Page 1

BERNINA 830

Page 2

Dear BERNINA 830 customer,

032299.53.04_1204_B830_EN

Congratulations! With the purchase of the BERNINA

830, you have acquired the ultimate sewing and

embroidery system available in today’s market. By

purchasing this system, you have established that you

are a creative person who is looking for the opportunity

to explore and expand the unlimited world of creativity.

The use of modern, future-oriented technologies in the

computerized sewing and embroidery field coupled with

the tradition of BERNINA quality and reliability offer you

the best of the future and the best of the past. With the

BERNINA 830 system you will be able to sew faster,

smarter, longer, and more creatively- and with more

enjoyment. We have put all the dreams that our

customers have shared with us into this product.

BERNINA wants you to fully enjoy the enormous

possibilities that the BERNINA 830 sewing system

offers you. To do so, you must learn all the wonderful

features of the product. Therefore, don’t hesitate to

frequent your local BERNINA dealer and tap into the

knowledge of the BERNINA educators.

I wish you much happiness and great satisfaction while

enjoying your creative pastime.

H.P. Ueltschi

President

BERNINA International AG

CH-8266 Steckborn

www.bernina.com

Page 3

IMPORTANT SAFETY INSTRUCTIONS

032299.53.04_1204_B830_EN

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this sewing-/embroidery

computer.

When the sewing-/embroidery computer is not in use,

it should be disconnected from the electricity supply

by removing the plug from the outlet.

DANGER!

To reduce the risk of electrical shock:

1 An appliance should never be left unattended

when plugged in.

2 Always unplug this sewing-/embroidery computer

from the electrical outlet immediately after using

and before cleaning.

3 LED Radiation – Do not view directly with optical

instruments. Class 1M LED product.

Safety Instructions

WARNING!

To reduce the risk of burns, fire, electric shock or injury to

persons:

1 Use this sewing-/embroidery computer only for its

intended use as outlined in this manual. Use only

attachments, accessories and parts recommended

by the manufacturer.

2 Do not use the sewing-/embroidery computer as a

toy. Caution is advised when the sewing-/embroidery

computer is used by children, or near children. The

sewing-/embroidery computer is not intended for use

by persons (including children) with reduced

physical, sensory or mental capabilities or lack of

experience and knowledge, unless they have been

given supervision or instruction concerning use of

the sewing -/embroidery computer by a person

responsible for their safety. To ensure children do

not play with the sewing-/embroidery computer they

must be supervised.

3 Never operate this sewing-/embroidery computer if:

► the cord or plug are damaged

► it is not working properly

► it has been dropped or damaged

► it has fallen into water

Return the sewing-/embroidery computer to your

local authorized BERNINA dealer for examination or

repair.

4 Never operate the sewing-/embroidery computer

with any air openings blocked. Keep ventilation

openings of the sewing-/embroidery computer and

foot controller free from the accumulation of lint, dust

and loose cloth.

5 Keep fingers away from all moving parts. Special

care is required around the sewing needle.

6 Never drop or insert any objects into any openings

on the sewing-/embroidery computer.

7 Do not use the sewing-/embroidery computer

outdoors.

8 Do not operate the sewing-/embroidery computer

where aerosol products (sprays) or oxygen are being

used or where oxygen is being administered.

9 Do not pull or push fabric while stitching - this may

cause the needle to break.

10 Do not use bent needles.

11 Always use a proper BERNINA stitch plate. The

wrong plate can cause needle breakage.

12 To disconnect, turn all controls to the OFF («0»)

position, then remove the plug from the outlet. To

unplug, pull the plug not the cord.

13 Turn all controls OFF (to the «0» position) when

making any adjustments in the needle area - such as

changing or threading the needle, presser foot etc.

14 Always unplug the sewing-/embroidery computer

from the electrical outlet when removing covers,

lubricating, or when making other user servicing

adjustments mentioned in this instruction manual.

15 This sewing-/embroidery computer is provided with

double insulation (except USA and Canada). Use

only identical replacement parts. See instructions for

servicing of double-insulated products.

SERVICING DOUBLE

INSULATED PRODUCTS

In a double-insulated product two systems of insulation are

provided instead of grounding. No grounding means is

provided on a doubleinsulated product, nor should a

means for grounding be added to the product. Servicing a

doubleinsulated product requires extreme care and

knowledge of the system and should be done only by qualified service personnel. Replacement parts for a doubleinsulated product must be identical to those parts in the

product. A double-insulated product is marked with the

words «DOUBLE INSULATION» or «DOUBLE INSULATED».

The symbol

may also be marked on the product.

DISCLAIMER

No liability will be assumed for any possible damage which

arises from misuse of this sewing-/embroidery computer.

This sewing-/embroidery computer is intended for

household use only.

SAVE THESE

INSTRUCTIONS!

2

Page 4

Sewing

032299.53.04_1204_B830_EN

Accessory & Preparation

Functions & Settings

Main Stitch Categories

BERNINA World

Maintenance/Troubleshooting

Stitch & Motif Overview

Index

Page 5

Very important!

032299.53.04_1204_B830_EN

Risk of damage!

Helpful tips!

Text

Gayle Hillert, Herbert Stolz, Joanna Wild

Sewing & Embroidering Projects

Colette Cogley, Jeanne Delpit, Susan Fears, Claudia Giesser,

Gayle Hillert, Nina McVeigh, Pia Welsch, Joanna Wild

Screen Design & Drawings

sculpt.ch, CH-Steckborn

Photographs

Sterling Rice Group, USA

Patrice Heilmann, CH-Winterthur

Manual Design & Concept

Erika Vollenweider-Czibulya

Typesetting, Layout, DTP

Susanne Ribi, Erika Vollenweider-Czibulya

Copyright

2008 BERNINA International AG, CH-Steckborn

All rights reserved

For technical and product improvement reasons, the sewing computer‘s features, parts and accessory are subject to unannounced

changes and alterations at any time. The accessory included can differ from country to country.

Page 6

Accessory & Preparation

032299.53.04_1204_B830_EN

Accessory 6

Your Delivery 6

Sewing computer cover 6

Accessory 6

In plastic bag 6

Presser Feet 7

BERNINA Specialty presser feet 7

Accessory Box 8

Free Standing 8

Lay-out 9

Sewing Computer 10

Details 10

Preparation 12

Battery 12

Power Switch/Power Cable 12

Free-Hand-System (FHS)

Presser Foot Lifter 12

Changing the Presser Foot 22

Stitch plates 23

Feed-Dog and Fabric Feed 23

Sewing with the Height Compensation Tool 24

Sewing Corners 24

Thread Tension 25

Upper Thread Tension 25

Lower Thread Tension 25

Altering the Tension 25

Needles 26

Important facts about

Thread and Needles 26

Thread 26

Needle, Thread and Fabric 26

Needle/Thread 26

Guidelines 27

Overview 28

Foot Control 13

LED Sewing Light 13

Pivotable Triple Spool Holder 14

Bobbin 14

Winding the Bobbin 15

Interrupting the winding process 15

Removing/Inserting the Bobbin 16

Threading Lower Thread 16

Slide-on Table 17

Thread Cutter 17

Threading the Upper Thread 18

Double/Triple Needle 19

Thread-Guide-and-Lubricating Unit 20

As a thread-guide eyelet (Fig. 1) 20

As a thread lubricator (Fig. 2) 20

Assembly 20

Radial Thread Guide 21

Various Options of Application 21

Changing the Needle 22

Page 7

Your Delivery

032299.53.04_1204_B830_EN

Accessory

Sewing computer cover

► protects from dust and dirt

Accessory

► foot control

► power cable

► warranty card

► FHS presser foot lifter (Free Hand System)

► slide-on table

► seam guide for slide-on table

► Instructional DVD

► sewing computer cover

► accessory box

► thread lubricater

7

6

6

9

10

8

5

2

11

13

14

34

1

16

17

12

15

19

18

20

In plastic bag

1 4 bobbins

2 adjustable guides

3 wire threader for threading cording for bobbin play

4 tweezers

5 2 nets

6 cording attachment

7 magnifying glass adapter

8 small screwdriver, gray

9 touch pen

10 seam ripper

11 lint brush

12 multifunction tool

13 manual threader

14 spool disc small

15 holder for king-size spools, cone holder

16 height compensating tool

17 needle pack 130/705H

18 lubricator

19 monitoring mirror

20 hook cleaning tool

Page 8

Presser Feet

032299.53.04_1204_B830_EN

1C Reverse pattern foot 1D Reverse pattern foot 2A Overlock foot

3C Buttonhole foot 4D Zipper foot 5 Blindstitch foot

3A Automatic buttonhole

foot with slide

Accessory

18 Button sew-on foot

20C Open embroidery foot 40C Sideways motion foot 42 BSR foot

BERNINA Specialty presser feet

8 Jeans foot 50 Walking foot

It is recommended that BERNINA specialty

presser feet be used for specific sewing tasks

such as quilting, heirloom sewing, home

decorating, tailoring etc.

All the presser feet are shown in the

enclosed accessory catalog.

They are available at your BERNINA dealer.

7

Page 9

Accessory Box

032299.53.04_1204_B830_EN

Free Standing

► on the back of the box, pull both

extensions out until they click into

place

Accessory

8

Page 10

Lay-out

032299.53.04_1204_B830_EN

Accessory

The box is equipped as standard with

one small A and one large B drawer

as well as a compartment for bobbin

holders C and presser feet D.

► to remove a bobbin, press the

compartment holder E lightly

D

C

G

E

F

A

B

► buttonhole foot with slide no. 3A

can be stored in the left compartment F

► store the needle range supplied in

the special compartment G

9

Page 11

Details

032299.53.04_1204_B830_EN

8

Sewing Computer

10

13

7

6

2

1

5

4

3

20

9

11

12

19

21

15

17

14

16

18

23

24

25

32

31

26

27

28

33

30

22

29

17

16

34

35

36

38 39

37

10

Page 12

33

032299.53.04_1204_B830_EN

41

40

1 Bobbin cover

2 Stitch plate

3 Attachment base for special accessories

4 Presser foot

5 Needle clamp

6 Thread guide

7 Screen

8 Carrying handle

9 System Settings

‣ Setup button

‣ Tutorial button

‣ Creative Consultant button

‣ Help button

‣ Eco button

‣ Sewing-/Embroidery mode button

‣ «clr» clear button

10 Stitch width knob

11 Stitch length knob

12 Needle position buttons

13 Bobbin winder

14 Thread cutter for bobbin winder

15 Threading slit

16 Triple spool pin

17 Telescope

18 Bobbin pre-tension

19 Slide-on table socket

20 Darning hoop connection

21 FHS (Free Hand System) connection

22 Slide speed control

23 Automatic needle threader

24 Needle stop up/down button

25 Presser foot up/down button

26 Securing button

27 Pattern end button

28 Automatic thread cutter

29 Start/stop button

30 Quick reverse button

31 Special-accessories port

32 BSR connection

33 BERNINA Dual Feed

34 Handwheel

35 USB connection

36 PC connection

37 Foot control socket

38 Power switch on/off («I», «0»)

39 Power plug socket

40 Connection for Magnifying glass

(optional accessory)

41 Thread cutter on head frame

42 Embroidery module connection

Sewing Computer

42

11

Page 13

Battery

032299.53.04_1204_B830_EN

Power Switch/Power Cable

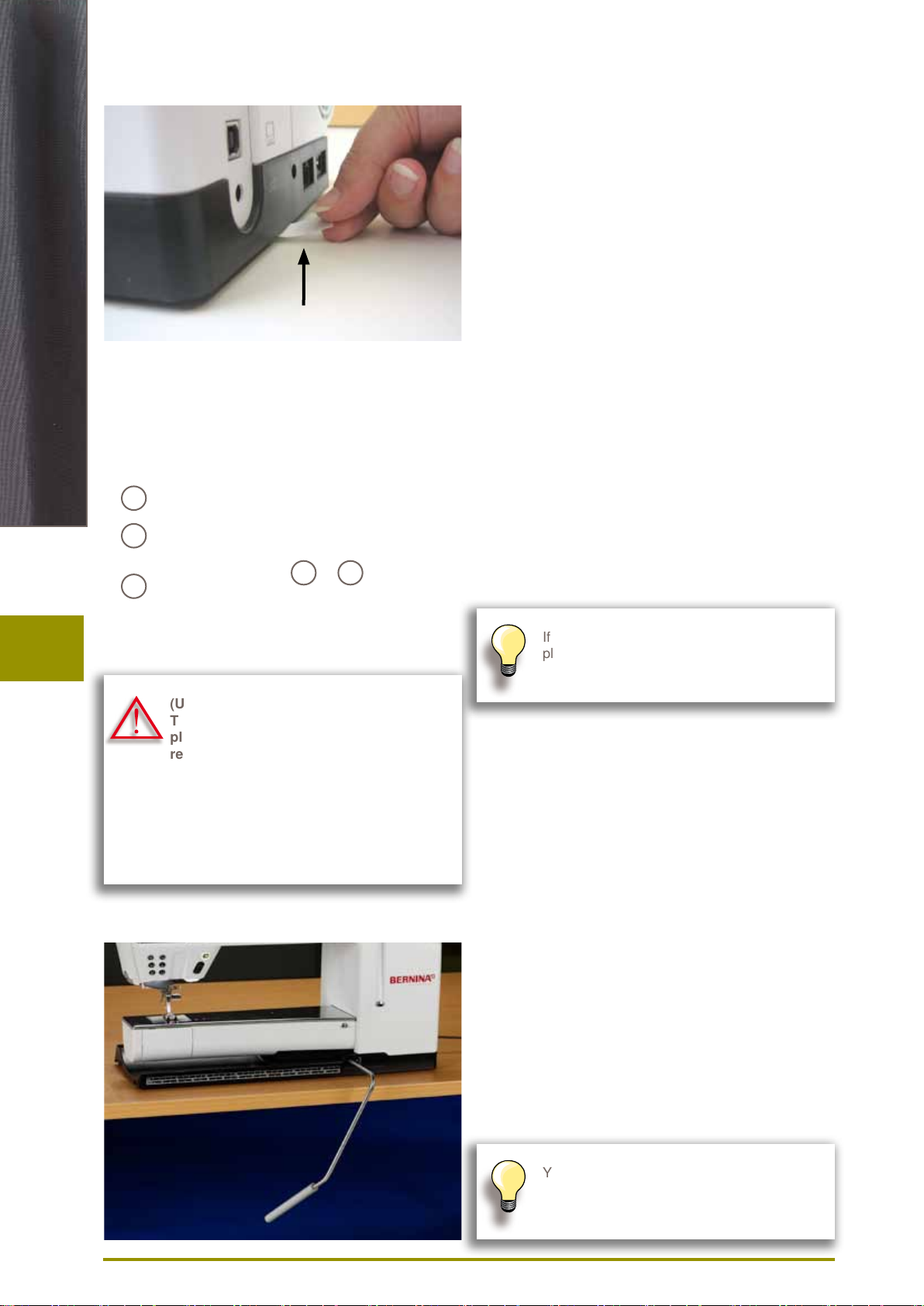

Please remove the protective sticker of the battery

before taking the sewing computer in use.

A Power Switch

The sewing computer is switched on («I») and off («0»)

with the power switch.

