Bakemax BMFBM001, BMFBM01 Installation Manual

French Bread Moulder

BMFBM001

Operations Manual

CONTENTS

1. PREFACE .......................................................................................... P2

2. INTRODUCTION OF THE MACHINE ........................................ P2

3. THE SPECIFICATION OF THE MACHINE AND

THE NAMES OF THE PARTS ....................................................... P2

4. METHODS OF THE TRANSPORTATION AND

PEDESTAL INSTALLATION....................................................... P4

5. INSTALLATION AND CAUTIONS ............................................ P5

6. OPERATING INSTRUCTION AND SAFETY CAUTIONS P6

7. CLEANING AND MAINTENANCE .................................................. P7

8. ADJUSTMENT AND REPAIR ............................................................ P8

9. ELECTRIC CIRCUIT DIAGRAM ........................................................ P ll

1. PREFACE

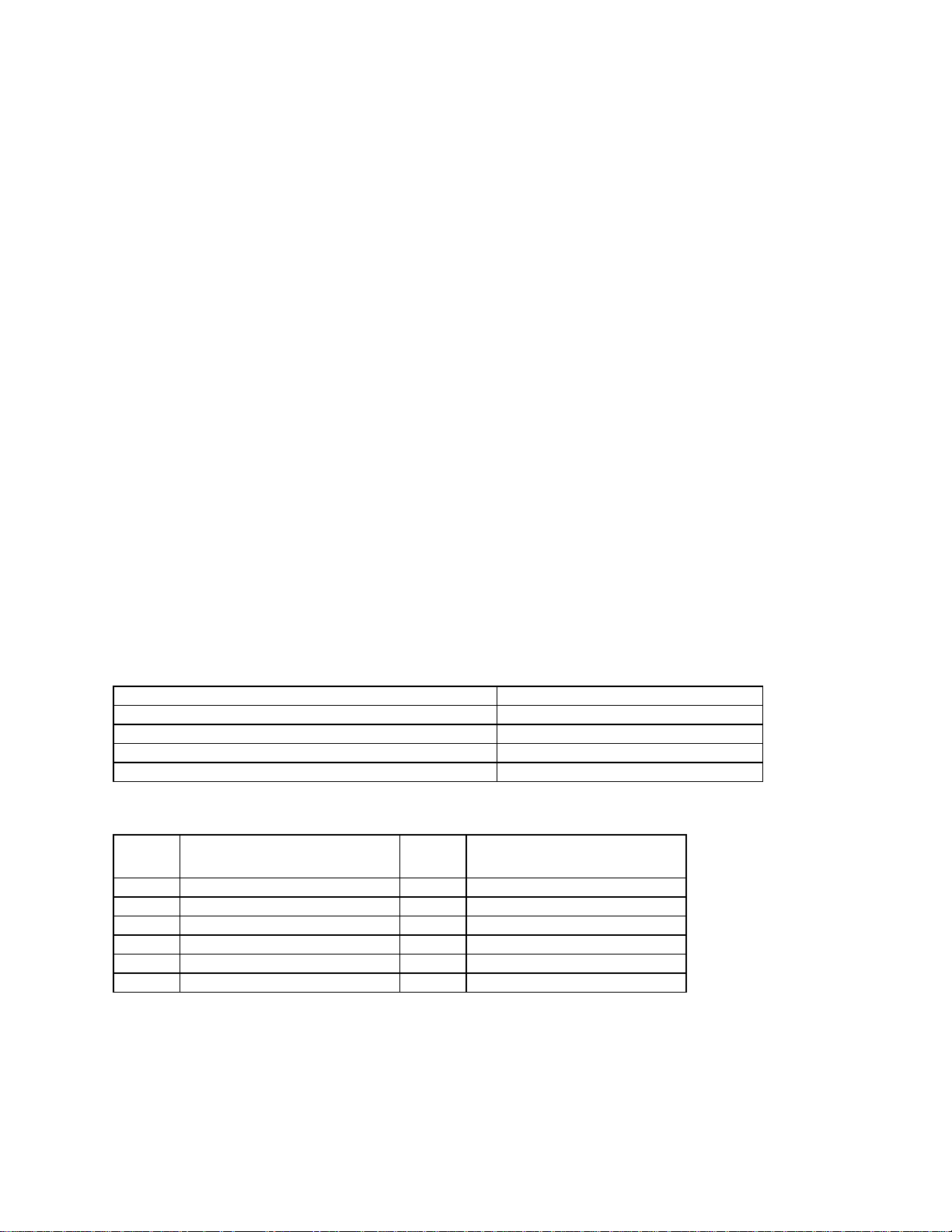

Weight of dough

50g~1250g

Power

0.75kw

Dimension of machine (w*d*h)

98cm*85*cm* 150cm

Dimension of carton(w*d*h)

