Atlas Copco GA90, GA110, GA132, GA160, GA200 Instruction Book

...

Atlas Copco Stationary Air Compressors

Important

1. This book applies to the compressors from serial number

AIF-024 378 onwards.

2. This book must be used together with the "User manual for Elektronikon

®

regulator", printed matter no.

2920 1291 0x.

*2920125102*

No. 2920 1251 02

Registration code: APC G ≥ 90/'99 / 38 / 995

Replaces 2920 1251 01

2000-01

GA90 - GA110 - GA132 - GA160 - GA200 - GA250 - GA315

GA90 W - GA110 W - GA132 W - GA160 W - GA200 W GA250 W - GA315 W

Instruction Book

• Copyright 2000, Atlas Copco Airpower n.v., Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies

in particular to trademarks, model denominations, part numbers and drawings.

• This instruction book meets the requirements for instructions specified by the machinery directive

98/37/EC and is valid for CE as well as non-CE labelled machines

2920 1251 02

2

Instruction book

This instruction book describes how to handle the machines to ensure safe operation, optimum efficiency and long service life.

Read this book before putting the machine into operation to ensure correct handling, operation and proper maintenance from the

beginning. The maintenance schedule comprises measures for keeping the machine in good condition.

Keep the book available for the operator and make sure that the machine is operated and that maintenance is carried out according

to the instructions. Record all operating data, maintenance performed, etc. in an operator's logbook available from Atlas Copco.

Follow all relevant safety precautions, including those mentioned on the cover of this book.

Repairs must be carried out by trained personnel from Atlas Copco who can be contacted for any further information.

In all correspondence mention the type and the serial number, shown on the data plate.

For all data not mentioned in the text, see sections "Preventive maintenance schedule" and "Principal data".

The company reserves the right to make changes without prior notice.

Page

5 Adjustments and servicing procedures . . . . . . . . . . . . . . 32

5.1 Air filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2 Coolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3 Safety valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Principal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 Readings on display . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Programmable settings . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.3 Settings of safety valves . . . . . . . . . . . . . . . . . . . . . . . . 34

7.4 Settings of overload relay, circuit breakers and fuses . 34

7.4.1 Motor overload relay and fuses for

GA/GA W - 50 Hz with ABB motors . . . . . . . 34

7.4.2 Motor overload relay and fuses for

GA/GA W - 60 Hz with ABB motors . . . . . . . 34

7.4.3 Motor overload relay and fuses for

GA/GA W - 60 Hz with Siemens motors . . . . 35

7.4.4 Fan motor circuit breakers for GA - 50 Hz . . . 36

7.4.5 Fan motor circuit breakers for GA - 60 Hz . . . 36

7.5 Compressor specifications . . . . . . . . . . . . . . . . . . . . . . 36

7.5.1 Reference conditions . . . . . . . . . . . . . . . . . . . . 36

7.5.2 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.5.3 Specific data of GA/GA W 90 up to -160

7.5 bar - 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.5.4 Specific data of GA/GA W 90 up to -160

10 bar - 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.5.5 Specific data of GA/GA W 90 up to -160

13 bar - 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.5.6 Specific data of GA/GA W 90 up to -160

100 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5.7 Specific data of GA/GA W 90 up to -160

125 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5.8 Specific data of GA/GA W 90 up to -160

150 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5.9 Specific data of GA/GA W 90 up to -160

200 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 39

7.5.10 Specific data of GA/GA W 200 and -250

7.5 bar - 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 39

7.5.11 Specific data of GA/GA W 200 and -250

10/13 bar - 50 Hz . . . . . . . . . . . . . . . . . . . . . . 39

7.5.12 Specific data of GA/GA W 200 up to -315

100 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5.13 Specific data of GA/GA W 200 up to -315

125 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5.14 Specific data of GA/GA W 200 up to -315

150 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5.15 Specific data of GA/GA W 250 and -315

200 psi - 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . 41

7.6 Conversion list of SI units into British/US units . . . . . 41

Contents

Page

1 Leading particulars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Elektronikon

®

control system . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Elektronikon regulator . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.3 Compressor control modes . . . . . . . . . . . . . . . . 8

1.2.4 External compressor status indication . . . . . . . . 8

1.2.5 External communication . . . . . . . . . . . . . . . . . . 8

1.3 Regulating system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.1 Air flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.2 Condensate drain system . . . . . . . . . . . . . . . . . . 9

1.3.3 Oil system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.4 Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.5 Regulating system . . . . . . . . . . . . . . . . . . . . . . 12

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1 Dimension drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Installation proposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Electric cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.1 GA - 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.2 GA W - 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.3 GA/GA W - 60 Hz (except for Canada/USA) . 20

2.3.4 GA/GA W - 60 Hz (Canada/USA) . . . . . . . . . 23

2.4 Pictographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5 Cooling water requirements . . . . . . . . . . . . . . . . . . . . . 24

3 Operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Preparation for initial start-up . . . . . . . . . . . . . . . . . . . 25

3.2 Before starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 Routine starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4 Starting after emergency stop or shut-down . . . . . . . . 26

3.5 During operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5.1 Checking the display . . . . . . . . . . . . . . . . . . . . 27

3.6 Manual unloading/loading . . . . . . . . . . . . . . . . . . . . . . 28

3.7 Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.8 Taking out of operation. . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 Preventive maintenance schedule for the compressor . 29

4.2 Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.1 Fan motors (GA only) . . . . . . . . . . . . . . . . . . . 30

4.2.2 Drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3 Oil specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3.1 Roto-injectfluid . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4 Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5 Oil filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.6 Storage after installation . . . . . . . . . . . . . . . . . . . . . . . . 31

4.7 Service kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2920 1251 02

3

Instruction book

1 LEADING PARTICULARS

1.1 General description

GA90 up to GA315 and GA90 W up to GA315 W are singlestage, oil-injected screw compressors, driven by an electric

motor and enclosed in a sound-insulated bodywork.

GA90 up to GA315 are air-cooled, abbreviated as "GA". GA90

W up to GA315 W are water-cooled, abbreviated as "GA W".

The compressors are available for a maximum working pressure

of:

- 7.5, 10 or 13 bar(e) for 50 Hz versions

- 107, 132, 157 or 200 psig for 60 Hz versions

GA and GA W include mainly:

- Air filter(s)

- One or two compressor elements 1)

- One or two unloaders 1)

- Air receiver/oil separator

- Air cooler

- Oil cooler(s)

- Drive motor

- Drive coupling

- Gear casing

- Elektronikon® control system

- Safety valves

Energy recovery

The compressors can easily be provided with the Atlas Copco

energy recovery systems to recover the major part of the

compression heat in the form of hot water.

Heavy-duty filters

A heavy-duty filter kit is available as option allowing the

compressor to operate in heavily contaminated surroundings.

Oil/water separation

Atlas Copco has oil/water separators (type OSM), especially

designed for GA/GA W compressors, to separate oil from

condensate to meet the requirements of the local environmental

codes.

1.2 Elektronikon® control system

1.2.1 Elektronikon regulator

1.2.1.1 Automatic control of compressor operation

The regulator maintains the net pressure between programmable

limits by automatically loading and unloading the compressor.

A number of programmable settings, e.g. the unloading and

loading pressures, the minimum stop time and the maximum

number of motor starts are taken into account.

