Page 1

SERVICE MANUAL

Model:

PDP-5016

Safety Precaution

Technical Specifications

Block Diagram

Circuit Diagram

Basic Operations & Circuit Description

Main IC Specifications

Trouble Shooting Manual of PDP Module

Spare Part list

Exploded View

If You Forget Your V-CHIP Password

Software Upgrade

This manual is the latest at the time of printing, and does not

include the modification which may be made after the printing,

by the constant improvement of product.

Page 2

Safety Precaution

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product’s enclo

sure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

CAUTION: TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE COVER

(OR BACK). NO USER-SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL ONLY.

PRECAUTIONS DURING

SERVICING

1. In addition to safety, other parts and

assemblies are specified for conformance with

such regulations as those applying to spurious

radiation. These must also be replaced only

with specified replacements.

Examples: RF converters, tuner units, antenna

selection switches, RF cables, noise-blocking

capacitors, noise-blocking filters, etc.

2. Use specified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

3. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulating Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulating sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side components

(transformers, power cords, noise blocking

capacitors, etc.), wrap ends of wires securely

about the terminals before soldering.

5. Make sure that wires do not contact heat

generating parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

6. Check if replaced wires do not contact sharply

edged or pointed parts.

7. Make sure that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

MAKE YOUR CONTRIBUTION

TO PROTECT THE

ENVIRONMENT

Used batteries with the ISO symbol

for recycling as well as small accumulators

(rechargeable batteries), mini-batteries (cells) and

starter batteries should not be thrown into the

garbage can.

Please leave them at an appropriate depot.

WARNING:

Before servicing this TV receiver, read the

SAFETY INSTRUCTION and PRODUCT

SAFETY NOTICE.

SAFETY INSTRUCTION

The service should not be attempted by anyone

unfamiliar with the necessary instructions on this

apparatus. The following are the necessary

instructions to be observed before servicing.

1. An isolation transformer should be connected in

the power line between the receiver and the

AC line when a service is performed on the

primary of the converter transformer of the set.

2. Comply with all caution and safety related

provided on the back of the cabinet, inside the

cabinet, on the chassis or picture tube.

3. To avoid a shock hazard, always discharge the

picture tube's anode to the chassis ground

before removing the anode cap.

4. Completely discharge the high potential voltage

of the picture tube before handling. The picture

tube is a vacuum and if broken, the glass will

explode.

Page 3

5. When replacing a MAIN PCB in the cabinet,

always be certain that all protective are

installed properly such as control knobs,

adjustment covers or shields, barriers, isolation

resistor networks etc.

6. When servicing is required, observe the original

lead dressing. Extra precaution should be given

to assure correct lead dressing in the high

voltage area.

7. Keep wires away from high voltage or high

tempera ture components.

8. Before returning the set to the customer,

always perform an AC leakage current check

on the exposed metallic parts of the cabinet,

such as antennas, terminals, screwheads,metal

overlay, control shafts, etc., to be sure the set

is safe to operate without danger of electrical

shock. Plug the AC line cord directly to the

AC outlet (do not use a line isolation

transformer during this check). Use an AC

voltmeter having 5K ohms volt sensitivity or

more in the following manner.

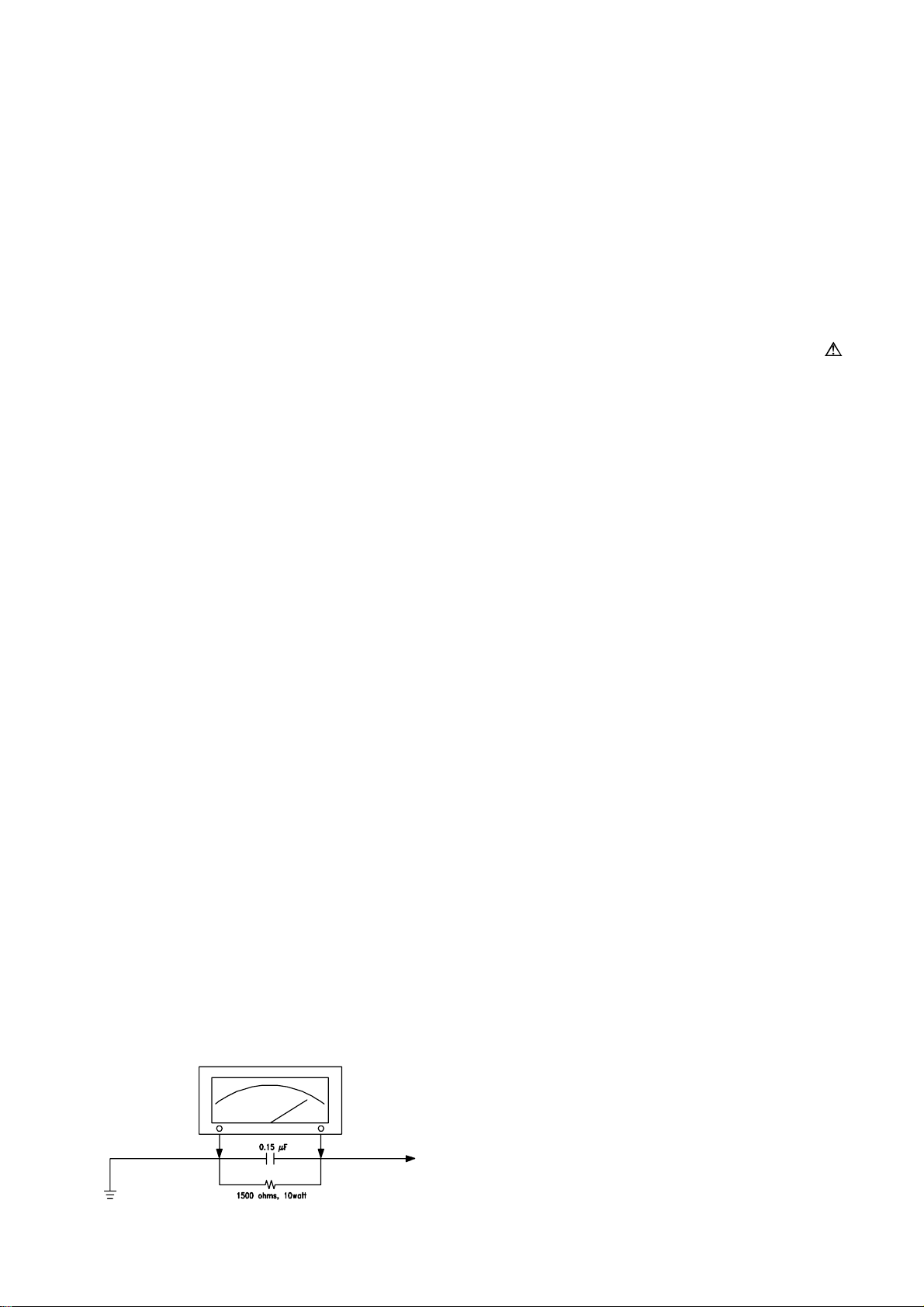

Connect a 1.5K ohm 10 watt resistor paralleled

by a 0.15µF AC type capacitor, between a

good earth ground (water pipe, conductor etc.,)

and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination

of the 1.5K ohm resistor and 0.15 uF

capacitor. Reverse the AC plug at the AC

outlet and repeat the AC voltage measurements

for each exposed metallic part.

The measured voltage must not exceed 0.3V

RMS.

This corresponds to 0.5mA AC. Any value

exceeding this limit constitutes a potential

shock hazard and must be corrected

immediately.

The resistance measurement should be done

between accessible exposed metal parts and

power cord plug prongs with the power switch

"ON". The resistance should be more than

6M ohms.

AC VOLTMETER

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this

apparatus have special safety-related

characteristics.

These characteristics are offer passed

unnoticed by visual spection and the protection

afforded by them cannot necessarily be obtained

by using replacement components rates for a

higher voltage, wattage, etc.

The replacement parts which have these

special safety characteristics are identified by

marks on the schematic diagram and on the parts

list.

Before replacing any of these components,

read the parts list in this manual carefully. The

use of substitute replacement parts which do not

have the same safety characteristics as specified

in the parts list may create shock, fire, or other

hazards.

9. Must be sure that the ground wire of the AC

inlet is connected with the ground of the

apparatus properly.

Good earth ground

such as the water

pipe, conductor,

etc.

AC Leakage Current Check

Place this probe

on each exposed

metallic part

Page 4

Technical Specifications

MODEL :

PDP-5016

50” Plasma Display

DATE FIRST ISSUED

REVISIONS

ISSUED DATE DESCRIPTION RAISED BY :

ISSUE

1

RAISED BY

CHECKED BY

NUMBER OF PAGES

9

SPECIFICATION AGREED : SIGNATURE DATE

R & D DEPARTMENT

COMMERCIAL DEPARTMENT

PRODUCTION DEPARTMENT

Q/A DEPARTMENT

CUSTOMER

SPECIFICATION APPROVED :

.

NOTE :

Only documents stamped “Controlled Document” to be used for manufacture of production parts.

......................................................................................

......

......................................................................................

......

......................................................................................

.......

......................................................................................

.......

......................................................................................

.......

SIGNATURE :

...........................

...

...........................

...

...........................

...

...........................

...

...........................

...

DATE :

Page 5

Technical Specifications

PDP-5016

CONTINUATION PAGE

NUMBER

2 OF 9 PAGES

1. Standard Test Conditions

All tests shall be performed under the following conditions, unless otherwise specified.

1.1 Ambient light

≦0.1Cd/m

: 150ux (When measuring IB, the ambient luminance

2

)

1.2 Viewing distance

: 50cm in front of PDP

1.3 Warm up time

: 30 minutes

1.4 PDP Panel facing

: no restricted

1.5 Measuring Equipment

: PC, Chroma 2225 signal generator (with Chroma digital

additional card) or equivalent, Minolta CA100 photometer

1.6 Magnetic field

: no restricted

1.7 Control settings

: Brightness, Contrast, Tint, Color set at Center(50)

1.8 Power input

: 100~240Vac

1.9 Ambient temperature : 20°C ± 5°C (68°F ± 9°F)

1.10 Display mode

: 31.5KHz/60Hz (Resolution 1366 x 768)

1.11 Other conditions

:

1.11.1 With image sticking protection of PDP module, the luminance will descend

by time on a same still screen and rapidly go down in 5 minutes. When

measuring the color tracking and luminance of a same still screen, be sure t

o accomplish the measurement in one minute to ensure its accuracy.

1.11.2 Due to the structure of PDP, the extra-high-bright same screen should not

hold over 5 minutes for fear of branding on the panel.

Page 6

Technical Specifications

PDP-5016

CONTINUATION PAGE

NUMBER

3 OF 9 PAGES

ELECTRICAL CHARACTERISTICS

2. Power Input

2.1 Voltage

: 100 ~ 240VAC

2.2 Input Current

: 5.0 /2.5A

2.3 Maximum Inrush Current

: <30 A (FOR AC110V ONLY)

Test condition : Measured when switched off for at least 20 mins

2.4 Frequency

: 50Hz to 60Hz(±3Hz)

2.5 Power Consumption

: ≤ 480W

Test condition : full white display with maximum brightness and

contrast

2.6 Power Factor

: Meets IEC1000-3-2

2.7 Withstanding voltage

: 1.5kVac or 2.2kVdc for 1 sec

3. Display

3.1 Screen Size : 50” Plasma display

3.2 Aspect Ratio : 16:9

3.3 Pixel Resolution : 1366x768

3.4 Peak Brightness : 1000 cd/m² (Panel module without filter)

3.5 Contrast Ratio (Dark room) : 4000:1 (Panel module without filter)

3.6 Viewing Angle : Over 160°

3.7 OSD language : English

4. Signal

4.1 AV & Graphic input

4.1.1 TV standard : NTSC,PAL/N,PAL/M

4.1.2 TV Tuning system : PLL 181CH

4.1.3 CATV : 125CH

4.1.4 Composite signal : CVBS

4.1.5 Y,C Signal : S-Video

4.1.6 Component signal : Y, Pb/Cb, Pr/Cr, HDTV compatible

4.1.7 Graphic I/P : Analog: D-sub 15pin detachable cable

Digital: DVI

4.1.8EDID compatibility : DDC 1.3

4.1.9 I/P frequency : f

: 31.5kHz to 60kHz/fV: 56.25Hz to 75Hz (1024X768

H

recommended)

Page 7

Technical Specifications

PDP-5016

CONTINUATION PAGE

NUMBER

4 OF 9 PAGES

4.2 Audio input

Audio I/P(L/Rx5) : 1 for DVI / D-Sub

1 for Y/ Pb/Pr

1 for Y/ Cb/Cr

1 for CVBS

1 for S-Video

4.3 AV output

Audio&Video O/P(RCAx3) : Monitor out(Video & Audio L/R)

4.4 Other function

: PIP/POP/PBP, Picture size, Picture Still, Sound mode,Last

memory, Timer, MTS

5. Environment

5.1 Operating environment

5.1.1 Temperature : 5º to 33°C

5.1.2 Relative humidity: 20% to 85%(non-condensing)

5.2 Storage and Transport

5.2.1 Temperature : -20°C to 60°C(-4º to 140°F)

5.2.2 Relative humidity: 5% to 95%

6. Panel Characteristics

6.1 Type : LG50X2

6.2 Size : 50”, 1190mm(width)x7005mm(height)x59mm(depth)±1

mm)

6.3 Aspect ratio : 16:9

6.4 Viewing angle : Over 160°

6.5 Resolution : 1366X768

6.6 Weight : 22.0kg ±0.5 kg (Net)

6.7 Color : 1024(R)X1024(G)X1024(B) COLORS

6.8 Contrast : Average 60:1 (In a bright room with 150Lux at center)

Typical 4000:1 (In a dark room 1/100 White Window

pattern at center).

6.9 Peak brightness : Typical 1000cd/㎡ (1/25 White Window)

6.10 Color Coordinate Uniformity

: Contrast; Brightness and Color control at normal

setting

Test Pattern : Full white pattern

Average of point A,B,C,D and E +/- 0.01

Page 8

Technical Specifications

PDP-5016

CONTINUATION PAGE

NUMBER

5 OF 9 PAGES

6.11 Color temperature

: Contrast at center (50); Brightness center (50);

Color temperature set at Natural

x=0.300±0.02

y=0.300±0.02

6.12 Cell Defect Specifications

Subject to Panel supplier specification as appends.

