Page 1

User Guide

Site Master Cable and Antenna Analyzer with Spectrum Analyzer

S331E, 2 MHz to 4 GHz

S332E, 2 MHz to 4 GHz, Spectrum Analyzer, 100 kHz to 4 GHz

S361E, 2 MHz to 6 GHz

S362E, 2 MHz to 6 GHz, Spectrum Analyzer, 100 kHz to 6 GHz

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

Part Number: 10580-00252

Published: January 2010

Copyright 2009 Anritsu Company

Revision: B

Page 2

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for one year from the date of shipment.

Anritsu’s obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to Anritsu for

warranty repairs. Obligation is limited to the original purchaser. Anritsu is not liable for consequential

damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear. Also,

the warranty does not apply to defects resulting from improper or inadequate maintenance by the

Buyer, unauthorized modification or misuse, or operation outside of the environmental specifications of

the product. No other warranty is expressed or implied, and the remedies provided herein are the

Buyer’s sole and exclusive remedies.

DISCLAIMER OF WARRANTY

DISCLAIMER OF WARRANTIES. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE

LAW, ANRITSU COMPANY AND ITS SUPPLIERS DISCLAIM ALL WARRANTIES, EITHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WITH REGARD TO THE

SOFTWARE PRODUCT. THE USER ASSUMES THE ENTIRE RISK OF USING THE PROGRAM.

ANY LIABILITY OF PROVIDER OR MANUFACTURER WILL BE LIMITED EXCLUSIVELY TO

PRODUCT REPLACEMENT.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES . TO THE MAXIM UM EX TENT PERMIT TED BY

APPLICABLE LAW, IN NO EVENT SHALL ANRITSU COMPANY OR ITS SUPPLIERS BE LIABLE

FOR ANY SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGE S WHATSOEVER

(INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS,

BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMAT ION, OR ANY OTHER PECUNIARY

LOSS) ARISING OUT OF THE USE OF OR INABILITY TO USE THE SOFTWARE PRODUCTS,

EVEN IF ANRITSU COMPANY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAM AGES.

BECAUSE SOME STATES AND JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR IN CIDENTAL DAMAGES, THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

TRADEMARK ACKNOWLEDGMENTS

VxWorks is a registered trademark, and WindML is a trademark of Wind River Systems, Inc.

BTS Master

is a trademark of Anritsu Company.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers as a

guide for the proper installation, operation and maintenance of Anritsu Company equipment and

computer programs. The drawings, specifications, and information contained herein are the property of

Anritsu Company, and any unauthorized use or disclosure of these drawings, specifications, and

information is prohibited; they shall not be reproduced, copied, or used in whole or in part as the basis

for manufacture or sale of the equipment or software programs without the prior written consent of

Anritsu Company.

UPDATES

Updates, if any, can be downloaded from the Documents area of the Anritsu Website at:

http://www.us.anritsu.com

For the latest service and sales contact information in your area, please visit:

http://www.anritsu.com/contact.asp

Page 3

Page 4

Page 5

CE Conformity Marking

VxWorks Runtime WindML Target License

NI Device License

2000-1421

License 2000-1189

3-2000-1486

WindRiver USB Runtime License

2000-1372

Anritsu affixes the CE Conformity marking onto its conforming products in accordance with

Council Directives of The Council Of The European Communities in order to indicate that

these products conform to the EMC and LVD directive of the European Union (EU).

C-tick Conformity Marking

Anritsu affixes the C-tick marking onto its conforming products in accordance with the

electromagnetic compliance regulations of Australia and New Zealand in order to indicate

that these products conform to the EMC regulations of Australia and New Zealand.

Notes On Export Management

This product and its manuals may require an Export License or approval by the government

of the product country of origin for re-export from your country.

Before you export this product or any of its manuals, please contact Anritsu Company to

confirm whether or not these items are export-controlled.

When disposing of export-controlled items, the products and manuals need to be broken or

shredded to such a degree that they cannot be unlawfully used for military purposes.

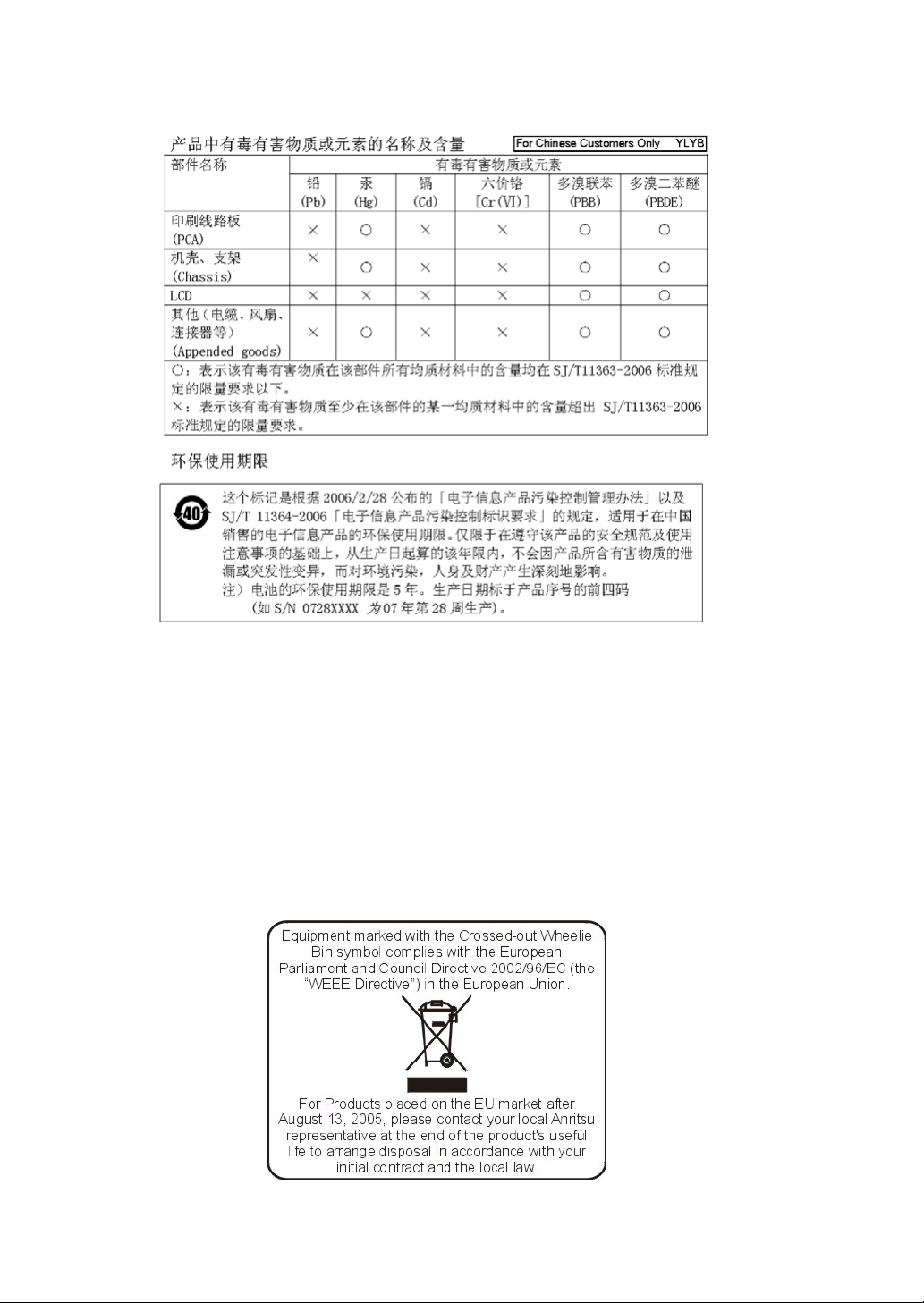

Mercury Notification

This product uses an LCD backlight lamp that contains mercury. Disposal may be regulated

due to environmental considerations. Please contact your local authorities or, within the

United States, the Electronics Industries Alliance (www.eiae.org ) for di spo sal or recyclin g

information.

Page 6

Page 7

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu

Company uses the following symbols to indicate safety-related information. For your own

safety, please read the information carefully before operating the equipment.

