Page 1

The DCode

™

Universal Mutation

Detection System

Catalog Numbers

170-9080 through 170-9104

For technical service call your local Bio-Rad office or in the U.S., call 1-800-4BIORAD (1-800-424-6723)

Page 2

Warranty

The DCode universal mutation detection system lid, tanks, casting stand, gradient mixer,

and accessories are warranted against defects in materials and workmanship for 1 year. If

any defects occur during this period, Bio-Rad will repair or replace the defective parts at our

discretion, without charge. The following defects, however, are excluded:

1. Defects caused by improper operation.

2. Repair or modification done by anyone other than Bio-Rad Laboratories or an authorized agent.

3. Damage caused by substituting alternative parts.

4. Use of fittings or spare parts supplied by anyone other than Bio-Rad Laboratories.

5. Damage caused by accident or misuse.

6. Damage caused by disaster.

7. Corrosion caused by improper solvent†or sample.

This warranty does not apply to parts listed below:

• Fuses

• Glass plates

• Electrodes

For any inquiry or request for repair service, contact Bio-Rad Laboratories. Inform

Bio-Rad of the model and serial number of your instrument.

Important: This Bio-Rad instrument is designed and certified to meet EN61010-1* safety

standards. Certified products are safe to use when operated in accordance with the instruction

manual. This instrument should not be modified or altered in any way. Alteration will:

• Void the manufacturer’s warranty

• Void the EN61010-1 safety certification

• Create a potential safety hazard

Bio-Rad Laboratories is not responsible for any injury or damage caused by the use of this

instrument for purposes other than those for which it is intended, or by modifications of the

instrument not performed by Bio-Rad Laboratories or an authorized agent.

The Model 475 Gradient Delivery System is covered by U.S. patent number 5,540,498.

Practice of PCR is covered by U.S. patent numbers 4,683,195; 4,683,202; 4,899,818

issued to Cetus Corporation, which is a subsidiary of Hoffmann-LaRoche Molecular Systems,

Inc. Purchase of any of Bio-Rad’s PCR-related products does not convey a license to use

the PCR process covered by these patents. To perform PCR, the user of these products must

obtain a license.

© 1996 Bio-Rad Laboratories

All Rights Reserved

† The DCode system tank is not compatible with chlorinated hydrocarbons (e.g., chloroform), aromatic hydrocarbons (e.g., toluene,

benzene), or acetone. Use of organic solvents voids all warranties.

* EN61010-1 is an internationally accepted electrical safety standard for laboratory instruments.

Page 3

Table of Contents

Section 1 General Safety Information ..........................................................1

1.1 Caution Symbols........................................................................................1

1.2 Precautions During Set-up .........................................................................1

1.3 Precautions During a Run..........................................................................1

1.4 Precautions After a Run.............................................................................2

1.5 Safety ........................................................................................................2

Section 2 Introduction ...................................................................................2

2.1 Introduction to Mutation Detection Technology...........................................2

Section 3 Product Description......................................................................2

3.1 Packing List ...............................................................................................2

3.2 System Components and Accessories.......................................................5

Section 4 Denaturing Gel Electrophoresis (DGGE, CDGE, TTGE)............11

4.1 Introduction to Denaturing Gradient Gel Electrophoresis (DGGE) ............11

Reagent Preparation................................................................................13

Gel Volumes ............................................................................................15

Sample Preparation .................................................................................16

Temperature Controller............................................................................17

Preheating the Running Buffer.................................................................18

Assembling the Perpendicular Gradient Gel Sandwich ............................18

Casting Perpendicular Gradient Gels .......................................................22

Assembling the Parallel Gradient Gel Sandwich ......................................24

Casting Parallel Gradient Gels .................................................................26

4.2 Introduction to Constant Denaturing Gel Electrophoresis (CDGE)............28

Reagent Preparation................................................................................29

Gel Volumes ............................................................................................31

Sample Preparation .................................................................................31

Temperature Controller............................................................................32

Preheating the Running Buffer.................................................................33

Assembling the CDGE Gel Sandwich ......................................................33

Casting CDGE Gels.................................................................................35

4.3 Introduction to Temporal Temperature Gradient Gel Electrophoresis

(TTGE) ....................................................................................................36

Calculating the Run Parameters ..............................................................37

Reagent Preparation................................................................................38

Gel Volumes ............................................................................................40

Sample Preparation .................................................................................40

Preheating the Running Buffer.................................................................40

Assembling the TTGE Gel Sandwich .......................................................40

Temperature Controller............................................................................41

Casting TTGE Gels..................................................................................43

Section 5 Heteroduplex Analysis................................................................44

5.1 Introduction to Heteroduplex Analysis ......................................................44

5.2 Reagent Preparation................................................................................45

5.3 Gel Volumes ............................................................................................47

5.4 Sample Preparation .................................................................................48

5.5 Temperature Controller............................................................................48

5.6 Adding the Running Buffer .......................................................................49

5.7 Assembling the Heteroduplex Analysis Gel Sandwich .............................50

Page 4

5.8 Casting Heteroduplex Analysis Gels ........................................................51

Section 6 Single-Stranded Conformational Polymorphism (SSCP) .........52

6.1 Introduction to SSCP ..............................................................................52

6.2 Reagent Preparation ...............................................................................54

6.3 Gel Volumes ............................................................................................56

6.4 Sample Preparation ................................................................................56

6.5 Temperature Controller............................................................................57

6.6 Cooling the Running Buffer and Chiller Settings.......................................58

6.7 Assembling the SSCP Gel Sandwich.......................................................58

6.8 Casting SSCP Gels .................................................................................60

Section 7 Protein Truncation Test (PTT).....................................................61

7.1 Introduction to PTT .................................................................................61

7.2 Reagent Preparation ...............................................................................62

7.3 Gel Volumes ............................................................................................64

7.4 Sample Preparation .................................................................................64

7.5 Temperature Controller............................................................................65

7.6 Adding the Running Buffer .......................................................................66

7.7 Assembling the PTT Gel Sandwich..........................................................66

7.8 Casting PTT Gels ....................................................................................68

Section 8 Electrophoresis...........................................................................69

8.1 Assembling the Upper Buffer Chamber....................................................69

8.2 Sample Loading.......................................................................................71

8.3 Running the Gel.......................................................................................71

8.4 Removing the Gel ....................................................................................73

8.5 Staining and Photographing the Gel ........................................................74

Section 9 Troubleshooting Guide ..............................................................75

9.1 Equipment ..............................................................................................75

9.2 Applications .............................................................................................77

Section 10 Specifications..............................................................................81

Section 11 Maintenance ................................................................................82

Section 12 References...................................................................................82

Section 13 Instruments and Reagents for Mutation Detection

Electrophoresis ..........................................................................83

Page 5

Section 1

General Safety Information

1.1 Caution Symbols

Read the manual before using the DCode system. For technical assistance, contact your

local Bio-Rad Office or in the U.S., call Technical Services at 1-800-4BIORAD (1-800-424-6723).

DC power to the DCode system is supplied by an external DC voltage power supply. This power

supply must be ground isolated so that the DC voltage output floats with respect to ground. All BioRad power supplies meet this important safety requirement. Regardless of which power supply

is used, the maximum specified operating parameters for the system are:

• Maximum voltage limit 500 VDC

• Maximum power limit 50 watts

AC current for controlling temperature to the system, and DC current for electrophoresis,

provided by the external power supply, enter the unit through the lid assembly, which provides

a safety interlock. DC current to the cell is broken when the lid is removed. Do not attempt to circumvent this safety interlock. Always disconnect the AC cord from the unit and the cord

from the DC power supply before removing the lid, or when working with the cell.

Definition of Symbols

Caution, risk of electric shock.

Caution

Caution, hot surface.

1.2 Precautions During Set-up

• Do not use near flammable materials.

• Always inspect the DCode system for damaged components before use.

• Always place the DCode system on a level bench-top.

• Always place the lid assembly on the buffer tank with the AC and DC power cords

disconnected.

• Always connect the system to the correct AC and DC power sources.

1.3 Precautions During a Run

• Do not run the pump when it is dry. Always add buffer to the “Fill” line when

pre-chilling and/or preheating the buffer; always keep the buffer below “Max” level during

electrophoresis.

• Do not touch any wet surface unless all the electrical sources are disconnected.

• Do not put anything on the top surface of the DCode system module.

1

Page 6

1.4 Precautions After a Run

• Always turn off power switches and unplug all cables to DC and AC sources. Allow the

heater tube to cool down (approximately 1 minute) before removing it from the tank. The

ceramic tube may be very hot after shut-down. Do not touch the ceramic tube after turn-

ing off the power.

• Do not cool the hot ceramic tube in cool liquids.

• Always store the electrophoresis/temperature control module on the aluminum DCode

lid stand for maximum stability. Caution: the heater tube may be hot after use

1.5 Safety

This instrument is intended for laboratory use only

This product conforms to the “Class A” standards for electromagnetic emissions intended for laboratory equipment applications. It is possible that emissions from this product may

interfere with some sensitive appliances when placed nearby or in the same circuit as those

appliances. The user should be aware of this potential and take appropriate measures to

avoid interference.

Section 2

Introduction

2.1 Introduction to Mutation Detection Technology

Detecting single base mutations is of utmost importance in the field of molecular genetics.

Screening for deletions, insertions, and base substitutions in genes was initially done by Southern

blotting. Many techniques have been developed to analyze the presence of mutations in a DNA

target. The most common methods include: Single-Strand Conformational Polymorphism

1

(SSCP), Denaturing Gradient Gel Electrophoresis2(DGGE), carbodiimide3(CDI), Chemical

Cleavage of Mismatch4(CCM), RNase cleavage,5Heteroduplex analysis,6and the Protein

Truncation Test7(PTT). A new technique for mutation detection is Temporal Temperature

Gradient Gel Electrophoresis8(TTGE). Bio-Rad reduced this technique to a simple, reproducible

method on the DCode system. TTGE uses a polyacrylamide gel containing a constant concentration of urea. During electrophoresis, the temperature is increased gradually and uniformly. The result is a linear temperature gradient over the course of the electrophoresis run. Many

labs used combination of methods to maximize mutation detection efficiency.

The DCode system is a vertical electrophoresis instrument for the detection of gene

mutations. The DCode system can be used to perform any vertical gel-based mutation

detection method. The system is optimized for DGGE, CDGE, TTGE, SSCP, PTT and

Heteroduplex Analysis. Some of the advantages of the DCode system include uniform buffer

temperature around the gel, buffer circulation, buffer temperature runs from 5 to 70 °C and a

modular design to allow customization.

Section 3

Product Description

3.1 Packing List

The DCode system is shipped with the following components. If items are missing or damaged, contact your local Bio-Rad office.

2

Page 7

The DCode System for DGGE (10 cm and 16 cm systems)

Item Quantity

Instruction manual 1

Warranty card (please complete and return) 1

Electrophoresis/temperature control module 1

Electrophoresis tank 1

Casting stand with sponges 1

Sandwich core 1

DCode lid stand 1

16 cm glass plates (16 cm system) 2 sets

10 cm glass plates (10 cm system) 2 sets

Sandwich clamps 2 sets

Spacers, grooved, 1 mm 2 sets

Middle spacer, 1 mm (10 cm system) 2

Prep comb, 1 well, 1 mm (16 cm system) 2

Prep comb, 2 well, 1 mm (10 cm system) 2

16-well comb, 1 mm 1

Comb gasket for 0.75 & 1 mm spacers 1

Comb gasket holder 1

Model 475 gradient former 1

Syringes: 10 ml, 30 ml 2 each

Tubing 3 feet

Luer couplings 4

Luer syringe locks 2

Syringe sleeves 4

Syringe cap screws 2

Y-fitting 5

Control reagent kit for DGGE, CDGE, TTGE 1

DCode System for CDGE

Item Quantity

Instruction manual 1

Warranty card (please complete and return) 1

Electrophoresis/temperature control module 1

Electrophoresis tank 1

Casting stand with sponges 1

Sandwich core 1

DCode lid stand 1

Glass plates, 16 cm 2 sets

Sandwich clamps 2 sets

Spacers, 1 mm 2 sets

20-well combs, 1 mm 2

Control reagent kit for DGGE, CDGE, TTGE 1

3

Page 8

DCode System for TTGE

Item Quantity

Instruction manual 1

Warranty card (please complete and return) 1

Electrophoresis/temperature control module 1

Electrophoresis tank 1

Casting stand with sponges 1

Sandwich core 1

DCode lid stand 1

Glass plates, 16 cm 2 sets

Sandwich clamps 2 sets

Spacers, 1 mm 2 sets

20-well combs, 1 mm 2

Control reagent kit for DGGE, CDGE, TTGE 1

DCode System for SSCP

Item Quantity

Instruction manual 1

Warranty card (please complete and return) 1

Electrophoresis/temperature control module 1

Electrophoresis cooling tank 1

Casting stand with sponges 1

Sandwich core 1

DCode lid stand 1

Sandwich clamps 2 sets

Glass plates, 20 cm 2 sets

Spacers, 0.75 mm 2 sets

20-well combs, 0.75 mm 2

Control reagent kit for SSCP 1

DCode System for Heteroduplex Analysis

Item Quantity

Instruction manual 1

Warranty card (please complete and return) 1

Electrophoresis/temperature control module 1

Electrophoresis tank 1

Casting stand with sponges 1

Sandwich core 1

DCode lid stand 1

Sandwich clamps 2 sets

Glass plates, 20 cm 2 sets

Spacers, 0.75 mm 2 sets

20-well combs, 0.75 mm 2

Control reagent kit for Heteroduplex Analysis 1

4

Page 9

DCode System for Protein Truncation Test

Item Quantity

Instruction manual 1

Warranty card (please complete and return) 1

Electrophoresis/temperature control module 1

Electrophoresis tank 1

Casting stand with sponges 1

Sandwich core 1

DCode lid stand 1

Sandwich clamps 2 sets

Glass plates, 20 cm 2 sets

Spacers, 1 mm 2 sets

20-well comb, 1 mm 2

3.2 System Components and Accessories

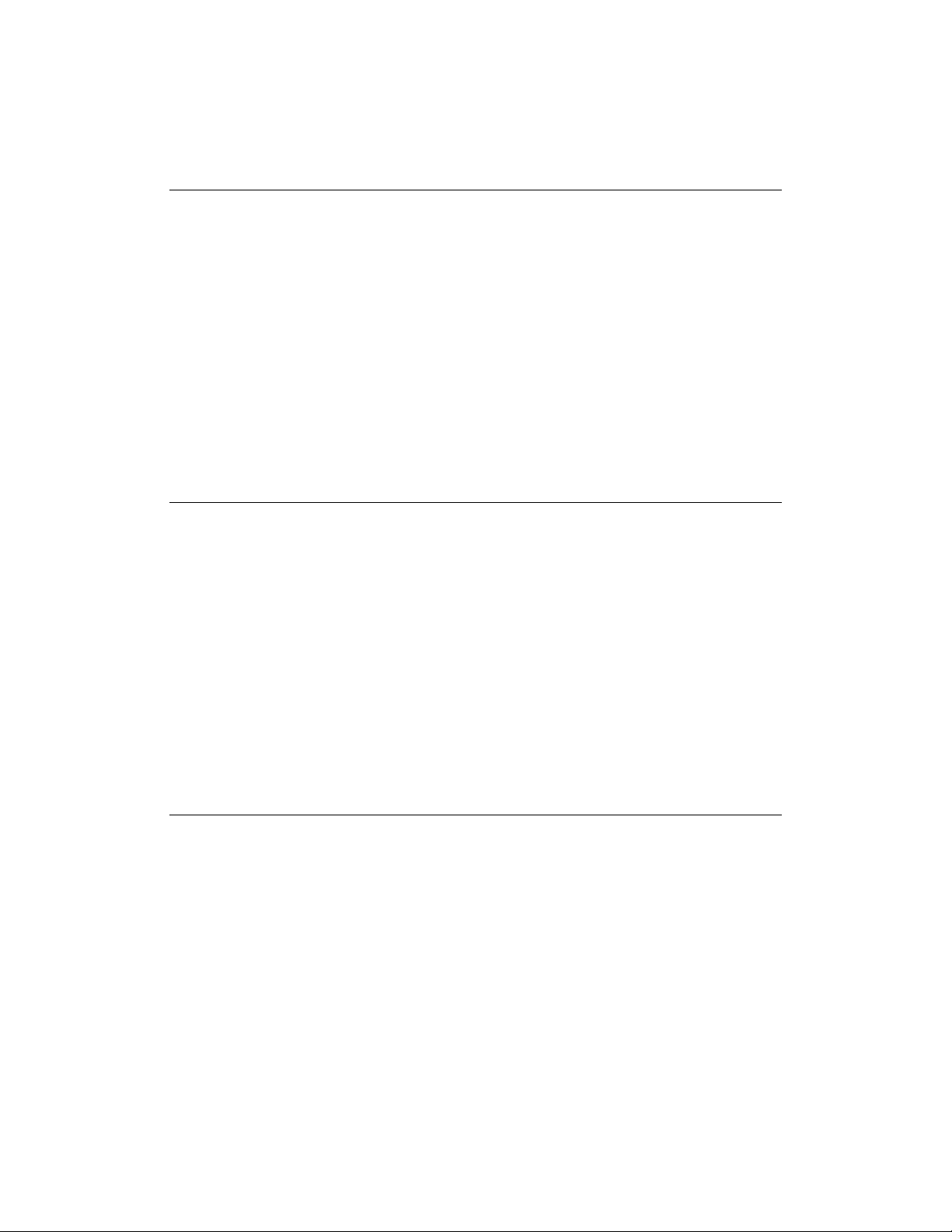

Fig. 3.1. The DCode system.

