Page 1

HR-16/HR-16B Drum Machines

Service Manual

V1.00

7/27/95

HR-16/HR16B Service Manual 1.00 i 03/31/06

Page 2

PREFACE

This document is intended to assist the service technician in the operation, maintenance and repair of the HR16 and HR-16B Drum Machines. Together with the HR-16/B Reference Manual, this document provides a

complete description of the functionality and serviceability of these machines. Any comments or suggestions

you may have pertaining to the document are welcome and encouraged.

READ THIS!

In addition to any purchase price that Alesis may charge as consideration for Alesis selling

or otherwise transferring this service manual (“Manual”) to you, if you are not a service and

repair facility (“Service Center”) authorized by Alesis in writing to be an authorized Service

Center, Alesis sells or transfers the Manual to you on the following terms and conditions:

Only Service Centers authorized by Alesis in writing are authorized to perform service and

repairs covered by an Alesis warranty (if any), and transfer of the Manual to you does not

authorize you to be an authorized Service Center. Therefore, if you perform, or if the

Manual is used to perform, any service or repairs on any Alesis product or part

thereof, any and all warranties of Alesis as to that product and any service contract

with Alesis for that product shall be voided and shall no longer apply for such

product, even if your services or repairs were done in accordance with the Manual.

All service or repairs done by you or with reference to the Manual shall be solely your

responsibility, and Alesis shall have no liability for any such repairs or service work. All

such service or repairs are performed at the sole risk of the person performing the

service or repairs. You agree that all such work will be performed in a competent,

professional and safe manner at all times and to indemnify and fully hold Alesis and its

successors and assigns harmless in the event of any failure to so perform.

Your purchase of the Manual shall be for your own ultimate use and shall not be for

purposes of resale or other transfer.

As the owner of the copyright to the Manual, Alesis does not give you the right to copy the

Manual, and you agree not to copy the Manual without the written authorization of Alesis.

Alesis has no obligation to provide to you any correction of, or supplement to, the Manual,

or any new or superseding version thereof.

Alesis shall have the right to refuse to sell or otherwise transfer repair parts or materials to

you in its sole discretion. You shall not use, sell or otherwise transfer spare or replacement

parts supplied by Alesis to you (i) to repair or be used in products manufactured for or by

third parties or (ii) to any third parties for any purpose.

You shall not make any warranties or guarantees with respect to the products of Alesis or

the use thereof on behalf of Alesis or in your own name.

The foregoing describes the entire understanding related to sale or transfer of the Manual

to you, and no other terms shall apply unless in a writing signed by an authorized

representative of Alesis.

HR-16/HR16B Service Manual 1.00 ii 03/31/06

Page 3

WARNINGS

TO REDUCE THE RISK OF ELECTRIC SHOCK OR FIRE, DO NOT EXPOSE THIS PRODUCT

TO WATER OR MOISTURE.

CAUTION

RISK OF ELECTRIC SHOCK

The arrowhead symbol on a lightning flash inside a triangle is intended to alert the user to the

presence of un-insulated "dangerous voltage" within the enclosed product which may be of

sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point inside a triangle is intended to alert the user to the presence of

important operating, maintenance and servicing instructions in the literature which

accompanies the product.

DO NOT OPEN

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same type or equivalent type

recommended by the equipment manufacturer.

Battery Manufacturer: Tadiran

Type: TL-5101

Rating 3.6V

REPAIR BY ANY PERSON OR ENTITY OTHER THAN AN AUTHORIZED ALESIS SERVICE

CENTER WILL VOID THE ALESIS WARRANTY.

PROVISION OF THIS MANUAL DOES NOT AUTHORIZE THE RECIPIENT TO COMPETE

WITH ANY ALESIS DISTRIBUTOR OR AUTHORIZED REPAIR SERVICE CENTER IN THE

PROVISION OF REPAIR SERVICES OR TO BE OR MAKE REPAIRS AS AN AUTHORIZED

SERVICE CENTER.

ALL REPAIRS DONE BY ANY ENTITY OTHER THAN AN AUTHORIZED ALESIS SERVICE

CENTER SHALL BE SOLELY THE RESPONSIBILITY OF THAT ENTITY, AND ALESIS SHALL

HAVE NO LIABILITY TO THAT ENTITY OR TO ANY OTHER PARTY FOR ANY REPAIRS BY

THAT ENTITY.

HR-16/HR16B Service Manual 1.00 iii 03/31/06

Page 4

SAFETY SUGGESTIONS

Carefully read the applicable items of the operating instructions and these safety suggestions before using this

product. Use extra care to follow the warnings written on the product itself and in the operating instructions.

Keep the operating instructions and safety suggestions for reference in the future.

1. Power Source. The product should only be connected to a power supply which is described either in the operating instructions or

in markings on the product.

2. Power Cord Protection

nothing will be placed on or against them.

3. Grounding the Plug

plug can only be used in a grounding power outlet. If the plug does not insert into the outlet you are using, the outlet probably is

not a grounding type of power outlet. Contact your electrician to replace the obsolete outlet with a grounding type of outlet instead

of defeating the safety feature of the grounding type of plug.

4. Periods of Non-use

unplugged from the AC outlet.

5. Foreign Objects and Liquids

6. Water or Moisture

7. Heat

8. Ventilation

may cause overheating, which may damage the product.

9. Mounting

and rack should be moved carefully. Quick movements, excessive force or uneven surfaces may overturn the combination which

may damage the product and rack combination.

10. Cleaning

11. Service

user. For any other service required, the product should be taken to an authorized service center as described in the operating

instructions.

12. Damage to the Product

when:

. Do not place the product near heat sources such as stoves, heat registers, radiators or other heat producing equipment.

. When installing the product, make sure that the product has adequate ventilation. Improperly ventilating the product

. The product should only be used with a rack which the manufacturer recommends. The combination of the product

. The product should only be cleaned as the manufacturer recommends.

. The user should only attempt the limited service or upkeep specifically described in the operating instructions for the

a. Liquid has spilled or objects have fallen into the product,

b. The product is exposed to water or excessive moisture,

c. The AC power supply plug or cord is damaged,

d. The product shows an inappropriate change in performance or does not operate normally, or

e. The enclosure of the product has been damaged.

. AC power supply cords should be placed such that no one is likely to step on the cords and such that

. This product has a 3-wire grounding type of plug (a plug with a grounding pin) for safety purposes. This

. If the product is not used for any significant period of time, the product's AC power supply cord should be

. Take care not to allow liquids to spill or objects to fall into any openings of the product.

. The product should not be used near any water or in moisture.

. Qualified service personnel should service the unit in certain situations including without limitation

HR-16/HR16B Service Manual 1.00 iv 03/31/06

Page 5

General Troubleshooting

While this manual assumes that the reader has a fundamental understanding of electronics and basic

troubleshooting techniques, a review of some of the techniques used by our staff may help.

1. Visual Inspection - A short visual inspection of the unit under test will often yield results without the need

of complex signal analysis (burnt, or loose components are a dead giveaway).

2. Self Test - Alesis products that utilize microprocessor control contain built in test software which

exercises many of the units' primary circuit functions. Self test should always be done following any

repair to ensure basic functionality.

3. Environmental Testing - Applying heat and cold (heat gun/freeze spray) will often reveal thermally

intermittent components (Clock crystals, I.C.s, and capacitors are particularly prone to this type of

failure).

4. Burn in Testing - Leaving a unit running overnight often reveals intermittent failures such as capacitors

that begin to leak excess current after a significant amount of time.

5. Cable Checks - Wiggling cables can reveal intermittent failures such as loose cables or poorly soldered

headers. Remember to check power supply cables as well.

6. Flexing the PC Board - Poor solder joints and broken traces can often be found by pressing the PC Board

in various places.

7. Tapping Componants - Somtimes tapping on a component (particularly crystals) will cause it to fail.

8. Power Down/up - Turning the unit off and back on rapidly several times may reveal odd reset and/or

power supply failures.

9. Reset Threshold - A Variac (variable transformer) can be used to check reset threshold levels. This can be

particularly useful in helping customers with low line problems.

10. Compressors - Using a compressor/limiter is often helpful when attempting to solve low level noise

problems, as well as assisting with DAC adjustments.

11. Sweep Tests - Sweep generators are very useful in checking the frequency response envelopes of antialiasing filters.

12. Piggybacking - Piggybacking I.C.s is particularly useful when troubleshooting large sections of logic.

This is especially true when working with older units.

HR-16/HR16B Service Manual 1.00 v 03/31/06

Page 6

TABLE OF CONTENTS

PREFACE.....................................................................................................ii

READ THIS! .................................................................................................ii

WARNINGS..................................................................................................iii

SAFETY SUGGESTIONS............................................................................iv

General Troubleshooting..............................................................................v

1.0 General Description ...............................................................................1

1.1 Main PC Board Revisions .................................................1

2.0 Power Supply.........................................................................................1

2.1 Battery Backup..................................................................2

2.2 PUP Circuit........................................................................2

3.0 The 8031................................................................................................3

3.1 Reset.................................................................................3

3.2 Memory Mapped I/O..........................................................4

3.3 Keypad I/O.........................................................................4

3.4 MIDI I/O.............................................................................4

4.0 DM3AG ASIC.........................................................................................5

4.1 Mask ROMs.......................................................................5

5.0 Analog Signal Paths...............................................................................6

5.1 Drum Signal Output...........................................................6

5.2 Piezo/Data Slider Input......................................................6

5.3 Tape I/O.............................................................................6

5.4 Tape Output.......................................................................7

5.5 Tape Input .........................................................................7

6.0 Test Procedures.....................................................................................7

6.1 General Testing.................................................................8

6.2 Internal Diagnostics and Hidden Keys..............................8

6.3 DAC Adjustments..............................................................8

7.0 Updates and Corrections .......................................................................9

7.1 New SRAM Supply Circuit.................................................9

7.2 Glass Zener (D15).............................................................9

7.3 Dirty Cliff jacks...................................................................10

7.4 Ground CE.........................................................................10

7.5 RF resistor......................................................................... 10

7.6 10K MIDI Resistor (R5).....................................................11

