Page 1

A64 CS Stacker Quick Reference

This Quick Reference contains supply loading information, setup, general care, and maintenance procedures for

the Avery Dennison® A64 Cutter/Stacker. For more detailed information, refer to the Operator’s Handbook

available on our Web site (www.monarch.com).

Information in this document supercedes information in previous versions. Check our Web site for the latest

documentation and release information.

Warning:

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in

accordance with the instruction manuals, may cause interference to radio communications. It has been tested and

found to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules,

which are designed to provide reasonable protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference in which case the user,

at his own expense, will be required to take whatever measures may be required to correct the interference.

Getting Started

1. Set up your printer. Refer to the documentation provided with your printer for more information.

2. Unpack the stacker and packing material from the box.

The box should contain:

• Stacker base and tray assembly (with the “Stacker Full” cable attached to tray)

• Power cord and stacker interface cable

3. Set the stacker to the left side of the printer.

4. Alignment the printer to the stacker.

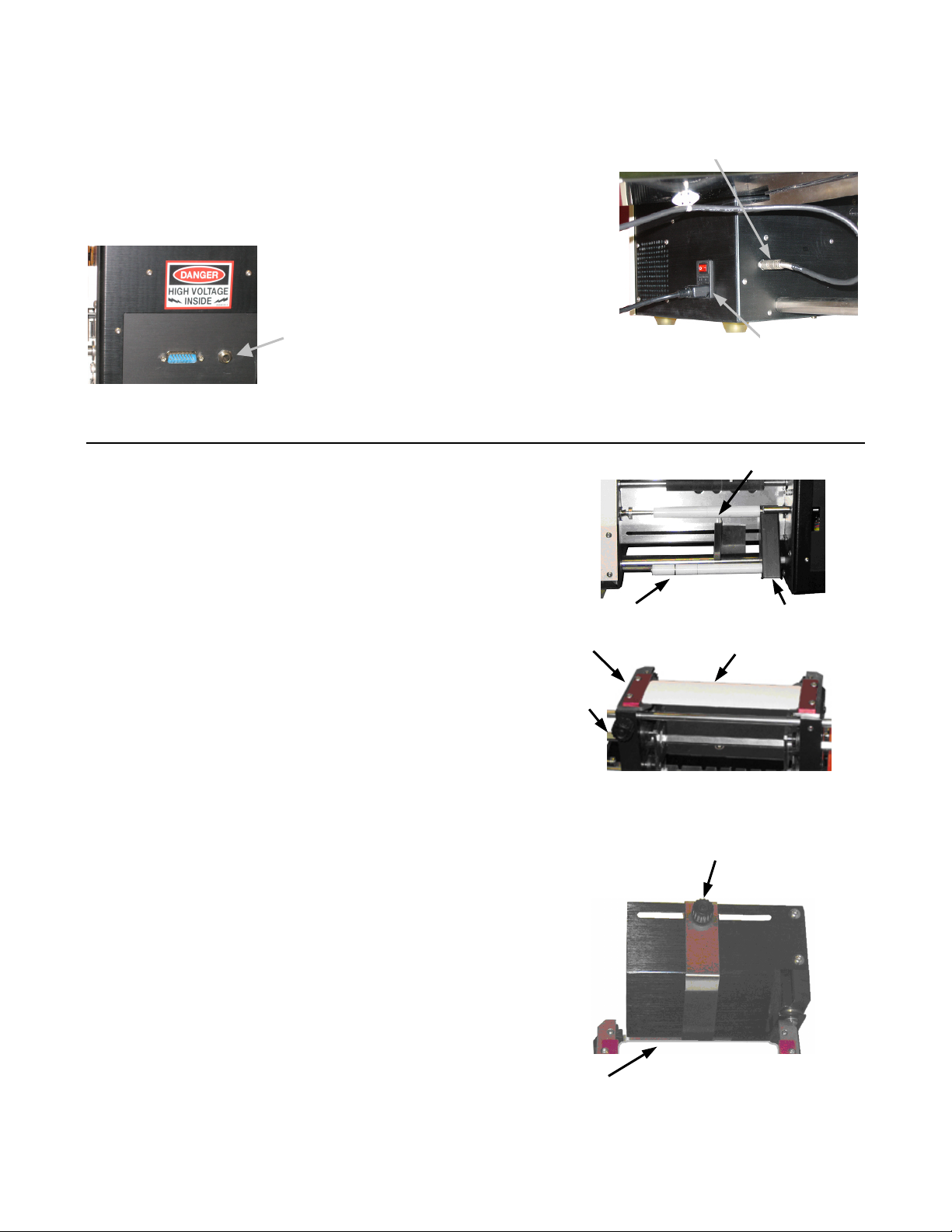

5. Attach the stacker tray assembly.

• Align the slotted holes of the tray with the studs on the stacker base.

