Page 1

User Guide

MA244xxA Microwave USB Peak Power Sensors

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

http://www.anritsu.com

Part Number: 10585-00033

©Copyright 2021 Anritsu Company

Published: February 2021

Revision: C

Page 2

Unauthorized Use or Disclosure

Anritsu Company has prepared the product user documentation for use by Anritsu Company personnel and

customers as a guide for the proper installation, operation, and maintenance of Anritsu Company equipment and

software programs. The drawings, specifications, and information contained therein are the property of Anritsu

Company, and any unauthorized use of these drawings, specifications, and information is prohibited; they shall not be

reproduced, copied, or used in whole or in part as the basis for manufacture or sale of the equipment or software

programs without the prior written consent of Anritsu Company.

Export Management

The Anritsu products identified herein and their respective manuals may require an Export License or approval by

the government of the product country of origin for re-export from your country. Before you export these products or

any of their manuals, please contact Anritsu Company to confirm whether or not these items are export-controlled.

When disposing of export-controlled items, the products and manuals must be broken or shredded to such a degree

that they cannot be unlawfully used for military purposes.

Front-2 PN: 10585-00033 Rev. C MA244xxA UG

Page 3

Table of Contents

Chapter 1—General Information

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Manual Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3 Instrument Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-4 Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-5 Instrument Care and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

ESD Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-6 Contacting Anritsu for Sales and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2—Installation

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Repacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-4 Installing MA244xxA Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3—Getting Started

3-1 MA244xxA Input Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Connecting the MA244xxA Peak Power Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-3 Status LED Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-4 Starting the MA244xxA Peak Power Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-5 MA244xxA Peak Power Analyzer Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Dockable Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Available Resources Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Virtual Power Analyzer Main Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Trace View Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Virtual Power Analyzer Lower Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

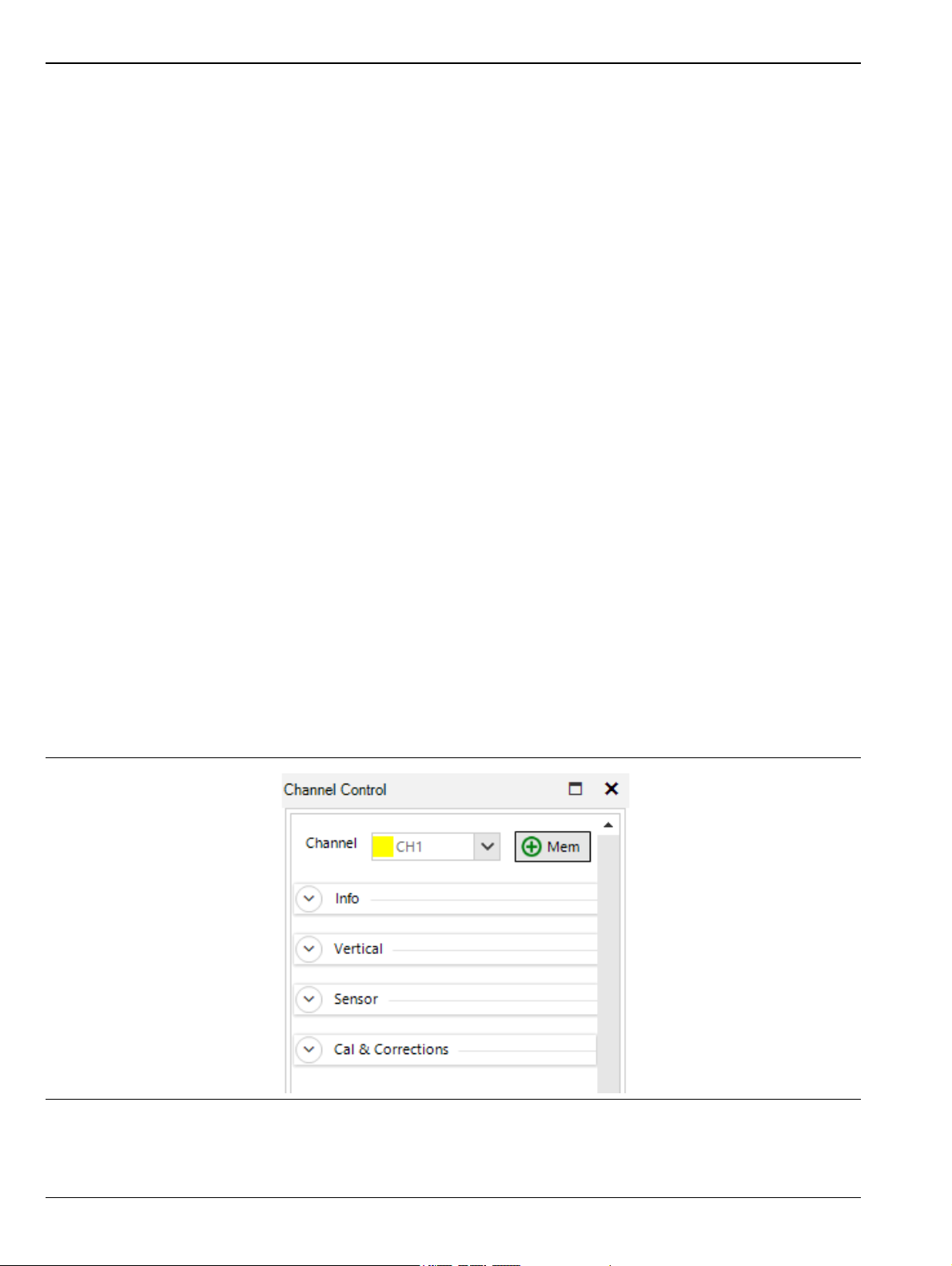

Channel Control Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

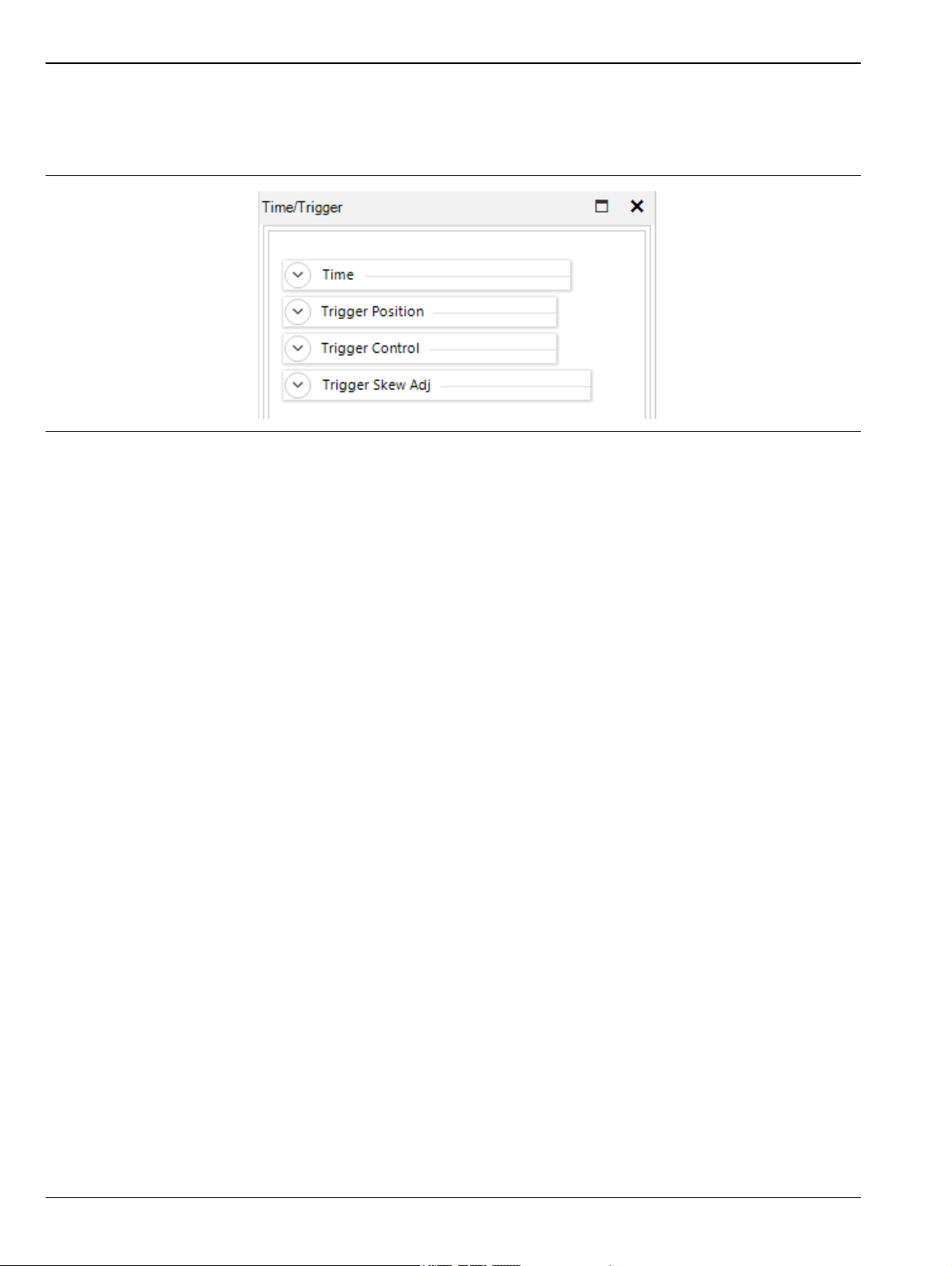

Time / Trigger Settings Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Marker Settings Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Pulse Definitions Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Stat Mode Control Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Automatic Measurements Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Display (Graph) Settings Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

CCDF View Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Statistical Measurements Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Chapter 4—Operation

4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 The Trace View Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

The Main Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

MA244xxA UG PN: 10585-00033 Rev. C Contents-1

Page 4

Table of Contents (Continued)

Time/Trigger Control Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Channel Control Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Automatic Measurements Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Pulse Definitions Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Marker Settings Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Statistical CCDF Graph Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Statistical Mode Control Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Statistical Measurements Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Meter View Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Acquisition Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Archiving Measurement Setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4-3 Multichannel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Multichannel Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4-4 Data Buffer Mode (API Remote Programming Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Data Buffer Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Data Buffer Mode User Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Chapter 5—Making Measurements

5-1 Pulse Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Pulse Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Standard IEEE Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Marker Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-3 Automatic Statistical Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Contents-2 PN: 10585-00033 Rev. C MA244xxA UG

Page 5

Chapter 1 — General Information

1-1 Introduction

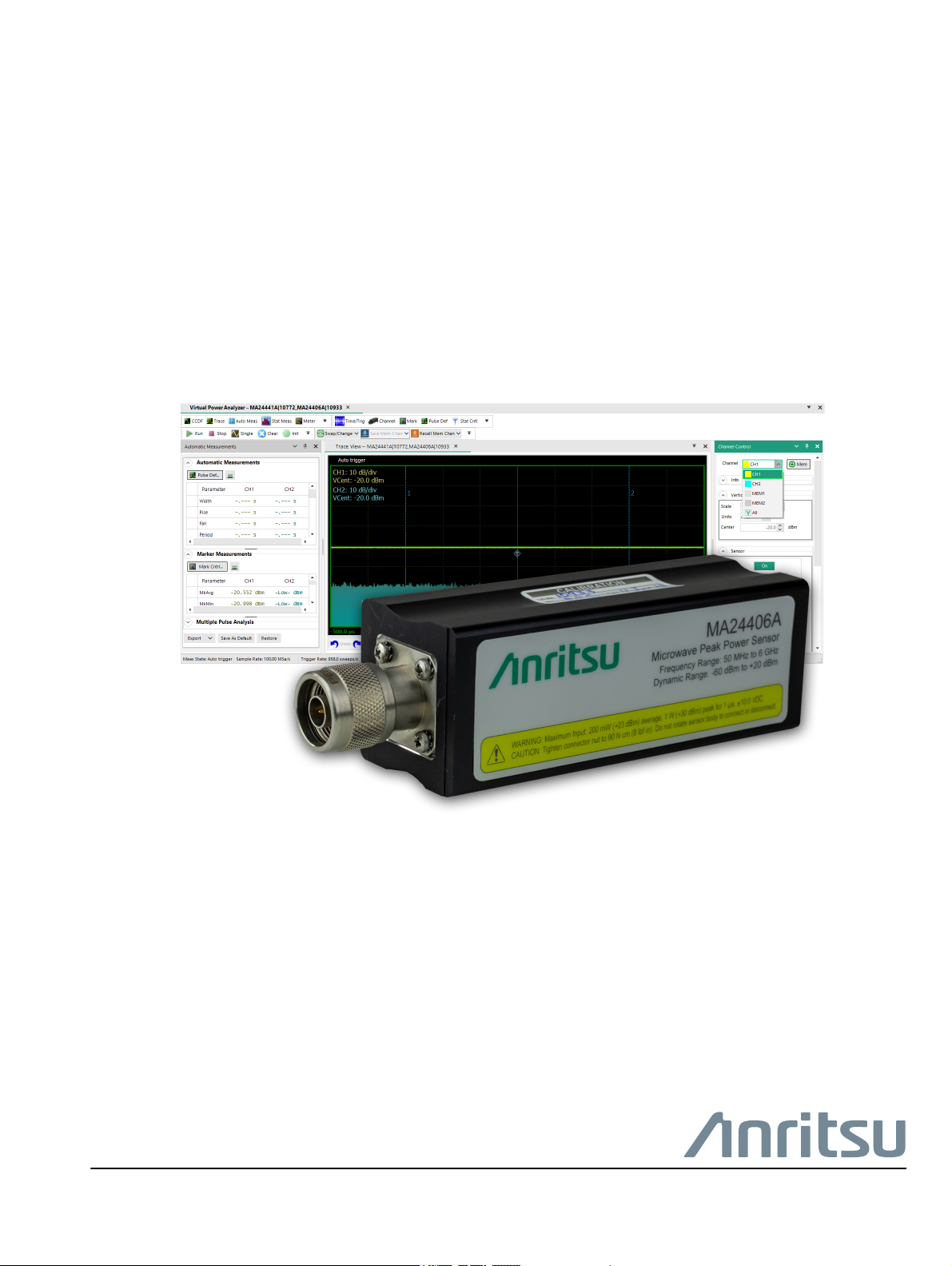

The MA244xxA Microwave USB Peak Power Sensors (MA244xxA Peak Power Sensorss) are designed to

provide accurate, peak-power measurements from 50 MHz to 6 GHz, 18 GHz, and 40 GHz with up to 80 dB of

dynamic range and 195 MHz of video bandwidth. The sensors employ real-time processing, a unique parallel

processing methodology that performs the multi-step process of RF power measurement. While conventional

power meters and USB sensors perform steps serially resulting in long re-arm times and missed data,

Anritsu’s MA244xxA Peak Power Sensors capture, display, and measure every pulse, glitch, and detail with

virtually no gaps in data and with zero latency.

