Page 1

Documentation

BC8050 und BC8150

Bus Terminal Controller with RS485 or RS232 Interface

Version:

Date:

3.0.0

2017-07-18

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation........................................................................................................... 5

1.2 Safety instructions .......................................................................................................................... 6

1.3 Documentation issue status............................................................................................................ 7

2 Product overview.......................................................................................................................................8

2.1 BCxx50 Overview ........................................................................................................................... 8

2.2 The principle of the Bus Terminal ................................................................................................... 9

2.3 The Beckhoff Bus Terminal system ................................................................................................ 9

2.4 Technical data .............................................................................................................................. 11

2.4.1 Technical Data - BCxx50 ................................................................................................11

2.4.2 Technical data - RS485 ...................................................................................................13

2.4.3 Technical Data - RS232...................................................................................................14

2.4.4 Technical Data - PLC.......................................................................................................15

3 Mounting and wiring ...............................................................................................................................16

3.1 Mounting ....................................................................................................................................... 16

3.1.1 Dimensions ......................................................................................................................16

3.1.2 Installation........................................................................................................................17

3.2 Wiring............................................................................................................................................ 18

3.2.1 Potential groups, insulation testing and PE .....................................................................18

3.2.2 Power supply....................................................................................................................19

3.2.3 Programming cable..........................................................................................................21

3.2.4 RS232 Connection...........................................................................................................22

3.2.5 RS485 connection............................................................................................................23

4 Parameterization and Commissioning ..................................................................................................24

4.1 Start-up behavior of the Bus Terminal Controller ......................................................................... 24

4.2 Setting the Address ...................................................................................................................... 25

4.3 Baud rate ...................................................................................................................................... 26

4.4 Configuration ................................................................................................................................ 26

4.4.1 Overview ..........................................................................................................................26

4.4.2 Creating a TwinCAT configuration ...................................................................................28

4.4.3 Downloading a TwinCAT configuration............................................................................28

4.4.4 Uploading a TwinCAT configuration ................................................................................30

4.4.5 Resources in the Bus Terminal Controller .......................................................................32

4.4.6 ADS connection via serial interface .................................................................................34

4.5 RS232 interface ............................................................................................................................ 36

4.5.1 TwinCAT Configuration - RS232 Interface.......................................................................36

4.6 K-bus ............................................................................................................................................ 38

4.7 Configuration software KS2000 .................................................................................................... 40

5 Programming ...........................................................................................................................................41

5.1 BCxx50 PLC features ................................................................................................................... 41

5.2 TwinCAT PLC ............................................................................................................................... 41

5.3 TwinCAT PLC - Error codes ......................................................................................................... 42

5.4 Remanent data ............................................................................................................................. 45

5.5 Allocated flags .............................................................................................................................. 46

5.6 Local process image in delivery state........................................................................................... 46

5.7 Mapping the Bus Terminals .......................................................................................................... 48

BC8050 und BC8150 3Version: 3.0.0

Page 4

Table of contents

5.8 Local process image in the TwinCAT configuration...................................................................... 49

5.9 Creating a boot project ................................................................................................................. 50

5.10 Communication between TwinCAT and BX/BCxx50 .................................................................... 50

5.11 Up- and downloading of programs................................................................................................ 52

5.12 Libraries ........................................................................................................................................ 55

5.12.1 Libraries overview ............................................................................................................55

5.12.2 Seriell_Set data structure.................................................................................................56

5.12.3 TcBaseBCxx50 ................................................................................................................58

5.13 Program transfer........................................................................................................................... 61

5.13.1 Program transfer via the serial interface ..........................................................................61

5.14 Process image .............................................................................................................................. 62

5.14.1 Modbus Process Image ...................................................................................................62

5.14.2 KS8000 Process Image ...................................................................................................62

6 RS232 - Interface .....................................................................................................................................64

6.1 Protocol......................................................................................................................................... 64

6.1.1 Modbus ............................................................................................................................64

6.1.2 Protocol Overview............................................................................................................74

6.1.3 KS8000 protocol ..............................................................................................................74

6.2 Introduction to the system............................................................................................................. 77

6.2.1 Overview of the physical structure of RS232 ...................................................................77

6.2.2 Topology of the physical RS232 structure .......................................................................78

7 Error handling and diagnosis.................................................................................................................79

7.1 Diagnostics ................................................................................................................................... 79

7.2 Diagnostic LEDs ........................................................................................................................... 80

8 Appendix ..................................................................................................................................................82

8.1 First steps with the BC8150.......................................................................................................... 82

8.2 Switching between controllers ...................................................................................................... 82

8.3 Example programs for serial communication................................................................................ 84

8.4 Firmware Update .......................................................................................................................... 85

8.5 General operating conditions........................................................................................................ 87

8.6 Test standards for device testing.................................................................................................. 90

8.7 Bibliography .................................................................................................................................. 90

8.8 List of Abbreviations ..................................................................................................................... 90

8.9 Support and Service ..................................................................................................................... 91

BC8050 und BC81504 Version: 3.0.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

BC8050 und BC8150 5Version: 3.0.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

WARNING

CAUTION

Attention

Note

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the

life and health of persons.

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

BC8050 und BC81506 Version: 3.0.0

Page 7

Foreword

1.3 Documentation issue status

Version Comment

3.0.0 • Migration

2.0.0 • BC8050 added

1.1.1

1.1.0 • Notes to meet the UL requirements added.

1.0.1 • Minor routine corrections

1.0.0 • First public issue (only available in German)

BC8150 firmware

For updating your firmware you need a serial cable, the KS2000 configuration software, or the firmware

update program.

Document version BC8050 BC8150

Firmware version Hardware version Firmware version Hardware version

3.0.0 B0 04 B1 08

2.0.0 B0 00 B1 04

1.1.1 - - B0 00

1.1.0 - - B0 00

1.0.1 - - B0 00

1.0.0 - - B0 00

• ADS communication example added [}84]

The firmware and hardware versions (delivery state) can be found on the sticker on the underside of the Bus

Terminal Controller.

BC8050 und BC8150 7Version: 3.0.0

Page 8

Product overview

2 Product overview

2.1 BCxx50 Overview

Bus Terminal Controllers are Bus Couplers with integrated PLC functionality. The BCxx50 Bus Terminal

Controllers have a fieldbus interface, are intelligent slaves and can be used as decentralized intelligence

within the system. They are located in a cost-optimized and compact housing. In contrast to the BCxx00

range, the BCxx50 range supports up to 255Bus Terminals via the K-Bus extension.

The Bus Terminal Controller is programmed using the TwinCAT programming system according to IEC

61131-3. The BCxx50 configuration/programming interface is used for loading the PLC program. If the

TwinCAT software PLC is in use, the PLC program can also be loaded via the fieldbus.

The inputs and outputs of the connected Bus Terminals are assigned in the default setting of the mini-PLC.

Each individual Bus Terminal can be configured in such a way that it exchanges data directly through the

fieldbus with the higher-level automation device. Similarly, pre-processed data can be exchanged between

the Bus Terminal Controller and the higher-level controller via the fieldbus.

Fieldbus interface

The variants of the BCxx50 series Bus Terminal Controllers differ in terms of their fieldbus interfaces.

Various versions cover the most important fieldbus systems:

• BC3150: PROFIBUS DP

• BC5150: CANopen

• BC5250: DeviceNet

• BC8050: RS485, various protocols

• BC8150: RS232, various protocols

Programming

The BCxx50 devices are programmed according to the powerful IEC 61131-3 standard. Like for all other

BECKHOFF controllers, the TwinCAT automation software is the basis for parameterization and

programming. Users therefore have the familiar TwinCAT tools available, e.g.PLC programming interface,

System Manager and TwinCAT Scope. Data is exchanged optionally via the serial interface (COM1) or via

the fieldbus through Beckhoff PC FCxxxx fieldbus cards.

Configuration

The configuration is also carried out using TwinCAT. The fieldbus interface can be configured and

parameterized via the System Manager. The System Manager can read all connected devices and Bus

Terminals. After the parameterization, the configuration is saved on the BCxx50 via the serial interface. The

configuration thus created can be accessed again later.

