Page 1

06/06 Rev. 3.05-01 OPERATING MANUAL

ALX 92x

Setup

Winding pattern ............................................. 2

Selecting the printing material .......................4

Thermal transfer / direct thermal printing .. 4

Label material ............................................ 4

Thermal transfer ribbon .............................5

Inserting label material .................................. 6

Removing spent backing paper ................. 6

Removing glue residue .............................6

Inserting a new label roll ........................... 7

Inserting ribbon ............................................11

Removing spent ribbon ............................11

Inserting a new ribbon roll ........................12

Settings .......................................................13

Ribbon tension .........................................13

Label sensor ............................................14

Adjustment button for printhead pressure 15

Dispensing edge ......................................16

Dispenser parameters .............................16

Material Parameters ................................17

Index ............................................................18

Page 2

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

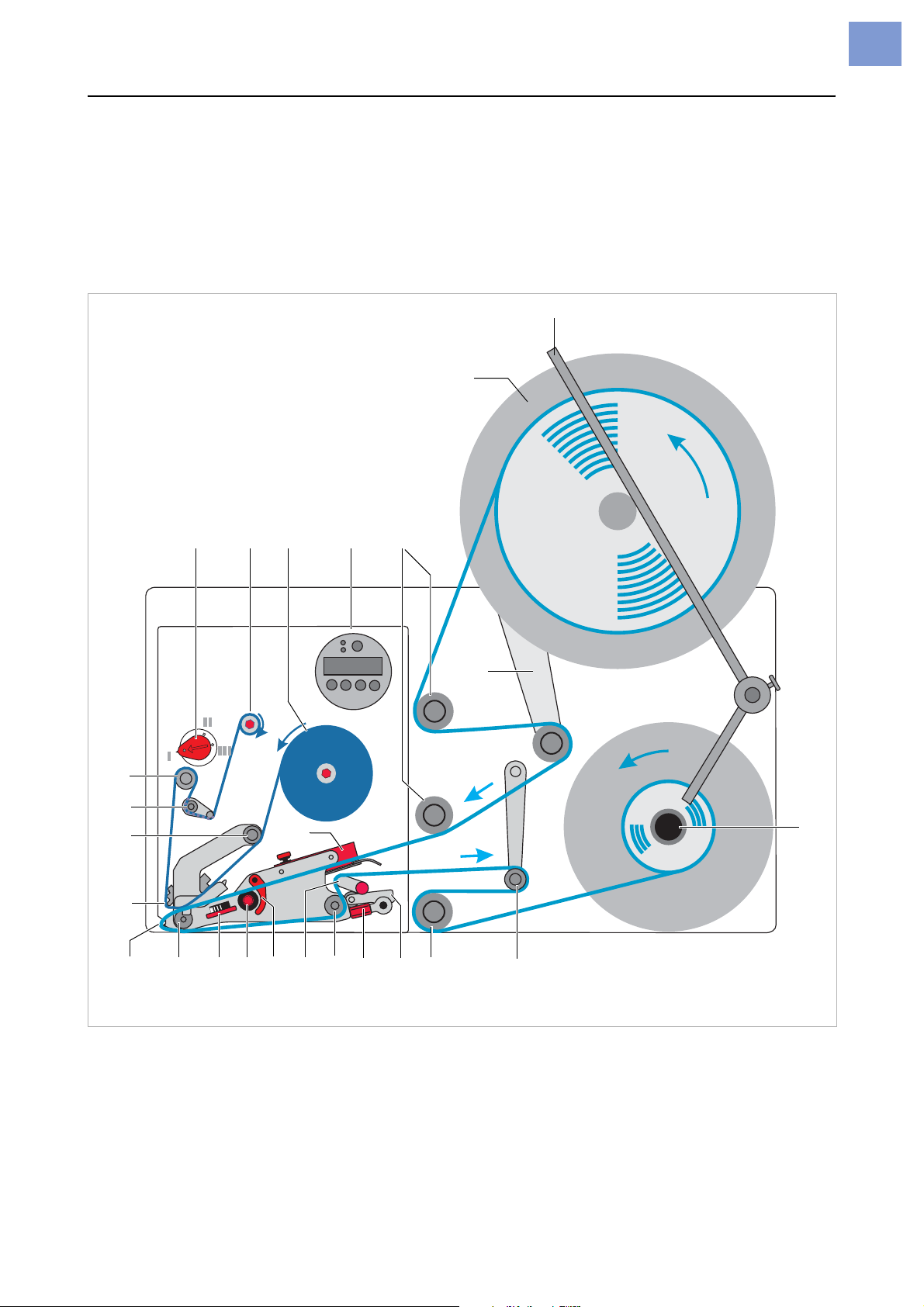

Winding pattern

The winding diagram shows the winding direction of material and ribbon

through the ALX92x.

« Follow this basic scheme when inserting/changing material and ribbon.

¯Only specially trained staff to insert and change the ribbons and material.

8

7

Z0189.cdr

2

24

23

22

21

1 23 4 5

15

1617181920

6

9

5

1011121314

[1] Material and ribbon path in the ALX92x (left version).