Before You Begin

Read the Anritsu Power Meters, Power Sensors, and Power Analyzer Product Information, Compliance, and

Safety Guide (PN: 10100-00066) for important safety, legal, and regulatory notices before operating the

equipment.

Additional Documentation

Table 1-1. Related Manuals

Document Part Number Description

10100-00066 Important Product Information, Compliance, and Safety Notices

11410-01127 Microwave USB Peak Power Sensors Technical Data Sheet

10585-00034 Programming Manual

For additional information and literature covering your product, visit the product page of your instrument and

select the Library tab: https://www.anritsu.com/en-us/test-measurement/products/ma24400a

1-2 Manual Organization

This User Manual provides the information needed to install, operate, and maintain the MA244xxA Peak

Power Sensors.

The manual is organized into these seven chapters:

Chapter 1, “General Information” presents summary descriptions of the sensors and their principal features,

accessories, and options. Also included are specifications for the instrument.

Chapter 2, “Installation” provides instructions for unpacking the sensor, setting it up for operation, connecting

power, and signal cables, and initial power-up.

Chapter 3, “Getting Started” describes the basic operation of the Microwave Peak Power Sensors and the

Power Analyzer Software.

Chapter 4, “Operation” describes, in detail, the Graphical User Interface (GUI) of the Power Analyzer Software

and the MA244xxA Peak Power Sensors.

Chapter 5, “Making Measurements” provides definitions for key terms used in this manual and on the GUI

displays, as well as methodologies used to calculate automated pulse, marker, and statistical measurements.

MA244xxA UG PN: 10585-00033 Rev. C 1-1

Page 6

1-3 Instrument Description General Information

1-3 Instrument Description

This modular product line offers speed and accuracy in a USB form-factor. The new line includes 6, 18 and 40

GHz models, and measures wideband modulated signals.

The MA244xxA Peak Power Sensors are the latest series of products from Anritsu that turn your PC or laptop

using a standard USB 2.0 port into a state-of-the-art peak power analyzer without the need for any other

instrument. Power measurements from the MA244xxA Peak Power Sensors can be displayed on your computer

or can be integrated into a test system with a set of user-defined software functions.

The MA244xxA Peak Power Sensors include the models MA24406A, MA24408A, MA24418A, MA24440A,

MA24419A, and MA24441A. Collectively, they cover a frequency range of 50 MHz to 40 GHz and offer

broadband measurements with rise times as fast as 3 ns, time resolution of 100 ps, and video bandwidths up to

195 MHz.

The MA244xxA Peak Power Sensors enable rapid-pulse integrity determinations. Effective sampling rate is up

to one hundred times faster than conventional power sensors. This makes finer waveform details visible. The

sensors perform automatic capture of pulse power, overshoot, droop, edge delay, skew timing, and edge

transition times.

The MA244xxA Peak Power Sensors have exceptional trigger stability—of less than 100 ps trigger jitter

regardless of the trigger source—which yields greater waveform detail because a stable trigger point yields a

stable waveform. Using dedicated trigger circuitry rather than software-based, triggering provides precise

time-stamping of relative trigger-to-sample delay. This precision permits the use of random interleaved

sampling (RIS) for repetitive waveforms. This results in an effective sampling rate of 10 GS/s, which permits

accurate, direct-measurement of fast timing events without requiring interpolation between samples.

Real-time processing offers new possibilities for power integrity measurements because every pulse is analyzed

and none are discarded. Trace acquisition, averaging, and envelope times are drastically reduced, resulting in

simultaneous analysis of average, peak, and minimum power values.

The MA244xxA Peak Power Sensors are supported by the MA244xxA Peak Power Analyzer, a Windows-based

software package that provides control and readout of the sensors. It is an easy-to-use program that provides

both time and statistical domain views of power waveforms with variable peak hold and persistence views. It

supports power measurements using automated pulse and statistical measurements, power level, and timing

markers. The GUI application is easily configured with dockable or floating windows and measurement tables

that can be edited to show only the measurements of interest.

The MA244xxA Peak Power Sensors are ideal for manufacturing, design, research, and service in commercial

and military applications such as telecommunications, avionics, RADAR, and medical systems. They are the

instrument of choice for fast, accurate, and highly-reliable RF power measurements, equally suitable for

product development, compliance testing, and site-monitoring applications.

1-2 PN: 10585-00033 Rev. C MA244xxA UG

Page 7

General Information 1-4 Architecture

1-4 Architecture

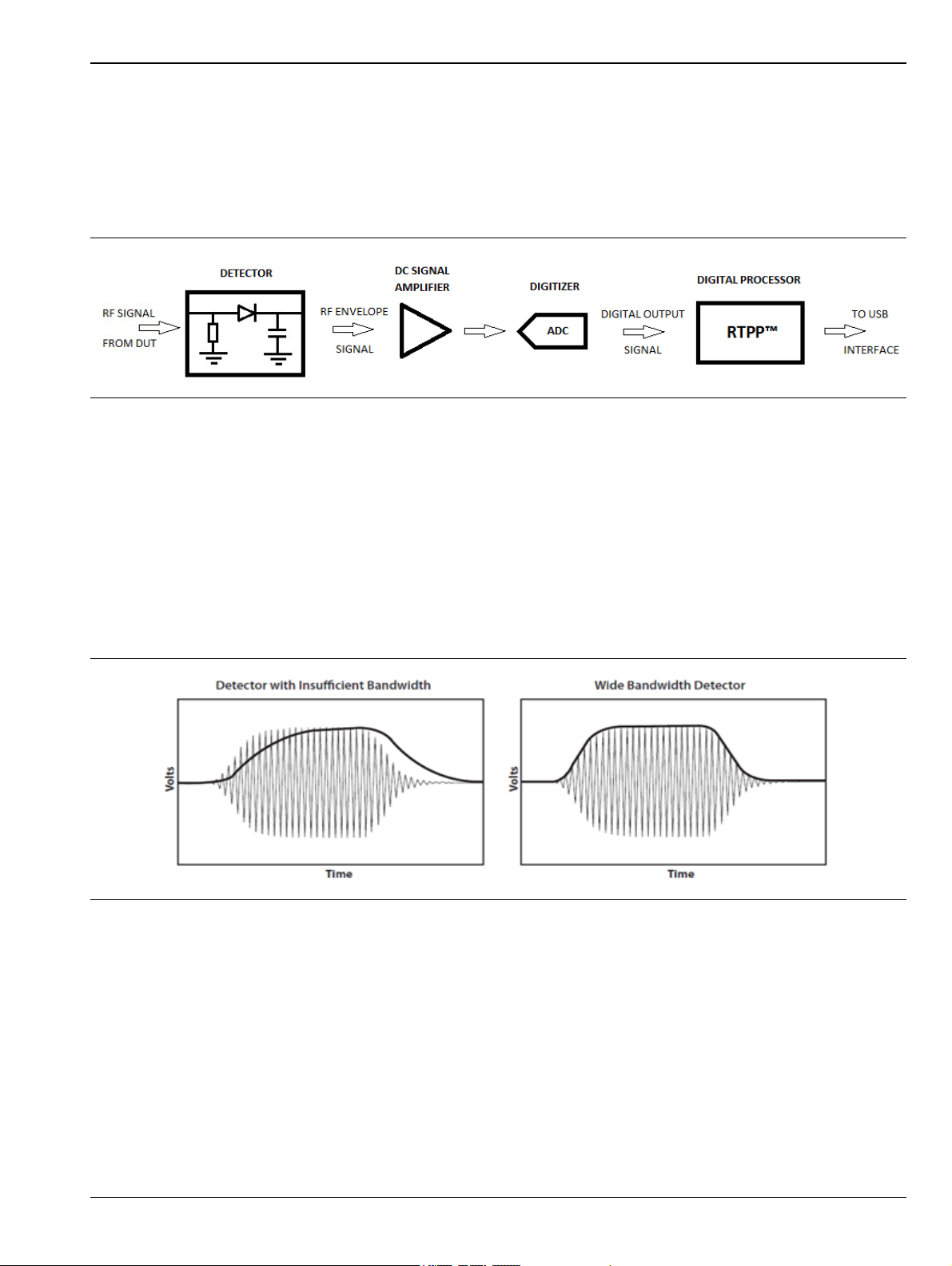

The sensor functions as an ultra-fast, calibrated, power-measurement tool, which acquires and computes the

instantaneous, average, and peak RF power of a modulated, wideband RF signal. The internal A/D converter

samples the detected RF signal at up to 100 megasamples/second (MSa/s), and a digital signal processor carries

out the work of forming the digital samples into a correctly scaled and calibrated trace on the display.

Figure 1-1 shows a block diagram of the peak power sensor.

Figure 1-1. MA244xxA Peak Power Sensors Block Diagram

The first and most critical stage of a peak power sensor is the detector, which removes the RF carrier signal

and outputs the amplitude of the modulating signal. The width of the detector’s video bandwidth dictates the

sensor’s ability to track the power envelope of the RF signal. The image on the left of Figure 1-2 shows how a

detector with insufficient bandwidth is unable to track the signal’s envelope effectively, affecting the accuracy

of the power measurement.

The image on the right shows sufficient video bandwidth to track the envelope accurately. The fast detectors

used in peak-power sensors are by their nature non-linear, so shaping procedures within the digital processor

must be used to linearize their response. When measuring instantaneous peak power, a high-sample rate is

important to ensure that no information is lost. The MA244xxA Peak Power Sensors have a sample rate of 100

MS/s, enabling capture and analysis of power versus time waveforms at a very high resolution.

Figure 1-2. Comparison of Bandwidth Detectors

MA244xxA UG PN: 10585-00033 Rev. C 1-3

Page 8

1-5 Instrument Care and Preventive Maintenance General Information

1-5 Instrument Care and Preventive Maintenance

Instrument care and preventive maintenance consist of proper operation in a suitable environment, occasional

cleaning of the instrument, and inspecting and cleaning the RF connectors and all accessories before use.

Clean the instrument with a soft, lint-free cloth dampened with water or water and a mild cleaning solution.

Caution To avoid damaging the display or case, do not use solvents or abrasive cleaners.

Connector Care

Clean the RF connectors and center pins with a cotton swab dampened with denatured alcohol. Visually

inspect the connectors. The fingers of the N(f) connectors and the pins of the N(m) connectors should be

unbroken and uniform in appearance. If you are unsure whether the connectors are undamaged, gauge the

connectors to confirm that the dimensions are correct. Visually inspect the test port cable(s). The test port

cable should be uniform in appearance and not stretched, kinked, dented, or broken.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the Type-N connectors.

The recommended torque is 12 lbf·in (1.35 N · m). The recommended torque for K connectors (2.92 mm) is

8 lbf·in (0.9 N·m). Inadequate torque settings can affect measurement accuracy. Over-tightening connectors

can damage the cable, the connector, the instrument, or all of these items.

Visually inspect connectors for general wear, cleanliness, and for damage such as bent pins or connector rings.

Repair or replace damaged connectors immediately. Dirty connectors can limit the accuracy of your

measurements. Damaged connectors can harm the instrument. Connection of cables carrying an electrostatic

potential, excess power, or excess voltage can damage the connector, the instrument, or both.

Connecting Procedure

1. Carefully align the connectors. The male connector center pin must slip concentrically into the contact

fingers of the female connector.

2. Align and push connectors straight together. Do not twist or screw them together. A slight resistance can

usually be felt as the center conductors mate.

3. To tighten, turn the connector nut, not the connector body. Major damage can occur to the center

conductor and to the outer conductor if the connector body is twisted.

4. If you use a torque wrench, initially tighten by hand so that approximately 1/8 turn or 45 degrees of

rotation remains for the final tightening with the torque wrench.

Relieve any side pressure on the connection (such as from long or heavy cables) in order to assure

consistent torque. Use an open-end wrench to keep the connector body from turning while tightening

with the torque wrench.

Do not over-torque the connector.

Disconnecting Procedure

1. If a wrench is needed, use an open-end wrench to keep the connector body from turning while loosening

with a second wrench.

2. Complete the disconnection by hand, turning only the connector nut.

3. Pull the connectors straight apart without twisting or bending.

1-4 PN: 10585-00033 Rev. C MA244xxA UG

Page 9

General Information 1-6 Contacting Anritsu for Sales and Service

ESD Caution

The MA244xxA power sensors, like other high performance instruments, are susceptible to electrostatic

discharge (ESD) damage. Coaxial cables and antennas often build up a static charge, which (if allowed to

discharge by connecting directly to the instrument without discharging the static charge) may damage the

MA244xxA input circuitry. Instrument operators must be aware of the potential for ESD damage and take all

necessary precautions.

Operators should exercise practices outlined within industry standards such as JEDEC-625 (EIA-625),

MIL-HDBK-263, and MIL-STD-1686, which pertain to ESD and ESDS devices, equipment, and practices.

Because these apply to the MA244xxA power sensors, it is recommended that any static charges that may be

present be dissipated before making connection. It is important to remember that the operator may also carry

a static charge that can cause damage. Following the practices outlined in the above standards will ensure a

safe environment for both personnel and equipment.

1-6 Contacting Anritsu for Sales and Service

Customers having questions or equipment problems should visit this website and select the services in your

region: http://www.anritsu.com/contact-us.

MA244xxA UG PN: 10585-00033 Rev. C 1-5

Page 10

1-6 Contacting Anritsu for Sales and Service General Information

1-6 PN: 10585-00033 Rev. C MA244xxA UG

Page 11

Chapter 2 — Installation

1

2

6

5 4 3

2-1 Introduction

This chapter contains unpacking and repacking instructions, installation instructions for the software, and

power requirements for the sensors.

