Page 1

MAINTENANCE MANUAL

Site Master™ S820A

Antenna and Coax/Waveguide Analyzer

Interface

Serial

Battery

Charging

12V

External

(45C mA)

12-15V DC

Port

Test

Det

820A

1

START

CAL

3

SAVE

SETUP

5

LIMIT

7

SAVE

DISPLAY

9

ON

OFF

AUTO

SCALE

CAL

RECALL

SETUP

MARKER

RECALL

DISPLAY

PRINT

RF

2

ESCAPE

CLEAR

4

6

8

ENTER

0

RUN

HOLD

Figure 1. Site Master S820A

1. INTRODUCTION

This manual provides maintenance instructions for

the Site Master S820A Antenna and Coax/ Wave

guide Analyzer. It describes the product and provides

performance verification procedures, parts replace

-

ment procedures, and a replaceable parts list.

2. DESCRIPTION

The Site Master (Figure 1) is a hand held SWR/RL

(standing wave ratio/return loss) and Distance-ToFault measurement instrument. It combines a syn

thesized source, VSWR Bridge, and receiver on a

single printed circuit board (PCB). An optional

power monitor is also available. A block diagram is

shown in Figure 2.

3. PERFORMANCE VERIFICATION

Paragraphs 4 through 7 contain tests that can be

used to verify the performance of the Site Master

model S820A having any version of firmware.

3.1. Initial Setup for Testing

1. Press and hold the

then press the

ESCAPE/CLEAR key,

ON/OFF key to turn on the

Site Master. (This sets the instrument to

the factory preset state.)

2. Release the

ESCAPE/CLEAR key and use

the Up/Down Arrow key to adjust the

contrast to give a readable display.

490 JARVIS DRIVE ¨ MORGAN HILL, CA 95037-2809

P/N: 10580-00031

REVISION D

PRINTED: FEBRUARY 2003

COPYRIGHT 1999-2003 ANRITSU CO.

