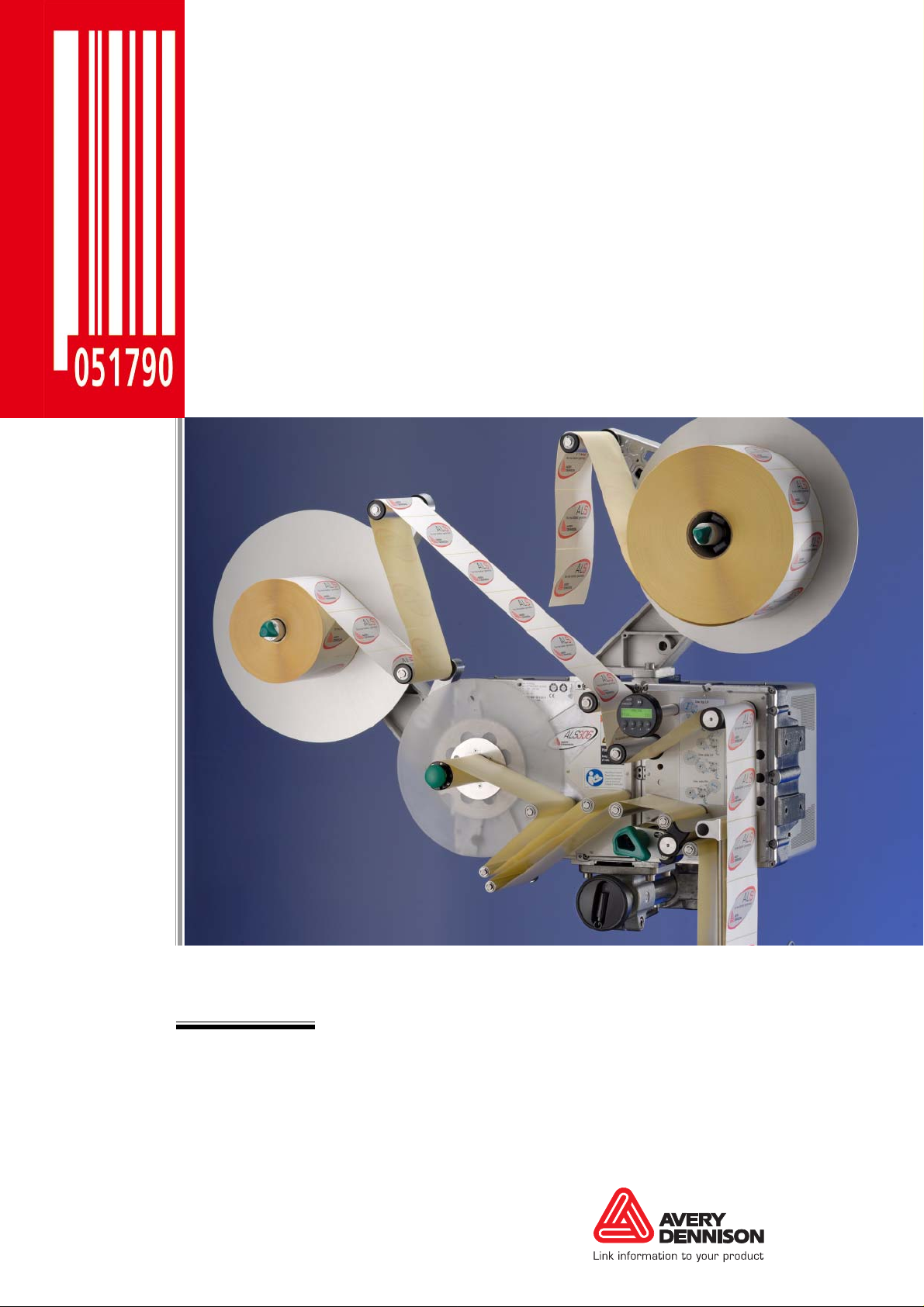

Page 1

USER MANUAL

Label Dispenser

ALS

306

309

Edition 05 (10/08)

Page 2

CONTENTS

ALS

306

309

GB

1 Please note

1.1 General notes

1.1.1 Validity and binding effect of this manual . . . . 5

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Technical status . . . . . . . . . . . . . . . . . . . . . . . . .5

Copyright. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1.2 Illustrations and descriptions. . . . . . . . . . . . . . 6

Signs and symbols . . . . . . . . . . . . . . . . . . . . . . . 6

Dangers and risk notes . . . . . . . . . . . . . . . . . . . .6

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Button symbols . . . . . . . . . . . . . . . . . . . . . . . . . .6

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Supplementary information . . . . . . . . . . . . . . . . .6

1.2 Safety instructions

1.2.1 Information and qualifications. . . . . . . . . . . . . 7

Follow the instructions. . . . . . . . . . . . . . . . . . . . .7

Keep the product information at hand. . . . . . . . . 7

Ensure the required qualifications are met . . . . .7

1.2.2 Operational safety of the unit . . . . . . . . . . . . . 8

Proper usage. . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Protection against injuries by electrical current. .8

Protection against injuries by mechanical action.9

Protection against injuries by chemicals . . . . . . .9

1.2.3 Before beginning production. . . . . . . . . . . . . 10

Due diligence of the operating company and the

service technician . . . . . . . . . . . . . . . . . . . . . . .10

Due diligence of the user. . . . . . . . . . . . . . . . . .10

1.2.4 Safety notes on the unit . . . . . . . . . . . . . . . . 11

2 Product description

2.1 Overview

2.1.1 Components . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.2 Control panel. . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating LED. . . . . . . . . . . . . . . . . . . . . . . . . .14

Error LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

LCD display. . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.1.3 Connection arrangement . . . . . . . . . . . . . . . 15

Connections on the rear side of the device. . . .15

2.1.4 Mode of operation. . . . . . . . . . . . . . . . . . . . . 16

2.1.5 Technical specifications. . . . . . . . . . . . . . . . 17

Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . .17

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Label sensor . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . .17

Electronics. . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Internal Interfaces . . . . . . . . . . . . . . . . . . . . . . .18

Status messages, test functions,

product profiles . . . . . . . . . . . . . . . . . . . . . . . . .18

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Environmental conditions . . . . . . . . . . . . . . . . .19

Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Certificates. . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.1.6 Design models . . . . . . . . . . . . . . . . . . . . . . . 20

2.2 Options

External control panel . . . . . . . . . . . . . . . . . . . .21

Fixed dispensing edge. . . . . . . . . . . . . . . . . . . .21

Swivelling dispensing edge . . . . . . . . . . . . . . . .21

Spring-loaded dispensing edge. . . . . . . . . . . . .21

Pneumatic dispensing edge . . . . . . . . . . . . . . .22

Outer diameter control sensor. . . . . . . . . . . . . .22

Cable kit for internal outer diameter control. . . .22

Additional material guide disk . . . . . . . . . . . . . .23

Capacitive label sensor . . . . . . . . . . . . . . . . . . .23

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Applicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Applicator interface . . . . . . . . . . . . . . . . . . . . . .23

2.3 Operating modes

2.3.1 Dispensing mode . . . . . . . . . . . . . . . . . . . . . 24

Stopping/Continuing the dispensing mode . . . .24

Changing the counter reading . . . . . . . . . . . . . .24

Starting the unit in configuration mode . . . . . . .24

Counting labels backwards . . . . . . . . . . . . . . . .24

Online settings. . . . . . . . . . . . . . . . . . . . . . . . . .25

2.3.2 Configuration mode . . . . . . . . . . . . . . . . . . . 26

Function of the double-arrow button . . . . . . . . .26

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.4 Function descriptions

2.4.1 Overview of functions. . . . . . . . . . . . . . . . . . 28

2.4.2 Notes on function descriptions. . . . . . . . . . . 30

2.4.3 LABEL SETUP menu. . . . . . . . . . . . . . . . . . 30

2.4.4 MACHINE SETUP menu . . . . . . . . . . . . . . . 31

3

Page 3

CONTENTS

ALS

306

309

GB

3 Before operation

3.1 Electrical connections

3.1.1 Power supply connection . . . . . . . . . . . . . . . 32

Connecting the power cable . . . . . . . . . . . . . . .32

Disconnecting the power cable . . . . . . . . . . . . .32

3.1.2 Connecting sensors . . . . . . . . . . . . . . . . . . . 33

3.2 Inserting label material

3.2.1 Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . 34

3.2.2 Inserting a label roll. . . . . . . . . . . . . . . . . . . . 35

Removing spent backing paper. . . . . . . . . . . . .35

Removing glue residue . . . . . . . . . . . . . . . . . . .35

Inserting a new label roll . . . . . . . . . . . . . . . . . .35

3.2.3 Threading diagrams . . . . . . . . . . . . . . . . . . . 36

Threading the label web at the dispensing

edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Threading the label web onto the drive roller . . 40

Threading the label web to the rewinder. . . . . . 40

3.3 Mechanical settings

3.3.1 Adjusting the unwinder’s core diameter . . . . 41

3.3.2 Positioning the pressure roller . . . . . . . . . . . 41

3.3.3 Positioning the label sensor . . . . . . . . . . . . . 42

3.3.4 Setting the dancer arm restoring force . . . . . 42

4.3 Using product profiles

4.3.1 What are product profiles?. . . . . . . . . . . . . . 50

4.3.2 Loading a product profile . . . . . . . . . . . . . . . 50

4.3.3 Storing a product profile. . . . . . . . . . . . . . . . 50

Selecting the memory location . . . . . . . . . . . . .50

Entering profile names. . . . . . . . . . . . . . . . . . . .50

4.3.4 Deleting a product profile. . . . . . . . . . . . . . . 51

5 After operation

5.1 Maintenance and cleaning

5.1.1 Cleaning agents. . . . . . . . . . . . . . . . . . . . . . 52

5.1.2 Regular maintenance. . . . . . . . . . . . . . . . . . 53

Removing paper debris . . . . . . . . . . . . . . . . . . .53

Renewal of the dust filter liner . . . . . . . . . . . . . .53

6 Operational failures

6.1 Status messages

6.1.1 Types of status messages . . . . . . . . . . . . . . 54

Error messages. . . . . . . . . . . . . . . . . . . . . . . . .54

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.1.2 List of warnings . . . . . . . . . . . . . . . . . . . . . . 54

