Page 1

Operator's Handbook

28028

0

Monarch 9855

®

Printer

®

TC9855OH Rev. AJ 5/15

345

2

Sh

Dayt

ip

6

Fr

on,

01

9

8

7

6

5

4

3

2

From:

ip

8901

7

56

4

3

2

01

9

78

:

m

o

o

Ohi

Sh

a

D

©2003 Avery Dennison Corp. All rights reserved.

:

om

r

F

p

i

yton, Ohio

Sh

Da

y

ton

h

O

,

Page 2

Each product a nd program carr ies a respective wr itten warrant y, the only warrant y

on which th e customer can rely. A very Dennis on Corp. r eserves th e right to m ake

changes in the pr oduct, the progr ams, and their av ailability at an y time and without

notice. A lthough Aver y Denniso n Corp. has m ade ever y effort to pr ovide com plete

and accurate i nformation in th is manual, Aver y Dennison Corp. sha ll not be liable

for any omissio ns or inaccuraci es. Any update will be incorporated in a later

edition of this manua l.

2003 Avery Den nison Corp. All rig hts reserved. No part of this publicatio n may

be reproduc ed, transm itted, stor ed in a retr ieval syst em, or trans lated into any

language in an y form by any means, wi thout the prior wr itten permission of Avery

Dennison Corp.

WARNING

This equipm ent has been tested and found to c omply with t he limits f or a Class A

digital device , pursuant to Part 15 of the FCC Rules. Thes e limits are des igned to

provide reaso nable protect ion against harmf ul interference when the equipm ent is

operated in a commer cial environm ent. This e quipment g enerates, us es, and ca n

radiate radi o frequency energ y and, if not instal led and used in accor dance with

the instruc tion manua l, may cause harmful i nterferenc e to radio c ommunicat ions.

Operation of this equip ment in a r esidential area is lik ely to cause harmful

interferenc e in which c ase the us er will be r equired to c orrect th e interfer ence at

his own expe nse.

CANADIAN D.O.C. W ARNING

This digital apparatus does not ex ceed the Class A lim its for rad io noise

emissions f rom digita l apparatus set out in t he Radio In terference Regulations of

the Canadia n Departm ent of Comm unications.

Le présent a ppareil nu mérique n ’émet pas de bruits rad ioélectriq ues dépassan t

les limites app licables aux app areils numériq ues de la classe A pr escrites dans l e

Réglement s ur le brou illage radi oélectrique édicte p ar le ministèr e des

Communicat ions du Cana da.

Trademarks

Monarch, 7411, 9825, 9850, 9855, and 9860 are trademarks of Avery Dennison Retail Information

Services LLC.

Avery Dennison® is a trademark of Avery Dennison Corp.

HP Jet Admin and HP Web Jet Admin are trademarks of Hewlett-Packard, Inc.

Hewlett-Packard is a registered trademark of of Hewlett-Packard, Inc.

Centronics is a registered trademark of Centronics Data Computer Corporation.

TrueType is a registered trademark of Apple Computer, Inc.

Other products are trademarks or registered trademarks of their respective countries and are hereby acknowledged.

Avery Denn ison Printer Systems Di vision

170 Monarch Lane

Miamisburg , OH 45342

Page 3

TABLE OF CONTENTS

GETTING STARTED ....................................................................................... 1-1

Audience.................................................................................................. 1-2

Using this Manual ..................................................................................... 1-2

Unpacking the Printer ............................................................................... 1-3

Shipping the Printer ............................................................................... 1-3

9445™ Printer Online Emulation ................................................................ 1-4

Ordering Programmer's Manuals ................................................................ 1-4

About Monarch® MPCL™ Toolbox Utilities.................................................. 1-4

Connecting the Power Cable...................................................................... 1-4

Establishing Communications .................................................................... 1-5

Connecting the Communication Cable ..................................................... 1-5

Using the Control Panel ............................................................................ 1-6

Printer Status Lights .............................................................................. 1-6

Button Functions ................................................................................... 1-6

Display ................................................................................................. 1-7

Selecting a Function ................................................................................. 1-7

Exiting an Option ...................................................................................... 1-8

LOADING SUPPLIES ..................................................................................... 2-1

Loading Labels or Tags ............................................................................. 2-2

Loading Labels for the Optional Peel Mode ............................................. 2-7

Using the Optional Tear Bar ...................................................................... 2-9

Using String Tag Supply .......................................................................... 2-10

String Tag Considerations .................................................................... 2-10

Adjusting the Wide/Narrow Knobs ............................................................ 2-12

Table of Contents i

Page 4

LOADING RIBBON ......................................................................................... 3-1

Loading Ribbon ........................................................................................ 3-2

Using a High Energy Ribbon ...................................................................... 3-4

High Energy Ribbon Limitations .............................................................. 3-5

SETTING SUPPLY OPTI ONS .......................................................................... 4-1

Setting the Supply Type ............................................................................ 4-3

Setting the Ribbon .................................................................................... 4-4

Setting the Speed ..................................................................................... 4-5

Setting the Feed Mode .............................................................................. 4-6

Setting the Backfeed ................................................................................. 4-7

Changing the Position Settings .................................................................. 4-8

Setting the Print Position ....................................................................... 4-8

Setting the Supply Position .................................................................. 4-10

Setting the Margin Position .................................................................. 4-11

Setting the Cut Position ....................................................................... 4-12

Setting the Dispense Position ............................................................... 4-13

Setting the Backfeed Distance .............................................................. 4-14

Using Batch Separators .......................................................................... 4-15

Using Skip Index .................................................................................... 4-16

Setting the Knife Control ......................................................................... 4-17

Setting the Error Action ........................................................................... 4-18

Setting the Print Contrast ........................................................................ 4-20

Enabling the Verifier ............................................................................... 4-22

ii Operator's Handbook

Page 5

SETTING COMMU NICATIONS ........................................................................ 5-1

Setting the Baud Rate ............................................................................... 5-2

Setting the Word Length ............................................................................ 5-2

Setting the Stop Bits ................................................................................. 5-3

Setting the Parity ...................................................................................... 5-3

Setting the Flow Control ............................................................................ 5-4

Resetting to Default Values ....................................................................... 5-4

Using Parallel Communications .................................................................. 5-5

Setting the Port ..................................................................................... 5-5

Setting the Mode ................................................................................... 5-6

SETTING DEFAULTS ..................................................................................... 6-1

Setting the Monetary Sign ......................................................................... 6-3

Setting the Secondary Sign ....................................................................... 6-4

Setting the Number of Decimal Places ........................................................ 6-5

Setting the Slashed Zero Appearance ........................................................ 6-5

Setting the Power-Up Mode ....................................................................... 6-6

Changing the Prompt Set .......................................................................... 6-6

Setting the Numeric Format ....................................................................... 6-7

Using Flash Storage ................................................................................. 6-8

Disabling Image Errors .............................................................................. 6-9

Ignoring Configuration Packets ................................................................ 6-10

Using Error Retry Mode ........................................................................... 6-11

Adjusting the Image Length ..................................................................... 6-12

Using Flash Memory ............................................................................... 6-14

Formatting Flash Memory ..................................................................... 6-14

Checking Available Flash Memory ........................................................ 6-15

Packing Flash Memory ......................................................................... 6-16

Table of Contents iii

Page 6

Memory Guidelines ................................................................................. 6-17

Setting Batch Options ............................................................................. 6-18

Setting Up the Network Printer ................................................................ 6-18

Setting Up the RFID Printer ..................................................................... 6-18

USING SCRIPTS ............................................................................................ 7-1

Initial Script Startup Procedures ................................................................ 7-2

Viewing Script Information ......................................................................... 7-2

Downloading a Script ................................................................................ 7-3

Enabling a Script ...................................................................................... 7-4

Deleting a Script ....................................................................................... 7-5

Enabling Status Polling ............................................................................. 7-6

Using Immediate Commands...................................................................... 7-7

PRINTING ..................................................................................................... 8-1

Printing .................................................................................................... 8-1

On-Demand Mode Printing......................................................................... 8-2

Printing an Error Label .......................................................................... 8-2

Pausing a Batch ....................................................................................... 8-3

Restarting a Batch .................................................................................... 8-3

Canceling a Paused Batch ......................................................................... 8-4

Repeating a Batch .................................................................................... 8-6

Offline Printing ......................................................................................... 8-6

Special Printing Considerations ................................................................. 8-7

Printing TrueType® Fonts ......................................................................... 8-8

Licensing Your Fonts ................................................................................ 8-8

CARE & MAINTE NANCE ................................................................................ 9-1

Clearing Label Jams ................................................................................. 9-1

Cleaning .................................................................................................. 9-1

Replacing the Printhead ............................................................................ 9-5

iv Operator's Handbook

Page 7

DIAGNOSTICS & TROUBLESHOOTING ......................................................... 10-1

Factory Set Password ............................................................................. 10-1

Checking the Software Version ................................................................ 10-1

Printing a Test Label ............................................................................... 10-2

Checking Supply Quality ......................................................................... 10-3

Using Password Protection ...................................................................... 10-4

Enabling the Password (System Administrators only) ............................. 10-4

Service Diagnostics ................................................................................ 10-5

Troubleshooting...................................................................................... 10-6

Error Messages ...................................................................................... 10-7

Common Errors ...................................................................................... 10-8

SPECIFCATIONS ........................................................................................... A-1

Printer ..................................................................................................... A-1

Tag Cut Dimensions .............................................................................. A-2

Supplies .................................................................................................. A-3

String Tag Supplies ............................................................................... A-4

Ribbon Specification ................................................................................. A-5

About Ribbons ...................................................................................... A-5

Cable Pinouts ........................................................................................... A-6

ACCESSORIES & OPTIONS ........................................................................... B-1

Accessories ............................................................................................. B-1

Packaging Materials .............................................................................. B-2

Factory-Installed Options .......................................................................... B-2

Ethernet Information .............................................................................. B-3

RF Information ...................................................................................... B-3

MENU STRUCTURE ....................................................................................... C-1

GLOSSARY .................................................................................................. G-1

INDEX .............................................................................................................. 1

Table of Contents v

Page 8

vi Operator's Handbook

Page 9

Cancel All

Print Mode

Batch Entry

Repeat

Batch

Batch

Options

Setup

Scripts

Diagnostics

Supply

Contrast

Defaults

Network

Port

Settings

Flash

Memory

Verifier

RFID

1

GETTING STARTED

The Monarch® 9855® printer let s you print text, graphics, and bar

codes on thermal transf er (ribbon) and thermal direct la bels or tags. The

9855 printer prints labels cont inuously (in one strip) or on-demand (one label

at a time).

You can print on aperture, die cut, black mark, or continuous (n on-indexed)

supplies. Continuous supply must be used in continuous mod e. See

"Supply Type" in Chapter 4 f or more information about the suppl y types.

This chapter includes information about

♦ unpacking the printer

♦ connecting the power cord

♦ connecting the communicat ion cable

♦ using the printer's con trol panel.

Several chapters of this manua l have one or more charts showi ng the

printer's menu struct ure. For example:

Main Menu

The black boxes show where you are; the bordered boxes sho w how you got

there.

Refer to the MonarchNet2™ Operating Instructions f or information about the

Network menu.

Refer to the RFID Applicat ion Notes for informat ion about the RFID menu.

Getting Started 1-1

Page 10

Audience

The Operator's Handbook is f or the person who prints and app lies labels.