Page 2

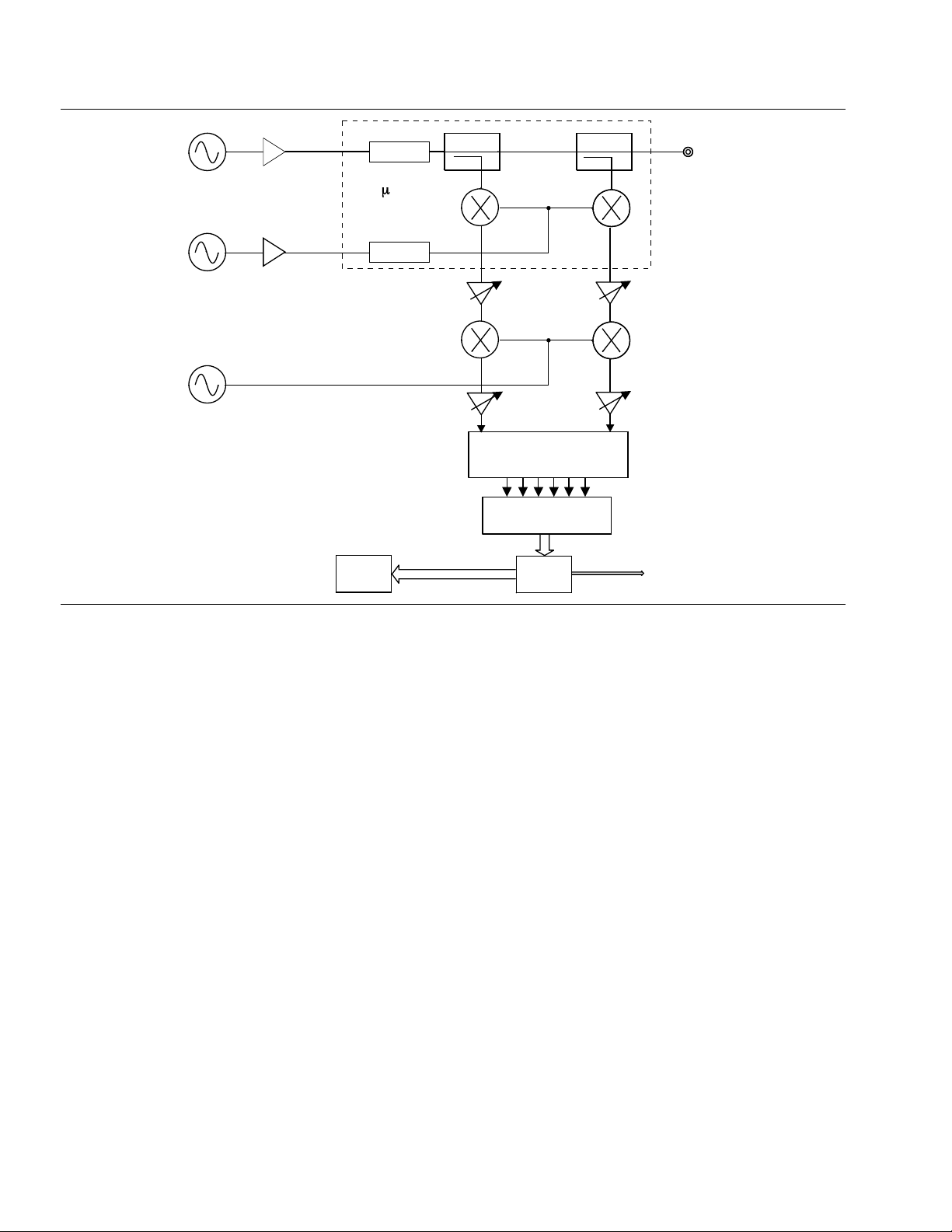

RF

Source

Local

Oscillator

Multiplier

Wave

Module

Multiplier

Coupler Coupler

Test

Port

Incident

Local

Oscillator

Display

Figure 2. Site Master Block Diagram

4. FREQUENCY ACCURACY

The following test can be used to verify the CW frequency accuracy of the Site Master. Measurement

calibration of the Site Master is not required for this

test.

a. Equipment Required:

Reflected

Synchronous

Detector

A/D Converter

CPU

3. Press the

press the

4. Press the

press the

Serial

Port

F1 soft key, set to 9 GHz, then

ENTER key.

F2 soft key, set to 9 GHz, then

ENTER key.

5. Connect the RF cable from the Site Mas

ter Test Port to the RF Input on the

MS2602A.

-

·

Spectrum Analyzer

Anritsu Model MS2602A

b. Procedure:

6. Set up the Spectrum Analyzer as follows:

(a) Press Preset.

(b) Press Center and enter 1 GHz.

(c) Press the Max Hold button.

1. Press and hold the

then press the

Site Master. (This sets the instrument to

the factory preset state.)

ESCAPE/CLEAR key,

ON/OFF key to turn on the

7. If the Site Master has gone into the hold

mode, press the

RUN/HOLD key to make

the measurement.

8. Use the Spectrum Analyzer marker to

NOTE

Before continuing, allow a five

measure the center of the response. The

frequency should be 1 GHz ±75 kHz.

minute warm up for the internal

circuitry to stabilize.

NOTE

Nominal power is approximately

2. Press the

FREQ soft key.

0 - 10 dBm at 1 GHz.

2 Site Master S820A MM

Page 3

5. RETURN LOSS VERIFICATION

The following test can be used to verify the accuracy

of return loss measurements. Verification is per

formed by measuring the Source Match and Cor

-

rected Directivity. This method eliminates the uncer

tainties of measuring standard offset. Measurement

calibration of the Site Master is required for this

test.

Refer to the RF Measurement Chart on page 12, and

the Return Loss Verification worksheet on page 13.

8. Use the RF Measurement Chart to corre

late the peak-to-peak ripple reading to a

return loss value in dB. The measured

value should be:

£ –18 dB (3.3 - 10.5 GHz)

-

£ –14 dB (10.5 - 20 GHz).

9. Remove the 22KF50 Open / Short.

10. Connect the 29KF50-15 Precision Offset

Termination to the open end of the air

-

line.

11. Press the

AUTOSCALE key.

a. Equipment Required:

19K50 Precision Airline

·

22KF50 Open / Short

·

22K50 Open / Short

·

29KF50-15 Precision Offset Termination

·

· 28K50 Precision Termination

b. Procedure:

1. Press and hold the

then press the

ESCAPE/CLEAR key,

ON/OFF key to turn on the

Site Master. (This sets the instrument to

the factory preset state.)

NOTE

Before continuing, allow a five

minute warm up for the internal

circuitry to stabilize.

2. Perform an OSL calibration over the fre

quency range of the unit using the 22K50

Open/Short and the 28K50 Precision Ter

mination. Verify that noise spikes are be

low 44 dB and that the trace is smooth.

Repeat as required.

12. Measure and record the worst case

peak-to-peak ripple.

13. Add this value to the mean value of the

29KF50-15 Precision Offset Termination.

14. Use the RF Measurement Chart to corre

late the reading to a return loss value in

dB. The measured value should be:

£ –29 dB (3.3 - 20 GHz).

15. Remove the airline and Precision Offset

Termination.