Symbols Used in Manuals

Danger

This indicates a very dangerous procedure that could result in serious injury

or death, or loss related to equipment malfunction, if not performed properly.

Warning

Caution

This indicates a hazardous procedure that could result in light-to-severe

injury or loss related to equipment malfunction, if proper precautions are not

taken.

This indicates a hazardous procedure that could result in loss related to

equipment malfunction if proper precautions are not ta ken.

Safety Symbols Used on Equipment and in Manuals

The following safety symbols are used inside or on the equipment near operation locations to

provide information about safety items and operation precautions. Ensure that you clearly

understand the meanings of the symbols and take the necessary precautions before operating

the equipment. Some or all of the following five symbols may or may not be used on all

Anritsu equipment. In addition, there may be other labels attached to products that are not

shown in the diagrams in this manual.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

This indicates a compulsory safety precaution. The required operation is indicated

symbolically in or near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or

near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

Site Master User Guide PN: 10580-00252 Rev. B Safety-1

Page 8

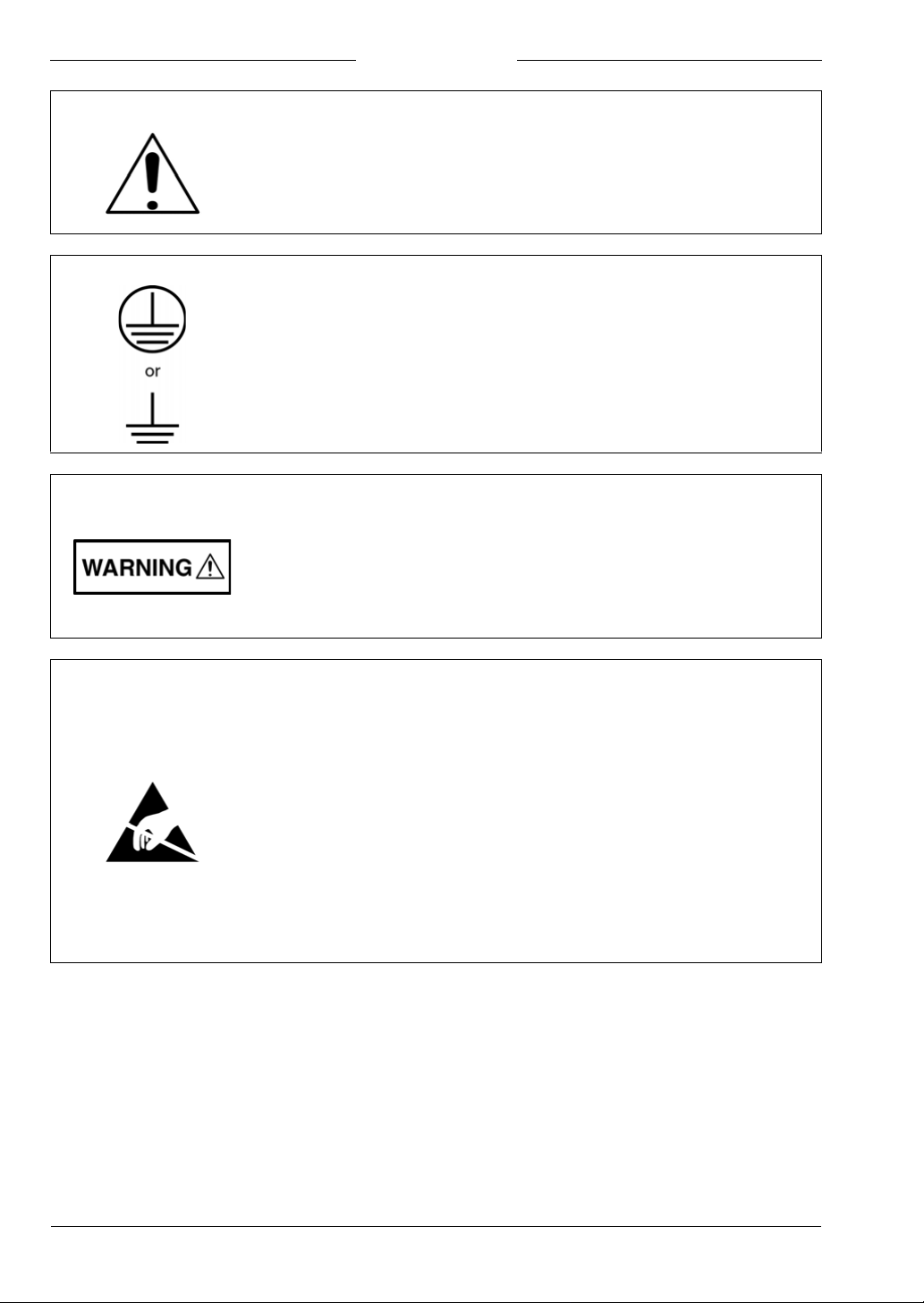

For Safety

Warning

Warning

Warning

Always refer to the operation manual when working near locations at

which the alert mark, shown on the left, is attached. If the operation,

etc., is performed without heeding the advice in the operation

manual, there is a risk of personal injury. In addition, the equipment

performance may be reduced. Moreover, this alert mark is sometimes

used with other marks and descriptions indicating other dangers.

When supplying power to this equipment, connect the accessory

3-pin power cord to a 3-pin grounded power outlet. If a grounded

3-pin outlet is not available, use a conversion adapter and groun d the

green wire, or connect the frame ground on the rear panel of the

equipment to ground. If power is supplied without grounding the

equipment, there is a risk of receiving a severe or fata l electric shock.

This equipment can not be repaired b y the operator . Do not attempt to

remove the equipment covers or to disassemble inte rn al

components. Only qualified service technicians with a knowledge of

electrical fire and shock hazards should service this equipment.

There are high-voltage parts in this equipment presenting a risk of

severe injury or fatal electric shock to untrained personnel. In

addition, there is a risk of damage to precision components.

Caution

Electrostatic Discharge (ESD) can damage the highly sensitive

circuits in the instrument. ESD is most likely to occur as test devices

are being connected to, or disconnected from, the instrument’ s front

and rear panel ports and connectors. You can protect the instrument

and test devices by wearing a static-discharge wristband.

Alternatively, you can ground yourself to discharge any static charge

by touching the outer chassis of the grounded instrument before

touching the instrument’s front and rear panel ports and connectors.

Avoid touching the test port center conductors unless you are

properly grounded and have eliminated the possibility of static

discharge.

Repair of damage that is found to be caused by electrostatic

discharge is not covered under warranty.

Safety-2 PN: 10580-00252 Rev. B Site Master User Guide

Page 9

Table of Contents

Chapter 1—General Information

1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Chapter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3 Available Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-4 Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-5 Standard Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-6 Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-7 Additional Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-8 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-9 Site Master Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-10 Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-11 Calibration Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-12 Annual Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-13 ESD Caution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-14 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-15 Soft Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-16 Tilt Bail Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-17 Secure Environment Workplace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Site Master Memory Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Erase All User Files in Internal Memory . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Recommended Usage in a Secure Environment . . . . . . . . . . . . . . . . 1-10

Chapter 2—Instrument Overview

2-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Chapter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Turning On the Site Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-4 Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Front Panel Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Touch Screen Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Keypad Menu Keys (1 to 9). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-5 Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-6 Test Panel Connector Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Site Master User Guide PN: 10580-00252 Rev. B Contents-1

Page 10

2-7 Symbols and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Calibration Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Battery Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Additional Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-8 Data Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Numeric Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Text Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-9 Mode Selector Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Chapter 3—Quick Start Guide

3-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Measurement Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-3 Cable & Antenna Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Select the Measurement Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Set the Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Set the Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Turn on Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Single Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

DTF Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Calibrate with OSL Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-4 Spectrum Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Set Start and Stop Frequencies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Enter the Center Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Select a Signal Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Set the Measurement Frequency Bandwidth. . . . . . . . . . . . . . . . . . . . . 3-7

Set the Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Power Offset Set Up for Compensating External Loss . . . . . . . . . . . . . 3-8

Set the Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Single Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Segmented Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Create a Limit Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Setting Up Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Select a Smart Measurement Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Contents-2 PN: 10580-00252 Rev. B Site Master User Guide

Page 11

3-5 Saving Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3-6 Useful MST Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Converting Files to .DAT File Format . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Group Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Print All to PDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Chapter 4—File Management