The regulator stops the compressor whenever possible to reduce

the power consumption and restarts it automatically when the

net pressure decreases. In case the expected unloading period

is too short, the compressor is kept running to prevent tooshort standstill periods.

Warning

A number of time-based automatic start/stop commands may

be programmed. 2) Take into account that a start command

will be executed (if programmed and activated), even after

manually stopping the compressor.

1.2.1.2 Protecting the compressor

Shut-down

If the temperature at the outlet of the compressor elements

exceeds the programmed shut-down level, the compressor will

be stopped. This will be indicated on display (4-Fig. 3a) and

general alarm LED (3) will blink. The compressor will also be

stopped in case of overload of the drive motor and on GA also

in case of fan motor overload.

Remedy the trouble and reset the message on the display before

restarting. See "User manual for Elektronikon® regulator",

section "Submenu ST ATUS DAT A".

Shut-down warning

Before the shut-down level for the compressor element outlet

temperature is reached, a message will appear on display (4Fig. 3a) and general alarm LED (3) will light up, to warn the

operator that the shut-down warning level is exceeded. The

shut-down warning level is a programmable setting below the

shut-down level.

The message disappears as soon as the cause of the trouble is

remedied.

1.2.1.3 Monitoring components subject to service

The regulator continuously monitors the oil, oil filters, oil

separator, drive motor grease and air filters. Each input is

compared to programmed maximum time intervals or pressure

drops. If these limits are exceeded, a message will appear on

display (4-Fig. 3a) to warn the operator to replace the indicated

component, to change the oil or to grease the motor as the case

may be.

1) GA/GA W 90 up to -160 are equipped with one compressor

element and unloader, all other types have two compressor

elements and unloaders.

2) This funcion is called the Timer function. See "User manual for

Elektronikon regulator", section "Submenu TIMERS".

2920 1251 02

4

Instruction book

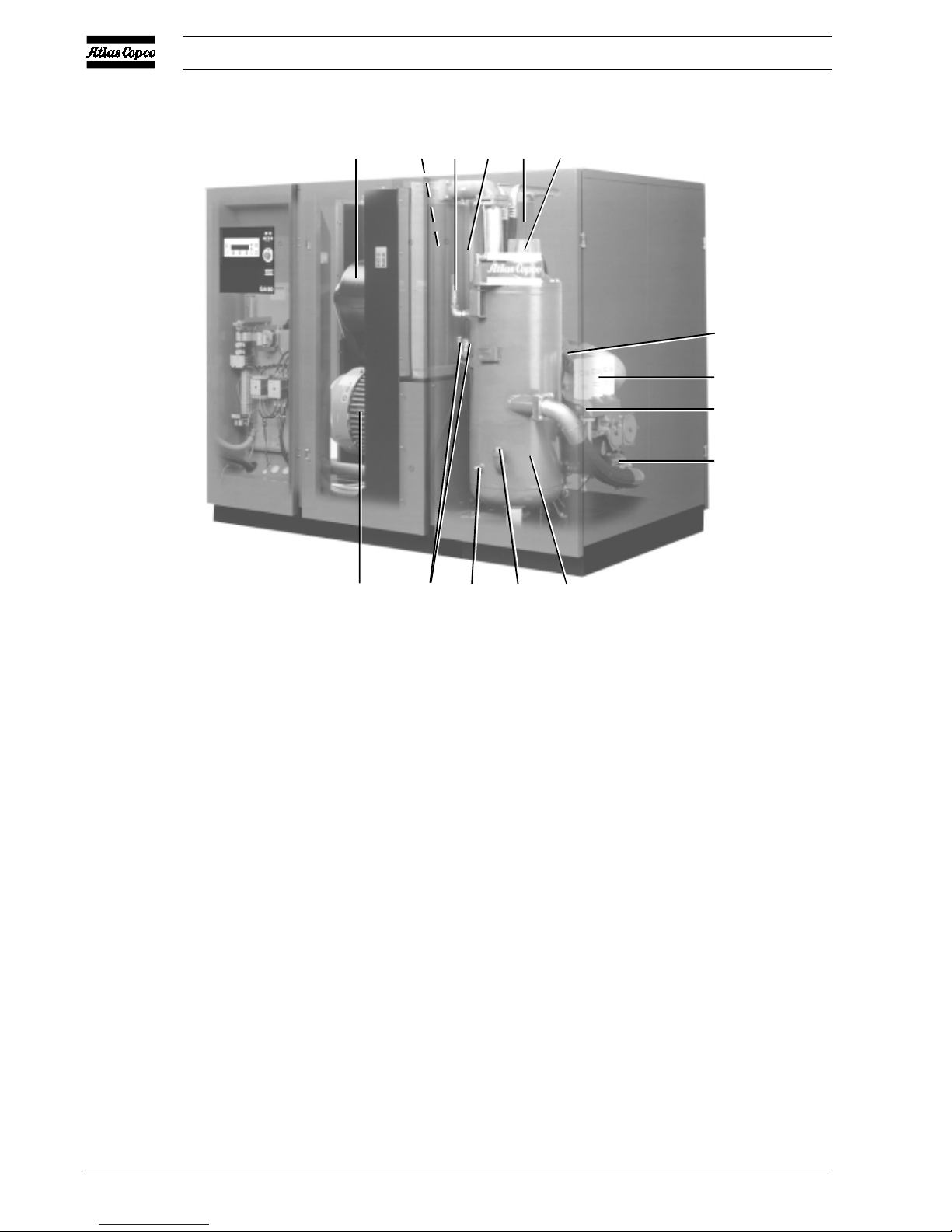

Fig. 1a GA90

AF. Air filter

AR. Air receiver/oil separator

Ca. Air cooler

Co. Oil cooler

CV. Check valve

DP1. Oil drain plug, air receiver

DP4. Oil drain plug, oil cooler

E. Compressor element

FC1. Oil filler plug

FC2. Oil filler plug (only to be used at

initial start-up)

FN2. Fan

Gl. Oil level indicator

M1. Drive motor

OF . Oil filters

SV. Safety valve

UA. Unloader

Vp. Minimum pressure valve

Vs. Oil stop valve

Y1. Loading solenoid valve

Figs. 1. GA90 and GA110 W

50314F

M1 DP1/4

GL

FC1 AR

UA

OF

E

CV

AF FN2CaSV

Co

Vp

2920 1251 02

5

Instruction book

1.2.1.4 Automatic restart after voltage failure

For compressors leaving the factory, this function is made

inactive. If desired, the function can be activated. Consult

Atlas Copco.

Warning

If activated and provided the regulator was in the automatic

operation mode and the compressor control mode (local, remote

1 or remote 2 - see section 1.2.3) was not changed during the

voltage failure, the compressor will automatically restart if the

supply voltage to the module is restored within a programmed

time period (this time period is called the power recovery

time).

The power recovery time can be set between 1 and 254 seconds

or to 0. If the power recovery time is set to 0, the compressor

will always restart after a voltage failure, no matter how long it

takes to restore the voltage.

1.2.1.5 Permissive start

After a start command (either automatic start by the electronic

regulator or manual start), the permissive start function is

operating: if the oil injection pressure at the compressor

elements exceeds the programmed level, the compressor will

not start (indicated as <<Start failure>>). See "User manual

for Elektronikon regulator", section "Programmable settings

for GA90/315".