BC8050 und BC81508 Version: 3.0.0

Page 9

2.2 The principle of the Bus Terminal

Product overview

Fig.1: The principle of the Bus Terminal

2.3 The Beckhoff Bus Terminal system

Up to 256 Bus Terminals, with 1 to 16I/O channels per signal form

The Bus Terminal system is the universal interface between a fieldbus system and the sensor / actuator

level. A unit consists of a Bus Coupler as the head station, and up to 64 electronic series terminals, the last

one being an end terminal. Up to 255 Bus Terminals can be connected via the K-bus extension. For each

technical signal form, terminals are available with one, two, four or eight I/O channels, which can be mixed

as required. All the terminal types have the same mechanical construction, so that difficulties of planning and

design are minimized. The height and depth match the dimensions of compact terminal boxes.

Decentralised wiring of each I/O level

Fieldbus technology allows more compact forms of controller to be used. The I/O level does not have to be

brought to the controller. The sensors and actuators can be wired decentrally, using minimum cable lengths.

The controller can be installed at any location within the plant.

Industrial PCs as controllers

The use of an Industrial PC as the controller means that the operating and observing element can be

implemented in the controller's hardware. The controller can therefore be located at an operating panel, in a

control room, or at some similar place. The Bus Terminals form the decentralised input/output level of the

controller in the control cabinet and the subsidiary terminal boxes. The power sector of the plant is also

controlled over the bus system in addition to the sensor/actuator level. The Bus Terminal replaces the

conventional series terminal as the wiring level in the control cabinet. The control cabinet can have smaller

dimensions.

BC8050 und BC8150 9Version: 3.0.0

Page 10

Product overview

Bus Couplers for all usual bus systems

The Beckhoff Bus Terminal system unites the advantages of a bus system with the possibilities of the

compact series terminal. Bus Terminals can be driven within all the usual bus systems, thus reducing the

controller parts count. The Bus Terminals then behave like conventional connections for that bus system. All

the performance features of the particular bus system are supported.

Mounting on standardized mounting rails

The installation is standardized thanks to the simple and space-saving mounting on a standardized mounting

rail (EN60715, 35mm) and the direct wiring of actuators and sensors, without cross connections between

the terminals. The consistent labelling scheme also contributes.

The small physical size and the great flexibility of the Bus Terminal system allow it to be used wherever a

series terminal is also used. Every type of connection, such as analog, digital, serial or the direct connection

of sensors can be implemented.

Modularity

The modular assembly of the terminal strip with Bus Terminals of various functions limits the number of

unused channels to a maximum of one per function. The presence of two channels in one terminal is the

optimum compromise of unused channels and the cost of each channel. The possibility of electrical isolation

through potential feed terminals also helps to keep the number of unused channels low.

Display of the channel state

The integrated LEDs show the state of the channel at a location close to the sensors and actuators.

K-bus

The K-bus is the data path within a terminal strip. The K-bus is led through from the Bus Coupler through all

the terminals via six contacts on the terminals' side walls. The end terminal terminates the K-bus. The user

does not have to learn anything about the function of the K-bus or about the internal workings of the

terminals and the Bus Coupler. Many software tools that can be supplied make project planning,

configuration and operation easy.

Potential feed terminals for isolated groups

The operating voltage is passed on to following terminals via three power contacts. You can divide the

terminal strip into arbitrary isolated groups by means of potential feed terminals. The potential feed terminals

play no part in the control of the terminals, and can be inserted at any locations within the terminal strip.

Up to 64Bus Terminals can be used in a terminal block, with optional K-bus extension for up to 256Bus

Terminals. This count does include potential feed terminals, but not the end terminal.

Bus Couplers for various fieldbus systems

Various Bus Couplers can be used to couple the electronic terminal strip quickly and easily to different

fieldbus systems. It is also possible to convert to another fieldbus system at a later time. The Bus Coupler

performs all the monitoring and control tasks that are necessary for operation of the connected Bus

Terminals. The operation and configuration of the Bus Terminals is carried out exclusively by the Bus

Coupler. Nevertheless, the parameters that have been set are stored in each Bus Terminal, and are retained

in the event of voltage drop-out. Fieldbus, K-bus and I/O level are electrically isolated.

If the exchange of data over the fieldbus is prone to errors or fails for a period of time, register contents (such

as counter states) are retained, digital outputs are cleared, and analog outputs take a value that can be

configured for each output when commissioning. The default setting for analog outputs is 0 V or 0 mA. Digital

outputs return in the inactive state. The timeout periods for the Bus Couplers correspond to the usual

settings for the fieldbus system. When converting to a different bus system it is necessary to bear in mind the

need to change the timeout periods if the bus cycle time is longer.

BC8050 und BC815010 Version: 3.0.0

Page 11

Product overview

The interfaces

A Bus Coupler has six different methods of connection. These interfaces are designed as plug connectors

and as spring-loaded terminals.

2.4 Technical data

2.4.1 Technical Data - BCxx50

Technical data BCxx5x

Processor 16bit micro-controller

Diagnostics LEDs 2 x power supply, 2 x K-Bus

Configuration and programming software TwinCAT PLC

Fieldbus interface BC8050 BC8150

Fieldbus RS485:

- KS8000 protocol

- ModbusRTU

- ModbusASCII

RS232

- Serial ADS

- KS8000 protocol

- ModbusRTU

- ModbusASCII

Interfaces

Serial interface COM1 (RS232 for configuration and programming, automatic baud rate

detection 9600/19200/38400 baud)

Terminal Bus (K-Bus) 64 (255 with K-bus extension)

BC8050 und BC8150 11Version: 3.0.0

Page 12

Product overview

Technical data BC8050/BC8150

Digital peripheral signals 2040 inputs/outputs

Analog peripheral signals 1024 inputs/outputs

Configuration possibility via TwinCAT or the controller

Maximum fieldbus byte

depending on fieldbus

number

Maximum number of bytes -

2048bytes of input data, 2048bytes of output data

PLC

Bus connection D-sub,9-pin

Power supply (Us) 24VDC (-15% /+20%) Use a 4A fuse or an NEC Class2 power supply to

meet the UL requirements!

Input current (Us) 60mA + (total K-bus current)/4

Starting current approx. 2.5 x continuous current

K-bus current (5V) maximum 1000mA

Power contact voltage (Up) maximum 24V

Power contact current load

maximum 10A

DC

(Up)

Recomm. back-up fuse (Up) ≤10A

Dielectric strength 500V (power contact/supply voltage/fieldbus)

Weight approx. 100g

Dimensions (W x H x D) approx. 44mm x 100mm x 68mm

Permissible ambient

-25°C ... +60°C

temperature range during

operation

Permissible ambient

-40°C ... +85°C

temperature range during

storage

Relative humidity 95% no condensation

Vibration/ shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC immunity/ emission conforms to EN61000-6-2/ EN61000-6-4

