Anritsu MG3696A, MG3695A, MG3694A, MG3693A, MG3692A User Manual

...

SERIES

MG369XA

SYNTHESIZED SIGNAL GENERATORS

OPERATION MANUAL

490 JARVIS DRIVE

MORGAN HILL, CA 95037-2809

P/N: 10370-10353

REVISION: H

PRINTED: APRIL 2005

COPYRIGHT 2005 ANRITSU CO.

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for three years from the date of shipment.

Anritsu's obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyersshall prepaytransportation chargesfor equipmentreturned toAnritsu for

warranty repairs.Obligation is limitedto the originalpurchaser.Anritsu is notliable for consequen

tial damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear.

Also,the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer, unauthorized modificationor misuse,or operation outside ofthe environmental specifications of the product. No other warranty is expressed or implied, and the remedies provided herein

are the Buyer's sole and exclusive remedies.

TRADEMARK ACKNOWLEDGMENTS

Adobe Acrobat is a registered trademark of Adobe Systems Incorporated.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers

as a guide for the proper installation, operation, and maintenance of Anritsu Company equipment

and computer programs. The drawings, specifications, and information contained herein are the

property of Anritsu Company, and any unauthorized use or disclosure of these drawings, specifica

tions,and information isprohibited; they shallnot be reproduced,copied,or used inwhole or inpart

as the basis for manufacture or sale of the equipment or software programs without the prior writ

ten consent of Anritsu Company.

-

-

-

UPDATES

Updates to this manual, if any, may be downloaded from the Anritsu Internet site at:

http://www.anritsu.com.

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully BEFORE operating the equipment.

WARNING WARNING indicates a hazard.It calls attention to a procedure that

could result in personal injury or loss of life if not performed properly.

Do not proceed beyond a WARNING notice until the indicated condi

tions are fully understood and met.

CAUTION CAUTION indicates a hazard.It calls attention to a procedure which,

if not performed properly, could result in damage to or destruction of a

component of the instrument. Do not proceed beyond a CAUTION note

until the indicated conditions are fully understood and met.

The instrument is marked with this symbol to indicate that it is necessary for the user to refer to the instructions in the operation manual.

-

Indicates ground.

MG369XA OM Safety-1

For Safety

WARNING

When supplying power to this equipment, always use a

three-wire power cable connected to a three-wire power line

outlet. If power is supplied without grounding the equip

ment in this manner, there is a risk of receiving a severe or

fatal electric shock.

WARNING

Before changing the fuse,always remove the power cord

from the power outlet. There is the risk of receiving a fatal

electric shock if the fuse is replaced with the power cord

connected.

Always use a new fuse of the type and rating specified by

the fuse markings on the rear panel of the instrument.

-

WARNING

There are no operator serviceable components inside.Refer

servicing of the instrument to qualified service technicians.

To prevent the risk of electrical shock or damage to preci

sion components, do not remove the equipment covers.

WARNING

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment

may be impaired.

-

Safety-2 MG369XA OM

Table of Contents

Chapter 1 General Information

1-1 Scope of Manual ............................1-3

1-2 Introduction ..............................1-3

1-3 Description ...............................1-3

1-4 Identification Number .........................1-3

1-5 Electronic Manual ...........................1-4

1-6 Related Manuals ............................1-4

GPIB Programming Manual .................1-4

Maintenance Manual .....................1-4

1-7 Options .................................1-4

1-8 Performance Specifications ......................1-8

1-9 Recommended Test Equipment ....................1-8

Chapter 2 Installation

2-1 Introduction ..............................2-3

2-2 Initial Inspection............................2-3

2-3 Preparation For Use ..........................2-3

2-4 Rack Mounting Kit Installation ....................2-5

Preliminary .........................2-5

Procedure ..........................2-5

Power Requirements .....................2-8

Power Connection ......................2-8

Standby Operation ......................2-9

Warmup Time ........................2-9

Operating Environment ...................2-9

2-5 GPIB Setup and Interconnection...................2-10

Interface Connector .....................2-10

Cable Length Restrictions ..................2-10

GPIB Interconnection ....................2-10

Setting the GPIB Address ..................2-11

Selecting the Line Terminator ................2-12

Interface Language .....................2-12

MG369XA OM i

Table of Contents (Continued)

2-6 Preparation for Storage/Shipment ..................2-13

Preparation for Storage ...................2-13

Preparation for Shipment ..................2-13

2-7 Anritsu Service Centers .......................2-14

Chapter 3 Local (Front Panel) Operation

3-1 Introduction ..............................3-5

Typographic Conventions ...................3-5

3-2 Front Panel Layout...........................3-6

Line Key ...........................3-6

Data Display Area ......................3-6

Data Entry Area .......................3-7

RF Output Control Key....................3-7

RF Output Connector.....................3-7

3-3 Data Display Area ...........................3-8

Menu Display Format ....................3-9

Menu Keys .........................3-10

3-4 Data Entry Area ...........................3-12

3-5 Instrument Start-Up .........................3-14

Powering Up the MG369XA .................3-14

Start-Up Display ......................3-14

Standby Operation .....................3-14

Self-Testing the MG369XA .................3-15

Resetting to Default Parameters...............3-15

3-6 Entering Data.............................3-17

Opening the Parameter ...................3-17

Editing the Current Value ..................3-18

Entering a New Value ....................3-19

3-7 CW Frequency Operation.......................3-20

Selecting CW Mode .....................3-20

Selecting a CW Frequency..................3-20

Selecting a Power Level ...................3-22

CW Ramp..........................3-23

Phase Offset ........................3-24

Electronic Frequency Control ................3-25

ii MG369XA OM

Table of Contents (Continued)