• Align the fingers of the tray with grooves on the top rollers.

• Center the two screw holes and start the captive screws from underneath the base. Make

sure the tray fingers do not touch the black transport roller.

• Tighten the screws.

Underside of Tray

Slotted Holes

Screw Holes

Studs

Captive Screws

Studs

Top view of Base

TC9864CSQR Rev. AA 6/08 ©2008 Avery Dennison Corp All rights reserved.

Page 2

6. Connect the stacker full cable and stacker communication

r

r

cable between the stacker and your printer.

7. Plug the power cord to the stacker and the other end into a

grounded electrical outlet.

Communication Cable

Communication Cable

Connecto

Connecto

Threading Supply

Stacker Full Cable

Power Cord

1. Make sure the stacker is disabled. The stacker is disabled

when the READY light is red.

2. Threading tags between tag guides:

• Thread tags under the dancer rollers and push against

the fixed guide.

• Slide the outer tag guide towards the tags leaving

space between the guides for the tags to move freely.

3. Set the pusher tag width:

Outer Guide

• Loosen the thumbscrew on the outer tag

pusher.

Thumbscrew

• Place a sample tag between the guides and

slide the outer guide towards the tag leaving

space between the guides for the tags to

move freely.

• Tighten the thumbscrew.

4. Adjust the tag stack support bar:

• Loosen the thumbscrew on the tag support bar.

• Slide the bar left or right to the middle of the tags.

Dancer Rollers

Thumbscrew

Outer Guide

Fixed Guide

Sample Tag

• Tighten the thumbscrew.

Sample Tag

2

Page 3

5. Adjust the side bar guide:

• The side bar is attached with magnets.

• Align the side bar with the notch of the outer tag

pusher. Make sure the side bar is parallel to the

edge of the tray.

ote: Adjust the sensors if you use tags with a

N

notch, swiftach hole, or a flag document.

Side Bar Guide

Notch

See “Making Sensor Adjustments” for more information.

6. Press START/STOP to enable the stacker.

The READY light is green when the stacker is enabled and ready to cut and stack tags. When the printer begins

printing, the stacker automatically feeds, cuts, and stacks the tags.

Note: After pressing START/STOP, if the stacker does not see the notch or sensor mark within

16 inches of supply, the stacker automatically disables and the READY light turns red.

Making Sensor Adjustments

The stacker uses three types of sensors: the transmissive sensor, the flag sensor, and the reflective sensor.

Test sensors by feeding tags through the stacker. To feed tags, disable the stacker and advance tags by manually

turning the feed roller. If the NOTCH light does not light, the sensors may need to be adjusted.

Setting the Transmissive Sensor

The transmissive sensor is located on the front of the knife assembly and is used for cutting tags with a notch or a

Swiftach hole.

Note: When the position of the transmissive sensor is set correctly, the NOTCH light flashes as

tags pass the sensor.

• Make sure the stacker is disabled. The stacker is disabled when the READY light is red.