Using this Manual

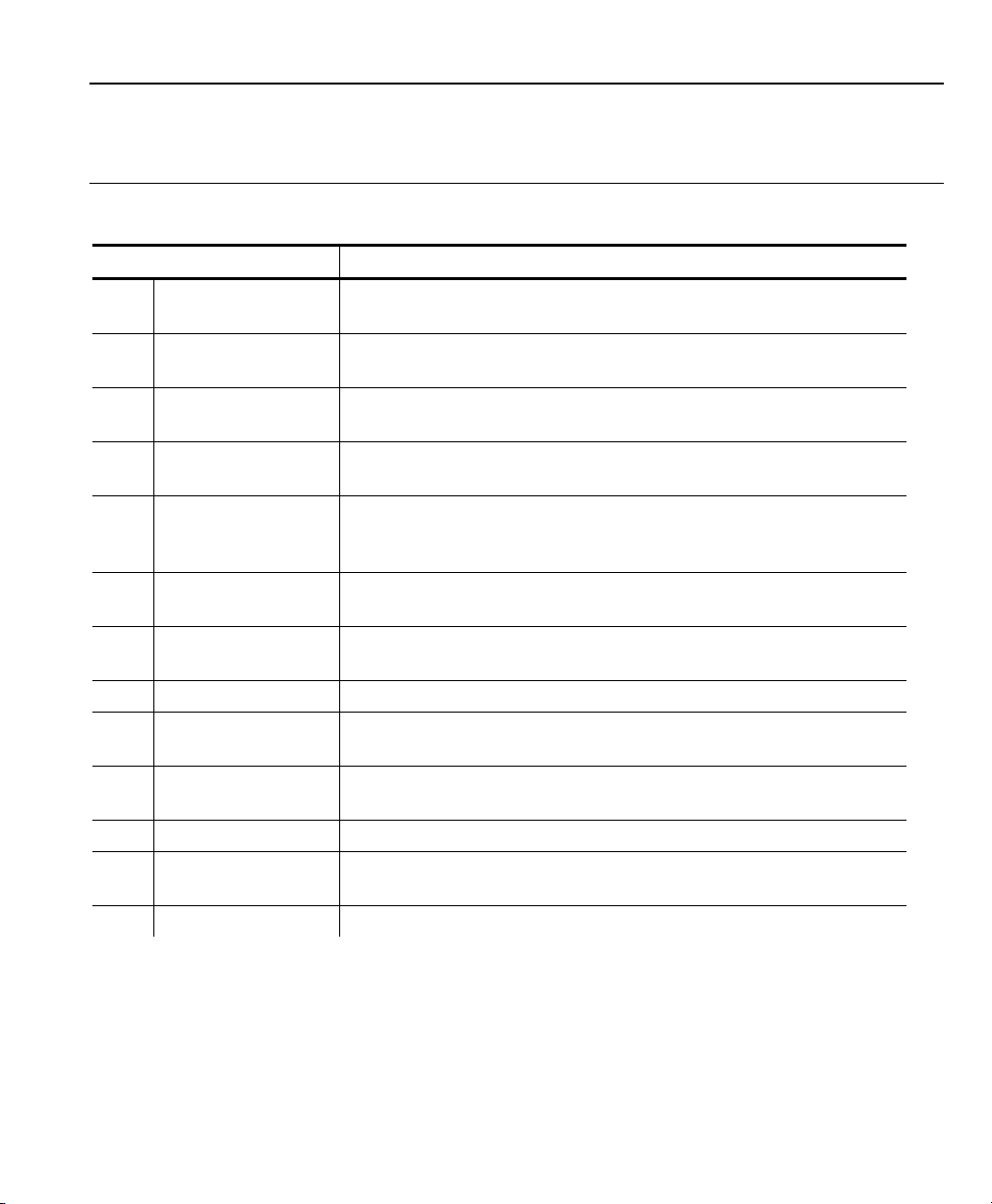

Following is a summary of t he contents of this manual.

Chapter Contents

1 Getting Start ed Contains infor mation abo ut connect ing the pow er

cable and using the control panel.

2 Loading

Supplies

3 Loading Ri bbon Describes how to load a roll of ribbon and lists high-

4 Setting Supply

Options

5 Setting

Communication

Values

6 Setting Def aults Using the D efaults m enu to set the monetar y sign,

7 Using Scripts Using the Scripts menu to load a s cript, ena ble a

8 Printing Explains how to print labels and use the Paus e menu.

9 Care &

Maintenance

10 Diagnostics &

Troubleshooting

A Specifications Contains pr inter and su pply specif ications.

B Accessories &

Options

C Menu Structure Contains a chart of the printer’s men u options.

Describes how to load a roll of su pply, fan-fold

supply, and tag s upply.

energy ribbo n information.

Using the Supply menu to set the various supp ly

options (su pply, ribb on, feed m ode, etc.).

Using the Port Settings menu to se t the seria l and

parallel com municatio n values (ba ud rate, par ity,

etc.).

number of decim al places, prom pt set, etc.

script, delet e a script, etc.

Describes ho w to clear a label jam , clean the printer,

and replace the print head.

Describes ho w to print a test label and lists common

problems an d their sol utions.

Contains pr inter acces sories and optional e quipment.

1-2 Operator's Handbook

Page 11

Unpacking the Printer

After you unpack the printer, you should have the printer, a power cord, and

a ribbon take-up core (may alread y be on take-up reel). Keep the bo x and

packaging material in case the printer ever needs repa ir.

Shipping the Prin ter

If you need to ship the printer to a different location:

1. Remove the ribbon roll, if one is loaded.

2. Remove the supply roll, if one is loaded.

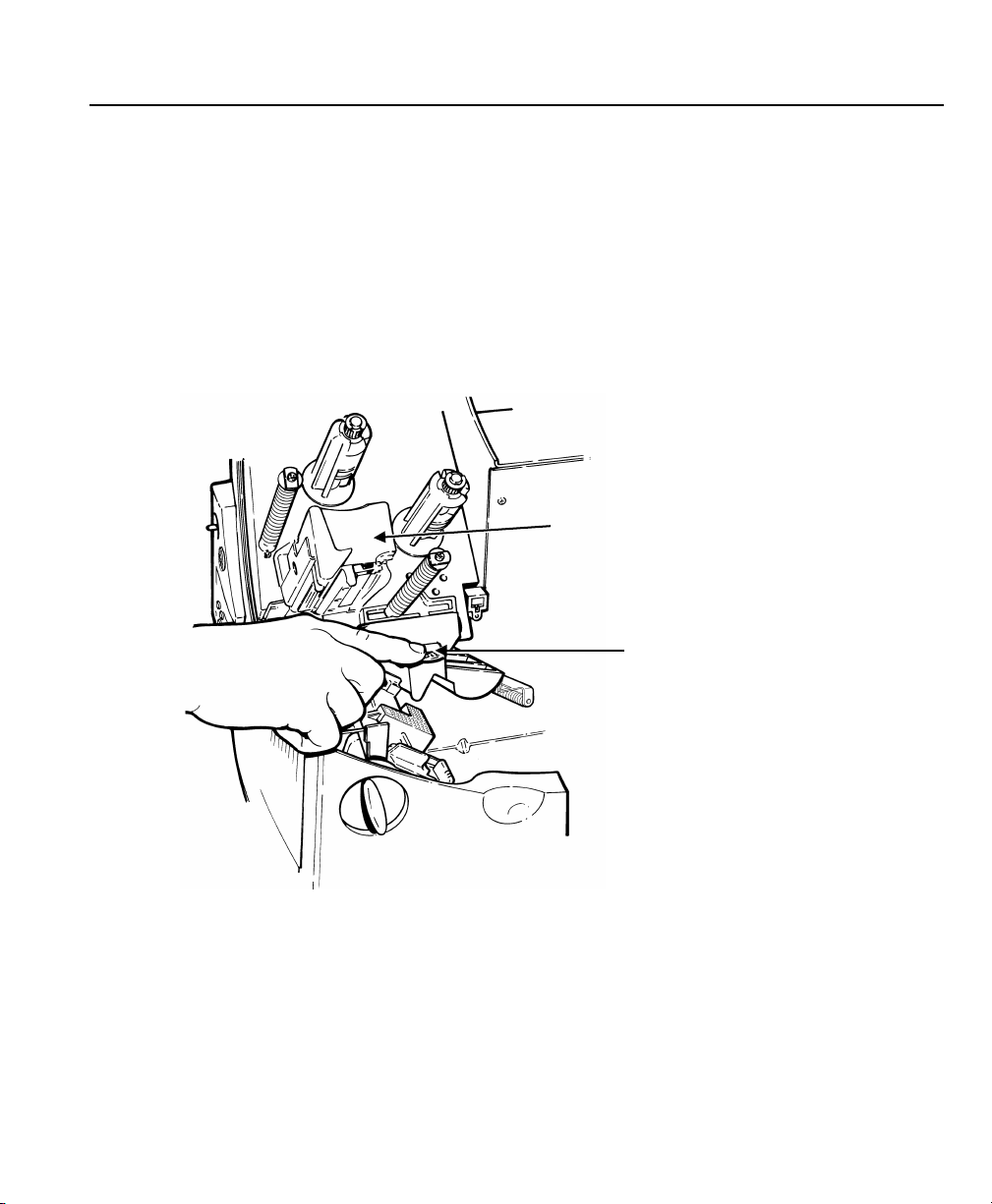

3. Close the printhead by press ing down on the thumb well unti l you hear it

click into p lace.

Thumb Well

4. Place the printer in the orig inal box and secure with packag ing material.

Make sure the printer is a dequately packed to avoid damage during

shipment. See Appendix B, "Acces sories & Options" for the pack aging

materials part numbers.

Getting Started 1-3

Page 12

9445™ Printer Online Emulation

The 9855 printer using 203 dpi (dots per inch) printing s upports 94x5

emulation. You can send 94x5 data st reams to this printer.

Refer to your 9445 Program mer's Manual for inform ation about 94x5 data

streams.

Ordering Programmer's Manuals

The Packet Reference Manual, which describes how to creat e format and

batch packets for print ing labels, how to config ure the printer online, how to

diagnose printer error messages, and how to perfor m other advanced

techniques can be downloaded f rom our Web site

(www.monarch.averydennison.com

hard-copy version (part number TC9800PM).

). You can print this manual or order a

About Monarch® MPCL™ Toolbox Utilities

The Monarch® MPCL™ Toolbox util ities are available on our W eb site and

are free to download. T his group of development utilities he lps you

configure the printer , customize fonts, and download f iles. Monarch MPCL

Toolbox utilities are n ot label production software. Call Custome r Service

for information about labe l production software.

Connecting the Power Cable

The power supply automat ically switches between 115V or 230V . No

operator settings are r equired.

1. Plug the power cable into the so cket. Plug the other end of the cable

into a grounded electr ical outlet.

Note: Only use a cer tified power cable with proper voltage for the co untry

of installation.