4-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Managing Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Save Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Save Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Quick Name Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Recall Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Recall Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Copying Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Deleting Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Delete Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3 File Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-4 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Save Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Save Location Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Save On Event Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Recall Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Copy Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Delete Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Chapter 5—System Operations

5-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 System Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

System Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Display Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-4 Preset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-5 Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-6 Updating Site Master Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-7 Site Master Firmware Emergency Repair. . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Site Master User Guide PN: 10580-00252 Rev. B Contents-3

Page 12

Chapter 6—GPS (Option 31)

6-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Chapter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-3 Activating the GPS Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-4 Saving and Recalling Traces with GPS Information. . . . . . . . . . . . . . . . . . 6-3

Saving Traces with GPS Information. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Recalling GPS Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-5 GPS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Chapter 7—Bias Tee (Option 10)

7-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Chapter 8—Master Software Tools

8-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-2 MST Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-3 Feature Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-4 Installing MST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-5 Connecting to the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-6 Updating Site Master Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Appendix A—Measurement Guides

A-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Index

Contents-4 PN: 10580-00252 Rev. B Site Master User Guide

Page 13

Chapter 1 — General Information

1-1 Introduction

This chapter provides information about frequency range, available options, additional

documents, general overview, preventive maintenance, and annual verification requirements

for the Anritsu Handheld S331E, S361E, S332E, and S362E Site Master models. Throughout

this manual, the term Site Master will refer to the S331E, S361E, S332E, and S362E.

1-2 Chapter Overview

• “Available Models” on page 1-1

• “Available Options” on page 1-2

• “Standard Accessories” on page 1-2

• “Optional Accessories” on page 1-3

• “Additional Documents” on page 1-3

• “General Description” on page 1-3

• “Site Master Specifications” on page 1-4

• “Preventive Maintenance” on page 1-4

• “Calibration Requirements” on page 1-4

• “Annual Verification” on page 1-4

• “ESD Caution” on page 1-5

• “Battery Replacement” on page 1-5

• “Soft Carrying Case” on page 1-7

• “Tilt Bail Stand” on page 1-8

• “Secure Environment Workplace” on page 1-9

1-3 Available Models

Table 1-1 lists the Site Master models and frequency ranges described in this User Guide.

Table 1-1. Site Master Models

Model Frequency Range

S331E Cable & Antenna Analyzer, 2 MHz to 4 GHz

S361E Cable & Antenna Analyzer, 2 MHz to 6 GHz

S332E Cable & Antenna Analyzer, 2 MHz to 4 GHz, Spectrum Analyzer, 100 kHz to 4 GHz

S362E Cable & Antenna Analyzer , 2 MHz to 6 GHz, Spectrum Analyzer, 100 kHz to 6 GHz

Site Master User Guide PN: 10580-00252 Rev. B 1-1

Page 14

1-4 Available Options General Information

1-4 Available Options

Available options for the Site Master models are shown in Table 1-2.

Table 1-2. Available Options

S331E S332E S361E S362E Description

S331E-0021 S332E-0021 S361E-0021 S362E-0021 2-Port Transmission Measurement

S331E-0010 S332E-0010 S361E-0010 S362E-0010

S331E-0031 S332E-0031 S361E-0031 S362E-0031

S331E-0019 S332E-0019 S361E-0019 S362E-0019 High-Accuracy Power Meter

S332E-0029 S362E-0029 Power Meter

S332E-0025 S362E-0025 Interference Analyzer

S332E-0027 S362E-0027 Channel Scanner

S332E-0090 S362E-0090 Gated Sweep

S332E-0028 S362E-0028

S332E-0509 S362E-0509 AM/FM/PM Analyzer

S331E-0098 S332E-0098 S361E-0098 S362E-0098 Standard Calibration to Z540

S331E-0099 S332E-0099 S361E-0099 S362E-0099

Bias-Tee (Requires Option 0021 on

S331E and S361E)

GPS Receiver (Requires Antenna

P/N 2000-1528-R)

C/W Signal Generator (Requires

CW Signal Generator Kit, P/N 69793)

Premium Calibration to Z540 plus test

data

1-5 Standard Accessories

The Anritsu Site Master includes a one year warranty which includes: battery, firmware,

software, and Certificate of Calibration and Conformance. The following items are supplied

with the product.

Table 1-3. Standard Accessories for Site Master Models

Part Number Description

10580-00252 Site Master User Guide

3-68736 Soft Carrying Case

MST CD: Master Software Tools, User/Measurement Guides,

2300-498

633-44 Rechargeable Li-Ion Battery

40-168-R AC-DC Adapter

806-141-R Automotive Cigarette Lighter 12 VDC Adapter

3-2000-1498 USB A/5-pin mini-B Cable, 10 feet/305 cm

11410-00484 Site Master S331E, S332E, S361E, S362E Technical Data Sheet

Programming Manual, Troubleshooting Guides, Application Notes,

Data Sheet

1-2 PN: 10580-00252 Rev. B Site Master User Guide

Page 15

General Information 1-6 Optional Accessories

When using the Automotive Cigarette Lighter 12 VDC Adapter, Anritsu Part

Caution

Number 806-141-R, always verify that the supply is rated for a minimum of

60 Watts at 12 VDC, and that the socket is clear of any dirt or debris. If the adapter

plug becomes hot to the touch during operation, then discontinue use immediately.

1-6 Optional Accessories

The Site Master Technical Data Sheet (P/N 11410-00484) contains a list and description of

available optional accessories. The data sheet is available on the Master Software Tools

CD-ROM provided with the instrument or the Anritsu web site: http://us.anritsu.com.

1-7 Additional Documents

This user guide is specific to the Site Master and includes a general description about the

Site Master. For information about Cable & Antenna Measurement, Spectrum Analysis,

Interference Analysis, 2-port Transmission Measurements, Power Meter, and Master

Software Tools, refer to the individual Measurement Guides listed in Appendix A,

“Measurement Guides”.

1-8 General Description

The Site Master S331E/S361E is a hand held cable and antenna analyzer designed to make

Return Loss, VSWR, Cable Loss, and Distance-To-Fault (DTF) measurements in the field.

The cable and antenna analyzer also includes 1-port phase and smith chart measurements.

The 2-port transmission measurement option includes two power levels and access to a

built-in 32 volt bias tee (Option 10).

The S332E/S362E is an integrated multi-functional test instrument that eliminates the need

to carry and learn multiple test sets. In addition to the cable & antenna measurements, the

S332E/S362E can be configured to include a Spectrum Analyzer, 2-port Transmission

Measurement, Interference Analyzer, Channel Scanner, CW Signal Generator, AM/FM/PM

Analyzer, Power Meter, and High Accuracy Power Meter. A GPS receiver can be added to

both the S331E/S361E and the S332E/S362E Site Master models.

The bright 8.4" TFT color display provides easy viewing in a variety of lighting conditions and

the combination of a touch screen and keypad enables users to navigate menus with the touch

screen and enter numbers with the keypad. All Site Master models are equipped with a

Li-Ion battery delivering more than four hours of battery life for the S331E/S361E and more

than three hours of battery life for the S332E/S362E Site Masters.

The internal memory is large enough to store approximately 2,000 traces or setups.

Measurements and setups can also be stored in a USB flash drive or transferred to a PC using

the included USB cable.

Master Software Tools (MST), a PC based software program, can be used to create reports,

view and organize data, analyze historical data, add markers and limit lines, rename traces

and trace analysis. Please see Chapter 8 for a brief overview of Ma ster Software Tools a nd the

Master Software Tools Users Guide (.pdf file is availabl e on the MST CD-ROM) for additional

information. (.DAT files can be opened with the legacy Handheld Software Tools (HHST)

application.)

Site Master User Guide PN: 10580-00252 Rev. B 1-3

Page 16

1-9 Site Master Specifications General Information

1-9 Site Master Specifications

Refer to the Site Master Technical Data Sheet (P/N 11410-00484) for general specifications,

detailed measurement specifications for all available measurement modes, ordering

information, power sensors, and available accessories. The data sheet is included with the

instrument and also available on the Master Software Tools CD-ROM. It is also available on

the Anritsu Website: http://us.anritsu.com.

1-10 Preventive Maintenance

Site Master preventive maintenance consists of cleaning the unit and inspecting and cleaning

the RF connectors on the instrument and all accessories. Clean the Site Master with a soft,

lint-free cloth dampened with water or water and a mild cleaning solution.