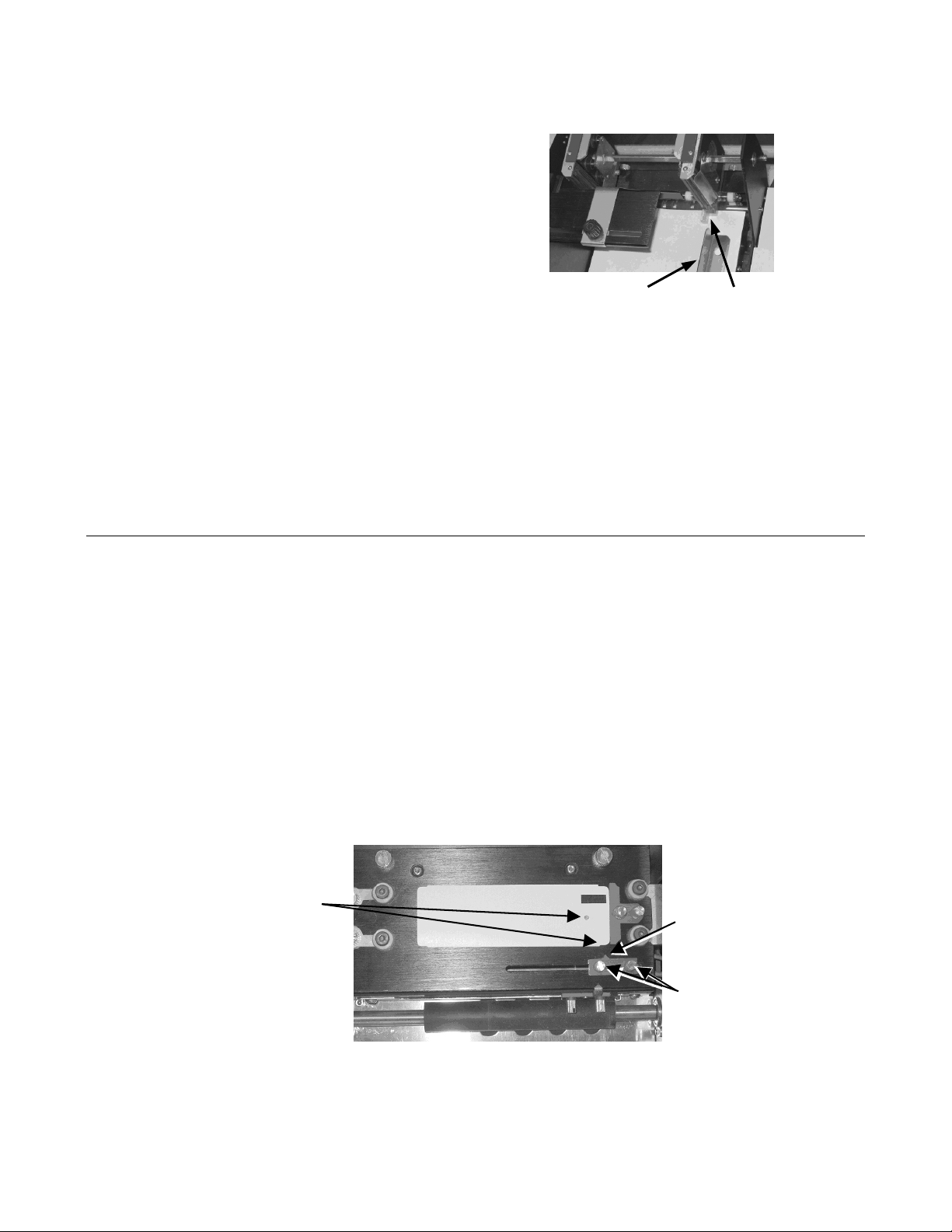

• Place a sample tag against the guide on the knife assembly.

• Loosen the sensor thumbscrews and slide it until the arrow is pointing to the notch or hole.

• Tighten the thumbscrews.

Align Arrow with

Notch or Hole

Arrow

Thumbscrews

3

Page 4

Setting the Flag Sensor

The flag sensor is located on the bottom of the knife assembly and is used to cut tags with a printed

flag mark.

Note: When the position of the flag sensor is set correctly, the FLAG light flashes as tags pass

the sensor.

• Make sure the stacker is disabled. The stacker is disabled when the READY light is red.

• Place a sample tag against the guide on the knife assembly.

• Loosen the sensor thumbscrews and slide it until the arrow is pointing to the middle of the flag mark.

• Tighten the thumbscrews

•

Flag Mark

Arrow

Thumbscrews

Setting the Reflective Sensor

The Reflective Sensor is located behind the knife assembly, visible from the bottom of the stacker.

The reflective sensor can be moved by hand. Normally, no adjustment is necessary for this sensor.

4

Page 5

Power On/Off

r

1. Turn on the circuit breaker, then turn on the power

switch.

