Page 1

Artisan Technology Group is your source for quality

new and certified-used/pre-owned equipment

FAST SHIPPING AND

DELIVERY

TENS OF THOUSANDS OF

IN-STOCK ITEMS

EQUIPMENT DEMOS

HUNDREDS OF

MANUFACTURERS

SUPPORTED

LEASING/MONTHLY

RENTALS

ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Ins traVew “ REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

www.instraview.com

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment ^

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com ^ for more

information on price quotations, drivers, technical

specifications, manuals, and documentation

Page 2

MP1777A

10 GHz Jitter Analyzer

Remote Control

Operation Manual

Vol. 2

Fourth Edition

To ensure that the equipment is used safely, read

the "For Safety" in the MP1777A 10 GHz Jitter Ana

lyzer Operation Manual first.

Keep this manual with the equipment.

APR.

2005

ANRITSU CORPORATION

Document No.: M-W14S3AE-4.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the follow

ing safety symbols to indicate safety-related information. Insure that you clearly understand the meanings of the

symbols BEFORE using the equipment.

Some or all of the symbols may not be used on this equipment. In addition, when drawings are included in this

manual, labels on the equipment may not be shown on them.

Safety Symbols Used in Manual

A KiOCD /\ indicates a very dangerous procedure that could result in death or serious

injury if not performed properly.

1»# * rj 1^11^^ This indicates a hazardous procedure that could result in death or serious injury if

VVMrilNIIMVj ¿_A not performed properly.

^*1 This indicates a hazardous procedure or danger that could result in light-to-severe

¿-lA injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and/or in Manual

The following safety symbols are used inside or on the equipment near operation locations, and./or in manual to

provide information about safety items and operation precautions. Insure that you clearly understand the mean

ings of the symbols and take the necessary precautions BEFORE using the equipment.

This indicates a prohibited operation. The prohibited operation is indicated sym

bolically in or near the barred circle.

This indicates an obligatory safety precaution. The obligatory operation is indi

cated symbolically in or near the circle.

This indicates warning or caution. The contents are indicated symbolically in or

near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

MP1777A

10 GHz Jitter Analyzer Remote Control

Operation Manual Vol. 2

10 September 1998 (First Edition)

20 September 2002 (Fourth Edition)

Copyright © 1998-2002, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The contents of this manual may be changed without prior notice.

Printed in Japan

II

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

A

For Safety

WARNING A

ALWAYS refer to the operation manual when working near locations at

which the alert mark shown on the left is attached. If the operation, etc.,

is performed without heeding the advice in the operation manual, there

is a risk of personal injury. In addition, the equipment performance may

be reduced.

Moreover, this alert mark is sometimes used with other marks and de

scriptions indicating other dangers.

2. When supplying power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet, if a grounded 3-pin outlet

is not available, before supplying power to the equipment, use a conver

sion adapter and ground the green wire, or connect the frame ground on

the rear panel of the equipment to ground. If power is supplied without

grounding the equipment, there is a risk of receiving a severe or fatal

electric shock.

3. This equipment cannot be repaired by the user. DO NOT attempt to

Repair

warningA

Falling Over turned on its side, etc,, it will be unstable and may be damaged if it fal's

open the cabinet or to disassemble internal parts. Only Anritsu-trained

service personnel or staff from your sales representative with a knowl

edge of electrical fire and shock hazards should service this equipment.

There are high-voltage parts in this equipment presenting a risk of se

vere injury or fatal electric shock to untrained personnel. In addition,

there is a risk of damage to precision parts.

4. This equipm.ent should be used in the correct position. If the cabinet is

over as a result of receiving a slight mechanical shock.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

Battery Fluid

LCD

For Safety

WARNING A

5. DO NOT short the battery terminals and never attempt to disassemble it

or dispose of it in a fire. If the battery is damaged by any of these ac

tions, the battery fluid may leak.

This fluid is poisonous.

DO NOT touch it, ingest it, or get in your eyes. If it is accidentally in

gested, spit it out immediately, rinse your mouth with water and seek

medical help. If it enters your eyes accidentally, do not rub your eyes,

irrigate them with clean running water and seek medical help. If the

liquid gets on your skin or clothes, wash it off carefully and thoroughly.

6. This instrument uses a Liquid Crystal Display (LCD); DO NOT subject

the instrument to excessive force or drop it. if the LCD is subjected to

strong mechanical shock, it may break and liquid may leak.

This liquid is very caustic and poisonous.

DO NOT touch it, ingest it, or get in your eyes. If it is ingested acciden

tally, spit it out immediately, rinse your mouth with water and seek medi

cal help. If it enters your eyes accidentally, do not rub your eyes, irrigate

them with clean running water and seek medical help. If the liquid gets

on your skin or clothes, wash it off carefully and thoroughly.

IV

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Changing Fuse

A

Cleaning

ACAUTI0N/Æ,t

>18 kg

HEAVY WEIGHT.

For Safety

CAUTION A

1. Before changing the fuses, ALWAYS remove the power cord from the

poweroutlet and replace the blown fuses. ALWAYS use new fuses of

the type and rating specified on the fuse marking on the rear panel of the

cabinet.

T__A indicates a time-lag fuse.

There is risk of receiving a fatal electric shock if the fuses are replaced

with the power cord connected.

2. Keep the power supply and cooling fan free of dust.

- Clean the power inlet regularly. If dust accumulates around the power

pins, there is a risk of fire.

- Keep the cooling fan clean so that the ventilation holes are not ob

structed. If the ventilation is obstructed, the cabinet may overheat

and catch fire.

3. Use two or more people to lift and move this equipment, or use a trolley.

There is a risk of back injury, if this equipment is lifted by one person.

Changing memory

back-up battery

Disposing the batteries

4. This equipment uses a lithium battery to back-up the memory. This bat

tery must be replaced by a service engineer when it has reached the end

of its useful life: contact the Anritsu sales section or your nearest repre

sentative.

NOTE: The battery used in this equipment has a maximum useful life

of 7 years. It should be changed before this period has

elapsed.

5. The main unit of the MP1777A uses lithium batteries. When disposing of

the batteries, make sure to conform with the local regulation.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

VI

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Equipment Certificate

Anritsu Corporation certifies that this equipment was tested before shipment using

calibrated measuring mstruinents with direct traceability to public testing organiza

tions recognized bv national research laboratories including the Hlectrotechnical

Laboratory, the National Research Laboratory of Metrology and the Communications

Research Laboratory, and was found to meet the published specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a malfunction iiccurs

w ithin I y ear after shipment due to a manufacturing fault, provided that this w arranty

is rendered void under any or all of the following conditions.

• The lault is tMiiside the scope ol the warranty contiitions described m the operation

manual.

• d’he fault IS due to misiiantlling. misuse, or unauthorized modificaiion or repair of

the equipment by the customer.

• The fault is due to severe usage clearly e.vceeding normal usage.

• The fault is due to improper or insufficient intiintenance by the customer.

• The fault is due to natural disaster including fire, flooding, earthquake, etc.

• 'fhe fault is due to use of non-specified peripheral equipment, peripheral pans,

consumables, etc,

• The fault is due to use of a non '.pecified power supply or in a non-specified instal

lation location.

In addition, this w arranty is valid only for the original equipment purchaser, it is not

transferable if the equipment is resokl.

.Anritsu Ciirpomtioii will not accept liability for eijuipmem faults due to unforeseen

and unusual circumstances, nor for faults due to niishandiitis bv the customer.

Anritsu Corporation Contact

If this equipment develops a fault, contact .Anritsu Coiqioiation or its representatives

at the tiddress in this manual.

Vii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Notes On Export Management

This product and its manuals may require an Export License/Approval by

the Government of the product’s country of origin for re-export from your

country.

Before re-exporting the product or manuals, please contact us to confirm

whether they are export-controlled items or not.

When you dispose of export-controlled items, the products/manuals are

needed to be broken/shredded so as not to be unlawfully used for military

purpose.

Trademark and Registered Trademark

Quick Basic is a registered trademark of Microsoft Corporation.

vm

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

Composition of the MP1777A Operation Manual

The operation manual for the MP1777A lO GHz Jitter Analyzer ii, composed of the two \olunies shown below .

\oltime that suits the intended applicatiein of the product.

VOL. 1

Operation manual for the main unit

the

MP1777A

Operation Manual

Operation manual for the main unit:

Operation manual for remote control: This manual describes remote control and prcn ides proeram example-

VOL. 2

I'his manual prosades an outline of the MPI777A and its speeilieatmns,

iiid describes its panel, pertormance and operation.