System Components

and Accessories Description

Electrophoresis Tank The electrophoresis tank is a reservoir for the running buffer.

Electrophoresis Cooling Tank The electrophoresis cooling tank has two ceramic cooling

(SSCP only) fingers inside the electrophoresis tank (Figure 3.2). Two

quick-release connectors are connected to an external

chiller to chill the running buffer. The electrophoresis

cooling tank should not be used for heated buffer runs

(i.e., DGGE, CDGE or TTGE).

Fig. 3.2. Electrophoresis cooling tank.

5

Model 475

Gradient Former

Electrophoresis/temperature

control module

Casting stand with

perpendicular assembly

Electrophoresis tank

Core

Casting

stand

Ceramic

cooling

fingers

Page 10

Fig. 3.3. Electrophoresis/Temperature Control Module.

System Components

and Accessories Description

Electrophoresis/Temperature The control module contains the heater, stirrer, pump,

Control Module and electrophoresis leads to operate the DCode

system (Figure 3.3). Combined with the lower buffer tank,

the control module acts to fully enclose the

system. The control module should be placed so that the

tip of the stirring bar fits inside the support hole of the tank.

The clear loading lid is a removable part that contains four

banana jacks which function as a safety interlock. It should

be left in place at all times except while loading samples.

Core The sandwich core holds one gel assembly on each side

(Figure 3.4). When attached, each gel assembly forms one

side of the upper buffer chamber. The inner plate is

clamped against a rubber gasket on the core to provide a

greaseless seal for the upper buffer chamber.

Fig. 3.4. Core

6

Buffer level

interlock

Temperature

sensor

Buffer

recirculation pump

Buffer

recirculation port

Ceramic heater

Stirrer

Temperature

controller

Page 11

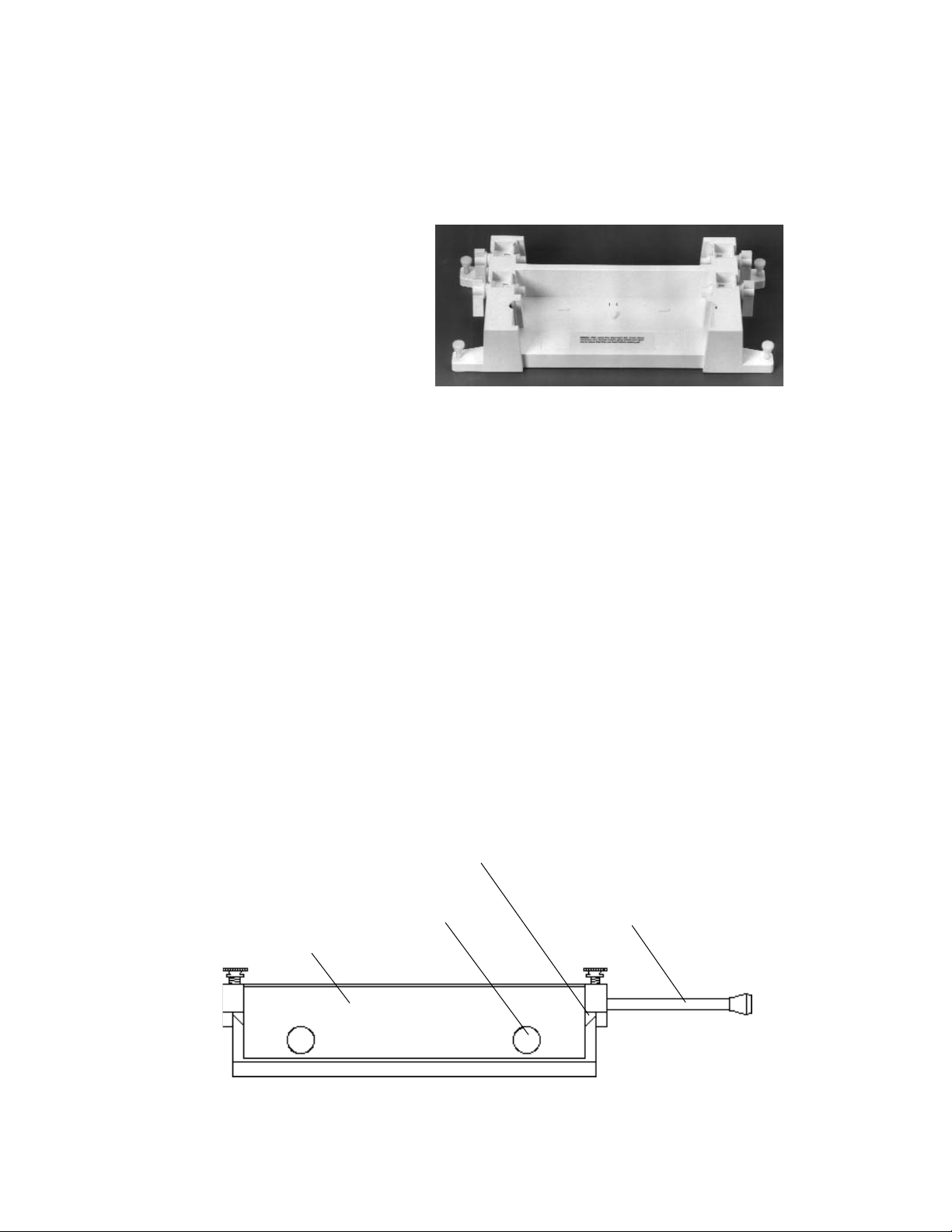

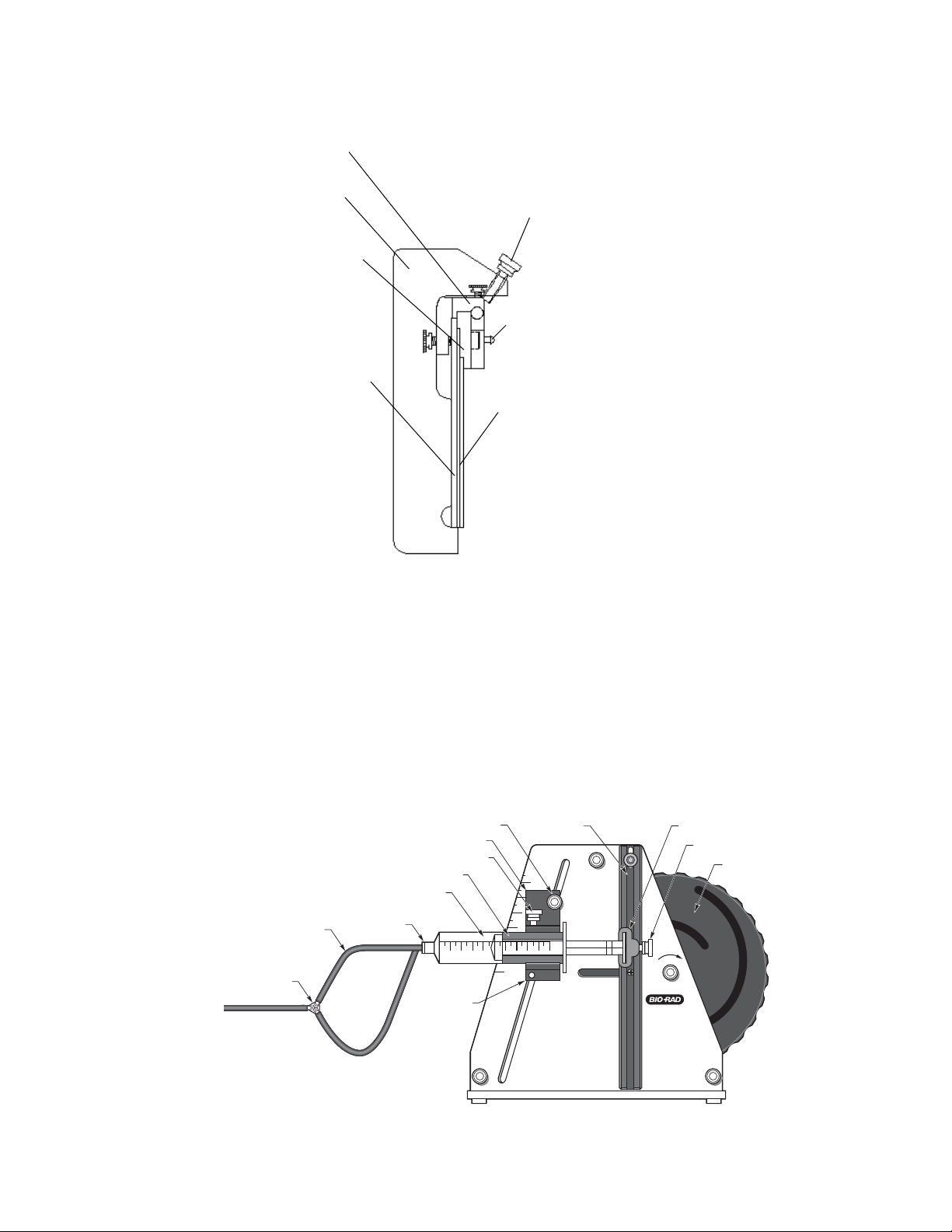

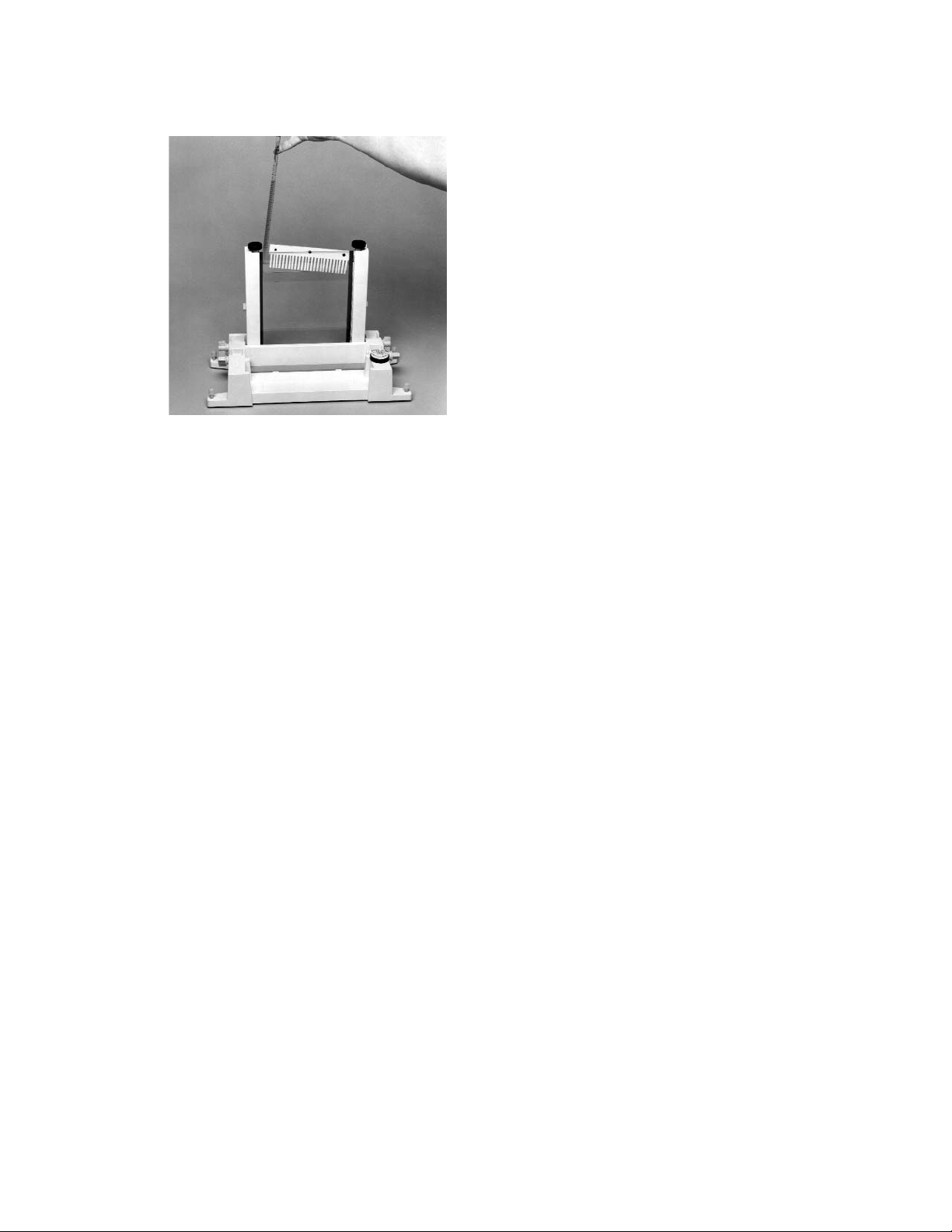

Casting Stand The casting stand holds the gel sandwich upright

while casting a gel (Figure 3.5). With the cam levers

engaged, the sponge seals the bottom of the gel

while the acrylamide polymerizes.

Fig. 3.5. Casting Stand.

Sandwich Clamps The sandwich clamps consist of a single screw

mechanism which makes assembly, alignment, and

disassembly of the gel sandwich an effortless task.

The clamps exert an even pressure over the entire

length of the glass plates. A set consists of a left and

right clamp.

Alignment Card The alignment card simplifies sandwich assembly by

keeping the spacers in the correct position.

Comb Gasket Holder The comb gasket holder holds the comb gasket that

prevents (DGGE only) leakage of acrylamide during gel

casting (Figure 3.6). The front of the holder has two

screws which are used to secure the comb gasket

against the glass plate. The top of the comb gasket

holder also has two tilt rod screws which control the

position of the tilt rod during gel casting. The opposite

side of the comb gasket holder has two vent ports. There

are two sizes of comb gasket holder: a 1 mm size for

1 mm and 0.75 mm spacer sets and a 1.5 mm size for

the 1.5 mm spacer set.

Fig. 3.6. Comb gasket holder.

7

Notched step

Gasket holder

Comb gasket screws

Tilt rod

Page 12

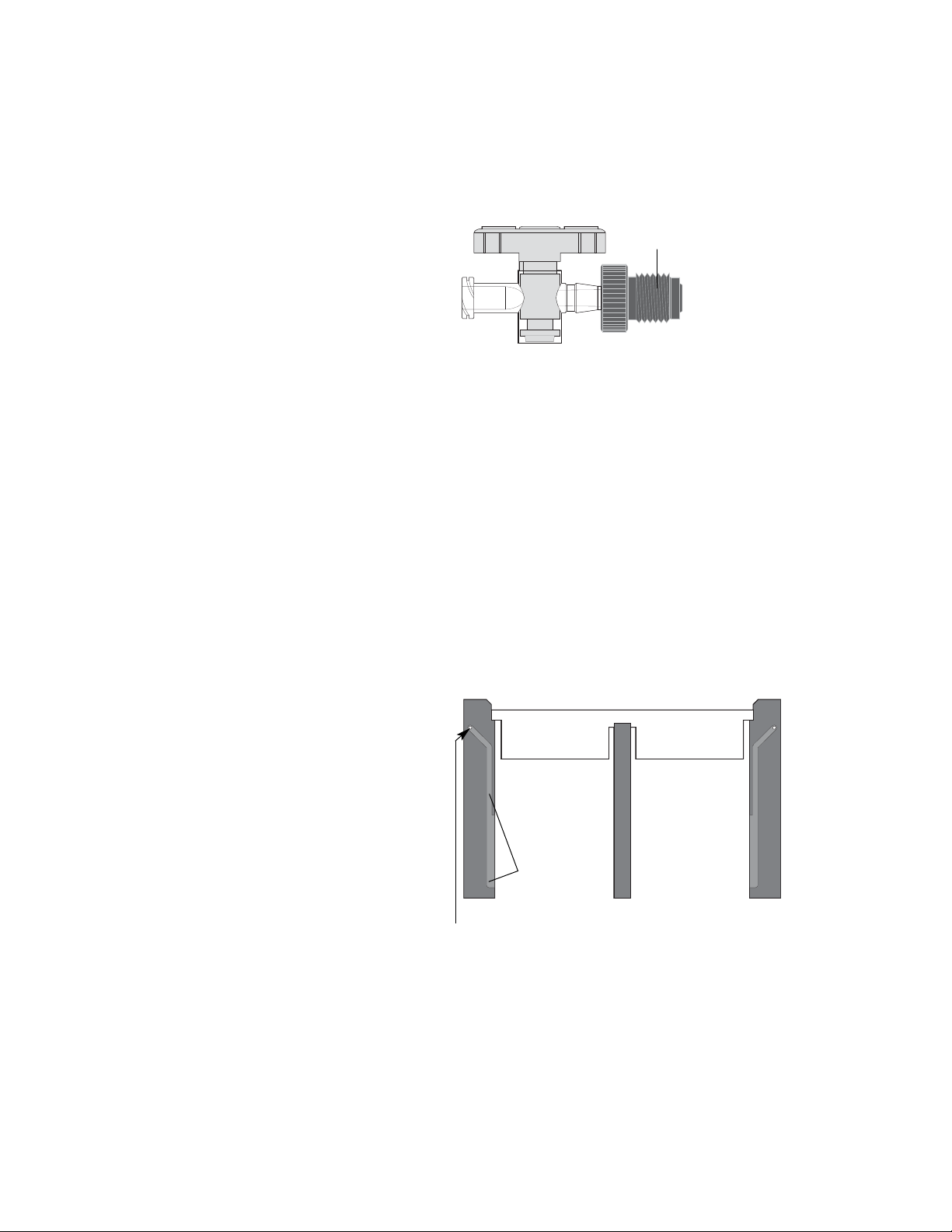

Stopcocks (DGGE only) The gel solution is introduced via the stopcock at the

inlet port on the sandwich clamp when casting a perpendicular gel (Figure 3.7).

