Atlas Copco ZT, ZT15, ZR, ZT22, ZT18 Instruction Book

...

Instruction book

Atlas Copco Stationary Air Compressors

ZT15, ZT18, ZT22, ZT30, ZT37, ZT45

ZR30, ZR37, ZR45

Instruction book

Copyright 2004, Atlas Copco Airpower n.v., Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in

particular to trademarks, model denominations, part numbers and drawings.

This instruction book meets the requirements for instructions specified by the machinery directive

98/37/EC and is valid for CE as well as non-CE labelled machines

No. 2920 1472 03

Replaces 2920 1472 02

Registration code: APC Z<55 + VSD / 38 / 392

2004-05 www.atlascopco.com

2920 1472 03 1

Instruction book

This instruction book describes how to handle and operate the subject machine(s) to ensure safe

operation, optimum working economy and long service life.

Read this book before putting the machine into operation to ensure correct handling, operation and

proper maintenance from the beginning. The maintenance schedule comprises measures for keeping

the compressor in good repair.

Keep the book available for the operator(s) and make sure that the compressor is operated and that

maintenance is carried out according to the instructions. Record all operating data, maintenance work

effected, etc. in an operator's logbook available from Atlas Copco. Follow all applicable safety

precautions, amongst others those mentioned in this book.

Repairs must be carried out by trained personnel from Atlas Copco who can also be contacted for any

further information.

In all correspondence mention the type and the serial number, shown on the data plate.

For all data not mentioned in the text, see sections "Preventive maintenance schedule" and "Principal

data".

The company reserves the right to make changes without prior notice.

2920 1472 03 2

Instruction book

1 LEADING PARTICULARS................................................................................................................... 5

1.1 General description........................................................................................................................ 5