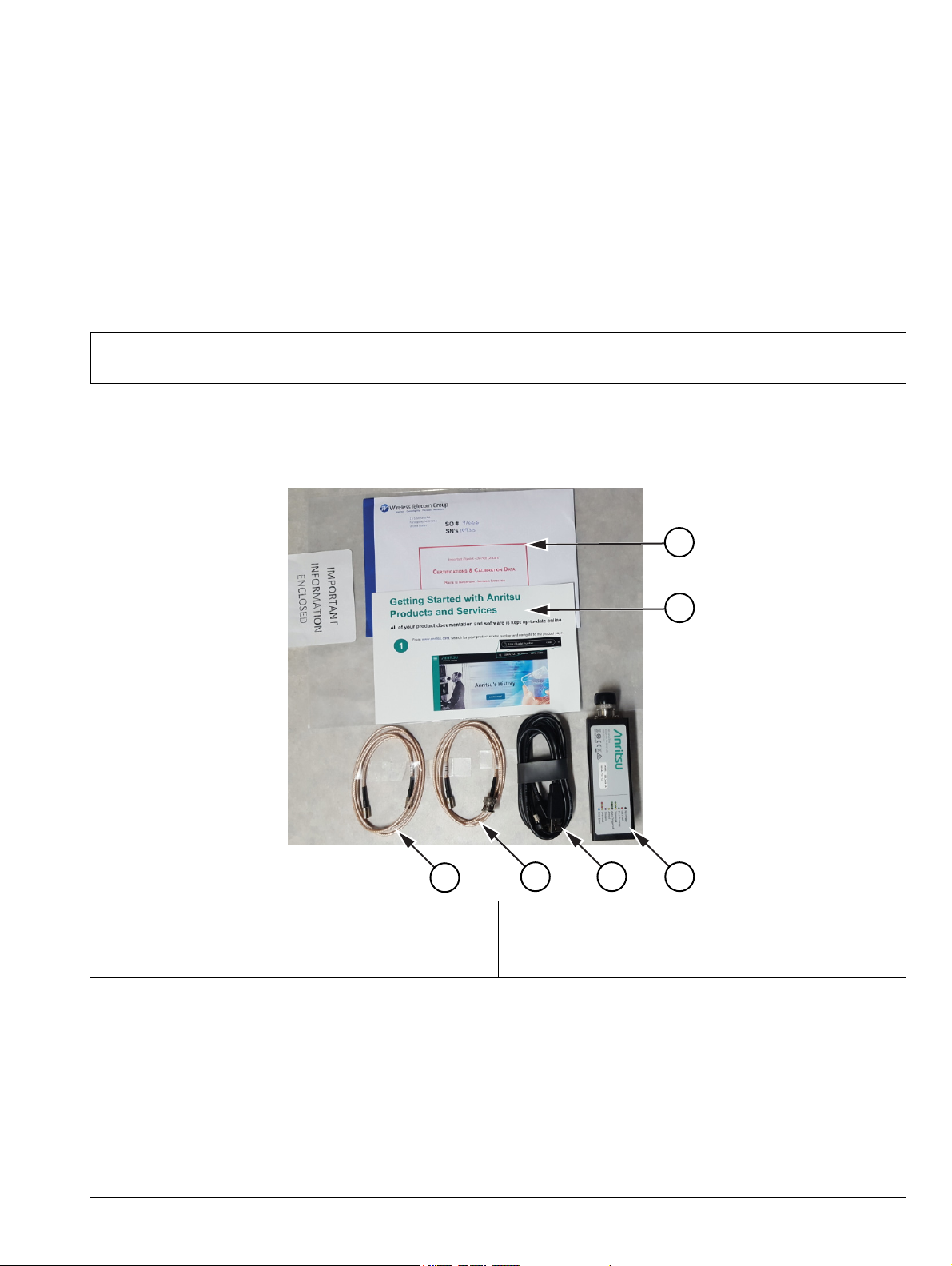

2-2 Unpacking

Caution

The MA244xxA Peak Power Sensors are shipped complete and are ready to use upon receipt. Verify the items

in your power sensor package as shown in Figure 2-1, If any of the items are missing or damaged, refer to

contact Anritsu Customer Service.

Follow all ESD (electro-static discharge) precautions and procedures when handling, connecting, or

disconnecting the MA244xxA Peak Power Sensors.

1. Calibration Certificate

2. Information Card

3. MA244xxA Power Sensor

Figure 2-1. MA244xxA Peak Power Sensors Kit

4. USB Type-A Cable (6 ft)

5. External Trigger Multi-I/O Cable (SMB to BNC)

6. Trigger Sync Cable (SMB to SMB)

2-3 Repacking

When repacking the sensor, use the original packing materials or equivalent.

MA244xxA UG PN: 10585-00033 Rev. C 2-1

Page 12

2-4 Installing MA244xxA Software Installation

2-4 Installing MA244xxA Software

This section describes the installation and use of the MA244xxA USB Peak Power Sensor software. Before you

start, check your computer for compatibility against these minimum computer characteristics:

Caution

• Processor: 1.3 GHz or higher, recommended

• RAM: 512 MB (1 GB or more, recommended)

• Operating System:

• Hard-disk free space: 1.0 GB free space to install or run

• Display resolution: 800x600 (1280x1024 or higher, recommended)

• Interface: USB 2.0 high-speed

Installation Procedure

MA244xxA provides a PC User Interface for making Peak Power Measurements.

To install the MA244xxA Peak Power Analyzer software:

1. Download the latest MA244xxA USB Peak Power Sensor software from the Anritsu Website:

https://www.anritsu.com/en-us/test-measurement/support/downloads/software/dwl19784

2. Click Download

3. Select Run to start the installation.

4. Click through the installation screens. The installation creates a folder on the users PC that is located

here: C:\Program Files (x86)\MA24400A Peak Power Analyzer. Open the folder to launch

AnritsuPowerAnalyzer.exe. Once launched, the MA244xxA PC User Interface will appear as shown in

Figure 2-2.

Do not connect the MA244xxA Peak Power Sensors to your PC until you have installed the

MA244xxA Peak Power Analyzer software.

• Microsoft® Windows® 10

• Microsoft® Windows® 8 (32-bit and 64-bit)

• Microsoft® Windows® 7 (32-bit and 64-bit)

Figure 2-2. MA244xxA PC Interface Display

2-2 PN: 10585-00033 Rev. C MA244xxA UG

Page 13

Chapter 3 — Getting Started

This chapter provides MA244xxA Peak Power Sensors basic connection and operation. For a detailed

functional description, see Chapter 4, “Operation."

3-1 MA244xxA Input Power Requirements

The MA244xxA Peak Power Sensors require 2.5 Watts at 5 Volts, this is supplied via a USB port. Therefore,

power sensor MUST be connected to a USB 2.0 compatible port that is able to supply 500 mA.

Usually a USB 2.0 port is capable of supplying 500 mA current through its port. When an

Note

3-2 Connecting the MA244xxA Peak Power Sensors

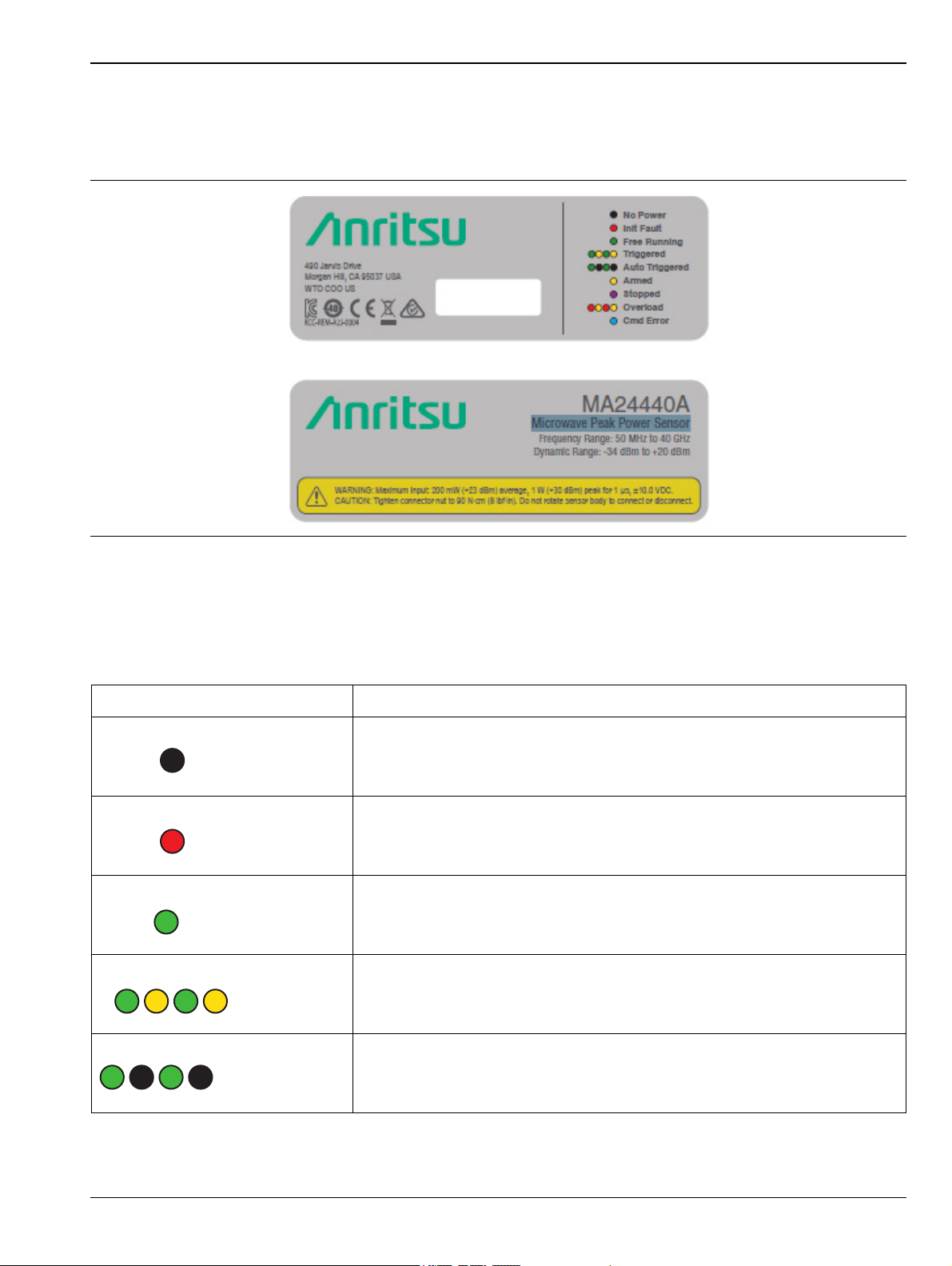

The rear panel of the MA244xxA Peak Power Sensors, shown in Figure 3-1, has two connectors and a status

LED. The larger connector is a USB Type B receptacle used to connect the MA244xxA Peak Power Sensors to

the host computer. The connector labeled MULTI I/O is an SMB plug and can serve as a trigger input, a status

output, or as a trigger-synchronizing interconnection when multiple MA244xxA Peak Power Sensors are used.

un-powered USB hub is used (sometimes the hub is internal), available current may need to be

shared between connected devices.

Figure 3-1. The Power Sensor Rear Panel

Note

Caution

To connect the sensor to the PC and to an RF source:

MA244xxA UG PN: 10585-00033 Rev. C 3-1

The MA244xxA Peak Power Analyzer software must be installed prior to connecting the sensor but

should not be started until the sensor is connected.

Follow all ESD (electrostatic discharge) precautions and procedures when handling, connecting, or

disconnecting the MA244xxA Peak Power Sensors.

Page 14

3-1 MA244xxA Input Power Requirements Getting Started

1. Connect the power sensor to your PC with the supplied USB cable. The cable should be secured

(hand-tight only) to the sensor using the captive screw on the USB plug. See Figure 3-2

Figure 3-2. Captive Screw for the USB Cable

2. Connect the MA244xxA Peak Power Sensors to the RF signal to be measured. All MA244xxA Peak

Power Sensors models are equipped with either a precision Type-N male RF connector (for applications

up to 20 GHz) or a precision 2.92 mm male RF connector (for applications up to 40 GHz).

Use the connecting and disconnecting procedures described in “Instrument Care and Preventive

Maintenance” on page 1-4.

Caution

Do not exceed the specified RF input power as specified on the front label. See Figure 3-3 for

location of this information.

Ensure that you do not apply any excessive forces to the sensor after it is connected.

Figure 3-3. MA24406A With N-Type Connector

3. Connect additional sensors according to your needs. See “Multichannel Operation” on page 4-29 for

connection schemes for multichannel situations.

Up to eight sensors can be connected to the MA244xxA Peak Power Analyzer.

4. Start the MA244xxA Peak Power Analyzer. Refer to “Starting the MA244xxA Peak Power Analyzer”.

3-2 PN: 10585-00033 Rev. C MA244xxA UG

Page 15

Getting Started 3-3 Status LED Codes

No Power

Init Fault

Free Runing

Triggered

Auto Triggered

3-3 Status LED Codes

The rear panel shown in Figure 3-1 on page 3-1 includes a status LED. The color and flash pattern indicate the

sensor’s status as indicated on the label on the side panel shown in Figure 3-4.

Figure 3-4. Information Labels on the MA244xxA Peak Power Sensors

The information labels (see Figure 3-3 and Figure 3-4) on the MA244xxA Peak Power Sensors contain

information on the maximum input power levels and a description of the various status LED flash patterns.