Caution To avoid damaging the display or case, do not use solvents or abrasive cleaners.

Clean the RF connectors and center pins with a cotton swab dampened with denatured

alcohol. Visually inspect the connectors. The fingers of the N(f) connectors and the pins of the

N(m) connectors should be unbroken and uniform in appearance. If you are unsure whether

the connectors are undamaged, gauge the connectors to confirm that the dimensions are

correct.

Visually inspect the test port cable(s). The test port cable should be uniform in appearance,

and not stretched, kinked, dented, or broken.

1-11 Calibration Requirements

Anritsu recommends annual calibration and performance verification by local Anritsu

service centers. The Cable and Antenna Analyzer mode requires calibration standards for

OPEN, SHORT, and LOAD (OSL) or InstaCal module, which are sold separately.

1-12 Annual Verification

Anritsu recommends an annual calibration and performance verification of the Site Master

and the OSL calibration components and InstaCal module by local Anritsu service centers.

The Site Master is self-calibrating and there are no field-ad justab le compon ents. The OS L

calibration components are crucial to the integrity of the calibration. As a result, they must be

verified periodically to ensure performance conformity. This is especially important if the

OSL calibration components have been accidentally dropped or over-torqued.

Contact information for Anritsu Service Centers is available at:

http://www.anritsu.com/Contact.asp

1-4 PN: 10580-00252 Rev. B Site Master User Guide

Page 17

General Information 1-13 ESD Caution

1-13 ESD Caution

The Site Master, like other high performance instruments, is susceptible to electrostatic

discharge ( ESD) damage. Coaxial cables and antennas often build up a static charge, which

(if allowed to discharge by connecting directly to the Site Master without discharging the

static charge) may damage the Site Master input circuitry. Site Master operators must be

aware of the potential for ESD damage and take all necessary precautions.

Operators should exercise practices outlined within industry standards such as JEDEC-625

(EIA-625), MIL-HDBK-263, and MIL-STD-1686, which pertain to ESD and ESDS devices,

equipment, and practices. Because these apply to the Site Master, it is recommended that any

static charges that may be present be dissipat ed before connecting coax ial cables or antennas

to the Site Master. This may be as simple as temporarily attaching a short or load device to

the cable or antenna prior to attaching to the Site Master. It is important to remember that

the operator may also carry a static charge that can cause damage. Following the practices

outlined in the above standards will ensure a safe environment for both personnel and

equipment.

1-14 Battery Replacement

The battery can be replaced without the use of tools. The battery compartment is located on

the lower left side of the instrument (when you are facing the measurement display). To

remove the battery:

1. Slide the catch toward the bottom of the instrument

2. Pull the top of the door away from the unit

3. Lift out the battery door.

4. Remove the battery pack from the instrument by grabbing the battery lanyard and

pulling out.

Replacement is the opposite of removal. The battery key side (slot below the contacts) sh ou ld

be facing the front on the unit and slide in first.

When inserting the battery the battery label should face the ba ck of th e in strume nt

Note

and the guide slot on the battery should be below the contacts. If the ba ttery door

does not latch closed, the battery may be inserted incorrectly.

Site Master User Guide PN: 10580-00252 Rev. B 1-5

Page 18

1-14 Battery Replacement General Information

Figure 1-1. Battery Compartment

The battery that is supplied with the Site Master may need charging before use. The battery

can be charged while it is installed in the Site Master by using either the AC-DC Adapter

(40-168-R) or the 12-Volt DC adapter (806-141-R), or outside the Site Master with the

optional Dual Battery Charger (2000-1374). Refer to “Battery Symbols” on page 2-11 for a

description of battery symbols.

Use only Anritsu Company approved batteries, adapters, and chargers with this

instrument.

Note

Anritsu Company recommends removing the batter y for long -t er m sto ra g e of the

instrument.

When using the Automotive Cigarette Lighter 12 VDC Adapter, Anritsu Part

Caution

Number 806-141-R, always verify that the supply is rated for a minimum of 60

Watts @ 12 VDC, and that the socket is clear of any dirt or debris. If the adapter

plug becomes hot to the touch during operation, then discontinue use immedia tely.

1-6 PN: 10580-00252 Rev. B Site Master User Guide

Page 19

General Information 1-15 Soft Carrying Case

1-15 Soft Carrying Case

The Site Master can be operated while in the soft carrying case. On the back of the case is a

large storage pouch for accessories and supplies.

To install the instrument into the soft carrying case:

1. The front panel of the case is secured with hook-and-loop fasteners. Fully close the front

panel of the case. When closed, the front panel supports the shape of the case while you

are inserting the Site Master.

2. Place the soft carrying case face down on a stable surface, with the front panel fully

closed and laying flat.

The soft case has two zippers near the back. The zipper closer to the front of the

case opens to install and remove the instrument. The zipper closer to the back of

Note

3. Open the zippered back of the case.

4. Insert the instrument face down into the case, take care that the connectors are

properly situated in the case top opening. You may find it easier to insert the

connectors first, then pull the corners over the bottom of the Site Master.

the case opens an adjustable support panel that can be used to provide support for

improved stability and air flow while the instrument is in the case. This support

panel also contains the storage pouch.

Figure 1-2. Instrument Inserted into the Soft Carrying Case

5. Close the back panel and secure with the zipper to secure the Site Master.

Site Master User Guide PN: 10580-00252 Rev. B 1-7

Page 20

1-16 Tilt Bail Stand General Information

The soft carrying case includes a detachable shoulder strap, which can be connected to the

D-rings of the case.

Caution

The soft case has panel openings for the fan inle t and exhaust por t s. Do not block

the air flow through the panels when the unit is operating.

1-16 Tilt Bail Stand

A Tilt Bail is attached to the back of the Site Master for desktop operation. The tilt bail

provides two settings of backward tilt for improved stability. To deploy the tilt bail, pull the

bottom of the tilt bail away from the back of the instrument. To store the tilt bail, push the

bottom of the bail towards the back of the instrument until it attaches to the Site Master.

Note

Do not use the tilt bail while the instrument is in the soft case. The soft case has an

adjustable support panel in the back zipper.

Figure 1-3. Tilt Bail Extended

1-8 PN: 10580-00252 Rev. B Site Master User Guide

Page 21

General Information 1-17 Secure Environment Workplace

1-17 Secure Environment Workplace

This section details the types of memory in the Site Master, how to delete stored user files in

internal memory, and recommended usage in a secure environment workplace.

Site Master Memory Types

The instrument contains non-volatile disk-on-a-chip memory, EEPROM, and volatile DRAM

memory. The instrument is also supplied with an external USB flash drive. The instrument

does not have a hard disk drive or any other type of volatile or non-volatile memory.

Disk-On-A-Chip (DOC)

DOC is used for storage of instrument firmware, factory calibration information, user

measurements, setups, and .jpg screen images. User information stored on the DOC is erased

by the master reset process described below.

EEPROM

This memory stores the model number, serial number, and calibration data for the

instrument. Also stored here are the user-set operating parameters such as frequency range.

During the master reset process all operating parameter stored in the EEPROM are set to

standard factory default values.

RAM Memory

This is volatile memory used to store parameters needed for the normal operation of the

instrument along with current measurements. This memory is reset whenever the

instrument is restarted.

External USB Flash Drive

This memory may be selected as the destination for saved measurements and setups for the

instrument. The user can also copy the contents of the internal disk-on-chip memory to the

external flash memory for storage or data transfer. The external Flash USB can be

reformatted or sanitized using software on a PC.

Refer to the Chapter 4, “File Management” for additional information on saving and copying

files to the USB flash drive.

Erase All User Files in Internal Memory

Perform a Master Reset:

1. Turn the instrument on.

2. Press the Shift button then the System (8) button.

3. Press the System Options submenu key.

4. Press the Reset key, then the Master Reset key.

5. A dialog box will be di splayed on the screen warning that all settings will be returned to

factory default values and all user files will be deleted. This deletion is a standard file

delete and does not involve overwriting exiting information.