3-8 Sweep Frequency Operation .....................3-26

Analog Sweep Mode .....................3-26

Selecting Analog Sweep Mode ................3-26

Setting Sweep Time .....................3-27

Step Sweep Mode ......................3-28

Selecting Step Sweep Mode .................3-28

Setting Step Size, Dwell Time, and Sweep Time .......3-29

Selecting a Sweep Trigger ..................3-31

Manual Sweep Mode ....................3-32

Selecting Manual Sweep Mode................3-33

Selecting a Sweep Range ..................3-33

Selecting a Power Level ...................3-36

Frequency Markers .....................3-36

Selecting Alternate Sweep Mode...............3-38

List Sweep Mode ......................3-42

Selecting List Sweep Mode .................3-43

List Frequency Editing ...................3-45

List Power Editing .....................3-46

Selecting a List Sweep Range ................3-48

Selecting a List Sweep Trigger ...............3-49

3-9 Fixed Power Level Operation.....................3-51

Selecting Fixed Power Level Mode ..............3-51

Selecting a Power Level ...................3-51

Level Offset .........................3-54

3-10 Power Level Sweep Operation ....................3-56

Selecting CW Power Sweep Mode ..............3-56

Setting CW Power Sweep Step Size and Dwell Time .....3-57

Selecting a CW Power Sweep Trigger ............3-57

Selecting a Power Level Sweep Range ............3-59

Selecting a Sweep Frequency/Step Power Mode .......3-61

Setting Power Level Step Size ................3-62

3-11 Leveling Operations .........................3-63

Selecting a Leveling Mode..................3-63

Attenuator Decoupling ...................3-66

ALC Power Slope ......................3-67

User Cal (User Power Level Flatness Calibration) ......3-69

MG369XA OM iii

Table of Contents (Continued)

3-12 System Configuration.........................3-75

Accessing the System Configuration Menu ..........3-75

Configuring the Front Panel ................3-76

Configuring the Rear Panel .................3-77

Configuring the RF .....................3-78

Configuring the GPIB ....................3-80

Setting Increment Sizes ...................3-83

3-13 Saving/Recalling Instrument Setups.................3-84

Saving Setups........................3-84

Recalling Setups ......................3-85

Erasing Stored Setups....................3-85

3-14 Secure Operation ...........................3-86

Memory Profile and Security Issues .............3-86

3-15 Reference Oscillator Calibration ...................3-87

3-16 Signal Modulation ..........................3-90

Accessing Modulation Modes ................3-90

Amplitude Modulation Operating Modes ...........3-91

Providing Amplitude Modulation ..............3-91

Frequency Modulation Operating Modes ...........3-94

Providing Frequency Modulation ..............3-95

Phase Modulation Operating Modes .............3-99

Providing Phase Modulation ................3-100

Pulse Modulation Operating Modes.............3-104

Providing Pulse Modulation ................3-105

3-17 Internal Power Meter (Option 8) ..................3-114

3-18 Scan Modulation (Option 20) ....................3-117

Chapter 4 Local Operation—Menu Maps

4-1 Introduction ..............................4-3

4-2 Menu Map Description.........................4-3

Chapter 5 Operation Verification

5-1 Introduction ..............................5-3

5-2 Test Equipment ............................5-3

5-3 Test Records ..............................5-4

iv MG369XA OM

Table of Contents (Continued)

5-4 Initial MG369XA Checkout ......................5-4

Power Up ..........................5-4

Self-Test ...........................5-4

Resetting the MG369XA ...................5-4

Warmup Time ........................5-4

5-5 CW Frequency Accuracy Test .....................5-5

Test Setup ..........................5-5

Test Procedure ........................5-5

5-6 Level Accuracy and Flatness Tests..................5-10

Test Setup .........................5-10

Power Level Accuracy Test Procedure ............5-11

Power Level Flatness Test Procedure ............5-12

Chapter 6 Operator Maintenance

6-1 Introduction ..............................6-3

6-2 Error and Warning/Status Messages .................6-3

Self-Test Error Messages ...................6-3

Normal Operation Error and Warning/Status Messages ....6-8

6-3 Troubleshooting............................6-11

6-4 Routine Maintenance.........................6-14

Cleaning the Fan Filters...................6-14

Cleaning the Data Display..................6-14

Replacing the Line Fuses ..................6-14

Chapter 7 Use With Other Instruments

7-1 Introduction ..............................7-3

7-2 Master-Slave Operation ........................7-4

Connecting the Instruments .................7-4

Initiating Master-Slave Operation ..............7-5

Master-Slave Operation....................7-7

Master-Slave Operation in VNA Mode ............7-7

Terminating Master-Slave Operation .............7-9

7-3 Use with a 56100A Scalar Network Analyzer ............7-10

Connecting the MG369XA to the 56100A ..........7-10

7-4 Use with a 8003 Scalar Network Analyzer .............7-11

Connecting the MG369XA to the 8003 ............7-11

Setting Up the MG369XA ..................7-12

Initiating 8003 SNA Operation ...............7-13

MG369XA OM v

Table of Contents (Continued)

7-5 Use with a HP8757D Scalar Network Analyzer...........7-15

Connecting the MG369XA to a HP8757D ..........7-15

Setting Up the MG369XA ..................7-16

Initiating HP8757D SNA Operation .............7-18

7-6 IF Up-Conversion (Option 7) .....................7-19

MG369XA Mixer Setup ...................7-20

Appendix A Rear Panel Connectors

A-1 Introduction ..............................A-1

A-2 Rear Panel Connectors ........................A-1

A-3 Connector Pin-out Diagrams .....................A-1

Appendix B Performance Specifications

Subject Index

vi MG369XA OM

Chapter 1

General Information

Table of Contents

1-1 Scope of Manual ............................1-3

1-2 Introduction ..............................1-3

1-3 Description ...............................1-3

1-4 Identification Number .........................1-3

1-5 Electronic Manual ...........................1-4

1-6 Related Manuals ............................1-4

GPIB Programming Manual .................1-4

Maintenance Manual .....................1-4

1-7 Options .................................1-4

1-8 Performance Specifications ......................1-8

1-9 Recommended Test Equipment ....................1-8

Figure 1-1. Series MG369XA Synthesized Signal Generator

1-2 MG369XA OM

Chapter 1 General Information

1-1 Scope of Manual This manual provides general information,installation, and operating

information for the Anritsu series MG369XA synthesized signal gener

ator. Throughout this manual, the terms MG369XA, signal generator,

and synthesizer will be used interchangeably to refer to the instru

ment. Manual organization is shown in the table of contents.