Operation manual for remote control

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Table of Contents

For Safety............................................................ Hi

Composition of the MP1777A Operation Manual.. I

Section 1 Outline

1.1 Interface Function

1.2 System Setup Example........................................................................1-3

Section 2 GPIB Interface

2.1 GPIB Interface Functions.....................................................................2-2

2.2 Device Message List............................................................................2-3

2.3 Bus Commands....................................................................................2-4

2.4 Connecting the GPIB Cable.................................................................2-5

2.5 Setting GPIB.........................................................................................2-6

2.6 Initializing the Device

Sections Listener Input Format

3.1 Listener Input Program Message Format

3.2 Functional Elements of Program Message..........................................3-4

3.3 Program Data Format

.............................................

................................................................................

.................................

...........................................................................

.........................

............................................

........................................................................

1-1

1-2

2-1

2-8

3-1

3-2

3-14

Section 4 Talker Output Format

4.1 Talker Output Response Message Format

4.2 Functional Elements of Response Message

Section 5 Common IEEE488.2 Commands

5.1 Common IEEE488.2........................................................................... 5-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

........................

..........................................

.......................................

.....

4-1

4-2

4-3

5-1

Page 12

Section 6 Status Report

6.1 Configuration of MP1777A Status Registers.................................6-2

6.2 Status Registers Specified by IEEE488.2

6.3 Status Register Specified by SCPI................................................6-6

6.4 Status Register Specific to MP1777A

6.5 Reading, Writing and Clearing Status Registers........................... 6-8

..........................................

...................................

...........................................

6-1

6-4

6-7

Section 7 SCPI Outline

7.1 Outline ..........................................................................................7-2

7.2 Command Structure

7.3 Command Description Method......................................................7-4

7.4 Compounding Commands.............................................................7-5

7.5 Parameter......................................................................................7-6

Section 8 Device Message Details

8.1 Response Format..........................................................................8-2

8.2 Buffer Size Stipulations

8.3 Device-Specific Commands..........................................................8-5

Appendix A SCPI Error Messages

A.1 Command Errors.........................................................................A-2

A.2 Run Time Errors

A.3 Device-Specific Errors..................................................................A-5

A. 4 Query Errors.................................................................................A-6

...........................................

....................................................................

.........................

.................................................................

.....................

..........................................................................

. A-1

7-1

7-3

8-1

8-4

A-4

Appendix B Details of Initialization Command

Functions

B. 1 Initiaiizing Bus..............................................................................B-2

B.2 Initializing Message......................................................................E-3

B.3 Initializing Device

B.4 Device Status at Power Activation ..................................................B-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

.........................................................................

.......................................

B-1

B-4

\\\

Page 13

IV.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

Section 1 Outline

'I’hc MP1777A 10 CiH/ Jitter Analyzer enables automation of measurement when connected with an external controller.

The GPIB interlace is used for connection. I'his section pros'iiles explanations ol' interface functions and sS steni setup

extimples.

1.1 Interface Function................................................................................. 1-2

1.2 System Setup Example........................................................................ 1-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-1

Page 15

Section 1 Outline

1.1 Interface Function

The MP1777A has a connector for remote control on the back face.

Remote control of devices is enabled by fitting GPIB.

The GPIB setting is performed on the Secondary system screen in the Main setup screen.

GPIB interface: The GPIB interface for this device conforms to the IEEE (Institute of Electrical and Electronic Engi

neers) standards, 488.1-1987. The software conforms to the standards IEEE488.2 and SCPI (Standard

Commands for Programmable Instruments). (See the Section 7 for more infomiation.)

This device incorporates the following interface functions.

■ Control of functions except for certain functions such as power source switch and Local key.

• Reading of all the setup conditions and screen display.

1-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

1.2 System Setup Example

The figure below slrows an example ol'aystem setup using: an interface.

Control from a host computer

When connected to a host computer, the de\ ice performs automatic measurement.

1.2 System Setup Example

MP1777A

Host computer

Fig. 1-1 Block Diagram

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-:

Page 17

Section 1 Outline

1-4.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Section 2 GPIB interface

[his section provides descriptions ot the CjPIB interlace iunctions and scttitic method in the event that the interiacc

used as an option.

2.1 GPIB Interface Functions

2.2 Device Message List

2.3 Bus Commands................................................................................... 2-4

2.4 Connecting the GPIB Cable

2.5 Setting GPIB ....................................................................................... 2-6

2.6 Initializing the Device........................................................................... 2-8

2.6.1 Initializing the Bus................................................................... 2-8

2.6.2 Initializing the Message

2.6.3 Initializing the Device.............................................................. 2-9

2.6.4 Device Status at Power Activation

....................................................................

...........................................................................

................................................................

..........................................................

..........................................

2-2

2-3

2-5

2-8

2-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-1

Page 19

Section 2 GPIB Interface

2.1 GPIB Interface Functions

This device only functions as a device and does not function as a controller. Accordingly, the GPIB interface has the

following functions.

Table 2-1 GPIB Interface Functions

Cord Interface Function

SHI All the source handshake functions is available.

AHl All the acceptor handshake functions is available.

Basic talker functions is available.

T5

L4

SRI

RLl

PPO No parallel port function is available.

DCl

DTI

CO No system controller functions is available.

Serial port function is available.

Talk only mode function is available.

Talker cancellation function is by MLA available.

Basic listener functions is available.

No listen only mode function is available.

Listener cancellation function is by MTA available.

All the service request functions is available.

All the remote and local functions is available.

All the device clear functions is available.

All the device trigger functions is available.

IEEE488.2 Standards

Incorporation of all the functions as the standard features

Incorporation of all the functions as the standard features

The device shall incorporate one of the following sub

sets: T5, T6, TE5 or TE6.

The device shall incorporate one of the following sub

sets: L3, L4, LE3 or LE4.

Incorporation of all the functions as the standard features

RLO (no functions) or RLl (all functions)

PPO (no functions) or PPl (all functions)

Incorporation of all the functions as the standard features

DTO (no functions) or DTI (all functions)

CO (no functions), C4 and C5, or one of the following

sub-sets: C7, C9 or C11.

2-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

2.2 Device Message List

2.2 Device Message List

Device iiicssaizes are data nicssaees exchanged betv'.cen thie controller and the device via the system interface when tlie

bus is set to the data mode (when the ATN line is set at "H"). and are classified into two types, the program messages and

response messages.

fhe prrieram messages are ASC.’II data messages transferred from the controller to the de^vice. while the response nies-

saees are tlata messaees transferred from the device to the controller.

Froeram and response messages are ftirlher classified into tfie following message types.

Table 2-2 Device Message List

Program Message

(See the Section 4 for more information.)

Program instructions

•Commands unique to the des iee

(See the Section 7 for more information.)

•Common IHFE4SS.2 commands

(See the Section .7 "Status Report" for more infor

mation. )

f-’rogram (lueries

Controller

Response Message

(See the Section 5 for more information.)

Status messages

(See the Section b "SCPI Outline" for more infomiation )

Response messages

MP1777A

Fig. 2-1 Device Message

d'he messages mentioned above are exchanged throngfi the I/O buffer of the device. 'Fhe following section pros ides a

brief description of tiie f/() buffer.

Table 2-3 I/O Buffer

Input Buffer

.Л t IR) i hirst In l-drst Out) type memorx area to tempo- ' A f-ihO type memor> area for the queue. .ЛИ iiie D.-\B's

rarily s'ore D.AB (progr.im messages and срасгу messag- I (response messages) outputs from the device to the con

es i before ihev are svntacticaily anal\/ed. ' troller arc stored in tiiis memory until the controller fin-

filis de\ ice has an tni ii! hut'ler of d.^b bvtes In si/ss ■ isb.es reading ah the liiessages.

Output Queue

2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Section 2 GPIB Interface

2.3 Bus Commands

Bus commands refer to internal interface communications exchanged when the bus is set to the command mode (when the

ATM line is set at "L"). The table below shows a list of bus commands.

Table 2-4 Details of Bus Commands

Bus Command

DCL (Device clear) Initializes the exchange of messages among all the devices connected to the GPIB

bus.

SDC (Selected Device Clear) Initializes the exchange of messages among addressed devices. The operations are

the same as those for DCL.

GET (Group Execute Trigger) Performs the same operations as those triggered when the Start/Stop key is pressed.

IFC (Interface Clear) Initializes the interface.