Fig. 3.7. Stopcock

Comb and Spacer Set The 7.5 x 10 cm gel format consist of two “mirror image

(DGGE only)spacers, one middle spacer and a dual

prep comb for two 7.5 x 10 cm gels (Figure 3.8). The

spacers have a groove and injection port hole for

casting. The middle spacer between the two gels fits

into the middle notch of the dual comb and allows the

air to escape through the comb gasket holder vent port.

The 16 x 16 cm gel format consist of two different

spacers, one with the groove and injection port hole

for casting and one with a short groove toward the

injection port hole for air to escape. A single prep comb

without a middle spacer is provided with the 16 x 16 cm

gel format.

Fig. 3.8. Dual prep comb and spacer set for two 7.5 x 10 cm gels.

Comb and Spacer Set Different types of combs and spacers are provided with

the different DCode systems. Spacer lengths are

10 cm, 16 cm or 20 cm, with a thickness of 0.75 or

1.0 mm. Combs come with 16 or 20 wells and a

thickness of 0.75 or 1.0 mm.

8

Inlet fitting

Injection port holes

groove

Page 13

Fig. 3.9. Pressure clamp.

Pressure Clamp The pressure clamp provides consistent pressure to

the (DGGE only) comb gasket before securing it to the plate assembly

to provide a seal (Figure 3.9).

DCode Lid Stand The DCode lid stand provides a stand when the

electrophoresis/temperature control module (lid) is not in

use. The stand must be used to properly support and

protect the lid components when the lid is not on the

electrophoresis tank.

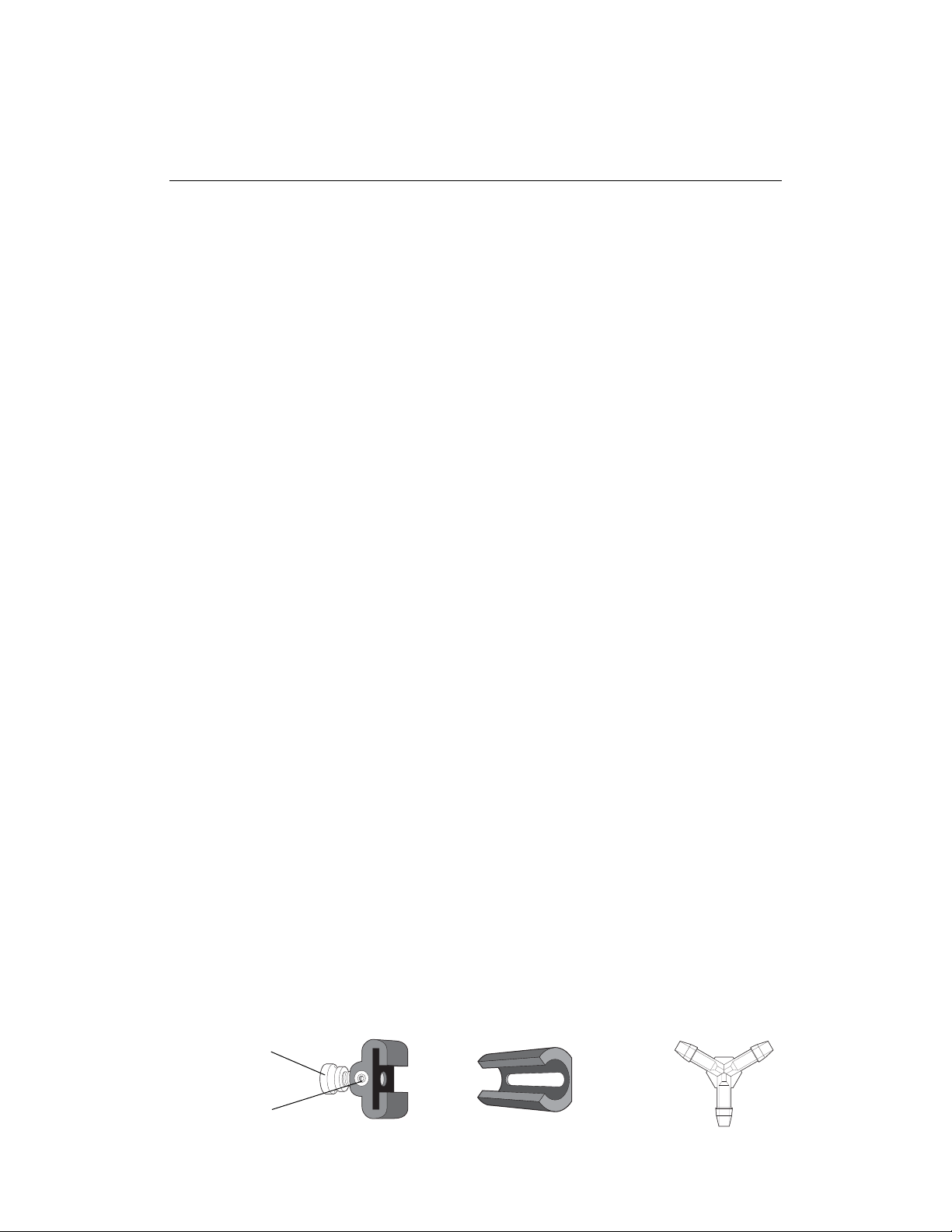

Fig. 3.10. Model 475 Gradient Delivery System.

9

Gasket holder

Comb gasket

Air vent

Pressure clamp

Pressure

clamp screw

Large glass plate

Small glass plate

Luer fitting

VOLUME

10 ML SYRINGE

4

MODEL 475

GRADIENT DELIVERY

SYSTEM

THIS SIDE FOR

HIGH DENSITY SOLUTION

(BOTTOM FILLING)

LOW DENSITY SOLUTION

(TOP FILLING)

Syringe holder

DELIVER

Cam

Plunger cap screw

Plunger cap

Lever

Y-Fitting

Tubing

Syringe

Syringe sleeve

Syringe holder screw

Volume setting indicator

Volume adjustment screw

1234 5 6 78910

10

7

6

5

5 6

Page 14

Model 475 System Components

Description (DGGE System only)

Syringe Two pairs each of 10 and 30 ml disposable syringes are

provided. The 10 ml syringes are for gel volumes less than

10 ml. The 30 ml syringes are for gel volumes greater than

10 ml. For proper gel casting, use matching syringe sizes.

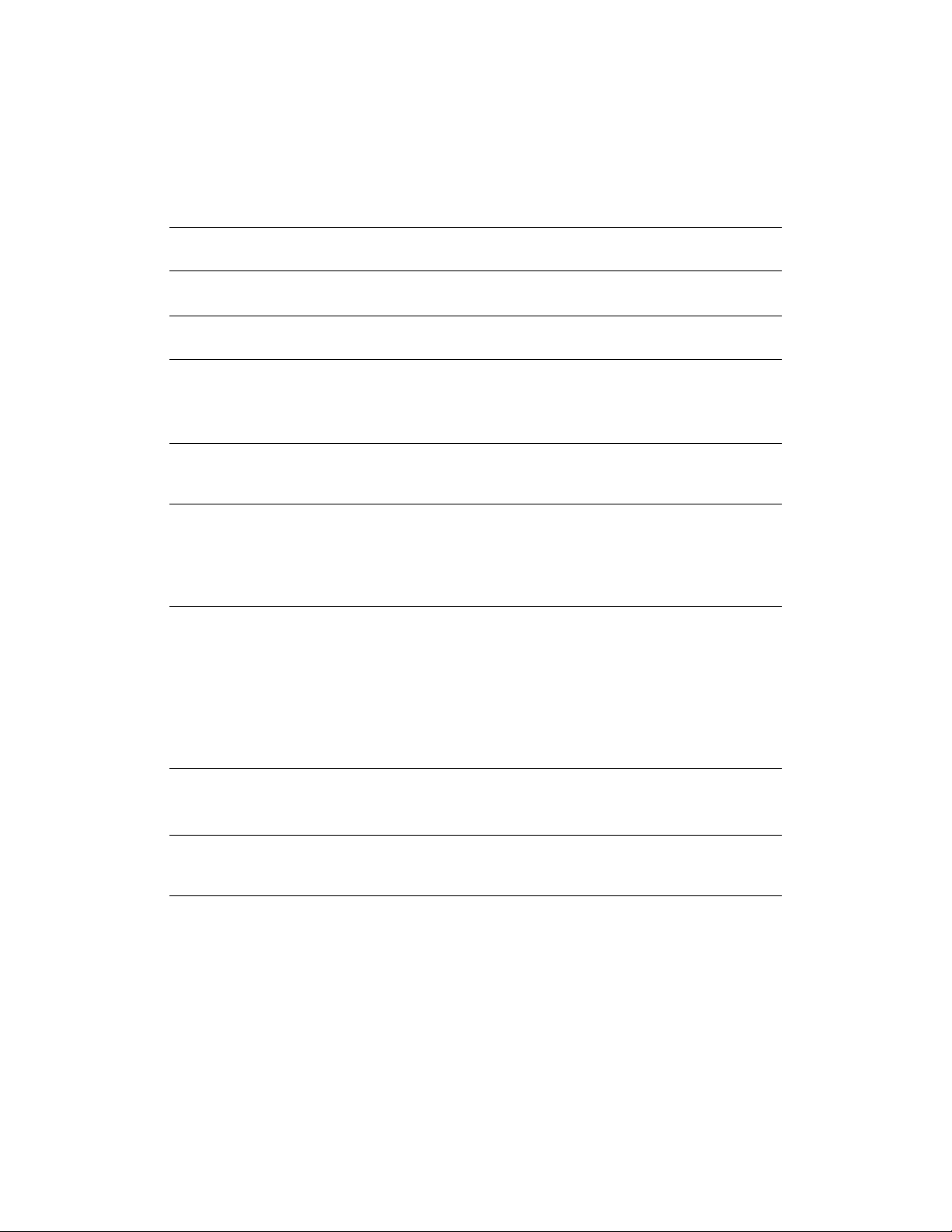

Plunger Caps/ There are two plunger caps, one for each syringe. The

Plunger Cap Screw plunger caps fit both the 10 and 30 ml syringes (Figure 3.11).

Lever Attachment Screw The lever attachment screw is on the plunger cap. This

screw fits into the groove of the lever and conducts the driving

force of the cam in dispensing the gel solution.

Syringe Sleeve One pair of syringe sleeves for each size syringe is

provided (Figure 3.12). The sleeve is a movable adaptor to

mount the syringe in the holder. The sleeve should conform to

the syringe. If the syringe is too tight or too loose, adjust the

sleeve by pushing or pulling.

Syringe Holder/ The syringe holder is next to the lever. It holds the syringe

Syringe Holder Screw in place and controls the delivery volume. The syringe is held

in the holder by tightening the holder screw against the sleeve.

Volume Adjustment Screw The volume adjustment screw is on both sides of the syringe

holder (Figure 3.10). It adjusts the holder to the desired delivery

volume.

Volume Setting Indicator The volume setting indicator is at the top corner of the syringe

holder nearest the volume setting numbers (Figure 3.10).

Lever The position of the lever is controlled by the rotation of the

cam (Figure 3.10). The lever must be in the vertical or start

position before use.

Tygon Tubing One length of Tygon™tubing is provided. Cut the tubing into two

15.5 cm and one 9 cm lengths. The longer pieces are used to

transport the gel solution from the syringes into the Y-fitting. The

short piece will transport the gel solution from the Y-fitting to

the gel sandwich.

Y-Fitting The Y-fitting mixes the high and low density gel

solutions (Figure 3.13).

Luer Fitting/Coupling There are two luer fittings that fit both 10 and 30 ml syringes.

The fittings twist onto the syringe and connect to the Tygon

tubing on the other end. A luer coupling is used on one end

of the 9 cm tubing to connect it to the gel sandwich stopcock.

10

Fig. 3.11. Plunger Cap Fig. 3.12. Syringe sleeve Fig. 3.13. Y-Fitting

Lever

attachment

screw

Plunger cap

screw

Page 15

Section 4

Denaturing Gel Electrophoresis (DGGE, CDGE, TTGE)

4.1 Introduction to Denaturing Gradient Gel Electrophoresis (DGGE)

Denaturing Gradient Gel Electrophoresis (DGGE) is an electrophoretic method to identify

single base changes in a segment of DNA. Separation techniques on which DGGE is based were

first described by Fischer and Lerman.

2

In a denaturing gradient acrylamide gel,

double-stranded DNA is subjected to an increasing denaturant environment and will melt in

discrete segments called "melting domains". The melting temperature (Tm) of these domains is

sequence-specific. When the Tmof the lowest melting domain is reached, the DNA will become

partially melted, creating branched molecules. Partial melting of the DNA reduces its mobility in

a polyacrylamide gel. Since the Tmof a particular melting domain is sequence-specific, the

presence of a mutation will alter the melting profile of that DNA when compared to wild-type. DNA

containing mutations will encounter mobility shifts at different positions in the gel than the

wild-type. If the fragment completely denatures, then migration again becomes a function of

size (Figure 4.1).

Fig. 4.1. An example of DNA melting properties in a perpendicular denaturing gradient gel. At a low concentration of denaturant, the DNA fragment remains double-stranded, but as the concentration of denaturant increases,

the DNA fragment begins to melt. Then, at very high concentrations of denaturant, the DNA fragment can completely

melt, creating two single strands.

In DGGE, the denaturing environment is created by a combination of uniform temperature,

typically between 50 and 65 °C and a linear denaturant gradient formed with urea and

formamide. A solution of 100% chemical denaturant consists of 7 M urea and 40% formamide.

The denaturing gradient may be formed perpendicular or parallel to the direction of

electrophoresis. A perpendicular gradient gel, in which the gradient is perpendicular to the

electric field, typically uses a broad denaturing gradient range, such as 0–100% or 20–70%.

2

In parallel DGGE, the denaturing gradient is parallel to the electric field, and the range of

denaturant is narrowed to allow better separation of fragments.9Examples of perpendicular

and parallel denaturing gradient gels with homoduplex and heteroduplex fragments are shown

in Figure 4.2.

11

Double strand

Single strands

Denaturant

Wild Type

Mutant

100%0%

Partially melted

"wild type"

Partially melted

"mutant"

Electrophoresis

Denaturant

0%

*

Partially melted

“mutant”

Partially melted

“wild type”

100%

Electrophoresis

Single strands

Wild Type

*

Mutant

Double strand

Page 16

Fig. 4.2. A. Perpendicular denaturing gradient gel in which the denaturing gradient is perpendicular to the

electrophoresis direction. Mutant and wild-type alleles of exon 6 from the TP53 gene amplified from primary breast

carcinomas and separated by perpendicular DGGE (0–70% denaturant) run at 80 V for 2 hours at 56 °C. The first two

bands on the left are heteroduplexes and the other two bands are the homoduplexes. B. Parallel denaturing gradient

gel in which the denaturing gradient is parallel to the electrophoresis direction. Mutant and wild-type alleles of

exon 8 from the p53 gene separated by an 8% acrylamide:bis (37.5:1) gel with a parallel gradient of 40–65% denaturant.

The gel was run at 150 V for 2.5 hours at 60 °C in 1x TAE buffer. Lane 1 contains the mutant fragment, lane 2 contains the

wild-type fragment, lane 3 contains both the mutant and wild-type fragments.

