Page 1

QUICK REFERENCE

This Quick Reference contains supply loading and general care

and maintenance procedures for the Monarch® 9906 printer. For

more detailed information, refer to the Operator’s Handbook

available on our Web site (www.monarch.com

about creating formats, configuring the printer, or programming

the printer, refer to the Packet Reference Manual on our Web

site.

Review the safety information in the Regulatory Compliance

document included with your printer. Information in this

document supercedes information in previous versions. Check

our Web site for the latest documentation and

release information.

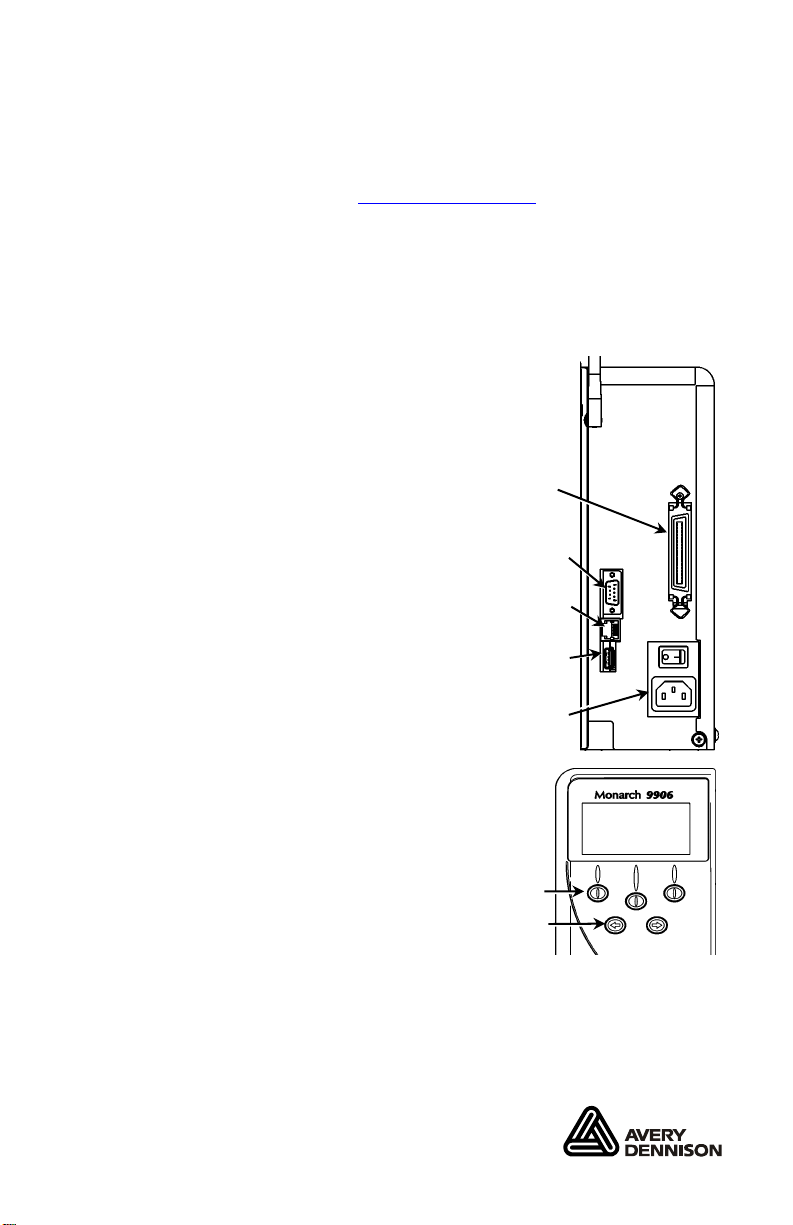

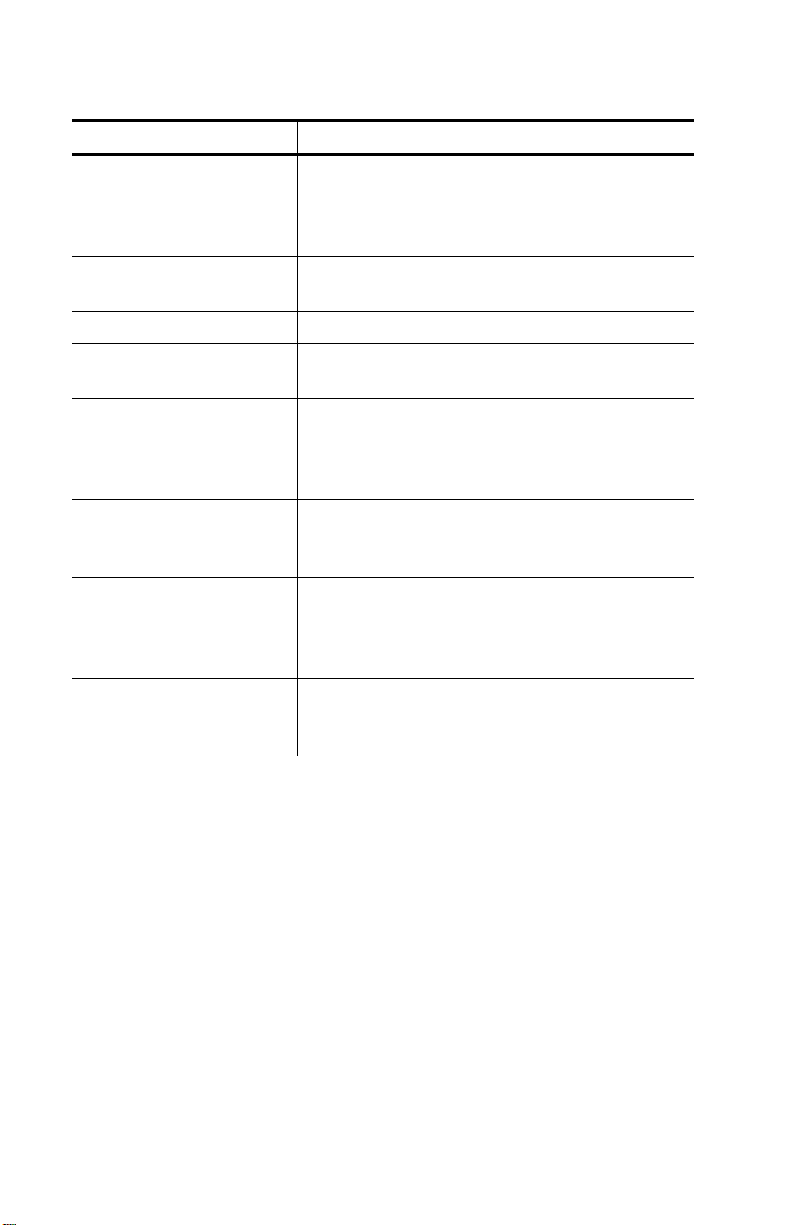

Connecting the Cables

The power supply automatically

switches between 115V and 230V.

1. Plug the power cable into the

socket and the other end into

a grounded electrical outlet.

2. Connect the communications

cable into the appropriate port.

3. Turn on the printer. Press ( I )

to turn on and ( O ) to turn off

the printer.

Using the Control Panel

The control panel consists of a fourline LCD display, three function

buttons, and two navigation buttons.

The function of each button varies

depending on the task.

The LCD display:

Indicates power when text or

other information is shown

Indicates conditions requiring

immediate attention (low battery,faults, errors) using a red

background

Shows menu prompts, printer settings, function button

assignments, values, etc.

Parallel Port

(optional)

Device USB

Power Cable

Connection

Navigation

Buttons

). For information

Serial Port

Host USB

Function

Buttons

MPCL

FEED

Online

TLabel MENU

Monarch is a trademark of Avery Dennison

Retail Information Services LLC.

Avery Dennison is a trademark of Avery Dennison Corp.

TC9906NAQR Rev. AD 9/12 2010 Avery Dennison Corp. All rights reserved.