Preparation

E

D

A B

C

(USA/Canada only):

The sewing computer has a polarized

plug (one blade wider than the other). To

reduce the risk of electrical shock, this

plug is intended to fit in a polarized outlet

only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician

to install the proper outlet. Do not modify

the plug in any way!

Free-Hand-System (FHS) Presser Foot Lifter

I the sewing computer is switched on

0 the sewing computer is switched off

B Power connection

C Foot control connection

D PC connection

E USB stick connection

If the sewing computer is kept in a cold room,

place it in a warm room for 1 hour before use.

12

The FHS is used to raise and lower the Presser Foot.

Attaching the Free Hand System

► insert into the opening; you should be able to operate

the FHS with your knee in your normal sitting position

Raising and Lowering the Presser Foot

► with knee push FHS to the right

► the presser foot is raised and the feed-dog is lowered

simultaneously. Tension is released

► the feed-dog is raised as soon as the first stitch is sewn

Your dealer can adjust the FHS if necessary.

Page 14

Foot Control

032299.53.04_1204_B830_EN

A

Sewing Speed

► sewing speed is controlled by pressure on the foot

control

Raise or Lower the Needle

► entire foot rests comfortably on Foot Pedal

► tap the Foot Control with your heel to raise or lower the

needle

Cable tidy

B

► wind the cable around the reel

► insert the cable end (plug) into A

When sewing

► unwind the cable to the desired length and slip into B

or C

C

Preparation

(USA/Canada only):

Use only foot controller type LV1 or WFC1

with sewing computer model 830.

LED Sewing Light

The LED sewing light illuminates the sewing area with no

shadows and has a very long service life.

A defective sewing light must only be

replaced by a technician.

Take the sewing-/embroidery computer

to your BERNINA dealer.

13

Page 15

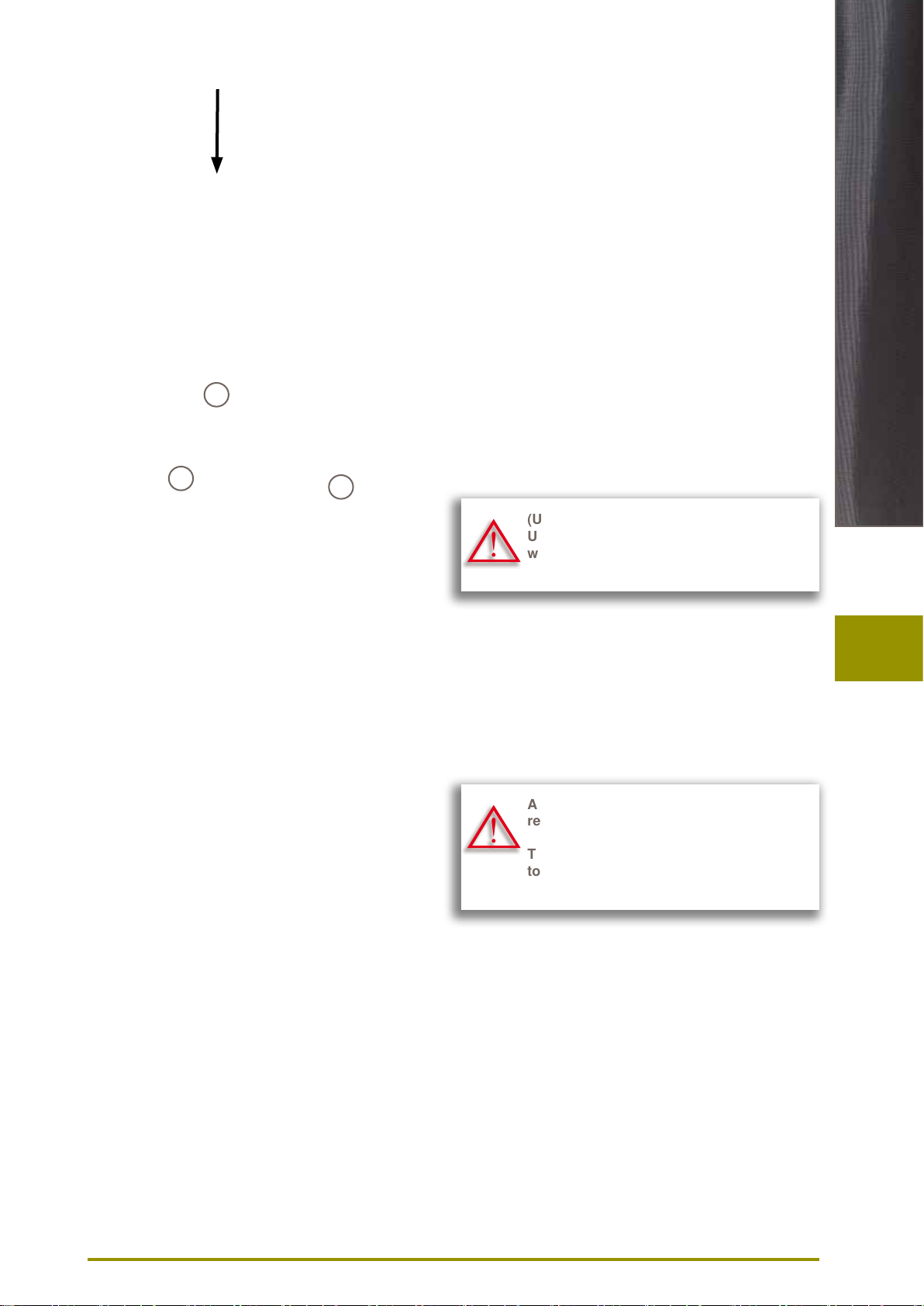

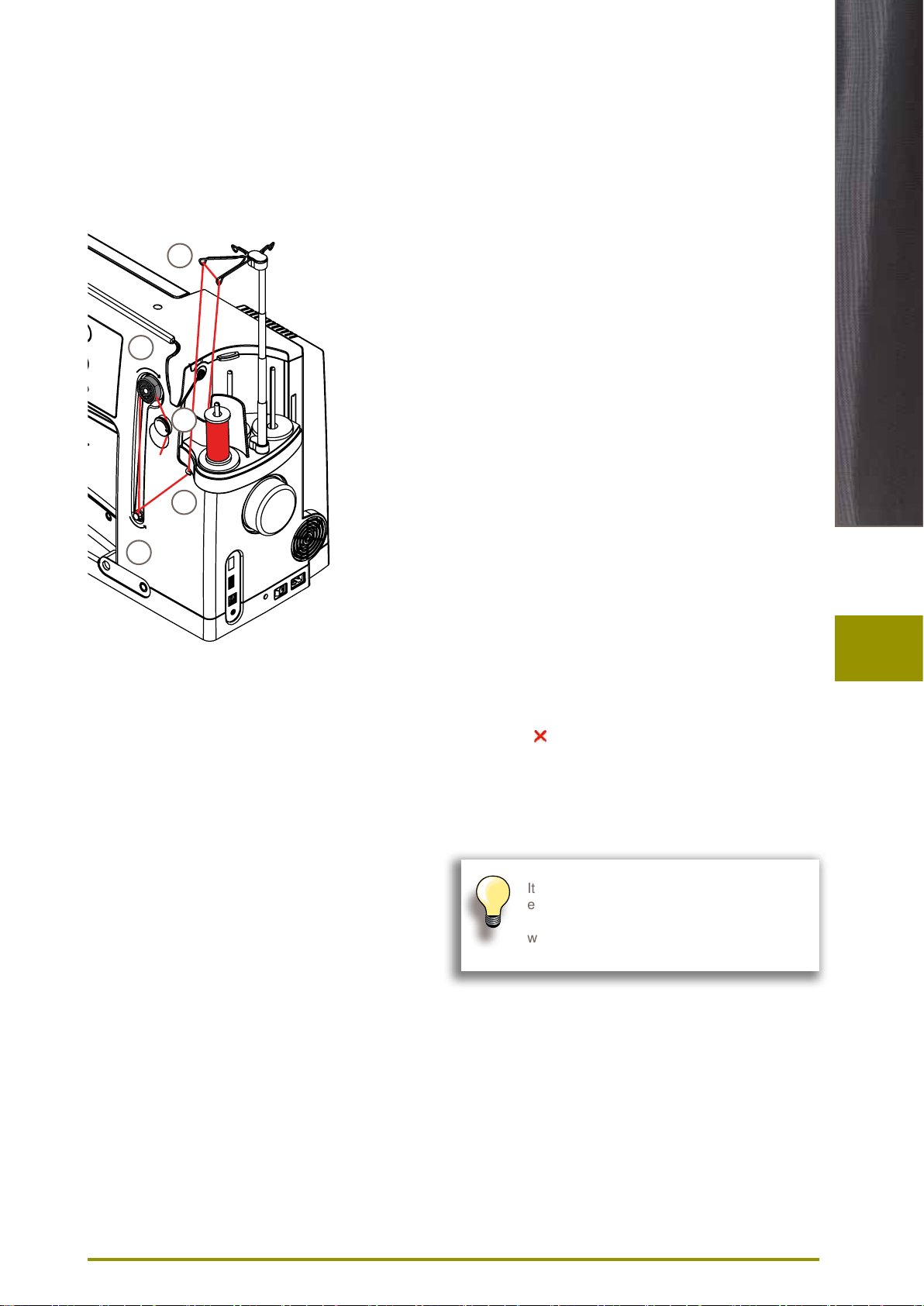

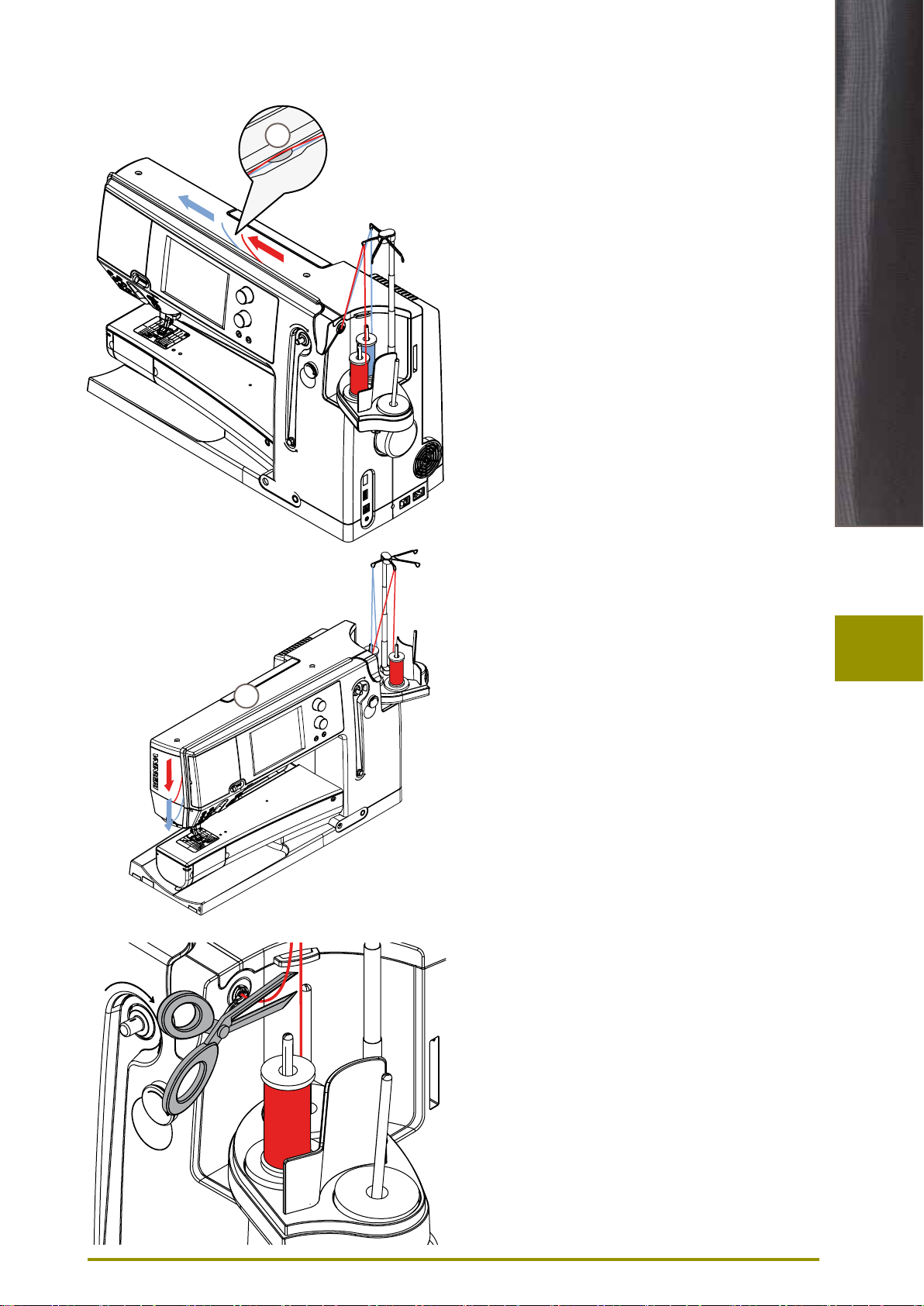

Pivotable Triple Spool Holder

032299.53.04_1204_B830_EN

A

► remove spool-pin cover vertically upwards

► pull out the telescopic rod and ensure that all the parts

snap into place

► swing spool pin to the right until it is engaged. This

ensures a good overall view and access to the spool

pins

► eyelet A is used when winding a bobbin

Preparation

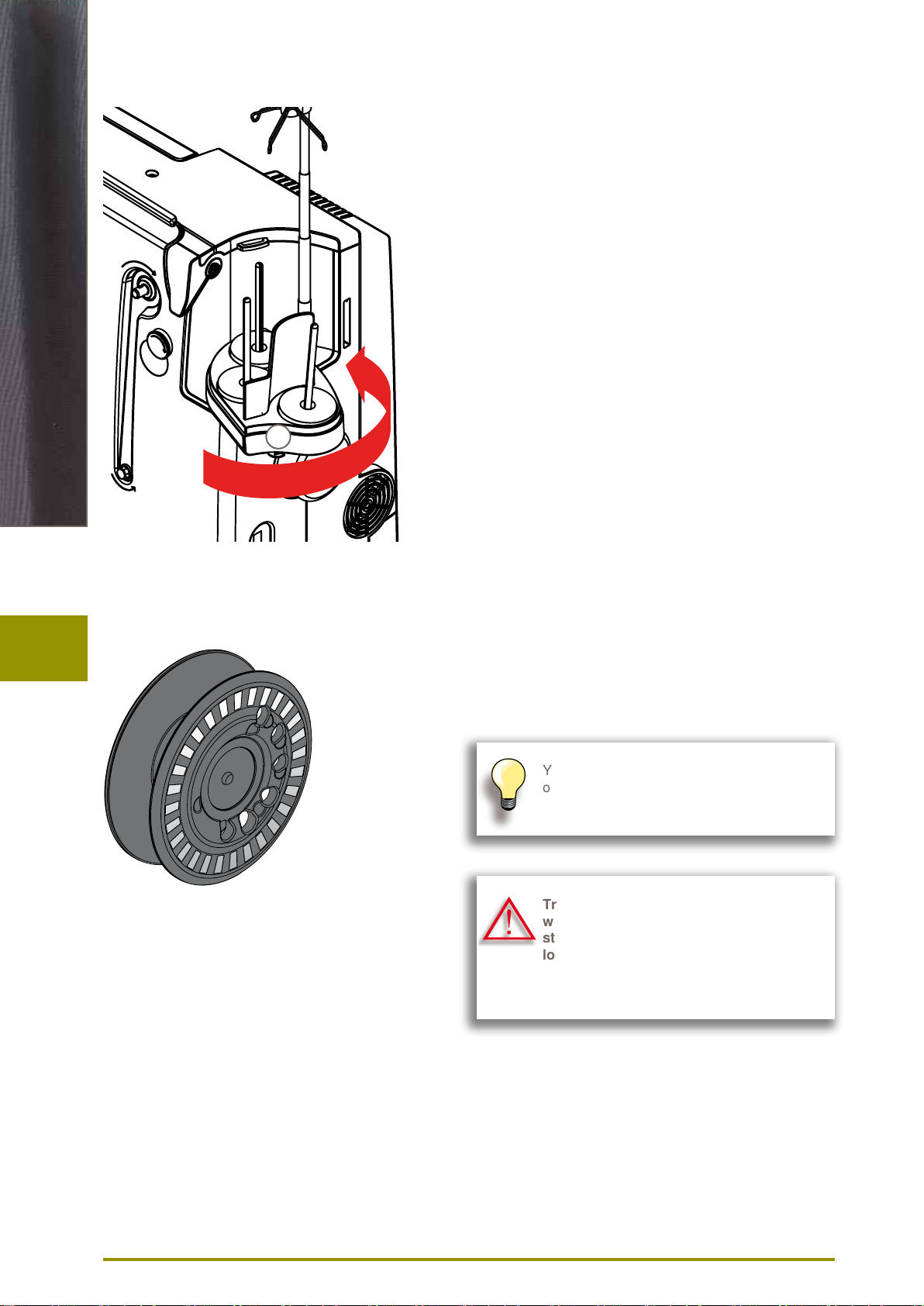

Bobbin

The 830 bobbin, exclusive to BERNINA, supplies till 40%

more lower thread. If the bobbin is not inserted correctly,

an error message is displayed.

