Page 1

1

activeARC

®

active500EM

Access Control Data Networking Switch

Hardware Installation Guide

Package contents

Item Units

active500EM 1

Metal brackets 2

Screws 8

Rubber feet 4

RJ-45 Console Cable 1

US power cord 1

activeARC® Support Contact Card 1

Safety precautions

WARNING: Before working on this equipment, be aware of good

safety practices and the hazards involved with electrical circuits.

WARNING: To reduce risk of fire hazard and electric shock, do not

install the unit near wet or damp locations.

CAUTION: To reduce the risk of fire, use only number 26 AWG or

larger UL Listed or CSA Certified telecommunication line cord for all

network and telecommunication connections.

• Keep the product in a dry, clean, and dust-free location. Use only a soft,

damp cloth to clean the product. Inspect and maintain the site and

switch regularly.

• DO NOT expose the product to liquid or moisture.

• DO NOT expose the product to extreme temperatures.

Description of hardware

Front panel

Type active500EM

RJ-45 24

Combo port (SFP

and RJ-45 port)

4

Console port 1 RJ-45 serial console port

Uplinks 4 SFP

LEDS 24 LEDs of the port and 5 LEDs of the system

function

Console description

The active500EM has a RJ-45 serial console port for local and telnet

configuration. The console port supports asynchronous mode. To achieve

asynchronous mode, set the data bit as 8, the stop bit as 1, the parity bit as

none, and the default baud rate as 9600bps.

In addition, the baud rates supported by the console port under Bootrom

mode includes 14400, 19200, 38400, 57600, and 115200(bps). The setting

will not take effect until after the switch is rebooted.