-

-

-

3. Remove the 28K50 Termination.

4. Connect a 19K50 Precision Airline to the

test port.

5. Connect a 22KF50 Open / Short to the

open end of the airline.

6. Press the

AUTOSCALE key.

7. Measure and record the worst case

peak-to-peak ripple.

Site Master S820A MM 3

Page 4

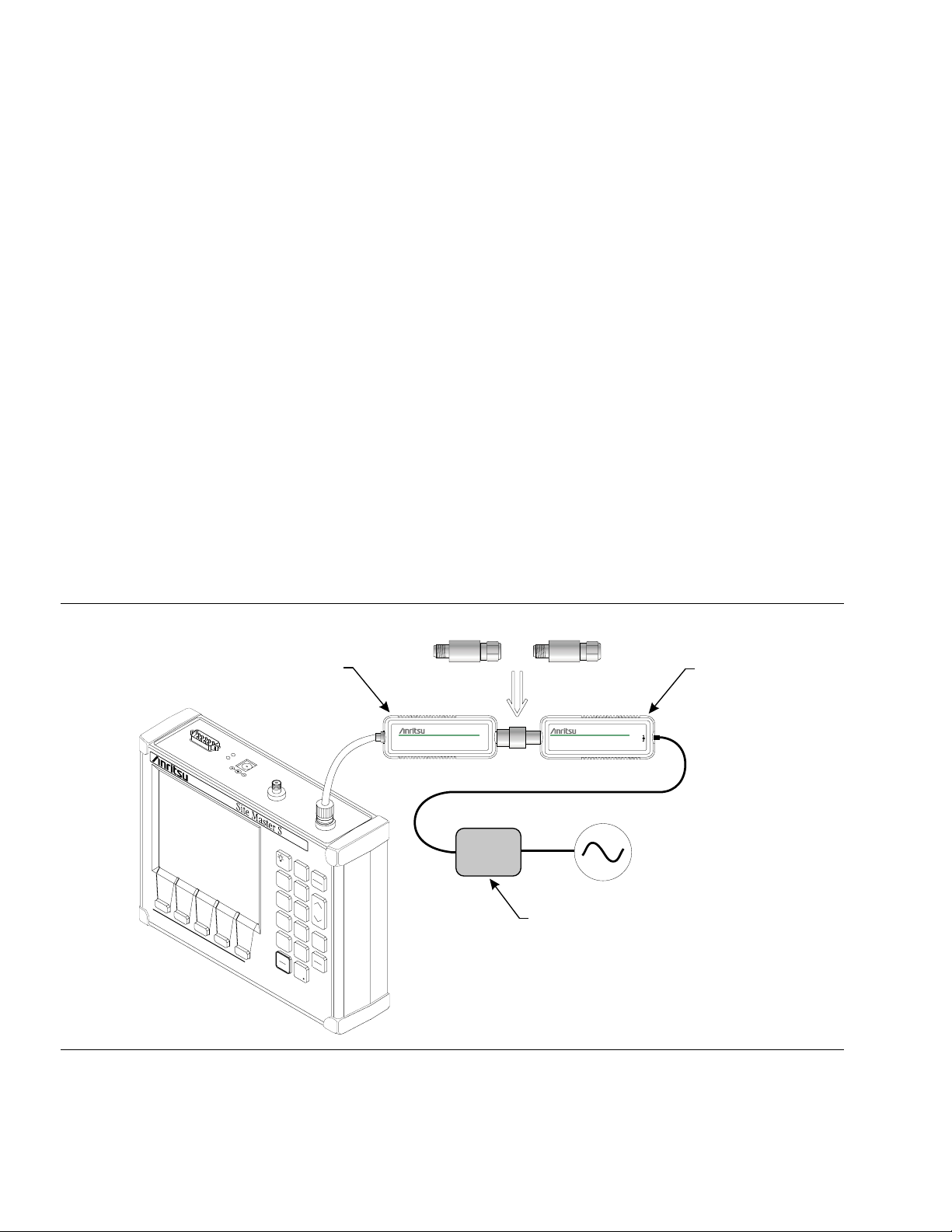

6. POWER MONITOR VERIFICATION

If the Power Monitor (Option 5) is installed in the

Site Master, the following test can be used to verify

the accuracy of the power measurements. Measure

ment calibration of the Site Master is not required

for this test.

a. Equipment Required:

2. Connect the MA2418A Reference Source

to the input of the 560-7N50B RF detec

-

tor.

-

3. Connect the RF Detector output to the

RF Detector input of the Site Master.

4. Connect the DC power supply to the ap

propriate line voltage to supply power to

the MA2418A Reference Source.