When running a denaturing gradient gel, both the mutant and wild-type DNA fragments are

run on the same gel. This way, mutations are detected by differential migration of mutant and

wild-type DNA. The mutant and wild-type fragments are typically amplified by the polymerase

chain reaction (PCR) to make enough DNA to load on the gel. Optimal resolution is attained

when the molecules do not completely denature and the region screened is in the lowest

melting domain. The addition of a 30–40 base pair GC clamp to one of the PCR primers insures

that the region screened is in the lower melting domain and that the DNA will remain partially

double-stranded.34An alternative to GC clamps is using psoralen derivative PCR primers called

ChemiClamp primers.10Because ChemiClamps covalently link the two DNA strands at one

end, they should not be used when isolating a DNA fragment which is going to be sequenced

from a gel. The size of the DNA fragments run on a denaturing gel can be as large as 1 kb in

length, but only the lower melting domains will be available for mutation analysis. For complete

analysis of fragments over 1 kb in length, more than one PCR reaction should be performed.

11

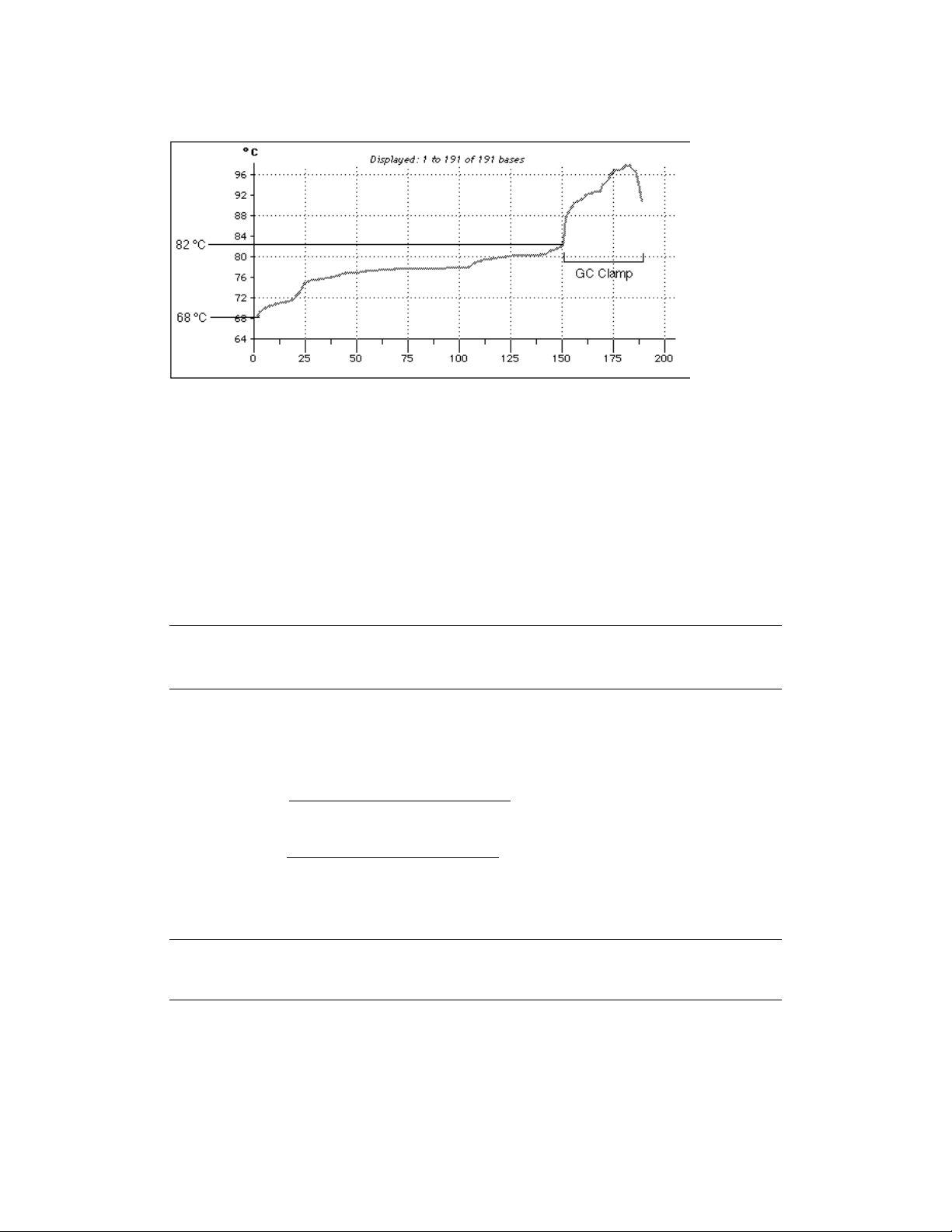

The thermodynamics of the transition of double-stranded to single-stranded DNA have been

described by a computer program developed by Lerman.12Bio-Rad offers a Macintosh

®

computer program, MacMelt™software, which calculates and graphs theoretical DNA melting

profiles. Melting profile programs can show regions of theoretical high and low melting domains

of a known sequence. Placement of primers and GC clamps can be optimized by analysis of

placement effect on the DNA melting profile.

The method of creating heteroduplex molecules helps in detecting homoduplex mutations.

This process is typically done when it is not originally possible to resolve a homoduplex

mutation. Analysis of heteroduplex molecules can, therefore, increase the sensitivity of DGGE.

Heteroduplexes can be formed by adding the wild-type and mutant template DNAs in the same

PCR reaction or by adding separate PCR products together, then denaturing and

allowing them to re-anneal. A heteroduplex has a mismatch in the double-strand causing a

distortion in its usual conformation; this has a destabilizing effect and causes the DNA strands

to denature at a lower concentration of denaturant (Figure 4.3). The heteroduplex bands always

migrate more slowly than the corresponding homoduplex bands under specific conditions.

12

AB

0%

40%

70%

65%

Page 17

Fig. 4.3. An example of wild-type and mutant DNA fragments that were denatured and re-annealed to

generate four fragments: two heteroduplexes and two homoduplexes run on a parallel

denaturing gradient gel. The melting behavior of the heteroduplexes is altered so that they melt at a lower denaturant

concentration than the homoduplexes and can be visualized on a denaturing gradient gel.

Reagent Preparation

The concentration of denaturant to use varies for the sample being analyzed with the

DCode system. Typically a broad denaturing gradient range is used, such as 0–100% or

20–70%. The concentration of acrylamide can also vary, depending on the size of the

fragment analyzed. Both 0% and 100% denaturant should be made as stock solutions. A

100% denaturant is a mixture of 7 M urea and 40% deionized formamide. Reagents for

casting and running a DGGE gel are included in the DCode Electrophoresis Reagent Kit for

DGGE/CDGE, catalog number 170-9032.

For different percent crosslinking, use the equation below to determine the amount of Bis

to add. The example stock solution below is for an acrylamide/bis ratio of 37.5:1.

40% Acrylamide/Bis (37.5:1)

Reagent Amount

Acrylamide 38.93 g

Bis-acrylamide 1.07 g

dH2O to 100.0 ml

Filter through a 0.45 µ filter and store at 4°C.

13

Wild Type DNA Mutant DNA

Wild-Type DNA

Mutant DNA

wt + mut

wt

20%

60%

mut

Heteroduplex

DNA

Homoduplex

DNA

Homoduplexes

Heteroduplexes

Denature and reanneal

Denaturant

Denature and reanneal

Homoduplex

DNA

wt mut wt + mut

Heteroduplex

DNA

Heteroduplexes

Homoduplexes

Page 18

Polyacrylamide gels are described by reference to two characteristics:

1) The total monomer concentration (%T)

2) The crosslinking monomer concentration (%C)

%T =

gm acrylamide + gm bis-acrylamide

x 100

Total Volume

%C =

gm bis-acrylamide

x 100

gm acrylamide + gm bis-acrylamide

50x TAE Buffer

Reagent Amount Final Concentration

Tris base 242.0 g 2 M

Acetic acid, glacial 57.1 ml 1 M

0.5 M EDTA, pH 8.0 100.0 ml 50 mM

dH2O to 1,000.0 ml

Mix. Autoclave for 20–30 minutes. Store at room temperature.

The table below provides the percentage acrylamide/bis needed for a particular size range.

Gel Percentage Base Pair Separation

6% 300–1000 bp

8% 200–400 bp

10% 100–300 bp

0% Denaturing Solution

6% Gel 8% Gel 10% Gel

12% Gel

40% Acrylamide/Bis 15 ml 20 ml 25 ml 30 ml

50x TAE buffer 2 ml 2 ml 2 ml 2 ml

dH2O 83 ml 78 ml 73 ml 68 ml

Total volume 100 ml 100 ml 100 ml 100 ml

Degas for 10–15 minutes. Filter through a 0.45 µ filter. Store at 4°C in a brown bottle for

approximately 1 month.

100% Denaturing Solution

6% Gel 8% Gel

10% Gel 12% Gel

40% Acrylamide/Bis 15 ml 20 ml 25 ml 30 ml

50x TAE buffer 2 ml 2 ml 2 ml 2 ml

Formamide (deionized) 40 ml 40 ml 40 ml 40 ml

Urea 42 g 42 g 42 g 42 g

dH2O to 100 ml to 100 ml to 100 ml to 100 ml

Degas for 10–15 minutes. Filter through a 0.45 µ filter. Store at 4°C in a brown bottle for

approximately 1 month. A 100% denaturant solution requires re-dissolving after storage. Place

the bottle in a warm bath and stir for faster results.

14

Page 19

For denaturing solutions less than 100%, use the volumes for acrylamide, TAE and water

described above in the 100% Denaturing Solution. Use the amounts indicated below for urea

and formamide.

Denaturing Solution 10% 20% 30% 40% 50% 60% 70% 80% 90%

Formamide (ml) 4 8 12 16 20 24 28 32 36

Urea (g) 4.2 8.4 12.6 16.8 21 25.2 29.4 33.6 37.8

10% Ammonium Persulfate

Reagent Amount

Ammonium persulfate 0.1 g

dH2O 1.0 ml

Store at –20°C for about a week.

DCode Dye Solution

Reagent Amount Final

Concentration

Bromophenol blue 0.05 g 0.5%

Xylene cyanol 0.05 g 0.5%

1x TAE buffer 10.0 ml 1x

Store at room temperature. This reagent is supplied in the DCode electrophoresis reagent

kit for DGGE, CDGE.

2x Gel Loading Dye

Reagent Amount Final

Concentration

2% Bromophenol blue 0.25 ml 0.05%

2% Xylene cyanol 0.25 ml

0.05%

100% Glycerol 7.0 ml

70%

dH2O 2.5 ml

Total volume 10.0 ml

Store at room temperature.

1x TAE Running Buffer

Reagent Amount

50x TAE buffer 140 ml

dH2O 6,860 ml

Total volume 7,000 ml

Gel Volumes

Linear Denaturing Gradient Gels

The table below provides the required gradient delivery system setting per gel size desired.

The volume per syringe is for the amount required for each low and high density syringe, and

the volume adjustment setting sets the gradient delivery system for the proper delivery of

solutions. The 7.5 x 10 cm and 16 x 16 cm size gels are recommended for the perpendicular gel

formats, whereas the 16 x 10 cm and 16 x 16 cm gel formats are recommended for parallel

denaturing gels. The volume per syringe requires a larger volume of reagent than the volume

setting indicates, because the excess volume in the syringe is needed to push the correct amount

of gel solution into the gel sandwich.

15

Page 20

Volume Volume

per Adjustment

Spacer Size Gel Size Syringe Setting

0.75 mm 7.5 x 10 cm 5 ml 3.5

16 x 10 cm 8 ml 6.5

16 x 16 cm 11 ml 9.5

1.00 mm 7.5 x 10 cm 6 ml 4.5

16 x 10 cm 11 ml 9.5

16 x 16 cm 16 ml 14.5

1.50 mm 7.5 x 10 cm 8 ml 6.5

16 x 10 cm 15 ml 13.5

16 x 16 cm 24 ml 22.5

Spacer Thickness 16 x 16 cm Gel 16 x 10 cm Gel

0.75 mm 25 ml 15 ml

1.00 mm 30 ml 20 ml

1.50 mm 45 ml 26 ml

Sample Preparation

1. It is important to optimize the PCR reaction to minimize unwanted products which may

interfere with gel analysis. PCR products should be evaluated for purity by agarose gel

electrophoresis before being loaded onto a denaturing acrylamide gel.

2. For a perpendicular denaturing gel, load about 1–3 µg of amplified DNA per well

(usually 50% of a 100 µl PCR volume from a 100 ng DNA template). Both wild-type and

mutant samples are mixed together and run on the same gel.

3. For a parallel denaturing gel, load 180–300 ng of amplified DNA per well (usually 5–10%

of a 100 µl PCR volume from a 100 ng DNA template). A wild-type control should be run

on every gel.

4. Add an equal volume of 2x gel loading dye to the sample.

5. Heteroduplexes can be generated during PCR by amplifying the mutant and wild-type samples

in the same tube. If the samples are amplified in separate tubes, then heteroduplexes can be

formed by mixing an equal amount of mutant and wild-type samples in one tube. Heat the tube

at 95 °C for 5 minutes, then place at 65°C for 1 hour, and let slowly cool to room temperature.

