Page 1

C 659 P X UK

5-ring cooker with new "7 cuochi" oven

Instructions for installation and use

Page 2

W arning

To maintain the EFFICIENCY and SAFETY of this appliance, we recommend:

• call only the Service Centers authorized by the man ufacturer

• alwa ys use original Spare P arts

1 This appliance is intended for non-professional use

within the home.

2 These instructions are only for those countries whose

symbols appear in the booklet and on the serial no. plate

of the appliance.

3 This owner’ s manual is for a class 1 appliance (installed

independently) or class 2, sub-class 1 appliances

(installed between two cabinets).

4 Before using your appliance, read the instructions in this

owner’ s manual carefully since it provides all the information

you need to ensure safe installation, use and maintenance .

Always keep this owner’s manual close to hand since you

may need to ref er to it in the future.

5 When you have removed the packing, check that the

appliance is not damaged. If you have any doubts, do not

use the appliance and contact your nearest Ariston Service

Centre. Never lea ve the packing components (plastic bags ,

polystyrene foam, nails, etc.) within the reach of children since

they are a source of potential danger .

6 The appliance must be installed only by a qualified technician

in compliance with the instructions provided. The

manufacturer declines all liability for improper installation,

which may result in personal injury and damage to property.

7 The electrical safety of this appliance can only be guaranteed

if it is correctly and efficiently earthed, in compliance with

regulations on electrical safety. Always ensure that the

earthing is efficient. If you hav e any doubts, contact a qualified

technician to check the system. The manuf acturer declines

all liability for damage resulting from a system which has not

been earthed.

8 Before plugging the appliance into the mains, chec k that the

specifications indicated on the date plate (on the appliance

and/or packaging) correspond with those of the electrical

and gas systems in your home.s

9 Check that the electrical capacity of the system and sockets

will support the maximum power of the appliance, as indicated

on the data plate. If you have any doubts , contact a qualified

technician.

10 An omnipolar switch with a contact opening of at least 3 mm

or more is required for installation.

11 If the socket and appliance plug are not compatib le, have the

socket replaced with a suitable model b y a qualified technician,

who should also check that the cross-section of the sock et

cable is sufficient for the pow er absorbed by the appliance .

The use of adaptors, multiple sock ets and/or extensions , is

not recommended. If their use cannot be avoided, remember

to use only single or multiple adapters and extensions which

comply with current safety regulations. In these cases, never

exceed the maximum current capacity indicated on the

individual adaptor or extension and the maximum power

indicated on the multiple adapter .

12 Do not leave the appliance plugged in if it is not in use. Switch

off the main switch and gas supply when you are not using

the appliance.

13 The openings and slots used for ventilation and heat

dispersion on the back and below the contr ol panel must

never be covered.

14 The user must not replace the supply cable of this appliance.

Always contact an after-sales service centre which has been

authorised by the manufacturer if the cable has been

damaged or needs replacement.

15 This appliance must be used for the purpose for which it was

expressly designed. Any other use (e.g. heating rooms) is

considered to be improper and consequently dangerous. The

manufacturer declines all liability for damage resulting from

improper and irresponsible use.

16 A number of fundamental rules must be followed when using

electrical appliances. The following are of particular

importance:

• Do not touch the appliance when your hands or feet are

wet.

• Do not use the appliance barefooted.

• Do not use extensions, but if the y are necessary, caution

must be ex ercised.

• Never pull the power supply cable or the appliance to

unplug the appliance plug from the mains.

• Never leav e the appliance exposed to atmospheric agents

(rain, sun etc.).

• Do not allow children or persons who are not familiar with

the appliance to use it, without supervision.s

17 Always unplug the appliance from the mains or s witch off the

main switch before cleaning or carrying out maintenance.

18 If you are no longer using an appliance of this type, remember

to make it unserviceable by unplugging the appliance from

the mains and cutting the supply cable. Also make all

potentially dangerous parts of the appliance safe, above all

for children who could play with the appliance.

19 T o avoid accidental spillage do not use cookware with une ven

or deformed bottoms on the burners. Turn the handles of

pots and pans inwards to avoid knocking them over

accidentally.

20 Some parts of the appliance remain heated for a long time

after use. Mak e sure not to touch them.

21 Never use flammable liquids such as alcohol or gasoline,

etc. near the appliance when it is in use .

22 When using small electric appliances near the hob, keep the

supply cord away from the hot parts.

23 Make sure the knobs are in the “•”/”o” position when the

appliance is not in use.s

24 When the appliance is in use, the heating elements and

some parts of the oven door become extremely hot.

Make sure you don't touch them and keep children well

away .

25 Gas appliances require regular air exchange to ensure

trouble-free performance. When installing the cooker,

follow the instructions provided in the paragraph on

“Positioning” the appliance.

26 If the cooker is placed on a pedestal, take the necessary

precautions to prevent the same from sliding off the pedestal

itself.

27 Some of the models ha v e a glass hob co v er. This could

crack if ov erheated so make sure all the burners or electric hot plates are off before closing it.

2

Page 3

Installation

The following instructions should be read by a qualified

technician to ensure that the appliance is installed, regulated

and technically serviced correctly in compliance with current

regulations.

Important: remember to unplug the appliance from the

mains before regulating the appliance or carrying out

any maintenance work.

Positioning

Important: this unit may be installed and used only in

permanently ventilated rooms according to the British Standards

Codes Of Practice: B .S. 6172/B.S. 5440, P ar . 2 and B .S. 6891

Current Editions. The following requirements must be observed:

a) The cooker should not be installed in a bed sitting room with

a volume of less than 20m3. If it is installed in a room of

volume less than 5m3 an air vent of effectiv e area of 110cm

is required, if it is installed in a room of volume between 5m

and 10m3 a supplementary airvent area of 50cm2 is required,

if the volume exceeds 11m3 no airvent is required. Ho wever ,

if the room has a door or a window which opens directly to

the outside no air vent is required ev en when the volume is

between 5m3 and 11m3.

b) During prolonged use of the appliance y ou may consider it

necessary to open a window to the outside to improve

ventilation.

c) If there are other fuel burning appliances in the same room,

B.S.5440 Part 2 Current Edition, should, be consulted to

determine the requisite air vent requirements.

