Page 1

Installation/User’s Guide

Agilent J3916A HSSI WanProbe

Page 2

Consumer Warranty Statement

Consumer Warranty Statement

AGILENT TECHNOLOGIES, INC. LIMITED WARRANTY STATEMENT

AGILENT PRODUCT DURATION OF LIMITED WARRANTY

HSSI WanProbe 1 year

Agilent warrants to you, the end-user customer, that Agilent hardware,

accessories and supplies will be free from defects in materials and workmanship

after the date of purchase, for the period specified above. If Agilent receives

notice of such defects during the warranty period, Agilent will, at its option,

either repair or replace products which prove to be defective. Replacement

products may be either new or like-new.

Agilent warrants to you that Agilent software will not fail to execute its

programming instructions after the date of purchase, for the period specified

above, due to defects in material and workmanship when properly installed and

used. If Agilent receives notice of such defects during the warranty period,

Agilent will replace software media which does not execute its programming

instructions due to such defects.

Agilent does not warrant that the operation of Agilent products will be

uninterrupted or error free. If Agilent is unable, within a reasonable time, to

repair or replace any produ ct to a cond it ion as warranted, you will be ent it l ed to a

refund of the purchase price upon prompt return of the product.

Agilent products may contain remanufactured parts equivalent to new in

performance or may have been subject to incidental use.

Warranty does not apply to defects resulting from (a ) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supplies not

supplied by Agilent , (c) unauthorized modification or misuse, (d) operation

outside of the published environmental specifications for the product, or (e)

improper site preparation or maintenance.

ii

Page 3

Consumer Warranty Stat ement

AGILENT MAKES NO OTHER EXPRESS WARRANTY OR CONDITION

WHETHER WRITTEN OR ORAL. TO THE EXTENT ALLOWED BY LOCAL

LAW, ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY, SATISFACTORY QUALITY, OR FITNESS FOR A

PARTICULAR PURPOSE IS LIMITED TO THE DURATION OF THE

EXPRESS WARRANTY SET FORTH ABOVE. Some countries, states or

provinces do not allow limitations on the duration of an implied warranty, so the

above limitation or exclusion might not apply to you. This warranty gives you

specific legal rights an d you might also have other rig hts th at vary fr om country t o

country, state to state, or province to province.

TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS

WARRANTY STATEMENT ARE YOUR SOLE AND EXCLUSIVE

REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL

AGILENT OR ITS SUPPLIERS BE LIABLE FOR LOSS OF DATA OR FOR

DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST

PROFIT OR DATA), OR OTHER DAMAGE, WHETHER BASED IN

CONTRACT, TORT, OR OTHERWISE. Some countries, States or provinces do

not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW

ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS STATEMENT,

EXCEPT TO THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE,

RESTRICT OR MODIFY AND ARE IN ADDITION TO THE MANDATORY

ST ATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO

YOU.

iii

Page 4

Operating Restrictions

The following warnings and operating information are shown in French followed

by the English translation.

MISE ENGARDE

MISE ENGARDE

Restrictions d'utilisation

L'utilisateur se doit d'observer les mesures de précaution

énumérées ci-dessous pour tou tes les ph ases d 'u tili sati on ,

de service et de réparation de cet appareil. Le fait de ne

pas s'y conformer équivaut à ne pas respecter les mises en

gardes spécifique s contenu es da ns ce manu el et cons titue

une violation des norme s de sécurité relatives à la

conception, la fabrication et l'utilisation prévue de cet

appareil. La société Agilent Technologies, Inc. n'assume

aucune responsabilité envers un client qui manquerait de

se conformer à ces exigences.

Mise à la t erre

Afin de minimiser les risques de choc électrique, le

chÀssis et le cabinet de l'apparei l doivent être mis à la

terre. L'appareil est équipé d'un cordon d'alimentation

muni d'une fiche hom oloqu é e à trois lames, com patib le

c.a. La prise murale et la prise femelle de la rallonge

électrique doivent respecter les normes de sécurité de la

«Commision électrotechnique internationale» (IEC).

Cet appareil répond aux normes

de la «Classe de sécurité I» et

est muni d'un fil de mise à la

terre pour votre protection.

Pour prévenir les risques de

choc électrique, la broche de

mise à la terre du cordon

d'alimentation ne doit pas être

désactivée.

WARNING

WARNING

Operating Restrictions

The following general safety precatuions must be observed

during all phases of oper ation, service, and r epair of this

instrument. Failure to comply with these precautions with

specific warnings in this manual violate safety standards of

design, manufacture, an d intended use of this instrument.

Grounding

To minimize shock hazard, the instrument chassis and

cabinet must be connected to an electrical ground. The

instrument is equipped with a three-conductor AC power

cable compatible with an approved three-contact electrical

outlet. The power jack and mating plug of th e power cord

must meet International Electrotechnical Commission (IEC)

safety standards.

This product is a Safety Class I

instrument with a protective earth

terminal.

For protection f rom electric shock

hazard, power cord ground must

not be defeated.

iv

Page 5

Environnement

Ne faites pas fonctionner cet appareil en présence de gaz

inflammables ou de vapeurs dangereuses. L'utilisation de

n'importe quel appareil électrique dans ces conditions

constitue un risque élevé pour votre sécurité.

Service et ajustement

Des «tensions dangereuses» résident dans cet appareil. Par

conséquent, le service et l'ajustement doivent être effectués

uniquement par une personne qualifiée.

Ne remplacez pas de composantes lorsque le cordon

d'alimentation est sous tension. Il p ourrait y avoir présence

de «tensions dangereuses» même lorsque l'appar eil est

déconnecté.

Environment

Do not operate the instrument in the presence of flammable

gases or fumes. Operation of any electrical instrument in

such an environment constitutes a definite safety hazard.

Service and Adjustment

Dangerous voltages exist within this instrument. Service

and adjustment of this instrumen t is to be perfor med only by

trained service personnel.

Do not replace components with the power cable connected.

Dangerous voltages may be present even when the power

cable is disconnected.

Ne faites pas de service interne ou d'ajustement sauf en

présence d'une autre personne, capable de prodiguer les

premiers soins et de pratiquer la réanimation.

Service non aut orisé

L'installation de pièces étrangères, ou toute modification

apportée à l'appareil sans le consentement de Agilent

Technologies, Inc. est formellement interdit. Le fait de

procéder à de tels modifications sans autorisation pourrait

entraîner l'annulation de la garantie de l'appareil ou de tout

contrat de service.

Pour un service et des réparations autorisées, retournez

l'appareil à un point de vente et service Agilent

Technologies, Inc..

Do not perform internal servicing or adjustment unless

another person, c apable of rendering first aid and

resuscitation is present.

Unauthorized Service

The installation of substitute parts or the installation of any

instrument modification not authorized by Agilent

Technologies, Inc. is specifically forbidden. The

performance of such unauthori zed service can negate the

instrument warranty or any maintenance agreements.

Return the instrument to a Agilent Technologies, Inc. Sales

and Service Office for authorized service and repair.

v

Page 6

Notice

Notice

© Copyright Agilent Technologies, Inc.

All Rights Reserved

Reproduction, adapta tion, or translation without prior written permission is

prohibited, except as allowed under the copyright laws.

The information contained in this document is subject to change without notice.

Agilent Technologies, Inc. makes no warranty of any kind with regard to th is

material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

Agilent Technologies assumes no responsibility for the use or reliability of it s

software on equipment that is not furnished by Agilent Technologies.

Agilent Technologies

This document contains pro prietary in formation that is protected by c opyright. All

rights are reserved. No part of this document may be photocopied, reproduced, or

translated to another language without the prior written consent of Agilent

Technologies, Inc.

Agilent Technologies, Inc.

NetMetrix Division

5070 Centennial Boulevard

Colorado Springs, Colorado 80919-2497

vi

Page 7

Safety Information

Safety Information

Before you use thi s instru ment, be sure to pa y speci al att ention to the “S afety” an d

“Warning” topics in this Manual. Failure to comply with the p recautions or w ith

specific warnings in this book violates safety standards of design, manufacture,

and intended use of this instrument. Agilent assumes no liability for the

customer’s failure to comply with these requirements.

Electric Shock Hazard.

Do not remove the system covers. To avoid electric

shock, use only the supplied power cords and connect only to properly grounded

(3-pin) wall outlets.

Explosion Hazard.

Fire Hazard.

Do not operate in the presence of flammable gases.

For continued protection against fire hazard replace only with fuse

of same type and rating.

Indoor Use.

Cleaning.

solution of soap and water.

This instrument is designed for indoor use.

To clean the instrument, use a damp cloth moistened with a mild

Do not

use harsh chemicals.

Do not

let water get into

the instrument.

Product Damage.

the product shows visible damage,

fails to perform,

has been stored in unfavorable conditions, or

has been subject to severe transport stresses.

Do not use this product when:

Make the product inoperative and secure it against any unintended operation.

Contact yo ur nearest Agilent Sales office for assistance.

Defects and Abnormal Stresses.

Whenever this inst rument has be en damaged or

wet, make the product inoperative and secure it against any unintended operation.

vii

Page 8

Warning Symbols Used in This Book

Warning Symbols Used in This Book

Instruction book symbol: the product will be marked with this symbol when it is

necessary for the user to refer to the instruction book in order to protect against

damage.

Indicates potential for electrical shock.

WARN IN G

CAUTION

An operating procedure, prac tice, etc. which, if not correctly foll owed could result

in personal injury or loss of life.

An operating procedure, practice, etc. which, if not strictly observed, could result

in damage to, or destruction of, equipment or software.