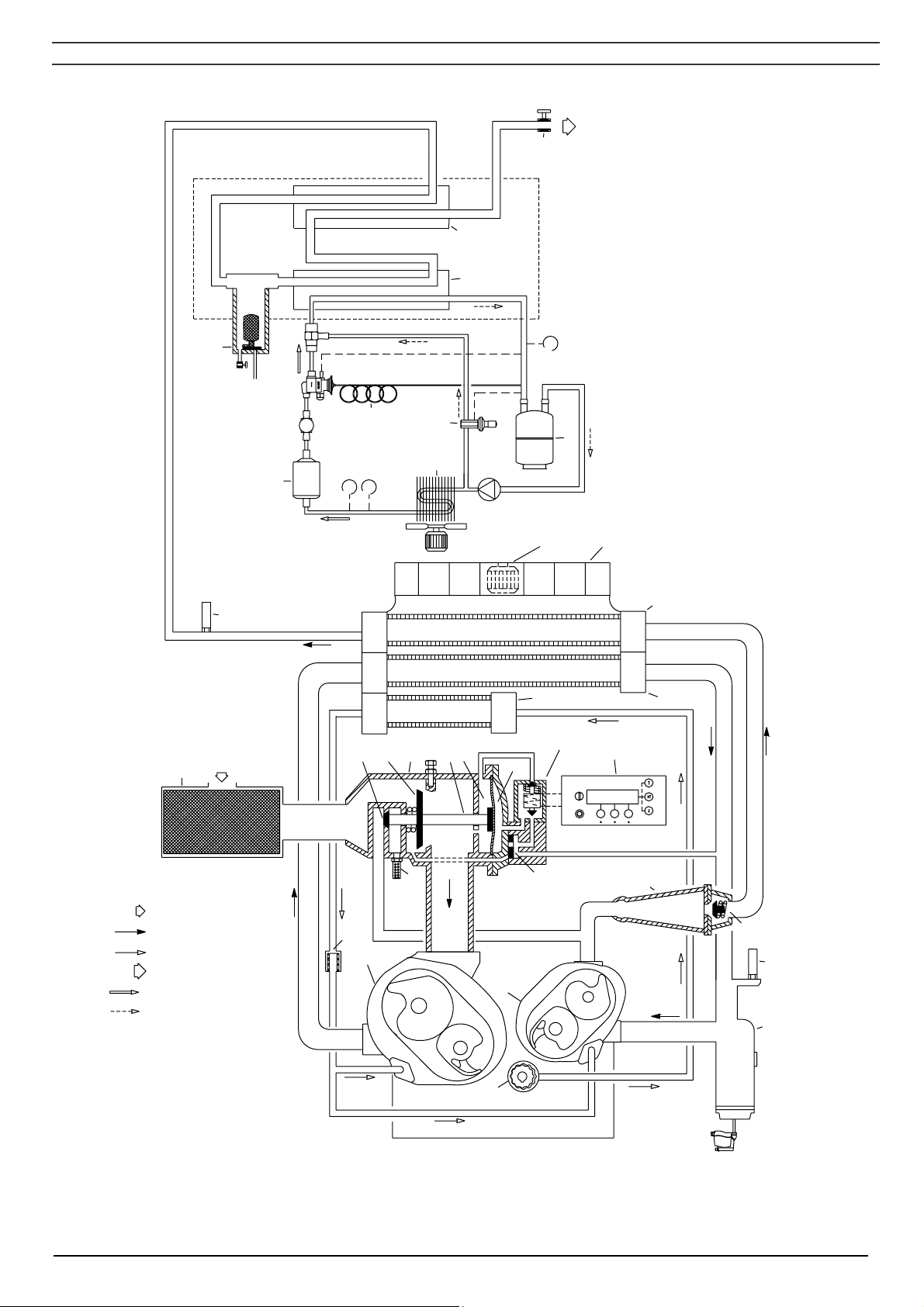

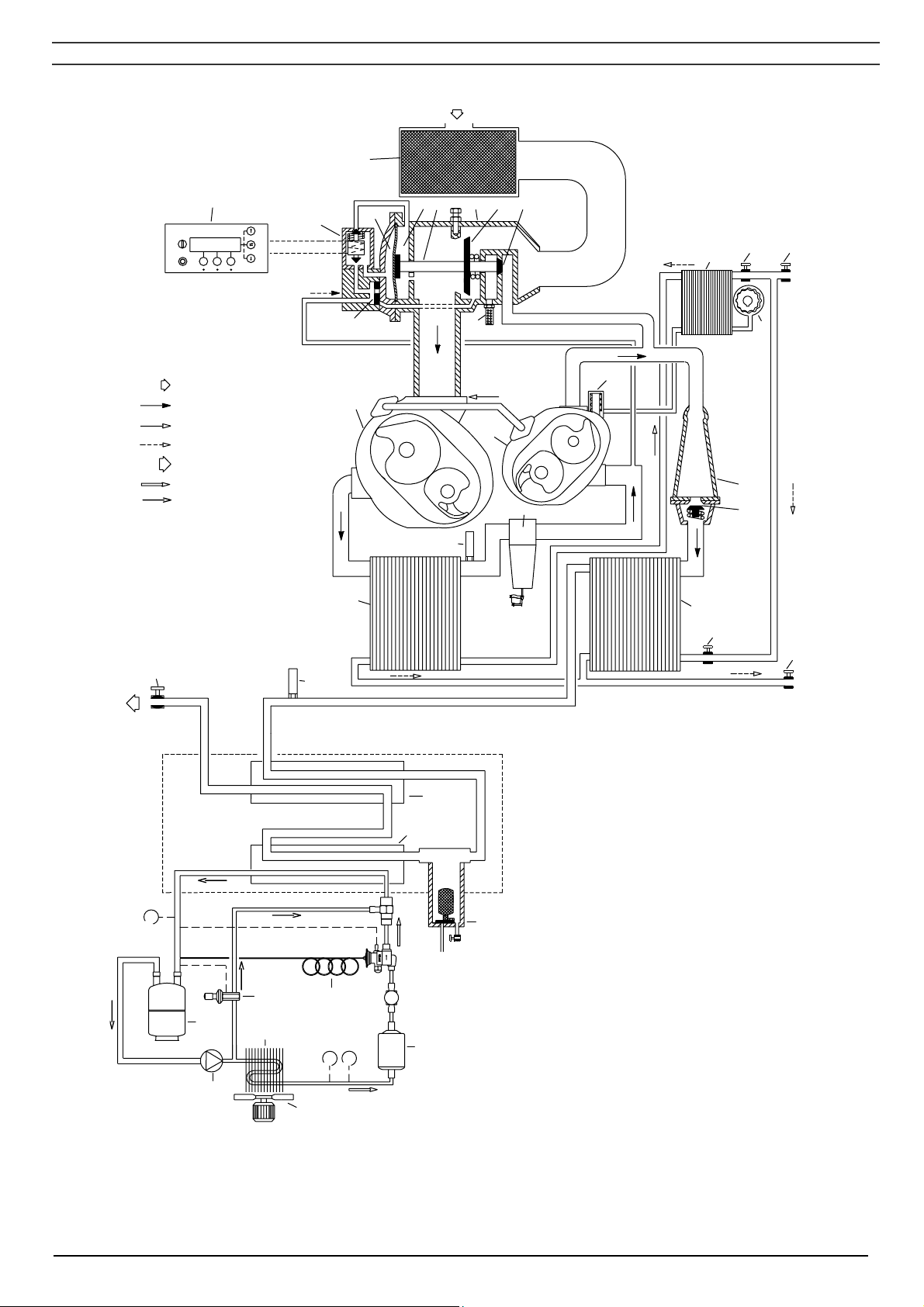

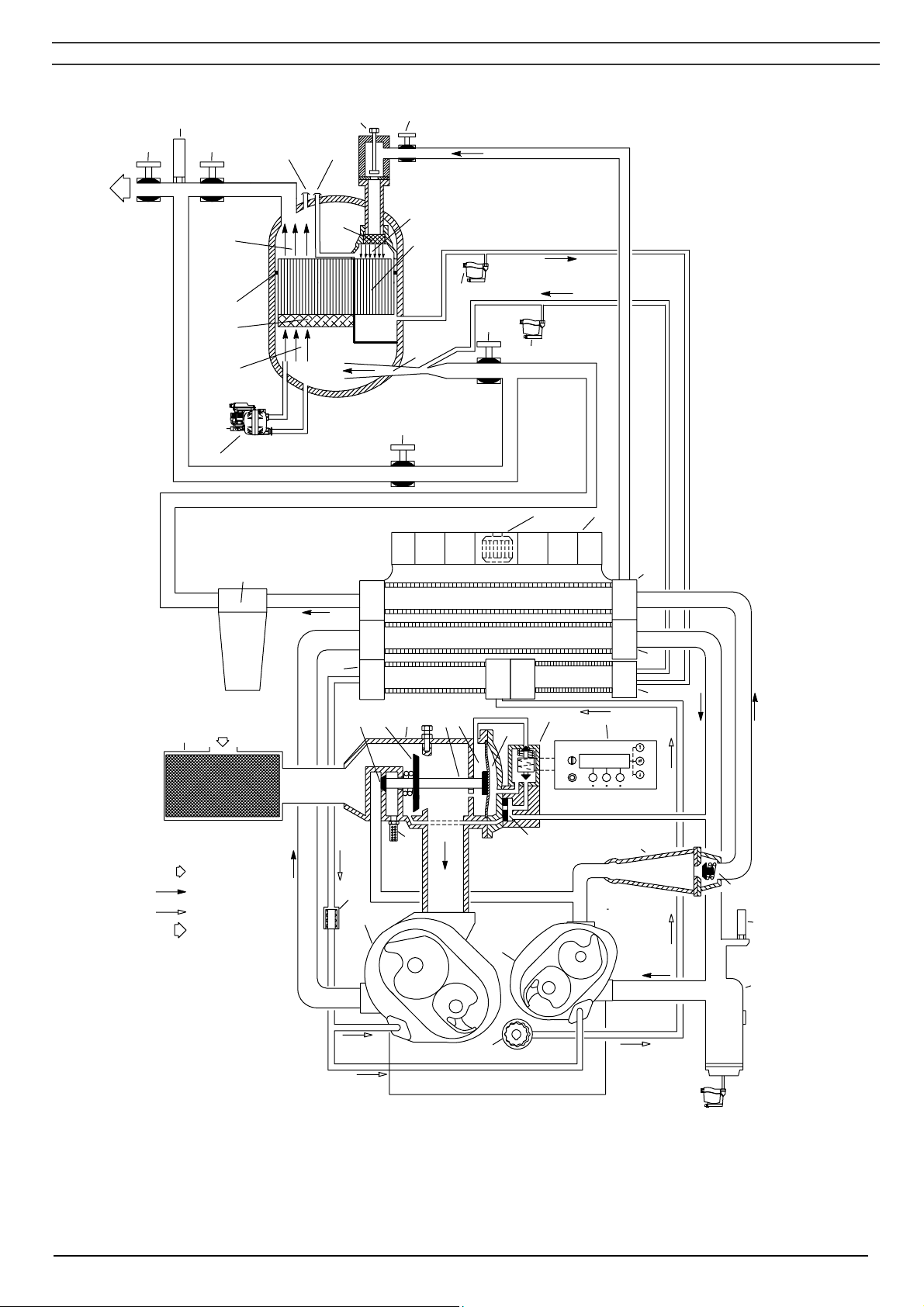

1.2 Air flow (Figs. 1.6/1.7) .................................................................................................................. 10

1.3 Condensate drain system (Figs. 1.6/1.7).....................................................................................10

1.4 Oil system (Figs. 1.6/1.7)............................................................................................................. 10

1.5 Cooling system (Figs. 1.6/1.7) ..................................................................................................... 10

1.6 Air dryer on Full-Feature.............................................................................................................. 17

1.6.1 Compressors with an ID dryer (Figs. 1.6) ............................................................................. 17

1.6.2 Compressors with an IMD dryer (Figs. 1.7) .......................................................................... 17

1.7 Electrical system .......................................................................................................................... 18

1.8 Elektronikon control system......................................................................................................... 19

1.8.1 Automatic control of the compressor..................................................................................... 19

1.8.2 Protecting the compressor .................................................................................................... 19

1.8.3 Service warning..................................................................................................................... 19

1.8.4 Automatic restart after voltage failure ...................................................................................19

1.9 Control panel................................................................................................................................ 20

1.9.1 LEDs/buttons/keys ................................................................................................................ 20

1.9.2 Display................................................................................................................................... 21

1.9.3 Function keys (5-Fig. 1.10) ................................................................................................... 21

1.9.4 Emergency stop button (S3-Fig. 1.10) .................................................................................. 22

1.10 Menu-driven control programs................................................................................................... 22

1.10.1 Function of control programs .............................................................................................. 22

1.10.2 Main screen......................................................................................................................... 23

1.10.3 External compressor status indication ................................................................................ 23

2 INSTALLATION ................................................................................................................................. 25

2.1 Dimension drawings..................................................................................................................... 25

2.2 Installation proposal (Figs. 2.6/2.7).............................................................................................. 30

2.3 Electric cables.............................................................................................................................. 34