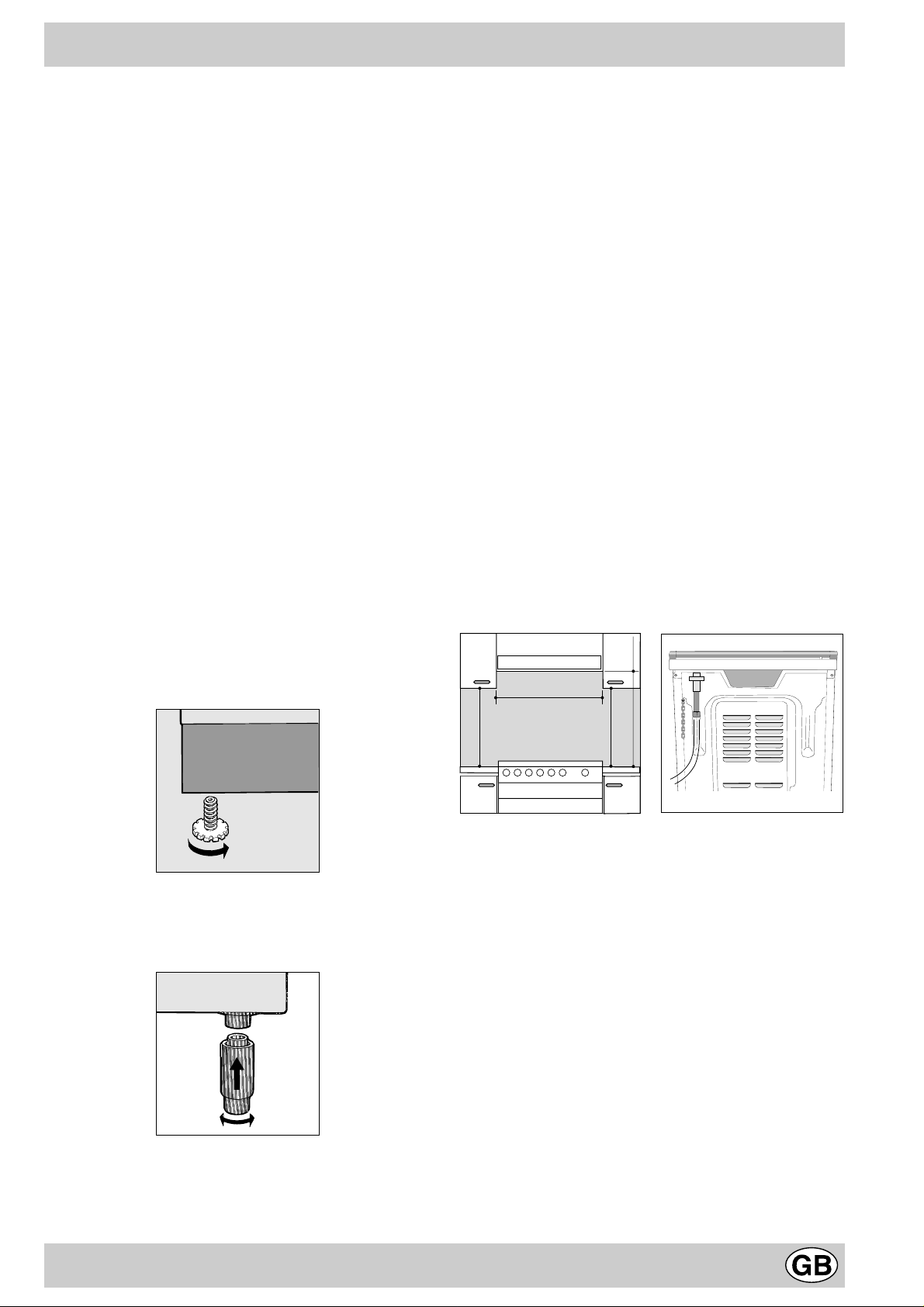

Levelling your appliance (only on a f ew models)

Y our cook er is supplied with feet for lev elling the appliance. If

necessary, these feet can be screwed into the housings in

the corners of the cooker base.

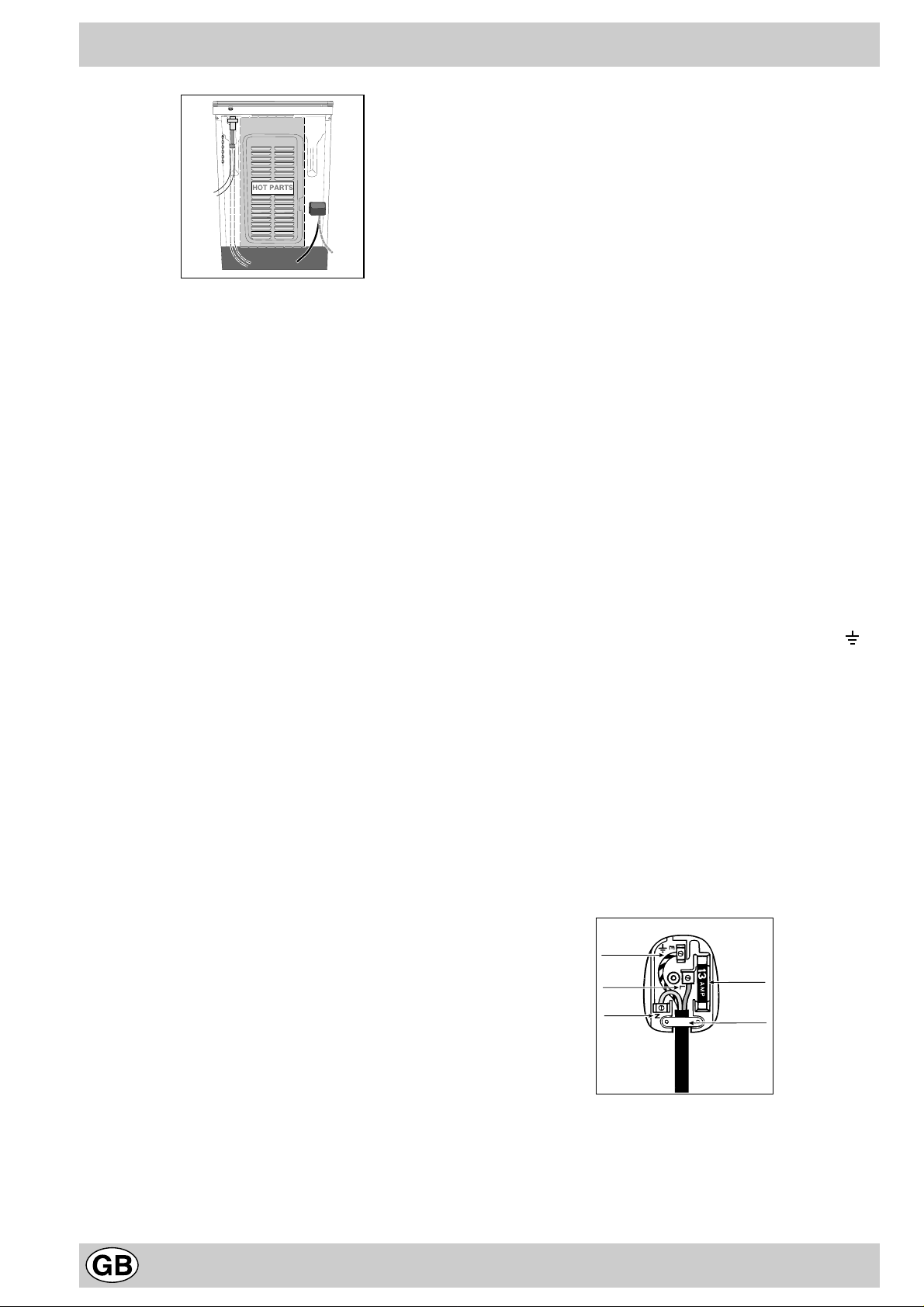

that of the hob. If the cooker is placed touching walls or sides

of neighbouring cabinets, these must be capable of

withstanding a temperature rise of 50°C above room temperature. For a correct installation of the cooker the following

precautions must be followed:

a) The cooker may be located in a kitchen, a kitonen/diner

or bed sitting room, but not in a bathroom or shower room.

b) The furniture units next to the cooker , that is higher than

the working boards, must be placed at least 110mm from

the edge of the board. Curtains must not be fitted

immediately behind the cooker or within 110 mm. of the

sides of the cooker .

c) The hoods must be installed according to the

requirements in the hood handbook.

d) Wall cabinets may be fitted in line with the sides of the

2

3

base units, providing that the lower edge of the w all cabinet

is a minimum of 420 mm. above the worktop. The minimum

distance combustible material kitchen units can be fitted

directly above the worktop is 700 mm (Fig. A).

e) The wall in contact with the back of the cooker must be of

flameproof material.

f) The cooker is fitted with a safety chain that must be

attached to a hook, secured to the wall behind the

appliance.