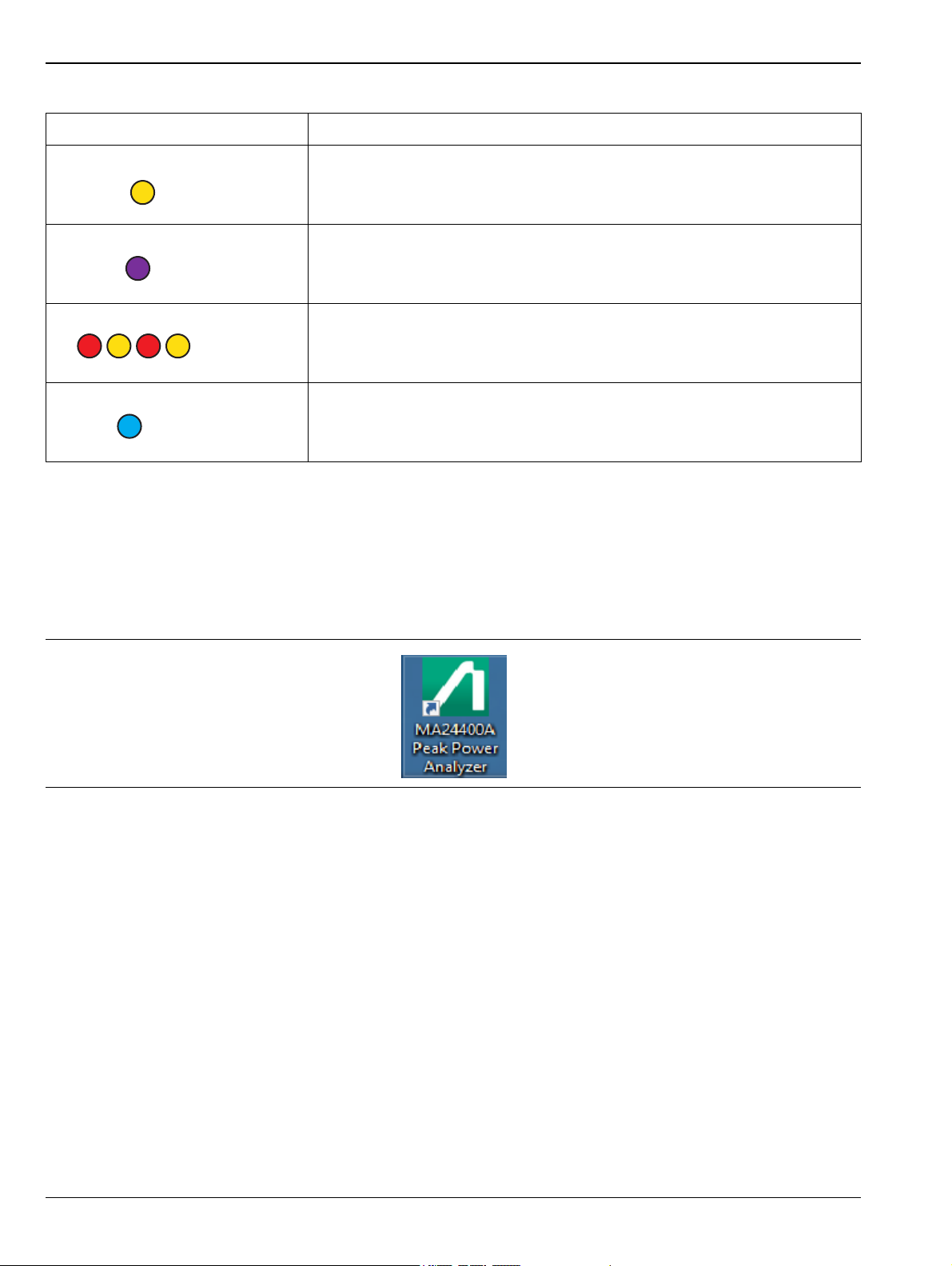

Table 3-1. LED Status Indicators

Icon Description

No Power: No input power detected.

Init Fault: Initialize meter setting failed.

Free Running: Generating horizontal sweeps asynchronously, without

regard to trigger conditions.

Triggered: Indicates a preset triggered condition has occurred.

Auto Triggered: Automatically generates a trace if no trigger edges are

detected for a period of time.

MA244xxA UG PN: 10585-00033 Rev. C 3-3

Page 16

3-4 Starting the MA244xxA Peak Power Analyzer Getting Started

Armed

Stopped

Overload

Cmd Error

Tab le 3- 1 . LED Status Indicators

Icon Description

Armed: Meter is armed and waiting for trigger event.

Stopped: Measurement Stopped.

Overload: Input power is too high. Reduce input power.

Cmd Error: Command Error return. Measurement is not valid.

3-4 Starting the MA244xxA Peak Power Analyzer

After you have installed the software and connected the power sensor to the PC, you are ready to make

measurements using the MA244xxA Peak Power Analyzer.

To start making measurements:

1. Start the MA244xxA Peak Power Analyzer by double-clicking the desktop icon.

Figure 3-5. MA244xxA Peak Power Analyzer Desktop Icon

A splash screen welcomes you to the application.

3-4 PN: 10585-00033 Rev. C MA244xxA UG

Page 17

Getting Started 3-4 Starting the MA244xxA Peak Power Analyzer

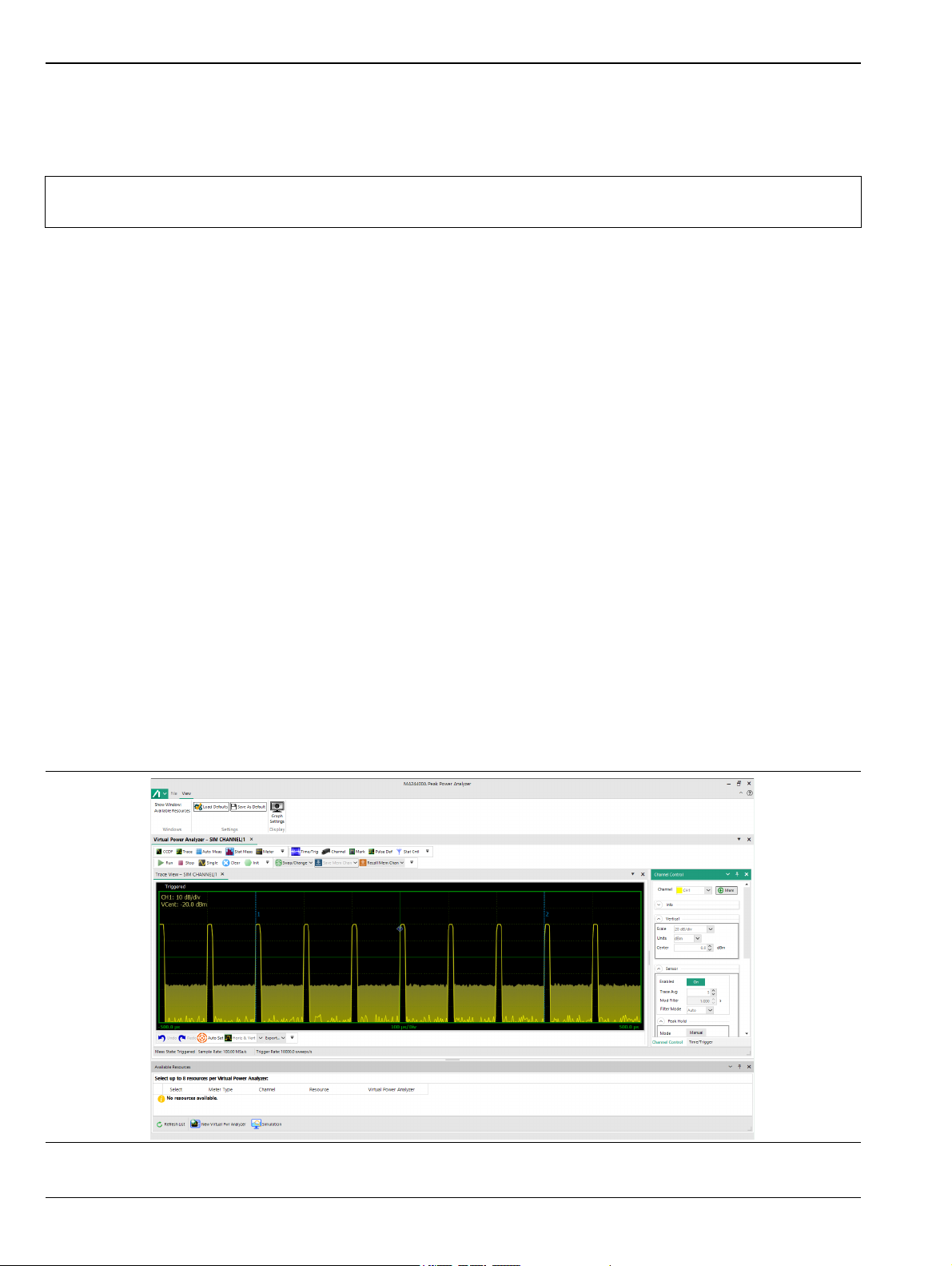

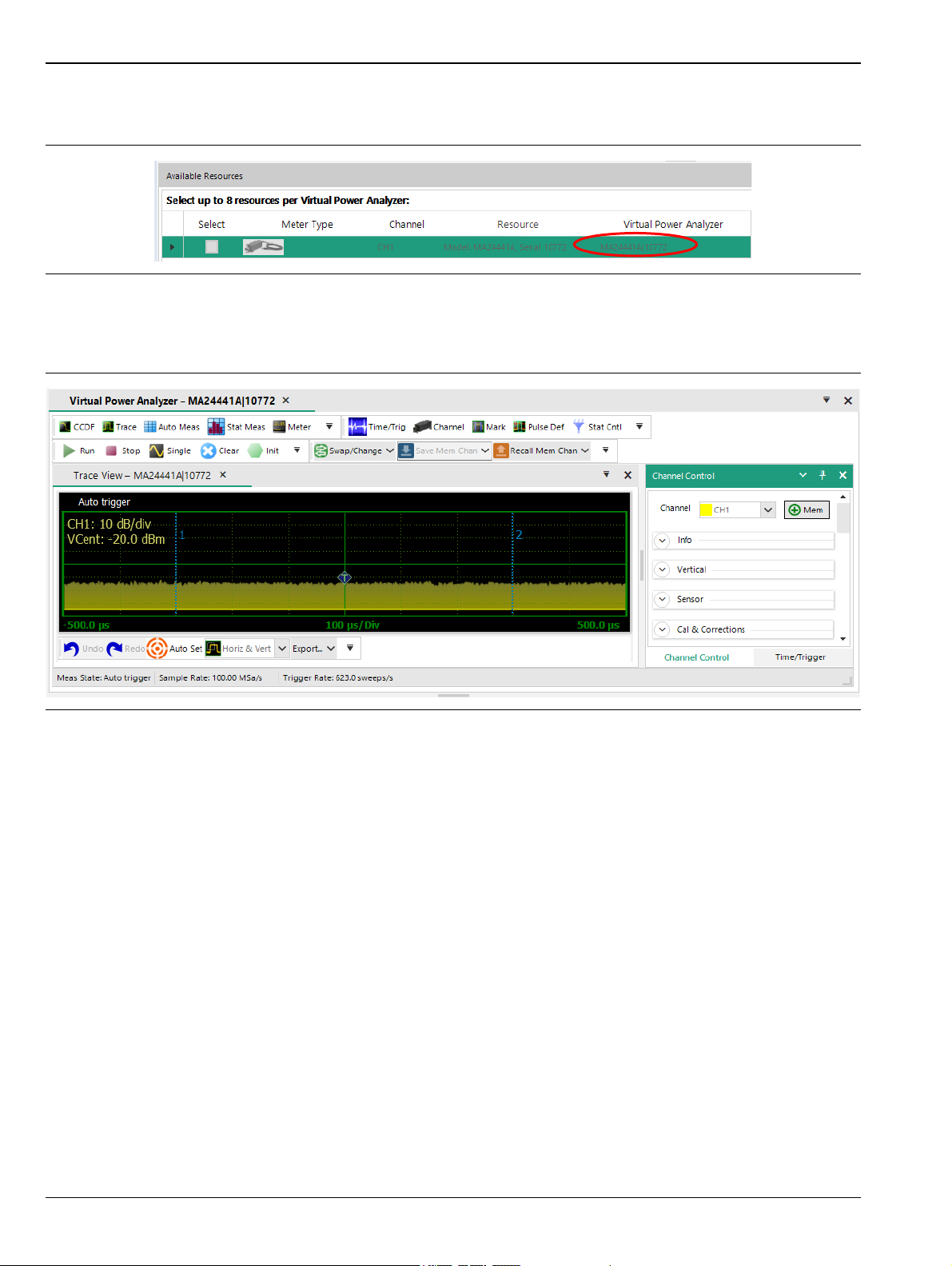

If no sensors are connected, the MA244xxA Peak Power Analyzer displays the No resources available

message as shown in Figure 3-6. If this is the case, close the analyzer, connect one or more sensors and

restart the analyzer.