You can preselect a bobbin fill of 25%, 50%

or 100%.

Treat the bobbins with care. Keep the

white sensor surfaces free of scratches or

stains to ensure correct functioning of the

lower thread indicator. Store the bobbins

in the respective compartment of the

accessories box.

14

Page 16

Winding the Bobbin

032299.53.04_1204_B830_EN

1

4

5

2

3

Preparation

► turn power switch on (to «I»)

► place empty bobbin on Pin, white mark in front

► the bobbin winding screen appears

► the amount of bobbin fill is recognized by the system

and displayed by bar below the selectable bobbin fill

► place thread spool on the front spool pin and thread the

respective guides 1 on the telescope

Winding the Bobbin

► hold thread with both hands, guide the thread in the

thread guide on the swivel plate 2 in the direction of the

arrows and around the bobbin pre-tension 3

► wind the thread one to two times around the empty

bobbin 4 following the direction of the arrows and pull

any excess thread in the direction of the arrows, cut off

on the thread cutter 5

► select the bobbin filling, standard = 100%

► «Start» field = touch bobbin symbol

► adjust the winding speed with the «+» or «-» icon or with

the stitch width knob

► winding process stops as soon as the selected fill

percentage is reached

► remove the bobbin and pull the thread over the thread

cutter

► the screen is closed

Manual Winding Mode

► touch «man»

► the winder will run as long as the «bobbin» icon is

pressed

Preparation

Interrupting the winding process

► the winding process can be interrupted by touching

«Start»-(bobbin) icon, and the screen closed by

touching

► Continuing the winding process

‣ touch «bobbin» icon (it appears in the place of the

clock) = the winding screen opens

‣ touch «Start»-to start winding process

It is possible to wind the bobbin while

embroidering.

We recommend, however, to reduce the

winding speed.

15

Page 17

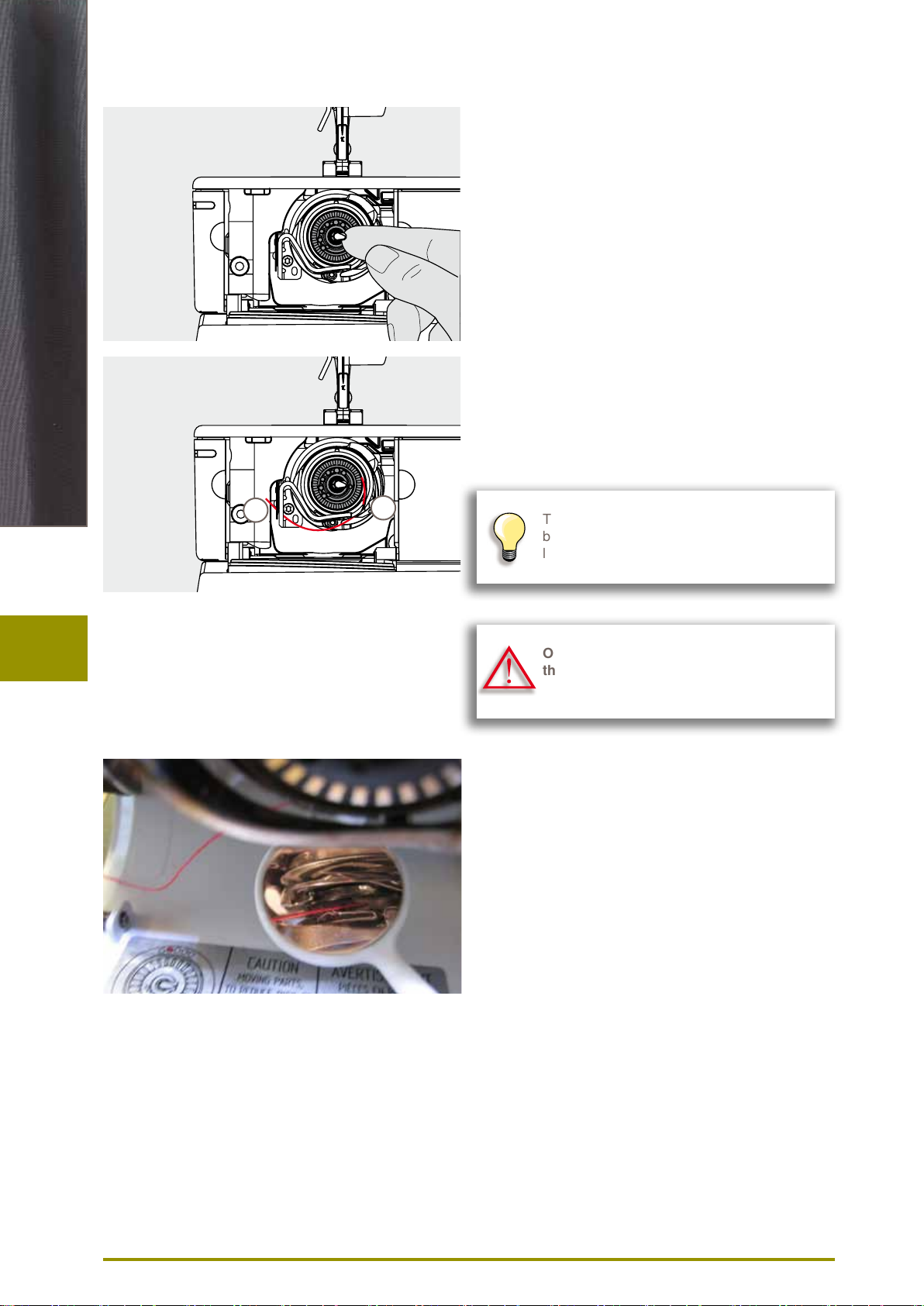

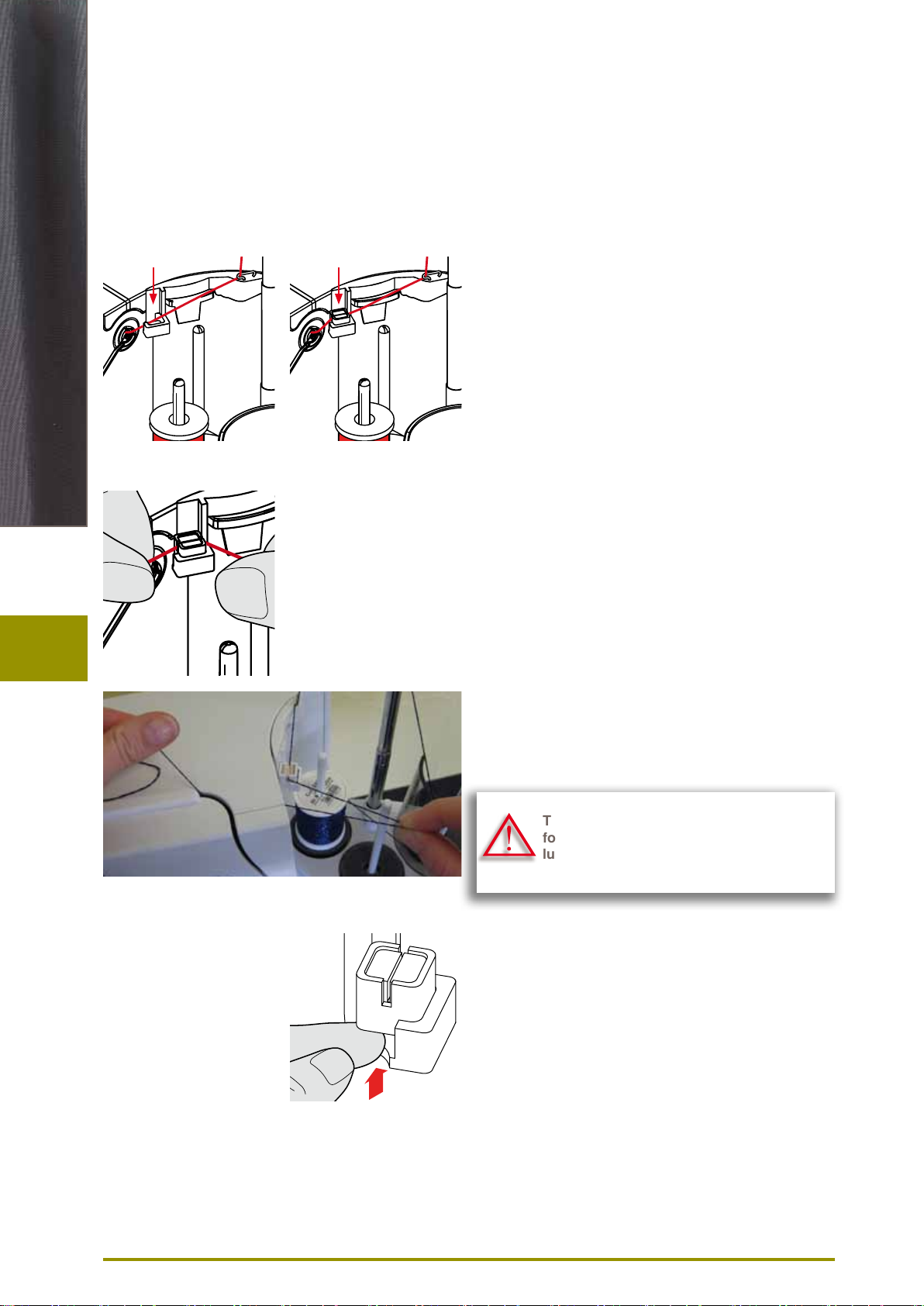

Removing/Inserting the Bobbin

032299.53.04_1204_B830_EN

Removing the Bobbin

► open bobbin cover, the hook system swings to the front

► push the latch in the center of the bobbin to the left, the

bobbin pops out and can be removed

Inserting the Bobbin

► with bobbin markings facing the front, place the bobbin

into the hook and push until it clicks into place

Threading Lower Thread

► pull the thread to the right into slit A, then left under the

spring

► pull thread over thread cutter B and cut

► close the bobbin cover slowly, the hook swings back to

the rear

Preparation

B

A

The bobbin thread does not have to be

brought up as the loose end is just the right

length to start sewing.

Only remove the bobbin if the hook is at

the end position (threading position).

Check the threading path

After threading the hook, hold the mirror under the

swung-out hook unit as shown in the pictures below.

► Position of bobbin thread when threaded for sewing

16

Page 18

Slide-on Table

032299.53.04_1204_B830_EN

The slide-on table increases the sewing surface.

Attaching the Table

► raise the needle and presser foot

► from the left, push table to the right over the free-arm

and push firmly so that it engages over the fixing cam

Removing the Table

► raise needle and presser foot

► press the button down and remove to the left

Remove the slide-on table only when

bobbin cover is closed.