1-2 Introduction This chapter contains general information about the series MG369XA

signal generators. It includes a general description of the instrument

and information on its identification number, related manuals, options,

and performance specifications. A listing of recommended test equip

ment is also provided.

1-3 Description The series MG369XA synthesized signal generators are microproces-

sor-based,synthesized signal sources with high resolution phase-lock

capability. They generate both discrete CW frequencies and broad (full

range) and narrow band step sweeps across the frequency range of

2 GHz to 65 GHz.Options are available to extend the low end of the

frequency range to 0.1 Hz.All functions of the signal generator are

fully controllable locally from the front panel or remotely (except for

power on/standby) via the IEEE-488 General Purpose Interface Bus

(GPIB). Table 1-1,page 1-5,lists models, frequency ranges, and maxi

mum leveled output.

-

-

-

-

1-4 Identification

Number

All Anritsu instruments are assigned a unique six-digit ID number,

such as “020312”. The ID number is imprinted on a decal that is af

fixed to the rear panel of the unit.Special-order instrument configura

tions also have an additional specials number tag attached to the rear

panel of the unit, such as SM1234.

When ordering parts or corresponding with Anritsu Customer Service,

please use the correct serial number with reference to the specific in

strument's model number (for example, model MG3693A synthesized

signal generator, serial number: 020312).

-

-

MG369XA OM 1-3

-

Options General Information

1-5 Electronic Manual Updated manuals are available for download from the Anritsu web

site, www.anritsu.com.

1-6 Related Manuals This is one of a three manual set that consists of an operation manual,

a GPIB programming manual, and a maintenance manual.

GPIB

Programming

Manual

Maintenance

Manual

The Series MG369XA Synthesized Signal Generator

GPIB Programming Manual provides information

for remote operation of the signal generator with

product specific commands sent from an external

controller via the IEEE 488 General Purpose Inter

face Bus (GPIB). It contains a general description of

the GPIB and bus data transfer and control func

tions, a complete listing and description of all

MG369XA GPIB product specific commands, and

several programming examples. The Anritsu part

number for the GPIB programming manual is

10370-10354.

The Series MG369XA Synthesized Signal Generator

Maintenance Manual supplies service information

for all models in the MG369XA series.The service

information includes functional circuit descriptions,

block diagrams, performance verification tests, calibration procedures, troubleshooting data, and assembly and component removal/replacement

procedures. The Anritsu part number for the maintenance manual is 10370-10355.

-

1-7 Options The series MG369XA synthesizer provides a wide array of instrument

configurations through a series of base model and option configura

tions. Table 1-1, on page 1-5, is a sample list with performance specifi

cations of the available models and options.Refer to Appendix B,

MG3690A RF/Microwave Signal Generators product brochure

p/n: 11410-00327, for current information.