Page 2

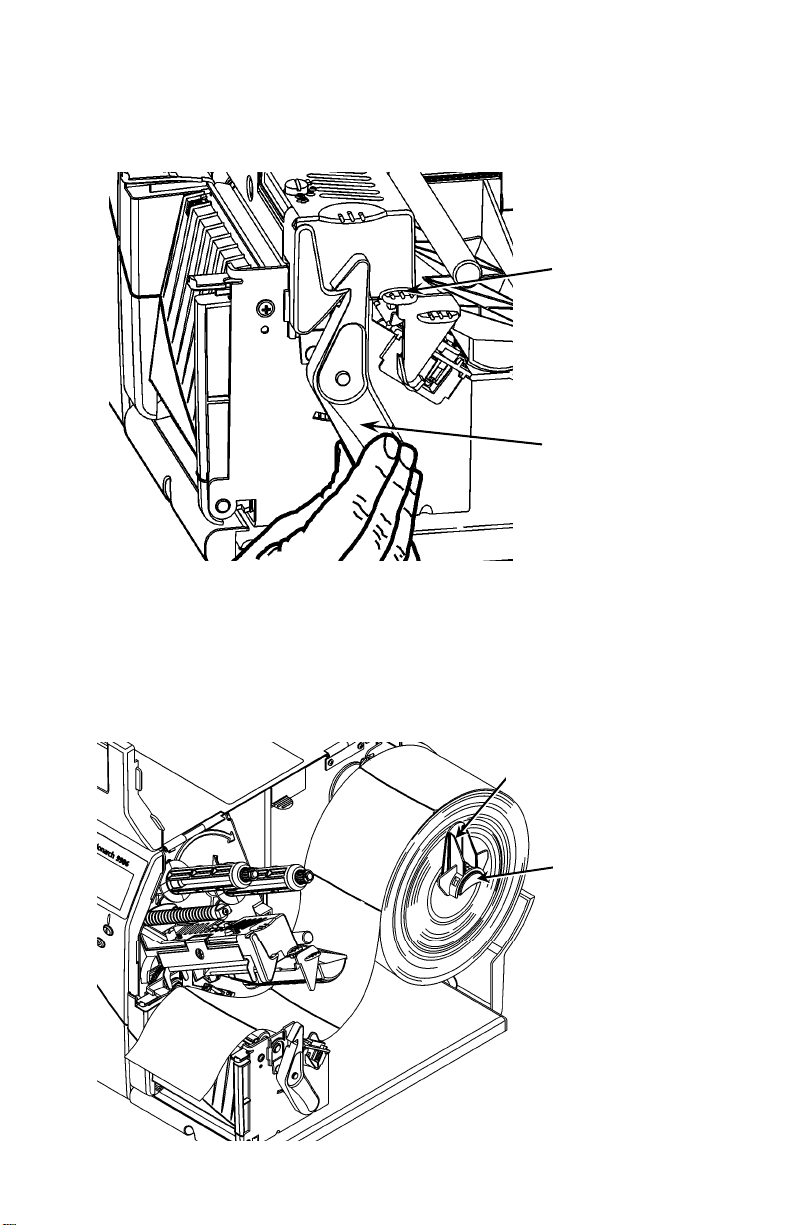

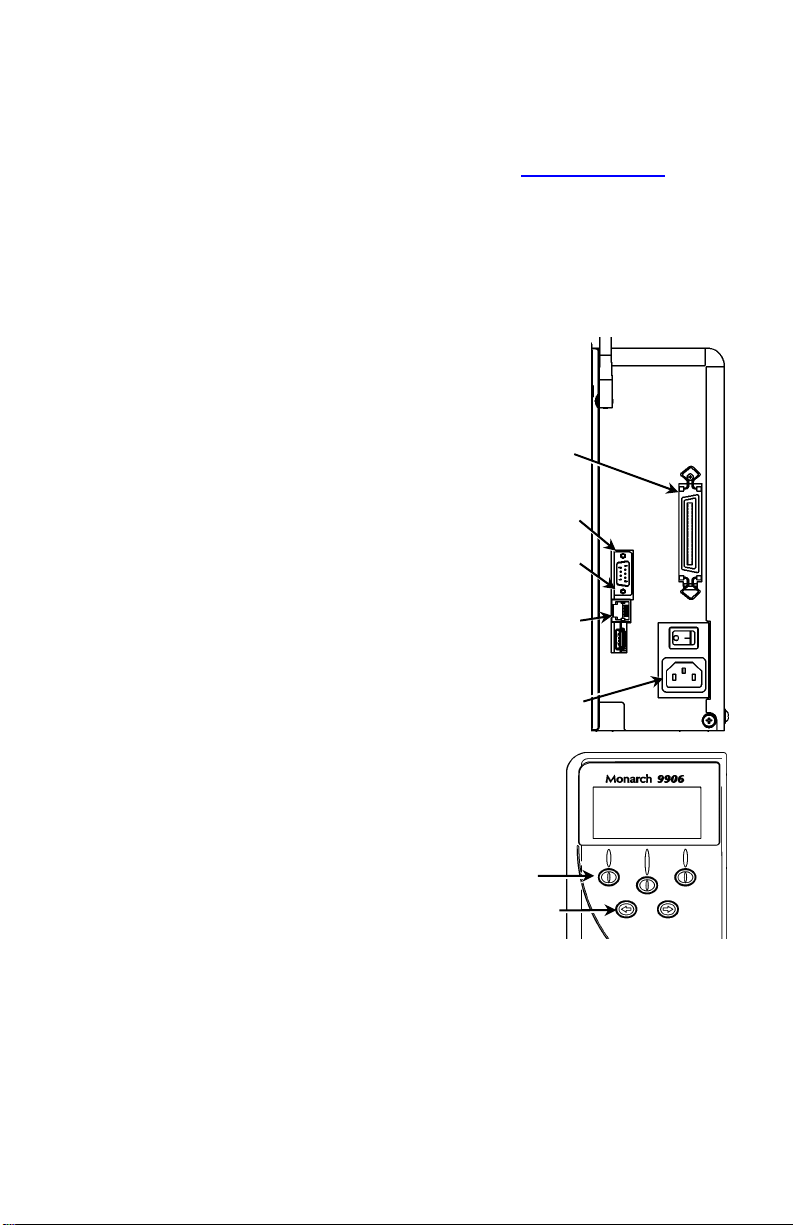

Loading Labels or Tags

1. Open the cover.

2. Unlock the printhead by turning the retaining latch.

Printhead Tab

Retaining Latch

3. Lift the printhead assembly using the printhead tab until the

assembly locks into place.

4. Place the roll of supply on the supply holder, located against

the inside of the printer.

5. Adjust the supply holder guide so that it barely touches the

roll, making sure the supply roll turns freely.

2-EN

Supply Holder Guide

Supply Holder

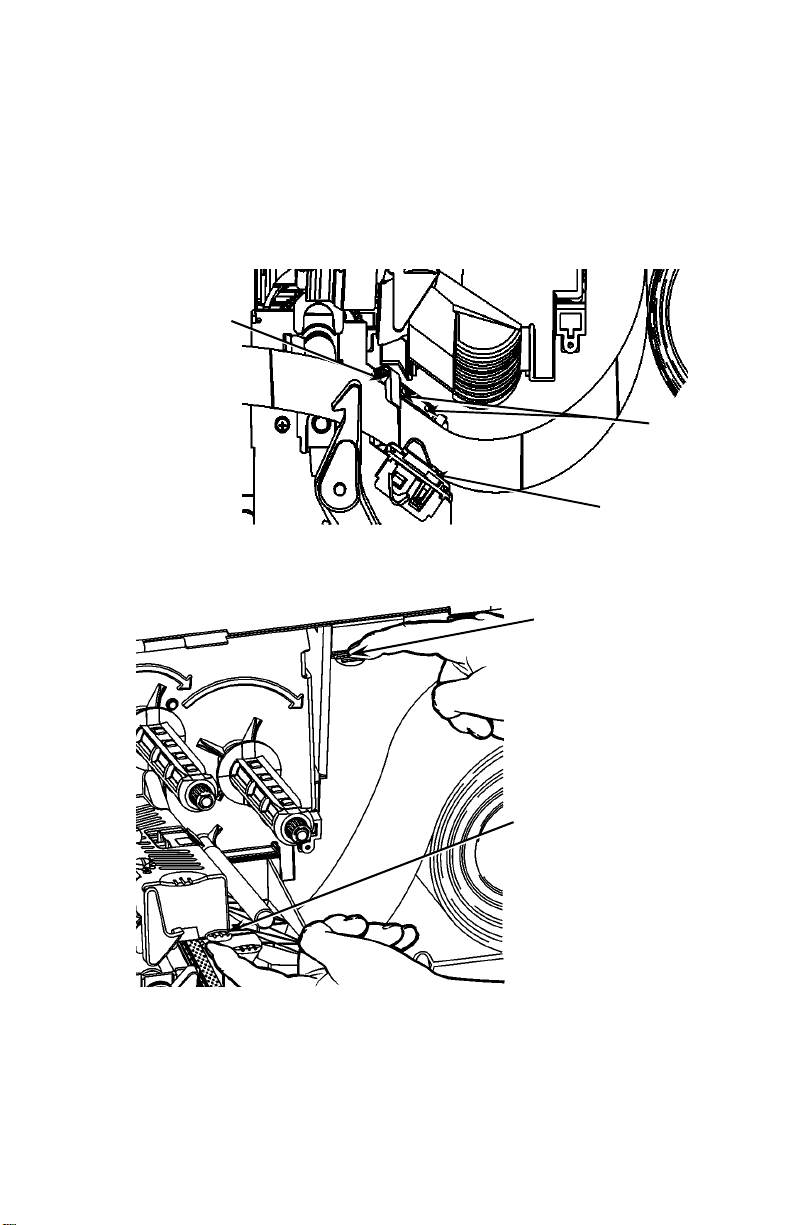

Page 3

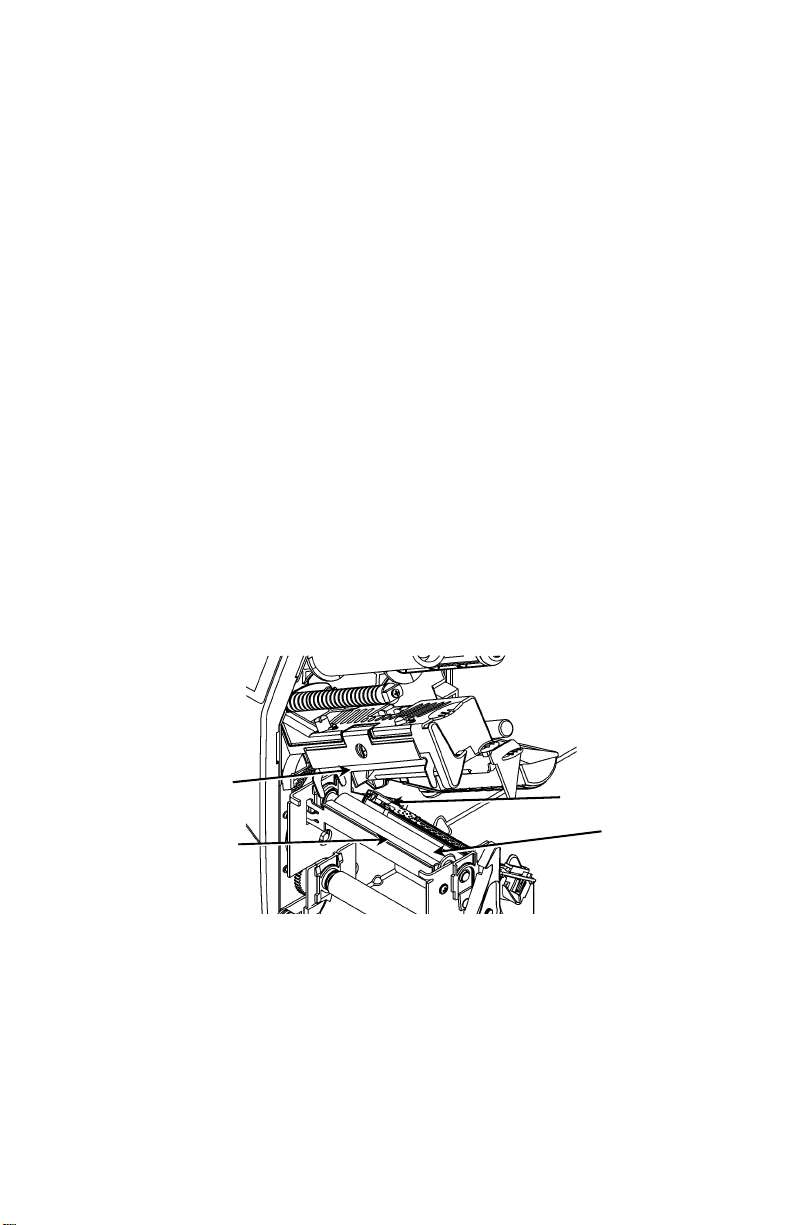

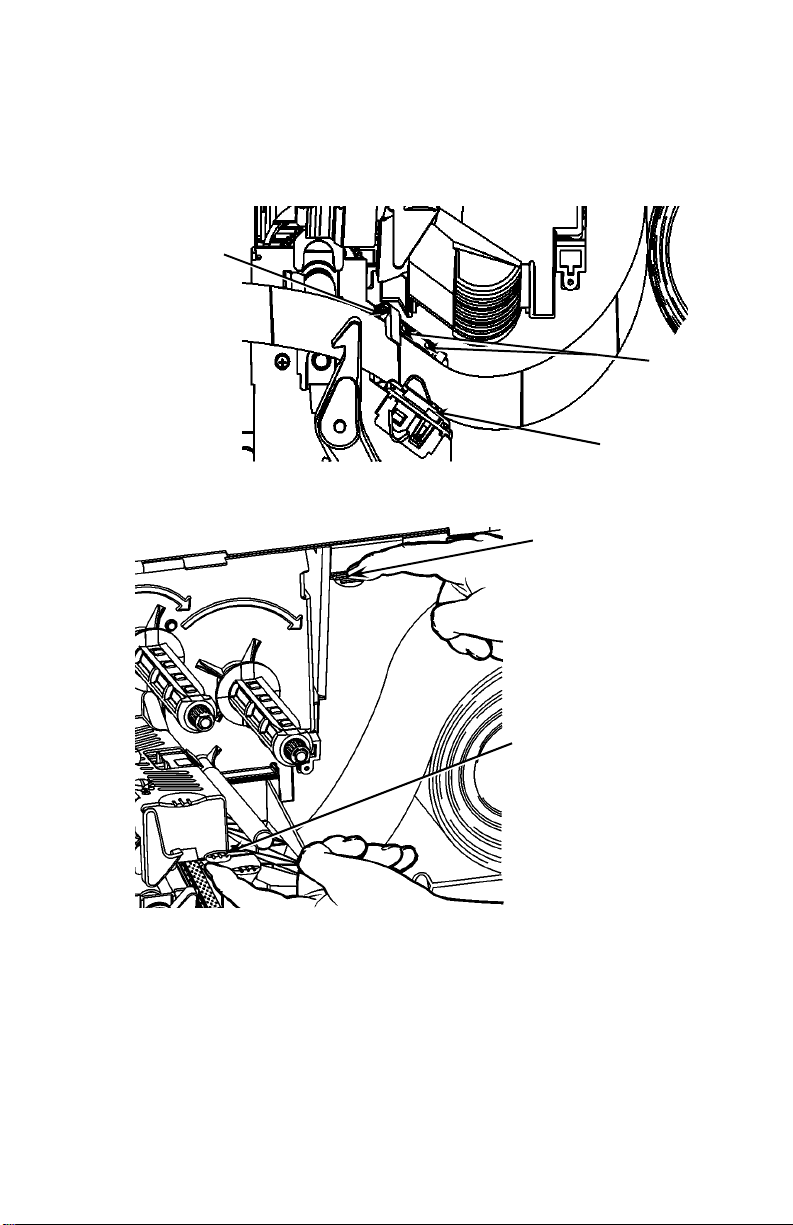

6. Push down on the supply lever to unlock the supply guide.

7. Lay the label strip across the supply guide so that a few

inches extend past the front of the printer.

8. Tuck the supply under the nibs and in between the die cut

sensor.

9. Adjust the supply guide so that it barely touches the supply.

Push up on the supply lever to lock the supply guides into

place.

Die Cut

Sensor

Nibs

Supply Lever

10. Hold the printhead assembly by the printhead tab while

pushing the printhead release.