2. Turn on the printer. Press ( I ) to turn on and ( O ) to turn off the printer.

1-4 Operator's Handbook

Page 13

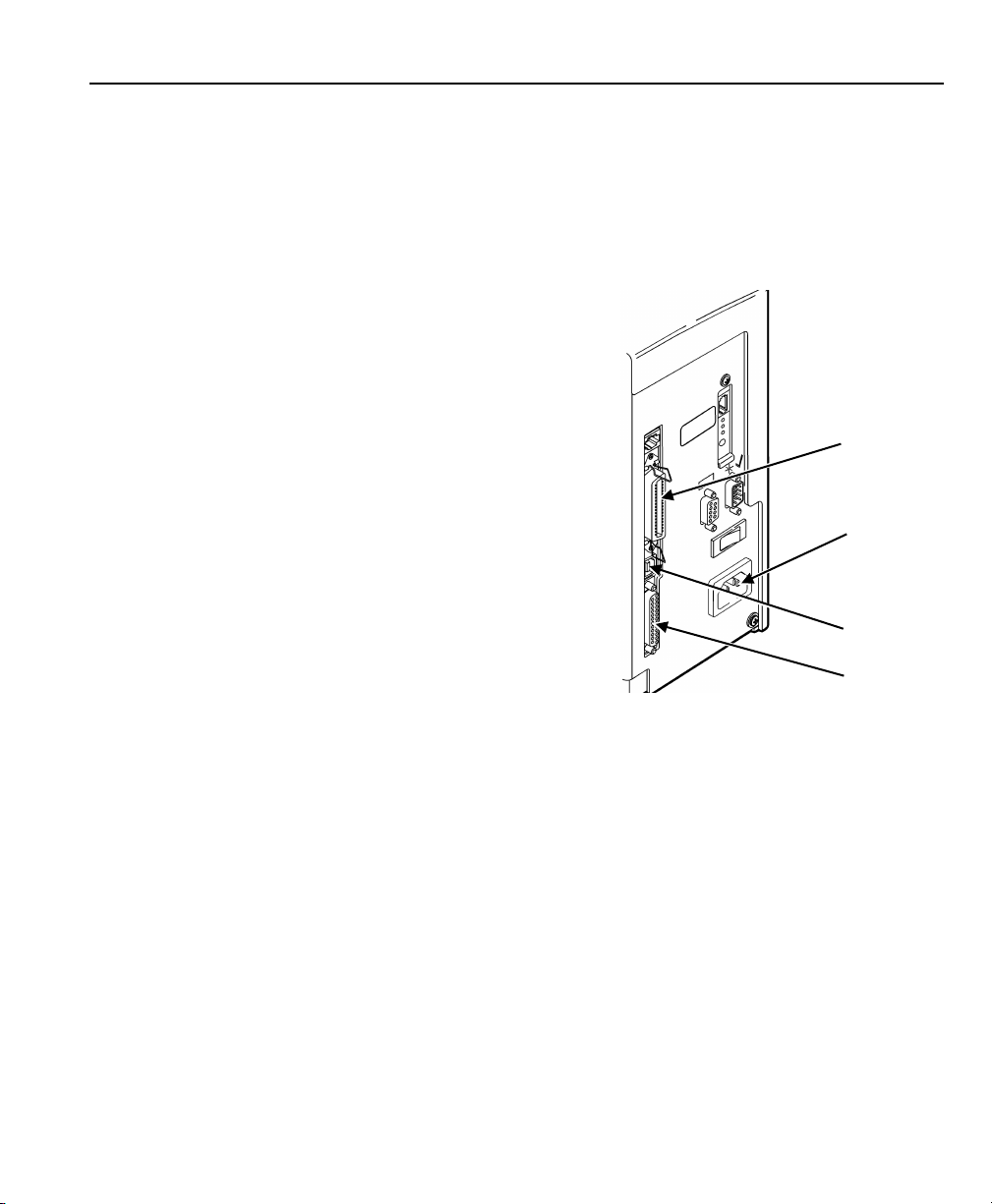

Parallel Port

goes here

USB Port

Serial Port

Establishing Communications

Before the printer can accept print jobs from the host, you must:

♦ Connect the communication cab le to the printer and to the host .

♦ Set the communication values o n the printer to mat ch those at the host.

(Only required if you are using the serial port.)

♦ Make sure the printer is off before connecting the cable to t he

communication port.

Ask your System Administrat or which

method to use to communicate with t he host:

Serial Communication

9 to 25-pin cable

(Part #119806)

25 to 25-pin cable

(Part #126826)

Parallel Communication

IEEE-1284 or

Centronics® mode cable (Par t #126805)

Power Cable

Connecting the C ommunication Cable

Connect the communication cab le into the

appropriate port. Secur e the cable with the connecting screws (serial) or

spring clips (parallel).

If you are communicating with t he host through the serial port , make sure the

printer's communication values match those at the host . The factory default

values are 9600 Baud, 8 bit dat a frame, 1 stop bit, no parity, and DTR flow

control.

The printer also has a USB (Uni versal Serial Bus) Version 1.1

communication port. Dri vers are available on our W eb site for a variety of

operating systems.

Note: The pr inter supports a baud rate up to 115 200. Make sure your host

is capable of communicati ng at the speed you select fo r the printer.

Getting Started 1-5

Page 14

Using the Control Panel

The control panel has a t wo-lin e LCD display, 2 status light s, and five

buttons. The control pane l displays error codes/mess ages, and allows you

to setup/configur e the printer.

Printer Sta tus Lights

Power:

The printer shows a stead y green light

when it is on.

The Power light blinks when the b attery

needs to be recharged (only on

battery-powered/cart mo dels).

Fault:

The printer shows a blinking am ber

light when there is a printer er ror.

Button Functions

Feed/Cut:

Enter/Pause:

1-6 Operator's Handbook

♦ Prints a label in the on-demand m ode.

♦ When the printer is online, f eeds a blank label if

♦ Prints a label with error info rmation that is useful to

♦ When the printer is online, cuts the supply when

♦ When the printer is off line, changes the displayed

When the printer is online, pa uses the current print job or

resumes a paused print j ob. When the printer is offline,

selects the displayed m enu item.

there is no print job.

your System Administrator if an error is displayed.

pressed and held for two second s if a knife is

installed.

value by one or 10.

Page 15

Cancel All

Print Mode

Batch Entry

Repeat

Batch

Batch

Options

Setup

Scripts

Diagnostics

Supply

Contrast

Defaults

Network

Port

Settings

Flash

Memory

Verifier

RFID

Escape/Clear:

♦ When an error is present, clears the error.

♦ When a job (batch) is printing, cancels the print job

(batch). See "Canceling a Paused B atch" in Chapter

8 for more information.

♦ When the printer is online ( without errors), enter s the

offline menu mode.

♦ When the printer is in t he of fline menu mode, returns

the display to the next hig her menu.

When the printer is in t he offline menu mode, displays th e

previous menu item.

When the printer is in t he offline menu mode, displays th e

next menu item.

AND

In online mode, prints a t est label when you press the

buttons at the same time. Hold for one second and release.

Display

The display shows a three-dig it error code and brief messag e to identify any

problem the printer may ha ve. For a description of the pr oblem, look up the

error code in Chapter 10, "Diagnostics & Troubleshoot ing."

Selecting a Function

The Main menu has several funct ions (operating modes). T hese functions

are shown in the chart belo w. See Appendix C, “Menu Structure” f or a

complete list of menu options.

Main Menu

Note: If t he printer displays PRINT MODE Ready when you turn it on,

press Escape/Clear to disp lay the Main menu.

Getting Started 1-7

Page 16

To display menu options, pr ess or .

1. When the screen displays a rig ht arrow, press to display more

options.

MAIN MENU

Cancel All

2. When the screen displays a le ft arrow, press to display more o ptions.

MAIN MENU

Diagnostics

3. When the screen displays a le ft and a right arrow, press either or

to display more options.

MAIN MENU

Print Mode

4. When you see the menu option you want, press Enter/Pause to s elect it.

The Main Menu controls the print er's setup and operation. Through the

Setup Menu, you can select a sub-menu f or the supply, contrast, default, or

port settings. Each of t hose sub-menus have several options, such as

ribbon, speed, monetary symbo ls, and baud rate.

Exiting an Option

To exit an option, press Escape/Clear once.

1-8 Operator's Handbook

Page 17

2

LOADING SUPPLIES

This chapter describ es how to load:

♦ a roll of supply

♦ fan-fold supply

♦ a roll of tag supply.

There are three types of s upplies:

Thermal Direct heat activated supplies that do not use a ribbon for

printing.

Thermal Transfer standard supplies that require a ribbon for printing.

High Energy scratch, chemical, and t emperature resistant supplies

that require an elevated heat setting for resin ribbon

applications. See "Using a High Energy Ribbon" in

Chapter 3 for more informat ion.

If you are using thermal dire ct supplies, do not load a rib bon.

If you switch from black mark to die cut supplies, make sur e the printer's

supply type is set correc tly. See "Supply Type" in Chapter 4 for more

information. Your System Administrator can also send the s upply setup

packet to change the supply t ype. Refer to the optional Pack et Reference

Manual for more inf ormation about sending the suppl y setup packet.

Loading Supplies 2-1

Page 18

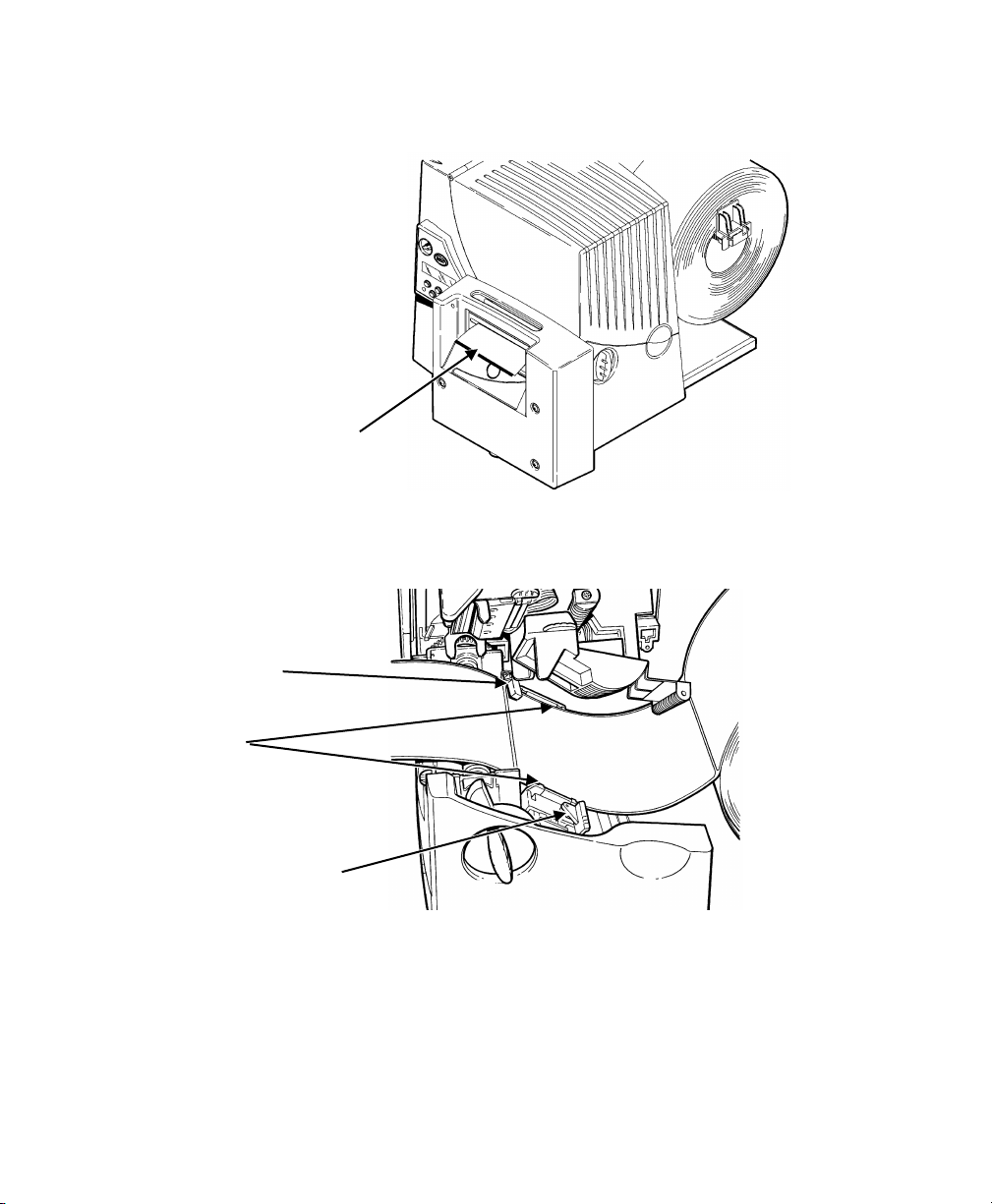

Loading Labels or Tags

Printhead Tab

Make sure the printer is conf igured for the correct supply t ype.

1. Open the cover.

2. Unlock the printhead by tur ning the retaining latch .

3. Lift printhead assemb ly using the printhead tab unt il t he assembly locks

into place.

2-2 Operator's Handbook

Deflector Tab

Page 19

4. Place the roll of supply on the sup ply holder. For labels, t he supply

unrolls from the top or t he bottom. For tags, make sure t he supply

unrolls from the botto m, because tag rolls are wound fa ce in.

Note: Do not pick up the printer by the supply hol der.

Supply Holder

Guides

Supply Roller

5. Adjust the supply holder g uides so the sides barely touch the ro ll. Make

sure the supply roll turns freely.