7.7 MIDI Pullup........................................................................ 11

7.8 RF Shields......................................................................... 11

7.9 LCD Contrast Adjustments................................................11

7.10 DAC Drift .........................................................................12

7.11 Old Keypad PC Boards...................................................12

7.12 Lifting R41 .......................................................................12

7.13 Reset Capacitor...............................................................12

7.14 Sram Capacitor ...............................................................12

7.15 Tape Capacitors..............................................................13

7.16 RF chokes .......................................................................13

7.17 AQ reset threshold ..........................................................13

7.18 AQ R116..........................................................................13

7.19 Volume Slider Wiring.......................................................13

7.20 PUP Capacitor.................................................................14

8.0 Common Solutions.................................................................................15

9.0 Service Parts List ...................................................................................18

10.0 Software History...................................................................................20

11.0 MIDI Implementation............................................................................23

12.0 Service Manual History........................................................................31

INDEX...........................................................................................................32

HR-16/HR16B Service Manual 1.00 vi 03/31/06

Page 7

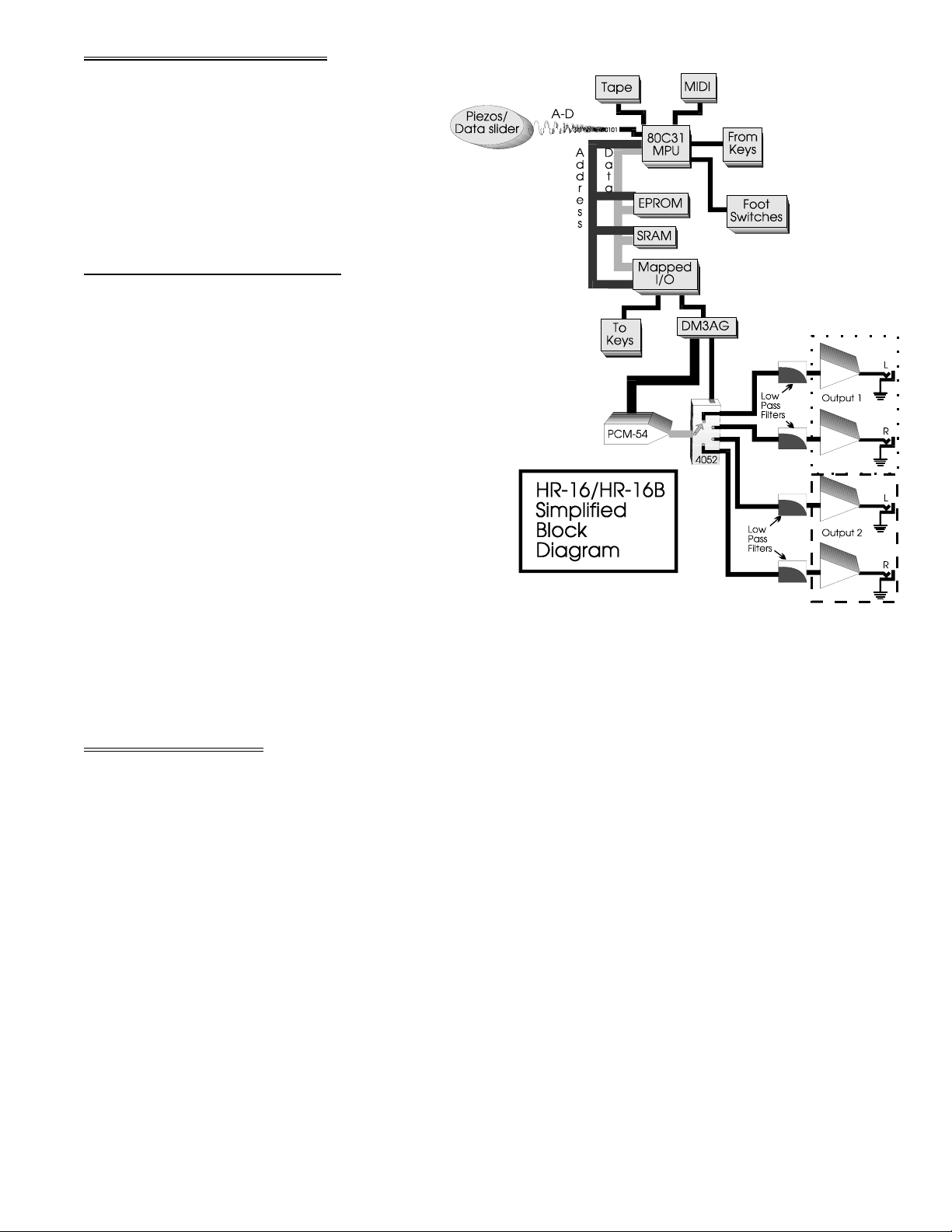

1.0 General Description

Diagram 1 provides a simplified

block diagram to show major sub

systems. Note that the schematic

reference designations and pinouts

used in this manual refer to the AQ

revision of both the main PCB, and

schematic.

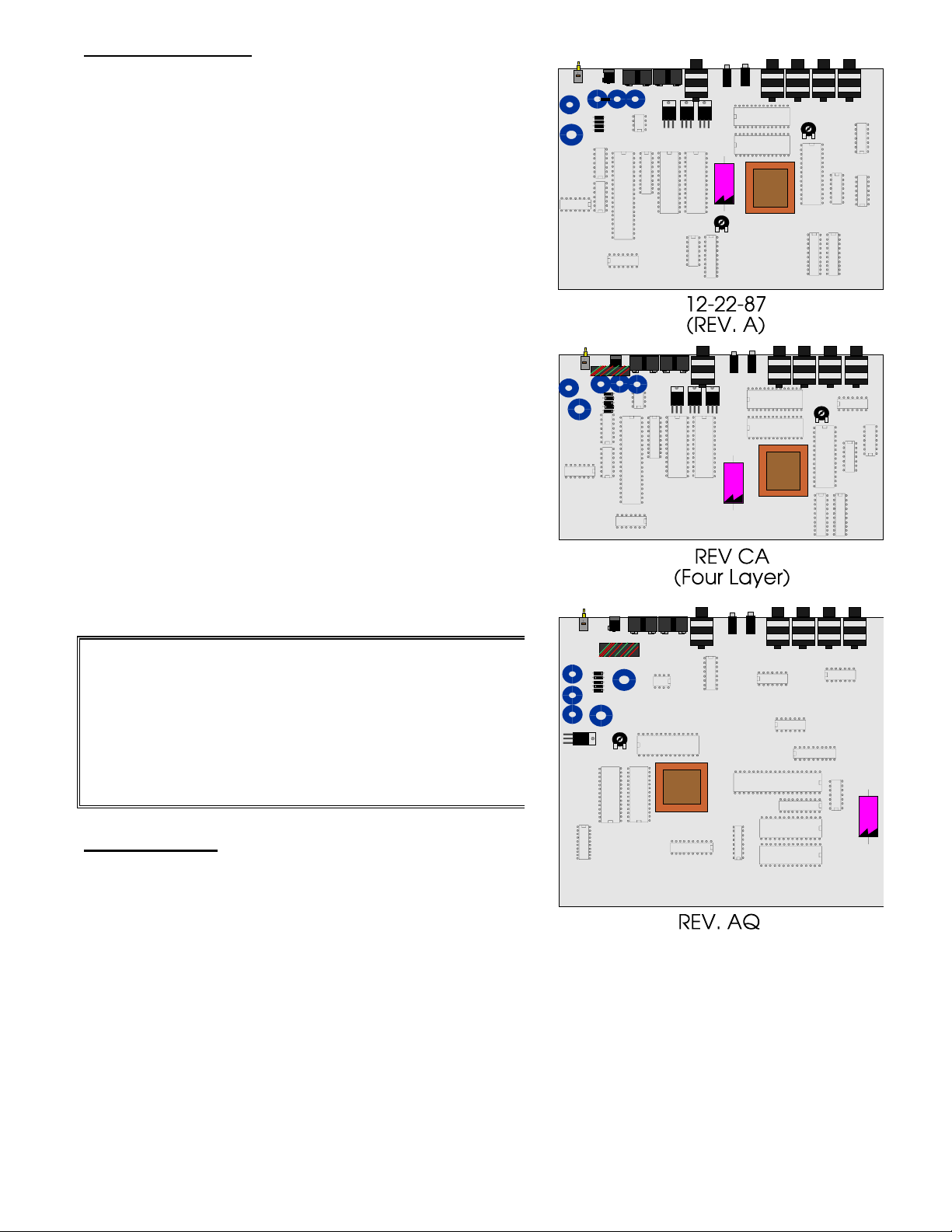

1.1 Main PC Board Revisions

There are 3 major main PC

Board revisions.

• A-This was the initial release. This

board revision will require the most

extensive updating of the three.

• CA-This version of the board was a

4 layer design. While offering

several advantages over the older

version (improved R.F.

characteristics, smaller size, etc.) it

was found to be extremely difficult to

service (internal shorts can only be

repaired using lifted pins and

jumpers).

• AQ-This was the final revision. This

revision will of course need the

fewest updates, and should be

relatively easy to troubleshoot.

Diagram 2 is provided in order to assist with board revision identification.

2.0 Power Supply

The power supply begins with the 9 Volt A.C., adapter (Alesis P2 [mini plug] or P3 [barrel]

types). Input from J1 is R.F. filtered before on/off switch S1. From there it is split for the +12V, -12V,

and +5V rails. The +12V rail consists of a voltage doubler (C1, C3, and D2, D3), a 7812 regulator

(U8), and a filter capacitor (C6). The -12V rail is a "mirror" of the +12V rail, consisting of voltage

doubler (C2, C4, and D1, D4), a 7912 regulator (U9), and a filter capacitor (C7). The +5V rail

consists of a rectifier diode (D5), a filter capacitor (C5), a 7805 regulator (U10), and a multitude of

0.1µF bypass capacitors. Note that the raw +10V line used by the microprocessor reset, and the

SRAM power supply (when retrofitted), is located at the input to the 7805 regulator. Note that

revision AQ (the latest) boards also incorporate several R.F. suppression chokes and current

limiting resistors. These have resulted in a few unique situations that may need to be dealt with (see

section 7.16 for details)

Diagram 1

HR-16/HR16B Service Manual 1.00 1

Page 8

2.1 Battery Backup

Battery backup is actually more complicated

than it might first appear, as it depends on a good

system reset (see section 3.1 for details) in order to

function properly. The actual backup circuit consists

of a battery (3V - 3.6V Lithium), a 10K resistor (R97)

for checking standby current (see below), a

"steering" diode (D7), a filter capacitor (C59), and a

transistor/resistor/diode combination that acts as a

steering diode. This combination may be missing on

older board revisions, and must be installed (see

section 7.1) to prevent data corruption due to a

significant difference between Vcc and the amplitude

of the data buss.

SRAM standby current should always be

checked. While the unit is off, check the voltage

across R97. If the voltage is higher than 80mV

(specification, although a 1 to 20mV range is more

normal) then a problem exists. Usually it indicates a

bad (or simply wrong) SRAM, or a short somewhere

along the MEM PWR line. Note that for a short time

Sony 58256-PM (high power) SRAMs were being

installed at the factory, causing batteries to drain in

about 1 year. They should be replaced with low

power versions (58256-LP) when found, in order to

eliminate excess battery drain. We are currently

using Hitachi 62256ALPs as replacements.

CAUTION:Danger of explosion if battery is

incorrectly replaced. Replace only with the same type or

equivalent type recommended by the equipment

manufacturer.