16

Page 21

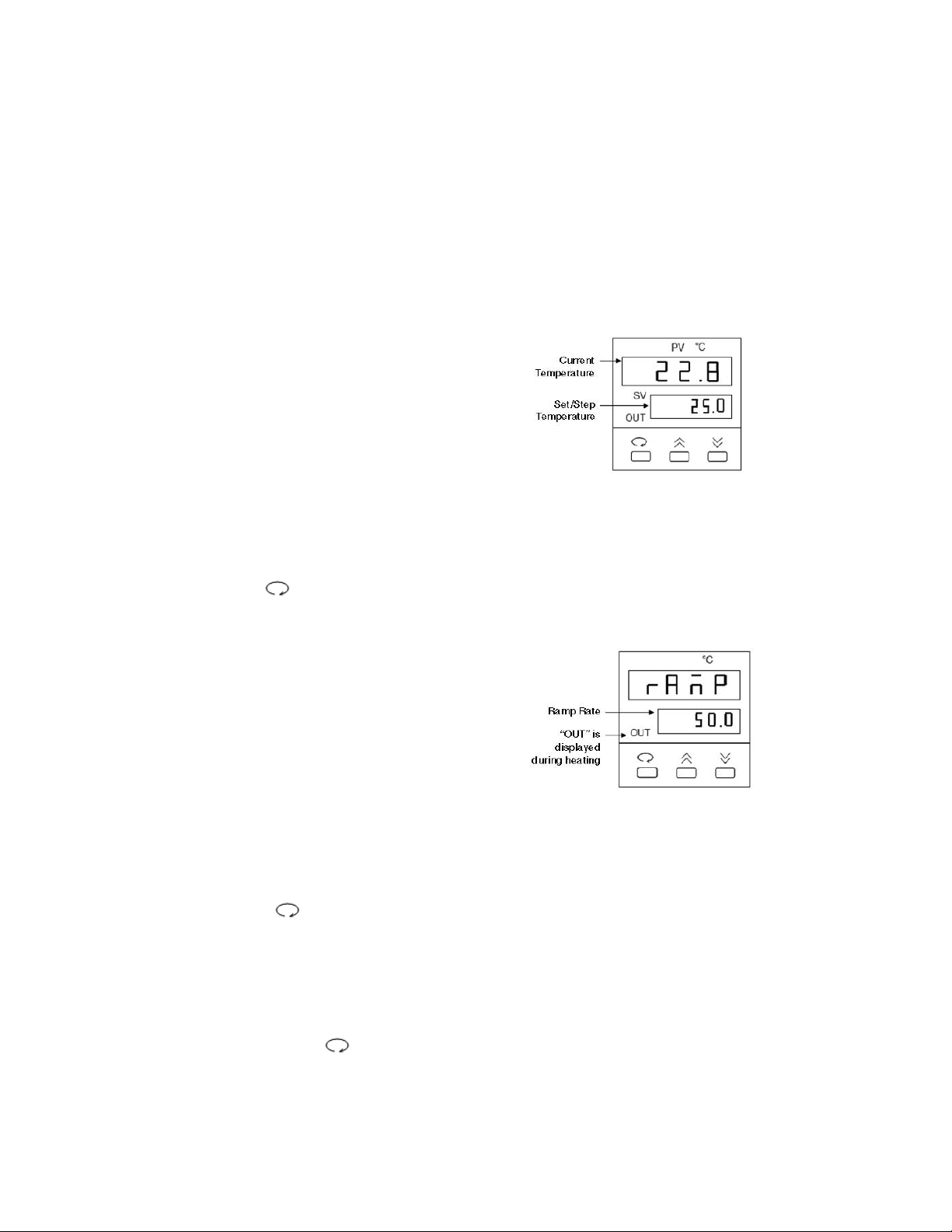

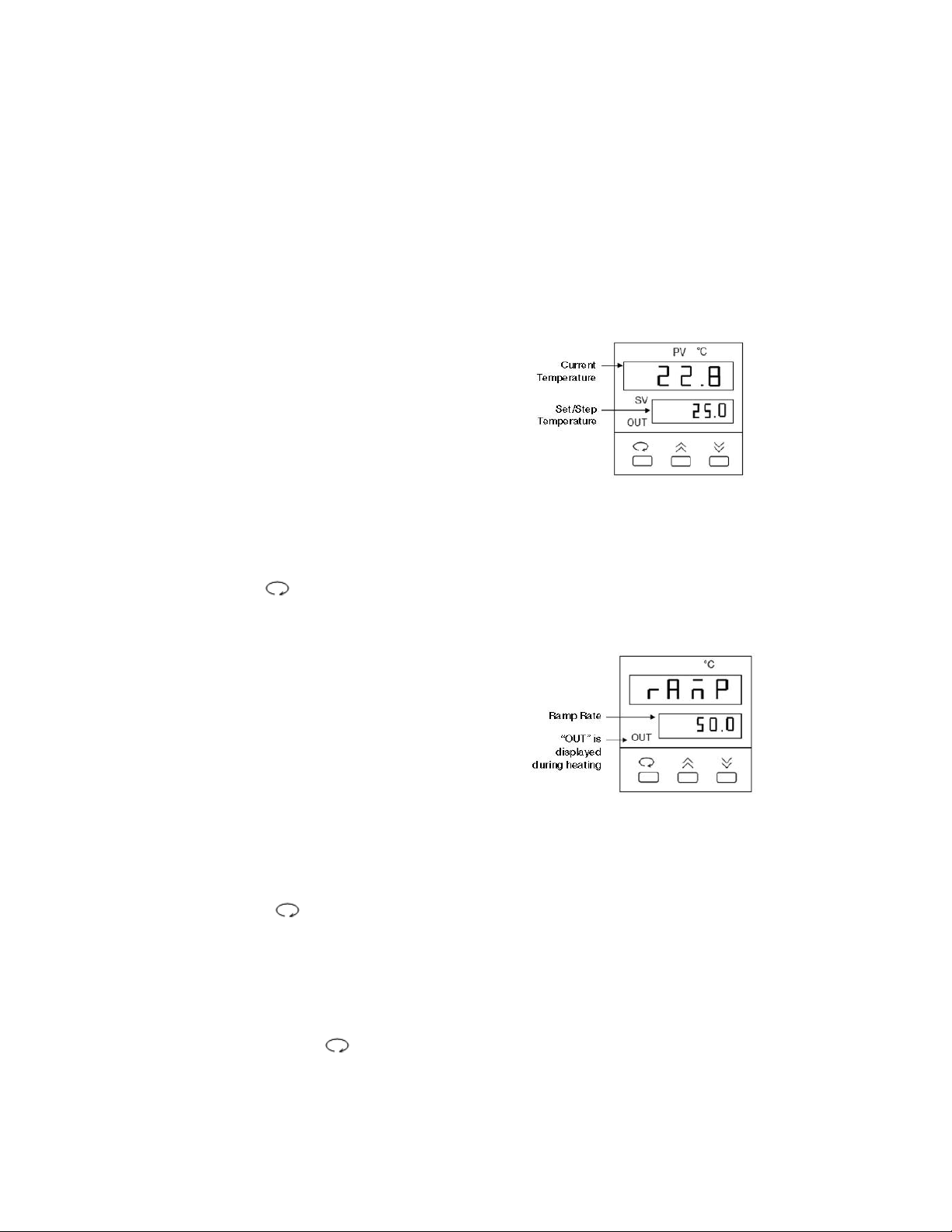

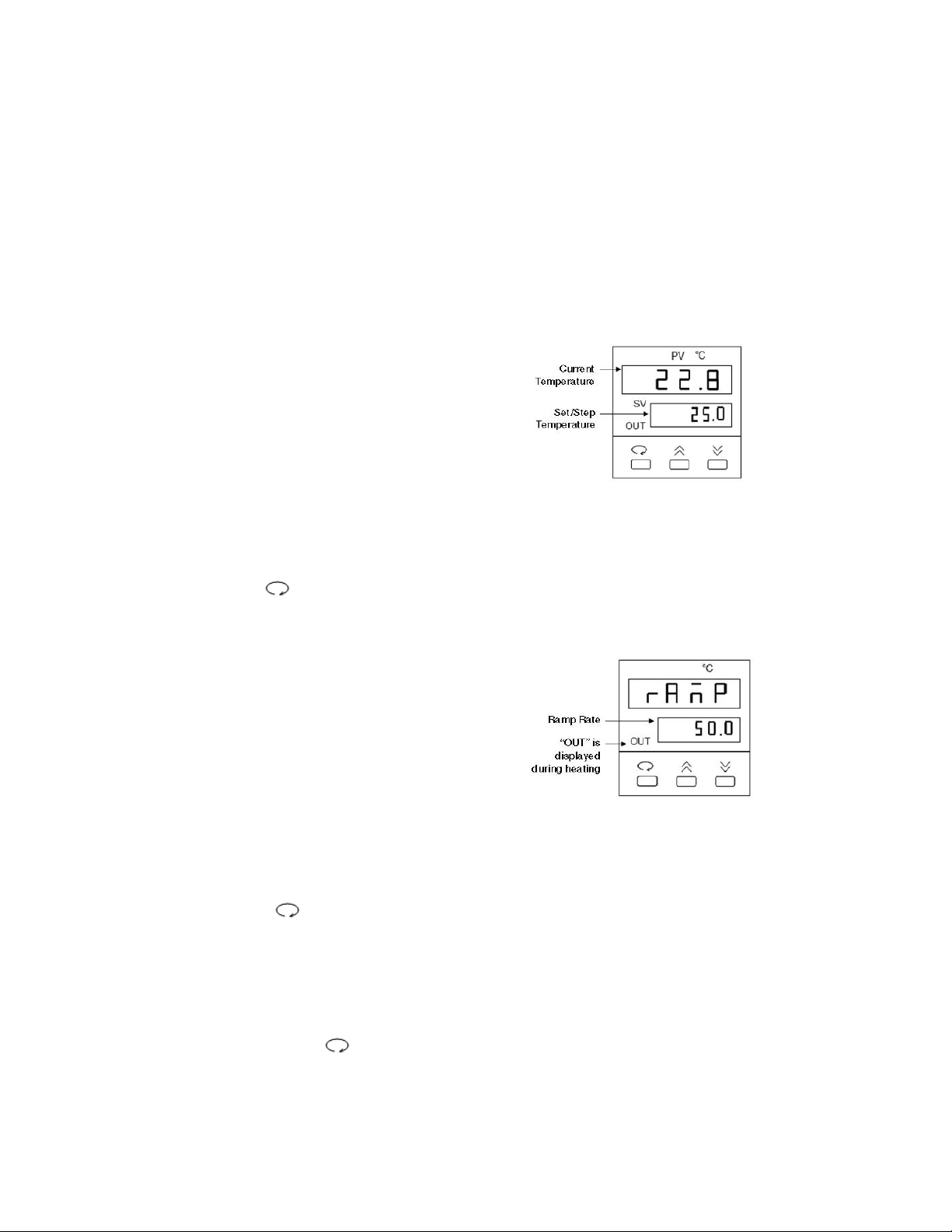

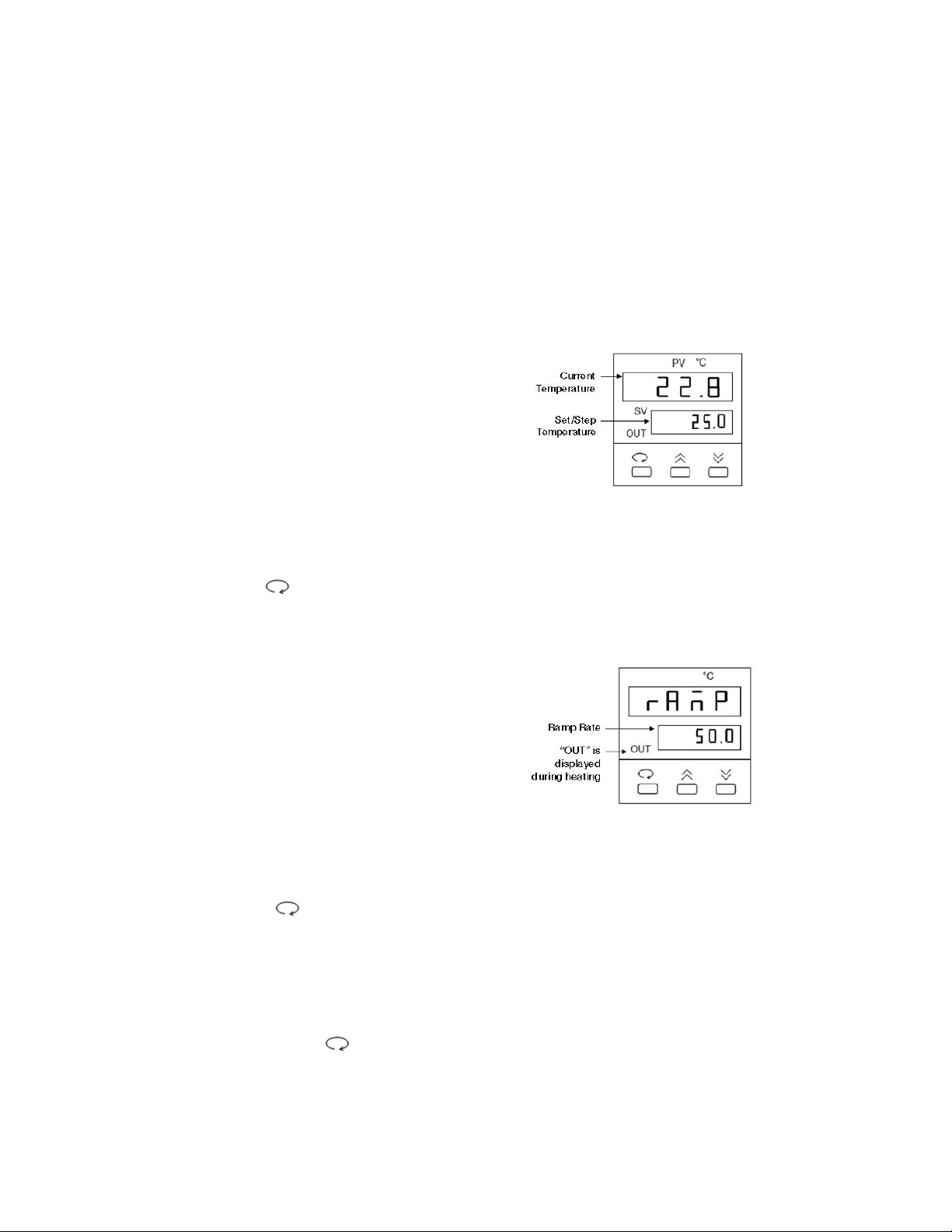

Temperature Controller

The temperature controller maintains the desired buffer temperature in the DCode system.

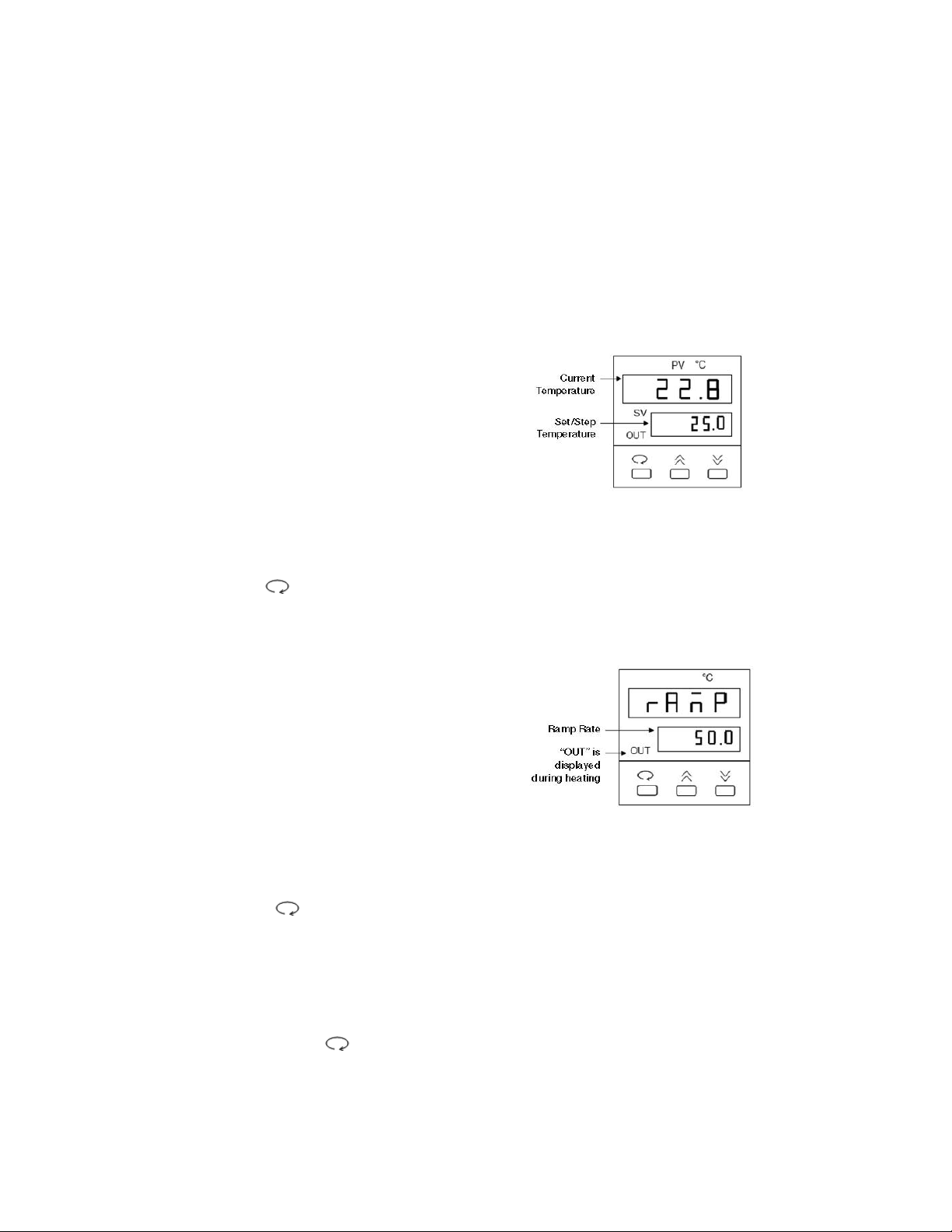

Turning on the Controller

Turn the controller on by pressing the power button and wait for the controller to

initialize. The controller will display the following screens in order:

• The program code

• The date code and serial code

• The hours used

• The temperature control screen (see Fig. 1).

The controller is now ready to be

programmed.

Setting the Set Temperature and Ramp Rate

1. From the temperature control screen,

use the arrow keys to adjust the Set

Temperature to your desired target

temperature in °C (Fig. 1)

2. Use the key to display the ramp

control screen. (Fig. 2.)

3. From the ramp control screen, use

the arrow keys to set the desired

temperature Ramp Rate in °C per hour.

Note that the maximum ramp rate for

the DCode is 50°C /hr. If the target

Ramp Rate is set using the controller

to higher than 50°C /hr the maximum

ramp rate of 50°C /hr will be used.

4. To toggle between the temperature control

screen and the ramp control screen, or to

review the set temperature and ramp rate,

press the key at any time

Note: Following programming by default the controller displays the Step Temperature rather

than the Set Temperature (see Fig 1. below). The step temperature is the next temperature

value the system will reach as it heats/cools to reach set temperature. To display the Set

Temperature press the key.

17

Fig. 1. Temperature Control Screen.

Fig. 2. Ramp Control Screen.

Page 22

Pre-heating the Running Buffer

1. Fill the electrophoresis tank with 7 L of 1x TAE running buffer.

Note: It is recommended that the running buffer not be reused. Reusing the running buffer

may affect the migration rate and band resolution.

2. Place the temperature control module on top of the electrophoresis tank. Attach the power

cord to the temperature control module and turn the power, pump, and heater on. The

clear loading lid should be on the temperature control module during preheating.

3. Set the temperature controller to the desired temperature. Set the temperature ramp rate

to 200 °C/hr to allow the buffer to reach the desired temperature the quickest.

4. Preheat the buffer to the set temperature. It can take 1 to 1.5 hours for the system to heat

the buffer up to the set temperature. Heating the buffer in a microwave helps reduce the

preheating time.

