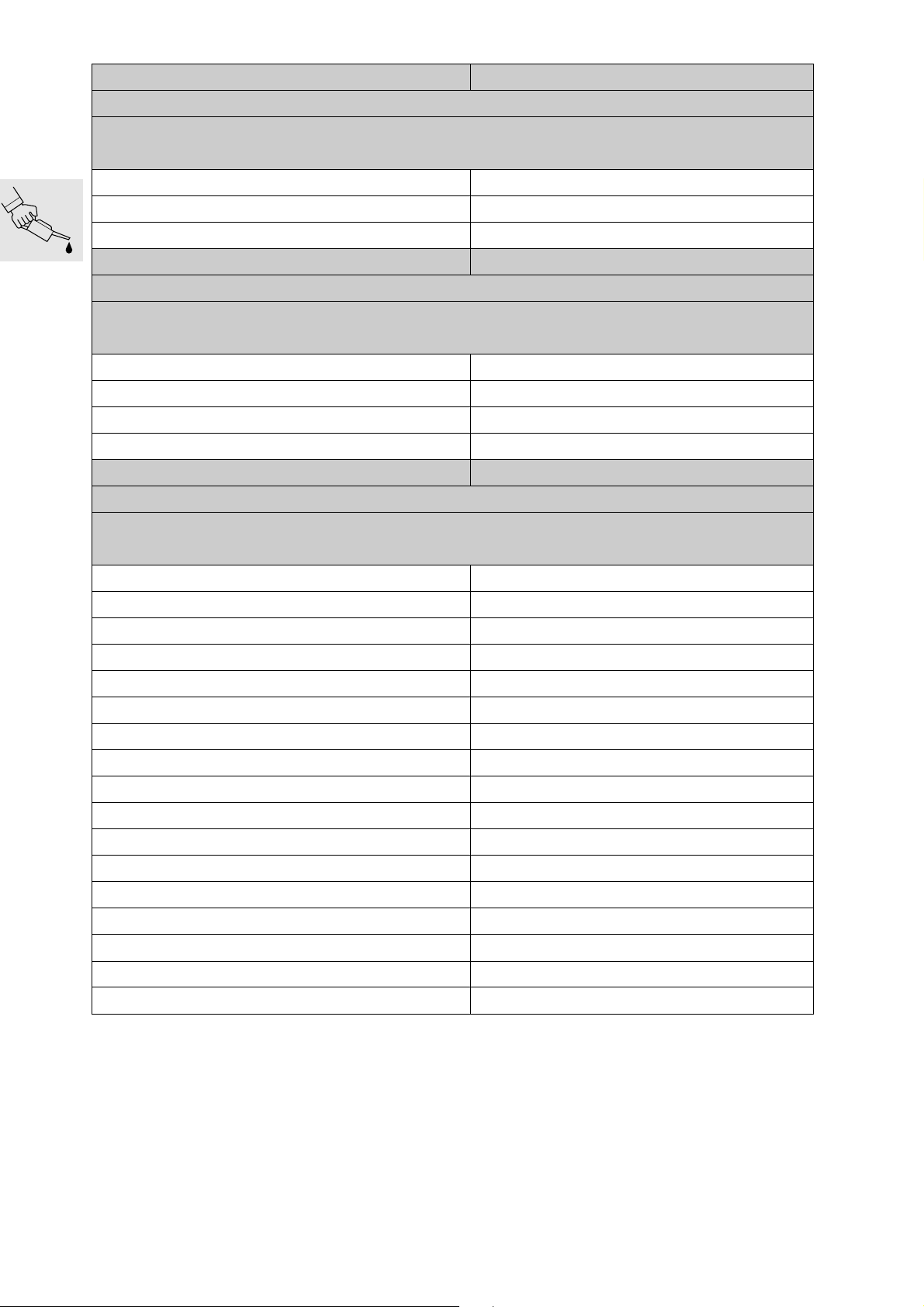

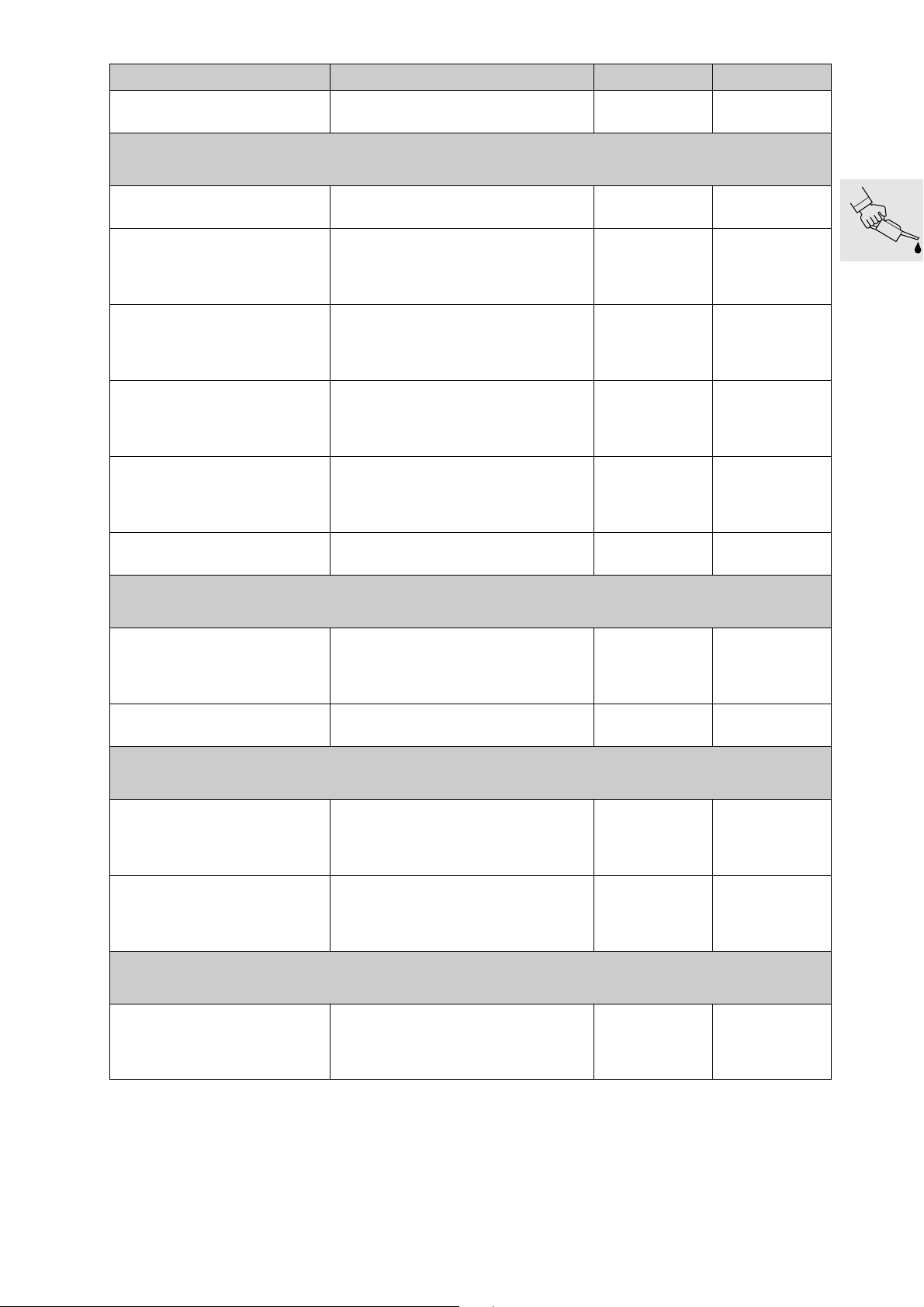

00

00 Tightening torques

operating fluids

Contents

Torque specifications

11 Engine

...........................................................................................................................................3

12 Engine electrical system

13 Fuel injection system

16 Fuel tank

.......................................................................................................................................4

17 Cooling system

18 Silencer (muffler)

21 Clutch

24 Gearbox

31 Front forks

32 Steering

............................................................................................................................................5

........................................................................................................................................5

...................................................................................................................................6

........................................................................................................................................6

33 Final-drive unit

34 Brakes

36 Wheels

46 Frame

51 Equipment

52 Seats

...........................................................................................................................................7

..........................................................................................................................................8

............................................................................................................................................8

...................................................................................................................................9

............................................................................................................................................ 10

61 Electrical equipment

62 Instruments

63 Lights

........................................................................................................................................... 11

............................................................................................................................... 11

65 Optional extras

72 Seat belts

................................................................................................................................... 11

.................................................................................................................3

..............................................................................................................4

.........................................................................................................................4

.......................................................................................................................5

...........................................................................................................................7

............................................................................................................. 10

........................................................................................................................ 11