Printhead Release

Printhead Tab

EN-3

Page 4

11. Close the printhead by pressing down on the thumb well until

you hear it click into place.

12. Close the printer’s cover.

13. Press FEED.

Loading Labels for the Optional Peel Mode

1. Remove the labels from the first 10 inches of the liner.

2. Press down on the exit cover tabs to open the exit cover.

3. Feed the liner over the peel bar, along the chute, and out

through the lower opening in the exit cover.

Peel Bar

Platen Roller

Lower Opening

Peel Roller

4. Close the exit cover.

5. Close the printer’s cover.

6. Press FEED.

For additional supply loading options, refer to the Operator’s

Handbook.

4-EN

Page 5

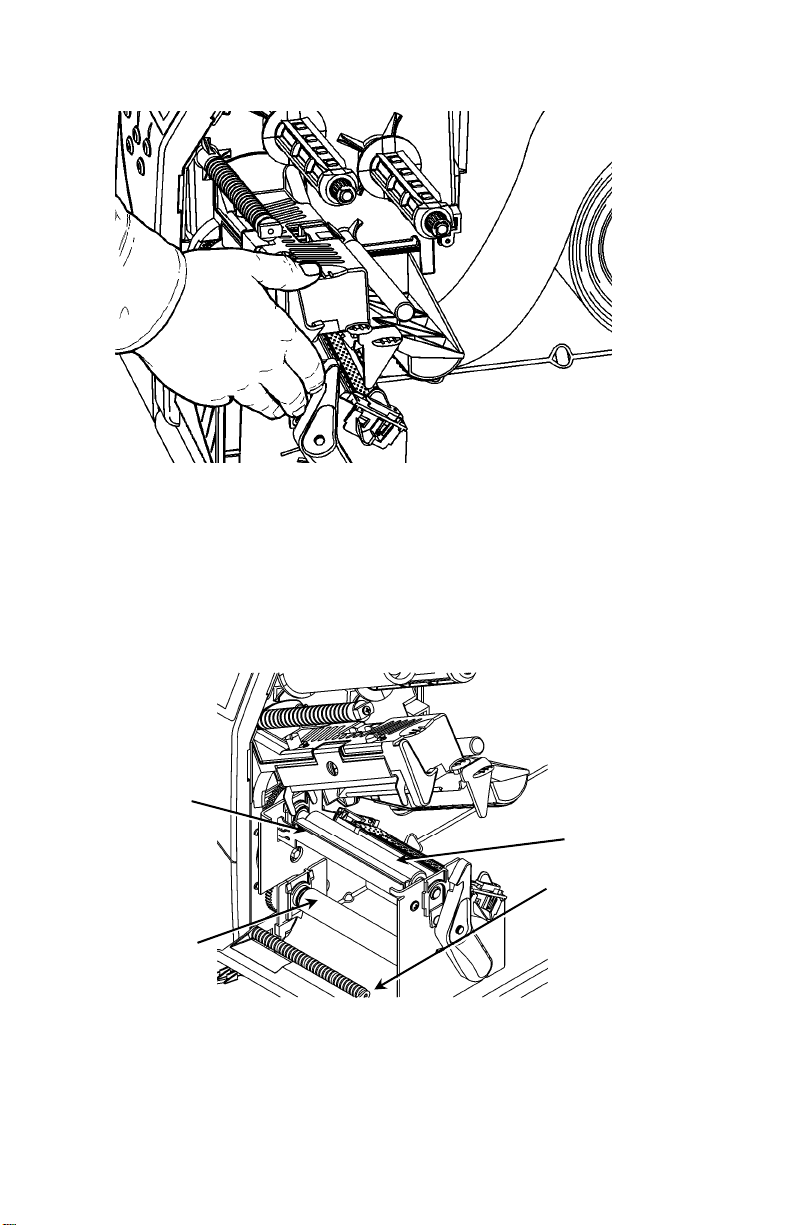

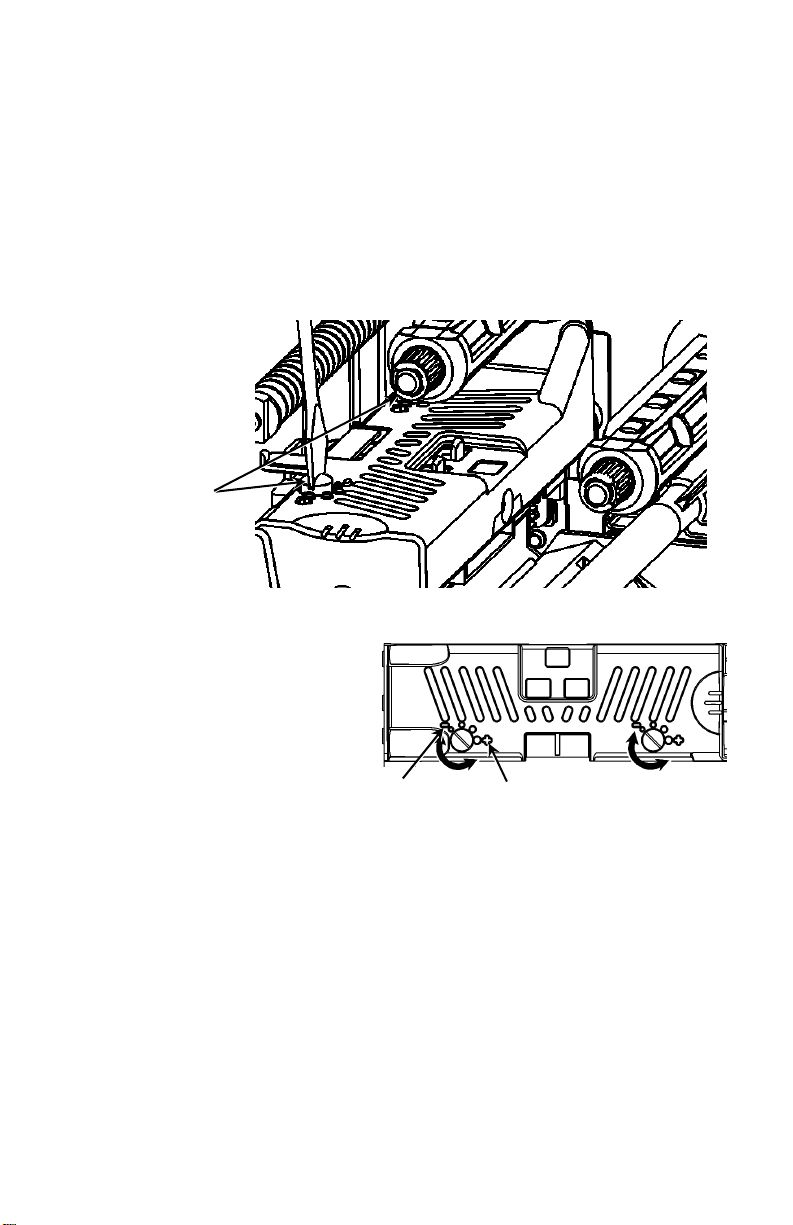

Adjusting the Printhead Pressure Dials

The default setting is least pressure, which provides optimal

printing in most cases. If you see smudging, ribbon wrinkling, or

poor print quality, you may need to adjust the printhead pressure

dials.

The two dials are located on either edge of the printhead

assembly (inside and outside). The dials may be set to different

positions; however, the inside dial should be equal to or more

pressure than the outside dial. When using 4” wide supply both

knobs should be set at equal pressure. Use a coin or flathead

screwdriver to adjust the dials.

Printhead

Pressure Dials

Each dial has four settings:

Least pressure

Light pressure

Medium pressure

Most pressure

Print a test label to check the printhead pressure; make

adjustments as necessary. Refer to the Operator’s Handbook for

additional information.

Least

Pressure

Most Pressure

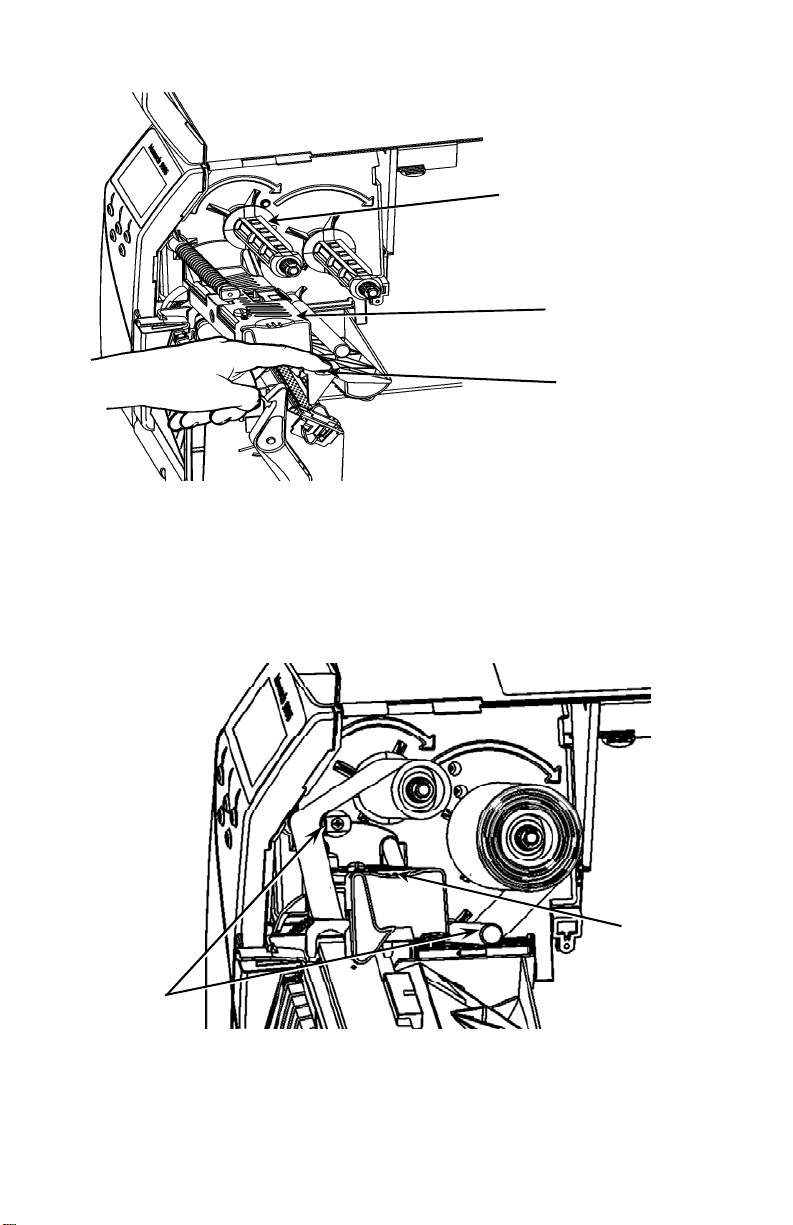

Loading Ribbon

1. Open the cover.

2. Unlock the printhead by turning the printhead retaining latch.

3. Lift the printhead assembly using the printhead tab until the

assembly locks into place.

EN-5

Page 6

4.

Push the deflector tab down.

Take-up Reel

Printhead

Assembly

Deflector Tab

5. Slide the extra ribbon core onto the take-up reel as far as it

will go.

6. Remove the new ribbon from the package.

7. Slide the ribbon all the way onto the back reel. Carefully

unwind a few inches from the bottom of the ribbon roll.

8. Feed the ribbon under both ribbon rollers and printhead.

Thumb

well

Ribbon

Rollers

9. Make sure the ribbon is straight and centered throughout the

path.

10. Tape the ribbon to the take-up core.

11. Rotate the take-up core until the leader is past the printhead.

6-EN

Page 7

12.

Remove any slack in the ribbon by turning the take-up reel

clockwise.

13. Hold the printhead assembly by the printhead tab while

pressing down on the printhead release.

14. Close the printhead by pressing down on the thumb well until

you hear it click into place.

15. Close the printhead. Close the printer’s cover.

16. Press FEED.

Cleaning

Clean the printhead as described to maintain printhead life.

Caution: Do not use sharp objects to clean the printhead or

touch the printhead; this may damage the printhead

and require a service charge.

1. Turn off the printer, open the cover and the printhead

assembly.

2. Remove the label roll and ribbon (when cleaning the

printhead).