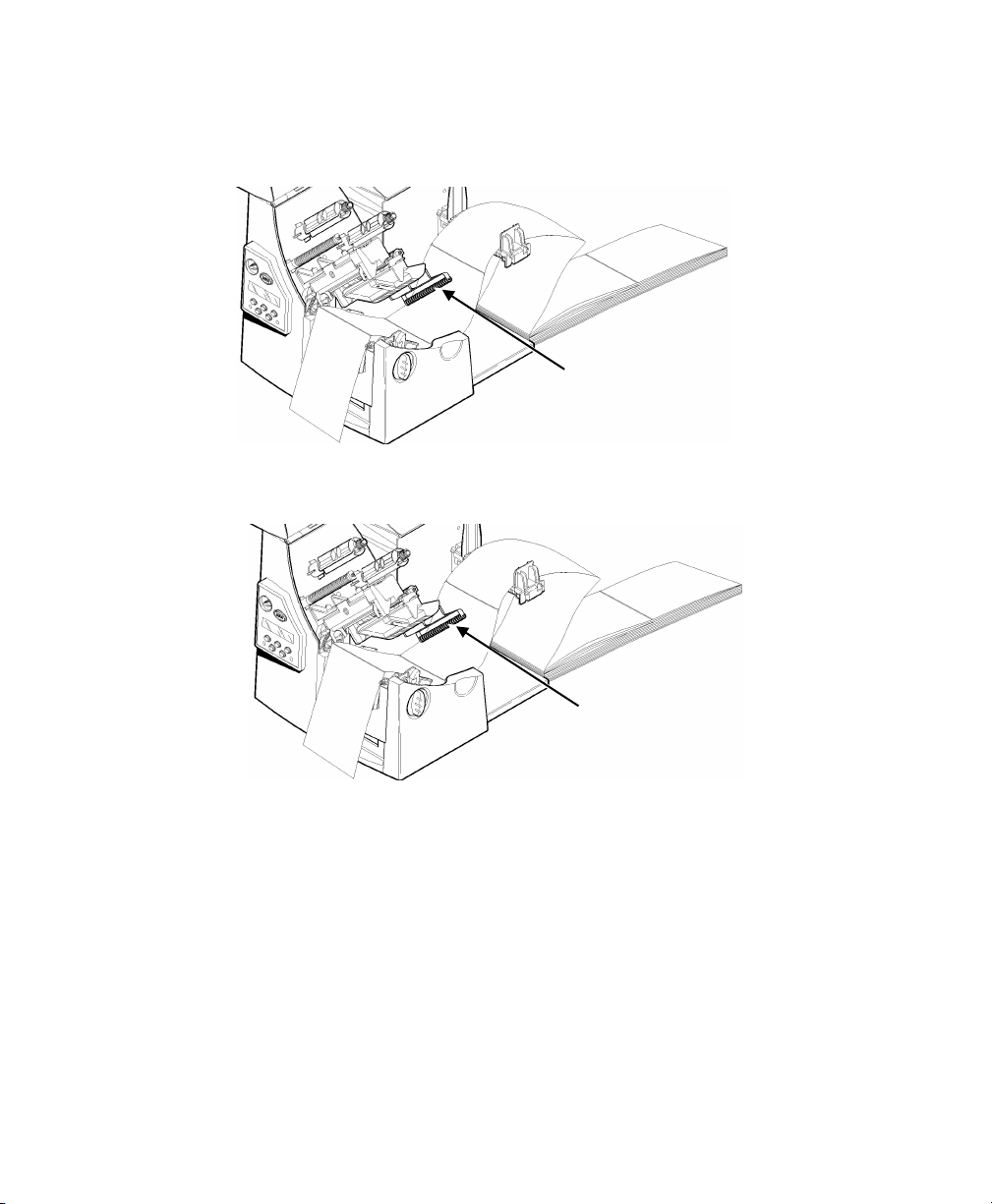

If you are using fan-fold supplies , place the supply stack behind

the printer, label side facing up.

6. Push down on the supply lever to u nlock the supply guides.

7. Lay the label strip across t he supply guide so that a few inches extend

past the front of the printer . Tuck the supply under the nibs an d in

between the die cut sensor. Do not feed supply between the suppl y

roller and deflector.

Loading Supplies 2-3

Page 20

For fan-fold supplies, la y the label strip over the supply hold er and

across the supply guide so that a few inches extend past the f ront of

the printer. Tuck the supply und er the nibs and in between the d ie

cut sensor.

Supply Roller

2-4 Operator's Handbook

Supply Roller

Page 21

Sensor

For tag supplies using the opti onal knife, feed the supply thr ough

the knife. Make sure at least 0. 5 inches of supply is past the k nife.

Tag

8. Adjust the supply guides so the y touch the supply. Push up on the

supply lever to lock the supp ly guides into place.

Die Cut

Nibs

Supply Lever

Loading Supplies 2-5

Page 22

9. Hold the printhead assem bly by the printhead tab while pr essing down on

the printhead release .

10. Close the printhead by press ing down on the thumb well until you hear it

click into p lace.

Thumb Well

11. Close the cover.

12. Press Feed/Cut to position the supp ly under the printhead.

You may need to adjust the wide/na rrow knobs depending on the widt h of

your supply. See "Adjusting the Wide/Narrow Knobs" for more

information.

Note: If t he printer will be unused for extended p eriods of time, we

recommend leaving the print head unlatched.

2-6 Operator's Handbook

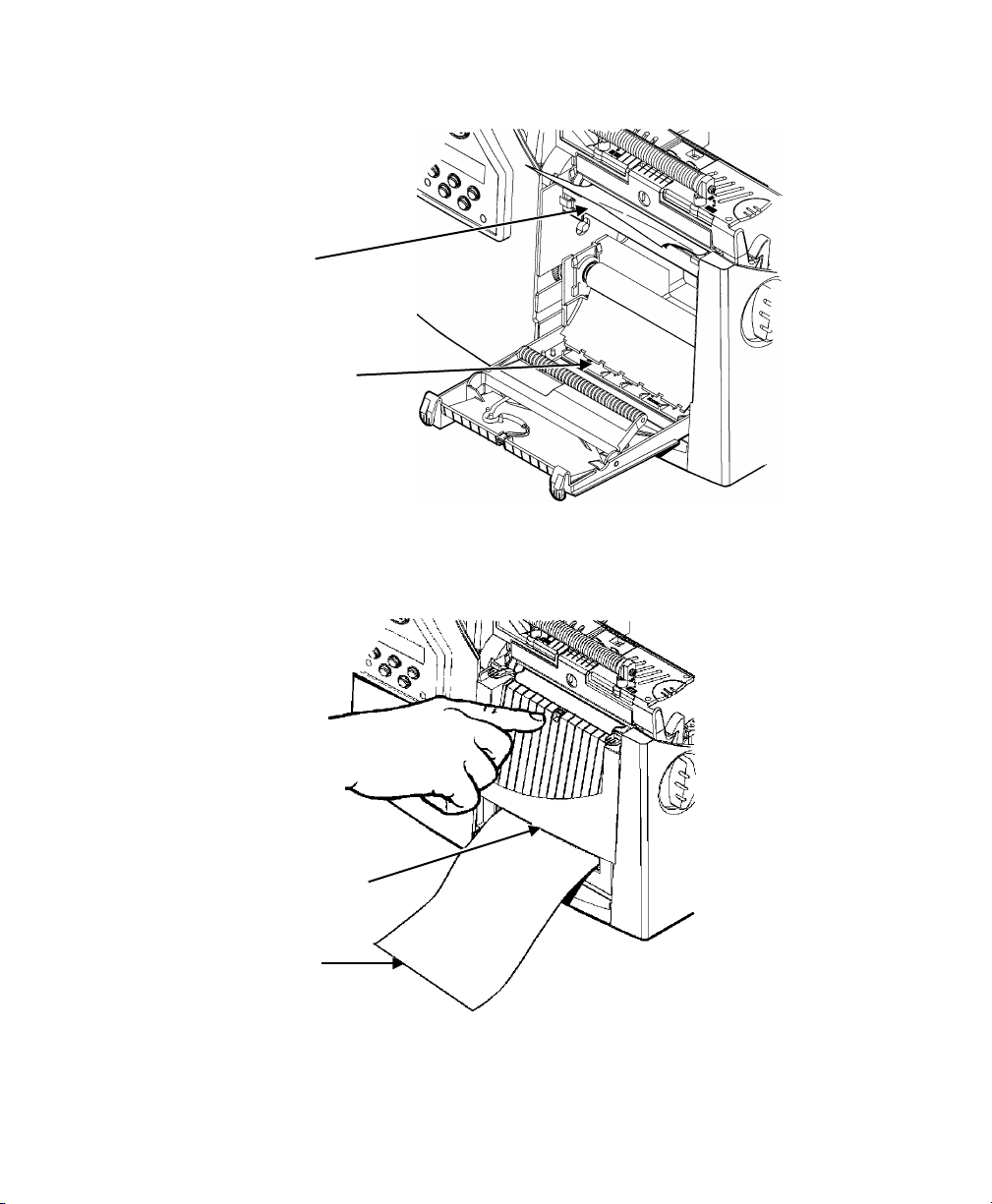

Page 23

Exit Cover

Loading Labels for the Optional Peel Mode

Peel mode is an option that must be purchased separatel y. In peel mode,

the printer separates t he backing paper from the label. T he next label is not

printed until the complet ed one is removed from the printer. Make sure the

printer is configured f or on-demand mode and the correct supply type.

The minimum feed lengt h is 1.5 inches for peel mode. We recom mend using

0.5-inch gap supplies in pee l mode when backfeed is disabled. Hold the

leading edge of peeled labe ls when printing on stock longer than six inches.

You must use non-perforate d supplies for peel mode. Follow th e steps for

loading supplies from the previous section. T hen, follow these steps afte r

you close the printhead.

1. Remove the labels from t he first 10 inches of the backing pa per.

2. Press down on the exit cover t abs to open the exit cover on the f ront of

the printer.

Loading Supplies 2-7

Page 24

3. Feed the backing paper over t he peel bar.

Peel Bar

Lower Opening

4. Feed the backing paper t hrough the lower opening of t he exit cover.

Close the exit cover. Pul l down on the backing paper to remove any

slack.

Tear Edge

Backing Paper

When removing the backing paper , pull up across the sawtoothed tear edge. Make sur e the backing paper tears at t he edge.

2-8 Operator's Handbook

Page 25

5. Close the printer's cover.

6. Press Feed/Cut to position the supp ly under the printhead.

Using the Optional Tear Bar

Note the following chang e to loading labels if you have purcha sed the

optional tear bar. Tear labe ls against the tear bar. You cannot t ear tags

with the tear bar.

Slide the supply between t he tear bar and peel bar. It may be easier if you

cut or fold one corner of t he supply first.

Tear Bar

Peel Bar

Note: Do not tea r both label and backing paper at the same time.

♦ Tear labels against the t ear bar.

♦ Tear backing paper against the tear edge.

Tear Edge

Backing Paper

Loading Supplies 2-9

Page 26

Using String Tag Supply

String tags are used in a variet y of applications, such as je welry tags and

item marking.

String Tag Consi derations

♦ Thermal direct printin g, fan-fold supplies, and the k nife are not supported

with string t ags.

♦ The maximum print speed wit h s tring tags is 6.0 inches per sec ond (ips).

♦ A non-print zone of 0.250 inches (6.4 mm) exists on the string si de of the

tag.

♦ Use the wide setting for st ring tags.

Make sure the printer is conf igured for the correct suppl y type.

1. Open the cover.

2. Unlock the printhead by turning the retaining latch.

3. Lift printhead assembly using the printhead tab until the assembly locks

into place.

4. Shake the roll of string tags down to untangle the roll.

2-10 Operator's Handbook

Page 27

Sensor

5. Place the roll of supply on the supply holder with the strings facing out.

6. Adjust the supply holder guides so the sides barely touch th e roll. Make

sure the supply roll turns freely.

7. Push down on the supply lever to unlock the supply guides. T he supply

guides have been angled slig htly for string tag supplies.

8. Lay the supply across the supply guide so that a f ew inches extend past

the front of the printer . Tuck the supply under the nibs and in be tween

the die cut sensor.

9. Adjust the supply guides so they touch the supply. Push up on t he supply

lever to lock the suppl y guides into place.

Die Cut

Nib

Supply Lever

Loading Supplies 2-11

Page 28

10. Hold the printhead assembl y by the printhead tab while press ing down on

the printhead release .

11. Close the printhead b y pressing down on the thumb wel l until you hear it

click into p lace.

12. Close the cover.

13. Press Feed/Cut to posit ion the supply under the print head.

If the printer will be unused f or extended periods of tim e, we recommend

leaving the printhead unlat ched.