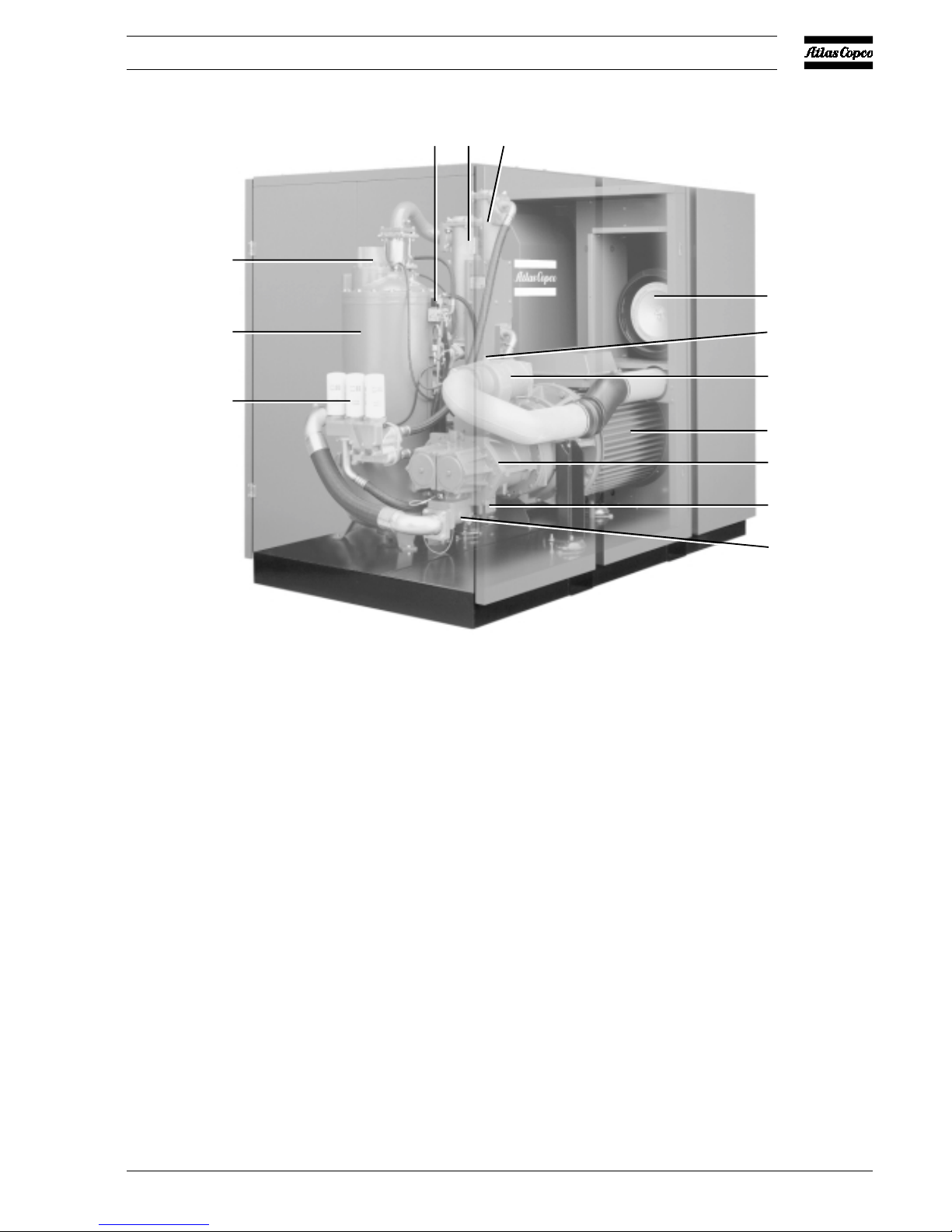

Fig. 1b GA110 W

50315F

Y1

Ca Co

Vp

AR

OF

M1

E

Vs

CV

AF

FC2

UA

2920 1251 02

6

Instruction book

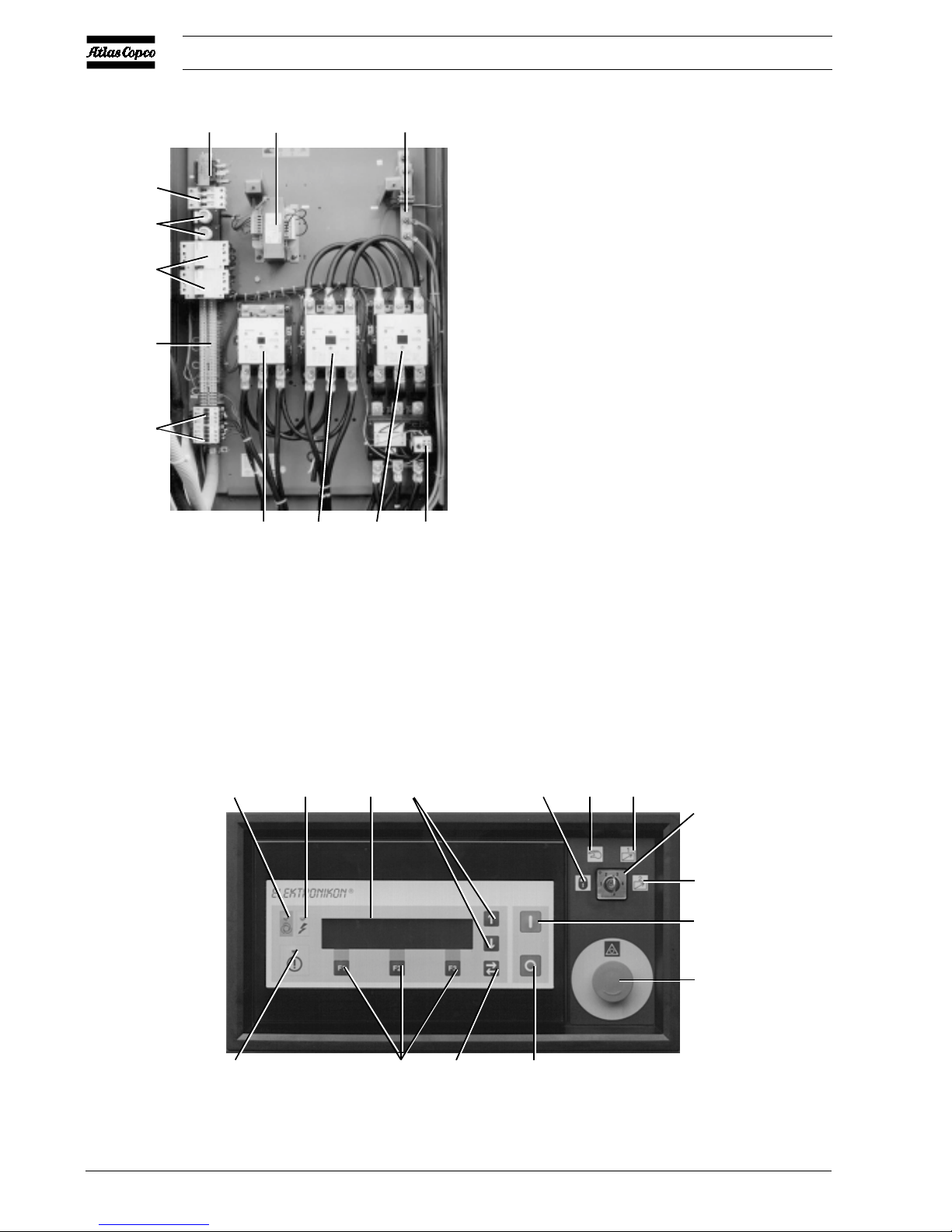

F1/F2. Fuses

F3/F5. Circuit breakers

F21. Overload relay, drive motor (M1)

K15/16. Fan motor contactors 1)

K21. Line contactor

K22. Star contactor

K23. Delta contactor

Q15/16. Fan motor circuit breakers 1)

T1/T2. Transformers

1X1. T erminal strip

1X3. Earthing rail

1) One contactor/circuit breaker on GA90 and -1 10, two

contactors/circuit breakers on GA132 up to -315, not

provided on GA W.