Page 3

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

3

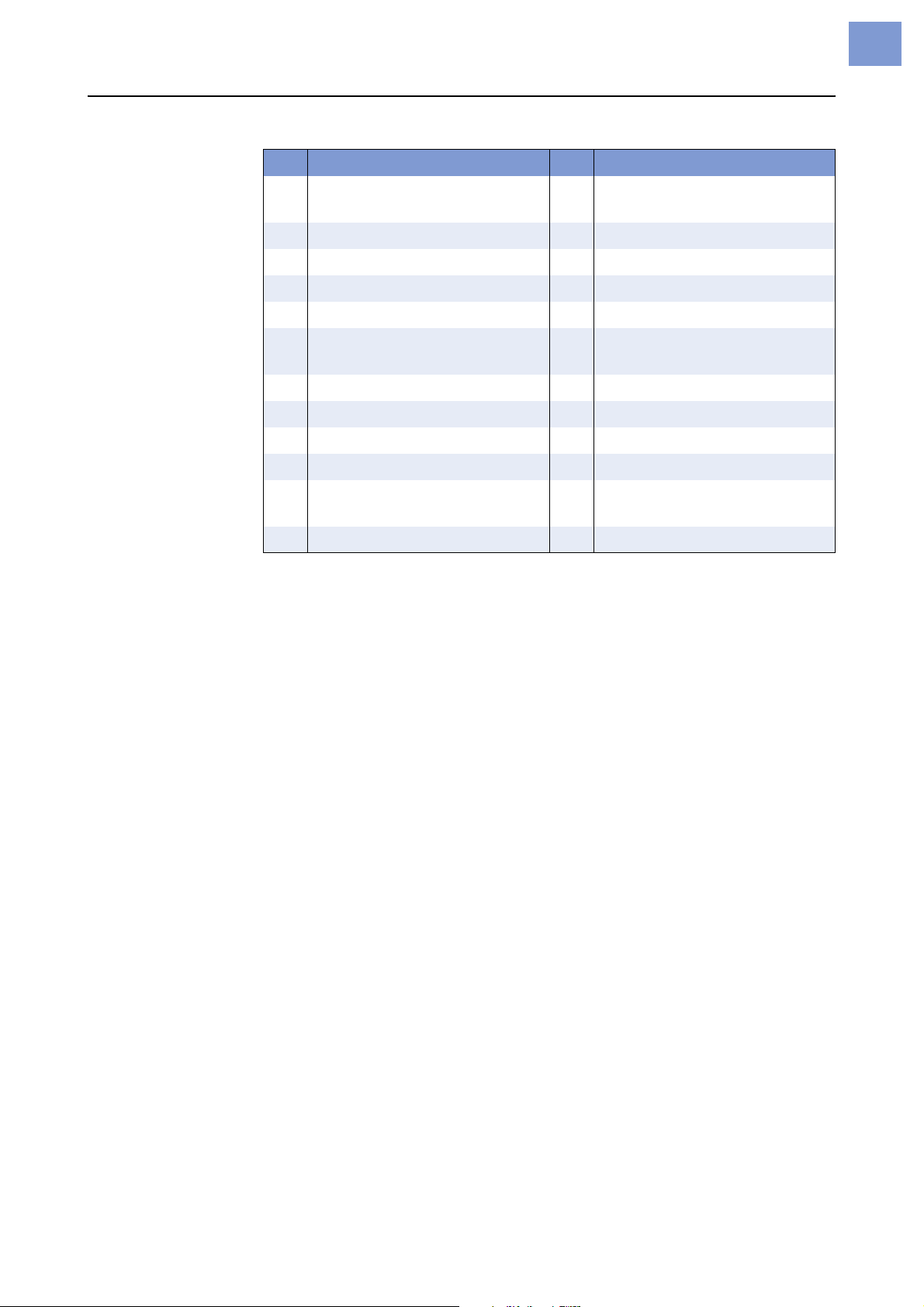

Names of parts

No. Name No. Name

1 Adjustment knob for printhead

pressure

2 Ribbon rewinding mandrel 14 Deflection roll

3 Ribbon unwinding mandrel 15 Material guide

4 Operation panel 16 Opener

5 Deflection roll 17 Brake roller

6 Material dancer arm 18 Adjustment wheel for label

7 Material unwinder 19 Print roller

8 Guiding rod 20 Dispensing edge

9 Backing paper rewinder 21 Printhead

10 Backing paper dancer arm 22 Ribbon deflection axle

11 Pressure roller 23 Ribbon deflection roller with

12 Lever for pressure roller 24 Ribbon roller

[Tab. 1] ALX 92x operating parts

13 Feed roller

sensor

stress relief

Page 4

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Selecting the printing material

Thermal transfer / direct thermal printing

The ALX92x can print onto label material using the direct thermal mode or

thermal transfer mode.

Direct thermal Direct thermal printing is done without ribbon. The direct thermal process

requires label material with a temperature-sensitive coating. The printout is

produced by applying precise bursts of heat to the material under the

printhead. This changes the colour of the coating.

4

Thermal

transfer

Material

roughness

Printhead

temperature

Thermal transfer printing is done with (thermal transfer) ribbon on “normal”

label material. The printout is produced by applying precise bursts of heat to

the thermal transfer ribbon under the printhead. This transfers the colour

particles to the label.

Label material

The ALX92x was developed for printing on self-adhesive stock.

Pay attention to the following factors when selecting label material:

• The roughness of the material surface

• The printhead temperature required for the colour transfer

• Size of the material roll. The following dimensions need to be checked:

Outside-/inside diameter of the material roll and the material width

If the material is very rough, the printhead will be worn down more quickly

than when using a smooth material. This is an important aspect of thermal

printing. With thermal transfer printing, this doesn’t pose such a problem,

because you can – and indeed should – select a ribbon that is wider than the

material. This means that the printhead is protected over the entire width of

the material.

High printhead temperatures can similarly cause problems. The material and

the ribbon take longer to cool. As a result, the print quality may degrade –

particularly at high print speeds. The printhead also wears down more

quickly.

¯The printing result is highly dependent on the right combination of label

material and thermal transfer ribbon. The surface of the label material

determines which thermal transfer ribbons produces the best adhesion.

Unsuitable ribbons can lead to poor printing results.

P Further information can be found in the topic section Technical data, section

“Label material”.

Page 5

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Thermal transfer ribbon

The following is recommended for thermal transfer ribbons:

• The back of the ribbon should be coated so that it produces no static or

friction (Backcoating). If this isn’t the case, the printhead may be damaged by

static discharge coming off the ribbon surface.

• The ribbons need to be designed for “corner edge” printheads.

• Ribbons should be able to handle print speeds of up to 400mm/s (16ips).

• Size of the ribbon roll: The following dimensions need to be checked: outside/

inside diameter of the ribbon roll, ribbon width.

CAUTION! - Thermal transfer ribbons without these properties can degrade

the performance of the printer and the print quality as well as damage the

printhead!