Operations

2-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

2.4 Connecting the GPIB Cable

2.4 Connecting the GPIB Cable

(Àninect the tiPIli cable to the Gl’lB tangential line located on the btick panel of this dev ice.

S\stents usnu; GPIEi come under the following restrictions.

l-ollow the conditions set out below to connect devices.

• No. of dev ices enabled to be connected < 15 units

• Total cable leiiL'th < 2 m x number of devices (20 m ma.ximtim )

GPIB

Connector

GPIB

- T-'-

t's

Fig, 2-2 Sketch of GPIB Cable

GPIB

Cable

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2~5

Page 23

Section 2 GPIB Interface

2.5 Setting GPIB

To use GPIB as a remote interface, set the device to the local mode and set the address by performing key input on the

front panel.

Table 2-5 Details of Setting when GPIB Interface is Used

Details of Setting

Address setting

Perform the setting shown above on the Secondary system screen in the Main setup screen.

(1) (a) Pressing the Setup key causes the Main setup screen to open.

The Main setup screen has "Setup" indicated on the left top section of the screen.

Setup

Bit Rate

Jitter Setting; Equalizer

Clock

Interface [Tx&Rx]

Setting Item

Address Oto 30

Time XX ; XX : XX XX/XXX/XX

[ 2,488 M ]

[ OFF ]

[ Internal ]

Setting Range

Fig. 2-3 Main setup Screen

(b) Moving the cursor to the shaded section of the figure above and pressing the Setup key causes a window as

shown below to open. To select the Secondary system screen, move the cursor onto "System" using the cursor

key and press the Set key.

Fig. 2-4 Screen Selection Window

2-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

2.5 Setting GPIB

(a) [’erforniing tlie operations mentioned in I causes the screen to shift to the Secondary system screen as shown

below. Move the black and white reversing cursor to the position marked * 1 and perform each setting. See the

operation manual lor the main unit for more information on setting.

Setup

Buzzer

Date & Time adjust

System

[ OFF

[ 00 : 11 : 17 01/Jan,''95

Time 00:11 : 23

Address

Fig. 2-5 Secondary System Screen (When GPIB Interface is Used)

01/Jan,'95

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-7

Page 25

Section 2 GPIB Interface

2.6 initializing the Device

IEEE488.2 stipulates three levels of system initialization: initialization of the bus, message and device.

Table 2-6 Types of System Initialization

Level

1 Initialization of the bus Initializes the functions of all the interfaces connected to the bus with the IFC

2 Initialization of the message Disables the function to report to the controller that the initialization of the

3 Initialization of the device Returns the device to the original state unique to the device by *RST, regard

Type of Initialization Outline

message from the controller.

exchange of messages among all the devices on GPIB and relevant operations

are completed by DCL, one of the GPIB bus commands, and that the initial

ization of the exchange of messages among specified devices on GPIB and

relevant operations are completed by SCL, also one of the GPIB bus com

mands.

less of the status during past usage.

2.6.1 Initializing the Bus

IFC: Initialization of the bus by the IFC statement

Function: Switches the IFC line into an active state for about 100 |is and initializes the interface function of all the

devices connected to the GPIB bus line. IFC can be transmitted only by the system controller.

2.6.2 Initializing the Message

DCL and SDC: Initialization of the exchange of messages by the DCL and SDC bus commands

Initializes the exchange of messages for all the devices on GPIB or specified devices on GPIB.

Functions: Initialization of the message exchange is aimed at setting preparations to enable the controller to send

new instructions in the event that sections related to the message exchange in devices are set in a state

inappropriate for the control to be executed from the controller because, for example, other programs

were executed earlier, although changing the panel setting is not required.

DCL: Initializes the message exchange among all the devices on GPIB.

SDC: Initializes the message exchange among specified devices.

2-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

2.6 Initializing the Device

2.6.3 Initializing the Device

<RST; Initializaiion of the dcMce by the ^-^RST eommand

Function: Returns the device function to the original sttite unique to the device, regardless of tlie status ol past

usage.

Tfie original state in regard to tins device refers to the state where the power sotu'ce switch has been

turned ON agtiin.

( Descriptions are provided for the state of the device at fiower actis aiion.)

2.6.4 Device Status at Power Activation

When tlie pocver is ;icti\ated. the device sv\ itches into the following stale :

( I ) .State set when the power source was turncil Of-’F die last time.

(di The input buffer and output queue are cleared.

(3i The s\nta\ anaiw.er. run time controllei. and response production module are rcwet.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-9

Page 27

Section 2 GPIB Interface

2-10.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Section 3 Listener Input Format

riiis section provides explanations t)l the tormat rif tiie program message th;it the listener (this niettsuritig instrument)

receives from the talker (cciturollen.

As tile commands unique to the device conform to SCPl, llie extimples given m this section use SCPI coinmaiids.

3.1 Listener Input Program Message Format

3.2 Functional Elements of Program Message

3.2.1 <TERMINATED PROGRAM MESSAGE>

3.2.2 <PROGRAM MESSAGE TERMINATOR> ............................. 3-5

3.2.3 <white space>......................................................................... 3-5

3.2.4 <PROGRAM MESSAGE> ...................................................... 3-6

3.2.5 <PROGRAM MESSAGE UNIT SEPARATOR> ..................... 3-7

3.2.6 <PROGRAM MESSAGE UNIT>

3.2.7 <COMMAND MESSAGE UNIT> and <QUERY MESSAGE UNIT>.... 3-8

3.2.8 <COMMAND PROGRAM HEADER>

3.2.9 <QUERY PROGRAM HEADER>

3.2.10 <PROGRAM HEADER SEPARATOR>

3.2.11 <PROGRAM DATA SEPARATOR>

3.3 Program Data Format......................................................................... 3-14

3.3.1 <CHARACTER PROGRAM DATA>

3.3.2 <DECIMAL NUMERIC PROGRAM DATA>.......................... 3-16

3.3.3 <BOOLEAN PROGRAM DATA>

3.3.4 <STR1NG PROGRAM DATA>

.............................................

...........................................

..............................

.............................................

...................................

........................................

................................

....................................

.....................................

...........................................

.............................................