Fig. 2. Electric cabinet (typical example)

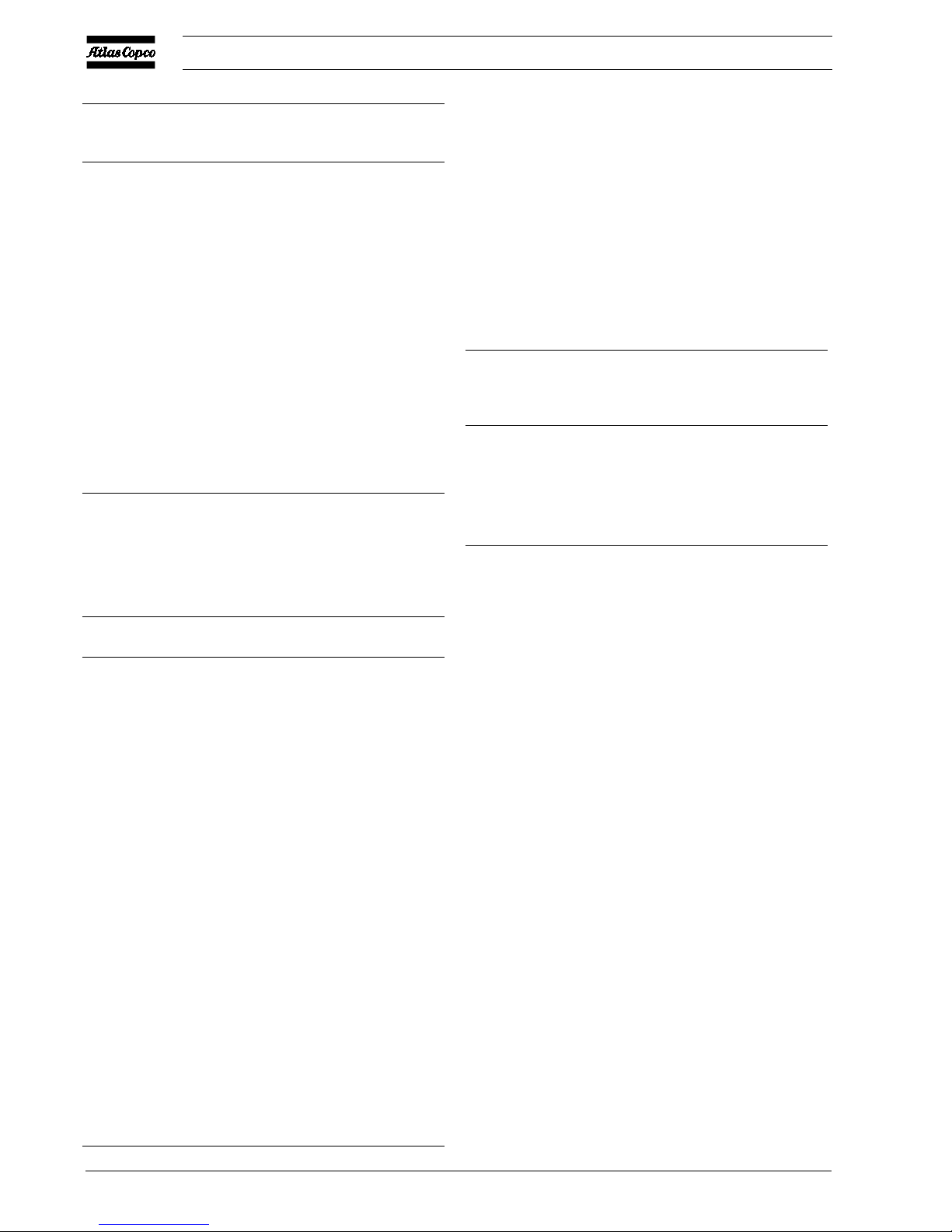

Fig. 3a. Control panel

K22 K23 K21

F21

50309F

T2

T1

1X3

F3/4/5

F1/2

Q15/16

1X1

K15/16

12

46

10 11

12

13

S5

8

S2

3

57

9

50749F

2920 1251 02

7

Instruction book

1.2.2 Control panel (Fig. 3a)

Indicators, keys and buttons

Ref. Designation

1 Automatic operation Indicates that the regulator is auto-

LED matically controlling the com-

pressor: the compressor is loaded,

unloaded, stopped and restarted

depending on the air consumption

and the limitations programmed in

the regulator.

2 Voltage on LED Indicates that the voltage is

switched on.

3 General alarm LED Is alight if a shut-down warning

condition exists. See section 1.2.1.

Blinks if a shut-down condition

exists, if a sensor used to protect

the compressor is out of order or

after an emergency stop. See

section 1.2.1.

4 Display Indicates messages concerning the

compressor operating condition, a

service need or a fault. See "User

manual for Elektronikon

regulator" sections "Submenu

STATUS DATA" and "Submenu

SERVICE".

Ref. Designation

5 Function keys Keys to control and program the

compressor. See below.

6 Scroll keys Keys to scroll through the display.

7 Tabulator key Key to go to the next field of the

display.

8 Start button Push button to start the

compressor. LED (1) lights up

indicating that the regulator is

operative (in automatic operation).

The LED goes out after unloading

the compressor manually.

9 Stop button Push button to stop the

compressor. LED (1) goes out.

The compressor will run unloaded

for 30 seconds before stopping.

S2 Emergency stop Push button to stop the compressor

button immediately in case of emergency .

After remedying the trouble,

unlock the button by turning it

anti-clockwise.

S5 Control mode switch Key switch to select the

compressor control modes. See

section 1.2.3.

Selecting a menu

To facilitate controlling the compressor , menu-driven programs

are implemented in the Elektronikon regulator. Use function

keys (5) to select the menus to program and monitor the

compressor. The "User manual for Elektronikon regulator"

deals elaborately with all regulator functions.

Function keys

The functions of the keys vary depending on the displayed menu.

The actual function is indicated just above the relevant key.