Figure 3-6. No Resources View Available

With a sensor connected, the Available Resources window shows a list of the connected devices

Figure 3-7. Available Resources Box

2. In the Available Resources window, check select boxes for one or more connected sensors.

Figure 3-8. Selecting a Sensor from the Available Resources List

MA244xxA UG PN: 10585-00033 Rev. C 3-5

Page 18

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

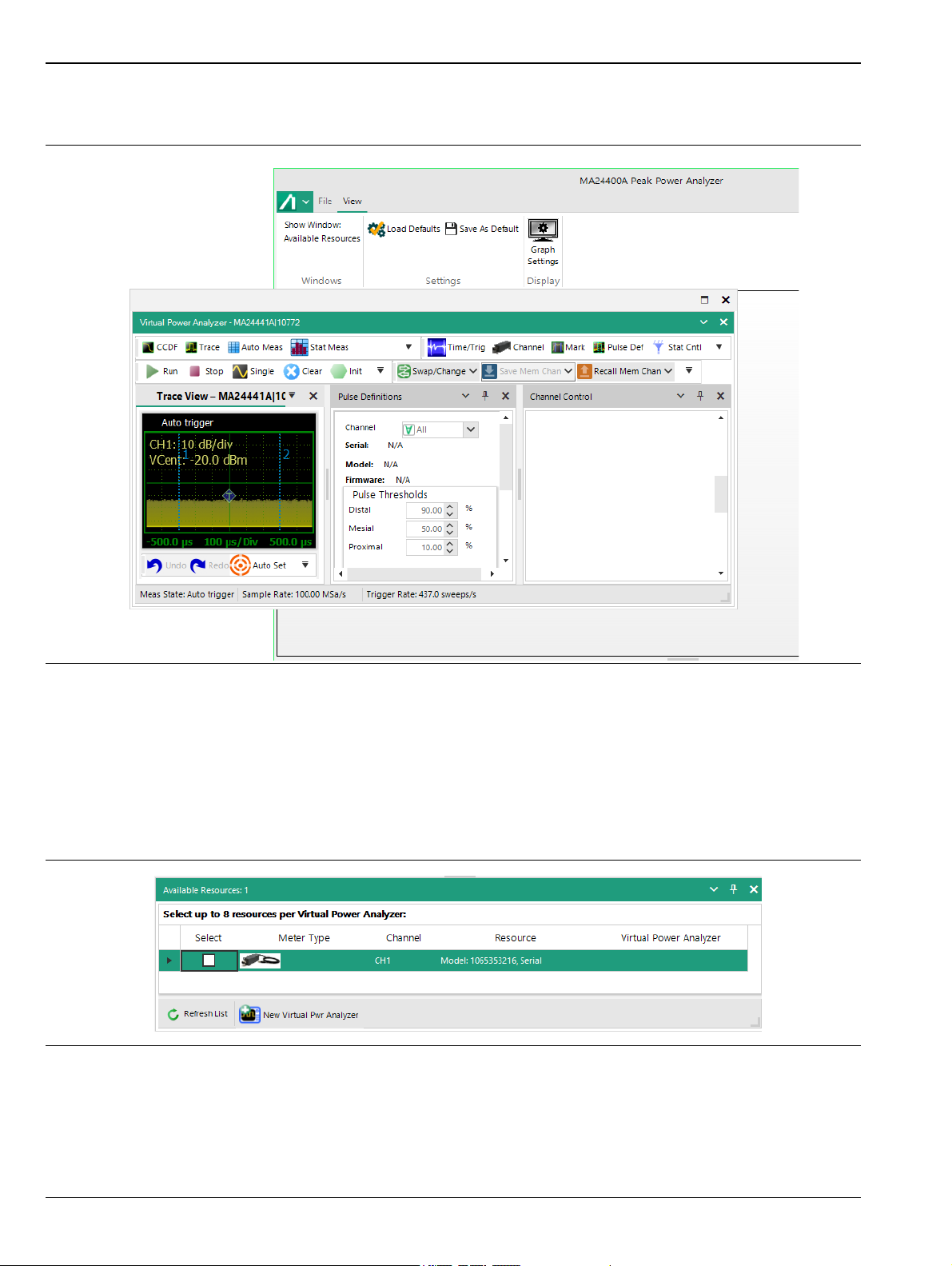

3. Click New Virtual Pwr Analyzer. This launches a new Virtual Power Analyzer instance containing trace

and control panels, and adds the Virtual Power Analyzer name to the Available Resource entries.

Figure 3-9. The Available Resources Box Shows Assigned Devices

4. If you have an RF signal connected to the USB sensor, the measured signal's waveform appears in the

trace window.

Figure 3-10. Initial View of the Virtual Power Analyzer

A Virtual Power Analyzer is analogous to a bench-top RF power analyzer with one or more sensors connected.

Time and trigger controls are typically common to all sensors within a MA244xxA Peak Power Analyzer, while

channel-specific controls are available for most other settings. This offers users the familiar, multi-channel

approach common to power meters and oscilloscopes.

When independent control of timebase-related settings is desired, you may open multiple MA244xxA Peak

Power Analyzer windows, each with their own sets of controls.

3-5 MA244xxA Peak Power Analyzer Basics

Dockable Windows

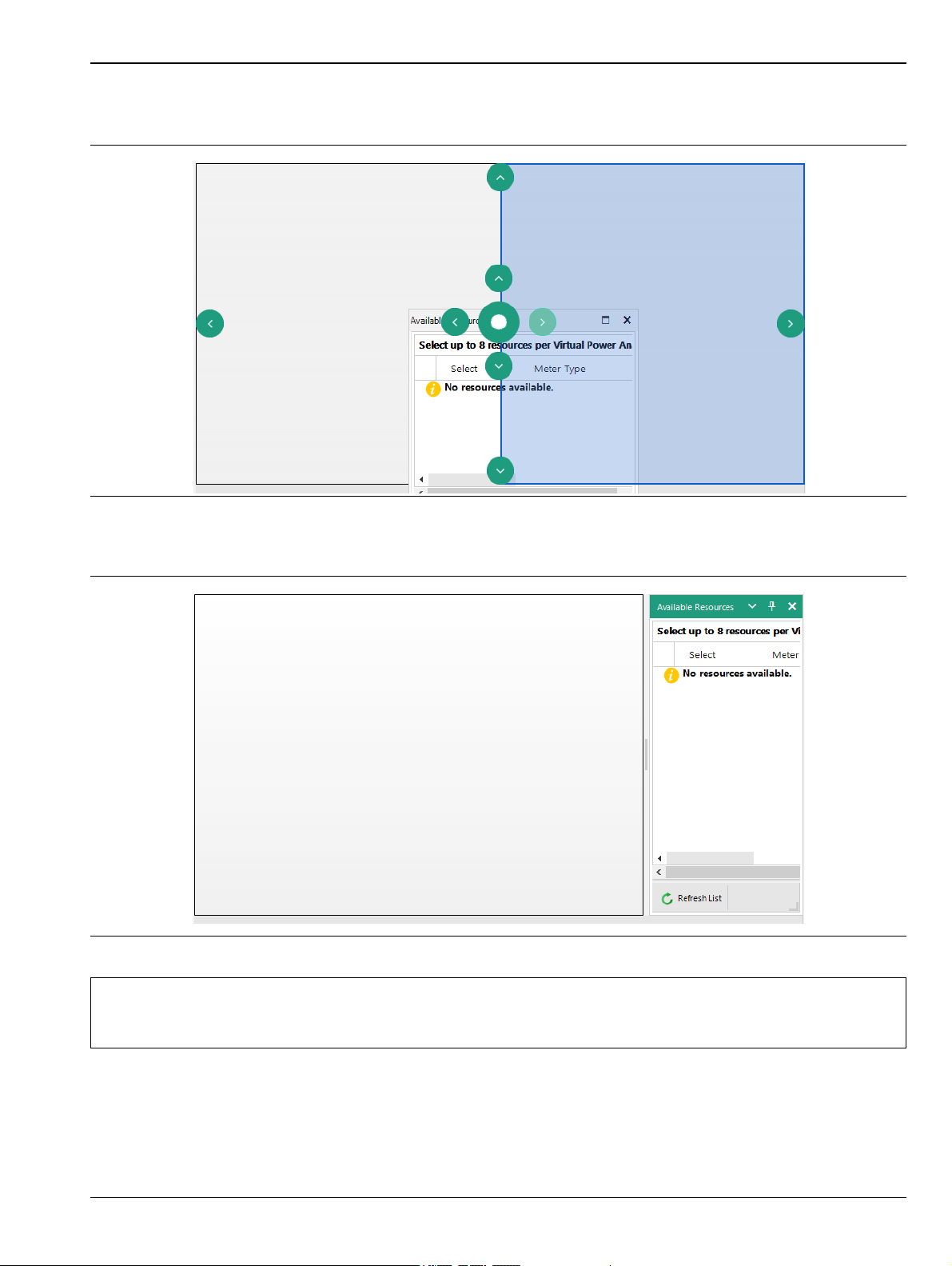

The MA244xxA Peak Power Analyzer uses dockable windows that allow you to arrange the various windows

into the configuration of your choice. You can drag a docked window by clicking its title bar. This action enables

them to move the window to a different docked position or undock it.

To dock tool windows:

1. Click and hold the title bar of the tool window you want to dock.

2. Start dragging the window.

Guide arrows appear pointing toward the four sides of the main window.

3-6 PN: 10585-00033 Rev. C MA244xxA UG

Page 19

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

3. When the tool window you are dragging reaches the location where you want to dock it, move the pointer

over the corresponding portion of the guide diamond. The designated area is shaded blue.

Figure 3-11. Docking a Window

4. To dock the window in the position indicated, release the mouse button.

Figure 3-12. Docking a Window to the Right-side of the Main Window

Each of the tool windows may be positioned by dragging in any direction within the main window.

Note

Figure 3-11 on page 3-7 is one example; but you can rearrange tool windows as you prefer to see

them within the main software window or onto the desktop; Figure 3-13 shows this.

5. Docked windows can be overlapped. By selecting individual tabs, it is possible to resize and reposition

each tool window.

MA244xxA UG PN: 10585-00033 Rev. C 3-7

Page 20

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

6. Docked windows can also be moved partially or completely out of the MA244xxA Peak Power Analyzer

main window.

Figure 3-13. Partial Window Repositioning

Available Resources Window

Sensors can be selected from the Available Resources window. A description for each connected resource

indicates the hardware version, model, and channel information, including alias. Users can select up to eight

resources per Virtual Power Analyzer instance. After selecting sensors, click New Virtual Pwr Analyzer and a

new Virtual Power Analyzer instance opens for those sensors with default configurations suitable for pulse

measurements.

Figure 3-14. Selecting a Sensor Using the Available Resources Box

3-8 PN: 10585-00033 Rev. C MA244xxA UG

Page 21

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

Virtual Power Analyzer Main Toolbar

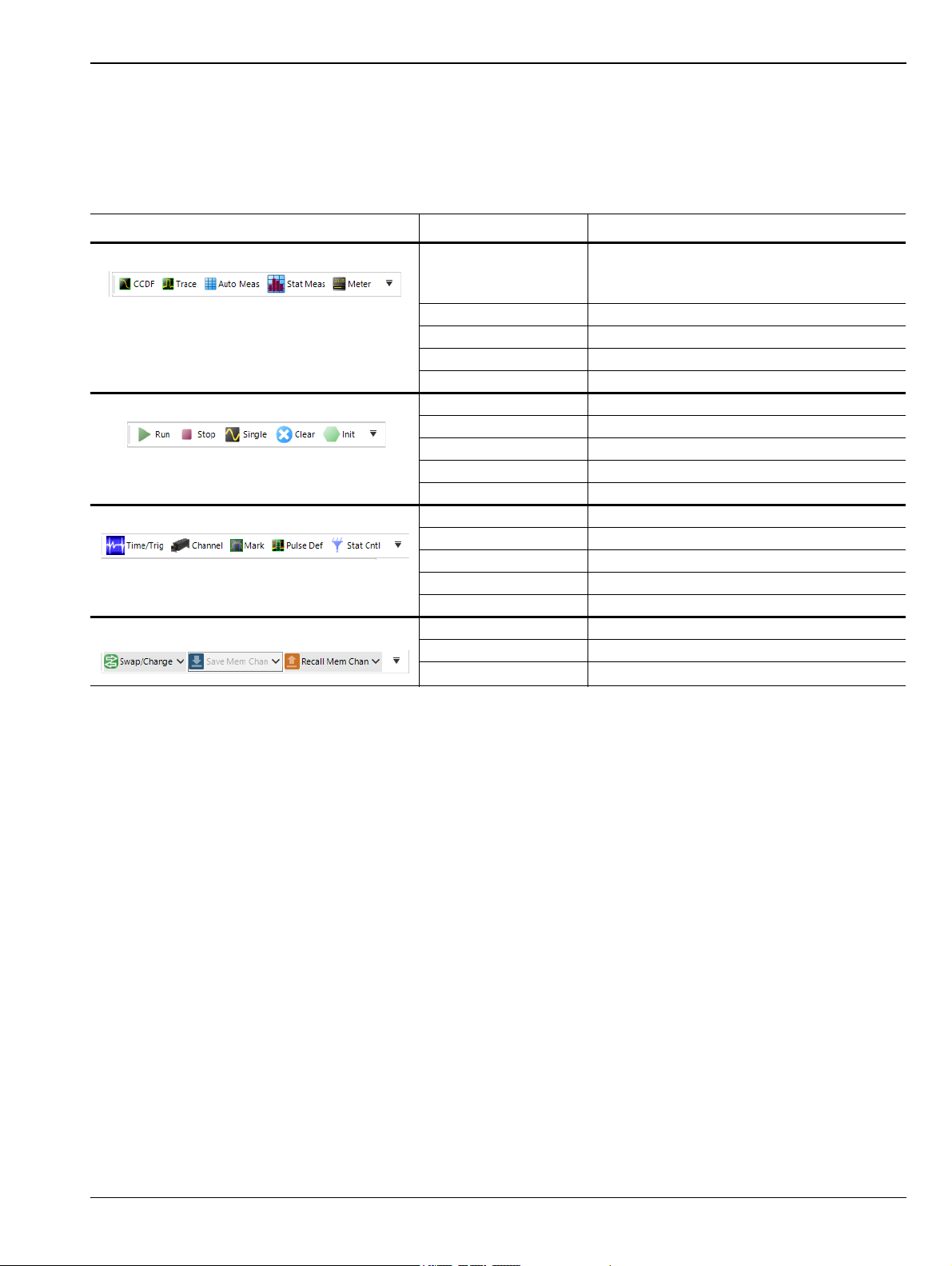

Each Virtual Power Analyzer window displays a main toolbar at the top of its window which hosts shortcuts to

commonly used functions and measurement modes. The main toolbar is subdivided into smaller toolbars by

function; the order of tools in each toolbar may be customized or the groups may be dragged and dropped as

needed to provide more usable arrangements.

Toolbar Tool Description

Measurement Control CCDF Opens the CCDF window

(Complementary Cumulative Distribution

Function)

Trace Opens the trace window

Auto Meas Opens the auto measurement window

Statistical Meas Opens the stat measurement window

Meter Opens the meter view

Acquisition Control Run Starts a capture

Stop Stops a capture

Single Performs a single sweep

Clear Clears measurement buffer

Init Initializes meter settings

Control Windows Time/Trig Views time and trigger settings

Channel Views channel controls

Mark Opens marker control form

Pulse Def Opens pulse definition editor

Stat Cntl Opens stat mode control editor

Memory Channel

Swap/Change Swaps the USB power meter for a channel

Save Mem Channel Saves (archives) a memory channel

Recall Mem Channel Loads an archived memory channel

Figure 3-15. Main Toolbar Toolbars

MA244xxA UG PN: 10585-00033 Rev. C 3-9

Page 22

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

With each of these tools is associated a dialog; these are described in Chapter 4 in more detail. When several

are open simultaneously you can switch between them using the shortcuts at the bottom of the dialog.

Figure 3-16. Toolbar Shortcuts: Left View is Docked; Right View is Undocked.