Page

.......................................................................................................4

Table of service products

....................................................................................................... 12

00.1

00.2

00

Torque specifications

Model C1

Connection

11 Engine

Oil drain plug, magnetic Nm 20

Threaded plug, oil strainer Nm 30

Oil filter cover Nm 10

Threaded TDC set plug Nm 15

Alternator

Alternator cover up to engine no.: 745 594 Nm 10

Alternator cover from engine no.: 745 595 Nm 12

Ignition trigger, Tapite screw Nm 6 LOCTITE 243

Holder for alternator cable, Tapite screw Nm 6 LOCTITE 243

Reluctor to crankshaft, locking fluid Nm 30 LOCTITE 243

One-way clutch, locking fluid Nm 30 LOCTITE 243

Alternator to cover Nm 10

Chain tensioning rail, locking fluid Nm 10 LOCTITE 243

Cylinder head

Cylinder head cover Nm 10

Collar nut Nm 30 ±1

Securing screw Nm 10

Spark plug Nm 15

Camshaft sprockets, locking fluid Nm 30 LOCTITE 243

Bearing cap Nm 10

Chain guide, locking fluid Nm 10 LOCTITE 243

Plug for chain tensioner Nm 35

Vent screw Nm 9

Dual temperature sensor, locking fluid Nm 15 LOCTITE 243

Housing

Starter motor Nm 10

Oil pressure switch, locking fluid Nm 12 LOCTITE 243

Oil pressure valve Nm 30

Stud (tie bolt) Nm 10

Housing screws Nm 10

Oil pump, Tapite screw Nm 6 LOCTITE 243

Water-pump housing, Tapite screw Nm 6 LOCTITE 243

Spring strut at bottom Nm 21

00.3

Model C1

Connection

12 Engine electrical system

Spark plug Nm 15

Ignition coil to frame Nm 5

Ignition trigger, Tapite screw Nm 6 LOCTITE 243

Reluctor to crankshaft, locking fluid Nm 30 LOCTITE 243

One-way clutch, locking fluid Nm 30 LOCTITE 243

Alternator to cover Nm 10

Starter motor Nm 10

Model C1

Connection

13 Fuel injection system

Fuel filter clamp Nm 5

Holder for injection nozzle (self-tapping) Nm 4 LOCTITE 243

Pressure regulator clamp Nm 9

BMS control unit Nm 5

Intake manifold Nm 9

Air plenum clamp Nm Hand-tight

Air filter housing (inner/outer) Nm 9

Throttle cable Nm 8

Spring strut at bottom Nm 21

Model C1

Connection

16 Fuel tank

Fuel filter clamp Nm 5

Bracket, fuel tank to frame Nm 9

Union nut (fuel-pump unit) Nm 20

Baseplate to frame

Bracket for washer fluid reservoir on frame

Bracket for washer fluid reservoir/ABS control unit on frame

Model C1

Connection

Nm 9

Nm 9

17 Cooling system

Drain plug Nm 10

Vent screw Nm 9

Bracket for seat latch, right, to frame Nm 42

Bracket for seat latch, left, to frame Nm 5

00.4

Model C1

Connection

17 Cooling system

Expansion tank to frame upright Nm 3

Front frame to cross brace Nm 14

Air duct to fan shroud Nm 9

Radiator to front frame Nm 9

Fan shroud to radiator Nm 9

Air duct to front frame Nm 9

Filler bowl to front frame Nm 9

Coolant pipe clamp to frame Nm 9

Screw clamp on engine Nm Hand-tight

Bleeder screw to engine Nm 9

Model C1

Connection

18 Silencer (muffler)

Shield to holder Nm 5

Exhaust pipe to cylinder head Nm 15

Silencer to auxiliary swing arm Nm 21

Oxygen sensor to silencer Nm 23

Model C1

Connection

21 Clutch

Vent cover for variator Nm 9

Variator cover Nm 10

Driven variator (clutch drum) Nm 60

Locknut on driven variator, locking fluid Nm 50 LOCTITE 243

Model C1

Connection

24 Gearbox

Variator

Vent cover for variator Nm 9

Variator cover Nm 10

Drive variator, locking fluid Nm 60 LOCTITE 243

Cover, drive variator Nm 4

Driven variator (clutch drum) Nm 60

Locknut of driven variator, locking fluid Nm 50 LOCTITE 243

00.5

Model C1

Connection

24 Gearbox

Gearbox

Gearbox cover Nm 11

Gearbox drain plug Nm 20

Gearbox filler plug Nm 5

Model C1

Connection

31 Front forks

Fork cross brace to frame (screw stud) locking fluid

Leading link to telescopic tube cross brace

locking fluid