Seam Guide

► press the release button and insert into the groove

(underside of table) from left or right

► can be moved over the entire table length

Preparation

Thread Cutter

Scale

► «0» corresponds to the center needle position

on Head Frame

► pull both threads from back to front over the cutter

► threads release automatically as soon as the first stitch

is sewn

at bobbin winder

► after winding bobbin, pull thread in direction of arrow

over thread cutter

17

Page 19

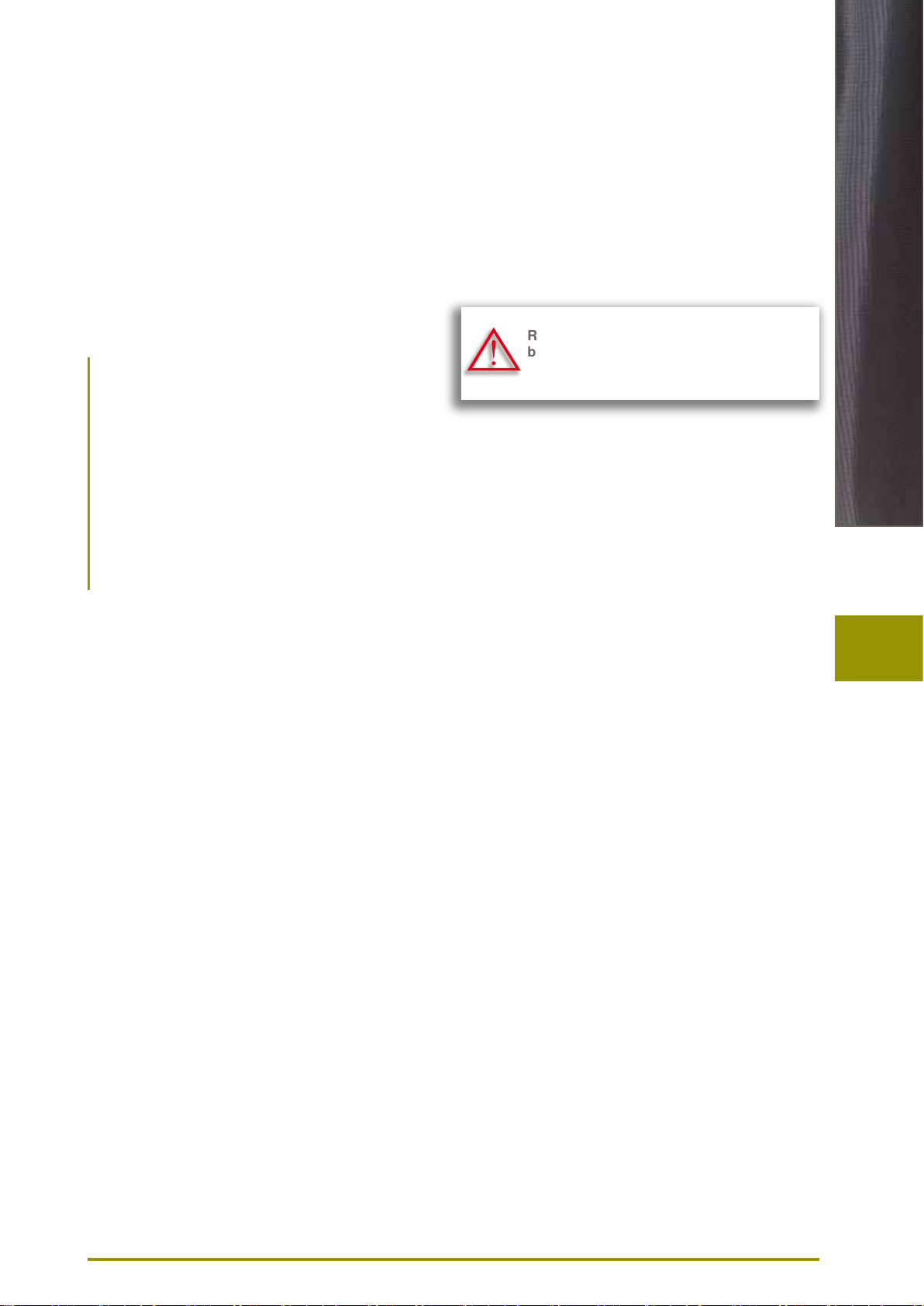

Threading the Upper Thread

032299.53.04_1204_B830_EN

Automatic threading

► place thread spool on the rear or center spool pin

► thread the corresponding guide on the telescopic rod,

hold with both hands and guide into the threading

opening of the sewing computer, taking it up to the

thread guide in the needle clamp A and B and pull from

back to front over the thread cutter C

► touch the automatic threader button, a message and an

animation appear

► during threading the start-stop button is illuminated red

► if the thread has not been threaded correctly, an error

message appears

► close the message with and start again

► if the thread has been threaded correctly the start-stop

button is illuminated green

Manual threading

► follow the two first steps as described above

► touch «Manual threading» icon on screen

► press «Automatic threading» button, then thread the

needle by hand

Preparation

► when using unruly threads, slip the net over

the upper thread spool

► large net for large spools, small net for

small spools

► this prevents the upper thread from slipping

and gives an even thread feed

► place the thread(s) under the presser foot

and to the back before starting to sew

Do not start the threaded sewing-/

embroidery computer if there is no fabric

on the stitch plate.

The sewing-/embroidery computer must

be switched ON for threading.

C

18

B

A

Page 20

Double/Triple Needle

032299.53.04_1204_B830_EN

Double Needle

A

► touch the «Security Program» icon

► touch the appropriate needle icon (double needle) in the

Security Program screen

► place a thread spool on the center spool pin and one on

the rear spool pin and thread the corresponding guides

on the telescopic rod

► insert the two threads together into the threading slit,

guiding the thread of the rear spool pin behind the

thread-tension disc A while guiding the thread of the

center spool pin in front of the tension disc A. Then

guide the two threads through the thread guide at the

needle clamp

► touch the icon «Manual Threading» on the threading

animation screen. Next touch the illuminated automatic

threading button

► using the manual threader in your accessory kit,

manually thread the left needle and then the right

needle

Triple Needle

► in the Security Program select triple needle

► place a thread spool on each spool pin and thread the

respective guides on the telescopic rod

► thread as usual, guiding the thread from the rear and

center spool pin in the threading slit to the rear of

thread tension disc A and the thread from the front

spool pin in front of the tension disc A

Preparation

A

Changing the thread

► cut the spool thread before the pre-tension and pull out

of the sewing computer to front near the needle

19

Page 21

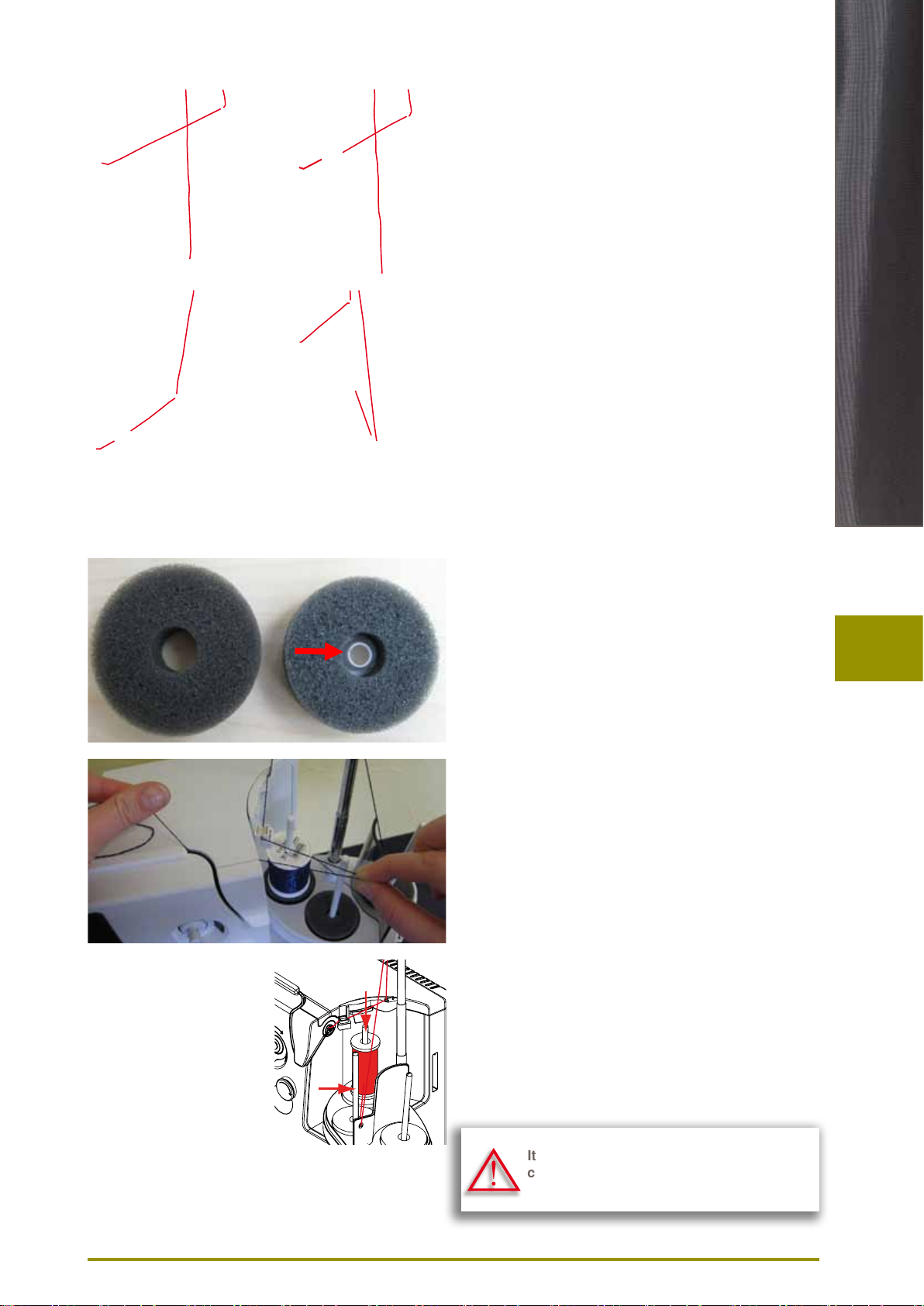

Thread-Guide-and-Lubricating Unit

032299.53.04_1204_B830_EN

As a thread-guide eyelet (Fig. 1)

Use the unit without lubricator for a controlled guiding of the thread into the pretensioner, e.g. when using lively thread

types.

As a thread lubricator (Fig. 2)

Using the lubricator is advisable when using e.g. threads with high function values, metallic threads, loosely twisted

thread types etc. The silicone fluid improves the threads‘ gliding properties considerably and therefore helps to produce

flawless stitching results.

Assembly

► insert the unit into the spool-holder cover fixture and

push down entirely (Fig. 1)

► insert the lubricator into the holder on the left side of the

unit, taking care to place the lubricator in such way that

the openings for the thread are in line with the thread

flow or thread direction (Fig. 2)

► moisten the felt, add a few drops of silicone fluid

1

2

► place the thread spool onto the middle or rear spool pin

as usual. Then guide the thread through the respective

eyelet of the telescopic rod and the eyelet of the

thread-guide-and-lubricating unit

Preparation

3

4

► hold the thread with both hands, pull it in to the slit of the

felt, pulling it down as far as it goes so that it‘ll stay in

the felt during machine operation (Fig. 3)

► continue and complete threading the sewing computer

as normal

► take care that the felt remains moistened. It mustn‘t dry

out. Apply some drops of silicone fluid once in a while to

keep it moist

► during the initial threading of the sewing computer and

when the radial thread release is used it is advisable to

pull an extra inch of thread from the spool before the

threader button is pushed (Fig. 4)

The silicone fluid must ONLY be used

for thread lubrication. Never use it to

lubricate the hook system!

When using the Thread-Guide-and-Lubrification Unit and

depending on the type of thread used it might be necessary to reduce the upper-thread tension slightly to achieve

perfect stitching results,

► to remove the Thread-Guide-and-Lubrification Unit,

push the entire unit up

20

Reattach the Thread-Guide-and-Lubrification Unit. Thread

the sewing computer as usual, including the eyelet of the

unit (Fig. 2).

Page 22

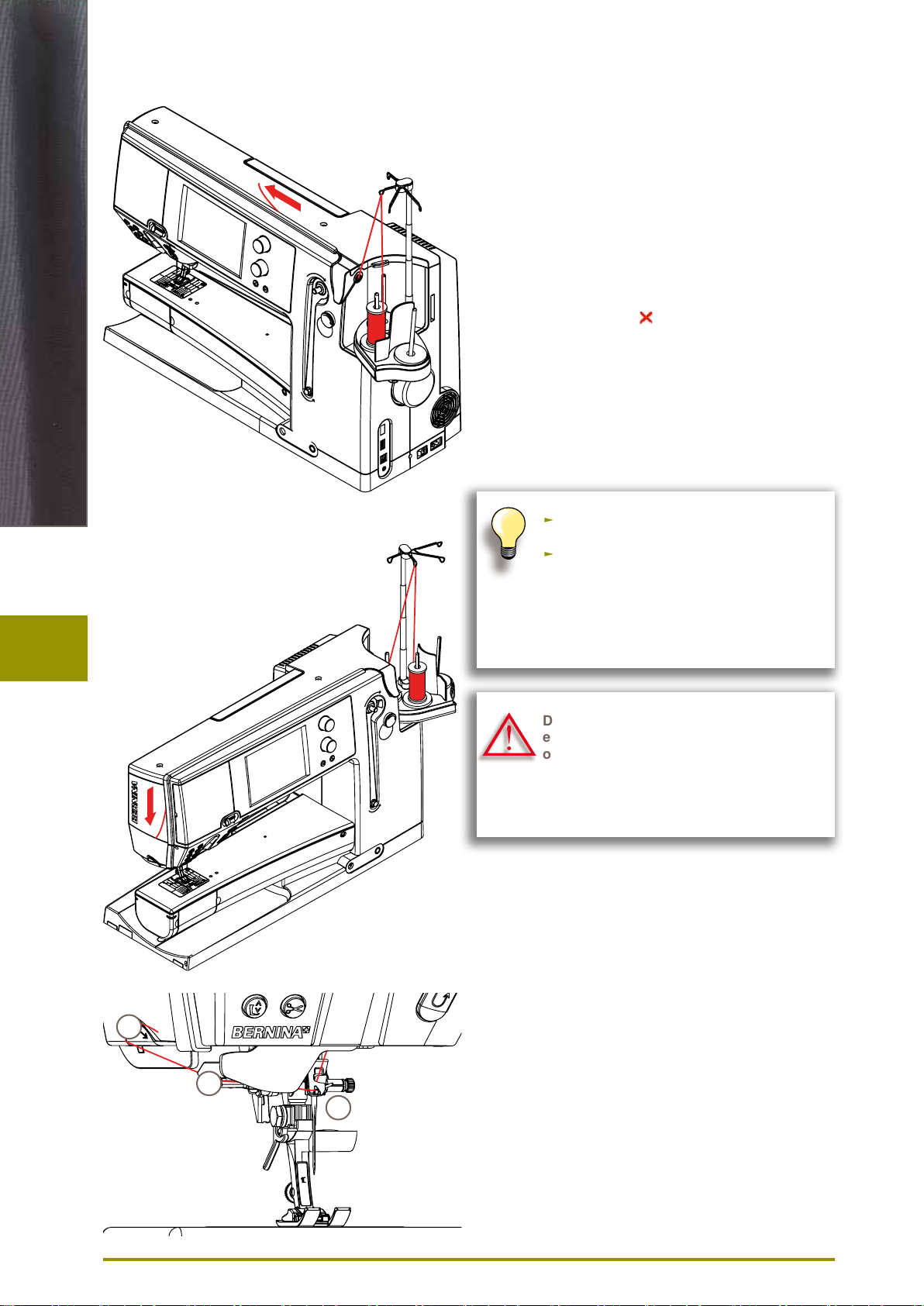

Various Options of Application

032299.53.04_1204_B830_EN

► Vertical thread unwinding (with or without lubricator)

from normal spool pin or optional multiple spool holder

(Fig. 1-3)

1

3

2

4

Radial Thread Guide

► Radial thread unwinding (with or without lubricator)

(Fig. 4)

► during the initial threading of the sewing computer and

when the radial thread release is used it is advisable to

pull an extra inch of thread from the spool before the

threader button is pushed (Fig. 5)

Preparation

How to use the thread guide

► it is preferable to replace the standard foam disc with

the foam rotary disc (with white plastic inner part) on

the rear spool pin

The extra thread guide ensures the consistent thread

release, when using threads i.e. metallic, lively or even

wounded thread spools.

► place thread spool on spool pin and guide thread

through thread guide. Then run thread via middle eyelet

of telescopic rod. Continue threading the sewing

computer as normal

► during the initial threading of the sewing computer and

when the radial thread release is used it is advisable to

pull an extra inch of thread from the spool before the

threader button is pushed

5

Any of the two spool pins (see arrow markings) can be

used. However, it is best to use the rear pin due to its more

favourable unwinding angle. Refrain from using the pin of

the winder.

In order to achieve perfect stitching results, it might be

necessary to reduce the upper-thread tension slightly when

using the radial thread unwinding and depending on the

thread used.

It is absolutely essential to use the

correct foam disc under the thread spool.