3-10 PN: 10585-00033 Rev. C MA244xxA UG

Page 23

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

Trace Group

Trigger Group

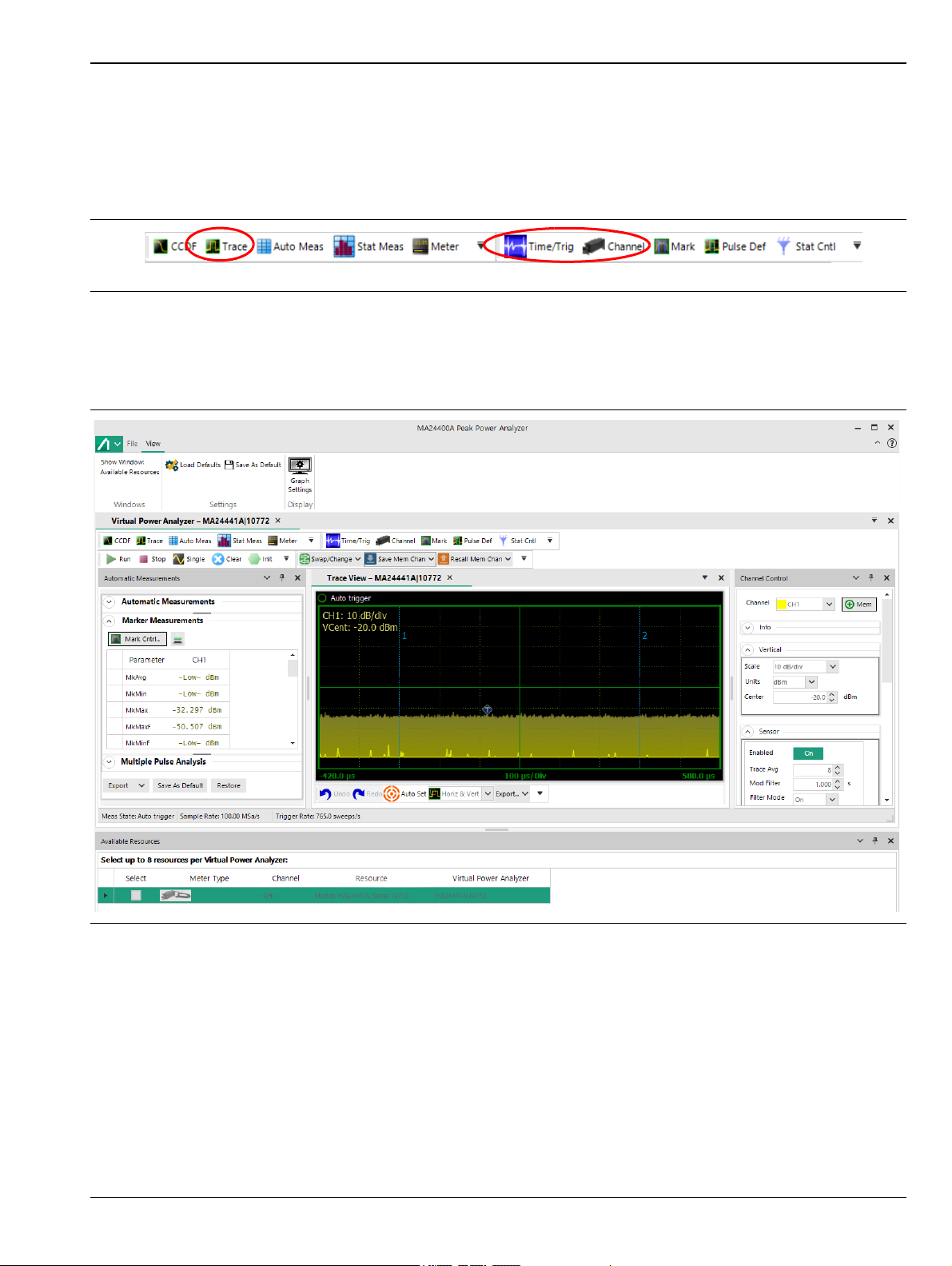

Trace View Window

To display a pulse measurement, select the Trace button from the Measurement toolbar. This is the default

view for a Virtual Power Analyzer instance.

The Channel and Time/Trig(ger) settings are related to pulse measurement can be selected from the Control

toolbar and can be applied to the measurement.

Figure 3-17. The Trace, Channel, and Time/Trigger Buttons

A Virtual Power Analyzer instance, in a configuration suitable for pulse measurements, is shown in

Figure 3-18. This shows a large trace window, automatic measurements, and a tabbed control box for time and

channel settings.

Figure 3-18. Main Application Window of the MA244xxA Peak Power Analyzer

The Virtual Power Analyzer allows you to directly enter numeric values for most settings in the Channel

Control and Time/Trigger windows. For many of the controls, additional methods such as increment/decrement

or preset buttons are available.

MA244xxA UG PN: 10585-00033 Rev. C 3-11

Page 24

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

Virtual Power Analyzer Lower Toolbar

Trace Pan and Zoom

The mouse can be used to select a zoom area to view detail in an area of interest on the displayed waveform.

The highlighted dragged rectangular area indicates the minimum area that will be shown when the zoom

operation completes.

Horizontal pan or zoom adjusts the timebase (within preset values) and the trigger delay to highlight an area

of interest without vertical rescaling.

You can also directly pan or zoom to waveform areas of interest by selecting any option from the lower toolbar

of the trace window. Available options for zoom/pan control are: Horizontal & Vertical, Horizontal, Pan and

None.

Clicking the Trace View display, dragging a zoom box, and releasing the mouse button results in the trace being

expanded to show the area outlined by the zoom indicators.

AutoSet

The Auto Set button tries to configure level scaling, trigger level, and timing for a best-fit display based upon

amplitude and timing of the applied signal. All other parameters are set to defaults. If the Auto Set process

fails, all settings are left untouched.

You can undo or redo an action with the undo and redo buttons.

Trace Data Export

Any trace window can be exported and saved or printed as a PDF or CSV document by selecting PDF or CSV

from the Export drop-down menu. An exported trace file can easily be imported into a spreadsheet or other

report file or documentation.

Channel Control Window

Select the Channel button of the Trigger group and a dockable sidebar appears, by default, on the right-hand

side of the main application window. This allows you to change all the related settings that control one or more

sensor channels. The Channel Control is defined by these parameters.

Figure 3-19. Channel Control Dialog

3-12 PN: 10585-00033 Rev. C MA244xxA UG

Page 25

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

Channel

Select one channel to update from the drop-down list or select All channels (available only with multiple

channels) to simultaneously update all measurement channels (up to 8) for most settings.

Memory Pull-down

You can select the stored memory channels.

Info Group

Serial: Displays the serial number of the sensor.

Model: Displays the model number of the sensor.

Firmware: Displays the date of the firmware version.

FPGA: Displays the FPGA version.

Mark Control: Brings up the Mark Control dialog.

Pulse Definition: Brings up the Pulse Definition dialog.

Vertical Group

Scale: Sets vertical amplitude scaling and centering of the displayed waveform. These settings

affect only the Trace display.

Units: Selects dBm, Watts, or Volts measurement units. Selection affects displayed text,

measurements, and trace.

Center: The center frequency for the display.

Sensor Group

Sensor Enabled: Enable or disable individual connected sensors.

Trace Avg: Sets number of acquired sweeps averaged together for displayed trace in pulse/triggered

modes. Useful for noisy signals.

Mod Filter: Sets the modulation filter integration time.

Filter Mode: Sets manual or automatic filter integration time window for measurements in modulated

(non-triggered) acquisition modes.

Video BW: Selects sensor video bandwidth, high or low.

Frequency: Sets measurement frequency for the applied RF signal.

Peak Hold Group

Mode: Sets the mode of the sensor to either manual or tracking.

Decay Count: Sets peak hold duration (# of sweeps).

Cal&Corrections Group

Offset: Compensates reading for external gain/loss.

Zero and Fixed Cal : Performs sensor zeroing or fixed calibration by selecting each specific button.

Clear User Cal: Clears any user calibration for the sensor selected (refer to “Channel” on page 3-13).

Fixed Cal: Performs a calibration at 0 dBm at the currently set frequency.

MA244xxA UG PN: 10585-00033 Rev. C 3-13

Page 26

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

Time / Trigger Settings Window

Click the Time/Trig button of the Trigger group to customize all related settings for both timebase and trigger of

a pulse signal. Refer “Time/Trigger Control Window” on page 4-5 for details.

Figure 3-20. Time and Trigger Dialog

Time

Timebase: Acquisition time in seconds per division. The power sensors use a fixed grid of 10

divisions for the sweep extents. Settings are in a 1-2-5 sequence. Consult series

specifications for timebase range.

Trigger: Delay The trigger delay can be adjusted by manually entering a numerical value into the

field or using the up-down arrow keys. Refer to “Time Control” on page 4-6.

Trigger Position

The trigger position can be changed by entering numerical values into the Divisions field, clicking the

scroll arrows, dragging the slide control, or by clicking the L/M/R (Left/Middle/Right) indicators. Refer to

“Trigger Position Control” on page 4-7.

Trigger Control

Source: Several trigger modes are available for each trigger source under Trigger Control section.

Multiple trigger sources are available under the drop-down list including both Internal

and External selection.

Mode: Select Normal, Auto, AutoLevel or Free run.

Level: Sets trigger level when trigger source is INT and trigger mode is Auto or Normal.

Slope: Selects rising- or falling-edge triggering.

Holdoff: Sets trigger holdoff time.

Holdoff Mode : Selects between Normal or Gap.

Trigger Skew

Adjustment: Adjusts the skew for internal trigger with master trigger output, and also external and

slave triggers. Skew adjustments allow you to calibrate out-trigger delay between sensors

so the you can measure the propagation delay of the DUT from input to output. Manual

skew adjustments can be made by entering the skew value in the numeric entry field.

The button to the right of each skew adjustment is the Auto-Skew, which allows

automatic adjustment of the skew. Refer to“Trigger Skew Adj(ust)” on page 4-9.

3-14 PN: 10585-00033 Rev. C MA244xxA UG

Page 27

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

Marker Settings Window

Click Mark of the Control Windows toolbar to control settings for time markers and reference lines of a pulse

signal. refer to “Marker Settings Window” on page 4-20.

Figure 3-21. Marker Settings Window

Markers: Allow you to change both Marker 1 and Marker 2 time positions by using either arrow

keys or entering numerical values into the fields. It also displays the time delta value

between the two markers. You may also drag the markers in the active window and their

values will be reflected in this window.

Reference Lines: Also known as Horizontal Markers, they can be enabled by selecting the On/Off button for

each individual channel. After they are enabled, users may select several options for

automatic amplitude tracking from the Tracking drop-down list: Off, Markers,

TopBottom, DistalMesial and DistalProximal. Two reference lines can be set by using

up/down arrow keys. Horizontal markers are useful to determine the difference with

regard to loss.

MA244xxA UG PN: 10585-00033 Rev. C 3-15

Page 28

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

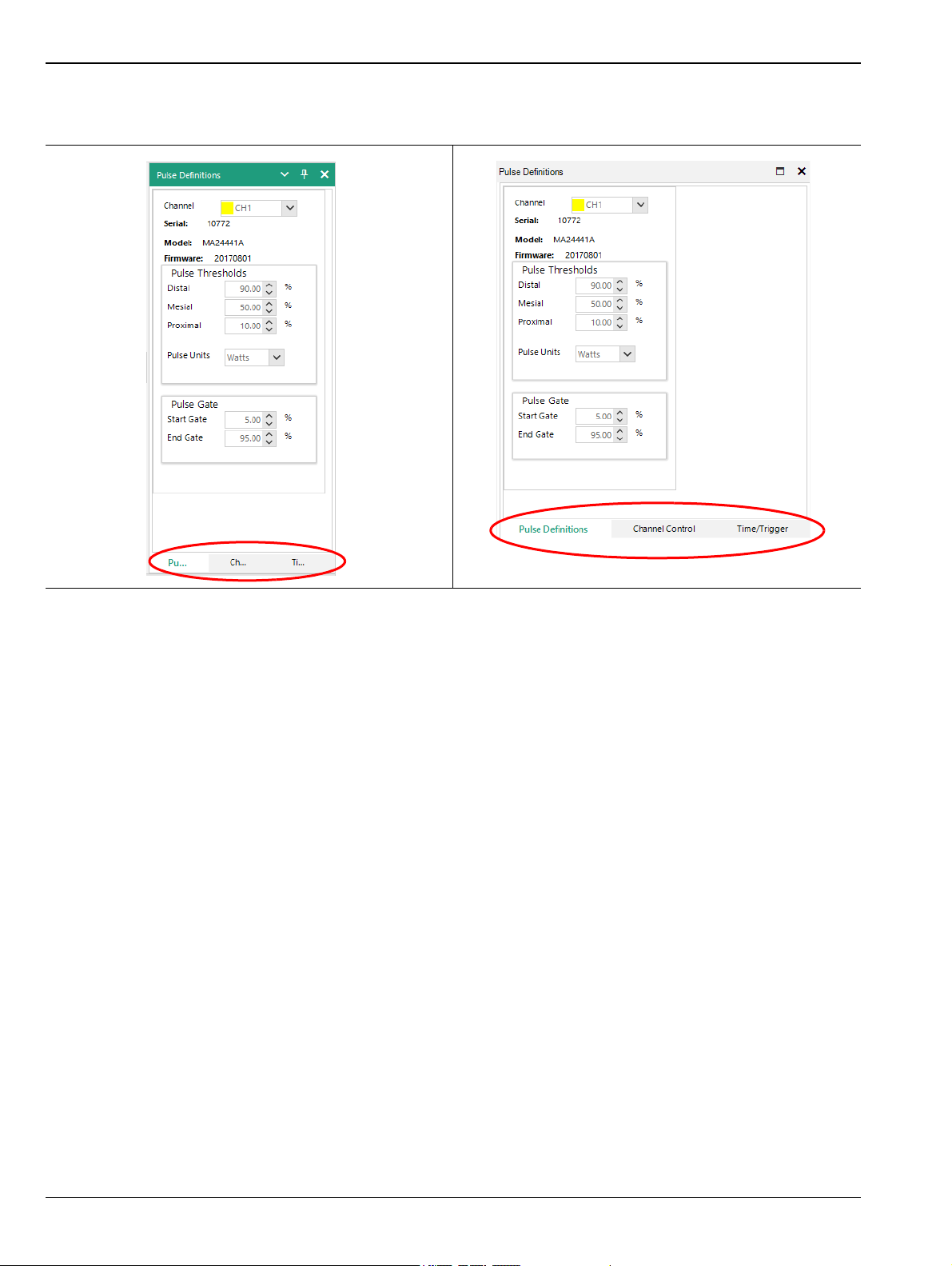

Pulse Definitions Window

Click Pulse Def of the Trigger group to access settings for the pulse definitions. Refer to “Pulse Definitions

Window” on page 4-19.