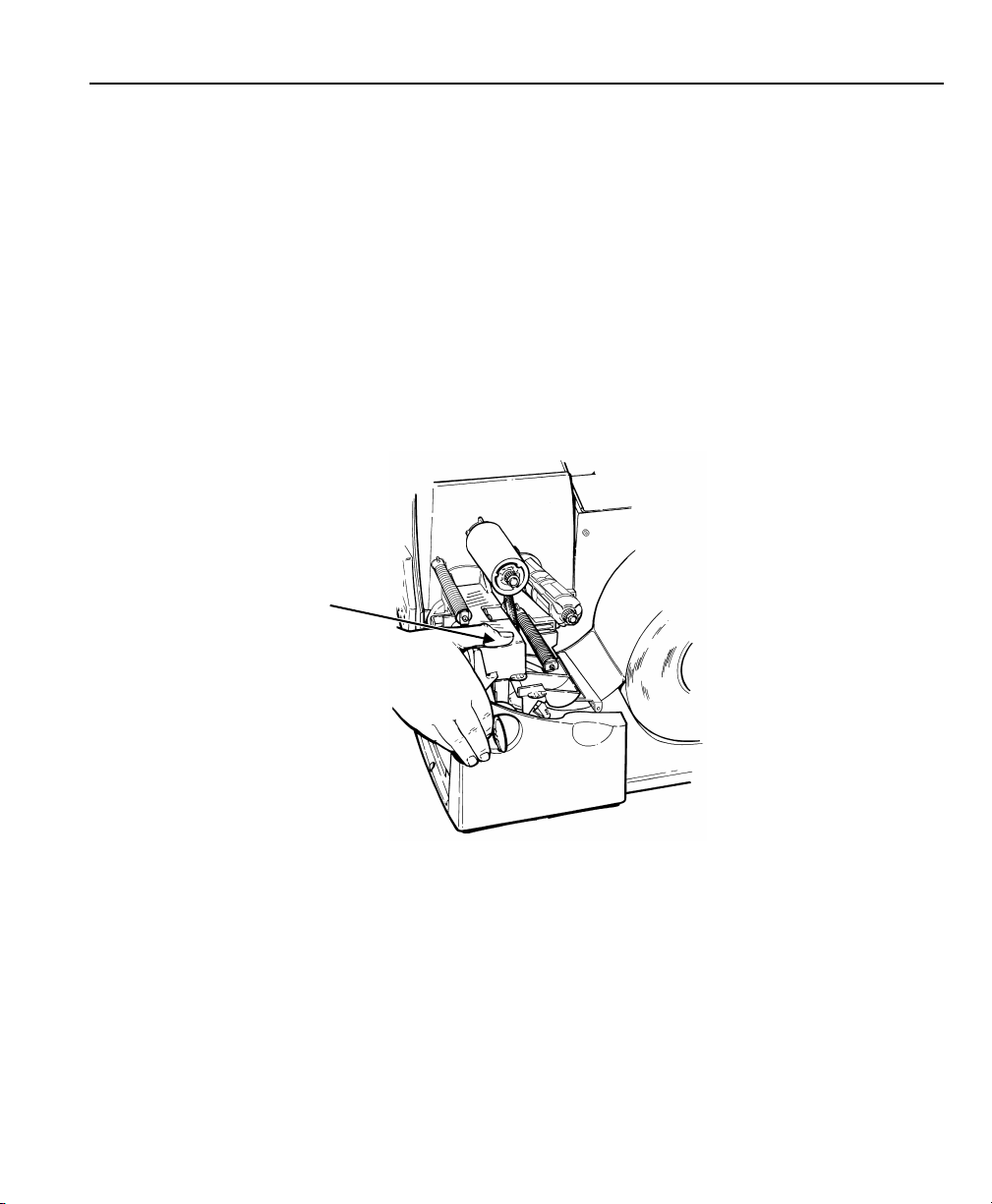

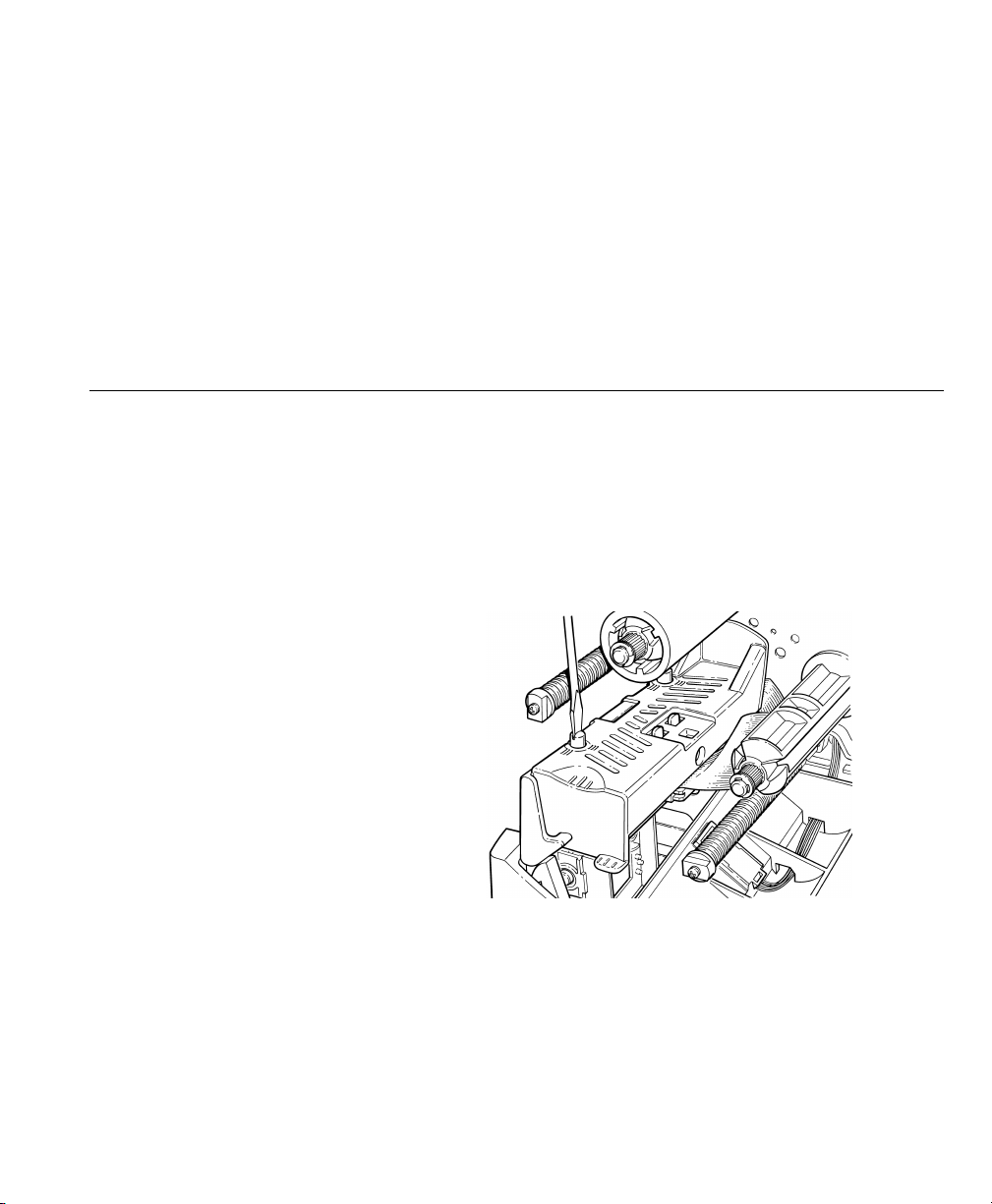

Adjusting the Wide/Narrow Knobs

You may need to adjust the t wo wide/narrow knobs according t o the width of

your supply. For supply that is mor e than two inches, adjust the k nobs to

the wide setting. For supply that is two inches or less, adjust t he knobs to

the narrow setting. For s tring tag supply, use the wide set ting (knobs are

down).

You must adjust both of the k nobs to the same position.

If you experience ribbon

smudging in cold, dry

environments, adjust t he

wide/narrow knobs to the

wide setting .

For wide supplies, push

down and turn the

wide/narrow knobs

clockwise with a

screwdriver.

For narrow supplies, tur n the wide/narrow knobs counter-c lockwise wit h a

screwdriver until it po ps back up.

Note: The adj ustment is shown in the wide pos ition.

2-12 Operator's Handbook

Page 29

3

LOADING RIBBON

This chapter describes how to load a ribbon roll.

There are different ribbon requirements for the thr ee types of supplies:

Thermal Direct do not use a ribbon for printing .

Supplies

Thermal Transfer require a ribbon for pr inting.

Supplies

High Energy require a ribbon able to wit hstand high temperatures .

Supplies

If you are using thermal direc t supplies, do not load a rib bon.

If you are using high energ y supply, be sure to use a high energ y ribbon.

See "Using a Hig h Energy Ribbon" for more information. To set ribbon

options at the printer, s ee "Ribbon" in Chapter 4.