7. Front Panel Control Button

7.1 CH Up / Down Button : Push the key to changing the channel up or down.

When selecting the item on OSD menu.

Volume Up/ Down Button : Push the key to increase the volume up or down.

When selecting the adjusting item on OSD menu

increase or decrease the data-bar.

Menu Button : Enter to the OSD menu.

Source Select Button : Push the key to select the input signals source.

7.2 Stand by Button : Switch on main power, or switch off to enter power

Saving modes.

7.3 Main Power Switch : Turn on or off the unit.

8. OSD Function

8.1 Picture : State (Normal,Dark,Bright,User); Display (Bright,contrast,Color,Hue)

Temp (warm,Cool,Normal,User);

Position (H-posit,V-posit,Phase,H-size,Auto Adjust)

8.2 Sound : Setup (Mode,AVC,Volume,Balance);

Equalizer (120HZ,500HZ,1.5KHZ,5KHZ,10KHZ)

BBE Setup (Gain,Treble,Bass)

8.3 OSD : Size (Panorama,16:9,Normal,Anamorphic,Letter Box,TV Mode)

OSD Set (Language,OSD Position,Time Out)

Option (Burn Protect, Version)

V-Chip , C/C

8.4 Layout : Layout (Full Screen,PIP,Split Screen,Grid,POP 3,POP 12)

PIP Set (Sub Win Source,Sub Win Size,PIP Size.PIP Position)

8.5 Time : Sleep (30Min,60Min,90Min,120Min,180Min)

Wake Up (Time Edit,Volume,TV Mode,Channel)

Time Set

8.6 TV Set : TV Set (Auto Search,Manul Search,System,MTS,Auto Fine,Fine)

CH Edit

Page 9

Technical Specifications

PDP-5016

CONTINUATION PAGE

NUMBER

6 OF 9 PAGES

9. Agency Approvals

Safety UL60950

Emissions FCC class B

10. Reliability

11.1 MTBF

: 20,000 hours(Use moving picture signal at 25°C ambient)

11. Accessories : User manual x1, Remote control x1, Stand x1, Power cord x1,

Battery x 2, Accessories box x 1,Speaker x 2,Speaker wire x2

Page 10

Technical Specifications

12. Support the Signal Mode

A .D-Sub Mode (VGA or DVI)

PDP-5016

CONTINUATION PAGE

NUMBER

7 OF 9 PAGES

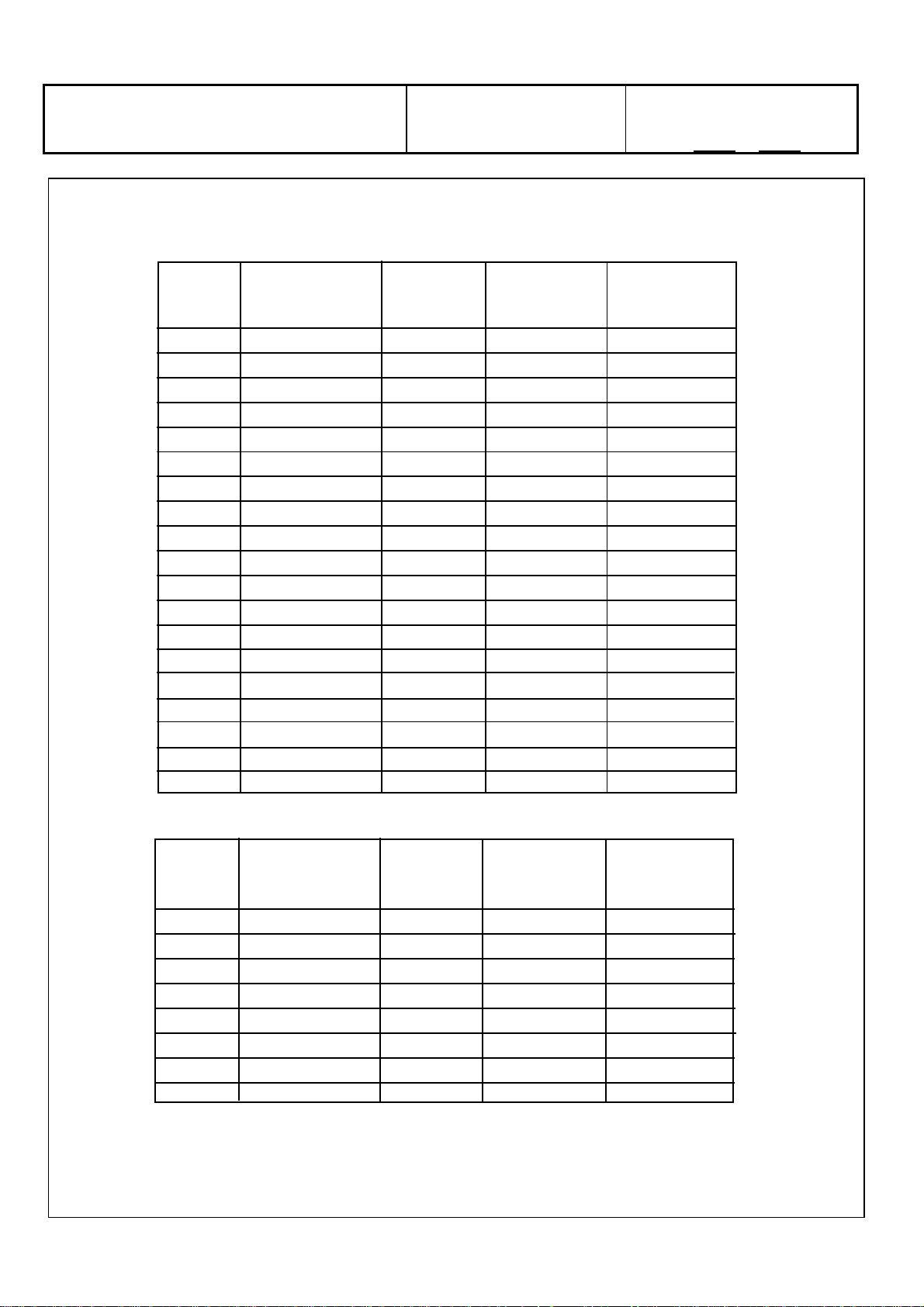

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Resolution

640 x 400

640 x 480

640 x 480

640 x 480

640 x 480

720 x 400

800 x 600

800 x 600

800 x 600

800 x 600

832 x 624

1024 x 768

1024 x 768

1024 x 768

1152 x 864

1152 x 864

1152 x 864

1280 x 960

1280 x 1024

Horizontal

Frequency

(KHz)

31.47

31.50

35.00

37.50

37.86

31.47

35.16

37.90

46.90

48.08

49.00

48.40

56.50

60.00

54.53

63.86

67.52

60.02

64.00

Vertical

Frequency

(Hz)

70.08

60.00

67.00

75.00

72.81

70.08

56.25

60.32

75.00

72.19

74.00

60.00

70.00

75.00

61.13

70.02

75.02

60.02

60.01

Dot Clock

Frequency

(MHz)

25.17

25.18

30.24

31.50

31.50

28.32

36.00

40.00

49.50

50.00

57.27

65.00

75.00

78.75

80.37

94.51

108.03

108.04

108.00

B.DTV Mode

NO.

1

2

3

4

5

6

7

8

Resolution

480 i

576 i

480p(720x480)

576p(720x576)

720p(1280x720)

720p(1280x720)

1080i(1920x1080)

1080i(1920x1080)

Horizontal

Frequency

(KHz)

15.734

15.625

31.468

31.25

45.00

37.50

28.125

33.75

Vertical

Frequency

(Hz)

59.94

50.00

59.94

50.00

60.00

50.00

50.00

60.00

Dot Clock

Frequency

(MHz)

13.50

13.50

27.00

27.00

74.25

74.25

74.25

74.25

- When the signal received by the Display exceeds the allowed range, a warning message “Out Of Range”

shall appear on the screen.

- You can confirm the input signal format from the “OSD Menu”.

Page 11

Technical Specifications

13. Remote Control

PDP-5016

CONTINUATION PAGE

NUMBER

8 OF 9 PAGES

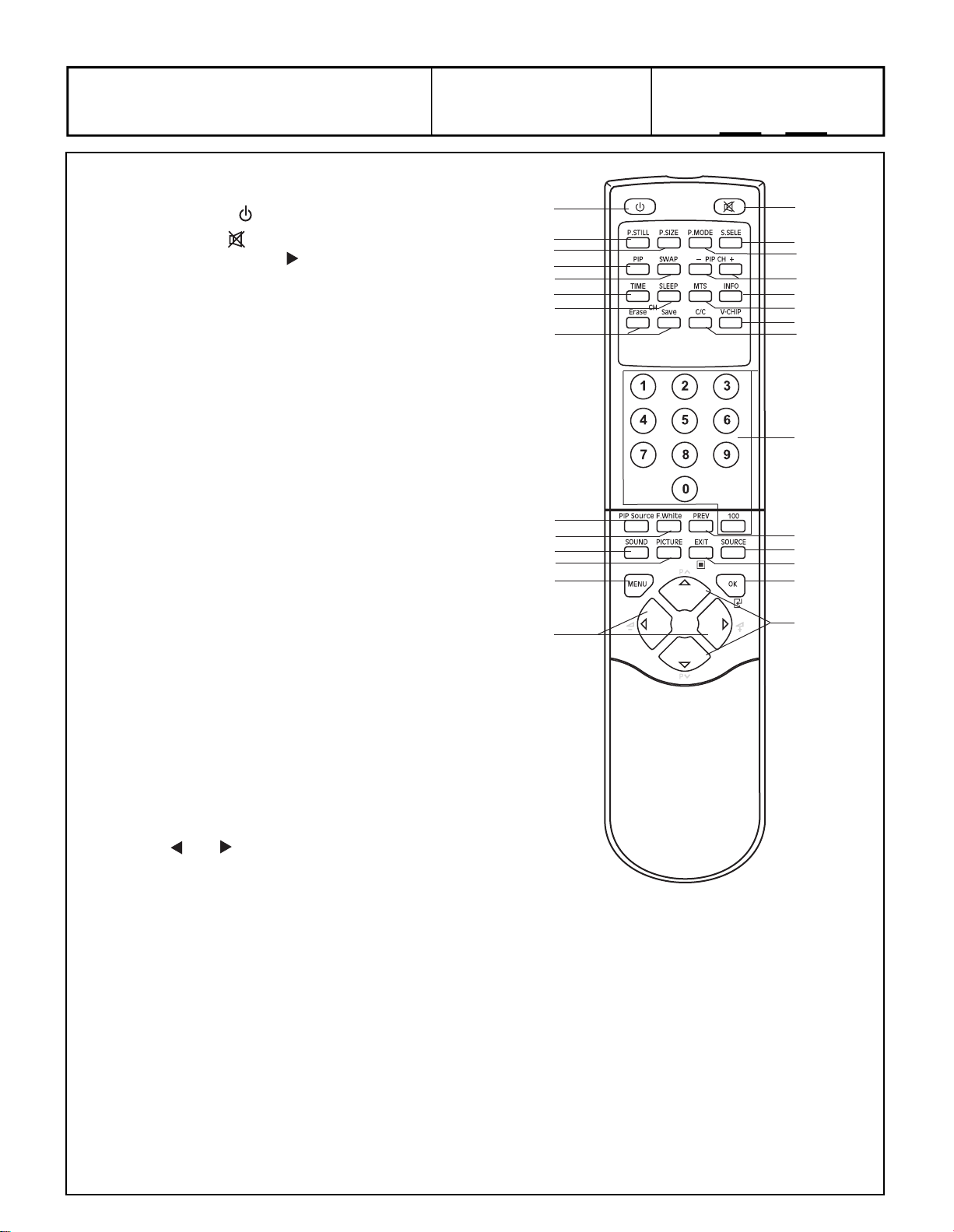

Power ( ): Press to turn on and off.

Mute (

again or press

P.STILL: Press to freeze the picture. Press

again to restore the picture.

P.SIZE: Press to cycles through the picture

size: Normal, Fill Screen, Anamorphic,

Letter Box or TV Mode, Panorama..

P. MODE: Press to cycles through the

picture mode: Normal, Bright, Dark, User.

S.SELE: Press to cycles through the sound

select: Main window sound or Sub window

sound.

PIP: Press to turns on PIP (picture-in picture) feature. Such as Full Screen, PIP or

Split Screen.

SWAP: Press to switches the Main window

or Sub window pictures.

PIP CH+ : Press to select Sub window

Channel Up.

PIP CH- : Press to select Sub window

Channel Down.

TIME: Press to display the current time.

SLEEP: Press repeatedly until it displays

the time in minutes (30 Min, 60 Min, 90 Min,

120 Min, 180 Min or Off ) that you want the

PDP to remain on before shutting off. To

cancel Sleep Time, press SLEEP repeatedly

until Sleep Off appears. And you can press

or to select sleep time shut down.

MTS: Press repeatedly to cycle through the

Multi-channel TV sound (MTS) options:

Mono, Stereo and SAP (Second Audio

Program).

INFO: Press to display on-screen information. Press it again to turn the display off.

CH Erase, CH Save buttons: Press to erase or save channel.

C/C: Press to select the Closed Caption mode.

V-Chip: Press to select the child protect mode.

Number buttons: Press 0~9,100 to select a channel; the channel changes after 2

seconds.

PIP Source: Press to select the signal for Sub Window.(Only for PIP.)

F.WHITE: Press to show a full white picture.

PREV: Press it returns to the last viewed channel.(Only for TV.)

): Press to mute the sound. Press

to restore the sound.

(Continued on next page)

Page 12

CONTINUATION PAGE

Technical Specifications

SOUND: Press to select different sound system, such as Normal, Flat, News, Cinema,

User or BBE Digital.

PICTURE: Press to select “BRIGHTNESS”, “COLOR”, “CONTRAST”, ”HUE” or

“SHARPNESS”, and you can use

EXIT: Press to return or exit OSD menu.