Battery Manufacturer: Tadiran

Type: TL-5101

Rating 3.6V

2.2 PUP Circuit

The PUP (quiet Power UP) circuit is designed

to prevent the unit from making noise during power

up. Note that this circuit will not be present on the

earliest main PC boards. The circuit utilizes the

RESET line (section 3.1) to control the power supply

lines to U20, which is the final active stage before the output jacks. Since both rails operate

similarly, we'll only take the time to explain the operation of the + rail.

During power up, the RESET line is held low until the regulators are fully functioning. At this

point, Q11 is turned off by RESET via R104. This has the affect of turning off Q10 by allowing the

base of Q10 to pull high via R101. As soon as the reset line goes low, Q11 will turn on, pulling the

base of Q10 lower. Q10 is now biased into saturation, allowing roughly +12V to be fed to the opamps. C65 is provided for extra filtering. The - rail consists of R99, R100, R105, Q12-Q13, and C64.

Diagram 2

HR-16/HR16B Service Manual 1.00 2

Page 9

C62 was added to the analog rails of the op-amp to prevent oscillation during power up, and may

need to be added to some older units (see section 7.20).

3.0 The 8031

The 8031 MPU is the heart of the HR-16's control section. It handles everything from keypad

input and MIDI I/O, to sequencing. Note that the 8031 data buss serves a dual purpose. This buss

multiplexes between low order addresses (1st 8 bits), and data. Latch U7 is used to hold the low

order address half, during 8031 read and write cycles. The EPROM (U11) is used to hold 8031

program information. The SRAM (U12) holds system variables, as well as user sequence data. Z1

provides the 12MHz 8031 clock. MIDI I/O is handled through the 8031's built in RXD (Read Serial

Data), and TXD (Transmit Serial Data) ports. Tape I/O and piezo input is handled through the built

in 8031 I/O ports. DM3AG ASIC control, and LCD output are handled through memory mapped I/O

(see section 3.2). Keypad decoding uses both forms of I/O (see section 3.3).

3.1 Reset

The 8031 reset circuit is perhaps the single most important circuit in the HR-16. When this

circuit is functioning incorrectly, problems ranging from loss of battery backup to a complete lock-up

of the machine can occur. A thorough knowledge of the operation of this circuit will greatly facilitate

troubleshooting this unit.

This circuit uses the differential between raw +10V and regulated +5V to generate the

required signals for system RESET. This is necessary due to fact that the system MUST be in a

reset state while powering down, otherwise random noise on the 8031 data and address busses

could corrupt SRAM data, and destroy any hope that the battery backup will work. R28, R29, and

the 5.1V zener diode (D15) work together as a voltage divider to the base of Q4, and is designed so

that transistor Q4 will turn on when the raw +10V supply is roughly 7V. This is to ensure that

RESET does not occur until after the +5V regulator is fully functioning (i.e. +5V rail is solid). If

RESET occurs too early, noise on the +5V rail can cause data corruption. Before the Q4 turn on

threshold, Q5 remains turned on (the base of the transistor being pulled up by R30). This in turn

holds the voltage across C20 at .3 volts. This is below the threshold (set by R25 and R96)

necessary to turn on the comparator U1 (pins 10, 11 and 13), leaving the reset line high (pulled up

by R10). Once the raw supply has reached a sufficient level to turn on Q4 (roughly 7V), Q4 will pull

the base of Q5 low, turning it off. This allows C20 to begin charging through R24. Once C20 has

charged to roughly 2.5V, the comparator will switch states and hold it low (due to the hysteresis

established by R27). This completes the reset cycle during power up.

During power down, the opposite occurs, ensuring that the 8031 is held in a reset state

during power down as well. This is necessary in order to prevent random data from being written

into the SRAM during shutdown. Be aware that this can cause unusual unit lockups to occur if the

circumstances are just right. For example, if an HR-16 was shut off while in record mode, it's

possible the 8031 was put into reset in the middle of writing a two byte pointer into memory. If only

one of those bytes is written before reset, then it may point to an incorrect location in memory

(battery backup holds the incorrect data). When the unit is powered back up, the incorrect pointer

may send the software into "never never land" where the only way to recover is to reinitialize the

unit.

HR-16/HR16B Service Manual 1.00 3

Page 10

3.2 Memory Mapped I/O

In order to easily control the vast number of hardware functions that the 8031 needs to

access, a system of memory mapped I/O is used. The basic idea is to make hardware functions

appear to the 8031 as unused memory locations. That way all that the software has to do is write to

a memory location in order to send that information to a specific device such as the LCD, or ASIC.

74HC138 (U13) performs the majority of the work in this circuit. Two things are required

before U13 becomes active. 1> A15 must be low (i.e. the 8031 is accessing the lower 32K of

address space). 2> The 8031 WRite line must be active (the 8031 is performing a memory write).

A15 is used to directly control which function (memory or I/O) is active.

Once U13 is enabled, addresses A8-A10 are decoded by it, and the latch corresponding to

the value of the decoded address is strobed. At this point, data on the 8031 data buss is "written"

into the latch.

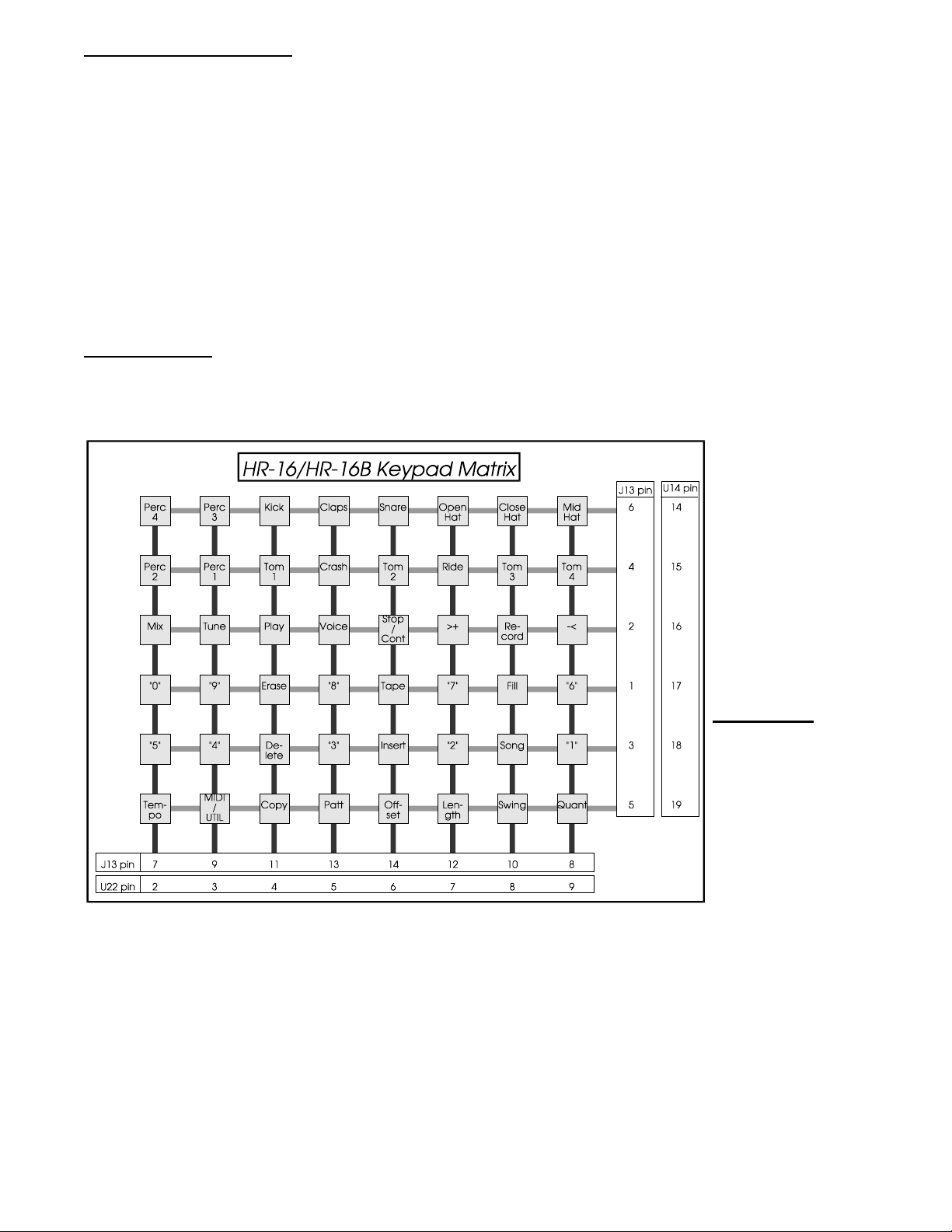

3.3 Keypad I/O

Keypad I/O is handled through a simple polling process Each row of the keypad matrix is

pulled low one at a time (via U14 which is memory mapped). If any button along the row is pressed,

the corresponding

column input (U22) will

appear high. If no

buttons are pressed, all

column inputs will

appear as a low. D9D15 and R42-R47

provide protection for

the outputs of U14. Use

diagram 3 to localize

individual button

failures.

3.4 MIDI I/O

The MIDI

hardware is a standard

implementation. MIDI

out begins at the

8031's TXD port (pin

11) and travels via R6

to the darlington pair

Q1/Q2. Note that the

Diagram 3

may require the addition of an external pullup resistor for the MIDI out to function correctly (see

section 7.7).

MIDI in consists mostly of the opto isolator (U4), protection diode D6, pullup R7, and

threshold resistor R5. Note that the threshold resistor may need to be changed in order to eliminate

false MIDI triggers (see section 7.6).