Installation position variable

Protection class IP20

BC8050 und BC815012 Version: 3.0.0

Page 13

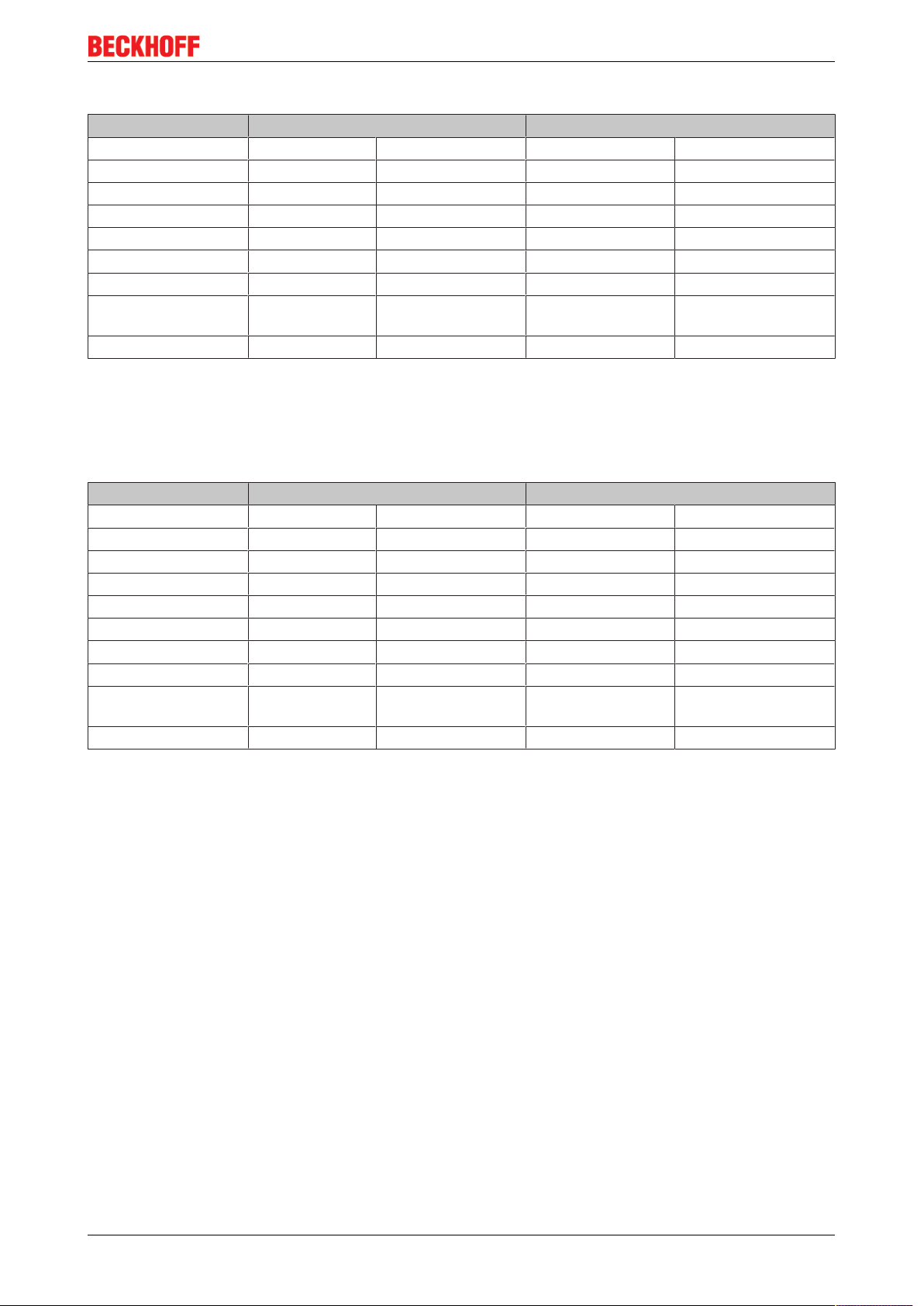

2.4.2 Technical data - RS485

Product overview

Fig.2: BC8050

System data RS485 (BC8050)

Protocols • Address 1-39 serial ADS)*, KS8000 protocol (automatic recognition of

the protocol and the baud rate (9600, 19200, 38400 baud, fixed data

frame, 8 data bits, even parity, one stop bit)

• Address 40-59 ModbusRTU (fixed baud rate 1200, 2400, 4800, 9600,

19200, 38400, DEFAULT 9600 baud, 8 bit data, optionally even, odd, no

default no parity)

Number of I/O modules 32 (99 with repeater)

Number of I/O points depending on controller

Data transfer medium shielded copper cable 2 x 0.25 mm², cable type A according to EN 50 170

Segment length up to 1200m

Data transfer rate 1200 - 38400baud

Topology RS485 line

Transmission time depending on protocol and baud rate

)* only via the configuration interfaces, not via RS485.

BC8050 und BC8150 13Version: 3.0.0

Page 14

Product overview

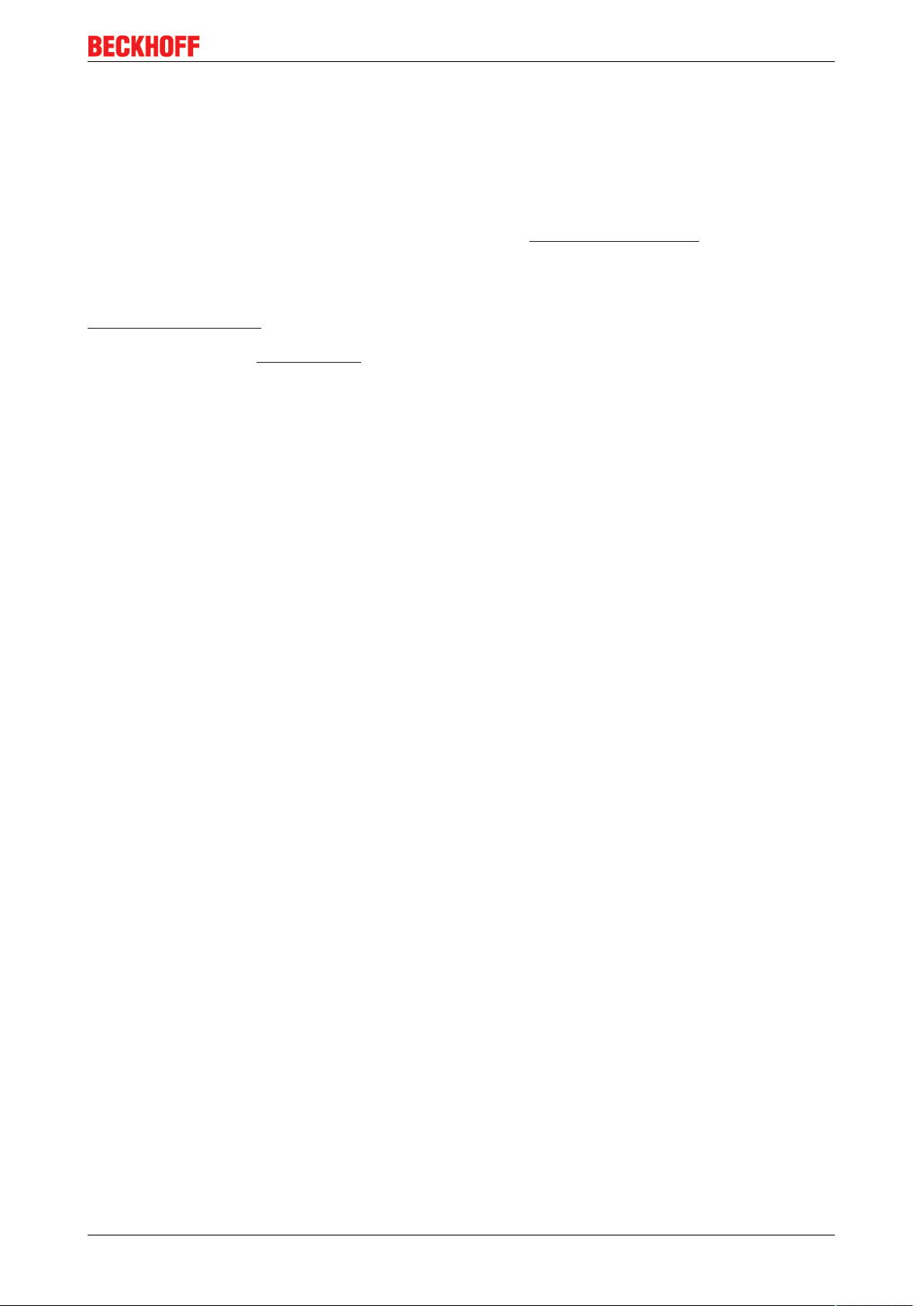

2.4.3 Technical Data - RS232

Fig.3: BC8150

System data RS232 (BC8150)

Protocols • Address 1-39 serial ADS, KS8000 protocol (automatic recognition of the

protocol and the baud rate (9600, 19200, 38400 baud, fixed data frame, 8

data bits, even parity, one stop bit)

• Address 40-59 ModbusRTU (fixed baud rate 1200, 2400, 4800, 9600,

19200, 38400, DEFAULT 9600 baud, 8 bit data, optionally even, odd, no

default no parity)

Number of I/O modules 1

Number of I/O points depending on controller

Data transfer medium shielded copper cable, 3 x 0.25 mm²

Segment length up to 15m

Data transfer rate 1200 - 38400baud

Topology RS232 peer to peer

Transmission time depending on protocol and baud rate

BC8050 und BC815014 Version: 3.0.0

Page 15

Product overview

2.4.4 Technical Data - PLC

PLC data BCxx5x

Programmability via serial programming interface or via the fieldbus

Program memory 48kbyte

Source code memory 128kbyte

Data memory 32kbyte

Remanent flags 2kbyte

PLC cycle time Approx. 3.0ms for 1000 IL commands (without I/O cycle)

Programming languages IEC 6-1131-3 (IL, LD, FBD, ST, SFC)

Runtime 1 SPS Task

Online Change Yes

Up/Down Load Code Yes/Yes

BC8050 und BC8150 15Version: 3.0.0

Page 16

Mounting and wiring

3 Mounting and wiring

3.1 Mounting

3.1.1 Dimensions

The Beckhoff Bus Terminal system is characterized by low physical volume and high modularity. When

planning a project it must be assumed that at least one Bus Coupler and a number of Bus Terminals will be

used. The mechanical dimensions of the Bus Couplers are independent of the fieldbus system.