6. Press the ENTER button to complete the master reset.

7. The instrument will reboot and the reset is comp let e.

Site Master User Guide PN: 10580-00252 Rev. B 1-9

Page 22

1-17 Secure Environment Workplace General Information

Recommended Usage in a Secure Environment

Set the Site Master to save files to the external USB Flash drive:

1. Attach the external Flash drive and turn the instrument on.

2. Press the Shift button then the File (7) button.

3. Press the Save submenu key.

4. Press the Change Save Location submenu key, then select the USB drive with the

rotary knob, Up/Down arrow keys, or the touchscreen.

5. Press the Set Location submenu key.

The external USB drive is now the default location for saving files.

1-10 PN: 10580-00252 Rev. B Site Master User Guide

Page 23

Chapter 2 — Instrument Overview

2-1 Introduction

This chapter provides a brief overview of the Anritsu Site Master. The intent of this chapter is

to acquaint the user with the instrument. For detailed measurement information, refer to a

specific measurement guide listed in Appendix A, “Measurement Guides”.

2-2 Chapter Overview

• “Turning On the Site Master” on page 2-1

• “Front Panel Overview ” on page 2-2

• “Display Overview ” on page 2-6

• “Test Panel Connector Overview” on page 2-9

• “Symbols and Indicators” on page 2-11

• “Data Entry” on page 2-13

• “Mode Selector Menu” on page 2-14

2-3 Turning On the Site Master

The Anritsu Site Master S331E/S361E models are capable of approximately four hours and

the S332E/S362E models are capable of approximately three hours of continuous operation

from a fully charged, field-replaceable battery (see Section 1-14 “Battery Replacement”

on page 1-5).

The Site Master can also be operated from a 12 Vdc source (which will also simultaneously

charge the battery). This can be achieved with either the Anritsu AC-DC Adapter (Anritsu

part number 40-168-R) or 12 Vdc Automotive Cigarette Lighter Adapter (Anritsu part

number 806-141-R). Both items are included wi th th e S it e M aster (Table 1-3).

When using the Automotive Cigarette Lighter 12 VDC Adapter, Anritsu

Part Number 806- 1 41 -R, always ver i fy that the supply is rated for a minimum of

Caution

60 Watts @ 12 VDC, and that the socket is clear of any dirt or debris. If the

adapter plug becomes hot to the touch during operation, discontinue use

immediately.

Site Master User Guide PN: 10580-00252 Rev. B 2-1

Page 24

2-4 Front Panel Overview Instrument Overview

Touch Screen

Main Menu Keys

On/Off Button

Shift Key

Numeric Keypad/

Shift Menu Keys (1 to 9)

Printed in Blue

Touch Screen

Submenu Keys

Fan Inlet Port

Fan Inlet Port

Fan Exhaust

Port

Calibration

Status and Type

To turn on the Site Master, press the green On/Off button on the front panel (Figure 2-1)

Figure 2-1. Site Master Overview

The Site Master takes approximately sixty seconds to complete power warm-up and to load

the application software. At the completion of this process, the instrument is ready for use.

2-4 Front Panel Overview

The Site Master menu-driven interface is easy to use and requires little training. The

Site Master uses a touch screen and keypad for data input. The five bottom menu keys and

eight submenu keys on the right side are touch screen keys. The menu and submenu keys will

vary depending upon the selected mode of operation, see “Mode Selector Menu” on page 2-14.

Numeric keys 1 through 9 are dual purpose, depending upon the current mode of operation.

The dual-purpose keys are labeled with a number on the key itself and the alternate function

is printed in blue above each of the keys. Use the blue Shift key to access the functions printed

on the panel. The Escape key, used for aborting data entry, is the oval button located above

numeric key 9. The rotary knob, the four arrow keys, and the keypad can be used to change

the value of an active parameter.

The Menu key provides graphical icons of all the installed measurement modes and user

defined short-cuts (see “Menu Key” on page 2-3). The locations of the keys are shown in

Figure 2-1.

Note

Keep the fan inlet and exhaust ports clear of obstructions at all times for proper

ventilation and cooling of the instrument.

2-2 PN: 10580-00252 Rev. B Site Master User Guide

Page 25

Instrument Overview 2-4 Front Panel Overview

Front Panel Keys

Menu Key

Press this key to display a grid of shortcut icons for installed measurement modes and user

selected menus and setup files.

Figure 2-2 shows the Menu key screen with shortcut icons for the installed measurement

modes. Touch one of the icons in the top two rows to change modes. These icons are

preinstalled and can not be moved or deleted.

Figure 2-2. Menu Key Screen, Icons for Installed Measurements

Note

Site Master User Guide PN: 10580-00252 Rev. B 2-3

The display of the Menu screen will vary depending on Site Master model and

installed options.

Page 26

2-4 Front Panel Overview Instrument Overview

Figure 2-3 shows the Menu key screen with shortcut icons for the installed measurement

modes and four rows of user-defined shortcuts to menus and setup files.

Press and hold down any key for a few seconds to add a shortcut to this screen.To add

shortcut setup files (.stp), open the recall menu and hold down on the file name for several

seconds. Then select the location for the shortcut.

Figure 2-3. Menu Key Screen

User-defined shortcuts will stay in memory until deleted. To delete or move a shortcut button,

press the Menu key then press and hold the shortcut for approximately 3 seconds. The

Customize Button dialog box will open to allow a button to be deleted or moved. Press Esc to

exit the Menu shortcut display.

Note

The Factory Default reset will delete all user created shortcut icons from the Menu

screen. Refer to the “Reset Menu” on page 5-6 for additional information.

Help for the Menu shortcut screen is available by pressing the icon in the lower-right corner

of the display.

Esc Key

Press this key to cancel any setting that is currently being made.

Enter Key

Press this key to finalize data input or select a highlighted item from a list.

Arrow Keys

The four arrow keys (around the Enter key) are used to scroll up, down, left, or right. The

arrow keys can often be used to change a value or to change a selection from a list. This

function is similar to the function of the rotary knob. The arrow keys are also used to move

markers.

2-4 PN: 10580-00252 Rev. B Site Master User Guide

Page 27

Instrument Overview 2-4 Front Panel Overview

Shift Key

Pressing the Shift key and then a number key executes the function that is indicated in blue

text above the number key. When the Shift key is active, its icon is displayed at the top-right

of the measurement display area by the battery charge indicator.

Figure 2-4. Shift Key Icon

Number Keypad

The Number keypad has two functions: The primary function is number entry. The secondary

function of the number keypad is to list various menus. See “Keypad Menu Keys (1 to 9)”

on page 2-5.

Rotary Knob

Turning the rotary knob changes numerical values, scrolls through selectable items from a

list, and moves markers. Values or items may be within a dialog box or an edit window.

Touch Screen Keys

Main Menu Touch Screen Keys

These five main menu keys are horizontally arranged along the lower edge of the touch

screen. The main menu key functions change to match specific instrument Mode settings. The

main menu keys generate function-specific submenus. The various measurement modes are

selected by pressing the Shift key and then the Mode (9) key. Descriptions of the various

measurement modes can be found in the applicable Measurement Guides listed in

Appendix A, “Measurement Guides”.

Note

Submenu Touch Screen Keys

These submenu keys are arranged along the right-hand edge of the touch screen. The

submenu labels change as instrument measurement settings change. The current submenu

title is shown at the top of the submenu key block.

Available measurement modes are based on mode l and options purchased. Refer

to Table 1-1 and Table 1-2 for additional information.

Keypad Menu Keys (1 to 9)

Pressing the Shift key and then a number key selects the menu function that is printed in

blue characters above the number key. See Figure 2-1 on page 2-2.

Not all Secondary Function Menus are active in various measurement modes. If any one of

these menus is available in a specific instrument mode of operation, then it can be called from

the number keypad. It may also be available from a main menu key or a submenu key.

The Preset Menu (1) and System Menu (8) are described in Chapter 5, “System Operations ”.

The Sweep Menu (3), Measure Menu (4), Trace Menu (5), and Limit Menu (6) vary depending

on measurement mode, see the Measurement Guides listed in Appendix A for information.

The File Menu (7) is described in Chapter 4, “File Management”. The Mode Menu (9) is

described in “Mode Selector Menu” on page 2-14.