21

Page 23

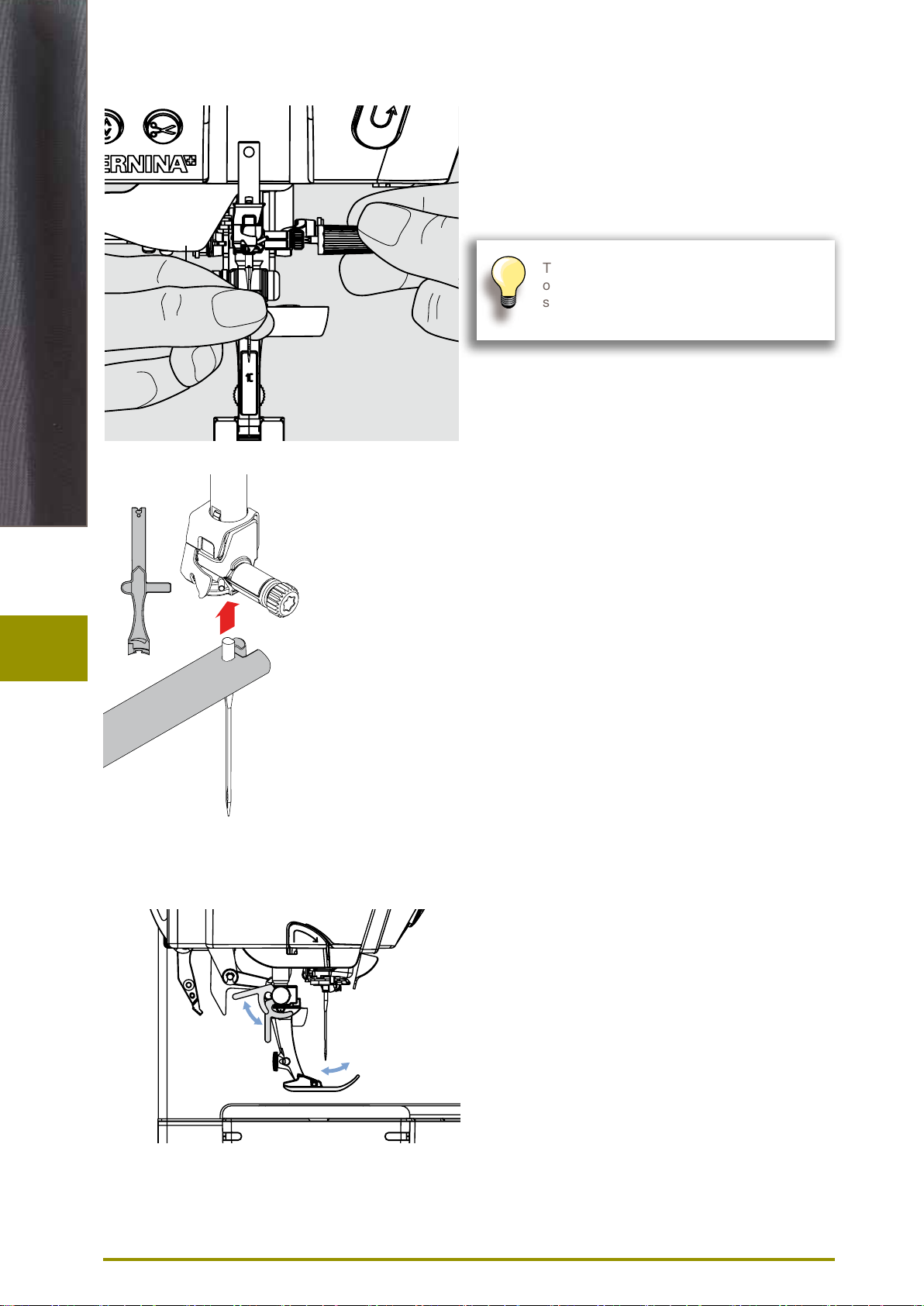

Changing the Needle

032299.53.04_1204_B830_EN

Preparation

► raise the needle

► lower the presser foot and turn the power switch to «0»

Removing the Needle

► loosen the clamp screw with the gray screwdriver and

pull needle down

Turn the handwheel to lower the needle in

order to get better access to the fastening

screw.

Inserting the Needle

► flat side of needle to the back

► insert the needle with the mulitfunction tool as far as it

will go

► tighten needle clamp screw

Changing the Presser Foot

22

► raise the needle and presser foot

► turn power switch to «0» (off)

Releasing the Presser Foot

► raise the clamping lever

► remove presser foot

Attaching the Presser Foot

► guide the presser foot upwards over the cone

► touch the clamping lever down

Page 24

Stitch plates

032299.53.04_1204_B830_EN

9mm

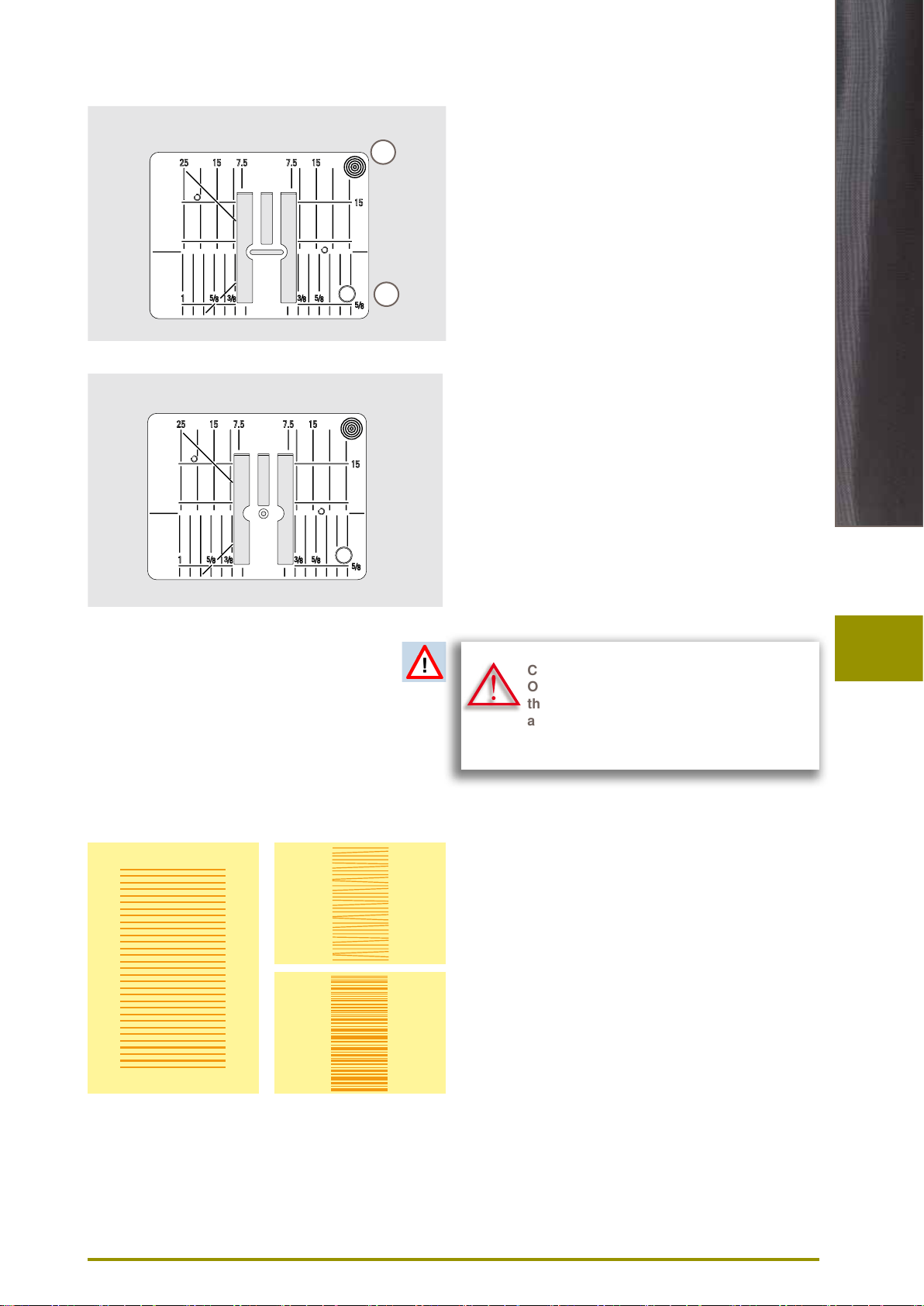

Stitch Plate Markings

► the stitch plates are marked horizontally, vertically and

B

A

diagonaly in mm and inches

► markings help with sewing e.g. precise seaming and top

stitching

► horizontal markings are helpful for sewing corners and

buttonholes etc.

► diagonal markings are helpful for Quilt piecing

► the vertical markings refer to the distance from the

needle to the marking

► needle insertion point is position «0» (= center needle

position)

► measurements are marked to the right and to the left of

center needle position

Removing the Stitch Plate

► raise the presser foot and needle

► turn power switch to «0» (off)

► press the stitch plate down at the right back corner B

until it flips up

► remove stitch plate

Straight Stitch Plate

Feed-Dog and Fabric Feed

Replacing the Stitch Plate

► place the stitch plate over the opening A and press

down until it clicks into place

Changing the Stitch Plate

On attaching the straight-stitch plate or

the 5.5-mm stitch plate, it is imperative to

adjust the settings in Security Program

accordingly (see p. 35).

With each stitch the feed-dog moves forward one step. The

length of this step is determined by the stitch length

selected.

With a very short stitch length the steps are very short. The

fabric moves relatively slowly under the presser foot, even

at full sewing speed, e.g. buttonholes and satin stitch and

decorative stitches are sewn with a very short stitch length.

Preparation

Let the fabric feed fabric

evenly.

Pulling, pushing or holding

back the fabric will result in

uneven stitches.

23

Page 25

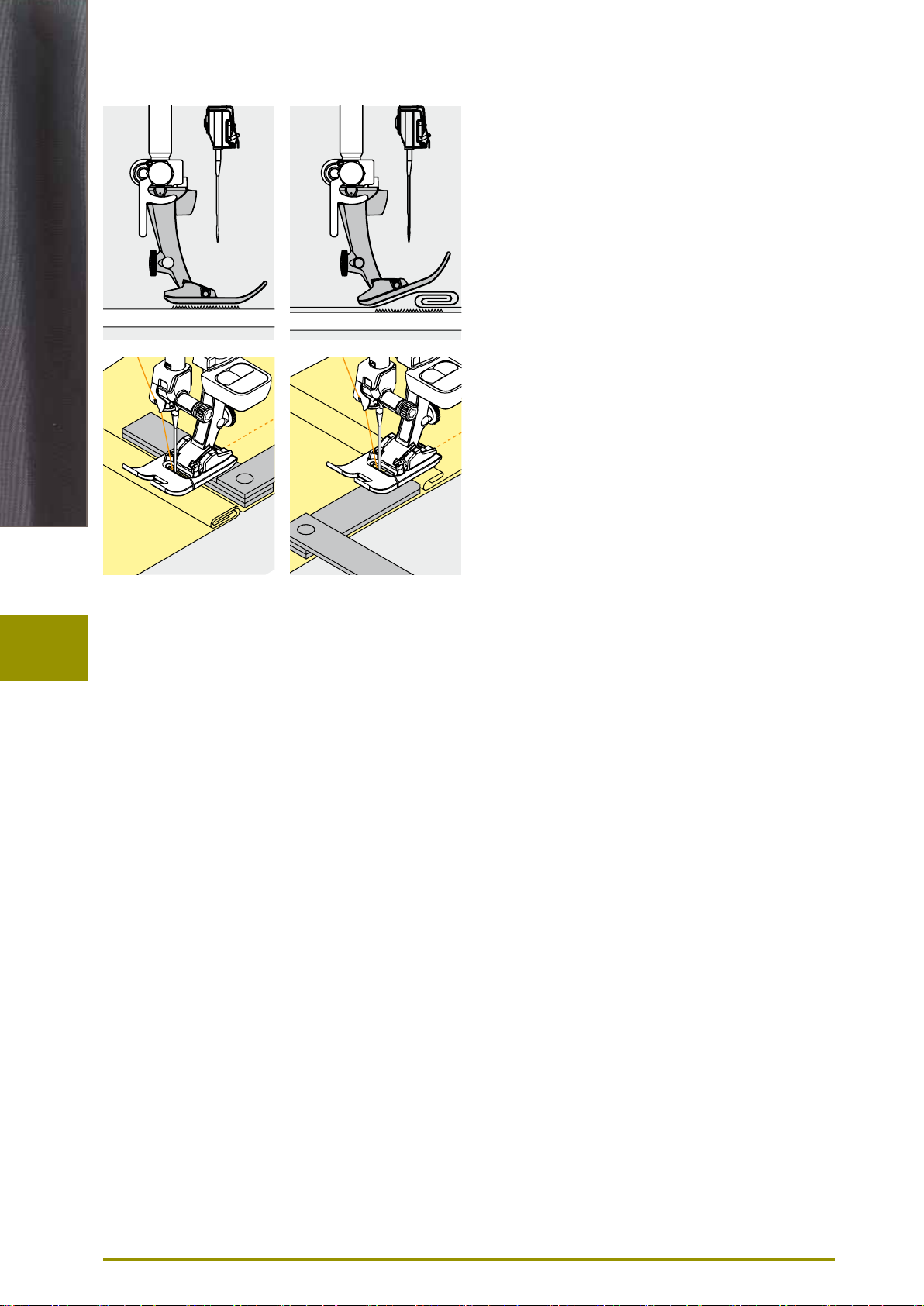

Sewing with the Height Compensation Tool

032299.53.04_1204_B830_EN

Preparation

The feed-dog works accurately if the presser foot is level.

If the presser foot is at an angle when sewing over a thick

seam, the feed-dog cannot grip. The fabric may jam.

To level the presser foot as required, place one, two or

three height-compensating plates behind the needle under

the presser foot.

To level the front of the foot, place one or more plates

under the right of the presser foot close to the needle.

Sew until the presser foot has passed the thick area and

remove the plates.

Sewing Corners

Due to the width of the stitch plate hole the outer feed-dog

rows are relatively far apart.

When sewing corners the fabric does not feed well, since

only a part of the fabric is on the feed-dog.

Correct this by placing one or more plates close to the

edge of the fabric.