Loading Ribbon 3-1

Page 30

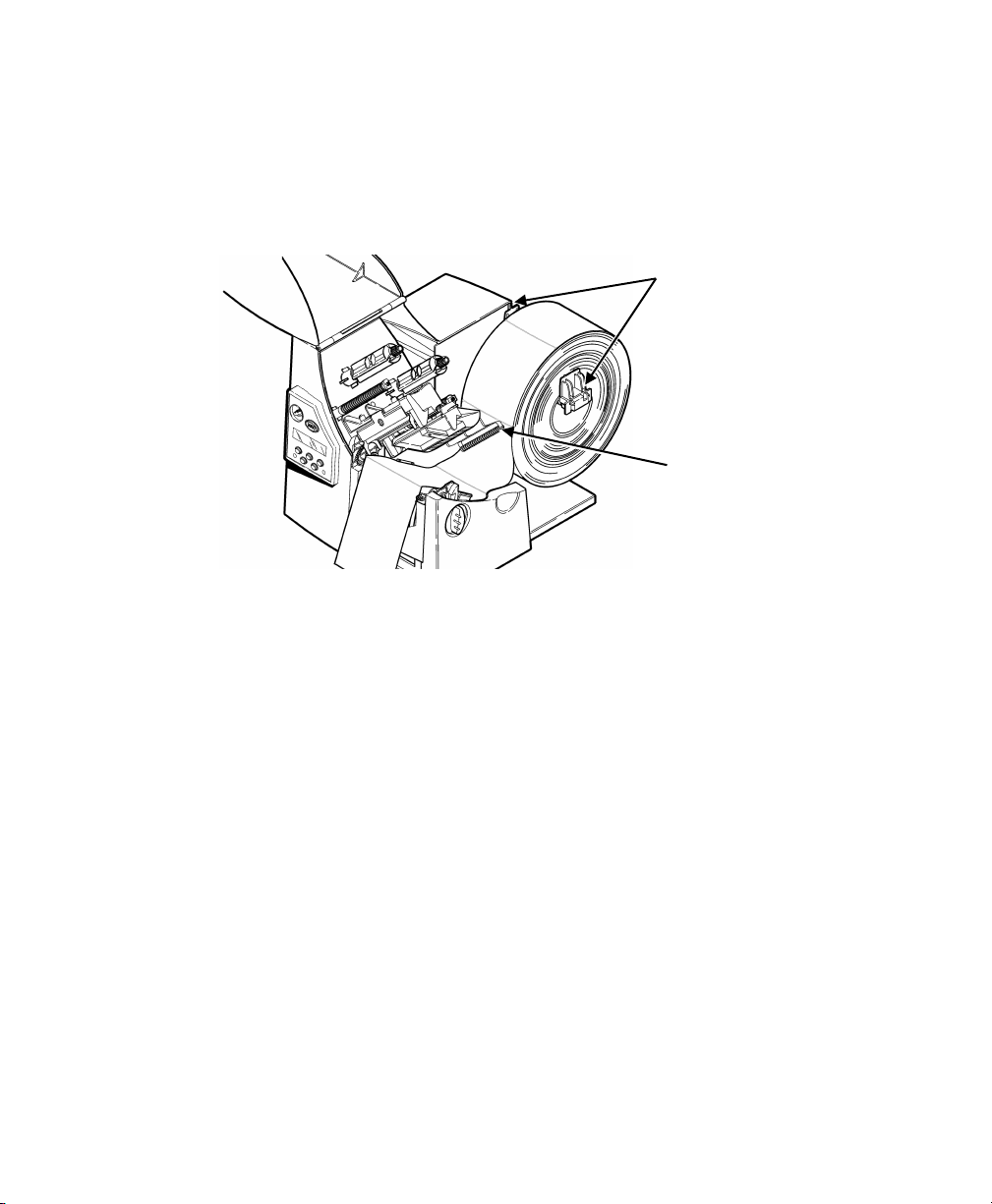

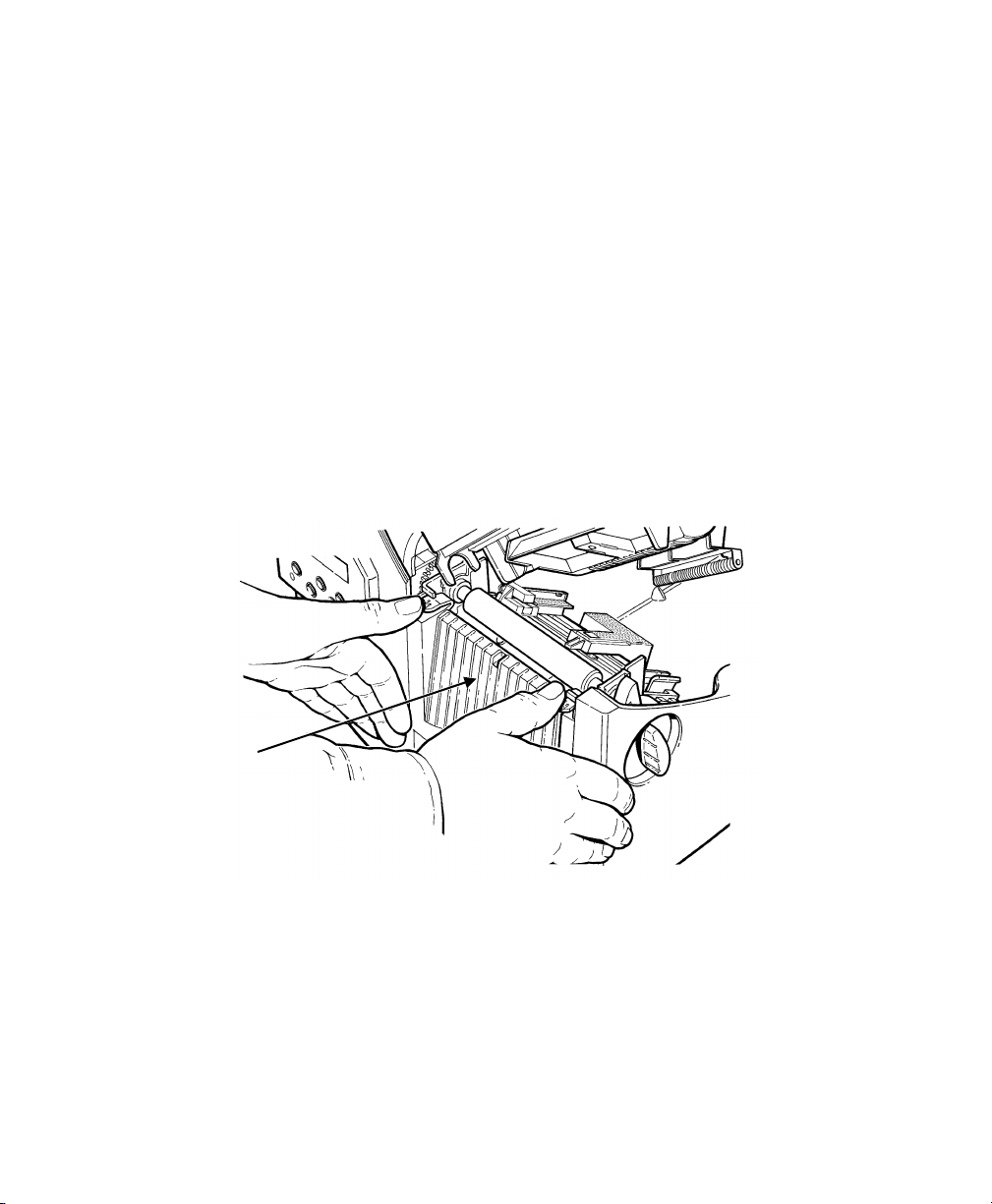

Loading Ribbon

Make sure the printer is conf igured to use a ribbon.

To load ribbon:

1. Open the cover.

2. Unlock the printhead by tur ning the retaining latch .

3. Lift printhead assemb ly using the printhead tab unt il the assembly locks

into place.

Printhead

Assembly

Deflector

Tab

4. Push the deflector tab do wn.

5. Slide the extra ribbon cor e on the take-up reel as far as it will g o with the

"This End Out" writing facing out. Use your empty ribbon cor e as the

take-up core. The take-up core onl y fits on the take-up reel one way.

(An extra take-up core is availa ble by ordering part number 117961.)

3-2 Operator's Handbook

Page 31

Take-up Core

Take-up Reel

Ribbon Rollers

6. Remove the new ribbon fr om the package as shown. Do not wrinkle or

crush the new ribbon.

7. Slide the ribbon onto the bac k reel as far as it will go. T he ribbon roll

only fits on the reel one way. Carefully unwind a few inches of ribbon

from the bottom of the roll.

Note: Mak e sure the “Monarch This End Out” writing is facing out.

The ribbon only fits on the ree l one way.

8. Carefully feed the ribbon under both ribbon rollers and pr inthead as

shown.

9. Align the ribbon and mak e sure it is straight and centered thr oughout the

path.

10. Tape the ribbon to the tak e-up core. Do not tape the ribbon to the

take-up reel.

11. Rotate the take-up core until t he leader is past the printhead.

Loading Ribbon 3-3

Page 32

12. Remove any slack in the ribbon b y turning the take-up reel clock wise.

13. Hold the printhead assem bly by the printhead tab while pr essing down on

the printhead release .

14. Close the printhead by press ing down on the thumb well unti l you hear it

click into place. Close t he cover.

Thumb Well

Using a High Energy Ribbon

High energy ribbon is an option for this printer. It enables you to print on

high energy (TUFF-MARK®) suppl ies.

When you select high energ y ribbon for the printer sett ing, you are setting

the printer to a higher print ing temperature. Select this s etting only after you

have loaded a high energy ribbo n and supply or it may damage your

printhead. See "Ribbon" in Chapter 4 for mor e information.

3-4 Operator's Handbook

Page 33

High Energy Ribb on Limitations

When using the high energy ribb on option:

♦ Use a print speed of 2.5IPS (inch es per second).

♦ Printhead warranty is redu ced to 100,000 inches.

♦ Serial bar codes cannot be pr inted.

♦ Do not use peel mode.

♦ No more than 20% of the supply shou ld have print (black coverag e).

CAUTION: The high energy ribbon may break or stick to the supply when

more than 20% of the supply conta ins print.

♦ Only white high energy suppl y should be used for bar code p rinting.

♦ Reverse fonts cannot be used.

♦ A non-printing area of at least .1 inch (2.54 mm) must exist on the lef t

and right edge of the ribbon.

♦ Do not print horizontal l ines or bars.

♦ Graphics are limited.

Loading Ribbon 3-5

Page 34

3-6 Operator's Handbook

Page 35

Cancel All

Print Mode

Batch

Entry

Repeat

Batch

Batch

Options

Setup

Scripts

Diagnostics

Supply Contrast

Defaults

Network

Port

Settings

Flash

Memory

Verifier RFID

Type

Index

Ctrl

Action

4

SETTING SUPPLY OPTIONS

This chapter explains how to select the supply type, ribb on, speed,

feed mode, backfeed, pr int position, supply positio n, margin position, cut

position, dispense po sition, backfeed dista nce, separators, skip index mode,

set knife control, and set error action.

This chapter also explai ns how to adjust the print contr ast and enable the

verifier.

Main Menu

Supply

Ribbon Speed Feed Mode Backfeed Positioning Separators Skip

Knife

Error

Your System Administrat or may limit access to this menu to pr event supply,

network, script, or communication settings from being changed. If password

protection is turned o n, you see

Enter Passwor d

_ _ _ _ _ _

when you try to access the set up menu. Get the password from your System

Administrator to conti nue.

Setting Supply Options 4-1

Page 36

The options are listed in the t able below.

Option

Choices

Default

Supply Type Aperture/D ie Cut/Black

Mark/Continuous

Ribbon No/Yes/Hig h Energy Yes

Speed 2.5/4.0/6.0/8.0/10.0/12.0/Default Default

Feed Mode Continuous/On-Demand Continuous

Backfeed Off/On/Extended Off

Print Posi tion -450 to 450 0

Supply Posit ion -300 to 300 0

Margin Pos ition -99 to 99 0

Cut Position -300 to 300 0

Dispense

Position

Backfeed

Distance

Separators No/Yes/Long No

Skip Index No/Yes No

Knife Control -20 to 20 0

Error Actio n Normal

Contrast -699 to 699 0

50 to 200 65

10 to 200 65

Overstrik e/Continue x1

Overstrik e/Continue x2

Overstrik e/Continue x3

Overstrik e/Continue x4

Overstrik e/Continue x5

Die Cut

Normal

To exit an option without c hanging the setting, pr ess Escape/Clear.

4-2 Operator's Handbook

Page 37

Setting the Supply Type

You can print on aperture, black mark, die cut, or continuous su pplies. You

have to tell the printer which supplies you are using.

Note: If you are us ing edge aperture supplies , use the die cut setting. If

you are using center aperture sup plies, use the aperture set ting.

To change the setting, f rom the Main Menu, select Setup, then S upply. If

password protection i n enabled, press Feed/Cut three times, then press

Enter/Pause before you s ee the Setup Menu options. Then, follow these

steps.

1. Press or until you see

SUPPLY

Supply Type

2. Press Enter/Pause to set the s upply type option. The current setting is

displayed, for example:

SUPPLY T YPE

Black Mark

3. Press or to see the other options. After you disp lay the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

Setting Supply Options 4-3

Page 38

Setting the Ribbon

You have to tell the printer if your supplies require a ribbon. To change the

setting, from the Main Menu, s elect Setup, then Supply. Then, follow these

steps.

1. Press or until you see

SUPPLY Ribbon

2. Press Enter/Pause to set t he ribbon option. The current s etting is

displayed, for exampl e:

RIBBON

Yes

3. Press or to see the other options. After you disp lay the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

Note: If you set the Ribbon option to Yes, instal l a ribbon before printing .

If you want to use a high energ y ribbon, select high energy f or the

ribbon.

4-4 Operator's Handbook

Page 39

Setting the Speed

You can change the print speed f or bar codes or graphics. If you select

"default" for speed, formats with serial bar codes automat ically print at 2.5

ips and formats with paral lel bar codes print at 6.0 ips. 12. 0 ips printing is

an option that must be purchased se parately.

Note: If you chang e the speed, you must resend your formats or turn the

printer off and back on before the change takes eff ect.

To change the setting, f rom the Main Menu, select Setup, then S upply.

Then, follow these steps.

1. Press or until you see

SUPPLY

Speed

2. Press Enter/Pause to set t he speed option. The current sett ing is

displayed, for exampl e:

SPEED

Default

3. Press or to see the other options. After you disp lay the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

Note: For addit ional high speed printing information, see Chapter 8,

"Printing."

Setting Supply Options 4-5

Page 40

Setting the Feed Mode

You can use continuous or on-dem and printing. On-demand print ing allows

you to remove a label bef ore printing the next one.

To change the setting, f rom the Main Menu, select Setup, then S upply.

Then, follow these steps.

1. Press or until you see

SUPPLY

Feed Mode

2. Press Enter/Pause to set t he feed mode. The current setting is

displayed, for exampl e:

FEED MODE

Continuous

3. Press or to see the other option. After you disp lay the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

4-6 Operator's Handbook

Page 41

Setting the Backfeed

Backfeed works by advancing ea ch printed label to the desir ed dispense

position. Once that label is removed, the next label to be print ed is backed

up underneath the printhe ad. In continuous mode, onl y the last label in the

batch is advanced to the dispe nse position. Extended back feed is available

on this printer with a k nife installed. Extended backf eed feeds a tag far

enough out to be cut and backf eeds the next tag to the print head line.