2.3.1 ZT15 up to ZT22 IEC............................................................................................................. 34

2.3.2 ZT15 up to ZT22 CSA/UL ..................................................................................................... 34

2.3.3 ZT/ZR30 up to ZT/ZR45 IEC.................................................................................................35

2.3.4 ZT/ZR30 up to ZT/ZR45 CSA/UL.......................................................................................... 35

2.4 Pictographs (Figs. 2.9 and 2.10).................................................................................................. 38

2.5 Cooling water requirements......................................................................................................... 39

2.5.1 Type of the system ................................................................................................................ 39

2.5.2 Cooling water parameters ..................................................................................................... 39

3 OPERATING INSTRUCTIONS .......................................................................................................... 43

3.1 Initial start-up ............................................................................................................................... 43

3.2 Starting (Fig. 3.4) ......................................................................................................................... 48

3.3 During operation (Fig. 3.4)........................................................................................................... 48

3.3.1 Checking the display (2-Fig. 3.4) .......................................................................................... 48

3.3.2 On compressors with an IMD dryer (Fig. 1.5) ....................................................................... 50

3.4 Stopping (Fig. 3.4) ....................................................................................................................... 50

3.5 Taking out of operation ................................................................................................................ 50

4 MAINTENANCE ................................................................................................................................. 51

4.1 Preventive maintenance schedule for the compressor................................................................ 51

4.1.1 Regular service operations ................................................................................................... 51

4.1.2 Service kits ............................................................................................................................ 51

4.1.3 Service agreements .............................................................................................................. 51

4.1.4 Service plan........................................................................................................................... 52

4.2 Motor greasing ............................................................................................................................. 52

4.2.1 Fan motor (ZT) ...................................................................................................................... 52

4.2.2 Drive motor (M1-Fig. 1.2) ...................................................................................................... 52

4.3 Oil specifications .......................................................................................................................... 52

4.4 Storage after installation .............................................................................................................. 52

4.5 Service kits................................................................................................................................... 52

5 SERVICING PROCEDURES ............................................................................................................. 54

2920 1472 03 3

Instruction book

5.1 Air filter (AF-Fig. 1.3).................................................................................................................... 54

5.2 Oil and oil filter change (Fig. 3.3)................................................................................................. 54

5.3 Safety valves................................................................................................................................ 54

6 PROBLEM SOLVING ........................................................................................................................ 55

7 PRINCIPAL DATA ............................................................................................................................. 56

7.1 Readings on display (2-Fig. 3.4).................................................................................................. 56

7.2 Settings of safety valves .............................................................................................................. 56

7.3 Settings of overload relay - circuit breakers – fuses.................................................................... 57

7.4 Compressor specifications........................................................................................................... 59

7.5 Conversion list of SI units into British/American units ................................................................. 61

5.1.1 Recommendations ................................................................................................................ 54

5.1.2 Servicing................................................................................................................................ 54

7.1.1 ZT15 up to ZT22.................................................................................................................... 56

7.1.2 ZT30 up to ZT45.................................................................................................................... 56

7.1.3 ZR30 up to ZR45................................................................................................................... 56

7.3.1 ZT15 up to ZT22 IEC............................................................................................................. 57

7.3.2 ZT15 up to ZT22 CSA/UL ..................................................................................................... 57

7.3.3 ZT/ZR30 up to ZT/ZR45 IEC.................................................................................................58

7.3.4 ZT/ZR30 up to ZT/ZR45 CSA/UL.......................................................................................... 58

7.4.1 Reference conditions ............................................................................................................ 59

7.4.2 Limitations ............................................................................................................................. 59

7.4.3 Specific data of ZT15 up to ZT22..........................................................................................59

7.4.4 Specific data of ZT30 up to ZT45..........................................................................................60

7.4.5 Specific data of ZR30 up to ZR45 ......................................................................................... 60

8 INSTRUCTIONS FOR USE OF PULSATION DAMPER................................................................... 62

9 PED .................................................................................................................................................... 62

9.1 Components subject to 97/23/EC Pressure Equipment Directive ............................................... 62

9.2 Overall rating................................................................................................................................ 62

2920 1472 03 4

Instruction book

1 LEADING PARTICULARS

1.1 General description

ZT15 up to ZT45 and ZR30 up to ZR45 are two-stage tooth compressors, driven by an electric motor.

The compressors deliver oil-free air. ZT are air-cooled and ZR are water-cooled.

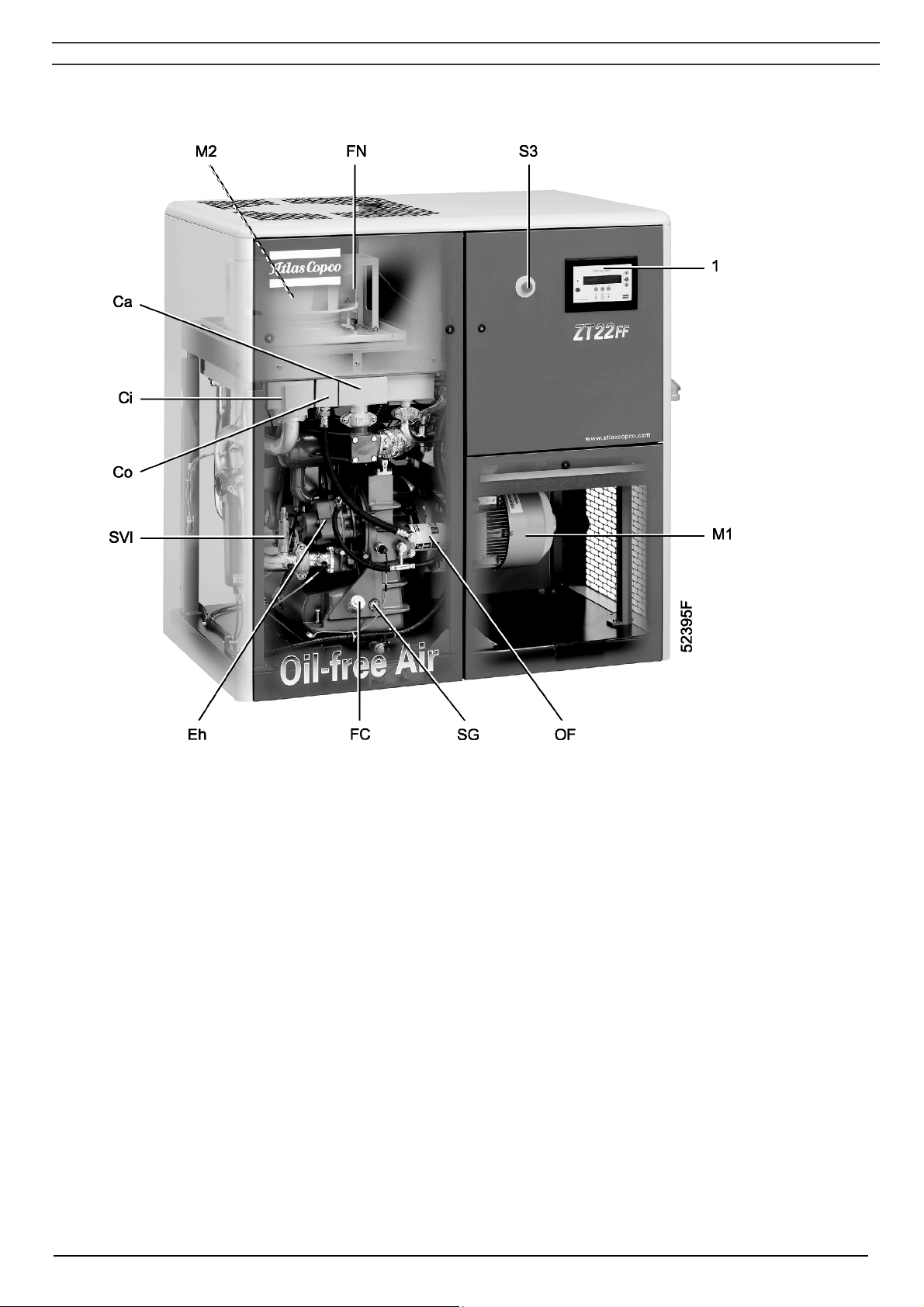

The compressors are enclosed in a sound-insulated bodywork and include mainly (Figs. 1.2 up to 1.4):