Fig.4: BCxx50

The total width of the fieldbus station is the width of the Bus Coupler/Bus TerminalController plus the width

of the Bus Terminals being used (incl. KL9010 bus end terminal). Depending on design, the Bus Terminals

are 12mm or24mm wide. The height is 100mm.

The BCxx50 series Bus TerminalControllers are 68mm deep.

BC8050 und BC815016 Version: 3.0.0

Page 17

Mounting and wiring

3.1.2 Installation

The Bus Coupler and all the Bus Terminals can be clipped, with a light press, onto a 35 mm mounting rail. A

locking mechanism prevents the individual housings from being pulled off again. For removal from the

mounting rail the orange colored tension strap releases the latching mechanism, allowing the housing to be

pulled off the rail without any force.

Fig.5: Release the locking mechanism by pulling the orange tab

Up to 64 Bus Terminals can be attached to the Bus Coupler on the right hand side. When plugging the

components together, be sure to assemble the housings with groove and tongue against each other. A

properly working connection cannot be made by pushing the housings together on the mounting rail. When

correctly assembled, no significant gap can be seen between the attached housings.

Fig.6: Power contact on the left

Bus Terminals should only be pulled or plugged in switched-off state.

Insertion and removal of Bus Terminals is only permitted when switched off. The electron-

Attention

ics in the Bus Terminals and in the Bus Coupler are protected to a large measure against

damage, but incorrect function and damage cannot be ruled out if they are plugged in under power.

The right hand part of the Bus Coupler can be compared to a Bus Terminal. Eight connections at the top

enable the connection with solid or fine wires from 0.08 mm² to 2.5 mm². The connection is implemented with

the aid of a spring device. The spring-loaded terminal is opened with a screwdriver or rod, by exerting gentle

pressure in the opening above the terminal. The wire can be inserted into the terminal without any force. The

terminal closes automatically when the pressure is released, holding the wire safely and permanently.

BC8050 und BC8150 17Version: 3.0.0

Page 18

Mounting and wiring

3.2 Wiring

3.2.1 Potential groups, insulation testing and PE

Potential groups

A Beckhoff Bus Terminal block usually has three different potential groups:

• The fieldbus interface is electrically isolated (except for individual Low Cost couplers) and forms the

first potential group.

• Bus Coupler/ Bus Terminal Controller logic, K-bus and terminal logic form a second electrically

isolated potential group.

• The inputs and outputs are supplied via the power contacts and form further potential groups.

Groups of I/O terminals can be consolidated to further potential groups via potential supply terminals or

separation terminals.

Fig.7: Potential groups of a Bus Terminal block

Insulation testing

The connection between Bus Coupler/ Bus Terminal Controller and Bus Terminals is realized automatically

by latching the components. The transfer of the data and the supply voltage for the intelligent electronics in

the Bus Terminals is performed by the K-bus. The supply of the field electronics is performed through the

power contacts. Plugging together the power contacts creates a supply rail. Since some Bus Terminals (e.g.

analog Bus Terminals or 4-channel digital Bus Terminals) are not looped through these power contacts or

not completely the Bus Terminal contact assignments must be considered.

The potential feed terminals interrupt the power contacts, and represent the start of a new supply rail. The

Bus Coupler / Bus Terminal Controller can also be used for supplying the power contacts.

PE power contacts

The power contact labelled PE can be used as a protective earth. For safety reasons this contact mates first

when plugging together, and can ground short-circuit currents of up to 125A.

BC8050 und BC815018 Version: 3.0.0

Page 19

Mounting and wiring

Fig.8: Power contact on the left

It should be noted that, for reasons of electromagnetic compatibility, the PE contacts are capacitively

coupled to the mounting rail. This can both lead to misleading results and to damaging the terminal during

insulation testing (e.g. breakdown of the insulation from a 230 V power consuming device to the PE

conductor). The PE supply line at the Bus Coupler / Bus Terminal Controller must be disconnected for an

insulation test. In order to uncouple further feed locations for the purposes of testing, the feed terminals can

be pulled at least 10 mm out from the connected group of other terminals. In that case, the PE conductors do

not have to be disconnected.

The power contact with the label PE must not be used for other potentials.

3.2.2 Power supply

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state

DANGER

Supply of Bus Terminal Controller and Bus Terminals (Us)

The Bus Terminal Controller requires a supply voltage of 24 VDC.

The connection is made by means of the upper spring-loaded terminals labelled 24V and 0V. This supply

voltage is used for the electronic components of the Bus Coupler/Bus Terminal Controllers and (via the Kbus) the electronic components of the Bus Terminals. It is galvanically separated from the field level voltage.

before starting mounting, disassembly or wiring of the components!

BC8050 und BC8150 19Version: 3.0.0

Page 20

Mounting and wiring

Fig.9: Terminal points for the Bus Terminal Controller supply

Fig.10: UL identification

Note the UL requirements for the power supply.

To comply with the UL requirements, the 24VDC supply voltage for Us must originate

DANGER

• from an isolated source protected by a fuse of max. 4A (according to UL248) or

• from a voltage supply complying with NECclass2.

An NECclass2 voltage source must not be connected in series or parallel with another

NECclass2 corresponding voltage source!

No unlimited voltage sources!

To comply with the UL requirements, Us must not be connected with unlimited voltage

DANGER

sources.

Power contacts supply (Up)

The bottom six connections with spring-loaded terminals can be used to feed the supply for the peripherals.

The spring-loaded terminals are joined in pairs to a power contact. The feed for the power contacts has no

connection to the voltage supply for the BC electronics.

The spring-loaded terminals are designed for wires with cross-sections between 0.08mm2 and 2,5mm2.

The assignment in pairs and the electrical connection between feed terminal contacts allows the connection

wires to be looped through to various terminal points. The current load from the power contact must not

exceed 10A for long periods. The current carrying capacity between two spring-loaded terminals is identical

to that of the connecting wires.

BC8050 und BC815020 Version: 3.0.0

Page 21

Mounting and wiring

Power contacts

On the right hand face of the Bus Terminal Controller there are three spring contacts for the power contact

connections. The spring contacts are hidden in slots so that they cannot be accidentally touched. By

attaching a Bus Terminal the blade contacts on the left hand side of the Bus Terminal are connected to the

spring contacts. The tongue and groove guides on the top and bottom of the Bus Terminal Controllers and of

the Bus Terminals guarantees that the power contacts mate securely.

3.2.3 Programming cable

Use the KS2000-Z2 programming cable for serial programming of the Bus Terminal Controller. This cable is

included in the scope of supply of the KS2000 software, or it can be ordered separately (order identifier

KS2000-Z2).

Fig.11: Programming cable KS2000-Z2

KS2000-Z2

The programming cable offers the option of programming the BCxx50 via the serial interface.

Do not interrupt the ground connection for the supply voltage

When the programming cable (between BCxx50 and PC) is connected, the ground connec-

Attention

tion of the Bus Terminal controller must not be interrupted or disconnected, since this may

destroy the programming cable.

BC8050 und BC8150 21Version: 3.0.0

Page 22

Mounting and wiring

3.2.4 RS232 Connection

Nine-pin D sub

The cable is connected via a 9-pin D-Sub connector on the left side of the Bus Terminal Controller.

A three-core cable with shield should be used, with the shield being connected to the D-Sub connector

casing.

Pin assignment of the RS232 D-Sub socket

Fig.12: RS232 pin assignment

Cable

The cable must be crossed type. GND is connected 1:1. Only use assigned and described pins.

Fig.13: Three-core cable with shield, crossed

BC8050 und BC815022 Version: 3.0.0

Page 23

Mounting and wiring

3.2.5 RS485 connection

Nine-pin D sub

The cable is connected via a 9-pin D-Sub connector on the left side of the Bus Terminal Controller.

A two-core cable with shielding should be used. The shielding should be connected to signal ground (GND).

Pin assignment of the RS485 D-sub socket

Fig.14: RS485 pin assignment

Cable

The BC8050 can establish connections to several devices; the maximum permitted cable length is 1200m.

Fig.15: Two-core cable with shield

BC8050 und BC8150 23Version: 3.0.0

Page 24

Parameterization and Commissioning

4 Parameterization and Commissioning

4.1 Start-up behavior of the Bus Terminal Controller

When the Bus Terminal Controller is switched on it checks its state, configures the K-bus, creates a

configuration list based on the connected Bus Terminals and starts its local PLC.