Figure 3-22. Pulse Definitions Menu

Channel: The channel to which the definitions will be applied.

Serial: The serial number of the unit. (Not applicable when all channels are selected.)

Model: The model number of the unit. (Not applicable when all channels are selected.)

Firmware: The version number of the installed firmware on the unit. (Not applicable when all

channels are selected.)

Pulse Thresholds:

Pulse definition settings allow you to define distal, mesial, and proximal values for pulse thresholds. You

may change the pulse unit between watts and volts.

Pulse Gate

Pulse Start and End Gates can be changed both numerically and by using the up/down arrow keys. It is

not necessary that the two of them total to 100%.

Chapter 5, “Making Measurements” contains a detailed description of the Pulse Threshold level and the pulse

measurement process.

3-16 PN: 10585-00033 Rev. C MA244xxA UG

Page 29

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

Stat Mode Control Window

Click Stat Cntl of the Trigger group to access settings for the pulse definitions. Refer to “Statistical Mode

Control Window” on page 4-23.

Figure 3-23. Pulse Definitions Menu

Capture: Set to On to capture the stat mode.

Reset: Click to reset all the parameters.

Te rm Ac t io n : The action to take upon termination: Decimate, Restart, and Stop.

Term Count (Msa): Type or use the arrow buttons to enter a sample limit.

Terminal Time (s): The time in seconds for the sample period to end.

Horiz Offset (dB): Use the up-down arrow buttons to modify the amount of offset.

Horiz Scale: Choose the scale from six fixed values from 0.1dB to 5.0dB.

Cursor Type: Choose between percent (%) and power.

Cursor Pos (%): The position of the cursor in Type units.

Gating: Choose between Freerun and Markers.

Mark Cntrl: Opens the Marker Settings dialog.

MA244xxA UG PN: 10585-00033 Rev. C 3-17

Page 30

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

Automatic Measurements Window

Select the Auto Meas button to display three tabulated fields with lists of parameters for Multiple Pulse

Measurements, Automatic Measurements, and Marker Measurements. Figure 3-21 is an example screenshot

for Automatic Measurements displayed for a typical pulse measurement. Refer to “Automatic Measurements

Display” on page 4-15

Figure 3-24. Automatic Measurements Window: Collapsed View

All parameters are customizable and may be edited or deleted from these lists. A part of or the whole table may

be copied and pasted into a spreadsheet. Adding screenshots from the Export>PDF you make any custom

report file along. Export>CSV exports all the parameters from these lists to a CSV file.

To add a row to any table click on the table icon or Click here to add a new row. You may select from any of the

parameters in the drop-down list. Generally, this feature is used to replace any row that was deleted.

Figure 3-25. Selecting Automatic Parameters

Click Restore to restore all the factory default values to the parameter in the lists.

3-18 PN: 10585-00033 Rev. C MA244xxA UG

Page 31

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

Customize Field Parameters

All field parameters under automatic measurement are customizable. They can be edited or deleted from the

list by selecting individual parameters with the right mouse button. Right-click a parameter to access its Edit

pop-up.

Figure 3-26. Pulse Measurement Pop-up

Export or Copy Field Parameters

The whole or partial automatic table or field can be copied and pasted into any spreadsheet or document.

Control+click those rows needed to make a custom report, and include screenshots captured by the application.

Figure 3-27. Select Multiple Parameters and Right-click to Copy

MA244xxA UG PN: 10585-00033 Rev. C 3-19

Page 32

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

Display (Graph) Settings Window

Select Graph Settings from the window toolbar to customize data and trace colors for each measurement

channel, and enable or disable trace display features such as Average, Envelope, Maximum, Minimum, and

Persistence.

Figure 3-28. Graph Setting Icon

It is also possible to adjust marker color, background, grid colors, and more under Graph Colors section of the

display settings.

Figure 3-29. Display Settings

3-20 PN: 10585-00033 Rev. C MA244xxA UG

Page 33

Getting Started 3-5 MA244xxA Peak Power Analyzer Basics

CCDF View Window

For statistical measurements, select the CCDF (Complementary Cumulative Distribution Function) icon from

menu bar to view a CCDF graph. The sidebar on the CCDF screen allows adjustment of horizontal scale,

horizontal offset, cursor type, cursor position, and dB offset. You can also enable/disable capture or reset the

statistical data acquisition.

Figure 3-30. CCDF Graph

MA244xxA UG PN: 10585-00033 Rev. C 3-21

Page 34

3-5 MA244xxA Peak Power Analyzer Basics Getting Started

Statistical Measurements Window

Click the Stat Meas button to display a tabulated list of statistical measurements. Figure 3-31 is an example

parameters text display for statistical measurements.

Figure 3-31. Statistical Measurements Window

This data can also be exported by holding Shift and pressing the up or down arrow keys until all the rows

needed are selected. Right-click on any of the selected rows and click Copy.

Figure 3-32. Exporting Data

3-22 PN: 10585-00033 Rev. C MA244xxA UG

Page 35

Chapter 4 — Operation

4-1 Introduction

This chapter presents the procedures for using the MA244xxA Peak Power Analyzer to operate the MA244xxA

Peak Power Sensors. All the display windows that control the sensors are illustrated and accompanied by

instructions for each control in the window.

The MA244xxA Peak Power Analyzer is a Windows-based software program that provides immediate RF

power measurements from MA244xxA Peak Power Sensors without the need for programming on your

Windows OS-based computer. RF power measurements from the power sensor can be displayed on your

computer or can be integrated into a test system using an Application Program Interface (API).

This section of the manual requires that the MA244xxA Peak Power Analyzer is installed on a

Note

4-2 The Trace View Display

The Trace View shown in Figure 4-1, “Horizontal and Vertical Zoom on a Trace” is the default view when a

Virtual Power Analyzer is first opened. It displays a trace of power versus time. The readout in the upper left

corner shows the channel number of the trace, the vertical scale factor, and the vertical center. In Figure 4-1,

CH1 is displayed with a vertical scale of 10 dB/div(ision) and a vertical center of –20 dBm.

• The horizontal scale of the trace in the Trace View window is shown at the bottom of the grid. At the

center of the horizontal axis is the horizontal scale factor. Numbers at the right and left ends of the

horizontal axis show the trace start and end times relative to the trigger.

• The two vertical blue lines labeled 1 and 2 are markers used for measurements of the displayed signals.

Refer to “Marker Settings Window” on page 4-20.

• The bar at the bottom of the Trace View window provides useful tools that can be used to optimize the

trace display and archive the trace(s):

computer using the instructions provided in Chapter 2, “Installation” and that one or more sensors

are connected according to instructions provided in Chapter 3, “Getting Started”.

• The Export button is used to export any trace window as a PDF or CSV document. These exported

trace files can be used for a report or document.

• The Undo and Redo buttons work in conjunction with the display expansion (zoom) function to

remove (Undo) and restore (Redo) changes in display scaling.

• Autoset provides an automatic setup of the trace display scaling that optimizes the trace view in

the Trace View window.

• The pull-down menu selects the zoom mode from these options:

• Horiz(ontal) & Vert(ical), refer to “Trace Zoom: Horizontal and Vertical”

• Horizontal, refer to “Trace Zoom: Horizontal Only” on page 4-2

• Pan allows you to click and drag the trace either horizontally or vertically. You may also

drag the trace symbol to adjust the position of the trace.

• None prevents all zoom and pan actions.

MA244xxA UG PN: 10585-00033 Rev. C 4-1

Page 36

4-2 The Trace View Display Operation

Trace Zoom: Horizontal and Vertical

The analyzer has a trace-zoom feature which lets you to drag a rectangular box (like the one shown in

Figure 4-1) around the trace to zoom onto a special area of the displayed waveform. The rectangular area

indicates the area that is enlarged when the mouse button is released. The zoom area is constrained to the

preset timebase settings and trigger Vernier limits. Note in Figure 4-1 that the zoom horizontal scale changes

from 10 µs/div to 1 µs/div (the nearest available fixed timebase setting). Vertical scaling is similarly

constrained.

Figure 4-1. Horizontal and Vertical Zoom on a Trace

Trace Zoom: Horizontal Only

Horizontal-only display expansion (zoom) is accomplished by clicking on the trace view and dragging the mouse

horizontally. A shaded box outlines the area to be expanded. Releasing the mouse button rescales the trace.

Figure 4-2. Horizontal Zoom

4-2 PN: 10585-00033 Rev. C MA244xxA UG

Page 37

Operation 4-2 The Trace View Display

Formatting Trace View Display Settings

In the upper left-hand corner, click View (next to File) and then click the Graph Settings icon. This opens the

Display Settings popup as shown in Figure 4-3.

Figure 4-3. The Display Settings Popup

The Display Settings popup is used to configure the Graph View. The elements to be displayed can be chosen

and their colors may be selected, along with the background color.

The upper section of the Display Settings, labeled Trace, controls the configuration of the selected trace. There

can be a maximum of eight traces. The configuration of each trace includes the trace color, the choice of five

viewable trace attributes, and the trace refresh time. Trace attributes include graphical view of the average

value, envelope, maximums, minimums, and persistence (trace history). The defaults are Show Avg and Show

Envelope. Each of the selected elements is overlaid on the trace.

The sensor acquires all three traces (average, min and max) when required for a trace. These are

used for several of the marker measurements, such as interval, peak-to-average, and others. The

sensor also tracks Min and Max (highest maximum trace and lowest minimum trace points) as well

Note

as MinF and MaxF (minimum and maximum filtered) which are the highest and lowest points on the

average trace. The former measurements are useful for looking at modulation, while the latter are

most useful for seeing systematic peaks and dips (for example, ringing) of a repetitive waveform with

the noise reduced.

A check box for Disable HW Acceleration can be checked if the computer does not have a monitor or graphics

card or if it is operated remotely using Remote Desktop.

Note This change takes effect the next time a trace window is opened.

MA244xxA UG PN: 10585-00033 Rev. C 4-3

Page 38

4-2 The Trace View Display Operation

The lower section of the Display Settings popup provides controls for color choices for trace grid, border, and

background. Markers, axis label, and crosshair color selections are also included. Color choices are made by

clicking on the ellipsis symbol (…) adjacent to each element. This brings up the Color Dialog palette used to set

the desired color for the element

The Main Toolbar

The MA244xxA Peak Power Analyzer always displays the Main Toolbar at the top of the main program

window and contains shortcuts to commonly used functions and measurements. The Main Toolbar can be

customized as discussed below. Figure 4-4 shows the Main Toolbar:

Figure 4-4. The Main Toolbar

The Main toolbar contains three sections. The group of shortcuts on the left, including CCDF, Trace, Auto

Meas (Measurement) and Stat Meas (Statistical Measurement) comprise the Measurement Windows toolbar

and bring up trace display or measurement panels. The middle group with Time/Trig (Trigger), Channel,

Mark, Pulse Def (Definitions) and Stat Cntl (Statistical Control) are the Control Windows toolbar. They cause

setup and control windows to be displayed. The right-most group including Run, Stop, Single, Clear, and Init

(Initialize) are the Acquisition Control toolbar and affect the state of the acquisition.

Any of the toolbars may be separated from the Main Toolbar and re-positioned by clicking on the ellipsis

symbol at the left end of any of the groups and dragging the toolbar.

The drop-down menu bar on the right of each section allows you to edit the tools bar by adding or removing any

of the items under the Items tab. The toolbars tab allows you to show or hide the toolbars.

The Acquisition Control Toolbar

The buttons on this toolbar control the state of the acquisition:

Run: Starts the measurement acquisition and allows it to run continuously until stopped.

Stop: Stops the measurement acquisition.

Single: Starts a single measurement acquisition and then stops.

Clear: Erases the acquired data trace. Useful when clearing single or averaged acquisitions.

Init: Initializes or resets all settings for the active Virtual Power Meter to default values.

The Measurement Control Toolbar

The buttons on this toolbar create Trace View and CCDF Graph displays as well as the automated power

measurement and statistical Measurement tabular display windows:

CCDF: This button turns on the complementary cumulative distribution function (CCDF)

display. If the CCDF display is already opened but hidden behind the Trace View display,

clicking this button brings the CCDF trace to the foreground. Refer to “Statistical CCDF

Graph Display” on page 4-22.

Trace: This button turns on the Trace View trace that displays power versus time. Refer to “The

Trace View Display” on page 4-1.

Auto Meas: This button opens Automatic Measurement windows showing the automatic Pulse and

Marker Measurements tables. Refer to “Automatic Measurements Display” on page 4-15.

Stat Meas: This button opens the Statistical Measurements window displaying the measurements

associated with the CCDF Graph. Refer to “Statistical Measurements Display”

on page 4-24

4-4 PN: 10585-00033 Rev. C MA244xxA UG

Page 39

Operation 4-2 The Trace View Display

The Control Windows Toolbar

The buttons on this toolbar control the setup windows for the acquisition, and measurement functions.

Time/Trig: This button displays the Time/Trigger control windows. Refer to “Time/Trigger Control

Window” on page 4-5.

Channel: This button brings up the Channel Control Window, allowing control of the vertical range

and offset as well as sensor-related settings. Refer to “Channel Control Window”

on page 4-10.

Mark: This button causes the Marker Settings window to be displayed. Marker and reference

lines can be controlled from here. Refer to “Marker Settings Window” on page 4-20.

Pulse Def: This button displays the Pulse Definitions window controlling the pulse measurement

thresholds, units, and gating. Refer to “Pulse Definitions Window” on page 4-19.

Stat Cntl: This button brings up the Stat Mode Control window with scaling and population control

for the CCDF display. Refer to “Statistical Mode Control Window” on page 4-23.