viii

Page 9

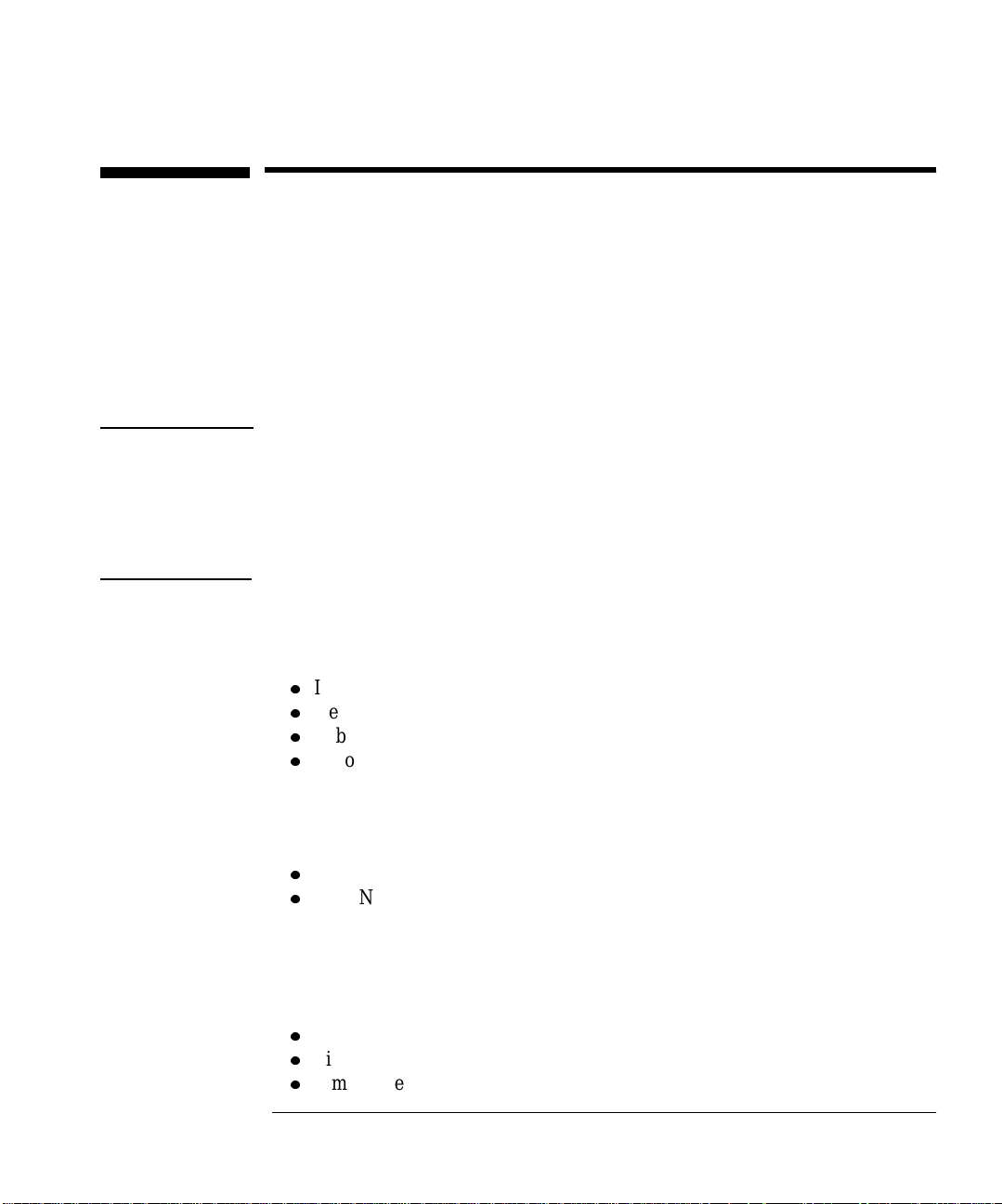

Conventions Used in this Book

g

Conventions Used in this Book

NOTE

An operating procedure, prac tice, or informat ion of impor tance , is separ ated fr om

normal text as shown in this NOTE.

Terminology and conventions in this manual are handled with the following

methods:

z

Keys on the keyboard such as

(page down) or F1 (function key #1)

P

Dn

are printed in the characters you see here.

z

Text that you should type is printed in characters such as:

Filename.ext

z

In some cases, you must press two keys simultaneously. This is represented

as

CTRL + Q

.

ix

Page 10

Trademarks

Trademarks

Agilent is a registered trademark and OpenView is a trademark of

Hewlett-Packard Company.

Microsoft, LAN Manager, MS-DOS, and Windows are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries.

UNIX is a registered trademark in the United States and other countries, licensed

exclusively through X /Open Company Limited.

Ethernet is a tradem ark of Xerox Corporation.

Hayes is a registered trademark of Hayes MicroComputer Products, Inc.

IBM and Token-Ring are trademarks of International Business Machines

Corporation.

Sun and Solaris are registered trademarks of Sun Microsystems, Inc.

SPARC is a registered trademark of SPARC International, Inc. Products bearing

the SPARC trademark are based on an architecture developed by Sun

Microsystems, Inc.

Novell and NetWare are registered trademarks of Novell Inc.

x

Page 11

Printing History

Printing History

New editions are complete revisions of this book. Update packages may contain

new or additional material and be released between editions. See the date of the

current edition on the back cover of this book.

First Edition . . . . . . . . . . . . . . . . . . November 1999 J3916-99501

Additional Help

You can obtain additional assistance in the U.S. by calling U.S. Response Center

at 888 699 7280, or Internationally by calling your local Agilent Sales Office.

xi

Page 12

Additional Help

xii

Page 13

Contents

Consumer Warranty Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Operating Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Warning Symbols Used in This Book . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Conventions Used in this Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Printing History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Additional Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation and Configuration Overview. . . . . . . . . . . . . . . . . . . . . . . . . 4

Local Terminal Configuration and Installation . . . . . . . . . . . . . . . . . 4

Installation and Bootp Server Configuration . . . . . . . . . . . . . . . . . . 4

Probe Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Supported MIBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Management Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Access Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rear Panel Telemetry LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10Base-T/100Base-TX Telemetry Interface Status LEDs . . . . 11

Token-Ring Telemetry Interface Status LED . . . . . . . . . . . . . . 12

HSSI WAN Interface Status LEDs . . . . . . . . . . . . . . . . . . . . . . 13

CONFIG Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Included Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Optional Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Local Terminal Configuration. . . . . . . . . . . . . . . . . . . 15

Probe Configuration Using a Local Terminal . . . . . . . . . . . . . . . . . . . . 17

Using the Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Modify/View Configuration Values . . . . . . . . . . . . . . . . . . . . . . . . 22

Modify/View Security Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

xiii

Page 14

Modify/View Interface Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fast Ethernet Telemetry Interface Configuration . . . . . . . . . . 25

Token-Ring Telemetry Interface Configuration . . . . . . . . . . . 29

HSSI WAN Interface Configuration . . . . . . . . . . . . . . . . . . . . 33

Display Interface Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Modify/View Serial Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . 36

Exiting the Main Menu and Restarting the Probe. . . . . . . . . . . . . . . . . . 40

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Selecting a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installing the Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Rack or Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Wall Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 9

Connecting to the Network (Out-of-Band) . . . . . . . . . . . . . . . . . . . 49

Connecting to 10MB/s Ethernet Telemetry Networks. . . . . . . 50

Connecting to 10Base-T/100Base-TX Telemetry Networks. . 51

Connecting to Token-Ring Telemetry Networks. . . . . . . . . . . 53

About the Information in the Following Sections . . . . . . . . . . . . . . 56

Connecting to a HSSI System (In-Band) . . . . . . . . . . . . . . . . . . . . . 56

HSSI Monitor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Connecting to the Serial Port (Out-of-Band) . . . . . . . . . . . . . . . . . . 59

Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Modem Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Data Switch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Starting the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 7

Verifying the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Out-of-Band Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Ethernet Telemetry Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 69

HSSI Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4 Bootp Server Configuration . . . . . . . . . . . . . . . . . . . . 71

Probe Configuration Using a Bootp Server . . . . . . . . . . . . . . . . . . . . . . 73

Bootp Server Setup on an HP or Sun System . . . . . . . . . . . . . . . . . . . .75

Starting the Bootp Server on an HP or Sun System . . . . . . . . . . . .77

Bootp Server Setup on a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Using Microsoft LAN Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Using Novell NetWare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

xiv

Page 15

Starting the PC Bootp Server . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Configuring the Bootptab File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Example Bootptab File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5 Probe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Restarting the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Warm Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Cycling Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Selecting the Warm Start Menu Item . . . . . . . . . . . . . . . . . . . . 94

Cold Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pressing the CONFIG Button Twice. . . . . . . . . . . . . . . . . . . . . 95

Selecting the Cold Start Menu Item . . . . . . . . . . . . . . . . . . . . . 96

6 Download New Firmware . . . . . . . . . . . . . . . . . . . . . . 97

Downloading Firmware using an HP-UX W orkstation and a Terminal100

Install New Download Firmware on an HP-UX Workstation . . . 100

Download Firmware to the Probe . . . . . . . . . . . . . . . . . . . . . . . . . 101

Downloading Firmware using a Networked PC and a Terminal . . . 104

Setup TFTP Server for Downloading . . . . . . . . . . . . . . . . . . . . . . 104

Download Firmware to the Probe . . . . . . . . . . . . . . . . . . . . . . . . . 104

Xmodem Download of Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

A Cables and Connectors . . . . . . . . . . . . . . . . . . . . . . . 113

HSSI Connectors and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

HSSI Null Modem Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Token-Ring Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Serial Port Interface Cabl es . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Cable Connector Pin-Outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

The Probe’s RS-232 Port Pin-Out. . . . . . . . . . . . . . . . . . . . . . 120

The Probe’s RS-232 Modem Cable Connectors. . . . . . . . . . . 121

25-pin Terminal/PC Cable Connectors . . . . . . . . . . . . . . . . . . 122

9-pin Terminal/PC Cable Connectors . . . . . . . . . . . . . . . . . . . 122

UTP Network Connector Pin-Out. . . . . . . . . . . . . . . . . . . . . . 123

STP Network Connector Pin-Out . . . . . . . . . . . . . . . . . . . . . . 124

xv

Page 16

B Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Probe Memory Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Glossary

Index

Agilent Technologies, Inc. Offices

xvi

Page 17

Figures

Figure 1-1: The Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 1-2: Probe System Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 1-3: Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 1-4: Rear Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2-1: Probe Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-2: Probe Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-3: Modify/View Configuration Values Menu . . . . . . . . . . . . 22

Figure 2-4: Modify/View Security Values Menu . . . . . . . . . . . . . . . . . 24

Figure 2-5: Modify/View Interface Values Menu (Fast Ethernet) . . . 26

Figure 2-6: Modify/View Interface Values Menu (Token Ring) . . . . . 30

Figure 2-7: Modify/View Interface Values Menu (HSSI WAN) . . . . . 33

Figure 2-8: Display Interface Summary . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 2-9: Modify/View Serial Port Settings Menu . . . . . . . . . . . . . 37

Figure 3-1: Install the Probe in a Rack or Cabinet. . . . . . . . . . . . . . . . . 46

Figure 3-2: Install the Probe on a Wall . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 3-3: Probe Rear Panel (Token-Ring Option shown) . . . . . . . . . 50

Figure 3-4: Connecting the Probe to a 10MB/s Ethernet Network . . . 51

Figure 3-5: Connecting the Probe to a 10Base-T/100Base-T Network 53

Figure 3-6: Connecting the Probe Using RJ-45 Connectors . . . . . . . . 54

Figure 3-7: Connecting the Probe using a Media Filter . . . . . . . . . . . . 55

Figure 3-8: Connecting the Probe Using Data & DB-9 Connectors . . 56

Figure 3-9: HSSI System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 3-10: Close-up of the HSSI Interface . . . . . . . . . . . . . . . . . . . . 57

Figure 3-11: HSSI Monitor In-Line Connection . . . . . . . . . . . . . . . . . 58

Figure 3-12: Probe Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 3-13: Probe Modem Connection . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 3-14: Probe Data Switch Connection . . . . . . . . . . . . . . . . . . . . 66

Figure 5-1: Probe Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 6-1: Probe Main Menu (HP-UX Workstation) . . . . . . . . . . . . . 102