The most common functions are listed below:

Designation Function

(4-Fig. 3a)

Add T o add compressor start/stop commands (day/

hour)

Cancel To cancel a programmed setting when

programming parameters

Delete T o delete compressor start/stop commands

Limits To show limits for a programmable setting

List To list programmed start/stop commands

(day/hour)

Compressor outlet 7.0 bar

Automatically loaded

Menu Show More Unload

F1 F2 F3

Fig. 3b. Example of the main display

Status data

↓

Main Screen Select

F1 F2 F3

Fig. 3c. Example of a main menu

2920 1251 02

8

Instruction book

Designation Function

(4-Fig. 3a)

Load T o load the compressor manually

Main Screen To return from a menu to the main display

(Fig. 3b)

Menu Starting from the main display (Fig. 3b), to

initiate the main menu (Fig. 3c) which gives

access to submenus

Starting from a submenu, to return to the main

menu (Fig. 3c)

Modify T o modify programmable settings

Show More T o have a quick look at the compressor status

Program To program modified settings

Reset To reset a timer or message

Return To return to a previously shown option or

menu

Select To select a submenu or to read more details

of a selection shown on the display

Unload To unload the compressor manually

1.2.3 Compressor control modes

Key switch (S5-Fig. 3a) allows the operator to select four control

modes:

Key position Compressor control mode

10 Compressor off.

11 Local control mode (remote control mode

is made inactive):

- The compressor can only be controlled

by the buttons on the control panel.

- The compressor can be started and

stopped via function Timer (see section

1.2.1), if programmed and activated.

12 Remote control mode 1 (local control is

made inactive):

- The compressor can only be started and

stopped by an ES100 sequence selector

or by external switches. Do not use

maintained-action buttons in case of

remote starting/stopping.

- Compressor start/stop commands via

function T imer (see section 1.2.1) are still

possible, if programmed and activated.

- Emergency stop button (S2) remains

active.

13 Remote control mode 2. The compressor

can be controlled by an ES-type controller or

by computer. Consult Atlas Copco.

Important

- The regulator will only react to a new control mode if the

new position of the control mode switch is maintained for

3 seconds.

- To avoid unauthorized switching over to another control

mode, take out the key after selecting the required mode.

1.2.4 External compressor status indication

Terminal strip (1X1-Fig. 2) is provided with auxiliary contacts

for external indication of:

Indication Relay Terminals Max. load

on strip

1X1

Automatic operation K06 50-51 10 A / 230 V AC

W arning K07 52-53 10 A / 230 V AC

Shut-down K08 54-55 10 A / 230 V AC

Control mode

REMOTE 1 -- 56-57 10 A / 230 V AC

Warning

Stop the compressor and switch off the voltage before

connecting external equipment.

1.2.5 External communication

If it is desired to connect the compressor to an Atlas Copco ES

system (e.g. to an ES100 sequence selector), an optional

communication module (COM1) needs to be installed.

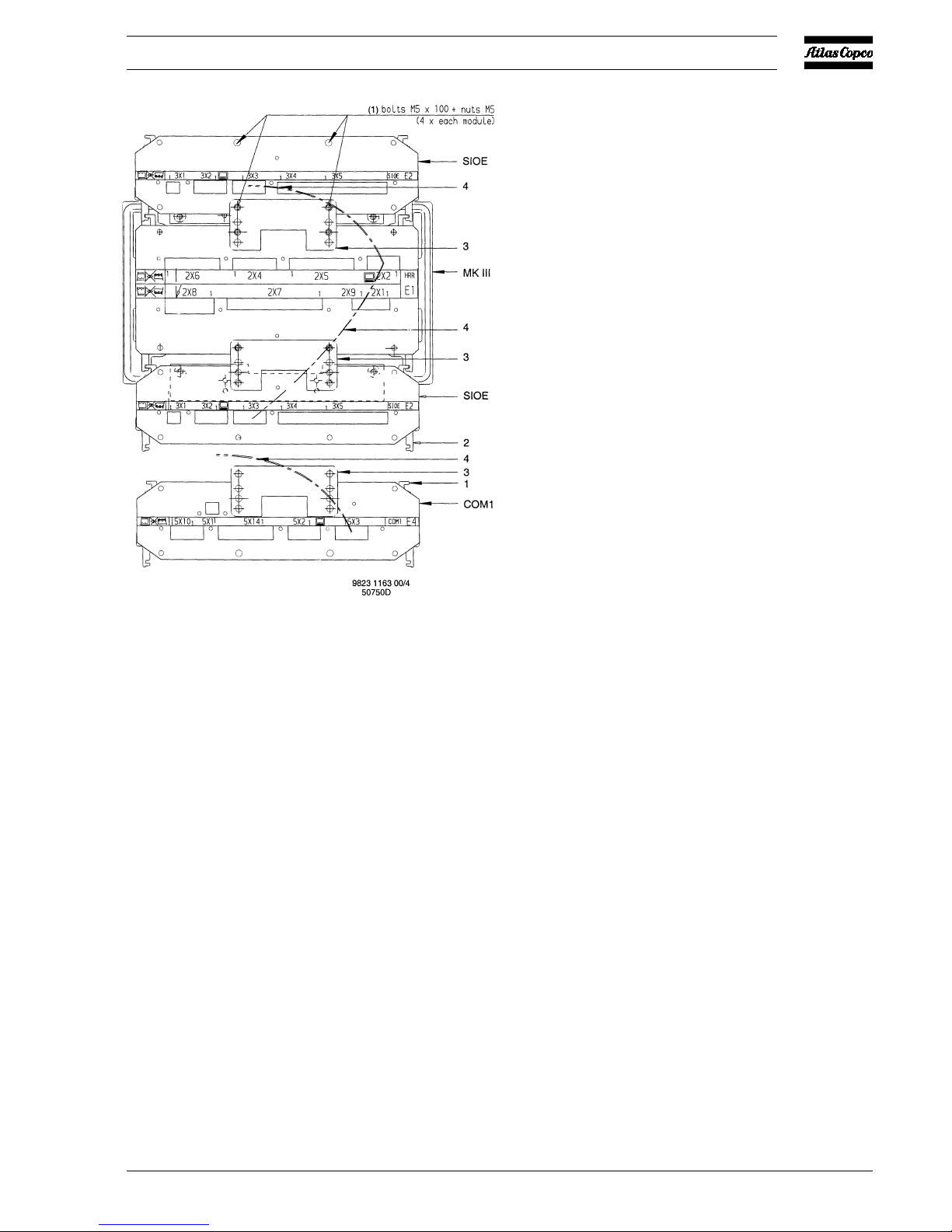

Installation (Fig. 4)

1. Fit the communication module (COM1) and fix it using

plate (3).

2. Connect the 24V power supply from terminals (11 and

12) of terminal strip (1X1) to connector (5X1) of

communication module (COM1).

3. Connect an earth cable between module (COM1) and the

module of the regulator.

4. Connect the cable delivered with the COM1 module from

connector (5X3) of the COM1 module to a free ..X2

connector on a module of the compressor regulator.

5. Consult Atlas Copco to check the installation and to have

the communication software loaded.