3-2

3-4

3-4

3-7

3-10

3-12

3-13

3-13

3-15

3-1 7

3-17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

Section 3 Listener Input Format

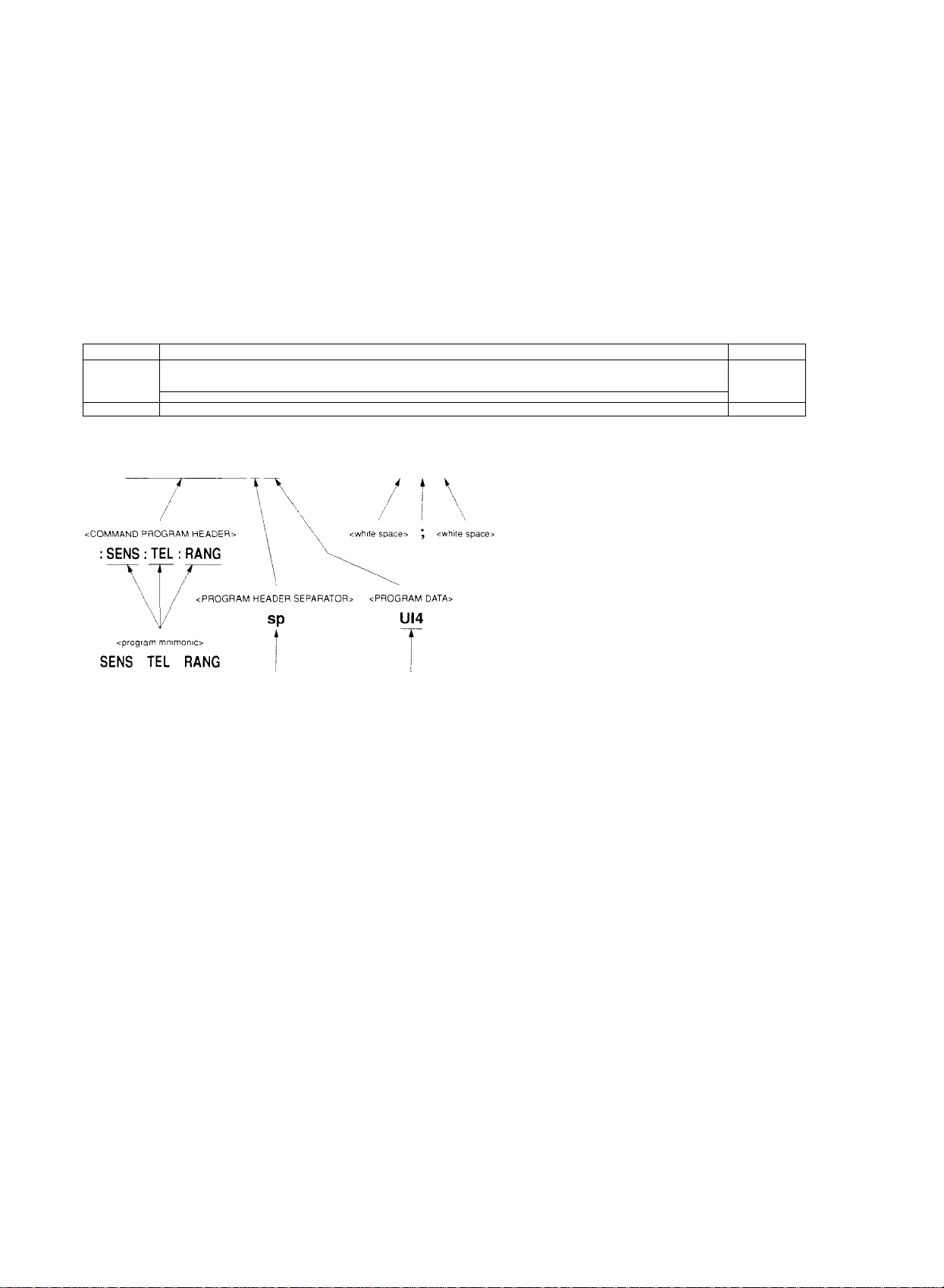

3.1 Listener Input Program Message Format

The following section shows program messages when, for example, 4 UI is selected for the reception jitter and the

reception signal is set to 9953M.

<TERMINATED PROGRAM MESSAGE>

Address 3

Listener address specification

A' '' ' V ^

Listener

(device)

/

( WRITE (0)03 : SENS : TEL ; RANG UI4 ; ; SENS ; TEL ; BRAT M9953" <NL>

\ / / V V

N /' / '\ '\

<PROGRAM MESSAGE UNIT>

: SENS : TEL : RANG UI4

<white space>

<PROGRAM MESSAGE>

<PROGRAM MESSAGE UNIT SEPARATOR»

sp ; sp

<boolean program data>

UI4

<PROGRAM MESSAGE TERMINATOR>

Talker

(controller)

<PROGRAM MESSAGE UNIT» SP <NL>

; SENS : TEL : BRAT M9953^, \

\

\ <white space> NL

: SENS : TEL : BRAT

<PROGRAM HEADER <PROGRAM DATA>

SEPARATOR>

The program message format comprises a sequence of functional elements divided into the units of minimum level to

express functions. The uppercase letters in angled brackets ( < and > ) in the figure above show examples of functional

elements. The functional elements are further divided into elements called the coding elements. The lowercase letters in

angled brackets ( < and > ) in the figure above show examples of coding elements.

The following pages provide explanations of the program message format using the functional syntax diagram and coding

syntax diagram.

• Functional syntax diagram: Graphic representation of selection of functional elements along specific routes

• Coding syntax diagram: Graphic representation of selection of coding elements along specific routes

3-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

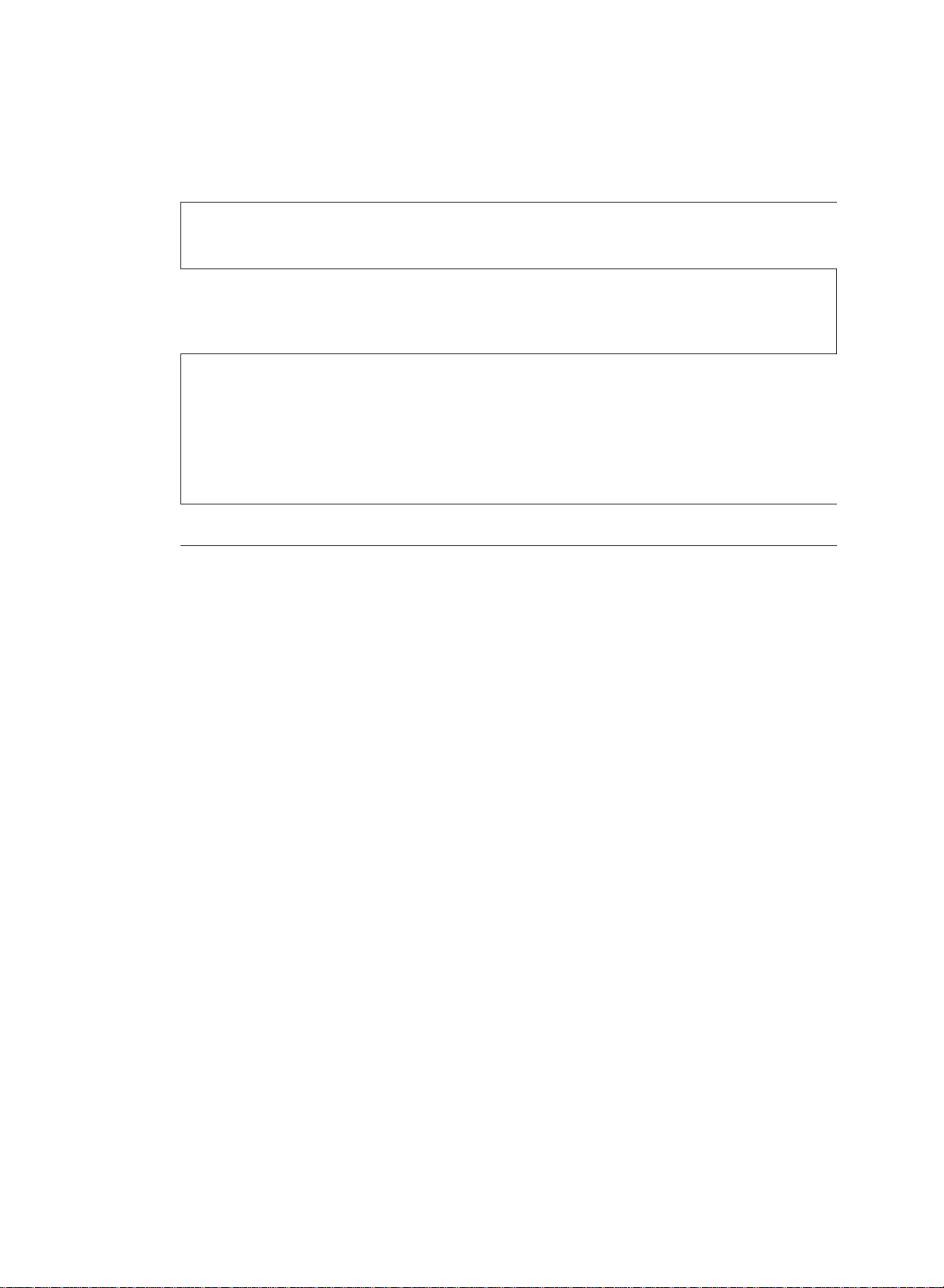

The WKIlTe and RTAD coniniands take tlic foilo\vin>t fonnals.

WRITE @

Outputs data to the device.

■a rumiaL

WRITE @

Data-

Device number : Data

Arithmetic expression

Character string expression

3.1 Listener Input Program Message Format

i

<Example>

The same as the example given on the previous page.

WRITE @03 : SENS ; TEL : RANG UI4 ; : SENS : TEL ; BRAT M9953"

i

Listener address

(in case that the GPIB address of the 10 GHz Jitter Analyzer is set at 3)

READ @

Substitutes the data input from the device to the variable.

K Format-------------------------------------------------------------

READ @Device number : Variable

<Example> Substitutes the data input from the device (input tangential line setting)

to the variable, A$.

WRITE @03 SENS : TEL : RANG')'" <- Inquires about the input

READ @03 : A$ tangential line setting,

i

Listener address

(in case that the GPIB address of the 10 GHz Jitter Analyzer is set at 3)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-3

Page 31

Section 3 Listener Input Format

3.2 Functional Elements of Program Message

This measuring instrument accepts the program message by detecting the terminator located at the end of the program

message. The following section explains each functional element of the program message.

3.2.1 <TERMINATED PROGRAM MESSAGE>

The <TERMINATED PROGRAM MESSAGE> is defined as follows.

<PROGRAM

<PROGRAM MESSAGE>

.