SOURCE: Press to select the signal sources directly. Such as TV, AV1, S-VIDEO,

YCbCr, YPbPr, Analog RGB or Digital RGB.

MENU: Press to display the OSD Menu.

OK: Press to enter or confirm.

used for the selection of the program when the OSD Menu is not shown on the screen.

used for the adjustment of volume when the OSD Menu is not shown on the screen.

/ : They are used as / buttons in the OSD Menu screen and they can be

/ : They are used as

/ buttons in the OSD Menu screen and they can be

or to adjust.

PDP-5016

NUMBER

9 OF 9 PAGES

PHYSICAL CHARACTERISTICS

14. Power Cord

Length : 1.8m nominal

Type : optional

15. Cabinet

15.1 Color

: silver colour as defined by colour plaque reference number

15.2 Weight

Net weight : 51.8kg

Gross weight : 74kg

15.3 Dimensions (with stand&speak)

Width : 1227.8mm

Height : 739.8mm

Depth : 120.6mm

Page 13

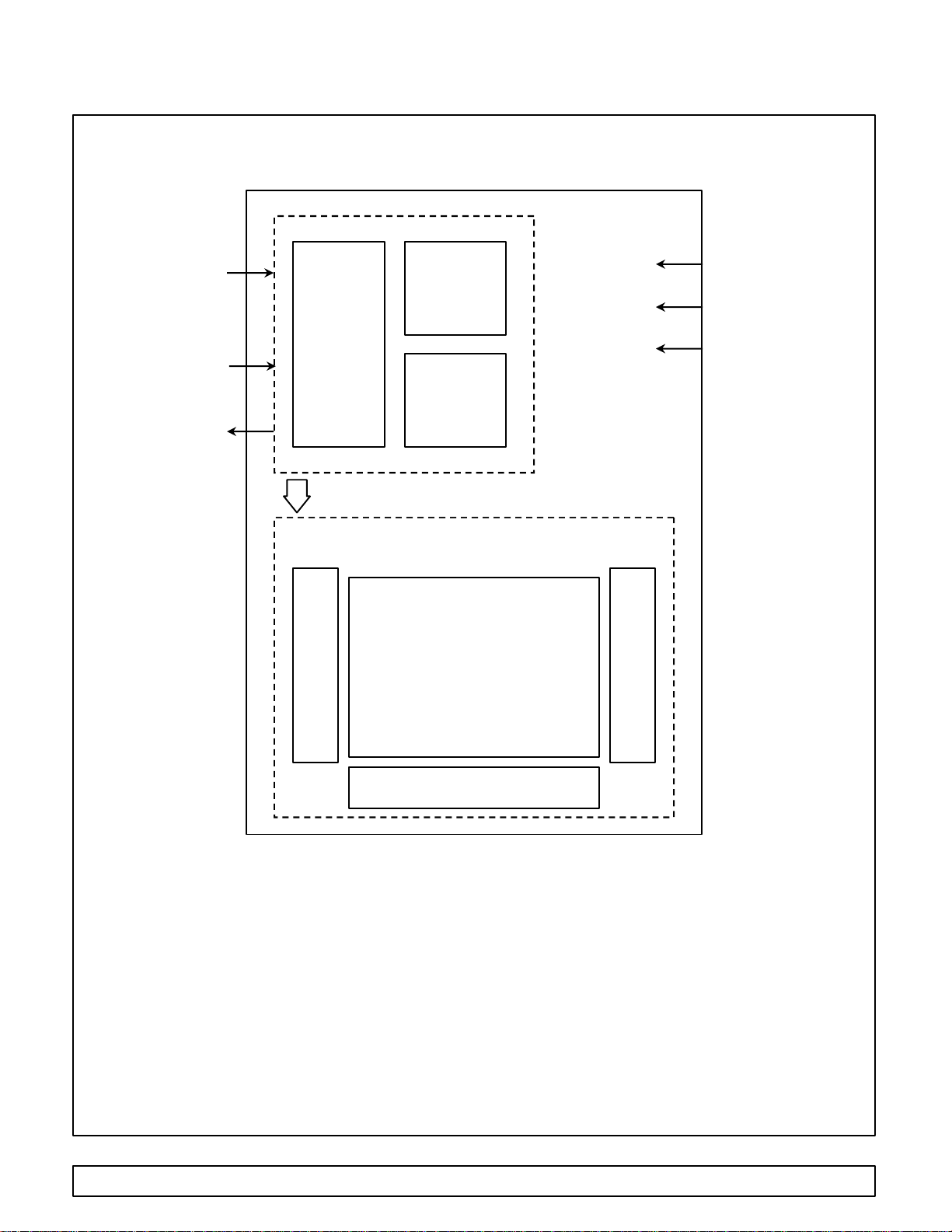

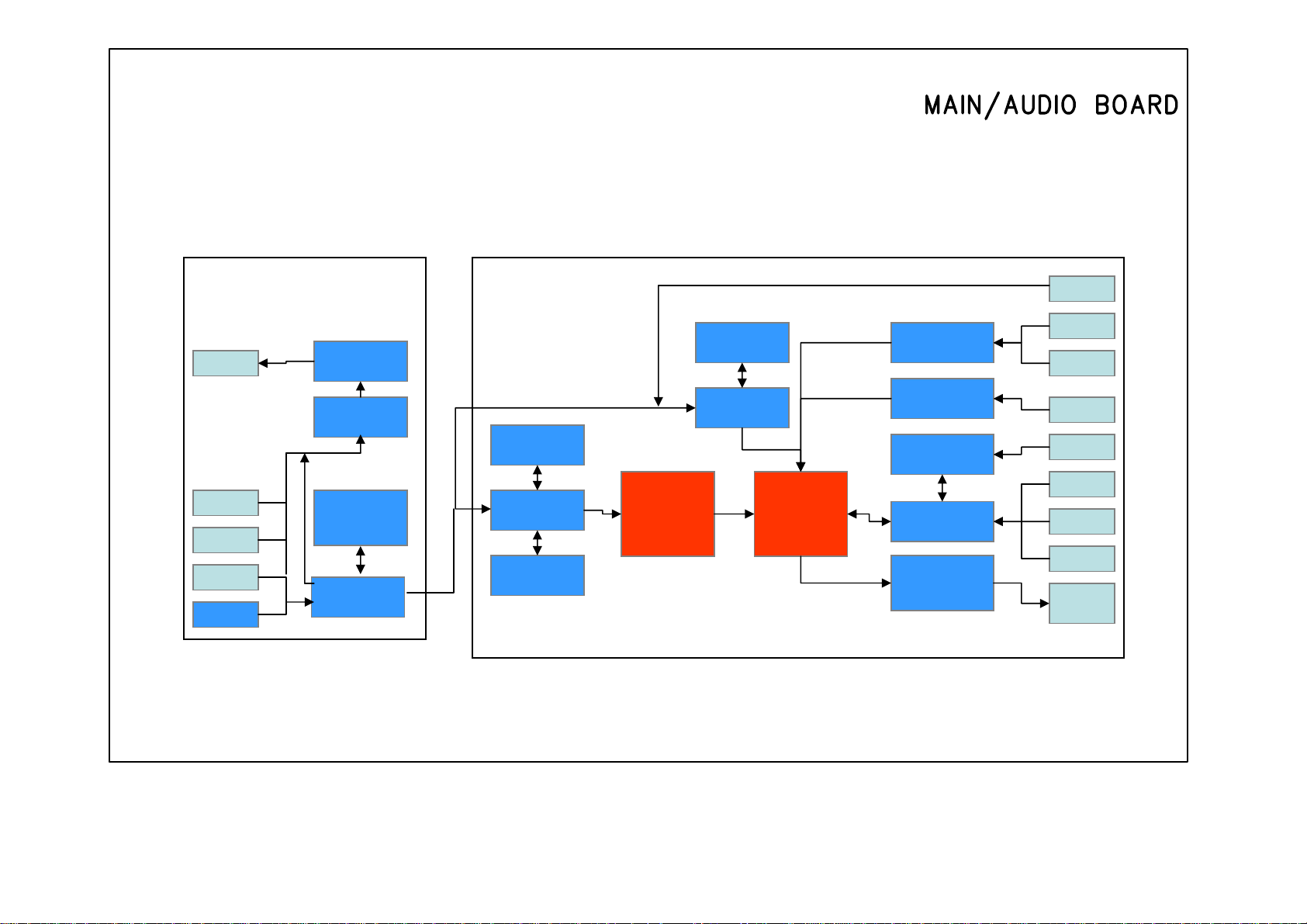

Block Diagram

Product Specification of PDP Module

LVDS Input

Control Signal

(Serial Interface)

APL Data

Memory

Input

Controller

Interface

Controller

Driver

Timing

Controller

Display data, Driver timing

Color Plasma Display Panel

1366 X 768 pixels

Scan Driver

Vs(180V~190V)

Va(55V~65V)

Vcc(+5V)

Common sustain driver

Address Driver

☞ Applied Voltage level is specified at the time when Full-White pattern is displayed on the panel.