Site Master User Guide PN: 10580-00252 Rev. B 2-5

Page 28

2-5 Display Overview Instrument Overview

Date/Time

GPS Icon

GPS Location

Save

Battery

Charge

Submenu

Touch Screen

Keys

Measurement

Settings

Summary

Calibration

Status, Type

Main Menu

Touch Screen Keys

Marker Table

Frequency

Standard

Trace

Measurement

Title

LED Indicators

Power LED

The Power LED is located to the left of the On/Off key. The LED is solid green when the unit

is on and slowly blinks when the unit is off but has external power.

Charge LED

The Charge LED is located to the right of the On/Off key. The LED slowly blinks when the

battery is charging and is solid green when the battery is fully charged.

2-5 Display Overview

Figure 2-5 and Figure 2-6 illustrate some of the key information areas of the Site Master in

Cable and Antenna mode and Spectrum Analyzer mode. For detailed information on either

mode, refer to the Measurement Guides listed in Appendix A, “Measurement Guides”.

Figure 2-5.

2-6 PN: 10580-00252 Rev. B Site Master User Guide

Cable and Antenna Analyzer Return Loss Measurement Display

Page 29

Instrument Overview 2-5 Display Overview

Date/Time

GPS Icon

GPS Location

Save

Battery

Charge

Submenu

Touch Screen

Keys

Measurement

Settings

Summary

Main Menu

Touch Screen Keys

Marker Table

Frequency

Standard

Trace

Measurement

Title

Figure 2-6. Spectrum Analyzer Display (S332E and S362E only)

Site Master User Guide PN: 10580-00252 Rev. B 2-7

Page 30

2-5 Display Overview Instrument Overview

Default Colors Black & White

High ContrastNight Vision

In addition to the default color display, Site Master offers the following display settings:

Black & White for printing and viewing in broad daylight con di ti on s

Night Vision optimized for night-time viewing

High Contrast for other challenging viewing conditions

Figure 2-7. Site Master Display Settings

2-8 PN: 10580-00252 Rev. B Site Master User Guide

Page 31

Instrument Overview 2-6 Test Panel Connector Overview

RF Out

USB Type A

External

Power

GPS

USB Mini-B

RF In

External

Reference

External

Trigger

2-6 Test Panel Connector Overview

Test panel connectors for the Site Master S332E are shown in Figure 2-8.

Figure 2-8. S332E Test Panel Connector

External Power

The external power connector is used to power the unit and for battery charging. Input is

12 VDC to 15 VDC at up to 5.0 A. The green flashing Power LED near the power switch

indicates that the instrument has external power.

When using the AC-DC Adapter, always use a three-wire power cable that is

Warning

connected to a three-wire power line outlet. If power is su pplied withou t grounding

the equipment in this manner, then th e user is at risk of receiving a severe or fatal

electric shock.

USB Interface – Type A

The Site Master has two Type A USB connectors that accept USB Flash Memory devices for

storing measurements, setups data, and screen images.

USB Interface – Mini-B

The USB 2.0 Mini-B connector can be used to connect the Site Master directly to a PC. The

first time the Site Master is connected to a PC, the normal USB device detection by the

computer operating system will take place. The CD-ROM that is shipped with the instrument

contains a driver for Windows XP that is installed when Master Software Tools is installed.

Drivers are not available for earlier versions of the Windows operating system. During the

driver installation process, place the CD-ROM in the computer drive and specify that the

installation wizard should search the CD-ROM for the driver.

Note

For proper detection, Master Software Tools should be installed on the PC prior to

connecting the Site Master to the USB port.

Site Master User Guide PN: 10580-00252 Rev. B 2-9

Page 32

2-6 Test Panel Connector Overview Instrument Overview

Headset Jack

The headset jack provides audio output from the built-in AM/FM/SSB demodulator for testing

and troubleshooting wireless communication systems. The jack accepts a 2.5 mm 3-wire

miniature phone plug such as those commonly used with cellular telephones.

Ext Trigger In (S332E, S362E Models)

A TTL signal that is applied to the External Trigger female BNC input connector causes a

single sweep to occur. In the Spectrum Analyzer mode, it is used in zero span, and triggering

occurs on the rising edge of the signal. After the sweep is complete, the resultant trace is

displayed until the next trigger signal arrives.

RF In

50 Ω Type-N female connector. Maximum input is +26 dBm at 50 VDC.

RF Out/Reflection In

RF output, 50 impedance, for reflection measurements. Maximum input is +23 dBm at

±50 VDC.

GPS Antenna Connector

The GPS antenna connection on the Site Master is type SMA-female. GPS function is

described in Chapter 6, “GPS (Option 31) ”.

2-10 PN: 10580-00252 Rev. B Site Master User Guide

Page 33

Instrument Overview 2-7 Symbols and Indicators

2-7 Symbols and Indicators

The following symbols and indicators indicate the instrument status or condition on the

display.

Calibration Symbols

The current calibration status and type is displayed in the upper-left of the screen when in

Cable & Antenna Analyzer mode. See Figure 2-5 on page 2-6. The five status messages are

described next.

Cal Status: ON, Flex

The Site Master has been calibrated with discrete Open, Short, and Load components. This is

a FlexCal calibration indicating it is possible to change the frequency range after calibration.

Cal Status: ON, Standard

The Site Master has been calibrated with discrete Open, Short, and Load components. This is

a Standard calibration indicating it is not possible to change the frequency range after

calibration without performing another calibration.

Cal Status: ON, Flex, Insta

The Site Master has been calibrated with the InstaCal module. This is a FlexCal calibration

indicating it is possible to change the frequency range after calibration.

Cal Status: ON, Standard, Insta

The Site Master has been calibrated with the InstaCal module. The Site Master has been

calibrated with discrete Open, Short, and Load components. This is a Standard calibration

indicating it is not possible to change the frequency range after calibration without

performing another calibration.

Cal Status Off:

The Site Master has not been calibrated.

For calibration procedures refer to the Cable & Antenna Measurement Guide

(PN: 10580-00241) listed in Appendix A.

Battery Symbols

The battery symbol above the display indicates the charge remaining in the battery. The

colored section inside the symbol changes size and color with the charge level.

Figure 2-9. Battery Status

Green: Battery is 30% to 100% charged

Yellow: Battery is 10% to 30% charged

Red: Battery 0% to 10% charged

Lightning Bolt: Battery is being charged (any color symbol)

Detailed battery information is also available in the Status dialog box (System > Status).

Site Master User Guide PN: 10580-00252 Rev. B 2-11

Page 34

2-7 Symbols and Indicators Instrument Overview

When either the AC-DC Adapter (40-168-R) or the 12 Volt DC adapter (806-141-R) is

connected, the battery automatically receives a charge, and the battery symbol with the

lightning bolt is displayed (Figure 2-10).

Figure 2-10. Battery Charging Icon

The green Charge LED flashes when the battery is charging, and remains on steady when the

battery is fully charged.

Caution Use only Anritsu-approved batteries, adapters, and chargers with this instrument.

When operating from external power without a battery installed, the battery symbol is

replaced by a red plug body (Figure 2-11).

Figure 2-11. Battery Not Installed

Additional Symbols

Single Sweep

Single Sweep is selected. Press

Floppy Icon

Shortcut to the Save submenu. Touch the icon to open the touch screen keyboard for saving

measurements, setups, or screen displays.

Continuous in the Sweep menu to resume continuous sweeping.

2-12 PN: 10580-00252 Rev. B Site Master User Guide

Page 35

Instrument Overview 2-8 Data Entry

2-8 Data Entry

Numeric Values

Numeric values are changed using the rotary knob, arrow keys, or the keypad. Pressing one

of the main menu keys will display a list of submenus on the right side of the touch screen.

When the value on a submenu key is displayed in red, it is ready for changing. When using

the rotary knob or arrow keys the changing value is shown on the submenu and in red on the

graticule. When using the keypad, the new value is shown in red on the graticule and the

submenu changes to Units. Selecting a unit for the new value completes the entry.

Parameter Setting

Pop-up list boxes or edit boxes are used to provide selection lists and selection editors. Scroll

through a list of items or parameters with the arrow keys, the rotary knob, or the touch

screen. These list boxes and edit boxes frequently display a range of possible values or limits

for possible values.

Finalize the input by pressing the Enter key. At any time before finalizing the input, press the

escape (Esc) key to abort the change and retain the previously existing setting.