- Air filter (AF)

- Load/no-load valve (TV)

- Low-pressure compressor element (El)

- Intercooler (Ci)

- High-pressure compressor element (Eh)

- Aftercooler (Ca)

- Electric motor (M1)

- Drive coupling

- Gear casing

- Elektronikon

- Safety valves (SVh/SVl)

Full-Feature compressors are additionally provided with an air dryer (Figs. 1.3/1.5), which removes

moisture from compressed air. See section 1.6.

WorkPlace Air System compressors operate at a very low noise level.

®

regulator (1-Fig. 1.2)

Fig. 1.1 General view

AV Air outlet valve

S3 Emergency stop

button

1 Elektronikon

regulator

2 Electric cable

entry

3 Condensate

drains

2920 1472 03 5

Instruction book

Ca Aftercooler

Ci Intercooler

Co Oil cooler

Eh High-pressure compressor element

FC Oil filler plug

FN Fan

M1 Drive motor

M2 Fan motor

OF Oil filter

SG Oil level sight-glass

SVl Low-pressure safety valve

S3 Emergency stop button

1 Elektronikon regulator

Fig. 1.2 Front view

2920 1472 03 6

Instruction book

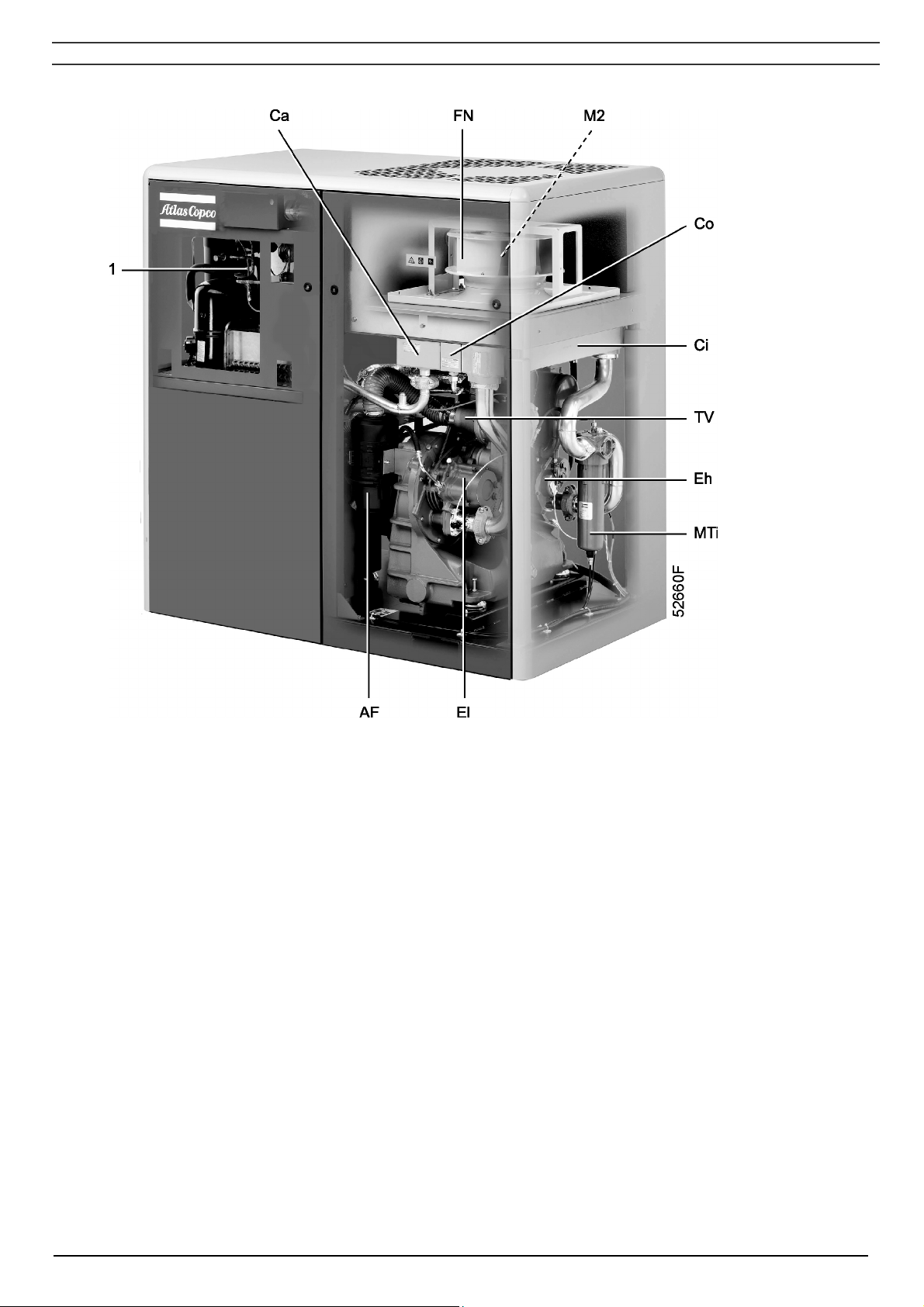

AF Air filter

Ca Aftercooler

Ci Intercooler

Co Oil cooler

Eh High-pressure compressor element

El Low-pressure compressor element

FN Cooling fan

MTi Condensate trap, intercooler

M2 Fan motor

TV Load/no-load valve

1 ID dryer

Fig. 1.3 Rear view, Full-Feature (ID dryer)