Figure 6-2: Probe TFTP Download Menu (HP-UX Workstation) . . . 103

Figure 6-3: Probe Main Menu (Networked PC) . . . . . . . . . . . . . . . . . 106

Figure 6-4: Probe TFTP Download Menu (Networked PC) . . . . . . . 107

xvii

Page 18

Figure 6-5: Probe Main Menu (XMODEM) . . . . . . . . . . . . . . . . . . . .109

Figure 6-6: Probe XMODEM Download Menu . . . . . . . . . . . . . . . . . 109

Figure A-1: Data Connector Color Coded Connection Points . . . . . . . 124

Figure B-1: Probe Memory Allocation . . . . . . . . . . . . . . . . . . . . . . . . 129

xviii

Page 19

Tables

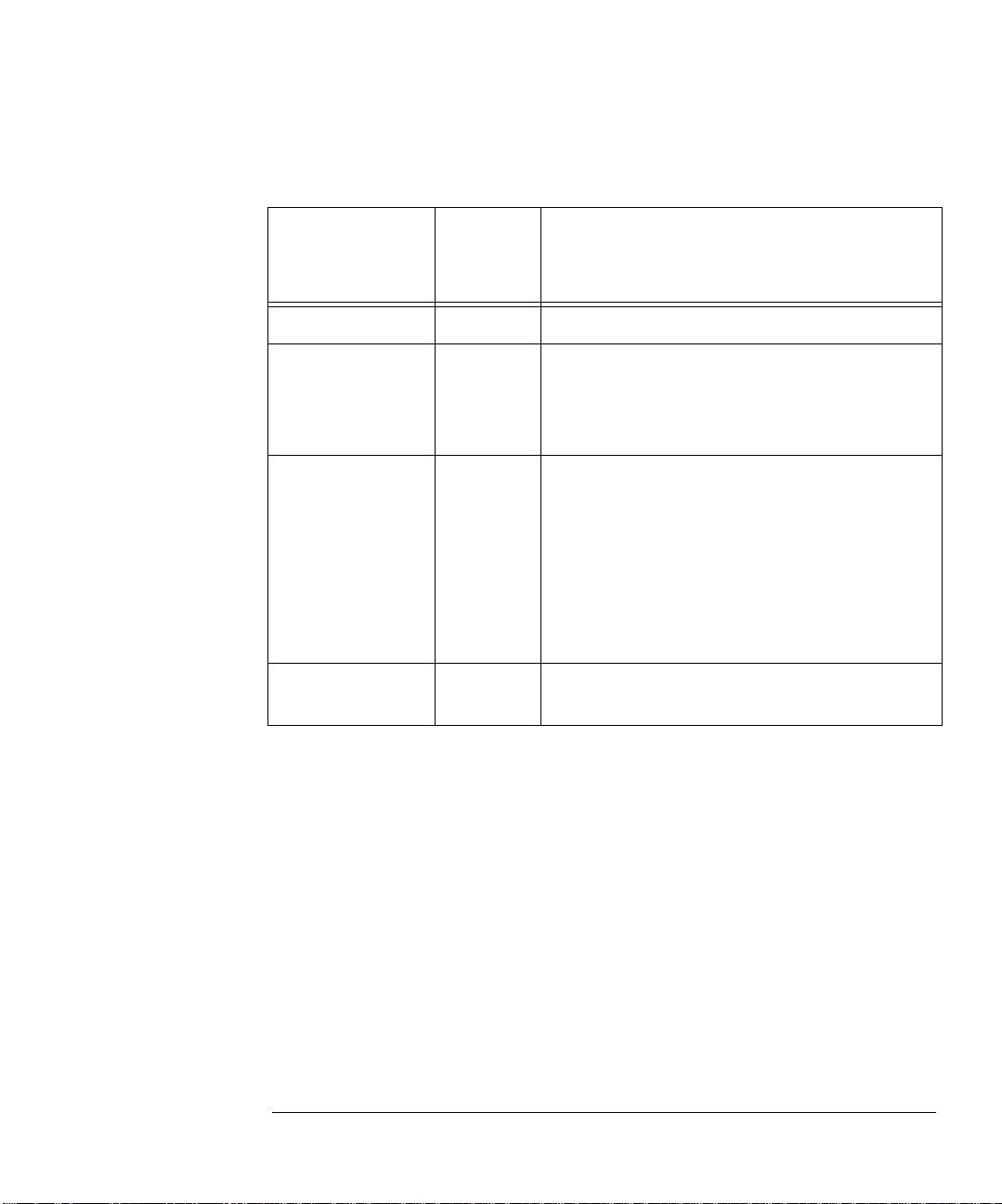

Table 1-1: Private MIB Access Security Privileges. . . . . . . . . . . . . . . . . 9

Table 4-1: Minimum Requirements for a Bootp Server. . . . . . . . . . . . . 74

Table 4-2: Bootp Server Bootptab Files . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 4-3: Bootptab File Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 4-4: Bootp Process Verification . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 5-1: Probe Data and Parameters Reset by Warm or Cold Start . . 92

Table A-1: HSSI Interface Cable Pinout . . . . . . . . . . . . . . . . . . . . . . . 115

Table A-2: HSSI Null Modem Cable Pinout . . . . . . . . . . . . . . . . . . . 116

Table A-3: Token-Ring Cable Type, Vp, and Impedance . . . . . . . . . . 118

Table A-4: Serial Port Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . 119

Table A-5: Probe RS-232 Port Pin-Out . . . . . . . . . . . . . . . . . . . . . . . . 120

Table A-6: Probe to Modem Cable Min. Pin-Out (25-Pin to 25-Pin) . 121

Table A-7: Probe to 25-Pin Terminal Cable Min. Pin-Out . . . . . . . . . 122

Table A-8: Probe to 9-Pin Terminal Cable Min. Pin-Out . . . . . . . . . . 122

Table A-9: UTP (Type 3) Network Connector Pin-Outs . . . . . . . . . . 123

Table A-10: STP (Type 1) Network Connector Pin-Outs . . . . . . . . . . 124

xix

Page 20

xx

Page 21

1

Introduction

Page 22

Introduction

Introduction

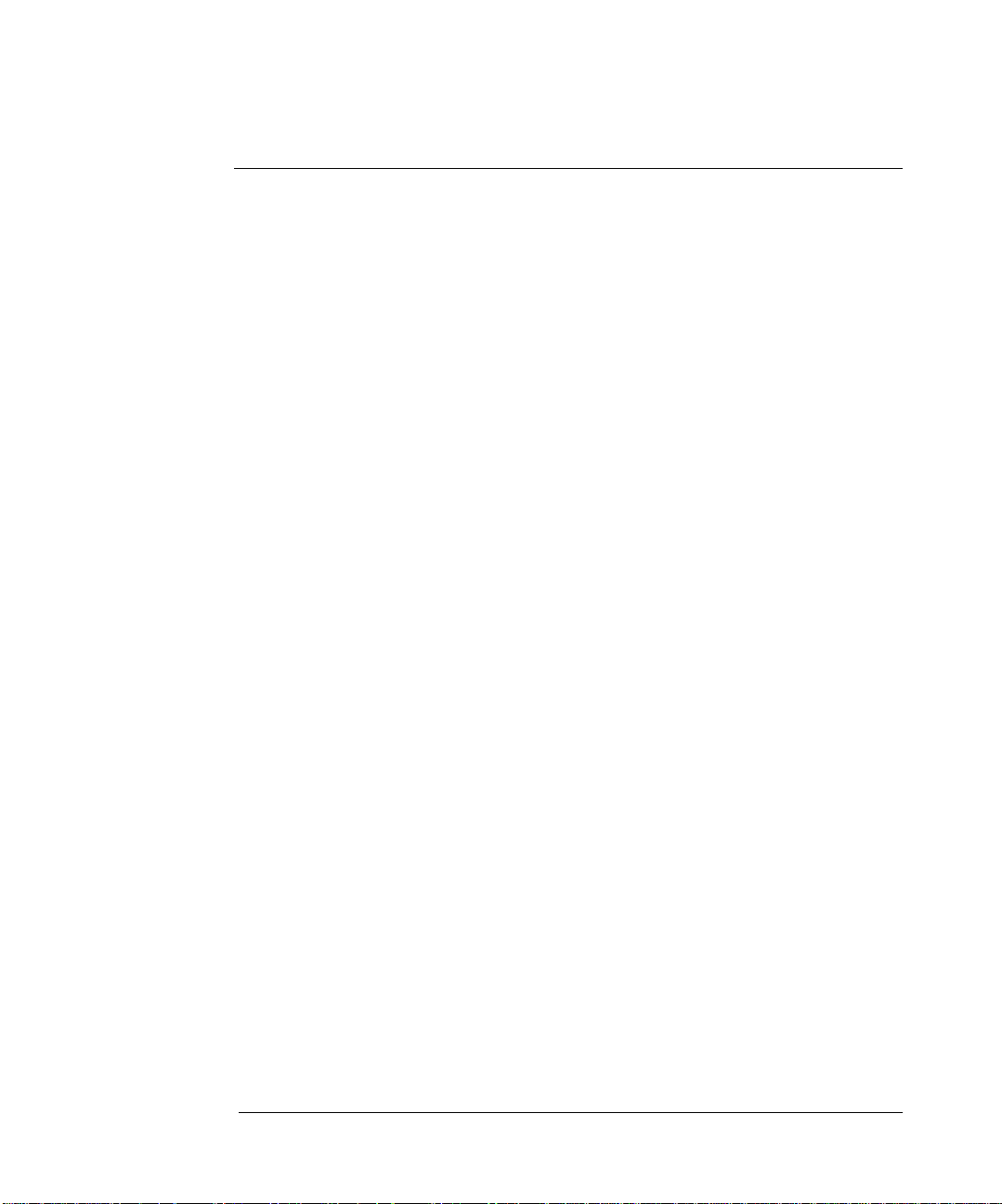

This chapter introduces the Agilent J3916A HSSI WanProbe, shown in Figure 11 on page 3, including its installation and configuration options.

You can use your WanProbe with the NetMetrix/UX software, supported by

HP-UX and Solaris. The term “NetMetrix” is used in this manual to refer to

Agilent NetMetrix/UX.

The Agilent J3916A HSSI WanProbe is a MIPS-based, SNMP-managed WAN

interface monitor for HSSI Wide Area Networks (WAN). The WanProbe is an

intelligent device that must be physically located at the site where the WAN

circuits reside.

The base hardware configuration supports a HSSI WAN interface, a 10Base-T/

100Base-TX telemetry int erface, and a SLIP connection. The HSSI WanProbe can

also be ordered with a Token-Ring telemetry interface. The HSSI WAN interface

supports monitoring bot h d ir ect io ns of a full-duplex circuit simultaneousl y. Probe

data is retrieved using SNMP via a LAN or SLIP connection.

The 10Base-T/100Base-TX telemetry interface uses an RJ-45 connector. The

Ethernet telemetry interface uses an AUI connector. The optional Token-Ring

telemetry interface uses either an RJ-45 or DB-9 connector. The HSSI WAN

interface uses industry-standard connectors.

2

Page 23

Introduction

Figure 1-1: The Probe

The HSSI WanProbe has 32 MB of memory (optionally 64 or 128 MB), and uses

FLASH EPROM. Probe firmware upgrades are easily downloaded over the LAN

to multiple probes simultaneously. You can also download firmware using the

probe’s serial port.

The WanProbe maintains a variety of statistical measurements on network

performance, continuously keeping track of traffic levels, errors, and other

important trends. Alarm thresholds can be set to a number of parameters to

immediately alert the network manager or initiate a packet trace to capture the

details of an event for later analysis. Traffic and error levels are monitored for the

WAN connection on a per-PCV basis.