Note: some models can have their gas connection

inverted. It is important to make sure the safety chain

is always situated on the side which corresponds to

the hose holder (Fig. B).

HOOD

Min. mm.

600

mm.

420

Min.

mm. with hood

420

650

Min. mm.

min.

mm. without hood

700

min.

Mounting the legs (only on a few models)

Press-fit legs are supplied which fit under the base of your

cooker.

Installation of the cooker

The cooker is prepared with protection degree against

excessive heating of type X, the appliance can theref ore be

installed next to cabinets, provided the height does not e xceed

Fig. A Fig. B

Gas connection

The cooker should be connected to the gas-supply by a corgi

registered installer. Dur ing installation of this product it is

essential to fit an approved gas tap to isolate the supply from

the appliance for the conv enience of any subsequent removal

or servicing. Connection of the appliance to the gas mains

or liquid gas must be carried out according to the prescribed

regulation in force, and only after it is ascertained that it is

adaptable to the type of gas to be used. If not, follow the

instructions indicated in the paragraph headed “Adaptation

to different gas types”. In the case of connection to liquid

gas, by tank, use pressure regulators that conform to the

regulation in force. The gas supply must be connected to the

left of the appliance. Be sure that the hose does not pass

through the rear of the cooker touching hot parts.

3

Page 4

HOT PARTS

GREEN &

YELLOW

BROWN

BLUE

13 amp fuse

CROSS-BAR

CORD GRIP

Important: make sure the supply pressure conforms with the

values shown in the table entitled “Caracteristics of the burners

and nozzles”. When the cooker is installed between cabinets

(recessed), the gas connection must be effected by an

approved flexible hose with bayonet fitting

(BS 669 Current Edition). The gas inlet for the cookers is a

threaded G 1/2 gas female fitting.

Connecting the gas supply

To make the connection, a flexible hose should be used

corresponding to the current gas regulations which are:

• the hose must nev er be at any point in its lenght in contact

with the “hot” parts of the cooker;

• the hose must never be longer than 1,5 metre;

• the hose must not be subject to any tension or torsional

stress and it must not have an y excessiv ely narrow curves

or bottlenecks;

• the hose must be easy to inspect along its entire length to

check its condition;

• the hose must always be in good condition, ne v er attempt

to repair.

Important: the installation must comply with gas safety

(installation and use) regulations 1984. In all cases f or the above,

by low , a qualified, corgi appro ved engineer must be called f or

installation.

Electrial connection

Po wer supply voltage and frequency: 230-240V a.c. 50 Hz.

Note: the supply cable must be positioned so that it never

reaches at any point a temperature 50°C higher than the room

temperature. The cable must be routed a way from the rear vents.

Should you require it, you may use a longer cable, however,

you must ensure that the cable supplied with the appliance is

replaced by one of the same specifications in accordance with

current standards and legislation.

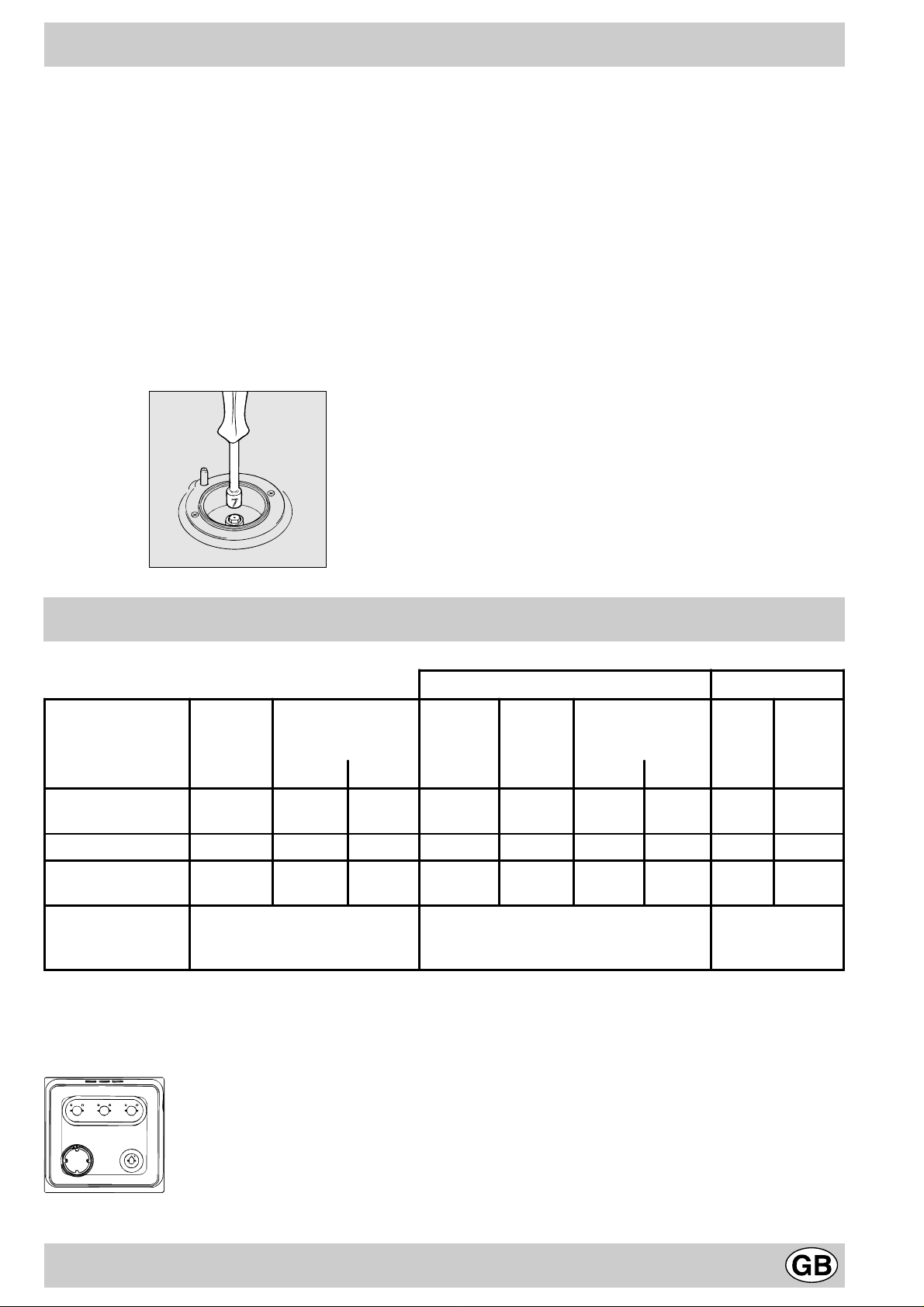

Y our appliance is supplied with a 13 amp fused plug that can be

plugged into a 13 amp socket for immediate use . Before using

the appliance please read the instructions below .