Brake line bracket on fork cross brace Nm 5

Fork stanchion to fork cross brace Nm 52

Handlebar to fork cross brace Nm 21

Leading-link joints Nm 41

Clamp screws for leading-link joints Nm 9

Spring strut to leading link Nm 41

Ball joint to telescopic fork cross brace Nm 230

Clamp of telescopic tube to telescopic tube

cross brace

Eyebolts Nm 8

Lock to easy-lift mechanism Nm 4

Model C1

Connection

32 Steering

Nm 83 LOCTITE 243

Nm 127 LOCTITE 2701

Nm 25

ABS sensor to telescopic tube Nm 9

Combination switch Nm 4

Brake light switch Nm Hand-tight

Throttle cable Nm 8

Clamp screw for brake lever fitting Nm 9

Brake line to brake lever fitting Nm 18

Handlebar to fork cross brace Nm 21

Locknut for handlebar lever pivot pin Nm 3

00.6

Model C1

Connection

33 Final-drive unit

Top suspension strut Nm 41

Spring strut at bottom Nm 21

Auxiliary swing arm to brake caliper holder

M, screw locking fluid10

Auxiliary swing arm to brake caliper mount

M8

Model C1

Connection

34 Brakes

Brake caliper at telescopic tube Nm 41

Banjo bolt to brake caliper Nm 18

Bleed screw in brake caliper Nm 14

6-point nut to final-drive shaft

(rear wheel),

Auxiliary swing arm to brake caliper holder,

M10 bolt, with locking fluid

Auxiliary swing arm to brake caliper mount,

M8

Auxiliary swing arm to powertrain cradle Nm 21

Expansion tank cap Nm 1

use only once

Nm 60 LOCTITE 243

Nm 21

Nm 130

Nm 60 LOCTITE 243

Nm 21

Suspension strut to brake caliper carrier Nm 21

ABS sensor to brake caliper carrier Nm 9

ABS sensor to telescopic tube Nm 9

Brake disc Nm 21

ABS reluctor ring Nm 5

Baseplate to frame

Bracket for washer fluid reservoir on frame

Brake lines to ABS control unit, M12x1 Nm 18

Brake lines to ABS control unit, M10x1 Nm 18

Union, brake hose/brake line Nm 18

Bracket on frame joint Nm 5

Brake line to brake lever fitting Nm 18

All fasteners, brake line to frame Nm 5

Nm 9

00.7

Model C1

Connection

36 Wheels

Stub axle, locking fluid Nm 30

Quick-release axle clamp screws Nm 21

Brake caliper at telescopic tube Nm 41

6-point nut to final-drive shaft (rear wheel),

use only once

Nm 130

Auxiliary swing arm to brake caliper holder,

locking fluid, M10

Auxiliary swing arm to powertrain cradle, M8 Nm 21

Spring strut at bottom Nm 21

Model C1

Connection

46 Frame

Body panels to body panels Nm 2,8

Body panels to frame Nm 2,8

Lightweight foam element to frame Nm 5

Foam part to cross member Nm 5

Air plenum to rear wheel mudguard Nm 12

Roof/windscreen to cross bar Nm 5

Windscreen to bracket Nm 5

Bracket, wiper motor to roof frame Nm 5

Rear mudguard to powertrain cradle Nm 12

Air filter housing to powertrain cradle Nm 12

Nm 60 LOCTITE 243

Crash element shoulder bar to frame Nm 9

Holder, crash element to frame Nm 9

Rear frame to frame Nm 21

Suspension strut to rear frame Nm 41

Joint

Nut to frame, front left, M28 Nm 105

Screw to frame, front left, M28 Stage 1 20

Screw to frame, front left, M28 Stage 2 Back off 1/2 turn

Screw to frame, front right Nm 73

Rubber bush to frame Nm 42

Rubber bush to joint Nm 42

Powertrain cradle to joint Nm 73

Joint swinging arms to each other Nm 73

Easy-lift mechanism

Spring strut to leading link Nm 41

Articulated-lever mechanism to frame Nm 21

00.8

Model C1

Connection

46 Frame

Attachment of control cam of large hand lever, locking fluid

Stand to frame Nm 41

Switch (easy-lift mechanism) stand to frame Nm 8

Spring holder (easy-lift mechanism) to frame Nm 21

Bowden cable retaining bracket to frame Nm 21

Lock of Bowden cable Nm 8

Auxiliary swing arm to powertrain cradle Nm 21

Eyebolt to frame Nm 8

Shoulder bar

Seat to frame Nm 21

Head restraint to frame Nm 21

Shoulder bar, top, to frame M10 Nm 41

Shoulder bar, top, to frame M8 Nm 21

Shoulder bar, bottom, to frame M6 (clamping screw)