6.1.3 List of error messages . . . . . . . . . . . . . . . . . 55

4 Operation

4.1 Start-up and shutdown

4.1.1 Turning on the unit . . . . . . . . . . . . . . . . . . . . 43

4.1.2 Starting label dispensing. . . . . . . . . . . . . . . . 43

Dispensing with a product sensor . . . . . . . . . . .43

Dispensing without a product sensor . . . . . . . .43

4.1.3 Stopping the dispensing process . . . . . . . . . 44

4.2 Configuration and monitoring

4.2.1 Function menu settings. . . . . . . . . . . . . . . . . 45

Label pitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Label stop position . . . . . . . . . . . . . . . . . . . . . .45

Dispensing speed . . . . . . . . . . . . . . . . . . . . . . .46

Suppressing start signals . . . . . . . . . . . . . . . . . 46

Label position on the product . . . . . . . . . . . . . .47

4.2.2 Monitoring functions . . . . . . . . . . . . . . . . . . . 48

Material end / Roll diameter . . . . . . . . . . . . . . .48

Missing labels . . . . . . . . . . . . . . . . . . . . . . . . . .49

Material tear . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4

Page 4

1PLEASE NOTE

ALS

306

1.1 GENERAL NOTES

1 PLE ASE NOTE

1.1 GENERAL NOTES

1.1.1 Validity and binding effect of this manual Contents

The present manual refers exclusively to the ALS 30x

label dispensers. It is written for the purpose of

ensuring professional usage and calibration of the unit.

Prerequisites for the use and adjustment are the

professional installation and configuration of the unit.

For any technical questions you may have that are not

described in this manual, see:

£ The service manual of the label dispenser

or

£ Request a technician from one of our sales partners.

– Our sales representatives are available to assist

you, particularly with configuring the unit as well as

in the case of malfunctions.

Technical status

Copyright

Avery Dennison holds all rights to this manual and its

appendices. Reproduction, reprinting or any other

types of duplication, even of portions of this manual,

may only be carried out with express written consent.

Third persons, in particular competitors, should not be

given access to the information in this manual.

Printed in Germany

Manufacturer

Avery Dennison Deutschland GmbH

Ohmstrasse 3

85386 Eching, Germany

Phone: +49-8165-925-0

Fax: +49-8165-3143

http://www.machines.averydennison.com

309

GB

Technical status: 10/2008

Software version: 1.33

Avery Dennison reserves the right:

– To make modifications to construction parts,

components and software, as well as to employ

comparable components in place of the parts

specified, in keeping with technical advances.

– To modify information in this document.

No commitment will be made to expand these

modifications to include any units delivered earlier.

5

Page 5

1PLEASE NOTE

ALS

306

1.1 GENERAL NOTES

1.1.2 Illustrations and descriptions Signs and symbols

Various information types are indicated in diff er en t

ways within the document in order to simplify

readability and comprehension.

Sentences starting with an arrow are instructions and

guidelines.

£ Perform the instructions one after another in the

specified order.

The following information begins with a dash:

–Lists

– Mode descriptions

– Descriptions of prior steps

– Prerequisites for following actio ns

Dangers and risk notes

309

GB

Figures

Texts are accompanied by figures where necessary.

Figures are indicated using figure numbers in [square

brackets]. A capital letter after a figure number, for

example [12A], refers to a specific section of the figure.

Generally, the label dispenser shown is a right-handed

version. The left-handed version is only shown where it

is necessary to differentiate between the two.

Button symbols

– The buttons of the control panel are depicted as

symbols.

– The symbols are depicted with a ‘+’ (PLUS SIGN)

between them if more than one button is to be

pressed. +

Important directions that you must absolutely observe

are particularly emphasized:

WARNING!

A warning refers to risks that can lead to

serious injury or death! The warning

contains safety measures to protect the

relevant persons.

£ Always follow the instructions.

CAUTION!

A caution indicates risks that can lead to

property damage or injuries to persons

(minor injuries). The caution note contains

instructions for preventing da ma ge s .

£ Always follow the instructions.

Parameters

Parameters are displayed in grey in the text with the

following structure, MENU NAME > Function name.

Supplementary information

The expert symbol indicates actions that are

only to be performed by qualified and specially

trained personnel.

The information symbol indicates notes and

recommendations, as well as additional

information.

Equipment:

– Equipment, for example lubricants or

cleaning agents

6

Page 6

1PLEASE NOTE

ALS

306

1.2 SAFETY INSTRUCTIONS

1.2 SAFETY INSTRUCTIONS

1.2.1 Information and qualifications Follow the instructions

WARNING!

Safe and efficient operation of the label

dispenser can only be guaranteed if you

observe all necessary information.

Product liability and warranty claims can

only be asserted if the unit was operated in

accordance with the directions in the

manual.

£ Before operating the unit, read the oper-

ating instructions and all other notes

carefully.

£ Observe the additional safety and warn-

ing notes on the label dispenser.

£ Only permit competent people to opera te

and configure the label dispenser.

Keep the product information at hand

With respect to this manual:

£ It should be kept at the location where the

unit is installed and be available to the

operator.

£ It should always be legible.

£ If the unit is sold, the manual should be made

available to the new owner.

£ The safety and warning notes affixed to the

unit itself must be kept clean and legible.

Missing or damaged signs must be replaced.

309

GB

Ensure the required qualifications are met

£ Ensure that only trained and authorized personnel

operate, configure and service the un it.

£ Only allow qualified and well-trained expert

personnel or service technicians to perform

configurations.

£ The responsibilities with regard to operation,

configuration and maintenance shou ld be cl ea rly

defined and consistently maintained.

£ In addition, personnel should also be instructed on

a regular basis in matters of occupational safety and

environmental protection.

Qualification for operation

The instruction of personnel using the unit must ensure

that:

– The operating personnel can use the unit on their

own and safely.

– The operating personnel can remedy small

operational disruptions on their own.

£ At least two people must be instructed in the unit’s

usage.

£ Enough label material must be provided for testing

and instructional purposes.

Qualifications for configuring

The configuration of the controls requires qualified expertise:

– Personnel configuring the unit must be

acquainted with the functionality of the label

dispenser.

– Personnel configuring the unit must be

acquainted with the modes of operation

within the facility in which the label dispenser

is integrated.

– The personnel co nfiguring the unit must be

able to use the additional menus properly

and appropriately for specific project

requirements.

7

Page 7

1PLEASE NOTE

ALS

306

1.2 SAFETY INSTRUCTIONS

1.2.2 Operational safety of the unit Proper usage

The label dispenser is a fully automatic unit for attaching self-adhesive labels to products or packaging.

The company operating the unit must install it with suitable equipment to protect operating personnel from

danger; for example, the danger of the hands or fingers

being crushed by reaching in between the pro duct and

the dispensing edge.

WARNING!

Improper usage of the unit can cause

accidents, property damage and production

downtime!

£ Only use the unit in accordance with the

instructions specified in this manual.

£ Do not operate the unit without the re-

quired safeguards.

£ Only configure the unit in accordance

with this manual and with the required

care.

£ Only use original accessories.

£ Do not make any modifications or altera-

tions to the unit.

£ Repairs to the device may only be per-

formed by authorised specialists who are

aware of the risks involved.

309

GB

£ Only link the unit to devices that fulfil the

SELV (safety extra-low voltage) circuit requirements specified in EN60950.

£ Make sure that the power switch at the

machine is accessible.

£ In case of emergency, switch off the de-

vice.

WARNING

The unit is not protected against splashing

water in its standard model.

£ Keep the unit dry.

£ If liquids have penetrated the unit, switch

it off and disconnect or unplug the power

cable immediately. Inform a service technician.

CAUTION

A too high or low supply voltage can damage

the unit.

£ Only operate the device using the system

voltage indicated on the nameplate.

£ Ensure that the mains voltage set on the

unit is the same voltage as that provided

by the electricity supplier.

Protection against injuries by electrical current

WARNING!

The machine operates using mains voltage!

Touching live electrical parts may exp os e

you to hazardous electrical currents and

may lead to burns.

£ Only operate the unit once the housing

has been reassembled properly.

£ The machine may only be connected by

authorised specialists, who are aware of

the risks involved.

£ Before cleaning, switch off the unit and

remove the power cable from the socket.

8

Page 8

1PLEASE NOTE

ALS

306

1.2 SAFETY INSTRUCTIONS

Protection against injuries by mechanical action

WARNING!

Risk of injury due to moving and rapidly

rotating parts!

– Long hair, loose jewellery, long sleeves,

and so on are not permissible when using

the unit.

£ Sufficient protective clothing must be

worn.

£ Keep moving parts free from obstruc-

tions even when the unit is not switched

on, if there is a chance the machine might

be turned on.

£ Switch off the machine before making

any mechanical settings.

£ Do not wear ties, loose clothing, jewel-

lery, wrist watches or similar items on

your person when near the operating

unit.

309

GB

WARNING!

There is a risk that you may get your fingers

or hands crushed on the dispensing edge by

products on the conveyor belt!

£ Never reach between the product and the

dispensing edge while the unit is in operation or ready for operation.

£ Never reach behind the safety guard or

remove it while the unit is in operation.

Protection against injuries by chemicals

CAUTION!