W ARNING - THIS APPLIANCE MUST BE EAR THED.

THE FOLLOWING OPERATIONS SHOULD BE CARRIED

OUT BY A QUALIFIED ELECTRICIAN.

Removing the plug:

If your appliance has a non-rewireable moulded plug and you

should wish to remove it to add a cable e xtension or to re-route

the mains cable through partitions, units etc., please ensure

that either:

• the plug is replaced by a fused 13 amp re-wireable plug

bearing the BSI mark of approval.

or:

• the mains cable is wired directly into a 13 amp cable outlet,

controlled by a switch, (in compliance with BS 5733) which

is accessible without moving the appliance.

Please note: for appliances with a rating greater than 13 amp

(eg: electric hob, doub le ovens and freestanding electric cookers

etc.) the mains cable must be wired into a cooker output point

with a rating of 45 amp. In this case the cable is not supplied.

Disposing of the plug:

Ensure that before disposing of the plug itself, you make the

pins unusable so that it cannot be accidentally inserted into a

socket. Instructions for connecting cab le to an alternative plug:

Important: the wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

If the colours of the wires in the mains lead do not correspond

with the coloured markings identifying the terminals in your plug,

proceed as follows:

Connect Green & Yellow wire to terminal marked “E” or or

coloured Green or Green & Yellow.

Connect Brown wire to terminal marked “L” or coloured Red.

Connect Blue wire to terminal marked “N” or coloured Blac k.

If a 13 amp plug (BS 1363) is used it must be fitted with a 13

amp fuse. A 15 amp plug m ust be protected by a 15 amp fuse,

either in the plug or adaptor or at the distribution board. If y ou

are in any doubt about the electrical supply to your machine,

consult a qualified electrician before use.

How to connect an alternative plug:

The wires in this mains lead are coloured in accordance with

the following code:

BLUE “NEUTRAL” (“N”)

BROWN “LIVE” (“L”)

GREEN AND YELLO W “EARTH” (“E”)

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA approved fuse to

BS 1362 should always be used, and the fuse co ver re-fitted. If

the fuse cover is lost, the plug must not be used until a

replacement is obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must be of the correct

colour as indicated by the coloured marking or the colour that is

embossed in words on the base of the plug. Replacements can

be obtained directly from your nearest Service Depot.

Disposing of the appliance

When disposing of the appliance please remove the plug by

cutting the mains cable as close as possible to the plug body

and dispose of it as described above.

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of gas with

4

Page 5

respect to the gas for which it was produced (indicated on

the label attached to the lid), follow these steps:

a) replace the hose holder mounted on the appliance with

that supplied in the bag of “cooker accessories”.

Important: the hose holder for liquid gas is marked 8, the

hose holder for methane gas is marked 13. Always fit the

sealing gasket.

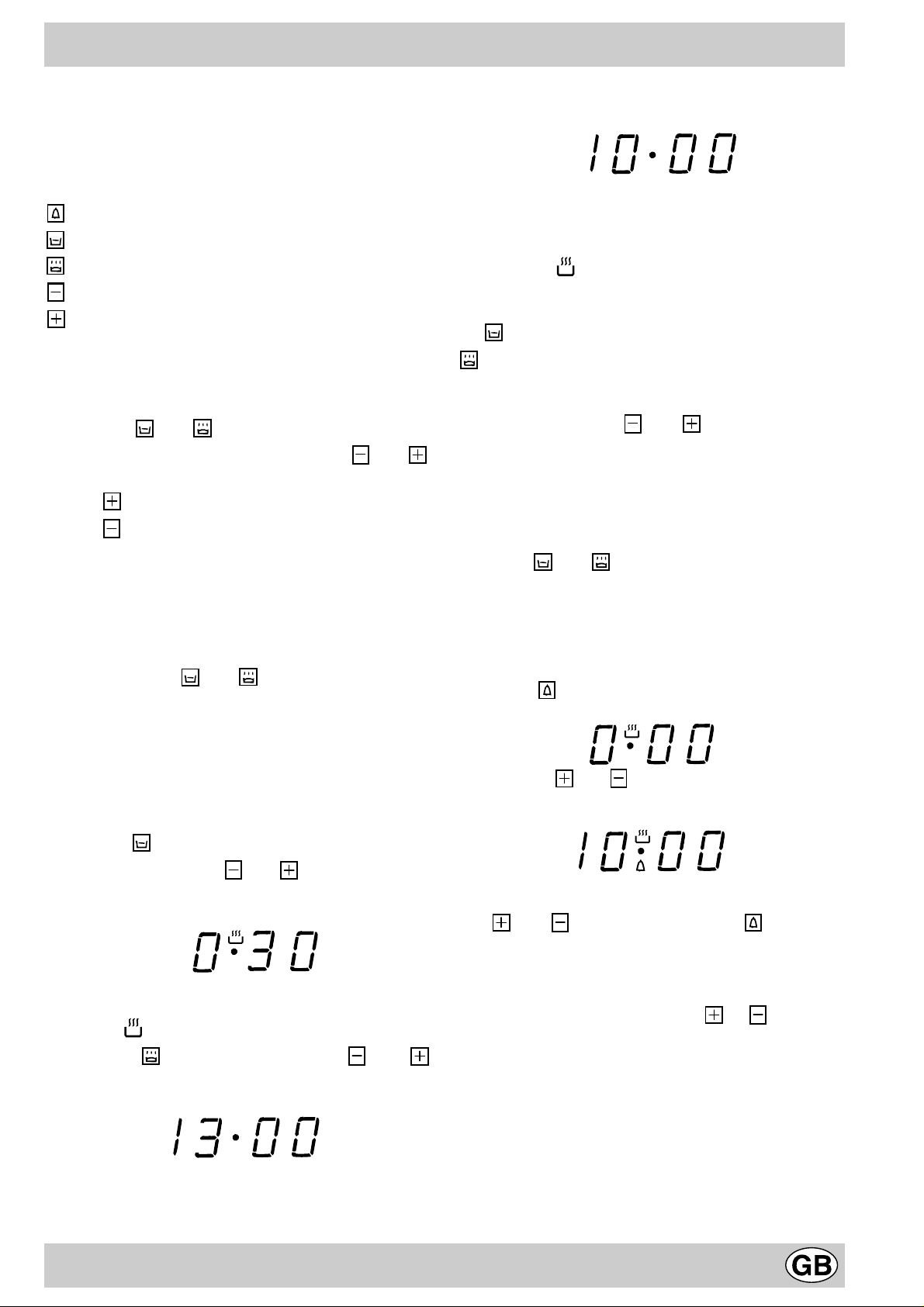

b) Replacing the burner nozzles on the hob:

• remove the grids and slide the burners from their

housings;

• unscrew the nozzles using a 7 mm sock et spanner , and

replace them with nozzles for the new type of gas (see

table 1 “Burner and nozzle characteristics”).