24

Page 26

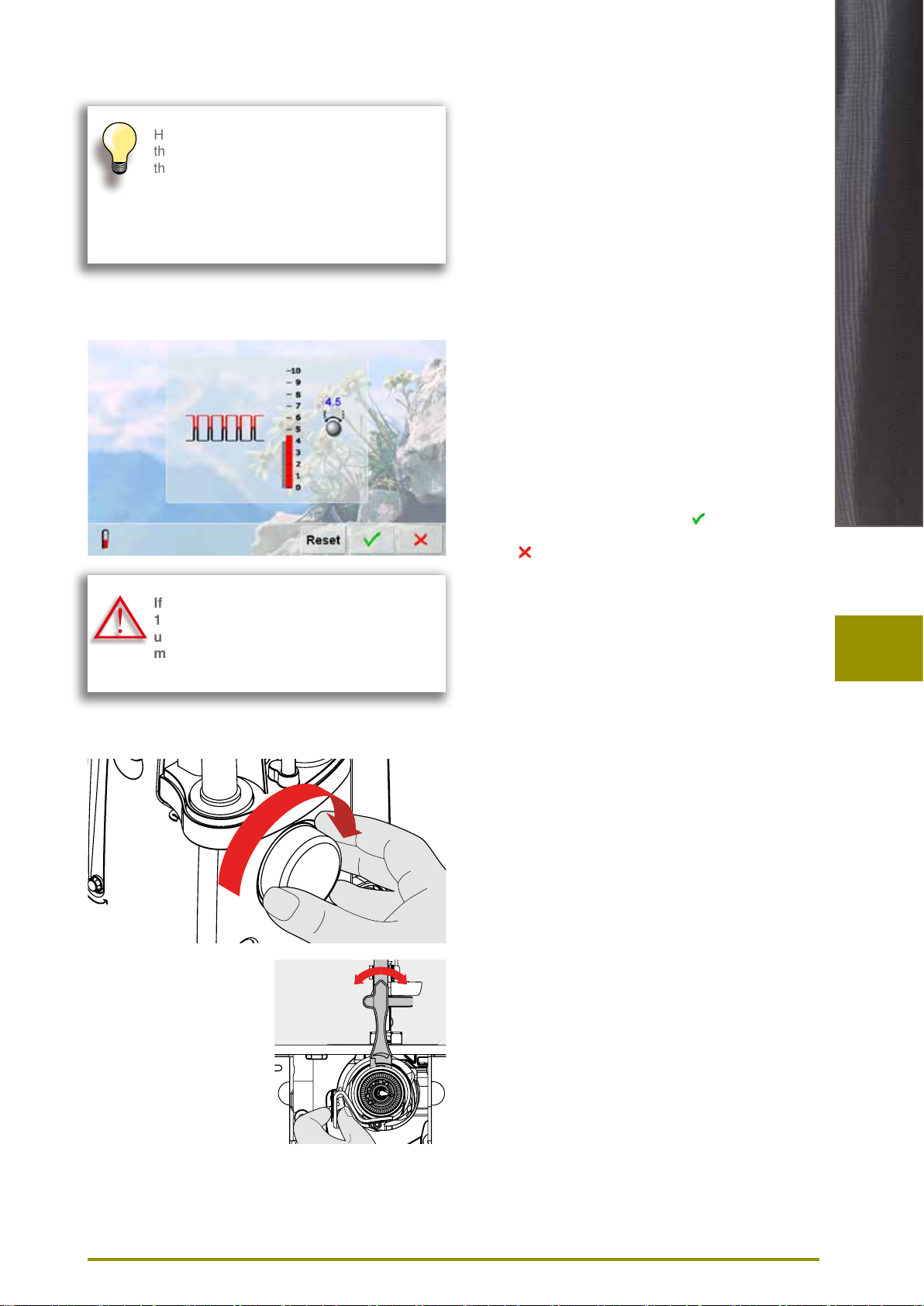

Thread Tension

032299.53.04_1204_B830_EN

Upper Thread Tension

Higher upper thread tension = the upper

thread is tightened, which pulls the lower

thread up to the topside of fabric.

Lower upper thread tension = the upper

thread is loosened, which enables it to be

pulled to the backside of the fabric.

If the thread tension is set to a value below

1 for embroidery, there is a higher risk of

unwanted loop occurrence. A warning

message will appear.

Basic settings are applied automatically when a stitch

pattern or program is selected.

Optimal upper thread tension is set in the factory. For this,

Metrosene threads 100/2 weight (Mettler, Switzerland) are

used in the bobbin and also in the upper thread.

When using decorative thread, tension adjustments may

be neccessary to receive optimal stitching results.

Altering the Tension

► touch the icon and the optimal stitch formation (stitch

formation in the fabric) is displayed

► the red bar on the scale shows the basic value

► turn the stitch width or stitch length knob to the left or

the right = the thread tension is loosened or tightened

► the tension alteration is indicated on the right side of the

thread tension scale

► the tension alteration only affects the stitch selected

► the alteration is shown on the scale (red) and in the

function icon

► the basic setting remains visible (gray) when a change

is made

► the settings are saved by touching

► touch «Reset» to return to basic settings

► touch , settings do not change

► delete: with «clr», «Reset», also when turning off the

sewing computer

Preparation

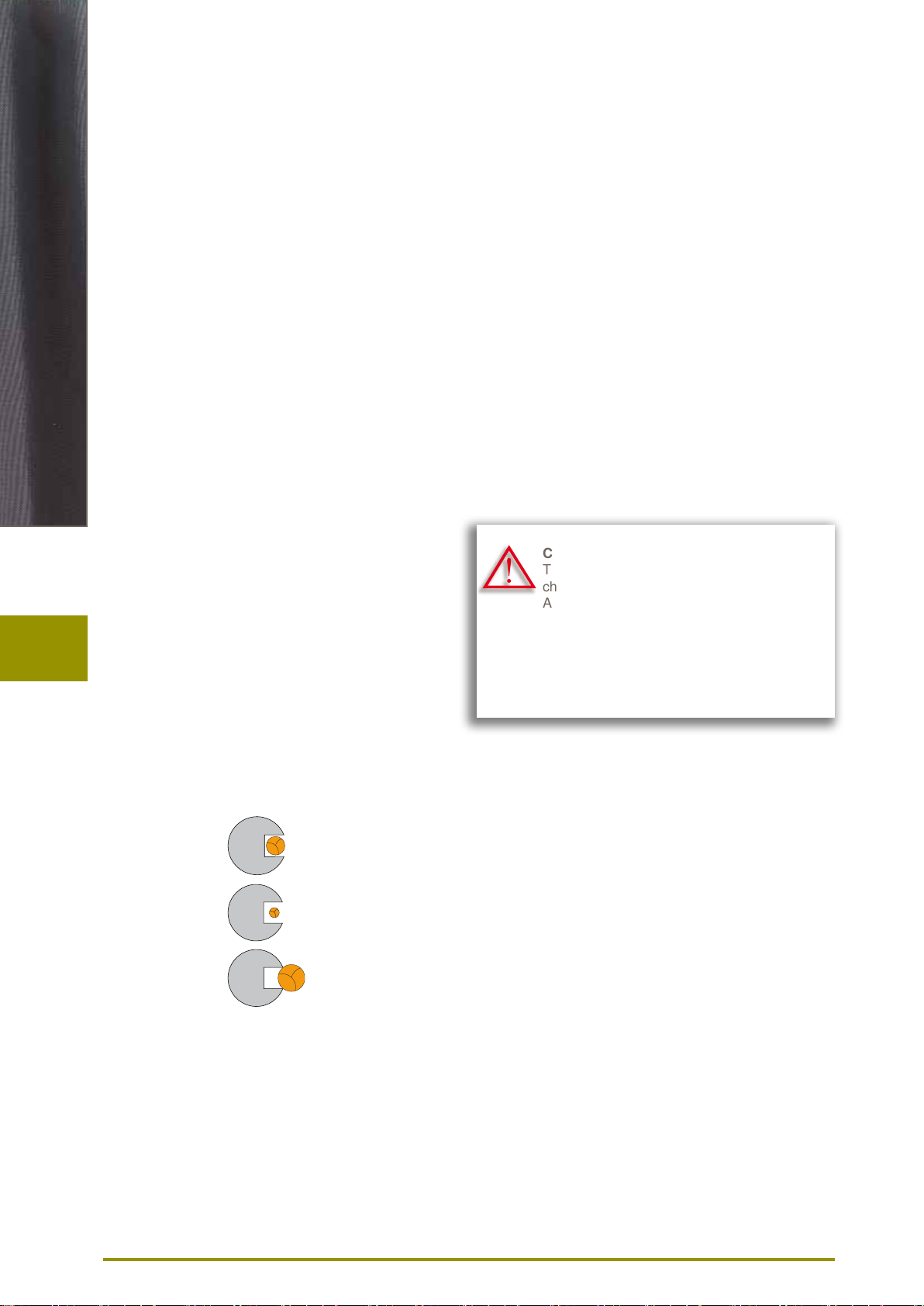

Lower Thread Tension

► hold bobbin case firmly with your left hand; with your

right hand, turn the hand wheel clockwise until the

setting tool can be slid over the lug at the slider

► basic value:

‣ lug of the slider matches with the marking of the

bobbin carrier, or

‣ lug is shifted 1-2 points to the right, or

‣ lug is shifted 1-2 points to the left

► turn lug to the left with the setting tool = thread tension

becomes looser

► turn lug to the right with the setting tool = thread tension

becomes tighter

► change per point = 4 g

► bring hook into the position shown in the illustration by

turning the handwheel clockwise in order to be able to

thread it properly

25

Page 27

Important facts about Thread and Needles

032299.53.04_1204_B830_EN

Thread

The thread is chosen according to its intended use. For a perfect sewing result,

thread and fabric quality play an important role. Use of quality brands is

recommended.

Cotton Thread

► cotton thread has the advantage of being a natural fiber and is therefore

particularly suited for sewing cotton fabrics

► mercerized cotton thread has a slight sheen and is preshrunk

Polyester Thread

► polyester thread has a high tensile strength and is particularly colorfast

► polyester thread is more resiliant than cotton thread and is recommended

where a strong and elastic seam is required

Needle, Thread and Fabric

Care should be taken when matching the needle and thread.

The correct needle size does not just depend on the thread selected but also

on the fabric to be used. The fabric weight and type determines which thread

weight, needle size and needle tip to use.

Needles

Needle/Thread

Checking Needle Condition

The condition of the sewing needle should be

checked and the needle replaced regularly.

A defective needle does not just damage the

fabric but also the sewing computer.

As a guide:

Replace the needle before starting a new

sewing project.

Correct Combination

To sew optimally, the thread should travel smoothly down the long groove on

the front of the needle.

Thread Too Thin or Needle Too Thick

The thread has too much clearance in the groove; there may be skipped

stitches or damage to the thread.

Thread Too Thick or Needle Too Thin

The thread rubs on the edges of the groove and can get jammed. This can

break the thread.

26

Page 28

Guidelines

032299.53.04_1204_B830_EN

Fabric/Thread Needle size

Fine fabrics:

Fine thread (darning thread,

embroidery thread) 70–75

Medium weight fabrics:

Normal thread 80–90

Heavy weight fabrics: 100, 110, 120

130/705 H - S / 70

130 Shank length

705 Flat shank

H Needle scarf

S Needle point (here e.g. medium ball point)

Needle

70 Needle size (shank diameter)

27

Page 29

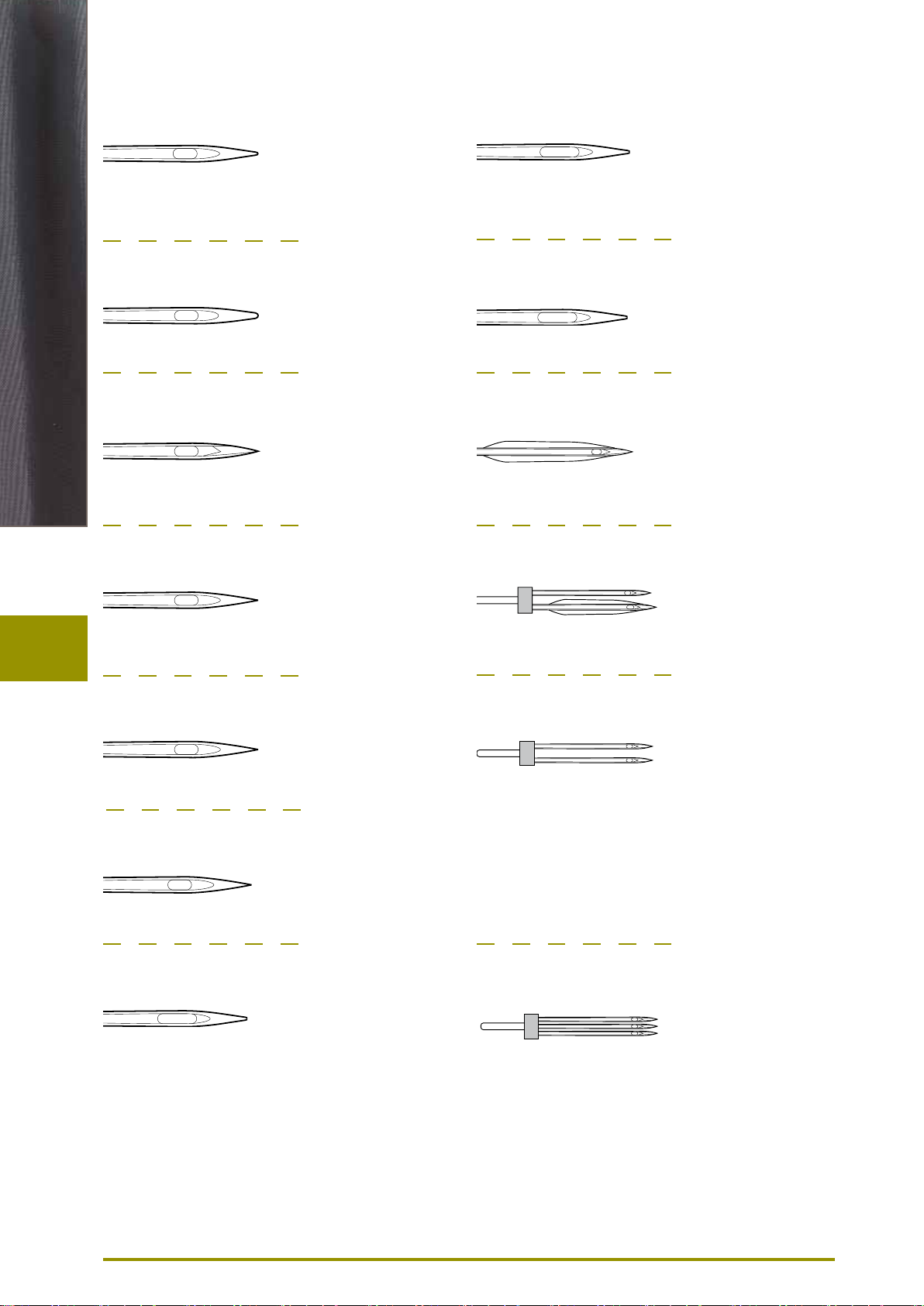

Overview

032299.53.04_1204_B830_EN

Needle

Universal

130/705 H/60 –100

Normal point,

slightly rounded

For nearly all natural and synthetic

fabrics (woven and knitted)

Jersey/Stretch

130/705 H-S, H-SES, H-SUK/70–90

Ball point

Jersey, stretch fabrics

Leather

130/705 H-LL, H-LR/90–100

With cutting point

All types of leather, synthetic leather,

plastic, sheeting

Metafil

130/705 H-MET/75-90 or H-SUK/90-100

Large eye

Sewing with metallic threads

Cordonnet (Topstitching)

130/705 H-N/80–100

Small ball point, long eye

Topstitching with thick thread

Wing needle (hemstitch needle)

130/705 HO/100–120

Wide needle (wing)