Armor APR600 (Avery part no. 2240-600-xxx) is a recommended ribbon

type.

5

¯The thermal transfer ribbon should only be slightly wider than the label

material.

• If an overly narrow ribbon is used, the border of the label material interferes

with the printhead – which wears it down more quickly.

• If an overly wide ribbon is used, creasing may occur in the ribbon. This can

led to poor printing results.

P For more details on the permissible dimensions of ribbon rolls, refer to

Technical data

, “Thermal Transfer Ribbon”.

Page 6

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Inserting label material

WARNING!

• Rotating parts can trap items and

draw them in!

« When working on the device, do

not wear loose jewellery, long

sleeves, long hair, and similar.

« Close the devices cover before

printing.

• During operation, the printhead

can become hot.

« Be careful when touching the

printhead!

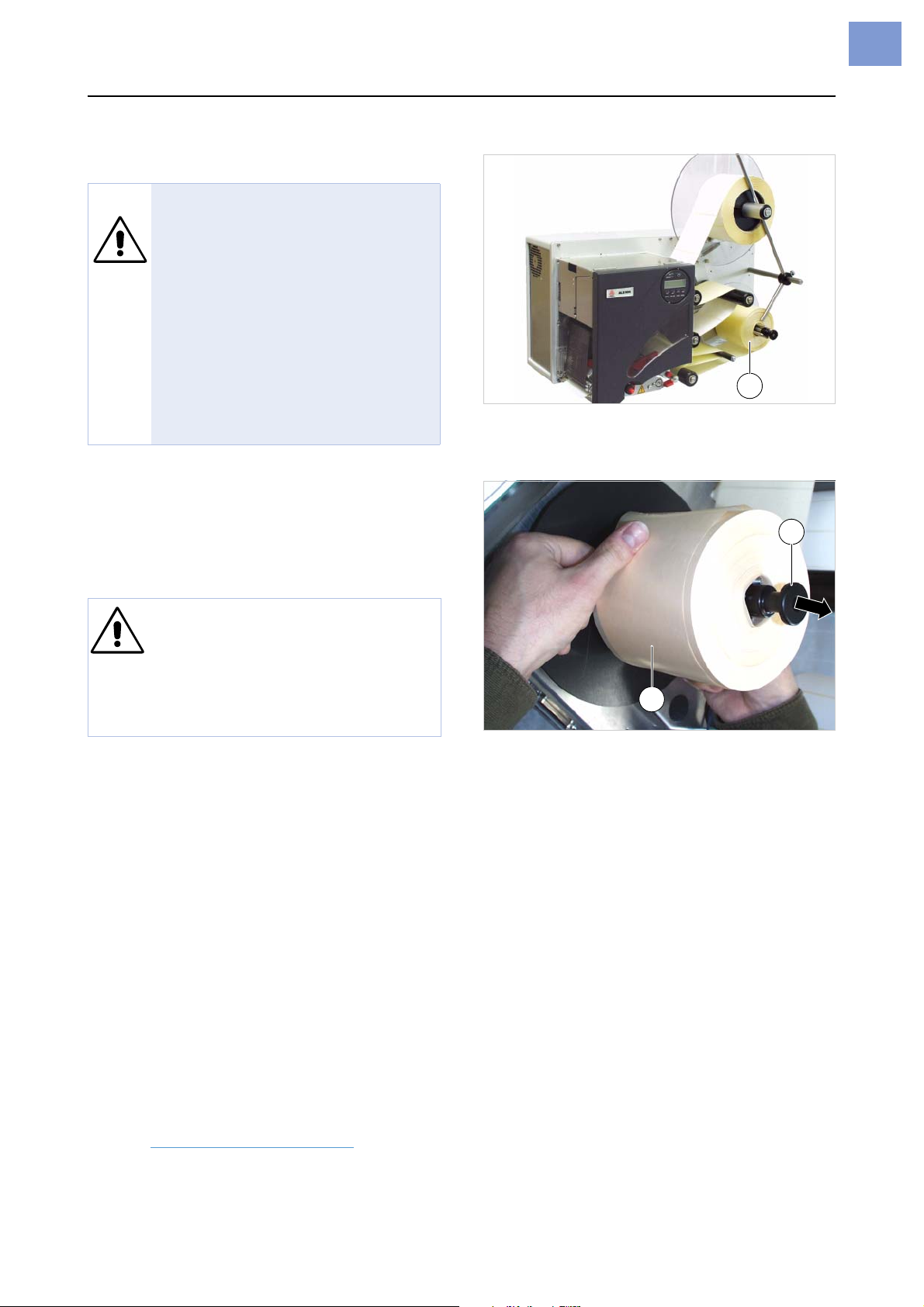

Removing spent backing paper

[1] Rewound backing paper on the ALX 92x (A).

A

6

The backing paper rewinder can exactly

rewind the amount of backing paper remaining from a material roll with 300mm diameter [2A].

CAUTION! - A backing paper roll

exceeding the diameter limit can

stall and damage the machine!

« Always remove the backing paper

from the rewinder if you insert a

new material roll!

Assuming backing paper has gathered on

the rewinder:

1. Pull out the release button [2B].

The tensioning mechanism of the rewinder

is slackened.

2. Remove the rewound backing paper.

Removing glue residue

B

A

[2] Removing rewound backing paper.

A Backing paper roll

B Release button

« If necessary, clean the following compo-

nents:

• Printhead

• Dispensing plate

• Deflection rollers

• Drive roller

• Pressure rollers

P Follow the directions provided in topic sec-

tion Maintenance and Cleaning

.

Page 7

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Inserting a new label roll

1. Turn thumb screw [3A] loose and swivel

guide rod [3B] aside.

2. Push the material roll onto the unwinder

[3C] with the appropriate adapter rings.

The material roll should turn in an anticlockwise direction when unwinding.

3. Swivel guide rod to the unwinder axle as

illustrated [3] and shift it close to the material roll. Tighten the thumb screw again.

B

C

A

7