The I/O LEDs flash when the Bus Terminal Controller starts up. If the system is in an error-free state, the I/O

LEDs should stop flashing after approx. 2-3 seconds. In the event of a fault the error type determines which

LED flashes (see chapter Diagnostic LEDs).

Fig.16: Start-up behavior of the Bus Terminal Controller

BC8050 und BC815024 Version: 3.0.0

Page 25

Parameterization and Commissioning

4.2 Setting the Address

The address must be set via the two rotary selection switches. The default setting is 11.

The BC8150 Bus Terminal Controller supports different protocols.

Address 1 to 39

Automatic recognition of the following protocols

• Serial ADS, automatic baud rate detection, default 38400 baud, fixed data frame (8,e,1)

• KS8000 protocol, automatic baud rate detection, default 38400 baud, fixed data frame (8,e,1)

• KS2000 protocol, automatic baud rate detection, default 38400 baud, fixed data frame (8,e,1)

• ModbusASCII protocol, automatic baud rate detection, default 38400 baud, fixed data frame (8,e,1)

• TwinCAT PLC, protocol automatic baud rate detection default 38400 baud, fixed data frame (8,e,1)

Address 40 to 59

• ModbusRTU, configurable baud rate, default 9600, configurable data frame default 8,n,1

Changing the address

The switches can be set to the required position using a screwdriver. Ensure that the switches engage

correctly. The lower switch is the ten-multiplier, the upper switch is the one-multiplier. The address change

becomes active immediately.

Example

You want to set address 34:

• Lower rotary selection switch Sx11: 3

• Upper rotary selection switch Sx10:4

Fig.17: Setting the node ID

Special functions using the address switch

In addition, the address switch can be used for following functions. To this end the associated address has to

be set (as long as the coupler is switched off), only the end terminal may be connected (KL9010), and the

coupler must then be connected to the supply voltage.

Address 99: Factory setting

Address 98: Delete boot project

Address 97: Delete TwinCAT configuration

BC8050 und BC8150 25Version: 3.0.0

Page 26

Parameterization and Commissioning

4.3 Baud rate

The Bus Coupler features automatic baud rate detection. When the supply voltage is switched on, the Bus

Coupler searches for the current baud rate and stores it as long as the supply voltage is present.

Restarts the bus coupler for automatic baud rate detection

If the master baud rate is changed, the Bus Coupler has to be switched off and on again in

Note

Linear extension of RS 232

Baud rate in kbit/sec 9,6 19,2 38,4

Permissible cable length in m 15 15 15

order to restart automatic baud rate detection.

4.4 Configuration

4.4.1 Overview

Configuration types

The Bus Terminal controllers of the BCxx50, BCxx20 and BXxx00 series can be configured in two different

ways: DEFAULT CONFIG or TwinCAT CONFIG.

DEFAULT-CONFIG

Bus Terminals are mapped in the order they are inserted, i.e. first the complex Bus Terminals followed by the

digital Bus Terminals.

The complex Bus Terminals are mapped as follows:

• Word Alignment

• complex representation

The process image depends on the connected terminals!

The process image changes when a terminal is added or removed!

CAUTION

The data of the fieldbus slaves interface are referred to as PLC variables. The PLC variables have

addresses from %QB1000 and %IB1000

The DEFAULT CONFIG (without PLC program) can also be used for writing and testing of the Connected

Bus Terminals. To this end, the Bus Terminal Controller must be scanned in the System Manager, and

FreeRun mode must be enabled (to use this function, no PLC program may be active on the Bus Terminal

Controller).

TWINCAT-CONFIG

In the TwinCAT CONFIG the Bus Terminals and PLC variables can be freely linked as required (TwinCAT

System Manager file required). The configuration is transferred to the coupler via the System Manager

andADS.

The following is required for the TwinCAT configuration (TC file):

• Via the fieldbus (PROFIBUS, CANopen, Ethernet)

PROFIBUS: (BC3150, BX3100)

◦ PC with FC310x from version 2.0 and TwinCAT 2.9 build 1000

◦ BX3100 with CIF60 or CP5412

BC8050 und BC815026 Version: 3.0.0

Page 27

Parameterization and Commissioning

◦ TwinCAT 2.9 build 946

(NOTE: with PROFIBUS cards from Hilscher only one ADS communication is permitted, i.e.

either System Manager or PLC Control)

CANopen: (BC5150, BX5100)

◦ PC with FC510x from version 1.76 TwinCAT build 1030

DeviceNet: (BC5250, BX5200)

◦ on request

Ethernet: (BC9050, BC9020, BC9120, BX9000)

◦ PC with TwinCAT 2.10 build 1322

• Via the serial ADS TwinCAT 2.9 build 1010

◦ BX3100 version 1.00

◦ BX5100 version 1.00

◦ BX5200 version 1.10

◦ BX8000 version 1.00

◦ BC3150, BC5150, BC5250, BC9050, BC9020, BC9120 from firmware B0

◦ For BC8150 from TwinCAT 2.10 build 1243

BCxx50 and BXxx00 can be parameterized via the System Manager of the TwinCAT program.

• Variable I/O mapping

• Type-specific PROFIBUS data (BC3150 and BX3100 only)

• RTC (real-time clock) (BX series only)

• SSB (Smart System Bus) (BX series only)

• PLC settings

• K-Bus settings

The configuration can be transferred to the BCxx50 or BXxx00 via fieldbus ADS protocol or serial ADS

protocol.

The TwinCAT configuration can be used to link variables, I/Os and data. The following is possible:

• PLC - K-BUS

• PLC fieldbus (e.g.PROFIBUS slave interface to PLC)

• K-bus fieldbus (only for BX controllers)

• Support for TwinSAFE terminals (only BX controllers from firmware 1.17)

In addition, the TwinCAT configuration can be used to parameterize special behavior, for example whether

data are preserved or set to "0" in the event of a fieldbus error.

The real-time clock can be set via a tab in the system manager.

Work steps

1. Setting the fieldbus address

2. Open the System Manager and create a TC file

3. Configure fieldbus data in the TC file

4. Save the TC file

5. Opening a new system manager, creating a PC file and reading in saved TX file

6. Creating a link to a PLC task

7. Saving the configuration

8. Starting the TwinCAT system

9. Open the TC file in the System Manager, complete the configuration and transfer it to the BCxx50,

BCxx20 or BXxx00

10. Transfer the program to BCxx50, BCxx20 or BXxx00

11. Creating a boot project

BC8050 und BC8150 27Version: 3.0.0

Page 28

Parameterization and Commissioning

4.4.2 Creating a TwinCAT configuration

In order to configure a Bus Terminal Controller of the BCxx50, BCxx20 or BXxx00 series, create a BX file in

the System Manager. To simplify matters, files for the basic units have already been prepared. Open the

corresponding Bus Terminal Controller with New from Template.

Fig.18: Creating a TwinCAT configuration

Select the corresponding Bus Terminal Controller.

Fig.19: Selecting the Bus Terminal Controller

All Bus Terminal Controller components are now available:

• Fieldbus interface

• K-bus interface [}38]

• PLC Program

• SSB (only Bus Terminal Controllers of the BX series)

Please refer to the relevant chapter for device configuration.

4.4.3 Downloading a TwinCAT configuration

The TwinCAT configuration is loaded into the Bus Terminal Controller via ADS protocol.

Serial ADS protocol

(all Bus Terminal Controllers of the BXxx00 and BCxx50 series)

Enter the serial ADS connection, as described in the chapter Serial ADS [}34].

BC8050 und BC815028 Version: 3.0.0

Page 29

Parameterization and Commissioning

ADS protocol via the fieldbus

(BC3150, BC5150, BC9x20, BC9050, BX3100, BX5100, BX9000 only)

A prerequisite is that TwinCAT operates as master and is engaged in data exchange, i.e. the physical and

fieldbus configuration must be complete, and data exchange must take place between the master

(e.g.fieldbus master card) and the Bus Terminal Controller.

Choose Target System

Select the Bus Terminal Controller onto which the configuration is to be loaded. Use the function key F8 to

open the dialog for downloading your file to the corresponding device.

Fig.20: Downloading a TwinCAT configuration

Select the corresponding Bus Terminal Controller.

Fig.21: Selecting the Bus Terminal Controller

The state of the Bus Terminal Controller is shown at the bottom right of the System Manager.

Fig.22: State of the Bus Terminal Controller

BC8050 und BC8150 29Version: 3.0.0

Page 30

Parameterization and Commissioning

In Config mode / FreeRun the configuration can now be downloaded to Bus Terminal Controller. If the Bus

Terminal Controller is in Stop mode, ADS communication is not yet activated. In this case, it is not possible

to download the configuration.