Hemstitching

Jeans

130/705 H-J/80–110

Very fine sharp point

Heavy weight fabrics such as jeans,

canvas, overalls

Microtex

130/705 H-M/60–90

Especially fine sharp point

Micro fiber fabrics and silk

Quilting

130/705 H-Q/75–90

Fine sharp point

Straight and topstitching

Embroidery

130/705 H-SUK/70–90

Double wing needle

130/705 H-ZWI-HO/100

For special effects with hemstitch

embroidery

Double needle

130/705 H-ZWI/70–100

Needle distance: 1.0/1.6/2.0/

2.5/3.0/4.0/6.0/8.0

Visible hems in stretch fabrics, pin tucks,

decorative sewing

Triple needle

130/705 H-DRI/80

28

Large eye, slight ball point

Embroidery on all natural and synthetic

fabrics

Needle distance: 3.0

For decorative sewing

Page 30

Functions & Settings

032299.53.04_1204_B830_EN

Overview 30

Function Buttons 30

Display 32

Functions 34

Sewing 34

Setup Program 36

Entry Screen 36

Display 37

Wallpaper 37

Sewing 38

Securing stitches on/off 38

Embroidery 40

Adjusting Embroidery Settings 40

Fabric Thickness 40

Calibrating the Hoop 40

Screen Calibration 41

Monitoring 42

Information 43

Version 44

Service Data 44

Update 44

Cleaning the sewing/embroidery computer 45

Cleaning 45

Cleaning the needle threading mechanism 45

Lubricating the hook 45

Packing position 46

Calibrating buttonhole foot no. 3A 46

Reset/Delete User Data 47

Creative Consultant 49

General 49

Help Program 50

General 50

Stitch Pattern 50

Functions 50

Balance 51

Balance Description 51

Practical and Decorative Stitches 51

Corrections 51

Sideways Motion Stitches 51

BERNINA Dual Feed 52

Balance/Presser Foot Pressure 52

Presser Foot Pressure Settings 52

ECO 53

ECO Description 53

Tutorial 48

Overview of Topics 48

Page 31

Function Buttons

032299.53.04_1204_B830_EN

Overview

Start/Stop Button

► starts and stops the sewing computer when

operating it without foot control

► slightly raise the presser foot when turning or

moving the project while sewing - hover

position

Quick Reverse Button/Backstepping

► secures the seam beginning and end: sews in

reverse as long as the button is pressed

► used to program the buttonhole length

► used to program the darning length

► used to determine end of stitching in straight

stitch Securing stitch no. 5

► used for securing in Quilters Securing

Program no. 1324

► switching for accurate stitch-by-stitch back-

stepping (exact retracing of the last 200

needle penetrations)

Pattern End

► a stop symbol which appears during sewing

indicates that the function is activated

► sewing computer stops at the end of the active

single pattern or the active pattern of a

combination

Automatic Thread Cutter

► upper and lower threads are cut automatically

► 2-6 securing stitches can be programmed in

the setup program - these are sewn before the

thread is cut

When using metallic or cordonnet thread,

use the thread cutter on the head frame

only.

Automatic Needle Threader

► touch button = completes the threading

process and threads the needle

Double, triple and wing needles require

manual threading after the button has been

pressed.

Use the automatic needle threader for needle

sizes 70 - 120. Metallic threads, thick threads

like cordonnet and difficult to work with

threads should be threaded by hand.

The automatic threader mustn‘t be

activated with one of these presser feet

attached:

nos. 50, 55, 80, 85 and 86.

Needle Stop Up/Down

In the default setting the needle symbol is

displayed above the presser foot indicator.

► touch the button briefly:

‣ the needle is raised or lowered (as when

tapping the foot control with your heel)

► touch the button longer:

‣ the needle is lowered, the needle symbol is

displayed below

‣ the sewing computer stops with the needle

down

‣ this becomes your default setting

► touch the button longer again:

‣ the needle is raised, the needle symbol is

displayed above

‣ the sewing computer stops with the needle

up

30

Page 32

Overview

032299.53.04_1204_B830_EN

Presser Foot Position

► touch the button = the presser foot is lowered

and raised slightly again so the fabric can be

easily positioned. When sewing starts the foot

is lowered on to the material

► touch the button again = the presser foot is

raised and the Feed-dog is simultaneously

lowered

Automatic Securing Program

► touch the button before the sewing starts or

during sewing = single patterns are secured at

the end, with the selected number of stitches

programmed

► touch the button before starting a combination

= the first pattern is secured at the end, with

the number of stitches programmed

► touch the button while stitching a combination

= the active pattern is secured at the end, with

the number of stitches programmed

► the sewing computer stops automatically after

all securing variations

► the number and type of the securing stitches

can be programmed in the setup program

Slide Speed Control

► the motor speed is infinitely

variable with the slide

Altering Needle Positions

► touch left button – the needle

moves to the left

► touch right button – the needle

moves to the right

► quick change – hold the button

down

► total of 11 needle positions

(5 left, 5 right, 1 center)

Stitch Width/Length (Multifunction) Knobs

► to adjust stitch width or length

► to alter thread tension

► to alter presser foot pressure

► to adjust the sewing direction when

in «directional sewing»

► to adjust button size or the slit size

of the buttonhole

► to adjust the balance

31

Page 33

Display

032299.53.04_1204_B830_EN

Menu Selection

A

B

C

D

E

F

G

A Practical stitches

B Decorative stitches

C Alphabets

D Buttonholes

E Quilt stitches

F Personal Program

G History

Overview

H

I

J

K

L

M

N

H Setup Program

I Tutorial

J Creative Consultant

K Help

L ECO

M Embroidery/Sewing

mode

N clr - Delete

Stitch Display

O Stitch Pattern

selections

System Settings

O

32

Page 34

Selection

032299.53.04_1204_B830_EN

P Single/Combi mode

P

Q

Q Scroll up/down

Stitch Altering Area

R Display of the stitch

pattern selected

Overview

R

Functions

S Balance

T Thread tension

U Pressure foot

pressure

V Multi-Directional

sewing

W Securing function

X Pattern repeat

Y Security program

Z Lower Feed Dog

Za Stitch selection by

number

S T U V

Zb Time/Alarm

W X Y Z ZbZa

33

Page 35

Sewing

032299.53.04_1204_B830_EN

Active functions are highlighted in blue, inactive functions are gray.

The multifunction keys are switched off by keeping them pressed a few seconds.

Functions

Confirm Selection

► activate or confirm change/selection

Leave Active Screen

► close application

► return to the last active screen

Long stitch

► the sewing computer sews every second

stitch (max. stitch length 12mm)

► can be used for practical and decorative

stitches

► exception: buttonholes and sideways motion

stitches

Mirror Image (Up/Down)

► the sewing computer sews the selected stitch

pattern in vertical Mirror Image (up/down – determined by the sewing direction)

Mirror Image (Left/Right)

► the sewing computer sews the selected stitch

pattern in horizontally Mirror Image (left/right

– determined by the sewing direction)

Stitch Counter

► when the desired length is achieved (e.g. first

buttonhole bead or straight stitch), touch the

Quick Reverse Button

► the display changes to «auto» (for the

buttonhole, only after length of second bead is

determined by pressing the Quick Reverse

Button)

► the stitch pattern selected is temporarily

programmed

Pattern Extend 2-5x

► touch the icon one or more times, the

numbers 2-5 appear

► stitch integrity is maintained

► stitch pattern is extended

Pattern begin

► the needle moves to the beginning of a stitch

pattern or program

Buttonhole Length Direct Entry

► enter buttonhole length via stitch width or

stitch length knob. Number in mm

Pattern repeat 1-9x

► touch the icon several times, the numbers 1-9

appear

► number 1: the sewing computer stops at the

end of an individual stitch or stitch combina-

tion

► numbers 2-9: the sewing computer stops at

the end of a stitch or stitch combination after

the number of repeats selected

Moving single stitch patterns

► move single stitch patterns of combinations

horizontally, vertically or diagonally

Moving multiple stitch patterns

► move parts of stitch patterns combinations

horizontally, vertically or diagonally

Retrieve

► switches between the stitches combined

► active stitch is shown in color and can be

moved

Manual Buttonhole

► special screen appears

► sew manual buttonhole in 5 or 7 steps

(depending on buttonhole type)

Programming Buttonhole Length

► icon is automatically highlighted in blue when

a buttonhole is selected

► set the buttonhole length with the Quick

Reverse Button or directly program the length

displayed by pressing the icon

► function turns inactive after programming the

length

► if a new length is to be programmed, touch

icon again

Feed-dog position

► touch the icon «lower feed-dog» = feed-dog is

lowered

► the lowered feed-dog is shown by the red,

flashing symbol

Buttonhole Slit Width

► set the buttonhole slit width to between 0.1mm

and 2.0mm using the Stitch Width or the Stitch

Length Knob

► the standard width is 0.6mm

Securing

► touch icon before sewing starts = single

pattern is secured at the start with 4 securing

stitches

► touch icon during sewing individual stitches =

individual stitches will be secured at the end,

the sewing computer stops

► program the function within a pattern combina-

tion = each individual pattern of the combination can be secured at the start or the end

Multi-function button

► only active in combination mode

► when selected, a screen with further functions

appears

Lettering size in alphabets

► when alphabet is selected, the lettering size is

9mm

► when the function is selected, «2» is activated

and the alphabet is sewn with 6mm lettering

size

34

Page 36

Lettering size in monograms

032299.53.04_1204_B830_EN

► when monogram is selected, the lettering size

is 30mm

► touch the icon several times

► the blue area shows the lettering size:

1 = 30mm (standard)

2 = 20mm

3 = 15mm

Thread tension

► change upper thread tension

► the respective value is visible in the icon

Presser foot pressure

► increase or decrease the presser foot pressure

using the multifunction knobs

► the respective value is visible in the icon

Connecting Stitches

► opens the screen to add connecting stitches

Combination subdivider (1)

► each combination or memory folder can be

subdivided into several parts

► only those parts where the cursor is located

will be sewn

► to sew another part, the cursor must be

placed in this part

Combination subdivider (2)

► each combination can be subdivided as

desired

► after stopping, the needle moves to the next

part to be sewn

Presser foot indicator

► number of presser foot recommended is

shown for the stitch pattern selected

► if the presser foot is raised it is indicated with

an animation

► touch the icon

► screen is opened with further presser foot

options

Back Stepping

► the last 200 needle penetrations of a stitch

pattern are retraced, i.e. sewn backwards

(see p. 80 on how to select the function)

Save

► save stitch pattern combinations and lettering

Delete

► e.g. single stitch pattern, pattern combina-

tions, memory bank contents, stitch pattern in

personal program etc.

Balance

► balance forward and reverse stitches

► balance sideways motion stitches

► balance dual feed

Stitch selection by numbers

► select individual stitch pattern by inputting the

stitch pattern number

Time/Alarm

► set the current time (hh:mm) in the upper part

of the screen using the «+» and «-» icons

► touch the alarm button in the lower part of the

display

► set the alarm time using the «+» and «-» or

the multifunction knobs. A personal message

can be input using the keyboard

► the current time now appears in red numbers

Multi-Directional Sewing

► use the stitch width knob to rotate the stitch

pattern or combination in 0.5° steps, the stitch

length knob for 1° steps or the direct-selection

buttons for rotating in 45° steps into the

desired direction

► the sewing direction is shown in the left part of

the display

► the start is marked with a green dot and the

end with a red cross

► the function only appears if the selected stitch

can be sewn in multiple directions

Test-sew first on a piece of the fabric you

intend to use for the sewing project.

Security Program

► when selecting the respective needle icon the

stitch width will be limited automatically

► this prevents the inserted special needle

(double needle etc.) from hitting the presser

foot or stitch plate = avoiding needle breakage

► the numbers on the needles represent the

distance in mm between the needles

► by selecting the standard needle icon the

standard needle is active again and the stitch

width limitation is switched off

► by selecting the corresponding stitch plate the

stitch width is automatically limited, so the

inserted standard needle cannot hit the stitch

plate

► the function remains active even when the

sewing computer is turned off and on

Functions

Permanent reverse sewing

Upper/Lower Case

File Drawers

► the sewing computer sews backwards

permanently (see p. 80 on how to select the

function)

► switch from upper case to lower case lettering

► saved stitches are visible

Single Mode

► the Single Mode is always active (blue) when

turning on the sewing computer and only the

selected stitch can be sewn

Combi Mode

► touch the button

► the Combi Mode is active (blue) and stitch

combinations can be programmed

35

Page 37

Entry Screen

032299.53.04_1204_B830_EN

The Setup Program enables you to personalize the touch screen according to your own

requirements and preferences.

After setting the sewing computer to your personal requirements, all changes made in the

Setup Program are saved, even when the sewing computer is switched off. Exceptions

from this rule are outlined within the description of the function concerned in each case.

Setup Program

1

4

7

2

5

8

3

6

9

Selection Menu

1 Display (screen) settings

2 Sewing settings

3 Embroidery settings

4 Display (screen) calibration

5 Monitoring settings

6 Information

7 Update sewing computer

8 Cleaning the sewing/embroidery computer

9 Reset basic settings

36

Customized alterations are saved even

when the sewing computer is switched off.

Alterations can be re-programmed at

any time.

The System Settings can be changed using

the stitch width and stitch length knobs and

the «+/-» icons.

«Reset» button resets to the basic System

Settings.

Page 38

Display

032299.53.04_1204_B830_EN

2

Brightness

1

► turn stitch width knob or touch the «+» or «-» icon the

brightness 1 of the screen is altered

► alterations are indicated by the number in the bar and

the blue background of the «+» or «-» icons

► the basic settings are indicated by a dark bar

3

4

Sewing Light

► when icon 2 is active, the sewing light is on

► when the icon is inactive, the sewing light is off

► the brightness can be set with the stitch length knob or

the «+» or «-» icon

Welcome Text

► create or change Welcome Text 3

► space bar is at the bottom of the letter keys

► welcome text 4 appears in the text icon above the letter

keys

► touch the text icon = text entered is completely deleted

► text entered is deleted from right to left

► «ABC» all in upper case (standard)

► «abc» all in lower case

► «1,2,3» numbers and mathematical

character

► «Ä À Á», «ä à á» and

«@ #» upper and lower special characters

Setup Program

Wallpaper

Select desired screen wallpaper.

► choose from different images

► default image = edelweiss

37

Page 39

Sewing

032299.53.04_1204_B830_EN

Motor Speed

1

2

► alter maximum sewing speed 1

► the number in the bar is the stitches per minute; the

basic value is indicated by a dark bar

Setup Program

3

The tension alteration affects all stitches and

stitch patterns and is saved even when the

sewing-/embroidery computer is switched off.