Refer to 3.2.4

The <TERMINATED PROGRAM MESSAGE> constitutes a data message that incorporates all the functional elements

necessary for the controller to send data to this measuring instrument.

To complete the transfer of the <PROGRAM MESSAGE>, the <PROGRAM MESSAGE TERMINATOR> is added to

the end of the <PROGRAM MESSAGE>.

MESSAGE

TERMINATOR>

Refer to 3.2.2

Example: <TERMINATED PROGRAM MESSAGE> to send two instructions

3-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

3.2 Functional Elements of Program Message

3.2.2 <PROGRAM MESSAGE TERMINATOR>

The <PR()CiRAM MESSAGE TERMlNArOR> in the case of using the GPIH interface is defined as follows.

<white space>

NL

--------------------- aEND

Refer to 3.2.3 J

NL i

le <PROGRAM MHSS.AGE TF.RMIN.‘\TOR> ends a sequence of one or multiple <FR()(iRAM .MH.SS.AGli I'NTT;

cments ot certain leneth.

NL;

F.ND:

Defined a.s a single .A-SGII code h\te 0.-\ ( 10 of deeinial digit). Nameh. this constitutes an .ASC'll

control character EE' (Line Feed) and performs the new line operalions to return the printing position to

the same character position on the next line. .As this eauses printing to start from a new line, it is also

called the Ni. (New Line).

Generates the EfOl signal b\- setting the E(.)l (Fhid-or-ldentifv) line, which is one of the GPU.-! control

buses, to TRUE, (the LOW level).

'Erie Statements to control the HOI line includes the EOl ON/OFE statement.

3.2.3 <white space>

'I’he <w Elite space> is defined as follow s

<white space

character>

Ehe <white space character> is defined as the single .ASCII code b\ te in the ranges of .ASCII code bytes of between (K)

and 09 and between 013 to 20 ideeiinal digits, 0 to 9 and I I to 32i.

1 he .ASCII control svmbol and blank s_\ nibol w ith an exception of the New Lane arc included in the range. Howev er, this

measuring instrument does not inteqrrct them as ASCII control symbols but sinipK' processes them as space or skips

readiiie them.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-5

Page 33

Section 3 Listener Input Format

3.2.4 <PROGRAM MESSAGE>

The <PROGRAM MESSAGE> is defined as follows.

The <PROGRAM MESSAGE> is composed of a sequence of zero, one or multiple <PROGRAM MESSAGE UNIT>

elements.

The <PROGRAM MESSAGE UNIT> elements signify programming instructions or data to be sent from the controller to

this measuring instrument. The <PROGRAM MESSAGE UNIT SEPARATOR> is used as the separator for delimitting

multiple <PROGRAM VIESSAGE UNIT> elements.

Example: Selects the reception jitter range of 4 UI and sets the reception signal to 9953M.

<PROGRAM MESSAGE>

^^

: SENS : TEL : RANG U14 ; : SENS : TEL : BRAT M9953

T

cPROGRAM MESSAGE UNIT SEPARATOR>

<PROGRAM MESSAGE UNIT>

<PROGRAM MESSAGE UNIT>

3-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

3.2 Functional Elements of Program Message

3.2.5 <PROGRAM MESSAGE UNIT SEPARATOR>

1 he <PR()GRAM MESSAGE L'MT SEPARA'r()R> is defined as follovss.

<white space>

Refer to 3.2.3

The <\\hiie spaco is defined as follovs s.

<white space

character>

I he <PROGR.'\M MESSAGE GMT SEP.AR.\d’OR> di\ ides a .sequence of nuiliiple <PROGk,\M MESS.AGE ENl

eleinenis w ithin ttie range of the <I^ROCrR.-\M M1',SS.‘\GE>.

fhis measuring instrument interprets a semicolon ( ; ) as the separator tor the <PROGR,\M ME.SSAfiE IcNI I >.

Therefore, the <white space character> located before and after the semicolon I ; ) is skip.ped.

Nonetheless, the <white space character> is effective in facilitating the reading of ilie program.

3.2.6 <PROGRAM MESSAGE UNIT>

I he <PROGR.'\M MESSAGE UNIT> is defined as follows.

<COMMAND MESSAGE>

Refer to 3.2.7

kQUERY MESSAGE UNITe

Refer to 3.2.7

The <PROGRAM .MESSAGE UN1T> comprises the <COM.MAND MESSAGE l’MT>, which constitutes a single com

mand message received bv this measuring itistrument. or <QEER't' MESS.AGE UNIT>, whicli constitutes ;i single query

mess.ice.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-7

Page 35

Section 3 Listener Input Format

3.2.7 <COMMAND MESSAGE UNIT> and <QUERY MESSAGE UNIT>

(1) The <COMMAND MESSAGE UNIT> is defined as follows.

Example: Sets the data.

3-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

I'he <QUHRY MHSSACiEi UMT> is defined as follows.

3.2 Functional Elements of Program Message

<PROGRAM \

DATA

SEPARATOR>

Refer to 3.2.11 / "

<QUERY

PROGRAM

HEADER>

Refer to 3.2.9

Example: Inquires about the analyzed data of the error or alarm.

<PROGRAM

HEADER

SEPARATOR>

.^Refer to 3.2.10,

<PROGRAM DATA>

.. PROGRAM 3A~A >

: CALC : TGR : DATA? 1995,3,27,12,54

^ " '' i V V k i

"PCGBAV HEADER SEPARATOR;.

5PY PROGRAM HEAT

Wiien the proertmi data follows tlie program header of <CO.\1M.‘\ND MESS.ACiE L'N'llG and <QUER'i’ ME.S.S.A(iE

t^NlTo. a space character is alvs a\s entered between them as a separator. The progrtini application, function ;ind opera

tion c;in be identified b\' the program header. In the absence ot’ the program data t(> lollow the program header, the

program header alone expresses the application, funenon and operation to be executed ni this measuring instrument.

■; = ROGRAV DATA ;EPARATOR>

flic <COMM.-\ND PROGR.AM HE.ADER> in the program lieader functions as a command to be used b\ the controller to

control this measuring instrument, while the <QUFRY PROGRM llE,ADEFf> is a query command that the controller

preliminanlv sends lo this measuring instrument so that the cinnroller will be able to receive the response message Irom

this measuring instrument. It is alw a\ s characterized b\ the addition of the quer\ indicator, or a question mark i 1 ), to the

end of the header.

3-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

Section 3 Listener Input Format

3.2.8 <COMMAND PROGRAM HEADER>

The <COMMAND PROGRAM HEADER> is defined as follows.

The <while space> can be placed before each header.

(1) The <Instrument-Control Headers> are defined as follows.

(2) The <common command program header> is defined as follows.

_________________________>

f3) The <program mnemonio is defined as follows.

3-10

<program mnemonio

Refer to (3) of 3.2.8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

3.2 Functional Elements of Program Message

3.2.8.1 <COMMAND PROGRAM HEADER>

The <COMMAND PROGRAM HEADI’R> expresses the appiication, f unction and operation of tlie program data to he

executed hv this measuring instrument. In the absence of the program data to follow the command program header, the

command program lieader alone expresses the application, function and operation to be executed in this measuring instru

ment.

The <program mnemonio expresses th.ese meanings b\ .ASCII code ciiaracters, and is generally called the mnemonic.

3.2.8.2 <program mnemonio

The header of the mnemonic ah\ ays begins \v iih an uppercase or lowercase character. Then, it is followed b_\ an arbiirarx

combm.ilion of uppercase characters (.A to Z), lowercase characters (a to z), an underline ( _ ). and digits from 0 to d, lie

mnemonic come-, in a ma.ximum length of I 2 characters, with no space inserted between characters.

(1) <upper,lower case alpha>

.'''pecified as a single .ASCII code byte m the range of .ASCII code b\ tes between 4 1 and .d.A, and 6 I and 7.\ ib.o to 4()

and 97 to 122 of decimal digits = uppercase characters (,A to Zi and lowercase characters (a to zi).

(2) <digit>

S|iecified as a single .ASCII code byte in the range of .ASCII code b\tes between 30 and 39 (4S to .37 of decimal digits

= numerical values between 0 and 9).

(3) (_)

Specifieii as ;i single .ASCII code b\te in ilie range of .ASCII code b_\te of 31- (93 ofdecimal digit = underlmei.

3.2.8.3 <!nstrument-Controi Headers>

Flic <lnstrument-Ccintrol Headers> are specified by SCPI. .As the de\ ice-specific commands of this measuring instru

ment conform to SCPI, the command format used is that of this programming language.