124cm*93cm* 104cm

Net weight / gross weight

210kgs/250kgs

1

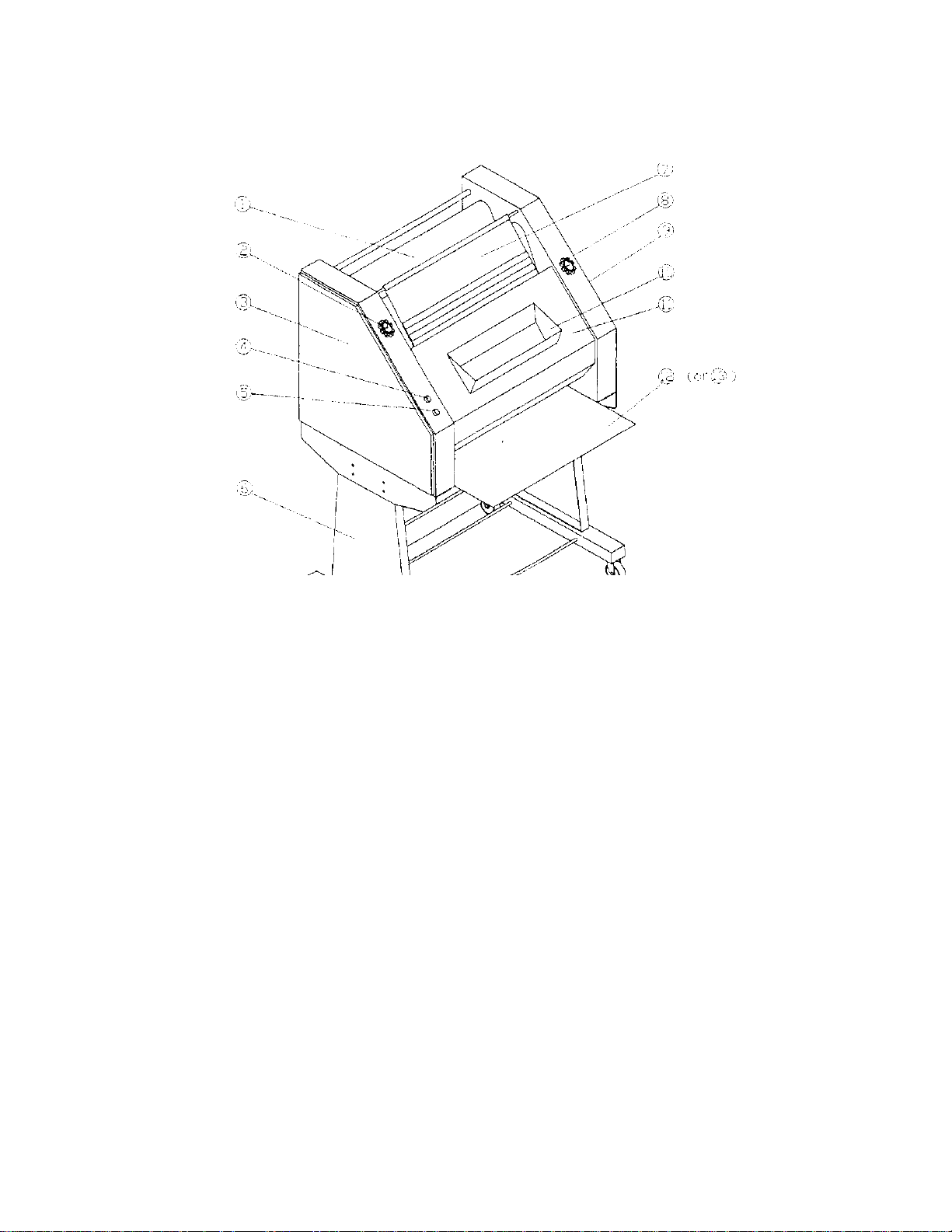

Movable caisson

(moulding board)

8

Moulding control

2

Roller control

9

Right panel

3

Left panel

10

Dough entry

4

Power "on"

11

Front panel

5

Power "off"

12

Output plate

6

Pedestal

13

Moulding belt

7

Canvas

14

Overload cut-out switch

French Dough Moulder/ Roller is the best helper for you to roll and mould

Dough pieces. It can be your most efficient working partner for making bread and earning

money if you refer to this instruction manual for usage and maintenance.

2. INTRODUCTION OF THE MACHINE

French Dough Moulder/ Roller has the function to roll, press and mould

dough to be the products you need in diameter and length. The maximum production is about

1200pcs/hour and the ideal moulding of dough is from 50 to 1250 grams.

The moulder is designed to meet the professional use of modern bakeries; it has the function

of pressing, rolling, and moulding the dough of loaves; it applies to dough moulding of toast,

baguettes, croissants, and other kinds of bread.

For best quality, the entry of dough is made by a set of 3 rollers to press dough easily and

another set of 2 moulding belts turns in different directions to press, roll, and mould the

dough to meet the diameter and length you need. We also can add the adjustable moul ding

belts, outside the entry to control the speed of output of the dough.

3. THE SPECIFICATION OF THE MACHINE AND THE NAMES OF THE FARTS

SPECIFICATION OF THE MACHINE:

MECHANICAL DESCRIPTION:

4. METHOD OF TRANSPORTATION AND PEDESTAL INSTALLATION

Loading...

Loading...