Roof frame

Front roof bar (clamp) Nm 21

Rear roof bar (clamp) Nm 21

Nm 2 LOCTITE 243

Nm 9

Roof frame cross brace Nm 21

Mirror brackets Nm 5

Luggage system

Top bracket to frame Nm 8

Bracket to rear frame Nm 21

Top bracket to bracket Nm 21

Lock carrier Nm 5

Head restraint to frame Nm 21

Model C1

Connection

51 Equipment

Ignition lock to frame Nm 9

Seat latch Nm 9

Seat bench lock to left rear side panel Nm 3

Striker on rear storage compartment Nm 3

Lock cylinder on rear storage compartment Nm 7

Striker of storage compartment Nm 3

Lock cylinder on storage compartment Nm 7

Lock bolt for luggage rail Nm 3

00.9

Model C1

Connection

51 Equipment

Mirror bracket to frame Nm 5

Mirror to mirror bracket Nm 4

Cover on mirror arm Nm 3

Model C1

Connection

52 Seats

Seat to frame Nm 21

Seat lock Nm 9

Backrest Nm Hand-tight

Head restraint to frame Nm 21

Model C1

Connection

61 Electrical equipment

Combination switch Nm 4

Battery cable to battery Nm 3

Battery cable to starter relay Nm 3

Control current cables to starter relay Nm 0,4

Voltage regulator to frame Nm 12

BMS control unit to frame Nm 5

Wipe/wash sensor to frame Nm 3

Earth cable to frame Nm 5

Wiper arms Nm 9

Clamp, cable harness to frame Nm 5

Horn to frame Nm 8

Windscreen wiper motor to bracket Nm 5

Wiper motor bracket to roof frame Nm 5

Stationary shaft, wiper motor Nm 9

Cable to starter Nm 5

Bracket of starter relay to frame Nm 5

Bracket of wiring harness to frame Nm 5

00.10

Model C1

Connection

62 Instruments

Instrument cluster to instrument panel Nm 3

Cable clamp to instrument cluster Nm 1

Cable terminal to instrument cluster Nm 0.5

Model C1

Connection

63 Lights

Front/rear turn signal lens Nm 2

Front turn signal to fairing Nm 2

Rear turn signal to license plate holder Nm 3

Headlight subframe Nm 9

Taillamp cluster Nm 5

Model C1

Connection

65 Optional extras

Alarm system

Control unit Nm Hand-tight

Motion sensor Nm Hand-tight

Bracket/ignition coil Nm 5

Fun audio system

Volume control Nm Hand-tight

Amplifier Nm 2

Speaker front trim panel Nm 2

Speaker bracket Nm 4

Model C1

Connection

72 Seat belts

Seat belt inertia reel to frame Nm 42

Belt buckle to belt-buckle mount Nm 42

Belt-buckle mount to frame Nm 42

Secondary mudguard Nm 5

00.11

Table of service products

Item Use Order number Quantity

Lubricant

StaburagsNBU30PTM High-performance lubricating paste 07 55 9 056 992

Optimoly MP 3 High-performance lubricating paste 07 55 9 062 476

Optimoly TA High-temperature assembly paste 18 21 9 062 599

Silicone grease 300, heavy Insulation grease 07 58 9 058 193

Retinax EP2

Contact spray Contact spray 81 22 9 400 208

Chain spray Drive chain

Shell HDX2

Klüber paste 46 MR 401

Wheel, steering head and taper roller

bearing grease

Variator rollers

driven variator (pins and bearing)

against fretting corrosion

spacer, variator shaft spline, clutch

drum

crankshaft and outer disc

Shaft seal seats

Ball-bearing seats, shaft journals,

bearing shells, outer ø

Small-end bore, piston pin

83 22 9 407 845

72 60 2 316 676

72 60 2 316 667

11 00 7 660 830

11 00 7 660 831

75 g (2.65 oz)

tube

100 g (3.53 oz)

tube

100 g (3.53 oz)

tube

10 g (0.35 oz)