Page 14

Block Diagram

Speaker

SCART1

Video2

S-Video

Tuner x 2

Sub Board

TDA8946

Audio AMP

MSP34x0G

Audio Decoder

uPD64083

Separator

M52790

A/V Switch

3D Y/C

Main Board

Z86229

V-Chip / CC

VPC3230D

Vide Decoder

SDA5550

TVText Pro

PW1231

De-

Interlacer

Z86229

V-Chip / CC

VPC3230D

Video Decoder

Processor

PW181

Image

AD9883A

ADC

Sil161B

DVI Receiver

MAX232C

RS232C

W78E65B

System Control

THC63LVDM83

LVDS

Transmitter

YCrCb

YPbPr

D-SUB15

DVI

D-SUB9

IR

Keypad

LED

LDVS

Header

Page 15

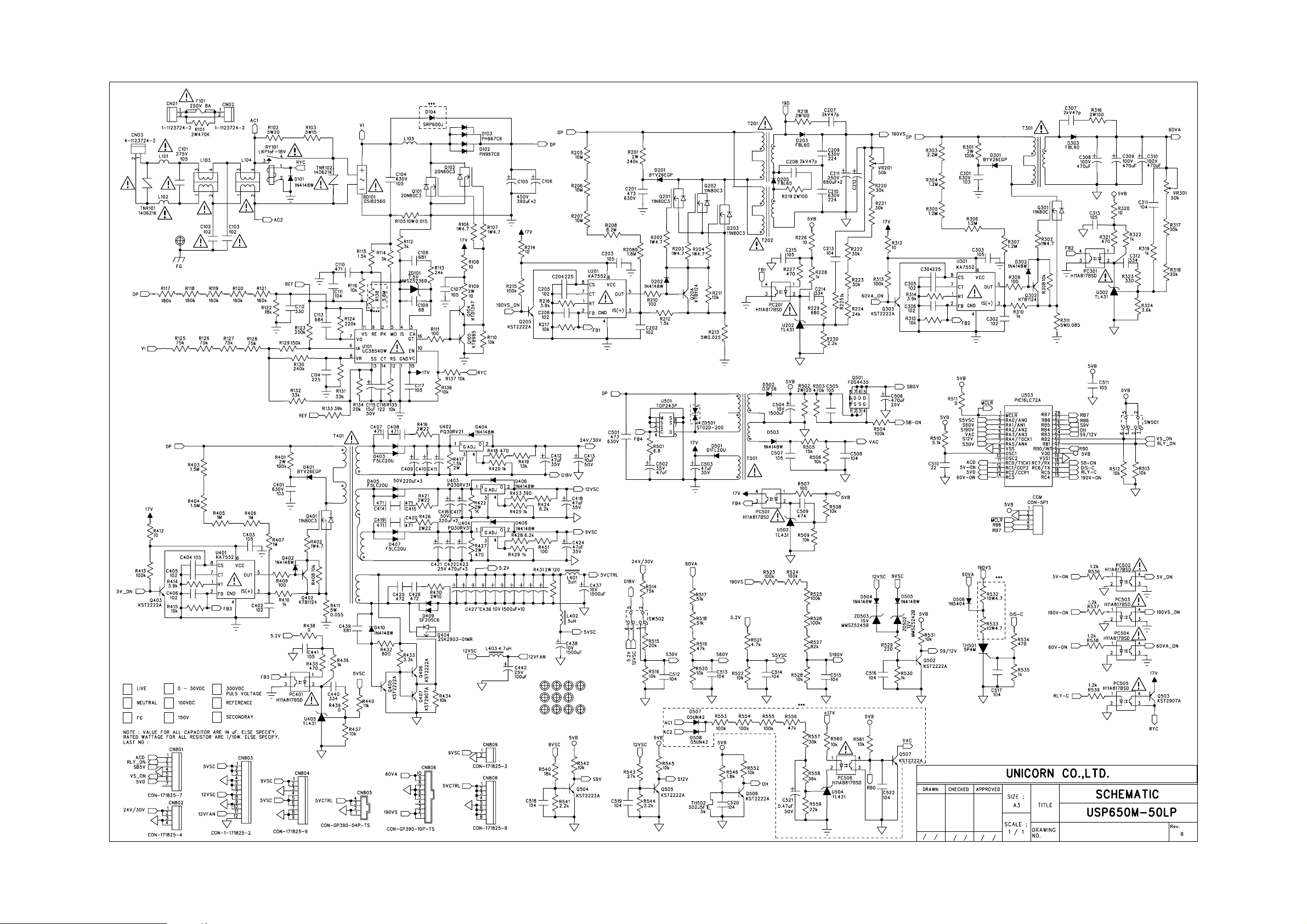

Circuit Diagram

- Power supply board of PDP Module, USP650M-50LP

- Main (Video) board

- Audio/Tuner board

- Keypad board

- Remote control receiver board

- Remote control board

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

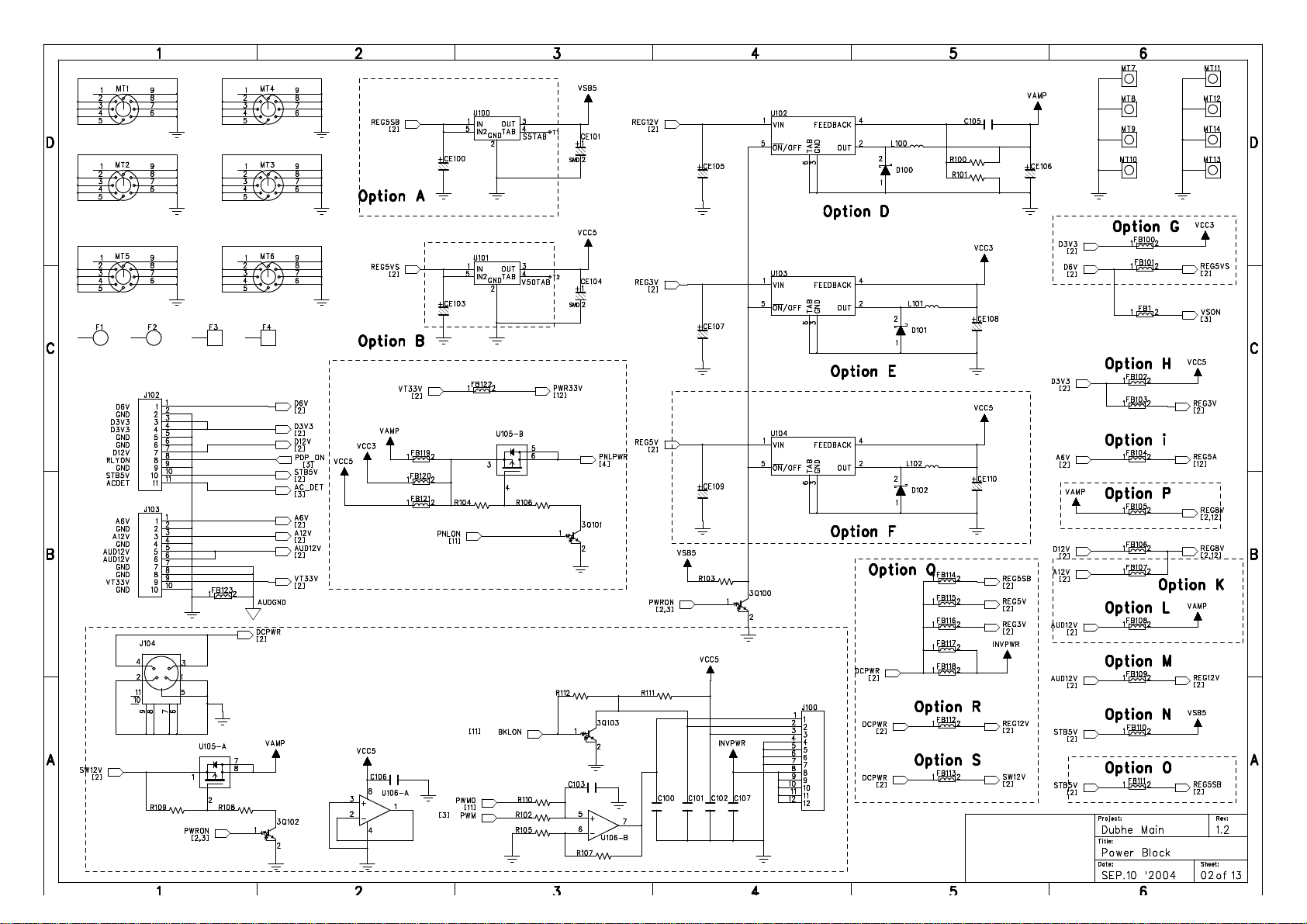

Dbh1S4909V12.sch-2 - Thu Oct 07 00:30:42 2004

Page 30

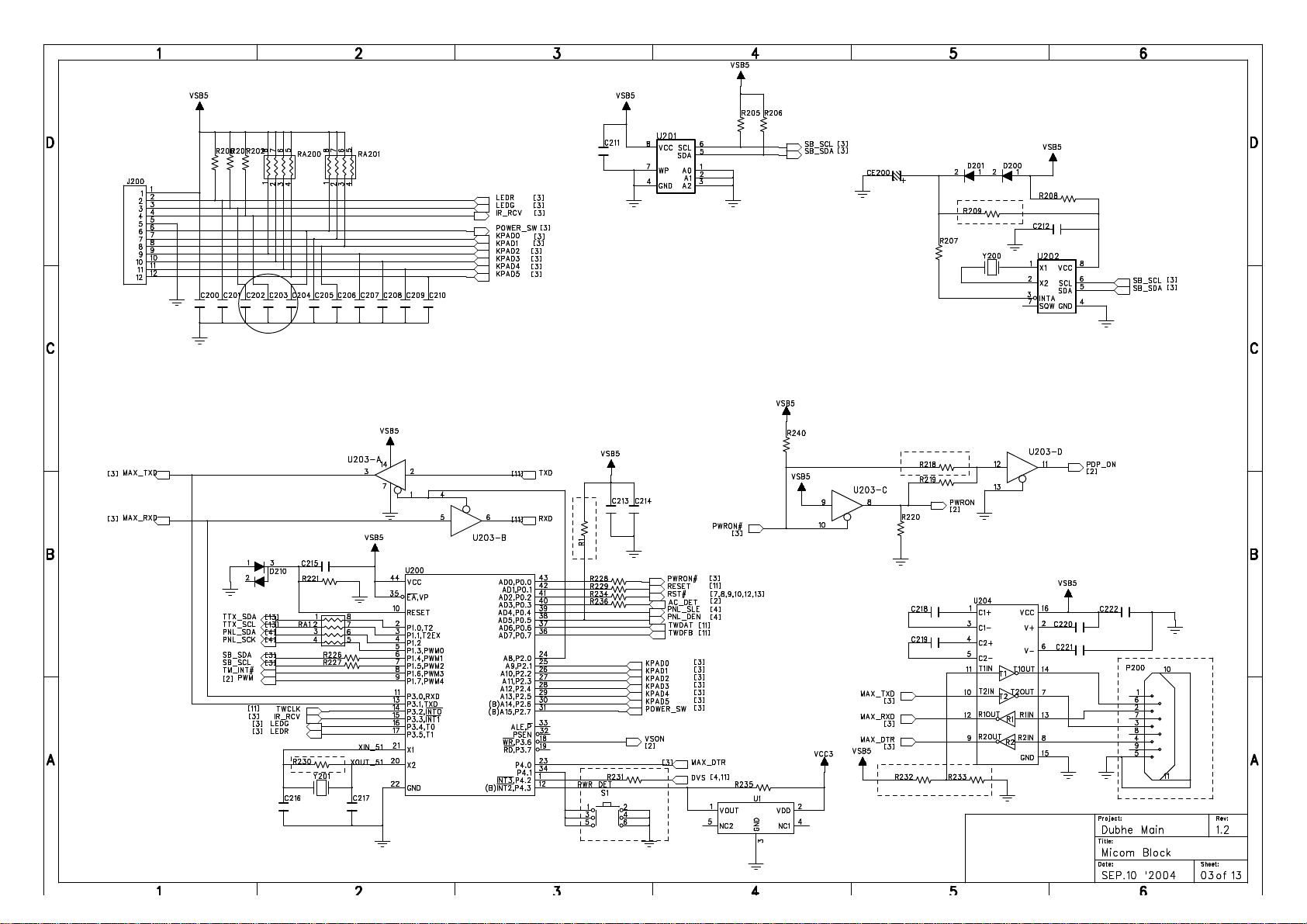

Dbh1S4909V12.sch-3 - Thu Oct 07 00:30:43 2004

Page 31

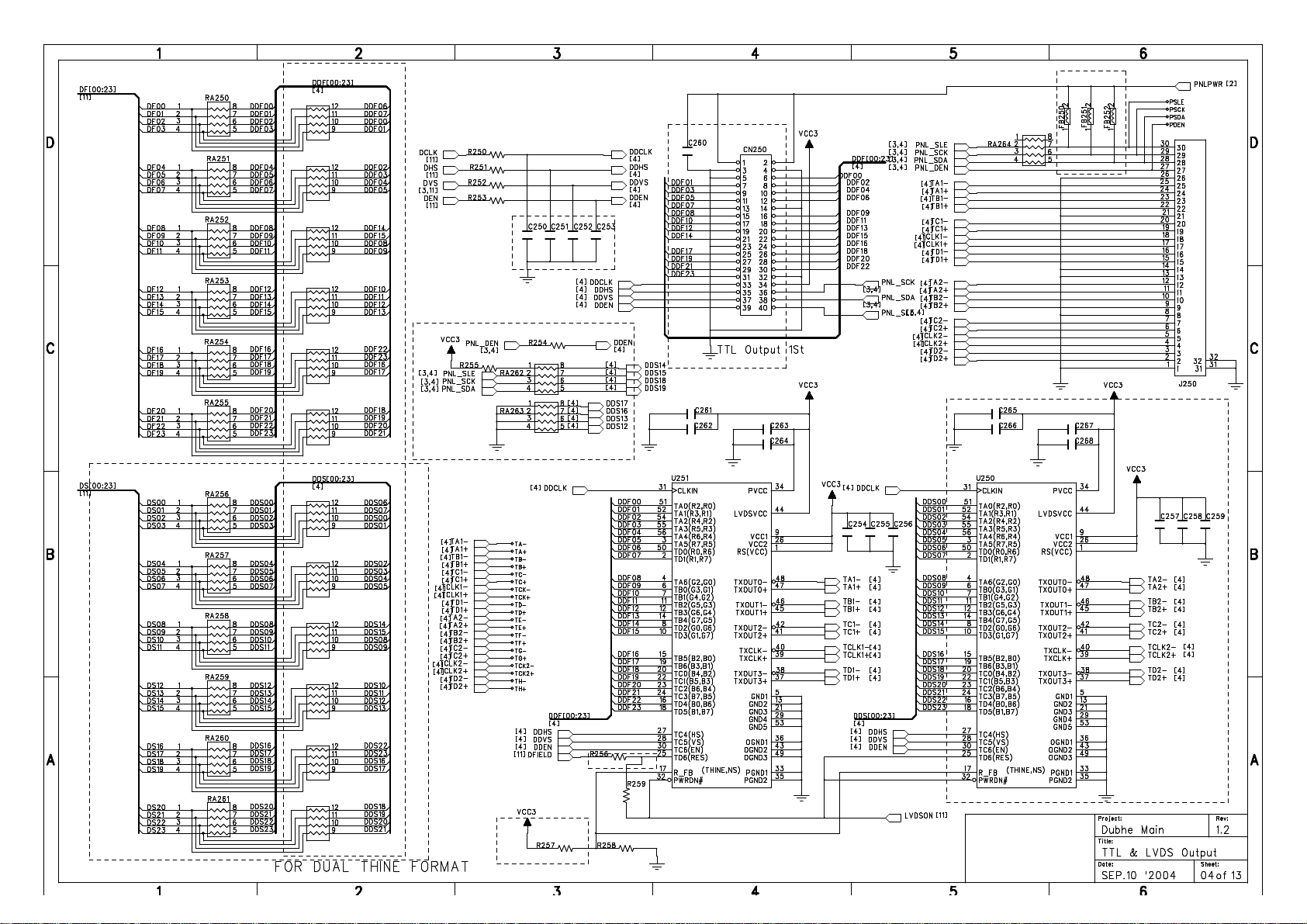

Dbh1S4909V12.sch-4 - Thu Oct 07 00:30:45 2004

Page 32

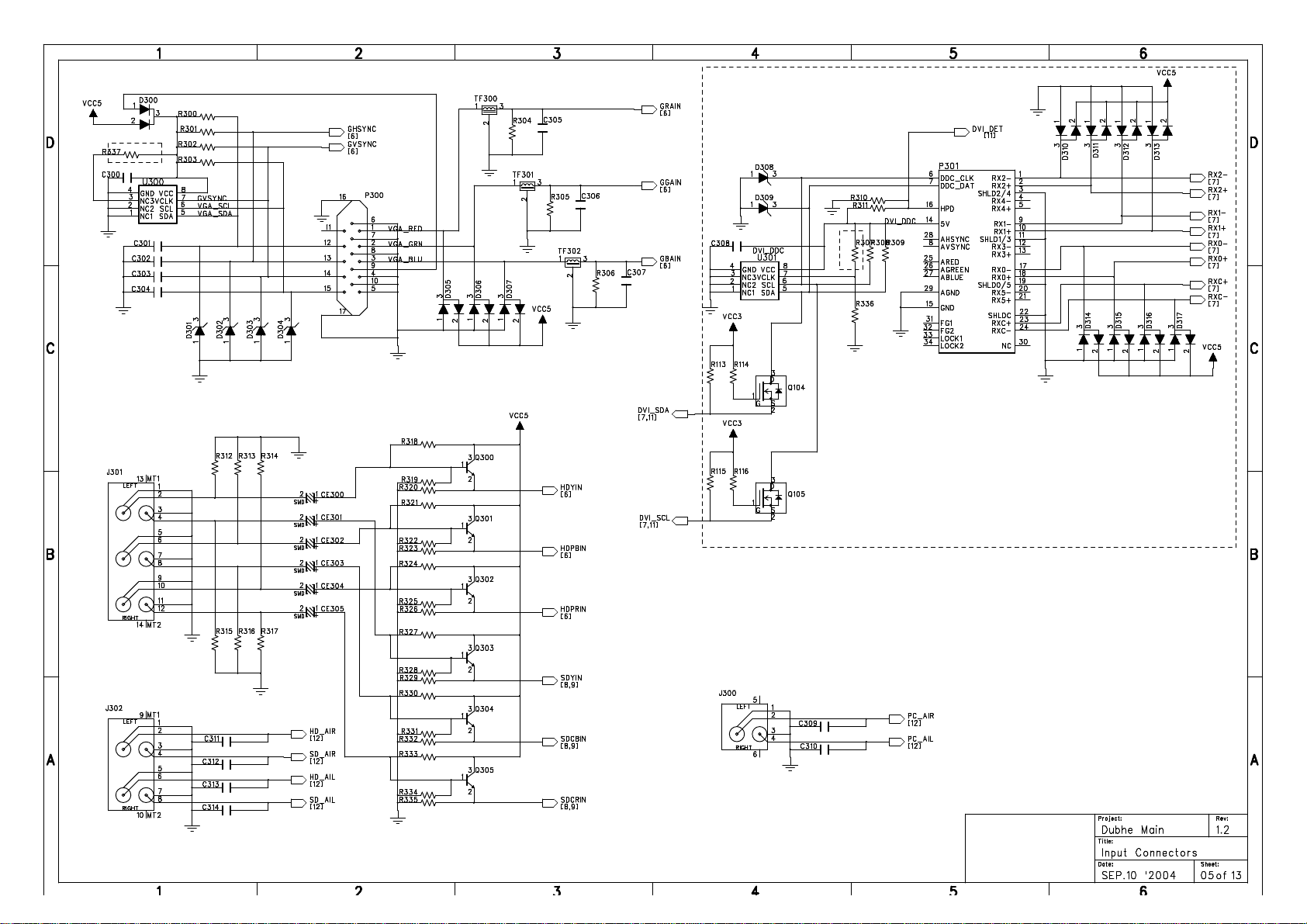

Dbh1S4909V12.sch-5 - Thu Oct 07 00:30:47 2004

Page 33

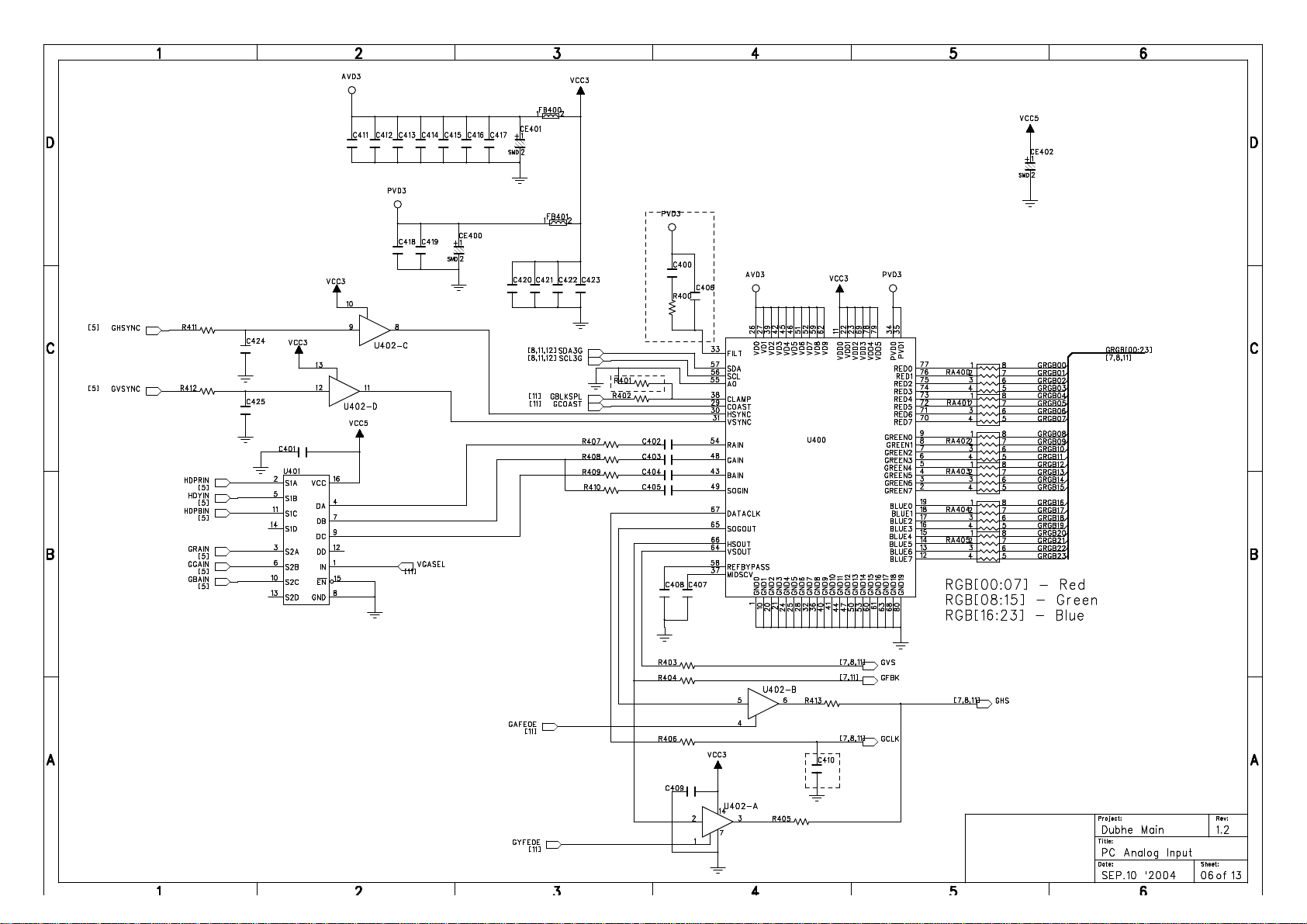

Dbh1S4909V12.sch-6 - Thu Oct 07 00:30:49 2004

Page 34

Dbh1S4909V12.sch-7 - Thu Oct 07 00:30:50 2004

Page 35

Dbh2S4909V12.sch-2 - Thu Oct 07 00:32:34 2004

Page 36

DUBHE OSD Ver1.1_NAKS.sch-1 - Mon Oct 18 11:47:11 2004

Page 37

0025.sch-1 - Mon May 16 09:25:50 2005

Page 38

Basic Operations & Circuit Description

MODULE

There are 1 pc. panel and 12 pc.s PCB including 2 pc.s Y/Z Sustainer board, 2 pc.s Y Drive

board, 6 pc.s X Extension boards, 1 pc. Control (Signal Input) and 1 pc. Power

board in the Module.

SET

There are 5 pc.s PCBs including 1 pc. Tuner/Audio board, 1 pc. Keypad board, 1 pc.

Remote Control Receiver board, 1 pc. L/R Speakers and 1 pc. Main (Video) board in the SET.

Page 39

Y-Driver Top

Y-Sustainer

Y-Driver Bottom

X-extension Bottom L/C/R

Local Key

Stand

Main (Video)

Tuner/Audio

EMI Filter & AC

Inlet

X-extension Top L/C/R

Power Supply

Control board Assy.

External Speaker

Terminals

Z-Sustainer

Page 40

PCB function

1. Power:

(1). Input voltage: AC 110V~240V, 47Hz~63Hz.

Input range: AC 90V(Min)~265V(Max) auto regulation.

(2). To provide power for PCBs.

2. Main (Video InterFace) board: To converter TV signals, S signals, AV signals, Y Pb/

Cb Pr/Cr signals, DVI signals and D-SUB signals to digital ones and to transmit to

Control board.

3. Control board: Dealing with the digital signal for output to panel.

4. Y-Sustainer / Z-Sustainer board:

(1). Receiving the signals from Control and high voltage supply.

(2). Output scanning waveform for Module.

5. Y-Drive board: Receive signal from Y sustainer, output horizontal scanning waveform to the panel.

6. X extension board (6pcs): Output addressing signals.

7. Tuner/Audio Board

convert TV RF signal to video/audio signal and send to Main board.

: :

: Process and Amplifying the audio signal to speakers and

: :

Page 41

PCB failure analysis

1. CONTROL : a. Abnormal noise on screen. b. No picture.

2. MAIN (video): a. Lacking color, Bad color scale.

b. No voice.

c. No picture but with signals output, OSD and back light.

d. Abnormal noise on screen.

3. POWER: No picture, no power output.

4. Z - Sustainer :a. No picture.

b. Color not enough.

c. Flash on screen.

5. Y - Sustainer : Darker picture with signals.

6. X - Extension : Abormal vertical noise on screen.

7. Audio Bard: a. No voice. (Make sure Mute/OFF) .

b. Noise.

Page 42

Basic operation of Plasma Display

1. After turning on power switch, power board sends 5Vst-by Volt to Micro Processor

2. The micro Processor memorize the last state of Power, When the last state of

power is on or receive power on signal from local Key or Remote control, Micro

Processor will send on control signal to power. Then Power sends (5Vsc, 9Vsc,

24V and RLYON, Vs ON) to PCBs working. This time VIF will send signals to

display Image, OSD on the panel and start to search available signal sources.

If the audio signals input, them will be amplified by Audio AMP and transmitted to

Speakers.

3. If some abnormal signals are detected (for example: over volts, over current, over

temperature and under volts), the system will be shut down by Power off.

Page 43

Main IC Specifications

- PW181 Image Processor, Scaler

- PW1231 Digital Video Signal Processor

- uPD64083 Three –Dimensional Y/C Separation LSI

With On-Chip Memory

- AD9883A 110MSPS/140MSPS Analog Interface

- VPC 323XD Comb-filter Video Processor

- Si161B Panel Link Receiver

- Z86229 NTSC Line 21 CCD decorder

- MSP34x0G Multistandard Sound Processor

Page 44

PW181

Product Specification

General Description