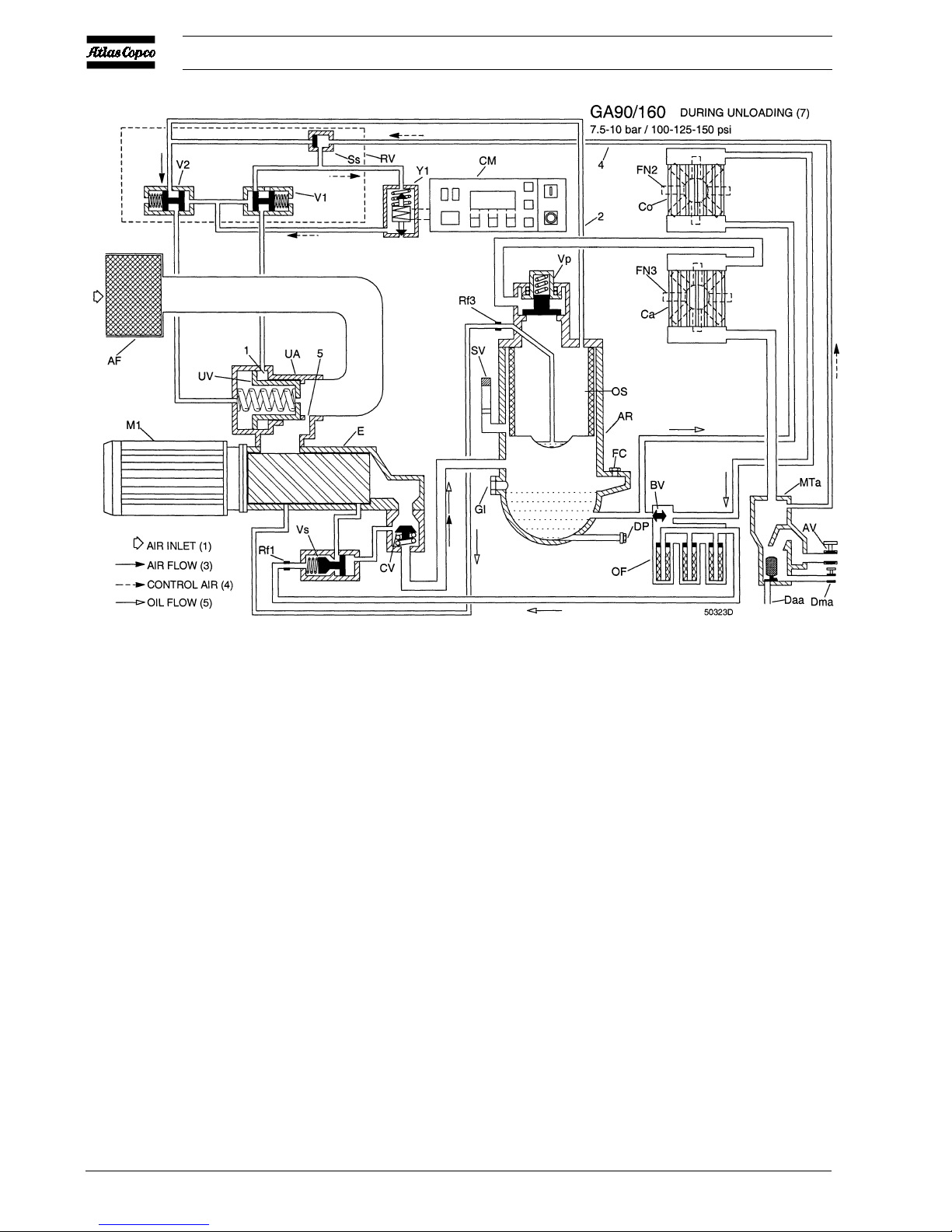

1.3 Regulating system (Figs. 5)

1.3.1 Air flow

GA/GA W 90 up to -160

Air drawn through filter (AF) and unloader (UA) is compressed

2920 1251 02

9

Instruction book

in compressor element (E). Compressed air and oil are

discharged to air receiver/oil separator (AR) via check valve

(CV). In the oil separator compressed air is separated from the

oil. The air is blown via minimum pressure valve (Vp) to air

cooler (Ca). The cooled air is discharged through moisture

trap (MTa) and outlet valve (AV) towards the air net.

Check valve (CV) prevents blow-back of compressed air.

GA/GA W 200 up to -315

Air drawn through filters (AF) and unloaders (UA1 and UA2)

is compressed in compressor elements (E1 and E2).

Compressed air and oil are discharged to air receiver/oil

separator (AR) via check valves (CV1 and CV2). In the oil

separator compressed air is separated from the oil. The air is

blown via minimum pressure valve (Vp) to air cooler (Ca).

The cooled air is discharged through moisture trap (MT a) and

outlet valve (AV) towards the air net.

Check valves (CV1 and CV2) prevent blow-back of compressed

air.

All GA/GA W

Minimum pressure valve (Vp) prevents the receiver pressure

from dropping below a minimum pressure. The valve has a

built-in check valve.

1.3.2 Condensate drain system

A moisture trap (MTa) is installed downstream of the air cooler

to prevent condensate from entering the air outlet pipe. The

trap is provided with a float valve for automatically draining

condensate (Daa) and with a manual drain valve (Dma).

1.3.3 Oil system

GA/GA W 90 up to -160

Air pressure forces the oil from receiver (AR) through oil

cooler(s) (Co), filters (OF) and valve (Vs) to compressor

element (E) and the lubrication points.

COM1. Communication module

MKIII. Electronic regulator

SIOE. Expansion modules (upper module not always

installed)

1. Guide

2. Slot

3. Plate

4. Cable

Fig. 4. Installation of communication module (typical

example)

2920 1251 02

10

Instruction book

Oil stop valve (Vs) prevents compressor element (E) from

flooding with oil when the compressor is stopped.

Valve (BV) by-passes oil cooler(s) (Co) when starting the

compressor from cold condition to ensure rapid warming of

the oil to normal working temperature.

GA/GA W 200 up to -315

Air pressure forces the oil from receiver (AR) through oil

cooler(s) (Co), filters (OF) and valves (Vs1 and Vs2) to

compressor elements (E1 and E2) and the lubrication points.

Oil stop valves (Vs1 and Vs2) prevent compressor elements

(E1 and E2) from flooding with oil when the compressor is

stopped.

Valves (BV) by-pass oil cooler(s) (Co) when starting the

compressor from cold condition to ensure rapid warming of

the oil to normal working temperature.

All GA/GA W

In receiver (AR) most of the oil is removed from the air

centrifugally. Almost all of the remaining oil is removed by

separator element (OS).

1.3.4 Cooling system

The system includes air cooler (Ca) and oil cooler (Co) (GA

W 132 up to -315 have two oil coolers).

On GA, the coolers are cooled by fans (FN2/3) (GA90 and 110 are provided with one fan). GA W are provided with a

cooling water system.