3. Press down on the exit cover tabs to open the exit cover.

4. Spray the supply path, including supply sensor, with

compressed air to remove dust.

5. Use a CLEAN-STRIP (part number 120350) to clean and

remove adhesive build-up from the platen roller, peel bar,

sensor, and printhead.

Printhead

Peel Bar

6. Let the printer dry, then reload supplies.

7. Close the exit cover.

8. Close the printhead assembly and the printer’s cover.

9. Turn on the printer. Press FEED.

Sensor

Platen Roller

EN-7

Page 8

Selecting the Interpreter

The 9906 printer includes four Interpreter options; MPCL, MLI,

WMS XML, and Easy-Plug. For more information about MLI refer

to the MLI Quick Reference, for more information about WMS

XML refer to the XML Quick Reference, for more information

about Easy-Plug refer to the Easy-Plug Manual included on the

CD-ROM.

From the Main Menu, select Setup, then:

1. Press or until Interpreter is on the display.

SETUP

Interpreter

MPCL

CHANGE BACK

2. Press CHANGE then press until Easy-Plug is on the display.

MAIN MENU

Interpreter

Easy-Plug

SET CANCEL

3. Press SET to save the change.

The printer reboots automatically after selecting an

interpreter. This process may take several seconds.

When you print test labels with MLI set as the interpreter,

the model number appears as M9906MLI.

When you print test labels with Easy-Plug set as the

interpreter, the model number appears as M9906EP.

8-EN

Page 9

RFID (if installed)

The 9906 printer with RFID has been engineered to program

(encode) an RFID (Radio Frequency Identification) label

(commonly called “RFID tags”) before the label’s format is

printed. RFID tags contain an embedded RFID inlay (chip and

antenna).

RFID is only available using die cut or black mark supplies.

The printer supports Class 1 Generation 2 (C1Gen2) protocol

encoding.

RFID supplies can be damaged by static electricity.

Ground yourself by touching metal, such as the

printer’s metal base, before handling the supplies.

The UHF radio operates in the 902 – 928 MHz frequency range

in accordance with FCC Rules and Regulations.

RFID Setup Menu

Use the RFID Setup Menu to Read a tag, set the RF Power, and

Clear Data.

The Read Tag menu item lets you read the EPC data

programmed into an RFID tag.

Refer to the RFID Web Setup Utility at

http://www.servisource1.com/prnutil/rfidsetup

Power setting.

The printer stores the number of successful and failed

programmed tags. Clear this record using the Clear Data menu

item. Depending on your application and volume of labels

printed, you may want to clear this data daily or after each batch.

To access the RFID settings, from the Main Menu select Setup,

then RFID.

to set the RF

SETUP

← RFID →

SELECT BACK

If the RFID tag is not programmable for any reason, the label

may print with an overstrike pattern, indicating that it should not

be used. Your System Administrator should set the desired Error

Action accordingly.

If you see RFID errors 740 – 749, see your System

Administrator.

Refer to the Operator’s Handbook and Application Notes for more

information.

EN-9

Page 10

Troubleshooting

This section lists common problems and their solutions.

Problem Action

Error message

appears during

startup

Does not print.

Does not feed. Adjust the printhead pressure dials.

Partially printed data.

Light/Heavy printing,

printing shadows or

voids.

Serial bar codes do

not scan.

Liner is wrapped

around platen or peel

roller.

Printer does not read

or program the RFID

tag.

Turn off the printer, wait fifteen seconds

and then turn on the printer. Call

Customer Service if the error message

reappears.

Check supply and ribbon, send a

corrected format and batch packet.

Clean the printhead, send a corrected

format packet.

Clean the printhead, change supply,

adjust the print contrast, check the

printhead pressure dials, check the

ribbon.

Leave printhead unlatched when not in

use, use a print speed of 2.5 ips, adjust

the print contrast.

Carefully remove the liner. Make sure

the liner tears at the saw-toothed tear

edge when using backfeed and peel

mode.

See your System Administrator

10-EN

Page 11

Common Errors

Error Description/Action

002 Name must be 1 to 8 characters insid e quotes.

005 Invalid supply width.

018 Invalid code page selection.

025 Data length is too long.

101 Format referenced by batch not in memory.

400 Invalid character following {.

403 Field separator was not found.

409 Printer memory is full. Delete unused items.

410 Parity mismatch.

411 Framing error (baud rate mis match).

412 Flow control mismatch.

413 Online receive buffer is full. Check flo w control.

611 Font, bar code, or density in the batch does not fit the format.

612 Data in this line of the batch is missi ng or doesn’t m atch format.

613 Reference point off supply.

614 Portion of field off supply or inv alid character in t he pack et.

703

704

751

752 Printer sensed a mark in the wrong place.

753 Printer sensed a mark that is too lo ng.

754

755 Printhead is open. Close th e printhead.

756 Load supply and/or clean th e sensor.

757

758

763

765

768

Printer sensed a calibration of different-sized black m arks.

Make sure the correct supply type is loaded.

Printer has not sensed a supply mark when expected or is out

of supplies. Make sure your printer is set to the appro priate

supply type. Reload supply. Clean the sensor.

Printer did not sense a black mark when expect ed. Press

ESCAPE to continue printing. Change supply.

Check for a ribbon jam or remove any slack in the r ibbon. Load

a new ribbon.

Load supply (supply length mismatch). Press FEED.

Supply is not seen, on-demand sensor is brok en, or a label was

removed too quickly. Check for a label jam or reload suppli es.

Waiting to dispense label. Press FEED.

Printhead has less than 8 bad dots and c an shift bar code fi elds

to avoid bad dots. Press ESCAPE to continue printing.

Printhead has more than 8 bad dots or is not connected.

Connect or replace the printhead.

EN-11

Page 12

RFID Errors

See the RFID Application Notes for more information. Check with your System

Administrator about the format. The printer do es not recalibrate (feed a blank

label) after an RFID error.

Error Description/Action

052

053

226

228

229

230

715 Invalid data length/data mismatch in the RFID Data Field. This

732 RFID Hardware Error. A non-RFID printer received a format

740

741 RFID tag missing - not found in the area inside the printer where

742 Tag erase failed. The RFID tag was found in the RF F ield, but

743 Program tag failed. The RFID tag was found in the RF F ield, but

744 Tag locked fail. The RFID tag is unable to b e programmed

746 Lock tag fail. The RFID tag has not been l ocked to prevent

747 Time out failure. An RFID command (read, program, etc.) has

748 Invalid data length/data mismatch from RFID interrogator

749 RFID Verify Fail. The RFID verification process failed after

Data type in the RFID Data Field is invalid .

The starting block in the RFID Data Field is inv alid.

Rule Record Line xx. Upload device is invalid.

Memory class identifier is invalid.

Byte code is invalid.

Lock code is invalid.

error also occurs when there is an error in the Expanded

C1Gen2 fields.

containing an RFID Data Field.

Command, hardware, or memory allocation error.

the RFID tag is programmed. Check supply loadin g. Make sure

the RFID tag was not moved out of the programmable ran ge.

could not be erased.

could not be programmed.

because it is already locked.

reprogramming.

failed to complete in the maximum amount of allowed time.

module.

writing (programming) tag.

12-EN

Page 13

MANUEL DE REFERENCE RAPIDE

Ce Manuel de référence rapide présente les procédures relatives au ch argement

des consommables et à l’entretien général de l’imprimante Monarch® 9906.

Pour obtenir des informations détaillées, reportez-vous au Operato r’s Handbook

(Manuel de l’opérateur) disponible sur notre site Web (www.monarch.com

de plus amples informations sur la création de formats et la con figuration ou la

programmation de l’imprimante, reportez-vous au Packet Reference Manual

disponible sur notre site Web.

Consultez les informations relatives à la sécurité figurant dans le document Conformité

réglementaire fourni avec l’imprimante. Les informations contenues dans le présent

document remplacent celles des versions précédentes. Consultez notre site Web pour

télécharger la documentation et les informations de version les plus récentes.

Remarque : L’imprimante Monarch® 9906 utilise le pilote Monarch® 9855®.

Branchement des câbles

L’alimentation bascule automatiquement entre 115 V et 230 V.

1. Branchez une extrémité du câble d’alimentation

sur le connecteur de l’imprimante et l’autre

dans une prise électrique mise à la terre.

2. Connectez le câble de communication

au port approprié.

3. Mettez l’imprimante sous tension. Appuyez

sur (I) pour la mettre sous tension et sur (O)

pour la mettre hors tension.

Utilisation du panneau

de commandes

Le panneau de commandes se compose

d’un affichage à cristaux liquides de

quatre lignes, de trois boutons de

fonction et de deux boutons de

navigation. La fonction de chaque

bouton varie en fonction de la tâche

à exécuter. L’affichage à cristaux liquides :

indique la mise sous tension lorsque du texte

ou d’autres informations sont affichées ;

indique par un arrière-plan rouge les

conditions nécessitant une attention

immédiate (batterie faible, pannes,

erreurs) ;

affiche les invites de menu, les

paramètres de l’imprimante, les

affectations des boutons de fonction,

les valeurs, etc.

Port

parallèle

(en option)

Port série

USB de l’hôte

USB du

périphérique

Connecteur

du câble

d’alimentation

MPCL

FEED

Boutons de

fonction

Boutons de

navigation

). Pour

Online

TLabel MENU

FR-1

Page 14

Chargement des étiquettes

1. Ouvrez le couvercle.

2. Débloquez la tête d’impression en faisant tourner le loquet de r etenue.

Tête d’impression

Loquet de retenue

3. Soulevez le mécanisme de la tête d’impression en le saisissant par la

languette jusqu’à son blocage en position.

4. Placez le rouleau d’étiquettes sur le support, situé contre l’intérieur de l’imprimante.

5. Réglez le guide du porte-support de sorte qu’il soit à peine en contact avec

le rouleau, en veillant à ce que ce dernier tourne librement .

2-FR

Guide du porte-support

Porte-support

Page 15

6. Enfoncez le levier des étiquettes afin de débloquer le guide d’étiquettes .

7. Placez la bande d’étiquettes sur le guide de manière à ce qu’elle dépasse

d’une dizaine de centimètres à l’avant de l’imprimante.

8. Placez les étiquettes sous les picots du guide et au centre du capteur de

coupure.

9. Réglez le guide de sorte qu’il soit à peine en contact avec l’étiquette. Tirez

sur le levier des étiquettes afin de bloquer les guides dans leur position.

Capteur de

coupure

Picots

Levier des

étiquettes

10. Maintenez le mécanisme de la tête d’impression par sa languette tout en

appuyant sur le dispositif de déblocage.

Déblocage de la

tête d’impression

Tête d’impression

FR-3

Page 16

11. Fermez la tête d’impression en exerçant une pression du pouce à

l’emplacement prévu à cet effet jusqu’à ce que vous entendiez un déclic.

12. Fermez le couvercle de l’imprimante.

13. Appuyez sur FEED (Avance).

Chargement des étiquettes pour le mode de

décollement disponible en option

1. Décollez les étiquettes de la bande sur les 25 premiers centimètres.

2. Appuyez sur les languettes du couvercle de sortie pour o uvrir ce dernier.

3. Placez la bande sur la barre de décollement, le long de la glissière, puis

sortez-la en passant par l’ouverture inférieure d u couvercle de sortie.

Barre de

décollement

Rouleau de

décollement

4. Fermez le couvercle de sortie.

5. Fermez le couvercle de l’imprimante.

6. Appuyez sur FEED (Avance).

Pour en savoir plus sur les autres options de chargement d’éti quettes, report ezvous au Operator’s Handbook (Manuel de l’opérateur).

4-FR

Cylindre

Ouverture

inférieure

Page 17

Réglage des cadrans à pression de la tête

d’impression

Le réglage par défaut est la pression minimale, qui permet un e impression

optimale dans la plupart des cas. En cas de maculage, de plissage du rub an ou

d’une mauvaise qualité d’impression, vous serez peut-être amené à régle r les

cadrans.

Les deux cadrans sont situés de chaque côté de la tête d’impression (à

l’intérieur et à l’extérieur). Ils peuvent être réglés sur des positions différentes ;

mais la pression du cadran intérieur doit être égale ou sup érieure à celle du

cadran extérieur. Avec les étiquettes de 10 cm de large (4 po uces), les deux

boutons doivent réglés sur la meme pression. Pour régler les cadrans, servezvous d'une pièce ou d'un tournevis à lame plate.