2920 1472 03 7

Instruction book

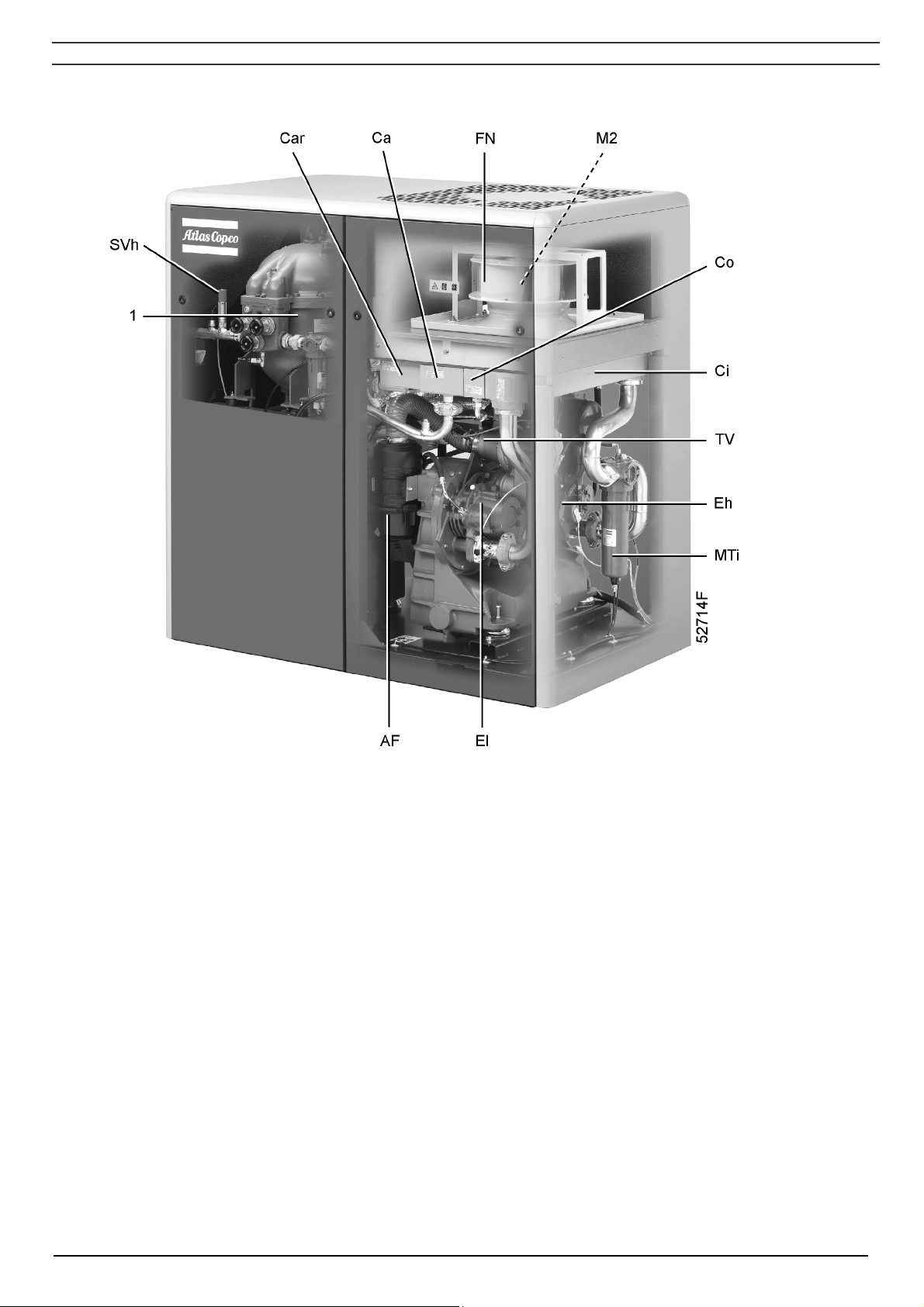

AF Air filter

Ca Aftercooler

Car Cooler, regeneration air

Ci Intercooler

Co Oil cooler

Eh High-pressure compressor element

El Low-pressure compressor element

FN Cooling fan

MTi Condensate trap, intercooler

M2 Fan motor

SVh High-pressure safety valve

TV Load/no-load valve

1 IMD dryer

Fig. 1.4 Rear view, Full-Feature (IMD dryer)

2920 1472 03 8

Instruction book

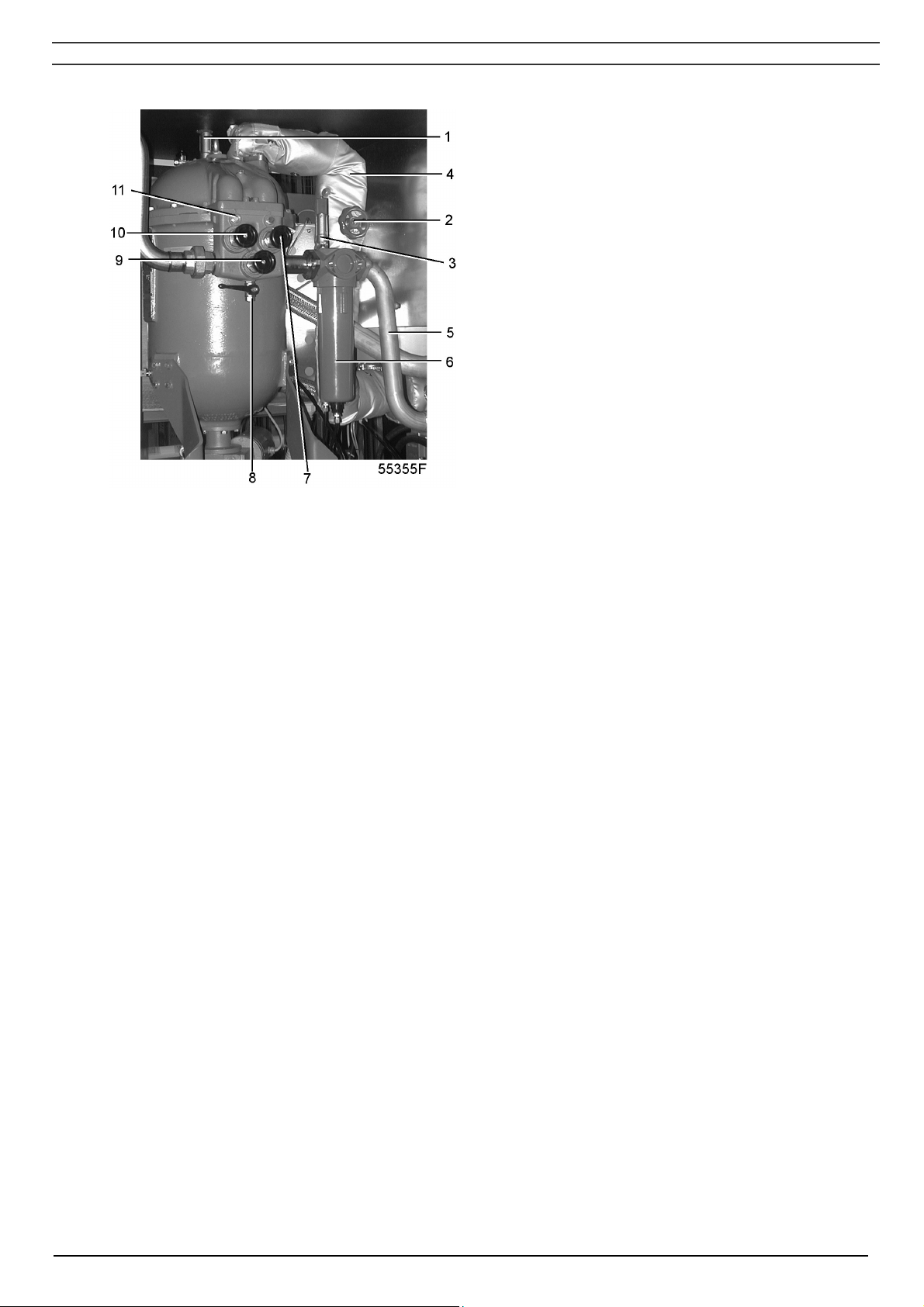

1 Safety valve

2 Shut-off valve, regeneration air

3 Safety valve

4 Inlet regeneration air

5 Inlet pipe, wet compressed air

6 Condensate trap, aftercooler

7 Dryer inlet valve

8 Manual drain valve

9 Dryer by-pass valve

10 Dryer outlet valve

11 Moisture indicator

Fig. 1.5 IMD dryer

2920 1472 03 9

Instruction book

1.2 Air flow (Figs. 1.6/1.7)

Air drawn through filter (AF) is compressed in low-pressure compressor element (El) and discharged

to intercooler (11). The cooled air is further compressed in high-pressure compressor element (Eh)

and discharged through pulsation damper (AS) and aftercooler (15). A check valve (CV) is provided

downstream of the pulsation damper.