tube

100 g (3.53 oz)

tube

300 ml

(0.53 Imp pint/

0.32 US quart)

spray

50 ml

(0.088 Imp pint/

0.053 US quart)

spray

300 ml

(0.53 Imp pint/

0.32 US quart)

spray

400 g (14.12 oz)

tube

60 g (2.12 oz)

tube

MOLYKOTE 111

Never Seez Compound Oxygen sensor 83 23 9 407 830

Sealants

3-Bond 1110 B Surface sealant 07 58 9 056 998

3-Bond 1209 Surface sealant 07 58 9 062 376

omni VISC 1002 Surface sealant (max. 200 °C/392 °F) 07 58 1 465 170

Loctite 574 Surface sealant 81 22 9 407 301

Curil K 2 Heat-conductive sealant 81 22 9 400 243

00.12

Water pump, water pump chamber,

shaft seals

11 00 7 660 832

100 g (3.53 oz)

tube

100 g (3.53 oz)

tube

5 g (0.18 oz)

tube

30 g (1.06 oz)

tube

90 g (3.18 oz)

tube

50 ml

(0.088 Imp pint/

0.053 US quart)

tube

250 g (8.83 oz)

can

Item Use Order number Quantity

Hylomar SQ 32 M Permanently elastic sealant 81 22 9 400 339

Adhesives and retainers

100 g (3.53 oz)

tube

Loctite 648 Joint adhesive (low clearance) 07 58 9 067 732

Loctite 638 Joint adhesive (greater clearance) 07 58 9 056 030

Loctite 243 Thread retainer, medium-strength 07 58 9 056 031

Loctite 270 Thread retainer, strong 81 22 9 400 086

Loctite 2701 Thread retainer, strong 33 17 2 331 095

Loctite 454 Cyanacrylate adhesive (gel) 07 58 9 062 157

Cleaners

Brake cleaner Brake cleaner 83 11 9 407 848

Metal Polish Polish for chrome-plated parts 82 14 9 400 890

5 g (0.18 oz)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

10 ml

(0.018 Imp pint/

0.010 US quart)

bottle

20 g (0.71 oz)

tube

600 ml

(1.056 Imp pint/

0.634 US quart)

spray

100 g (3.53 oz)

tube

Testing agents

Penetrant MR 68

Developer MR 70

Installation aids

BMW cooling spray

Crack testing agent for aluminium

housings

Crack testing agent for aluminium

housings

Cooling components before assembly

83 19 9 407 855

81 22 9 407 495

83 19 9 407 762

500 ml

(0.880 Imp pint/

0.528 US quart)

spray

500 ml

(0.880 Imp pint/

0.528 US quart)

spray

300 ml

(0.53 Imp pint/

0.32 US quart)

spray

00.13

00.14

00

00 Pre-delivery check

Contents

Check transport container for damage

Damage in Germany

Damage in export markets

Unpack C1

Place C1 on stand ............................................................................................................................ 19

Take the C1 from the stand ..............................................................................................................21

...................................................................................................................................... 18

Check C1 for damage

.................................................................................................................... 17

....................................................................................................... 17

..............................................................................................................23

..........................................................................17

Page

Check package contents to determine whether consignment is complete

23

Fill and charge the battery

Use BMW MoDiTeC/DIS plus to access stored error codes

Check tyre inflation pressures

Add fuel

............................................................................................................................................ 25

....................................................................................................24

..............................25

............................................................................................25

.

Operation check as final inspection

Final cleaning

Vehicle delivery

............................................................................................................................... 26

............................................................................................................................ 26

................................................................................25

00.15

00.16

00

Check transport container for damage

Inspect the transport container immediately for

•

damage as soon as the C1 is delivered, remembering to check for collateral damage if indicated

Damage in Germany

Record the damage on the consignment waybill

•

Read transport damage information sheet

•

Inform supplier (freight expediter, rail, etc.) and

•

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

80788 München

Tel. 089/143 276 32

Fax. 089/143 276 39

immediately

Damage in export markets

Record damage on the consignment waybill

•

National response arrangements apply

•

Submit questions to:

Bavaria Wirtschaftsagentur GmbH

Abteilung ZW - 12

80788 München

Tel. +49 89 143 276 32

Fax. +49 89 143 276 39

Inform supplier (freight expediter, etc.) immedi-

•

ately

00.17

Unpack C1

Open shipping container at strap holes (enlarged

•

openings) on left and right sides

Remove any enclosed packages

•

–Luggage rack

Cut open along the line indicated (follows path of

•

strap)

Dismantle shipping container

•

e

Attention:

Loosen straps without yet removing!