The PW181 ImageProcessor is a highly integrated

“system-on-a-chip” that interfaces computer graphics and

video inputs in virtually any format to a fixed-frequency flat

panel display.

Computer and video images from NTSC/PAL to WUXGA

at virtually any refresh rate can be resized to fit on a fixedfrequency target display device with any resolution up to

WUXGA. Video data from 4:3 aspect ratio NTSC or PAL

and 16:9 aspect ratio HDTV or SDTV is supported. Multiregion, nonlinear scaling allows these inputs to be resized

optimally for the native resolution of the display.

Advanced scaling techniques are supported, such as

format conversion using multiple programmable regions.

Three independent image scalers coupled with frame

locking circuitry and dual programmable color lookup

tables create sharp images in multiple windows, without

user intervention.

Embedded SDRAM frame buffers and memory controllers

perform frame rate conversion and enhanced video

processing completely on-chip. A separate memory is

dedicated to storage of on-screen display images and

CPU general purpose use.

Advanced video processing techniques are supported

using the internal frame buffer, including motion adaptive,

temporal deinterlacing with film mode detection. When

used in combination with the new third-generation scaler,

this advanced video processing technology delivers the

highest quality video for advanced displays.

Both input ports support integrated DVI 1.0 content

protection using standard DVI receivers.

A new advanced OSD Generator with more colors and

larger sizes supports more demanding OSD applications,

such as on-screen programming guides. When coupled

with the new, faster, integrated microprocessor, this OSD

Generator supports advanced OSD animation techniques.

Video

TV

Signal

Input

TV Tu n e r

Com puter

Video

Decoder

ADC/

TMDS

Crystal

PW181

TV

Signal

Com puter

TV Tu n e r

Video

Input

ADC/

TMDS

Video

Decoder

PW181 System Block Diagram

ROM

Features

• Third-generation, two-dimensional filtering techniques

• Third-generation, advanced scaling techniques

• Second-generation Automatic Image Optimization

• Frame rate conversion

• Video processing

• On-Screen Display (OSD)

• On-chip microprocessor

• JTAG debugger and boundary scan

• Picture-in-picture (PIP)

• Multi-region, non-linear scaling

• Hardware 2-wire serial bus support

Applications

• Multimedia Displays

• Plasma Displays

• Digital Television

Device Application Package

PW181-10V Up to XGA Displays

PW181-20V Up to UXGA Displays

352 PBGA

Dis pla y

Programmable features include the user interface, custom

start-up screen, all automatic imaging features, and

special screen effects.

PRELIMINARY / CONFIDENTIAL

Page 45

110 MSPS/140 MSPS Analog Interface

a

FEATURES

140 MSPS Maximum Conversion Rate

300 MHz Analog Bandwidth

0.5 V to 1.0 V Analog Input Range

500 ps p-p PLL Clock Jitter at 110 MSPS

3.3 V Power Supply

Full Sync Processing

Sync Detect for “Hot Plugging”

Midscale Clamping

Power-Down Mode

Low Power: 500 mW Typical

4:2:2 Output Format Mode

APPLICATIONS

RGB Graphics Processing

LCD Monitors and Projectors

Plasma Display Panels

Scan Converters

Microdisplays

Digital TV

R

AIN

G

AIN

B

AIN

HSYNC

COAST

CLAMP

FILT

SCL

SDA

for Flat Panel Displays

FUNCTIONAL BLOCK DIAGRAM

CLAMP

CLAMP

CLAMP

SYNC

PROCESSING

AND CLOCK

GENERATION

SERIAL REGISTER

AND

A

0

POWER MANAGEMENT

A/D

A/D

A/D

AD9883A

8

R

OUTA

8

G

OUTA

8

B

OUTA

MIDSCV

DTACK

HSOUT

VSOUT

SOGOUT

REF

AD9883A

REF

BYPASS

GENERAL DESCRIPTION

The AD9883A is a complete 8-bit, 140 MSPS monolithic analog

interface optimized for capturing RGB graphics signals from

personal computers and workstations. Its 140 MSPS encode

rate capability and full power analog bandwidth of 300 MHz

supports resolutions up to SXGA (1280 × 1024 at 75 Hz).

The AD9883A includes a 140 MHz triple ADC with internal

1.25 V reference, a PLL, and programmable gain, offset, and

clamp control. The user provides only a 3.3 V power supply,

analog input, and Hsync and COAST signals. Three-state

CMOS outputs may be powered from 2.5 V to 3.3 V.

The AD9883A’s on-chip PLL generates a pixel clock from the

Hsync input. Pixel clock output frequencies range from 12 MHz to

140 MHz. PLL clock jitter is 500 ps p-p typical at 140 MSPS.

When the COAST signal is presented, the PLL maintains its

output frequency in the absence of Hsync. A sampling phase

adjustment is provided. Data, Hsync, and clock output phase

relationships are maintained. The AD9883A also offers full sync

processing for composite sync and sync-on-green applications.

A clamp signal is generated internally or may be provided by

the user through the CLAMP input pin. This interface is fully

programmable via a 2-wire serial interface.