In addition to using SNMP and selected RMON MIB groups, the WanProbe uses

Agilent priv ate MIB exten sions to provid e additional capabilities. Multiple

SNMP trap addresses, or groups of addresses, can be defined for event

notification. A real-time utilization variable provides the alarm capability at

instantaneous peaks of network load. An additional Out-of-Band connection to

the probe can be established using Serial Link Internet Protocol (SLIP), either

directly, using a modem, or by using a data switch.

3

Page 24

Introduction

Installation and Configuration Overview

Installation and Configuration Overview

To quickly install and configure your probe, it is important for you to understand

the available configuration and installation options. Configuration consists of

setting the probe parameters (IP address, for example). Installation consists of

physically installing the probe and connecting it to the network.

Local Terminal Configuration and Installation

This method of installation and configuration requires that you first configure the

probe and then instal l the probe. These proc edures are detailed in “Local Terminal

Configuration and Installation” on page 4 and “Installation” on page 41.

Installation and Bootp Server Configuration

This method of installation and configuration requires that you first install the

probe and then configure the probe. These procedures are detailed in

“Installation” on page 41 and “Bootp Server Configuration” on page 71.

4

Page 25

Introduction

Probe Overview

Probe Overview

This section provides some general information on the Agilent J3916A HSSI

WanProbe.

NOTE

The HSSI WanProbe repeats the received signal. There is a few milliseconds

interruption to network traffic if the probe loses power.

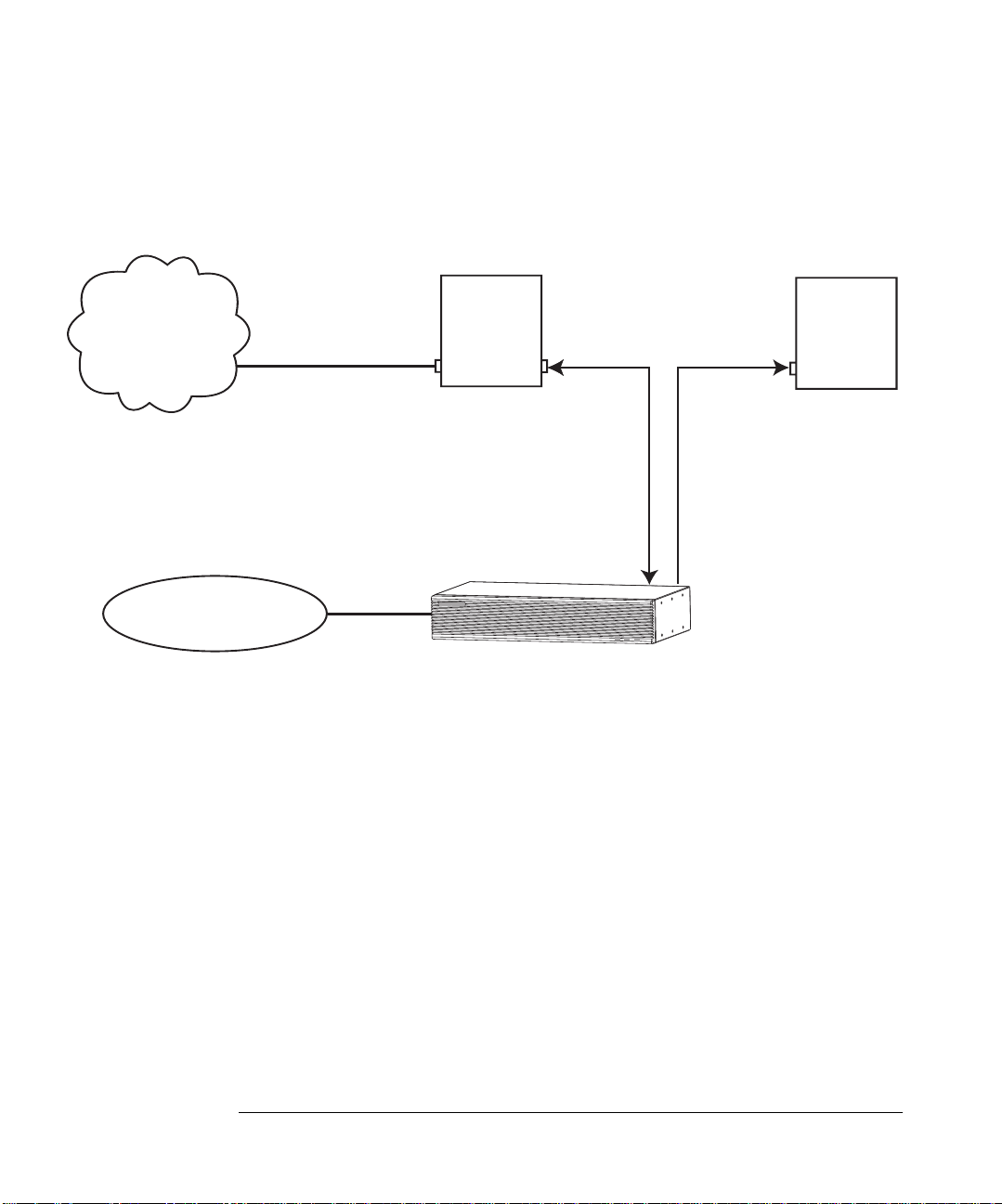

System Overview

A typical probe distributed monitoring system consists of the following:

z

One or more WanProbes

z

One or more NetMetrix management stations, using NetMetrix

Figure 1-2 on page 6 shows a WanProbe system example.

5

Page 26

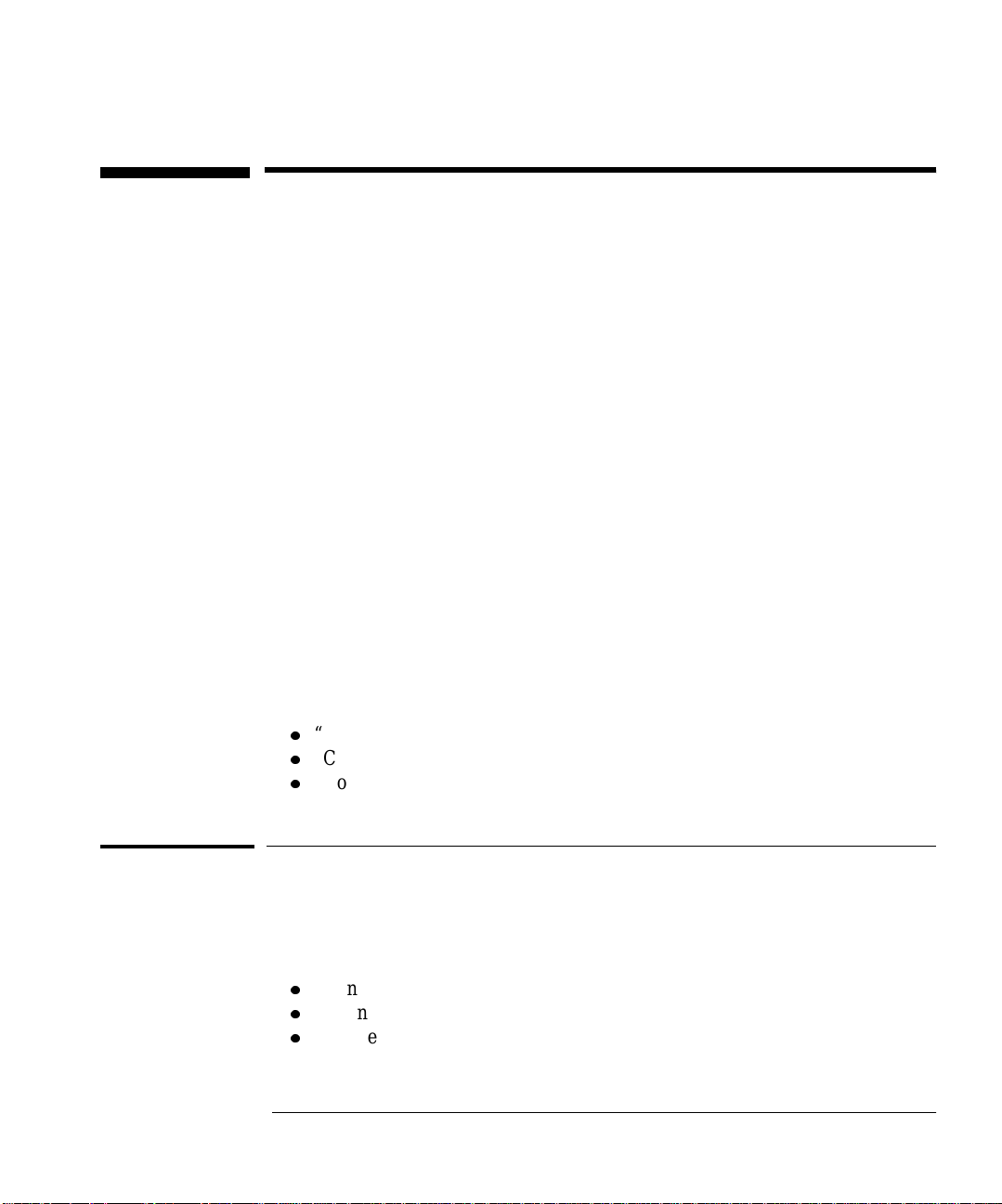

Introduction

Probe Overview

WAN

Network

Telemetry Network

(Ethernet or Token-Ring)

T3/E3

DSU/CSU

T3 or E3 from Telco

Agilent HSSI WanProbe

Figure 1-2: Probe System Example

Router

HSSI HSSI

6

Page 27

Introduction

Probe Overview

Supported MIBs

The W anProbe use s SNMP, MIB-II, Agilent priv ate MIB extensions, and sel ected

RMON MIB groups (groups 3,7,8, and 9) to provide the following features:

Alarms

z

Filters

z

Packet Capture

z

Events

z

Log

z

Tra p

z

Signaling Layer Statistics

z

Signaling Layer Historical Statistics

z

Frame Relay Protocol Statistics

z

Frame Relay Historical Protocol Statistics

z

PPP* Protocol Statistics

z

PPP* Historical Protocol Statistics

z

Per PVC Frame Relay Protocol Statistics

z

Per PVC Frame Relay Historical Protocol Statistics

z

Per PVC PPP* Protocol Statistics

z

Per PVC PPP* Historical Protocol Statistics

z

* PPP refers to PPP, HDLC, or SDLC.

The WanProbe implements groups 3, 7, 8, and 9 of RFC 1757,the Remote

Network Monitoring Management Information Base (RMON-1 MIB). Refer to

the RFC for more information.

The WanProbe also implements the Agilent Private MIB, which contains all

WAN statistics and allows for configuration and administration of the probe. It

provides enhanced authentication features, specification of trap destinations,

remote download of new firmware revisions, serial line control, and other

features. The Agilent Private MIB is available electronically with NetMetrix.

7

Page 28

Introduction

Probe Overview

Management Stations

You can use a management station to communicate with the probe and gather

network data. The manageme nt stati on pres ents i nformat ion in an easy -to-u se and

easy-to-understand text and graphic format.