Some parameters (such as for antennas or couplers) can be added to list boxes by creating

them and importing them using Master Software Tools.

Text Entry

When entering text, as when saving a measurement, the touch screen keyboard is displayed

(Figure 2-12). Characters are entered directly with the touch screen keyboard. The keypad

can be used for numeric entry. The left and right arrow keys will scroll the cursor through the

filename. See “Save Menu” on page 4-8 for additional information.

Figure 2-12. Touch Screen Keyboard

Site Master User Guide PN: 10580-00252 Rev. B 2-13

Page 36

2-9 Mode Selector Menu

To access the functions under the Mode menu, select the Shift key, then the Mode (9) key. Use

the directional arrow keys, the rotary knob, or the touch screen to highlight the selection, and

press the Enter key to select. The list of modes that appear in this menu will vary depending

upon the options that are installed and activated in the instrument. Figure 2-13 is an

example of the Mode menu. Your instrument may not show the same list. The current mode is

displayed below the battery symbol.

Figure 2-13. Mode Selector Menu

The Menu key is another option to quickly change measurement modes. Press the Menu key

then select one of the Measurement icons in the top two rows (Figure 2-2 on page 2-3).

2-14 PN: 10580-00252 Rev. B Site Master User Guide

Page 37

Chapter 3 — Quick Start Guide

3-1 Introduction

This chapter provides a brief overview of basic measurement setups. For detailed

measurement information, refer to a specific measurement guide listed in

Appendix A, “Measurement Guides”. This chapter provides quick start measurement

information for the following measurement modes:

• Section 3-3 “Cable & Antenna Analyzer” on page 3-2

• Section 3-4 “Spectrum Analyzer” on page 3-7

3-2 Measurement Mode Selection

Press the Menu key and use the touch screen to select the appropriate measurement icon.

Figure 3-1. Menu Screen with Icons for Installed Measurement Modes

Note The display of the Menu screen will vary depending on installed options.

Site Master User Guide PN: 10580-00252 Rev. B 3-1

Page 38

3-3 Cable & Antenna Analyzer Quick Start Guide

3-3 Cable & Antenna Analyzer

Set the instrument to Cable & Antenna Analyzer mode as described in the previous section.

Select the Measurement Type

Press the Measurement main menu key and select the appropriate measurement.

Figure 3-2. Menu Screen with Icons for Installed Measurement Modes

Set the Frequency

1. Press the Freq/Dist main menu key.

2. Press the Start Freq submenu key and use the keypad, rotary knob, or the arrow keys to

enter the start frequency.

3. Press the St op Freq submenu key and use the keypad, rotary knob, or the arrow keys to

enter the stop frequency.

Set the Amplitude

1. Press the Amplitude main menu key.

2. Press the Top submenu key and use the keypad, rotary knob, or the arrow keys to edit

the top scale value. Press Enter to set.

3. Press the Bottom submenu key and use the keypad, rotary knob, or the arrow keys to

edit the bottom scale value. Press Enter to set.

Note

3-2 PN: 10580-00252 Rev. B Site Master User Guide

For Amplitude in Smith Chart measurements, refer to “Smith Chart” on page 2-23

of the Cable & Antenna Measurement Guide listed in Appendix A.

Page 39

Quick Start Guide 3-3 Cable & Antenna Analyzer

Turn on Markers

1. Press the Marker main menu key.

2. Press the Marker 1 2 3 4 5 6 submenu key and select t he marker number 1 button using

the touch screen. The underlined number on the Marker submenu key indicates the

active marker.

3. Use the arrow keys, the keypad, or the rotary knob to move the marker. The current

value for the selected marker is shown above the upper-left corner of the graph. It is

also possible to drag the marker using the touch screen.

4. Delta Markers are available fo r each of the six reference markers. For the selected

marker, Toggle the Delta On/Off submenu key to turn on the Delta marker.

Peak/Valley Auto Markers

When making Return Loss and VSWR measurements, the Peak/Valley Auto feature can be

used to automatically turn on Marker 1 to peak, Marker 2 to valley, and display M1 and M2

in the Marker Table. This feature is not available for DTF measurements.

1. Press the Marker main menu key.

2. Press the Peak/Valley Auto key.

Site Master User Guide PN: 10580-00252 Rev. B 3-3

Page 40

3-3 Cable & Antenna Analyzer Quick Start Guide

Single Limit Line

1. Press Shift and then Limit (6) to enter the Limit menu.

2. Press the Limit On/Off key to turn on the Limit.

3. Press Single Limit and then use the numeric keypad, the arrow keys, or the rotary knob

to change the limit value and then press Enter.

Note

4. Press the Limit Alarm key to turn on or off the Limit Alarm.

Refer to the Cable & Antenna Measurement Guide listed in Appendix A for

creating multi-segment limit lines.

Figure 3-3. Single Limit Lines

3-4 PN: 10580-00252 Rev. B Site Master User Guide

Page 41

Quick Start Guide 3-3 Cable & Antenna Analyzer

DTF Setup

1. Press the Measurements main menu key and select DTF Return Loss or DTF VSWR.

2. Press the Freq/Dist main menu key.

3. Press the Units submenu key and select m to display distance in meters or ft to display

distance in feet.

4. Press DTF Aid and use the touch screen, or arrow keys to navigate through all the DTF

parameters.

a. Set Start Distance and Stop Distance. Stop Distance needs to be smaller than

Dmax.

b. Enter the Start and Stop frequencies.

c. Press Cable, select the appropriate cable from the cable list and press Enter.

d. Press Continue.

Figure 3-4. DTF Aid

5. Press Shift then Calibrate (2) to calibrate the instrument. Refer to “Calibrate with OSL

Calibration” on page 3-6 for additional information.

6. Press the Marker main menu key and set the appropriate markers.

7. Press Shift and Limit (6) to enter and set the appropriate limit lines.

8. Press Shift and File (7) to save the measurement. See the User Guide for details.

Site Master User Guide PN: 10580-00252 Rev. B 3-5

Page 42

3-3 Cable & Antenna Analyzer Quick Start Guide

Power Charge

+/-

.

0

3

Sweep

2

Calibrate

1

Preset

6

Limit

5

Trace

4

Measure

9

Mode

8

System

7

File

Shift

Esc

Enter

Menu

SiteMaster

S331E

OPEN

LOAD

SHORT

CALIBRATION

RFOUT/REFLECTION

TEST PORT

TEST PORT CABLE (OPTIONAL)

Calibrate with OSL Calibration

Note

Refer to the Cable & Antenna Measurement Guide listed in Appendix A for

calibration details.

1. Press the Freq/Dist main menu key and enter the appropriate frequency range

2. Press Shift then Calibrate (2) key.

3. Select Standard or FlexCal.

4. Press Start Cal and follow instructions on screen.

5. Connect Open to RF Out and press the Enter key.

6. Connect Short to RF Out and press the Enter key.

7. Connect Load to RF Out and press the Enter key.

8. Verify that the calibration has been properly performed by checkin g that the Cal Status

message is now displaying “ON, Standard” or “ON, FlexCal”.

Figure 3-5. Calibration Setup with OSL Cal

3-6 PN: 10580-00252 Rev. B Site Master User Guide

Page 43

Quick Start Guide 3-4 Spectrum Analyzer

3-4 Spectrum Analyzer

Set the instrument to Spectrum Analyzer mode as described in Section 3-2 “Measurement

Mode Selection” on page 3-1.

Set Start and Stop Frequencies

1. Press the Freq main menu key.

2. Press the Start Freq submenu key.

3. Enter the desired start frequency using the keypad, the arrow keys, or the rotary knob.

When entering a frequency using the keypad, the submenu key labels change to GHz,

MHz, kHz, and Hz. Press the appropria te unit key. Pressing the Enter key has the same

affect as pressing the MHz submenu key.

4. Press the Stop Freq submenu key.

5. Enter the desired stop frequency.

Enter the Center Frequency

1. Press the Freq main menu key.

2. Press the Center Freq submenu key.

3. Ent er the desired center frequency using the keypad, the arrow keys, or the rotary knob.

When entering a frequency using the keypad, the submenu key labels change to GHz,

MHz, kHz, and Hz. Press the appropria te unit key. Pressing the Enter key has the same

affect as pressing the MHz submenu key.