Fabricated in an advanced CMOS process, the AD9883A is

provided in a space-saving 80-lead LQFP surface-mount plastic

package and is specified over the 0°C to 70°C temperature range.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel:

Fax:

Page 46

PW1231A

Product Specification

General

The PW1231A is a high-quality, digital video signal

processor that incorporates Pixelworks’ patented

deinterlacing, scaling, and video enhancement

algorithms. The PW1231A accepts industry-standard

video formats and resolutions, and converts the input into

many desired output formats.The highly efficient video

algorithms result in excellent quality video.

The PW1231A combines many functions into a single

device, including a memory controller, auto-configuration,

and others. This high level of integration enables simple,

flexible, cost-effective solutions that require fewer

components.

Crysta l

Video

PW1231A

System Block Dia gram

Video

Decoder

PW1231A

PW1231AL

SDRAM

Digital

Output

Features

• Built-In Memory Controller

• Motion-Adaptive Deinterlace Processor

• Intelligent Edge Deinterlacing

• Digital Color/Luminance Transient Improvement (DCTI/DLTI)

• Interlaced Video Input Options, including NTSC and PAL

• Independent horizontal and vertical scaling

• Copy Protection

• Two-Wire Serial Interface

8100 SW Nyberg Road

Tualatin, OR 97062 USA

Telephone: 503.612.6700

FAX: 503.612.6713

www.pixelworks.com

Applications:

For use with Digital Displays

• Flat-Panel (LCD, DLP) TVs

• Rear Projection TVs

• Plasma Displays

• LCD Multimedia Monitors

• Multimedia Projectors

Device Application Package

PW1231A

PW1231AL

NOTE: “L” denotes lead (Pb) free

Up to XGA 160-pin PQF

P/N 001-0097-00 Rev B

PRELIMINARY—CONFIDENTIAL

July 2003

Page 47

DATA SHEET

MOS INTEGRATED CIRCUIT

PD64083

µµµµ

THREE-DIMENSIONAL Y/C SEPARATION LSI WITH ON-CHIP MEMORY

DESCRIPTION

The µPD64083 realizes a high precision Y/C separation and a noise reduction by the three-dimension signal

processing for NTSC signal.

This product has the On-chip 4-Mbit memory for flame delay, 2ch of high precision internal 10-bit A/D converter, and

adapting 10-bit signal processing (only for luminance signal) and high picture quality. The

single-chip system of 3D Y/C separation.

This LSI includes the Wide Clear Vision ID signal (Japanese local format) decoder and ID-1 signal decoder.

PD64083 is completely

µ

FEATURES

•

On-chip 4-Mbit frame delay memory.

•

4 Operation mode (Compatible to the µPD64082)

Motion adaptive 3D Y/C separation (for Composite video input)

Frame recursive Y/C NR (for Y/C separated video input)

Frame comb type YNR + 1H delayed C signal (for Y/C separated video input)

2D Y/C separation + Frame recursive Y/C NR (for Composite video input)

•

Embedded A/D converter (2ch), D/A converter (2ch), clock generator.

•

Embedded Y coring, Vertical enhancer, Peaking filter, and Noise detector.

•

Embedded WCV-ID decoder and ID-1 decoder.

•

I2C bus control.

•

Dual power supply of 2.5 V and 3.3 V.

For digital : DV

For analog : AV

For DRAM : DV

For I/O : DV

DDIO

= 2.5 V

DD

= 2.5 V

DD

DDRAM

= 3.3 V

= 2.5 V

ORDERING INFORMATION

Part number Package

PD64083GF-3BA 100-pin plastic QFP (14 × 20)

µ

Document No. S15849EJ1V0DS00 (1st edition)

Date Published January 2002 NS CP (K)

Printed in Japan

2

Page 48

PRELIMINARY DATA SHEET VPC 323xD

Comb Filter Video Processor

1. Introduction

The VPC 323xD is a high-quality, single-chip video

front-end, which is targeted for 4: 3 and 16:9, 50/60-Hz

and 100/120 Hz TV sets. It can be combined with other

members of the DIGIT3000 IC family (such as

DDP 331x) and/or it can be used with 3rd-party products.

The main features of the VPC 323xD are

– high-performance adaptive 4H comb filter Y/C sepa-

rator with adjustable vertical peaking

– multi-standard color decoder PAL/NTSC/SECAM

including all substandards

– four CVBS, one S-VHS input, one CVBS output

– two RGB/YC

component inputs, one Fast Blank

rCb

(FB) input

– integrated high-quali ty A/D converters and associ-

ated clamp and AGC circuits

– multi-standard sync proces sing

– linear horizontal scaling (0.25 ... 4), as well as

non-linear horizontal scaling ‘Panoramavision’

– PAL+ preprocessing

– peak ing, contrast, brightness, color saturation and

tint for RGB/YC

and CVBS/S-VHS

rCb

– high-qual ity soft mixer controlled by Fast Blank

1

1

1

----- -

-- -

– PIP processing for four picture sizes ( , or

1

---

of normal size) with 8-bit resolution

36

---

,,

4

16

9

– 15 predefined PIP display configurations and expert

mode (fully programmable)

– control interface for external field memory

2

–I

C-bus interface

– one 20.25-MHz crystal, few external components

– 80-p in PQFP pack age

1.1. System Architecture

Fig.1–1 shows the block diagram of the video processor

– li ne-locked c lock, data and sync, or 656-output

interface

CIN

VIN1

VIN2

VIN3

VIN4

VOUT

RGB/

YCrCb

FB

RGB/

YCrCb

Analog

Front-end

AGC

2×ADC

Analog

Component

Front-End

4 x ADC

Adaptive

Comb

Filter

NTSC

PAL

Y/G

Processing

U/B

V/R

FB FB

Matrix

Contrast

Saturation

Brightness

Tint

Color

Decoder

NTSC

PAL

SECAM

Saturation

Tint

Y

Cr

Cb

Y

Cr

Cb

Mixer

Y

2D Scaler

Panorama

Cr

Cb

Brightness

Clock

Gen.

PIP

Mode

Contrast

Peaking

2

I

C Bus

Output

Formatter

ITU-R 656

ITU-R 601

Memory

Control

Sync

+

Clock

Generation

Y OUT

CrCb

OUT

YCOE

FIFO

CNTL

LL C lock

H Sync

V Sync

AVO

Fig.1–1:Block diagram of the VPC323xD

Micronas

2

C Bus20.25 MHz

I

Page 49

SiI 161B PanelLink® Receiver

Data Sheet

General Description Features

The SiI 161B receiver uses PanelLink Digital

technology to support high-resolution displays up to

UXGA (25-165MHz). This receiver supports up to true

color panels (24 bits per pixel, 16M colors) with both

one and two pixels per clock.

All PanelLink products are designed on a scaleable

CMOS architecture, ensuring support for future

performance enhancements while maintaining the

same logical interface. System designers can be

assured that the interface will be stable through a

number of technology and performance generations.

PanelLink Digital technology simplifies PC and display

interface design by resolving many of the system level

issues associated with high-speed mixed signal design,

providing the system designer with a digital interface

solution that is quicker to market and lower in cost.

• Low Power Operation: 280mA max. current

consumption at 3.3V core operation

• Time staggered data output for reduced ground

bounce and lower EMI

• Sync Detect feature for Plug & Display

• Cable Distance Support: over 5m with twisted-

pair, fiber-optics ready

• ESD tolerant to 5kV (HBM on all pins)

• Compliant with DVI 1.0 (DVI is backwards

compatible with VESA

®

P&DTM, FPDI-2

DFP)

• HSYNC de-jitter circuitry enables stable operation

even when HSYNC contains jitter

• Low power standby mode

• Automatic entry into standby mode with clock

detect circuitry

• Standard and Pb-free packages (see page 25).

August 2002

TM

and

Page 50

4'.+/+0#4; 41&7%6#2'%+(+%#6+10

<

+0'

'%1&'4

• Complete Stand-Alone Line 21 Decoder for Closed-

Captioned and Extended Data Services (XDS)

• Preprogrammed to Provide Full Compliance with

EIA–608 Specifications for Extended Data Services

• Automatic Extraction and Serial Output of Special

XDS Packets (Time of Day, Local Time Zone, and

Program Blocking)

• Programmable XDS Filter for a Specific XDS Packet

• Cost-Effective Solution for NTSC Violence Blocking

inside Picture-in-Picture (PiP) Windows

!"

#$%

&%

" '

• Minimal Communications and Control Overhead Pro-

vide Simple Implementation of Violence Blocking,

Closed Captioning, and Auto Clock Set Features

• Programmable, On-Screen Display (OSD) for Creat-

ing Full Screen OSD or Captions inside a Picture-inPicture (PiP) Window

• User-Programmable Horizontal Display Position for

easy OSD Centering and Adjustment

2

• I

C Serial Data and Control Communication

• Supports 2 Selectable I

2

C Addresses

Capable of processing Vertical Blanking Interval (VBI)

data from both fields of the video frame in data, the Z86229

Line 21 Decoder offers a feature-rich solution for any television or set-top application. The robust nature of the

Z86229 helps thedevice conformto thetransmission format

defined in the Television Decoder Circuits Actof 1990,and

in accordance with the Electronics Industry Association

specification 608 (EIA–608).

The Line 21data stream can consist of data from several data

channels multiplexed together. Field 1 consists of four data

channels: two Captions and two Texts. Field 2 consists of

five additional data channels: two Captions, two Texts, and

Extended Data Services (XDS). The XDS data structure is

defined in EIA–608. The Z86229 can recover and display

data transmitted on any of these nine data channels.

The Z86229 can recover and output to a host processor via

2

C serial bus. The recovered XDS data packet isfurther

the I

defined in the EIA–608 specification. The on-chip XDS filters in the Z86229 are fully programmable, enabling recovery ofonly those XDS data packetsselected bythe user.This

functionality allows the device to extract the required XDS

information with proper XDS filter setup for compatibility

in a variety of TVs, VCRs, and Set-Top boxes.

In addition, the Z86229 is ideally suited to monitor Line 21

video displayed in a PiP window for violence blocking,

CCD, and other XDS data services. A block diagram of the

Z86229 is illustrated in Figure 1.

Page 51

PRELIMINARY DATA SHEET MSP 34x0G

Multistandard Sound Processor Family

Release Note: Revision bars indicate significant

changes to the previous edition. The hardware and

software description in this document is valid for

the MSP 34x0G version B8 and following versions.

1. Introduction

The MSP 34x0G family of single-chip Multistandard

Sound Processors covers the sound processing of all

analog TV-Standards worldwide, as well as the NICAM

digital sound standar ds. The full TV sound process ing ,

starting with analog sound IF signal-in, down to processed analog AF-out, is performed on a single chip.

Figure 1–1 shows a simplified functional block diagram

of the MSP 34x0G.

This new generation of TV sound processing ICs now

includes versions for processing the multichan nel television sound (MTS) signal conforming to the standard

recommended by the Broadcast Television Systems

Committee (BTSC). The DBX noise reduction, or alternatively, Micronas Noise Reduction (MNR) is performed alignment free.

Other processed standards are the Japanese FM-FM

multiplex standard (EIA-J) and the FM Stereo Radio

standard.

Current ICs have to perform adjustment procedu res in

order to achieve good stereo sepa ration for BTSC and

EIA-J. The MSP 34x0G has optimum stereo performance without any adjustments.

All MSP 34xxG versions are pin compatible to the

MSP 34xxD. Only minor modifications are necessary

to adapt a MSP 34xxD controlling software to the

MSP 34xxG. The MSP 34x0G further simplifies controlling software. St andard selection requi res a single

2

C transmission only.

I

The MSP 34x0G has built-in automatic functions: The

IC is able to detect the actual sound standard automatically (Automatic Standard Detection). Furthermore,

pilot levels and identification sign als can be evaluated

internally with subsequent switching between mono/

stereo/bilingual; no I

2

C interaction is necessar y (Auto-

matic Sound Selectio n) .

The MSP 34x0G can handle very high FM deviations

even in conjunction with NICAM processing. This is

especially impor tant for the introduction of NICAM in

China.

The ICs are produced in submicron CMOS technology.

The MSP 34x0G is available in the following packages:

PLCC68 (not intended for new design), PSDIP64,

PSDIP52, PQFP80, and PLQFP64.

Sound IF1

Sound IF2

I2S1

I2S2

SCART1

SCART2

SCART3

SCART4

MONO

ADC

SCART

DSP

Input

Select

De-

modulator

ADC

Pre-

processing

Prescale

Prescale

Fig. 1–1: Simplified functional block diagram of the MSP 34x0G

Loud-

speaker

Sound

Processing

Headphone

Sound

Processing

Source Select

DAC

DAC

DAC

DAC

SCART

Output

Select

Loudspeaker

Subwoofer

Headphone

I2S

SCART1

SCART2

Micronas

Page 52

- 2 -

PDP Module is a display device to be divided into a Panel part

and a Drive part. The Panel part consists of

Electrodes, Phosphor, various dielectrics and gas, and the Drive

part includes electronic circuitry and PCB.

When using/handling this PDP Module, pay attention to the

below warning and cautions.

Warning?

Indicates a hazard that may lead to death or injury if the

warning is ignored and the product is handled incorrectly.

Caution?

Indicates a hazard that can lead to injury or damage to

property if the caution is ignored and the product is handled

incorrectly.

Ⅰ. WARNING

(1) Do not supply a voltage higher than that specified to this

product. This may damage the product and may cause a

fire.

(2) Do not use this product in locations where the humidity is

extremely high, where it may be splashed with water, or

where flammable materials surround it.

Do not install or use the product in a location that does no

satisfy the specified environmental conditions. This may

damage the product and may cause a fire.

(3) If a foreign substance (such as water, metal, or liquid) gets

inside the product, immediately turn off the power.

Continuing to use the product, it is may cause fire or

electric shock.

(4) If the product emits smoke, and abnormal smell, or makes

an abnormal sound, immediately turn off the power.

Continuing to use the product, it may cause fire or electric

shock.

(5) Do not disconnect or connect the connector while power to

the product is on. It takes some time for the voltage to drop

to a sufficiently low level after the power has been turned

off.

Confirm that the voltage has dropped to a safe level before

disconnecting or connecting the connector.

(6) Do not pull out or insert the power cable from/to an outlet

with wet hands. It may cause electric shock.

(7) Do not damage or modify the power cable. It may cause

fire or electric shock.