RF Detector, 10 MHz to 20 GHz,

·

Anritsu 560-7N50B

10 dB Attenuator, Weinshel 1R-10

·

30 dB Attenuator, Weinshel 1R-30

·

RF Reference Source, 0.050 GHz,

·

Anritsu MA2418A

DC Power Supply, Anritsu 2000-933

·

b. Procedure

1. Connect the DC power supply to the

MA2418A Reference Source. (Refer to

Figure 3.)

560-7N50B

RF Detector

Interface

Serial

12V

External

Charging

Battery

(45C mA)

12-15V DC

Port

Test

820A

5. Press and hold the

then press the

ESCAPE/CLEAR key,

ON/OFF key to turn on the

Site Master. (This sets the instrument to

the factory preset state.)

6. Press the

MODE soft key.

7. Use the Up/Down Arrow key to highlight

POWER MONITOR, then press ENTER.

8. Press the

ZERO soft key to zero the power

monitor.

When complete,

ZERO ADJ:ON is dis

-

played in the message area.

9. Verify that the power monitor reading is

0.0 dBm ±1 dB.

Attenuators

MA2418A

Reference Source

MA2418AReference Source

W

50MHz, 50

0dBm

Det

RF

20mA

15-24VDC

AUTO

SCALE

1

START

CAL

2

ESCAPE

CLEAR

CAL

3

SAVE

SETUP

4

RECALL

SETUP

5

LIMIT

6

MARKER

7

SAVE

DISPLAY

8

ENTER

RECALL

DISPLAY

9

0

RUN

ON

HOLD

OFF

PRINT

2000-933 DC Power Supply

Site Master w/ Option 5 Installed

Figure 3. Power Monitor Verification

4 Site Master S820A MM

Page 5

10. Connect the output of the MA2418A Ref

erence Source to the two attenuators so

as to add 40 dB of attenuation (Figure 3).

11. Connect the MA2418A Reference Source

and the attenuators to the input of the

560-7N50B RF detector.

-

b. Procedure

1. Connect the test equipment as shown in

Figure 3.

2. Press the Power key on the 541XXA to

On.

12. Verify that the power monitor reading is

now –40.0 dBm ±2 dB.

7. TERMINATION VERIFICATION

This test can be used to verify the accuracy of termi

nations used with the Site Master. The test uses the

precision return loss mode of the 541XXA Scalar

Measurement System. Measurements of termina

tions using this mode provide results that are trace

able to the NIST (National Institute of Standards

and Technology) standards for the precision airline.

a. Equipment Required:

· Scalar Measurement System,

Anritsu 54161A/69A

· Offset SWR Autotester,

Anritsu 560-98KF50-15

· Precision Airline, Anritsu 19KF50

· Open/Short, Anritsu 22K50

· 50 Ohm Termination, Anritsu 28K50

·

Source Adapter, Anritsu K220B

3. Press the System Menu key.

4. Using the Menu up-down keys: Highlight

RESET, then press the Select key.

5. At the RESET MENU display, use the

-

Menu up-down keys to highlight

RESET TO FACTORY DEFAULTS, then

press the Select key.

-

6. Set the signal source for the frequency

range as follows:

(a) Press the Frequency key.

(b) Using the Data Entry Keypad or

Data Entry Knob, set the START fre

quency to 0.01 GHz. Press the Enter

key.

(c) Using the Data Entry Keypad or

Data Entry Knob, set the STOP frequency to 20.0 GHz. Press the Enter

key.

7. Press the Channel 2 Display On/Off key

to Off.

8. Press the Channel 1 Menu key.

Open/Short

50 Ohm

Termination

541XXA Scalar Measurement System

B

A

Source

Adapter

Figure 4. 541XXA Precision Return Loss TestSetup

Precision

Air Line

Termination

under Test

Beadless

End

Offset SWR

Autotester

Connect Dashed Line Connections

When Directed By Procedure

Site Master S820A MM 5

Page 6

9. Using the Menu up-down keys: Highlight

10.0 dB/DIV OFFSET1: PRECSN RL (A)

2: OFF

+0.0dB

2 GHz/DIV

START: 0.0100 GHz

401 pts

STOP: 20.0000 GHz

LEVEL +7.0 dBm

54147A

PRECISION

RETURN LOSS

CALIBRATION

CONNECT OPEN

TO AIRLINE

PRESS SELECT

WHEN READY

1

10.0 dB/DIV OFFSET1: PRECSN RL (A)

2: OFF

+0.0dB

2 GHz/DIV

START: 0.0100 GHz

401 pts

STOP: 20.0000 GHz

LEVEL +7.0 dBm

54147A

CURSOR

1: -46.02 dB

PRESS SELECT

FOR

CURSOR MENU

10.0050 GHz

1

PRECISION RL, then press the Select

key.