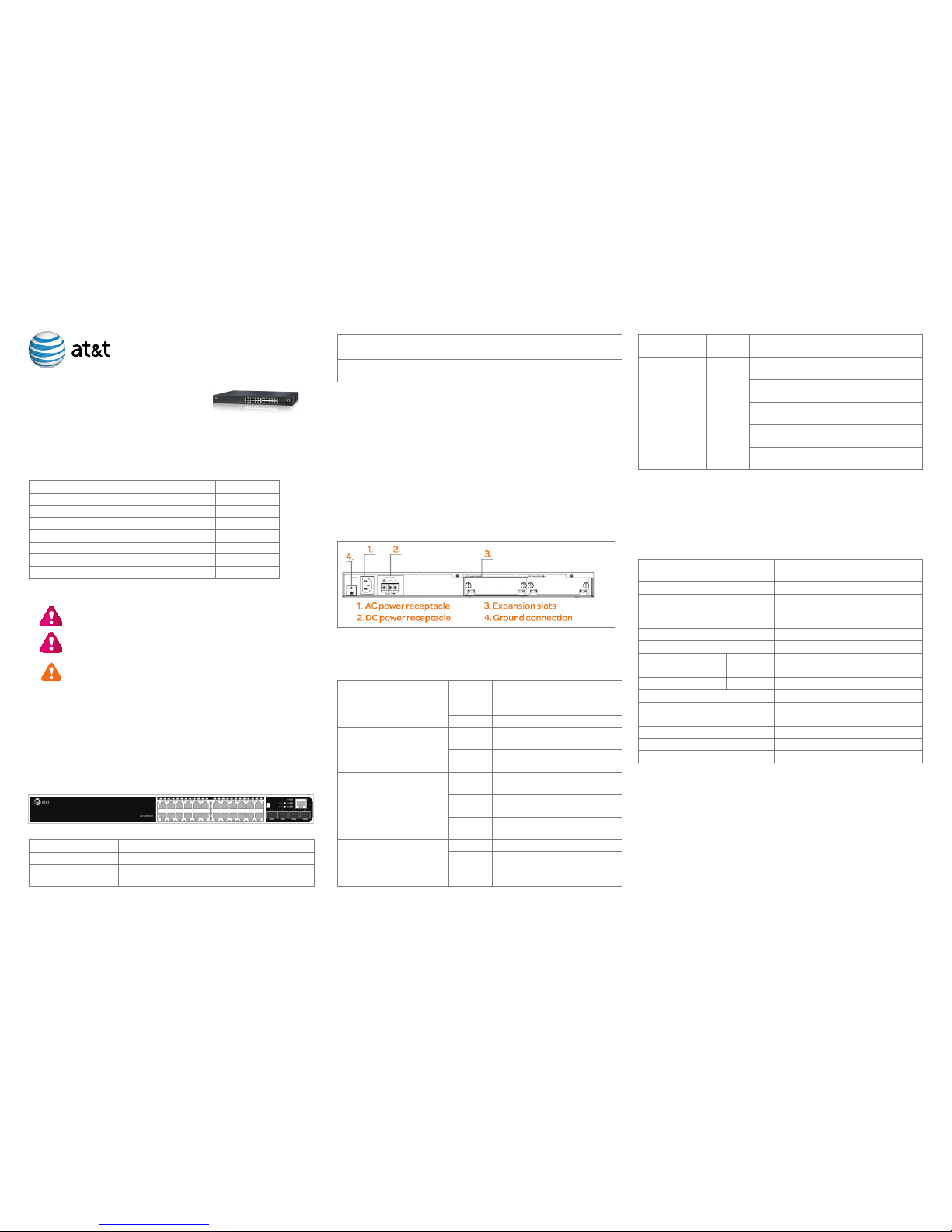

Back panel

The active500EM has one 100-240V 50/60Hz 5A AC power receptacle,

one standby DC power receptacle (48V), one ground connection, and two

expansion slots.

Status LEDs

The active500EM includes 24 port LEDs, power LED, AC power LED, system

automatic diagnoses LED, and 1/2 state LED of the extended module.

LED Panel

symbol

Status Description

Power LED PWR Green Power is operating normally.

Off Power is off or malfunctioning.

Redundancy

power LED

RPU Green Redundancy power unit is

charging.

Off Redundancy power unit is off or

malfunctioning.

System

automatic

diagnoses LED

DIAG Blink

(Green)

System automatic diagnoses

are underway.

Green System automatic diagnoses

completed.

Amber System automatic diagnose is

malfunctioning.

Extended

module LED

Module1/

Module2

Green Extended module is installed.

Amber The installed extended module

is disabled.

Off No extended module.

LED Panel

symbol

Status Description

Link/Activity Amber Ports are in the link state of 10M

or 100M.

Green Ports are in the link state of

1000M.

Blink

(Amber)

Ports are in the active state of

10M or 100M.

Blink

(Green)

Ports are in the active state of

1000M.

Off No link connection or link

connection has failed.

Power system

AC Power - Rated AC power voltage range: 100V-240V

Current: AC: 5A

Frequency: 50/60Hz (±3Hz)

System specifications

Dimension (W x H x D) 440x328.4x43.4 mm

(17.33 x 12.93 x 1.71 in.)

Extended card dimension (Wx H) 107x145.9 mm (4.21x5.75 in.)

Weight 4.85kg (9.67 lb)

Fixed port 20 RJ-45 ports and 4 combo ports (4

SFP and 4 RJ-45)

Management port 1 RJ-45 serial console port

Extended slot 2

Power input AC 100V–240V

DC -48V (-48V– -60V)

Max consumption System 160W

Operating temperature 0°C–50°C

Storage temperature -40°C–70°C

Relative humidity 5%–95%, non-condensing

Mean time between failure Min 120,000 hours MTBF

Maximum operating altitude 7000 ft (2km)

Current AC: 5A; DC: 4A

IMPORTANT: The weight is the machine chassis weight with two extended

modules.

Environmental requirements

• The switch must be installed in a clean area; otherwise, the switch may

be damaged by electrostatic adherence.

• The switch must be maintained within system specifications.

• Ensure sufficient spacing around the switch for good air circulation.

• Avoid placing the switch in direct sunlight. Keep the switch away from

heat sources and strong electromagnetic interference sources.

Page 2

2

• The switch must be mounted to a standard 19’’ rack or placed on a

clean, level desktop.

• The switch must be installed near an accessible power socket outlet.

When using DC input power, please make sure that a 4A circuit breaker

is used and is available near the controller installation site for easy

power off.

• The switch can be installed at a maximum altitude of 7,000 feet (2km).

• The DC power supply is screwed directly into the back of the

active500EM, creating a permanent connection. Therefore, an

appropriate disconnect device should be provided externally to the

active500EM in the case an urgent shutdown is required. The following

types of disconnect devices can be used:

• The main supply plug on the power supply cord.

• An appliance coupler.

• An isolating switch.

• A circuit-breaker.

• Any equivalent device.

Security warnings

• Do not place anything on top of the switch.