(1) <short form mnemonio and <long form mnemonic>

Corresponds to the short form and long form of the SCPI commands. The stipulations of <program mnemonio

mentioned above appK' as the\ tire its the mnemonic stipulations.

(2) <numeric suffix>

Specified as a single .ASCII code b\tc in the range of .ASCII code bytes between 30 and 39 (4S to 37 ofdecimal digit

= numerical wilues between 0 and 9).

3.2.8.4 <common command program header>

The <common command |srogram header> aK\a> s has an asterisk ( i betöre the <prograr,. mnemonio.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-11

Page 39

Section 3 Listener Input Format

3.2.9 <QUERY PROGRAM HEADER>

The <QUERY PROGRAM HEADER> is defined as follows.

The <white space> can be placed before each header.

(1) The <Instrument-Control Headers> are defined as follows.

(2) The <common query program header> is defined as follows.

__________

<program mnemonio

^

Refer to (3) of 3.2.8

3.2.9.1 <QUERY PROGRAM HEADER>

The <QUERY PROGRAM HEADER> is a query command, that the controller preliminarily sends to this measuring

instrument so that the controller will be able to receive the response message from this measuring instrument.

It is always characterized by the addition of the query indicator, or a question mark ( ? ), to the end of the header.

The <QUERY PROGRAM HEADER> format mentioned above comes with the query indicator, or a question mark ( ? ),

added to the end of the header

As other features are the same as those for the <COMMAND PROGRAM HEADER>, see the Section 3.2.8 "<COM

MAND PROGRAM HEADER>" for more information.

3-12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

3.2 Functional Elements of Program Message

3.2.10 <PROGRAM HEADER SEPARATOR>

The <PR()GR.\M HHADhT'! SEF^ARATOK> is tiefined as follov. s.

<white space>

Refer to 3.2.3

The <PROGR,\M UliAIdHR .SFPARATOR> is used as a separator between tiie <COMM AND F’ROCiRAM HEADf:R>

or <Q)L'l:R'i’ PROtiR.AM 11E/\DER> and <PRO(iR.\M D.A'F.Ao. When multiple <wliite space characters;- are found

between the program header and program data, the first <w hire sptice ch;iracier;> is interpreted as the separator, and other

■e\\ hite sptice characters;- are skipped.

Nonetheless die <while space chanicter> is eflective m facilitating reading of the program.

This means tnat onlv one header separator is alwtigs iound between the header ami data to signal tiie end of the inogram

as w ell as the begimimg of the progrtini ilata.

3.2.11 <PROGRAM DATA SEPARATOR>

The <PROGRA.M DATA SEPARATC)R> is defined as follows.

<white space>

Refer to 3.2.3

When the <COMMAND PROGRAM HEADER> or <QUERY PROGRAM HEADER> has multiple parameters, the

<PROGiF,AM [),\ I'.A SEP.AR.-\TOR> is used to separtite these parameters.

When this data separator is used, a comma i . ) is alwa\s necessar\' but the <whiie space ch;iracter> is not necessarilg

required, fhe <w hite space character;- located before or after a comma t , ) w ill be skipped. However, the <w hite space

character;- is effective in faeiiitatmg reading of the program.

"RCG‘=AV ZA~A>

<white space>

Refer to 3.2.3 j f"

SYSTfDATE 1993,7,15

✓ i V

.IRAM RSACER :

;a'a SE''A = AT

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

Section 3 Listener Input Format

3.3 Program Data Format

This section provides explanations of the format of <PROGRAM DATA> illustrated by the functional syntax diagram of

the Section 3.2.7 "<COMMAND MESSAGE UNIT> and <QUERY MESSAGE UNIT>" from among formats of pro

gram messages terminated as mentioned in the earlier sections.

The functional elements of <PROGRAM DATA> are used to transfer parameters of various types related to the program

header. The sections shaded in the figure below are the program data used by this measuring instrument.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

3.3 Program Data Format

3.3.1 <CHARACTER PROGRAM DATA>

I’lie <CHARAC rER PROGRAM DA'I A> expresses a short ninemonic data and is defined as foiiovvs.

<program mnemonio

Refer to (3) of 3,2,8

: SENSe : MEASure ; TYPE SlNGIe (Mnemonic data to express single measurement)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

M5

Page 43

Section 3 Listener Input Format

3.3.2 <DECIMAL NUMERIC PROGRAM DATA>

The <DECIMAL NUMERIC PROGRAM DATA> expresses a numeric value of a decimal digit and is defined as follows.

(1) The <mantissa> is defined as follows.

(2) The <exponent> is defined as follows.

This measuring instrument uses the integer type of decimal digits.

Integer type

Expresses the integer values of decimal digits. The underline ( _ ) stands for a space.

^ Zero (0) enabled to be input at the header......................................005

•" Space between a sign and digit disabled

- Space enabled to be inserted to follow a numeric value

* The plus sign can be either added or omitted..................................+5, 5

'■ A comma disabled to be used to separate digits

.......................................

................+5___

..........................

+5 (good), +_5 (no good)

1,234 (no good)

3-16

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

3.3 Program Data Format

3.3.3 <BOOLEAN PROGRAM DATA>

I'hc <BOOI,liAN PROCiRAM D.\1'A> refers to l!ie program dat:i specified bv SCPI and expresses ;i theoretical value.

As values to cirrrespond to the trutii and falsitxa ON and OFF of the <CHARACTFR PROCiR.XM f).‘\TA> and I and 0 of

the cDFClMAL NUMERIC PROGRAM !.),-VrA> are defined.

:SOURce:TELecom: Jitter ON

: SOURce: TELecom: Jitter 1

3.3.4 <STRING PROGRAM DATA>

The cSTRING PROGR.WI expresses a character string in double c|uotatioiis ( " i or single quotations i ' i anti is

tiefined as folKsw s.

<inserted'

<non-single

quote char>

<inserted'>

<non-double

quote char>

( 1 1 oiiiserted’o is specified b\ a single ASCII sigti t'f \ alue 27 (39 of decimal digit = ' i.

( 2 1 <non-sing!e quote char> is specified b\ a single s\SCII sign of ;i \ alue other than 27 ( "^9 ol’ decimal digit = ’ ».

|3| <insertcd'> is specified by a single .CSCIl sign of value 22 (.34 of decimal digit = " ).

(4) <nt'n*d('uhle quote ciiar> is specified by a single ASCII sign ot a v alue oilier than 22 (34 of decimal digit = "

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

-17

Page 45

Section 3 Listener Input Format

3-18.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

Section 4 Talker Output Format

This section pro\'ides explanations of tiie format of the response messages to be returned from the talker (dec ice) to the

listener (controlIcr).

4.1 Talker Output Response Message Format

4.2 Functional Elements of Response Message............................................. 4-3

4.2.1 <TERMINATED RESPONSE MESSAGE>

4.2.2 <RESPONSE MESSAGE TERMINATOR>

4.2.3 <RESPONSE MESSAGE>

4.2.4 <RESPONSE MESSAGE UNIT SEPARATOR>

4.2.5 <RESPONSE MESSAGE UNIT> ...................................................... 4-5

4.2.6 <RESPONSE DATA SEPARATOR>........................................... 4-5

4.2.7 <RESPONSE DATA> ........................................................................ 4-6

................................................................

...............................................

.............................

.......................................

.......................

4-2

4-3

4-3

4-4

4-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4-1

Page 47

Section 4 Talker Output Format

4.1 Talker Output Response Message Format

The figure below shows responses to the query for the selection of the receiving jitter range,; SENS ; TEL ; RANG?, and

to the query for the sign speed of the received signal, : SENS : TEL : BRAT?.

As the SCPI response has no header, the response only consists of data.

Like the program message, the response message format comprises a sequence of functional elements divided into the

units of minimum level to express functions. The uppercase letters in angled brackets ( < and > ) in the figure above show

examples of functional elements. The functional elements are further divided into elements called the coding elements.

The lowercase letters in angled brackets ( < and > ) in the same figure above show examples of coding elements. Accord

ingly, the same syntactical notational convention is used for the talker and the listener.

4-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

4.2 Functionai Elements of Response Message

4.2 Functional Elements of Response Message

4.2.1 <TERMINATED RESPONSE MESSAGE>

I'hc < rr.RMIN,‘\ TED RF.SPONSK MFSSAGE> is defined as follows.