10. At the PRECISION RETURN LOSS

menu display, use the Menu up-down

keys to highlight FINAL, then press the

Select key.

11. Press the Calibration key.

12. At the CALIBRATION menu display, use

the Menu up-down keys to highlight

START CAL, then press the Select key.

13. At the PRECISION RETURN LOSS

CALIBRATION menu display prompt,

connect the Offset SWR Autotester to

Input A, if you have not done so yet.

14. Connect the precision air line to the Off

set SWR Autotester test port. Position

the air line pointing vertically upward.

Downward or horizontal positions make

connector pin alignment difficult.

NOTE

Ensure that the beadless end of

the precision airline is at the

measurement connection point.

Press the Select key to start the calibra

tion process.

Figure 5. Example of a Good Connection

-

20. When the calibration is complete, remove

the 50 Ohm Termination.

21. Connect the Termination under Test to

the beadless end of the air line and press

the Select key to begin the measurement.

22. Observe that the waveform displayed resembles that shown in Figure 6.

-

15. Press the Select key when ready.

16. At the PRECISION RETURN LOSS

CALIBRATION menu prompt, connect

the Open to the beadless end of the air

line. Press the Select key to start the

calibration.

17. Verify that the display resembles that

shown in Figure 5.

CAUTION

During both calibration and mea

surement, be sure to properly

align the beadless connector of the

airline. When the connectors are

mis-aligned, a spike will usually

be visible on the display.

18. At the next menu prompt, remove the

19. At the next menu prompt, remove the

Open and connect the Short to the

beadless end of the airline. Press the Se

lect key to start the calibration process.

Short and connect the 50 Ohm Termina

tion to the beadless end of the air line.

-

-

Figure 6. Direct Readout of the Precision Return Loss

23. Press the Cursor On/Off key to On.

24. Observe the CURSOR menu readout for

the return loss reading. The minimum

-

return loss reading for the 28K50 termi

nator should be:

£ –34 dB (3.3 - 18.5 GHz)

-

£ –29 dB (18.5 - 20 GHz).

6 Site Master S820A MM

Page 7

8. BATTERY PACK REMOVAL

This procedure provides instructions for removing

the battery pack. Refer to Figure 7 during this proce

dure.

1. Place the Site Master face up on a work sur

face.

2. Remove the four corner rubber bumpers (1).

5. Remove the bottom half (5) and fold it over to

lay upside down on the work surface.

-

6. Disconnect the red/black cable of the battery

pack from J6 (6) of the Main RF PCB assem

-

bly (3).

-

7. Remove the four screws (7) holding the bat

tery bracket (8) in place and lift the bracket

clear.

3. Remove the four screws (PN 900-811) (2).

4. While holding the two halves of the Site Mas

ter together, turn it over and set it face down

on the work surface.

CAUTION

In the next step, the Main RF PCB

assembly (3) and test port panel (4)

must stay with the front panel.

9

Detail A

8

8. Remove the battery assembly (9).

-

5

7(4Places)

6

3

10

Raised

Wedge

2(4Places)

N274

Power

External

Interface

Serial

Charging

Battery

(850mA)

12.5-15VDC

Ports

Tes t

Det

RF

4

1(4Places)

Figure 7. Site Master Battery Removal

Site Master S820A MM 7

Page 8

9. BATTERY PACK REPLACEMENT

10. BATTERY DISPOSAL

This procedure provides instructions for replacing

the battery pack. Refer to Figure 7 during the proce

dure.

1. Install the new battery assembly (9).

2. Replace the battery bracket (8) and insert

the four screws (7) to hold the battery

bracket in place.

3. Reconnect the red/black cable of the battery

pack battery to J6 (6) on the main RF PCB

assembly (3).

4. Set the bottom half in place.

5. While holding the two halves together, turn

the Site Master over and lay it face up on the

work surface.

6. Reinstall the four screws (2).

7. Install the rubber bumpers (1) on all four

corners of the instrument.

The battery used in the Site Master is a recharge

able nickel-cadmium (NiCd) battery and is covered

by the Battery Directive (91/157/EEC). As such, the

battery is marked as follows to indicate controlled

disposal.

This marking indicates that

the battery is a recyclable

product.

This marking indicates that

the battery requires separate

collection and shows the

chemical system (Nickel/

Cadmium).

Component

Nickel 19 to 26%

Cadmium 17 to 22%

% of Cell

Weight

This marking indicates the

heavy-metal component

concentration as a percentage

of battery cell weight.