-

-

-

1-4 MG369XA OM

General Information Options

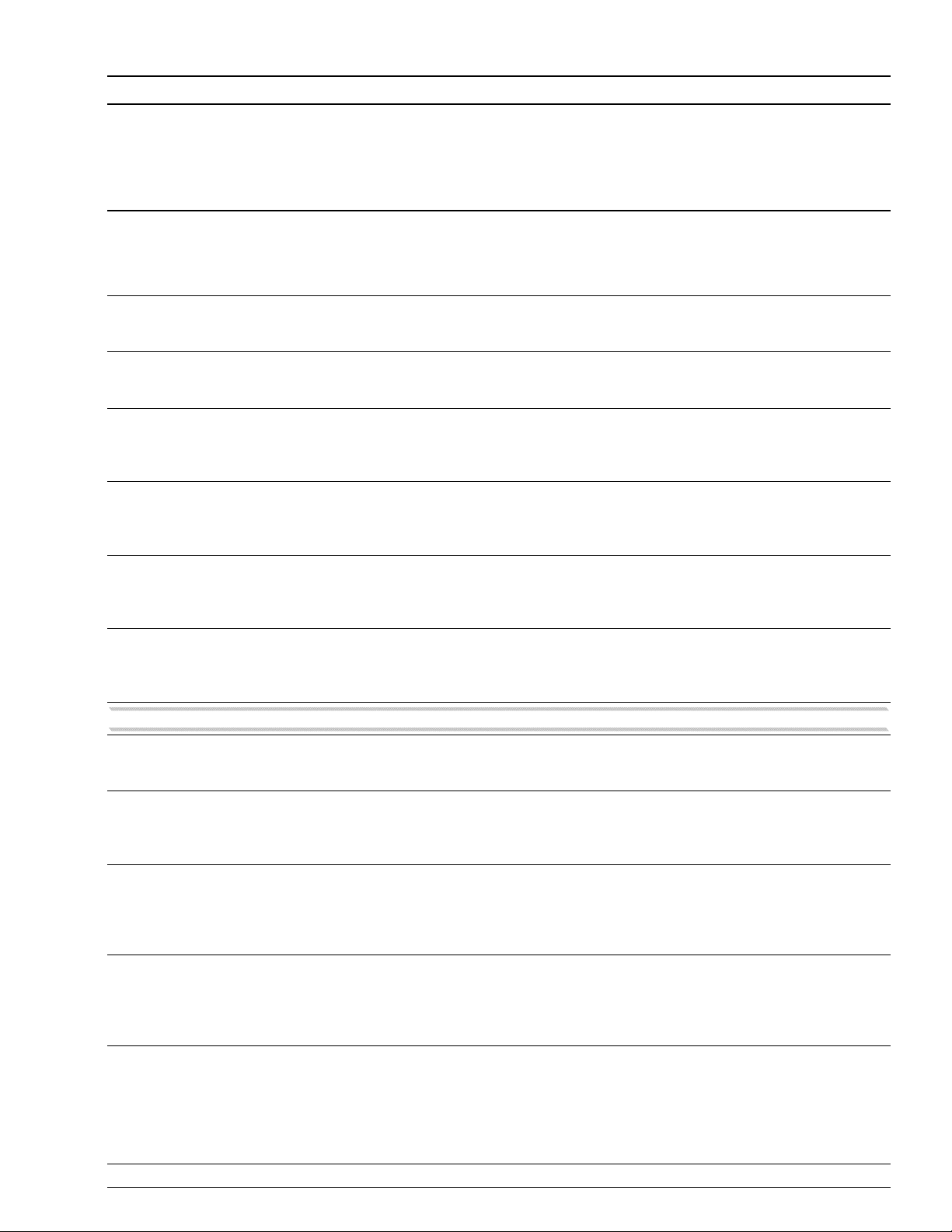

Table 1-1. Series MG369XA Models

Model

Number

MG3691A

MG3692A

MG3693A

MG3694A

MG3695A

MG3696A

Configuration

w/opt 4

w/opt 5

Standard

w/opt 4

w/opt 5

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

Frequency

Range

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £8.4 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £30.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £40.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £50.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £65.0 GHz

Max Leveled

Output Power

+17.0 dBm

+17.0 dBm

+13.0 dBm

+17.0 dBm

+17.0 dBm

+13.0 dBm

+13.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+13.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+12.0 dBm

+12.0 dBm

+10.0 dBm

+3.0 dBm

+12.0 dBm

+12.0 dBm

+10.0 dBm

+3.0 dBm

Max Leveled

Output Power

w/Step Attenuator

+15.0 dBm

+15.0 dBm

+11.0 dBm

+15.0 dBm

+15.0 dBm

+11.0 dBm

+11.0 dBm

+11.0 dBm

+7.0 dBm

+3.0 dBm

+11.0 dBm

+11.0 dBm

+7.0 dBm

+3.0 dBm

+10.0 dBm

+10.0 dBm

+8.0 dBm

+0.0 dBm

+10.0 dBm

+10.0 dBm

+8.0 dBm

+0.0 dBm

*

Max Leveled

Output Power

w/Electronic

Step Attenuator

+13.0 dBm

+13.0 dBm

+9.0 dBm

Not Available

Not Available

Not Available

Not Available

Not Available

With Option 15 (High Power) Installed

w/opt 4

MG3691A

MG3692A

MG3693A

MG3694A

Note: For models with Option 22, rated output power is reduced by 2 dB.

* Typical 60 - 65 GHz.

w/opt 5

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

Standard

Option 4

Option 5

Standard

Standard

Standard

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £8.4 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £10.0 GHz

>10.0 – £20.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £10.0 GHz

>10.0 – £20.0 GHz

>20.0 – £30.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £10.0 GHz

>10.0 – £20.0 GHz

>20.0 – £40.0 GHz

+19.0 dBm

+19.0 dBm

+19.0 dBm

+19.0 dBm

+19.0 dBm

+19.0 dBm

+17.0 dBm

+15.0 dBm

+15.0 dBm

+15.0 dBm

+12.0 dBm

+14.0 dBm

+15.0 dBm

+15.0 dBm

+15.0 dBm

+12.0 dBm

+14.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+15.0 dBm

+14.0 dBm

+14.0 dBm

+14.0 dBm

+10.0 dBm

+12.0 dBm

+14.0 dBm

+14.0 dBm

+14.0 dBm

+10.0 dBm

+12.0 dBm

+15.0 dBm

+15.0 dBm

+13.0 dBm

Not Available

Not Available

Not Available

MG369XA OM 1-5

Options General Information

Option 1A: Rack Mounting with Slides—Rack mount kit containing a set of track slides (90° tilt

capability), mounting ears, and front panel handles for mounting the instrument in a

standard 19-inch equipment rack.

Option 1B: Rack Mounting without Slides—Modifies rack mounting hardware to install unit in a

console that has mounting shelves. Includes mounting ears and front panel handles.

Option 2X: 110 dB Mechanical Step Attenuator—Adds a 10 dB per step attenuator with a 110 dB

range. Output power is selected directly in dBm on the front panel (or via GPIB).Rated RF

output power is reduced. This option comes in different versions based on instrument

configuration.

Option 2E: 120 dB Electronic Step Attenuator—Adds a 10 dB per step attenuator with a 120 dB

range for models having a high-end frequency of £20 GHz.Output power is selected directly

in dBm on the front panel (or via GPIB). Rated RF output power is reduced.

Option 3: Ultra-Low Phase Noise—Adds new modules that significantly reduces single-sideband

phase noise,³2 GHz.

Option 4: Digital Down Converter—Adds a digital down converter for ultra-low phase noise for

0.01 to 2.2 GHz RF coverage.

Option 5: Analog Down Converter—Adds an analog down converter for 0.01 to 2 GHz RF coverage.

Option 7: IF Up-Conversion—Adds an internal 40 GHz mixer for up-converting an IF signal. Not

available in MG3695A, MG3696A,or with Option 18.

Option 9X: Rear Panel RF Output—Moves the RF output connector to the rear panel.

Option 10: User-Defined Modulation Waveform Software—Adds a software package that pro

vides the ability to serially (or via GPIB) download user-defined waveforms into the mem

ory of the internal waveform generator. Requires an external PC and an instrument with

an internal low frequency generator (Option 23).

Option 12: External Frequency and Phase Modulation—Adds external FM/FM capabilities via a

rear panel BNC connector. Requires an external modulating signal input or an internal low

frequency generator (Option 23).

Option 13X: External Pulse Modulation—Adds external pulse modulation capability via a rear panel

BNC connector. Requires an external modulating signal input.