• replace all the components by repeating the steps in

reverse order .

c) Minimum regulation of the hob burners:

•

turn the tap to minimum;

• remove the knob and adjust the regulation scre w, which

is positioned in or next to the tap pin, until the flame is

small but steady.

N.B.: in the case of liquid gas, the regulation screw must

be screwed in to the bottom.

• check that the flame does not turn off when you turn the

tap quickly from high to low .

d) Regulating the primary air of the burners:

The primary air of the burners requires no regulation.

Important

On completion of the operation, replace the old rating stick er

with one indicating the new type of gas used. This stick er is

available from our Service Centres.

Note

Should the pressure of the gas used be different (or vary)

from the recommended pressure, it is necessary to fit a

suitable pressure regulator onto the inlet pipe in compliance

with current National Regulations relative to “regulators for

channelled gas”.

Burner and Nozzle Specifications

Table 1 Liquid gas Natural gas

Burner Diameter

(mm)

Auxiliary

(Small) (A)

55 1,00 0,4 30 50 73 71 79 95

Tr ipl e Crown(TC) 130 3,25 1,5 63 91 236 232 133 309

Half Fish- Kettl e

(SP)

- 1,50 0,7 41 60 109 107 98 143

Supply

pressures

Maximum ( mba r )

* At 15°C and 1013 mbar- dry gas

** Propane P.C .S. = 50.37 MJ/kg

*** Butane P.C.S . = 49.47 MJ/kg

Natural P.C.S. = 37.78 MJ/m

Thermal power

kW (p.c.s.*)

By-Pass

1/100

Nozzle

1/100

Flow*

g/h

Nomin. Ridot. (mm) (mm) *** ** (mm)

Nominal (mbar)

Minimum (mbar)

3

37 **

25 **

45 **

28-30 ***

20 ***

35 ***

Nozzle

1/100

Flow*

20

17

25

l/h

SP SP

SP

TC

A

C 659 P X UK

5

Page 6

Technical Specifications

Mains frequency and voltage of the electric section and charac teristics of the gas secti on

Model Gas section Electric section

Class

C 659 P X UK II2H3+

(1) The values in g/h ref er to the c apaci ties with l iquid ga s (Butan e, Propan e).

Inner Dimensions of the Oven:

Width: 40 cm

Depth: 39 cm

Height: 34 cm

Inner Volume of the Oven:

53 Liters

Inner Dimensions of the Food Warmer:

Width: 43 cm

Depth: 43 cm

Height: 13.5 cm

Voltage and Frequency of Po wer Suppl y:

see data plate

Rated power

kW (1)

8,75 (636 g/h - G30)

(625 g/h - G31)

This appliance conforms with the following European

Economic Community directives:

- 73/23/EEC of 19/02/73 (Low V oltage) and subsequent

modifications;

- 89/336/EEC of 03/05/89 (Electromagnetic

Compatibility) and subsequent modifications;

- 90/396/EEC of 29/06/90 (Gas) and subsequent

modifications (only for models which use gas);

Voltage

240V~ 50Hz 2900W

Burners:

adaptable for use with all the types of gas indicated on

the data plate.

- 93/68/EEC of 22/07/93 and subsequent modifications.

6

Page 7

A

Cooker with the New "7 cuochi" Oven

B

E

K

G

F

A Tray f or Catching Overflows

B Gas Burners

C Electronic Lighting Device

D Top Grate

E Control Panel

F Adjustable Feet or Legs

G Dripping Pan or Baking Sheet

H Flame Failure De vice for Cooktop Burners

D

C

PO

L M Q N

K Oven Racks

L Selector Knob

M Thermostat Knob

N Control Knobs for Gas Burners on Hob

O Thermostat Light

P Green Light

Q The electronic cooking programmer

H

7

Page 8

How T o Use Y our Appliance

The various features of cooker are controlled through the

knobs and buttons located on the control panel

Control Knobs for the Gas Burners on the Hob (N)

The position of the gas burner controlled by each one of the

knobs is shown by a solid ring “•”. To light one of the burn-

ers, hold a lighted match or lighter near the burner and, at

the same time, press down and turn the corresponding knob

counter clockwise to the maximum setting. Each burner

can be operated at its maximum, minimum or intermediate

power. Sho wn on the knob are the different symbols for off

“•” (the knob is on this setting when the symbol corresponds

with the reference mark on the control panel), for maxim um

and minimum .

To obtain these settings, turn the knob counter clockwise

with respect to the off position. T o turn off the burner , turn the

knob clockwise until it stops (corresponding again with the

“•” symbol).

Electronic Ignition for the Gas Cooktop

Some models are fitted with electronic ignition built inside

the knob; in such cases, the ignition device “C” is present.

To light a specific burner push the corresponding knob all

the way in and turn it counter-clockwise to maximum

keeping it pressed down until the burner lights. Important:

Should the burner flames accidentally go out, turn off

the control knob and wait at least 1 minute before trying

to relight.

Models with Flame Failure Device

These models are identified by the presence of a flame detection device (see detail H).

Important: Since the top burners are equipped with a safety

device, after lighting the burner keep the knob pressed in

for about 6 seconds to allow the gas to pass until the safety

thermocouple is heated.

Gas Cut Off (only a few models)

This cooker has a safety cut out feature which switches

off the burners when you close the cover. This device is

provided as a safety f eature in case the cover is lowered

with the burners on. Alw ays turn off the gas and allow the

burners to cool before closing the cov er. Failure to follow

these instructions may cause the glass cover to shatter.

Keep the cover open when using the oven.

Attention: The first time you use the ov en w e recommend

that you set the thermostat on the highest setting and leave

the oven on for about a half of an hour with nothing in it.

Then, open the oven door and let the room air. The odour

that is often detected during this initial use is due to the evaporation of substances used to protect the oven during storage

and until it is installed.

Attention: Only use the bottom shelf of the oven when using

the rotisserie to cook (where present). F or all other types of

cooking, never use the bottom shelf and ne ver place anything

on the bottom of the oven when it is in operation because

this could damage the enamel. Always place your cookware

(dishes, aluminium foil, etc. etc.) on the grate pro vided with

the appliance inserted especially along the oven guides.

N.B.: Should the appliance be equipped with an electronic

programmer , to use the electric oven, just press buttons

and at the same time (the symbol will appear on the

display) before selecting the desired cooking function.

The Oven Control Knobs

The

7 Cuochi

convection ov ens with those of the more modern f orced air

ventilation models. It is an extremely versatile appliance that

allows you to easily and safely choose betw een 7 diff erent

cooking modes. The various features offered by the

“7 Cuochi” ov en are selected by means of the knobs located

on the control panel:

L - selector knob (identified by the symbol);

M - thermostat knob (identified by the symbol).