Spent nickel-cadmium batteries are valuable resources. Because they are reusable, do not throw

them away. Arrange for proper return for recycling

in your locality. If you do not have access to proper

disposal methods, return the battery pack to your

Anritsu service center. Service centers will dispose of

the unit at no charge. Anritsu Service Centers are

listed on page 14 of this manual.

-

8 Site Master S820A MM

Page 9

11. KEY PAD MEMBRANE REPLACEMENT

12. LCD REPLACEMENT

This procedure provides instructions for replacing

the key pad membrane. Refer to Figure 7 (page 7)

during this procedure.

1. Place the Site Master face up on a work sur

face.

2. Remove the four corner rubber bumpers (1).

3. Remove the four screws (PN 900-811) (2).

4. While holding the two halves of the Site Mas

ter together, turn it over and set it face down

on the work surface.

CAUTION

In the next step, the PCB Assy (3)

and test port panel (4) must stay

with the front panel.

5. Remove the bottom half (5) and fold it over to

lay upside down on the work surface.

6. Disconnect the red/black cable of the battery

pack from the main PCB assembly connector

J6 (6).

This procedure provides instructions for replacing

the Liquid Crystal Display (LCD). Refer to Figure 7

(page 7) during this procedure.

-

-

1. Place the Site Master face up on a work sur

face.

2. Remove the four corner rubber bumpers (1).

3. Remove the four screws (PN 900-811) (2).

4. While holding the two halves of the Site

Master together, turn it over and set it face

down on the work surface.

CAUTION

In the next step, the PCB Assy (3)

and test port panel (4) must stay

with the front panel.

5. Remove the bottom half (5) and fold it over to

lay upside down on the work surface.

6. Disconnect the red/black cable of the battery

pack from the main PCB assembly connector

J6 (6).

-

7. Remove the screw (10) located on the bottom

side of the main PCB assembly next to the

RF Bridge assembly .

8. Pull the PCB assemblies clear from the top

half of the case.

9. Lift the keypad membrane clear from the

keypad assembly.

10. Install a new membrane.

NOTE

Carefully use pliers to pull the rub

ber tabs tight to ensure that the

membrane is flush with the PCB.

11. Reverse the above procedure to re-assemble

the Site Master.

-

7. Remove the screw (10) located on the bottom

side of the main PCB assembly next to the

RF Bridge assembly .

8. Pull the PCB assemblies clear from the top

half of the case.

9. Remove the grey/brown cable of the LCD as

sembly from the main PCB assembly connec

tor J8.

10. Remove the four screws from the LCD PCB

assembly.

11. Carefully remove the 20-way ribbon cable

from the connector on the keypad PCB as

sembly.

12. Install the new LCD PCB assembly. Use

thread locker on the LCD mounting screws.

13. Reverse the above procedure to re-assemble

the Site Master.

-

-

-

Site Master S820A MM 9

Page 10

13. MAIN PCB AND RF MODULE ASSEMBLY

REPLACEMENT

12. Remove the four standoffs and the EMI

shield cloth.

This procedure provides instructions for replacing

the main PCB and RF module assembly. Refer to

Figure 7 (page 7) during this procedure.

NOTE

The test port panel is replaced as

part of the main PCB assembly.

1. Place the Site Master face up on a work sur

face.

2. Remove the four corner rubber bumpers (1).

3. Remove the four screws (PN 900-811) (2).

4. While holding the two halves of the Site

Master together, turn it over and set it face

down on the work surface.

CAUTION

In the next step, the PCB Assy (3)

and test port panel (4) must stay

with the front panel.

5. Remove the bottom half (5) and fold it over to

lay upside down on the work surface.

NOTE

If the Power Monitor (Option 5) is in

stalled, remove the two screws hold

ing the Option 5 PCB assembly to

the test port panel and unsolder the

wires from pins 1 through 4 of the RF

Detector connector on the test port

panel.

-

13. Carefully remove the serial number from the

test port panel.

14. Install the serial number on the replacement

test port panel.

15. Reverse the above procedure to re-assemble

the Site Master.

-

-

6. Disconnect the red/black cable of the battery

pack from the main PCB assembly connector

J6 (6).

7. Remove the screw (10) located on the bottom

side of the main PCB assembly next to the

RF Bridge assembly.

8. Pull the PCB assemblies clear from the top

half of the case.

9. Disconnect the grey/brown cable of the LCD

assembly from the main PCB assembly con

nector J8.

10. Remove the four screws holding the LCD as

sembly, but do not disconnect the 20-way

connector from the keypad PCB assembly.