• Do not install, move, or relocate the switch and its modules when the

switch is in operation.

• Do not open the switch shell.

• Do not drop metals into the switch. This can cause the switch to shortcircuit.

• Do not touch the power plug or power socket.

• Use standard power sockets, which have overload and leakage

protection.

• Have the emergency power switch on site. In case of emergency, switch

off the power immediately.

Preventing electrostatic discharge damage

CAUTION: Improper power supply system grounding,

extreme fluctuation of the input source, and transients (or

spikes) can result in larger error rate or hardware damage.

Electrostatic discharges (ESD) can cause damage to internal circuits and

the entire switch, and may cause physical injury. To avoid ESD damage:

• Ensure proper grounding of the device.

• Perform regular cleaning to reduce dust.

• Maintain proper temperature and humidity.

• Always wear an ESD wrist strap and antistatic uniform when in contact

with the switch.

Installation notice

• Read the instructions carefully before installation and operation. Prepare

installation materials, tools and installation site.

• Use the brackets and screws provided in the accessory kit with the proper

tools to perform the installation. Always wear an antistatic uniform and

ESD wrist straps. Use standard cables and connectors.

• Clean the site after installation, and ensure the switch is well grounded

before powering on.

CAUTION: Potential risks include: electric leakage, power

supply arcing, power line breakage, overloaded circuit, and

electrical short circuit. If electrical shock, fire, or electrical

short circuit occurs, cut off electricity and seek help.

Device installation

Required tools

• Screwdrivers, both Phillips (crosshead) and Standard (flat-head)