Cadrans de

pression de la

tête d’impression

Chaque cadran comporte

quatre réglages :

Pression minimale

Pression légère

Pression moyenne

Pression maximale

Imprimez une étiquette de test pour vérifier la pression de l a tête; procédez

ensuite à des ajustements si nécessaire. Pour plus d’informations, repo rtez-vous

au manuel de l’opérateur (Operator’s Handbo ok, en anglais un iquement).

Pression

minimale

Pression

maximale

Installation du ruban

1. Ouvrez le couvercle.

2. Débloquez la tête d’impression en faisant tourner son loquet de retenue.

3. Soulevez le mécanisme de la tête d’impression en le saisissant par la

languette jusqu’à son blocage en position.

FR-5

Page 18

4. Enfoncez la languette du déflecteur.

p

Bobine réceptrice

Mécanisme

de la tête

d’im

ression

Languette du

déflecteur

5. Faites glisser le mandrin de ruban supplémentaire le plus loin possible sur la

bobine réceptrice.

6. Retirez le nouveau ruban de sa boîte.

7. Faites passer le ruban jusqu’à la bobine arrière. Dé roulez soigneusement

une dizaine de centimètres du bas du rouleau de ruba n.

8. Faites soigneusement passer le ruban sous les rouleaux et la tête d'impression.

Les

rouleaux

9. Veillez à ce que le ruban soit bien droit et centré sur toute sa longueur.

10. Attachez le ruban au mandrin récepteur.

11. Faites tourner le mandrin récepteur jusqu’à ce que le repère dépasse la tête

d’impression.

6-FR

Pression

du pouce

Page 19

12. Tendez le ruban en tournant la bobine réceptrice dans le sens des aiguilles

d’une montre.

13. Maintenez le mécanisme de la tête d’impression par sa languette tout en

appuyant sur le dispositif de blocage.

14. Fermez la tête d’impression en exerçant une pression du pouce à

l’emplacement prévu à cet effet jusqu’à ce que vous entendiez un déclic.

15. Fermez-la. Fermez le couvercle de l’imprimante.

16. Appuyez sur FEED (Avance).

Nettoyage

Vous devez nettoyer l’imprimante comme décrit pour en préserver la durée de

vie utile.

Attention : N’utilisez pas d’objets pointus pour nettoyer la têt e d’impression

1. Mettez l’imprimante hors tension et ouvrez le couvercle et le mécanisme de

la tête d’impression.

2. Retirez le rouleau d'étiquettes et le rub an (lor s du nett oyag e de la tê te d’impr essio n).

3. Appuyez sur les languettes du couvercle de sortie pour o uvrir ce dernier.

4. Pour enlever la poussière et les particules déposées sur le capteur,

vaporisez de l'air comprimé.

5. Servez-vous de l'article CLEAN-STRIP (n° de référence 120 350) pour

nettoyer et enlever l'accumulation d'adhésif sur le cylindre, la barr e de

décollement, le capteur et la tête d'impression.

et ne touchez pas cette dernière avec vos doigts. Cela risquerait

d’endommager l’imprimante et d’entraîner des frais d’entretien

supplémentaires.

Tête

d'impression

Barre de

décollement

6. Laissez sécher l’imprimante, puis rechargez les étiquettes.

7. Fermez le couvercle de sortie.

8. Fermez le mécanisme de la tête d’impression et le couvercle de

l’imprimante.

9. Mettez l’imprimante sous tension. Appuyez sur FEED (Avance).

Capteur

Cylindre

Sélection de I'interpréteur

L'imprimante 9906 comprend quatre options d'in terpréteur: MP CL, MLI, WMS

XML et Easy-Plug. Pour plus d'informations sur MLI, consultez le Manuel d e

référence rapide de MLI; pour plus d'informations sur WMS XML, cons ultez le

Manuel de référence rapide de XML; pour plus d'informations sur Easy-Plug,

consultez le Manuel d'Easy-Plug inclus sur le CD-ROM.

FR-7

Page 20

Dans le menu principal, choisissez Configurer, puis:

1. Appuyez sur ou sur jusqu'à ce que l'inte rpréteur s'affiche à l'écran.

SETUP

Interpreter

MPCL

CHANGE BACK

2. Appuyez sur CHANGE, puis sur jusqu'à ce qu'Easy-Plug s'affiche à l'écran.

MAIN MENU

Interpreter

Easy-Plug

SET CANCEL

3. Appuyez sur SET pour enregistrer votre modification.

L'imprimante redéma rre automatiquement après la sélection d'un

interpréteur. Cette opération peut prendre plus ieurs secondes.

Lorsque vous imprimez des é tiquettes de test en ayant co nfiguré MLI

comme interpréteur, le numéro du modèle affiché est M9906MLI.

Lorsque vous imprimez des é tiquettes de test en ayant co nfiguré Easy-

Plug comme interpréteur, le numéro du modèle affiché est M9906EP.

RFID (si installé)

L'imprimante 9906 avec RFID a été conçue pour p rogrammer (c oder) une

étiquette d'identification par radiofréquence (couramment appelée « étiquette

RFID ») avant impression du format de l’étiquette. Les étiq uettes RFID

contiennent une incrustation RFID (puce et antenne).

La technologie RFID est uniquement disponible dans les consommables de type

pré-découpés ou Black Mark.

L'imprimante prend en charge le codage multi-protocole Class 1 Generation 2

(C1Gen2).

Les consommables RFID sont sensibles à l'électricité statique, qui

peut les endommager. Mettez-vous à la terre en to uchant une

pièce en métal, comme le socle métallique de l'imprimante, avant

de manipuler les consommables.

La radio fonctionne dans la plage de fréquences de 902 à 928 MHz

conformément aux règles et réglementations de la FCC.

Menu RFID Setup (Configuration RFID)

Utilisez le menu RFID Setup (Configuration RFID) pour Read Tag (Lire une

étiquette), Set RF Power (Régler la puissance RF) et Clear Da ta (Effacer les

données).

L'option de menu Read Tag (Lire une étiquett e) vous permet de lire les données

EPC programmées dans l'étiquette RFID.

SETUP

← RFID →

SELECT BACK

Pour régler le niveau de puissance RF, reportez-vous au RFID Web Setup Utility

à http://www.ser visource1.com/prnutil/rfids etup

8-FR

.

Page 21

L'imprimante enregistre le nombre d'étiquettes dont la pr ogrammation a réussi

ou échoué. Effacez cet enregistrement en utilisant l'option de menu Clear Data

(Effacer les données). Selon votre application et le volume d’étiquettes

imprimées, vous pourrez décider d'effacer ces données chaque jou r ou après

chaque lot.

Pour accéder aux paramètres RFID, à partir de Main Menu (M enu principal),

sélectionnez Setup (Configuration), puis RFID.

Si l'étiquette RFID n’est pas programmable pour une raison quelconque, il est

possible qu'elle s'imprime avec un motif de surimpression, indiquant qu 'elle ne

doit pas être utilisée. Votre administrateur système devra définir la mesure

corrective appropriée.

Si vous voyez s'afficher les erreurs RFID (740 à 749), consultez votre

administrateur système.

Pour plus d’informations, reportez-vous au Manuel d e l'opérateur et aux Notes

d'application.

Dépannage

Cette section présente les problèmes couramment rencontrés et la solu tion

correspondante.

Problème Solution

Un message d'erreur

s’affiche lors de la

mise en route.

L’imprimante n’imprime

pas.

Problème

d’alimentation de

l’imprimante.

Impression partielle

des données.

Impression trop

claire/trop foncée,

impression d’ombres

ou d'espaces vides.

Pas de lecture des

codes à barres en

série.

La bande est enroulée

autour du cylindre ou

du rouleau de

décollement.

L'imprimante ne lit ou

ne programme pas

l'étiquette RFID.

Mettez l’imprimante hors tension, attendez une

quinzaine de secondes, puis rallumez-la. Si le

message d’erreur réapparaît, contactez le service

clientèle.

Vérifiez l’approvisionnement en étiquettes et le

ruban, envoyez un paquet de formats et de lots

corrigés.

Réglez les cadrans à pression de la tête

d’impression.

Nettoyez la tête d’impression, envoyez un paquet de

format corrigé.

Nettoyez la tête d’impression, remplacez les

étiquettes, réglez le contraste d’impression, vérifiez

les cadrans à pression de la tête, vérifiez le ruban.

Laissez la tête d’impression déverrouillée lorsqu’elle

n’est pas en service, utilisez une vitesse

d’impression de 2,5 pps, réglez le contraste

d’impression.

Retirez délicatement la bande. Veillez à ce qu’elle se

déchire sur le bord coupant dentelé en mode de

recul ou de décollement.

Consultez votre administrateur système

FR-9

Page 22

Erreurs courantes

Erreur Description/Solution

002 Le nom doit comprendre entre 1 et 8 caractères placés entre guillemets.

005 Largeur d’étiquette incorrecte.

018 Sélection de page de code incorrecte.

025 Longueur des données trop élevée.

101 Format auquel renvoie le lot non placé en mémoire.

400 Caractère incorrect après {.

403 Séparateur de champ introuvable.

409 Mémoire de l’imprimante saturée. Supprimez les éléments inutilisés.

410 Différence de parité.

411 Erreur de débit (vitesse en bauds différente).

412 Erreur de contrôle de flux.

413 Mémoire tampon de réception saturée. Vérifiez le contrôle de flux.

611 Police, code à barres ou densité du lot ne convenant pas au format.

612 Données de lot introuvables ou ne correspondant pas au format.

613 Point de référence hors étiquette.

614 Portion du champ hors étiquette ou caractère incorrect dans le paquet.

703 Détection par l’imprimante d’un calibrage de marques noires de tailles

704 L’imprimante n’a pas détecté de repère de lecture au moment

751 L’imprimante n’a pas détecté de repère noir à l’endroit attendu.

752 L’imprimante a détecté un repère de lecture mal placé.

753 L’imprimante a détecté un repère de lecture trop long.

754 Soit il s’agit d’un bourrage de ruban soit le ruban a besoin d’être

755 La tête d’impression est ouverte. Fermez-la.

756 Chargez des étiquettes et/ou nettoyez le capteur.

757 Réapprovisionnez l’imprimante en étiquettes (longueur des

758 Les étiquettes n’ont pas été détectées, le capteur d’étiquettes à l’unité

763 En attente de récupération d’étiquette. Appuyez sur FEED

765 La tête d’impression compte moins de 8 mauvais points et peut déplacer

768 La tête d’impression compte plus de 8 mauvais points ou elle n’est

différentes. Assurez-vous que le bon type d’étiquettes est chargé.

attendu ou elle est à cours d'étiquettes. Assurez-vous que

l’imprimante est réglée sur le type d’étiquettes approprié.

Réapprovisionnez l’imprimante en étiquettes. Nettoyez le capteur.

Appuyez sur ESCAPE (Echap) pour continuer l’impression.

Rechargez des étiquettes.

retendu. Installez un nouveau ruban.

étiquettes incorrecte). Appuyez sur FEED (Avance).

ne fonctionne pas ou une étiquette a été retirée trop rapidement.

Vérifiez qu’il n’y a pas de bourrage ou rechargez des étiquettes.

(Avance).

les champs de codes à barres pour continuer l’impression. Appuyez sur

ESCAPE (Echap) pour continuer l’impression.

pas connectée. Connectez ou remplacez la tête d’impression.

10-FR

Page 23

Erreurs RFID

Pour de plus amples informations, consultez les Notes d'application RFID. P our

plus d'informations, consultez votre administrateur s ystème. L'imprima nte ne se

recalibre pas (avancée d'une étiquette vierge) après une e rreur RFID

quelconque.