Operating materials such as cleaning agents

or the solvents in glues can be damaging to

health.

£ Always follow the instructions, use and

safety regulations specified by the manufacturer!

9

Page 9

1PLEASE NOTE

ALS

306

1.2 SAFETY INSTRUCTIONS

1.2.3 Before beginning production Due diligence of the operating company

and the service technician

£ Ensure that the following prerequisites are fulfilled in

accordance with the service instructions:

– The machine is installed properly and configured in

accordance with the guidelines.

– All required safety mechanisms ha ve been installed.

– The unit has perform ed at least one successfu l test

run.

– The unit is connected to the power supply.

£ The users have the required personal protective

equipment, for example, a hairnet. Ensure that the

protective equipment is utilised correctly.

309

GB

Due diligence of the user

£ Check that the safety installations are working

properly.

£ Inspect the machinery for any visible damage.

Report any ascertained defects immediately.

£ Use the required personal protective equipment

correctly, for example, wear a hairnet.

£ Remove any unnecessary materials and objects

from the operating area of the unit.

£ Ensure that only authorised persons are with in th e

operating range of the machine.

£ Ensure that starting up the machine will not injure

anyone.

10

Page 10

1PLEASE NOTE

ALS

306

1.2 SAFETY INSTRUCTIONS

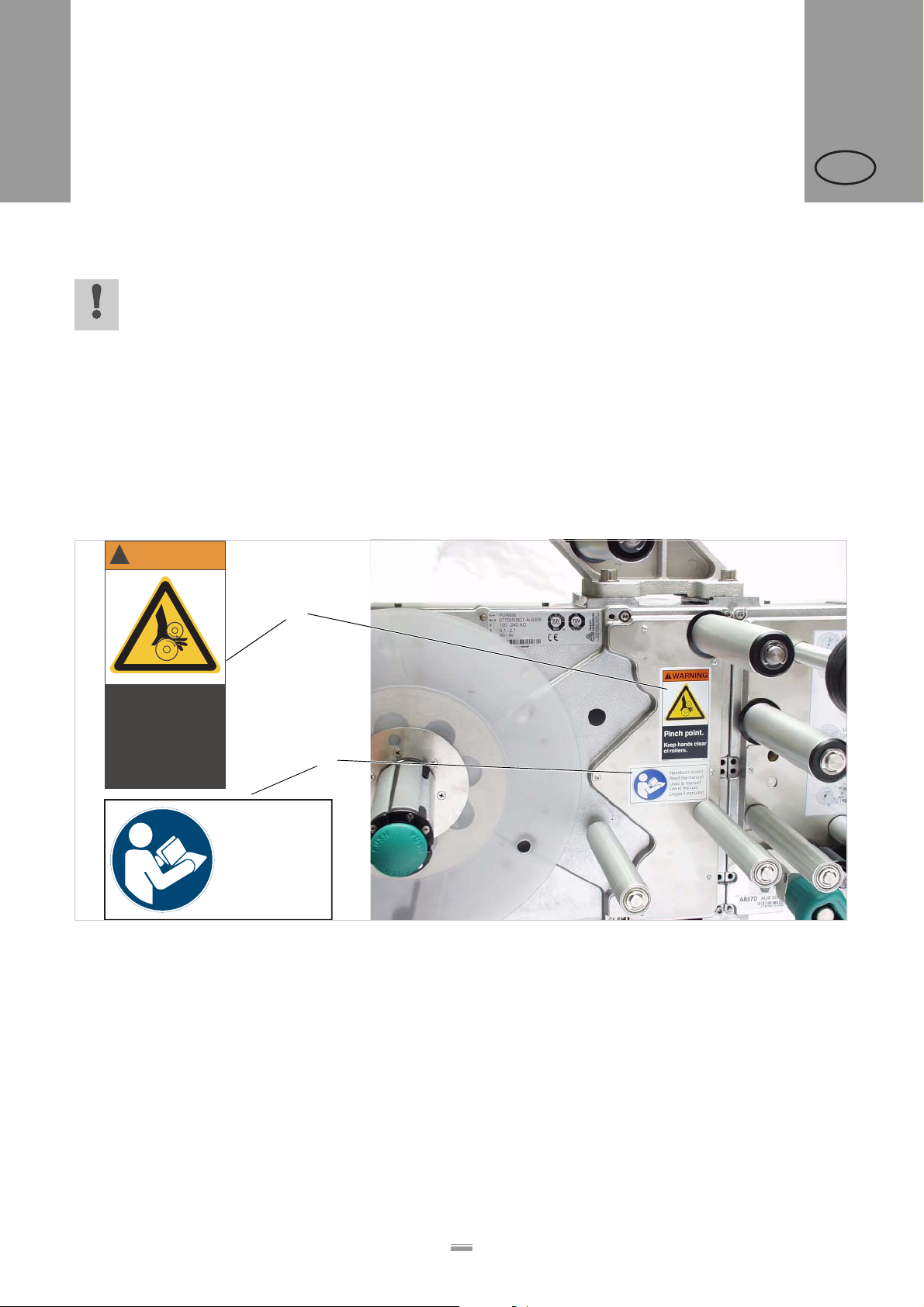

1.2.4 Safety notes on the unit

CAUTION!

Warning notes on the unit represent

important information for the personnel

using it.

£ Do not remove warning notes.

£ Replace any missing or illegible

warnings.

The ‘Pinch Point’ warning [1A] note warns you of the

danger posed by the machine’s ro tating parts; they can

trap items and draw them in.

The blue label ‘Read manual’ [1B] demands that users

read the unit instructions.

!

WARNING

309

GB

A

Pinch point.

Keep hands clear

of rollers.

A5346

Handbuch lesen!

Read the manual!

Lisez le manuel!

Lea el manual!

Legga il manuale!

[1] A Left: ‘Pinch Point’ warning. Right: Position of the warning note

on the ALS30x. Item number of the label: A5346.

B Left: ‘Read manual’ notice. Right: Position of the notice on the

ALS30x. Item number of the label: A5331.

B

11

Page 11

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

2 PRODUCT DESCRIPTION

2.1 OVERVIEW

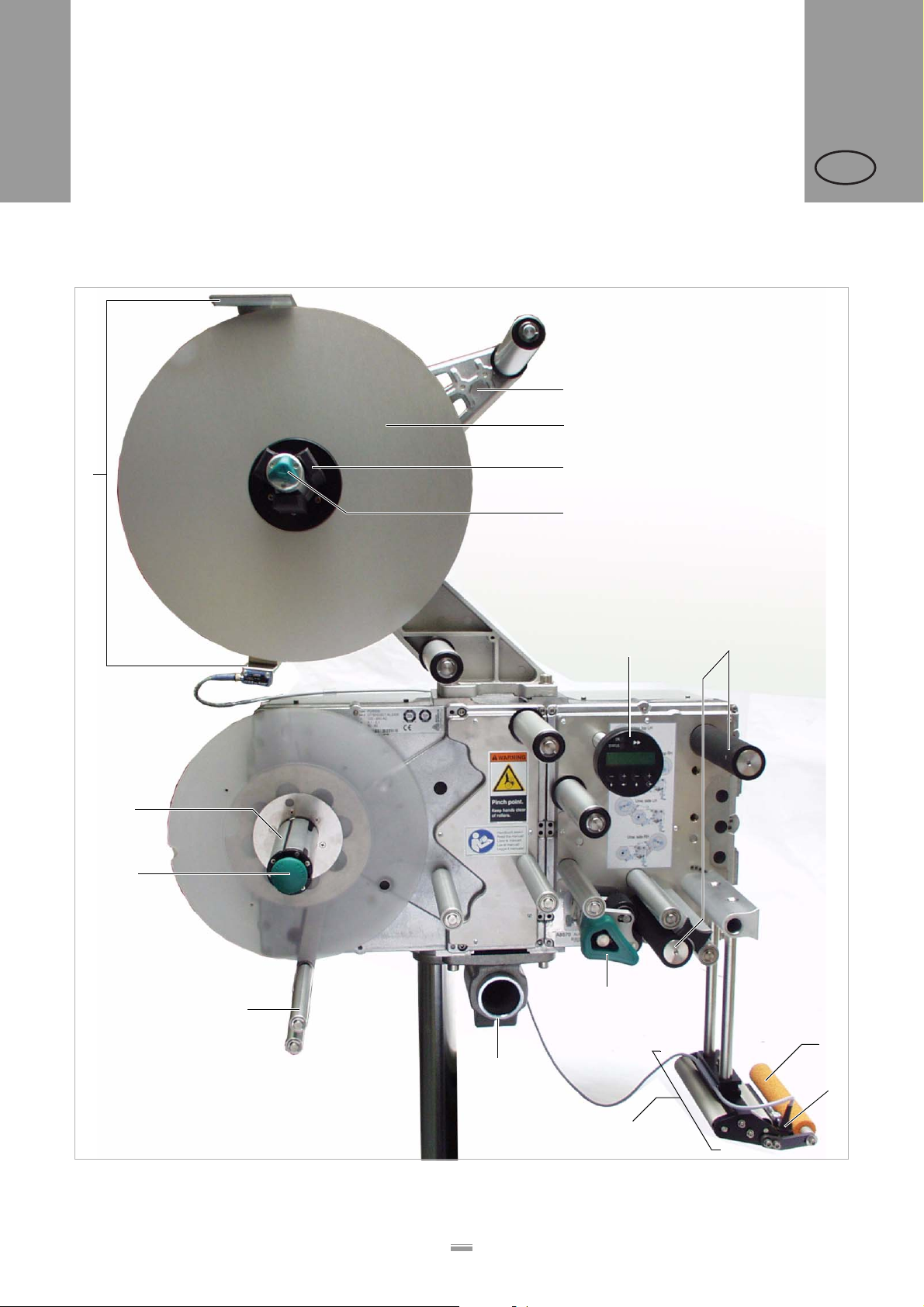

2.1.1 Components

O

309

GB

A

B

C

D

N

M

E

L

K

J

F

G

H

[2] ALS306 Label Dispenser (right-handed version).