Using the Control Panel

The following table describes how to use the control panel to set up the stacker.

Circuit Breaker

Power Switch

Indicator/Key Description

START/STOP

FEED

MODE

ARROW KEYS

POWER

READY

FLAG

NOTCH

ERROR

LCD Display

Enables and disables the stacker. When the stacker is disabled, the

READY light is red. The stacker does not cut or feed tags, but the

feed roller can be turned by hand. When the stacker is enabled, the

READY light is green. As tags are ready from your printer, the stacke

feeds, cuts, and stacks the tags.

Advances one tag.

Sets the stacker’s operating mode. Modes can be changed to use the

stacker with different kinds of tags or allow service procedures like

calibration to be performed. See “About the Menu Overview” for more

information about modes.

Sets modes and toggling between options.

Indicates the power is on, when lit.

Indicates the stacker is ready to cut and stack, when green.

Indicates that the stacker is disabled, when red.

Flashes when a sensor mark is detected.

Flashes each time the sensor sees a tag notch, a sensor mark, or a

Swiftach hole.

Indicates an error, when flashing. Check the display for the error

message.

Shows error messages and mode settings.

5

Page 6

About the Menu Overview

The stacker has three mode menus shown below.

Press the MODE key to navigate through the main menu and display each mode.

Press START/STOP to select a mode. Use the ARROW keys to select options within a mode.

Mode Selection Customize Modes Service & Diagnostics

1. Standard Notch 1. Standard Cut Master Cutline Adjustment

2. 1.222 Swiftach 2. 1.222 Swiftach Sensor Status

3. 1.250 Swiftach 3. 1.250 Swiftach Cycle Count

4. 1.375 Swiftach 4. 1.375 Swiftach Reset to Factory Defaults

5. User defined 5. User defined Motor Tests

6. User defined 6. User defined Web Test

7. User defined 7. User defined Knife Motor Test

8. User defined 8. User defined Transport Motor Test

9. User defined 9. User defines Pusher Motor Test

10. User defined 10. User defined Check LCD

Check Keypad

Check Memory

For each specify: For each specify: Sensor Trip Points

Flags? YES/NO/EXT Sensor Type: Transmissive Sensor Adjust

Transmissive Reflective Sensor Adjust

Reflective Flag Sensor Adjust

Offset: mm LCD Contrast Adjustment

Speed Setup

Note: Modes 5 through 10 display in Mode Selection only after they are defined in the

Customize Modes menu.

6

Page 7

Cleaning

1. Turn off the stacker.

2. Remove any tags.

3. Pull the black release block to open the knife assembly.

4. Use compressed air or a small brush to clean the sensors.

5. For better access to the sensors, loosen the transport thumbscrews and remove the transport assembly.

6. Install the transport assembly.

7. Close the knife assembly.

8. Clean the feed roller.

Transport Thumbscrews

Release Block

Knife Swing Assembly

Feed Roller

7

Page 8

Error Messages

Error Messages are shown on the display and the ERROR light flashes. Press STOP/START to clear the error

message and return to READY.

Error Action

OUT OF PAPER

PAPER JAM

PUSHER JAM

KNIFE JAM

STACKER FULL

INTERLOCK OPEN

INTERNAL ERROR 01

There are no tags in the stacker. Check to see if

the printer is out of supply.

Tags have jammed in the stacker or the sensor is

blocked or dirty. Check the paper path for the jam.

Make sure the sensor is positioned properly and

is not blocked. Clean the sensor.

The pusher assembly is jammed. Check for

proper alignment of the pusher assembly. The

pusher assembly is where tags are guided and

pushed onto the stacker. Look for blockage in the

stacker area.

Tags are jammed at the knife.

Remove any jammed tags.

The stacker tray is full of tags. Remove the

stacked tags from the tray.

The knife assembly is open, or the plastic shield is

not secure (if so equipped). Close the knife

assembly or plastic shield so it is completely

latched.

An internal time-out occurred. Use Motor on the

Service & Diagnostics menu to check all motors

for proper functioning.

CONFIRM MODES

If you cannot fix a problem, call service.

8

The non-volatile RAM area is not initialized, or the

RAM area is corrupted. Set the proper modes and

continue.

Loading...

Loading...