4

5 6

Thread Tension

► alter the basic setting (0) of the upper thread tension 2

by plus or minus 20%

0 = basic settings

Securing stitches on/off

► function 3 is active = standard

► if the automatic thread cutter is used to cut the threads,

4 securing stitches will be stitched when resuming

sewing

► function is inactive = no securing stitches will be stitched

Automatic Securing Program

► the number and type of the securing stitches can be

programmed

► standard = four securing stitches in the same place

► select function 4 for forward securing stitches

► 3-6 securing stitches can be programmed

38

Automatic Thread Cutter

► if function 5 is activated, the upper and lower thread are

automatically cut after sewing

Raise Presser Foot

► if function is activated 6 the presser foot is raised after

securing

► if function is not activated, the presser foot stays down

Page 40

Needle Stop Adjustment

032299.53.04_1204_B830_EN

► if the automatic thread cutter and the «raise presser

foot» function are switched off when securing, the

7

needle stop position 7 can be selected

► standard = sewing computer stops with the needle up

while the presser foot stays down after securing

► touch «Needle down» icon

► the sewing computer stops with the needle down after

securing

Automatic Thread Cutter and Securing

Stitches

► the number and type of securing stitches before the

thread is cut can be programmed

► touch function 8 for securing stitches in place or function

9 for forward securing stitches

► two to six securing stitches can be programmed

► standard = no securing stitches programmed

8

9

Setup Program

1 2 3

4

Presser foot position when needle stop

down

► with activated icon 1, the presser foot remains down

when the sewing computer stops

► with activated icon 2, the presser foot is raised enough

to pivot the fabric (hover position)

► with activated icon 3, the presser foot is raised into its

highest position

Hover position of presser foot

► the stitch width and stitch length multi-function knobs

can be used to set the clearance from 0mm to 7mm in

maximum (standard clearance is 2 mm)

► the set value, i.e. the clearance between the fabric and

the presser foot, is displayed in icon 4

39

Page 41

Embroidery

032299.53.04_1204_B830_EN

Setup Program

Adjusting Embroidery Settings

► the motor speed and thread tension can be adjusted the

same way as in sewing mode, and the automatic thread

cutter activated or deactivated (will cut the threads at

color changes if activated)

1

2 3

Fabric Thickness

► if the fabric 1 is more than 4mm thick, e.g. toweling,

select the 7.5mm or 10mm icon

► this ensures that the embroidery hoop is only moved

when the needle is no longer in the material

Thread-Cutting After Start of Embroidering

► with active field 2, the embroidery computer will stop

after approx. 7 stitches and the thread ends can be cut

► with inactive field, the embroidery computer won‘t stop

Securing Stitches

► function 3 is active = standard securing

► i.e. selecting a embroidery motif, threading or cutting the

threads using the automatic thread cutter will trigger the

stitching of 3 securing stitches

► function is inactive = no securing stitches will be

stitched, i.e. the lower thread must be taken up either

manually (handwheel) or by «back heel kicking» the foot

control. The threads must be held when starting to

embroider

To calibrate the hoop, select «Next Page».

Calibrating the Hoop

«Adjust Reference Position» calibrates the needle to the

center of the hoop.

Adjustments can only be done if the embroidery module is

attached.

40

► select the required hoop and follow the instructions on

the screen

Page 42

Screen Calibration

032299.53.04_1204_B830_EN

► place embroidery template into the embroidery hoop

► the hoop position is detected and the needle positioned

in the center

► if the needle is not positioned exactly in the center of the

embroidery template, use the arrow icons to position it

accurately

► touch until the selection menu appears

► the adjustment is saved

The calibration screen can also be opened

this way:

► switch sewing-/embroidery computer off

(to «0»)

► touch the two needle positioning buttons

on the front panel and keep them pressed

► switch sewing-/embroidery computer on

(to «I») and as soon as the calibration

screen is opened, release the two buttons

Setup Program

► touch the calibration icon

► another screen appears

► with touch pen touch the center of the cross. The cross

moves to the next position

► repeat this until all three positions shown are calibrated

► touch

to save settings

41

Page 43

Monitoring

032299.53.04_1204_B830_EN

Setup Program

Audio System

► sounds can be activated or deactivated 1

2

1

Selecting Stitch Pattern/Function/BSR

► stitch patterns and function selection 2 can be confirmed

acoustically

► touch the speaker icon until you hear the desired sound

► there are six different sounds to choose from

► this icon is blue and the sound is indicated by a number

(1-6)

► the sounds for functions (center) and the sound for

quilting with BSR (bottom) can be activated or deactiva-

ted in the same way

► deactivation is the last option shown when scrolling

through the different sounds

Monitoring Functions

The following monitoring functions can be activated or

deactivated:

Upper thread indicator

Lower thread indicator

Optimum interlocking of upper and lower thread

Sewing without thread

► blue with open eye = function active

► gray with closed eye = function inactive

► the sound type for the monitoring functions is set in the

audio settings for function

Sewing without thread

► don‘t thread the sewing computer with upper thread

(or remove it entirely)

► press the large field on the left

► sewing without thread is activated

► the other three monitoring functions are deactivated and

disappear

► the automatic thread cutter is deactivated

► selecting another presser foot or switching the sewing

computer off deactivates the function

42

Page 44

Information

032299.53.04_1204_B830_EN

Needle Chart

► select the needle inserted

► when the sewing computer is switched on, the needle

selected will be displayed

► touch the arrow icon to scroll through to the needle

types

Setup Program

Language

► scroll through the languages by touching the arrow

icons and select the language required

Dealer Details

► by pressing the respective gray bar the following

information about your BERNINA dealer can be entered:

‣ store name

‣ last name, first name

‣ telephone number

‣ website or e-mail address

43

Page 45

Setup Program

032299.53.04_1204_B830_EN

Version

► the current versions of the sewing computer and the

embroidery module (must be connected to the sewing

computer) can be seen

► the total number of stitches and the number of stitches

sewn since the last servicing by the BERNINA dealer

are displayed

Service Data

Service data of the actual condition of your sewing

computer can be saved on a USB stick and sent to your

authorized BERNINA dealer:

► insert the USB stick into your sewing-/embroidery

computer

► touch «LOG»

► after the data is saved remove the USB stick

Update

Updating

► insert BERNINA USB stick with the new software

version

► touch «Update»

► touch «Update» again to start the process

► it is then determined if:

‣ a BERNINA USB stick is inserted

‣ there is enough free space available (at least 10 MB)

‣ the correct software version is on the stick

► the data and settings are accepted

► if the update was successful, a message appears and

the sewing computer is ready to sew again

► if the update cannot be started or if there are problems

during the update process, an error message appears

Do not remove the BERNINA USB stick

until there is a message which indicates

the end of the update.

44

Page 46

Cleaning the sewing/embroidery computer

032299.53.04_1204_B830_EN

Cleaning

► clean the sewing-/embroidery computer according to the

instructions

► touch field 1

► the thread catcher of the automatic thread cutter moves

to the right

► carefully remove any thread remnants with the tweezers

► touch field 3

► the automatic thread cutter is re-initialized and then

ready for operation

Setup Program

Cleaning the needle threading

mechanism

► clean the needle threading mechanism according to the

instructions and animation

Lubricating the hook

► lubricating the hook according to the instructions and

animation

45

Page 47

Setup Program

032299.53.04_1204_B830_EN

Packing position

Do not move the embroidery arm of the embroidery module

by hand. Follow the on-screen instructions to fit the

embroidery module back into its original packaging.

Calibrating buttonhole foot no. 3A

► attach buttonhole foot no. 3A

► press the Start-/Stop button (green) on the head frame

► the buttonhole foot will move forward and backward

► buttonhole foot will calibrate and sewing computer will

indicate that the calibration has been successful

► the buttonhole foot is now set for this particular sewing

computer, and should only be used with this one

46

Page 48

Reset/Delete User Data

032299.53.04_1204_B830_EN

Choose from the following options by pressing the Reset

button:

1

2

A B C

1 Reset Settings

2 Delete User Data

Setup Program

Reset Settings

Choose from the following options by pressing bar 1:

A Reset Sewing

B Reset Embroidery

C Reset All

► touch the bar whose settings are to be returned to the

basic settings

► confirm with

► the previous screen appears

► touch until the selection menu appears

Delete User Data

Choose from the following options by pressing bar 2:

D

E

F

1

2

D Sewing «Personal Program»

E Embroidery «My Designs»

F Embroidery «Memory Stick» (the Memory Stick

must be inserted in the sewing computer)

► touch the bar that the settings are to be deleted

► confirm with

► the data is deleted and the previous screen appears

► touch

until the selection menu appears

47

Page 49

Overview of Topics

032299.53.04_1204_B830_EN

The Tutorial provides information and explanations about the different areas of sewing

and embroidering.

1

2

3

4

5

Tutorial

1 Threading

2 Needles

3 Presser foot

4 BERNINA Stitch Regulator (BSR)

5 Troubleshooting

6

6 Freehand system FHS

7 Miscellaneous

8 Embroidery

9 Buttonholes

10 Quilting

11 Techniques

11

10

9

8

7

► select desired topic, e.g. presser foot

► topic overview about the presser foot appears

► select desired topic, e.g. changing the presser foot

► information on the desired topic is shown

► use the stitch width or stitch length knob, the finger or the

touchscreen pen to scroll through the text in the screen

► animations can be stopped or replayed by touching the

icon in the bottom right corner

► touch the animation with your finger or the touchscreen

pen and travel to the right or left

► the playing of the animation is controlled manually now

► touch the animation again to switch back to automatic

playing mode

48

► use these two icons to go to the previous or next page

► touch to close the Tutorial screen

► the last active screen appears

Page 50

General

032299.53.04_1204_B830_EN

The Creative Consultant provides information and help with various sewing techniques.

After selecting the fabric and the desired sewing technique suggestions for suitable

needles, presser feet etc. are displayed.

Presser foot pressure and upper thread tension are set automatically.

Fabric Types

► the most commonly used fabric types are listed in three

categories

► select the desired fabric type e.g. Silk

► if the material used is not shown, select a similar fabric

Overview of Sewing Techniques

► the possible sewing techniques appear on selecting a

fabric type

‣ Seams

‣ Overcasting

‣ Blindhem

‣ Buttonholes

‣ Zippers

‣ Decorative stitching

‣ Machine quilting

‣ Free-motion stitching

‣ Appliqué

► select the desired sewing technique, e.g. buttonhole

► if the desired technique cannot be found on this list,

select a related technique

Creative Consultant

Recommendations

► recommendations for the fabric selected and the desired

technique are shown

► links to the respective topics in the Tutorial are

displayed

► additional information regarding engaging links for more

information

► select buttonhole link

► information on buttonholes appears

► use the stitch width or stitch length knob to scroll within

the text

► the Creative Consultant home screen is displayed

► select to display the screen containing the

suggested stitch pattern

► select to close the Creative Consultant screen

► the last active screen appears

49

Page 51

General

032299.53.04_1204_B830_EN

The Help Program contains information about individual stitch patterns and

functions in the screen. No matter which screen is displayed, the help feature for

stitches and functions of the screen can be opened.

► touch the «?» icon

► select the desired stitch pattern or the desired function

Stitch Pattern

This screen displays the following information:

► name of the stitch pattern

► suitable materials

► main areas of application

Help Program

Functions

This screen displays the following information:

► function name

► function explanation

► main areas of application

► select to close the Help screen

► the last active screen appears

50

Page 52

Balance Description

032299.53.04_1204_B830_EN

The sewing computer is tested and optimally set before it leaves the factory. Different

fabrics, threads, stabilizers and interfacings can affect programmed stitches so that they

are not sewn out properly.

These effects can be corrected with the electronic Balance so that the stitch formation

can be adjusted where necessary to suit the fabric.

Practical and Decorative Stitches

► in the left portion of the screen the stitch pattern is

displayed in its original form (as programmed)

► in the right portion of the screen the alterations made

are directly visible

► the corrections can be made while sewing (with opened

screen)

Corrections

► the stitch sewn on the fabric (e.g. the Honeycomb stitch)

opens up and it does not look correct:

‣ turn the stitch length knob until the stitch in the right

portion of the screen is identical with the stitch on the

fabric

Balance

Sideways Motion Stitches

► in the left portion of the screen the stitch is displayed in

its original form

► in the right portion of the screen the alterations made

are directly visible

► the corrections can be made while sewing (with opened

screen)

The stitch sewn on the fabric (e.g. stitch no. 809) is

vertically and horizontally distorted.

Vertical Corrections

► turn the stitch length knob until the stitch on the right

portion of the screen is identical with the stitch on the

fabric

Horizontal Corrections

► turn the stitch width knob until the stitch on the right

portion of the screen is identical with the stitch on the

fabric

51

Page 53

Presser Foot Pressure Settings

032299.53.04_1204_B830_EN

Balance/Presser Foot Pressure

BERNINA Dual Feed

► standard = the fabric is evenly fed by the dual feed and

the feed-dog together

Top layer of fabric is fed too slowly = «becomes» longer

compared to the bottom layer

► turn the stitch width or stitch length knob clockwise to

speed up the feeding of the top layer of fabric – evening

out the feeding speed difference between the two layers

Top layer of fabric is fed too quickly = «becomes» shorter

compared to the bottom layer

► turn the stitch width or stitch length knob counterclock-

wise to slacken the feeding speed of the top layer of

fabric – evening out the feeding speed difference

between the two layers

► changes made to the selected pattern or the dual feed

are deleted

► select to save the changes and close the screen

► select to close the screen; the original settings are

kept

Adjusting the Pressure

► the presser foot pressure scale appears on touching the

«Presser Foot Pressure» icon

► turning the stitch width or stitch length knob to the left or

the right decreases or increases the presser foot

pressure

52

► with thick or multilayered fabric (e.g. when quilting) turn

one of the multifunction knobs to the left to decrease the

pressure (minus value)

► the presser foot is slightly raised, making it easier to

move the fabric

► touch

► touch «Reset» to reset to the basic setting

to save the setting

Page 54

ECO Description

032299.53.04_1204_B830_EN

When work is interrupted for longer periods, the sewing-/embroidery computer can be put

into energy-saving mode.

► touch the button

► screen goes dark

► power consumption is reduced and the sewing light

turned off

► this mode also acts as a child safety feature

► nothing can be selected on screen (buttons are locked),

and the sewing-/embroidery computer cannot be started

► touch button again = sewing-/embroidery computer is

ready for use

ECO

53

Page 55

54

032299.53.04_1204_B830_EN

Page 56

Main Stitch Categories

032299.53.04_1204_B830_EN

Stitch Patterns 56

Selection 56

via Screen 56

by Stitch Number 56

Selecting a Presser Foot 56

Customizing Stitch Patterns 57

Altering Stitch Width and Stitch Length 57

Altering Needle Position 57

Securing with Quick Reverse Button on Head Frame 57

Temporary Altered Stitch Memory 57

For All Stitch Types and Materials 57

Resetting to the Factory Setting 57

Practical Stitches 58

Practical Stitches Description 58

Decorative Stitches 60

Decorative Stitches Description 60

Tapering 61

Setting 61

Combining with Functions 62

Mirroring Decorative Stitches 62

Long Stitch Function 62

Pattern Extend 62

Pattern Extend with Long Stitch 63

Double, Triple or Wing Needle 63

Automatic 72

Direct Entry Length 72

Button Measurement 72

Programming 73

Automatic Buttonhole 73

Standard and Stretch Buttonhole 73

Round and keyhole buttonholes 73

Hand-look buttonhole 74

Stitch Counter Buttonhole 74

All Buttonhole Types 74

In Long-Term Memory 75

Button Sew-On Program 75

Eyelet Program 76

Sewing Eyelets 76

Punching Eyelets 76

Quilt Stitches 77

Quilt Stitches Description 77

Personal Program 78

Creating a Customized Stitch Menu 78

Preparing Stitch Patterns 78

Personal Screen 78

Altering Stitch Patterns 79

Combi Mode 64