I

12

Page 12

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

A Dancer arm

– Keeps the label material stretched tight evenly.

– Arrests the rotation of the material roll if tension

diminishes.

B Unwinder

– Spread core mandrel grasps the label roll.

C Core diameter adapter

– For adjusting the diameter of the dispenser mandrel

to match the core diameter of the label roll.

D Adjusting knob

– Turning this in a clockwise direction secures the

label roll on the unwinder.

E Control panel

– For sending commands to the device and for

displaying operating states and error messages.

– An optional external control panel can also be

connected to the device.

F Drive roller

– Drives the label material forwards.

G Pressure roller

– Prints the label once it is stuck to the product.

H Label sensor

– Stops the label feed after a label has been

dispensed.

309

GB

I Dispensing edge

– Pictured: fixed L-shape dispensing edge.

– Optional available are: swivelling L-shape

dispensing edge, spring-loaded L-sh ape dispensing

edge, pneumatic L-shape dispensing edge.

J Pressure mechanism

– Presses the pressure roller against the drive roller.

– Prevents the backing paper from slipping through.

– Releases automatically once the backing paper has

been drawn around the drive roller.

K Mounting flange

L Dancer arm

– Controls the rewind speed.

M Release button

– Pressing this button reduces the diameter of the

rewinder core.

– Allows the easy removal of the rewound backing

paper.

N Rewinder

– Rolls up the used backing paper.

O External roll diameter sensor (option)

– Generates a warning signal, if the critical roll diame-

ter is reached.

13

Page 13

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

2.1.2 Control panel

Operating LED

Lights up green when the device is switched on.

Error LED

Lights up red when an error occurs.

LCD display

– Displays functions, configured values, operating

states and error messages.

– What is displayed at any one time depends on the

operating status of the device; these screens are

explained in the section “Operating modes” on

page 24.

A

B

C

D

[3] The ALS30x control panel (in dispensing mode)

A Operating LED

B Error LED

C LCD display

D Buttons

ON

STATUS

Labels

–

Online

+

–

292

+

309

GB

Buttons

The functions of the buttons depend on the operating

status of the device; these functions ar e exp la ine d in

the section “Operating modes” on page 24.

Language

– The display language can be selected from a choice

of 7 languages.

– Default setting is English

– For selecting another language see chapter

“Functions” on page 27

14

Page 14

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

2.1.3 Connection arrangement

Connections on the rear side of the device

A Label sensor

B Product (start) sensor

C Rotary encoder (for automatic speed adaption)

D Alternative label sensor

E Roll diameter sensor (for external OD-control on

unwinder 1 or 2)

F Signal inputs (optional)

G Signal outputs (optional)

A B C

F

I

G

309

GB

S

M

ED

H

L

N

KJ

H not applied

1)

IOD

J OD-sensor 1

K OD-sensor 2 (for internal OD-control on unwin-

L OD-sensor 2

M PLC signal interface

N USB device interface

O Plug-in card slot (CompactFlash cards)

P Connection for external control panel (RS485)

Q Serial interface (RS232)

R Network connection (Ethernet 10/100)

S Optional: Applicator Interface (AI)

T Power supply connection

-sensor 1 (for internal OD-control on unwin-

der 1)

der 2)

For information on connecting the unit see

chapter “Power supply connection” on

page 32.

T

[4] Connections on the machine rear side.

O

P

Q

R

For information on connecting the sensors

see chapter “Connecting sensors” on

page 33.

1) OD = Outer Diameter

15

Page 15

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

2.1.4 Mode of operation

In labelling mode, the label web is first pulled from the

label roll around the dancer arm [5A], which consistently maintains even tension in the label web. The feed

rollers [5D] in front of and behind the dispensing

edge [5C] draw the label web across the dispensing

plate. The label is peeled from the backing paper on the

dispensing plate and is pressed onto the product by the

pressure roller [5B].

The feed roller drives the label web forwards the length

of one label and stops until the next product arrives at

the dispensing plate. The feed is started by the product

sensor mounted on the conveyor belt. The stop control

provided by the label sensor on the dispensing edge

ensures the feed is halted as soon as a gap is detected

between two labels.

E

309

GB

A

D

The spent backing paper runs from the dispensing

edge around the drive roller [5D] to the rewinder [5E].

The dancer arm regulates the rewinding speed.

The entire operation of the label dispenser is controlled

and monitored electronically. If errors occur, the d evice

controls output an appropriate notification for the operator. If necessary, the labelling operating mode is halted automatically. An electronic signal is output at the

same time. The signal can be fed to an external controller and evaluated.

D

B

C

[5] The ALS30x Label Dispenser is ready for operation in its

idle mode.

A Dancer arm

B Pressure roller

C Dispensing edge

D Drive rollers

E Rewinder

16

Page 16

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

2.1.5 Technical specifications

Characteristics

Dispensing speed 1):

ALS306

ALS309

Labelling halt precision

the peeling edge:

Variable speed:

Constant speed:

Speed control: Fixed setting or automatic

Precision internal

OD-control

1) The maximum usable dispensing speed depends on the label geometry.

max. 60m/min

max. 45m/min

at

< ±1mm

< ±0.5mm

speed adaption via the

rotary encoder

OD ±3%

Label sensor

Distance to peel edge

L-shape dispensing

edge: 19mm

Transmission sensor: Wenglor OPT242-P800

optical, NPN

Power supply

System voltage: 100-240V (AC) at

60/50Hz power frequency (permissible tolerance

±10%)

Current consumption: max. 5.1A at 100 V

max. 2.1A at 240V

Power consumption: max. 510VA

309

GB

Labels

Label material: Converted self-adhesive

label material with liner

Internal rewinding yes

Material passage width

ALS306

ALS309

Minimum label width: 20 mm

Label length: 20 - 600mm

Label roll:

Winding direction

Unwinder (outer) Ø:

Rewinder (outer) Ø:

Core (inner) Ø:

2) Material passage width = Width of Label + Liner. Depending on the

dispensing edge width.

2)

:

up to 160mm

up to 233mm

inner or outer

up to 400mm

up to 270mm

38.1/76.2 /101.6mm

(1.5/3 /4")

Fuses: Fuses integrated in the

power supply

3) Not accessible for user or service technician.

3)

Electronics

Processor: 32Bit CPU MIPS Core

RAM: 16MB

ROM: 4MB

Realtime-clock none

Control panel: graphical display with

128x32 pixels, 2/4 lines,

5 buttons

17

Page 17

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

Interfaces Internal Interfaces

Sensor interfaces for

external sensors

Label sensor:

Alternative label

sensor:

Product sensor:

APSF-sensor (Rotary

encoder):

External OD-control

sensor:

Internal sensor inter-

faces:

Material unwinder

(plug in each case 4pin M12)

Wenglor OPT242-P800

optical, NPN, 24V, controllable sensitivity

PNP/NPN, 24V

PNP/NPN, 24V

single-phase/two-phase,

PNP/P-P, 24V, max.

20kHz

PNP, 24V

Light barrier

RFID Connection for RFID

Applicator Interface Connection for Applicator

4) Not yet available

Status messages, test functions, product profiles

Automatic halt, if ... the label roll is spent or

Test functions: Automatic diagnostics

309

GB

read/write unit (special

equipement)

Interface (AI) board (special equipement)

no gap was found.

...the max. admissible

number of missing labels

is reached.

check when switched on

4)

Pressure roller

Dancer arm

PLC interface

Outputs:

Inputs:

Data interfaces:

Serial:

Ethernet:

USB:

not used

bi-phase light barrier en-

coder

D-Sub15, optically insu-

lated, optionally via two

8-pin M12 (separate inputs/outputs in each

case)

4x PNP, 24V, a maximum of 500mA/channel,

total permissible output

current: 1500mA

3x PNP/NPN, 24V

RS232C (D-Sub 9),

max. 115200 Baud

10/100 BaseT (RJ45)

Device V1.1 (USB B),

‘Full speed’ operating

mode, 12MBit/s

Output of system data via

data interface

Status indicators: Label counter

Operating hours counter

Storage locations for

product profiles:

up to 16

Dimensions

Width x height x depth:

ALS306

ALS309

Weight:

ALS306

ALS309

5) Measurements without the dispensing edge bracket and dispensing edge

6) without unwinder

7) with unwinder on top side

5)

726 x 389 x 386mm

726 x 802 x 386mm

726 x 389 x 470mm

726 x 802 x 470mm

54kg

56kg

6)

7)

6)

7)

CF card:

Control panel

interface:

Slot for 1 CompactFlash

card

RS485 (Mini DIN 6 connection) for remote control

18

Page 18

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

Environmental conditions

Operating temperature: 5 to 40°C

Humidity: 30 to 85%, (non-con-

densing)

Noise

(at a distance of 1m):

Protection class: IP 21

Integration

Mounting positions: side / bottom / rear

Labelling positions: top / side / bottom

Holder for L-shape

dispensing edges:

L-shape dispensing

edges:

72dB(A)

Short holder (single

mounted):

Pivotable in steps of 15°

in a range of 0° to 90°.

Long holder (double

mounted):

Pivotable: 0° or 90°.