Extended backfeed eliminat es printed tags being lef t between the printhead

and knife. Extended backf eed works with the selected cut modes. Refer to

the optional Packet Ref erence Manual to learn how to def ine the Backfeed

Control Packet. Extended back feed does not work with non-indexed

(continuous) supply/m ode. Do not use backfeed (norm al or extended) with

supplies less than 0.75 inches.

Note: W e recommend using 0.5-inch gap supplies in pee l mode when

backfeed is disabled.

To change the setting, f rom the Main Menu, select Setup, then S upply.

Then, follow these steps.

1. Press or until you see

SUPPLY

Backfeed

2. Press Enter/Pause to set t he backfeed option. The current setting is

displayed, for exampl e:

BACKFEED

On

3. Press or to see the other options. After you disp lay the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

Setting Supply Options 4-7

Page 42

Changing the Position Settings

This menu includes select ions to change the print, supp ly, margin, cut, and

dispense positions along with the backfeed distance.

When you see

Enter print pos

[-450/450]: +0

Feed/Cut acts as a toggle s witch to change the value by 10 or 1. For

example, to make the print posit ion 23 (from the default of 0), press

Feed/Cut, then press twice (20) , press Feed/Cut again and pr ess three

times (23).

Setting the Pri nt Position

This function adjusts wher e data prints verticall y on the supply. Adjust the

print if it is too close to t he top or bottom of the supply, or o vertypes the preprinted area. One dot is 0. 0049 inch.

♦ If the data is too close to t he bottom, increase the number.

♦ If the data is too close to t he top, decrease the number.

Note: Changing this setting only aff ects new formats sent to the printer.

4-8 Operator's Handbook

Page 43

To change the setting, f rom the Main Menu, select Setup, Suppl y, then

Positioning. T hen, follow these steps.

1. Press or until you see

POSITIONING

Print Pos

2. Press Enter/Pause. T he current setting is displa yed, for example:

Enter print pos

[-450/450]: +0

3. Press or to change the print position. Pressing decreases the

value (moves the image down); incre ases it (moves the image up) .

4. Press Enter/Pause when the number you need appe ars. Press

Escape/Clear until you see the Main Menu.

Setting Supply Options 4-9

Page 44

Setting the Supply Positi on

This function adjusts t he machine to print at the vertica l 0,0 point on the

supply.

Note: The su pply position adjustment should only be made on initial

printer setup. For f ormat adjustments, change the pr int position.

You may need to adjust the suppl y in or out to allow

♦ tags and labels to be removed.

♦ die cut labels to be removed easi ly.

The adjustments are in dots (0.0049 inch).

♦ Increase the number to f eed more supply out of the chute.

♦ Decrease the number to feed les s supply out of the chute.

This option takes eff ect on the next label or tag print ed. Changing supply

position may also affect print position.

To change the setting, f rom the Main Menu, select Setup, Suppl y, then

Positioning. T hen, follow these steps.

1. Press or until you see

POSITIONING

Supply Pos

2. Press Enter/Pause. T he current setting is displa yed, for example:

Enter supply pos

[-300/300]: +0

3. Press or to change the suppl y position. Pressing decreases the

value (feeds less supply); incr eases it (feeds more suppl y).

4. Press Enter/Pause when the number you need appears. Press

Escape/Clear until you see the Main Menu.

4-10 Operator's Handbook

Page 45

Setting the Margin Positi on

This function adjusts wher e the format prints horizont ally on the supply. The

adjustments are in dots (0.0049 inch), which is the small est measurement

the printer recognizes.

The width of the print ar ea depends on your supply size. Maximum width is

four inches. When you move the imag e to the right or left on t he supply,

avoid moving the image t oo close to either edge, because it may not print.

Print too far to the l eft. Print too far to the ri ght.

♦ If the data is too clos e to the left side, increase t he number.

♦ If the data is too close to t he right side, decrease the number .

Note: Changing this setting only aff ects new formats sent to the printer.

To change the setting, f rom the Main Menu, select Setup, Suppl y, then

Positioning. Then, follow these steps.

4. Press or until you see

POSITIONING

Margin Pos

5. Press Enter/Pause. The curr ent setting is displayed, f or example:

Enter margi n pos

[-99/99]: +0

6. Press or to change the margin position. Pressing decreases the

value (moves the image to ward the left side of the supply); increases

it (moves the image toward the r ight side of the supply).

7. Press Enter/Pause when the number you need appears. Press

Escape/Clear until you see the Main Menu.

Setting Supply Options 4-11

Page 46

Setting the Cut Pos ition

This function adjusts wher e the tag is cut. The printer adj usts the cut

position according to t he black marks on the supply. You ma y need to adjust

for aperture supplies. Increase to move the cut up; decrease t o move the

cut down.

To change the setting, f rom the Main Menu, select Setup, Suppl y, then

Positioning. Then, follow these steps.

1. Press or until you see

POSITIONING

Cut Pos

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

Enter knife adj

[-300/300]: +0

3. Press or to change the cut position. Press ing decreases the

value (moves the cut down); incr eases it (moves the cut up).

Note: W e do not recommend setting a positive cu t position while using

extended backfeed. You may cut off the leading edge of t he next

tag.

4. Press Enter/Pause when the number you need appears. Press

Escape/Clear until you see the Main Menu.

4-12 Operator's Handbook

Page 47

Setting the Dispense Posi tion

This function adjusts t he stopping point of the label.

To change the setting, f rom the Main Menu, select Setup, Suppl y, then

Positioning. Follow these s teps.

1. Press or until you see

POSITIONING

Dispense Pos

2. Press Enter/Pause.

DISPENSE POS

[50/200]: + 65

3. Press or to change the dispense posit ion. Pressing decreases

the value; increases it.

4. Press Enter/Pause when the number you need appears. Press

Escape/Clear until you see t he Main menu.

Setting Supply Options 4-13

Page 48

Setting the Backfeed Distance

This is the amount to move the labe l backwards. The backf eed distance

cannot be greater than t he dispense position. If you mak e the backfeed

distance greater than the dispense position, the disp ense position

automatically changes t o match the backfeed distance.

The backfeed distance should eq ual the dispense position. An exc eption is

when you are tearing labels, instead of peeling. Then, the backfeed distance

must be 30 dots (0.15 inches) l ess than the dispense position t o account for

improper tearing of butt cut supplies. You will have a 30-dot non-pr int zone

on your supply, but this pre vents exposed adhesive under the pr inthead.

To change the setting, f rom the Main Menu, select Setup, Suppl y, then

Positioning. Follow these s teps.

1. Press or until you see

POSITIONING

Backfeed D is

2. Press Enter/Pause.

BACKFEED DIS

[10/200]: + 65

3. Press or to change the dispense posit ion. Pressing decreases

the value; increases it.

4. Press Enter/Pause when the number you need appears.

Press Escape/Clear until you see t he Main menu.

4-14 Operator's Handbook

Page 49

Using Batch Separators

A batch separator is an extra t ag printed in between batches with a pinstripe

pattern. If you select " Long" for the separator, a double-len gth (two tags)

separator prints. For non-in dexed supply, the batch separat or is always six

inches long. If you have the Monarch® 928™ stacker installed, the batch

separator is 3.66 inches long . The name of the batch is shown on t he batch

separator.

Batch Separator

Note: Changing this setting only aff ects new formats sent to the printer.

To change the setting, f rom the Main Menu, select Setup, then S upply.

Then, follow

these steps.

1. Press or until you see

SUPPLY

Separators

2. Press Enter/Pause to set t he batch separators option. The cur rent

setting is displayed, f or example:

SEPARATORS

No

3. Press or to see the other options. After you disp lay the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

Setting Supply Options 4-15

Page 50

Using Skip Index

You can use the skip index mode to sk ip (or ignore) a sense mar k and print

an image over multiple labe ls, if necessary. For example, if you have 4.0"

long supplies loaded, but your image is 8.0" long, enable s kip index mode to

print the 8.0" long imag e on two labels. The image length is de termined by

the format header. See your System Administrator or the option al Packet

Reference Manual for more information. The skip index feat ure is useful

when you have a single f ormat that contains two labels, such a s a shelf

label and a carton label.

Note: W hen designing the format, make sur e text or graphics do not print

in the gap of label rolls.

To change the setting, f rom the Main menu, select Setup, then S upply.

1. Press or until you see

SUPPLY

Skip Index

2. Press Enter/Pause to set t he skip index mode. You will see the cur rent

setting, for example:

SKIP INDEX

No

3. Press or to see the other options. After you disp lay the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

4-16 Operator's Handbook

Page 51

Setting the Knife Control

You may notice unevenly cut ta gs on one end or the other of your supp ly

(one end may appear longer t han the other). Use the knife con trol

adjustment to balance t he cut tag length from tag-to-tag.

You may need to make this adjust ment

♦ on initial printer setup .

♦ if you load a differ ent supply type (thickness) f rom the last ones printed.

♦ when you change the print speed.

♦ when you change to a diffe rent tag size from the last ones printe d.

To change the setting, f rom the Main Menu, select Setup, then S upply.

Then, follow these st eps.

1. Press or until you see

SUPPLY

Knife Ctrl

2. Press Enter/Pause. T he current setting is displa yed, for example:

Enter knife ctrl

[-20/20]: +0

3. Press or to change the knif e control. You may need to experiment

and cut a few test tags to check the tag cut length. Pressing

decreases the value; increases it .

Note: Depending on how unevenly the tags are c ut, always start with a

small number, such as +- 1 or 2.

4. Press Enter/Pause when the number you need appears.

Press Escape/Clear until you see the Main Menu.

Setting Supply Options 4-17

Page 52

Setting the Error Action

Error Action

Standard

Peel

Verifier

with Peel

RFID wit h

Peel

Overstrike/Continue 1 -5

No

No

No

Normal (no overstrike)

Yes

Yes

Yes

The recovery action from an e rror condition is in the Setup, Sup ply Menu.

You can change how the printer res ponds to a bad scan. The choices

include normal and overstrik e/continue one to five consec utive bad scans.

The overstrike pattern is created to prevent someone f rom using a bad label.

Selecting overstrik e and continue 1x-5x sets the number of times the printer

prints an overstrike patt ern on consecutively bad labe ls before generating an

error. The user must clear the er ror before operation ca n continue.

Do not use the overstrike action w ith

♦ Peel mode

♦ String tag supplies

For more information about the error actions, see t he following table.

Consider this scenario w hen the error action is set to overst rike/continue 3x:

If the printer errors on the first label, an overstrik e pattern is printed, but the

printer attempts to r eprint the image up to three times. If the third

consecutive label also g enerates an error, an overstrike pat tern is printed;

however, the printer st ops and the error message is displa yed. The operator

must resolve the error condit ion before printing continues.

In the above example, if the third label did NOT generate an er ror,

♦ the batch image is printed

♦ the consecutive error count er is reset

♦ the printer continues pr ocessing the batch.

4-18 Operator's Handbook

Page 53

Normal (default)

The printer errors and t he condition causing

the error is displayed. T he error must be

cleared before operat ion can continue. An

operator must press Escape/Clear to clear the

error and continue print ing. No overstrike

pattern is printed.

Overstrike/Continue 1x

Overstrike/Continue 2x

Overstrike/Continue 3x

Overstrike/Continue 4x

Overstrike/Continue 5x

The printer prints an overst rike pattern on one,

two, three, four, or five consecutive labels and

stops printing afte r the selected number of

overstrike patterns ha ve been printed. An

operator must press Escape/Clear to clear the

error and continue print ing. Do not use the

label with the overstri ke pattern.

Note: The printer re-calibrat es (feeds a blank

label) after a motion or verif ier error.

To change the setting, f rom the Main Menu, select Setup, then S upply. Then

follow these steps.

1. Press or until you see

SUPPLY

Error Act ion

2. Press Enter/Pause. T he current setting is displa yed, for example:

ERROR ACTION

Ostrk/Cont 1x

3. Press or to see the other options. Af ter you display the option you

want, press Enter/Pause.