Memory Channel Toolbar

The Memory Channel is a reference trace that appears on the Trace View when Mem+ is enabled. The Memory

Channel toolbar contains Swap/Change, Save Mem(ory) Chan(nel), and Upload Mem(ory) Chan(nel) options, and

these control the sensor connection source and the saving and recalling Mem(ory) traces.

Swap/Change: Allows you to change sensors for a particular session if more than one are connected.

Save Mem Chan: Saves the current memory channel archive to a user-selected folder on the computer.

Recall Mem Chan: Recalls a stored memory channel archive to the Memory Channel Trace on the Trace

View.

Time/Trigger Control Window

Pressing the Time/Trig button icon the Control Windows toolbar brings up the Time/Trigger control window.

Figure 4-5. The Time/Trigger Control Window

This window has these sections: Time (time base and delay), Trigger Position, Trigger Control, and Trigger

Skew Adj(ust). Any of these sections can be opened or collapsed by clicking the up/down arrow buttons to the

left of the section title.

MA244xxA UG PN: 10585-00033 Rev. C 4-5

Page 40

4-2 The Trace View Display Operation

Time Control

These settings affect the horizontal scaling of the acquired waveform.

Figure 4-6. Time Control Settings

Timebase: Controls the timebase or horizontal scale of the acquisition and is noted on the horizontal

axis label of the Trace View. The Timebase pull-down menu permits selection of fixed

timebase ranges from 5 ns/div to 50 ms/div (sensor series dependent) in a 1-2-5

progression.

Click the icon to reset the trigger delay to zero seconds.

Trig(ger) Delay: This setting can be adjusted either manually, by entering a numerical value into the

field, or by using the up-down arrow keys.

The trigger delay time is set in seconds with respect to the trigger. Positive values mean

that the trace display shows a time interval after the trigger event. This positions the

trigger event to the left of the trigger point on the display, and is useful for viewing

events during a pulse, or some fixed-delay time after the rising edge trigger. Negative

trigger delay means that the trace display shows a time interval before the trigger event,

and is useful for looking at events preceding the trigger edge.

Pressing the '0' button to the right of the trigger delay entry field resets the trigger delay

to zero.

The range of trigger delay times is dependent on the timebase setting and is summarized

in Table 4-1. Note the range also depends upon the trigger position.

Tab le 4- 1 . Trigger Delay Summary

Timebase Setting Trigger Delay Range

5 ns/div to 10 us/div –1.26 ms to 100 ms

20 us/div –1.26 ms to 200 ms

50 us/ div –5.04 ms to 200 ms

100 us/ div –6.3 ms to 500 ms

200 us/div –12.6 ms to 1

500 us/div –31.5 ms to 1 s

1 ms/div –63 ms to 1 s

2 ms/div to 10 ms/div –126 ms to 1 s

20 ms/div –252 ms to 1 s

50 ms/div –628 ms to 1 s

4-6 PN: 10585-00033 Rev. C MA244xxA UG

Page 41

Operation 4-2 The Trace View Display

Trigger delay ranges in Table4-1 onpage4-6 are for the trigger position set to 0 divisions (Left). If

Note

trigger delay and position settings result in a pretrigger capture interval greater than 1.26 ms, the

sensor automatically reduces the sample rate to avoid overflowing its pretrigger memory.

Trigger Position Control

This setting affects the position of the acquired waveform.

Figure 4-7. Trigger Position Setting

Trigger Position: This control sets the location of the trigger point on the acquired trace waveform. It can

be changed by entering numerical values into the Divisions field from –30 to +30

divisions, by positioning the horizontal slider bar, or by clicking on the L, M or R

indicators to select one of three default positions: Left (zero divisions), Middle (five

divisions) or Right (ten divisions).

Trigger Control

Settings in the Trigger Control group provide controls to affect these aspects of a trigger: the source, mode,

level, slope, holdoff duration, and holdoff mode.

Figure 4-8. Trigger Control Setting

MA244xxA UG PN: 10585-00033 Rev. C 4-7

Page 42

4-2 The Trace View Display Operation

Source: The trigger source can be any of the resource channels (CH1, CH2, etc.), or the Ext(ernal)

trigger input signal. The Ind(ependent) trigger setting allows each connected sensor to

trigger independently from its own RF input.

The external trigger is attached to the MA244xxA Peak Power Sensors via the multi-I/O

connector adjacent to the USB port on the MA244xxA Peak Power Sensors. The

connector is an SMB type. The external trigger requires a TTL signal level, minimum

pulse width of 10 ns, and maximum frequency of 50 MHz.

In a multichannel set-up, the sensors can be triggered independently as described above

or in a master/slave configuration. In master/slave configuration, one channel (CH1,

CH2, etc.) is selected as the source (master) and the remaining sensors automatically

operate in slave mode. See multichannel mode for additional information.

Mode: There are four available trigger modes: Normal, Auto, Autolevel, and Freerun.

Normal Triggers when the amplitude of selected trigger source transitions above the

preset trigger level when positive trigger slope is selected or if it transitions below the

preset trigger level when negative trigger slope is selected. No automatic trigger actions

take place.

Auto Operates in much the same way as Normal trigger mode, but automatically

generates a trace if no trigger edges are detected for a period of time. If a triggerable

signal edge occurs during auto-trigger operation, the trigger system resynchronizes with

the signal. For trigger rates below approximately 10 Hz, the Auto trigger time delay

might interfere with resynchronization. Use Normal mode if this occurs.

AutoLevel Performs the same function as Auto and, in addition, automatically sets the

trigger level based on the peak-to-peak amplitude of the signal. For many signals this

provides a fully automatic trigger system. For slow rate signals and complex level

patterns, it might not produce the desired display. Use Normal mode if this occurs.

Freerun Generates horizontal sweeps asynchronously, without regard to trigger

conditions. This mode is useful for locating low duty-cycle events visually.

Level: Sets the threshold level for the trigger signal in the Auto and Normal trigger modes. The

trigger level can be entered numerically or changed by using arrow keys. The trigger

level range has a maximum value of 20 dBm and a minimum range that is sensor model

dependent (refer to the sensor specifications for your specific sensor model)

The trigger range is automatically adjusted to include the dB Offset parameter selected

in the Cal & Corrections section of the Channel Control window. For example, if the

trigger level = 10 dBm and the dB Offset is changed from 0 to 20 dB, then the

offset-adjusted trigger level is adjusted to 30 dBm. Likewise, the maximum trigger level

range is extended to 40 dBm. The trigger level set point and setting range are both

shifted upward by 20 dB

Slope: Sets the trigger slope or polarity. When set to Pos(itive), trigger events are generated

when a signal's rising edge crosses the trigger level threshold. When Neg(ative) is

selected, trigger events are generated when the falling edge of the pulse crosses the

threshold. Trigger slope can be selected by using Pos and Neg button boxes under slope.

Holdoff (Time): The holdoff time, in microseconds, can be entered and adjusted numerically to 0.01 µs

resolution, or using the up and down arrow keys in 1 µs increments. The effect of Holdoff

time depends on the Holdoff Mode.

Holdoff Mode: There are two trigger holdoff modes: Normal and Gap.

Normal Normal trigger holdoff is used to disable the trigger for a specified amount of

time after each trigger event. The holdoff time starts immediately after each valid trigger

edge, and not permit any new triggers until the time has expired. When the holdoff time

is up, the trigger re-arms, and the next valid trigger event (edge) causes a new sweep.

4-8 PN: 10585-00033 Rev. C MA244xxA UG

Page 43

Operation 4-2 The Trace View Display

This feature is used to help synchronize the MA244xxA Peak Power Sensors with burst

waveforms such as a TDMA or GSM frame. For periodic burst signals, the trigger holdoff

time should be set slightly shorter than the burst or frame repetition interval.

Gap Gap or frame holdoff is very useful for packet-based communication signals where

the transmission burst contains deep modulation which may fall briefly below the trigger

threshold, or when bursts or pulses are of varying length and spacing, and so make

normal holdoff ineffective. In most cases, the off time between transmission bursts, or

frames, is considerably longer than the instantaneous modulation dips.

In Gap Holdoff the trigger is not armed until the trigger source remains inactive (below

the trigger threshold for positive trigger slope, or above the threshold for negative slope)

for at least the set duration. So if trigger polarity is positive, and gap holdoff is set for 1

µs, then the signal must stay below the trigger level for at least 1 µs before the trigger is

armed. Then, the next rising edge following a gap of 1 µs or longer triggers the

acquisition.

Trigger Skew Adj(ust)

Trigger Skew aligns the edge crossing with the trigger point for each of the trigger sources. This is done

internally by adding a trim value to the trigger delay setting. Because the different trigger sources (Int

(internal), Ext (external), and Slave) have different delays, the system stores a value for each.

Trigger Skew requires a fast RF pulse (Trise < 10 ns) to adjust Int skew. To auto-adjust Ext also requires a fast

RF pulse aligned with a fast external trigger pulse applied to the sensor's MIO input. Adjusting the Slave

source requires two sensors connected to a common, fast RF pulse (Trise < 10 ns) and interconnected for

cross-trigger via their MIO inputs. You can deskew one setting at a time until all three sources are calibrated.

Deskewing can be done automatically by clicking the double slope icon on the left of ns, shown in Figure 4-9.

Automatic deskewing requires a fast-edge, repetitive signal.

Figure 4-9. The Automatic Deskew Icons

MA244xxA UG PN: 10585-00033 Rev. C 4-9

Page 44

4-2 The Trace View Display Operation

Channel Control Window

The Channel Control window allows you to change all related settings to control sensor channels.

Memory Channel

Figure 4-10. Channel Control Dialog

The MA244xxA Peak Power Analyzer has the capability of handling multiple control channels by selecting

each individually from the drop-down list. The Channel Control settings are defined by these parameters.

Channel

Channel selects an individual channel or, for multi-channel operation, all measurement channels from the

drop-down list. The channel labeled MEM1 is a memory channel which is a reference trace that can be stored

and recalled as needed. See Figure 4-10.

The Mem button causes the current trace to be stored in the Memory Channel. The current memory channel

can be stored to the computer hard drive using the Save Mem Chan button in the Memory Channel toolbar.

Likewise, a previously stored memory trace can be recalled using the Upload Mem Chan button.

To turn off the Memory Channel, select MEM1 or MEM2 from the Channel drop down menu, then click On next

to Enabled in the Sensor menu (see Figure 4-16, “Channel Control: Sensor Group”) to select Off.

Info

Shows the pertinent information for the selected sensor. The model number, serial number, and firmware and

FPGA versions for the selected channel are displayed in this group.

Figure 4-11. Channel Control: Info Group

4-10 PN: 10585-00033 Rev. C MA244xxA UG

Page 45

Operation 4-2 The Trace View Display

Advanced: Displays the Sensor Info popup (see Figure 4-12).

Figure 4-12. Channel Control: Sensor Group

The popup has these tabs:

Sensor Data contains identification and calibration information for the sensor.

Cal Factors contains the frequency response calibrations factors for both high and low

bandwidth calibration.

Hardware Info contains information on the current state of the sensor hardware

including the detector temperature and key power source voltage readings.

Mark Control: Brings up the Marker Settings control dialog (see Figure 4-13).

Figure 4-13. Channel Control: Info Marker Settings Dialog

MA244xxA UG PN: 10585-00033 Rev. C 4-11

Page 46

4-2 The Trace View Display Operation

Pulse Definition: Brings up the Pulse Definition dialog; refer to “Pulse Definitions Window” on page 4-19.

Figure 4-14. Channel Control: Info Pulse Definitions Dialog

Vertical

These controls affect the vertical settings for the selected power sensor.

Figure 4-15. Channel Control: Vertical Group

Scale: Vertical scale sets the scaling of the level axis of the Trace View based on the selection of

units as shown in Table 4-2.

Tab le 4- 2 . Vertical Scale range for each Units setting

Units Scale

dBm 0.1, 0.2, 0.5 1, 2, 5, 10, 20, 50 dB/div

Watts 1 pW to 500 MW/div in a 1-2-5 progression

Volts 1 µV to 100 kV/ div in a 1-2-5 progression

Units: The trace presentation may be shown in units of dBm, Watts or Volts. The Units

selection determines the range of the scale values. Note that the Units setting also affects

text measurement values in the Measurement windows.

Center: Set the power or voltage level of the horizontal centerline of the graph for the specified

channel in the selected channel units. The center position can be entered numerically or

adjusted by using up and down arrow keys.

4-12 PN: 10585-00033 Rev. C MA244xxA UG

Page 47

Operation 4-2 The Trace View Display

Sensor

These settings control the acquisition parameters for the selected power sensor.

Figure 4-16. Channel Control: Sensor Group

Enabled: Individual sensors or all the selected sensors can be enabled or disabled by using the

alternate action On/Off button. This functionality also enables or disables the MEM

channels.

Trace Avg: Trace averaging can be used to reduce display noise on both the visible trace, and on

automatic marker and pulse measurements. Trace-averaging is a continuous process in

which the measurement points from each sweep are weighted (multiplied) by an

appropriate factor and averaged into the existing trace data points. In this way, the most

recent data always have the greatest effect upon the trace waveform, and older

measurements are decayed at a rate determined by the averaging setting and trigger

rate. This averaging technique is often referred to as 'exponential' averaging because

averaging imposes a first-order Infinite Impulse Response (IIR) exponential filter with a

time constant of n, where n is the Trace Avg (number of averages) setting.

Sensor Avg: Sensor averaging can be set by selecting a number of averages from 1 (no averaging) to

16384 in binary steps using the up and down arrow buttons in the Trace Avg field.

For timebase settings of 200 ns/div and faster, the sensor acquires samples using a technique called

equivalent time or random interleaved sampling (RIS). In this mode, not every pixel on the trace gets

Note

updated on each sweep, and the total number of sweeps needed to satisfy the average setting is

increased by the sample interleave ratio of that particular timebase. At all times the average trace is

the average of all samples for each pixel, and the min/max are the lowest and highest of that same

block of samples for each pixel.

Mod Filter: Sets the modulation filter integration time. It is used in modulated mode measurements

and does not affect the pulse mode (triggered) measurements shown in the trace view.

The modulation filter is a sliding window filter which averages samples taken within a