To activate the TwinCAT configuration select Ctrl+Shift+F4 or Activate Configuration.

Fig.23: Activating the TwinCAT configuration

The current configuration is loaded onto the Bus Terminal Controller. The display will show Store Config, and

the BUS and I/O LED will flash. Once the configuration is successfully loaded onto Bus Terminal Controller,

TwinCAT Config should appear in the display of a BXxx00. The corresponding program can now be

transferred to the Bus Terminal Controller (program-download via the fieldbus).

4.4.4 Uploading a TwinCAT configuration

The TwinCAT configuration is loaded into the Bus Terminal Controller via ADS protocol.

Serial ADS protocol

(all Bus Terminal Controllers of the BCxx50, BCxx20 and BXxx00 series)

Enter the serial ADS connection, as described in the chapter Serial ADS [}34].

ADS protocol via the fieldbus

(BC3150, BC5150, BC9x20, BC9050, BX3100, BX5100, BX9000 only)

A prerequisite is that TwinCAT operates as master and is engaged in data exchange, i.e. the physical and

fieldbus configuration must be complete, and data exchange must take place between the master

(e.g.fieldbus card) and the Bus Terminal Controller.

Choose Target System

Select the Bus Terminal Controller onto which the configuration is to be loaded. Use the function key [F8] to

open the dialog for downloading your file to the corresponding device.

BC8050 und BC815030 Version: 3.0.0

Page 31

Parameterization and Commissioning

Fig.24: Choose Target System

Select the corresponding Bus Terminal Controller.

Fig.25: Selecting the Bus Terminal Controller

The state of the Bus Terminal Controller is shown at the bottom right of the System Manager.

Fig.26: State of the Bus Terminal Controller

Click on the red folder. The TwinCAT configuration will now be uploaded.

BC8050 und BC8150 31Version: 3.0.0

Page 32

Parameterization and Commissioning

Fig.27: Uploading the TwinCAT configuration

4.4.5 Resources in the Bus Terminal Controller

The memory resources assigned in the Bus Terminal Controller are shown in the System Manager in the

Resources tab of the Bus Terminal Controller.

Mapping code

The mapping code is required for calculating the TwinCAT configuration (see Figure Memory for the code

mapping). The percentages are added here. In the example from Fig. Memory for code mapping, 8% of the

memory is allocated to the mapping calculation.

Fig.28: Memory for code mapping

Data memory mapping

Data memory for mapping. The values are to be considered individually, i.e. each value can be up to 100%.

BC8050 und BC815032 Version: 3.0.0

Page 33

Fig.29: Data memory mapping

Parameterization and Commissioning

Used code and data memory

Fig. Code and data memory (1) "Used PLC code" in %.

Fig. Code and data memory (2) "Used PLC data" in %.

Fig. Code and data memory (3) "Used PLC source" in %.

Fig.30: Code and data memory

Other memory

Fig. Other Memory (1) "Used Near Heap" is required for the COM interface and SSB. %values.

Fig. Other Memory (2) "Used Huge Heap" is required for the ADS communication. %values. This value

should be less than 30%.

Fig. Other Memory (3) "Used File Area" is required for the TwinCAT configuration, the TSM file and the

16kbyte flash access. %values.

BC8050 und BC8150 33Version: 3.0.0

Page 34

Parameterization and Commissioning

Fig.31: Other memory

4.4.6 ADS connection via serial interface

(from firmware version 1.xx or 0.99x, Bus Terminal Controllers of the BX series and for all BCxx50)

From TwinCAT 2.9 build 1020 (TwnCAT level PLC, NC or NCI)

Use only a serial connection

To ensure trouble-free operation of the ADS link via the serial interface, only a serial con-

Note

Note

nection to the BX controller is allowed.

After successful configuration via the System Manager, close the System Manager before

starting programming.

AMS Net ID in delivery state (default)

For BX9000

The default AMS Net ID is 172.16.21.20.1.1. If the IP address of the BX9000 is changed,

the AMS Net ID of the BX9000 also changes. There is a menu option for displaying the current AMS Net ID.

Example: If you change the IP address to 10.2.3.7, the AMS Net ID changes to

10.2.3.7.1.1.

For BC9050, BC9020, BC9120

The default AMS Net ID is 172.16.xxx.[DIP switch].1.1. If the IP address of the BX9xxx is

changed, the AMS Net ID of the BX9xxx also changes.

Example: If you change the IP address to 10.2.3.7, the AMS Net ID changes to

10.2.3.7.1.1.

BC9050: DEFAULT 172.16.21.[DIP-Switch].1.1

BC9020: DEFAULT 172.16.22.[DIP-Switch].1.1

BC9120: DEFAULT 172.16.23.[DIP-Switch].1.1

Initializing the ADS connection

Enter the Bus Terminal Controller in the remote connection under TwinCAT. Click on the TwinCAT icon and

open the features menu. The following settings can be made under the >AMS Remote< tab.

BC8050 und BC815034 Version: 3.0.0

Page 35

Parameterization and Commissioning

Fig.32: Properties of the remote connection

Remote Name: Any

AMS-Net-ID: 1.1.1.1.1.1 (Default)

Address: COM Port: Baud rate, parity, data bits, stop bits

Transport: Select "COM port"

When the Bus Terminal Controller is switched on, the default AMS Net ID is always "1.1.1.1.1.1" (except all

Ethernet Controllers).

The AMS Net ID can be changed as required. Please note that the new AMS Net ID cannot be changed

again in this way.

If you need to change the new AMS Net ID again, you have to restart the Bus Terminal Controller, so that

the AMS Net ID is reset to the default AMS Net ID, "1.1.1.1.1.1".

You can now change the AMS Net ID again.

Strings can only be entered at the second call

No strings can be entered under address when the dialog is first called (see above). Enter

Note

The communication starts when TwinCAT is in Config mode (TwinCAT icon is blue) or RUN mode (TwinCAT

icon is green). The COM interface remains open until a TwinCAT stop occurs (TwinCAT icon is red). It is

then available again for other programs. No error message is issued if the COM interface is used by another

program during a TwinCAT restart (e.g.by the KS2000 configuration software).

the name, AMS Net ID and transport type and close the dialog. With the second call you

can enter your COM port.

AMS Net ID after ADS connection via the fieldbus

If you have addressed the Bus Terminal Controller with an ADS connection via the fieldbus

Note

BX series: reading the AMS Net ID

The current AMS Net ID can be read from the menu via the display of BX series Bus Terminal Controller.

AMS

1.1.1.1.1.1

before the serial ADS was used, the AMS Net ID was automatically changed by the System

Manager. In this case a new serial ADS connection is only possible, if the AMS Net ID is

adjusted.

AMS Net ID

BC8050 und BC8150 35Version: 3.0.0

Page 36

Parameterization and Commissioning

4.5 RS232 interface

4.5.1 TwinCAT Configuration - RS232 Interface

TwinCAT 2.10 Build 1243 or higher is required for using the TC configuration.

Open the BC8150 template project.

Fig.33: Selection dialog "New from Template"

Select BC8150.

Fig.34: Selection of Bus Controller

Open the device (BC8150) and click on BC8150. On the right in the System Manager there are two tabs, i.e.

General and Communication Properties. Select Communication Properties. The following settings are

available. Watchdog setting - at 0 ms the watchdog is disabled, adjustable up to 64000 ms max. The baud

rate and parity are only valid if the address switch is set to 40-59. The input and output sizes are calculated

from the attached variables.

BC8050 und BC815036 Version: 3.0.0

Page 37

Parameterization and Commissioning

Fig.35: "Communication Properties" tab

Open the BC8150 and right-click on Inputs for setting up inputs or Outputs for setting up outputs to be

received or sent via the RS232 interface.

Fig.36: Creating variables (inputs, outputs)

Please not that an even start address (0, 2, 4, 6, ...) has to be selected for variables with a size of 2 bytes or

greater.

Fig.37: Definition of variables

BC8050 und BC8150 37Version: 3.0.0

Page 38

Parameterization and Commissioning

4.6 K-bus

Bus Terminal and end terminal required

To operate a Bus Terminal Controller of the BC or BX series, at least one Bus Terminal

Note

BX Settings tab

with process image and the end terminal must be connected to the K-bus.

Fig.38: BX Settings tab

Check Terminals during Start-up

When a boot project is created, the current Bus Terminal configuration is stored. The connected Bus

Terminals are checked when the Bus Terminal Controller restarts. If this option is selected, the Bus Terminal

Controller does not enter into data exchange. The PLC project will not be started.