Erreur Description/mesure corrective

052 Le type de données dans le champ de données RFI D doit être 0, 1,

226 Ligne d'enregistrement de règle xx. L'appareil de téléchargeme nt

228 L'identifiant de classe de mémoire est incorrect.

229 Le pseudo-code binaire est incorrect.

230 Le code de verrouillage est incorrect.

715 Invalid data length/data mismatch dans le champ de données RFI D

740 Command, hardware, inventory, or memory allocation e rror (Erreur

741 RFID tag missing (Étiquette RFID manquante) - n'a pas été tro uvée

742 Tag erase failed (Échec d'effacement d'étiquette). L'étiquette RF ID

743 Program tag failed (Échec de programmation d'étiquet te).

744 Tag locked fail (Échec de verrouillage d'étiquette). Il est impossible

746 Lock tag fail (Échec de verrouillage d'étiquette). L'étiquette RF ID n'a

747 Time out failure (Échec pour dépassement de délai

748 Invalid data length/data mismatch from RFID interrogator

749 RFID Verify Fail (Échec de vérification RFID). Le processus de

2 ou 3.

est incorrect.

(Longueur des données non valide/non-concordance de d onnées).

Cette erreur se produit également en présence d’une erreur d ans

les champs de données Expanded C1Gen2.

de commande, matériel, inventaire ou mémoire). Il existe peut -être

une erreur d'allocation de mémoire ou de matériel R FID.

dans zone à l'intérieur de l'imprimante où l'étiquette RFID est

programmée. Vérifiez le chargement de consommable. Assurezvous que l'étiquette RFID ne s'est pas déplacée en dehors de la

plage programmable.

a été détectée dans le champ RF, mais elle n'a pas pu être e ffacée.

L'étiquette RFID a été détectée dans le cham p RF, mais elle n'a pas

pu être programmée.

de programmer l'étiquette RFID, car elle est déjà verrouillée.

pas été verrouillée pour empêcher une reprogrammation.

d'activation). Une commande RFID (lecture, programmation,

etc.) ne s'est pas exécutée dans le délai imparti.

module (Longueur des données non valide/non-concordance

de données issues du module interrogateur RFID). Le module

interrogateur RFID a détecté un problème au niveau des

données reçues de l'imprimante.

vérification RFID a échoué après écriture (program mation) de

l'étiquette.

FR-11

Page 24

12-FR

Page 25

REFERÊNCIA RÁPIDA

ç

Esta Referência Rápida contém procedimentos de carregam ento de

consumíveis, cuidados gerais e manutenção para a impressora Monarch® 9906.

Para obter informações mais detalhadas, consulte o Manual do utilizador

disponível no nosso Web site (www.monarch.com

sobre como criar formatos, configurar a impressora ou pro gramar a impressora ,

consulte o Packet Reference Manual no nosso Web site.

Leia as informações de segurança no documento Conf ormidade Regula mentar

incluído com a impressora. As informações neste documento s ubstituem as

informações em versões anteriores. Consulte o nosso Web site par a obter a

documentação mais recente e informações sobre lançamentos.

Nota: A impressora Monarch® 9906 utiliza o controlador Monarch® 9855®.

Ligar os cabos

A fonte de alimentação alterna automaticamente

entre 115 V e 230 V.

1. Ligue o cabo de alimentação à ficha e

a outra extremidade a uma toma da

eléctrica com terra.

2. Ligue o cabo de comunicações

à porta adequada.

3. Ligue a impressora. Prima ( I ) para

ligar e ( O ) para desligar a impressora.

Utilizar o Painel de controlo

O painel de controlo consiste num ecrã

LCD de quatro linhas, três botões de

função, e dois botões de navegação.

A função de cada botão varia

consoante a tarefa. O ecrã LCD:

Indica a energia quando é

apresentado texto ou outra

informação.

Indica condições que requerem atenção

imediata (bateria fraca, avarias, erros)

utilizando um fundo vermelho.

Mostra solicitações de menu,

definições de impressora,

atribuições de botões

de função, valores, etc.

). Para obter informações

Porta paralela

(opcional)

Porta

de série

Anfitr i ão US B

Dispositivo

USB

Ligação de cabo

de alimentação

Botões de

fun

ão

Botões de

navegação

MPCL

Online

FEED TLABEL

MENU

PT-1

Page 26

Carregar etiquetas

1. Abra a tampa.

2. Desbloqueie a cabeça de impressão rodando o trinco.

Aba da cabeça

de impressão

Trinco

3. Levante a cabeça de impressão utilizando a respectiva aba até que bloqueie

no devido lugar.

4. Coloque o rolo de alimentação no respectivo suporte, situad o contra o

interior da impressora.

5. Ajuste a guia do suporte de alimentação de forma a tocar apenas ligeiramente

no rolo, certificando-se de que o rolo de alimentação roda livremente.

Guia do suporte

de alimentação

Suporte de

alimentação

6. Pressione a alavanca de alimentação para baixo pa ra desbloquear a guia de

alimentação.

2-PT

Page 27

7. Disponha a faixa de etiquetas na guia de alimentação de forma a que alguns

cm se prolonguem para além da parte dianteira da impr essora.

8. Coloque a alimentação sob os limites e entre o sensor de corte .

9. Ajuste a guia de alimentação de forma a tocar apenas ligeiram ente na

alimentação. Empurre a alavanca de alimentação para cim a para bloquea r

as guias de alimentação no devido lugar.

Sensor de

corte

Limites

Alavanca de

alimentação

10. Segure a cabeça de impressão pela aba enquanto pressiona o dispositivo

de libertação da mesma.

Dispositivo de

libertação da cabeça

de impressão

Aba da cabeça

de impressão

PT-3

Page 28

11. Feche a cabeça de impressão pressionando a cavidade para polegar até a

p

ouvir encaixar no respectivo lugar.

12. Feche a tampa da impressora.

13. Prima FEED (Alimentação).

Carregar etiquetas para o modo de fita opcional

1. Remova as etiquetas dos primeiros 25 cm de linha.

2. Pressione as abas da tampa de saída para abrir a tampa de saída.

3. Alimente a linha sobre a barra de fita, a par da calha, e pa ra fora atr avés da

abertura inferior na tampa de saída.

Barra de fita

Rolo de

im

ressão

Abert u r a

Rolo de fita

4. Feche a tampa de saída.

5. Feche a tampa da impressora.

6. Prima FEED (Alimentação).

Para opções de carregamento de consumíveis opcionais, cons ulte o Manual d o

utilizador.

4-PT

inferior

Page 29

Ajustar os indicadores de pressão da cabeça de

impressão

A predefinição é a pressão mínima, o que fornece uma imp ressão ideal na

maioria dos casos. Se notar manchas, enrugamento da fita ou qualidade fraca

da impressão, pode ser necessário ajustar os indicadores de pressão da cabeça

de impressão.

Os dois indicadores estão situados em ambas as extremidades do conjunto d a

cabeça de impressão (interior e exterior). Os indicadores p odem ser definidos

para diferentes posições; No entanto, o indicador interior deve ter uma pressão

igual ou superior ao indicador exterior. Ao utilizar um a entrada de 4 polegadas,

ambos os botões devem estar regulados a uma pressão igual. Utilize uma

moeda uma chave de cabeça plana para ajustar os indicadores .

Indicadores de pressão

da cabeça de impressão

Cada indicador tem quatro

definições:

Pressão mínima

Pressão reduzida

Pressão média

Pressão máxima

Imprima uma etiqueta de teste para verificar a p ressão da cabeça de impressã o;

efectue regulações, conforme necessário. Consulte o Man ual do utilizador para

informações adicionais.

Pressão

mínima

Pressão máxima

Carregar fita

1. Abra a tampa.

2. Desbloqueie a cabeça de impressão rodando o trinco da mesma.

3. Levante a cabeça de impressão utilizando a respectiva aba até que bloqueie

no devido lugar.

PT-5

Page 30

4. Pressione a aba deflectora para baixo.

Bobina receptora

Cabeça de

impressão

Aba deflectora

5. Faça deslizar o núcleo de fita adicional para a bobina receptora, o máximo

que conseguir.

6. Retire a fita nova da embalagem.

7. Faça deslizar a fita totalmente para a bobina receptora. Desbobine

cuidadosamente alguns cm da parte inferior do rolo de fita.

8. Alimente cuidadosamente a fita sob ambos os rolos de fita e cabeça de

impressão.

Cavidade para

polegar

Rolos

de fita

9. Certifique-se de que a fita está direita e centrada ao longo do caminho.

10. Prenda a fita ao núcleo receptor.

11. Rode o núcleo receptor até o início da fita estar para além da cabeça de

impressão.

12. Remova qualquer folga na fita rodando a bobina receptora no sentido dos

ponteiros do relógio.

13. Segure a cabeça de impressão pela aba enquanto pressiona o dispositivo

de libertação da mesma.

6-PT

Page 31

14. Feche a cabeça de impressão pressionando a cavidade para polegar para

baixo até a ouvir encaixar no respectivo lugar.

15. Feche a cabeça de impressão. Feche a tampa da impressora.

16. Prima FEED (Alimentação).

Limpar

Deve limpar a cabeça de impressão conforme descrito para m anter o tempo d e

vida da cabeça de impressão.

Cuidado: Não utilize objectos afiados para limpar a cabeça de impressão ou

1. Desligue a impressora, abra a tampa e a cabeça de im pressão.

2. Remova o rolo de etiquetas e a fita (ao limpar a cabeça de impressão).

3. Pressione as abas da tampa de saída para abrir a tampa de saída.

4. Para remover pó e resíduos do sensor, utilize ar comprimido.

5. Utilize uma CLEAN-STRIP (referência 120350) para limpar e remover o

adesivo acumulado no rolo de impressão, na barra de fita , no sensor e n a

cabeça de impressão.

Cabeça de

impressão

tocar na mesma. Tal poderá danificar a cabeça de impressão e

exigir uma taxa de serviço.

Sensor

Barra de fita

6. Permita que a impressora seque e coloque os consumíveis novament e.

7. Feche a tampa de saída.

8. Feche a cabeça de impressão e a tampa da impressora.

9. Ligue a impressora. Prima FEED (Alimentação).

Rolo de

impressão

Seleccionar o Intérprete

A impressora 9906 inclui quatro opções de Intérprete; MPCL, MLI, WMS XML e

Easy-Plug. Para obter mais informações sobre MLI, consulte Referência Rá pida

sobre MLI (MLI Quick Reference), para obte r mais informações sobre WMS

XML, consulte Referência Rápida sobre XML (XML Quick Re ference), pa ra obter

mais informações sobre Easy-Plug, consulte o Manual Easy-Plug (Easy-Plug

Manual) incluído no CD-ROM.

No Menu Principal (Main Menu), seleccione Configurar (S etup) e:

1. Prima ou até que o Intérprete seja apresentado.

SETUP

Interpreter

MPCL

CHANGE BACK

PT-7

Page 32

2. Prima ALTERAR (CHANGE) e, de seguida, prima até que o Easy-Plug

seja apresentado.

MAIN MENU

Interpreter

Easy-Plug

SET CANCEL

3. Prima CONFIGURAR (SET) para guardar a alteração.

A impressora reinicia-se autom aticamente após seleccionar um

intérprete. Este processo pode demorar alguns segun dos.

Ao imprimir etiquetas de t este com MLI definido como intérprete, o

número do modelo aparece como M9906MLI.

Ao imprimir etiquetas de t este com Easy-Plug d efinido como intérprete,

o número do modelo aparece como M9906EP.

RFID (se instalado)

A impressora 9906 com RFID foi concebida para programar (c odificar) uma

etiqueta RFID (Identificação por Radiofrequência) (denomin adas “etiquetas

RFID”) antes de o formato da etiqueta ser impre sso. As etiquetas RFID contêm

uma aplicação RFID integrada (chip e antena).

RFID só está disponível no corte de moldes ou consumíveis de marca negra.

A impressora suporta a codificação de protocolo Classe 1 Geração 2 (C1Gen2).

Os consumíveis RFID podem ser danificados pela electricidade

estática. Toque em metal, como a base metálica da impressora,

antes de lidar com os consumíveis.

O rádio UHF funciona na gama de frequência 902 – 928 MHz em

conformidade com as normas e regulamentações da FCC.

Menu de configuração RFID

Utilize o menu Setup (Configuração) RFID para ler uma etiqueta, configurar a

potência RF e apagar dados.

A opção de menu Read Tag (Ler etiqueta) per mite ler os dados EPC

programados numa etiqueta RFID.

Consulte o RFID Web Setup Utility em

http://www.servisource1.com/prnutil/rfidsetup

RF.