4. Lay the material around deflection rollers

[4A] and dancer arm [4B].

P Continued overleaf

[3] ALX92x with half used up label roll.

A

A

[4] Threading the label material around deflection rollers (A)

and dancer arm (B).

B

Page 8

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

5. Open the front cover.

6. Set the material guide to the width of the

label material. To do this loose n the thumb

screw [5A] at the front material guide, shift

the material guide [5B] crossways to the

feed direction and tighten thumb screw

again.

A

¯ The label material should slide easily

between the material guides.

B

[5] Adjusting the material guide (B).

7. Press the opener [6A] to raise the contact

rollers [6B]. Push the beginning of the

label material through underneath the contact rollers and the print head.

8

8. Position the contact rollers while pressing

down the opener [7].

¯ Both contact rollers should press down

the material symmetrically.

P Continued overleaf

B

A

[6] Inserting the label material at the print module.

[7] Positioning the contact rollers.

Page 9

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

9. Peel labels off the backing paper for a

stretch of appr. 50cm [8].

[8] Peeling some labels off .

10.Open the pressure roller lever [9A] by

pressing it downwards.

9

11.Pull the backing paper backwards underneath the printing module and insert it as

illustrated [9].

12.ALX925/926: Loosen the two thumb

screws [10B] at the spring-suspended

blocks. Position the spring-suspended

blocks [10A] in a way that the contact rolls

press symmetrically on the backing paper.

Retighten the thumb screws.

ALX924: Loosen the thumb screw [10B].

Position the spring-suspended block [10A]

in a way that the contact roll presses in the

middle on the backing paper . Retighten the

thumb screw.

A

[9] Threading the backing paper underneath the printing

module.

B

A

13.Tighten the backing paper backwards and

close the lever [11].

[10] Spring-suspended block (A) at a ALX924.

[11] Closing the pessure roller lever.

Page 10

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

14.Thread the backing paper around dancer

arm [12A] and deflection roller as illustrated [12].

10

15.Pull out the release button [12B].

16.Insert the end of the backing paper into the

rewinder as illustrated [13].

17.Push in the locking knob.