8031's internal pullup is

not very strong, and

older units (revision A)

HR-16/HR16B Service Manual 1.00 4

Page 11

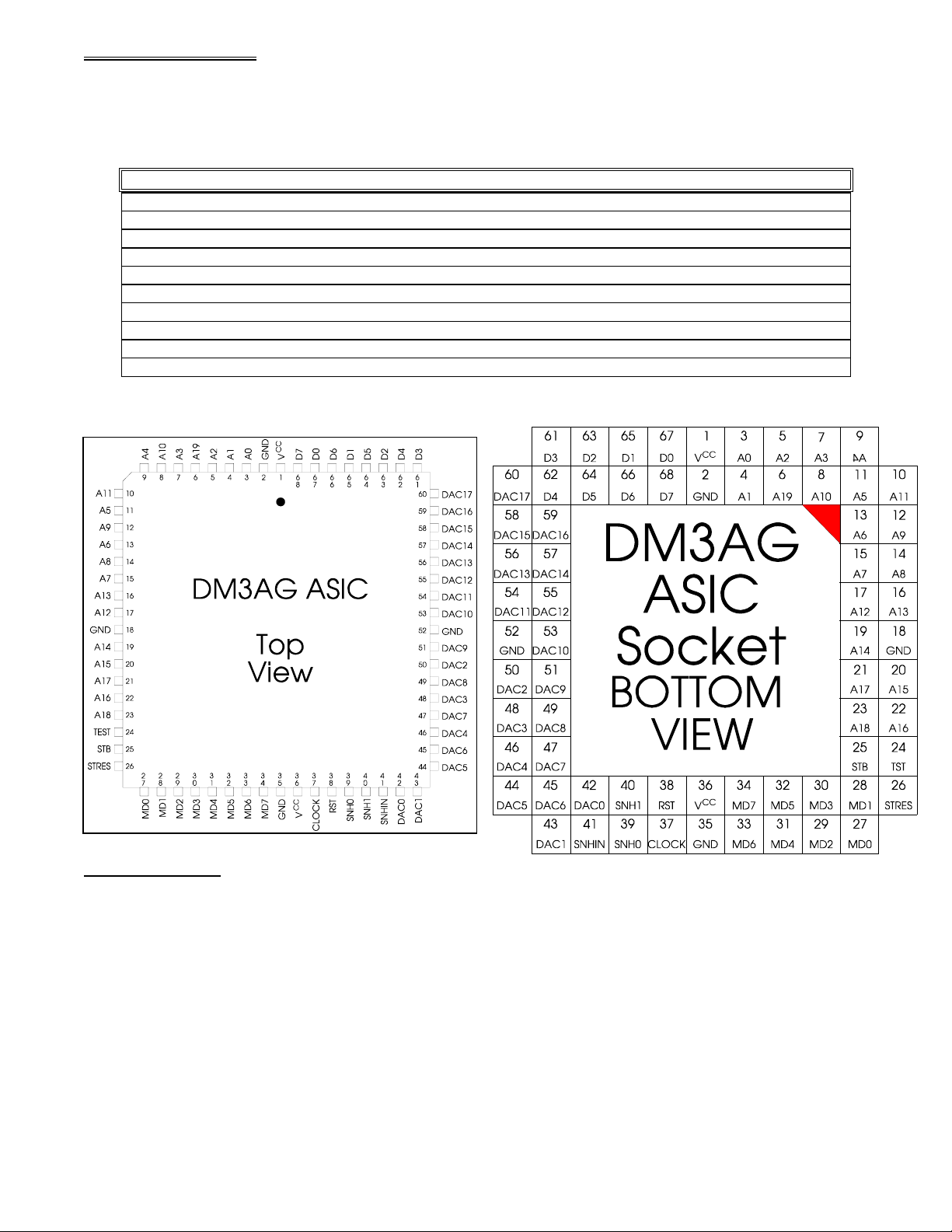

4.0 DM3AG ASIC

The DM3AG ASIC is a complex LSI device, specifically designed for the purpose of playing

percussion samples. Obviously, the internal workings of such a device are beyond the scope of this

manual. However, a brief description of some of the important pins follows.

NAME PIN#(s) Function

MD0-MD7 27-34 8031 Data Buss Input.

CLOCK 37 Asic Clock Input (6MHz in HR-16).

DAC0-DAC16 42-51, 53-60 Output to DAC.

A0-A19 3-17, 19-23 Mask Address Buss

D0-D7 61-68 Mask Rom Data Buss

SNH0 39 Output Sample and Hold Control

SNH1 40 " " " " "

SNHIN 41 Output Sample and Hold Inhibit.

STRES 26 Instruction reset strobe.

STB 25 Instruction latch strobe.

Diagram 4

4.1 Mask ROMs

Diagram 5

The mask ROMs contain the all of the sample information. The 18 bit address buss allows for

2 megabytes per mask ROM. Address line A19 from the ASIC is actually used in conjunction with

Q15 to switch the Mask ROM CE lines (pin 22) such that only one device is enabled at any given

time.

HR-16/HR16B Service Manual 1.00 5

Page 12

5.0 Analog Signal Paths

5.1 Drum Signal Output

The output of the DM3AG ASIC is an 18 bit value. This may seem a little strange at first,

since we are using a 16 bit DAC. R63 and R73-R75 provide the binary weighted resistor network

necessary to achieve a full 18 bit output.

The PCM-54 DAC adjust circuit consists of R52, R53, R54, C34, and trimpot R90 (see

section 6.3 regarding adjustment).

The output of the DAC is sent via R68 to the 4052 analog switch (U19), where the ASIC

controls to which output (out1 left/right or out2 left/right) the final signal will be sent. (Note that

stereo panning is achieved by sending the same signal to the left and right sides separately.)

Each output section (consisting of 1/4 of U20, 1/4 of U21, and misc. resistors and capacitors)

serves the dual purposes of filtering and buffering (with a little gain added in). In the case of output

1, the signal is fed through the volume slider (via J11)(see section 7.19 regarding differences in

wiring) before final output to the 1/4 inch jacks.

5.2 Piezo/Data Slider Input

Successive approximation is the method used to determine the value of the keypad piezo

crystals (keypad velocity), and the data slider. It is a heuristic approach to the process of analog to

digital conversion. The idea is to divide the process into short, manageable sections. Each

significant binary weight (starting with the Most Significant Bit) is taken in turn, thus requiring only 8

comparisons to achieve a final value.

74HC04s U2 and U3 (replaced by a single 74HC540 [U2] in revision AQ PC boards) combine

with the binary weighted resistor network (R16-R20, and SIP R22) to form a simple 8 bit digital to

analog converter. The 8031 sends values to the DAC via it's internal I/O ports. The analog

equivalent of these values is compared to the actual input signals via comparators U1 (pins 2, 4,

and 5 for the data slider) and U1 (pins 8, 9, and 14 for the piezos). The 8031 reads the result of the

comparison through I/O port P3.4 (pin 14) or port P3.5 (pin 15) and proceeds according to that

result. The data slider is read directly via R23 (with C16 acting as a filter to reduce "jitter"). However

the piezos require a little bit of wave shaping and translation before they can be read. First, the

signal is A.C. coupled by C50, and rectified by D19. Q3 is then used to translate the signal into a 0V

to 5V range (the piezos can produce up to about 50V). The signal is now ready for conversion.

5.3 Tape I/O

Tape output is very simple, while tape input is somewhat more complicated. This is due to

the fact that tape backup and tape sync have different requirements. Data transfers need data

integrity which implies guaranteed highs and lows, while tape sync needs tight timing and fast

transistions. It's important to remember that not all tape decks are created equal. Probably the

largest factor involved is the decks input and output capacitances. These can greatly affect the

signals sent to and from the deck, and may cause some decks to be incompatible with the tape I/O

needs of the HR-16. However, these cases should be rare, as the components chosen for the HR16 are based on the industry "standards" that most manufacturers adhere to.

While we have heard many complaints regarding tape back up, we have actually found very

few actual tape failures. Most of the complaints arise from user error, so below is a list of successful

backup and tape sync strategies.

1. When attempting to save to a stereo cassette deck, use only the 1 channel (using both channels

may result in odd phase cancellations during playback).

2. Avoid using any noise reduction systems (i.e. Dolby, or DBX) as these can distort the timing of

the pulse train that contains the data.

HR-16/HR16B Service Manual 1.00 6

Page 13

3. Avoid using adapters for two reasons. 1> Some adapters contain built in attenuators that can

result in extremely reduced levels, both to and from the tape. 2> Oxidation and "wear and tear"

can cause adapters to become intermittent.

4. Always make several copies of each "save". It's especially smart to make copies on at least 2

different tapes as well. This reduces the chances that tape dropouts will cause loss of data.

5. Always use normal bias tapes, as high bias tapes actually end up recording noise, which could

make it past the wave shaping circuitry and cause false triggers.

6. Always verify tapes after saving them. This helps reduce the chances of bad saves. Note

however that the HR-16 does not compare the tape to the contents of memory. It simply verifies

that the information on the tape is valid HR-16 data.

7. Experimentation with record and playback levels usually lead to better results.

Trouble shooting tape problems should begin with listening to the data tape audibly. This can

help the technician determine if the problem occurs during tape save or load. If unusual dropouts

are heard then the problem is either just a bad tape, bad cable, or the tape save circuit. Normal

sounding tapes usually indicate a tape load problem. Only practice will help you determine what is

"normal".

5.4 Tape Output

The tape output hardware is simply the 8031 output port P3.2 (pin 12), a pullup resistor

(R40), and a voltage divider (R39 and R39) for achieving a line level output. The output during tape

save or type sync out applications will appear as a .5V pulse train, but only if the tape out is NOT

connected to a deck (the decks A.C. coupling will distort the output).

5.5 Tape Input

In it's simplest form the tape input consists of an integrator (under software control of the

8031) and a threshold detector (U1C). Input from J5 is passed through a current limiting resistor

(R112) and on to the integrator (C11, C23, R86). The software controls the integration

characteristics through Q16 via memory mapped I/O latch U14 (see section 3.2). While the unit is in

'TAPE SYNC IN' mode, U14/P12 is held high, turning on Q16 and sinking the majority of current

through the integrator to ground. This provides for faster operation of the detection circuitry. D17 is

used to prevent leakage of the integrator signals through the control circuitry during 'TAPE

LOAD/VERIFY' operations (when U14/P12 is low).

The threshold detection circuitry surround U1C is relatively straight forward. R14 and R15

establish the threshold level with R12 and C9 acting as a filter to stabilize the threshold level and

prevent oscillation. R21 establishes some hysteresis and R13 is a pullup for the open collector

output of the LM339. The output of the '339 is sent directly to the 8031 in the form of an interrupt

line. Forcing the 8031 to respond immediately to tape input is necessary due to the timing

constraints required for I/O (especially in tape sync situations).

6.0 Test Procedures

If possible, user data should always be saved (DataDisk, or equivalent, recommended) prior

to servicing. While this may not be immediately possible (or possible at all), it should be attempted

as soon as possible.

HR-16/HR16B Service Manual 1.00 7

Page 14

6.1 General Testing

General testing should, at a minimum, consist of self test, and a short audio test (including

testing key response and recording and playing back a pattern). More extensive testing would

include:

♦ Checking battery backup

♦ Actually sending and receiving MIDI information

♦ Saving and loading data from tape

♦ Copying full patterns to themselves, then to other patterns so that memory

becomes completely full (this ensures that the 8031 address buss functions

correctly, as the self test does not take addressing into consideration).

6.2 Internal Diagnostics and Hidden Keys

Below is a list of the key presses necessary to activate hidden functions.

Power up while holding "ERASE", "DELETE", and "RECORD"------------Clear memory/Reinitialize system.

Power up while holding "QUANT" and "MIDI UTIL"---------------------------Self test.