A impressora armazena o número de etiquetas programad as com sucesso e

sem sucesso. Apague este registo através da opção de menu Clear Da ta

(Apagar dados). Dependendo da sua aplicação e do volume de etiquetas

impressas, convém apagar estes dados diariamente ou após cada lot e.

Para aceder às definições RFID, a partir do menu principal, sel eccione Setup

(Configuração) e, de seguida, RFID.

para definir o nível de potência

SETUP

← RFID →

SELECT BACK

Se, por algum motivo, a etiqueta RFID não for pro gramável, a etiqueta p ode

imprimir com um padrão de riscas, indicando que não deve ser utilizada. O s eu

administrador de sistema deve definir a acção de erro pretendida,

adequadamente.

8-PT

Page 33

Detecção e resolução de problemas

Esta secção lista problemas comuns e respectivas soluções.

Problema Acção

Surge uma mensagem

de erro durante o

arranque.

Não imprime. Verifique os consumíveis e a fita, envie um pacote

Não alimenta. Ajuste os indicadores de pressão da cabeça de

Dados parcialmente

impressos.

Impressão

leve/pesada, sombras

de impressão ou

vazios.

Os códigos de barra

de série não

digitalizam.

A linha está envolvida

no rolo de impressão

ou fita.

A impressora não lê

nem programa a

etiqueta RFID.

Desligue a impressora, aguarde quinze segundos, e

volte a ligá-la. Contacte o Apoio ao cliente caso a

mensagem de erro surja novamente.

de lote e formato corrigido.

impressão.

Limpe a cabeça de impressão, envie um pacote de

formato corrigido.

Limpe a cabeça de impressão, mude o consumível,

ajuste o contraste de impressão, verifique os

indicadores de pressão da cabeça de impressão,

verifique a fita.

Deixe a cabeça de impressão destrancada quando

não estiver em utilização, utilize uma velocidade de

impressão de 2,5 ips, ajuste o contraste de

impressão.

Remova a linha cuidadosamente. Certifique-se de

que a linha rasga no limite dentado ao utilizar o

modo de fita e retroalimentação.

Consulte o administrador do sistema

PT-9

Page 34

Erros comuns

Erro Descrição/Acção

002 O nome deve ter entre 1 e 8 caracteres entre as pas.

005 Largura de alimentação inválida.

018 Selecção de página de código inválida.

025 Extensão de dados demasiado longa.

101 Formato referenciado por lote não se encontra na memória.

400 Caracter inválido após {.

403 Separador de campo não encontrado.

409 A memória da impressora está cheia. Elimine itens não utilizados.

410 Falha de concordância de paridade.

411 Erro de enquadramento (falha de concordância de v elocidade de

412 Falha de concordância do controlo de fluxo.

413 O buffer de recepção online está cheio. Verifique o controlo do fluxo.

611 O tipo de letra, código de barras ou densidade no lote nã o se adapta

612 Os dados nesta linha do lote estão em falta ou não corr espondem ao

613 Ponto de referência fora da alimentação.

614 Parte do campo fora da alimentação ou caracter inválido no pa cote.

703 A impressora detectou uma calibração de marcas pretas de diferentes

704 A impressora não detectou uma marca de alimentação quando esperado

751 A impressora não detectou uma marca preta quando espera do. Prima

752 A impressora detectou uma marca no local errado.

753 A impressora detectou uma marca demasiado longa.

754 Verifique se a fita está encravada ou remova qualquer f olga na mesma.

755 A cabeça de impressão está aberta. Feche a cabeça de impressão.

756 Carregue consumíveis e/ou limpar o sensor.

757 Carregue consumíveis (falha de concordância de extensão de

758 O consumível não é visto, o sensor a pedido está partido, ou uma

763 A aguardar para dispensar etiqueta. Prima FEED (Alim entação).

765 A cabeça de impressão tem menos de 8 pontos maus e pode muda r

768 A cabeça de impressão tem mais de 8 pontos maus ou não está ligad a.

transmissão).

ao formato.

formato.

tamanhos. Certifique-se de que é carregado o tipo de alimentação correcto.

ou está sem consumíveis. Certifique-se de que a impressora está definida

para o tipo de consumível adequado. Carregue c o n s u m í v e i s . Li m p a r o

sensor

ESCAPE para continuar a impressão. Mude o consumível.

Carregue uma nova fita.

consumíveis). Prima FEED (Alimentação).

etiqueta foi retirada antes do tempo. Verifique se a eti queta está

encravada ou carregue consumíveis.

campos de códigos de barras para evitar pontos maus. Prima ESC APE

para continuar a impressão.

Ligue ou substitua a cabeça de impressão.

10-PT

Page 35

Erros RFID

Consulte as Notas de aplicação RFID para mais informações. Consulte o seu

administrador de sistema acerca do formato. A impressora não recalibra

(introduza uma etiqueta em branco) após um e rro RFID.

Erro Descrição/Acção

052 O tipo de dados no campo de dados RFID é inválido.

053 O bloco inicial no campo de dados RFID é inválido.

226 Rule Record, linha xx. O dispositivo de carregamento é inválid o.

228 O identificador da classe de memória é inválido.

229 O código de bytes é inválido.

230 O código de bloqueio é inválido.

715 Comprimento de dados inválido/não correspondência dos dados no

732 Erro de hardware RFID. Uma impressora não RFID receb eu um formato

740 Erro de comando, hardware ou atribuição de m emória.

741 Etiqueta RFID em falta - não encontrada na áre a no interior da

742 Falha ao apagar etiqueta. A etiqueta RFID foi encontrada no c ampo

743 Falha ao programar etiqueta. A etiqueta RFI D foi encontrada n o campo

744 Falha por bloqueio da etiqueta. A etiqueta RFID nã o pode ser

746 Falha ao bloquear etiqueta. A etiqueta RFID não foi blo queada par a

747 Falha por tempo esgotado. Não foi possível concluir um com ando RFID

748 Comprimento de dados inválido/não correspondência dos dados a partir

749 Falha ao verificar RFID. Falha do processo de verificação RFID após

campo de dados RFID. Este erro também ocorre q uando existe um erro

nos campos C1Gen2 expandidos.

com um campo de dados RFID.

impressora onde a etiqueta RFID está programada. V erifique o

carregamento de consumíveis. Certifique-se de que a eti queta RFID n ão

foi movida para fora do intervalo programável.

RFID, mas não pôde ser apagada.

RF, mas não pôde ser programada.

programada porque já está bloqueada.

evitar uma reprogramação.

(leitura, programação, etc.) dentro do espaço de tempo pe rmitido.

do módulo interrogador RFID.

programação da etiqueta.

PT-11

Page 36

12-PT

Page 37

REFERENCIA RÁPIDA

En esta Referencia rápida se describen los procedimientos de colocación del

papel y de cuidados generales y mantenimiento para la impr esora Monarch ®

9906. Para obtener información más detallada, consulte el manual del operad or

(Operator’s Handbook) que se encuentra disponible en nuestro sitio web

(www.monarch.com

configurar y programar la impresora, consulte Packet Reference Manual en

nuestro sitio web.

Revise la información de seguridad indicada en el document o Regulato ry

Compliance (Cumplimiento de normativas) incluido con la impresora.

La información de este documento tiene priorid ad sobre la de versiones

anteriores. En nuestro sitio web podrá encontrar además la doc umentación y las

utilidades más recientes.

Nota: La impresora Monarch® 9906 utiliza el controlador Monarch® 9855®.

Conexión de los cables

La fuente de alimentación cambia automáticamente entre

115 V y 230 V.

1. Enchufe

y el otro extremo a una toma eléctrica

con conexión a tierra.

2. Enchufe el cable de comunicaciones

en el puerto apropiado.

3. Encienda

encenderla y ( O ) para apagar la.

Uso del panel de control

El panel de control consiste de una pantalla

de cuatro líneas, tres botones de

LCD

función y dos botones de navegación.

El funcionamiento de cada botón es

diferente según la tarea. Pantalla LCD:

Indica el encendido cuando se

muestra texto u otra información

Indica las condiciones

que requieren una atención inmediata

(batería agotada, fallos, errores) con

un fondo rojo

Muestra los indicadores de menú,

los ajustes de la impresora,

la asignación de los botones

de función, valores, etc.

). Para obtener información sobre cómo c rear formatos, y

el cable de alimentación en la toma

Puerto

para

lelo

(opcional)

la impresora. Pulse ( I ) para

Puerto serie

USB de host

USB de

dispositivo

Conexión

del cable de

alimentación

Botones de

función

Botones de

navegación

MPCL

FEED

On

line

TLABEL

MENU

ES-1

Page 38

Carga de etiquetas

1. Abra la tapa.

2. Suelte el cabezal de impresión haciendo girar el seguro que lo sujeta.

Lengüeta del

cabezal

Seguro

3. Levant

4. Coloque el rollo de etiquetas en el portarrollos, situado cont ra el interior de

5. Ajuste la guía del portarrollos de forma que apenas toque el rollo y

e la estructura del cabezal de impresión usando la lengüeta d el

cabezal hasta que la estructura quede fija.

la impresora.

asegúrese de que el rollo gira libremente.

Guía del portarrollos

Portarrollos

2-ES

Page 39

6. Empuje la

7. Haga pasar la tira de etiquetas por la guía de mane ra que sobresalga n por

delante de la impresora unos cuantos centímetros.

8. Pliegue el rollo de etiquetas por debajo de los picos y entre el sensor de

corte.

9. Ajuste la guía de manera que apenas toque las etiquetas. Leva nte la

palanca para fijar las guías en su lugar.

Sensor de

corte

10. Sosteng

empuja hacia abajo el liberador del cabezal.

palanca hacia abajo para liberar las guías de etiquetas.

Picos

Palanca para

papel

a la estructura del cabezal de impresión por la lengüeta mient ras

Liberación del

cabezal

Lengüeta del

cabezal

ES-3

Page 40

re el cabezal presionando sobre la depresión para el p ulgar hasta oír

p

11. Cier

que se introduce con un chasquido.

ierre la tapa de la impresora.

12. C

13. Pulse FEED (Alimentar).

Colocación de etiquetas para el mod o de despegado opcional

1. Despegue las etiquetas de los 25 cm iniciales del papel de base.

2. Presione sobre las lengüetas de la tapa de salida para abrirla.

3. Coloque el papel de base sobre la barra de despegado, a lo la rgo de la guía

y fuera por la abertura inferior en la tapa de s alida.

Rodillo de

latina

Barra de

despegado

Rodillo de

d

espegado

4. Cierre la

5. Cierre la tapa de la impresora.

6. Pulse FEED (Alimentar).

Para la carga de otras opciones de papel, consulte el manual del operador

(Operator’s Handbook).

4-ES

tapa de salida.

Abert u r a

inferior

Page 41

Ajuste de los diales de presión del cabezal

El ajuste predeterminado es la menor presión, que ofrece u na impresión óptim a

en la mayoría de casos. Si observa que la cinta se embo rrona o se arruga , o

que la impresión es de mala calidad, puede ser necesario ajustar los diales de

presión del cabezal.

Ambos diales están colocados en cada borde del conjunto del cabezal (en el

interior y el exterior). Los diales se pueden ajustar en distintas posiciones; sin

embargo, el dial interior debe estar igual o c on más presión que el e xterior.

Cuando utilice papel de 10 cm de ancho, ambas rue das deben estar ajusta das

en idéntica presión. Utilice una moneda o un destornillador de p unta plana para

ajustar los diales.

Diales de p

del cabezal

Cada

Presión mínima

Presión ligera

Presión mediana

Presión máxima

Imprima una etiqueta de prueba para comprobar la pr esión del cabezal; realice

los ajustes necesarios. Consulte el manual del operador (Operator ’s Handbook)

para obtener más información.

resión

dial tiene cuatro posiciones.

Presión

mínima

Presión máxima

Colocación de una cinta

1. Abra la tapa.

2. Suelte el cabezal de impresión haciendo girar el seguro que lo sujeta.

3. Levante la estructura del cabezal de impresión usando la lengü eta del

cabezal hasta que la estructura quede fija.

ES-5

Page 42

4. Empuje la

5. Deslice el núcleo de la cinta sobre la bobina de enrollado hasta su tope.

6. Saque la cinta nueva del envoltorio.

7. Deslice la cinta hasta su tope en la bobina trasera. Con cuidado, des enrolle

unos cuantos centímetros de cinta desde la parte inferior del rollo.