<RESPONSE

:RESPONSE MESSAGE>

Refer to 4.2.3

The <TliRMlNATT,D PROGR.AM MES.S.AGF> constitutes ;i data message that incorpoiaites all the functional elements

necessarc' for the ttilker de\ ice to send data to the controller.

To complete the transfer of the <REPON.SH ME.S.SAGE>. the <REPONSH ME.S.SAGE TERMINATOR> is added to the

end of the <REPONSE ME.S.SAGE>.

Example: <TERM ¡SATED REPOSSE MESS AG E> concatenating two message units

fyiESSAGE

TERMINATOR>

Refer to 4.2.2

e-HIINATED -E.o'^GNSE MESSAGE-

Listener i.

(device) L

sespon.se message

_________

(

U!4 ; M9953 <NL>

" V V i A

<GE5P0NSE MESSAGE TEOM'NA^0R>

Address 3

Talker

(controlier)

Functional elements

4.2.2 <RESPONSE MESSAGE TERMINATOR>

( I i rile <RE.SPON.SE ME.S.S.AGE rERM[N.AT'OR> in case the GPIB interface is used is defined as follows.

- NL

T he <RE.SPON,SE ME.S.SAGE T ERMlN'ATOR> comes after the last oRESPONSi-i MESSAGE UNlTo. and ends a

sequence of one or multiple <RESPONSF: MESS.AGE LfNIT> elements of a certain length.

sEND

Example: Indicates an example of the program to read the state of receiving jitter range currently set.

10 WRITE @03 ; SENS : TEL ; RANG'!’"

20 READ @03 : A$

30 PRINT AS

40 END

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4-3

Page 49

Section 4 Talker Output Format

4.2.3 <RESPONSE MESSAGE>

The <RESPONSE MESSAGE> is defined as follows.

The <RESPONSE MESSAGE> is composed of a sequence of one or multiple <RESPONSE MESSAGE UNIT> ele

ments

The <RESPONSE MESSAGE UNIT> element signifies a single message to be sent from this measuring instrument to the

controller. The <RESPONSE MESSAGE UNIT SEPARATOR> element is used as the separator to delimit multiple

<RESPONSE MESSAGE UNIT> elements.

Example:

Indicates responses to queries for the selection of receiving jitter range and for the setting of sign speed of received signal.

4.2.4 <RESPONSE MESSAGE UNIT SEPARATOR>

The <RESPONSE MESSAGE UNIT SEPARATOR> is defined as follows.

The <RESPONSE MESSAGE SEPARATOR> separates with a semicolon ( ; ) that constitutes the <UNIT

SEPARARATOR>, the <RESPONSE MESSAGE UNIT> elements when a sequence of multiple <RESPONSE MES

SAGE UNIT> elements is output as one <RESPONSE MESSAGE>.

4-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

4.2 Functional Elements of Response Message

4.2.5 <RESPONSE MESSAGE UNIT>

Tlie <R[iSP().\SH MESSAGE ENHA is defined as follows.

<RESPONSE

DATA

SEPARATOR>

Refer to 4.2.6

<RESPONSE DATA>

Refer to 4.2.7

The <RH.SPON'SE MES.SAGE LtNldA of this measuring instrument is ti response messttge unit with no header and only

returns data (if measured results.

4.2.6 <RESPONSE DATA SEPARATOR>

The <RESPONSE D.ATs\ SF.P,\R.AT(.)R> is defined as follow '

1 he <RH.SPO.\'.SE DAI .A SfiP.AR.A 1 OR> is used to separate data when multiple <RESPONSE DAT.-\> are output.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4-f

Page 51

Section 4 Talker Output Format

4.2.7 <RESPONSE DATA>

The shaded sections in the figure below refer to the <RESPONSE DATA> used by this measuring instrument

The response data to be returned depends on the query message.

4-6.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 52

Section 5 Common IEEE488.2 Commands

This section providec descriptions of the common Ii-iTE488.2 commands supported b\' this device.

The common commands can he used by the CiPIB interface.

The common commands supported b\' this device are all sequential commands.

5.1 Common IEEE488.2

..........................................................................

5-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 53

Section 5 Common IEEE488.2 Commands

5.1 Common IEEE488.2

The table below lists common IEEE488.2 commands supported by this device.

Table 5-1 List of Common IEEE488.2 Commands

Mnemonic

*IDN? Identification Query

*OPC

*OPC?

=^WAI

=i=CLS

*ESE

*ESE?

=i=ESR?

*SRE

*SRE?

Operation Complete Command

Operation Complete Query

Wait Continue Command

Clear Status Command

Standard Event Status Enable Command

Standard Event Status Enable Query

Standard Event Status Register Query

Service Request Enable Command

Service Request Enable Query

Read Status Byte Query

Description

*PSC

*PSC?

*SAV

*RCL

*OPT?

Power On Status Clear Command

Power On Status Clear Query

Save Command

Recall Command

Option Identification Query

5-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 54

IDN? Identification Query

5.1 Common IEEE488.2

Response

Funciion

lixatiiple of use

OPC

Parameter

Function

Example of use > vRCT, I : *OPC

OPC?

Response

<ARBITRARY ASCII RHSPONSt DA'rA>

<Name of product nianufacturer>. <Model name>. <Senal No.>. <F-inmv are Revision No.>

In this device: ANRITSU, MP1777A. 0. Ol

Reports data including the name ot product manufacturer and model name.

> ADN?

< ANRITSL7 MPI777A, 0, Ol

Operation Complete Command

None

Sets the bit (> (bit to end operations) of the standard event status register and sw itches SR(7

ON w hen the execution of the previous instruction is completed.

Operation Complete Query

<.\'Rl NLAIPRIC RHSPONSFI DAd A>

Function

P.vaniple of use

WAI

Parameter

Function

Example of use

Returns I when the e.xecution of the previous instruction is completed.

> sRCL I : sOPC?

< I

Wait Continue Command

None

Keeps the commencement of the e.xeeution (.if the next instruction on hold until the executioi

ot'the prec ious instruction is completed.

(Executes the overlap command as the sequential command.)

This function IS effective onlv for the previous instruciion.

> sWAl

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-3

Page 55

Section 5 Common IEEE488.2 Commands

^CLS

Parameter

Function

Example of use

^ESE

Parameter

Function

Clear Status Command

None

Clears all the status composition excluding the output queue and MAV summary message

Flowever, the enable register and Transition filter are not cleared.

Clears both the output queue and MAV bit when *CLS is sent immediately after the <PRO

GRAM MESSAGE TERMINATOR>, and at the same time, before the <Query MESSAGE

UNIT> element.

> *CLS

Standard Event Status Enable Command

<DECIMAL NUMERIC PROGRAM DATA>

Integer value between 0 and 255.

Set as the parameter the sum total of the bits desired to be enabled among the standard event

status enable register.

Set 1 for enable and 0 for disable.

See the Section for the "Status Byte" for the composition of the register of this device.

Sets and clears the standard event status enable register.

Example of use

^ESR?

Response

Function

Example of use

Sets bits 2 and 4 of the standard event status enable register.

> *ESE20

Standard Event Status Register Query

<NR1 NUMERIC RESPONSE DATA>

Integer value between 0 and 255.

Set as the response the sum total of the bits of the standard event status register.

See the Section for the "Status Byte" for the composition of the register of this device.

Inquires about the current value of the standard event status register.

When a command error is found.

> *ESR?

< 32

5-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 56

SRE Service Request Enable Command

5.1 Common IEEE488.2

[’arametcr

Piinctioii

Pxampie of use

<DFX'1MAL. NUMf-TRIC PROGRAM DA'1'A>

Integer value between 0 and 255.

Set as the parameter the sum tottil of the hits desired to be enabled among the ser\ ice request

enable register.

Set 1 for enable and 0 for disable.

See tlie Section for the "Status B\ te" for the composition ot the register of this dev ice.

Sets ;ind clears the service request enable register.

Sets bit 4 of the service request enable register.

> rSRF 10

SRE? Service Request Enable Query

Response

0 hunction

Example of use

<NR1 NUMERIC RESPONSE D.A 1A>

Integer value between 0 and 255.

Set as the response tiie sum total of the bits of tlie service enttble register.

See the Section for the "Status Byte" for the composition ol’ the register of this device.

Inquires about the current value of the service request entible register.

>’SRE?

< 16

STB? Read Status Byte Query

Response

•unction

frxample of use

<NR1 NLAIERIC RESPONSE DA r'A>

Integer v alue between 0 and 255.

Set as tlie response the sum total of the hits of the status byte register.