Hold "PATT" and press "VOICE"--------------------------------------------------DAC Adjust mode (press "STOP" to exit).

Be aware that the self test will erase all internal memory (equivalent to reinitializing).

To perform the internal diagnostics, connect a MIDI cable between MIDI in and out. Connect

a 1/8 inch cable between Tape in and out. Activate the self test (keys above). the order of items

tested is:

1 ROM Test Tests EPROM for errors

2 RAM Test Tests SRAM for errors

3 MIDI I/O Test Tests MIDI input/output functions

4 TAPE I/O Test Tests Tape input/output functions

5 LED Test Lights each front panel LED for a couple seconds

6 DAC Adjust Enters DAC adjust mode (press stop to exit).

6.3 DAC Adjustments

The only adjustment necessary in the HR-16 is the DAC adjustment. This is normally done at

the end of the HR-16's internal diagnostics, however holding the "PATT" button and pressing the

"VOICE" button simultaneously also starts the DAC adjust routine. While this routine is running,

adjust R90 (the trimpot near the PCM-54 DAC) so that a minimum of noise is heard during each

drum hit. A DAC that is out of adjustment will "buzz", particularly at the end of the sample. Note that

you may have to turn your amplifier up in order to hear this signal. Once the adjustment is complete,

hitting the "STOP" button ends the DAC adjust routine.

HR-16/HR16B Service Manual 1.00 8

Page 15

7.0 Updates and Corrections

Diagram 6

Diagram 8

2N4401

Diagram 7

7.1 New SRAM Supply Circuit

• All Revisions.

The new SRAM supply circuit (See diagram

7) supplies a solid 5V to the SRAM, preventing

input data from being higher in amplitude than

the supply voltage, which can cause data

corruption. First, remove the original diode (D8),

then install the new circuit. Diagram 8 shows the

location to install the circuit in Revision A & CA

PC boards, while diagram 6 shows the location

for revision AQ PC boards. The installation of

this circuit is highly recommended, and is

absolutely necessary if a 58257 SRAM is in the

unit. This is because '257s are much more

sensitive to supply voltage the older '256

SRAMs.

7.2 Glass Zener (D15)

• Revisions A & CA.

For a short time, glass package 1N5231B

zener diodes were used instead of the more

familiar metal package. These were found to be

unreliable, and should be replaced with metal

package zeners.

HR-16/HR16B Service Manual 1.00 9

Page 16

7.3 Dirty Cliff jacks

• All Revisions.

Occasionally, oxidation will build up on the cliff jack

contacts, causing the jack normaling to fail. When this

happens, some drum sounds will be "lost" when using the

unit in mono. (Only one cable plugged in). The solution is

to thoroughly clean the normaling contacts (See diagram 9

for location).

Diagram 9

7.4 Ground CE

• All Revisions.

It was discovered that many units returned

for odd crashes all appeared to have a common

component (National EPROMs). After further

investigation it was revealed that it was not due

to defective components, but due to a minor

"incompatibility". It was determined that using CE (pin 20) to

enable the device took too long, and the 8031 would

occasionally attempt to read it's instructions before the data

was valid. The solution to this effect was to leave the

EPROM permanently enabled, and use OE (pin 22), which

operates much faster, to control it's access to the data buss.

On revision A PC boards, this requires cutting a trace,

scraping the solder mask from the closest ground trace and

adding a jumper (see diagram 11). On revision CA PC

boards, this requires that pin 20 of the EPROM be lifted out

of the socket, and a jumper installed (see diagram 10). On

revision AQ PC boards, pin 22 of the EPROM must also be

lifted, the end (away from the 8031) of R110 is lifted, and a

jumper between the two is added. While non National

EPROMs do not seem exhibit this scenario, it's

recommended that this update be performed on all units.

7.5 RF resistor

• Revision A.

An improvement of R.F. characteristics can be

achieved by installing a 470Ω into the ASIC clock line. The

best location to accomplish this is between the 74HC04 (U6)

and the nearby feed through. The trace on the solder side of

Diagram 11

the PC board can then be cut (see diagram 12 for details).

Diagram 10

HR-16/HR16B Service Manual 1.00 10

Page 17

7.6 10K MIDI Resistor (R5)

• All Revisions.

Since the HR-16 was released,

we have found that a 10K resistor

provides a better signal threshold

level to the opto isolator than the

original 47K specified in the design. If

the older value of 47K is found, then a

12K or 13K resistor soldered in

parallel with R5 will achieve the

Diagram 12

desired threshold level.

7.7 MIDI Pullup

• Revision A.

Some early units were prone to sending false or incorrect

data through the MIDI out. This was traced to insufficient pull up

resistance in the 8031's TXD port. This can be solved by installing

a 4.7K resistor between R6 and R7 as shown in diagram 13.

Diagram 13

7.8 RF Shields

• Revision A.

In an effort to further reduce the R.F. emissions of the HR-16, a self sticking R.F. shield was

introduced. Care should be taken when installing the shield, as wrinkles in the shield may easily

cause shorts to the main PC board. The tab of the shield should

make a firm mechanical contact to ground when the board is in

place (for a short time revision CA main PC boards were

manufactured with the solder mask covering the ground plane that

will need to be scraped off in order to achieve a proper connection)

If this is not done correctly, this may actually create more R.F. noise

than before (the shield starts acting as a capacitivly coupled

antenna). Also note that some PC board revisions have the DAC

adjust trimpot on the bottom of the board for external access. On

these units, either cutting a out a circle around the trimpot, or the

addition of electrical tape will insulate the trimpot from the shield.

7.9 LCD Contrast Adjustments

• All Revisions.

Normally the LCD contrast is adjusted at the factory.

However, in the event an older LCD is replaced, or the contrast is

not enough to suit the user, it may be necessary to change the

hardware to achieve a suitable contrast level. Diagram 14A shows

the changes needed to convert older revisions so that the trimpot

will function in a more appropriate range. Diagram 14B shows the

latest configuration used on older revisions to achieve a nominal

contrast level. In revision AQ boards, the only way to change

contrast is by adding (or removing, if one is present) a jumper

across D21 (located by J12).

Diagram 14

HR-16/HR16B Service Manual 1.00 11

Page 18

7.10 DAC Drift

• All Revisions.

It has been found that some PCM-54's

linearity tend to drift with time and temperature. In

order to improve the linearity 1 leg of R60, one leg

of C47, and pin 27 of the PCM-54 should be lifted

and soldered together (see diagram 15). This

should only be necessary if the user complains of

noise after the unit warms up.

7.11 Old Keypad PC Boards

• Revision A

The original HR-16 came with standard PCB

type contacts (tinned copper traces), but these

were found to oxidize over time. This was

especially evident when the unit was used in a

moisture rich environment (such as near the

ocean). We have since switched to using PC

Boards with carbon contacts. We recommend

Diagram 15

replacing the older type PC Boards with the newer

variety. In the event that the newer board is unavailable (emergency rushes, etc.) it is possible to

clean the old keypad contacts with a pencil eraser. While this will restore operation to the unit, such

a measure is strictly temporary, as the contacts will eventually reoxidize.

7.12 Lifting R41

• Revision A

It was found that the feed through below R41 (located near the battery) would occasionally

short directly to the resistor above it. If this happens then battery backup will not function. The

simplest solution is to lift one or both leads of the resistor slightly with a soldering iron (pushing them

up through from the bottom of the board is probably the easiest). This should prevent any physical

contact of the resistor to the feed through.

7.13 Reset Capacitor

• Revision A & CA

The blue monolithic block RAM capacitors used throughout the board were found to be

unreliable when used in timing critical applications due to excess leakage current. C20 is a prime

example of just such an application. If C20 leaks too much, it acts as a voltage divider with R24, and

never exceeds the threshold voltage required to finish the reset process. A large percentage of

"locked up" units can be repaired by replacing this capacitor with either a ceramic disk or film

(WIMA) type of capacitor. This replacement is recommended regardless of whether the capacitor

seems to be failing or not.

7.14 Sram Capacitor

• Revision A

The blue monolithic block RAM capacitors used throughout the board were found to be

unreliable when used in timing critical applications due to excess leakage current. In this case the

capacitor causes excess battery drain, and is the primary cause of battery failure. These capacitors

should be replaced with either a ceramic disk or film (WIMA) type of capacitor, regardless of

whether the capacitor seems to be failing or not.

HR-16/HR16B Service Manual 1.00 12

Page 19

7.15 Tape Capacitors

• Revision A & CA

The blue monolithic block RAM capacitors used throughout the board were found to be

unreliable when used in timing critical applications due to excess leakage current. Here, the

capacitors reside in the tape input path (C11 and C23), and may cause the distortion of incoming

tape signals. Such distortions can cause the loss of tape loading capabilities. These capacitors

should be replaced with either a ceramic disk or film (WIMA) type of capacitor if tape loading failures

occur.

7.16 RF chokes

• Revision CA & AQ

Occasionally the R.F. chokes on these board revisions (located near the power input jacks)

will bust a lead during shipping. When this occurs, it may not be possible to repair the choke. In this

case it is O.K. to remove the choke and add jumpers across its old location. In most cases this

shouldn't be necessary as the units should have had their chokes hot glued to the board at the

factory. Any units that have loose chokes need to be glued (hot glue recommended) to prevent

future damage.

7.17 AQ reset threshold

• Revision AQ

During the development of the AQ main PC board,

one of the prime considerations was to reduce R.F.

emissions to virtually 0. Towards this end, a 100 ohm

resistor (R133) was introduced between the raw supply

voltage and the rest of the circuitry to reduce power supply

noise. This had the effect of increasing the threshold of the

RESET circuit, and was found to cause some units to reset

repeatedly in low power situations (i.e. use of lots of lights

in a club could cause fluctuation in the local power by 15V

to 20V, causing the unit to reset over and over again). R28

is part of the threshold circuit for the RESET line. Originally

valued at 3K, the new value is 1.5K (easily obtained by

adding an additional 3K in parallel). This will bring the

threshold into a more reasonable range.

7.18 AQ R116

• Revision AQ

Again an attempt to reduce power supply noise, this

resistor was found to sometimes reduce the power supply

level to the 8031 (and surrounding circuitry) to below the

required 4.75V. It is recommended that a jumper be

soldered across this resistor (located between the 8031

and U6).

7.19 Volume Slider Wiring

Note that the wiring of the volume slider changed

between Revisions CA and AQ. Diagram 16 shows the

correct wiring for each board style.

Diagram 16

HR-16/HR16B Service Manual 1.00 13

Page 20

7.20 PUP Capacitor

• Revision CA

When the PUP circuit first appeared, it was found that the circuit would occasionally oscillate

on power up, causing noise. This was eliminated by adding a bypass capacitor (later incorporated

as C62) across the power supply pins of U20 (pins 4 and 11).