Option 14: Amplitude Modulation—Adds external AM capability via a rear panel BNC connector.

Requires an external modulating signal input or an internal low frequency generator (Op

tion 23).

Option 15X: High Power Output—Adds high-power RF components to the instrument providing in

creased RF output power. This option comes in different versions based on instrument con

figuration.

-

-

-

-

-

Option 16: High-Stability Time Base—Adds an ovenized 10 MHz crystal oscillator with frequency

stability of <5 x 10

–10

/day.

1-6 MG369XA OM

General Information Options

Option 17: Delete Front Panel—Deletes the front panel for use in remote control applications where

a front panel display or keyboard control are not needed.

Option 18: mmW Bias Output—Adds a rear panel BNC Twinax connector to bias the 5400-xWRxx

millimeter wave source modules.Not available with Option 7.

Option 22: 0.1 Hz to 10.0 MHz Audio Frequency—Adds frequency coverage below 10 MHz. The fre

quency resolution below 10 MHz is 0.02 Hz.Rated RF output power is reduced.

Option 23: Low Frequency Generator—Provides modulation waveforms for internal AM, FM,or

FM. Not available without Option 12 or 14.

Option 24: Internal Pulse Generator—Provides pulse waveforms for internal pulse modulation. Not

available without Option 13.

Option 25X: Analog Modulation Suite—The analog modulation suite bundles Options 12, 13, 14,23

and 24,offering internal and external AM,FM, FM, and pulse modulation. This option co

mes in different versions,based on instrument configuration.

-

-

MG369XA OM 1-7

Recommended Test Equipment General Information

1-8 Performance

Specifications

1-9 Recommended Test

Equipment

The series MG369XA synthesized signal generator performance speci

fications are provided in Appendix B.

Table 1-2 lists the recommended test equipment for performing the se

ries MG369XA synthesized signal generator operation verification

tests in Chapter 5.

Table 1-2. Recommended Test Equipment

Instrument Critical Specification Recommended Manufacturer/Model

Frequency

Counter

or

Frequency

Counter

with

Cable Kit

and

External

Mixer

Range: 0.01 to 40 GHz

Input Z: 50W

Resolution: 1Hz

Other: External Time Base

Input

Range: 0.01 to 65 GHz

Input Z: 50W

Resolution: 1Hz

Other: External Time Base

Input

Anritsu Model MF2414B

EIP Microwave, Inc. Models 538B,

548B, or 578B,

with

Cable Kit: Option 590 and

External Mixer:

Option 91 (26.5 to 40 GHz)

Option 92 (40 to 60 GHz)

Option 93 (60 to 90 GHz)

-

-

Power Meter,

with

Power

Sensor

Oscilloscope Bandwidth: DC to 150 MHz

Range: –30 to +20 dBm

(1mW to 100 mW)

Vertical Sensitivity: 2 mV/

division

Horizontal Sensitivity: 50 ns/

division

Anritsu Model ML2437A or ML2438A,

with

Power Sensor:

MA2474A (0.01 to 40 GHz)

MA2575A (0.01 to 50 GHz)

Tektronix, Inc. Model TAS485

1-8 MG369XA OM

Chapter 2

Installation

Table of Contents

2-1 Introduction ..............................2-3

2-2 Initial Inspection............................2-3

2-3 Preparation For Use ..........................2-3

2-4 Rack Mounting Kit Installation ....................2-5

Preliminary .........................2-5

Procedure ..........................2-5

Power Requirements .....................2-8

Power Connection ......................2-8

Standby Operation ......................2-9

Warmup Time ........................2-9

Operating Environment ...................2-9

2-5 GPIB Setup and Interconnection...................2-10

Interface Connector .....................2-10

Cable Length Restrictions ..................2-10

GPIB Interconnection ....................2-10

Setting the GPIB Address ..................2-11

Selecting the Line Terminator ................2-12

Interface Language .....................2-12

2-6 Preparation for Storage/Shipment ..................2-13

Preparation for Storage ...................2-13

Preparation for Shipment ..................2-13

2-7 Anritsu Service Centers .......................2-14

Chapter 2 Installation

2-1 Introduction This chapter provides installation instructions for the series

MG369XA synthesized signal generator. It includes information on ini

tial inspection,preparation for use, storage, reshipment,and General

Purpose Interface Bus (GPIB) setup and interconnections.

2-2 Initial Inspection Inspect the shipping container for damage.If the shipping container or

cushioning material is damaged, retain until the contents of the ship

ment have been checked against the packing list and the signal gener

ator has been checked for mechanical and electrical operation.

If the shipment is incomplete or if the signal generator is damaged

mechanically or electrically, notify your local sales representative or

Anritsu Customer Service. If either the shipping container is damaged

or the cushioning material shows signs of stress, notify the carrier as

well as Anritsu. Keep the shipping materials for the carrier's inspection.