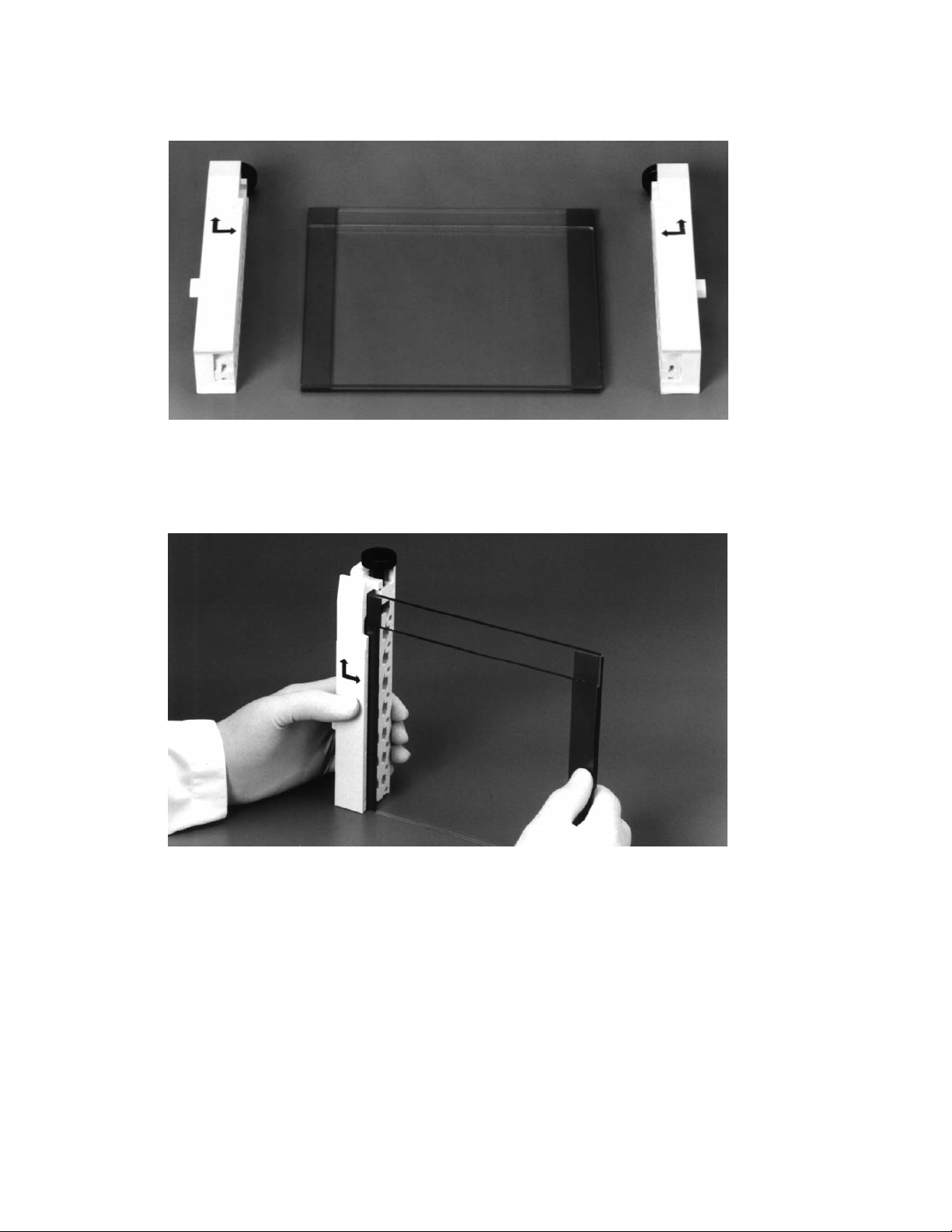

Assembling the Perpendicular Gradient Gel Sandwich

For perpendicular gel formats, 7.5 x 10 cm (dual) and 16 x 16 cm (single) gel sandwich sizes

are recommended. These two different perpendicular gel formats consist of a set of spacers that

provide casting at the side of the gel sandwich via the stopcock. To insure proper alignment,

make sure all plates and spacers are clean and dry before assembly. Use caution when

assembling the glass plate sandwiches. Wear gloves and eye protection at all times.

1. Assemble the gel sandwich on a clean surface. Lay the large rectangular plate down first,

then place the left and right spacers of equal thickness along the short edges of the larger

rectangular plate. To assemble perpendicular gradient gels, place the spacers so that the

holes on the spacers are at the top of the plate with the grooved side of the spacer against

the larger glass plate. When properly placed, the notched edges of the spacers will face

each another.

2. Place a short glass plate on top of the spacers so that it is flush with the bottom edge of

the long plate.

3. Loosen the single screw of each sandwich clamp by turning counterclockwise. Place each

clamp by the appropriate side of the gel sandwich with the locating arrows facing up and

toward the glass plates (Figure 4.5).

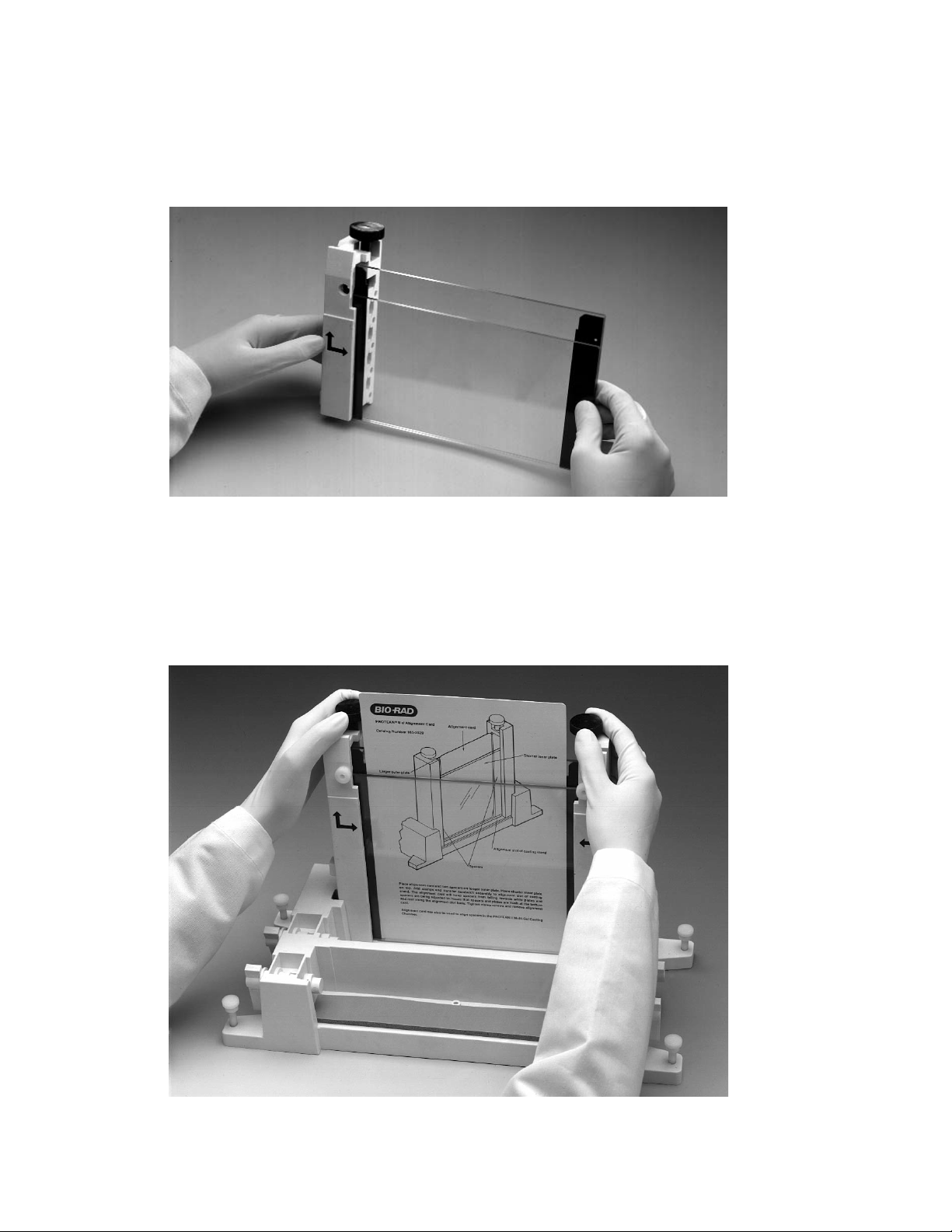

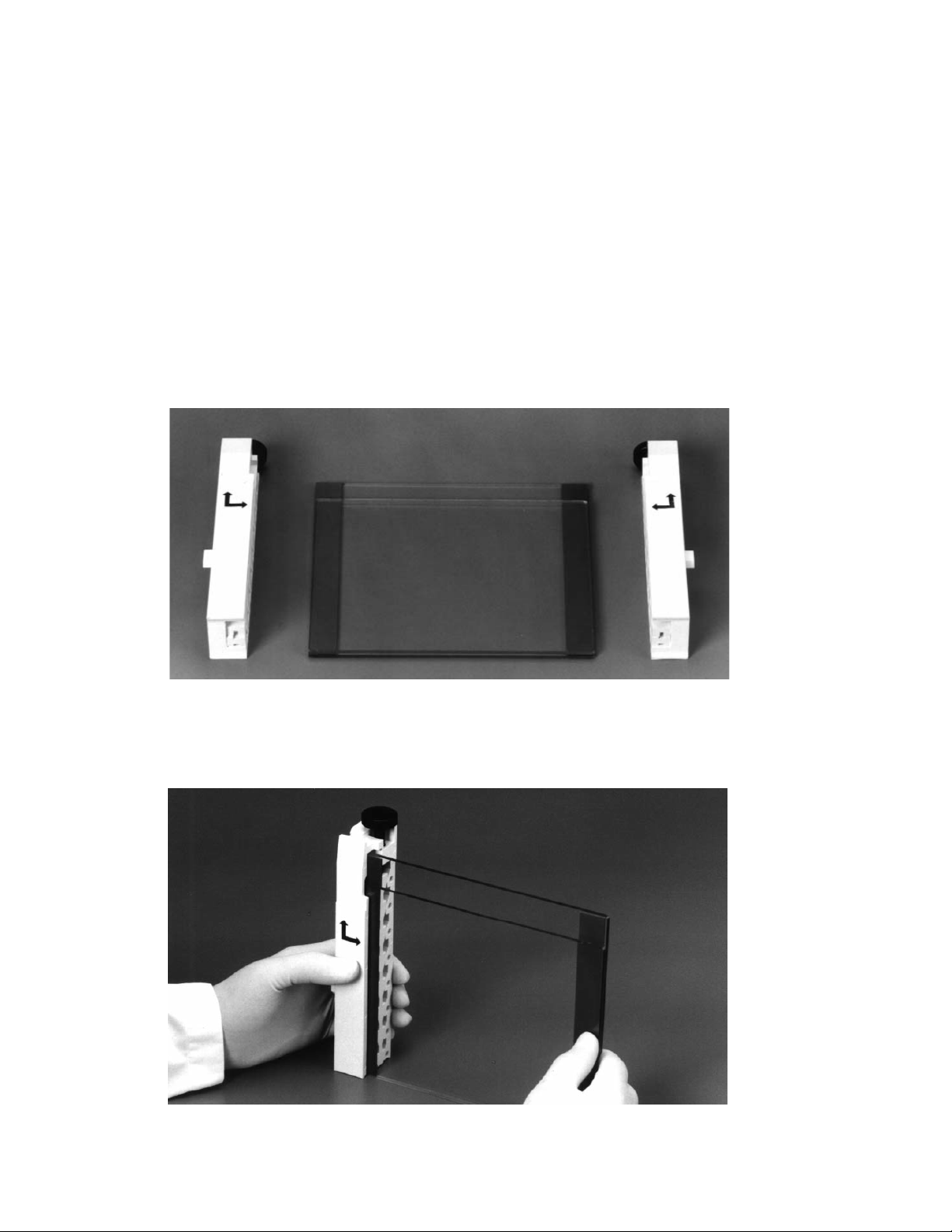

Fig. 4.5. Positioning glass plates, spacers, and clamps.

18

Page 23

4. Grasp the gel sandwich firmly. Guide the left and right clamps onto the sandwich so

that the long and short plates fit the appropriate notches in the clamp (Figure 4.6). Tighten

the screws enough to hold the plates in place.

Fig. 4.6. Attaching the clamps to the glass plate assembly.

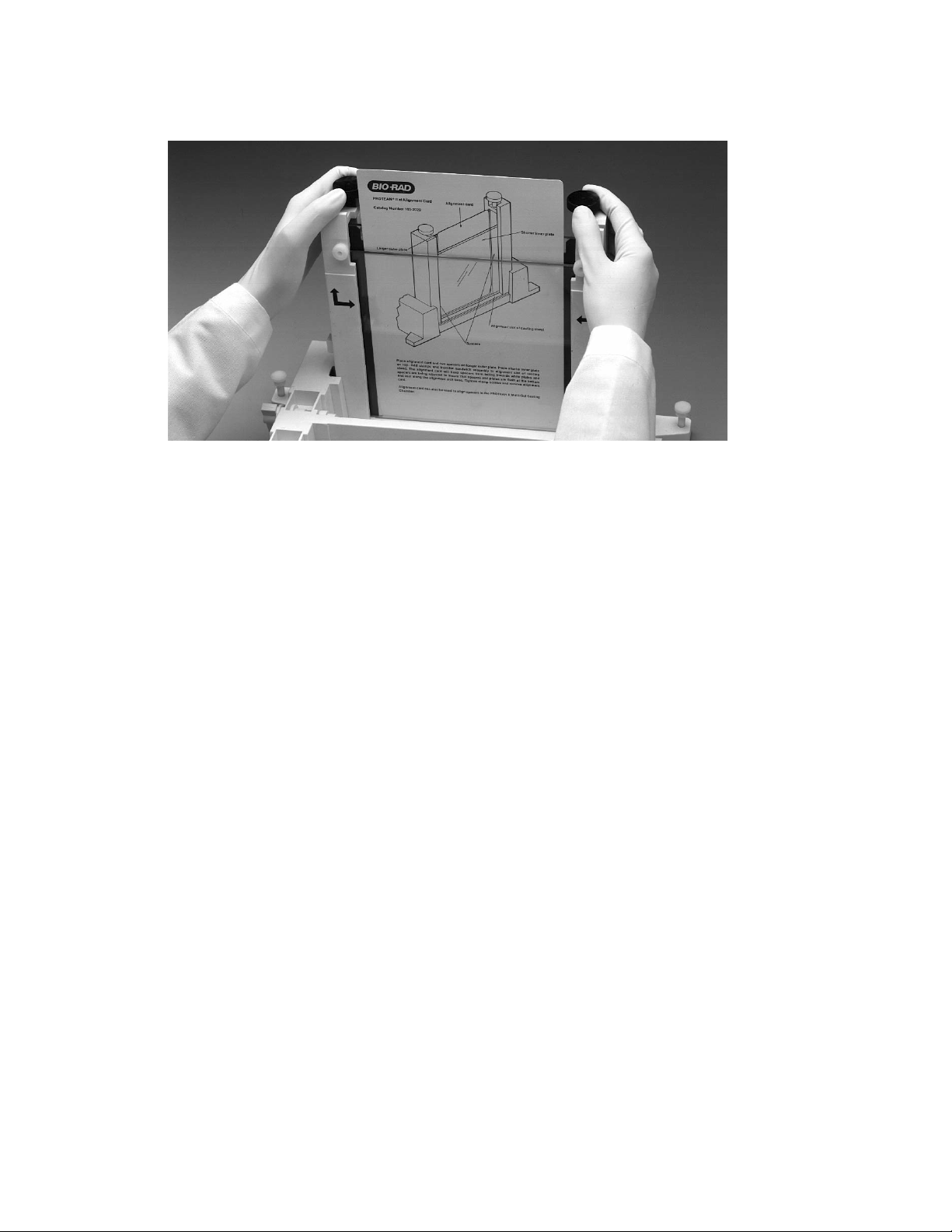

5. Place the sandwich assembly in the alignment slot (the slot without cams) of the casting

stand with the short glass plate forward (Figure 4.7). Loosen the sandwich clamps and

insert an alignment card to keep the spacers parallel to the clamps.

Note: Always use the alignment slot and alignment card to set the spacers in place. Failure

to use these can result in gel leakage when casting, as well as buffer leakage during the

run.

Fig. 4.7. Aligning spacers in the sandwich assembly.

19

Page 24

6. Align the plates and spacers by simultaneously pushing inward on both clamps at the

locating arrows while, at the same time, pushing down on the spacers with your thumbs.

Tighten both clamps just enough to hold the sandwich in place. Pushing inward on both

clamps at the locating arrows will insure that the spacers and glass plates are flush against

the sides of the clamps (Figure 4.7).

7. Remove the alignment card. Then, remove the sandwich assembly from the casting stand

and check that the plates and spacers are flush at the bottom. If they are not flush, realign

the sandwich and spacers (Repeat steps 5–7).