The management station uses NetMetrix software. NetMetrix management

applications allow you to review and reconf igure the pr obe parameter s (such as IP

address, trap destina tions, filters , and packe t captu res), t o manage th e infor mation

collected by the pr obe (includin g statisti cs, historic al studie s, alarms, and capt ured

packet traces), and to monitor local or remote networks (by gathering network

statistics from Agilent Probe agents as network monitors).

Refer to your NetMetrix documentation for more informa tion.

Access Security

A network administrator can disable standard RMON functions as a security

precaution. A security menu allows the network administrator to disable the

RMON-1 packet capture capabilities of the probe to prevent network users from

viewing network traffic. TFTP firmware downloads can be disabled to prevent

users from do wnloading ea rlier versions of the probe firmware. For more

information, refer to “Modify/View Security Values” on page 24.

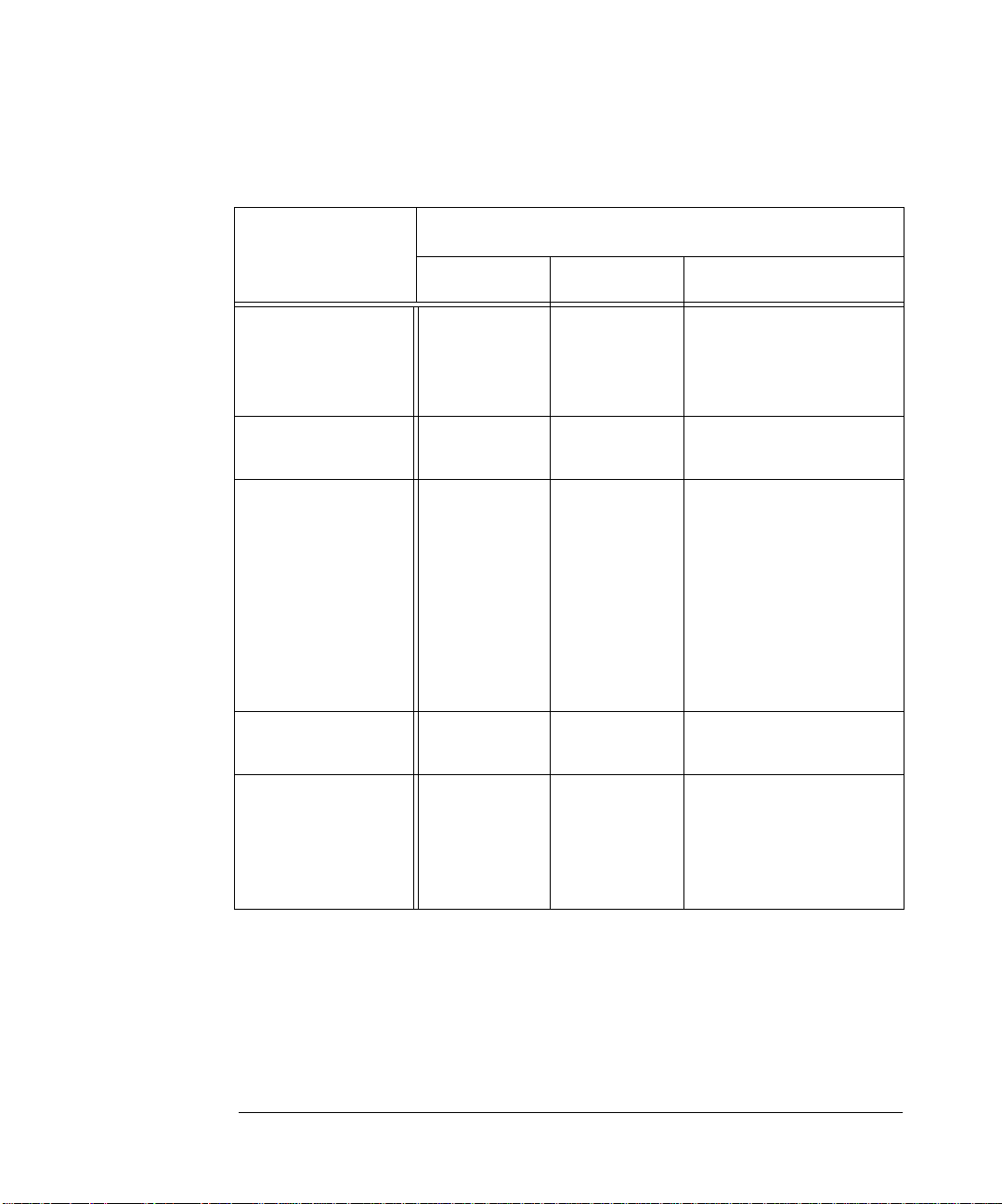

The probe private MIB uses a fou r-level access contr ol scheme. An access level is

assigned for each community string. The access level is an integer value between

one and four, with increasing degrees of authorization granted for higher

authorization numbers. Each higher level is granted the rights of all lower levels

in addition to the specific privileges of that level. Table 1-1 on page 9 shows

specific access privileges by level.

8

Page 29

Introduction

Probe Overview

Default

Community

Level Permissions

Name

public 1 Read access to MIB-II objects.

rmon 2 Read access to MIB-II, RMON MIB, and the

probe MIB objects, excluding the objects in

the accessControl group and in the

captureBuffer Table.

rmon_admin 3 Write access to RMON MIB an d the probe

MIB objects, excluding the objects in the

probeAdmin, interface, and accessControl

groups.

Read access to MIB-II, RMON MIB

(including the captureBuffer Table), and the

probe MIB objects, excluding those in the

accessControl group.

Agilent _admin 4 Read and write access to all MIB-II, RMON

MIB, and the probe MIB objects.

Table 1-1: Private MIB Access Security Privileges

9

Page 30

Introduction

Status LEDs

Status LEDs

The probe has status LEDs for the base hardware configuration (t he 10Base-T/

100Base-TX telemetry interface), for the HSSI WAN interface, and for the

optional Token-Ring telemetry i nterf ace. Thes e LEDs a re loc ated on t he fro nt and

back panels of the probe. (Figure 1-3 on page 11 shows the LEDs on the front of

the porbe and Figure 1-4 on page 12 shows the LEDs on the back of the probe.)

Front Panel LEDs

The ~ Line On, Activity, and Fault LEDs are on the front of the probe.

~ Line On

power.

Activity

Ethernet telemetry network or transmitted by the probe. When flashing, the

frequency shows the amount of traffic. During periods of steady traffic, it may

appear to stay on solid.

Fault

. This yellow LED is t urned on when the probe ne eds to b e reset , repair ed, or

replaced or when new firmware is downloaded. The Fault LED is normally on

during the power-on self-test, but turns off after a successful self-test or when a

cold or warm start is completed.

Power

or

. This green LED is turned on when data is being received from the

. This green LED is turned on when the probe is receiving

10

Page 31

Figure 1-3: Front Panel LEDs

Introduction

Status LEDs

Rear Panel Telemetry LEDs

The telemetry LEDs are located on the back of the probe. (See Figure 1-4.)

10Base-T/100Base-TX Telemetry Interface Status LEDs

On the back of the probe, there are LEDs associated specifically with each

interface and a Power LED. The 10Base-T/100Base-TX telemetry interface has

LEDs for Activity, Link and Collision.

Link.

This green LED is turned on when the probe is attached to a 10Base-T/

100Base-TX network.

Collision.

network.

This yellow LED is turned on when the probe detects collisions on the

11

Page 32

Introduction

Status LEDs

HSSI WAN Interface Status LEDs

Port 1

Fault

To DTE From DCE

HSSI Interface

RS-232

Power

Data

Clock

Config.

Figure 1-4: Rear Panel LEDs

Token-Ring Telemetry Interface Status LED

The optional Token-Ring telemetry interface has an LED for

LED is turned on when data is being received from the network or transmitted by

the probe. When flashing, the frequency shows the amount of traffic. During

periods of steady traffic, the LED may appear to stay on solid.

Port 2

AUI

Fault

Activity

Collision

Data

Clock

100Base-T

10Base-T/100Base-TX Status LEDs

Token-Ring Telemetry Status LED

Activity

DB-9

RJ-45

Token-Ring Telemetry INTERFACE

Activity

. This green

12

Page 33

Introduction

Status LEDs

HSSI WAN Interface Status LEDs

The HSSI WAN interface has a pair of In and Out LEDs for Data and Clock

functions. It also has a Fault LED for the microprocessor contained on the WAN

interface. (See Figure 1-4.)

Data

. These green LEDs are turned on when valid frames are received from the

network by the HSSI interface . When flashing, the frequency shows the amount

of traffic. During periods of steady traffic, the LED may appear to stay on solid.

Clock

. These green LEDs are turned on when the HSSI interface detects a clock

signal on the interface.

Fault

. These yellow LEDs are t ur ned off when the HSSI interfac e is r unni ng. It is

normal for these LEDs to flash during initialization or when a network error is

detected.

CONFIG Button

The CONFIG button is used to configure the probe from a terminal or to restart

the probe. The CONFIG button is recessed and located on the back of the probe

near the RS-232C connector. You will need to use a narrow, pointed object (l ike a

pen) to press the CONFIG button.

To configure the probe using a local terminal (or PC emulating a terminal),

connect a terminal to the probe using a null modem cable and push the CONFIG

button to display the probe Main Menu. This operation is described in “Local

Terminal Configuration” on page 15.

You can restart the probe (with a warm start or cold start) using the CONFIG

button. (See “Probe Operation” on page 89.)

13

Page 34

Introduction

Status LEDs

Included Parts

The following items are included with your Agilent J3916A HSSI WanProbe:

Agilent J3916A HSSI WanProbe

z

Agilent J3916A HSSI WanProbe Installation/User’s Guide—this manual

z

(J3916-99501)

Bootp Software 3.5-inch Disk, for PCs

z

Hardware Kit (5064-0339)

z

Two Mounting Brackets for the Agilent Probe

Four 10-mm #M4 Mounting Screws

Four 5/8-in #12-24 Mounting Screws

Four Self-Adhesive rubber feet

Power Cord, one of the following:

z

Australian (8120-1369)

Danish (8120-2957)

European (8120-1689)

Japanese (8120-4753)

South Africa (8120-4600)

Swiss (8120-2104)

United Kingdom (8120-1351)

United States/Canada 125 V (8120-1378)

United States/Canada 250 V (8120-0698)

Optional Accessories

The following Agilent Probe accessories can be purchased from Agilent :

Null Modem Cable—9 pin to 25 pin (Agilent 24542G)

z

14

Page 35

2

Local Terminal Configuration

Page 36

Local Terminal Configuration

Local Terminal Configuration

This chapter describes how to use a local terminal to configure your Agilent

J3916A HSSI WanProbe so that it can communicate via a network. If you plan to

use the Bootp server method of configuration, skip to “HSSI WAN Interface

Configuration” on page 33 and then continue with “Installation” on page 41.

16

Page 37

Probe Configuration Using a Local Terminal

Local Terminal Configuration

Probe Configuration Using a Local Terminal

An initial configuration of the probe is necessary before it can communicate over

the LAN telemetry network interface or serial port. Th e WAN interface must be

configurated before monitoring can o ccur . You perform the configurati on by using

a series of configur ation menus that provide a numbe r of options (f ields) to choo se

from.