(8) If the power cable is damaged, or if the connector is loose,

do not use the product: otherwise, this can lead to fire or

electric shock.

(9) If the power connector or the connector of the power cable

becomes dirty or dusty, wipe it with a dry cloth. Otherwise,

this can lead to fire.

(10) PDP Module uses a high voltage (Max.450V dc). Keep

the cautions concerning electric shock and do not touch

the Device circuitry when handling the PDP Unit. And

because the capacitor of the Device circuitry may remain

charged at the moment of Power OFF, standing by for 1

minute is required in order to touch the Device circuitry.

Ⅱ. CAUTIONS

(1) Do not place this product in a location that is subject to

heavy vibration, or on an unstable surface such as an

inclined surface. The product may fall off or fall over,

causing injuries.

(2) Before disconnecting cable from the product, be sure to

turn off the power. Be sure to hold the connector when

disconnecting cables. Pulling a cable with excessive force

may cause the core of the cable to be exposed or break

the cable, and this can lead to fire or electric shock.

(3) This product should be moved by two or more persons. If

one person attempts to carry this product alone, he/she

may be injured.

(4) This product contains glass. The glass may break, causing

injuries, if shock, vibration, heat, or distortion is applied to

the product.

(5) The temperature of the glass of the display may rise to

80°C or more depending on the conditions of use.

If you touch the glass inadvertently, you may be burned.

(6) If glass surface of the display breaks or is scratched, do

not touch the broken pieces or the scratches with bare

hands. You may be injured.

(7) PDP Module requires to be handled with care not to be

touched with metal or hard materials, and must not be

stressed by heat or mechanical impact.

(8) There are some exposed components on the rear panel of

this product. Touching these components may cause an

electric shock.

(9) When moving the product, be sure to turn off the power

and disconnect all the cables. While moving the product,

watch your step. The product may be dropped or all,

leading to injuries of electric shock.

SAFETY PRECAUTIONS

Page 53

English

(10) In order to protect static electricity due to C-MOS circuitry of

the Drive part, wear a wrist band to protect static electricity

when handling.

(11) If cleaning the Panel, wipe it with a soft cloth moistened with

water or a neutral detergent and squeezed, being careful not

to touch the connector part of the Panel. And don’t use

chemical materials like thinner or benzene.

(12) If this product is used as a display board to display a static

image, “image sticking” occurs. This means that the luminance

of areas of the display that remain lit for a long time drops

compared with luminance of areas that are lit for a shorter

time, causing uneven luminance across the display.

The degree to which this occurs is in proportion to the

luminance at which the display is used. To prevent this

phenomenon, therefore, avoid static images as much as

possible and design your system so that it is used at a low

luminance, by reducing signal level difference between bright

area and less bright area through signal processing.

(13) Because PDP Module emits heat from the Glass Panel part

and the Drive circuitry, the environmental temperature must

not be over 40°C.

The temperature of the Glass Panel part is especially high

owing to heat from internal Drive circuitry. And because the

PDP Module is driven by high voltage, it must avoid

conductive materials.

(14) If inserting components or circuit board in order to repair, be

sure to fix a lead line to the connector before soldering.

(15) If inserting high-power resistor(metal-oxide film resistor or

metal film resistor) in order to repair, insert it as 10mm away

as from a board.

(16) During repairs, high voltage or high temperature components

must be put away from a lead line.

(17) This is a Cold Chassis but you had better use a cold

transformer for safety during repairs. If repairing electricity

source part, you must use the cold transformer.

(18) Do not place an object on the glass surface of the display.

The glass may break or be scratched.

(19) This product may be damaged if it is subject to excessive

stresses (such as excessive voltage, current, or temperature).

The absolute maximum ratings specify the limits of these

stresses.

(20) The recommended operating conditions are conditions in

which the normal operation of this product is guaranteed. All

the rated values of the electrical specifications are guaranteed

within these conditions.

Always use the product within the range of the recommended

operating conditions. Otherwise, the reliability of the product

may be degraded.

(21) This product has a glass display surface. Design your

system so that excessive shock and load are not applied to

the glass. Exercise care that the vent at the corner of the glass

panel is not damaged.

If the glass panel or vent is damaged, the product is

inoperable.

(22) Do not cover or wrap the product with a cloth or other

covering while power is supplied to the product.

(23) Before turning on power to the product, check the wiring of

the product and confirm that the supply voltage is within the

rated voltage range. If the wiring is wrong or if a voltage

outside the rated range is applied, the product may

malfunction or be damaged.

(24) Do not store this product in a location where temperature

and humidity are high. This may cause the product to

malfunction. Because this product uses a discharge

phenomenon, it may take time to light (operation may be

delayed) when the product is used after it has been stored for

a long time. In this case, it is recommended to light all cells for

about 2 hours (aging).

(25) This product is made from various materials such as glass,

metal, and plastic. When discarding it, be sure to contact a

professional waste disposal operator.

(26) If faults occur due to arbitrary modification or disassembly,

LG Electronics is not responsible for function, quality or other

items.

(27) Use of the product with a combination of parameters,

conditions, or logic not specified in the specifications of this

product is not guaranteed. If intending to use the product in

such a way, be sure to consult LGE in advance.

(28) Within the warranty period, general faults that occur due to

defects in components such as ICs will be rectified by LGE

without charge. However, IMAGE STICKING due to

misapplying the above (12) provision is not included in the

warranty. Repairs due to the other faults may be charged for

depending on responsibility for the faults.

- 3 -

Page 54

Heat Sink

Formation and Specification of Module

No

1

2

3

No

1

2

3

4

5

6

7

8

9

10

Connector

P3[Y SUS B/D]

P4[Y SUS B/D]

P3[CTRL B/D]

Name

Connector Ass’y

Connector Ass’y

Connector Ass’y

Connector Ass’y

CABLE, FLAT

CABLE, FLAT

Connector Ass’y

CABLE, FLAT

Heat Sink

Bare PCB

Input Signal

Video Signal

BOARD

Z-XR, Y-XL

XR-XC

Y-Z

Y-Ctrl

Ctrl-XL, XC

Ctrl-Y

XR-Z

XC-XR

4023 ASIC

CTRL B/D

CTRL B/D

Y SUS B/D

Y SUS B/D

Y DRV Top B/D

Y DRV Bottom B/D

Z SUS B/D

Z SUS B/D

X LT B/D

X RT B/D

X CT B/D

X CB B/D

X LB B/D

X RB B/D

Va, Vs

5V

P/N

6631Q15001A

6631Q15001B

6631Q25027B

6631Q25029A

6850QX0013C

6850QV0001A

6631Q12005C

6850QX0012A

4920Q30001A

6870QCC011B

6870QCC010A

6870QYC002B

6870QYC003A

6870QDC003A

6870QFC003A

6870QZC002A

6870QZC003A

6870QLC006A

6870QRC006A

6870QXC008A

6870QXC009A

6870QLC007A

6870QRC007A

Power cable ass’y

Signal cable ass’y

Description

1.5mm 5-pin, 130mm

1.5mm 5-pin, 330mm

2.5mm 12-pin, 900mm

2.5mm 8-pin, 170mm

0.5mm 60-pin, 210mm, non-shield type

1.0mm 30-pin, 70mm

1.25mm 12-pin, 320mm

0.5mm 60-pin, 40mm

heat sink for 4023 ASIC

Ass’y P/N: 6871QCH045A

Ass’y P/N: 6871QCH044A for 50X2##7#

Ass’y P/N: 6871QYH032B

Ass’y P/N: 6871QYH038A for 50X2##7#

Ass’y P/N: 6871QDH080A

Ass’y P/N: 6871QDH081A

Ass’y P/N: 6871QZH036B

Ass’y P/N: 6871QZH043A for 50X2##7#

Ass’y P/N: 6871QLH035C

Ass’y P/N: 6871QRH041C

Ass’y P/N: 6871QXH024C

Ass’y P/N: 6871QXH025C

Ass’y P/N: 6871QLH036C

Ass’y P/N: 6871QRH042C

Quantity

4

2

1

1

6

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 55

English

- 9 -

1. Checking for no Picture

A screen doesn’t display at all and condition of black pattern or power off.

(1) Check whether the CTRL B/D LED(D2) is turned on or not.

(2) Check the power and signal cable of CTRL B/D.

(3) Check the power connection of X B/D, Y B/D and Z B/D.

(4) Check the connection of X B/D, Y B/D and Z B/D to CTRL B/D.

(5) After measure the output wave of X, Y and Z B/D, find the trouble of B/D by comparing with below figure and replace.

- Measure Point fo Y B/D : TP (Bead B41)

- Measure Point fo Z B/D : TP ((Bead B11)

- Measure Point fo X B/D : COF TP

(6) Check the SCAN IC.

(7) Check the DATA COF.

(8) Replace the CTRL B/D.

<Y B/D Output wave - 1FRAME>

<COF Output wave - 1FRAME>

<COF Output wave - 1SF>

<Z B/D Output wave - 1FRAME>

<COF Output wave - Enlargement>

Trouble Shooting

Page 56

- 10 -

2. Hitch Diagnosis Following

Display Condition

2-1. 3/11 or 4/11 of the screen doesn’t be

shown

(1) Confirm the power connector of X B/D is well plugged in

which is correspond to not showing screen.

(2) Confirm the connector that is connected between CTRL

B/D and X B/D correspond to not showing part.

(3) Replace relevant X B/D.

[[

Relationship between screen and X B/D

Screen X B/D

Top Left of the Screen 3/11 <--> X Right Top B/D

Top Center of the Screen 4/11 <--> X Center Top B/D

Top Right of the Screen 4/11 <--> X Left Top B/D

Bottom Left of the Screen 3/11 <--> X Right Btm B/D

Bottom Center of the Screen 4/11 <--> X Center Btm B/D

Bottom Right of the Screen 4/11 <--> X Left Btm B/D

[[

Screen Display Form

2-2. The screen doesn’t be shown as Data

COF

(Include not be shown part of Data COF quantity or a part)

(1) The problem between Data COF and X B/D is more

possible that the screen is not be shown as data COF.

(2) Confirm the connector of Data COF is well connected to X

B/D. Correspond to the part that screen is not showing

(3) Confirm whether the Data COF is failed and replace X B/D

[[

Example of the screen display form

(Anything of the 7 Data COF can be shown beside below

pictures)

: All

: Partial

: not at all

[[

How to examine Data COF IC

i) Top of the Screen

(4/11 or 3/11)

ii) Bottom of the Screen

(4/11 or 3/11)

Display

Not display

ANODE Pattern (GND)

CATHOD Pattern and examine the Diode

to the pure or reverse direction.

1

GND

1

Measure the third resistance value

Resistance

2

2

Page 57

English

- 11 -

2-3. It Generates Unusual Pattern of Data

COF IC unit

(1) In case of generating unusual pattern of Data COF IC unit

as below picture, there is problem in the check that is input

into Data COF IC

(2) In case of <case 1, 2, 3>

- confirm the connection of Data COF connector

- replace the relevant X B/D

(3) In case of <case 4, 5>

- confirm the connector that is connected from CTRL to X B/D

- Replace relevant XB/D or CTRL B/D

[[

Screen Display Form

2-4. Regular Stripe is Generated about the

Quantity of one Data COF IC or more

(1) In case of generating regular stripe about the quantity of

one Data COF IC, there is problem at the input of data of X

B/D

In case of generating regular stripe about the quantity of

two Data COF IC, that means the data which is conveyed

from CTRL B/D doesn’t conveyed well.

(2) Confirm the XB/D connection connector plugged in well.

Correspond to unusual screen.

(3) Replace relevant XB/D or CTRL B/D.

[[

Relationship between screen and X B/D

Screen X B/D

Top Left of the Screen 3/11 <--> X Right Top B/D

Top Center of the Screen 4/11 <--> X Center Top B/D

Top Right of the Screen 4/11 <--> X Left Top B/D

Bottom Left of the Screen 3/11 <--> X Right Btm B/D

Bottom Center of the Screen 4/11 <--> X Center Btm B/D

Bottom Right of the Screen 4/11 <--> X Left Btm B/D

[[

Screen Display Form

<Case 1>

<Case 2>

<Case 3>

<Case 4>

<Case 5>

Unusual screen comes out

about one IC quantity in

one COF

Unusual screen comes out

across one quantity about

two IC quantities in one

COF

Unusual screen comes out

about 4IC quantities in

one COF

Unusual screen comes out

as a unit of Data COF IC

through one X B/D

Unusual screen comes out

as a unit of Data COF IC

through Top or Bottom

screen

It comes out partial

field about the quantity

of one IC or more or

It may come out together

at other field of screen.

Page 58

- 12 -

2-5. The screen display has a problem for

Scan FPC.

(1) It’s may be a problem between Scan FPC and Y DRV B/D.

(2) Check the connection of Y B/D and Scan FPC.

(3) If the Scan IC is failed, replace the Y DRV B/D.

[[

Screen Display Form(1/12 of Screen)

[[

Check a method of SCAN IC

Change the Vpp Pin into ANODE and GND Pin into CATHOD

and then test the Diode with forward or reverse direction.

2-6. The screen has a vertical line with

regular gap.

(A vertical stripe flash at especial color)

(1) This is a problem about control B/D.

(2) Replace Control B/D.

[[

Screen Display Form

2-7. A data copy is happened into vertical

direction

(1) In this case, it’s due to incorrect marking of scan wave.

(2) Replace a Y DRV B/D or Y SUS B/D.

[[

Screen Display Form

The screen display is very good

The screen display is a poor

The screen has a vertical line

with regular gap

<Case 1 : Entire Copy>

<Display Pattern>

<Case 2 : Top Copy>

<Case 3 : Bottom Copy>

<Case 4 : Entire Copy>

Page 59

English

- 13 -

2-8. The screen has one or several vertical

line

(1) In this case, It isn’t a problem about controller B/D or X

B/D.

(2) It may cause followings.

- It’s out of order a panel

- Open or short of DATA COF FPC attached panel

- It’s out of order a DATA COF attached panel

(3) Replace Module.

[[

Screen Display Form

2- 9. The screen has one or several

horizontal line

(1) In this case, it isn’t a problem about controller B/D or X

B/D.

(2) It may cause followings.