-

-

-

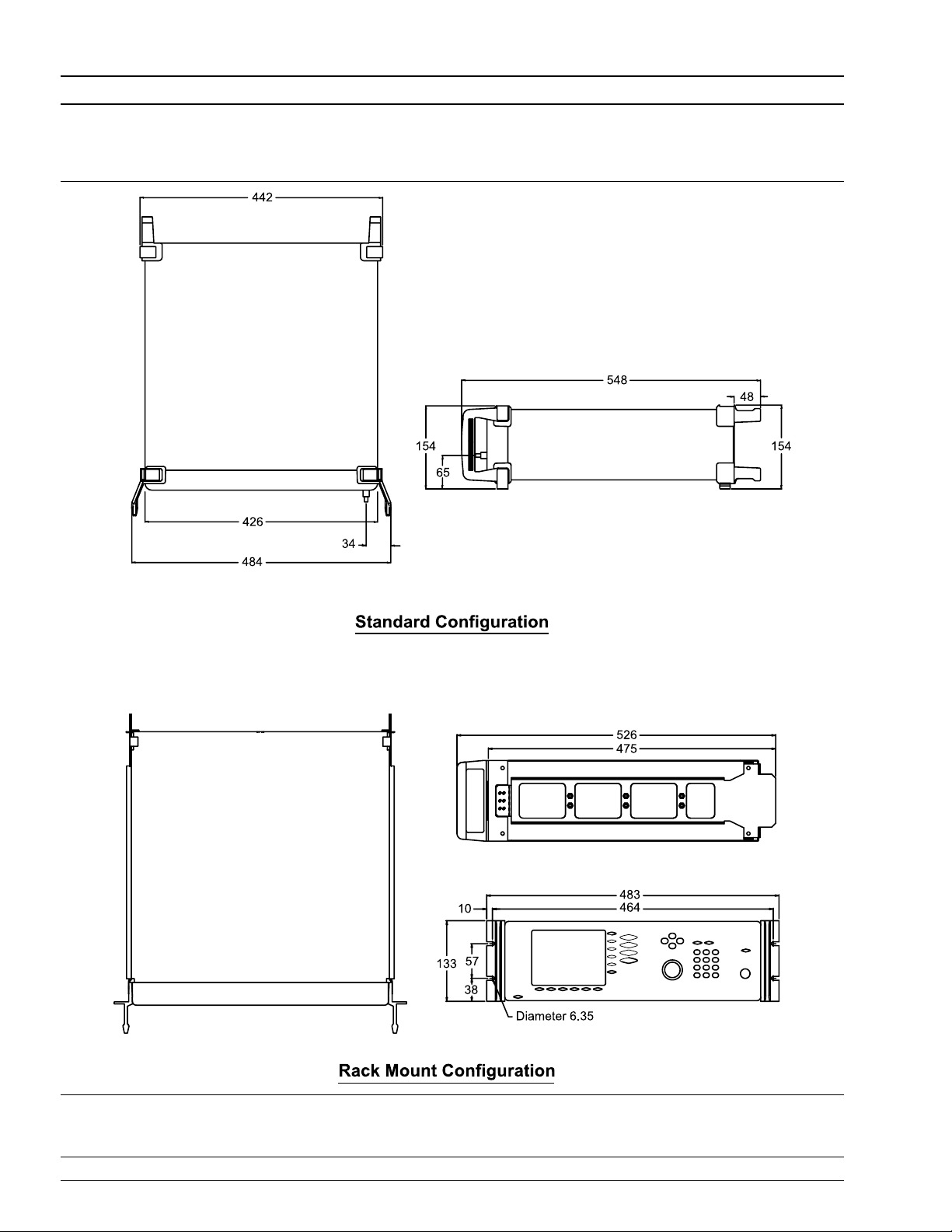

2-3 Preparation For Use Preparation for use consists of installing the instrument into a

suitable operating location and connecting the signal generator to a

power source.The following paragraphs provide these procedures

along with information about power requirements, warmup times,and

the operating environment. Figure 2-1, on the following page,

illustrates the basic outer dimensions of the instrument.

MG369XA OM 2-3

Preparation For Use Installation

Figure 2-1. MG369XA Outline Dimensions (in millimeters)