HR-16/HR16B Service Manual 1.00 14

Page 21

8.0 Common Solutions

A thorough knowledge of the software history can help solve a great many situations quickly.

Also be aware that with devices as full of options as the HR-16(B), there are even more possibilities

for user error (i.e. the user claims that MIDI out isn't working, but on checking the settings, the tech

finds that both MIDI clock, and DRUM NOTES OUT are turned off). Understanding how the user

has the unit in his (her) setup is an important tool in troubleshooting units that act like there is

nothing wrong with them.

While it is simply beyond the scope of this manual to present every possibility, the chart

below offers a majority of solutions to common situations.

Complaint Possible Cause Solutions

Unit is truly "dead". (No lights, or sound) Blown power supply. Replace and retest.

+5V rectifier blown (D5). (Note that 1N4001s

Blown DM3AG ASIC. (occasionally these

Blown +5V filter capacitor (C5)

Faulty or broken power jack. Troubleshoot and repair as necessary.

Faulty or broken power switch. Troubleshoot and repair as necessary.

Broken lead on power choke. Troubleshoot and repair as necessary. (see

Blown monolithic filter capacitor. (Any of the

Unit powers up, but does not function. (No

LCD display, all LEDs on, buttons don't work,

etc.)

C-20 leaking excessively. Troubleshoot and repair as necessary. (see

Faulty 8031, EPROM, or SRAM. Troubleshoot and repair as necessary. (see

Faulty DM3AG ASIC. (Pulling down the 8031

Faulty I/O latch pulling down lines on data

Other faulty reset component. Troubleshoot and repair as necessary. (see

Open or short in 8031 data buss. Troubleshoot and repair as necessary. (see

Open or short in 8031 address buss. Troubleshoot and repair as necessary. (see

Faulty LCD pulling down lines on data buss. Test with new LCD.

LCD shows no, or scrambled display (the rest

of the unit seems to function normally).

Faulty LCD cable. Replace and retest.

Faulty 74HC138 (U13), or open between U13

Intermittent reset. C-20 leaking excessively. Troubleshoot and repair as necessary. (see

Faulty 8031, EPROM, or SRAM. Troubleshoot and repair as necessary. (see

D15 is glass package type (Revision A or CA

R116 is pulling 8031 Vcc too low (revision AQ

were used originally, but some were found to

be unreliable. We have since switched to

using 1N4004s exclusively.)

devices will "short" and pull down the 5V

supply rail)

Usually blown capacitors will display a

"distended" appearance.

small blue RAM capacitors used as bypass

capacitors can become shorted and pull the

rail low. We are currently using ceramic disk

capacitors as replacements exclusively)

Unit is simply "crashed". Reinitialize memory and test.

data buss.)

buss.

Faulty LCD. Test with new LCD.

and LCD header.

only).

only).

Complaint Possible Cause Solutions

Troubleshoot and repair as necessary.

Remove ASIC and attempt power up. Also

note that this type of ASIC failure usually

causes the ASIC to become extremely hot to

the touch.

Troubleshoot and repair as necessary.

section 7.16)

Troubleshoot and repair as necessary. Note

that when these capacitors fail, they often turn

brown from overheating, and some will

occasionally just burn up.

section 7.13)

section 3.X)

Troubleshoot and repair as necessary.

Troubleshoot and repair as necessary. (see

section 3.2)

section 3.1)

section 3.X)

section 3.X)

Troubleshoot and repair as necessary.

section 7.13)

section 3.X)

Replace with metal package type (see section

7.2).

Add jumper across resistor.

HR-16/HR16B Service Manual 1.00 15

Page 22

Intermittent reset. (cont.) R28 (reset threshold) is wrong value. (Revision

Other faulty component is 8031 reset circuit. Troubleshoot and repair as necessary.

No sound at all. Faulty DM3AG ASIC, PCM-54 DAC, 4052

Faulty volume slider. Test AUX outs. Repair as necessary.

User error (i.e. drum pads set to wrong

No sound from a particular drum. User error (i.e. drum pads set to wrong

Dirty, or broken cliff (1/4") jack. This is

Faulty Analog switch. Troubleshoot and repair as necessary.

Faulty op-amp (U20, U21) or component in

Component failure in keypad circuitry. (This is

Intermittent buttons. Old keypad PC Board. Replace with new style keypad PC board and

Dirty rubber keypad. Clean keypad contacts with non-residue

Faulty ribbon cable. Replace and retest.

No (or intermittent) MIDI out. Needs MIDI pullup resistor. Add if necessary (see section 7.7).

Faulty Transistor (Q1 or Q2). Troubleshoot and repair as necessary.

Faulty 8031. Troubleshoot and repair as necessary.

No (or intermittent) MIDI in. Faulty opto-isolator (U4). Replace and retest.

Threshold resistor (R5) wrong value. See section 7.6.

Faulty 8031. Troubleshoot and repair as necessary.

No tape out. Broken 1/8" jack (J6). Replace and retest.

User error. See section 5.3.

Faulty 8031. Troubleshoot and repair as necessary.

No tape in. Broken 1/8" jack (J5). Replace and retest.

User error. See section 5.3.

Faulty 8031. Troubleshoot and repair as necessary.

Faulty integrator capacitor (C11 or C23). Replace and retest.

Faulty comparator (U1). Troubleshoot and repair as necessary.

Data slider not working at all. Faulty slide potentiometer. Replace and retest.

Broken wire between slider and keypad PC

Faulty ADC circuit. (Usually if this is the case,

Faulty 8031. Replace and retest.

Data slider skipping numbers. Faulty ADC circuit. (most likely a short or open

Foot switches not working. Broken cliff (1/4") jack. Troubleshoot and repair as necessary.

Faulty 8031. Replace and retest.

Not retaining memory when power removed.

(No battery backup. Battery is dead.)

Faulty or incorrect SRAM. See section 2.1.

SRAM not in standby mode while power off

Faulty battery. Replace capacitor and battery. Check battery

Not retaining memory when power removed.

(No battery backup. Battery is not dead.)

Faulty SRAM. Replace and retest.

Drum pads not sensitive to velocity. Broken Piezo lead. Troubleshoot and replace as necessary.

Faulty cable. Replace and retest.

Faulty ADC circuit. Troubleshoot and repair as necessary.

Unit "crashes" constantly. Faulty reset circuit. Troubleshoot and repair as necessary.

Faulty 8031, EPROM, or SRAM.

Open or short in address or data busses. Troubleshoot and repair as necessary.

Faulty DM3AG ASIC pulling down data buss.

AQ only).

analog switch, or op-amp.

outputs, volumes set to )etc.).

outputs, volumes set to )etc.). This is

particularly noticeable on drums that panned

hard left or right (TOM 1 and TOM 3 of the

default drum kit).

particularly noticeable on drums that panned

hard left or right (TOM 1 and TOM 3 of the

default drum kit).

surrounding circuitry.

actually fairly rare, but it can happen).

board.

the keypad velocity will not work either.)

in the binary weighted resistor network).

Faulty SRAM bypass capacitor (blue

monoblock type).

(CE pin 20 not held high).

Faulty reset circuit (not going into reset during

power down).

Add another 3K resistor in parallel (see section

7.17).

Troubleshoot and repair as necessary.

Check operating parameters.

Check operating parameters. Adjust them as

necessary.

Troubleshoot and repair as necessary. (see

section 7.3)

Troubleshoot and repair as necessary.

Troubleshoot and repair as necessary. (see

section 3.3)

retest.

cleaner (such as Blue Shower).

Troubleshoot and repair as necessary. (see

section 5.2)

Troubleshoot and repair as necessary. (see

section 5.2)

Replace capacitor and battery. Check battery

current (see section 2.1).

Troubleshoot and repair as necessary.

current (see section 2.1).

Troubleshoot and repair as necessary.

Complaint Possible Cause Solutions

Unit "crashes" constantly. (cont.) Faulty I/O latch pulling down data buss. Troubleshoot and repair as necessary.

Faulty front panel cable. Replace and retest.

Incorrect data slider wiring. Check slider wiring. Repair as necessary.

HR-16/HR16B Service Manual 1.00 16

Page 23

Some or all drum sounds are distorted. PCM-54 DAC out of adjustment. Adjust according to section 6.3.

Faulty PCM-54 DAC. Replace and retest.

Incorrect EPROM. (Oftentimes users will

attempt to install the HR-16A/B EPROM into

their new HR-16B. WRONG! This EPROM is

intended to be used only in the HR-16, and

does not have the correct MASK ROM

addressing tables to play HR-16B sounds).

Faulty DM3AG ASIC. Replace and retest.

Faulty power supply rail. Troubleshoot and repair as necessary.

Faulty PUP circuit (one rail not making it to the

op-amp).

Volume slider only works for 1/2 of it's range. Slider wiring incorrect for particular main PC

Board revision.

Check and replace if necessary.

Troubleshoot and repair as necessary.

See section 7.19.

All Trademarks are property of their respective companies.

HR-16/HR16B Service Manual 1.00 17

Page 24

9.0 Service Parts List

GROUP DESCRIPTION PART # QTY POSITION PCB NOTES

ASY PCB, D1 MAIN REV AQ 8-20-0038 1 REV: AQ

ASY PCB, D1 KEYPAD 8-20-0040 1

ASY CASE TOP ASSY D1 8-20-0009 1

ASY CASE TOP ASSY D2 8-20-0010 1

CAB 14 PIN DIL 7 4-18-0714 3

CAB 5 PIN SIL 5 4-19-0505 1

CAP 0.1 MFD CERDISC 1-02-0104 23 C11,23,60,61,66-71,73-83,73,80 MAIN

CAP 2200 MFD ELEC 1-08-2200 1 C5 MAIN

CAP 330 MFD ELEC 1-09-0337 3 C1-3 MAIN

CAP 470 MFD ELEC 1-09-0477 1 C4 MAIN

CAP 4.7 MFD ELEC 1-12-0475 7 C6-9,22,64,65 MAIN

CER 100 PFD CERDISC 1-02-0101 1 C63 MAIN

CER 150 PFD CERDISC 1-02-0151 11 C71,84-90,92-94 MAIN

CER 27 PFD CERDISC 1-02-0270 2 C18,19 MAIN

CON 14 PIN DIL HDR 4-14-0014 5 J12-14, (2 ON KPD PCB)