Loosen straps

•

C1000340

C1000350

00.18

e

Attention:

Ensure that it will be possible to fold out the stand!

Place C1 on stand

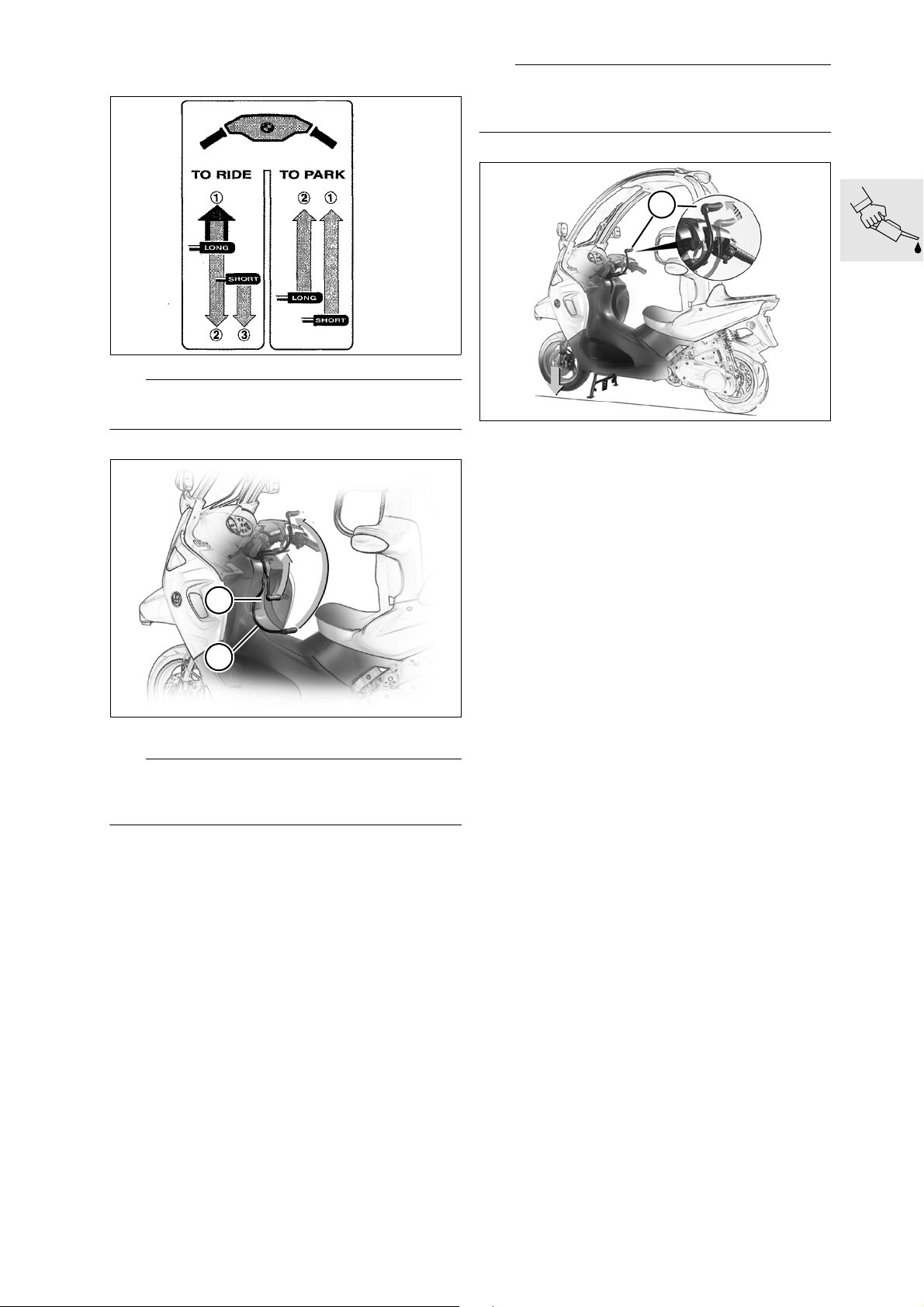

L

Note:

Note instruction plate on instrument trim!

C1000360

L

Note:

The easy-lift mechanism has overload protection.

Fold out the stand with foot if necessary!