- It’s out of order a panel

- Open or short of SCAN FPC attached panel

- It’s out of order a SCAN IC attached panel

(3) Replace Y DRV B/D

[[

Screen Display Form

2-10. The screen displays input signal

pattern but the brightness is dark

(1) In this case, Z B/D operation isn’t complete.

(2) Check the power cord of Z B/D.

(3) Check the signal connector of Z B/D and Controller B/D.

(4) Replace the Controller B/D or Z B/D.

2-11. The screen displays other color

partially on full white screen or happens

discharge partially on full black screen.

(1) Check the declination of Y B/D set up, set down wave.

(2) Check the declination of Z B/D의 ramp wave.

(3) Measure each output wave with oscilloscope(more than

200MHz).

2-12. A center of screen is darker than

a edge of screen at full white pattern.

(1) In this case, Va voltage which goes over to X_Board from

Z_Board seems problem, check the connector.

(2) When no problem with shift connector, replace the Y_B/D

and Z_B/D each or Y & Z_B/D simultaneously.

(3) When not change after (1), (2) item managing, replace the

PSU(Power Supply).

[[

Screen Display Form

2-13. It doesn’t display a specified

brightness at specified color

(1) Check the connector of CTRL B/D input signal.

(2) Replace the CTRL B/D.

It may show several vertical

lines in a quarter or other

division part of screen

including left case.

It may show several

horizontal lines including

left case.

Page 60

3. Checking for Component Damage

3-1. Y IPM(IC2, IC7) or Z IPM(IC9, IC11) Damage

(1) When the internal Sustain_FET of Y IPM or Z IPM is

damaged, screen doesn’t be shown or electric discharge is

generated.

O Test Point: GND~B41(Y B/D), GND~B11(Z B/D)

O Wave format: B41(Y B/D) or B11(Z B/D) has no wave

output

(2) When the internal ER_FET of Y IPM or Z IPM is damaged,

Y IPM or Z IPM emission is increased.

O Test Point: GND~B41(Y B/D), GND~B11(Z B/D)

O Wave format: As shown (Fig. 1)

O Measurance position: Y B/D(B41), Z B/D(B11)

Sustain section enlarge(Full White Pattern)

3-2. FET Ass’y(Y B/D: HS2, 5, 6) Damage

(1) When Set_Up FET is damaged, screen doesn’t be shown

O Test Point: Enlarge the after measuring GND~B41(Y B/D)

O Wave format: As shown (Fig. 2)

(2) When Set_Down FET is damaged, electric discharge of

entire screen is generated.

O Test Point: Enlarge the after measuring GND~B41(Y B/D)

O Wave format: As shown (Fig. 3)

O Measurance position: Reset section enlargement wave of

B41(Y B/D) (Full White Pattern)

Set Up waveform

does not come out

(Fig. 1) When the ER_FET is damaged

<IPM Normal Output Wave >

(Fig. 2) When the Set_Up FET is damaged

(Fig. 3) When the Set_Down FET is damaged

<FET Ass’y Normal Output Wave >

Set Down waveform

does not come out

- 14 -

Page 61

English

3-3. SCAN IC(Y drv B/D: IC1~12) Damage

(1) In case of SCAN IC poor, one horizontal line may open at

screen.

O Test Point: GND ~ Output ICT measurance of Y drive B/D

O Wave format: As shown (Fig. 4)

(2) Screen may not shown when SCAN IC is damaged by

external electricity or spark.

O Test Point: GND ~ Output ICT measurance of Y drive B/D

O Wave format: Output wave format isn’t output (You can

see the damage for SCAN IC)

(3) Screen shaked horizontally when Y drv B/D Top and

Bottom cable is poor

O Test Point: GND ~ Output ICT measurance of Y drive B/D

O Wave format: As shown (Fig. 5)

(4) In case of shorting the SCAN IC output by a dust, foreign

substance, it may overlap two horizontal lines on screen.

O Test Point: GND ~ Output ICT measurance of Y drive B/D

O Wave format: As shown (Fig. 6)

O Measurance position: Output ICT of Y drive B/D

SCAN section enlarge (Full White Pattern)

Normal Wave

(Fig. 4) When SCAN IC is poor

(Fig. 5) When occurance the Scan Noise

Break the SCAN Pulse

Decrease in voltage of

SCAN Pulse

Widen the Pulse width

100V

60V

(Fig. 6) When SCAN IC output is short

SCAN Section

<SCAN IC Normal Output Wave >

- 15 -

Page 62

3-4. COF Damage

(1) In case of shorting or opening the IC output of COF, it may

show one or several vertical lines.

O Test Point: Enlarge the after measuring output TP of

COF~GND.

O Wave format: As shown Output of (Fig. 7)

In case of normal wave output, when STB signal is

generated, maintain High output. And when STB signal

is generated again must be fall Low.

But when IC of COF is poor, STB signal is not generated

Output falls with Low.

(2) In case of being damage IC of COF or power resistance,

the screen doesn’t be shown or happens discharge partially.

O Test Point: Enlarge the after measuring output TP of

COF~GND

O Wave format: Output wave doesn’t come out

O Measurance position: Enlarge the after measuring output

TP of COF (Full White Pattern)

3-5. Crystal(CTRL B/D: X2) damage

(1) When Crystal is damage, the screen doesn’t be shown.

O Test Point: Measuring 3pin of GND~Crystal(Ctrl B/D: X2)

O Wave format: Output wave doesn’t come out

(2) In case of unusual launch of the Crystal, it may blink the

screen.

O Wave format: As shown (Fig. 8)

O Measurance position: Measuring 3pin of Crystal(X2:

100MHz) (Full White Pattern)

(Fig. 7) When IC output of COF is poor

<COF Normal Output Wave >

(Fig. 8) When Crystal is poor

<Crystal Normal Output Wave >

- 16 -

Page 63

English

4. Shift breakdown component

compatibility consideration

4-1. Scan IC follows in application,

compatibility of Y DRV Top, Bottom B/D

(1) When B/D applicated SN755866 is breakdown, you must

mutually only replace Top B/D and Bottom B/D applicated

SN755866.

(2) When IC of B/D applicated SN755866 IC is breakdown, you

must only replace SN755866 IC.

Different IC application being not right

[ When replacing the IC, notice

To prevent dust, fix the same IC after removing the silicon

and then it again stick the IC.

B/D applicated SN755866

TOP: 6871QDH080A

BTM: 6871QDH081A

When B/D is breakdown

When IC is breakdown

Only use B/D applicated SN755866

TOP: 6871QDH080A

BTM: 6871QDH081A

B/D applicated SN755866

TOP: 6871QDH080A

BTM: 6871QDH081A

Silicon Part No.: 7254Q00002A(Tube Type)

7254Q00002B(Can Type)

Only use SN755866 IC

IC: 0ILNRTI020A

- 17 -

Page 64

Block Diagram

Page 65

SPARE PART LIST

50" PDP (WXGA) 100V/60HZ USA

Quantity

Item Component Description/Country Origin Unit Summary

一. ELECT PART

1 E2301-559001 IC TDA8946J AUDIO AMPLIFIER PCS 1

2 E3213-011001 SOCKET ANT F/RCA PCS 1

3 E3403-002004 TUBE SUMITUBE D3.0 BLK 600V M 0.04

4 E3403-004001 TUBE SUMITUBE D5.0 BLK 600V M 0.5

5 E3413-003001 CABLE COAXIAL RCA/F FOR USA L=45 PCS 1

6 E3421-926014 WIRE ASSY P2.5 11P+10P/12P+7P+4P PD PCS 1

7 E3421-926020 WIRE ASSY 1H2.5(AMP)-2T(8MM) L=680MM PCS 1

8 E3421-926024 WIRE ASSY (LVDS W/EMI) L=270MM 31P ( PCS 1

9 E4406-069001 FILTER EMI CTNF-100B FOR 4 PCS 1

10 E4901-001001 FAN 60X60X15MM DC9V 3500RPM PCS 2

11 E6205-001005 DISPLAY PDP LG-WXGA 50" 50X2A PCS 1

12 E7801-056002 PCB ASSY MAIN IVPC_DVI_CCD (E-ROOM) PCS 1

13 E7801-056201 PCB ASSY TUNER NTSC PCS 1

14 774P50SB01-01 POWER ASSY PCS 1

15 771-42AF01-01 SPK JACK PCB ASSY PCS 1

16 771-50SB03-01 IR RECEIVE PCB ASSY PCS 1

17 771-42D105-01 KEY PCB ASSY PCS 1

二. MECH PART

1 244-34B811-01 GIFT BOX HANDLE 34B8 PCS 2

2 248-46D201-01 HANDLE FOR PLASMA PCS 2

3 263-42D101-01S POWER LENS 42D1 PCS 1

4 269-42D101-01L REMOTE LENS 42D1 PCS 1

5 322-42P101-01 REMOTE LENS RUBBER SPACER PDP-42TP1 PCS 1

6 322-42P102-01 POWER LENS RUBBER SPACER PDP-42TP1 PCS 1

7 322-42P103-01 SEPARATE RUBBER SPACER FOR REMOTE AN PCS 1

8 326-064510-50 SPONGE CUSHION 645X10X5.0MM W/ADHESI PCS 2

9 326-115010-50 SPONGE CUSHION 1150X10X5.0MM W/ADHES PCS 2

10 361-101261-01 CABLE TIE PCS 24

11 367-42D101-01 EDGE SADDLE 14MM 42D1 PCS 4

12 379-42P102-01 FILTER RUBBER BAR B PDP-42TP1 PCS 6

13 384-42D103-04H PVC SHEET FOR E-ROOM PCB USA PCS 1

14 387-50AD01-01H MODEL PLATE AKAI ENG PDP5016H H PCS 1

15 388-42D103-01H CAUTION PLATE ENG 42D1 H PCS 1

16 388-42P101-01 PC SHEET FOR REMOTE PCB 42P1 94V0 PCS 1

17 388-42SB04-01H POWER PLATE SANSUI 42SB PCS 1

18 388-50AD01-01H SPEAKER PLATE FOR PDP50HAD PCS 1

19 400-50AD01-01 FRONT CABINET(AL) SANDBLAST SILVER W PCS 1

20 402-50SB02-01S BACK COVER FOR 50" LG PCS 1

21 420-50SB01-01S MAIN BRACKET FOR 50" LG PCS 2

Page 66

22 423-50SB01-01S FILTER SUPPORT FOR TOP PCS 1

23 423-50SB03-01S FILTER SUPPORT FOR SIDE PCS 2

24 423-50SB04-01S FILTER SUPPORT FOR BOTTOM PCS 1

25 426-50SB01-01S AV2 BRACKET PCS 1

26 426-50SB03-01S POWER BRACKET PCS 1

27 429-50AD07-01 REMOTE PCB BRACKET PCS 1

28 429-50AD08-01S SUPPORT BRACKET PCS 1

29 429-50SB05-01S CONNECT BRACKET PCS 4

30 429-50SB06-01S SHIELD BOX BRACKET PCS 2

31 429-50SB07-01 FAN BRACKET-L PCS 2

32 429-50SB08-01 FAN BRACKET-R PCS 2

33 430-42D102-01 HEAT SINK FOR E-ROOM 42D1 PCS 1

34 436-42D113-01S TERMINAL SHEET FOR E-ROOM PCB USA PCS 1

35 457-42D101-01 CLAMP ID=4.3MM L=46MM PCS 10

36 481-42D105-01 SHIELD BOX FOR USA RF 42D1 PCS 1

37 481-42D113-01S SHIELD BOX FOR E-ROOM PCB PCS 1

38 483-42D103-01 SHIELD COVER FOR E-ROOM PCB 42D1 PCS 1

39 483-42D104-01 SHIELD COVER TOP FOR 42D1 PCS 1

40 483-50SB11-01 SHIELD SHEET PCS 1

41 486-50AD01-01 NAME PLATE AKAI SIL/BLACK 50AD PCS 1

42 553-002509-40A EMI SHIELD GASKET 25X9X4.0MM W/CONDU PCS 4

43 553-005009-25A SHIELD GASKET 50X9X2.5MM W/CONDUCTIV PCS 2

44 553-006509-40A SHIELD GASKET 65X9X4.0MM W/CONDUCTIV PCS 4

45 553-015009-40A EMI SHIELD GASKET 150X9X4.0MM W/COND PCS 8

46 553-020009-40A SHIELD GASKET 200X9X4.0MM W/CONDUCTI PCS 2

47 553-024509-40A SHIELD GASKET 245X9X4.0MM W/CONDUCTI PCS 2

48 553-026009-40A EMI SHIELD GASKET 260X9X4.0MM W/COND PCS 2

49 553-028009-40A EMI SHIELD GASKET 280X9X4.0MM W/COND PCS 2

50 553-039509-10A SHIELD GASKET 395X9X1.0MM W/CONDUCTI PCS 1

51 553-067009-40A EMI SHIELD GASKET 670X9X4.0MM W/COND PCS 2

52 553-114009-40A EMI SHIELD GASKET 1140X9X4.0MM W/CON PCS 2

53 554-090030-01 SHIELD CLOTH 90X30MM W/CONDUCTIVE AD PCS 1

54 563-119- SERIAL NO. LABEL PCS 1

55 568-P46T02-02 WARNING LB ENG 42SF NIL PCS 1

56 579-42D103-02 ON/OFF LB ENG 42D1 NIL PCS 1

57 579-42D105-01 PROTECTIVE EARTH LABEL FOR ESA 42TD1 PCS 1

58 579-50AD01-01 BAR CODE LABEL AKAI W/SERIAL NO PD5 PCS 2

59 579-50AD02-01 SERIAL NO/BAR CODE LABEL 50HA (USA) PCS 1

60 590-50AD01-01 WARRANTY CARD ENG AKAI PDP5006H PCS 1

61 601-305008-00 MACH.SCREW CTS 3X8 BZN + PCS 2

62 602-305006-00 MACH. SCREW PAN-WASHER 3X6 B ZNP +H PCS 17

63 602-305006-10 MACH.SCREW WHR 3X6 NIP + PCS 31

64 602-407008-00 MECH. SCREW PAN-WASHER 4X8 B ZNP +H PCS 2