8. When a good alignment and seal are obtained, tighten the clamp screws until it is finger-tight.

9. Place the proper comb in the sandwich and align it against the notches in the spacers. For

the 7.5 x 10 cm perpendicular gradient gel, insert the middle spacer into the center of the

sandwich until it fits into the middle notch on the comb. Straighten the spacer and the comb.

The bottom of the middle spacer should also be flush against the glass plates (Figure 4.8).

Note: The proper comb for a 7.5 x 10 cm gel is the dual comb that requires a middle

spacer to separate the two 7.5 x 10 cm gels, whereas the 16 x 16 cm gel comb is a

single comb that does not require a middle spacer.

Fig. 4.8. Positioning the middle spacer in a 7.5 x 10 cm gel sandwich assembly.

10. Inspect the comb gasket to insure that the comb gasket is free of gel material. Remove

any polymerized material in the comb gasket vent ports. The soft comb gasket should

lay flat within the comb gasket holder.

Note: To remove the soft comb gasket from the holder, push the gasket away from the

four holes in the holder. To replace the comb gasket, insert the gasket into the holder

with the thick portion in first. Place one corner of the gasket against the top portion of the

holder. With a flat spatula, guide the four tabs into the four holes. Carefully run the

spatula across the gasket to completely set the gasket in place.

20

Page 25

11. Stand the sandwich assembly upright on a flat surface. Loosen the comb gasket holder

screws until the threads can no longer be seen. Mark an arrow on the middle of the screw head

using a permanent marker (this will be the marker for adjusting the proper screw tension). With

the comb gasket screws and the long plate facing you, slide the comb gasket holder down over

the top of the assembled glass sandwich. When the comb gasket is properly placed, the

angled cuts on the edges of the comb gasket will rest on the complementary angled cuts at

the top of each spacer. Turn the screws until they just make contact with the glass plate, then

twist the screws an additional 1/4 turn.

12. Before the screws can be completely tightened, the pressure clamp must be attached to the

sandwich assembly. Loosen the pressure clamp screw. Mark an arrow on the middle of the

screw head using a permanent marker (this will be the marker for adjusting the proper screw

tension). Lay the pressure clamp on a flat surface so that the notched cut-out faces the

ceiling and the pressure clamp screw points up and away from you.

13. Without touching the comb gasket holder, turn the assembled glass sandwich so that the comb

gasket screws are facing down and the vent ports are facing up. Center the assembly over the

pressure clamp and allow the assembly to rest on top of it. A properly placed pressure clamp

will be situated on the middle of the sandwich with the notched cut-out against the bottom of

the glass plate. Proper placement of the sandwich assembly in the pressure clamp will insure

that equal force is applied to the comb gasket holder during the final tightening of the screws.

Twist the pressure clamp screw until it makes contact with the comb gasket holder, then

tighten the pressure clamp screw two additional turns (use the arrow to keep track of the turns).

Note: Check to insure that the bottom of the glass plates are still flush. If the plates are

off-set, one or both of the sandwich clamps may not be tightened. Repeat steps 5–13.

14. Tighten the comb gasket screws an additional one turn. If it is tightened more, the

glass plates may crack. For a proper seal, check to see that the notches on both the

comb gasket and spacers are sealed against each other. It is important that the gasket

is placed properly to prevent leakage while casting. Remove the pressure clamp.

15. Twist the injection port fitting into the holes on the sandwich clamps. Do not over-tighten; it will

damage the O-ring and cause leakage. A snug fit is all that is needed to place the injection

port against the glass plate assembly. Push a stopcock into each of the injection port fittings.

Make sure that the fit is snug. A loose stopcock may cause leakage during casting.

16. Place the gray sponge onto the front casting slot. The camshafts on the casting stand should

have the handles pointing up and pulled out. Place the sandwich on the sponge with the shorter

plate facing forward. When the sandwich is placed correctly, press down on the sandwich and

turn the handles of the camshaft down so that the cams lock the sandwich in place.

a. For a 7.5 x 10 cm dual gel sandwich, only half of the sandwich is cast at a time. Open

the stopcock and unplug the vent port on the side of the sandwich where the gel is

being cast. To prevent leakage the other half of the sandwich should have a closed

stopcock and plugged vent port.

b. For a 16 x 16 cm gel sandwich, both vent ports should be plugged to prevent leakage

during casting. The 16 x 16 cm spacers are one orientation only, thus the special

casting groove is always on the right-hand side and the smaller, shorter groove on the

left-hand side of the gel sandwich.

17. Tilt the gel sandwich assembly and casting stand using the tilt rod as a leg. Adjust the tilt

level to the highest etched line on the rod (the one farthest from the black tilt-rod cap) for

the 7.5 x 10 cm format and the lowest etched line on the rod for the 16 x 16 cm format.

18. Familiarize yourself with the Model 475 Gradient Delivery System before casting

perpendicular gradient gels.

21

Page 26

Casting Perpendicular Denaturing Gradient Gels

1. One length of Tygon tubing is provided and should be cut into two 15.5 cm lengths and one

9 cm length. The longer pieces of Tygon tubing will be used to conduct the gel solution

from the syringes into the Y-fitting. The short piece of Tygon tubing will conduct the gel

solution from the Y-fitting to the gel sandwich. Connect one end of the 9 cm Tygon tubing

to the Y-fitting and connect a luer coupling to the other end of the 9 cm tubing. Connect luer

fittings onto the two long pieces of tubing. Connect the luer fittings to 10 ml or 30 ml syringes.

Do not connect the long Tygon tubing to the Y-fitting at this time.

2. Label one of the syringes LO (for the low density solution) and one HI (for the high density

solution). Attach a plunger cap onto each syringe plunger “head.” Position the plunger "head"

in the middle of the plunger cap and tighten enough to hold the plunger in place. Position the

cap in the middle for proper alignment with the lever on the gradient delivery system. Slide

each syringe into a syringe sleeve. Move the sleeve to the middle of the syringe, keeping the

volume gradations visible. Make sure that the lever attachment screw is in the same plane

as the flat or back side of the sleeve. This is very important for proper attachment of the

syringe to the lever.

Note: Insure that the tubing is free of any gel material by pushing water through the tubing with

the syringe. The tubing should be free of material before casting, remove any remaining water

from the tubing.

3. Rotate the cam wheel counterclockwise to the vertical or start position. To set the desired

delivery volume, loosen the volume adjustment screw. Place the volume setting indicator

located on the syringe holder to the desired volume setting. Tighten the volume adjustment

screw. For 7.5 x 10 cm gels (1 mm thick), set the volume setting indicator to 4.5. For

16 x 16 cm gels (1 mm thick), set the volume setting indicator to 14.5. Refer to Section 4.1.

4. From the stocks solutions, pipet out the desired amounts of the high and low density gel

solutions into two disposable test tubes, Section 4.1.

Optional: To visually check the formation of the gradient, add 100 µl of DCode dye

solution per 5 ml high density solution.

Note: The gel solution volume should be greater than the amount set on the volume

adjustment lever. For example, if the setting indicator is set at 4.5, the syringe should

contain 5 ml of the gel solution. This extra solution is needed to push the correct amount

into the gel sandwich.

The steps below are time-sensitive (about 7–10 minutes). Insure that steps 1 through

4 are done before proceeding further. Be thoroughly familiar with the following steps

before casting the gel.

5. Add a final concentration of 0.09% (v/v) each of ammonium persulfate and TEMED

solutions. The 0.09% (v/v) concentrations allow about 5–7 minutes to finish casting the gel

before polymerization. Cap and mix by inverting several times. With the syringe connected

to the tubing, withdraw all of the high density solution into the HI syringe. Do the same for

the low density solution into the LO syringe.

Note: Acrylamide is a very hazardous substance. Use caution: wear gloves and eye

protection at all times. Avoid skin contact.

6. Carefully remove air bubbles from the LO syringe by turning it upside down (plunger cap

towards the bench) and gently tapping. Push the gel solution to the end of the tubing. Do

not push it out of the tubing as loss of gel solution will disturb the volume required to cast

the desired gel.

22

Page 27

7. Place the LO syringe into the gradient delivery system syringe holder (LO density side) by

holding the syringe by the plunger and inserting the lever attachment screw into the lever

groove. Do not handle the syringe. It will dispense the gel solution out of the syringe.

Casting a perpendicular gel is referred to as a bottom filling method, so place the LO

syringe on the correct side of the gradient system.

8. Carefully remove the air bubbles from the HI syringe by turning it upside down (plunger

cap towards the bench) and gently tapping. Push the gel solution to the end of the tubing.

Do not push it out of the tubing as loss of gel solution will disturb the volume required to

cast the desired gel.

9. Place the HI syringe into the gradient delivery system syringe holder (HI density side) by

holding the syringe by the plunger and inserting the lever attachment screw into the lever

groove. Do not handle the syringe. It will dispense the gel solution out of the syringe.

10. Slide the tubing from the low density syringe to one end of the Y-fitting. Do the same for

the high density syringe.

11. Connect the 9 cm tubing with the luer coupling on the sandwich assembly stopcock. Insure

that the stopcock is open and that the vent port is unplugged for the half of the sandwich

being cast.

Note: For a 16 x 16 cm single gel, both stopcocks are open during casting. After casting,

both stopcocks are closed.

12. Rotate the cam wheel slowly and steadily to deliver the gel solution. It is important to cast the

gel solution at a steady pace to avoid disturbances between gel solutions within the sandwich.

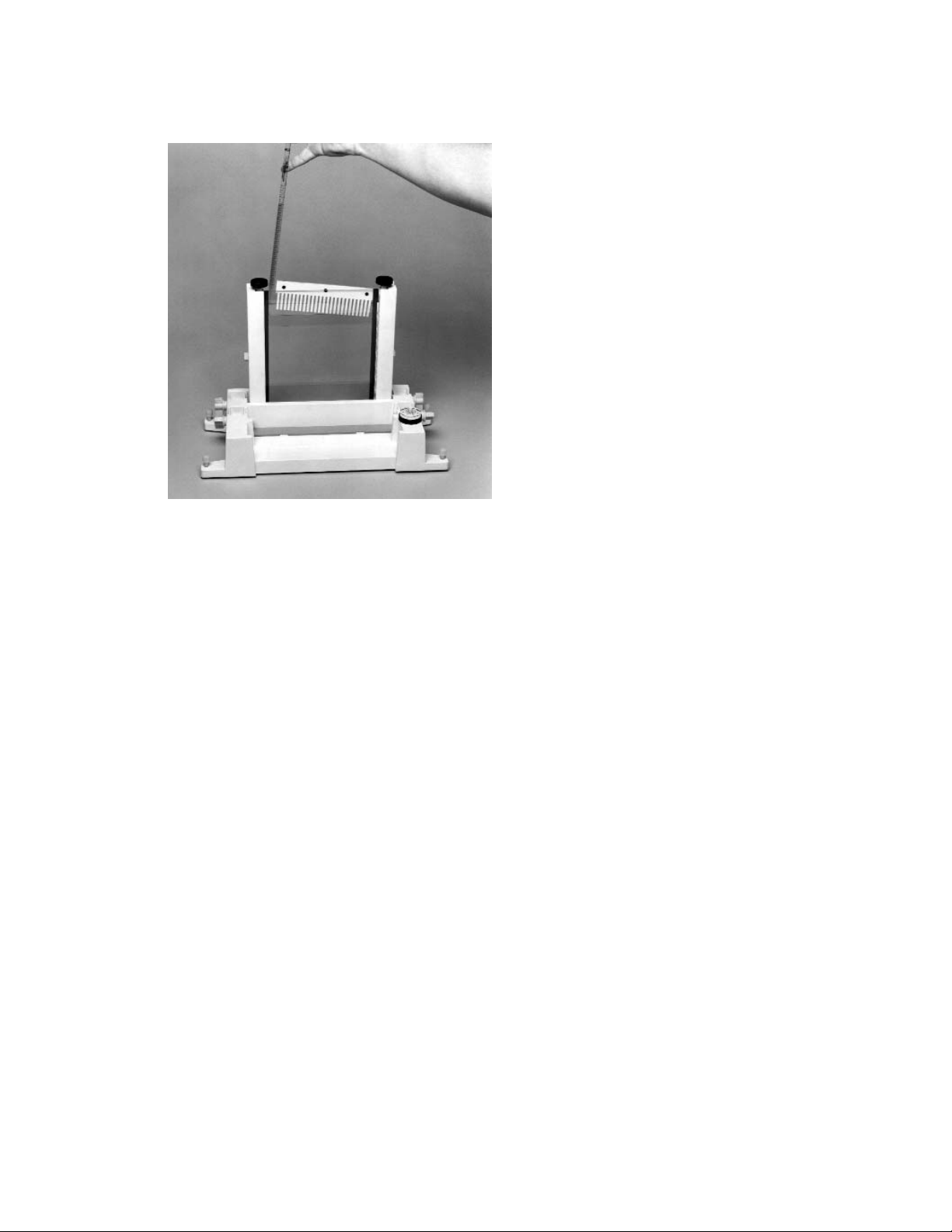

Fig. 4.9. Casting a perpendicular gradient gel using the Model 475 gradient delivery system.

13. Plug the vent port and close the stopcock on the gel sandwich when the cam wheel has

reached the stop position. Carefully level the gel sandwich by adjusting the gasket tilt rod.

Be sure to loosen the tilt rod screw and not the sandwich clamp screw.

Note: For a properly cast perpendicular gradient gel it is extremely important to level the

sandwich assembly after casting.

23

Page 28

14. Immediately remove the tubing from the sandwich assembly stopcock. Place the tubing into

a beaker of water and reverse the cam on the Gradient Delivery System. This will rinse the

tubing and Y-fitting. Remove both syringes from the syringe holder on the gradient delivery

system. Detach the syringe tubing from the Y-fitting. Run or push water out through the

syringe, tubing and Y-fitting several times to get rid of any residual gel solution. It is extremely

important that this is done quickly after casting to avoid any gel polymerization.

15. Let the gel polymerize for about 60 minutes. To cast the other half of the 7.5 x 10 cm gel

format, remove the gasket tilt rod and place it on the other side of the comb gasket. Repeat

steps 4 through 15.

Note: If casting a single 7.5 x 10 cm gel, let the gel solution polymerize for 60 minutes. Carefully

remove the comb gasket; leave the comb in place and pipette (on an opening near the

spacer) a 10 ml gel solution plus initiators in the uncast half of the sandwich to create a dam.

16. After polymerization, remove the comb by pulling it straight up slowly and gently.

17. Continue with Section 8 for electrophoresis.

Assembling the Parallel Gradient Gel Sandwich

For parallel gel formats, a 16 x 16 cm gel sandwich size is recommended. The parallel gel

format does not require special casting grooves in the spacers, so the straight edge portion

(ungrooved side) of the spacers is used. To insure proper alignment, make sure all plates

and spacers are clean and dry before assembly. Use caution when assembling the glass

plate sandwiches. Wear gloves and eye protection at all times.

1. Assemble the gel sandwich on a clean surface. Lay the large rectangular plate down first, then

place the left and right spacers of equal thickness along the short edges of the larger

rectangular plate. To assemble parallel gradient gels, place the spacers so that the grooved

opening of the spacers face the sandwich clamps. When properly placed, the grooved side of

the spacers and the notches will face the sandwich clamps, and the hole is located near the

top of the plates.

2. Place the short glass plate on top of the spacers so that it is flush with the bottom edge

of the long plate.

3. Loosen the single screw of each sandwich clamp by turning each screw counterclockwise.

Place each clamp by the appropriate side of the gel sandwich with the locating arrows

facing up and toward the glass plates (Figure 4.10).

Fig. 4.10. Positioning glass plates, spacers, and clamps.

24

Page 29

4. Grasp the gel sandwich firmly. Guide the left and right clamps onto the sandwich so that

the long and short plates fit the appropriate notches in the clamp. Tighten the screws

enough to hold the plates in place (Figure 4.11).

Fig. 4.11. Attaching the clamps to the glass plate assembly.

