Page 1

External Brake Resistor AX2090-BW5x-xxxx BECKHOFF Drive Technology

Technical Documentation

Eiserstr. 5

Version: 1.0 33415 Verl

Date: 11.9.2009 Germany

Language: EN

Article no.: TDenAX-2090-BW5x-0400 Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: Info@beckhoff.com

Internet: www.beckhoff.com

Beckhoff Automation GmbH

Please read carefully before commissioning!

Foreword

Liability conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for safety, including all the

relevant laws, regulations and guidelines.

The documentation has been prepared with care. The products described are, however, constantly under development. For this reason, the

documentation may not always be have been fully checked for consistency with the performance data, standards or other characteristics described.

None of the statements in this manual represent a guarantee for as set out in § 443 of the German Civil Code or a statement about the assumed

use according to the contract as set out in § 434 para. 1 clause 1 no. 1 of the German Civil Code. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without warning. No claims for the modification of products that have already been

supplied may be made on the basis of the data, diagrams and descriptions in this documentation.

Copyright

© These instructions are protected by copyright. Any reproduction or third party use of this publication, whether in whole or in part, without the

written permission of Beckhoff Automation GmbH, is forbidden.

Appropriate use

The brake resistors from the AX2090-BW5x-xxxx series are exclusively designed for direct application with an AX5000 series servo drive or the

AX5021 brake module. They are designed for installation as components in electrical installations and machines together with the servo drive or the

brake module, and this is their only purpose.

Scope of supply

The scope of supply includes the following components:

Brake resistor from the required performance class, technical documentation and packaging

If one of the components is damaged please notify the logistics company and Beckhoff Automation GmbH immediately.

Security

Safety rules

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for safety, including all the

relevant laws, regulations and guidelines.

Caution – Danger of death!

Even when the AX5000 is disconnected from the mains voltage, dangerous voltage continues to be present at the "X02" terminals

DANGER

WARNING

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the application. Modifications to hardware or

software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are familiar with the applicable national

standards. Knowledge of machine safety legislation is compulsory.

Product description

Warning

The external brake resistors of the AX2090-BW5x-xxxx series are able to convert the dynamic energy generated during braking of a servomotor into

heat. The series covers a wide continuous power and peak power range. The built-in temperature switch enables the system to respond

immediately to any overload of the brake resistor through analysis in the AX5000 or the PLC. All brake resistors of the AX2090-BW5x-xxxx series

are UL and CSA approved.

of the DC link for at least 5 minutes. Never touch the terminals within this period.

Caution - Risk of injury through hot surfaces!

The temperature of the brake resistor housing surface may reach over 200 °C. Please ensure that the housing has cooled down

below 40 °C before touching it.

Caution - Destruction of the equipment

The brake resistor may only be connected to individual AX5000 devices or AX5021 brake modules. It must never be used in a drive

system without the AX5021 brake module, since this may lead to its destruction through overload.

Page 2

Page 2/4

Caution - Destruction of the brake resistor and consequential damage

The built-in temperature switch must be monitored, so that the machine can be stopped in a controlled manner and switched off in

the event of an overloading of the brake resistor.