B

A

[12] Threading the backing paper around the tensioning arm

(A).

18.Turn the rewinder manually anti-clockwise

until the backing paper is tightened [14].

[13] Threading the backing paper around the rewinder.

[14] Tightening the backing paper.

Page 11

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Inserting ribbon

WARNING!

• Rotating parts can trap items and draw them in!

« When working on the printer, do not wear loose jewellery, long sleeves,

long hair, and similar.

« Close the devices cover before printing.

• During operation, the printhead can become hot.

« Be careful when touching the printhead!

¯ Skip this section if you intend to print

directly onto thermal material.

P For information on choosing a suitable

thermal transfer ribbon, refer to section

Selecting the printing material

on page 4.

11

Removing spent ribbon

CAUTION! - If the diameter of the

ribbon wound on the take-up roll

becomes too great, the machine’s

operation will be impaired.

« Always remove a used ribbon before

inserting a new ribbon roll.

Assuming spent ribbon has gathered on

the rewinding mandrel:

1. Remove the roll of used ribbon from the

rewinding mandrel.

2. Pull the empty ribbon core off the unwinding mandrel and put it on the rewinding

mandrel.

3. Put the ribbon roll on the unwinding

mandrel.

4. Insert the ribbon as described in the following.

Page 12

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Inserting a new ribbon roll

1. Open the hood.

2. Put the ribbon roll on the lower right ribbon

mandrel [15C]. Put an empty take-up roll

on the upper left ribbon mandrel.

B

¯ The ribbon must unwind anti-clockwise.

(Only valid for ribbon rolls which have the

coloured side facing inwards)

3. Guide the ribbon end under the ribbon

deflection [15B] and thread through to the

side of the printhead [15A].

4. Pull the ribbon under the printhead from

the side, then, unwinding some ribbon,

smoothen it out [16].

A

[15] Inserting the ribbon roll onto the ribbon unwinding mandrel

(C).

C

12

5. Draw ribbon upwards and guide it around

the ribbon roller [17A], the ribbon deflection roller [17B] and the strain relief [17C] .

6. Attach the ribbon end to the empty take-up

roll.

Winding direction: clockwise [18A].

A

[18] Winding direction of ribbon rewinding mandrel (A)

[16] Smoothening out the ribbon.

A

B

C

[17] A Ribbon roller

B Ribbon deflection roll

C Strain relief

Page 13

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Settings

Ribbon tension

To achieve an optimal print result, the

ribbon has to run without creases. This is

achieved by correctly setting the torque for

the rewinding mandrel and the braking

torque for the unwinding mandrel.

The factory settings cover a wide range of

different ribbon widths. Nevertheless,

adjustment can be necessary if very

narrow or very wide ribbons are being

used.

The braking torque of the ribbon mandrels

can be set by adjusting the red hexagonal

plastic nuts [19A] on the ribbon mandrels.

Turn clockwise to increase the torque.

Caps [19B] protect the nuts against being

adjusted by accident.

A

13

The ribbon must run evenly and free of

creases between the mandrels while being

fed through. The following indications can

help you correct the settings:

• The ribbon is slack or in folds or winds on

to the rewinding mandrel too loosely.

« Increase torque / braking torque (turn red

hex nut clockwise).

• The ribbon clearly stretches or it tears

during printing. The ribbon is not being

transported adequately.

« Decrease torque / braking torque (turn red

hex nut anti-clockwise).

B

[19] Ribbon mandrels on a ALX92x.

A Ribbon rewinding mandrel (without cap)

B Ribbon unwinding mandrel (without cap)

Page 14

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Label sensor

The ALX92x is equipped with a light transmission sensor for punch recognition:

Setting the label sensor

Turning the red adjustment wheel [20B]

moves the sensor up to 80mm (4“/5“

modules) or 100mm (6“ modules) across

the material. A dial [20A] displays the

value.

Reading the value:

14

Value = punch position – 2 mm

… whereby the following applies:

• Punch position:

Distance of the punch from the (inner) edge

of the material [21A].

• Value:

Value on dial, set by rotating the red wheel.