When the selector knob is on any other setting than that

identified by the “0”, symbol, the oven light turns on. The

setting identified by the symbol makes it possible to turn

the oven light on without having an y of the oven heating elements on.

1. Convection Mode

- Position of the “L” knob:

- Position of the “M ” knob: between 50°C and Max

On this setting, the light comes on and the top and bottom

heating elements are activated. This is the classic, tr aditional

type oven which Ariston has perfected, with e xceptional heat

distribution and reduced energy consumption. The convection oven is still unequalled when it comes to cooking dishes

made up of several ingredients , e.g. cabbage with ribs, stews ,

etc. Excellent results are achieved when preparing meatbased dishes as well (braised meats, stew, goulash, wild

game, ham etc.) which need to cook slowly and require basting or the addition of liquid. It still remains the best system f or

cooking pastries and fruit in general. When cooking in convection mode, only use one dripping-pan or cooking rack at

a time, otherwise the heat distribution will be uneven. Select

from among the various rack heights based on whether the

dish needs more or less heat from the top or bottom.

2. Pastry Mode

- Position of the “L” knob:

- Position of the “ M” knob: between 50° and Max

The fan will start and all of the heating elements will turn on.

This provides a delicate heating process with a prev alence

of heat from the bottom. This mode is ideal for baking and

cooking delicate foods - especially pastries that need to rise

because the heat coming from the bottom helps the leavening process. Some advice:

oven combines the adv antages of traditional

• Always preheat the oven;

• Never place more than one dish in the ov en at a time;

• The rack (unless cooking directly on the dripping-pan)

should be used because it allows for better air circulation; In any case, do not leave unused dripping-pans in

the oven;

• Position the rack at the third or second height from the

bottom in order to take full advantage of the heat rising

8

Page 9

from the bottom of the oven; Place the pastry pan in the

centre of the rack;

• Do not open the door when cooking pastries in order to

prevent rapid temperature changes that could impede

the cooking process and make the pastry drop.

3. Pizza Mode

- Position of the "L" knob:

- Position of the “M” knob: between 50°C and Max

The bottom and circular heating elements, as well as the

fan, will come on. This combination rapidly heats the oven

due to the large amount of power used by the appliance

(2900 W), which results in the production of considerable

heat coming prevalently from the bottom and from f orced air

circulation. The pizza mode is ideal for foods which need

high temperatures to cook, like pizza and large roasts. Use

only one dripping-pan or rack at a time. However, if more

than one is used, they must be switched half way through

the cooking process.

4. V entilation Mode

- Position of the “L” knob:

- Position of the “M” knob: between 50°C and Max

Both the heating elements and the fan will come on. Since

the heat remains constant and uniform throughout the oven

due to the fan at the bottom, the air cooks and browns f ood

uniformly over its entire surface. With this mode, you can

also cook various dishes at the same time, as long as their

respective cooking temperatures are the same. A maximum

of 2 rack lev els can be used at the same time , f ollowing the

instructions in the section entitled, "Cooking On More Than

One Rack". This cooking mode is ideal for au gratin dishes

or those which require an extended cooking time like lasagne etc...

Moreover , the excellent heat distribution makes it possible to

use lower temperatures when cooking roasts. This results in

less loss of juices, meat which is more tender and a decrease in the loss of weight for the roast. The v entilated mode

is especially suited for cooking fish, which can be prepared

with the addition of a limited amount of condiments, thus

maintaining their flavour and appearance . Excellent results

can also be attained when cooking vegetable-based side

dishes like cabbage, beats , courgettes, aubergines, peppers,

etc.

Desserts: leavened cakes are also perf ect f or the ventilated

mode. Moreo ver, this mode can also be used to thaw white

or red meat, fish and bread by setting the temperature to

80°-100°C. To thaw more delicate foods , set the thermostat

to 50°C or use only the cold air circulation feature by setting

the thermostat to 0°C.

5. Grill

- Position of the “L” knob:

- Position of the “ M” knob: Max

The central heating element of the grill will come on. The

incandescent heating element cooks food by means of thermal radiation directed downward. The extremely high and

direct temperature of the grill makes it possible to brown the

surface of meats and roasts while locking in the juices to

keep them tender . The grill is also highly recommended for

dishes that require high temperature on the surface: beef

steaks, veal, entrecôte, filets , hamburger etc...

6. Double Grill

- Position of the “L” knob :

- Position of the “M” knob : Max

This oversized grill has a completely new design, increasing

cooking efficiency by 50%. The double grill also eliminates

pockets of unheated air in the corners of the oven.

7. V entilated Double Grill

- Position of the “L” knob:

- Position of the “M” knob: betw een 50 and 200°C

This combination of features increases the eff ectiv eness of

the unidirectional thermal radiation of the heating elements

through forced air circulation of the air throughout the ov en.

This helps prevents foods from burning on the surface, allowing the heat to penetrate into the food. Excellent results

are achieved with k ebabs made with meats and vegetables,

sausages, ribs, lamb chops, chicken, quail, pork chops , etc.

This mode is also ideal for cooking fish steaks, like swordfish, tuna, grouper etc.

Note: All grill modes (features 5, 6 and 7) must be used with

the oven door closed.

Thermostat Light (O)

This light indicates that the oven is heating. When it turns off,

the temperature inside the oven has reached the setting made

with the thermostat knob. At this point, the light will turn on

and off as the oven maintains the temperature at a constant

level.

Green Light (P)

This light comes on when any of the electrical heating elements in the oven hav e been turned on.

Practical Advice on Using the Burners

In order to obtain the best performance, keep in mind the

following:

• Use the appropriate cookware for each burner (see ta-

ble) so that the flames do not extend be yond the bottom

of the cookware;

• Only flat bottom cookware should be used;

• At the boiling point, turn the knob to minimum;

• Always use a lid with the cookware .

Burner ø Cookware diameter (cm)

Auxiliary (A) 10 - 14

Semi-Fischburner (SP) 16 - 20

Ultrarapid (UR) 24 - 26

N.B. Some models are equipped with 2 reduction grids. These

grids should be used with the rear right and left “Half FishKettle” burners (Fig.A) and the auxiliary burner (Fig.B) when

cookware with a diameter of less than 12 cm is used.

Fig. A Fig. B

9

Page 10

3rd Oven Glass

In order to further decrease the temperature of the oven door

and reduce energy consumption, a supplemental kit has been

made available. This kit should be installed if the oven is

used in the presence of small children. To install the protective glass for the o ven door (code 053413), contact your nearest Merloni Eletrodomestici Service Centre indicated on the

list provided with the appliance.

Attention

Do not place cookware on the bottom of the oven because

this will result in uneven cooking as the bottom elements

would burn the food and the cookware impede proper circulation of the heated air. Furthermore, the curved surface of

the bottom (which ensures increased stiffness and resistance to deformation) does not provide a stable support surface.

Practical Advice on Using the Rear "Half Fish-Kettle"

Burners

The three rear burners, or Half Fish-Kettle b urners, are eliptic

in form and can be turned up to 90°. This makes the cooktop

more flexible in terms of how it can be used.