Optional:

–Fixed

– Swivelling

– Spring-loaded

– Pneumatic

309

GB

Certificates

– CE, TÜV/GS, FCC, CCC, GOST, NRTL, US/CA

– The regulation DIN EN 55022 demands for class A

devices the following text to be printed in the

manual:

„WARNING: This is a class A product. In a domestic

environment this product may cause radio

interference in which case the user may be required

to take adequate measures.“

– The FCC regulation demands the following

information text for class A devices:

„NOTE: This equipment has been tested and found

to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment is

operated in a commercial environment. This

equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference in which case

the user will be required to correct the interference

at his own expense“

19

Page 19

2PRODUCT DESCRIPTION

ALS

306

2.1 OVERVIEW

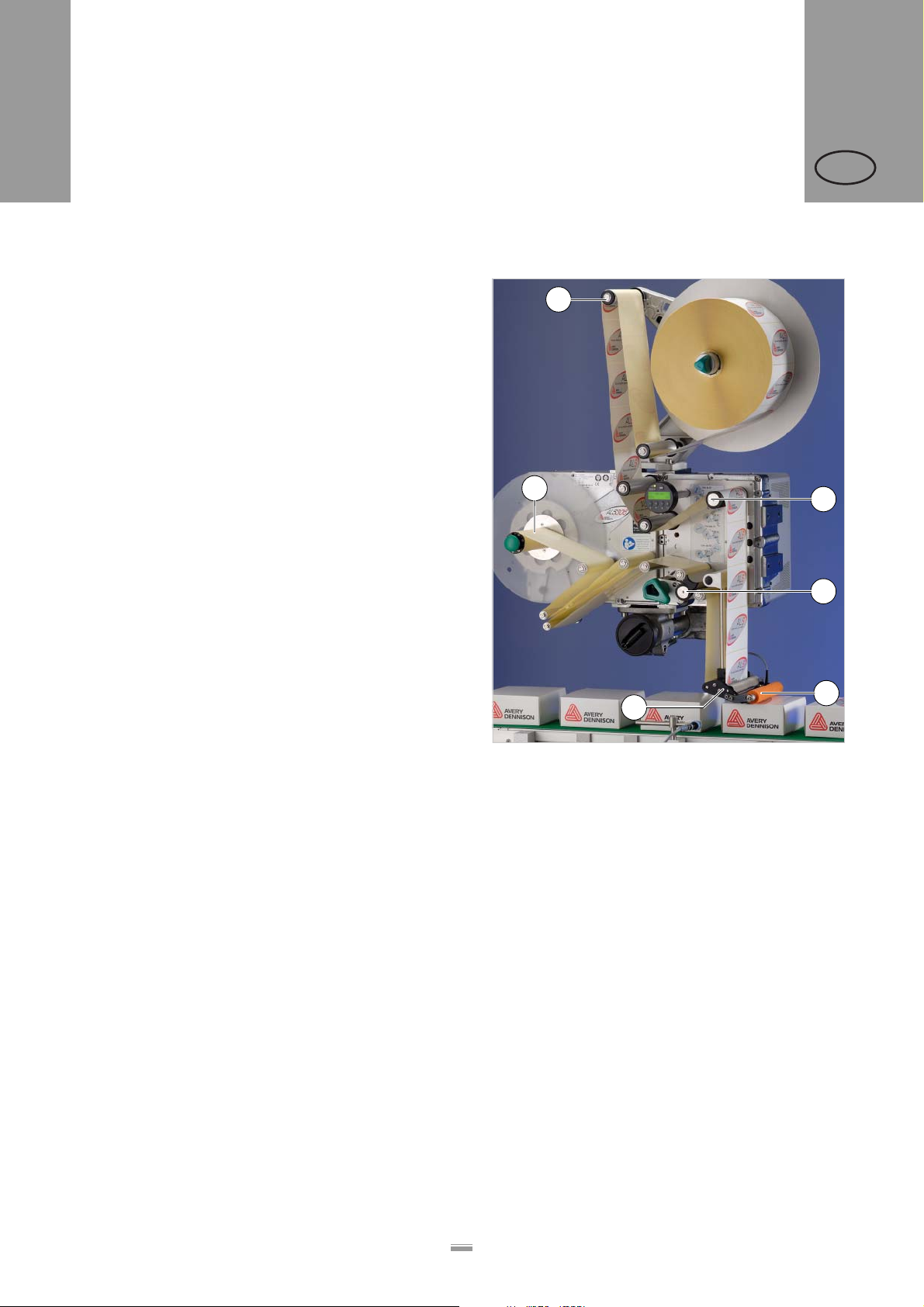

2.1.6 Design models

The ALS30x can be adapted to client requirements under several aspects:

Aspect Adaption

Conveyor direction Right-handed (RH) /

Left-handed (LH) machine

Mounting position

of the machine

Mounting point at

the machine

Unwinder amount 1/2

Unwinder moun-

ting point

Horizontal / vertical

Top / side labelling

Top / bottom / right / left / rear

side

Top (right / left)

Side (right / left)

309

GB

The label dispenser operation described in this

manual is based on the right-handed version

with the features pictured in [6]. Other versions

are only taken into account if the explanations

or figures of the designs differ significantly.

[8] ALS30X (RH) with the following features:

Conveyor direction = from left to right

Mounting position = vertical / side labelling

Unwinder amount = 1

Unwinder mounting point = top right

[6] ALS30X (RH) with the following features:

Conveyor direction = from left to right

Mounting position = horizontal / top labelling

Unwinder amount = 1

Unwinder mounting point = top left

[7] ALS30X (LH) with the following features:

Conveyor direction = from right to left

Mounting position = horizontal / top labelling

Unwinder amount = 2

Unwinder mounting point = lateral left and right

20

Page 20

2PRODUCT DESCRIPTION

ALS

306

2.2 OPTIONS

2.2 OPTIONS

External control panel

– An external control panel can be connected in

addition to the integrated control panel.

– An external control panel is useful if the standard

control panel is difficult to access due to the position

in which the unit is installed.

Fixed dispensing edge

– The dispensing edge has a fixed connection to the

brackets.

– To adjust the vertical position, lift/lower the entire

device.

– The slope angle can be adjusted by rotating the

brackets (see the service manual for further details).

309

GB

[9] External control panel

Swivelling dispensing edge

– The position of the dispensing edge can be adjusted

vertically.

– The device need not be moved to adjust the position

of the dispensing edge; the device’s mounting need

not be dismantled.

Spring-loaded dispensing edge

– The dispensing edge is pivoted. A torsion spring in

the dispensing head presses the dispensing edge

downwards and onto the surface of the product.

– Allows compensation for height differences

between the products or on the product surface.

[10] Standard dispensing edge

[11] Swivelling dispensing edge

[12] Spring-loaded dispensing edge

21

Page 21

2PRODUCT DESCRIPTION

ALS

306

2.2 OPTIONS

Pneumatic dispensing edge

– The dispensing edge is pivoted in the dispensing

head. Compressed air presses the dispensing edge

onto the surface of the product.

– Allows compensation for height differences

between the products or on the product surface.

309

GB

Outer diameter control sensor

The outer diameter control sensor (OD sensor) triggers

a warning, if the label roll outer diameter falls below a

certain, adjustable value.

Cable kit for internal outer diameter control

Those cables are required to connect the sensors,

which are integrated in the unwinder, to the contr ol unit

of the ALS30x. If connected, the internal OD-control

can be used. For 2 unwinders, 2 cable kits are requir ed.

[13] Pneumatic dispensing edge

A

[14] OD sensor (A)

[15] Cable kit for internal outer diameter control

22

Page 22

2PRODUCT DESCRIPTION

ALS

306

2.2 OPTIONS

Additional material guide disk

The additional material guide disk [16]A] improves the

lateral guiding of the material roll. This option is especially recommended, if very narrow material (< 30mm

width) is processed.

Capacitive label sensor

309

GB

A

[16] Additional material guide disk (A)

Optional sensor, required for processing transparent

labels [17]. The sensor is mounted to the rods of the

dispensing edge holder.

Printer

If necessary, you can mount a hot stamp printer (not

available from Avery Dennison) onto the holder rods of

the dispensing edge.

Example of use: Printing consecutive numbers onto labels.

Applicator

If it is not possible to label directly from the dispensing

edge, you can fit an applicator to the label dispenser.

Various types of applicators are available that depend

on the given requirements.

Simple applicators can be controlled directly via the

PLC signal interface that is available as standard.

[17] Capacitive label sensor with bracket and cable.

Applicator interface

Additional board; allows almost all types of applicators

to be controlled.

23

Page 23

2PRODUCT DESCRIPTION

ALS

306

2.3 OPERATING MODES

2.3 OPERATING MODES

2.3.1 Dispensing mode

This is the operating mode of the unit when switched

on. You can carry out the functions listed in the sections

below.

If text such as ‘Prof 5 xxxxxxxx’ is displayed

instead of ‘ONLINE’:

– The ‘xxxxxxxx’ product profile (m em o ry

location 5) is activated.

– For more information, see the ‘Using product

profiles’ section.

Stopping/Continuing the dispensing mode

Stopping the dispensing mode:

£ Press the button.

– Display:

ONLINE

Stopped: xxx

309

ON

STATUS

Online

–

292

+

Labels

–

A

[18] Control panel in dispensing mode (292 labels dispensed)

A Explanation of buttons in dispensing mode

+

GB

Continuing the dispensing mode:

£ Press the button.

Changing the counter reading

£ Set the counter reading using the MACHINE SETUP >

Dispense counter function.

Starting the unit in configuration mode

To start the unit in configuration mode:

£ Set MACHINE SETUP > Turn-on mode to ‘Offline’.

Counting labels backwards

To count dispensed labels backwards from a starting

value to zero:

£ Set LABEL SETUP > Stop count. mode to ‘Enabled’.

£ Use the LABEL SETUP > Label stop quan. function to

define the starting value.

24

Page 24

2PRODUCT DESCRIPTION

ALS

306

2.3 OPERATING MODES

Online settings

The machine is in dispensing mode.

To switch to the online settings mode:

£ Press the button.

– The display shows the dispensing speed [19A] and

the start offset [19C].