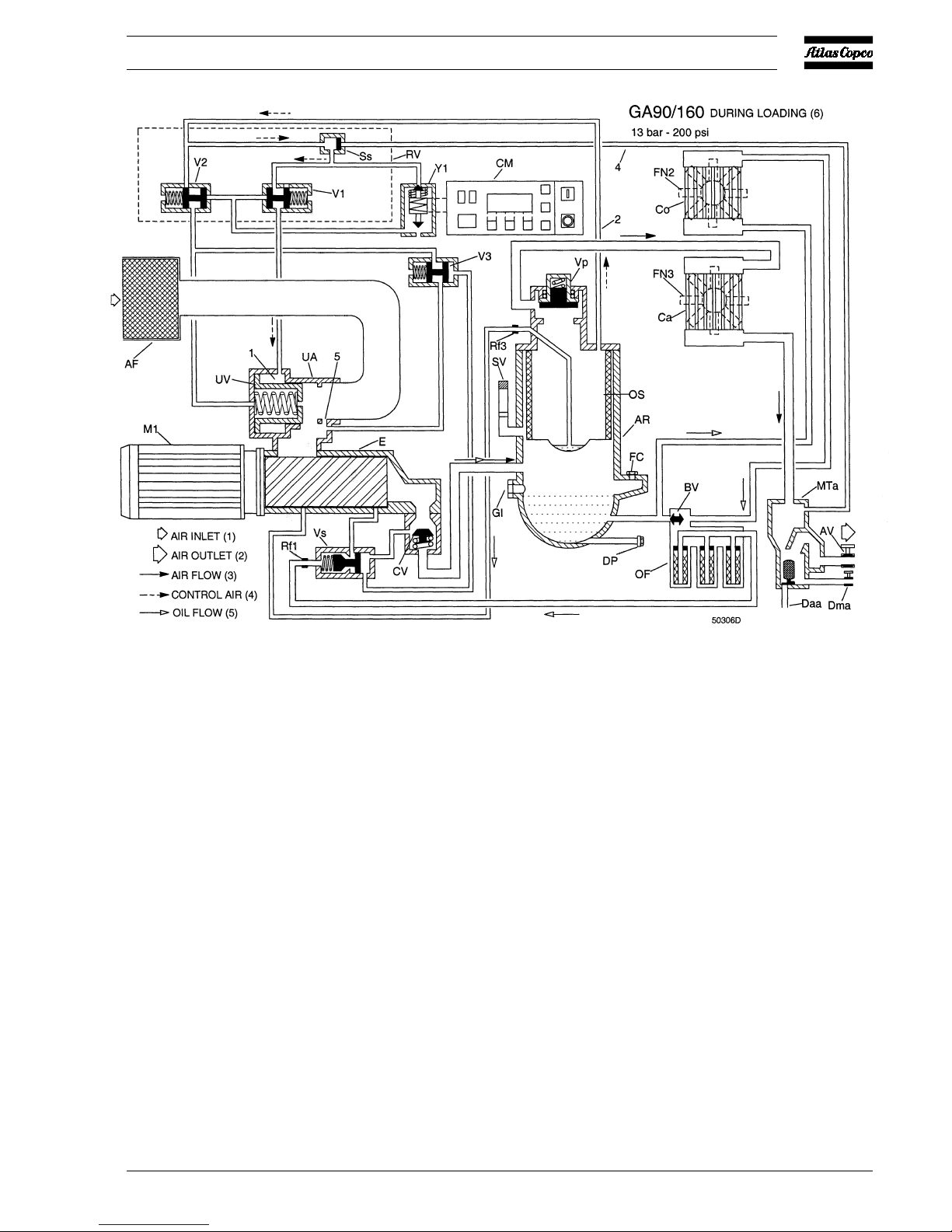

Fig. 5a GA90 up to -160 during unloading (7.5-10 bar/100-125-150 psi)

2920 1251 02

11

Instruction book

AF . Air filter(s)

AR. Air receiver/oil separator

AV. Air outlet valve

BV. Thermostatic by-pass valve(s),

oil cooler(s)

Ca. Air cooler

CM. Elektronikon® regulator

Co. Oil cooler(s)

CV. Check valve

CV1. Check valve

CV2. Check valve

Daa. Automatic condensate drain

outlet

Dma. Manual condensate drain valve

DP1. Drain plug, oil

E. Compressor element

E1. Compressor element

E2. Compressor element

FC. Filler plug, oil

FN2/3. Fans

Gl. Oil level indicator

MTa. Moisture trap

M1. Drive motor

OF . Oil filters

OS. Oil separator element

Rf1/3. Restrictors

R V. Regulating valve

Ss. Pressure selector valve

SV. Safety valve

UA. Unloader

UA1. Unloader

UA2. Unloader

UV. Unloading valve

UV1. Unloading valve

UV2. Unloading valve

Vp. Minimum pressure valve

Vs. Oil stop valve

Vs1. Oil stop valve

Vs2. Oil stop valve

V1. Control valve for unloading

valve

V2. Vent valve

V3. Vent valve 1)

Y1. Loading solenoid valve

1. Chamber

2. Flexible, control air or blowoff air

3. Flexible, blow-off air

4. Flexible, control air

5. By-pass hole, unloader

1) For GA/GA W 90 up to -160: only provided on 13 bar/200 psi versions

Figs. 5 Regulating systems

Fig. 5b GA90 up to -160 during loading (13 bar / 200 psi)

2920 1251 02

12

Instruction book

1.3.5 Regulating system

The system is controlled by Elektronikon® regulator (CM)

which keeps the net pressure within programmable pressure

limits by automatically loading and unloading the compressor

depending on the air consumption.

1.3.5.1 Unloading

If the air consumption is less than the air delivery of the

compressor, the net pressure increases. When the net pressure

reaches the upper limit of the working pressure (unloading

pressure), solenoid valve (Y1) is de-energized. The plunger of

the valve moves downwards by spring force:

GA/GA W 90 up to -160

1. Control pressure is fed via flexible (2) and selector valve

(Ss) through solenoid valve (Y1) to valves (V1 and V2).

2. The plungers of valves (V1 and V2) move against spring

force.

3. Control pressure present in chamber (1) of unloader (UA)

is vented to atmosphere through valve (V1). Unloading

valve (UV) closes by spring force.

4. Receiver pressure is released to unloader (UA):

- through flexible (2) and valve (V2)

- on 13 bar/200 psi compressors also through valve (V3)

as this valve is kept open by air from the outlet of

compressor element (E)

5. As the receiver pressure decreases, selector valve (Ss)

switches over.