Auto K-Bus Reset

Once a K-bus error has been rectified, the Bus Terminal Controller automatically resumes the data

exchange.

Once a K-Bus error has been rectified, the outputs become active again immediately!

CAUTION

Clear Outputs on Breakpoint

If breakpoints are set in PLC Control, the K-Bus is no longer processed, i.e. the outputs are set to a safe

state (zero).

K-Bus Sync Mode

Ensure that the outputs are reactivated immediately and that analog outputs retain their

programmed value, if this is not dealt with in your PLC project.

Writing and reading of the Bus Terminals can take place synchronously with task 1 or the fieldbus.

BC8050 und BC815038 Version: 3.0.0

Page 39

Parameterization and Commissioning

K-Bus Re-Trigger

If the processor is busy dealing with the PLC project or the SSB, the K-Bus cannot be processed for a

certain amount of time. This leads to triggering of the Bus Terminal watchdog and dropping of the outputs.

The Bus Terminal Controller is set such that the K-bus watchdog is re-triggered 3 times after 85ms. The KBus watchdog would then be activated.

K-Bus Re-Trigger 0: 100ms

K-Bus Re-Trigger 1: 2x85ms=170ms

K-Bus Re-Trigger 2: 3x85ms=255ms

K-Bus Re-Trigger 3: 4x85ms=340ms

Reaction on K-Bus Error

In the event of a K-Bus error, the K-Bus inputs are set to "0" or retain their last state.

Response on PLC-Stop

The user can set the behavior of the fieldbus output data in the event of the PLC project being stopped. The

master will use these data as input data. In the event of a PLC stop, the data can be set to "0" or remain

unchanged.

BX Diag tab

Display of the cycle time for task 1, K-bus, fieldbus processing and the SSB load.

Fig.39: BX Diag tab

Factory Settings: the Bus Terminal Controller is set to its delivery. These settings are reactivated via Restart

System or by switching the system off and on again (display shows DEFAULT-CONFIG).

Reset Maximum Values: resets the maximum values

BC8050 und BC8150 39Version: 3.0.0

Page 40

Parameterization and Commissioning

K-Bus variables

PLC interface: Not supported (only included for moving CX or BX projects)

K-bus state: see Diagnostics

4.7 Configuration software KS2000

Bus Terminal controllers of the BCxx50, BXxx20 and BXxx00 series cannot be parameterized and

configured with the KS2000 configuration software. These devices must be configured with the TwinCAT

System Manager.

The KS2000 configuration software offers configuration and diagnostic support for the Bus Terminals

attached to the Bus Terminal Controller.

It is advisable to set the baud rate in the KS2000 configuration software and the BCxx50 BCxx20 and

BXxx00 to 38400 baud (8 data bits, even, 1 stop bit).

COM1 - automatic baud rate detection

The COM 1 interface of the BXxx00 features automatic baud rate detection between

Note

9.6kbaud and 56.4kbaud.

Required KS2000 version

Configuration or diagnostics of Bus Terminals at BXxx00 is supported from KS2000 version

Note

In some Bus Terminals (e.g.KL25xx, KL6811, KL6201, KL6401) the following parameters must be set in

order to be able to use the configuration dialogs:

• A PLC project or boot project must be deactivated.

• The BX controller must be in its default configuration. Set the manufacturer’s setting or switch to Config

Mode in the TwinCAT System Manager (blue TwinCAT icon).

• The BX controller must be in FreeRun mode. Activate it with the TwinCAT System Manager.

You can now log in with the KS2000 configuration software via ADS (port 100) or the serial cable and use

the KS2000 dialogs in the Bus Terminals.

4.3.14.

BC8050 und BC815040 Version: 3.0.0

Page 41

Programming

5 Programming

5.1 BCxx50 PLC features

Description Value

Data memory 32kbyte

Program memory 48kbyte minus task-configuration minus POUs during online

change

Source code memory 128kbyte

RETAIN 2kbyte

INPUT 2kbyte

OUTPUT 2kbyte

FLAG 4kbyte

Max. variable size 16kbyte

Max. POUs Limited by memory

5.2 TwinCAT PLC

The Beckhoff TwinCAT Software System turns any compatible PC into a real-time controller with a multi-PLC

system, NC axis control, programming environment and operating station. The TwinCAT programming

environment is also used for programming the BC/BX. If you have TwinCAT PLC (Windows NT4/2000/XP)

installed, you can use the fieldbus connection or the serial port for downloading and debugging software.

TwinCAT I/O or TwinCAT PLC can also be used as the Ethernet Master (host), in order to exchange process

data with the Bus Terminal Controller. TwinCAT provides you with the System Manager as a configuration

tool, as well as the drivers and the ADS protocol.

Bus Terminal Controllers of the BCxx50, BCxx20 and BXxx00 series

These 2nd-generation Bus Terminal Controllers are configured with the TwinCAT System Manager and

programmed with TwinCAT PLC Control. TwinCAT PLC must be installed for these couplers (WindowsNT4,

Windows2000, WindowsXP).

Programming and program transfer

• via the serial interface [}61]

• via the fieldbus interface (only for Bus Terminal controllers for PROFIBUS, CANopen and Ethernet)

Online change

The Bus Terminal Controllers of the BX series and the BCxx50 support online change. This means that the

PLC program is replaced with a new program without interrupting the program. The switch-over to the new

program occurs after the task is completed. This means that two versions of the PLC program have to be

stored. 512kbyte are available, which therefore have to be divided by two, leaving 256kbyte for the actual

PLC program. In addition, several kbyte are required for task configuration etc. During an online change,

dynamic data are stored in memory. Should a program approach the memory limit (program size greater

than 240kbyte), the online change may no longer work, even though the program may still be written to the

BX after "Rebuild all".

When is online change not available?

Online change is not available under certain conditions,.

• Inserting of a new library

• Changing the task setting

• "Rebuild all"

BC8050 und BC8150 41Version: 3.0.0

Page 42

Programming

• Controller memory limit is almost reached (PLC program greater than 90%)

5.3 TwinCAT PLC - Error codes

Error type Description

PLC compiler error Maximum number of POUs (...) exceeded

PLC compiler error Out of global data memory ...

Error POUs

For each function block one POU (process object unit) is created. 256 function blocks are available by

default.

Fig.40: Maximum number of POUs exceeded

If libraries are integrated this value may be insufficient. In this case, the number of POUs should be

increased.

To this end, open in PLC Control under Projects/Options...

Fig.41: Menu path Projects / Options / Controller Settings

...the controller settings.

BC8050 und BC815042 Version: 3.0.0

Page 43

Fig.42: Controller settings

Changing these settings will deactivate online changes.

Programming

Global memory error

Fig.43: Global memory insufficient

2 x 16kbyte of data are available by default. If large data quantities are to be used, this range should be

increased. A maximum of 14 data segments are possible for the BX.

Fig.44: Menu path Projects / Options / Build

BC8050 und BC8150 43Version: 3.0.0

Page 44

Programming

Fig.45: Build

BC8050 und BC815044 Version: 3.0.0

Page 45

Programming

5.4 Remanent data

2000kbyte of remanent data are available for the BX controller. These data are declared as VARRETAIN in

PLC Control:

Example

VARRETAIN

Test:BOOL;

Count:INT;

END_VAR

Retain data are located between VAR RETAIN and END_VAR. These data are stored in a NOVRAM and

are consistent across the whole 2kbyte range. The RETAIN data are stored in the NOVRAM after each

cycle. For 2kbyte approx. 2ms are required (for 1kbyte approx. 1ms). The variables can be configured

locally or globally. Allocated variables (%MB, %QB, %IB) cannot be used as remanent data.

Do not use VAR_RETAIN in function blocks

VAR_RETAIN should not be used in function blocks. All FB data are copied into the retain

Note

Note

memory. This leads to an unnecessary increase in cycle time, and the retain memory is

filled with unnecessary data.

Do not use variables with address as remanent data

Variables that have been assigned an address (%MB, %QB, %IB) must not be used as remanent data.

Example for remanent data in the function block

This should be avoided, if possible, since all the data of a function block, in which even just a single

remanent bit is found, are stored by default. A program sample can be found below.