– The button assignments are as shown on the

buttons.

– You can increase (‘+’ button) or lower (‘–’ button)

both settings in the dispensing mode [19D].

Dispensing speed:

– Setting range: [2.0…60.0] m/min

– Display fix: The dispensing speed is constant.

– Display var: The dispensing speed automatically

adjusts to the speed of the conveyor belt (‘speed

adaption’).

Start offset:

– Setting range: [0.0…999.9] mm

– The start offset indicates the distance between the

product sensor and the dispensing edge.

309

GB

ABC

ON

STATUS

–

Offset

0.0

+

D

Speed

12.2 fix

–

+

EFGH

[19] Control panel in the online settings mode

A Dispensing speed display (here: 12.2 m/min constant)

B Dispense label button

C Start offset display (here: 0 mm)

D Explanation of buttons in online settings mode

E Button to lower dispensing speed

F Button to increase dispensing speed

G Button to lower start offset

H Button to increase start offset

Dispensing manually

– To manually trigger the dispensing of individual

labels:

£ Press the button.

– Dispensing speed: As specified in the setting (see

above).

To switch back to dispensing mode:

£ Press the buttons + .

25

Page 25

2PRODUCT DESCRIPTION

ALS

306

2.3 OPERATING MODES

2.3.2 Configuration mode

The machine is in dispensing mode.

Switching to configuration mode:

£ Press the button twice.

– Display:

OFFLINE

£ Press the button.

– Display:

LABEL SETUP

– LABEL SETUP is the name of the first menu that is

currently active.

– In configuration mode, the button assignments are

as shown below the buttons.

ON

STATUS

OFFLINE

–

+

LABEL SETUP

MACHINE SETUP

A

–

309

GB

+

B

Function of the double-arrow button

To dispense individual labels:

£ Press the button briefly (less than two

seconds).

– Dispensing speed: As specified in the configuration;

‘Speed Adaption’ is not active.

To automatically calibrate the label length:

£ Hold down the button for a while (longer than

two seconds).

Menus

In configuration mode, you have access to several

menus providing a fixed sequence of functions that can

be carried out.

You can set the unit so that some of the menu s are not

shown.

Figure [20] shows the button functions for switching

between the individual menus and for leaving them.

INTERFACE. PARA

I/O BOARD

APPLICATOR PARA

SERVICE/DIAGNOS.

SERVICE DATA

[20] Menu selection and button functions in configuration mode.

A Button for triggering a dispensing procedure and for

starting the measurement of lengths.

B Explanation of buttons in configuration mode

C Menus

C

26

Page 26

2PRODUCT DESCRIPTION

ALS

306

2.3 OPERATING MODES

Functions

Every submenu contains functions for setting the unit

controls.

Figure [21] shows the button functions for changing

settings using the MACHINE SETUP > Language function as

an example.

309

GB

MACHINE SETUP

MACHINE SETUP

Store Prod.Prof.

15x

MACHINE SETUP

Language

Language

English

AB

Language

German

[21] Button functions for setting the MACHINE SETUP >

Language function.

A Button to ‘Accept changes’

B Button to ‘Cancel changes’

27

Page 27

2PRODUCT DESCRIPTION

ALS

306

2.4 FUNCTION DESCRIPTIONS

2.4 FUNCTION DESCRIPTIONS

2.4.1 Overview of functions

LABEL SETUP MACHINE SETUP INTERFACE PARA SIGNAL INTERFACE APPLICATOR PARA

Load prod.profil Store prod.prof. > EASYPLUGINTERPR Interface mode Operation enable

Gap detect mode Del. prod.profil Interface > PLC INTERFACE Applicator type

Dispense speed Dispense counter Spooler mode End dispense mod Apply mode

Slew speed Factory settings Dispenser ID no. Disp. end delay Start mode

Label pitch Parameter to CF Spo oler size End pulse width Start error stop

Lab. stop offset Auto Sensor Adj. Offline mode Start delay

Start offset Sensor Adjust Interface delay > APPLICATOR INT. Blow on time

Product length Speed Adaption Applicator type Dwell time

Multi label mode Encoder Type

Label 2 offset

Label 3 offset

1)

1)

Encoder Resol.

Encoder Diameter 3)No. of data bits Blow on time

3)

> COM1 PORT Apply mode Restart delay

3)

Baud rate Dwell time

6)

7)

Position timeout

Apply comp. time

Miss. label tol. Tandem Operation Parity Restart delay

Stop count. mode Tandem Synch.

4)

Stop bits Position timeout

8)

Label stop quan. 2)Tandem Distance 4)Data synch. Apply comp. time

Light sens. type Frame error

Labelsen. InType > ACTIVE INPUTS

Startsen. In.Typ > NETWORK PARAM. Start signal

Start disp. mode IP Addressassign Inhibit signal

Start error stop IP address OD sensor signal

Turn-on mode Net mask

Language Gateway address

Access authoriz. Port address

Material end err Ethernet speed

Materialend warn MAC Address

OD Sensor mode SNMP Agent

OD Sens. polarity

5)

FTP server

WEB server

WEB display refr

Time client

DHCP host name

1) Only appears if LABEL SETUP > Multi label mode =

„2 labels/start“ oder „3 labels/start“.

2) Only appears if LABEL SETUP > Stop count. mode = Enabled

3) Only appears if MACHINE SETUP > Speed Adaption = On

4) Only appears if MACHINE SETUP > Tandem Operation =

Enabled

5) Only appears if MACHINE SETUP > OD Sensor mode = „Error“

or „Warning“

6) Only appears if Applicator type = PEP, PEP Blow on, Reverse

PEP or BTS

7) Does not appear if applicator type = PEP

8) Does not appear if applicator type = ASA

9) Only appears with AI board installed

7)

6)

8)

309

GB

9)

[22] Functions menu – part 1 (grey shading = function is described in the following).

28

Page 28

2PRODUCT DESCRIPTION

ALS

306

2.4 FUNCTION DESCRIPTIONS

SERVICE/DIAGNOS. SERVICE DATA

Sensor Test > MODULE FW VERS. > DISPLAY DATA

Compactflashtest System version Display version

Test functions System revision Display serial #

Diagnosis to CF System date Remote disp. vers.

Bootloader Remote disp. #

uMon

Applicator int.

> OPERATION DATA

Serv. operations > MEMORY DATA

Tot. mat. length Ram memory size

1)

(continued)

> CF CARD SLOT

Card in slot

309

GB

2)

2)

Dispensing cycl. Flash mem size

Operation time Default values

> POWERSUPPLYDATA

Type

Version

Serial number

PS temperature

Standby+On time

On time

> CPU BOARD DATA

CPU identifier

PCB Revision

FPGA version

MAC Address

Serial number

Production date

1) Only when applicator

interface is installed.

2) Only if a remote display is

connected.

[23] Functions menu – part 2.

PCB part number

Board part numb.

29

Page 29

2PRODUCT DESCRIPTION

ALS

306

2.4 FUNCTION DESCRIPTIONS

2.4.2 Notes on function descriptions

The following chapters only describe those functions

that are necessary for operating an ALS30x that has

been configured and set up. These functi on s ar e

highlighted in grey in the overview.

Settings of functions that are not described in

the following may only be changed by qualified

service technicians. These functions are

described in the service manual.

The settings range or the individual settings for

a function are shown in square brackets.

– The default value is italicised for functions

that have individual settings.

– Settings that consist of several words are

shown in quotation marks.

2.4.3 LABEL SETUP menu

Load prod. profil function:

– Loads product profiles from the internal database.

– Prod u ct pr of ile s co ntain product-specific settings.

– You can select a maximum of 16 product profiles.

– You can only select product profile numbers that

have profiles already stored for them.

– See chap. 4.3.2 on page 50

Gap detect mode function:

– After one of the following events, the printer must al-

ways search for the punch, that is initialize the label

material: a

changing the label material.

– Settings: [Manual, „Autom. Forward“]

Manual: The operator has to initialize the material

always manually by pressing the feed key several

times.

Autom. Forward: The material initialization is always

done automatically, if necessary.

Dispense speed function:

– The speed at which the label is dispensed

– Setting range: [0.0…60.0]m/min; default: 10.0

– See chap. “Dispensing speed” on page 46

Slew speed function:

– Feed speed during initialisation

– Setting range: [0.0…60.0]m/min; default: 1.0

fter switching the device on; after

309

GB

Label pitch function:

– Label pitch = label length+space

– Setting range: [5.0…600.0] mm

– See chap. “Label pitch” on page 45

Lab. stop offset function:

– Stop position of the label on the dispensing plate

– Setting range: [0.0…999.9] mm; default: 20.0

– See chap. “Label stop position” on page 45

Start offset function:

– Distance between the product sensor and the top of

the dispensing plate

– Setting range: [15.0…999.9] mm; default: 15.0

– See chap. “Label position on the product” on

page 47

Product length function:

– With this function activated, the machine ignores all

start signals, until the product has passed the dis-

pensing edge

– Setting range: [0.0…1999.9] mm; default: 0.0

– See chap. “Suppressing start signals” on page 46

Multi label mode function:

– Settings: [Disabled, „2 labels/start“, „3 labels/start“]

Disabled: Each start signal causes printing of one

label.

„2 labels/start“: Each start signal causes printing of

2 labels.

„3 labels/start“: Each start signal causes printing of

3 labels.

Label 2 offset function:

– Defines the distance of the 2nd label for the

LABEL SETUP > Multi label mode function (see above).

The distance is measured from the front label edge

of the preceding label.

– Setting range: [x…9999.9] mm; Default: x, with

x = LABEL SETUP > Label pitch.

Label 3 offset function:

– Defines the distance of the 3rd label for the

LABEL SETUP > Multi label mode function (see above).