8. Pase la cinta por debajo de los rodillos y del cabezal de impresión.

lengüeta del deflector hacia abajo.

Bobina de

enrollado

njunto

Co

del cabezal

Lengüeta del

deflector

Depresión para

Debajo de

los rodillos

9. Asegúrese de que la cinta esté recta y centrada en su recorrido.

10. Pegue

11. Gire el mandril de enrollado hasta que el principio pase el cabezal de impresión.

12. Tense la cinta girando el carrete de enrollado hacia la derecha.

13. Sostenga la estructura del cabezal de impresión por la lengüet a mientras

14. Cierre el cabezal de impresión empujando sobre la depresión para el pulgar

16. Pulse FEED (Alimentar).

6-ES

la cinta en el mandril de enrollado.

empuja hacia abajo el liberador del cabezal de impresión.

hasta que oiga que encaje.

Ciérrelo. Cierre la tapa de15. la impresora.

el pulgar

Page 43

Limpieza

Es necesario limpiar el cabezal de impresión como se describe más abajo para

prolongar su vida útil.

Precaución: No utilice objetos afilados para limpiar el cabezal de

impresión ni lo toque con los dedos, pues podría

estropearse y necesitar su sustitución.

1. Apague la impresora y abra la tapa y el conju nto del cabezal d e impresión.

2. Extraiga el rollo de etiquetas y la cinta (para limpiar el cabez al de impresión).

3. Presione sobre las lengüetas de la tapa de salida para abrirla.

4. Para eliminar el polvo y los residuos del sensor, utilice aire comprimido.

5. Utilice una CLEAN-STRIP (número de referencia 120350) para limpiar y

eliminar la acumulación de adhesivo en el rodillo de platina, la barra de

despegado, el sensor y el cabezal de impresión.

Cabezal de

impresión

Sensor

Barra de

despegado

6. Deje q

7. Cierre la tapa de salida.

8. Cierre el conjunto del cabezal y la tapa de la impresora.

9. Encienda la impresora. Pulse FEED (Alimentar).

ue la impresora se seque antes de volver a colocar el papel.

Rodillo de

platina

Selección del intérprete

La impresora 9906 incorpora cuatro opciones de intérp rete: MPCL, MLI, W MS

XML y Easy-Plug. Para obtener más información sobre M LI consulte la guía

rápida de MLI, para obtener más información sobre WMS XML consulte la guía

rápida de XML, para obtener más información sobre Easy-Plug consulte el

manual de Easy-Plug que se incluye en el CD-ROM.

En el menú principal, seleccione Setup (Configuración) y después:

1. Pulse o hasta que se mu estra el intérpre te en la pantalla.

SETUP

Interpreter

MPCL

CHANGE BACK

2. Pulse CHANGE y hasta que se muestre Easy-Pl ug en la pantalla.

MAIN MENU

Interpreter

Easy-Plug

SET CANCEL

ES-7

Page 44

3. Pulse SET pa

La impresora se reinicia automá ticamente después de seleccionar un

intérprete. Este proceso puede tardar varios se gundos.

Cuando se imprimen etiq uetas con MLI defi nido como el intérp rete, el

número de modelo que aparece es M9906MLI.

Cuando se imprimen etiq uetas con Easy-Pl ug definido como e l

intérprete, el número de modelo que aparece es M9906EP.

ra guardar el cambio.

RFID (si instalado)

La impresora 9906 con RFID se ha concebido para qu e programe (codifiqu e) un

transpondedor RFID (Radio Frequency Ide ntification), también llamado “tag o

etiqueta RFID”, antes de imprimir el formato de la etiqueta Los trans pondedores

RFID contienen un dispositivo RFID (chip y antena ).

La función RFID sólo está disponible en impresoras que utilizan etiquetas

troqueladas o de marca negra.

La impresora es compatible con codificación de protocolo de Clase 1,

Generación 2 (C1Gen2).

Los consumibles de RFID son sensibles a la electricidad estática, y

podrían resultar dañados. Descárguese tocando alg ún metal, por

ejemplo la base metálica de la impresora, antes de manipular los

transpondedores.

La r

adio UHF opera en la gama de frecuencias de 902 a 928 MHz de acue rdo

con las normas y reglas de la FCC.

Menú de configuración de RFID

Utilice el menú

la potencia de RF, y borrar los datos.

El elemento de menú Read Tag (Leer etiqueta) permit e leer los datos EPC

programados en una etiqueta RFID.

RFID Setup (Configuración RFID) para leer una etiqueta, ajustar

SETUP

← RFID →

SELECT BACK

e la RFID Web Setup Utility en

Consult

http://www.servisource1.com/prnutil/rfidsetup

RF.

La impresora almacena el número de etiquetas programad as fallidas e

imprimidas con éxito. Borre este registro con el elemento de menú Clear Data

(Borrar datos). Dependiendo de la aplicación y de la cantidad de etiq uetas

impresas, puede ser recomendable borrar estos datos a dia rio o después de

cada lote.

Para cambiar los parámetros, en el menú principal, seleccione Setup

(Configuración) y entonces RFID.

Si la etiqueta RFID no puede programarse por alguna razón, p uede imprimirse

con un patrón de tachado, que significa que no debe usa rse. El administrador

del sistema debería ajustar el parámetro Error Action.

Si ve los errores de RFID 740 – 749, consulte al administrador del sistema .

Consulte el manual del operador (Operator’s Handbook) y las notas de

aplicación (Application Notes) para obtener más información.

8-ES

para ajustar el nivel de potencia de

Page 45

Solución de problemas

En esta sección se relacionan los problemas más frecuentes y sus posibles

soluciones.

Problema Acción

Al encender aparece

un mensaje de error.

No imprime. Compruebe el papel y la cinta, envíe un paquete

No hace avanzar las

etiquetas.

Impresión parcial de

datos.

Impresión muy

clara/oscura,

impresión con sombras

o espacios vacíos.

Los códigos de barras

en serie no se leen.

El papel de base se

enrolla en el rodillo de

pletina o de

despegado.

La impresora no lee ni

programa la etiqueta

de RFID.

Apague la impresora, espere quince segundos y

enciéndala de nuevo. Si el mensaje de error

persiste, llame al servicio técnico.

corregido de formato y lote.

Ajuste de los diales de presión del cabezal.

Limpie el cabezal de impresión, envíe un paquete

corregido de formato.

Limpie el cabezal de impresión, cambie el papel,

ajuste el contraste de impresión, compruebe los

diales de presión, compruebe la cinta.

Deje el cabezal abierto cuando no use la impresora,

utilice una velocidad de impresión de 2,5 pps, ajuste

del contraste de impresión.

Retire con cuidado el papel de base. Asegúrese de

que el papel pueda separarse por el extremo

dentado cuando se utilice el modo de retroceso y de

despegado.

Consulte al administrador del sistema.

ES-9

Page 46

Errores frecuentes

Error Descripción/acción

002 El nombre debe tener entre 1 y 8 caracteres y estar entrecomill ado.

005 Ancho de papel no válido.

018 Selección de página de códigos no válida.

025 La longitud de los datos es excesiva.

101 El formato al que se hace referencia en el lote no se encuentra en la

400 El carácter que sigue a { no es válido.

403 No se encontró el separador de campo.

409 La memoria de la impresora está llena. Borre los elementos sin uso.

410 Incompatibilidad de paridad.

411 Error de trama (incompatibilidad de velocidad en baudios).

412 Incompatibilidad de control de flujo.

413 La memoria temporal de recepción está llena. Compruebe el control de flujo.

611 La fuente, el código de barras o la densidad del lote no se aju stan al

612 Faltan los datos de esta línea del lote o no son compatibles con el formato.

613 Punto de referencia fuera de la etiqueta.

614 Porción de campo fuera del papel o carácter no válido e n el paquete.

703 La impresora detectó una calibración de marcas negras de dife rente

704 La impresora no detectó una marca de papel dentr o de la longitud

751 La impresora no detectó una marca de papel esperada. Pulse ESCAPE

752 La impresora ha detectado una marca en un lugar equivoca do.

753 La impresora ha detectado una marca demasiado larga.

754 Compruebe si la cinta está atascada o elimine la holgura en la cinta.

755 El cabezal de impresión está abierto. Ciérrelo.

756 Coloque papel y limpie el sensor.

757 Coloque papel (la longitud del papel no coincide). Pulse FEED

758 No se detecta el papel, el sensor a demanda está ave riado o se ha

763 Esperando a dispensar la etiqueta. Pulse FEED (Alimentar).

765 El cabezal de impresión tiene menos de 8 puntos defectuos os y puede

768 El cabezal de impresión tiene más de 8 puntos defectuosos o no est á

memoria.

formato.

tamaño. Asegúrese que se colocó el tipo correcto de etiquetas.

esperada o no quedan etiquetas. Asegúrese de que la imp resora esté

ajustada para el tipo de papel correctoColocar las etiquetas. Limpie el

sensor.

(Escape/Borrar) para seguir imprimiendo. Cambie el papel.

Coloque una cinta nueva.

(Alimentar).

sacado una etiqueta con demasiada rapidez. Compruebe si ha y atasco

o vuelva a colocar las etiquetas.

desplazar los campos de código de barras para evitar esos pu ntos.

Pulse ESCAPE (Escape/Borrar) para seguir imprimiendo.

conectado. Conecte o sustituya el cabezal de impresión.

10-ES

Page 47

Errores RFID

Para los errores, consulte las Notas d e aplicación para R FIDMP. Consulte al

administrador del sistema acerca del formato correcto. La impresora no se

recalibra (hace avanzar una etiqueta en blanco) después de lo s errores de RFID.

Error Descripción/acción

052 El tipo del campo de datos de RFID no es válida.

226 Regla de línea de registro xx. El dispositivo de descarga debe ser H

228 El identificador de clase de la memoria no es válido.

229 El código de byte no es válido.

230 El código de bloqueo no es válido.

715 Invalid data length/data mismatch (Longitud de datos no válida

740 Command, hardware, inventory, or memory allocation e rror (Error de

741 RFID tag missing (Falta etiqueta de RFID ). No se encuent ra la

742 Tag erase failed (No se pudo borra r la etiqueta). Se encontró la

743 Program tag failed (No se pudo programar la etiqueta ). Se encontró

744 Tag locked fail (Etiqueta ya bloquead a). La etiqueta de RFID no

746 Lock tag fail (No se pudo bloquear la etiquet a). La etiqueta de RFID

747 Time out failure (Fallo de tiempo supera do). Algún comand o de RFID

748 Invalid data length/data mismatch from RFID in terrogator modu le

749 RFID Verify Fail (Error de verificación de RFID). El proceso de

(Host) para la opción 6.

o discrepancia de datos). Los datos del campo de datos de

RFID tienen una longitud incorrecta o el tipo de datos

seleccionado no corresponde al de los datos introducidos.

Este error también ocurre cuando hay un error en los campos

de C1 gen. 2 ampliados.

comando, hardware, inventario o asignación de memoria). Pu ede

haber un error en algún dispositivo de RFID o en la asignación de

memoria.

etiqueta en el campo de RF. La etiqueta de RFID no se ha

encontrado en el campo de RF (zona dentro de la impreso ra en que

se programa la etiqueta de RFID). Compruebe que hay

abastecimiento de papel. Si modificó la posición del papel o la de

impresión, asegúrese de que la etiqueta de RFID no se salió d el

margen programable.

etiqueta de RFID en el campo de RF, pero no pudo borrarse.

Aumente el número de intentos.

la etiqueta RFID en el campo de RF, pero no pudo programar se.

Aumente el número de intentos.

puede programarse porque ya está bloqueada. Se considera una

etiqueta de RFID defectuosa.

no se ha bloqueado para impedir que se reprograme. S e considera

una etiqueta de RFID defectuosa.

(leer, programar, etc.) no ha terminado en el tie mpo máximo

permitido.

(Longitud de datos no válida o discrepancia de datos en el mó dulo

interrogador de RFID). El módulo interroga dor de RFID ha

encontrado un problema en los datos recibidos de la impresora .

verificación de RFID ha fallado después de grabar (prog ramar) la

etiqueta. Se considera una etiqueta de RFID defectuosa.

ES-11

Page 48

12-ES

Loading...

Loading...