Function block test (no program code required - in ST semicolon is sufficient)

FUNCTION_BLOCKTest

VAR_INPUT

END_VAR

VAR_OUTPUT

END_VAR

VAR

END_VAR

VAR_IN_OUT

Counter:INT;

END_VAR

MAIN program

PROGRAMMAIN

VAR

fb_Test:Test;

END_VAR

VARRETAIN

iCounter1:INT;

END_VAR

fb_Test(Counter:=iCounter1);

BC8050 und BC8150 45Version: 3.0.0

Page 46

Programming

5.5 Allocated flags

4kbyte of allocated flags are available. They can be used to assign different variable types to the same

address, e.g. for converting strings to bytes. Data can also be placed here that can be read or written via

ADS by the controller.

Allocated variables are not remanent data

For the Bus Terminal Controllers of the BX series and the BCxx50 the allocated variables

Note

Reading/writing of allocated flags via ADS

The flags may also be read via the controller and ADS. In PROFIBUS, the DPV-1 services are used for this

purpose, in CANopen SDO communication is used.

The AmsNetID can be obtained from the System Manager, or it can be displayed via the Bus Terminal

Controller menu.

The PLC port number is 800.

Index group Meaning Index offset (value range)

0x4020 Flag (only BXxxx0) 0..4096

are not saved as remanent data.

Example

BX program

VAR

Flag_01AT%MB0:WORD;

END_VAR

TwinCAT PC/CX master program

VAR

fbADRSREAD:ADSREAD;

Flag_M:WORD;

END_VAR

fbADRSREAD(

NETID:='172.16.3.0.2.3',(*AMSNetIdBX*)

PORT:=800,(*800-PLC*)

IDXGRP:=16#4020,(*0x4020hexfalgs*)

IDXOFFS:=0,(*byteoffset*)

LEN:=2,(*Lenghtbyte*)

DESTADDR:=ADR(Merker),

READ:=TRUE,

TMOUT:=t#1s);

IFNOTfbADRSREAD.BUSYTHEN

fbADRSREAD(READ:=FALSE);

END_IF

5.6 Local process image in delivery state

The process image of the BX/BCxx50 consists of an input, output and flag area. In addition, there are

unallocated data without fixed address. They are created without specifying an address. For this type of

variable 256/48 kB of memory are available on the BX/BCxx50. The maximum size of a variable or structure

(array) is 16kbyte. For the allocated data 2048 bytes of input data and 2048 bytes of output data are

available. The BX/BCxx50 has 4 kB of memory for the allocated flag area. In the delivery state (default

configuration) of the BX/BCxx50, fixed addresses are allocated for all connected Bus Terminals. The data for

fieldbus communication start from address offset 1000

. The fieldbus data length depends on the fieldbus

dec

system used.

Inputs Outputs

Bus Terminal %IB0 ... Bus Terminal %QB0 ...

Fieldbus data (PLC variables) %IB1000 ... Fieldbus data (PLC variables) %QB1000 ...

... %IB2047 maximal ... %QB2047 maximal

BC8050 und BC815046 Version: 3.0.0

Page 47

Programming

Differences in the protocols

The data for the higher-level master, Modbus or KS8000 protocol are stored in the BC8150 from address

1000. For Modbus the maximum data length is 512 bytes and does not have to be set within the range 1 to

126 words. For the KS8000 protocol the number of data from address 1000 is preset to 8 words or 16 bytes

inputs and 8 words or 16 bytes outputs. The BC8150 will reject data telegrams that do not match this number

exactly and issue an error. This data length can be parameterized via a function block in the BC8150.

If the Modbus protocol is used, data access to the BC8150 flag area is recommended. This area can be read

and or written to without triggering the watchdog. The ADS protocol can access all data. The whole process

image can be accessed via port 800, and the process image from address 1000 via port 300. If port address

800 is used, the data are only available for read access. If the serial ADS is used, it is recommended to

access the flag area that can be reached via port 800 and IndexGroup 0x4020.

Addressing of the connected Bus Terminals

The default setting is for all the connected Bus Terminals to be assigned to the local process image.

Mapping within the Bus Terminal Controller is carried out according to the following rule:

First all the complex Bus Terminals, in the sequence they are physically inserted, followed by the digital Bus

Terminals which are filled to a byte. The default mapping of the complex Bus Terminals is:

• complete evaluation

• Intel format

• Word Alignment

Example structure

Bus Terminal Controller: 1 x BX/BCxx50

Position 1: 1 x KL1012

Position 2: 1 x KL1104

Position 3: 1 x KL2012

Position 4: 1 x KL2034

Position 5: 1 x KL1501

Position 6: 1 x KL3002

Position 7: 1 x KL4002

Position 8: 1 x KL6001

Position 9: 1 x KL9010

Process image

Bus Terminal Position Input image Output image

KL1501 5 %IB0...%IB5 %QB0...%QB5

KL3002 6 %IB6...%IB13 %QB6...%QB13

KL4002 7 %IB14...%IB21 %QB14...%QB21

KL6001 8 %IB22...%IB29 %QB22...%QB29

KL1012 1 %IX30.0..30.1 -

KL1104 2 %IX30.1..30.5 -

KL2012 3 - %QX30.0..30.1

KL2034 4 - %QX30.2..30.5

KL9010 9 - -

BC8050 und BC8150 47Version: 3.0.0

Page 48

Programming

Show associated variables

If you do not know the address of the Bus Terminals that you have assigned to the local

Note

PLC (BX/BCxx50):

Perform your hardware configuration in the System Manager. After you have entered all the

Bus Terminals and PLC variables, click with the right mouse button on the BX/BCxx50 in

the hardware tree, and select the menu item Export variables information.... A file is saved,

and this file can be inserted in the System Manager under Project - Import. Now you will

have the entry TwinCAT import under the global variables, and you will find here all the

variables that you have assigned to the local PLC (BX/BCxx50).

5.7 Mapping the Bus Terminals

The precise assignment of the byte-oriented Bus Terminals may be found in the configuration guide for the

particular bus terminal. This documentation is available on the Beckhoff Products&Solutions CD or on the

Internet under http://www.beckhoff.de.

Byte oriented Bus Terminals Bit oriented Bus Terminals

KL15x1 KL10xx, KL11xx, KL12xx, KL17xx, KM1xxx

KL25xx KL20xx, KL21xx, KL22xx, KL26xx, KL27xx, KM2xxx

KL3xxx

KL4xxx

KL5xxx

KL6xxx

KL7xxx

KL8xxx

KL9110, KL9160, KL9210, KL9260

BC8050 und BC815048 Version: 3.0.0

Page 49

Programming

5.8 Local process image in the TwinCAT configuration

The TwinCAT configuration (TwinCAT CONFIG) enables free mapping between fieldbus, K-bus and PLC

variables. Variables can be linked independent of their address via the System Manager.

Fig.46: Changing variable links

Fig.47: Linking a variable with an input

In the default configuration all Bus Terminals are assigned fixed addresses. If a Bus Terminal is inserted, the

whole address range may be shifted. The TwinCAT configuration enables allocated variables to be linked to

a Bus Terminal, as required. This is parameterized in the System Manager, and the configuration is then

downloaded to the Bus Terminal Controller (see TwinCAT configuration [}26]). It is also possible to upload

an existing TwinCAT configuration.

BC8050 und BC8150 49Version: 3.0.0

Page 50

Programming

5.9 Creating a boot project

The following memory resources are available for generating the boot project

• approx. 250kbyte flash on the Bus Terminal controllers of the BX series;

• approx. 48kbyte flash on the Bus Terminal controllers of the BCxx50 series.

PLC Control

After logging into TwinCAT PLC Control, a boot project can be created.

• Opening a PLC project

• Selecting the target system (or selection the serial interface)

• Logging into the BX/BCxx50

• Creating a boot project (Online\Create boot project)

The PLC LED lights up green once a valid boot project is available on the BX/BCxx50.

In the Bus Terminal controllers of the BX series, the PLC LED flashes orange while boot project is created.

The PLC LED lights up orange if no boot project is available on the BX.

Deleting a boot project

The boot project can be deleted from the Bus Terminal Controller. The following steps must be followed:

• Opening the project

• Logging into the Bus Terminal Controller

• Deleting the boot project (Online\Delete boot project)

The PLC LED lights up orange when the boot project is deleted.

Using the current project as boot project

After an online change the old project is still shown as boot project. To use the current

Note

Bypassing the start of the boot project*

With the Bus Terminal controllers of the BX series, starting of the boot project during booting can be

prevented by pressing the Navi button. This does not delete the boot project. The project is reloaded when

the Bus Terminal Controller is rebooted.

* from version 0.85

project (after the online change) as the boot project, the boot project has to be recreated.

5.10 Communication between TwinCAT and BX/BCxx50