See the Section for the "Status Bvtc" for the composition of the register of this device.

Inquires about the current value of the status bvtc register including the MSS (Master Sumniarv Status) bit.

In the absence of errors or event queue

>-SIB’

< 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 57

Section 5 Common IEEE488.2 Commands

*PSC Power On Status Clear Command

Parameter

Function

Example of use

i<PSC?

Response

Function

<DECIMAL NUMERIC PROGRAM DATA>

0 ....................Sets the power ON status clear flag to false.

1

...................

Determines whether or not to clear each enable register of the service request, standard event

status and parallel poll of the status report module when the power is switched ON.

When the mode is set to 0. the enable register will not be cleared and the device is enabled to

generate SRQ after the power source is turned ON.

When the mode is set to 1, the enable register will be cleared and the device is disabled to

generate SRQ after the power source is turned ON.

Generates SRQ without clearing the power ON status flag.

> =^PSC 0 ; *SRE 32 ; *ESE 128

Sets the power ON status clear flag to true.

Power On Status Clear Query

<NR1 NUMERIC RESPONSE DATA>

0

....................

1

...................

Inquires about the truth or falsity of the power ON status clear flag.

Sets the power ON status clear flag to false.

Sets the power ON status clear flag to true.

Example of use

*SAV

Parameter

Function

Example of use

> *PSC?

<0

Save Command

<DECIMAL NUMERIC PROGRAM DATA>

1 to 10

...........

4-4

Writes the current device setting into the memory of specified number.

There is no limit to the state to be saved. See the Table 7-1 in the Section 7.5 "Parameter".

As an SCPI command that has the same function, : SYSTem : MEMory ; STORe is avail

able.

Writes the current setting into the memory number 1.

> *SAV 1

5-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 58

*RCL Recall Command

5.1 Common IEEE488.2

Parameter

Function

Example of use

<DECIMAL NUMERIC PROGRAM DATA>

Oto 10

Calls the memory of a specified number and, by doing so, returns the device to the previous

state.

There is no limit to the state to be loaded. See the Table 7-1 in the Section 7.5 "Parameter".

As an SCPI command which has the same function, : SYSTem : MEMory : RECall is avail

able.

Calls the information stored in memory number 1 and performs setting.

> *RCL 1

*OPT? Option Identification Quet7

Response

<ARB1TRARY ASCII RESPONSE DATA>

Characters to correspond to the option or unit

Option

Interface (Bit Rate) selection condition option

Standard

• 2,488 M, 4,977 M, 9,953 M

Interface (Bit Rate) selection condition option

Option 01

• 2,494 M, 4,988 M, 9,977 M

Interface (Bit Rate) selection condition option

Option 02

• 2,666 M, 5,332 M, 10,644 M

Interface (Bit Rate) selection condition option

Option 04

• 3,062 M, 6,125 M, 12,249 M

Interface (Bit Rate) selection condition option

Option 05

• 3,069 M, 6,138 M, 12,276 M

Interface (Bit Rate) selection condition option

Option 06

• 2,677 M, 5,355 M, 10,709 M

Interface (Bit Rate) selection condition option

Option 07

• 2,578 M, 5,156 M, 10,313 M

Character

OPTO

OPTI

OPT2

OPT4

OPT5

OPT6

OPT7

Function

Example of use

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Reports on the list of options and units mounted.

Reports on options and units mounted all delimited by a comma.

Options 01 and 02 are mounted.

> *OPT?

< OPTl, OPT2

5-7

Page 59

Sections Common IEEE488.2 Commands

Element

(1) CHARACTER

RESPONSE DATA

Example:

ABC

DEFG

(2)NR1 NUMENIC

RESPONSE DATA

Example:

123

+ 123

-1234

(3) NR2 NUMENIC

RESPONSE DATA

Example:

12.3

+ 12.34

-12.345

Function

Expresses short mnemonic data.

<response

mnemonio

Expresses integer values of decimal digits.

Expres.ses fixed point numerical values.

(4) NR3 NUMENIC

RESPONSE DATA

Example:

1.23E+45

-12.3E+45

Expresses real numbers of decimal digits with exponent.

5-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 60

5.1 Common IEEE488.2

Element

(5) STRING

RESPONSE DATA

Example:

"1234"

"ABCD"

"1234.5"

(6) ARBITARY ASCII

RESPONSE DATA

Example:

<ASCII> <ASCII

Byte> NLaEND

Function

Expresses a character string in double quotations (").

Sends ASCII data bytes excluding the NL character without delimiting them. For this rea

son, NLaEND (or NL only) is placed next to the last data, and the data is accordingly ter

minated without an exit point.

An example of using the GPIB interface is shown below.

<ASC1I

data byte>

NL

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-9

Page 61

Section 5 Common IEEE488.2 Commands

5-10.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 62

Section 6 Status Report

The configuration of the status registers of the MP1777A conforms to the SCPI stipulations. (SCPI: Standard Command

for Programmable Instruments, see the Section 7 for more information.)

This section provides descriptions of the configuration of status registers and definition of the status register bit specific

to the device.

6.1 Configuration of MP1777A Status Registers............................................ 6-2

6.2 Status Registers Specified by IEEE488.2

6.3 Status Register Specified by SCPI.............................................................. 6-6

6.4 Status Register Specific to MP1777A

6.5 Reading, Writing and Ciearing Status Registers

...................................................

.........................................................

......................................

6-4

6-7

6-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6-1

Page 63

Section 6 Status Report

6.1 Configuration of MP1777A Status Registers

SCPI stipulates that the status register configuration must conform to the configuration specified by IEEE488.2 and

incorporate the SCPI OPERation status register and QUEStionable status register specific to SCPI.

The figure below shows a simple block diagram of status registers mounted on this device. (Explanations of the bit

position and width to be provided later)

Fig. 6-1 Block Diagram of Status Registers

Registers specified by IEEE488.2 are event register and status byte register.

Register specified by SCPI is OPERation status register.

Device-specific register is INSTrument status register.

6-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 64

6.1 Configuration of MP1777A Status Registers

Status registers excluding the registers specified by IEEE488.2 are configured as follows.

Condition Transition Event

register filter register

Event enable

register

Summary Message

Fig. 6-2 Block Diagram of each Status Register

Table 6-1 Definitions of Register and Filter

Register and Filter

Condition register

-

Monitors the device status and performs real-time change in accordance w'ith the device

status.

For this reason, this register does not store the status.

Definition

Transition filter

-

-

Event register

Event enable register

Sets the condition register details to the event register.

The transition filter comes in three modes, depending on the changes of the condition regis

ter to be evaluated.

Positive direction change; The event becomes true only when the corresponding condition

changes from false to true.

Negative direction change; The event becomes true only when the corresponding condition

changes from true to false.

Both direction change; The event becomes true when a change into the positive or

negative direction takes place.

Stores the output of the transition filter.

Selects the bit of corresponding Event Register to trigger a shift of summary message to true.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6-3

Page 65

Section 6 Status Report

6.2 Status Registers Specified by IEEE488.2

IEEE488.2 specifies the two status registers shown below.

Table 6-2

Status Register

Status byte register

Standard event status register

Standard event status

enable register

0

1

Definitions of Status Registers Specified by IEEE488.2

Definition

A register to set RQS and seven summary message bits.

Being used in combination with the service request enable register, this register sets

SQR ON when the logical OR of the two is not zero. RQS is system reserved in bit 6

and this bit reports to the external controller the presence of service request.

Sets eight types of events the device will encounter as standard events.

The logical OR output bit is summarized and displayed in bit 5 of the status byte

register as the ESB (Event Status Bit) summary message.

Standard event

status register

— 0

OPC

NOT USED

QYE

DDE

EXE

CME

NOT USED

PON

Error/event queue

Service request

enable register

6-4

Logica OR

Status byte

register

0

1

►MSS6 RQS-

Logical OR

Service Request

Generation

NOT USED

0

NOT USED

OUEQUESMAV --------ESB ----------

7 OPER

i

----------

--------

Output queue

QUEStionable

status register

OPERation

status register

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 66

6.2 Status Registers Specified by IEEE488.2

The tables below show the definition of register bit specified by IEEE488.2.

Table 6-3 Definition of Status Byte Register Bit

Bit

DB2 QUE

DB4

DBS ESB (Event Summary Bit) Standard event status register summary

DB6 RQS (Request Service)

DB7 OPER (OPERation status register summary)

MAY (Massege Available) Indicates that the output queue is not empty.

MSS (Master Summary Status)

Status Byte Register Definition