Warning

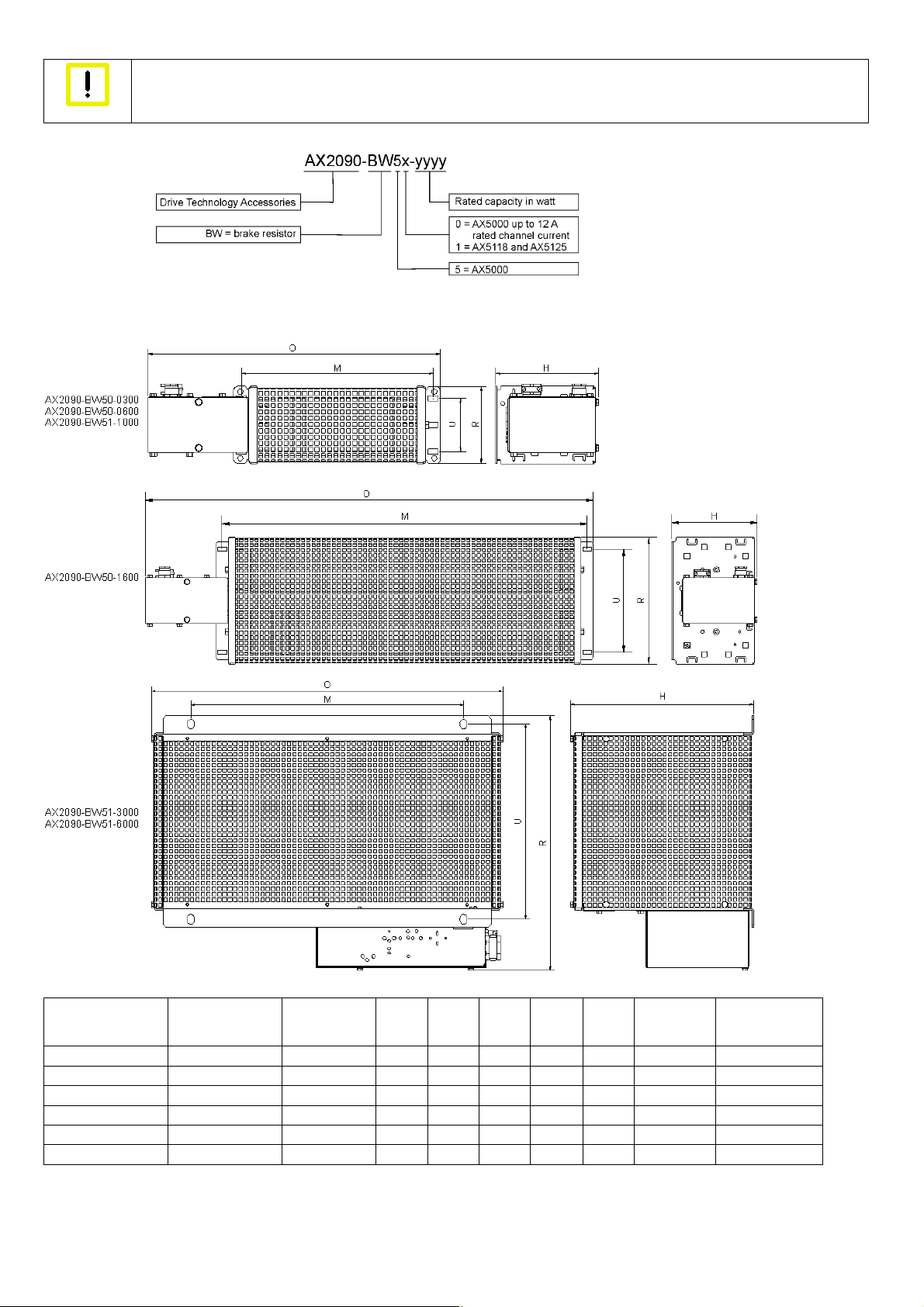

Type key

Mechanical installation

Dimensions and technical data

Dimensions and technical data

Type Nominal capacity

[W]

*

Resistance [Ω]