Example: Punch centre = 11 mm from the

left edge; subtracting 2 mm gives a value of

9mm.

« To make the setting, turn the wheel [20B]

until the desired value is aligned with the

mark [20A].

¯ Round labels: To ensure in those

cases, that the label start is correctly

identified, a punch offset can be preset.

This may be done by manually setting the

printer (Parameter

X - print offset

command.

) or by the appropriate control

PRINT PARAMETERS >

A

B

[20] Setting the label sensor

A Dial

B Adjustment wheel

A

[21] Measuring the punch position (A).

Page 15

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Adjustment button for printhead pressure

The material width and / or material

thickness influence the pressure applied by

the thermal transfer printhead on the print

roller.

There are three possible settings for

pressure [23]:

I Setting for thin / narrow material

II Setting for material of medium width /

thickness

III Setting for thick / broad material

Setting

The red adjustment knob [22A] [23] is

located above the ribbon roller in the front

plate and can be adjusted with a coin or

large screwdriver.

A

15

« To set medium pressure, turn the arrow

[23A] to position „II“ until it slots gently into

place.

« To set a higher pressure, turn the arrow to

position „III“ until it slots gently into place.

CAUTION! - Failure to set for the

correct pressure causes the printhead

to wear down more quickly and leads

thus to a shorter service life.

« Always select the lightest possible

pressure necessary to produce an

acceptable print result.

« Excessive pressure can lead to the

premature wearout of the printhead.

Factory settings

Setting „I“, for thin / narrow material

[22] A Adjustment knob for the printhead pressure

A

[23] A Adjustment knob for the printhead pressure

Page 16

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Dispensing edge

By inclining the dispensing edge, the

dispensing position can be fine adjusted

without having to change the machine

position:

1. Undo the screws [24B] on both of the side

mounting plates. Access the screws from

beneath.

Tool: 2.5mm Allen key

2. Turn the dispensing edge [24A] to the

desired position.

3. Tighten the screws.

16

Dispenser parameters

Set the following parameters prior to first

operating the machine.

• PRINT PARAMETERS > Dispense Mode

Determines sequence of the printerdispenser process (normal 1:1 mode,

batch mode or true 1:1 mode)

• PRINT PARAMETERS > Dispenseposition

Setting the adhesive edge, with which the

label after dispensing adheres to the

backing paper[25].

• SYSTEM PARAMETER > Start source

Setting the trigger signal source for the

printer-dispenser process (foot switch,

sensor or USI)

P For details on how to set parameters, refer

to Informa tion on printouts and parameters

in the “Using the Parameter Menu” section.

A

[24] Long dispensing edge (option) (feed roller disassembled

for better viewing).

Dispensed label

Dispensing edge

[25] Dispensing position (=home position) shown schematically.

Dispense position

Backing paper

B

Z0040E.cdr

Page 17

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Material Parameters

Using the following parameters, you can

tell the device which kind of labelling

material is supposed to be processed:

• PRINT PARAMETERS > Material type

Sets material type (punched or endless).

• PRINT PARAMETERS > Material length

Sets material length (measured from label

start to label start, that is label length plus

one gap length). Setting not relevant for

endless material.

• PRINT PARAMETERS > Material width

Sets material width.

P For details on how to set parameters, refer

to Informa tion on printouts and parameters

in the “Using the Parameter Menu” section.

17

Page 18

06/06 Rev. 3.05-01 OPERATING MANUAL Setup

ALX 92x

Index

18

B

Backcoating

Braking torque, ribbon 13

D

Direct thermal printing

H

Hexagonal plastic bolt, red

I

Inserting ribbon

L

Label material

Label sensor, setting 14

5

11

4

4

13

R

Ribbon mandrels

Ribbon slack 13

Ribbon tears 13

Ribbon tension 13

S

Setting material parameters

Setting the dispenser parameters 16

Setting the label sensor 14

Setting the printhead pressure 15

T

Thermal transfer printing

Torque, ribbon 13

W

Wheel for setting label sensor

Winding diagram 2

13

17

4

14

Loading...

Loading...