The distance is measured from the front label edge

of the preceding label.

– Setting range: [x…9999.9] mm; Default: x, with

x = LABEL SETUP > Label pitch.

30

Page 30

2PRODUCT DESCRIPTION

ALS

306

2.4 FUNCTION DESCRIPTIONS

Miss. label tol. function:

– Missing label tolerance

– The maximum permissible number of successive

missing labels on the label strip

– Setting range: [0…10] mm; default: 1

– See chap. “Missing labels” on page 49

Stop count. mode function:

– Settings: [enabled, disabled]

Enabled: Dispenser counter counts backwards,

starting with the value that has been set using the

LABEL SETUP > Dispense counter function. When the

counter reaches zero, no further labels are

dispensed.

Disabled: The dispenser counter counts forwards,

which means that the dispenser counter is

incremented with each label that is dispensed.

309

GB

Turn-on mode function:

– The operating mode of the unit after it is turned on.

– Settings: [Online, Offline]

Online: Dispensing mode

Offline: Configuration mode

Language function:

– Language of the displayed text

– Settings: [English, French, German, Spanish, Ital-

ian, Dutch, Danish]

Label stop quan. function:

– After this amount of dispensed labels, the dispenser

stops

– Function only appears, if LABEL SETUP >

Stop count. mode = „Enabled“

– Setting range: [0…99999]; default: 0

2.4.4 MACHINE SETUP menu

Store prod. prof. function:

– Storing a product profile, see chap. “Storing a prod-

uct profile” on page 5 0 .

Del. prod.profile function:

– Deleting a product profile, see chap. “Deleting a

product profile” on page 51.

Start error stop function:

– Determines how the machine responds in the event

of a product start error. A product start error occurs

when a new start signal arrives before the current

dispensing cycle has ended.

– Settings: [On, Off]

On: Start errors are issued. If a start error occurs,

the device stops and displays a relevant error

message.

Off: Start errors are ignored.

31

Page 31

3BEFORE OPERATION

ALS

306

3.1 ELECTRICAL CONNECTIONS

3 BEFORE OPERATION

3.1 ELECTRICAL CONNECTIONS

3.1.1 Power supply connection

WARNING!

This machine operates using mains voltage!

Touching live electrical parts may exp os e

you to hazardous electrical currents and

may lead to burns.

£ Make sure that the machine is switched

off before you connect the power cable.

£ The mains connection of the machine

may only be done by authorised

specialists, who are aware of the risks

involved.

£ The power cable should not be more than

3 m long.

£ Only operate the device using the syst em

voltage indicated on the nameplate.

309

GB

A

[24] Power supply (A) on the ALS 30x.

Connecting the power cable

The machine ships with a separate machine-side power connector.

The power cable must be produced by an

authorised specialist who is aware of the risks

involved.

For information about producing the power

cable refer to the Service Manual.

£ Make sure that the power switch [25A] is set to ‘O’

(off).

£ Connect the power cable [25B] to the machine.

£ Close the locking clip [25C].

Disconnecting the power cable

£ Make sure that the power switch [26A] is set to ‘O’

(off).

£ Open the locking clip [26B] .

£ Pull the connector off.

C

A

B

[25] Power cable (B) plugged in.

B

A

[26] Locking clip (B) closed.

32

Page 32

3BEFORE OPERATION

ALS

306

3.1 ELECTRICAL CONNECTIONS

3.1.2 Connecting sensors

£ Check whether the required sensors are connecte d

before turning on the unit [27].

The minimum required sensors:

– Label sensor (installation location: dispensing edge)

– Product sensor (installation location: conveyor belt)

Additional optional sensors:

– Rotary encoder (required for speed adaption)

– External roll diameter sensor (provides advance

warning of the end of a label roll)

– Alternative label sensor; for example, capacitive

sensor, used to detect transparent labels.

Sensors for internal OD-control:

– Requires cabel kit A9767. For two unwinders, two

cable kits are required.

£ Connect 2 cables for each unwinder to the unwinder

[28A] and to the rear side [27F-I] of the machine.

A B C

D

309

GB

E

You can find further information regarding suitable sensor types, pin assignments, and so on

in the service manual.

F G H I

[27] Sensor connectors:

A Label sensor

B Product sensor

C Optional: Rotary encoder

D Optional: Alternative label sensor

E Optional: External roll diameter (RD) sensor

F Internal OD-control at unwinder 1

G Internal OD-control at unwinder 1

H Internal OD-control at unwinder 2

I Internal OD-control at unwinder 2

A

[28] Connectors (A) for internal OD-control at the unwinder.

33

Page 33

3BEFORE OPERATION

ALS

306

3.2 INSERTING LABEL MATERIAL

3.2 INSERTING LABEL MATERIAL

3.2.1 Prerequisites

– The label dispenser is turned off at the main

switch [29A] (switch set to ‘O’).

£ Check that the safety installations are working

properly.

£ Inspect the machinery for any visible damage.

Report any defects immediately.

£ Remove any unnecessary materials and objects

from the operating area of the unit.

£ Make sure that only authorised persons are within

the operating range of the machine.

£ Use the required personal protective equipment

correctly; forexample, wear a hairnet, safety

glasses.

309

GB

A

[29] Main switch (A) on the housing.

34

Page 34

3BEFORE OPERATION

ALS

306

3.2 INSERTING LABEL MATERIAL

3.2.2 Inserting a label roll

WARNING!

Risk of injury due to moving and rapidly

rotating parts!

£ Before inserting the label roll, ensure that

the device is turned off at the main

switch.

£ Do not under any circumstances turn the

device on before the label web is

threaded in completely.

Removing spent backing paper

Assuming backing paper has gathered on the rewinde r

[30A] :

£ Press the release button [30B].

– The tensioning mechanism of the rewinder is

slackened.

£ Remove the rewound backing paper.

309

GB

B

Removing glue residue

£ If necessary, clean the following components:

– Dispensing plate

– Deflection rollers

– Drive rollers

– Pressure roller

£ Follow the directions provided in section

“Maintenance and cleaning” on page 52.

Inserting a new label roll

£ Push the material roll [31A] onto the unwinder as far

as it will go.

£ Rotate the rotary knob [31B] in a clockwise direction

until the label roll sits tightly.

£ Run the label web around the deflection roller and

the dancer arm roller [31C] as shown in the figure.

A

[30] A Rewound backing paper

B Release button

C Backing paper path

B

A

C

C

[31] Inserting the material roll.

35

Page 35

3BEFORE OPERATION

ALS

306

3.2 INSERTING LABEL MATERIAL

3.2.3 Threading diagrams

309

GB

[32] Threading guide for ALS30x (dotted line = roll with labels facing inwards).

36

Page 36

3BEFORE OPERATION

ALS

306

3.2 INSERTING LABEL MATERIAL

309

GB

A

[33] Threading guide for ALS30x with a 45° rotated dispensing edge (dotted line = roll with labels facing inwards).

37

Page 37

3BEFORE OPERATION

ALS

306

3.2 INSERTING LABEL MATERIAL

A

B

[34] Threading guide for ALS30x with a 90° rotated dispensing edge (dotted line = roll with labels facing inwards).

For use with a swivelling angle

additional deviation rollers must be installed:

– Long dispensing edge holder: 2 rollers [33A,

B]

– Short dispensing edge holder: 1 roller [32A]

1) 0°: Dispensing edge holder shows vertically downwards with the machine

mounted in horizonta lly.

1)

of 30° or more,

309

GB

38

Page 38

3BEFORE OPERATION

ALS

306

3.2 INSERTING LABEL MATERIAL

Threading the label web at the dispensing edge

Fixed [35] and swivelling L-shape dispensing edges:

£ Unroll 2.5m of label web and remove the labels from

it.

£ Pass the backing paper around the first deflection

roller [35A] and through the slot in the sensor [35B].

£ Feed the backing paper under the pressure roller

[35C] to the dispensing plate [35D].

£ Feed the backing paper around the dispensing pla te

to the second deflection roller [35E].

Spring loaded [36] and pneumatic [37] L-shape dispen-

sing edges:

£ Additionally pass the backing paper between the

two slim deflection rollers at the joint [36A] [37A].

309

GB

A

B

C

A

A

[37] Path of the label web at the pneumatic dispensing edge (option).

E

D

[35] Path of the label web at the dispensing edge.

A 1st deflection roller

B Label sensor

C Pressure roller

D Dispensing plate

E 2nd deflection roller

A

A

[36] Path of the label web at the spring loaded dispensing edge

(option).

39

Page 39

3BEFORE OPERATION

ALS

306

3.2 INSERTING LABEL MATERIAL

Threading the label web onto the drive roller

£ Open the pressure roller. To do so, rotate the lever

[38A] in a clockwise direction.

£ Feed the backing paper around the deflection rollers

[38B] and the drive roller [38C].

£ Close the pressure roller. To do so, rotate the lever

[39], until it snaps in noticeably.

A

[38] Open the pressure roller.

B

C

309

GB

B

Threading the label web to the rewinder

£ Feed the backing paper around the deflection rollers

and the dancer arm as illustrated [40].

[41] Fastening the backing pape r to the rewinder.

£ Clamp the backing paper to the rewinder a s sho wn

and tighten it [40][41].

£ Manually rotate the rewinder by one turn.

[39] Close the pressure roller.

[40] Backing paper thr eading around deflection rollers and dancer

arm.

40

Page 40

3BEFORE OPERATION

ALS

306

3.3 MECHANICAL SETTINGS

3.3 MECHANICAL SETTINGS

3.3.1 Adjusting the unwinder’s core

diameter

Tool:

– 3 mm hexagon (Allen) screwdriver

The unwinder can be adjusted with core adapters [42A]

to fit the inner diameter of the label roll. The adapters

must be fitted and dismantled in different ways

depending on this diameter:

– 38.1mm (1”) core

£ Unscrew the screws [42B] (2 for each adapter) and

remove the adapters.