NOTE

This chapter covers all the information you will need to perform the initial

configuration of the probe with the exception of, the

firmware

start and Exit and Cold start and Exit

XMODEM Download new firmware

and

menu items. These topics are explained

TFTP Download new

menu items and the

Warm

in Chapter 6 “Download New Firmware” and Chapter 5 “Probe Operation”,

respectively.

The initial configuration for the Ethernet LAN Telemetry network (10Base-T or

100Base-TX) communication includes:

z

IP Address

z

Default Gateway IP Address (if required)

z

Subnet Mask (if required)

z

Autodiscovery Echo Interval

The initial configuration for the optional Token-Ring LAN Telemetry interface

includes:

z

Ring Speed

z

Ring Number

The following configuration parameters are used to display time and date

information in the user interface only. A separate internal clock is used to timestamp data collected from the network.

z

Date

z

Time

z

Time Zone

17

Page 38

Local Terminal Configuration

Probe Configuration Using a Local Terminal

The initial configuration for communication over the serial port includes:

Serial Port IP Address

z

Serial Port Subnet Mask (if required)

z

Serial Port Speed

z

Serial Port Mode

z

Modem Control String (if required)

z

The initial configuration for the HSSI WAN interface parameters includes:

Data Sense

z

Link Type

z

Clock Speed

z

(Refer to “HSSI WAN Interface Configuration” on page 33 for additional

information.)

18

Page 39

Local Terminal Configuration

Using the Main Menu

Using the Main Menu

To configure the probe, connect a terminal directly to the probe and use the probe

Main Menu.

NOTE

The probe is not available to the network when you are using the configuration

menus.

To view the probe Main Menu:

1. Connect a terminal or a personal computer (PC) emulating a terminal to the

probe RS-232 connector using a null modem cable. Refer to Appendix A,

“Cables and Connectors” on page 113 for more information on cables.

2. Configure the terminal for 8 bits/character, 1 stop bit, no parity, Xon/Xoff

handshaking, and a baud rate of 9600.

3. Connect the power cord to the probe and to a power source (either 100-120/

VAC or 220-240/VAC). The probe does not have a power switch, but is

turned on by connecting to a power source.

19

Page 40

Local Terminal Configuration

Using the Main Menu

4. Start the configuration by quickly pressing the CONFIG button on the back

of the probe one time only. After about 10 seconds, the probe displays its

Main Menu on the terminal. Figure 2-1 shows the location of the CONFIG

button and Figure 2-2 on pa ge 21 shows the probe’s Main Menu. If the Main

Menu is not displayed, verify that the previous steps in this procedure have

been performed correctly.

Power

NOTE

Data

Clock

Fault

HSSI Interface

Config.

Config. Button

Figure 2-1: Probe Rear Panel

The probe CONFIG button is recessed. This requires the use of a narrow, pointed

object (like a pen) to press the CONFIG button.

The probe executes a cold start if you press the CONFIG button twice within one

second. If th is happens, wait for the cold start to be completed and press the

CONFIG button again to enter the configuration mode.

A warm start or cold start is completed when the Fault LED goes off. If traffic is

present, the Activity LED flashes to show traffic.

Port 1

To DTE From DCE

RS-232

AUI

Port 2

Fault

Activity

Collision

Data

Clock

100Base-T

Activity

DB-9

RJ-45

Token-Ring Telemetry INTERFACE

20

Page 41

Local Terminal Configuration

Main Menu - Revision

[1]Modify/View configuration values ->

[2]Modify/View security values ->

[3]Modify/View interface values ->

[4]Display interface summary

[5]TFTP Download new firmware ->

[6]XMODEM Download new firmware ->

[7]Warm start and Exit

[8]Cold start and Exit

Figure 2-2: Probe Main Menu

Using the Main Menu

NOTE

Item 5 (TFTP Download new firmware) is not displayed if the Allow TFTP

firmware downloads menu item is not enabled. Refer to “Modify/View Security

Values” on page 24 for more information on enabling this menu item.

If item 5 (TFTP Download new firmware) is not displayed, the number used to

access items 6, 7, and 8 will be different.

21

Page 42

Local Terminal Configuration

Using the Main Menu

Modify/View Configuration Values

To configure items in the Modify/View Configuration Values menu:

1. On the Main Menu, Press 1,

the Modify/View Configuration Values menu.

Modify/View Configuration Values Menu - Firmware Rev

Memory configuration x Mbytes

[1]Autodiscovery Echo Interval (sec.) 1800

[2]Date Wed 05/05/98

[3]Time 09:12:00

[4]Time zone PST8PDT

S.Save changes and exit

0.Cancel changes and exit

Modify/View configuration values

. You see

Figure 2-3: Modify/View Configuration Values Menu

2. Press a number to select a field and then type the corresponding values

necessary to configure the probe to operate on your network.

Autodiscovery Press 1 and then type the autodiscovery echo interval, in

Echo Interval seconds (optional). This parameter sets the time interval the

probe uses to transmit the autodiscovery frame used by HP

OpenView to maintain the network map.

The default value is 30 minutes (1800 seconds). A value of

zero results in no autodiscovery frame transmission.

22

Page 43

Local Terminal Configuration

Using the Main Menu

Date Press 2 and then type the day of the week and then the date in

month/day/year format (mm/d d/y y, through 1999 or

mm/dd/yyyy, starting 2000).

Time Press 3 and then type the time of day in hours, minutes,

seconds (hh:mm:ss) for m at.

Time Zone Press 4 and then type your time zone in one to 15 characters

(optional).

The Time Zone characters are stored for your convenience

and are used to time-stamp probe information.

NOTE

The recommended practice is to use the format of Time Zone, hours from

Greenwich mean time, and then Daylight Saving Time, such as PST8PDT for

Pacific Standard Time (the default). The probe does not automatically update the

Time field when your local time changes between standard time to daylight

savings time.

The values you enter for date and time take effect as soon as you enter them. All

other parameters do not take effect until you select the Save Changes and Exit.

3. Press S to save the configuration changes and return to the Main Menu.

4. Press 0 to cancel your current changes and return to the Main Menu.

23

Page 44

Local Terminal Configuration

Using the Main Menu

Modify/View Security Values

To configure security values for probe access, you use the Modify/View Security

Values menu.

1. On the Main Menu, press 2,

Modify/View Security Values menu (Figure 2-4) .

Modify/View Security Values Menu - Firmware Rev

[1]Allow packet capture Yes [2]Allow TFTP firmware downloads Yes [3]Allow Packet Generation Yes [4]Allow duplicate and changed IP checking Yes S.Save changes and exit

0.Cancel changes and exit

Modify/View securi ty values

. You see the

Figure 2-4: Modify/View Security Values Menu

2. Press a number to select a field and then type the corresponding values

necessary to configure the probe to operate on your network. See “Access

Security” on page 8 for more information on security.

Allow Packet Press 1 and then type Yes to allow or No to not allow

Capture packet capture.

Allow TFTP Press 2 and then type Yes to allow or No to not allow

Firmware Downloads TFTP firmware downloading.

24

Page 45

Local Terminal Configuration

Using the Main Menu

Allow Packet Press 3 and then type Yes to allow or No to not allow

Generation packet generation.

Allow duplicate and Press 4 and then type Yes to allow or No to not allow

changed IP checking checking of duplicate and changed IP addresses.

3. Press S to save your changes and return to the Main Menu.

4. Press 0 to cancel your current changes and return to the Main Menu.

Modify/View Interface Values

Use the Modif y/View interface Values menu to configure the probe port interface

settings. This procedure involves two steps—selecting the port and then setting

the configuration. For example, the options for the port configuration are:

[1] 1.1/Ethernet

z

[2] 1.2/Serial

z

[3] 3.1/Frame_Relay

z

[4] 3.1/HSSI

z

NOTE

NOTE

Refer to “Display Interface Summary” on page 36 for information on port types

and port numbers for the installed interfaces.

Port 1 is always t he Ethernet telemetry interface (the 10Base-T/100Base-TX with

RJ-45 and AUI connectors).

Fast Ethernet Telemetry Interface Configuration

Use the following procedure to configure the Fast Ethernet Telemetry Interface:

1. On the Main Menu, Press 3,

Modify/View Interface Values menu (Figure 2-5 ).

Modify/View interf ace values

. You see the

25

Page 46

Local Terminal Configuration

Using the Main Menu

Modify/View Interface Values Menu - Firmware Rev

MAC Address 00 00 C6 XX XX XX

Interface Type Ethernet

[1]Port 1.1 Ethernet

[2]Port Type Telemetry

[3]IP address 0.0.0.0

[4]Default gateway IP address 0.0.0.0

[5]Subnet mask 255.0.0.0

[6]Physical Connector RJ-45

[7]Link Speed Auto Negotiate

S.Save changes and exit

0.Cancel changes and exit

Figure 2-5: Modify/View Interface Values Menu (Fast Ethernet)

2. Press a number to select a field and then type the corresponding values

necessary to configure the probe to operate on your network.

26

Page 47

Local Terminal Configuration

Using the Main Menu

NOTE

Port Press

and then press 1 again to display th e current Ethernet

1

port configuration parameters and current settings.

If the optional Token-Ring telemetry interface is not installed, the probe will not

allow you to change the Fast Ethernet interface’s port type from telemetry.

If the Token-Ring telemetry interface is installed, you can configure either the

Fast Ethernet int erfac e or the Token-Ring interfac e as the telem etr y inter face . The

Fast Ethernet interface comes from the factory configured as Telemetry and the

Token-Ring interface comes configured as Monitor/Transmit and is disabled.

“Disabled” in this case means that the interface does not function at all, not as a

Telemetry port nor as a Monitor/Transmit port. If you configure the Token-Ring

interface as Telemetry, the Fast Ethernet interface automatically becomes

configured as Monitor/Transmit and is disabled.

Port Type The Fast Ethernet interface is alwa ys a Telemetry port. The

telemetry port does not maintain network statistics for the

Fast Ethernet interface. The telemetry interface only allows

the retrieval of WAN network statistics. Port 1 is the Fast

Ethernet interface and it is the telemetry port by default. If the

Token-Ring interface is also installed, you can select either

the Fast Ethernet or the Token-Ring interface (but not both)

as the telemetr y port. Refer to “Token-Ring Telemetry

Interface Configuration” on page 29 for information on

configuring the Token-Ring interface. The probe must be

configured with exactly one telemetry port.

27

Page 48

Local Terminal Configuration

Using the Main Menu

The Telemetry port only receives packets destined to the

telemetry port’s IP address, can transmit packets onto the

network, and is used for SNMP co mmunications to t he probe.

It requires the IP A ddress, Subnet Mask, and Default

Gateway IP Address fields. The foll owing apply to Telemetry

ports:

HP OpenView can discover the inte rface

z

The interface is IP addressable

z

The interface responds to RMON-1

z

The interfa ce will transmit all traps from the prob e

z

The interface will transmit all extended RMON packets

z

sample from Monitor -on ly por ts, M onitor /Transmit ports.

IP Address Press 3 and then type the IP address for the probe. If the IP

address is 0.0.0.0, the probe will tr ansmit Bootp Reque sts

for configuration information (including IP address) over the

network. (This does not apply t o port s conf igu red as Monitor Only .)

CAUTION

Default Gateway Press 4 and then type the default gateway IP address for the

probe

IP Address Optional

Subnet Mask Press 5 and then type the subnet mask for the probe.