O [mm] R [mm] H [mm] M [mm] U [mm] Weight [kg] AX5000

at 40° C

AX2090-BW50-0300 300 47 349 92 120 230 64 2 AX5x01-AX5112

AX2090-BW50-0600 600 47 549 92 120 430 64 3 AX5x01-AX5112

AX2090-BW50-1600 1600 47 649 185 120 530 150 5,8 AX5x01-AX5112

AX2090-BW51-1000 1000 23 749 92 120 630 64 4 AX5118, AX5125

AX2090-BW51-3000 3000 23,4 490 355 255 380 270 8 AX5118, AX5125

AX2090-BW51-6000 6000 23,2 490 455 255 380 370 12 AX5118, AX5125

*) 4% output reduction per 10 K temperature difference

Page 3

Page 3/4

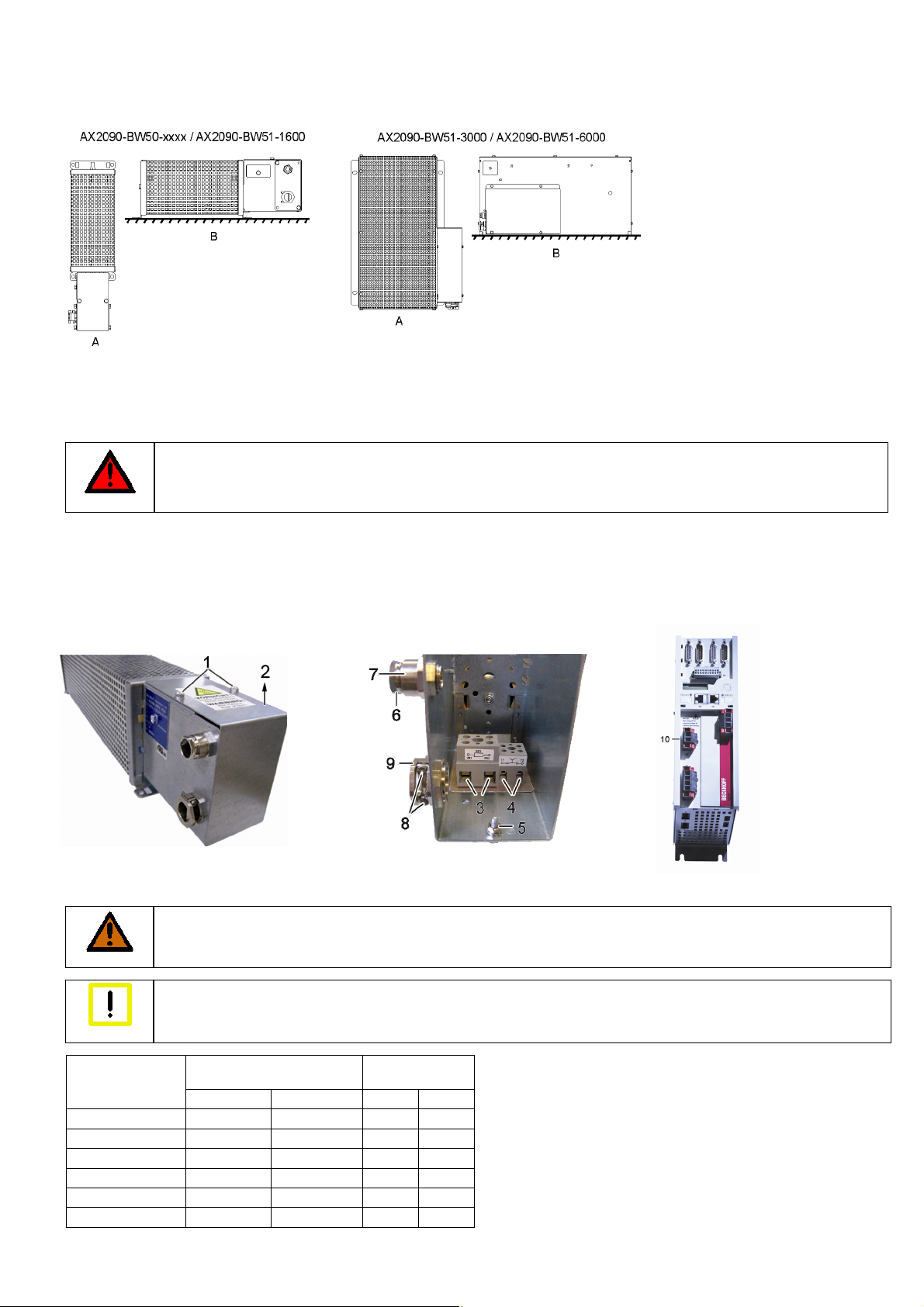

Mounting positions and distances

(A) = vertical installation is only permitted according to the diagram (terminal box facing downwards).

(B) = horizontal installation

For all mounting positions the following minimum distances must be adhered to:

200 mm to adjacent components, walls etc. and 300 mm to components, ceilings etc. above. If the device is installed vertically (A), the minimum

distance to components, floors etc. below is 200 mm in order to allow unobstructed flow of air to the brake resistor.