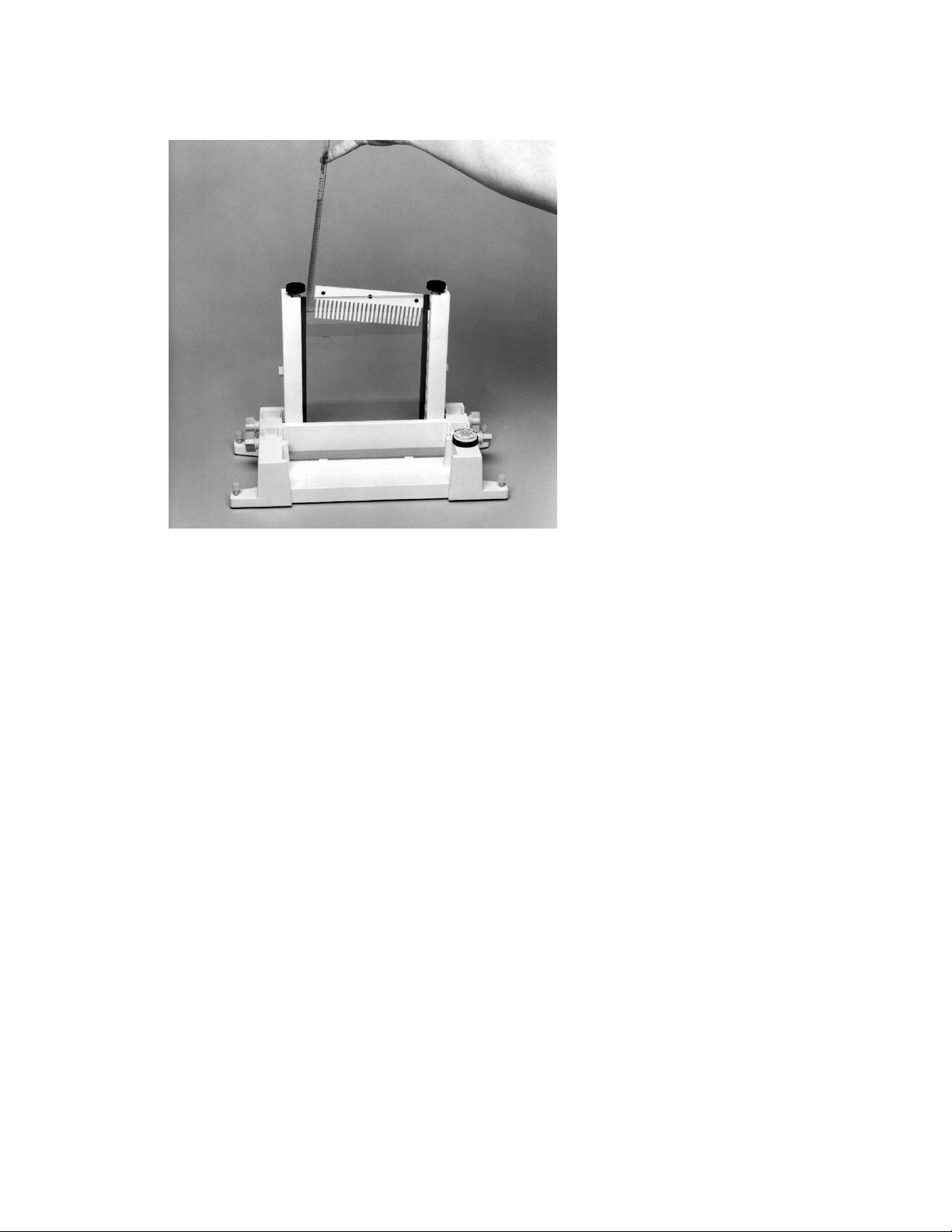

5. Place the sandwich assembly in the alignment slot (the slot without cams) of the casting

stand with the short glass plate forward (Figure 4.12). Loosen the sandwich clamps and

insert an alignment card to keep the spacers parallel to the clamps.

Note: Always use the alignment slot and alignment card to set the spacers in place. Failure

to use these can result in gel leakage while casting, as well as buffer leakage during the

run.

6. Align the plates and spacers by simultaneously pushing inward on both clamps at the

locating arrows while at the same time pushing down on the spacers with your thumbs;

tighten both clamps just enough to hold the sandwich in place. Pushing inward on both

clamps at the locating arrows will insure that the spacers and glass plates are flush against

the sides of the clamps (Figure 4.12).

Fig. 4.12. Aligning spacers in the sandwich assembly.

25

Page 30

7. Remove the alignment card. Remove the sandwich assembly from the casting stand and

check that the plates and spacers are flush at the bottom. If the spacers and glass plates

are not flush, realign the sandwich and spacers to obtain a good seal (Repeat steps 5–7).

8. When a good alignment and seal are obtained, tighten the clamp screws until it is finger-tight.

Casting Parallel Denaturing Gradient Gels

1. Place the gray sponge onto the front casting slot. The camshafts on the casting stand should

have the handles pointing up and pulled out. Place the sandwich assembly on the sponge

with the shorter plate facing you. When the sandwich is placed correctly, press down on

the sandwich and turn the handles of the camshaft down so that the cams lock the sandwich

in place. Position the gel sandwich assembly by standing it upright.

2. One length of Tygon tubing is provided and should be cut into two 15.5 cm lengths and one

9 cm length. The longer pieces of Tygon tubing will be used to conduct the gel

solution from the syringes into the Y-fitting. The short piece of Tygon tubing will conduct the

gel solution from the Y-fitting to the gel sandwich. Connect one end of the 9 cm Tygon

tubing to the Y-fitting and connect a luer coupling to the other end of the 9 cm tubing. Connect

luer fittings onto the two long pieces of tubing. Connect the luer fittings to 30 ml syringes. Do

not connect the long Tygon tubing to the Y-fitting at this time.

3. Label one of the syringes LO (for the low density solution) and one HI (for the high

density solution). Attach a plunger cap onto each syringe plunger “head.” Position the

plunger "head" in the middle of the plunger cap and tighten enough to hold the plunger

in place. Position the cap in the middle for proper alignment with the lever on the

gradient delivery system. Slide each syringe into a syringe sleeve. Move the sleeve to

the middle of the syringe, keeping the volume gradations visible. Make sure that the lever

attachment screw is in the same plane as the flat or back side of the sleeve. This is very

important for proper attachment of the syringe to the lever.

Note: Insure that the tubing is free of any gel material by pushing water through the

tubing with the syringe. The tubing should be free of material before casting, remove any

remaining water from the tubing.

4. Rotate the cam wheel counterclockwise to the vertical or start position. To set the desired

delivery volume, loosen the volume adjustment screw. Place the volume setting indicator

located on the syringe holder to the desired volume setting. Tighten the volume adjustment

screw. For 16 x 16 cm gels (1 mm thick), set the volume setting indicator to 14.5. Refer to

Section 4.1.

5. From the stocks solutions, pipet out the desired amounts of the high and low density gel

solutions into two disposable test tubes (refer to the Section 4.1).

Optional: To visually check the formation of the gradient, add 100 µl of DCode dye

solution per 5 ml high density solution.

The steps below are time-sensitive (about 7–10 minutes). Insure that steps 2

through 5 are done before proceeding further. Be thoroughly familiar with the

following steps before casting the gel.

6. Add the final concentration of 0.09% (v/v) each of ammonium persulfate and TEMED

solutions. The 0.09% (v/v) concentrations allow about 5–7 minutes to finish casting the gel

before polymerization. Cap and mix by inverting several times. With the syringe connected

to the tubing, withdraw all of the high density solution into the HI syringe. Do the same for

the low density solution into the LO syringe.

Note: Acrylamide is a very hazardous substance. Use caution: wear gloves and eye

protection at all times. Avoid skin contact.

26

Page 31

7. Carefully remove air bubbles from the LO syringe by turning the syringe upside down

(plunger cap towards the bench) and gently tapping the syringe. Push the gel solution to

the end of the tubing. Do not push it out of the tubing as loss of solution will disturb the

volume required to cast the desired gel.

Note: The gel solution volume should be greater than the amount set on the volume adjustment

lever. For example, if the indicator setting is set at 14.5, the syringe should contain 15 ml of

solution. This extra solution is needed to deliver the correct amount for casting.

8. Place the LO syringe into the gradient delivery system syringe holder (LO density side) by

holding the syringe by the plunger and inserting the lever attachment screw into the lever

groove. Do not handle the syringe. It will dispense the gel solution out of the syringe. Casting

a parallel gel is referred to as a top filling method, so place the LO syringe on the correct

side of the gradient system.

9. Carefully remove the air bubbles from the HI syringe by turning the syringe upside down

(plunger cap towards the bench) and gently tapping the syringe. Push the solution to the

end of the tubing. Do not push it out of the tubing as loss of solution will disturb the volume

required to cast the desired gel.

10. Place the HI syringe into the gradient delivery system syringe holder (HI density side) by

holding the syringe by the plunger and inserting the lever attachment screw into the lever.

Do not handle the syringe. It will dispense the gel solution out of the syringe.

11. Slide the tubing from the low density syringe over one end on the Y-fitting. Do the same

for the high density syringe.

12. Attach a 19 gauge needle to the coupling. Hold the beveled side of the needle at the

top-center of the gel sandwich and cast (Figure 4.13). For convenience, the needle can

be taped in place.

Fig. 4.13. Casting a parallel gradient gel.

13. Rotate the cam wheel slowly and steadily to deliver the gel solution. It is important to cast

the gel solution at a steady pace to avoid any disturbances between the gel solutions

within the gel sandwich.

14. Carefully insert the comb to the desired well depth and straighten. Let the gel polymerize

for about 60 minutes.

27

Page 32

15. Place the tubing and needle into a beaker of water and reverse the cam on the Gradient

Delivery System. This will rinse the tubing and Y-fitting. Remove both syringes from the

syringe holder on the gradient delivery system. Detach the syringe tubing from the Y-fitting.

Run or push water out through the syringe, tubing, and Y-fitting several times to get rid of any

residual gel solution. It is very important that this is done quickly after casting to avoid

premature gel polymerization.

16. After polymerization, remove the comb by pulling it straight up slowly and gently.

17. Continue with Section 8 for electrophoresis.

4.2 Introduction to Constant Denaturing Gel Electrophoresis (CDGE)

Constant Denaturing Gel Electrophoresis is a modification of DGGE. In CDGE, the

denaturant concentration that gives optimal resolution from a parallel or perpendicular DGGE

gel is held constant.13The optimal concentration of denaturant to use for a CDGE is

determined from the maximum split between wild-type and mutant DNA, as seen in the

perpendicular or parallel denaturing gel. To calculate the concentration of denaturant for a

CDGE gel, first place a fluorescent ruler along the axis of the denaturant gradient when taking

a photograph. Then, determine the distance along the gradient where the maximum split is

seen between bands. In the example in Figure 4.14, the distance is 5 cm. Divide this

distance by the length of the gel and multiply by the denaturant range. For example, (5–8) x

50% = 31 %. Add this number to the starting denaturant concentration to determine the

optimum concentration to use for CDGE (20% + 31% = 51%). The same calculation can be

applied to samples that are run on a parallel DGGE gel.

After a mutation has been identified by previous DGGE gels, a CDGE gel can be used to

rapidly screen samples for the presence of a mutation. With no gradient required, rapid, highthroughput screening is possible. As in DGGE, the formation of heteroduplex analysis can

help in resolving wild-type and mutated fragments when it is not possible to detect a mutation

by running homoduplex fragments. An example of a CDGE gel is shown in Figure 4.15.

Fig. 4.14. Example of perpendicular DGGE gel used for determining the optimum denaturant

concentration used in a CDGE gel. The distance along the gradient where the maximum split seen between

samples is 5 cm. The denaturant concentration of the gradient at this distance is 51%. Therefore, the CDGE gel should

use a denaturant concentration of 51%.

28

20%

70%

Page 33

12 3

Fig. 4.15. Constant denaturing gel. Amplified mutant and wild-type alleles of exon 8 from the p53 gene.

Separation by CDGE run at 130 V for 2.5 hours on a 10% acrylamide gel in 51% denaturant at 56 °C. Lane 1, mutant

allele; lane 2, wild-type allele; lane 3, mutant and wild-type allele.

Reagent Preparation

The concentration of denaturant is determined from a perpendicular or parallel DGGE

gel. The concentration of acrylamide may vary, depending on the size of the fragment that is

being analyzed. Both 0% and 100% denaturant should be made as stock solutions. A 100%

denaturant is a mixture of 7 M urea and 40% deionized formamide. Reagents for casting and

running CDGE gels are included in the DCode electrophoresis reagent kit for DGGE/CDGE,

catalog number 170-9032.

For different percent crosslinking, use the equation below to determine the amount of Bis

to add. The example stock solution below is for an acrylamide/bis ratio of 37.5:1.

40% Acrylamide/Bis (37.5:1)

Reagent Amount

Acrylamide 38.93 g

Bis-acrylamide 1.07 g

dH2O to 100.0 ml

Filter through a 0.45 µ filter and store at 4°C.

For different percent crosslinking, use the equation below to determine the amount of Bis

to add. The example stock solution is for an acrylamide/bis ratio of 37.5:1.

Polyacrylamide gels are described by reference to two characteristics:

1) Total monomer concentration (%T)

2) Crosslinking monomer concentration (%C)

%T =

gm acrylamide + g bis-acrylamide

x 100

total volume

%C =

gm bis-acrylamide

x 100

gm acrylamide + g bis-acrylamide

29

Page 34

50x TAE Buffer

Reagent Amount Final Concentration

Tris base 242.0 g 2 M

Acetic acid, glacial 57.1 ml 1 M

0.5 M EDTA, pH 8.0 100.0 ml 50 mM

dH2O to 1,000.0 ml

Mix. Autoclave for 20–30 minutes. Store at room temperature.

0% Denaturing

Solution 6% Gel 8% Gel 10% Gel 12% Gel

40% Acrylamide/Bis 15 ml 20 ml 25 ml 30 ml

50x TAE buffer 2 ml 2 ml 2 ml 2 ml

dH2O 83 ml 78 ml 73 ml 68 ml

Total volume 100 ml 100 ml 100 ml 100 ml

Degas for about 10–15 minutes. Store at 4°C in a brown bottle for approximately 1 month.

100% Denaturing

Solution 6% Gel 8% Gel 10% Gel 12% Gel

40% Acrylamide/Bis 15 ml 20 ml 25 ml 30 ml

50x TAE buffer 2 ml 2 ml 2 ml 2 ml

Formamide (deionized) 40 ml 40 ml 40 ml 40 ml

Urea 42 g 42 g 42 g 42 g

dH2O to 100 ml to 100 ml to 100 ml to 100 ml

Degas for about 10–15 minutes. Store at 4°C in a brown bottle for approximately 1 month.

A 100% denaturant solution requires re-dissolving after storage. Place the bottle in a warm

bath and stir for faster results.

To cast constant denaturing gradient gels, use the formula below to determine the volume of

0% and 100% denaturing solutions needed to achieve the desired denaturant concentration.

1. (% desired denaturant) (total gel volume needed) = ml of 100% denaturant solution

2. (total gel volume needed) - (ml of 100% denaturant) = ml of 0% denaturant solution

Example: To cast a 52% constant denaturing gel, use 30 ml total volume for a 16 x 16 cm

gel with a 1.0 mm spacer.

1. (0.52)(30 ml) = 15.6 ml of 100% denaturing solution needed

2. (30 ml)–(15.6 ml) = 14.4 ml of 0% denaturing solution needed

The table below provides the percentage acrylamide/bis needed for a particular size range.

Gel PercentageBase Pair Separation

6% 300–1,000 bp

8% 200–400 bp

10% 100–300 bp

10% Ammonium Persulfate

Reagent

Amount

Ammonium persulfate 0.1 g

dH2O 1.0 ml

Store at –20°C for about a week.

30

Page 35

DCode Dye Solution

Reagent

AmountFinal Concentration

Bromophenol blue 0.05 g 0.5%

Xylene cyanol0.05 g 0.5%

1x TAE buffer10.0 ml 1x

Store at room temperature.

2x Gel Loading Dye

Reagent

AmountFinal Concentration

2% Bromophenol blue 0.25 ml 0.05%

2% Xylene cyanol 0.25 ml 0.05%

100% Glycerol7.0 ml 70%

dH2O 2.5 ml

Total volume 10.0 ml

Store at room temperature.

1x TAE Running Buffer

Reagent Amount

50x TAE buffer 140 ml

dH2O 6,860 ml

Total volume 7,000 ml

Gel Volumes

The table below provides the required volume per gel size and spacer thickness.

Spacer Thickness 16 x 16 cm Gel 16 x 10 cm Gel

0.75 mm 25 ml 15 ml

1.00 mm 30 ml 20 ml

1.50 mm 45 ml 26 ml

Sample Preparation

1. It is important to optimize the PCR reaction to minimize unwanted products which may

interfere with gel analysis. The PCR products should be evaluated for purity by agarose

gel electrophoresis before being loaded onto a denaturing acrylamide gel.

2. For a constant denaturing gel, load about 180–300 ng of amplified DNA per well (usually

5–10% of a 100 µl PCR volume from a 100 ng DNA template). A wild-type control should

be run on every gel.

3. Add an equal volume of 2x gel loading dye to the sample.

4. Heteroduplexes can be generated during PCR by amplifying the mutant and wild-type

samples in the same tube. If the samples are amplified in separate tubes, then heteroduplexes can be formed by mixing an equal amount of mutant and wild-type samples

in one tube. Heat the tube at 95°C for 5 minutes, then place at 65°C for 1 hour, and let

slowly cool to room temperature.

31

Page 36

Temperature Controller