– 76.2mm (3”) core

£ Screw on the adapters, as is shown in Figure [42].

B

B

A

[42] Core adapter positions for a core diameter of 76.2mm.

309

GB

– 101.6 mm (4”) core

£ Screw on the adapters, as is shown in Figure [43].

3.3.2 Positioning the pressure roller

£ Open the pressure roller [44B]. To do so, rotate th e

lever [44C] until the roller snaps up.

£ Release thumb screw [44A].

£ Align the pressure roller over the backing paper so

that it is centred.

£ Close the pressure roller.

£ Screw the thumb screw tight.

[43] Core adapter positions for a core diameter of 101.6mm.

A

C

B

[44] Setting the position of the pressure roller (B).

41

Page 41

3BEFORE OPERATION

ALS

306

3.3 MECHANICAL SETTINGS

3.3.3 Positioning the label sensor

£ Release the thumb screw.

£ Position the sensor along the axle in such a way as

to allow it to register the spaces between the labels.

The LED [45A] lights up when the sensor is

positioned over a label.

3.3.4 Setting the dancer arm

restoring force

309

GB

B

A

[45] Label sensor from Wenglor, model OPT242-P800

The unwinder dancer arm is preset in a way, that a wide

range of label materials can be processed whithout having to change the dancer arms restoring force.

Even so, very narrow label material can under certain

circumstances tear off or expand in a way which results

in poor labelling precision. In those cases, the restoring

force must be decreased.

£ Loosen the lock-ring [47B]. To do so, hold the

adjustment ring [47A] and turn the lock-ring

opposite the direction indicated by the pictured

arrow.

£ Turn the adjustment ring [47A] in arrow direction

[47 arrow] to increase the restoring force.

Turn the adjustment ring [47A] against arrow

direction [47 arrow] to decrease the restoring force.

£ Retighten the lock ring against the adjustment ring.

A service technician can restore the factory setting, see service manual chap. 6.2.3 section

„Adjusting restoring force of dancer arm“.

A

[46] Restoring spring (A) at the unwinder dancer arm.

B

A

[47] A Adjustment ring

B Lock-ring

42

Page 42

4OPERATION

ALS

306

4.1 START-UP AND SHUTDOWN

4 OPERATION

4.1 START-UP AND SHUTDOWN

4.1.1 Turning on the unit

£ Set the main switch [48A] of the unit to ‘I’ (On).

– The following messages are displayed during the

start process:

ALS306 RH:

V 1.33

(machine type and firmware version)

Memory: 16 MB

Flashcard 48 MB

(the machine’s RAM, as well as the CF card’s

memory, if a card is inserted)

ONLINE

Label 0

309

GB

A

[48] Main switch (A) of the ALS 30x

– Once switched on, the ALS30x is in dispensing

mode; in other words, triggering the product sensor

will cause a label to be dispensed.

– You can find more information on the dispensing

mode in the section “Dispensing mode” on page 24.

4.1.2 Starting label dispensing

Dispensing with a product sensor

Once switched on, the ALS30x is in dispensing mode;

this means that triggering the product sensor will cause

a label to be dispensed.

Prerequisites:

– The label length must be specified.

– The product sensor must be connected.

– The sensors must be configured correctly

(PNP/NPN).

Dispensing without a product sensor

It is also possible to trigger the dispensing process

without a product sensor:

– The machine is in dispensing mode:

£ Press the button.

– The machine is in configuration mode:

£ Press the button briefly (less than two

seconds).

43

Page 43

4OPERATION

ALS

306

4.1 START-UP AND SHUTDOWN

4.1.3 Stopping the dispensing

process

– The machine is in dispensing mode:

£ Press the button.

– Display:

ONLINE

Stopped: xxx

– The dispenser stops.

309

GB

44

Page 44

4OPERATION

ALS

306

4.2 CONFIGURATION AND MONITORING

4.2 CONFIGURATION AND MONITORING

4.2.1 Function menu settings

Label pitch

£ Switch to configuration mode

Calibrating the label pitch automatically:

£ Hold down the button for a while (longer than

two seconds).

Or: Enter the label pitch manually:

£ Measure the label pitch [49C].

£ Call the LABEL SETUP > Label pitch function.

£ Enter the measured value in millimetres.

[49] A Label web

309

GB

AB

C

B Label

C Label pitch

Label stop position

Prerequisites:

– The label length must be specified.

The next label to be dispensed waits in the label stop

position. Here it is useful if the label protrudes over the

dispensing edge a little [50].

ALS30x labellers are pre-configured for use

with the supplied label sensor. If this sensor is

employed, the label stop position setting will

only require minimal correction.

Correcting the default setting:

£ Call the LABEL SETUP > Lab. stop offset function.

£ Increase the value to increase the overhang or

lower the value to reduce the overhang.

The value ‘0’ will cause the label to stop with its front

edge directly under the label sensor.

The front edge of the next label to be dispensed sh ould

be flush with the dispensing edge:

£ Enter the distance [50A] between the label sensor

and the dispensing edge.

The front edge of the label to be dispensed should

overhang:

£ Add the length of the overhang to the distance

between the label sensor and the dispensing edge.

A

[50] Label stop position (A)

45

Page 45

4OPERATION

ALS

306

4.2 CONFIGURATION AND MONITORING

Dispensing speed

You can set the dispensing speed to a fixed value or

you can configure it to automatically adjust to the speed

of the conveyor belt (speed adaption). The second

option requires you to connect a rotary encoder that

measures and relays the conveyor speed to the

dispenser.

Configuring a fixed value:

£ Use the two left buttons to set the speed in

dispensing mode (online settings) (see “Online

settings” on page 25).

Or use the function menu settings:

£ Call the LABEL SETUP > Dispense speed function and

set the speed you require.

Configuring speed adaption:

£ Turn the function on by setting MACHINE SETUP >

Speed Adaption to ‘Yes’.

£ Set MACHINE SETUP > Encoder Resol. and

MACHINE SETUP > Encoder Diameter as

appropriate for the employed rotary

encoder.

309

GB

– See the service manual for information on suitable

rotary encoders.

Suppressing start signals

A start signal can be prematurely triggered by the

shape of the product or reflective surfaces, what can

cause erroneous labelling. In case of a product causing

unwanted additional start signals while the product

passes the dispensing edge, those signals can be

suppressed by setting function LABEL SETUP >

Product length to the product length.

Example [51]:

If the product [D] reaches the product sensor [C], a start

signal is sent and the machine dispenses a label. The

recesses in the product trigger additional start signal s;

the product would be labelled several times. With the

product length [A] set in the LABEL SETUP > Product length

function, the machine ignores all start signals until the

product has passed the dispensing edge.

B

A

C

D

[51] A Product length

B Label

C Product sensor

D Product with recesses (arrows)

46

Page 46

4OPERATION

ALS

306

4.2 CONFIGURATION AND MONITORING

Label position on the product

Prerequisites:

– The label length must be specified.

– The label stop position must be set.

Configuration in dispensing mode:

£ Use the two right buttons to set the start offset (see

“Online settings” on page 25).

Or use the function menu settings:

£ Call the LABEL SETUP > Start Offset function and set the

start offset.

– The label should be flush with the front edge of the

product:

£ Enter the distance between the product sensor and

the dispensing edge [52A].

[52] Distance between the product sensor (left) and the

309

GB

A

dispensing edge (right).

– The label should be stuck at a distance from the

front edge of the product:

£ Increase the start offset by the distance [53A] to the

product’s front edge.

A

[53] Distance (A) between the label and the product’s front

47

Page 47

4OPERATION

ALS

306

4.2 CONFIGURATION AND MONITORING

4.2.2 Monitoring functions

While in dispensing mode, an electronic controller

monitors the following functions:

Material end / Roll diameter

(OD = outer diameter)

To enable a quick renewal of the material roll, the

machine can alarm the operator before the end of the

material roll is reached. This provides the OD-control,

which is available in two versions:

– Internal OD-control

The machine control elaborates the signa ls coming

from two sensors, which are integrated into the

material unwinder.

Before this function can be applied, the two sensors

must be connected with two external cables

(accessory) to the machine.

309

GB

– External OD-control (accessory)

A light barrier attached to the material unwinder is

triggered, if the roll OD falls below a certain value.

Depending on the configuration and setting of the

machine, different messages appear in case of material

end or the roll diameter falling below the critical value:

Material end Critical OD reached

Error message Warning Error message

No OD-control Status num: 5001

No gap found

Internal OD-control

External OD-control none

[54] Messages for monitoring label stock.

1) If MACHINE SETUP > Material end err = „On“

2) If MACHINE SETUP > RD Kontroll Mode = „Warning“

3) If MACHINE SETUP > OD sensor mode = „Error“

If a warning occurs:

– Labelling operation is continued.

£ Press the button, to delete the warning.

£ Prepare for inserting a new material roll.

Status num: 5002

Material end

1)

none none

ONLINE

Material low

ONLINE

OD sensor warn.

2)

none

Status num: 5065

OD material end

3)

48

Page 48

4OPERATION

ALS

306

4.2 CONFIGURATION AND MONITORING

If an error message occurs:

– The machine stops.

£ Press the button to delete the message.

£ Remove the rewound backing paper.

£ Insert a new material roll (see “Inserting a label roll”

on page 35).

Missing labels

A label missing from the label roll does not normally

affect the dispensing operation, because the label feed

continues until a label’s edge passes under the label

sensor.

Nonetheless, it can be important that missing labels are

reported. By configuring the function LABEL SETUP >

Miss. label tol., you can specify whether an error message

is triggered after one or several missing labels.

309

GB

Material tear

If the material path tears, one of these two messages

appears:

Status num: 5002