Electrical installation

Caution – Danger of death!

Disconnect the AX5000 from the mains before installing the brake resistor!

Even when the AX5000 is disconnected from the mains voltage, dangerous voltage continues to be present at the "X02" terminals

DANGER

Remove the two screws (1) and remove the cover (2) in direction of the arrow. Connect an adequately dimensioned cable (see section Cables) to

the terminals (3) of the resistor and the earthing stud (5) and take it out of the terminal box through the strain-relief assembly (9). Ensure adequate

strain relief with the two screws (8). Connect the other side of the cable to the DC link contact connector X2 (10) of the AX5000. The connector is

supplied with the AX5000. Connect the earthing cable to the earthing conductor of the control cabinet.

Connect an adequately dimensioned cable to the potential-free N/C contact (4) of the temperature switch and take it out of the terminal box through

the strain-relief assembly (7) (see section Temperature switch). Ensure adequate strain relief with the nut (6).

Install the cover (2) in reverse order.

Cables

We recommend

WARNING

Warning

Type

AX2090-BW50-0300 1,5 16 0,75 18

AX2090-BW50-0600 1,5 16 0,75 18

AX2090-BW50-1600 1,5 16 0,75 18

AX2090-BW51-1000 2,5 12 0,75 18

AX2090-BW51-3000 2,5 12 0,75 18

AX2090-BW51-6000 2,5 12 0,75 18

We recommend wire end sleeves.

of the DC link for at least 5 minutes. Never touch the terminals within this period.

Beckhoff motor cables for connecting the brake resistors.

Caution - Fire hazard!

The brake resistors become very hot. Only use cables with adequate heat resistance.

EMC safety

Use only shielded cables.

Brake resistor Temperature

switch

2

[mm

] [AWG] [mm2] [AWG]

Page 4

Page 4/4

y cy

Temperature switch

Destruction of the brake resistor

The temperature switch is only used for temperature

monitoring. The brake resistor is not switched off.

Warning

The temperature switch has a potential-free N/C contact, which enables

immediate response to any overload of the brake resistor through analysis in

the AX5000 or the PLC. Connect the cable directly to a free input of plug "X06".

Then parameterise it such that the AX5000 stops the motor(s) with an

emergency ramp or the PLC reads and processes this input.

Short-term capacity

Type

AX2090-BW50-0300 180 2

AX2090-BW50-0600 180 2

AX2090-BW50-1600 180 2

AX2090-BW51-1000 180 2

AX2090-BW51-3000 85 2

AX2090-BW51-6000 85 2

Switching

temperature

[°C] [A]

Brake resistors are usually not operated continuously, but only exposed to short-time duty. In the following section the permitted short-term capacity

is calculated based on the continuous power, overload factor and duty cycle.

Duty cycle

The dut

y cycle is a relative value that depends on the switch-on time (t

)and the cycle time. Cycle times up to 120 sec. are used directly in the

on

calculation. Should the cycle time exceed 120 sec., the maximum relevant cycle time of 120 sec. is used in the calculation.

Example 1 Example 2

= 60 s ton = 40 s

t

on

Cycle time = 280 s Cycle time = 100 s

Dut

cle = 50 % Duty cycle = 40 %

Overload factor

Calculation formula:

Short-term capacity = continuous power x overload factor

Switching current

24 VDC or 230 VAC

Overtemperature and continuous power at 100% duty cycle

If your application requires a higher continuous power than the specified nominal capacity, you can accept this state if a higher brake resistor

temperature is permitted. The following diagram shows the overtemperature v. the continuous power.

Normal operating range, max. 130%:

This operating range is recommended for

maximum service life and error-free

operation.

Permitted operating range, max. 160%:

This operating range is still permitted,

although it results in shorter service life with

higher failure probability.

Inadmissible operating range, more than 160%:

In this operating range there is a risk of

destruction of the brake resistor through

overheating. Due to the high temperatures

the adjacent components are also at risk.

Destruction of the brake resistor and adjacent components

Always ensure adequate ventilation of the brake resistor, since the temperatures of the housing surface may exceed 200 °C.

Warning

Loading...

Loading...