To rotate by 90° the “half fish-kettle” burners, proceed as

follows:

• Make sure that the burners are cool;

• Lift the burner completely out of its housing;

• Replace it in its housing in the position desired;

• Make sure that the burners are positioned correctly before

use.

In particular, the three rear burners may be used together or

separately with pots of different shapes and dimensions, as

follows:

• Single burner for medium size cookw are (diameter of

20-22 cm) (Fig. O).

• double burner as a “fish-kettle” for oval containers

and rectangular or square containers (minimum

dimensions 18x28 cm, maximum 18x35 cm) (Fig. P);

• triple burner or with the grill plate provided with the

appliance (Fig. Q).

Fig. Q

Practical tips for the use of the grill plate

The instructions that follow are valid for the use of the grill

plate that is supplied with the appliance.

The preheating should be carried out with the command

knobs for the three burners in the maximum position . T o

carry out cooking, use the position indicated in the table below.

Food Weight Preheating

time in

minutes

Kg knobs at

maxi mum

Pork chops

(3)

Beef chops

(2)

Sausages

(n°4)

Meat

kabobs (3)

Hamburgers (3)

Toast n°3 5 2-3 Maximum

Bread 3 slices 5 2-3 Maximum

Aubergines

Roast

tomatoes

Salmon 3 slices 5 5-7 Minimum

Chicke n

breast (3)

Note: cooking times are approximate and may vary in

accordance wi t h per s on al tas t es.

0,5-0,6 5 14-16 Minimum

0,5-0,6 5 12-14 Mini mum

0,4-0,5 5 16-18 Mini mum

0,4-0,5 5 14-16 Mini mum

0,4-0,5 5 10-12 Minimum

3-4

slices

4 slices 5 10-12 Minimum

0,4 5 6-8 Maximum

5 4-5 Maximu m

Time in

minutes

Cooking

Knob

position

Fig. O Fig. P

10

Page 11

The electronic cooking programmer

This feature allows you to program the oven or the grill as

follows :

• delay ed start for a specific length of time;

• immediate start for a specific length of time;

• timer .

Button Functions:

: timer - hours and minutes;

: cooking time;

: end cooking time;

: set cooking time - backward;

: set cooking time - forw ard.

How to reset the digital clock.

After the appliance has been connected to the power supply ,

or when the power has gone out, the clock display will

automatically reset to 0:00 and begin to blink.

• Press the and buttons consecutively and then

reset the time (within 4 seconds) using the and

buttons.

The button sets the time forward.

The button sets the time backward.

Whenever the time must be reset, f ollow this same procedure.

Manual Operation of the Oven

After resetting the time, the program automatically switches

to the manual mode.

Note: To reset the manual mode after each “automatic”

cooking, press the and buttons simultaneously .

Start delayed cooking with preset duration

The length of the cooking program as well as the time at

which the cooking program ends must be set. If we assume

that the time displayed on the timer is 10:00:

1. Turn the ov en control knobs to the feature and temper ature desired (e.g. conv entional ov en, 200°C);

4. After the button has been released, the current time will

be displayed after appro ximately 4 seconds:

A

The letter "A" will light up reminding you that the length

and end cooking time were programmed in automatic

mode. At this point, the ov en will turn on automatically at

12:30 and then turn off after 30 minutes. When the oven is

turned on, the symbol will be displayed for the entire

cooking time. At any time during the cooking process, the

length of the cooking time can be displayed b y pressing

the button, and the end cooking time by pressing the

button.

After the cooking time has expired, the timer will ring

for several minutes; to turn it off , simply press an y of

the buttons except the and buttons.

Immediate start with preset duration

By programming just the duration (points 1 and 2 of the

“Start delayed cooking with preset duration” section),

cooking will start up immediately.

T o cancel a cooking sc hedule already pr ogrammed

Press the and buttons simultaneously.

Timer Feature

The timer feature allows you to enter a giv en amount of time

from which the timer begins to count down. This f eature does

not turn the oven on or off; it merely sounds when the time

has expired.

When the button has been pressed, the display will

read as follows:

Then use the and buttons to set the desired time.

After the button has been released, the timer will start to

count down and the current time will be display ed.

2. Press the button and then set the cooking time (within

four seconds) using the and buttons. Let us sup-

pose that we set the cooking time at 30 minutes. The

display will read as follo ws:

A

After the button has been released, the current time will

be displayed again after appro ximately 4 seconds, along

with the symbol and the letter "A" (AUT O);

3. Press the button and then use the and

buttons to set the time for when the cooking program

should end. Let us suppose this time to be 1:00 p .m.

A

After the time has expired, an acoustical signal will be emitted,

which can be turned off by pressing any of the buttons (except

the and buttons) at this point the symbol will

also turn off.

Correction/Cancellation of Data

• The data entered can be changed at any time by pressing

the corresponding button and the or buttons.

• When the data for the length of the cooking time is

cancelled, the data for the end cooking time are also

cancelled automatically , and vice v ersa.

• If the ov en has been programmed, it will not accept end

cooking times which are before the start of the cooking

process.

11

Page 12

Practical Cooking Advice

The 7 cuochi oven off ers a wide range of alternatives which

allow you to cook any type of f ood in the best possible wa y .

The various features make it possib le to select the lev el of

heat and to direct it as you like: from the bottom, from above

or uniformly. With time you will learn to make the best use

of this versatile cooking appliance and the following directions are only a guideline which may be varied according

to your own personal experience.

Preheating

If the oven must be preheated (this is generally the case

when cooking leavened foods), the "pizza mode"

(setting three) can be used to reach the desired temperature as quickly as possible in order to sa ve on energy . Once

the food has been placed in the oven, the most appropriate cooking mode can then be selected.

Cooking on More Than One Rack

If you have to cook on more than one rack at the same

time, use only setting 4, “ventilated mode, ” which is the

only one that is appropriate for this type of cooking. The

rack heights used should be the three centre ones, as the

bottom and top racks receiv e too much direct heat, which

could burn more delicate foods. If three racks are used at

the same time, the food on the middle rac k will take a little

longer to cook. Therefore , leave it in the oven f or an additional few minutes. If you are preparing a complete meal

with all three racks at the same time, place the dish that

calls for a low er cooking temper ature (generally pastries)

on the middle rack.

Using the grill

The 7 cuochi oven off ers you three different grilling modes.

Use setting 5 “The Grill,” for small portions. Although

electrical consumption is a mere 1200 W, it allows you to

grill small portions like toasted sandwiches, hotdogs, etc.,

to perfection. P osition the food under the centre of the g rill

because only the central part of the top heating element is

turned on. Food placed in the corners will not cook prop-

erly. Setting 6 “The Double Grill”, allows you to grill

along the entire surface area of the grill. Use this mode

when you have food distributed uniformly throughout the

oven and you would like to brown the items uniformly.

Setting 7 “The Double V entilated Grill”, is e xtremely

useful for grilling foods rapidly, as the distribution of heat

makes it possible not only to brown the surf ace, b ut also to

cook the bottom part. It can also be used to grill large pieces

of meat or fowl without a rotisserie. Moreover, it can also

be used for browning f oods at the end of the cooking process.