Physical Press 6 and choose a physical connector. The menu displays

Connector the physical connectors that are available. You can use the

RJ-45 or AUI connector. If you select AUI, item s 7 and 8

(Link Speed and Full/Half Duplex) are not available. AUI is

10MB/s half-duplex.

If you manually select the Link Speed, be careful to configure it correctly. If you

configure the Link Speed for 100 MB/s and you connect the probe to a

10MB/s network, the probe will generate 100% utilization for that segment.

28

Page 49

Local Terminal Configuration

Using the Main Menu

Link Speed Press 7 and select the Link Speed as Auto Negotiate,

10MB/s, or 100MB/s.

Parameters do not take effect until you select the Save Changes and Exit menu

item.

3. Press S to save your configuration changes and return to the Main Menu.

4. Press 0 to cancel you r changes and return to the Main Menu.

Token-Ring Telemetry Interface Configuration

If the optional Token-Ring telemetry interface is not installed, skip this section

and continue with “HSSI WAN Interface Configuration” on page 33. Otherwise,

use the foll owing proce dure to configure items in the Modify/View Interface

Values menu for the Token-Ring Telemetry Interface:

1. On the Main Menu, Press 3, Modify/View Interface Values. You see the

Modify/View Interface Values menu (Figure 2-6 ).

29

Page 50

Local Terminal Configuration

Using the Main Menu

Modify/View Interface Values Menu - Firmware Rev

MAC Address 00 00 C6 XX XX XX

Interface Type Token Ring

[1]Port 3

[2]Port Type Telemetry

[3]IP address 0.0.0.0

[4]Default gateway IP address 0.0.0.0

[5]Subnet mask 0.0.0.0

[6]Token Ring Speed (Mbps) 16

[7]Ring Number -1

S.Save changes and exit

0.Cancel changes and exit

Figure 2-6: Modify/View Interface Values Menu (Token Ring)

2. Press a number to select a field and then type the corresponding values

necessary to configure the probe to operate on your network.

Port Press

display the Token-Ring port configuration parameters along

with the current set tings. The port nu mber for th e T oken -Ring

interface (if installed) d epends on where it is installed. Refer

to “Display I nterface Summary” on page 36 for informatio n

on port types and port numbers for the installed interfaces.

You can then view or configure the Token-Ring port

configuration parameters.

30

and then press the number of the Token-Ring port to

1

Page 51

Local Terminal Configuration

Using the Main Menu

NOTE

If the Token-Ring telemetry interface is installed, you can configure either the

Fast Ethernet int erfac e or the Token-Ring interfac e as the telem etr y inter face . The

Fast Ethernet interface comes from the factory configured as Telemetry and the

Token-Ring interface comes configured as Monitor/Transmit and is disabled.

“Disabled” in this case means that the interface does not function at all, not as a

Telemetry port nor as a Monitor/Transmit port. If you configure the Token-Ring

interface as Telemetry, the Fast Ethernet interface automatically becomes

configured as Monitor/Transmit and is disabled.

Port Type Press

and select the port type as Telemetry. Making this

2

configuration change will dis abl e the Ethernet telemetry port

(port 1). You can select either the Token-Ring or the Fast

Ethernet interface (but not both) as the telemetry port. The

telemetry port does not maintain network statistics for the

T oken-Ring inter face. The telemetry inter face only allows the

retrieval of WAN ATM network statistics. Refer to “Fast

Ethernet Telemetry Interface Configuration” on page 25 for

information on configuring the Fast Ethernet interface. The

probe must be configured with exactly one telemetry port.

IP Address Press 3 and then type the IP address for the probe. If the IP

address is 0.0.0.0, the probe will tr ansmit Bootp Reque sts

for configuration information (including IP address) over the

network. This does not apply to ports configured as MonitorOnly.

Default Gateway Press 4 and then type the default gateway IP address for the

probe

IP Address (optional).

Subnet Mask Press 5 and then type the subnet mask for the probe.

Token-Ring Press 6 to modify or view the network speed setting.

Speed The default configuration is set to 16 Mbps network speed.

You can enter values of 4 or 16 for 4 Mbps or 16 Mbps

respectively or enter Auto to automatically sense the ring

speed.

31

Page 52

Local Terminal Configuration

Using the Main Menu

NOTE

Selecting Auto to automatically sense the ring speed does not function in all

network installa ti ons . If the probe fails to insert into the r ing with the Token -Ri ng

Speed set to Auto, select a fixed speed of 4 or 16 to match your network.

Ring Number Press 7 and then typ e the local ring number (in decimal) for

your network. Set to -1 for use with ring p arameter servers

for automatic setting of the ring number, and set to <x> to

explicitly set the ring number, where x is the ring number in

decimal.

Parameters do not take effect until you select the Save Changes and Exit

menu item.

3. Press S to save the configuration changes and return to the Main Menu.

4. Press 0 to cancel your current changes and return to the Main Me nu.

32

Page 53

Local Terminal Configuration

Using the Main Menu

HSSI WAN Interface Configuration

Use the following procedure to configure the HSSI WAN Interface:

1. On the Main Menu, Press 3,

Modify/View Interface Values menu (Figure 2-7 ).

Modify/View Interface Values Menu - Firmware Rev

Interface Type HSSI

[1]Port 3.1 HSSI

[2]Port Type Monitor-only

[3]Data Sense Normal

[4]Link Type Frame Relay

[5]Clock Speed 52 Mb

S.Save changes and exit

0.Cancel changes and exit

Modify/View Interf ace Values

. You see the

Figure 2-7: Modify/View Interface Values Menu (HSSI WAN)

2. Press a number to select a field and then type the corresponding values

necessary to configure the probe to operate on your network.

33

Page 54

Local Terminal Configuration

Using the Main Menu

Port Press

and then type the HSSI WAN interface port number

1

to display the HSSI WAN port configuration parameters

along with their current settings. Refer to “Display Interface

Summary” on page 36 for information on port types and port

numbers for the installed interfaces. You can then view or

configure the HSSI WAN port’s configuration parameters.

The following are your HSSI port choices:

[3] 3.1/Frame_Relay

z

[4] 3.1/HSSI

z

Port Type The port type is set to Monitor-only.

Data Sense Press

and then select the format of the bit stream (the Data

3

Sense type) as Normal, Inverted, or NRZI (Non-Return to

Zero Invert, on zeros).

Normal means that the data bits are not inverted or, in other

words, that a M ar k r epresents a binary 1. Inverted means that

the data bits are inverted or, in other words, that a Mark

represents a binary 0. NRZI means that bit timing is

determined from the clocking signals present on the HSSI

interface and succ essive Mark s or Spaces repr esent a binar y 1

and changes from Mark to Space or from Space to Mark

represent a binary 0.

Link Type Press

Relay, HDLC, SDLC, or PPP.

34

and then select the link layer analysis type as Frame

4

Page 55

Local Terminal Configuration

Using the Main Menu

Clock Speed Press

and then select one of the following Clock Speeds:

5

[1]1Mb [2]1.5Mb [3]2Mb [4]2.5Mb [5]3Mb [6]3.5Mb [7]4Mb [8]4.5Mb [9]5Mb [10]5.5Mb [11]6Mb [12]6.5Mb [13]7Mb [14]7.5Mb [15]8Mb [16]8.5Mb [17]9Mb [18]9.5Mb [19]10Mb [20]10.5Mb [21]11Mb [22]11.5Mb [23]12Mb [24]12.5Mb [25]13Mb [26]13.5Mb [27]14Mb [28]14.5Mb [29]15Mb [30]15.5Mb [31]16Mb [32]16.5Mb [33]17Mb [34]17.5Mb [35]18Mb [36]18.5Mb [37]19Mb [38]19.5Mb [39]20Mb [40]20.5Mb [41]21Mb [42]21.5Mb [43]22Mb [44]22.5Mb [45]23Mb [46]23.5Mb [47]24Mb [48]24.5Mb [49]25Mb [50]25.5Mb [51]26Mb [52]26.5Mb [53]27Mb [54]27.5Mb [55]28Mb [56]28.5Mb [57]29Mb [58]29.5Mb [59]30Mb [60]30.5Mb [61]31Mb [62]31.5Mb [63]32Mb [64]32.5Mb [65]33Mb [66]33.5Mb [67]34Mb [68]34.1Mb [69]34.5Mb [70]35Mb [71]35.5Mb [72]36Mb [73]36.5Mb [74]37Mb [75]37.5Mb [76]38Mb [77]38.5Mb [78]39Mb [79]39.5Mb [80]40Mb [81]40.5Mb [82]41Mb [83]41.5Mb [84]42Mb [85]42.5Mb [86]43Mb [87]43.5Mb [88]44Mb [89]44.21Mb [90]44.5Mb [91]45Mb [92]45.5Mb [93]46Mb [94]46.5Mb [95]47Mb [96]47.5Mb [97]48Mb [98]48.5Mb [99]49Mb [100]49.5Mb [101]50Mb [102]50.5Mb [103]51Mb [104]51.5Mb [105]52Mb

35

Page 56

Local Terminal Configuration

Using the Main Menu

Display Interface Summary

Use the following procedure to display the Interface Summary screen

(Figure 2-8). This screen lists the Interface, Port Type, and IP Address.

1. On the Main Menu, press 4,

Display Inte rface Summary listing Interface, the Por t Type, and Port IP

Address.

Display Interface Summary

Interface Port Type IP Address

---------------- ---------------- ----------------

1.1/Ethernet Telemetry 15.6.72.216

1.2/Serial NA 0.0.0.0

3.1/Frame_Relay Monitor-only NA

3.1/HSSI Monitor-only NA

Display Interface Sum mary

. You see the

Figure 2-8: Display Interface Summary

2. Press Enter to return to the Main Menu.

Modify/View Serial Port Settings

You use the Modify/View Interface Values Men u to vie w or mod if y the se rial port

settings. Use the following procedure to configure the probe serial port:

1. On the Main Menu,

Modify/View Interface Val ues Menu.

36

Press 3, Modify/View Interface Values

. You see the

Page 57

Local Terminal Configuration

Using the Main Menu

Modify/View Interface Values Menu - Firmware Rev

Interface Type Serial

[1]Port 1.2 Serial

[2]Port Type NA

[3]Serial port IP address 0.0.0.0

[4]Serial port subnet mask 255.255.252.192

[5]Serial port speed 9600

[6]Serial port mode Direct

[7]Serial port hardware flow control On

[8]Modem Init String ^s^M^d1^sATE0Q0V1X4

S0=1...

[9]Modem Hangup String ^d2^s+++^d2^sATH0^M^d2

[10]Modem Connect Responses /CONNECT/300/CONNECT/1200/

...

[11]Modem No-Connect Responses /NO CARRIER/BUSY/NO

DIALT...

S.Save changes and exit

0.Cancel changes and exit

Figure 2-9: Modify/View Serial Port Settings Menu

2. Select Interface Type and then type Serial.

3. Press 1, Port and then type the Serial Port Number. You see the

current serial port settings (Figure 2-9).

37

Page 58

Local Terminal Configuration

Using the Main Menu

4. Press a number to select a field and then type the corresponding values

necessary to configure the probe to operate on your network.