1.3 Condensate drain system (Figs. 1.6/1.7)

Two condensate traps are installed: one downstream of the intercooler (MTi) to prevent condensate

from entering the high-pressure compressor element (Eh) and one downstream of the aftercooler

(MTa) to prevent condensate from entering the air outlet pipe. The condensate traps are provided with

a float valve to automatically drain condensate and with a manual drain valve.

For Full-Feature compressors with an ID dryer (Figs. 1.6), the condensate trap downstream the

aftercooler is replaced by a condensate trap (5) in the dryer.

Full-Feature compressors with an IMD dryer (Figs. 1.7) have three additional electronic water drains:

- One on the IMD

- One upstream and downstream the regeneration air cooler

1.4 Oil system (Figs. 1.6/1.7)

Oil is circulated by pump (OP) from the sump of the gear casing through cooler (16) and oil filter (OF)

towards the bearings and timing gears.

The oil system is protected by a valve that opens if the oil pressure should rise above a given value.

The valve is located in the oil filter housing.

1.5 Cooling system (Figs. 1.6/1.7)

ZT compressors

The compressors are provided with an air-cooled oil cooler (16), intercooler (11) and aftercooler (15).

An electric motor-driven fan (FN) generates the cooling air.

ZR compressors

The oil cooler, intercooler and aftercooler are water-cooled.

The water system includes three parallel circuits:

- One for the oil cooler and intercooler.

- One for the aftercooler.

- One circuit is only for compressors with an IMD dryer and contains the regeneration cooler.

Each of these circuits has a separate regulating valve (see section 3.1)

2920 1472 03 10

Instruction book

AV

6

7

5

AF

SVh

8

12

13

10

9

M3

FN2

M2

FN1

15

UV

TV

UA

16

Y1

2

3

1

CM

Elektronikon

F1 F2

11

F3

US

4

AS

AIR INLET (1)

AIR FLOW (2)

OIL FLOW (3)

AIR OUTLET (5)

REFRIGERANT FLUID (6)

OF

El

Eh

CV

SVl

REFRIGERANT GAS (7)

MTi

OP

55347D

EWDi

Fig. 1.6a ZT compressors with an ID dryer

2920 1472 03 11

Instruction book

AF

CM

Elektronikon

F1 F2 F3

AIR INLET (1)

AIR FLOW (2)

OIL FLOW (3)

WATER FLOW (4)

AIR OUTLET (5)

REFRIGIRANT FLUID

REFRIGERANT GAS

(7)

(6)

Y1

2

1

4

El

11

3

SVl

US

UA

Eh

TV

UV

MTi

EWDi

OF

171819

16

OP

AS

CV

15

AV

12

13

M3

10

SVh

8

FN1

Fig. 1.6b ZR compressors with an ID dryer

14

6

7

5

9

55346D

2920 1472 03 12

Instruction book

AF Air filter

AS Pulsation damper

AV Air outlet valve (customer’s installation)

CM Control module

CV Check valve

Eh High-pressure compressor element

El Low-pressure compressor element

EWDi Electronic drain, low-pressure element

FN1 Fan, compressor coolers

FN2 Fan, condenser

M2 Fan motor, compressor coolers

M3 Refrigerant compressor

MTi Condensate trap, intercooler

OF Oil filter

OP Oil pump

SVh Safety valve, high-pressure element

SVi Safety valve, low-pressure element

TV Load/no-load valve

UA Unloader

US Silencer

Y1 Loading solenoid valve

1 Chamber

2 Plunger

3 Chamber

4 Diaphragm

5 Condensate trap, dryer

6 Air/air heat exchanger

7 Air/refrigerant heat exchanger/evaporator

8 Capillary tube

9 Accumulator

10 Refrigerant condenser

11 Intercooler

12 Hot-gas by-pass valve

13 Liquid refrigerant filter/dryer

14 Water outlet valve (customer’s installation)

15 Aftercooler

16 Oil cooler

17 Regulating valve, oil cooler and intercooler water circuit

18 Regulating valve, aftercooler water circuit

19 Water inlet valve (customer’s installation)

Note: References 14 up to 19 apply to ZR compressors only

Figs. 1.6 Flow diagrams/regulating systems for Full-Feature compressors with ID dryer

2920 1472 03 13

Instruction book

AV

SVh

7

28

21

20

19

18

17

5

6

9

8

10

12

29

26

14

27

29

13

FN1

AF

AIR INLET (1)

AIR FLOW (2)

OIL FLOW (3)

AIR OUTLET (5)

MTa

15

16

OF

UV

TV

UA

2

3

US

El

Eh

Y1

1

4

CM

Elektronikon

F1F2F3

11

22

AS

CV

SVl

MTi

OP

55365D

EWDi

Fig. 1.7a ZT compressor with IMD dryer

2920 1472 03 14

Instruction book

AF

CM

Elektronikon

F3

F1 F2

AIR INLET (1)

AIR FLOW (2)

OIL FLOW (3)

WATER FLOW (4)

AIR OUTLET (5)

Y1

2

1

4

El

11

3

SVl

US

UA

Eh

TV

MTi

EWDi

UV

OF

23

16

AS

15

24

31

OP

CV

30

7

SVh

28

21

20

19

18

17

5

6

9

AV

Fig. 1.7b ZR compressor with IMD dryer

8

10

29

12

29

22

25

MTa

26

14

27

55364D

2920 1472 03 15

Instruction book

AF Air filter

AS Pulsation damper

AV Air outlet valve (customer’s installation)

CM Elektronikon regulator

CV Check valve

Eh High-pressure compressor element

El Low-pressure compressor element

EWDi Electronic water drain, intercooler

FN1 Cooling fan

MTa Condensate trap, aftercooler

MTi Condensate trap, intercooler

OF Oil filter

OP Oil pump

SVh High-pressure safety valve

SVl Low-pressure safety valve

TV Load/no-load valve

UA Unloader

US Silencer

UV Unloading valve

Y1 Loading solenoid valve

1 Chamber

2 Plunger

3 Chamber

4 Diaphragm

5 Valve for (+) connection, pressure difference gauge

6 Valve for (-) connection, pressure difference gauge

7 Throttle valve, regeneration inlet air

8 Shut-off valve, hot regeneration inlet air

9 Strainer

10 Sealing sector, regeneration air inlet (unsaturated side)

11 Intercooler

12 Rotor

13 Fan motor, air coolers

14 Ejector

15 Aftercooler

16 Oil cooler

17 Electronic water drain, inlet air

18 Water separator, inlet air

19 Demister

20 Rotor sealing arrangement

21 Dry air outlet compartment

22 Regeneration air cooler

23 Regulating valve, oil cooler and intercooler water circuit

24 Regulating valve, aftercooler water circuit

25 Regulating valve, regeneration air cooler water circuit

26 IMD air inlet valve

27 IMD by-pass valve

28 IMD outlet valve

29 Electronic drains, regeneration air cooler

30 Water shut-off valve, water outlet (customer’s installation)

31 Shut-off valve, water inlet (customer’s installation)

Figs. 1.7 Flow diagram/regulating system, ZT Full-Feature with IMD dryer

2920 1472 03 16

Instruction book

1.6 Air dryer on Full-Feature

Full-Feature compressors are provided with a dryer which removes moisture from compressed air.

Two dryer types are available: a refrigerant-type dryer (ID dryer) and an adsorption-type dryer (IMD

dryer).