1

C1000370

Push up long lever (1) on easy-lift mechanism

•

until it reaches the end of its travel

– The front wheel lifts clear of the ground

– Keep a firm grip on the lever

Slowly move the long lever (1) back until the de-

•

tent engages

Check to verify that the C1 is standing securely

•

2

1

C100BA56

e

Attention:

Excessive strain can damage the easy-lift mechanism!

Hold C1 vertical

•

Centre the handlebar

•

Pull up short lever (2) on easy-lift mechanism

•

– The stand extends

00.19

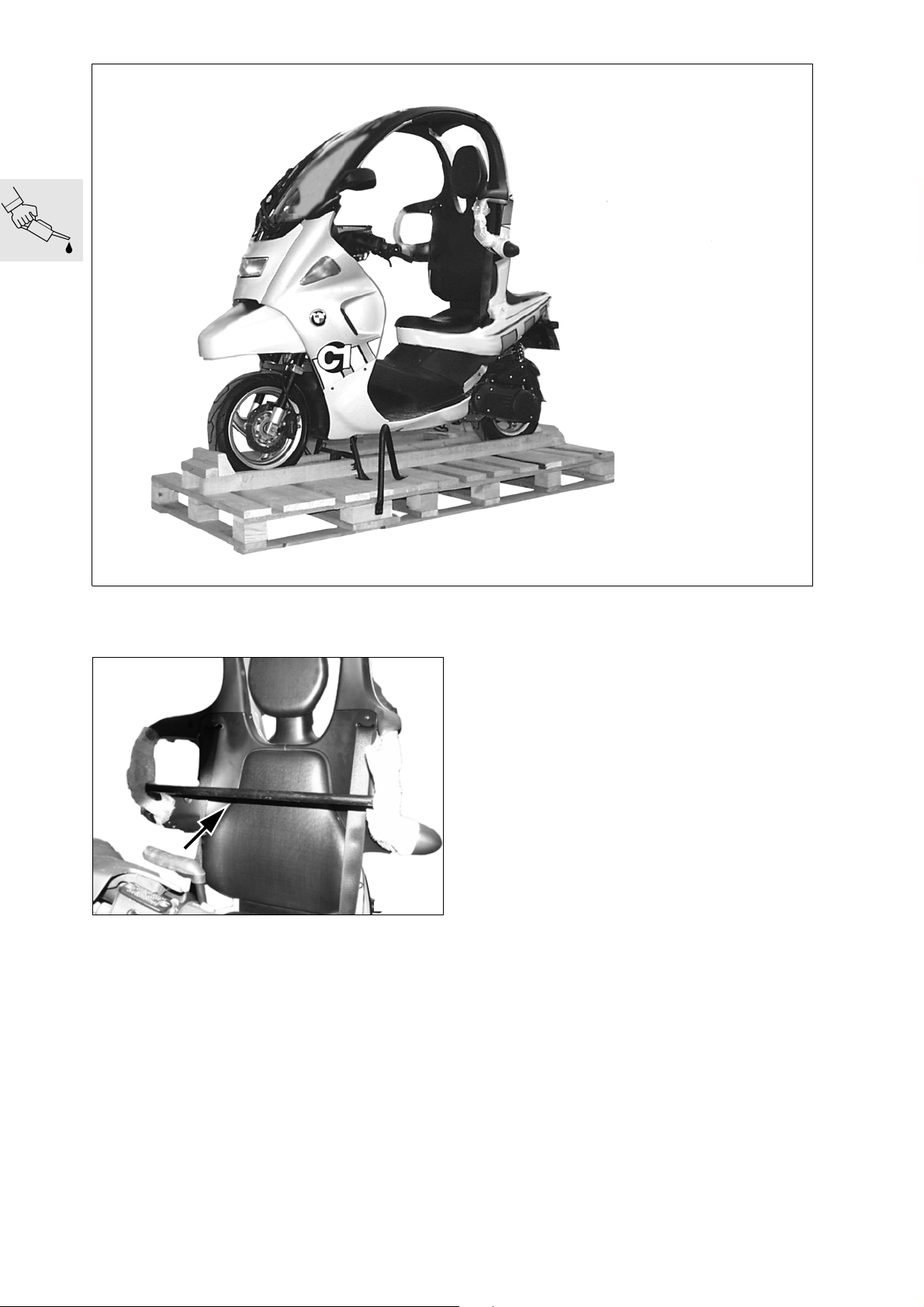

Release and remove straps

•

C1000390

Remove cross member (arrow, shipping brace)

•

C1000380

00.20

Loading...

Loading...