11. Use pliers to gently squeeze the nine plastic

spacer heads to release them from the Key

pad PCB assembly and carefully pull the

Keypad PCB with the LCD assembly from

the main PCB assembly.

-

-

-

10 Site Master S820A MM

Page 11

14. REPLACEABLE PARTS

Replaceable parts for the Site Master are listed in

Table 1.

Table 1. Parts List

Part Number Description Qty

Accessories

10580-00030

10580-00007

2300-347 Software Tools, Site Master 1

40-115 Power Supply 1

806-62 Cable Assy, Cig Plug, Female 1

800-441 Serial Interface Cable Assy 1

D41955 Carrying Case 1

B42893 EMI Shield 1

C41761 Liquid Crystal Display Assy 1

ND45417 Battery Pack Kit 1

ND52636

D41766-3 Keypad PCB Assy 1

D40864-2 Membrane Keypad, Main 1

C41767 Membrane, Soft Keys 1

User's Guide, Site Master

S820A

Battery Replacement and

Disposal Guide

Replaceable Parts

Main PCB Assy,S820Awith

mwave module and cables

Part Number Description Qty

Hardware

1

1

1

790-171 Silicon Pad 1

761-10

790-52 Washer, #4, Shoulder, Nylon 1

900-257 Pan Head Screw, 0.312 4

790-445 Spacer PCB, 0.625, Self Mount 9

900-800 Pan Head Screw, #4, 0.312 1

900-811 Pan Head Screw, #4 4

900-326 Nut, Kep, 4-40, 0.312 4

900-697 Pan Head Screw, 4-40, 0.312 3

900-138

B41753 Gasket, LCD 1

D40861-3 Case 1

C40863 Bumper 4

B48182 ID Label, Model S820A 1

Cap Vinyl, Black, round, 0.625

ID

Screw, Pan, 2-56/patchlock,

0.18

Case Parts

1

4

Site Master S820A MM 11

Page 12

Table 2. RF Measurement Chart

(1 + X)

X

(REF)

PHASOR

INTERACTION

(1 - X)

Conversion tables for Return Loss, Reflection Coefficient, and SWR with tabular values for inter

action of a small phaser x with a large phaser (unity reference) expressed in dB related to refer

ence.