6. On 13 bar/200 psi compressors, as the pressure at the

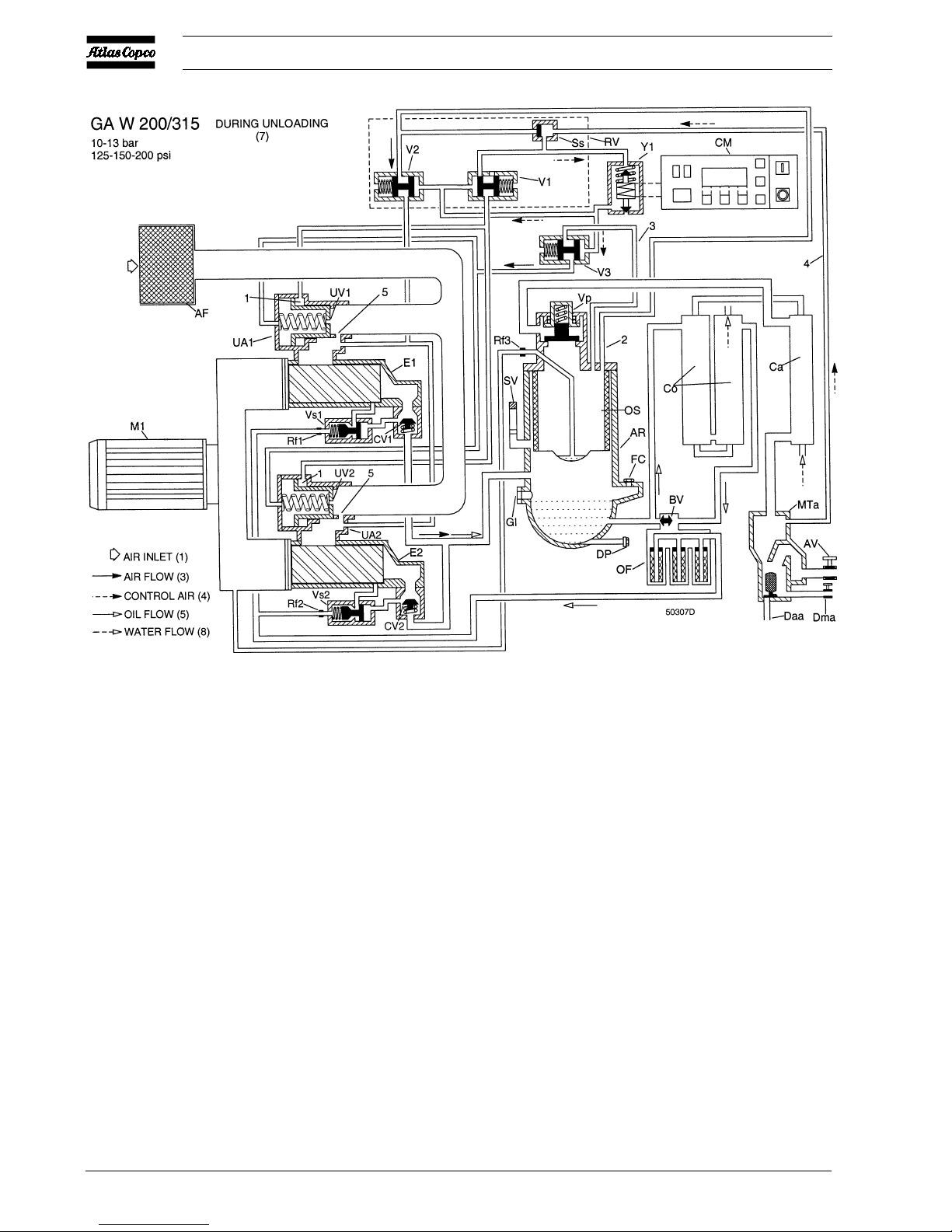

Fig. 5c GA W 200 up to -315 during unloading (10-13 bar/125-150-200 psi)

2920 1251 02

13

Instruction book

outlet of compressor element (E) decreases, valve (V3)

closes by spring force and stops blowing off air.

7. Valve (V2) allows the small flow of air, which remains

drawn in through by-pass hole (5), to blow off from

receiver (AR) via flexible (2) to unloader (UA).

8. Air delivery is stopped (0 %), the compressor runs

unloaded.

GA/GA W 200 up to -315

1. Control pressure is fed via flexible (2) and selector valve

(Ss) through solenoid valve (Y1) to valves (V1, V2 and

V3).

2. The plungers of valves (V1, V2 and V3) move against

spring force.

3. Control pressure present in chambers (1) of unloaders

(UA1 and UA2) is vented to atmosphere through valve

(V1). Unloading valves (UV1 and UV2) close by spring

force.

4. For 7.5 bar/100 psi compressors, receiver pressure is

released:

- through flexible (2) and valve (V2) to unloader (UA1)

- through flexible (3) and valve (V3) to unloader (UA2)

5. For 10/13 bar/125/150/200 psi compressors, receiver

pressure is released:

- through flexible (2) and valve (V2) to unloaders (UA1

and UA2)

- through flexible (3) and valve (V3) to unloaders (UA1

and UA2)

6. As the receiver pressure decreases, selector valve (Ss)

switches over.

7. Valves (V2 and V3) allow the small flow of air, which

remains drawn in through by-pass holes (5), to blow off

from receiver (AR) via flexibles (2 and 3) to unloaders

(UA1 and UA2).

8. Air delivery is stopped (0 %), the compressor runs

unloaded.

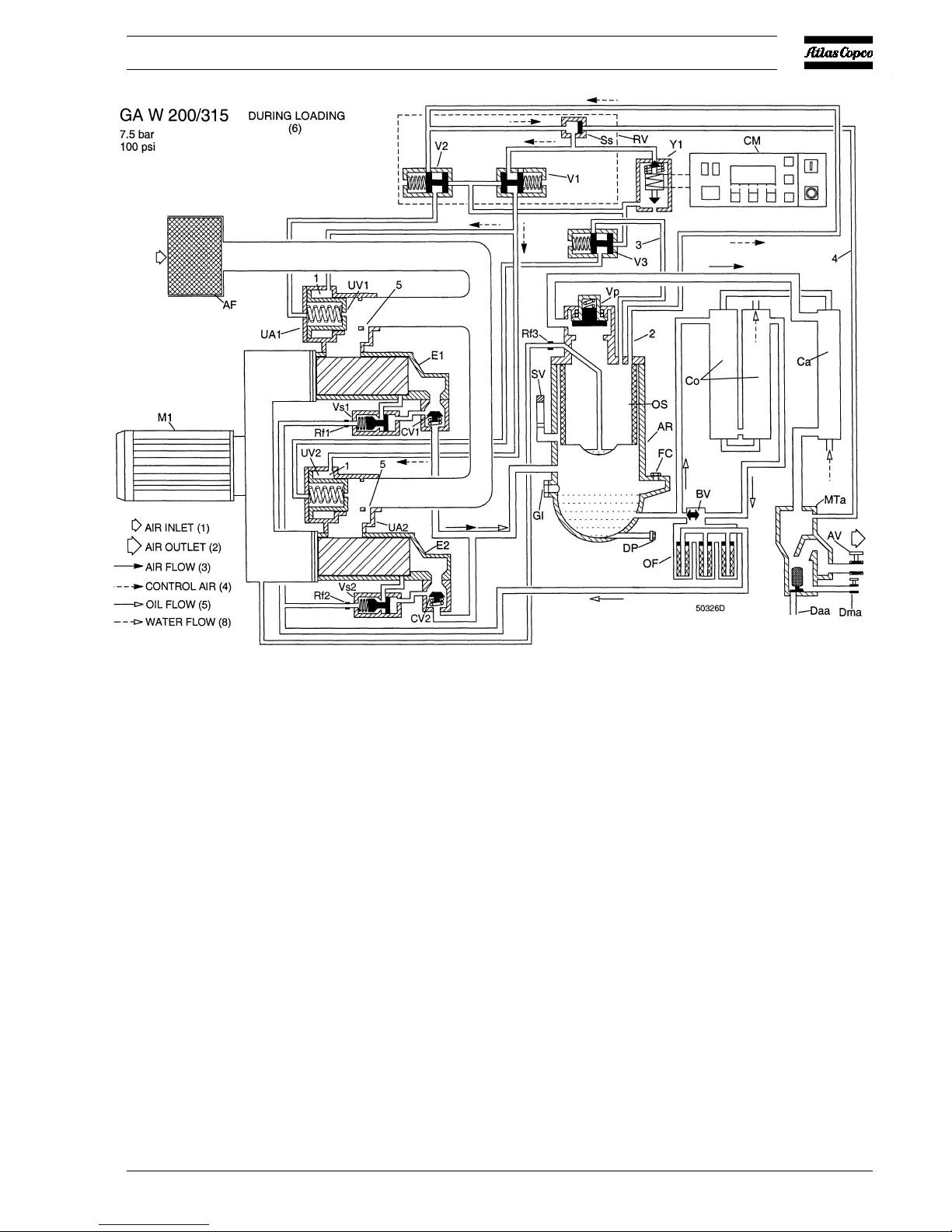

Fig. 5d GA W 200 up to -315 during loading (7.5 bar/100 psi)

Loading...

Loading...