Important: always use the grill with the oven door

closed. This will allow you both to attain excellent results and to save energy (about 10%). When using any

of the three grilling modes, it is recommended that the thermostat knob be turned to the highest setting, as it is the

most efficient way to use the grill (which utilizes infrared

rays). If necessary, however, the thermostat can be set to

lower temperatures by simply turning the knob to the desired setting. T o pre vent fat and grease from dripping onto

the bottom of the oven, place the dripping-pan beneath

the rack used for grilling.

Baking Pastries

When baking pastries, always place them in the ov en after

it has been preheated. Make sure you wait until the oven

has been preheated thoroughly (the red “O” light will turn

off). The temperature is normally around 160°C. Do not

open the door while the pastry is cooking in order to prevent it from dropping. Batters must not be too runny, as

this will result in prolonged cooking times. In gener al:

Pastry is too dry

Increase the temperature by 10°C and reduce the

cooking time.

Pastry dropped

Use less liquid or lower the temperature by 10°C.

Pastry is too da rk on t op

Place it on a lower rack, lower the temperature, and

increase the cooking t ime.

Cooked well on the inside but sticky on the outside

Use less liquid, l ower the temperature, and increas e the

cooking time.

The pastry sticks to the pan

Grease the pan well and sprinkl e it wit h a dusting of

flour.

I used more than one level and they are not all at

the same cooking point

Use a lower temperature setting. It is not necessary to

remove the food from all the racks at the same time.

Cooking Pizza

For best results when cooking pizza, use setting 3 “The

Pizza Oven”:

• Preheat the oven f or at least 15 min utes;

• Use a light aluminium pizza pan, placing it on the broiler

supplied with the oven. If the dripping-pan is used, this

will extend the cooking time, making it difficult to get a

crispy crust;

• Do not open the oven door frequently while the pizza is

cooking;

• If the pizza has a lot of toppings (three of four), it is

recommended that the mozzarella cheese be placed

on top halfway through the cooking process.

Cooking Fish and Meat

Meat must weigh at least 1 Kg in order to prevent it from

drying out. When cooking white meat, fowl and fish, use

low temperature settings (150°C-175°C). For red meat that

should be well done on the outside while tender and juicy

in the inside, it is a good idea to start with a high tempera-

12

Page 13

ture setting (200°C-220°C) for a short time, then turn the

oven down afterw ards. In general, the larger the roast, the

lower the temperature setting. Place the meat on the centre of the rack and place the dripping pan beneath it to

catch the fat. Mak e sure that the rac k is inserted so that it

is in the centre of the oven. If you would like to increase

the amount of heat from below, use the low rack heights.

Practical Cooking Advice

For sav oury roasts (especially duck and wild game), dress

the meat with lard or bacon on the top.

Selection

Knob Setting

1 Convection

Mode

2 Pastry Mode

3 Pizza Mode

4 Ventilation

Mode

Type of Food Wt.

Duck

Roast beef

Roast pork

Biscuits

Cakes

Pies

Pizza

Roast beef

Chicken

Pizza (several levels)

Lasagne

Baked Tagliatelle

Baked Pasta

Lamb

Chicken

Mackere l

Sea Bream

Chocolate cake

(Kg)

1

1

1

-

0.5

1

0.5

1

1

1

1

1

1

1

1

1

1.5

1

Rack Position

From Oven

Bottom

3

3

3

3

3

2/3

3

3

2/3

2/3

3

3

3

2

3

2

2

3

Preheating Time

(minutes)

15

15

15

15

15

15

15

10

10

15

10

10

10

10

15

10

10

10

Thermostat

Knob

Setting

200

200

200

160

180

180

220

200

180

220

180

180

180

180

200

180

180

160

Cooking

Time

(minutes)

65-75

70-75

70-80

15-20

20-30

45-50

15-20

45-55

60-70

15-20

30-35

20-30

20-30

40-45

60-70

50-55

55-60

50-60

5 Grill Mode

6 Double Grill

Mode

7 Double Grill

Ventilation

Mode

NB: cooking times are approximate and may vary according to personal taste.

Sole and squid

Calamari and shrimp

Kabobs

Cod fillets

Grilled vegetables

Veal steaks

Chops

Hamburgers

Mackerel

Grilled chicken

Stuffed cuttle-fish

1

1

1

1

1

1.5

1

1

1.5

1.5

4

4

4

3-4

4

4

3

4

2

2

5

5

5

5

5

5

5

5

5

5

Max

Max

Max

Max

Max

Max

Max

Max

200

200

8

4

10

8-10

15-20

25

7

20-25

55-60

40-45

13

Page 14

Routine Maintenance and Cleaning

Before each operation, disconnect the cooker from

the electrical supply. To ensure that the appliance lasts

a long time, it must be thoroughly cleaned frequently,

keeping in mind that:

· The enamelled parts and the self-cleaning panels are

washed with warm water without using any abrasive

powders or corrosive substances which could ruin

them;

· The inside of the oven should be cleaned fairly often

while it is still warm, using warm water and detergent

followed b y careful rinsing and drying;

· The flame spreaders should be washed frequently with

hot water and detergent, taking care to eliminate any

scale;

· In cookers equipped with automatic lighting, the

terminal part of the electronic instant lighting devices

should be cleaned frequently and the gas outlet holes

on the flame spreaders should be checked to make

sure they are free of any obstructions;

· Stainless steel may become marked if it comes into

contact with very hard water or harsh detergents

(containing phosphorous) for long periods of time. After

cleaning, it is advisable to rinse thoroughly and dry. It

is also recommended that drops of water be dried;

• It is recommended that the grill plate be cleaned when

it is still hot, using the knobs provided to move it from

the cooking rack to the sink. The grill plate should be

washed with non-abrasive detergent.

Replacing the Oven Lamp

· Disconnect the oven from the power supply by means

of the omnipolar switch used to connect the appliance

to the electrical mains; or disconnect the plug if it is

accessible;

· Remove the glass cover of the lamp-holder;

· Remove the lamp and replace with a lamp resistant to

high temperatures (300°C) with the following

characteristics:

- V oltage 240V

- W attage 25W

- Type E14

· Replace the glass cover and connect the oven to the

mains.

Greasing the Taps

The taps may jam in time or they ma y become difficult to

turn. If so, the y must be cleaned internally and the grease

replaced.

N.B.: This operation m ust be performed by a technician

authorised by the manufacturer .

· On models with glass covers, the covers should be

cleaned with hot water; the use of rough cloths or

abrasives is to be av oided.

N.B.: Avoid closing the cover while the gas burners

are still warm. Remo ve the grill plate (if present) before

closing the cover.

Important: per iodically check the wear of the gas hose

and substitute it if there are any defects; we recommended

changing it every year.

14

Page 15

15

Page 16

viale Aristide Merloni, 47 - 60044 Fabriano

tel. 0732/6611 - telex 560196 - fax 0732/662954

www .Merloni.com

Cucina 5 fuochi con forno "Nuovo 7 Cuochi" (GB)

01/02 - 195032906.00 Xerox Business Services - Docutech

Loading...

Loading...