4. Press Escape/Clear until you see the Main Menu.

Note: Depending on the selected error action, you may or may not see a

label with the overstri ke pattern.

Setting Supply Options 4-19

Page 54

Setting the Print Contrast

Cancel All

Print Mode

Batch Entry

Repeat

Batch

Batch

Options

Setup

Scripts

Diagnostics

Supply

Contrast

Defaults

Network

Port

Settings

Flash

Memory

Verifier

RFID

The print contrast cont rols the darkness of the printing on your supply. The

range is -699 to +699 and the def ault is 0. Having the correct print contrast

setting is important becaus e it affects how well your bar code s scan and how

long your printhead last s. You can use a verifier to check the bar code print

quality.

Main Menu

High contrast setting s may

♦ require additional pri nthead cleaning.

♦ create bar code growth, lead ing to reduced scanning.

CAUTION: Setting the print contrast higher than 399 reduces the print head

warranty to 100,000 inches and m ay damage the printhead.

1. From the Main Menu, press or until you see

MAIN MENU

Setup

2. Press Enter/Pause. You will be at the Setup menu. Press or until

you see

SETUP

Contrast

3. Press Enter/Pause. The current setting is displayed, for example:

Enter contr ast

[-699/+699]: +0

4. Press or to change the contrast. Pressing darkens the print;

lightens the print.

4-20 Operator's Handbook

Page 55

Feed/Cut acts as a toggle s witch to change the value by 10 or 1.

For example, to make the cont rast 50 (from the default of 0), press

Feed/Cut, then press five times (50 ).

5. Press Enter/Pause to select either "Yes" or "No" to print a test label and

check the print contrast . Press Enter/Pause.

6. Press Escape/Clear until you see the Main Menu.

We recommend you check the bar code print quality with a bar code verifier.

If you do not have a bar code verif ier or scanner, check the bar code

visually. A bar code that is in spe c has complete bars, clear sp aces, and

small alphanumeric charac ters look complete. An in spec bar code may not

look as good as one that is too dark , but it has the highest scan rate.

Dark IN SPEC Light

Setting Supply Options 4-21

Page 56

Enabling the Verifier

The verifier scans and check s the quality of bar codes as they ar e printed.

The optional verifier m ust be purchased separately. T he verifier scans

parallel bar codes; it c annot scan serial bar codes.

The verifier must be enabled and s et up before you can scan bar codes.

For additional set up procedures, refer to your verifier's Operating

Instructions.

To enable the verifier, from the Main Menu, select Setup, t hen Verifier.

Then follow these steps.

1. Press or until you see

VERIFIER

State

2. Press Enter/Pause. The current setting is displayed, for example:

VERIFIER

Disabled

3. Press or to see the other option. Af ter you display the option you

want, press Enter/Pause. Press Escape/Clear until you see the Main

Menu.

4-22 Operator's Handbook

Page 57

Cancel All

Print Mode

Batch Entry

Repeat

Batch

Batch

Options

Setup

Scripts

Diagnostics

Supply

Contrast

Defaults

Network

Port

Settings

Flash

Memory

Verifier

RFID

Serial

Comm

Parallel

Comm

5

SETTING COMMUNICATIONS

This chapter tells you ho w to set the serial or parallel

communication values. These values provide the link f or normal online

printing.

Main Menu

You need to set your Serial Comm v alues to match your computer' s online

communications. Before ente ring the communication value s, see your

System Administrator.

The serial communication values are listed in the table b elow.

Option Choices Default

Baud rate 1200/2400/4800/9600/19200/

9600

38400/57600/115200

Word length 7/8 8

Stop bits 1/2 1

Parity None/Odd/Even None

Flow control None/Xon/Xoff/DTR/CTS DTR

Reset No/Yes No

Setting Communications 5-1

Page 58

Setting the Baud Rate

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Serial Comm. If password protect ion in enabled, press Feed/Cut three

times, then press Enter/Pause bef ore you see the Setup Menu opt ions.

Then, follow these steps.

1. Press or until you see

SERIAL COMM

Baud Rate

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

BAUD RAT E

9600

Press or to display the baud rate you n eed, then press Enter/Pause.

Press Escape/Clear until you see the Main Menu.

Setting the Word Length

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Serial Comm. Then, follo w these steps.

1. Press or until you see

SERIAL COMM

Word Length

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

WORD LENGTH

8

3. Press or to display the word length you need, then press

Enter/Pause. Press Escape/Clear u ntil you see the Main Menu.

5-2 Operator's Handbook

Page 59

Setting the Stop Bits

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Serial Comm. Then, follo w these steps.

1. Press or until you see

SERIAL COMM

Stopbits

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

STOPBITS

1

3. Press or to display the number of stop bits you nee d, then press

Enter/Pause. Press Escape/Clear u ntil you see the Main Menu.

Setting the Parity

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Serial Comm. Then, follo w these steps.

1. Press or until you see

SERIAL COMM

Parity

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

PARITY

None

3. Press or to display the parity you need, then press Enter/Pause.

Press Escape/Clear until you see the Main Menu.

Setting Communications 5-3

Page 60

Setting the Flow Control

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Serial Comm. Then, follo w these steps.

1. Press or until you see

SERIAL COMM

Flow Control

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

FLOW CONTROL

DTR

3. Press or to display the flow control you need, then press

Enter/Pause. Press Escape/Clear u ntil you see the Main Menu.

XON is 17; XOFF is 19. Set flow contr ol to DTR for PC computers

(unless you have XON/XO FF software).

Resetting to Default Values

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Serial Comm. Then, follo w these steps.

1. Press until you see

SERIAL COMM

Reset

2. Press Enter/Pause.

Are you sure?

No

Press or to make your selection, then p ress Enter/Pause. If you select

"Yes," the following de faults are restored: 9600 baud, No parity, 8 bit word

length, and 1 stop bit. Press Escape/Clear until you see the Main Menu.

5-4 Operator's Handbook

Page 61

Using Parallel Communications

The parallel communications m enu allows you to set the values for the active

parallel port. The values a re listed in the table below.

Note: Tur n the printer off and back on when you c hange the port or mode

settings.

Option Choices Default

Port External/Internal External

Mode Compatible/IEEE-1284 Compati ble (Centro nics mode)

Setting the Port

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Parallel Comm. Then, follo w these steps.

1. Press or until you see

PARALLEL COMM

Port

2. Press Enter/Pause.

PORT

External

3. Use or to select either "External" or "Internal." Press Enter/Pause.

The internal port is used f or printer options installed inside the printer,

such as the Ethernet comm unication port. The external por t is used to

connect a printer cable or external device directly to t he parallel port.

4. Press Escape/Clear until you see the Main Menu.

Setting Communications 5-5

Page 62

Setting the Mode

To change the setting, f rom the Main Menu select Setup, Port Settings, then

Parallel Comm. Then, follo w these steps.

1. Press or until you see

PARALLEL COMM

Mode

2. Press Enter/Pause.

MODE

Compatible

3. Use or to select either "Compatib le" or "IEEE1284." Press

Enter/Pause. Use compat ible mode for a computer connectio n to the

printer with a parallel cab le. Use IEEE-1284 for bi-directiona l Ethernet

communications. See Appen dix B, "Accessories & Options" for more

information about Ether net options.

4. Press Escape/Clear until you see the Main Menu.

5-6 Operator's Handbook

Page 63

Cancel

All

Print Mode

Batch

Entry

Repeat

Batch

Batch

Options

Setup

Scripts

Diagnostics

Supply Contrast

Defaults

Network

Port

Settings

Flash

Memory

Verifier

RFID

Error

6

SETTING DEFAULTS

This chapter explains how to select the monetary sig n, secondary

sign, decimal places, slashe d zero, power-up mode, prom pt set, imaging

errors, ignore conf iguration packets, disable er ror retry, and adjust the

image length.

This chapter also explai ns how to format flash, check the available flash

memory, and pack flash memor y.

Monetary

Sign

Secondary

Sign

Decimal

Places

Slashed

Zero

Powerup Mode

Prompt

Set

Flash

Storage

No

Image

Ignore

Config

Error

Retry

Adjust

Length

You can set your printer c onfigurations to fit your dail y operation, using

either the offline menus or the online configuration opt ion. After an option is

selected in the online c onfiguration or offline Setup Menu, the option is

saved when the printer is t urned off.

Setting Defaults 6-1

Page 64

The default options are listed in the table below.

Option

Choices

Default

Monetary sign None/USA/UK/Japan/

Germany/France/Spain/

Italy/Sweden/Finland/

Austria/India/Russia/

Korea/Thailand/China/Euro-Dollar

Secondar y Sign No/Yes No

Decimal Plac es 0/1/2/3 2

Slashed Zer o No/Yes No

Power-up Mode Online/Offline Online

Prompt Set English/French/German/

Spanish-ES/Japanese/Portuguese/

Italian/Swedish/Spanish 2/

Danish/Dutch/Finnish/Norwegian

Numeric Form at

Flash Storage Disabled/Enabled Disabled

No Image Errors Disabled/Enabled Disabled

Ignore Confi g Disabled/Enabled Disabled

Error Retr y Disabled/Enabled Enabled

Adjust Lengt h -30 to 30 0

Default, Ar abic-Indic, Eastern

Arabic

USA

English

Default

The monetary sign, secondar y sign, and decimal places optio ns are used in

conjunction with optio n 42. Refer to the optional Packet R eference Manual

for more information.

Note: The se ttings for Monetary Sign, Secondar y Sign, Slashed Zero, and

Decimal Places are applied when a format is downloaded. Cha nging

the settings does not aff ect batches already in the printer.

6-2 Operator's Handbook

Page 65

Country

Currency

Description

€

Setting the Monetary Sign

You can also select None if you do not want a monetary sign to pr int in price

fields. The monetary sign s available for 15 countries ar e shown in the table

below.

USA $ dollar

UK £ pound

Japan ¥ yen

Germany

France F franc

Spain P peseta

Italy L. lira

Sweden Kr krona

Finland

Austria

India Rs rupee

Russia

Korea

Thailand

China ¥ yuan

Euro-Dollar

1

2

6

3

5

deutsche m ark

markka

schilling

ruble

won

baht

euro-dollar

To change the setting, f rom the Main Menu, select Setup, then D efaults. If

password protection i n enabled, press Feed/Cut three times, then press

Enter/Pause before you s ee the Setup Menu options. Then, follow these

steps. To exit an option withou t changing the setting, press Escape/Clear.

1. Press or until you see

DEFAULTS

Monetary Sign

Setting Defaults 6-3

Page 66

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

MONETARY S IGN

USA

3. Press or until you see the country's mo netary sign you want.

4. Press Enter/Pause. Press Escape/Clear until you see the Main menu.

Setting the Secondary Sign

If you select USA as the monetar y sign, you can print amounts less than

$1.00 either by using a dollar sign and decimal ($0.30) or by using a cent

sign (30¢).

♦ If you set the secondary sign opt ion to No, prices under $1.0 0 will print

like this: $ .4 5

♦ If you set the secondary sign opt ion to Yes, prices under $1.0 0 will print

like this: 45¢

The same option applies to t he appropriate secondar y sign for monetary

signs other than USA.

To change the setting, f rom the Main Menu, select Setup, then D efaults.

Then, follow these steps.

1. Press or until you see

DEFAULTS

Secondar y Sign

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

SECONDAR Y SIGN

No

3. Press or until you see the option you want . Then press

Enter/Pause. Press Escape/Clear u ntil you see the Main menu.

6-4 Operator's Handbook

Page 67

Setting the Number of Decimal Places

You can set the printer for 0, 1, 2, or 3 places after the decimal in a price

field. In U.S. currency, you might print prices like this: $24.00 (2 decimal

places) or like this: $24 (0 decima l places).

1. Press or until you see

DEFAULTS

Decimal Places

2. Press Enter/Pause. The curr ent setting is displayed, f or example:

DECIMAL PLACES

2

3. Press or until you see the option you want . Then press

Enter/Pause. Press Escape/Clear until you see the Main menu.

Setting the Slashed Zero Appearance

The slashed zero feature let s you select how you want the zero character

printed; either without a slash, 0 or, with a slash, Ø.