• ESD wrist strap & antistatic uniform

Installing the switch

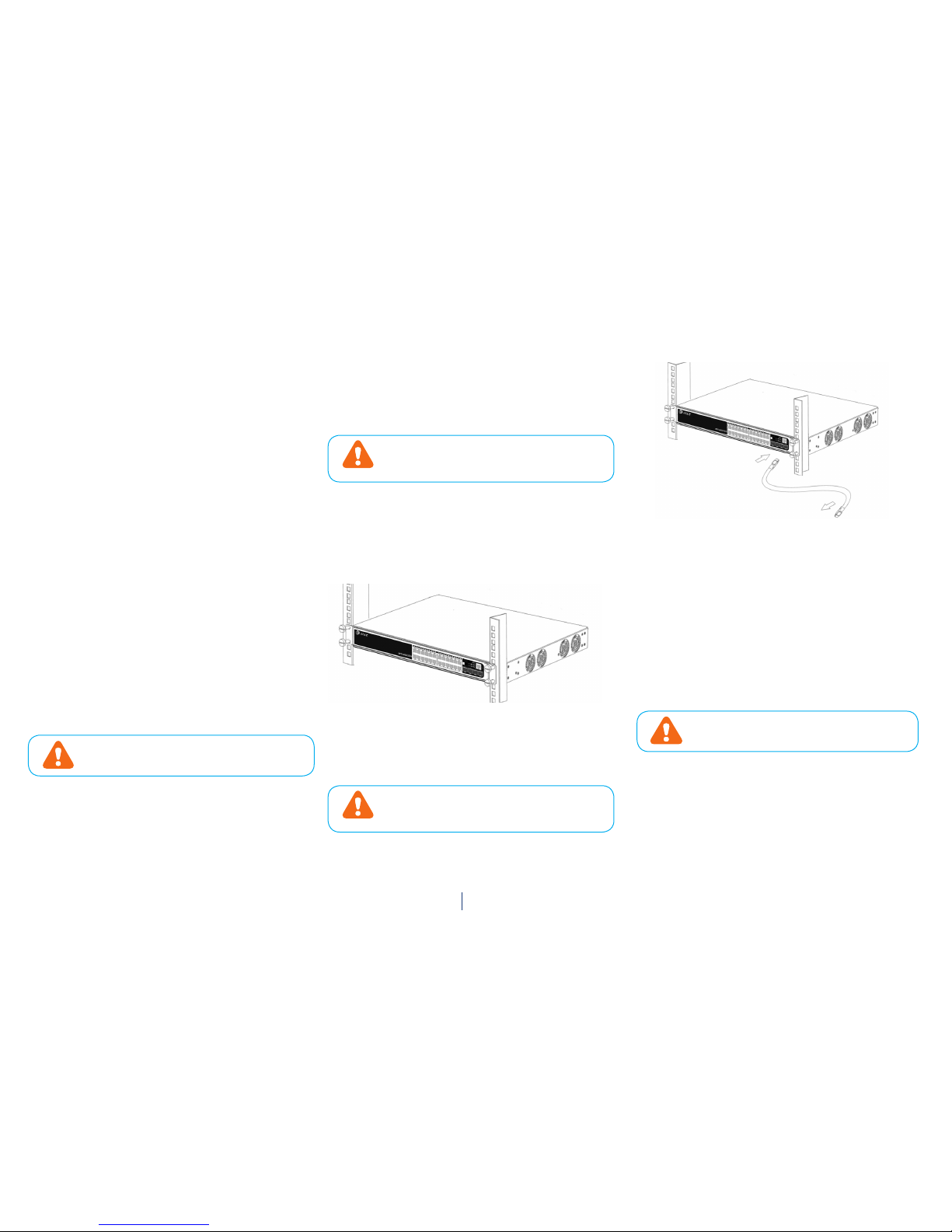

To mount the active500EM on the 19’’ rack:

1. Attach the two brackets on the active500EM with screws provided in the

accessory kit.

2. Put the bracket-mounted switch into a standard 19’’ rack. Fasten the

active500EM to the rack with the screws provided. Leave enough space

around the switch for good air circulation.

CAUTION: The brackets are used to mount the switch to the

rack, and are not load-bearing. Place a rack shelf under the

switch. Do not place anything on top of the switch. Do not

block the vents on the switch to ensure the proper operation.

Connecting the console

The active500EM provides a serial console port.

To connect the console to the active500EM Access Control switch:

1. Attach the console cable (included) end to the console port of the

switch.

2. Connect the other side of the console cable to a COM port .

3. Turn on both the switch and the COM port, and configure the switch

through the COM port.

Copper cable cable connection

1. Insert one end of the Ethernet cable into the RJ-45 Ethernet port in the

switch copper port.

2. Insert the other end of the Ethernet cable into the RJ-45 Ethernet port

of the other device.

3. Check all status indicators for the corresponding ports; a lit LED

indicates that the link has been established. Otherwise, the link is not

ready and the cable should be examined.

CAUTION: Verify the label above the port before

connecting cables. Connecting to the wrong port may

damage the switch.

AC power supply connection

1. Insert one end of the power cable (included) into the power source

socket, and the other end into a standard power socket.

2. Check if the power status indicator in the front panel of the switch is

lit. The active500EM is self-adjustable for the input voltage. When the

input voltage is in the range printed on the switch surface, the switch

can operate correctly.

Page 3

3

3. When the switch is powered on, it executes self-test procedures and

starts up.

CAUTION: The input voltage must be within the required

range; otherwise the switch can be damaged or may

malfunction. Do not open the switch shell as physical

injury may occur.

Switch management

Network administrators can use a simple-to-configure web Graphical User

Interface (GUI) to manage and maintain the switch on their network.

Login web network management

The default Web login process and details are identified below. The default

Web login information includes:

Username: admin

Password: admin

IP address of the switch: 192.168.1.1

1. Connect the switch to PC by using an Ethernet cable (not included) to

connect the PC to one of the switch’s Ethernet ports.

2. Configure the IP address for the PC and ensure that it can

communicate with the switch. The connection between the switch and

PC can be done by a direct connection or through the network.

For example, change the IP address to 192.168.1.17 to ensure that the PC

and switch are in the same IP subnet.

3. Launch your PC’s web browser and type http://192.168.1.1 in the

address bar. Press Enter.

4. On the login page, type admin in the Username field, and type admin in

the Password field. Click Login.

5. To quit and exit, click the log off button on the upper right corner on the

web network management page.

© 2014 International Communications Corporation, Inc. All Rights Reserved. AT&T and the AT&T

logo are trademarks of AT&T Intellectual Property licensed to lnternational Communications

Corporation, Riverside, California. Printed in U.S.A. Issue 5.1 AT&T 04/28/14. activeARC is a

registered trademark of International Communications Corporation,Inc.

Contact information

Phone: 1-855.MYARC11 (855.692.7211)

E-mail: support@activearc.att-mail.com

sales@activearc.att-mail.com

www.att.com/activearc

activeARC® web management

The web network management page includes: navigation bar, configuration

area, and help area shown below.

Loading...

Loading...