Serial port IP address Press 3 and then type the serial port IP address for the

probe. The default Serial Port IP Address is 0.0.0.0.

Serial port Press 4 and then type the serial port subnet mask for

subnet mask the probe (optional). It is recommended that you do not

change the serial port subnet mask unless there is a

conflict. The default Serial Port Subnet Mask is

255.255.255.192.

Serial port speed Press 5 and then type a serial port speed (300 to 38,400

baud) for the probe’s SNMP connection. The default is

9600 baud. This speed is used only for Out-of-Band

access to the probe using SNMP. It does not affect the

serial connection for the local termina l, which is fixed at

9600 baud.

Make sure that the serial port speed is set to less than or

equal to the maximum speed of the modem to be used.

Serial port mode Press 6 and then select the ser ial port mode by pres sing 1

for direct connection (the default) or 2 for modem

connection.

Serial port hardware Press 7 and then select hardware flow control Off by

flow control pressing 1 or hardware flow control On (the default) by

pressing 2.

Modem Init St ring Press 8 and then type the modem initialization string.

Only the first 20 characters of the 256 character

maximum will be displayed in the M odify/View Serial

Port Settings menu. The default is

^s^M^d1^sATEOQOV1X4 S0=1 S2=43^M.

38

Page 59

Local Terminal Configuration

Using the Main Menu

Modem Hangup String Press 9 and then type Only the first 20 characters of the

256 character maximum will be displayed in the Modify/

View Serial Port Settings menu. The default is

^d2^s+++^d2^sATHO^M^d2.

Modem Connect Press 10 to enter the modem connect responses. Only

Responses the first 20 characters of the 256 character maximum will

be displayed in the Modify/View Serial Port Settings

menu. The default is /CONNECT/300/CONNECT

1200/1200/CONNECT 2400/2400/CONNECT

4800/4800/CONNECT 9600/9600/CONNECT

14400/14400/CONNECT 19200/19200/

CONNECT 38400/38400/.

Modem No-Connect Press 11 to enter the modem no-connect responses.

Responses Only the first 20 characters of the 256 character

maximum will be displayed in the M odify/View Serial

Port Settings menu. The default is /NO CARRIER/

BUSY/NO DIALTONE/NO ANSWER/ERROR/.

5. Press S to save the configuration changes and return to the Main Menu.

6. Press 0 to cancel your current changes and return to the Main Me nu.

39

Page 60

Exiting the Main Menu and Restarting the Probe

1. On the Main menu, Press 7 to execute a warm start or press 8 to execute a cold start.

A cold start is required if yo u change the IP Address, De fault Gateway, or

Subnet Mask. For either menu choice, the probe exits the Main Menu and

restarts normal operations.

2. If you are performing the initial probe configuration, prepare the probe for

installation by disconnecting the power cord. You will not lose your initial

configuration information.

NOTE

A warm start resets all data collected by the probe. A cold start resets all data

collected by the pr obe and also resets any user-confi gur at ion information, such as

history studies, filters, and alarms to their default values. Refer to “Probe

Operation” on page 89 for more information on what is reset by warm and cold

starts.

After the probe restarts (boots), it operates normally using the new configuration

information. The warm start or cold start occurs immediately and there is no

visual indication of when it finishes.

40

Page 61

3

Installation

Page 62

Installation

Installation

This chapter describes how to install the Agilent J3916A HSSI WanProbe.

Installing an Agilent probe consists of the following tasks:

z

“Selecting a Location” on page 43

z

“Installing the Probe” on page 44

z

“Connecting the Probe” on page 49

z

“Starting the Probe” on page 67

z

“Verifying the Installation” on page 68

If you plan to configure the probe from a local ter mina l and have not yet done so,

go to “Probe Configuration Usi ng a Loca l Terminal” on page 17, and perform the

configuration now.

42

Page 63

Selecting a Location

Installation

Selecting a Location

Select a location for your probe where it will be the most useful. The probe must

be connected to a LAN to retrieve data. The data that can be retrieved was

previously monitored from traffic present on the WAN where it is attached.

Consider the following installation requirements when selecting a location for

your probe:

z

A flat surface that i s lar ge enough to suppo rt the probe (requires clear ance at

rear and sides for cooling and rear panel access), adequate wall space, or

double high space in a 19 inch rack or cabinet.

z

A grounded power outlet (either 100-120/VAC or 220-240/VAC).

z

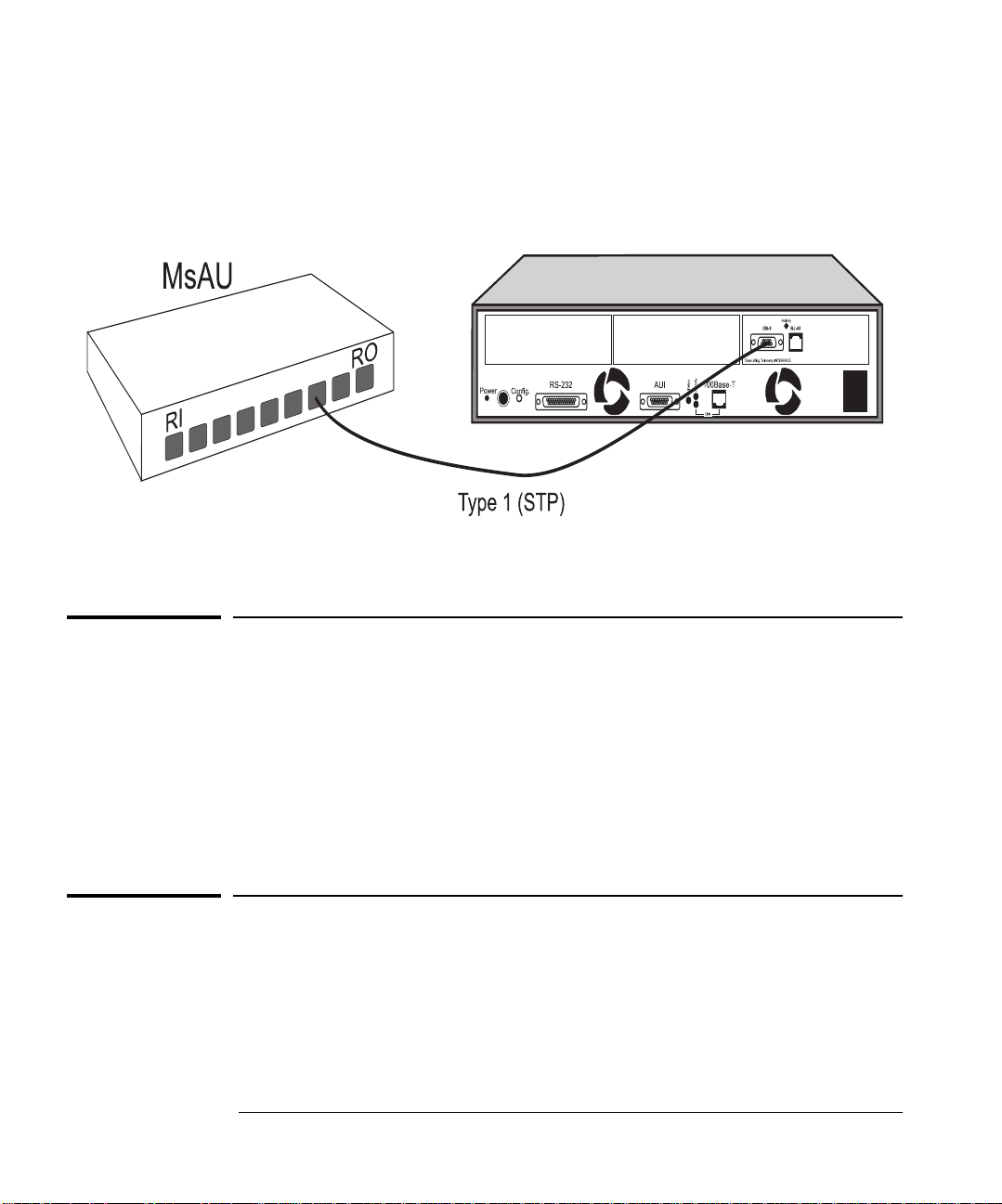

Access to a Fast Ethe rnet connect ion t ap or to a Token-Ring network MsAU

connection (if the Token-Ring Telemetry option is installed).

NOTE

z

Access to the WAN connection to monitor.

z

Access to an RS-232C connection (required only for Out-of-Band

communication).

z

Access to a phone line and a modem within 50 feet (required only for Outof-Band communication using a modem connection).

The MAC addresses for the probe can be found on the r ear pane l. It is a good id ea

to make a note of the interface and its address

prior

to installing your probe

because some installation m ethods make it difficult to see the rear panel without

removing the probe.

43

Page 64

Installation

Installing the Probe

Installing the Probe

This section describes how to install your probe. First decide which installation

method you are going to use and then install the probe using one of the following

methods:

z

“Table Installation” on page 45

z

“Rack or Cabinet Installation” on page 45

z

“Wall Installation” on page 47

CAUTION

not

Do

attach the power cord to the probe until the probe is completely installed.

If the power cord is already attached to the probe, remove it now (you will not

lose any configuration parameters). The probe does not have a pow er switch but

becomes operational when the power is attached.

44

Page 65

Installing the Probe

Installation

Table Installation

Use the following procedure to install the probe on a table:

1. Attach the self-adhesi ve ru bber fee t t o the bot t om of the probe as marked in each corner.

2. Place the probe on a flat surface (refer to the requirements as listed in

“Selecting a Location” on page 43).

Rack or Cabinet Installation

You can install the probe in a rack or cabinet with either the front or rear panel

facing out. You may want the rear panel facing out so that you can see the status

LEDs for each port. (The front panel Fault and Activity LEDs indicate when the

10Base-T/100Base-TX telemetry interface LEDs are lit.)

Make sure you have screws that fit your rack (or cabinet) before installing the

probe as noted in Step 3 below.

Use the following procedure to install the probe in a rack or cabinet:

1. Attach the installation brackets to the probe with the 10-mm #M4 screws

(included), using a POZIDRIV #2 or cross-head screwdriver. See Figure

3-1.

2. Position the probe in the rack (or cabinet) and slide it up or down until the

rack holes line up with the holes in the brackets.

3. Attach the probe to the rack with the 5/8-in. #12-24 scre ws (included). Some

cabinets require 5/8-in. #10-32 screws (available as Agilent part number

2680-0302) instead of the 5/8-in. #12-24 screws.

Figure 3-1 shows a rack or cabinet installation.

45

Page 66

Installation

Installing the Probe

Figure 3-1: Install the Probe in a Rack or Cabinet

46

Page 67

Installing the Probe

Installation

Wall Installation

Use the following procedure to install the probe on a wall:

1. Attach the installation brackets to the probe with the 10-mm #M4 screws

(included), using a POZIDRIV #2 or cross-head screwdriver. See Figure

3-2.

2. Attach the probe to a wood surface (minimum 1/2-in. plywood or

equivalent) on a wall with 5/8-in. #12 wood screws or equivalent (not

included).

Figure 3-2 shows a wall installation.

47

Page 68

Installation

Installing the Probe

Figure 3-2: Install the Probe on a Wall

48

Page 69