Relative to Unity Reference

SWR Reflection

Coefficient

17.3910

8.7242

5.8480

4.4194

3.5698

3.0095

2.6146

2.3229

2.0999

1.9250

1.7849

1.6709

1.5769

1.4935

1.4326

1.3767

1.3290

1.2880

1.2528

1.2222

1.1957

1.1726

1.1524

1.1347

1.1192

1.1055

1.0935

1.0829

1.0736

1.0653

1.0580

1.0515

1.0458

1.0407

1.0362

1.0322

1.0287

1.0255

1.0227

1.0202

1.0180

1.0160

1.0143

1.0127

1.0113

1.0101

1.0090

1.0080

1.0071

1.0063

1.0057

1.0050

1.0045

1.0040

1.0036

1.0032

1.0028

1.0025

1.0022

1.0020

0.8913

0.7943

0.7079

0.6310

0.5623

0.5012

0.4467

0.3981

0.3548

0.3162

0.2818

0.2512

0.2239

0.1995

0.1778

0.1585

0.1413

0.1259

0.1122

0.1000

0.0891

0.0794

0.0708

0.0631

0.0562

0.0501

0.0447

0.0398

0.0355

0.0316

0.0282

0.0251

0.0224

0.0200

0.0178

0.0158

0.0141

0.0126

0.0112

0.0100

0.0089

0.0079

0.0071

0.0063

0.0056

0.0050

0.0045

0.0040

0.0035

0.0032

0.0028

0.0025

0.0022

0.0020

0.0018

0.0016

0.0014

0.0013

0.0011

0.0010

Return

Loss

(dB)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

X

dB

Below

Refer

ence

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

REF+XdBREF–XdBREF ± X

-

5.5350

5.0780

4.6495

4.2489

3.8755

3.5287

3.2075

2.9108

2.6376

2.3866

2.1567

1.9465

1.7547

1.5802

1.4216

1.2778

1.1476

1.0299

0.9237

0.8279

0.7416

0.6639

0.5941

0.5314

0.4752

0.4248

0.3796

0.3391

0.3028

0.2704

0.2414

0.2155

0.1923

0.1716

0.1531

0.1366

0.1218

0.1087

0.0969

0.0864

0.0771

0.0687

0.0613

0.0546

0.0487

0.0434

0.0387

0.0345

0.0308

0.0274

0.0244

0.0218

0.0194

0.0173

0.0154

0.0138

0.0123

0.0109

0.0097

0.0087

–19.2715

–13.7365

–10.6907

–8.6585

–7.1773

–6.0412

–5.1405

–4.4096

–3.8063

–3.3018

–2.8756

–2.5126

–2.2013

–1.9331

–1.7007

–1.4988

–1.3227

–1.1687

–1.0337

–0.9151

–0.8108

–0.7189

–0.6378

–0.5661

–0.5027

–0.4466

–0.3969

–0.3529

–0.3138

–0.2791

–0.2483

–0.2210

–0.1967

–0.1751

–0.1558

–0.1388

–0.1236

–0.1100

–0.0980

–0.0873

–0.0778

–0.0693

–0.0617

–0.0550

–0.0490

–0.0436

–0.0389

–0.0346

–0.0309

–0.0275

–0.0245

–0.0218

–0.0195

–0.0173

–0.0155

–0.0138

–0.0123

–0.0109

–0.0098

–0.0087

Peak to

Peak

Ripple

dB

24.8065

18.8145

15.3402

12.9073

11.0528

9.5699

8.3480

7.3204

6.4439

5.6884

5.0322

4.4590

3.9561

3.5133

3.1224

2.7766

2.4703

2.1986

1.9574

1.7430

1.5524

1.3828

1.2319

1.0975

0.9779

0.8714

0.7765

0.6919

0.6166

0.5495

0.4897

0.4365

0.3890

0.3467

0.3090

0.2753

0.2454

0.2187

0.1949

0.1737

0.1548

0.1380

0.1230

0.1096

0.0977

0.0871

0.0776

0.0692

0.0616

0.0549

0.0490

0.0436

0.0389

0.0347

0.0309

0.0275

0.0245

0.0219

0.0195

0.0174

-

-

12 Site Master S820A MM

Page 13

Source Match

Peak-to-Peak Ripple:

Return Loss Value:

Corrected Directivity

Peak-to-Peak Ripple:

Return Loss Value:

Sum of RLVand mean

(should be £ 32 dB):

RETURN LOSS VERIFICATION WORKSHEET

Site Master S820A MM 13

Page 14

Table 3. Anritsu Service Centers

UNITED STATES

ANRITSU COMPANY

685 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

FAX: 408-776-1744

ANRITSU COMPANY

10 NewMaple Ave., Suite 305

Pine Brook, NJ 07058

Telephone: 973-227-8999

FAX: 973-575-0092

ANRITSU COMPANY

1155E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo 440. Sala 2401

CEP22250-040,Rio de Janeiro,RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

700 Silver Seven Road, Suite 120

Kanata, Ontario K2V 1C3

Telephone: (613) 591-2003

FAX: (613) 591-1006

CHINA (SHANGHAI)

ANRITSU ELECTRONICS CO LTD

2F,Rm.B, 52 Section Factory Bldg.

NO 516 Fu Te Road (N)

Waigaoqiao Free Trade Zone

Pudong, Shanghai 200131

PR CHINA

Telephone: 86-21-58680226

FAX: 86-21-58680588

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf

Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES (P) LTD

A-23 Hauz Khas

New Delhi, India 110 016

Telephone: 011-685-3959

FAX: 011-686-6720

ISRAEL

TECH-CENT, LTD

4 Raul ValenbergSt.

Tel-Aviv, Israel 69719

Telephone: 972-36-478563

FAX: 972-36-478334

ITALY

ANRITSU Sp.A

Rome Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-2299-711

FAX: 06-50-22-4252

JAPAN

ANRITSU CUSTOMER SERVICE LTD.

1800 Onna Atsugi—shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

KOREA

ANRITSU SERVICE CENTER

8F Hyunjuk-Bldg, 832-41

Yeoksam-Dong

Kangnam-Gu

Seoul, 135-080, Korea

Telephone: 82-2-553-6603

FAX: 82-2-553-6605

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD

10, Hoe Chiang Road

#07-01/02

Keppel Towers

Singapore 089315

Telephone:65-282-2400

FAX:65-282-2533

SOUTH AFRICA

ETESCSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

Fax: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botvid Center

Fittja Backe 13A

145 84

Stockholm, Sweden

Telephone: (08) 534-707-00

FAX: (08)534-707-30

TAIWAN

ANRITSU COMPANY

7F, NO.316, Sec.1,

Nei Hu Road

Taipei, Taiwan, R.O.C.

Telephone: 886-2-8751-2126

FAX: 886-2-8751-1817

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-43-3200

FAX: 015-82-73-1303

14 Site Master S820A MM

Page 15

NOTES

Page 16

Loading...

Loading...