The center frequency and span is shown at the bottom of the screen.

Select a Signal Standard

1. Press the Freq main menu key.

2. Press the Signal Standard submenu key. The Signal Standards dialog box opens.

3. Highlight a signal standard and press Enter to select.

4. Press the Channel submenu key to change the channel value in the Channel Editor.

The signal standard is shown in yellow at the top of the screen.

Set the Measurement Frequency Bandwidth

1. Press the BW main menu key to display the BW menu.

• Press the RBW and/or the VBW submenu key to manually change the values.

• Set RBW and VBW automatically by pressing the Auto RBW submenu key or the

Auto VBW submenu key.

2. Press the RBW/VBW submenu key to change the resolution bandwidth and vi deo

bandwidth ratio.

3. Press the Span/RBW submenu key to change the span width to resolution bandwidth

ratio.

Site Master User Guide PN: 10580-00252 Rev. B 3-7

Page 44

3-4 Spectrum Analyzer Quick Start Guide

Set the Amplitude

Press the Amplitude main menu key to display the Amplitude menu.

Set Amplitude Reference Level and Scale

1. Press the Reference Level submenu key and use the arrow keys, rotary knob, or the

keypad to change the reference level. Press Enter to set the reference level value.

2. Press the Scale submenu key and use the arrow keys, rotary knob, or the keypad to

enter the desired scale. Press Enter to set the scale value.

Set Amplitude Range and Scale

1. Press the Auto Atten submenu key to set an optimal reference level based on the

measured signal.

2. Press the Scale submenu key.

3. Enter the desired scale units by using the keypad, the arrow keys, or the rotary knob.

Press Enter to set. The y-axis scale is automatically renumbered.

Power Offset Set Up for Compensating External Loss

To obtain accurate results, compensate for any external attenuation by using power offset.

In power offset mode, the compensation factor is in dB. (External attenuation can be created

by using an external cable or an external high power attenuator.)

Press the RL Offset submenu key and use the keypad, the arrow keys, or the rotary knob to

enter the desired offset value. When using the rotary knob, the value changes in increments

of 0.1 dB. Using the Left/Right arrow keys changes the value in 10% increments of the value

shown on the Scale submenu key. When using the Up/Down arrow keys, the value changes in

the increment shown on the Scale submenu key. When using the keypad, enter the new value

then press Enter or the dB submenu key to set the value. The power offset is displayed in the

instrument settings summary column on the left side of the measurement display.

Set the Span

1. Press the Span main menu key or the Freq main menu key followed by the

Span submenu key.

2. To select full span, press the Full Span submenu key. Selecting full span overrides any

previously set Start and Stop frequencies.

3. For a single frequency measurement, press the Zero Span submenu key.

To quickly move the span value up or down, press the Span Up 1-2-5 or Span

Note

3-8 PN: 10580-00252 Rev. B Site Master User Guide

Down 1-2-5 submenu keys These keys facilitate a zoom-in, zoom-out feature in a

1-2-5 sequence.

Page 45

Quick Start Guide 3-4 Spectrum Analyzer

Single Limit Line

Press the Limit menu key to display the Limit menu.

1. Press the Limit (Upper / Lower) submenu key to select the desired limit line,

Upper or Lower.

2. Activate the selected limit line by pressing the On Of f submenu key so that On is

underlined.

3. Press the Limit Move submenu key to display the Limit Move menu. Press the first

Move Limit submenu key and use the arrows keys, rotary knob, or keypad to change the

dBm level of the limit line.

4. Press the Back submenu key to return to the Limit menu.

5. If necessary, press the Set Default Limit submenu key to redraw the limit line in view.

Segmented Limit Lines

The following procedure creates limit lines for a Return Loss Measurement. Limits are set to

12 dB between 1000 MHz and 1400 MHz and to 15 dB between 1600 MHz and 2000 MHz.

1. Press the Limit (Upper / Lower) submenu key to select the desired limit line, Upper or

Lower.

2. Activate the selected limit line by pressing the On Of f submenu key so that On is

underlined.

3. Press the Limit Move submenu key to display the Limit Move menu.

Create a Sample Segmented Limit Line

4. Press the Move Limit submenu key and use the number keys to enter a limit va lue of

12 dB. The limit value can also be moved by using the arrow keys or the rotary knob.

Press the Back submenu key to return to the Limit menu.

5. Press the Limit Edit submenu key to display the Edit menu.

6. Press the Add Point submenu key.

7. Press the Frequency submenu key and enter 1400 MHz.

8. Press the Add Point submenu key

9. Press the Frequency submenu key and enter 1600 MHz.

Site Master User Guide PN: 10580-00252 Rev. B 3-9

Page 46

3-4 Spectrum Analyzer Quick Start Guide

Create a Limit Envelope

1. Press Shift then Limit (6) to open the Limit menu.

2. Select Limit Envelope.

3. Press the Create Envelope key.

Figure 3-6. Limit Envelope

3-10 PN: 10580-00252 Rev. B Site Master User Guide

Page 47

Quick Start Guide 3-4 Spectrum Analyzer

Setting Up Markers

Press the Marker main menu key to display the Marker menu.

Selecting, Activating, and Placing a Marker

1. Press the Marker 1 2 3 4 5 6 submenu key and then select the desired marker using the

touch screen marker buttons. The selected marker is underlined on the Marker

submenu key.

2. Press the On Off su bmenu key so that On is underlined. The selected marker is

displayed in red and ready to be moved.

3. Use the rotary knob to place the marker on the desired frequency.

4. Repeat steps 1 through 3 to activate and move additional markers.

Selecting, Activating, and Placing a Delta Marker:

1. Press the Marker 1 2 3 4 5 6 submenu key and select the desired delta marker. The

selected marker is underlined.

2. Press the Delta On Off submenu key so that On is underlined. The selected marker is

displayed in red and ready to be moved.

3. Use the rotary knob to place the delta marker on the desired frequency.

4. Repeat steps 1 through 3 to activate and move additional markers.

Viewing Marker Data in a Table Format

1. Press the More submenu key.

2. Press the Marker Table On Off submenu key so that On is underlined. All marker and

delta marker data are displayed in a table under the measurement graph.

Figure 3-7. Marker Table

Site Master User Guide PN: 10580-00252 Rev. B 3-11

Page 48

3-4 Spectrum Analyzer Quick Start Guide

Select a Smart Measurement Type

In Spectrum Analyzer mode, press Shift then Measure (4) and select a smart measurement

using the submenu keys.

Figure 3-8. Spectrum Analyzer Measure Menu

3-12 PN: 10580-00252 Rev. B Site Master User Guide

Page 49

Quick Start Guide 3-5 Saving Measurements

3-5 Saving Measurements

Measurement files can be stored in the following formats:

.VNA or .DAT for Cable and Antenna analyzer measurements

.SPA for Spectrum Analyzer measurements

Saving files in .VNA or .SPA is recommended as it enables users to edit, view, and analyze

traces with Master Software Tools (MST).

Anritsu recommends saving files to the internal memory and then transferring the

files to an external USB memory device if needed. Refer to Chapter 4, “Copying

Files” for more details.

The .DAT file format is only recommended for users who need to work with this

format or prefer using Handheld Software Tools (HHST). Traces saved as .DAT

can be viewed, edited, and analyzed with Handheld Software Tools. If the DUAL

Note

measurement display is turned on, files will be saved as Filename_1 and

Filename_2.

.DAT is only supported for Return Loss, VSWR, Cable Loss, DTF RL, DTF VSWR

and only supports 137, 275, 551 data points. 1102 and 2204 data points are not

supported in the .DAT file format. Use the .VNA file format if these resolutions are

required.

.DAT files cannot be recalled to the instrument for viewing. If this is required, use

the .VNA file format.

Procedure for saving files:

1. Press Shift then File (#7).

2. Press Save Measurement.

3. Press Change Save Location and set the current location to be the USB flash drive or

internal memory, and then press Set Location.

4. Press Chan ge T ype (Se tup/JPG/…) and select Measurement .VNA or Measurement .DAT

or Measurement (when in Spectrum Analyzer mode).

5. Enter the file name using the keyboard and press Enter.