2-4 MG369XA OM

Installation Rack Mounting Kit Installation

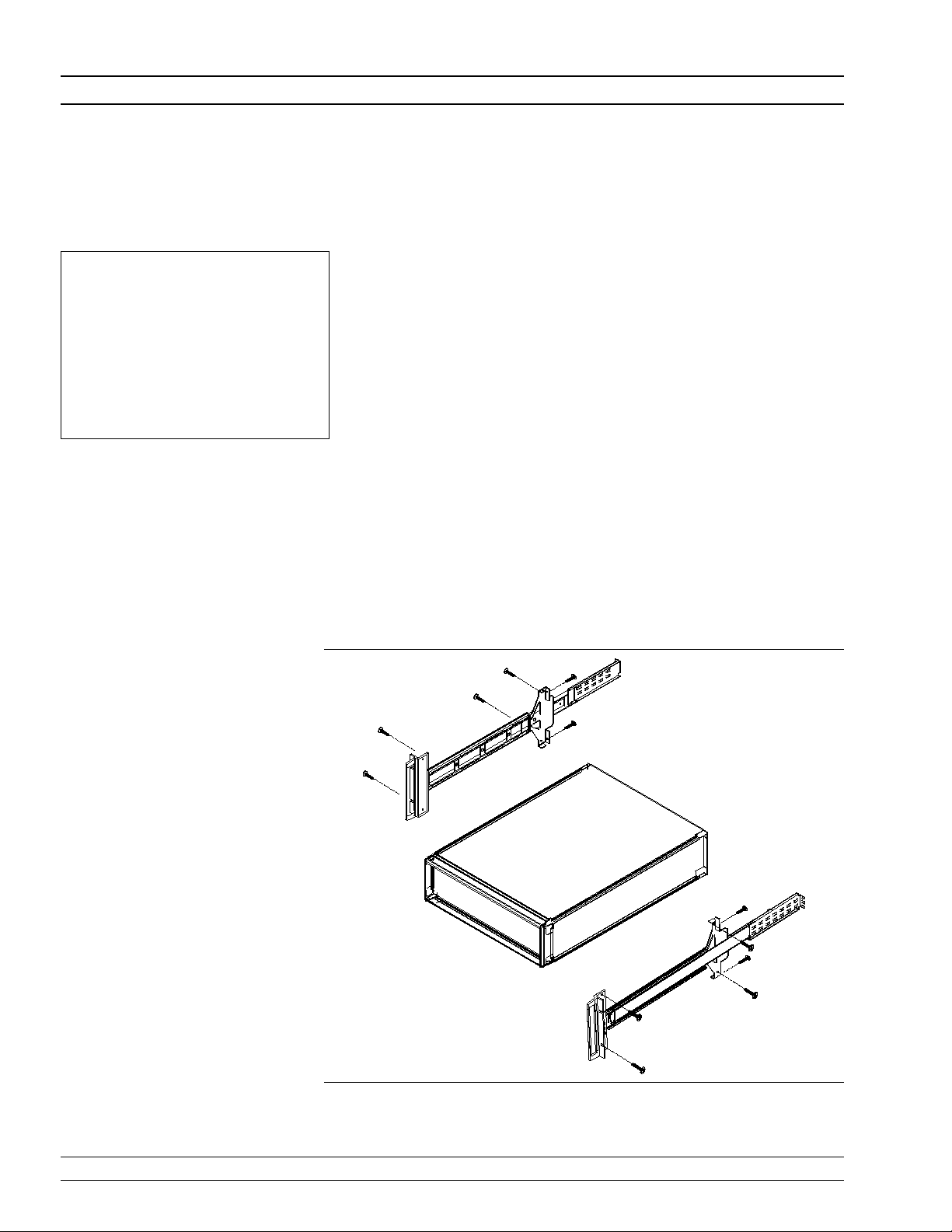

2-4 Rack Mounting Kit

Installation

The rack mounting kit (Option 1A) contains a set of track slides (90°

tilt capability),mounting ears, and front panel handles for mounting

the signal generator in a standard equipment rack. The following pro

cedure provides instructions for installing the rack mounting hard

ware on to the instrument. The rack mounting kit (Option 1B) uses

the same inner assembly without the slide.This procedure may also be

used for installing the Option 1B rack mount assembly. Refer to Fig

ures 2-3 and 2-4 during this procedure.

Preliminary Disconnect the power cord and any other cables

from the instrument.

Procedure Install the rack mounting hardware as follows:

Step 1. Using a Phillips screwdriver, remove the

screws and the front handle assemblies

from the instrument. (For instruments

not having front handles,remove the

screws and the front top and bottom feet

from the instrument.) Retain the screws.

Step 2. Remove the four feet from the rear of the

instrument. Retain the screws.

-

-

-

Figure 2-3. Front Handle and Feet Removal

Rear Feet

(4)

MG369XA OM 2-5

Rack Mounting Kit Installation Installation

Step 3. Remove the inner slide assemblies from

the outer slide assemblies.

Step 4. Place the left side inner slide assembly

NOTE

The screws with green heads have

metric threads. When it becomes

necessary to replace any of these

screws, always use the exact re

placement green-headed screws to

avoid damage to the instrument.

Anritsu P/N’s: 905-8 (long);

Z-951102 (short).

Step 5. Insert two green-headed screws through

-

Step 6. Insert two green-headed screws through

onto the instrument case with the handle

towards the front of the instrument (Fig

ure 2-4).

the holes in the slide assembly behind the

handle and into the metric tapped holes

in the side of the instrument.

the holes near the rear of the slide assem

bly and into the metric tapped holes in

the side of the instrument.

-

-

Step 7. Insert the two SAE threaded screws (re

moved from the feet) through the 90° tabs

on the rear of the slide assembly and into

the rear panel of the instrument.

Step 8. Using the Phillips screwdriver, tighten all

screws holding the left side slide assembly to the instrument chassis.

-

Figure 2-4. Rack Mounting Hardware Installation

2-6 MG369XA OM

Installation Rack Mounting Kit Installation

Step 9. Place the right side inner slide assembly

onto the instrument case with the handle

towards the front of the instrument.

Step 10. Insert two green-headed screws through

the holes in the slide assembly behind the

handle and into the metric tapped holes

in the side of the instrument.

Step 11. Insert two green-headed screws through

the holes near the rear of the slide assem

bly and into the metric tapped holes in

the side of the instrument.

-

Step 12. Insert the two SAE threaded screws (re

moved from the feet) through the 90° tabs

on the rear of the slide assembly and into

the rear panel of the instrument.

Step 13. Using the Phillips screwdriver,tighten all

screws holding the right side slide assembly to the instrument chassis.

Step 14. Using the appropriate hardware, install

the outer slide assemblies onto the equipment rack.

Step 15. Lift the signal generator into position.

Align the inner and outer slide assemblies and slide the instrument into the

rack. Realign the hardware as needed for

smooth operation.

-

MG369XA OM 2-7

Rack Mounting Kit Installation Installation

WARNING

When supplying power to this equipment, always use a

three-wire power cable connected to a three-wire power line

outlet. If power is supplied without grounding the equip

ment in this manner, there is a risk of receiving a severe or

fatal electric shock.

-

Power

Requirements

Power

Connection

The signal generator accepts 90 to 264 Vac, 48 to

440 Hz,single-phase power. Power consumption is

300 VA maximum.The signal generator is intended

for Installation Category (Over Voltage Category) II.

To connect the MG369XA to the power source, plug

the female end of the power cable into the input line

voltage receptacle on the rear panel (Figure 2-2).

Then plug the male end of the power cord into a

three-wire power line outlet. Turn on the rear panel

power switch.This automatically places the signal

generator in operation (front panel OPERATE LED

on).

Figure 2-2. Signal Generator Rear Panel Showing Power Connection

2-8 MG369XA OM

Installation Rack Mounting Kit Installation

y

CAUTION

Before installing the MG369XA in its operating environ

ment, ensure that all airflow passages at the sides and rear

of the instrument are clear. This is of particular importance

whenever the unit is being rack-mounted.

Keep the cooling fan filters clean so that the ventilation

holes are not obstructed. A blocked fan filter can cause the

instrument to overheat and shut down.