1.6.1 Compressors with an ID dryer (Figs. 1.6)

Compressed air circuit of the dryer

Compressed air enters heat exchanger (6) and is cooled by the outgoing dried air. Water in the

incoming air starts to condense. The air then flows through heat exchanger/evaporator (7) where the

refrigerant evaporates, causing the air to be further cooled to close to the evaporating temperature of

the refrigerant. More water in the air condenses. The cold air then flows through condensate trap (5),

where all the condensate is separated from the air. The condensate collects in the condensate trap

and is automatically drained. The cold, dried air flows through heat exchanger (6), where it is warmed

up by the incoming air.

Refrigeration circuit of the dryer

Compressor (M3) delivers high-pressure refrigerant gas, which flows through condenser (10) where

most of the refrigerant condenses.

The liquid flows through liquid refrigerant dryer/filter (13) to capillary tube (8). The refrigerant leaves

the capillary tube at evaporating pressure.

The refrigerant enters evaporator (7) where it withdraws heat from the compressed air by further

evaporation at constant pressure. The heated refrigerant leaves the evaporator and is sucked in by

the compressor.

1.6.2 Compressors with an IMD dryer (Figs. 1.7)

Air drying circuit of the dryer

Wet air from the aftercooler (15) enters the dryer through inlet valve (26) and the nozzle of ejector

(14). The air leaving the aftercooler is normally saturated.

In the demister (18), water droplets are removed from the air. The air is then led through rotor (19),

which adsorbs the water vapour. The dried air leaves the dryer through outlet valve (28).

Regeneration air circuit of the dryer

Hot unsaturated regeneration air flows through shut-off valve (8) and throttle valve (7) through the wet

rotor channels (12). Since the hot air has a lower vapour pressure than the wet rotor channels, it will

dry the rotor.

The hot saturated air is then cooled down in regeneration air cooler (22) and led to the suction

chamber of ejector (14), where it is mixed with the wet compressed air from the compressor

aftercooler.

Drain system of the dryer

The condensate is collected in three EWD (Electronic Water Drains-Fig. 1.8). A sensor continuously

measures the liquid level. As soon as the collector is filled up to a certain level, the outlet opens,

discharging the condensate. When the collector has been emptied, the outlet closes quickly without

wasting compressed air.

If the controller registers a malfunction, the red alarm LED (Fig. 1.8) starts flashing and the electronic

drain valve will automatically change to the alarm mode, opening and closing the valve according to a

built-in sequence. This condition continues until the fault is remedied. If the fault is not remedied

automatically, maintenance is required. Consult your Atlas Copco Customer Centre.

2920 1472 03 17

Instruction book

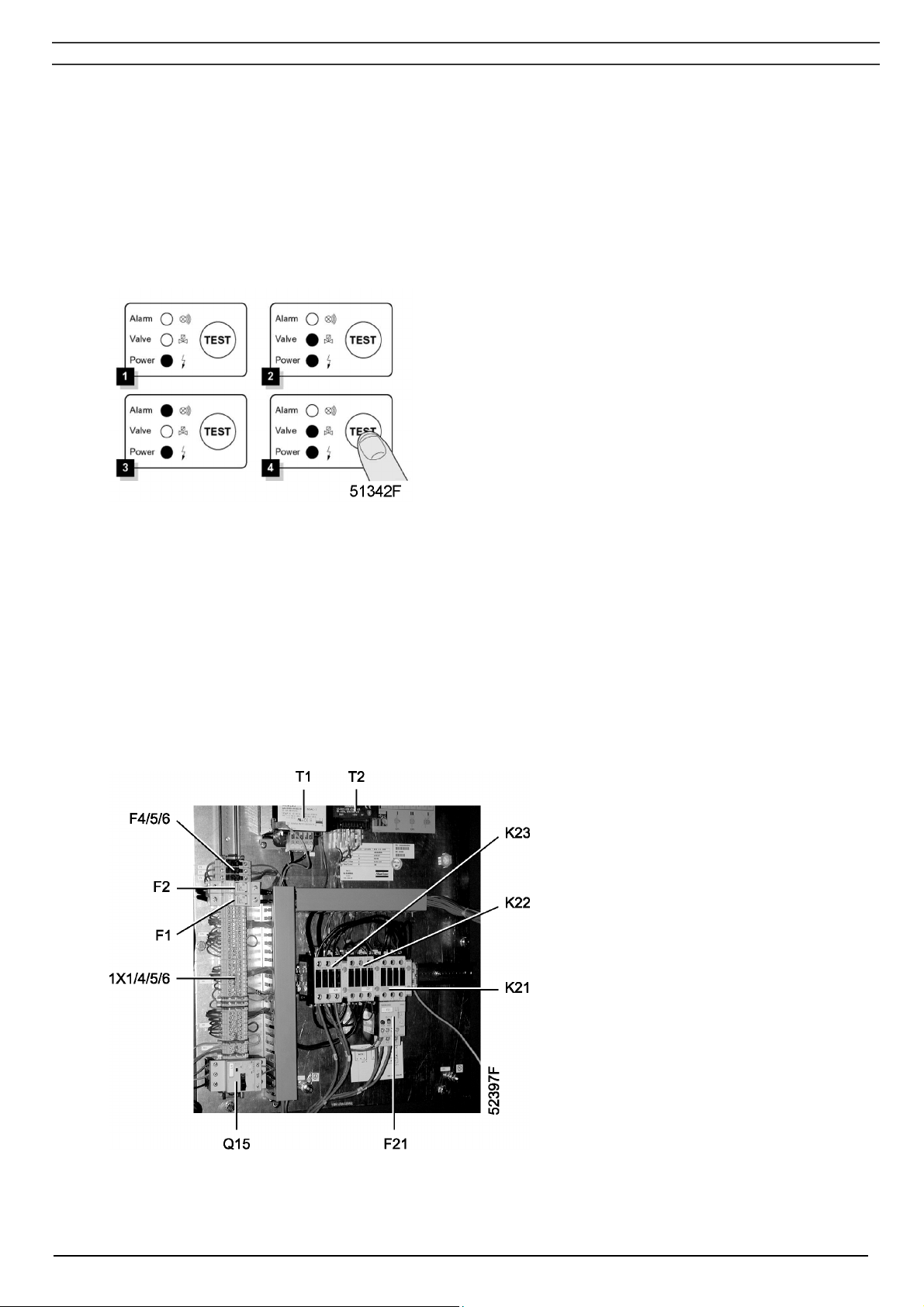

Testing the EWD

Functional test

Briefly press the TEST button (Fig. 1.8) and check that the valve opens for condensate discharge.

Checking the alarm signal

- Press the test button for at least 1 minute

- Check that the alarm LED flashes

- Release the test button.

Fig. 1.8 Control panel of Electronic Water Drain (EWD)

1.7 Electrical system

The system mainly includes:

- Elektronikon regulator (1-Fig. 1.1)

- Emergency stop button (S3-Fig. 1.1)

- Electric cabinet (Fig. 1.9)

- Drive motor (M1-Fig. 1.2)

- Pressure and temperature sensors

F1/2 Fuses

F4/5/6 Fuses

F21 Overload relay, drive motor

K21 Line contactor

K22 Star contactor

K23 Delta contactor

Q15 Circuit breaker, fan motor (on ZT)

T1 Main transformer

T2 Transformer, control circuit

1X1/4/5/6 Terminal strips

Fig. 1.9 Electric cabinet, typical

example

2920 1472 03 18

Instruction book

1.8 Elektronikon control system

In general, the Elektronikon regulator has following functions:

- automatic control of the compressor

- protecting the compressor

- monitoring components - service warning

- automatic restart after voltage failure

1.8.1 Automatic control of the compressor

The regulator maintains the net pressure between programmable limits by automatically loading and

unloading the compressor. A number of programmable settings, e.g. the unloading and loading

pressures, the minimum stop time and the maximum number of motor starts are taken into account.