CON 5 PIN SIL HDR 4-15-0005 1 J11 MAIN

FIL 1000 PFD FILM 1-20-0102 7 C16,31,37,48,49,57,58 MAIN

FIL 0.01 MFD FILM 1-20-0103 4 C34,50,60,62 MAIN

FIL 0.1 MFD FILM 1-20-0104 3 C17,20,59 MAIN

FIL 2200 PFD FILM 1-20-0222 8 C30,31,34,41,42,44-46 MAIN

FIL 0.022 MFD FILM 1-20-0223 4 C26-29 MAIN

FIL 0.047 MFD FILM 1-20-0473 1 C15 MAIN

HDW 6-32x1/4 PP BLK 5-00-0003 1 TO220 REG MAIN

HDW 4-24x1/4 PF ZNC 5-00-0009 4 SLIDE POT

HDW 3-24x3/8 PP HILO 5-00-0013 4 LCD BEZEL

HDW 4-24x5/16 PPB PLAST 5-00-1002 18 CASE/PCB

HDW 1-72x3/16 SP 5-00-2001 4 SLIDE POT BRACKET

HDW #6 INT STAR WASHER 5-01-0002 1 MAIN

HDW 1/2 STANDOFF 6-32 5-02-0003 1 MAIN

HDW SLIDE POT BRACKET 9-03-1016 2

HDW WHITE VINYL STRIP 9-13-1007 2

IC 7805 +5 V T0220 2-11-7805 1 U10 MAIN NATIONAL ONLY

IC 78L12 +12 V T092 2-13-7812 1 U8 MAIN NATIONAL ONLY

IC 79L12 -12 V T092 2-13-7912 1 U9 MAIN NATIONAL ONLY

IC 74HC138 2-14-0138 1 U13 MAIN

IC 74HC540 2-14-0540 1 U2 MAIN

IC 74HC541 2-14-0541 1 U22 MAIN

IC 74HC573 2-14-0573 1 U7 MAIN

IC 74HC574 2-14-0574 2 U14,23 MAIN

IC 74HC04 2-14-7404 1 U6 MAIN

IC TL084 (LF347) 2-21-0084 2 U20,21 MAIN

IC LM339 2-22-0339 1 U1 MAIN

IC CD4052 2-23-4052 1 U19 MAIN RCA ONLY

IC 6N138 2-24-0138 1 U13 MAIN

IC 32Kx8 SRAM 2-17-0257 1 U12 MAIN

IC 27C256 V1.09 2-19-0256 1 U11 MAIN HR-16 ONLY

IC 27C256 V2.02 2-19-0256 1 U11 MAIN HR-16B ONLY

IC 80C31 2-20-8031 1 U5 MAIN

IC PCM54HP DAC 2-25-0054 1 U18 MAIN

IC DM3 ASIC 2-27-0002 1 U17 MAIN

IC 622 MASK ROM 2-27-0003 1 U15 MAIN HR-16 ONLY

IC 623 MASK ROM 2-27-0004 1 U16 MAIN HR-16 ONLY

IC 3B5 MASK ROM 2-27-0007 1 U15 MAIN HR-16B ONLY

IC 3B6 MASK ROM 2-27-0008 1 U16 MAIN HR-16B ONLY

JAC 5 PIN DIN JACK 4-00-0001 2 J2,3 MAIN

JAC 1/4 CLIFF (MONO) 4-02-0001 5 J4,7-10 MAIN

JAC 3.5mm JACK (P2) 4-16-0001 2 J5,6 MAIN

JAC 3.5mm BAR JACK (P3) 4-16-0002 1 J1 MAIN

LCD LCD MODULE 9-44-1000 1

LIT USER'S MANUAL 7-51-1003 1 KYPD

ME 1N4148 SIGNAL DIODE 2-00-4148 12 D6-14,17,20,21 MAIN

ME 1N4001 POWER DIODE 2-01-4001 5 D1-5 MAIN

ME 1N5231B ZENER 2-02-5231 1 D15 MAIN METAL PACKAGE ONLY

ME MPS 2369 TRANS. 2-03-2369 3 Q6,14,15 MAIN

ME 2N4401 NPN TRANS. 2-03-4401 12 Q1-5,7-9,11,12,16,17 MAIN

ME 2N4403 PNP TRANS. 2-04-4403 2 Q10,13 MAIN

ME LED (RED) RL55 3-02-0002 9 KYPD

ME PIEZO 7-00-0001 4 KYPD

ME 12 MHz CER RES 7-01-0003 1 Z1 MAIN

ME LRG TORROID 7-30-0002 1 L1 MAIN

ME SM TORROID (1 WIRE) 7-30-0003 1 L2 MAIN

ME LITHIUM BATTERY 7-05-0001 1 B1 MAIN

ME DPDT SWITCH (ALPHA) 6-02-0001 1 SW1 MAIN

MIS REAR PANEL OVERLAY 9-13-1003 1

MIS RUBBER STRIP 8-3/4 9-23-1007 1

PLS CASE BOTTOM 9-11-1006 1

PLS KEY CAPS (WHT) 9-11-1007 16 HR-16 ONLY

PLS KEY CAP (BLK) 9-11-1025 16 HR-16B ONLY

PLS LCD BEZEL 9-11-1009 1

PLS SLIDE POT KNOB 9-11-1010 2

PLS ALPHA SWITCH CAP 9-11-1011 1

POT 10K TRIMPOT 0-08-0103 1 R90 MAIN

POT 10KB SLIDE POT MONO 0-09-1009 1

POT 10KB SLIDE POT STER 0-09-1010 1

RES 100 1/8W 5% 0-00-0101 3 R75,120,133 MAIN

GROUP DESCRIPTION PART # QTY POSITION PCB NOTES

RES 1K 1/8W 5% 0-00-0102 17 R23,29,35,36,48,49,50,51,64,67,69,72,91,92,112,114,115 MAIN

HR-16/HR16B Service Manual 1.00 18

Page 25

RES 10K 1/8W 5% 0-00-0103 15 R5,30,32,39,52,53,82,86,97,99,103,104,106,113,121 MAIN

RES 100K 1/8W 5% 0-00-0104 5 R19,25,27,73,96 MAIN

RES 1M 1/8W 5% 0-00-0105 1 R31 MAIN

RES 10M 1/8W 5% 0-00-0106 1 R54 MAIN

RES 1.2K 1/8W 5% 0-00-0122 1 R38 MAIN

RES 15 1/8W 5% 0-00-0150 1 R116 MAIN

RES 1.5M 1/8W 5% 0-00-0155 1 R21 MAIN

RES 2K 1/8W 5% 0-00-0202 4 R65,66,70,71 MAIN

RES 200K 1/8W 5% 0-00-0204 3 R18,26,74 MAIN

RES 220 1/8W 5% 0-00-0221 19 R1-4,42-44,42-44,76-81,83-85 MAIN

RES 2.2K 1/8W 5% 0-00-0222 3 R41,123,124 MAIN

RES 3K 1/8W 5% 0-00-0302 2 R28,37 MAIN

RES 300K 1/8W 5% 0-00-0304 1 R63 MAIN

RES 3.3M 1/8W 5% 0-00-0335 1 R24 MAIN

RES 390K 1/8W 5% 0-00-0394 1 R17 MAIN

RES 470 1/8W 5% 0-00-0471 13 R7,68,117-119,125-132 MAIN

RES 4.7K 1/8W 5% 0-00-0472 16 R6,8,10,13-15,33,34,40,88,89,94,95,107,122,135 MAIN

RES 47K 1/8W 5% 0-00-0473 1 R11 MAIN

RES 470K 1/8W 5% 0-00-0474 1 R12 MAIN

RES 5.1K 1/8W 5% 0-00-0512 4 R100-102,105 MAIN

RES 51K 1/8W 5% 0-00-0513 1 R20 MAIN

RES 560 1/8W 5% 0-00-0561 4 R108-111 MAIN

RES 5.6K 1/8W 5% 0-00-0562 8 R55-62 MAIN

RES 820K 1/8W 5% 0-00-0824 1 R16 MAIN

RES 24K 8 PIN SIP 0-06-2438 1 R22 MAIN

RES 24K 9 PIN SIP 0-06-2439 1 R93 MAIN

RUB TOP KEYPAD 9-21-1002 1

RUB BOT KEYPAD 9-21-1004 1

RUB ROUND RUBBER FEET 9-23-1004 4

SOC 68 PIN ASIC SOCKET 4-12-0068 1 U17 MAIN

HR-16/HR16B Service Manual 1.00 19

Page 26

10.0 Software History

DATE VERSION COMMENTS

11/1/87 1.01 First production release

12/1/87 1.02 1) Fixes tape sync output so that when more than four drums are played on the same

beat, the sync output pulse width does not change.

2) Changed MIDI test routine so that an extra byte is sent out before testing MIDI to

accommodate 8051s that have indeterminate data in the UART on power up.

12/14/87 1.03 1) Fixes MIDI Song Pointer input bug that caused the HR-16 to continue from the

wrong location if in song mode and a tempo was stored in the first step of the song.

2) Fixes test routine display to read HR-16 instead of MMT-8.

12/16/87 1.04 1) Fixes cassette output bug that would occasionally cause a pattern to output data

much longer than it should, which would make the cassette interface unusable.

12/30/87 1.05 1) Fixes cassette input bug that would cause data to be corrupted if only pattern 99 is

loaded in from tape.

2) Fixes bug that would not recall the voice settings of a pattern after it had been

loaded from tape (loading one pattern only). Previously, the pattern would have to be

reselected after loading it from tape before the voices would recall their proper settings.

1/4/88 1.06 1) Fixes cassette input bug that would cause pattern 99 to be erased if a single pattern

or song was loaded in, or a cassette was verified.

6/15/88 1.07 1) Fixes bug that when adding beats to the beginning of a pattern, any drums more than

one that occurred on beat 1 would remain on beat 1 instead of moving past the inserted

beats.

2) Fixes bug that would cause an incorrect display if aborting "LOAD ONE PART"

before tape data has begun when previously in song mode, and aborting "LOAD ONE

SONG" before tape data has begun when previously in part mode.

3) Increased delay loops in display routines so that fewer LCD displays would be

rejected in production.

4) Added feature that allows MIDI program selection of patterns to work while a part

is playing. If a new program number is received over MIDI, this program number will

be selected to be the NEXT pattern number to play when the current pattern is finished.

This functions exactly as if the new pattern number had been selected from the keypad.

If a song is playing, MIDI program commands will still be ignored.

5) Added feature that allows MIDI program change commands to select songs if the

HR-16 is in song mode, and not playing. Previously, MIDI program change commands

were ignored while in song mode.

6) Revised service routines so that the DAC test can be entered directly by holding

PATT and pressing VOICE while not in PLAY mode. The DAC test now plays a tom

at low level once per second for easier calibration.

1.08 Not released.

HR-16/HR16B Service Manual 1.00 20

Page 27

8/25/88 1.09 1) Fixes bug that caused the HR-16 to send out an incorrect MIDI song position

pointer if any tempo change steps occurred in the song previous to the current song

position.

2) Fixes bug that caused the HR-16 to send out an incorrect MIDI song position

pointer if an empty pattern (8 beats, no drum events) was used in a step of a song

previous to the current song position.

3) Added feature that allows "spot erasing" while in record mode when quantize is off.