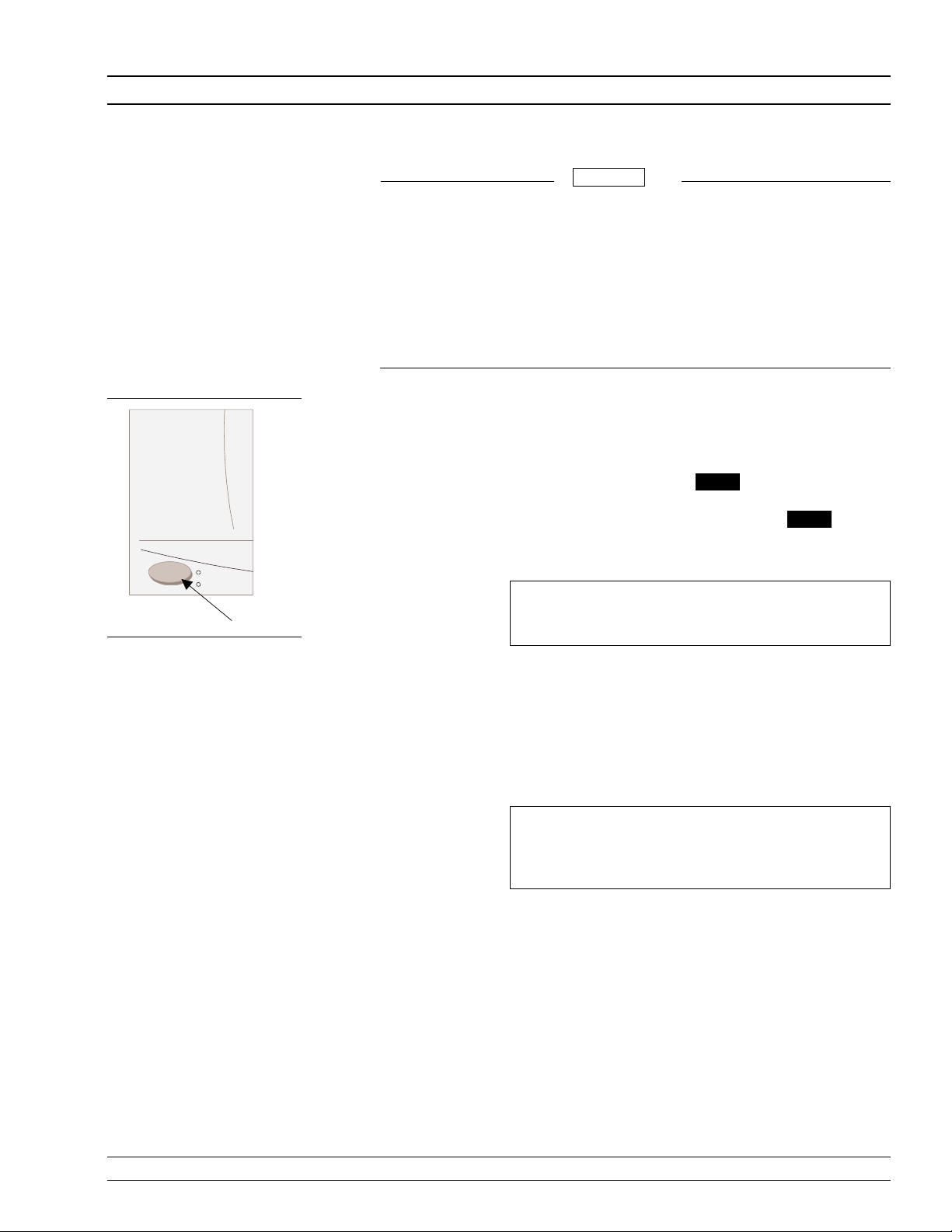

Standby

Operation

Whenever the signal generator is not being used it

should be left connected to the power source and

placed in standby. This keeps the internal time base

frequency reference at operating temperature.

On the front panel, press LINE to switch the

MG369XA from OPERATE (green LED on) to

STANDBY (orange LED on). (Hold the LINE key

down for at least ½ second to prevent power-off of

the unit.)

L i n e

O p e r a t e

S t a n d b y

L i n e K e

During standby operation, the fan runs continuously.

NOTE

Warmup Time

Operating

Environment

From Standby–When placing the MG369XA in operation from standby, allow 30 minutes warmup to

assure stable operation.

From a Cold Start (0°C)–The signal generator re

quires approximately 120 hours (5 days) of warm up

to achieve specified frequency stability with aging.

NOTE

Instruments disconnected from ac power for

morethan 72 hours require 30 days to return to

specified aging.

The MG369XA can be operated within the following

environmental limits.

q

Temperature: 0°Cto50°C

q

Humidity: 5 to 95% relative at 40°C

q

Altitude: up to 4600 meters

q

Cooling: Internal cooling is provided by forced

airflow from the fans mounted on the rear

panel

-

MG369XA OM 2-9

GPIB Setup and Interconnection Installation

2-5 GPIB Setup and

Interconnection

The MG369XA provides automated microwave signal generation via

the GPIB. The following paragraphs provide information about inter

face connections, cable requirements, setting the GPIB operating pa

rameters, and selecting the external interface language.

Interface

Connector

Cable Length

Restrictions

Interface between the signal generator and other de

vices on the GPIB is via a 24-wire interface cable.

This cable uses connector shells having two connec

tor faces. These double-faced connectors allow for

the parallel connection of two or more cables to a

single device.

The GPIB can accommodate up to 15 instruments at

any one time. To achieve design performance on the

bus, proper timing and voltage level relationships

must be maintained. If either the cable length be

tween separate instruments or the cumulative cable

length between all instruments is too long,the data

and control lines cannot be driven properly and the

system may fail to perform. Cable length restrictions are as follows:

q No more than 15 instruments may be installed

on the bus

q

Total cumulative cable length (in meters) may

not exceed two times the number of bus instruments or 20 meters—whichever is less

-

-

-

-

-

NOTE

For low EMI applications, the GPIB cable

should be a fully shielded type with wellgrounded metal-shell connectors.

GPIB

Interconnection

The only interconnection required for GPIB opera

tion is between the signal generator and the control

ler. This interconnection is via a standard GPIB

cable. The Anritsu part number for such a cable is

2100-1, -2, or -4 (1, 2, or 4 meters in length).

-

2-10 MG369XA OM

-

Loading...

Loading...