The regulator stops the compressor whenever possible to reduce the power consumption and restarts

it automatically when the net pressure decreases. In case the expected stopping period is too short,

the compressor is kept running to prevent too-short standstill periods.

Warning

A number of time-based automatic start/stop commands may be programmed. Take into account that

a start command will be executed (if programmed and activated), even after manually stopping the

compressor.

1.8.2 Protecting the compressor

Shut-down and motor overload

Several temperature and pressure sensors are provided on the compressor. If one of these

measurements (temperature at LP element outlet, temperature at HP element outlet, intercooler

pressure as well as oil pressure) exceeds the programmed shut-down level, the compressor will be

stopped. This will be indicated on the control display.

The compressor will also be stopped in case of overload of the drive motor.

Consult the safety precautions as mentioned in section 4 and remedy the trouble. See also the User

manual for Elektronikon regulator, section “Status data menu”.

Shut-down warning

If the regulator detects a temperature or pressure just below the programmed shut-down level, this will

be indicated on the control panel to warn the operator before the shut-down level is reached.

The message disappears as soon as the warning condition disappears.

1.8.3 Service warning

A number of service operations are grouped (called Level A, B, C, ...). Each level has a programmed

time interval. If a time interval is exceeded, a message will appear on display (2-Fig. 1.10) to warn the

operator to carry out the service actions belonging to that level. See section 4.

1.8.4 Automatic restart after voltage failure

The regulator has a built-in function to automatically restart the compressor if the voltage is restored

after voltage failure. For compressors leaving the factory, this function is made inactive. If desired,

the function can be activated. Consult Atlas Copco.

2920 1472 03 19

Instruction book

Warning

If activated and provided the module was in the automatic operation mode, the compressor will

automatically restart if the supply voltage to the module is restored within a programmed time period.

The power recovery time (the period within which the voltage must be restored to have an automatic

restart) can be set between 1 and 255 seconds or to Infinite. If the power recovery time is set to

Infinite, the compressor will always restart after a voltage failure, no matter how long it takes to restore

the voltage. A restart delay can also be programmed, allowing e.g. two compressors to be restarted

one after the other.

1.9 Control panel

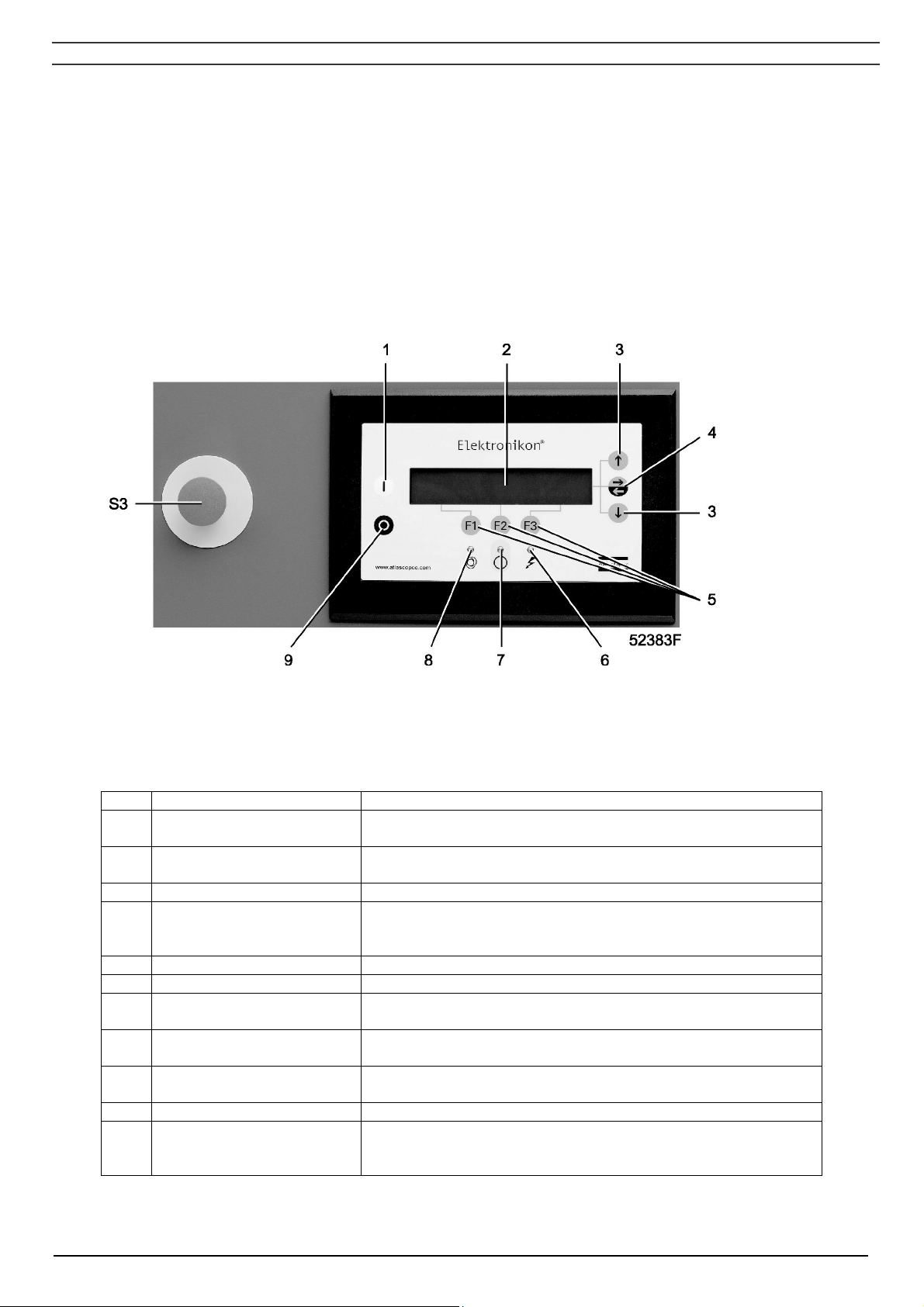

Fig. 1.10 Control panel

1.9.1 LEDs/buttons/keys

Ref. Designation Function

1 Start button Push button to start the compressor. LED (8) lights up,

indicating that the Elektronikon regulator is operative.

2 Display Indicates messages concerning the compressor operating

condition, a service need or a fault.

3 Scroll keys Keys to scroll upwards or downwards through the display.

4 Tabulator key Key to select the parameter indicated by a horizontal arrow.

Only the parameters followed by an arrow pointing to the right

are accessible for modifying.

5 Function keys Keys to control and program the compressor. See section 1.9.3.

6 Voltage on LED Indicates that the voltage is switched on.

7 General alarm LED Is alight if a shut-down warning condition exists. See section

1.8.2.

7 General alarm LED Blinks if a shut-down condition exists, if an important sensor is

out of order or after an emergency stop. See section 1.8.2.

8 Automatic operation LED Indicates that the regulator is automatically controlling the

compressor.

9 Stop button Push button to stop the compressor. LED (8) goes out.

S3 Emergency stop button Push button to stop the compressor immediately in case of

emergency. After remedying the trouble, unlock the button by

pulling it out.

2920 1472 03 20

Loading...

Loading...