This means that the erase button and a drum button can be held down while recording

with quantize off in order to erase all drum events (quantized or not) that occur during

the time that the buttons are held down.

4) Added more steps of shuffle resolution, and changed the percentage display

relationship to the clock. The original shuffle values and new values are shown below:

QUANT OLD SHUFFLE NEW SHUFFLE

1/4 0, 50% 0, 50%

1/6 0-16, 50%-75% 0-24, 50%-68.8%

1/8 0-12, 50%-75% 0-16, 50%-66.7%

1/12 0-8, 50%-75% 0-12, 50%-68.8%

1/16 0-6, 50%-75% 0-8, 50%-66.7%

1/24 0-4, 50%-75% 0-6, 50%-68.8%

1/32 0-3, 50%-75% 0-4, 50%-66.7%

1/48 0-1, 50%-62.5% 0-2, 50%-62.5%

1/64 0, 50% 0-1, 50%-58.3%

OFF 0, 50% 0,50%

Despite the displayed percentage being smaller in the new values, there are actually

more shuffle steps than before. The old displayed percentages represented the ratio

between the clock location of the shuffled beat, and the clock location half way

between two un-shuffled beats. The new percentage represents the percentage of the

total time of two occurring beats that the first of a shuffled pair will take. For example,

1/16 notes set to shuffle 8 (shifting every other 16th note 8 clocks late), will result in

the first 16th note getting 32 clocks, and the second 16th note getting 16 clocks (instead

of 24 each when shuffle=0). This results in the first 16th note getting 66.7% of the total

time of both 16th notes (32/48=66.7%), which is equivalent to 16th note triplets. This

percentage representation is more useful than the old percentage.

?/?/89 2.00 HR-16 and HR-16/B:

1) Fixes lots o' bugs.

2) Add lots o' features.

?/?/90 2.01 HR-16/B only:

1) Changed JAM BLOCK name to BLOCK.

7/3/90 2.02 HR-16 and HR-16/B:

1) Fixed bug which caused single step with swing on to advance in incorrect amounts.

If swing was advanced by 1 while in 16th not quantize, the steps would be 23/96,

48/96, 71/96 instead of 25/96, 48/96. 73/96. This is now fixed.

2) Added copyright notice on power on.

3/10/92 2.03 HR-16 and HR-16/B:

HR-16/HR16B Service Manual 1.00 21

Page 28

1) Fixed bug which caused a wrong amount of silence at the beginning of a pattern if

its length was changed to a shorter value from the top and there was no drum event on

the old or new downbeat. For example, if no events existed on beats 1 and 2, and the

length from top was changed to be shorter by one beat, the amount of silence before the

first event would be wrong.

2) Fixed bug which caused sysex loading to be garbled if any real-time MIDI

information was received during the sysex dump. This seemed to only be a problem

with IBM MPU-401 interfaces.

3) All individual’s names have been removed from the software.

HR-16/HR16B Service Manual 1.00 22

Page 29

11.0 MIDI Implementation

ALESIS HR-16/HR-16B MIDI SYSTEM EXCLUSIVE

FORMAT

The following information is provided as a guide for programmers wishing to modify the data received via

MIDI from the HR-16 for the purpose of interchanging patterns from separate block dumps, modification of

drum setups, MIDI channel assignments, etc. Great care must be taken to insure that all modified addresses

are valid, since one incorrect value (the length of a pattern, for example) could result in all data being lost in

the HR-16. These errors may not show up immediately, since the incorrect values may not be accessed by the

HR-16 until a particular pattern or song is selected. Therefore, it is recommended that any data manipulation

programs be thoroughly tested after loading into the HR-16 by selecting and recording on many patterns and

songs before assuming that the data is valid.

For any of the sysex commands to be transmitted or received, the SYSEX ENABLE function (MIDI/UTIL

page 15) must be turned on. All 11 possible commands will be transmitted in the following format:

HEX COMMENTS

F0H SYSTEM EXCLUSIVE STATUS BYTE

00H

00H

0EH ALESIS I.D. NUMBER

01H HR-16 I.D. NUMBER

00H-0AH SYSEX COMMAND

... DATA

F7H EOX

The following sysex commands are transmitted and received by the HR-16:

00H COMPLETE MEMORY DUMP

A system exclusive MIDI data dump from the HR-16 is initiated by holding the TAPE button down, pressing

(and releasing) the left arrow button once, and then pressing the RECORD button. This command is followed

by a block of data representing the contents of the HR-16's memory. In order to optimize the data transfer, 8

MIDI bytes are used to transmit each block of 7 HR-16 data bytes. If the 7 data bytes are looked at as one 56bit word, the format for transmission is eight 7-bit words beginning with the most significant bit of the first

byte, as follows:

SEVEN HR-16 BYTES:

0: A7 A6 A5 A4 A3 A2 A1 A0

1: B7 B6 B5 B4 B3 B2 B1 B0

2: C7 C6 C5 C4 C3 C2 C1 C0

3: D7 D6 D5 D4 D3 D2 D1 D0

4: E7 E6 E5 E4 E3 E2 E1 E0

5: F7 F6 F5 F4 F3 F2 F1 F0

6: G7 G6 G5 G4 G3 G2 G1 G0

HR-16/HR16B Service Manual 1.00 23

Page 30

TRANSMITTED AS:

0: 0 A7 A6 A5 A4 A3 A2 A1

1: 0 A0 B7 B6 B5 B4 B3 B2

2: 0 B1 B0 C7 C6 C5 C4 C3

3: 0 C2 C1 C0 D7 D6 D5 D4

4: 0 D3 D2 D1 D0 E7 E6 E5

5: 0 E4 E3 E2 E1 E0 F7 F6

6: 0 F5 F4 F3 F2 F1 F0 G7

7: 0 G6 G5 G4 G3 G2 G1 G0

In order to use the data properly, it must be decoded properly into HR-16 byte format. The following list

gives the data locations within the "unpacked" (decoded) block of data, starting with the first byte of the

block being 000. NOTE: All absolute addresses must have an offset of 8200H added to them (e.g., an

absolute pointer to a pattern that starts at 35AH should have the pointer value 855AH).

000H-0C7H DON'T CARE

0C8H MIDI channel

0C9H Receive MIDI drum triggers (0=off, 1=on)

0CAH Transmit MIDI drum triggers (0=off, 1=on)

0CBH MIDI note assignment of CLICK (0-127)

0CCH MIDI note assignment of KICK (0-127)

0CDH MIDI note assignment of SNARE (0-127)

0CEH MIDI note assignment of CLS HAT (0-127)

0CFH MIDI note assignment of MID HAT (0-127)

0D0H MIDI note assignment of OPEN HAT (0-127)

0D1H MIDI note assignment of CLAPS (0-127)

0D2H MIDI note assignment of PERC 3 (0-127)

0D3H MIDI note assignment of PERC 4 (0-127)

0D4H MIDI note assignment of TOM 1 (0-127)

0D5H MIDI note assignment of TOM 2 (0-127)

0D6H MIDI note assignment of TOM 3 (0-127)

0D7H MIDI note assignment of TOM 4 (0-127)

0D8H MIDI note assignment of RIDE (0-127)

0D9H MIDI note assignment of CRASH (0-127)

0DAH MIDI note assignment of PERC 1 (0-127)

0DBH MIDI note assignment of PERC 2 (0-127)

0DCH MIDI echo (0=off, 1=on)

0DDH MIDI program select (0=off, 1=on)

0DEH Clock mode (0=MIDI & internal, 1=internal only, 2=tape)

0DFH MIDI clock out (0=off, 1=on)

0E0H Auto start (0=off, 1=on)

0E1H Click value

0E2H Click in play (0=off, 1=on)

0E3H Manual voice/tune/mix (0=off, 1=on)

0E4H Pad dynamics (0-0AH)

0E5H Song loop (0=off, 1=on)

0E6H Sysex enable (0=off, 1=on)

0E7H-0EBH Software version: 5 asc ii bytes, starting with a space (20H) if an HR-16, or a "B" (42H) if an

HR-16B, followed by a 4 digit version number (e.g., "2.00", or 32H, 2EH, 30H, 30H)

0ECH-F3H DON'T CARE

0F4H 0

0F5H-FDH DON'T CARE

HR-16/HR16B Service Manual 1.00 24

Page 31

0FEH 27H

0FFH 0B5H

100H-187H DON'T ALTER(this can be DON'T CARE if manual voice/tune/mix is off)

188H-191H DON'T CARE

192H-1A1H 0

1A2H-1FFH DON'T CARE

200H MSB of absolute pointer to pattern 00

201H LSB of absolute pointer to pattern 00

202H MSB of absolute pointer to pattern 01

203H LSB of absolute pointer to pattern 01

204H MSB of absolute pointer to pattern 02

205H LSB of absolute pointer to pattern 02

" " " " "

2C6H MSB of absolute pointer to pattern 99

2C7H LSB of absolute pointer to pattern 99

2C8H-2CCH DON'T ALTER

2CDH LSB of absolute pointer to first byte past SONG 99 data

2CEH MSB of absolute pointer to first byte past SONG 99 data

2CFH-2D0H DON'T ALTER

2D1H LSB of FF00H minus data in 0CDH & 0CEH

2D2H MSB of FF00H minus data in 0CDH & 0CEH

2D3H-2D4H DON'T ALTER

2D5H Shuffle amount (0-24, 0=50%)

2D6H-2D7H DON'T ALTER

2D8H Tempo (20-255)

2D9H Quant clock count (must correspond to Quant value 0-9: 96, 64, 48, 32, 24, 16, 12, 8, 6, 1)

2DAH Quant value (0-9)

2DBH-2FFH DON'T CARE

300H-301H DON'T ALTER

302H MSB of absolute pointer to song 00

303H LSB of absolute pointer to song 00

304H MSB of absolute pointer to song 01

305H LSB of absolute pointer to song 01

306H MSB of absolute pointer to song 02

307H LSB of absolute pointer to song 02

" " " " "

3C8H MSB of absolute pointer to song 99

3C9H LSB of absolute pointer to song 99

3CAH-3CCH DON'T ALTER

3CDH-3D2H DON'T CARE

3D3H-3D6H DON'T ALTER

3D7H-3FFH DON'T CARE

400H-? PATTERN 00 DATA

The pattern and song data must be dealt with in a specific manner:

1) All pattern and song data must be in consecutive order, i.e., pattern 05 data cannot be before pattern

02's data. The order for the data should be pattern 00 through 99, followed by song 00 through 99.

HR-16/HR16B Service Manual 1.00 25

Page 32

2) If a pattern or song does not exist, its MSB pointer will = 0, which is an illegal pointer address. Since

there will be no data for this pattern, it is skipped, i.e., if pattern 04 is empty, pattern 05's data follows

after pattern 03's data.